2011-01-08

50 11 69 47 01 -2 CE 1

PLEASE READ PRIOR TO INSTALLATION FOR SAFETY.

AC input power must be disconnected before any wiring to the AC motor drive

is made.

DANGER

Even if the power has been turned off, a charge may still remain in the DC-link

capacitors with hazardous voltages before the POWER LED is OFF. Please do

not touch the internal circuit and components.

There are highly sensitive MOS components on the printed circuit boards.

These components are especially sensitive to static electricity. Please do not

touch these components or the circuit boards before taking anti-static

measures. Never reassemble internal components or wiring.

Ground the AC motor drive using the ground terminal. The grounding method

must comply with the laws of the country where the AC motor drive is to be

installed.

DO NOT install the AC motor drive in a place subjected to high temperature,

direct sunlight and inflammables.

Never connect the AC motor drive output terminals U/T1, V/T2 and W/T3

CAU TION

directly to the AC mains circuit power supply.

Only qualified persons are allowed to install, wire and maintain the AC motor

drives.

Even if the 3-phase AC motor is stop, a charge may still remain in the main

circuit terminals of the AC motor drive with hazardous voltages.

If the AC motor drive is stored in no charge condition for more than 3 months,

the ambient temperature should not be higher than 30 °C. Storage longer than

one year is not recommended, it could result in the degradation of the

electrolytic capacitors.

NOTE

The content of this manual may be revised without prior notice. Please consult our distributors or download the most updated

version at http://www.delta.com.tw/industrialautomation

Table of Contents

SUMMARY OF UPDATES .............................................................................................................0-1

CHAPTER 1 INTRODUCTION.......................................................................................................1-1

CHAPTER 2 INSTALLATION .......................................................................................................2-1

CHAPTER 3 UNPACKING.............................................................................................................3-1

CHAPTER 4 WIRING.....................................................................................................................4-1

CHAPTER 5 MAIN CIRCUIT TERMINALS ..................................................................................5-1

CHPATER 6 CONTROL TERMINALS...........................................................................................6-1

CHAPTER 7 OPTIONAL ACCESSORIES ..................................................................................7-1

CHAPTER 8 OPTION CARDS.......................................................................................................8-1

CHAPTER 9 SPECIFICATION.......................................................................................................9-1

CHAPTER 10 DIGITAL KEYPAD.................................................................................................10-1

CHAPTER 11 SUMMARPY OF PARAMETERS..........................................................................11-1

CHPAPTER 12 DESCRIPTION OF PARAMETER SETTINGS...................................................12-1

CHAPTER 13 WARNING CODES...............................................................................................13-1

CHAPTER 14 FAULT CODES AND DESCRIPTIONS.................................................................14-1

CHAPTER 15 CANOPEN OVERVIEW........................................................................................15-1

CHAPTER 16 PLC FUNCTION....................................................................................................16-1

Application

Control BD V1.00;

Keypad V1.00;

Summary of UpdatesC2000 Series

r

Summary of Updates

The following changes summarize the differences to the C2000 Simplified Manual, Version

5011694700.

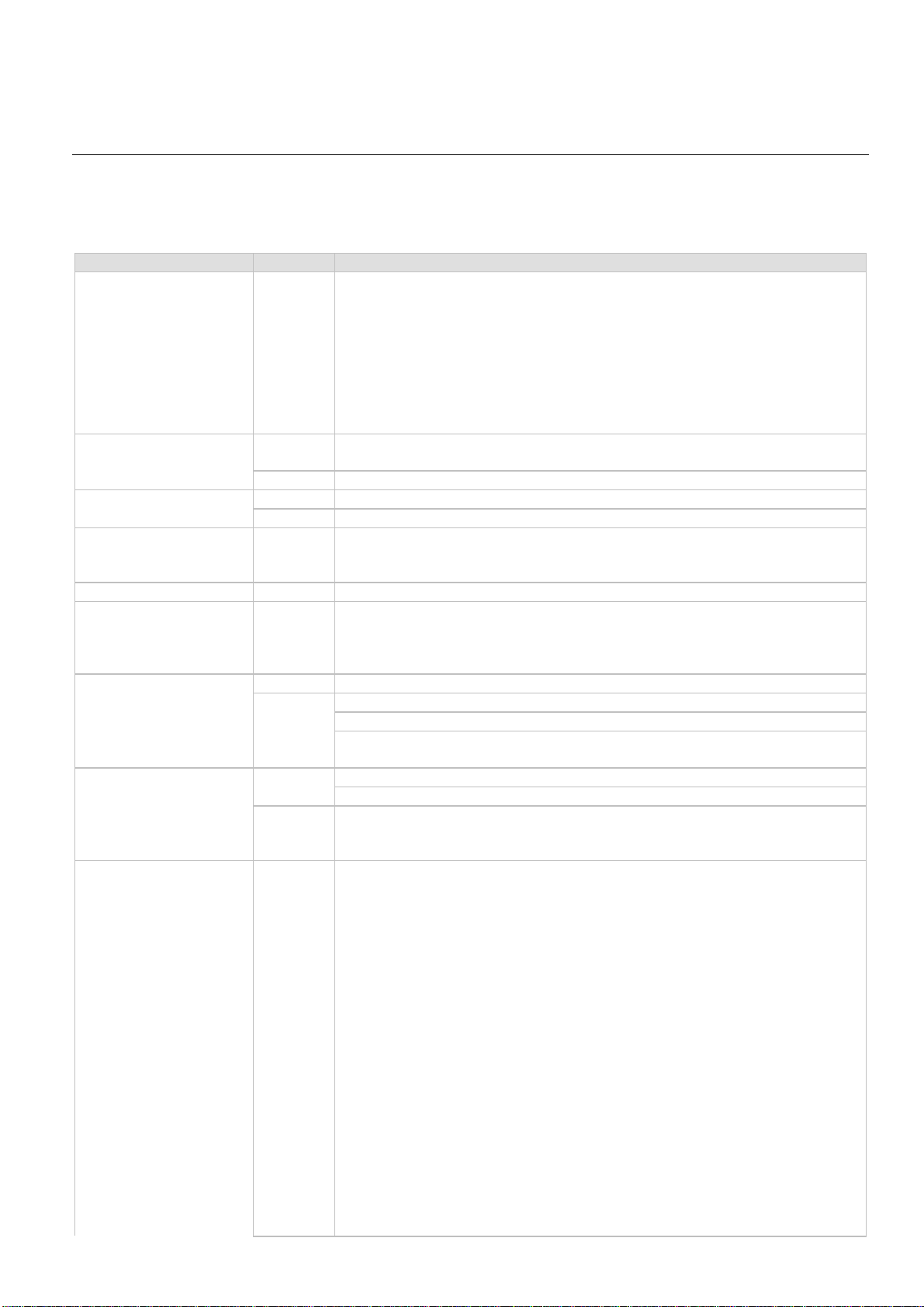

Chatpers Changes Detail

[Table of Content] New New Chapters:

• Chapter 2 Installation

• Chapter 7 Optional Accessories

• Chapter 12 Description of Parameter Settings

• Chapter 15 CANopen Overview

• Chapter 16 PLC Function

• (Applicable model, AC motor drive selection)

Applicable model

AC motor drive selection

[01 Introduction]

[03 Unpacking] New FRAME F~H

[04Wiring] New RB-RC power protection system diagram

Updates Wiring diagram 1, 2

[05 Main circuit terminal]

[06 Control circuit

terminal]

[08 Option cards] New Steps to remove key cover

New Frame FRAME A~H

KPC-CC01 digital keypad

Update Serial number

New Mounting clearances and wiring information [02 Installation]

Update Unpacking details moved to CH3

FRAME H secure the drive

FRAME F~H lifting weight

Control circuit description

Figure1,2

Figure 3 FRAME E-H DC-LINK

New Main circuit terminal specification FRAME F~H

Update

Update Control terminal specification: wire gauge, torque,

Main circuit terminal diagram 3

Terminal signs +1, - and description

Main circuit terminal specifications

Frame A~E (max. and min. wire gauge,torque, note, diagram)

Steps to removes the key cover and wiring New

Removable terminal block figure

Descripton and factory settings: MI11~MI8 terminals, SG+ & SG- terminals

Steps to remove the terminal block

EMC-D611A I/O & Relay extension card

EMC-PG01L PG card and wiring diagrams(can be operate by

Pr.10-00~10-02)

EMC-PG01O PG card and wiring diagrams(can be operate by

Pr.10-00~10-02)

EMC-PG01U:

description, wiring diagram, terminal Screw Sepecifications

EMC-PG01R:

description, wiring diagram, terminal Screw Sepecifications

CMC-MOD01:

feature, product file, CMC-MOD01 installation to C2000, p arameter setting fo

Ethernet, removal, basic register, LED indicator& troubleshoots

CMC-PD01:

feature, product file, installation, LED indicator& troubleshoots

CMC-DN01:

feature, product file, LED indicator& troubleshoots

CMC-EIP01:

feature, product file, installation, Connecting CMC-EIP01 to VFD-C2000,

parameter setting for Ethernet, removal, basic register, LED indicator&

troubleshoots

0-1

[09 Specification]

[10 Digital Keypad]

[11 Summary of

Parameters]

EMC-COP01: RJ45 Pin definition, Specifi cation

Update RJ45 (Socket) for digital keypad

Option card diagrams for Slot 1~3

EMC-D42A: Descriptons for COM and MI10~MI13

EMC-R6AA: Description

EMC-PG01O PG OUT V+, V-, A/O, B/O, Z/O

Remove ABZ1 Encoder signal type, AB2 Pulse signal type

New

230V FRAME F specification

460V FRAME F~H specification

Operation temperature and protection level

Update

230V/460V

Nomal load: carrier frequency

Operational voltage range

230V

EMC Filter EMI Filter

460V EMI Filter Description and Note

Control method

Certification

Delete

230V/460V

Heavy load& Normal load: load capacity and max. output frequency (Hz)

Torque characteristic

Overload capacity

Ambient temperature

*Reduced by 2%Irated/1℃

New Digital Keypad: KPC-CC01 Function

Update

Keypad picture

Descriptions of Keypad Functions

Change LED keypad to KPC-CE01

CANopen~”RUN”

CANopen~”ERR”

ONLY LED change to KPC-CE01

Remove Digital keypad operation procedure

New

Parameters

Group 00

Pr.00-00 Settings: 39, 41, 43, 45, 47, 49, 51, 93

Pr.00-04 Settings: 2~8, 21,24~31

Pr 00-05

Pr.00-25~Pr.00-50

Pr.01-46

Pr.02-54

Pr.03-31~03-33

Pr.04-30~04-44

Group 5

Pr.05-00 Settings: 4, 5, 6, 12

Pr.05-33~05-43

Pr.06-17~06-22 Settings: 66~107, 111

Pr.06-55~06-73

Pr.10-22

Pr.11-41~11-46

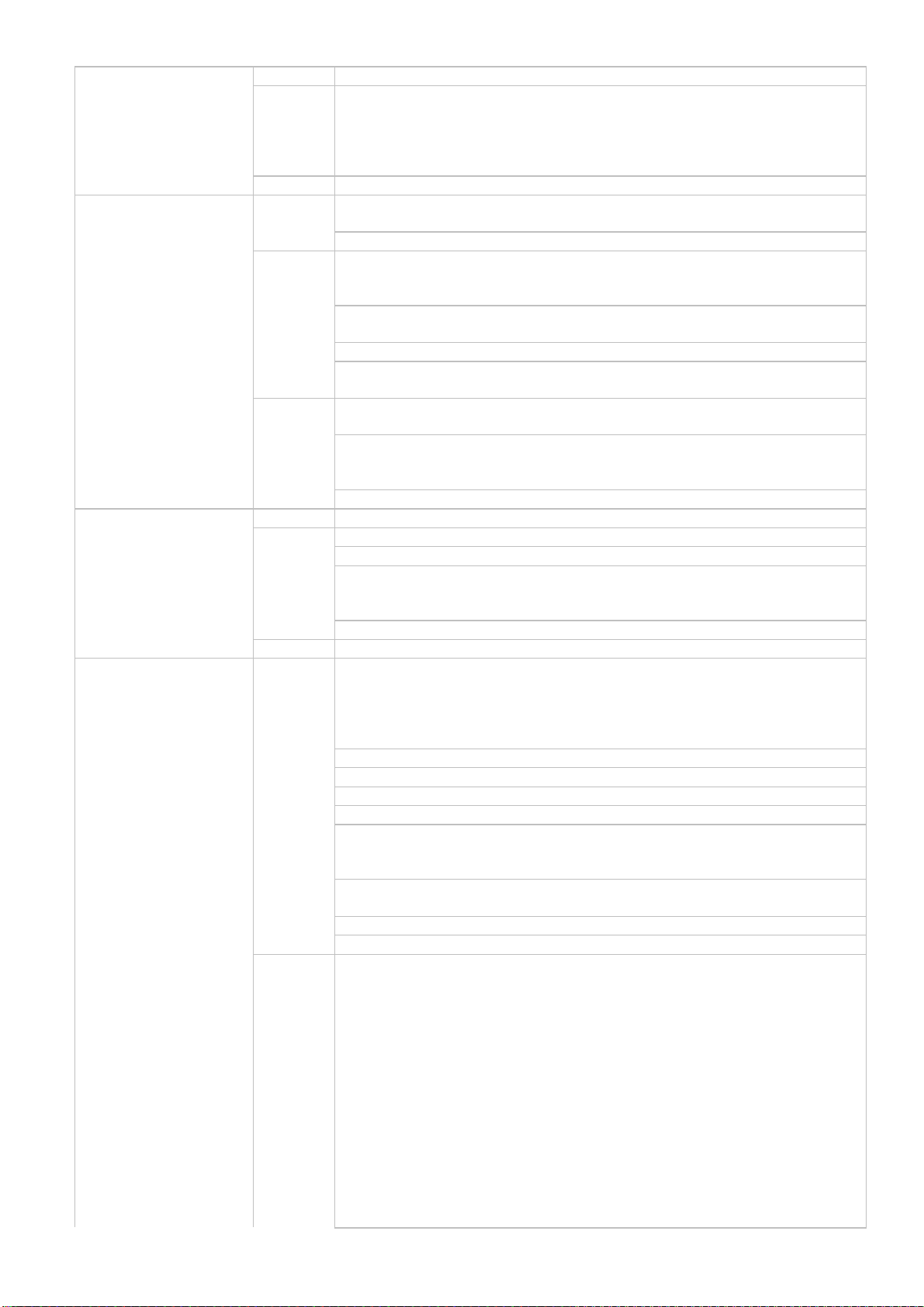

Update Goup 00

Pr00-09 Reserved

Pr.00-10 Settings: 1~3

Pr.00-11 Settings: 0~5

Pr. 00-12 point-to-p oint po sition mode

Pr.00-13 Settings: 0~2

Pr.00-14 Reserved

Pr.00-17

Normal load 230V (460V)

1-15HP [1-20HP] 2~15KHz

20-50HP [25-100HP] 2~10KHz

60-100HP [125-475HP] 2~09KHz

Heavy load

1-475HP 2~6KHz

0-2

Summary of UpdatesC2000 Series

Pr.00-19 PLC Command Mask

Pr.00-20 Source of Master Frequency Command(AUTO)

Pr.00-21 Settings: 0~5

Pr.00-24 Memory of Frequen cy Command

Pr. 02-01~02-08 Settings: 6, 10, 18, 31~33, 35, 37, 41~47, 49, 54~70

Pr.00-14 Reserved

Group 01

Pr. 01-02~01-06, 01-20~01-21, 01-36~01-40: Factory Settings

Goup 02

Pr.02-09 1: up/down constant speed (Pr.02-10)

Pr.02-11

Pr.02-13~02-17 Settings: 10, 13, 14, 39, 40, 43~49, 51, 52

Pr.02-19 Terminal counting value attained (returns to 0)

Pr.02-20 Preliminary counting value attained (not return to 0)

Pr.02-33 Output Current Level Setting for Multi-function External Terminals

Pr.02-34

Pr.02-35

Pr.02-37

Pr.02-48

Goup 03

Pr.03-00~03-02 Settings: 1 1, 12~17, 18~19

Pr.03-10

Pr.03-20~03-23 Settings: 19~23

Pr.03-26~03-30

Factory settings in 03-20~03-23, 03-21 03-24

Group 04

Pr.04-15~04-29

Group 05

Pr.05-01 Settings: 10~120% of drive’s rated current

Pr.05-06~05-09, 05-18~05-21 setting range

Pr.05-12~05-13

Group 06

Pr.06-00~06-01

Pr.06-03~06-04

Pr.06-07

Pr.06-10

Pr.06-12

Pr.06-17~06-22 Settings: 15, 17,19,20,21,25,28,29,32,39,40,52,53,64,65

Pr.06-31~06-54

Group 07

Pr.07-05

Pr.07-07

Pr.07-10

Pr.07-24~07-27

Pr.07-29

Pr.07-31~07-33

Group 08

Pr.08-00

Pr.08-20

Group 09

Pr.09-30

Pr.09-35

Pr.09-37~09-39

Pr.09-43

Pr.09-45

Group 10

Pr.10-00

Pr.10-17~10-18

Pr.10-21

Group 11

Pr.11-00

Pr.11-03~11-06

Pr.11-08

0-3

[13 Warning Codes]

[14 Fault Codes and

Descriptions]

Pr.11-10

Pr.11-24

Pr.11-28~11-34

Pr.11-40

Remove Pr. 01-47~01-50

New LCM display screen example

Error code:

“SE3”, “PGFB”, “Cldn”, “Cadn”, “CFrn”, “PLSF”, “PCGd”, “PCbF”, “PCnL”,

“PCCt”, “PCSF”, “PCSd”, “PCAd”, “Ecby”

Update LED display content

“ANL” description

Remove LCM display example

All display icons

New Fault display screen example

Fault code:

“ovA”, “ovd”, “ovn”, “ovS”, “PWR”, “uC”, “LMIT”, “ryF”, “PGF5”, “ocU”, “ocV”,

“OPHL”, “OPHL”, “OPHL”, “TRAP”

Update LCM display icons

Fault codes:

“CE1”, “CE2”, “CE3”, “CE4”, “CE10”, “CP10” ,

“dEb”, “Uocc” A, “Vocc” B, “Wocc” C

Remove LED display content

Fault code:

“UC1”, “UC2”

0-4

Chapter 1 IntroductionC2000 Series

Chapter 1 Introduction

Receiving and Inspection

After receiving the AC motor drive, please check for the following:

1. Please inspect the unit after unpacking to assure it was not damaged during shipment.

2. Make sure that the part number printed on the package corresponds with the part number indicated

on the nameplate.

3. Make sure that the voltage for the wiring lie within the range as indicated on the nameplate.

4. Please install the AC motor drive according to this manual.

5. Before applying the power, please make sure that all the devices, including power, motor, control

board and digital keypad, are connected correctly.

6. When wiring the AC motor drive, please make sure that the wiring of input terminals “R/L1, S/L2,

T/L3” and output terminals”U/T1, V/T2, W/T3” are correct to prevent drive damage.

7. When power is applied, select the language and set the parameter groups via the digital keypad

(KPC-CC01).

8. After applying the power, please trial run with the low speed and then increase the speed gradually

to the desired speed.

