Operating manual

Multifunction Data Logger

HD31

www.deltaohm.com

English

Keep for future reference.

Companies / Brands of GHM

HD31 - 2 - V1.6

TABLE OF CONTENTS

1 INTRODUCTION.................................................................................................... 5

2 DESCRIPTION....................................................................................................... 6

2.1 DISPLAY DESCRIPTION .......................................................................................... 7

2.2 KEY TO THE SYMBOLS IN THE STATUS BAR .................................................................... 8

2.3 OVERVIEW OF THE FUNCTIONS IN THE COMMAND BAR ...................................................... 9

2.4 HELP FUNCTION ............................................................................................... 11

3 MEASUREMENT MODE......................................................................................... 12

3.1 SELECTING A MEASUREMENT LINE............................................................................ 13

3.2 SELECTING THE MEASUREMENT UNIT ........................................................................ 13

3.3 CHANGING THE QUANTITY VIEWED IN THE DISPLAY LINE .................................................. 14

3.4 DERIVED QUANTITIES AND NUMBER OF MEASUREMENT LINES DISPLAYED.............................. 14

3.5 DISPLAYING THE DIFFERENCE BETWEEN TWO HOMOGENEOUS QUANTITIES ............................. 17

3.6 DISPLAYING THE RELATIVE MEASUREMENT (REL) ........................................................ 18

3.7 HOLDING THE MEASUREMENT ON THE DISPLAY (HOLD).................................................. 18

3.8 MEASUREMENT GRAPH......................................................................................... 19

4 THE PROBES ....................................................................................................... 22

4.1 PRT TEMPERATURE PROBES .................................................................................. 22

4.1.1 SETTING THE INSTRUMENT TO READ A PRT PROBE WITHOUT SICRAM MODULE .......... 24

4.2 THERMOCOUPLE TEMPERATURE PROBES ..................................................................... 25

4.3 RELATIVE HUMIDITY AND TEMPERATURE COMBINED PROBES ............................................. 26

4.3.1 DISCOMFORT INDEX AND NET INDEX ........................................................... 26

4.4 PRESSURE PROBES ............................................................................................. 28

4.4.1 ZEROING DIFFERENTIAL PRESSURE PROBES ..................................................... 28

4.4.2 PEAK VALUE RESET ................................................................................. 29

4.5 AIR SPEED PROBES............................................................................................. 30

4.5.1 FLOW-RATE MEASUREMENT ....................................................................... 30

4.5.2 NOTES ON FLOW MEASUREMENTS ................................................................ 30

4.5.3 HOT-WIRE AIR SPEED PROBES AP471S... ..................................................... 31

4.5.4 AIR SPEED VANE PROBES AP472S... ........................................................... 34

4.5.5 AP473S... MODULES FOR PITOT TUBES ........................................................ 36

4.5.6 ZEROING AIR SPEED PROBES ..................................................................... 38

4.6 VP472 MODULE FOR THE CONNECTION OF PYRANOMETERS AND ALBEDOMETERS ..................... 40

4.7 PHOTOMETRIC AND RADIOMETRIC PROBES WITH SICRAM MODULE .................................... 41

4.7.1 INTEGRATION ....................................................................................... 42

4.8 CO

2

PROBES .................................................................................................... 46

4.9 VP473 AND IP472 MODULES FOR MEASURING DIRECT VOLTAGE AND CURRENT ...................... 47

HD31 - 3 - V1.6

5 RECORD FUNCTION ............................................................................................ 48

5.1 SELECTING A QUANTITY FOR THE RECORD FUNCTION ................................................... 48

5.2 SAMPLE ACQUIS ITION .......................................................................................... 49

5.3 DISPLAYING M IN IMUM, AVERAGE AND MAXIMUM VALUES ................................................. 50

5.4 RESETTING AND DISABLING THE RECORD FUNCTION .................................................... 50

5.5 RECORD FUNCTION BEHAVIOR AT LOGGING STARTUP................................................... 51

5.6 RECORD FUNCTION AND RELATIVE MEASUREMENT ...................................................... 51

6 SETTING DATE AND TIME ................................................................................... 52

7 LOGGING ............................................................................................................ 53

7.1 SETTING THE AUTOMATIC LOGGING INTERVAL OR THE MANUAL LOGGING............................... 53

7.2 SELECTING THE MEASUREMENT LINES FOR LOGGING ...................................................... 54

7.3 MANUALLY START/STOP AUTOMATIC LOGGING ............................................................. 55

7.4 PROGRAMMING AUTOMATIC LOGGING START/STOP TIME.................................................. 55

7.5 AUTO-OFF DURING AUTOMATIC LOGGING ................................................................... 57

7.6 MANUAL LOGGING.............................................................................................. 58

7.7 PDF REPORT ................................................................................................... 59

7.8 DISPLAYING LOGGING SESSIONS IN THE SD MEMORY CARD ............................................. 61

7.9 STORED DATA GRAPH .......................................................................................... 63

7.10 DELETING LOGGING SESSIONS IN THE SD MEMORY CARD ................................................ 64

7.11 DISPLAYING THE AMOUNT OF FREE MEMORY AVAILABLE IN THE SD MEMORY CARD.................... 65

7.12 LOGGING AND RECORD AND INTEGRAL FUNCTIONS................................................... 66

8 PROTECTED MODE .............................................................................................. 67

8.1 PASSWORD CHANGE FOR THE PROTECTED MODE ........................................................... 67

8.2 ENABLING/DISABLING THE PROTECTED MODE .............................................................. 68

9 MEASUREMENT SETTINGS .................................................................................. 70

9.1 TYPE OF CALIBRATION TO BE USED FOR PROBES ........................................................... 70

9.2 TEMPERATURE COMPENSATION ............................................................................... 72

9.3 BAROMETRIC PRESSURE COMPENSATION .................................................................... 74

9.4 SELECTING THE DUCT FOR FLOW RATE MEASUREMENTS ................................................... 76

9.5 PITOT OR DARCY TUBE COEFFICIENT ........................................................................ 78

9.6 AIR SPEED MEASUREMENT AVERAGE ......................................................................... 80

10 PRINTING MEASUREMENTS ................................................................................ 82

10.1 SETTING THE BAUD RATE OF THE INSTRUMENT ............................................................ 82

10.2 SENDING MEASUREMENTS FOR PRINTING ................................................................... 83

10.3 RECEIVING MEASUREMENTS INTO PC........................................................................ 83

11 INFORMATION ON INSTRUMENT AND PROBES ................................................... 84

12 USE OF THE BATTERY ......................................................................................... 85

12.1 AUTOMATIC SWITCH-OFF FUNCTION ......................................................................... 85

12.2 DISP LAY BR IGHTNESS ......................................................................................... 86

HD31 - 4 - V1.6

12.3 PROLONGING BATTERY LIFE .................................................................................... 88

12.4 REPLACING THE BATTERY ....................................................................................... 88

12.5 IMPORTANT WARNINGS ......................................................................................... 89

13 CALIBRATION ..................................................................................................... 90

13.1 CALIBRATION OF TEMPERATURE-ONLY PROBES WITH PRT SENSOR...................................... 90

13.1.1 NEW TUNING OPTION FOR PRT SENSORS.................................................... 91

13.1.2 PARAMETERS OPTION FOR PRT SENSORS.................................................... 92

13.2 CALIBRATION OF THERMOCOUPLE TEMPERATURE PROBES.................................................. 93

13.3 CALIBRATION OF COMBINED RELATIVE HUMIDITY AND TEMPERATURE PROBES ............................. 94

13.3.1 CALIBRATION OF THE TEMPERATURE SENSOR OF RH/T COMBINED PROBES ................ 94

13.3.2 CALIBRATION OF THE RELATIVE HUMIDITY SENSOR ............................................ 95

13.4 CALIBRATION OF PP472 MODULE (BAROMETRIC PRESSURE) ............................................. 99

13.5 CALIBRATING THE CO

2

PROBE .................................................................................100

13.5.1 ZERO/FRESH AIR OPTION FOR CO

2

PROBES................................................100

13.5.2 LINEAR GAINS OPTION FOR CO

2

PROBES ...................................................101

13.6 CALIBRATION OF VP473 MODULES (VOLTAGE) AND IP472 (CURRENT) .................................103

13.6.1 DEFINITION OF LINEAR CORRESPONDENCE.....................................................104

13.6.2 MEASUREMENT UNIT OF THE ASSOCIATED QUANTITY .........................................105

13.6.3 DISPLAYING THE ASSOCIATED QUANTITY.......................................................106

14 COMMUNICATING WITH A PC ........................................................................... 108

14.1 STORED DATA TRANSFER TO PC.............................................................................110

14.2 SERIAL COMMANDS ...........................................................................................111

15 FIRMWARE UPDATE .......................................................................................... 116

16 RESET OF THE INSTRUMENT............................................................................. 117

17 USAGE INSTRUCTIONS AND WARNINGS .......................................................... 118

18 INSTRUMENT STORAGE .................................................................................... 119

19 SAFETY INSTRUCTIONS.................................................................................... 119

20 TECHNICAL FEATURES...................................................................................... 120

20.1 TECHNICAL FEATURES OF PROBES AND SICRAM MODULES IN LINE WITH THE INSTRUMENT........121

20.1.1 TEMPERATURE WITH PLATINUM SENSORS (PRT)..............................................121

20.1.2 TEMPERATURE WITH THERMOCOUPLE SENSORS................................................122

20.1.3 RELATIVE HUMIDITY AND TEMPERATURE ........................................................126

20.1.4 PRESSURE ..........................................................................................127

20.1.5 AIR SPEED..........................................................................................129

20.1.6 PHOTOMETRY AND RADIOMETRY .................................................................131

20.1.7 CO

2

(CARBON DIOXIDE) .........................................................................138

21 ORDER CODES .................................................................................................. 139

APPENDIX .............................................................................................................. 148

HD31 - 5 - V1.6

1 INTRODUCTION

HD31 is a portable multifunction and data logger instrument. It has a large (43 x 58 mm) color

graphic LCD display.

