Page 1

Page 2

Page 3

Page 4

Preface

Thank you for choosing DELTA’s high-performance VFD-B Series. The VFD-B Series is

manufactured with high-quality components and materials and incorporates the latest

microprocessor technology available.

This manual is to be used for the installation, parameter setting, troubleshooting, and daily

maintenance of the AC motor drive. To guarantee safe operation of the equipment, read the

following safety guidelines before connecting power to the AC motor drive. Keep this operating

manual at hand and distribute to all users for reference.

To ensure the safety of operators and equipment, only qualified personnel familiar with AC motor

drive are to do installation, start-up and maintenance. Always read this manual thoroughly before

using VFD-B series AC Motor Drive, especially the WARNING, DANGER and CAUTION notes.

Failure to comply may result in personal injury and equipment damage. If you have any questions,

please contact your dealer.

PLEASE READ PRIOR TO INSTALLATION FOR SAFETY.

DANGER!

1. AC input power must be disconnected before any wiring to the AC motor drive is made.

2. A charge may still remain in the DC-link capacitors with hazardous voltages, even if the power

has been turned off. To prevent personal injury, please ensure that power has been turned off

before opening the AC motor drive and wait ten minutes for the capacitors to discharge to safe

voltage levels.

3. Never reassemble internal components or wiring.

4. The AC motor drive may be destroyed beyond repair if incorrect cables are connected to the

input/output terminals. Never connect the AC motor drive output terminals U/T1, V/T2, and

W/T3 directly to the AC mains circuit power supply.

5. Ground the VFD-B using the ground terminal. The grounding method must comply with the laws

of the country where the AC motor drive is to be installed. Refer to the Basic Wiring Diagram.

6. VFD-B series is used only to control variable speed of 3-phase induction motors, NOT for 1-

phase motors or other purpose.

7. VFD-B series shall NOT be used for life support equipment or any life safety situation.

Page 5

WARNI NG!

1. DO NOT use Hi-pot test for internal components. The semi-conductor used in the AC motor

drive is easily damaged by high-pressure.

2. There are highly sensitive MOS components on the printed circuit boards. These components

are especially sensitive to static electricity. To prevent damage to these components, do not

touch these components or the circuit boards with metal objects or your bare hands.

3. Only qualified persons are allowed to install, wire and maintain AC motor drives.

CAUTION!

1. Some parameter settings will cause the motor to run immediately after applying power.

2. DO NOT install the AC motor drive in a place subjected to high temperature, direct sunlight,

high humidity, excessive vibration, corrosive gases or liquids, or airborne dust or metallic

particles.

3. Only use AC motor drives within specification. Failure to comply may result in fire, explosion or

electric shock.

4. To prevent personal injury, please keep children and unqualified people away from the

equipment.

5. When the motor cable between the AC motor drive and motor is too long, the layer insulation of

the motor may be damaged. Please use a frequency inverter duty motor or add an AC output

reactor to prevent damage to the motor. Refer to appendix B Reactor for details.

6. The rated voltage for the AC motor drive must be ≤ 240V (≤ 480V for 460V models, ≤ 600V for

575V models) and the mains supply current capacity must be ≤ 5000A RMS (≤10000A RMS for

the ≥ 40hp (30kW) models).

Page 6

Table of Contents

Preface ............................................................................................................. i

Table of Contents .......................................................................................... iii

Chapter 1 Introduction................................................................................ 1-1

1.1 Receiving and Inspection ...................................................................1-1

1.1.1 Nameplate Information................................................................ 1-1

1.1.2 Model Explanation ...................................................................... 1-1

1.1.3 Series Number Explanation ........................................................ 1-2

1.1.4 Drive Frames .............................................................................. 1-2

1.2 Appearances ...................................................................................... 1-2

1.3 Preparation for Installation and Wiring ............................................... 1-4

1.3.1 Remove Keypad ......................................................................... 1-4

1.3.2 Remove Front Cover................................................................... 1-6

1.4 Lifting.................................................................................................. 1-7

1.5 Storage............................................................................................... 1-8

Chapter 2 Installation and Wiring .............................................................. 2-1

2.1 Ambient Conditions ............................................................................2-1

2.2 Installation .......................................................................................... 2-1

2.3 Dimensions......................................................................................... 2-3

2.4 Wiring ............................................................................................... 2-12

2.4.1 Basic Wiring.............................................................................. 2-13

Page 7

2.4.2 External Wiring..........................................................................2-18

2.4.3 Main Terminals Connections..................................................... 2-19

2.4.4 Control Terminals ...................................................................... 2-21

2.4.5 Main Circuit Terminals............................................................... 2-26

Chapter 3 Start Up .......................................................................................3-1

3.1 Preparations before Start-up...............................................................3-1

3.2 Operation Method ...............................................................................3-2

3.3 Trial Run .............................................................................................3-2

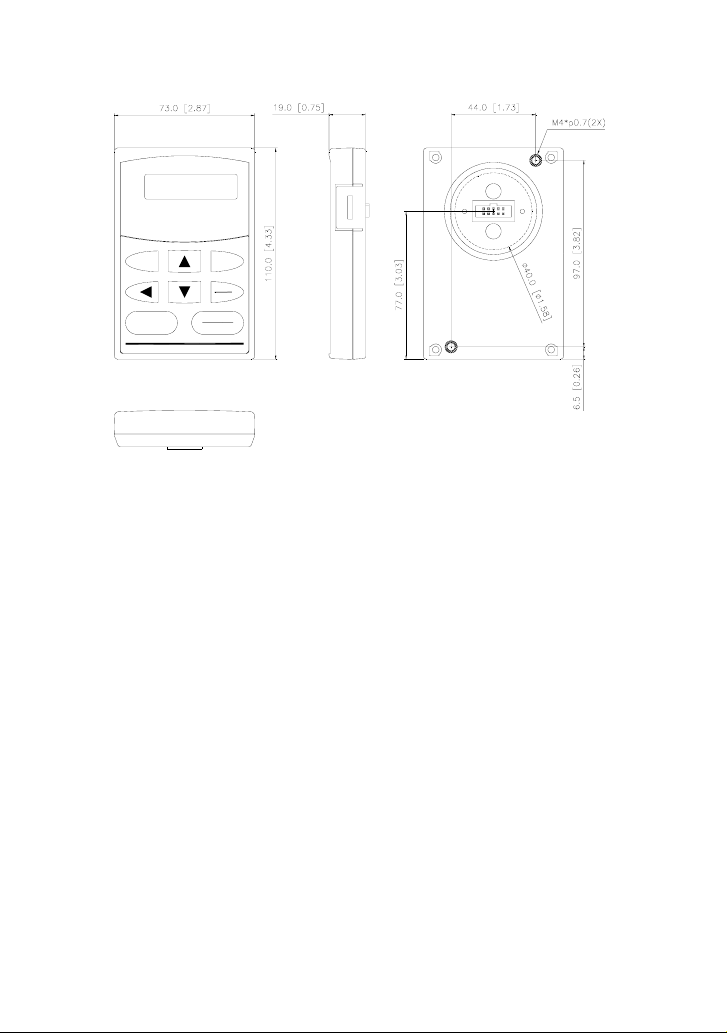

Chapter 4 Digital Keypad Operation ..........................................................4-1

4.1 Description of the Digital Keypad VFD-PU01......................................4-1

4.2 How to Operate the Digital Keypad VFD-PU01 ..................................4-3

Chapter 5 Parameters..................................................................................5-1

5.1 Summary of Parameter Settings......................................................... 5-2

5.2 Parameter Settings for Applications..................................................5-18

5.3 Description of Parameter Settings ....................................................5-23

Chapter 6 Fault Code Information ..............................................................6-1

6.1 Common Problems and Solutions ......................................................6-1

6.2 Reset ..................................................................................................6-4

Chapter 7 Troubleshooting.........................................................................7-1

7.1 Over Current (OC) ..............................................................................7-1

7.2 Ground Fault.......................................................................................7-2

7.3 Over Voltage (OV) ..............................................................................7-2

7.4 Low Voltage (Lv).................................................................................7-3

7.5 Over Heat (OH)...................................................................................7-4

7.6 Overload ............................................................................................. 7-4

Page 8

7.7 Display of PU01 is Abnormal.............................................................. 7-5

7.8 Phase Loss (PHL) ..............................................................................7-5

7.9 Motor cannot Run............................................................................... 7-6

7.10 Motor Speed cannot be Changed..................................................... 7-7

7.11 Motor Stalls during Acceleration....................................................... 7-8

7.12 The Motor does not Run as Expected .............................................. 7-8

7.13 Electromagnetic/Induction Noise ...................................................... 7-9

7.14 Environmental Condition ..................................................................7-9

7.15 Affecting Other Machines ............................................................... 7-10

Chapter 8 Maintenance and Inspections ................................................... 8-1

Appendix A Specifications ........................................................................ A-1

Appendix B Accessories ........................................................................... B-1

B.1 All Brake Resistors & Brake Units Used in AC Motor Drives..............B-1

B.1.1 Dimensions and Weights for Brake Resistors ............................ B-4

B.1.2 Specifications for Brake Unit ......................................................B-6

B.1.3 Dimensions for Brake Unit..........................................................B-7

B.2 AMD - EMI Filter Cross Reference.....................................................B-8

B.2.1 Dimensions............................................................................... B-12

B.3 PG Card (for Encoder) .....................................................................B-20

B.3.1 PG02 Installation ......................................................................B-20

B.3.1.1 PG Card and Pulse Generator (Encoder) ......................... B-21

B.3.1.2 PG-02 Terminal Descriptions............................................B-23

B.3.2 PG03 ........................................................................................B-25

B.3.2.1 Installation......................................................................... B-25

Page 9

B.3.2.2 PG Card and Pulse Generator (Encoder)..........................B-26

B.3.2.3 PG-03 Terminal Descriptions ............................................B-27

B.4 Remote Controller RC-01 ................................................................ B-30

B.5 Remote Panel Adapter (RPA 01) .................................................... B-31

B.6 AC Reactor...................................................................................... B-32

B.6.1 AC Input Reactor Recommended Value ...................................B-32

B.6.2 AC Output Reactor Recommended Value ................................B-33

B.6.3 Applications for AC Reactor......................................................B-35

B.7 Zero Phase Reactor (RF220X00A) ................................................. B-37

B.8 DC Choke Recommended Values................................................... B-36

B.9 No-fuse Circuit Breaker Chart ......................................................... B-38

B.10 Fuse Specification Chart ............................................................... B-39

B.11 PU06 ............................................................................................. B-40

B.11.1 Description of the Digital keypad VFD-PU06 ..........................B-40

B.11.2 Explanation of Display Message .............................................B-40

B.11.3 Operation Flow Chart..............................................................B-41

Appendix C How to Select the Right AC Motor Drive.............................. C-1

C.1 Capacity Formulas ............................................................................C-2

C.2 General Precaution ...........................................................................C-4

C.3 How to Choose a Suitable Motor....................................................... C-5

Page 10

Chapter 1 Introduction

A

1.1 Receiving and Inspection

This VFD-B AC motor drive has gone through rigorous quality control tests at the factory before

shipment. After receiving the AC motor drive, please check for the following:

Check to make sure that the package includes an AC motor drive, the User Manual/Quick

Start and CD, dust covers and rubber bushings.

Inspect the unit to assure it was not damaged during shipment.

Make sure that the part number indicated on the nameplate corresponds with the part

number of your order.

1.1.1 Nameplate Information

Example for 1HP/0.75kW 3-phase 230V AC motor drive

AC Drive Model

Input Spec.

Output Spec.

Output Frequency Range

Enclosure type

Serial Number & Bar Code

MODE : VFD007B23A

INPUT : 3PH 200-240V 50/60Hz 5.7A

OUTPUT : 3PH 0-240V 5.0A 1.9kVA 1HP

Freq. Range : 0.1~400Hz

ENCLOSURE: TYPE 1

007B23A0T5011230

1.1.2 Model Explanation

VFD

007

Revision July 2008, BE16, SW V4.08 & V5.00 1-1

23

B

Ver si on Typ e

Mains Input Voltage

21: Single phase230V

43: Three phase460V

B Se ri es

Applicable motor capacity

007: 1 HP(0.7kW) 150: 20HP(15kW)

022: 3 HP(2.2kW) 220: 30 HP(22kW)

037: 5 HP(3.7kW) 300: 40HP(30kW)

055: 7.5HP(5.5kW) 370: 50 HP(37kW)

075: 10 HP(7.5kW) 450: 60HP(45kW)

110: 15 HP(11kW) 550: 75HP(55kW)

Series Name ( ariable requency rive)

VF D

23: Three phase230V

53:575 Three phaseV

750: 100HP(75kW)

Page 11

Chapter 1 Introduction|VFD-B Series

1.1.3 Series Number Explanation

0170T007B23A

Product ion number

Product ion week

Production year 2007

Product ion factory

230V 3-phase 1HP(0.75kW)

(Taoyuan)

Model

If the nameplate information does not correspond to your purchase order or if there are

any problems, please contact your distributor.

1.1.4 Drive Frames

Frame Power range Models

A 1hp (0.75kW) VFD007B23A/43A/53A

A1 1-2hp (0.75-1.5kW) VFD007B21A, VFD015B21A/23A/43A/53A

A2 2-3hp (1.5-2.2kW) VFD015B21B/23B, VFD022B23B/43B/53A

B 3-5hp (2.2-3.7kW) VFD022B21A, VFD037B23A/43A/53A

VFD055B23A/43A/53A,

C 7.5-15hp (5.5-11kW)

D 20-30hp (15-22kW)

E 40-60hp (30-45kW)

E1 40-100hp (30-75kW)

Please refer to Chapter 2.3 for exact dimensions.

