Page 1

Instruction Manual PMC-24V050W1AA

1. Safety Instructions

• To ensure sufficient convection cooling, always maintain a safety

distance of >20mm from all ventilated surfaces while the device is in

operation.

• The device is not recommended to be placed on low thermal

conductive surface, for example, plastics.

• Note that the enclosure of the device can become very hot

depending on the ambient temperature and load of the power supply.

Do not touch the device while it is in operation or immediately after

power is turned OFF. Risk of burning!

• Do not touch the terminals while power is being supplied. Risk of

electric shock.

3. Installation of the Device

Refer to Fig. 2:

A Mounting holes for power supply assembly onto the mounting surface. Power

supply shall be mounted on minimum 2 mounting holes using M3 screw,

minimum 5mm length.

B This surface belongs to customer’s end system or panel where the power

supply is mounted.

C Connector

Side Mounting (Vertical)

Base Mounting (Vertical)

Side Mounting (Horizontal)

• Prevent any foreign metal, particles or conductors to enter the

device through the openings during installation. It can cause:

- Electric shock; Safety Hazard; Fire; Product failure

• Warning: When connecting the device, secure Earth connection

before connecting L and N. When disconnecting the device, remove

L and N connections before removing the Earth connection.

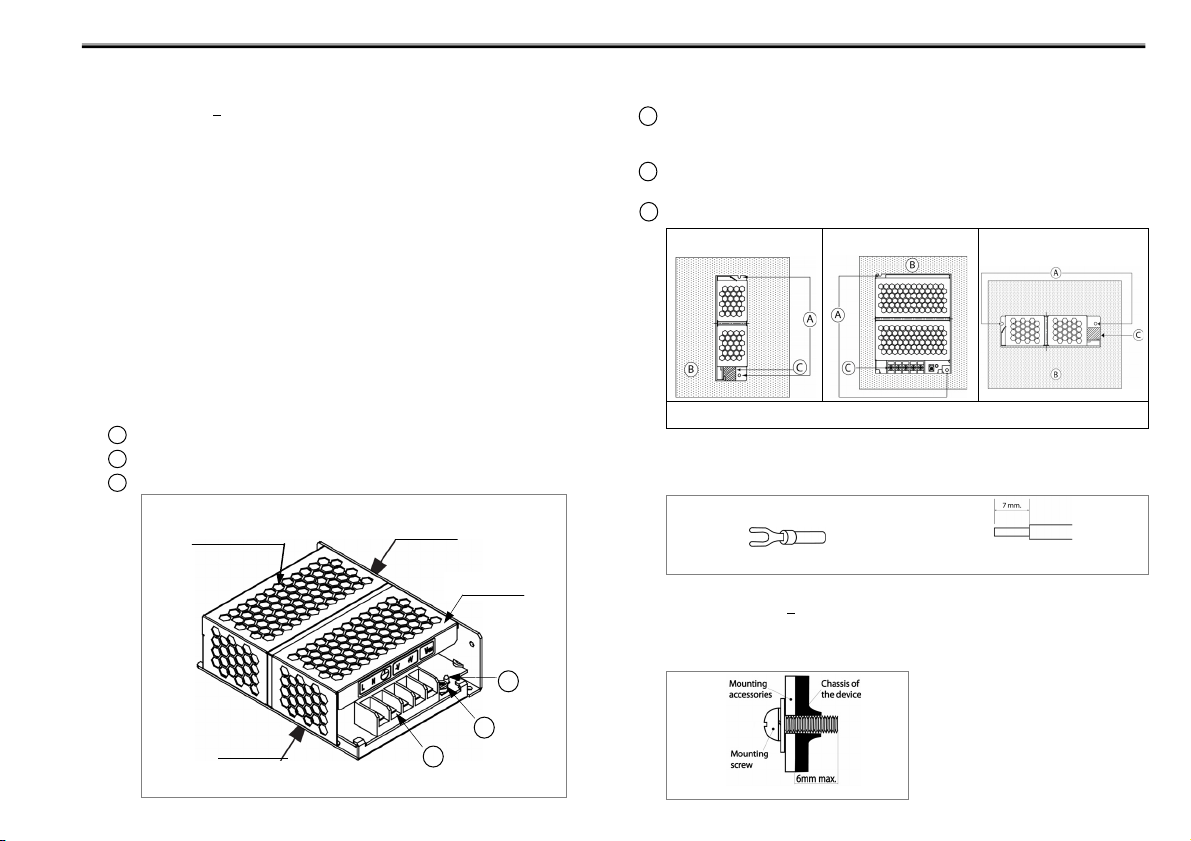

2. Device Descriptions

Refer to Fig. 1:

1 Input & Output terminal block connector

2 DC voltage adjustment potentiometer

3 DC OK control LED (green)

Ventilated surface

Base surface

Side surface

Fig. 1 Device Descriptions

Top

3

2

4. Installation of Mounting Accessories

Fig. 2 Mounting

• Use flexible cable (stranded or solid), AWG no. 22-12. The torque at the

Connector shall not exceed 13Kgf.cm The insulation stripping length should

not exceed 0.275” or 7mm

Fig. 3 Wire Type

Stripped wire

• Only use M3 screw <

Lug

6mm through the base mounting holes. This is to keep

a safety distance between the screw and internal components.

• Refer to Fig. 4:

Recommended mounting tightening torque: 4 ~ 8Kgf.cm

Fig. 4 Mounting Screw

www.delta.com.tw/industrialautomation

Page 2

!ֹϡᄲځ!

