Page 1

RTU-EN01

Modbus TCP Remote I/O Communication Module

Operation Manual

DVP-0213920-01

Page 2

Page 3

Modbus TCP Remote I/O Communication Module RTU-EN01

Introduction

3 This operation manual only provides introductory information on electrical specification, installation and wiring.

3 RTU-EN01 is an OPEN-TYPE device and therefore should be installed in an enclosure free of airborne dust, humidity,

electric shock and vibration. The enclosure should prevent non-maintenance staff from operating the device (e.g. key

or specific tools are required to open the enclosure) in case danger and damage on the device may occur. DO NOT

touch any terminal when the power is switched on.

3 Please read this manual carefully and follow the instructions to avoid damage on the product or harm on staff.

Table of Content

1 INTRODUCTION....................................................................................................................3

1.1 Features ......................................................................................................................................3

1.2 Specifications ..............................................................................................................................3

2 PRODUCT PROFILE & OUTLINE.........................................................................................4

2.1 Dimension ...................................................................................................................................4

2.2 Product Profile.............................................................................................................................5

2.3 LED Indicators.............................................................................................................................5

2.4 RUN/STOP Switch ......................................................................................................................6

2.5 RJ-45 PIN Definition....................................................................................................................6

2.6 RS-232 PIN Definition .................................................................................................................6

2.7 RS-485 PIN Definition .................................................................................................................6

3 INSTALLATION & WIRING....................................................................................................6

3.1 Connecting RTU-EN01 to DVP Slim Series Digital Input/Output Module....................................6

3.2 Installing RTU-EN01 and DVP Slim Series Digital Input/Output Module onto DIN Rail ..............7

3.3 How to Connect RTU-EN01 to Network ......................................................................................7

4 WORD DEVICES & BIT DEVICES IN RTU-EN01 .................................................................8

4.1 Basic Registers (BR)...................................................................................................................8

4.2 Explanations on BR.....................................................................................................................9

4.3 External Input Contacts (RX).....................................................................................................12

4.4 External Output Contacts (RY)..................................................................................................12

4.5 Control Register for Extension Modules (RCR).........................................................................12

4.6 Word Devices & Bit Devices for Timers (T) ...............................................................................13

4.7 Word Devices & Bit Devices for Counters (C)...........................................................................14

4.8 Bit Devices for Real-Time Clock (R)..........................................................................................14

5 MODBUS COMMUNICATION .............................................................................................15

5.1 Function Codes Supported .......................................................................................................15

5.2 Exception Codes Supported .....................................................................................................15

5.3 Device Type & Device Address .................................................................................................16

DVP-PLC Operation Manual

1

Page 4

Modbus TCP Remote I/O Communication Module RTU-EN01

6 SETTING UP SOFTWARE................................................................................................... 16

6.1 Setting up Communications & Searching for Communication Modules in DCISoft .................. 16

6.2 Recording IP Address ............................................................................................................... 18

6.3 Basic Settings........................................................................................................................... 19

6.4 Network Settings ...................................................................................................................... 21

6.5 Setting up Time Server............................................................................................................. 22

6.6 IP Filter ..................................................................................................................................... 23

6.7 Smart PLC Setting: IF-THEN.................................................................................................... 24

6.8 Smart PLC Setting: Timer......................................................................................................... 25

6.9 Smart PLC Setting – Counter ................................................................................................... 25

6.10 Smart PLC Setting – RTC.........................................................................................................26

6.11 Analog Input/Output Modules ................................................................................................... 27

6.12 I/O Monitoring Table.................................................................................................................. 29

6.13 Setting up Gateway .................................................................................................................. 30

6.14 Virtual COM ............................................................................................................................. 33

6.15 Security Setting ........................................................................................................................ 35

6.16 Returning to Default Settings.................................................................................................... 36

6.17 Web Function............................................................................................................................ 36

7 APPLICATION EXAMPLES – DCISOFT............................................................................. 42

7.15 Smart PLC: IF-THEN................................................................................................................ 42

7.16 Smart PLC: Timer..................................................................................................................... 43

7.17 Smart PLC: Counter ................................................................................................................. 44

7.18 Smart PLC: RTC....................................................................................................................... 45

7.19 Virtual COM .............................................................................................................................. 46

Microsoft® and Windows Internet Explorer® are the registered trade mark or trade mark of Microsoft

Corporation in the United States and other countries.

Java® is the registered trade mark or trade mark of Sun Microsystems, Inc. in the United States or other

countries.

The companies and products mentioned in this operation manual can be the trade mark possesd by the

owner of that trade mark right.

2

DVP-PLC Operation Manual

Page 5

Modbus TCP Remote I/O Communication Module RTU-EN01

1 Introduction

To ensure correct installation and operation of RTU-EN01, please read this manual carefully before using your

RTU-EN01. RTU-EN01is an Ethernet remote I/O module for remote setting through Delta’s DCISoft. RTU-EN01

supports maximum 256 digital input/output points. RTU-EN01 supports Modbus TCP protocol and can be used

for remote monitoring with graphic control software or human machine interface. RTU-EN01 can also be used as

a Modbus TCP gateway, supporting the conversion from Modbus TCP commands to Modbus ASCII/RTU. In

addition, in MDI/MDI-X auto-detect, jump wire is not needed when you choose the network cable.

1.1 Features

z Supporting smart PLC functions, counter, timer and real-time clock. Able to operate independently without

control of PLC main processing unit or programming.

z Able to auto-detect 10/100 Mbps transmission speed; MDI/MDI-X auto-detect.

z Supporting maximum 16 digital input/output modules (Max. 256 I/O points) and 8 analog input/output

modules.

z Supporting maximum 16 sets of Modbus TCP connections.

z Supporting Modbus TCP/Modbus gateway (supporting Master mode, connectable to maximum 32 devices).

z Parameters can be set up on webpage.

1.2 Specifications

Ethernet interface

Interface RJ-45 with Auto MDI/MDIX

Transmission method 802.3, 802.3u

Transmission cable Category 5e, 100m (Max)

Transmission speed 10/100 Mbps Auto-Detection

Communication protocol ICMP, IP, TCP, UDP, DHCP, NTP, Modbus TCP, HTTP

Serial communication interface (COM1)

Interface Mini Dim

Transmission method RS-232

Communication speed 19,200 bps

Communication format Stop bit: 1; Parity bit: None; Data bit: 8

Communication protocol Delta Configuration

Transmission cable DVPACAB215 / DVPACAB230 / DVPACAB2A30

Serial communication interface (COM2)

Interface 3 PIN feed-through terminal

Transmission method RS-485

Transmission distance 1,200m

Communication speed

Communication format Stop bit: 1, 2; Parity bit: None, Odd, Even; Data bit: 7, 8

Communication protocol

110, 150, 300, 600, 1,200, 2,400, 4,800, 9,600, 19,200, 38,400, 57,600, 115,200

bps

Modbus ASCII、Modbus RTU

DVP-PLC Operation Manual

3

Page 6

Modbus TCP Remote I/O Communication Module RTU-EN01

Environment

ESD (IEC 61131-2, IEC 61000-4-2): 8KV Air Discharge

EFT (IEC 61131-2, IEC 61000-4-4): Power Line:±2KV, Digital Input: ±2KV,

Communication I/O: ±2KV

RS (IEC 61131-2, IEC 61000-4-3): 80MHz ~ 100MHz, 10V/m. 1.4GHz ~ 2.0GHz,

Noise immunity

Operation 0ºC ~ 55ºC (temperature), 50 ~ 95% (humidity), pollution degree 2

Storage -25ºC ~ 70ºC (temperature), 5 ~ 95% (humidity)

Shock/vibration

immunity

10V/m

Conducted Susceptibility Test (EN61000-4-6, IEC61131-2 9.10): 150kHz ~ 80MHz,

3V/m

Surge Test (Biwave IEC61132-2, IEC61000-4-5): Power line 0.5KV DM, Ethernet

0.5KV CM, RS-485 0.5KV CM

International standards: IEC61131-2, IEC 68-2-6 (TEST Fc)/IEC61131-2 & IEC

68-2-27 (TEST Ea)

Certificates

Electrical specification

Power supply voltage 24VDC (-15% ~ 20%) (with DC input polarity reverse protection)

