Page 1

Automation for a Changing World

Delta AC Servo Drive

ASDA-B2 Series

Page 2

High Precision. High Response. Cost Effective.

Delta Electronics' new high-performance, cost-effective ASDA-B2 series servo motors and drives meet the

requirements for general-purpose machine tools and enhance the competitive advantage of servo systems.

The power rating of the ASDA-B2 series ranges from 0.1kW to 3 kW. The superior features of this series

emphasize built-in functions for general-purpose applications and saving the cost of mechatronics integration.

Delta's ASDA-B2 makes it convenient to complete the setting of assembly, wiring and operation. The ASDA-B2

also provides different control modes for different applications.

Transporting and Conveying Equipment

Electric Discharge Machines (EDM)

Cutting Machines

1

Page 3

Sawing Machines

Table of Contents

3

Features

5

Model Explanation

6

Product Line-up

7

Part Names and Functions

9

Standard Connection Examples

12

Selection of Regenerative Resistor

12

Safety Information

13

Servo Drive Specifications

15

Servo Drive Dimensions

19

Servo Motor Specifications

23

Servo Motor Dimensions

23

Speed-Torque Curve (T-N Curves)

27

Optional Accessories

33

Accessories Combinations

2

Page 4

Features

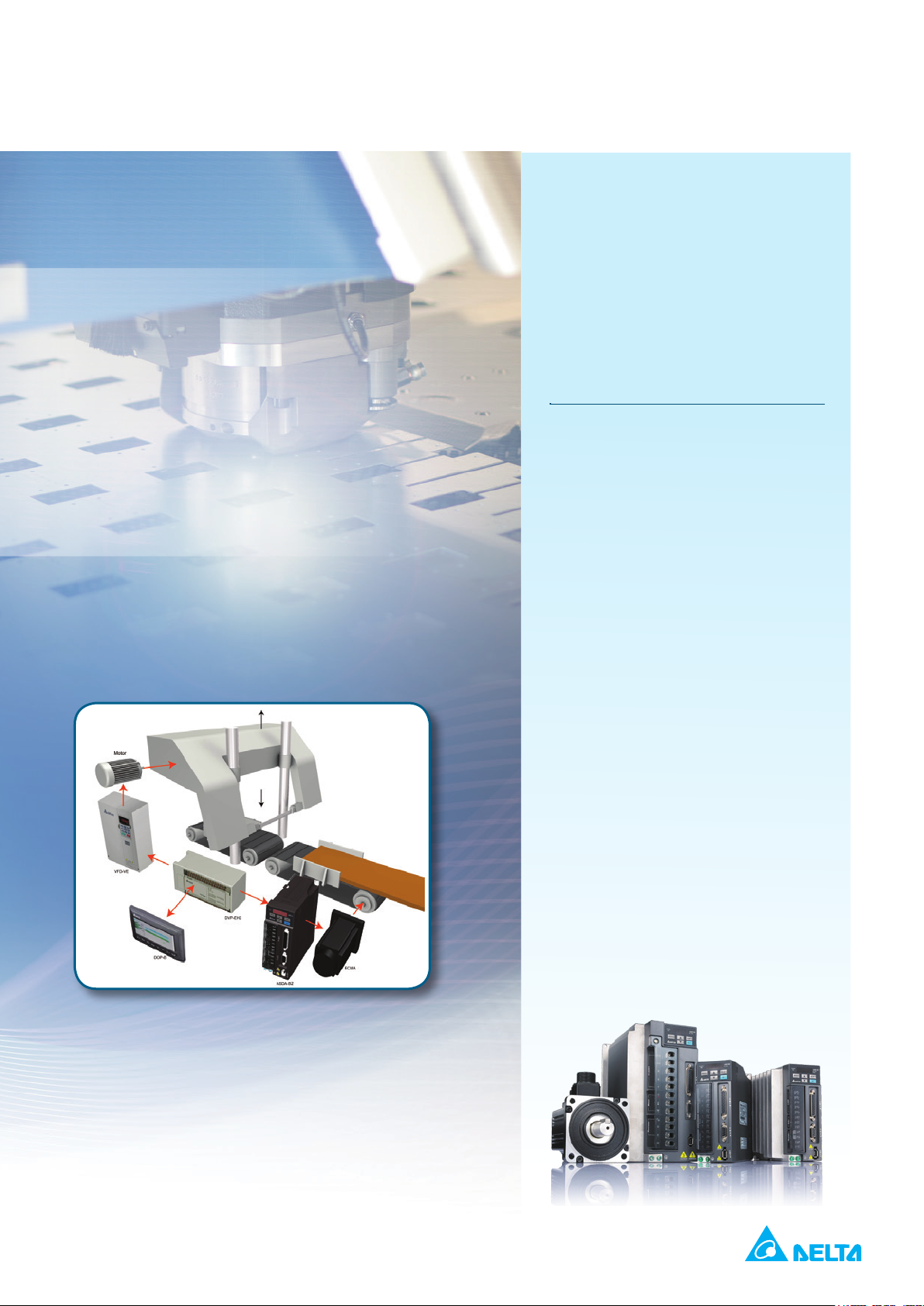

Implements High Precision Positioning Control

►

ASDA-B2 series servo drives support 20-bit and 17-bit encoders. The series satisfies the demand of

high-precision positioning control and stable operation at lower speeds.

►

Applying the encoder with a higher resolution can reduce the cogging torque and improve the motor's

precision.

2500ppr of Torque Ripple

►

Outstanding performance with higher speed: Up to 550Hz frequency response and settling time is

17-bit of Torque Ripple

below 1ms.

►

10ms acceleration time from -3000r/min to 3000r/min when running without load.

Example: Servo motor frame sizes 60mm and 400W

Satisfies a Variety of Industry Demands

►

Three control modes available: Built-in position, Speed, and Torque. (Speed and Torque mode can

be controlled by internal parameters or analog voltage.)

►

High-speed differential command (up to 4Mpps) for

high precision positioning control.

►

Three notch filters are provided to suppress the

mechanical resonance efficiently and make the

system operate more smoothly.

►

Lead friction compensation parameter is specified for

the application of circular interpolation, Z-axis motion

and ball screw to reduce the loading of the controller.

►

For bar feeders and other equipment requiring high torque output,

motor protection parameters are offered to protect the mechanical system.

3

Page 5

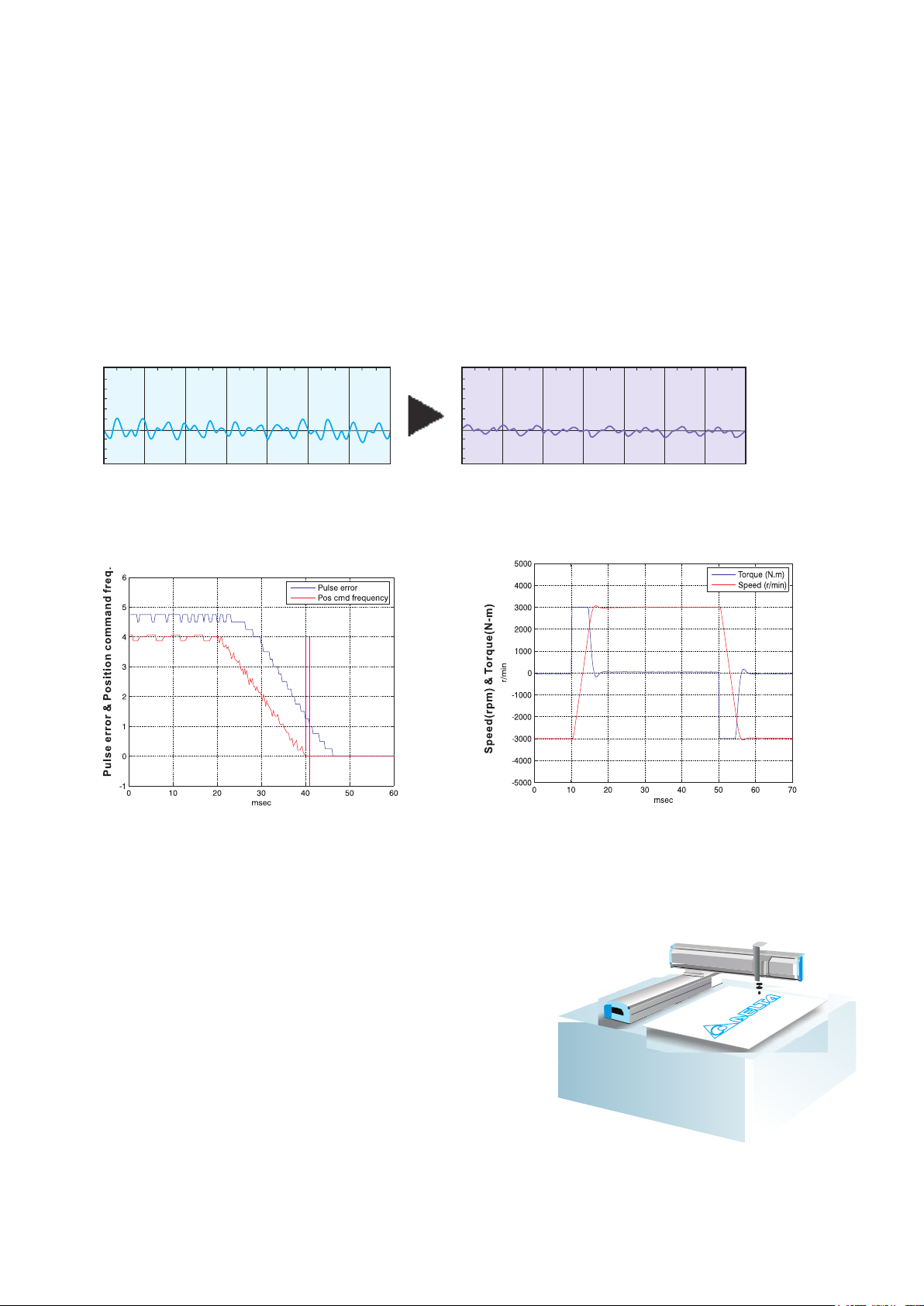

Offers Easy-To-Install Solution For Simple Start-Up

►

ASDA-B series share the same power cables and

encoder cables for easy installation and setup without

extra accessories.

Separated

power supply

for main circuit

and control

circuit

►

Servo motor provides brake, oil seal, and other optional

configurations for different applications.

►

Separated power supply for main circuit and control

circuit is easier to maintain the mechanism.

►

400W or above servo drives have built-in regenerative

resistors, which simplify wiring and reduce the

installation cost.

►

Individual connector (2 sets) for analog signal output,

which also simplifies the wiring.

MON1

MON2

Supports two analog outputs

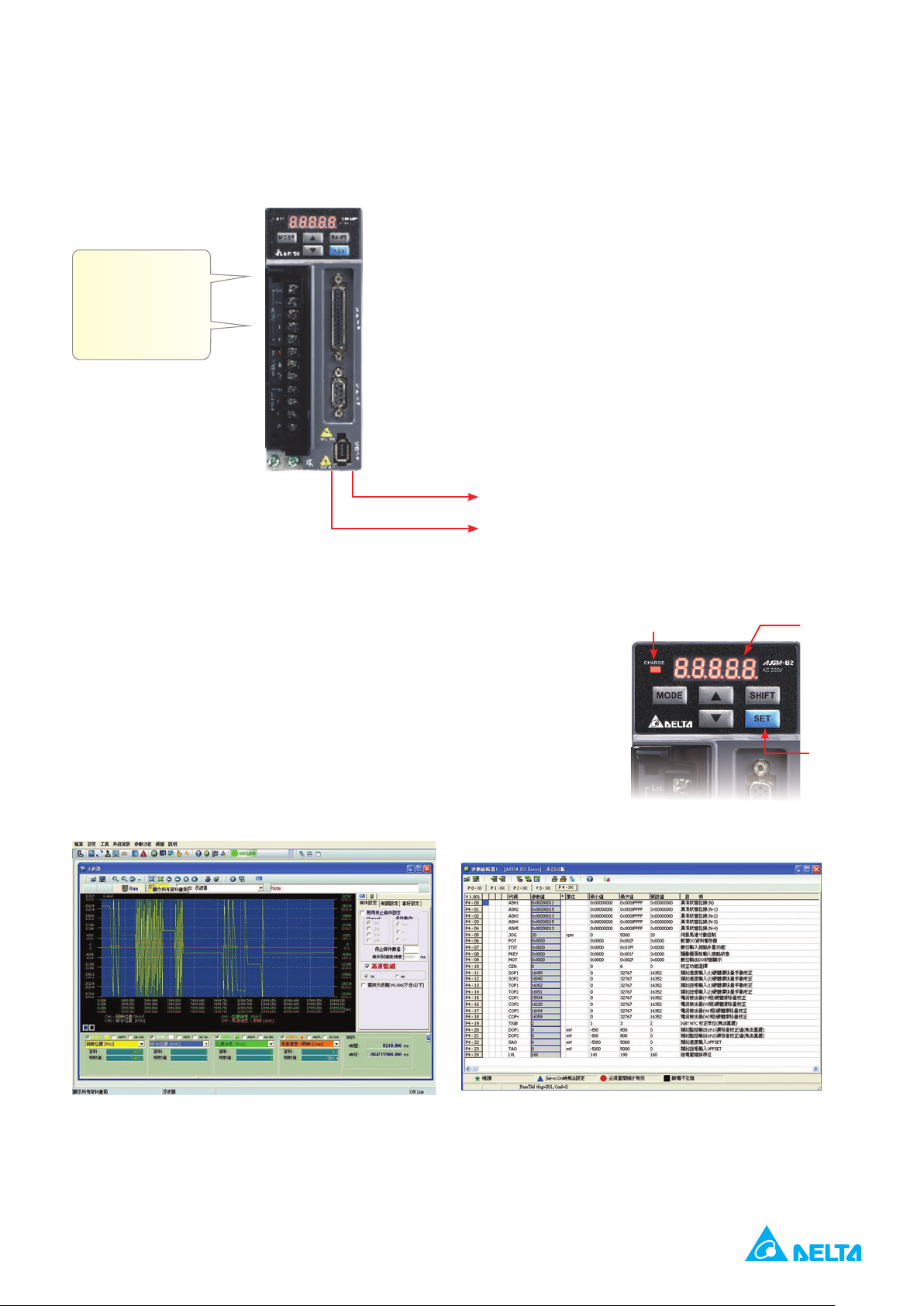

Fulfills Easy-To-Use Requirements For Versatile Operation

►

User-friendly motor sizing software allows users to select the motor.

►

ASDA-Soft configuration software (tuning software) is provided to

meet performance requirements quickly.

►

Easy-to-use digital keypad is ideal for setting parameters and enables

users to directly monitor the servo drive and servo motor.

►

Specific software communication cable ASD-CNUS0A08 (Optional)

can improve communication quality and convenience of operation.

(please refer to optional accessories on page 28)

Charge LED

LED Display

LED Display

顯示部

顯示部

Operation

Operation

Panel

Panel

►

On-line monitoring function for 4 channels

(similar to a digital oscilloscope) is available.

