Installation and Operation Manual

RPI M50A_120

RPI M50A_122

Europe

This manual applies for solar inverter models:

● RPI M50A_120 (with string fuses and surge protec-

tion devices)

● RPI M50A_122 (with string fuses only)

with rmware version:

DSP: 1.31 / RED: 1.12 / COM: 98.26

The latest version of this manual is available at

www.solar-inverter.com.

Delta Energy Systems (Germany) GmbH

Tscheulinstrasse 21

79331 Teningen

Germany

© Copyright – Delta Energy Systems (Germany) GmbH – All rights reserved.

This manual is included with our solar inverter and is intended for use by the installer and

end user.

The technical instructions and illustrations in this manual are to be treated as condential

and no part of this manual may be reproduced without prior written permission from Delta

Energy Systems. Maintenance technicians and end users may not release the information contained in this manual, and may not use it for purposes not directly associated with

the proper use of the solar power inverter.

All information and specications can be modied without prior notice.

2

Installation and Operation Manual for RPI M50A

Table of Contents

Table of Contents

1. About this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.1 Purpose of this manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.2 Target audience of this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Warnings and symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1.4 Conventions used in this manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2. General safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3. Intended use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

4. Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.1 Scope of delivery. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.2 Components and connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.3 Display, buttons, status LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.4 String fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.5 Surge protection devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.5.1 AC side. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.5.2 AC side. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.6 Air inlets and fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.7 Electrical connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.7.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.7.2 AC/DC disconnection switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.7.3 AC connector (AC output) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.7.4 DC connectors (DC inputs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.7.5 Communication port 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.7.6 Communication port 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.7.7 Grounding connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4.8 Information on the type label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5. Planning the installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1 Where to mount the solar inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

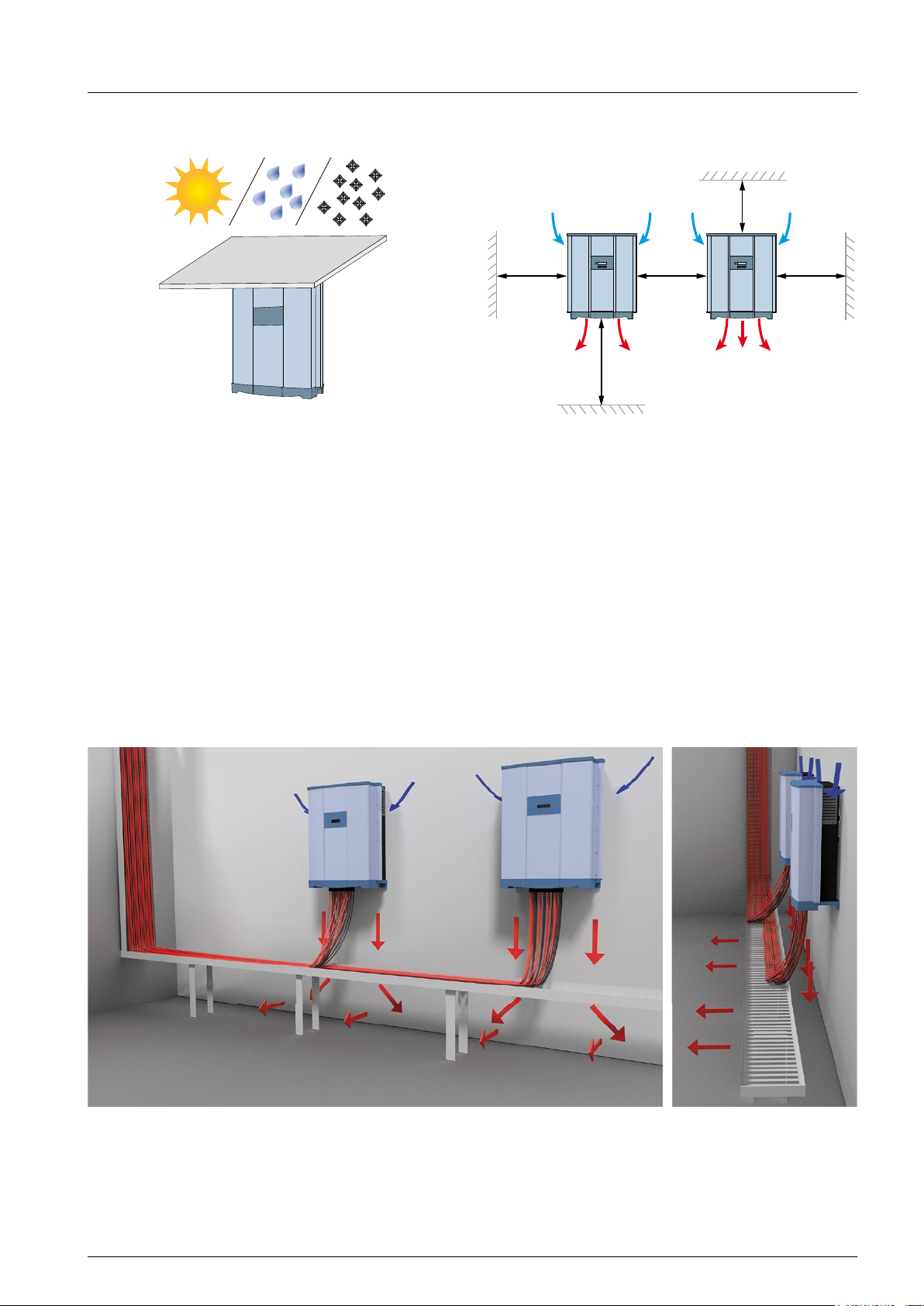

5.2 Outdoor installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.3 Ambient conditions and air circulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

