Page 1

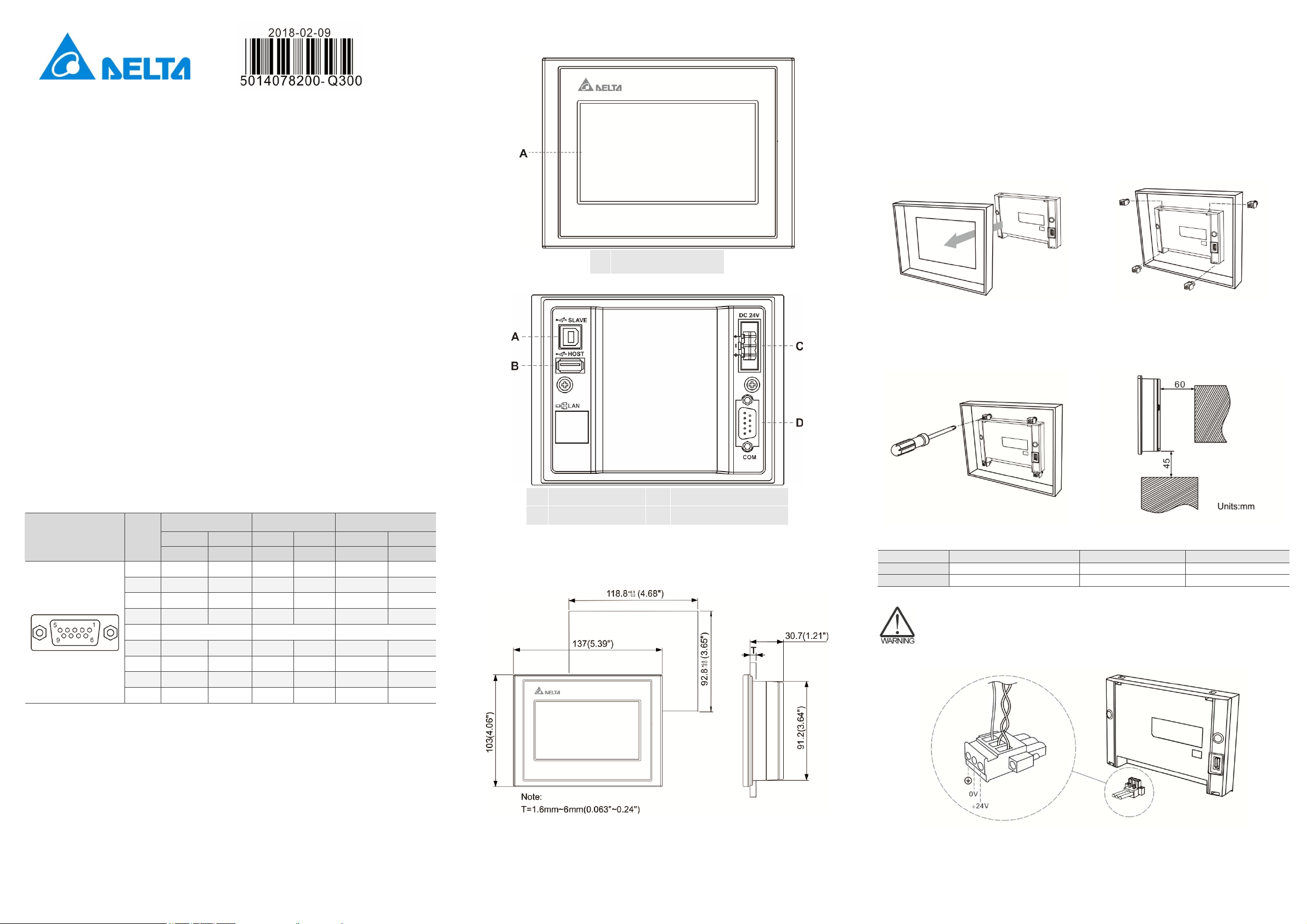

(3) Description of each part

(5) Installation and wiring

DOP-103BQ

Instruction Sheet

(1) General precautions

Thank you for purchasing this product. This instruction sheet provides information about the DOP-100

series HMI. Before using this product, please read through this instruction sheet carefully to ensure the

correct use of the product. Please keep this sheet handy for quick reference whenever needed. Before

finishing reading this sheet, please follow the instructions below:

Install the product in an indoor location, which is free of vapor, corrosive and inflammable gas and

liquids.

Please refer to the wiring diagram when connecting the wires.

Ensure your HMI is correctly grounded. The grounding method must comply with the national

electrical standard (please refer to NFPA 70: National Electrical Code, 2005 Ed.).

Do not disassemble the HMI or change the wiring when power is on.

Do not touch the power supply when power is on, or it may cause electric shock.

When the HMI displays a low power notification and requires a battery change, please contact

your local distributor or Delta Customer Service Center for the replacement. Do not change the

batteries by yourself.

This product can be used with other industrial automation equipment. Please read through this

sheet carefully and install the product according to the instructions to avoid danger.

Cleaning method: please use a dry cloth to clean the product.

This product must be used at an altitude below 2,000 m.

If the equipment is used in a manner not specified by the manufacturer, the protection provided by

the equipment may be impaired.