The monitoring data can be 16-bit (4 channels)

and 32-bit (2 channels).

►

Multi-functional parameter editor enables

users to edit, modify, upload / download and

print desired parameters

4

in real time.

Page 6

Model Explanation

ASDA-B2 Series Servo Drives

ASD - B2 -

Product Name:

AC Servo Drive

Series

B2

ECMA Series Servo Motors

ECM A - C1 06 02 E S

Product Name

ECM: Electrical Commutation Motor

04 21

- L

Model Type

L: Standard

Input Voltage and Phase:

21: 220V 1-phase

23: 220V 3-phase

Rated Output Power

01: 100W

02: 200W

04: 400W

07: 750W

Standard Shaft Dimensions: S

Specified Shaft Dimensions:

7=14mm 3=42mm

10: 1kW

15: 1.5kW

20: 2kW

30: 3kW

Driving Type

A: AC Servo Motor

Series

Rated Voltage / Rated Speed

C: 220V / 3000rpm

E: 220V / 2000rpm

F: 220V / 1500rpm

G: 220V / 1000rpm

Encoder Type

1: 20-bit (Incremental type)

2: 17-bit (Incremental type)

M: 13-bit (Magnetic air type)

Shaft Type and

Round Shaft

(with fixed

screw holes)

(with fixed

screw holes)

Motor Frame Size

04: 40mm 10: 100mm

06: 60mm 13: 130mm

08: 80mm 18: 180mm

09: 86mm

5

Oil Seal

Keyway

Keyway

No

Brake

No Oil

Seal

With

Brake

No Oil

Seal

- - C D

E F - -

P Q R S

No

Brake

With

Oil Seal

Rated Output Power

01: 100W 09: 900W

02: 200W 10: 1kW

03: 300W 15: 1.5kW

04: 400W 20: 2kW

05: 500W 30: 3kW

06: 600W

07: 700W

With

Brake

With

Oil Seal

Page 7

Product Line-up

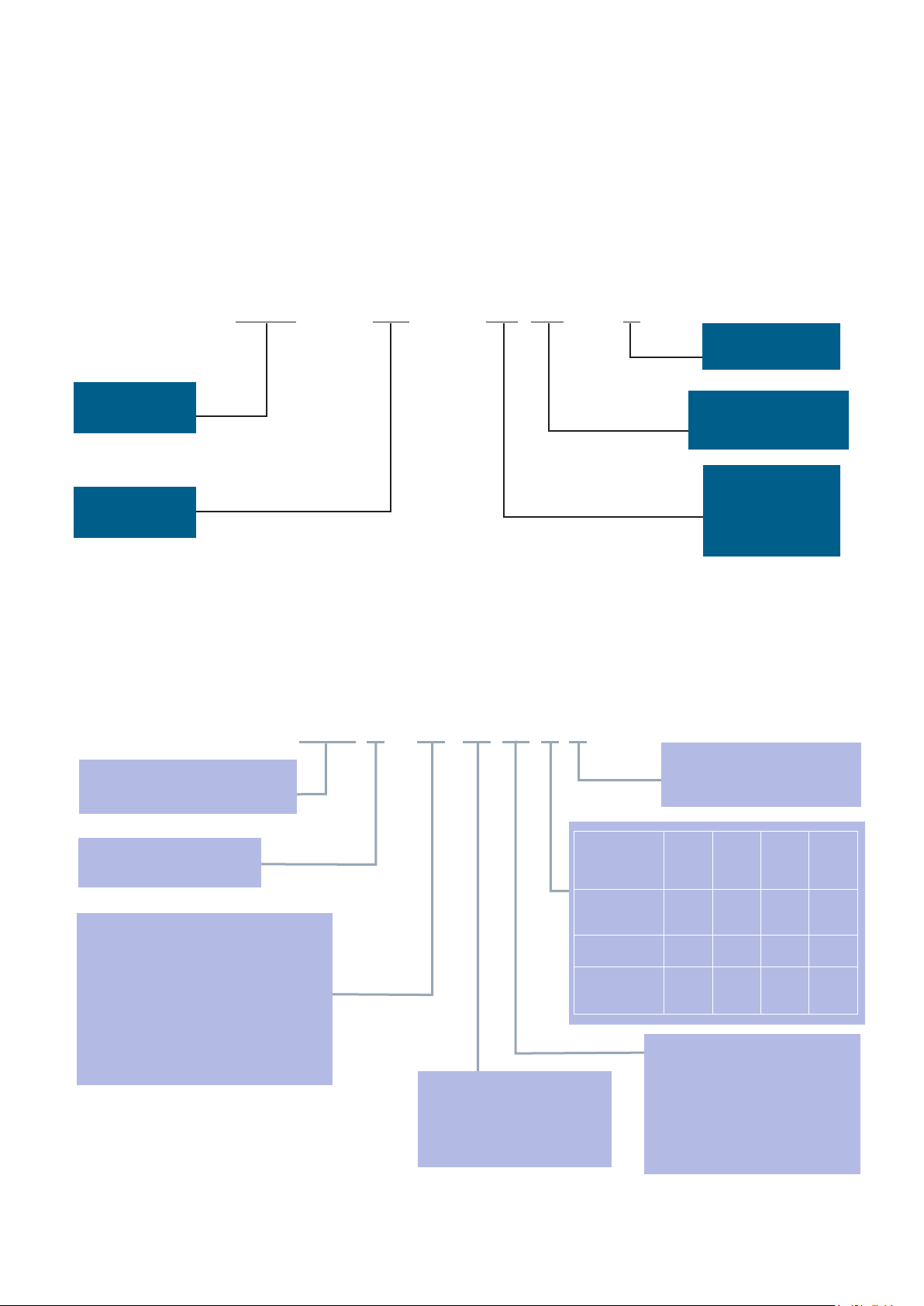

Servo Drive

0.1kW 200 W 400 W 750 W 1.0 kW 1.5 kW 2 kW 3 kW

ASD-B2-0121- L

Servo Motor

ECMA-C 0401 S

ASD-B2-0221- L ASD-B2-0421- L ASD-B2-0721-L ASD-B2-1021-L ASD-B2-1521-L ASD-B2-2023-L ASD-B2-3023- L

ECMA-C 0602 S

ECMA-C 0604 S

ECMA-C

ECMA-C

ECMA-E

ECMA-G

0604 H

0804 7

1305 S

1303 S

ECMA-C

ECMA-C

ECMA-G

ECMA-GM1306PS

ECMA-C

0807 S

0807 H

1306 S

0907 S

ECMA-C 1010 S

ECMA-E 1310 S

ECMA-G

ECMA-GM1309PS

ECMA-C

ECMA-F

1309 S

0910 S

1308 S

ECMA-E 1315 S

ECMA-C 1020 S

ECMA-F

ECMA-E

ECMA-E

ECMA-F

1313 S

1320 S

1820 S

1318 S

ECMA-E 1830 S

ECMA-F

ECMA-E

ECMA-C

1830 S

1835 S

1330 4

Note:

1. (

) in the model names represent shaft end / brake or the number of oil seals.

) in the model names encoder types ( =1: Incremental encoder, 20-bit; =2:Incremental encoder, 17-bit).

2. (

6

Page 8

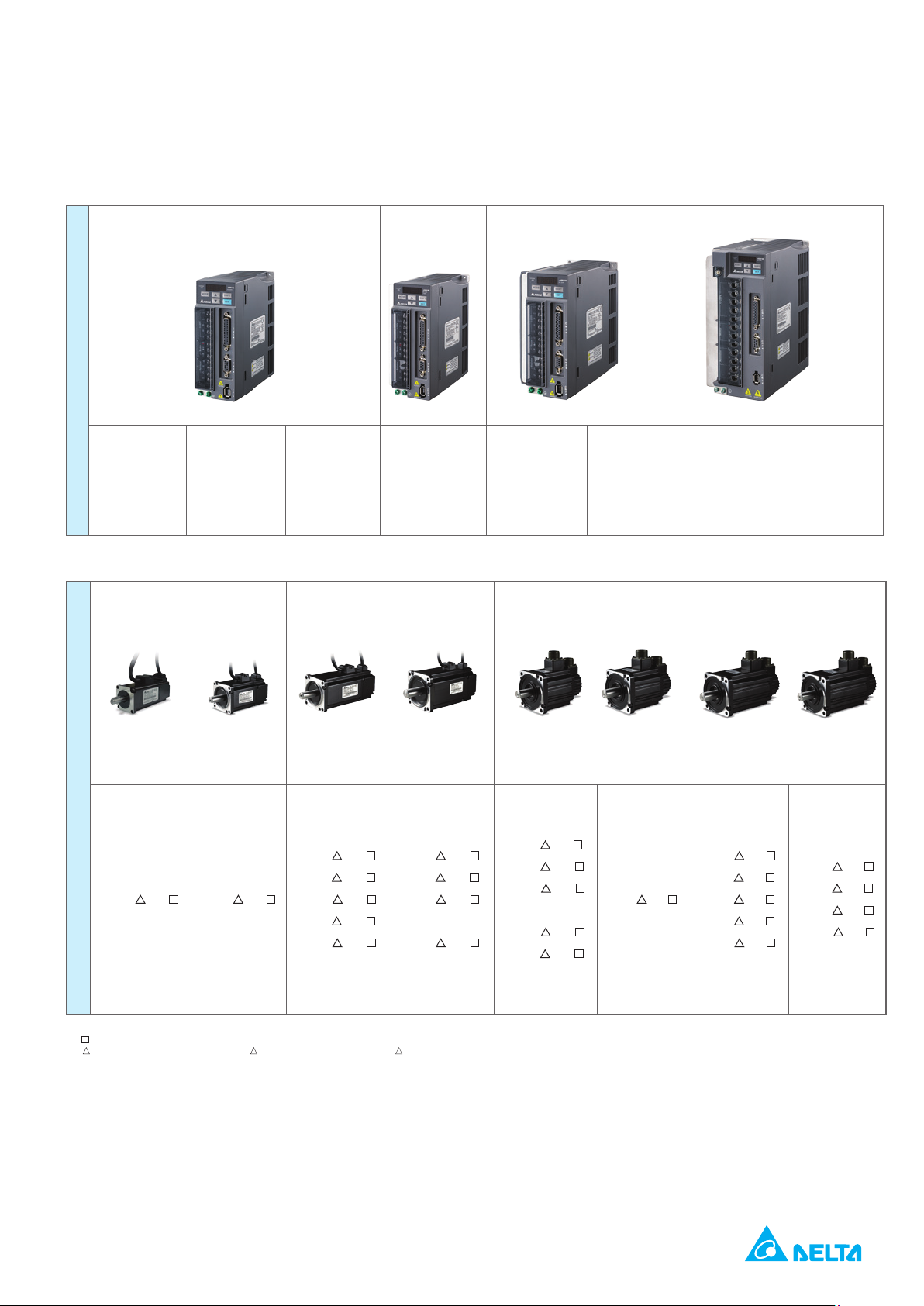

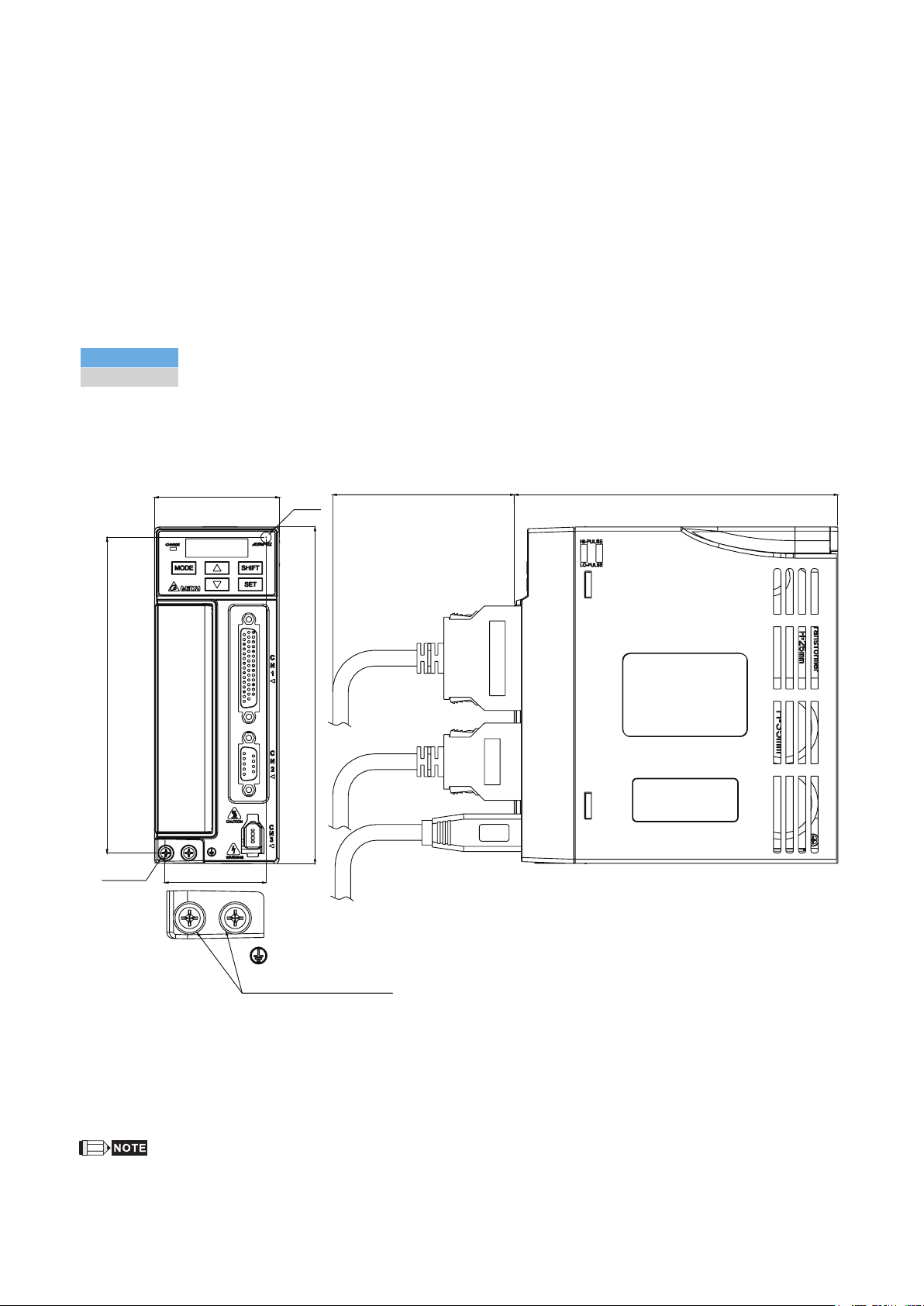

Part Names and Functions

LED Display

■

The 5-digit, 7-segment LED displays the

servo status or fault codes.

Charge LED

■

A lit LED indicates that either power is connected

to the servo drive or a residual charge is present

in the drive's internal power components.

Operation Panel

■

Function keys used to perform status display, monitor

and diagnostic, function and parameter setting.

