De Luxe 311-BBS Owner's Manual

i

“r-’

So

De

SEWNG

OWNER’S

MANUAL

MODEL

31FBBS

C

MACHIN

r

1

are

You

Machine.

many

years

now

øive

Ihe

of

owner

your

trouble

of

machine

free

predson

a

proper

service.

engineered

care

and

i

will

Sewing

provide

CONTENTS

Description

Operating

Winding

Adjusting

Setting

Opening

Removing

Setting

Threading

Threading

Preparing

Removing

Adjusting

Adjusting

Thread

Adjusting

Regulating

Regulating

balance

the

to

the

needle

or

the

the

bobbin

the

the

for

the

the

under

tension

the

pressure

the

of

bobbin

wind

closing

upper

drop

Sewinginreverse

Regulating

Regulating

Straight

width

length

stitching

machine

wheel

on

bobbin

case

bobbin

needle

sewing

material

thread

feed

length

of

of

.

the

the

case

case

thread

tension

on

of

zigzag

zigzag

and

bobbin

hinge

tension

material

stitch

stitch

stitch

stop

plate

motion

10

10

11-

11

12

12

13

13

14

14

15

2

3

4

5

5

6

6

7

7

8

9

Creative

Samples

Sewlight

Embroidering

Darn

or

monogram

Accessories

Making

Blind

Stretch

Button

Narrow

buttonholes

stitch

stitch

Sewing

hemming

Hemming

Cloth

guide

Quilting

Zipper

guide

foot

Cleaning

Oiling

the

Hints

on

Needle

For

anti

portable

Installing

Adjust

the

embroidery

of

creative

with

sewing

and

inserting

the

shuttle

machine

smooth

sewing

thread

installation

sewing

head

motor

embroidery

hoop

a

without

mechanism

sizes

in

belt

lace

cabinet

hoop

in

one

operation

15

16

16

17

17

18

19

20

21

22

23

24

24

25

26

27

30

31

33

Needle

Hinged

Presser

Needle

Needle

Thread

Face

Needle

Upper

Arm

Stretch

plate

plate

foot

bar

cutter

plate

clamp

thread

thread

lever

thread

screw

tension

guide

guide

regplator

1

2

3

4

5

6

7

S

9

10

l’r.ssure

Thread

Upper

Zigzag

cover

Top

Spool

Zigzag

Zigzag

Bobbin

Balance

regulator

take

thread

window

pin

lock

lever

winder

wheel

up

guide

release

ever

16

17

18

11

12

13

14

15

Hohb:n

Rubber

Stitch

Stitch

Reverse

Bobbin

Drop

Bed

feed

plate

winder

ring

length

length

feed

winder

tension

regulator

(push

lever

regulator

dial

push

bracket

button

button

type)

19

20

21

22

23

24

25

26

27

28

29

2

‘p

OPERATING

Hold

the

turn

the

stop

balance

without

—

A

To

wheel

operating

lock

balance

balance

motion

to

BALANCE

wheel

knob

run

freely,

the

stitching

wheel,

(A)

(B)

turn

WHEEL

firmly

toward

so

that

mechanism.

the

stop

AND

with

you,

the

motion

STOP

your

thus

bobbin

MOTION

left

permitting

can

knob

hand

be

away

and

the

wound

from

you.

3

I

I

BOBBIN

spool

12”

the

to

wind

bobbin,

the

will

you

bobbin

thread

sewing.

to

balance

THE

of

of

bobbin

the

on

unevenly,

up

the

touch

and

and

sew

thread

thread

seven

spindle

put

the

stop

bobbin,

the

run

full,

is

remove

and

wheel.

on

through

or

(A)

slide

the

latch

push

balance

the

will

it

wind

spool

the

tension

eight

the

of

tension

bobbin

(B).

lever

the

wheel.

machine

automatically

bobbin

the

bobbin

(6)

pin

bracket.

toward

times

the

(C)

Then

and

winder.

to

spindle

down

turn

to

come

retighten

bobbin

bracket

on

slowly

simultaneously,

you.

left

wind

the

and

to

Shou

or

(A)

and

halan

thc

a

balar

do

dn

Wi

Tb

rip

bc

st

i

WINDING

the

Place

about

out

on

thread

bobbin

the

set

bobbin

the

required.

as

set

To

After

evenly.

