i

1

Contents

Section Description Page

1. General Information ............................................................................... 6

1.1 About this Manual .......................................................................... 6

1.2 General Warnings / Notes on Safety............................................. 6

1.3 Validity ............................................................................................ 7

1.4 Product Description ....................................................................... 7

1.5 How it Works .................................................................................. 8

1.6 Additional Information ................................................................... 8

2. Installation and Wiring .......................................................................... 9

2.1 Instruction before Installation ....................................................... 9

2.2 Unpacking ....................................................................................... 9

2.3 Package Inspection ...................................................................... 10

2.4 Identify of Inverter ........................................................................ 10

3. Product Overview ................................................................................ 11

3.1 Dimension ..................................................................................... 11

3.2 Function Introduction .................................................................. 12

3.2.1 LCD Display and Buttons .................................................... 12

3.2.2 Inverter Input / Output Interface ......................................... 13

4. Installation ............................................................................................ 14

4.1 Installing Location ....................................................................... 14

4.2 Mounting ....................................................................................... 14

5. Wiring.................................................................................................... 18

5.1 Preparation before Wiring ........................................................... 18

5.2 AC Grid Connection: 3-Phase+PE or 3-Phase+N+PE ............... 20

5.2.1 Required Protective Devices and Cable Cross-sections . 20

5.3 DC Connection (from PV Array) .................................................. 24

5.4 Communication Module Connections ........................................ 26

5.4.1 RS-485 Connection .............................................................. 26

5.4.2 EPO Functions ..................................................................... 28

5.4.3 Dry Contact Connection ...................................................... 28

6. Active / Reactive Power Control and Fault Ride Through ................ 29

6.1 Active Power Control ................................................................... 29

6.1.1 Power Limit .......................................................................... 29

6.1.2 Power vs. Frequency ........................................................... 30

6.2 Reactive Power Control ............................................................... 31

6.2.1 Fixed Active Factor cosφ .................................................... 31

2

6.2.2 Active Factor cosφ(P) ......................................................... 31

6.2.3 Fixed Reactive Power .......................................................... 32

6.2.4 Reactive Power / Voltage Characteristic Q(U) ................... 32

6.3 Fault Ride Through (FRT) ............................................................ 33

7. Turn on/off PV inverter ........................................................................ 35

7.1 Home Page ................................................................................... 37

7.2 LCD Flow Chart ............................................................................ 37

7.2.1 Power Meter ......................................................................... 37

7.2.2 Energy Log ................................ ................................ ........... 38

7.2.3 Event Log ............................................................................. 38

7.2.4 Operation Data ..................................................................... 39

7.2.5 Inverter Information ............................................................. 39

7.2.6 Settings ................................................................................ 40

7.2.6.1 Personal Setting ...................................................... 40

7.2.6.2 Coefficient Setting .................................................. 41

7.2.6.3 Installation Settings ................................................ 41

7.2.6.4 Active/Reactive Power Control .............................. 44

7.2.6.4.1 Power Limit ............................................... 45

7.2.6.4.2 Power vs. Frequency ................................ 45

7.2.6.4.3 Constant cosφ ........................................... 46

7.2.6.4.4 cosφ(P) ...................................................... 46

7.2.6.4.5 Constant Reactive Power ......................... 47

7.2.6.4.6 Q(U) ............................................................ 47

7.2.6.5 FRT (Fault ride through) ......................................... 48

8. Maintenance ......................................................................................... 49

8.1 Clean Fan ...................................................................................... 49

8.2 Replace Fan .................................................................................. 50

8.3 Clean Air Outlets .......................................................................... 50

9. Measurement, Error message and Trouble Shooting ....................... 51

9.1 Measurement ................................................................................ 51

9.2 Error Message & Trouble Shooting ............................................ 54

10. De-Commissioning .............................................................................. 60

10.1 De-Commissioning Procedure .................................................... 60

11. Technical Data ...................................................................................... 61

11.1 Specification ................................................................................. 61

3

Figure

Section Description Page

Figure 1-1 Solar system operation illustration ................................................. 8

Figure 2-1 Unpacking process ........................................................................ 9

Figure 2-2 Wooden case unpacking process .................................................. 9

Figure 2-3 The identification label ................................................................. 10

Figure 3-1 Dimension of RPI-M8/ M10/ M12/ M15A/ M20A .......................... 11

Figure 3-2 Dimension of RPI-M15/ M20/ M30 ............................................... 11

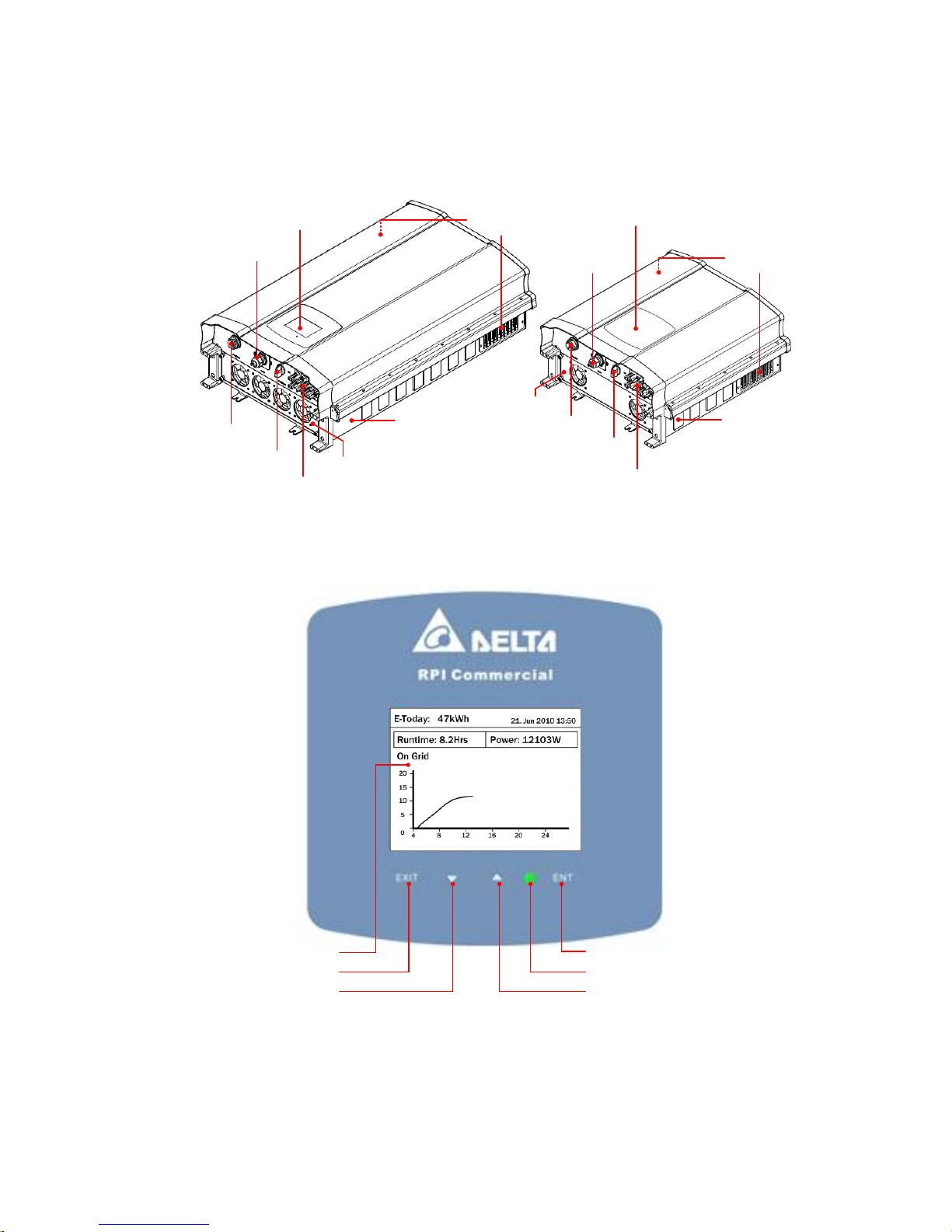

Figure 3-3 Inverter exterior objects ............................................................... 12

Figure 3-4 LCD display and control panel ..................................................... 12

