Page 1

FEATURES

High Efficiency: 88%@ 1.8V/15A, 3.3V/15A

Standard footprint:57.9mmx36.8mmx8.5mm

(2.28”×1.45”×0.33”)

Industry standard pin out

2:1 input voltage range

Fixed frequency operation

Fully protected: OTP, OCP, OVP, UVLO

No minimum load required

1500 V isolation and basic insulation

Two independent power train and separate

trim for each output

ISO 9001, TL 9000, ISO 14001, QS9000,

OHSAS18001 certified manufacturing

facility

UL/cUL 60950 (US & Canada) Recognized,

and TUV (EN60950) Certified

CE mark meets 73/23/EEC and 93/68/EEC

directives

Delphi Series Q48DR, 87W-100W, Quarter Brick

Dual Output, DC/DC Power Modules:

48V in, 1.8V and 3.3V, 15A out each channel

The Delphi Series Q48DR Quarter Brick Dual, 48V input, dual output,

isolated DC/DC converters are latest offering from one of the world’s

largest power supply manufacturers — Delta Electronics, Inc. This

product family provides up to 100 watts of power or 15A of output current

(each channel simultaneously) in an industry standard footprint. Both

output channels can be used independently of each other with option to

trim each channel either in the same direction or in reversion direction.

With creative design technology and optimized circuit, these converters

possess outstanding electrical and thermal performance, as well as

extremely high reliability under highly stressful operating conditions. All

the models are fully protected from abnormal input/output voltage,

current, and temperature conditions. The Delphi Series converters meet

all safety requirements with basic insulation.

OPTIONS

Optional second trim pin for

independent trim of the two outputs

Positive On/Off logic

Short pin lengths available

APPLICATIONS

Telecom/DataCom

Wireless Networks

Optical Network Equipment

Server and Data Storage

Industrial/Test Equipment

DATASHEET

DS_Q48DR1R833_03162007

1

Page 2

TECHNICAL SPECIFICATIONS (T

=25°C, airflow rate=300 LFM, Vin=48Vdc, nominal Vout unless otherwise noted.)