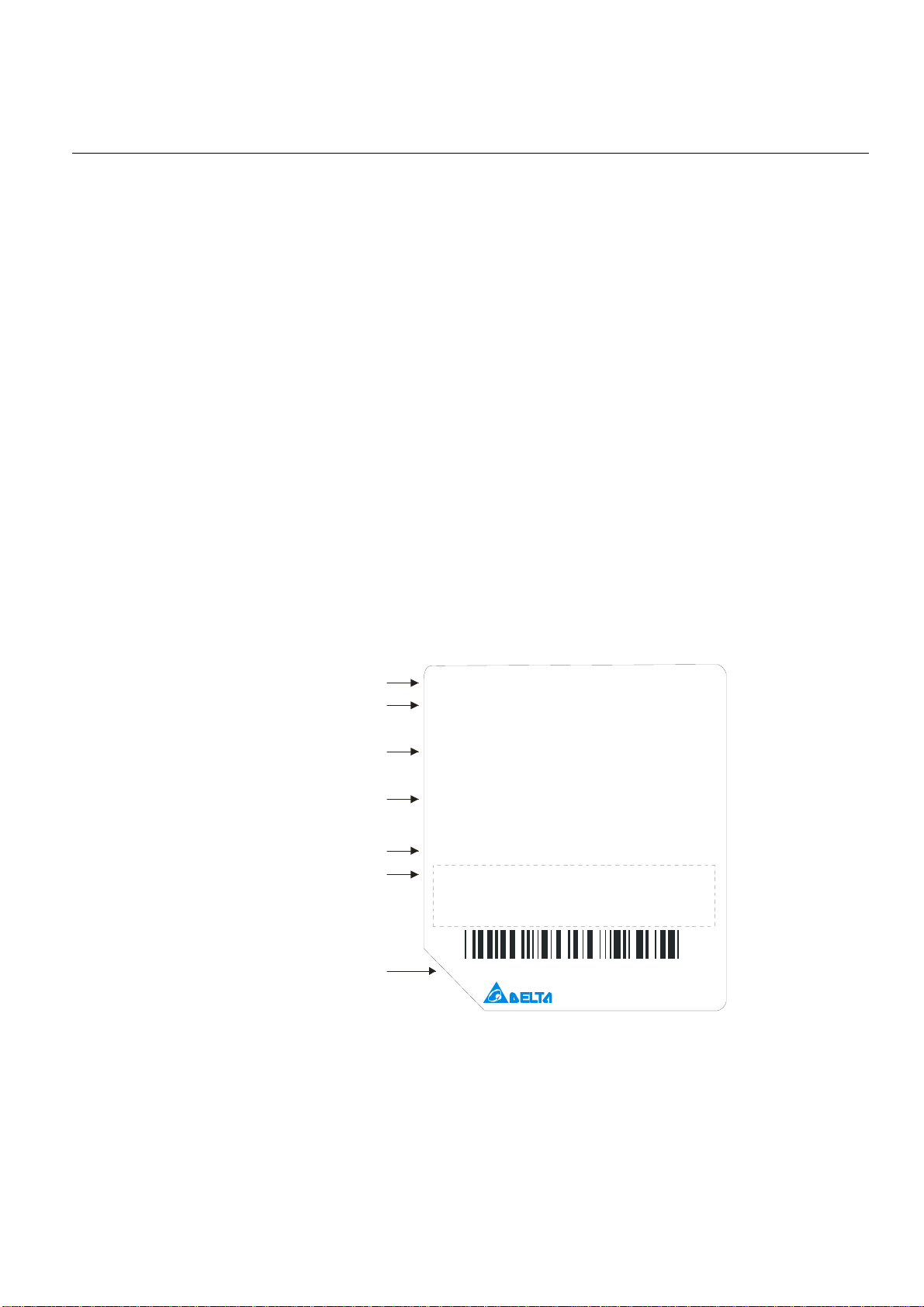

Nameplate Information

AC Drive Model

Input Voltage/Current

Output Voltage/Current

Frequency Range

Firmware Vers ion

Certifications

MODEL:VFD007C43A

INPUT:

Normal Duty: 3PH 380-480V 5 0/60Hz 4 .3A

Heavy Duty: 3PH 38 0-480V 50/60Hz 4.1A

OUTPU T:

Normal Dut y: 3PH 0-480V 3A 2.4KVA 1HP

Heavy Duty: 3PH 0-4 80V 2.9A 2.3KVA 1HP

FREQUENCY RANGE:

Normal Du t y: 0- 600H z

Heavy Duty: 0-300Hz

Versi on:

V0.30

Serial Number

007C43A7T9300002

DE LTA ELECTR ONIC S. INC.

MADE IN XXXXXXX

1-1

W

Chapter 1 IntroductionC2000 Series

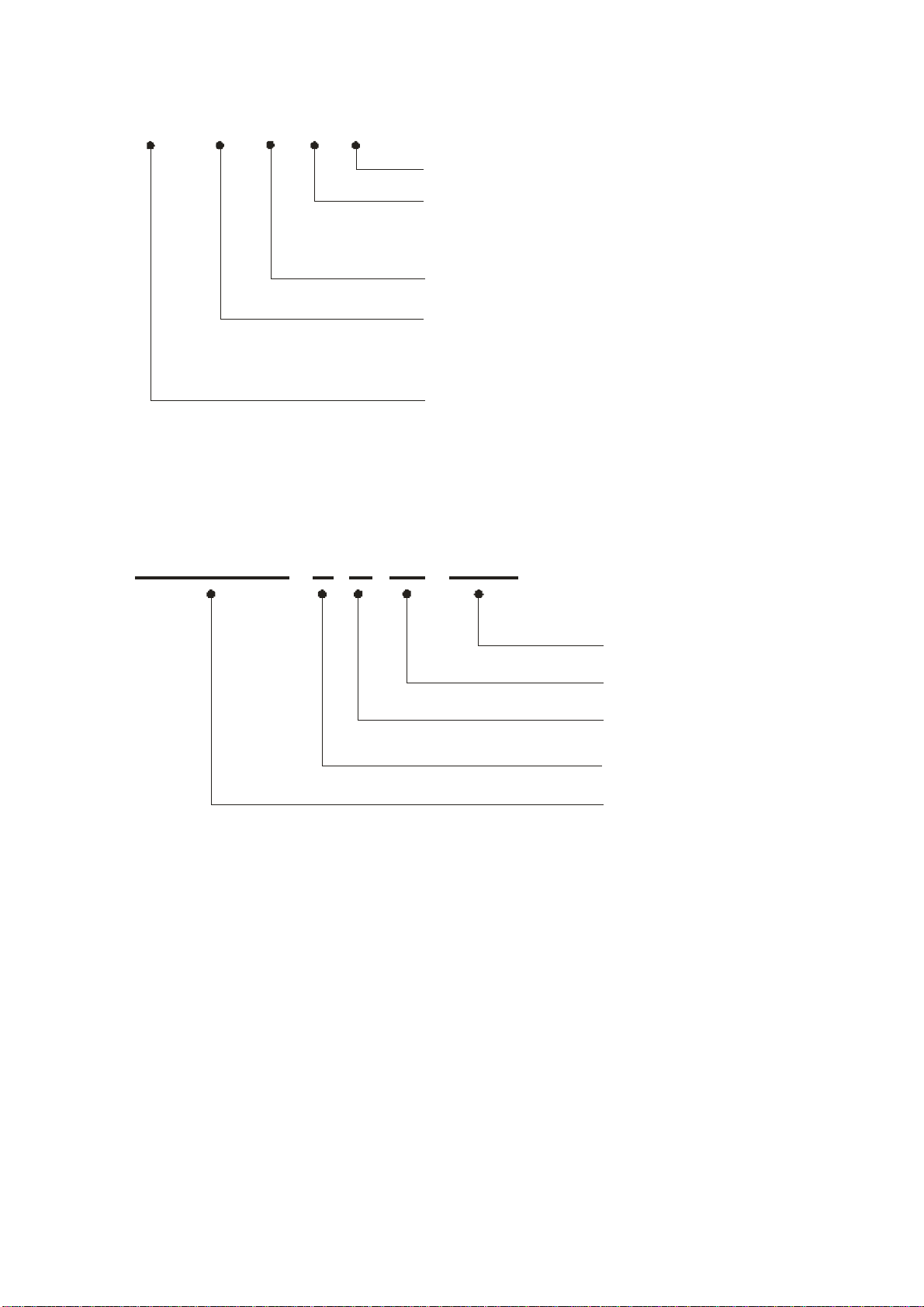

Model Name

VFD007C43A

Version type

Input voltage

23:230V 3-PHASE

43:460V 3-PHASE

C2000 series

Applicable motor capacity

007:1HP(0.75kW)~ 3350:475HP(335k

Refer to the specifications for details

Serial Number

007C43A0 T 9 30 0002

Series name(Variable Frequency Drive)

T: Tauyuan W: Wujian

S: Shanghai

460V 3-PHASE 1HP(0.75kW)

Production number

Production week

Production year

Production factory

Model number

1-2

Chapter 1 IntroductionC2000 Series

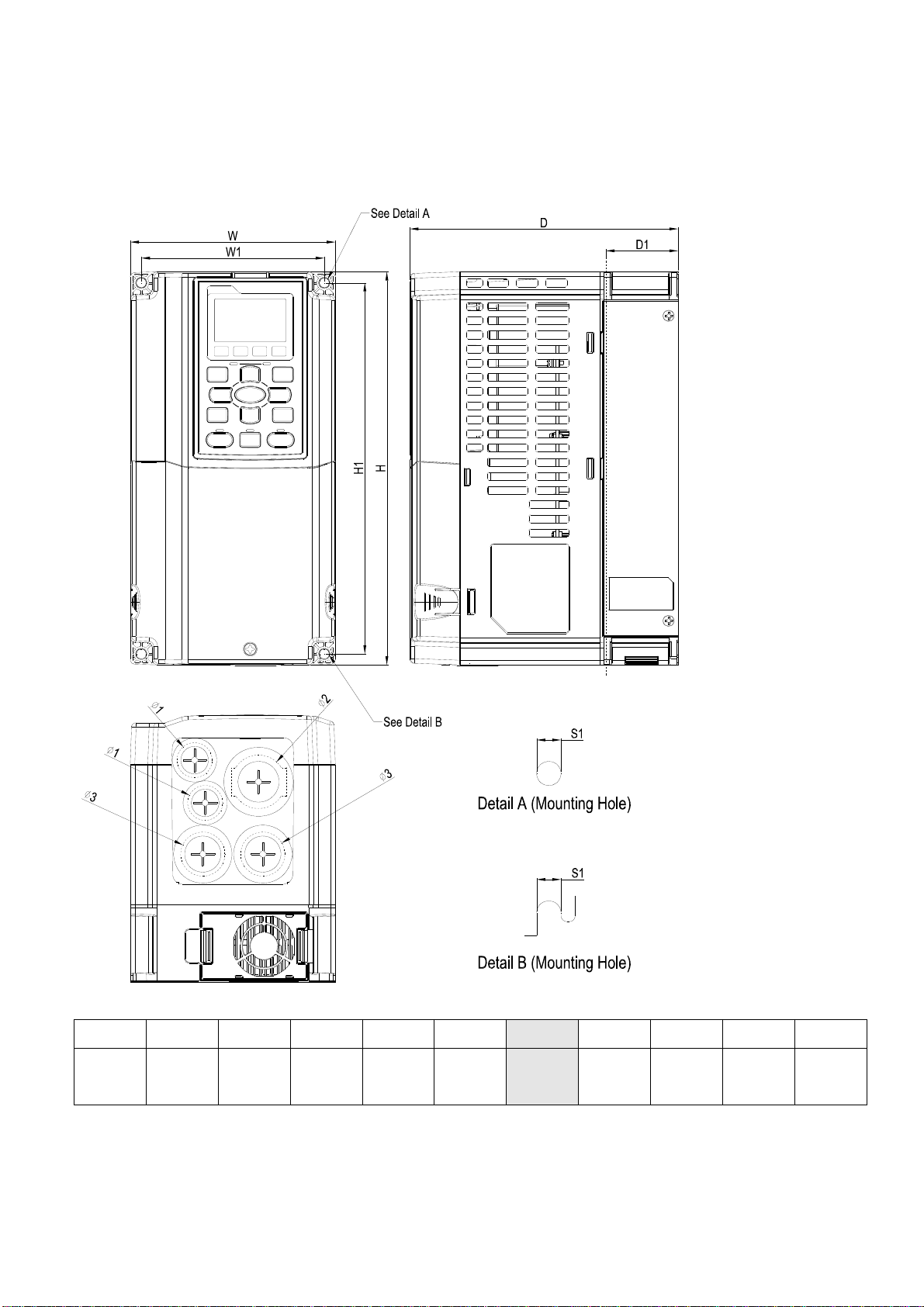

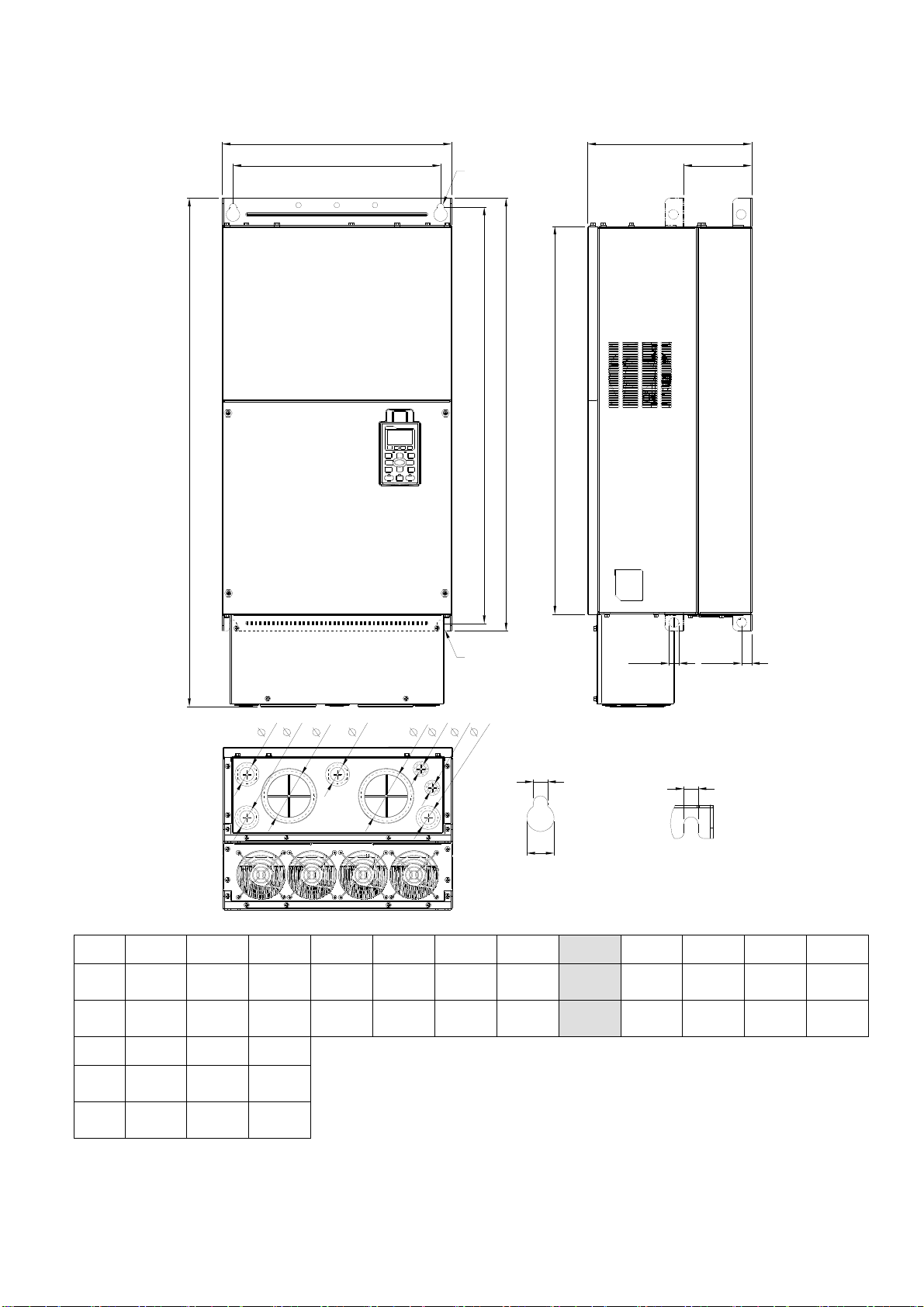

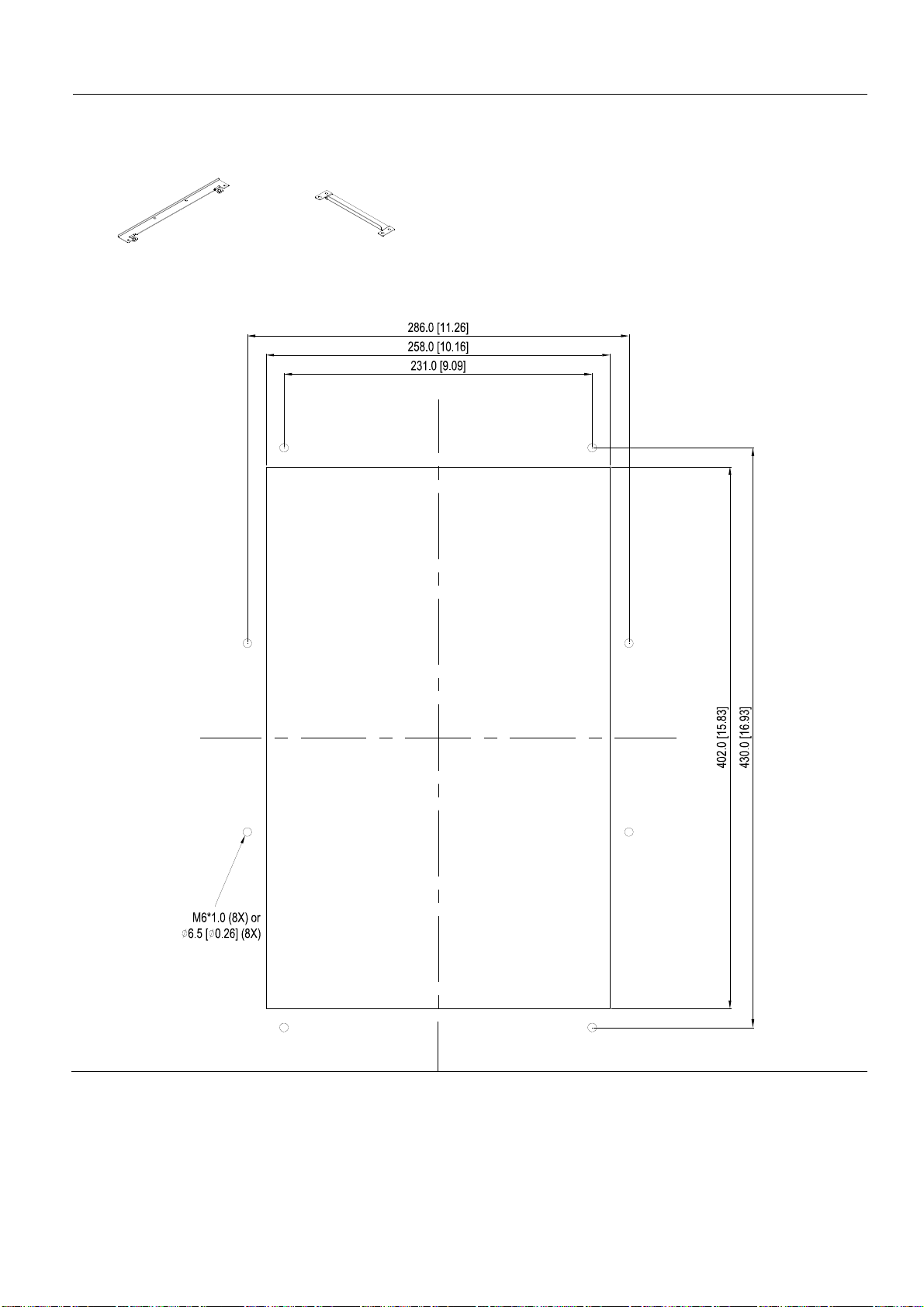

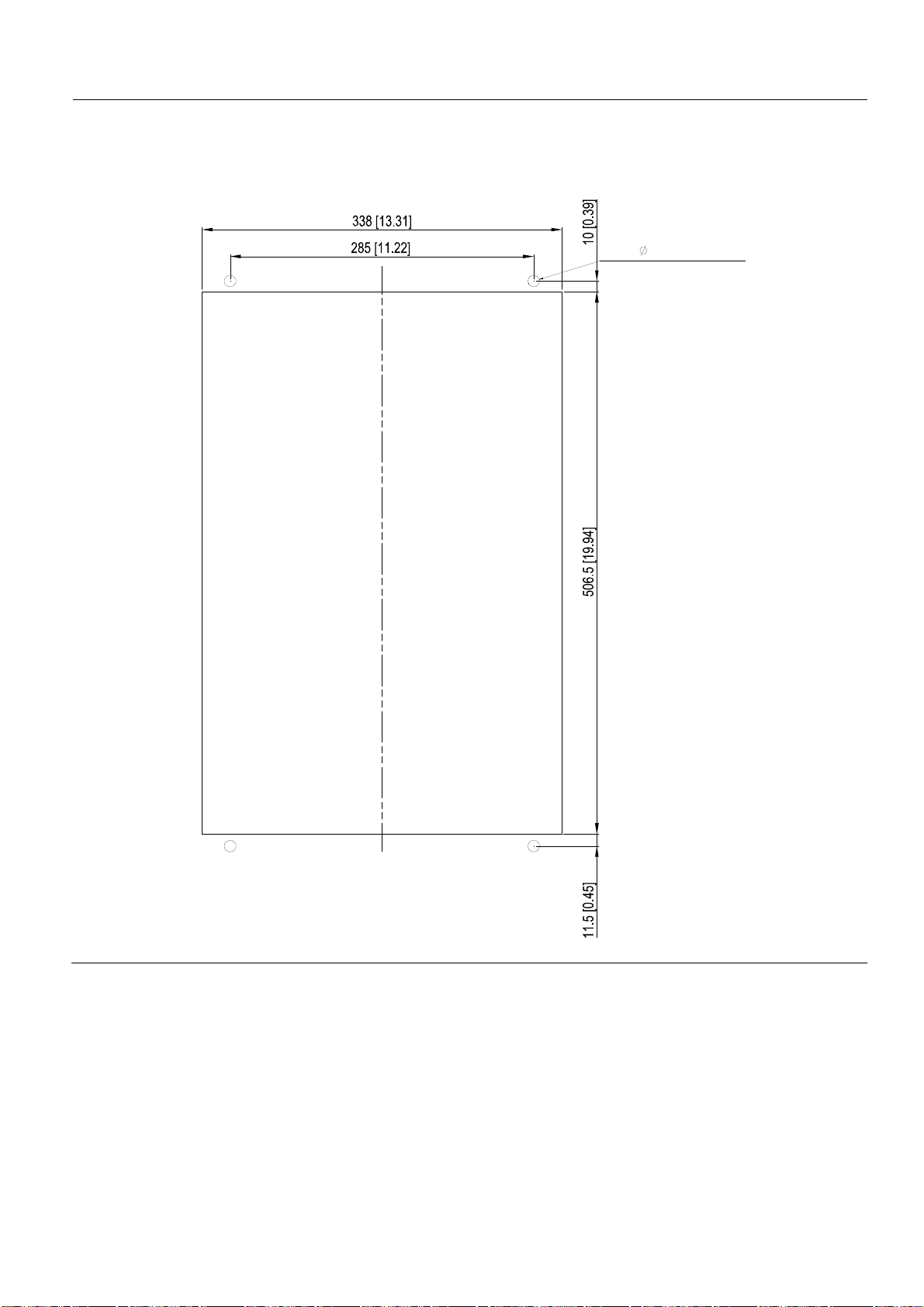

Dimensions

Frame A

VFD007C23A; VFD007C43A/E; VFD015C23A; VFD015C43A/E; VFD022C23A; VFD022C43A/E;

VFD037C23A; VFD037C43A/E; VFD040C43A/E; FD055C43A/E

Unit: mm [inch]

Frame

A1

NOTE: Model VFD007C43E; VFD015C43E; VFD022C43E; VFD037C43E; VFD040C43E; VFD055C43E will be available for

W H D W1 H1

130.0

[5.12]

ordering soon. Please contact your local distributor or Delta representative for detailed launch schedule.