When

Cut

In

pushing

setting

ring

toward

the

the

for

order

the

shown,

rubber

wheel

bin

0

wheel

loosen

4

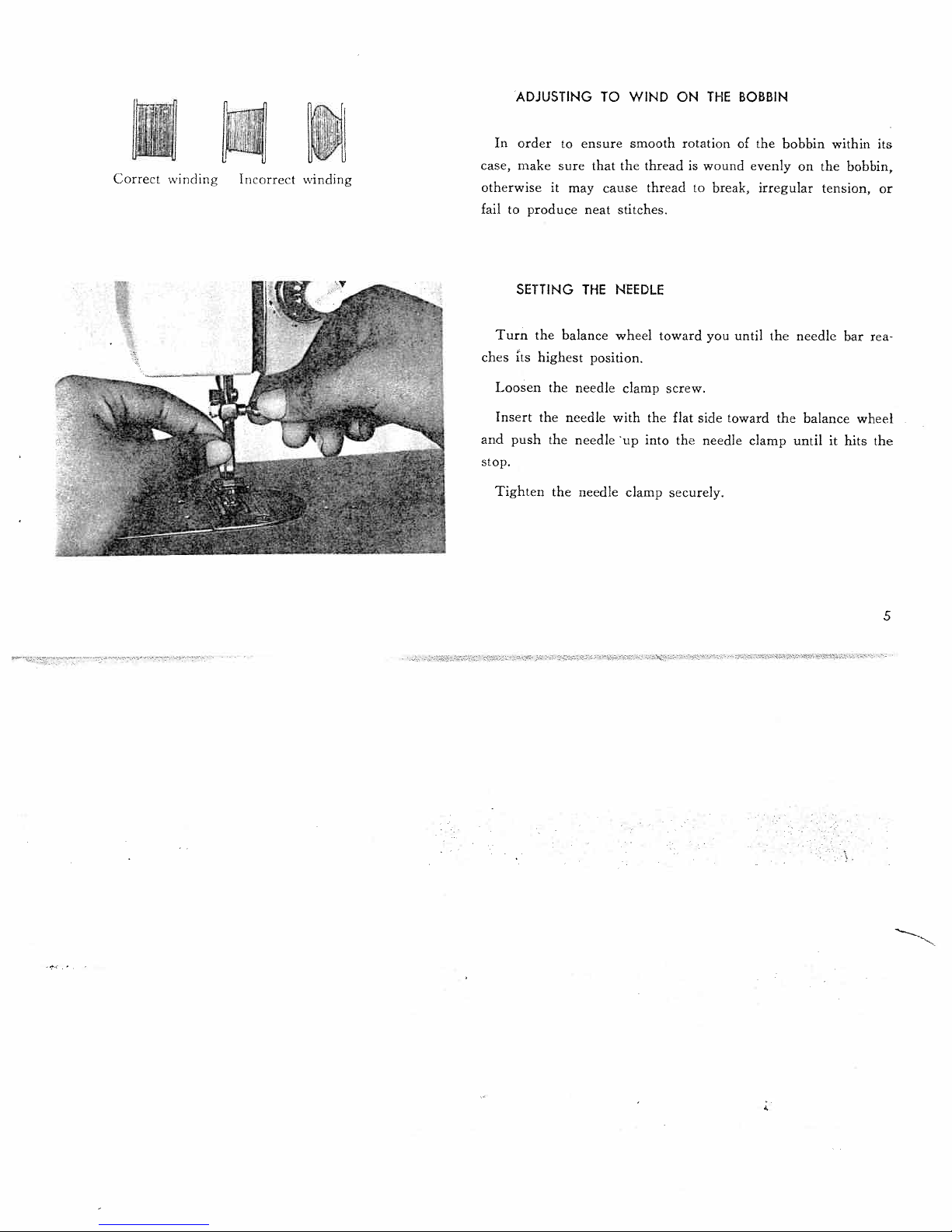

Correct

winding

incorrect

winding

ADJUSTING

In

order

make

case,

otherwise

to

fail

produce

sure

it

to

ensure

may

that

neat

TO

the

cause

stitches.

