Chapter 3 Intrinsically Safe Fieldbus Applications

This chapter provides information about fieldbus applications that provide

Intrinsically Safe (IS) power to fieldbus devices located in hazardous areas. The

Pepperl+Fuchs FieldConnex® Fieldbus Power Hub and FieldConnex® FieldBarrier

provide Intrinsically Safe power for both Intrinsically Safe – entity applications and

FISCO (Fieldbus Intrinsically Safe COncept)applications. Refer to the

Pepperl+Fuchs (P+F) documentation and/or visit the DeltaV website

(www.easydeltav.com) and follow the links for additional information on these

products.

Ensure that the fieldbus devices and all components used in the application are rated

and certified for IS applications.

Warning In any hazardous area installation it is important to read and follow the device

manufacturer's design and installation documents. Failure to follow the

documentation could result in an unapproved and unsafe application.

Additionally, in hazardous locations follow your plant's procedures for making

the area safe during installation and maintenance operations.

DC Power Considerations for Intrinsically Safe Applications

The basic IS application uses the Fieldbus Power Hub with the FBPS-1.500 Isolated

Power Supply Module to provide power to field devices connected through one or

more IS Field Barriers.

The available power to a field device depends on the length and resistance

characteristics of the fieldbus cable to each Field Barrier and the output characteristics

of the Field Barrier to the field device. T

make the example calculations in Table 6 on page 53

maximum distance for a given load on the Fieldbus Power Hub for applications using

Intrinsically Safe Fieldbus Applications 51

he P+F segment calculator tool was used to

. The calculations show the

2, 3, and 4 Field Barriers to connect up to 16 field devices. The calculations are based

on the following assumptions:

Power Supply Voltage = 28.0 VDC @ 500 mA

Minimum Voltage at last Barrier = 16 VDC

Minimum Device Voltage = 9 VDC

Maximum Voltage drop from cable to last barrier = 12 VDC

Redundant H1 connected at a load of 24 mA

Each device has an average load of 20 mA

Ensure that any device load on a spur output from the field barrier is 30 mA or

less

Each Barrier spur has a maximum of one device connected.

Barriers and Devices are connected on one end of the cable and the Fieldbus

Power Hub is connected on the other end of the cable

Each device is connected on a 10 meter maximum spur cable.

Barriers are inter-connected on a 10 meter maximum trunk cable.

Fieldbus Type A 18 AWG cable @ 22 ohms/km (44 ohms/km loop resistance) at

22

°C

Maximum Distance (km) = (Allowed Loop V drop / Loop current) / Loop

resistance per km

There will be different restrictions and limitations on your segment if these

assumptions do not hold for your segment layout. If your devices average more than

20 mA per device, reduce the maximum cable length indicated in the table for that

number of devices or reduce the number of devices on the segment. Refer to the

device documentation for information on current requirements for the device.

When referring to Table 6, remember the Redundant Series 2 H1 card requires 24 mA

of fieldbus power.

The loads listed are the normal loads required by the barriers and devices. However,

the numbers take into account the additional current required if the smallest load on

one barrier is accidentally shorted (during a maintenance operation) to protect the

segment from being affected.

If these assumptions do not properly represent your specific application, it is

recommended that a calculation be completed to verify that the segment design

adequately meets your process requirements.

52 Fieldbus Installations in a DeltaV Digital Automation System

Table 6 Distance per Load on the Fieldbus Power Hub with Field Barriers

Number of

Devices / Load

(mA)

1 / 20 1875 75 1850 103 1575 131

2 / 40 1850 94 1625 123 1400 151

3 / 60 1675 112 1425 143 1250 171

4 / 80 1500 130 1275 161 1125 192

5 / 100 1325 149 1150 180 1025 211

6 / 120 1200 163 1050 198 950 231

7 / 140 1000 184 975 218 875 250

8 / 160 1000 208 900 237 800 267

9 / 180 N/A N/A 825 256 750 288

10 / 200 N/A N/A 775 274 700 307

11 / 220 N/A N/A 725 290 650 325

12 / 240 N/A N/A 725 316 625 346

Distance (meters) and Power Supply Load (mA)

Max

Distance

with 2

Barriers

Power Supply

Load

with 2 Barriers

Max

Distance

with 3

Barriers

Power Supply

Load with 3

Barriers

Max

Distance

with 4

Barriers

Power Supply

Load with 4

Barriers

13 / 260 N/A N/A N/A N/A 600 366

14 / 280 N/A N/A N/A N/A 550 378

15 / 300 N/A N/A N/A N/A 525 395

16 / 320 N/A N/A N/A N/A 525 422

16 / 340 N/A N/A N/A N/A 475 429

16 / 360 N/A N/A N/A N/A 425 433

Fieldbus Power Hub

Refer to “Pepperl+Fuchs Fieldbus Power Hub for Redundant Fieldbus Power” on

page 39 for information on the Fieldbus Power Hub system.

