Operating manual

Ultrasonic anemometers

HD51.3D4R

HD51.3D4R-AL

www.deltaohm.com

English

Keep for future reference.

Companies / Brands of GHM

HD51.3D4R - 2 - V1.2

TABLE OF CONTENTS

1 INTRODUCTION.................................................................................................... 3

2 TECHNICAL SPECIFICATIONS ............................................................................... 4

3 DESCRIPTION....................................................................................................... 5

4 MEASURING PRINCIPLE OF WIND SPEED AND DIRECTION .................................. 6

5 INSTALLATION ..................................................................................................... 7

5.1 ALIGNMENT OF THE INSTRUMENT .............................................................................. 8

5.2 ELECTRICAL CONNECTIONS ..................................................................................... 9

5.2.1 RS232 SERIAL CONNECTION ..................................................................... 10

5.2.2 RS485 SERIAL CONNECTION ..................................................................... 10

5.2.3 RS422 SERIAL CONNECTION ..................................................................... 11

5.2.4 ANALOG OUTPUTS CONNECTION.................................................................. 12

5.2.5 CONNECTION OF HEATING SYSTEM............................................................... 12

5.2.6 AUXILIARY RS485 SERIAL OUTPUT CONNECTION.............................................. 13

5.3 SERIAL OUTPUT PROTOCOL.................................................................................... 13

6 CONFIGURATION................................................................................................ 14

6.1 SERIAL COMMANDS ............................................................................................ 14

7 ASCII PROPRIETARY MODE ................................................................................ 25

8 NMEA MODE........................................................................................................ 26

9 MODBUS-RTU MODE ........................................................................................... 28

10 INSTRUMENT STORAGE ...................................................................................... 30

11 SAFETY INSTRUCTIONS...................................................................................... 30

12 ORDERING CODES .............................................................................................. 31

HD51.3D4R - 3 - V1.2

1 INTRODUCTION

HD51.3D4R e HD51.3D4R-AL are 2-axes ultrasonic static anemometers with integrated

heater. The heater prevents the accumulation of snow and ice formation, allowing accurate

measurements in all environmental conditions.

HD51.3D4R-AL is equipped with an enhanced heater, for rapid defrosting, and an ano-

dized aluminum alloy housing with anti-corrosion coating that makes it possible to use the

instrument even in a particularly aggressive atmosphere (e.g., marine environment). The

anemometer satisfies the requirements of the MIL-STD-810G Method 509.6 standard (salt

fog anti-corrosion test). The high immunity to electromagnetic disturbances makes the anemometer suitable for measurements in electrically noisy environments (e.g., industrial environments, wind farms, etc.).

The anemometers measure:

• Wind speed up to 80 m/s (HD51.3D4R-AL) or 85 m/s (HD51.3D4R).

• Wind direction.

• Wind Gust.

• Atmospheric pressure (with internal sensor).

The average of wind speed and direction over a period configurable up to 10 minutes is calculated.

Available outputs:

• RS232, RS485 and RS422 isolated serial outputs with NMEA and MODBUS-RTU

standard protocols and ASCII proprietary protocol.

• Two analog outputs, for wind speed and direction or for velocity U-V cartesian compo-

nents, which are factory-configurable within 4÷20

mA (standard), 0÷1 V, 0÷5 V or

0÷10

V (to be specified when ordering).

Mounting on ∅ 40

mm mast. The electric connection is performed through the M23 connector

situated at the bottom of the instrument.

Power supply of the instrument (excluding heater) 12…30 Vdc. Power supply of the heater 24

Vdc.

All instrument sensors are factory-calibrated and do not require additional interventions of the

user (field calibration is not required).

The absence of moving parts minimizes the instrument maintenance.

HD51.3D4R - 4 - V1.2

2 TECHNICAL SPECIFICATIONS

HD51.3D4R HD51.3D4R-AL

Wind speed

Used sensor Ultrasounds

Measuring range 0…85 m/s 0…80 m/s

Resolution 0.01 m/s

Accuracy ± 0.2 m/s or ± 2%, the greatest (0…60 m/s), ± 3% (> 60 m/s)

Wind direction

Used sensor Ultrasounds

Measuring range

0…359.9°. In order to avoid oscillations of the analog output

around 0°, the extended range 0…539.9° can be set.

Resolution 0.1°

Accuracy ± 2° RMSE (wind speed > 2 m/s)

Atmospheric Pressure

Used sensor Piezoresistive

Measuring range 300…1100 hPa

Resolution 0.1 hPa

Accuracy ± 0.5 hPa @ 20 °C

General features

Instrument power supply

(excluding heater)

12…30 Vdc

Heater power supply 24 Vdc ± 10%

Instrument power consumption

(excluding heater)

60

mA @ 24 Vdc

Heater power consumption 15 W @ 24 Vdc 80 W @ 24 Vdc

Serial outputs Isolated RS232, RS485 and RS422

Communication protocols NMEA, MODBUS-RTU, ASCII proprietary

Analog outputs

2 analog outputs, for wind speed and direction or for velocity

U-V cartesian components.

Output at choice among 4…20

mA (standard, max. load 500 Ω),

0…1

V, 0…5 V and 0…10 V

The outputs are isolated from the power supply

Measurement interval From 250 ms to 1 s

Wind speed averaging interval Configurable from 1 s to 10 min

Wind Gust calculation interval Configurable from 1 s to 10 min

Electrical connection 19-pole M23 male connector

Operating temperature -40…+60 °C

Protection degree IP 66

Anti-corrosion test According to MIL-STD-810G Method 509.6

(48 hours of exposure + 48 hours of drying)

Survival speed 90 m/s 100 m/s

Weight 640 g approx. 1.4 kg approx.

Housing

ASA with aluminum and

AISI 316 metal parts

Anodized aluminum alloy

and AISI 316

Installation on mast ∅ 40 mm external and ∅ 36 mm internal

HD51.3D4R - 5 - V1.2

Dimensions:

150

179 (HD51.3D4R)

188 (HD51.3D4R-AL)

40 ext.

36 int.

50

3 DESCRIPTION

1. Ultrasonic sensors for the measurement of wind speed and direction.

2. Fixing clamp to Ø 40 mm mast.

3. Ø 40

mm mast.

HD51.3D4R - 6 - V1.2

4 MEASURING PRINCIPLE OF WIND SPEED AND DIRECTION

Wind speed and direction are determined by measuring the time taken by ultrasonic pulses to

cover the distance from the transducer that generates the pulse to the receiving transducer.

The instrument uses 2 pairs of transducers oriented along two orthogonal axes. Detecting the

wind speed along two axes allows determining not only the intensity but also the wind direction.

The instrument measures the travel time of the ultrasonic pulse between the two transducers

of the same pair in both directions. The travel times in the two opposed directions are defined

as t

A

(forward direction time) and tR (reverse direction time).

If wind speed is zero, t

A

and tR values are the same. In the presence of wind, one of the two

time values is greater than the other and the comparison between the two time values allows

determining the direction and the intensity of the wind.

Measuring the travel time in both directions allows cancelling the dependence of the transmission speed of ultrasounds in the air from the environmental conditions of temperature, humidity and barometric pressure.