A

PARAMETER NOTES and CONDITIONS Q48DR1R833NRFA

Min. Typ. Max. Units

ABSOLUTE MAXIMUM RATINGS

Input Voltage

Continuous 80 Vdc

Transient (100ms) <100ms 100 Vdc

Operating Temperature Please refer to figure 27 for measuring point -40 114 °C

Storage Temperature -55 125 °C

Input/Output Isolation Voltage 1500 Vdc

INPUT CHARACTERISTICS

Operating Input Voltage 36 48 75 Vdc

Input Under-Voltage Lockout

Turn-On Voltage Threshold 33 34 35 Vdc

Turn-Off Voltage Threshold 31 32 33 Vdc

Lockout Hysteresis Voltage 1 2 3 Vdc

Maximum Input Current 100%load, 36Vin 2.9 A

No-Load Input Current 100 150 mA

Off Converter Input Current 5 10 mA

Inrush Current(I2t) 0.015 A2s

Input Reflected-Ripple Current P-P thru 12µH inductor, 5Hz to 20MHz 10 mA

Input Voltage Ripple Rejection 120Hz 50 dB

OUTPUT CHARACTERISTICS

Output Voltage Set Point

Output Voltage Regulation

Over Load

Over Line Vin=36V to 75V,Io1=Io2=full load

Cross Regulation Worse Case ±5 ±10 mV

Over Temperature

Total Output Voltage Range Over sample load, line and temperature

Output Voltage Ripple and Noise 5Hz to 20MHz bandwidth

Peak-to-Peak Io1, Io2 Full Load, 1µF ceramic, 10µF tantalum

RMS Io1, Io2 Full Load, 1µF ceramic, 10µF tantalum

Operating Output Current Range

Output DC Current-Limit Inception

DYNAMIC CHARACTERISTICS

Output Voltage Current Transient 48V, 10µF Tan & 1µF Ceramic load cap, 0.1A/µs

Positive Step Change in Output Current Iout1from 50% Io, max to 75% Io, max

Negative Step Change in Output Current Iout2 from 75% Io, max to 50% Io, max

Cross dynamic Each channel independence 20 mV

Settling Time (within 1% Vout nominal) 150 US

Turn-On Transient

Start-up Time, From On/Off Control 10 15 MS

Start-up Time, From Input 10 15 mS

Maximum Output Capacitance Full load; 5% overshoot of Vout at startup

EFFICIENCY

100% Load Iout1, Iout2 full load, 48vdc Vin 88 %

60% Load Iout1, Iout2 60% of full load, 48vdc Vin 88 %

ISOLATION C HARACTERISTICS

Input to Output 1500 Vdc

Isolation Resistance 10 MΩ

Isolation Capacitance 3000 pF

FEATURE CHARACTERISTICS

Switching Frequency 350 kHz

ON/OFF Control, (Logic Low-Module ON)

Logic Low Von/off at Ion/off=1.0mA 0 0.8 V

Logic High Von/off at Ion/off=0.0 µA 18 V

ON/OFF Current Ion/off at Von/off=0.0V 1 mA

Leakage Current Logic High, Von/off=15V 50 uA

Output Voltage Trim Range

Output Over-Voltage Protection Over full temp range; %of nominal Vout 115 122 130 %

