RPI M30A/M50A

Operation and Installation Manual

Grid-tie Transfomerless Solar Inverter

The power behind competitiveness

www.deltaww.com

English 1

77

153

简体中文

繁體中文

1. General Information

1.1. About this Manual

1.2. Product Description

1.3. Additional Information

2. Product Overview

2.1. Unpack the Inverter

2.2. Checking Unit and Accessories

2.3. Product Label

2.4. Exterior Objects

3. Installation

4. Wiring

4.1 Preparation Before Wiring (Models with Fuses)

4.2. Preparation Before Wiring (Models without Fuse)

4.3. AC Grid Connection: 3-Phase+PE or 3-Phase+N+PE

4.3.1. Required Protective Devices and Cable Cross-sections

4.4. DC Connection from PV Array

4.5. Communication Module Connections

4.5.1. RS-485 Connection

4.5.2. EPO Functions & Digital Input

4.5.3. Dry Contact Connection

5. Turn On PV Inverter

5.1. LCD Flow Chart

5.2. First startup

5.2.1. Home Page

5.2.2. Power Meter

5.2.3. Energy Log

5.2.4. Event Log

5.2.5. Inverter Information

5.2.6. General Settings

5.2.7. Install Settings

5.2.7.1. Inverter ID

5.2.7.2. Insulation

5.2.7.3. Country

5.2.7.4. Grid Settings

5.2.7.5. Dry Contact

5.2.7.6. EPO

5.2.7.7. AC connection

5.2.7.8. Max. Power

5.2.8. Active/Reactive power

5.2.8.1. Power Limit

5.2.8.2. Power vs. Frequency

5.2.8.3. P(V)

5.2.8.4. Constant cosphi

5.2.8.5. Cosphi (P)

5.2.8.6. Constant Q

5.2.8.7. Q(V)

5.2.9. FRT (Fault ride through)

6.Maintenance

6.1. Replace Surge Protection Device (SPD)

6.2. Replace Internal String Fuse

6.3. Clean Fan

6.4. Replace Fan

6.5. Clean Air Inlets

7.Error message and Trouble Shooting

8.De-Commissioning

9.Technical Data

5

5

5

5

6

6

6

9

10

12

16

16

21

31

31

35

36

37

38

39

40

40

41

41

42

42

43

44

44

45

45

46

46

47

48

49

49

49

50

50

50

51

52

52

53

53

54

55

56

58

59

60

60

61

67

68

Contents

03

Safety Instructions

This manual uses the following instructions for conveying important safety related information.

CAUTION !

Machine and equipment damage may occur if this hazardous situation is not

avoided.

WARNING !

Death and serious injury may occur if this hazardous situation is not

avoided.

Repair work on the device should ONLY be carried out by the manufacturer.

No user serviceable parts inside.

In Australia, installation and maintenance work shall be conducted by qualified

electrician and shall comply with Australian Regulations.

DANGER !

To avoid risk of electrical shock, do not open the solar inverter. Death and

serious injury will occur if this hazardous situation is not avoided.

WARNING ! BURN HAZARD

The unit may reach high temperatures and the device surface can

become hot. Sufficient cooling time is necessary for optimal yield.

04

1.General Information

1.1. About this Manual

This manual is to provide the explanation and procedures for installing,

operating, maintaining, and troubleshooting of RPI M30A/ RPI M50A solar

inverters.

1.2. Product Description

This device is a 3-phase grid-tied solar inverter which does not support offgrid functionality.

The operation of solar inverter is shown as the Figure 1-1. Inverters convert

the

DC input power supplied from the PV Array into 3-phase AC output power

to Grid.

Figure 1-1 Solar system operation illustration

1.3. Additional Information

For more detailed or other related product information, please visit

http://www.deltaww.com

PV Array Electrical GridSolar Inverter

3PH

AC Distribution

box

Surge arrestor

AC breaker

3 phase, N, PE

05

General Information

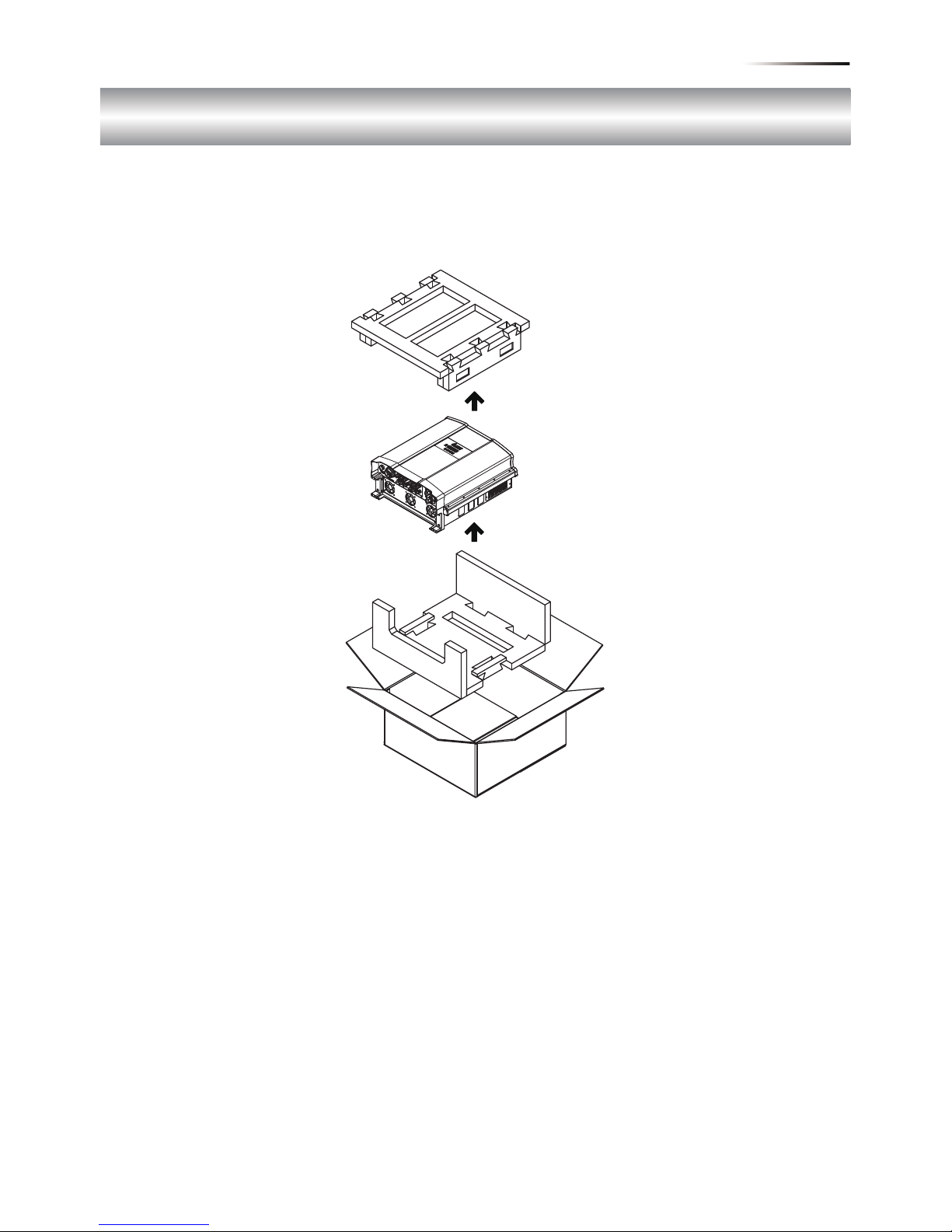

Figure 2-1 Unpack the inverter

The unpacking procedure of RPI M30A/ M50A is shown as Figure 2-1.

2.Product Overview

2.1 Unpack the Inverter

2.2 Checking Unit and Accessories

Unforeseeable events causing damage or movement may occur during

shipment. Please check following items upon receiving your inverter.

• Check the damage on the packaging.

• Check if all the accessories are in the package.

The standard accessories are shown in following tables and figures:

For RPI M30A, Please refer to Figure 2-2 and Table 2-1.

For RPI M50A, Please refer to Figure 2-3 and Table 2-2.

•

Check the model number and the serial number on the packaging is identical

with the model number and serial number on the unit itself.

If there is any visible damage to the inverter/accesories or any damage to

the packaging, please contact your inverter supplier.

06

Product Overview

Figure 2-2 Packing list of M30A

RPI M30A

Object Qty Description

1 PV Inverter 1 pcs

1 pcs

1 pcs

1 pcs

RPI series solar inverter

2 User Manual

The Instruction to provide the information of safety,

Installation, specification, etc.

3 AC Plug

Mounting Bracket

Connector for AC connection

Wall mounting bracket to mount the solar inverter

on the wall.

4

5

DC Plug 6 sets Connector for DC connection

Table 2-1 Packing list of M30A

※These products does not provide grounding fuse. Users can choose 1000V/

1A Midget size grounding fuse if needed.

①

②

⑤

④

③

07

Product Overview

Figure 2-3 Packing list of M50A

RPI M50A

Object Qty Description

1 PV Inverter 1 pcs

1 pcs

1 pcs

1 pcs

RPI series solar inverter

6 Holder 1 pcs Holder for Grounding Fuse

7 Bus-bar 2 pcs Bus-bar for DC+ or DC- Parallel Connection.

2 User Manual

The Instruction to provide the information of safety,

Installation, specification, etc.

3 AC Plug

Mounting Bracket

Connector for AC connection

Wall mounting bracket to mount the solar inverter

on the wall.

4

5

DC Plug 10 sets Connector for DC connection

Table 2-2 Packing list of M50A

※These products does not provide grounding fuse. Users can choose 1000V/

1A Midget size grounding fuse if needed.

①

②

⑤ ⑥

⑦

④③

08

Product Overview

2.3 Product Label

RPI M50A RPI M30A

Please refer to Figure 2-4 for the location of product label. You can identify

the model number and the specifications by the information on the label.

RPI M30A and M50A series have 3 models. The differences between them

are having surge protection devices (SPD) and internal strings fuse or not.

For more detail information, please see the table 2-3.

Figure 2-4 Product label

Model Name Part Number

RPI303FA0E1100

RPI503FA0E0000

RPI503FA0E0200

SPD

X

V

X

Internal Fuse

X

V

V

RPI M30A_121

RPI M50A_120

RPI M50A_122

Table 2-3 Model name

09

Product Overview

2.4 Exterior Objects

Display

Air inlet

Label

RPI M50A

Display

Air inlet

Label

RPI M30A

Input / Output

Interfaces

Input / Output

Interfaces

The Inverter’s exterior objects are shown in Figure 2-5. The detailed input/

output interfaces illustration is shown in Figure 2-6. Different models have

different number of DC input strings.

