Delta Elektronika PSC-232 module, PSC-232, PSC-232 P146, PSC-232 P148, PSC-488 module Operating Manual

...Page 1

OPERATING MANUAL

PSC-232 module PSC-488 module

PSC-232 PSC-488

PSC-232 P146

PSC-232 P148

Page 2

DELTA ELEKTRONIKA BV PSC SERIES

PSC manual

1 Features ..............................................................................................................page 3

2 Languages ..........................................................................................................page 3

3 Models.................................................................................................................page 3

4 Accessories supplied with the PSC ....................................................................page 4

5 Dimensions ........................................................................................................page 4

6 Specifications ......................................................................................................page 4

6.1 Power .............................................................................................................page 4

6.2 EMC ...............................................................................................................page 4

6.3 Isolation..........................................................................................................page 4

6.4 Ambient temperature .....................................................................................page 4

6.5 Analog outputs ...............................................................................................page 4

6.6 Analog inputs .................................................................................................page 5

6.8 Logic inputs ....................................................................................................page 5

6.9 Logic outputs..................................................................................................page 5

6.7 Status monitoring ...........................................................................................page 5

6.10 Led indicator...................................................................................................page 6

7 GPIB capabilities.................................................................................................page 6

7.1 Restrictions ....................................................................................................page 6

8 Switch settings ....................................................................................................page 7

8.1 Address switch...............................................................................................page 7

8.2 PORQS switch ...............................................................................................page 7

8.3 DPL command switch ....................................................................................page 7

8.4 RS232 communication switch........................................................................page 7

8.5 Baudrate.........................................................................................................page 7

8.6 Factory pre-settings .......................................................................................page 7

9 Connections ........................................................................................................page 8

9.1 RS232 Interface .............................................................................................page 8

9.2 Pin assignment of the 15P connector ...........................................................page 8

10 Conventions ........................................................................................................page 9

10.1 Frequently used ASCII symbols ....................................................................page 9

10.2 Summary of Data types .................................................................................page 9

10.3 Booleans ........................................................................................................page 9

10.4 Numerical data formats..................................................................................page 9

11 Installation of the PSC.......................................................................................page 10

11.1 PSC-488 module..........................................................................................page 10

11.2 PSC-488.......................................................................................................page 10

11.3 PSC-232 module..........................................................................................page 10

11.4 PSC-232, P146 or P148 ..............................................................................page 11

12 Calibration of the PSC ......................................................................................page 11

12.1 Configuration setting ....................................................................................page 11

12.2 Voltage DAC Offset calibration ....................................................................page 11

12.3 Voltage DAC gain calibration .......................................................................page 12

12.4 Voltage ADC Offset calibration ....................................................................page 12

12.5 Voltage ADC gain calibration .......................................................................page 12

12.6 Current DAC Offset calibration ....................................................................page 12

12.7 Current DAC gain calibration.......................................................................page 13

12.8 Current ADC offset calibration .....................................................................page 13

12.9 Current ADC gain calibration.......................................................................page 14

12.10 Change IDN string .......................................................................................page 14

13 Power on Settings .............................................................................................page 15

14 Languages ........................................................................................................page 16

14.1 Delta Programming Commands ..................................................................page 16

14.2 IEEE 488.2 Common Commands................................................................page 17

14.2.1 Status reporting.......................................................................................page 17

14.2.2 *SRE ......................................................................................................page 17

14.2.3 Register diagram ....................................................................................page 18

14.2.4 *STB?......................................................................................................page 19

CONTENTS

Page 3

PSC SERIES DELTA ELEKTRONIKA BV

14.2.5 *CLS........................................................................................................page 20

14.2.6 *ESE........................................................................................................page 20

14.2.7 *ESR? ....................................................................................................page 20

14.2.8 DSE.........................................................................................................page 21

14.2.9 DSR? ......................................................................................................page 21

14.2.10 DSC? ......................................................................................................page 22

14.2.11 DEE ........................................................................................................page 22

14.2.12 DER? ......................................................................................................page 22

14.2.13 DEC? ......................................................................................................page 22

14.2.14 *OPC.......................................................................................................page 23

14.2.15 *RST .....................................................................................................page 23

14.2.20 *IDN? .....................................................................................................page 24

14.2.16 *TST?......................................................................................................page 24

14.2.17 *WAI........................................................................................................page 24

14.2.18 *SAV........................................................................................................page 24

14.2.19 *RCL .....................................................................................................page 24

14.3 SCPI commands..........................................................................................page 25

14.3.1 SOurce:VOltage:MAximum.....................................................................page 25

14.3.2 SOurce:CUrrent:MAximum .....................................................................page 25

14.3.3 CAlibration:CUrrent:OFfset ....................................................................page 25

14.3.4 CAlibration:CUrrent:OFfset?...................................................................page 25

14.3.5 CAlibration:CUrrent:GAin........................................................................page 25

14.3.6 CAlibration:CUrrent:GAin?......................................................................page 25

14.3.7 CAlibration:VOltage:OFfset ....................................................................page 25

14.3.8 CAlibration:VOltage:GAin .......................................................................page 25

14.3.9 CAlibration:CUrrent:MEasure:OFfset .....................................................page 25

14.3.10 CAlibration:CUrrent:MEasure:GAin ........................................................page 25

14.3.11 CAlibration:VOLTage:MEASure:OFFSet................................................page 26

14.3.12 CAlibrate:VOltage:MEasure:GAin...........................................................page 26

14.3.13 PAssword................................................................................................page 26

14.3.14 SOurce:FUnction:RSD<wsp><boolean>................................................page 27

14.3.15 SOurce:FUnction:OUtA<wsp><boolean> ..............................................page 27

14.3.16 SOurce:FUnction:OUtB <wsp> <boolean> ............................................page 27

14.3.17 SOurce:FUnction:OUTP<wsp>{ON|OFF} ..............................................page 27

14.3.18 SOurce:FUnction:FRontpanel Lock........................................................page 27

14.3.19 REMote and LOCal.................................................................................page 27

REMote:CV ............................................................................................page 28

REMote:CV? ..........................................................................................page 28

LOCal:CV................................................................................................page 28

REMote:CC ............................................................................................page 28

REMote:CC? ..........................................................................................page 28

LOCal:CC................................................................................................page 28

14.3.20 SOurce:CUrrent <wsp> .........................................................................page 28

14.3.21 SOurce:VOltage <wsp> ..........................................................................page 29

14.3.22 MEasure:VOltage? .................................................................................page 29

14.3.23 MEasure:CUrrent?..................................................................................page 29

14.3.24 CH...........................................................................................................page 29

14.3.25 Help?.......................................................................................................page 29

14.3.26 SEnse:DIgital:DAta? ...............................................................................page 29

14.3.27 SEnse:DIgital:EXtendeddata? ................................................................page 29

14.3.28 SEnse:DIgital:SWitch?............................................................................page 29

14.3.29 CU...........................................................................................................page 30

15 Error numbers....................................................................................................page 31

15.1 Command Error ...........................................................................................page 31

15.2 Execution Error ............................................................................................page 31

15.3 Device specific Error ....................................................................................page 31

15.4 Query Error ..................................................................................................page 31

16 Software examples and programs ....................................................................page 32

CONTENTS

Page 4

DELTA ELEKTRONIKA BV PSC SERIES

OP ER AT ING MAN UAL FOR POWER SUP PLY CON TROL LERS

Ex ter nal PSC mod ule

1 Features

The PSC is an RS232 or IEEE488 interface, designed for an analog programmable power supply.

The PSC sets output voltage and current and reads the voltage, current and status. The PSC also

controls Remote/Local, Remote Shut Down etc. Up to 15 PSC’s can be connected to only one RS232

port or IEEE488 bus. The analog voltages can be calibrated by software. The calibration settings can be

saved in non volatile memory and recalled at power on.

2 Languages

The PSC allows three groups of commands:

• IEEE488.2 Common Commands

• SCPI (Standard Commands for Programmable Instruments)

• DPL (Delta Programming Languages) emulation mode of the PSC 44M

For communication with the PSC languages like Basic, Pascal, C, Visual Basic, Delphi, Testpoint or

LabView can be used. Some free software examples are available on www.DeltaPowerSupplies.com.

There is an external model for bench, rail or rack mounting and there are PSC card sets to use inside a

power supply.