Function Keys:

MODE: Mode selection

SHIFT: For shifting the cursor to the left

▲

: For increasing values

▼

: For decreasing values

SET: For storing data

Control Circuit Terminal

(L1c, L2c)

■

Used to connect 200~230 V

single-phase or three-phase VAC supply.

, 50 / 60Hz

AC

Main Circuit Terminal

(R, S, T)

■

Used to connect 200~230 VAC, 50 / 60Hz

commercial power supply.

Servo Motor Output (U, V, W)

■

Used to connect the servo motor. Never connect the

output terminal to the main circuit power as the AC

servo drive may be damaged beyond repair if incorrect

cables are connected to the output terminals.

Regenerative Resistor

■

1. When using an external resistor, connect it to

P ⊕ and C, and ensure an open circuit between

P ⊕ and D.

2. When using an internal resistor, ensure the

circuit is closed between P ⊕ and D, and the

circuit is opened between P ⊕ and C.

3. When using the external braking unit, connect the

braking unit to P ⊕ and

circuit between P ⊕ and D, and P ⊕ and C

4. When using the external brake module, please

connect it to P and

, and ensure an open

.

.

Ground Terminal

7

Page 9

I/O Interface

Used to connect Delta's DVP series

■

PLC or other external controllers for

controlling I/O signals.

Motor Encoder Interface

Used to connect the encoder.

■

Serial Communication

Used to connect PLC, HMI, and

■

other controllers for RS - 485 /

RS - 232 serial communication.

Port

Reserved

Analog Voltage Output Terminal

■

Used to provide two analog monitor

outputs, MON1 and MON2.

Heatsink

■

Used to secure servo drive and for

heat dissipation.

Please note that this only introduces servo drive's basic functions.

Specic models may have different functions.

8

Page 10

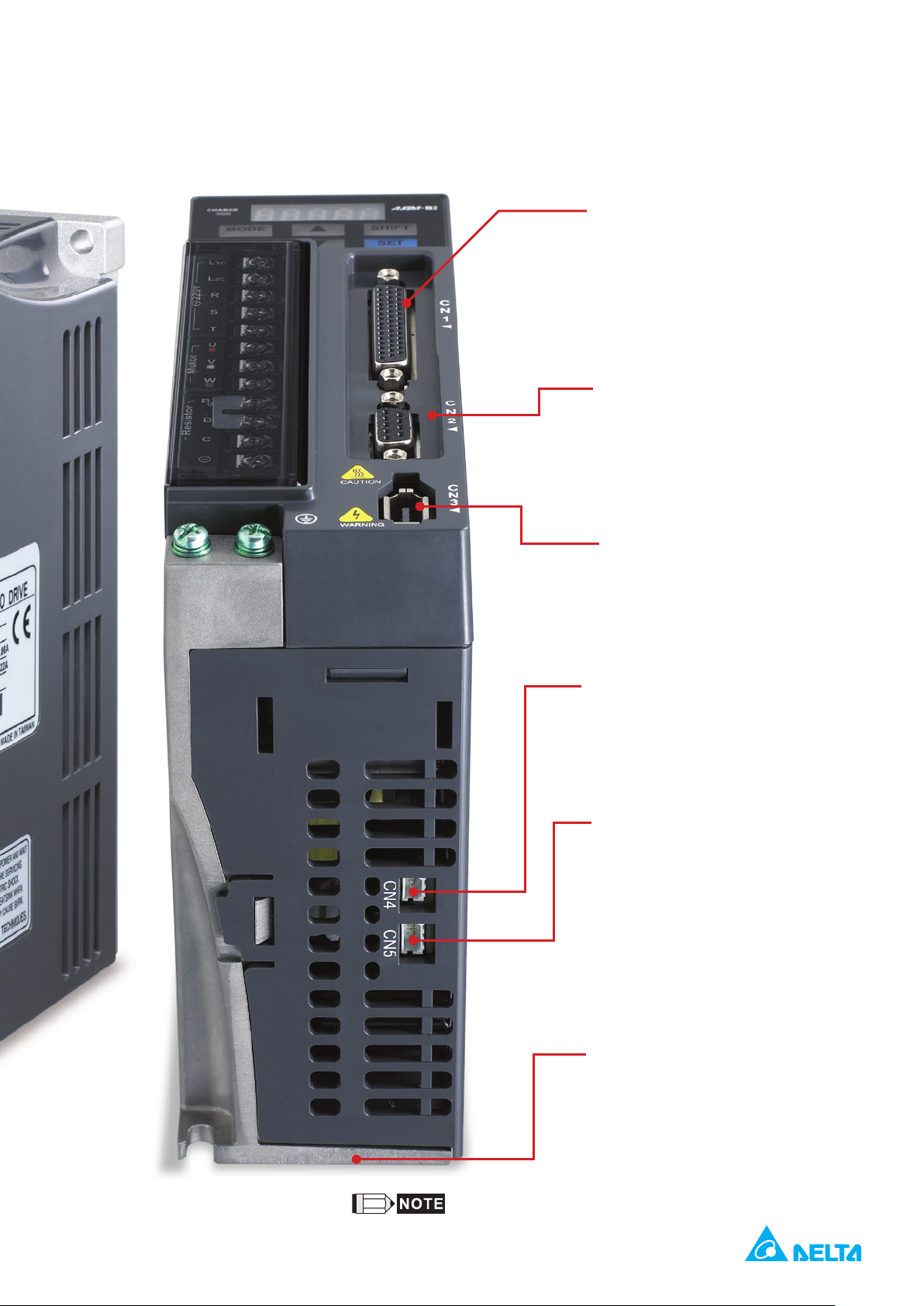

Wiring

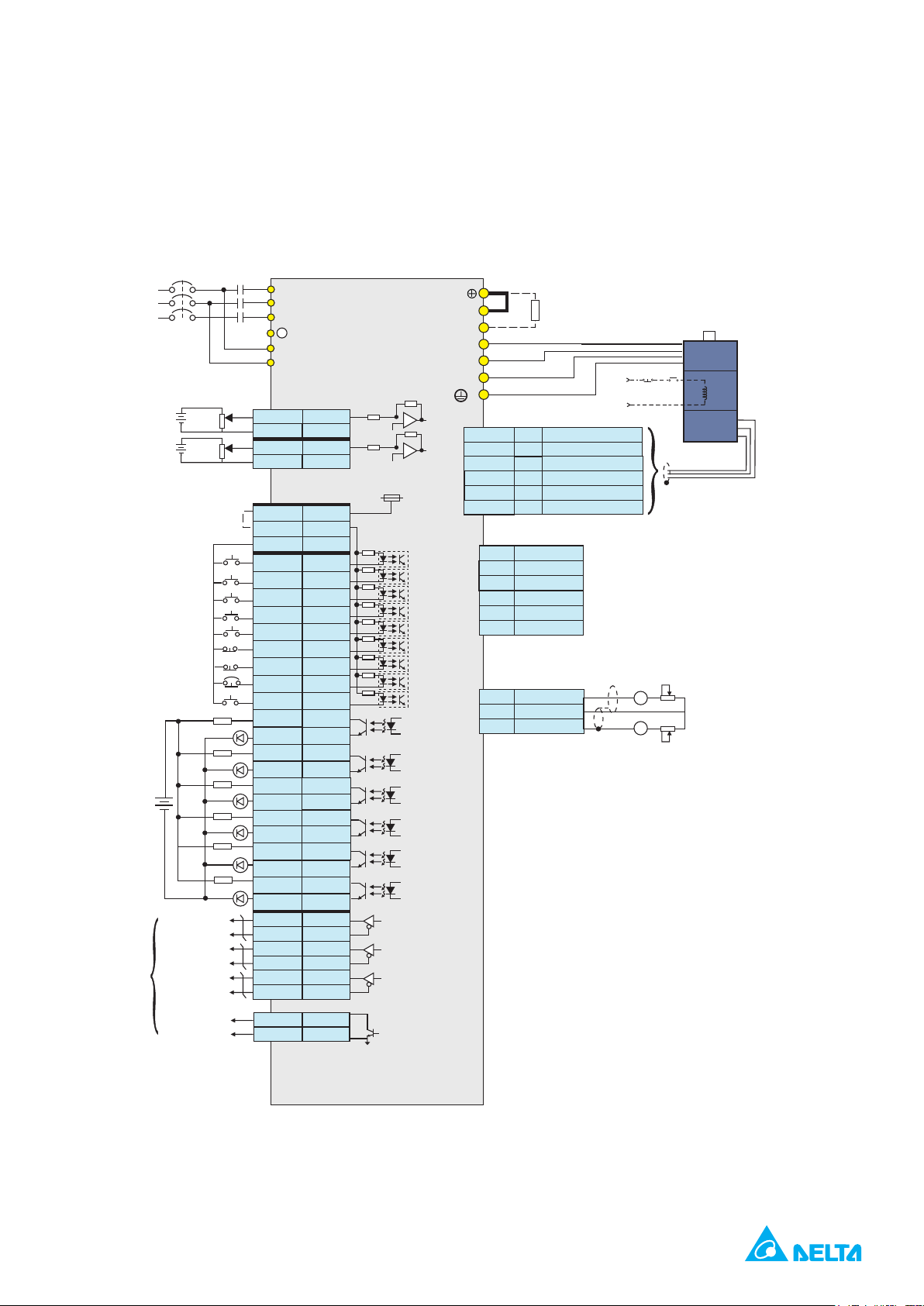

Position (Pt) Control Mode (for Pulse Command Input)

Pul se inpu t, for th e use of in ternal

pow er supp ly (Ope n-colle ct or i np ut )

Controller Servo Drive

PULL_ HI

SG

Pul se inpu t, for th e use of ex ternal

pow er supp ly (Ope n-colle ct or i np ut )

Controller

PULL_H I

+

DC24V

-

/PULSE

SG

Pul se inpu t (Line dri ve r)

This is a 5V system,do not connect

to 24V of power supply.

Controller

SIGN

/SIGN

PULSE

/PULS E

SG

Caution: Because this photocoupler is a

unidirectional optocoupler, please pay

close attention on the current

direction of input pulse command.

Hig h-spe ed pulse in put

(Li ne rece iver)

This is a 5V system,do not connect

to 24V of power supply.

Controller

SG

GND

Caution: Ensure that the ground terminal of the

controller and the servo drive

are connected to each other.

/SIGN

/PULS E

COM-

/SIGN 37

VDD

35

2kΩ

41

39

37

43

41

42 HSIG N

40 /HSI GN

38 HPUL SE

36 /HPU LSE

19 GND

17

35

2kΩ

37

2kΩ

41

14

2kΩ

Servo Drive

51Ω

51Ω

51Ω

51Ω

100kΩ

100Ω

DC24V

Approx.

2kΩ

75Ω

75Ω

Approx.

2kΩ

75Ω

75Ω

Servo Drive

Approx.

2kΩ

75Ω

75Ω

Approx.

2kΩ

75Ω

75Ω

Max. input

pulse frequency

is 500kpps

Max. input

pulse frequency

is 500kpps

Servo Drive

2kΩ

2kΩ

2kΩ

2kΩ

Max. input

pulse

frequency

is 200kpps

Max. input

pulse

frequency

is 200kpps

Max. input

pulse

frequency

is 200kpps

Max. input

pulse

frequency

is 200kpps

AC 20 0/230 V

Thr ee-ph ase

50/ 60Hz

Hig h-spe ed puls e

inp ut (Lin e recei ver)

24V

Enc oder

pul se outp ut

(PG D ividi ng

Rat io Outp ut)

MCCB

Pul se inpu t

(Li ne driv er)

10kΩ10 V

*3

SON

CCLR

TCM0

TCM1

ARST

CWL

CCWL

EMGS

0

SRD Y

1.5 kΩ

ZSP D

1.5 kΩ

1.5 kΩ

TPO S

1.5 kΩ

1.5 kΩ

ALR M

0

1.5 kΩ

A phas e pulse

B pha se puls e

Z pha se puls e

Z pha se open

col lecto r

2C

CN1

Serv o Dr ive

Ω

10k

DC2 4V

Ω

5k

5kΩ

5k

Ω

5k

Ω

5kΩ

5k

Ω

5k

Ω

5kΩ

5k

Ω

Max. o utput

mA

curr ent 50

volt age 30V

10kΩ

*3

MC

R

S

T

-

L1C

L

/SI GN

37

SIG N

39

/PU LSE

41

43

PUL SE

18

T-RE F

19

GND

/HS IGN

40

HSI GN

42

36

/HP ULSE

38

HPU LSE

VDD

17

COM +

11

COM -

14

9

DI1

10

DI2

34

DI3

8

DI4

33

DI5

32

DI6

31

DI7

30

DI8

12

DI9

DO1 +

7

DO1 -

6

DO2 +

5

DO2 -

4

DO3 +

3

DO3 -

2

DO4 +

1

DO4 -

26

DO5 +

28

DO5 -

27

DO6 +

16

DO6 -

15

OA

21

/OA

22

OB

25

/OB

23

OZ

13

/OZ

24

44

OCZ

19

GND

NOTE:

*1. 200W and below drives do not provide

built-in regenerative resistor.

*2. The brake coil has no polarity.

*3. Please refer to SINK / SOURCE modes

P

D

C

U

V

W

CN2

4

5

Res erved

Res erved

8

6,7

CN3

6

5

4

3

2

1

CN5

1

2

3

*1

Reg enera tive

Res istor

Red

Whi te

Bla ck

Gre en

T+

Blu e

T -

Blu e/Bla ck

-

-

-

-

+5V

Red & R ed/Wh ite

GND

Bla ck & Blac k/Whi te

RS4 85-

RS4 85+

RS2 32_RX

-

RS2 32_TX

GND

MON 1

GND

MON 2

24V

SG

SG

Pow er

Sup ply

(

EMGS

BRKR

*2

Bra ke

Enc oder

V

Twis ted-p air

10k Ω

or tw isted -

10k Ω

shi eld cab le

V

Twis ted-p air

or tw isted shi eld cab le

Use a r elay or o pen-c ollec tor tra nsist or to inp ut sign al

NPN t ransi stor wi th mult iple em itter f inger s (SINK M ode)

Wir ing of DI s ignal , for the u se of

int ernal p ower su pply

B

PNP t ran sisto r with mu ltipl e emitt er fing ers(S OURCE M ode)

Wir ing of DI s ignal , for the u se of

int ernal p ower su pply

R

B

Serv o Drive

VDD

C

COM+

E

Approx.

4.7kΩ

SON

COM-

Serv o Drive

VDD

SON

Approx.

4.7kΩ

E

COM+

COM-

C

Wir ing of DI s ignal , for the u se of

ext ernal p ower su pply, in ducti ve load

DC24 V

Approx.

4.7kΩ

DC24 V

Wir ing of DI s ignal , for the u se of

ext ernal p ower su pply

DC24 V

DC24 V

Approx.

4.7kΩ

Serv o Drive

COM+

SON

Serv o Drive

SON

COM+

Approx.

4.7kΩ

Approx.