Power fuse capacity 1.85A/30VDC, Polyswitch

Power consumption 2W

Insulation voltage 500VDC

Weight 116g

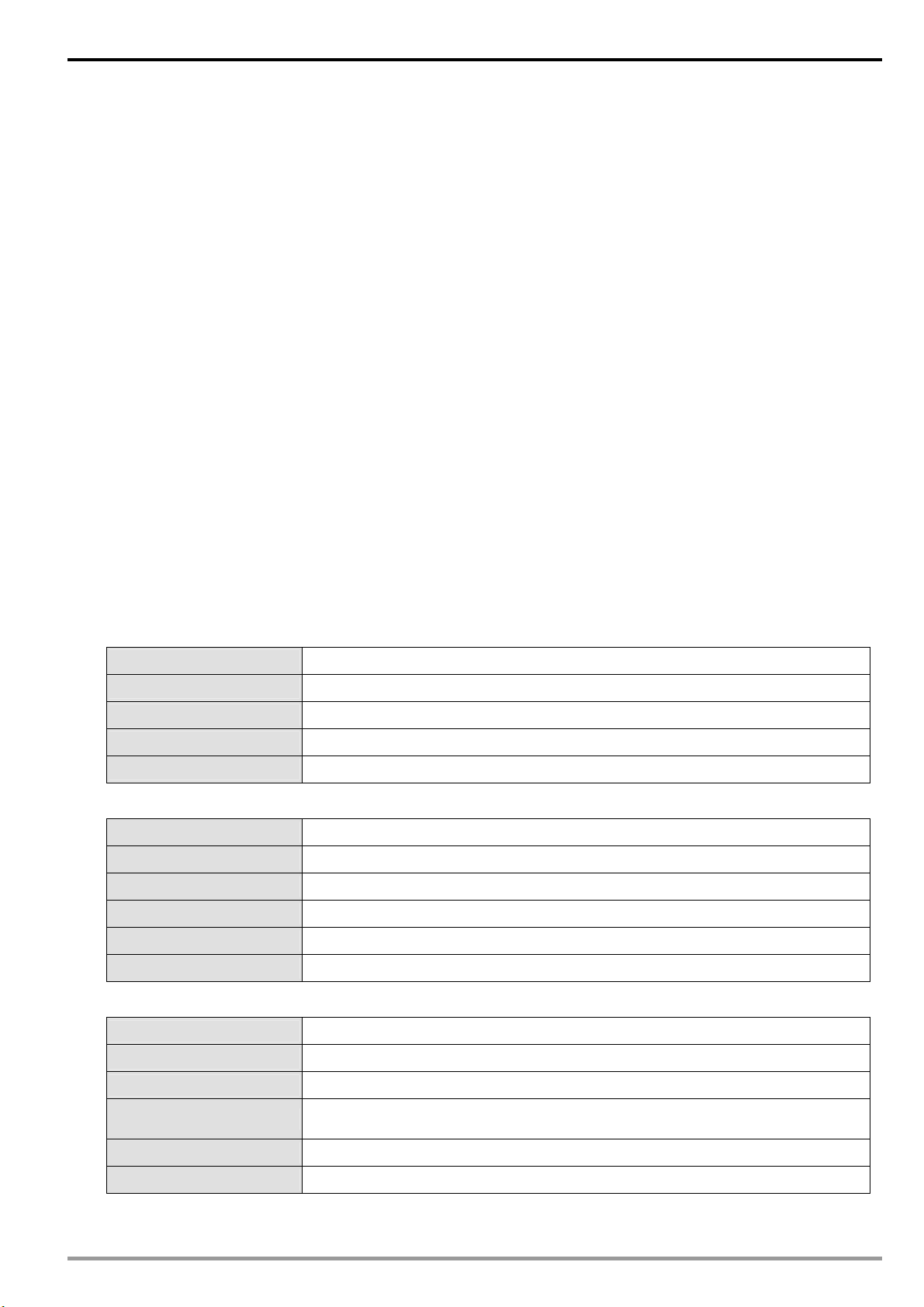

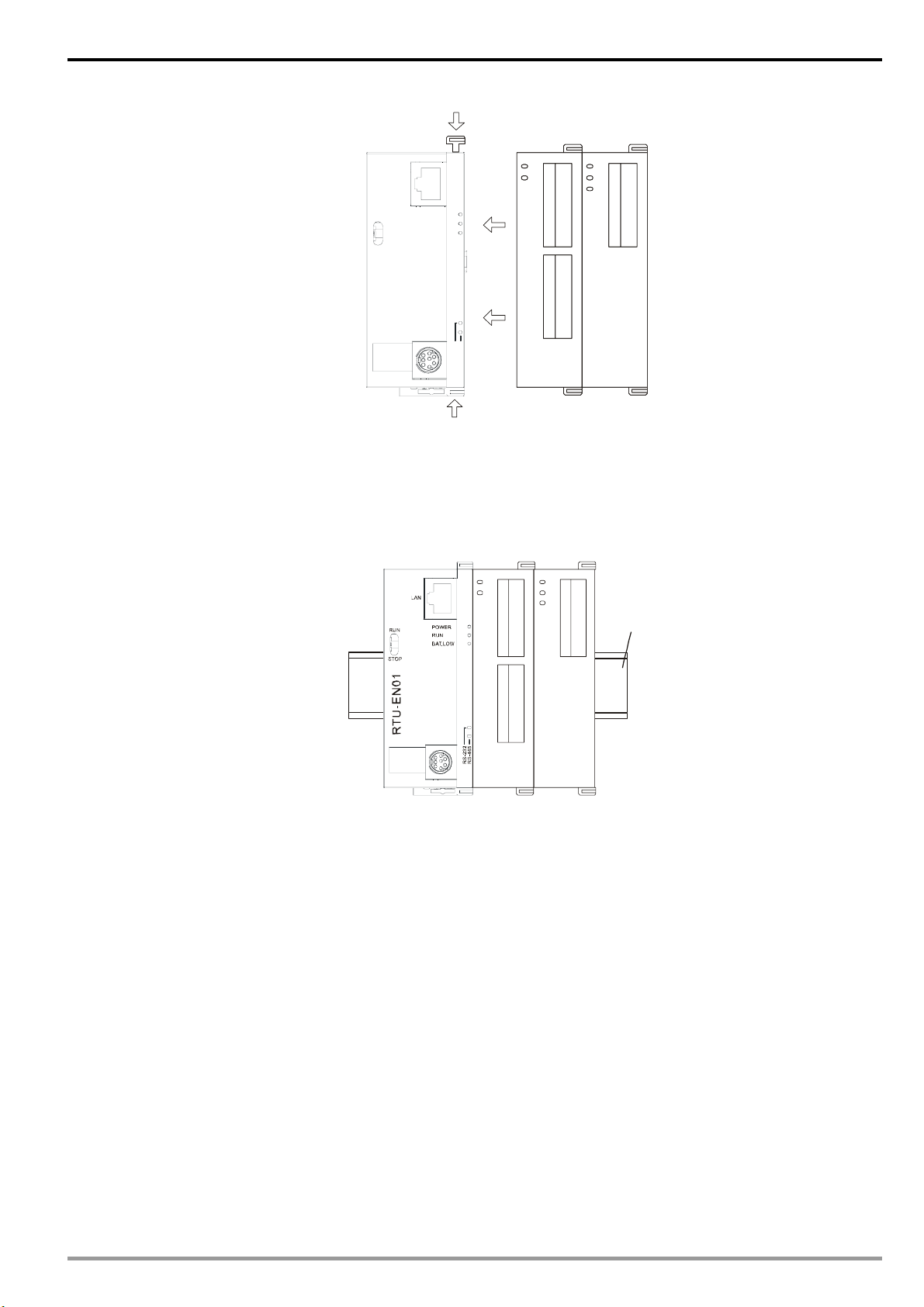

2 Product Profile & Outline

2.1 Dimension

37.4

LAN

RUN

STOP

POWER

BAT.LOW

RUN

60

4

RTU-EN01

RS-485

RS-232

Unit: mm

DVP-PLC Operation Manual

Page 7

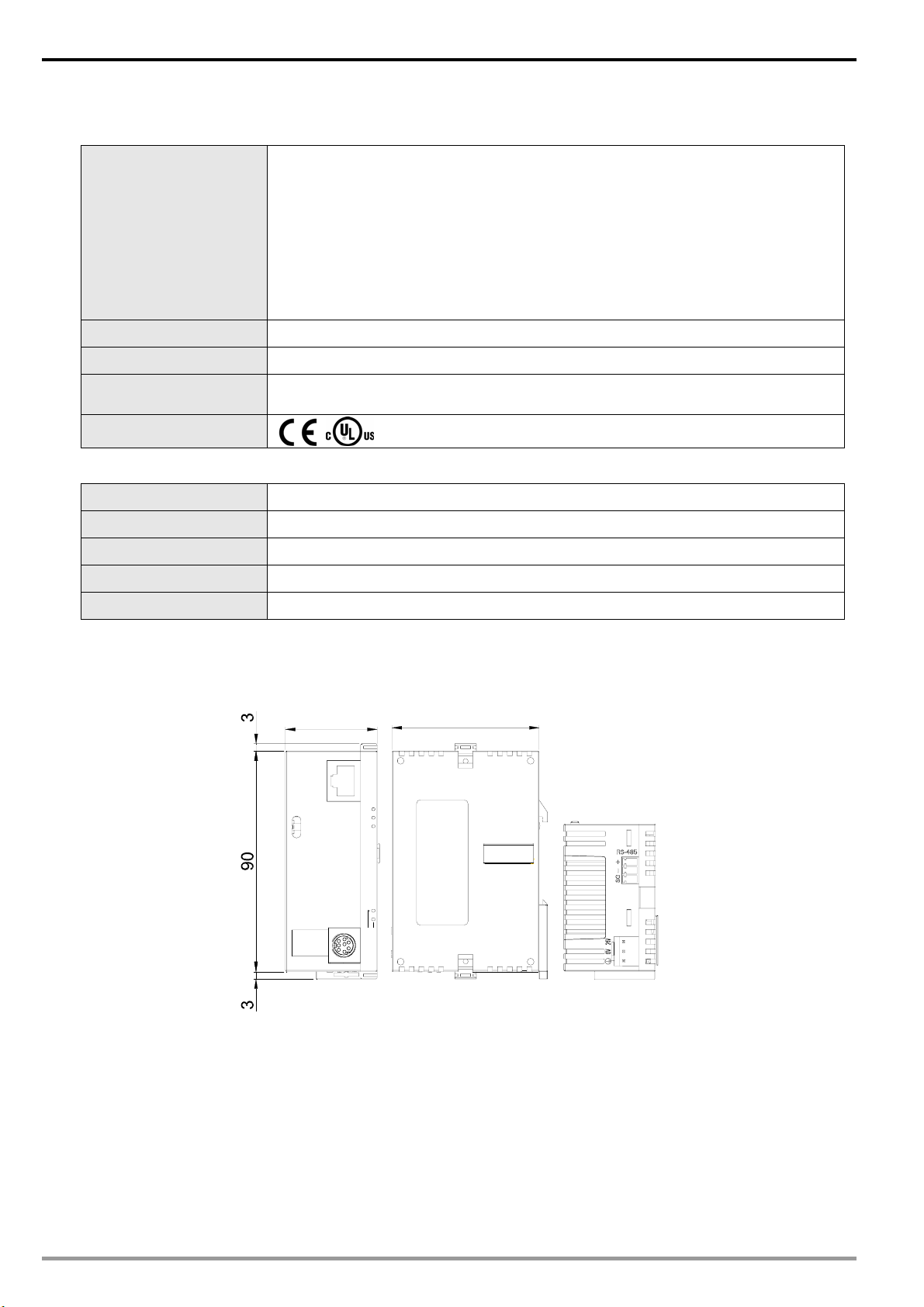

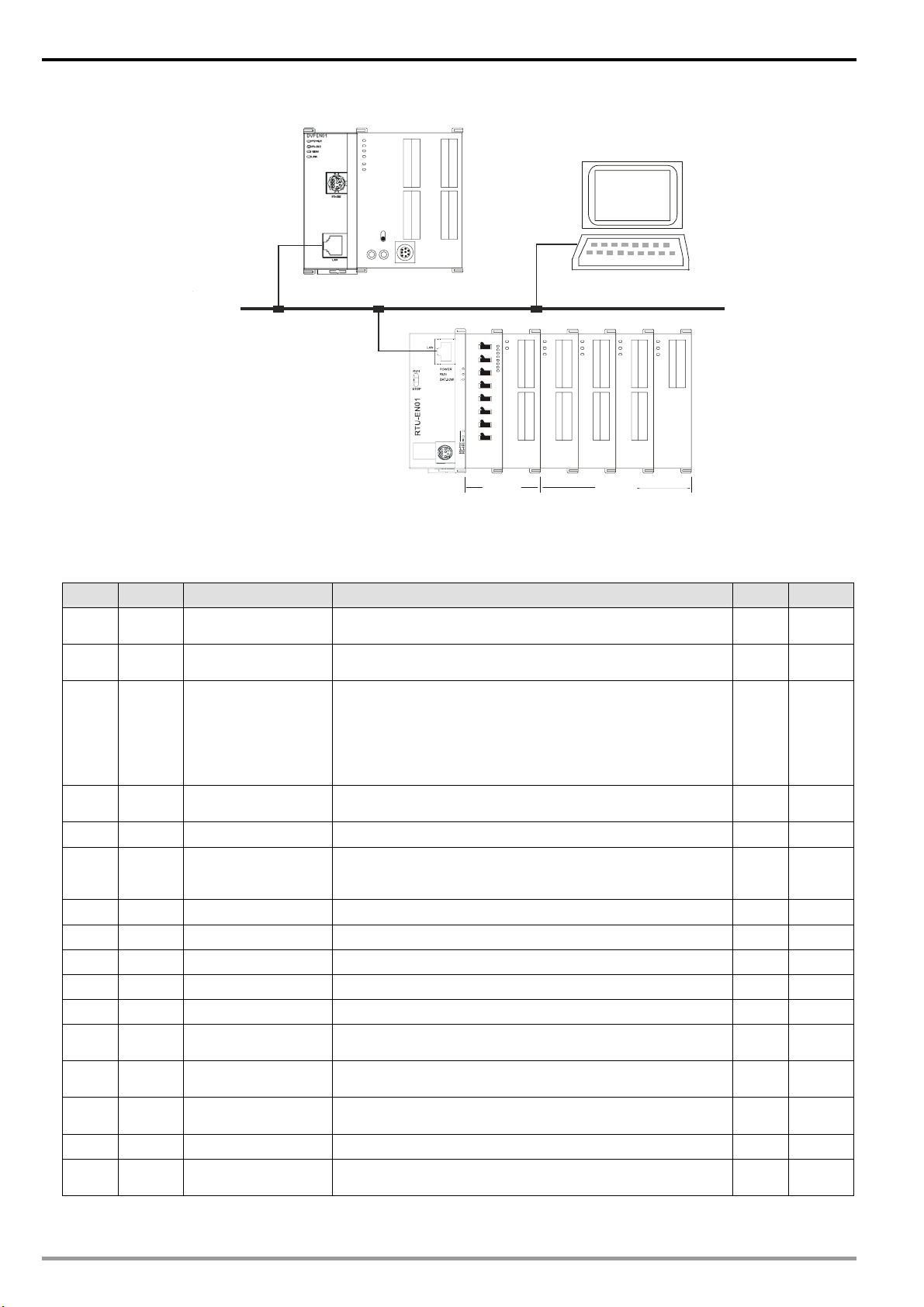

2.2 Product Profile

1. POWER indicator 12. RS-485 communication port

2. RUN indicator 13. Extension module positioning hole

3. BAT.LOW indicator 14. Nameplate

4. RUN/STOP switch 15. Extension port

5. RS-232 indicator 16. DIN rail (35mm)

6. RS-485 indicator 17. Extension module fixing clip

7. LINK/ACK indicator 18. DIN rail clip

8. SPEED indicator 19. Power supply port

9. Digital display 20. 3P terminal block (standard accessory)

10. Ethernet communication port

11. RS-232 communication port

Modbus TCP Remote I/O Communication Module RTU-EN01

21. Power supply connection cable (standard

accessory)

2.3 LED Indicators

LED Color Function

POWER Green Power supply indication

RUN Green RUN/STOP indication

BAT.LOW Red Battery in low power indication

RS-232 Yellow Displaying communication status of RS-232 port

RS-485 Yellow Displaying communication status of RS-485 port

LINK/ACT Green Displaying the status of network

SPEED Yellow Displaying the speed of network connection

DVP-PLC Operation Manual

5

Page 8

Modbus TCP Remote I/O Communication Module RTU-EN01

2.4 RUN/STOP Switch

Status Explanation

1. RUN indicator on RTU-EN01 is ON.

RUN

STOP

RUN Æ STOP

STOP

RUN

2. Analog input/output module is in RUN status.

3. Smart PLC function is running.

1. Analog input/output module switches from RUN to STOP status.

2. Y points on digital input/output module are all OFF.

1. RUN indicator on RTU-EN01 is OFF.

2. Analog input/output module is in STOP status.

3. Smart PLC function stops.

STOP Æ RUN

1. RTU-EN01 re-detects the information on the right-side module.

2. Analog input/output module switches from STOP to RUN status.

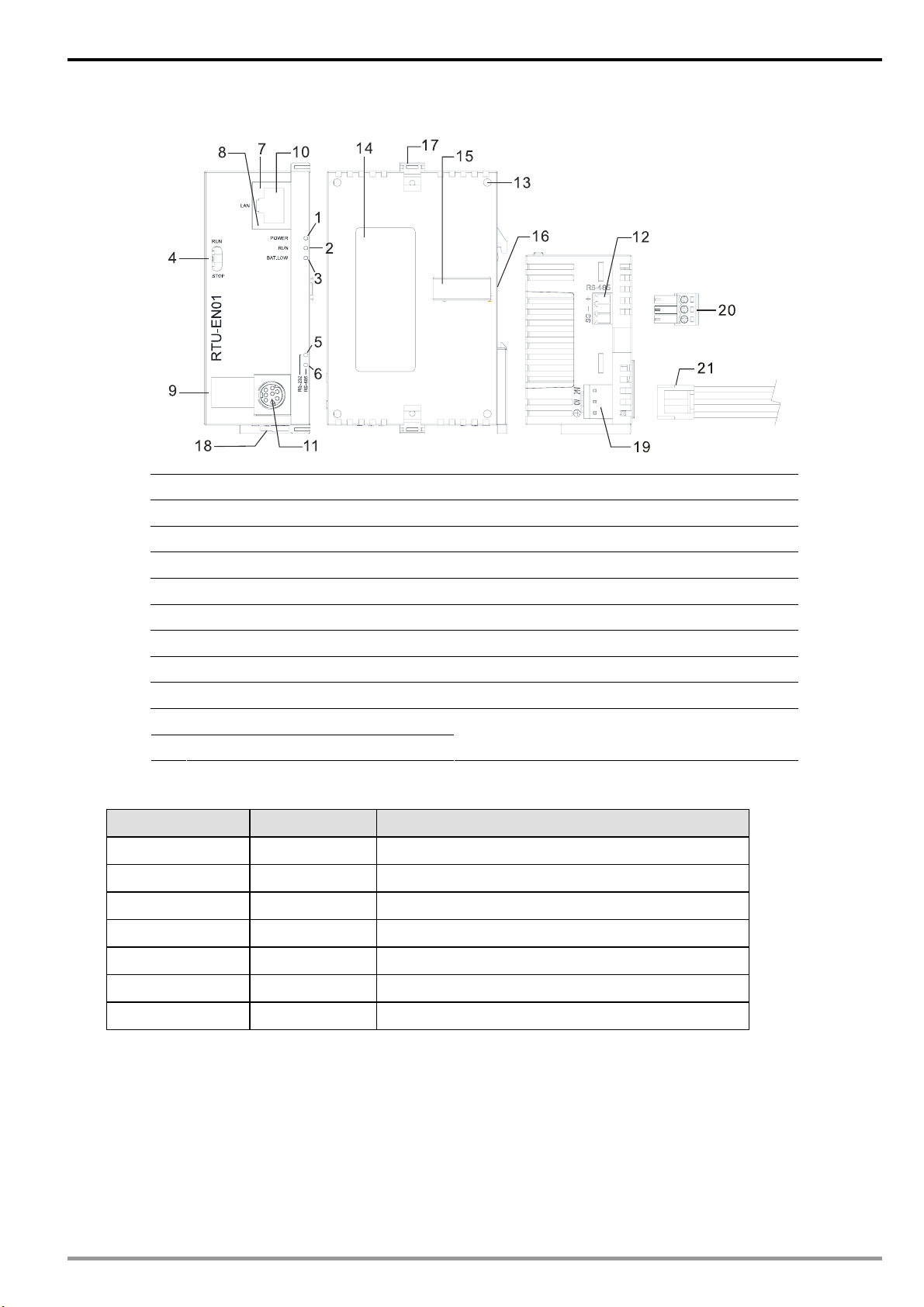

2.5 RJ-45 PIN Definition

PIN Signal Definition PIN Signal Definition

1 Tx+

2 Tx-

3 Rx+

4 -- N/C 8 -- N/C

Positive pole for data

transmission

Negative pole for data

transmission

Positive pole for data

receiving

5 -- N/C

6 Rx-

7 -- N/C

Negative pole for data

2.6 RS-232 PIN Definition

PIN Signal Definition PIN Signal Definition

1 -- N/C 5 Tx Transmission data

2 -- N/C 6 -- N/C

3 -- N/C 7 -- N/C

4 Rx Reception data 8 GND Ground

receiving

2.7 RS-485 PIN Definition

PIN Signal Definition

1 SG Ground of data

2 D- Negative pole for data

3 D+ Positive pole for data

3

2

1

3 Installation & Wiring

In this section, we will introduce how to connect RTU-EN01 to other devices and the network.