Figure 2-5 Inverter’s exterior objects

10

Product Overview

Figure 2-6 Input / output interface

AC Connector

380/400Vac, 3Ph

Fan *5Manual

Switch

String1

String2

String3

Communication

-RS-485 *2

-EPO *1

-Dry Contact *2

-Digital Input*6

DC1 DC2

String8

String9

String10

-String4

String5

-String6

String7

RPI M50A

DC1 DC2

String1

String2

String3 String4

String5

String6

AC Connector

380/400Vac, 3Ph

Fan *3

Manual

Switch

Communication

-RS-485 *2

-EPO *1

-Dry Contact *2

-Digital Input*6

RPI M30A

11

Product Overview

CAUTION !

The unit should not be installed in direct sunlight.

WARNING !

• Do not install the unit near or on flammable surfaces.

• Please mount the unit tightly on a solid/smooth surface.

3.Installation

This unit is designed to be wall-mounted. Please ensure the installation is

perpendicular to the floor and the AC plug at the bottom. Do not install the

device on a slanting wall.

To mount the inverter on the wall, please follow the procedure below:

1.Screw the mounting bracket on the wall with 12 M6 Phillips head screws.

Please refert to Figure 3-3.

2.Attach the inverter to the mounting bracket.

3.Fix the inverter with 2 M6 Phillips head screws.

Please refer to Figure 3-4.

12

Installation

Figure 3-1 Mounting bracket dimension

Figure 3-2 Recommended installation

90

Not

Recommended

Not

Recommended

Keep >30 cm from floor and

water if installed this way

13

Installation

M6 Screw *6

Wall

M6 Screw *6

Figure 3-3 Screw the mounting bracket

Figure 3-4 Attach to the bracket and fasten with screws

14

Installation

CAUTION !

• The bracket supplied with the unit is specially designed and should be

the only mounting device used for the unit.

•

It is recommended to install the inverter in a suitable location which offers

non-obscured and safe access, in turn ensuring easy access for service

and maintenance.

• Please leave an appropriate gap in between units when installing several

solar inverter systems as shown in Figure 3-5.

• Please install solar inverter at an eye level to allow easy observation for

operation and parameter setting.

• Ambient temperature -25

° C~60° C.(power de-rating above 40° C)

> 30 cm

> 20 cm

> 50 cm

> 30 cm

> 30 cm

Figure 3-5 Proper installation gap

15

Installation

4.1 Preparation Before Wiring (Models with Fuses)

4. Wiring

WARNING!SHOCK HAZARD

Whenever a PV array is exposed to sunlight, a shock hazard may exist due

to output wires or exposed terminals. To reduce the risk of shock during

installation, cover the array with an opaque (dark) material and ensure that

the Disconnect Device in the inverter is set to OFF before commencing any

wiring.

• M50A has 15A DC fuse in each Plus and Minus DC connector, the

maximum current of each string should not exceed 10A.

• For models with fuses, PV arrays can connect to the inverter directly, but

parallel connection at external DC distribution box is not recommended

due to the limits of DC fuse. Please refer to Figure 4-1 for the detail wiring

illustrations.

• If you want inverter working at parallel input mode (only 1 MPPT), please

install 2 bus bar kits in the inverter as shown in Figure 4-2. The outer wiring

at DC side is same as Firgure 4-1.

• When grounding the solar array, an isolation transformer is required

because the RPI series does not have galvanic isolation between the

DC-input and AC-output. In addition, Users must install a 1000V/1A midget

size grounding fuse and 1 or 2 bus bar kits in the inverter.

Wiring illustrations please refer to Figure 4-3, Figure 4-4.

• When solar array is grounded,the PID function can not be enable,and the

insulation have to be setting “Plus Grounded” or “Minus Grounded”.

•

It must to keep DC and AC power off when disconnected the DC connector.

•

Different DC connections type need different settings of insulation detection.

Please refer to 5.2.7 Install Settings for further information.

16

Wiring

Figure 4-1 floating string with separate connection

1

2

3

4

L1

L2

L3

N

PE

Communication

Wiring

1

2

3

AC Wiring

DC Wiring

Must be Separate

PV strings

*

* RPI M30A can support 3P3W system.

+-+

-

+

-

1

2

3

4

L1

L2

L3

N

PE

Communication

Wiring

1 2

3

AC Wiring DC Wiring

Must be Separate

PV strings

*

* RPI M50A can support 3P3W system.

++++

- -- -

RPI M50A

RPI M30A

17

Wiring

bus bar kit *2

DC1+

DC2+

DC1-

DC2-

String 1~5 +

String 6~10 +

String 1~5 -

String 6~10 -

RPI M50A

Figure 4-2 Force M50A operate in parallel mode

18

Wiring

Communication

Wiring

1 2

3

AC Wiring DC Wiring

Separated

connection only

- -- -

Isolated

transformer

Utility

To

Inverter

3Ph,

400Vac

3Ph,

400Vac

++++

DC1+

DC2+

DC1-

DC2-

String 1~5 +

String 6~10 +

String 1~5 -

String 6~10 -

1A

Grounding fuse

bus bar kit

Figure 4-3 Minus grounding of M50A with fuse

19

Wiring

Communication

Wiring

1 2

3

AC Wiring DC Wiring

Separated

connection only

- -- -

Isolated

transformer

Utility

To

Inverter

3Ph,

400Vac

3Ph,

400Vac

++++

1A

Grounding fuse

bus bar kit *2

DC1+

DC2+

DC1-

DC2-

String 1~5 +

String 6~10 +

String 1~5 -

String 6~10 -

Figure 4-4 Plus grounding of M50A with fuse

20

Wiring

4.2 Preparation Before Wiring (Models without Fuse)

• RPI M30A_121 does not have internal strings fuse. Each string can accept

maximum current 30A. It can use one pair of DC connector for each input

(DC1 and DC2)

• For floating PV array, inverter can accept DC input in parallel connection

or separate connection.

• When grounding the solar array, an isolation transformer at AC side is

required and DC inputs must be parallel connection due to the RPI-series

not having galvanic isolation between the DC-input and AC-output.

• When solar array is grounded,the PID function can not be enable,and the

insulation have to be setting “Plus Grounded” or “Minus Grounded”.

•

Different DC connection type needs different settings of insulation detection.

About setting, please refer to 5.2.7 Install Settings.

Figure 4-5 floating string of M30A_121

1

2

3

4

L1

L2

L3

N

PE

Communication

Wiring

1

2

3

PV Array

AC Wiring

DC Wiring

Parallel or

Separate

*

* RPI M30A can support 3P3W system.

DC Distribution box

DC1 DC2

21

Wiring

Figure 4-6 Plus or minus grounding wiring of M30A_121

Communication

Wiring

1

3

PV Array

AC Wiring

Must be Parallel

Connection

Do not enable the PID function and set

the insulation with “Plus Grounded” or

“Minus Grounded”.

DC Distribution box

(Plus-GND or Minus-GND)

Z

Z

or

Isolated

transformer

Utility

To

Inverter

3Ph,

400Vac

3Ph,

400Vac

Must install a

transformer

2

DC Wiring

22

Wiring

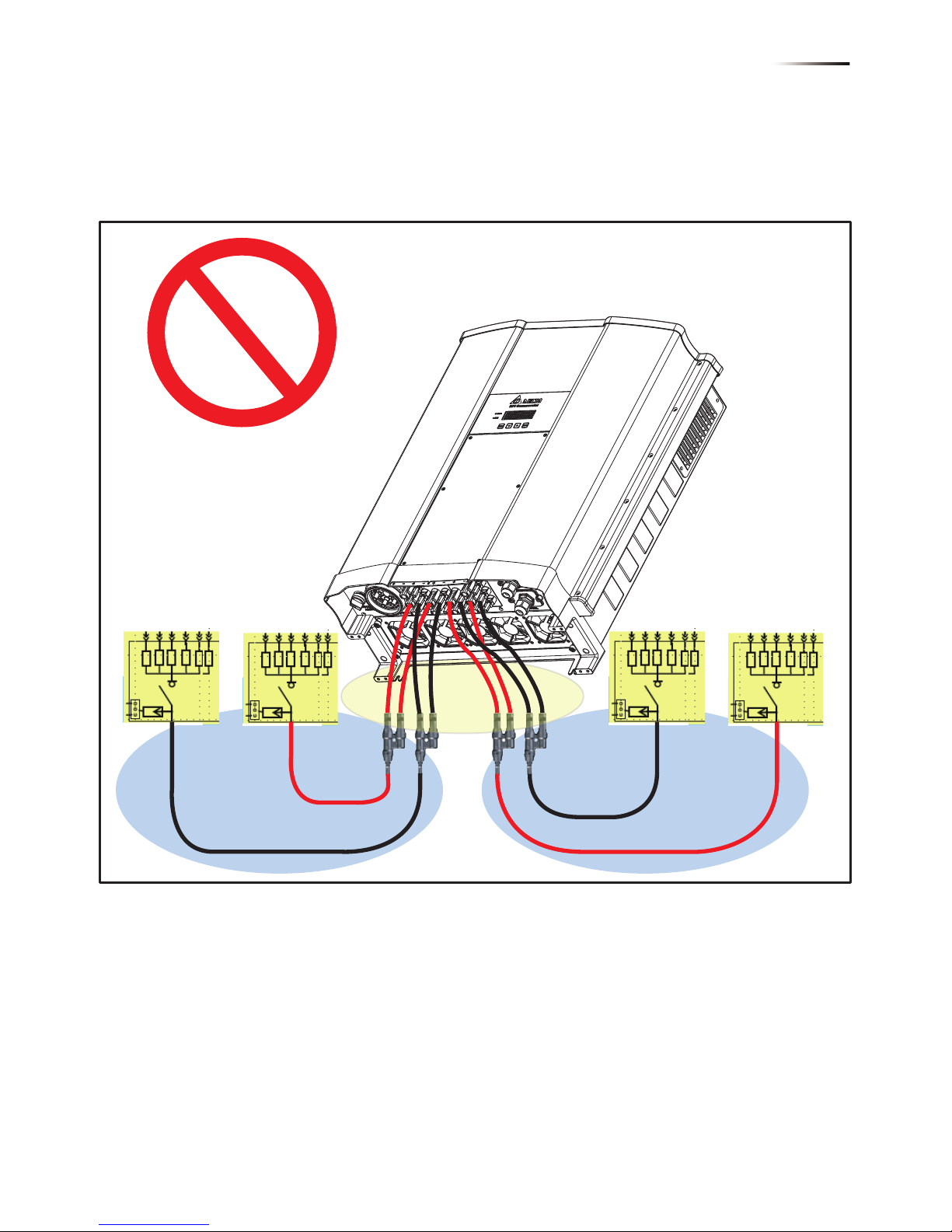

Connection with PV Combiner Box

M50A:

Note for Field Wiring

Due to the limitation of physical wire also the DC connector used in the

inverter, the absolute maximum current of each DC connector should be

always observed as following table to keep fire risk away.