In ter nal PSC card

3 Models

MODELS RS232 GPIB USE

PSC-232 module

PSC-232

PSC-232 P146

PSC-232 P148

PSC-488 module

PSC-488

PSC-232 P254

PSC-488 P255

page 3 MANUAL May 2008

•

•

•

•

••

••

••

•

Bench/rail/rack

SM1500/6000 card set

SM3000 card set

ES150 card set

Bench/rail/rack

SM800/1500/6000 card set

SM800 card set

SM800 card set

Page 5

PSC SERIES DELTA ELEKTRONIKA BV

4 Accessories supplied with the PSC

seirosseccA

884-CSP

884-CSPeludom

232-CSP

232-CSPeludom

232-CSP841P

232-CSP641P

RS232 cable

Analog cable

Line cord

Rail Mounting clip

CD ROM

* = except in combination with SM3000 (Option P164)

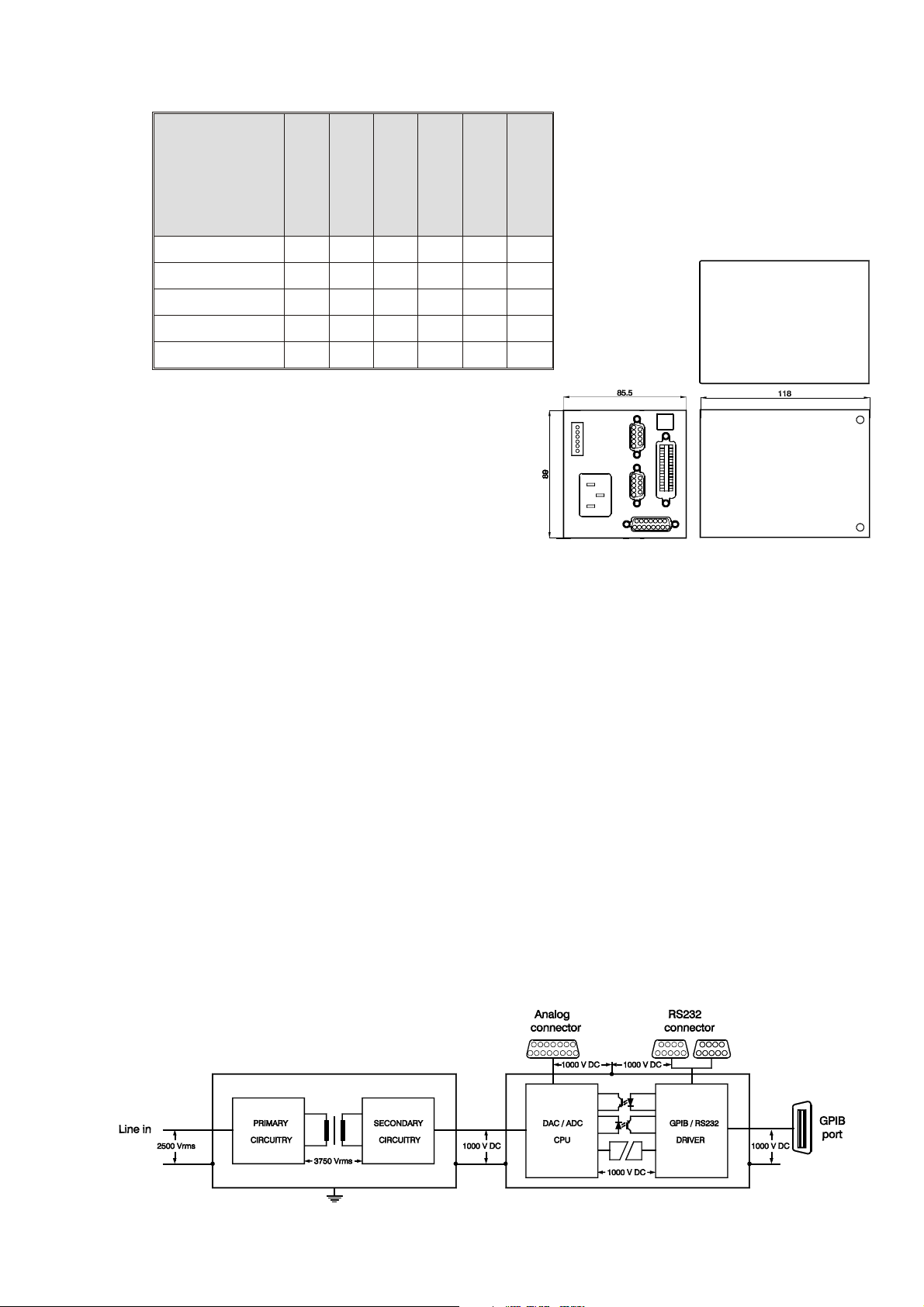

5 Dimensions

PSC-488 module and PSC-232 module:

89 x 85.5 x 118 mm, 0.8 kg

Enclosure: IP20

6 Specifications

6.1 Power

Range: 98-264 VAC 48-62 Hz

for DC-voltage contact factory

Power consumption: 10 W

Hold-up time: 300 ms, Vin = 230 VAC

6.2 EMC

Emission : EN 61000-6-3

EN 55022 B

Immunity : EN 61000-6-2

6.3 Isolation

Analog/logic in/outputs to case : 1000 V DC

GPIB or RS232 to case : 1000 V DC

Line input to case : 2500 V AC

••••••*

••

••

••

••••••

Dimensions PSC-232 and PSC-488 modules

6.4 Ambient temperature

Operating: 0 to 55 °C (Ext model)

Storage: -20 to +70 °C

6.5 Analog outputs

80 ms, Vin = 110 VAC

The analog outputs can be individually set on

0-5 V The settings can be reported.

Calibration is by software. Settings can be

saved in non-volatile memory. Analog in- and

outputs have a common zero

• 2 analog outputs with buffered 14 bit D AC

• Output range 0 to 5 V

• Full scale software adjustment > 200 mV

• Offset software adjustment > 200 mV

• Resolution 0.33 mV / 5 V output

• Linearity error 1 LSB

• TC typical 30 ppm / °C

Isolation schematic diagram

May 2008 MANUAL page 4

Page 6

DELTA ELEKTRONIKA BV PSC SERIES

6.6 Analog inputs

The analog inputs can be individually read.

Calibration is done by software. Settings

can be saved in non-volatile memory.

Analog in- and outputs have a common

zero

• Full scale software adjustment

• 2 x analog input channels with 16 bit

ADC Input range 0 to 5 V

• Offset software adjustment

• Resolution 0.1 mV / 5 V input

• Linearity error +/- 2 LSB

• TC typical 5 ppm / °C

Read Back Resolution

The read back resolution depends on the

voltage and current range of the power

supply that is used with the PSC.

Range Decimals

6.7 Status monitoring

The PSC provides TTL /CMOS compatible status

inputs for monitoring signal changes and fail signals

of the power-supply as CC mode, Current or

Voltage Limit, DC Fail, AC Fail and Over

Temperature. See power supply manual.

Status Weight Name

11 CC

2 2 LIM

3 4 DCF

4 8 ACF

516 OT

6 32 PSO

7 64 InpA

8 128 InpB

0 - 5.9999 4

6.000 - 59.999 3

60.000 - 599.99 2

Example with power supply SM52-30:

The voltage range is 52 V. After

programming the unit to 50 V, the read

back value has 3 decimals, see table;

V

readback = 50.000 V. The 3 digits after the

decimal point give a resolution of 1 mV.

This means that for 50 V the number of

steps is 50000. From the next table it can

be seen that the resolution is better than

15 bit.

Bit Steps

12 4096

13 8192

14 16384

15 32768

6.8 Logic inputs

The PSC-488 module and the PSC-232 module

provide two 1000 V opto isolated logic inputs, InpA

and InpB for custom use.

The inputs are 470 ohm, Logic high = 2.5 ... 8 V

(15 mA max), Logic low = 0 V.

The two inputs have a common zero.

The maximum reverse voltage = 6 V.

6.9 Logic outputs

The PSC-488 module and the PSC-232 module

also provide two opto isolated logic outputs for

custom use: OutA and OutB.

The opto coupler outputs have an open collector

and a common zero. The maximum voltage is 50 V

and the maximum current is 5 mA.

Total power dissipation = 150 mW.

16 65536

User logic in/outputs for external PSC-488 module

and PSC-232 module

Analog in/ outputs

page 5 MANUAL May 2008

Page 7

PSC SERIES DELTA ELEKTRONIKA BV

6.10 Led indicator

The PSC-232 module and the PSC-488 module have LEDs on the front panel.

LED PSC-232 module PSC-488 module

PWR

LSN

TLK

ERR

RDY

••

•

7 GPIB capabilities

The PSC-488 supports the following standard IEEE488.1-1987 capabilities.

ID code Capability

T6 Basic talker, Serial poll, Un address if MLA

L4 Basic listener, Un addressed if MTA

SH1 Source handshake

AH1 Acceptor handshake

SR1 Service request

Power on

•

•

•

Listener mode

Talker mode

Device in error

Device ready for

command.

•

•

•

•

•

RL0 Remote / local

PP0 Parallel poll

DC1 Device clear

DT0 Device trigger

C0 Controller

E2 Three state driver

7.1 Restrictions

Up to 15 devices can be connected to the IEEE 488

instrument bus (can be increased by with a bus

extender). The maximum cable length to connect a

group of instruments is 2 meters x number of devices

or 20 meters, whichever is less. Cable configurations

may be star, linear or a combination of the two. Each

of the devices must have a specific address code. The

PSC-488 module has a device address code switch on

the rear panel next to the GPIB connector. It has to be

set to the appropriate binary code for the desired

address.

•

•

GPIB CONNECTOR

May 2008 MANUAL page 6

Page 8

DELTA ELEKTRONIKA BV PSC SERIES

8 Switch settings

8.1 Address switch

When setting the address use any address from 1 up to 30.

The address is a 5 bit binary number which can be set with

switch A1 to A5.

Switch A1 is the LSB and switch A5 is the MSB.

For example address 1 is 00001 (A1 = on, A2-A5 = off) and

address 30 is 11110 (A1 = off, A2-A5 = on).

8.2 PORQS switch

Only for DPL mode.

A8

is the PORQS switch. With switch POSRQ in the ON position, not only a SRQ at power-on

but also the request for service capability is enabled.

8.3 DPL command switch

A7 is the language switch on PSC-488 models.

When the DPL switch is ON, the PSC is in PSC 44M emulation mode.

The switch OFF means the PSC is in PSC-488 mode, SCPI language.

8.4 RS232 communication switch

A6 is used on PSC-488 models only.

When the RS232 switch is ON, the PSC is in RS232 mode.

The switch OFF means the PSC is in GPIB mode.

