Delta Products MH300 Series, MS300 Series Catalog

Automation for a Changing World

Delta High Performance /

Standard Compact Drive

MH300 Series / MS300 Series

Compact and Intelligent

the new standard for Micro drives

The automation industry today continues to face challenges such as increasing competition and rising costs.

In addition to improving productivity and reducing labor, the driving force for automation is shifting to higher efciency,

optimal quality, and most importantly, exibility and compatibility for a wide range of applications.

Delta's MH300 and MS300 series are a new generation high performance and standard compact vector control drives

that inherit Delta’s superior drive technology—all in a compact drive that reduced 40% in size.

A variety of essential functions are built-in as standard, including: PLC capacity for simple programming needs, a

communication slot for various communication cards, and a USB port to make data uploads and downloads fast and

easy. This saves the need for additional hardware, while providing more installation space for the power cabinet.

Other key features include: Support for both IM and PM motor control for application exibility, an STO function

to ensure worry-free operation while protecting facilities from damage, and a simplied wiring process with a new

screwless wiring design of terminal blocks for quick installation.

Saving space, reducing setup and wiring time, and providing high efciency and stability system, the MH300 and

MS300 are your key to improving market competiveness and ensuring success.

1

Models Overview

Standard Models

High Speed Models

Exterior Design and Interfaces

Optional Cards

03 07

Optimized Space

Utilization

Compact Design

Side-by-Side Installation

Outstanding Drive

Performance

Support IM and PM Motors

High Starting Torque

Enhanced Braking Capability

08

Fast Response to Load Changes

Deceleration Energy Backup (DEB)

09

Stable, Safe and Reliable

Safety Standards Compliance

Enhanced Conformal Coating

Built-in EMC Filter

IP40 Models

11

12

Wide Range of Applications

Machine Tools

Woodworking Machines

Automatic Tool Changers (ATC)

Water Pumps

Packaging Machines

13 15

Textile Machines

Strong System Support

Multi-motor Control

Pulse Control

Built-in PLC

High Speed Applications

24 VDC Power Supply

High Overload Capability

Built-in Brake Chopper

Closed Loop Control

Supports Various Communications

Easy to Install

Application Parameter Settings

Built-in USB port

Screwless Wiring of Control Terminal

Specifications

Product Specifications

Wiring

Dimensions

Accessories

Model Name Explanation

Ordering Information

2

Models Overview

Standard Models

115V single-phase

Applicable Motor Output (kW) 0.2 0.4 0.75

Applicable Motor Output (HP) 0.25 0.5 1

Frame Size A C

230V single-phase

Applicable Motor Output (kW) 0.2 0.4 0.75 1.5 2.2

Applicable Motor Output (HP) 0.25 0.5 1 2 3

Frame Size A B C

230V single-phase (Built-in EMC filter)

Applicable Motor Output (kW) 0.2 0.4 0.75 1.5 2.2

Applicable Motor Output (HP) 0.25 0.5 1 2 3

Frame Size B C

230V 3-phase

Applicable Motor Output (kW) 0.2 0.4 0.75 1.5 2.2 3.7 / 4 5.5 7.5 11 15

Applicable Motor Output (HP) 0.25 0.5 1 2 3 5 7.5 10 15 20

Frame Size A B C D E F

460V 3-phase

Applicable Motor Output (kW) 0.4 0.75 1.5 2.2 3.7 / 4 5.5 7.5 11 15 18.5 22

Applicable Motor Output (HP) 0.5 1 2 3 5 7.5 10 15 20 25 30

Frame Size A B C D E F

460V 3-phase (Built-in EMC filter)

Applicable Motor Output (kW) 0.4 0.75 1.5 2.2 3.7 / 4 5.5 7.5 11 15 18.5 22

Applicable Motor Output (HP) 0.5 1 2 3 5 7.5 10 15 20 25 30

Frame Size B C D E F

3

High Speed Models

230V single-phase

Applicable Motor Output (kW) 1.5 2.2

Applicable Motor Output (HP) 2 3

Frame Size C

230V single-phase (Built-in EMC filter)

