Operating manual

Seat accelerometer

HD

2030MSP

www.deltaohm.com

English

Keep for future reference.

Companies / Brands of GHM

HD2030MSP - 2 - V1.0

INDEX

1 INTRODUCTION .................................................................................................... 3

2 TECHNICAL CHARACTERISTICS ............................................................................ 4

3 DESCRIPTION ....................................................................................................... 5

4 USE ....................................................................................................................... 6

5 STORAGE ............................................................................................................ 10

6 SAFETY INSTRUCTIONS ...................................................................................... 10

7 ORDERING CODES .............................................................................................. 11

HD2030MSP - 3 - V1.0

1 INTRODUCTION

HD2030MSP is an accelerometer suitable for the measurement of vibrations transmitted by seats to the occupants of passenger and work vehicles.

The mechanical design is compliant with the requirements of ISO 10326-1.

The seat pad consists of a thin circular rubber pad housing a low profile tri-axial accelerometer.

The accelerometer is suitable for the measurement of human exposure to whole-body

vibrations, according to ISO 2631, ISO 10326-1, ISO 7096 and ISO 8041.

The transducer is based on MEMS technology and the electrical interface is IEPE/ICP

compatible for reliable signal transmission.

The device measures the acceleration imparted to the body in three orthogonal axes

with a sensitivity of 100 mV/(m/s

2

) nominally.

The tri-axial accelerometer HDWBV-100, mounted at the center of the rubber pad

HD2030PAD, is housed an anodized aluminum case provided with a threaded hole,

suitable for sensor calibration, and a 4-pin M5 connector compatible with

HD2030.CAB3M cables.

Reference markets are:

Control of vibration risk for drivers of passenger and work vehicles

Measurement of vibrations in the automotive industry

Laboratory measurements

HD2030MSP - 4 - V1.0

2 TECHNICAL CHARACTERISTICS

SENSOR

Sensing element MEMS inertial sensor

Number of axis 3

PERFORMANCES

Sensitivity @ 15.915 Hz 100 mV/(m/s2)

Range F.S. (@24V supply voltage) ± 50 (m/s2)

