Demon 1902 User Manual

625 STREET DEMON™

Part Numbers: 1900, 1901, & 1902

INSTRUCTION MANUAL

LIT701

US Patent # D648746S

www.demoncarbs.com

1

Table of Contents

INTRODUCTION ..................................................................................................................................................................... 3

Recommended Parts and Accessories ............................................................................................................................... 3

Removal of Existing Carburetor .......................................................................................................................................... 3

Installation of Street Demon™ Carburetor ......................................................................................................................... 4

Connecting the Throttle Linkage ......................................................................................................................................... 5

Connecting the Transmission Linkage ............................................................................................................................... 5

GM TH350, 200R4 /700R4 .................................................................................................................................................. 5

Ford Kick-Down Linkage .................................................................................................................................................. 6

Chrysler Applications ....................................................................................................................................................... 6

Vacuum Lines ........................................................................................................................................................................ 7

Electric Choke ....................................................................................................................................................................... 7

Air Cleaner ............................................................................................................................................................................. 8

Priming the Carburetor ......................................................................................................................................................... 8

Mechanical Fuel Pump ...................................................................................................................................................... 8

Electric Fuel Pump ............................................................................................................................................................ 8

Ladies and Gentlemen, Start Your Engines! ...................................................................................................................... 8

Preliminary Tuning and Adjustments ................................................................................................................................. 8

Curb Idle Speed and Mixture Adjustments ......................................................................................................................... 8

Fuel Pressure......................................................................................................................................................................... 9

PERFORMANCE TUNING AND ADJUSTMENT ................................................................................................................. 10

Secondary Air Valve Tuning .............................................................................................................................................. 10

Accelerator Pump Tuning and Adjustment ...................................................................................................................... 10

Main Metering Tuning ......................................................................................................................................................... 11

Theory of Operation ........................................................................................................................................................ 11

Tuning ............................................................................................................................................................................... 12

Steady State Cruise Tuning ........................................................................................................................................ 13

Part Throttle Acceleration Tuning (25% to 75% throttle) ......................................................................................... 13

Choosing the Correct Metering Rod and Step-Up Springs ..................................................................................... 13

Wide Open Throttle Tuning ......................................................................................................................................... 13

Long Duration Camshaft Tuning ................................................................................................................................ 14

Tuning for Elevation .................................................................................................................................................... 14

Removal and Installation of Metering Rods, Step-Up Springs and Jets ....................................................................... 14

Metering Rod and Step-Up Spring Replacement ......................................................................................................... 14

Primary/Secondary Jet Replacement & Float Level Check & Adjustment ................................................................ 14

Winter Fuel ........................................................................................................................................................................... 16

Care and Cleaning ............................................................................................................................................................... 16

Troubleshooting .................................................................................................................................................................. 16

Demon Carburetion™ Limited Warranty .......................................................................................................................... 20

2

INTRODUCTION

Part Number

Description

1921

Street Demon™ calibration kit

1950

Idle kick-up solenoid and bracket

1951

Street Demon™ TPS kit (for use with electronic transmissions requiring a TPS signal)

1952

GM throttle linkage cable attachment bracket

1953

Throttle cable and transmission kickdown bracket

1954

Ford kickdown spring and perch kit

1958

Billet Throttle Cable Bracket

1959

Billet Detent Bracket for 1958 Throttle Cable Bracket

160049

Universal carburetor installation kit

124007

Chrysler throttle stud

786004

Demon chrome 14” air cleaner assembly

1920

Street Demon™ rebuild kit

Street Demon™ Carburetors™ have many unique features that make them one of the best

performing carburetors in the market! Whether it is street / strip performance, or just getting the most

out of your hot rod, the Street Demon™ will give you optimum performance. This manual will

discuss the special points and unique features of the carburetor, and the correct procedures for

proper installation and tuning. The goal is to help you understand the thoughts behind the Street

Demon™, and to increase your knowledge of carburetion. Please read and understand this manual

completely to assure that you get the most out of your new Street Demon™ carburetor.

If you experience any installation questions, problems, or issues, please contact our technical service

department between the hours of 8AM and 5PM CST M-F @ 1-270-901-3346.

DO NOT RETURN TO THE PLACE OF PURCHASE, unless instructed to do so by technical service.

Recommended Parts and Accessories

Removal of Existing Carburetor

1. Remove the air cleaner, exercising care to carefully detach any vacuum lines from the air cleaner and marking them

so they can be reassembled to the air cleaner in the same manner.

