Page 1

External door mount

HEX150PC series

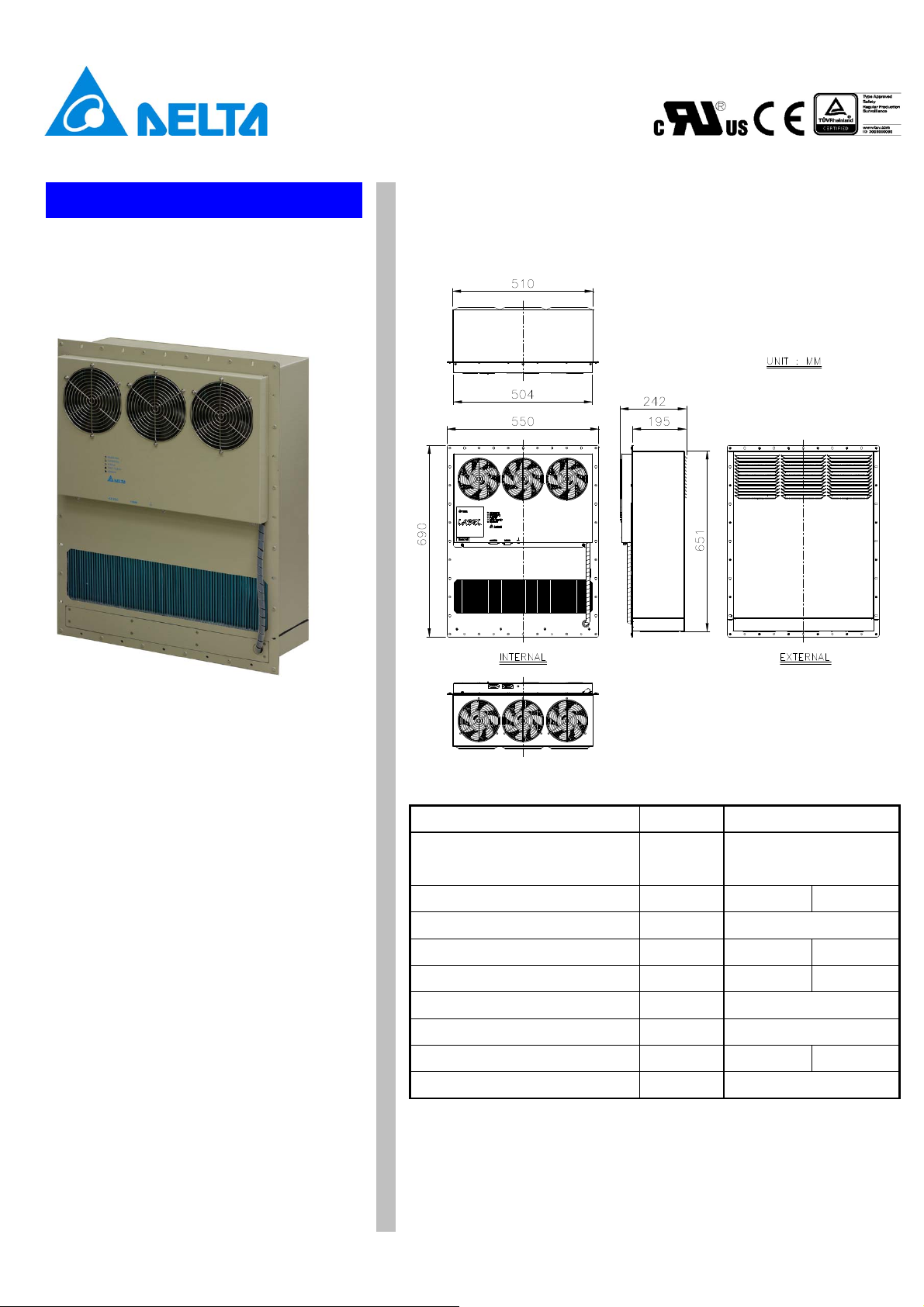

Dimension drawing

Features Unit

◆ IP55 waterproof at external side

◆ "One touch" dry run t est and dust cleaning

◆ Standalone temperat ure control W/K (W/℉

◆ Clear LED status i ndicator

◆ Dry contact alarm output

Design VDC

◆ Air to air heat exchange

◆ Rated voltage at 48V

◆ Reduntant fan quantity design

◆ High efficiency and reliable fan

◆ Easy installation and maintenance

Operating temperature range -10 ~ +65

* Note : The cooling capacity (W/K , W/°C or W/℉) is defined as Q/ (TI-TA)

Q : Heat dissipation (W) from inside of cabinet

TI : Return temperature of internal air circuit (K , °C or ℉)

TA : Ambient temperature of external air circuit (K , °C or ℉)

* Specifications are subject to change without notice.