8.5 Baudrate

For PSC-232 models the switches A7 and A8 are baudrate switches.

Baudrate A8 A7

Address switch

2400 off off

4800 off on

9600 on off

8.6 Factory pre-settings

PSC-488:

Address 8

SCPI Language

RQS 0

A1, A2, A3, A5, A6, A7, A8 = off

A4 = on

PSC-232

Channel 1

SCPI Language

9600 baud

A2, A3, A4, A5, A6, A7 = off

A1 and A8 = on

:

page 7 MANUAL May 2008

Page 9

PSC SERIES DELTA ELEKTRONIKA BV

9 Connections

9.1 RS232 Interface

Connector from PC:

D 9 F conn.

Pin 2 TXD

Pin 3 RXD

Pin 5 GND

Connector to next PSC:

D 9 M conn.

Pin 2 RXD

Pin 3 TXD

Pin 5 GND

For connection to the PC or to the next PSC use a 1:1 cable with 1 female and 1 male connector.

Do not use a null modem cable.

Baudrate : 2400 - 9600 baud

Databits : 8

Stopbits : 2

Paritybits : none

Signal level : -10 V to +10 V

Maximum cable length : 15 m

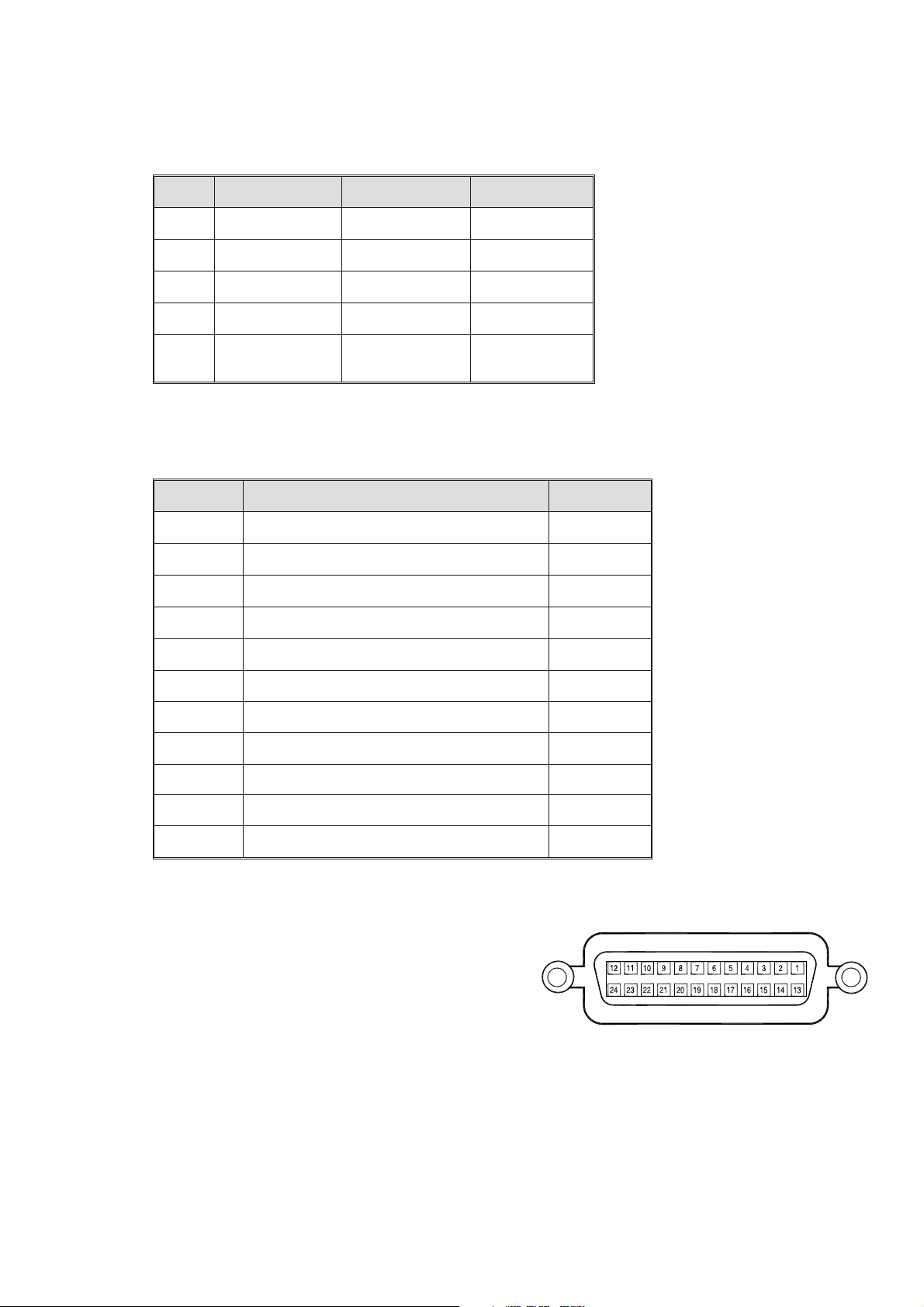

9.2 Pin assignment of the 15P connector

PIN DESCRIPTION PSC In/Output Abbreviation

1 Analog common Analog common AGND

2 Current Monitor Analog Input I MON

3 Current Programming Analog Output I PROG

4 Constant Current status Digital Input CC

5 Remote Shut Down logic output Digital Output RSD

6 Power sink overload Digital Input PSO 1)2)

7 Not Connected NC

8 Digital common Digital common DGND

9 Not Connected NC

10 Voltage Monitor Analog Input V MON

11 Voltage Programming Analog Output V PROG

12 Over Temperature Digital Input O.T. 1)

13 Limit Status Digital Input LIM 1)

14 DC Fail Digital Input DCF 1)

15 AC Fail Digital Input ACF 1)

9F Pole D connector 9M Pole D connector

15 pole D connector

1) Check the power supply manual if the power supply supports the status.

2) If an SM7020-D or SM3004-D is used in combination with a

PSC module, remove the jumper on P532 or otherwise the

autoranging will not work properly.

First remove the screws from the bottom and top of the PSC in

order to remove the cover from the cabinet. Then remove the

jumper on the PCB P532.

May 2008 MANUAL page 8

Page 10

DELTA ELEKTRONIKA BV PSC SERIES

10 Conventions

Angle brackets < > Indicate that words or characters enclosed in angular brackets

symbolize a program code parameter.

Brackets { } Brackets indicate one of the several parameters may be entered.

For example { 1|0|ON|OFF}.

Square brackets [ ] All items between square brackets are optional.

Boldface Boldface and computer font is used to show command syntax in the text.

Controller A computer used to communicate with an instrument.

Instrument A device that implements SCPI (PSC-488).

10.1 Frequently used ASCII symbols

Symbols DEC HEX Codes Display Description

EOT 4 04 \04 end of transmission

LF 10 0A \n line feed (command terminator)

CR 13 0D \r carriage return

ESC 27 1B \1B escape

WSP 32 20 \s space

10.2 Summary of Data types

Example NDEC Decimal

Digit character 0....9 8

Hexadecimal character 0..9 & A....F #hFA 250

Binary character 0 or 1 #b0101 5

String character 0....9 and A....Z

NDEC = Non-decimal HEX, OCT, BIN (Hexadecimal, Octal, Binary)

10.3 Booleans

A Boolean parameter is normally used to specify a binary condition which is either True or False.

Booleans can have one of the following values:

ON or 1 means condition is True.

OFF or 0 means condition is False.

Example: OUTputA ON or OUTputA 1.

10.4 Numerical data formats.

Symbol Meaning example

<NR1> Signed integer value 1234

<NR2> Floating point value without an exponent 12.345

page 9 MANUAL May 2008

Page 11

PSC SERIES DELTA ELEKTRONIKA BV

11 Installation of the PSC

When the External PSC module is used for the

first time, it must be configured and calibrated

together with the power supply. The card set

types are factory configured and calibrated.

11.1 PSC-488 module

This type of PSC is for rail or rack mounting, the

unit can be mounted to the rear side of the power

supply using a rail. Connect and install the PSC

as follows:

Connection of the PSC-488 module

• When used with a SM7020-D or with a SM3004-D

remove the link on P532 (see comment 2 on page 8)

• Set the address switches to 8

A1, A2, A3, A5 = OFF and A4 = ON.

• Set the GPIB communication switch A6 = OFF.

• Set SCPI language switch A7 = OFF.

• Set RQS switch A8 = OFF.

• Connect the 15 pole analog cable between the PSC and the power supply.

• Connect a GPIB cable between the PC and the PSC.

• Connect the line-cord.

• Switch the power supply to “programming” (see power supply manual).

• Go to section 12 of this manual.

11.2 PSC-488

This is a card set, mounted inside the power supply. Connect and install the PSC as follows:

• Set the address switches to 8

A1, A2, A3, A5 = OFF and A4 = ON.

• Set the GPIB communication switch A6 = OFF.

• Set SCPI language switch A7 = OFF.

• Set RQS switch A8 = OFF.

• Connect a GPIB cable between the PC and the PSC.

• Switch the power supply to “programming” (see power supply manual).

• Go to section 12 of this manual.

11.3 PSC-232 module

This type PSC is for rail or rack mounting, the unit can be mounted to the rear side of the power supply

using a rail. Connect and install the PSC as follows:

• When used with a SM7020-D or with a SM3004-D,

remove the link on P532 (see comment 2 on page 8)

• Set the DIP switch to channel (address) 1. A2, A3, A4, A5 = OFF and A1 = ON.

