Demon 421441 User Manual

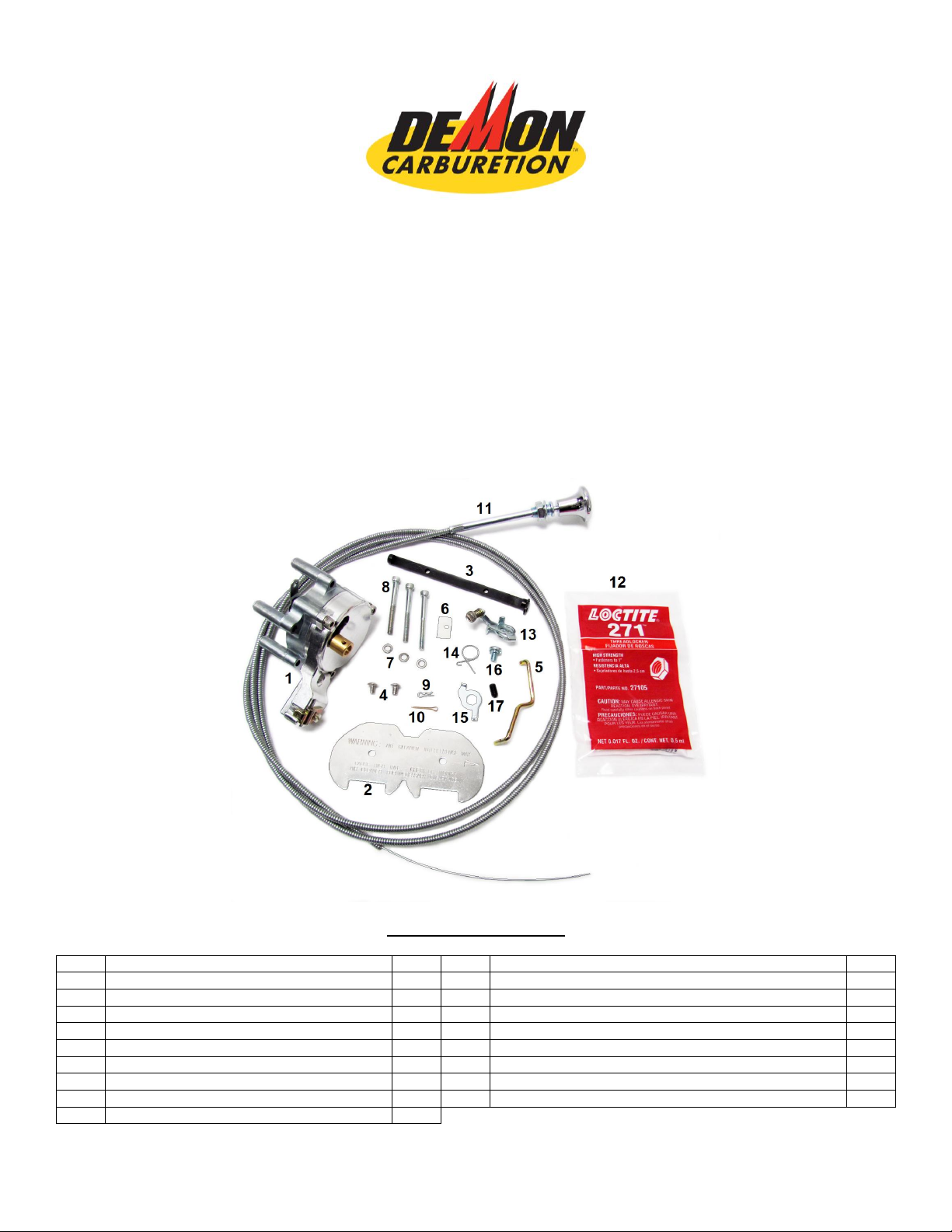

Item

Description

Qty.

Item

Description

Qty.

1

Manual Choke Pod Assembly

1

10

1/2” Cotter Pin

1

2

Choke Flap

1

11

6 ft. Choke Cable

1 3 Choke Shaft with Lever

1

12

Tube of Loctite® 271 (packaged)

1 4 #8 x 32 TPI Torx® Head Screws

2

13

Fast Idle Assembly (plate, spring, & screw)

1 5 Choke Rod

1

14

Shaft Spring

1

6

Nylon Main Body Block Off Plate

1

15

Outer Shaft End Plate

1

7

#8 Lock Washers

3

16

#10-32 x .31” Phillips Pan Head Screw w/ Lockwasher

1 8 #8 1-3/4” Socket Head Cap Screws

3

17

#10-32 x .38” Set Screw

1 9 1/2” Retainer Pin

1

DEMON™ CARBURETOR MANUAL CHOKE KIT

#421441

CHOKE INSTALLATION INSTRUCTIONS

LIT703

This manual choke kit is designed to be used on any Demon™ Carburetor with a choke tower. This covers the

Road Demon Jr.™ and Road Demon™ series carburetors as well as both Twin Squirter (mechanical

secondary) and Vacuum Secondary Speed Demon™ carburetors. READ THESE INSTRUCTIONS

THOROUGHLY before installing the Demon™ Carburetion Manual Choke Kit. If you have any questions,

please contact our technical department at 270-901-3346.

