RPI-H3/H5

Operation and Installation Manual

Grid-tie Transformerless Solar Inverter

The power behind competitiveness

www.deltaww.com

Table of Contents

1. General Information

1.1 About this Manual

1.2 Safety Symbol & Instruction

1.3 Validity

1.4 Product Description

1.5 How It Works

1.6 Additional Information

2. Installation and Wiring

2.1 Instruction before Installation

2.2 Unpacking

2.3 Package Inspection

2.4 Identification Label

3. Product Overview

3.1 Dimension

3.2 Function Introduction

3.2.1 LCD Display and Buttons

3.2.2 Inverter Input/Output Interface

4. Installation

4.1 Installing Location

4.2 Mounting

5. Wiring

5.1 Preparation before Wiring

5.2 AC Grid Connection: L + N + PE

5.2.1 Required Protective Devices and Calbe Cross Sections

5.3 DC Connection (from PV Array)

5.4 Communication Module

5.4.1 RS-485 Connection

6. Active/Reactive Power Control and LVRT(optional)

6.1 Active Power Control

6.1.1 Power Limit

6.1.2 Power vs. Frequency

6.2 Reactive Power Control

6.2.1 Fixed power Factor cosφ(VDE-AR-N 4105,CEI 0-21)

6.2.2 cosφ(P) (VDE-AR-N 4105,CEI 0-21)

6.2.3 Fixed Reactive Power In Var(CEI 0-21)

6.2.4 Reactive Power / Voltage Characteristic Q(U)(CEI 0-21)

6.3 Low Voltage Ride Through (LVRT)

07

07

07

07

08

08

08

09

09

09

10

11

13

13

14

15

16

17

17

17

22

22

24

25

26

27

27

29

29

29

29

30

31

31

31

32

33

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

3

7. Turn on/off PV inverter

7.1 Start-up Procedures

7.1.1 PV array DC Votlage Checking

7.1.2 AC Utility Voltage Checking

7.1.3 Starting up the Inverter

7.2 Inverter Setting

7.2.1 Country Setting

7.2.2 AC configuration Setting

7.2.3 Connecting the Communication Wiring

7.2.4 Inverter ID Setting

7.3 LCD Flowchart

7.3.1 Event list

7.3.2 Country Selection

7.3.3 Language Selection

7.3.4 Insulation Mode

7.3.5 Settings

7.3.6 Cosphi Settings (Only useable for RPI-H3)

7.3.7 Italy Self-test

8. Maintenance

9. Measurement, Error message and Trouble Shooting

9.1 Measurement

9.2 Error Message & Trouble Shooting

10. De-Commissioning

11. Technical Data

11.1 Specifications

Appendix A : Multi-function Relay

A.1 Multi-function relay output connection

Appendix B : Digital Input

34

34

34

34

34

35

35

36

38

38

38

40

40

41

42

42

43

44

45

46

46

47

53

54

54

56

57

58

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

4

Figure 1-1 : Solar inverter system operation illustration

Figure 2-1 : Unpacking process

Figure 2-2 : The identification label for RPI-H3

Figure 2-3 : The identification label for RPI-H5

Figure 3-1 : Dimension of RPI-H3

Figure 3-2 : Dimension of RPI-H5

Figure 3-3 : Inverter exterior objects

Figure 3-4 : LCD display and control panel

Figure 3-5 : Input/Output interface

Figure 4-1 : Screw the mounting bracket for RPI-H3

Figure 4-2 : Screw the mounting bracket for RPI-H5

Figure 4-3 : Correct and incorrect installation illustration

Figure 4-4 : Proper installation gap

Figure 5-1 : Connection of system

Figure 5-2 : Connection of a system for solar array grounding

Figure 5-3 : AC configurations

Figure 5-4 : AC plug illustration

Figure 5-5 : DC Wiring illustration

Figure 5-6 : Communication module

Figure 5-7 : Multi-inverter connection illustration

Figure 6-1 : Power vs. frequency characteristic

Figure 6-2 : cosφ(P) characteristic

Figure 6-3 : Q(U) characteristic

Figure 6-4 : LVRT characteristic

Figure 7-1 : Country setting

Figure 7-2 : AC confguration setting-1

Figure 7-3 : AC confguration setting-2

Figure 7-4 : Inverter ID setting

Figure 7-5 : LCD flowchart

Figure 7-6 : Event log flowchart

Figure 7-7 : Conutry selection

Figure 7-8 : Language selection

Figure 7-9 : Insulation Mode

Figure 7-10 : Setting page

Figure 7-11 : Cosphi Settings (Only useable for RPI-H3)

Figure 7-12 : Italy self-test flowchart

Figure A-1 : Multi-function relay on dry contact

Figure A-2 : Dry contac location

Figure B-1 : Pin assignment at ripple control receiver

Figure Index

08

09

11

12

13

13

14

15

16

18

19

20

21

22

23

24

25

26

27

28

30

31

32

33

35

36

37

38

39

40

40

41

42

42

43

44

57

57

58

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

5

Table 2-1 : Packing list

Table 5-1 : Recommended upstream protection

Table 5-2 : AC wire requirement

Table 5-3 : Cable size

Table 5-4 : Definition of RS-485

Table 5-5 : RS-485 data format

Table 7-1 : Country list

Table 7-2 : Language list

Table 9-1 : Measurement and message

Table 9-2 : Error message

Table 11-1 : Specifications

Table Index

10

25

25

26

27

28

41

41

46

47

54

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

1 General Information

1.1 About this Manual

This manual provides the detailed information of specification, installation procedures

and all related function settings about the solar inverter model- RPI-H3/RPI-H5.

Installation technicians must be well-trained and qualified for installing solar system

and must follow all the safety instructions and installation procedures.

1.3 Validity

This user manual describes the installation procedures, maintenance, technical data

and safety instruction of the following solar inverter models under DELTA brand.

• RPI-H3_110

• RPI-H3_010

• RPI-H5

1.2 Safety Symbol & Instruction

Machine and equipment damage may occur if not avoid the hazardous situation

CAUTION !

WARNING !

Death and serious injuries may occur if not avoid the hazardous situation

WARNING:BURN HAZARD!

The enclosure temperature may exceed over 70° C while operating.

Danger may occur owing to hot surface. Please do not touch!!

DANGER!

Death and serious injuries will occur if not avid the hazardous situation

7

General Information

1.4 Product Description

This device is a single phase grid-tie solar inverter. It converts direct current (DC)

electricity from photovoltaic power collected from PV Array into single phase alternating

current (AC) to feed the excess capacity back to the local main electrical grid.

This inverter allows wide voltage input range (125~600Vdc for RPI-H3 and 200~1000Vdc

for RPI-H5) and high performance efficiency based on user’s friendly operation design.

In addition, special DSP(Digital Signal Processor)design decreases the circuit complication

and electronic components. Please note that this device does not support off-grid function.

The features for RPI-H3/RPI-H5 are shown below.

1.5 How it Works

The operation of solar inverter is shown as the Figure 1-1. In order to save energy and

electricity, solar inverter convert the DC input power supplied from the PV Array into

single-phase AC output power to Grid.

1.6 Additional Information

For more detailed information for RPI-H3/RPI-H5 or other related product information,

please visit http://www.deltaww.com.

Features

• Power Rating : 3 kVA(RPI-H3), 5 kVA(RPI-H5)

• Single Phase (L + N + PE), Grid-tie, Transformerless solar inverter

• Maximum efficiency : > 97.0%(RPI-H3), > 97.5 %( RPI-H5)

• Europe efficiency: 96.2(RPI-H3), 97.0%(RPI-H5)

• Reactive power capability (Cap 0.8 – Ind 0.8)

• Total harmonic distortion (THD < 3%) @ full load

• 1 MPP Trackers

• 16×2 LCD display

Electrical GridSolar InverterPV Array

Figure 1-1 : Solar inverter system operation illustration

8

General Information

2 Installation and Wiring

2.1 Instruction before Installation

Due to variety of users’ installation environment, reading this manual thoroughly before

installation is strongly recommended. All the installation and start-up procedures must

be undertaken by professional and well-trained technician.