Applicable Motor Output (kW) 1.5 2.2

Applicable Motor Output (HP) 2 3

Frame Size C

230V 3-phase

Applicable Motor Output (kW) 1.5 2.2 3.7 / 4 5.5 7.5 11 15

Applicable Motor Output (HP) 2 3 5 7.5 10 15 20

Frame Size B C D E F

460V 3-phase

Applicable Motor Output (kW) 1.5 2.2 3.7 / 4 5.5 7.5 11 15 18.5 22

Applicable Motor Output (HP) 2 3 5 7.5 10 15 20 25 30

Frame Size B C D E F

460V 3-phase (Built-in EMC filter)

Applicable Motor Output (kW) 1.5 2.2 3.7 / 4 5.5 7.5 11 15 18.5 22

Applicable Motor Output (HP) 2 3 5 7.5 10 15 20 25 30

Frame Size B C D E F

4

Models Overview

Hardware Design

Compact design and user-friendly interface

Removable Keypad

Press to remove; for

remote operation away

from drive

MH300 Series

5 digits 16 segments

LCD display, quick

setting wheel dial,

left-shift function key

MS300 Series

5 digits 7 segments

LED display,

frequency knob,

Up and Left/Down

function keys

Built-in USB Port

Easy and fast

programming setting,

update and real-time

monitoring and tuning

Specified Product

Label

Input/output current,

voltage and protection

rating

Screwless Top Cover

Design

Simply press on the left and

right hand sides to remove

the top cover for wiring

Removable RFI

Jumper

Applicable for different

application needs

Removable Fan

Easy to replace and

maintain for a longer

lifetime

5

Option Cards

A wide selection of option cards for highly flexible applications

PG Cards

ABZ Signal

Line driver

Resolver

PM motors

I/O Cards

I/O Analog

Relay Cards

(for MH300)

ABZ Signal

Open collector

(for MH300)

(for MH300)

External Power Supply

Card (DC 24V)

Communication Cards

CANopen*

* For MS300 only

PROFIBUS DP EtherNet/IP

MODBUS TCP EtherCAT*

DeviceNet

Form A ×3 Form C ×2

* For MH300 only

MS300 series built-in I/O slot ×1MH300 series built-in I/O slot ×2

6

Optimized Space Utilization

Compact Design

The MH300 and MS300 Series feature powerful

functions but come in smaller sizes.

Compared with current models, the MH300 and MS300

Series feature up to a 40% size reduction to effectively

optimize installation spaces.

Side-by-Side Installation

Supports side-by-side installation with operating

temperatures of -20˚C ~ 40˚C. Enables highly flexible and

highly efficient installation.

Existing low power

drive models

Reduced

in size by

40%

Substantial savings in space!

