Page 1

Delta Standard Compact Drive

MS300 Series User Manual

Page 2

PLEASE READ PRIOR TO INSTALLATION FOR SAFETY.

AC input power must be disconnected before any wiring to the AC motor drive is made.

Even if the power has been turned off, a charge may still remain in the DC-link

DANGER

capacitors with hazardous voltages before the POWER LED is OFF. Please do not

touch the internal circuit and components.

There are highly sensitive MOS components on the printed circuit boards. These

components are especially sensitive to static electricity. Please do not touch these

components or the circuit boards before taking anti-static measures.

Never reassemble internal components or wiring.

Ground the AC motor drive using the ground terminal. The grounding method must

comply with the laws of the country where the AC motor drive is to be installed.

DO NOT install the AC motor drive in a place subjected to high temperature, direct

sunlight and inflammables.

Never connect the AC motor drive output terminals U/T1, V/T2 and W/T3 directly to the

CAU TION

AC mains circuit power supply.

The rated voltage of the AC motor drive must be 115V for 110V models, 240V for

230V models, and 480V for 460V models.

Only qualified persons are allowed to install, wire and maintain the AC motor drives.

Even if the 3-phase AC motor is stop, a charge may still remain in the main circuit

terminals of the AC motor drive with hazardous voltages.

If the AC motor drive is stored in no charge condition for more than 3 months, the

ambient temperature should not be higher than 30°C. Storage longer than one year is

not recommended, it could result in the degradation of the electrolytic capacitors.

Pay attention to the following when transporting and installing this package (including

wooden crate, wood stave and carton box)

1. If you need to sterilize, deform the wooden crate or carton box, please do not

use steamed smoking sterilization or you will damage the VFD.

2. Please use other ways to sterilize or deform.

3. You may use high temperature to sterilize or deform. Leave the packaging

materials in an environment of over 56°C for 30 minutes.

Type of electrical supply system (3WYE) to which the drive shall be connected.

NOTE

For a detailed explanation of the product specification, the cover or the safety shields will be disassembled, as

described in graphic mode. As for the product in operation, please install the top cover and wiring correctly

according to the provisions. Refer to the manual operation to ensure safety.

The figures in this instruction are only for reference, they may be slightly different from the one you have, but it will

not affect your customer rights.

The content of this manual may be revised without prior notice. Please consult our distributors or download the

latest version at

http://www.deltaww.com/services/DownloadCenter2.aspx?secID=8&pid=2&tid=0&CID=06&itemID=060101&typeID

=1&downloadID=&title=&dataType=&check=0&hl=en-US

I

Page 3

Table of Contents

CHAPTER 1 INTRODUCTION ................................................................................................. 1-1

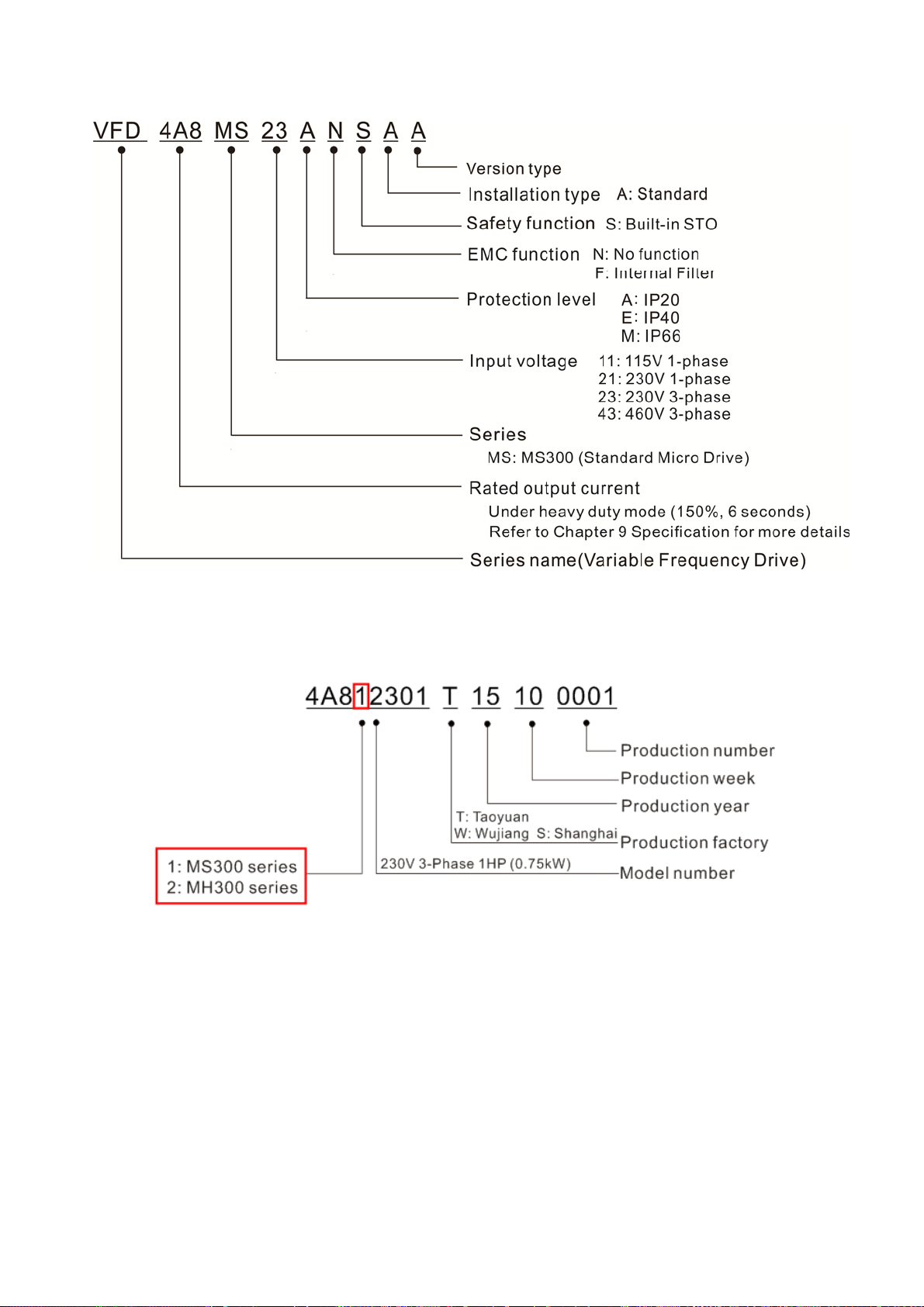

1-1 Nameplate Information................................................................................................1-2

1-2 Model Name...............................................................................................................1-3

1-3 Serial Number..............................................................................................................1-3

1-4 RFI Jumper..................................................................................................................1-4

CHAPTER 2 DIMENSION ........................................................................................................ 2-1

Frame A……………………………………………………..……………………………………2-1

Frame B……………………………………………………………..……………………………2-2

Frame C……………………………………………………………..……………………………2-3

Frame D…………………………………………………………..………………………………2-4

Frame E…………………………………………………………..………………………………2-5

Frame F…………………………………………………………..………………………………2-6

Digital Keypad…………..……………………………………………………………………….2-7

CHAPTER 3 INSTALLATION ................................................................................................... 3-1

CHAPTER 4 WIRING ............................................................................................................... 4-1

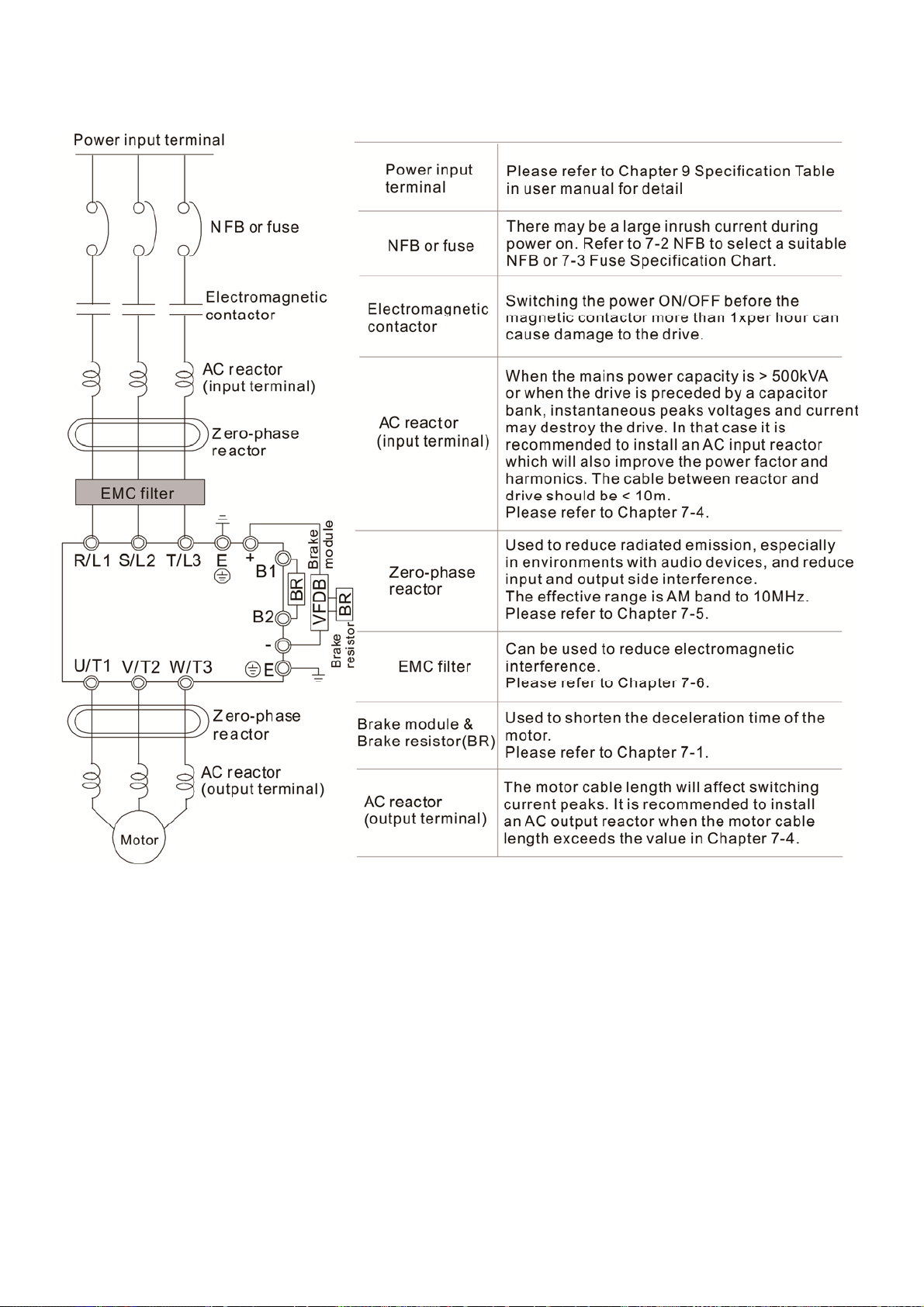

4-1 Wiring...........................................................................................................................4-3

4-2 System Wiring Diagram...............................................................................................4-6

CHAPTER 5 MAIN CIRCUIT TERMINALS ............................................................................ 5-1

5-1 Main Circuit Diagram....................................................................................................5-4

5-2 Main Circuit Terminals..................................................................................................5-5

Frame A………………..………………………………..……………………………………5-6

Frame B………..………………………………………………..……………………………5-7

Frame C………..………………………………………………..……………………………5-8

Frame D………...……………………………………………….……………………………5-9

Frame E…………...…..………………………………………….…………………………5-10

Frame F………….…….……………………………………….……………………………5-11

CHPATER 6 CONTROL TERMINALS ..................................................................................... 6-1

CHAPTER 7 OPTIONAL ACCESSORIES ............................................................................... 7-1

7-1 All Brake Resistors and Brake Units Used in AC Motor Drives...................................7-2

7-2 Non-fuse Circuit Breaker............................................................................................7-5

7-3 Fuse Specification Chart ...........................................................................................7-7

7-4 AC/DC Reactor...........................................................................................................7-9

7-5 Zero Phase Reactor.................................................................................................7-23

7-6 EMC Filter.................................................................................................................7-26

7-7 EMC Shield Plate....................................................................................................7-30

7-8 Capacitive Filter.........................................................................................................7-33

II

Page 4

7-9 Conduit Box…..........................................................................................................7-35

7-10 Fan Kit.....................................................................................................................7-43

7-11 Keypad Panel Mounting ……..................................................................................7-44

7-12 DIN-Rail Mounting...................................................................................................7-45

7-13 Mounting Adapter Plate………………………………….……………………………7-47

CHAPTER 8 OPTION CARDS .................................................................................................. 8-1

8-1 Option Card Installation................................................................................................8-2

8-2 CMM-MOD01 Modbus/TCP Option Card.....................................................................8-7

8-3 CMM-PD01 PROFIBUS Option Card.........................................................................8-10

8-4 CMM-DN01 DeviceNet Option Card..........................................................................8-12

8-5 CMM-EIP01 Modbus TCP/EtherNet IP Option Card..................................................8-15

8-6 CMM-COP01 CANopen Option Card.........................................................................8-18

8-7 EMM-BPS01 Back-up Power Supply Card................................................................8-20

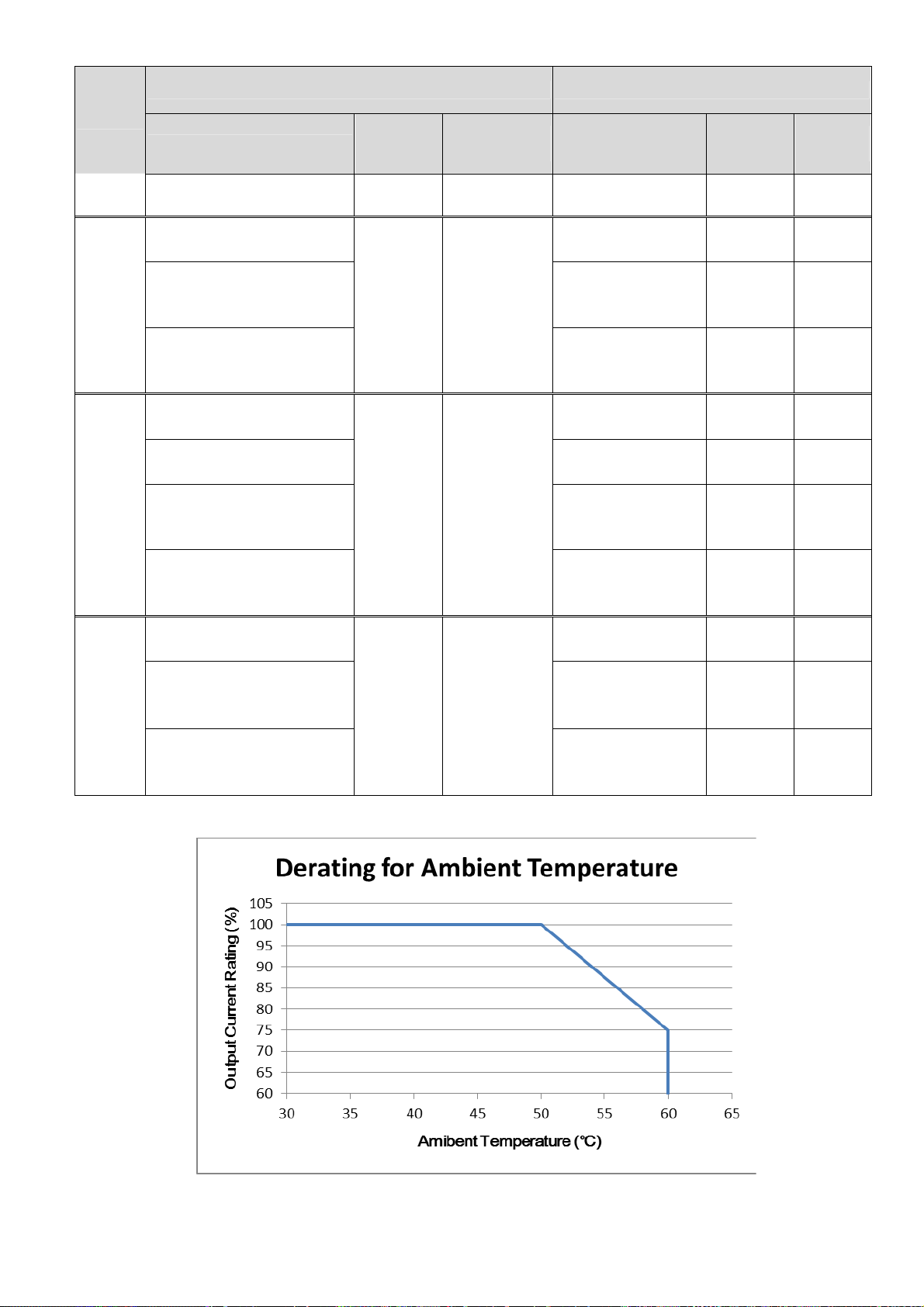

CHAPTER 9 SPECIFICATION .................................................................................................. 9-1

9-1 115V Series…………………………….......................................................................9-2

9-2 230V Series………………………………......................................................................9-3

9-3 460V Series………………………………......................................................................9-5

9-4 Environment for Operation, Storage and Transportation……………………...............9-8

9-5 Derating of Ambient Temperature and Altitude……………………................................9-9

CHAPTER 10 DIGITAL KEYPAD ........................................................................................... 10-1

CHAPTER 11 SUMMARPY OF PARAMETERS SETTINGS .................................................. 11-1

CHAPTER 12 DESCRIPTION OF PARAMETER SETTINGS .......................................... 12-00-1

12-1 Description of Parameter Settings……………………..……………………………12-00-1

12-2 Adjustment & Application…………………………………………………………….. 12.2-1

CHAPTER 13 WARNING CODES .......................................................................................... 13-1

CHAPTER 14 ERROR CODES .............................................................................................. 14-1

CHAPTER 15 CANOPEN OVERVIEW ................................................................................... 15-1

CHAPTER 16 PLC FUNCTION APPLICA TIONS ................................................................... 16-1

CHAPTER 17 SAFETY TORQUE OFF FUNCTION………………………..…………………….17-1

17-1 The Drive Safe Function Failure Rate.....................................................................17-2

17-2 Safe Torque Off Terminal Function Description......................................................17-2

17-3 Wiring Diagram.......................................................................................................17-3

17-4 Parameter...............................................................................................................17-4

17-5 Operating Sequence Description............................................................................17-4

17-6 Error Code..................................................................................................17-6

Application

Control Board: V 1.0

III

Page 5

[ This page intentionally left blank ]

IV

Page 6

Chapter 1 IntroductionMS300

Chapter 1 Introduction

1-1 Nameplate Information

1-2 Model Name

1-3 Serial Number

1-4 RFI Jumper

1-1

Page 7

Chapter 1 Introduction MS300

After receiving the AC motor drive, please check for the following:

1. Please inspect the unit after unpacking to ensure it was not damaged during shipment. Make sure

that the part number printed on the package corresponds with the part number indicated on the

nameplate.