DOP-103BQ (front view)

DOP-103BQ (rear view)

A Operation / display area

Precautions:

Incorrect installation may result in malfunction.

To ensure the HMI is well ventilated, make sure there is sufficient space between the HMI and the

adjacent objects or walls.

This product should be used on a case / platform which conforms to enclosure Type 4X standard (for

indoor use only).

The maximum panel thickness for mounting must be no greater than 5 mm.

Installation steps:

Step 1:

Put the waterproof gasket into the HMI and then

insert the HMI into the panel cutout.

Step 3:

Tighten the screws with the torque less than

0.5 N-M / 0.7 N-M to avoid damage to the plastic

case.

DOP-103BQ torque: 4.41 lb-inch (0.5 N-M)

Step 2:

Place the fasteners into the slots and tighten the

screws until reaching the panel cutouts.

Step 4:

For heat dissipation, please keep a minimum

clearance of 60 mm on the rear of the HMI.

(2) Communication port pin assignment

DOP-103BQ COM port

MODE1 MODE2 MODE3

COM Port Pin

Note: mark “-” means connection is not required.

1 - - D+ - - TXD+

2 RXD - - - RXD -

3 TXD - - - TXD -

4 - D+ - D+ - RXD+

5 GND GND GND

6 - - D- - - TXD-

7 RTS - - - RTS -

8 CTS - - - CTS -

9 - D- - D- - RXD-

COM1 COM2 COM1 COM2 COM1 COM2

RS-232 RS-485 RS-485 RS-485 RS-232 RS-422

A

USB slave

Power input terminal

C

(24 AWG wire min.)

(4) Mounting dimensions

DOP-103BQ

B

D

USB host

COM1

Wiring:

Type Wire gauge (AWG) Stripped length To rq u e

Solid

Stranded

Please refer to the following diagram when wiring the power connector. The temperature

rating of the cable must be greater than 75

24 - 12 7 - 8 mm 5 kg-cm (4.3 lb-in)

24 - 12 7 - 8 mm 5 kg-cm (4.3 lb-in)

o

C (167oF).

Operation temperature: 0

Storage temperature: -20

o

o

C to 50oC (32oF to 122oF)

C to 60oC (-4oF to 140oF)

Page 2

(6) Hardware specifications

Model DOP-103BQ

Panel type 4.3" TFT LCD (65535 colors)

Resolution 480 x 272 pixels

Backlight

Display

Display range 95.04 x 53.856 mm

LED backlight (half-life under room temperature 25oC > 20,000 hours) *1

Brightness 400 cd/m² (Typ.)

CPU

Flash ROM

RAM

Touchscreen

4-wire resistive touchscreen > 1,000,000 operated

ARM Cortex-A8 (800 MHz)

256 Mbytes

256 Mbytes

Buzzer Multi-tone frequency (2 K – 4 KHz) / 80 dB

Network interface N/A

USB 1 USB slave Ver 2.0; 1 USB host Ver 2.0

SD N/A

COM1 RS-232 (supporting flow control) / RS-485*2

Serial

communication

port

COM2

RS-422 / RS-485*2

COM3 N/A

Auxiliary function key N/A

Calendar Built-in

Cooling method Natural cooling

Approvals

Panel waterproof level IP65 / NEMA 4

Operation voltage*2

CE / UL (please use shielding network cable and magnetic ring with the filter of

300 ohm / 100 MHz)

DC +24V (-15% to +15%) (please use an isolated power supply)

Supplied by Class 2 or SELV circuit (isolated from MAINS by double insulation)

Leakage current 500 VAC for 1 minute (between DC24V terminal and FG terminal)

Power consumption*2

Backup battery

Backup battery life

(subject to operation temperature and condition)

5.67W (Max) *3

3V lithium battery CR2032 × 1

About 3 years or more at 25oC

Operation temperature 0oC to 50oC (32oF to 122oF)

Storage temperature -20oC to +60oC (-4oF to 140oF)

Operating environment

Vibration resistance

Shock resistance

Dimension

(W) x (H) x (D) mm

Mounting dimension

(W) x (H) mm

Weight

10% to 90% RH [0oC - 40oC], 10% to 55% RH [41oC - 50oC];

pollution degree: 2

Conforms to IEC61131-2: continuous vibration 5 Hz - 8.3 Hz with amplitude

3.5 mm; 8.3 Hz - 150 Hz with amplitude 1G

Conforms to IEC60068-2-27:

11 ms, 15 G Peak, in X, Y, Z directions each for 6 times

137 x 103 x 37.1

118.8 x 92.8

Approx. 280g

Note:

1. The half-life of the backlight is defined as the maximum luminance being reduced by 50% when the

maximum drive current is supplied to the HMI. The life of LED backlight shown here is estimated at the

room temperature of 25

2. The withstand voltage of the isolated power circuit is 1500V peak for 1 minute.

3. The HMI power consumption is the power consumed when the HMI is not connecting with other

peripheral devices. To ensure normal operation of the HMI, the recommended capacity of the power

supply is 1.5 to 2 times of the specified power consumption.

4. Isolated power supply is recommended.

5.

6. DOP-100 series can be used with other industrial automation equip

sheet carefully and install the product according to the instructions to avoid danger.

o

C with ambient humidity.

ent. Please read through this

m

Loading...

Loading...