• Set the Baudrate switch to 9600 baud. A6, A7 = OFF and A8 = ON.

• Connect the 15 pole analog cable between the PSC and the power supply.

• Connect the 9 pole RS232 cable between the PC comport and the PSC.

• Connect the line cord.

• Switch the power supply to “programming” (see power supply manual).

• Start the program Cal232.exe (on the CD) and follow the instructions on the screen.

May 2008 MANUAL page 10

Page 12

DELTA ELEKTRONIKA BV PSC SERIES

11.4 PSC-232, P146 or P148

These are card sets, mounted inside the power supply.

Connect and install the PSC as follows:

• Set the DIP switch to channel 1. A2, A3, A4, A5 = OFF

and A1 = ON.

• Set the Baudrate switch to 9600 baud. A6, A7 = OFF and

A8 = ON.

• Connect the 9 pole RS232 cable between the PC comport

and the PSC.

12 Calibration of the PSC

For easy calibration, a CD with a calibration program is supplied with the PSC-488 and PSC-232. You

can download the latest version from Internet www.DeltaPowerSupplies.com

file supplied with the calibration program.

. First read the “ReadMe”

12.1 Configuration setting

•

Switch on the power of the power supply.

• Run the LabView program “PSC488_v61.exe”.

• Select “PSC488 Calibration.vi”.

• Click “OK”.

• Select tab “Start”.

• Select “PSC address” 8.

• Set the “Power supply voltage range”.

• Set the “Power supply current range”.

• When password protected, enable “Reset calibration”.

• Click “run continuously” in menu bar:

• Click “Config”.

• If configuration fails, repeat from configure.

• When configuration is successful, the program.

switches automatically to tab 1.

Start screen: Voltage and current configuration

12.2 Voltage DAC Offset calibration

•

Connect a digital mV meter to the output terminals of

the power supply.

• Click “Continue”.

The program sets the current and the voltage.

The “Actual offset” will be displayed.

• Enter the DVM value in mV.

• Click “Continue”.

• When calibration fails, repeat.

• When calibration is successful, the program switches

automatically to tab 2.

Voltage calibration connection

Screen 1: Voltage DAC Offset calibration

page 11 MANUAL May 2008

Page 13

PSC SERIES DELTA ELEKTRONIKA BV

12.3 Voltage DAC gain calibration

•

Switch the digital voltage meter to the right range

(maximum output voltage of the power supply).

• Click “Continue”.

• Enter the DVM value.

• Click “Continue”.

• When calibration fails, repeat.

• When calibration is successful, the program switches

automatically to tab 3.

Screen 2: Voltage DAC gain calibration

12.4 Voltage ADC Offset calibration

•

Switch the digital voltage meter to the right range.

See “Set voltage”.

• Click “Continue”.

• Enter the DVM value.

• Click “Continue”.

• When calibration fails, repeat.

• When calibration is successful, the program switches

automatically to tab 4.

12.5 Voltage ADC gain calibration

•

Switch the digital voltage meter to the right range

(maximum output voltage of the power supply).

• Click “Continue”.

• Enter the DVM value into “Input” control.

• Click “Continue”.

• Check “Measure new voltage”.

• Click “Continue”.

• When calibration fails, repeat.

• When calibration is successful, the program switches

automatically to tab 5.

12.6 Current DAC Offset calibration

The program has set the voltage and current to zero, so

you can safely change the connections of the power

supply.

Screen 3: Voltage ADC offset calibration

Screen 4: Voltage ADC gain calibration

• Connect a shunt and a D.V.M. (or zero flux ampere

meter) on the output terminals.

• Click “Continue”.

• The program sets the current and the voltage.

May 2008 MANUAL page 12

Current calibration connection

Page 14

DELTA ELEKTRONIKA BV PSC SERIES

• Measure the shunt voltage with the D.V.M. and

calculate the current.

Enter the value.

• Click “Continue”.

• Click "Continue" to set the output to zero.

• When calibration fails, repeat.

• When calibration is successful, the program switches

automatically to tab 6.

Screen 5: Current DAC offset calibration

12.7 Current DAC gain calibration

The program has set the voltage and current to zero, so

you can safely change the connections of the power

supply.

• Connect a shunt and a D.V.M. (or zero flux ampere

meter) on the output terminals.

• Click “Continue”.

The program sets the current and the voltage.

• Measure the shunt voltage with the D.V.M. and

calculate the current.

• Enter the value.

• Click “Continue”.

• Click "Continue" to set the output to zero.

• When calibration fails, repeat.

• When calibration is successful, the program

switches automatically to tab 7.

12.8 Current ADC offset calibration

•

Switch the digital ampere meter to the right range.

See “Set current”.

• Click “Continue”.

• Enter the DVM value.

• Click “Continue”.

• Click "Continue" to set the output to zero.

• When calibration fails, repeat.

• When calibration is successful, the program

switches automatically to tab 8.

Screen 6: Current DAC gain calibration

Screen 7: Current ADC offset calibration

page 13 MANUAL May 2008

Page 15

PSC SERIES DELTA ELEKTRONIKA BV

12.9 Current ADC gain calibration

•

Switch the digital ampere meter to the right range.

See “Set current”.

• Click “Continue”.

• Enter the DVM value.

• Click “Continue”.

• Check “Measure new current”.

• Click “Continue”.

• When calibration fails, repeat.

• When calibration is successful, the program

switches automatically to tab 9.

Screen 8: Current ADC gain calibration

12.10 Change IDN string

The IDN string can be changed. The suffix of the PSC

is entered in field 2. Field 4 is reserved for a custom

string. This calibration program enters the calibration

date in this field.

• Select a button INT,EXT, P146 or P148.

The red characters are the new IDN text.

• Click "Continue".

• Reset the PSC

(Switch the power of the PSC off.

Wait untill all LEDs are off

Switch on the PSC power).

• Click "Continue".

• The new IDN string is displayed in the black

indicator “New IDN string”.

End of calibration.

Screen 9: Change IDN string

May 2008 MANUAL page 14

Page 16

DELTA ELEKTRONIKA BV PSC SERIES

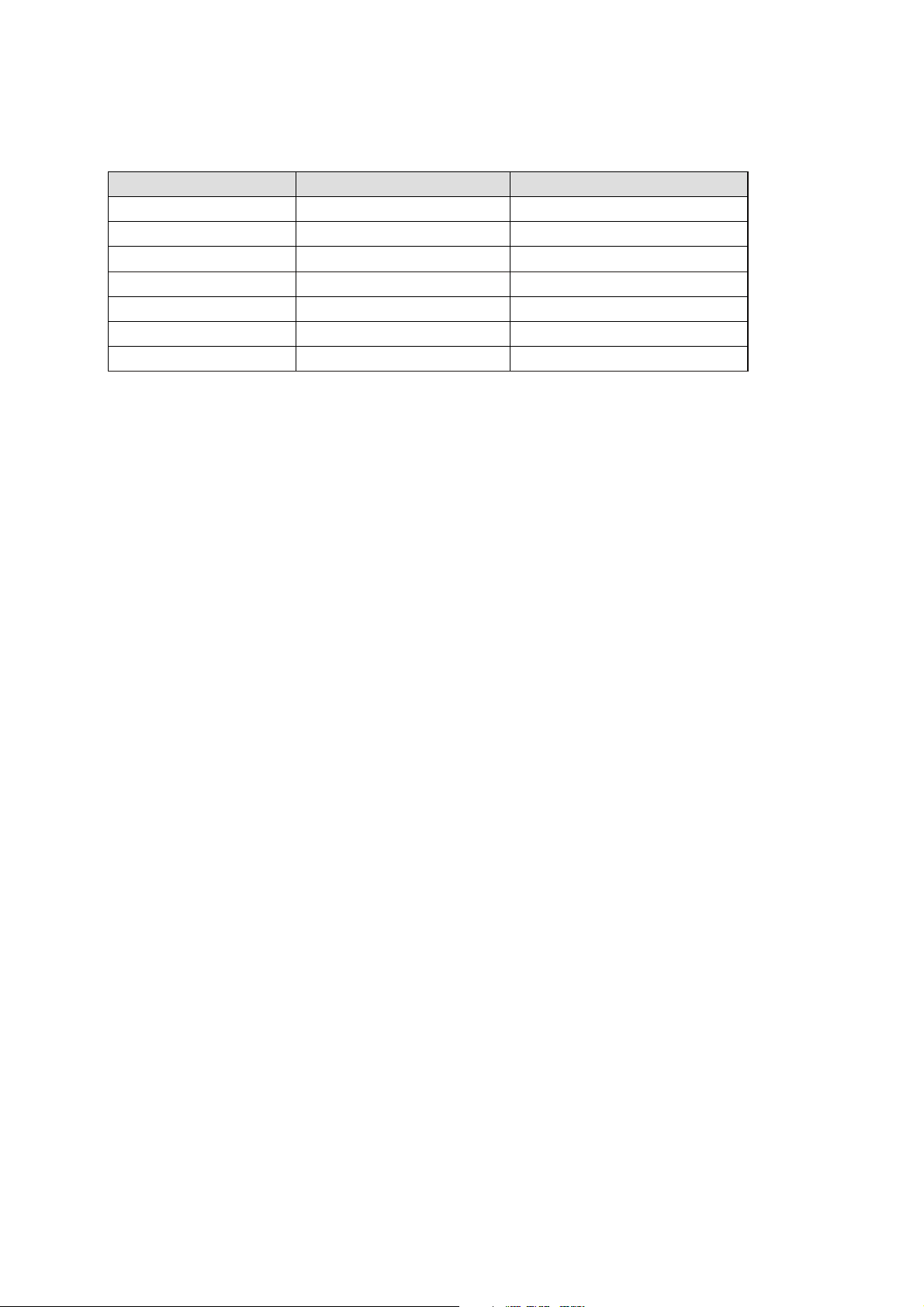

13 Power on Settings

When shipped, the PSC-488 module and the PSC-232 module are set to the configuration listed in table.