7

Outstanding Drive

Safe Motor Stop

DEB Return Time

DEB

Decelerate to Stop

Unexpected Power Shut Down

Input Voltage

Motor Speed

Time

Performance

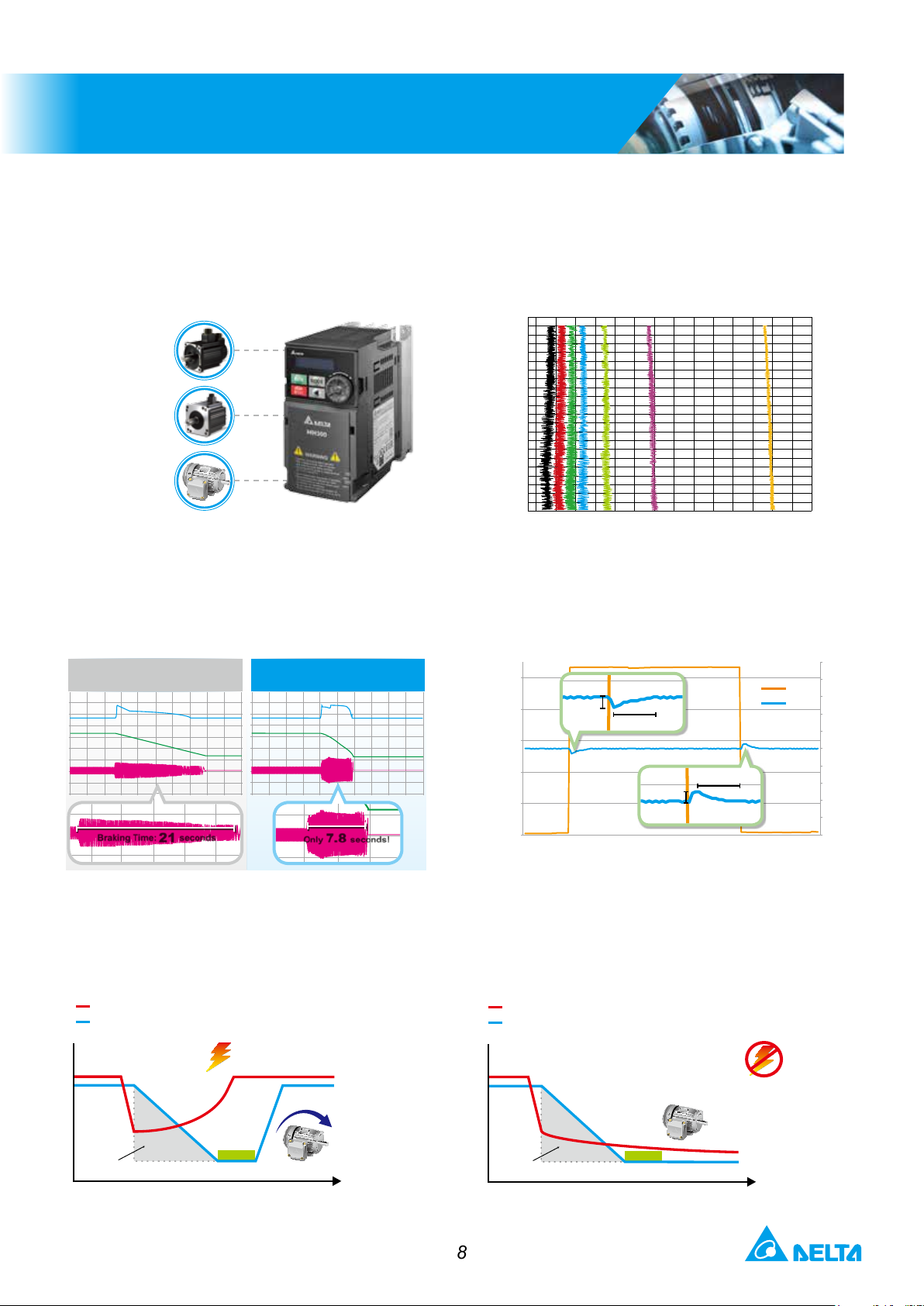

Supports IM and PM Motors

The MH300 and MS300 Series both feature 4

independent induction motor control parameters.

The MH300 Series can support up to 8

independent induction motor control parameters.

Surface Permanent

Magnet (SPM) Motors

Interior Permanent

Magnet (IPM) Motors

Induction Motors

Enhanced Braking Capability

Set up the deceleration energy control mode to shorten

braking time by adjusting the motor speed and current.

This feature also delivers savings from braking resistors.

Standard Mode

Braking Time:

21

seconds

Deceleration Energy

Control Mode

7.8

Only

seconds!

High Starting Torque

Delivers 200% high starting torque with a low speed

control of 0.5Hz. This feature provides outstanding

machine stability and is suitable for dynamic loading

applications.

42

38

34

30

26

22

N-m

18

14

10

8

4

0

0 25 50 75 100 125 150 175

200 225 250 275 300 325 350

rpm

Fast Response to Load Impact

Fast response to sudden load impact on speeds to

ensure stable production and high quality output.