2.2 Unpacking

Unpacking process is shown as Figure 2-1.

RPI-H3

RPI-H5

Figure 2-1 : Unpacking process

a. b. c. d.

a. b. c. d.

9

Installation and Wiring

2.3 Package Inspection

Unknown situations may occur during shipments. Please check if there is any damage

on the wooden carton. After opening the package, please check both outer case and

inner part of this inverter as below.

Check the right side of the case to ensure the model number and the specification is

the same as the model you purchased previously.

1. Check the inverter model number and the specifications are the same as the model

you purchased previously.

2. Check if the is any loose component.

3. Check if all the accessories are in the package, the standard accessories are list

as Table 2-1:

RPI-H3 / RPI-H5

Object

PV Inverter

User Manual

AC Plug

Wall-Mount

Bracket

M5 Nut

Qty

1

1

1

1

2

Description

3kVA(RPI-H3), 5kVA(RPI-H5) solar inverter

Table 2-1 : Packing list

The Instruction to provide the information of safety,

Installation, specification, etc.

Connector for AC connection

Wall-mount bracket to mount the solar inverter securely

on the wall

To fix solar inverter on the bracket

Spring Washer 2 To fix solar inverter on the bracket

Plain Washer 2 To fix solar inverter on the bracket

When there is any outer or inner damage on inverter or any incompleteness or

damages on the packaged accessories, please contact your inverter supplier.

CAUTION !

DC Plug 2 MC4 connector for DC connection

10

Installation and Wiring

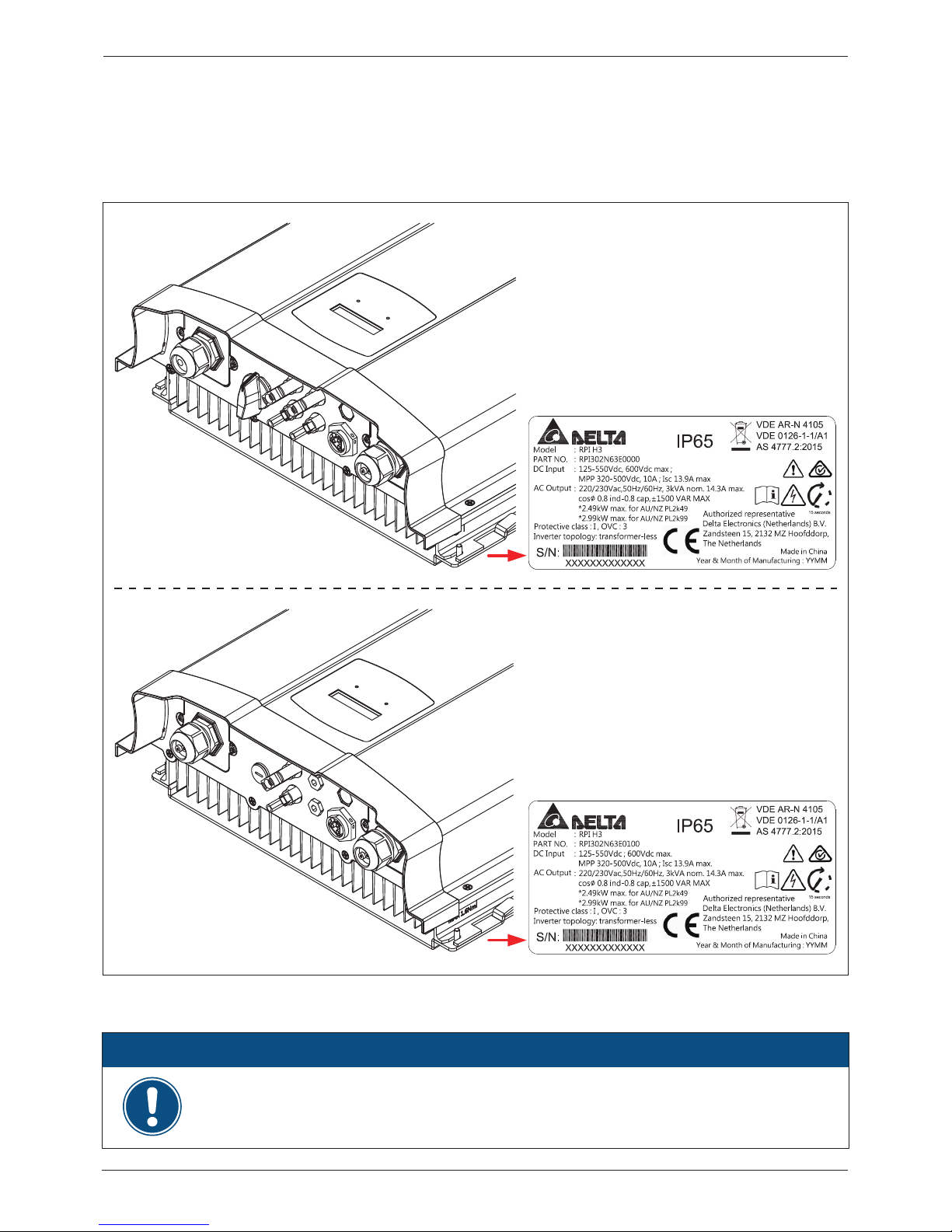

2.4 Identification Label

Users can identify the model number by the information on the product label.

The model number, specifications as well as the series No. is specified on the product

label. Regard to the label location, please refer to Figure 2-2, Figure 2-3.

Figure 2-2 : The identification label for H3

RPI-H3_110

(RPI302N63E0000)

RPI-H3_010

(RPI302N63E0100)

The DC switch is only presented in the -110 models. Model series -010 does

not have the DC switch.

NOTE

11

Installation and Wiring

Figure 2-3 : The identification label for H5

RPI-H5

12

Installation and Wiring

3 Product Overview

3.1 Dimensions

Figure 3-1 : Dimension of RPI-H3

Figure 3-2 : Dimension of RPI-H5

13

Product Overview

3.2 Function Introduction

Inverter’s exterior objects are shown on the Figure 3-3, and the detailed description is

in sections 3.2.1 and 3.2.2.

LCD / LED display and

buttons

DC Switch

DC connectors

AC connector

Communication

connections

Label

Dry connector & Digital input

Figure 3-3 : Inverter exterior objects

RPI-H3

RPI-H5

LCD / LED display and

buttons

DC Switch

DC connectors

AC connector

Communication

connections

Label

H3_110: DC Switch

(H3_010: No DC switch)

14

Product Overview

Figure 3-4 : LCD display and buttons

3.2.1 LCD Display and Buttons

15

Product Overview

RPI-H3_110

RPI-H5

DC connector*2

AC connector

Communication

RS-485*2

DC switch

Dry connector & Digital input

RPI-H3_010

DC connector*1

AC connector

Communication

RS-485*2

Stopper

(Avoid Physical Impact)

Dry connector & Digital input

DC connector*2

AC connector

Communication

RS-485*2

DC switch

3.2.2 Inverter Input/Output Interface

Figure 3-5 : Input/Output interface

16

Installation

4 Installation

4.1 Installation Location

Do not install the unit at the location that directly expose to sunlight.

CAUTION! Machine and equipment damage may occur

WARNING! Death and serious injuries may occur.

● Do not install the unit near/on the flammable objects.

● Please mount the unit tightly on the solid/smooth wall.

● In order to ensure the safety of installers, installer shall be at

least two people to process the installation.

● When moving the Inverter, installer shall not stand under machines.

4.2 Mounting

This unit is a wall-mounting system. Please ensure the installation is perpendicular

and with AC plug at the bottom. Do not install the device on a slanting wall.