Intrinsically Safe Fieldbus Applications 53

Field Barrier for Intrinsically Safe Applications in Hazardous Locations

The Field Barrier connects up to four field devices located in hazardous locations to

the fieldbus segment and provides short circuit protection to each device. Ensure that

any device load on a spur output from the field barrier is 30 mA or less. Figure 11

shows a Field Barrier for four devices.

S1 terminator switch

Spur connections

Spur connections 1-4

10+11 13+1412s 16+1715s 19+18s 20 21s

ON

S1 BUS

TERM.

OFF

PWR

_

1

2

3

4

Figure 11 Field Barrier for Four Devices

1B 2B

14

3+ 4-

5s 6s

Trunk connections

7

- 8+

Trunk connections 1-2

Installing and Connecting the Fieldbus Power Hub

Refer to “Installing and Connecting the Fieldbus Power Hub” on page 46 for

information on installing the Motherboard, Power Supply Modules, and Diagnostics

Modules and connecting the Fieldbus Power Hub.

54 Fieldbus Installations in a DeltaV Digital Automation System

Installing and Connecting the Field Barrier

Refer to Figure 11 on page 54.

¾ To install and connect a Field Barrier

1. Securely attach the Field Barrier at the desired location.

2. For the Trunk segment connection: connect the positive (+) segment wire to the

positive, connect the negative (-) segment wire to the negative, and connect the

segment shield (S) to the S.

3. Remove the shorting jumpers (1B, 2B) so that the Trunk (S) shields are isolated

from, not connected to the Field Barrier case.

4. For each device connection: connect the positive (+) spur wire to the positive,

connect the negative (-) spur wire to the negative, and connect the shield wire (S)

to the S.

5. The Spur (S) shields must be connected to the Field Barrier case and isolated at

the device in the field. The best way to ground the output shields at the barrier is

with a mechanical connection through a metal gland or bar at the barrier.

6. If this Field Barrier is at the end of the segment, the terminator switch S1 should

be in the On position. If this is not the end of the segment, ensure that the

terminator switch S1 is in the Off position.

7. If the segment continues and connects to another Field Barrier, continue the

Trunk segment by connecting the Trunk Out connections to the next Field

Barrier and proceed with steps 3, 4, and 5.

8. Ensure that the shorting jumpers (1B, 2B) are removed on all Field Barriers, so

that the Trunk (S) shields are isolated from not connected to the Field Barrier

case.

9. If this Barrier is the end of the segment, ensure that the terminator switch S1 is

in the On position.

Verifying the Installation

Refer to “Verifying the Installation” on page 48.