All configurable parameters can be changed and stored by the user.

Function Command Value

Voltage range

Current range

Text field #2 in IDN string

Text field #4 in IDN string

Password

SOurce:VOltage:MAximum

SOurce:CUrrent:MAximum

TYpe

CUstom

PAssword

Remote shut down 0

Remote 1

At power-on the Service Request Enable Register and the Standard Event Status Enable Register are

cleared.

5

5

“EXT” | “INT” | “P146” | “P148”

“Not Calibrate”

“Default”

page 15 MANUAL May 2008

Page 17

PSC SERIES DELTA ELEKTRONIKA BV

14 Languages

This section describes the operation of the three groups of commands.

The Groups are: Delta Programming Languages DPL, Standard Commands Programmable Instruments

SCPI, and Common commands.

• Delta Programming commands is a PSC 44M compatible language. With the DIP switch A8 ON

and A7 OFF the DPL is active. The DPL mode emulates the commands of the old PSC 44M and

the 12 bit DAC and ADC.

• Common commands are mnemonic commands beginning with a star. The query commands are

followed by a question mark. The common commands are defined in the IEEE488.2 standard and

control status reporting, synchronization and conditions of the power supply and the PSC-488.

• Standard Commands for Programmable Instruments SCPI.

These commands are used to configure and calibrate the PSC, to set voltage and current and to

read back voltage,current and status of the Power Supply.

Note: Terminator for all commands is LF.

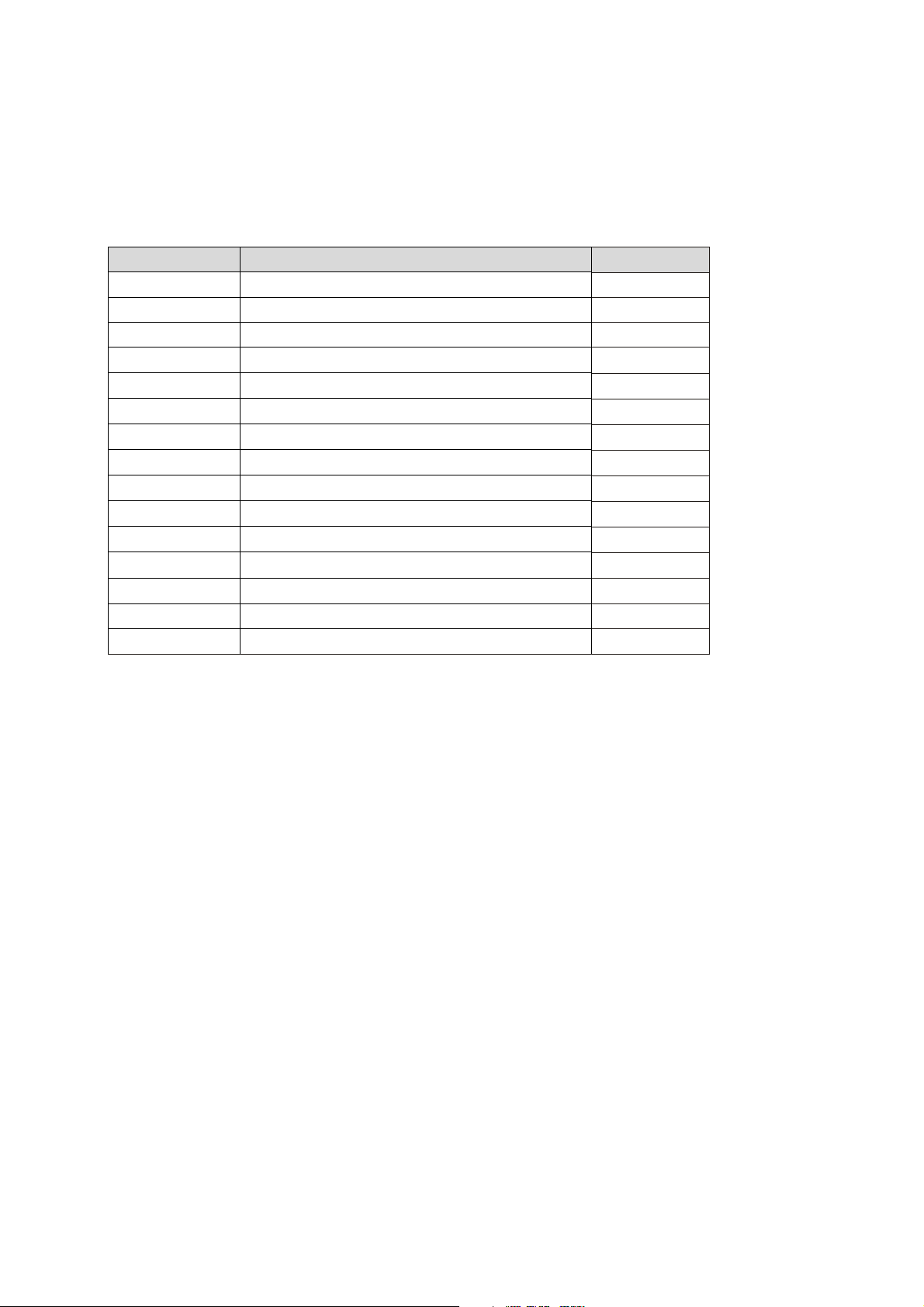

14.1 Delta Programming Commands

MNEMONICS FUNCTION

SA

SB

FU

FI

U

I

ERR?

ID?

MA?

MB?

SCPI

Step mode A channel (voltage)

Step mode B channel (current)

Input maximum voltage of the power supply

Input maximum current of the power supply

Set output voltage of the power supply

Set output current of the power supply

Report the last error

Report the Identify of the PSC

Read the measured output voltage of the power supply

Read the measured output current of the power supply

Switch to the SCPI parser

PSC 44 emulating mode.

The PSC-488 emulates in this mode the PSC 44 language including the 14 to 12 bit conversion. The calibration is by

the PSC-488 software. To calibrate the PSC-488 set the DIP switch A6 and A7 to OFF prior to using the calibrating

program (See chapter calibration) and after the calibration the DIP switch must be set to A7 = ON (Delta

Programming Languages).

For more details read the PSC 44M manual.

When in SCPI mode, the command “DPL” switches the PSC-488 to DPL mode.

May 2008 MANUAL page 16

Page 18

DELTA ELEKTRONIKA BV PSC SERIES

14.2 IEEE488.2 Common Commands.

The mnemonic common commands have three letters and begin with a star, the query commands are

followed by a question mark (?). Common commands are defined by the IEEE STD 488.2-1987 standard

and control status reporting, synchronization, power-on conditions and stored operating parameters of

the PSC-488.

The PSC-488 contains the following common commands.

MNEMONICS Description

*IDN?

*RST

*TST?

*OPC

*OPC?

*WAI

*CLS

*ESE

*ESE?

*ESR?

*SRE

*SRE?

*STB?

*SAV

*RCL

14.2.1 Status reporting

Identification query.

Device Reset command.

Self test query.

Operation complete command.

Operation complete query.

Wait to continue command.

Clear status command.

Standard event status enable command.

Standard event status enable query.

Standard event status register query.

Service request enable command.

Service request enable query.

Read status byte query.

Save calibration values to non-volatile memory.

Recall values from non-volatile memory.

Only PSC-488

•

•

•

•

•

•

•

•

•

•

The status structure of the PSC-488 is used to reflect the power supply condition and to report all kind of

events that have happened. The various status models are ultimately reported in the Status Byte

Register, giving a complete organized status of the power supply. Status model, registers and queues

are reported in one of the summary bits of the Status Byte Register. The Service Request Enable

Register selects which Status Byte bits will cause a Service Request (SRQ) on the GPIB.

From the Status Byte Register, which is returned as response to a serial poll from a controller, it is

always possible to trace back the event that caused the corresponding summary bit to be set.

The diagram shows the interrelations.

14.2.2 *SRE

The Service Request Enable Command specifies the bit values of the Service Request Enable Register.

This register determines which conditions from the Status Byte Register will cause a Service Request

(SRQ) are summarized in the Master Summary Status -MSS- of the Status Byte Register.

A bit value 1 in the Service Request Enable Register selects the corresponding Status Byte Register

condition. The bit value of bit 6 (RQS/MSS) is ignored. The command parameter is specified as a

decimal using the <Nrf> format; when rounded to an integer value and expressed base 2 (binary),

the parameter represents the bit value of the Standard Event status Enable Register. Alternatively, the

command parameter may use a non-decimal numeric format (hexadecimal, octal or binary) to express

the register’s bit setting.

*SRE?

The Service Request Enable Query returns a decimal value, which expressed in base 2, reflects the bit

values of the Service Request Enable Register. Bit 6 is always set to 0.

page 17 MANUAL May 2008

Page 19

PSC SERIES DELTA ELEKTRONIKA BV

14.2.3 Register diagram

May 2008 MANUAL page 18

Page 20

DELTA ELEKTRONIKA BV PSC SERIES

14.2.4 *STB?