3.1 Connecting RTU-EN01 to DVP Slim Series Digital Input/Output Module

z Open the fixing clips on the right top and bottom sides on RTU-EN01. Meet the extension port on RTU-EN01

and the digital input/output module.

z Press and fix the clips on the digital input/output module. Make sure the contact between the modules is fine.

6

DVP-PLC Operation Manual

Page 9

Modbus TCP Remote I/O Communication Module RTU-EN01

LAN

RUN

STOP

POWER

RUN

BAT.LOW

A

P

1

0

N

E

U

T

R

2

5

3

8

2

4

-

-

S

S

R

R

P

S

S

6

6

1

1

-

P

P

V

V

D

D

A

D

D

2

2

0

0

-

P

P

V

V

D

D

3.2 Installing RTU-EN01 and DVP Slim Series Digital Input/Output Module onto DIN Rail

z Use standard 35mm DIN rail.

z Open the DIN rail clips on RTU-EN01 and the digital input/output module and insert the modules onto the rail.

z Press the clips to fix the modules onto the rail.

35mm DIN rail

P

S

6

1

P

V

D

A

D

2

0

P

V

D

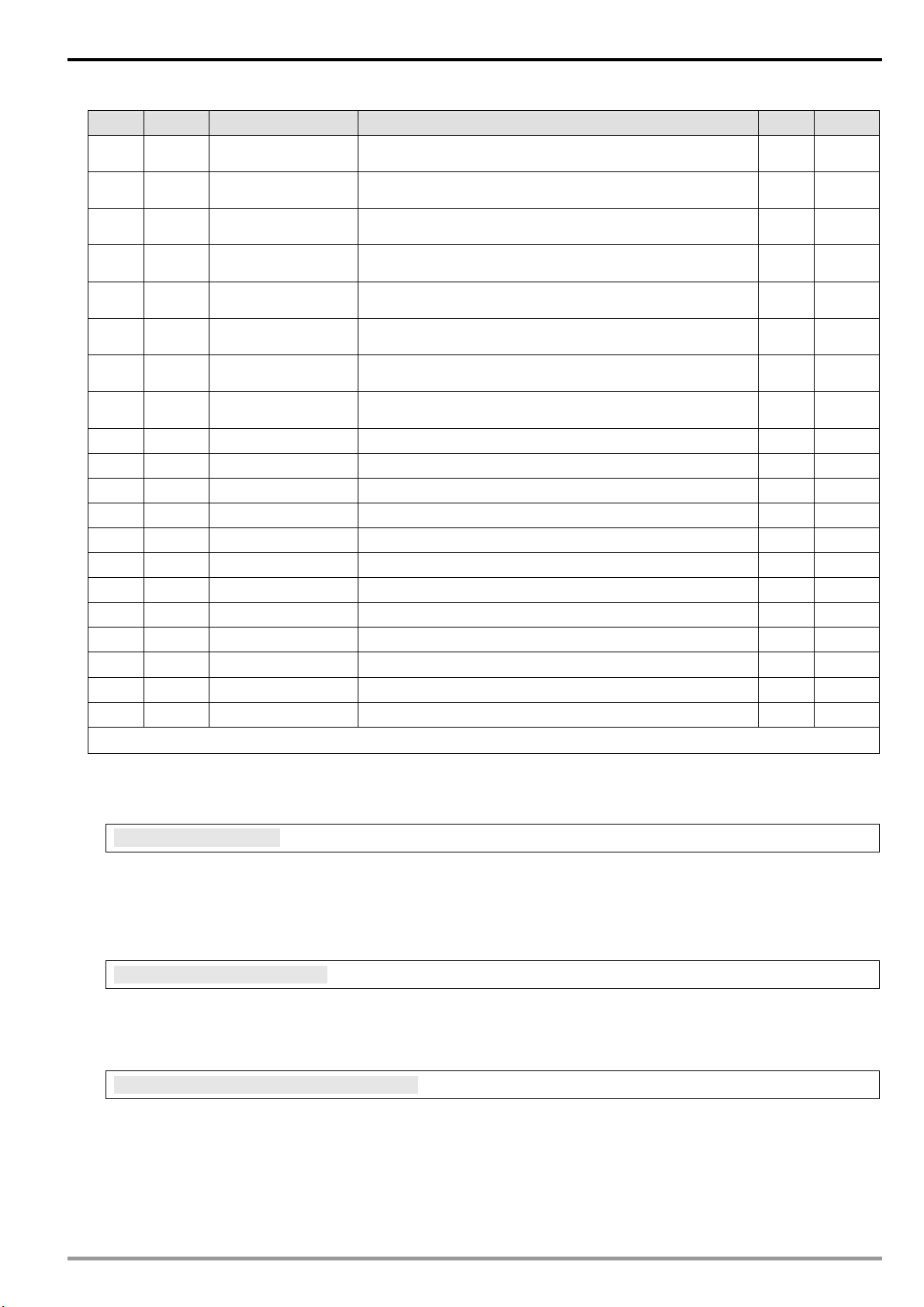

3.3 How to Connect RTU-EN01 to Network

Connect RTU-EN01 to the Ethernet hub by CAT-5e twisted pair. Since RTU-EN01 has Auto MDI/MDIX function,

CAT-5e twisted pair does not need to jump wire. See below for the connection between the PC and RTU-EN01

modules:

DVP-PLC Operation Manual

7

Page 10

Modbus TCP Remote I/O Communication Module RTU-EN01

O

O

DVPEN01-SL

DVP28SV

DVP28SV

RUN

STOP

Ethernet

RTU-EN01

4 Word Devices & Bit Devices in RTU-EN01

4.1 Basic Registers (BR)

COM2

T

S

8

0

P

V

D

DI/D

PC

P

D

C

S

6

1

P

V

D

T

A

4

4

0

0

-

P

P

V

V

D

D

AI/A

A

T

D

P

2

4

0

0

-

P

P

V

V

D

D

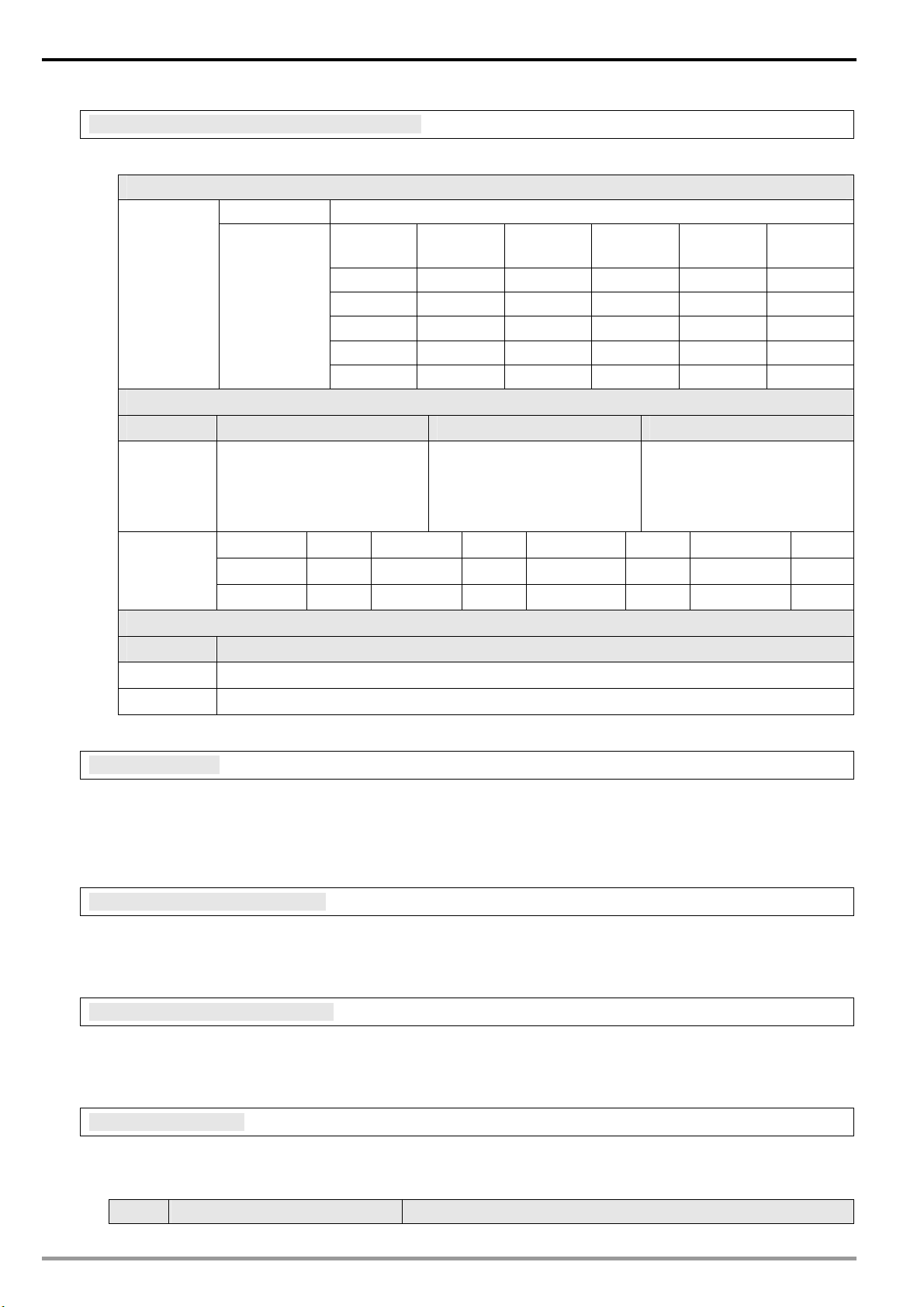

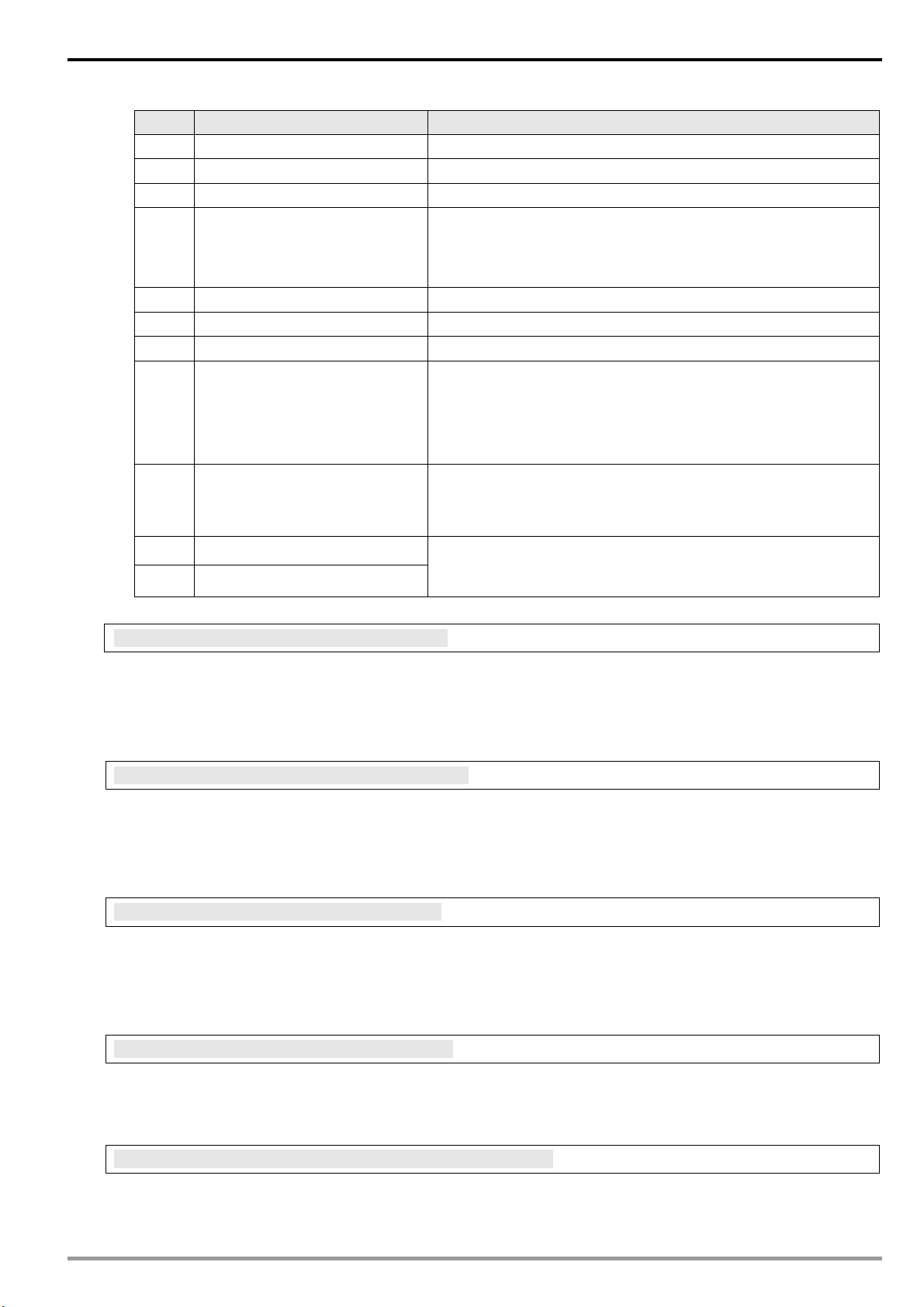

BR# Attribute Content Explanation Default Latched

0 R Model name

1 R Firmware version

Set up by the system; read only. The model code of

RTU-EN01= H’0600.

Displaying the current firmware verision in hex, e.g. V1.2 is

indicated as high byte = 0x01 and low byte = 0x20.

H’0600 YES

YES

Displaying the data in decimal form. 10,000s digit and 1,000s

digit are for “month”; 100s digit and 10s digit are for “day”. For

2 R

Release date of the

version

1s digit: 0 = morning; 1 = afternoon.

YES

Example: 12191 indicates the version released in the afternoon

of December 19.

3 R/W

Start/Stop PLC

function

NO

4 Reserved . NO

COM2

5 R/W

communication

settings

RS-485 communication settings. Please refer to the table of

baud rate setting and communication format setting.

H’0368 YES

6 R/W Address For setting up the station address K’1 YES

7 R Number of DI points Range: 0 ~ 256 NO

8 R Number of DO points Range: 0 ~ 256 NO

9 R Error code Displaying the errors. Please refer to the table of error codes. NO

10 Reserved NO

11 R /W

12 R/W

13 R/W

Communication

time-out

Communication delay

time

TCP connection idle

time

For setting up the communication time-out (ms) in Modbus

TCP mode.

For setting up the minimum interval time between every

communication datum.

