Page 1

Automation for a Changing World

Delta Fan/Pump

Vector Control Drive

CP2000

Series

Page 2

WHY CP2000?

Delta Industrial Automation Green Technology

Delta Industrial Automation introduces the CP2000 Series AC motor drive for

energy-saving HVAC systems and for pump and fan applications. The CP2000

Series is equipped with special HVAC parameters and PID control functions

for efcient operation, as well as multi-segment V/F control curve and soft

start functions to assist frequent torque change and constant

output applications with energy-saving performance.

1

Page 3

2

Page 4

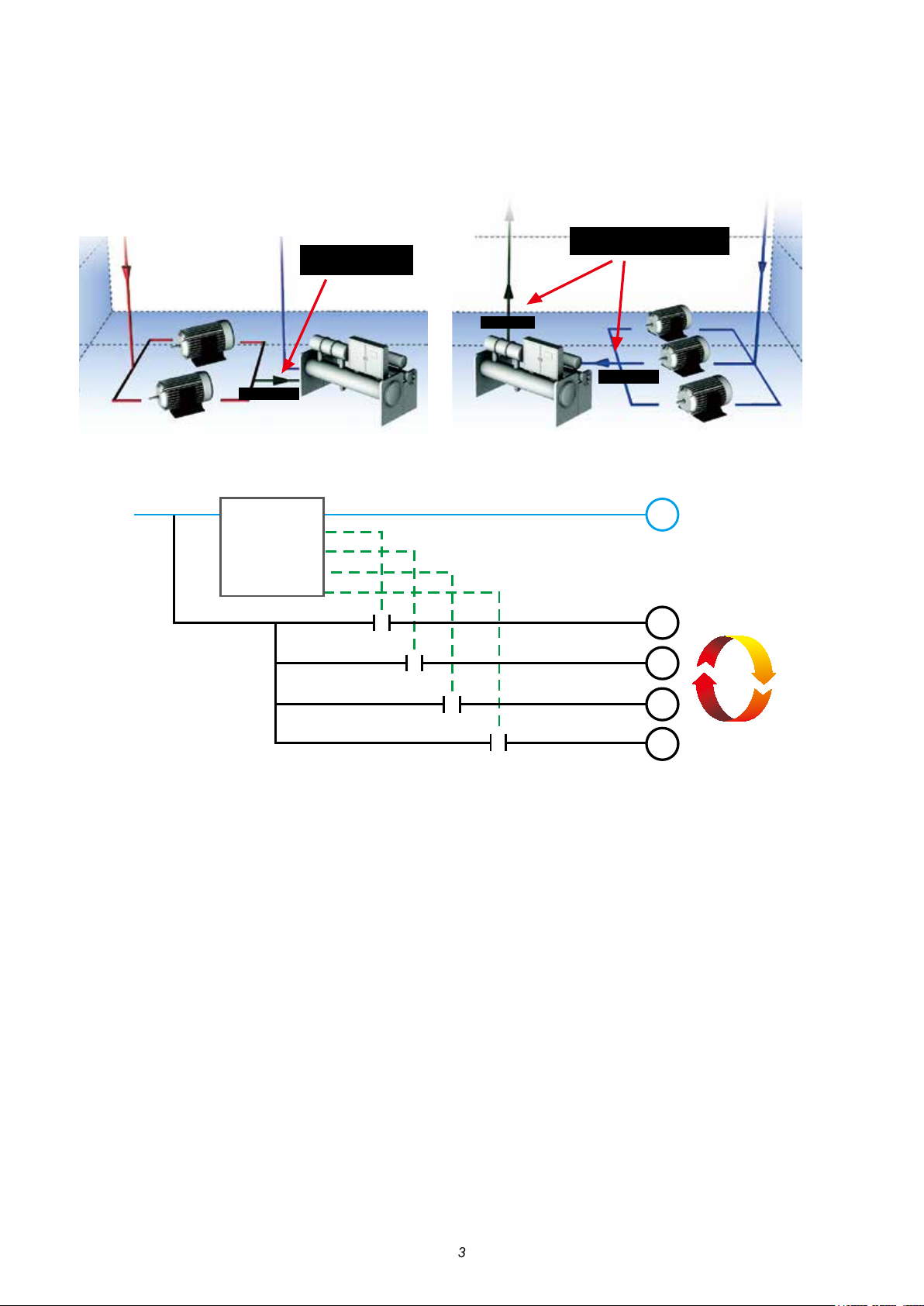

Water Circulation Pump Control

Measures cool water

return temperature

Cool Water

Circulation Pump

lce water

Cool water

Figure1: Multi-Pump Control

Measures cool water and return

water temperature

Ice Water

Circulation Pump

Water inlet

RST

Variable Frequency

M

Control of Pumps

CP2000

MC1

MC2

MC3

MC4

Figure 2: Fixed Amount and Circulation Control

M1

M2

M3

Circulation Control

M4

Features

►

LCD keypad - An easy-to-use text panel with TP Editor software allows users to customize the main page screen

►

Quick setting functions to support self-dened parameter groups and parameter duplication for fast and easy

installation

►

Modular design for exible extension and easy maintenance

►

High-speed communications include BACnet and MODBUS. Optional communication cards are available upon

purchase: PROFIBUS DP, DeviceNet, MODBUS TCP, EtherNet/IP and CANopen

►

Extended life cycle

►

Enhanced conformal coating on PCBs for superior durability in critical environments

►

Fire mode and bypass functions: continuous pressure to extract smoke when emergencies occur

►

Various modes for fans/pump applications including PID control, sleep/wake up functions, ying start and skip

frequency

►

Multi-pumps synchronous control of up to 8 motors at one time and provides xed amount and xed time

circulation control

►

Built-in 10 K steps PLC programming capacity and Real Time Clock (RTC)

3

Page 5

Advanced Drive Technology

High Performance Variable

Frequency Drive Technology

1.Sensorless Vector Control (SVC)

2.Dual rating design

(Light duty & Normal duty)

3.Excellent variable torque control of

asynchronous motors

Modular Design

1.Hot pluggable LCD keypad

2.I/O extension card

3.Various communication cards

4.Removable fans

Environmental Adaptability

Versatile Drive Control

1.Built-in PLC function

2.Built-in brake unit*

3.Networking drive system

4.Auto energy saving

*Note: Please refer to the Product Specication for more details.

1.50°C operation temperature

2.Built-in DC choke*

3.Coated circuit boards

4.Built-in EMC lter*

5.International safety standard

CE/UL/CUL

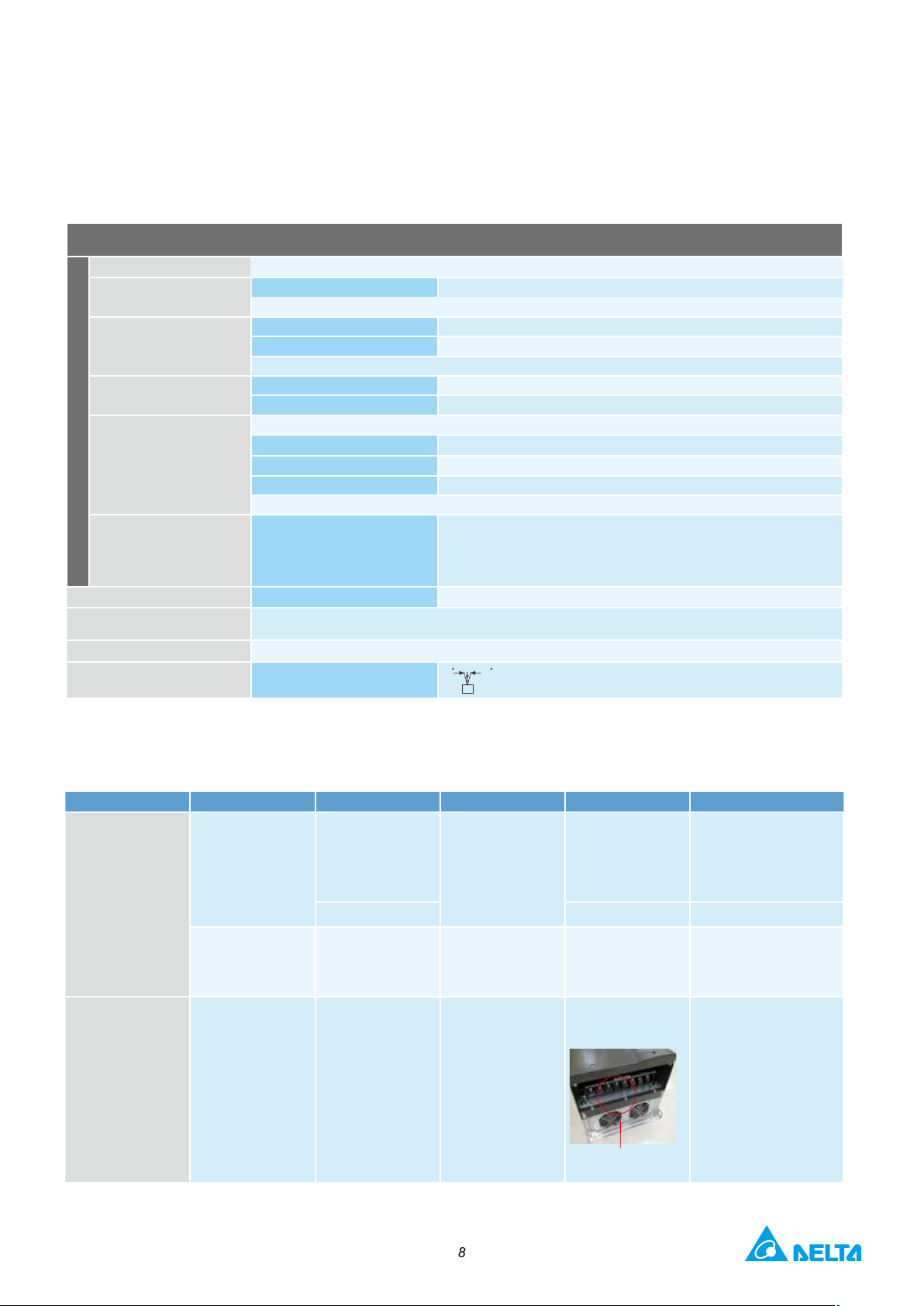

Standard Models

Power range:

230 V (kW) 0.75 1.5 2.2 3.7 5.5 7.5 11 15 18.5 22 30 37 45 55 75 90

230 V (HP) 1 2 3 5 7.5 10 15 20 25 30 40 50 60 75 100 125

Frame Size A B C D E

230 V 0.75 ~ 90 kW, 460 V 0.75 ~ 500 kW

460 V (kW) 0.75 1.5 2.2 3.7 4.0 5.5 7.5 11 15 18.5 22 30 37

460 V (HP) 1 2 3 5 5 7.5 10 15 20 25 30 40 50

Frame Size A B C

460 V (kW) 45 55 75 90 110 132 160 185 220 280 315 355 400 500

460 V (HP) 60 75 100 125 150 175 215 250 300 375 425 475 536 675

Frame Size D0 D E F G

Power range:

575 V (kW) 1.5 2.2 3.7 5.5 7.5 11 15

575 V (HP) 2 3 5 7.5 10 15 20

Frame Size

690 V (kW) 18.5 22 30 37 45 55 75 90 110 132 160 200

690 V (HP) 25 30 40 50 60 75 100 125 150 175 215 270 335 425

Frame Size C D E F G

690 V (kW) 400 450 560 630

690 V (HP) 530 600 745 840

Frame Size H

575 V 1.5 ~ 15 kW, 690 V 18.5 ~ 630 kW

A B

H

250

315

4

Page 6

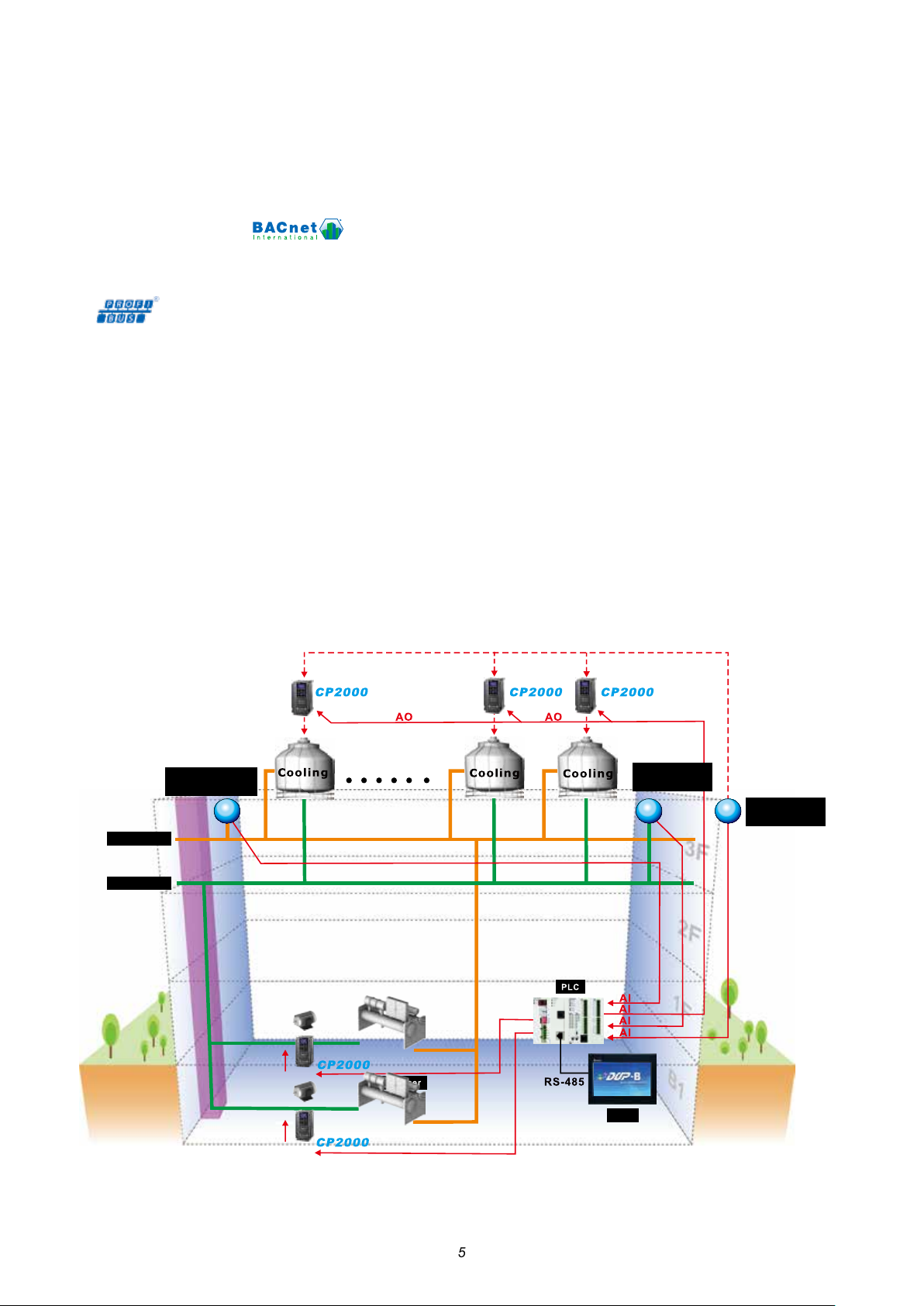

High-Speed Network

►

Advanced network functions

▪ Built-in

RS-485 (MODBUS)

▪ Built-in BACnet MS/TP

►

Various communication card options

DeviceNet、MODBUS TCP、EtherNet/IP、CANopen (DS402)

、

Building Automation Applications

►

4-point adjustable V/F control - Real-time adjustment of output voltage under variable torque load

environments, especially for pump and fan applications.

►

Flying start and auto restart after momentary power loss functions, suitable for fan application.

►

Skip frequency function avoids mechanical resonance and protects the equipment.

►

Low-current protection function prevents free load operation.

►

Built-in BACnet communication protocol saves wiring for building automation applications.

Water outlet

Water inlet

Water

outlet temperature

HMI

Water inlet

temperature

Wet bulb

temperature

5

Page 7

Improves Motor Performance

►

Sensorless Vector Control (SVC) and auto-tuning functions to improve motor performance for variable

torque load applications.

►

Deceleration Energy Backup (DEB) function decelerates motor to a stop when sudden power failure

occurs to protect the equipment from damage.

►

Auto adjusting acceleration/deceleration speed, reduces mechanical vibration when activating and

stopping the equipment and provides smooth operation.

►

Energy saving control functions include PID control, sleep/wakeup mode and auto-energy saving mode.

Pressure measured

by pressure sensor

Chilled water

Proportional

electromagnetic valve

ACU Ventilation Fan

Return water

Built-in PLC Function

►

Built-in 10 K steps PLC function supports independent and distributed control when connecting to a

network system for high operation exibility.

►

Real Time Clock (RTC) function facilitates the PLC program writing process for ON/OFF chronology,

daylight saving operation and many other settings.

Standards

■CE

Low Voltage:

EN61800-5-1

■UL, cUL

■C-Tick

■ROHS

EMC:

EN61000-3-12, EN61800-3, IEC61000-6-2, IEC61000-6-4,

IEC61000-4-2, IEC61000-4-3, IEC61000-4-4, IEC61000-4-5, IEC61000-4-6, IEC61000-4-8

6

Page 8

Modular Design

Powerful motor drive control functions. The modular design satises various system applications

with higher exibility and is easy to maintain. Accessories include input/output extension cards,

communication cards, hot pluggable LCD keypad, removable terminal blocks and removable fans.

• KPC-CC01 keypad

• Standard RJ45 cable for remote operation.

• Easy to install and remove with one press.

• RFI Jumper

• Remove the safety screws

and press on both side tabs to

remove the cover.

• The product nameplate shows the

input/output voltage, input /output

current, frequency range, and

more.

• Modular fan design, easy to

replace and clean, extending product

life.

High Adaptability to Environment

►

Built-in DC choke to supress harmonics*

►

Built-in EMC lter for noise suppression*

►

Enhanced conformal coating on PCBs for

superior durability in critical environments.

Heat

►

The electronic components of the drive are

isolated from the cooling system to reduce

heat interference. Dissipated heat can be

discharged by ange-mounting installation,

and forced fan cooling can import cold air

into the heat sink. The heat dissipation

performance is optimized by these two

cooling methods.

Note: Please refer to the Product Specication for more detail

dissipation

7

Dust-proof

Interference

immunity

Page 9

Environment for Operation, Storage and

DO NOT expose the AC motor drive to harsh environments, such as dust, direct sunlight, corrosive / ammable gasses, humidity, liquid or vibrations.

Installation Location

Package Drop

Impact

1

Transportation

The salts in the air must be less than 0.01 mg / cm2 per year.

IEC60364-1 / IEC60664-1 Pollution degree 2, indoor use only

Surrounding

Temperature

Rated Humidity

Air Pressure

Environment

Pollution Level

Altitude

Vibration

Operation Position

Storage / Transportation -25 ºC ~ +70 ºC

Only allowed at non-condensation, non-frost, non-conductive environment.

Operation Max. 95%

Storage / Transportation Max. 95%

Only allowed at non-condensation, non-frost, non-conductive environment.

Operation / Storage 86 to 106 kPa

Transportation 70 to 106 kPa

IEC60721-3-3

Operation Class 3C2; Class 3S2

Storage Class 1C2; Class 1S2

Transportation Class 2C2; Class 2S2

Only allowed at non-condensation, non-frost, non-conductive environment.

If the AC motor drive is installed at an altitude of 0 to 1000m, follow normal

Operation

Storage / Transportation ISTA procedure 1A (according to weight) IEC60068-2-31

1.0 mm, peak to peak value range from 2 Hz to 13.2 Hz; 0.7 G ~ 1.0 G range from 13.2 Hz to 55 Hz;

1.0 G range from 55 Hz to 512 Hz. Comply with IEC 60068-2-6.

IEC / EN 60068-2-27

Max. allowed offset angle ±10 º

(under normal installation position)

operation restrictions. If it is installed at altitude 1000 ~ 3000 m, decrease 1% of

rated current or lower 0.5 ºC of temperature for every 100m increase in altitude.