Load

rpm

1300

1280

1260

1240

1220

1200

1180

1160

1140

1120

1100

Load (%)

100

80

60

40

20

0

7 rpm

200 ms

200 ms

6 rpm

Time

* Actual deceleration performance would depends on different system loads

Deceleration Energy Backup (DEB)

Controls the motor's deceleration to a stop when a sudden power outage occurs and accelerates it to its

previous speed when power returns.

Input Voltage

Motor Speed

Power Blink Off

DEB

Decelerate to Stop

Motor Flying Start

DEB Return Time

Time

8

Input Voltage

Motor Speed

Unexpected Power Shut Down

Safe Motor Stop

DEB

Decelerate to Stop

DEB Return Time

Time

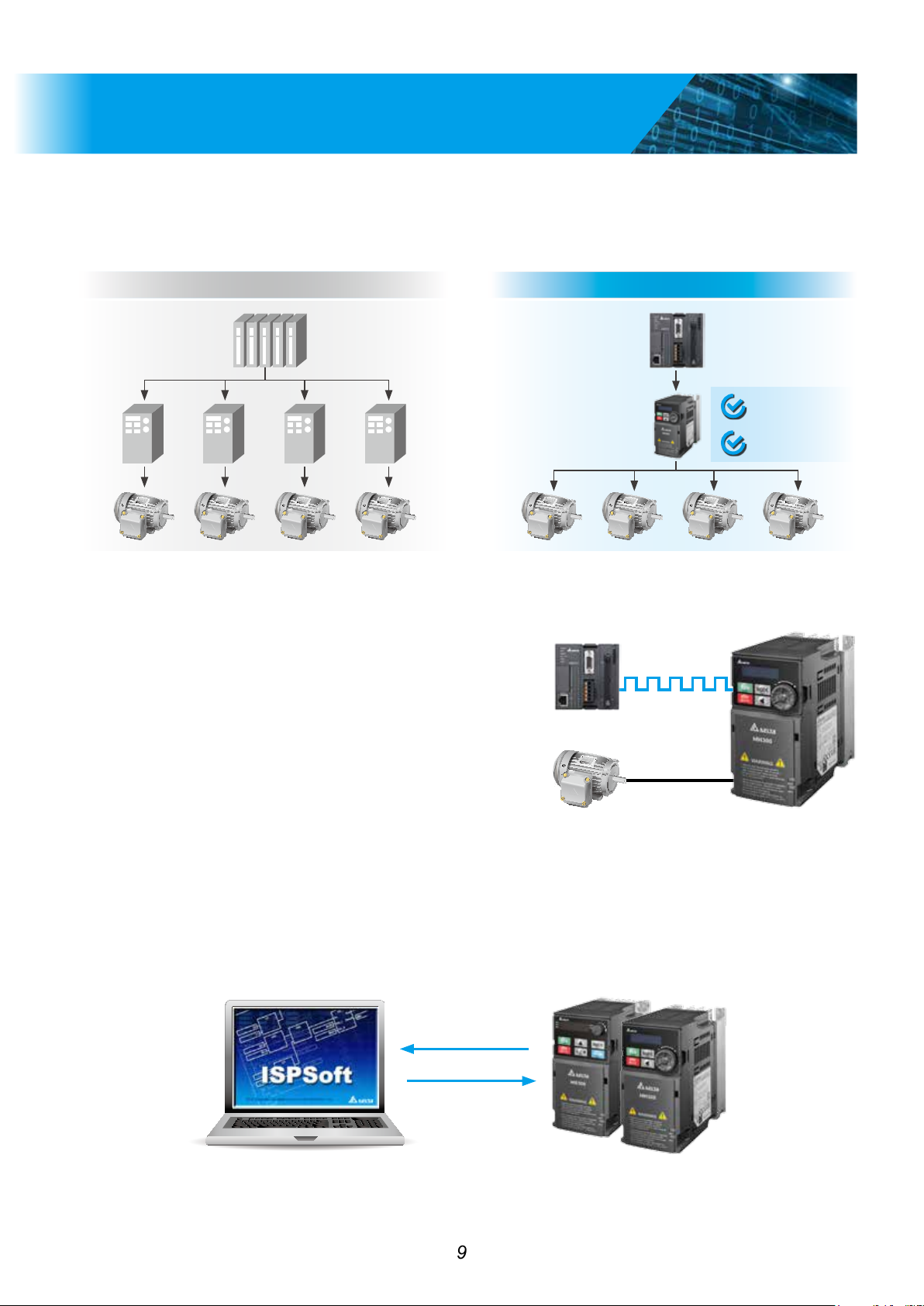

Strong System Support

Multi-motor Control

MH300 Series supports 8 induction motors switching control.

MS300 Series supports 4 induction motors switching control.

Controller Controller

Traditional

AC Motor

Drives

MH300 / MS300

Multi-motor ControlTraditional Control

Reduces system

costs

Saves installation

space

Pulse Input

Controller

MH300

Pulse

Supports dual pulse input signal from controller or

feedback signal from encoder without additional PG

card; achieves simple closed-loop control.

MS300

Supports single pulse input signal from controller.

Motor

Built-in PLC

MH300 built-in PLC capacity (5K steps) and MS300 built-in PLC capacity (2K steps); to provide

distributed control and independent operation via network connection.