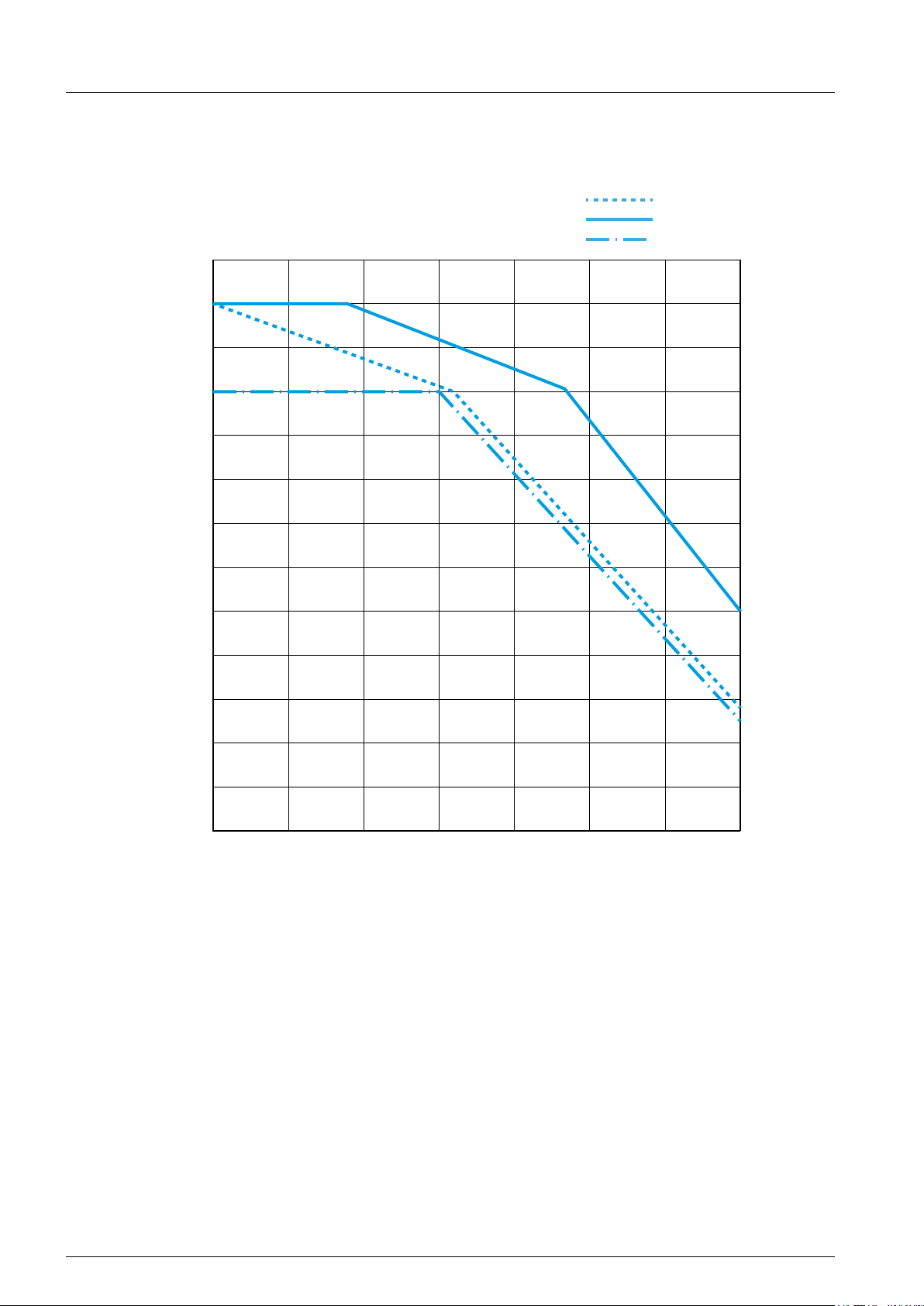

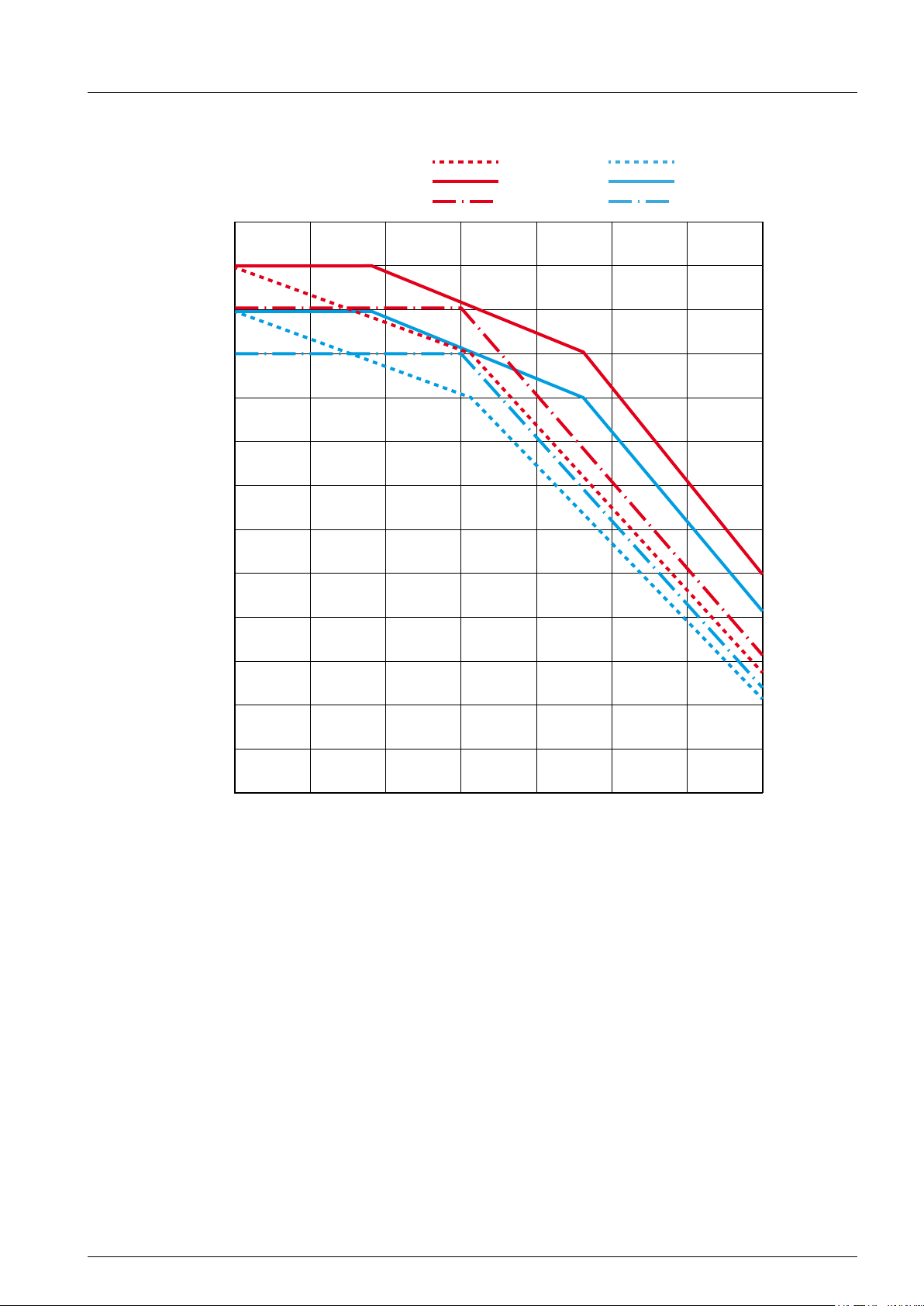

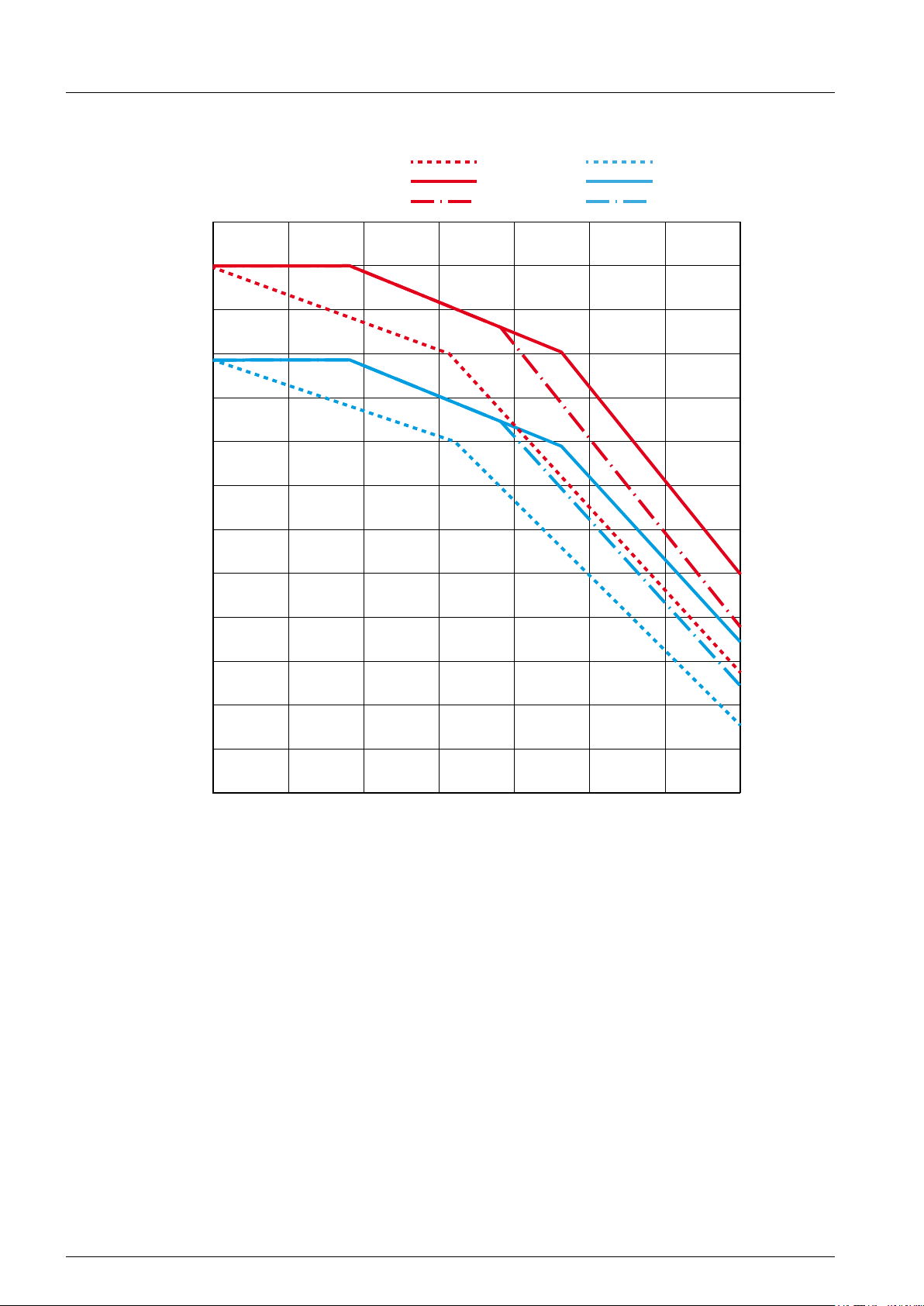

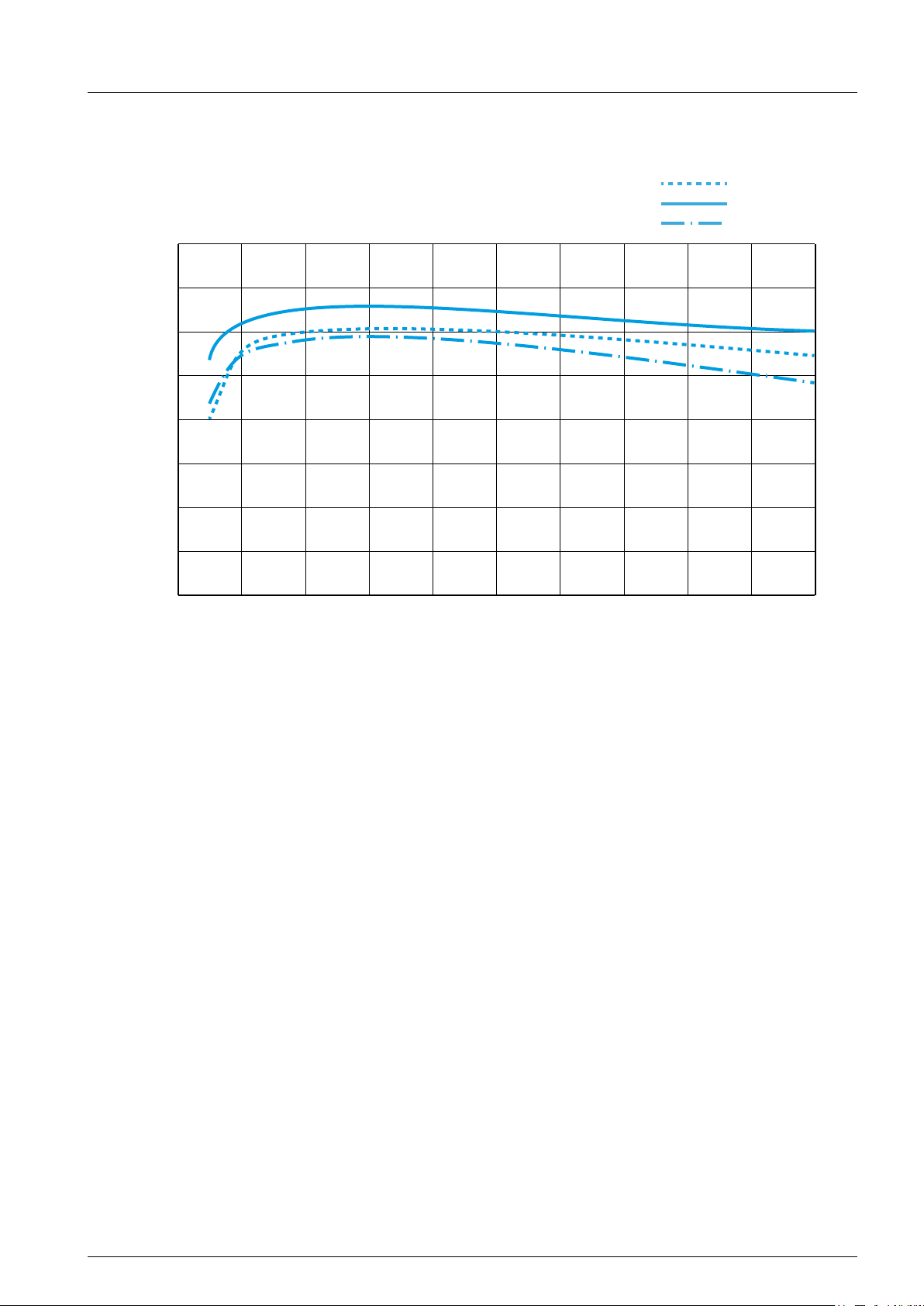

5.4 Temperature derating curves. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.5 Efciencycurve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

5.6 Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

5.7 AC connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

5.8 DC connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.8.1 Symmetrical and asymmetrical power input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.8.2 Use with solar modules that do not need to be grounded. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

5.8.3 Use with solar modules that have to be grounded. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

5.8.4 Using DC1 and DC2 with only one MPP tracker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5.9 Connecting to a datalogger via RS485. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5.10 Circuit diagram of string fuses and SPDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5.11 What you need . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.1 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.2 Mounting the inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.3 Grounding the inverter housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

6.4 Connecting to the grid (AC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

6.5 Connecting to the solar modules (DC) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.5.1 Safety instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.5.2 Cablespecication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.6 Using DC1 and DC2 with only one MPP tracker (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

6.7 Connecting communication port I (optional) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.7.1 RS485 and VCC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Installation and Operation Manual for RPI M50A

3

Table of Contents

6.7.2 Dry contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.7.3 Digital inputs and EPO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

6.8 Wiring communication port 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.8.1 First steps for all cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.8.2 Wiring a single inverter for RS 485 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

6.8.3 Wiring multiple inverters for RS 485. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

6.8.4 Wiring the dry contacts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.8.5 Wiring the digital inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.8.6 Finishing the wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

6.9 Putting labels on the inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

7. Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

8. Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

8.2 Current grid settings (inverter information). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

8.3 Display language. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

8.4 Date and time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

8.5 Baud rate for RS485 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

8.6 Inverter ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

8.7 Insulation mode and insulation resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

8.8 Grid settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.8.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.8.2 Voltage protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

8.8.3 Frequency protection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

8.8.4 Reconnection time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

8.8.5 P Ramp Up. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

8.9 EPO (External Power Off) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

8.10 AC Connection type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

8.11 Max. Power (Maximum feed-in power). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

8.12 Power limitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

8.13 Power versus frequency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

8.14 Constant cos phi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

8.15 Cos phi (P) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

8.16 Constant Q . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

8.17 Q (V) - Apparent power versus voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

8.18 FRT (Fault Ride Through) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

9. Measurements and statistics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

9.1 Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

9.2 Energy log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

9.3 Event log . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

9.4 Inverter information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

10. Error messages and trouble shooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

10.1 Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

10.2 Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

10.3 Faults. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

11. Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

11.1 Regular maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

11.2 Replacing the fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

11.3 Cleaning the fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

11.4 Cleaningtheairlters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

11.5 Replacing surge protection devices (SPD) on the DC side . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

11.6 Replacing surge protection devices (SPD) on the AC side . . . . . . . . . . . . . . . . . . . . . . . . . . .100

11.7 Replacing string fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

12. Decommissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .103

13. Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .105

4

Installation and Operation Manual for RPI M50A

1. About this manual

1. About this manual

1.1 Purpose of this manual

This manual is part of the inverter and will help you

become familiar with the inverter.

Always follow the safety instructions given in this

manual. You can help keep the product durable and

reliable during its use by handling it carefully.

Read the manual carefully and thoroughly and follow

the instructions contained therein. This manual contains important information on the installation, commissioning and operation of the solar inverter.

Always follow the general safety instructions (see

“2 General safety instructions”, p. 7).

Store the manual in a safe place near the inverter, so

that installer and operator have easy access to this

manual.

The solar inverter can be safely and normally operated if installed and used in accordance with this

manual. Delta Energy Systems is not responsible for

damage incurred by failure to comply with the installation and operating instructions in this manual.

1.3 Warnings and symbols

Where hazards may arise when working with the solar

inverter, the following hazard levels and symbols are

used to indicate these hazards:

DANGER

DANGER indicates a hazardous situation

which, if not avoided, will result in death or

serious injury.

WARNING

WARNING indicates a hazardous situation

which, if not avoided, could result in death or

serious injury.

CAUTION

CAUTION indicates a hazardous situation

which, if not avoided, could result in minor or

moderate injury.

NOTICE

ATTENTION is used to address practices not

related to physical injury.

1.2 Target audience of this manual

This manual is aimed at qualied electricians who

have received a sufcient training to apply safe meth-

ods of work to install a micro-generator in compliance

with the requirements of the applying standard.

Only chapter “9 Measurements and statistics”,

p. 85 is relevant to the operator. All other activities

may only be performed by qualied electricians.

A note provides general information on using

the solar inverter. A note does not indicate

hazardous situations.

Where required, further, supplementary warning

symbols are used. Type and source of the hazard is

explained in the safety instructions or warnings.

This symbol is a warning of a risk of

electric shock due to high voltage.

The symbol is a warning of a hot surface.

This symbol is a warning of general

hazards.

Installation and Operation Manual for RPI M50A

5

1. About this manual

1.4 Conventions used in this manual

Order of instructions

Numbered instructions must be performed in the

specied order.

1. First instruction step

→ When the solar inverter reacts to a step, this

reaction is marked with an arrow.

2. Second instruction step

3. Third instruction step

Instructions consisting of only one step or when the

order of the instruction steps is not important, are

shown as follows:

► Instruction step

► Instruction step

Device buttons and LEDs

Device buttons and LEDs are shown in this manual as

follows:

Buttons on the solar inverter:

LEDs on solar inverter:

LED symbol Meaning

Information on Display

Information shown on the solar inverter display

includes menus, settings and messages.

This information is shown in this manual as follows:

Menu names: User settings menu

Parameter names: Cos phi parameter.

AlArm LED

LED stays on.

LED ashes.

LED is off.

ESC

button.

6

Installation and Operation Manual for RPI M50A

2. General safety instructions

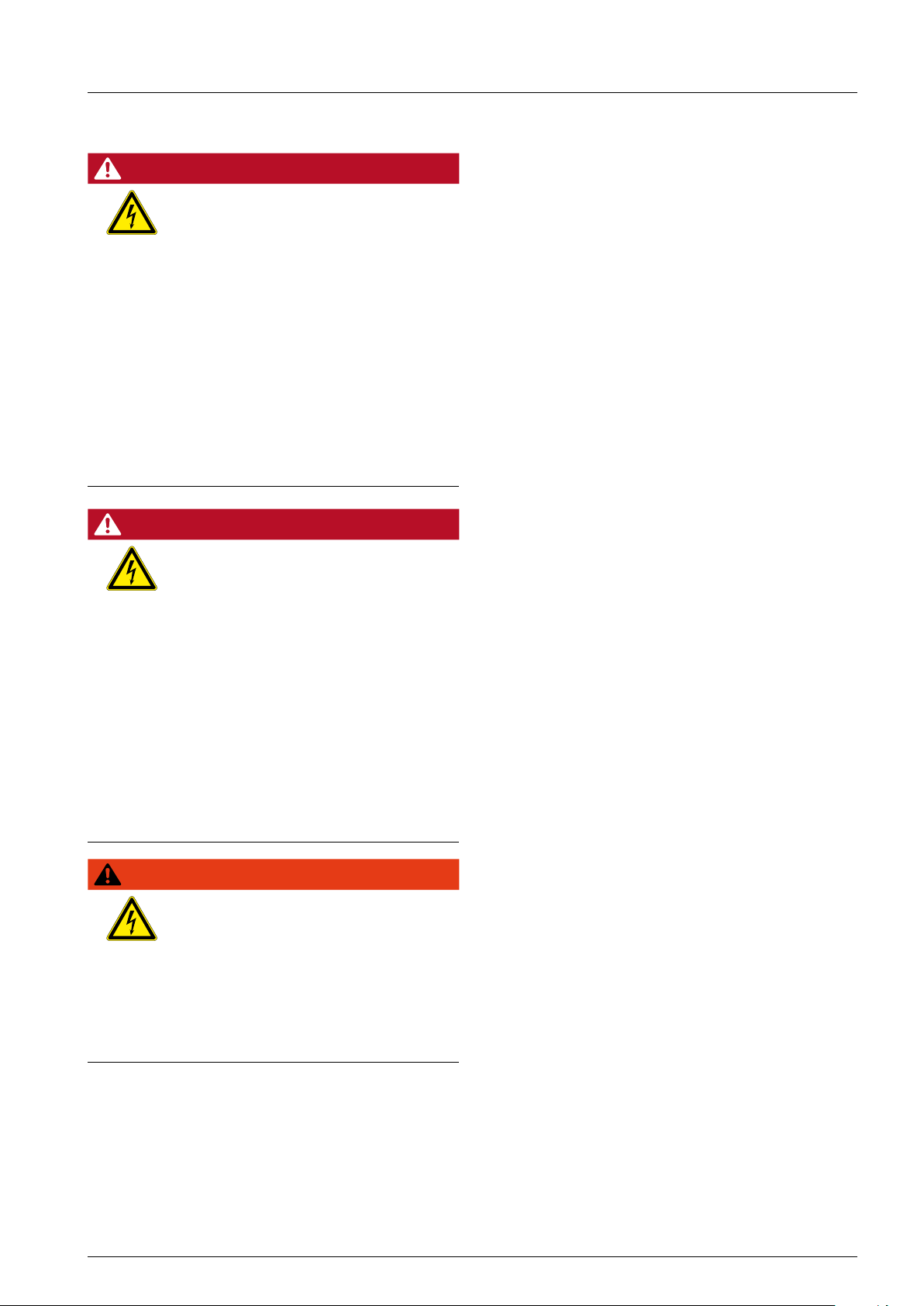

2. General safety instructions

DANGER

High electrocution

Potentially fatal voltage is applied to

the solar inverter during operation. This

potentially fatal voltage is still present

for 10 seconds after all power sources

have been disconnected.

► Always disconnect the inverter from

power before installation, open the

AC/DC isolating switch and make

sure neither can be accidentally

reconnected.

► Only the cover from the fuse section

may be removed. Never open other

parts of the inverter.

► Wait at least 10 seconds until the

capacitors have discharged.

DANGER

High electrocution

Potentially fatal voltage may be applied to the DC connections of the solar

inverter. When light is falling on solar

modules, they immediately start producing energy. They do so, even when

the sun is not shining.

► Never disconnect the solar modules

when the solar inverter is powered.

► First switch off the grid connection

so that the solar inverter cannot

feed energy into the grid.

► Turn the AC/DC isolating switch to

position OFF.

► Make sure the DC connections can-

not be accidentally touched.

WARNING

High electrocution

When you remove the cover from the

fuse section, protection degree is no

longer IP65.

► Remove the cover only when it is

really necessary.

► Do not remove the cover when it is

raining and the inverter is wet.

► Close the cover tightly after work.

● The solar inverter can be safely and normally

operated if installed and used in accordance with

this manual (see IEC 62109-5.3.3). Delta Energy

Systems is not responsible for damage incurred

by failure to observe the installation and operating instructions in this manual. For this reason, be

sure to observe and follow all instructions!

● Installation and commissioning may only be per-

formed by qualied electricians using the installation and commissioning instructions found in this

manual.

● The solar inverter must be disconnected from

power and the solar modules before any work on

it can be performed.

● The solar inverter has a high leakage current

value. The ground wire must be connected before

commissioning.

● Do not remove any warning signs that the manu-

facturer has installed on the solar inverter.

● Improper handling of the solar inverter may result

in physical injury and damage to property. For

this reason, observe and follow all general safety

instructions and warnings.

● The solar inverter contains no components that

must be maintained or repaired by the operator or

installer. All repairs must be performed by Delta

Energy Systems. Opening the cover will void the

warranty.

● Do not disconnect any cables when the solar

inverter is powered due to risk of a fault arc.

● To prevent lightning strikes, follow the relevant

regulations applicable in your country.

● The surface of the solar inverter can become very

hot during operation. Use safety gloves when

working on the solar inverter.

● The solar inverter is very heavy. The solar inverter

must be lifted and carried by at least three people.

● Only devices in compliance with SELV

(EN 69050) may be connected to the RS485 and

USB interfaces.

● All connections must be sufciently insulated in

order to comply with the IP65 protection rating.

Unused connections must be closed by placing

cover caps on the solar inverter.

Installation and Operation Manual for RPI M50A

7

3. Intended use

3. Intended use

The solar inverter may only be used as intended.

Proper use of the solar inverter meets the following

criteria:

● Use in stationary PV systems connected to the

local power grid for converting the direct current in

the PV system to alternating current and feeding it

into the grid

● Use within the specied power range (see

“13 Technical data”, p. 105) and under the

specied ambient conditions (see “5 Planning the

installation”, p. 18).