4.7kΩ

Caution: Do not use dual power supply. Failure to

observe this caution may damage the servo drive.

WARNI NG

9

Page 11

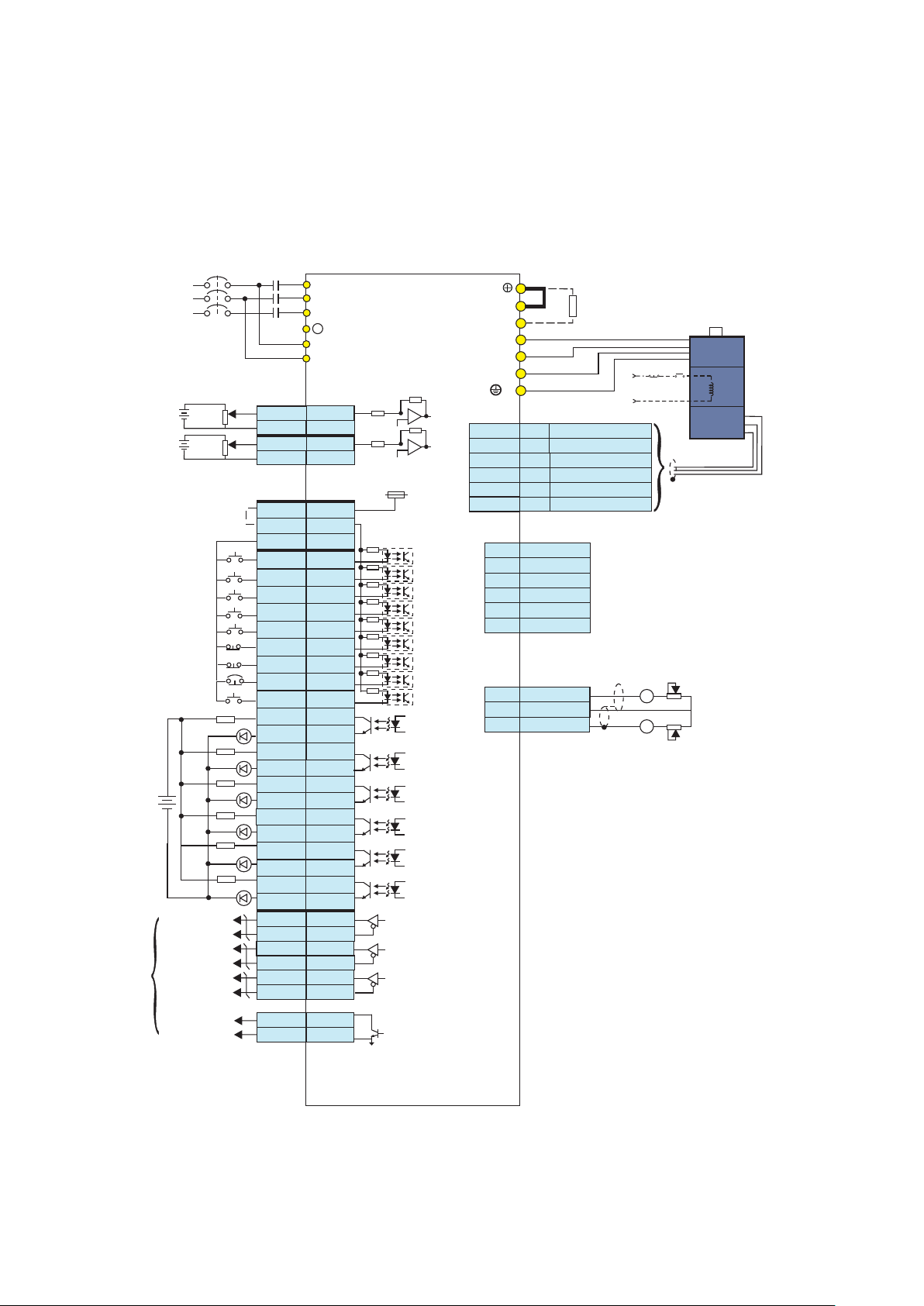

Speed (S) Control Mode

AC 200/230V

Three-phase

50/60Hz

Encoder

pulse output

(PG Dividing

Ratio Output)

MCCB

TRQL M

CCWL

EMGS

24V

A phase pulse

B phase pulse

Z phase pulse

Z phase open

collector

10kΩ10 V

10kΩ10 V

SON

SPD0

SPD1

ARST

CWL

SRD Y

ZSP D

TSP D

BRK R

ALR M

0

0

1.5 kΩ

1.5 kΩ

1.5 kΩ

1.5 kΩ

1.5 kΩ

1.5 kΩ

MC

V-REF

GND

T-REF

GND

VDD

COM+

COM-

DI1

DI2

DI3

DI4

DI5

DI6

DI7

DI8

DI9

DO1+

DO1-

DO2+

DO2-

DO3+

DO3-

DO4+

DO4-

DO5+

DO5-

DO6+

DO6-

OA

/OA

OB

/OB

OZ

/OZ

OCZ

GND

R

S

T

-

L1 C

L

Servo D riv e

*1

P

D

C

Red

U

White

2C

CN1

20

19

18

19

10kΩ

10kΩ

10kΩ

10kΩ

DC24V

17

11

14

9

10

34

8

33

32

31

30

12

Ω

5k

Ω

5k

5kΩ

Ω

5k

Ω

5k

5k

Ω

5kΩ

5kΩ

5kΩ

7

6

5

4

3

2

1

26

28

27

16

15

21

22

25

23

13

24

44

19

Max. o utput

mA

curr ent 50

volt age 30V

V

Black

W

Green

CN2

4

5

Reserved

Reserved

8

6,7

CN3

6

5

4

*3

3

2

1

CN5

1

2

3

Regenerative

Resistor

T+

Blue

T -

Blue/Black

-

-

-

-

+5V

Red & Red/White

GND

Black & Black/White

RS485-

RS485+

RS232_RX

-

RS232_TX

GND

MON1

GND

MON2

Power

24V

EMGS

(

BRKR

*2

Supply

Brake

Encoder

Twisted-pair

or twistedshield cable

SG

V

V

SG

10kΩ

10kΩ

Twisted-pair

or twistedshield cable

NOTE :

*1. 20 0W and be low dri ves d o no t pro vi de

buil t-in re gener ati ve r esi st or.

*2. Th e brake c oil has n o pol ar ity.

*3. Pl ease re fer to SI NK / SOUR CE mode s

10

Page 12

Wiring

Torque (T) Control Mode

AC 200/230V

Three-phase

50/60Hz

Encoder

pulse output

(PG Dividing

Ratio Output)

SPDL M

TCM0

TCM1

ARST

CCWL

EMGS

24V

A phase pulse

B phase pulse

Z phase pulse

SON

CWL

SRD Y

ZSP D

TSP D

BRK R

ALR M

0

MCCB

10kΩ10 V

10kΩ10 V

0

1.5 kΩ

1.5 kΩ

1.5 kΩ

1.5 kΩ

1.5 kΩ

1.5 kΩ

MC

V-REF

GND

T-REF

GND

VDD

COM+

COM-

DI1

DI2

DI3

DI4

DI5

DI6

DI7

DI8

DI9

DO1+

DO1-

DO2+

DO2-

DO3+

DO3-

DO4+

DO4-

DO5+

DO5-

DO6+

DO6-

OA

/OA

OB

/OB

OZ

/OZ

20

19

18

19

17

11

14

9

10

34

8

33

32

31

30

12

7

6

5

4

3

2

1

26

28

27

16

15

21

22

25

23

13

24

R

S

T

-

L1 C

L

2C

CN1

Servo D riv e

10kΩ

10kΩ

10kΩ

10kΩ

DC24V

5kΩ

Ω

5k

Ω

5k

5k

5k

5kΩ

5k

5k

5k

*3

Ω

Ω

Ω

Ω

Ω

P

D

C

U

V

W

CN2

4

5

Reserved

Reserved

8

6,7

CN3

6

5

4

3

2

1

CN5

1

2

3

*1

Red

White

Black

Green

T+

Blue

T -

Blue/Black

-

-

-

-

+5V

Red & Red/White

GND

Black & Black/White

RS485-

RS485+

RS232_RX

-

RS232_TX

GND

MON1

GND

MON2

Regenerative

Resistor

24V

SG

EMGS

Power

BRKR

*2

Supply

Brake

Encoder

Twisted-pair

or twistedshield cable

(

SG

V

V

10k Ω

10k Ω

Twisted-pair

or twistedshield cable

Z phase open

collector

OCZ

GND

44

19

Max. o utput

curr ent 50mA

volt age 30V

NOTE :

*1. 20 0W and be low d ri ves d o not pro vide

buil t-in re gen er ati ve r esi stor.

*2. The br ake c oi l has n o po lar ity.

*3. Pl ease re fer t o SI NK / SO UR CE mo de s

11

Page 13

Selection of Regenerative Resistor

Safety Information

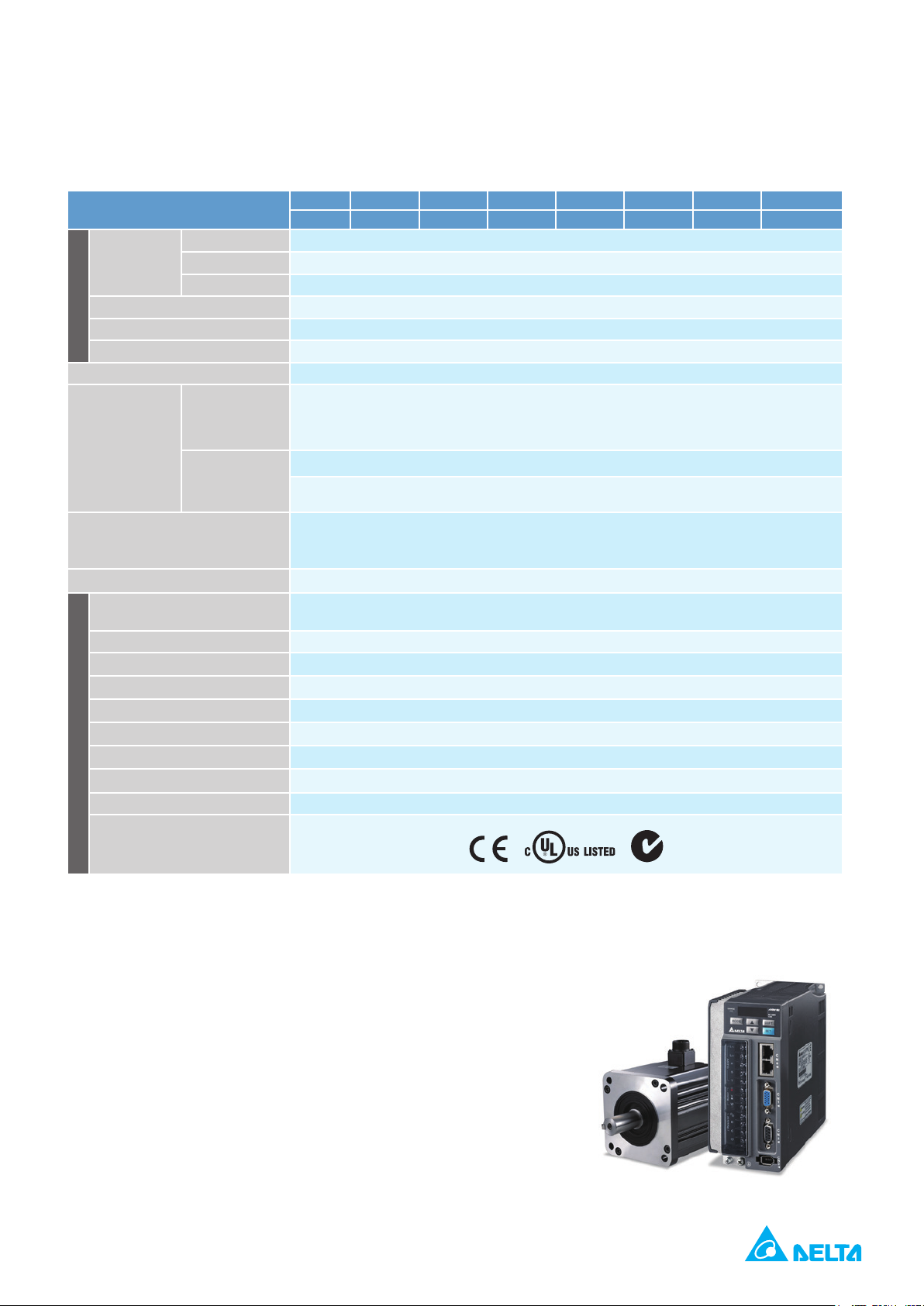

Servo Drive (kW)

Recommended Specifications for

Built-in Regenerative Resistor

Resistance (Ohm)

(parameter P1-52)

Capacity (Watt)

(parameter P1-53)

The capacity of

built-in

regenerative

resistor (Watt)

Min. Allowable

Resistance (Ohm)

0.1 -- -- -- 60Ω

0.2 -- -- -- 60Ω

0.4 100Ω 60W 30W 60Ω

0.75 100Ω 60W 30W 60Ω

1.0 40Ω 60W 30W 30Ω

1.5 40Ω 60W 30W 30Ω

2.0 20Ω 100W 50W 15Ω

3.0 20Ω 100W 50W 15Ω

Note:

1) 100W ~ 200W of B2 servo drives have no built-in regenerative resistor.

2) When the fault, ALE05 (Regeneration Error) occurs, please increase the regenerative resistor capacity or decrease the regenerative resistor resistance

(the regenerative resistor resistance should not be less than the minimum allowable resistance listed in the above table.)

3) If the issue persists, please purchase regenerative resistor module.

4) When connecting to regenerative resistor in parallel, make sure that the total resistance value of the regenerative resistors is not less than the minimum allowable resistance listed in

the above table.

Global Standards

EMC Standard

Conducted &

Radiated Emissions

CE Marking

Protection Degree

Vibration

Shock

Pollution Degree

Ambient Temperature

Cooling Type

ASDA-B2 series is designed to fully comply with demanding international standards, such as IEC and EN

for all fields of industrial automation technology.

EN61000-4-6 Level 3

EN61000-4-3 Level 3

EN61000-4-2 Level 2 and Level 3

EN61000-4-4 Level 3

EN61000-4-8 Level 4

EN61000-4-5 Level 3

Complies with EN550011 Class A Group 1, with external EMC lter

CE recognized. Complies with Directive 2006/95/EC of the European Parliament and EMC Directive 2004/108/EC.

IEC/EN50178, IEC/EN60529

IP20

1 G less than 20 Hz, 0.6 G 20 to 50 Hz. Complies with IEC/EN50178

15gn 11 ms. Complies with IEC/EN600028-2-27

Degree 2. Complies with IEC/EN61800-5-1

Operating: 0 ºC ~ 55 ºC (If operating temperature exceeds the specications, forced cooling will be required.)