9

High-Speed Applications

DC 24V External Power

High-speed models are available in both

MH300 and MS300 series to support

high-speed processing.

External power supply is available when main

power failure occurs to ensure uninterrupted

communication and to protect the system.

MH300

Type Model

Standard VFD

High-speed VFD

MS300

Type Model

Standard VFD

High-speed VFD

MH

MH

MS

MS

Frequency

Setting

SAA 0 ~ 599 Hz

SHA 0 ~ 2000 Hz

OFF

Frequency

Setting

SAA 0 ~ 599 Hz

SHA 0 ~ 1500 Hz

High Overload Capability

• Normal duty: rated current 120% for 60 seconds; 150% for 3 seconds.

Controller

24 VDC

MH300 / MS300

• Heavy duty: rated current 150% for 60 seconds; 200% for 3 seconds.

Built-in Braking Chopper

Larger braking torque capability is provided

when use with an additional braking resistor.

Closed-Loop Control

Optional PG card is available for MH300

to support closed-loop control function and

providing higher precision of motor speed

control.

Versatile Communication Interfaces

• MH300, built-in RS-485 (MODBUS) and CANopen.

• MS300, built-in RS-485 (MODBUS).

More communication cards are available upon selection:

Communication MH300 MS300

MODBUS Built-in Built-in

PROFIBUS DP Optional Optional

DeviceNet Optional Optional

MODBUS TCP Optional Optional

EtherNet/IP Optional Optional

CANopen Built-in Optional

EtherCAT Optional (To be announced)