250.0

[9.84]

170.0

[6.69]

116.0

[4.57]

236.0

[9.29]

1-3

D1* S1 Φ1 Φ2 Φ3

45.8

[1.80]

6.2

[0.24]

22.2

[0.87]

34.0

[1.34]

D1*: Flange mounting

28.0

[1.10]

Chapter 1 IntroductionC2000 Series

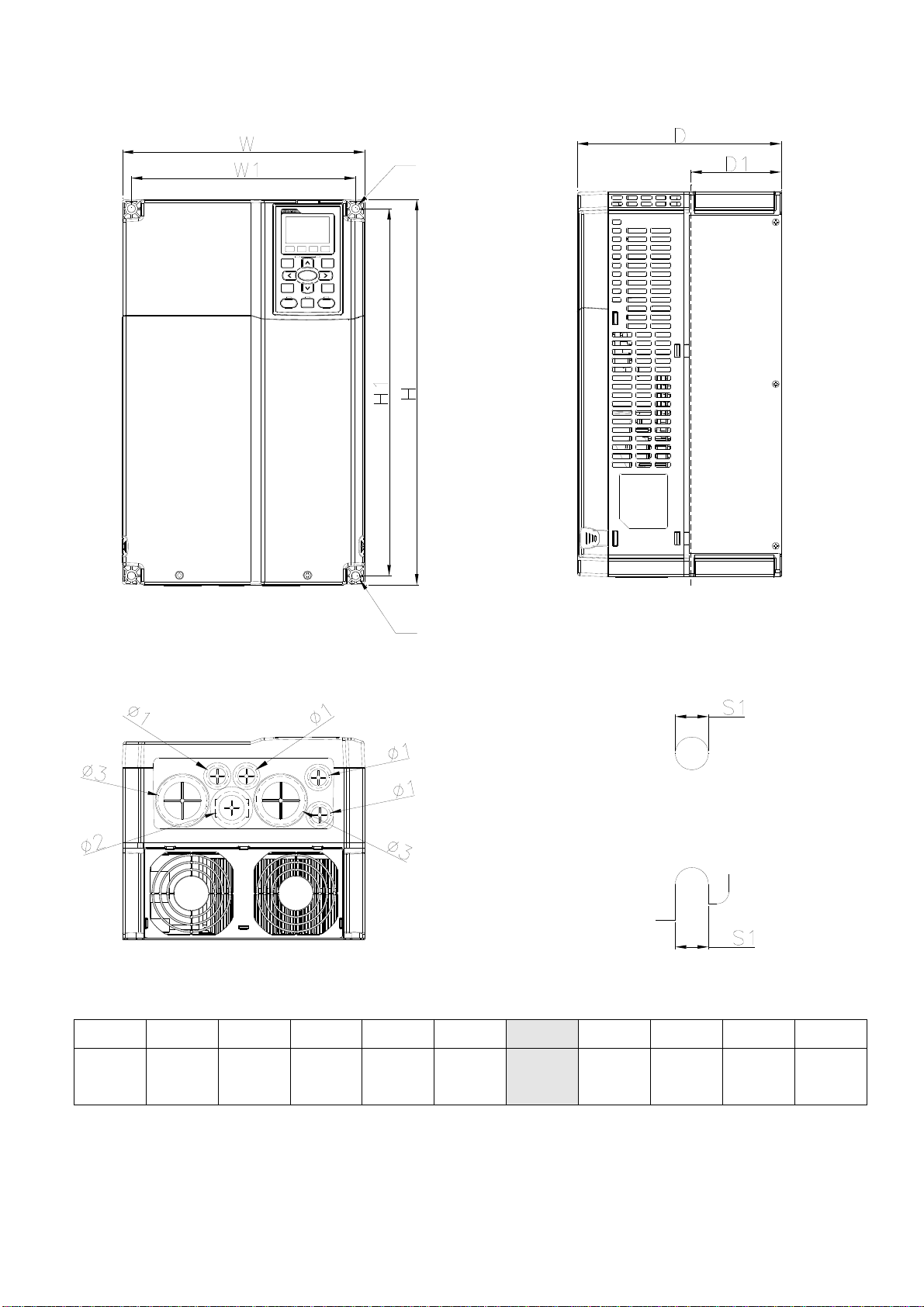

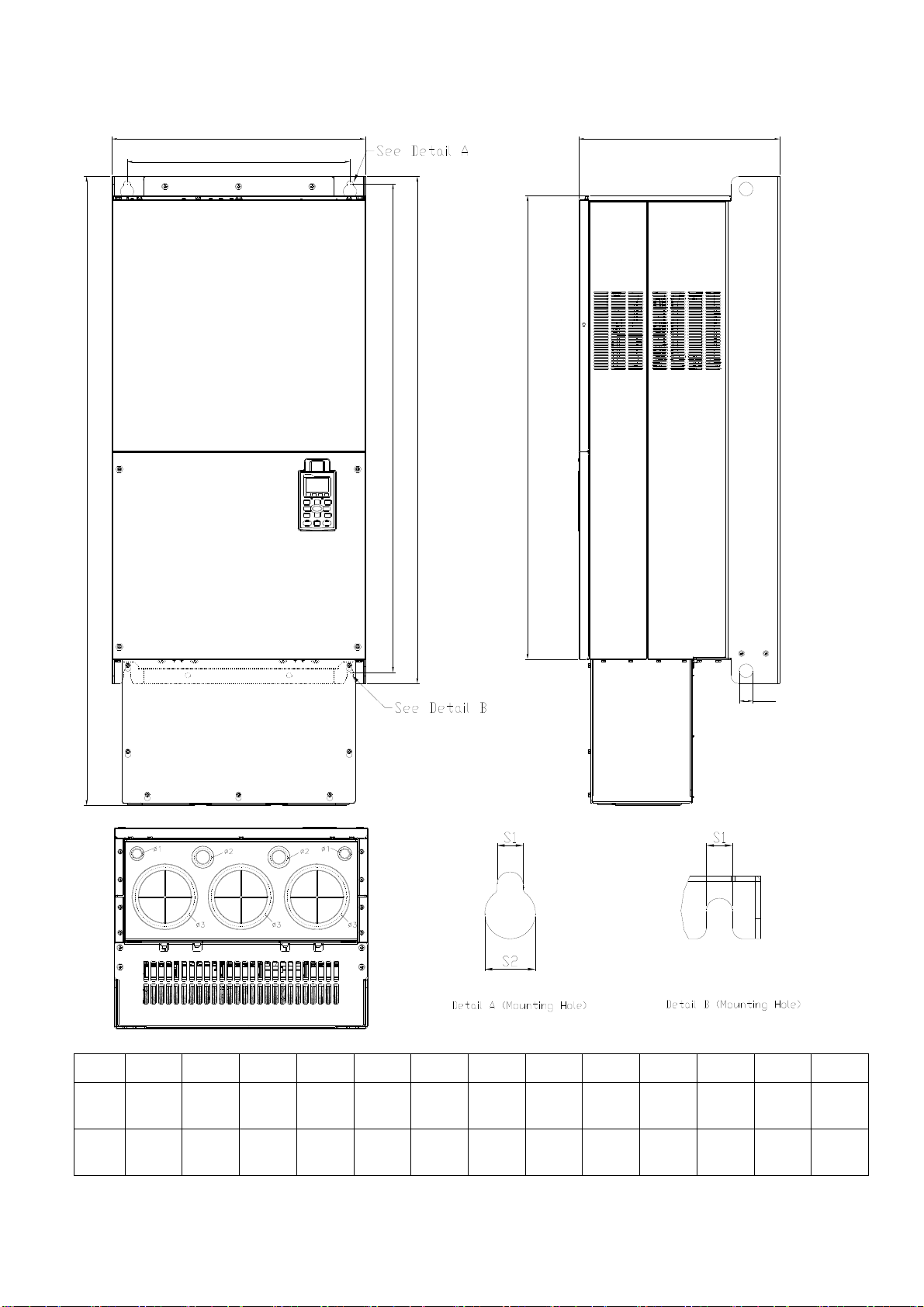

Frame B

VFD055C23A; VFD075C23A; VFD075C43A/E; VFD110C23A; VFD110C43A/E; VFD150C43A/E

See Detail A

Frame

B1

See Detail B

W H D W1 H1

190.0

[7.48]

320.0

[12.60]

190.0

[7.48]

173.0

[6.81]

303.0

[11.93]

Detail A (Mounting Hole)

Detail B (Mounting Hole)

Unit: mm [inch]

D1* S1 Φ1 Φ2 Φ3

77.9

[3.07]

8.5

[0.33]

22.2

[0.87]

34.0

[1.34]

28.0

[1.10]

D1*: Flange mounting

NOTE: Model VFD075C43E; VFD110C43E; VFD150C43E will be available for ordering soon. Please contact your local distributor

or Delta representative for detailed launch schedule.

1-4

Chapter 1 IntroductionC2000 Series

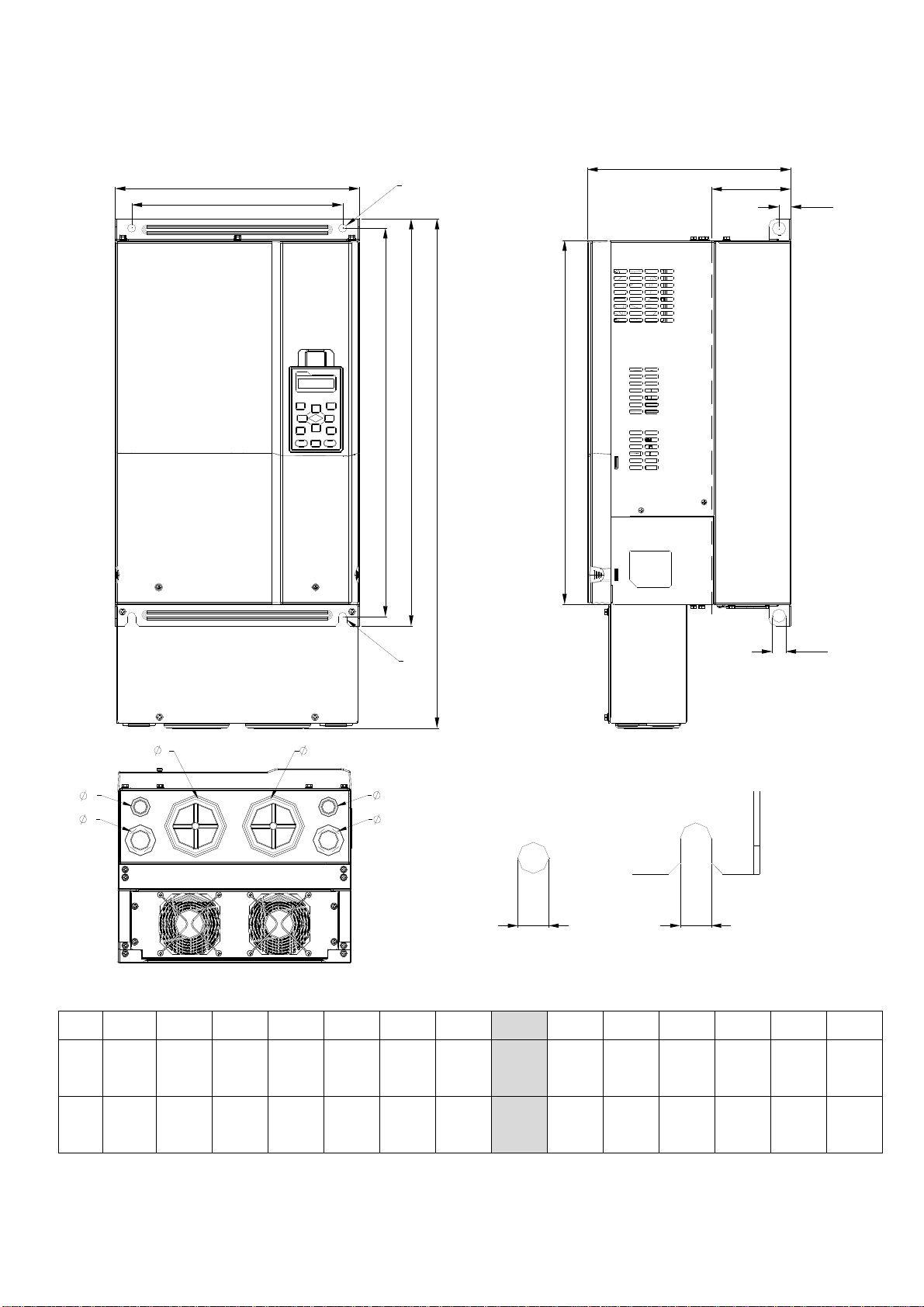

Frame C

VFD150C23A; VFD185C23A; VFD185C43A/E; VFD220C23A; VFD220C43A/E; VFD300C43A/E

See Detail A

Frame

C1

See Detail B

W H D W1 H1

250.0

[9.84]

400.0

[15.75]

210.0

[8.27]

231.0

[9.09]

381.0

[15.00]

Detail A (Mounting Hole)

Detail B (Mounting Hole)

Unit: mm [inch]

D1* S1 Φ1 Φ2 Φ3

92.9

[3.66]

8.5

[0.33]

22.2

[0.87]

34.0

[1.34]

50.0

[1.97]

D1*: Flange mounting

NOTE: Mode VFD185C43E; VFD220C43E; VFD300C43E will be available for ordering soon. Please contact your local

distributor or Delta representative for detailed launch schedule.

1-5

Chapter 1 IntroductionC2000 Series

Frame D

D1: VFD300C23A; VFD370C23A; VFD370C43A; VFD450C43A; VFD550C43A; VFD750C43A

D2: VFD300C23E; VFD370C23E; VFD370C43E; VFD450C43E; VFD550C43E; VFD750C43E

D

W

W1

SEE DETAIL A

D1

D2

H2

H1

H3

H

S2

SEE DETAIL B

1

3

2

1

3

2

S1S1

DETAIL A

(MOUNTING HOLE)

DETAIL B

(MOUNTING HOLE)

Unit: mm [inch]

Frame W H D W1 H1 H2 H3 D1* D2 S1 S2 Φ1 Φ2 Φ3

330.0

D1

[12.99]

330.0

D2

[12.99]

- 275.0

[10.83]

688.3

[27.10]

275.0

[10.83]

285.0

[11.22]

285.0

[11.22]

550.0

[21.65]

550.0

[21.65]

525.0

[20.67]

525.0

[20.67]

492.0

[19.37]

492.0

[19.37]

1-6

107.2

[4.22]

107.2

[4.22]

16.0

[0.63]

16.0

[0.63]

11. 0

[0.43]

11. 0

[0.43]

18.0

[0.71]

18.0

[0.71]

- - -

76.2

[3.00]

D1*: Flange mounting

34.0

[1.34]

22.0

[0.87]

Chapter 1 IntroductionC2000 Series

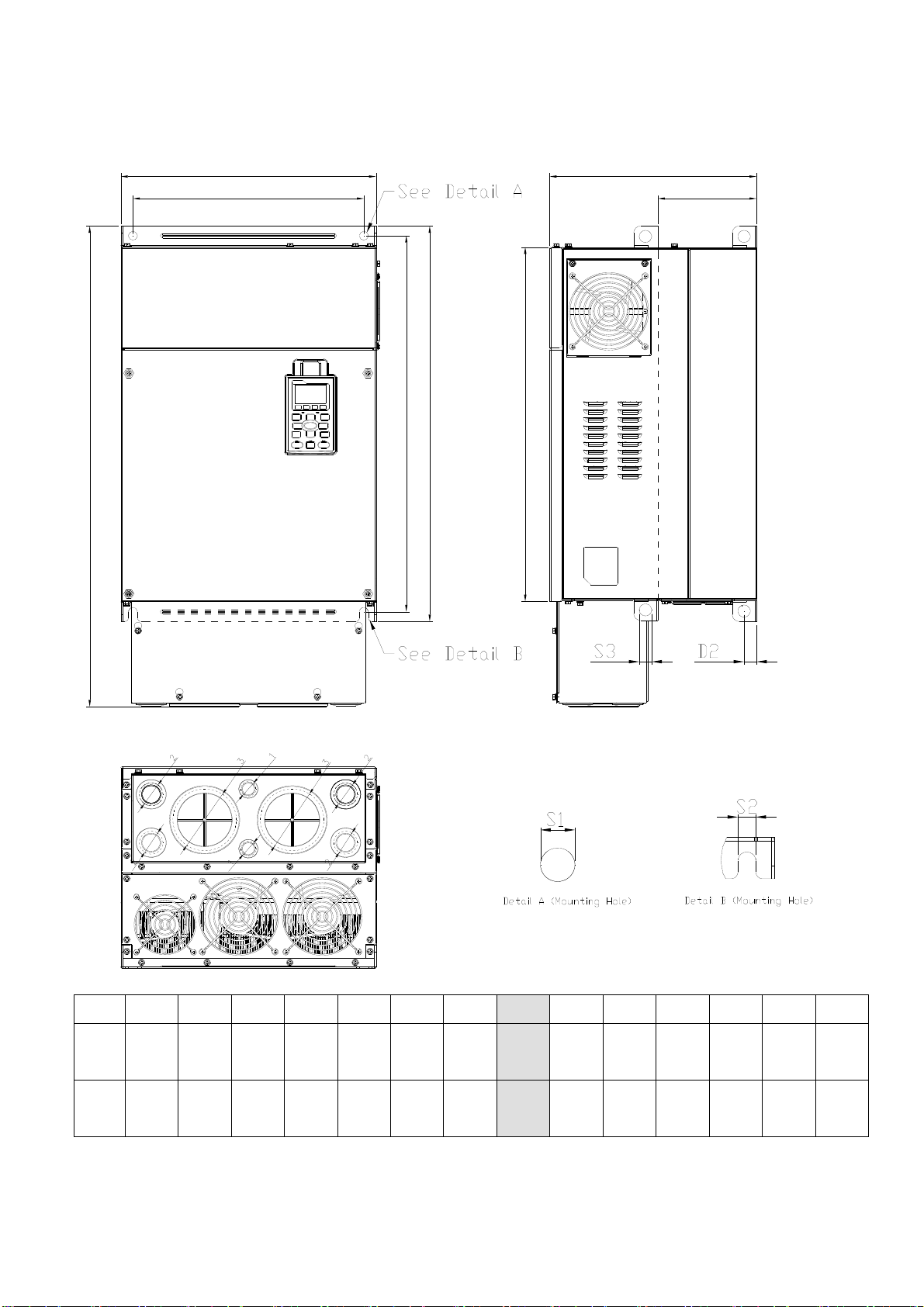

Frame E

E1: VFD450C23A; VFD550C23A; VFD750C23A; VFD900C43A; VFD1100C43A

E2: VFD450C23E; VFD550C23E; VFD750C23E; VFD900C43E; VFD1100C43E

W

W1

H1

H2

H

H3

D

D1

Frame

E1

E2

?