Maximum altitude for Corner Grounded TN system is 2000m; for application over

2000m, please contact Delta for more details.

0 10

Specication for Operation Temperature and

Protection Level

Model Frame Top Cover Conduit Box Protection Level OperationTemperature

230 V & 460 V:

ND: -10 ° C ~ 50 ° C

LD: -10 ° C ~ 40 ° C

V & 690 V:

575

-10 ° C ~ 50 ° C

-10 ° C ~ 40 ° C

-10 ° C ~ 40 ° C

230 V & 460 V:

ND: -10 ° C ~ 50 ° C

LD: -10 ° C ~ 40 ° C

690 V:

-10 ° C ~ 50 ° C

(ND = Normal Duty

LD = Light Duty)

VFDxxxxCPxxx-21

VFDxxxxCPxxx-00

Frame A ~ C

230 V: 0.75 ~ 30 kW

460 V: 0.75 ~ 37 kW

575 V: 1.5 ~ 15 kW

690 V: 18.5 ~ 37 kW

Frame D ~ H

230 V: > 37 kW

460 V: > 45 kW

690 V: > 45 kW

Frame D ~ H

230 V: > 37 kW

460 V: > 45 kW

690 V: > 45 kW

Remove top cover

Standard with top cover IP20/UL Type1/NEMA1

N/A Conduit box IP20/UL Type1/NEMA1

N/A No conduit box

Standard conduit plate

IP20/UL Open Type

IP00

IP20 / UL Open Type

Protection degree for

the circled area is IP00;

other areas are IP20

8

Page 10

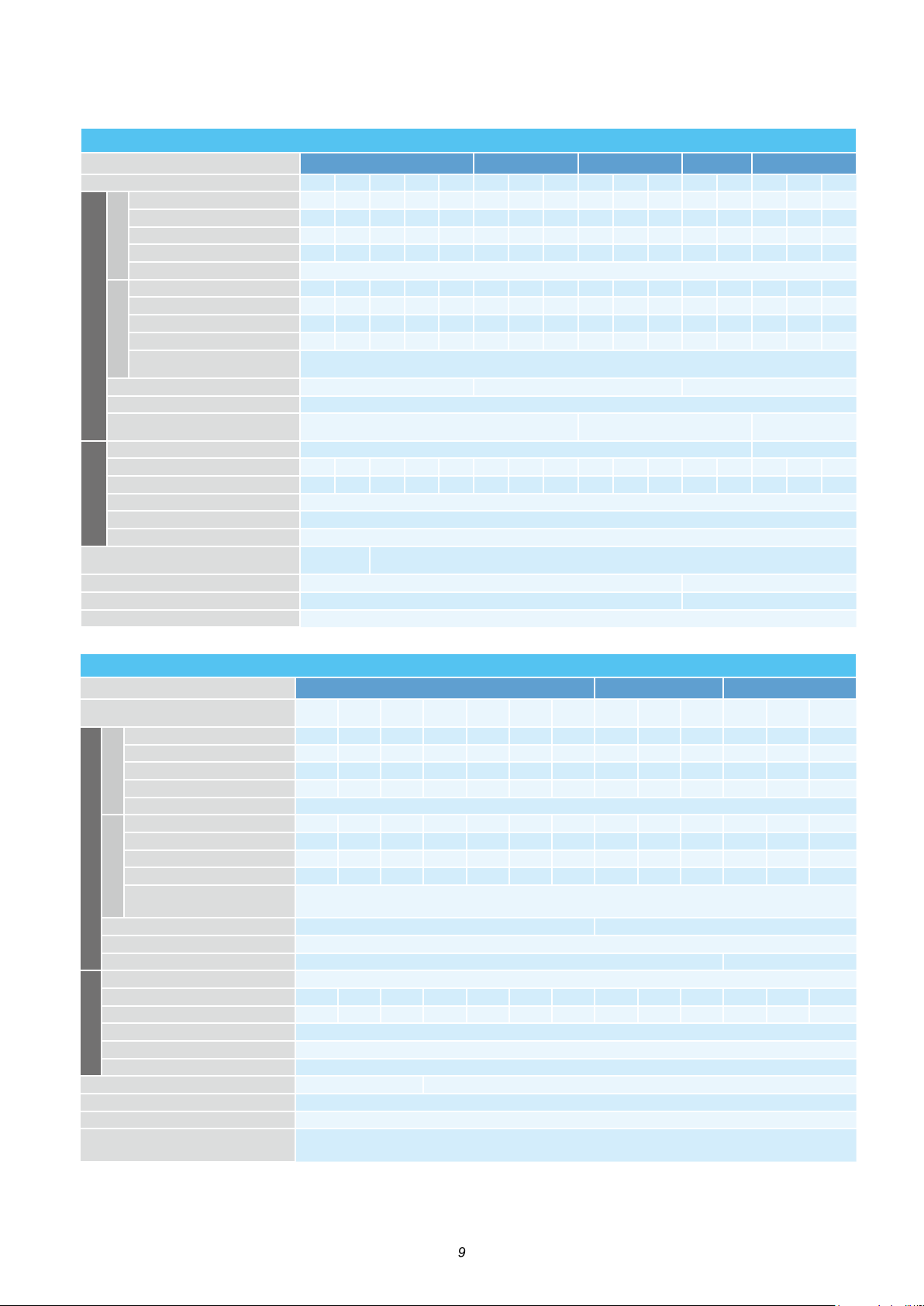

460 V

Models VFD-����CP43�-��

VFD-����CP4E�-��

Rated Output Capacity (kVA)

Rated Output Current (A)

Applicable Motor Output ( kW)

Applicable Motor Output (HP)

Overload Tolerance

Rated Output Capacity (kVA)

2.2

2.4

3.2

4.8

7.2

8.4101419253036

48

Rated Output Current (A)

1.7

Applicable Motor Output ( kW)

Applicable Motor Output (HP)

Efciency (%)

Power Factor

Carrier Frequency (kHz)

Max. Output Frequency (Hz)

Input Current (A) Light Duty

Input Current (A) Normal Duty

Rated Voltage / Frequency

Operating Voltage Range

323 ~ 528 V

Frequency Tolerance

47 ~ 63 Hz

Cooling Method

Braking Chopper

Frame A, B, C, Built-in

DC Choke

Frame A, B, C, Optional

Frame A, B, C of VFD____CP4E_-__; EMC lter Built-in

Frame A, B, C of VFD____CP43_-__; N / A

Specifications

230 V

A

BCD

E

Model VFD-����CP23�-��

Rated Output Capacity (kVA)

Rated Output Current (A)

Applicable Motor Output ( kW)

Applicable Motor Output (HP)

Rated Output Capacity (kVA)

1.2

2.0

3.2

4.4

6.810132026303648587286

102

Rated Output Current (A)

3

Applicable Motor Output (HP)

Efciency (%)

Power Factor

Max. Output Frequency (Hz)

Input Current (A) Light Duty

Input Current (A) Normal Duty

Rated Voltage / Frequency

Operating Voltage Range

170 ~ 265 V

Frequency Tolerance

47 ~ 63 Hz

Natural

cooling

Braking Chopper

Frame A, B, C, Built-in

Frame D and above: Optional

DC Choke

Frame A, B, C, Optional

Frame D and above: Built-in 3%

EMC Filter

Frame Size

LIGHT DUTY

Overload Tolerance 120% of rated current for 1 minute during every 5 minutes

Applicable Motor Output ( kW) 0.4 0.75 1.5 2.2 3.7 5.5 7.5 11 15 18.5 22 30 37 45 55 75

Output Rating

Overload Tolerance

NORMAL DUTY

Carrier Frequency (kHz)

Input Rating

007 015 022 037 055 075 11 0 150 185 220 300 370 450 550 750 900

2.0 3.0 4.0 6.0 8.4 12 18 24 30 36 42 58 72 86 110 128

5 7.5 10 15 21 31 46 61 75 90 105 146 180 215 276 322

0.75 1.5 2.2 3.7 5.5 7.5 11 15 18.5 22 30 37 45 55 75 90

1 2 3 5 7.5 10 15 20 25 30 40 50 60 75 100 125

5 8 11 17 25 33 49 65 75 90 120 146 180 215 255

0.5 1 2 3 5 7.5 10 15 20 25 30 40 50 60 75 100

120% of rated current for 1 minute during every 5 minutes;

160% of rated current for 3 seconds during every 25 seconds

96 96.5 97

> 0.98

2 ~ 15 kHz

(default setting 8 kHz)

599.00 Hz 400.00 Hz

6.4 9.6 15 22 25 35 50 65 83 100 116 146 180 215 276 322

3.9 6.4 12 16 20 28 36 52 72 83 99 124 143 171 206 245

3-phase

AC 200 V ~ 240 V (-15% ~ +10%),50 / 60 Hz

2 ~ 10 kHz

(default setting 6 kHz)

AC

2 ~ 9 kHz

(default setting 4 kHz)

Cooling Method

Frame Size

LIGHT DUTY

Output Rating

Overload Tolerance

NORMAL DUTY

Input Rating

Fan Cooling

Optional

A B C

007 015 022 037 040 055 075 11 0 150 185 220 300 370

2.4 3.3 4.4 6.8 8.4 10.4 14.3 19 25 30 36 48 58

3 4.2* 5.5* 8.5* 10.5 13* 18* 24* 32* 38* 45 60* 73*

0.75 1.5 2.2 3.7 4.0 5.5 7.5 11 15 18.5 22 30 37

1 2 3 5 5 7.5 10 15 20 25 30 40 50

120% of rated current for 1 minute during every 5 minutes

3.0 4.0 6.0 9.0 10.5 12 18 24 32 38 45 60

0.4 0.75 1.5 2.2 3.7 4.0 5.5 7.5 11 15 18.5 22 30

0.5 1 2 3 5 5 7.5 10 15 20 25 30 40

120% of rated current for 1 minute during every 5 minutes;