2. Remove the existing carburetor by the following procedure:

A. Carefully disconnect the fuel line.

WARNING: Carefully protect the open end of the fuel lines, so that no foreign particles can enter. Wrap the

end of the fuel line with a clean lint-free cloth.

B. Disconnect and mark all vacuum lines and wiring (if any) to the carburetor.

C. Disconnect the PCV hose.

D. Disconnect the choke rod or heat tubes (if equipped).

E. Disconnect and remove the throttle linkage and automatic kickdown linkage. Save all retaining clips.

3

F. Unbolt and remove the carburetor from the manifold.

FITTING TYPE

MANUFACTURER

PART NUMBER

# 6 MALE INLET

SNIPER PERFORMANCE

60406421 (BLUE)

60406423 (BLACK)

#6 STANDARD

EARL’S

991942ERL

3. If the intake manifold is being changed at this time, install the new manifold according to the manifold manufacturer’s

directions.

Installation of Street Demon™ Carburetor

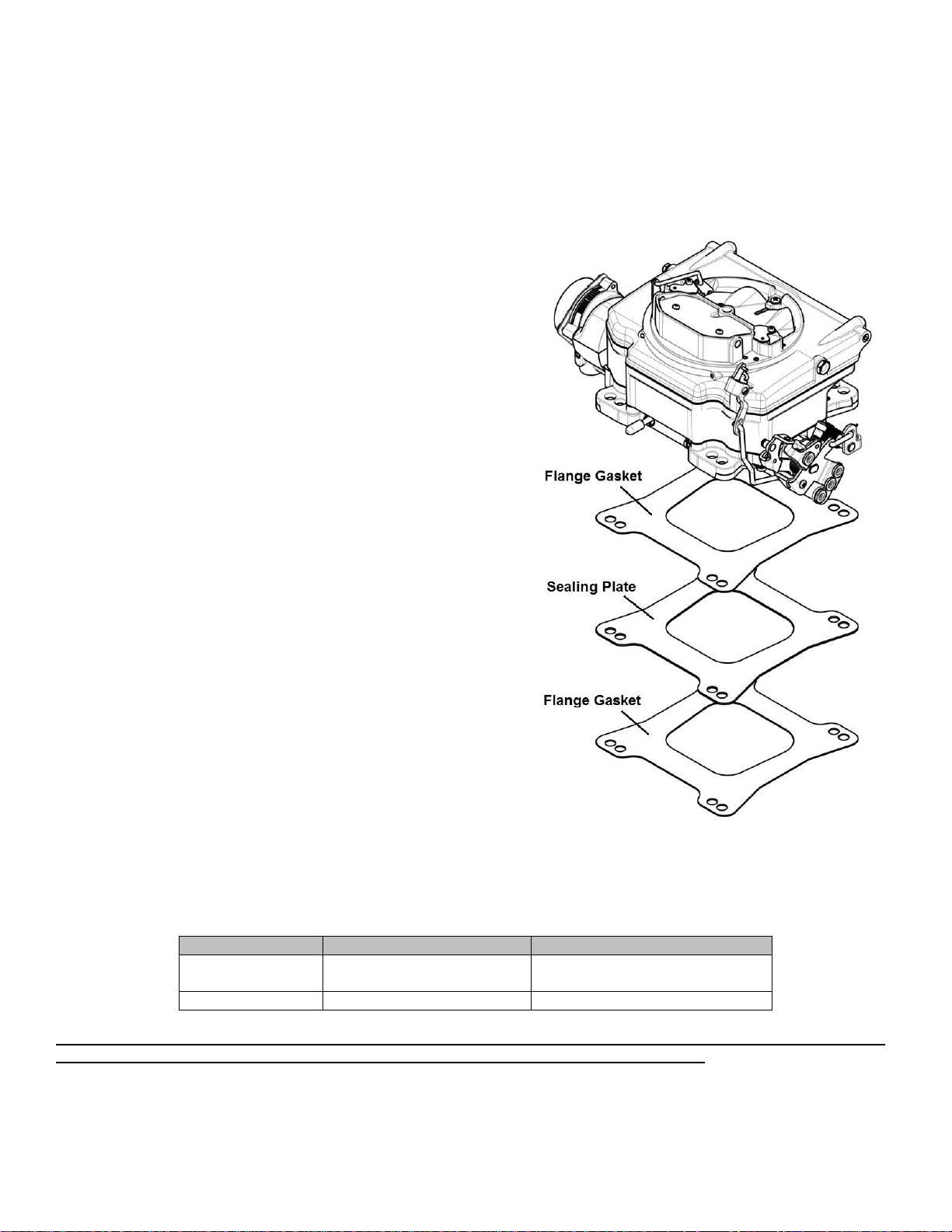

1. Install the carburetor-mounting studs (provided) in the proper location on the intake manifold carburetor flange.

2. Place a new carburetor flange gasket, sealing plate and

second flange gasket provided with the carburetor, in the

proper position on the intake manifold (Fig. 1).