VFD075B23A/43A/53A,

VFD110B23A/43A/53A

VFD150B23A/43A/53A,

VFD185B23A/43A/53A,

VFD220B23A/43A/53A

VFD300B43A/53A, VFD370B43A/53A,

VFD450B43A/53A

VFD300B23A, VFD370B23A,

VFD550B43C/53A, VFD750B43C/53A

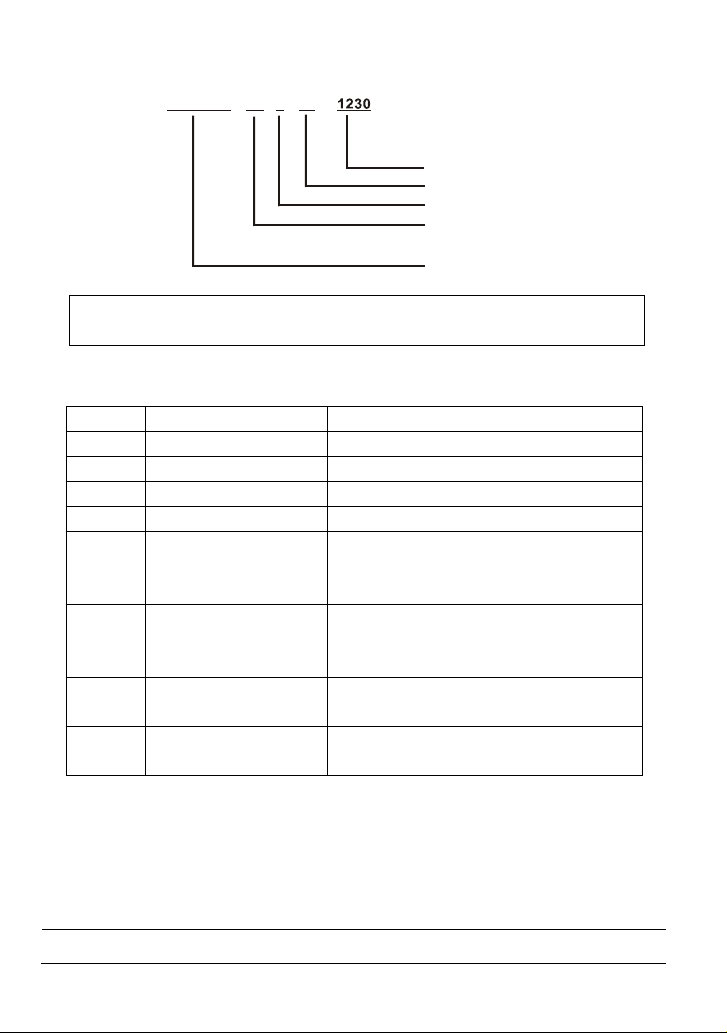

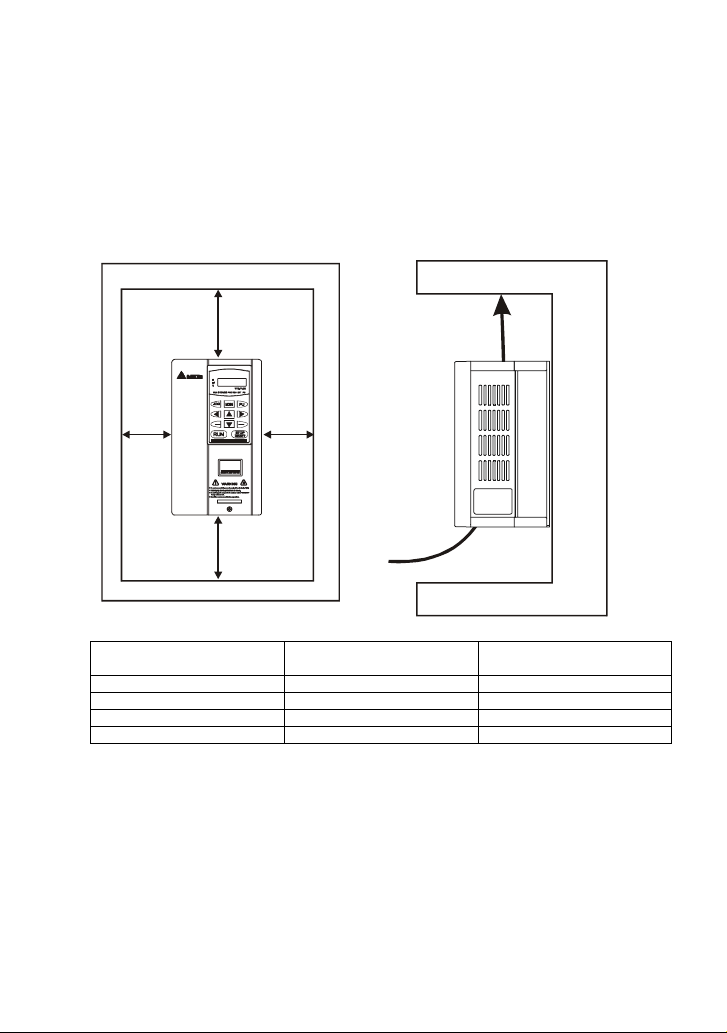

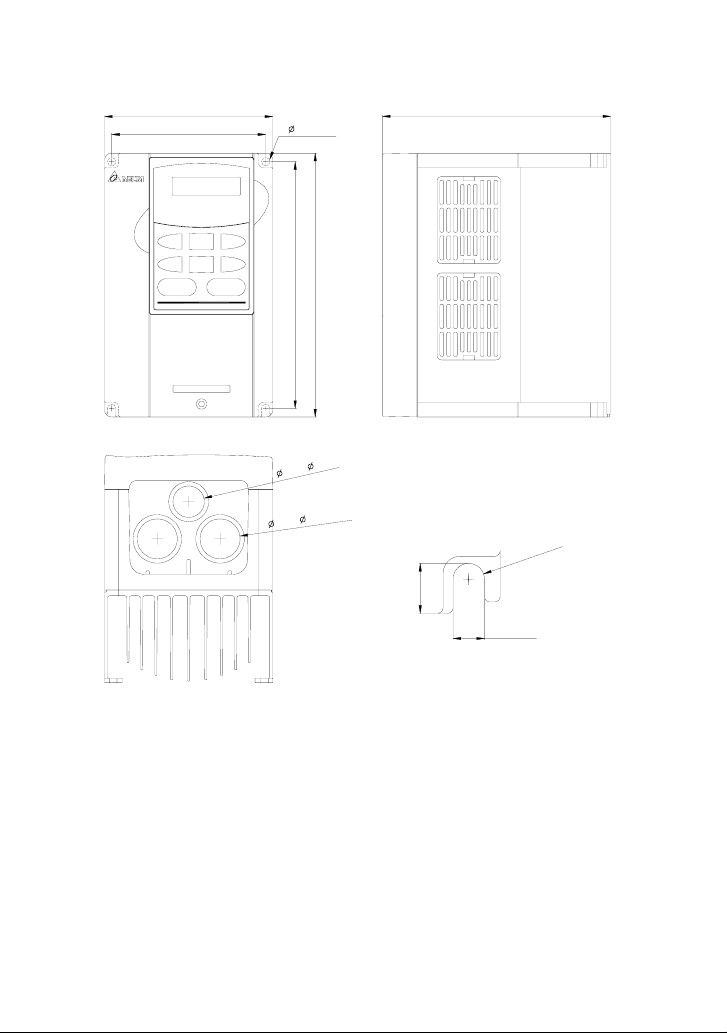

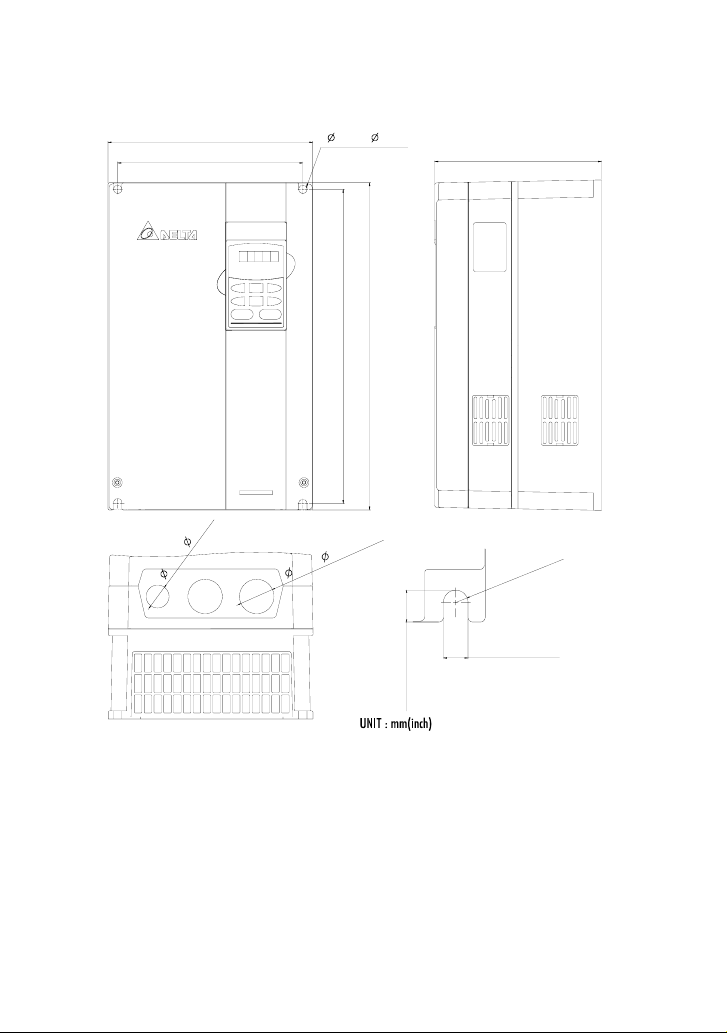

1.2 Appearances

(Refer to chapter 2.3 for exact dimensions)

1-3HP/0.75-2.2kW (Frame A, A1, A2) 3-5HP/2.2-3.7kW (Frame B)

1-2 Revision July 2008, BE16, SW V4.08 & V5.00

Page 12

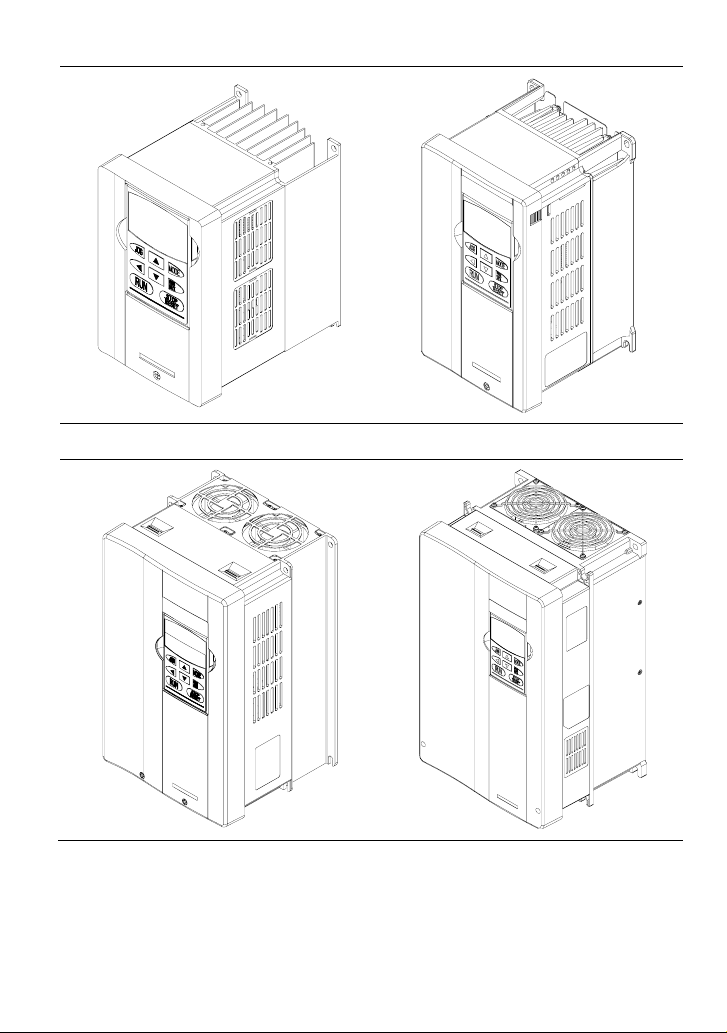

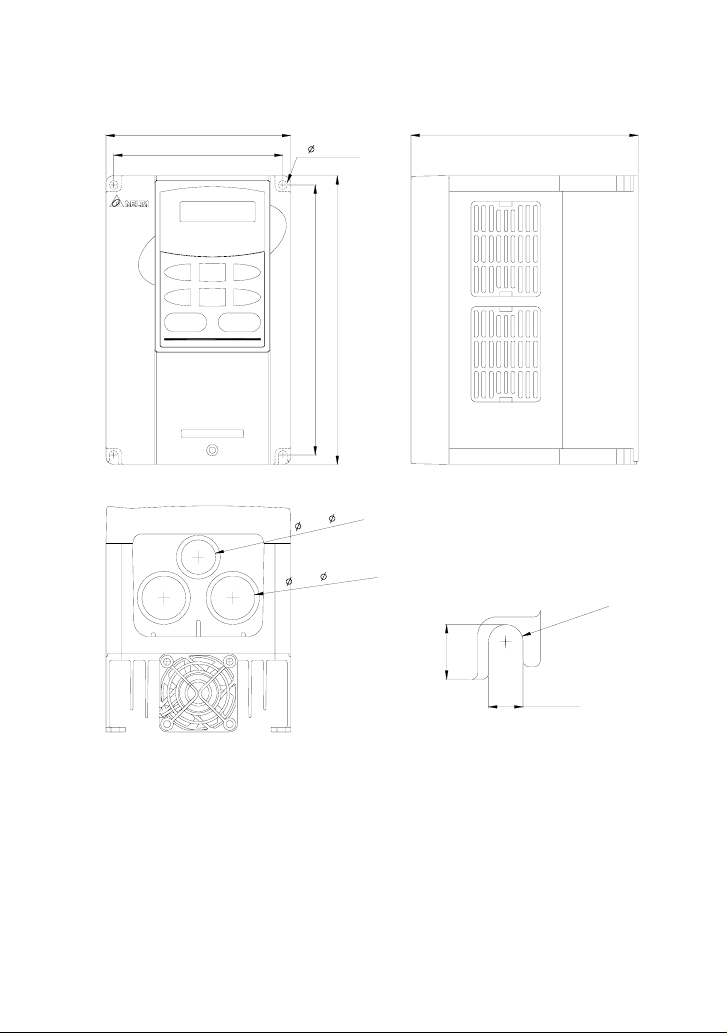

Chapter 1 Introduction|VFD-B Series

7.5-15HP/5.5-11kW (Frame C) 20-30HP/15-22kW (Frame D)

Revision July 2008, BE16, SW V4.08 & V5.00 1-3

Page 13

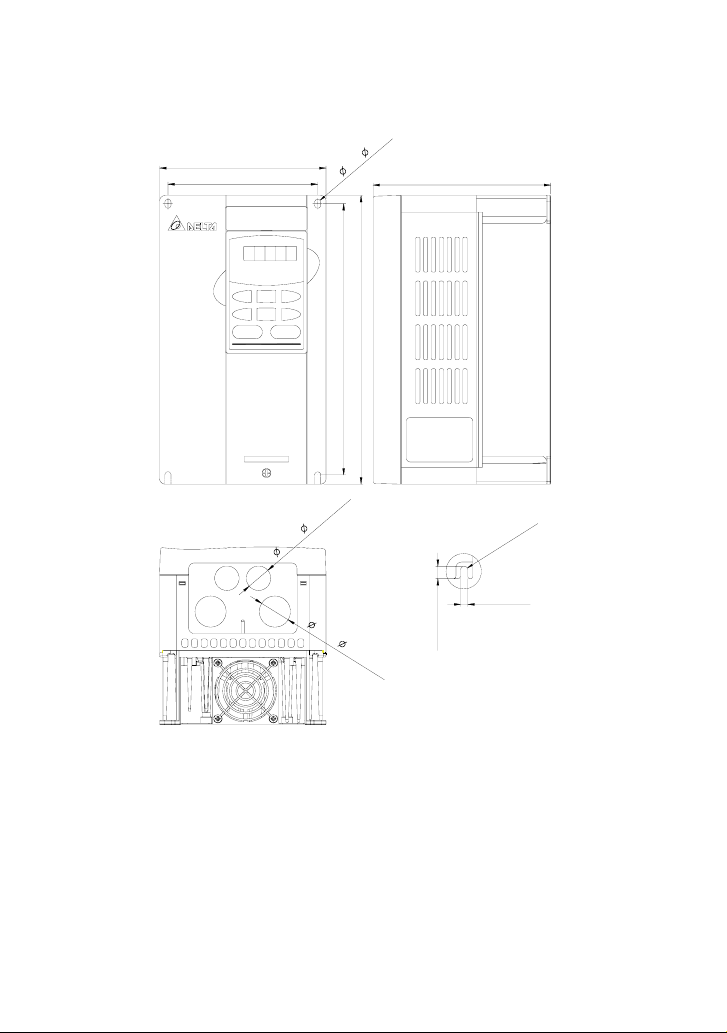

Chapter 1 Introduction|VFD-B Series

40-100HP/30-75kW (Frame E, E1) 75-100HP/55-75kW (Frame F)