?

W H D W1 H1 H2 H3

370.0

?

?

300.0

?

335.0

?

?

?

589

560.0

528.0

-

[14.57]

370.0

[14.57]

715.8

[28.18]

[11.81]

300.0

[11.81]

[13.19

335.0

[13.19

[23.19]

589

[23.19]

[22.05]

560.0

[22.05]

[20.80]

528.0

[20.80]

Unit: mm [inch]

D1* D2 S1, S2 S3 ψ1 ψ2 ψ3

143.0

[5.63]

143.0

[5.63]

18.0

[0.71]

18.0

[0.71]

13.0

[0.51]

13.0

[0.51]

18.0

[0.71]

18.0

[0.71]

- - -

22.0

[0.87]

34.0

[1.34]

D1*: Flange mounting

92.0

[3.62]

1-7

Chapter 1 IntroductionC2000 Series

Frame F

F1: VFD900C23A; VFD1320C43A; VFD1600C43A; F2: VFD900C23E; VFD1320C43E; VFD1600C43E

See Detail A

W

W1

H

See Detail A

H1

H2

H3

D

D1

Frame

F1

F2

Frame

F1

F2

See Detail B

2

1

2

2

W H D W1 H1 H2 H3

420.0

[16.54]

420.0

[16.54]

ψ1 ψ2 ψ3

92.0

[3.62]

92.0

[3.62]

300.0

[11.81]

940.0

[37.00]

35.0

[1.38]

35.0

[1.38]

300.0

[11.81]

22.0

[0.87]

22.0

[0.87]

380.0

[14.96]

380.0

[14.96]

800.0

[31.50]

800.0

[31.50]

1

3

3

2

Detail A (Mounting Hole)

770.0

[30.32]

770.0

[30.32]

717.0

[28.23]

717.0

[28.23]

S1

S2

S3

Detail B (Mounting Hole)

D2

S1

Unit: mm [inch]

D1* D2 S1 S2 S3

124.0

[4.88]

124.0

[4.88]

18.0

[0.71]

18.0

[0.71]

13.0

[0.51]

13.0

[0.51]

25.0

[0.98]

25.0

[0.98]

D1*: Flange mounting

18.0

[0.71]

18.0

[0.71]

1-8

Chapter 1 IntroductionC2000 Series

Frame G

G1: VFD1850C43A; VFD2200C43A; G2: VFD1850C43E; VFD2200C43E

W

W1

D

H2

H1

H

H3

S3

Frame

G1

G2

Unit: mm [inch]

W H D W1 H1 H2 H3 S1 S2 S3 ψ1 ψ2 ψ3

500.0

[19.69]

500.0

[19.69]

1240.2

[48.83]

-

397.0

[15.63]

397.0

[15.63]

440.0

[217.32]

440.0

[217.32]

1000.0

[39.37]

1000.0

[39.37]

963.0

[37.91]

963.0

[37.91]

913.6

[35.97]

913.6

[35.97]

1-9

13.0

[0.51]

13.0

[0.51]

26.5

[1.04]

26.5

[1.04]

27.0

[1.06]

27.0

[1.06]

- - -

22.0

[0.87]

34.0

[1.34]

117.5

[4.63]

Chapter 1 IntroductionC2000 Series

Frame H

H1: VFD2800C43A; VFD3150C43A; VFD3550C43A

H2: VFD2800C43E-1; VFD3150C43E-1; VFD3550C43E-1

H3: VFD2800C43E; VFD3150C43E; VFD3550C43E

Frame

H1

H2

H3

Unit: mm [inch]

W H D W1 W2 W3 W4 W5 W6 H1 H2 H3 H4

700.0

[27.56]

700.0

[27.56]

700.0

[27.56]

1745.0

[68.70]

1745.0

[68.70]

-

398.0

[15.67]

404.0

[15.91]

404.0

[15.91]

-

800.0

[31.50]

800.0

[31.50]

630.0

[24.80]

290.0

[11.42]

- -

- -

- - - -

500.0

[19.69]

500.0

[19.69]

1-10

630.0

[24.80]

630.0

[24.80]

760.0

[29.92]

760.0

[29.92]

1729.0

[68.07]

1729.0

[68.07]

1435.0

[56.50]

1403.0

[55.24]

- -

- -

-

1701.6

[66.99]

1701.6

[66.99]

Chapter 1 IntroductionC2000 Series

Frame H5 D1 D2 D3 D4 D5 D6 S1 S2 S3 ψ1 ψ2 ψ3

1346.6

H1

[53.02]

1346.6

H2

[53.02]

1346.6

H3

[53.02]

45.0

[1.77]

51.0

[2.01]

51.0

[2.01]

- - - - -

[1.50]

[1.50]

38.0

38.0

[2.56]

[2.56]

65.0

65.0

204.0

[8.03]

204.0

[8.03]

68.0

[2.68]

68.0

[2.68]

137.0

[5.39]

137.0

[5.39]

13.0

[0.51]

13.0

[0.51]

13.0

[0.51]

26.5

[1.04]

26.5

[1.04]

26.5

[1.04]

25.0

[0.98]

25.0

[0.98]

25.0

[0.98]

- - -

- - -

[0.87]

22.0

[1.34]

34.0

117.5

[4.63]

1-11

Chapter 1 IntroductionC2000 Series

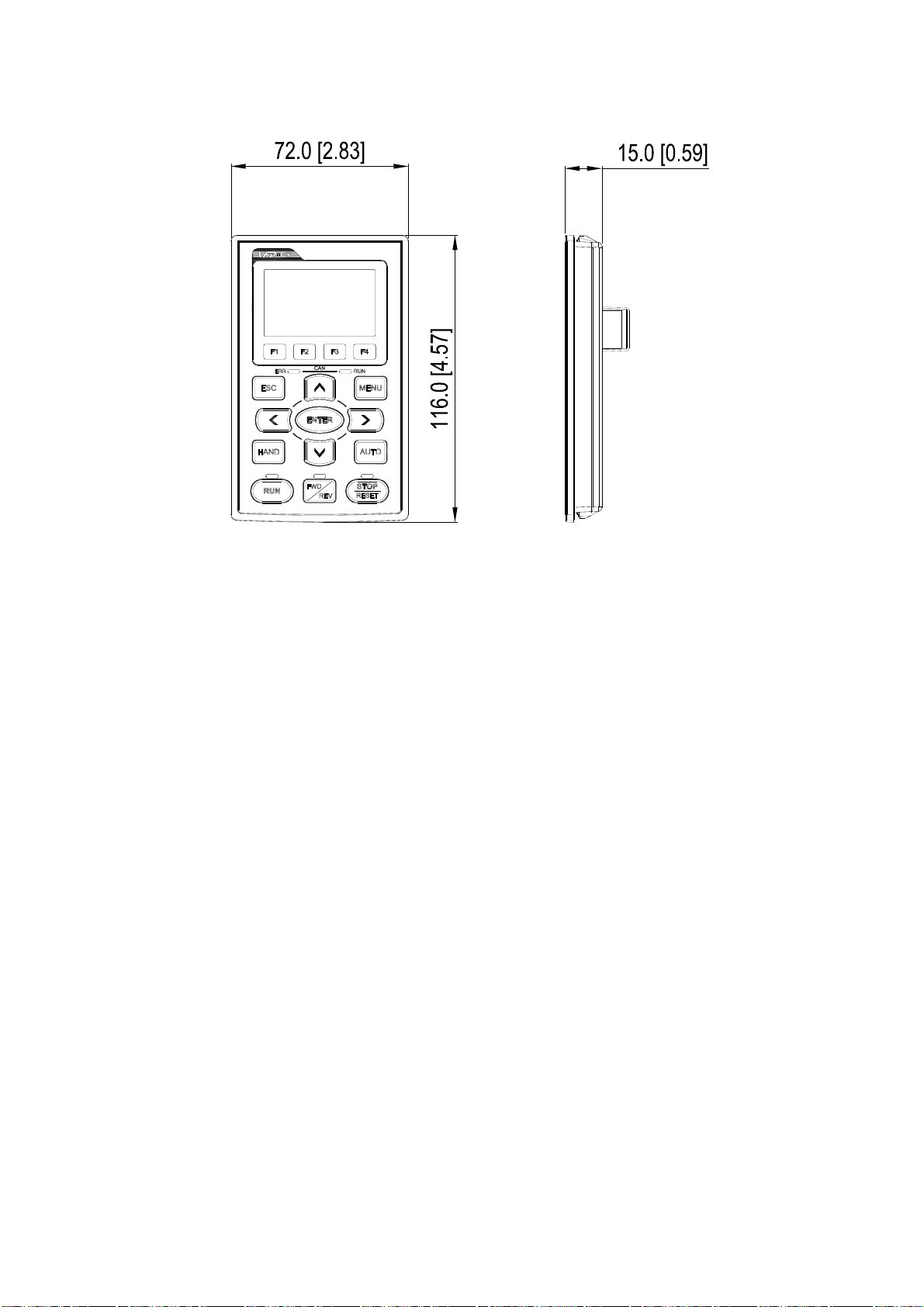

Digital Keypad

KPC-CC01

1-12

Chapter 2 InstallationC2000 Series

Chapter 2 Installation

The appearances shown in the following figures are for reference only.

Airflow direction: (Blue arrow) inflow (Red arrow) outflow

Single drive: installation

(Frame A-H)

Side-by-side installation(Frame A-C)

Multiple drives: side-by-side installation(Frame A,B,C, G, H)

Multiple drives: side-by-side installation (Frame D, E, F) Install a barrier between the drives.

2-1

f

Chapter 2 InstallationC2000 Series

Multiple drives side-by-side installation in rows (Frame A,B,C )

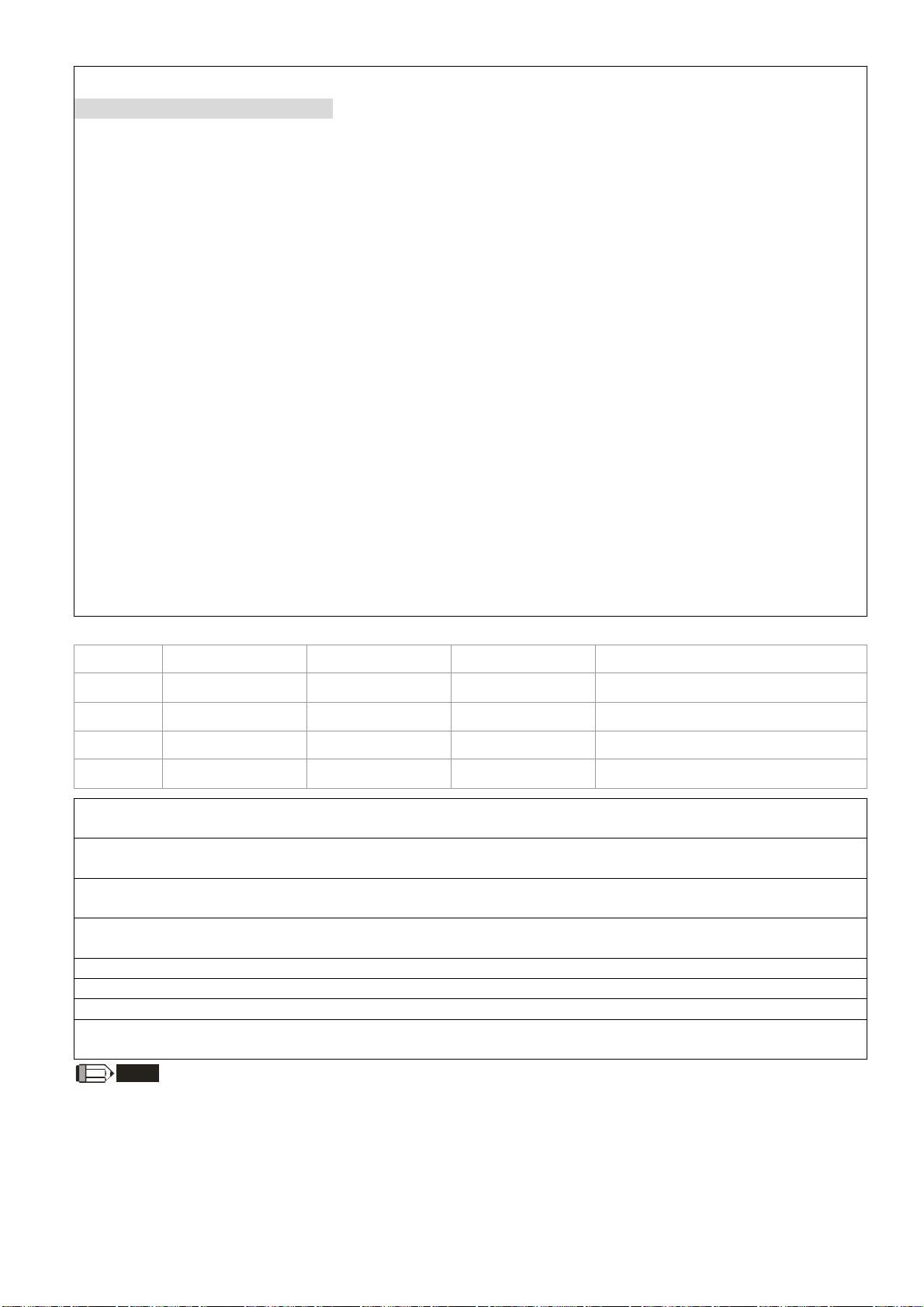

Ta: Frame A~G Ta*: Frame H

For installation in rows, it is recommended installing a barrier between the drives. Adjust the size/depth o

the barrier till the temperature measured at the fan’s inflow side is lower than the operation temperature.

Operation temperature is the defined as the temperature measured 50mm away from the fan’s inflow

side. (As shown in the figure below)

Minimum mounting clearance

Frame A (mm) B (mm) C (mm) D (mm)

A~C 60 30 10 0

D~F 100 50 - 0

G 200 100 - 0

H 350 0 0

200 (100, Ta=40℃)

Frame A VFD007C23A; VFD007C43A/E; VFD015C23A; VFD015C43A/E; VFD022C23A;

VFD022C43A/E; VFD037C23A; VFD037C43A/E; VFD040C43A/E; VFD055C43A/E;

Frame B VFD055C23A; VFD75C23A; VFD075C43A/E; VFD110C23A; VFD110C43A/E;

VFD150C43A/E;

Frame C VFD150C23A; VFD185C23A; VFD185C43A/E; VFD220C23A; VFD220C43A/E;

VFD300C43A/E;

Frame D VFD300C23A/E; VFD370C23A/E; VFD370C43A/E; VFD450C43A/E; VFD550C43A/E;

VFD750C43A/E;

Frame E VFD450C23A/E; VFD550C23A/E; VFD750C23A/E; VFD900C43A/E; VFD1100C43A/E;

Frame F VFD900C23A/E; VFD1320C43A/E; VFD1600C43A/E;

Frame G VFD1850C43A; VFD2200C43A; VFD1850C43E; VFD2200C43E;

Frame H VFD2800C43A; VFD3150C43A; VFD3550C43A; VFD2800C43E-1; VFD3150C43E-1;

VFD3550C43E-1;VFD2800C43E; VFD3150C43E; VFD3550C43E;

NOTE

1. It is the minimum distance required for frame A~D. If drives are installed closer than the minimum mounting clearance, the

fan may not function properly.

2. Model VFD007C43E; VFD015C43E; VFD022C43E; VFD037C43E; VFD040C43E; VFD055C43E; VFD075C43E;

VFD110C43E; VFD150C43E; VFD185C43E; VFD220C43E; VFD300C43E will be available for ordering soon. Please

contact your local distributor or Delta representative for detailed launch schedule,

2-2

Chapter 2 InstallationC2000 Series

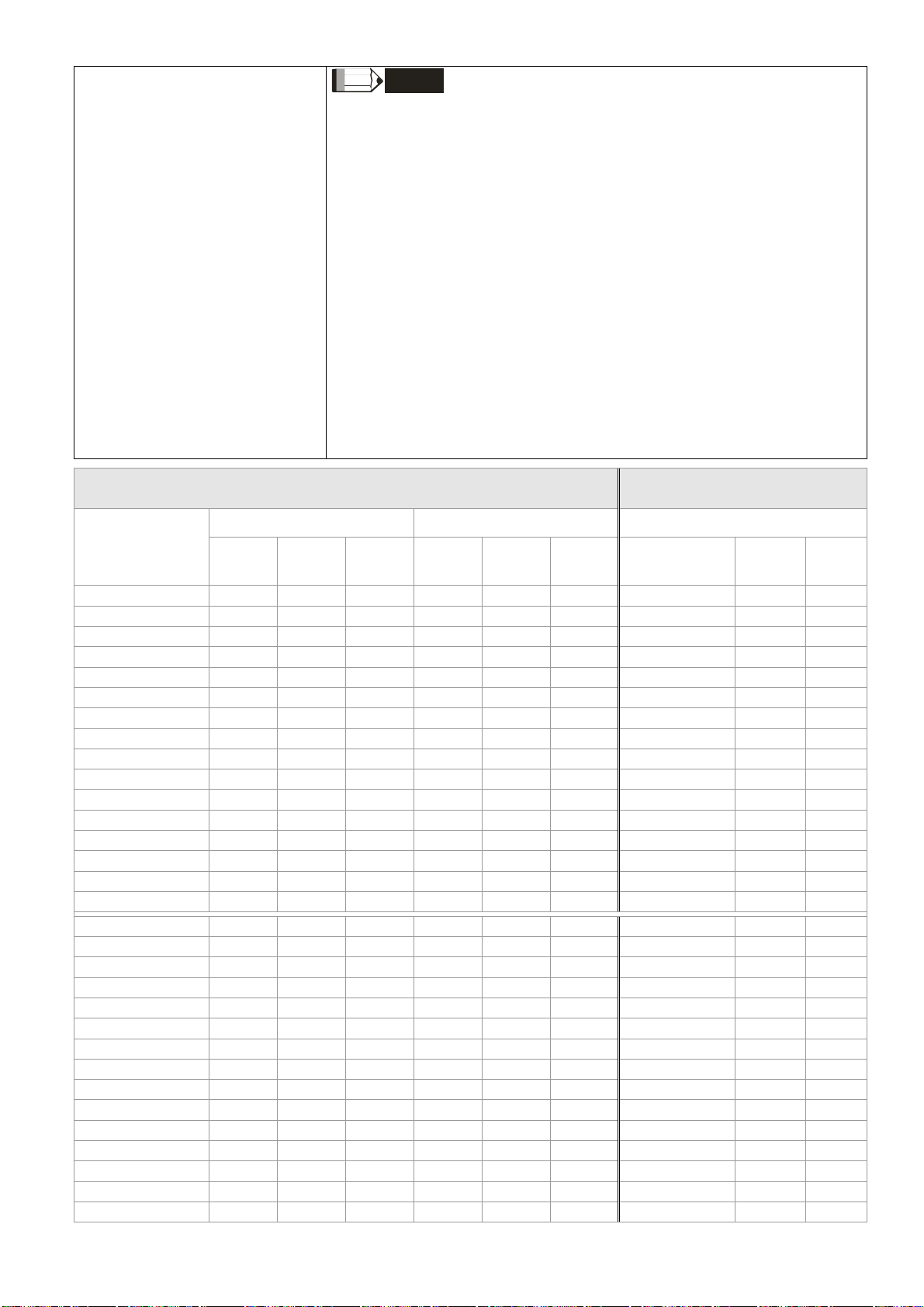

NOT E

※ The mounting clearances shown in the left figure are NOT for installing the

drive in a confined space (such as cabinet or electric box). When installing

in a confined space, besides the same minimum mounting clearances, it

needs to have the ventilation equipment or air conditioner to keep the

surrounding temperature lower than the operation temperature.

※ The following table shows heat dissipation and the required air

volume when installing a single drive in a confined space. When

installing multiple drives, the required air volume shall be multiplied

by the number the drives.

※ Refer to the chart (Air flow rate for cooling) for ventilation equipment

design and selection.

※ Refer to the chart (Power dissipation) for air conditioner design and

Air flow rate for cooling

selection.

Power dissipation of AC motor

drive

Flow Rate (cfm) Flow Rate (m3/hr) Power Dissipation

Model No.