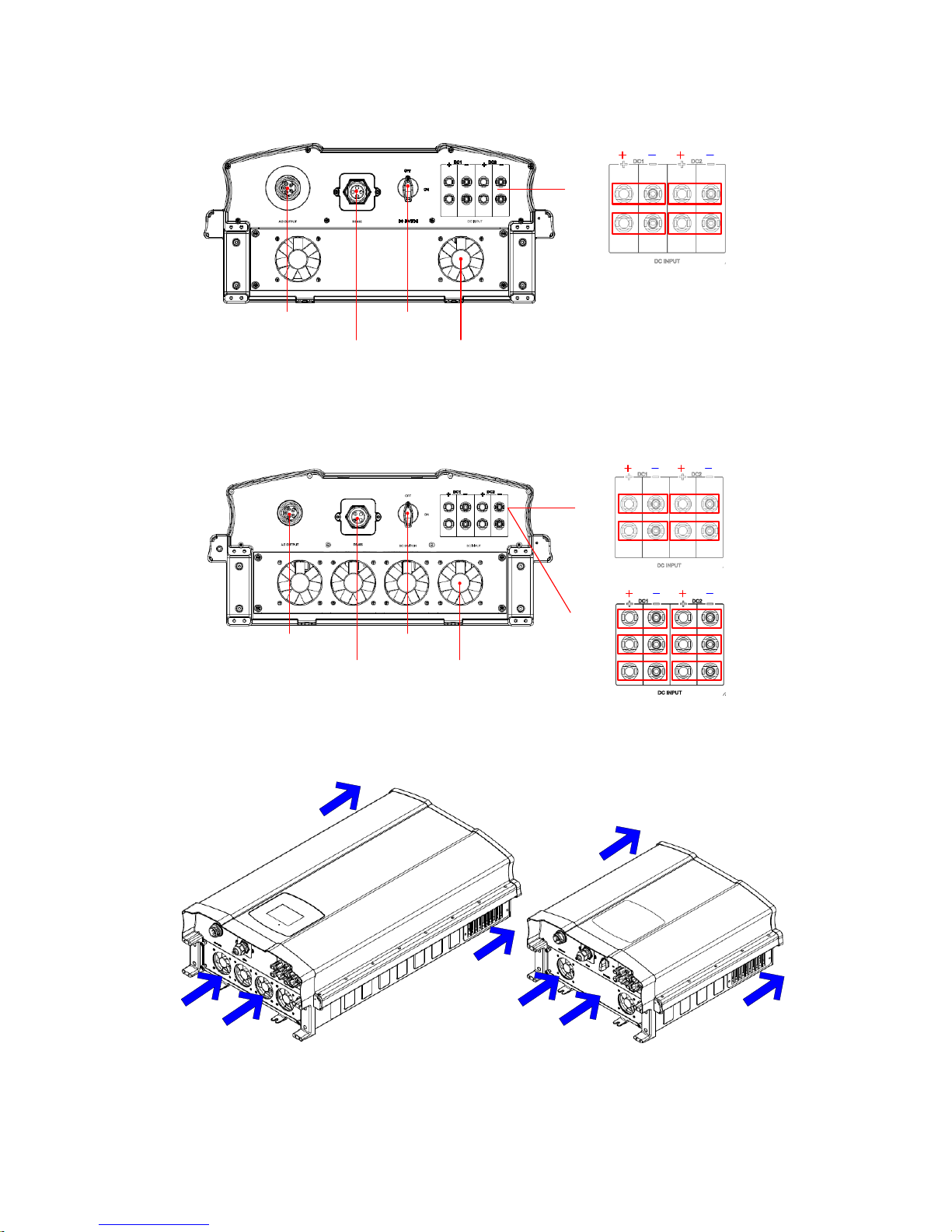

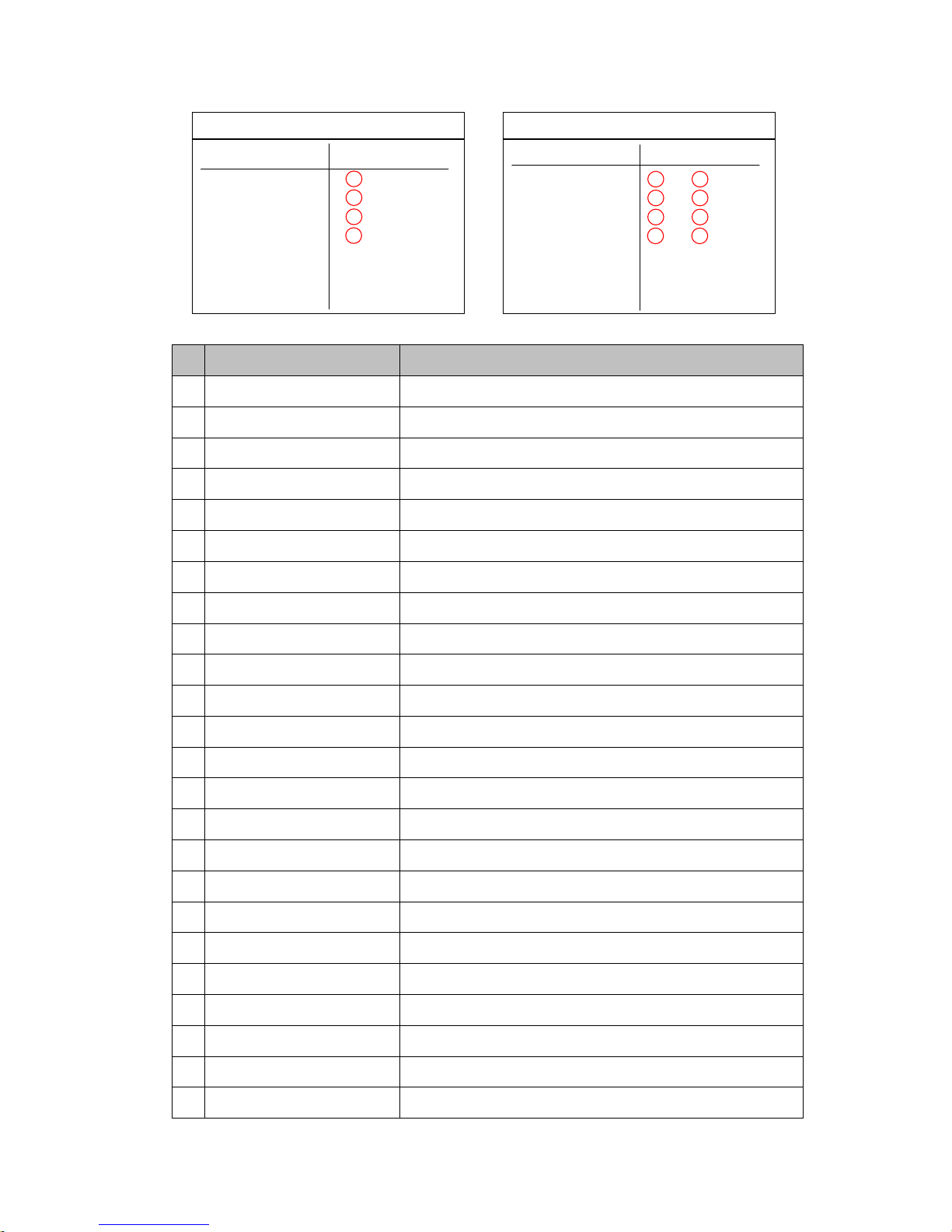

Figure 3-5 Input/Output interfaces of M8/ M10/ M12/ M15A/ M20A .............. 13

Figure 3-6 Input/Output interfaces of M15/ M20/ M30 ................................... 13

Figure 3-7 Air outlet illustration ..................................................................... 13

Figure 4-1 Screw the mounting bracket ........................................................ 15

Figure 4-2 Correct and incorrect installation illustration ................................ 16

Figure 4-3 Proper installation gap ................................................................. 17

Figure 5-1 Connection of a system for floating DC inputs ............................. 18

Figure 5-2 Connection of system with positive/negative ground ................... 19

Figure 5-3 Stripping the wire ......................................................................... 21

Figure 5-4 AC plug illustrationfor M8/ M10/ M12/ M15/ M15A/ M20/ M20A. . 22

Figure 5-5 AC plug illustration for M30 .......................................................... 23

Figure 5-6 DC Wiring illustration ................................................................... 25

Figure 5-7 Communication module ............................................................... 26

Figure 5-8 Multi-inverter connection illustration ............................................ 27

Figure 5-9 Dry contact port & Assignments ................................................... 28

Figure 6-1 Power vs. frequency characteristic .............................................. 30

Figure 6-2 cosφ(P) characteristic .................................................................. 31

Figure 6-3 Q(U) characteristic. ...................................................................... 32

Figure 6-4 Borderlines of the voltage profile of a type-2 generating plant at the

network connection point .............................................................................. 34

Figure 6-5 FRT characteristic ........................................................................ 34

Figure 7-1 LCD display &control panel ......................................................... 35

Figure 7-2 Select county page ...................................................................... 36

Figure 7-3 Select language page .................................................................. 36

Figure 7-4 Home page .................................................................................. 37

Figure 7-5 Menu page ................................................................................... 37

4

Figure 7-6 Power meter page ....................................................................... 37

Figure 7-7 Energy log flow chart ................................................................... 38

Figure 7-8 Event log flow chart ..................................................................... 38

Figure 7-9 Operation data flow chart ............................................................. 39

Figure 7-10 Inverter information page ........................................................... 39

Figure 7-11 Setting page ............................................................................... 40

Figure 7-12 Personal setting page ................................................................ 40

Figure 7-13 Coefficient setting page ............................................................. 41

Figure 7-14 Install setting page –User mode ................................................ 42

Figure 7-15 Insulation setting ........................................................................ 42

Figure 7-16 Install setting page – Installer mode .......................................... 42

Figure 7-17 Grid setting page ....................................................................... 43

Figure 7-18 Active/Reactive powersetting page ............................................ 44

Figure 7-19 Power limit setting page ............................................................. 45

Figure 7-20 Power vs. frequency setting page. ............................................. 45

Figure 7-21 Constant cosφ setting page ....................................................... 46

Figure 7-22 cosφ(P) setting page ................................................................. 46

Figure 7-23 Constant Reactive Power setting page ...................................... 47

Figure 7-24 Q(U) setting page ...................................................................... 47

Figure 7-25 FRT setting page ....................................................................... 48

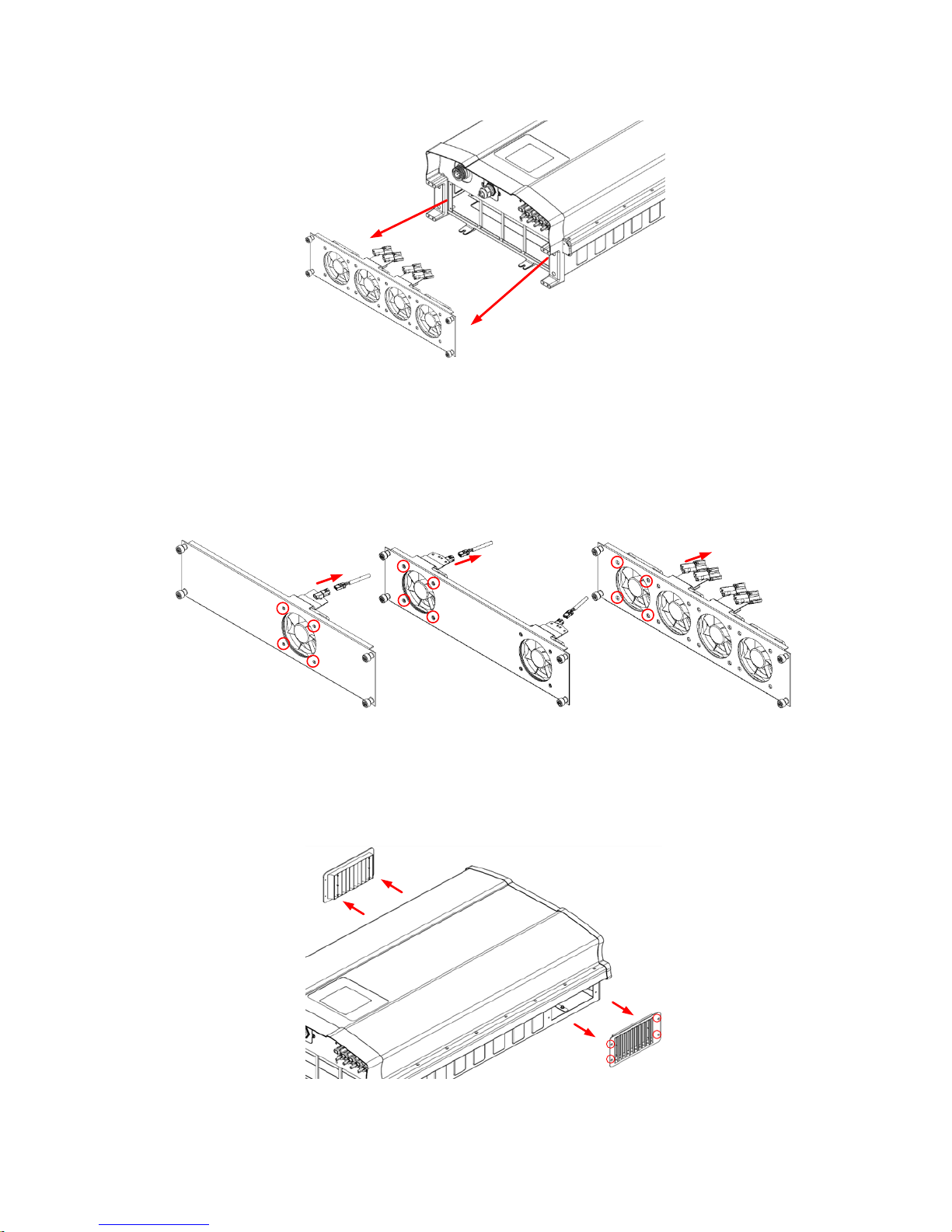

Figure 8-1 dissembling fan connections ........................................................ 49

Figure 8-2 disassembling fan overview ......................................................... 50

Figure 8-3 Disassembling fan ....................................................................... 50

Figure 8-4 Disassembling air outlets ............................................................. 50

5

Table

Section Description Page

Table 2-1 Packing list .................................................................................... 10

Table 5-1 Recommended upstream protection ............................................. 20

Table 5-2 Wire size of AC input ..................................................................... 20

Table 5-3 The wiring system of the inverter. .................................................. 23

Table 5-4 Maximum rating of input power ..................................................... 24

Table 5-5 Cable size ..................................................................................... 24

Table 5-6 Definition of RS 485 pin................................................................. 26

Table 5-7 RS-485 data format ....................................................................... 27

Tabel 5-8 Terminal resister setting ................................................................ 27

Tabel 5-9 EPO functions ............................................................................... 28

Table 7-1 LED indicator ................................................................................. 36

Table 7-2 Grid setting parameters ................................................................. 43

Table 9-1 Measurement and message .......................................................... 51

Table 9-2 Error Message ............................................................................... 54

Table 9-3 Warning Message ......................................................................... 55

Table 9-4 Fault Message ............................................................................... 56

Table 11-1 Specification for RPI-M8/ M10/ M12 ............................................ 61

Table 11-2 Specification for RPI-M15/ M20/ M30 .......................................... 64

Table 11-3 Specification for RPI-M15A/ M20A .............................................. 67

6

1. General Information

1.1 About this Manual

Congratulations on the purchase of your Delta RPI-M8/ M10/ M12/ M15/ M15A/

M20/ M20A/ M30 grid-tied solar inverter. This manual will assist you in becoming

familiar with this product. Please observe all safety regulations and take into

account technical connection conditions required at your local grid utility.