It is equipped with 3 independent inputs. Each input can be connected to individual and combined SICRAM probes (intelligent and interchangeable probes capable to store calibration data

into memory) for the measurement of several physical qualities:

• Temperature

• Relative humidity

• Barometric and differential pressure

• Air speed

• Illuminance (lux) and Irradiance

• Carbon dioxide (CO

2

)

• Direct voltage and current

The type of probes connected to the different inputs is automatically recognized by the instrument. The probes are supplied factory- calibrated and are interchangeable.

By connecting a combined relative-humidity and temperature probe, the instrument calculates

the derived humidity quantities: dew-point temperature, wet-bulb temperature, absolute humidity, mixing ratio, partial vapor pressure, saturated steam pressure, enthalpy. The DI (Discomfort Index) and the NET (Net Effective Temperature) indexes are calculated as well.

The instrument’s inputs can also be connected to non SICRAM probes, by using the relevant

interface modules between instrument and probe.

The display can show up to 36 quantities, three of which can be displayed simultaneously in numeric format. A real-time measured quantity graph is shown in the display.

The measuring unit can be selected according to the measured physical quantity.

Data logging function with data storage in CSV format directly into the SD-type Memory Card, for

a long logging time (for example, with a 4 GB SD-type card, the logging lasts several months

even when recording several quantities with the minimum logging interval of 1 second). Userconfigurable storage interval. Manual or programmed logging start/stop. Logging date/time storage of each sample (automatically creates measurement reports in PDF format in the memory

card). Manual RECORD function (acquires the current measurement by simply pressing a button)

or automatic RECORD function (acquires the current measurement once per second) for the calculation of minimum, mean and maximum values of the measured quantities.

HOLD function (holds current measurements on the display), REL function (difference with regard to a stored value) and DIFF function (difference between two homogeneous measurements, e.g., between the measurements of two temperature probes).

Functions reserved through user password. USB port with mini-USB connector for PC connection, for configuration and download of the acquired data. DeltaLog9 application software

supplied with the instrument.

It is provided with MSD (Mass Storage Device) mode, in which the instrument is seen by the PC

as a SD card reader, thus allowing direct access to the memory card for displaying, copying or

deleting the logging files.

Serial output for the print of the displayed measurements on a RS232C input printer. The Baud

Rate can be set from 1200 to 115200.

Lithium ion rechargeable battery. Automatic switch-off (may be disabled) after user-configurable

downtime (2, 5, 10, 15, 20 or 30 minutes) for preserving the battery life. External power supply

through USB input (with mini-USB connector) by connecting a 5 Vdc power supply unit or a PC

USB port (500 mA at least). With an external power supply unit connected, the battery is recharged and the automatic switch-off is automatically disabled.

HD31 - 6 - V1.6

2 DESCRIPTION

Fig. 2.1: instrument description

HD31 - 7 - V1.6

1. Input B, 8-pole DIN45326 connector.

2. Input A, 8-pole DIN45326 connector.

3. F2 function key: activates the central command in the command bar.

4. F1 function key: activates the left command in the command bar.

5. SELECT key: scrolls cyclically forward the main commands in the command bar.

6. S key: in "Measure" mode, scrolls cyclically upwards the measurements on the display;

in the menu, it scrolls through the available options.

7. T key: in "Measure" mode, scrolls cyclically downwards the measurements on the dis-

play; in the menu, it scrolls through the available options.

8. SD card housing. To introduce the card, push it into the slot until it clicks into place,

which ensures the correct insertion. To remove the card, push it until you hear the release click.

CAUTION: to avoid data loss, do not remove the card if logging is active. Stop

logging before removing the card.

9. RS232C serial output with RJ12 (6P6C) connector for connecting the printer.

10. USB port with mini-USB for connecting a PC or external power supply device.

11. HOLD key: holds the measurement to the current value.

12. ON/OFF key: turns the instrument on/off.

13. ESC key: in "Measure" mode, scrolls cyclically backward the main commands in the

command bar; in the menu, it allows returning to the higher menu level; cancels the current operation without modifying the instrument parameters.

14. F3 function key: activates the right command in the command bar.

15. Color graphic LCD display.

16. Input C, 8-pole DIN45326 connector.

2.1 DISPLA Y DESCRIPTION

Fig. 2.1.1: dis

play description

17. Status bar: shows information about logging state, battery charge level, presence of SD

card, USB connection state, etc.

18. Display of the first measurement.

19. Date and time. During execution of the commands the line shows information messages.

20. Command bar (indications vary according to the function enabled).

21. Display of the third measurement.

22. Display of the second measurement.

HD31 - 8 - V1.6

2.2 KEY TO THE SYMBOLS IN THE STATUS BAR

Instrument connected to a USB port on your PC

Instrument connected to a USB port on your PC and communicating

Instrument connected to the external power supply unit

Instrument in MSD mode (Mass Storage Device): connected to the PC, it works as

an SD card reader

SD card inserted in the instrument

Logging session enabled. The logging interval, in the case of automatic recording,

or the MANL indication, in the case of manual recording, is shown under the symbol; the interval background turns light blue during acquisition time.

Auto-off between two logging instants activated

Start and stop logging instants programmed by the user

Only the logging start time is programmed

Only the logging stop time is programmed

"Monitor" function active (enabled by DeltaLog9 software)

The reduced level of brightness for the display is set

Reduced brightness level temporarily suspended following the push of a key (the

level will return to its “reduced” state after a few moments of inactivity)

Auto-off function activated

(*)

Auto-off function disabled or temporarily suspended (for example, following the

activation of the logging)

(*)

Power supply activated for hot-wire air speed probes or CO

2

probes

Battery charge between 67% and 100%

(**)

Battery charge between 34% and 66%

(**)

Battery charge between 4% and 33%

(**)

Battery charge less than 4%

(**)

(*)

The symbol is off if the instrument is connected to the external power supply unit or to the USB port

of the PC.

(**)

The symbol flashes when the battery is charging.

HD31 - 9 - V1.6

2.3 OVERVIEW OF THE FUNCTIONS IN THE COMMAND BAR

F1, F2 and F3 keys allow selecting the functions indicated in the display command bar. Press

the SELECT key to scroll cyclically through the main functions available in the command bar (or

alternatively the ESC key to scroll the functions in the opposite direction).

Some features include sub-functions (displayed in the command bar when you select the main

function by pressing the corresponding function key) or opening a menu. The scheme in Fig.

2.3.1 illustrates the functions listed using the SELECT key and the corresponding sub-functions.

Fig. 2.3.1: functions in the command bar

Th

e commands shown in the scheme are briefly outlined below. For a detailed description,

please refer to the sections in the manual for the respective functions.

1. LOG (logging): logging on and off. If logging is not enabled, the following sub-functions

appear:

RUN: manual start of the logging.

PROG (program): setting the programmed start and stop of the logging.

SEL (select): selects the measurement line indicated by the cursor on the display for

logging. If the measurement line has been already selected, the selection is canceled.

If logging is enabled, the following sub-functions appear instead of RUN and SEL:

STOP: manual stop of the logging.

MANL (manual): manual acquisition of a sample (function enabled only if the setting

of the logging interval is MANUAL).

2. MENU: opens the configuration menu of the instrument.

3. USB: activation and deactivation of the MSD (Mass Storage Device) to read the SD card

from the PC (see paragraph 14.1 at page 110).

4. IN

(input): selection of the quantities to be displayed. The following sub-functions are

shown:

<<<: scrolls backward the available quantities in the display line indicated by the cursor.

DIFF: displays the difference between the quantity currently indicated by the cursor

and an equivalent quantity, if available. If there are several equivalent quantities,

press repeatedly F2 until the desired quantity is selected.

>>>: scrolls forward the quantities available in the display line indicated by the cursor.

5. UNIT: selects the measurement unit. The following sub-functions are shown:

<<<: scrolls backwards the measurement units available for the quantity shown in the

display line indicated by the cursor.