Note that, the following value is provided to identified and checked the

justification for field wiring instead of the DC current rating of inverter.

-Normally, the output current of combiner box is larger than 16A.

Thus it can’t be used as the following diagram (Shown as Figure 4-7).

M50A is not suitable to connected with PV combiner box.

RPI M30A_121 32A

RPI M50A_120 16A

RPI M50A_122 16A

Table 4-1 Maximun current rating of each DC connector

Figure 4-7

>16A >16A

>16A

>16A

23

Wiring

-Also, you can’t use two or more branch to share the current from combiner

box to each dc connector of inverter (Shown as Figure 4-8).

Because the current might not be symmetric among the branch,the current

of one branch might larger than the limitation still.

Figure 4-8

>16A

>16A

>16A

>16A

Strictly forbiden

Risk of fire on internal

entrance cabling

M50A:

24

Wiring

The following diagram shown risky connection with M30A and PV combiner

box. As Figure 4-10 shown , the left pair of dc connector will suffer DC input

current more than the limitation 32A.Thus it is not suitable for use.

Figure 4-10

M30A:

>32A

>32A

25

Wiring

As Figure 4-11 shown , the branch plug might suffer the DC current lager

than its limitation. Thus it is not suitable for use.

*Note that the max current rating of MC4 brauch commercially available is

30A.

Figure 4-11

>30A

*Note

>30A

M30A:

26

Wiring

To Use RPI M50A with 12 PV string

• To apply branch connector on specific indicated DC input connectors.

• To replace relative string fuse for the branch from 15A to 25A by opening

the middle front cover.

The Specific DC input connectors

The inverter equips with 10 pair DC connector.

When 12 string applied, branch plug are required. See following illustrate.

RPI M50A

String 1

String 2

String 3

String 5

String 4

String 6

String 7

String 8

String 9

String 10

String 1

String 2

String 3

String 5

String 6

String 8

String 9

String 11

String 12

String 10

String 7

String 4

Branch Plug

27

Wiring

For this application, the inverter provides specific 2 pairs of DC input connectors

to connect with branch plugs. Both 2 pairs of DC input connectors indicated

by symbols shown as following picture. Note that for Dc input connectors

other than the specific two are forbidden with such application.

28

Wiring

The Relative String Fuse for the branch plug

The inverter provide string fuse with rating 15A in default.

When 2 PV string are connected via branch plug to the specific DC connector,

the current passed through specific connector will be higher than that with

only one PV string. The rating of string fuse for the specific Dc connector

should be enlarged, 25A is recommended. Please refer to Sec 6.2 to find

where String Fuse are. 4 string fuse applied on the specific Dc connector

are indicated as group “Max 25A”.

29

Wiring

Material List for application with 12 String

MC4 Branch Plug

25A String Fuse

-Male Cable Coupler (For polarity +) ,2 Pcs required per inverter

-Female Cable Coupler (For polarity –) ,2 Pcs required per inverter

Male Cable Coupler Female cable coupler

Vendor/Model No

Multi-Contact/PV-AZS4

Vendor/Model No

Multi-Contact/PV-AZB4

Little Fuse /0SPF025.T - 1000V/25A ,4 pcs required per inverter

Male cable coupler Female cable coupler

30

Wiring

4.3 AC Grid Connection: 3-Phase+PE or 3-Phase+N+PE

WARNING!

Before commencing AC wiring, please ensure AC breaker is switched off.

4.3.1. Required Protective Devices and Cable Cross-sections

It is recommended to install an upstream circuit breaker between AC side

and inverter side for over current protection.

The AC cable must be jacketed and meet the specifications in table 4-3.

If there is any conflict between table 4-3's specification and local electrical

code, please follow the electrical code.

RPI M30A and M50A support both 3P3W (3phase and PE) and 3P4W

(3phase, N and PE) connections.

* For M30A model,

End sleeve is not able to be installed if 25mm

2

or 4AWG is applied.

* For M50A models,

End sleeve for each wire is necessary if 25mm2 or 3AWG is applied.

End sleeve is not able to be installed if 1AWG is applied.

Model Upstream circuit breaker

RPI M30A

RPI M50A 100A

60A

Model Current Rating Recommended TorqueWire Size* Cable size

65 A

100 A

RPI M30A

RPI M50A 3 N.m

2.5 N.m

G N L1 L3L2

N

L1

L2

L3

PE

To solar inverter

AC plug

Table 4-2 Recommended upstream protection

Table 4-3 AC input cable requirement

25-38mm

2

3-1AWG

16mm

2

6-4AWG

37-44mm

23-31mm

Wiring

31

CAUTION!Machine and equipment damage may occur.

• Make sure to choose proper size for AC cable.

•

Failed to follow these instructions may cause AC plug damage.

• AC plug’s installation must meets the local electrical code.

• If there is any conflict between installation instruction and electrical

code, please follow the electrical code.

Follow the steps below to strip the wires before assembling the AC plug:

• Remove 55 mm (2.2 inch) of AC cable outer jacket.

• Trim the L1, L2, L3, and N wire to 52.5 mm (2.0 inch).

• Strip 12 mm (0.5 inch) of insulation from all wires ends for RPI M30A.

• Strip 18 mm (0.7 inch) of insulation from all wires ends for RPI M50A.

Figure 4-12 Striping the wires

32

Wiring

Assemble the AC plug and wires as the procedures shown in Figure 4-13

(RPI M30A) and Figure 4-14 (RPI M50A). The sequence of L1~ L3 can be

connected randomly. However, N and PE must be connected correctly.

1. Fixed this part

2. Rotate to loosen

the AC plug

3. Depart the AC plug.

L1

L2

L3

N

PE

L1

L2

L3

N

PE

4. Insert the wires

5. Tighten the screws to

fixed the wires.

5. Reassemble the AC plug

Inverter

7. Rotate to tighten

the plug

8. Rotate the gland to

fix wires

6. Connect the AC plug

to inverter

Figure 4-13 AC plug illustration for M30A

33

Wiring

Fix it

Rotate to loose the AC plug

L1

L2

N

PE

L3

Cable

L1

L2

L3

N

PE

Cable

Rotate to tighten the inserter

Rotate gland to fix cable

Fix it

Inverter

Rotate to tighten the plug

AC plug

Socket

AC plug

Cable

Figure 4-14 AC plug illustrationfor M50A.

34

Wiring

After wiring, installer should choose the AC connection type on the control

panel. About setting, please refer to 5.2.7 Install Settings.

The AC voltage should be as followings:

3P3W 3P4W

L1-L2: 400 Vac ± 10% L1-N: 230 Vac ± 10%

L1-L3: 400 Vac ± 10% L2-N: 230 Vac ± 10%

L2-L3: 400 Vac ± 10% L3-N: 230 Vac ± 10%

4.4 DC Connection from PV Array

WARNING!

• When undertaking DC wiring, please ensure the correct polarities

are connected.

•

When undertaking DC wiring please ensures that the power switch on

the PV array is OFF.

CAUTION!

• The connection number of PV Array, open circuit voltage and power

of all strings in DC1 must be coherent.

•

The connection number of PV Array, open circuit voltage and power of

all strings in DC2 must be coherent.

• The maximum open circuit voltage of PV Array cannot exceed 1000V.

• Any device installed between PV Array and inverter must meet the

following specifications:

Rated voltage > open-circuit voltage of PV Array.

Rated current > short-circuit current of PV Array.

• The input power to the inverter should not higher than the rated power

shown in table 4-4.

Type of limit RPI M30A RPI M50A

Maximum input power 35kW 52.5 kW

DC1 or DC2 23.5 kW 36.8 kW

Table 4-4 Maximum rating of input power

35

Wiring

Model Current Rating Wire size

RPI M30A_121 DC 30A 6 mm / 10 AWG

2

RPI M50A_120 DC 15A 4 - 6mm / 12 - 10 AWG

2

RPI M50A_122 DC 15A 4 - 6mm / 12 - 10 AWG

2

Table 4-5 Cable size

Figure 4-15 DC Wiring illustration

Figure 4-16 Communication module

DC wiring polarities are divided into positive and negative, which is shown

in Figure 4-15. The connection shall be coherent with the indication marked

on inverter.

PV-KBT4/6 Ⅱ

PV-KST4/6 Ⅱ

4.5 Communication Module Connections

Please refer to Figure 4-16 for the Communication Module illustration.

The module provides VCC, RS-485, dry contact, EPO, and Digital Input

terminals for different use.

** Please using diameter Φ3.5 ~ Φ4.9 cable wires. **

EPO*1 &

Digital Inputs*6

Dry Contact*2

VCC & RS-485

Terminal Resistor & VCC Switch

36

Wiring

4.5.1. RS-485 Connection

The pin definition of RS-485 is shown in table 4-6. Different RS-485

connection needs different set up of the terminal resistor.

•

When single inverter is installed, the terminal resistor on its communication

module should be switched ON.

• When multi-inverters in chain as shown in Figure 4-17, only the first and

last inverter’s terminal resistor must be switched ON.

Please refer to table 4-7 for the terminal resister setting.

Pin Function

1 VCC (+12V)

2 GND

3 DATA+

4 DATA-

5 DATA+

6 DATA-

Table 4-6 Definition of RS 485 pin

Figure 4-17 Multi-inverter connection illustration

1 2 3 4 5 6

Data Format:

Baud rate: 9600, 19200 (default), or 38400

Data bits: 8

Stop bit: 1

Parity: N/A

RS485/USB

or

RS485/RS232

Terminal Resistor

120Ω(1/2W)

DATA+ to DATA-

Terminal Resistor

120Ω(1/2W)

DATA+ to DATA-

37

Wiring

Switch 1 Switch 2

VCC ON Terminal Resistor ON

VCC OFF Terminal Resistor OFF

OFF

ON

Tabel 4-7 Terminal resister setting

Figure 4-18 EPO functions

Tabel 4-8 Definition of digital input & EPO functions

4.5.2. EPO Functions & Digital Input

Communication Module has 1 set of emergency power off function (EPO).

Users can customize EPO function in Install Settings page. Please refer

to section 5.2.7.6 EPO. RPI M30A/ M50A also provides 6 sets of digital

input function (K1~K6). Please refer to Table 4-8 for the digital input setting.

