Page 1

Series Digital Controller

Instruction Sheet

Thank you very much for purchasing DELTA DTC Series Temperature Controller. Please read this instruction sheet before using your DTC

series to ensure proper operation, and please keep this instruction sheet handy for quick reference.

Caution

DANGER! Caution! Electric Shock!

DTC series is an OPEN-TYPE device and therefore should be installed in an enclosure free of airborne dust, humidity, electric shock and

vibration. The enclosure should prevent non-maintenance staff from operating the device (e.g. key or specific tools are required to open the

enclosure) in case danger and damage on the device may occur.

WARNING!

1. Prevent dust or metallic debris from falling into the controller that will cause malfunction. DO NOT modify or disassemble the controller.

DO NO use extra terminals.

2. Do not install and/or use the controller in places subject to:

(a) dust or corrosive gases and liquid (b) high humidity and high radiation (c) vibration and shock

3. Switch off the power when wiring or changing input sensors.

4. Be sure to use compensating wires that match the thermocouple types when extending or connecting the thermocouple wires.

5. Shorten the wire when wiring a platinum resistance thermometer (RTD) to the controller, and separate power cable from load wires to

prevent interference and conductive influence.

6. Make sure the power cable and signals device are installed correctly before switching on the power of DTC; otherwise serious damage

may occur.

7. DO NOT touch the terminals or repair the controller when the power is on to prevent electric shock.

8. Wait at least one minute after the power is off to allow the capacitor to discharge. DO NOT touch any internal circuit within this period.

9. DO NOT touch the internal terminals no matter the power is on or off.

10. DO NOT place other heating source (e.g. power supply) in parallel with DTC during the installation. Please keep proper space in

between.

Model Name Explanation

DTC

Series name DTC: Delta C series temperature controller

1 Controller position 1: First controller 2: Controller connected in parallel

2 Auxiliary output groups

3 4 Optional

5 Main output type

(DTC1000/2000 model): DC24V input, 2 outputs, relay output for output 2, RS-485 communication.

(DTC1001/2001 model): DC24V input, 1 output, 1 CT input, and RS-485 communication.

0: standard, 2 outputs, no auxiliary output

1: 1 auxiliary output. Not available now.

00: Standard

01: CT input

R: Relay output SPST, 250VAC, 3A

V: Voltage pulse output 12V +10% ~ -20%

12

4

3

2: 2 auxiliary outputs. Not available now

02: EVENT input. Not available now

C: Current output 4 ~ 20mA

L: Linear voltage output 0 ~ 10V

5

Function & Specification

Power supply DC24V. Isolated switching power

Voltage range Rated voltage: 90% ~ 110%

Power consumption Rated 24 VDC, Max. 24 W combined, 3W + 3W x number of DTC2000 controllers (Max. 7)

- 1 -

Page 2

Thermocouple: K, J, T, E, N, R, S, B, L, U, TXK

Input sensors

Sampling rate Analog input: 0.15 sec. Thermocouple or platinum RTD: 0.4 sec.

Control method PID , programmable PID, Manual, ON/OFF

Output types

Output function

Alarm 13 alarm modes

Communication RS-485 digital communication, 2,400bps ~ 38,400bps

Communication protocol Modbus protocol, ASCII/RTU format

Internal connection Internal terminals available to transmit 24V power supply and communication signals

Vibration resistance 10 ~ 55Hz, 10m/s2 for 10mins, each in X, Y and Z direction

Shock resistance Max. 300m/s2, 3 times in each 3 axes, 6 directions

Ambient temperature 0 ~ 50°C

Storage temperature -20 ~ +65°C

Altitude < 2,000m

Ambient humidity 35% ~ 85% RH (non-condensing)

Pollution degree 2

Platinum RTD: Pt100, JPt100

Linear DC input: 0 ~ 5V, 0 ~ 10V, 0 ~ 20mA, 4 ~ 20mA, 0 ~ 50mV

Relay: SPST, Max. load 250VAC, 3A resistive load

Voltage pulse: 12VDC, Max. output current: 40mA

Current: DC 4 ~ 20mA (Load resistance: < 500)

Analog voltage: 0 ~ 10V (Load resistance: > 1,000)

Control output, alarm output, proportional output

Proportional output is available only when output 1 is linear voltage/current output.