GENERAL SPECIFICATIONS

MTBF Io=80% of Io, max; Ta=25°C,300FLM 3.0 M hours

Weight 26.5 grams

Over-Temperature Shutdown Please refer to figure 27 for measuring point 122 °C

Vin=48V, Io=Io.max, Tc=25 ℃

Io1=Io, min to Io, max, Io2=0A Vout 1

Io2=Io, min to Io, max, Io1=0A Vout 2

Tc=-40 ℃ to 85 ℃

Vout 1 0 15

Vout 2 0 15

Vout 1 100% 150%

Vout 2 100% 150%

Pout ≦ max rated power

Vout 1 1.771 1.800 1.829

Vout 2 3.247 3.300 3.353

±5 ±10 mV

Vout 1

Vout 2

Vout 1 1.746 1.854 V

Vout 2 3.201 3.399 V

Vout 1 40 80

Vout 2 40 80

Vout 1 10 30

Vout 2 10 30

Vout 1 100

Vout 2

Vout 1 100

Vout 2

Vout 1 10000

Vout 2 10000

±3 ±10 V

±15 ±50

-10 +10 %

100

100

mV

mV

Vdc

mV

mV

µF

A

DS_Q48DR1R833_03162007

2

Page 3

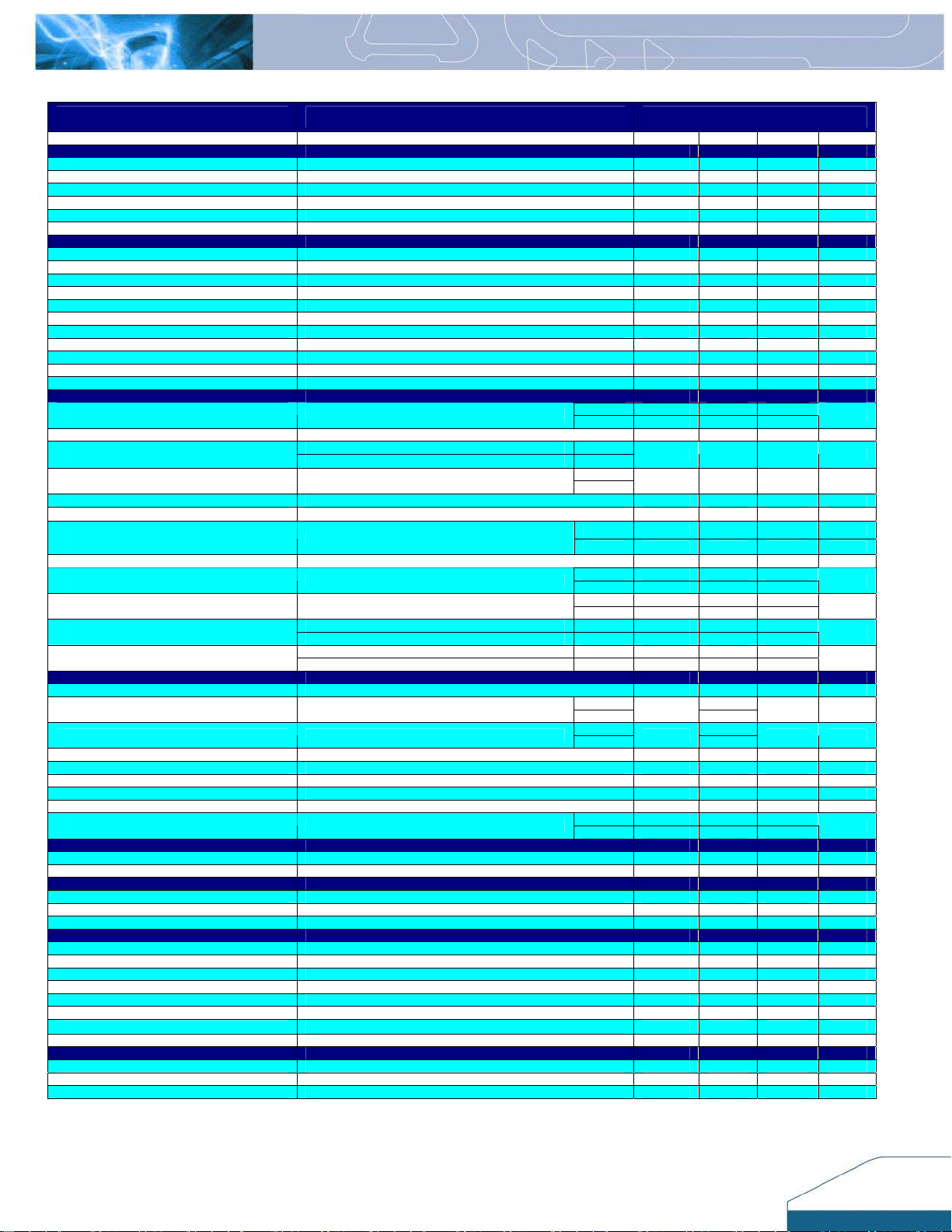

ELECTRICAL CHARACTERISTICS CURVES

Figure 1: Efficiency vs. load current Iout1 for minimum,

nominal, and maximum input voltage at 25

Figure 3: Efficiency vs. load current Iout1 and Iout2 for

minimum, nominal, and maximum input voltage at 25

Iout1=Iout2

°C, for Iout2=7.5A.