It have to disable the function of Active/Reactive power, P-F and P(U) when

digital input setting is working.

EPO & Digital Input

Inverter’s action

Emergency power off (EPO)

0% active power

Maximum 30% active power

Maximum 60% active power

Maximum 100% active power

Reserved

Reserved

Short

V1 & K0

V1 & K1

V1 & K2

V1 & K3

V1 & K4

V1 & K5

V1 & K6

38

Wiring

4.5.3. Dry Contact Connection

RPI M30A/ M50A provide 2 sets of Dry Contact. These 2 Dry Contacts are

linked together and have the same function. The function can be customized

by users, please refer to section 5.2.7.5 Dry Contact.

Figure 4-19 Dry contact port & Assignments

Dry

Contact 1

Dry

Contact 2

39

Wiring

RPI M30A/ M50A include a 4x20 character type LCD display and 2 LED

lights to indicate inverter’s status. For physical characteristics.

Please refer to table 5-1 for more information about inverter’s statuses

and LED inducator.

The following section will introduce the functions that can be adjusted by

users through the LCD panel. When you are adjusting settings, LCD panel

will change the display cursor from “►” to “ ”.

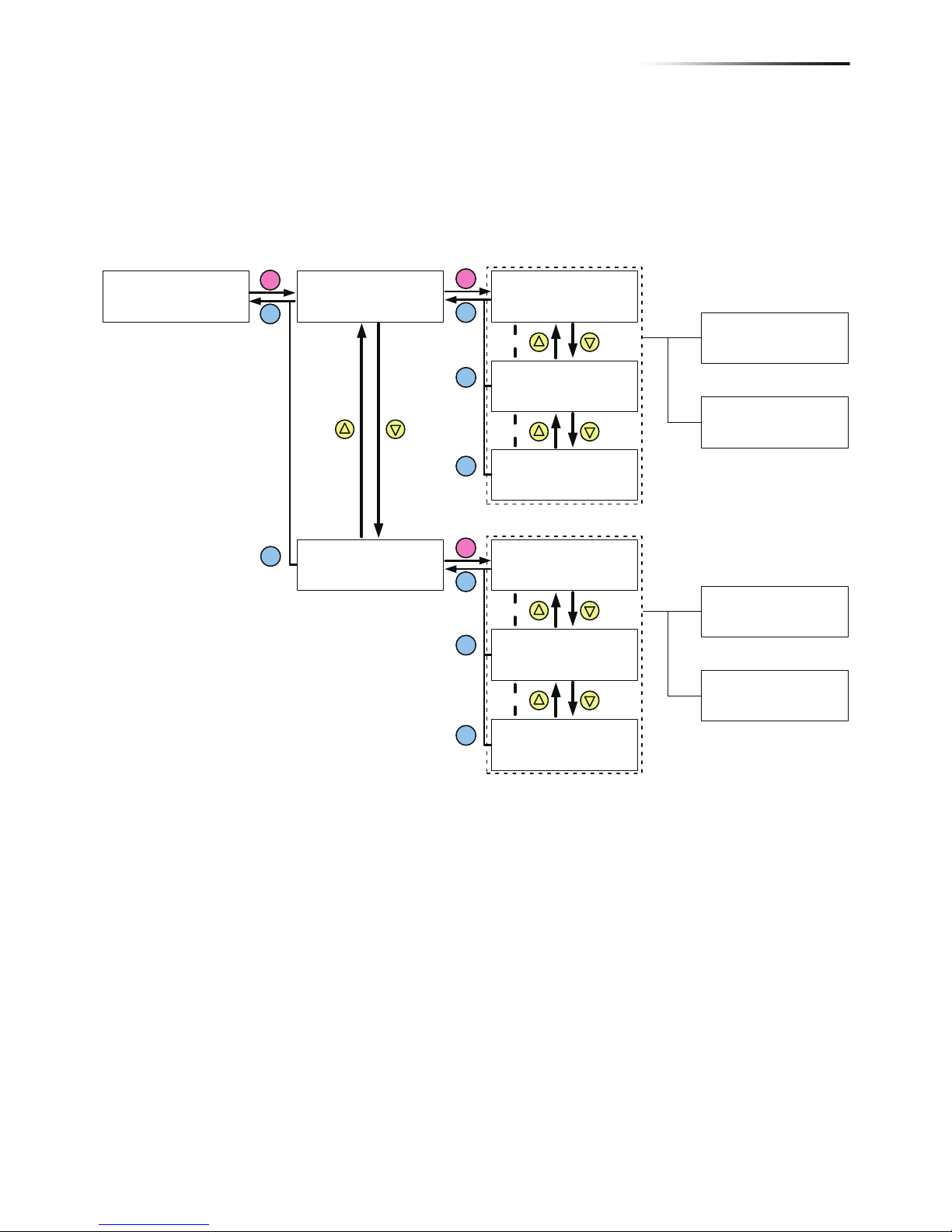

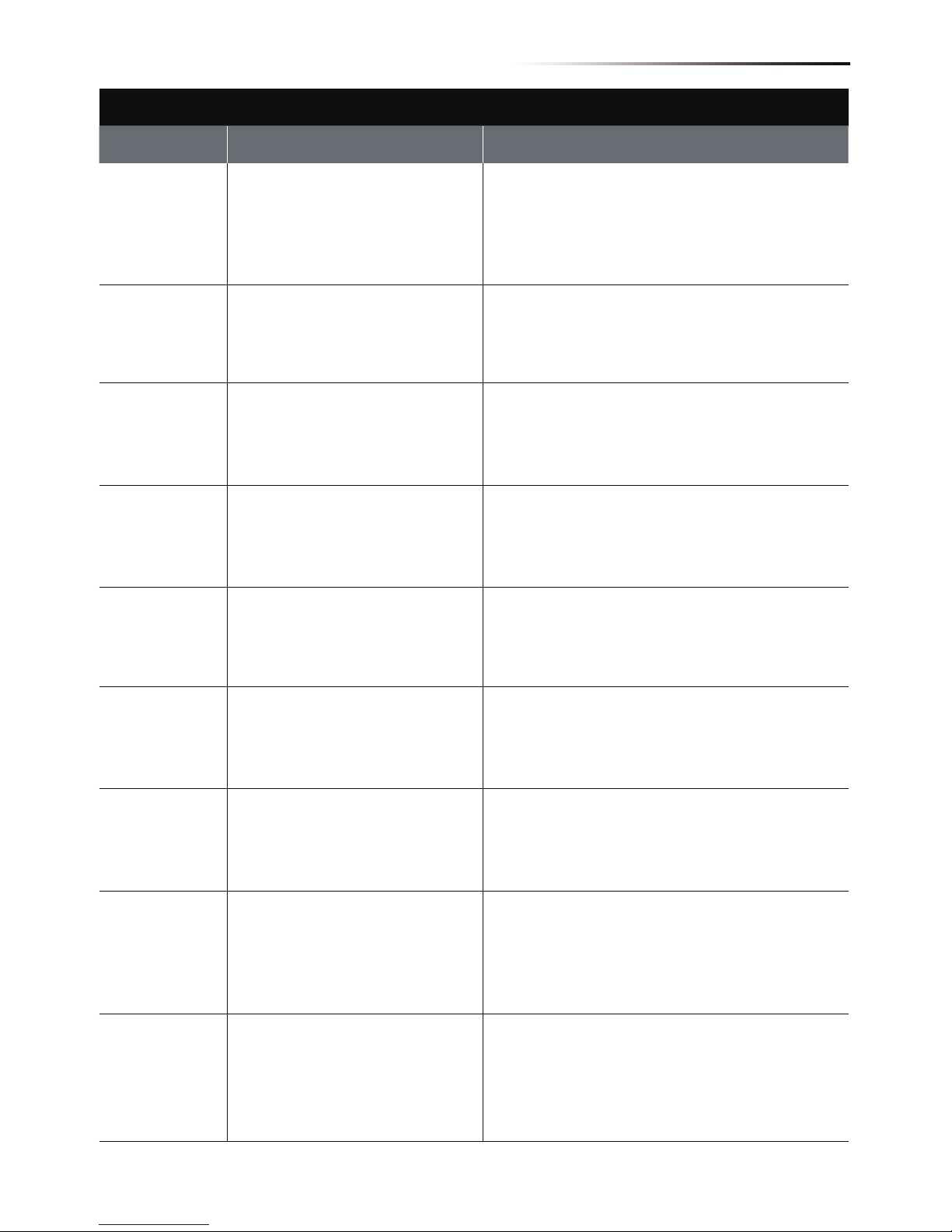

5.1 LCD Flow Chart

Power Meter

Energy Log

Event Log

Inverter Information

General Settings

Install Settings

Active/Reactive Power

FRT

5.2.2

5.2.3

5.2.4

5.2.5

5.2.6

5.2.7

5.2.8

5.2.9

5.Turn On PV Inverter

WARNING ! BURN HAZARD

The enclosure temperature may exceed 70°C while inverter is operation.

A dangerous burn hazard is present in this situation.

Figure 5-1 panel indicator

40

Turn on PV inverter

Condition Green LED Red LED

Standby or Countdown FLASH * OFF

Power ON ON OFF

Error or Fault OFF ON

Night time (No DC) OFF OFF

Bootloader mode FLASH *

* ON 1s / OFF 1s

Table 5-1 LED indicator

Figure 5-2 Country and language settings for first startup

Figure 5-3 Home page

5.2 First startup

At first startup, users have to feed in AC power and switch on the Manual

Switch. Inverter will start up on AC power and LCD display panel will come

live. Please set Language and Country according to your region and make

sure that there is no any error, fault or warning showing on home page.

Now you can feed in DC power and wait for inverter initially self-test about

2 minutes. If there is enough power generated from PV array, inverter will

start to feen in power to grid.

First Startup(M30A/ M50A)

ENT

Are you sure to

set country :

XXX

Yes / ►No

EXIT

ENT

EXIT

Select Country,

AU/NZ

Austria

Belgium

►

Select Language,

English

Deutsch

Français

►

5.2.1. Home Page

When inverter is operating normally, the LCD will display the homepage

as shown in Figure 5-3, user can get the information about output power,

inverter status, E-today, date and time.

Pressing any key in home page can users enter the main menu. Press

ESC at main manu or wait 5 minutes without any operation, the display

will return to homepage.

21. Jun 2013 13:50

Status:

Power:

E-Today:

7935

192

W

kWh

On Grid

Today Energy

Inverter Status

Output Power

Day - Time

41

Turn on PV inverter

5.2.2. Power Meter

This page displays voltage, current and power from both AC and DC side.

5.2.3. Energy Log

User can view the inverter’s life energy and life runtime via Energy Log page.