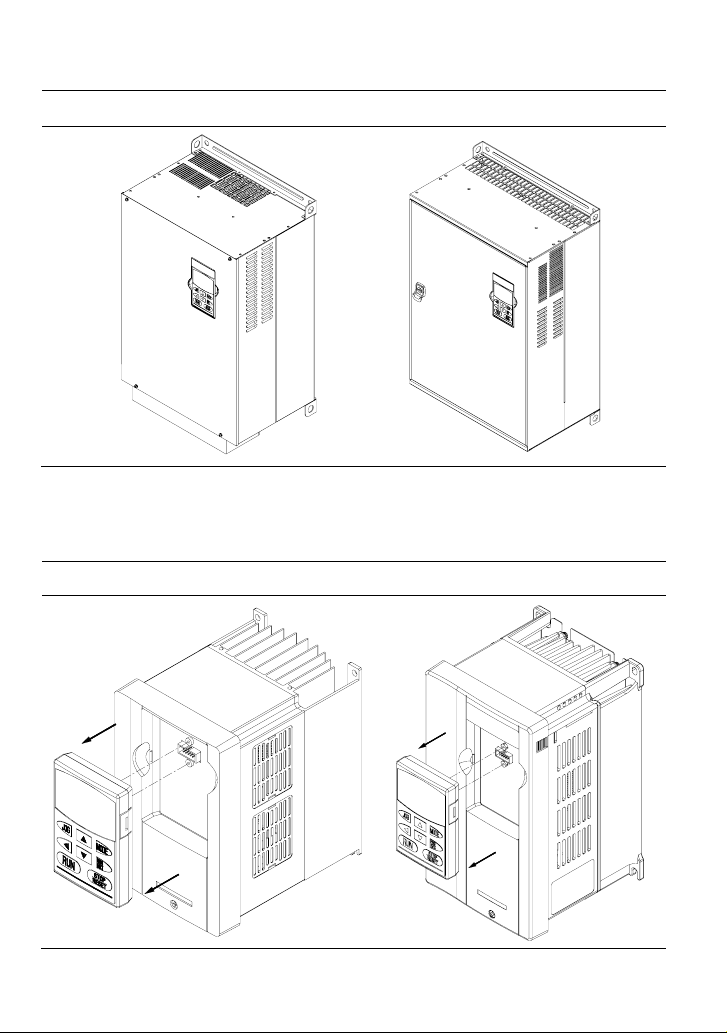

1.3 Preparation for Installation and Wiring

1.3.1 Remove Keypad

1-3HP/0.75-2.2kW (Frame A, A1, A2) 3-5HP/2.2-3.7kW (Frame B)

1-4 Revision July 2008, BE16, SW V4.08 & V5.00

Page 14

Chapter 1 Introduction|VFD-B Series

7.5-15HP/5.5-11kW (Frame C) 20-30HP/15-22kW (Frame D)

40-100HP/30-75kW (Frame E, E1) 75-100HP/55-75kW (Frame F)

Revision July 2008, BE16, SW V4.08 & V5.00 1-5

Page 15

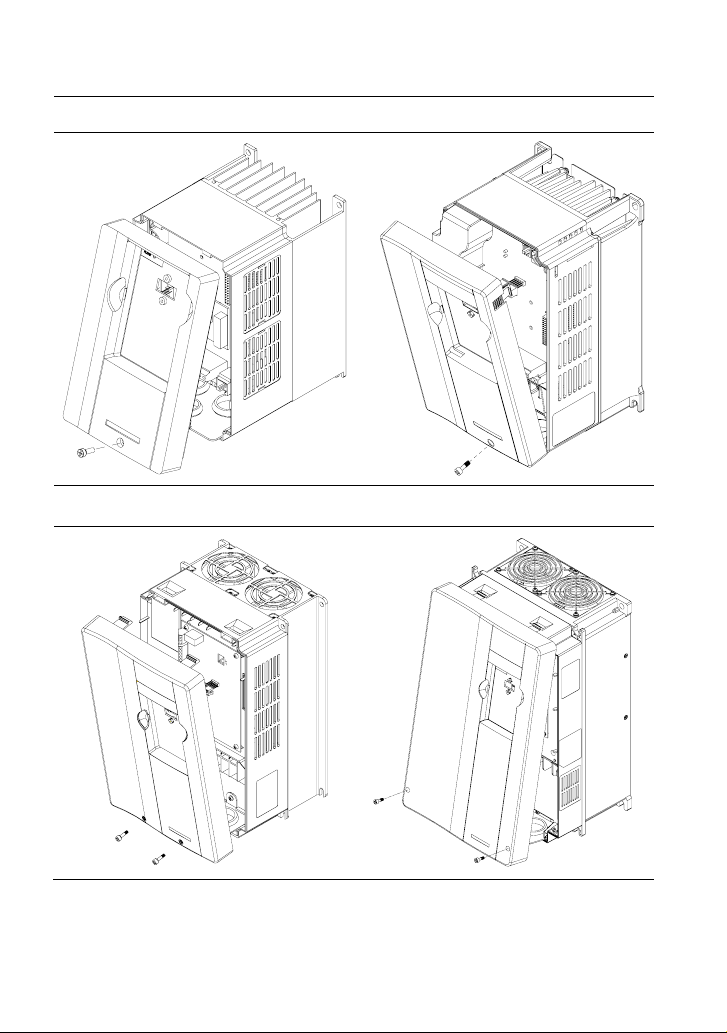

Chapter 1 Introduction|VFD-B Series

1.3.2 Remove Front Cover

1-3HP/0.75-2.2kW (Frame A, A1, A2) 3-5HP/2.2-3.7kW (Frame B)

7.5-15HP/5.5-11kW (Frame C) 20-30HP/15-22kW (Frame D)

1-6 Revision July 2008, BE16, SW V4.08 & V5.00

Page 16

Chapter 1 Introduction|VFD-B Series

40-100HP/30-75kW (Frame E, E1) 75-100HP/55-75kW (Frame F)

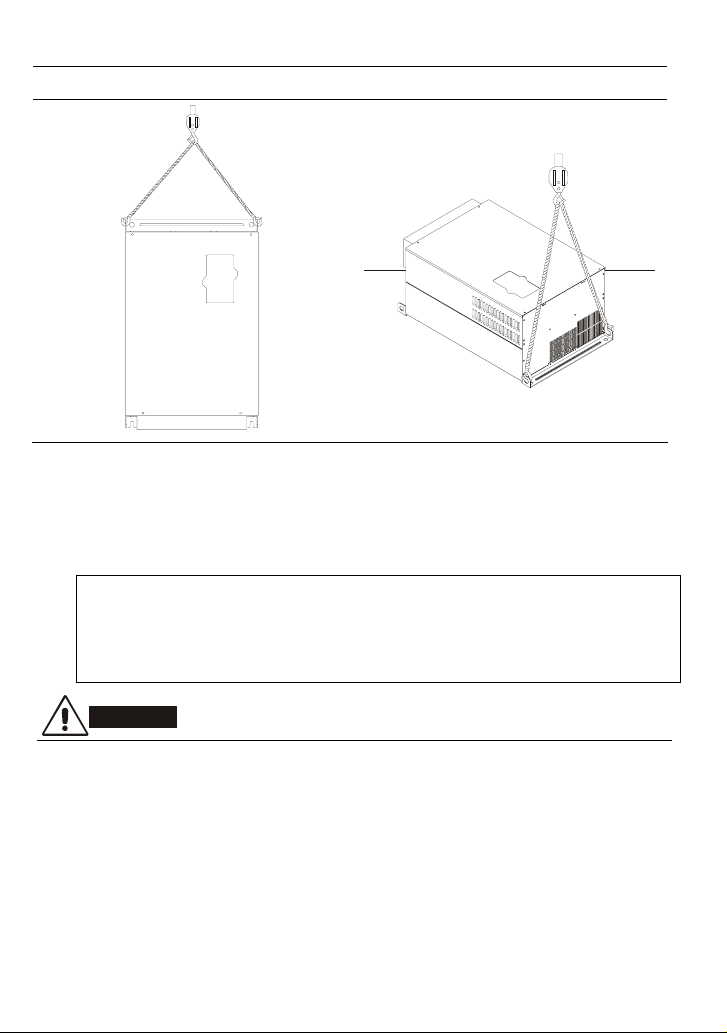

1.4 Lifting

Please carry only fully assembled AC motor drives as shown in the following.

For 40-100HP (Frame E, E1 and F)

Step 1 Step 2

Revision July 2008, BE16, SW V4.08 & V5.00 1-7

Page 17

Chapter 1 Introduction|VFD-B Series

Step 3 Step 4

1.5 Storage

The AC motor drive should be kept in the shipping carton or crate before installation. In order to

retain the warranty coverage, the AC motor drive should be stored properly when it is not to be

used for an extended period of time. Storage conditions are:

Store in a clean and dry location free from direct sunlight or corrosive fumes.

Store within an ambient temperature range of -20 °C to +60 °C.

Store within a relative humidity range of 0% to 90% and non-condensing environment.

Store within an air pressure range of 86 kPA to 106kPA.

CAUTION!

1. DO NOT store in an area with rapid changes in temperature. It may cause condensation and

frost.

2. DO NOT place on the ground directly. It should be stored properly. Moreover, if the surrounding

environment is humid, you should put exsiccator in the package.

3. If the AC motor drive is stored for more than 3 months, the temperature should not be higher

than 30 °C. Storage longer than one year is not recommended, it could result in the degradation

of the electrolytic capacitors.

4. When the AC motor drive is not used for a long time after installation on building sites or places

with humidity and dust, it’s best to move the AC motor drive to an environment as stated above.

1-8 Revision July 2008, BE16, SW V4.08 & V5.00

Page 18

Chapter 2 Installation and Wiring

2.1 Ambient Conditions

Install the AC motor drive in an environment with the following conditions:

Operation Air Temperature: -10 ~ +40°C (14 ~ 104°F)

Storage

Transportation

Pollution Degree 2: good for a factory type environment.

Relative Humidity: <90%, no condensation allowed

Atmosphere pressure: 86 ~ 106 kPa

Installation Site Altitude: <1000m

Vibration: <20Hz: 9.80 m/s

20 ~ 50Hz: 5.88 m/s

Temperature: -20°C ~ +60°C (-4°F ~ 140°F)

Relative Humidity: <90%, no condensation allowed

Atmosphere pressure: 86 ~ 106 kPa

Vibration: <20Hz: 9.80 m/s

20 ~ 50Hz: 5.88 m/s

2

(1G) max

2

2

(1G) max

2

(0.6G) max

(0.6G) max

CAUTION!

1. Operating, storing or transporting the AC motor drive outside these conditions may cause

damage to the AC motor drive.

2. Failure to observe these precautions may void the warranty!

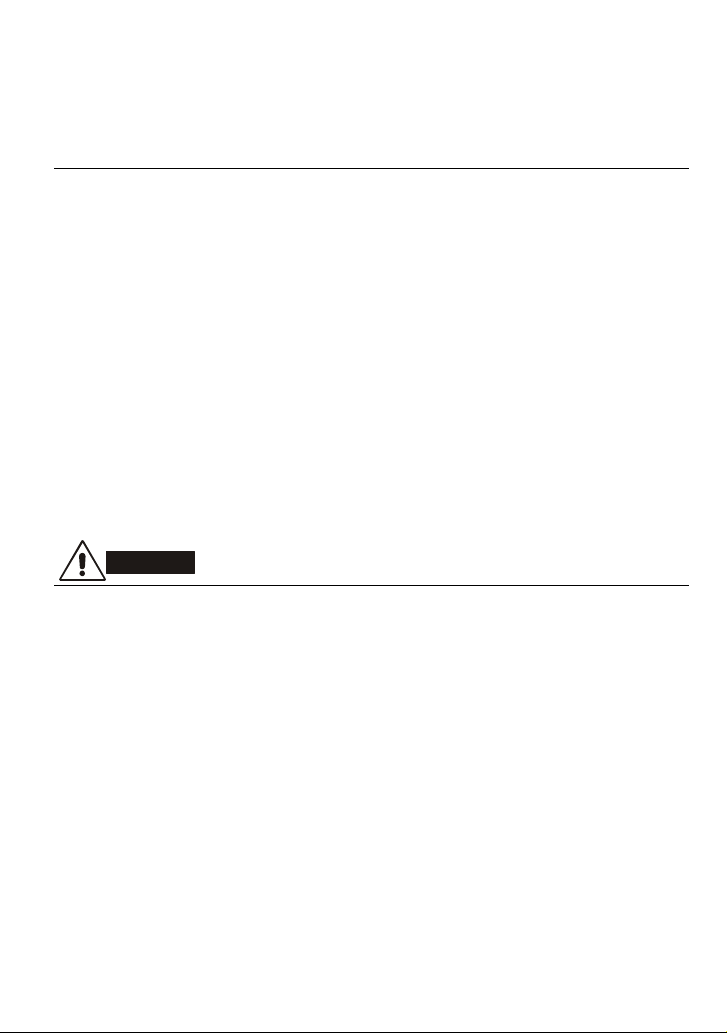

2.2 Installation

1. Mount the AC motor drive vertically on a flat vertical surface by using bolts or screws. Other

directions are not allowed.

2. The AC motor drive will generate heat during operation. Allow sufficient space around the unit

for heat dissipation.

3. The heat sink temperature may rise to 90°C when running. The material on which the AC motor

drive is mounted must be noncombustible and be able to withstand this high temperature.

4. When the AC motor drive is installed in a confined space (e.g. cabinet), the surrounding

temperature must be within 10 ~ 40°C with good ventilation. DO NOT install the AC motor drive

in a space with bad ventilation.

Revision July 2008, BE16, SW V4.08 & V5.00 2-1

Page 19

Chapter 2 Installation and Wiring|VFD-B Series

5. When installing multiple AC motor drives in the same cabinet, they should be adjacent in a row

with enough space in-between. When installing one AC motor drive below another one, use a

metal separation barrier between the AC motor drives to prevent mutual heating.

6. Prevent fiber particles, scraps of paper, saw dust, metal particles, etc. from adhering to the

heatsink.