K’5000 YES

K’0 YES

For setting up idle time for TCP communication. Unit: second K’30 YES

14 ~ 22 Reserved NO

23 R

Number of analog I/O

modules

Max. 8 NO

8

DVP-PLC Operation Manual

Page 11

Modbus TCP Remote I/O Communication Module RTU-EN01

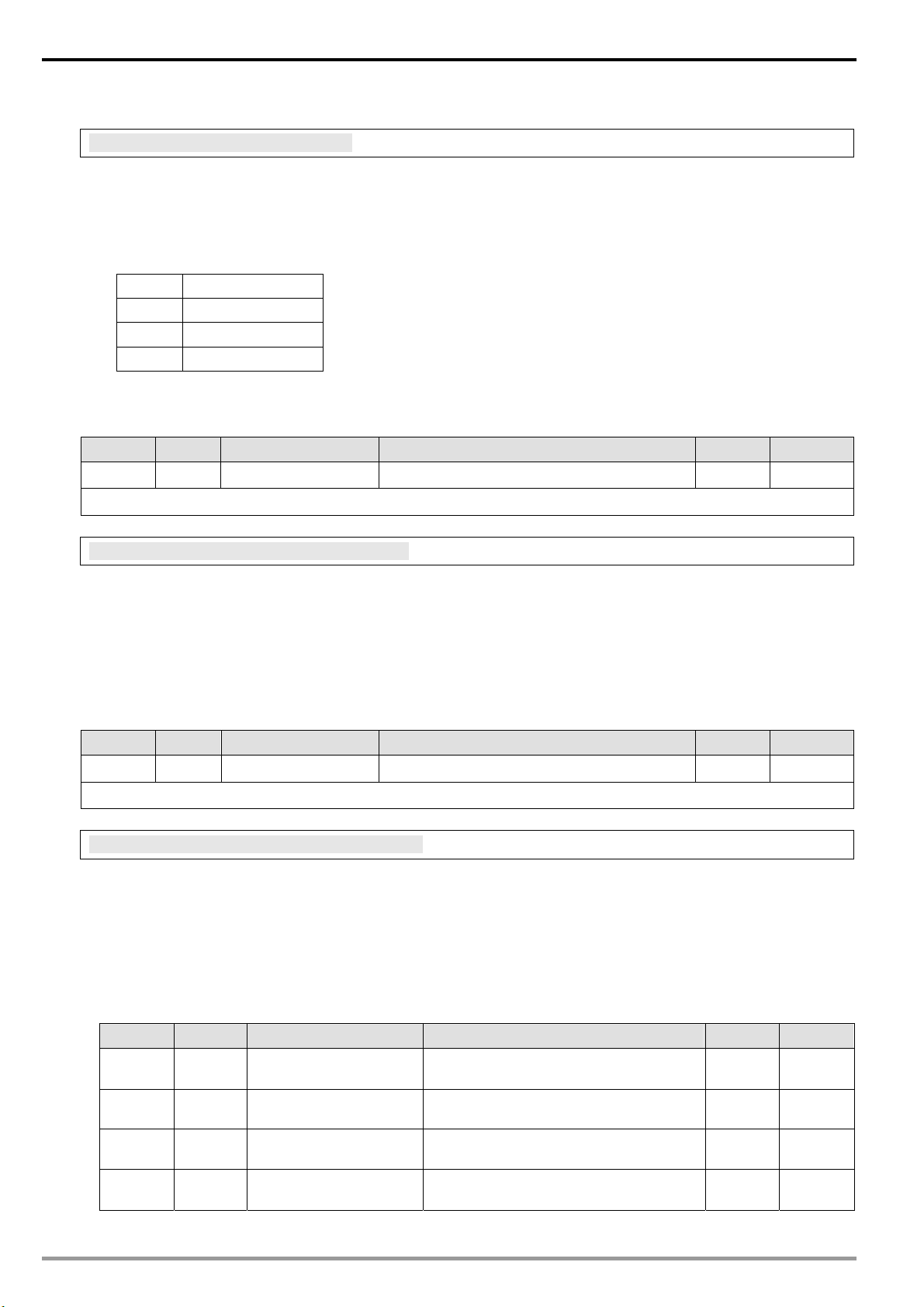

BR# Attribute Content Explanation Default Latched

24 R

25 R

26 R

27 R

28 R

29 R

30 R

31 R

32 ~ 49 Reserved NO

50 R/W RTC settings Settings of the real-time clock NO

51 R/W Year Range: 1970 ~ 2099 YES

52 R/W Week Range: 1 ~ 7 YES

53 R/W Month Range: 1 ~ 12 YES

54 R/W Day Range: 1 ~ 31 YES

55 R/W Hour Range: 0 ~ 23 YES

56 R/W Minute Range: 0 ~ 59 YES

57 R/W Second Range: 0 ~ 59 YES

58 ~ 59 Reserved NO

60 Reserved NO

61 ~ 63 Reserved 0 NO

Symbol “R” refers to ready only; “R/W” refers to read and write.

ID of the 1st analog

I/O module

ID of the 2nd analog

I/O module

ID of the 3rd analog

I/O module

ID of the 4th analog

I/O module

ID of the 5th analog

I/O module

ID of the 6th analog

I/O module

ID of the 7th analog

I/O module

ID of the 8th analog

I/O module

ID of the 1st analog I/O module NO

ID of the 2nd analog I/O module NO

ID of the 3rd analog I/O module NO

ID of the 4th analog I/O module NO

ID of the 5th analog I/O module NO

ID of the 6th analog I/O module NO

ID of the 7th analog I/O module NO

ID of the 8th analog I/O module NO

4.2 Explanations on BR

BR#0: Model Name

Explanations:

1. Model code of RTU-EN01 = H’0600.

2. You can read the model code in the program to see if the extension module exists.

BR#1: Firmware Version

Explanations:

The firmware version of RTU-EN01 is displayed in hex, e.g. H’0100 indicates version V1.00

BR#2: Release Date of the Version

Explanations:

Displaying the data in decimal form. 10,000s digit and 1,000s digit are for “month”; 100s digit and 10s digit are for

“day”. For 1s digit: 0 = morning; 1 = afternoon.

Example: 12191 indicates the version released in the afternoon of December 19.

DVP-PLC Operation Manual

9

Page 12

Modbus TCP Remote I/O Communication Module RTU-EN01

BR#5: COM2 Communication Settings

Explanations:

b0 ~ b3

Interface Explanation

Content

b7 b6 ~ b5 b4

Explanation

Content

Content Explanation

0x02 Modbus RTU Master

0x03 Modbus ASCII Master

BR#6: Address

Baud rate

(bps)

Data

COM2

RS-485

Data

0x1 110 0x6 2,400 0xB 57,600

0x2 150 0x7 4,800 0xC 115,200

0x3 300 0x8 9,600

0x4 600 0x9 19,200

0x5 1,200 0xA 38,400

b4 ~ b7

Stop bit

0: 1 Stop bit

1: 2 Stop bits

Parity bit

00 : None parity bit

01 : Odd parity bit

11 : Even parity bit

0000 (0) 7-N-1 0011 (3) 8-O-1 1000 (8) 7-N-2 1011 (B) 8-O-2

0001 (1) 8-N-1 0110 (6) 7-E-1 1001 (9) 8-N-2 1110 (E) 7-E-2

0010 (2) 7-O-1 0111 (7) 8-E-1 1010 (A) 7-O-2 1111 (F) 8-E-2

b8 ~ b15

Baud rate

(bps)

Data bit

0 : 7 Data bits

1 : 8 Data bits

Data

Baud rate

(bps)

Explanations

For filling in or reading the Modbus address. The address will be displayed in the message display after being set

up. Range: 1 ~ 247.

BR#7: Number of DI Points

Explanations

Read the number of digital input points from BR#7. Range: 0 ~ 256. Max. I/O points: 256.

BR#8: Number of DO Points

Explanations

Read the number of digital output points from BR#8. Range: 0 ~ 256. Max. I/O points: 256.

BR#9: Error Code

Explanations:

Error code = 0 refers to no error occurring.

Code Indication How to correct

10

DVP-PLC Operation Manual

Page 13

Modbus TCP Remote I/O Communication Module RTU-EN01

Code Indication How to correct

F0 Returning to default setting --

F1 RTU-EN01 being powered --

F2 Power supply in low voltage Check if the power supply of the module works normally.

1. Check if the settings of smart PLC are incorrect.

F3 Internal error. Manufacturing error.

F5 Network connection error Check if RTU-EN01 is connected normally to the network.

F6 Insufficient TCP connection Check if the number of connected modules exceeds the maximum.

F7 RS-485 setting error Check if the RS-485 communication format is correct.

F8 IP setting error

F9 Right-side module error

04 Slave error

0b No response from station

2. Re-power RTU-EN01. If the error still exists, try step 3.

3. Reset RTU-EN01. If the error still exists, send the module back to

the manufacturer for repair.

1. DHCP request failure.

2. IP setting error.

3. MASK setting error.

4. Gateway does not exist in the same subnet.

5. Returning to default setting.

Check if the configuration of the right-side module has been modified. If

the error still exists, check if the number of I/O points exceeds the

maximum and whether the there are more than 8 analog I/O modules

connected.

1. Check if RTU-EN01 and RS-485 is connected normally.

2. Check if the series transmission speed is consistent with that of other

nodes on the network.

BR#11: Communication Time-out (ms)

Explanations:

For setting up the communication time-out. Default = 5,000ms. For example, if you wish to set up the

communication time-out to 7 seconds manually, write 7000 to BR#11. Range: 5 ~ 65,535.

BR#12: Communication Delay Time (ms)

Explanations:

For setting up the minimum interval time between every Modbus command. Default = 0ms. For example, if you

wish to set up the communication delay time to 100ms manually, write 100 into BR#12. Range: 0 ~ 65,535.

BR#13: TCP Connection Idle Time (s)

Explanations:

For setting up the TCP connection idle time. Default = 30 seconds. For example, if you wish to set up the idle time

to 7 seconds manually, write 7 into BR#13. Range: 5 ~ 65,535.

BR#23: Number of Analog I/O Modules

Explanations:

Read the number of right-side modules from BR#23. Max. 8.

BR#24 ~ #31: ID of the 1st ~ 8th Analog I/O Module

Explanations:

st

Read the ID of the 1

~ 8th analog I/O modules from BR#24 ~ BR#31.

DVP-PLC Operation Manual

11

Page 14

Modbus TCP Remote I/O Communication Module RTU-EN01

BR#50 ~ BR#57: RTC Settings

Explanations:

For setting up the real-time clock (RTC). When BR#9 = 1, RTU-EN01 will stop to update the RTC values to

BR#10 ~ #16. Once the setup is completed, RTU-EN01 will set BR#9 to 0.

Allowed range for RTC: 1970/01/01 00:00:00 ~ 2037/12/31 23:59:59

BR#9

0 No action

1 RTC stops

2 RTC being set

4.3 External Input Contacts (RX)

RX# Attribute Content Explanation Default Latched

0 ~ 255 R/W External input contact Input points on analog I/O module OFF NO

Symbol “R” refers to ready only; “R/W” refers to read and write.

RX#0 ~ #255: External Input Contact

Explanations:

The right-side extension interface on RTU-EN01 is able to connect to DVP-Slim series digital I/O modules.

RTU-EN01 supports maximum 256 I/O points.

4.4 External Output Contacts (RY)

RY# Attribute Content Explanation Default Latched

0 ~ 255 R/W External output contact Output points on analog I/O module OFF NO

Symbol “R” refers to ready only; “R/W” refers to read and write.

RY#0 ~ #255: External Output Contact

Explanations:

The right-side extension interface on RTU-EN01 is able to connect to DVP-Slim series digital I/O modules.

RTU-EN01 supports maximum 256 I/O points.

4.5 Control Register for Extension Modules (RCR)

RCR# Attribute Content Explanation Default Latched

st

analog I/O

0 ~ 49 R/W

50 ~ 99 R/W

100 ~ 149 R/W

150 ~ 199 R/W

12

The 1

module

nd

The 2

module

rd

The 3

module

th

The 4

module

analog I/O

analog I/O

analog I/O

Control register for the 1st analog I/O

module

Control register for the 2nd analog I/O

module

Control register for the 3rd analog I/O

module

Control register for the 4th analog I/O

module

-- NO

-- NO

-- NO

-- NO

DVP-PLC Operation Manual

Page 15

Modbus TCP Remote I/O Communication Module RTU-EN01

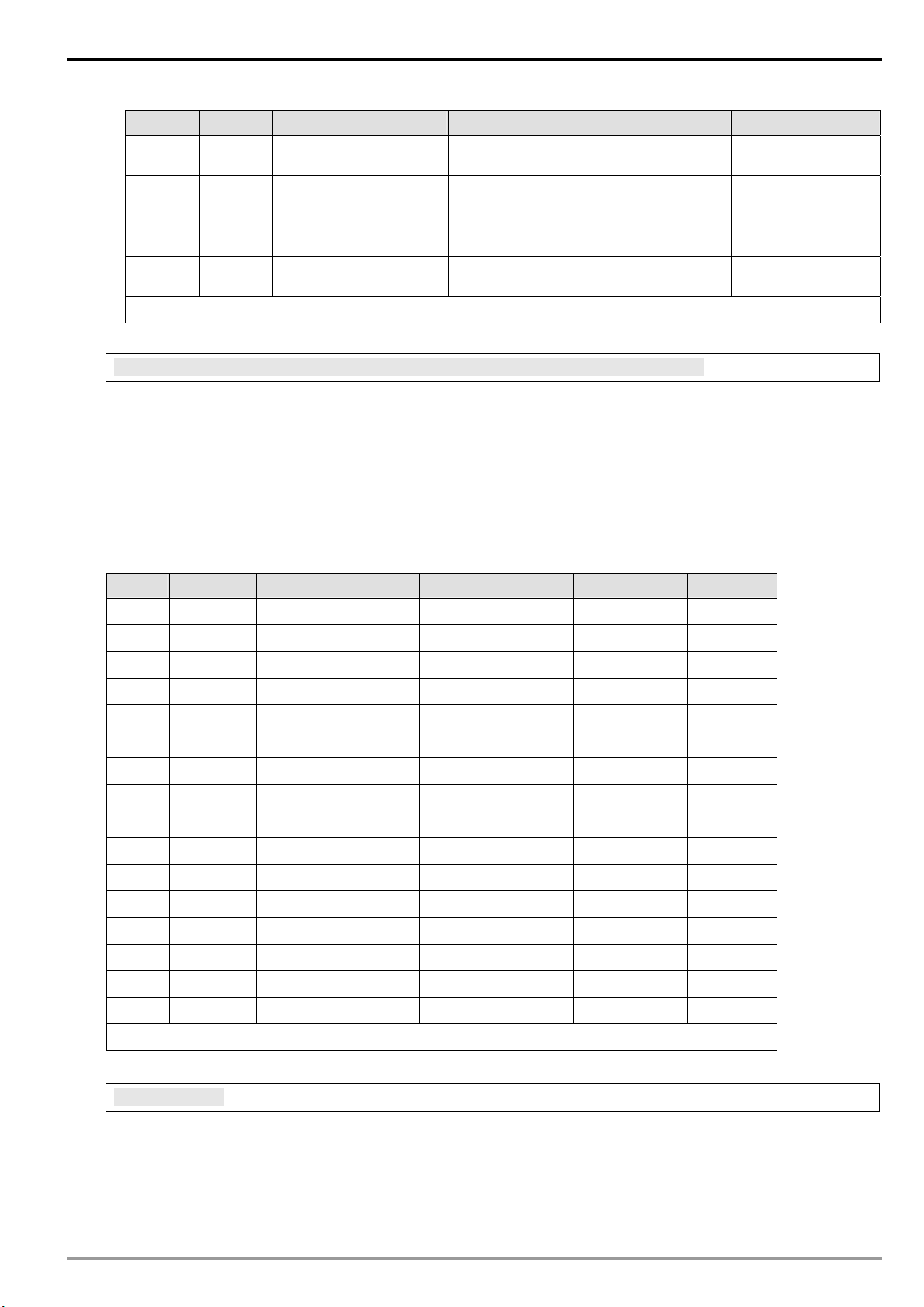

RCR# Attribute Content Explanation Default Latched

th

analog I/O

200 ~ 249 R/W

250 ~ 299 R/W

300 ~ 349 R/W

350 ~ 399 R/W

Symbol “R” refers to ready only; “R/W” refers to read and write.