Measurement along first axis Measurement along second axis

The travel times of the ultrasonic pulses are given by:

W

A

VC

D

t+=

W

R

VC

D

t−=

Where:

D = Distance between the two transducers of the same pair

C = Sound speed

V

W

= Component of wind speed along the measurement axis

Measuring the two travel times allows determining the wind speed component:

⎟

⎠

⎞

⎜

⎝

⎛

−⋅=

RA

W

tt

D

V

11

2

U

axis

Transducer

Transduce

r

Transduce

r

T

ransduce

r

V axis

HD51.3D4R - 7 - V1.2

5 INSTALLATION

To install the instrument, pass the connection cable inside the support mast and connect the

19-pole M23 female connector of the cable to the 19-pole M23 male connector situated at the

bottom of the instrument. Ensure connection stability by tightening the connector external nut.

Align the instrument (see par. 5.1), then fix it on the support mast by tightening the cable tie

a

t the bottom of the instrument.

21

Ø36 min

∅40

The support mast, having 40

mm maximum outer diameter and 36 mm minimum inner diame-

ter, should be positioned on a stable surface and must be connected to ground.

The HD54.3D4R-AL model must be connected to ground by means of the threaded

hole on the instrument body (see the figure above). Insert the cable lug of the

ground cable into the fixing screw and tighten the screw to the instrument body.

The instrument should be installed vertically and in an open area, far from obstructions located

in the vicinity that might alter the natural air flow. Any close objects (such as buildings, trees,

pylons, etc.) should be at a distance equal to at least ten times their height.

10 x H

H

In the presence of close objects, it is advisable to place the instrument at a height of 10

m.

Threaded hole fo

r

ground connection

(only HD35.3D4R-AL)

HD51.3D4R - 8 - V1.2

For open-space installations, the instrument can be installed using the HD2005.20 (2 m) or

HD2005.20.1 (3

m) tripod.

If the instrument is installed on a building, the height of the instrument should be at least 1.5

times the minimum value between the height of the building and the roof longest diagonal.

5.1 ALIGNMENT OF THE INSTRUMENT

The case has a reference arrow at the bottom: align the arrow with the geographical North.

If a magnetic compass is used for alignment, take into account that the geographic North differs from the magnetic North indicated by the compass. The difference, named magnetic

declination, depends on the area where the instrument was installed (for example, about 15°

in North-America and less than 3° in Europe).

If wind speed and direction values are given in polar coordinates, 0° angle corresponds to a

wind coming from North.

Take into account that the instrument measures the wind direction with respect to the reference

arrow on the housing (the instrument is not equipped with a magnetic compass for the automatic compensation of the direction).

Arrow fo

r

alignement

to North

Su

pp

orting plate

of ultrasonic sensors

HD51.3D4R - 9 - V1.2

5.2 ELECTRICAL CONNECTIONS

All connections are performed through a 19-pole M23 male connector situated at the bottom of

the instrument. The figure and the table below show numbers and function of the connector

contacts and the corresponding colors of the optional CP51.x cable wires:

Connector

pin number

CP51.x cable

wire color

Symbol Description

1 White/Red Not used

2 White/Grey Not used

3 Yellow/Brown RX + Serial receive (input) positive

4 Brown/Green HEAT - Heater power supply negative

5 Violet HEAT + Heater power supply positive (24 Vdc)

6 Brown HEAT - Heater power supply negative

7 Grey/Brown HEAT + Heater power supply positive (24 Vdc)

8 Yellow GND Serial ground (isolated from V –)

9 Grey TX -

Serial transmission (output) negative

“DATA –” main RS485 output

10 White/Yellow AUX_B “DATA +” auxiliary RS485 output (D+)

11 White AUX_A “DATA –” auxiliary RS485 output (D-)

12 Black V - Instrument power supply negative

13 Green RX - Serial receive (input) negative

14 Pink/Brown OUT 1 Analog output 1 positive

15 Blue GND Analog ground (isolated from V –)

16 Red/Blue OUT 2 Analog output 2 positive

17 White/Green TX +

Serial transmission (output) positive

“DATA +” main RS485 output

18 -- Not used

19 Red V + Instrument power supply positive (12…30 Vdc)

-- Grey/Red SHIELD Cable shield

Connecto

r

Reference

Visible side

male

connector

HD51.3D4R - 10 - V1.2

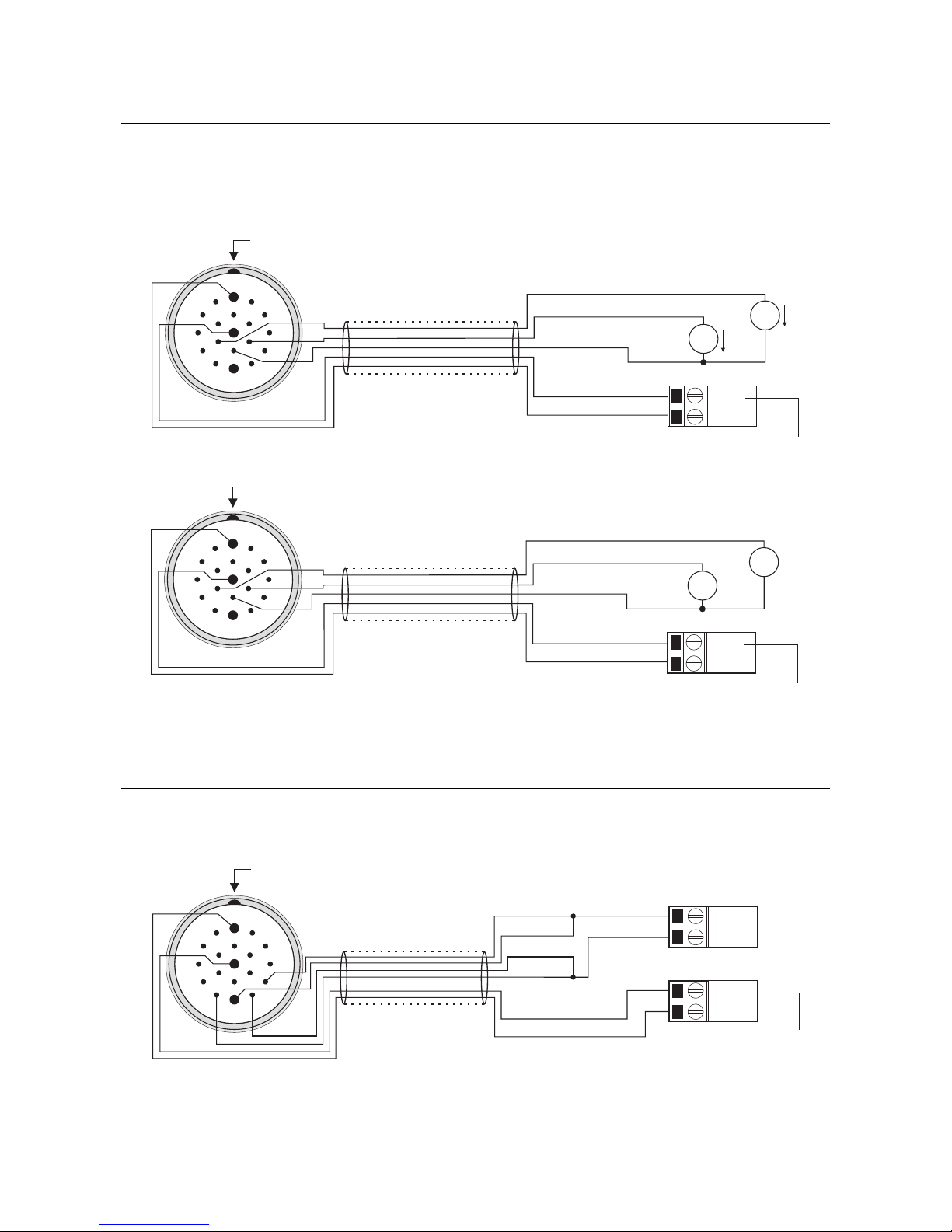

5.2.1 RS232 SERIAL CONNECTION

TX-

RX+

GND

V+

V-

12345

6789

TX

PC

15

1

2

3

4

5

6

7

11

12

13

1416

17

18

19

RX

8

10

9

Lmax = 15m

V+

V-

For RS232 connection, TX-, RX+ and serial GND signals (pin 9, 3 and 8 of M23 connector) are