The dimensions of mounting bracket are shown as figure below. There are 7 pcs(RPI-

H3)/12pcs(RPI-H5) of M5 screws required for mounting plate. Fix the supplied wallmount plate securely on the wall before mounting the inverter to the mounting plate.

17

Installation

Figure 4-1 : Screw the mounting bracket for RPI-H3

18

Installation

Figure 4-2 : Screw the mounting bracket for RPI-H5

19

Installation

Figure 4-3 : Correct and incorrect installation illustration

4-3-a

90°C

4-3-b

4-3-c

20

Installation

>50cm

>50cm

>30cm>30cm >30cm

• The location and hardware should be a solid surface or a firm holder

that suitable for the weight of inverter.

• Suggested to install the inverter to the location which offers free and

safe access. It would streamline the service and maintenance

• Please leave an appropriate gap in between when installing singe/

several solar inverter systems.

• Please install solar inverter at an eye level to allow easy observation for

operation and parameter setting.

• Ambient temperature -20°C~60°C.(power derating above 40°C)

CAUTION !

There shall be sufficient space for product operation as shown as the

Figure 4-4. If necessary, installer can increase the gap space for sufficient

operation space.

Figure 4-4 : Proper installation gap

21

Installation

5 Wiring

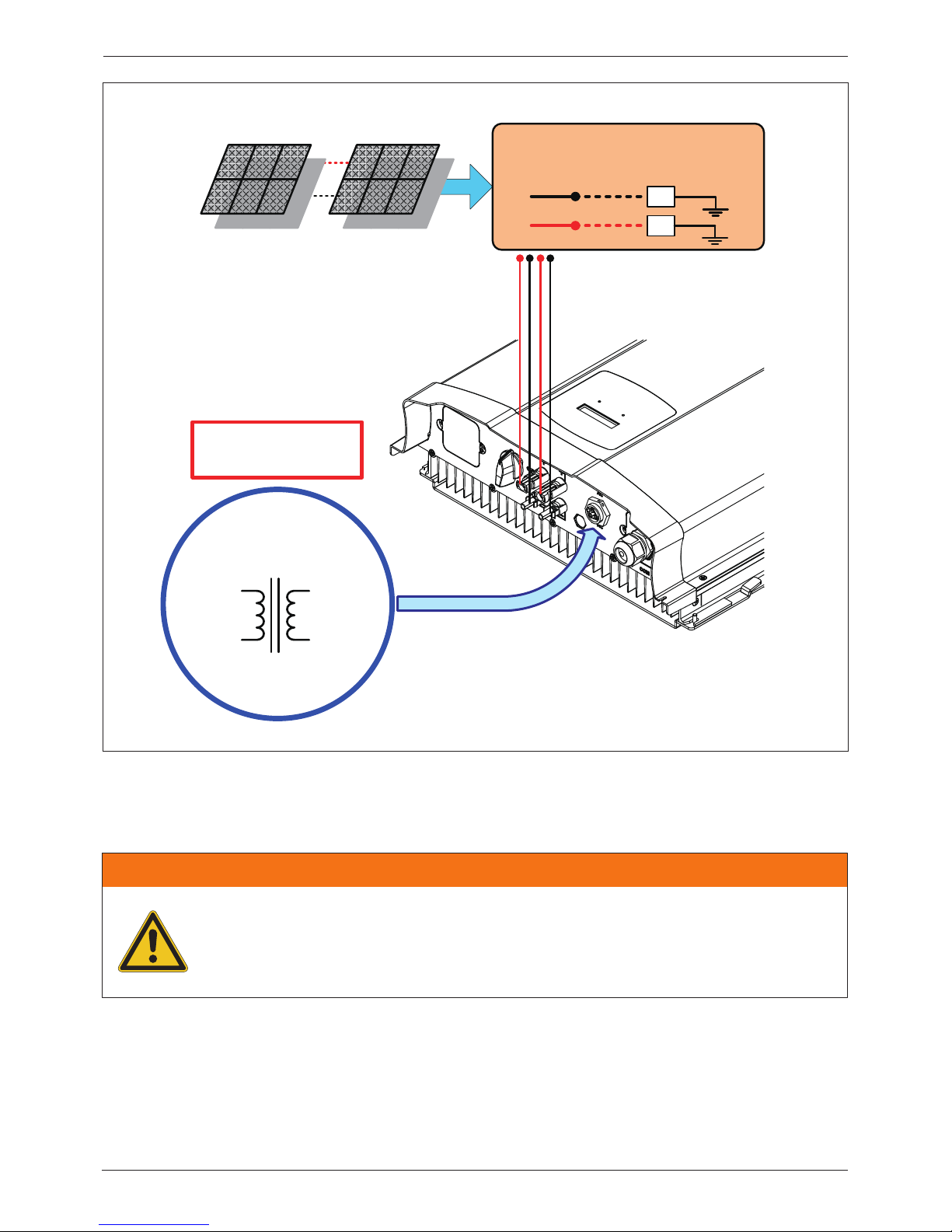

5.1 Preparation before Wiring

1. Make sure whether the voltage values, polarities are correct.

2. When grounding of the solar array is necessary, an isolation transformer is required

due to the RPI-H3/RPI-H5 not having a galvanic isolation between the DC-input and

AC-output.

3. The ground fault detection is a fixed internal setting. It always works and can not be

modified.

4. The whole system wiring is shown as in Figure 5-1 and Figure 5-2.

5.

Please refer to Figure 5-1 for the connection. Inverter can accept DC inputs in parallel

(1 MPP tracker/2 parallel inputs).

Figure 5-1 : Connection of system

1

AC Wiring

Communication

Wiring

3

2

DC Wiring (Parallel)

Distribution box

PV Array

22

Wiring

Figure 5-2 : Connection of a system for solar array grounding

Isolated

transformer

Utility

To

Inverter

1Ph,

230Vac

1Ph,

230Vac

Must install a

transformer

Distribution box

(Plus-GND or Minus-GND)

Z

Z

or

PV Array

WARNING! SHOCK HAZARD

Whenever a PV array is exposed to sun-light, a shock hazard exists at the

output wires or exposed terminals. To reduce the risk of shock during installation,

cover the array with an opaque (dark) material and ensure that Disconnect

Device is set to OFF before commencing any wiring.

23

Wiring

5.2 AC Grid Connection : L + N + PE

WARNING !

Before commencing AC wiring, please ensure AC breaker is switched off.

For RPI-H5, users must aware that AC configuration Setting must be set correctly

otherwise this device can not work. There are two types of AC configurations (shown

in figure 5-3) that are used in electricity systems. For “AC Configurat.” setting please

see chapter 7.2.2

Star configuration (3 phases + Neutral): L–N (default),

The voltage between each phase and the neutral is

230/220 V. The voltage between two phases is 400/380V.

Delta configuration (3 phased wires only) : L–L, The voltage

between two phases are 230/220V. As there is no neutral,

there is no phase-neutral voltage.

L1

N

L2

u

w

V

1

1

1

L3

L1

L2

L3

Figure 5-3 : AC configurations

24

Wiring

5.2.1

Required protective devices and cable cross-sections

Power rating Upstream circuit breaker

3.75kVA(RPI-H3), 6.25 kVA(RPI-H5) 20A(RPI-H3), 30A(RPI-H5)

Table 5-1 : Recommended upstream protection

Wire sizeCurrent Rating Torque

>20A (RPI-H3), >30 A (RPI-H5) 3-4mm

2

/ 12 AWG 0.8~1Nm

Table 5-2 : AC wire requirement

Figure 5-4 : AC plug illustration

Please use proper wire to connect correct poles (According to the Table 5-2).

• The AC voltage should be as following.

L-N: 230 Vac±10

PE

N

L

25

Wiring

5.3 DC Connection (from PV Array)

• The maximum open circuit voltage of the PV Array must not exceed

600V (RPI-H3) / 1000V (RPI-H5).