The Read Status Byte Query reports the contents of the Status Byte Register. The register contains the

summary status of all overlaying registers and status queues. When the Status Byte Register is read by

a serial poll from the GPIB, the RQS bit is returned on bit position 6. The *STB? query returns the MSS

bit on bit position 6. Reading the status byte by a serial poll or with the *STB? query does not affect its

contents. The only exception to this rule is the RQS bit. This bit is always cleared after a serial poll. The

other bits are cleared only when the overlaying status structure, which caused the summary bit or with

*CLS.

Bit MNE Description Status Byte Register

0 DSB

1 DEB

2 Not used

3 Not used

4MAV

5 ESB

6MSS

6 RQS

7 Not used

Device

Status

Device

Extended

Status

Message

Available

Event

Summary Bit

Master

Summary

Status.

Requested

Service.

Contains the summary of the Device Status register.

Contains the summary of the Device Extended status register.

Only used by power supply with internal CPU (SM6000)

Indicates the ‘non-empty’ status of the Output Queue; this bit is set

True when at least one byte is available in the queue. It is set to

False when the Output Queue is empty.

Contains the summary of the Standard Event Status register.

Returned as a response to the *STB? query. Indicates that there is

an event that caused the device to request for service. The MSS bit

is cleared when the events in the overlaying status structure that

caused the service request, are cleared.

Sent as a response to a serial poll over the GPIB. Indicates that the

device requested for service; this means that a SRQ message was

issued on the GPIB. It differs from the MSS bit in the fact that the

RQS bit is cleared after the serial poll. It is only set True again

when a new event occurs that requires service.

For each status structure there is an Event register, that reflects the events themselves, and an Event x

Enable

• Register. The Event Enable register selects which events are summarized into the Status Byte

Register.

• The Status Byte Register can be read by either Serial Poll or by the *STB? query. The Status Byte

Register is cleared only by clearing its overlaying structures.

• The Service Request Enable Register allows to select particular bits from the Status Byte to generate

a Service Request (SRQ) on the GPIB.

page 19 MANUAL May 2008

Page 21

PSC SERIES DELTA ELEKTRONIKA BV

14.2.5 *CLS

This Clear Status Command clears the device’s status structures.

• All Event Registers summarized in the Status Byte.

• The Standard Event Status Register.

• Sets the device into the Operation Complete Command Idle State.

• Sets the device into the Operation Complete Query Idle State.

Note:

The *CLS command does not effect the Output Queue. However if there is data in the Output Queue and

a *CLS command immediately followed by a Program Message Terminator is received, the Output

Queue will cleared.

Standard Event status Register

This register contains the events that are standardized by IEEE488.2.

Common Commands are provided to access the values associated with the Standard Event Status.

14.2.6 *ESE

The Standard Event Status Enable Command specifies the bit values of the Standard Event Status

Enable Register. This register determines which events from the standard Event Status Register are

summarized in bit 5, the Event Summary Bit - ESB - of the Status Byte Register.

A bit value 1 in the Standard Event Status Enable Register selects the corresponding event bit in the

Standard Event Status Register to be reported in the Event Summary Bit.

The command parameter is specified as a format, a decimal integer value from 0 to 255 and expressed

base 2 (binary), the parameter represents the bit value of the Standard Event Status Enable Register.

*ESE?

The Standard Event Status Enable Query returns a decimal value, which expressed in base 2 reflects

the bit values of the Standard Event Status Enable Register.

14.2.7 *ESR?

The *ESR? query causes the Standard Event Status Register is cleared.

Example:

send —-> *ESR?

read <—- 28 equals the binary value 00011100

The bits 4 (EXE), 3 (DDE) and 2 (QYE) are set. This means that an Execution Error, a Device

Dependent Error and a Query Error has occurred since the last time this register was read.

Note:

The next *ESR? query will return a zero value, if no new events have occurred.

May 2008 MANUAL page 20

Page 22

DELTA ELEKTRONIKA BV PSC SERIES

BIT MNE Name Description of the standard Event Status Register

0 OPC Operation complete indicates whether an operation is completed or is still pending.

1 QRC Request Control Not implemented. Always set to 0.

This error will occur when the Message Exchange Protocol is

violated. For example, when a query was sent to the instrument

and subsequently a new command is sent without first having read

the entire response data from the previous query. Also trying to

read data from the PSC-488 without first sending a query to the

instrument will cause this error.

2 QYE Query Error

In general a query error is reported because of:

• incorrect query response handling.

• an un terminated or interrupted action.

• a buffer deadlock because the input buffer and output

queue are overflown.

• indefinite response from the PSC-488.

3 DDE

4 EXE Execution Error

5 CME Command Error

6 URQ User Request Indicates that the user has requested for a service.

7 PON Power-on

14.2.8 DSE

Device Status Enable

This command specifies the bit values of the Device Status Enable Register. This register determines

which events from the Device are summarized in bit 7 of the Status Byte Register. A bit value 1 in the

DSE selects the associated bit in the DSR (Device Status event Register) to be reported in Bit 0 of the

Status Byte Register, the Device Summary Status bit 0.

DSE?

The Device Status Enable query returns a decimal value, which expressed in base 2, reflects the bit

values of Device Status Enable Register. The returned value is a NR1 response data type.

Device Dependent

Error

This error indicates that the PSC-488 could not properly complete

some device specific operations.

indicates that a syntactical valid program message is received that

can not be executed due to some device specific conditions.

This error indicates that the instrument detected a syntax or

semantic error.

Indicates that the device’s has been turned off and on since the

last time that the register was read or cleared.

14.2.9 DSR?

The Device event Status Register captures transitions in its condition register. An event bit becomes true

when the associated condition bit makes a logical 0 to 1 or 1 to 0 transition. The command DSR? returns

a decimal value, which expressed in base 2, reflects the bit values of the Device event Status Register.

Execution of this query causes the Device Status Enable Register to be cleared. The returned value is a

NR1 response data type.

page 21 MANUAL May 2008

Page 23

PSC SERIES DELTA ELEKTRONIKA BV

14.2.10 DSC?

The Device Status Condition register contains the power supply’s status, and returns a decimal value,

which expressed in base 2, reflects the bit values of the Device Status. Execution of this query will not

clear this register. The returned value is a NR1 response data type. See the power supply manual to

check which statuses are available

BIT MNE Description Device Status Condition register

0 CC Constant Current

1 LIM Limit

2 DCF DC Fail

3 ACF AC Fail

4 O.T. Over Temperature

5 PSO Power Sink Overload

6 InpA (CCR) User input A (CCR when used in a power supply with internal CPU)

7 InpB (CVR) User input B (CVR when used in a power supply with internal CPU)

14.2.11 DEE

This register is only available when a power supply is used with an internal CPU.

Device Extended status Enable. This command specifies the bit values of the Device Extended status

Enable Register. This register determines which events from the Device Extended status Register are

summarized in bit 1 of the Status Byte Register. A bit value 1 in the Device Extended status Enable

Register selects the corresponding bit in the Device Extended status Register to be reported in Bit 1 of

the status byte, the Device Summary Extended status bit.

DEE?

The Device Extended status Enable query returns a decimal value, which expressed in base 2, reflects

the bit values of Device Extended status Enable Register. The returned value is a NR1 response data

type.

Bit MNE Description Device Extended status condition Register

0 HOT High temperature

1 INTL Interlock

2 VLIM Voltage limit

3 ILIM Current limit

4 CV Constant voltage mode

5 OUTP Output on

6 RSD Remote shut down

7 FPL Front panel lock

14.2.12 DER?

The Device Extended status Register contains the power supply Extended status change , and returns a

decimal value, which expressed in base 2, reflects the bit values of the Device Extended status register.

Execution of this query causes the Device Extended status Register to be cleared. The returned value is

a NR1 response data type.

14.2.13 DEC?

The Device Extended status Condition register contains the power-supply status, and returns a decimal

value, which expressed in base 2, reflects the bit values of the register. The returned value is a NR1

response data type. See the power supply manual to check which statusses are available.