The 5

module

th

The 6

module

th

The 7

module

th

The 8

module

analog I/O

analog I/O

analog I/O

RCR#0 ~ #399: Control Register for Right-Side Analog I/O Modules

Explanations:

By reading/writing RCR in RTU-EN01, you are able to store or retrieve the data in the control register (CR) inside

the analog input/output module.

Example: RCR#0 corresponds to CR#0 in the 1

analog I/O module. Extension module closest to RTU-EN01 is regarded the 1

Control register for the 5th analog I/O

module

Control register for the 6th analog I/O

module

Control register for the 7th analog I/O

module

Control register for the 8th analog I/O

module

st

analog I/O module. RCR#260 corresponds to CR#10 in the 6th

st

module.

-- NO

-- NO

-- NO

-- NO

4.6 Word Devices & Bit Devices for Timers (T)

T# Attribute Register/coil name Explanation Default Latched

0 R/W Timer 0 Timer 0/OFF NO

1 R/W Timer 1 Timer 0/OFF NO

2 R/W Timer 2 Timer 0/OFF NO

3 R/W Timer 3 Timer 0/OFF NO

4 R/W Timer 4 Timer 0/OFF NO

5 R/W Timer 5 Timer 0/OFF NO

6 R/W Timer 6 Timer 0/OFF NO

7 R/W Timer 7 Timer 0/OFF NO

8 R/W Timer 8 Timer 0/OFF NO

9 R/W Timer 9 Timer 0/OFF NO

10 R/W Timer 10 Timer 0/OFF NO

11 R/W Timer 11 Timer 0/OFF NO

12 R/W Timer 12 Timer 0/OFF NO

13 R/W Timer 13 Timer 0/OFF NO

14 R/W Timer 14 Timer 0/OFF NO

15 R/W Timer 15 Timer 0/OFF NO

Symbol “R” refers to ready only; “R/W” refers to read and write.

T#0: Timer 0

Explanations:

When the timer is enabled, it will start to time according to the settings. When the timing reaches the target, the

bit device T0 will be ON. When the bit device is reset, the word device will be reset to 0 as well.

DVP-PLC Operation Manual

13

Page 16

Modbus TCP Remote I/O Communication Module RTU-EN01

T#1 ~ #15: Timer 1 ~ 15

Explanations:

Please refer to T#0.

4.7 Word Devices & Bit Devices for Counters (C)

C# Attribute Register/coil name Explanation Default Latched

0 R/W Counter 0 Counting up/down counter 0/OFF NO

1 R/W Counter 1 Counting up/down counter 0/OFF NO

2 R/W Counter 2 Counting up/down counter 0/OFF NO

3 R/W Counter 3 Counting up/down counter 0/OFF NO

4 R/W Counter 4 Counting up/down counter 0/OFF NO

5 R/W Counter 5 Counting up/down counter 0/OFF NO

6 R/W Counter 6 Counting up/down counter 0/OFF NO

7 R/W Counter 7 Counting up/down counter 0/OFF NO

8 R/W Counter 8 Counting up/down counter 0/OFF NO

9 R/W Counter 9 Counting up/down counter 0/OFF NO

10 R/W Counter 10 Counting up/down counter 0/OFF NO

11 R/W Counter 11 Counting up/down counter 0/OFF NO

12 R/W Counter 12 Counting up/down counter 0/OFF NO

13 R/W Counter 13 Counting up/down counter 0/OFF NO

14 R/W Counter 14 Counting up/down counter 0/OFF NO

15 R/W Counter 15 Counting up/down counter 0/OFF NO

Symbol “R” refers to ready only; “R/W” refers to read and write.

C#0: Counter 0

Explanations:

When the counter is enabled and RX turns from OFF to ON, counting up or counting down will be set

according to the settings. When the counting reaches the target, the counting will stop, and the bit device C0

will be set to ON. When the bit device is reset, the word device will be reset to 0 as well.

C#1 ~ #15: Counter 1 ~ 15

Explanations:

Please refer to C#0.

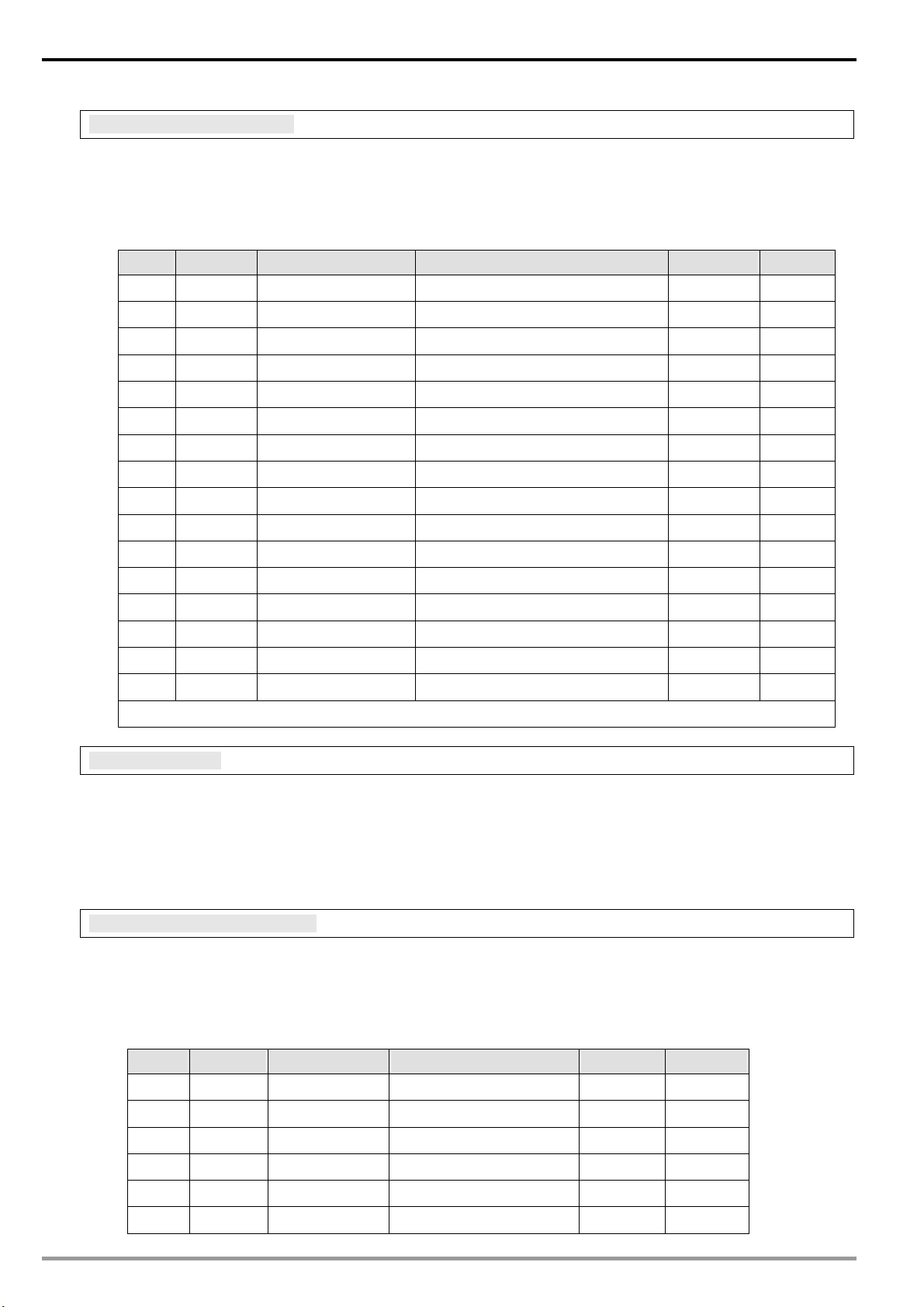

4.8 Bit Devices for Real-Time Clock (R)

R# Attribute Content Explanation Default Latched

0 R/W RTC 0 Real-time clock OFF NO

1 R/W RTC 1 Real-time clock OFF NO

2 R/W RTC 2 Real-time clock OFF NO

3 R/W RTC 3 Real-time clock OFF NO

4 R/W RTC 4 Real-time clock OFF NO

5 R/W RTC 5 Real-time clock OFF NO

14

DVP-PLC Operation Manual

Page 17

R#0: RTC 0

Modbus TCP Remote I/O Communication Module RTU-EN01

R# Attribute Content Explanation Default Latched

6 R/W RTC 6 Real-time clock OFF NO

7 R/W RTC 7 Real-time clock OFF NO

8 R/W RTC 8 Real-time clock OFF NO

9 R/W RTC 9 Real-time clock OFF NO

10 R/W RTC 10 Real-time clock OFF NO

11 R/W RTC 11 Real-time clock OFF NO

12 R/W RTC 12 Real-time clock OFF NO

13 R/W RTC 13 Real-time clock OFF NO

14 R/W RTC 14 Real-time clock OFF NO

15 R/W RTC 15 Real-time clock OFF NO

Symbol “R” refers to ready only; “R/W” refers to read and write.

Explanations:

When the RTC function is enabled, and the assigned trigger condition is true, RTU-EN01 will set the bit device R0

to ON and continue to output or stop according to the set time.

R#1 ~ #15: RTC 1 ~ 15

Explanations:

Please refer to R#0.

5 Modbus Communication

5.1 Function Codes Supported

Function code Explanation Devices supported

0x02 Read digital input point RX, RY, T, R, C

0x03 Read register BR, T, C, RCR

0x05 Write single bit device RY, T, R, C

0x06 Write single register BR, T, C, RCR

0x0F Write multiple bit devices RY, T, R, C

0x10 Write multiple registers BR, T, C, RCR

0x17 Read/write multiple registers BR, T, C, RCR

5.2 Exception Codes Supported

Exception code Explanation

0x01 Illegal function

0x02 Illegal data address

0x03 Illegal data value

0x04 Slave device failure

0x0b Gateway target device failed to respond.

DVP-PLC Operation Manual

15

Page 18

Modbus TCP Remote I/O Communication Module RTU-EN01

5.3 Device Type & Device Address

Discrete input

Device type Modbus address (Hex) 6-digit Modbus address (Dec) Number

RX 0x0400 ~ 0x04FF 101025 ~ 101280 256

Coil

RY 0x0500 ~ 0x05FF 001281 ~ 001537 256

T 0x1600 ~ 0x160F 005633 ~ 005649 16

R 0x1900 ~ 0x190F 006401 ~ 006416 16

C 0x1E00 ~ 0x1E0F 007681 ~ 007696 16

Holding register

Device type Modbus address (Hex) 6-digit Modbus address (Dec) Number

BR 0x0000~0x0040 400001~400064 64

T 0x1600~0x160F 405633~405649 16

C 0x1E00~0x1E0F 407681~407696 16

RCR 0x3000~0x3190 412289~412689 400

6 Setting up Software

This section gives instructions on how to set up RTU-EN01 by DCISoft and explanations on each setup page.

RTU-EN01 is set up by UDP port 20006; therefore, you have to be aware of the relevant settings of the firewall.

See the explanations below on the software.

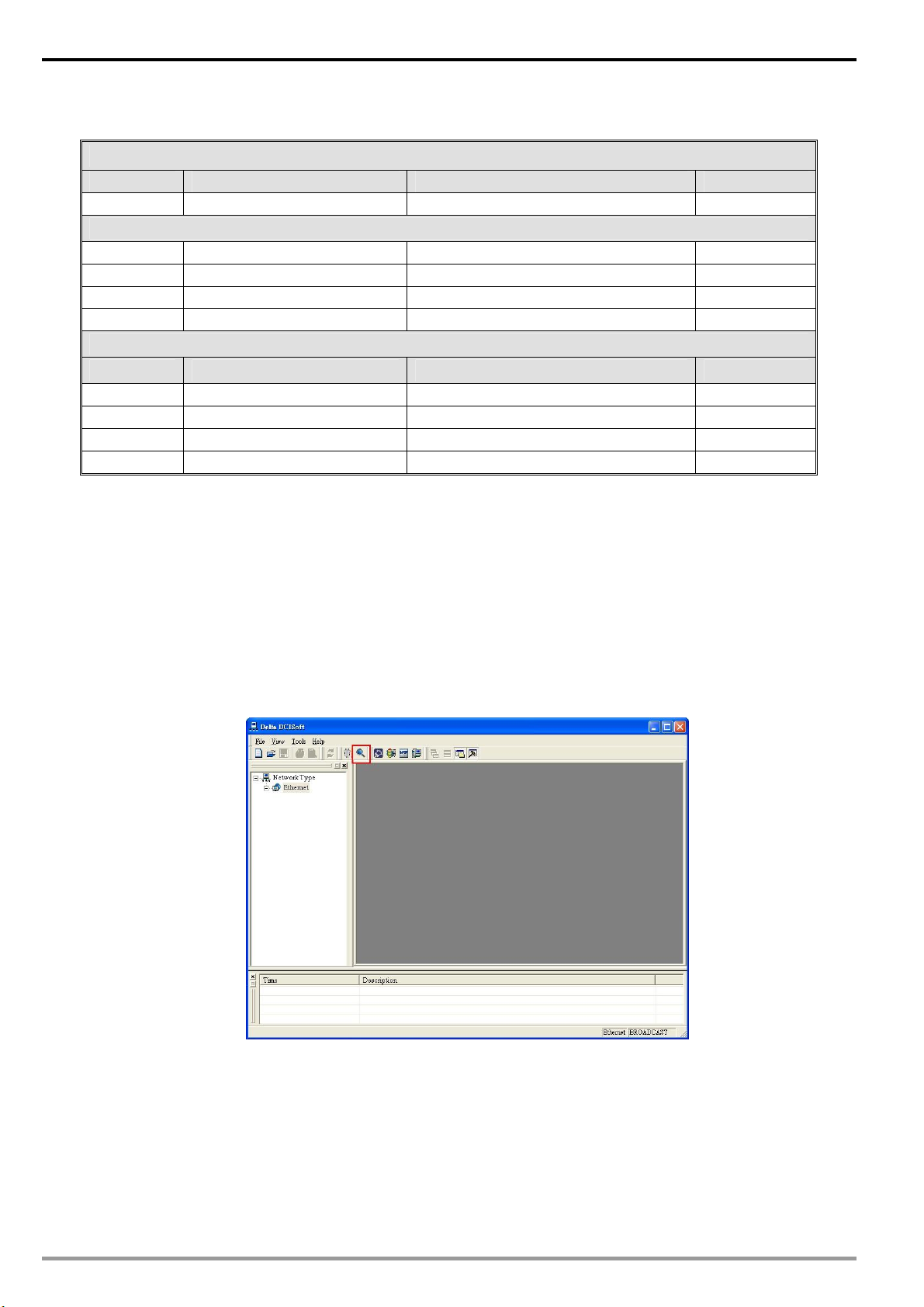

6.1 Setting up Communications & Searching for Communication Modules in DCISoft

Broadcast search

1. Open DCISoft on the PC and click on the “IP Search” icon.

16

DVP-PLC Operation Manual

Page 19

Modbus TCP Remote I/O Communication Module RTU-EN01

2. You will see the communication module found.

DVP-PLC Operation Manual

17

Page 20

Modbus TCP Remote I/O Communication Module RTU-EN01

3. Double-click on the module to be set up to enter the setup page. The first page overviews the basic status of

the module and information on the right-side module.