INCLUDED IN THIS BOX

1

You will need the following tools to help with the installation:

Small Hammer

Small Drift (punch)

3/32" Allen Wrench

9/64" Allen Wrench

T15 Torx Driver

.316 Diameter Drill

Needle Nose Pliers

Small Flat Blade Screw Driver

#2 Phillips Head Screw Driver

Small File

INSTALLATION

1. Remove the carburetor from the vehicle and drain any fuel into a “fuel safe” container.

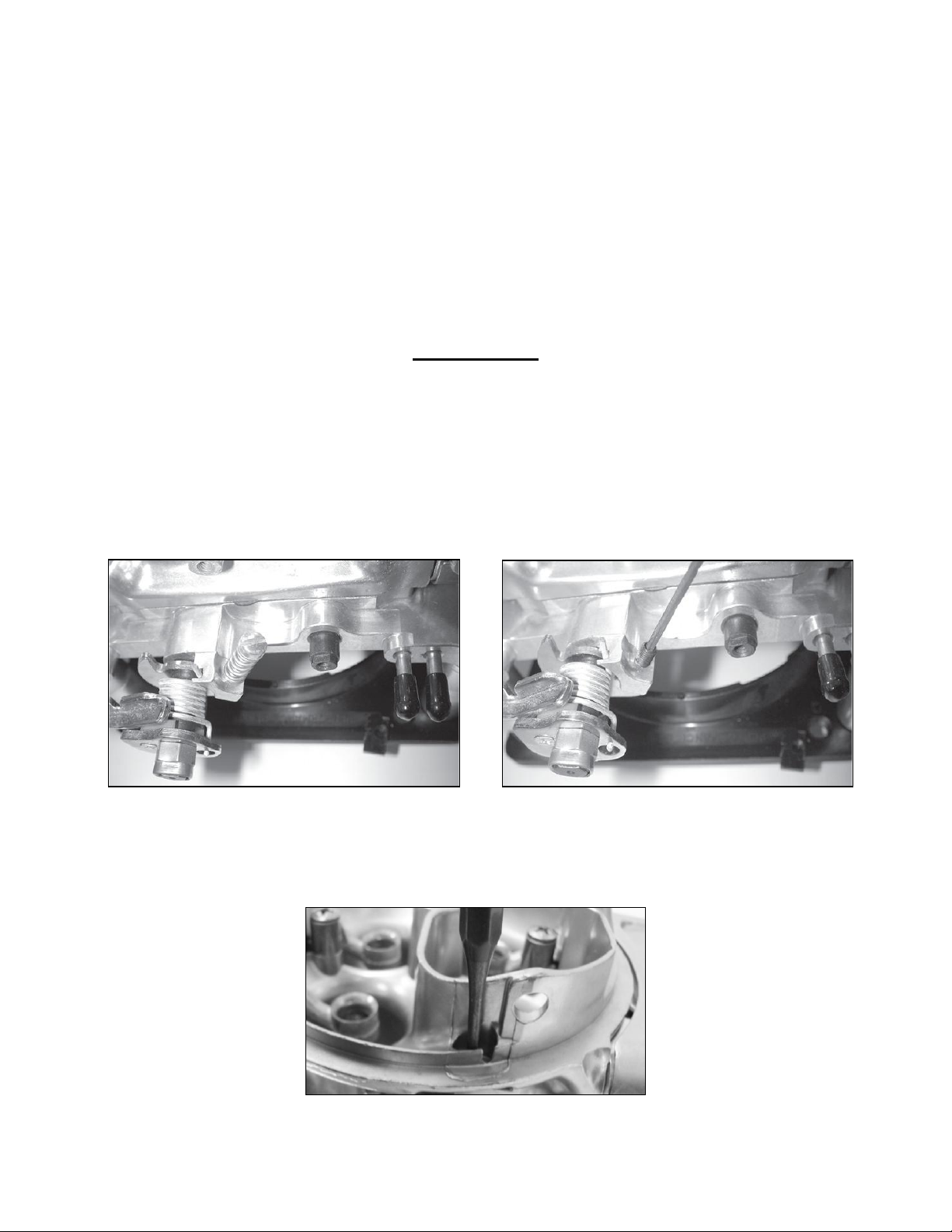

2. If your carburetor is a Speed Demon™ Twin Squirter (mechanical secondary), it is equipped with a slotted

screw to control the secondary butterfly position. This must be changed to the #10-32 x .38 set screw

included with the kit (if you do not, the linkage can bind). This will require you to reset the secondary

throttle shaft. Set the secondary butterflies to the bottom of the transfer slot so you cannot see any of the

slot at idle (butterflies closed), but with any movement of the secondary butterflies you will begin to see the

slot. (Refer to the Demon™ carburetor instruction manual for further information.)

Figure 2 Figure 3

3. Using a small drift pin punch, knock out the sealing slug on the right side of the choke horn in the main

body. It is precut at the factory and should press out very easily. Once you’ve removed the slug, deburr the

hole to make sure the choke rod doesn’t bind or hang.