2. Make sure that the mains voltage is within the range as indicated on the nameplate. Please install

the AC motor drive according to this manual.

3. Before applying the power, please make sure that all devices, including mains power, motor, control

board and digital keypad, are connected correctly.

4. When wiring the AC motor drive, please make sure that the wiring of input terminals “R/L1, S/L2,

T/L3” and output terminals”U/T1, V/T2, W/T3” are correct to prevent damage to the drive.

5. When power is applied, select the language and set parameters via the digital keypad (KPMS-LE01).

When executing a trial run, please begin with a low speed and then gradually increase the speed

until the desired speed is reached.

1-1 Nameplate Information

1-2

Page 8

1-2 Model Name

Chapter 1 IntroductionMS300

1-3 Serial Number

1-3

Page 9

Chapter 1 Introduction MS300

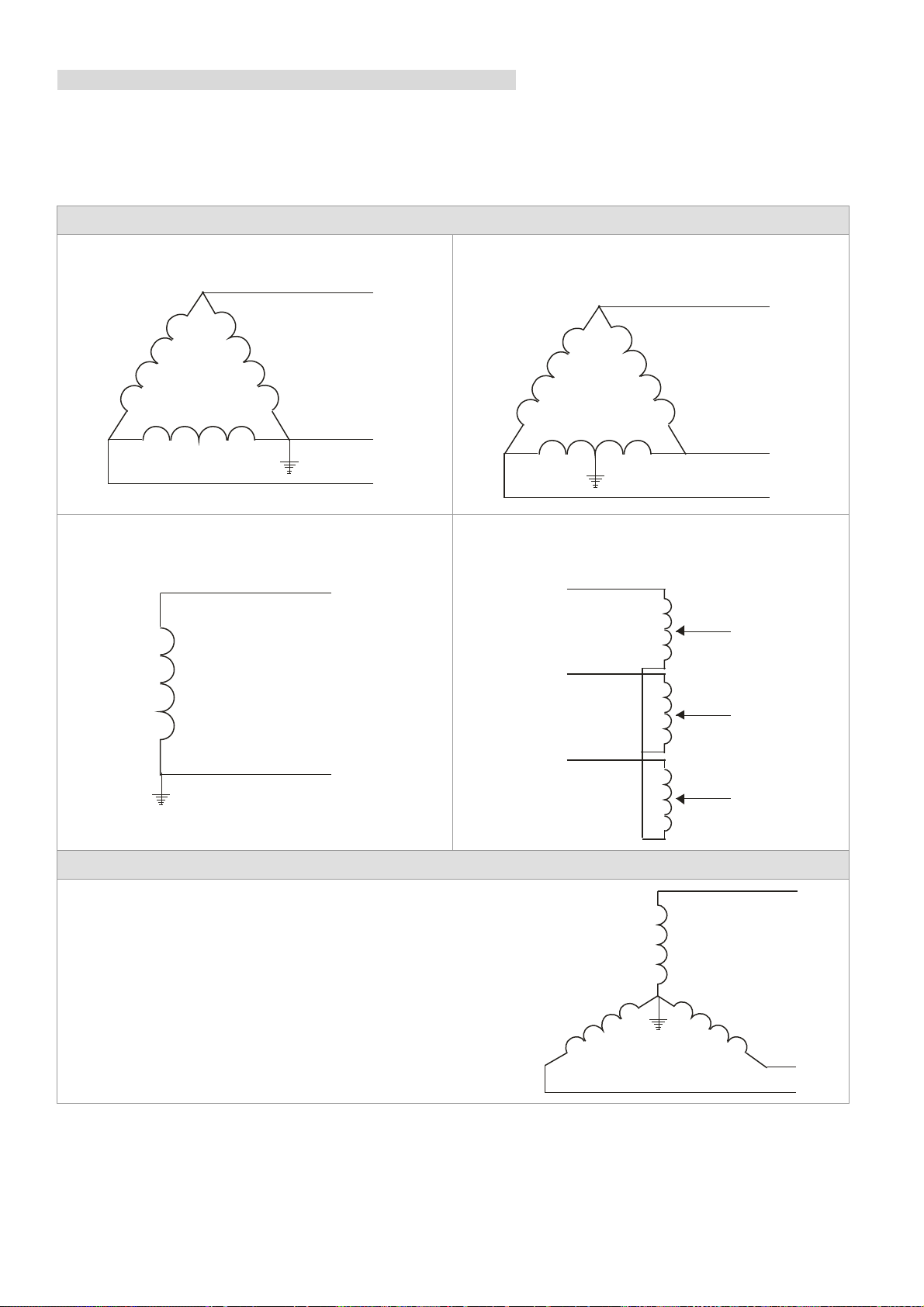

1-4 RFI Jumper

(1) In the drive there are Varistor / MOVs, which are connected from phase to phase and from phase to

ground, to protect the drive against mains surges or voltage spikes.

Because the Varistors / MOVs from phase to ground are connected to ground via the RFI jumper, the

protection will be ineffective when the RFI jumper is removed.

(2) In the models with built-in EMC filter the RFI jumper connects the filer capacitors to ground to form a

return path for high frequency noise to isolate the noise from contaminating the mains power.

Removing the RFI jumper strongly reduces the effect of the buiolt-in EMC filter.

(3) Although a single drive complies with the international standards for leakage current, an installation

with several drives with built-in EMC filter can trigger the RCD. Removing the RFI jumper helps, but

the EMC performance of each drive would is no longer guaranteed.

Frame A~F Screw Torque: 4~6 kg-cm / [3.5~5.2 lb-in.] / [0.39~0.59 Nm]

Loosen the screw and remove the RFI Jumper (as shown below). Fasten the screw again after the RFI

Jumper is removed.

Frame B~F (model with built-in EMC filter)

Remove the RFI Jumper with a screwdriver (as shown below).

1-4

Page 10

Chapter 1 IntroductionMS300

Isolating main power from ground:

When the power distribution system of the drive is a floating ground system (IT) or an asymmetric ground

system (TN), the RFI Jumper must be removed. Removing the RFI Jumper disconnects the internal

capacitors from ground to avoid damaging the internal circuits and to reduce the ground leakage current.

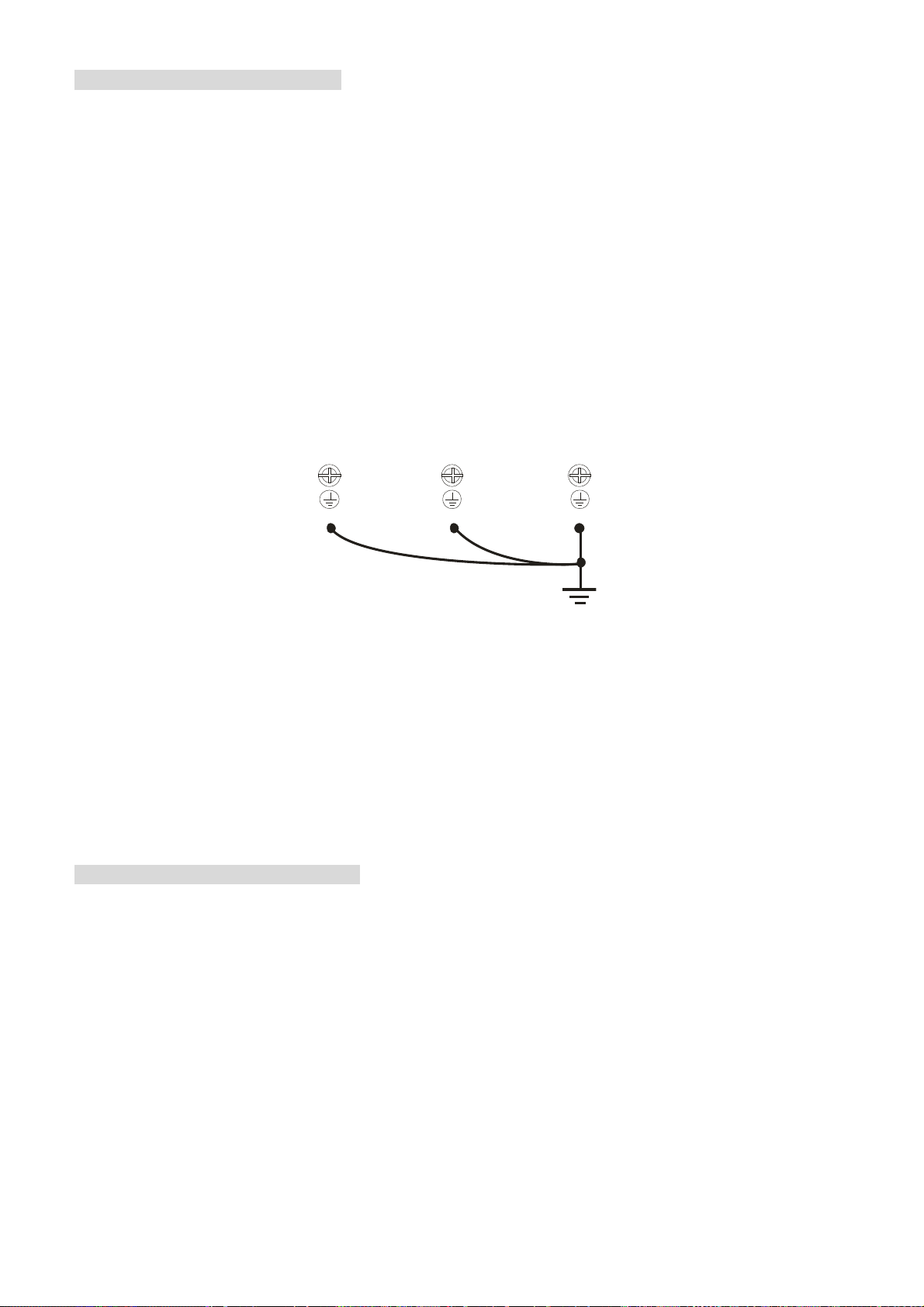

Important points regarding ground connection

To ensure the safety of personnel, proper operation, and to reduce electromagnetic radiation, the

drive must be properly grounded during installation.

The diameter of the cables must comply with the local safety regulations.

The shield of shielded cables must be connected to the ground of the drive to meet safety regulations.

The shield of shielded power cables can only be used as the ground for equipment when the

aforementioned points are met.

When installing more drives, do not connect the grounds of the drives in series but connect each drive

to ground.

Ground terminal

Wrong wiring setup for ground wires

Pay particular attention to the following points:

Do not remove the RFI jumper while the power is on.

Removing the RFI jumper will also disconnect the built-in EMC filter capacitors. Compliance with the

EMC specifications is no longer guaranteed.

The RFI jumper may not be removed if the mains power is a grounded power system.

The RFI jumper may not be removed while conducting high voltage tests. When conducting a high

voltage test to the entire facility, the mains power and the motor must be disconnected if the leakage

current is too high.

Floating Ground System (IT Systems)

A floating ground system is also called an IT system, an ungrounded system, or a high

impedance/resistance (greater than 30 Ω) grounded system.

Disconnect the RFI Jumper.

Check whether there is excess electromagnetic radiation affecting nearby low-voltage circuits.

In some situations, the transformer and cable naturally provide enough suppression. If in doubt, install

an extra electrostatic shielded cable on the power supply side between the main circuit and the control

terminals to increase security.

Do not install an external EMC filter. The EMC filter is connected to ground through the filter

capacitors, thus connecting power input to ground. This is very dangerous and can easily damage the

drive.

1-5

Page 11

1

1

1

1

1

Chapter 1 Introduction MS300

Asymmetric Ground System (Corner Grounded TN Systems)

Caution: Do not remove the RFI jumper while the input terminal of the drive carries power.

In the following four situations, the RFI jumper must be removed. This is to prevent the system from

grounding through the RFI and filter capacitors, damaging the drive.

RFI jumper must be removed

1. Grounding at a corner in a triangle configuration

L

L2

L3

3. Grounding at one end in a single-phase

configuration

L

2. Grounding at a midpoint in a polygonal

configuration

L

L2

L3

4. No stable neutral grounding in a three-phase

autotransformer configuration

L

L1

L2

N

RFI jumper can be used

Internal grounding through RFI capacitors, which reduce

electromagnetic radiation. In a symmetrically grounding

power system with higher EMC requirements, an EMC filter

can be installed. As a reference, the diagram on the right is

a symmetrical grounding power system.

L2

L3

L3

L

L2

L3

1-6

Page 12

Chapter 2 Dimensions MS300

Chapter 2 Dimension

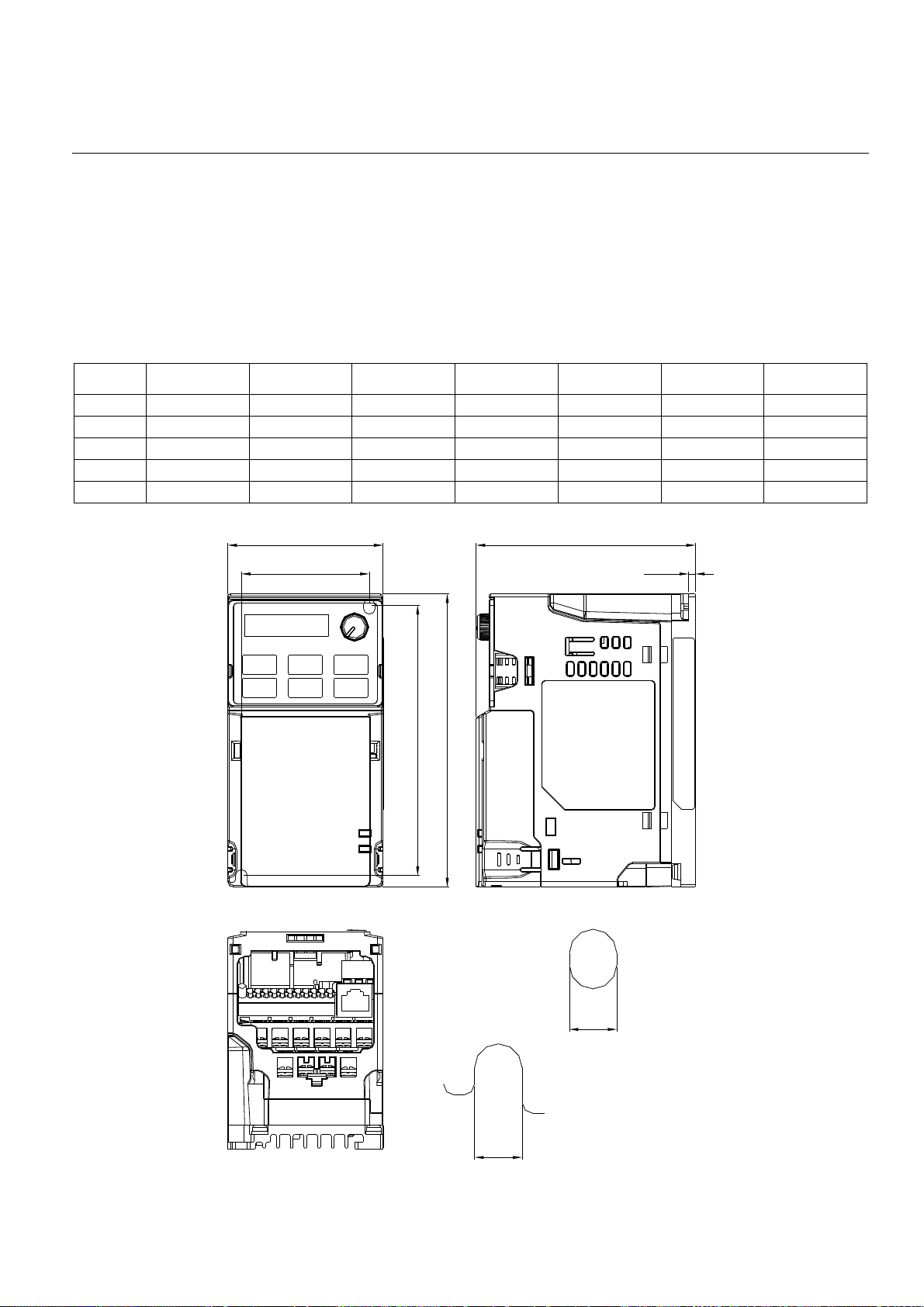

Frame A

A1: VFD1A6MS11ANSAA; VFD1A6MS11ENSAA; VFD1A6MS21ANSAA; VFD1A6MS21ENSAA;