1.2 General Warnings / Notes on Safety

Careful handling of the product will contribute to service life durability and

reliability. Both are essential to ensure maximum yield from your product. As

some of the solar inverter models are heavy, two people may be required for

lifting purposes.

CAUTION!

During operation of electrical devices, certain parts are under

dangerous voltage.

Inappropriate handling can lead to physical injury and material

damage.

Always adhere to the installation regulations. Installation may

only be conducted by certified electricians.

WARNING!

Repair work on the device should ONLY be carried out by the

manufacturer. No user serviceable parts inside.

Please observe all points in the operation and installation manual.

Isolate the device from the grid and the PV modules before

undertaking work on the device.

DANGER!

To avoid risk of electrical shock, do not open the solar inverter.

The inverter contains no internal user-serviceable parts. Opening

the inverter will void the warranty.

Dangerous voltage is present for 5 minutes after disconnecting all

sources of power.

Remember that the unit has a high leakage current. The PE

conductor MUST be connected prior to commencing operation.

7

WARNING:BURN HAZARD

The unit may reach very high temperatures and the device

surface can become quite hot. Sufficient cooling time is

necessary for optimal yield.

1.3 Validity

This user manual describes the installation process, maintenance, technical data

and safety instructions of the following solar inverter models under the DELTA

brand.

◆RPI-M8 ◆ RPI-M10 ◆ RPI-M12

◆RPI-M15 ◆ RPI-M15A ◆ RPI-M20

◆RPI-M20A ◆ RPI-M30

1.4 Product Description

This device is a 3-phase grid-tied solar inverter. It converts direct current (DC)

electricity from the PV array into 3-phase alternating current (AC) which feeds

the excess generated power back to the local grid.

This inverter allows for a wide voltage range (200~1000V) and has a high

performance efficiency and user friendly design and operation. Please note these

devices do not support off-grid functionality.

The features for RPI-M8/ M10/ M12/ M15/ M15A/ M20/ M20A/ M30 are shown

below.

Features

Power Rating:8/ 10/ 12/ 15/ 20/ 30 kVA

3Phase, Grid-tie, Transformerless solar inverter

Maximum efficiency:> 98 %

Europe efficiency: >97.5%

Reactive power capability (Cap 0.8 – Ind 0.8)

Low output current harmonic distortion (THD < 3%) @ full load

2 MPP Trackers

Record up to 30 event logs.

5” LCD display

8

1.5 How it Works

The operation of solar inverter is shown as the figure 1-1. In order to save energy

and electricity, solar inverter convert the DC input power supplied from the PV

Array into 3-phase AC output power to Grid.

PV Array

Electrical Grid

Solar Inverter

DC Distribution

box

3PH

AC Distribution

box

Surge arrestor

Fuse

DC switch

Surge arrestor

AC breaker

3 phase, N, PE

E-Today: 47kWh

21. Jun 2010 13:50

Runtime: 8.2Hrs Power: 12103W

On Grid, Derating, cosφ – Ind 0.9

20

15

10

5

0

4 8 12 16 20 24

Figure 1-1 Solar system operation illustration

1.6 Additional Information

For more detailed information for RPI-M8/ M10/ M12/ M15/ M15A/ M20/ M20A/

M30 or other related product information, please visit http://www.deltaww.com.

9

2. Installation and Wiring

2.1 Instruction before Installation

Due to the variety of users and installation environments, it is recommended to

read this manual thoroughly before installation. Installation of the unit and

start-up procedures must be carried out by accredited technicians.

2.2 Unpacking

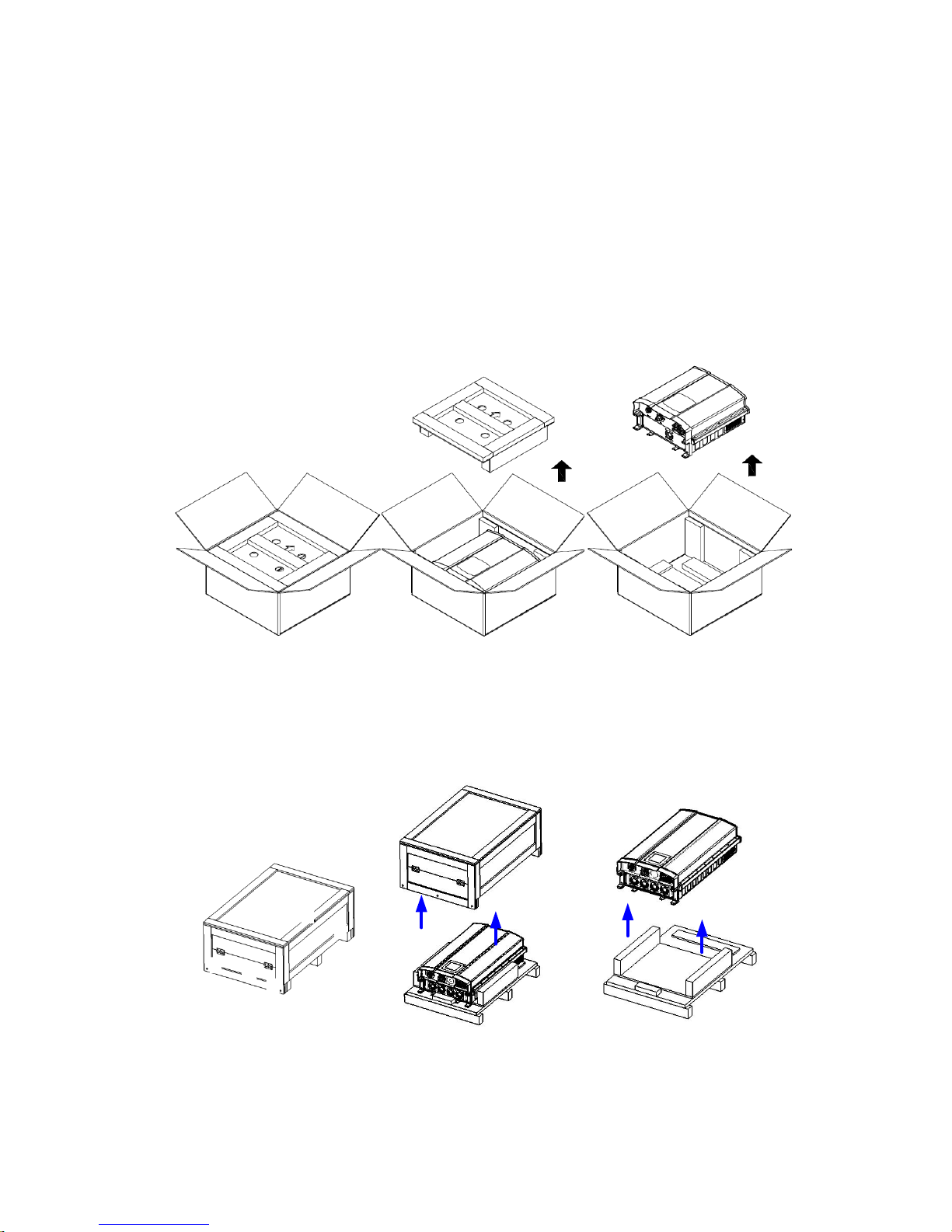

Unpacking process for RPI-M8/ M10/ M12/ M15A/ M20A is shown as Figure 2-1.

a. b. c.

Figure 2-1 Unpacking process

Unpacking process for RPI-M15/ M20/ M30 is shown as Figure 2-2.

5

4

6

1

2

3

a. b. c.

Figure 2-2 Wooden case unpacking process

10

2.3 Package Inspection

Unforeseeable events causing damage or movement may occur during shipment.

Please check for damage on the wooden carton upon receiving your inverter.

Please check the model number and the serial number on the packaging is

identical with the model number and serial number on the unit itself.

Check if all the accessories are in the package, the standard accessories are list

as Table 2-1:

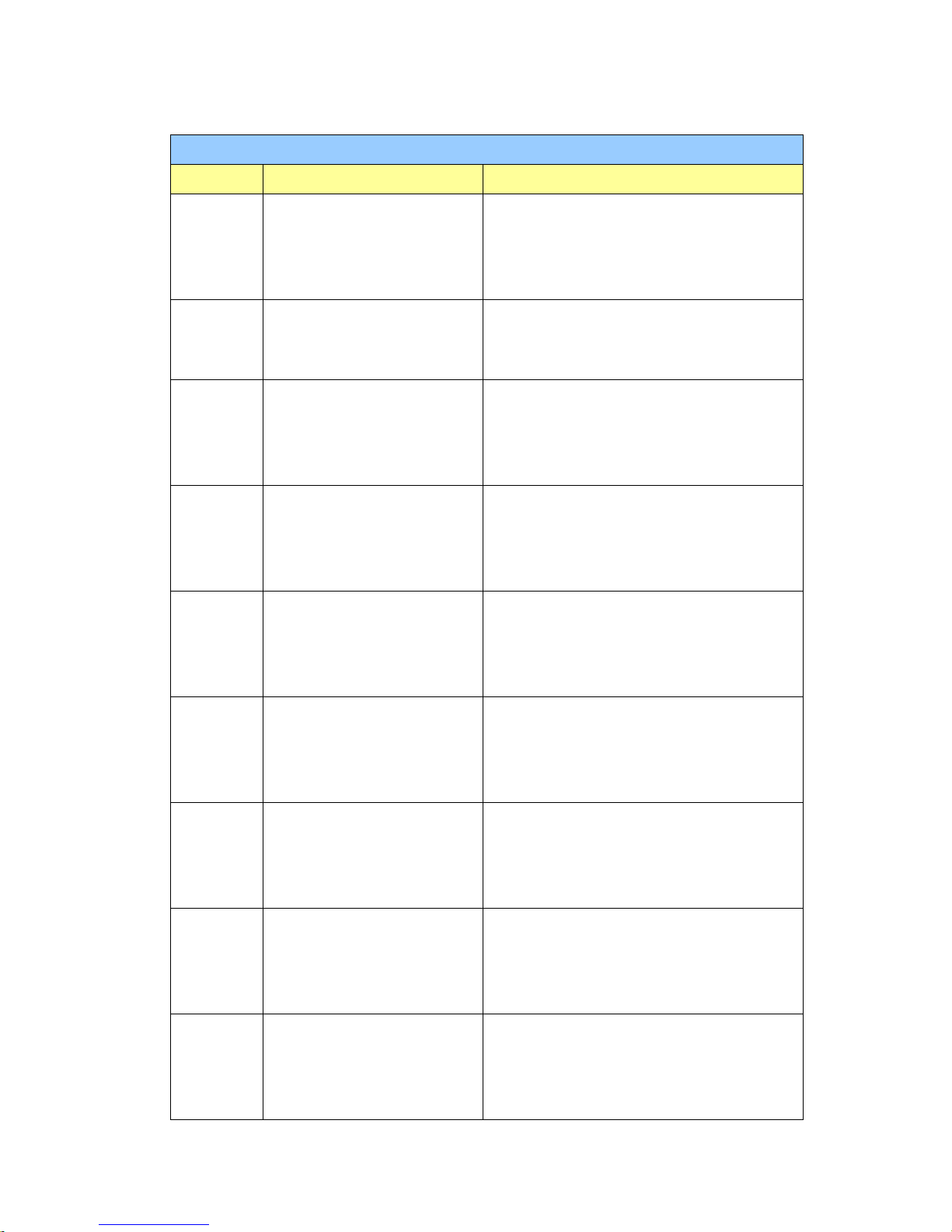

Table 2-1 Packing list

RPI-M8/ M10/ M12/ M15/ M15A/ M20/ M20A/ M30

Object

Qty

Description

PV Inverter

1

RPI-M8/ M10/ M12/ M15/ M15A/ M20/

M20A/ M30 solar inverter

User Manual

1

The Instruction to provide the information

of safety, Installation, specification, etc.