used, to be connected respectively to RX, TX and GND signals of RS232 port on PC (pin 2, 3

and 5 of 9-pole SubD connector). The length of RS232 cables should not exceed 15

m.

5.2.2 RS485

SERIAL CONNECTION

15

1

2

3

4

5

6

7

11

12

13

1416

17

18

19

8

10

9

DATA+

DATA-

GND

V+

V-

220Ω

220Ω

ShieldShield

Lmax = 1200m

TX+

TX-

GND

V+

V-

DATA+

DATA-

Thanks to RS485 connection, multiple instruments can be connected to a multi-point network.

Instruments are connected in sequence through a twisted-pair shielded cable for signals and a

third wire for ground.

Line terminations should be placed at the two ends of the network. The cable shield should be

connected to both ends of the line.

The maximum number of devices that can be connected to the RS485 line (Bus) depends on the

load characteristics of the devices to be connected. The RS485 standard requires that the total

load does not exceed 32 unit loads. The load of an HD51.3D4R… anemometer is equal to ¼ of

unit load. If the total load is greater than 32 unit loads, divide the network into segments and

Reference

of female

connector (solder side)

Power supply

Power su

p

ply

RS232 Port

PLC, datalo

gg

er o

r

RS485/USB or RS485/RS232

converter for PC

Other sensors with

RS485 output

Termination

T

ermination

Reference of female

connector (solder side)

HD51.3D4R - 11 - V1.2

add a signal repeater between a segment and the successive one. Line termination should be

applied at both ends of each segment.

The maximum length of the cable depends on the transmission speed and the cable characteristics. Typically, the maximum length is 1200

m. The data line should be kept separated from

any power lines in order to prevent interference with the transmitted signal.

Each instrument on the network is univocally identified by an address. Multiple transmitters

with the same address should not be placed on the network.

If the instrument is connected to a data logger, the possibility to connect multiple sensors to

the network depends on the data logger capacity to manage multiple sensors.

Before connecting the instrument to the network, configure address and Baud Rate (see chapter 6).

5.

2.3 RS422

SERIAL CONNECTION

15

1

2

3

4

5

6

7

11

12

13

1416

17

18

19

8

10

9

V+

V-

220Ω220Ω

ShieldShield

Lmax = 1200m

TX+

RX+

TX-

RX-

GND

V+

V-

RX+

RX-

TX+

TX-

GND

220Ω220Ω

RS422 standard is used for point-to-point connection on long distances. The instrument is connected to a PC/data logger through a shielded cable with two twisted pairs for signals and an

additional wire for ground. The extremities of the connections should end with line terminators.

The maximum length of the cable depends on the transmission speed and the cable characteristics. Typically, the maximum length is 1200

m. The data lines should be kept separated from

any power lines in order to prevent interference with the transmitted signal.

Before connecting the instrument to the network, configure address and Baud Rate (see chapter 6).

Powe

r su

p

ply

PLC, datalogger o

r

RS485/USB or RS485/RS232

converter for PC

Termination

T

ermination

Reference of female

connector (solder side)

HD51.3D4R - 12 - V1.2

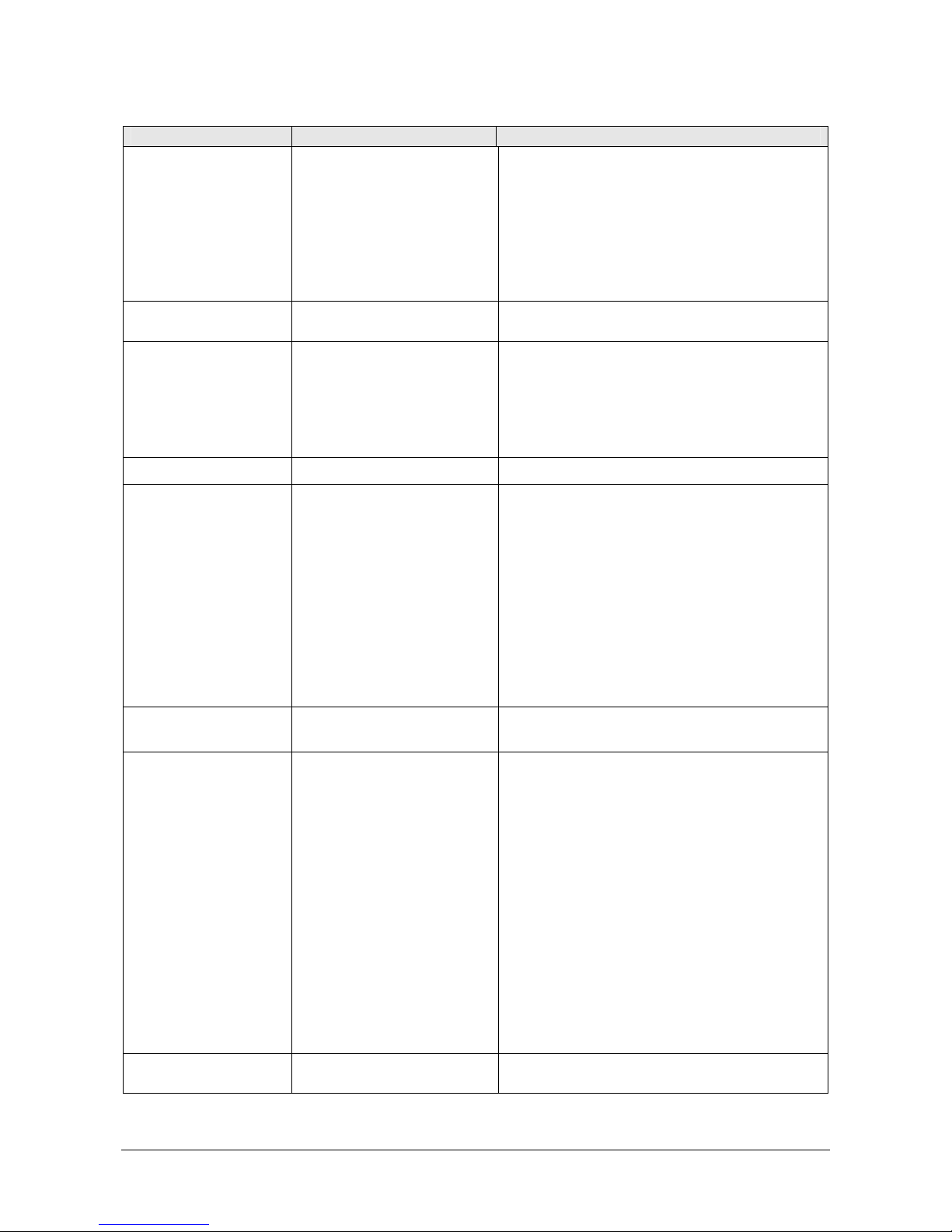

5.2.4 ANALOG OUTPUTS CONNECTION

Connect the outputs according to one of the two schemes below, depending on the output

type, current (standard) or voltage (on request), available in the instrument. OUT 1 and

OUT 2 are associated to wind speed and direction respectively. In order to change the type of

speed and direction measurements associated to the outputs (e.g., to associate to the outputs

the U-V cartesian components), see chapter 6.

