PCI-M324 User Guide

www.deltaww.com

Industrial Automation Headquarters

Delta Electronics, Inc.

Taoyuan Technology Center

18 Xinglong Road, Taoyuan District,

Taoyuan City 33068, Taiwan (R.O.C.)

TEL: 886-3-362-6301 / FAX: 886-3-371-6301

Asia

Delta Electronics (Shanghai) Co., Ltd

No.182 Minyu Road, Pudong Shanghai,

People's Republic of China

Post code : 201209

TEL: 86-21-68723988 / FAX: 86-21-6872-3996

Customer Service: 400-820-9595

Delta Electronics (Japan), Inc.

Tokyo Ofce

2-1-14 Minato-ku Shibadaimon,

Tokyo 105-0012, Japan

TEL: 81-3-5733-1111 / FAX: 81-3-5733-1211

Delta Electronics (Korea), Inc.

1511, Byucksan Digital Valley 6-cha, Gasan-dong,

Geumcheon-gu, Seoul, Korea, 153-704

TEL: 82-2-515-5303 / FAX: 82-2-515-5302

Delta Electronics Int’l (S) Pte Ltd.

4 Kaki Bukit Ave 1, #05-05, Singapore 417939

TEL: 65-6747-5155 / FAX: 65-6744-9228

Delta Electronics (India) Pvt. Ltd.

Plot No 43 Sector 35, HSIIDC

Gurgaon, PIN 122001, Haryana, India

TEL: 91-124-4874900 / FAX : 91-124-4874945

Delta Electronics (Thailand) Public Company Limited

909 Soi 9, Moo 4,Bangpoo Industrial

Estate(Epz) Pattana 1rd., Tambol Phraksa

Amphur Muang, Samutprakarn 10280 Thailand

TEL: 66(0)2-709-2800

Delta Energy Systems Austral Pty Ltd.

Unit 20-21, 45 Normanby rd, Notting Hill Vic 3168, Australia

TEL: 61-3-9543-3720

Americas

Delta Products Corporation (USA)

Raleigh Ofce

P.O. Box 12173, 5101 Davis Drive,

Research Triangle Park, NC 27709, U.S.A.

TEL: 1-919-767-3800 / FAX: 1-919-767-3969

Delta Greentech (Brasil) S.A.

Sao Paulo Ofce

Rua Itapeva, 26 - 3° andar Edicio Itapeva One-Bela Vista

01332-000-São Paulo-SP-Brazil

TEL: 55-11-3568-3855 / FAX: 55-11-3568-3865

Delta Electronics Int. Mexico

Mexico Ofce

Via Dr. Gustavo Baz 2160, La Loma

C.P. 54060, Estado de México

TEL: 55-2628-3015

*We reserve the right to change the information in this manual without prior notice.

EMEA

Delta Electronics (Netherlands) B.V.

Eindhoven Ofce

De Witbogt 20, 5652 AG Eindhoven, The Netherlands

TEL: 31 (0) 40-8003800 / FAX: 31 (0) 40-8003898

MAIL: Sales.IA.EMEA@deltaww.com

MAIL: Sales.IA.Benelux@deltaww.com

Delta Energy Systems (France) S.A

ZI du bois Chaland 2 15 rue des Pyrénées,

Lisses 91056 Evry Cedex

MAIL: Sales.IA.France@deltaww.com

Delta Energy Systems (Spain) S.L.

Ctra. De Villaverde a Vallecas, 265 1º Dcha Ed.

Hormigueras – P.I. de Vallecas 28031 Madrid

C/Llul, 321-329 (Edif. CINC) | 22@Barcrelona | 08019 Barcelona

MAIL: Sales.IA.Iberia@deltaww.com

Delta Energy Systems Srl (Italy)

Via Senigallia 18/2 – 20161 Milano (MI)

Piazza Grazioli 18 – 00186 ROMA

MAIL: Sales.IA.Italy@deltaww.com

Delta Energy Systems (Germany) GmbH

Coesterweg 45, D-59494 Soest

MAIL: Sales.IA.DACH@deltaww.com

Delta Energy Systems LLC (CIS)

Vereyskaya Plaza II, ofce 112 Vereyskaya str.

17 121357 Moscow

MAIL: Sales.IA.RU@deltaww.com

Delta Greentech Ltd. (Turkiye)

Şerifali Mevkii Barbaros Bulvari Söyleşi Sokak

No:19 K:1 Yukari Dudullu 34775 Ümraniye

İstanbul Sarigazi V.D 2740624765

MAIL: Sales.IA.Turkey@delta-emea.com

Delta Energy Systems (AG Dubai BR)

P.O. Box 185668, Gate 7, 3rd Floor, Hamarain Centre,

Dubai, United Arab Emirates

MAIL: Sales.IA.MEA@deltaww.com

November, 2017 i

Preface

Thank you for purchasing this product. This user guide provides hardware specifications and other

information about the PCI-M324 motion control card.

This user guide includes:

Product Overview

Installation

Signal Connection Interface

Terminal Board

Wiring

EzDMC Functions

Product features of the PCI-M324 motion control card

PCI-M324 is a motion control card with DSP (Digital Signal Processor) as the core design,

and the controlling method between the servo drive is with the use of pulse output. Through the

high-performance chip to calculate the motion trajectory, it provides synchronous timing control for

multiple axes and DI/O processing functions. With the general motion software library and

diagnostic tool for the graphic interface, program development becomes easier, which also

simplifies the system construction and troubleshooting for users.

How to use this user guide

You can refer to the information in this user guide when using the PCI-M324 motion control card.

This user guide provides the hardware electrical specifications and wiring examples of the

PCI-M324 card. Prior to connecting to external devices, please read this user guide to understand

the features of each I/O pin of the PCI-M324 card and the hardware configuration.

Delta technical services:

Please consult your Delta equipment distributor or Delta Customer Service Center if you encounter

any problems.

ii November, 2017

(This page is intentionally left blank.)