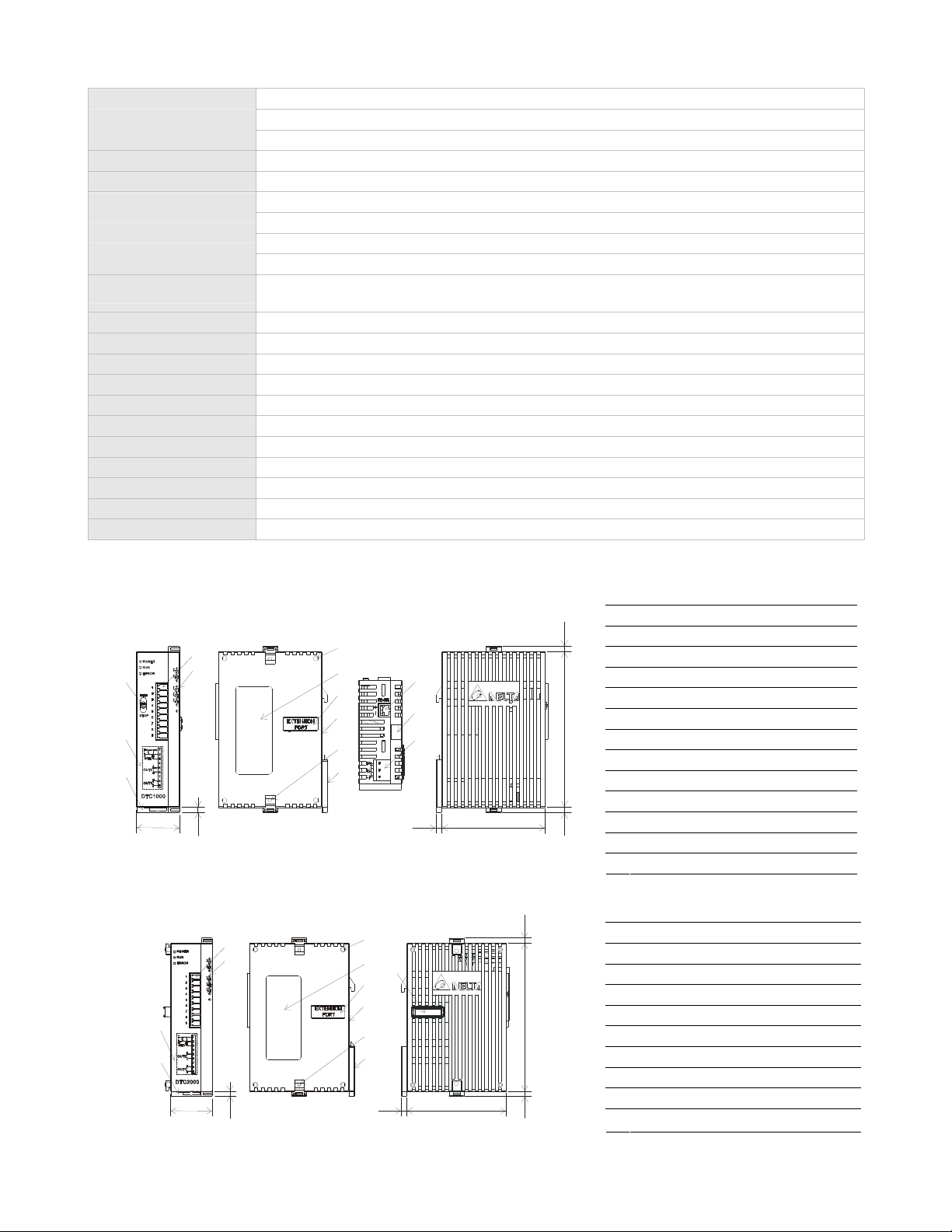

Product Profile & Outline

4

25.2

5

0

.

4

1

2

3

3

4

1

2

25.2

0

.

4

6

7

8

10

9

3

5

6

10

7

9

8

2

DTC1000/1001 R/V/C/L

1 RUN/STOP switch

0

.

3

2 Wiring and Model name

3 DIN rail clip

11

4 I/O terminals

5 LED indicators

12

13

6 Mounting hole

0

.

0

9

7 Specification label

8 Extension port

9 Extension clip

10 DIN rail

0

60.03.4

11 RS-485 communication port

.

3

12 Extension clip

13 DC power input

0

.

3

DTC2000/2001 R/V/C/L

1 Wiring and Model name

2 DIN rail clip

3 I/O terminals

4 LED indicators

0

.

0

9

5 Mounting hole

6 Specification label

7 Extension port

8 Extension clip

60.03.4

0

.

3

9 DIN rail

10 Extension port

- 2 -

Page 3

Input

DTC series supports the following input sensors:

Input Sensor Register Value Available Range

0 ~ 50mV linear voltage input 17 0 ~ 50mV

4 ~ 20mA linear current input 16 4 ~ 20mA

0 ~ 20mA linear current input 15 0 ~ 20mA

0 ~ 10V linear voltage input 14 0 ~ 10V

0 ~ 5V linear voltage input 13 0 ~ 5V

Platinum RTD (Pt100) 12 -200 ~ 600°C (-328 ~ 1,112°F)

Platinum RTD (JPt100) 11 -20 ~ 400°C (-4 ~ 752°F)

Thermocouple TXK type 10 -200 ~ 800°C (-328 ~ 1,472°F)

Thermocouple U type 9 -200 ~ 500°C (-328 ~ 932°F)

Thermocouple L type 8 -200 ~ 850oC (-328 ~ 1562°F)

Thermocouple B type 7 100 ~ 1,800°C (212 ~ 3,272°F)

Thermocouple S type 6 0 ~ 1,700°C (32 ~ 3,092°F)

Thermocouple R type 5 0 ~ 1,700°C (32 ~ 3,092°F)

Thermocouple N type 4 -200 ~ 1,300°C (-328 ~ 2,372°F)

Thermocouple E type 3 0 ~ 600°C (32 ~1,112°F)

Thermocouple T type 2 -200 ~ 400°C (-328 ~ 752°F)

Thermocouple J type 1 -100 ~ 1,200°C (-148 ~ 2,192°F)

Thermocouple K type 0 -200 ~ 1,300°C (-328 ~ 2,372°F)

Note 1: The current input is built-in with 249 precision resistor. See “How To Set up Current Input” section.