>>>: scrolls forward the measurement unit available for the quantity shown in the dis-

play line indicated by the cursor.

6. REL: displays the relative measurement, that is the difference between the current value

and the one stored when the key was pressed, in the display line indicated by the cursor.

Conf iguration Menu

Hot

-

wire power supply

Connection mode

Relative measure

Print of measures

Offset correction

Reset of peak value

HD31 - 10 - V1.6

7. REC (record): calculation of minimum, average and maximum values. The following sub-

functions appear:

AUTO: starts the automatic update, once per second, of the minimum, average and

maximum values.

MANL (manual): updates the minimum, average and maximum values taking into ac-

count the measurement at the time when the command is selected.

SEL (select): selects the measurement line indicated by the cursor on the display for the

REC function. If the measurement line is already selected, the selection is cancelled.

If an integral measurement is selected, (with illuminance or irradiance measurements),

REC function is replaced by ITG function.

ITG (integral): calculation of the integral. The following sub-functions appear:

RUN: starts the calculation of the integral.

SEL (select): selects the measurement line indicated by the cursor on the display for the

ITG function. If the measurement line is already selected, the selection is cancelled.

8. VIEW: views the minimum, average and maximum values (calculated with the REC func-

tion) of the selected quantity. The following sub-functions appear:

MIN: displays the quantity minimum value in the display line indicated by the cursor.

Press the function key again to return to the current measurement value.

AVRG (average): displays the quantity average value in the display line indicated by

the cursor. Press the function key again to return to the current measurement value.

MAX: displays the quantity maximum value in the display line indicated by the cursor.

Press the function key again to return to the current measurement value.

If an integral measurement is selected (with illuminance or irradiance measurements), the

VIEW function is replaced by the V/T function.

V/T (Value/Time): setting integration limits. The following sub-functions appear:

VAL (value): sets the threshold for the stoping of the integral calculation.

TIME: sets the integration time limit.

CLR (clear): sets to zero the integration time and threshold limit.

9. DEL: deletes minimum, average and maximum values (or the integral calculation, with ITG

function). The following sub-functions appear:

CANC (cancel): disables the REC function (or ITG) and deletes the minimum, average

and maximum values (or the integral calculation, in the case of ITG function).

CLR (clear): resets the minimum, average and maximum value calculation (or the in-

tegral calculation, in the case of ITG function).

10. PRINT: sends the three measurements displayed when the key is pressed to the printer

connected with the RS232C output. Also the information about the connected probes (type

of probe, serial number, type of calibration used) are printed.

11. PL

OT: displays the real-time graphics of the measurement indicated by the cursor on the

display. The following sub-functions appear:

X: displays the vertical cursors.

ΔX: sets the scale of abscissae.

Y: displays the horizontal cursors and the zoom functions of the axis of ordinates.

12. HOTW (hot-wire): supplies or removes power to the hot-wire air speed probe.

13. ZERO: corrects the offset of the probes provided with this function.

14. PEAK: resets the peak value of the pressure probes.

Note: some functions may appear disabled (grayed out) according to the selected quantity and

the instrument state.

HD31 - 11 - V1.6

2.4 HELP FUNCTION

The instrument is provided with a quick HELP function that briefly describes the meaning of the

symbol appearing in the display status bar and the function of the commands available through

the SELECT key.

To access the HELP function:

1. Press the SELECT key to display

the MENU command in the command bar.

2. Select the MENU command by

pressing the F2 key.

3. If necessary, select the HELP item using S and T keys, then

press F3 key (OK command) to confirm.

4. The HELP of the commands available with the SELECT key ap-

pears. To cycle through the list of commands, select repeatedly “<<<” (F1 key) or “>>>” (F3 key)

5. To display the help of the symbols appearing in the display

status bar, select the ICON command by pressing F2 key.

6. To cyclically scroll the symbols’ list, repeatedly select “<<<”

(F1 key) or “>>>” (F3 key). To return to the Help of the

commands, select the FKEY command by pressing the F2 key.

7. Press ESC key twice to exit the menu and return to the mea-

surement mode.

HD31 - 12 - V1.6

3 MEASUREMENT MODE

Switching on and off the instrument is obtained by pressing the ON/OFF key.

Fig. 3.1: ON/OFF key

At

startup, the instrument checks for the probes connected to inputs and, after a few seconds,

goes to the standard measurement mode, displaying the measured quantities. The instrument

displays three measurement lines at the same time.

The quantities appearing on the display are identified by the letter (A, B or C) corresponding to

the input channel connected to the probe measuring the quantity, followed by a sequential

number helping to differentiate the various quantities measured by the same probe (combined

probes) or any derived quantities.

When the instrument is first switched on, it lists the available quantities depending on the

number and type of the connected probes, choosing among A1, B1, C1, A2, B2, C2, A3, B3,

C3.... For instance, if input A is connected to a humidity/temperature combined probe, and in-

put B to a Pt100 probe, the automatic configuration will organize the display as follows:

• First line (A1): relative humidity in %RH;

• Second line (B1): temperature of the Pt100 single probe;

• Third line (A2): temperature of the combined probe.

By default, derived quantities are not displayed; see paragraph 3.4. for their display.

I

f there are more than three quantities, use S and T keys to cyclically scroll upward or downward the list of the available quantities. During the scrolling operation, a small sequential

number appears over the quantity identifier, marking the position of the measurement in the

list.

Fig. 3.2: measurements display

W

ith the next switch-on, the instrument displays the list of the quantities as it appears at

switch-off.

Measurement unit

of the quantity

Measurement position

in the displayed list

(during scrolling only)

Quantity

identifier

Measured value

HD31 - 13 - V1.6

Note: the recognition of the probes occurs when the instrument is on; if a probe is connected

when the instrument is on, the instrument has to be turned off and on to display the new

probe measures.

3.1 SELECTING A MEASUREMENT LINE

Some functions of the instrument have effect on the selected measurement line, indicated by a

check mark next to the quantity identifier. Use the S and T keys to select a measurement

line. The currently selected measurement line is highlighted with the first press of the S or T

key: repeatedly press the S or T key until the desired measurement line is highlighted and

wait some seconds for the checkmark to appear.

Fig. 3.1.1: selecting a measurement line

3.2 SELECTING THE MEASUREMENT UNIT

Several measurement units are available for some quantities (temperature, pressure, air

speed, ...). To change the measurement unit of a quantity in a measurement line:

1. Select the desired measurement line using S and T keys.

2. Press SELECT until the UNIT

command in the command bar is

selected, then select the command

by pressing F2.

Note: if the quantity has no measurement unit available for selection

or RECORD and/or LOG functions

are enabled, the command is disabled.

3. Select “<<<” (F1 key) or “>>>” (F3 key) to cyclically scroll

the available measurement units.

4. Press ESC to exit the UNIT command.

If several quantities of the same type (e.g. several temperatures) are shown in different measurement lines, you can set different measurement units for each measurement line.

The measurement unit change affects the display and the immediate print of the measurements (PRINT command). The data already stored in the SD card maintain the meas-

urement units selected at storage.

Check mark

Check mark

HD31 - 14 - V1.6

3.3 CHANGING THE QUANTITY VIEWED IN THE DISPLAY LINE

A quantity can be displayed in any measurement line of the display:

1. Select the desired line with S and T keys.

2. Press the SELECT key to display

the IN command in the command

bar, then select the command by

pressing F1 key.

3. Select “<<<” (F1) or “>>>” (F3) to cyclically scroll the

available quantities.

If you don’t want quantities to be displayed in the line, select

"––".

4. Press ESC to exit the IN command.

The same quantity can be displayed in several lines, e.g., for the simultaneous display of minimum and maximum values, or the current value and the average value, etc. (note: to display the

minimum, average and maximum values of a quantity you need to activate the RECORD function,

see chapter 5).

3.4 DERIVED QUANTITIES AND NUMBER OF MEASUREMENT LINES DISPLAYED

The number of measurement lines displayed can be configured. Up to 36 measurement lines can

be displayed. The number of measurement lines displayed at the same time is always 3, further

measurement lines can be seen by scrolling the list upward or downward using S and T keys.

By default, the instrument displays only the quantities measured by the probes and the main

derived quantities. For instance, connecting a combined relative humidity and temperature

probe displays only the temperature, the relative humidity and the dew point temperature, but

not the other derived quantities: absolute humidity, mixing ratio, etc. To enable any other derived quantities as well, or to disable some of the visible quantities, proceed as follows:

1. Press SELECT to display the MENU

command in the command bar, then

select the command by pressing F2.

HD31 - 15 - V1.6

2. Select the SETUP item using S and T, then press F3 (OK

command) to confirm.

3. Select the CHANNELS item using S and T, then press F3

(OK command) to confirm.

4. Select the A, B or C input of the instrument, using S and T,

then press F3 (OK command) to confirm.