Frequency response (f3dB) 0.2 Hz ÷ 700 Hz

Frequency response (f10%) 0.4 Hz ÷ 350 Hz

Frequency response (f5%) 0.6 Hz ÷ 230 Hz

Resonant frequency (MEMS transducer) > 5 kHz

Linearity error (FSO) ± 0.5 %

Transverse sensitivity < 5%

Residual noise (0.4 Hz ÷ 100 Hz) < 0.005 m/s2

ELECTRICAL CHARACTERISTICS

Output IEPE

Compliance (supply) voltage range +18 ÷ +28 V

Constant current supply 2 mA ÷ 4 mA

Output bias voltage 13.0 V ÷ 15.0 V

Output impedance <100 ohm

Ground isolation Case grounded

ENVIRONMENTAL CHARACTERISTICS

Shock limit 1000 G

Operating temperature range -20°C ÷ 60°C

Temperature coefficient 0.01 %/°C

Protection rating IP65

PHYSICAL CHARACTERISTICS

Weight 410 g

Size 250 mm diameter,

12 mm height

Connector 4-pin M5

Material Anodized aluminum

accelerometer inserted in

a rubber pad

HD2030MSP - 5 - V1.0

3 DESCRIPTION

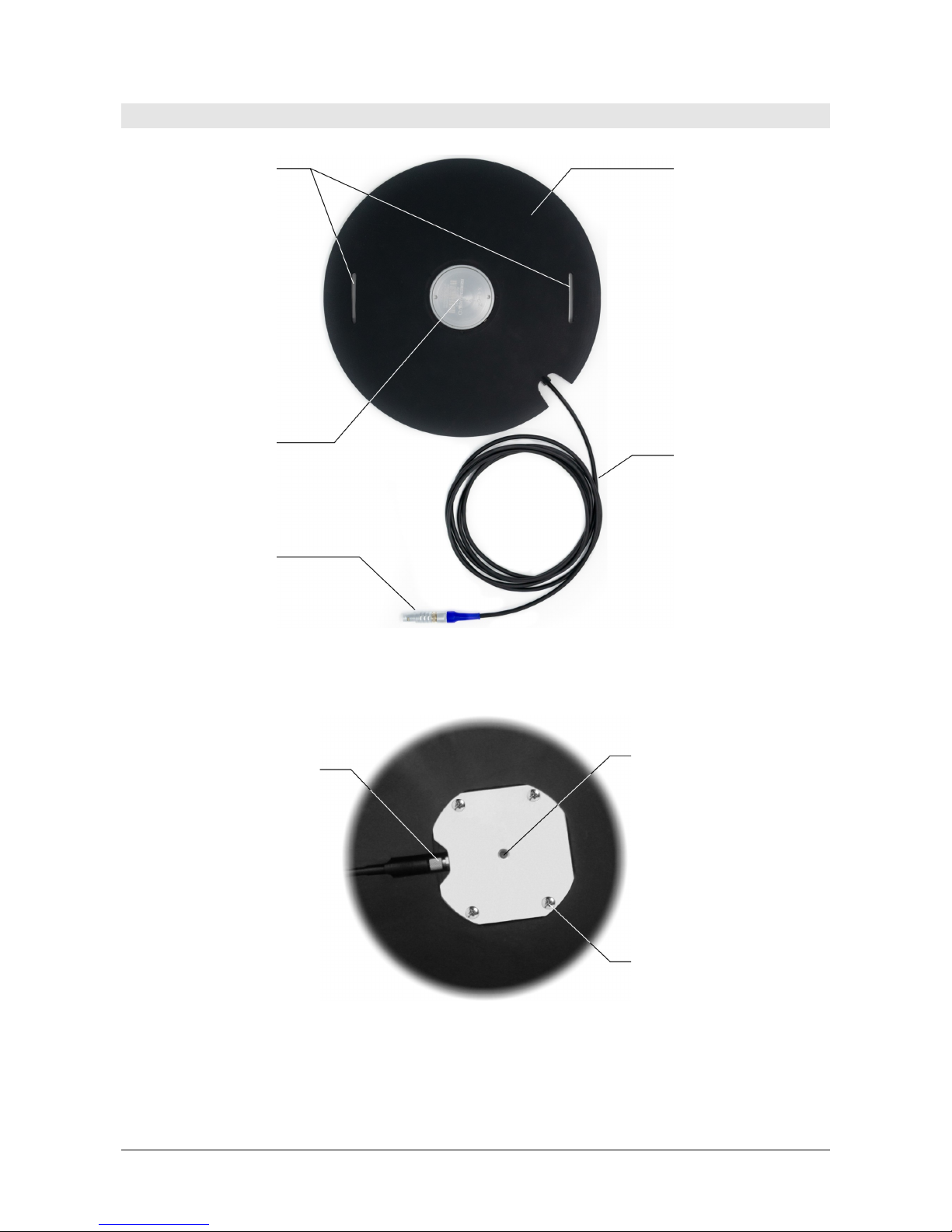

Fig. 3.1: Top side

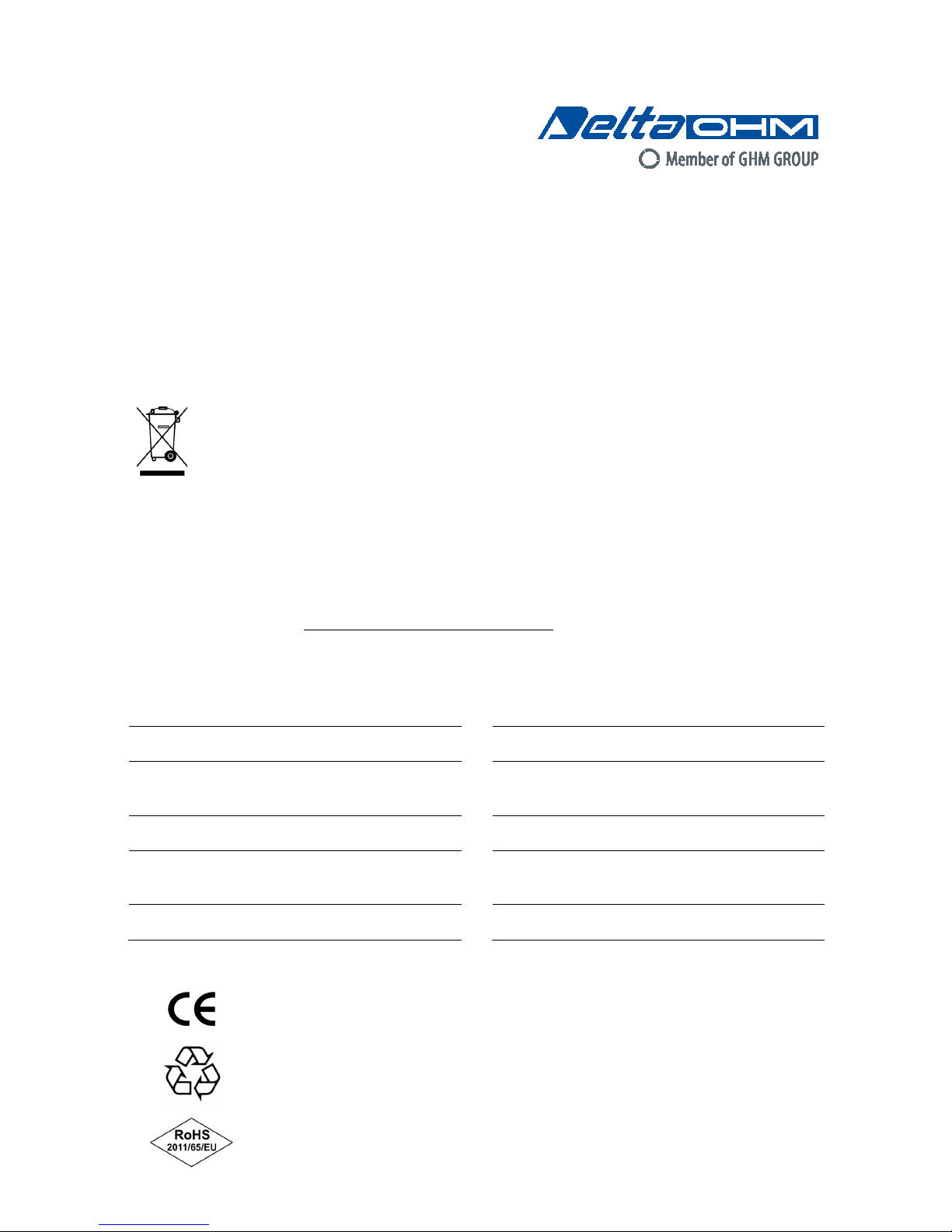

Fig. 3.2: Detail of bottom side

Rubber pad

HD2030.CAB3M-xM

cable

(optional)

Slots for the strap

(not supplied)

for fixing to the

back of the seat

Sensor

position

4-pole

connector

10-32 UNF

threaded hole

Screws for fixing

the

sensor to the

ru

bber pad

M5 connector

HD2030MSP - 6 - V1.0

4 USE

The rubber pad must be fixed to the seat or the backrest so that it is interposed between the seat itself and the body part subject to vibrations. For the fixing it is possible to use tape or a strap (not supplied), by passing it through the appropriat slots

provided in the pad.

The sensor detects the acceleration imparted to the body on three orthogonal axes. It

is necessary to accurately orient the axes of the accelerometer according to the reference system established by ISO 2631-1. The orientations of the axes along which the

sensor detects the acceleration are printed on the top of the accelerometer. The analog output signal corresponding to the X and Y axes increases when the sensor is subjected to an acceleration in the direction of the arrows printed on the housing. The

analog output signal corresponding to the Z axis increases when the sensor is subjected to an acceleration upwards.

Fig. 4.1: Reference axes of the accelerometer

The accelerometer is equipped with a male 4-pole M5 connector having the following

pinout:

Numero Pin Descrizione

1 …

2 …

3 …

4 …

Fig. 4.2: M5 connector pinout

Reference

axes

Reference

HD2030MSP - 7 - V1.0

For the connection to the HD2030 and HD2070 vibration analyzers, the optional

HD2030.CAB3M-xM cables can be used.