160% of rated current for 3 seconds during every 25 seconds

96 96.5

> 0.98

2 ~ 15 kHz (

4.3 6.0 8.1 12.4 16 20 22 26 35 42 50 66 80

3.5 4.3 5.9 8.7 14 15.5 17 20 26 35 40 47 63

3-phase

default

8 kHz) 2 ~ 10 kHz (

599.00 Hz

AC 380 V ~ 480 V (-15% ~ +10%), 50 / 60 Hz

AC

default

6 kHz)

EMC Filter

*Rated current for B type model (e.g. VFD015CP43B-21)

Natural cooling Fan cooling

9

Page 11

460 V

Frame Size

Model VFD-���� CP43�-��

450

550

750

900

Rated Output Capacity (kVA)

Rated Output Current (A)

Applicable Motor Output (HP)

Overload Tolerance

Rated Output Capacity (kVA)

Rated Output Current (A)

Applicable Motor Output ( kW)

Applicable Motor Output (HP)

Efciency (%)

Power Factor

Max. Output Frequency (Hz)

Input Current (A) Light Duty

Input Current (A) Normal Duty

Rated Voltage / Frequency

Operating Voltage Range

323 ~ 528 V

Frequency Tolerance

47 ~ 63 Hz

Cooling Method

Fan cooling

Braking Chopper

DC Choke

EMC Filter

Frame D and above: Optional

Model VFD-���C53A-21

Applicable Motor Output (HP)

LIGHT DUTY

NORMAL DUTY

Efciency (%)

Power Factor

Carrier Frequency (kHz)

Input Current (A) Light Duty

Input Current (A) Normal Duty

Rated Voltage / Frequency

Operating Voltage Range

446 ~ 660 VAC

Frequency Tolerance

47 ~ 63 Hz

AC Drive Weight

3 ± 0.3 Kg

4.8 ± 1 Kg

Cooling Method

Natural cooling

Fan cooling

Braking Chopper

Built-in

DC Choke

Optional

Applicable Motor Output ( kW)

LIGHT DUTY

Output Rating

Overload Tolerance

NORMAL DUTY

Carrier Frequency (kHz)

Input Rating

D0 D E F G H

1100 1320 1600 1850 2200 2800 3150 3550 4000 5000

73 88 120 143 175 207 247 295 367 422 491 544 613 773

91 110 150* 180 220 260* 310 370* 460 530 616 683 770 930

45 55 75 90 110 132 160 185 220 280 315 355 400 500

60 75 100 125 150 175 215 250 300 375 425 475 536 675

120% of rated current for 1 minute during every 5 minutes

58 73 88 120 143 175 207 247 295 367 438 491 544

73 91 110 150 180 220 260 310 370 460 550 616 683

37 45 55 75 90 110 132 160 185 220 280 315 355

53 60 75 100 125 150 175 215 250 300 375 425 475

120% of rated current for 1 minute during every 5 minutes;

160% of rated current for 3 seconds during every 25 seconds

97 97.5

> 0.98

2 ~ 10 kHz

(default setting 6 kHz)

2 ~ 9 kHz

(default setting 4 kHz)

599.00 Hz 400.00 Hz

91 110 150 180 220 260 310 370 460 530 616 683 770

74 101 114 157 167 207 240 300 380 400 494 555 625

3-phase

AC 380 V ~ 480 V (-15% ~ +10%), 50 / 60 Hz

AC

Frame D and above: Optional

Frame D and above: Built-in 3%

720

866

450

600

930

866

575 V

Frame Size

015 022 037 055 075 110 150

2 3 5 7.5 10 15 20

Rated Output Capacity (kVA)

Rated Output Current (A)

Applicable Motor Output (kW)

Applicable Motor Output (HP)

Rated Output Capacity (kVA)

Rated Output Current (A)

Output*

Applicable Motor Output (kW)

Applicable Motor Output (HP)

3 4.3 6.7 9.9 12.1 18.7 24.2

3 4.3 6.7 9.9 12.1 18.7 24.2

1.5 2.2 3.7 5.5 7.5 11 15

2 3 5 7.5 10 15 20

2.5 3.6 5.5 8.2 10 15.4 19.9

2.5 3.6 5.5 8.2 10 15.5 20

0.75 1.5 2.2 3.7 5.5 7.5 11

1 2 3 5 7.5 10 15

3.8 5.4 10.4 14.9 16.9 21.3 26.3

3.1 4.5 7.2 12.3 15 18 22.8

Input

* Parameter 00-16; available load modes: Light Duty (LD) and Normal Duty (ND); default setting is LD mode

A B

97 98

2 ~15 kHz (default setting 4 kHz)

-Phase

3

525 VAC ~ 600 V

> 0.98

( -15% ~ +10%), 50 / 60 Hz

AC

10

Page 12

F

G

H

Model VFD-���CP63A-��

Rated Output Capacity (kVA)

Applicable Motor Output ( 690V, kW)

Applicable Motor Output ( 690V, HP)

Applicable Motor Output (575V, HP)

Rated Output Current (A)

Applicable Motor Output ( 690V, kW)

132

160

200

250

315

355

450

630

Applicable Motor Output ( 690V, HP)

Applicable Motor Output (575V, HP)

150

150

200

250

350

400

450

500

Rated Output Current (A)

Efciency (%)

Power Factor

Input Current (A) Light Duty

Input Current (A) Normal Duty

Rated Voltage / Frequency

Operating Voltage Range

446 ~ 759 VAC

Frequency Tolerance

47 ~ 63 Hz

AC Drive Weight

88 ± 1.5 Kg

135 ± 4 Kg

243 ± 5 Kg

Cooling Method

Fan cooling

Braking Chopper

Frame D and above (optional)

DC Choke

Frame D and above (built-in)

Specifications

Frame Size

Model VFD-���CP63A-��

Output*

LIGHT DUTY

Rated Output Capacity (kVA)

Applicable Motor Output ( 690V, kW)

Applicable Motor Output ( 690V, HP)

Applicable Motor Output (575V, HP)

Rated Output Current (A)

NORMAL DUTY

Rated Output Capacity (kVA)

Applicable Motor Output ( 690V, kW)

15

18.522303745557590110

Applicable Motor Output ( 690V, HP)

Rated Output Current (A)

Efciency (%)

Power Factor

Carrier Frequency (kHz)

Input

Input Current (A) Light Duty

Input Current (A) Normal Duty

Rated Voltage / Frequency

Operating Voltage Range

446 ~ 759 VAC

Frequency Tolerance

47 ~ 63 Hz

AC Drive Weight

10 ± 1.5 Kg

39 ± 1.5 Kg

61 ± 1.5 Kg

Cooling Method

Fan cooling

Braking Chopper

Frame C (built-in)

Frame D and above (optional)

DC Choke

Frame C (optional)

Frame D and above (built-in)

Applicable Motor Output (575V, HP)

690 V

C D E

185 220 300 370 450 550 750 900 1100 1320

29 36 43 54 65 80 103 124 149 179

18.5 22 30 37 45 55 75 90 11 0 132

25 30 40 50 60 75 100 125 150 175

20 25 30 40 50 60 75 100 125 150

24 30 36 45 54 67 86 104 125 150

24 29 36 43 54 65 80 103 124 149

20 25 30 40 50 60 75 100 125 150

15 20 25 30 40 50 60 75 100 125

20 24 30 36 45 54 67 86 104 125

97

2 ~ 9 kHz (default setting 4 kHz)

29 36 43 54 65 81 84 102 122 147

24 29 36 43 54 65 66 84 102 122

3-Phase 525 VAC ~ 690 V

> 0.98

( -15% ~ +10%), 50 / 60 Hz

AC

690 V

Frame Size

1600 2000 2500 3150 4000 4500 5600 6300

215 263 347 418 494.5 534.7 678.5 776

160 200 250 315 400 450 560 630

215 270 335 425 530 600 745 850

LIGHT DUTY

Rated Output Capacity (kVA)

Output*

NORMAL DUTY

Carrier Frequency (kHz)

Input

* Parameter 00-16; available load modes: Light Duty (LD) and Normal Duty (ND) ; default setting is LD mode

150 200 250 350 400 450 500 675

180 220 290 350 430 465 590 675

179 215 239 347 402.5 442.7 534.7 776

175 215 270 335 425 475 600 850

150 180 220 290 350 385 465 675

97 98

2 ~ 9 kHz (default setting 4 kHz)

178 217 292 353 454 469 595 681

148 178 222 292 353 388 504 681

-Phase

3

525 VAC ~ 690 V

> 0.98

( -15% ~ +10%), 50 / 60 Hz

AC

2 ~ 9 kHz

(default setting

3 kHz)

11

Page 13

General Specifications

Control Characteristics

Control Method

Starting Torque

V / F Curve

Torque Limit

Frequency Output Accuracy

Output Frequency Resolution

Accel. / decel. Time

Protection Characteristics

Over-Temperature Protection

Control Mode

Speed Response Ability

Max. Output Frequency (Hz)

Overload Tolerance

Frequency Setting Signal

Main Control Function

Fan Control

Motor Protection

Over-Current Protection

Over-Voltage Protection

Stall Prevention

Restart After Instantaneous

Power Failure

Grounding Leakage Current

Protection

International Certications

Pulse Width Modulated (PWM)

230 V / 460 V

1: V / F (V / F control), 2: SVC (Sensorless Vector Control), 3: PM (Permanent Magnet Motor)

575 V / 690 V

1: V / F,2: SVC

Reach up to 150% or above at 0.5 Hz

4 point adjustable V / F curve and square curve

5 Hz

Light Duty: Max. 130% torque current; Normal Duty: Max. 160% torque current

230 V model: 599.00 Hz (55 kW and above: 400.00 Hz)

460 V model: 599.00 Hz (90 kW and above: 400.00 Hz)

575 V / 690 V

Digital command: ±0.01%, -10 °C ~ +40 °C, Analog command: ±0.1%, 25 ±10 °C

Digital command: 0.01 Hz; Analog command: Max. output frequency x 0.03 / 60 Hz (±11 bit)

Light duty: 120% of rated current for 1 minute

Normal duty: 120% of rated current for 1 minute;160% of rated current for 3 seconds

0 ~ +10 V, 4 ~ 20 mA, 0 ~ 20 mA

0.00 ~ 600.00 / 0.0 ~ 6000.0 seconds

Fault restart Torque limit Smart stall Dwell 3-wire sequence

Speed search Parameter copy JOG frequency Slip compensation Torque compensation

S-curve accel / decel Energy saving control

PID control

(with sleep function)

Over-torque detection MODBUS communication (RS-485 RJ45, Max. 115.2 kbps)

230 V model: Model with spec higher than VFD185CP23 (included) are PWM control;

Model with spec lower than VFD150CP23 (not included) are on / off switch control.