Any of the following uses of the solar inverter is considered improper:

● Isolated operation. The solar inverter has anti-

islanding and other monitoring features.

● Use in mobile PV systems.

8

Installation and Operation Manual for RPI M50A

3. Intended use

Installation and Operation Manual for RPI M50A

9

4. Product overview

Europe

4. Product overview

4.1 Scope of delivery

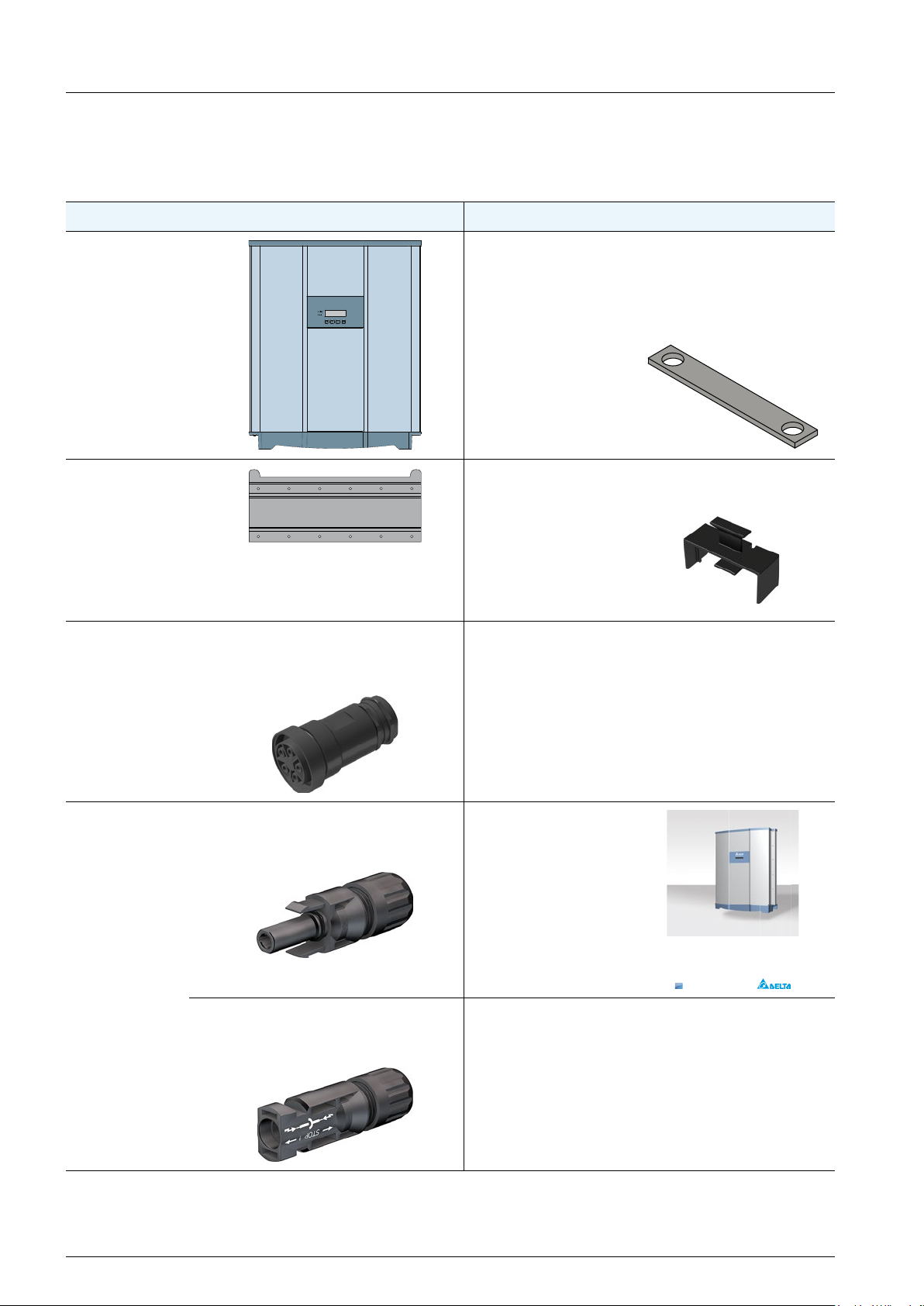

Part Qty Image/Description Part Qty Image/Description

Inverter 1

DC bus bar 2 Used when the solar mod-

ules have to be grounded

and for connecting the

two DC inputs to one MPP

tracker.

Mounting plate 1 DC Fuse holder 1 Used when the solar mod-

ules have to be grounded.

AC plug 1 China Aviation Optical-

Electrical Technology Co.

PVE5T125KE36

Screw for

grounding the

inverter housing

1 An appropriate screw with

washer, washer spring

and toothed ring is already

mounted to the inverter

DC plugs 10 Multi-Contact MC4 plug for

DC+ (32.0017P0001-UR for

2

4/6 mm

)

10 Multi-Contact MC4 plug for

DC– (32.0016P0001-UR for

4/6 mm2)

Quick Installation Guide and

General Safety

Instructions

1

Installation and Operation Manual

RPI M50A

10

Installation and Operation Manual for RPI M50A

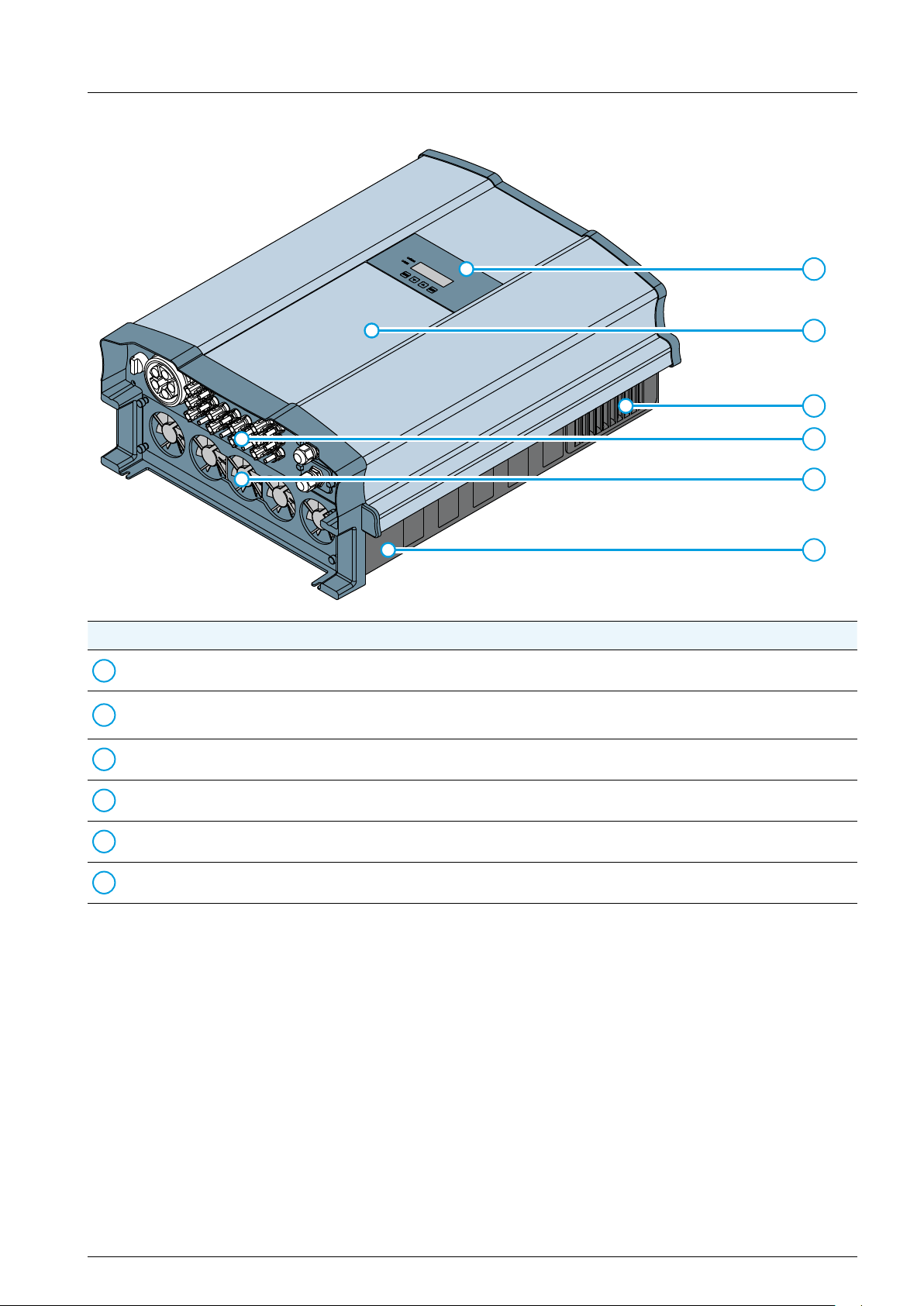

4.2 Components and connectors

2

4. Product overview

1

2

3

4

5

No. Component / connector Description

Display, buttons, status LEDs See “4.3 Display, buttons, status LEDs”, p. 12

1

String fuses and AC/DC overvoltage protection

Air inlets See “4.5 Air inlets and fans”, p. 13

3

Electrical connectors See “4.6 Electrical connectors”, p. 14

4

Fans See “4.5 Air inlets and fans”, p. 13

5

Type label See “4.7 Information on the type label”, p. 17

6

See “4.4 String fuses and AC/DC surge protection

device”, p. 12

6

Installation and Operation Manual for RPI M50A

11

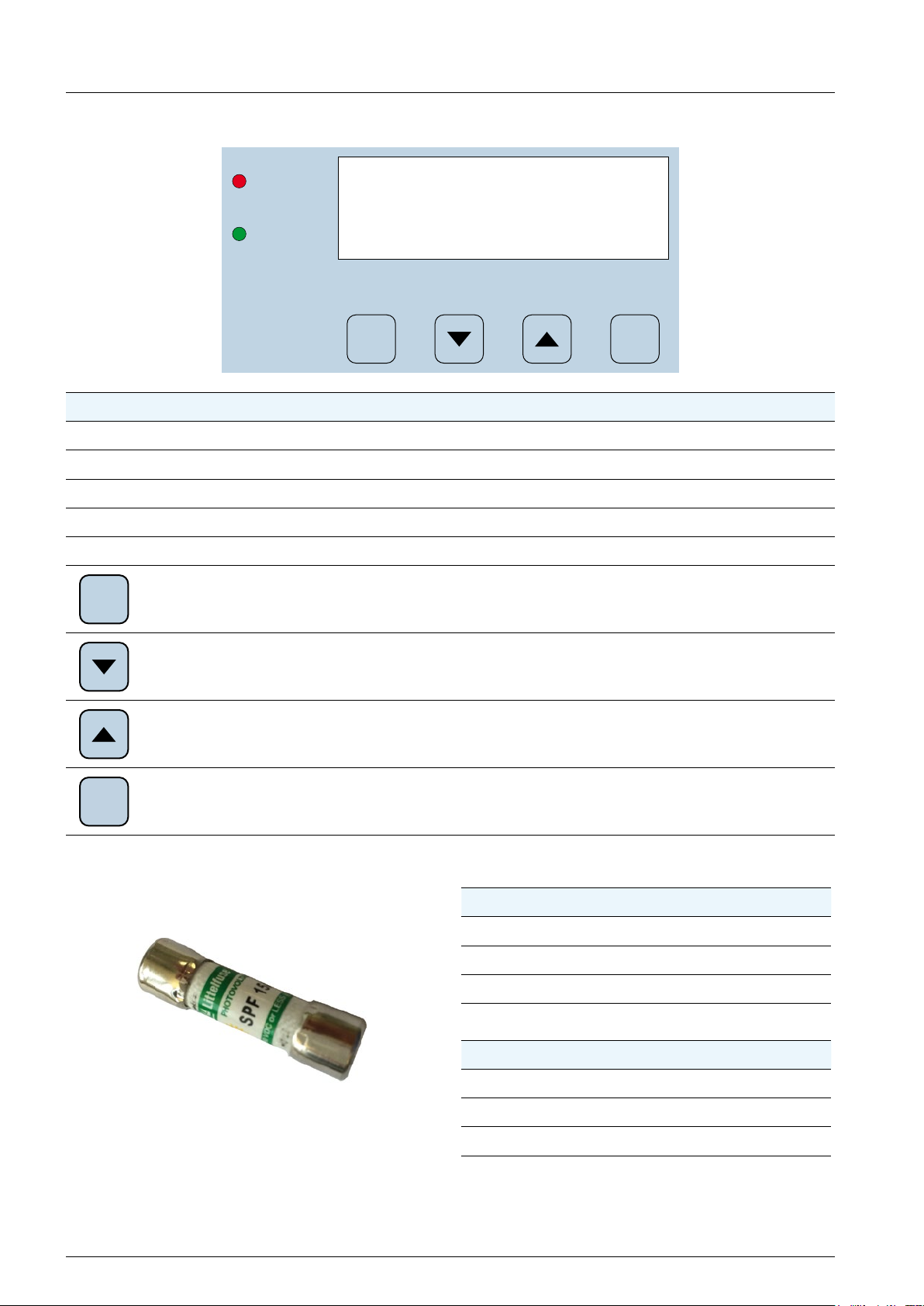

4. Product overview

GrID

AlArm

4.3 Display, buttons, status LEDs

Alarm

Grid

ESC ENT

Label Designation Usage

LEDs

Buttons

ESC

ENT

Grid Green; lights up when the inverter feeds into the grid

Alarm Red; indicates and error, fault, or warning

Escape Exit current menu. Cancel value setting.

Move down Move downwards in menu. Set value (decrease).

Move up Move upwards in menu. Set a value (increase).

Enter

Select menu item. Open con gurable value for editing. Finish editing

(adopt set value).

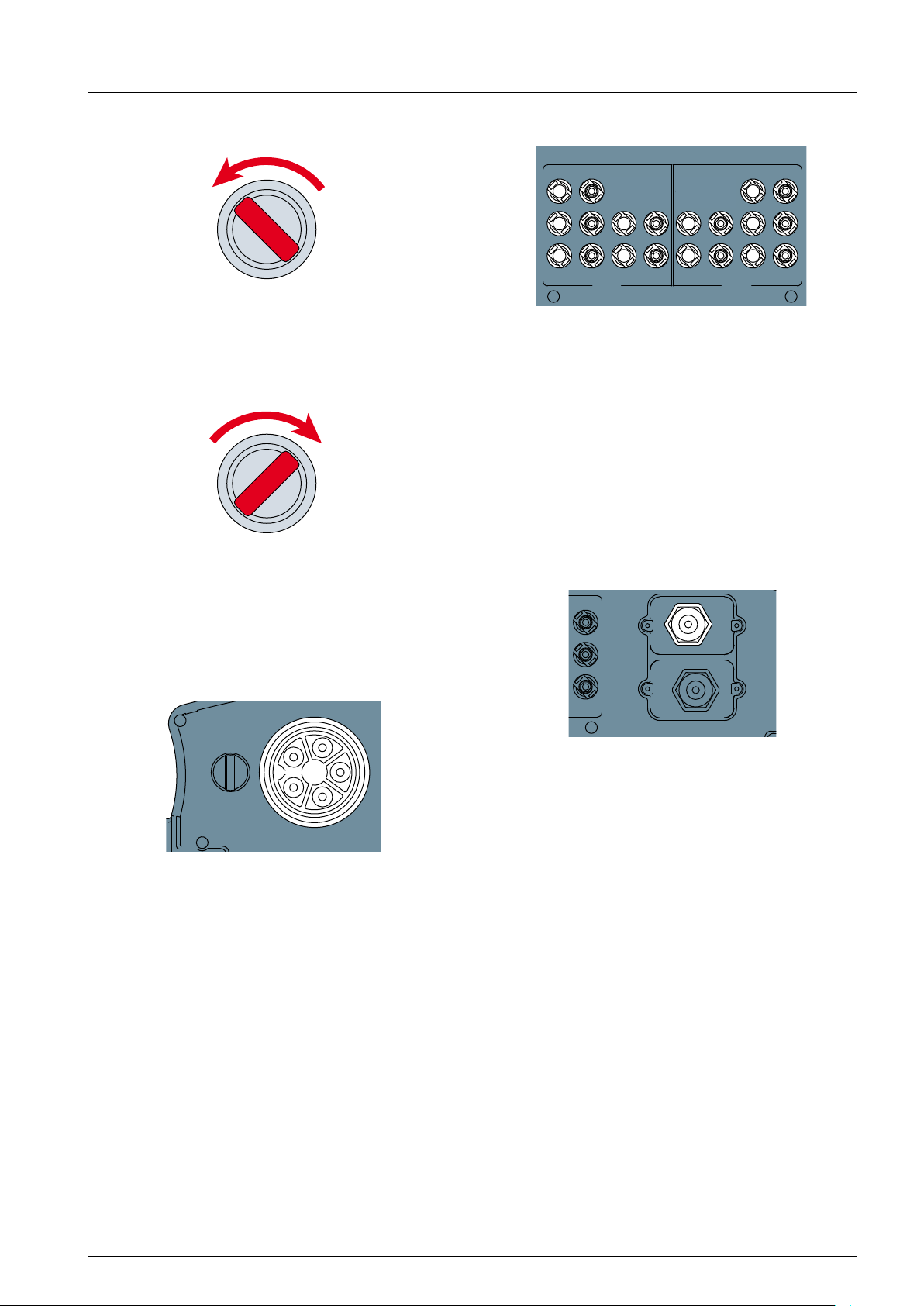

4.4 String fuses

The RPI M50A is equipped with string fuses on the

DC side.