External Internal Total External Internal Total

Loss External

(Heat sink)

Internal Total

VFD007C23A - - - - - - 33 27 61

VFD015C23A 14 - 14 24 - 24 56 31 88

VFD022C23A 14 - 14 24 - 24 79 36 115

VFD037C23A 10 - 10 17 - 17 113 46 159

VFD055C23A 40 14 54 68 24 92 197 67 264

VFD075C23A 66 14 80 112 24 136 249 86 335

VFD110C23A 58 14 73 99 24 124 409 121 529

VFD150C23A 166 12 178 282 20 302 455 161 616

VFD185C23A 166 12 178 282 20 302 549 184 733

VFD220C23A 146 12 158 248 20 268 649 216 865

VFD300C23A/E 179 30 209 304 51 355 913 186 1099

VFD370C23A/E 179 30 209 304 51 355 1091 220 1311

VFD450C23A/E 228 73 301 387 124 511 1251 267 1518

VFD550C23A/E 228 73 301 387 124 511 1401 308 1709

VFD750C23A/E 246 73 319 418 124 542 1770 369 2139

VFD900C23A/E 224 112 336 381 190 571 2304 484 2788

VFD007C43A/E - - - - - - 33 25 59

VFD015C43A/E - - - - - - 45 29 74

VFD022C43A/E 14 - 14 24 - 24 71 33 104

VFD037C43A/E 10 - 10 17 - 17 103 38 141

VFD040C43A/E 10 - 10 17 - 17 116 42 158

VFD055C43A/E 10 - 10 17 - 17 134 46 180

VFD075C43A/E 40 14 54 68 24 92 216 76 292

VFD110C43A/E 66 14 80 112 24 136 287 93 380

VFD150C43A/E 58 14 73 99 24 124 396 122 518

VFD185C43A/E 99 21 120 168 36 204 369 138 507

VFD220C43A/E 99 21 120 168 36 204 476 158 635

VFD300C43A/E 126 21 147 214 36 250 655 211 866

VFD370C43A/E 179 30 209 304 51 355 809 184 993

VFD450C43A/E 179 30 209 304 51 355 929 218 1147

VFD550C43A/E 179 30 209 304 51 355 1156 257 1413

2-3

R

%

R

%

Chapter 2 InstallationC2000 Series

Air flow rate for cooling

Power dissipation of AC motor

drive

Flow Rate (cfm) Flow Rate (m3/hr) Power Dissipation

Model No.

External Internal Total External Internal Total

Loss External

(Heat sink)

Internal Total

VFD750C43A/E 186 30 216 316 51 367 1408 334 1742

VFD900C43A/E 257 73 330 437 124 561 1693 399 2092

VFD1100C43A/E 223 73 296 379 124 503 2107 491 2599

VFD1320C43A/E 224 112 336 381 190 571 2502 579 3081

VFD1600C43A/E 289 112 401 491 190 681 3096 687 3783

VFD1850C43A/E 454 771 4589

VFD2200C43A/E 454 771 5772

VFD2800C43A/E 769 1307 6381

VFD3150C43A/E 769 1307 7156

VFD3550C43A/E

※ The required airflow shown in chart is for installing single drive in a

769

1307

confined space.

※ When installing the multiple drives, the required air volume should

be the required air volume for single drive X the number of the

drives.

※ Model VFD007C43E; VFD015C43E; VFD022C43E; VFD037C43E;

VFD040C43E; VFD055C43E; VFD075C43E; VFD110C43E;

VFD150C43E; VFD185C43E; VFD220C43E; VFD300C43E will be

available for ordering soon. Please contact your local distributor or

Delta representative for detailed launch schedule.

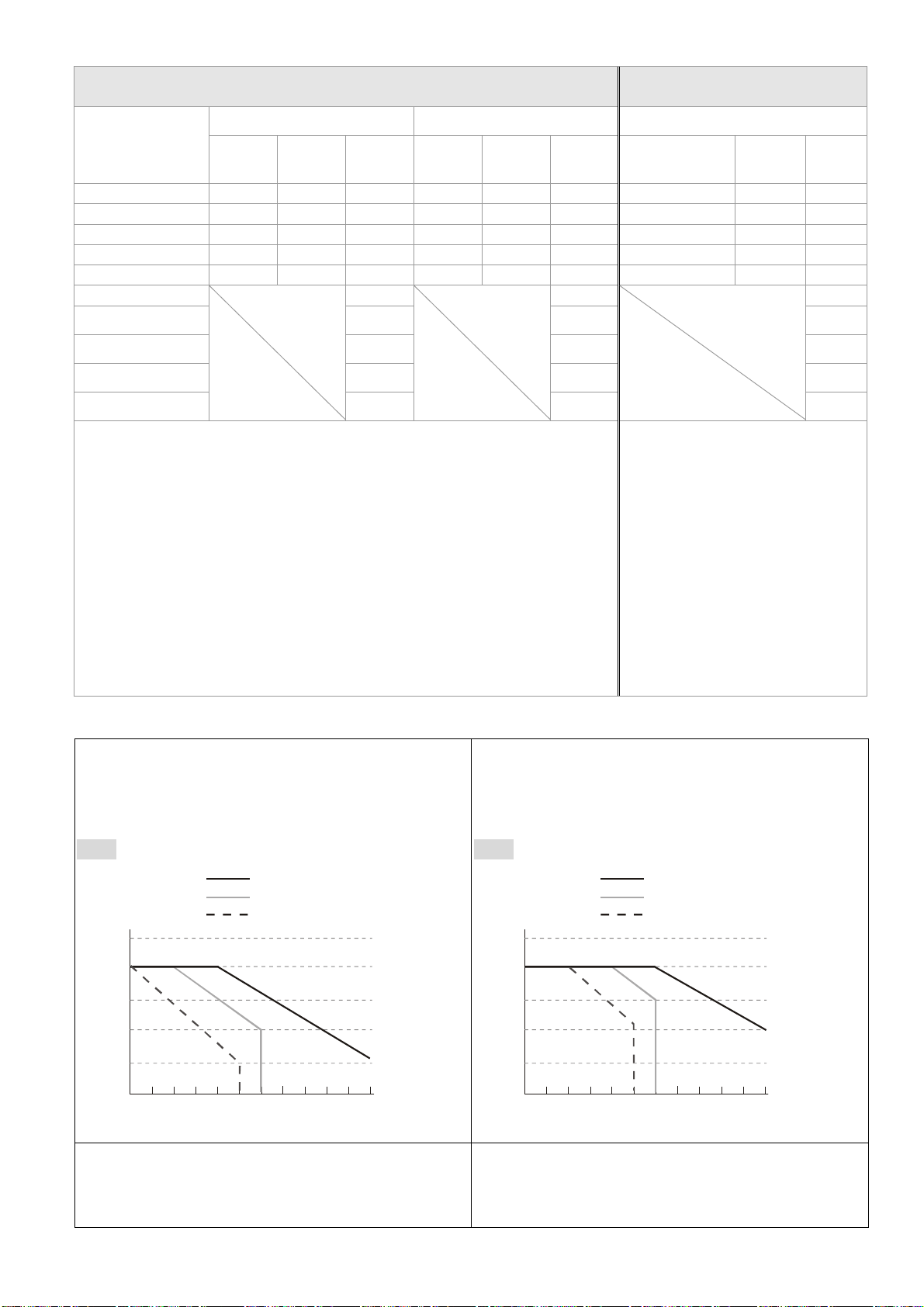

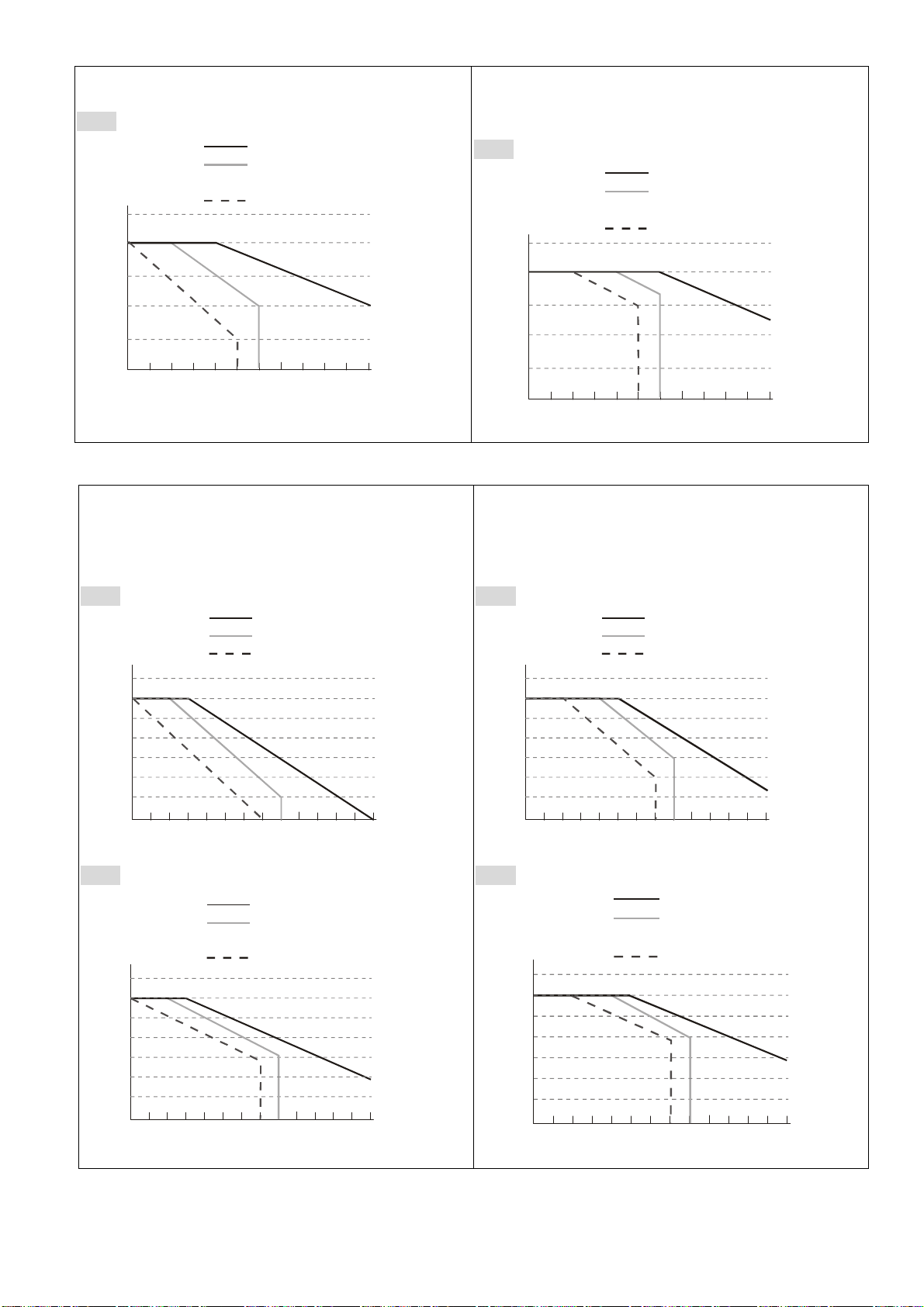

Derating curve diagram: Normal Duty

Setting =1

Setting = 0 or 2

(50℃: UL open-type)

(40℃:UL type1 or open type_size by size)

460V

Setting = 0 or 2

(40℃: UL open-type)

(30℃: UL type1 or open type_size by size)

460V

8007

※ The heat dissipation shown

in the chart is for installing

single drive in a confined

space.

※ When installing the multiple

drives, volume of heat

dissipation should be the

heat dissipated for single

drive X the number of the

drives.

※ Heat dissipation for each

model is calculated by rated

voltage, current and default

carrier.

110

100

)

90

ati o(

80

70

60

4 5 6 7 8 9 10 11 12 13 14 15

Setting =1

Setting = 0 or 2

VFD007 ~1 50 C4 3A/ E

VFD185 ~5 50 C4 3A/ E

VFD750~3 550C43A/E

Fc (kHz)

VFD007 ~1 50 C4 3A/E

VFD185 ~5 50 C4 3A/E

VFD750 ~3 55 0C 43 A/ E

110

100

)

90

80

atio(

70

60

4 5 6 7 8 9 101112131415

Fc (kHz )

Setting = 0 or 2

2-4

R

%

R

%

R

%

R

%

R

%

R

230V

110

100

)

atio(

(50℃: UL open-type)

(40℃:UL type1 or open type_size by size)

VFD007 ~110C23A

VFD150 ~ 37 0C23A;

VFD300 ~ 37 0C23E

VFD450 ~ 90 0C23A/E

90

80

70

230V

110

100

)

atio(

Chapter 2 InstallationC2000 Series

(40℃: UL open-type)

(30℃: UL type1 or open type_size by size)

VFD007 ~110C23A

VFD150 ~3 70 C2 3A ;

VFD300 ~3 70 C2 3E

VFD450 ~9 00 C2 3A /E

90

80

60

4 5 6 7 8 9 10 11 12 13 14 15

Fc (kHz)

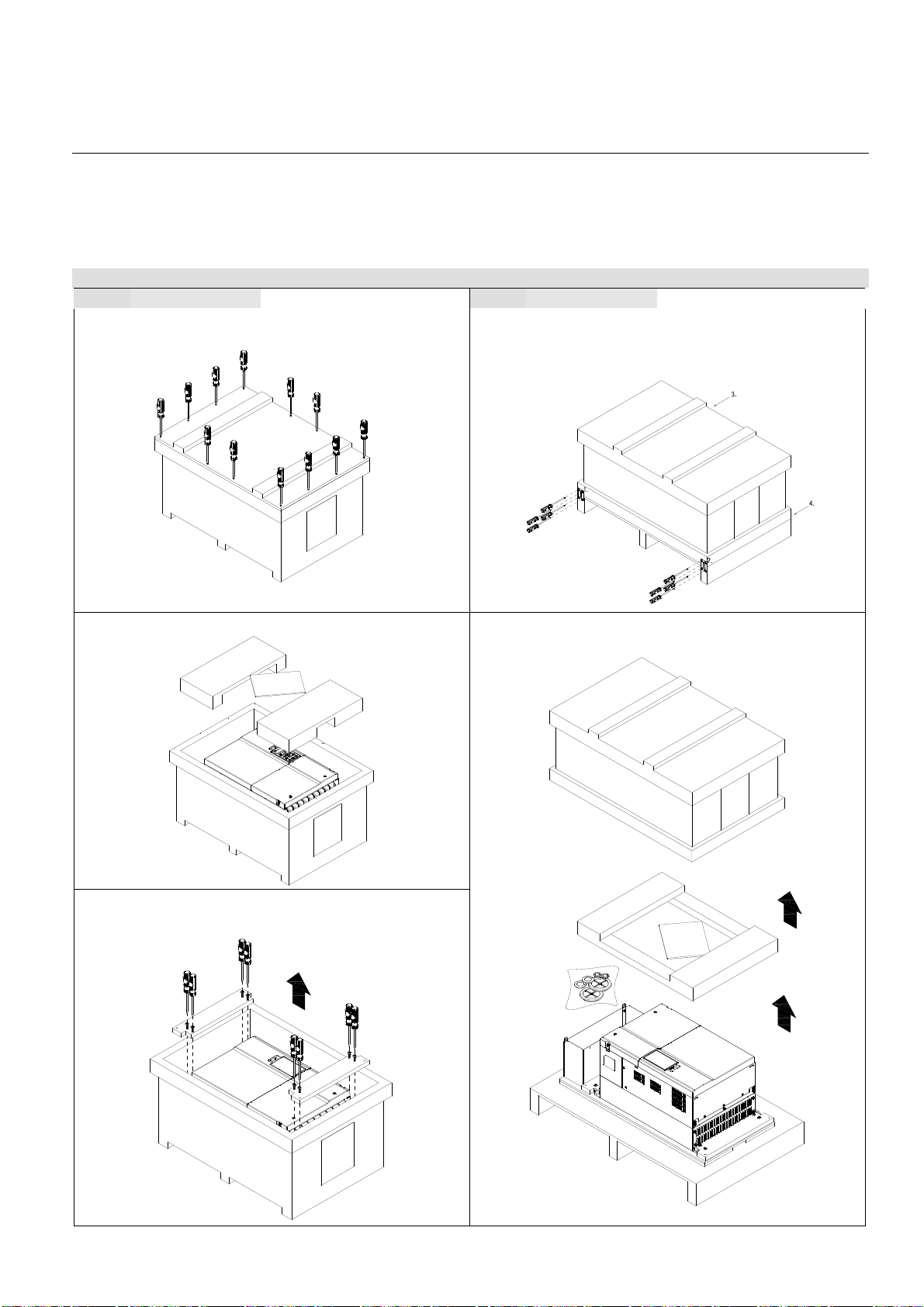

Derating curve diagram: Heavy Duty

Setting =1

Setting = 0 or 2

(50℃: UL open-type)

(40℃: UL type1 or open type_size by size)

460V

VFD007 ~1 50 C4 3A/ E

VFD185 ~5 50 C4 3A/ E

VFD750~3 550C43A/E

110

100

)

90

80

atio(

70

60

50

40

3

2 5 6 7 8 9 10 11 12 13 14 15

4

Fc (kHz)

230V

VFD007~110C23A

VFD150~3 70 C2 3A;

VFD300~3 70 C2 3E

VFD450~9 00 C2 3A/ E

110

100

)

90

80

70

atio(

60

50

40

2 5 6 7 8 9101112131415

3

4

Fc (kHz)

70

60

4 5 6 7 8 9 10 11 12 13 14 15

Fc (kHz)

Setting = 0 or 2

(40℃: UL open-type)

(30℃: UL type1 or open type_size by size)

460V

VFD007 ~1 50 C43A/E

VFD185 ~5 50 C43A/E

VFD750 ~3 55 0C 43 A/ E

110

100

)

90

80

70

atio(

60

50

40

3

2 5 6 7 8 9 10 11 12 13 14 15

4

Fc (kHz)

230V

VFD007 ~110C23A

VFD150 ~3 70 C2 3A;

VFD300 ~3 70 C2 3E

VFD450 ~9 00 C2 3A/ E

110

100

90

80

70

atio(%)

60

50

40

2 5 6 7 8 9101112131415

3

4

Fc (kHz)

2-5

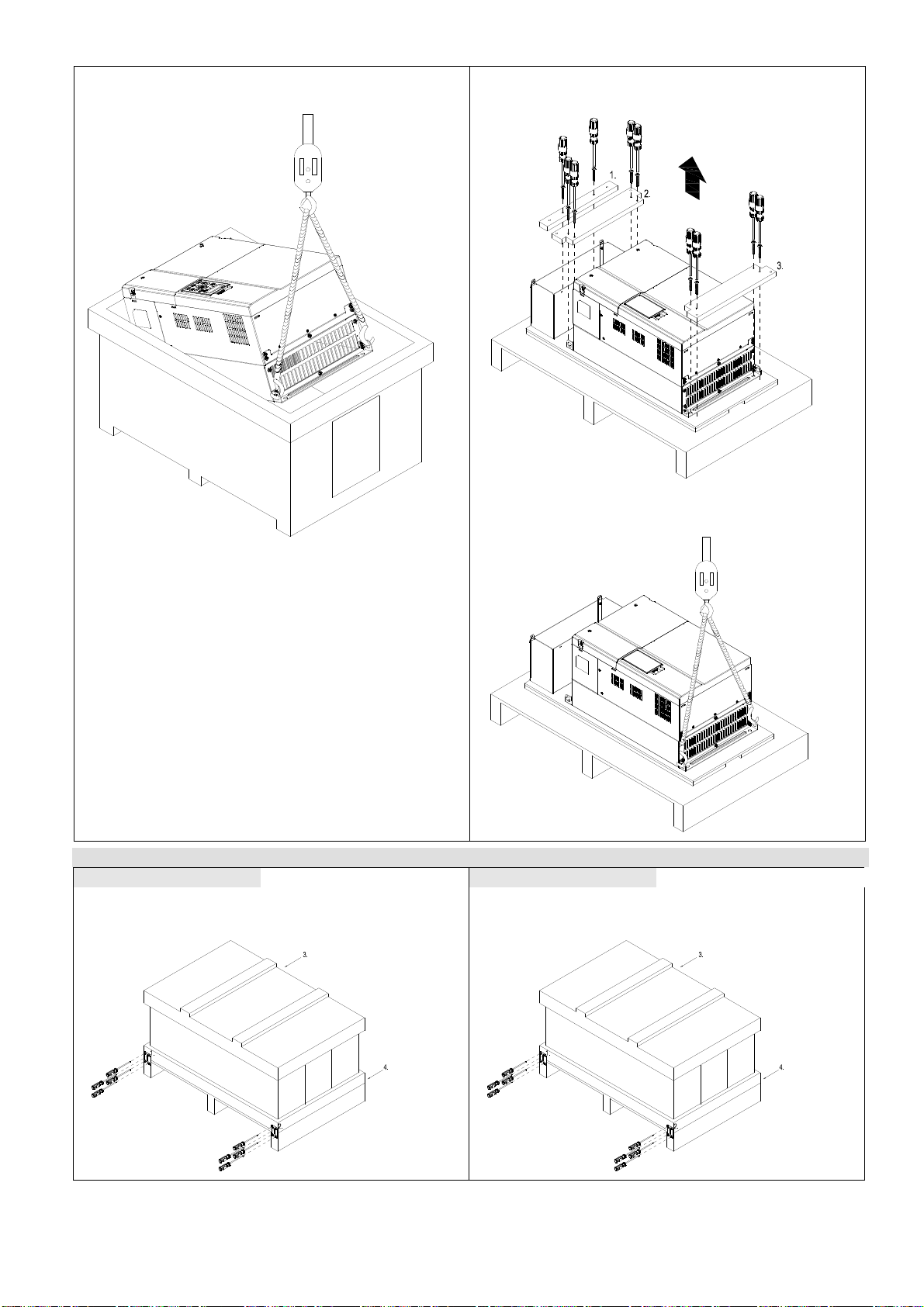

Chapter 3 UnpackingC2000 Series

Chapter 3 Unpacking

The AC motor drive should be kept in the shipping carton or crate before installation. In order to retain the

warranty coverage, the AC motor drive should be stored properly when it is not to be used for an

extended period of time.