Main feature Specification

Dimension (H x W x D)

Cooling capacity

Rated voltage 48

Operating current 2.6 5.8

Opearting power 125 279

Operating voltage range 40 ~ 60

Noise (1.5 meter) 65.0 73.0

Weight 20 (44)

*Note

mm

(inch)

VDC

A

W

°C

dB-A

Kg (Lb)

690 x 550 x 242

(27 x 22 x 10)

100 (56) 135 (75)

)

Page 2

HEX150PC Heat Exchanger

Instruction Manual

Page 3

Table of contents

1. Version ......................................................................................................... 1

2. Description ................................................................................................... 1

2-1. General ................................................................................................ 1

2-2. Specification ....................................................................................... 1

2-3. Environmental condition ................................................................... 2

3. Installation ................................................................................................... 2

3-1. Outline drawing .................................................................................. 2

3-2. Mounting panel cutout and waterproof foam sticking .................... 3

4. Electrical specification ................................................................................ 3

4-1. Connection and LED indicator (on HEX panel) ................................ 3

4-2. Standalone control mode ................................................................... 5

5. Mechanical feature ...................................................................................... 6

5-1. Thermal path and Airflow baffle ....................................................... 6

5-2. Configuration ..................................................................................... 6

6. Maintenance and Replacement .................................................................. 7

6-1. Maintenance ....................................................................................... 7

6-2. Replacement ...................................................................................... 8

7. MTBF and Reliability ................................................................................... 8

7-1. MTBF................................................................................................... 8

7-2. Relibability ......................................................................................... 8

8. Safety ............................................................................................................ 9

9. Accessory .................................................................................................... 9

9-1. Power cable ........................................................................................ 9

9-2. Function cable ................................................................................... 9

10. General Safety and Warnings ................................................................... 9

Page 4

HEX150PC Heat Exchanger Instruction Manual

1. Version

Rev. Description Drawn Approved Issue date

00 Issue spec. Nick Wang Adam Chen 2016/1/25

01 Add sectioni 10 Nick Wang Adam Chen 2016/6/10

2. Description

2-1 . General

Delta Heat Exchanger (HEX) is designed for direct air to air heat

exchange to remove heat from the cabinet.

The internal and the external air circulation loops of the HEX are

separated to prevent the introduction of dust, humidity and dirt. The fan on

the external air loop conforms to IP55 protection rating.

2-2 . Specification

Outline Dimension (H x W x D)

Cooling Capacity (*Note 1)

Rated Voltage VDC 48

Rated Current (*Note 2) A 6.3

Operating Voltage Range VDC 40 - 60

Operating Current A 2.6 5.8

Operating Power Consumption W 125 279

Acoustic Noise at 1.5M (SPL) dB-A 65.0 73.0

Main feature Unit

mm

(in)

W/K (W/℉)

Model Number

HEX150PC

690 x 550 x 242

(27 x 22 x 10)

100 (56) 135 (75)

Weight Kg (Lb) 20 (44)

* Note1 : The cooling capacity (W/K , W/°C or W/℉) is defined as Q/ (TI-TA)

Q : Heat dissipation (W) from inside of cabinet

TI : Return temperature of internal air circuit (K , °C or ℉)

TA : Ambient temperature of external air circuit (K , °C or ℉)

*Note 2 : Rated current is announcement of safety

Page 1

Page 5

2-3 . Environmental condition

Description Specification

HEX150PC Heat Exchanger Instruction Manual

Operating

Storage

Humidity

Ingress protection

(on external side)l

3. Installation

3-1 . Outline drawing

-10°C ~ +65°C (-14°F ~ 149°F)

-40°C ~ +70°C (-40°F ~ 158°F)

External air circuit: 0 ~ 100% RH

IEC60529 IP55 (NEMA 3)

GR-487 720hrs salt spray

(1) Material : Aluminum sheet t=1.5mm

(2) Finish : Power paint , Color RAL7032

(3) Dimensional tolerance : ± 1mm [0.04”]

Page 2

Page 6

HEX150PC Heat Exchanger Instruction Manual

3-2 . Mounting panel cutout and waterproof foam sticking

:

:

4. Electrical specification

4-1. Connection and LED indicator (on HEX panel)

Power Connection

on panel plate : CVILUX 3W3CS0000100000

mate with : CVILUX 3W3CP0000100000

COMM connection

on panel plate : CVILUX CD5115PA100

mate with : CVILUX CD5115SA100

Page 3

Page 7

HEX150PC Heat Exchanger Instruction Manual

User can follow dry contact definition that is Normal Close (N.C.) to

detect abnormal status from pin 10 & pin 11

Definition N. C

Connection Pin 10 & Pin 11

Control board, NTC and fan are in

normal status

NTC resistance is over range such as

“open circuit” or “short circuit”

Fan speed is lower than 50% of

definition or fan is locked

Dry contact max. rating : 75VDC/50mA

LED indicator

CLOSE

OPEN

OPEN

INNER FAN / OUTER FAN / STATUS LEDs indicate fan and NTC

sensor status .

Depress "TEST" button to start auto-test of outer and inner fans

running from low to high speed. Turn off by depressing the “TEST” button

again .