OUT 2

OUT 1

V+

V-

V+

V-

15

1

2

3

4

5

6

7

11

12

13

1416

17

18

19

8

10

9

A

I

1

A

I

2

GND

Current outputs are active. Load resistance: RL ≤ 500 Ω.

OUT 2

OUT 1

V+

V-

V+

V-

15

1

2

3

4

5

6

7

11

12

13

1416

17

18

19

8

10

9

V

V

1

V

V

2

+

+

GND

Load resistance: RL ≥ 10 kΩ.

5.2.5 C

ONNECTION OF HEATING SYSTEM

The heater power supply is separated from the instrument’s main power supply.

15

1

2

3

4

5

6

7

11

12

13

1416

17

18

19

8

10

9

V+

V-

HEAT-

HEAT-

HEAT+

HEAT+

V+

V-

HEATHEAT+

The heat circuit is switched on below +4

°C. After switching on, the heating is switched off

when the temperature exceeds +10

°C.

Power su

pply

Power suppl

y

Reference of female

connector (solder side)

Reference o

f

female

connector (solder side)

Reference o

f

female

connector (solder side)

Inst

r

ument

power supply

Heate

r

power supply

Current outputs 4…20mA

Volta

g

e outputs

HD51.3D4R - 13 - V1.2

5.2.6 AUXILIARY RS485 SERIAL OUTPUT CONNECTION

The auxiliary RS485 serial output can be used as an alternative to the main serial connection

for connecting the instrument to the PC, for the configuration of the instrument via serial

commands or the use of the HD52.3D-S application software.

The advantage of the auxiliary RS485 serial output is that it is always available to receive

commands from the PC via a standard serial communication program or the HD52.3D-S appli-

cation software (the main serial output, instead, is not available if it is busy with one of the

operating protocols). Furthermore, the auxiliary RS485 serial output allows using long cables.

The auxiliary RS485 serial output does not work with the operating protocols (NMEA, MODBUSRTU or ASCII proprietary).

For connecting the auxiliary RS485 serial output to the PC, the optional RS51K can be used.

The kit includes the SWD10 power supply and the RS485/USB adapter with:

o screw terminals for the connection to the CP51… cable (not included);

o USB connector for the connection to the PC;

o jack connector for connecting the SWD10 power supply.

To use the RS51K kit, the drivers included in the HD52.3D-S software package, downloadable

from Delta OHM website, should be installed in the PC (see the guide to USB drivers installation in the Documentation section of the software package).

5.3 SERIAL OUTPUT PROTOCOL

Unless otherwise requested, at the first power up the instrument main serial output starts in

configuration mode and waits to receive the commands for setting the operating parameters

(see chapter 6) or the connection with the H

D52.3D-S application software.

In this case, in order to activate an operating protocol (NMEA, MODBUS-RTU or ASCII proprietary) it is necessary to set it with the appropriate serial command (CUMn, see chapter 6) or

w

ith the aid of the HD52.3D-S application software.

If the instrument is set up to work with an operating protocol, the protocol becomes active 10

seconds after power on (in the first 10 seconds the instrument waits for a possible command

to enter configuration mode, as explained in chapter 6).

T

he auxiliary RS485 serial output is always in configuration mode.

Reference of female

connector (solder side)

SWD10

T

o PC

RS485/USB

adapter

Power su

pply

HD51.3D4R - 14 - V1.2

6 CONFIGURATION

Configuration mode allows to read the instrument general info (firmware version, serial number, …) and to set the instrument operation mode and operation parameters. The configuration of the instrument can be done in two ways:

• With the aid of HD52.3D-S application software (see the instructions of the software).

• By sending serial commands (listed in paragraph 6.1) via a standard communication

pr

ogram.

If a standard communication program is used, the program communication parameters should

be set as follows:

• Baud rate = 115200

• Data bits = 8

• Parity = None

• Stop bits = 2

• Flow control = None

For the configuration, the instrument can be connected to the PC:

• Via auxiliary RS485 (see paragraph 5.2.6 for the connection).

T

he auxiliary RS485 serial output is always in configuration mode and therefore it is al-

ways available to receive commands from the PC.

• Via RS232 (see paragraph 5.2.1 for the connection).

T

he instrument can receive commands from the PC via RS232 only if it is in configuration

mode (factory setting, unless otherwise requested).

If the instrument is not set in in configuration mode but in one of the available operating

modes (NMEA, MODBUS-RTU or ASCII proprietary), to enter configuration mode it is necessary to send within 10 seconds from power on (if the instrument is already pow-

ered, disconnect and reconnect the power supply) the serial command @ (if a standard

communication program is used) or the request of connection with the HD52.3D-S application software, if the application software is used.

6.1 SERIAL COMMANDS

Instrument control:

Command Reply Description

@ &| Allows entering configuration mode if the

instrument is set up in an operating mode.

It must be sent within 10 seconds from

power on.

#

Info on operating mode

Exits from the configuration mode activated

with the command @.

Operating Mode:

Command Reply Description

CUMn &| Sets instrument in mode:

Configuration if n=0

ASCII proprietary if n=2

NMEA if n=4

MODBUS-RTU if n=5

Default : Configuration (n=0)

RUM & n| Reads mode set in the instrument

Note 1: after sending the CUMn command, the instrument remains in configuration mode.

Power cycle the instrument to activate the set operating mode.

HD51.3D4R - 15 - V1.2

Parameters for ASCII proprietary mode:

Command Reply Description

CU2Bn &| Sets Baud Rate for ASCII proprietary

mode to:

9600 if n=3

19200 if n=4

38400 if n=5

57600 if n=6

115200 if n=7

Default : 115200 (n=7)

RU2B & n| Reads Baud Rate setting for ASCII

proprietary mode

CU2In &| Sets interface for ASCII mode to:

RS232 if n=0

RS485 if n=1

RS422 if n=2

Default : RS485 (n=1)

RU2I & n| Reads interface setting for ASCII mode

CU2Mn &| Sets parity and stop bits for ASCII mode

to:

8N1 if n=0 [No parity, 1 stop bit]

8N2 if n=1 [No parity, 2 stop bits]

8E1 if n=2 [Even parity, 1 stop bit]

8E2 if n=3 [Even parity, 2 stop bits]

8O1 if n=4 [Odd parity, 1 stop bit]

8O2 if n=5 [Odd parity, 2 stop bits]

The number of data bits is fixed to 8

Default : 8N2 (n=1)