AC Plug

1

Connector for AC connection

Mounting Bracket

1

Wall mounting bracket to mount the solar

inverter on the wall

Caution: If there is any visible damage to the inverter/accesories or any

damage to the packaging, please contact your inverter supplier.

2.4 Identify of Inverter

Users can identify the model number by the information on the product label. The

model number, specification and the series No. is specified on the product label.

Regard to the label location, please refer to the figure 2-3.

RPI-M15/ M20/ M30RPI-M8/ M10/ M12 RPI-M15A/ M20A

Figure 2-3 The identification label

11

3. Product Overview

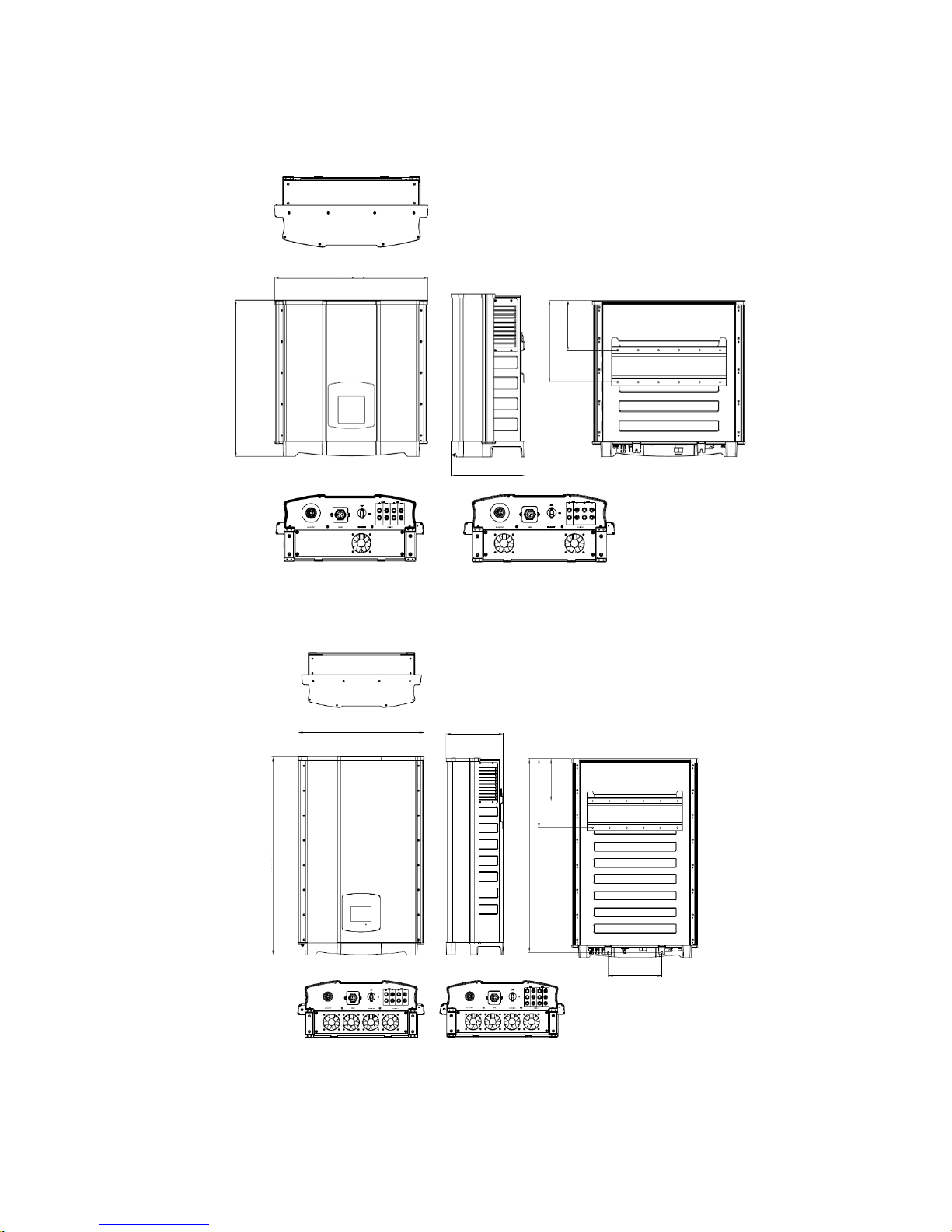

3.1 Dimension

Top view

Front view Side view Back view

Bottom view

326 [12.8]

198 [7.8]

278 [10.9]

612 [24.1]

625 [24.6]

RPI-M8/ M10/ M12 RPI-M15A/ M20A

Figure 3-1 Dimension of RPI-M8/ M10/ M12/ M15A/ M20A

Top view

Front view Side view Back view

RPI-M30RPI-M20 / RPI-M15

Bottom view

331 [13.0]

203 [8.0]

278 [10.9]

960 [37.8]

612 [24.1]

931 [36.6]

260 [10.2]

Figure 3-2 Dimension of RPI-M15/ M20/ M30

12

3.2 Function Introduction

The Inverter’s exterior objects are shown in Figure 3-3. The detailed description

can be found in sections 3.2.1 and 3.2.2.

LCD/LED Display

and Buttons

DC Connectors

AC Connectors

Communication

Connetions

DC Switch

Air outlets

Label

DC Switch

AC Connectors

Communication

Connetions

LCD/LED Display

and Buttons

Air outlets

RPI-M15/ M20/ M30

RPI-M8/ M10/ M12/

M15A/ M20A

Label

DC Connectors

Fan*4

Fan*1 or 2

Figure 3-3 Inverter exterior objects

3.2.1 LCD Display and Buttons

EXIT: Exit Menu

UP: Move Up

Down: Move Down

LCD Display ENT: Enter Menu or Confirm

LED Indicator (GRN/RED)

Figure 3-4 LCD display and control panel

13

3.2.2 Inverter Input / Output Interface

Communication

-RS-485 *2

-EPO *2

-Dry Contact *2

DC1

DC2

RPI-M8/ M10/ M12/ M15A/ M20A

Fan*1 or 2

AC Connector

230/400Vac, 3Ph

DC Switch

String1

String2

String3

String4

Figure 3-5 Input/Output interfaces of M8/ M10/ M12/ M15A/ M20A

AC Connector

230/400Vac, 3Ph

Fan *4

DC1 DC2

RPI-M30

DC1 DC2

RPI-M15/ M20

DC Switch

String1

String2

String3

String4

String1

String2

String3

String4

String5

String6

Communication

-RS-485 *2

-EPO *2

-Dry Contact *2

Figure 3-6 Input/Output interfaces of M15/ M20/ M30

Figure 3-7 Air outlet illustration

14

4. Installation

4.1 Installing Location

WARNING!

Do not install the unit near or on flammable surfaces.

Please mount the unit tightly on a solid/smooth surface.

CAUTION!

The unit should not be installed in a direct sunlight.

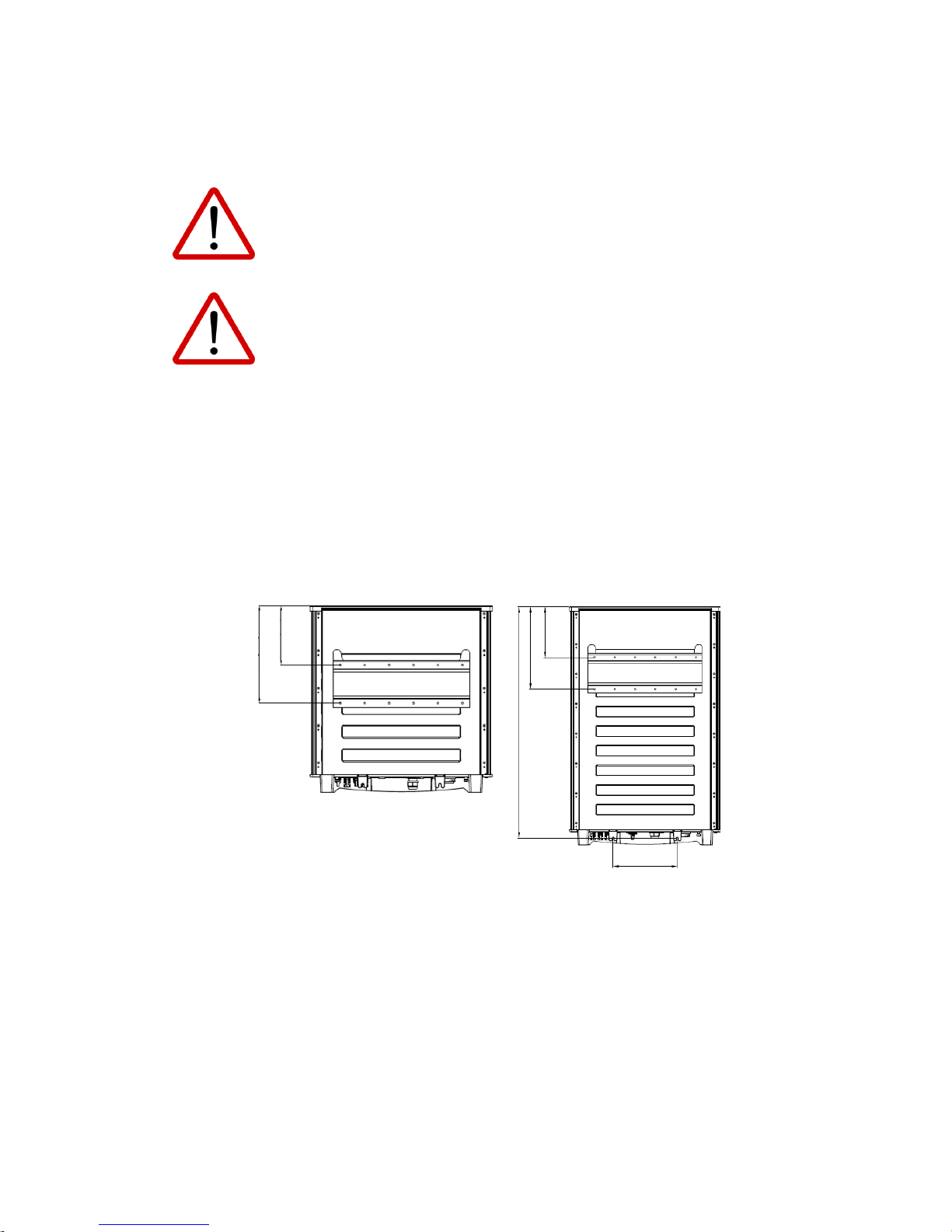

4.2 Mounting

This unit is designed to be wall-mounted. Please ensure the installation is

perpendicular to the wall and the AC plug at the base of the unit. Do not install

the device on a slanting wall. The dimensions of the mounting bracket are shown

in the figure below. There are 12pcs of M6 screws required for mounting plate.

Fix the supplied wall-mount plate securely on the wall before attaching the

inverter onto the mounting plate.