Type

Manufacturer Littelfuse

Part number 0SPF015.T

12

Rate current 15 A

Rate voltage 1000 V

or

Manufacturer Hollyland

Part number 10GPV15UO

Rate current 15 A

Rate voltage 1000 V

Installation and Operation Manual for RPI M50A

4. Product overview

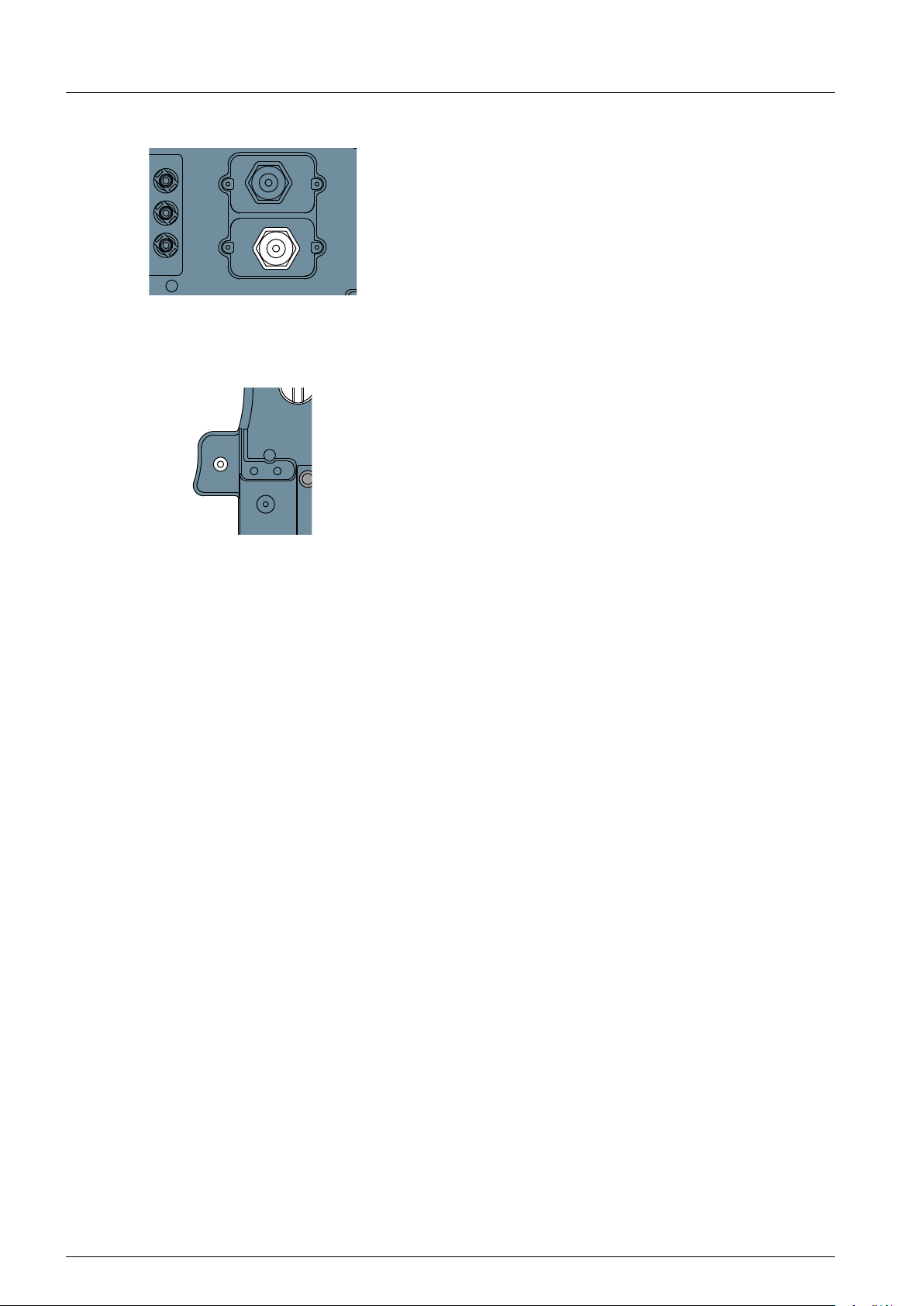

4.5 Surge protection devices

4.5.1 AC side

The M50A_120 additionally has surge protection

devices type 2 on the AC and the DC side.

Type

Manufacturer GEHE

Part number GPU1-C40/690

Voltage U

Current I

Current I

Voltage U

C

n

max

P

690 V

AC

15 kA (8/20)

30 kA (8/20)

≤ 2.5 kV

4.6 Air inlets and fans

Air is intaken from the environment through the air

inlets on the upper left and upper right side of the

inverter. The air is used to cool the inverter. The

warmed-up air is ejected at the fans on the bottom

side of the inverter.

For a detailed description of the cooling principle, see

“5.3 Ambient conditions and air circulation”, p. 19.

For a detailed description how to clean or replace the

fans, see “11. Maintenance”, p. 95.

4.5.2 AC side

The M50A_120 additionally has surge protection

devices type 2 on the AC and the DC side.

Type

Manufacturer GEHE

Part number GPU1-ZS1000*

Voltage U

Current I

Current I

Voltage U

C

n

max

P

1120 V

DC

20 kA (8/20)

40 kA (8/20)

≤ 3.9 kV

Installation and Operation Manual for RPI M50A

13

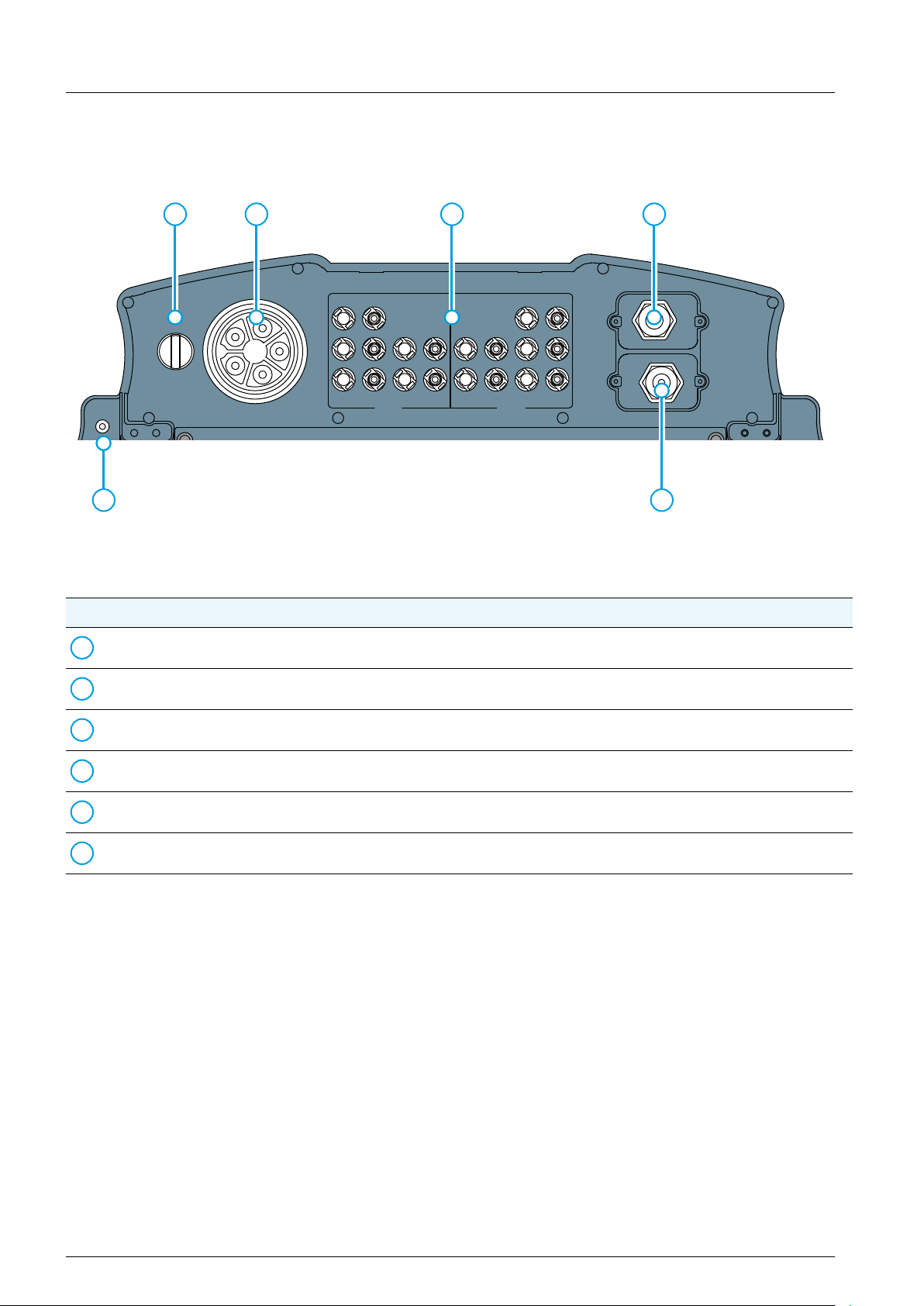

4. Product overview

4.7 Electrical connectors

4.7.1 Overview

1 2 3 4

+– +– +– +–

DISCONN.

AC/DC

ON

DC 1 DC 2

AC OUTPUT DC INPUT

OFF

6 5

Fig. 4.1: Overview electrical connectors

No. Component / connector Description

AC/DC disconnection switch See “4.6.2 AC/DC disconnection switch”, p. 15

1

2

AC connector (AC output) See “4.6.3 AC connector (AC output)”, p. 15

DC connectors (DC inputs) See “4.6.4 DC connectors (DC inputs)”, p. 15

3

Communication port 1 See “4.6.5 Communication port 1”, p. 15

4

COMM.

Communication port 2 See “4.6.6 Communication port 2”, p. 16

5

Grounding screw See “4.6.7 Grounding connection”, p. 16

6

14

Installation and Operation Manual for RPI M50A

4. Product overview

+– +– +– +–

+–

4.7.2 AC/DC disconnection switch

OFF ON

DISCONN AC/DC

The inverter is disconnected from the grid (AC) and

the solar modules (DC) when the AC/DC disconnec-

tion switch is in position OFF.

OFF ON

DISCONN AC/DC

4.7.4 DC connectors (DC inputs)

DC 1 DC 2

DC INPUT

The DC connectors (DC inputs) are used for connecting inverter to the solar module string(s).

Connector type:

● Multi-contact MC4

● 10 pairs with female socket for DC+ and male

socket for DC–.

● 10 pairs of plugs are delivered with the inverter

For technical specications, see “13. Technical data”,

p. 105.

4.7.5 Communication port 1

The inverter is connected to the grid (AC) and the

solar modules (DC) when the AC/DC disconnection

switch is in position ON.

4.7.3 AC connector (AC output)

DISCONN.

AC/DC

ON

AC OUTPUT

OFF

The AC connector is used for connecting the inverter

to the grid.

Usage of the AC connection:

● Feeding AC current into the grid.

● Powering up the display when no DC voltage is

available via the DC connectors (DC inputs).

The inverter can be connected to:

COMM.

Functions of Communication port 1:

● 1 x RS485 in/out (e.g. for connecting to a datalog-

ger)

● 6 x Digital inputs (e.g. for connecting to a ripple

receive controller)

● 2 x Dry contacts (e.g. for connecting to an exter-

nal relais)

● 1 x VCC contacts (e.g. for connecting to an exter-

nal relais)

For a detailed description, see “6.7 Connecting com-

munication port I (optional)”, p. 45.

● 5-wire grid sytems 3P4W (L1, L2, L3, N, PE)

● 4-wire grid systems 3P3W (L1, L2, L3, PE).

AC plug type:

China Aviation Optical-Electrical Technology Co.

PVE5T125KE36

The AC plug is delivered with the inverter.

Installation and Operation Manual for RPI M50A

15

4. Product overview

+–

DISCONN.

4.7.6 Communication port 2

COMM.

Communication port 2 is not available on this inverter.

4.7.7 Grounding connection

AC/DC

The grounding connection is used for grounding the

housing of the inverter.

The grounding screw (M6) with washer spring,

washer and toothed ring is already mounted to the

inverter.

For a detailed description, see “6.3 Grounding the

inverter housing”, p. 39.

16

Installation and Operation Manual for RPI M50A

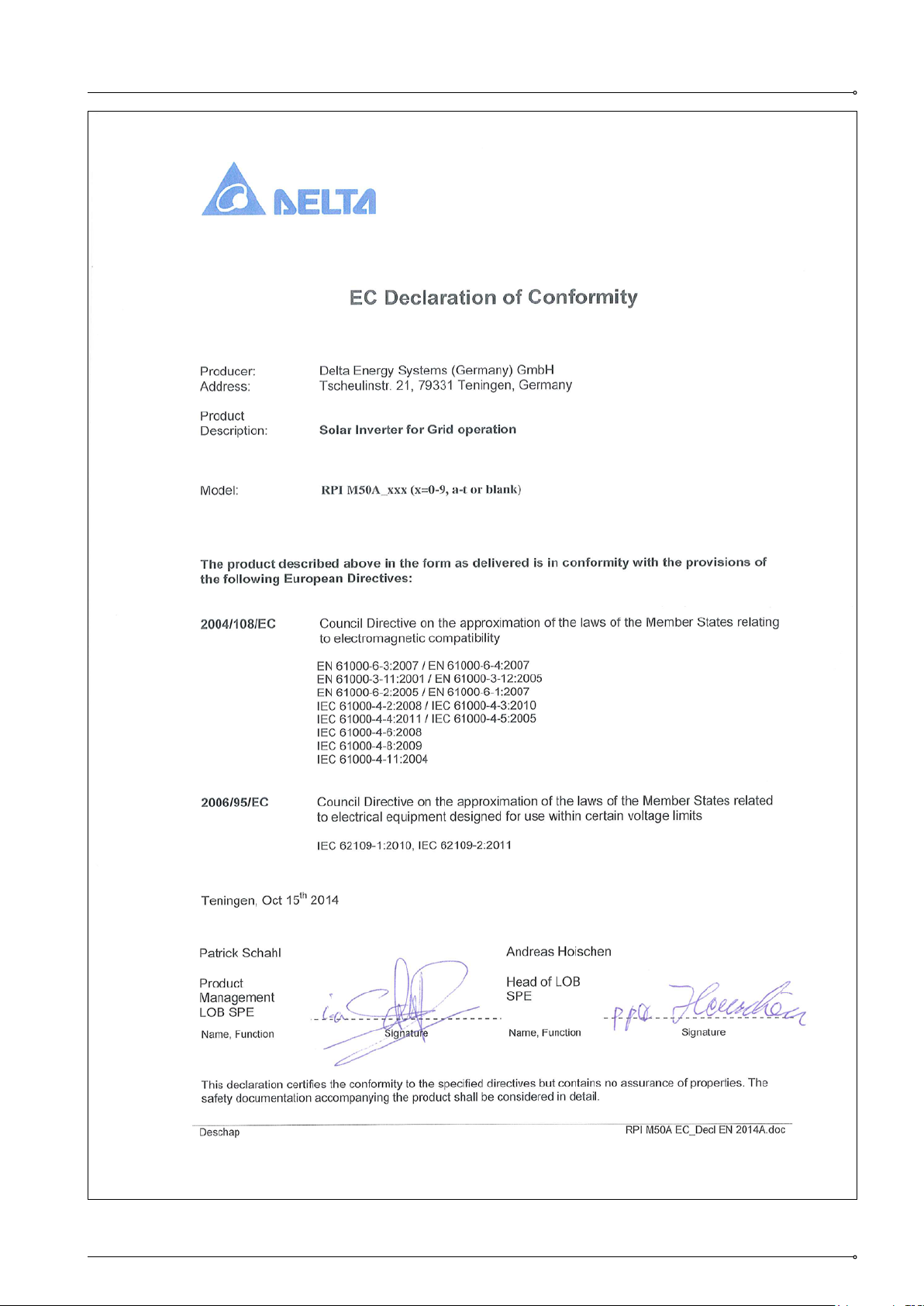

4.8 Information on the type label

Fig. 4.2: RPI M50A_120 type label Fig. 4.3: RPI M50A_122 type label

Information on type label Description

This inverter has no transformer.