INNER FAN

Normal GREEN

Failed* RED

Normal

Blinking

OUTER FAN STATUS

GREEN

RED

GREEN

RED

Blinking

N/A

(touch TEST / CLEAN)

Failed*

GREEN

Blinking

GREEN

Blanking

N/A

(touch TEST / CLEAN)

RED

RED

* FAN failed : Fan speed is lower than 50% of definition or fan is locked

* STATUS Failed : NTC resistance is over range such as “open circuit” or

“short circuit”

Page 4

Page 8

NTC temperature sensor

User can switch inner sensor (on control panel) or external

sensor (COMM port Pin7 & Pin8 ) via J13 connector on controller as

shown below to change sensor location .

4-2. Standalone control mode

HEX can detect ambient temperature to control cooling capacity .

Internal fan and external fan speed default settings are shown below

HEX150PC Heat Exchanger Instruction Manual

Cooling capacity (W/K) vs. Temperature

Inner fan speed vs. Temperature Outer fan speed vs. Temperature

Page 5

Page 9

5. Mechanical feature

5-1 . Thermal path and Airflow baffle

With forced convection using the axial fan, warm air generated by the

equipment will be blown into the internal return opening and pass though

the HEX, then flow out from internal supply opening. The air supply of the

cold air will be used to cool down the system; On the opposite side, cooler

air from the surrounding environment will be drawn in from the external air

inlet side , and push the heat of the HEX out from the external air exhaust

side. The thermal exchange path is shown in the figure below .

HEX150PC Heat Exchanger Instruction Manual

5-2 . Configuration

Item Q'ty

Description

1 1 Chassis assy

2 6 Fan guard

3 1 Controller

4 3 Internal fan

5 3 External fan

6 1 Heat exchange CORE

7 1 Internal plate assy

8 1 External plate assy

Page 6

Page 10

6. Maintenance and Replacement

Be sure to SHUT DOWN the power before proceeding with any

maintenance or component replacement .

6-1. Maintenance

Monthly

Use brush and low pressure air to remove dust or any debris on both

internal/external air inlet and air outlet opening .

Quarterly

Follow below maintenance sequence

Internal loop maintenance :

* The maintenance is from the internal side .

HEX150PC Heat Exchanger Instruction Manual

* Use screw driver to remove screw on upper

portion of chassis assy (Item 1) .

* Disassemble the internal plate assy (Item 7) and disconnect

fan from controller (Item 3) . Note the connection location .

* Use brush and low pressure air to remove dust on

internal plate assy (Item 7) , internal fan (item 4) and heat

exchange core opening .

* Hold internal plate assy (Item 7) and connect fan to controller

(Item 3) .

* Re-attach internal plate assy (Item 7) and use screw driver to

secure screw with chassis assy (Item 1) .

External loop maintenance :

* The maintenance is from the external side .

* Use screw driver to remove the screw on bottom portion of

chassis assy (Item 1) .

* Disassemble and hold external plate assy (Item 8) , no need

to disconnect external fan .

* Use brush and low pressure air to remove dust on external

plate assy (Item 8) , external fan (Item 5) and heat exchange

CORE opening .

* Re-attach external plate assy back (Item 8) and use screw

driver to secure screw with chassis assy (Item 1) .

Page 7

Page 11

HEX150PC Heat Exchanger Instruction Manual

Test

Power on and depress “TEST” button on panel to proceed with

auto test . Follow LED status to check that HEX has resumed to normal

function after maintenance .

6-2. Replacement

Delta HEX is designed with dry contact alarm output and LED

indicator on panel shown below to describe abnormal situation .

Refer to Section 4-1 for checking abnormal part is internal fan ,

external fan or controller for abnormalities .

In cases of parts abnormality , Delta will follow the reading and submit

spare part(s) below for replacement .

Internal fan P/N : AFB1548EH-BJ51

External fan P/N : AFB1548VH-CA18

Controller P/N : HEX150PC-000C

User can then refer to maintaince sequence on previous page , or

request Delta authorized support for assistance .

7. MTBF and Reliability

7-1. MTBF

L10 Fan life is expected to be minimum 80,000 hours continuous

operation at 40°C with 15 ~ 65%RH .@ label rated voltage

7-2. Relibability

Test item Condition

High temperature IEC 60068-2-2

Low temperature IEC 60068-2-1

High temp. / High humidity IEC 60068-2-14 TEST Nb

Temperature cycle IEC 60068-2-3

Vibration ETSI 300 019-1-4 CLASS 4.1

Ingress protection

(External side)

IEC 60529 IP55 (NEMA 3)

GR-487 720hrs salt spray

Package bump IEC 60068-2-29

Page 8

Page 12

8. Safety

9. Accessory

9-1. Power cable

9-2. Function cable

HEX150PC Heat Exchanger Instruction Manual

10. General Safety and Warnings

* Some electronic parts have a high operating temperature .

Use caution at all times.

* Incorrect installation may cause damage and/or injury.

* Installation and maintenance should be performed only by qualified

personnel . Use caution at all times.

* Ensure the grounding wire is connected before powering on the system.

* Ensure the cover and the mounting hardware are secure upon installation.

* All the cables connected to the unit must confirm to UL standards.

Page 9

Loading...

Loading...