VFD1A6MS23ANSAA; VFD1A6MS23ENSAA

A2: VFD2A8MS23ANSAA; VFD2A8MS23ENSAA

A3: VFD2A5MS11ANSAA; VFD2A5MS11ENSAA; VFD2A8MS21ANSAA; VFD2A8MS21ENSAA

A4: VFD1A5MS43ANSAA; VFD1A5MS43ENSAA

A5: VFD4A8MS23ANSAA; VFD4A8MS23ENSAA; VFD2A7MS43ANSAA; VFD2A7MS43ENSAA

Unit: mm [inch]

Frame W H D W1 H1 D1 S1

A1 68.0 [2.68] 128.0 [5.04] 96.0 [3.78] 56.0 [2.20] 118.0 [4.65] 3.0 [0.12] 5.2 [0.20]

A2 68.0 [2.68] 128.0 [5.04] 110.0 [4.33] 56.0 [2.20] 118.0 [4.65] 3.0 [0.12] 5.2 [0.20]

A3 68.0 [2.68] 128.0 [5.04] 125.0 [4.92] 56.0 [2.20] 118.0 [4.65] 3.0 [0.12] 5.2 [0.20]

A4 68.0 [2.68] 128.0 [5.04] 129.0 [5.08] 56.0 [2.20] 118.0 [4.65] 3.0 [0.12] 5.2 [0.20]

A5 68.0 [2.68] 128.0 [5.04] 143.0 [5.63] 56.0 [2.20] 118.0 [4.65] 3.0 [0.12] 5.2 [0.20]

W

D

W1

H1

D1

H

S1

Mounting Hole

S1

2-1

Mo u n ting H o l e

Page 13

Chapter 2 Dimensions MS300

Frame B

B1: VFD7A5MS23ANSAA; VFD7A5MS23ENSAA; VFD4A2MS43ANSAA; VFD4A2MS43ENSAA

B2: VFD4A8MS21ANSAA; VFD4A8MS21ENSAA

B3: VFD1A6MS21AFSAA; VFD2A8MS21AFSAA; VFD4A8MS21AFSAA; VFD1A5MS43AFSAA;

VFD2A7MS43AFSAA; VFD4A2MS43AFSAA

Unit: mm [inch]

Frame W H D W1 H1 D1 S1

B1 72.0 [2.83] 142.0 [5.59] 143.0 [5.63] 60.0 [2.36] 130.0 [5.63] 6.4 [0.25] 5.2 [0.20]

B2 72.0 [2.83] 142.0 [5.59] 143.0 [5.63] 60.0 [2.36] 130.0 [5.63] 3.0 [0.12] 5.2 [0.20]

B3 72.0 [2.83] 142.0 [5.59] 159.0 [6.26] 60.0 [2.36] 130.0 [5.63] 4.3 [0.17] 5.2 [0.20]

W

W1

H1

D

D1

H

S1

Mounting Hole

S1

Detail A (Mounting Hole)

2-2

Page 14

Chapter 2 Dimensions MS300

Frame C

C1: VFD4A8MS11ANSAA; VFD4A8MS11ENSAA; VFD7A5MS21ANSAA; VFD7A5MS21ENSAA;

VFD11AMS21ANSAA; VFD11AMS21ENSAA; VFD11AMS23ANSAA; VFD11AMS23ENSAA;

VFD17AMS23ANSAA; VFD17AMS23ENSAA; VFD5A5MS43ANSAA; VFD5A5MS43ENSAA;

VFD9A0MS43ANSAA; VFD9A0MS43ENSAA

C2: VFD7A5MS21AFSAA; VFD11AMS21AFSAA; VFD5A5MS43AFSAA; VFD9A0MS43AFSAA

Unit: mm [inch]

Frame W H D W1 H1 D1 S1

C1 87.0 [3.43] 157.0 [6.18] 152.0 [5.98] 73.0 [2.87] 144.5 [5.69] 5.0 [0.20] 5.5 [0.22]

C2 87.0 [3.43] 157.0 [6.18] 179.0 [7.05] 73.0 [2.87] 144.5 [5.69] 5.0 [0.20] 5.5 [0.22]

W

W1

H1

D

D1

H

S1

Mounting Hole

S1

Mounting Hole

2-3

Page 15

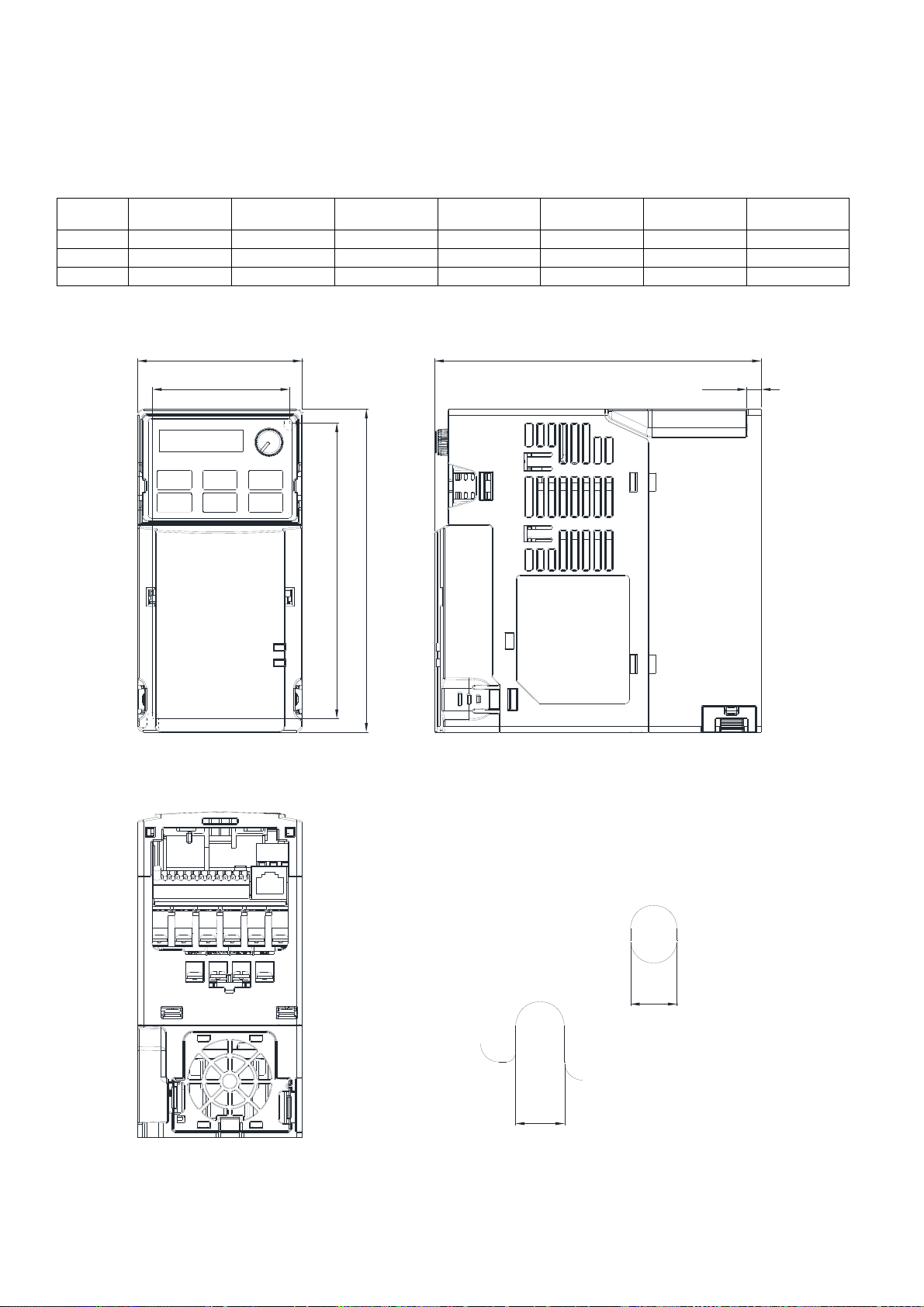

Chapter 2 Dimensions MS300

Frame D

D1: VFD25AMS23ANSAA; VFD25AMS23ENSAA; VFD13AMS43ANSAA; VFD13AMS43ENSAA;

VFD17AMS43ANSAA; VFD17AMS43ENSAA

D2: VFD13AMS43AFSAA; VFD17AMS43AFSAA

Unit: mm [inch]

Frame W H D W1 H1 D1 S1

D1 109.0 [4.29] 207.0 [8.15] 154.0 [6.06] 94.0 [3.70] 193.8 [7.63] 6.0 [0.24] 5.5 [0.22]

D2 109.0 [4.29] 207.0 [8.15] 187.0 [7.36] 94.0 [3.70] 193.8 [7.63] 6.0 [0.24] 5.5 [0.22]

W

W1

H1

D

D1

H

S1

Mounting Hole

S1

Mounting Hole

2-4

Page 16

Chapter 2 Dimensions MS300

Frame E

E1: VFD33AMS23ANSAA; VFD33AMS23ENSAA; VFD49AMS23ANSAA; VFD49AMS23ENSAA;

VFD25AMS43ANSAA; VFD25AMS43ENSAA; VFD32AMS43ANSAA; VFD32AMS43ENSAA

E2: VFD25AMS43AFSAA; VFD32AMS43AFSAA

Unit: mm [inch]

Frame W H D W1 H1 D1 S1

E1 130.0 [5.12] 250.0 [9.84] 185.0 [7.83] 115.0 [4.53] 236.8 [9.32] 6.0 [0.24] 5.5 [0.22]

E2 130.0 [5.12] 250.0 [9.84] 219.0 [8.62] 115.0 [4.53] 236.8 [9.32] 6.0 [0.24] 5.5 [0.22]

W

W1

H1

D

D1

H

S1

Mounting Hole

S1

Mounting H ole

2-5

Page 17

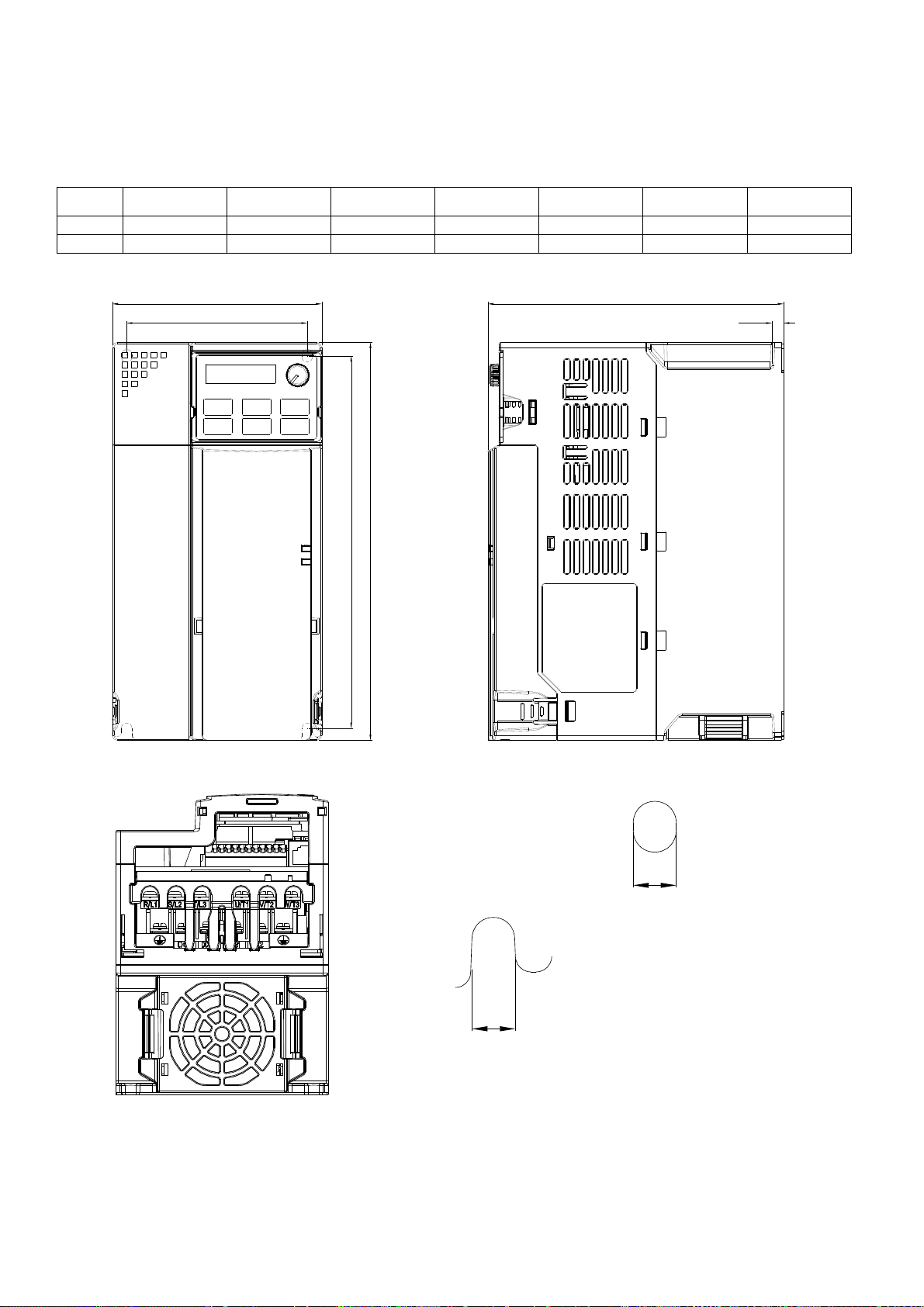

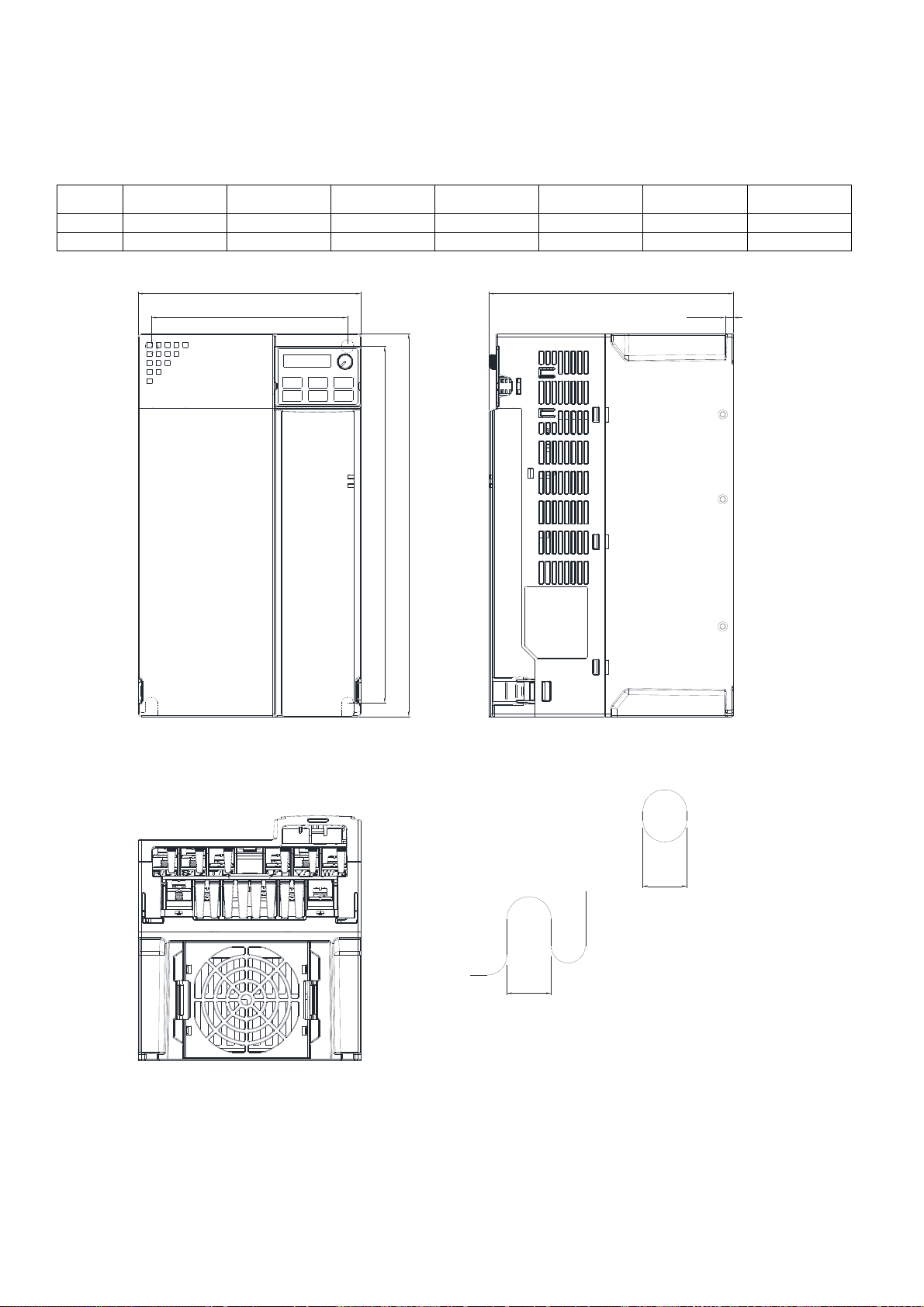

Chapter 2 Dimensions MS300

Frame F

F1: VFD65AMS23ANSAA; VFD65AMS23ENSAA; VFD38AMS43ANSAA; VFD38AMS43ENSAA;