V 230 230 230

I 11.5 11.5 11.5

P 2645 2645 2645

L1 L2 L3AC

Power:

Frequency:

E-Today:

AC

7935

50.00

24

W

Hz

kWh

ENT

or

V 544 472

I 8.0 8.3

P 4350 3915

DC1 DC2DC

ENT

or

Figure 5-4 Power meter page

Figure 5-5 Energy log Page

Energy Log

Life Energy:

Runtime:

29200

7302

kWh

Hrs

42

Turn on PV inverter

5.2.4. Event Log

Event Log has two subpages: Error Events page and Grid Report page.

Error Events page displays all the events (Error and Fault) and it can show

30 records at a time. Grid Report page only displays the error that occurred

at grid side, and it can show 5 records at a time.

1. 20/02/2013 15:30

AC Freq High

2. 19/02/2013 09:30

AC Volt Low

29. 20/02/2013 15:30

AC Freq High

30. 19/02/2013 09:30

AC Volt Low

ENT

EXIT

ENT

or

ENT

or

EXIT

Error Events

Grid Report

►

Error Events

Grid Report

►

1. 20/02/2013 15:30

No Gird

2. 19/02/2013 09:30

AC Volt Low

5. 20/02/2013 15:30

AC Freq High

ENT

or

ENT

or

ENT

EXIT

EXIT

Figure 5-6 Event log Page

43

Turn on PV inverter

5.2.5. Inverter Information

This page can helps user to recognize the inverter. First section displays

serial number, installation date, ID, and firmware version. Another 3 sections

displays the settings of inverter functions. For more infromation about

these settings, please refer to 5.2.7 Install Settings, 5.2.8 Active/Reactive

power, and 5.2.9 FRT (Fault ride through).

5.2.6. General Settings

Users can set Language, Date and Time, and RS-485 communication

baud rate in this page.

Figure 5-7 Inverter information page

Figure 5-8 General settings page

Language

Date and Time

Baud Rate

►

ENT

or

S/N: RN11179CB0

Install: 30/04/2014

DSP 1.80 Red. 1.65

Comm. 1.65 ID: 002

ENT

or

AC connection:

Max. Power:

Dry Cont:

EPO:

3P4W

52500W

Insulation

Normal Close

Country:

Insulation:

Baud Rate:

Germany MV

1200k

19200bps

ENT

or

►

Grid Settings

Active Pwr Settings

React Pwr Settings

FRT Settings

Link to settings page but read only

44

Turn on PV inverter

5.2.7. Install Settings

To enter Install Settings page, users have to enter correct password.

There are 3 sets of password with different permissions: user level, installer

level, and manufacturer level. The following sub-sections will introduce

the setting items in Install Settings page of user level and installer level.

CAUTION!

The settings in Install Settings page can only be adjusted by qualified

installers or engineers. Changing these settings may result in damage

to the inverter and other equipment.

Inverter ID: 002

Insulation

Country

Grid Settings

►

DC Injection

Dry Contact

RCMU

EPO

►

ON

Normal Close

AC Connection

Anti-islanding

Max Power

Return to Factory

►

3P4W

ON

52500W

User Level:

- Inverter ID

- Insulation

- Country

- Dry Contact

- EPO

- AC Connection

- Max. Power

Manufacturer Level:

- All Settings

Installer Level:

- Inverter ID

- Insulation

- Country

- Grid Settings

- Dry Contact

- EPO

- AC Connection

- Max. Power

Figure 5-9 Install settings page

Figure 5-10 Inverter ID page

5.2.7.1. Inverter ID

Inverter ID is used in RS-485 communication, for PC recognizing the

inverter. If users connect several inverters together via RS-485, each

inverter must have different ID.

ENT

EXIT

Setting ID:

ID = 0

02

Inverter ID: 002

Insulation

Country

Grid Settings

►

45

Turn on PV inverter

Figure 5-11 Insulation page

Figure 5-12 Country page

5.2.7.2. Insulation

Before connecting to grid, inverter will measure the impedance between

the PV array and PE first. M30A & M50A models provide 4 types of

impedance measurement methods (ON, Plus Grounded, Minus Grounded,

and OFF) and 2 impedance limits. Installer must select the appropriate

method based on PV array’s wiring.

5.2.7.3. Country

Each country has its own electricity regulations. Installer must select the

country correctly.

ENT

EXIT

ENT

EXIT

EXIT

Inverter ID: 002

Insulation

Country

Grid Settings

►

Mode: ON

Resistance: 1200kΩ

►

ON

Plus Grounded

Minus Grounded

OFF

►

ENT

EXIT

Mode: ON

Resistance: 1200kΩ

►

1200kΩ

700kΩ

►

ENT

EXIT

Inverter ID: 002

Insulation

Country

Grid Settings

►

AU/NZ

Austria

Belgium

China

►

46

Turn on PV inverter

5.2.7.4. Grid Settings

Grid settings page includes the voltage and frequency protection points.

These protection points are linked to electricity regulations.

If there is no any special requirement, please do not change any grid settings.

Figure 5-13 Grid Settings page

Inverter ID: 002

Insulation

Country

Grid Settings

►

ENT

EXIT

Voltage Protection

Freq. Protection

Reconnect T

P Ramp Up

►

ENT

EXIT

High Off

High On

High Off T

Low Off

►

276.0V

259.0V

0.3s

184.0V

Low On

Low Off T

Hi Off Slow

Hi On Slow

►

219.0V

0.3s

276.0V

259.0V

Hi Off Sl T

Lo Off Slow

Lo On Slow

Lo Off Sl T

►

600.0s

184.0V

219.0V

1.0s

Voltage Protection

Freq. Protection

Reconnect T

P Ramp Up

►

ENT

EXIT

High Off

High On

High Off T

Low Off

►

51.50Hz

50.05Hz

0.1s

47.50Hz

Low On

Low Off T

Hi Off Slow

Hi On Slow

►

47.55Hz

0.1s

65.00Hz

64.95Hz

Hi Off Slow T

Lo Off Slow

Lo On Slow

Lo Off Slow T

►

5.0s

45.00Hz

45.55Hz

5.0s

600s

6000%/m

600s

6000%/m

EXIT

EXIT

EXIT

EXIT

EXIT

If user enters wrong settings

Wrong Settings

If user enters wrong settings

Wrong Settings

Press ▲&▼ 5s

Do you want to set

U to the max range?

Yes / ►No

Do you want to set

F to the max range?

Yes / ►No

Press ▲&▼ 5s

47

Turn on PV inverter

5.2.7.5. Dry Contact

Users can choose the trigger condition of dry contact. There are 8 options

in the setting page: Disable, On Grid, Fan Fail, Insulation, Alarm, Error,

Fault, and Warning. Please refer to Table 5-2 for more details about these

options.

Dry Contact Trigger Timing

No action.

Inverter is connecting to grid.

Fan Fail occurs.

Insulation test fail.

Any error, fault, or warning occurs.

Any Error occurs.

Any Fault occurs.

Setting

Disable

On Grid

Fan Fail

Insulation

Alarm

Error

Fault

Any Warning occurs.Warning

Table 5-2 Dry Contact Trigger Setting

Figure 5-14 Dry Contact page

DC Injection

Dry Contact

RCMU

EPO

►

On Grid

ON

Normal Close

ENT

EXIT

►

Alarm

Error

Fault

Warning

►

Disable

On Grid

Fan Fail

Insulation

EXIT

48

Turn on PV inverter

5.2.7.6. EPO

EPO function has 2 detection methods: Normal Open and Normal Close.

Normal Open means EPO pins are usually open-circuited. When these

two pins are short-circuited, inverter will shut down immediately.

Normal Close is contrary to Normal Open. Please choose an appropriate

detection method according to your needs.

5.2.7.7. AC connection

RPI M30A and M50A models can support 3P3W and 3P4W system.

Please select the correct AC wiring type.

5.2.7.8. Max. Power

Electricity regulation in some area requests that inverter must have power

limit function. In these areas, users can adjust Max. Power to limit the

maximum output power of the inverter.

DC Injection

Dry Contact

RCMU

EPO

►

ON

Normal Close

Figure 5-15 EPO page

Figure 5-16 EPO page

Figure 5-17 Max. Power page

AC Connection

Anti-islanding

Max. Power

Return to Factory

►

3P4W

ON

52500W

AC Connection

Anti-islanding

Max. Power

Return to Factory

►

3P4W

ON

52500W

49

Turn on PV inverter

Figure 5-18 Active/Reactive power page

Figure 5-19 Power Limit page

Figure 5-20 Power vs Frequency page

5.2.8. Active/Reactive power

A password is required to enter Active/Reactive Power page.

This page includes two kinds of function: active power control and reactive

power control. In active power control function, there are 3 control modes:

Power Limit, Power vs. Frequency, and P(V). In reactive power control

function, there are 4 control modes: Constant cosphi, cosphi(P), Constant

Q, and q(V). These modes will be introduced in next section.

5.2.8.1. Power Limit

This control mode can reduce the output power to a percentage of inverter’s

rated power. Users can limit the output power by set the Set Point in Power

Limit page.

5.2.8.2. Power vs. Frequency

Inverter will reduce output power when grid frequency rises up if this mode

enabled. Users can tune the parameters in Power vs. Frequency page

to change the inverter’s behavior.

Power Limit

Power vs. Frequency

P(V)

►

ENT

EXIT

Mode:

Set Point:

►

ON

100%

Power Limit

Power vs. Frequency

P(V)

►

Mode

F start

F recovery

Gradient

►

ENT

EXIT

EXIT

ON

50.20 Hz

50.20 Hz

40%

T recovery

►

300s

ENT

EXIT

Active Power Ctrl

Reactive Power Ctrl

►

Warning:

Adj. would affect

energy production.

Password:

****

50

Turn on PV inverter

P

Pm

f

start =

f

(Hz)

Gradient

P

Pm

f

recovery

f

start

f

(

Hz

)

Gradient

Germany MV & ItalyOthers

f

recoveryfprotection

f

protection

Figure 5-21 Power vs Frequency parameters

Figure 5-22 P(V) page

5.2.8.3. P(V)

When grid voltage rises up to a lock-in voltage(V lock-in) and inverter’s

present output power is greater than lock-in power(P lock-in), inverter

will reduce the output power and keep it at a certain value(P lock-out)

until grid voltage drop back to lock-out voltage(V lock-out) and passing

a certen time(T revcovery).

Power Limit

Power vs. Frequency

P(V)

►

ENT

EXIT

EXIT

Mode

P lock-in

P lock-out

V lock-in

►

OFF

20%

5%

253.0V

V lock-out

T recovery

►

248.4V

300s

51

Turn on PV inverter

5.2.8.4. Constant cosphi

Inverter can feed in a fixed reactive power to grid. Users can set the power

factor(cosphi) in Constant cosphi page.