May 2008 MANUAL page 22

Page 24

DELTA ELEKTRONIKA BV PSC SERIES

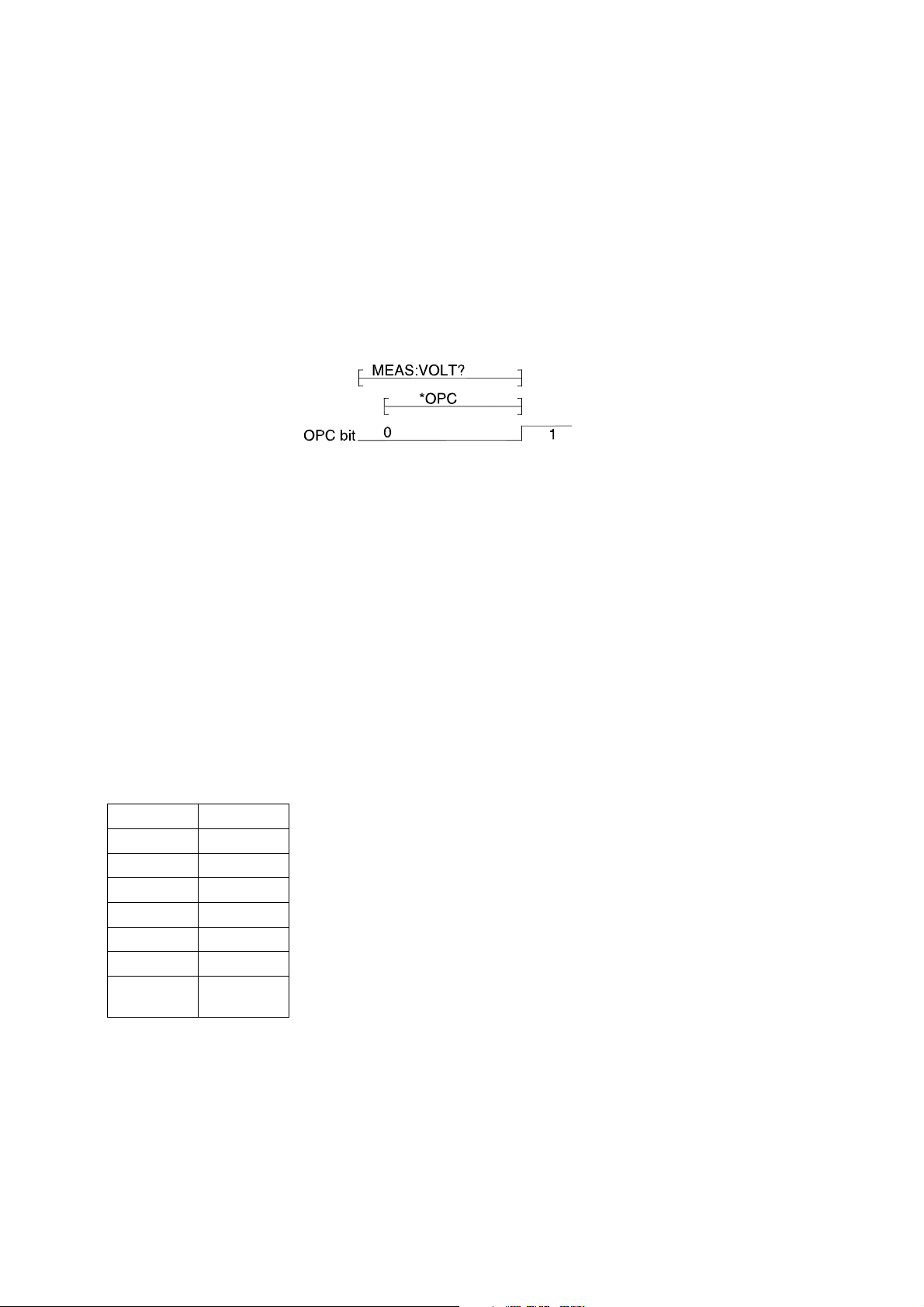

14.2.14 *OPC

The Operation Complete Command allows for synchronization between a controller and several devices.

It causes the instrument to set the Operation Complete Command -OPC- bit in the Standard Event

Status Register to be set true when all selected pending operations have been finished. This implies that

all device operations initiated by previous programming commands have been entirely completed or

aborted.

Example:

Send —-> MEAS:VOLT?

Send —-> *OPC

The timing diagram related to the internal execution of these commands is shown in the following figure:

There are two methods of synchronization between application programs and the PSC-488:

• Use the OPC event bit to generate a Service Request. During the instrument operation, the

application program can perform other tasks if the Service Request is used as interrupt.

• Read the *OPC bit (bit 0) from the standard event register using the common query *ESR?.

Wait until the OPC bit becomes set to true.

*OPC?

The Operation Complete Query is a method for synchronization. The Operation Complete Query places

an ASCII character"1" in the device Output Queue when all pending operations have been finished.

14.2.15 *RST

The *RST command resets the device dependent functions except for memorized configuration settings,

protected settings and calibration data.

Voltage 0 V

Current 0 A

Output Disable

RSD off

REM on

REM CV on

REM CC on

Front

panel

Unlock

page 23 MANUAL May 2008

Page 25

PSC SERIES DELTA ELEKTRONIKA BV

14.2.16 *TST?

The Self-Test Query causes the device to execute an internal self-test and reports detected errors.

The PSC-488 will output the ASCII character 0 (20 hex) when the test is passed without failures.

14.2.17 *WAI

The Wait-to-Continue Command is useful after an overlapped command to force sequential execution.

The *WAI command will prevent the instrument from executing any further command or query until it has

finished the actions started by the overlapped command.

14.2.18 *SAV

Saves settings and calibration data in non-volatile memory registers. It is possible to protect the

calibration data with a password. Normally the password is “DEFAULT” and not protected.

After the command password<wsp>DEFAULT,<new_password> the new password is active and the

*SAV works only with the password parameter *SAV <new_password> .

14.2.19 *RCL

Recalls the settings and calibration data previously stored with the *SAV command.

14.2.20 *IDN?

The Identification Query is used to identify the PSC within a system. The response to the *IDN? is an

<instrument_identifier> which is organized into four fields, mutually separated by commas (2C-hex).

Field 1 Manufacturer

Field 2 Model Version

Field 3 Serial number

Field 4 Custom string

The maximum number of characters is 72.

Note:

The syntax for the *IDN? response is Arbitrary ASCII Response Data. The IEEE488.2 standard requires

this data type to be terminated with a Response Message Terminator. Therefore, controllers should send

the *IDN? query as the last query message unit in a terminated program message. If not, the device will

generate a Query Error and will not send the response to the subsequent queries.

The following documents will assist you with programming the IEEE488 interface:

Standard Codes, Formats, Protocols and Common Commands for use with IEEE Std 488.1-1987, IEEE

Standard digital interface for programmable instrumentation, IEEE std 488.2-1992 , Published by the

Institute of Electrical and Electronics Engineers),

345 East 47th street, New York, NY 10017-2394, USA

ISBN 1-55937-238-9

DELTA ELEKTRONIKA BV DELTA ELEKTRONIKA BV

PSC-488 module V 1.0.0, PSC-232 V 1.0.0,

123456789012, 123456789012,

TST. 05\03\01 30 V / 10 A

May 2008 MANUAL page 24

Page 26

DELTA ELEKTRONIKA BV PSC SERIES

14.3 SCPI commands

14.3.1 SOurce:VOltage:MAximum

14.3.2 SOurce:CUrrent:MAximum

These commands are used to enter the maximum voltage and maximum current range of the used

power supply. For example, the Delta power supply model SM35-45 has a range of 35 volt and 45

ampere. The SOur:VOlt:MAx<wsp>35 and the SOur:CUrr:MAx<wsp>45 have to be given before the

voltage and current set commands. Save the configuration values in non-volatile memory with the *SAV

command. The next time settings will automatically recalled at power on.

SOur:VOlt:MAx? and SOur:CUrr:MAx? read back the voltage and current settings.

14.3.3 CAlibration:CUrrent:OFfset

CA:CU:OF<wsp><NR1>

Used to calibrate the zero-offset of the current programming.

14.3.4 CAlibration:CUrrent:OFfset?

Reads-back the present offset calibration value of the current programming.

14.3.5 CAlibration:CUrrent:GAin

Used to calibrate the full-scale of the current programming.

14.3.6 CAlibration:CUrrent:GAin?

Reads-back the present full scale calibration value of the current programming.

14.3.7 CAlibration:VOltage:OFfset

Used to calibrate the zero-offset of the voltage programming.

CAlibration:VOltage:OFfset?

Reads-back the present offset calibration value of the voltage programming.

14.3.8 CAlibration:VOltage:GAin

Used to calibrate the full-scale of the voltage programming.

CAlibration:VOltage:GAin?

Reads-back the present full-scale calibration value of the voltage programming.

14.3.9 CAlibration:CUrrent:MEasure:OFfset

Used to calibrate the zero-offset of the current monitoring.

CAlibration:CUrrent:MEasure:OFfset?

Reads-back the present offset calibration value of the current monitoring.

14.3.10 CAlibration:CUrrent:MEasure:GAin

Used to calibrate the full-scale of the current monitoring.

CAlibration:CUrrent:MEasure:GAin?

Reads-back the present full scale calibration value of the current monitoring.

page 25 MANUAL May 2008

Page 27

PSC SERIES DELTA ELEKTRONIKA BV

14.3.11 CAlibration:VOLTage:MEASure:OFFSet

Used to calibrate the zero-offset of the voltage monitoring.

CAlibration:VOltage:MEASure:OFfset?

Reads-back the present offset calibration value of the voltage monitoring.

14.3.12 CAlibrate:VOltage:MEasure:GAin

Used to calibrate the full-scale of the voltage monitoring.

CAlibrate:VOltage:MEasure:GAin?

Reads-back the present full scale calibration value of the voltage monitoring.

14.3.13 PAssword

From factory, the password is set to “DEFAULT” and *SAV can be used without parameter.

With the command PAssword<wsp>DEFAULT,<New_password> the protection is activated.

“DEFAULT” is the factory default string, <New_password> is the new password.

The string is maximum 8 characters and is not case sensitive. Execution of the *SAV command without

valid password causes an execution error 15 (Illegal password).

A few examples:

PA DEFAULT,MYPASSW<LF>

Changes the factory default password into a new password.

After this command the *SAV command works only with a valid password as parameter.

The command:*SAV MYPASSW<LF>.

PA <current_password>,<new_password>

Changes the current password into a new password.

PA MYPASS,DEFAULT

Changes the current password into the factory default. Protection is disabled.

PAssword?

This query returns a 0 if the access is not protected. Otherwise a 1 is returned when the acces is

protected with a password.

Forgotten password. With the command PAssword:Reset or abbriviated PA:R the PSC comming into a

non calibrated state and the password are set to “DEFAULT”.