Note 2: Default setting: Pt100 input.

The range of linear input and feedback value is adjustable. Range of input feedback: -999 ~ 9,999. Take 0 ~ 20mA input as example, -999

refers to 0mA input, and 9,999 refers to 20mA input. If we change the range to 0 ~ 2,000, 0 will refer to 0mA input, and 2,000 will refer to 20mA

input. 1 display scale = 0.01mA.

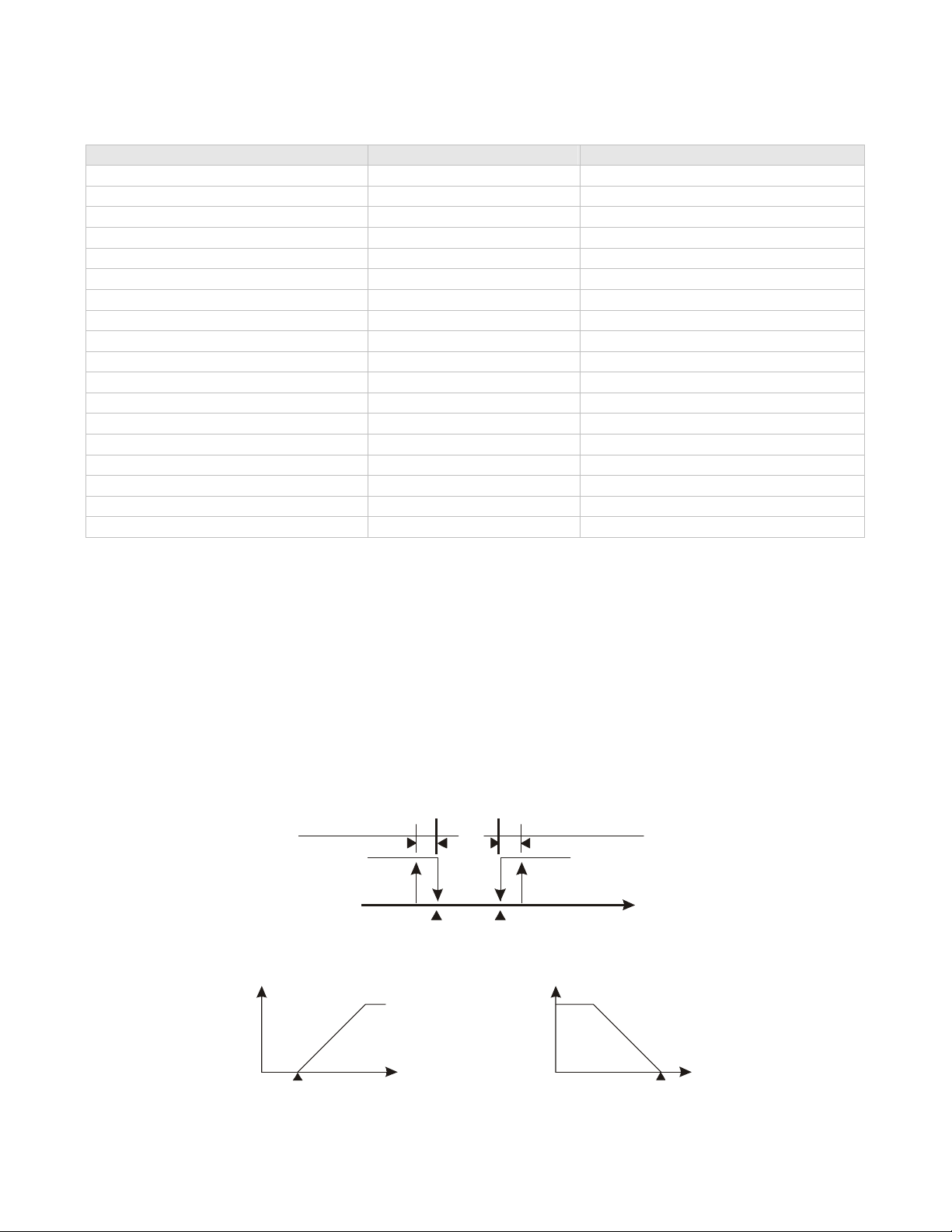

Output

There are several output types available from DTC series: Control Output (heating/cooling), Alarm Output and Proportional Output.

Control Output

DTC series offers 2 outputs for heating or cooling control. If you require dual loop output, the 2 outputs should be set to different actions

(heating or cooling). If you require the 2 outputs are set to the same control action, only the control cycle of output 1 will be valid, and the 2

outputs will act at the same time.

The control methods include: PID control, ON/OFF control, Manual control and programmable PID control.