November, 2017

Table of Contents

Product Overview

1.1 Function description ·························································································· 1-2

1.2 Specifications ·································································································· 1-3

1.3 Safety precautions ···························································································· 1-4

1.4 Operational safety instructions ············································································ 1-4

1.5 Supported software ·························································································· 1-5

1.6 Application development ···················································································· 1-6

Installation

2.1 Product packaging and accessories ····································································· 2-2

2.2 PCB diagram ··································································································· 2-3

2.3 Hardware installation ························································································ 2-4

2.3.1 Hardware setting ························································································ 2-4

2.3.2 PCI slot selection ······················································································· 2-4

2.3.3 Installation procedure ·················································································· 2-4

2.3.4 Troubleshooting ························································································· 2-4

2.4 Driver software installation ················································································· 2-5

2.5 Connector pin description··················································································· 2-6

2.5.1 CN1: I/O signal port ···················································································· 2-6

2.5.2 CN3: position comparison triggering signal port ················································ 2-9

2.5.3 RSW1: switch for card ID number setting ······················································ 2-10

2.5.4 JP1: select jumper according to input signal type (NPN / PNP) ··························· 2-11

2.5.5 JP2: internal pulse (DDA) 5V ground and external +24V ground signal jumper ······ 2-12

Signal Connection Interface

3.1 Operation interface ··························································································· 3-2

3.1.1 Mechanical DI/O interface ············································································ 3-2

3.1.2 Servo drive DI/O interface ············································································ 3-9

3.1.3 Servo drive pulse I/O interface ···································································· 3-15

3.1.4 Position comparison triggering signal output interface ······································ 3-18

3.1.5 Position latch signal input interface ······························································ 3-21

November, 2017

Terminal Board

4.1 DB-100S general terminal board ·········································································· 4-2

4.2 DB-M324 adapter board with signal indicator·························································· 4-3

Wiring

5.1 Terminal board wiring example ············································································ 5-2

Hardware Configuration API

6.1 Introduction to EzDMC functions·········································································· 6-2

6.2 Operate M324 functions with EzDMC ··································································· 6-3

6.3 Find PCI-M324 card ·························································································· 6-3

6.4 4-axis motion function control ·············································································· 6-4

6.5 Function description of File and Simulation ···························································· 6-7

November, 2017 1-1

Product Overview

PCI-M324 is a 4-axis pulse type motion control card for 4-axis servo or stepping motion

control. This chapter includes the function descriptions, specifications, safety

instructions, and other information of the PCI-M324 motion control card to help you

quickly understand the product features.

000

1.1 Function description ··········································································· 1-2

1.2 Specifications ··················································································· 1-3

1.3 Safety precautions ············································································· 1-4

1.4 Operational safety instructions ····························································· 1-4

1.5 Supported software ············································································ 1-5

1.6 Application development ····································································· 1-6

Product Overview PCI-M324 User Guide

1-2 November, 2017

1

1.1 Function description

PCI-M324 is a 4-axis motion control card using a standard PCI interface. It generates

high-frequency control pulses (3.2 MHz) to control the stepper motor or servo motor. With the

4-axis motion control function, it provides 2-axis circular interpolation motion control, 4-axis linear

interpolation, or continuous interpolation motion control at constant speed. Multiple PCI-M324

motion control cards can operate simultaneously in one system and perform motion control

functions. To allow users to quickly learn to operate the control card, Delta developed software

auxiliary tools to help you complete the application development and wiring test work in the

shortest possible time.

The four main axis controls of the PCI-M324 motion control card are built-in with the incremental

encoder interface, which can correct the incorrect mechanical data transmission. PCI-M324 is

equipped with precise and fast-motion position comparison and triggering functions, and does

not take up additional CPU resources. In addition, the interfaces for the contacts, servo motor

drive control, and general I/O signal control have a very intuitive design for wiring, so that

beginners can quickly get hold of the motion control basics and reduce product losses for system

integrators due to wiring errors. The motion control function includes acceleration / deceleration

of linear motion and S-curve control, arbitrary 2-axis circular interpolation, 2- / 3-axis linear

interpolation, continuous motion, 35 homing modes, etc. When executing these complex motion

control functions, your CPU computing resources can deal with other applications without being

occupied by the motion control functions.

PCI-M324 User Guide Product Overview

November, 2017 1-3

1

1.2 Specifications

Product features

(1) Maximum 3.2 MHz, 4-axis pulse output

(2) Linear, circular, and continuous interpolations

(3) Programmable acceleration / deceleration time

(4) Programmable pulse output and interrupt functions

(5) Position comparison and signal trigger

Motion control specifications

(1) Pulse output control: OUT / DIR, CW / CCW, AB Phase

(2) Pulse output rate: maximum 3.2 Mpps

(3) Total number of pulse signals: 32 bits (±2,147,483,648 pulses)

(4) Homing modes: 35 types

(5) Speed curve control: T-curve and S-curve

(6) Interpolation modes: linear, circular, and continuous

(7) Total number of counter signals: 32-bit up / down counter x 4

(8) Position latch input: LTC x 4

(9) Position compare output: CMP x 2

(10) Incremental encoder input: ±EA x 4, ±EB x 4

(11) Encoder Z-phase signal input: ±EZ x 4

(12) Mechanical DI interface: PEL x 4, MEL x 4, ORG x 4, SLD x 4

(13) Servo drive interface: ALM x 4, RDY x 4, SVON x 4, INP x 4, ERC x 4

(14) General input point: IN x 4

(15) General output point: OUT x 4

(16) I/O pin type: optically isolated with 2.5 KV

RMS

on all 100-pin SCSI

General electrical specifications

(1) PCI specification: 2.2; 32-bit support, 3.3 / 5 VDC operation type

(2) Power consumption: typical +5 VDC at 0.5A

(3) Operating temperature: 0°C - 50°C (32°F - 122°F)

Product Overview PCI-M324 User Guide

1-4 November, 2017

1

1.3 Safety precautions

To avoid electric shock resulting in serious damage, please check the following precautions

before installing the equipment:

(1) Before moving the host computer, please unplug the computer power cord from the

power outlet.

(2) When adding hardware to the system, please connect the device's signal cable before

connecting the power cord; when removing hardware from the system, please disconnect

the device's signal cable before disconnecting the power cord. If possible, turn off the

computer's power supply before installing the hardware.

(3) Before connecting or disconnecting any signal cables from the motherboard, please make

sure all power cables are unplugged.

(4) Before using the interface card or expansion card, it is recommended that you first seek

professional assistance, as these devices may interfere with the grounded circuits.

(5) Please make sure the voltage power supply unit is adjusted to the standard level used in

the country / region where the machine is installed. If you are unsure of the supplying

voltage of the given area, please contact the local power company for more information.

(6) If the power supply unit is damaged, do not repair it by yourself. Please contact technicians

or distributors for assistance.

1.4 Operational safety instructions

Before you install a hardware device, please review the information provided in this user guide.

(1) Before using the product, make sure all cables and power cords are properly connected.

If you find any major defects, please contact your distributor as soon as possible.

(2) To avoid short circuit, please put away all unused screws, paper clips, and other parts.

Please do not leave them on the motherboard or the host computer.

(3) Dust, humidity, and severe temperature changes can affect the product lifespan.

Thus, avoid placing the product in places with these conditions.

(4) Do not place the host computer on an unstable surface.

(5) If you have any technical questions regarding the use of this product, please contact a

certified technician for assistance.