°C, for

Figure 2: Efficiency vs. load current Iout2 for minimum,

nominal, and maximum input voltage at 25

Figure 4: Power dissipation vs. load current for minimum,

nominal, and maximum input voltage at 25°C. for Iout1=Iout2

°C, for Iout1=7.5A

DS_Q48DR1R833_03162007

3

Page 4

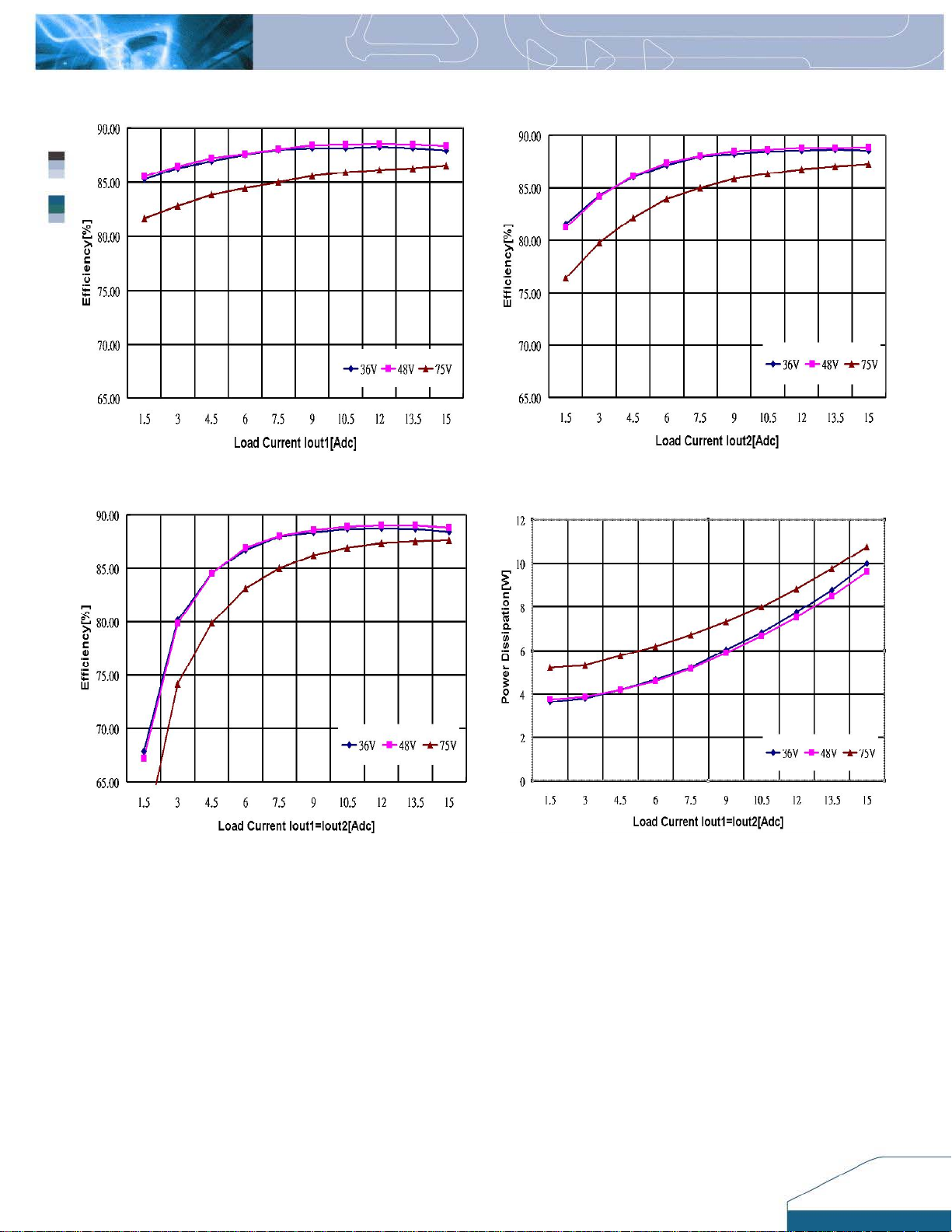

ELECTRICAL CHARACTERISTICS CURVES

Vout2

Vout1

Figure 5: Turn-on transient at zero load current(2ms/div).

Vin=48V. Negative logic turn on. Top Trace: Vout; 1V/div;

Bottom Trace: ON/OFF input: 5V/div

Vout2

Vout2

Vout1

Figure 6: Turn-on transient at full rated load current (resistive

load) (2 ms/div). Vin=48V. Negative logic turn on. Top Trace:

Vout; 1V/div; Bottom Trace: ON/OFF input: 5V/div

Vout2

Vout1

Figure 7: Turn-on transient at zero load current (2ms/div).

Vin=48V. Positive logic turns on. Top Trace: Vout; 1V/div;

Bottom Trace: ON/OFF input: 5V/div

Figure 8: Turn-on transient at full load current (2ms/div).

Vin=48V. Positive logic turns on. Top Trace: Vout; 1V/div;

Bottom Trace: ON/OFF input: 5V/div

Vout1

DS_Q48DR1R833_03162007

4

Page 5

ELECTRICAL CHARACTERISTICS CURVES

)

ELECTRICAL CHARACTERISTICS CURVES

Ch1

Ch2

Ch3

Ch4

Figure 9: Output voltage response to step-change in load

Fteigure 9: Typical full load input characteristics at room

current Iout2 (75%-50%-75% of Io, max; di/dt = 2.5A/µs) at

mperature

Iout1=7.5A. Load cap: 470µF, 35m

Ω

ESR solid electrolytic

capacitor and 1µF ceramic capacitor. Ch1=Vout2

(100mV/div), Ch2=Iout2 (7.5A/div), Ch3=Vout1 (100mV/div) ,

Ch4=Iout1 (7.5A/div) Scope measurement should be made

using a BNC cable (length shorter than 20 inches). Position

the load between 51 mm to 76 mm (2 inches to 3 inches)

from the module.

