Page 1

Evaluation Procedure

r

r

t

Delta Delphi Series 48Vin

S48SR and S48SS

The Delphi Series S48SR and S48SS,

48V input, single output, isolated DC/DC

converters are the latest offering from one

of the world’s largest power supply

manufacturers ― Delta Electronics, Inc.

With creative design technology and

optimization of component placement,

these converters possess outstanding

electrical and thermal performance, as well

as extremely high reliability under highly

stressful operating conditions. All models

are protected from abnormal input/output

voltage and current conditions. An

encapsulated version is available for the

most robust performance in harsh

environments.

This document guides the user through the

evaluation procedures to qualify a Delphi

module. The data shown in this Evaluation

Procedure is for the 3.3V unit. Please refe

to the appropriate technical data sheet fo

detailed performance and technical

information for Delphi units with differen

output voltages.

Delphi Series S48SR and S48SS

1.0 Purpose

This document guides the user to perform

electronic measurements on a Delphi

S48SR, 15W or a S48SS, 15W DC/DC

converter using the Delta Evaluation Board.

2.0 Relevant Documentation

The document and general knowledge listed

below is relevant to this evaluation

procedure:

2.1 S48SR or S48SS Series Applicable

Data Sheet

2.2 2”×1” Power Module Evaluation Board

Schematic

2.3 2”×1” Power Module Evaluation Board

Layout

2.4 General Test and Safety Procedures

2.5 ESD Protection

Evaluation Procedure

EP_SP

Version X1.0 November 2002

1

Delta Electronics, Inc.

Page 2

3.0 Equipment Required

3.1 (1) 0 ~ 80 V @ 0 ~10 A Power Supply (Chroma 6230K-80 or Equivalent)

3.2 (1) 4 Channel 150 MHz Oscilloscope, (1) 1× scope probe, (1) 10× scope probe

(Yokogama DL 1540C or Equivalent)

3.3 (1) 4 1/2 Digital Multimeter (DVM3) (HP34401A or Equivalent)

3.4 (2) 3 1/2 Digital Multimeter (DVM1 and DVM2) (FLUKE 45 or Equivalent)

3.5 (1) 300W Electronic or Resistive Load (Chroma 6304)

4.0 Equipment Set-Up and Description

4.1 Connect one wire from the “+” lead of the Power Supply (Item 3.1) to the “10A” of the

DVM1 (Item 3.4). Then connect one wire from the “Common” of the DVM1 to the

“Vin +” pin of the Evaluation Board.

4.2 Connect one wire from the “-” lead of the Power Supply to the “Vin -“ pin of the

Evaluation Board. Note: Use 10 AWG wire or similar for all connections in sections 4.1

and 4.2. Use twisted pair to reduce noise coupling.

4.3 Connect the plus “+” and minus “-“ connection wires from the multimeter (item 3.3) to

the “SVin +” and “SVin -” Pin on the Evaluation Board. The multimeter is designated

DVM2, above in Paragraph 3.0, Section 3.4.

4.4 Connect the plus “+” and minus “-“ connection wires from the multimeter (item 3.3) to

the “Sense +” and “Sense -” Pin on the Evaluation Board. The multimeter is designated

DVM3, above in Paragraph 3.0, Section 3.3.

4.5 Connect a BNC cable (length less than 20 inches) from BNC1 of the Evaluation Board

to Channel 1 of the oscilloscope (item 3.2).

4.6 Connect a BNC cable (length less than 20 inches) from BNC2 of the Evaluation Board

to Channel 2 of the oscilloscope (item 3.2).

4.7 Connect the Positive and Negative power leads of the Electronic load (assuring correct

polarity), or a resistive load to the Evaluation Board output terminal pin (“Vout +” for

positive power lead and “Vout -” for the negative power lead).

2

Page 3

5.0 Thermal of the Converter

It is imperative that sufficient airflow be provided to the converter at all times during all

portions of testing. Please refer to the applicable data sheet for the proper cooling and

derating necessary to achieve accurate results when testing the converter.