PCI-M324 User Guide Product Overview

November, 2017 1-5

1

1.5 Supported software

Programming Library

You can develop relevant applications on the Windows XP / 7 platform. By categorizing the

motion control related API into usage condition and application, and with the programming guide,

you can quickly develop relevant applications.

EzDMC

EzDMC is an auxiliary software that can be operated on Windows XP / 7. Prior to developing the

application, you can use the auxiliary program to check and set the hardware contact logic status

to make sure that the external wiring is correct. You can also use this program to control the

wired servo drive and motor to assist in the adjustment and testing of the machine. In the initial

stage of using PCI-M324 for program development, you can also use EzDMC to simplify the

parameter setting and functional test verification, which can help new users to reduce the time

required for learning and development.

Product Overview PCI-M324 User Guide

1-6 November, 2017

1

1.6 Application development

Software application development structure

Window XP / 7

HM1 / Programming

BCB++ / VB /

VC++/C#

EzDMC

Motion API

Master station

PCI-M324

SCSI 100 Pins

Cable

Terminal board

Motor #1

Motor #2

Motor #3

Motor #4

Flow chart

The following is a flow chart for the application development process to help you understand

how to use this user guide for the connection and reference of the program development.

The connection between chapters and the sequence, as well as the development of the

application, can be seen in the flow chart.

Start

1. Install hardware

2. Select and set jumper

wire

3. Connect all wiring

Activate EzDMC:

set system parameter

Activate EzDMC:

verify system parameter

setting

Use the control card

function library to

develop the application

Is the system

working properly?

No

Yes

End

Refer to PCI-M324

Function Library

Programming

Guide for details

Refer to Chapter 6

for details

Refer to Chapter 6

for details

Refer to Chapters 2, 3,

4, and 5 for details

November, 2017 2-1

Installation

This chapter describes how to install the PCI-M324 motion control card. Please follow

the installation procedure below.

000

2.1 Product packaging and accessories ······················································· 2-2

2.2 PCB diagram ···················································································· 2-3

2.3 Hardware installation ·········································································· 2-4

2.3.1 Hardware setting .....................................................................................2-4

2.3.2 PCI slot selection ....................................................................................2-4

2.3.3 Installation procedure ..............................................................................2-4

2.3.4 Troubleshooting ......................................................................................2-4

2.4 Driver software installation ··································································· 2-5

2.5 Connector pin description ···································································· 2-6

2.5.1 CN1: I/O signal port .................................................................................2-6

2.5.2 CN3: position comparison triggering signal port ................................ .......2-9

2.5.3 RSW1: switch for card ID number setting .............................................. 2-10

2.5.4 JP1: select jumper according to input signal type (NPN / PNP) .............. 2-11

2.5.5 JP2: internal pulse (DDA) 5V ground and external +24V ground

signal jumper ........................................................................................ 2-12

Installation PCI-M324 User Guide

2-2 November, 2017

2

2.1 Product packaging and accessories

The package should contain the following items:

Standard

Advanced 4-axis servo or stepping PCI-M324 motion control card x 1

PCI-M324 driver CD-ROM x 1

PCI-M324 User Guide x 1

Optional

Motion control terminal block

SCSI 100-pin signal connector cable

If there are missing or damaged standard parts, please contact the distributor for the

replacement parts. Please keep the packaging material in case of future shipping needs.

PCI-M324 User Guide Installation

November, 2017 2-3

2

2.2 PCB diagram

This is the general structure of the PCI-M324 motion control card displaying the positions for

CN1, JP1, JP2, CN3, and RSW1.

Description of each connector on the PCI-M324 card is as follows:

Name

Function

CN1

SCSI 100 pins, 4-axis motion control I/O signal port

CN3

Position comparison triggering signal port

JP1

Select jumper according to input signal type (NPN / PNP)

JP2

Pulse output I/O and external +24V ground signal jumper

RSW1

Card ID switch

Installation PCI-M324 User Guide

2-4 November, 2017

2

2.3 Hardware installation

2.3.1 Hardware setting

The PCI-M324 is a standard Plug and Play expansion device for PCs. Whether the use of

memory space configuration or I/O port configuration, or other basic system required functions,

these are configured by the BIOS of the PC system. You do not need to set the hardware.

2.3.2 PCI slot selection

When your PC system is built-in with ISA and PCI expansion slots, please do not insert the

PCI-M324 card into the ISA expansion slot. In addition to the shape not matching, this product is

designed for PCI compatible devices, thus it can only function when inserted into a standard PCI

expansion slot.

2.3.3 Installation procedure

Please read this user guide carefully and adjust the functions of RSW1, JP1, and JP2 according

to the requirements before installation to meet your system development needs.

(1) Turn off the power. Make sure that the PC power supply is completely disconnected and turn

off the power for the connected devices, such as the printer, modem, and screen.

(2) Remove the cover of your PC. Install the PCI-M324 card only in the standard PCI expansion

slot. Please do not install it in the ISA or EISA expansion slot.

(3) Before you take out the card from the packaging, please neutralize the static electricity that

might be on your body to avoid damaging the product.

(4) Insert the PCI-M324 card into the appropriate PCI standard expansion slot, then tighten the

screws to fix the card onto the PC expansion slot.

(5) Make sure to disconnect the power supply before removing the PCI-M324 card.

2.3.4 Troubleshooting

If the system cannot start properly, please turn off the system first and disconnect the power.

Remove the cover of your PC. Next, make sure the PCI-M324 card is properly installed, such as

if the screws are loose or if the card is detached from the PCI expansion slot. Remove the

PCI-M324 card from the PCI slot and restart the PC to check that the PC system is working

properly. If the PC system is working properly, please reinstall the PCI-M324 card by following

the installation procedure in Section 2.3.3. If the system still cannot start properly, please contact

your distributor for assistance.

PCI-M324 User Guide Installation

November, 2017 2-5

2

2.4 Driver software installation

Please note the following before installing the driver and application software:

(1) The driver for this product is currently only compatible with Windows XP / 7. Before installing

this product, please make sure that the operating system meets the requirement of this

product.

(2) Insert the Autorun driver CD-ROM into your CD-ROM drive and let the system automatically

run the setup program.

(3) When the setup program is launched, please follow the instructions for installing the

product-related driver and auxiliary application.

(4) After the product-related driver and auxiliary application are installed, restart the operating

system to ensure that the driver is installed. Please also make sure that the auxiliary

application works properly after you restart the operating system.

Installation PCI-M324 User Guide

2-6 November, 2017

2

2.5 Connector pin description

This section provides detailed specifications and functions of the PCI-M324 motion control card

I/O signal terminals.