Single Output Control:

Heating hysteresis

ON

Heating

OFF

Set Point

Figure1: ON/OFF Control

Output

100%

Cooling

0

Set Point

Figure 2: PID Control, Cooling) Control Figure 3: PID Control, Heating Control

PV

Set Point

Cooling hysteresis

Cooling

Output

100%

0

PV

Heating

Set Point

PV

- 3 -

Page 4

Dual Output Control:

Deadband

Heating hysteresis

ON

Heating

OFF

Set Point

Figure 4: ON/OFF Control

Deadband: Dead

Output

Heating Cooling

0

Set Point

Figure 5: PID control Figure 6: PID Control

Bandwidth: Positive

PV

Cooling hysteresis

Cooling

Output

Heating

0

Set Point

PV

Deadband: Dead

Bandwidth: Negative

Cooling

PV

Programmable PID Control & Parameters Setting

The programmable PID control includes 8 patterns (Pattern 0 ~ 7). Each pattern contains 8 steps (Step 0 ~ 7) and parameters: “link pattern”,

“cycle” and “the number of steps”.

Start Pattern: The user can set up which pattern is the start pattern for the programmable control.

Steps: Includes the settings of the two parameters, set point X and execution time T, indicating that the set point (SV) has to rise to

temperature X after the period of execution time T. If the result of the set point X is the same as that of the previous setting, the process is

called “Soak”; otherwise, it is called “Ramp”. Therefore, the programmable control is also known as Ramp/Soak control. The default setting

of the first step is Soak control. The temperature will first rise to the set point X and remain at X. The total execution time is T.

Link Pattern: The pattern to be executed following the current pattern. If the setting is not 0 ~ 7, the set point will remain at the last pattern.

Cycle: The additional number of cycles for a pattern. For example, if the parameter is set to 2, it refers to the pattern has to execute

additional twice, totaling the execution to 3 times including the original one.

The Number of Steps: The number of steps in each pattern (range: 0 ~ 7). For example, if the parameter is set to 2, it refers to the pattern

will execute Step 0 ~ Step 2, and other steps will not be executed.

The Execution: Available settings include “run”, “program hold”, “program stop” or “stop”.

1. When this parameter is set to “run”, the program will start its execution from step 0 of the start pattern.

2. When this parameter is set to “program hold”, the program will stop and the temperature will stop at the SV before the program stops. If

the user sets to “run” again, the program will resume the step before the program stops and execute by the remaining time.

3. When this parameter is set to “program stop”, the program will stop and the temperature will stop at the SV before the program stops. If

the user sets to “run” again, the program will execute again from Step 0 of the start pattern.

4. When this parameter is set to “stop”, the program will stop, and the control output will be disabled.

Proportional Output:

If Output 1 of this DTC series is linear voltage or current, the user can set it to “Proportional Output”. Proportional output refers to the output

varies with the input. For example, if the input range is set to 0 ~ 1,000, and when the input value is 0, the output will be 0mA or 0V. When the

input value is 1,000, the output will be 20mA or 10V.