• The recommended PV power connect to inverter is 3600W (RPI-H3) /

5950W (RPI-H5).

• The device installed between PV Array and inverter must meet the rating of

voltage higher than this device’s maximum input voltage.

CAUTION !

WARNING !

• When doing DC wiring, please choose the proper wiring by connect to the

correct polarity.

• When doing DC wiring, please confirm that PV Array’s power switch is off.

DC wiring polarities are divided into positive and negative, which is as shown in

Figure 5-5. The connection shall be coherent with the indication marked on inverter.

Table 5-3 : Cable size

Figure 5-5 : DC Wiring illustration

Current Rating Wire size

DC 15 A (RPI-H3)

DC 17.5 A (RPI-H5)

2-3mm

2

/ 14 AWG

3-4mm

2

/ 12 AWG

PV-KBT 4/6 Ⅱ

PV-KST 4/6 Ⅱ

26

Wiring

5.4 Communication Module

The Communication Module supports the function of communication with computer,

and provides 2 ports of RS-485 .When using this module, the first step is to take off

the cover located at the right bottom of inverter and pull out the RS485 socket as shown

in Figure 5-6.

Figure 5-6 : Communication module

5.4.1 RS-485 Connection

The pin definition of RS-485 is shown as in Table 5-4 and protocol settings are listed

in Table 5-5. The wiring of multi-inverter connection is shown as figure 5-7.

Table 5-4 : Definition of RS-485

PIN

FUNCTION

1

VCC

2

GND

3

4

5

6

DATA+

DATA

-

DATA+

DATA

-

Terminal resistor switch

27

Wiring

Figure 5-7 : Multi-inverter connection illustration

Data Format :

Baud rate : 19200

Data bits :8

Stop bit :1

Parity :N/A

Pin Layout:

Pin Function

4 DATA5 DATA+

RS485 / USB

Or

RS485 / RS232

Table 5-5 : RS-485 data format

RS-485 Data format

Baud rate

9600 / 19200

Data bit

8

Stop bit

Parity

1

N/A

28

Wiring

6

Active/Reactive Power Control and LVRT (Optional)

6.1 Active Power Control

6.1.1 Power Limit

Users can reduce inverter output power by set percentage of actual or rated power.

There are 2 settings for active power and 4 settings for reactive power control based on the

requirement from network operator.

6.1.2 Power vs. Frequency

According to VDE-AR-N 4105 (5.7.3.3):

At frequencies between 50.2Hz and 51.5Hz, all adjustable power generation systems

shall reduce (for frequency increase) or increase (for frequency decrease) the active

power Pm generated instantaneously (at the time of exceeding the mains frequency

50.2Hz; freezing the value on the current level) with a gradient of 40% of Pm per Hertz).

According to CEI 0-21 (8.5.3.2):

Within a frequency range from 50.3Hz to 51.5Hz, all adjustable production plants

equipped with static converters have to be able to reduce the currently generated active

power in case of an increase of the frequency with a variable droop of 2% to 5% with

a default value of 2.4% (with corresponds to a power gradient of 83.3%/Hz).

User can set all necessary settings to meet the requirements from network operator.

Please refer to actual Power vs. Frequency for the settings procedure.

29

Active/Reactive Power Control and LVRT (Optional)

Power vs. frequency curve for VDE-AR-N 4105

Power vs. frequency curve for CEI-021

P

0

Gradient 40% Pm/ Hz

Pm

Fstart(50,2Hz)

P

0

Fstart (50,3Hz )

Gradient 83.3% Pimax / Hz

Pimax

Figure 6-1 : Power vs. frequency characteristic

6.2 Reactive Power Control

With active power output, it must be possible to operate the generating plant in any

operating point with at least a reactive power output corresponding to a active factor

at the network connection point of

cos ϕ = 0.8 underexcited to 0.8 overexcited

(VDE-AR-N 4105,CEI 0-21 cos ϕ = 0.9 underexcited to 0.9 overexcited)

Values deviating from the above must be agreed upon by contract. With active power

output, either a fixed target value for reactive power provision or a target value variably

adjustable by remote control (or other control technologies) will be specified by the

network operator in the transfer station. The setting value is either

1. fixed power factor cosφ (VDE-AR-N 4105 ,CEI 0-21)

2. displacement factor/active power characteristic curve cosφ(p)

(VDE-AR-N 4105 ,CEI 0-21)

3. fixed reactive power in Var.(CEI 0-21)

4. reactive power/voltage characteristic Q(U). (CEI 0-21)

30

Active/Reactive Power Control and LVRT (Optional)

6.2.1

Fixed Power Factor cosφ (VDE-AR-N 4105,CEI 0-21)

Users can set power factor from Cap 0.8 to Ind 0.8 (inverter would stop reactive power

control if output power is below 20% rated power).

6.2.2 cosφ(P) (VDE-AR-N 4105,CEI 0-21)

Once user enables this method, inverter will deliver reactive power according to output

active power at that moment. Figure 6-2 is an example.

6.2.3 Fixed Reactive Power In Var.(CEI 0-21)

Once user enables this method, inverter will deliver reactive power (ie. Q) according

to the fixed reactive power setting. The setting range is from Cap 48.4% to Ind 48.4%.

Cap 0.9

Ind 0.9

P/Pn

1

cos

φ

0.5

P1

P2

Upper limit

lower limit

0.2

No cos φ (P)

is allowed

Figure 6-2 : cosφ(P) characteristic

31

Active/Reactive Power Control and LVRT (Optional)

6.2.4

Reactive Power / Voltage Characteristic Q(U)(CEI 0-21)

Once user enables this method, user can set Q vs. Grid voltage operation curve as below.

U

Q/Sn

(%)

U1s

U2s

U1i

U2i

Qmin(48.4%)

Qmax(48.4%)

U

Q/Sn

(%)

U1s

U2s

U1i

U2i

TypeA

TypeB

Figure 6-3 : Q(U) characteristic

32

Active/Reactive Power Control and LVRT (Optional)

6.3 Low Voltage Ride Through (LVRT)

According to CEI 0-21, 8.5.1

To avoid undue separation from the network if voltage dips occur, a generation system

with over 6 kW total power must be able to comply with certain functional requirements,

which are known as LVRT(Low Voltage Ride Through) in international literature.

100%

0

time(ms)

U

grid

/

U

n

2

1

90 %

40 %

3

200 400

0%

85 %

110%

Figure 6-4 : LVRT characteristic

33

Active/Reactive Power Control and LVRT (Optional)

7 Turn PV inverter on/off

7.1 Start-up Procedures

WARNING:BURN HAZARD!

The enclosure temperature may exceed over 70°C while operating.

Danger may occur owing to hot surface. Please do not touch!

After installation, please confirm the AC, DC, and Communication connection

are correct. When solar irradiation is sufficient, the device will operate automatically

after no mistakes on self-auto test (about 2 minutes at 1st startup of a day).

The display includes 16×2 LCD display and LED indicator for inverter status.

There are green and red colors for LED indicator to represent different inverter

working status.

7.1.1 PV Array DC Voltage Checking

1.

Uncover the PV arrays and expose them to full sunlight. The sunlight must be intense

enough to produce the required output voltage.

2. Measure the PV array open circuit DC voltage across the DC positive (+) and

negative (-) terminals.

7.1.2 AC Utility Voltage Checking

Using an AC voltmeter measures the AC open circuit utility voltage between L1 (L) and

L2 (N). Ensure the voltage is at approximately the nominal value. The inverter operates

with a line-to-line voltage range around the nominal value.

See “11. Technical data”, output section for the utility voltage operating range for your

inverter model.

7.1.3 Starting up the Inverter

1.Switch the DC and AC disconnection switches (breakers) to “ON”.