(1) CN1 connector (male); (2) CN1 I/O signal connector (female)

2.5.1 CN1: I/O signal port

Pin

Mark

I/O

Description

Pin

Mark

I/O

Description

1

24V

Power +24V / 200 mA

51

24V

Power +24V / 200 mA

2

EGND

24V ground signal

52

EGND

24V ground signal

3

EMG

I

Emergency stop signal

53

EMG

I

Emergency stop signal

4

MEL_1

I

1st mechanical negative

limit signal

54

MEL_3

I

3rd mechanical negative

limit signal

5

PEL_1

I

1st mechanical positive

limit signal

55

PEL_3

I

3rd mechanical positive

limit signal

6

ORG_1

I

1st origin position signal

56

ORG_3

I

3rd origin position signal

7

SLD_1

I

1st deceleration point

signal

57

SLD_3

I

3rd deceleration point

signal

8

MEL_2

I

2nd mechanical negative

limit signal

58

MEL_4

I

4th mechanical negative

limit signal

9

PEL_2

I

2nd mechanical positive

limit signal

59

PEL_4

I

4th mechanical positive

limit signal

10

ORG_2

I

2nd origin position signal

60

ORG_4

I

4th origin position signal

11

SLD_2

I

2nd deceleration point

signal

61

SLD_4

I

4th deceleration point

signal

12

RDY_1

I

1st servo ready

62

RDY_3

I

3rd servo ready

13

INP_1

I

1st servo in place signal

63

INP_3

I

3rd servo in place signal

14

ALM_1

I

1st servo alarm

64

ALM_3

I

3rd servo alarm

15

DI_1

I

1st axis GPIO input

65

DI_3

I

3rd axis GPIO input

16

RDY_2

I

2nd servo ready

66

RDY_4

I

4th servo ready

17

INP_2

I

2nd servo in place signal

67

INP_4

I

4th servo in place signal

18

ALM_2

I

2nd servo alarm

68

ALM_4

I

4th servo alarm

PCI-M324 User Guide Installation

November, 2017 2-7

2

Pin

Mark

I/O

Description

Pin

Mark

I/O

Description

19

DI_2

I

2nd axis GPIO input

69

DI_4

I

4th axis GPIO input

20

EGND

24V ground signal

70

EGND

24V ground signal

21

SVON_1

O

1st servo on

71

SVON_3

O

3rd servo on

22

ERC_1

O

1

st

clear servo error

counter

72

ERC_3

O

3

rd

clear servo error

counter

23

ALMC_1

O

1st servo alarm clearing

output

73

ALMC_3

O

3rd servo alarm clearing

output

24

DO_1

O

1st axis GPIO output

74

DO_3

O

3rd axis GPIO output

25

SVON_2

O

2nd servo on

75

SVON_4

O

4th servo on

26

ERC_2

O

2

nd

clear servo error

counter

76

ERC_4

O

4

th

clear servo error

counter

27

ALMC_2

O

2nd servo alarm clearing

output

77

ALMC_4

O

4th servo alarm clearing

output

28

DO_2

O

2nd axis GPIO output

78

DO_4

O

4th axis GPIO output

29

EA+_1

I

1

st

A phase encoder

signal (+)

79

EA+_3

I

3

rd

A phase encoder

signal (+)

30

EA-_1

I

1st A phase encoder

signal (-)

80

EA-_3

I

3rd A phase encoder

signal (-)

31

EB+_1

I

1st B phase encoder

signal (+)

81

EB+_3

I

3

rd

B phase encoder

signal (+)

32

EB-_1

I

1st B phase encoder

signal (-)

82

EB-_3

I

3rd B phase encoder

signal (-)

33

EZ+_1

I

1st Z phase encoder

signal (+)

83

EZ+_3

I

3

rd

Z phase encoder

signal (+)

34

EZ-_1

I

1st Z phase encoder

signal (-)

84

EZ-_3

I

3rd Z phase encoder

signal (-)

35

EA+_2

I

2

nd

A phase encoder

signal (+)

85

EA+_4

I

4

th

A phase encoder

signal (+)

36

EA-_2

I

2nd A phase encoder

signal (-)

86

EA-_4

I

4th A phase encoder

signal (-)

37

EB+_2

I

2

nd

B phase encoder

signal (+)

87

EB+_4

I

4

th

B phase encoder

signal (+)

38

EB-_2

I

2nd B phase encoder

signal (-)

88

EB-_4

I

4th B phase encoder

signal (-)

39

EZ+_2

I

2

nd

Z phase encoder

signal (+)

89

EZ+_4

I

4

th

Z phase encoder

signal (+)

40

EZ-_2

I

2nd Z phase encoder

signal (-)

90

EZ-_4

I

4th Z phase encoder

signal (-)

41

DDA 5V

DDA 5V voltage output,

I < 100 mA

91

DDA 5V

DDA 5V voltage output,

I < 100 mA

42

IGND

DDA 5V ground signal

92

IGND

DDA 5V ground signal

43

DIR+_1

O

1st direction pulse

signal (+)

93

DIR+_3

O

3rd direction pulse

signal (+)

44

DIR-_1

O

1st direction pulse

signal (-)

94

DIR-_3

O

3rd direction pulse

signal (-)

45

OUT+_1

O

1

st

output pulse signal (+)

95

OUT+_3

O

3

rd

output pulse signal (+)

46

OUT-_1

O

1

st

output pulse signal (-)

96

OUT-_3

O

3

rd

output pulse signal (-)

Installation PCI-M324 User Guide

2-8 November, 2017

2

Pin

Mark

I/O

Description

Pin

Mark

I/O

Description

47

DIR+_2

O

2nd direction pulse

signal (+)

97

DIR+_4

O

4th direction pulse

signal (+)

48

DIR-_2

O

2nd direction pulse

signal (-)

98

DIR-_4

O

4th direction pulse

signal (-)

49

OUT+_2

O

2

nd

output pulse signal (+)

99

OUT+_4

O

4

th

output pulse signal (+)

50

OUT-_2

O

2

nd

output pulse signal (-)

100

OUT-_4

O

4

th

output pulse signal (-)

Note:

1. GPIO is short for General Purpose Input / Output.

2. Pin 41, Pin 91: DDA 5V voltage output, I < 100 mA. Only for checking the 5V signal detection, not recommended as

5V voltage output.

PCI-M324 User Guide Installation

November, 2017 2-9

2

2.5.2 CN3: position comparison triggering signal port

This section provides detailed specifications and functions of the PCI-M324 CN3.

(1) CN3 connector (male); (2) CN3 connector (female)

The following table shows the CN3 pin definition:

Pin

Mark

Description

1

3.3V CMP_OUT

CMOS 3.3V triggering signal outputs when position reached

2

DGND

CMOS 3.3V ground signal

3

DGND

CMOS 3.3V ground signal

4

1.65(V) Vref

1.65V LVDS reference voltage

Installation PCI-M324 User Guide

2-10 November, 2017

2

2.5.3 RSW1: switch for card ID number setting

This is the RSW1 switch knob. Card ID is the value corresponding to the position the knob is

assigned to. The setting value range is 0 - 15.