RU2M & n| Reads current setting of parity and stop

bits for ASCII mode

CU1Dcccccc &| Sets measurements order in the string sent

in ASCII proprietary mode

In the sequence ccccccccccc, each character

identifies a measurement according to the

following correspondence:

0 ⇒ Barometric Pressure

5 ⇒ Wind speed (coordinates U,V)

7 ⇒ Wind speed (intensity)

8 ⇒ Wind Direction (Azimuth)

G ⇒ Wind Gust (intensity and direction)

S ⇒ Sound speed

T ⇒ Sonic Temperature

E ⇒ Errors

Default : 780TE

(see Note 2)

RU1D & ccccccccccc| Reads measurements order in the string

sent in ASCII proprietary mode

HD51.3D4R - 16 - V1.2

Command Reply Description

CU2Rnnnn &| Sets transmission interval of string with

measurements in ASCII proprietary mode

to nnnn seconds

The interval should range within 1 and

3600 seconds

Default : 1 second

RU2R & nnnn| Reads transmission interval of string with

measurements in ASCII proprietary mode

NOTE 2 : MEASUREMENTS ORDER

In the measurement string sent by the instrument in ASCII proprietary mode, measurements

can be set in arbitrary order: one should simply indicate the desired order in the sequence of

characters "cccccc" sent by the command C1UD. The sequence of characters "cccccc" can have

a variable length up to a maximum of 16 characters.

Example: if the sequence of characters is set to 780, wind speed, wind direction and barometric pressure measurements will appear from left to right in the data string sent by the instrument.

If information on error conditions is requested (E character), three numbers with the following

meaning will appear in the data string sent by the instrument:

1. First number = error code identifying the transducers and the type of error.

The number is composed by two digits. The first digit indicates the transducer that

presents the error, according to the numeration indicated in the figure:

1

2

4

3

N

Digit 0 indicates that no errors are present in the ultrasonic transducers.

The second digit of the error code indicates the type of error: 0 = no errors;

1 = transducer broken, electric interruption, path obstruction; Other = codes re-

served to technical service.

2. Second number = heating status: 0 = off, 1 = housing heating is on, 2 = housing heat-

ing and transducers heating are both on.

3. Third number = number of invalid measurements.

Example: if 21 0 2 appears in correspondence to the error condition in the data string sent by

the instrument, it means that an error occurred in the transducer number 2, that the heating is

turned off and that two measurements have been rejected due to the error occurrence.

N

(

North

)

arrow

on the opposite side

V

axis

U axis

Y

axis

X axis

HD51.3D4R - 17 - V1.2

Parameters for NMEA mode:

Command Reply Description

CU4Bn &| Sets Baud Rate for NMEA mode to:

2400 if n=1

4800 if n=2

9600 if n=3

19200 if n=4

38400 if n=5

57600 if n=6

115200 if n=7

Default : 4800 (n=2)

RU4B & n| Reads Baud Rate setting for NMEA mode

CU4In &| Sets interface for NMEA mode to:

RS232 if n=0

RS485 if n=1

RS422 if n=2

Default : RS485 (n=1)

RU4I & n| Reads interface setting for NMEA mode

CU4Mn &| Sets parity and stop bits for NMEA mode

to:

8N1 if n=0 [No parity, 1 stop bit]

8N2 if n=1 [No parity, 2 stop bits]

8E1 if n=2 [Even parity, 1 stop bit]

8E2 if n=3 [Even parity, 2 stop bits]

8O1 if n=4 [Odd parity, 1 stop bit]

8O2 if n=5 [Odd parity, 2 stop bits]

The number of data bits is fixed to 8

Default : 8N1 (n=0)

RU4M & n| Reads current setting of parity and stop

bits for NMEA mode

CU4Rnnn &| Sets transmission interval of string with

measurements in NMEA mode to nnn seconds

The interval should range within 1 and 255

seconds

Default : 1 second

RU4R & nnn| Reads setting of transmission interval of

string with measurements in NMEA mode

HD51.3D4R - 18 - V1.2

Parameters for MODBUS-RTU mode:

Command Reply Description

CU5Annn &| Sets MODBUS address to nnn

The address should range within 1 and 247

Default : 1

RU5A & nnn| Reads the MODBUS address setting

CU5Bn &| Sets the Baud Rate for MODBUS mode to:

9600 if n=3

19200 if n=4

38400 se n=5

57600 se n=6

115200 se n=7

Default : 19200 (n=4)

RU5B & n| Reads Baud Rate setting for MODBUS

mode

CU5In &| Sets interface for MODBUS mode to:

RS232 if n=0

RS485 if n=1

RS422 if n=2

Default : RS485 (n=1)

Note: with RS232 option you can connect to PC

or datalogger 1 instrument only; option useful

to do tests without RS232/RS485 conversion.

RU5I & n| Reads interface setting for MODBUS mode

CU5Mn &| Sets parity and stop bits for MODBUS

mode to:

8N1 if n=0 [No parity, 1 stop bit]

8N2 if n=1 [No parity, 2 stop bits]

8E1 if n=2 [Even parity, 1 stop bit]

8E2 if n=3 [Even parity, 2 stop bits]

8O1 if n=4 [Odd parity, 1 stop bit]

8O2 if n=5 [Odd parity, 2 stop bits]

The number of bits is fixed to 8

Default : 8E1 (n=2)

RU5M & n| Reads the setting of parity and stop bits

for MODBUS mode

CU5Wn &| Sets waiting time after transmission in

MODBUS mode to:

Immediate reception if n=0

(violates protocol)

Waiting 3.5 characters if n=1

(respects protocol)

Default : Waiting 3.5 characters (n=1)

RU5W & n| Reads current setting of waiting time after

transmission in MODBUS mode

HD51.3D4R - 19 - V1.2

Units of measurement:

Command Reply Description

CGUVn &| Sets measuring unit of wind speed:

m/s if n=1

cm/s if n=2

km/h if n=3

knot if n=4

mph if n=5

Default : m/s (n=1)

RGUV n| Reads the wind speed measuring unit set

in the instrument

CGUTn &| Sets temperature measuring unit:

°C if n=1

°F if n=2

Default : °C (n=1)

RGUT n| Reads the temperature measuring unit set

in the instrument

CGUPn &| Sets pressure measuring unit:

mbar if n=1

[Note:1 mbar=1 hPa]

mmHg if n=2

inchHg if n=3

mmH

2

O if n=4

inchH

2

O if n=5

atm if n=6

Default : mbar (n=1)

RGUP n| Reads the pressure measuring unit set in

the instrument

General parameters:

Command Reply Description

CGHn &| Enables/disables heating:

Disables if n=0 Enables if n=1

Default : Enabled (n=1)

RGH n| Reads heating enabling state set in the in-

strument

CWCnnnn &| Sets wind speed threshold to nnnn value (in

hundredths of m/s)

Value should range within 0 and 100

hundredths of m/s (= 0…1 m/s)

Default : 20 (= 0.2 m/s)

(see Note 3)

RWC & nnnn| Reads the wind speed threshold value set in

the instrument (in hundredths of m/s)

CWaLnnn &| Sets time interval for the calculation of aver-

age speed and average direction to nnn value

Value should range within 1 and 600 s

Default : 1 s

HD51.3D4R - 20 - V1.2

Command Reply Description

RWaL & nnn| Reads the time interval for the calculation

of average speed and average direction set

in the instrument

CWaMn &| Sets the method for the calculation of

average speed and average direction:

If n=0: scalar average.