Route the connecting cable so that the connection point with the sensor is not subjected to stress. Minimize the possibility of cable movements, by securing it with cable

ties or tape. Do not route the cable near power lines, to avoid interferences on the

sensor output signal.

The accelerometer must be powered with constant current. Use only power

sources equipped with the current regulating function or use a current regulating diode as shown below:

Fig. 4.3: Sensor connection

If the accelerometer is connected to the HD2030 or HD2070 analyzer, the power supply and current regulation functions are performed by the analyzer.

In order to remove the bias voltage from the sensor output signal and obtain only the

AC component, connect the sensor output to the measuring instrument using a decoupling capacitor.

DO not power the accelerometer with voltage and corrente outside the limits

specified in the technical characteristics table, in order not to damage the internal electronic circuit.

Power supply

(18…28 V)

Measuring instrument

input

Accelerometer

GND

Decoupling

capacitor

Current regulating diode

(2…4 mA)

HD2030MSP - 8 - V1.0

5 FIXING FOR CALIBRATION

The accelerometer is supplied with a double threaded screw for fixing the sensor to

the vibrating base of a calibration system.

Fig. 5.1: Double threaded screw

The contact surface (vibrating base) of the sensor must be smooth and flat. Before

fixing the sensor it is advisable to clean the surface and apply a light film of grease/oil

(or equivalent fluid) to fill small gaps between the contact surface and the sensor and

improve the vibration transmissibility.

To fix the accelerometer using a screw it is sufficient a 1-2 Nm tightening force, compatible with a manual operation. For maximum measurements repeatability, the use

of a torque wrench is recommended.

As an alternative to screw mounting, in case the contact surface is not provided with a

threaded hole, it is possible to fix the sensor using:

adhesive material (double-sided tape, wax or quick glue);

a magnet.

Mounting with adhesive material or a magnet can reduce the sensor response to higher frequencies, especially in the mounting with magnet.

Mounting with adhesive material:

The sensor can be fixed with adhesive material to the contact surface:

directly;

through an adapter, fixing the sensor to the adapter (preferably using the screw)

and gluing the adapter to the contact surface.

If the sensor is fixed directly to the contact surface with glue or wax, be careful not to

obstruct the threaded hole at the bottom of the sensor; moreover, do not use too

much glue that could make the removal of the sensor difficult. In order to remove a

glued sensor, use a debonder product suitable for the type of glue used, avoiding to

force the sensor.

Sensor

Double threaded

screw

Vibrating base

HD2030MSP - 9 - V1.0

Fig. 5.2: Fixing with adhesive

Mounting with magnet:

Fix the sensor to the magnet (preferably using the screw) and place the magnet on

the contact surface.

Fig. 5.3: Fixing with magnet on a flat surface

For non-flat surfaces, dual-rail magnets can be used.

Fig. 5.4: Fixing with dual-rail magnet

For uneven surfaces, glue a flat metal base onto the surface, than place the sensor

with the magnet on the metal base.

Place the sensor with the magnet on the contact surface gently, to avoid damaging

the sensor due to the high accelerations caused by the magnet attraction.

Sensor

Double

threaded

screw

Adhesive

Adapter

Sensor

Double

threaded

screw

Magnet

Sensor

Dual-rail

magnet

HD2030MSP - 10 - V1.0

6 STORAGE

Storage conditions:

Temperature: -20...+60 °C.

Humidity: less than 90 %RH no condensation.

For storage, avoid places where:

There is a high level of humidity;

Instruments are exposed to direct sun radiation;

Instruments are exposed to a high temperature source;

There is vapor, salt and/or corrosive gases.

7 SAFETY INSTRUCTIONS

General instructions for safety

The transducer has been manufactured and tested in compliance with the safety standard EN61010-1:2010 “Safety requirements for electrical equipment for measurement,

control and laboratory use” and left the factory in a safe and secure technical condition.

The regular functioning and operational safety of the transducer can be ensured only if

all normal safety measures, as well as the specific measures described in this manual,

are followed.