4. The next page is for basic network setup. Consult your Internet Service Provider for relevant network setting.

For other settings, see BR#11 ~ BR#13.

6.2 Recording IP Address

The IP list allows the user to select modules directly and designate a module for search. Recording IP address

means to add this RTU-EN01 to the list, allowing the user to see RTU-EN01 in the search.

Recording IP address

18

DVP-PLC Operation Manual

Page 21

Modbus TCP Remote I/O Communication Module RTU-EN01

IP list:

In the list, you will see the network IPs already used. Click “Add” to record the known IP address

into the list and next search for the module on the network by designated IP.

Click the icon to search for the module.

6.3 Basic Settings

The basic settings include parameters such module name, network settings and communication time.

The basics

DVP-PLC Operation Manual

19

Page 22

Modbus TCP Remote I/O Communication Module RTU-EN01

1. Module name:

There can be many RTU-EN01 modules on the network. Thus, you can set up a module name for each

module to identify the module when you need to use them.

2. Network setup:

Enable dynamic IP (DHCP) or static IP. Consult your ISP for other relevant settings.

A. IP configuration:

There are 2 types of IP, static IP and DHCP.

Static IP: Preset or manually modified by the user.

DHCP: Automatically updated by the server. There must be a server in the LAN.

IP Explanation

Static The user enters the IP address, subnet mask and gateway.

DHCP DHCP server offers the IP address, subnet mask and gateway.

B. IP address:

IP address is the location of the equipment on the network. Every equipment connected to the network

has to have an IP address. Incorrect IP address will result in connection failure. Consult your ISP for

how to set up IP address. The default IP for RTU-EN01 is 192.168.1.5.

C. Netmask:

Subnet mask is an important parameter for setting up the subnet, used for seeing if the destination IP

and the local equipment are in the same subnet. If not, the equipment will send the packet to the

20

gateway, and the gateway will send the packet to another subnet. Incorrect setting may cause the

destination equipment unable to communicate to RTU-EN01. To see if your setting is correct, conduct

bitwise AND operations between your IP and subnet mask and destination IP and subnet mask. If the

two values obtained are the same, the two IPs are in the same subnet. The default subnet mask of

RTU-EN01 is 255.255.255.0.

D. Gateway:

Gateway is the window for two different subnets, allowing the two ends in different subnets to

communicate. For example, if the LAN has to be connected to WAN, it will need a gateway to bridge

DVP-PLC Operation Manual

Page 23

Modbus TCP Remote I/O Communication Module RTU-EN01

the communication. The IP of the gateway has to be in the same subnet as RTU-EN01. The default

gateway of RTU-EN01 is 192.168.1.1.

3. Timer setting:

For setting up TCP connection idle time, Modbus time-out and minimum delay time for every

communication data. Please refer to the explanations on BR#11, BR#12, and BR#13.

6.4 Network Settings

The first step for all the equipment to connect to the network is to have its own IP (Internet Protocol) address. The

IP address is like a number for every equipment to be identified on the network.

Setting up static IP of the PC

1. Enter Control Panel → Network Connection → click “Local Area Connection".

2. You will see the “Local Area Connection Status” window. Click “Properties”.

3. Click “Internet Protocol (TCP/IP)”.

DVP-PLC Operation Manual

21

Page 24

Modbus TCP Remote I/O Communication Module RTU-EN01

4. Enter “192.168.0.2” into IP address. Click “OK” to complete the IP address setting of the PC.

6.5 Setting up Time Server

RTU-EN01 offers real-time clock (RTC) functions. You can set up your own time for RTU-EN01 or update the time

through NTP server.

Setup page

22

DVP-PLC Operation Manual

Page 25

Modbus TCP Remote I/O Communication Module RTU-EN01

1. Enable time server:

RTU-EN01 execute automatic time correction from the NTP server on the network every 6 hours to

ensure the time is correct in the RTC. To enable this function, you have to set up first the IP

address of the NTP server and the time zone and daylight saving time which your RTU-EN01 is in.

2. Start daylight saving time

Daylight Saving Time; also known as summer time, is a conventional local time adopted by many

countries in the world on a seasonal basis. Most commonly DST is obtained by adjusting the

official local time forward, by one hour, for the spring, summer, and early autumn periods.

3. Time server:

IP address of the time server. You can acquire correct time from the time server to correct the time

in the MPU.

4. Time zone:

There are 24 time zones on earth and follow Greenwich Mean Time (GMT) as the standard time.

Select the time zone you are in and adjust the offset between the time of your city and Coordinated

Universal Time (UTC).

5. Clock setup:

Set up the time in RTU-EN01. You can set the time to the same as the PC in operation, or you may

as well set up the time manually.

6.6 IP Filter

The IP filter is used for restricting the connection of the network in case some uncertain UP will cause errors. Only

the IP set within a certain range can establish a connection. Other IPs will be rejected.

Setting up IP filter

1. Enable IP filter:

DVP-PLC Operation Manual

23

Page 26

Modbus TCP Remote I/O Communication Module RTU-EN01

Check the box to enable IP filter.

2. Begin IP address:

Start IP addresses allowed to establish connection. Max. 8 IPs are allowed.

3. End IP address:

End IP addresses allowed to establish connection. Max. 8 IPs are allowed.

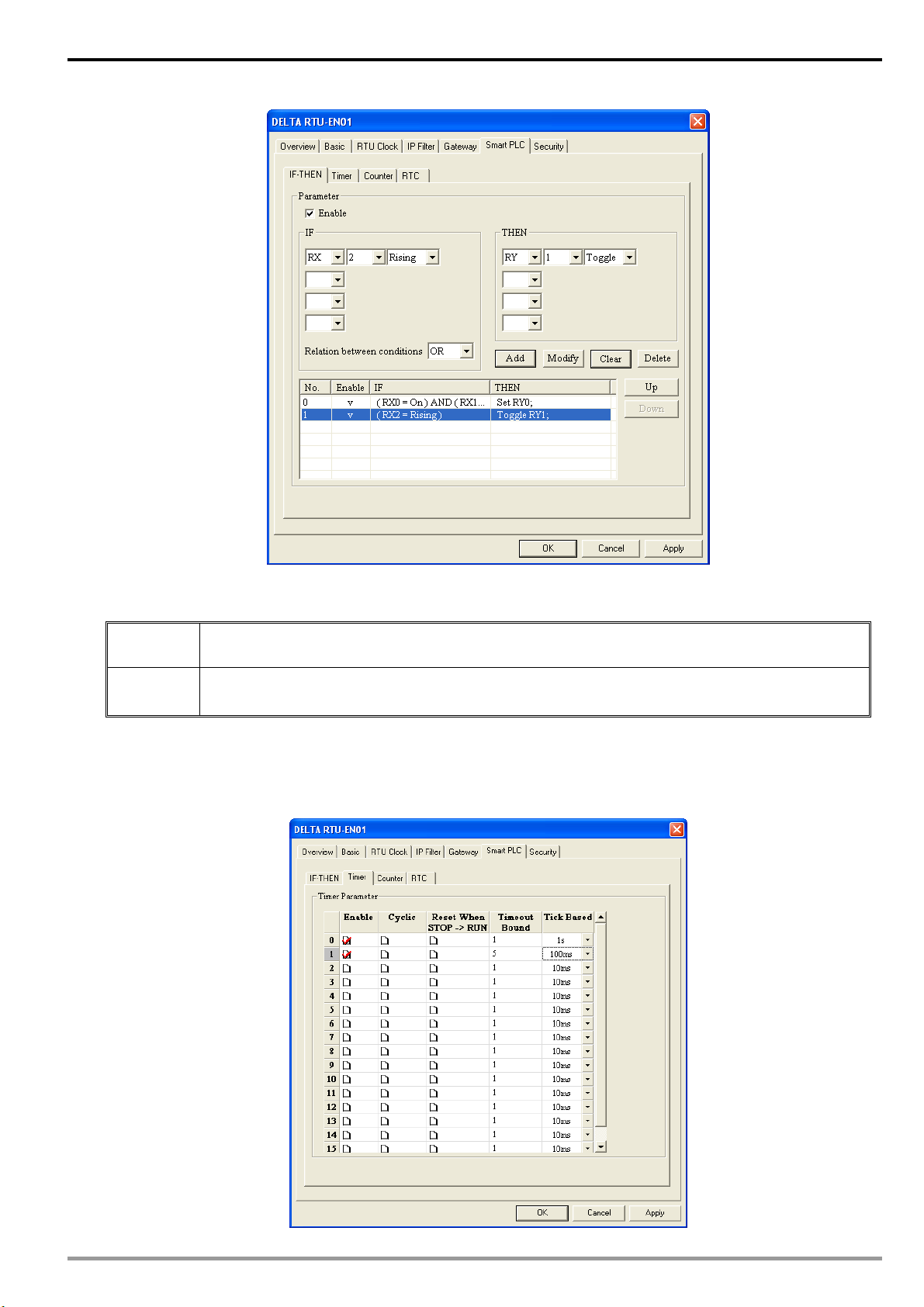

6.7 Smart PLC Setting: IF-THEN

RTU-EN01 has the independent Smart PLC function. IF-THEN is able to execute the corresponding function of

the condition set up by the user and combine with the functions of counter, timer, RTC, digital I/O points and

analog I/O modules. You can use AND or OR as the trigger condition. There are 16 IF-THEN functions in

RTU-EN01.

IF-THEN

1. Enable:

Check the box to enable IF-THEN.

24

2. IF:

For the trigger condition, you can select bit devices RX, RY, C, T, RT or word device RCR and set

them to ON, OFF, Rising, Falling, >, <, =, <>, >= or <=. The trigger condition can be AND or OR.

When the device is a register, the allowed trigger range will be K-32,768 ~ K32,767.

3. THEN:

For the execution, you can select bit devices RY, C, T, RT or word device RCR and set them to Set,

Reset, Toggle or set up a value for them. Please refer to the explanations on IF#13 ~ IF#24. When

the device is a register, the allowed trigger range will be K-32,768 ~ K32,767.

4. Add, Modify, Clear, Delete:

All the settings above can be added to the IF-THEN table below, or you can modify, clear or delete

the settings.

5. Up, Down:

DVP-PLC Operation Manual

Page 27

Modbus TCP Remote I/O Communication Module RTU-EN01

You can move the IF-THEN setting upwards or downwards to change the execution order of them.

6.8 Smart PLC Setting: Timer

RTU-EN01 has the independent Smart PLC function. The timer is able to time following the system time. There

are 16 timers in RTU-EN01. The timing range is 10ms ~ 655,35s.

Timer

1. Enable:

Decide whether to enable the timer in this column.

2. Cyclic:

Decide whether to reset the timer and re-start the timing when the timing reaches the target in this

column.

3. Reset when STOP->RUN:

Decide whether to reset the timer when the system goes from STOP to RUN.

4. Timeout bound:

The time for the timer to reach the target. Range: 10ms ~ 65,535s.

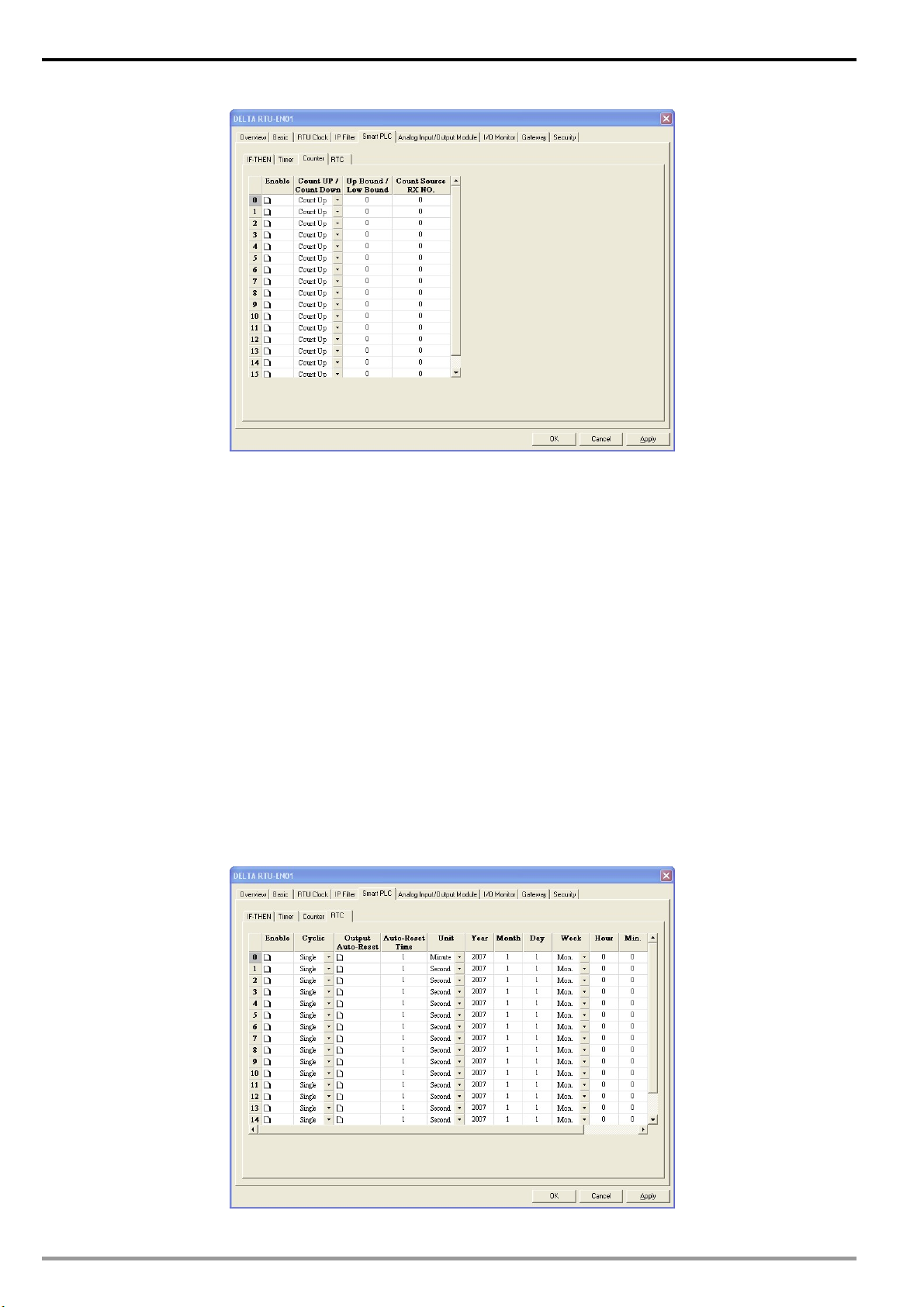

6.9 Smart PLC Setting – Counter

RTU-EN01 has the independent Smart PLC function. The counter can be triggered by the external input points

RX. When RX turns from OFF to ON, the counter will start to count. There are 16 counters in RTU-EN01,

responsible for counting up and counting down. The counting range is -32,768 ~ 32,767.