May 2008 MANUAL page 26

Page 28

DELTA ELEKTRONIKA BV PSC SERIES

14.3.14 SOurce:FUnction:RSD<wsp><boolean>

The command SOurce:FUnction:RSD<wsp>{ON|1}or abbreviated SO:FU:RSD<wsp>{ON|1} disables

the output of the power supply. The command SOurce:FUnction:RSD<wsp>{OFF|0}or abbreviated

SO:FU:RSD<wsp>{OFF|0} enables the output again.

SOurce:FUnction:RSD?

The query SOurce:FUnction:RSD? or abbreviated SO:FU:RSD? returns 1 when the power supply is

disabled. Otherwise a 0 is returned.

14.3.15 SOurce:FUnction:OUtA<wsp><boolean>

The command SOurce:FUnction:OUtA<wsp>1 or abbreviated SO:FU:OUA<wsp>1 sets the open

collector output A of the PSC-488 to 1.

The command SO:FU:OUtA<wsp>0 sets the open collector output A of the PSC-488 to 0.

SOurce:FUnction:OUtA?

The query SOurce:FUnction:OUtA? or SO:FU:OUA? returns 0 if the digital output A is set to 0.

Otherwise , a 1 is returned.

14.3.16 SOurce:FUnction:OUtB <wsp> <boolean>

The command SOurce:FUnction:OUtB<wsp>1or abbreviated SO:FU:OUB<wsp>1 set the open collector

output B of the PSC-488 to 1.

The command SO:FU:OUA<wsp>0 set the open collector output B of the PSC-488 to 0.

SOurce:FUnction:OUtB?

The query SOurce:FUnction:OUtB? or SO:FU:OUB? returns 0 if the digital output B is set to 0.

Otherwise , a 1 is returned.

14.3.17 SOurce:FUnction:OUTP<wsp>{ON|OFF}

The command SOurce:FUnction:OUTP {on|off} or abbreviated SO:FU:OUTP {on|off} enables (on) or

disables (off) the output of the power supply.

SOurce:FUnction:OUTP?

The query SOurce:FUnction:OUTP? Or SO:FU:OUTP? Returns O when the output is disabled, or 1

when the output is enabled.

14.3.18 SOurce:FUnction:FRontpanel Lock

The command SOurce:FUnction:FRontpanel<wsp>{Lock|Unlock} or SO:FU:FR<wsp> {L|U} locks or

unlocks the front panel pushbuttons. See the power supply manual for details.

SOurce:FUnction:FRontpanel:Lock?

The query SOurce:FUnction:FRontpanel:Lock? Or SO:FU:FR:L? Returns 1 when the front panel is

locked. Otherwise a 0 is returned.

14.3.19 REMote and LOCal

The command REMote switches the power supply to remote-control. The command LOCal switches the

power supply back to manual control.

On some power supplies the selection Remote or Local is done by switches on the power supply itself.

On these power supplies the commands REmote and LOcal have no effect.

page 27 MANUAL May 2008

Page 29

PSC SERIES DELTA ELEKTRONIKA BV

REMote?

The query REMote? returns 0 when the power-supply in local mode. and in remote mode, a 1 is

returned.

LOCal

Warning: After the command LOCal, the power supply will return to the potentiometers settings on the

front panel.

Example: If the front-panel voltage potentiometer is set to 35 volt, the power supply output will go to 35V

after the command LOCal. Set the potmeters for voltage and current on the front panel to a safe value

prior to using the LOCal and REMote commands.

REMote:CV

When the programming switch 2 of ‘SW A’ are set to on, the command REM:CV switches the power

supply to voltage remote-control. The command LOC:CV switch the power supply back to manual

voltage control.

On some power supplies the selection Remote or Local is done by switches on the power supply itself.

On these power supplies the command REMote :CV has no effect.

REMote:CV?

The query REM:CV? returns 0 when the power supply in voltage local mode and in voltage remote

mode, a 1 is returned.

LOCal:CV

Warning: After the command LOC:CV, the power supply will return to the potentiometer setting on the

front panel (Also see the LOCal command).

REMote:CC

The command REM:CC switches the power supply to current remote-control. The command LOC:CC

switch the power supply back to manual current control.

On some power supplies the selection Remote or Local is done by switches on the power supply itself.

On these power supplies the command REMote :CC has no effect.

REMote:CC?

The query REM:CC? returns 0 when the power supply in current local mode. and in current remote

mode, a 1 is returned.

LOCal:CC

Warning: After the command LOC:CC, the power supply will return to the potentiometer setting on the

front panel. (Also see the LOCal command).

14.3.20 SOurce:CUrrent <wsp>

This command sets the output current of the power supply. The mode of operation depends upon the

load.

SOurce:CUrrent?

This query returns the present setting of the current.

May 2008 MANUAL page 28

Page 30

DELTA ELEKTRONIKA BV PSC SERIES

14.3.21 SOurce:VOltage <wsp>

This command sets the output voltage of the power supply. The mode of operation depends upon the

load.

SOurce:VOltage?

This query returns the present setting of the voltage.

Note that both voltage and current have to be programmed. It is necessary that the values of both

current and voltage are non zero, otherwise the power supply can not function properly. If zero volts is

programmed, then the current is limited to zero. If zero current is programmed, then the voltage will not

rise!

14.3.22 MEasure:VOltage?

This query returns the voltage measured at the power supply sense terminals.

14.3.23 MEasure:CUrrent?

This query returns the current delivered by the power supply.

Wait for a response from the power supply because it needs time to collect data and send it to the

computer.

Note:

When you write a program, you have to take care of the timing.

The ADC needs some time to measure the voltage or current.

See example programs on www.DeltaPowerSupplies.com.

14.3.24 CH

The channel command CH<wsp>n is the first command that should be executed to enable the

PSC-232xxx type with that channel number. Each unit must have a unique channel number between 0

and 30. The channel can be set with the DIP switch on the front panel of the PSC-232 module or on the

back side of an power supply.

CH?

The command CH? Reads the channel number of the active PSC-232 and communicates this back to

the computer.

14.3.25 Help?

The query HELP? returns a list of PSC commands.

14.3.26 SEnse:DIgital:DAta?

The Device Status Condition register contains the power supply status and returns a decimal value,

which expressed in base 2, reflects the bit values of the register. The returned value is a NR1 response

data type. See the power supply manual if the status available.

14.3.27 SEnse:DIgital:EXtendeddata?

The Device Extended status Condition register contain the power supply status and returns a decimal

value, which expressed in base 2, reflects the bit values of the register. The returned value is a NR1

response data type. See the power supply manual if the status available.

14.3.28 SEnse:DIgital:SWitch?

The Digital switch Condition register contain the power supply DIP switch status and returns a decimal

value, which expressed in base 2, reflects the bit values of the register. The returned value is a NR1

response data type. See the power supply manual if the DIP switch status is available.

page 29 MANUAL May 2008

Page 31

PSC SERIES DELTA ELEKTRONIKA BV

14.3.29 CU

With the CU command you can change the custom string of the identity string. See chapter 14.2.20.

The string must have 15 characters including the <lf> and is send via RS232.

Some examples:

CU<WSP>CAL. 01-02-2003 Calibration date

CU<WSP>SM 70-20 no 007 Power supply type and inventory number

After this command you can check it with query *IDN? to display the identify string.

With *SAV you can store the new information in non volatile memory.

May 2008 MANUAL page 30

Page 32

DELTA ELEKTRONIKA BV PSC SERIES

15 Error numbers

There are four groups of standardized errors, which are reported in the Standard Event Status and in the

Error/Event Queue, namely:

Classification

Command Error bit 5 - CME

Execution Error bit 4 - EXE

Device-Specific Error bit 3 - DDE

Query Error bit 2 - QYE

15.1 Command Error

This error indicates that the instrument detected a syntax or semantic error.

15.2 Execution Error

This error indicates that a syntactical valid program message is received that can not be executed due to

some device specific conditions.

15.3 Device specific Error

This error indicates that the PSC-488 could not properly complete some device specific operations.

15.4 Query Error

Standard Event

Register

This error will occur when the Message Exchange Protocol is violated.

For example, when a query was sent to the instrument and subsequently a new command is sent

without first having read the entire response data from the previous query. Also trying to read data from

the PSC-488 without first sending a query to the instrument will cause this error.

In general a query error is reported because of:

• Incorrect query response handling.

• An unterminated or interrupted action.

• A buffer deadlock because the input buffer and output queue are overflown.

• Indefinite response from the PSC-488.

Error number

1 Syntax error

2 Channel-number error

3 Numerical-value error

4 Command without full-scale

5 Maximum voltage range error

6 Maximum current range error

7 Data out of range

8...12, 16 Non volatile memory error

13 Checksum error

14 Overflow

page 31 MANUAL May 2008

Page 33

PSC SERIES DELTA ELEKTRONIKA BV

15 Illegal password

17 Invalid character

18 Not connected with PSU

19 Command not support, wrong configuration

16 Software examples and programs

Files on CD ROM or web site:

• Datasheet

• Manual

• RS232 and GPIB Calibration Program

• IBIC test scripts

• Labview VI for PSC-232 and for PSC-488

WEEE (Waste Elec trical & Elec tronic Equipment)

Correct Disposal of this Prod uct

Ap pli ca ble in the Eu ro pean Union.

This mark ing shown on the prod uct, its packing or its literature in dicates that it shoul d not be

disposed with other wastes at the end of its work ing life, but shoul d be col lected sep arately to

re cy cle it re spon si bly to pro mote the sus tain able re use of ma te rial re sources.

May 2008 MANUAL page 32

Loading...

Loading...