NOTE: The sealing plate is required for the proper function

of the idle circuit which aids in idle fuel atomization

along with a reduction in heat transfer from the

intake manifold.

NOTE: If installing the Street Demon™ on a factory cast iron

spread bore style manifold, a spacer may be

required for proper throttle opening.

3. Place the carburetor on top of the flange gasket on the

manifold. Install the hold down nuts and snug down

progressively in a “crisscross” pattern (60-80 in./lbs.).

4. Open and close the throttle a few times to ensure the throttle

operates smoothly with no binding or sticking.

WARNING: Over tightening may result in a warped or

cracked carburetor throttle body.

WARNING: Any sticking, binding, or other interference in

the throttle linkage could result in

uncontrolled engine speed. This could result

in engine damage or personal injury.

5. In some cases, the existing fuel line will have to be cut and

connected with a length of rubber fuel hose and a clamp. The

Street Demon™ carburetor comes with three fuel fittings.

5/16” hose barb, 3/8” hose barb (installed) and a 3/8” inverted

flare fuel fitting for a hard line. Select the appropriate fuel fitting

and install into the carburetor making sure to use the new fuel

inlet fitting gasket also supplied in the kit. Figure 1

Optional Fuel Inlet Fittings

Street Demon™ 9/16"- 24 threaded fuel inlet boss accepts the following optional fittings:

If installation requires cutting the metal fuel line, cut the fuel line with a good tube cutter. This will minimize the chance of

producing metal chip particles. If a hacksaw must be used, then metal chips must be removed.

WARNING: During the fuel line installation, DO NOT allow any foreign particles to enter the fuel lines, which

could then cause flooding and may result in a fire.

WARNING: Keep the fuel line away from the EGR valve (if equipped) on the intake manifold.

4

WARNING: In all cases where the fuel line has been cut, it is essential that it be clean to ensure that no metal

particles enter the fuel bowl after the new carburetor installation. Remove the fuel line at the

pump and blow the line clean with compressed air. DO NOT use the procedure where the coil

wire is disconnected, the engine cranked for a few revolutions, and the fuel collected in a

container. This procedure is unsafe because sparking can occur either at the coil or at the

distributor end of the coil wire and ignite any fuel spilled in the engine compartment.

MAINTENANCE WARNING: Fuel system components, including fuel lines and the carburetor, should be

inspected periodically to assure no fuel leakage and to ensure the soundness of the hoses. Today’s clean

emissions engines provide higher temperatures in the engine compartment. These high temperatures promote

faster aging of non-metallic materials.

Hoses that exhibit surface cracks, when bent to 180°, should be replaced. The presence of liquid fuel demands

tightening of fittings, hose replacement, and re-torquing of the fuel system component flange nuts.

Connecting the Throttle Linkage

NOTE: Before connecting the linkage, operate the throttle lever to assure the correct travel (no sticking or

binding), by opening to wide-open throttle and back to closed throttle several times. Correct any

sticking or binding conditions before proceeding.

NOTE: If installing on a GM vehicle where the throttle cable needs to utilize the large hole in the top of the

throttle lever, a part # 1952 GM throttle linkage cable attachment bracket will be needed.