1. щБఢቑ!

• 與通風表面保持至少 20mm 的安全距離,以確保對流冷卻充分。

• 本產品不適合擺放在低熱導體,例如:塑膠。

• 受環境溫度及產品負載的影響,本機外殼溫度會很高,因此在上電時或切

斷電源後短時間內不要觸摸本機,以免燙傷。

• 請勿在上電時觸摸連接端子,以防電擊危險。

• 安裝過程中,應避免金屬元件或金屬導體通過空隙或通風孔進入到產品

內,否則會引起下列狀況。

-電擊 ; 安全危害 ; 火災 ; 產品異常

• 警告:在連接產品電源供應時,產品必須先接地然後才接 L 和 N。當要解

開電源供應時,必須先把 L 和 N 解開然後才把接地解開。

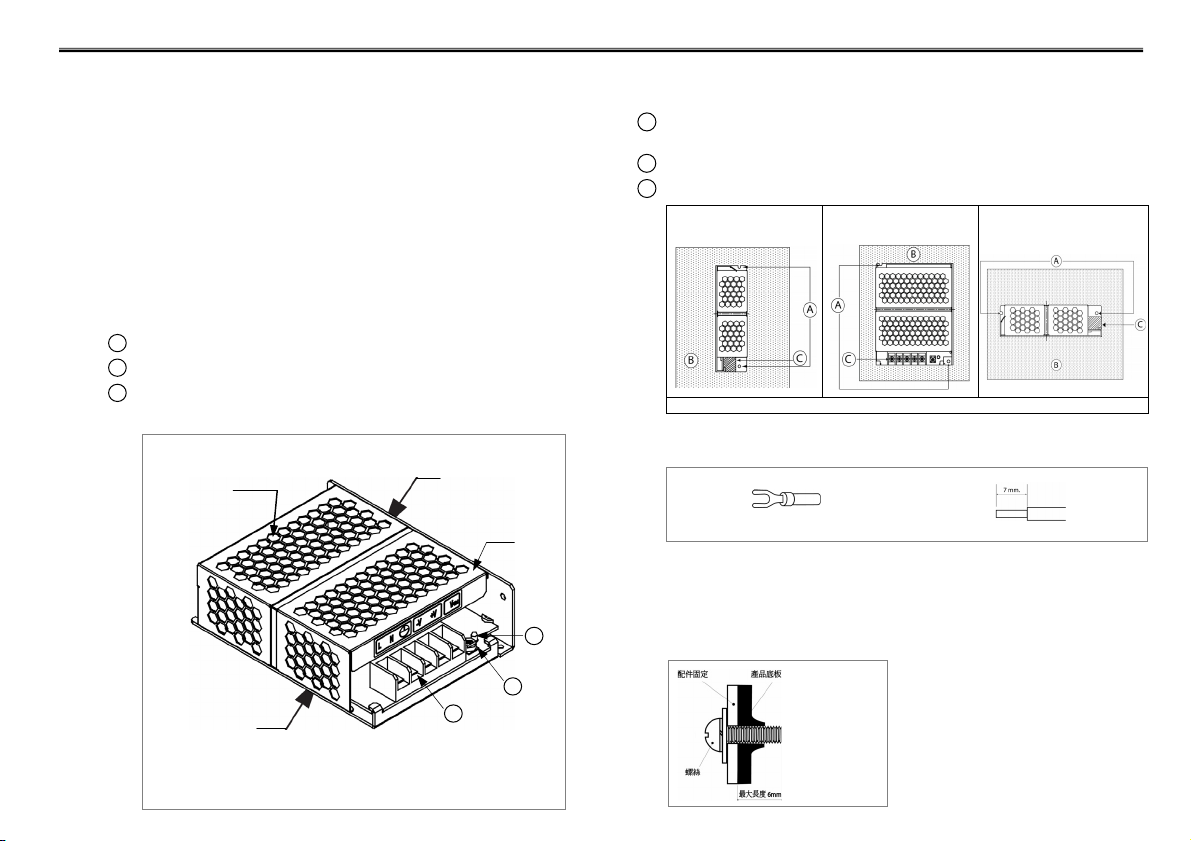

2. யݡγ៍!

依據圖一 :

1 輸入/輸出連接端子

2 直流電壓調節電位器

3 直流電控制 OK 指示燈 (綠色)

通風表面

底面

圖一 產品外觀介紹

側面

PMC-24V050W1AA

3. யݡؠё!

依據圖二:

在把產品安裝在固定表面時,將螺絲鎖入此固定孔. 產品應該用長度至少 5mm 的

A

M3 螺絲鎖入至少兩個固定孔。

此固定表面為客戶系統表面。

B

輸入/輸出連接端子。

C

ݬۡࢬؠ!

• 電線的設計可使用多股或實心,AWG no.22-12。扭矩不應該超過 13Kgf.cm 剝線的

ݬۡغࢬؠ!

圖二 固定方位

πࢬؠ!

長度不應該超過 0.275” 或者 7mm。

頂面

接線端子

圖三 電線類型

剝線

4. ІЪщ྅!

• 在把配件裝上產品時,請使用長度不超過 6mm 的 M3 螺絲鎖入產品底面的固定孔。

這是為了確保螺絲和內部元件間有足夠的絕緣距離。

3

2

1

• 依據圖四:

建議配件固定螺絲扭矩為 4 ~ 8Kgf.cm

圖四 固定螺絲

www.delta.com.tw/industrialautomation

Loading...

Loading...