Storage: -20 ºC ~ 65 ºC

ASD-B2-0121-B, ASD-B2-0221-B, ASD-B2-0421-B, ASD-B2-0721-B Natural Air Circulation

ASD-B2-1021-B, ASD-B2-1521-B, ASD-B2-2023-B, ASD-B2-3023-B Fan Cooling

Altitude

IEC: International Electrotechnical Commission

EN: Europaischen Normen

EMC: Electromagnetic Compatibility

IP: Ingress Protection Ratings

Altitude 1000m or lower above sea level

12

Page 14

Specications

ASDA-B2 Series

01020407101520

30

Time Constant

Command Source

Bandwidth

100 W 200 W 400 W 750 W 1 kW 1.5 kW 2 kW 3 kW

Phase / Voltage

Input Current

Input Current

Power Supply

(3PH)

(1PH)

Continuous Output Current

Cooling System

Encoder Resolution

Main Circuit Control

Control Mode

Regenerative Resistor

Max. Input Pulse Frequency

Pulse Type

Command Source

Smoothing Strategy

E-gear Ratio

Torque Limit Operation

Position Control Mode

Feed Forward Compensation

Voltage Range

Analog Input

Command

Input Resistance

Speed Control Range*1

Smoothing Strategy

Torque Limit

Speed Control Mode

Speed Accuracy

*2

(Units: Arms)

(Units: Arms)

(Units: Arms)

Three-phase 170 ~ 255 VAC , 50/60 Hz ±5%

0.7 1.11 1.86 3.66 4.68 5.9 8.76 9.83

0.9 1.92 3.22 6.78 8.88 10.3 - -

0.9 1.55 2.6 5.1 7.3 8.3 13.4 19.4

Natural Air Circulation Fan Cooling

17-bit (160,000 p/rev)

SVPWM (Space Vector Pulse Width Modulation) Control

Auto / Manual

None Built-in

Transmitted by differential: 500 K (low speed) / 4 Mpps (high-speed)

Pulse + Direction, A phase + B phase, CCW pulse + CW pulse

Transmitted by open-collector: 200 Kpps

External pulse

Low-pass filter

Electronic gear N/M multiple N: 1 ~ (226 -1) / M: 1 ~ (231 -1)

External analog signal / Internal parameters

±0.01% at 0

(1/50 < N/M < 25600)

Set by parameters

Set by parameters

0 ~ ±10 V

DC

10 KΩ

μs

2.2

1:5000

Low-pass and S-curve filter

Set by parameters or via analog input

Maximum 550 Hz

±0.01% at 0 to 100% load fluctuation

±0.01% at ±10% power fluctuation

o

C to 50 oC ambient temperature fluctuation

Three - phase

170 ~ 255 V

, 50 / 60 Hz

AC

±5%Single-phase 200 ~ 255 VAC , 50/60 Hz ±5%

13

Page 15

Specications

ASDA-B2 Series

01020407101520

30

Time Constant

Command Source

Analog Monitor Output

Altitude

IP Rating

Analog Input

Command

Smoothing Strategy

Speed Limit

Torque Control Mode

Digital Input /

Output

Protective Functions

Voltage Range

Input Resistance

Input

Output

100 W 200 W 400 W 750 W 1 kW 1.5 kW 2 kW 3 kW

0 ~ ±10 V

DC

10 KΩ

μs

2.2

External analog signal / Internal parameters

Low-pass filter

Set by parameters or via analog input

Monitor signal can set by parameters (Output voltage range: ±8 V)

Servo on, Fault reset, Gain switch, Pulse clear, Zero clamp, Command input reverse control, Torque limit,

Speed limit, Speed command selection, Speed / position mode switching, Speed / torque mode switching,

Torque / position mode switching, Emergency stop, Positive/negative limit, Forward / reverse operation torque

limit, Forward/reverse JOG input, E-gear N selection, Pulse input prohibition

Encoder signal output (A, B, Z Line Driver / Z Open collector)

Servo on, Servo ready, Zero speed, Target speed reached, Target position reached, Torque limiting, Servo

alarm, Brake control, Early warning for overload, Servo warning

Over current, Overvoltage, Under voltage, Overheat, Excessive speed deviation, Excessive position deviation,

Encoder error, Emergency stop, Communication error, Short-circuit protection of terminal U, V, W and CN1,

CN2, CN3

Communication Interface

Installation Site

Atmospheric Pressure

Operating Temperature

Storage Temperature

Humidity

Vibration

Environment

Power System

Indoor location (avoid direct sunlight), no corrosive liquid and gas

Altitude 1000 m or lower above sea level

0 ºC ~ 55 ºC (If operating temperature is above 45 ºC, forced cooling will be required)

Under 20 Hz, 9.80665 m/s2 (1G), 20 ~ 50 Hz 5.88 m/s2 (0.6 G)

RS-232 / RS-485

(avoid oil mist, flammable gas, dust)

86 kPa ~ 106 kPa

-20 ºC ~ 65 ºC

0 to 90% (non-condensing)

(-4 ºF to 149 ºF)

IP20

TN System*3

IEC/EN 61800-5-1

Approvals

Footnote:

*1. When it is in rated load, the speed ratio is: the minimum speed (smooth operation) / rated speed.

*2. When the command is the rated speed, the velocity correction ratio is: (rotational speed with no load - rotational speed with full load) / rated speed.

*3. TN system: The neutral point of the power system connects to the ground directly. The exposed metal components connect to the ground via the protective earth conductor.

14

Page 16

Dimensions

ASD-B2-1021

ASD-B2-0221

ASD-B2-0421

( 100 W / 200 W / 400 W )

Weight

1.07 (2.36)

15 2( 5. 98 )

Ground Terminal

60 .2 (2 .3 7)

49 (1 .9 2)

Ø5 (0.19)

16 2( 6. 37 )

70 (2.76)

15 5. 9( 6. 13)

Screw: M4 x 0.7

Mounting Screw Type: 14 (kgf-cm)

1) Dimensions are in millimeters (inches); Weights are in kilograms (kg) and (pounds (lbs)).

2) Dimensions and weights of the servo drive may be updated without prior notice.

15

Page 17

ASD-B2-0721

(750W)

Weight

1.54 (3.40)

15 2( 5. 98)

Ground Terminal

79 .5 (3.12)

49 (1 .9 2)

Ø5 (0.19)

16 2( 6. 37)

70 (2.76) 16 3.4(6 .43 )

Screw: M4 x 0.7

Mounting Screw Type: 14 (kgf-cm)

1) Dimensions are in millimeters (inches); Weights are in kilograms (kg) and (pounds (lbs)).

2) Dimensions and weights of the servo drive may be updated without prior notice.

16

Page 18

Dimensions

Weight

ASD-B2-1021

ASD-B2-1521

(1kW / 1.5kW)

1.72 (3.79)

152( 5.98 )

5( 0.19 )

Ground Terminal

85 .1 (3.35)

74 (2.91)

70 (2.76)

Ø6 (0.23)

162( 6.3 7)

Screw: M4 x 0.7

Mounting Screw Type: 14 (kgf-cm)

18 9. 4( 7.45 )

1) Dimensions are in millimeters (inches); Weights are in kilograms (kg) and (pounds (lbs)).

2) Dimensions and weights of the servo drive may be updated without prior notice.

17

Page 19

ASD-B2-2023

2.67 (5.88)

ASD-B2-3023

(2kW / 3kW)

Weight

21 3( 8.38 )

5. 5(0. 21 )

Ground Terminal

113. 7(4. 47 )

10 2( 4.01 )

Ø6 (0.23)

22 5( 8. 85 )

Screw: M4 x 0.7

Mounting Screw Type: 14 (kgf-cm)

70 (2.76 )

19 8. 2( 7. 8)

1) Dimensions are in millimeters (inches); Weights are in kilograms (kg) and (pounds (lbs)).

2) Dimensions and weights of the servo drive may be updated without prior notice.

18

Page 20

□

Servo Motor Specications

Low Inertia Series

04 C 06 C 08 C 09 C 10 C 13

Model: ECMA Series

Rated power (kW) 0.1 0.2 0.4 0.4 0.75 0.75 1.0 1.0 2.0 3.0

Rated torque (N-m)

Maximum torque (N-m) 0.96 1.92 3.82 3.82 7.16 7.14 8.78 9.54 19.11 28.65

Rated speed (r/min) 3000 3000 3000 3000

Maximum speed (r/min) 5000 3000 5000 4500

Rated current (A) 0.90 1.55 2.6 2.6 5.1 3.66 4.25 7.3 12.05 17.2

Maximum current (A) 2.70 4.65 7.8 7.8 15.3 11 12.37 21.9 36.15 47.5

Power rating (kW/s) 27.7 22.4 57.6 24.0 50.4 29.6 38.6 38.1 90.6 71.8

Rotor inertia

(x10-4kg-m

Mechanical constant (ms) 0.75 0.80 0.53 0.74 0.62 1.72 1.20 0.74 0.61 1.11

Torque constant-KT (N-m/A) 0.36 0.41 0.49 0.49 0.47 0.65 0.75 0.44 0.53 0.557

Voltage constant-KE(mV/(r/min) 13.6 16 17.4 18.5 17.2 24.2 27.5 16.8 19.2 20.98

Armature resistance (Ohm) 9.30 2.79 1.55 0.93 0.42 1.34 0.897 0.20 0.13 0.0976

Armature inductance (mH) 24.0 12.07 6.71 7.39 3.53 7.55 5.7 1.81 1.50 1.21

Electric constant (ms) 2.58 4.3 4.3 7.96 8.36 5.66 6.35 9.3 11.4 12.4

Insulation class Class A (UL), Class B (CE)

Insulation resistance >

Insulation strength

Weight (kg) (without brake) 0.5 1.2 1.6 2.1 3.0 2.9 3.8 4.3 6.2 7.8

Weight (kg) (with brake) 0.8 1.5 2.0 2.9 3.8 3.69 5.5 4.7 7.2 9.2

Max. radial shaft load (N) 78.4 196 196 245 245 245 245 490 490 490

Max. thrust shaft load (N) 39.2 68 68 98 98 98 98 98 98 98

Power rating (kW/s) (with brake) 25.6 21.3 53.8 22.1 48.4 29.3 37.9 30.4 82 65.1

Rotor inertia

(x10-4kg-m

Mechanical constant

(ms) (with brake)

Brake holding torque [Nt-m (min)]

Brake power consumption

(at 20 ºC) [W]

Brake release time [ms (Max)] 5 10 10 10 10 10 10 10 10 10

Brake pull-in time [ms (Max)] 25 70 70 70 70 70 70 70 70 70

Vibration grade ( μm ) 15

Operating temperature ( ºC) 0 ºC to 40 ºC (32 ºF to 104 ºF)

Storage temperature ( ºC) -10 ºC to 80 ºC (-14 ºF to 176 ºF)

Operating humidity 20 to 90% RH (non-condensing)

Storage humidity 20 to 90% RH (non-condensing)

Vibration capacity 2.5 G

IP Rating

*1

2

)(without brake)

2

) (with brake)

C

01 02 04

0.32 0.64 1.27 1.27 2.39 2.39 3.18 3.18 6.37 9.55

0.037 0.177 0.277 0.68 1.13 1.93 2.62 2.65 4.45 12.7

0.04 0.192 0.30 0.73 1.18 1.95 2.67 3.33 4.95 14.0

0.81 0.85 0.57 0.78 0.65 1.74 1.22 0.93 0.66 1.22

*2

0.3 1.3 1.3 2.5 2.5 2.5 2.5 8 8 10.0

7.3 6.5 6.5 8.2 8.2 8.2 8.2 18.7 18.7 19.0

IP65 (when waterproof connectors are used, or when an oil seal is used to be fitted to

S 04 07 07 10 10 20 30

100 MΩ, 500 V

1.8k V

the rotating shaft (an oil seal model is used))

, 1 sec

AC

DC

Approvals

Footnote:

* 1 Rate torque values are continuous permissible values at 0~40 ºC ambient temperature when attaching with the sizes of heatsinks listed below:

ECMA-__04 / 06 / 08 : 250 mm × 250 mm × 6 mm

ECMA-__10 : 300 mm × 300 mm × 12 mm

ECMA-__13 : 400 mm × 400 mm × 20 mm

ECMA-__18 : 550 mm × 550 mm × 30 mm

ECMA-__22 : 650 mm × 650 mm × 30 mm

Material type : Aluminum F40, F60, F80, F100, F130, F180, F220

*2 The holding brake is used to hold the motor shaft, not for braking the rotation. Never use it for decelerating or stopping the machine.

19

Page 21

Servo Motor Specications

Medium / High Inertia Series

13 E 18 G 13

Model: ECMA Series

Rated power (kW) 0.5 1.0 1.5 2.0 2.0 3.0 3.5 0.3 0.6 0.9

Rated torque (N-m)

*1

05 10 15 20 20 30 35 03 06 09

2.39 4.77 7.16 9.55 9.55 14.32 16.71 2.86 5.73 8.59

Maximum torque (N-m) 7.16 14.3 21.48 28.65 28.65 42.97 50.13 8.59 17.19 21.48

Rated speed (r/min) 2000 1000

Maximum speed (r/min) 3000 2000

Rated current (A) 2.9 5.6 8.3 11.01 11.22 16.1 19.2 2.5 4.8 7.5

Maximum current (A) 8.7 16.8 24.9 33.03 33.66 48.3 57.6 7.5 14.4 22.5

Power rating (kW/s) 7.0 27.1 45.9 62.5 26.3 37.3 50.8 10.0 39.0 66.0

Rotor inertia

(x10-4kg-m

2

)(without brake)

8.17 8.41 11.18 14.59 34.68 54.95 54.95 8.17 8.41 11.18

Mechanical constant (ms) 1.91 1.51 1.10 0.96 1.62 1.06 1.08 1.84 1.40 1.06

Torque constant-KT (N-m/A) 0.83 0.85 0.87 0.87 0.85 0.89 0.87 1.15 1.19 1.15

Voltage constant-KE(mV/(r/min) 30.9 31.9 31.8 31.8 31.4 32.0 32 42.5 43.8 41.6

Armature resistance (Ohm) 0.57 0.47 0.26 0.174 0.119 0.052 0.052 1.06 0.82 0.43

Armature inductance (mH) 7.39 5.99 4.01 2.76 2.84 1.38 1.38 14.29 11.12 6.97

Electric constant (ms) 12.96 12.88 15.31 15.86 23.87 26.39 26.39 13.55 13.50 16.06

Insulation class Class A (UL), Class B (CE)

Insulation resistance >

Insulation strength

Weight (kg) (without brake) 6.8 7.0 7.5 7.8 13.5 18.5 18.5 6.8 7.0 7.5

Weight (kg) (with brake) 8.2 8.4 8.9 9.2 17.5 22.5 22.5 8.2 8.4 8.9

Max. radial shaft load (N) 490 490 490 490 1176 1470 490 490 490 490

Max. thrust shaft load (N) 98 98 98 98 490 490 98 98 98 98

Power rating (kW/s) (with brake) 6.4 24.9 43.1 57.4 24.1 35.9 48.9 9.2 35.9 62.1

Rotor inertia

(x10-4kg-m

Mechanical constant

(ms) (with brake)

2

) (with brake)

Brake holding torque [Nt-m (min)]

Brake power consumption

(at 20 ºC) [W]

8.94 9.14 11.90 15.88 37.86 57.06 57.06 8.94 9.14 11.9

2.07 1.64 1.19 1.05 1.77 1.10 1.12 2.0 1.51 1.13

*2

10.0 10.0 10.0 10.0 25.0 25.0 25.0 10.0 10.0 10.0

19.0 19.0 19.0 19.0 20.4 20.4 20.4 19.0 19.0 19.0

Brake release time [ms (Max)] 10 10 10 10 10 10 10 10 10 10

Brake pull-in time [ms (Max)] 70 70 70 70 70 70 70 70 70 70

Vibration grade ( μm ) 15

Operating temperature ( ºC) 0 ºC to 40 ºC (32 ºF to 104 ºF)

Storage temperature ( ºC) -10 ºC to 80 ºC (-14 ºF to 176 ºF)

Operating humidity 20 to 90% RH (non-condensing)

Storage humidity 20 to 90% RH (non-condensing)

Vibration capacity 2.5 G

IP Rating

Approvals

E

100 MΩ, 500 V

1.8k V

IP65 (when waterproof connectors are used, or when an oil seal is used to be fitted to

the rotating shaft (an oil seal model is used))

AC

DC

, 1 sec

Footnote:

* 1 Rate torque values are continuous permissible values at 0~40 ºC ambient temperature when attaching with the sizes of heatsinks listed below:

ECMA-__04 / 06 / 08 : 250 mm × 250 mm × 6 mm

ECMA-__10 : 300 mm × 300 mm × 12 mm

ECMA-__13 : 400 mm × 400 mm × 20 mm

ECMA-__18 : 550 mm × 550 mm × 30 mm

ECMA-__22 : 650 mm × 650 mm × 30 mm

Material type : Aluminum F40, F60, F80, F100, F130, F180, F220

*2 The holding brake is used to hold the motor shaft, not for braking the rotation. Never use it for decelerating or stopping the machine.