If n=1: vector average.

Default : vector average (n=1)

(see Note 4)

RWaM & n| Reads the method for the calculation of the

average speed and average direction set in

the instrument

CWgLnnn &| Sets time interval for the calculation of av-

erages in Wind Gust measurement to nnn

value

Value should range within 1 and 100 s

Default : 3 s (standard WMO value)

(see Note 6)

RWgL & nnn| Reads the time interval for the calculation

of averages in Wind Gust measurement set

in the instrument

CWgMn &| Sets the method for the calculation of

averages in Wind Gust measurement:

scalar average if n=0

vector average if n=1

Default : vector average (n=1)

Note: see the description of the command

CWaMn for the meaning of scalar average

and vector average.

RWgM & n| Reads the method for the calculation of av-

erages in Wind Gust measurement set in

the instrument

CWgOnnn &| Sets time interval for detecting the maximum

of the averages in Wind Gust measurement

to nnn value

Value should range within 1 and 600 s

Default : 60 s

(see Note 6)

RWgO & nnn| Reads the time interval for detecting the

maximum of the averages in Wind Gust

measurement set in the instrument

cor n cor| Sets the measurement rate to n measure-

ments/s

Value should range within 1 and 4

Default : 4

ror n samples per second Reads the measurement rate set in the in-

strument

HD51.3D4R - 21 - V1.2

NOTE 3 : WIND SPEED THRESHOLD VALUE

If the wind speed is very low, the determination of the direction can result inaccurate. The instrument allows setting the threshold value of speed below which the direction value is frozen

on the last acquired value.

N

OTE 4 : SCALAR AVERAGE AND VECTOR AVERAGE

Scalar average: the average intensity is calculated as average of intensities. For the calculation of the average direction, also called “prevailing direction”, the velocity versor (unit vector

having the same direction of the velocity vector) is considered for each measurement, and the

versor coordinates along the measurement axes are calculated, then the average of the coordinates along each axis is calculated. The two average coordinates determine the average versor

and therefore the average direction. The average direction is expressed according to the extended characteristic for the analog output (see Note 5).

Vector average: for each measurement, the coordinates of the velocity vector along the

measurement axes are calculated and then the average of the coordinates along each axis is

calculated. The average intensity and the average direction are those determined by the two

average coordinates.

N

OTE 5 : WIND D IRECTION EXTENDED CHARACTERISTIC

With 0÷359.9° wind direction measuring range, the analog output continues to oscillate between maximum and minimum scale if the direction continues to slightly fluctuate around 0°:

This effect can be reduced through the extended ("wrap-around") characteristic of wind direction. In this mode, the wind direction is considered as corresponding to 0÷539.9° range instead of 0÷359.9°. The wide output fluctuation occurs the first time that the wind direction

goes from 0 to 359.9°; if later the “physical” direction goes back to 0°, the analog output will

always remain around 360°. Using the extended characteristic, the behavior of the above

graph changes into the following:

HD51.3D4R - 22 - V1.2

If 539.9° value is exceeded in extended mode, the output goes to the value corresponding to

180°.

The table below shows the correspondence between the value of the analog output and the direction of the wind in the two modes.

4…20mA output 0…1V output 0…5V output 0…10V output

Wind

direction

standard extended standard extended standard extended standard extended

0° 4.00 4.00 0.00 0.00 0.00 0.00 0.00 0.00

180° 12.00 9.33 0.50 0.33 2.50 1.67 5.00 3.33

360° 20.00 14.67 1.00 0.67 5.00 3.33 10.00 6.67

540° -- 20.00 -- 1.00 -- 5.00 -- 10.00

NOTE 6 : WIND GUST MEASUREMENT

The Wind Gust measurement is determined as follows:

• the wind speed averages (according to the method set with the CWgM command, by de-

fault vector averages) in a time interval equal to that set with the CWgL command (by

default 3 seconds) are calculated continuously;

• the maximum value of the averages calculated in the previous point is detected over a

time interval equal to that set with the CWgO command (by default 60 seconds); the

maximum value detected is the measure of Wind Gust.

HD51.3D4R - 23 - V1.2

Analog outputs:

Command Reply Description

RAT & n| Reads the analog output type:

4…20/0…20 mA if n=0

0…1 V if n=1

0…5 V if n=2

0…10 V if n=3

CAFxnn &| Sets offset and direction of the analog output

x (x=1 or 2) to:

Standard if nn=00

[ex. 4…20 mA , 0...1 V , 0...5 V , 0...10 V]

Without offset if nn=01

[ex. 0…20 mA]

With offset if nn=02

[ex. 0.2...1 V , 1...5 V , 2...10 V]

Inverted if nn=04

[ex. 20…4 mA , 1...0 V , 5...0 V , 10...0 V]

Inverted without offset if nn=05

[ex. 20…0 mA]

Inverted with offset if nn=06

[ex. 1...0.2 V , 5...1 V , 10...2 V]

Default : Standard (nn=00)

RAFx & nn| Reads offset and direction setting of the ana-

log output x (x=1 or 2)

CAMn &| Association of the analog outputs:

If n= 0:

Output 1 = Mean wind speed

Output 2 = Mean wind direction (with ex-

tended characteristic if the

average is scalar)

If n= 1 (

see Note 7):

Output 1 = Instant wind speed component

along V-axis

Output 2 = Instant wind speed component

along U-axis

If n= 2 (Tunnel mode,

see Note 8):

Output 1 = Instant wind speed component

along the direction indicated b

y

the arrow on the instrument

case

Output 2 = Instant wind direction referred

to the direction indicated by

the arrow on the instrument

case

Default : n=0

RAM & n| Reads the association of analog outputs

HD51.3D4R - 24 - V1.2

Command Reply Description

CAHn &| Associates full scale of wind speed analog

output to:

5 m/s if n=0 50 m/s if n=9

10 m/s if n=1 55 m/s if n=10

15 m/s if n=2 60 m/s if n=11

20 m/s if n=3 65 m/s if n=12

25 m/s if n=4 70 m/s if n=13

30 m/s if n=5 75 m/s if n=14

35 m/s if n=6 80 m/s if n=15

40 m/s if n=7 85 m/s if n=16

45 m/s if n=8 90 m/s if n=17

Default : 75 m/s (n=14)

RAH & n| Reads the value corresponding to the wind

speed analog output full scale

NOTA 7 : U,V COMPONENTS

By selecting the U and V components, the speed value associated to the initial scale of the two

analog outputs is equal to the opposite of the speed value associated to the full scale of the

outputs.

For example, if the speed full scale value is set to 60 m/s, the speed range associated to the

analog outputs is -60…+60 m/s.

N

OTA 8 : TUNNEL MODE

The arrow on the instrument case should be aligned with the direction of the tunnel.

The output 2 is set to full scale value if the wind blows in the direction of the arrow, and to initial

scale value if the wind blows in the opposite direction.

The initial scale of output 1 is associated to the speed value opposite to that associated to the

output full scale.