PCI-M324 User Guide Installation

November, 2017 2-11

2

2.5.4 JP1: select jumper according to input signal type (NPN / PNP)

This section introduces the PCI-M324 motion control card using the short-circuit latch for NPN /

PNP switching.

The following table shows the JP1 pin definition:

Pin

Mark

Description

1

I24 V

Internal +24V voltage contact

2

ICOM

Input signal internal common contact

3

EGND

24V ground signal

Note:

1. NPN mode: Pin 1 & Pin 2 short circuit. (Default)

2. PNP mode: Pin 2 & Pin 3 short circuit.

Installation PCI-M324 User Guide

2-12 November, 2017

2

2.5.5 JP2: internal pulse (DDA) 5V ground and external +24V ground

signal jumper

This section introduces the PCI-M324 motion control card using the short-circuit latch for

common or individual grounding for the 5V ground and external ground signal.

The following table shows the JP2 pin definition:

Pin

Mark

Description

1

Not in use

Reserved (not in use)

2

IGND

DDA pulse ground signal

3

EGND

24V ground signal

November, 2017 3-1

Signal Connection Interface

This chapter introduces the PCI-M324 signal connection interface.

000

3.1 Operation interface ············································································ 3-2

3.1.1 Mechanical DI/O interface .......................................................................3-2

3.1.2 Servo drive DI/O interface .......................................................................3-9

3.1.3 Servo drive pulse I/O interface .............................................................. 3-15

3.1.4 Position comparison triggering signal output interface............................ 3-18

3.1.5 Position latch signal input interface ........................................................ 3-21

Signal Connection Interface PCI-M324 User Guide

3-2 November, 2017

3

3.1 Operation interface

3.1.1 Mechanical DI/O interface

Mechanical limit signal PEL & MEL (axis control signal / DI signal)

Endpoint setting function: in general, when executing motion control, users will set two limit

sensors between a fixed distance. Setting the moving range of the motion axis avoids the risk of

improper mechanical operation or control. The PEL and MEL endpoint sensor signals are

connected to the PCI-M324 and servo drive at the same time, so that both the drive and the

control card can effectively stop the motion beyond the allowable moving range.

Pin

Mark

I/O

Description

Pin

Mark

I/O

Description

4

MEL_1

I

1st mechanical limit signal (-)

54

MEL_3

I

3rd mechanical limit signal (-)

5

PEL_1

I

1st mechanical limit signal (+)

55

PEL_3

I

3rd mechanical limit signal (+)

8

MEL_2

I

2nd mechanical limit signal (-)

58

MEL_4

I

4th mechanical limit signal (-)

9

PEL_2

I

2nd mechanical limit signal (+)

59

PEL_4

I

4th mechanical limit signal (+)

(1) Sink mode (NPN mode)

24VDC

+24V

0V

Sink

IN

Internal Circuit

Power Supply

JP1 Sink

1 2

3

Filter

Controller

EGND

24V

JP1

24V JP1

3.3V

(2) Source mode (PNP mode)

24VDC

Source

Internal circuit

Power supply

JP1 source

1 2

3

3.3V

Controller

Filter

0V

EGND

+24V

IN

24V

JP1

EGND

JP1

24VDC

PCI-M324 User Guide Signal Connection Interface

November, 2017 3-3

3

ORG (axis control signal / DI signal)

Determine the starting position of the motion control: the mechanical action error and execution

order of the motion command will change the zero position of the servo drive and the starting

position of the mechanical device. Thus, for open-type control mechanical devices, you need to

execute homing after a certain motion distance or operation time to ensure the accuracy of the

motion control.

Pin

Mark

I/O

Description

Pin

Mark

I/O

Description

6

ORG_1

I

1st origin position signal

56

ORG_3

I

3rd origin position signal

10

ORG_2

I

2nd origin position signal

60

ORG_4

I

4th origin position signal

(1) Sink mode (NPN mode)

24VDC

+24V

0V

Sink

IN

Internal Circuit

Power Supply

JP1 Sink

1 2

3

Filter

Controller

EGND

24V

JP1

24V JP1

3.3V

(2) Source mode (PNP mode)

24VDC

Source

Internal circuit

Power supply

JP1 source

1 2

3

Controller

Filter

0V

EGND

+24V

IN

24V

JP1

EGND

JP1

24VDC

3.3V

Signal Connection Interface PCI-M324 User Guide

3-4 November, 2017

3

SLD (axis control signal / DI signal)

Deceleration point signal control: when the motion-controlled object passes through the sensor

point, the motion speed reduces to the set deceleration motion control speed. When SLD control

mode is required, enable the SLD function first. For more information, please refer to the

PCI-M324 Programming Guide.

Pin

Mark

I/O

Description

Pin

Mark

I/O

Description

7

SLD_1

I

1st deceleration point signal

57

SLD_3

I

3rd deceleration point signal

11

SLD_2

I

2nd deceleration point signal

61

SLD_4

I

4th deceleration point signal

(1) Sink mode (NPN mode)

24VDC

+24V

0V

Sink

IN

Internal Circuit

Power Supply

JP1 Sink

1 2

3

Filter

Controller

EGND

24V

JP1

24V JP1

3.3V

(2) Source mode (PNP mode)

24VDC

Source

Internal circuit

Power supply

JP1 source

1 2

3

Controller

Filter

0V

EGND

+24V

IN

24V

JP1

EGND

JP1

24VDC

3.3V

PCI-M324 User Guide Signal Connection Interface

November, 2017 3-5

3

DI (axis control signal / DI signal)

Digital signal input for axis control, which can connect to external digital signals to provide

reference signals to each PCI-M324 axis control.

Pin

Mark

I/O

Description

Pin

Mark

I/O

Description

15

DI_1

I

1st axis GPIO input

65

DI_3

I

3rd axis GPIO input

19

DI_2

I

2nd axis GPIO input

69

DI_4

I

4th axis GPIO input

Note: GPIO is short for General Purpose Input / Output.

(1) Sink mode (NPN mode)

24VDC

+24V

0V

Sink

IN

Internal Circuit

Power Supply

JP1 Sink

1 2

3

Filter

Controller

EGND

24V

JP1

24V JP1

3.3V

(2) Source mode (PNP mode)

24VDC

Source

Internal circuit

Power supply

JP1 source

1 2

3

Controller

Filter

0V

EGND

+24V

IN

24V

JP1

EGND

JP1

24VDC

3.3V

Signal Connection Interface PCI-M324 User Guide

3-6 November, 2017

3

EMG (global signal / DI signal)

Emergency stop signal input point: when the emergency stop is in action, the motion control

pulse output of each axis stops the output and enters the safety protection state. You can

operate all motion axes only when this signal is cleared.