Risk of death by electrocution

Potentially fatal voltage is present when the inverter is in operation that remains for

10 seconds after being disconnected from power.

10 s

Never open the inverter. The inverter contains no components that must be maintained or repaired by the operator or installer. Opening the cover will void the warranty.

4. Product overview

Read the manual delivered with the inverter before working with the inverter and

follow the instructions contained in the manual.

The housing of the inverter must be grounded if this is required by local regulations.

DC Input

200-1000Vdc DC input voltage range

MPPT 520-800Vdc MPP input voltage range with full power (with symmetrical load)

1000Vdc Maximum DC input voltage

50A*2 max. Maximum DC input current per DC input (50 A for each DC input)

Isc: 60A*2 max. DC short circuit current

AC Output

220/380, 230/400 Vac AC Nominal voltage

3P3W or 3P4W The inverter can be connected to 3-wire systems (3 phases + PE) and 4-wire sys-

tems (3 phases + N + PE)

50/60 Hz AC Nominal frequency

50kW nom. Nominal active power

55kW/55kVA Maximum active/reactive power

80A max. Maximum AC current

cos φ 0.8 ind ~ 0.8 cap Range of cos φ

IP Code: IP65 (Electronics) Protection degree for the electronics according to EN 60529

Protective Class: I Safety class according to EN 61140

AC Over voltage category: III AC overvoltage category according to IEC 62109-1

Installation and Operation Manual for RPI M50A

17

5 Planning the installation

?

?

?

?

✔

✘ ✘

5. Planning the installation

NOTE

This chapter is for planning the installation only and is not related to do any

real actions.

Some of the actions can be dangerous. Chapter “6. Installation”, p. 37

describes all actions and the possibly

related risks in detail.

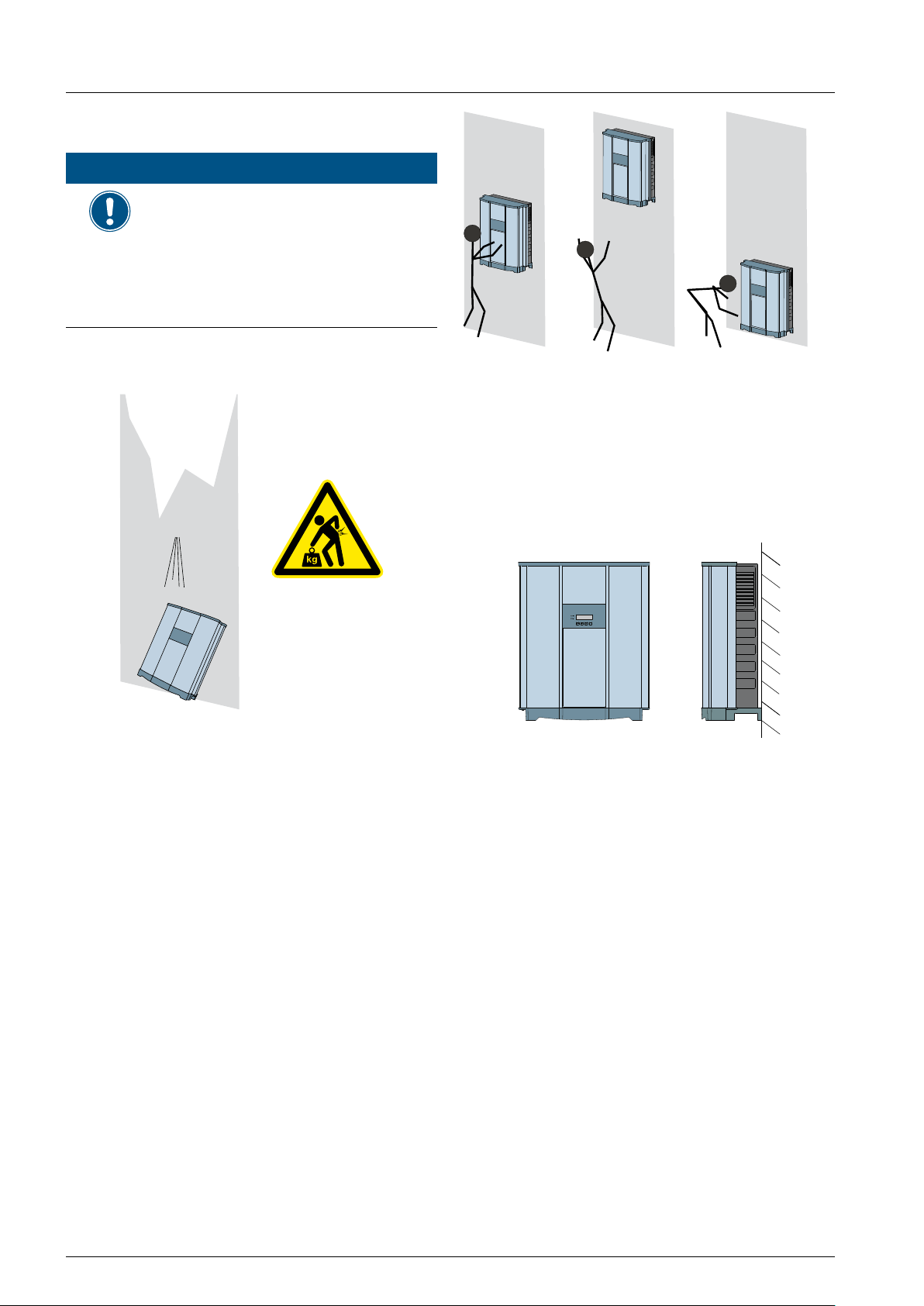

5.1 Where to mount the solar inverter

Fig. 5.2: Where to mount the inverter 2

► Mount the solar inverter so that the LEDs and dis-

play can be easily seen and that the buttons can

be operated. Make sure the reading angle and

installation height are sufcient.

74 kg

Fig. 5.1: Where to mount the inverter 1

► The solar inverter is very heavy. The solar inverter

must be lifted and carried by at least three people.

► Always use the mounting plate supplied with the

solar inverter.

► Check that the wall is capable of bearing the

heavy load of the device.

► Use dowels and screws that are suitable for the

wall material and the heavy weight.

► Mount the solar inverter on a vibration-free wall to

avoid disruptive vibrations.

► Possible noise emissions can be disruptive when

the device is used in living areas or in buildings

with animals. Therefore, choose your installation

location carefully.

Fig. 5.3: Mounting orientation

► Mount the solar inverter vertically.

18

Installation and Operation Manual for RPI M50A

5 Planning the installation

5.2 Outdoor installations

Fig. 5.4: Outdoor installations

► The solar inverter has protection degree IP65 and

can be installed indoors or in protected outdoor

areas (that means outdoor but protected by a roof

against direct sun, rain or snow).

5.3 Ambient conditions and air circulation

>20 cm

>30 cm>30 cm >30 cm

>80 cm

Fig. 5.5: Mounting distances and air circulation

► Ensure adequate air circulation. Hot air must be

able to dissipate downward. Keep enough space

around each inverter.

► Do not install inverters directly above one another.

Otherwise, the lower inverter is warmed up by the

upper one.

► Consider the operating temperature range (see

“13. Technical data”, p. 105).

When the operating temperature range is exceeded, the solar inverter reduces the amount of power

generated.

Installation and Operation Manual for RPI M50A

Fig. 5.21: Air fl ow around solar inverter

19

5 Planning the installation

5.4 Temperature derating curves

P/P

(Pn = 50 kW)

n

115%

110%

105%

100%

95%

90%

S [VA] = P [W]

800 V

600 V

520 V

DC

DC

DC

85%

80%

75%

70%

65%

60%

55%

50%

25 30 35 40 45 50 55 60

Ambient temperatures [°C]

Fig. 5.6: Temperature derating curve (cos φ = 1.0)

20

Installation and Operation Manual for RPI M50A

P/P

Ambient temperatures [°C]

(Pn = 50 kW)

n

115%

110%

105%

100%

95%

90%

85%

5 Planning the installation

P [W]S [VA]

800 V

600 V

520 V

DC

DC

DC

800 V

600 V

520 V

DC

DC

DC

80%

75%

70%

65%

60%

55%

50%

25 30 35 40 45 50 55 60

Fig. 5.7: Temperature derating curve (cos φ = 0.95)

Installation and Operation Manual for RPI M50A

21

5 Planning the installation

Ambient temperatures [°C]

P/P

(Pn = 50 kW)

n

115%

110%

105%

99%

95%

90%

85%

800 V

600 V

520 V

DC

DC

DC

P [W]S [VA]

800 V

DC

600 V

DC

520 V

DC

80%

75%

70%

65%

60%

55%

50%

25 30 35 40 45 50 55 60

Fig. 5.8: Temperature derating curve (cos φ = 0.90)

22

Installation and Operation Manual for RPI M50A

5.5 Efciency curve

Efficiency

100%

99%

98%

97%

96%

95%

94%

5 Planning the installation

800 V

DC

600 V

DC

520 V

DC

93%

92%

15 2050 10 25 30 35 40 45 50

Power [kW]

Fig. 5.9: Efciency curve

Installation and Operation Manual for RPI M50A

23

5 Planning the installation

5.6 Dimensions

107

30

31

158.7

172.8

25

82

Fig. 5.10: Dimensions of mounting plate

612 278

460

Fig. 5.11: Dimensions of inverter

740

24

Installation and Operation Manual for RPI M50A

5 Planning the installation

G N L1 L3L2

N

L1

L2

L3

PE

To solar inverter AC

plug

5.7 AC connection

Always adhere to the specic regulations applicable in

your country or region.

Always adhere to the specic regulations dened by

your grid operator.

For the safety of the user and for the security of your installation, install required safety and protection devices that

are applicable for your installation environment (example:

automatic circuit breaker and/or overcurrent protection

equipment).

Use the proper upstream circuit breaker to protect the

inverter:

Model Upstream Circuit Breaker

RPI M50A 100 A

2

NOTE

The value of the tripping current mainly

depends on the quality of the solar

modules, the size of the PV array and

environmental conditions (e.g. humidity). The tripping current of the residual

current device must not be less than

the specied minimum tripping current.

Permitted earthing systems

Earthing

System

Permitted Yes Yes Yes Yes No

AC grid voltage requirements

3P3W 3P4W

L1-L2 400 V

L1-L3 400 V

L2-L3 400 V

TN-S TN-C TN-C-S TT IT

± 20% L1-N 230 VAC ± 20%

AC

± 20% L2-N 230 VAC ± 20%

AC

± 20% L3-N 230 VAC ± 20%

AC

Fig. 5.12: Where to place upstream circuit breakers

in the system

The inverter is not capable of feeding in DC residual currents due to its design. It fullls this requirement in accordance with DIN VDE 0100-712.

The possibilities of faults were examined by Delta

without taking the integrated RCMU (residual-current

monitoring unit) into account. When examining

these faults in terms of the current valid installation

standards, no danger in combination with a type A

upstream residual-current device (RCD) can occur.

Therefore faults that would otherwise require the use

of a type B residual-current device due to the inverter

can be excluded.

The integrated all-pole sensitive RCMU is certied

according VDE 0126 1-1/A1:2012-02 §6.6.2 for a tripping current of 300 mA. RCD Type A can be used for

this inverter, according to the following table.

M50A

Minimum tripping current of the

mA ≥300

RCD

Installation and Operation Manual for RPI M50A

25

5 Planning the installation

5.8 DC connection

NOTICE

Machine and equipment damage may occur.

Exceeding the maximum current per DC input can cause an overheating of the DC inputs.

► Always consider the maximum current of the DC inputs when planning the installation.

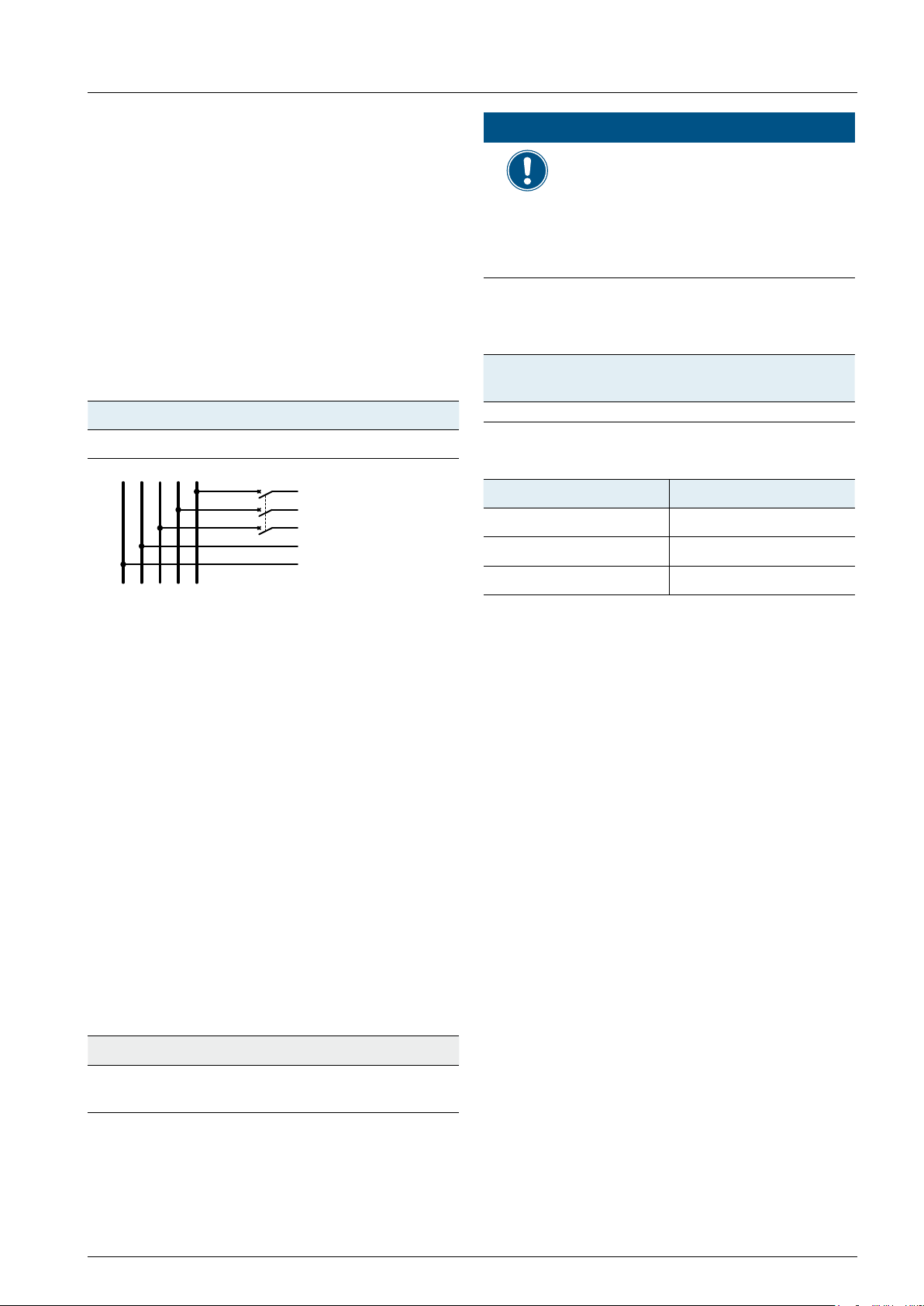

5.8.1 Symmetrical and asymmetrical power input

The inverter operates using two separate MPP trackers that can handle both symmetrical and asymmetrical

power input. This allows you to set up complex PV system designs. For example: east/west-facing roof (asymmetric load) or a south facing roof such as a dormer (asymmetrical load).