The AC motor drive is packed in the crate. Follows the following step for unpack:

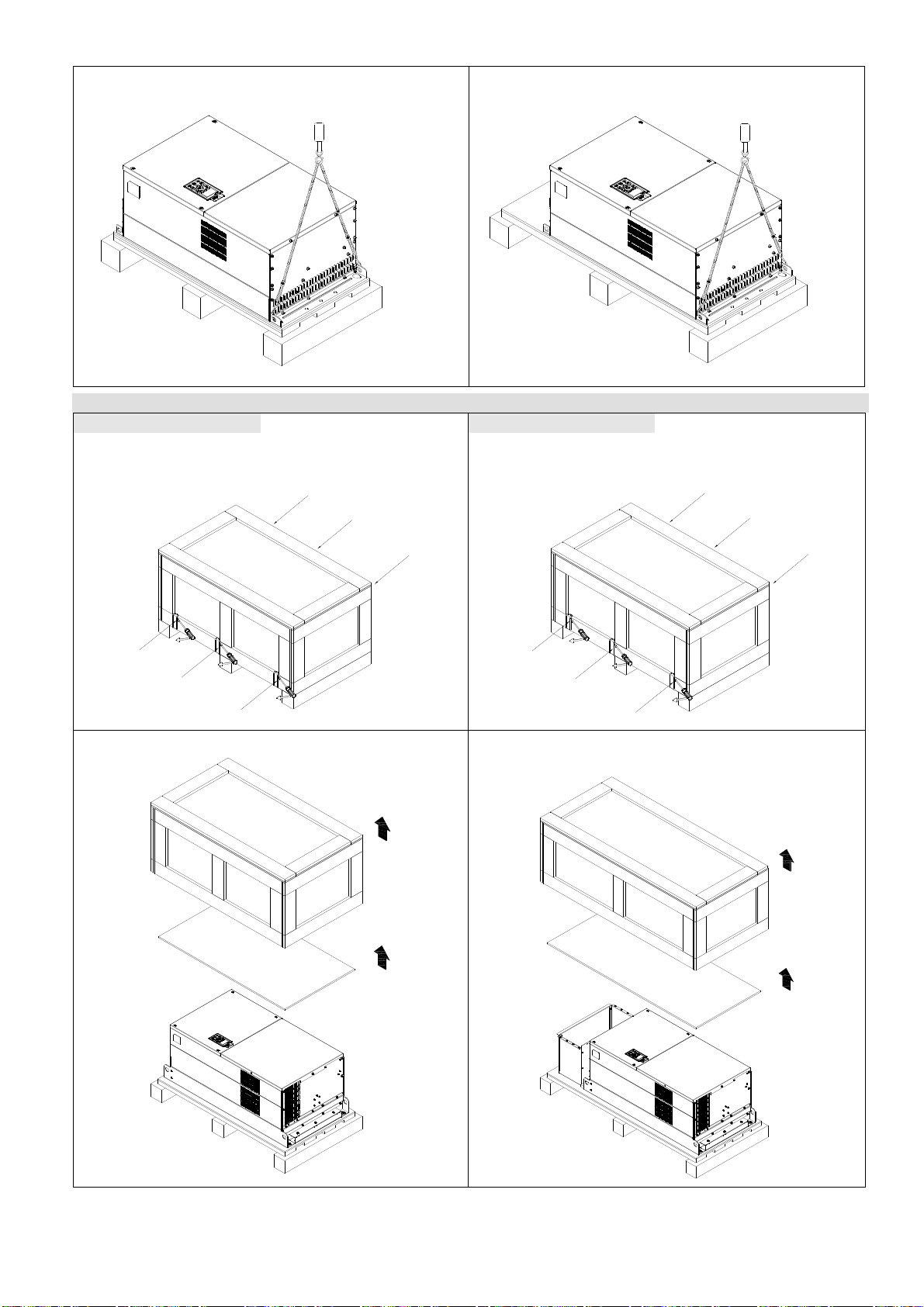

Frame D

Crate 1 (VFDXXXCXXA) Crate 2 (VFDXXXCXXE)

Loosen the 12 cover screws to open the crate.

Loosen all of the screws on the 4 iron plates at the

four bottom corners of the crate. 4 screws on each

of the iron plate.

Remove the EPEs and manual.

Loosen the 8 screws that fastened on the pallet,

remove the wooden plate.

Remove the crate cover, EPEs, rubber and

manual.

3-1

Chapter 3 UnpackingC2000 Series

Lift the drive by hooking the lifting hole. It is now

ready for installation.

Loosen the 10 screws on the pallet, remove the

wooden plate.

Lift the drive by hooking the lifting hole. It is now

ready for installation.

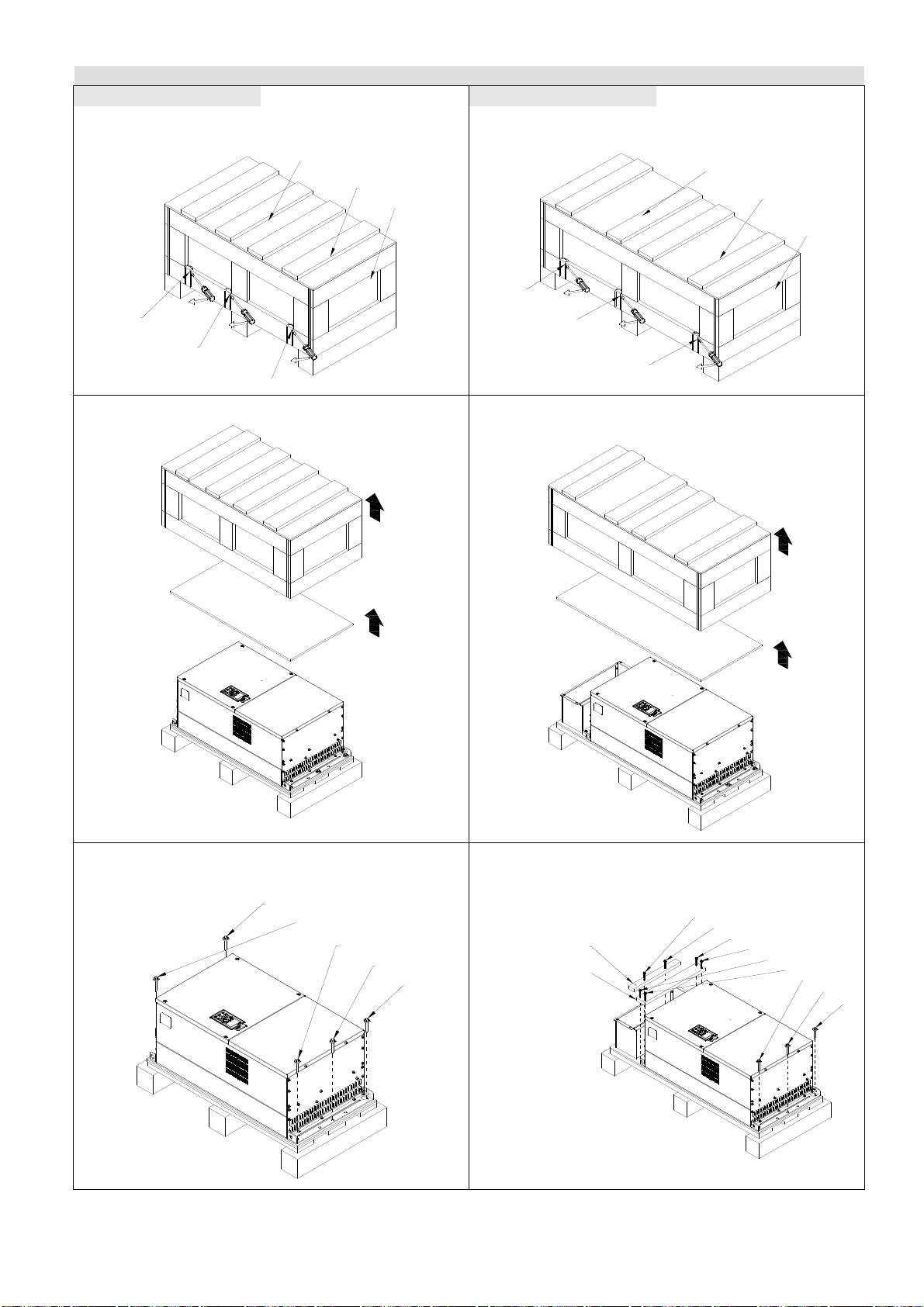

Frame E

Crate 1 (VFDXXXCXXA) Crate 2 (VFDXXXCXXE)

Loosen the 4 screws on the iron plates. There are

4 iron plates and in total of 16 screws.

Loosen the 4 screws on the iron plates. There are

4 iron plates and in total of 16 screws.

3-2

Chapter 3 UnpackingC2000 Series

Remove the crate cover, EPEs and manual.

Remove the crate cover, EPEs, rubbers and

manual.

Loosen the 8 screws on the pallet as shown in the

following figure.

Lift the drive by hooking the lifting hole. It is now

ready for installation.

Loosen the 10 screws on the pallet and remove the

wooden plate.

Lift the drive by hooking the lifting hole. It is now

ready for installation.

3-3

Chapter 3 UnpackingC2000 Series

Frame F

Crate 1 (VFDXXXCXXA) Crate 2 (VFDXXXCXXE)

Remove the 6 clips on the side of the crate with a

flat-head screwdriver. (As shown in figure below.)

Remove the 6 clips on the side of the crate with a

flat-head screwdriver. (As shown in figure below.)

6

5

4

1

2

3

Remove the crate cover, EPEs and manual.

6

5

4

1

2

3

Remove the crate cover, EPEs, rubbers and

manual.

Loosen the 5 screws on the pallet

as shown in the following figure.

5

4

Loosen the 9 screws on the pallet and remove the

wooden plate.

9

8

3

2

wood plate2

wood plate1

1

7

6

5

4

3

2

1

3-4

6

6

Chapter 3 UnpackingC2000 Series

Lift the drive by hooking the lifting hole. It is now

ready for installation

.

Lift the drive by hooking the lifting hole. It is now

ready for installation.

Frame G

Crate 1 (VFDXXXCXXA) Crate 2 (VFDXXXCXXE)

Remove the 6 clips on the side of the crate with a

flathead screwdriver. (As shown in figure below.)

4

5

Remove the 6 clips on the side of the crate with a

flathead screwdriver. (As shown in figure below.)

4

5

1

2

3

Remove the crate cover, EPEs and manual.

1

2

3

Remove the crate cover, EPEs, rubber and manual.

3-5

Chapter 3 UnpackingC2000 Series

Loosen the 5 screws as shown in following figure:

3

4

5

1

2

Lift the drive by hooking the lifting hole. It is now

ready for installation.

Loosen the 9 screws and remove the wooden plate.

3

4

11

5

6

7

8

9

12

wood plate5

wood plate4

10

wood plate1

wood plate2

wood plate3

2

Lift the drive by hooking the lifting hole. It is now

ready for installation.

1

3-6

Chapter 3 UnpackingC2000 Series

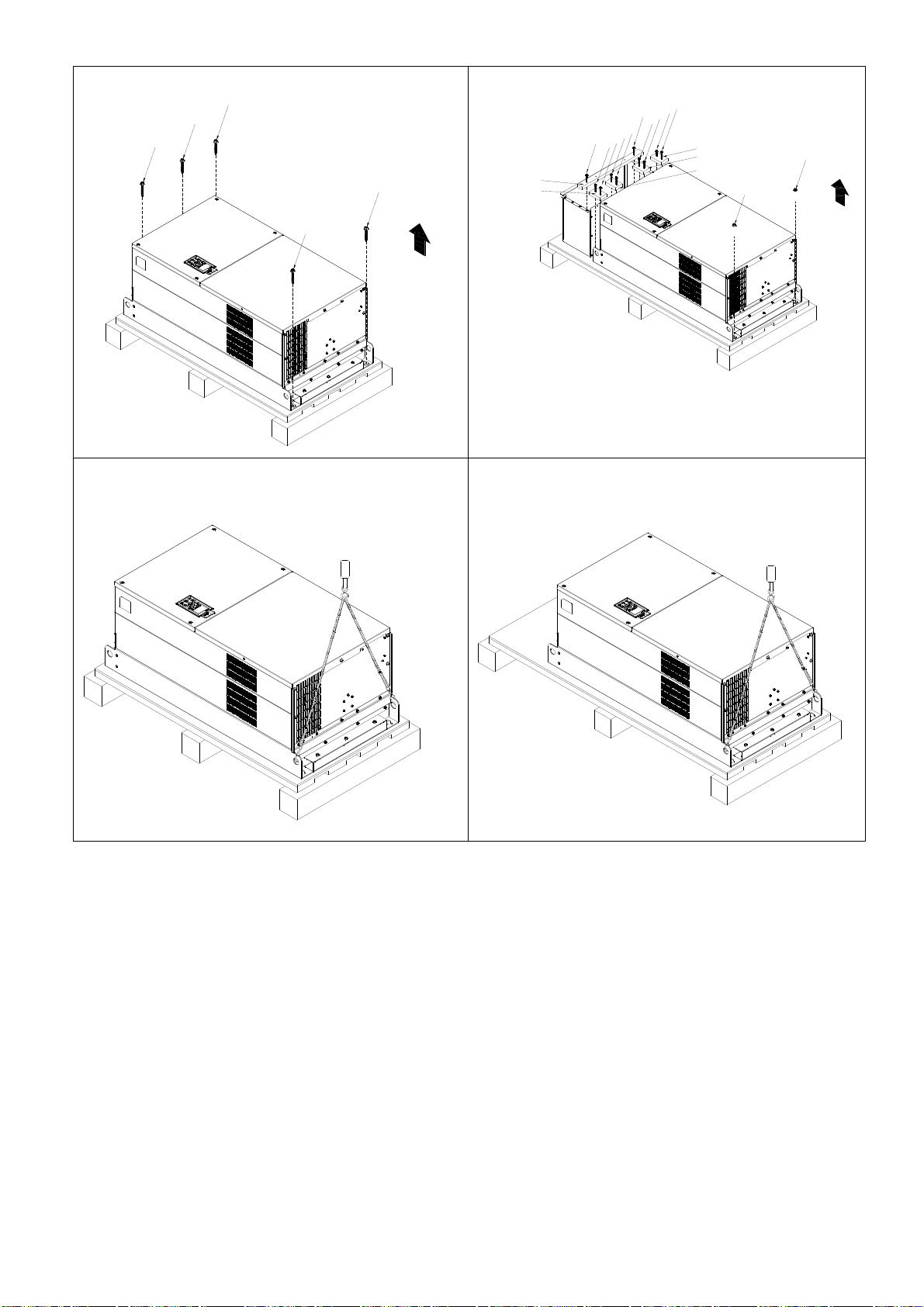

Frame H

Crate 1 (VFDXXXCXXA) Crate 2 (VFDXXXCXXE-1)

Remove the 8 clips on the side of the crate with a

flathead screwdriver. (As shown in figure below.)

Remove the 8 clips on the side of the crate with a

flathead screwdriver. (As shown in figure below.)

Remove the crate cover, EPEs and manual.

Loosen the 6 screws on the top then remove 6

metal washers and 6 plastic washers as shown in

figure below.

Remove the crate cover, EPEs, rubbers and

manual.

Loosen the 6 screws on the top then remove 6

metal washers and 6 plastic washers as shown in

figure below.

3-7

Chapter 3 UnpackingC2000 Series

Lift the drive by hooking the lifting hole. It is now

ready for installation.

Loosen 6 of the M6 screws on the side and remove

the 2 plates, as shown in below. The removed

screws and plates can be used to secure the AC

motor drive from the external.

Secure the drive from the external. (Skip to the

next step if it is not necessary in your case.)

Loosen 8 of M8 screws on the both sides and place

the 2 plates that were removed from the last step.

Fix the plates to AC motor drive by fasten 8 of the

M8 screws. (As shown in below)

Torque: 150~180kg-cm (130.20~156.24lb-in.)

Lift the drive by hooking the lifting hole. It is now

ready for installation.

3-8

Chapter 3 UnpackingC2000 Series

Frame H

Crate 3 (VFDXXXCXXE)

Use flathead screwdriver to remove the clips on the side of the crate, 8 clips in total.

Remove the crate cover, EPEs, rubber and manual.

Loosen the 6 screws on the cover, remove 6 metal washers and 6 plastic washers as shown in below:

3-9

Chapter 3 UnpackingC2000 Series

Loosen 6 of the M6 screws on the side and removes the 2 plates, as shown in following figure. The

removed screws and plates can be used to secure AC motor drive from the external.

Secure the drive from the internal.

Loosen 18 of the M6 screws and remove the top

cover as shown in figure 2. Mount the cover (figure

1) back to the drive by fasten the M6 screws to the

two sides of the drive, as shown in figure 2.

Torque: 35~45kg-cm (30.38~39.06lb-in.)

Secure the drive from the external.

Loosen 8 of the M8 screws on the both sides and

place the 2 plates that were removed from the last

step. Fix the plates to rive by fasten 8 of the M8

screws. (As shown in figure below).

Torque: 150~180kg-cm (130.20~156.24lb-in.)

Figure 1

Top cover (Use M12 screws)

Figure 2

3-10

Chapter 3 UnpackingC2000 Series

Fasten 6 of the M6 screws that were removed from last step back to the AC motor drive. As shown in

figure below:

Lift the drive by hooking the lifting hole. It is now ready for installation.

Frame H Secure the drive

(VFDXXXCXXA)

Screw: M12*6

Torque: 340-420kg-cm [295.1-364.6lb-in.]

3-1 1

Chapter 3 UnpackingC2000 Series

(VFDXXXCXXE) & (VFDXXXCXXE-1)

Secure the drive from internal.

Screw: M12*8

Torque: 340-420kg-cm [295.1-364.6lb-in.]

Secure the drive from the external.

Screw: M12*8

Torque: 340-420kg-cm [295.1-364.6lb-in.]

3-12

The Lifting Hook

The arrows indicate the lifting holes, as in figure below: (Frame D~H).

Chapter 3 UnpackingC2000 Series

D

G

Figure 1

E

Figure 2

F

Figure 3

Figure 4

Figure 5

3-13

Chapter 3 UnpackingC2000 Series

Ensure the lifting hook properly goes through the

lifting hole, as shown in the following diagram.

(Applicable for Frame D~G)

(Applicable to Frame H)

Ensure the angle between the lifting holes and the

lifting device is within the specification, as shown

in the following diagram.

(Applicable to Frame H)

3-14

Weight

Chapter 3 UnpackingC2000 Series

VFDXXXXCXXA VFDXXXXCXXE

VFDXXXXCXXA VFDXXXXCXXE

VFDXXXXCXXA

37.6 kg(82.9 Ibs.)

D

63.6 kg(140.2 Ibs.)

E

85kg(187.2 Ibs.)

VFDXXXXCXXE

D

E

88kg(193.8 Ibs.)

40 kg(88.2 Ibs.)

66 kg(145.5 Ibs.)

VFDXXXXCXXA

130kg(286.5 Ibs.) 138kg(303.9 lbs)

VFDXXXXCXXE

H1: VFD2800C43A; VFD3150C43A; VFD3550C43A; 235kg (518.1lbs)

H2: VFD2800C43E-1; VFD3150C43E-1; VFD3550C43E-1; 257kg (566.6lbs)

3-15

Chapter 3 UnpackingC2000 Series

H3: VFD2800C43E; VFD3150C43E; VFD3550C43E; 263kg (579.8lbs)

3-16

Chapter 4 WiringC2000 Series

Chapter 4 Wiring

Wiring Diagram for Frame A~C

* It provides 3-phase power

Fuse/NFB(No Fuse Breaker)

R(L1)

S(L2)

T(L3)

Recommended Ci rcuit

when power supply

is turned OFF by a

fault output.