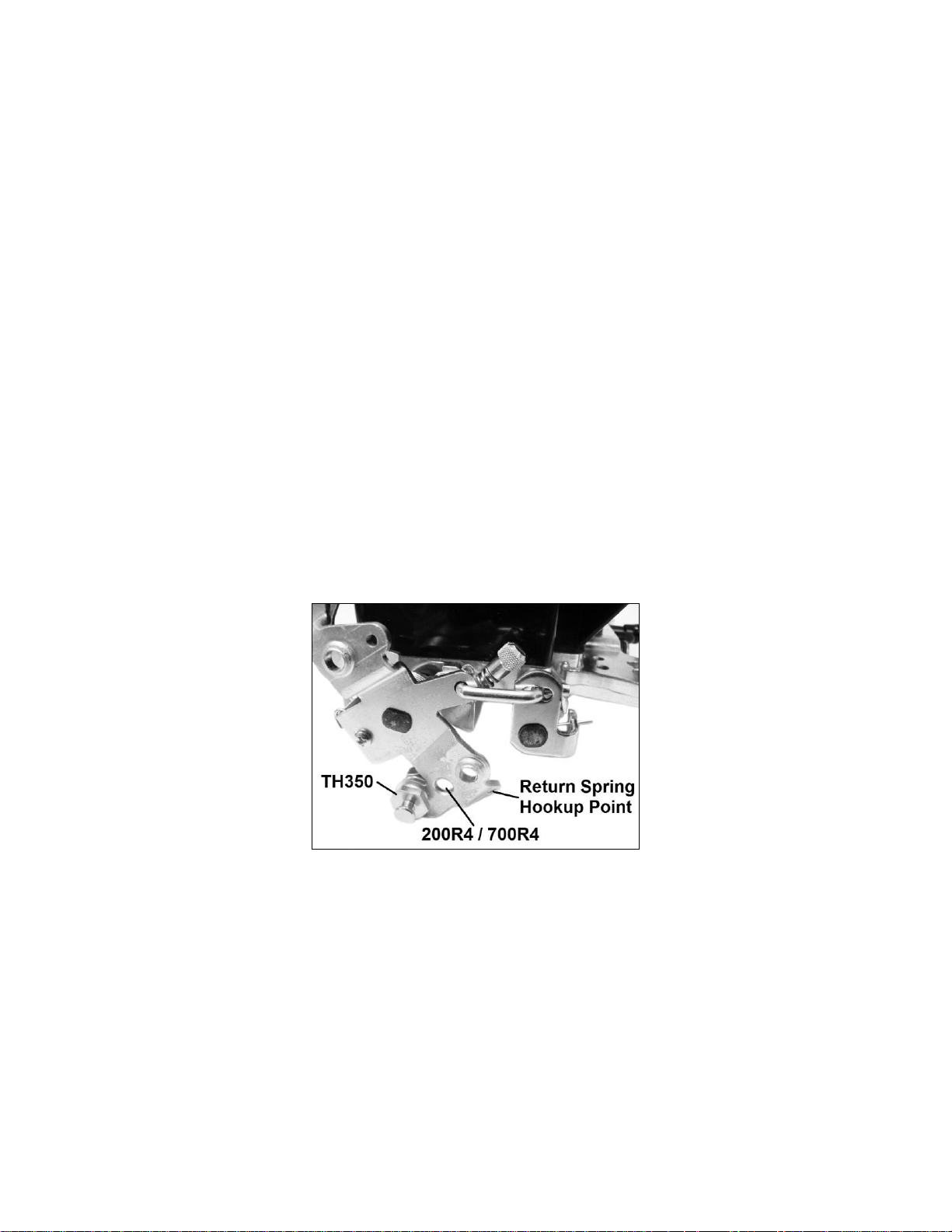

With the pedal held firmly against a stop or the floorboard, pull the carburetor to its wide open position. Adjust the linkage

rod or cable to the proper length, and then attach it to the baseplate linkage. Remember, the pedal should make contact

with a positive stop, just as the carburetor gets to wide open throttle. With the linkage rod or cable attached to the

baseplate, make sure the carburetor can return to its curb idle position. Install your return spring(s) to the bottom of the

throttle lever as shown in Figure 2, and check again for smooth operation to wide open throttle, and then closed again.

Figure 2

Connecting the Transmission Linkage

GM TH350, 200R4 /700R4

Attach the transmission kickdown stud (supplied) into the proper hole location on the throttle lever as seen in (Fig. 2).

Attach the TV cable to the stud and adjust per transmission manufacturer’s specifications, using Chilton®, Motor®, or

other repair manual designed for your specific transmission.

WARNING: If you are unfamiliar with overdrive transmission TV cable adjustments, consult a qualified

transmission expert. Failure to properly adjust the TV cable on overdrive transmissions can lead

to poor shifting and / or transmission failure. Demon Carburetion assumes no responsibility for

transmission damage or failure caused by improperly adjusted TV cables.

5

NOTE: If this carburetor is to be used in an application utilizing an electronic transmission that requires a

throttle position sensor signal to operate properly, Demon has you covered. Part # 1951 Street Demon

TPS kit is designed to bolt directly to your new Street Demon™ carburetor to provide the needed TPS

signal to an electronic transmission. Consult the installation manual for the 1951 Street Demon TPS kit

for installation and adjustment instructions.

Ford Kick-Down Linkage

All Street Demon™ Carburetors come with a Ford kick-down linkage. If running a Ford automatic and the kickdown

linkage is needed, a spring and perch kit (Part # 1954) is required.

NOTE: Street Demon™ Carburetors will not work with a Ford AOD transmission.