Back view

331 [13.0]

203 [8.0]

931 [36.6]

260 [10.2]

326 [12.8]

198 [7.8]

Back view

15

M6 Screw M6 Screw

M6 Screw *6

Wall

M6 Screw *6

> 125cm

> 70cm > 80cm

> 80cm

Inverter #1 Inverter #2

Figure 4-1 Screw the mounting bracket

16

90

Figure 4-2 Correct and incorrect installation illustration

CAUTION!

◆ The bracket supplied with the unit is specially designed and

should be the only mounting device used for the unit.

◆ It is recommended to install the inverter in a suitable location

which offers non-obscured and safe access, in turn ensuring

easy access for service and maintenance.

◆ Please leave an appropriate gap in between units when

installing several solar inverter systems.

◆ Please install solar inverter at an eye level to allow easy

observation for operation and parameter setting.

◆ Ambient temperature -20°C~60°C.(power derating above

40°C)

◆ It is essential to ensure sufficient space for product operation

as shown in Figure 4-3.

17

> 60 CM

> 60 CM

> 60 CM

> 60 CM

> 60 CM

Figure 4-3 Proper installation gap

18

5. Wiring

5.1 Preparation before Wiring

1. Ensure voltage values and polarities are correct.

2. When grounding the solar array, an isolation transformer is required due to

the RPI-series not having galvanic isolation between the DC-input and

AC-output.

3. The ground fault detection is a fixed internal setting. It cannot be modified.

4. Whole system wiring and connections can be seen in Figure 5-1 and 5-2.

5. Inverter can accept DC inputs in parallel (1 MPP tracker/2 parallel inputs).

6. Different DC connection type needs different settings of insulation detection.

About setting, please refer to 7.2.6.3 Install Setting.

1

2

3

4

L1

L2

L3

N

PE

Communication

Wiring

1

2

3

PV Array

AC Wiring

DC Wiring

Parallel or

Separate

DC Distribution box

DC1 DC2

*

* Some models can support 3P3W

system, please refer to table 5-3.

Figure 5-1 Connection of a system for floating DC inputs

19

Isolated

transformer

Utility

To

Inverter

3Ph,

400Vac

3Ph,

400Vac

Must be Parallel

Connection

PV Array

DC Distribution box

(Plus-GND or Minus-GND)

Z

Z

or

Must install a

transformer

Some models can support 3P3W

system, please refer to table 5-3.

Figure 5-2 Connection of system with positive/negative ground

WARNING! SHOCK HAZARD

Note: Whenever a PV array is exposed to sunlight, a shock hazard

may exist due to output wires or exposed terminals. To reduce the

risk of shock during installation, cover the array with an opaque

(dark) material and ensure that the Disconnect Device in the

inverter is set to OFF before commencing any wiring.

20

5.2 AC Grid Connection: 3-Phase+PE or 3-Phase+N+PE

WARNING! Death and serious injuries may occur.

Before AC wiring, please ensure AC breaker is switched off.

5.2.1 Required Protective Devices and Cable Cross-sections

It is recommended to install upstream circuit breakers between AC side and

inverter side for over current protection.

Table 5-1 Recommended upstream protection

Model

Upstream circuit breaker

RPI-M8

20A

RPI-M10

20A

RPI-M12

30A

RPI-M15

30A

RPI-M15A

30A

RPI-M20

40A

RPI-M20A

40A

RPI-M30

60A

G N L1 L3L2

N

L1

L2

L3

PE

To solar inverter AC

plug

The AC cable must be jacked and meet the specification in table 5-2.

Table 5-2 Wire size of AC input

Model

Current Rating

Wire size

Torque

Temperature

RPI-M8

40 A

5 - 8 mm2

0.7 N m

Meet UL 10070

RPI-M10

RPI-M12

RPI-M15

RPI-M15A

RPI-M20

RPI-M20A

RPI-M30

60 A

10 mm2 or 6 AWG

3 N m

Meet UL 10070

21

AC’s wiring can be separated into 3-phase and PE (3P3W) or 3-phase, N, and

PE (3P4W). Only some models can support 3P3W system. Please refer to table

5-3. The following instruction is based on 3P4W. If the grid system is 3P3W,

please ignore the description of N.

CAUTION! Machine and equipment damage may occur.

◆ Make sure to choose the correct wire size AC cable.

◆ Failure to follow these instructions may cause AC plug

damage.

Follow the steps below to strip the wires before assembling the AC plug:

a) Trim the L1, L2, L3, and N wire to 52.5 mm (2.0 inch).

b) Strip 12 mm (0.5 inch) of insulation from all wire ends.

c) Remove 55 mm (2.2 inch) of AC cable outer jacket.

Figure 5-3 Stripping the wire

22

Assemble the AC plug and wires as the procedures shown in figure 5-4(for all

models except RPI-M30) and figure 5-5(for RPI-M30 model only). Inverter allows

either positive or negative phase sequence. That means the sequence of L1~ L3

can be reversed. However, N and PE must be connected correctly.

L1

L2

N

PE

L3

Inverter

Fix it

Rotate to loose the AC plug

Inverter

Rotate to tighten the inserter

Rotate to tighten the plug

Rotate gland to

fix cable

Cable

AC Plug

AC plug

1 : L1

2 : L2

3 : L3

4 : N

: PE

Cable

Cable

Cable

L1

L2

L3

N

PE

Socket

Align the biggest latch of the AC plug and the socket

Figure 5-4 AC plug illustrationfor M8/ M10/ M12/ M15/ M15A/ M20/ M20A.

23

L1

L2

N

PE

L3

L1

L2

L3

N

PE

Fix it

Rotate to loose the AC plug

AC plug

Rotate to tighten the AC plug

Inverter

Rotate to tighten the plug

Rotate gland to

fix cable

Figure 5-5 AC plug illustration for M30

Table 5-3 The wiring system of the inverter.

Model

Wiring

RPI-M8/ M10/ M12

RPI-M15/ M20

P/N: RPIXX3N5430098 or 09

3P3W+PE

╳

╳

3P4W+PE

Model

Wiring

RPI-M15/ M20

P/N: RPIXX3N5431000

RPI-M15A/ M20A/ M30

3P3W+PE

3P4W+PE

After wiring, installer should choose the AC connection type on the control panel.

About setting, please refer to 7.2.6.3 Install Setting.

The AC voltage should be as followings:

3P3W 3P4W

L1-L2: 400 Vac 10% L1-N: 230 Vac 10%

L1-L3: 400 Vac 10% L2-N: 230 Vac 10%

L2-L3: 400 Vac 10% L3-N: 230 Vac 10%

24

5.3 DC Connection (from PV Array)

WARNING!

When undertaking DC wiring, please ensure the correct

polarities are connected.

When undertaking DC wiring, please ensure that the power

switch on the PV array is OFF.

CAUTION!

◆ The connection number of PV Array, open circuit voltage and

power of String_1 and String _2 must be coherent.

◆ The connection number of PV Array, open circuit voltage and

power of String _3 and String _4 must be coherent.

◆ The maximum open circuit voltage of PV Array cannot be

higher than 1000V.

◆ The range of MPP Voltage of Input1 and Input2 shall be in

350~800 Vdc.

◆ The device installed between PV Array and inverter must meet

the following specifications:

a.) Rated voltage > open-circuit voltage of PV Array.

b.) Rated current > short-circuit current of PV Array.

◆ The input power to the inverter should not higher than the

rated power shown in table 5-4.

Table 5-4 Maximum rating of input power

Type of limit

RPI-M8

RPI-M10

RPI-M12

RPI-M15

Total input power

8.8 kW

11 kW

13.2 kW

16.5 kW

Input1 or Input2

5.9 kW

7.4 kW

8.8 kW

8.25 kW

Type of limit

RPI-M15A

RPI-M20

RPI-M20A

RPI-M30

Total input power

16.5 kW

22 kW

22 kW

32 kW

Input1 or Input2

8.25 kW

11 kW

11 kW

16 kW

Table 5-5 Cable size

Model

Current Rating

Wire size

Temperature

M8

DC 10A

2 - 3mm2 / 14 AWG

Meet UL 10070

M10/ M12

DC 20A

3 - 5mm2 / 12 AWG

Meet UL 10070

M15A/ M20A

DC 34A

5 - 6mm2 / 10 AWG

Meet UL 10070

M15/ M20/ M30

DC 34A

5 - 6mm2 / 10 AWG

Meet UL 10070

25

DC wiring polarity is divided into positive and negative, which is shown as in

Figure 5-6. The connection shall be coherent with the indication marked on

inverter.

PV-KBT4/6 Ⅱ

PV-KST4/6 Ⅱ

Figure 5-6 DC Wiring illustration

26

5.4 Communication Module Connections

The Communication Module supports the functions of communication with a

computer. There are two types of modules. One has RJ45-type RS-485

connector, and the other has terminals-type RS-485 connector.

Terminal Resistor

Dry contact

(3A / 28V)

RS-485

EPO

(Emergency Power off)

VCC

GND

RS-485

+

-

+

-

EPO

(Emergency Power off)

RJ45-type Terminals-type

Figure 5-7 Communication module

5.4.1 RS-485 Connection

The pin definition of RS-485 is shown as in table 5-6. Installers should switch ON

the terminal resistor when single inverter is installed. The wiring of multi-inverter

connection is shown as figure 5-8. Installers should switch ON terminal resister

at the first and last devices of the RS485 chain as shown in Figure 5-8. The other

terminal resisters should be switched OFF. Please refer to table 5-8 for the

terminal resister setting.

Table 5-6 Definition of RS 485 pin

Pin

Function

Pin

Function

1 2 3 4 5 6

4

DATA-

1

VCC (+12V)

5

DATA+

2

GND

7

VCC (+12V)

3

DATA+

8

GND

4

DATA-

5

DATA+

6

DATA-

RJ45-type

Terminals-type

27

Terminal Resister

Terminal Resister

PIN FUNCTION

4

5

7

8

DATA-

DATA+

VCC(+12V)

GND

Data Format:

Baud rate: 9600

Data bits: 8

Stop bit: 1

Parity: N/A

Pin Layout:

120Ω(1/2W)

DATA+ to DATA-

120Ω(1/2W)

DATA+ to DATA-

RS485/USB

or

RS485/RS232

Figure 5-8 Multi-inverter connection illustration

Table 5-7 RS-485 data format

RS-485 Data format

Baud rate

9600, 19200, or 38400

Data bit

8

Stop bit

1

Parity

N/A

Tabel 5-8 Terminal resister setting

OFF

ON

1 2

OFF OFF

ON

ON

ON

ON

OFF

OFF

SW

Terminal

Resistor

ON

1 2

SW ON

SW OFF

28

5.4.2 EPO Functions

RJ45-type Communication Module provides 2 sets of emergency power off

function (EPO1 and EPO2). Terminals-type Communication Module only has 1

set of EPO (EPO1). When the outer external switch is shorted, the inverter will

shutdown immediately.

Tabel 5-9 EPO functions

EPO1

EPO2

Short

Pin1 & Pin2

Enable EPOs

Short

Pin4 & Pin5

5.4.3 Dry Contact Connection

RPI-series provides 1 set of Dry Contact function. When inverter is on grid, Com

& NO2 will be shorted. When the Fan Fail is detected, Com & NO1 will be

shorted.

Figure 5-9 Dry contact port & Assignments

29

6. Active / Reactive Power Control and Fault Ride Through

Installers can adjust Active/Reactive power control only when Grid System are

set to: Germany MV, Germany LV, Italy LV, or Italy MV (a password is required to

change these settings). Fault ride through (FRT) can only be adjusted when Grid

System is set to: Germany MV, Italy MV, or Italy LV.