Instrument information:

Command Reply Description

G1 &VPnn.nn yyyy/mm/dd| Version and date of firmware

RGS &nnnnnnnn| Serial number of instrument

RGI &ccc…ccc| User code

CGIccc…ccc &| Sets user code to ccc…ccc

(max. 34 characters)

HD51.3D4R - 25 - V1.2

7 ASCII PROPRIETARY MODE

In ASCII proprietary mode, the instrument sends automatically the acquired measurements at

regular intervals. The interval is factory-set to 1 second and is configurable from 1 to 3600

seconds. To change the interval, you should enter in configuration mode and send the command CU2Rnnnn, where nnnn indicates the interval value in seconds (see chapter 6 fo

r de-

tails regarding the setting of operation parameters).

Communication parameters should be set in your PC as follows:

• Baud rate: same as the setting in the instrument (default = 115200)

• Data bits: 8

• Parity: same as the setting in the instrument (default = None)

• Stop bits: same as the setting in the instrument (default = 2)

The instrument sends measurements in the following format:

<M1><M2>…<Mn><CR><LF>

with <M1><M2>…<Mn> = values of the first, second,…., nth measurement

<CR> = ASCII character Carriage Return

<LF> = ASCII character Line Feed

Fields <M1><M2>…<Mn> consist of 8 characters each. Measurement values are justified

right; spaces can be added to the left margin of the values to obtain the 8 character length requested by the fields.

The sequence of the measurement values <M1><M2>…<Mn> is configurable (command

CU1Dcccccc, see chapter 6).

E

XAMPLE

Supposing that the instrument measures the following values (the measuring unit is not considered, being not output by the instrument): M1=28.30, M2=359.3, M3=998.3, the data

string sent by the instrument takes the form:

28.30 359.3 998.3<CR><LF>

HD51.3D4R - 26 - V1.2

8 NMEA MODE

NMEA protocol, mainly used in the nautical field and in satellite-based navigation systems,

specifies that only one of the devices connected can send data, while the others can only act

as recipients.

In NMEA mode, the instrument sends automatically the acquired measurements at regular intervals. The interval is factory-set to 1 second and can be configured within 1 and 255 seconds. To change the interval you should access the configuration mode and send CU4Rnnn

command, where nnn indicates the interval value in seconds (see chapter 6 f

or details regard-

ing the setting of operation parameters).

Communication parameters should be set in the PC or data logger as follows:

• Baud rate: same as the setting in the instrument (default = 4800)

• Data bits: 8

• Parity: same as the setting in the instrument (default = None)

• Stop bits: same as the setting in the instrument (default = 1)

The instrument is compatible with NMEA 0183 V4.00 protocol.

The protocol establishes that data are sent in the following format:

$<Prefix>,<Data>*<hh><CR><LF>

with <Prefix> = field consisting in 5 alphanumeric characters: the first two indicate the type

of transmitting device, the other three indicate the type of transmitted data

<Data> = values measured by the instrument, separated by commas

<hh> = checksum, consisting in two hexadecimal characters

<CR> = character ASCII Carriage Return

<LF> = character ASCII Line Feed

The checksum is calculated by performing the exclusive OR of all characters ranging within $

and * symbols. The 4 most significant bits and the 4 less significant bits of the result are converted in hexadecimal. The hexadecimal value corresponding to the most significant bits is

transmitted as the first.

The instrument regularly sends a string in the following general format requested by the protocol:

$IIMDA,x.x,I,x.x,B,x.x,C,x.x,C,x.x,x.x,x.x,C,x.x,T,x.x,M,x.x,N,x.x,M*hh<CR><LF>

The fields related to quantities not measured by the instrument are empty (multiple consecutive commas appear to indicate the missing fields).

Barometric pressure, inHg (mercury inches)

Barometric pressure, ba

r

Air temperature ⇒ not available, empty field

Water temperature ⇒ not available, empty field

Relative humidity

⇒

not available, empty field

Absolute humidity

⇒

not available, empty field

Dew Point ⇒ not available, empty field

Wind direction with respect to geographic North, degrees

⇒ not available, empty field

Wind direction with respect to magnetic North, degrees

Wind speed, knot

Wind speed, m/s

HD51.3D4R - 27 - V1.2

The previous string is followed by a second string ($IIXDR…) provided for measurements not

implemented in these instruments.

E

XAMPLE

Suppose that there are the following environmental conditions:

o Wind speed = 5.60 m/s (=10.88 knot)

o Wind direction with respect to magnetic North = 38.7°

o Barometric pressure = 1014.9 hPa (= 30.0 inHg)

The string sent by the instrument is:

$IIMDA,30.0,I,1.0149,B,,C,,C,,,,C,,T,38.7,M,10.88,N,5.60,M*34<CR><LF>

For additional information regarding the protocol, visit the site "www.nmea.org".

HD51.3D4R - 28 - V1.2

9 MODBUS-RTU MODE

In MODBUS-RTU mode, the instrument sends the acquired measurements only if specifically

requested by the PC, PLC or data logger.

Communication parameters should be set in the PC or data logger as follows:

• Baud rate: same as the setting in the instrument (default =19200)

• Data bits: 8

• Parity: same as the setting in the instrument (default = even)

• Stop bits: same as the setting in the instrument (default = 1)

MEASUREMENTS READING (function 04h)

The Modbus function code 04h (Read Input Registers) allows reading the values measured by

the instrument. The following table lists the Input Registers available.

Modbus Input Registers

Register

number

Quantity Format

1 Instantaneous wind speed (x100)

unsigned 16 bits

2 Instantaneous wind direction in degrees (x10)

unsigned 16 bits

3

Sonic temperature measured by the transducers pair of

the X axis (x10)

16 bits

4

Sonic temperature measured by the transducers pair of

the Y axis (x10)

16 bits

5

Average of the two sonic temperatures measured by the

two transducers pairs (x10)

16 bits

8

Barometric pressure (x1000 if the unit of measurement is

atm, x10 in the other cases)

unsigned 16 bits

11 Average wind speed (x100) unsigned 16 bits

12 Average wind direction in degrees (x10) unsigned 16 bits

15

Wind direction in degrees (x10) with extended feature

(see page 21)

un

signed 16 bits

16 Wind speed (x100) along V-axis unsigned 16 bits

17 Wind speed (x100) along U-axis unsigned 16 bits

18

Status register

bit0=1 ⇒ Speed measurement error

bit1=1 ⇒ Not used

bit2=1 ⇒ Not used

bit3=1 ⇒ Not used

bit4=1 ⇒ Pressure measurement error

bit5=1 ⇒ Not used

unsigned 16 bits

19

Wind speed unit of measurement

0 ⇒ m/s 3 ⇒ knot

1 ⇒ cm/s 4 ⇒ mph

2 ⇒ km/h

unsigned 16 bits

20

Temperature unit of measurement

0 ⇒ °C 1 ⇒ °F

unsigned 16 bits

HD51.3D4R - 29 - V1.2

Register

number

Quantity Format

21

Atm. pressure unit of measurement

0 ⇒ mbar (=hPa) 3 ⇒ mmH

2

O

1 ⇒ mmHg 4 ⇒ inchH

2

O

2 ⇒ inchHg 5 ⇒ atm

unsigned 16 bits

22 Wind Gust intensity (x100) unsigned 16 bits

23 Wind Gust direction in degrees (x10) unsigned 16 bits

Note: for quantities with configurable measurement unit, the measurement value is expressed in

the unit set in the instrument.

For additional information regarding the protocol, visit the site "www.modbus.org".