Intrinsically Safe Fieldbus Applications 55

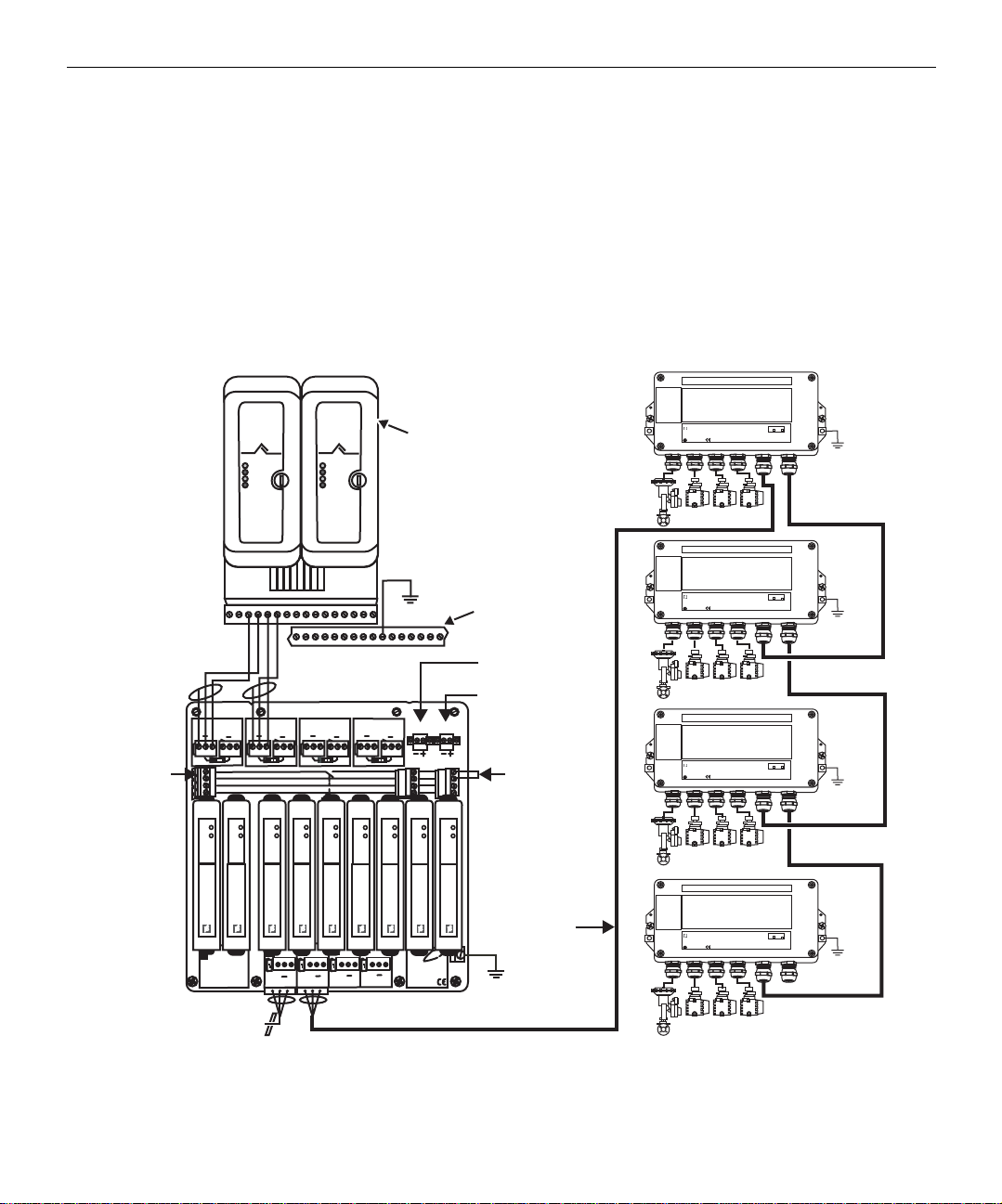

Intrinsically Safe Application Example

A

Figure 12 shows an application that uses a redundant pair of Series 2 H1 cards with

redundant fieldbus power and intrinsic safety barrier protection for 16 devices on a

long (0.5 km) trunk cable. If a failure occurs on an H1 card, a 24 V power supply, or a

fieldbus power supply, the segments continue to operate as expected. A status

indication on connected alarms alerts the operator that an error has occurred. It is

assumed that the application design follows the criteria specified in “DC Power

Considerations for Intrinsically Safe Applications” on page 51. Therefore, if a short

occurs when a device is installed or removed from the segment, only that device is

affected; the rest of the segment is unchanged.

Series 2

Power/Active

Error

Port 1

Port 2

Series 2

Power/Active

Error

Port 1

Port 2

Redundant

Series 2 H1

cards

Field Barrier

PEPPERL+FUCHS

F2D0-FB-E

x4

TERMINATOR

ON

T - OFF

OFF

GND

Fieldbus

H1

Fieldbus

H1

T - OFF

GND

Carrier

Field Barrier

PEPPERL+FUCHS

F2D0-FB-E

x4

TERMINATOR

ON

OFF

GND

shield bar

Port 1

Port 2

Primary

24 VDC

Secondary

24 VDC

SEC

PWR

Alarm

Field Barrier

PEPPERL+FUCHS

F2D0-FB-E

x4

TERMINATOR

ON

T - OFF

OFF

GND

jumper

PWR

ERR

HD2

FBPS-

1.500

larm

contacts

Host A

Host A

Host A

Host B

SEG1

S

S ---

+

ON

PWR

ERR

HD2

FBPS-

1.500

Host B

SEG2

S

S ---

+

+

+

OFF

OFF

ON

Alarm

Diagnostic Bus

PWR

PWR

ERR

HD2

FBPS-

1.500

PWR

ERR

ERR

HD2

HD2

FBPS-

FBPS-

1.500

1.500

Host A

Host B

Host B

SEG3

S

S

S ---

+

+

OFF

ON

ON

PWR

PWR

ERR

ERR

HD2

HD2

DMB

FBPS-

1.500

PRI

SEG4

PWR

S ---

+

+

OFF

PWR

PWR

ERR

ERR

HD2

HD2

FBPS-

FBPS-

1.500

1.500

T - ON

PEPPERL-FUCHS

Fieldbus Power Hub

Fieldbus Motherboard

OFF

+

Segment 1

SOFF

+

SOFF

S

+

Segment 2

Segment 3

+

Segment 4

FieldConnex

SOFF

T - ON

with drain wire

GND

0.5 km Cable

Shielded pair

Field Barrier

PEPPERL+FUCHS

F2D0-FB-E

x4

TERMINATOR

ON

OFF

GND

Figure 12 IS Application with 16 Devices Using the Fieldbus Power Hub and Field Barrier

56 Fieldbus Installations in a DeltaV Digital Automation System

Loading...

Loading...