There are 2 settings for active power control and 4 settings for reactive power

control that can be configured based on the requirement of the local network

operator. It can be configured to have active power control and/or one of the

reactive power control functions.

6.1 Active Power Control

6.1.1 Power Limit

According to BDEW’s technical guideline in page 25 (June 2008 version):

It must be possible to operate the generating facility at reduced power output. In

the cases listed below, the network operator is entitled to require a temporary

limitation of the power feed-in or disconnect the facility:

- potential danger to secure system operation,

- congestion or risk of overload on the network operator’s network,

- risk of islanding,

- risk to the steady-state or dynamic network stability,

- rise in frequency endangering the system stability,

- repairs or implementation of construction measures,

- within the scope of generation management/ feed-in management/ network

security

- management (see „Grundzüge zum Erzeugungsmanagement“)

User can reduce inverter output power by set percentage of actual or rated power.

Please refer to 7.2.6.4.1 Power Limit for the settings procedure.

30

6.1.2 Power vs. Frequency

There’re 2 different operation curves that depend on Country setting.

Germany LV: follow the curve in Figure 6-1-a

Germany MV/ Italy BT/ Italy MT: follow the curve in Figure 6-1-b

legend:

Pm is the power generated at the time of exceeding f

start

P is the feeding power

f is the mains frequency

fstart is the frequency when the power reduction starts

fstop is the frequency when there is has zero power

Gradient is the slope of power reduction

Configuration can be made to meet the requirements from the network operator.

Please refer to 7.2.6.4.2 Power vs. Frequency for the settings procedure.

P

Pm

fstart

fstop

f

(Hz)

Gradient

P

Pm

f

recovery

f

start

f

stop

f

(

Hz

)

Gradient

6-1-a 6-1-b

Figure 6-1 Power vs. frequency characteristic

31

6.2 Reactive Power Control

According to BDEW:

With active power output, it must be possible to operate the generating plant in

any operating point with at least a reactive power output corresponding to a

active factor at the network connection point of

cos φ = 0.95 underexcited to 0.95 overexcited

Values deviating from the above must be agreed upon by contract. In the

consumer reference arrow system (see Annex B.4), that means operation in

quadrant II (under-excited) or III (overexcited).With active power output, either a

fixed target value for reactive power provision or a target value variably

adjustable by remote control (or other control technologies) will be specified by

the network operator in the transfer station. The setting value is either

a) a fixed active factor cosφ or

b) a active factor cosφ(P) or

c) a fixed reactive power in MVar or

d) a reactive power/voltage characteristic Q(U).

6.2.1 Fixed Active Factor cosφ

Configurations can be made to set the power factor from Cap 0.8 to Ind 0.8

(inverter would stop reactive power control if output power is below 10% rated

power).

6.2.2 Active Factor cosφ(P)

Once user enables this method, inverter will deliver the reactive current

according to output active power in that moment. The below figure is an example.

Please refer to 7.2.6.4.4 cosφ(P) for the settings procedure.

Cap 0.85

Ind 0.85

P/Pn

1

cosφ

Figure 6-2 cosφ(P) characteristic

32

6.2.3 Fixed Reactive Power

When this function is enabled, the inverter will send reactive power (ie. Q) in

relation to the fixed reactive power setting. The range is Cap 53% to Ind 53%.

6.2.4 Reactive Power / Voltage Characteristic Q(U)

After selecting “Q(U) control”, User can adjust “Q” against the Grid voltage

operation curves shown in Figure 6-3.

V

1s

V

2s

V

1i

V

2i

Q

i limit

Q

s limit

V

V

1s

V

2s

V

1i

V

2i

Q

i limit

Q

s limit

V

Q

CurveA CurveB

Figure 6-3 Q(U) characteristic.

33

6.3 Fault Ride Through (FRT)

According to BDEW:

2.5.1.2 Dynamic network support

Dynamic network support means voltage control in the event of voltage drops

within the high and extra-high voltage network with a view to avoiding

unintentional disconnections of large feed-in power, and thus network collapse.

In the light of the strong increase in the number of generating plants to be

connected to the medium-voltage network, the integration of these plants into the

dynamic network support scheme is becoming ever more important.

Consequently, these generating plants must generally participate in dynamic

network support even if this is not required by the network operator at the time of

the plant’s connection to the network. That means that generating plants must be

able in technical terms

not to disconnect from the network in the event of network faults,

to support the network voltage during a network fault by feeding a reactive

current into the network,

not to extract from the medium-voltage network after fault clearance more

inductive reactive power than prior to the occurrence of the fault.

These requirements apply to all types of short circuits (i.e. to single-phase,

two-phase and three-phase short circuits).

Just like in the Transmission Code 2007 7, a distinction is made in these

guidelines between type-1 and type-2 generating plants with regard to their

behaviour in the event of network disturbances. A type-1 generating unit exists

if a synchronous generator is directly (only through the generator transformer)

connected to the network. All other plants are type-2 generating units.

The following conditions shall apply to type-2 generating plants, taking the

Transmission Code 2007, Section 3.3.13.5, into account:

Generating units must not disconnect from the network in the event of

voltage drops to 0 % Uc of a duration of ≤ 150 ms.

Below the blue line shown in Figure 2.5.1.2-2, there are no requirements

saying that generating plants have to remain connected to the network.

Voltage drops with values above the borderline 1 must not lead to instability or to

the disconnection of the generating plant from the network (TC2007; 3.3.13.5,

section 13; extended to asymmetrical voltage drops).

If the voltage drops at values above the borderline 2 and below the borderline 1,

generating units shall pass through the fault without disconnecting from the

network. Feed-in of a short-circuit current during that time is to be agreed with

the network operator. In consultation with the network operator, it is permissible

34

to shift the borderline 2 if the generating plant’s connection concept requires to

do so. Also in consultation with the network operator, a short-time disconnection

from the network is permissible if the generating plant can be resynchronized 2

seconds, at the latest, after the beginning of the short-time disconnection. After

resynchronization, the active power must be increased with a gradient of at least

10% of the nominal capacity per second (TC2007; 3.3.13.5, section 14).

Figure 6-4 Borderlines of the voltage profile of a type-2 generating plant at the network

connection point

RPI-M8/ M10/ M12/ M15/ M15A/ M20/ M20A/ M30 implements the FRT behavior

as the figure below, in area

1. Keep normally operate

2. Feed-in reactive current according to ΔU/Un and K factor

3. Short-time disconnect

4. Long-time disconnect

U/Un

IB/In

K factor

K factor

+10-10

100%

U1

0

t1

t2

Fault occurence

t3

time

Ugrid/Unom

2 3

4

1

U2

Udrop

Figure 6-5 FRT characteristic

35

7. Turn on/off PV inverter

WARNING:BURN HAZARD

The enclosure temperature may exceed over 70°C while operating.

To avoid injury, do not touch the surface of the inverter whilst the

unit is in operation.

After installation, please ensure the AC, the DC and communication connection

are correct. Switch on the DC switch. When enough power is generated from the

PV array, the device will operate automatically and will initially ‘self-test’. This

self-test takes approximately 2 minutes and will occur at first start-up of the day.

The display on the inverter includes a 320x240 pixel LCD display and LED

indicator lights to indicate inverter status. The green and red colour LED indicator

light represents different inverter statuses.

EXIT: Exit Menu

UP: Move Up

Down: Move Down

LCD Display ENT: Enter Menu or Confirm

LED Indicator (GRN/RED)

Figure 7-1 LCD display &control panel

36

Table 7-1 LED indicator

Condition

Green LED

Red LED

Standby or Countdown

FLASH

*1

OFF

Power ON

ON

OFF

Error or Fault

OFF

ON

Night time (No DC)

OFF

OFF

Bootloader mode

FLASH

*2

*1 ON 1s / OFF 1s

*2 ON 1s / OFF 1s, Green and Red are interleaving

On the first start up, the country and language has to be set. The system will

show the main menu after these are set.

21. Jun 2010 13:50

Select Country – 1/3

ENT

EXIT

21. Jun 2010 13:50

No Yes

Confirm Country

Australia

Austria

Belgium

China

Czech

England

France

Are you sure to set county :

xxxxxxxx

Figure 7-2 Select county page

21. Jun 2010 13:50

English

Deutsch

Français

Italiano

Español

Nederlands

Select Language

Figure 7-3 Select language page

37

7.1 Home Page

When inverter is operating normally, the LCD will display the homepage as

shown in Figure 7-4, user can get the information of output power, inverter status,

E-today, date and time.

E-Today: 47kWh

21. Jun 2010 13:50

Runtime: 8.2Hrs Power: 12103W

On Grid

20

15

10

5

0

4 8 12 16 20 24

Today Energy

Today Runtime

Inverter Status

Today Power Curve

Day - Time

Output Power

Figure 7-4 Home page

7.2 LCD Flow Chart

Press the EXIT button to enter the menu page (Figure 7-5). The option “E-today”

is the homepage.

Power Meter 7.2.1

Energy Log 7.2.2

Event Log 7.2.3

Operation Data 7.2.4

Inverter Information 7.2.5

Setting 7.2.6

Figure 7-5 Menu page

7.2.1 Power Meter

This page shows the information about input and output power.

Power Meter

Input1 Input2

P

V

I

W

V

A

1420

222

6.4

1480

224

6.6

Output

1455

225

6.5

Today Energy:

Today Runtime:

21. Jun 2010 13:50

kWh0

Today Earning:

Today CO2 Saved:

Hours0.0

0

kg0.0

€

Figure 7-6 Power meter page

Menu

Operation Data

E-Today

Power Meter

Event Log

Energy Log

Setting

Inverter Information

38

7.2.2 Energy Log

Press ENTER on this page to view the historical data on the power generated

from a yearly, monthly and daily basis.

21. Jun 2010 13:50

Energy Log - Total

Life Energy:

Life Runtime:

Total CO2 Saved:

kWh

Hours

kg

29200

3651

54312

21. Jun 2010 13:50

180

150

120

90

60

30

0

Energy Log - Month

2010.06

2010.05

1447

2690 kg

1 Day5 10 15 20 25 30

kWh

Month CO2 Saved:

180

150

120

90

60

30

0

Exit Day

E-Month: kWh

kWh06,Peak Day:

Energy Log - Year

2010

17033

2354

31681

4500

3750

3000

2250

1500

750

0

kg

Month

kWh

1 2 3 4 5 6 7 8 9 10 11 12 Month

Year CO2 Saved:

2009Exit Month

E-Year:

Peak Month:

kWh

kWh

21. Jun 2010 13:50

21. Jun 2010 13:50

2010.06

2010.04

Exit

Month CO2 Saved:

4612 kg

Day

180

150

120

90

60

30

0

1 Day10 15 20 25 30

Energy Log - Month

kWh

2010.05

5

Energy Log - Year

21. Jun 2010 13:50

2010

2009

2009

4500

3750

3000

2250

1500

750

0

Month

kWh

Month

1 2 3 4 5 6 7 8 9 10 11 12

2008

Exit Month

54312 kg

Year CO2 Saved:

21. Jun 2010 13:50

Energy Log - Day

2010.06.20

2010.06.212010.06.19

Exit

kg

kW

Hour

Day CO2 Saved:

149

Year

20

15

10

5

0

4 8 12 16 20 24

ENT

ENT

21. Jun 2010 13:50

Energy Log - Day

2010.06.21

46

14

86

kg

kW

Hour

Day CO2 Saved:

2010.06.20

20

15

10

5

0

4 8 12 16 20 24

Exit Year

kWh

kWh

Peak Hour:

E-Day:

EXIT EXIT

EXITENT ENT EXIT

ENT

EXIT

ENT ENT

May,

01 pm,

92

80

15 kWh

kWh

Peak Hour:

E-Day:

01 pm,

2480

E-Month:

kWh

kWh15,Peak Day: 95

29200

2490

E-Year:

Peak Month:

kWh

kWh

Jul,

Total Earning: 0 €

History

Figure 7-7 Energy log flow chart

7.2.3 Event Log

This page displays all the events (errors or fault) and it can show 30 records at at

a time. Press ENTER to view all the statistical data.