2.Check the inverter LCD. The startup screen should appear in several seconds,

(for the first time start up, select proper country and language. See “7.3.2 Country

Selection & 7.3.3 Language Selection”).

34

Turn PV inverter on/off

7.2 Inverter Setting

7.2.1 Country Setting

The first time you startup this device. Country Setting is required.

1.

In the country setting page, press “SEL” button (NEXT) to select your located country,

press “ENT” button to confirm this page.

2. Press “Enter” button to confirm your country setting.

NOTE:

Country

xxxxxx

Netherlands

N ex t / E nt er

xxxxxx

N / Y

SEL

ENT

ENT

SEL

ENT

Exit ?

N / Y

ENT

SEL

Belgium

N ex t / E nt er

ENT

Figure 7-1 : Country Setting

35

Turn PV inverter on/off

7.2.2 AC Configuration Setting

1. Turn on DC power and wait for the LCD display is ready, then press “SEL” button

until “Country XXX" is displayed.

2. Press and hold both “SEL” and “ENT” buttons for 10 seconds until “Language

XXXXXX” is shown.

3. Press “SEL” until “AC Configurat. XXXXXX” is shown.

4. Press “ENT” to enter AC Configuration Setting page, press “SEL” to flip between two

types of configuration. As your type of configurations is displayed, press ”ENT” to

confirm the setting.

DSP Comm. Red.

0000 0000 0000

Event List

Enter

Inverter

ID : XX

Country

XXX

Language

XXX

Insulation Mode

XXX

SEL

SEL

SEL

SEL

SEL

SEL

Event List Start

ENT

RS485 ID Setting

Start

SEL + ENT

> 3 sec.

Install Settings

Start

SEL + ENT

> 10 sec.

System

Information

xxxxxx

xxxxxx

Inverter

5.0kVA

Figure 7-2 : AC Configuration Setting-1

36

Turn PV inverter on/off

SEL

xxxxxx

Next

/

Enter

xxxxxx

N / Y

SEL

SEL

ENT

ENT

ENT

SEL

ENT

Exit

?

N / Y

SEL

xxxxxx

Next

/

Enter

Install

Settings

Install Settings

Start

Inverter

shut down

Language

xxxxxx

SEL

xxxxxx

Next

/

Enter

xxxxxx

N / Y

SEL

ENT

ENT

SEL

ENT

Country

xxxxxx

SEL

xxxxxx

Next

/

Enter

xxxxxx

N / Y

SEL

ENT

Country is

Empty

(default ) ?

Yes

ENT

No

SEL

ENT

Exit

?

N / Y

ENT

SEL

Exit

?

N / Y

ENT

SEL

xxxxxx

Next

/

Enter

xxxxxx

Next

/

Enter

AC Configurat.

xxxxxx

Figure 7-3 : AC Configuration Setting-2

37

Turn PV inverter on/off

7.2.3 Connecting the Communication Wiring

Multiple inverters could be monitored via RS-485 connection (Figure 5-7), but each

inverter’s ID must be set.

7.2.4 Inverter ID Setting

1. Turn on DC power and wait for the LCD display to be ok, then press “Select” button

until “Inverter ID: XX" is shown in the LCD.

2.

Press and hold both buttons (“Enter” first then “Select”) until entering setting ID screen,

then you could release the both buttons and set ID by pressing “Select” button, press

“Enter” button if the ID is correct (ID = 1 ~ 254).

3. Inverter ID is changed and saved.

7.3 LCD flowchart

Press any button will enter menu page (Figure 7-5), Today Output Energy is home page,

and several item is described in section 7.3.1 ~ 7.3.6.

Make sure the inverter ID is different from each other in the same train.

Single inverter could be monitored RS-485 connection.

NOTE

Setting ID

I D = 254 ?

Setting ID

Exit

?

Setting ID

I D = 1 ?

Setting ID

I D = X X + 1 ?

SEL

SEL

SEL

SEL

(SEL and ENT are pressed simultaneously

> 3 sec)

Setting ID

I D = X X ?

Setting ID

I D = X X + 1 ?

XX is current ID

ENT

ENT

SEL

SEL

(SEL is pressed >

2 sec)

yes

Setting ID

I D = X X + 1 0 ?

no

ENT

SEL

Inverter

I D : X X

Inverter

I D : X X

Figure 7-4 : Inverter ID Setting

38

Turn PV inverter on/off

Output 3600 W

Today 7200 Wh

Output Current

16 . 0 A

Utility

225 V 60 . 00 Hz

DC

:

320 V

5 . 9 A 1894 W

Today DC

3600 Wh

AC Life Energy

1234 KWh

DC Life Energy

617 KWh

Inverter

5 . 0 kW

Firmware rev.

0000 0000 0000

Event List

Enter

Inverter

ID : XX

Country

XXX

Language

XXX

Italy Selftest Process

Country is Italy

&&

Relay On

yes

Grounded Option

XXX

PAGE 2

PAGE 3

PAGE 4

PAGE 5

PAGE 6

PAGE 7

PAGE 8

PAGE 9

PAGE 10

PAGE 11

PAGE 12

PAGE 13

PAGE 14

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

PAGE 1

SEL

PAGE 15

Settings

Enter

Figure 7-5 : LCD flowchart

Page1 Today output energy

Page2 Grid voltage and frequency

Page3 Output current

Page4 Input voltage, current and power

Page5 Today input energy

Page6 Total output energy

Page7 Total input energy

Page8 Start page

Page9 Firmware version

Page10 Event list

Page11 Inverter ID

Page12 Country

Page13 Language

Page14 Grounded option

Page15 Settings

39

Turn PV inverter on/off

7.3.1 Event List

When entering this page, the display will show all the events (error or fault) and it can

show 16 records at most with the latest one on the top.

7.3.2 Country Selection

Users can select different countries in this page.

01:Grid Freq

Under Rating

02:Grid Volt

Under Rating

03:Empty

Clear Event Logs

Exit

/

Yes

16:Empty

SEL

ENT

SEL

SEL

SEL

Event List

Enter

SEL

Inverter

ID

:

XX

SEL

Event List

Enter

Figure 7-6 : Event log flowchart

Figure 7-7 : Country selection

NETHERLANDS

Next

/

Enter

BELGIUM

Next

/

Enter

XXXXXX

Next

/

Enter

NETHERLANDS

N / Y

BELGIUM

N / Y

XXXXXX

N / Y

SEL

SEL

SEL

SEL

ENT

ENT

ENT

(SEL and ENT are pressed simultaneously > 10 sec)

when page is Country (Page 12)

Country

XXX

Inverter

shut down

ENT

Country is Default

ENT

SEL

ENT

ENT

yes no

SEL

yes

Language

XXX

SEL

40

Turn PV inverter on/off

Table 7-1: Country list

Figure 7-8 : Language selection

RPI-H3/RPI-H5

Australia

Portugal

AU/NZ PL2K49

Spain RD661

AU/NZ PL2K99

Belgium

FR LV VFR2014

FRA-Is. 50Hz

Spain RD1699

Taiwan

Thailand MEA

Thailand PEA

FRA-Is. 60Hz

UK G59-3 230

Germany LV UK G59-3 240

India UK G83-2

Italy LV

Netherlands

New Zealand

7.3.3 Language Selection

When entering this page, user can set five different languages.