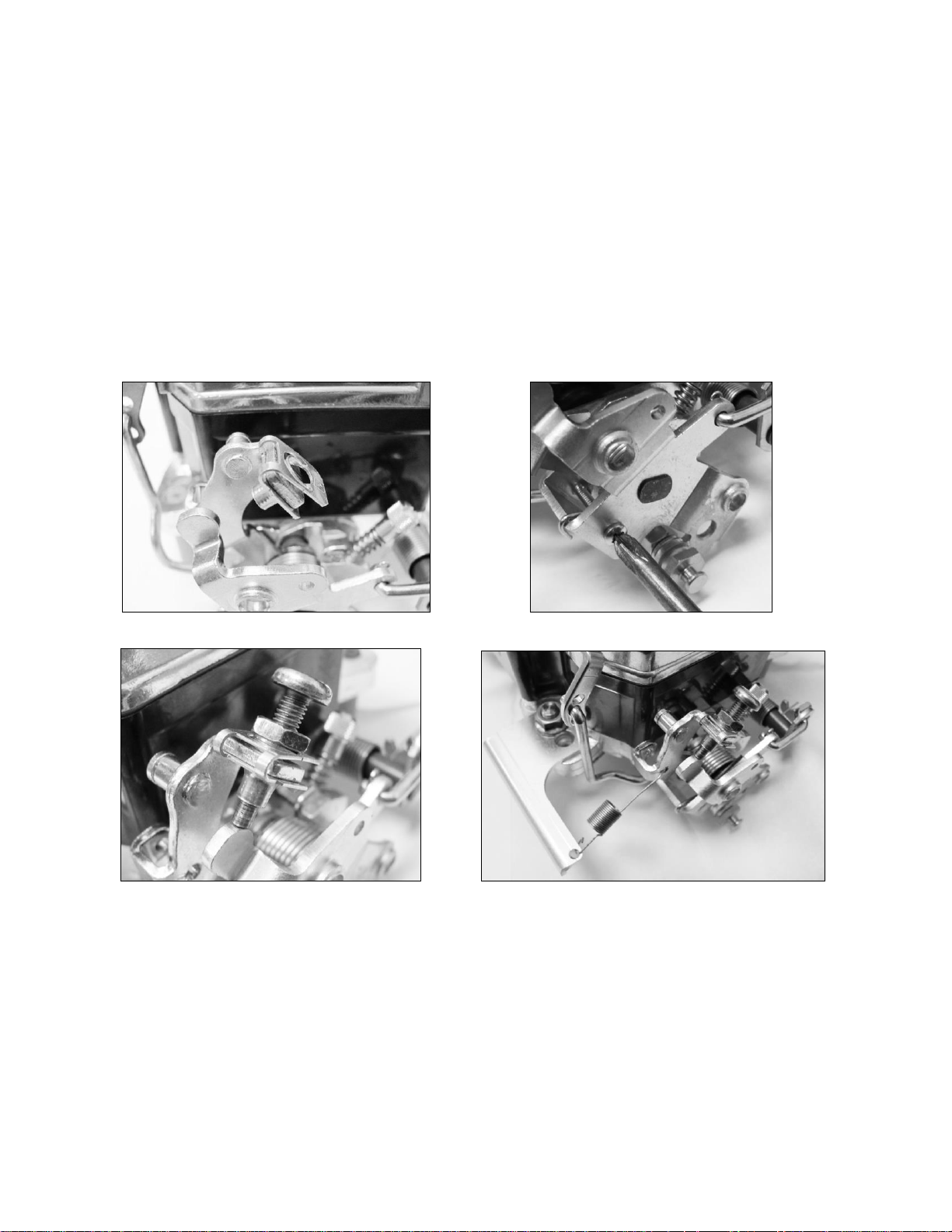

1. Press the screw retainer into position (Fig. 3).

2. Remove shipping screw (Fig. 4).

3. Install adjustment screw and locknut (Fig. 5). Consult the Ford Service Manual for proper setting.

4. Install the mounting bracket and return spring (Fig. 6).

Figure 3 Figure 4

Figure 5 Figure 6

WARNING: Install the transmission kickdown adjustment screw retainer, adjustment screw, and locknut, as

correctly indicated. Failure to attend to this detail may result in a sticking wide-open throttle or

dangerous uncontrolled engine speed.

Chrysler Applications

If installing on a Chrysler, it may be necessary to purchase and install a Chrysler throttle stud part # 124007 onto the

Street Demon™ carburetor as in figure 7 below.

6

Loading...

Loading...