Ch1

Ch1

Ch2

Ch3

Ch3

Ch4

Ch4

6

Figure 10: Output voltage response to step-change in load

F

igure 10: Output voltage response to step-change in load

current Iout1 (75%-50%-75% of Io, max; di/dt = 2.5A/µs) at

cu

rrent Iout2 (75%-50%-75% of Io, max; di/dt = 0.1A/µs) at

Iout2=7.5A. Load cap: 470µF, 35m

I

o

ut1=7.5A. Load cap: 10µF, tantalum capacitor and 1µF ceramic

capacitor and 1µF ceramic capacitor. Ch1=Vout2 (100mV/div),

ca

pacitor. Ch1=Vout2 (100mV/div), Ch2=Iout2 (7.5A/div),

Ch2=Iout2 (7.5A/div), Ch3=Vout1 (100mV/div), Ch4=Iout1

C

h3=Vout1 (100mV/div), Ch4=Iout1 (7.5A/div) Scope

(7.5A/div) Scope measurement should be made using a BNC

m

easurement should be made using a BNC cable (len gth shorter

cable (length shorter than 20 inches). Position the load between

th mm (2

an 20 inches). Position the load between 51 mm to 76

51 mm to 76 mm (2 inches to 3 inches) from the module.

inches to 3 inches) from the module.

Ω

ESR solid electrolytic

Ch1

Ch1

Ch2

Ch2

Ch3

Ch3

Ch4

Ch4

Figure 11: Output voltage response to step-change in load

current Iout2 and Iout1 (75%-50%-75% of Io, max; di/dt =

2.5A/µs). Load cap: 470µF, 35m

F

igure 11: Output voltage response to step-change in load

capacitor and 1µF ceramic capacitor. Ch1=Vout2

c

urrent Iout1 (75%-50%-75% of Io, max; di/dt = 0.1A/µs) at

(100mV/div), Ch2=Iout2 (7.5A/div), Ch3=Vout1 (100mV/div) ,

Io

ut2=7.5A. Load cap: 10µF, tantalum capacitor and 1µF

Ch4=Iout1 (7.5A/div) Scope measurement should be made

c

eramic capacitor. Ch1=Vout2 (100mV/div), Ch2=Iout2

using a BNC cable (length shorter than 20 inches). Position

(

7.5A/div), Ch3=Vout1 (100mV/div), Ch4=Iout1 (7.5A/div)

the load between 51 mm to 76 mm (2 inches to 3 inches)

S

cope measurement should be made using a BNC cable

from the module.

(l n 20 inches). Position the load between

ength shorter tha

51 mm to 76 mm (2 inches to 3 inches) from the module.

Ω

ESR solid electrolytic

Ch1

Ch2

Ch3

Ch4

Figure 12: Test set-up diagram showing measurement points for

Input Terminal Ripple Current and Input Reflected Ripple

Current.

cF : Output voltage response to step-change in load

igure 12

Note: Measured input reflected-ripple current with a simulated

u

rrent Iout2 and Iout1 (75%-50%-75% of Io, max; di/dt =

source Inductance (L

0.

1A/µs). Load cap: 10µF, tantalum capacitor and 1µF ceramic

battery impedance. Measure current as shown above

ca 7.5A/div),

pacitor. Ch1=Vout2 (100mV/div), Ch2=Iout2 (

of 12 µH. Capacitor Cs offset possible

TEST

Ch3=Vout1 (100mV/div), Ch4=Iout1 (7.5A/div) Scope

measurement should be made using a BNC cable (len gth shorter

than 20 inches). Position the load between 51 mm to 76 mm (2

inches to 3 inches) from the module.