Minimum Mounting Clearances

W

H

FWD

PROG

REV

DATA

W

Air Flow

H

HP

W

mm (inch)

1-5HP 50 (2) 150 (6)

7.5-20HP 75 (3) 175 (7)

25-75HP 75 (3) 200 (8)

100HP and above 75 (3) 250 (10)

H

mm (inch)

2-2 Revision July 2008, BE16, SW V4.08 & V5.00

Page 20

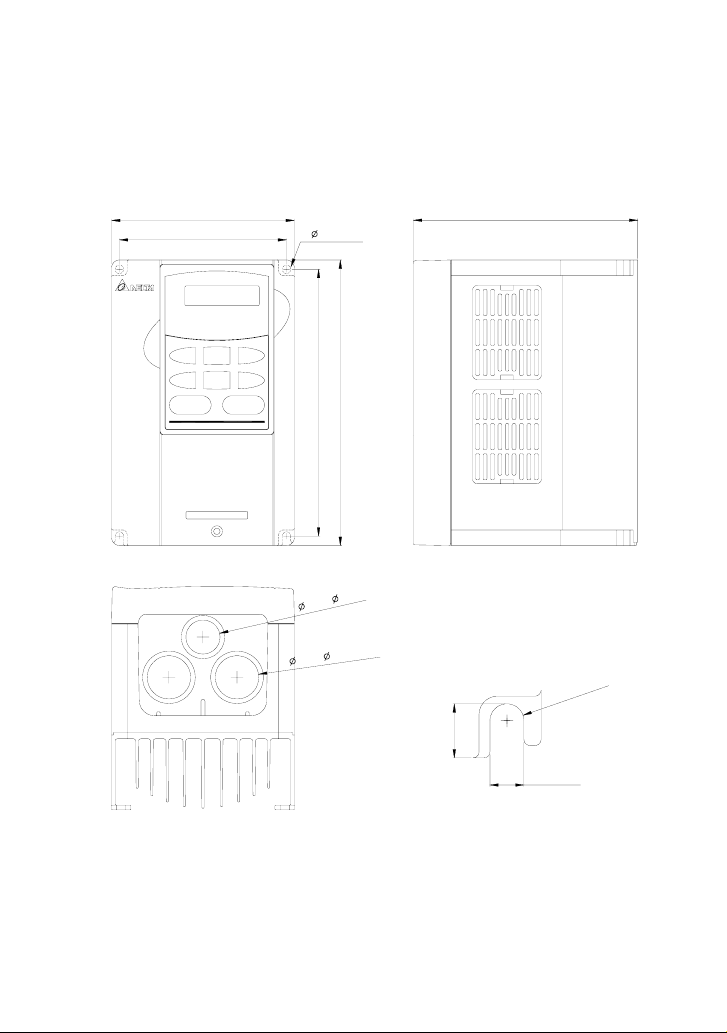

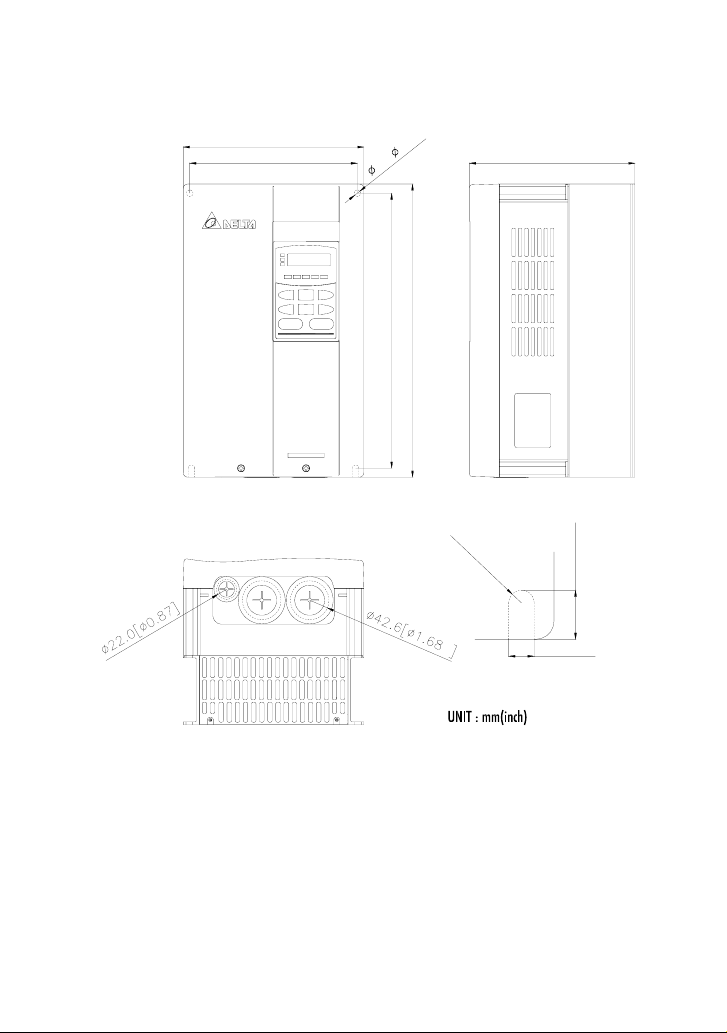

2.3 Dimensions

(Dimensions are in millimeter and [inch])

Frame A: VFD007B23A/43A/53A

118.0 [4.65]

108.0 [4.25]

5.5[0.22]

173.0 [6.81]

0[

22.

Chapter 2 Installation and Wiring|VFD-B Series

145.0 [5.71]

185.0 [7.28]

7]

8

.

0

2

8.7 [0.34]

5.5[0.22]

]

1

5[0.1

2.7

R

)

X

2

](

0

1

.

1

[

0

.

8

Revision July 2008, BE16, SW V4.08 & V5.00 2-3

Page 21

Chapter 2 Installation and Wiring|VFD-B Series

Frame A1: VFD007B21A, VFD015B21A/23A/43A/53A

118.0 [4.65]

108.0 [4.25]

8.

2

5.5[0.22]

173.0 [6.81]

0

.

2

2

0[

[ 0

185.0 [7.28]

]

7

8

.

)

X

2

(

]

0

1

.

1

160.0 [6.30]

]

1

1

.

[0

5

7

.

2

R

8.7 [0.34]

5.5[0.22]

2-4 Revision July 2008, BE16, SW V4.08 & V5.00

Page 22

Frame A2: VFD015B21B/23B, VFD022B23B/43B/53A

118.0 [4.65]

108.0 [4.25]

8

2

5.5[0.22]

173.0 [6.81]

0

.

2

2

[

0

.

185.0 [7.28]

7]

8

.

0

[

)

X

2

](

0

.1

1

Chapter 2 Installation and Wiring|VFD-B Series

145.0 [5.71]

[0.11]

2.75

R

8.7 [0.34]

5.5[0.22]

Revision July 2008, BE16, SW V4.08 & V5.00 2-5

Page 23

Chapter 2 Installation and Wiring|VFD-B Series

Frame B: VFD022B21A, VFD037B23A/43A/53A

150.0 [5.91]

135.0 [5.32]

0

[

0

.

2

2

2

8

.

8

2

(

]

7

.

0

[

[

5

.

6

244.3 [9.63]

260.0[10.24]

)

X

1

.

1

0

]

(2

UNIT : mm(inch)

]

6

2

.

0

160.2 [6.31]

]

3

.1

0

[R

5

2

.

3

R

6.5[0.26]

11.3 [0.44]

X

)

2-6 Revision July 2008, BE16, SW V4.08 & V5.00

Page 24

Chapter 2 Installation and Wiring|VFD-B Series

Frame C: VFD055B23A/43A/53A, VFD075B23A/43A/53A, VFD110B23A/43A/53A

]

200.0 [7.88]

185.6 [7.31]

8

.2

0

[

.0

7

323.0 [12.72]

303.0 [11.93]

R3

183.2 [7.22]

.

5

[

R

0

.

1

4

]

13.5 [0.53]

7.0 [0.28]

Revision July 2008, BE16, SW V4.08 & V5.00 2-7

Page 25

Chapter 2 Installation and Wiring|VFD-B Series

Frame D: VFD150B23A/43A/53A, VFD185B23A/43A/53A, VFD220B23A/43A/53A

250.0 [9.84]

226.0 [8.90]

]

0

1

.

1

[

0

.

8

2

.

2

4

10.0 [ 0.39]

384.0 [15.12]

6

.

1

[

0

205.4 [8.08]

403.8 [15.90]

)

X

2

(

]

5

[

0

.

R5

]

0

2

.

0

R

10.0 [0.39]

13.0 [0.51]

2-8 Revision July 2008, BE16, SW V4.08 & V5.00

Page 26

Chapter 2 Installation and Wiring|VFD-B Series

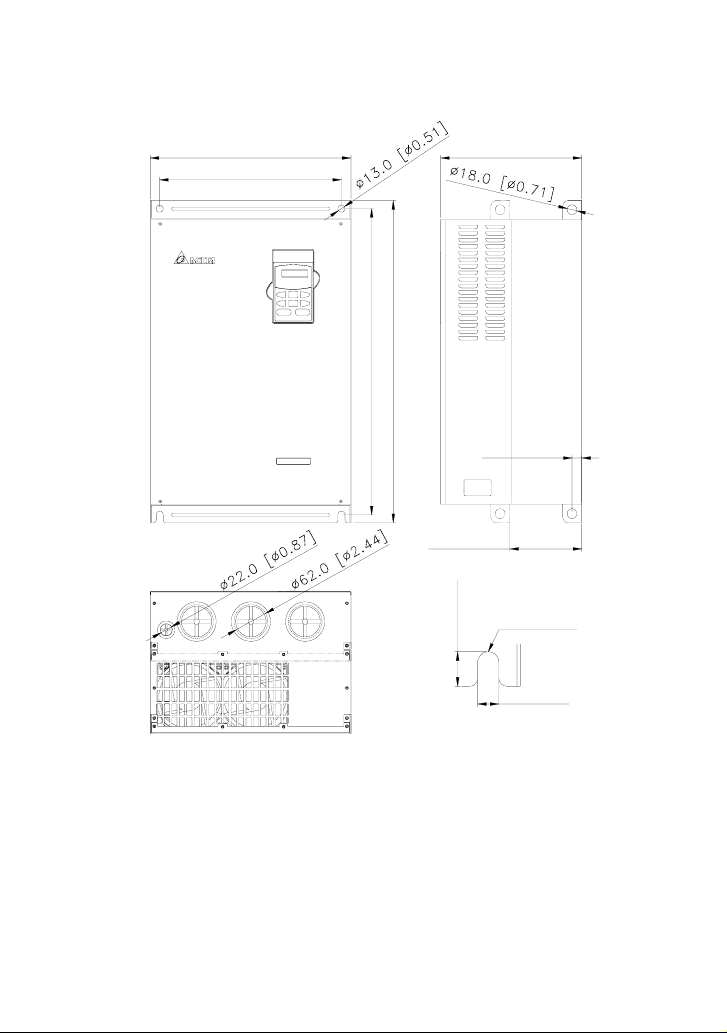

Frame E: VFD300B43A/53A, VFD370B43A/53A, VFD450B43A/53A

370.0 [14.57] 260.0 [10.24]

335.0 [13.19]

589.0 [23.19]

560.0 [22.05]

18.0 [0.71]

132.5 [5.22]

21.0[0.83]

R6.5[0.25]

13.0[0.51]

Revision July 2008, BE16, SW V4.08 & V5.00 2-9

Page 27

Chapter 2 Installation and Wiring|VFD-B Series

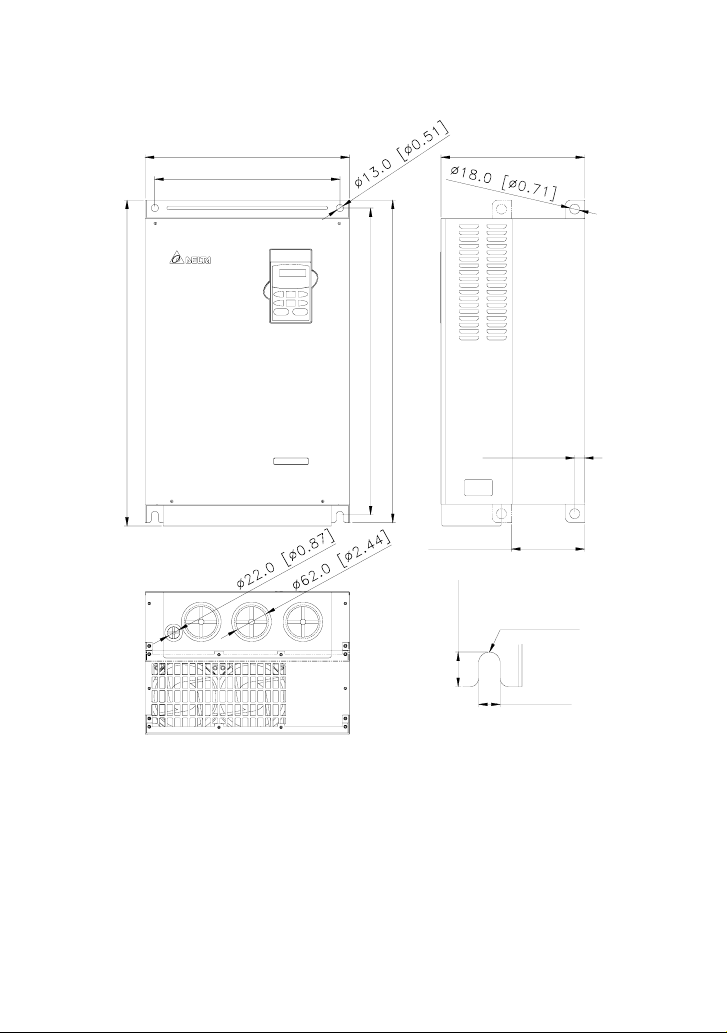

Frame E1: VFD300B23A, VFD370B23A, VFD550B43C/53A, VFD750B43C/53A

370.0 [14.57] 260.0 [10.24]

335.0 [13.19]

589.0 [23.19]

595.0 [23.43]

560.0 [22.05]

18.0 [0.71]

132.5 [5.22]

21.0[0.83]

R6.5[0.25]

13.0[0.51]

2-10 Revision July 2008, BE16, SW V4.08 & V5.00

Page 28

Chapter 2 Installation and Wiring|VFD-B Series

Revision July 2008, BE16, SW V4.08 & V5.00 2-11

Page 29

Chapter 2 Installation and Wiring|VFD-B Series

VFD-PU01

F

H

U

RUN

VFD- PU01

STOP

REVFWDJOG

STOP

RESET

MODE

PROG

DATA

JOG

RUN

2.4 Wiring

After removing the front cover, check if the power and control terminals are clear of debris. Be sure

to observe the following precautions when wiring.

General Wiring Information

Applicable Codes

All VFD-B series are Underwriters Laboratories, Inc. (UL) and Canadian Underwriters Laboratories

(cUL) listed, and therefore comply with the requirements of the National Electrical Code (NEC) and

the Canadian Electrical Code (CEC).

Installation intended to meet the UL and cUL requirements must follow the instructions provided in

“Wiring Notes” as a minimum standard. Follow all local codes that exceed UL and cUL

requirements. Refer to the technical data label affixed to the AC motor drive and the motor

nameplate for electrical data.

The "Line Fuse Specification" in Appendix B, lists the recommended fuse part number for each

VFD-B Series part number. These fuses (or equivalent) must be used on all installations where

compliance with U.L. standards is a required.

2-12 Revision July 2008, BE16, SW V4.08 & V5.00

Page 30

Chapter 2 Installation and Wiring|VFD-B Series

2.4.1 Basic Wiring

Make sure that power is only applied to the R/L1, S/L2, T/L3 terminals. Failure to comply

may result in damage to the equipment. The voltage and current should lie within the range

as indicated on the nameplate.

Check the following items after completing the wiring:

1. Are all connections correct?

2. No loose wires?

3. No short-circuits between terminals or to ground?

A charge may still remain in the DC bus capacitors with hazardous voltages even if the power has

been turned off. To prevent personal injury, please ensure that the power is turned off and wait ten

minutes for the capacitors to discharge to safe voltage levels before opening the AC motor drive.

DANGER!

1. All the units must be grounded directly to a common ground terminal to prevent electric shock,

fire and interference.

2. Only qualified personnel familiar with AC motor drives are allowed to perform installation, wiring

and commissioning.

3. Make sure that the power is off before doing any wiring to prevent electric shocks.

Basic Wiring Diagrams

Users must connect wires according to the circuit diagrams on the following pages. Do not plug a

modem or telephone line to the RS-485 communication port or permanent damage may result. The

pins 1 & 2 are the power supply for the optional copy keypad PU06 only and should not be used for

RS-485 communication.

Revision July 2008, BE16, SW V4.08 & V5.00 2-13

Page 31

Chapter 2 Installation and Wiring|VFD-B Series

Figure 1 for models of VFD-B Series

VFD007B 21A/23A/43A/5 3A, VFD015B21A /21B/23A/23B/43A/53A , VFD022B23B/43B/53A

* Three phase input power may apply to single phase drives.

* For the single phase drives, the AC input line can

be connected to any two of the three input terminals R,S,T

Fuse/NFB(None Fus e Br eaker)

R(L1)

S(L2)

T(L3)

Recommended Circuit when

power supply is turned OFF

by a fault output .

The contact will be ON

when the fault occurs to

turn off the power and

protect the power system.