Output

10V or 20mA

Negative

10V or 20mA

output slope

Output

Positive output slope

0V or 4mA

PV Low

PV High

PV PV

Figure 7: Proportional Output

- 4 -

0V or 4mA

PV Low PV High

Page 5

H

L

H

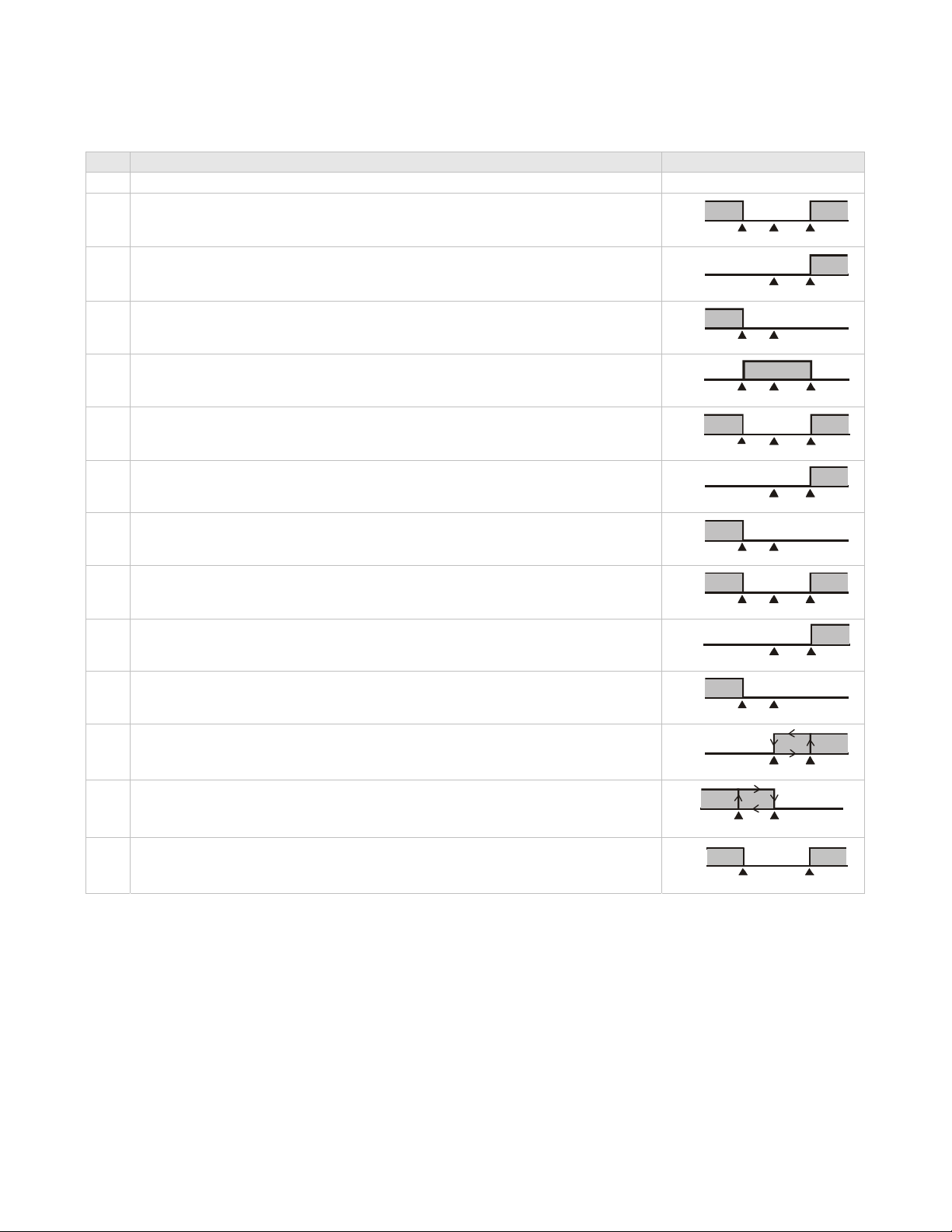

Alarm Output

DTC series offers 13 alarm modes. When the PV exceeds or falls below SV, the alarm output will be enabled. See the table below for the 13

modes.

Mode Alarm Type Alarm Output Operation

0 No alarm OFF

Alarm output will be enabled when the temperature reaches upper and lower limits.

1

Alarm will be enabled when the PV exceeds SV + AL-H or falls below SV – AL-L.

Alarm output will be enabled when the temperature reaches the upper limit.

2

Alarm will be enabled when the PV exceeds SV + AL-H.

Alarm output will be enabled when the temperature reaches the lower limit.

3

Alarm will be enabled when the PV falls below SV – AL-L.

4 Alarm will be enabled when the PV is between SV + AL-L and SV – AL-L.

Alarm output will be enabled when the temperature reaches the absolute value of the upper and

lower limits.

5

Alarm will be enabled when the PV exceeds AL-H or falls below AL-L.

Alarm output will be enabled when the temperature reaches the absolute value of the upper

limit.

6

Alarm will be enabled when the PV exceeds AL-H.

Alarm output will be enabled when the temperature reaches the absolute value of the lower

limit.

7

Alarm will be enabled when the PV falls below AL-L.

Standby upper/lower limit alarm

8

Alarm will be enabled when the PV reaches SV and exceeds SV + AL-H or falls below SV –

AL-L.

Upper limit standby alarm

9

Alarm will be enabled when the PV reaches SV and exceeds SV + AL-H.

Lower limit standby alarm

10

Alarm will be enabled when the PV reaches SV and falls below SV – AL-L

Upper limit hysteresis alarm

11

Alarm will be enabled when the PV exceeds SV + AL-H and disabled when the PV falls below

SV + AL-L.

Lower limit hysteresis alarm

12

Alarm will be enabled when the PV falls below SV – AL-H and disabled when the PV exceeds

SV – AL-L.

CT alarm output:

13

This alarm operates when the current measured by transformer (CT) is lower than AL-L or

higher than AL-H

Note: AL-H and AL-L include AL1H, AL2H, AL1L and AL2L. When Output 1 is set to Alarm Output, use AL1H (1024H) and AL1L (1025H).

When Output 2 is set to Alarm Output, use AL2H (1026H) and AL2L (1027H).

OFF

OFF

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

ON

OFF

OFF

ON

ON

ON

ON

AL-

AL-L SV AL-H

SV

SV

AL-L

AL-L

SV

AL-L

AL-L

SV

AL-L

SV AL-H

AL-L SV

AL-L

AL-L

AL-H

AL-H

AL-H

AL-H

AL-H

AL-

AL-H

AL-

CT Function

1. When CT is adopted, the communication address 106AH of the alarm output should be set to 02H only.

2. When CT is adopted, the alarm mode should be set to 13 and the communication address 1021H to 0DH only.

3. The user can adjust the upper limit and lower limit of CT Alarm. If the current detected by CT exceeds the upper/lower limit, ALM 2 will be

set to “1".

1039H: Status of CT Alarm

1026H: Upper limit of CT Alarm (unit: 0.1A) Max. setting: 40.0A; Default setting: 100 (10.0A)

1027H: Lower limit of CT Alarm (unit: 0.1A) Min. setting: 0; Default setting: 5 (0.5A)

102BH: Current detected by CT (unit: 0.1A)

CT only measures current when there is control output; otherwise only the previous CT value will be displayed.