5. The list of the available measured and calculated quantities,

relevant to the selected input is displayed. The checkmark

next to a quantity indicates that the quantity measurement is

enabled (appears in the display). Using S and T, select the

quantity to be enabled or disabled, then press F1 (SEL com-

mand) to toggle between the enabled and disabled states of

the quantity.

6. Press F3 (OK command) to confirm.

Note: the enabled state of several quantities can be changed by selecting them one at a

time, before confirming; the changed quantities are displayed in yellow to highlight

changes.

The instrument allows the setting of the quantity enable state to be saved, so as to be able to restore it afterwards and cancel any changes carried out thereafter.

HD31 - 16 - V1.6

Select the BKUP command (F2 key) to save or restore the saved

setting.

Select the SAVE command (F1) to save the setting. Select the

LOAD command (F2) to restore the previously saved setting. Select the BASIC command (F3) to return to the default setting.

Press F3 (OK command) to confirm the restore operation.

Press ESC to return to the previous menu.

Number of displayed measurement lines:

The number of the displayed measurement lines is automatically updated when quantities are

enabled or disabled. If you want a different measurement number to be displayed, e.g. to

show simultaneously both the current value of a quantity and the relevant statistical information (Min, Max, Avg), the number of displayed measurement lines can be set manually:

1. Select the CHANNELS NUM. item in the CHANNELS menu,

using S and T, then press F3 (OK command) to confirm.

2. Set the number of measurement lines to be displayed using

S and T (select the RESET command with F2 key to set the

default number), then press F3 (OK command) to confirm.

Note: the current setting is shown in white, while the other

available settings appear in yellow to show that they are not

the current setting.

3. The instrument returns to CHANNELS NUM item, repeatedly press ESC to exit the menu.

HD31 - 17 - V1.6

3.5 DISPLAYING THE DIFFERENCE BETWEEN TWO HOMOGENEOUS QUANTITIES

A measurement line can display the difference between the values of two homogeneous quantities, e.g. the difference between the values measured by two Pt100 probes, by two thermocouple probes, by two equal pressure probes etc.

The difference between the measurements of two different probes cannot be calculated, even

if they refer to the same physical quantity, e.g. between the measurement of a Pt100 probe

and a thermocouple probe, or between the measurement of two pressure probes having a different full scale value.

To display the difference between the values of two homogeneous quantities:

1. Select the first of the two quantities (e.g. A2, if you want A2-B1 to be displayed) using S

and T keys.

2. Press SELECT to display the IN

command in the command bar,

then select the command by pressing F1.

3. Select the DIFF command by pressing F2.

Note: if a quantity consistent with the one selected is not

available, the command is disabled.

4. The selected measurement line shows the difference between

the value of the quantity originally included in the line (e.g. A2)

and the value of another available homogeneous quantity.

If several homogeneous quantities are available, repeatedly

select the DIFF command (F2 key) to display the desired dif-

ference.

To disable the difference display, repeatedly select the DIFF

command (F2 key) to display again the value of the quantity

originally present in the line.

5. Press ESC to exit the IN command.

HD31 - 18 - V1.6

3.6 DISPLAYING THE RELATIVE MEASUREMENT (REL)

The instrument allows the relative measurement of the quantities to be displayed, i.e. the difference between the current measurement value and a reference value, consisting in the measurement value at the moment of the REL function activation.

To activate the relative measure:

1. Select the quantity you want the relative measure to be enabled, using S and T.

2. Press SELECT to display the REL

command in the command bar,

then select the command by pressing F3.

3. The selected measurement line shows the difference between

the quantity current value and the reference value, consisting in

the measurement value at the moment of the REL command

activation. The reference value is displayed in the upper part of

the measurement line (followed by the symbol REL).

Select again the REL command (F3 key) to disable the display of the relative measure and return to the current measurement value.

3.7 HOLDING THE MEASUREMENT ON THE DISPLAY (HOLD)

The HOLD function holds the current measurement values on the display. The function affects all

the measurement lines. When the HOLD function is active, the measurement values on the display are not updated, but remains set to the value present at the moment of the function activation.

Press HOLD to activate the function. The function activation is highlighted by the orange bars

over and under the measurement area on the display, and by the word HOLD flashing in the

top bar. The clock in the bottom bar remains stopped to the moment the key was pressed.

Fig. 3.7.1: HOLD function activation

Pr

ess again HOLD to disable the HOLD function and return to the current measurement val-

ues.

Orange bars

Reference value

HD31 - 19 - V1.6

3.8 MEASUREMENT GRAPH

The graph of a quantity measured by the instrument can be shown in the display. Zoom functions and vertical and horizontal cursors are available during the graphical representation, allowing the graph to be analyzed in detail.

Select the quantity you want the graph to be displayed using S and T. Press SELECT to display

the PLOT command in the command bar, then press F3.

Fig. 3.8.1: PLOT c

ommand

If the graph of another quantity was previously started, a message appears asking to confirm the

change: select YES (F3 key) to continue (or press F1 to select NO and exit). The quantity

graph appears on the display.

Fig. 3.8.2: graph display

T

he minimum and maximum values of the ordinate axis (y-axis) are shown at the left of the

graph. Over the graph, in the middle, there is the ordinate scale: ΔY is the difference between

two horizontal lines of the graph grid. Under the graph, in the middle, there is the abscissa

scale: ΔX is the difference between two vertical lines of the graph grid.

Horizontal cursors and ordinate axis scale:

By selecting the Y command (F3 keys), the horizontal cursors and the zoom commands of the

ordinate axis are displayed.

The CUR command (F2 key) activates alternatively the lower or the upper cursor. The active

cursor is light blue, while the non-active cursor is white. You can move the active cursor using S

and T. The positions of the two cursors appear in the command bar.

HD31 - 20 - V1.6

Fig. 3.8.3: horizontal cursors

Th

e ZOOM command (F3 key) enlarges the graph area included between the two horizontal

cursors: the minimum and maximum values of the ordinate axis are equal to the values indicated by the lower and the upper cursor respectively. The indication AUTO (automatic ordinate

scale) is replaced by the indication ZOOM over the graph, on the right.

The AUTO command (F1 key) allows zooms to be disabled and to return to the automatic ordinate scale.

Fig. 3.8.4: AUTO c

ommand

Vertical cursors and x-axis scale:

Selecting X command (F1 key) displays the vertical cursors of the abscissa axis (x-axis).

The CUR command (F2 key) activates alternatively the lower or the upper cursor. The active

cursor appears light blue, while the non-active cursor is white. The active cursor can be moved

using <<< (F1 key) and >>> (F3 key) commands. The time distance between cursors (Δx) and

the difference of the two measurements in correspondence with the cursors (Δy) appear over the

command bar.

Fig. 3.8.5: vertical cursors

P

ress ESC to return to the previous command level.

The time interval between two vertical lines of the graph grid is set by default to 1 minute. Select

ΔX command (F2 key) to change the interval.

Upper cursor

Lower cursor

Lower cursor

p

osition Upper cursor position

Right cursor

Left cursor

Difference of measures in correspondence with the cursors

Time distance between cursors

HD31 - 21 - V1.6

Fig. 3.8.6: command ΔX

T

he available intervals can be cyclically set to: 1 min, 5 min, 10 min, 30 min, 1 hour, 2 hours,

4 hours through the NEXT command (F3 key).

Fig. 3.8.7: x-axis scale setting

T

he time interval returns to the default value (1 min) by selecting the BACK command (F1

key).

The sequential number of the selected interval appears under the graph on the right (e.g. 2/7

indicates the second interval of the seven available, that is 5 min).

If the interval returns to 1 minute (with the BACK command, or by setting the value from 4

hours to 1 minute with the NEXT command), the graph is reinitialized.

HD31 - 22 - V1.6

4 THE PROBES

The probes of the instrument are equipped with an “intelligent” module acting as interface between the probe and the instrument. Inside the module there is a microprocessor circuit with

permanent memory performing different functions:

• allows the instrument to recognize the type of connected probe: Pt100, thermocouple, hu-

midity probe, pressure probe, anemometric probe, photo/radiometric probe, ...;

• stores into memory the probe calibration data: in this way the probe can be indifferently

connected to the three inputs of the instrument or to another instrument with no need to

be recalibrated;

• recognizes the instrument with which it was calibrated (user-calibration);

• maintains the factory-calibration data and those concerning the last calibration made by

the user, with the possibility of choosing one of the two calibrations for each of the probes

connected to the instrument;

• stores into memory a serial number allowing the unique identification of the probe, a useful

feature in case several probes of the same type are simultaneously used.

The recognition of SICRAM probes takes place when the instrument is started or after a reset.

SICRAM probes are supplied factory-calibrated and don’t normally require further interventions

from the user. Nevertheless, a new calibration can be carried out if needed. See chapter 13 for

u

ser-calibration of the probes.

4.1 PRT TEMPERATURE PROBES

Pt100 probes with SICRAM module can be connected. The probes have a 4 wire connection and

the excitation current is chosen in such a way as to minimize the sensor’s self-heating effect.