DS_Q48DR1R833_03162007

5

Page 6

ELECTRICAL CHARACTERISTICS CURVES

V

)

Figure 13: Input Terminal Ripple Current-ic, at full rated

output current and nominal input voltage with 12µH source

impedance and 33µF electrolytic capacitor (500 mA/div,

2us/div).

StripCopper

Vo(+)

10u 1u

SCOPE RESISTI

LOAD

Vo(-)

Figure 14: Input reflected ripple current-i

source inductor at nominal input voltage and rated load c urrent

(20 mA/div, 2us/div).

, through a 12µH

s

Figure 15: Output voltage noise and ripple measurement

test setup

DS_Q48DR1R833_03162007

Figure 16: Output voltage ripple at nominal input voltage and

rated load current (Iout1=Iout2=15A)(20 mV/div, 1us/div

trace: Vout2(20mV/div), Bottom trace(20mV/div)

Load capacitance: 1µF ceramic capacitor and 10µF tantalum

capacitor. Bandwidth: 20 MHz. Scope measurements should be

made using a BNC cable (length shorter than 20 inches). Position

the load between 51 mm to 76 mm (2 inches to 3 inches) from

the module.

. Top

6

Page 7

ELECTRICAL CHARACTERISTICS CURVES

Figure 17: Output voltage vs. load current Iout1 showing

typical current limit curves and converter shutdown points.

Figure 18: Output voltage vs. load current Iout2 showing typical

current limit curves and converter shutdown points.

DS_Q48DR1R833_03162007

7

Page 8

DESIGN CONSIDERATIONS

Input Source Impedance

The impedance of the input source connecting to the

DC/DC power modules will interact with the modules

and affect the stability. A low ac-impedance input

source is recommended. If the source inductance is

more than a few µH, we advise adding a 10 to 100 µF

electrolytic capacitor (ESR < 0.7 Ω at 100 kHz)

mounted close to the input of the module to improve the

stability.

Layout and EMC Considerations

Delta’s DC/DC power modules are designed to operate

in a wide variety of systems and applications. For

design assistance with EMC compliance and related

PWB layout issues, please contact Delta’s technical

support team. An external input filter module is

available for easier EMC compliance design.

Application notes to assist designers in addressing

these issues are pending release.

Safety Considerations

The power module must be installed in compliance with

the spacing and separation requirements of the enduser’s safety agency standard, i.e., UL60950,

CAN/CSA-C22.2 No. 60950-00 and EN60950:2000 and

IEC60950-1999, if the system in which the power

module is to be used must meet safety agency

requirements.

When the input source is 60 Vdc or below, the power

module meets SELV (safety extra-low voltage)

requirements. If the input source is a hazardous voltage

which is greater than 60 Vdc and less than or equal to

75 Vdc, for the module’s output to meet SELV

requirements, all of the following must be met:

The input source must be insulated from any

hazardous voltages, including the ac mains, with

reinforced insulation.

One Vi pin and one Vo pin are grounded, or all the

input and output pins are kept floating.

The input terminals of the module are not operator

accessible.

If the metal baseplate is grounded the output must

be also grounded.

A SELV reliability test is conducted on the system

where the module is used to ensure that under a

single fault, hazardous voltage does not appear at

the module’s output.

Do not ground one of the input pins without grounding

one of the output pins. This connection may allow a

non-SELV voltage to appear between the output pin

and ground.

The power module has extra-low voltage (ELV) outputs

when all inputs are ELV.

This power module is not internally fused. To achieve

optimum safety and system protection, an input line

fuse is highly recommended. The safety agencies

require a normal-blow fuse with 7A maximum rating to

be installed in the ungrounded lead. A lower rated fuse

can be used based on the maximum inrush transient

energy and maximum input current.

Soldering and Cleaning Considerations

Post solder cleaning is usually the final board assembly

process before the board or system undergoes

electrical testing. Inadequate cleaning and/or drying

may lower the reliability of a power module and

severely affect the finished circuit board assembly test.

Adequate cleaning and/or drying is especially important

for un-encapsulated and/or open frame type power

modules. For assistance on appropriate soldering and

cleaning procedures, please contact Delta’s technical

support team.