Counter

DVP-PLC Operation Manual

25

Page 28

Modbus TCP Remote I/O Communication Module RTU-EN01

1. Enable:

Decide whether to enable the counter in this column.

2. Count up/count down:

Decide whether the counter will be counting up or counting down.

3. Up bound/low bound:

The upper bound and lower bound of the counting. Range: -32,768 ~ 32,767.

4. Count source RX NO.:

No. of the external input point RX of the counting source. Range: RX#0 ~ RX#255.

6.10 Smart PLC Setting – RTC

RTU-EN01 has the independent Smart PLC function. The real-time clock (RTC) can be triggered by the system at

specific time. There are 16 RTCs in RTU-EN01. You can designate the trigger time or trigger the RTC on a

monthly, weekly or daily basis. Please refer to the explanations on RS#0 ~ RS#159.

RTC

26

DVP-PLC Operation Manual

Page 29

Modbus TCP Remote I/O Communication Module RTU-EN01

1. Enable:

Decide whether to trigger the RTC in this column.

2. Cyclic:

Decide to trigger the RTC only once, or trigger it on a daily, weekly or monthly basis.

3. Output auto-reset:

After the RTC is triggered, decide whether to retain the output for a period of time and reset the

RTC automatically. R (Coil) will be OFF when the time for reset is reached.

4. Auto-reset time, Unit:

If you select to auto-reset the RTC, the bit device in RTC will retain the output for a period of time.

Range: 1s ~ 24hr.

Range for second as unit: 1 ~ 32,767

Range for minute as unit: 1 ~ 3,600

Range for hour as unit: 1 ~ 24

5. Year, Month, Day, Hour, Minute, Second, Week:

The time to trigger the RTC. If you would like to trigger it only once, only Year, Month, Day, Hour,

Minute and Second need to be set. If you would like to trigger on a daily basis, only Hour, Minute

and Second need to be set. If you would like the RTC to be triggered on a weekly basis, you only

need to set up Week, Hour, Minute and Second. If the RTC is triggered monthly, set up only Day,

Hour, Minute and Second.

6.11 Analog Input/Output Modules

RTU-EN01 offers control registers (CR) for analog I/O modules and is built-in with mapping tables of CR for

read/write. The user can check the CR to be read/written and use Delta’s communication module DVPEN01-SL to

map the CR directly to D registers in DVP-SV series PLC and read/write the D register through PLC program,

controlling the analog I/O module connected to RTU-EN01. RTU-EN01 supports maximum 64 data

reading/writing.

f This function works with DVPEN01-SL of firmware V2.0 or versions above.

Analog I/O modules

DVP-PLC Operation Manual

27

Page 30

Modbus TCP Remote I/O Communication Module RTU-EN01

1. Corresponding table:

Open DCISoft and it will automatically load in the control register information on the analog I/O

modules. (When using Web settings, you have to load in the EDS file for analog I/O module by

yourself.) Check the CR you are to read or write to establish a mapping table. DVPEN01-SL will

map the CR established in the table to D register in DVP-SV series PLC. The user will be able to

operate the analog I/O module connected to RTU-EN01 by the value stored in D register.

2. Read:

Check the CR (read) to be added to the mapping table. Click “Apply” and the checked CR will be

added.

3. Write:

Check the CR (write) to be added to the mapping table. Click “Apply" and the checked CR will be

added.

4. Clean mapping list:

Once applied, clear all the information in the mapping table.

5. CR No.:

The number of control register for all analog I/O modules connected to RTU-EN01.

6. R/W:

28

Indicating whether the CR can be read or written.

7. Register name:

The name of the CR for the analog I/O modules.

8. Present value:

The present value in the CR for the analog I/O modules.

9. Format:

The display format for the present value in the CR. Available formats: hex, signed decimal integer

and binary integer.

DVP-PLC Operation Manual

Page 31

Modbus TCP Remote I/O Communication Module RTU-EN01

6.12 I/O Monitoring Table

RTU-EN01 is able to monitor internal registers on-line. Scroll the table to monitor bit devices RX, RY, T, C, R,

RCR and BR and the bit status and present value in the register. You can choose to monitor decimal or hex

present value.

I/O monitoring table:

1. Device:

Select an internal register in RTU-EN01.

Bit devices: RX, RY, T, C, R

Registers: T, C, R, RCR, BR.

2. Number:

Select the bit devices and registers to be monitored by their numbers.

RX#0 ~ RX#255, total 256 bits.

RY#0 ~ RY#255, total 256 bits.

DVP-PLC Operation Manual

29

Page 32

Modbus TCP Remote I/O Communication Module RTU-EN01

T#0 ~ T#15, total 16 bits and 16 registers.

C#0 ~ C#15, total 16 bits and 16 registers.

R#0 ~ R#15, total 16 bits and 16 registers.

RCR#0 ~ RCR#399, total 400 registers.

BR#0 ~ BR#63, total 64 registers.

3. Format:

Select the format of the register to be monitored, decimal (Dec) or hexadecimal (Hex).

f Once the number and format are set, click “Apply” to save the setting and start the monitoring.

4. Start/Stop monitor:

Start or stop the saved and applied device number to be monitored. Unapplied saved settings will

be deleted.

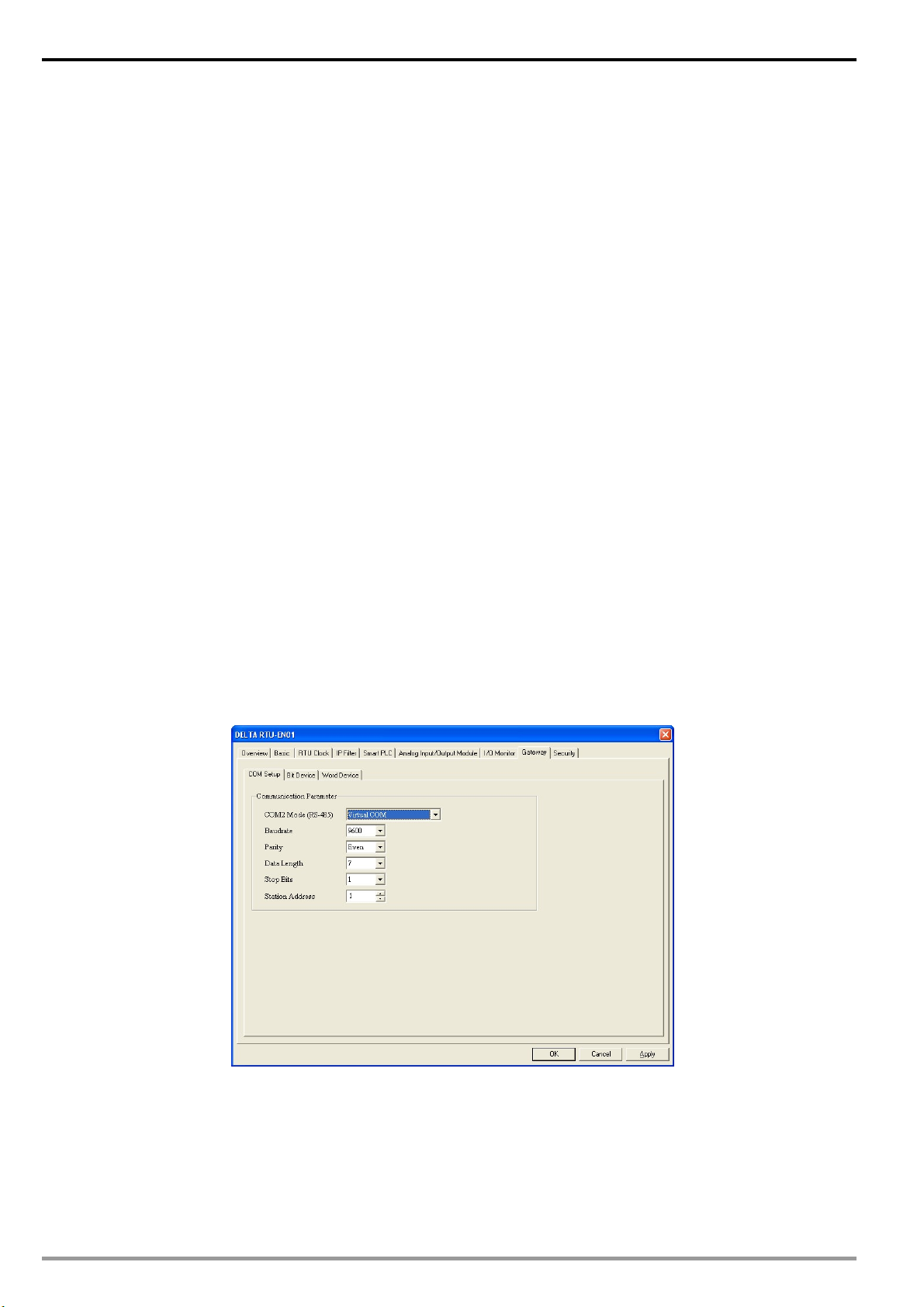

6.13 Setting up Gateway

RTU-EN01 offers Modbus TC P to RS-485 gateway functions. By setting up RTU-EN01, you can read the data in

specific devices on the network. Gateway functions help you fast store and retrieve data and offers on-line

monitoring for maximum 100 bit data and word data. The data can be temporarily stored in RTU-EN01, speeding

up the write/read and response time.

Gateway setup page

30

1. COM Setup

COM2 Mode (RS-485):

You can choose Modbus ASCII Master, Modbus RTU Master or Virtual COM.

Baudrate:

The baud rate for communication.

DVP-PLC Operation Manual

Page 33

Modbus TCP Remote I/O Communication Module RTU-EN01

Parity

Data length

Stop bits

Station address:

The Modbus address.

2. Bit device

For setting up the addresses for the bit type serial slave device and reading or the content in the

designated slave.

Station address:

Enter the address of slave to be monitored. (Max. 16 slaves)

MODBUS (Hex):

Enter the 4-digit hex Modbus address of the slave to be monitored.

MODBUS (Dec):

Enter the 6-digit decimal Modbus address of the slave to be monitored.

Account:

Enter the number of slaves to be monitored continuously (Max. 100).

DVP-PLC Operation Manual

31

Page 34

Modbus TCP Remote I/O Communication Module RTU-EN01

3. Word device

For setting up the addresses for the word type serial slave device and reading or the content in the

designated slave.

Station address:

Enter the address of slave to be monitored. (Max. 16 slaves)

MODBUS (Hex):

Enter the 4-digit hex Modbus address of the slave to be monitored.

MODBUS (Dec):

Enter the 6-digit decimal Modbus address of the slave to be monitored.

Account:

Enter the number of slaves to be monitored continuously (Max. 100).

f Once the information of slave monitoring is set, click "Apply" to save the setting and start the

monitoring. Incomplete device information will be deleted.

Format:

Select the format of the register to be monitored, decimal (Dec), hexadecimal (Hex) or

binary.

Start/Stop monitor

Start or stop the saved and applied device number to be monitored. Unapplied saved

32

settings will be deleted.

Note:

The default is in cache enabled mode. You can set up maximum 16 sets of slave information for

the monitored bits and words (Max. 100 data). Under the cache mode, you are able to send the

read data back to the registers in RTU-EN01.

DVP-PLC Operation Manual

Page 35

Modbus TCP Remote I/O Communication Module RTU-EN01

6.14 Virtual COM

The virtual COM converts the data sent to RS-232 port into Ethernet.

Select Virtual COM for COM2 mode (RS-485).

The default setting for listen port is 20001.

Open the setup page for Virtual COM.

DVP-PLC Operation Manual

33

Page 36

Modbus TCP Remote I/O Communication Module RTU-EN01

Press “Search”, and you will see all the connected devices on the network

Select the device and click “OK”. Information on the device will be loaded in automatically. Press “OK”

to complete the setup.

Once the setup is completed, you will then be able to see the virtual COM just set in “Computer

Management”.

34

DVP-PLC Operation Manual

Page 37

Modbus TCP Remote I/O Communication Module RTU-EN01

6.15 Security Setting

To prevent the set values in RTU-EN01 from being modified, you can set up passwords to lock the settings in

RTU-EN01.

Setting up password

1. Login:

Log in to check and modify parameters.

2. Password setup:

Check the “Modify” box to set up the password.

3. Password:

Enter maximum 4 characters. Leave it blank to clear the password.

4. Confirm password:

Enter the new password again.

Note:

Once the password is locked, all the pages cannot be set up unless you unlock the password.

DVP-PLC Operation Manual

35

Page 38

Modbus TCP Remote I/O Communication Module RTU-EN01

However, if you set up RTU-EN01 by RS-232, you can return the setting to default one whether the

password is locked or not. For example, if you have locked RTU-EN01 but forget the password,

you have to return RTU-EN01 to default setting by RS-232, and all the settings will return to default

ones.

6.16 Returning to Default Settings

If you need to clear all the settings after many modifications have been done on the settings and return the

settings to default ones, check the “Factory Setting” box.

Returning to default settings

Check “Factory Setting” box and click on “Yes”.

Note:

If you set up RTU-EN01 by RS-232, you can return to settings to default ones whether the

password is locked or not. It will take approximately 10 seconds to return to default settings, so DO

NOT switch off the power within the 10 seconds.