If your instrument needs to be connected to sensors that are not equipped with SICRAM module, one of the following two accessories will have to be placed between sensor and instrument:

• TP471: “intelligent” module with microprocessor and permanent memory, designed for

4-wire Pt100 Platinum sensors (PRT).

• TP47: connector without microprocessor and memory, designed for 4-wire Pt100 and 2-

wire Pt1000 Platinum sensors (PRT).

TP471 and TP47 are provided with fairlead and cable grommet for 5 mm max diameter cables.

Proceed as follows:

1. Unscrew the fairlead and pull the cable grommet out, remove the identification label, un-

screw the ring nut on the opposite side of the module/connector.

Fig. 4.1.1: opening the module/connector

2. P

ass the sensor cable through the fairlead and cable grommet.

3. Open the two module/connector shells and connect the PRT sensor to the printed circuit as

shown in the figures below. Take care that the welding is clean and skillfully made.

HD31 - 23 - V1.6

Fig. 4.1.2: connecting 4-wire Pt100 sensor to TP471 module

Fig. 4.1.3: connecting 4-wire Pt100 sensor to TP47 connector

Fig. 4.1.4: connecting 2-wire Pt1000 sensor to TP47 connector

4. C

lose the two shells, insert the gasket in the module/connector, screw the fairlead and the

ring. Make sure that the cable is not twisted when screwing the fairlead.

Fig. 4.1.5: PRT sensor connected to the module/connector

S

ee paragraph 13.1 at page 90 for PRT probe calibration.

HD31 - 24 - V1.6

4.1.1 SETTING THE INSTRUMENT TO READ A PRT PROBE WITHOUT SICRAM MODULE

If a PRT probe without SICRAM module is connected, the type of connected probe must be set

in the instrument:

1. Turn the instrument off and connect the probe.

2. Turn the instrument on.

3. Press SELECT to display the MENU

command in the command bar, then

select the command by pressing F2.

4. Select the SETUP item using S and T, then press F3 (OK

command) to confirm.

5. Select the CHANNELS item using S and T, then press F3

(OK command) to confirm.

6. Using S and T, select the input (A, B or C) of the instru-

ment to which the probe is connected, then press F3 (OK

command) to confirm.

HD31 - 25 - V1.6

7. Using S and T, select the probe type: "SICRAM" (default),

“DIRECT Pt100” or “DIRECT Pt1000”.

Note: the current setting appears in white color, while the

other available settings are in yellow color to highlight that

they are not the current setting.

8. Press F3 (OK command) to confirm.

9. Turn the instrument off and then back on.

Note: the probe type setting is maintained if the instrument is switched off with the probe

connected; the setting returns to the default value (“SICRAM”) instead if the instrument is

switched off when the probe is disconnected.

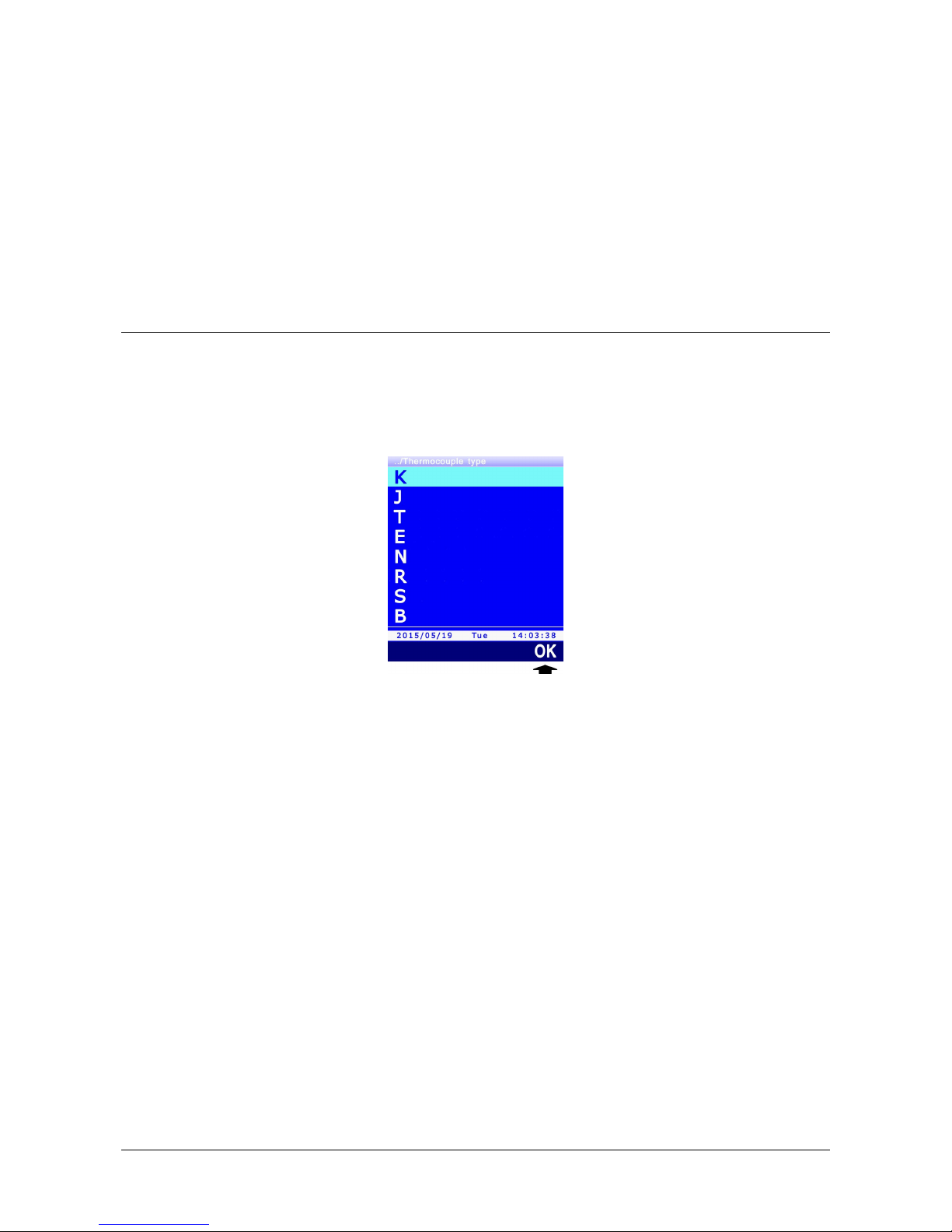

4.2 THERMOCOUPLE TEMPERATURE PROBES

K, J, T, E, R, S, B and N-type thermocouple temperature probes can be connected. A SICRAM

module has to be placed between the probe and the instrument choosing from the modules below:

• TP471D0: 1-input module without cold junction compensation.

• TP471D: 1-input module with internal sensor for cold junction compensation.

• TP471D1: 2-input module with internal sensor for cold junction compensation.

If TP471D0 module is used, without cold junction compensation, the cold junction will have to

be kept at a temperature of 0 °C using a melting ice bath.

TC

Fig. 4.2.1: cold junction at 0 °C

If TP

471D and TP471D1 modules are used, the cold junction temperature is measured by the

internal sensor and is used by the instrument to compensate the thermocouple measurement.

The instrument displays also the cold junction temperature (as second quantity, e.g. A2, for

the 1-input module, and as third quantity, e.g. A3, for the 2-input module).

See paragraph 13.2 at page 93 to set the type of thermocouple connected to the modules.

Copper

Melting ice bath

HD31 - 26 - V1.6

4.3 RELATIVE HUMIDITY AND TEMPERATURE COMBINED PROBES

The relative humidity and temperature combined probes use a capacitive sensor for the measurement of relative humidity and a Pt100 sensor for the measurement of temperature. By connecting a relative humidity and temperature

combined probe, the instrument can display, be-

sides the two primary quantities, the following derived humidity quantities as well:

• Saturated vapor pressure (Svp) in hPa

• Partial vapor pressure (Pvp) in hPa

• Mixing ratio in g/kg (vapor grams in 1 kg of dry air)

• Enthalpy in J/g

• Absolute humidity in g/m3 (vapor grams in 1 cubic meter of dry air)

• Dew point Temperature (Td)

• Wet bulb Temperature (Tw)

• Discomfort index (DiscIdx)

• NET index (NetIdx)

Note: the calculation of the derived quantities is made taking into consideration a ba-

rometric pressure fixed value equal to 1013.25 hPa.

For measuring, place the probe avoiding areas where fast temperature variations may occur

creating condensation. The measurement in no condition of fast temperature variations is almost immediate. On the contrary, if fast temperature variations occur, you have to wait the

sensors and the probe body to reach thermal balance in order to obtain accurate measurements.

See paragraph 13.3 at page 94 for the calibration of relative humidity and temperature combi

ned probes.