Pin

Mark

I/O

Description

Pin

Mark

I/O

Description

3

EMG

I

Emergency stop signal

53

EMG

I

Emergency stop signal

(1) Sink mode (NPN mode)

Internal circuit

+24V

ISO

IN

Controller

Filter

24V

EGND

24VDC

Power supply

24V

0V

EGND

N.O

N.C

PCI-M324 User Guide Signal Connection Interface

November, 2017 3-7

3

DO (axis control signal / DO signal)

Digital signal output for axis control, which can output digital signals to other peripheral devices.

The four main motion axes of PCI-M324 are built-in with the DO function.

Pin

Mark

I/O

Description

Pin

Mark

I/O

Description

24

DO_1

O

1

st

GPIO output

74

DO_3

O

3

rd

GPIO output

28

DO_2

O

2

nd

GPIO output

78

DO_4

O

4th GPIO output

Note: GPIO is short for General Purpose Input / Output.

(1) O.C mode

EGND

ISO

I < 10 mA

N.O

N.C

VCCID

Internal circuit

Controller

24V

EGND

OUT

24VDC

Power supply

24V

0V

Signal Connection Interface PCI-M324 User Guide

3-8 November, 2017

3

CMP (pulse output control / output signal)

Position comparison function: when the motion control position matches the program's position

comparison setting, the PCI-M324 generates a pulse signal. PCI-M324 has built-in functions for

two high-elastic CMP comparators: Channels #0 and #1. Please refer to Section 3.1.4 for

hardware interface details.

Pin

Mark

Description

1

3.3V CMP_OUT

CMOS 3.3V triggering signal outputs when position reached

2

DGND

CMOS 3.3V ground signal

3

DGND

CMOS 3.3V ground signal

4

1.6(V) Vref

LVDS reference voltage

(1) CMP signal circuit CMOS connection diagram

OUT

GND

Internal circuit

(2) CMP signal circuit LVDS connection diagram

OUT

GND

Internal circuit

Vref

PCI-M324 User Guide Signal Connection Interface

November, 2017 3-9

3

3.1.2 Servo drive DI/O interface

ALM (axis control signal / DI signal)

Servo drive alarm: when the servo drive is in error, it issues an alarm to the PCI-M324 to notify

the control system that the current motion control cannot work properly.

Pin

Mark

I/O

Description

Pin

Mark

I/O

Description

14

ALM_1

I

1st servo alarm

64

ALM_3

I

3rd servo alarm

18

ALM_2

I

2nd servo alarm

68

ALM_4

I

4th servo alarm

(1) Sink mode (NPN mode)

24VDC

+24V

0V

Sink

IN

Internal Circuit

Power Supply

JP1 Sink

1 2

3

Filter

Controller

EGND

24V

JP1

24V JP1

3.3V

(2) Source mode (PNP mode)

24VDC

Source

Internal circuit

Power supply

JP1 source

1 2

3

Controller

Filter

0V

EGND

+24V

IN

24V

JP1

EGND

JP1

24VDC

3.3V

Signal Connection Interface PCI-M324 User Guide

3-10 November, 2017

3

SVON (axis control signal / DO signal)

The output of the Servo On signal enables or disables the operation of the current connecting

servo drive.

Pin

Mark

I/O

Description

Pin

Mark

I/O

Description

21

SVON_1

O

1st servo on

71

SVON_3

O

3rd servo on

25

SVON_2

O

2nd servo on

75

SVON_4

O

4th servo on

(1) O.C mode

EGND

ISO

I < 10 mA

N.O

N.C

VCCID

Internal circuit

Controller

24V

EGND

OUT

24VDC

Power supply

24V

0V

PCI-M324 User Guide Signal Connection Interface

November, 2017 3-11

3

RDY (axis control signal / DI signal)

Servo drive ready signal input: the input of the ready signal notifies the users that the servo drive

is ready and can operate normally.

Pin

Mark

I/O

Description

Pin

Mark

I/O

Description

12

RDY_1

I

1st servo ready

62

RDY_3

I

3rd servo ready

16

RDY_2

I

2nd servo ready

66

RDY_4

I

4th servo ready

(1) Sink mode (NPN mode)

24VDC

+24V

0V

Sink

IN

Internal circuit

Power supply

JP1 sink

1 2

3

Filter

Controller

EGND

24V

JP1

24V JP1

3.3V

(2) Source mode (PNP mode)

24VDC

Source

Internal circuit

Power supply

JP1 source

1 2

3

Controller

Filter

0V

EGND

+24V

IN

24V

JP1

EGND

JP1

3.3V

Signal Connection Interface PCI-M324 User Guide

3-12 November, 2017

3

INP (axis control signal / DI signal)

Servo in place notification function: notifies the users that the servo drive has reached the

specified target position.

Pin

Mark

I/O

Description

Pin

Mark

I/O

Description

13

INP_1

I

1st servo in place signal

63

INP_3

I

3rd servo in place signal

17

INP_2

I

2nd servo in place signal

67

INP_4

I

4th servo in place signal

(1) Sink mode (NPN mode)

24VDC

+24V

0V

Sink

IN

Internal circuit

Power supply

JP1 sink

1 2

3

Filter

Controller

EGND

24V

JP1

24V JP1

3.3V

(2) Source mode (PNP mode)

24VDC

Source

Internal circuit

Power supply

JP1 source

1 2

3

Controller

Filter

0V

EGND

+24V

IN

24V

JP1

EGND

JP1

3.3V

PCI-M324 User Guide Signal Connection Interface

November, 2017 3-13

3

ALMC (axis control signal / DO signal)

Output signal for clearing the servo drive alarm.

Pin

Mark

I/O

Description

Pin

Mark

I/O

Description

23

ALMC_1

O

1st alarm clearing signal

73

ALMC_3

O

3rd alarm clearing signal

27

ALMC_2

O

2nd alarm clearing signal

77

ALMC_4

O

4th alarm clearing signal

(1) O.C mode

EGND

ISO

I < 10 mA

N.O

N.C

VCCID

Internal circuit

Controller

24V

EGND

OUT

24VDC

Power supply

24V

0V

Signal Connection Interface PCI-M324 User Guide

3-14 November, 2017

3

ERC (axis control signal / DO signal)

Error value clearing function: when the following conditions occur, PCI-M324 outputs an ERC

signal to the servo drive.

(1) PEL and MEL signals are triggered.

(2) EMG hardware circuit is triggered.

(3) Software EMG stop signal is triggered (API: _m324_emg_stop_erc).

(4) Force output ERC signal is triggered (API: _m324_set_erc_on).