- 5 -

Page 6

4. When CT function is set, ALM1 can be set as well. However, if ALM1 is triggered and there is no alarm output, only the status of ALM1

will be displayed (see 102AH).

LED Display

1. When power is normal, POWER LED will be on.

2. After DTC is switched on, all LED will be on. The communication protocol will be displayed in 1 second, followed by the communication

address in the next second.

3. RUN LED is on when the control is executing.

4. ERROR LED is on when errors occur in input, memory or communication.

5. When an output is executing, its corresponding output LED will be on.

6. AT LED flashes when PID parameters are being auto-tuned.

7. RX LED flashes when DTC receives communication signals. TX LED flashes when DTC sends out communication signals.

Communication protocol displayed on LED after the power of DTC is switched on:

AT TX RX O1 O2 Err Run

000: 2,400bps 001: 4,800bps 010: 9,600bps

011: 19,200bps 100: 38,400bps

Communication address display: AT (bit 6) and Run (bit 0) are combined to binary code.

Parity 00: None 01: Even

10: Odd

0: ASCII

1: RTU

0:2 Stop bits

1:1 Stop bit

Password Function

The default setting of the password is disabled. To enable the password function, enter the 4-character password in the specific

communication address. The password is protected by 3 levels.

1. Level 1: Only LED status, SV and PV can be read. No settings can be modified.

2. Level 2: Only LED status, SV and PV can be read. Only SV can be modified.

3. Level 3: All SV can be read. Only SV and auto-tuning can be modified.

4. Level 4: No password protection.

When a password is set (in 106EH ~ 1070H), the protection will enter Level 1. To enter other levels, enter the corresponding password (in

106BH ~ 106DH). After DTC is switched off, the protection will return to Level 1. To unlock the password protection, the user has to remove all

the passwords (in 106EH ~ 1070H).

The password protection level can be read in 106EH ~ 1070H:

bit b0 b1 b2 b3 b4 b5 b6

Status Level 1 Level 2 Level 3 Level 1 locked Level 2 locked Level 3 locked Unlocked

bit = 0 refers to no password is set. bit = 1 refers to the password has been set (b0 ~ b2). b3 ~ b6 display the current level status.

Synchronous Communication Protocol & Auto ID Setup

This function allows the user to set the communication protocol of DTC2000/2001 to the same protocol as set in the first DTC1000/1001. The

station IDs of DTC are arranged in decreasing order. Follow the steps below.

1. Set the auto communication ID of DTC1000/1001 to “1” (communication address: 1022H).

2. Switch off DTC1000/1001 before connecting it to DTC2000/2001. Switch it on again.

3. Default communication protocol: 9,600bps, 7 bits, Even, 1 stop bit, communication address 01.

4. This function will consume 3 ~ 5 seconds more when you switch on your DTC.

RS-485 Communication

1. Supports transmission speed: 2,400, 4,800, 9,600, 19,200, 38,400bps;

2. Does not support 7, N, 1 / 8, E, 2 / 8, O, 2 communication format;

3. Communication protocol: Modbus ASCII/RTU;

4. Function code: 03H (read

Address Setting Content Explanation

1000H Present temperature value (PV)

Max. 8 words in register), 06H (write 1 word into register), 01H (read Max. 16 bits of data), 05H (write 1 bit into register).

Unit: 0.1 degree. Analog input: 1EU.

The read values below indicate the occurrence of errors:

8002H: Temperature not acquired yet

8003H: Temperature sensor not connected

8004H: Incorrect sensor type

8006H: Unable to acquire temperature, ADC input error

8007H: Unable to read/write the memory

- 6 -

Page 7

Address Setting Content Explanation

1001H 0 Set point (SV) Unit: 0.1 degree. Analog input: 1EU.

1002H 6,000 Upper-limit of temperature range The content shall not be bigger than the range. Unit: 0.1°

1003H -200 Lower-limit of temperature range The content shall not be smaller than the range. Unit: 0.1°

1004H 12 Input sensor type See the table in “Input” section.

1005H 0 Control method 0: PID, 1: ON/OFF, 2: Manual, 3: programmable PID

1006H 0 Control method for Output 1

1007H 4 Control cycle of Output 1 0 ~ 99, 0: 0.5sec

1008H 4 Control cycle of Output 2

1009H 476 Proportional band value 1 ~ 9,999, Unit: 0.1°. Analog input: 1EU

100AH 260 Ti value 0 ~ 9,999

100BH 41 Td value 0 ~ 9,999

100CH 0 Default integration value 0 ~ 1,000, Unit: 0.1%

100DH 0

100EH 100 COEF setting when in dual control output

100FH 0

1010H 0 Hysteresis of Output 1 0 ~ 9,999, Unit: 0.1° or 1EU

1011H 0 Hysteresis of Output 2

1012H 0 Read/write output percentage of Output 1 Unit: 0.1%. “Write” is only applicable in manual mode.

1013H 0 Read/write output percentage of Output 2

1014H 0

1015H 0

1016H 0 Temperature offset regulation value -999 ~ +999, Unit: 0.1° or 1EU

1020H 0 Output mode for Alarm 1 See “Alarm Output” section.