HD51.3D4R - 30 - V1.2

10 INSTRUMENT STORAGE

Instrument storage conditions:

• Temperature: -40...+65

°C.

• Humidity: less than 90 %RH no condensation.

• In storing, avoid locations where:

• There is a high humidity level.

• The instrument is exposed to direct sunlight.

• The instrument is exposed to a high temperature source.

• There are high vibration levels.

• There is presence of vapor, salt and/or corrosive gas.

11 SAFETY INSTRUCTIONS

General safety instructions

The instrument has been manufactured and tested in accordance with the safety standard

EN61010-1:2010 “Safety requirements for electrical equipment for measurement, control and

laboratory use” and has left the factory in perfect safety technical conditions.

The instrument proper operation and operating safety can be ensured only if all standard safety measures as well as the specific measures described in this manual are followed.

The instrument proper operation and operating safety can be ensured only in the climatic conditions specified in this manual.

Do not use the instrument in places where there are:

• Rapid ambient temperature variations that may cause condensation.

• Corrosive or flammable gases.

• Direct vibrations or shocks to the instrument.

• High-intensity electromagnetic fields, static electricity.

If the instrument is moved from a cold place to a hot one, or vice versa, condensation formation can cause an instrument malfunction. In this case, you will have to wait for the instrument

temperature to reach ambient temperature before turning the instrument on.

User obligations

The instrument operator shall follow the directives and regulations below that refer to the

treatment of dangerous materials:

EEC directives on workplace safety

National low regulations on workplace safety

Accident prevention regulations

HD51.3D4R - 31 - V1.2

12 ORDERING CODES

HD51.3D4R 2-axis ultrasonic static anemometer. Measurement of wind speed and direc-

tion, U-V Cartesian components of wind speed, Wind Gust and barometric

pressure. Isolated RS232, RS485, and RS422 serial outputs. NMEA, MOD-

BUS-RTU and ASCII proprietary communication protocols. Two analog outputs for wind speed and direction, factory-configurable within 4÷20

mA

(standard), 0…1

V, 0…5 V or 0…10 V (to be specified when ordering).

Equipped with heater. Operating temperature -40…+60 °C. Instrument power supply 12…30

Vdc. Heater power supply 24 Vdc. Housing in ASA. Installa-

tion on mast ∅ 40

mm external and ∅ 36 mm internal. Input with 19-pole M23

male connector and 19-pole M23 female free connector. The HD52.3D-S

software, for instrument configuration and monitor, downloadable from Delta

OHM website is included. CP51… cable on request.

HD51.3D4R-AL 2-axis ultrasonic static anemometer. Measurement of wind speed and direc-

tion, U-V Cartesian components of wind speed, Wind Gust and barometric

pressure. Isolated RS232, RS485, and RS422 serial outputs. NMEA, MOD-

BUS-RTU and ASCII proprietary communication protocols. Two analog outputs for wind speed and direction, factory-configurable within 4÷20

mA

(standard), 0…1

V, 0…5 V or 0…10 V (to be specified when ordering).

Equipped with an enhanced heater for rapid defrosting. Operating tempera-

ture -40…+60 °C. Instrument power supply 12…30

Vdc. Heater power supply

24 Vdc. Housing in anodized aluminum alloy. Installation on mast

∅ 40

mm external and ∅ 36 mm internal. Input with 19-pole M23 male con-

nector and 19-pole M23 female free connector. The HD52.3D-S software, for

instrument configuration and monitor, downloadable from Delta OHM website

is included. CP51… cable on request.

ACCESSORIES

CP51… Connecting cable with 19-pole M23 female free connector on one end, open

wires on the other. Avialable lengths: 5

m (CP51.5), 10 m (CP51.10), 15 m

(CP51.15), 20

m (CP51.20), 30 m (CP51.30), 50 m (CP51.50) and 75 m

(CP51.75).

RS51K Kit for connecting the anemometer RS485 auxiliary output to a PC. It in-

cludes the SWD10 power supply and the RS485/USB adapter with:

o screw terminals for the connection to the CP51… cable (not included);

o USB connector for the connection to the PC;

o jack connector for connecting the SWD10 power supply.

HD52.30K Birds spikes.

HD2005.20 Tripod with adjustable legs for installing environmental sensors. Material:

anodized aluminum. Max. height 2 m. It can be fixed on a flat base with

screws or to the ground with pegs. Foldable legs for the transport.

HD2005.20.1 Tripod with adjustable legs for installing environmental sensors. Material:

anodized aluminum. Max. height 3 m. It can be fixed on a flat base with

screws or to the ground with pegs. Foldable legs for the transport.

CP52.C Additional 19-pole M23 female free connector.

DELTA OHM metrology laboratories LAT N° 124 are ISO/IEC 17025 accredited by ACCREDIA

for Temperature, Humidity, Pressure, Photometry/Radiometry, Acoustics and Air Velocity.

They can supply calibration certificates for the accredited quantities.

HD51.3D4R - 32 - V1.2

NOTES

HD51.3D4R - 33 - V1.2

NOTES

HD51.3D4R - 34 - V1.2

NOTES

GUARANTEE

TERMS OF GUARANTEE

All DELTA OHM instruments are subject to accurate testing, and are guaranteed for 24 months from the

date of purchase. DELTA OHM will repair or replace free of charge the parts that, within the warranty

period, shall be deemed non efficient according to its own judgement. Complete replacement is excluded

and no damage claims are accepted. The DELTA OHM guarantee only covers instrument repair. The

guarantee is void in case of incidental breakage during transport, negligence, misuse, connection to a

different voltage than that required for the appliance by the operator. Finally, a product repaired or

tampered by unauthorized third parties is excluded from the guarantee. The instrument shall be returned

FREE OF SHIPMENT CHARGES to your dealer. The jurisdiction of Padua applies in any dispute.

The electrical and electronic equipment marked with this symbol cannot be disposed of in public

landfills. According to the Directive 2011/65/EU, the european users of electrical and electronic

equipment can return it to the dealer or manufacturer upon purchase of a new one. The illegal

disposal of electrical and electronic equipment is punished with an administrative fine.

This guarantee must be sent together with the instrument to our service centre.

IMPORTANT: Guarantee is valid only if coupon has been correctly filled in all details.

Instrument Code:

HD51.3D4R HD51.3D4R-AL

Serial Number

RENEWALS

Date Date

Inspector Inspector

Date Date

Inspector Inspector

Date Date

Inspector Inspector

GHM GROUP – Delta OHM | Delta Ohm S.r.l. a socio unico

Via Marconi 5 | 35030 Caselle di Selvazzano | Padova | ITALY

Phone +39 049 8977150 | Fax +39 049 635596

www.deltaohm.com | info@deltaohm.com

The quality level of our instruments is the result of the constant development of the product. This may

produce some differences between the information written in this manual and the instrument you have

purchased. We cannot completely exclude the possibility of errors in the manual, for which we apologize.

The data, images and descriptions included in this manual cannot be legally asserted. We reserve the

right to make changes and corrections with no prior notice.

GHM GROUP – Delta OHM | Delta Ohm S.r.l. a socio unico

Via Marconi 5 | 35030 Caselle di Selvazzano | Padova | ITALY

Phone +39 049 8977150 | Fax +39 049 635596

www.deltaohm.com | info@deltaohm.com

V1.2

20/09/2018

Loading...

Loading...