6.0 Tests Performed

The following tests are performed at room temperature +25 C.

6.1 Input Characteristics

Input Voltage Range

Under Voltage Lockout

No Load Input Current

Disable Input Current (applies to S48SS version only)

6.2 Output Characteristics

Line Regulation

Load Regulation

Output Regulation

Output Overvoltage Protection

6.3 Dynamic Characteristics

Maximum Output Voltage Deviation (due to step change in load)

Response time (due to step change in load)

Soft Start Turn-On Time

6.4 Thermal Characteristics

Efficiency

3

Page 4

7.0 Test Set-Up

7.1 Initial Set-Up

1) Examine the part number of the power module to determine of the unit is defined

for positive or negative logic enable as follows:

S48SS3R304NR would denote negative logic, while S48SS3R304PR would

denote positive logic (S48SS only).

2) If the power module has positive logic, switching SW1 to position HI or floating will

enable the power converter. Switching SW1 to position Low will disable the power

converter.

3) If the power module has negative logic, switching SW1 to position Low will enable

the power converter. Switching SW1 to position HI or floating will disable the power

converter.

4) Multimeters (1) Ampere / Autorange

Multimeters (2 and 3) Voltage / Autorange

5) Scope

Timebase 10 mS

Trigger Auto

Channel (1)

Volts / Div 10V

Coupling DC

Channel (2)

Volts / Div 1V

Coupling DC

6) Electronic Load

Turn on the Electronic Load and adjust the current level. The total output current is

4.5A (15W) for the S48SR power module and 4.5A (15W) for the S48SS power

module. Ensure the output load does not exceed the recommended maximum

current.

7) SW2 is used for trimming the output voltage. Turn SW2 to the OFF position if the

function is not being used. Turn SW2 to the UP position if trimming up is required.

Turn SW2 to the DOWN position if trimming down is required.

7.2 Initial Power Up

1) Turn the Power Supply on and increase the input voltage (use DVM2 to monitor the

voltage) until it reaches 48V (or the desired value).

2) Toggle SW1 to the appropriate logic position to turn the power module on (S48SS

only).

3) The converter is now operating, which can be verified by observing the DVM3

(approximately 3.3V.) and Channel 2 of the oscilloscope (+3.3V output).

4

Page 5

4) The converter may also be turned on by switching SW1 to the appropriate logic

enable position and ramping the voltage manually or turning on the Power Supply

with a preset output voltage (S48SS only).

5) Toggle SW1 to the “OFF” position after performing each test (S48SS only).

8.0 Test and Evaluation

8.1 Input Characteristic

8.1.1 Input Voltage Range

The Delphi S48SS3R304NR and S48SR3R304ER DC/DC converters will operate at

full load from 36Vin to 75Vin, steady state. The converter features input undervoltage protection which will not allow the converter to start up unless the input

voltage exceeds the turn-on voltage threshold.

Test

1) Turn on the fan.

2) Set the enable switch SW1 to the appropriate logic enable position (defined in

Section 7.1. S48SS only).

3) Set the input voltage to desired operating point while monitoring DVM2.

4) Test the input under voltage circuit while observing DVM2, DVM3 and Channel

1, Channel 2 of the oscilloscope. Increase the input voltage until the output of

the converter reaches stability (3.3 volts.) This will occur between 33.8 and 35.8

volts (please refer to the datasheet for the detailed specification).

8.1.2 No Load Input Current

Test

1) Turn on the fan.

2) Set the enable switch SW1 to the appropriate logic enable position (S48SS only).

3) Set the input voltage to desired operating point while monitoring DVM2.

4) Remove the electronic or the resistive load (output load)

5) Note the input current from DVM1.

6) The following is the result of the No load Input Current of the DC/DC converter.

The No Load Input Current will be around 25 mA (please refer to the datasheet for

the detailed specification).