Figure 4

2

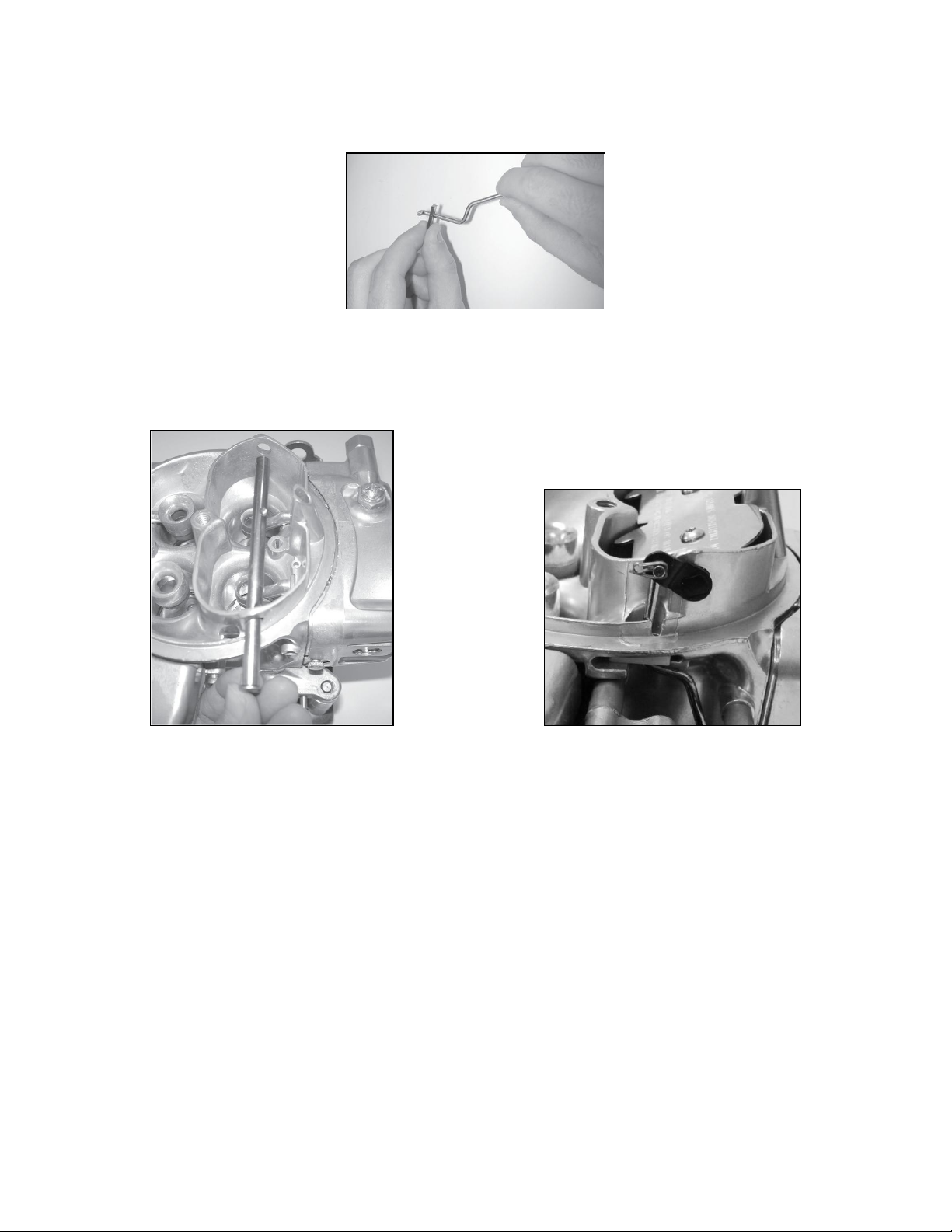

4. Insert the nylon main body block off plate into the cut out slot in the side of the main body.

5. Insert the small end of the choke rod through the bottom of the nylon main body block off plate towards the

top (Fig. 5).

Figure 5

6. Insert the choke shaft with lever through the choke tower (Fig. 6). Make sure the choke shaft with lever

moves freely before proceeding. If it does not you may need to resize the hole(s) going through the choke

tower or use a 0.316" drill bit to make sure the hole is the proper size.

Figure 6 Figure 7

7. Insert the choke rod through the hole on the end of the bracket on the choke shaft. Secure the rod with the

1/2" cotter pin (Fig. 7).

8. Use the two T15 Torx® head screws to secure the choke flap to the choke shaft (Fig. 8). The flap has

instructions stamped on its upper side. Make sure you can read the instructions and that the arrow points

towards the choke rod. NOTE: It is extremely important that the choke flap is centered so it moves freely

and does not bind. You may need to remove the flap to deburr the edges if it binds and reinstall. Once the

choke flap is centered and moving freely, remove the Torx® head screws one at a time. Place a drop of

Loctite® 271 on them and reinstall. Wipe any excess Loctite® off the screw heads or shafts before

proceeding.

3

Loading...

Loading...