VFD45AMS43ANSAA; VFD45AMS43ENSAA

F2: VFD38AMS43AFSAA; VFD45AMS43AFSAA

Unit: mm [inch]

Frame W H D W1 H1 D1 S1

F1 175.0 [6.89] 300.0 [11.81] 192.0 [7.56] 154.0 [6.06] 279.5 [11.00] 6.5 [0.26] 8.4 [0.33]

F2 175.0 [6.89] 300.0 [11.81] 244.0 [9.61] 154.0 [6.06] 279.5 [11.00] 6.5 [0.26] 8.4 [0.33]

W

W1

H1

D

D1

H

S1

Mounting Hole

S1

2-6

Mounting Hole

Page 18

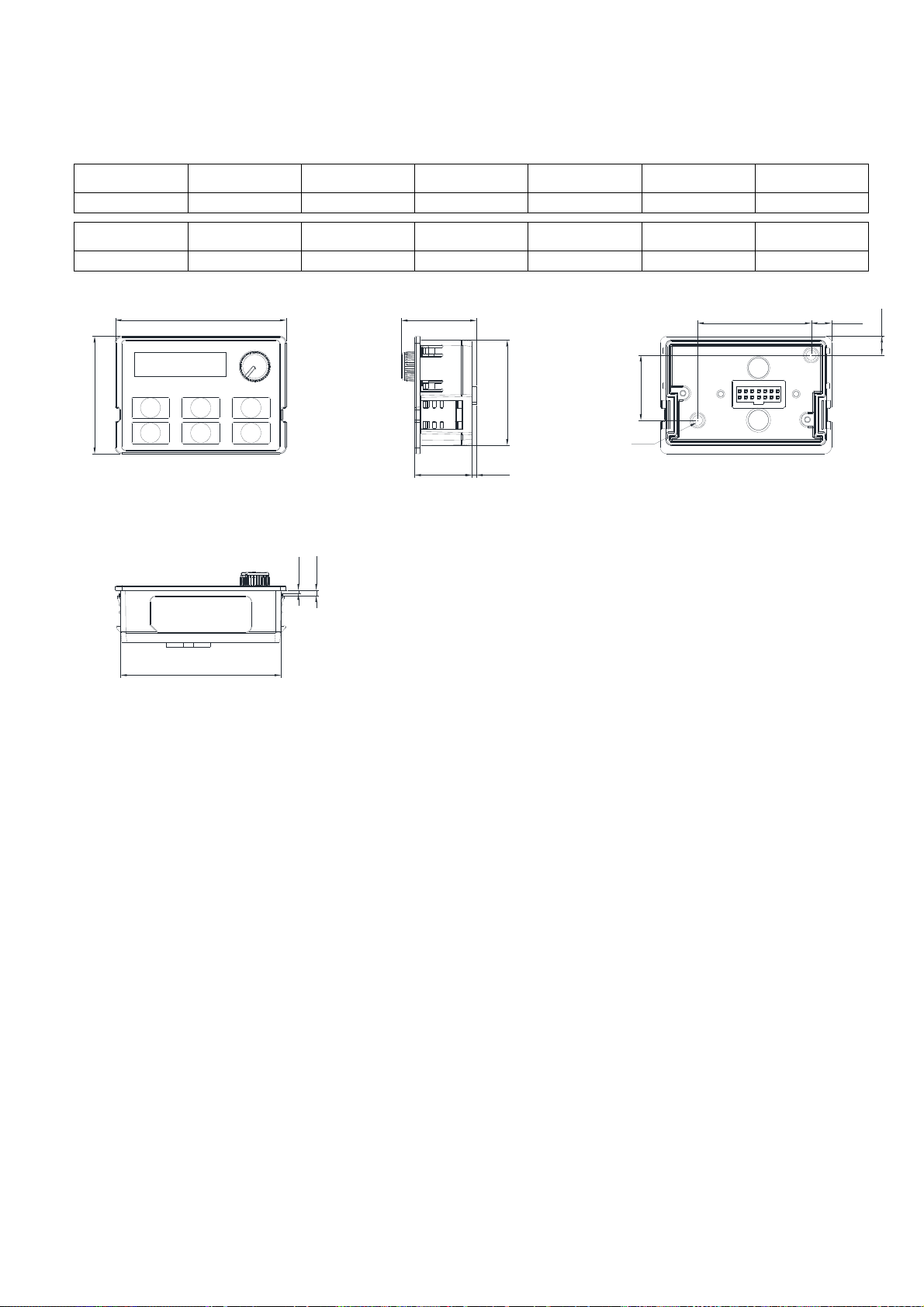

Chapter 2 Dimensions MS300

Digital Keypad

KPMS-LE01

Unit: mm [inch]

W W1 W2 W3 H H1 H2

68.0 [2.67] 63.8 [2.51] 45.2 [1.78] 8.0 [0.31] 46.8 [1.84] 42.0 [1.65] 26.0 [1.02]

H3 D D1 D2 D3 D4 S1

7.5 [0.31] 30.0 [1.18] 22.7 [0.89] 2.0 [0.08] 2.2 [0.09] 1.3 [0.05] M3*0.5(2X)

W

H

D3

D4

W1

D

D1 D2

H1

S1

H2

W2

W3

H3

2-7

Page 19

Chapter 2 Dimensions MS300

[ This page intentionally left blank ]

2-8

Page 20

Chapter 3 Installation MS300

Chapter 3 Installation

Minimum Mounting Clearance and Installation

Prevent fiber particles, scraps of paper, shredded wood saw dust, metal particles, etc. from adhering

to the heat sink

Install the AC motor drive in a metal cabinet. When installing one drive below another one, use a

metal separation between the AC motor drives to prevent mutual heating and to prevent the risk of

accidental fire.

Install the AC motor drive in Pollution Degree 2 environments only: normally only nonconductive

pollution occurs and temporary conductivity caused by condensation is expected.

The appearances shown in the following figures are for reference only.

Airflow direction:

Single drive installation

inflow outflow distance

Side-by-side horizontal installation

Minimum mounting clearance

o

Installation method A (mm) B (mm) C (mm)

Max. (Without derating) Max. (Derating)

Ambient temperature (

Single drive installation 50 30 - 50 60

Side-by-side horizontal installation 50 30 30 50 60

Zero stack installation 50 30 0 40 50

NOTE

The minimum mounting clearances A~C stated in the table above applies to AC motor drives installation. Failing to

follow the minimum mounting clearances may cause the fan to malfunction and heat dissipation problems.

C)

3-1

Page 21

Chapter 3 Installation MS300

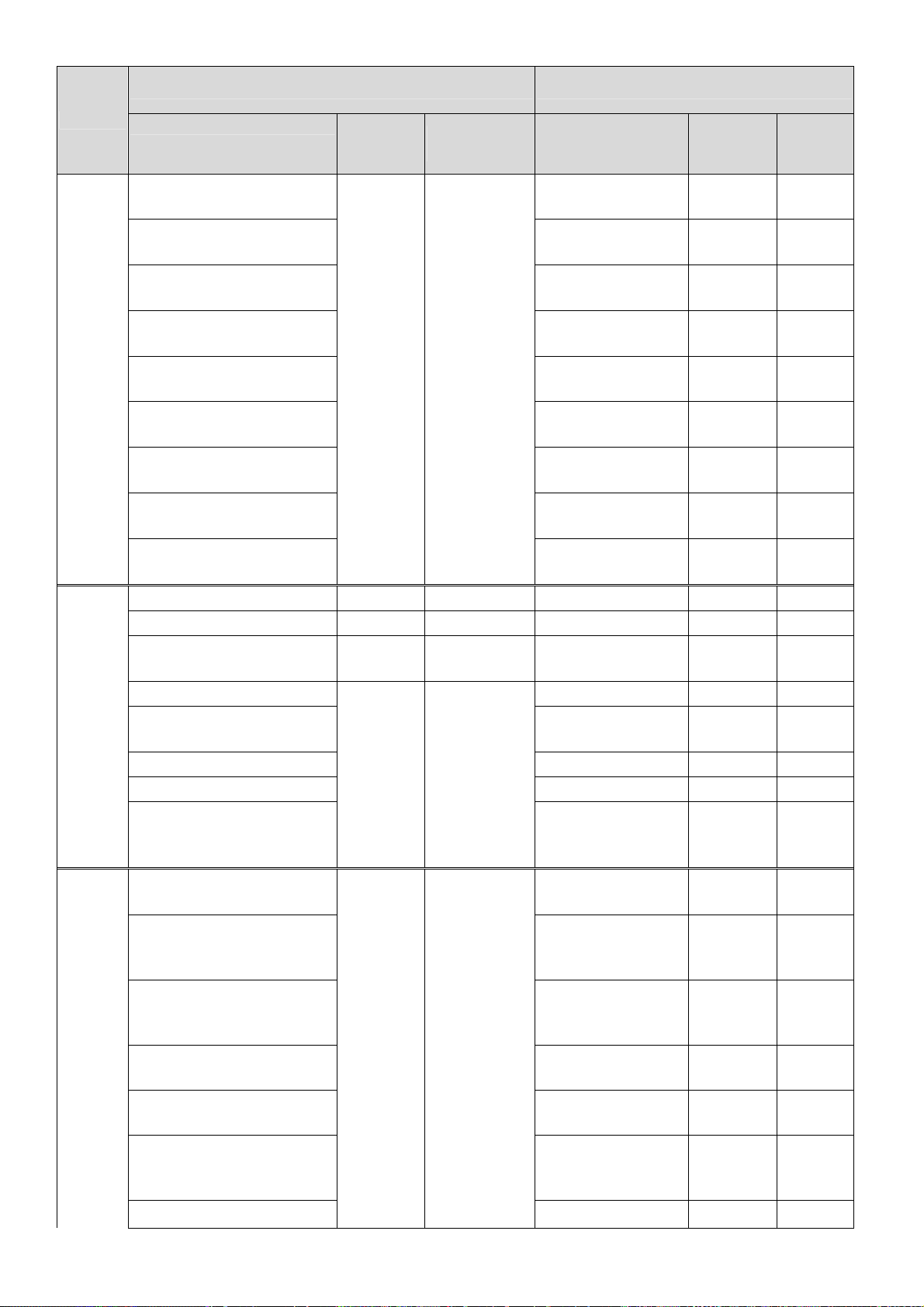

Air flow rate for cooling Power Dissipation

Frame

A

Model No.

VFD1A6MS11ANSAA

VFD1A6MS11ENSAA

VFD2A5MS11ANSAA

VFD2A5MS11ENSAA

VFD1A6MS21ANSAA

VFD1A6MS21ENSAA

VFD2A8MS21ANSAA

VFD2A8MS21ENSAA

VFD1A6MS23ANSAA

VFD1A6MS23ENSAA

VFD2A8MS23ANSAA

VFD2A8MS23ENSAA

VFD4A8MS23ANSAA

VFD4A8MS23ENSAA

VFD1A5MS43ANSAA

VFD1A5MS43ENSAA

VFD2A7MS43ANSAA

VFD2A7MS43ENSAA

Flow Rate

(Unit: cfm)

Flow Rate

(Unit: m3 / hr)

0.0 0.0

Loss External

(Heat sink, unit: W)

8.0 10.0 18.0

14.2 13.1 27.3

8.0 10.3 18.3

16.3 14.5 30.8

8.6 10.0 18.6

16.5 12.6 29.1

31.0 13.2 44.2

17.6 11.1 28.7

30.5 17.8 48.3

Internal

(Unit: W)

Total

(Unit: W)

B

C

VFD1A6MS21AFSAA 0.0 0.0 8.0 10.3 18.3

VFD2A8MS21AFSAA 10.0 16.99 16.3 14.5 30.8

VFD4A8MS21ANSAA

VFD4A8MS21ENSAA

VFD4A8MS21AFSAA

VFD7A5MS23ANSAA

VFD7A5MS23ENSAA

VFD1A5MS43AFSAA 17.6 11.1 28.7

0.0 0.0 29.1 20.1 49.2

29.1 20.1 49.2

50.1 24.2 74.3

10.0 16.99

VFD2A7MS43AFSAA 30.5 17.8 48.3

VFD4A2MS43ANSAA

VFD4A2MS43ENSAA

45.9 21.7 67.6

VFD4A2MS43AFSAA

VFD4A8MS11ANSAA

VFD4A8MS11ENSAA

29.1 23.9 53.0

VFD7A5MS21ANSAA

VFD7A5MS21ENSAA

46.5 31.0 77.5

VFD7A5MS21AFSAA

VFD11AMS21ANSAA

VFD11AMS21ENSAA

70.0 35 105

VFD11AMS21AFSAA

VFD11AMS23ANSAA

VFD11AMS23ENSAA

VFD17AMS23ANSAA

VFD17AMS23ENSAA

16.0 27.2

76.0 30.7 106.7

108.2 40.1 148.3

VFD5A5MS43ANSAA

VFD5A5MS43ENSAA

60.6 22.8 83.4

VFD5A5MS43AFSAA

VFD9A0MS43ANSAA 93.1 42 135.1

3-2

Page 22

Chapter 3 Installation MS300

Air flow rate for cooling Power Dissipation

Frame

D

E

F

Model No.

VFD9A0MS43ENSAA

VFD9A0MS43AFSAA

VFD25AMS23ANSAA

VFD25AMS23ENSAA

VFD13AMS43ANSAA

VFD13AMS43ENSAA

VFD13AMS43AFSAA

VFD17AMS43ANSAA

VFD17AMS43ENSAA

VFD17AMS43AFSAA

VFD33AMS23ANSAA

VFD33AMS23ENSAA

VFD49AMS23ANSAA

VFD49AMS23ENSAA

VFD25AMS43ANSAA

VFD25AMS43ENSAA

VFD25AMS43AFSAA

VFD32AMS43ANSAA

VFD32AMS43ENSAA

VFD32AMS43AFSAA

VFD65AMS23ANSAA

VFD65AMS23ENSAA

VFD38AMS43ANSAA

VFD38AMS43ENSAA

VFD38AMS43AFSAA

VFD45AMS43ANSAA

VFD45AMS43ENSAA

VFD45AMS43AFSAA

Flow Rate

(Unit: cfm)

23.4 39.7

53.7 91.2

67.9 115.2

Flow Rate

(Unit: m3 / hr)

Loss External

(Heat sink, unit: W)

192.8 53.3 246.1

132.8 39.5 172.3

164.7 55.8 220.5

244.5 79.6 324.1

374.2 86.2 460.4

234.5 69.8 304.3

319.8 74.3 394.1

492.0 198.2 690.2

423.5 181.6 605.1

501.1 200.3 701.4

Internal

(Unit: W)

Total

(Unit: W)

3-3

Page 23

Chapter 3 Installation MS300

[ This page intentionally left blank ]

3-4

Page 24

Chapter 4 WiringMS300

Chapter 4 Wiring

4-1 Wiring

4-2 System Wiring Diagram

4-1

Page 25

Chapter 4 WiringMS300

After removing the front cover, please check if the power and control terminals are clearly visible.

Please read following precautions to avoid wiring mistakes.

It is crucial to cut off the AC motor drive power before doing any wiring. A charge

may still remain in the DC bus capacitors with hazardous voltages even after the

DANGER

power has been turned off a short time. Therefore it is suggested to measure the

remaining voltage with a DC voltmeter on +1/DC+ and DC- before doing any

wiring. For your personnel saftery, please do not start wiring before the voltage

drops to a safe level < 25 Vdc. Wiring the installation with a remaning voltage

condition may cause injuries, sparks and short circuits.

Only qualified personnel familiar with AC motor drives is allowed to perform

installation, wiring and commissioning. Make sure the power is turned off before

wiring to prevent electric shocks.

The terminals R/L1、S/L2、T/L3 are for mains power input. If mains power is

wrongly connected to other terminals, it may result in damage to the equipment.

The voltage and current should lie within the range as indicated on the nameplate

(see Chapter 1-1).

All units must be grounded directly to a common ground terminal to prevent

electrical shocks or damage by lightning.

Please make sure to tighten the screw of the main circuit terminals to prevent

sparks due to the loosening of vibrations.

When wiring, please choose the wires with specification that complies with local

regulations for your personal safety.