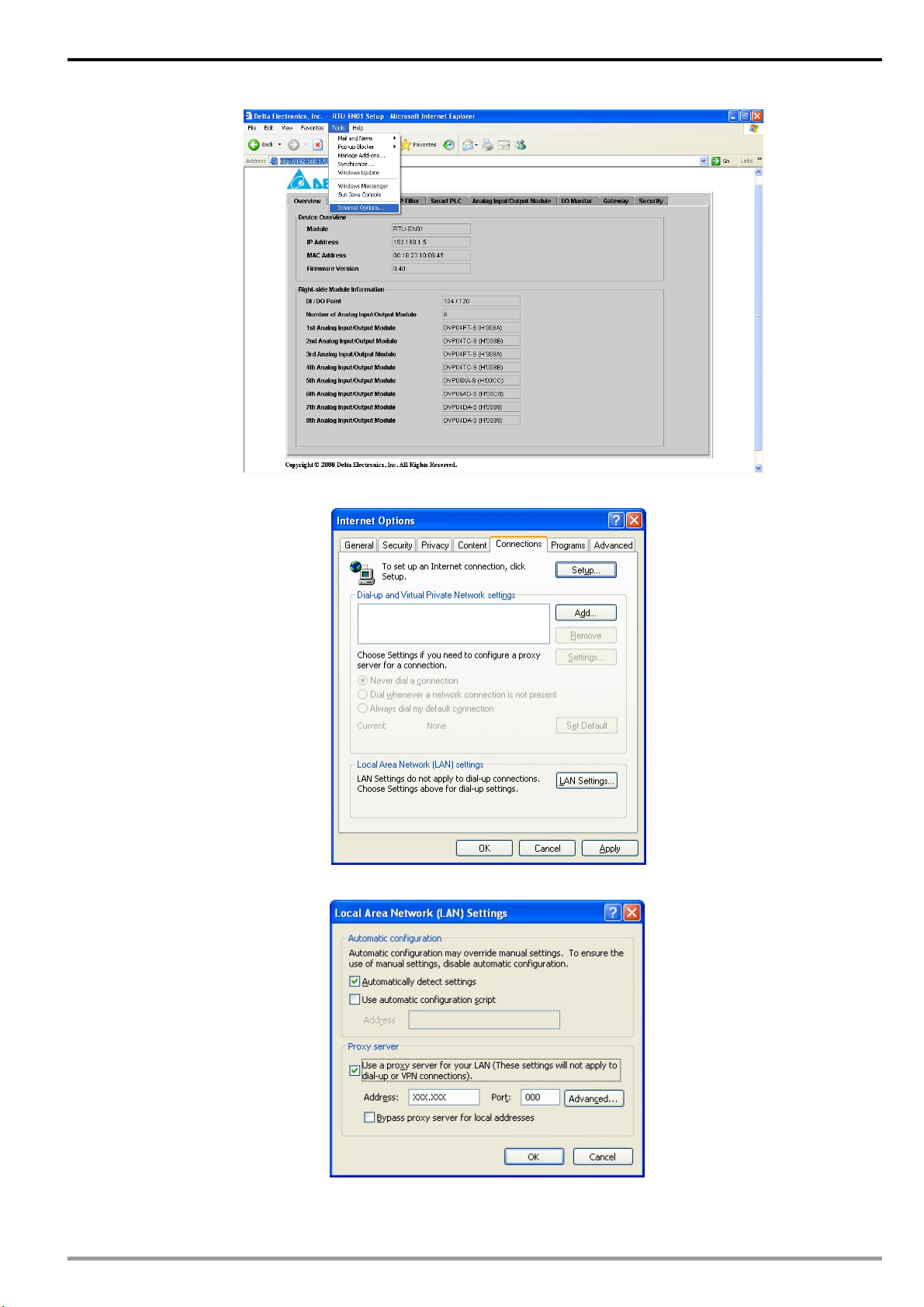

6.17 Web Function

RTU-EN01 offers Web function for the user to connect through Internet browser (e.g. Internet Explorer). You can

set up and monitor RTU-EN01 by this function.

1. See the connection method (as below) and 6.1 for how to set up communication.

36

DVP-PLC Operation Manual

Page 39

Modbus TCP Remote I/O Communication Module RTU-EN01

C

P

Ethernet

1

0

N

E

U

T

R

COM 2

RTU-EN01

P

T

S

S

6

8

0

1

-

-

P

P

V

V

D

D

C

D

T

A

4

4

0

0

-

P

P

V

V

D

D

DI/DO AI/AO

A

T

P

D

2

4

0

0

-

-

P

P

V

V

D

D

2. Open Internet Explorer and enter IP address “192.168.1.5” (default) of RTU-EN01. You can also copy the

IP address of RTU-EN01 in DCISoft and paste it to the address column on IE. Press “Enter” on keyboard to

open the webpage.

DVP-PLC Operation Manual

37

Page 40

Modbus TCP Remote I/O Communication Module RTU-EN01

3. To use the page of analog input/output modules on the web, download “DeltaR-Side-S_ENU.eds” file from

Delta’s website first and import the file to the page. Other settings are the same as the settings in DCISoft.

The webpage supports Java Runtime Environment (JRE) v1.4.2_xx and versions above.

4. Webpage troubleshooting

Unable to connect:

(1) Check if Java is correctly installed. Connect to the Java page to confirm.

(2) Check Proxy settings. Close Proxy or set up exceptions.

Close Proxy:

1. In IE, select “Tool” => “Internet Options…”.

38

DVP-PLC Operation Manual

Page 41

Modbus TCP Remote I/O Communication Module RTU-EN01

2. Select “Connections” and Click “LAN Settings…".

3. Uncheck “Proxy server” options and click "OK”.

DVP-PLC Operation Manual

39

Page 42

Modbus TCP Remote I/O Communication Module RTU-EN01

Set up exceptions:

1. Click “Advanced…” on Local Area Network (LAN) Settings page.

2. Enter the IP address “192.168.1.5” of RTU-EN01 in Exceptions.

3. Click “OK”.

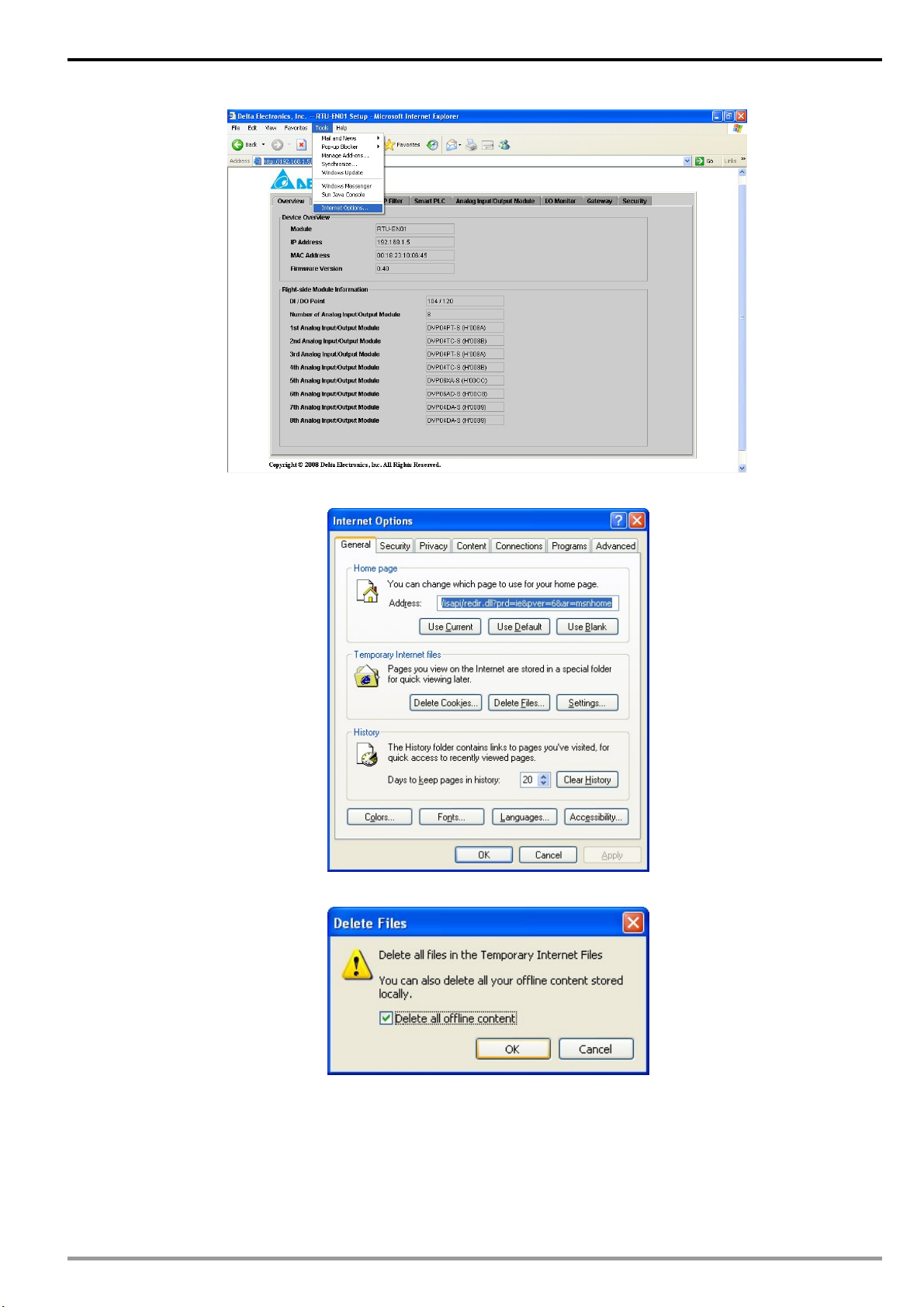

Abnormal webpage action: In this case, please clear your temporary Internet files.

Clear temporary Internet files:

1. In IE, select “Tool” => “Internet Options…”.

40

DVP-PLC Operation Manual

Page 43

Modbus TCP Remote I/O Communication Module RTU-EN01

2. In “General” page, click “Delete Files…” in Temporary Internet files column.

3. Check “Delete all offline content” and click "OK” to start the deletion.

4. Click “OK” to leave the “General” page.

DVP-PLC Operation Manual

41

Page 44

Modbus TCP Remote I/O Communication Module RTU-EN01

C

7 Application Examples – DCISoft

7.15 Smart PLC: IF-THEN

Application Setting up IF-THEN in Smart PLC functions by using DCISoft.

Steps

1. When RX#0 and RX#1 are ON, set RY0 to output.

2. When RX#2 turns from OFF to ON, set RY1 to reversing its direction.

1. See the connection method (as below) and 6.1 for how to set up communication.

P

Ethernet

1

0

N

E

U

T

R

COM 2

RTU-EN01

P

T

S

S

6

8

0

1

-

-

P

P

V

V

D

D

C

D

T

A

4

4

0

0

-

P

P

V

V

D

D

DI/DO AI/AO

T

P

4

0

P

V

D

A

D

2

0

P

V

D

2. Open the setup page and switch to “Smart PLC” page.

3. Select “RX 0 On” and “RX 1 On” in the IF column and select “AND” for the relation between conditions.

Next, select “RY 0 Set” in the THEN column and press “Add” to add the settings into the table below.

4. Select “RX 2 Rising” in the IF column and “RY 1 Toggle” in the THEN column. Press “Add” to add the

settings into the table below. Press “Apply” to store these settings into RTU-EN01.

42

DVP-PLC Operation Manual

Page 45

Modbus TCP Remote I/O Communication Module RTU-EN01

7.16 Smart PLC: Timer

Application

Steps

Setting up Smart PLC functions by DCISoft. After RY0 is On for 1 second, it will turn Off for 500

ms. This will repeat in cycle.

(1) Set up the timer: Timer 0 1s, Timer 1 500ms.

(2) Set up IF-THEN: When the timing reaches the target, RY0 will be On or Off.

1. Open the setup page and switch to “Smart PLC” page. Further switch to the “Timer” page.

2. Check to “Enable” Timer 0 and Timer 1 and set Timer 0 to “1s” and Timer 1 to “500ms”. Click “Apply” to

write the settings into RTU-EN01.

DVP-PLC Operation Manual

43

Page 46

Modbus TCP Remote I/O Communication Module RTU-EN01

7.17 Smart PLC: Counter

Application Setting up the counter by DCISoft. Once RX#1 counts for 5 times, RY0 will output.

Steps

(1) Set up counter C0: RX#1 counts up 5 times and reaches the target.

(2) Set up IF-THEN: When the counting reaches the target, RY0 will output.

1. Open the setup page and switch to “Smart PLC” page. Further switch to the “Counter” page.

2. Check to “Enable” Counter 0, select “Count Up”, set Up Bound to “5” and Count Source RX NO. to RX”1”.

Click "Apply” to write these settings into RTU-EN01.

3. Switch to “IF-THEN” page and check the “Enable” box. Select “C 0 On” in the IF column and “RY 0 Set” in

the THEN column. Click on “Add” to add the settings to the table below and press “OK” to save the settings

into RTU-EN01.

44

DVP-PLC Operation Manual

Page 47

Modbus TCP Remote I/O Communication Module RTU-EN01

7.18 Smart PLC: RTC

Application Setting up Smart PLC function by DCISoft. RY0 turns On at 08:00 and Off at 09:00 every day.

Steps

(1) Set up the RTC to be On at 08:00 every day and continue to be On for 1 hour.

(2) Set up IF-THEN: When the timing reaches the target, RY0 will be On or Off.

1. Open the setup page and switch to “Smart PLC” page. Further switch to the “RTC” page.

2. Check to “Enable” RTC 0 and set Cyclic to “Daily”, Auto-Reset Time to “60 Minute” and enabling time to

08:00:00. Press “Apply” to write the settings into RTU-EN01.

DVP-PLC Operation Manual

45

Page 48

Modbus TCP Remote I/O Communication Module RTU-EN01

3. Switch to “IF-THEN” page. Check the “Enable” box and select “RT0 On” in the IF column and “RY 0 Set” in

the THEN column. Press “Add” to add the settings to the table below.

4. Check “Enable” and select “RT0 Off” in the IF column and “RY 0 Reset” in the THEN column. Press “Add"

to add the settings to the table bellow and click on “OK” to save the settings into RTU-EN01.

7.19 Virtual COM

The virtual COM converts the data sent to RS-232 port into Ethernet. Virtual COM only

Application

Steps

connects to software supporting serial ports, e.g. Delta WPLSoft, VFDSoft, ASDASoft. See

the examples below for how to connect VFD-E series AC motor drive to VFDSoft through by

virtual COM.

(1) Select user-defined protocol and set the communication parameters for serial

master/slave to the same as the parameters in VFD-E.

(2) Set up virtual COM.

(3) Open Delta VFDSoft, set up the communication format and establish the connection.

1. Setting up virtual COM

Select Virtual COM for COM2 mode (RS-485) and set up the same communication parameters as

those in VFD-E.

46

DVP-PLC Operation Manual

Page 49

Modbus TCP Remote I/O Communication Module RTU-EN01

The default setting for listen port is 20001.

Open the setup page for Virtual COM.

Press “Search” and you will see all the connected devices on the network.

DVP-PLC Operation Manual

47

Page 50

Modbus TCP Remote I/O Communication Module RTU-EN01

Select the device and click “OK”. Information on the device will be loaded in automatically. Press “OK”

to complete the setup.

Once the setup is completed, you will then be able to see the virtual COM just set in “Computer

Management”.

2. Use Virtual COM in Delta VFDSoft.

48

Open Delta VFDSoft.

DVP-PLC Operation Manual

Page 51

Modbus TCP Remote I/O Communication Module RTU-EN01

Set up communication format

Use the Virtual COM (COM2) previously set for the setting of “Com Port”. Next, enter the

communication format (38400, 7, E, 1) for VFD-E. Click “Test”. Success flashing in green color means

the communication test is successful.

Click “OK” to establish a connection with VFD-D by VFDSoft.

DVP-PLC Operation Manual

49

Page 52

Modbus TCP Remote I/O Communication Module RTU-EN01

50

DVP-PLC Operation Manual

Loading...

Loading...