460 V model: Model with spec higher than VFD220CP43 (included) are PWM control;

Model with spec lower than VFD185CP43 (not included) are on / off switch control.

575 V / 690 V

Electronic thermal relay protection

230 V / 460 V

Light duty: Over-current protection for 200% rated current,

Normal duty: Over-current protection for 240% rated current,

Current clamp (Light duty: 130 ~ 135%);(Normal duty: 170 ~ 175%)

575 V / 690 V

Over-current protection for 225% rated current

Current clamp (Light duty: around 128 ~ 141%);(Normal duty: around 170 ~ 175%

230 V model: drive will stop when DC-BUS voltage exceeds 410 V

460 V model: drive will stop when DC-BUS voltage exceeds 820 V

575 V / 690 V

built-in temperature sensor

Stall prevention during acceleration, deceleration and running indepenently

Parameter setting up to 20 seconds

Leakage current is higher than 50% of rated current of the AC motor drive

model:

model

:

model: 599.00 Hz

, pulse input

Accel / Decel. Time

switch

Auto-Tuning (rotational,

stationary)

model

model

model

model: drive will stop when DC-BUS voltage exceeds

: PWM

:

:

control

DC injection braking

at start / stop

Frequency / lower limit

settings

BACnet

Communication

)

1189 V

Momentary power loss

ride thru

16-step speed (max.)

Note: EAC Certification is for 230V and 460V models only

12

Page 14

Wiring

Wiring Diagram for Frame A ~ C

*Input: 3-phase power

Fuse/NFB (No Fuse Breaker)

R (L1)

S(L 2)

T( L3)

NOTE

NOTE

It is recommended to

install a protective

circuit at RB-RC to

protect it from

system damage.

When fault occurs, the contact will switch

ON to shut the power and protect the

power system.

NOTE

RB1 and RC1 are the multifunction output

terminals

Factory setting:NPN(SINK)Mode

Please refer to Figure 2 for

wiring of NPN mode and PNP mode.

FWD/STOP

REV/STOP

Multi-step 1

Multi-step 2

Multi-step 3

Factory

setting

NOT E

NOT

Do NOT apply the main voltage directly

to above terminals.

NOT E

* 1

A jumper is factory-installed between DCM, SCM1

and SCM2. Remove the short circuiting jumper before

wiring these terminals.

A jumper is factory-installed between +24V, STO1

* 2

and STO2. Remove the short circuiting jumper before

wiring these terminals

S

T

O P

E

S

afet y PLC

Multi-step 4

A/

N

N A/

A/

N

N A/

Digital Signal Common

O FF

MC

ON

MC

S A

+ 2 4 V D C

*1

*2

Jumper

RB1

R C1

FW D

RE V

MI 1

MI 2

MI 3

MI 4

MI

MI 6

MI 7

MI

DC M

DC choke (optional)

-

+2 B2

R (L1 )

S (L2 )

T (L 3)

4

+2

CO M

5

8

+1

V

DCM

SC M1

SCM2

+ 24V

ST O1

S

T O 2

Brake resistor (optional)

U( T1 )

V(T 2)

W (T3)

RA1

at COS (0.4)

RC1

at COS (0.4)

RA2

Multifunction output terminals

RC 2

RA 3

at COS (0.4)

30V

RC 3

8 1

Option slot 1

SG ND

8 1

SG+

Communication extension card

Motor

IM

3~

Multifunction output terminals

250 Vac/3 A (N.C. )

30Vd c/5 A (N.O.)

30Vd c/3 A (N.C. )

d c/5 A (N .O.)

Analog Multifunction

Output Terminal

Analog Signal Common

Analog Multifunction

Output Terminal

)

A (250 Vac/3 N .O.

A (250 Vac/1.2 N.O.)

,estimate

,estimate

A (250 Vac /1.2 N.C.)

)

A (25 0Va c/3 N. O.

A (2 50 Vac/ 1.2 N. O.)

,estimate

MODBUS RS-485

Pi n 1~2, 7, 8:

Pi n 3, 6: SGN D

Pi n 4:SGPi n 5:SG+

Reserved

5K

+10V/20 mA

3

0~10 VDC or 0/4~20 mA

2

1

0~10 VDC or 0/4~20 mA

0~+10 V

Analog Multifunction

Output Terminal

+10 V

AVI1

ACI

AVI2

ACM

13

Option slot 3

I/O & RELAY extension card

Control terminals

Shielded leads & cable

Page 15

Wiring Diagram for Frame D0 and above

*Input: 3-phase power

Fuse/NFB (No Fuse Breaker)

R (L1 )

S (L2)

T (L3 )

O FF

SA

MC

ON

MC

NOTENOTE

It is recommended to

install a protective

circuit at RB-RC to

protect it from

system damage.

When fault occurs, the contact will switch

ON to shut the power and protect the

power system.

NOT E

RB1 and RC1 are the multifunction output

terminals

Factory setting:NPN(SINK)Mode

Please refer to Figure 2 for

wiring of NPN mode and PNP mode.

FWD/STOP

REV/STOP

Multi-step 1

Multi-step 2

Multi-step 3

Factory

setting

Multi-step 4

N A/

N A/

N

A/

N A/

NOT E

NOT

Do NOT apply the main voltage directly

to above terminals.

NOT E

* 1

A jumper is factory-installed between DCM, SCM1

and SCM2. Remove the short circuiting jumper before

wiring these terminals.

A jumper is factory-installed between +24V, STO1

* 2

and STO2. Remove the short circuiting jumper before

wiring these terminals.

E STO P

Safet y P LC

Digital Signal Common

+ 24 VD

*1

*2

+1/ DC+

R (L1)

S (L2)

T (L3)

-/ DC-

U (T1)

V (T2 )

W (T3)

Motor

IM

3~

RB 1

RC1

+ 2

CO M

FW D

RE V

MI 1

MI 2

MI 3

MI 4

MI

4 V

5

Multifunction output terminals

RA1

2 50Va c/3 A (N .C. )

at COS (0.4)

RC1

at COS (0.4)

30 Vdc /5 A (N. O.)

30 Vdc /3 A (N. C.)

RA2

A (2 50Va c/3 N.O .

A (2 50V ac/1 .2 N. O.)

A (2 50V ac /1.2 N. C.)

)

,estimate

,estimate

MI 6

MI 7

M

I

DC M

8

Multifunction output terminals

RC 2

250 Vac /3 N. O.

250 Vac /1.2 N .O .)

RA 3

at COS (0.4)

)

A (

A (

,estimate

30V dc /5 A (N. O.)

RC 3

Analog Multifunction

Output Terminal

C

DCM

Analog Signal Common

Analog Multifunction

Output Terminal

SC M1

SCM2

+ 24 V

S T O

ST O2

8 1

8 1

1

Option slot 1

MODBUS RS-485

SG ND

Pi n 1~2, 7, 8:

Pi n 3, 6: SGN D

SG+

Pi n 4:SGPi n 5:SG+

Communication extension card

Reserved

5K

+10 V/20 mA

3

0~10 VDC or 0/4~20 mA

2

1

0~10 VDC or 0/4~20 mA

0~+10 V

Analog Multifunction

Output Terminal

+10 V

AVI1

ACI

AVI2

ACM

14

Option slot 3

I/O & RELAY extension card

Control terminals

Shielded leads & cable

Page 16

Dimensions

mm

inch

MODEL

Digital Keypad

Frame A

VFD007CP23A-21

VFD015CP23A-21

VFD022CP23A-21

VFD037CP23A-21

VFD055CP23A-21

VFD007CP43A-21

VFD015CP43B-21

VFD022CP43B-21

VFD037CP43B-21

VFD040CP43A-21

VFD055CP43B-21

VFD075CP43B-21

Standard LCD keypad

VFD007CP4EA-21

VFD015CP4EB-21

VFD022CP4EB-21

VFD037CP4EB-21

VFD040CP4EA-21

VFD055CP4EB-21

VFD075CP4EB-21

VFD015CP53A-21

VFD022CP53A-21

VFD037CP53A-21

Optional selection:

LED keypad

W

W1

See Detail A

See Detail B

D

D1

S1

Detail A (Mounting Hole)

S1

Detail B (Mounting Hole)

Frame W H D W1 H1 D1* Ø Ø1 Ø2 Ø3

A

130.0 250.0 170.0 116.0 236.0 45.8 6.2 22.2 34.0 28.0

5.12 9.84 6.69 4.57 9.29 1.80 0.24 0.87 1.34 1.10

*D1: Flange mount.

15

Page 17

mm

Frame B

MODEL

MODEL

W

W1

See Detail A

D

D1

VFD075CP23A-21

VFD110CP23A-21

VFD150CP23A-21

VFD110CP43B-21

See Detail B

S1

VFD150CP43B-21

VFD185CP43B-21

VFD110CP4EB-21

Detail A (Mounting Hole)

VFD150CP4EB-21

VFD185CP4EB-21

VFD055CP53A-21

VFD075CP53A-21

VFD110CP53A-21

VFD150CP53A-21

Detail B (Mounting Hole)

S1

Frame W H D W1 H1 D1* S1 Ø1 Ø2 Ø3

B1

inch 7.48 12.60 7.48 6.81 11.93 3.07 0.33 0.87 1.34 1.72

Frame C

190.0 320.0 190.0 173.0 303.0 77.9 8.5 22.2 34.0 43.8

W

W1

See Detail A

D

D1

*D1: Flange mount.