Event Log

21. Jun 2010 13:50

1. 15/02/2010 17:02

2. 02/12/2009 09:13

3. 23/11/2009 15:28

4. 03/10/2009 06:02

5. 27/05/2009 05:52

6. 18/02/2009 16:46

AC Freq High

No Grid

HW Fan

Insulation

Insulation

HW DC Injection

Summary

21. Jun 2010 13:50

HW DC Injection

Temperature

HW NTC1 Fail

HW NTC2 Fail

HW NTC3 Fail

HW NTC4 Fail

Event Count

2

1

0

0

0

0

Event Summary – 1/8

1

0

ENT

EXIT

Figure 7-8 Event log flow chart

39

7.2.4 Operation Data

The operation data is split into 4 pages. It records the maximum and/or minimum

values of history; including voltage, current, power and temperature.

Operation Data – 1/4

21. Jun 2010 13:50

Input1

Voltage

Current

Power

Voltage

Current

Power

Input2

Maximum

(Vdc)

(A)

(W)

(Vdc)

(A)

(W)

811

25.2

11200

785

26.3

10301

Operation Data – 2/4

21. Jun 2010 13:50

L1

Voltage

Current

Power

Voltage

Current

Power

Voltage

Current

Power

L2

L3

Maximum

(Vdc)

(A)

(W)

(Vdc)

(A)

(W)

(Vdc)

(A)

(W)

247

30.5

6810

244

30.3

6756

245

30.1

6745

Operation Data – 4/4

21. Jun 2010 13:50

Temperature Max. Min.

Inside

Heatsink - 1

Heatsink - 2

Heatsink - 3

(℃)

(℃)

(℃)

(℃)

59.3

75.5

74.2

73.6

15.7

15.3

15.2

15.2

Operation Data – 3/4

21. Jun 2010 13:50

Output

Voltage

Current

Power

Frequency

(Vdc)

(A)

(W)

(Hz)

Maximum

247

30.5

20311

50.10

ENT

or

ENT

or

ENT

or

ENT

or

Figure 7-9 Operation data flow chart

7.2.5 Inverter Information

This page has the following information: serial number, firmware version,

installation date and inverter ID. If user wants to change inverter ID, please refer

to 7.2.6.3 Install Setting.

.

Inverter Information

21. Jun 2010 13:50

Serial Number

DSP-Version

Installation Date

AE46000006

05.Jan.2009

1.80

Red.-Version 1.17

Comm.-Version

1.99

Inverter ID 001

Country Custom

Figure 7-10 Inverter information page

40

7.2.6 Settings

The Settings page includes Personal, Coefficients, Installation, Active/Reactive

Power Control and FRT Settings.

Settings

21. Jun 2010 13:50

Coefficients Settings

Personal Settings

Install Settings

Active/Reactive Power Control

FRT

Figure 7-11 Setting page

7.2.6.1 Personal Setting

The language, date, time, screensaver, LCD brightness and contrast can be set

in the Personal Settings.

Personal Settings

21. Jun 2010 13:50

Language English

Date

Time

Screen Saver

21 / 06 / 2010

(DD/MM/YYYY)

Brightness

Contrast

[ ]

5 min[

]

3[

]

2[

]

13:50

Figure 7-12 Personal setting page

41

7.2.6.2 Coefficient Setting

Users can set the following parameters according their needs.

Coefficient Settings

21. Jun 2010 13:50

1.86

CO2 Saved kg/kWh

[ ]

Earning Value/kWh

Currency ($,€)

[

[

2.50

€

]

]

Figure 7-13 Coefficient setting page

7.2.6.3 Installation Settings

A password is required to enter the Installation Setting. These settings are

different for end customers and installers. The password once set, cannot be

reset. Once a the correct password has been entered, access to configure the

Inverter ID, Insulation, RCMU, Reconnection Time, Ramp-up Power and AC

Connection will be granted.

CAUTION !

The following settings can only be adjusted by installers or

engineers. Changing these settings may result in damage to the

inverter and other equipment.

Insulation: Inverter will measure the impedance between the Array and PE

before connecting to grid. If the impedance is lower than the value that is set

in Insulation Settings, inverter will stop connecting to grid. There are 6

modes users can select in Insulation settings: ON, Positive Ground,

Negative Ground, DC1 Only, DC2 Only, and Disable. After an analysis has

been made for the site, the impedance should be set to best suit the

environment of the installation.

DC Injection: Inverter will shutdown if the DC component in the AC current

is over the limit.

RCMU: If there is a leakage current between the input and output which

exceeds the limit, inverter will shutdown immediately.

Reconnction Time: The time before the inverter connects to grid.

Ramp-up Power: The rate of increase in the output power. (%/min)

42

AC connection: Depending on the site conditions, the two systems

available are 3P3W and 3P4W.

Install Settings

21. Jun 2010 13:50

Inverter ID

Insulation

RCMU

Password

21. Jun 2010 13:50

*

ENT

ENT

EXIT

Country ItalyMV

[ 001 ]

[ ON ]

Grid Settings

[ ]

Reconnection Time

[

]

60 s

Ramp-up Power

20

%/m

Install Settings

21. Jun 2010 13:50

AC Connection

[

]

3P4W

Figure 7-14 Install setting page –User mode

Install Settings

21. Jun 2010 13:50

Inverter ID

Insulation

RCMU

Insulation

21. Jun 2010 13:50

Mode

Resistance

ON

1200

[

[

]

] kohm

ENT

EXIT

Country ItalyMV

[ 001 ]

[ ON ]

Grid Settings

[ ]

Reconnection Time

[

]

60 s

Ramp-up Power

20

%/m

Figure 7-15 Insulation setting

The system will add the options DC-Injection, Return to Factory, Country and

Grid Setting once the technician password has been entered. In Grid Setting

selection, technician can adjust the protection parameters (OVR, UVR, OFR,

UFR, etc) to Utility. Before setting of the protection to Utility, please set the

country as “Custom.” Returning the inverter to factory settings will revert the

inverter setting back to default and remove all event and energy records.

Install Settings – 1/2

21. Jun 2010 13:50

DC Injection

Inverter ID

Insulation

RCMU

[ 001 ]

[ ON ]

Country ItalyMV

Grid Settings

Return to Factory [ Yes / No ]

Install Settings – 2/2

21. Jun 2010 13:50

20

[

]

Reconnection Time

[

]

Ramp-up Power

%/m

S

300

AC Connection [ ]

3P4W

Figure 7-16 Install setting page – Installer mode

43

21. Jun 2010 13:50

Grid Settings – 1/4

Vac High Off

Vac High On

Vac High Off T

Vac Low Off

Vac Low On

Vac Low Off T

276.0 V

253.0 V

0.5 s

184.0 V

195.5 V

0.5 s

[

[

[

[

[

[

]

]

]

]

]

]

21. Jun 2010 13:50

Grid Settings – 2/4

Vac High Off Slow

Vac High On Slow

Vac High Off Slow T

Vac Low Off Slow

Vac Low On Slow

Vac Low Off Slow T

276.0 V

253.0 V

0.5 s

184.0 V

195.5 V

0.5 s

[

[

[

[

[

[

]

]

]

]

]

]

21. Jun 2010 13:50

Grid Settings – 3/4

Fac High Off

Fac High On

Fac High Off T

Fac Low Off

Fac Low On

Fac Low Off T

52.00 Hz

50.50 Hz

1.5 s

47.00 Hz

49.95 Hz

5.00 s

[

[

[

[

[

[

]

]

]

]

]

]

21. Jun 2010 13:50

Grid Settings – 4/4

Reconnection Time

[ ]300 s

Figure 7-17 Grid setting page

There are 19 parameters on the Grid Settings page. Users can refer to table 7-2

for the function of each parameter.

Table 7-2 Grid setting parameters

Parameter

Description

Vac High Off

Inverter will be disconnected from the grid if the AC phase

voltage rises to this value.

Vac High On

Inverter will be reconnected to grid if the AC phase voltage

drops to this value.

Vac High Off T

If AC voltage reaches the Vac High Off value, the inverter will

be disconnected in this time.

Vac Low Off

The inverter will be disconnected from grid if the AC phase

voltage drops to this value.

Vac Low On

Inverter will be reconnected to grid if the AC phase voltage

rises to this value.

Vac Low Off T

If the AC voltage reaches to the Vac Low Off value, the inverter

will be disconnected in this time.

Vac High Off Slow

Same functionality as the Vac High Off, but the value must be

set lower.

Vac High On Slow

Same functionality as the Vac High On, but the value must be

set lower.

44

Vac High Off Slow T

Same functionality as the Vac High Off T, but the time must be

set longer.

Vac Low Off Slow

Same functionality as the Vac Low Off, but the value must be

set higher.

Vac Low On Slow

Same functionality as the Vac Low On, but the value must be

higher.

Vac Low Off Slow T

Same functionality as the Vac High Off T, but the time must be

longer.

Fac High Off

The inverter will be disconnected from grid if the AC frequency

rises to this value.

Fac High On

The inverter will be reconnected to grid if the AC frequency

drops to this value.

Fac High Off T

If AC frequency reaches the Fac High Off value, the inverter will

be disconnected in this time.

Fac Low Off

Inverter will be disconnected from if the AC frequency drops to

this value.

Fac Low On

Inverter will be reconnected to grid if the AC frequency rises to

this value.

Fac Low Off T

If AC frequency reaches the Fac Low Off value, the inverter will

be disconnected in this time.

Reconnection Time

The time before the inverter reconnects to grid.

7.2.6.4 Active/Reactive Power Control

User can enter this page only when the country is sets as Germany LV, Germany

MV, Italy LV, or Italy MV. User has to enter user’s password before enter this

page.

Password

21. Jun 2010 13:50

ENT

ENT

EXIT

ENT

EXIT

Active/Reactive Power

21. Jun 2010 13:50

Power vs. Frequency

Power Limit

Constant cosφ

cosφ(P)

Constant Reactive Power

Q(V)

*1

*2

*3

Settings

21. Jun 2010 13:50

Coefficients Settings

Personal Settings

Install Settings

Active/Reactive Power Control

FRT

Figure 7-18 Active/Reactive powersetting page

45

7.2.6.4.1 Power Limit

The power limit can be set by the percentage of actual/rated power. The Mode

will turn the power limiting on and off.

Active Power Control

21. Jun 2010 13:50

Actual/Rated Power

Set Point 100

Rated

[

[

]]%

Mode

ON[ ]

Figure 7-19 Power limit setting page

7.2.6.4.2 Power vs. Frequency

Please notice the gradient is different between Italy and other countries.

- Italy BT/ MT: used to calculate the frequency of zero power. Ie. Fstop =

Fstart + Gradient * 50

- For other countries (ex. Germany LV or MV): Gradient means the slope

of power reduction, ie/ -xx%/Hz

Recovery time is accessible only if Country is set as Italy BT or MT. This means

If the frequency is back to normal before the time runs out, the inverter has to

stay on the power at that certain period of time and it cannot increase the power.

a

b

c

d

e

f

P

Pm

fstart

fstop

f

(Hz)

Statism

P

Pm

f

recovery

f

start

f

stop

f

(

Hz

)

a

b

c

d

e

e

f

Active Power Control

21. Jun 2010 13:50

Start Frequency

Actual/Rated Power Actual

50.30

[

[

]

]

Stop Frequency

- -[ ]HzHz

- -[ ] Hz

Statism 40[ ] %

Mode ON[ ]

Recovery Frequency

Recovery Time

300

[

]

s

b

c

Statism

Figure 7-20 Power vs. frequency setting page.