Factory setting:

SINK Mode

Sink

Sw1

Source

Please refer to Figure 4

for wi ring of SIN K

mod e and SOU RCE

mode.

Factory

settin g

* Don't apply the mains voltage directly

to above terminals.

FWD/STOP

REV/STOP

JOG

E.F.

Multi-step 1

Multi-step 2

Multi-s tep 3

Multi-s tep 4

RESET

Accel/Decel prohibit

Counter

Digital Signal Common

5K

OFF

3

1

SA

MC

ON

2

4~20mA

-10 ~+10V

Analog Signal Common

Main circuit (power) terminals

Jumpe r

RB

MC

+10V

Power supply

+10V 20mA

AVI

Master Frequency

0 to 10V 4 7K

DC choke

(optional)

Brake resistor

(optio nal)

+2/B1

+1

R(L1)

S(L2)

T(L3)

E

RC

+24V

FWD

REV

MO1

JOG

EF

MI1

MI2

MI3

MO2

MO3

MI4

MI5

MI6

TRG

DCM

E

ACI

AUI

ACM

E

Control circuit terminals

B2

U(T1)

V(T2)

W(T3)

RB

RC

MCM

AFM

ACM

DFM

DCM

E

RA

Refer to Control

Ter min al Ex plan ati on

factory setti ng :

indicates during operation

48V50mA

facto ry setting:

Freq. Setting Indication

48V50mA

facto ry setting:

Low-voltage I ndication

48V50mA

Multi-function

Photocoulper O utput

Analog Multi-function Output

Te rm in al

factory setting: Analog freq.

/ current meter

Analog Signal common

E

Digital Frequency Output

Te rm in al

facto ry setting: 1:1

Duty=50%

Digital Signal Common

RS-485

Serial interface

1: EV 2: G ND

5:Reserved

4: SG+

6: Reserved

Shielded l eads & Cable

Motor

IM

3~

3: S G-

0~10VDC/2mA

2-14 Revision July 2008, BE16, SW V4.08 & V5.00

Page 32

Figure 2 for models of VFD-B Series

VFD0 22B21A, VFD 037B23A/ 43A/53A, VFD055B23A /43A/53A , VFD075B2 3A/43A/5 3A,

VFD110B23A/ 43A/53A

* Three phase input power may apply to single phase drives.

* For the single phase driv es, the AC input line can

be connected to any two of the three input terminals R, S,T

DC chock

(optional)

Fuse/NFB(None Fuse Breaker)

R(L1)

S(L2)

T(L3)

Recommended Circuit when

power supply is turned OFF

by a fault output.

The contact will be ON

when the fault occurs to

turn off the power and

protect the power system.

Fact ory Setti ng:

SINK Mode

Sink

Sw1

Source

Please refer to Figure 4

for w iring of S INK

mode and SOURCE

mode.

Factory

setting

* Don't apply the mains voltage directly

to above terminals.

OFF

FWD/STOP

REV/STO P

JOG

E.F.

Multi-step 1

Multi-step 2

Multi-step 3

Multi-step 4

RESET

Accel/Decel prohibit

Counter

Digital Signal Common

3

2

5K

1

4~20mA

-10~+10V

Analog Signal Common

Jumper

R(L1)

S(L2)

T(L3)

E

SA

ON

MC

MC

RB

RC

+24V

FWD

REV

JOG

EF

MI1

MI2

MI3

MI4

MI5

MI6

TRG

DCM

E

+10V

Power supply

+10V 20mA

AVI

Master Frequency

0 to 10V 4 7K

ACI

AUI

ACM

E

Chapter 2 Installation and Wiring|VFD-B Series

Br ake r esis tor (op tio nal )

Refer to Appendix B for the use of

special b rake resisto r

BR

+1

+2/B1

-(minus sig n)

B2

U(T1)

V(T2)

W(T3)

E

RA

Please refer to Control

RB

Terminal Explanation.

RC

MO1

MO2

MO3

Factory setting:

indicates during operation

48V50mA

Factory setting:

Freq. Setting Indication

48V50mA

Factory setting:

Low-voltage Indication

48V50mA

Multi-function

MCM

Photocoulper Output

AFM

ACM

E

Digital Frequency Output

DFM

Terminal

Factory setting: 1:1

Duty=50%

Digital Signal Common

DCM

RS-485

6 1

Seri al interf ace

1: EV 2: GND

4: SG+

6: Reserved

Analog Multi-function Output

Terminal

Factory default: Analog freq.

/ current meter

Analog Signal common

5:Reserved

Motor

IM

3~

0~10VDC /2mA

3: SG-

Main circuit (power) terminals

Control circuit ter minals

Shielded leads & Cable

Revision July 2008, BE16, SW V4.08 & V5.00 2-15

Page 33

Chapter 2 Installation and Wiring|VFD-B Series

s

Figure 3 for models of VFD-B Serie

VFD150B 23A/4 3A/53A, VFD220B 23A/4 3A/53A, VFD300B2 3A/43 A/53A,

VFD370B 23A/4 3A/53A, VFD450 B43A/ 53A, VFD550 B43C/53A , VFD750B43 C/53A

* Three phase input power may apply to single phase drives.

* For the single phase drives, the AC input line can

be connected to any two of the three input terminals R,S,T

Fuse/NFB(None F use Breaker)

R(L1)

S(L2)

T(L3)

Recommended Circuit when

power supply is turned O FF

by a fault output.

The contact will be ON

when the fault occurs to

turn off the power and

protect the power system.

Factory set ting:

SINK Mode

Sink

Sw1

Source

Please refer to Figure 4

for wi ring of SINK

mode and SOURCE

mode.

Factory

setting

* Don't apply the mains voltage directly

to above terminals.

VFD185B2 3A/43A/53A,

SA

MC

ON

OFF

FWD/STOP

REV/STOP

JOG

E.F.

Multi-s tep 1

Multi-step 2

Multi-step 3

Multi-step 4

RESET

Accel/Decel proh ibit

Counter

Digital Si gnal Common

3

2

5K

1

MC

4~20mA

-10~+10V

Analog Signal Common

Main c ircuit (po wer) term inals

DC chock

(optional)

Jumpe r

R(L1)

S(L2)

T(L3 )

E

RB

RC

+24V

FWD

REV

JOG

EF

MI1

MI2

MI3

MI4

MI5

MI6

TRG

DCM

E

+10V

Power supply

+10V 20mA

AVI

Master Frequency

0 to 10V 4 7K

ACI

AUI

ACM

E

VFDB

+2

+1

+1

-(minus sig n)

MO1

MO2

MO3

Control c ircuit terminals

Brake resistor/unit(optional)

Refer to Appendix B for the use of

special brake resistor/unit

U(T1)

V(T2)

W(T3)

Motor

IM

3~

E

RA

Ple ase r efer to Con trol

RB

Terminal Expl anation

RC

Factory setting:

indicates during operation

48V50mA

Factory setting:

Freq. Setting Indication

48V50mA

Factory setting:

Low-voltage Indication

48V50mA

Multi-function

MCM

Photocoulper Output

AFM

ACM

DFM

DCM

6

Analog Multi-function Output

Te rm i na l

factory setting: Analog fr eq.

/ current meter

Analog Signal common

E

Digital F requency Output

Te rm i na l

Factory setting: 1:1

Duty=50%

Digital Si gnal Common

RS-485

1

Seri al interf ace

1: EV 2: GND

4: SG+

5:Reserved

6: Reserv ed

Shielded l eads & Cable

3: SG-

0~10VDC/2mA

2-16 Revision July 2008, BE16, SW V4.08 & V5.00

Page 34

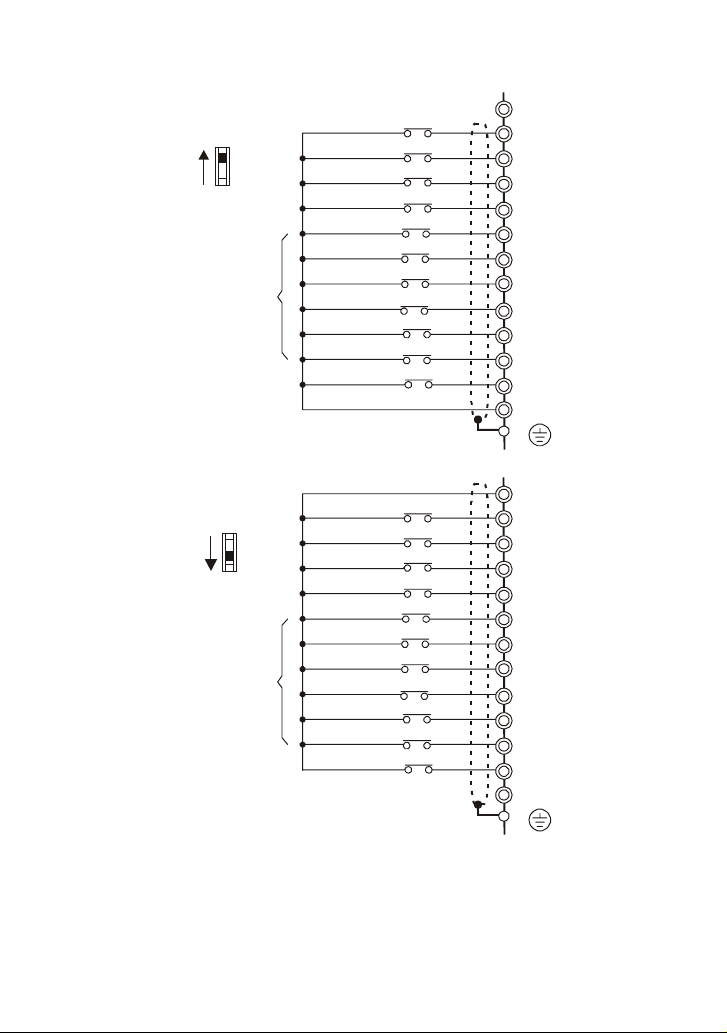

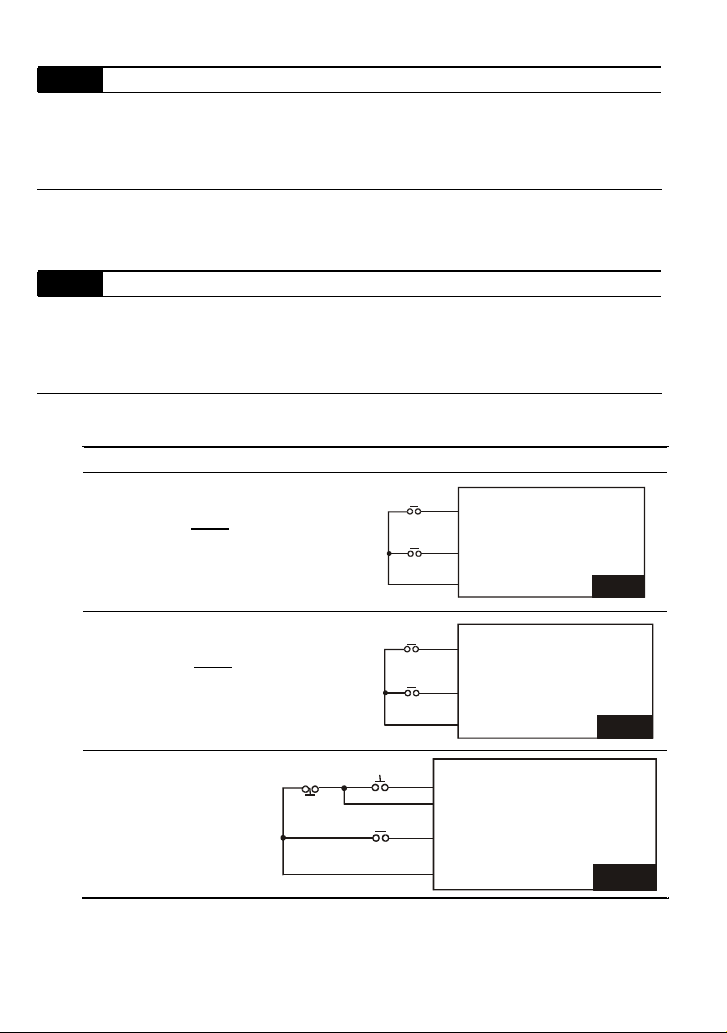

Figure 4 Wiring for SINK mode and SOURCE mode

SINK Mode

Sink

SW1

Source

Factory

setting

*Don't apply the mains voltage directly

to above terminals.

SOURCE Mode

Sink

Sw1

Source

Factory

setting

*Don't apply the mains voltage directly

to above terminals.

FWD/STOP

REV/STOP

JOG

E.F.

Multi-step1

Multi-step2

Multi-step3

Multi-step4

RESET

Accel./Decel. prohibit

Counter

Digital Signal Common

FWD/STOP

REV/STOP

JOG

E.F.

Multi-step1

Multi-step2

Multi-step3

Multi-step4

RESET

Accel./Decel. prohibit

Counter

Digital Signal Common

Chapter 2 Installation and Wiring|VFD-B Series

+24V

FWD

REV

JOG

EF

MI1

MI2

MI3

MI4

MI5

MI6

TRG

DCM

E

+24V

FWD

REV

JOG

EF

MI1

MI2

MI3

MI4

MI5

MI6

TRG

DCM

E

Revision July 2008, BE16, SW V4.08 & V5.00 2-17

Page 35

Chapter 2 Installation and Wiring|VFD-B Series

y

2.4.2 External Wiring

Power Suppl

EMI Filter

R/L1

U/T1 V/T2

S/L2

T/L 3

W/T3

FUSE /NFB

Magnetic

contact or

Input AC

Line Reactor

Zero- phase

Reactor

+1 DC

+2/B1

B2

-

E

Zero-phase

Reactor

Outp ut AC

Line Reactor

BR

Chock

BUE

Items Explanations

Power

supply

Please follow the specific power

supply requirements shown in

Appendix A.

There may be an inrush current

Fuse/NFB

(Optional)

during power up. Please check the

chart of Appendix B and select the

correct fuse with rated current. Use of

an NFB is optional.

Magnetic

contactor

(Optional)

Please do not use a Magnetic

contactor as the I/O switch of the AC

motor drive, as it will reduce the

operating life cycle of the AC drive.

Used to improve the input power

factor, to reduce harmonics and

provide protection from AC line

disturbances (surges, switching

Input AC

Line Reactor

(Optional)

spikes, short interruptions, etc.). AC

line reactor should be installed when

the power supply capacity is 500kVA

or more or advanced capacity is

activated .The wiring distance should

be

10m. Refer to appendix B for

≤

details.

Zero phase reactors are used to

Zero-phase

Reactor

(Ferrite Core

Common

BR

Choke)

(Optional)

reduce radio noise especially when

audio equipment is installed near the

inverter. Effective for noise reduction

on both the input and output sides.

Attenuation quality is good for a wide

range from AM band to 10MHz.

Appendix B specifies the zero phase

reactor. (RF220X00A)

EMI filter

(Optional)

Brake

Resistor

(Optional)

To reduce electromagnetic

interference, please refer to Appendix

B for more details.

Used to reduce the deceleration time

of the motor. Please refer to the chart

in Appendix B for specific Brake

Resistors.