5.2.8.5. Cosphi (P)

Cosphi (P) is a function that inverter will feed in reactive power when its

output active power reach the setting values. For country Italy MV and

Italy LV, users can set lock-in voltage and lock-out voltage to assign the

operation interval. When grid voltage reach the lock-in voltage(V lock-in),

inverter will enable cosphi (P) function automatically and disabled it when

grid voltage reach lock-out voltage(V lock-out).

►

Constant cosphi

Cosphi (P)

Constant Q

Q(V)

ENT

EXIT

Mode

cosphi

►

OFF

Ind 1.00

Figure 5-23 Constant cosphi page

Figure 5-24 Cosphi (P) page

►

Constant cosphi

Cosphi (P)

Constant Q

Q(V)

ENT

EXIT

EXIT

Mode

Q upper

P lower

Q lower

►

OFF

Ind 1.00

45%

Ind 0.90

P upper

V lock-in

V lock-out

►

90%

241.5V

230.0V

Q upper

Q lower

P/Pn

1

cosφ

P lower P upper

Figure 5-24 Cosphi (P) page

52

Turn on PV inverter

Figure 5-26 Constant Q parameters

Figure 5-27 Q(V) page

5.2.8.6. Constant Q

Like Constant cosphi function, users can assign a percentage of reactive

power in Constant Q page.

5.2.8.7. Q(V)

Q(V) is a control mode that inverter will provide reactive power accroding

to grid voltage. For country Italy MV and Italy LV, users can set lock-in

power and lock-out power to assign Q(V) function operation interval.

►

Constant cosphi

Cosphi (P)

Constant Q

Q(V)

ENT

EXIT

Mode

Fix Q

►

OFF

Ind 90%

►

Constant cosphi

Cosphi (P)

Constant Q

Q(V)

ENT

EXIT

EXIT

EXIT

Mode

V1s

V2s

Qs limit

►

OFF

248.4V

253.0V

Ind 44%

V1i

V2i

Qi limit

T delay

►

211.6V

207.0V

Cap 44%

10.00s

P lock-in

P lock-out

►

20%

5%

53

Turn on PV inverter

V

1s

V

2s

V

1i

V

2i

Q

i limit

Q

s limit

V

Q

V

1s

V

2s

V

1i

V

2i

Q

i limit

Q

s limit

V

Q

Curve A Curve B

Others Italy MV & Italy LV

Figure 5-28 Q(V) parameters

Figure 5-29 FRT page

Figure 5-30 FRT Parameters

5.2.9. FRT (Fault ride through)

Some area requests that inverter should keep connected to grid when

grid voltage drops suddenly in few seconds. In these areas, users can

enable FRT function and adjust the parameters to meet the requirement.

100%

U1

0

t1

Fault occurence

t3

time

U

grid/Unom

Umin

Udrop

Disconnect from grid

Stay connected

►

General Settings

Install Settings

Active/Reactive Pwr

FRT

ENT

EXIT

ENT

EXIT

EXIT

Mode

Dead Band

Vdrop

t1

►

OFF

-10%

0%

0.30s

U1

t3

K factor

►

20%

3.00s

2.0

Warning:

Adj. would affect

energy production.

Password:

****

54

Turn on PV inverter

6.1 Replace Surge Protection Device (SPD)

RPI M50A_120 model have surge protection device (SPD) at both DC and

AC side. Table 6-1 reveals the specifications of SPD.

Please check the unit regularly. If there are any impaired or loose parts, please

contact your solar installer. Ensure that there are no foreign objects in the path

of the heat outlet.

6.Maintenance

WARNING!

Before any maintenance, please switch AC and DC power off to avoid risk

of electronic shock.

SPD(DC) SPD(AC)

Temperature: -400C~850C

Item fail: Green light will turn off

Manufacturers: ShangHai GEHE Lighti

Temperature: -400C~850C

Item fail: Red upright bulb

Manufacturers: ShangHai GEHE Lighti

Table 6-1 SPD Specifications

Part number: GPU1-ZS1000 Y Part number: GPU1-C4/690/1P Y

Work voltage:1000 Vdc

Work voltage: 690 Vac

Work Amp In (8/20): 20kA

Work Amp In (8/20): 15kA

Rate Amp I max(8/20): 40kA

Rate Amp Imax (8/20): 30kA

55

Maintenance

Once the inverter encounters voltage spikes (e.g. struck by lighting),

SPD will protect the inverter and got damaged. If you find a warning message

“SPD Fail” shown on display panel, please follow the steps below to replace

the SPD.

1.Switch AC and DC power off and wait until LCD display turn off.

2.Loosen the 6 screws on the front cover. (Figure 6-1)

3.Recognize which SPD unit was damaged.

For DC SPD, find the one that green light was turned off.

For AC SPD, find the one that red bulb was erected. (Figure 6-2)

4.Pull out the damaged unit and replace a new one. (Figure 6-3)

5.Reassemble the inverter. Please be careful the waterproof tape for ensure

the protection degree.

Figure 6-1 Remove front cover

RPI M50A

56

Maintenance

Figure 6-3 Pull out the SPD unit

Figure 6-2 Recognize the damaged SPD unit

57

Maintenance

6.2 Replace Internal String Fuse

RPI M50A_120, and RPI M50A_122 models have internal string fuse in

each Plus and Minus DC connector. The specifications of these fuses are

revealed as below.

Please check the fuses if the power generation of inverter is abnormal.

1.Switch AC and DC power off and wait until LCD display turn off.

2.Loosen the 6 screws on the front cover. (Figure 6-1)

3.Pull out the fuse holder and check the fuse. (Figure 6-4)

4.Replace the fuse if necessary.

5.Reassemble the inverter. Please be careful the waterproof tape for ensure

the protection degree.

‐ Item: String Fuse (source 1)

‐ Part number: 10GPV15U0

‐ Rate amp: 15 A

‐ Rate voltage: 1000 V

‐ Manufacturers: Hollyland

‐ Item: String Fuse (source 2)

‐ Part number: 0SPF015.T

‐ Rate amp: 15 A

‐ Rate voltage: 1000 V

‐ Manufacturers: Littelfuse

Figure 6-4 Pull out the fuse

58

Maintenance

Figure 6-5 Replace the fuse

Figure 6-6 Diassembling fan panel

6.3 Clean Fan

Loosen the 4 screws shown in Figure 6-1. Once the screws are loose, pulling

the fan bracket out will expose the connectors. Each fan has one wire

connected.

59

Maintenance

Figure 6-7 Removal of a fan

Figure 6-8 Removal of air outlets

6.4 Replace Fans

In the event that a fan needs to be replaced, user should disassemble the

4 pcs screws around the fans and disconnect the connector right behind the

fan bracket. Then replace new fan and reassemble the 4pcs screws.

6.5 Clean Air Inlet

Unscrew the 4 screws of air inlets and clean them regularly.

60

Maintenance

7.Error message and Trouble Shooting

ERROR

Message Possible cause Action

AC Freq

High

(E01)

1.

Actual utility frequency is over

the OFR setting

2. Incorrect country setting

3. Detection circuit malfunction

1. Check the utility frequency on the

inverter terminal

2. Check country setting

3.

Check the detection circuit inside the

inverter

AC Freq

Low

(E02)

1.

Actual utility frequency is under

the UFR setting

2.

Incorrect country or Grid setting

3. Detection circuit malfunction

1. Check the utility frequency on the

inverter terminal

2. Check country & Grid setting

3.

Check the detection circuit inside the

inverter

Grid Quality

(E07)

Non-linear load in Grid and near

to inverter

Grid connection of inverter need to be

far away from non-linear load if necessary

HW Con.

Fail

(E08)

1. Wrong connection in AC plug

2. Detection circuit malfunction

1.

Check the AC connection, must accords

to manual

2.

Check the detection circuit inside the

inverter

No Grid

(E09)

1. AC breaker is OFF

2. Disconnect in AC plug

1. Switch on AC breaker

2.

Check the connection in AC plug and

make sure it connects to inverter

AC Volt

Low

(E10, E15,

E20)

1. Actual utility voltage is under

the UVR setting

2.

Incorrect country or Grid setting

3.

Wrong connections in AC plug

4. Detection circuit malfunction

1. Check the utility voltage connection

to the inverter terminal

2. Check country & Grid setting

3. Check the connection in AC plug

4.

Check the detection circuit inside the

inverter

AC Volt

High

(E11, E13,

E16, E18,

E21, E23)

1.

Actual utility voltage is over the

OVR setting

2.

Utility voltage is over the Slow

OVR setting during operation

3.

Incorrect country or Grid setting

4. Detection circuit malfunction

1.

Check the utility voltage on the inverter

terminal

2.

Check the utility voltage on the inverter

terminal

3. Check country & Grid setting

4. Check the detection circuit inside the

inverter

Solar1

High

(E30)

1. Actual Solar1 voltage is over

1000Vdc

2. Detection circuit malfunction

1. Modify the solar array setting, and

make the Voc less than 1000Vdc

2.

Check the detection circuit inside the

inverter

61

Error message and Trouble Shooting

ERROR

Message Possible cause Action

Solar2

High

(E31)

1. Actual Solar2 voltage is over

1000Vdc

2. Detection circuit malfunction

1. Modify the solar array setting, and

make the Voc less than 1000Vdc

2.

Check the detection circuit inside the

inverter

Insulation

(E34)

1. PV array insulation fault

2. Large PV array capacitance

between Plus to Ground or

Minus to Ground or both.

3. Detection circuit malfunction

1. Check the insulation of Solar inputs

2.

Check the capacitance, dry PV panel

if necessary

3.

Check the detection circuit inside the

inverter

Table 7-1 Error Message

Warning

Message Possible cause Action

Solar1

Low

(W01)

1.

Actual Solar1 voltage is under

the limit

2. Some devices were damaged

inside the inverter if the actual

Solar1 voltage is close to "0"

3. Detection circuit malfunction

1. Check the Solar1 voltage connection

to the inverter terminal

2. Check all switching devices in boost1

3. Check the detection circuit inside the

inverter

Solar2

Low

(W02)

1.

Actual Solar2 voltage is under

the limit

2. Some devices were damaged

inside the inverter if the actual

Solar2 voltage is close to "0"

3. Detection circuit malfunction

1.

Check the Solar2 voltage connection

to the inverter terminal

2.

Check all switching devices in boost2

3.

Check the detection circuit inside the

inverter

HW FAN

(W11)

1. One or more fans are locked

2.