(5) To follow the safety procedure, you must first clear the remaining command values in the

servo drive before starting the servo drive.

Pin

Mark

I/O

Description

Pin

Mark

I/O

Description

22

ERC_1

O

1

st

clear servo error

counter

72

ERC_3

O

3

rd

clear servo error

counter

26

ERC_2

O

2

nd

clear servo error

counter

76

ERC_4

O

4

th

clear servo error

counter

(1) O.C mode

EGND

ISO

I < 10 mA

N.O

N.C

VCCID

Internal circuit

Controller

24V

EGND

OUT

24VDC

Power supply

24V

0V

PCI-M324 User Guide Signal Connection Interface

November, 2017 3-15

3

3.1.3 Servo drive pulse I/O interface

OUT / DIR (pulse output control / DO signal)

Pulse output control function: PCI-M324 is built-in with six different pulse output control functions,

which are controlled by the DIR and OUT output interfaces. The hardware circuit is designed to

adopt the RS-422 differential line driver output interface, which can connect to RS-422

differential, optocoupler, and TTL unipolar interfaces.

Pin

Mark

I/O

Description

Pin

Mark

I/O

Description

43

DIR+_1

O

1st direction pulse signal (+)

93

DIR+_3

O

3rd direction pulse signal (+)

44

DIR-_1

O

1st direction pulse signal (-)

94

DIR-_3

O

3rd direction pulse signal (-)

47

DIR+_2

O

2nd direction pulse signal (+)

97

DIR+_4

O

4th direction pulse signal (+)

48

DIR-_2

O

2nd direction pulse signal (-)

98

DIR-_4

O

4th direction pulse signal (-)

45

OUT+_1

O

1

st

output pulse signal (+)

95

OUT+_3

O

3

rd

output pulse signal (+)

46

OUT-_1

O

1

st

output pulse signal (-)

96

OUT-_3

O

3

rd

output pulse signal (-)

49

OUT+_2

O

2

nd

output pulse signal (+)

99

OUT+_4

O

4

th

output pulse signal (+)

50

OUT-_2

O

2

nd

output pulse signal (-)

100

OUT-_4

O

4

th

output pulse signal (-)

Differential mode

(1) Differential output connects to differential input

Internal circuit

R

DIFF-

DIFF+

GND

Signal Connection Interface PCI-M324 User Guide

3-16 November, 2017

3

(2) Differential output connects to optocoupler

Internal circuit

Signal+

Signal-

4

5

6

1

3

R

DIFF+

DIFF-

7

5

6

(3) Differential output connects to single-ended input

Signal-

Signal+

DDA_GND

Internal circuit

R

DIFF-

DIFF+

GND

PCI-M324 User Guide Signal Connection Interface

November, 2017 3-17

3

Encoder A phase, B phase, and Z phase (axis control signal / DI signal)

Encoder A phase, B phase, and Z phase feedback pulse input counter function: connects to the

position feedback from the servo drive or external linear scale.

Pin

Mark

I/O

Description

Pin

Mark

I/O

Description

29

EA+_1

I

1st A phase encoder signal (+)

79

EA+_3

I

3

rd

A phase encoder signal (+)

30

EA-_1

I

1st A phase encoder signal (-)

80

EA-_3

I

3rd A phase encoder signal (-)

35

EA+_2

I

2

nd

A phase encoder signal (+)

85

EA+_4

I

4

th

A phase encoder signal (+)

36

EA-_2

I

2nd A phase encoder signal (-)

86

EA-_4

I

4th A phase encoder signal (-)

31

EB+_1

I

1st B phase encoder signal (+)

81

EB+_3

I

3

rd

B phase encoder signal (+)

32

EB-_1

I

1st B phase encoder signal (-)

82

EB-_3

I

3rd B phase encoder signal (-)

37

EB+_2

I

2

nd

B phase encoder signal (+)

87

EB+_4

I

4

th

B phase encoder signal (+)

38

EB-_2

I

2nd Z phase encoder signal (-)

88

EB-_4

I

4th B phase encoder signal (-)

33

EZ+_1

I

1st Z phase encoder signal (+)

83

EZ+_3

I

3

rd

Z phase encoder signal (+)

34

EZ-_1

I

1st Z phase encoder signal (-)

84

EZ-_3

I

3rd Z phase encoder signal (-)

39

EZ+_2

I

2

nd

Z phase encoder signal (+)

89

EZ+_4

I

4

th

Z phase encoder signal (+)

40

EZ-_2

I

2nd Z phase encoder signal (-)

90

EZ-_4

I

4th Z phase encoder signal (-)

Differential mode

(1) Differential input mode

Internal circuit

Signal+

AM26LS31CD

Signal-

6

5

4 3

1

330R

DIFF-

DIFF+

7

5

6

Signal Connection Interface PCI-M324 User Guide

3-18 November, 2017

3

3.1.4 Position comparison triggering signal output interface

PCI-M324 provides the position comparison triggering pulse output function, as shown in

Figure 3.1.4.1. In this example, the encoder feedback value of the servo motor is compared with

the P1 and P2 position set values. When the feedback value equals the P1 or P2 value, the

pulse signal outputs respectively to trigger the image acquisition card or CCD to take images.

The card provides two flexible high-speed comparator channels (Channels #0 and #1) for the

users to choose from. You can choose different pulse comparison sources and pulse output

interfaces according to the parameter settings to meet your application requirements.

P2 P1

Data

Comparator

Interrupt signal (to host PC)

Trigger Circuit

T2 T1

Encoder Motor

Workpiece

Encoder feedback

signal

Figure 3.1.4.1 Position comparison triggering example

PCI-M324 User Guide Signal Connection Interface

November, 2017 3-19

3

Channel #0 in-place comparator function description

The in-place comparator of Channel #0 has four sets of compare input sources for selection,

and they are the position counter values for axes #0, #1, #2, and #3. The output interface also

provides four sets of output interfaces for selection, and they are CMOS3.3V output, DO output

of each axis (24V), axis #3 RS422 DIR single serial output, and axis #3 RS422 dual serial output

at the same time (as shown in Figure 3.1.4.2).

Axis DO output 24V

RS-422 output

RS-422 output

CMOS3.3V

5V_GND

RS-422 Output

24V_GND

Axis #3 DIR

Axis #3 DIR /

Axis #3 OUT

Axis #3 OUT /

Axis#3 DIR

Axis#3 DIR /

Output interface

selection

Output selection

Comparator

Pulse width setting

Pulse width selection

Note: in the output selection function interface, you can only select

one channel for output. This means you cannot assign Channel #0

and Channel #1 at the same time for different signal output.