Motor

Output AC

Line Reactor

(Optional)

Motor surge voltage amplitude

depends on motor cable length. For

applications with long motor cable

(>20m), it is necessary to install a

2-18 Revision July 2008, BE16, SW V4.08 & V5.00

Page 36

Chapter 2 Installation and Wiring|VFD-B Series

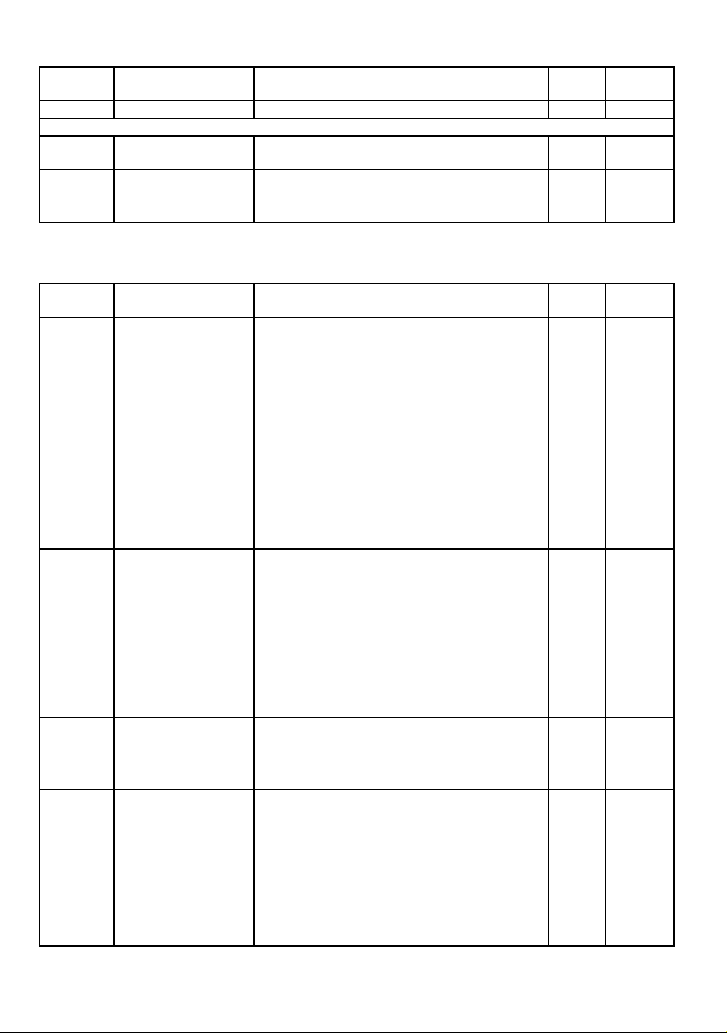

2.4.3 Main Terminals Connections

Terminal Symbol Explanation of Terminal Function

R, S, T R/L1, S/L2, T/L3 AC line input terminals (1-phase/3-phase)

U, V, W U/T1, V/T2, W/T3

P1, P2 +1, +2 Connections for DC Choke (optional)

P-B, P2/B1~B2 +2/B1~B2 Connections for Brake Resistor (optional)

P2~N, P2/B1~N +2~(-), +2/B1~(-) Connections for External Brake Unit (VFDB series)

Mains power terminals (R/L1, S/L2, T/L3)

Connect these terminals (R/L1, S/L2, T/L3) via a no-fuse breaker or earth leakage breaker to

3-phase AC power (some models to 1-phase AC power) for circuit protection. It is

unnecessary to consider phase-sequence.

It is recommended to add a magnetic contactor (MC) in the power input wiring to cut off

power quickly and reduce malfunction when activating the protection function of AC motor

drives. Both ends of the MC should have an R-C surge absorber.

Do NOT run/stop AC motor drives by turning the power ON/OFF. Run/stop AC motor drives

by RUN/STOP command via control terminals or keypad. If you still need to run/stop AC

drives by turning power ON/OFF, it is recommended to do so only ONCE per hour.

Do NOT connect 3-phase models to a 1-phase power source.

Control circuit terminals (U, V, W)

When the AC drive output terminals U/T1, V/T2, and W/T3 are connected to the motor

terminals U/T1, V/T2, and W/T3, respectively, the motor will rotate counterclockwise (as

viewed on the shaft end of the motor) when a forward operation command is received. To

permanently reverse the direction of motor rotation, switch over any of the two motor leads.

AC drive output terminals for connecting 3-phase

induction motor

Earth connection, please comply with local regulations.

Forward

running

Revision July 2008, BE16, SW V4.08 & V5.00 2-19

Page 37

Chapter 2 Installation and Wiring|VFD-B Series

DO NOT connect phase-compensation capacitors or surge absorbers at the output terminals

of AC motor drives.

With long motor cables, high capacitive switching current peaks can cause over-current, high

leakage current or lower current readout accuracy. To prevent this, the motor cable should

be less than 20m for 3.7kW models and below. And the cable should be less than 50m for

5.5kW models and above. For longer motor cables use an AC output reactor.

Use a well-insulated motor, suitable for inverter operation.

Terminals [+1, +2] for connecting DC reactor

To improve the power factor and reduce harmonics, connect a DC reactor between terminals

[+1, +2]. Please remove the jumper before connecting the DC reactor.

NOTE

Models of 15kW and above have a built-in DC reactor.

Terminals [+2/B1, B2] for connecting brake resistor and terminals [+1, +2/B1] for connecting

external brake unit

VFDB

Connect a brake resistor or brake unit in applications with frequent deceleration ramps, short

deceleration time, too low brake torque or requiring increased brake torque.

If the AC motor drive has a built-in brake chopper (all models of 11kW and below), connect

the external brake resistor to the terminals [+2/B1, B2].

Models of 15kW and above don’t have a built-in brake chopper. Please connect an external

optional brake unit (VFDB-series) and brake resistor. Refer to VFDB series user manual for

details.

Connect the terminals [+(P), -(N)] of the brake unit to the AC motor drive terminals

[+2(+2/B1), (-)]. The length of wiring should be less than 5m with twisted cable.

When not used, please leave the terminals [+2/B1, -] open.

BR

BR

B2

DC reactor

Jumper

+1

-(minus sign)

2-20 Revision July 2008, BE16, SW V4.08 & V5.00

Page 38

Chapter 2 Installation and Wiring|VFD-B Series

WARNI NG !

1. Short-circuiting [B2] or [-] to [+2/B1] can damage the AC motor drive.

Grounding terminals (

Make sure that the leads are connected correctly and the AC drive is properly grounded.

)

(Ground resistance should not exceed 0.1Ω.)

Use ground leads that comply with local regulations and keep them as short as possible.

Multiple VFD-B units can be installed in one location. All the units should be grounded

directly to a common ground terminal, as shown in the figure below. Ensure there are no

ground loops.

goodexcellent

not allowed

2.4.4 Control Terminals

Circuit diagram for digital inputs (SINK current 16mA.)

SINK Mode

multi-input

terminal

+24

SOURCE Mod e

Multi-Inp ut

Term ina l

DCM

DCM

Internal Circuit

+24V

Internal Circuit

Terminal symbols and functions

Terminal

Symbol

FWD Forward-Stop command

REV Reverse-Stop command

Revision July 2008, BE16, SW V4.08 & V5.00 2-21

Terminal Function

ON: Run in FWD direction

OFF: Stop acc. to Stop Method

ON: Run in REV direction

OFF: Stop acc. to Stop Method

Factory Settings (SINK)

ON: Connect to DCM

Page 39

Chapter 2 Installation and Wiring|VFD-B Series

Terminal

Symbol

Terminal Function

JOG Jog command

EF External fault

TRG External counter input

MI1 Multi-function Input 1

MI2 Multi-function Input 2

MI3 Multi-function Input 3

MI4 Multi-function Input 4

MI5 Multi-function Input 5

MI6 Multi-function Input 6

Digital Frequency Meter

(Open Collector Output)

DFM-DCM

DFM

internal circuit

Max: 48V

50mA

50%

100%

Factory Settings (SINK)

ON: Connect to DCM

ON: JOG operation

OFF: Stop acc. to Stop Method

ON: External Fault. Display “EF” and stop

acc. To Stop Method.

OFF: No fault

ON: At every pulse counter is advanced

by 1.

Refer to Pr.04-04 to Pr.04-09 for programming

the Multi-function Inputs.

Pulse voltage output monitor signal,

proportional to output frequency

Duty-cycle: 50%

Ratio: Pr.03-07

Min. load: 10KΩ

Max. current: 50mA

Max. voltage: 48VDC.

+24V DC Voltage Source

DCM Digital Signal Common

Multi-function Relay output

RA

(N.O.) a

+24VDC, 20mA

used for SOURCE mode.

Common for digital inputs and used for SINK

mode.

Resistive Load:

5A(N.O.)/3A(N.C.) 240VAC

5A(N.O.)/3A(N.C.) 24VDC

Multi-function Relay output

RB

(N.C.) b

RC Multi-function Relay common

Inductive Load:

1.5A(N.O.)/0.5A(N.C.) 240VAC

1.5A(N.O.)/0.5A(N.C.) 24VDC

Refer to Pr.03-00 for programming

2-22 Revision July 2008, BE16, SW V4.08 & V5.00

Page 40

Chapter 2 Installation and Wiring|VFD-B Series

Terminal

Symbol

MO1

MO2

MO3

Terminal Function

Multi-function Output 1

(Photocoupler)

Multi-function Output 2

(Photocoupler)

Multi-function Output 3

(Photocoupler)

Maximum 48VDC, 50mA

Refer to Pr.03-01 to Pr.03-03 for programming

Factory Settings (SINK)

ON: Connect to DCM

MO1~MO3-DCM

MO1~MO3

MCM

Internal Circuit

MCM Multi-function output common Common for Multi-function Outputs

+10V Potentiometer power supply +10VDC 20mA

Max: 48Vdc

50m A

Analog voltage Input

AVI

+10V

AVI

AVI cir cuit

Impedance: 47kΩ

Resolution: 10 bits

Range: 0 ~ 10VDC =

0 ~ Max. Output

Frequency (Pr.01-00)

Selection: Pr.02-00, Pr.02-13,

Pr.10-00

Frequency (Pr.01-00)

Analog current Input

ACI

ACM

ACI

internal circuit

ACI circuit

Set-up: Pr.04-00 ~ Pr.04-03

Impedance: 250Ω

Resolution: 10 bits

Range: 4 ~ 20mA =

0 ~ Max. Output

Selection: Pr.02-00, Pr.02-13,

ACM

internal circuit

Auxiliary analog voltage input

+10

AUI circuit

~

-10V

AUI

Revision July 2008, BE16, SW V4.08 & V5.00 2-23

AUI

ACM

internal circuit

Set-up: Pr.04-11 ~ Pr.04-14

Impedance: 47kΩ

Resolution: 10 bits

Range: -10 ~ +10VDC =

0 ~ Max. Output

Selection: Pr.02-00, Pr.02-13,

Set-up: Pr.04-15 ~ Pr.04-18

Pr.10-00

Frequency (Pr.01-00)

Pr.10-00

Page 41

Chapter 2 Installation and Wiring|VFD-B Series

Terminal

Symbol

AFM

ACM

Terminal Function

Analog output meter

ACM circuit

internal circuit

AFM

ACM

Analog control signal

(common)

0~10V

potentiometer

Max. 2mA

0 to 10V, 2mA

Impedance: 470Ω

Output current 2m A ma x

Resolution: 8 bits

Range: 0 ~ 10VDC

Function: Pr.03-05

Common for AVI, ACI, AUI, AFM

Factory Settings (SINK)

ON: Connect to DCM

Control signal wiring size: 18 AWG (0.75 mm2) with shielded wire.

Analog input terminals (AVI, ACI, AUI, ACM)

Analog input signals are easily affected by external noise. Use shielded wiring and keep it as

short as possible (<20m) with proper grounding. If the noise is inductive, connecting the

shield to terminal ACM can bring improvement.

If the analog input signals are affected by noise from the AC motor drive, please connect a

capacitor and ferrite core as indicated in the following diagrams:

C

ferrite core

AVI/ACI/AUI

ACM

wind each wires 3 times or more around the core

Digital inputs (FWD, REV, JOG, EF, TRG, MI1~MI6, DCM)

When using contacts or switches to control the digital inputs, please use high quality

components to avoid contact bounce.

Digital outputs (MO1, MO2, MO3, MCM)

Make sure to connect the digital outputs to the right polarity, see wiring diagrams.

When connecting a relay to the digital outputs, connect a surge absorber or fly-back diode

across the coil and check the polarity.

2-24 Revision July 2008, BE16, SW V4.08 & V5.00

Page 42

Chapter 2 Installation and Wiring|VFD-B Series

General

Keep control wiring as far away as possible from the power wiring and in separate conduits

to avoid interference. If necessary let them cross only at 90º angle.

The AC motor drive control wiring should be properly installed and not touch any live power

wiring or terminals.

NOTE

If a filter is required for reducing EMI (Electro Magnetic Interference), install it as close as

possible to AC drive. EMI can also be reduced by lowering the Carrier Frequency.

When using a GFCI (Ground Fault Circuit Interrupter), select a current sensor with sensitivity

of 200mA, and not less than 0.1-second detection time to avoid nuisance tripping. For the

specific GFCI of the AC motor drive, please select a current sensor with sensitivity of 30mA

or above.

DANGER!

Damaged insulation of wiring may cause personal injury or damage to circuits/equipment if it

comes in contact with high voltage.

Revision July 2008, BE16, SW V4.08 & V5.00 2-25

Page 43

Chapter 2 Installation and Wiring|VFD-B Series

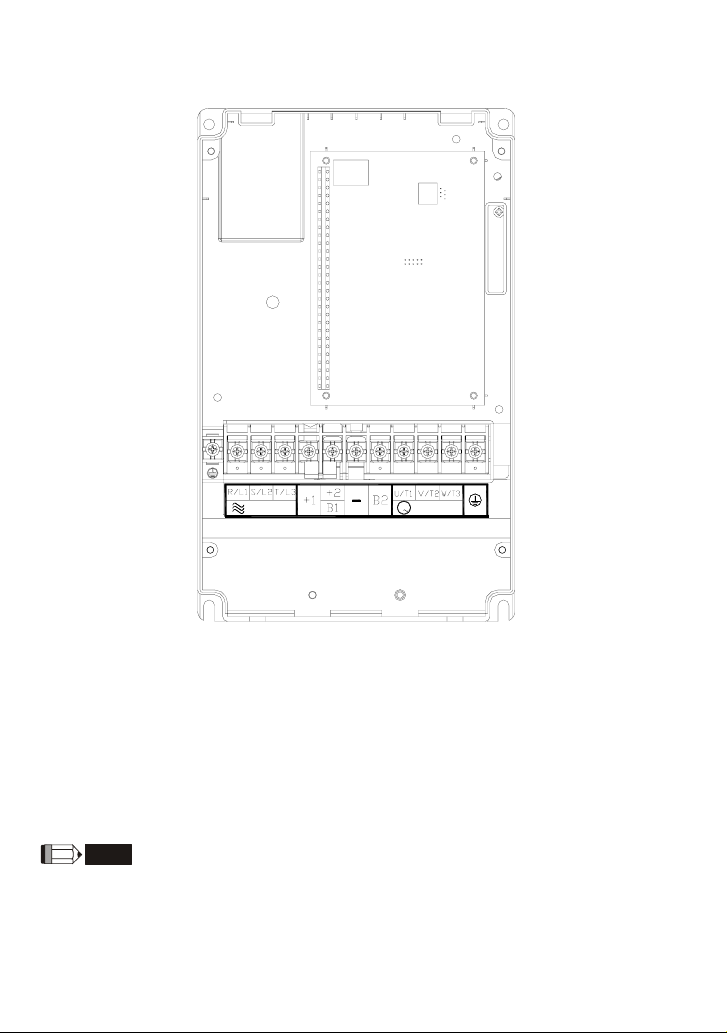

2.4.5 Main Circuit Terminals

Frame A, A1, A2: VFD007B21A/23A/43A/53A, VFD015B21A/21B//23A/23B/43A/53A,

VFD022B23B/43B/53A

S

R

/

/

L2

L1

T

/

+1 B2

L3

+2

UVW

/

/

/

B1

/

T3

T1

T2

Control Terminal

Torque: 4Kgf-cm (3 in-lbf)