20

Page 22

FΔ13

FΔ18

Servo Motor Specications

Medium high / High Inertia Series

Model: ECMA Series

Rated power (kW)

Rated torque (N-m)

Maximum torque (N-m)

*1

08 13 18 30

0.85 1.3 1.8 3.0

5.41 8.34 11.48 19.10

13.8 23.3 28.7 57.29

Rated speed (r/min) 1500

Maximum speed (r/min) 3000

Rated current (A) 7.1 12.6 13 19.4

Maximum current (A) 19.4 38.6 36 58.2

Power rating (kW/s) 21.52 34.78 52.93 66.4

Rotor inertia

(x10-4kg-m

2

)(without brake)

13.6 20 24.9 54.95

Mechanical constant (ms) 2.43 1.62 1.7 1.28

Torque constant-KT (N-m/A) 0.76 0.66 0.88 0.98

Voltage constant-KE(mV/(r/min) 29.2 24.2 32.2 35.0

Armature resistance (Ohm) 0.38 0.124 0.185 0.077

Armature inductance (mH) 4.77 1.7 2.6 1.27

Electric constant (ms) 12.55 13.71 14.05 16.5

Insulation class Class A (UL), Class B (CE)

AC

, 1 sec

DC

Insulation resistance >100 MΩ, 500 V

Insulation strength 1.8k V

Weight (kg) (without brake) 8.6 9.4 10.5 18.5

Weight (kg) (with brake) 10.0 10.8 11.9 22.5

Max. radial shaft load (N) 490 490 490 1470

Max. thrust shaft load (N) 98 98 98 490

Power rating (kW/s) (with brake) 19.78 32.66 50.3 63.9

Rotor inertia

(x10-4kg-m

Mechanical constant

(ms) (with brake)

2

) (with brake)

Brake holding torque [Nt-m (min)]

*2

14.8 21.3 26.2 57.06

2.65 1.73 1.79 1.33

10.0 10.0 10.0 25.0

Brake power consumption (at 20 ºC) [W] 19.0 19.0 19.0 20.4

Brake release time [ms (Max)]

Brake pull-in time [ms (Max)]

10

70

10 10 10

70 70 70

Vibration grade ( μm ) 15

Operating temperature ( ºC) 0 ºC~ 40 ºC

Storage temperature ( ºC) -10 ºC to 80 ºC (-14 ºF to 176 ºF)

Operating humidity 20 to 90% RH (non-condensing)

Storage humidity 20 to 90% RH (non-condensing)

Vibration capacity 2.5 G

IP Rating

IP65 (when waterproof connectors are used, or when an oil seal is used to be fitted to

the rotating shaft (an oil seal model is used))

Approvals

Footnote:

*1 Rate torque values are continuous permissible values at 0 ~ 40° C ambient temperature when attaching with the sizes of heatsinks listed below:

ECMA-__04 / 06 / 08 : 250mm x 250mm x 6mm

ECMA-__10 : 300mm x 300mm x 12mm

ECMA-__13 : 400mm x 400mm x 20mm

ECMA-__18 : 550mm x 550mm x 30mm

ECMA-__22 : 650mm x 650mm x 35mm

Material type : Aluminum – F40, F60, F80, F100, F130, F180

*2 The holding brake is used to hold the motor shaft, not for braking the rotation.

Never use it for decelerating or stopping the machine.

21

Page 23

CΔ06

CΔ08

Servo Motor Specications

High Inertia Series

Model: ECMA Series

Rated power (kW)

Rated torque (N-m)

Maximum torque (N-m)

Rated speed (r/min)

Maximum speed (r/min)

Rated current (A)

Maximum current (A)

Power rating (kW/s)

Rotor inertia

(x10-4kg-m

Mechanical constant (ms)

Torque constant-KT (N-m/A)

Voltage constant-KE(mV/(r/min)

Armature resistance (Ohm)

Armature inductance (mH)

Electric constant (ms)

Insulation class

Insulation resistance >

Insulation strength

Weight (kg) (without brake)

Weight (kg) (with brake)

Max. radial shaft load (N)

Max. thrust shaft load (N)

Power rating (kW/s) (with brake)

Rotor inertia

(x10-4kg-m2) (with brake)

Mechanical constant

(ms) (with brake)

Brake holding torque [Nt-m (min)]

Brake power consumption (at 20 ºC) [W]

Brake release time [ms (Max)]

Brake pull-in time [ms (Max)]

Vibration grade ( μm )

Operating temperature ( ºC)

Storage temperature ( ºC)

Operating humidity

Storage humidity

Vibration capacity

IP Rating

Approvals

*1

2

)(without brake)

*2

04 H 07 H

0.4 0.75

1.27 2.39

3.82 7.16

2.6 5.1

7.8 15.3

21.7 19.63

0.743 2.91

1.42 1.6

0.49 0.47

17.4 17.2

1.55 0.42

6.71 3.53

4.3 8.36

Class A (UL), Class B (CE)

1.8 3.4

2.2 3.9

196 245

68 98

21.48 19.3

0.751 2.96

1.43 1.62

1.3 2.5

6.5 8.2

10 10

70 70

-10 ºC to 80 ºC (-14 ºF to 176 ºF)

20 to 90% RH (non-condensing)

20 to 90% RH (non-condensing)

IP65 (when waterproof connectors are used, or when an oil seal is used to be fitted to

the rotating shaft (an oil seal model is used))

3000

5000

100 MΩ, 500 VDC

1.8k VAC, 1 sec

15

0 ºC~ 40 ºC

2.5 G

Footnote:

*1 Rate torque values are continuous permissible values at 0 ~ 40° C ambient temperature when attaching with the sizes of heatsinks listed below:

ECMA-__04 / 06 / 08 : 250mm x 250mm x 6mm

ECMA-__10 : 300mm x 300mm x 12mm

ECMA-__13 : 400mm x 400mm x 20mm

ECMA-__18 : 550mm x 550mm x 30mm

ECMA-__22 : 650mm x 650mm x 35mm

Material type : Aluminum – F40, F60, F80, F100, F130, F180

*2 The holding brake is used to hold the motor shaft, not for braking the rotation.

Never use it for decelerating or stopping the machine.

22

Page 24

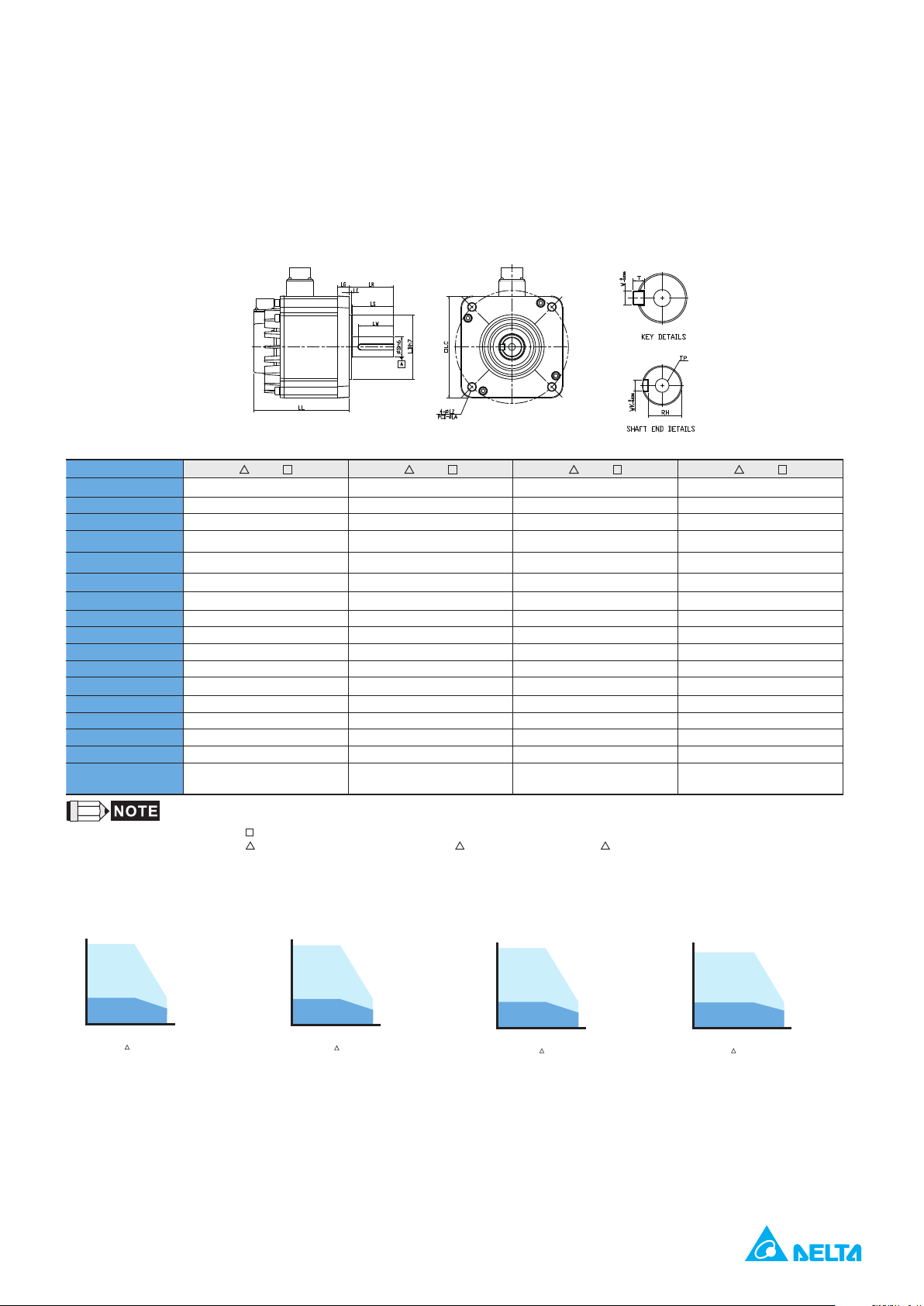

Servo Motor Dimensions

Motors - Frame Size 86mm and below (Units: mm)

Model

LC

LZ

LA

S

LB

(without brake) 100.6 105.5 130.7 145.8 112.3 138.3 151.1 130.2 153.2

LL

(with brake) 136.8 141.6 166.8 176.37 152.8 178 189 161.3 184.3

LL

LS

LR

LE

LG

LW

RH

WK

W

T

TP

C 0401 S C 0602 S C 0604 S C 0604 H C 0804 7 C 0807 S C 0807 H C 0907 S C 0910 S

40 60 60 60 80 80 80 86 86

4.5 5.5 5.5 5.5 6.6 6.6 6.6 6.6 6.6

46 70 70 70 90 90 90 100 100

8 (

30 (

+0

- 0.009

+0

- 0.021

) 14 (

) 50 (

+0

- 0.011

+0

- 0.025

) 14 (

) 50 (

+0

- 0.011

+0

- 0.025

) 14 (

) 50 (

+0

- 0.011

+0

- 0.025

) 14 (

) 70 (

+0

- 0.011

+0

- 0.030

) 19 (

) 70 (

+0

- 0.013

+0

- 0.030

) 19 (

) 70 (

+0

- 0.013

+0

- 0.030

) 16 (

) 80 (

+0

- 0.011

+0

- 0.030

20 27 27 27 27 32 32 30 30

25 30 30 30 30 35 35 35 35

2.5 3 3 3 3 3 3 3 3

5 7.5 7.5 7.5 8 8 8 8 8

16 20 20 20 20 25 25 20 20

6.2 11 11 11 11 15.5 15.5 13 13

3 5 5 5 5 6 6 5 5

3 5 5 5 5 6 6 5 5

3 5 5 5 5 6 6 5 5

M3

Depth 8

1) Dimensions are in millimeters. Actual measured values are in metric units.

2) Dimensions of the servo motor may be updated without prior notice.

3) The boxes (

4) The boxes (

M4

Depth 15M4Depth 15M4Depth 15M4Depth 15M6Depth 20M6Depth 20M5Depth 15M5Depth 15

) in the model names represent shaft end / brake or the number of oil seal.

) in the model names represent encoder types ( =1: Incremental encoder, 20-bit; =2: Incremental encoder, 17-bit).