5

Page 6

8.1.3 Input Current Module Off (S48SS only)

Test

1) Set the enable switch SW1 to the appropriate logic enable position to disable the

power supply (as defined in Section 7.1).

2) Adjust the input power supply to the desired operating point of interest while

monitoring DVM2.

3) Note the input current from DVM1.

4) This reading is the result of the Disable Input Current of the DC/DC converter.

The Disable Input current will be around 1 mA (please refer to the datasheet for the

detailed specification).

8.2 Output Characteristic

8.2.1 Line Regulation

Line Regulation is defined as the percentage change in output voltage caused by

varying the input voltage over the specified range (36 to 75 volts) while the output load

and temperature remain constant.

Test

1) Turn on the fan.

2) Set the enable switch SW1 to the appropriate logic enable position (S48SS only).

3) Set the output power to the desired operating point.

4) Adjust the input voltage across the converter’s input range (36 to 75 volts) while

monitoring DVM3.

5) Note the maximum +/- deviation of the output voltage over the full range of the

input operating voltage.

8.2.2 Load Regulation

Load Regulation is defined as the percentage change in output voltage caused by

varying the output load current over the specified range (no load to full load) while the

input voltage and temperature remain constant.

Test

1) Turn on the fan.

2) Set the enable switch SW1 to the appropriate logic enable position (S48SS only).

3) Set the input voltage to the desired operating point.

4) Adjust the output load across the converter’s operating load range (no load to full

load).

5) Note the maximum +/- deviation of the output voltage over the full range of the

operating load range.

6

Page 7

8.2.3 Output Ripple

Output Ripple is defined as the periodic AC component at the DC/DC converters

output voltage. The output ripple is measured in Peak to Peak and RMS values, both

done with a specific bandwidth.

Test

1) Turn on the fan.

2) Set the enable switch SW1 to the appropriate logic enable position.

3) Adjust the input voltage and output load to the desired operating point (S48SS

only).

4) Adjust Channel 2 on the oscilloscope to be AC coupled @ 2uS / Div and 50mV/Div

to use the 20 MHz bandwidth of the scope.

5) The output ripple of the DC/DC converter is measured at full load operating power.

8.3 Dynamic Characteristics

8.3.1 Output Voltage Deviation

Output Voltage Deviation is defined as the response of the converter to a sudden step

change in the output load current. The output voltage deviation is characterized by two

important parameters: Maximum Output Voltage Deviation and Response Time, which

is the length of time that the output voltage takes to return to 1% of its specified value

(please refer to the datasheet for the detailed specification).

Test -S48SS & S48SR

1) Turn on the fan.

2) Set the enable switch SW1 to the appropriate logic enable position (S48SS only).

3) Adjust the input voltage to the desired operating point.

4) Set Channel 2 on the oscilloscope to be AC coupled and to 50mV/Div and

5mS/Div. Set the trigger to auto and adjust the trigger point for a negative going

pulse.

5) Set the Electronic Load in dynamic mode and set it for the desired load transient.

6) Measure the positive Peak or negative Peak deviation and response time of the

output voltage during the load transient.

7

Page 8

8.3.2 Soft Start Turn-On Time

Soft Start Turn-On Time is defined as the time it takes for the output to rise to within

95% of its final value from the time when the converter is enabled. The rise time is

deliberately made slower to reduce the inrush current and to eliminate any overshoot

in the output voltage.

Test -S48SR & S48SS ( turn on the module by using the input power supply)

1) Turn on the fan.

2) Set the enable switch SW1 to the appropriate logic enable position (S48SS only).

3) Turn on the input Power Supply and set it to the desired operating point.

4) Set the input Power Supply disable by an external switch or use the input Power

Supply internal disable function.

5) Set Channel 1 on the oscilloscope to be DC coupled and to 1V/Div.

6) Connect a coaxial cable from Channel 1 to BNC2 on the Evaluation Board.

7) Set Channel 2 on the oscilloscope to be DC coupled and to 20V/Div.