Wire: 12-24 AWG (3.3-0.2 mm

Power Terminal

Torque: 18 kgf-cm (15.6 in-lbf)

Wire Gauge: 10-18 AWG (5.3-0.8 mm

Wire Type: Copper only, 75°C

2-26 Revision July 2008, BE16, SW V4.08 & V5.00

2

)

2

) stranded wire, 12-18 AWG (3.3-0.8 mm2) solid wire

Page 44

Frame B: VFD022B21A, VFD037B23A/43A/53A

Chapter 2 Installation and Wiring|VFD-B Series

+2

+1

B

R/L1 S/L2 T/L3

-

1

2

B

U/T1 V/T2 W/T3

Screw Torque :

18Kgf-cm

Wire Gauge :

18~10AWG

Control Terminal

Torque: 4Kgf-cm (3 in-lbf)

Wire: 12-24 AWG (3.3-0.2mm

Power Terminal

Torque: 18 kgf-cm (15.6 in-lbf)

Wire Gauge: 10-18 AWG (5.3-0.8mm

Wire Type: Stranded copper only, 75°C

Revision July 2008, BE16, SW V4.08 & V5.00 2-27

2

)

2

)

Page 45

Chapter 2 Installation and Wiring|VFD-B Series

Frame C: VFD055B23A/43A/53A, VFD075B23A/43A/53A, VFD110B23A/43A/53A

POWER

IM

MOTOR3

Control Terminal

Torque: 4Kgf-cm (3 in-lbf)

Wire: 12-24 AWG (3.3-0.2mm

Power Terminal

Torque: 30Kgf-cm (26 in-lbf)

Wire: 8-12 AWG (8.4-3.3mm

Wire Type: Stranded Copper only, 75°C

NOTE

To connect 6 AWG (13.3 mm

2-28 Revision July 2008, BE16, SW V4.08 & V5.00

2

)

2

)

2

) wires, use Recognized Ring Terminals

Page 46

Chapter 2 Installation and Wiring|VFD-B Series

Frame D: VFD150B23A/43A/53A, VFD185B23A/43A/53A, VFD220B23A/43A/53A

R/L1

S/L2

POWER

T/L3

+1-+2

+ DC DC

- ( ) ( )

IM

3

W/T3V/T2

MOTOR

Control Terminal

Torque: 4Kgf-cm (3 in-lbf)

Wire: 12-24 AWG (3.3-0.2 mm

Power Terminal

Torque: 30Kgf-cm (26 in-lbf)

Wire: 2-8 AWG (33.6-8.4 mm

Wire Type: Stranded Copper only, 75°C

NOTE

To connect 6 AWG (13.3 mm2) wires, use Recognized Ring Terminals

Revision July 2008, BE16, SW V4.08 & V5.00 2-29

2

)

2

)

Page 47

Chapter 2 Installation and Wiring|VFD-B Series

Frame E1: VFD300B23A, VFD370B23A, VFD550B43C, VFD750B43C, VFD550B53A,

VFD750B53A

POWER

ALARM

CHARGE

W/T3S/L2R/L1 T/L3 +2+1 U/T1 V/T2

POWER

Screw Torque:

200kgf-cm

(173in-lbf)

IM

MOTOR

3

Control Terminal

Torque: 4Kgf-cm (3 in-lbf)

Wire: 12-24 AWG (3.3-0.2 mm

Power Terminal

Torque: 200kgf-cm (173 in-lbf)

Wire Gauge: 1 - 3/0 AWG (42.4-85 mm

Wire Type: Stranded copper only, 75°C

2-30 Revision July 2008, BE16, SW V4.08 & V5.00

2

)

2

)

Page 48

Chapter 2 Installation and Wiring|VFD-B Series

Frame E: VFD300B43A, VFD370B43A, VFD450B43A, VFD300B53A, VFD370B53A,

VFD450B53A

POWER

ALARM

CHARGE

R/L1

S/L2 T /L3 U/T1 V/T2 2/T3

POWER

+1

-

+2

IM

MOTOR

3

Control Terminal

Torque: 4Kgf-cm (3 in-lbf)

Wire: 12-24 AWG (3.3-0.2 mm

Power Terminal

Torque: 58.7kgf-cm (50.9 in-lbf) max.

Wire Gauge: 2-6AWG (33.6-13.3 mm

Wire Type: Stranded copper only, 75°C

Revision July 2008, BE16, SW V4.08 & V5.00 2-31

2

)

2

)

Page 49

Chapter 2 Installation and Wiring|VFD-B Series

2-32 Revision July 2008, BE16, SW V4.08 & V5.00

Page 50

Chapter 3 Start Up

3.1 Preparations before Start-up

Carefully check the following items before proceeding.

Make sure that the wiring is correct. In particular, check that the output terminals U, V, W.

are NOT connected to power and that the drive is well grounded.

Verify that there are no short-circuits between terminals and from terminals to ground or

mains power.

Check for loose terminals, connectors or screws.

Verify that no other equipment is connected to the AC motor

Make sure that all switches are OFF before applying power to ensure that the AC motor

drive doesn’t start running and there is no abnormal operation after applying power.

Make sure that the front cover is correctly installed before applying power.

Do NOT operate the AC motor drive with humid hands.

Check the following items after applying power:

- The keypad should light up as follows (normal status with no error)

F

H

U

RUN REV

JOG

STOP

JOG

VFD-PU01

FWD

Whe n po wer i s ON, L EDs " F", " STO P" an d

"FWD" should light up. The display w ill

show "60.00" with the least significat ion "0"

flashing.

RUN

STOP

RESET

- If the drive has built-in fan (2.2kW and above) it should run. The factory setting of

Fan Control Pr.03-12=00 (Fan always on).

Revision July 2008, BE16, SW V4.08 & V5.00 3-1

Page 51

Chapter 3 Start Up|VFD-B Series

3.2 Operation Method

Refer to 4.2 How to operate the digital keypad VFD-PU01 and chapter 5 parameters for setting.

Please choose a suitable method depending on application and operation rule. The operation is

usually used as shown in the following table.

Operation Method Frequency Source

PU01 keypad

MI1

Operate from

external signal

MI2

DCM

Parameter

setting:

04-04=11

04-05=12

Operation

Command Source

RUN

STOP

RESET

External terminals

input:

FWD-DCM

REV-DCM

AVI, ACI, AUI

3.3 Trial Run

After finishing checking the items in “3.1 preparation before start-up”, you can perform a trial run.

The factory setting of the operation source is from the keypad (Pr.02-01=00).

1. After applying power, verify that LED “F” is on and the display shows 60.00Hz.

2. Setting frequency to about 5Hz by using

3. Pressing

you should press

please press

RUN

key for forward running. And if you want to change to reverse running,

STOP

RESET

key in

key.

F

H

U

key.

page. And if you want to decelerate to stop,

4. Check following items:

Check if the motor direction of rotation is correct.

Check if the motor runs steadily without abnormal noise and vibration.

Check if acceleration and deceleration are smooth.

If the results of trial run are normal, please start the formal run.

3-2 Revision July 2008, BE16, SW V4.08 & V5.00

Page 52

Chapter 3 Start Up|VFD-B Series

NOTE

1. Stop running immediately if any fault occurs and refer to the troubleshooting guide for solving

the problem.

2. Do NOT touch output terminals U, V, W when power is still applied to L1/R, L2/S, L3/T even

when the AC motor drive has stopped. The DC-link capacitors may still be charged to

hazardous voltage levels, even if the power has been turned off.

3. To avoid damage to components, do not touch them or the circuit boards with metal objects or

your bare hands.

Revision July 2008, BE16, SW V4.08 & V5.00 3-3

Page 53

Chapter 3 Start Up|VFD-B Series

This page intentionally left blank.

3-4 Revision July 2008, BE16, SW V4.08 & V5.00

Page 54

Chapter 4 Digital Keypad Operation

4.1 Description of the Digital Keypad VFD-PU01

F

H

U

JOG

Jog operation selector

M

oves cursor to the left

UP and DOWN Key

Sets the parameter

number and changes the

numerical data, such as

Master Frequency.

Left key

JOG

RUN

Display Message Descriptions

VFD-PU01

STOP

RESET

LED Display

Display frequency, current, voltage

and error, etc.

Part Number

Status Display

Display of drive status

MODE

Display mode selector

STOP/RESET

RUN key

Displays the AC drive Master Frequency.

Displays the actual output frequency present at terminals U/T1, V/T2, and

W/T3.

User defined unit (where U = F x Pr.00-05)

Displays the output current present at terminals U/T1, V/T2, and W/T3.

Displays the AC motor drive forward run status.

Revision July 2008, BE16, SW V4.08 & V5.00 4-1

Page 55

Chapter 4 Digital Keypad Operation|VFD-B Series

Display Message Descriptions

Displays the AC motor drive reverse run status.

The counter value (C).

Displays the selected parameter.

Displays the actual stored value of the selected parameter.

External Fault.

Display “End” for approximately 1 second if input has been accepted by

pressing

key. After a parameter value has been set, the new

value is automatically stored in memory. To modify an entry, use the

, and keys.

Display “Err”, if the input is invalid.

4-2 Revision July 2008, BE16, SW V4.08 & V5.00

Page 56

Chapter 4 Digital Keypad Operation|VFD-B Series

4.2 How to Operate the Digital Keypad VFD-PU01

Selection mode

START

F

H

U

NOTE: In the selection mode, press

To set par amet ers

F

H

U

NOTE: In the parameter setting mode, you can press

To shift c urs or

START

F

H

U

To modify data

START

F

H

U

MODE

F

H

U

MODE

F

H

U

to set the parameters.

F

H

U

MODE

F

H

U

F

H

U

F

H

U

move to previous display

MODE

F

H

U

F

H

U

F

H

U

MODE

F

H

U

parameter set successfully

F

H

U

parameter set error

to return to the selection mode.

F

H

U

F

H

U

F

H

U

MODEMO DE

GO START

To set direction

F

H

U

or

F

H

U

or

F

H

U

Revision July 2008, BE16, SW V4.08 & V5.00 4-3

Page 57

Chapter 4 Digital Keypad Operation|VFD-B Series

This page intentionally left blank.

4-4 Revision July 2008, BE16, SW V4.08 & V5.00

Page 58

Chapter 5 Parameters

The VFD-B parameters are divided into 12 groups by property for easy setting. In most

applications, the user can finish all parameter settings before start-up without the need for re-

adjustment during operation.

The 12 groups are as follows:

Group 0: User Parameters

Group 1: Basic Parameters

Group 2: Operation Method Parameters

Group 3: Output Function Parameters

Group 4: Input Function Parameters

Group 5: Multi-Step Speed and PLC Parameters

Group 6: Protection Parameters

Group 7: Motor Parameters

Group 8: Special Parameters

Group 9: Communication Parameters

Group 10: PID Control Parameters

Group 11: Fan & Pump Control Parameters

Revision July 2008, BE16, SW V4.08 & V5.00 5-1

Page 59

Chapter 5 Parameters|VFD-B Series

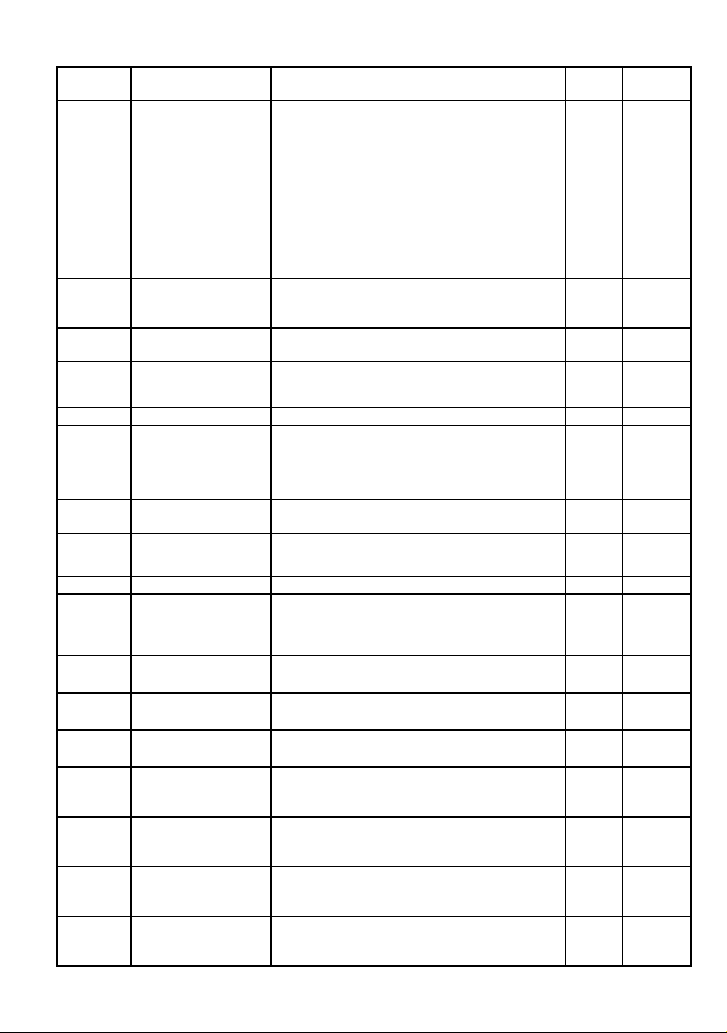

5.1 Summary of Parameter Settings

: The parameter can be set during operation.