Check following items after finishing the wiring:

1. Are all connections correct?

2. Any loose wires?

3. Any short-circuits between the terminals or to ground?

4-2

Page 26

4-1 Wiring

Chapter 4 WiringMS300

4-3

Page 27

Chapter 4 WiringMS300

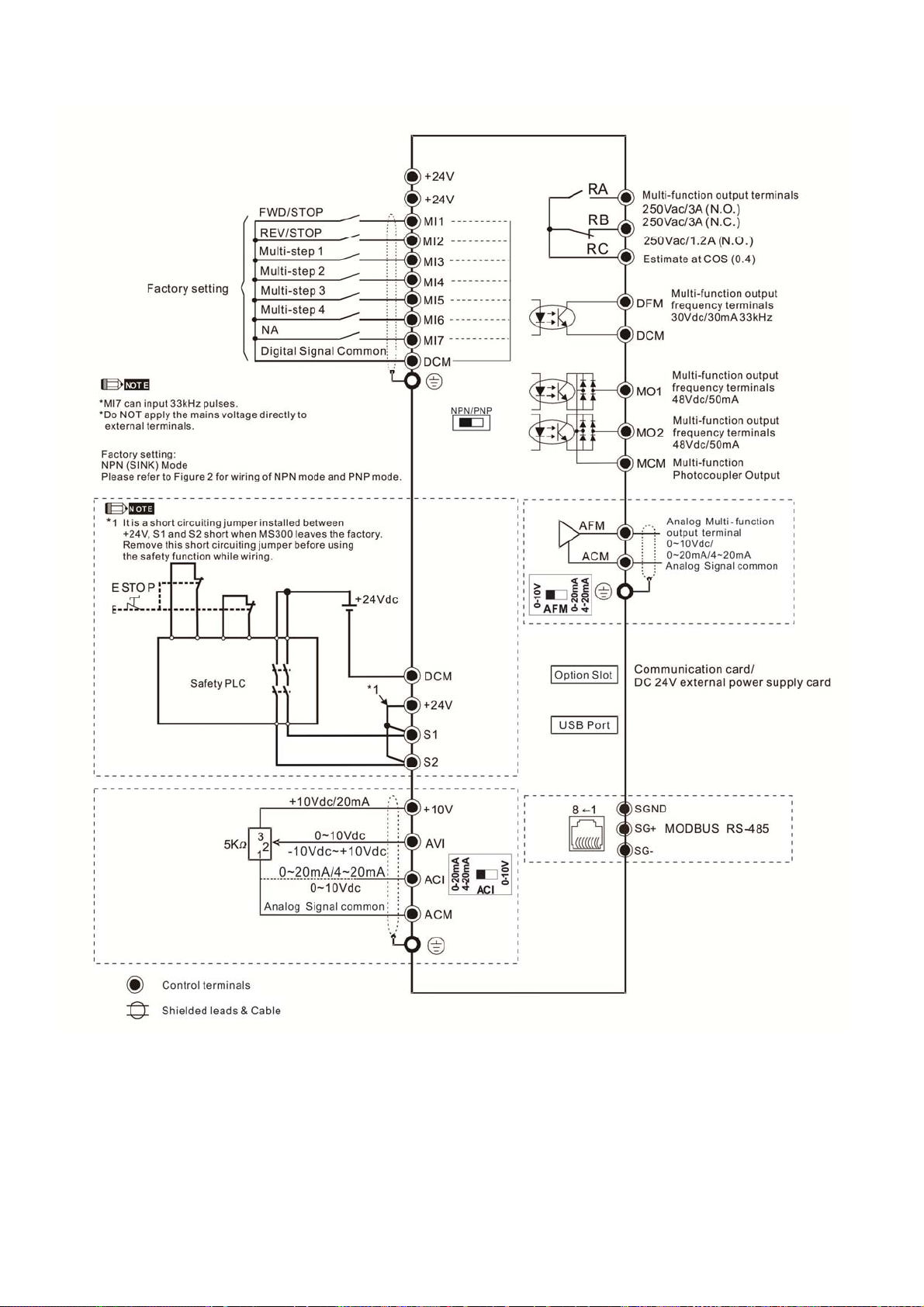

Figure 1

4-4

Page 28

Figure 2

SINK (NPN) / SOURCE (PNP) Mode

Chapter 4 WiringMS300

Sink Mode

with internal power (+24Vdc)

Sink Mode

with external power

internal

circuit

Source Mode

with internal power (+24Vdc)

Source Mode

with external power

internal

circuit

internal

circuit

external power +24V external power +24V

internal

circuit

4-5

Page 29

Chapter 4 WiringMS300

4-2 System Wiring Diagram

4-6

Page 30

Chapter 5 Main Circuit TerminalsMS300

Chapter 5 Main Circuit Terminals

5-1 Main Circuit Diagram

5-2 Main Circuit Terminals

5-1

Page 31

Chapter 5 Main Circuit TerminalsMS300

Fasten the main circuit terminal screws to prevent sparking by loose screws

due to vibration.

When needed, only use an inductive filter at the motor output terminals

DANGER

U/T1, V/T2, W/T3 of the AC motor drive. DO NOT use phase-compensation

capacitors or L-C (Inductance-Capacitance) or R-C

(Resistance-Capacitance), unless approved by Delta.

DO NOT connect brake resistor directly to +1/DC+ to DC-, +2/B1 to DC- to

prevent damage to the drive.

Ensure proper insulation of main circuit wiring in accordance with the

relevant safety regulations.

Main power terminals

R/L1, S/L2 and T/L3 have no phase-sequence requirement; they can be

connected in any sequence.

It is recommended adding a magnetic contactor (MC) at the power input to

cut off power quickly and reduce malfunctioning when the protection

function of the AC motor drive is activated. Both ends of the MC should have

an R-C surge absorber.

Please ensure voltages and currents are within specification.

When using a general GFCI (Ground Fault Circuit Interrupter), select a

sensitivity ≥200mA and ≥0.1s operation time to avoid nuisance tripping.

Please use conduits or shielded cables for the power wiring and ground

both ends of the conduit or shielded cables.

DO NOT run/stop the drive by turning the power ON/OFF. Run/stop the

drive by RUN/STOP command. If you still need to run/stop the drive by

turning power ON/OFF, it is strongly recommended to do so only ONCE per

hour.

To comply with UL standards, connect the drive to a 3WYE type of mains

power system.

Output terminals for main circuit

Use a well-insulated motor, suitable for inverter operation.

When the AC drive output terminals U/T1, V/T2, and W/T3 are connected to

the motor terminals U/T1, V/T2, and W/T3 respectively, the motor will rotate

counterclockwise (as viewed on the shaft end of the motor) when a forward

operation command is received. To permanently reverse the direction of

rotation, switch over any two motor leads.

Fo wa rd

Running

5-2

Page 32

1+2

/B1

2

/B1

2

Chapter 5 Main Circuit TerminalsMS300

Terminals for connecting DC reactor, external brake resistor and DC

circuit

These are the terminals for connecting the DC-reactor to improve the power

factor and harmonics. At delivery they are shorted by a jumper. Please

remove it before connecting the DC reactor.

The jumper must be fastened tight when it does not connect DC reactor, use

DC+/+1, +2/B1 to execute common DC bus, or connect with brake resistor,

otherwise the drive might lose power or the terminals will be broken.

DC reactor optional ( )

DC+/+

Connect a brake resistor in applications with frequent deceleration, short

deceleration time, too low braking torque or requiring increased braking

torque.

Brake res istor

(optional)

+

The external brake resistor should connect to the terminals [+2 / B1], [B2] of

AC motor drives.

DO NOT short circuit or connect a brake resistor directly to DC+/+1 and

DC-, +2/B1 to DC- otherwise the drive will be damaged.

DC+ and DC- are to be connected in common DC bus applications, please

refer to Chapter 5-1(Main Circuit Terminal) for the wiring terminal

specification and the wire gauge information.

B

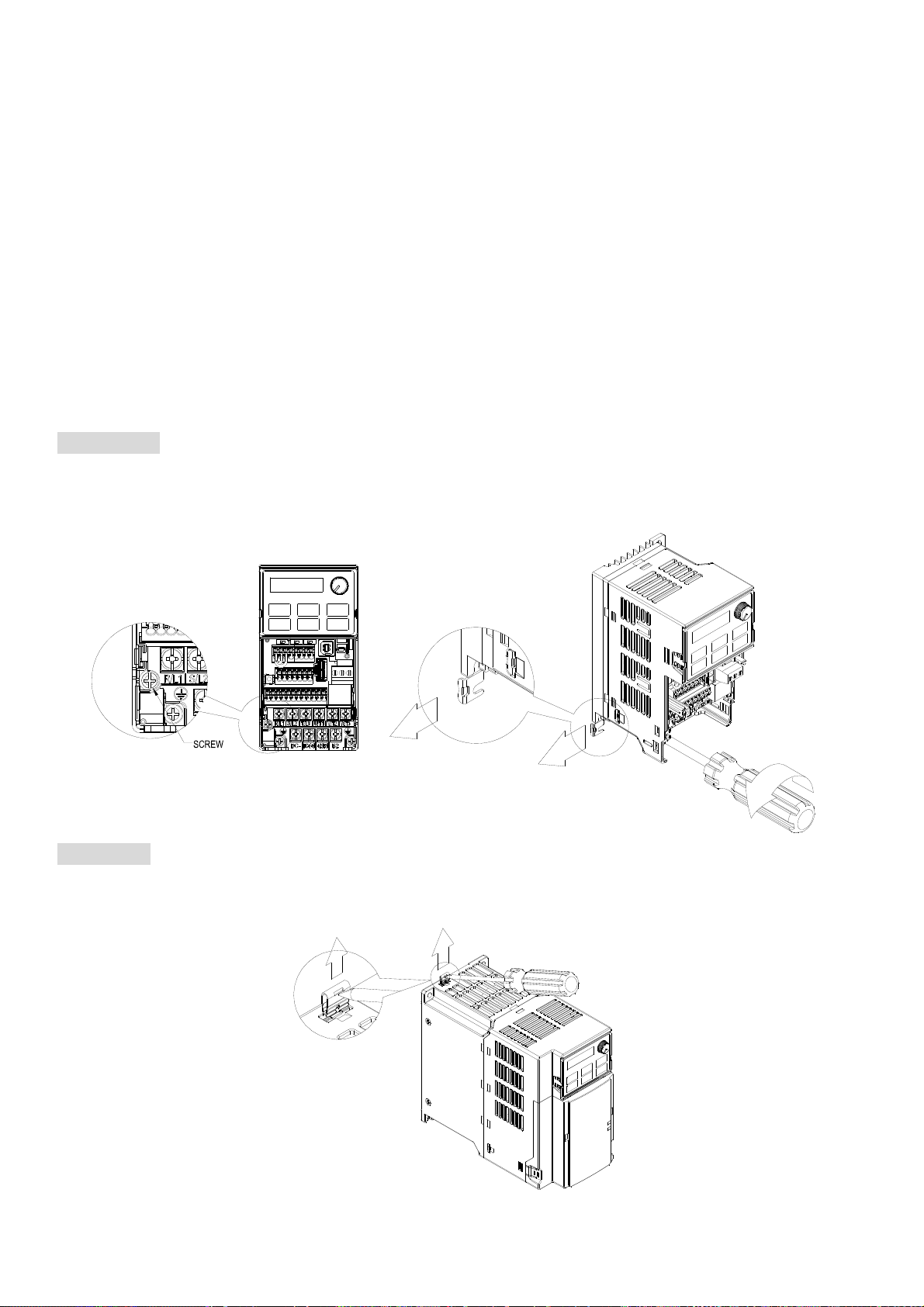

Remove the front cover

The front cover shall be removed before connecting the main circuit terminals and control circuit

terminals. Removing the cover acc. to the figure below.

The figure below shows Frame A model for example. Removing the cover on other frame sizes is

similar.

Press the clip on both sides, and take out by rotating.

5-3

Page 33

Chapter 5 Main Circuit TerminalsMS300

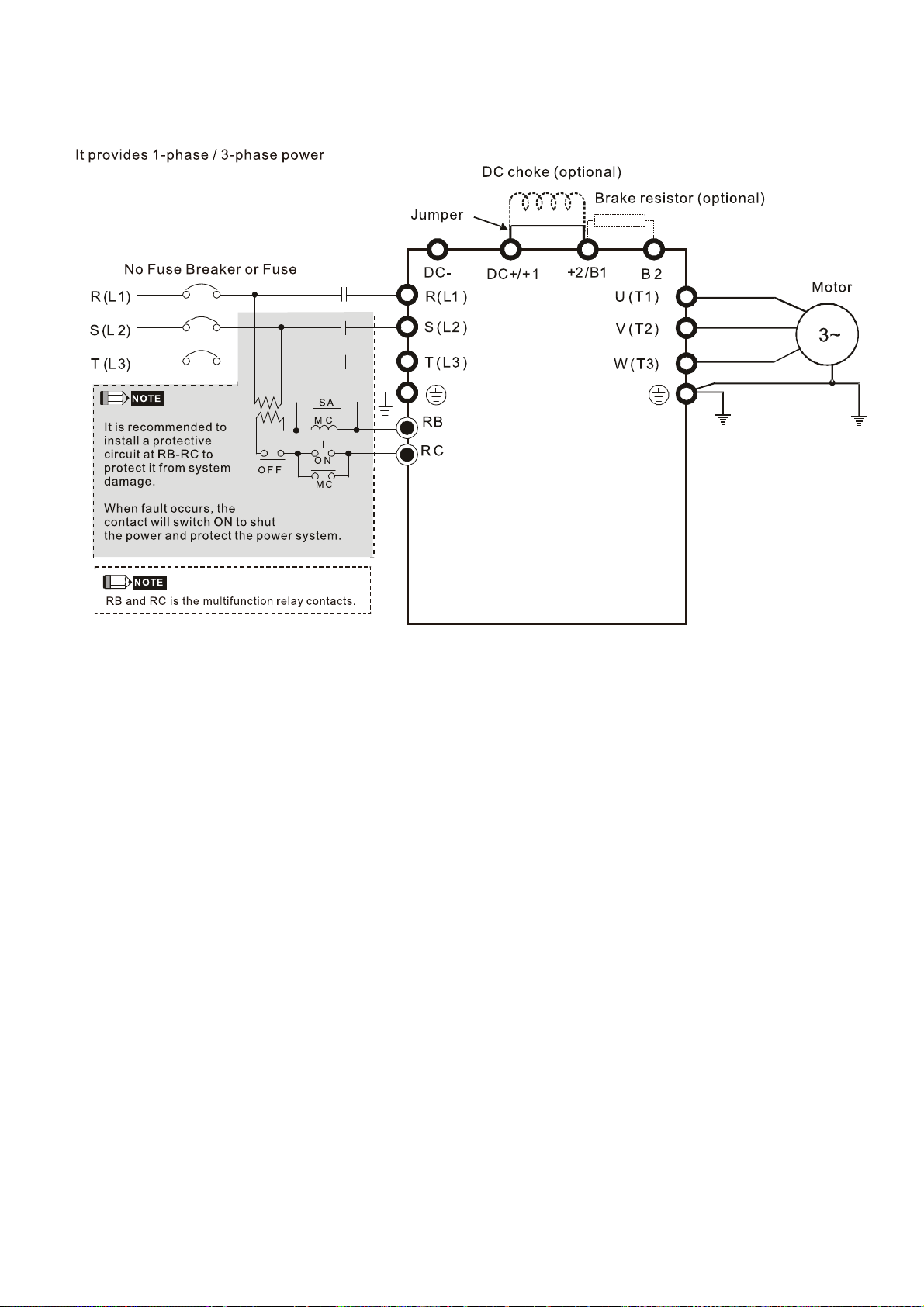

5-1 Main Circuit Diagram

Terminals Descriptions

R/L1, S/L2 Mains input terminals 1-phase

R/L1, S/L2, T/L3 Mains input terminals 3-phase

U/T1, V/T2, W/T3 Motor output terminals for connecting 3-phase

Connections for DC reactor to improve the power factor and harmonics.

+1, +2

The jumper needs to be removed in that case.

Connections for brake unit (VFDB series)

DC+, DC-

Common DC Bus

B1, B2 Connections for brake resistor (optional)

Earth connection, please comply with local regulations.

IM and PM motors.

5-4

Page 34

Chapter 5 Main Circuit TerminalsMS300

5-2 Main Circuit Terminals

It needs following additional terminal when wiring. The additional terminal dimension should comply

with the following figure 1.

After crimping the wire to the ring lug (must UL approved), UL and CSA approved R/C (YDPU2)

heat shrink tubing rated min 600Vac insulation shall be install over the live part. Please refer to the

following figure 2.

Dimensions of Ring Lug

Frame AWG

18

A

B

C

D

E

F

16

14

14

12

14

12

10

8

12

10

8

8

6

4

6

4

2

Kit P/N

RNBS

1-3.7

RNBS

2-3.7

RNBS

2-3.7

RNBS2-4

RNBS5-4

RNBS2-4

RNBS5-4

RNBS5-4

RNBS8-4

RNBS5-4

RNBS5-4

RNBS8-4

RNBS8-5

RNB14-5

RNBS22-5

RNBS14-6

RNBS22-6

RNBS38-6

A

(MAX) B (MAX)C (MIN)D (MAX)

9.8 3.2 4.8 4.1 3.7 13.0 4.2 6.6 0.8

12.1 3.6 6.1 5.6 4.3 13.0 4.5 7.2 1

17.8 5.0 6.1 7.2 4.3 13.0 5.5 8.0 1.2

17.8 5.0 6.1 7.2 4.3 13.0 5.5 8.0 1.2

27.1 6.1 10.5 11.5 5.3 13.0 6.5 12.2 1.7

35.0 9.0 13.3 14.0 6.2 13.0 19.5 18.0 1.8

d2

(MIN)E (MIN) F (MIN) W (MAX)t (MAX)

Unit: mm

5-5

Page 35

Chapter 5 Main Circuit TerminalsMS300

Frame A

Main circuit terminals:

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3,

,DC-, DC+/+1, +2/B1, B2,

Note: 1-phase model with no T/L3 terminal

Max.