English

Next

/

Enter

Italia

Next

/

Enter

France

Next

/

Enter

Deutschland

Next

/

Enter

Español

Next

/

Enter

English

N / Y

Italia

N / Y

France

N / Y

Deutschland

N / Y

Español

N / Y

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

SEL

ENT

ENT

ENT

ENT

ENT

Language

XXX

ENT

Language is default

no

ENT

ENT

ENT

ENT

ENT

XXX maybe Default , English , Italiano.etc

yes

SEL

Grounded option

XXX

Table 7-2 : Language list

RPI-H3/RPI-H5

English

Italiano

Français

Español

Deutsch

41

Turn PV inverter on/off

7.3.4Insulation Mode (Only useable for RPI-H5)

Insulation Mode

XXX

(SEL and ENT

are pressed simultaneously

> 30 sec)

SEL

Normal

Next

/

Enter

Negative

Next

/

Enter

Disable

Next

/

Enter

Normal

N / Y

Negative

N / Y

Disable

N / Y

SEL

SEL

SEL

SEL

SEL

ENT

ENT

ENT

XXX maybe Normal, Negative, Disable, Positive

ENT

ENT

ENT

SEL

Positive

Next

/

Enter

Positive

N / Y

SEL

ENT

ENT

SEL

Settings

Enter

Figure 7-9 : Insulation mode

Figure 7-10 : Setting page

7.3.5 Settings

Setting includes Personal Setting, Coefficients Setting, Install Setting and Italy Self-test.

Italy Self-test Setting will only exist when Italy is selected in country setting.

Wireless

ON

Ethernet Address

XXX.XXX.XXX.XXX

Wireless Address

Settings

Enter

ENT

SEL

SEL

SEL

ENT

On

Next

/

Enter

Off

Next

/

Enter

On

N / Y

Off

N / Y

SEL

SEL

SEL

SEL

ENT

ENT

ENT

ENT

XXX.XXX.XXX.XXX

42

Turn PV inverter on/off

7.3.6 Cosphi Settings (Only useable for RPI-H3)

Users can select different Cosphi settings in this page.

Figure 7-11 : Cosphi Settings (Only useable for RPI-H3)

PF Control

XXXX

Cosphi off

Next / Enter

ENT

Cosphi Ind 0 . 80

Next / Enter

Cosphi XXXX

N / Y

Range: Cosphi Ind 0.80 ~ Cosphi Cap 0.80

Cosphi off

Cosphi Ind 0 . 81

Next / Enter

SEL

ENT

SEL

Cosphi Ind 1 . 00

Next / Enter

SEL

ENT

ENT

ENT

SEL

ENT

SEL

Cosphi Cap 0 . 99

Next / Enter

SEL

Cosphi Cap 0 . 98

Next / Enter

SEL

Cosphi Cap 0 . 80

Next / Enter

SEL

ENT

ENT

ENT

SEL

Choose from the last setting

Default setting: Cosphi off &

Reset to “Cosphi off”after Country chage

SEL

43

Turn PV inverter on/off

7.3.7 Italy Self-test

Italy Self-test includes Uac High(UH), Uac Low(UL), Fac High(FH) and Fac Low(FL).

User can choose the selection of Uac High, Uac Low, Fac High, or Fac Low separately.

The final testing result will be shown on the operating page and saved, user can review

the results. If the Italy Self-test failed, this PV inverter would not operate anymore.

Please contact with Delta or your supplier of this PV inverter.

Figure 7-12 : Italy self-test flowchart

44

Turn PV inverter on/off

8 Maintenance

In order to ensure the normal operation of PV Inverter, please check up regularly at least once

each year or each half year. Check all the terminals, screws, cables are connected well.

If there are any impaired parts, please contact with the qualified technician to repair or replace

to the new spare part. To ensure that no foreign body stocks at the heat outlet, please clean up

once a half year by qualified technicians.

WARNING! Death and serious injuries may occur.

Before maintenance, please must disconnect AC and DC to avoid risk of

electronic shock.

45

Maintenance

Output 3600W

Today 7200Wh

9

Measurement, Error Message and Trouble Shooting

9.1 Measurement

Utility

225V 60.00Hz

Output Current

16.0A

DC: 320V

5.9A 1894W

Today DC

3600 Wh

DC Life Energy

617 kWh

AC Life Energy

1234kWh

1

2

4

6

8

3

5

7

Meaning

Actual power is generating

Energy generated today

Grid Voltage and Frequency

Actual Output AC current

DC input Voltage, Current, Watt

Today PV array energy supply .

Total Energy generated

Total PV array energy supply

Measurement

Output

Today

Utility

Output Current

DC

Today DC

AC Life Energy

DC Life Energy

No.

1

2

3

4

5

6

7

8

Table 9-1 : Measurement and message

46

Measurement, Error Message and Trouble Shooting

9.2 Error Message & Trouble Shooting

ERROR

Message

E01: Grid Freq.

Over Rating

E02: Grid Freq.

Under Rating

E07:Grid Quality

E09: No Grid

1. Actual utility frequency is over

the OFR setting

2. Incorrect country setting

3. Detection circuit malfunction

1. Actual utility frequency is

under the UFR setting

2. Incorrect country or Grid setting

3. Detection circuit malfunction

Non-linear load in Grid and near

to inverter

1. AC breaker is OFF

2. Disconnect in AC plug

3. Internal fuses are broken

1. Check the utility frequency on

the inverter terminal

2. Check country setting

3. Check the detection circuit inside

the inverter

1. Check the utility frequency on the

inverter terminal

2. Check country & Grid setting

3. Check the detection circuit inside

the inverter

Grid connection of inverter need to

be far away from non-linear load

if necessary

1. Switch on AC breaker

2. Check the connection in AC plug

and make sure it connects to

inverter

3. Replace fuses and check all

switching devices in boost &

inverter stages

E10: Grid Volt

Under Rating

1. Actual utility voltage is under the

UVR setting

2. Utility voltage is under the Slow

UVR setting during operation

3. Incorrect country or Grid setting

4. Detection circuit malfunction

1.&2. Check the utility voltage

connection to the inverter

terminal.

3. Check country & Grid setting

4. Check the detection circuit inside

the inverter

E13: Slow Over

Voltage Range

1. Actual utility voltage is over the

OVR setting

2. Incorrect country or Grid setting

3. Detection circuit malfunction

1. Check the utility voltage on the

inverter terminal

2. Check country & Grid setting

3. Check the detection circuit inside

the inverter

E11: Grid Volt

Over Rating

1. Actual utility voltage is over the

OVR setting

2. Utility voltage is over the Slow

OVR setting during operation

3. Incorrect country or Grid setting

4. Detection circuit malfunction

1.&2. Check the utility voltage on

the inverter terminal

3. Check country & Grid setting

4. Check the detection circuit

inside the inverter

E26:Slow Over

Frequency Range

1. Actual utility frequency is over

the OFR setting

2. Incorrect country or grid setting

3. Detection circuit malfunction

1. Check the utility frequency on

the inverter terminal

2. Check country setting

3. Check the detection circuit inside

the inverter

Possible cause Action

47

Measurement, Error Message and Trouble Shooting

ERROR

Message

E28: Slow Under

Voltage Range

E30: DC Volt

Over Rating

E32: L/N Reversed

(RPI-H5 only)

1. Actual utility voltage is under

the UVR setting

2. Incorrect country or Grid setting

3. Detection circuit malfunction

1. Actual Solar1 voltage is over

600Vdc (RPI-H3) or

1000Vdc (RPI-H5)

2. Detection circuit malfunction

1. Incorrect AC wiring

2. Incorrect AC connection setting

1. Check the utility voltage on the

inverter terminal

2. Check country & Grid setting

3.

Check the detection circuit inside

the inverter

1. Modify the solar array setting,

and make the Voc less than

600Vdc (RPI-H3) or

1000Vdc (RPI-H5)

2. Check the detection circuit inside

the inverter

1. Check if brown wire is connected

to Line and blue wire is connected

to Neutral.

2. Check display “AC configurat.”

setting.