4.3.1 DISCOMFORT INDEX AND NET INDEX

Environmental conditions affect our physiological well-being status: particular values of temperature, humidity and air speed are perceived as unpleasant or even intolerable. While it is

easy to quantify the relationship between well-being status and the measure of each variable

taken separately, it is even more complex to provide an indication about their combined effect.

For this reason, different evaluation systems have been introduced leading to the formulation

of climate qualitative indices (Comfort Indices).

The two indices provided by the instrument are the Discomfort Index and the NET index

(Net Effective Temperature). The first one depends only on temperature and relative humidity,

while the second one takes into consideration air speed as well. If an anemometric probe is

connected to the instrument, the speed measurement detected is used for the calculation of

the Net Index; if there is no probe connected, air speed is set equal to zero and its contribution is not taken into account.

Discomfort index:

3.46)3.1499.0(

100

81.0 +−••+•= T

H

TDI

with T = temperature in °C

H = relative humidity in %

On the basis of the value provided by the discomfort index, climate conditions are defined from

comfortable to unsustainable:

Comfortable

Slightly

uncomfortable

Uncomfortable

Very

uncomfortable

Unsustainable

68 70 75 80 86

HD31 - 27 - V1.6

NET index:

T

H

v

H

T

NI •

⎟

⎠

⎞

⎜

⎝

⎛

−•−

•+

+•−

−

−=

100

129.0

4.176.1

1

0014.068.0

37

37

75.0

With T = temperature in °C

H = relative humidity in %

v = air speed in m/s

NET index provides the so called “apparent temperature”: with optimum weather conditions, the

index value is close to the environmental T temperature. As weather conditions deteriorate, humidity and air speed influence become more and more evident and the index provides a temperature value that reflects human typical sensations, deviating even significantly from the ambient temperature value:

• in hot climate, the NET index rises as temperature and/or humidity level increases, but it

decreases with increasing wind force;

• in cold climate, the NET index decreases with temperature and with increasing humidity

and wind level.

HD31 - 28 - V1.6

4.4 PRESSURE PROBES

The following SICRAM modules can be connected to the instrument:

• PP471: module for connection to absolute, relative and differential pressure probes of the

TP704 and TP705 series. Connecting the module to the instrument displays both the instant

value and the peak value of pressure. The peak value is characterized by the word "peak"

alternating with the measurement unit.

• PP472: module for the detection of the barometric pressure in the range 600...1100 hPa.

• PP473S...: series of modules for the measurement of the differential pressure. Available

full scale values: 2.5 / 10 / 20 / 50 / 100 / 200 / 500 / 1000 / 2000 mbar.

Pressure can be displayed in the following measurement units: Pa, hPa, kPa, mbar, bar, atm,

mmHg, mmH

2

O, kgf/cm2, PSI, inHg, inH2O. See paragraph 3.2 at page 13 for the measure-

ment unit selection.

Some measurement units require the value to be displayed with a multiplication factor. If the

displayed value is followed by the indication “E+3”, it means that the value must be multiplied

by 1000; if on the contrary it is followed by the indication “E-3”, it means that the value must

be divided by 1000.

The differential probes may be set to zero (see next paragraph). See paragraph 13.4 at page

99 for the calibration of PP472 module for the barometric pressure measurement.

4.4.1 ZEROING DIFFERENTIAL PRESSURE PROBES

There can be a small difference between the two inputs of the differential probes, that’s why

the instrument, with equal pressure applied to the two probe inputs, doesn’t indicate zero value. A zeroing command for the differential value is available:

1. Leave the two inputs of the differential probe open, so as they may detect the same pressure.

2. Press SELECT to display the ZERO command in the command bar, then select the com-

mand by pressing F2.

Fig. 4.4.1: ZERO c

ommand

3. Select inputs A, B or C the probe is connected to by pressing F1, F2 or F3 respectively.

Fig. 4.4.2: selecting the differential probe for zeroing

HD31 - 29 - V1.6

4. The instant value is automatically zeroed.

4.4.2 PEAK VALUE RESET

The peak value detected by the probe connected to PP471 module can be reinitialized and set

equal to the instant value:

1. Press SELECT to display the PEAK command in the command bar, then select the com-

mand by pressing F2.

Fig. 4.4.3: PEAK c

ommand

2. Select inputs A, B or C the probe is connected to by pressing F1, F2 or F3 respectively.

Fig. 4.4.4: selecting the probe for peak value reset

3. T

he peak value is reset to the instant value.

Peak value reset during logging:

If the logging interval is lower than 60 seconds, the peak value is not zeroed: the acquired

value is therefore the highest peak since acquisition startup.

For logging intervals equal to or higher than 60 seconds, the peak value is on the contrary reinitialized after each acquisition: the stored peak value is therefore the one related to the single interval between two subsequent acquisitions.

Two different operation modes have been chosen for this reason: when the logging interval is

short, the set of the instant measures represents closely enough the pressure trend over time.

In the case of long intervals, the mere knowledge of the pressure value of each interval and of

the absolute peak value doesn’t provide sufficiently precise information: knowing each peak

value between two subsequent samplings provides additional information on the pressure time

trend.

HD31 - 30 - V1.6

4.5 AIR SPEED PROBES

The following probes/modules can be connected to the instrument:

• AP471S...: hot-wire air speed SICRAM probes.

• AP472S...: vane air speed SICRAM probes.

• AP473S...: SICRAM modules for Pitot tubes.

Some probes measure air temperature as well.

The selection of the type of probe to be used depends on the range of air speed and temperature to be measured: see the specifications of air speed probes at page 129.

Ai

r speed can be displayed in the following measurement units: m/s, km/h, ft/min, mph, knot.

See paragraph 3.2 at page 13 for the measurement unit selection.

TAB. 4.5.1: conversion table of air speed measurement units

m/s ft/min km/h mph knot

1 m/s 1 196.87 3.60 2.24 1.944

1 ft/min 0.00508 1 0.01829 0.01138 9.874·10-3

1 km/h 0.2778 54.69 1 0.6222 0.5399

1 mph 0.4464 87.89 1.6071 1 0.8689

1 knot 0.5144 101.27 1.852 1.151 1

4.5.1 FLOW-RATE MEASUREMENT

If an air speed probe is connected, the instrument can calculate the air flow rate of an air duct

or air vent orthogonal to the flow. For the calculation of the air flow rate, you need to configure

the value of the duct or air vent section as described in paragraph 9.4 at page 76.

T

he air flow rate can be displayed in the following measurement units: l/s, m

3

/s, m3/min, ft3/s,

ft

3

/min. See paragraph 3.2 for the measurement unit selection.

Note: in air flow measurements, use only one anemometric probe at a time, since only

one section is available for setting. There are no limitations instead to the simultaneous use of

several anemometric probes for air speed measures.

4.5.2 NOTES ON FLOW MEASUREMENTS

If the surface area of the considered measurement is large or there is air turbulence, e.g. in

front of a grid or a diffuser, air speed and air flow may vary both geographically (from one

point to another) and over time (in the same point but in subsequent moments). To obtain

most significant values, it is therefore advisable to average the acquired instant measurements. The instrument provides two methods for the calculation of the measured average

flow:

1) Use of the RECORD function: the function allows averaging of the acquired instant values starting from the moment of the function activation. Additionally, the function provides the minimum and maximum acquired values. See chapter 5 for the RECORD functio

n use.

2) Use of moving average: the function allows displaying the average of the last n in-

stant measurements - instead of the instant measurement – where n can be set from 1

to 100. See paragraph 9.5 at page 78 for the setting of the parameter n (FL

OW AVG.

TIME).

The presence of vent grills or diffusers with tilting flaps produces errors in the flow measurement

due to the generated turbulence, since part of the flow is slowed down by the obstacle repre-

HD31 - 31 - V1.6

sented by the flap, while the remaining flow proceeds at maximum speed. In this case, a channel having a length of about the double of the grill diagonal should be placed temporarily in front

of the grill and measurements should be taken at the channel’s end. The section to be considered for flow calculations will be that of the temporary channel placed between grill and probe.

D

L = 2 x D

Fig. 4.5.1: flow measurement in the presence of vent grills or diffusers

4.5.3 HOT-WIRE AIR SPEED PROBES AP471S...

AP471 S1 and AP471 S3 probes measure incident air flows up to 40 m/s; AP471 S2 and

AP471 S4 probes, equipped with omnidirectional sensor, measure air speed up to 5 m/s in any

direction of the air flow incident on the probe. Air speed measurement temperature is compensated in the range 0…+80 °C.

AP471 S4 probe is provided with supporting base and sensor protection.

AP471S1

AP471S2

AP471S3

Temporary channel

Probe

Duct section

Ventilation grill

DUCT

Flexible

HD31 - 32 - V1.6

AP471S4

Fig. 4.5.2: AP471S...series probes

AP

471 S1, AP471 S2 and AP471 S3 probes are provided with a cylindrical shield sliding longitudinally along a guide rail. The shield has two end of stroke positions which lock it in measurement condition (lowest level) or at rest condition (highest level).