Models

Wire

Gauge

VFD1A6MS11ANSAA

VFD1A6MS11ENSAA

VFD2A5MS11ANSAA

VFD2A5MS11ENSAA

VFD1A6MS21A SAA

VFD1A6MS21ENSAA

VFD2A8MS21ANSAA

VFD2A8MS21ENSAA

VFD1A6MS23ANSAA

VFD1A6MS23ENSAA

VFD2A8MS23ANSAA

VFD2A8MS23ENSAA

VFD4A8MS23ANSAA

VFD4A8MS23ENSAA

VFD1A5MS43ANSAA

VFD1A5MS43ENSAA

VFD2A7MS43ANSAA

VFD2A7MS43ENSAA

14 AWG

[2.1 mm

If you install at Ta 45°C above environment, please select copper

wire which have voltage rating 600V and temperature resistant 90°C

or above.

If you install at Ta 45°C environment, please select copper wire

which have voltage rating 600V and temperature resistant 75°C or

90°C.

For UL installation compliant, you have to use copper wires when

installation, the wire gauge is based on temperature resistant 75°C

which is according to the requirements and recommendations from

UL. Do not reduce the wire gauge when using higher temperature

wire.

Min. Wire

2

]

[0.82mm

[0.82mm

Gauge

16AWG

[1.3mm

14AWG

[2.1mm

16AWG

[1.3mm

14AWG

[2.1mm

18AWG

16AWG

[1.3mm

18AWG

Screw

2

]

2

]

2

]

2

]

M 3.5

2

]

2

]

2

]

Torque

(±10%)

9 kg-cm

[7.8 lb-in.]

[0.88 Nm]

5-6

Page 36

Chapter 5 Main Circuit TerminalsMS300

Frame B

Main circuit terminals:

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3,

,DC-, DC+/+1, +2/B1, B2,

Note: 1-phase model with no T/L3 terminal

Models

VFD1A6MS21AFSAA

VFD2A8MS21AFSAA

VFD4A8MS21ANSAA

VFD4A8MS21ENSAA

VFD4A8MS21AFSAA

VFD7A5MS23ANSAA

VFD7A5MS23ENSAA

VFD1A5MS43AFSAA

VFD2A7MS43AFSAA

VFD4A2MS43ANSAA

VFD4A2MS43ENSAA

VFD4A2MS43AFSAA

Max. Wire

Gauge

12 AWG

[3.3 mm

If you install at Ta 45°C above environment, please select copper

wire which have voltage rating 600V and temperature resistant 90°C

or above.

If you install at Ta 45°C environment, please select copper wire

which have voltage rating 600V and temperature resistant 75°C or

90°C.

For UL installation compliant, you have to use copper wires when

installation, the wire gauge is based on temperature resistant 75°C

which is according to the requirements and recommendations from

UL. Do not reduce the wire gauge when using higher temperature

wire.

Min. Wire

2

]

[2.1 mm2]

Gauge

14 AWG

Screw

M4

Torque

(±10%)

15 kg-cm

[13.0 lb-in]

[1.47 Nm]

5-7

Page 37

Chapter 5 Main Circuit TerminalsMS300

Frame C

Main circuit terminals:

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3,

,DC-, DC+/+1, +2/B1, B2,

Note: 1-phase model with no T/L3 terminal

Models

VFD4A8MS11ANSAA

VFD4A8MS11ENSAA

VFD7A5MS21ANSAA

VFD7A5MS21ENSAA

VFD7A5MS21AFSAA

VFD11AMS21ANSAA

VFD11AMS21ENSAA

VFD11AMS21AFSAA

VFD11AMS23ANSAA

VFD11AMS23ENSAA

VFD17AMS23ANSAA

VFD17AMS23ENSAA

VFD5A5MS43ANSAA

VFD5A5MS43ENSAA

VFD5A5MS43AFSAA

VFD9A0MS43ANSAA

VFD9A0MS43ENSAA

VFD9A0MS43AFSAA

Max. Wire

Gauge

8 AWG

[8.4 mm

If you install at Ta 45°C above environment, please select copper

wire which have voltage rating 600V and temperature resistant 90°C

or above.

If you install at Ta 45°C environment, please select copper wire

which have voltage rating 600V and temperature resistant 75°C or

90°C.

For UL installation compliant, you have to use copper wires when

installation, the wire gauge is based on temperature resistant 75°C

which is according to the requirements and recommendations from

UL. Do not reduce the wire gauge when using higher temperature

wire.

2

]

Min. Wire

Gauge

10 AWG

[5.3mm

[8.4mm

12 AWG

[3.3 mm

10 AWG

[5.3 mm

14 AWG

[2.1 mm

8 AWG

2

]

2

]

2

]

2

]

2

]

Screw

M4

Torque

(±10%)

20 kg-cm

[17.4 lb-in.]

[1.96 Nm]

5-8

Page 38

Chapter 5 Main Circuit TerminalsMS300

Frame D

Main circuit terminals:

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3,

, DC-, DC+/+1, +2/B1, B2,

Models

VFD25AMS23ANSAA

VFD25AMS23ENSAA

VFD13AMS43ANSAA

VFD13AMS43ENSAA

VFD13AMS43AFSAA

VFD17AMS43ANSAA

VFD17AMS43ENSAA

VFD17AMS43AFSAA

Max. Wire

Gauge

8 AWG

[8.4mm

If you install at Ta 45°C above environment, please select copper

wire which have voltage rating 600V and temperature resistant 90°C

or above.

If you install at Ta 45°C environment, please select copper wire

which have voltage rating 600V and temperature resistant 75°C or

90°C.

For UL installation compliant, you have to use copper wires when

installation, the wire gauge is based on temperature resistant 75°C

which is according to the requirements and recommendations from

UL. Do not reduce the wire gauge when using higher temperature

wire.

2

]

Min. Wire

Gauge

8 AWG

2

[8.4mm

10 AWG

[5.3mm

]

2

]

Screw

M4

Torque

(±10%)

20kg-cm

[17.4 lb-in.]

[1.96Nm]

5-9

Page 39

Chapter 5 Main Circuit TerminalsMS300

Frame E

Main circuit terminals:

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3,

, DC-, DC+/+1, +2/B1, B2,

Models

VFD33AMS23ANSAA

VFD33AMS23ENSAA

VFD49AMS23ANSAA**

VFD49AMS23ENSAA**

VFD25AMS43ANSAA

VFD25AMS43ENSAA

VFD25AMS43AFSAA

VFD32AMS43ANSAA

VFD32AMS43ENSAA

VFD32AMS43AFSAA

Max. Wire

Gauge

6 AWG

[13.3 mm

4 AWG

[21.2 mm

6 AWG

[13.3 mm

If you install at Ta 45°C above environment, please select copper wire

which have voltage rating 600V and temperature resistant 90°C or

above.

If you install at Ta 45°C environment, please select copper wire which

have voltage rating 600V and temperature resistant 75°C or 90°C.

For UL installation compliant, you have to use copper wires when

installation, the wire gauge is based on temperature resistant 75°C

which is according to the requirements and recommendations from UL.

Do not reduce the wire gauge when using higher temperature wire.

** These drives must be wired with ring terminal that dimensions are

specified.

Min. Wire

2

]

[13.3 mm2]

2

]

[21.2 mm2]

2

]

[8.4 mm2]

Gauge

6 AWG

4 AWG

8 AWG

Screw

M5

Torque

(±10%)

25 kg-cm

[21.7 lb-in.]

[2.45 Nm]

5-10

Page 40

Chapter 5 Main Circuit TerminalsMS300

Frame F

Main circuit terminals:

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3,

, DC-, DC+/+1, +2/B1, B2,

Models

VFD65AMS23ANSAA

VFD65AMS23ENSAA

VFD38AMS43ANSAA

VFD38AMS43ENSAA

VFD38AMS43AFSAA

VFD45AMS43ANSAA

VFD45AMS43ENSAA

VFD45AMS43AFSAA

Max. Wire

Gauge

2 AWG

[33.6 mm

If you install at Ta 45°C above environment, please select copper

wire which have voltage rating 600V and temperature resistant 90°

C or above.

If you install at Ta 45°C environment, please select copper wire

which have voltage rating 600V and temperature resistant 75°C or

90°C.

For UL installation compliant, you have to use copper wires when

installation, the wire gauge is based on temperature resistant 75°C

which is according to the requirements and recommendations from

UL. Do not reduce the wire gauge when using higher temperature

wire.

Min. Wire

Gauge

2 AWG

[33.6 mm

6 AWG

[13.3 mm

2

]

4 AWG

[21.2 mm

2

]

2

]

2

]

Screw

M6

Torque

(±10%)

40 kg-cm

[34.7 lb-in.]

[3.92 Nm]

5-11

Page 41

Chapter 5 Main Circuit TerminalsMS300

[ This page intentionally left blank ]

5-12

Page 42

Chapter 6 Control TerminalsMS300

Chapter 6 Control Terminals

Analog input terminals (AVI, ACI, ACM)

Analog input signals are easily affected by external noise. Use shielded wiring and

keep it as short as possible (<20 m) with proper grounding. If the noise is

inductive, connecting the shield to terminal ACM can bring improvement.

Use twisted-pair for weak analog signals.

If the analog input signals are affected by noise from the drive, please connect a

capacitor and ferrite core as indicated in the following diagram.

Wind each wire 3

times or more

around the core

Ferrite core

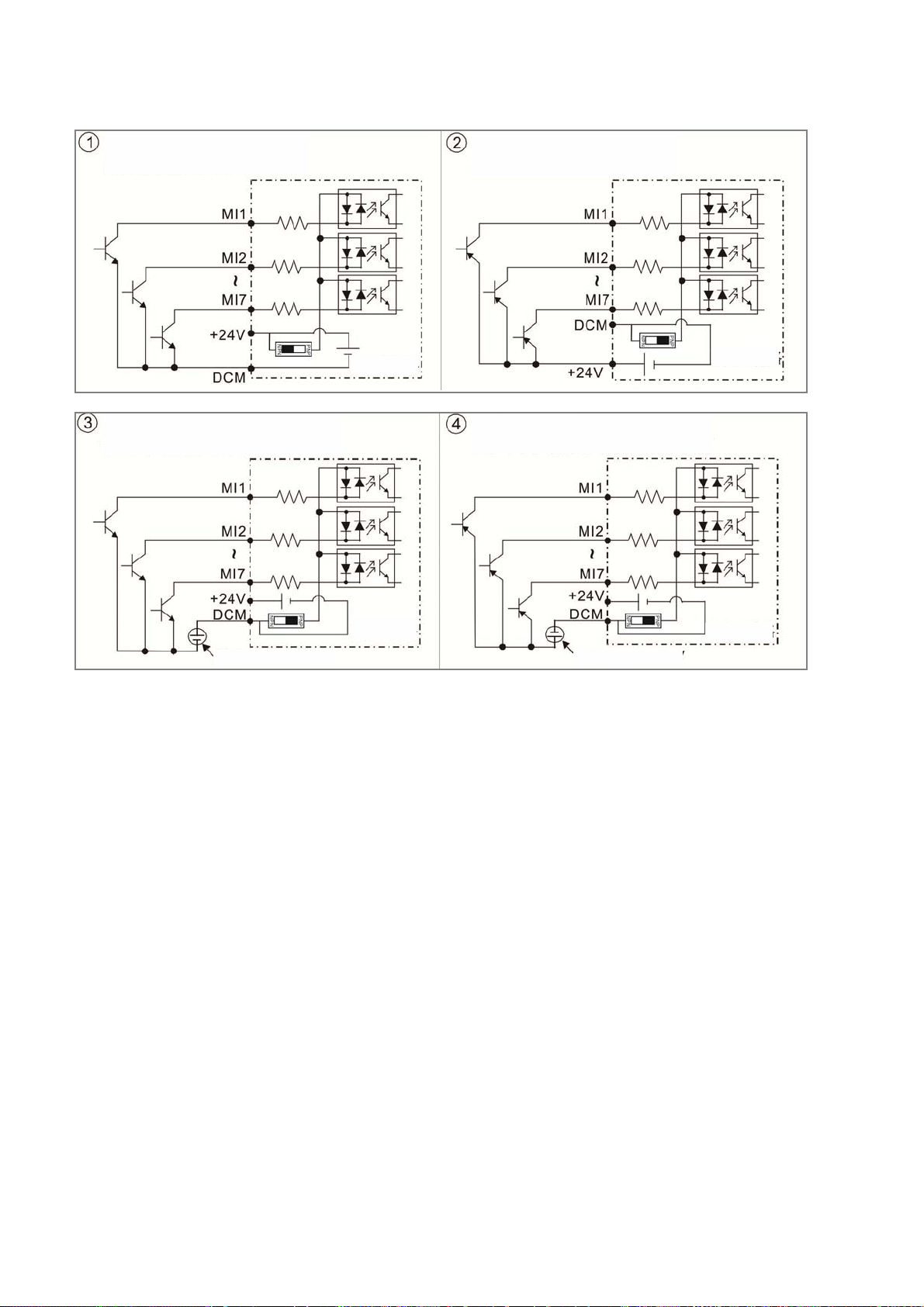

Contact input terminals(MI1~MI7, DCM, +24V)

Sink Mode

with internal power (+24Vdc)

Source Mode

with internal power (+24V dc)

internal

circuit

internal

circuit

Sink Mode

with external power

internal

circuit

exter nal power + 24V exter nal power + 24V

Source Mode

with external power

internal

circuit

When the photo-coupler is using internal power supply, the switch connection for Sink

and Source as below: MI-DCM: Sink mode, MI-+24 V: Source mode

Transistor Output Terminal (MO1, MO2, MCM)

Make sure to connect the digital outputs to the right polarity, see wiring diagram

When connecting a relay to the digital output, connect a surge absorber across the

coil and check the polarity.

6-1

Page 43

(

Chapter 6 Control TerminalsMS300

Specifications of Control Terminal

Specifications of RELAY Terminal

Wire Gauge: 20~18AWG [0.519~0.82 mm2]

Wire Gauge: 24~16 AWG [0.205~1.3 mm2];

Torque: 5 kg-cm / [4.3 Ib-in.] / [0.49 Nm]

4-20mA

0-20mA

ACI

S1

+24V

Safety function

+10V

MI1

MI2

MI3

0-10V

ACM

MI4

S2

0-10V

AFM

AVI

DCM

MI5

SG+

ACI

MI6

4-20mA

0-20mA

SG-

AFM

MI7

NPN

SGND

MO1

+24V

MCM

MO2

+24V

DCM

USB

DATAMATRIX

24P

32637012

SLOT 1

RELAY

DFM

DCM

RB

RA

RS485

Port

RC

PNP

Location Map of Control Terminal

Distribution Diagram of Control Terminal

Wiring precautions:

Delivery condition is +24V/ S1/ S2 shorted by jumper (as shown in figure above), please refer

to Chapter 4 Wiring for more details.

RELAY terminal is using PCB terminal block:

1. Tighten the wiring with slotted screwdriver, which is 3.5mm (wide) x 0.6mm (thick)

2. The ideal length of stripped wire at the connection side is 6~7mm.

3. When wiring bare wires, make sure they are perfectly arranged to go through the wiring

holes.

Control terminal is using spring clamp terminal block:

1. Tighten the wiring with slotted screwdriver, which is 2.5mm (wide) x 0.4mm (thick)

2. The ideal length of stripped wire at the connection side is 9mm.

3. When wiring bare wires, make sure they are perfectly arranged to go through the wiring

holes.

Wiring Specifications of Control Terminal

Conductor cross section solid

Conductor cross section stranded

Stranded with ferrules with plastic sleeve

Min. Wire Gauge Max. Wire Gauge

[0.519 mm

A B

14 8 3.5 1.4

Wire Gauge (AWG)

20 AWG

2

]

MAX)

D

18 AWG

[0.82 mm

20 AWG

[0.519 mm

W

2

]

2

]

Unit: mm

Ferrule: Type: AI 0,5 - 8 WH ,

Manufacturer: PHOENIX CONTACT

6-2

Page 44

r

Chapter 6 Control TerminalsMS300

Terminals Terminal Function Factory Setting (NPN mode)

+24V

MI1

~

MI7

DFM

DCM

MO1

Digital control signal common

(Source)

Multi-function input 1~7

Digital frequency meter

DFM

DCM

Digital frequency signal

common (Sink)

Multi-function Output 1

(photocoupler)

+24V ± 10 % 100 mA

Refer to parameters 02-01~02-07 to program the

multi-function inputs MI1~MI7.

Source Mode

ON: the activation current is 3.3 mA≧11Vdc

OFF: cut-off voltage≦5Vdc

Sink Mode

ON: the activation current is 3.3 mA ≦13Vdc

OFF: cut-off voltage≧19Vdc

When Pr. 02-00=0, MI1 and MI2 can be programmed

When Pr. 02-00≠0, the function of MI1 and MI2 is acc.

to Pr02-00 setting.

When Pr02-07=0, MI7 is pulse input with max.

frequency 33kHz (See Pr. 10-00, Pr. 10-02, Pr. 10-16)

DFM is a pulse-signal output; Duty-cycle: 50%

Min. load impedance R

: 1kΩ/100pf

L

Max. current: 30mA

Max. capacitive load: 100pF

Max. voltage: 30 Vdc ± 1 %

(when 30 Vdc / 30 mA /R

= 100 pf)

L

Max. output frequency: 33kHz

Internal current limiting resistor R: ≧1KΩ

Output load impedance R

L

Capacitive load≦100 pf

Resistive load≧1 kΩ,resistance determine the output

voltage value.