WIND

smooth

thread

thread

ON

THE

rotation

is

wound

to

of

break,

BOBBIN

the

evenly

irregular

bobbin

on

within

the

bobbin,

tension,

its

or

Turn

ches

Loosen

Insert

and

stop.

Tighten

SETTING

the

its

highest

the

the

push

the

the

THE

balance

position.

needle

needle

needle

needle

NEEDLE

wheel

clamp

the

with

into

up

clamp

toward

screw.

flat

the

securely.

you

side

needle

until

the

toward the

clamp

needle

balance

until

bar

rea

wheel

it

hits

the

5

OPENING

Our

To

open,

new

type

place

OR

hinge

finger

CLOSING

plate

in

recess

THE

HINGE

supersedes

and

the

lift.

PLATE

slide

plate.

at

Turn

its

Lift

REMOVING

the

highest

the

hinged

balance

position.

THE

plate

BOBBIN

wheel

and

toward

insert

CASE

you

thumb

until

and

needIe

the

forefinger

bar

of

le

hand.

Open

the

latch

bobbin

case

by

Inportant-—The

out

of

position

the

bobbin

of

holding

shuttle

if

case

the

hook

you

when

bobbin

the

latch.

and

useabent

the

case

bobbin

needle

as

shown

needle,

bar

case

is

and

can

or

try

lowered.

take

be

to

out

knocke

take

th

o

6

SETTING

Turn

the

its

and

sure

at

highest

Hold

the

position.

the latchofthe

forefingerofthe

that

the

topofthe

latchtomake

(I)

Position

Race

(4)

THE

BOBBIN CASE

balance wheel

threaded

left

bobbin

case

shuttle

sure

the

Finger.

Ring.

(5)

toward

hand,

position

race.

you until

bobbin

replace

finger

Then

case

the

is

release

bobbin caseislocked

(2)

Bobbin

Clips.

(6)

Case.

Shuttle

the

needle

between

bobbin

case.

fixedinthe

the

bobbin

in

position.

(3)

Shuttle

Hook.

barisat

the

thumb

Latch.

(7)

Make

notch

case

Race.

your

Hold

of

you.

Insert

then

Hold

your

THREADING

bobbin

the

left

the

hand

wound

with

right hand

the

bobbin

down

under

THE

case

the

bobbin

with

into the

the

BOBBIN

between

slotinthe

between

the

spring

CASE

thread

case,

until

the

pull

it

edge

the

on

enters

thumb

and

facing

thumb

top leading

the

thread

the

forefinger

up.

and

two

into

delivery

away

fingers

the

eye.

of

from

slot,

7

Place

and

point.

Pull

thread

down

into

up

under

and

lever

Return

guide

down

the

face

and

Thread

about

needle.

THREADING

(Upper

a

spool

raise

the

thread

guides

through

the

thread

the

arm

up

on

(6)

into

from

thread

(5)

through

plate

th

into

needle

needle

four

inches

Thread)

of

take-up

through

(1),(2)

the

tension

thread

the

right

through

the

lower

from

of

THE

NEEDLE

thread

lever

the

check

guide

eyeofthe

left.

to

the

guide

bar

thread

left

to

thread

on

to

slot

discs

spring

(5)

arm

right,

through

spool

its

of

(3)

(4)

tnkt

(7)

guide

pull.

higi

ui

thr

ins

8

(a)

(b)

(c)

(d)

PREPARING

Pull

sufficient

hand

needle.

the balance

down

the

of

the

will

the

needle

both

foot,

lower

the

hold

left

the

Turn

moves

When

end

thread

in

Lay

presser

ed,

turning

FOR

and

take-up

needle

be

ends

and

the

balance

SEWING

thread

the end,

up

thread

brought

plate.

thread

of

having

presser

through

wheel

again,

lever

bar

wheel

leaving

toward

thus

is

you are

with

up

under

inserted

lifter

toward

at

the

it

catching

its

it

needle

from

slack

you

highest

holding

through

andtothe

the

mat€rial

commence

and

you.

until

the

point,

the

and

under

and

the

the

the

needle

back

to

to

with

hand

thread.

pull

be

the

needle

the

under

hole

the

of

stitch

sew

to

by

Do

material,

machine

The

Never

foot.

not

try

as

this

operate

to

feeds

help

may

the

the

deflect

without

machine

feeding

the

any

without

the

of

neelle

and

assistance.

material

work

by

cause

under

pulling

it

to

the

the

break.

presser

9

REMOVING

THE

MATERIAL

(a)

(b)

(c)

(d)

(a)

(b)

the

Stop

presser

the

Lift

side

hand

Passing

down

Always

the

lightly

leave

sewing.