Fig. 4.5.3: description of AP471S1- AP471S2- AP471S3 probes

T

o reduce the amount of space when it is not used, the AP471 S4 probe is equipped with a

protection cylinder to be screwed onto the probe’s head (see fig. 4.5.2).

The probes of AP471 S… series are factory-calibrated and don’t require user-calibrations.

Before the measurement, set to zero the probe as indicated in paragraph 4.5.6 at page 38.

T

o perform the measurement, extend the telescopic rod for the necessary length ensuring that

the cable may slide freely and without efforts. Uncover the sensor and insert the probe in the

Flow direction line

Air speed sensor

Compensation sensor

Ambient temperature sensor

Cylindrical shield

HD31 - 33 - V1.6

air flow to be measured, keeping the arrow on top of the probe parallel to the flow, as indicated in the figures below. The probe must be kept orthogonal to the flow and not inclined.

OK NO

Fig. 4.5.4: positioning hot wire probes

P

robe power supply:

To reduce battery drain, the hot-wire probe is not powered at instrument startup: OFF appears

in place of air speed and flow measurements. To power the probe:

1. Press SELECT to display the HOTW command in the command bar, then select the com-

mand by pressing F1.

Fig. 4.5.5: HOTW command

2. OFF

indication on the display is replaced by the measurement.

Select again the HOTW command to switch off the probe.

Flow direction indicator

Probe top

HD31 - 34 - V1.6

AP471 S… probe speed sensor is heated and fire or explosion might occur, if

vapors or gases are present. Do not use the probe in the presence of flammable gases. Make sure there are no gas or explosive vapor leaks in the environment.

Care and maintenance of hot-wire probes:

The probe is a very sensitive device and should be handled with extreme care. Even a simple

shock, particularly with omnidirectional probes whose sensor is uncovered, can make the

probe unusable. Once the measure is finished, the sensor placed on the probe’s head should

be protected with the metal shield or with the threaded cylinder supplied. During use, the omnidirectional probe AP471 S4 should be protected with the special metallic grid provided. For

transportation, the sensor should be closed inside the protection cylinder by screwing it at the

probe’s end.

Do not touch with your fingers.

Use only alcohol to clean the probe.

4.5.4 AIR SPEED VANE PROBES AP472S...

AP472 S1 and AP472 S2 vane probes measure the speed and flow rate of an incident air flow.

AP472 S1 probe measures also the temperature through a type K thermocouple. They are

equipped, upon request, with an extensible telescopic rod (AST.1) which facilitates measure-

ments in hard-to-reach areas (e.g. air-vents).

The bigger diameters are suitable for flow measurements in the presence of low-to-medium air

speed turbulence (e.g. duct outlets). Lower diameters are suitable for applications where the

probe surface must be much smaller than the transversal section of the duct, inside which the

measurement is performed, e.g. aeration channels.

AP472 S1 AP472 S2

Fig. 4.5.6: probes of AP472S...series

HD31 - 35 - V1.6

The AP472 S… series probes are factory calibrated and don’t require user calibration.

ATTENTION: vane probes can be connected only to the C input of the instrument. If the

probe is connected to A or B inputs, the indication “Slot C” appears to indicate that the

probe should be moved to the C input .

To perform the measurement, extend the telescopic rod for the necessary length making sure

that the cable slides freely and without efforts. Insert the probe in the air flow to be measured,

keeping the propeller axis parallel to the flow, as indicated in the figures below. The probe

should be kept orthogonal to the flow and not inclined. The probe is correctly positioned in the

air flow when the maximum value is detected.

OK NO

Fig. 4.5.7: positioning vane probes

HD31 - 36 - V1.6

The probes AP472 S1 and AP472 S2 , plus auction telescoping AST.1 with swivel head, can use

a ∅ 16 mm rigid extension rod. To unscrew the handle (3) hold the probe body at the point

(1). Screw the rod top AP471S1.23.6 (4) on the screw (2). Other extension rods

AP471S1.23.6 can be added. The last element can be the handle (3) or the extension rod

AP471S1.23.7 (5).

Fig. 4.5.8: adding extensions to vane probes

Ca

re and maintenance of vane probes:

Probe performances, especially at the lowest speed, depend widely on the very low friction

with which the propeller rotates around its own axle. So as not to jeopardize this feature, it is

recommended not to force, lock or rotate the propeller with your fingers and not to introduce it

in air flows which could soil it, as far as possible.

4.5.5 AP473S... MODULES FOR PITOT TUBES

Pitot tube is a simple method for measuring air speed in difficult to access areas (e.g. aeration

ducts) and in the presence of high air speed and temperature. Since there is no air passage

through the Pitot tube, it is particularly indicated for measurements in harsh environments.

Fig. 4.5.9: Pitot tube measuring principle

Hole for total pressure

measurement

Hole for static

pressure

measurement

Static pressure

Speed pressure

Total pressure

HD31 - 37 - V1.6

The pressure inside the duct is the result of three different pressures:

1) barometric pressure (barometric B);

2) static pressure Ps;

3) dynamic pressure Pv due to non-null air speed inside the duct.

The formula below provides air speed in relation to the three pressures and of air temperature.

⎥

⎦

⎤

⎢

⎣

⎡

•

+

••••= Pv

Ps100.000

100.000

289

T

B

1000

1,291Cv

K[T]

Pa[Ps] [Pv]

mbar [B]

m/s[v]

°=

==

=

=

Pitot tube provides the difference between the pressure existing at the front inlet of the duct

and the pressure detected at the lateral air escapes that is the dynamic Pv:

(Ps+Pv) – Ps = Pv

Static pressure Ps represents the pressure difference between the inside of the duct in static

conditions and the barometric pressure. If Ps is lower than 2500 Pa (=25 mbar), the term

[100.000/(100.000+Ps)] can be disregarded, since the error committed is of about 1%.

B represents the barometric pressure existing at the moment of the measurement: the value

can be given by a barometric pressure probe connected to the instrument or it can be set manually (see paragraph 9.3 at page 74).

T

is the temperature detected by the thermocouple K present in some models of Pitot tubes. If

the Pitot tube is provided with a thermocouple K, an external thermocouple K with Mignon

connector can be added to the Pitot tube. In alternative, the temperature value can be added

manually. See paragraph 9.2 at page 72 for the setting of temperature compensation.

C is

the tube constant. See paragraph 9.5 at page 78 for the parameter setting.

In

order to connect a Pitot tube to the instrument, a SICRAM AP473 S….module must be

placed between the tube and the instrument. Any of the Pitot tubes can be connected to each

of the available modules, with the relevant thermocouple, if any. In standard temperature and

barometric pressure conditions, AP473 S1 model has a full scale of 40 m/s, AP473 S2 of

55 m/s, AP473 S3 model of 90 m/s and AP473 S4 model of 130 m/s.

AP473 S...modules are provided with two pressure inputs to be connected to the Pitot tube

outputs, and with a thermocouple K input.

By connecting a AP473 S... module, the instrument displays: air speed, the air temperature

detected by the thermocouple, flow rate and the Pv differential pressure.

In order to perform the measurement, insert the AP473 S... module connector into one of the

instrument inputs; connect the outputs of the Pitot tube (pressure and thermocouple) to the

module. The outputs of the Pitot tube must be connected to the module respecting the correct

polarity. The output oriented downwards of the Pitot tube, indicated in the figure below by the

plus sign (+), must be connected to the positive input of the module; the lateral output of the

Pitot tube, indicated in the figure below by the minus sign (-) must be connected to the

negative input of the module.

Insert the Pitot tube into the air flow to be measured, keeping the small rod at the base of the

tube parallel to the flow as indicated in the figure below.

HD31 - 38 - V1.6

Fig. 4.5.10: positioning the Pitot tube

Th

e error committed in the event of a misalignment is shown in the graph below:

+0.6

+0.4

+0.2

0.0

-0.2

-0.4

-0.6

-0.8

-1.0

-1.2

0 5° 10° 15°5°10°15°

P

v % E

RRO

R

A

NGLE

Fig. 4.5.11: misalignment error of the Pitot tube

T

he rotation angle around its own vertical axis with respect to the flow direction (yaw) is

shown in the abscissa (x-axis), while the % error on the measurement of the Pv differential

pressure is displayed in the y-axis (ordinate). As can be seen, a difference greater than 10°

leads to an error in the measurement of the differential pressure of less than 0.5%.

4.5.6 ZEROING AIR SPEED PROBES

With hot-wire and Pitot probes, the probe zero should be corrected before performing a measurement, i.e., ensure that - under wind-free conditions – the speed and flow rate values provided by the probe are equal to zero, at a temperature close to that of the air flow to be

measured.

1. As to AP471 S1, AP471 S2 and AP471 S3 probes, slide the cylindrical shield upwards until the

window of the air speed sensor on top of the probe is completely closed. As to the AP471 S4

probe, close the probe head with the protection cylinder. As to Pitot probes, leave the two

inputs of AP473S...module open, so as they detect the same pressure.