DFM-DCM voltage = external voltage * ( R

/ (RL+R) )

L

Programmable open-collector outputs, see Pr. 02-16 and

Pr. 02-17.

MO1

Multi-function Output 2

MO2

MO2

(photocoupler)

MCM

Multi-function Output

MCM

Max 48 Vdc 50 mA

Common

RA

Multi-function relay output 1

(Relay N.O. a)

Programmable relay output, see P

Resistive Load

3 A (N.O.) / 3 A (N.C.) 250 VAC

. 02-13.

5 A (N.O.) / 3 A (N.C.) 30 VDC

RB

Multi-function relay output 1

(Relay N.C. b)

Inductive Load (COS 0.4)

1.2 A (N.O.)/ 1.2 A (N.C.) 250 VAC

2.0 A (N.O.)/ 1.2 A (N.C.) 30 VDC

RC

Multi-function relay common

(Relay)

Various kinds of monitor signals output, e.g.: operation

frequency attained、overload indication etc..

6-3

、

Page 45

A

A

ACI

Chapter 6 Control TerminalsMS300

Terminals Terminal Function Factory Setting (NPN mode)

+10V Potentiometer power supply

Analog voltage input

AVI

internal circuit

internal circuit

nalog current input

ACI circuit

ACI

CM

internal circuit

+10.5 ± 0.5 Vdc / 20 mA

Programmable analog input, see Pr. 03-00

Impedance: 20kΩ

Range 0~Max. Output Frequency (Pr. 01-00):

0 ~ +10V / -10 ~ +10V

Range switching by Pr. 03-00 , Pr. 03-28

Programmable analog input, see Pr. 03-01

Impedance: 250Ω

Range 0~ Max. Output Frequency (Pr. 01-00):

0~20mA / 4~20mA / 0~10V

Range switching by Pr. 03-01 , Pr. 03-29

Multi-function analog voltage

output

Switch: the factory setting of AFM is 0~10V (Voltage

mode), use the switch and Pr. 03-31 to change to current

mode (0~20 mA / 4 mA~20 mA). Must follow the indication

on the back side of front cover or page 6-1 of user manual

when using the switch.

Voltage mode

Range: 0~10 V (Pr. 03-31=0) corresponding to the max.

AFM

operating range of the control object

Max. output current : 2 mA

Max. Load : 5 kΩ

Current mode

Range : 0~20 mA (Pr. 03-31=1) / 4 mA~20 mA (Pr.

03-31=2) corresponding to the max. operating

range of the control object

Max. load : 500 Ω

ACM Analog Signal Common Common for analog terminals

6-4

Page 46

Chapter 6 Control TerminalsMS300

Terminals Terminal Function Factory Setting (NPN mode)

Factory setting: S1/S2 shorted to +24V

Rated voltage: 24VDC ±10%; Max. voltage: 30VDC ±10%

S1,S2

Activation current: 6.67 mA ±10%

STO activation mode

Input voltage level: S1-DCM>0VDC or S2-DCM < 5VDC

STO response time ≤20ms (S1/S2 operate till the AC motor drive stop outputting current)

STO cut-off mode

DCM

Input voltage level: S1-DCM>11VDC and S2-DCM < 30VDC

Power removal safety function acc. to EN 954-1 and IEC / EN 61508

Note: Please refer to CH17 SAFE TORQUE OFF FUNCTION for more information.

SG+

SG-

SGND

Modbus RS-485

Note: Please refer to CH12 DESCRIPTION OF PARAMETER SETTINGS for more

information. (Pr. 12-09-1 to Pr. 12-09-17)

PIN 1, 2, 6: Reserved

PIN 3, 7: SGND

RJ-45

PIN 4: SG-

PIN 5: SG+

PIN 8: +10VS (provide KPC-CC01 power supply)

6-5

Page 47

Chapter 6 Control TerminalsMS300

[ This page intentionally left blank ]

6-6

Page 48

Chapter 7 Optional AccessoriesMS300

Chapter 7 Optional Accessories

7-1 All Brake Resistors and Brake Units Used in AC Motor Drives

7-2 Non-fuse Circuit Breaker

7-3 Fuse Specification Chart

7-4 AC/DC Reactor

7-5 Zero Phase Reactor

7-6 EMC Filter

7-7 EMC Shield Plate

7-8 Capacitive Filter

7-9 Conduit Box

7-10 Fan Kit

7-11 Keypad Panel Mounting

7-12 DIN-Rail Mounting

7-13 Mounting Adapter Plate

7-1

Page 49

Chapter 7 Optional Accessories MS300

The optional accessories listed in this chapter are available upon request. Installing additional

accessories to your drive would substantially improve the drive’s performance. Please select an

applicable accessory according to your need or contact the local distributor for suggestion.

7-1 All Brake Resistors and Brake Units Used in AC Motor Drives

115V 1-phase

Applicable

Motor

Model

HP KW

VFD1A6MS11XNSXX 0.25 0.2 0.1 80W 750Ω BR080W750 1 - 0.5 190.0 2 0.8

VFD2A5MS11XNSXX 0.5 0.4 0.3 80W 200Ω BR080W200 1 - 1.9 95.0 4 1.5

VFD4A8MS11XNSXX 1 0.75 0.5 80W 200Ω BR080W200 1 - 1.9 63.3 6 2.3

3

*

Braking

To rq u e

(kg-m)

*1 125 % Braking Torque 10 % ED *

Resistor value

spec. for each

AC motor Drive

Braking Resistor for

each Brake Unit

4

*

Part No.

Amount Usage

Braking

Current

(A)

Min.

Resistor

Value (Ω)

2

Max. Brake Torque

Max. Total

Braking

Current (A)

Peak

Power

(kW)

230V 1-phase

Model

VFD1A6MS21XNSXX

VFD1A6MS21AFSAA

VFD2A8MS21XNSXX

VFD2A8MS21AFSAA

VFD4A8MS21XNSXX

VFD4A8MS21AFSAA

VFD7A5MS21XNSXX

VFD7A5MS21AFSAA

VFD11AMS21XNSXX

VFD11AMS21AFSAA

Applicable

Motor

3

*

HP KW

0.25 0.2 0.1 80W 750Ω BR080W750 1 - 0.5 190.0 2 0.8

0.5 0.4 0.3 80W 200Ω BR080W200 1 - 1.9 95.0 4 1.5

1 0.75 0.5 80W 200Ω BR080W200 1 - 1.9 63.3 6 2.3

2 1.5 1 200W 91Ω BR200W091 1 - 4.2 47.5 8 3.0

3 2.2 1.5 300W 70Ω BR300W070 1 - 5.4 38.0 10 3.8

Braking

To rq u e

(kg-m)

*1 125 % Braking Torque 10 % ED *

Resistor value

spec. for each

AC motor Drive

Braking Resistor for

each Brake Unit

4

*

Part No.

Amount Usage

Braking

Current

(A)

Min.

Resistor

Value (Ω)

2

Max. Brake Torque

Max. Total

Braking

Current (A)

Peak

Power

(kW)

230V 3-phase

Applicable

Motor

Model

3

*

HP KW

VFD1A6MS23XNSXX 0.25 0.2 0.1 80W 750Ω BR080W750 1 - 0.5 190.0 2 0.8

VFD2A8MS23XNSXX 0.5 0.4 0.3 80W 200Ω BR080W200 1 - 1.9 95.0 4 1.5

VFD4A8MS23XNSXX 1 0.75 0.5 80W 200Ω BR080W200 1 - 1.9 63.3 6 2.3

VFD7A5MS23XNSXX 2 1.5 1 200W 91Ω BR200W091 1 - 4.2 47.5 8 3.0

VFD11AMS23XNSXX 3 2.2 1.5 300W 70Ω BR300W070 1 - 5.4 38.0 10 3.8

VFD17AMS23XNSXX 5 3.7 2.5 400W 40Ω BR400W040 1 - 9.5 19.0 20 7.6

VFD25AMS23XNSXX 7.5 5.5 3.7 1000W 20Ω BR1K0W020 1 - 19 16.5 23 8.7

VFD33AMS23XNSXX 10 7.5 5.1 1000W 20Ω BR1K0W020 1 - 19 14.6 26 9.9

VFD49AMS23XNSXX 15 11 7.4 1500W 13Ω BR1K5W013 1 - 29 12.6 29 11.0

VFD65AMS23XNSXX 20 15 10.2 2000W 8.6Ω

Braking

To rq u e

(kg-m)

*1 125 % Braking Torque 10 % ED *

Resistor value

spec. for each

AC motor Drive

Braking Resistor for

each Brake Unit

4

*

Part No.

BR1K0W4P3 2

Amount Usage

2 in

series

Braking

Current

(A)

44

2

Max. Brake Torque

Min.

Resistor

Value (Ω)

8.3 46 17.5

Max. Total

Braking

Current (A)

Peak

Power

(kW)

7-2

Page 50

460V 3-phase

Chapter 7 Optional AccessoriesMS300

Applicable

Motor

Model

3

*

HP KW

VFD1A5MS43XNSXX

VFD1A5MS43AFSAA

VFD2A7MS43XNSXX

VFD2A7MS43AFSAA

VFD4A2MS43XNSXX

VFD4A2MS43AFSAA

VFD5A5MS43XNSXX

VFD5A5MS43AFSAA

VFD9A0MS43XNSXX

VFD9A0MS43AFSAA

VFD13AMS43XNSXX

VFD13AMS43AFSAA

VFD17AMS43XNSXX

VFD17AMS43AFSAA

VFD25AMS43XNSXX

VFD25AMS43AFSAA

VFD32AMS43XNSXX

VFD32AMS43AFSAA

VFD38AMS43XNSXX

VFD38AMS43AFSAA

VFD45AMS43XNSXX

VFD45AMS43AFSAA

1

*

Standard braking torque is 125 %. Because of the limited resistor power, the longest operation time for 10% ED is 10sec. (on:

10 sec. / off: 90 sec.).

2

*

Please refer to the Brake Performance Curve for “Operation Duration & ED (%)” vs. “Braking Current”.

3

*

Calculation for braking torque is for a 4-pole motor 1800 rpm.

4

*

Resistors of 400W or lower should be fixed to the frame and at a surface temperature below 50°C.

0.5 0.4 0.3 80W 750Ω BR080W750 1 1 380.0 2 1.5

1 0.75 0.5 80W 750Ω BR080W750 1 1 190.0 4 3.0

2 1.5 1 200W 360Ω BR200W360 1 2.1 126.7 6 4.6

3 2.2 1.5 300W 250Ω BR300W250 1 3 108.6 7 5.3

5 3.7 2.5 400W 150Ω BR400W150 1 5.1 84.4 9 6.8

7.5 5.5 3.7 1000W 75Ω BR1K0W075 1 10.2 50.7 15 11.4

10 7.5 5.1 1000W 75Ω BR1K0W075 1 10.2 40.0 19 14.4

15 11 7.4 1500W 43Ω BR1K5W043 1 17.6 33.0 23 17.5

20 15 10.2 2000W 32Ω BR1K0W016 2

25 18 12.2 2000W 32Ω BR1K0W016 2

30 22 14.9 3000W 26Ω BR1K5W013 2

Braking

To rq u e

(kg-m)

Resistors of 1000W and above should be fixed on a surface with temperature below 350°C

*1 125 % Braking Torque 10 % ED *

Resistor value

spec. for each

AC motor Drive

Braking Resistor for

each Brake Unit

4

*

Part No.

Amount Usage

2 in

series

2 in

series

2 in

series

Braking

Current

(A)

24 26.2 29 22.0

24 26.2 29 22.0

29 23.0 33 25.1

2

Max. Brake Torque

Min.

Resistor

Value (Ω)

Max. Total

Braking

Current (A)

NOTE

1. Please select the resistance value, power and brake usage (ED %) acc. to Delta rules.

Definition for Brake Usage ED%

Explanation: ED (%) is defined to allow enough time for

the brake unit and brake resistor to

dissipate the heat generated by braking.

Recommended cycle time T0 is one

minute.

Peak

Power

(kW)

For safety concern, install a thermal overload relay (O.L) between the brake unit and the brake resistor in

conjunction with the magnetic contactor (MC) before to the drive for additional protection. The purpose of the

thermal overload relay is to protect the brake resistor from damage due to frequent or continuous braking.

Under such circumstances, just turn off the power to prevent damaging the brake resistor, brake unit and

drive.

2. If the drive or other equipment is damaged due to the fact that the brake resistors and brake modules in use

are not provided by Delta, warranty will be void.

7-3

Page 51

Trip

pin

g

tim

e

Chapter 7 Optional Accessories MS300

3. Take the safety of the environment into consideration when installing the brake resistors. If the minimum

resistance value is to be used, consult local dealers for the calculation of the power.

4. When using more than 2 brake units, equivalent resistor value of parallel brake unit can’t be less than the

value in the column “Minimum Equivalent Resistor Value for Each AC Drive” (the right-most column in the

table). Please read the wiring information in the user manual of brake unit thoroughly prior to operation

5. Thermal Overload Relay (TOR):

To choose a thermal overload relay is based on its overload capacity whether is appropriate to MS300. The

standard braking capacity of MS300 is 10% ED (Tripping time=10s). As shown in the figure below, thermal

overload relay continuously operates for 10 sec. and it can stand 260% overload (Host starting). Take a 460V,

15kW of MS300 as an example, its braking current is 24A (refer to the table on page 7-3), thus it can use the

thermal overload relay which rated current is 10A (10*260%=26A > 24A).

60

40

30

20

10

8

6

Second

4

3

2

1

0.8

0.6

0.4

0.3

0.8 1

2

1.5

Multiple of current setting

3

4

5

6810 1579

xln (A)

7-4

Page 52

7-2 Non-fuse Circuit Breaker

Comply with UL standard: Per UL 508, paragraph 45.8.4, part a.

Chapter 7 Optional AccessoriesMS300

Model

VFD1A6MS11ANSXX

VFD1A6MS11ENSXX

VFD2A5MS11ANSXX

VFD2A5MS11ENSXX

VFD4A8MS11ANSXX

VFD4A8MS11ENSXX

VFD1A6MS21ANSXX

VFD1A6MS21ENSXX

VFD1A6MS21AFSXX

VFD2A8MS21ANSXX

VFD2A8MS21ENSXX

VFD2A8MS21AFSXX

VFD4A8MS21ANSXX

VFD4A8MS21ENSXX

VFD4A8MS21AFSXX

VFD7A5MS21ANSXX

VFD7A5MS21ENSXX

VFD7A5MS21AFSXX

VFD11AMS21ANSXX

VFD11AMS21ENSXX

VFD11AMS21AFSXX

VFD1A6MS23ANSXX

VFD1A6MS23ENSXX

Voltage / 1-phase

(3-phase)

115V / 1φ

230V / 1φ

Current Input / Output (Max.) Breaker rating Input (A)

Normal duty Heavy duty Normal duty Heavy duty

6.8 A / 1.8 A 6.0 A / 1.6 A 17.68 20

10.1 A / 2.7 A 9.4 A / 2.5 A 26.26 25

20.6 A / 5.5 A 18.0 A / 4.8 A 53.56 50

3.8 A / 1.8 A 3.4 A / 1.6 A 9.88 15

6.7 A / 3.2 A 5.9 A / 2.8 A 17.42 20

10.5 A / 5.0 A 10.1 A / 4.8 A 27.3 30

17.9 A / 8.5 A 15.8 A / 7.5 A 46.54 45

26.3 A / 12.5 A 23.1 A / 11.0 A 68.38 70

2.2 A / 1.8 A 1.9 A / 1.6 A 5.72 15

VFD2A8MS23ANSXX

VFD2A8MS23ENSXX

VFD4A8MS23ANSXX

VFD4A8MS23ENSXX

VFD7A5MS23ANSXX

VFD7A5MS23ENSXX

VFD11AMS23ANSXX

VFD11AMS23ENSXX

VFD17AMS23ANSXX

VFD17AMS23ENSXX

VFD25AMS23ANSXX

VFD25AMS23ENSXX

VFD33AMS23ANSXX

VFD33AMS23ENSXX

VFD49AMS23ANSXX

VFD49AMS23ENSXX

VFD65AMS23ANSXX

VFD65AMS23ENSXX

VFD1A5MS43ANSXX

VFD1A5MS43ENSXX

VFD1A5MS43AFSXX

3.8 A / 3.2 A 3.4 A / 2.8 A 9.88 15

6.0 A / 5.0 A 5.8 A / 4.8 A 15.6 15

9.6 A / 8.0 A 9.0 A / 7.5 A 24.96 25

15.0 A / 12.5 A 13.2 A / 11.0 A 39 40

230V / 3φ

23.4 A / 19.5 A 20.4 A / 17.0 A 60.84 60

32.4 A / 27.0 A 30.0 A / 25.0 A 64.8 63

43.2 A / 36.0 A 39.6 A / 33.0 A 86.4 90

61.2 A / 51.0 A 58.8 A / 49.0 A 122.4 125

30.8 A / 28.0 A 27.5 A / 25.0 A 165.6 160

460V / 3φ 2.5 A / 1.8 A 2.1 A / 1.5 A 5.2 15

7-5

Page 53

Chapter 7 Optional Accessories MS300

Model

VFD2A7MS43ANSXX

VFD2A7MS43ENSXX

VFD2A7MS43AFSXX

VFD4A2MS43ANSXX

VFD4A2MS43ENSXX

VFD4A2MS43AFSXX

VFD5A5MS43ANSXX

VFD5A5MS43ENSXX

VFD5A5MS43AFSXX

VFD9A0MS43ANSXX

VFD9A0MS43ENSXX

VFD9A0MS43AFSXX

VFD13AMS43ANSXX

VFD13AMS43ENSXX

VFD13AMS43AFSXX

VFD17AMS43ANSXX

VFD17AMS43ENSXX

VFD17AMS43AFSXX

VFD25AMS43ANSXX

VFD25AMS43ENSXX

VFD25AMS43AFSXX

VFD32AMS43ANSXX

VFD32AMS43ENSXX

VFD32AMS43AFSXX

VFD38AMS43ANSXX

VFD38AMS43ENSXX

VFD38AMS43AFSXX

VFD45AMS43ANSXX

VFD45AMS43ENSXX

VFD45AMS43AFSXX

Voltage / 1-phase

(3-phase)

460V / 3φ

Current Input / Output (Max.) Breaker rating Input (A)

Normal duty Heavy duty Normal duty Heavy duty

4.2 A / 3.0 A 3.7 A / 2.7 A 8.58 15

6.4 A / 4.6 A 5.8 A / 4.2 A 13.26 15

7.2 A / 6.5 A 6.1 A / 5.5 A 18.72 20

11.6 A / 10.5 A 9.9 A / 9.0 A 30.16 30

17.3 A / 15.7 A 14.3 A / 13.0 A 34.6 32

22.6 A / 20.5 A 18.7 A / 17.0 A 45.2 45

30.8 A / 28.0 A 27.5 A / 25.0 A 61.6 60

39.6 A / 36.0 A 35.2 A / 32.0 A 79.2 80

45.7 A / 41.5 A 41.8 A / 38.0 A 91.4 90

53.9 A / 49.0 A 49.5 A / 45.0 A 107.8 100

7-6

Page 54

Chapter 7 Optional AccessoriesMS300

7-3 Fuse Specification Chart

The fuse specifications lower than below table is allowed.