ADJUSTING

cases

most

In

upper

the

ting

tension,

turn

The

by

make

tension

turn

anti-clockwise.

it

tension

little

sure

adjustments.

machine

and

threads

and

three

THE

the

thread

the

dial

the

until

that

bar

to

the

when

lever

the

rear

over

cut the

to

UPPER

perfect

tension.

tension

should

desired

presser

the

needleisat

and

of

the

threads.

four

TI{READ

stitch

dial

not

tension

draw

the

thread

inches

can

increase

To

clockwise,

turned

be

foot

its

the

material

machine.

cutter

of

thread

TENSION

obtained

be

abruptly

obtained,

is

down

is

as

the

and

highest

to

shown,

for

by

upper

to

and

when

poi

the

furti

regu

thr

decrea

but

alw

mak

1

lit

10

All

therefore

Should

spring

slightly

ADJUSTING

machines

it

is

seldom

it

become

screw

to

to

lessen

are

increase

the

UNDER

correctly

necessary

necessary

tension,

THREAD

adjusted

to

to

the

tension

using

the

TENSiON

before

alter

do

so,

small

the

tighten

and

screw

leaving

UNDER

loosen the

driver.

the

the

factory,

tension.

tension

screw

A

B

‘I—

A.

B.

C.

Perfect

Tight

Tight

Stitch.

Upper

Thread

Under Thread

Tension.

Tension.

(a)

(b)

(c)

THREAD

For

ordinary

should

material,

If

the

tensipn

on the

straight

in

illustration

If

the

tension

on the

straight

illustration

TENSION

be

locked

as

illustrated

bobbin

along

needle

along

(C).

stitching,

in

on

the

is

too

the

upper

(B).

on

the

is

too

under

the

the

(A).

needle

loose,

surface

bobbin

loose,

side

needle

center

thread

thread

the

of

the

the

and

of

is

needle

of the

bobbin

material,

the

the

too

material,

is

too

bobbin

thickness

tight,

thread

tight,

thread

as

threads

of

or

if

will

as

shown

or

if

will

shown

the

that

lie

that

lie

in

11

DROP

the

is

pushed

material

material,

three

FEED

feed

dog

tobemoved

completely

be

to

for

embroidery,

push

right

the

buttons

are

under

moved

the

button

always

the

freely

down

freely

center

completely

needle

hand

by

(mark

under

darning,

button

and

up

p!

e

cc

do

cv

and

left

enables

which

very

(marked

sewing,

when

THE

drops

required

is

darning.

button

the

is

convenient

light

the

SILK).

push

I

(,.

,

ADJUSTING

mechanism

This

the

when

embroidering

For

For

the

foot,

sewing

down

ordinary

UP),

When

DOWN.),

presser

pletely

(marked

material

it

A

12

To

and

down

When

darn

to

“Note:

press

presser

to

REGULATING

release

darning,

or

—When

foot,

pressure

(A)

embroider.

into

otherwise

increase

when

“A”

pressure

will

lower

reverting

position

PRESSURE

for

heavy

light

for

automatically

presser

the

to

to

give

the

machine

ON

materials,

materials,

release

bar

normal

the

MATERIAL

press

darning,

the

and

lever

sewing,

required

feed

not

will

(A)

etc.,

pressure.

yon

not

do

pressure

properly.

downwa

preSs’

re

are

forget

on

REGULATING

Turn

the

dial

shorten

longest.

L

the

stitch.

THE

LENGTH

to

the

right

to

Near

is

0

the

STITCH

OF

lengthen

shortest

and

stitch

the

and

left

to

5

the

is

to

I

I

To

of

end

machine

SEWING

sew

backward

a

seam,

will

sew

IN

REVERSE

press

backward

for

in

tying

the

the

button

as

long

threads

R,

as

as

the

far

at

as

button

the

it

beginning

will

go.

is

pressed.

or

The

13

Loading...

Loading...