8) Connect a coaxial cable from Channel 2 to BNC1 on the Evaluation Board.

9) Set the Timebase to 10 mS/Div.

10) Set the Trigger for a one time event and set the Trigger level at approximately 2V

on Channel 1.

11) Enable the input Power Supply to supply power and record the waveforms on the

oscilloscope.

Test-S48SS (turn on the module by using the Remote on/off feature)

1) Turn on the fan.

2) Set the enable switch SW1 to the appropriate logic disable position.

3) Turn on the input Power Supply and set the input voltage to the desired operating

point.

4) Set Channel 1 on the oscilloscope to be DC coupled and to 1V/Div.

5) Connect a coaxial cable from Channel 1 to BNC2 on the Evaluation Board.

6) Set Channel 2 on the oscilloscope to be DC coupled and to 2V/Div.

7) Set the Timebase to 10 mS/Div.

8) Set the Trigger for a one time event and set the Trigger level to approximately 2V

on Channel 2.

9) Connect the 10X probe (Channel 2) to the “ON/OFF” test point on the evaluation

board and connect the ground clip to the “Vin –“ pin on the evaluation board.

10) Set the enable switch SW1 to the appropriate logic position to enable power and

record the waveforms on the oscilloscope.

8

Page 9

Note: Different electronic loads may have dramatically different results because of

their input characteristics during Turn-On. If the Turn-On appears abnormal, replace

with an actual resistive load of appropriate value.

The Soft Start Turn-On Time of the converter provided in the Evaluation Kit was

measured with the Electronic Load set at 4.5A.

8.4 Thermal Characteristics

8.4.1 Efficiency

Efficiency is the ratio of total output power to the input power. It is typically measured

at full load and nominal input voltage.

Test

1) Turn on the fan.

2) Set the enable switch SW1 to the appropriate logic enable position (S48SS only).

3) Adjust the input voltage to the desired operation point.

4) Set the Electronic Load to the desired operating point..

5) Read and note the +3.3 output voltage (DVM3) and input voltage (DVM2).

6) Read and note the input and output currents from the DVM1 and the Electronic

Load.