46

7.2.6.4.3 Constant cosφ

When this Mode is activated, the inverter will maintain the power factor as a

constant value. The range is from Cap 0.80 to Ind 0.80.

Reactive Power Control

21. Jun 2010 13:50

cosφ Ind 0.90[ ]

Mode ON[ ]

Figure 7-21 Constant cosφ setting page

7.2.6.4.4 cosφ(P)

The output power factor would be affected by feeding power. Lock-in voltage and

Lock-out voltage are only adjustable if the country setting is either Italy BT or Italy

MT. The Inverter will feed-in reactive power depending on the active power once

the Grid voltage is higher than the Lock-in voltage. It will revert back to active

power when Grid voltage is lower than Lock-out voltage. For the countries other

than Italy, cosφ (P) control will not affect the Grid voltage.

a

b

c

d

Lock-out Voltage [ ]

Reactive Power Control

21. Jun 2010 13:50

Mode OFF[ ]

230.0

V

Lock-out Voltage

[ ]

Reactive Power Control

21. Jun 2010 13:50

Lower limit - cosφ

Upper limit - cosφ Cap 0.90

Ind 0.90

[

[

]

]

Lower Power 0[ ] %

Upper Power 100[ ] %

Lock-in Voltage 241.5[ ] V

Upper

Limit

Lower

Limit

P/Pn

1

cosφ

Lower

Power

Upper

Power

a

b

c

d

Figure 7-22 cosφ(P) setting page

47

7.2.6.4.5 Constant Reactive Power

When this Mode is activated, inverter will maintain the reactive power as a

constant value.

Reactive Power Control

21. Jun 2010 13:50

Mode

Reactive Power (Q/Sn) Cap 30

OFF

[

[

]

]

%

Figure 7-23 Constant Reactive Power setting page

7.2.6.4.6 Q(U)

RPI-series support two kind of Q(U) curves. Please refer to fiqure 7-24.

Reactive Power Control

21. Jun 2010 13:50

Qi limit

Qs limit Ind 44

Cap 44

[

[

]]%

%

V2i

207.0[ ]

V

V2s 253.0[ ]

V

211.6[ ]

V

V1i

V1s 248.4[ ]

V

Reactive Power Control

21. Jun 2010 13:50

5[ ]

%

Mode

OFF[ ]

Lock-out Power

20[ ]Lock-in Power %

Delay Time

10[ ]

s

a

b

c

d

e

f

g

V

1s

V

2s

V

1i

V

2i

Q

i limit

Q

s limit

V

Q

V

1s

V

2s

V

1i

V

2i

Q

i limit

Q

s limit

V

Q

Curve A

Curve B

a

b

c

d

e

f

g

a

b

c

d

e

f

g

Figure 7-24 Q(U) setting page

48

7.2.6.5 FRT (Fault ride through)

This function is only for Germany MV, Italy LV, and Italy MV. It is not

recommended that an end customers modify the default values.

U/Un

IB/In

K factor

K factor

+10-10

FRT – 1/2

21. Jun 2010 13:50

Dead band - Vh

K factor

Vdrop

U1

t1

+10[ ] %

[

[

[

[

2.0

5

20

150

]

]

]

]

%

%

ms

t2

[ 1.5 ] s

Dead band - Vl

-10[ ] %

a

b

c

d

e

f

g

ab

c

c

100%

U1

0

t1

t2

Fault occurence

t3

time

Ugrid/Unom

2 3

4

1

U2

Udrop

FRT – 2/2

21. Jun 2010 13:50

t3 [ 3.0 ]

s

Mode

ON[ ]

h

i

d

e

f

g h

Figure 7-25 FRT setting page

49

8. Maintenance

In order to ensure normal operation of the inverter, please check the unit

regularly. Check that all terminals, screws and cables are connected and appear

as they did upon installation. If there are any impaired or loose parts, please

contact your solar installer.

Ensure that there are no foreign objects in the path of the heat outlet and keep

the unit and its surroundings clean and tidy.

WARNING !

Before any maintenance, please switch AC and DC power off to

avoid risk of electronic shock.

8.1 Clean Fan

Loosen the 4 screws shown in Figure 8-1. Once the screws are loose, pulling the

fan bracket out will expose the connectors. As shown in Figure 8-1, there is one

wire per fan. The bracket is completely detachable once the connectors are

disconnected as shown in Figure 8-2.

1

2

3

4

RPI-M15/ M20/ M30

RPI-M8/ M10/ M12 RPI-M15A/ M20A

Figure 8-1 dissembling fan connections

50

Figure 8-2 disassembling fan overview

8.2 Replace Fan

In the event that a fan needs to be replaced, user should disassemble the 4 pcs

screws around the fans and disconnect the connector right behind the fan

bracket. Then replace new fan and reassemble the 4pcs screws.

RPI-M15/ M20/ M30

RPI-M8/ M10/ M12

RPI-M15A/ M20A

Figure 8-3 Disassembling fan

8.3 Clean Air Outlets

Disassembling the 4 screws of air outlet and cleaning it should be done regularly.

Figure 8-4 Disassembling air outlets

51

9. Measurement, Error message and Trouble Shooting

9.1 Measurement

Table 9-1 Measurement and message

E-Today: 47kWh

21. Jun 2010 13:50

Runtime: 8.2Hrs Power: 12103W

On Grid

20

15

10

5

0

4 8 12 16 20 24

1

2 3

Power Meter

Input1 Input2

P

V

I

W

V

A

1420

222

6.4

1480

224

6.6

Output

1455

225

6.5

Today Energy:

Today Runtime:

21. Jun 2010 13:50

kWh0

Today Earning:

Today CO2 Saved:

Hours0.0

0

kg0.0

€

4

5

6

7

8

9

10

11

12

13

14

15

16

21. Jun 2010 13:50

Energy Log - Total

Life Energy:

Life Runtime:

Total CO2 Saved:

kWh

Hours

kg

29200

3651

54312

Total Earning: 0 €

History

17

18

19

20

Energy Log - Year

2010

17033

2354

31681

4500

3750

3000

2250

1500

750

0

kg

Month

kWh

1 2 3 4 5 6 7 8 9 10 11 12 Month

Year CO2 Saved:

2009Exit Month

E-Year:

Peak Month:

kWh

kWh

21. Jun 2010 13:50

May,

21

22

23

21. Jun 2010 13:50

Energy Log - Month

2010.06

2010.05

1447

2690 kg

1 Day5 10 15 20 25 30

kWh

Month CO2 Saved:

Exit Day

E-Month: kWh

kWh06,Peak Day: 92

24

25

26

21. Jun 2010 13:50

Energy Log - Day

2010.06.21

46

14

86

kg

kW

Hour

Day CO2 Saved:

2010.06.20

20

15

10

5

0

4 8 12 16 20 24

Exit Year

kWh

kWh

Peak Hour:

E-Day:

01 pm,

27

28

29

Operation Data – 1/4

21. Jun 2010 13:50

Input1

Voltage

Current

Power

Voltage

Current

Power

Input2

Maximum

(Vdc)

(A)

(W)

(Vdc)

(A)

(W)

811

25.2

11200

785

26.3

10301

30

31

32

33

34

35

Operation Data – 2/4

21. Jun 2010 13:50

L1

Voltage

Current

Power

Voltage

Current

Power

Voltage

Current

Power

L2

L3

Maximum

(Vdc)

(A)

(W)

(Vdc)

(A)

(W)

(Vdc)

(A)

(W)

247

30.5

6810

244

30.3

6756

245

30.1

6745

36

37

38

39

40

41

42

43

44

52

Operation Data – 3/4

21. Jun 2010 13:50

Output

Voltage

Current

Power

Frequency

(Vdc)

(A)

(W)

(Hz)

Maximum

247

30.5

20311

50.10

45

46

47

48

Operation Data – 4/4

21. Jun 2010 13:50

Temperature Max. Min.

Inside

Heatsink - 1

Heatsink - 2

Heatsink - 3

(℃)

(℃)

(℃)

(℃)

59.3

75.5

74.2

73.6

15.7

15.3

15.2

15.2

53

54

55

56

49

50

51

52

No.

Measurement

Meaning

1

E-Today

Total energy generated today

2

Runtime

Operation time today

3

Power

Actual power is generating

4

Input1 - P

Power of DC Input1

5

Input1 - V

Voltage of DC Input1

6

Input1 - I

Current of DC Input1

7

Input2 - P

Power of DC Input2

8

Input2 - V

Voltage of DC Input2

9

Input2 - I

Current of DC Input2

10

Output - P

Power of AC output

11

Output- V

Voltage of AC output

12

Output- I

Current of AC output

13

Today Energy

Accumulate electricity generated today

14

Today Runtime

Accumulated operation time today

15

Today Earning

Accumulated dollars amount earned today

16

Today co2 saved

Accumulated CO2 emission retrenched today

17

Life Energy

Total energy generated to present time

18

Life Runtime

Accumulated operation time to present time

19

Total co2 saved

Accumulated CO2 emission retrenched to present time

20

Total Earning

Accumulated the total amount of money earned

21

Peak Month

The maximum energy generated of one month in that year.

22

E-Year

Total energy generated in that year

23

Year CO2 saved

Accumulated CO2 emission retrenched in that year

24

Peak Day

The maximum energy generated of one day in that month

53

25

E-Month

Total energy generated in that month

26

Month CO2 saved

Accumulated CO2 emission retrenched in that month

27

Peak Hour

The maximum energy generated of one hour in that day

28

E-Day

Total energy generated in that day

29

Day CO2 saved

Accumulated CO2 emission retrenched in that day

30

Input1 Voltage Maximum

The maximum DC Input1 voltage from history

31

Input1 Current Maximum

The maximum DC Input1 current from history

32

Input1 Power Maximum

The maximum DC Input1 power from history

33

Input2 Voltage Maximum

The maximum DC Input2 voltage from history

34

Input2 Current Maximum

The maximum DC Input2 current from history

35

Input2 Power Maximum

The maximum DC Input2 power from history

36

L1 Voltage Maximum

The maximum L1 phase voltage from history

37

L1 Current Maximum

The maximum L1 phase current from history

38

L1 Power Maximum

The maximum L1 phase power from history

39

L2 Voltage Maximum

The maximum L2 phase voltage from history

40

L2 Current Maximum

The maximum L2 phase current from history

41

L2 Power Maximum

The maximum L2 phase power from history

42

L3 Voltage Maximum

The maximum L3 phase voltage from history

43

L3 Current Maximum

The maximum L3 phase current from history

44

L3 Power Maximum

The maximum L3 phase power from history

45

Output Voltage Maximum

The maximum Grid voltage from history

46

Output Current Maximum

The maximum output current from history

47

Output Power Maximum

The maximum output power from history

48

Output Frequency Maximum

The maximum Grid frequency from history

49

Inside Max.

The maximum inverter inner temperature value

50

Heatsink-1 Max.

The maximum Heatsink-1 temperature value

51

Heatsink-2 Max.

The maximum Heatsink-2 temperature value

52

Heatsink-3 Max.

The maximum Heatsink-3 temperature value

53

Inside Min.

The minimum inverter inner temperature value

54

Heatsink-1 Min.

The minimum Heatsink-1 temperature value

55

Heatsink-2 Min.

The minimum Heatsink-2 temperature value

56

Heatsink-3 Min.

The minimum Heatsink-3 temperature value

54

9.2 Error Message & Trouble Shooting

Table 9-2 Error Message

ERROR

Message

Possible cause

Action

AC Freq

High

1. Actual utility frequency is over