) 16 (

) 80 (

Unit: mm

+0

- 0.011

+0

- 0.030

)

)

Speed-Torque Curves (T-N Curves)

Torque (N-m)

Intermittent Duty Zone

Continuous Duty Zone

Torque (N-m)

7.14

(298%)

6.00

(251%)

Intermittent Duty Zone

2.38

(100%)

Continuous Duty Zone

ECMA-C

0401 □S

ECMA-C 0907 □ S

Speed (r/min)

Speed (r/min)

Torque (N-m)

Intermittent Duty Zone

Continuous Duty Zone

ECMA-C

Torque (N-m)

8.78

(276%)

5.85

(184%)

Intermittent Duty Zone

3.18

(100%)

Continuous Duty Zone

ECMA-C

0602 □S

2,000 3,000

0910 □ S

Speed (r/min)

Speed (r/min)

23

Torque (N-m)

Intermittent Duty Zone

Continuous Duty Zone

ECMA-C

0604 □ S

ECMA-C 0604 □ H

ECMA-C 0804 □ 7

Speed (r/min)

Torque (N-m)

Intermittent Duty Zone

Continuous Duty Zone

ECMA-C 0807 □ S

ECMA-C 0807 □ H

Speed (r/min)

Page 25

Motors - Frame Size 100mm ~ 130mm (Units: mm)

Model C 1010 S C 1020 S C 1330 4 E 1305 S E 1310 S E 1315 S

LC 100 100 130 130 130 130

LZ 9 9 9 9 9 9

LA 115 11 5 145 145 145 145

S 22 (

LB 95 (

(不帶煞車)

LL

(帶煞車)

LL

+0

) 22 (

- 0.013

+0

) 95 (

- 0.035

153.3 199 187.5 147.5 147.5 167.5

192.5 226 216 183.5 183.5 202

LS 37 37 47 47 47 47

LR 45 45 55 55 55 55

LE 5 5 6 6 6 6

LG 12 12 11.5 11.5 11.5 11.5

LW 32 32 36 36 36 36

RH 18 18 20 18 18 18

WK 8 8 8 8 8 8

W 8 8 8 8 8 8

T 7 7 7 7 7 7

TP

M6

Depth 20

1) Dimensions are in millimeters. Actual measured values are in metric units.

2) Dimensions of the servo motor may be updated without prior notice.

3) The boxes (

4) The boxes (

) in the model names represent shaft end / brake or the number of oil seal.

) in the model names represent encoder types ( =1: Incremental encoder, 20-bit; =2: Incremental encoder, 17-bit).

+0

- 0.013

+0

- 0.035

M6

Depth 20

) 24 (

) 110 (

Depth 20

M6

+0

- 0.013

+0

- 0.035

) 22 (

) 110 (

Depth 20

M6

+0

- 0.013

+0

- 0.035

) 22 (

) 110 (

Depth 20

M6

+0

- 0.013

+0

- 0.035

) 22 (

) 110 (

Unit: mm

+0

- 0.013

+0

- 0.035

M6

Depth 20

)

)

Speed-Torque Curves (T-N Curves)

Torque (N-m)

Intermittent Duty Zone

Continuous Duty Zone

Torque (N-m)

Intermittent Duty Zone

Continuous Duty Zone

ECMA-C

ECMA-E

Speed (r/min)

1010 □ S

Speed (r/min)

1305 □ S

Torque (N-m)

Intermittent Duty Zone

Continuous Duty Zone

Torque (N-m)

Intermittent Duty Zone

Continuous Duty Zone

ECMA-C

ECMA-E

1020 □ S

Speed (r/min)

1310 □ S

Speed (r/min)

24

Torque (N-m)

Intermittent Duty Zone

Torque (N-m)

Continuous Duty Zone

ECMA-C

Intermittent Duty Zone

Continuous Duty Zone

ECMA-E

1315 □ S

Speed (r/min)

1330 □ 4

Speed (r/min)

Page 26

Servo Motor Dimensions

Motors - Frame Size 100mm ~ 130mm (Units: mm)

Model

LC

LZ 9 9 9 9 9 9 9

LA 145 145 145 145 145 145 145

S

LB

(without brake)

LL

(with brake)

LL

LS 47 47 47 47 47 47 47

LR 55 55 55 55 55 55 55

LE 6 6 6 6 6 6 6

LG 11.5 11.5 11.5 11.5 11.5 11.5 11.5

LW 36 36 36 36 36 36 36

RH 18 18 18 18 18 18 18

WK 8 8 8 8 8 8 8

W 8 8 8 8 8 8 8

T 7 7 7 7 7 7 7

TP

E

1320 S F 1308 S F 1313 S F 1318 S G 1303 S G 1306 S G 1309 S

130 130 130 130 130 130 130

22 (

110 (

+0

- 0.013

+0

- 0.035

) 22 (

) 110 (

+0

- 0.013

+0

- 0.035

) 22 (

) 110 (

+0

- 0.013

+0

- 0.035

) 22 (

) 110 (

+0

- 0.013

+0

- 0.035

) 22 (

) 110 (

187.5 152.5 187.5 202 147.5 147.5 163.5

216 181 216 230.7 183.5 183.5 198

M6

Depth 20

1) Dimensions are in millimeters. Actual measured values are in metric units.

2) Dimensions of the servo motor may be updated without prior notice.

3) The boxes (

4) The boxes (

) in the model names represent shaft end / brake or the number of oil seal.

) in the model names represent encoder types ( =1: Incremental encoder, 20-bit; =2: Incremental encoder, 17-bit).

M6

Depth 20

M6

Depth 20

M6

Depth 20

+0

- 0.013

+0

- 0.035

M6

Depth 20

) 22 (

) 110 (

Depth 20

M6

+0

- 0.013

+0

- 0.035

) 22 (

) 110 (

Depth 20

Unit: mm

+0

- 0.013

+0

- 0.035

M6

)

)

Speed-Torque Curves (T-N Curves)

Torque (N-m)

Intermittent Duty Zone

Continuous Duty Zone

Torque (N-m)

Intermittent Duty Zone

Continuous Duty Zone

ECMA-E

ECMA-G

Speed (r/min)

1320 □ S

Speed (r/min)

1303 □ S

Torque (N-m)

Intermittent Duty Zone

Continuous Duty Zone

Intermittent Duty Zone

Continuous Duty Zone

Speed (r/min)

1308 □ S

ECMA-F

Speed (r/min)

1306 □ S ECMA-G 1309 □S

ECMA-G

25

Torque (N-m)

Torque (N-m)Torque (N-m)

Intermittent Duty Zone

Continuous Duty Zone

ECMA-F

1313 □ S

Intermittent Duty Zone

Continuous Duty Zone

Speed (r/min)

Speed (r/min)

Torque (N-m)

Intermittent Duty Zone

Continuous Duty Zone

Speed (r/min)

ECMA-F 1318 □ S

Page 27

Motors - Frame Size 180mm (Units: mm)

Model E 1820 S E 1830 S F 1830 S E 1835 S

LC 180 180 180 180

LZ 13.5 13.5 13.5 13.5

LA 200 200 200 200

S 35 (

LB 114.3 (

(without brake)

LL

(with brake)

LL

LS 73 73 73 73

LR 79 79 79 79

LE 4 4 4 4

LG 20 20 20 20

LW 63 63 63 63

RH 30 30 30 30

WK 10 10 10 10

W 10 10 10 10

T 8 8 8 8

TP

1) Dimensions are in millimeters. Actual measured values are in metric units.

2) Dimensions of the servo motor may be updated without prior notice.

3) The boxes (

4) The boxes (

+0

) 35 (

- 0.016

+0

) 114.3 (

- 0.035

+0

) 35 (

- 0.016

+0

) 114.3 (

- 0.035

+0

) 35 (

- 0.016

+0

) 114.3 (

- 0.035

169 202.1 202.1 202.1

203.1 235.3 235.3 235.3

M12

Depth 25

) in the model names represent shaft end / brake or the number of oil seal.

) in the model names represent encoder types ( =1: Incremental encoder, 20-bit; =2: Incremental encoder, 17-bit).

M12

Depth 25

M12

Depth 25

+0

- 0.016

+0

- 0.035

M12

Depth 25

Unit: mm

)

)

Speed-Torque Curves (T-N Curves)

Torque (N-m)

28.65

(300%)

Intermittent Duty Zone

9.55

(100%)

6.40

(67%)

Continuous Duty Zone

ECMA-E 1820 □ S

3,0002,000

Speed (r/min)

Torque (N-m)

42.97

(300%)

Intermittent Duty Zone

14.32

(100%)

9.59

Continuous Duty Zone

(67%)

ECMA-E

2,000

1830 □ S

3,000

Speed (r/min)

Torque (N-m) Torque (N-m)

57.29

(300%)

Intermittent Duty Zone Intermittent Duty Zone

19.10

(100%)

9.55

Continuous Duty Zone Continuous Duty Zone

(50%)

1,500

ECMA-F

Speed (r/min) Speed (r/min)

3,000

1830 □ S ECMA-E 1835 □ S

26

50.13

(300%)

16.71

(100%)

11.20

(67%)

3,0002,000

Page 28

Optional Accessories

Power Cables

■

3m and 5m standard cables are available.

■

Individual connectors are also provided for

different demands.

■

Two types are selectable: with brake and

without brake.

CN1 I/O Connectors

■

Used to connect to external (host) controller

■

Delta Part Number: ASDBCNDS0044

CN1 Convenient Connector

■

Delta Part Number: ASD-IF-DS4444

Encoder Cables

■

3m and 5m standard cables are available.

■

Individual connectors are also provided

for different demands.

27

Page 29

Regenerative Resistors

■

Two kinds of regenerative resistors are

available, 400W/40Ω and 1kw/20Ω.

Terminal Block Modules

■

0.5m connection cable is provided for saving on

installation space.

■

Delta Part Number: ASD-MDDS4444

RS-485 Connectors

■

Used to connect multiple ASDA series products

by RS-485 interface through Modbus serial

communication.

■

Delta Part Number: ASD-CNIE0B06

ASD-Soft Software

Communication Cables (for PC)

■

Delta Part Number: ASD-CNUS0A08

The figures are for illustration purposes only. Actual models may

differ slightly in appearance from illustrations provided.

28

Page 30

Optional Accessories

Power Connectors

ASDBCAPW0000 ASD-CAPW1000

ASDBCAPW0100 ASD-CAPW2000

Power Cables

3106A-20-18S

3106A-24-11S

ASDBCAPW0203/0205

ASDBCAPW0303/0305

KST: SVBL1-3. 7

L

KST: SVBL1-3. 7

L

KST: RVBL1- 4

KST: RVBL1- 4

Item Part No.

ASDBCAPW0203 3000 ± 50 118 ± 2

1

ASDBCAPW0205 5000 ± 50 197 ± 2

2

L

mm inch

29

Item Part No.

ASDBCAPW0303 3000 ± 50 118 ± 2

1

ASDBCAPW0305 5000 ± 50 197 ± 2

2

L

mm inch

Page 31

mm

inch

Power Cables

ASDBCAPW1203/1205

3106A-20-18S

ASDBCAPW1303/1305

3106A-20-18S

KST: YF3.5-3SG

L

Item Part No. Straight

ASDBCAPW1203 3106A-20-18S 3000 ± 50 118 ± 2

1

ASDBCAPW1205 3106A-20-18S 5000 ± 50 197 ± 2

2

KST: YF3.5-3SG

L

Item Part No. Straight

ASDBCAPW1303 3106A-20-18S 3000 ± 50 118 ± 2

1

ASDBCAPW1305 3106A-20-18S 5000 ± 50 197 ± 2

2

L

mm inch

L

mm inch

ASD-CAPW2203/2205

3106A-24-11S

ASD-CAPW2303/2305

3106A-24-11S

KST: SVB3-4

KST: RVBL5-4

L

Item Part No. Straight

ASD-CAPW2203 3106A-24-11S 3000 ± 50 118 ± 2

1

ASD-CAPW2205 3106A-24-11S 5000 ± 50 197 ± 2

2

KST: SVB3- 4

L

KST: RVBL5- 4

Item Part No. Straight

ASD-CAPW2303 3106A-24-11S 3000 ± 50 118 ± 2

1

ASD-CAPW2305 3106A-24-11S 5000 ± 50 197 ± 2

2

L

mm inch

L

30

Page 32

Optional Accessories

Encoder Connectors

ASDBCAEN0000 D-SUB Connector 9P

ASDBCAEN1000

3106A-20-29S

Encoder Cables

ASDBCAEN0003/0005

ASDBCAEN1003/1005

D-SUB Connector 9P

L

D-SUB Connector 9P

Item Part No.

1 ASDBCAEN0003 3000 ± 50 118 ± 2

2 ASDBCAEN0005 5000 ± 50 197 ± 2

L

mm inch

L

D-SUB Connector 9P3106A-20-29S

Item Part No. Straight

1 ASDBCAEN1003 3106A-20-29S 3000 ± 50 118 ± 2

2 ASDBCAEN1005 3106A-20-29S 5000 ± 50 197 ± 2

L

mm inch

31

Page 33

I/O Signal Connector

RS-485 Connector

Dimensions are in mm

ASD-BCNDS0044

ASD-CNIE0B06

D-SUB 44 PIN PLUG

ASDBCAEN1000

D-SUB 15 PIN PLUG

1) More accessories for ASDA-B2 will be on the list.

2) Accessories images shown here may differ from the actual product.

Communication Cable between Drive and Computer (for PC)

ASD-CNUS0A08

L

80.1

22.5

(50)

1.8

Title Part No.Part No. : ASD-CNUS0A08

Cable L

21.2

Connector

RJ connector RJ-45

USB connector A-type (USB V2.0)

Dimensions are in mm

3000 ± 100 mm

118 ± 4 inch

Voltage Output Cable (Analog Signal)