Possible cause Action

E27:Slow Under

Frequency Range

1. Actual utility frequency is under

the UFR setting

2. Incorrect country or Grid setting

3. Detection circuit malfunction

1. Check the utility frequency on

the inverter terminal

2. Check country & Grid setting

3. Check the detection circuit inside

the inverter

48

Measurement, Error Message and Trouble Shooting

FAULT

Message

A01: DC Offset

Over Rating

A05: NTC Over

Temp

A06: Inside NTC

Circuit Fail

A08: Heat Sink

NTC1 Fail

1. Utility waveform is abnormal

2. Detection circuit malfunction

1. The ambient temp. is over 60°C

2. Detection circuit malfunction

1. Ambient temp. >100°C or <-24°C

2. Detection circuit malfunction

1. Boost heat sink temp.

>100°C or <-24°C

2. Detection circuit malfunction

1. Check the utility waveform.

Grid connection of inverter need

to be far away from non-linear

load if necessary

2. Check the detection circuit inside

the inverter

1. Check the installation ambient

and environment

2. Check the detection circuit inside

the inverter

1. Check the installation ambient

and environment

2. Check the detection circuit inside

the inverter

1. Check the installation ambient

and environment

2. Check the detection circuit inside

the inverter.

A09: Heat Sink

NTC2 Fail

1. Inverter heat sink temp.

>100°C or <-24°C

2. Detection circuit malfunction

1. Check the installation ambient

and environment

2. Check the detection circuit inside

the inverter

A15:DSP ADC

V

grid / Iout Fail

1.

Auxiliary power circuitry malfunction

2. Detection circuit malfunction

1.

Check the auxiliary circuitry inside

the inverter

2. Check the detection circuit inside

the inverter

A16:DSP ADC

V

in / Vbus Fail

1.

Auxiliary power circuitry malfunction

2. Detection circuit malfunction

1.

Check the auxiliary circuitry inside

the inverter

2. Check the detection circuit inside

the inverter

A17:DSP ADC

I

in / Iboost Fail

1.

Auxiliary power circuitry malfunction

2. Detection circuit malfunction

1.

Check the auxiliary circuitry inside

the inverter

2. Check the detection circuit inside

the inverter

A18:RED. ADC

V

grid Fail

1.

Auxiliary power circuitry malfunction

2. Detection circuit malfunction

1.

Check the auxiliary circuitry inside

the inverter

2. Check the detection circuit inside

the inverter

A19:DSP ADC

I

out_dc Fail

1.

Auxiliary power circuitry malfunction

2. Detection circuit malfunction

1.

Check the auxiliary circuitry inside

the inverter

2. Check the detection circuit inside

the inverter

Possible cause Action

49

Measurement, Error Message and Trouble Shooting

FAULT

Message

A20: Efficiency

Inconsistent

A22: Internal

Comm Fault_R

A23: Internal

Comm Fault_D

A24: Residual

Curr Over Rating

1. The calibration is incorrect

2.

Current feedback circuit is defective

1. Red. CPU is idling

2. The communication connection

is disconnected

1. DSP is idling

2. The communication connection

is disconnected

3. The communication circuit

malfunction

1. PV array insulation fault

2. Large PV array capacitance

between Plus to Ground or Minus

to Ground

3. Either side of boost driver or

boost choke malfunction

4. Detection circuit malfunction

1. Check the accuracy of current

and power

2.

Check the current feedback circuit

inside the inverter

1. Check reset and crystal in

Red. CPU

2. Check the connection between

Red. CPU and DSP

1. Check reset and crystal in DSP

2. Check the connection between

DSP and COMM

3. Check the communication circuit

1.

Check the insulation of Solar inputs

2. Check the capacitance

(+ <-> GND & - <-> GND),

must < 2.5uF. Install an external

transformer if necessary

3.

Check boost driver & boost choke

4. Check the detection circuit inside

the inverter

A25: Ground Fault

1. PV array insulation fault

2. Large PV array capacitance

between Plus to Ground or Minus

to Ground or both.

3. Detection circuit malfunction

1.

Check the insulation of Solar inputs

2. Check the capacitance, dry PV

panel if necessary

3. Check the detection circuit inside

the inverter

A27: RCMU

Circuit Fail

1. RCMU is disconnected

2. Detection circuit malfunction

1. Check the RCMU connection

inside the inverter

2. Check the detection circuit inside

the inverter

A28: Relay Short

1. One or more relays are sticking

2. The driver circuit for the relay

malfunction

1. Replace the defective relay(s)

2. Check the driver circuit inside

the inverter

A29: Relay Open

1.

One or more relays are abnormal

2. The driver circuit for the relay

malfunction

3. The detection accuracy is not

correct for Vgrid and Vout

1. Replace the defective relay(s)

2. Check the driver circuit inside

the inverter

3.

Check the Vgrid and Vout voltage

detection accuracy

Possible cause Action

50

Measurement, Error Message and Trouble Shooting

FAULT

Message

A37: AC Curr

Over Rating

A42: CT Current

Sensor Fail

Detection circuit malfunction

1.Inverter choke Fail

2.Output Filter Fail

3. Detection circuit malfunction

Check the detect circuit inside the

inverter

A35: Bus Volt

Over Rating

1. Driver for boost is defective

2. Voc of PV array is over

600Vdc (RPI-H3) or

1000Vdc (RPI-H5)

3. Surge occurs during operation

4. Detection circuit malfunction

1. Check the driver circuit for boost

inside the inverter

2. Modify the solar array setting,

and make the Voc less than

600Vdc (RPI-H3) or

1000Vdc (RPI-H5)

3. N/A

4. Check the detection circuit inside

the inverter

1.

Check Inverter choke inductance.

2. Check output filter capacitance.

3.

Check the detection circuit inside

the inverter

Possible cause Action

A36:Output Curr

Transient Over

1. Surge occurs during operation

2.

Driver for inverter stage is defective

3. Switching device is defective

4. Detection circuit malfunction

1. N/A

2.

Check the driver circuit in inverter

stage

3. Check all switching devices in

inverter stage

4. Check the detect circuit inside

the inverter

A31: Bus_P Over

Volt Rating

1. Driver for boost is defective

2. Voc of PV array is over

600Vdc (RPI-H3) or

1000Vdc (RPI-H5)

3. Surge occurs during operation

4. Detection circuit malfunction

1. Check the driver circuit for boost

inside the inverter

2. Modify the solar array setting,

and make the Voc less than

600Vdc (RPI-H3) or

1000Vdc (RPI-H5)

3. N/A

4. Check the detection circuit inside

the inverter

A30:

Bus Unbalance

1.

Not totally independent or parallel

between inputs

2. PV Array short to Ground

3. Driver for boost is defective or

disconnected

4. Detection circuit malfunction

1. Check the inputs connections

2. Check the PV Array insulation

3. Check the driver circuit for boost

inside the inverter

4. Check the detection circuit inside

the inverter

A33: Bus_N Over

Volt Rating

1. Driver for boost is defective

2. Voc of PV array is over

600Vdc (RPI-H3) or

1000Vdc (RPI-H5)

3. Surge occurs during operation

4. Detection circuit malfunction

1. Check the driver circuit for boost

inside the inverter

2. Modify the solar array setting,

and make the Voc less than

600Vdc (RPI-H3) or

1000Vdc (RPI-H5)

3. N/A

4. Check the detection circuit inside

the inverter

51

Measurement, Error Message and Trouble Shooting

FAULT

Message

A45: HW OOCP

A50:Zero Cross

Circuit Fail

1. WB1 WB2 misconnection.

2. Detection circuit malfunction

The detection circuit for

synchronous signal malfunction

1. Check the connection of WB1

and WB2.

2. Check the detection circuit inside

the inverter

Check the detection circuit for

synchronous signal inside the

inverter

A56:Hardware

Incompatibility

HW power rating incorrect

Check comm. HW power rating info.