DS_Q48DR1R833_03162007

8

Page 9

FEATURES DESCRIPTIONS

Over-Current Protection

The modules include an internal output over-current

protection circuit, which will endure current limiting for

an unlimited duration during output overload. If the

output current exceeds the OCP set point, the modules

will automatically shut down (hiccup mode).

The modules will try to restart after shutdown. If the

overload condition still exists, the module will shut down

again. This restart trial will continue until the overload

condition is corrected.

Over-Voltage Protection

The modules include an internal output over-voltage

protection circuit, which monitors the voltage on the

output terminals. If this voltage exceeds the overvoltage set point, the module will shut down.

The module will try to restart after shutdown. If the overvoltage condition still exists during restart, the module

will shut down again. This restart trial will continue until

the output voltage is within specification.

Over-Temperature Protection

The over-temperature protection consists of circuitry

that provides protection from thermal damage. If the

temperature exceeds the over-temperature threshold

the module will shut down.

The module will try to restart after shutdown. If the overtemperature condition still exists during restart, the

module will shut down again. This restart trial will

continue until the temperature is within specification.

Remote On/Off

The remote on/off feature on the module can be either

negative or positive logic. Negative logic turns the

module on during a logic low and off during a logic high.

Positive logic turns the modules on during a logic high

and off during a logic low.

Remote on/off can be controlled by an external switch

between the on/off terminal and the Vi(-) terminal. The

switch can be an open collector or open drain.

For negative logic if the remote on/off feature is not

used, please short the on/off pin to Vi(-). For positive

logic if the remote on/off feature is not used, please

leave the on/off pin to floating.

Figure 19: Remote on/off implementation

Output Voltage Adjustment (TRIM)

To increase or decrease the output voltage set point,

the modules may be connected with an external

resistor between the TRIM pin and either Vout1(+) or

RTN. The TRIM pin should be left open if this feature

is not used.

Figure 20: Circuit configuration for trim-down (decrease

output voltage)

If the external resistor is connected between the TRIM

and Vout1(+) pin, the output voltage set point

decreases (Fig. 20). The external resistor value is

from the table below.

DS_Q48DR1R833_03162007

9

Page 10

FEATURES DESCRIPTIONS (CON.)

Figure 21: Circuit configuration for trim-up (increase output

voltage)

If the external resistor is connected between the TRIM

and RTN, the output voltage set point increases (Fig.

21). The external resistor value is from table below.

Trim Resistor

(Vout Increase)

Δ [%] Rtrim-up [KΩ]

1 57.4

2 25.5

3 14.9

4 9.57

5 6.38

6 4.26

7 2.47

8 1.60

9 709

10 0

The output voltage can be increased by the trim pin,

When using trim; the output voltage of the module is

usually increased, which increases the power output of

the module with the same output current. Care should

be taken to ensure that the maximum output power of

the module remains at or below the maximum rated

power.

Trim Resistor

(Vout Decrease)

Δ [%]

Rtrim-down [KΩ]

1 70.2

2 31.2

3 18.2

4 11.7

5 7.80

6 5.20

7 3.34

8 1.95

9 867

10 0

DS_Q48DR1R833_03162007

10

Page 11

THERMAL CONSIDERATIONS

A

Y

Thermal management is an important part of the

system design. To ensure proper, reliable operation,

sufficient cooling of the power module is needed over

the entire temperature range of the module. Convection

cooling is usually the dominant mode of heat transfer.

Hence, the choice of equipment to characterize the

thermal performance of the power module is a wind

tunnel.

Thermal Testing Setup

Delta’s DC/DC power modules are characterized in

heated vertical wind tunnels that simulate the thermal

environments encountered in most electronics

equipment. This type of equipment commonly uses

vertically mounted circuit cards in cabinet racks in which

the power modules are mounted.

The following figure shows the wind tunnel

characterization setup. The power module is mounted

on a test PWB and is vertically positioned within the

wind tunnel. The space between the neighboring PWB

and the top of the power module is constantly kept at

6.35mm (0.25’’).

Thermal Derating

Heat can be removed by increasing airflow over the

module. The module’s hottest spot is less than +114°C.