Total

East Roof

West Roof

kW

East West

8:00 13:00 18:00

Fig. 5.13: Concept of 2-MPP-tracker system for asymmetrical power input

The following gures explain how symmetrical and asymmetrical power input is handled:

Symmetrical power input Asymmetrical power input

Input Current

I

max

Max. Power MPPT Range

Input Current

I

max

Max. Power MPPT Range

26

U

startup

U

max

U

startup

Input Voltage

Input Current DC 1 Input Current DC 2

Input Current DC 1 Input Current DC 2

Fig. 5.14: I-U curve for symmetrical and asymmetrical power input (schematic diagrams)

Installation and Operation Manual for RPI M50A

U

max

Input Voltage

5 Planning the installation

COMM.

For currents and voltages see “13. Technical data”, p. 105.

5.8.2 Use with solar modules that do not need to be grounded.

When you use PV modules that do not need to be

grounded, you can connect the DC inputs separately

or in parallel.

“Separate DC inputs” means each DC input is connected to a separate MPP tracker. “Parallel DC

inputs” means both DC inputs are connected to one

MPP tracker. With parallel DC inputs you cannot realize asymmetrical power inputs.

PV arrays can be connected to the inverter directly or externally parallel connection at DC distribution box.

PV array

AC wiring

3P3W 3P4W

1 - L1

2 - L2

3 - L3

4 - N

1 - L1

2 - L2

3 - L3

- PE

5 - PE

DISCONN.

AC/DC

ON

OFF

DC wiring

+– +– +– +–

DC 1 DC 2

AC OUTPUT DC INPUT

Fig. 5.15: System design with fl oating DC inputs

Separate or

parallel DC inputs

Installation and Operation Manual for RPI M50A

27

5 Planning the installation

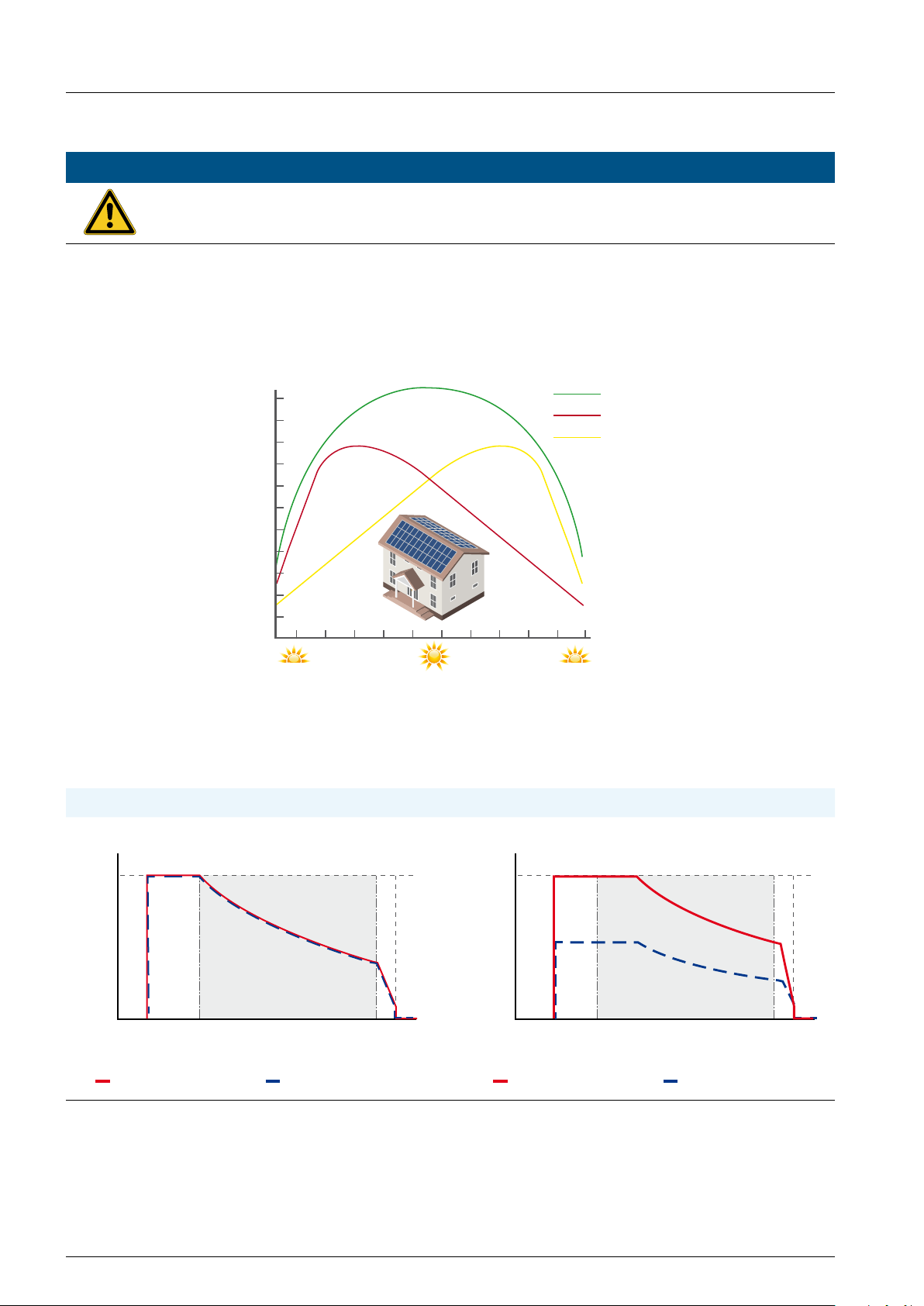

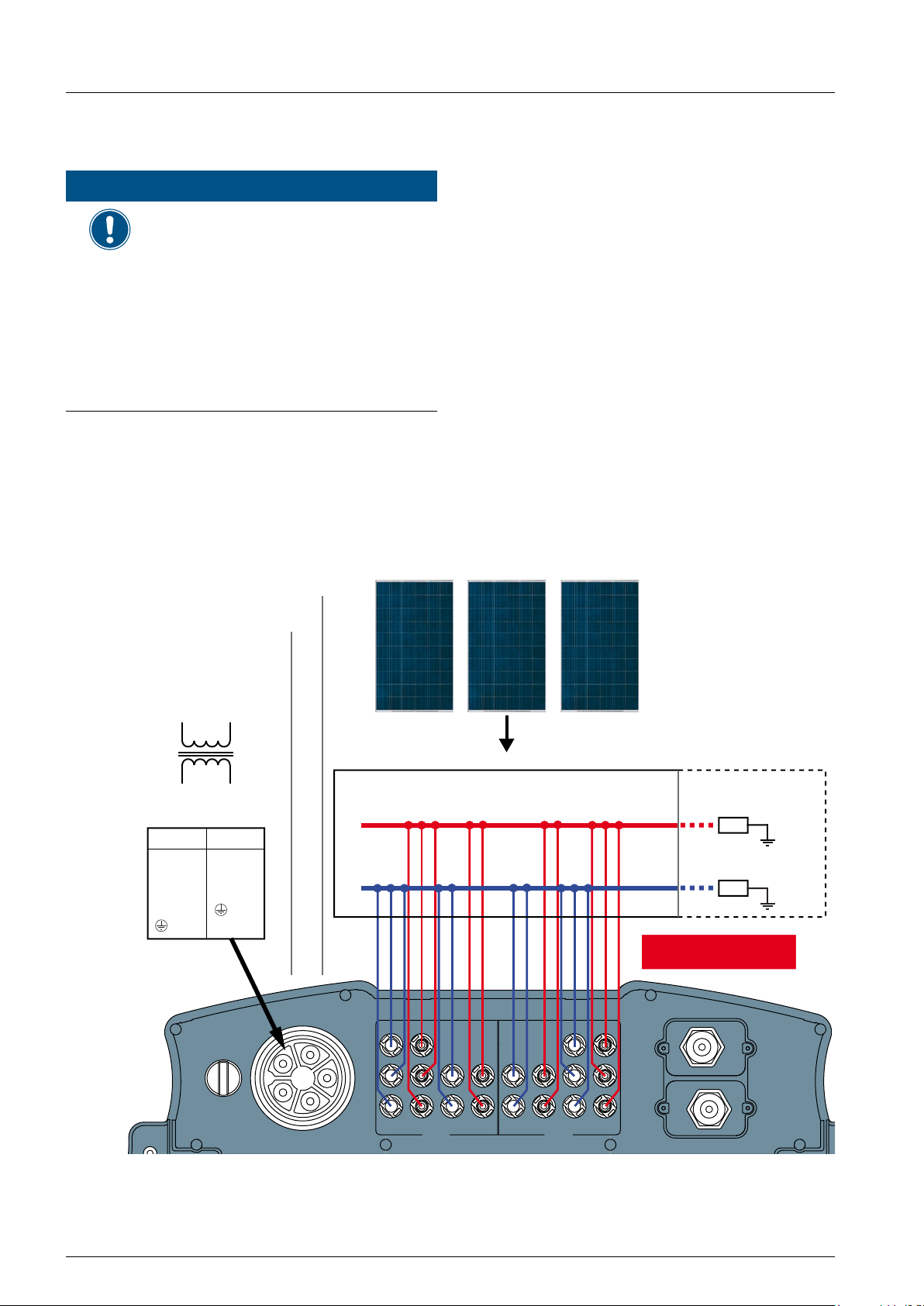

5.8.3 Use with solar modules that have to be grounded.

NOTICE

Machine and equipment damage

may occur.

► When the DC inputs are grounded,

all of the strings must be connected

in parallel and then connected to

the inverters.

► Additionally, an external isolation

transformer must be installed on

the AC side, otherwise, damage will

result and the inverter will not work

properly.

When the DC inputs are grounded, all of the strings

must be connected in parallel and then connected to

the inverter(s).

When the solar modules need to be grounded, an

external isolation transformer has to be implemented

to the AC side of the PV system as shown in Fig.

5.16, p. 28.

Depending on the DC connection type, different settings for insulation detection are needed, see “8.7

Insulation mode and insulation resistance”, p. 59.

You have to prepare the inverter for use with

grounded solar modules, see Fig. 5.17, p. 29 and

Fig. 5.18, p. 30. Because you have to remove the

cover of the fuse section, you should do this before

you hang the inverter on the wall and do it in a dry

environment. For a detailed description how to do

this, see “6.5 Connecting to the solar modules (DC)”,

p. 42.

PV array

AC wiring

3-phase, 230/400 V

star or delta connection

Isolated

transformer

Inverter

230/400 V

3P3W 3P4W

1 - L1

2 - L2

3 - L3

4 - N

5 - PE

Utility

OFF

AC

1 - L1

2 - L2

3 - L3

- PE

ON

AC

Distribution Box

+

–

+– +– +– +–

DC wiring

Positive grounding

Z

Negative grounding

Z

Parallel DC inputs only

28

DISCONN.

AC/DC

AC OUTPUT DC INPUT

DC 1 DC 2

COMM.

Fig. 5.16: System design with positive or negative grounding of the solar modules

Installation and Operation Manual for RPI M50A

1 x

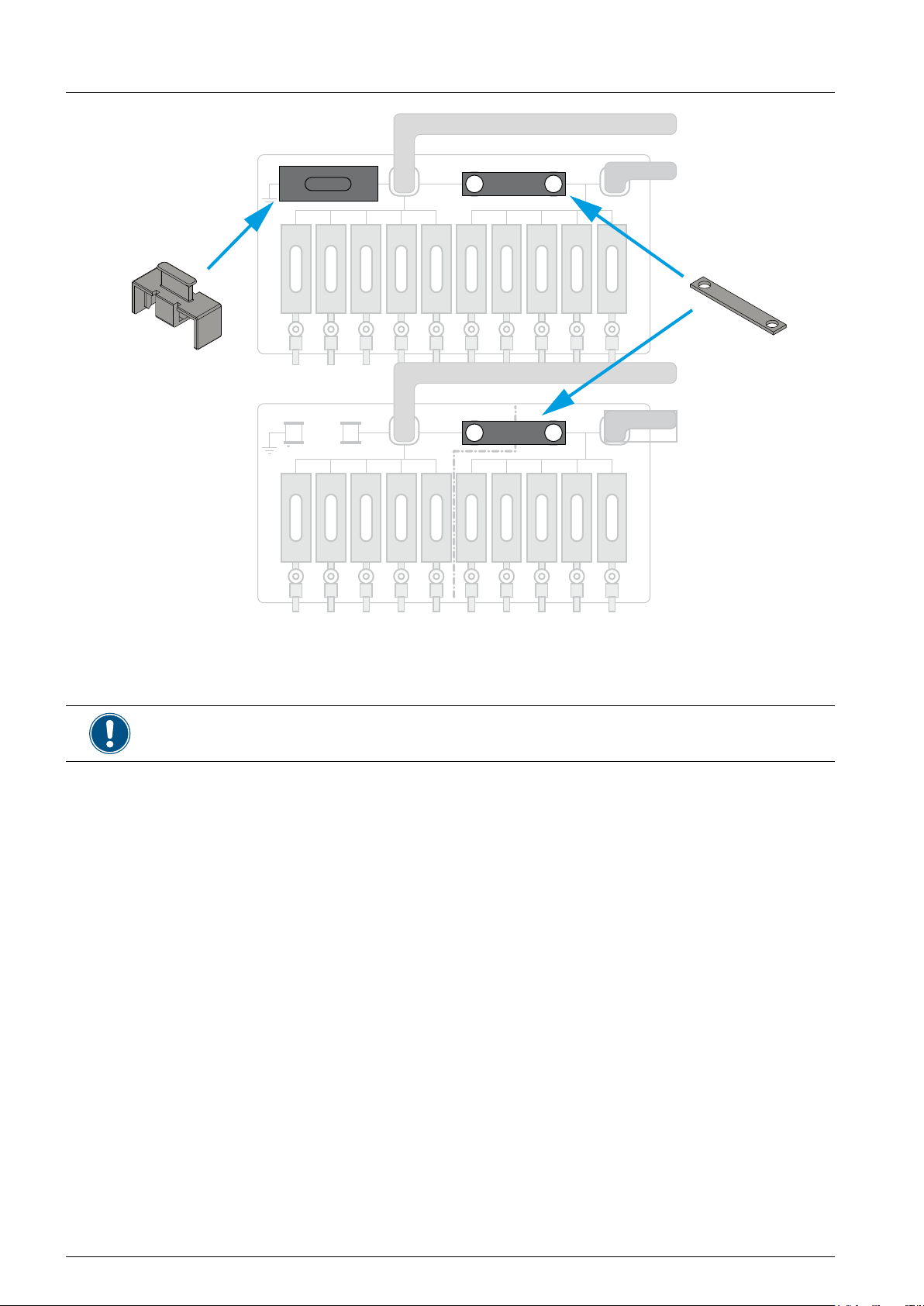

5 Planning the installation

DC1+

DC2+

1 x

+

Grounding fuse (1 A)

Fig. 5.17: Preparing the inverter for use with minus grounded solar modules

Fuse holder and DC bus bars are delivered with the inverter. The screws are already fastened

inside the inverter. You have to provide a grounding fuse with 1 A.

DC1-

DC bus barFuse holder

DC2-

Installation and Operation Manual for RPI M50A

Installation and Operation Manual for RPI M50A

29

29

5 Planning the installation

1 x

DC1+

DC2+

2 x

+

Grounding fuse (1 A)

Fig. 5.18: Preparing the inverter for use with plus grounded solar modules

Fuse holder and DC bus bars are delivered with the inverter. The screws are already fastened

inside the inverter. You have to provide a grounding fuse with 1 A.

DC1-

DC bus barsFuse holder

DC2-

30

30

Installation and Operation Manual for RPI M50A

Installation and Operation Manual for RPI M50A

5 Planning the installation

5.8.4 Using DC1 and DC2 with only one MPP tracker

When you want to use DC1 and DC2 with only one MPP tracker, you have to prepare the inverter as shown in

Fig. 5.19, p. 31.

Because you have to remove the cover of the fuse section, you should do this before you hang the inverter on

the wall and do it in a dry environment.

DC1+

DC2+

DC1-

DC2-

Fig. 5.19: Preparing the inverter for use with only one MPP tracker

Installation and Operation Manual for RPI M50A

31

5 Planning the installation

5.9 Connecting to a datalogger via RS485

The inverter can be connected to a datalogger via

RS485, e.g. for monitoring, changing settings or software updates.

To ensure the proper work of the data connection,

consider the following recommendation and instructions.

For a detailed description how to perform the activities

described in this section, see “6.7 Connecting commu-

nication port I (optional)”, p. 45.

When you connect a single inverter

● The termination resistor has to be switched on.

When you connect multiple inverters within the

same PV system

● On the last inverter in the chain, the termination

resistor has to be switched on.