1021H 0 Output mode for Alarm 2 See “Alarm Output” section.

1022H 0 Communication flag auto-set 0: Communication banned, 1: Communication auto-set

1023H 0 Control method for Output 2 0: Heating (default); 1: Cooling; 2: Alarm (DTC1000/2000 model)

1024H 40 Upper limit for Alarm 1 See “Alarm Output” section.

1025H 40 Lower limit for Alarm 1 See “Alarm Output” section.

1026H

100 Upper limit for CT Alarm CT Alarm lower limit ~ 400, 1 scale = 0.1A (DTC1001/2001 model)

1027H

102AH Read/write status b1: ALM2, b2: °C, b3: °F, b4: ALM1, b5: O2, b6:O1, b7: AT

102BH Read current detected by CT Unit = 0.1A (DTC1001/2001 model)

102CH 0 Positive/negative proportional output 0: positive, 1: negative

102EH LED status b0: RUN, b1: ERR, b2: O2, b3: O1, b4: RX, b5:TX b6: AT

102FH Software version V1.00 is indicated as 0x100

1030H 0 No. of start pattern 0 ~ 7

1032H Remaining time of the executed step Unit: second

1033H Remaining time of the executed step Unit: minute

1034H No. of currently executed step 0 ~ 7

1035H No. of currently executed pattern 0 ~ 7

Offset compensation value for proportional

control (when Ti=0))

Deadband setting when in dual control

output

Upper-limit regulation for analog linear

output

Lower-limit regulation for analog linear

output

40 Upper limit for Alarm 2

40 Lower limit for Alarm 2 See “Alarm Output” section. (DTC1000/2000 model)

5 Lower limit for CT Alarm 0 ~ CT Alarm upper limit, 1 scale = 0.1A (DTC1001/2001 model)

0: Heating (default); 1: Cooling; 2: Alarm; 3: Proportional (required

analog output)

0 ~ 99, 0: 0.5sec (Invalid when the 2 outputs are the same control.)

(DTC1000/2000 model)

0 ~ 1,000, Unit: 0.1%

1 ~ 9,999, Unit: 0.01

(1000/2000 model)

-999 ~ 9,999, Unit: 0.1° or 1EU

(1000/2000 model)

0 ~ 9,999, Unit: 0.1° or 1EU

(1000/2000 model)

Unit: 0.1%. “Write” is only applicable in manual mode.

(1000/2000 model)

1 scale = 2.8A = 1.3mV

1 scale = 2.8A = 1.3mV

See “Alarm Output” section.

(1000/2000 model)

- 7 -

Page 8

Address Setting Content Explanation

1036H

1037H 1,000 Upper limit of proportional output 0 ~ 100% upper limit of analog output, Unit: 0.1%

1038H 0 Lower limit of proportional output 0 ~ 100% lower limit of analog output, Unit: 0.1%

1039H CT Alarm status 0: Disabled, 1: Enabled (DTC1001/2001 model)

1040H~

1047H

1050H~

1057H

1060H~

1067H

1068H 1 Run/Stop setting 0: Stop, 1: Run, 2: Program end, 3: Program hold

1069H 0 Control selection of Output 1 0: Heating, 1: Cooling, 2: Alarm, 3: Proportional output

106AH 0 Control selection of Output 2

106BH 0

106CH 0

106DH 0

106EH 0

106FH 0

1070H 0

1071H 1 Read/write communication address 1 ~ 247

1072H 0 Read/write communication format 1: RTU, 0: ASCII

1073H 2 Read/write communication speed 0 ~ 4: 2,400 ~ 38,400

1074H 1 Read/write communication data length 0: 8 bits, 1: 7 bits

1075H 1 Read/write parity bit 0: None, 1: Even, 2: Odd

1076H 1 Read/write stop bit 0: 2 stop bits, 1: 1 stop bit

2000H~

203FH

2080H~

20BFH

5. Address and content of the bit register (read bits are stored starting from LSB, and written data is FF00H, set the bit as 1. 0000H sets the

bits data to “0”).

0811H Temperature unit display 0:°F, 1: °C (Default)

0813H Read/write auto-tuning status 0: End (Default), 1: Start

0814H Run/Stop setting 0: Stop, 1: Run (Default)

0815H Program hold flag 1: Program hold

0816H Program stop flag 1: Program stop

6. Communication format: Command 01: read bit, 05: write bit, 03: read word, 06: write word.

ASCII Mode

Read Command Read Response Message Write Command Write Response Message

Start word ’:’ ’:’ Start word ’:’ ’:’ Start word ’:’ ’:’ Start word ’:’ ’:’

Machine address 1 ‘0’ ‘0’ Machine address 1 ‘0’ ‘0’ Machine address 1 ‘0’ ‘0’ Machine address 1 ‘0’ ‘0’

Machine address 0 ‘1’ ‘1’ Machine address 0 ‘1’ ‘1’ Machine address 0 ‘1’ ‘1’ Machine address 0 ‘1’ ‘1’

Command 1 ‘0’ ‘0’ Command 1 ‘0’ ‘0’ Command 1 ‘0’ ‘0’ Command 1 ‘0’ ‘0’

Command 0 ‘3’ ‘1’ Command 0 ‘3’ ‘1’ Command 0 ‘6’ ‘5’ Command 0 ‘6’ ‘5’

Read dynamic value in programmable

control

7 Number of steps in a pattern 0 ~ 7 = N refers to the pattern will be executed from Step 0 to Step N.

0 Additional number of cycles for a pattern 0 ~ 199 refers to the pattern will be executed for 1 ~ 200 times.

No. of the link pattern for the current

0

pattern

Unlock Level 1 password protection.