To enhance system reliability, the power module should

always be operated below the maximum operating

temperature. If the temperature exceeds the maximum

module temperature, reliability of the unit may be

affected.

FACING PWB

PWB

THERMAL CURVES

Figure 23: Hot spot temperature measured point

*

The allowed maximum hot spot temperature is defin ed at

℃

114

110%

100%

90%

80%

70%

60%

50%

40%

30%

20%

10%

0%

20 25 30 35 40 45 50 55 60 65 70 75 80 85

Figure 24: Output load vs. ambient temperature and air velocity

@V

Q48DR1R833(Standard) Output Load vs. Ambient Temperature and Air Velocity

Output Load(%)

Natural

Convection

=48V(Transverse Orientation)

in

@ Vin = 48V (Transverse Orientation)

100LFM

200LFM

300LFM

600LFM

500LFM

400LFM

Ambient Temperature (℃)

AIR VELOCIT

AND AMBIENT

TEMPERATURE

MEASURED BELOW

THE MODULE

Note: Wind Tunnel Test Setup Figure Dim nsions are in millimeters and (Inche

Figure 22: Wind tunnel test setup

DS_Q48DR1R833_03162007

MODULE

50.8 (2.0”)

IR FLOW

12.7 (0.5”)

e

11

Page 12

MECHANICAL DRAWING

Pin No. Name Function

1

2

3

4

5

6

7

8

-Vin

ON/OFF

+Vin

+Vout2

TRIM

Output RTN

+Vout1

Optional

Notes:

1

2

DS_Q48DR1R833_03162007

Pins 1-8 are 1.00mm (0.040”) diameter

All pins are copper with Tin plating.

Negative input voltage

Remote ON/OFF

Positive input voltage

Positive output voltage2

Output voltage trim

Positive output voltage1

TRIM2

12

Page 13

PART NUMBERING SYSTEM

Q D R 1R8 33 N R

Form Factor Input

Q – Quarter

Brick

48

Number of

Voltage

48 - 36-75V D-Dual Output R-Open frame 2R5-2.5V

Outputs

Product

Series

Output

Voltage 1

3R3-3.3V

1R8-1.8V

1R5-1.5V

Output

Voltage 2

33-3.3V

50-5.0V

ON/OFF

Logic

N-Negative

(Default)

P-Positive

F A

Pin Length Option Code

R-0.170”

(Default)

N-0.145”

K-0.110”

F- RoHS 6/6

(Lead Free)

A - Standard

Functions

(Default)

B - with second

trim pin

MODEL LIST

MODEL NAME INPUT

Q48DR1R533NRFA 36V~75V 2.8A 1.5V/15A 3.3V/15A 87.5%

Q48DR1R833NRFA 36V~75V 2.9A 1.8V/15A 3.3V/15A 88.0%

Q48DR2R533NRFA 36V~75V 3.3A 2.5V/15A 3.3V/15A 88.0%

Q48DR3R350NRFA 36V~75V 3.8A 3.3V/15A 5.0V/10A 88.5%

OUTPUT

*

EFF @ Full Load

CONTACT:

USA:

Telephone:

East Coast: (888) 335 8201

West Coast: (888) 335 8208

Fax: (978) 656 3964

DCDC@delta-corp.com

Email:

WARRANTY

Delta offers a two (2) year limited warranty. Complete warranty information is listed on our web site or is available

upon request from Delta.

Information furnished by Delta is believed to be accurate and reliable. However, no responsibility is assumed by Delta

for its use, nor for any infringements of patents or other rights of third parties, which may result from its use. No license

is granted by implication or otherwise under any patent or patent rights of Delta. Delta reserves the right to revise

these specifications at any time, without notice

www.delta.com.tw/dcdc

Europe:

Phone: +41 31 998 53 11

Fax: +41 31 998 53 53

Email:

DCDC@delta-es.com

.

Asia & the rest of world:

Telephone: +886 3 4526107 ext 6220

Fax: +886 3 4513485

DCDC@delta.com.tw

Email:

DS_Q48DR1R833_03162007

13

Loading...

Loading...