9

Page 10

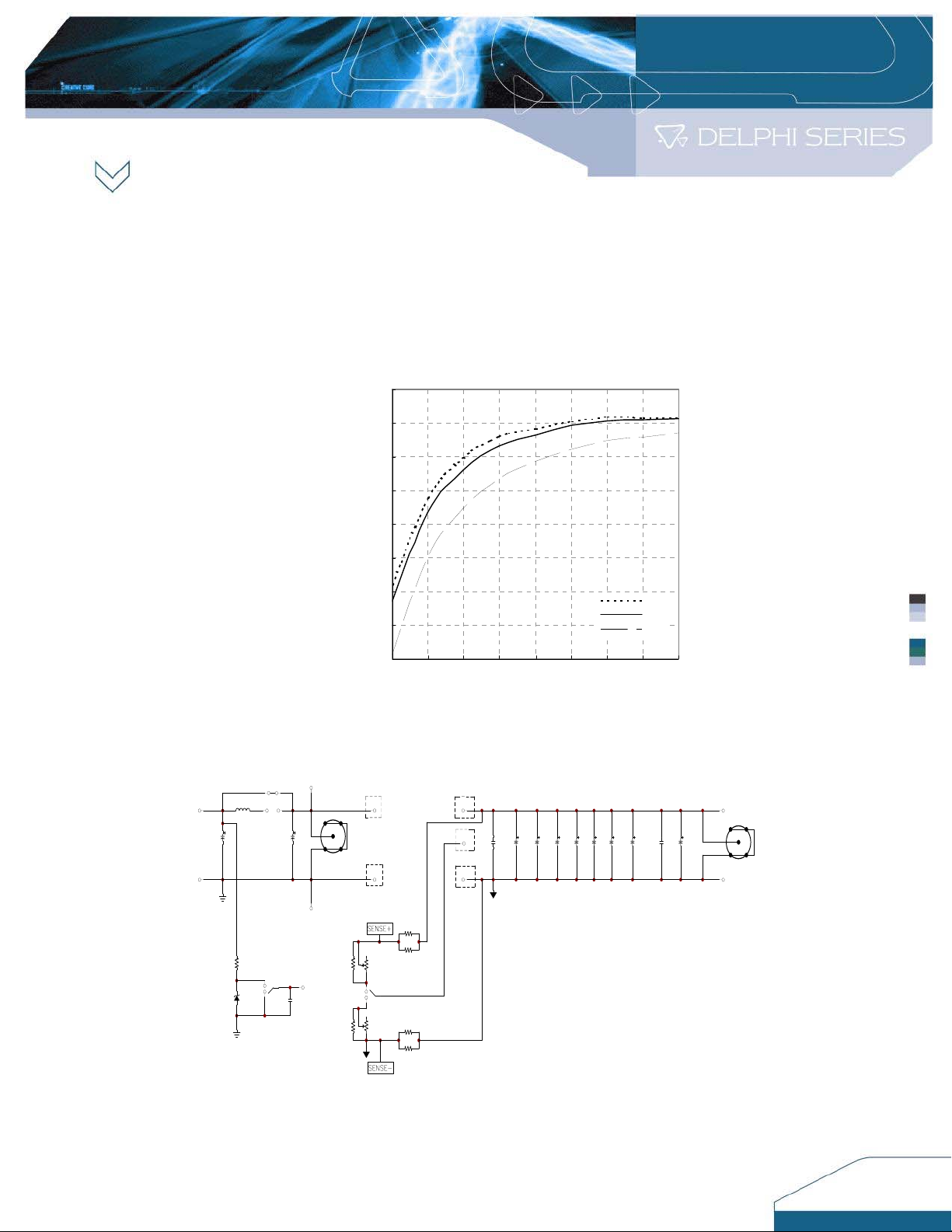

7) Use the following formulas to calculate the efficiency:

Efficiency= (Pout/Pin) × 100(%)

Pin = Iin × Vin

Pout = Iout × Vout

The following graph shows the efficiency results of the S48SS/S48SR

converters measured at different operating points.

90

85

EFFICIENCY (%)

80

75

70

65

60

55

50

0.5 1 1.5 2 2.5 3 3.5 4 4.5

Appendix A- Evaluation Board Schematic

L1

VIN+

NC BNC1

C2

NC

VIN-

R1

NC

NC

ZD1NC

Low

Hi

COPPER

SW1

1

3

Floating

2

NC C1

C3

68u/100V

ON/OFF

SVin+

SVin-

VIN+

VIN-

J2

J3

R3

NC

SW2

R2

NC

0

VR1

100K

DOWN

3

OFF

2

1

UP

J1

VR2

100K

J4

0

VOUT+

TRIM

C101NCC102NCC104

VOUT-

NC

NC

OUTPUT CURRENT (A)