VFD185CP23A-21

VFD220CP23A-21

VFD300CP23A-21

VFD220CP43A-21

VFD300CP43B-21

See Detail B

S1

VFD370CP43B-21

VFD220CP4EA-21

VFD300CP4EB-21

Detail A (Mounting Hole)

VFD370CP4EB-21

VFD185CP63A-21

VFD220CP63A-21

VFD300CP63A-21

VFD370CP63A-21

Detail B (Mounting Hole)

S1

Frame W H D W1 H1 D1* S1 Ø1 Ø2 Ø3

mm 250.0 400.0 210.0 231.0 381.0 92.9 8.5 22.2 34.0 50.0

C1

inch 9.84 15.75 8.27 9.09 15.00 3.66 0.33 0.87 1.34 1.97

16

*D1: Flange mount.

Page 18

Dimensions

Frame

WHDW1H1H2H3

D1*D2S1S2Ø1Ø2Ø3

Frame

WHDW1H1H2H3

D1*D2S1

S2

Frame

WHDW1H1H2H3

D1*D2S1S2Ø1Ø2Ø3

mm

Frame

WHDW1H1H2H3

D1*D2S1S2Ø1Ø2Ø3

mm

MODEL

FRAME_D1

FRAME_D0-1

MODEL

FRAME_D2

FRAME_D0-2

Frame D1 / D0-1

See Detail A

See Detail B

VFD370CP23A-00

VFD450CP23A-00

VFD750CP43B-00

VFD900CP43A-00

VFD450CP63A-00

VFD550CP63A-00

mm 330.0 - 275.0 285.0 550.0 525.0 492.0 107.2 16.0 11.0 18.0 - - -

D1

inch 12.99 - 10.83 11.22 21.65 20.67 19.37 4.22 0.63 0.43 0.71 - - -

D0-1

mm 280.0 - 255.0 235.0 500.0 475.0 442.0 94.2 16.0 11.0 18.0

inch 11.02 - 10.04 9.25 19.69 18.70 17.40 3.71 0.63 0.43 0.71

Frame D2 / D0-2

VFD450CP43S-00

VFD550CP43S-00

(Mounting Hole)

See Detail A

Detail A

Detail B

(Mounting Hole)

*D1: Flange mount.

VFD370CP23A-21

VFD450CP23A-21

VFD750CP43B-21

VFD900CP43A-21

VFD450CP63A-21

VFD550CP63A-21

D2

inch 12.99 27.10 10.83 11.22 21.65 20.67 19.37 4.22 0.63 0.43 0.71 3.00 1.34 0.87

D0-2

inch 11.02 21.19 10.04 9.25 19.69 18.70 17.40 3.71 0.63 0.43 0.71 2.47 1.34 0.87

See Detail B

VFD450CP43S-21

VFD550CP43S-21

Detail A

(Mounting Hole)

Detail B

(Mounting Hole)

330.0 688.3 275.0 285.0 550.0 525.0 492.0 107.2 16.0 11.0 18.0 76.2 34.0 22.0

280.0 614.4 255.0 235.0 500.0 475.0 442.0 94.2 16.0 11.0 18.0 62.7 34.0 22.0

*D1: Flange mount.

17

Page 19

Frame E1

mm

MODEL

MODEL

See Detail A

See Detail B

VFD550CP23A-00 VFD750CP63A-00

S1

S3 D2

S2

VFD750CP23A-00 VFD900CP63A-00

VFD900CP23A-00 VFD1100CP63A-00

VFD1100CP43A-00 VFD1320CP63A-00

Detail A

(Mounting Hole)

Detail B

(Mounting Hole)

VFD1320CP43B-00

Frame W H D W1 H1 H2 H3 D1* D2 S1 S2 S3 Ø1 Ø2 Ø3

E1

Frame E2

370.0 - 300.0 335.0 589.0 560.0 528.0 143.0 18.0 13.0 13.0 18.0 - - -

inch 14.57 - 11.81 13.19 23.19 22.05 20.80 5.63 0.71 0.51 0.51 0.71 - - -

*D1: Flange mount.

See Detail A

S1

S3 D2

S2

See Detail B

VFD550CP23A-21 VFD750CP63A-21

VFD750CP23A-21 VFD900CP63A-21

VFD900CP23A-21 VFD1100CP63A-21

VFD1100CP43A-21 VFD1320CP63A-21

Detail A

(Mounting Hole)

Detail B

(Mounting Hole)

VFD1320CP43B-21

Frame W H D W1 H1 H2 H3 D1* D2 S1 S2 S3 Ø1 Ø2 Ø3

mm 370.0 715.8 300.0 335.0 589.0 560.0 528.0 143.0 18.0 13.0 13.0 18.0 22.0 34.0 92.0

E2

inch 14.57 28.18 11.81 13.19 23.19 22.05 20.80 5.63 0.71 0.51 0.51 0.71 0.87 1.34 3.62

*D1: Flange mount.

18

Page 20

Frame

WHDW1H1H2H3

D1*D2S1S2S3Ø1Ø2

Ø3

mm

Dimensions

MODEL

MODEL

Frame F1

VFD1600CP43A-00

VFD1850CP43B-00

VFD1600CP63A-00

VFD2000CP63A-00

mm 420.0 - 300.0 380.0 800.0 770.0 717.0 124.0 18.0 13.0 25.0 18.0 - - -

F1

inch 16.54 - 11.81 14.96 31.50 30.32 28.23 4.88 0.71 0.51 0.98 0.71 - - -

Detail A

(Mounting Hole)

Detail B

(Mounting Hole)

*D1: Flange mount.

Frame F2

VFD1600CP43A-21

VFD1850CP43B-21

VFD1600CP63A-21

VFD2000CP63A-21

Frame W H D W1 H1 H2 H3 D1* D2 S1 S2 S3 Ø1 Ø2 Ø3

F2

420.0 940.0 300.0 380.0 800.0 770.0 717.0 124.0 18.0 13.0 25.0 18.0 92.0 35.0 22.0

inch 16.54 37.00 11.81 14.96 31.50 30.32 28.23 4.88 0.71 0.51 0.98 0.71 3.62 1.38 0.87

Detail A

(Mounting Hole)

Detail B

(Mounting Hole)

*D1: Flange mount.

19

Page 21

Frame G1

Frame

WHDW1H1H2H3S1S2S3Ø1Ø2Ø3

mm

mm

inch

MODEL

MODEL

W1

DW

S3

S1

S1

VFD2200CP43A-00

VFD2800CP43A-00

VFD2500CP63A-00

VFD3150CP63A-00

S2

Detail A

(Mounting Hole)

Detail B

(Mounting Hole)

Frame W H D W1 H1 H2 H3 S1 S2 S3 Ø1 Ø2 Ø3

G1

Frame G2

500.0 - 397.0 440.0 1000.0 963.0 913.6 13.0 26.5 27.0 - - -

19.69 - 15.63 217.32 39.37 37.91 35.97 0.51 1.04 1.06 - - -

W1

DW

VFD2200CP43A-21

VFD2800CP43A-21

VFD2500CP63A-21

VFD3150CP63A-21

G2

inch 19.69 48.83 15.63 217.32 39.37 37.91 35.97 0.51 1.04 1.06 0.87 1.34 4.63

S3

S1

S2

Detail A

(Mounting Hole)

S1

Detail B

(Mounting Hole)