Read/write allowed

Unlock Level 2 password protection. Use

Level 3.

Unlock Level 3 password protection. Use

Level 2

Unlock Level 1 password protection/Set up

password

Unlock Level 2 password protection/Set up

password

Unlock Level 3 password protection/Set up

password

SV temperature for Pattern 0 ~ 7.

0

SV for Pattern 0 is set in 2000H ~ 2007H

Execution time for Pattern 0~7.

0

Time for Pattern 0 is set in 2080H ~ 2087H

0 ~ 8, 8 refers to end of the program. 0 ~ 7 refers to the next pattern

No. following the current pattern.

0: Heating, 1: Cooling, 2: Alarm

(1000/2000 model)

Shall be the same as Level 1 password (106E)

Shall be the same as Level 2 password (106F)

Shall be the same as Level 3 password (1070)

Unlock password before setting it up.

Unlock password before setting it up.

Unlock password before setting it up.

Unit: 0.1°

0 ~ 900 (1 scale = 1 minute)

- 8 -

Page 9

Read Command Read Response Message Write Command Write Response Message

‘1’ ‘0’ ‘0’ ‘0’ ‘1’ ‘0’ ‘1’ ‘0’

Read staring address

of data/bit

Read length of

data/bit (word/bit)

LRC1 check ‘E’ ‘D’ ‘0’ LRC1 ‘F’ ‘E’ LRC1 ‘F’ ‘E’

LRC0 check ‘A’ ‘D’

End word 1 CR CR LRC1 check ‘0’ ‘E’ End word 1 CR CR End word 1 CR CR

End word 0 LF LF LRC0 check ‘3’ ‘4’ End word 0 LF LF End word 0 LF LF

End word 1 CR CR

End word 0 LF LF

LRC Check

LRC check sums up from “machine address” to “data content”, e.g. 01H + 03H + 10H+ 00H + 00H + 02H = 16H. Obtain 2’s complement EA.

RTU Mode

Read Command Read Response Message Write Command Write Response Message

Machine address 01H 01H Machine address 01H 01H Machine address 01H 01H Machine address 01H 01H

Command 03H 01H Command 03H 01H Command 06H 05H Command 06H 05H

Read start address

of data

Read length of data

(bit/word)

CRC low byte C0H BBH 03H CRC low byte DDH 8FH CRC low byte DDH 8FH

CRC high byte CBH A9H

CRC low byte BBH 77H

CRC high byte 15H 88H

CRC Program Example

unsigned int reg_crc = 0xffff; i = 0;

while (length--)

{

reg_crc ^= RTUData[i];

i ++;

for (j = 0; j < 8; j++)

{

if (reg_crc & 0x01) reg_crc = (reg_crc >> 1) ^ 0xA001;

else reg_crc = reg_crc >> 1;

}

}

return(reg_crc);

‘0’ ‘8’

‘0’ ‘1’ ‘0’ ‘1’ ‘0’ ‘1’ ‘0’ ‘1’

‘0’ ‘0’ ‘1’ ‘7’

‘0’ ‘0’ ‘F’ ‘0’ ‘0’ ‘F’ ‘0’ ‘F’

‘0’ ‘0’

‘0’ ‘0’ ‘0’ ‘E’ ‘0’ ‘E’ ‘0’

‘2’ ‘9’ ‘0’

10H 08H 10H 08H 10H 08H

00H 10H

00H 00H 01H 17H 03H FFH 03H FFH

02H 09H

Length of response

data (byte)

Data content in

1000H/081xH

Data content in

1001H

Length of response

data (byte)

Data content 1

Data content 2

‘4’ ‘2’ ‘0’ ‘8’ ‘0’ ‘8’

‘4’ ‘1’ ‘3’ ‘F’ ‘3’ ‘F’

‘0’ LRC0 ‘D’ ‘3’ LRC0 ‘D’ ‘3’

04H 02H Write data address

F4H 01H

20H CRC high byte E2H 9FH CRC high byte E2H 9FH

Write data address

To write data

content

Write data content

‘1’ ‘0’

‘8’ ‘0’

01H 10H

20H 00H

Write data address

Write data content

Write data address

Write data content

‘1’ ‘0’

‘8’ ‘0’

01H 10H

20H 00H

- 9 -

Page 10

R

R

Installation

How to connect maximum 8 DTC1000/2000 controllers by using DIN rail.

How to Set Up Current Input

For general input For current input (4 ~ 20mA, 0 ~ 20mA)

JUM PE

JP1

DE FA U LT SETTI NG

PIN HEADER

JP1

JUMPE

PIN HEADER

- 10 -

Loading...

Loading...