If the fa ult occurs, the

contact will be ON to turn off the

power and prot ect the power system.

OFF

Factory setting:

NPN (SINK) Mode

Please refe r to

following figure

for wiring of NPN

mode and PNP

mode.

Factory

setting

FWD/STOP

REV/STOP

Multi-step 1

Multi-step 2

Multi-step 3

Multi-step 4

N/A

N/A

N/A

N/A

NOTE

* MI8 can input pulses 100kHz

* Don't apply t he mains voltage directly

to above terminals.

Main circuit

(power) terminals

Control terminals

Digital Signal Common

power removal safety function

for EN954-1 and IEC/EN61508

Digital Signal Common

3

5K

2

1

Analog Signal Common

Modbus RS-485

CAN BUS

Pin 1~2, 7, 8: reserved

Pin 3, 6:GND

Pin 4:SGPin 5:SG+

MC

ON

MC

+10V/20mA

0~1 0V/ 0~2 0mA

4~2 0mA/0~10V

-10~+10V

-10V/20mA

SA

SG+

SG-

Jumper

-

R(L1)

S(L2)

T(L3)

RB

RC

+24V

COM

FWD

REV

MI1

MI2

MI3

MI4

MI5

MI6

MI7

MI8

DCM

S1

SCM

+10V

AVI

ACI

AUI

ACM

-10V

81

DC choke

(optional)

+2

81

Brake resistor

(optional)

+1

B1

Option

Slot 1

Option

Slot 2

Option

Slot 3

B2

U(T1)

V(T2)

W(T3)

RA1

RB1

RC1

RA2

RB2

RC2

AFM1

ACM

AFM2

Motor

IM

3~

Multi-function output terminals

250V ac/5A (N.O. )

250Vac/3A (N.C.)

250Vac/2A (N.O.)

Estimate at COS (0.4)

250Vac/1.2A (N.C.)

Estimate at COS (0.4)

30V dc/5A (N.O.)

30V dc/3A (N.C.)

Multi-function output

Multi-function output

DFM

frequency terminals

frequency terminals

30V30mA 100kHz

DCM

Multi-function output

MO1

frequency terminals

48V/50mA

Mult i-function output

MO2

frequency termina ls

48V/50mA

Multi-function

MCM

Photocoulper Output

Analog Multi-f unction

Outpu t Terminal

0~10VDC/-10~+10V

Analog Signal common

Analog Multi-f unct ion

Outpu t Te rminal

0~10VDC/4~20mA

IO

exte nsi on card

PG

exte nsi on card

IO &RELAY

exte nsi on card

Shielded leads & Cable

4-1

Chapter 4 WiringC2000 Series

Wiring diagram for frame D and above

* It provides 3-phase power

Please refer to Figure 3

Fuse/NFB(No Fuse Breaker)

R(L1)

S(L2)

T(L3)

Recommen ded Circuit

when power supply

is turned OFF by a

fault output.

If the fault occurs, the

contact will be ON to turn off the

power and protect the power s ystem.

Factory setting: NPN (SINK) Mode

Please refer to

following figure

for wiring of NPN

mode and PNP

mode.

* Do not apply the mains voltage directly

to above terminals.

Extern al Power I nput

Factory

setting

* Mi8 can input pulses 100kHz

OFF

FWD/STOP

REV/STOP

E.F.

JOG

Multi-step 1

Multi-step 2

Multi-step 3

Multi-step 4

RESET

Accel/Decel prohibit

Digital Signal Common

3

5K

1

Analog Signal Common

SA

MC

ON

MC

+10V 20mA

0 t o 1 0 V

2

4~2 0mA

-10~+10V

Power supply

-10V 20mA

R(L1)

S(L2)

T(L3)

RB

RC

24V

COM

FWD

REV

MI1

MI2

MI3

MI4

MI5

MI6

MI7

MI8

DCM

+10V

AVI

ACI

AUI

ACM

-10V

+/DC+

-/DC-

U(T1)

V(T2)

W(T3)

RA1

RB1

RC1

RA2

RB2

RC2

DFM

DCM

MO1

MO2

MCM

AFM1

ACM

AFM2

Motor

IM

3~

Multiple-function output

termi nals

250VAC/5A (N.O.)

250VAC/3A (N.O.)

250VAC/2A (N.O.)

Estimate at COS(0.4)

250VAC/1.2A (N.C.)

Estimate at COS(0.4)

30VAC/5A (N.O.)

30VAC/3A (N.C.)

Multi- func tion frequency

output terminals

30V30mA 100kHz

Multi- func tion frequency

output terminals

48V50 mA

Multi- func tion frequency

output terminals

48V50 mA

Multi- func tion

Photocoulper Output

Analog Multi-function

Output T erminal

0~10VD C/-10~+10V

Analog Signal common

Analog Multi-function

Output T ermi na

0~10VD C/4~2mA

Main circuit

(power) terminals

Control circuit terminals

Shielded leads & Cable

Modbus RS-485

CAN BUS

Pin 1~2,7,8:Reserved

Pin 3,6:GND

Pin 4:SGPin 5: SG+

IO& RELAY

extension card

SG+

SG-

81

Option

Slot 3

81

4-2

Option

Slot 1

Option

Slot 2

S1

SCM

power r emoval safety function

for EN954-1 and I EC/EN61508

Digital Signal Comm on

Communication

Extension card

PG

extension card

H

Figure 1

Chapter 4 WiringC2000 Series

Input power terminals for frame G and

Provides 3-phase power

Fus e or NFB (non-fuse breaker)

R

R/L11

R

R/L21

S

S/L12

S

S/L22

T

Figure 2

SINK(NPN)/SOURCE(PNP)Mode

1

Sink Mode Source Mode

with internal power (+24VDC)

MI1

T/L13

T/L23

T

2

with internal power (+24VDC)

It pr ovides 12-pulse power

Y

MI1

R/L11

S/L12

T/L13

R/L21

S/L22

T/L23

MI2

~

MI8

+24V

COM

DCM

3

Sink Mode Source Mode

with external power

MI1

MI2

internal circuit

4

with external power

~

MI8

+24V

COM

DCM

COM

+24V

MI1

MI2

MI8

+24V

COM

MI2

~

MI8

internal circuit

~

external power +24V

DCM

internal c ircuit

DCM

external power +24V

4-3

internal circuit

Chapter 4 WiringC2000 Series

Figure 3

Frame E~H, remove terminal r and terminal s before using DC-Link. (As circled in dotted line, uninstall the

gray section and properly store cable r and cable s. Cable r and cable s are not available in optional

accessories, do not dispose them.)

rs

4-4

Figure 1

Chapter 5 Main Circuit TerminalsC2000 Series

Chapter 5 Main Circuit Terminals

For frame A~C

* Provide 3-phase input power

Fuse/NFB (No Fuse Breaker)

R(L1)

S(L2)

T( L3)

Figure 2

For frame A~C

* Provide 3-phase input power

Jumper

-

R(L1)

S( L2)

T( L3)

Jum per

+2

DC choke

(optional)

+1

Brake resistor

(optio nal)

B1

B2

U(T1)

V(T2)

W(T3)

Brake resistor

(optional)

Mo tor

IM

3~

Fuse/NFB(No Fuse Breaker)

R(L1)

S( L2)

T( L3)

-

R(L1)

S( L2)

T( L3)

+2

+1

B1

U(T1)

V(T2)

W(T3)

B2

Mo to r

IM

3~

5-1

H

Chapter 5 Main Circuit TerminalsC2000 Series

Figure 3

Input power terminals for frame G and

Provides 3-phase power

Fus e or NFB (non-fuse breaker)

R

R/L11

R

It pr ovides 12-pulse power

R/L21

S

S/L12

S

S/L22

T

Terminals Descriptions

R/L1, S/L2, T/L3 AC line input terminals 3-phase

U/T1, V/T2, W/T3 AC drive output terminals for connecting 3-phase induction motor

Applicable to frame A~C

+1, +2

Connections for DC reactor to improve the power factor. It needs to remove the

T/L13

T/L23

T

Y

R/L11

S/L12

T/L13

R/L21

S/L22

T/L23

jumper for installation.

Connections for brake unit (VFDB series)

+1/DC+, -/DC-

B1, B2 Connections for brake resistor (optional)

(for 230V models: 22kW, built≦ -in brake unit)

(for 460V models: 30kW, built≦ -in brake unit)

Common DC Bus

Earth connection, please comply with local regulations.

Main power terminals

Do not connect 3-phase model to one-phase power. It is unnecessary to

consider phase-sequence for these terminals R/L1, S/L2 and T/L3.

It is recommended to add a magnetic contactor (MC) in the power input

wiring to cut off power quickly and reduce malfunction when activating

the protection function of the AC motor drive. Both ends of the MC

should have an R-C surge absorber.

Please make sure to fasten the screw of the main circuit terminals to

prevent sparks which is made by the loose screws due to vibration.

Please use voltage and current within the specification.

When using a general GFCI (Ground Fault Circuit Interrupter), select a

current sensor with sensitivity of 200mA or above and not less than

0.1-second operation time to avoid nuisance tripping.

Please use the shield wire or tube for the power wiring and ground the

two ends of the shield wire or tube.

Do NOT run/stop AC motor drives by turning the power ON/OFF.

5-2

Chapter 5 Main Circuit TerminalsC2000 Series

Run/stop AC motor drives by RUN/STOP command via control terminals

or keypad. If you still need to run/stop AC motor drives by turning power

ON/OFF, it is recommended to do so only ONCE per hour.

Output terminals for main circuit

When it needs to install the filter at the output side of terminals U/T1,

V/T2, W/T3 on the AC motor drive. Please use inductance filter. Do not

use phase-compensation capacitors or L-C (Inductance-Capacitance) or

R-C (Resistance-Capacitance), unless approved by Delta.

DO NOT connect phase-compensation capacitors or surge absorbers at

the output terminals of AC motor drives.

Use well-insulated motor, suitable for inverter operation.

Terminals for connecting DC reactor, external brake resistor, external

brake resistor and DC circuit

This is the terminals used to connect the DC reactor to improve the

power factor. For the factory setting, it connects the short-circuit object.

Please remove this short-circuit object before connecting to the DC

reactor.

DC reactor (optional)

+1

Connect a brake resistor or brake unit in applications with frequent

+2

deceleration ramps, short deceleration time, too low brake torque or

requiring increased brake torque.

B ra ke re si stor

Br ake re si stor

(optional )

B1

The external brake resistor should connect to the terminals (B1, B2) of

B2

(opti o nal )

BR

VFDB

+

Brake unit

(option al)

-

AC motor drives.

For those models without built-in brake resistor, please connect external

brake unit and brake resistor (both of them are optional) to increase

brake torque.

When the terminals +1, +2 and - are not used, please leave the terminals

open.

DO NOT connect [+1, -], [+2, -], [+1/DC+, -/DC-] or brake resistor directly

to prevent drive damage.

5-3

Chapter 5 Main Circuit TerminalsC2000 Series

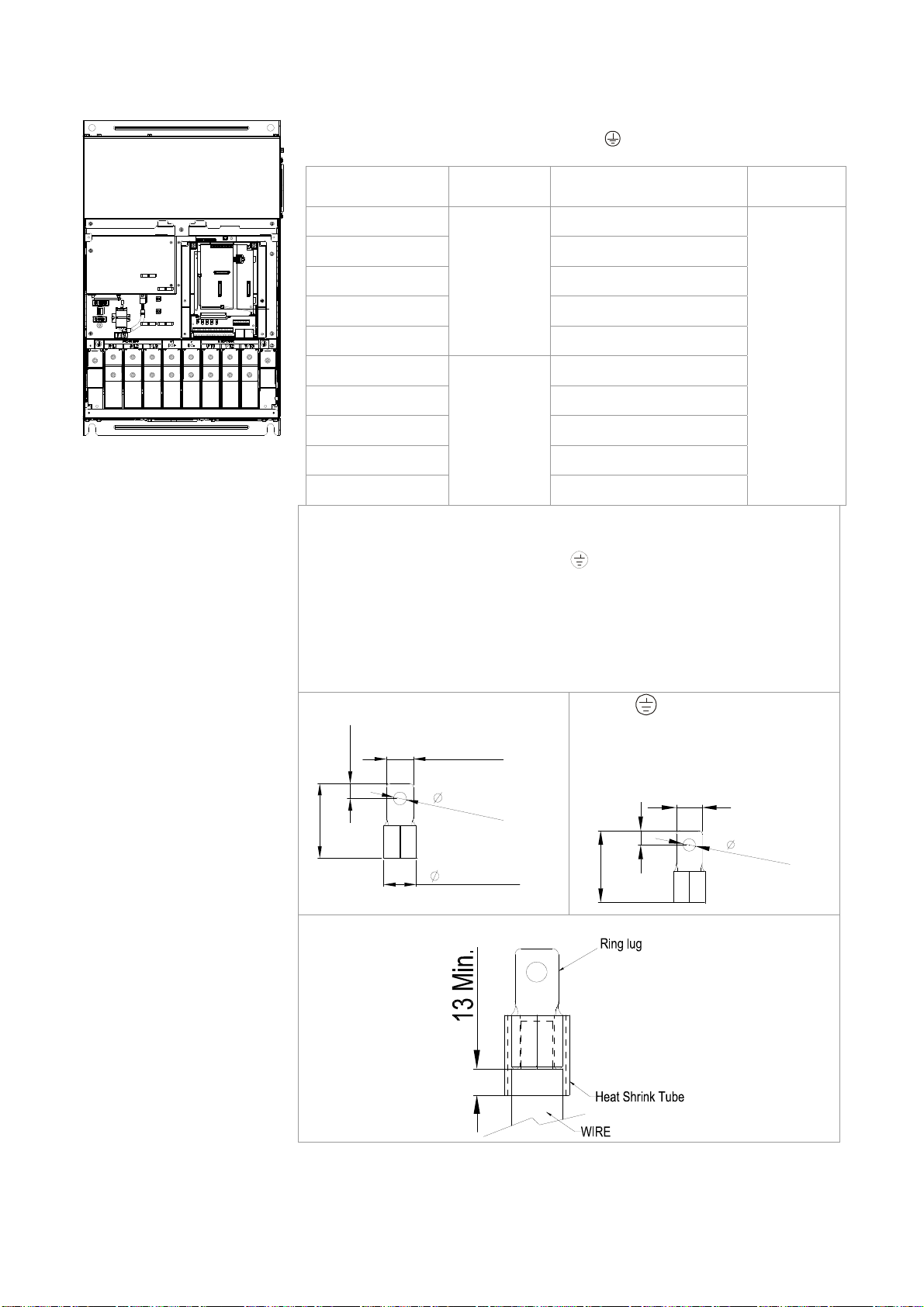

Main Circuit Terminals

Frame A

Main circuit terminals:

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3, , B1, B2, +1, +2, -

Models

Max. Wire

Gauge

Min. Wire Gauge

VFD007C23A 14 AWG (2.1mm2)

VFD015C23A 12 AWG (3.3mm2)

VFD022C23A 10 AWG (5.3mm2)

VFD037C23A 8 AWG (8.4mm2)

VFD007C43A 14 AWG (2.1mm2)

VFD007C43E 14 AWG (2.1mm2)

VFD015C43A 14 AWG (2.1mm2)

VFD015C43E 14 AWG (2.1mm2)

VFD022C43A 14 AWG (2.1mm2)

8 AWG

(8.4mm

2

)

VFD022C43E 14 AWG (2.1mm2)

VFD037C43A 10 AWG (5.3mm2)

VFD037C43E 10 AWG (5.3mm2)

VFD040C43A 10 AWG (5.3mm2)

VFD040C43E 10 AWG (5.3mm2)

VFD055C43A 10 AWG (5.3mm2)

VFD055C43E

10 AWG (5.3mm

2

)

UL installations must use 600V, 75℃ or 90℃ wire. Use copper wire

only.

Torque

(±10%)

M4

20kg-cm

(17.4 lb-in.)

(1.962Nm)

Frame B

Main circuit terminals:

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3, , B1, B2, +1, +2, -

Models

Max. Wire

Gauge

Min. Wire Gauge

VFD055C23A 8 AWG (8.4mm2)

VFD075C23A 6 AWG (13.3mm2)

VFD110C23A 4 AWG (21.2mm2)

VFD075C43A 8 AWG (8.4mm2)

VFD075C43E 10 AWG (5.3mm2)

VFD110C43A 8 AWG (8.4mm2)

4 AWG

(21.2mm

2

)

VFD110C43E 8 AWG (8.4mm2)

VFD150C43A 6 AWG (13.3mm2)

VFD150C43E

8 AWG (8.4mm

2

)

UL installations must use 600V, 75℃ or 90℃ wire. Use copper wire

only.

NOTE

Terminal D+ [+2 & +1]: T orque: 45 kg-cm [39.0lb-in.] (4.415Nm) (±10%)

VFD110C23A must use 600V, 90℃ wire when surrounding temperature

exceeds 45℃.

Torque

(±10%)

M5

35kg-cm

(30.4 lb-in.)

(3.434Nm)

5-4

Chapter 5 Main Circuit TerminalsC2000 Series

Frame C

Frame D

Main circuit terminals:

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3, , B1, B2, +1, +2, -

Models

Max. Wire

Gauge

Min. Wire Gauge

VFD150C23A 1 AWG (42.4mm2)

VFD185C23A 1/0 AWG (53.5mm2)

VFD220C23A 1/0 AWG (53.5mm2)

VFD185C43A 4 AWG (21.2mm2)

VFD185C43E 6 AWG (13.3mm2)

VFD220C43A 4 AWG (21.2mm2)

1/0 AWG

(53.5mm

2

)

VFD220C43E 4 AWG (21.2mm2)

VFD300C43A 2 AWG (33.6mm2)

VFD300C43E

3 AWG (26.7mm

2

)

UL installations must use 600V, 75℃ or 90℃ wire. Use copper wire

only.

NOTE

Terminal D+ [+2 & +1]: T orque: 90 kg-cm [78.2lb-in.] (8.83Nm) (±10%)

VFD220C23A must use 600V, 90℃ wire when surrounding temperature

exceeds 45℃.

Torque

(±10%)

M8

80kg-cm

(69.4 lb-in.)

(7.85Nm)

Main circuit terminals:

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3,

Models

Max. Wire

Gauge

, +1/DC+, -/DC-

Min. Wire Gauge

Torque

(±10%)

VFD300C23A 4/0 AWG (107mm2)

VFD370C23A 250MCM (127mm2)

VFD370C43A 1/0 AWG (53.5mm2)

VFD450C43A 2/0 AWG (67.4mm2)

VFD550C43A 3/0 AWG (85mm2)

VFD750C43A

VFD300C23E 3/0 AWG (85mm2)

VFD370C23E 4/0 AWG (107mm2)

VFD370C43E 1/0 AWG (53.5mm2)

VFD450C43E 1/0 AWG (53.5mm2)

300MCM

(152mm

4/0 AWG.

(107mm

2

)

300MCM (152mm

2

)

2

)

M8

200kg-cm

(173 lb-in.)

(19.62Nm)

VFD550C43E 2/0 AWG (67.4mm2)

VFD750C43E

4/0 AWG (107mm

2

)

1. UL installations must use 600V, 75oC or 90 oC wires. Use copper

wire only.

2. Figure 1 shows the terminal specification.

3. Figure 2 shows the specification of insulated heat shrink tubing

that comply with UL (600C, YDPU2).

Figure 1

Figure 2

5-5

Chapter 5 Main Circuit TerminalsC2000 Series

Frame E

Main circuit terminals:

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3, , +1/DC+, -/DC-

Models

Max. Wire

Gauge

Min. Wire Gauge

Torque

(±10%)

VFD450C23A 1/0AWG*2 (53.5mm2*2)

VFD550C23A 3/0AWG*2 (85mm2*2)

VFD750C23A 4/0 AWG*2 (107mm2*2)

Incorrect installation may

result in damage to option

or inverter.Pleas e r e fer to

operation manual for

installation instructions.

警告

錯誤的安裝將會導

致變頻器及選配品

損壞,安裝前請務

必參閱使用手冊後

才進行裝配。

VFD900C43A 1/0AWG*2 (53.5mm2*2)

VFD1100C43A

VFD450C23E 1/0AWG*2 (53.5mm2*2)

300MCM*2

(152mm

2

*2)

3/0AWG*2 (85mm

2

*2)

M8

200kg-cm

(173 lb-in.)

(19.62Nm)

VFD550C23E 2/0AWG*2 (67.4mm2*2)

VFD750C23E 3/0AWG*2 (85mm2*2)

4/0 AWG*2

(107mm

2

*2)

VFD900C43E 1/0AWG*2 (53.5mm2*2)

VFD1100C43E

2/0AWG*2 (67.4mm

2

*2)

1. UL installations must use 600V, 75oC or 90 oC wires. Use copper

wire only.