For installation in the United States, branch circuit protection must be provided in

accordance with the National Electrical Code (NEC) and any applicable local codes.

To fulfill this requirement, use the UL classified fuses.

For installation in Canada, branch circuit protection must be provided in accordance with

Canadian Electrical Code and any applicable provincial codes. To fulfill this requirement,

use the UL classified fuses.

Model

VFD1A6MS11ANSXX

VFD1A6MS11ENSXX

VFD2A5MS11ANSXX

VFD2A5MS11ENSXX

VFD4A8MS11ANSXX

VFD4A8MS11ENSXX

VFD1A6MS21ANSXX

VFD1A6MS21ENSXX

VFD1A6MS21AFSXX

VFD2A8MS21ANSXX

VFD2A8MS21ENSXX

VFD2A8MS21AFSXX

VFD4A8MS21ANSXX

VFD4A8MS21ENSXX

VFD4A8MS21AFSXX

VFD7A5MS21ANSXX

VFD7A5MS21ENSXX

VFD7A5MS21AFSXX

Voltage/ 1-phase

(3-phase)

115V / 1φ

230V / 1φ

Current Input / Output (Max.)

Normal duty Heavy duty

6.8 A / 1.8 A 6.0 A / 1.6 A

10.1 A / 2.7 A 9.4 A / 2.5 A

20.6 A / 5.5 A 18.0 A / 4.8 A

3.8 A / 1.8 A 3.4 A / 1.6 A

6.7 A / 3.2 A 5.9 A / 2.8 A

10.5 A / 5.0 A 10.1 A / 4.8 A

17.9 A / 8.5 A 15.8 A / 7.5 A

Branch Circuit Fuses Output

(A)

7.2

Class T JJS-10

10.8

Class T JJS-10

22

Class T JJS-25

7.2

Class T JJS-10

12.8

Class T JJS-15

20

Class T JJS-20

34

Class T JJS-35

VFD11AMS21ANSXX

VFD11AMS21ENSXX

VFD11AMS21AFSXX

VFD1A6MS23ANSXX

VFD1A6MS23ENSXX

VFD2A8MS23ANSXX

VFD2A8MS23ENSXX

VFD4A8MS23ANSXX

VFD4A8MS23ENSXX

VFD7A5MS23ANSXX

VFD7A5MS23ENSXX

VFD11AMS23ANSXX

VFD11AMS23ENSXX

VFD17AMS23ANSXX

VFD17AMS23ENSXX

VFD25AMS23ANSXX

VFD25AMS23ENSXX

230V / 3φ

50

26.3 A / 12.5 A 23.1 A / 11.0 A

Class T JJS-50

7.2

2.2 A / 1.8 A 1.9 A / 1.6 A

Class T JJS-10

12.8

3.8 A / 3.2 A 3.4 A / 2.8 A

Class T JJS-15

20

6.0 A / 5.0 A 5.8 A / 4.8 A

Class T JJS-20

32

9.6 A / 8.0 A 9.0 A / 7.5 A

Class T JJS-35

50

15.0 A / 12.5 A 13.2 A / 11.0 A

Class T JJS-50

78

23.4 A / 19.5 A 20.4 A / 17.0 A

Class T JJS-80

59.4

32.4 A / 27.0 A 30.0 A / 25.0 A

Class T JJS-60

7-7

Page 55

Chapter 7 Optional Accessories MS300

Model

VFD33AMS23ANSXX

VFD33AMS23ENSXX

VFD49AMS23ANSXX

VFD49AMS23ENSXX

VFD65AMS23ANSXX

VFD65AMS23ENSXX

VFD1A5MS43ANSXX

VFD1A5MS43ENSXX

VFD1A5MS43AFSXX

VFD2A7MS43ANSXX

VFD2A7MS43ENSXX

VFD2A7MS43AFSXX

VFD4A2MS43ANSXX

VFD4A2MS43ENSXX

VFD4A2MS43AFSXX

VFD5A5MS43ANSXX

VFD5A5MS43ENSXX

VFD5A5MS43AFSXX

Voltage/ 1-phase

(3-phase)

Current Input / Output (Max.)

Normal duty Heavy duty

43.2 A / 36.0 A 39.6 A / 33.0 A

61.2 A / 51.0 A 58.8 A / 49.0 A

82.8 A / 69.0 A 78.0 A / 65.0 A

2.5 A / 1.8 A 2.1 A / 1.5 A

4.2 A / 3.0 A 3.7 A / 2.7 A

6.4 A / 4.6 A 5.8 A / 4.2 A

7.2 A / 6.5 A 6.1 A / 5.5 A

Branch Circuit Fuses Output

(A)

79.2

Class T JJS-80

112.2

Class T JJS-110

151.8

Class T JJS-150

7.2

Class T JJS-10

12

Class T JJS-15

18.4

Class T JJS-20

26

Class T JJS-25

VFD9A0MS43ANSXX

VFD9A0MS43ENSXX

VFD9A0MS43AFSXX

VFD13AMS43ANSXX

VFD13AMS43ENSXX

VFD13AMS43AFSXX

VFD17AMS43ANSXX

VFD17AMS43ENSXX

VFD17AMS43AFSXX

VFD25AMS43ANSXX

VFD25AMS43ENSXX

VFD25AMS43AFSXX

VFD32AMS43ANSXX

VFD32AMS43ENSXX

VFD32AMS43AFSXX

VFD38AMS43ANSXX

VFD38AMS43ENSXX

VFD38AMS43AFSXX

VFD45AMS43ANSXX

VFD45AMS43ENSXX

VFD45AMS43AFSXX

460V / 3φ

42

11.6 A / 10.5 A 9.9 A / 9.0 A

Class T JJS-45

34.54

17.3 A / 15.7 A 14.3 A / 13.0 A

Class T JJS-35

45.1

22.6 A / 20.5 A 18.7 A / 17.0 A

Class T JJS-45

61.6

30.8 A / 28.0 A 27.5 A / 25.0 A

Class T JJS-60

79.2

39.6 A / 36.0 A 35.2 A / 32.0 A

Class T JJS-80

91.3

45.7 A / 41.5 A 41.8 A / 38.0 A

Class T JJS-90

107.8

53.9 A / 49.0 A 49.5 A / 45.0 A

Class T JJS-110

7-8

Page 56

Chapter 7 Optional AccessoriesMS300

7-4 AC/DC Reactor

Installing an AC reactor in the input side of AC motor drive can increase line impedance, improve

power factor, reduce input current, and reduce interference generated from motor drive. Also momentary

voltage surges or abnormal current spikes are reduced. For example, when the mains power capacity is

higher than 500 kVA, or a switching capacitor bank is used, momentary voltage and current spikes may

damage the AC motor drive’s internal circuit. An AC reactor in the input side of the AC motor drive

protects it by suppressing surges.

Installation

An AC input reactor is installed in series with the mains power to the three input phases R S T as

shown below:

AC reactor

Power inputs

Connecting an AC input reactor

115V / 1ø Normal duty / Heavy duty

115V / 50~60 Hz MS Series Normal Duty / Heavy Duty Input AC Reactor

Model

VFD1A6MS11ANSAA

VFD1A6MS11ENSAA

VFD2A5MS11ANSAA

VFD2A5MS11ENSAA

VFD4A8MS11ANSAA

VFD4A8MS11ENSAA

Rated Current

ND / HD (A

rms

)

Current (A

1.8 / 1.6 2.7 / 3.2 5.857 DR005D0585 5.857 DR005D0585

2.7 / 2.5 4.05 / 5 5.857 DR005D0585 5.857 DR005D0585

5.5 / 5 8.25 / 9.6 3.66 DR008D0366 3.66 DR008D0366

(input side)

Saturation

ND / HD

Input/ Output

Reactor (mH)

)

rms

B1

+

E

R/L1 S/L2 T/L3

B2

-

E

W/T3

V/T2

U/T1

M

Input Reactor

Delta Part #

DC Reactor

(mH)

DC Reactor

Delta Part #

230V / 1ø Normal duty / Heavy duty

230V / 50~60Hz MS Series Normal Duty / Heavy Duty Input AC Reactor

Model

VFD1A6MS21ANSAA

VFD1A6MS21ENSAA

VFD1A6MS21AFSAA

VFD2A8MS21ANSAA

VFD2A8MS21ENSAA

VFD2A8MS21AFSAA

Rated Current

ND / HD (A

rms

)

Current (A

1.8 / 1.6 2.7 / 3.2 14.031 DR004D1403

3.2 / 2.8 4.8 / 5.6 5.857 DR005D0585

Saturation

ND / HD

rms

Input/ Output

Reactor (mH)

)

7-9

Input Reactor

Delta Part #

DC Reactor

(mH)

DC Reactor

Delta Part #

14.031 DR004D1403

5.857 DR005D0585

Page 57

Chapter 7 Optional Accessories MS300

230V / 50~60Hz MS Series Normal Duty / Heavy Duty Input AC Reactor

Saturation

ND / HD

)

Current (A

Model

Rated Current

ND / HD (A

rms

VFD4A8MS21ANSAA

VFD4A8MS21ENSAA

5 / 4.8 7.5 / 9.6 3.66 DR008D0366

VFD4A8MS21AFSAA

VFD7A5MS21ANSAA

VFD7A5MS21ENSAA

8.5 / 7.5 12.75 / 15 2.662 DR011D0266 2.662 DR011D0266

VFD7A5MS21AFSAA

VFD11AMS21ANSAA

VFD11AMS21ENSAA

12.5 / 11 18.75 / 22 1.722 DR017D0172

VFD11AMS21AFSAA

230V / 3ø Phase Normal Duty / Heavy Duty

230V / 50~60Hz MS Series Normal Duty / Heavy Duty Input AC Reactor

Saturation

ND / HD

)

Current (A

Model

VFD1A6MS23ANSAA

VFD1A6MS23ENSAA

VFD2A8MS23ANSAA

VFD2A8MS23ENSAA

VFD4A8MS23ANSAA

VFD4A8MS23ENSAA

VFD7A5MS23ANSAA

VFD7A5MS23ENSAA

VFD11AMS23ANSAA

VFD11AMS23ENSAA

VFD17AMS23ANSAA

VFD17AMS23ENSAA

VFD25AMS23ANSAA

VFD25AMS23ENSAA

VFD33AMS23ANSAA

VFD33AMS23ENSAA

VFD49AMS23ANSAA

VFD49AMS23ENSAA

VFD65AMS23ANSAA

VFD65AMS23ENSAA

Rated Current

ND / HD (A

rms

1.8 / 1.6 2.7 / 3.2 2.536 DR005A0254 5.857 DR005D0585

3.2 / 2.8 4.8 / 5.6 2.536 DR005A0254 5.857 DR005D0585

5 / 4.8 7.5 / 9.6 2.536 DR005A0254 5.857 DR005D0585

8 / 7.5 12 / 15 1.585 DR008A0159 3.66 DR008D0366

12.5 / 11 18.75 / 22 0.746 DR017AP746 2.662 DR011D0266

19.5 / 17 29.25 / 34 0.507 DR025AP507 1.722 DR017D0172

27 / 25 40.5 / 50 0.32 DR033AP320 1.172 DR025D0117

36 / 33 54 / 66 0.216 DR049AP215 0.851 DR033DP851

51 / 46 76.5 / 92 0.216 DR049AP215 0.574 DR049DP574

69 / 65 103.5 / 130 0.169 DR075AP170 0.432 DR065DP432

Input/ Output

Reactor (mH)

)

rms

Input/ Output

Reactor (mH)

)

rms

Input Reactor

Delta Part #

Input Reactor

Delta Part #

DC Reactor

(mH)

DC Reactor

Delta Part #

3.66 DR008D0366

1.722 DR017D0172

DC Reactor

(mH)

DC Reactor

Delta Part #

460V /3ø Normal Duty / Heavy Duty

460V/ 50~60Hz MS Series Normal Duty Input AC Reactor

Model

VFD1A5MS43ANSAA

VFD1A5MS43ENSAA

VFD1A5MS43AFSAA

Rated

Current

ND / HD

(A

)

rms

1.8 / 1.5 2.7 / 3 8.102 DR003A0810 18.709 DR003D1870

Saturation

ND / HD

Current (A

Input/ Output

Reactor (mH)

)

rms

7-10

Input Reactor

Delta Part #

DC Reactor

(mH)

DC Reactor

Delta Part #

Page 58

Model

VFD2A7MS43ANSAA

VFD2A7MS43ENSAA

VFD2A7MS43AFSAA

VFD4A2MS43AFSAA

VFD4A2MS43ANSAA

VFD4A2MS43ENSAA

VFD5A5MS43AFSAA

VFD5A5MS43ANSAA

VFD5A5MS43ENSAA

VFD9A0MS43AFSAA

VFD9A0MS43ANSAA

VFD9A0MS43ENSAA

VFD13AMS43AFSAA

VFD13AMS43ANSAA

VFD13AMS43ENSAA

VFD17AMS43AFSAA

VFD17AMS43ANSAA

VFD17AMS43ENSAA

VFD25AMS43AFSAA

VFD25AMS43ANSAA

VFD25AMS43ENSAA

VFD32AMS43AFSAA

VFD32AMS43ANSAA

VFD32AMS43ENSAA

VFD38AMS43AFSAA

VFD38AMS43ANSAA

VFD38AMS43ENSAA

VFD45AMS43AFSAA

VFD45AMS43ANSAA

VFD45AMS43ENSAA

Chapter 7 Optional AccessoriesMS300

460V/ 50~60Hz MS Series Normal Duty Input AC Reactor

Rated

Current

ND / HD

(A

)

rms

3 / 2.7 4.5 / 5.4 6.077 DR004A0607 18.709 DR003D1870

4.6 / 4.2 6.9 / 8.4 4.05 DR006A0405 14.031 DR004D1403

6.5 / 5.5 9.75 / 11 2.7 DR009A0270 9.355 DR006D0935

10.5 / 9 15.75 / 18 2.315 DR010A0231 5.345 DR010D0534

15.7 / 13 23.55 / 26 1.174 DR018A0117 3.119 DR018D0311

20.5 / 17 30.75 / 34 0.881 DR024AP881 3.119 DR018D0311

28 / 25 42 / 50 0.66 DR032AP660 2.338 DR024D0233

36 / 32 54 / 64 0.639 DR038AP639 1.754 DR032D0175

41.5 / 38 62.25 / 76 0.541 DR045AP541 1.477 DR038D0147

49 / 45 73.5 / 90 0.405 DR060AP405 1.247 DR045D0124

Saturation

ND / HD

Current (A

Input/ Output

Reactor (mH)

)

rms

Input Reactor

Delta Part #

DC Reactor

(mH)

DC Reactor

Delta Part #

7-11

Page 59

Chapter 7 Optional Accessories MS300

AC input reactor dimension and specification:

Screw Location Torque

Terminal 5.32~7.09 kg-cm / [6.12~8.16 lb-in.] / [0.6~0.8 Nm]

PE bolt 8.86~10.63 kg-cm / [10.2~12.24 lb-in.] / [1.0~1.2 Nm]

Input AC reactor

Delta part #

DR005A0254 96 100 60 6*9 42 60 40 M4

DR008A0159 120 120 88 6*12 60 80.5 60 M4

DR011A0115 120 120 88 6*12 60 80.5 60 M4

DR017AP746 120 120 93 6*12 65 80.5 60 M4

DR025AP507 150 150 112 6*12 88 107 75 M4

DR033AP320 150 150 112 6*12 88 107 75 M4

Unit:mm

A B C D1*D2 E G1 G2 PE D

7-12

Page 60

Chapter 7 Optional AccessoriesMS300

Screw Location Torque

Terminal 10.63~12.4 kg-cm / [12.24~14.28 lb-in.] / [1.2~1.4 Nm]