500.0 1240.2 397.0 440.0 1000.0 963.0 913.6 13.0 26.5 27.0 22.0 34.0 117.5

20

Page 22

Dimensions

mm

inch

mm

inch

MODEL

Frame H1

VFD3150CP43A-00

VFD3550CP43A-00

VFD4000CP43A-00

VFD5000CP43A-00

Frame W H D W1 W2 W3 W4 W5 W6 H1 H2 H3 H4

H1

Frame H5 D1 D2 D3 D4 D5 D6 S1 S2 S3 Ø1 Ø2 Ø3

H1

700.0 1435.0 398.0 630.0 290.0 - - - - 1403.0 1346.6 - -

27.56 56.5 15.67 24.80 11.42 - - - - 55.24 53.02 - -

- 45.0 - - - - - 13.0 26.5 25.0 - - -

- 1.77 - - - - - 0.51 1.04 0.98 - - -

21

Page 23

HDW1W2W3

W4

mm

inch

D1D2D3D4D5

D6

mm

inch

MODEL

Frame H2

VFD3150CP43C-00

VFD3550CP43C-00

VFD4000CP43C-00

VFD5000CP43C-00

Frame W

H2

Frame H5

H2

Side fasteners

700.0 1745.0 404.0 630.0 500.0 630.0 760.0 800.0 - 1729.0 1701.6 - -

27.56 68.70 15.9 24.80 19.69 24.80 29.92 31.50 - 68.07 66.99 - -

- 51.0 38.0 65.0 204.0 68.0 137.0 13.0 26.5 25.0 - - -

- 2.0 1.50 2.56 8.03 2.68 5.4 0.51 1.04 0.98 - - -

Side fasteners

W5 W6 H1 H2 H3 H4

S1 S2 S3 Ø1 Ø2 Ø3

22

Page 24

Dimensions

HDW1W2W3

W4

mm

inch

D1D2D3D4D5

D6

mm

inch

MODEL

Frame H3

VFD3150CP43C-21

VFD3550CP43C-21

VFD4000CP43C-21

VFD5000CP43C-21

Frame W

H3

Frame H5

H3

Side fasteners

700.0 1745.0 404.0 630.0 500.0 630.0 760.0 800.0 - 1729.0 1701.6 - -

27.56 68.70 15.9 24.80 19.69 24.80 29.92 31.50 - 68.07 66.99 - -

- 51.0 38.0 65.0 204.0 68.0 137.0 13.0 26.5 25.0 22.0 34.0 117.5

- 2.0 1.50 2.56 8.03 2.68 5.4 0.51 1.04 0.98 0.87 1.34 4.63

Side fasteners

W5 W6 H1 H2 H3 H4

S1 S2 S3 Ø1 Ø2 Ø3

23

Page 25

690 V Frame H1

WHDW1W2W3W4W5W6H1H2H3H4

H5D1D2D3D4D5D6S1S2S3Ø1Ø2Ø3

MODEL

690V FRAME

_H1

VFD4000CP63A-00

VFD4500CP63A-00

VFD5600CP63A-00

VFD6300CP63A-00

框號

H1

H1

mm 700.0 - 398.0 - 630.0 290.0 - - - - 1435.0 1403.0 -

inch 27.56 - 15.67 - 24.80 11.42 - - - - 56.50 55.24 -

框號

mm 1346.6 45.0 - - - - - 13.0 26.5 25.0 - - -

inch 53.02 1.77 - - - - - 0.51 1.04 0.98 - - -

MODEL

24

Page 26

Dimensions

WHDW1W2W3W4W5W6H1H2H3H4

mm

inch

H5D1D2D3D4D5D6S1S2S3Ø1Ø2Ø3

mm

inch

MODEL

690V

690 V Frame H2

FRAME_H2

VFD4000CP63A-21

VFD4500CP63A-21

VFD5600CP63A-21

VFD6300CP63A-21

框號

H3

框號

H3

Side Fasteners

700.0 1745.0 404.0 800.0 630.0 - 500.0 630.0 760.0 1729.0 - - 1701.6

27.56 68.70 15.91 31.50 24.80 - 19.69 24.80 29.92 68.07 - - 66.99

1346.6 51.0 38.0 65.0 204.0 68.0 137.0 13.0 26.5 25.0 22.0 34.0 117.5

53.02 2.01 1.50 2.56 8.03 2.68 5.39 0.51 1.04 0.98 0.87 1.34 4.63

25

Page 27

▪ EMC-D611A

▪ EMC-R6AA

▪ EMC-BPS01

Accessories

▪ EMC-D42A

Terminals Description

COM

MI10 ~ MI13

I/O Extension Card

I/O Extension Card

MO10 ~ MO11

MXM

Terminals Description

AC AC power common for multi-function input terminal (Neutral)

MI10 ~ MI15

Common for multi-function input terminals

Select SINK (NPN) / SOURCE (PNP) in J1 jumper / external power supply

Refer to parameters 02-26 ~ 02-29 to program the multi-function inputs MI10 ~ MI13.

Internal power is applied from terminal E24: +24 V

External power +24 V

ON: the activation current is 6.5 mA; OFF: leakage current tolerance is 10 μA

Multi-function output terminals (photocoupler)

Duty-cycle: 50%; Max. output frequency: 100 Hz

Max. current: 50 mA; Max. voltage: 48 V

Common for multi-function output terminals MO10, MO11 (photocoupler)

Max 48 V

Refer to Pr. 02.26 ~ Pr. 02.31 for multi-function input selection

Input voltage: 100 ~ 130 V

Input impedance: 27 Kohm

Terminal response time: ON: 10 ms; OFF: 20 ms

50 mA

DC

: max. voltage 30 VDC, min. voltage 19 VDC, 30 W

DC

DC

; Input frequency: 57 ~ 63 Hz

AC

± 5% 200 mA, 5 W

DC

Relay

Extension Card

24V Power

Shift Card

Terminals Description

Refer to Pr. 02.36 ~ Pr. 02.41 for multi-function input selection

Resistive load:

RA10 ~ RA15

RC10 ~ RC15

3 A (N.O.) / 250 V

5 A (N.O.) / 30 V

Inductive load (COS 0.4)

2.0 A (N.O.) / 250 V

2.0 A (N.O.) / 30 V

I

t is used to output each monitor signal, such as for drive in operation, frequency attained or overload indication.

AC

DC

AC

DC

Terminals Description

When the AC motor drive power is off, the external power supply card provides external power to the

24 V GND

network system, PLC function, and other functions to allow continued operations.

Input power: 24

Maximum input current: 0.5 A

Note:

Do not connect the control terminal +24 V (Digital control signal common: SOURCE) directly to the EMC-BPS01 input terminal 24 V.

Do not connect control terminal GND directly to the EMC-BPS01 input terminal GND.

V

±5%

DC

26

Page 28

Accessories

▪ CMC-MOD01

Network Interface

Network Interface

Interface

Transmission speed

Transmission cable

PROFIBUS DP Connector

Transmission cable

Communication

GSD document

▪ CMC-EIP01

Network Interface

Transmission method

Features

►

MDI / MDI-X auto-detect

►

Supports MODBUS TCP protocol

►

AC motor drive keypad / Ethernet

conguration

►

E-mail alarm

►

Baud rate: 10 / 100 Mbps auto-detect

►

Virtual serial port

RJ-45 with Auto MDI / MDIX

Number of ports 1 Port

Transmission method IEEE 802.3, IEEE 802.3u

Category 5e shielding 100M

Network protocol

10 / 100 Mbps Auto-Detect

ICMP, IP, TCP, UDP, DHCP, SMTP,

MODBUS over TCP / IP, Delta Conguration

Features

►

MDI / MDI-X auto-detect

►

Supports MODBUS TCP and Ethernet / IP

protocol

Network Interface

Interface RJ-45 with Auto MDI / MDIX Transmission speed 10 / 100 Mbps Auto-Detect

Number of ports 1 Port

Transmission cable Category 5e shielding 100M

►

Baud rate: 10 / 100 Mbps auto-detect

IEEE 802.3, IEEE 802.3u

Network protocol

►

AC motor drive keypad / Ethernet

conguration

►

Virtual serial port

ICMP, IP, TCP, UDP, DHCP, SMTP,

MODBUS over TCP / IP, Delta Conguration

▪ CMC-PD01

Features

►

Supports PZD control data exchange

►

Supports PKW polling AC motor drive parameters

►

Supports user diagnosis function

►

Auto-detects baud rates; supports Max. 12 Mbps

Interface DB9 connector

Transmission method High-speed RS-485

Electrical isolation 500 V

Shielded twisted pair cable

DC

Message type Cyclic data exchange

Module name CMC-PD01

DELA08DB.GSD

Company ID 08DB (HEX)

Serial transmission

speed supported

(auto-detection)

9.6 kbps; 19.2 kbps; 93.75 kbps; 187.5 kbps;

125 kbps; 250 kbps; 500 kbps; 1.5 Mbps; 3 Mbps;

6 Mbps; 12 Mbps (bits per second)

27

Page 29

DeviceNet Connector

Interface

DeviceNet Connector

Interface

Communication protocol

▪ CMC-DN01

Features

Network Interface

Number of ports

Transmission speed

RJ-45 Pin denition

2

CAN_L

►

Based on the high-speed communication interface of Delta HSSP protocol, able to

conduct immediate control of an AC motor drive

►

Supports Group 2 only connection and polling I/O data exchange

►

For I/O mapping, supports Max. 32 words of input and 32 words of output

►

Supports EDS le conguration in DeviceNet conguration software

►

Supports all baud rates on DeviceNet bus: 125 kbps, 250 kbps, 500 kbps and extendable

serial transmission speed mode

►

Node address and serial transmission speed can be set up on AC motor drive

►

Power supplied from AC motor drive

5-Pin 5.08mm pluggable connector

Transmission method CAN

Transmission cable

Transmission speed

Network protocol DeviceNet protocol

▪ EMC-COP01

Interface RJ-45

Transmission method CAN

Transmission cable CAN standard cable

Communication protocol CANopen

Shielded twisted pair cable

(with 2 power cables)

125 kbps, 250 kbps, 500 kbps and

extendable serial transmission

speed mode

8~1

Male

1 Port

1 M 500 k 250 k 125 k 100 k 50 k

8~1

Female

50 PIN communication terminal

Transmission method SPI communication

Terminal function

Pin Pin name Denition

1 CAN_H CAN_H bus line (dominant high)

3 CAN_GND Ground / 0 V / V-

6 CAN_GND Ground / 0 V / V-

1. Communicating with AC motor drive

2. Transmitting power supply from AC motor drive

Delta HSSP protocol

CAN_L bus line (dominant low)

28

Page 30

▪ CANopen Communication Cable

Accessories

L

Model: TAP-CB05, TAP-CB10

L ± 10

8

H1

1

Title Part No.

1 UC-CMC003-01A 300 11.8

2 UC-CMC005-01A 500 19.6

3 UC-CMC010-01A 1000 39

8

H2

1

4 UC-CMC015-01A 1500 59

5 UC-CMC020-01A 2000 78.7

6 UC-CMC030-01A 3000 118.1

7 UC-CMC050-01A 5000 196.8

8 UC-CMC100-01A 10000 393.7

9 UC-CMC200-01A 20000 787.4

mm inch

▪ CANopen Breakout Box

66.50 [2.62]

Model: TAP-CN03

▪ Digital Keypad Accessories: RJ45 Extension Leads and CMC-EIP01 Cables

Applicable Models: CBC-K3FT, CBC-K5FT, CBC-K7FT, CBC-K10F, CBC-K16FT

Title Part No. Explanation

1 CBC-K3FT RJ45 extension lead, 3 feet (approximately 0.9 m)

2 CBC-K5FT RJ45 extension lead, 5 feet (approximately 1.5 m)

3 CBC-K7FT RJ45 extension lead, 7 feet (approximately 2.1 m)

4 CBC-K10FT RJ45 extension lead, 10 feet (approximately 3 m)

5 CBC-K16FT RJ45 extension lead, 16 feet (approximately 4.9 m)

29

Page 31

Ordering Information

Frame A

Frame B

Frame C

Frame D

Frame Size

Power

Range

230 V:

0.75 ~ 5.5 kW

460 V:

0.75 ~ 7.5 kW

575 V:

1.5 ~ 3.7 kW

230 V:

7.5 ~ 15 kW

460 V:

11 ~ 18.5 kW

575 V:

5.5 ~ 15 kW

230 V:

18.5 ~ 30 kW

460 V:

22 ~ 37 kW

690 V:

18.5 ~ 37 kW

230 V:

37 ~ 45 kW

460 V:

45 ~ 90 kW

690 V:

55 ~ 75 kW

VFD007CP 23A-21

VFD015CP 23A-21

VFD022CP 23A-21

VFD037CP 23A-21

VFD055CP 23A-21

VFD075CP 23A-21

VFD110CP 23A-21

VFD150CP 23A-21

VFD185CP 23A-21

VFD220CP 23A-21

VFD300CP 23A-21

Frame D1:

VFD370CP 23A-00

VFD450CP 23A-00

VFD750CP 43B-00

VFD900CP 43A-00

Frame D0-1:

VFD450CP 43S-00

VFD550CP 43S-00

VFD007CP 43A-21

VFD015CP 43B-21

VFD022CP 43B-21

VFD037CP 43B-21

VFD040CP 43A-21

VFD055CP 43B-21

VFD075CP 43B-21

VFD110CP 43B-21

VFD150CP 43B-21

VFD185CP 43B-21

VFD220CP 43A-21

VFD300CP 43B-21

VFD370CP 43B-21

Frame D2:

VFD370CP 23A-21

VFD450CP 23A-21

VFD750CP 43B-21

VFD900CP 43A-21

Frame D0-2:

VFD450CP 43S-21

VFD550CP 43S-21

Models

VFD007CP 4EA-21

VFD015CP 4EB-21

VFD022CP 4EB-21

VFD037CP 4EB-21

VFD040CP 4EA-21

VFD055CP 4EB-21

VFD075CP 4EB-21

VFD110CP 4EB-21

VFD150CP 4EB-21

VFD185CP 4EB-21

VFD220CP 4EA-21

VFD300CP 4EB-21

VFD370CP 4EB-21

VFD015CP 53A-21

VFD022CP 53A-21

VFD037CP 53A-21

VFD055CP 53A-21

VFD075CP 53A-21

VFD110CP 53A-21

VFD150CP 53A-21

VFD185CP 63A-21

VFD220CP 63A-21

VFD300CP 63A-21

VFD370CP 63A-21

Frame D1:

VFD450CP 63A-00

VFD550CP 63A-00

Frame D2:

VFD450CP 63A-21

VFD550CP 63A-21

Frame E

Frame F

Frame G

230 V:

55 ~ 90 kW

460 V:

110 ~ 132 kW

690 V:

75 ~ 132 kW

460 V:

160 ~ 185 kW

690 V:

160 ~ 200 kW

460 V:

220 ~ 280 kW

690 V:

250 ~ 315 kW

Frame E1:

VFD550CP 23A-00

VFD750CP 23A-00

VFD900CP 23A-00

VFD1100CP 43A-00

VFD1320CP 43B-00

Frame F1:

VFD1600CP 43A-00

VFD1850CP 43B-00

Frame G1:

VFD2200CP 43A-00

VFD2800CP 43A-00

Frame E2:

VFD550CP 23A-21

VFD750CP 23A-21

VFD900CP 23A-21

VFD1100CP 43A-21

VFD1320CP 43B-21

Frame F2:

VFD1600CP 43A-21

VFD1850CP 43B-21

Frame G2:

VFD2200CP 43A-21

VFD2800CP 43A-21

Frame E1:

VFD750CP 63A-00

VFD900CP 63A-00

VFD1100CP 63A-00

VFD1320CP 63A-00

Frame E2:

VFD750CP 63A-21

VFD900CP 63A-21

VFD1100CP 63A-21

VFD1320CP 63A-21

Frame F1:

VFD1600CP 63A-00

VFD2000CP 63A-00

Frame F2:

VFD1600CP63A-21

VFD2000CP63A-21

Frame G1:

VFD2500CP 63A-00

VFD3150CP 63A-00

Frame G2:

VFD2500CP 63A-21

VFD3150CP 63A-21

30

Page 32

Ordering Information

Power

Frame Size

Frame H

Frame H

(690 V Model)

Range

460 V:

315 ~ 500 kW

690 V:

400 ~ 630 kW

Frame H1:

VFD3150CP 43A-00

VFD3550CP 43A-00

VFD4000CP 43A-00

VFD5000CP 43A-00

Model Name

VFD 1100 CP 43 A - 2 1

Frame H2:

VFD3150CP 43C-00

VFD3550CP 43C-00

VFD4000CP 43C-00

VFD5000CP 43C-00

Models

Frame H3:

VFD3150CP 43C-21

VFD3550CP 43C-21

VFD4000CP 43C-21

VFD5000CP 43C-21

Frame H1:

VFD4000CP 63A-00

VFD4500CP 63A-00

VFD5600CP 63A-00

VFD6300CP 63A-00

Frame H2:

VFD4000CP 63A-21

VFD4500CP 63A-21

VFD5600CP 63A-21

VFD6300CP 63A-21

Installation Type

A, B, S Wall Mount

C Floor Mount

Product Series

CP CP2000

Applicable Motor Capacity

007: 0.75 kW ~ 6300: 630 kW

* Refer to product specification for detailed information

NEMA Protection Level

0 UL Open Type

1 NEMA 1

IP Protection Level

0 IP00

2 IP20

Input Voltage / Phase

23 230 V 3-Phase

43 460 V 3-Phase

4E 460 V 3-Phase (EMC lter built-in)

53 575 V 3-Phase

63 690 V 3-Phase

Product

Variable Frequency Drive

31

Page 33

Attention

Standard Motors

Output reactor

Please refer to manual to use the output

AC reactor when the output cable is long.

Torque Characteristics and

Temperature Rise

When a standard motor is drive controlled, the

motor temperature will be higher than with DOL

operation.

Please reduce the motor output torque when

operating at low speeds to compensate for less

cooling efficiency.

For continuous constant torque at low speeds,

external forced motor cooling is recommended.

Vibration

When the motor drives the machine, resonances

may occur, including machine resonances.

Abnormal vibration may occur when operating a

2-pole motor at 60Hz or higher.

Noise

When a standard motor is drive controlled, the

motor noise will be higher than with DOL

operation.

To lower the noise, please increase the carrier

frequency of the drive. The motor fan can be

very noisy when the motor speed exceeds 60Hz.

Special Motors

High-speed Motor

To ensure safety, please try the frequency

setting with another motor before operating the

high-speed motor at 120Hz or higher.

Explosion-proof Motor

Please use a motor and drive that comply with

explosion-proof requirements.

Submersible Motor & Pump

The rated current is higher than that of a

standard motor.

Please check before operation and select the

capacity of the AC motor drive carefully.

The motor temperature characteristics differ

from a standard motor, please set the motor

thermal time constant to a lower value.

Brake Motor

When the motor is equipped with a mechanical

brake, the brake should be powered by the

mains supply.

Damage may occur when the brake is powered

by the drive output. Please DO NOT drive the

motor with the brake engaged.

Gear Motor

In gearboxes or reduction gears, lubrication may

be reduced if the motor is continuously operated

at low speeds.

Please DO NOT operate in this way.

Synchronous Motor

These motors need suitable software for

control. Please contact Delta for more

information.

Environmental Conditions

Installation Position

1. The drive is suitable for installation in a place

with ambient temperature from -10

2. The surface temperature of the drive and

brake resistor will rise under specific

operation conditions. Therefore, please

install the drive on materials that are

noncombustible.

3. Ensure that the installation site complies with

the ambient conditions as stated in the manual.

o

C to 50oC.

Wiring

Limit of Wiring Distance

For the remote operation, please use

twist-shielding cable and the distance between

the drive and control box should be less than

20m.

Maximum Motor Cable Length

Motor cables that are too long may cause

overheating of the drive or current peaks due to

stray capacitance.

Please ensure that the motor cable is less than

30m.

If the cable length can't be reduced, please lower

the carrier frequency or use an AC reactor.

Choose the Right Cable

Please refer to current value to choose the right

cable section with enough capacity or use

recommended cables.

Grounding

Please ground the drive completely by using the

grounding terminal.

How to Choose the Drive

Capacity

Standard Motor

Please select the drive according to applicable

motor rated current listed in the drive

specification.

Please select the next higher power AC drive in

case higher starting torque or quick

acceleration/deceleration is needed.

Special Motor

Please select the drive according to: Rated

current of the drive > rated current of the motor

Transportation and Storage

Please transport and store the drive in a place

that meets environment specifications.

Peripheral Equipment

Molded-Case Circuit Breakers

(MCCB)

Please install the recommended MCCB or ELCB

in the main circuit of the drive and make sure that

the capacity of the breaker is equal to or lower

than the recommended one.

Add a Magnetic Contactor(MC) in

the Output Circuit

When a MC is installed in the output circuit of the

drive to switch the motor to commercial power or

other purposes, please make sure that the drive

and motor are completely stopped and remove

the surge absorbers from the MC before

switching it.

Add a Magnetic Contactor (MC) in

the Input Circuit

Please only switch the MC ONCE per hour or it

may damage the drive. Please use RUN/STOP

signal to switch many times during motor

operation.

Motor Protection

The thermal protection function of the drive can

be used to protect the motor by setting the

operation level and motor type

(standard motor or variable motor).

When using a high-speed motor or a

water-cooled motor the thermal time constant

should be set to a lower value.

When using a longer cable to connect the motor

thermal relay to a motor, high-frequency currents

may enter via the stray capacitance.

It may result in malfunctioning of the relay as the

real current is lower than the setting of thermal

relay. Under this condition, please lower the

carrier frequency or add an AC reactor to solve

this.

DO NOT Use Capacitors to Improve

the Power Factor

Use a DC reactor to improve the power factor of

the drive. Please DO NOT install power factor

correction capacitors on the main circuit of the

drive to prevent motor faults due to over current.

Do NOT Use Surge Absorber

Please DO NOT install surge absorbers on the

output circuit of the drive.

Lower the Noise

To ensure compliance with EMC regulations,

usually a filter and shielded wiring is used to

lower the noise.

Method Used to Reduce the Surge

Current

Surge currents may occur in the phase-lead

capacitor of the power system, causing an

overvoltage when the drive is stopped or at low

loads.

It is recommended to add a DC reactor to the

drive.

Single-phase Motor

Single-phase motors are not suitable for being

operated by an AC Motor Drive. Please use a

3-phase motor instead when necessary.

32

Loading...

Loading...