10

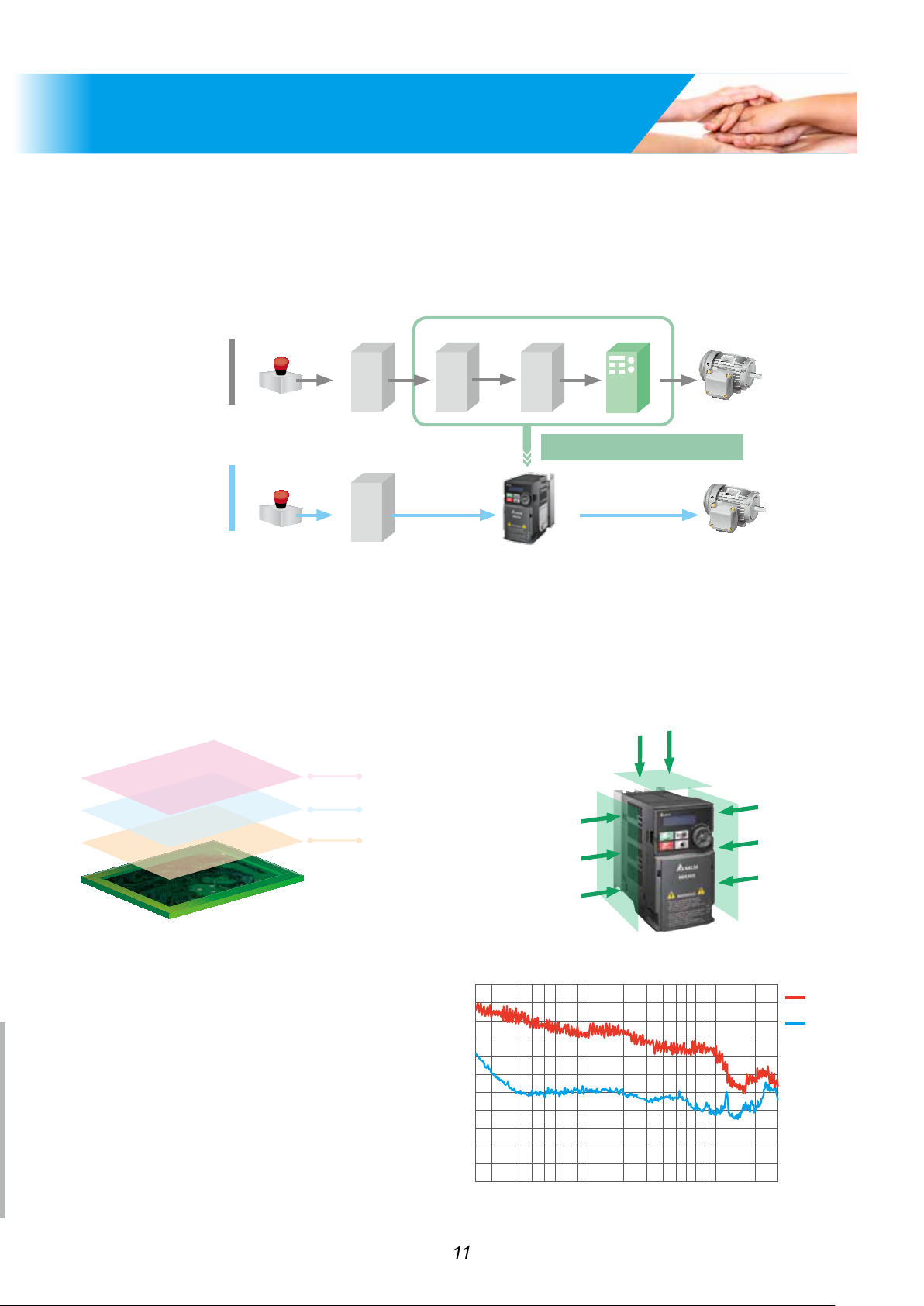

Stable, Safe and Reliable

Safety Standard

Integrated Sate Torque Off (STO), compliance with:

►

EN ISO 13849-1 Cat3 / PLd ► EN 61508 SIL2

►

EN 60204-1 Category 0 ► EN 62061 SIL CL 2

Emergency

Stop

Controller

Contactor 1

Traditional

Emergency

Integrated

Stop

STO

Controller MH300 / MS300

PCB Coating

100% PCB coating (IEC 60721-3-3 class 3C2

standard) ensures drive operation stability and

safety in critical environments.

Moisture proof

Contactor 2 AC motor drive

Saves Cost and Space!

IP 40 Models

Strengthened fan coating and concealed air vent

prevent dust and other particles from entering

the drive, suitable for critical environment

applications.

Corrosion proof

Dust proof

Built-in EMC Filter

Built-in Class A (C2) standard EMC filter; saves

on additional procurement cost and wiring time,

and provides more cabinet space for other

devices to use.

100

dBuV

50

0.0

0.150 0.5 5 30.000

MHz

11

No EMC Filter

Built-in EMC Filter

Quick to Install

Application Groups (Macro)

Simplifies the parameter setting process by grouping the parameters for different applications to use.