● If your datalogger has no internal termination re-

sistor, the termination resistor on the rst inverter

in the chain has to be switched on too.

● To each inverter a different inverter ID has to be

applied. This is necessary, so that the datalogger

or the maintenance software can identify each

inverter in the chain.

● The baud rate has to be the same on each in-

verter.

Cable and wire requirements

● Twisted and shielded cables with 2 solid wires.

● Cable diameter: 5 mm

● Wire cross-section: 1 mm

● The RS485 cables should lay with distance from

the AC cable and the DC cables to avoid interferences.

2

32

Installation and Operation Manual for RPI M50A

5.10 Circuit diagram of string fuses and SPDs

DC1+

DC1–

5 Planning the installation

DC2+

DC2–

DC side AC side

Overvoltage protection category II Overvoltage protection category II

Fig. 5.20: Circuit diagram string fuses and surge protection devices

Installation and Operation Manual for RPI M50A

Installation and Operation Manual for RPI M50A

33

33

5 Planning the installation

5.11 What you need

Beside the parts delivered with the inverter (see “4.1 Scope of delivery”, p. 10), you may need the following

addititional parts and tools.

Part Quantity Image/Description

For mounting the inverter

M6 mounting screws 12 The mounting plate has to be mounted with 12 M6 screws.

Depending on where you mount the inverter (e. g. on a brick wall,

concrete wall, metal frame etc.) you may need additional mounting

material.

This could be:

Wall plugs, washers, washer springs, nuts etc.

For connecting the inverter to the grid (AC)

AC cable - Use properly sized wire to connect to the correct poles (see table)

China Aviation

AC connector

Optical-Electrical

Technology Co.

PVE5T125KE36

Current rating 100 A

Min. / Max. cable diameter 37 ... 44 mm

Min. / Max. wire size 25 ... 35 mm

Recommended torque for terminal

screws

3 Nm

2

AC plug delivered with the inverter can be used with exible copper

cable.

When calculating the cross section of the cable, consider:

● material used

● thermal conditions

● cable length

● type of installation

● AC voltage drop

● power losses in cable

Always follow the system installation requirements dened for your

country!

France: Follow the system installation requirements dened by UTE

15-712-1 regarding minimum cable sections and protections against

overheating due to high currents!

34

34

Germany: Follow the system installation requirements dened by VDE

0100 712 regarding minimum cable sections and protections against

overheating due to high currents!

For a description how to connect the AC cable to the AC connector

see “6.4 Connecting to the grid (AC)”, p. 40.

Installation and Operation Manual for RPI M50A

Installation and Operation Manual for RPI M50A

Part Quantity Image/Description

5 Planning the installation

Wire ferrules (bootlace

pins) and crimping tool

4 or 5 Wire ferrules are needed for the wires of the AC cable to tightly mount

them to the AC connector.

4 (for 3-wire systems with 3 phases + PE)

5 (for 4-wire systems with 3 phases + N + PE)

You should use a crimping tool to fasten the wire ferrules to the wire.

For connecting the inverter to the solar modules (DC)

DC cable and DC plugs

a

10 pairs of DC plugs for the DC cable are delivered with the inverter: 32.0016P0001-UR and

32.0017P0001-UR. Follow the description in the table below if you need additional DC plugs.

b

DC connectors on the

Plugs for DC cable

inverter

DC–

a b

2

mm

4 / 6

^

10 5.5-9 32.0034P0001

mm

3–6 32.0014P0001-UR

5.5-9 32.0016P0001-UR

Multi-Contact

4 / 6 3-6 32.0015P0001-UR

5.5-9 32.0017P0001-UR

DC+

10 5.5-9 32.0035P0001

Safety caps up to 20 Safety caps secure the DC cables to the DC inputs so that they can-

not be removed without a special tool. To remove the safety caps,

an open end spanner is needed. The safety caps must be used in

France. Please check local regulations whether you have to use

safety caps.

Installation and Operation Manual for RPI M50A

Installation and Operation Manual for RPI M50A

35

35

5 Planning the installation

WARNING

Dual Supply

Do not work on this equipment until it is isolated from

both mains and on site generation supplies

Isolate on-site Generating Unit(s) at ………………………………………………….

Isolate mains supply at………………………………………………………

Warning – Only persons authorised by the DNO may remove the main cut out fuse

Part Quantity Image/Description

Open end spanner 1 The open end spanner is used to disconnect the DC cables from the

DC inputs.

For grounding the inverter housing

Cables Typically yellow/green copper cable with minimum wire size 6 mm

has to be used. Always consider local regulation regarding the cable

requirements.

For wiring the communication port

Cables Depending on which connectors you want to use (RS485, dry con-

tacts, digital inputs), you need the appropriate cables with wire size

2

.

1 mm

2

For using the inverter with grounded solar modules

Magnetic screw driver 1 If you need to open the cover of the fuse section, you should use a

magnetic screw driver, so that the screws cannot accidentally fall into

the inverter.

Grounding fuse 1 A grounding fuse with 1 A is needed. The fuse holder is delivered with

the inverter.

Other parts

Labels - Check local regulations whether you have to attach special safety

labels to the inverter.

36

36

Isolate both sources before

carrying out any work

Warning

Two sources of voltage present

- distribution network

- photovoltaic panels

Installation and Operation Manual for RPI M50A

Installation and Operation Manual for RPI M50A

6. Installation

6.1 Safety instructions

DANGER

High electrocution

Potentially fatal voltage is applied to

the solar inverter during operation. This

potentially fatal voltage is still present

for 10 seconds after all power sources

have been disconnected.

► Always disconnect the inverter from

power before installation, open the

AC/DC isolating switch and make

sure neither can be accidentally

reconnected.

► Only the cover from the fuse section

may be removed. Never open other

parts of the inverter.

► Wait at least 10 seconds until the

capacitors have discharged.

6 Installation

WARNING

High electrocution

When you remove the cover from the

fuse section, protection degree is no

longer IP65.

► Remove the cover only when it is

► Do not remove the cover when it is

► Close the cover tightly after work.

WARNING

Heavy weight

The inverter weighs about 73 kg.

► The inverter must be lifted and car-

Read chapter “5. Planning the installa-

tion”, p. 18 and this chapter before

you start installation.

really necessary.

raining and the inverter is wet.

ried by at least three people or with

an appropriate lifting equipment.

Installation and Operation Manual for RPI M50A

37

6 Installation

6.2 Mounting the inverter

WARNING

Heavy weight

► The inverter must be lifted and car-

ried by at least three people or with

an appropriate lifting equipment.

► Always use the mounting plate

delivered with the inverter.

Read chapter “5. Planning the installa-

tion”, p. 18 before you start installa-

tion.

1. Attach the mounting plate with 12 M6 screws to

the wall or to your mounting system. Use the ap-

propriate type and number of screws.

3. Check that the rail of the solar inverter hangs cor-

rectly in the mounting plate.

2. Hang the solar inverter onto the mounting plate.

4. Check that the bottom of the inverter is rmly po-

sitioned against the wall or the mounting system.

Also check that the inverter hangs vertically in all

directions.

38

Installation and Operation Manual for RPI M50A

6.3 Grounding the inverter housing

Typically yellow/green copper cable with minimum

wire size 6 mm2 has to be used.

Always consider local regulation regarding the cable

requirements.

Even when such regulations do not exist, it is usually

a good idea to ground the inverter housing for safety

reasons before you set-up the electricial connections.

Although there is an PE connection within the AC connection.

1. On the left side, ground the inverter housing. The

grounding screw is delivered with the inverter and

mounted to the inverter.

6 Installation

Toothed ring

Grounding cable

Washer

Washer spring

M6 Screw

Installation and Operation Manual for RPI M50A

39

6 Installation

6.4 Connecting to the grid (AC)

Read chapter “5. Planning the installa-

tion”, p. 18 before you start installa-

tion.

What you need

● AC plug (delivered with the inverter)

● AC cable

● Wire ferrules (bootlace pins)

● Crimping tool for wire ferrules

Wiring for 3P4W grid systems: 3 phases with 5 wires (L1, L2, L3, N) + PE

Important information regarding safety

DANGER

Risk of death or serious injury from

electrocution

► Set the AC/DC disconnection switch

to position OFF before connecting

or disconnecting the AC plug to the

inverter.

OFF ON

DISCONN AC/DC

Use wire end sleeves (bootlace pins) on each wire.

L3N

L3N

L2

PE

L1

L2PE

L1

L2

L3

N

PE

L1

Fig. 6.26: Wiring AC plug for 5-wire systems

Wiring for 3P3W grid systems: 3 phases with 4 wires (L1, L2, L3) + PE

L3

L3N

L2

PE

L1

L2PE

L1

L2

L3

PE

Use wire end sleeves (bootlace pins) on each wire.

40

L1

Fig. 6.27: Wiring AC plug for 4-wire systems

Installation and Operation Manual for RPI M50A

6 Installation

ATTENTION

Observe the correct polarity of the AC

plug. An incorrect con guration can

destroy the solar inverter.

1. Remove the cable sheath as shown and remove

12 mm of insulation from each wire end.

52.5 mm

10 mm

PE: 57.5 mm

2. Place the end sleeves on the exposed wire ends

and crimp them on.

► Slide the wires of the AC cable into the connec-

tions in the pin insert and screw tight. Observe the

correct phase sequence when doing this.

► Screw the nut

➀, cable housing ➁ and pin insert

➂ together. Tighten the nut to 5 Nm and the cable

housing to 1-2 Nm.

► Insert the AC plug into the AC socket ➁ on the

solar inverter and tighten the locking ring ➀ to a

torque of 6 to 8 Nm.

3. Connect the AC cable to the AC plug as described

below.

► Unscrew the nut and cable housing from the

socket insert.

► Slide the nut and cable housing onto the AC

cable.

► Fit a cable strain-relief clamp directly behind the

round plug when using cables of diameters between 11 and 13 mm. We recommend also using

a strain-relief clamp for cables of other diameters.

Installation and Operation Manual for RPI M50A

41

6 Installation

DC 2

6.5 Connecting to the solar modules (DC)

Read chapter “5. Planning the installa-

tion”, p. 18 before you start installa-

tion.

6.5.1 Safety instructions

OFF ON

DISCONN AC/DC

DANGER

Risk of death or serious injury from

electrocution

Potentially fatal voltage may be applied to

the DC connections of the solar inverter.

When light is falling on solar modules,

they immediately start producing energy.

They do so, even when the sun is not

shining.

► Never disconnect the solar modules

when the solar inverter is powered.

► First switch off the grid connection

so that the solar inverter cannot feed

energy into the grid.

► Turn the AC/DC isolating switch to

position OFF.

► Make sure the DC connections cannot

be accidentally touched.

NOTICE

Machine and equipment damage

may occur.

Exceeding the maximum current per

DC input can cause an overheating of

the DC inputs.

► Always consider the maximum cur-

rent of the DC inputs when planning

the installation.

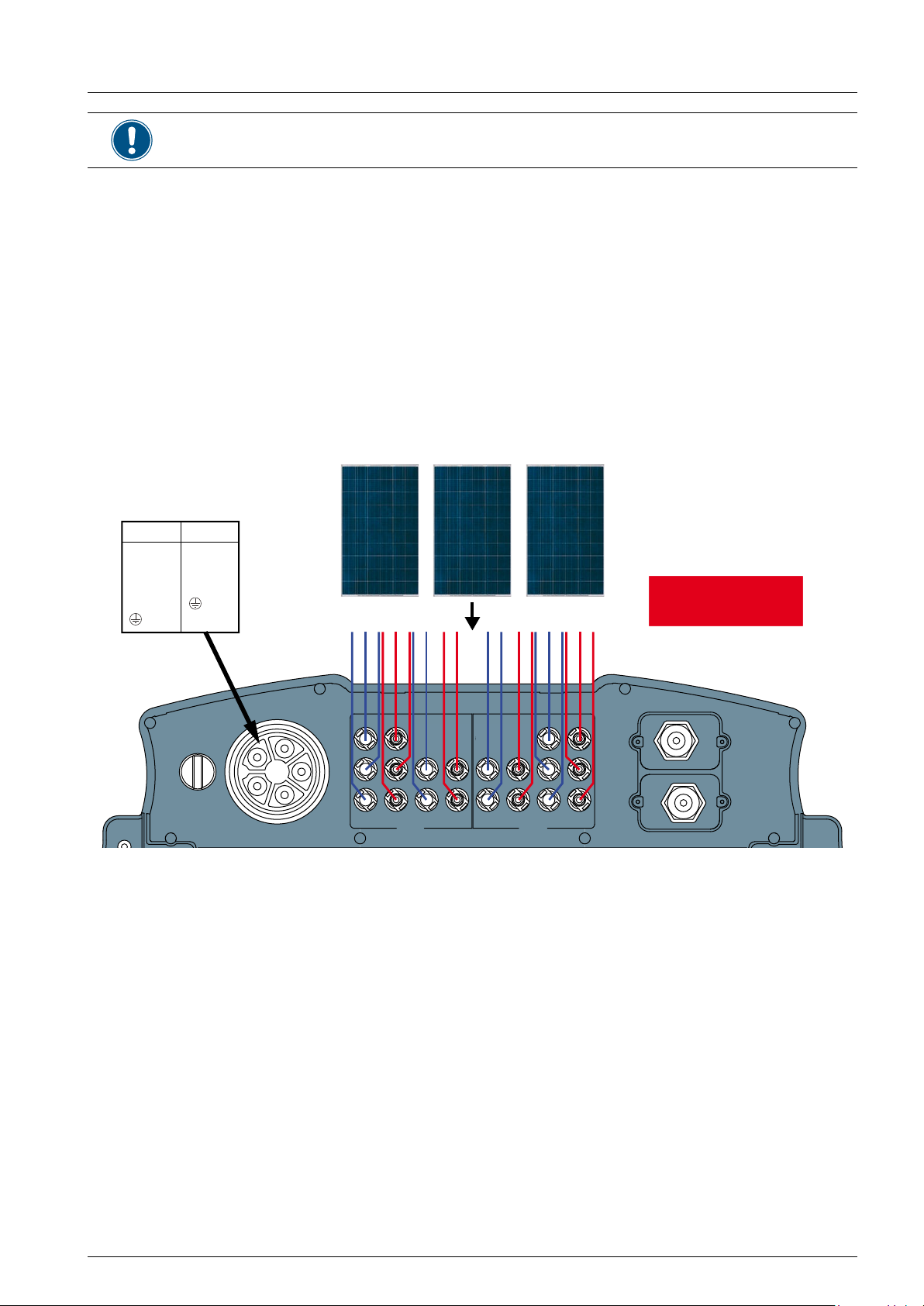

6.5.1.1 Polarity of the solar modules

Check the polarity of the DC voltage before you connect the solar modules. The negative DC pole of the

string is connected to the DC-MINUS connector; the

positive DC pole to the DC-PLUS connector, see “Fig.

6.22: Considering the polarity of the solar modules”,

p. 42.

–

–+ –+ +

+

DC 1

DC INPUT

Fig. 6.22: Considering the polarity of the solar mod-

ules

6.5.2 Cable specifi cation

Cable colors

NOTICE

NOTICE

42

Improperly sized PV array.

An improperly sized PV array can

cause damage to the inverter.

► Consider the technical speci ca-

tions of the inverter (input voltage

range, maximum currents and maximum input power, see “13. Techni-

cal data”, p. 105) when planning

the size of the PV array.

Penetrating humidity.

Humidity can penetrate through unused

DC connectors into the inverter.

► To ensure protection degree IP65,

protect all unused DC connectors

with the caps delivered with the

inverter.

Use a red cable for DC+ and a black cable for DC–.

Fig. 6.23: Colors for DC cables

Installation and Operation Manual for RPI M50A

6 Installation

Connector types

The Multi-Contact MC4 are delivered with the inverter.

The plugs can also be ordered from Multi-Contact

at www.multi-contact.de. The required size depends

on the wire cross-section and thickness of the cable

used.

DC connector type on

the inverter

The DC-MINUS connector is a male socket.

The DC-PLUS conenctor

is a male socket.

Counterpiece required

for the cable

A female plug is required

for the black DC cable.

A male plug is required

for the red DC cable.

6.6 Using DC1 and DC2 with only one MPP tracker (optional)

Only when you want to use DC1 and DC2 on one

MPP tracker, you need to connect the DC inputs as

described on this page.

WARNING

High electrocution

When you remove the cover from the

fuse section, protection degree is no

longer IP65.

► Remove the cover only when it is

really necessary.

► Remove the cover only when the

inverter is in a dry environment.