The regular functioning and operational safety of the transducer can only be guaranteed under the climatic conditions specified in the manual.

Do not use the transducer in places where there are:

Rapid ambient temperature variations that may cause condensation.

Corrosive or flammable gases.

High-intensity electromagnetic fields, static electricity.

If the transducer is transported from a cold environment to a warm one, or vice versa,

the formation of condensation may cause disturbances to its functioning. In this case,

wait until the temperature of the transducer reaches room temperature before putting

into operation.

Obligations of the User

The user of the transducer must ensure compliance with the following standards and

guidelines for the treatment of hazardous materials:

EEC directives on workplace safety

National low regulations on workplace safety

Accident prevention regulations

HD2030MSP - 11 - V1.0

8 ORDERING CODES

HD2030MSP IEPE tri-axial accelerometer with rubber pad for the measurement of

the vibrations transmitted to the whole body by the seats to the occupants of vehicles. Sensitivity 100 mV/(m/s

2

). 4-pole M5 connector.

10-32 UNF mounting screw for the sensor calibration is included.

The HD2030.CAB3M-xM cable has to be ordered separately.

Accessories

HD2030.CAB3M-2M Cable for connecting the accelerometer to the HD2030 or

HD2070 vibration analyzer. M5 4-pole connector on the accelerometer side, circular 4-pole push-pull connector on instrument side. Cable length 2 m.

HD2030.CAB3M-5M Cable for connecting the accelerometer to the HD2030 or

HD2070 vibration analyzer. M5 4-pole connector on the accelerometer side, circular 4-pole push-pull connector on instrument side. Cable length 5 m.

Delta OHM LAT N° 124 metrology laboratories are ISO/IEC 17025 accredited by ACCREDIA in Temperature, Humidity, Pressure, Photometry/Radiometry, Acoustics and

Air Speed. They can provide certificates for the accredited quantities.

GUARANTEE

TERMS OF GUARANTEE

All DELTA OHM instruments are subject to accurate testing, and are guaranteed for 24 months from the

date of purchase. DELTA OHM will repair or replace free of charge the parts that, within the warranty

period, shall be deemed non efficient according to its own judgement. Complete replacement is excluded

and no damage claims are accepted. The DELTA OHM guarantee only covers instrument repair. The

guarantee is void in case of incidental breakage during transport, negligence, misuse, connection to a

different voltage than that required for the appliance by the operator. Finally, a product repaired or

tampered by unauthorized third parties is excluded from the guarantee. The instrument shall be returned

FREE OF SHIPMENT CHARGES to your dealer. The jurisdiction of Padua applies in any dispute.

The electrical and electronic equipment marked with this symbol cannot be disposed of in public

landfills. According to the Directive 2011/65/EU, the european users of electrical and electronic

equipment can return it to the dealer or manufacturer upon purchase of a new one. The illegal

disposal of electrical and electronic equipment is punished with an administrative fine.

This guarantee must be sent together with the instrument to our service centre.

IMPORTANT: Guarantee is valid only if coupon has been correctly filled in all details.

Instrument Code:

HD2030MSP

Serial Number

RENEWALS

Date

Date

Inspector

Inspector

Date

Date

Inspector

Inspector

Date

Date

Inspector

Inspector

GHM GROUP – Delta OHM | Delta Ohm S.r.l. a socio unico

Via Marconi 5 | 35030 Caselle di Selvazzano | Padova | ITALY

Phone +39 049 8977150 | Fax +39 049 635596

www.deltaohm.com | info@deltaohm.com

The quality level of our instruments is the result of the constant development of the product. This may

produce some differences between the information written in this manual and the instrument you have

purchased. We cannot completely exclude the possibility of errors in the manual, for which we apologize.

The data, images and descriptions included in this manual cannot be legally asserted. We reserve the

right to make changes and corrections with no prior notice.

GHM GROUP – Delta OHM | Delta Ohm S.r.l. a socio unico

Via Marconi 5 | 35030 Caselle di Selvazzano | Padova | ITALY

Phone +39 049 8977150 | Fax +39 049 635596

www.deltaohm.com | info@deltaohm.com

V1.0

06/06/2018

Loading...

Loading...