One or more fans are defective

3. One ore more fans are

disconnected

4. Detection circuit malfunction

1. Remove the object that stuck in the

fan(s)

2. Replace the defective fan(s)

3. Check the connections of all fans

4. Check the detection circuit inside the

inverter

SPD Fail

1. Inverter was struck by lighting.

2.

One or more SPD are defective

3. One or more SPD are

disconnected

4. Detection circuit malfunction

1. Check inverter’s status

2. Replace the defective SPD

3. Check the connections of SPDs

4. Check the detection circuit inside the

inverter

Table 7-2 Warning Message

62

Error message and Trouble Shooting

FAULT

Message Possible cause Action

DC

Injection

(F01, F02,

F03)

1. Utility waveform is

abnormal

2. Detection circuit

malfunction

1. Check the utility waveform.

Grid connection of inverter need to be

far away from non-linear load if necessary

2. Check the detection circuit inside the

inverter

Temperature

(F05)

1. The ambient is over 60℃

(The installation is abnormal)

2.

Detection circuit malfunction

1. Check the installation ambient and

environment

2. Check the detection circuit inside the

inverter

Temperature

(F07)

1. Ambient temperature is

<-30 ℃

2. Detection circuit

malfunction

1. Check the installation ambient and

environment

2. Check the detection circuit inside the

inverter

HW NTC1

Fail

(F06)

1. Ambient temperature

>90℃ or <-30℃

2. Detection circuit

malfunction

1. Check the installation ambient and

environment

2. Check the detection circuit inside the

inverter

HW NTC2

Fail

(F08)

1. Ambient temperature

>90℃ or <-30℃

2. Detection circuit

malfunction

1. Check the installation ambient and

environment

2. Check the detection circuit inside the

inverter

HW NTC3

Fail

(F09)

1. Ambient temperature

>90℃ or <-30℃

2. Detection circuit

malfunction

1. Check the installation ambient and

environment

2. Check the detection circuit inside the

inverter

HW NTC4

Fail

(F10)

1. Ambient temperature

>90

℃ or <-30℃

2. Detection circuit

malfunction

1. Check the installation ambient and

environment

2. Check the detection circuit inside the

inverter

DC RLY

Fail

(F13)

1. Driver circuit for relay is

defective

2. Relay(s) is defective

3.

Detection circuit malfunction

(Inverter voltage)

1.

Check the input voltage, must >150Vdc

2. Replace the defective relay

3. Check the detection circuit inside the

inverter

HW DSP

ADC1

(F15)

1. Insufficient input power

2. Auxiliary power circuitry

malfunction

3. Detection circuit

malfunction

1.

Check the input voltage, must >150Vdc

2. Check the auxiliary circuitry inside the

inverter

3. Check the detection circuit inside the

inverter

63

Error message and Trouble Shooting

FAULT

Message Possible cause Action

HW DSP

ADC2

(F16)

1. Insufficient input power

2. Auxiliary power circuitry

malfunction

3. Detection circuit

malfunction

1.

Check the input voltage, must >150Vdc

2. Check the auxiliary circuitry inside the

inverter

3. Check the detection circuit inside the

inverter

HW DSP

ADC3

(F17)

1. Insufficient input power

2. Auxiliary power circuitry

malfunction

3. Detection circuit

malfunction

1.

Check the input voltage, must >150Vdc

2. Check the auxiliary circuitry inside the

inverter

3. Check the detection circuit inside the

inverter

1. Insufficient input power

2. Auxiliary power circuitry

malfunction

3. Detection circuit

malfunction

1.

Check the input voltage, must >150Vdc

2. Check the auxiliary circuitry inside the

inverter

3. Check the detection circuit inside the

inverter

1. Insufficient input power

2. Auxiliary power circuitry

malfunction

3. Detection circuit

malfunction

1.

Check the input voltage, must >150Vdc

2. Check the auxiliary circuitry inside the

inverter

3. Check the detection circuit inside the

inverter

HW Red

ADC1

(F18)

HW Red

ADC2

(F19)

HW Eff.

(F20)

1. The calibration is incorrect

2. Current feedback circuit is

defective

1. Check the accuracy of current and

power

2. Check the current feedback circuit

inside the inverter

HW

COMM1

(F23)

1. DSP is idling

2. The communication

connection is disconnected

3. The communication circuit

malfunction

1. Check reset and crystal in DSP

2. Check the connection between DSP

and COMM

3. Check the communication circuit

HW

COMM2

(F22)

1. Red. CPU is idling

2. The communication

connection is disconnected

1. Check reset and crystal in Red. CPU

2. Check the connection between Red.

CPU and DSP

Ground Cur.

(F24)

1. PV array insulation fault

2.

Large PV array capacitance

between Plus to Ground or

Minus to Ground

3. Either side of boost driver

or boost choke malfunction

4.

Detection circuit malfunction

1. Check the insulation of Solar inputs

2. Check the capacitance (+ <-> GND &

- <-> GND), must < 2.5uF. Install a

external transformer if necessary

3. Check boost driver & boost choke

4. Check the detection circuit inside the

inverter

64

Error message and Trouble Shooting

FAULT

Message Possible cause Action

HW Con. Fail

(F26)

1.

Power line is disconnected

inside the inverter

2. Current feedback circuit is

defective

1.

Check the power lines inside the inverter

2.

Check the current feedback circuit inside

the inverter

RCMU Fail

(F27)

1. RCMU is disconnected

2.

Detection circuit malfunction

1.

Check the RCMU connection inside the

inverter

2. Check the detection circuit inside the

inverter

1. One or more relays are

sticking

2. The driver circuit for the

relay malfunction

1. Replace the defective relay(s)

2.

Check the driver circuit inside the inverter

1. One or more relays are

abnormal

2. The driver circuit for the

relay malfunction

3. The detection accuracy is

not correct for Vgrid and Vout

1. Replace the defective relay(s)

2.

Check the driver circuit inside the inverter

3.

Check the Vgrid and Vout voltage detect

on accuracy

RLY Short

(F28)

RLY Open

(F13, F29)

Bus Unbal.

(F30)

1. Not totally independent or

parallel between inputs

2. PV Array short to Ground

3.

Driver for boost is defective

or disconnected

4.

Detection circuit malfunction

1. Check the inputs connections

2. Check the PV Array insulation

3. Check the driver circuit for boost inside

the inverter

4. Check the detection circuit inside the

inverter

HW Bus OVR

(F31, F33, F35)

1.

Driver for boost is defective

2. Voc of PV array is over

1000Vdc

3. Surge occurs during

operation

4.

Detection circuit malfunction

1. Check the driver circuit for boost inside

the inverter

2.

Modify the solar array setting, and make

the Voc less than 1000Vdc

3. N/A

4. Check the detection circuit inside the

inverter

AC Cur. High

(F36, F37, F38,

F39, F40, F41)

1. Surge occurs during

operation

2. Driver for inverter stage is

defective

3.

Switching device is defective

4.

Detection circuit malfunction

1. N/A

2.

Check the driver circuit in inverter stage

3. Check all switching devices in inverter

stage

4.

Check the detect circuit inside the inverter

HW CT A Fail

(F42)

1.

Test current loop is broken

2. CTP3 is defective

3.

Detection circuit malfunction

1.

Check the connection of CNP4 to CNM4

2. Replay CTP3 with new one

3. Check the detection circuit inside the

inverter

65

Error message and Trouble Shooting

FAULT

Message Possible cause Action

HW CT B Fail

(F43)

1.

Test current loop is broken

2. CTP4 is defective

3.

Detection circuit malfunction

1.

Check the connection of CNP4 to CNM4

2. Replace CTP4 with new one

3. Check the detection circuit inside the

inverter

HW CT C Fail

(F44)

1. Test current loop is broken

2. CTP5 is defective

3.

Detection circuit malfunction

1.

Check the connection of CNP4 to CNM4

2. Replace CTP5 with new one

3. Check the detection circuit inside the

inverter

1. Large Grid harmonics

2.

Switching device is defective

3.

Detection circuit malfunction

1.

Check the utility waveform. Grid connection

of inverter need to be far away from

non-linear load if necessary

2. Check all switching devices in inverter

stage

3. Check the detection circuit inside the

inverter

The detection circuit for

synchronal signal malfunction

Check the detection circuit for synchronal

signal inside the inverter

HW AC OCR

(F45)

HW ZC Fail

(F50)

DC Cur. High

(F60, F61,

F70, F71)

1. Switching device in boost

is defective

2.

Driver for boost is defective

3. Input current detection

circuit malfunction

1. Check all switching device in boost

2.

Check the driver curcuit for boost inside

the inverter

3. Check input current detection circuit

Table 7-3 Fault Message

66

Error message and Trouble Shooting

If it is necessary to put the device out of operation for maintenance and/or storage,

please follow the instructions below.

8.De-Commissioning

WARNING!

To avoid injuries, please follow the procedures:

• Switch off Manual Switch to shut down the inverter.

• Switch off AC circuit breaker to disconnect with electricity grid.

• Switch off the PV array switch to disconnect from the PV array.

• Use proper voltmeter to confirm that the AC and DC power are

disconnected from the unit.

• Remove the AC wiring immediately to completely disconnect from

electricity grid.

• Remove the DC wiring to disconnect from PV Array.

• Remove the communication module RS-485 connection from the

computer connection.

67

De-Commissioning

9.Technical Data

GENERAL

Enclosure

Operating temperature

Operating Altitude

Powder coated aluminum

-25~60℃, full power up to 40℃

(Please refer to figure 9-1 to 9-6.)

2000m

Relative humidity 0 – 100% non condensing.

Environmental category Outdoor, wet locations

Protection degree IP65 (Electronics)

Pollution degree II

Overvoltage category AC output :III, DC Input :II

Maximum backfeed

current to the array

0

Galvanic isolation NO

Safety class Class I metal enclosure with protective earth

Weight 74kg

Dimensions(W*H*D) 612 × 740 × 278mm

48.5kg

612 × 625 × 278mm

Connectors Weather resistant connectors

DC INPUT (Solar side)

Recommended PV power

Maximum input power

Nominal voltage

Operating voltage

Startup voltage

35kW 58kW

≦

38kW

≦

63kW

1000V 1100V*

Rated power

31.5kW 52.5kW

600Vdc

200Vdc – 1000 Vdc

> 250 Vdc

Start up power

40W

MPP tracker

Parallel inputs: 1 MPP tracker

Separate inputs: 2 MPP trackers

Absolute maximum voltage

RPI M30A RPI M50A

* Inverter stop operating when input voltage large than 1000V.