► Close the cover tightly after work.

You need the two DC bus bars delivered with the

inverter. The screws are already fastened to the connectors inside the fuse section.

You can download the manual from the Multi-Contact

website. This manual will also tell you which tools are

required.

France: Safety caps are needed

for each DC input that is connected to a string of solar modules.

It is recommended to use a special open-end spanner for the

MC4 DC connectors if you need

to disconnect MC4 DC connectors from the inverter. Otherwise

you might destroy the DC Connectors.

► You should use a magnetic screw

driver, so that the screws cannot

accidentally fall into the inverter.

1. Loosen the six screws of the fuse section cover.

2. Remove the cover from fuse section.

Installation and Operation Manual for RPI M50A

43

6 Installation

3. Mount one DC bus bar to connect the DC1+ bar

and the DC2+ bar.

Mount the other DC bus bar with two DC bar

screws to connect the DC1– bar and the DC2–

bar.

DC1+

DC2+

DC1-

DC2-

5. Fasten the six screws to the fuse section cover.

4. Put the cover on the fuse section and screw it

tightly with all six screws.

To ensure protection degree IP65, take care that

– the cover is correctly positioned and seals the

fuse section,

– the rubber at the fuse cover is not damaged or

dirty.

44

Installation and Operation Manual for RPI M50A

6 Installation

+–

1

6.7 Connecting communication port I (optional)

COMM.

Fig. 6.24: Position of the communication port I on the

inverter

6.7.1 RS485 and VCC

RS485 is used to connect the inverters of the PV

plant via a datalogger to a monitoring system.

VCC can be used for an external relais. To use VCC,

set DIP switch 1 to ON. When you do not use VCC,

always set DIP switch 1 to OFF.

For connecting RS485, Pins 3 to 6 are used.

If you want to use SOLIVIA Monitor, the Internet

based monitoring from Delta, you will also need a

SOLIVIA M1 G2 Gateway.

Default baud rate is 19200 which can be changed on

the inverter (see chapter “8.5 Baud rate for RS485”,

p. 57).

Pin assignment

Fig. 6.25: Connectors on the communication card

Pin Designation

Dry contacts

2

3 DC connectors (DC inputs)

4 Communication port 1

VCC switch and RS485 termination resistor

1 2 3 4 5 6

Pin Designation

1 VCC (+12 V; 0.5 A)

2 GND

3 DATA+ (RS485)

4 DATA– (RS485)

5 DATA+ (RS485)

6 DATA– (RS485)

Data format

Baud rate 9600, 19200, 38400;

Standard: 19200

Data bits 8

Stop bit 1

Parity not applicable

Installation and Operation Manual for RPI M50A

45

6 Installation

Switch for VCC and termination resistor

Connecting a single inverter to a datalogger

VCC

Termination

resistor

Connecting multiple inverters to a datalogger

If your datalogger has no integrated termination resistor, switch on the termination resistor on the rst inverter in

the RS485 line.

46

Installation and Operation Manual for RPI M50A

Data logger

6 Installation

6.7.2 Dry contacts

When the fans fail, Dry contact 1 is closed.

When the inverter feeds into the grid, Dry contact 2 is

closed.

Dry contact 2Dry contact 1

6.7.3 Digital inputs and EPO

The digital inputs can be used to connect an external

ripple control receiver for controlling the active power.

5 6 7 8

1 2 3 4

Pin Design. Short Assigned action

1 V1 - -

2 K0 V1 + K0

3 K1 V1 + K1

4 K2 V1 + K2

5 K3 V1 + K3

6 K4 V1 + K4

7 K5 V1 + K5 Reserved

8 K6 V1 + K6 Reserved

The relay for EPO can be set on the display to “normally open” or “normally closed”, see “8.9 EPO

(External Power Off)”, p. 67.

EPO (Emergency

Power Off)

Set maximum active

power to 0%

Set maximum active

power to 30%

Set maximum active

power to 60%

Set maximum active

power to 100%

Installation and Operation Manual for RPI M50A

47

6 Installation

6.8 Wiring communication port 1

6.8.1 First steps for all cables

Because all communication cables are connected

to the same communication port, you should do the

complete wiring at once.

1. Unscrew and remove the bolting.

3. Pull all cables you want to connect through the

bolting.

2. Unscrew and remove the cover.

6.8.2 Wiring a single inverter for RS 485

Wiring RS 485 depends on whether you want to connect a single or multiple inverters.

1. Connect the two wires to Pin D- and Pin D+.

48

Installation and Operation Manual for RPI M50A

6 Installation

2. Switch on DIP switch 2 to turn on the termination

resistor.

6.8.3 Wiring multiple inverters for RS 485

Wiring RS 485 depends on whether you want to connect a single or multiple inverters.

1. On the rst inverter in the RS485 chain, connect

the cable that comes from the datalogger to the

right Pin DC+ and Pin DC-.

3. On the second inverter, connect the cable that

comes from the rst inverter and the cable that

goes to the next inverter. Repeat these steps for

all other inverters in the RS485 chain, except for

the last inverter.

4. On the last inverter in the RS485 chain, connect

the cable that comes from the datalogger to the

right Pin DC+ and Pin DC-.

2. Connect the cable that goes to the second in-

verter in the RS485 chain to the left Pin DC+ and

Pin DC-.

5. On the last inverter in the RS485 chain, switch on

DIP switch 2 to turn on the termination resistor.

Installation and Operation Manual for RPI M50A

49

6 Installation

6.8.4 Wiring the dry contacts

You can use both dry contacts or only one.

1.

6.8.5 Wiring the digital inputs

You can use one of the digital inputs only. The im-

1.

ages below are examples. The rst image shows

the wiring for using the 60% power limitation

signal (Pin V1 and Pin K3).

6.8.6 Finishing the wiring

Depending on how many cables you connected and

whether it is a single inverter or an inverter in a chain

of multiple inverters, the nal wiring could look like

shown in the following two images.

The second image shows the wiring for using

EPO (Emergency Power Off, Pin V1 and Pin K0).

When you want to use multiple digital inputs, Pin

V1 is used for all of these digital inputs.

1. Screw the cover of the communication port onto

the inverter.

50

Installation and Operation Manual for RPI M50A

6 Installation

WARNING

Dual Supply

Do not work on this equipment until it is isolated from

both mains and on site generation supplies

Isolate on-site Generating Unit(s) at …………………………………………… …….

Isolate mains supply at………………………………………………………

Warning – Only persons authorised by the DNO may remove the main cut out fuse

2. Screw the bolting onto the cover.

6.9 Putting labels on the inverter

After nishing the installation, you have to put all

necessary labels onto the inverter. Check local regulations about which labels are needed. See some

samples below.

Warning

Two sources of voltage present

- distribution network

- photovoltaic panels

Isolate both sources before

carrying out any work

Installation and Operation Manual for RPI M50A

51

7. Commissioning

Français

Select language

CHINA 2013

CHINA MV

FRA-Is 50HZ

YES / NO

Are you sure to

E-actuelle: 0kWh

Etat: On Grid

10.Sep 2014 15:32

7. Commissioning

The inverter must be correctly installed, see “6. Installation”, p. 37.

For information on how the display is operated, see “4.3 Display, buttons, status LEDs”, p. 12.

OFF ON

To execute commissioning, the inverter needs to be powered either by AC

(the grid) or DC (the solar modules).

After powering up the inverter for the fi rst time, the Select language dialog

DISCONN AC/DC

➔

English

Deutsch

CZECH

ENGLAND

is shown.

1. Use the buttons and to select language English.

To confi rm your selection, press the button

ENT

.

2. Use the buttons and to select your country or grid type.

To confi rm your selection, press the button

ENT

.

set country:

United Kingdom

Puissance: 0W

► Check chapter “8. Settings”, p. 53 whether you need to adjust addtional set-

tings.

3. If the selected country is correct, use the buttons and to

select the entry YES.

To confi rm your selection, press the button

If you want to change your selection, press the button

→ The inverter starts a self-test which takes approximately 2 min-

utes. A countdown shows the remaining time on the display.

The basic setup is fi nished. The standard menu is shown.

þ

ENT

.

.

ESC

52

Installation and Operation Manual for RPI M50A

8 Settings

8. Settings

8.1 Overview

8.2 Current grid settings (inverter information) 54

8.3 Display language 55

8.4 Date and time 56

8.5 Baud rate for RS485 57

8.6 Inverter ID 58

8.7 Insulation mode and insulation resistance 59

8.8 Grid settings 61

8.9 EPO (External Power Off) 67

8.10 AC Connection type 68

8.11 Max. Power (Maximum feed-in power) 69

8.12 Power limitation 70

8.13 Power versus frequency 72

8.14 Constant cos phi 74

8.15 Cos phi (P) 76

8.16 Constant Q 78

8.17 Q (V) - Apparent power versus voltage 80

8.18 FRT (Fault Ride Through) 83

Installation and Operation Manual for RPI M50A

Installation and Operation Manual for RPI M50A

53

53

8 Settings

E-Today: 0kWh

Power: 0W

Status: On Grid

10.Sep 2014 15:32

Inverter Info.

8.2 Current grid settings (inverter information)

Overview

With this function you can see the current settings of the solar inverter.

Accessing the menu

Main menu > Inverter info.

1. When the default information is displayed, press any button to open the

Meter

Energy Log

Event Log

main menu. Otherwise, repeatedly press the button

menu is displayed.

2. Use the buttons and to select Inverter info.

To con rm your selection, press the button

ENT

.

3. Use the buttons and to scroll through the list.

4. To leave the menu, press the button

ESC

.

until the main

ESC

54

54

Installation and Operation Manual for RPI M50A

Installation and Operation Manual for RPI M50A

8.3 Display language

E-Today: 0kWh

Status: On Grid

Inverter Info.

Active/Reactive Pwr

FRT

Italiano

Overview

With this function you can set the language used in the display.

Accessing the menu

Main menu > General settings > Language

8 Settings

10.Sep 2014 15:32

Power: 0W

General Settings

Install Settings

Language

Date & Time

Baud rate

English

Deutsch

Français

1. When the default information is displayed, press any button to open the

main menu. Otherwise, repeatedly press the button

menu is displayed.

until the main

ESC

2. Use the buttons and to select General Settings.

To con rm your selection, press the button

ENT

.

3. Use the buttons and to select Language.

To con rm your selection, press the button

ENT

.

4. Use the buttons and to select a language.

To con rm your selection, press the button

ENT

.

Con gurable Parameters

Parameter Description Value range

Language

The language used in the display. –

Installation and Operation Manual for RPI M50A

Installation and Operation Manual for RPI M50A

55

55

8 Settings

E-Today: 0kWh

Power: 0W

Status: On Grid

10.Sep 2014 15:32

Inverter Info.

General Settings

Active/Reactive Pwr

FRT

Language

8.4 Date and time

Overview

With this function you can set date and time.

► For a precise calculation of the statistics in the inverter itself and in a monitoring system, date

and time have to be correct.

Accessing the menu

Main menu > General settings > Date & Time

1. When the default information is displayed, press any button to open the

Install Settings

Date & Time

Baud rate

10.Sep 2014 14:55

main menu. Otherwise, repeatedly press the button

menu is displayed.

until the main

ESC

2. Use the buttons and to select General Settings.

To con rm your selection, press the button

ENT

.

3. Use the buttons and to select Date & time.

To con rm your selection, press the button

ENT

.

4. Use the buttons and to change the currently marked (under-

lined) value.

When nished, press the button

→ The marking moves to the next value.

ENT

.

Con gurable Parameters

Parameter Description Value range

-

56

56

Date and time –

Installation and Operation Manual for RPI M50A

Installation and Operation Manual for RPI M50A

8.5 Baud rate for RS485

E-Today: 0kWh

Status: On Grid

10.Sep 2014 15:32

Inverter Info.

General Settings

Active/Reactive Pwr

FRT

Language

9600

Overview

With this function you can set the baud rate for the RS485 connection.

► If you connect multiple inverters via RS485, set the same baud rate on each inverter.

Accessing the menu

Main menu > General settings > Baud rate

1. When the default information is displayed, press any button to open the

8 Settings

Power: 0W

Install Settings

Date & Time

Baud rate

19200

38400

Con gurable Parameters

main menu. Otherwise, repeatedly press the button

menu is displayed.

ESC

2. Use the buttons and to select General Settings.

To con rm your selection, press the button

ENT

.

3. Use the buttons and to select Baud rate.

To con rm your selection, press the button

ENT

.

4. Use the buttons and to select a baud rate.

To con rm your selection, press the button

ENT

.

until the main

Parameter Description Value range

Baud rate

Installation and Operation Manual for RPI M50A

Installation and Operation Manual for RPI M50A

Sets the baud rate for the RS485

connection.

9600 | 19200 | 38400

57

57

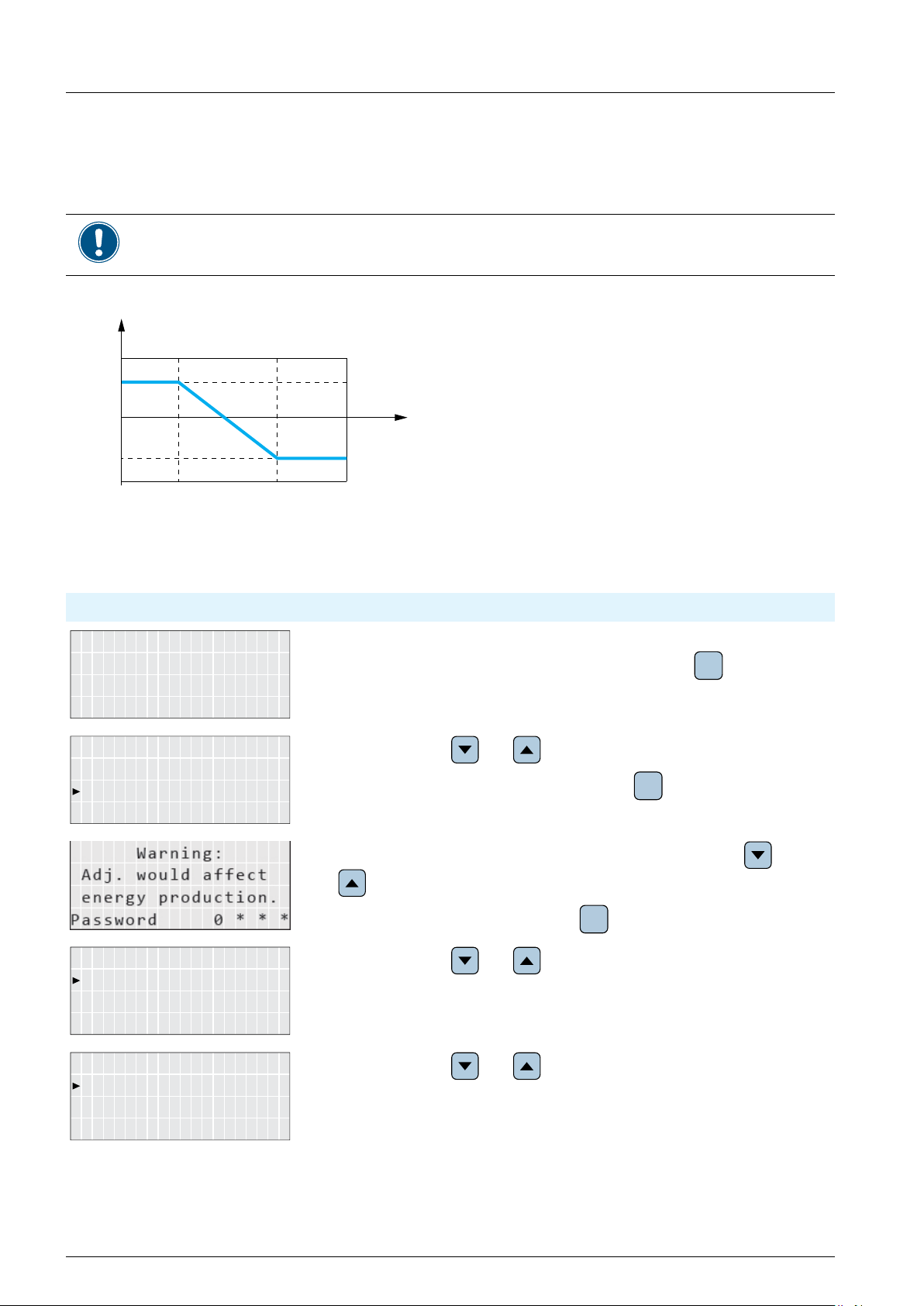

8 Settings

E-Today: 0kWh