Group 0 User Parameters

Parameter Explanation Settings

00-00 Identity Code of

Read-only ##

the AC motor drive

00-01 Rated Current

Read-only #.#

Display of the AC

motor drive

08: Keypad lock

00-02 Parameter Reset

09: All parameters are reset to factory settings

(50Hz, 220V/380V/575V)

10: All parameters are reset to factory settings

(60Hz, 220V/440V/575V)

00: Display the frequency command value (LED

F)

00-03

Start-up Display

Selection

01: Display the actual output frequency (LED H)

02: Display the content of user-defined unit

(LED U)

03: Multifunction display, see Pr.00-04

04: FWD/REV command

00: Display output current (A)

01: Display counter value (C)

02: Display process operation (1.tt)

03: Display DC-BUS voltage (u)

04: Display output voltage (E)

05: Output power factor angle (n)

06: Display output power (P)

07: Display actual motor speed (HU)

08: Display the estimated value of torque as it

00-04

Content of Multi

Function Display

relates to current (t)

09: Display PG numbers/10ms (G)

10: Display analog feedback signal value (b)(%)

11: Display AVI (U1.) (%)

12: Display ACI (U2.) (%)

13: Display AUI (U3.) (%)

14: Display the temperature of heat sink (°C)

00-05

User-Defined

Coefficient K

0.01 to 160.00 1.00

00-06 Software Version Read-only #.##

00-07 Password Input 00 to 65535 00

00-08 Password Set 00 to 65535 00

00: V/f Control

00-09 Control Method

01: V/f + PG Control

02: Vector Control

03: Vector + PG Control

Factory

Setting

00

00

00

00

Customer

5-2 Revision July 2008, BE16, SW V4.08 & V5.00

Page 60

Chapter 5 Parameters|VFD-B Series

Parameter Explanation Settings

Factory

Setting

00-10 Reserved

Group 1 Basic Parameters

Parameter Explanation Settings

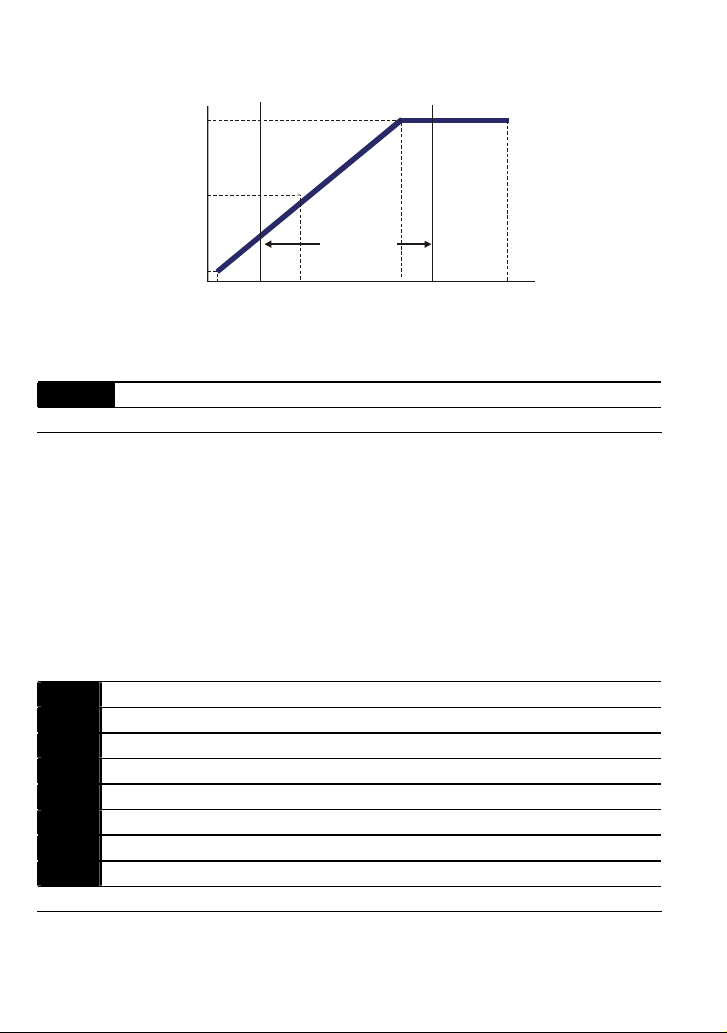

01-00

01-01

01-02

01-03

01-04

01-05

01-06

01-07

01-08

Maximum Output

Frequency (Fmax)

Maximum Voltage

Frequency (Fbase)

Maximum Output

Voltage (Vmax)

Mid-Point Frequency

(Fmid)

Mid-Point Voltage

(Vmid)

Minimum Output

Frequency (Fmin)

Minimum Output

Voltage (Vmin)

Output Frequency

Upper Limit

Output Frequency

Lower Limit

50.00 to 400.00 Hz 60.00

0.10 to 400.00 Hz 60.00

230V series: 0.1V to 255.0V 220.0

460V series: 0.1V to 510.0V 440.0

575V series: 0.1V to 637.0V 575.0

0.10 to 400.00 Hz 0.50

230V series: 0.1V to 255.0V 1.7

460V series: 0.1V to 510.0V 3.4

575V series: 0.1V to 637.0V 4.8

0.10 to 400.00 Hz 0.50

230V series: 0.1V to 255.0V 1.7

460V series: 0.1V to 510.0V 3.4

575V series: 0.1V to 637.0V 4.8

1 to 120%

0 to100 %

Factory

Setting

100

0

01-09 Accel Time 1 0.01 to 3600.0 sec 10.0

01-10 Decel Time 1 0.01 to 3600.0 sec 10.0

01-11 Accel Time 2 0.01 to 3600.0 sec 10.0

01-12 Decel Time 2 0.01 to 3600.0 sec 10.0

01-09 ~ 01-12: Factory setting for models of 30hp (22kW) and above is 60sec.

01-13 Jog Acceleration

Time

0.1 to 3600.0 sec

1.0

01-14 Jog Frequency 0.10 Hz to 400.00 Hz 6.00

00: Linear Accel/Decel

01-15

Auto acceleration /

deceleration (refer to

Accel/Decel time

setting)

01: Auto Accel, Linear Decel

02: Linear Accel, Auto Decel

03: Auto Accel/Decel (Set by load)

04: Auto Accel/Decel (set by Accel/Decel

00

Time setting)

01-16

01-17

Acceleration SCurve

Deceleration SCurve

00 to 07 00

00 to 07 00

01-18 Accel Time 3 0.01 to 3600.0 sec 10.0

01-19 Decel Time 3 0.01 to 3600.0 sec 10.0

01-20 Accel Time 4 0.01 to 3600.0 sec 10.0

Customer

Customer

Revision July 2008, BE16, SW V4.08 & V5.00 5-3

Page 61

Chapter 5 Parameters|VFD-B Series

Parameter Explanation Settings

Factory

Setting

01-21 Decel Time 4 0.01 to 3600.0 sec 10.0

01-18 ~ 01-21: Factory setting for models of 30hp (22kW) and above is 60sec.

01-22 Jog Deceleration

Time

01-23

Accel/Decel Time

Unit

0.1 to 3600.0 sec

00: Unit: 1 sec

01: Unit: 0.1 sec

02: Unit: 0.01 sec

1.0

01

Group 2 Operation Method Parameters

Parameter Explanation Settings

Factory

Setting

00: Digital keypad (PU01) UP/DOWN keys or

Multi-function Inputs UP/DOWN. Last

used frequency saved.

01: 0 to +10V from AVI

02: 4 to 20mA from ACI

02-00

Source of First

Master Frequency

Command

03: -10 to +10Vdc from AUI

04: RS-485 serial communication (RJ-11).

Last used frequency saved.

00

05: RS-485 serial communication (RJ-11).

Last used frequency not saved.

06: Combined use of master and auxiliary

frequency command

(See Pr. 02-10 to 02-12)

00: Digital keypad (PU01)

01: External terminals. Keypad STOP/RESET

enabled.

02-01

Source of First

Operation Command

02: External terminals. Keypad STOP/RESET

disabled.

03: RS-485 serial communication (RJ-11).

00

Keypad STOP/RESET enabled.

04: RS-485 serial communication (RJ-11).

Keypad STOP/RESET disabled.

00: STOP: ramp to stop; E.F.: coast to stop

02-02 Stop Method

01: STOP: coast to stop; E.F.: coast to stop

02: STOP: ramp to stop; E.F.: ramp to stop

00

03: STOP: coast to stop; E.F.: ramp to stop

230V&460V:1-5hp/0.75-3.7kW: 1-15kHz 15

7.5-25hp/5.5-18.5kW: 01-15kHz 09

02-03

PWM Carrier

Frequency

Selections

575V: 1-15hp/0.75-11kW: 01-10 kHz 06

30-60hp/22-45kW: 01-09kHz 06

75-100hp/55-75kW: 01-06kHz 06

20-60hp/15-45kW: 01-08 kHz 06

75-100hp/55-75kW: 01-06kHz 06

Customer

Customer

5-4 Revision July 2008, BE16, SW V4.08 & V5.00

Page 62

Parameter Explanation Settings

02-04

02-05

Motor Direction

Control

2-wire/3-wire

Operation Control

Modes

00: Enable forward/reverse operation

01: Disable reverse operation

02: Disabled forward operation

00: 2-wire: FWD/STOP, REV/STOP

01: 2-wire: FWD/REV, RUN/STOP

02: 3-wire operation

00: Disable. Operation status is not changed

even if operation command source Pr.0201 and/or Pr.02-14 is changed.

01: Enable. Operation status is not changed

even if operation command source Pr.02-

02-06 Line Start Lockout

01 and/or Pr.02-14 is changed.

02: Disable. Operation status will change if

operation command source Pr.02-01

and/or Pr.02-14 is changed.

03: Enable. Operation status will change if

operation command source Pr.02-01

and/or Pr.02-14 is changed.

00: Decelerate to 0 Hz

02-07

Loss of ACI Signal

(4-20mA)

01: Coast to stop and display “EF”

02: Continue operation by last frequency

command

00: Based on accel/decel time

02-08 Up/Down Mode

01: Constant speed

02: Based on accel/decel time, but frequency

command will be 0 when stopped.

Accel/Decel Rate of

Change of

02-09

UP/DOWN

0.01~1.00 Hz/msec 0.01

Operation with

Constant Speed

00: Digital keypad (PU01) UP/DOWN keys or

Multi-function Inputs UP/DOWN. Last

used frequency saved.

01: 0 to +10V from AVI

02: 4 to 20mA from ACI

03: -10 to +10Vdc from AUI

02-10

Source of the Master

Frequency

Command

04: RS-485 serial communication (RJ-11).

Last used frequency saved.

00: Digital keypad (PU01) UP/DOWN keys or

Multi-function Inputs UP/DOWN. Last

used frequency saved.

01: 0 to +10V from AVI

02: 4 to 20mA from ACI

03: -10 to +10Vdc from AUI

02-11

Source of the

Auxiliary Frequency

Command

04: RS-485 serial communication (RJ-11).

Last used frequency saved.

02-12

Combination of the

Master and Auxiliary

Frequency

Command

00: Master frequency + auxiliary frequency

01: Master frequency - auxiliary frequency

Chapter 5 Parameters|VFD-B Series

Factory

Setting

Customer

00

00

00

00

00

00

00

00

Revision July 2008, BE16, SW V4.08 & V5.00 5-5

Page 63

Chapter 5 Parameters|VFD-B Series

Parameter Explanation Settings

00: Digital keypad (PU01) UP/DOWN keys or

Multi-function Inputs UP/DOWN. Last

used frequency saved.

01: 0 to +10V from AVI

02: 4 to 20mA from ACI

02-13

Source of Second

Frequency

Command

03: -10 to +10Vdc from AUI

04: RS-485 serial communication (RJ-11).

Last used frequency saved

05: RS-485 serial communication (RJ-11).

Last used frequency not saved.

06: Combined use of master and auxiliary

frequency command (See Pr. 02-10 to 02-

12)

00: Digital keypad (PU01)

01: External terminals. Keypad STOP/RESET

enabled.

02-14

Source of Second

Operation Command

02: External terminals. Keypad STOP/RESET

disabled.

03: RS-485 serial communication (RJ-11).

Keypad STOP/RESET enabled.

04: RS-485 serial communication (RJ-11).

Keypad STOP/RESET disabled.

02-15

Keypad Frequency

Command

0.00 ~ 400.00Hz 60.00

Group 3 Output Function Parameters

Parameter Explanation Settings

00: No function

01: AC drive operational

02: Master frequency attained

03: Zero speed

04: Over torque detection

05: Base-Block (B.B.) indication

06: Low-voltage indication

03-00

03-01

Multi-Function

Output Relay (RA1,

RB1, RC1)

Multi-Function

Output Terminal

MO1

07: Operation mode indication

08: Fault indication

09: Desired frequency attained 1

10: PLC program running

11: PLC program step completed

12: PLC program completed

13: PLC program operation paused

14: Terminal count value attained

03-02

03-03

Multi-Function

Output Terminal

MO2

Multi-Function

Output Terminal

MO3

15: Preliminary count value attained

16: Auxiliary motor No.1

17: Auxiliary motor No.2

Factory

Customer

Setting

00

00

Factory

Customer

Setting

08

01

02

20

5-6 Revision July 2008, BE16, SW V4.08 & V5.00

Page 64

Chapter 5 Parameters|VFD-B Series

Parameter Explanation Settings

Factory

Setting

Customer

18: Auxiliary motor No.3

19: Heat sink overheat warning

20: AC motor drive ready

21: Emergency stop indication

22: Desired frequency attained 2

23: Software brake signal

24: Zero speed output signal

25: Under-current detection

26: Operation indication (H>=Fmin)

27: Feedback signal error

28: User-defined low-voltage detection

29: Brake control (Desired frequency attained

3)

03-04 Desired Frequency

0.00 to 400.00 Hz 0.00

Attained 1

00: Analog frequency meter

01: Analog current meter

02: Output voltage

03: Output frequency command

04: Output motor speed

05: Load power factor (cos90

o

00

to Cos0o)

03-05

Analog Output

Signal

03-06 Analog Output Gain 01 to 200% 100

03-07 Digital Output

01 to 20 01

Multiplying Factor

03-08 Terminal Count

00 to 65500 00

Value

03-09

03-10

03-11

Preliminary Count

Value

Desired Frequency

Attained 2

EF Active When

Preliminary Count

Value Attained

00 to 65500 00

0.00 to 400.00 Hz 0.00

00: Preliminary count value attained, no EF

display

01: Preliminary count value attained, EF

00

active

00: Fan always ON

01: 1 minute after AC motor drive stops, fan

will be OFF

03-12 Fan Control

02: AC motor drive runs and fan ON, AC

00

motor drive stops and fan OFF

03: Fan ON to run when preliminary heatsink

temperature attained

03-13

03-14

Brake Release

Frequency

Brake Engage

Frequency

0.00 to 400.00Hz 0.00

0.00 to 400.00Hz 0.00

Revision July 2008, BE16, SW V4.08 & V5.00 5-7

Page 65

Chapter 5 Parameters|VFD-B Series

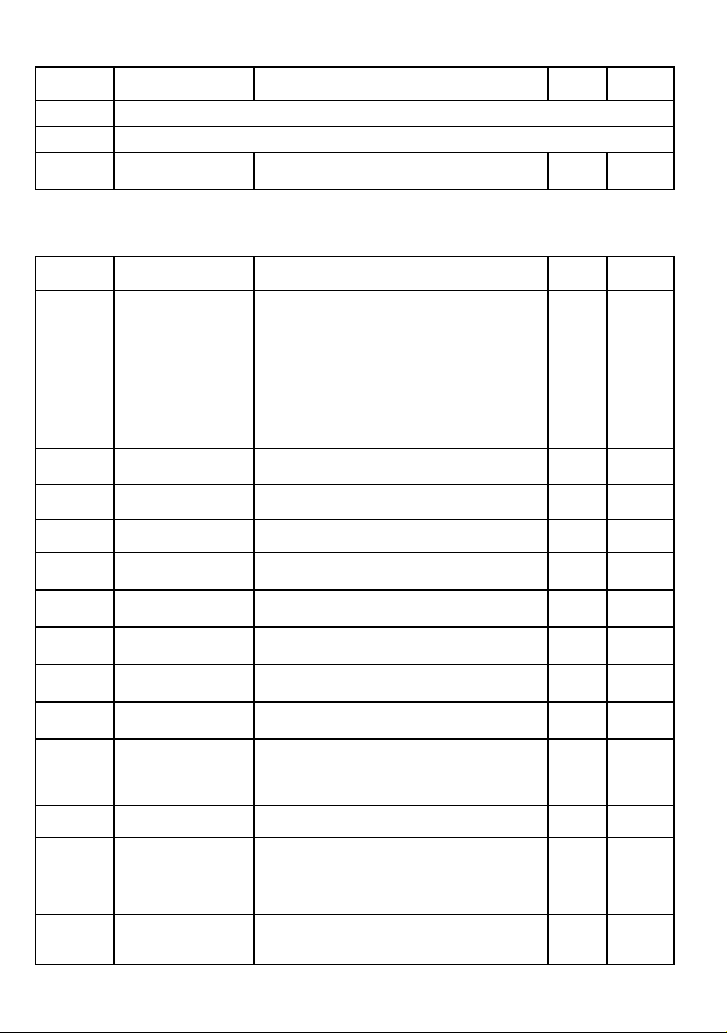

Group 4 Input Function Parameters

Parameter Explanation Settings

04-00

AVI Analog Input

Bias

04-01 AVI Bias Polarity

0.00~200.00 % 0.00

00: Positive bias

01: Negative bias

Factory

Setting

00

04-02 AVI Input Gain 1 to 200 % 100

AVI Negative Bias,

04-03

Reverse Motion

Enable/Disable

04-04 Multi-Function Input

Terminal 1 (MI1)

00: No AVI negative bias command