C103NCC107NCC108

NC

C109NCC110NCC105

NC

36Vin

48Vin

75Vin

1u/25V

C106

10u/25V

VOUT+

BNC2

VOUT-

10

Page 11

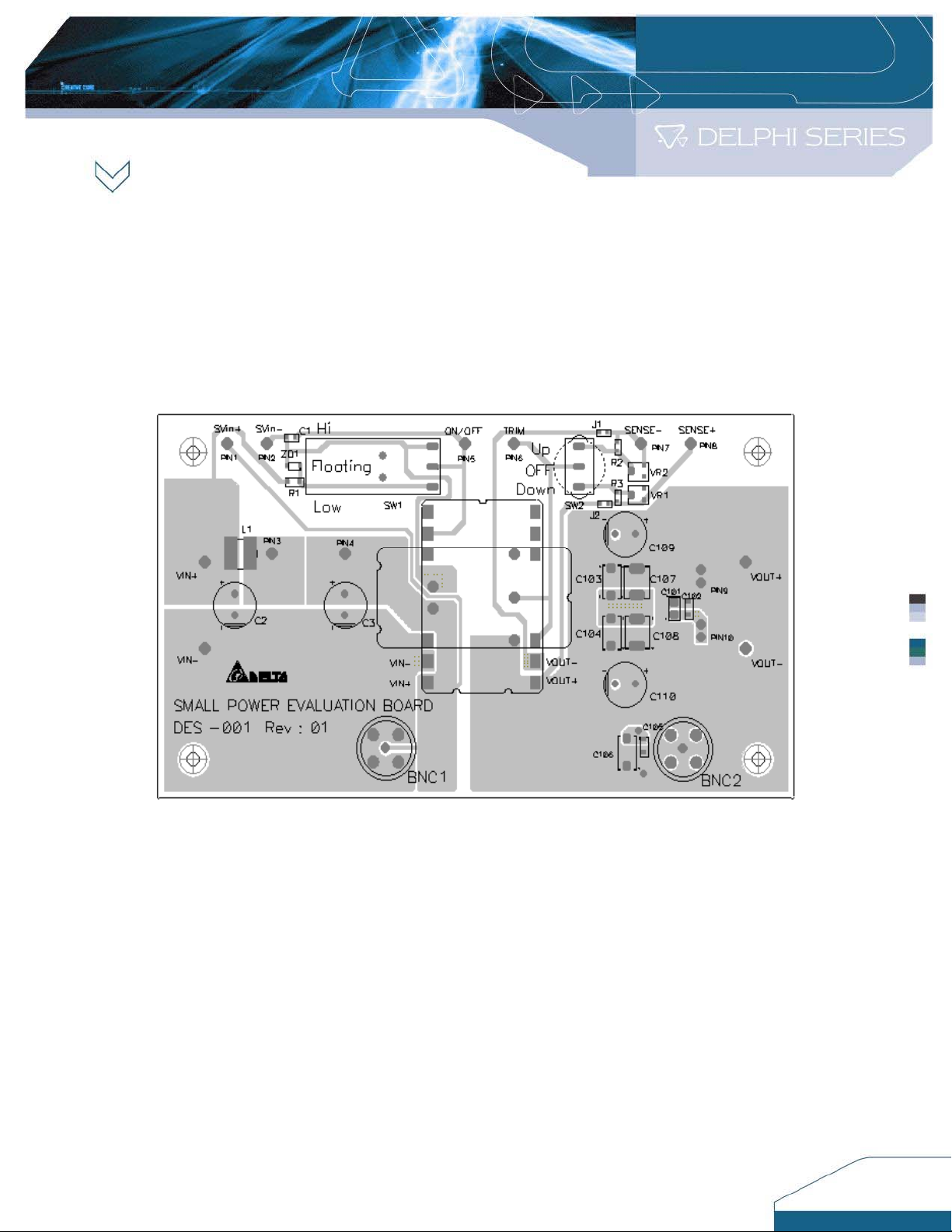

Appendix B - Evaluation Board Layout (Top View)