A60: DC1 Curr

Over Rating

1. Switching device in boost is

defective

2. Driver for boost is defective

3. Input current detection circuit

malfunction

1. Check all switching device in

boost

2. Check the driver circuit for boost

inside the inverter

3. Check input current detection

circuit

A70: DC1 Curr

Transient Over

1. Switching device in boost is

defective

2. Driver for boost is defective

3. Input current detection circuit

malfunction

1. Check all switching device in

boost

2. Check the driver circuit for boost

inside the inverter

3. Check input current detection

circuit

Possible cause Action

Table 9-2 : Error message

52

Measurement, Error Message and Trouble Shooting

10 De-Commissioning

De-Commissioning Procedure:

If it is necessary to put the device out of operation for RMA or maintenance, please follow the

instructions below.

WARNING!Death and serious injuries may occur.

To avoid injuries, please follow the procedures below,

1. Switch off AC circuit breaker to disconnect with electricity grid.

2. Switch off the PV Array switch to disconnect with PV Array.

3. Use proper voltage meter to confirm that the AC and DC power present

totally absent.

4. Remove the AC wiring immediately to completely disconnect with

electricity grid.

5. Remove the DC wiring to disconnect with PV Array.

6. Remove the Communication module RS-485 with the computer connection.

After finishing all the procedures, users can remove this machine.

53

De-Commissioning

11 Technical Data

11.1 Specifications

Model RPI-H3

GENERAL

RPI-H5

Enclosure

Operating temperature

Relative humidity

Galvanic isolation

Safety class

Overvoltage category

Maximum input power

Normal voltage

Operating voltage range

Absolute maximum voltage

MPP range (rated power)

Rated power

Maximum power

3000 VA

3000 VA (#1)

5000 VA

5000 VA

13 A

14.3 A

21.7 A

24.5 A

97.00%

96.20%

97.50%

97.00%

Voltage

Rated current

Max. current

Frequency

Total harmonic distortion

Power factor

Peak efficiency

EU efficiency

230Vac +/-20%

50/60 Hz

<3% with Rated power(#2)

>0.99@Rated power(#2)

Input connection

Startup voltage

MPPT tracker

Maximum input current

Powder-coated aluminium

-20~60°C, full power up to 40°C

Operating Altitude 2000m

0% – 95% non-condensing.

Environmental category Outdoor, wet locations

NO

Class I metal enclosure with protective earth

Pollution degree Internal: II, External: III

AC output: III, DC input: II

Flicker impedance Z = 0.4 + j 0.25 Ω (total impedance)

Three-phase combinations No

3200W 5425W

350 Vdc 650 Vdc

125~550 Vdc 200~1000 Vdc

600 Vdc 1000 Vdc

320~500 Vdc 310~850 Vdc

10 A 17.5 A

150 Vdc 250 Vdc

Maximum

short circuit current

13.9 A 24.5 A

1

MC4, 2 pairs

DC INPUT (Solar side)

AC OUTPUT (Grid side)

54

Technical Data

Model

Housing

Cooling

IP rating

External communication

Weight

Dimensions

Aluminum Extrude

2 RS-485 connection

21.5 kg15 kg

482 × 470 × 167 mm367 × 420 × 157 mm

Natural cooling

IP65 (Electronics)

AC OUTPUT (Grid side)

Safety

Grid interface

IEC 62109-1

IEC 62109-2

CE compliance

VDE 0126 A1

VDE AR-N 4105

UTE 15-712-1

EN 50438

C10/C11

G83-2

AS 4777(#3)

VDE AR-N 4105

RD1699

CEI-021

Emission IEC 61000-6-4, IEC 61000-6-3

Harmonics EN 61000-3-12

Variations and flicker EN 61000-3-11

Immunity EN 61000-6-2

Immunity

ESD

RS

EFT

Surge

CS

PFMF

IEC 61000-4-2

IEC 61000-4-3

IEC 61000-4-4

IEC 61000-4-5

IEC 61000-4-6

IEC 61000-4-8

REGULATIONS & DIRECTIVES

RPI-H3 RPI-H5

#1: (a) 2.49kW max. for Australia (AU / NZ PL 2K49) (H3)

(b) 2.99kW max. for Australia (AU / NZ PL 2K99) (H3)

(c) 3kW max. for Australia (AU / NZ) (H3)

#2: Disable reactive power control

#3: Not support AS4777.2:2015 Single-phase inverters used in three-phase combinations

Table 11-1 : Specifications

Internal fuse, 20 A/250 V*1 Internal fuse, 20 A/250 V*2

Output connection

Fuse

IP 67 single-phase

MECHANISM

55

Technical Data

Appendix A

Multi-function Relay

Inverter support one multi-function relay, the multi-function relay is available to external devices.

The device includes: flashing lights, Buzzer Etc. the multi-function relay allow following configuration.

• Fault indicator or Grid status indicator

• Power production

• Control of external loads

• Fan control

56

Appendix A

A.1 Multi-function relay output connection

The Dry contact connection provides a remote indication of inverter status. When inverter

operated in the normal condition, the dry contact is closed. User can use the Monitor modbus

SW tool, the multi-function relay will be configured as mentioned event setting. Please refer

to Figure A-1

Figure A-1 : Multi-function relay on Dry contact

Danger! Hazard of Electric shock.

Touching electronic components can damage components through

electrostatic discharge.

Figure A-2 : Dry contact location

Relay

Dry

contact

Equivalent circuit

Dry contact

12V

GND

Relay

57

Appendix A

Appendix B

Digital Input

To implementation of power management, the digital input interface receives the specifications

of the network operator via a ripple control receiver.

• Germany : The active power limitation in the stages 0%, 30%, 60% and 100%

• Italy : Power output of Max 6KW for PV plant installation.

Remote shutdown

Narrow Frequency limits between 49.5 Hz to 50.5Hz.

• Australia and New Zealand:

The inverter support the demand response mode(DRMs).

DRM 0 - Operate the disconnection device.

DRM 5 - Do not generate power.

DRM 6 - Do not generate at more than 50% of rated power.

DRM 7 - Do not generate at more than 75% of rated power.

And sink reactive power.

DRM 8 - Increase power generation.

(subject to constraints from other active DRMs)

• Customer : User defined.

Figure B-1 : Pin assignment at ripple control receiver

The inverter gives a voltage to Pin 6, and measures Pin 1 to 5.

The inverter can detect the state of the relay of the ripple control receiver.

The information which relay shall be controlled parameter by the network operator.

Ripple control receiver

Digital inputDigital input

D5

D4

D3

D2

D1

58

Appendix B

Pin Function

1

Digital input 1

2

Digital input 2

3

4

5

6

Digital input 3

Digital input 4

Digital input 5

Output

Cable requirements:

• Conductor cross-section: 0.205 mm² (AWG24) ~ 0.081 mm².(AWG28)

• Outside diameter of cable : 3.8mm ~ 5.2mm

• Please refer to UL 2464 computer cable guideline

Function

Country = Italy & Italy with SPI

No function

Remote off

Narrow

frequency limit.

Note: 1 = Relay is closed, 0 = Relay is open.

Note: 1 = Relay is closed, 0 = Relay is open.

D1

0

1

0

D2

0

0

1

D3

0

0

0

D4

0

0

0

D5

0

0

0

Output

1

1

1

Function

Country = Germany

No function

Active power =

0%

Active power =

30%.

Active power =

60%

Active power =

100%

D1

0

1

0

D2

0

0

1

D3

0

0

0

D4

0

0

0

D5

0

0

0

Output

1

1

1

0

0

0

0

1

0

0

1

0

0

1

1

Country = Australia or New Zealand

#1: Relay is closed, 0: Relay is open.

Function

No function

DRM 0

Disconnection device

DRM 5

Active power = 0

DRM 6

Active power < 50%

DRM 7

Active power < 75%

Sink reactive power

D1

0

1#

0

D2

0

0#

0

D3

0

0

0

D4

0

0

0

Output

1

1

1

0

0

0

0

0

1

1

0

1

1

DRM 8

Active power < 100%

Sink reactive power

0 1 0 0

D5

0

0

1

0

0

0 1

59

Appendix B

Version 04180115

5013208606

Loading...

Loading...