HD31 - 39 - V1.6

2. Press SELECT to display the ZERO

command in the command bar,

then select the command by pressing F2.

3. Select A, B or C input the probe is connected to by pressing

F1, F2 or F3 key respectively.

4. The instant value is automatically zeroed.

HD31 - 40 - V1.6

4.6 VP472 MODULE FOR THE CONNECTION OF PYRANOMETERS AND ALBEDOMETERS

SICRAM VP472 module allows pyranometers and albedometers to be connected to the instrument.

When connecting a pyranometer to the module, the instrument displays:

• the mV signal generated by the thermopile;

• the global radiation in W/m

2

.

When connecting an albedometer to the module, the instrument displays:

• the mV signal generated by the thermopile detecting incident light;

• the mV signal generated by the thermopile detecting reflected light;

• the net radiation, in W/m

2

, defined as the difference between the incident global radia-

tion and the diffuse global radiation.

• The albedo, defined as the relation between the reflected global radiation and the inci-

dent global radiation.

VP472 module is equipped with a 6-pole terminal block with screw connectors. Connect the pyranometer or the albedometer respecting the correct polarity of signals. The figures below

show the connection of the pyranometer (LP PYRA 02, LP PYRA 03, etc.) and of LP PYRA 05

and LP PYRA 06 albedometers. In case a single-output pyranometer is attached, connect only

input 1 of the module (incident radiation) and make a bridge between inputs 2. Connect the

cable shield to the ground terminal indicated by the “ground” symbol.

Fig. 4.6.1: connecting a pyranometer

Fig. 4.6.2: connecting LP PYRA 05 a

lbedometer

Red (+)

Blue (-)

Black

(shield)

Upper terminal block

Lower terminal block

Red (+)

Blue (-)

Black

(shield)

Pyranometer

Black (shield)

Yellow (- Reflected rad.)

Green (+Reflected rad)

LP PYRA 05

Lower

terminal

White (housing)

Blue (- Incident rad.)

Red (+Incident rad.)

Upper terminal block

HD31 - 41 - V1.6

Fig. 4.6.3: connecting LP PYRA 06 albedometer

I

n order to calculate the global radiation in W/m

2

with respect to the output voltage signal of the

pyranometer, the pyranometer sensitivity must be set in the instrument, supplied with the pyranometer itself. The sensitivity must be set in nV/(Wm

-2

) and range between 5000 and

30000 nV/(Wm

-2

). The default value is 10000 nV/(Wm-2). To set the sensitivity:

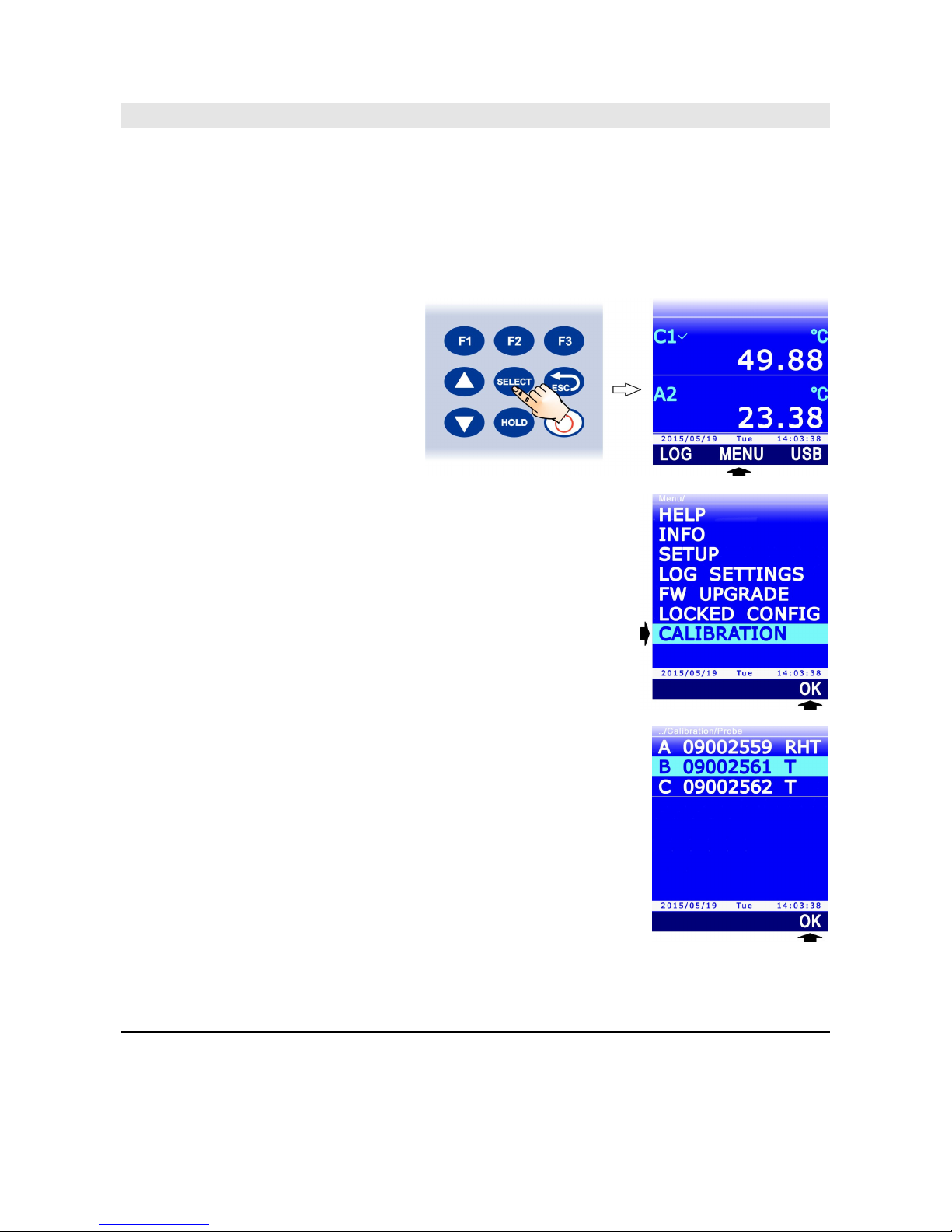

1. Press SELECT to display the MENU command in the command bar, then select MENU by

pressing the F2 key.

2. Select the CALIBRATION item using S and T, then press F3 (OK command) to confirm.

Note: CALIBRATION item is not shown if the instrument is in protected mode. See paragraph 8.2 to change the protection status.

3. Th

e list of the connected probes is displayed. Each probe is identified by its own serial number and by the type of measurement. Select VP472 module using S and T, then press F3

(OK command) to confirm.

4. Set the first digit of the pyranometer sensitivity which measures the incident radiation using S and T, then select the command "-->" (F2 key) to proceed to the next digit (the currently selected digit flashes). To return to the previous digit, select "<--" (F1 key). After

setting all the digits, press OK (F3 key) to confirm the value.

5. Set the first digit of the pyranometer sensitivity which measures the reflected radiation using S and T, then select the command "-->" (F2 key) to proceed to the next digit (the currently selected digit flashes). To return to the previous digit, select "<--" (F1 key). After

setting all the digits, press OK (F3 key) to confirm the value.

Note: the second sensitivity is necessary only if an albedometer is connected; if this isn't

the case, leave the default value.

6. Press ESC twice to return to the measurement mode.

4.7 PHOTOMETRIC AND RADIOMETRIC PROBES WITH SICRAM MODULE

The photometric and radiometric probes of LP471... series can be connected to the instrument.

The measurement unit is chosen by the instrument depending on the probe connected. If several measurement units are provided for the same probe, see paragraph 3.2 at page 13 for the

sel

ection of the desired unit.

All the probes are factory-calibrated and do not require user calibrations.

Lower

terminal

Upper terminal block

LP PYRA 06

Red (+)

Blue (-)

Black (shield)

Green (+)

Brown (-)

HD31 - 42 - V1.6

4.7.1 INTEGRATION

Besides the instant measurement, the instrument calculates and displays the time integral of

the acquired measurements (except for the LP 471 LUM2 probe):

where u(t) is the instant value of the input variable at time t. The sampling interval is fixed

and equal to 1 second.

The integral calculation is started manually. The operation can be stopped manually or automatically when the user-settable threshold values are reached. The maximum integration time

is 100 hours.

Integral measurements are featured by the indication INTEGRAL over the measurement unit.

If INTEGRAL-type measurements are not specifically selected for integral calculation, this is

enabled for all the available integral measurements. Integral calculation can be started only for

some INTEGRAL-type measurements, by specifically selecting them.

Selecting an INTEGRAL-type measurement for integral calculation:

1. Select the integral calculation to be enabled using S and T. Integral measurements are

featured by the indication INTEGRAL over the measurement unit.

2. Press SELECT to display the ITG

command in the command bar,

then select the command by pressing F1.

3. Select the SEL command by pressing F3.

4. The indication INTEGRAL over the measurement unit is replaced