11

Page 12

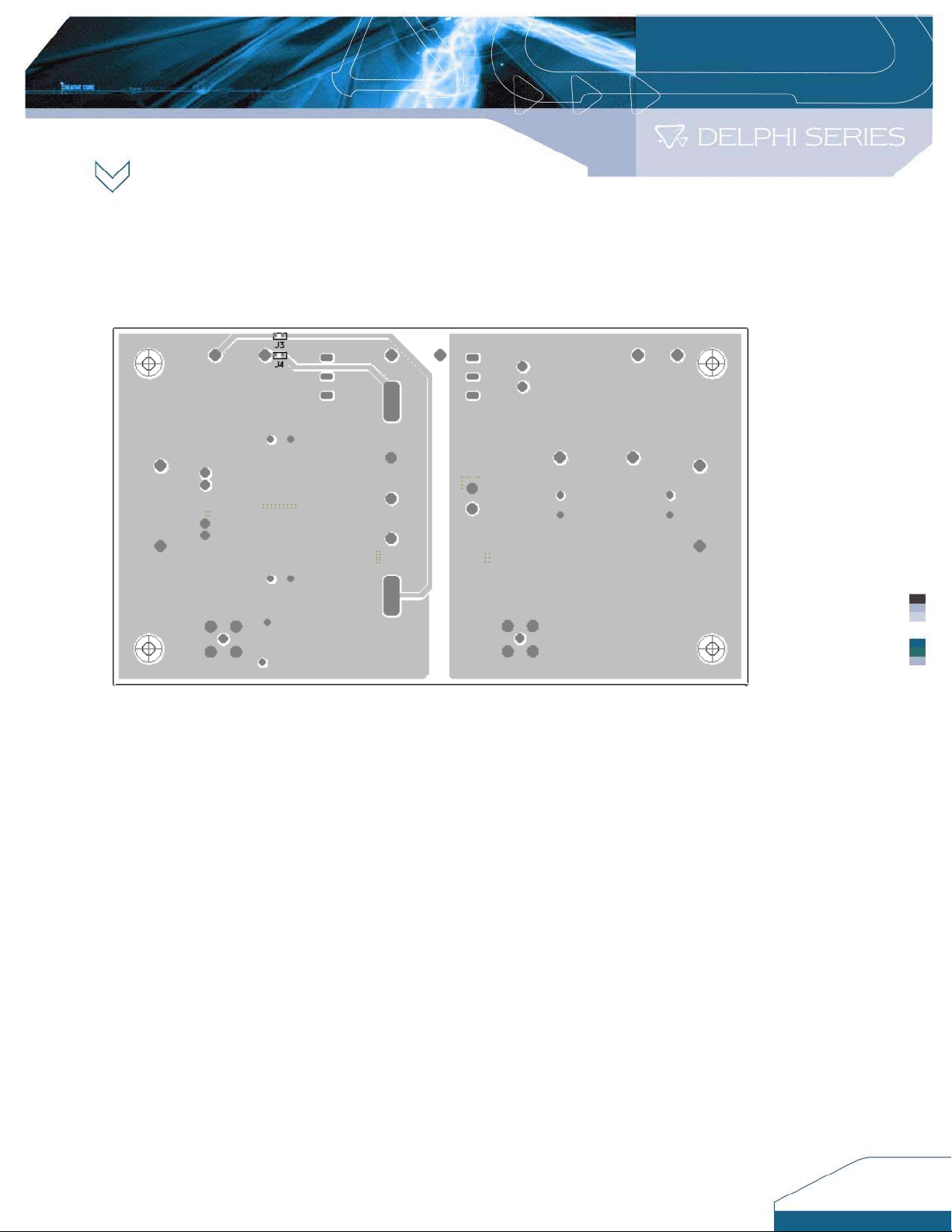

Appendix C- Evaluation Board Layout (Bottom View)

CONTACT DATA:

USA:

Telephone:

East Coast: (888) 335 8201

West Coast: (888) 335 8208

Fax: (978) 656 3964

Email: DCDC@delta-corp.com

www.deltaww.com

Europe:

Telephone:

France: +33 1 6485 1212

Germany: +49 89 370 62 897

UK: +44 777 195 6299

Fax: +33 1 6485 1212

Email: DCDC@euro.delta-corp.com

Asia:

Telephone: +886 3 4526107 x6202

Fax: +886 3 4331707

Email: DCDC@delta.com.tw

Warranty

Delta offers a two (2) year limited warranty. Complete warranty information is listed on our web site or is

available upon request from Delta.

Information furnished by Delta is believed to be accurate and reliable. However, no responsibility is assumed by

Delta for its use, nor for any infringements of patents or other rights of third parties, which may result from its

use. No license is granted by implication or otherwise under any patent or patent rights of Delta. Delta reserves

the right to revise these specifications at any time, without notice.

12

Loading...

Loading...