Applications

Selection

Machine

Tool

Fan

Compressor

Parameter

Setting

Built-in USB Port

Built-in USB port facilitates the drive setting,

updating, real-time monitoring and system

tuning process.

• No need of USB or RS-485 connectors.

• Supports offline (drive power off) parameter

setting/copying and system update.

DELTA VFDSoft

Conveyor

User-

define

Screwless Wiring of Control Terminal

Press on the cap to plug in the wire; easy to install

and remove.

Saves wiring time

12

Wide Range of Applications

Machine Tools

Features and Benefits

• Supports high-speed main spindle 2000Hz/1500Hz frequency output;

and is suitable for complex and high precision processing applications

• Timely acceleration/deceleration control to improve machinery

operation efficiency

• Built-in braking chopper to save on purchasing cost

• Built-in PLC capacity for flexible application needs

• Built-in STO function ensures operator safety and effectively reduces

accident risk

• Provides deceleration to stop function to protect tools from damage

and ensure operator safety

Woodworking Machines

Features and Benefits

• Timely acceleration/deceleration control, improves machinery

operation efficiency

• Built-in STO function ensures operator safety and effectively

reduces accident risk

• Built-in PLC capacity saves on purchasing cost

• Built-in EMC filter effectively reduces harmonics interference

• Compact in size and weight, easy to install and maintain

Automatic Tool Changers (ATC)

Features and Benefits

• Compact design of drive provides more cabinet space for other

devices to use

• Quick start and timely acceleration/deceleration control function

effectively shortens tool changing time and improves system

efficiency and productivity

• Simple structure is easy to install and maintain

• Built-in STO function ensures operator safety and effectively

reduces accident risk

HJGH K NVH FDH 22 SDF HJGHF GFY

HJGH K NVH FDH 02 SDF HJGUTYRK 457FY

HJGH K NVH FDH 18 SDF HDRWSJGK GJDFGDHFY

HJGH K NVH FDH 13 SDF HJGK GHG45FY

HJGH K NVH FDH 13 SDF HJGK GHG45FY

LEONA.CHO MOTOR

• Built-in braking chopper, saves on purchasing cost

13

Pumps Application

Features and Benefits

• Built-in PID feedback control

• Built-in PLC capacity saves on purchasing cost of PLC and relay

• Supports a wide range of input voltages which are suitable for

various types of pumps application and use in different countries

• Deceleration energy control mode shortens deceleration time

and reduces braking resister cost, also provides more space for

other devices to use

Packaging Machines

Features and Benefits

• Compact design of drive provides more cabinet space for other devices to use

• Built-in STO function ensures operator safety and effectively reduces accident rate

• Built-in braking chopper saves on system construction cost

• Built-in RS-485 (MODBUS) and various communication cards

upon selection (optional)

• High-speed pulse input

• Supports frequency command by pulse input to improve control precision.

• Precise and stable tension control provides high flexibility in using different

packaging materials

HJGH K NVH FDH 22 S DF HJG HF GFY

HJGH K NVH FDH 02 S DF HJG UTYRK 457F Y

HJGH K NVH FDH 18 S DF H DRWSJ GK GJD FGDHF Y

HJGH K NVH FDH 13 S DF HJG K GHG45 FY

HJGH K NVH FDH 13 S DF HJG K GHG45 FY

Textile Machines

Features and Benefits

• IP40 models provide excellent protection from a high dust, fiber or

moisture environment

• Improved heatsink design prevents fiber clogging the air way;

modular design of fan is easy to clean and provides longer lifetime

• Improved braking capability shortens the deceleration to stop time

and is suitable for sudden stop requirements

• Built-in STO function ensures operator safety and effectively reduces

accident rate

• Supports both induction motors and PM motors

• Provides deceleration to stop function to protect the equipment from

damage when sudden power failure occurs

14

Loading...

Loading...