3864471800

20 ± 5

Terminal Block Module

ASD-MDDS4444

Dimensions are in mm

Dimensions are in mm

1

2

3

32

Page 34

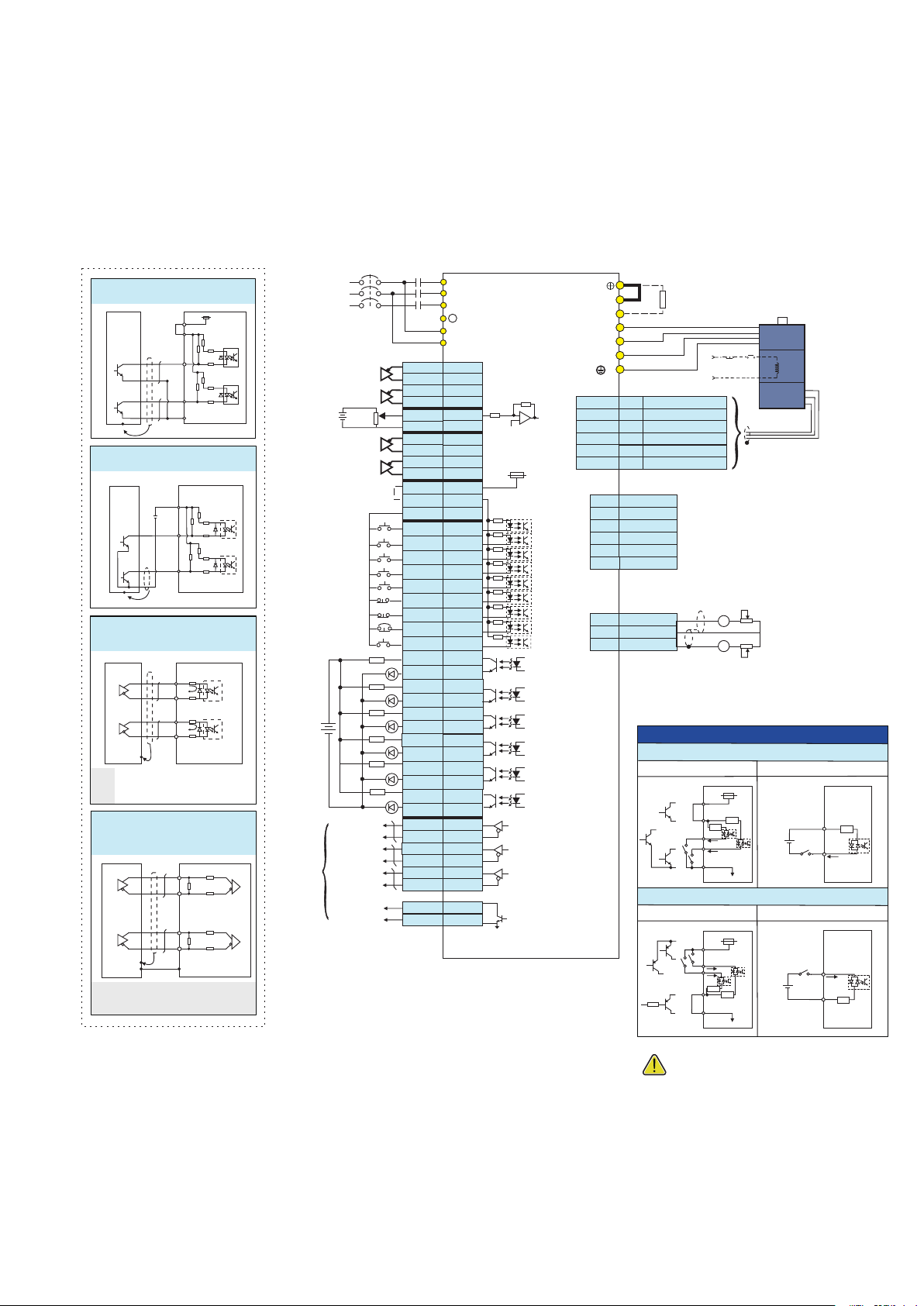

Accessories Combinations

100W Servo Drive and 100W Low Inertia Servo Motor

Servo Drive

Low Inertia Servo Motor ECMA-C△0401

Power Cables (Without Brake) ASDBCAPW020X

Power Connectors (Without Brake) ASDBCAPW0000

Power Cables (With Brake) ASDBCAPW030X

Power Connectors (With Brake) ASDBCAPW0100

Encoder Cables ASDBCAEN000X

Encoder Connectors ASDBCAEN0000

(X=3 indicates that the cable length is 3m; X=5 indicates that the cable length is 5m)

200W Servo Drive and 200W Low Inertia Servo Motor

Servo Drive ASD-B2-0221-B

Low Inertia Servo Motor ECMA-C△0602

Power Cables (Without Brake) ASDBCAPW020X

Power Connectors (Without Brake) ASDBCAPW0000

Power Cables (With Brake) ASDBCAPW030X

Power Connectors (With Brake) ASDBCAPW0100

Encoder Cables ASDBCAEN000X

Encoder Connectors ASDBCAEN0000

(X=3 indicates that the cable length is 3m; X=5 indicates that the cable length is 5m)

400W Servo Drive and 400W Low Inertia Servo Motor

ASD-B2-0121-B

S

S

Servo Drive ASD-B2-0421-B

ECMA-C△0604

Low Inertia Servo Motor

Power Cables (Without Brake) ASDBCAPW020X

Power Connectors (Without Brake) ASDBCAPW0000

Power Cables (With Brake) ASDBCAPW030X

Power Connectors (With Brake) ASDBCAPW0100

Encoder Cables ASDBCAEN000X

Encoder Connectors ASDBCAEN0000

ECMA-C△0804 7

ECMA-CM0604PS

(X=3 indicates that the cable length is 3m; X=5 indicates that the cable length is 5m)

400W Servo Drive and 400W High Inertia Servo Motor

Servo Drive ASD-B2-0421-B

High Inertia Servo Motor ECMA-C△0604

Power Cables (Without Brake) ASDBCAPW020X

Power Connectors (Without Brake) ASDBCAPW0000

Power Cables (With Brake) ASDBCAPW030X

Power Connectors (With Brake) ASDBCAPW0100

Encoder Cables ASDBCAEN000X

Encoder Connectors ASDBCAEN0000

(X=3 indicates that the cable length is 3m; X=5 indicates that the cable length is 5m)

S

H

33

Page 35

400W Servo Drive and 500W Medium Inertia Servo Motor

Servo Drive

Medium Inertia Servo Motor ECMA-E△1305

Power Cables (Without Brake) ASDBCAPW120X

Power Cables (With Brake) ASDBCAPW130X

Power Connectors ASD-CAPW1000

Incremental Encoder Cables ASDBCAEN100X

Encoder Connectors ASDBCAEN1000

(X=3 indicates that the cable length is 3m; X=5 indicates that the cable length is 5m)

ASD-B2-0421-B

400W Servo Drive and 300W High Inertia Servo Motor

Servo Drive ASD-B2-0421-B

High Inertia Servo Motor ECMA-G△1303

Power Cables (Without Brake) ASDBCAPW120X

Power Cables (With Brake) ASDBCAPW130X

Power Connectors ASD-CAPW1000

Encoder Cables ASDBCAEN100X

Encoder Connectors ASDBCAEN1000

(X=3 indicates that the cable length is 3m; X=5 indicates that the cable length is 5m)

S

S

750W Servo Drive and 600W High Inertia Servo Motor

Servo Drive ASD-B2-0721-B

High Inertia Servo Motor

Power Cables (Without Brake) ASDBCAPW120X

Power Cables (With Brake) ASDBCAPW130X

Power Connectors ASD-CAPW1000

Encoder Cables ASDBCAEN100X

Encoder Connectors ASDBCAEN1000

ECMA-G△1306

ECMA-GM1306PS

(X=3 indicates that the cable length is 3m; X=5 indicates that the cable length is 5m)

750W Servo Drive and 750W Low Inertia Servo Motor

Servo Drive ASD-B2-0721-B

ECMA-C△0807

Low Inertia Servo Motor

Power Cables (Without Brake) ASDBCAPW020X

Power Connectors (Without Brake) ASDBCAPW0000

Power Cables (With Brake) ASDBCAPW030X

Power Connectors (With Brake) ASDBCAPW0100

Encoder Cables ASDBCAEN000X

Encoder Connectors ASDBCAEN0000

(X=3 indicates that the cable length is 3m; X=5 indicates that the cable length is 5m)

ECMA-C△0907 7

ECMA-CM0807PS

S

S

34

Page 36

Accessories Combinations

750W Servo Drive and 750W High Inertia Servo Motor

Servo Drive

High Inertia Servo Motor ECMA-C△0807 □ H

Power Cables (Without Brake) ASDBCAPW020X

Power Connectors (Without Brake) ASDBCAPW0000

Power Cables (With Brake) ASDBCAPW030X

Power Connectors (With Brake) ASDBCAPW0100

Encoder Cables ASDBCAEN000X

Encoder Connectors ASDBCAEN0000

(X=3 indicates that the cable length is 3m; X=5 indicates that the cable length is 5m)

1kW Servo Drive and 850W Low Inertia Servo Motor

Servo Drive ASD-B2-1021-B

Low Inertia Servo Motor ECMA-F△1308

Power Cables (Without Brake) ASDBCAPW120X

Power Cables (With Brake) ASDBCAPW130X

Power Connectors ASD-CAPW1000

Encoder Cables ASDBCAEN100X

Encoder Connectors ASDBCAEN1000

(X=3 indicates that the cable length is 3m; X=5 indicates that the cable length is 5m)

ASD-B2-0721-B

S

1kW Servo Drive and 1kW Low Inertia Servo Motor

Servo Drive ASD-B2-1021-B

Low Inertia Servo Motor ECMA-C△1010

Power Cables (Without Brake) ASDBCAPW120X

Power Cables (With Brake) ASDBCAPW130X

Power Connectors ASD-CAPW1000

Encoder Cables ASDBCAEN100X

Encoder Connectors ASDBCAEN1000

(X=3 indicates that the cable length is 3m; X=5 indicates that the cable length is 5m)

1kW Servo Drive and 1kW Low Inertia Servo Motor

Servo Drive ASD-B2-1021-B

Low Inertia Servo Motor ECMA-C△0910

Power Cables (Without Brake) ASDBCAPW020X

Power Connectors (Without Brake) ASDBCAPW0000

Power Cables (With Brake) ASDBCAPW030X

Power Connectors (With Brake) ASDBCAPW0100

Incremental Encoder Cables ASDBCAEN000X

Encoder Connectors ASDBCAEN0000

(X=3 indicates that the cable length is 3m; X=5 indicates that the cable length is 5m)

S

S

35

Page 37

1kW Servo Drive and 1kW Medium Inertia Servo Motor

Servo Drive

Medium Inertia Servo Motor ECMA-E△1310

Power Cables (Without Brake) ASDBCAPW120X

Power Cables (With Brake) ASDBCAPW130X

Power Connectors ASD-CAPW1000

Encoder Cables ASDBCAEN100X

Encoder Connectors ASDBCAEN1000

(X=3 indicates that the cable length is 3m; X=5 indicates that the cable length is 5m)

ASD-B2-1021-B

1kW Servo Drive and 900W High Inertia Servo Motor

Servo Drive ASD-B2-1021-B

High Inertia Servo Motor

Power Cables (Without Brake) ASDBCAPW120X

Power Cables (With Brake) ASDBCAPW130X

Power Connectors ASD-CAPW1000

Encoder Cables ASDBCAEN100X

Encoder Connectors ASDBCAEN1000

(X=3 indicates that the cable length is 3m; X=5 indicates that the cable length is 5m)

ECMA-G△1309

ECMA-GM1309PS

S

S

1.5kW Servo Drive and 1.5kW Medium Inertia Servo Motor

Servo Drive ASD-B2-1521-B

Medium Inertia Servo Motor ECMA-E△1315

Power Cables (Without Brake) ASDBCAPW120X

Power Cables (With Brake) ASDBCAPW130X

Power Connectors ASD-CAPW1000

Encoder Cables ASDBCAEN100X

Encoder Connectors ASDBCAEN1000

(X=3 indicates that the cable length is 3m; X=5 indicates that the cable length is 5m)

2kW Servo Drive and 2kW Low Inertia Servo Motor

Servo Drive ASD-B2-2023-B

Low Inertia Servo Motor ECMA-C△1020

Power Cables (Without Brake) ASDBCAPW120X

Power Cables (With Brake) ASDBCAPW130X

Power Connectors ASDBCAPW1000

Encoder Cables ASDBCAEN100X

Encoder Connectors ASDBCAEN1000

(X=3 indicates that the cable length is 3m; X=5 indicates that the cable length is 5m)

S

S

36

Page 38

Accessories Combinations

2kW Servo Drive and 2kW Medium Inertia Servo Motor

Servo Drive

Medium Inertia Servo Motor ECMA-E△1320

Power Cables (Without Brake) ASDBCAPW120X

Power Cables (With Brake) ASDBCAPW130X

Power Connectors ASD-CAPW1000

Encoder Cables ASDBCAEN100X

Encoder Connectors ASDBCAEN1000

(X=3 indicates that the cable length is 3m; X=5 indicates that the cable length is 5m)

2kW Servo Drive and 2kW Medium Inertia Servo Motor

Servo Drive ASD-B2-2023-B

Medium Inertia Servo Motor ECMA-E△1820

Power Cables (Without Brake) ASD-CAPW220X

Power Cables (With Brake) ASD-CAPW230X

Power Connectors ASD-CAPW2000

Encoder Cables ASDBCAEN100X

Encoder Connectors ASDBCAEN1000

(X=3 indicates that the cable length is 3m; X=5 indicates that the cable length is 5m)

ASD-B2-2023-B

S

S

2kW Servo Drive and 1.3kW Medium High Inertia Servo Motor

Servo Drive ASD-B2-2023-B

Medium High Inertia Servo Motor ECMA-F11313

Power Cables (Without Brake) ASDBCAPW120X

Power Cables (With Brake) ASDBCAPW130X

Power Connectors ASD-CAPW1000

Encoder Cables ASDBCAEN100X

Encoder Connectors ASDBCAEN1000

(X=3 indicates that the cable length is 3m; X=5 indicates that the cable length is 5m)

2kW Servo Drive and 1.8kW Medium High Inertia Servo Motor

Servo Drive ASD-B2-2023-B

Medium High Inertia Servo Motor ECMA-F11318

Power Cables (Without Brake) ASDBCAPW120X

Power Cables (With Brake) ASDBCAPW130X

Power Connectors ASD-CAPW1000

Encoder Cables ASDBCAEN100X

Encoder Connectors ASDBCAEN1000

(X=3 indicates that the cable length is 3m; X=5 indicates that the cable length is 5m)

S

S

37

Page 39

3kW Servo Drive and 3kW Low Inertia Servo Motor

Servo Drive

Low Inertia Servo Motor ECMA-C△1330

Power Cables (Without Brake) ASDBCAPW120X

Power Cables (With Brake) ASDBCAPW130X

Power Connectors ASD-CAPW1000

Encoder Cables ASDBCAEN100X

Encoder Connectors ASDBCAEN1000

(X=3 indicates that the cable length is 3m; X=5 indicates that the cable length is 5m)

ASD-B2-3023-B

3kW Servo Drive and 3kW Medium Inertia Servo Motor

Servo Drive ASD-B2-3023-B

Medium Inertia Servo Motor ECMA-E△1830

Power Cables (Without Brake) ASD-CAPW220X

Power Cables (With Brake) ASD-CAPW230X

Power Connectors ASD-CAPW2000

Encoder Cables ASDBCAEN100X

Encoder Connectors ASDBCAEN1000

(X=3 indicates that the cable length is 3m; X=5 indicates that the cable length is 5m)

4

S

3kW Servo Drive and 3.5kW Medium Inertia Servo Motor

Servo Drive ASD-B2-3023-B

Medium Inertia Servo Motor ECMA-E△1835

Power Cables (Without Brake) ASD-CAPW220X

Power Cables (With Brake) ASD-CAPW230X

Power Connectors ASD-CAPW2000

Encoder Cables ASDBCAEN100X

Encoder Connectors ASDBCAEN1000

(X=3 indicates that the cable length is 3m; X=5 indicates that the cable length is 5m)

3kW Servo Drive and 3kW Medium High Inertia Servo Motor

Servo Drive ASD-B2-3023-B

Medium High Inertia Servo Motor ECMA-F△1830

Power Cables (Without Brake) ASD-CAPW220X

Power Cables (With Brake) ASD-CAPW230X

Power Connectors ASD-CAPW2000

Encoder Cables ASDBCAEN100X

Encoder Connectors ASDBCAEN1000

(X=3 indicates that the cable length is 3m; X=5 indicates that the cable length is 5m)

S

S

Other Accessories (for ASDA-B2 series all models)

Description Delta Part Number

Communication Cable between Servo

Drive and Computer

Regenerative Resistor 400W 100Ω BR400W040

Regenerative Resistor 1kW 1000Ω BR1K0W020

38

ASD-CARS0003

Loading...

Loading...