68

Technical Data

MPP range (rated power)

Balanced inputs (50/50)

520-800Vdc 520-800Vdc

700-800Vdc 700-800Vdc

Maximum unbalanced inputs

350-800Vdc

67%

33% 350-800Vdc

RPI M30A RPI M50A

DC INPUT (Solar side)

AC OUTPUT (Grid side)

Number of inputs

Rated current

Maximum short circuit

current per MPPT (Isc)

Nominal power

Maximum power

Voltage

Nominal current

Maximum current

Inrush current

Maximum output fault

current (rms)

Maximum output over

current protection

Frequency

Rated 50/60Hz

(Programmable 45Hz - 65Hz)

Total harmonic distortion < 3 %

Power factor

> 0.99 @ full power

Adjustable: 0.80 leading – 0.80 lagging

Tare loss

DC current injection

Maximum efficiency

EU efficiency

AC connector

<0.5% rated current

3 Ph + N + PE; 3-phase AC plug that meets IP67

and specifications in table 4-2.

6 pairs MC4 10 pairs MC4

30A * 2 50 A * 2

36A

(Each String 12A)

60A

(Each String 12A)

50kW / 50kVA

33kW / 33kVA

(Refer to figure 9-1 to 9-3 )

55kW / 55kVA

(Refer to figure 9-4 to 9-6 )

3Ph, 230/400Vac

43.5(230Vac) / 45.5(220Vac) 73A(230Vac) / 76A(220Vac)

50A 80A

150A/100μs 200A/100μs

88.6A 106.4A

57A 91.2A

< 3W < 2.5W

98.5 % 98.6 %

98.2 % 98.4 %

69

Technical Data

30kW / 30kVA

SYSTEM INFORMATION / COMMUNICATION

User interface

Black-on-white character type LCD display

Real time clock

30 events record

External communication 2 RS-485 connections

REGULATIONS & DIRECTIVES

CE conformity Yes

Grid interface

VDE-AR-N 4105

VDE0126-1-1

NB/T 32004

VDE0126-1-1

VDE-AR-N 4105

BDEW,UK G59/3

UTE C15-712

NB/T 32004

Emission EN 61000-6-3

Harmonics EN 61000-3-12

Variations and flicker EN 61000-3-11

Immunity EN 61000-6-2

Immunity

ESD IEC 61000-4-2

RS IEC 61000-4-3

EFT IEC 61000-4-4

Surge IEC 61000-4-5

CS IEC 61000-4-6

PFMF IEC 61000-4-8

Electrical safety IEC 62109-1/ -2

MISCELLANEOUS

Enclosure

Cooling Fan, 3pcs Fan, 5pcs

Mounting bracket

Aluminum with powder coating

Table 9-1 Specifications for RPI M30A/ M50A

RPI M30A RPI M50A

70

Technical Data

71

0.5

0.55

0.6

0.65

0.7

0.75

0.8

0.85

0.9

0.95

1

1.05

1.1

1.15

25℃30℃35℃40℃45℃50℃55℃60

℃

520V

600V

800V

P/Pn*

Pn*=30kW

Ambient Temperature

Temperature Derating of RPI M30A

cos(Φ)=1.0

Figure 9-1 M30A Thermal Derating Curve (cosφ=1.0)

Technical Data

72

Figure 9-2 M30A Thermal Derating Curve (cosφ=0.95)

0.5

0.55

0.6

0.65

0.7

0.75

0.8

0.85

0.9

0.95

1

1.05

1.1

1.15

25℃ 30℃ 35℃ 40℃ 45℃ 50℃ 55℃ 60℃

S(520V)

S(600V)

S(800V)

P(520V)

P(600V)

P(800V)

P/Pn*

Pn*=30kW

Ambient Temperature

Temperature Derating of RPI M30A

cos(Φ)=0.95

Technical Data

73

0.5

0.55

0.6

0.65

0.7

0.75

0.8

0.85

0.9

0.95

1

1.05

1.1

1.15

25℃30℃35℃40℃45℃50℃55℃60

℃

S(520V)

S(600V)

S(800V)

P(520V)

P(600V)

P(800V)

P/Pn*

Pn*=30kW

Ambient Temperature

Temperature Derating of RPI M30A

cos(Φ)=0.9

Figure 9-3 M30A Thermal Derating Curve (cosφ=0.9)

Technical Data

74

Figure 9-4 M50A Thermal Derating Curve (cosφ=1.0)

Ambient Temperature

50%

55%

60%

65%

70%

75%

80%

85%

90%

95%

100%

105%

110%

115%

25 30 35 40 45 50 55 60

℃

Temperature Derating of RPI M50A

520Vdc

600Vdc

800Vdc

P/Pn*

Cos(Ф) =1.0

*Pn=50kW

Ambient Temperature

Technical Data

75

Figure 9-5 M50A Thermal Derating Curve (cosφ=0.95)

50%

55%

60%

65%

70%

75%

80%

85%

90%

95%

100%

105%

110%

115%

25 30 35 40 45 50 55 60

℃

Temperature Derating of RPI M50A

P(520Vdc) S(520Vdc)

P(600Vdc) S(600Vdc)

P(800Vdc) S(800Vdc)

P/Pn*

*Pn=50kW

Cos(Ф) =0.95

Ambient Temperature

Technical Data

76

Figure 9-6 M50A Thermal Derating Curve (cosφ=0.9)

50%

55%

60%

65%

70%

75%

80%

85%

90%

95%

100%

105%

110%

115%

25 30 35 40 45 50 55 60

℃

Temperature Derating of RPI M50A

P(520Vdc) S(520Vdc)

P(600Vdc) S(600Vdc)

P(800Vdc) S(800Vdc)

P/Pn*

99%

*Pn=50kW

Cos(Ф) =0.9

Ambien Temperature

Technical Data

RPI M30A/M50A

操作手冊

三相并网型逆变器

The power behind competitiveness

www.deltaww.com

English 1

77

153

简体中文

繁體中文

1. 信 息

1.1. 关于此手册

1.2. 产品说明

1.3. 其他信息

2. 产品概观

2.1. 逆变器开箱

2.2. 检查内容物

2.3. 产品卷标

2.4. 外观介绍

3. 安装

4. 配线

4.1 配线前准备事项 (有DC保险丝之机种)

4.2. 配线前准备事项 (无DC保险丝之机种)

4.3. AC(市电端)之连接: 三相三线(3P+PE)或三相四线(3P+N+PE)

4.3.1. 保护装置与AC配线图

4.4. 直流输入端(太阳能板电源端) 之连接

4.5. 通讯接口之连接

4.5.1. RS-485之连接

4.5.2. 紧急关机装置与数字输入之连接

4.5.3. 干接点之连接

5. 逆变器开机

5.1. LCD 操作流程

5.2. 首次开机

5.2.1. 主画面

5.2.2. Power Meter

5.2.3. Energy Log

5.2.4. Event Log

5.2.5. Inverter Information

5.2.6. General Settings

5.2.7. Install Settings

5.2.7.1. Inverter ID

5.2.7.2. Insulation

5.2.7.3. Country

5.2.7.4. Grid Settings

5.2.7.5. Dry Contact

5.2.7.6. EPO

5.2.7.7. AC connection

5.2.7.8. Max. Power

5.2.8. Active/Reactive power

5.2.8.1. Power Limit

5.2.8.2. Power vs. Frequency

5.2.8.3. P(V)

5.2.8.4. Constant cosphi

5.2.8.5. Cosphi (P)

5.2.8.6. Constant Q

5.2.8.7. Q(V)

5.2.9. FRT (Fault ride through)

6.设备维护

6.1. 更换突波保护器 (SPD)

6.2. 更换DC保险丝

6.3. 清理风扇

6.4. 更换风扇

6.5. 清理进风口滤网

7.错误讯息与简易故障排除

8.卸除

9.技术数据

80

80

80

80

81

81

81

84

85

87

91

91

96

106

106

110

111

112

113

114

115

115

116

116

117

117

118

119

119

120

120

121

121

122

123

124

124

124

125

125

125

126

127

127

128

128

129

130

130

133

134

135

135

136

142

143

Contents

78

安全规范

本手册提供使用者以下几种常见安全规范:

注 意!

如若不遵守此规范则可能导致机器设备的损毁

警 告!

如若不遵守此规范则可能会导致人员的伤亡

本机任何维修动作只能由制造商进行

危 险!

如若不遵守此规范则将会导致人员的伤亡,

为了避免触电, 请勿私自打开本逆变器外壳

高温危险!

机器正常操作时表面温度可能会有烫伤的危险请勿碰触

79

1. 信 息

1.1 关于此手册

本手册将提供产品之电器规格、安装步骤以及相关设定等信息,本手册适用机

型为RPI M30A/ RPI M50A

1.2 产品说明

本产品为三相非隔离、市电并联型之太阳能逆变器(solar inverter)。

太阳光能量经由太阳能板(PV array)转换成可运用之直流电后,再由逆变器转

换成三相电流输出与市电并联,不支持独立运转(stand alone)

太阳能逆变器工作方式如图1-1, 将太阳能板的直流电源转换成三相交流电源

输出至市电, 达到节能省电的目的。

图 1-1 太阳能逆变器使用说明

1.3 其他信息

如果想获得RPI M30A/ RPI M50A更详细之信息或其它相关产品信息,

可链接至以下网站:http://www.deltaww.com

PV Array Electrical GridSolar Inverter

3PH

AC Distribution

box

Surge arrestor

AC breaker

3 phase, N, PE

80

信 息

图2-1开箱

RPI M30A/M50A之开箱步骤请参考图2-1。

2. 产品概观

2.1 逆变器开箱

2.2 检查内容物

由于逆变器于运送过程中, 有可能遭遇任何无法预估的状况, 因此建议您按照

以下项目逐项检查:

• 检查外包装箱是否有损坏或破损的现象。

• 检查各项配件是否齐全。详细的配件信息请参考以下的表与图:

RPI M30A机种请参考图2-2与表2-1。

RPI M50A机种请参考图2-3与表2-2。

• 检查外箱之机子型号、序号与包装内机子之型号、序号是否相符。

当您发现包装内、外部有任何损毁的情况或是附件有短缺、损毁,请立即联

系您的逆变器供货商。

81

产品概观

图2-2 M30A内容物清单

RPI M30A

物品 数量 说明

1 太阳能逆变器 1 pcs

1 pcs

1 pcs

1 pcs

RPI系列太阳能逆变器

2 使用说明书

安全规范、安装步骤、产品规格…等

3 AC 接头

壁挂板

AC 连接接头

将太阳能逆变器挂于墙上之壁挂板

4

5

DC 接头 6组 DC 连接接头

表2-1 M30A内容物清单

※本产品不提供接地保险丝,如有需求请自行选用1000V/1A之Midget型保险丝。

①

②

⑤

④

③

82