2. Specification of grounding wire

: 300MCM [152 mm2]

Torque: M8 180kg-cm (156 lb-in.) (17.64Nm) (±10%), as shown in

Figure 2.

3. Figure 1 shows the specification for ring lug.

4. Figure 3 shows the specification of insulated heat shrink tubing

that comply with UL (600C, YDPU2).

Figure 1

-4

+0

16

31MAX.

8

.

2

M

I

N

Figure 2

.

E

17.0MAX.

28.0MAX.

70MAX.

8

.

2

M

I

N

.

26.5MAX.

65.0MAX.

Figure 3

5-6

Chapter 5 Main Circuit TerminalsC2000 Series

Frame F

Main circuit terminals:

R/L1, S/L2, T/L3, U/T1, V/T2, W/T3, +1/DC+, -/DC-

Models

VFD900C23A 300MCM*2 (152mm2*2)

VFD1320C43A 4/0 AWG*2 (107mm2*2)

VFD1600C43A

VFD900C23E 4/0 AWG*2 (107mm2*2)

VFD1320C43E 3/0AWG*2 (85mm2*2)

VFD1600C43E

1. VFD900C23A/E installations must use 90 wire. ℃

2. For other model, UL installations must use 600V, 75 or 90 ℃℃

wire. Use copper wire only.

3. Specification of grounding wire

Torque: M8 200kg-cm (173 lb-in.) (19.62Nm) (±10%)

5. Figure 1 shows the specification for ring lug.

4. Figure 2 shows the specification of insulated heat shrink tubing

that comply with UL (600C, YDPU2).

Figure 1

Max. Wire

Gauge

300MCM*2

(152mm

4/0 AWG*2

(107mm

2

2

*2)

*2)

Min. Wire Gauge

300MCM*2 (152mm

4/0 AWG*2 (107mm

:300MCM*2 [152 mm2*2]

Figure 2

2

*2)

2

)

200kg-cm

(173 lb-in.)

(19.62Nm)

Torque

(±10%)

M8

-4

+0

16

31MAX.

8

.

2

M

I

N

.

70MAX.

26.5MAX.

5-7

Chapter 5 Main Circuit TerminalsC2000 Series

Frame G

Main circuit terminals:

R/L11, R/L12, S/L21, S/L22, T/L31, T/L32

Models

Max. Wire

Gauge

Min. Wire Gauge

Torque

(±10%)

VFD1850C43A 2/0AWG*4 (67.4mm2*4)

M8

VFD2200C43A 3/0AWG*4 (85mm2*4)

VFD1850C43E 1/0AWG*4 (53.5mm2*4)

VFD2200C43E

300MCM*4

(152mm

2

*4)

2/0AWG*4 (67.4mm

2

*4)

200kg-cm

(173 lb-in.)

(19.62Nm)

Main circuit terminals:

U/T1, V/T2, W/T3, +1/DC+, -/DC-

Models

Max. Wire

Gauge

Min. Wire Gauge

VFD1850C43A 400MCM*2 (203mm2*2)

VFD2200C43A 500MCM*2 (253mm2*2)

VFD1850C43E 300MCM*2 (152mm2*2)

VFD2200C43E

500MCM*2

(253mm

2

*2)

400MCM*2 (203mm

2

*2)

1. UL installations must use 600V, 75 or 90℃℃ wire. Use copper

wire only.

2. Use 600V, 90 wire ℃ for VFD2200C43A when the surrounding

temperature is over 45℃.

3. Figure 1 and Figure 2 show the specification for using ring lug.

Torque

(±10%)

M12

408kg-cm

(354lb-in.)

( 40Nm)

4. Specification for grounding wire

Torque: M8 180kg-cm (156 lb-in.) (17.64Nm)

: 300MCM*4 [152 mm2*2]

(±10%), as shown

in Figure 1

5. Figure 3 and Figure 4 shows the specification of insulated heat

shrink tubing that comply with UL (600C, YDPU2).

Figure 1

R/L11, R/L12, S/L21, S/L22,

T/L31, T/L32,

-4

+0

16

31MAX.

Figure2

U/T1, V/T2, W/T3, +1/DC+, -/DC-

42.0(MAX.)

21.0(MAX.)

54MAX.

8

.

2

M

I

Figure 3

N

.

26.5MAX.

2

1

42.0(MAX.)

Figure 4

)

.

N

I

M

(

2

.

70.0(MAX.)

5-8

Chapter 5 Main Circuit TerminalsC2000 Series

Frame H

Main circuit terminals:

R/11,R12,S/21,S/22,T/31,T/32,

U/T1,V/T2, W/T3, +1/DC+,

-/DC-

Models

Max. Wire

Gauge

Min. Wire Gauge

VFD2800C43A 4/0 AWG*4 (107mm2*4)

VFD3150C43A 300MCM*4 (152mm2*4)

VFD3550C43A 300MCM*4 (152mm2*4)

VFD2800C43E-1 3/0 AWG*4 (85mm2*4)

VFD3150C43E-1 4/0 A WG*4 (107mm2*4)

300MCM*4

(152mm

2

*4)

VFD3550C43E-1 250MCM*4 (127mm2*4)

VFD2800C43E 3/0 A WG*4 (85mm2*4)

VFD3150C43E 4/0 AWG*4 (107mm2*4)

VFD3550C43E

250MCM*4 (127mm

2

*4)

1. UL installations must use 600V, 75℃ or 90℃ wire. Use copper

wire only.

2. Figure 1 shows the specification for using the ring lug.

3. Specification of grounding wire

: 300MCM*4 [152 mm2*4],

Torque: M8 180kg-cm (156 lb-in.) (17.64Nm) (±10%), as

shown in figure 1.

4. Figure 2 shows the specification of heat shrink tubing that

comply with UL (600C, YDPU2).

Torque

(±10%)

M8

200kg-cm

(173 lb-in.)

(19.62Nm)

Figure 1

Figure 2

5-9

Chapter 6 Control TerminalsC2000 Series

Chapter 6 Control Terminals

For multi-function input and output terminal, remove the top cover before wiring

The appearances of following figures are for reference only.

The figures shown in the diagram below are for reference only.

Remove the cover for wiring. Frame A~H

Frame A&B

Loosen the screws and press the tabs on both sides

to remove the cover.

Screw torque: 12~15Kg-cm [10.4~13lb-in.]

Frame C&D

Screw torque: 12~15Kg-cm [10.4~13lb-in.]

Frame E

Screw torque: 12~15Kg-cm [10.4~13lb-in.] Slightly lift the cover then pull outward for removal.

6-1

Chapter 6 Control TerminalsC2000 Series

Frame F

Screw torque: 12~15Kg-cm [10.4~13lb-in.] Slightly lift the cover then pull outward for removal.

Frame G

Screw torque: 12~15Kg-cm [10.4~13lb-in.] Slightly lift the cover then pull outward for removal.

Frame H Screw torque: 14~16Kg-cm [12.15~13.89lb-in.] Slightly lift the cover then pull outward for

removal.

6-2

k

Chapter 6 Control TerminalsC2000 Series

AFM1

AFM1

AFM2

0-10V

-10-10V

+10V

-10V

AFM2

AVI

AUI

0-10V

0-20mA

ACI

ACM

MO1

0-10V

AVI

0-20mA

MO2

S1

SCM

0-20mA Open

ACI

MCM MI7

DFM

485

0-10V

MI1+24V

FWD

COM

MI4

REV

DCM

120

MI2

MI3

MI5

MI8MI6

RA2RC2 RB2 RB1RC1 RA1

SG-SG+

Removable Terminal Bloc

Control Terminal Specifications

Wire Gauge: 26~16AWG(0.1281-1.318mm2),

Torque: (A) 5kg-cm [4.31Ib-in.] (0.49Nm) (As shown in figure above)

(B) 8kg-cm [6.94Ib-in.] (0.78Nm) (As shown in figure above)

Wiring precautions:

Reserves 5mm and properly install the wire into the terminal; fasten the installation by a

slotted screwdriver. If the wire is stripped, sort the wire before install into the terminal.

Flathead screwdriver: blade width 3.5mm, tip thickness 0.6mm

In the figure above, the factory setting for S1-SCM is short circuit. The factory setting for

+24V-COM is short circuit and SINK mode (NPN); please refer to Chapter 4 Wiring for more

detail.

Terminals Terminal Function Factory Setting (NPN mode)

Digital control signal common

+24V5% 200mA

+24V

(Source)

Digital control signal common

Common for multi-function input terminals

COM

(Sink)

FWD-DCM:

FWD Forward-Stop command

ON forward running

OFF deceleration to stop

REV-DCM:

REV Reverse-Stop command

ON reverse running

OFF deceleration to stop

MI1

~

Multi-function input 1~8

MI8

Digital frequency meter

DFM

DFM

DCM

DCM Digital frequency signal common

Refer to parameters 02-01~02-08 to program the

multi-function inputs MI1~MI8.

ON: the activation current is 6.5mA 11Vdc≧

OFF: leakage current tolerance is 10μA 11Vdc ≦

Regard the pulse voltage as the output monitor

signal

Duty-cycle: 50%

Min. load impedance: 1kΩ/100pf

Max. current: 30mA

Max. voltage: 30Vdc

6-3

t

A

t

t

Chapter 6 Control TerminalsC2000 Series

Terminals Terminal Function

Multi-function Output 1

MO1

(photocoupler)

Factory Setting (NPN mode)

The AC motor drive releases various monitor

signals, such as drive in operation, frequency

attained and overload indication, via transistor (open

collector).

MO1

MO2

Multi-function Output 2

(photocoupler)

MCM Multi-function Output Common

RA1

RB1

RC1

RA2

RB2

RC2

+10V

-10V

Multi-function relay output 1

(N.O.) a

Multi-function relay output 1

(N.C.) b

Multi-function relay common

Multi-function relay output 2

(N.O.) a

Multi-function relay output 2

(N.C.) b

Multi-function relay common

Potentiometer power supply

Potentiometer power supply

Analog voltage input

MO2

MCM

Max 48Vdc 50mA

Resistive Load:

5A(N.O.)/3A(N.C.) 250VAC

5A(N.O.)/3A(N.C.) 30VDC

Inductive Load (COS 0.4):

2.0A(N.O.)/1.2A(N.C.) 250VAC

2.0A(N.O.)/1.2A(N.C.) 30VDC

It is used to output each monitor signal, such as

drive is in operation, frequency attained or overload

indication.

Analog frequency setting: +10Vdc 20mA

Analog frequency setting: -10Vdc 20mA

AVI

ACI

AUI

+10V

AVI circuit

AVI

ACM

internal circui

Analog current input

ACI

ACM

CI circui

internal circui

Auxiliary analog voltage input

+10

-10V

AUI

ACM

AUI circuit

~

internal circuit

Impedance: 20kΩ

Range: 4 ~ 20mA/0~10V =0~Max. Output

Frequency (Pr.01-00)

AVI switch, factory setting is 0~10V

Impedance: 250Ω

Range: 4 ~ 20mA/0~10V=0~Max. Output Frequency

(Pr.01-00)

ACI Switch, factory setting is 4~20mA

Impedance: 20kΩ

Range: -10~+10VDC=0~Max. Output

Frequency(Pr.01-00)

6-4

Chapter 6 Control TerminalsC2000 Series

Terminals

Terminal Function Factory Setting (NPN mode)

Impedance: 100kΩ (voltage output)

Output current: 20mA max

AFM1

Resolution: 0~10V corresponds to Max. operation

frequency

Range: 0~10V -10~+10V

AFM Switch, factory setting is 0~10V

Impedance: 100Ω (current output)

Output current: 20mA max

AFM2

Resolution: 0~10V corresponds to Max. operation

frequency

Range: 0~10V 4~20mA

AFM Switch, factory setting is 0~10V

ACM Analog Signal Common Common for analog terminals

S1

Power removal safety function for EN954-1 and IEC/EN61508

SCM

SG+

Modbus RS-485

PIN 1,2,7,8 :Reserved PIN 3, 6: GND

SG-

PIN 4: SG- PIN 5: SG+

NOTE: Wire size of analog control signals: 18 AWG (0.75 mm

2

) with shielded wire

Analog input terminals (AVI, ACI, AUI, ACM)

Analog input signals are easily affected by external noise. Use shielded wiring and keep it as

short as possible (<20m) with proper grounding. If the noise is inductive, connecting the shield to

terminal ACM can bring improvement.

If the analog input signals are affected by noise from the AC motor drive, please connect a

capacitor and ferrite core as indicated in the following diagram.

AVI/ACI/AUI

C

ACM

ferrite core

Wind each wires 3 times or more around the core

Digital inputs (FWD, REV, MI1~MI8, COM)

When using contacts or switches to control the digital inputs, please use high quality

components to avoid contact bounce.

Transistor outputs (MO1, MO2, MCM)

Make sure to connect the digital outputs to the right polarity.

When connecting a relay to the digital outputs, connect a surge absorber across the coil and

check the polarity.

6-5

Chapter 6 Control TerminalsC2000 Series

Remove the Terminal Block

1. Loosen the screws by screwdriver. (As shown in figure below).

2. Remove the control board by pulling it out for a distance 6~8 cm (as 1 in the figure) then lift the control

board upward(as 2 in the figure).

6-6

Chapter 7 Optional Accessories

The optional accessories listed in this chapter are available upon request. Installing additional

accessories to your drive would substantially improves the drive’s performance. Please select an

applicable accessory according to your need or contact the local distributor for suggestion.

• All Brake Resistors and Brake Units Used in AC Motor Drives

• Non-fuse Circuit Breaker

• Fuse (Specification Chart)

• AC Reactor

• Zero Phase Reactor

• DC Reactor

• EMI Filter

• Digital Keypad

• Panel Mounting

• Conduit Box Kit

• Fan Kit

• Flange Mounting Kit

• USB/RS-485 Communication Interface

7-1

All Brake Resistors and Brake Units Used in AC Motor Drives

230V

Applicable

Motor

Braking

Torque

(kg-m)

1 0.7 0.5 - BR080W200*1 80W200Ω 1.9 63.3 6 2.3

2 1.5 1.0 - BR200W091*1 200W91Ω 4.2 47.5 8 3.0

3 2.2 1.5 - BR300W070*1 300W70Ω 5.4 38.0 10 3.8

5 3.7 2.5 - BR400W040*1 400W40Ω 9.5 19.0 20 7.6

7.5 5.5 3.7 - BR1K0W020*1 1000W20Ω 19 14.6 26 9.9

10 7.5 5.1 - BR1K0W020*1 1000W20Ω 19 14.6 26 9.9

15 11 7.5 - BR1K5W013*1 1500W13Ω 29 13.6 28 10.6

20 15 10.2 - BR1K0W4P3*2 2 series 2000W8.6Ω 44 8.3 46 17.5

25 18 12.2 - BR1K0W4P3*2

30 22 14.9 - BR1K5W3P3*2

40 30 20.3 2015*2 BR1K0W5P1*2

50 37 25.1 2022*2 BR1K2W3P9*2

60 45 30.5 2022*2 BR1K5W3P3*2

75 55 37.2 2022*3 BR1K2W3P9*2

100 75 50.8 2022*4 BR1K2W3P9*2

125 90 60.9 2022*4 BR1K5W3P3*2

Brake

Unit HP kW

*4VFDB

*1 125%Braking Torque 10%ED *2 Max. Brake Torque

*3Braking Resistor series

for each Brake Unit

2 series

2 series

2 series

2 series

2 series

2 series

2 series

2 series

Resistor value

spec. for each

AC motor Drive

2000W8.6Ω 44 8.3 46 17.5

3000W6.6Ω 58 5.8 66 25.1

4000W5.1Ω 75 4.8 80 30.4

4800W3.9Ω 97 3.2 120 45.6

6000W3.3Ω 118 3.2 120 45.6

7200W2.6Ω 145 2.1 180 68.4

9600W2Ω 190 1.6 240 91.2

12000W1.65Ω 230 1.6 240 91.2

To ta l

Braking

Current (A)

Min.

Resistor

Value (Ω)

Max. Total

Braking

Current (A)

Peak

Power

(kW)

460V

Applicable

Motor

Braking

HP kW

1 0.7 0.5 - BR080W750*1 80W750Ω 1 190.0 4 3.0

2 1.5 1.0 - BR200W360*1 200W360Ω 2.1 126.7 6 4.6

3 2.2 1.5 - BR300W250*1 300W250Ω 3 108.6 7 5.3

5 3.7 2.5 - BR400W150*1 400W150Ω 5.1 84.4 9 6.8

5

7.5

10 7.5 5.1 - BR1K0W075*1 1000W75Ω 10.2 47.5 16 12.2

15 11 7.5 - BR1K5W043*1 1500W43Ω 17.6 42.2 18 13.7

20 15 10.2 - BR1K0W016*2 2 series 2000W32Ω 24 26.2 29 22.0

25 18 12.2 - BR1K0W016*2 2 series 2000W32Ω 24 23.0 33 25.1

30 22 14.9 - BR1K5W013*2 2 series 3000W26Ω 29 23.0 33 25.1

40 30 20.3 - BR1K0W016*4

50 40 25.1 4045*1 BR1K2W015*4

60 45 30.5 4045*1 BR1K5W013*4

75 55 37.2 4030*2 BR1K2W015*4 4 parallel 7200W10Ω 76 9.5 80 60.8

100 75

125 90 60.9 4045*2 BR1K5W013*8

150 110 74.5 4110*1 BR1K2W015*10

175 132 89.4 4160*1 BR1K5W012*12

Torque

(kg-m)

4.0

5.5

2.7

3.7

50.8 4045*2

Brake

Unit

*4VFDB

- BR1K0W075*1 1000W75Ω 10.2 54.3 14 10.6

*1 125%Braking Torque 10%ED *2 Max. Brake Torque

*3Braking Resistor series for

each Brake Unit

2 parallel,

2 series

2 parallel,

2 series

2 parallel,

2 series

BR1K2W015*8

2 parallel,

2 series

2 parallel,

2 series

5 parallel,

2 series

6 parallel,

2 series

Resistor

value spec.

for each AC

motor Drive

4000W16Ω 47.5 14.1 54 41.0

4800W15Ω 50 12.7 60 45.6

6000W13Ω 59 12.7 60 45.6

9600W7.5Ω 100 6.3 120 91.2

12000W6.5Ω 117 6.3 120 91.2

12000W6Ω 126 6.0 126 95.8

18000W4Ω 190 4.0 190 144.4

To ta l

Braking

Currnet (A)

Min.

Resistor

Value (Ω)

Max. Total

Braking

Current (A)

Peak

Power

(kW)

460V

7-2

Applicable

Motor

Braking

HP kW

Torque

(kg-m)

Brake

Unit

215 160 108.3 4160*1 BR1K5W012*12

250 185 125.3 4185*1 BR1K5W012*14

300 220 148.9 4110*2 BR1K2W015*10

375 280 189.6 4160*2 BR1K5W012*12

425 315 213.3 4160*2 BR1K5W012*12

475 355 240.3 4185*2 BR1K5W012*14

1

*

Calculation for 125% brake toque: (kw)*125%*0.8; where 0.8 is motor efficiency.

Because there is a resistor limit of power consumption, the longest operation time for 10%ED is 10sec (on: 10sec/ off:

90sec).

2

*

Please refer to the Brake Performance Curve for “Operation Duration & ED” vs. “Braking Current”.

3

*

For heat dissipation, a resistor of 400W or lower should be fixed to the frame and maintain the surface temperature below

50℃; a resistor of 1000W and above should maintain the surface temperature below 350 .℃

4

*

Please refer to VFDB series Braking Module Instruction for more detail on braking resistor.

NOTE

*1 125%Braking Torque 10%ED *2 Max. Brake Torque

*3Braking Resistor series for

each Brake Unit

6 parallel,

2 series

7 parallel,

2 series

5 parallel,

2 series

6 parallel,

2 series

6 parallel,

2 series

7 parallel,

2 series

Resistor

value spec.

for each AC

motor Drive

18000W4Ω 190 4.0 190 144.4

21000W3.4Ω 225 3.4 225 172.1

24000W3Ω 252 3.0 252 190.5

36000W2Ω 380 2.0 380 288.8

36000W2Ω 380 2.0 380 288.8

42000W1.7Ω 450 1.7 450 344.2

To ta l

Braking

Currnet (A)

Min.

Resistor

Value (Ω)

Max. Total

Braking

Current (A)

Peak

Power

(kW)

1. Definition for Brake Usage ED%

Explanation: The definition of the brake usage ED (%) is for assurance of enough time for the brake unit and brake resistor

to dissipate away heat generated by braking. When the brake resistor heats up, the resistance would increase with

temperature, and brake torque would decrease accordingly. Recommended cycle time is one minute.

For safety concern, install an overload relay (O.L) between the brake unit and the brake resistor in conjunction with the

magnetic contactor (MC) prior to the drive for abnormal protection. The purpose of installing the thermal overload relay is to