Compare

value set

Channel #1

enable

Position counter

AXIS#0AXIS#1AXIS

#2

AXIS

#3

Select compare

source

Figure 3.1.4.2 Diagram of Channel #0 in-place comparator

CMOS 3.3V output interface: please refer to Section 3.1.1 for the mechanical DI/O interface

CMP signal description. Please do not share use with Channel #1.

DO output interface of each axis: please refer to Section 3.1.1 for the mechanical DI/O interface

DO signal description.

Axis #3 RS-422 DIR single serial output interface: please refer to Section 3.1.3 for the servo

drive I/O interface pulse output description.

Axis #3 RS-422 dual serial output interface: please refer to Section 3.1.3 for the servo drive I/O

interface pulse output description. Please do not share use with Channel #1.

Signal Connection Interface PCI-M324 User Guide

3-20 November, 2017

3

Channel #1 in-place comparator function description

The in-place comparator of Channel #1 has four sets of compare input sources for selection,

and they are the position comparator values for axes #0, #1, #2, and #3. The output interface

also provides four sets of output interfaces for selection, and they are CMOS3.3V output,

DO output of each axis (24V), axis #3 RS-422 OUT single serial output, and axis #3 RS-422 dual

serial output at the same time (as shown in Figure 3.1.4.3).

Axis DO output 24V

RS-422 output

RS-422 output

CMOS3.3V

5V_GND

RS-422 Output

24V_GND

Axis #3 DIR

Axis #3 DIR /

Axis #3 OUT

Axis #3 OUT /

Axis#3 DIR

Axis#3 DIR /

Output interface

selection

Output selection

Comparator

Pulse width setting

Pulse width selection

Note: in the output selection function interface, you can only select

one channel for output. This means you cannot assign Channel #0

and Channel #1 at the same time for different signal output.

Compare

value set

Channel #1

enable

Position counter

AXIS#0AXIS#1AXIS

#2

AXIS

#3

Select compare

source

Figure 3.1.4.3 Diagram of Channel #1 in-place comparator

CMOS 3.3V output interface: please refer to Section 3.1.1 for the mechanical DI/O interface

CMP signal description. Please do not share use with Channel #0.

DO output interface of each axis: please refer to Section 3.1.1 for the mechanical DI/O interface

DO signal description.

Axis #3 RS-422 OUT single serial output interface: please refer to Section 3.1.3 for the servo

drive I/O interface pulse output description.

Axis #3 RS-422 dual serial output interface: please refer to Section 3.1.3 for the servo drive I/O

interface pulse output description. Please do not share use with Channel #0.

PCI-M324 User Guide Signal Connection Interface

November, 2017 3-21

3

3.1.5 Position latch signal input interface

PCI-M324 provides the position latch function as shown in Figure 3.1.5.1. In this example,

when the measuring probe touches the workpiece surface, it triggers the DI signal to execute

the position latch function, which records the position counter value in the latch counter.

Then, by reading the latch counter value, you can see the position value when triggered.

Workpiece

Measurement

Command

Feedback

Figure 3.1.5.1 Position latch function example

This card is designed with four sets of latch triggering source for selection. For details,

please refer to Figure 3.1.5.2.

Latch

Position counter

G

Set latch logic

Get latch data

Select latch source

DI

24V_GND

EZ+

EZ-

ORG

24V_GND

MEL

24V_GND

Figure 3.1.5.2 Position latch triggers source diagram

Axis DI, ORG, MEL input interfaces: please refer to Section 3.1.1 for the mechanical DI/O

interface DI, ORG, and MEL signals description.

EZ+ and EZ- input interfaces: please refer to Section 3.1.3 for the servo drive I/O interface pulse

input description.

Signal Connection Interface PCI-M324 User Guide

3-22 November, 2017

3

(This page is intentionally left blank.)

November, 2017 4-1

Terminal Board

PCI-M324 provides two types of terminal boards for you to choose from. They are

DB-100S general terminal board and DB-M324 adapter board with 25-pin D-SUB

connector and signal indicator. Please refer to the following sections for detailed

specifications and instructions.

000

4.1 DB-100S general terminal board ·························································· 4-2

4.2 DB-M324 adapter board with signal indicator ·········································· 4-3

Terminal Board PCI-M324 User Guide

4-2 November, 2017

4

4.1 DB-100S general terminal board

Specifications

(1) SCSI 100-pin 1.27 mm female connector

(2) Supports DIN rail mounting

(3) Dimension (L-157 x W-122 x H-45 mm)

(4) Pitch: 5.00 mm

(5) Wire diameter: 26 - 14 AWG

DB-100S illustration

Description of each DB-100S pin:

Mark

Function

CN1

SCSI 100-pin female connector (pin to pin)

Connector for the PCI-M324 servo motion control card and DB-100S

CN2

The terminal pins correspond to the CN1 pins

CN3

The terminal pins correspond to the CN1 pins

Note: the pin definition is the same as the CN1 on the PCI-M324 servo motion control card.

Please refer to Section 2.5.1.

PCI-M324 User Guide Terminal Board

November, 2017 4-3

4

4.2 DB-M324 adapter board with signal indicator

Specifications

(1) SCSI 100-pin P1.27 mm female connector

(2) D-SUB 25 P2.27 mm female connector

(3) Supports DIN rail mounting

(4) Dimension L-117 x W-215 x H-60 mm (PCB L-107 x W-209)

(5) Pitch: 5.00 mm

(6) Operating temperature: 0°C - 60°C (32°C - 140°F)

(7) Emergency stop input: EMG

(8) Mechanical I/O interface signal input: PEL x4, MEL x4, ORG x4, SLD x4

(9) Servo drive interface signal output: ALM x4, ALMC x4, RDY x4, SVON x4, INP x4, ERC x4

(10) GPIO point: DI x4, DO x4

(11) Power supply input: +24 VDC ± 10%; power consumption: 3W typical

(12) For DDA pulse level voltage output: +5 VDC (output from PCI-M324), I < 100 mA

(13) Indicator light: power indicator, emergency stop input indicator, mechanical I/O interface

signal indicator, servo drive interface signal output indicator, GPIO indicator

(14) DB-M324 is for NPN wiring type

Terminal Board PCI-M324 User Guide

4-4 November, 2017

4

DB-M324 illustration

Description of each DB-M324 pin:

Mark

Connector type

Function

CN1

SCSI 100-pin female connector

Connector for the PCI-M324 servo motion control

card and DB-M324

CN2

D-SUB 25 female connector

Axis 1 motor connector

CN3

D-SUB 25 female connector

Axis 2 motor connector

CN4

D-SUB 25 female connector

Axis 3 motor connector

CN5

D-SUB 25 female connector

Axis 4 motor connector

CN6

Plug-in terminal block connector

24V power input connector

CN7

Screw terminal block connector

Axis 1, 2 motor connector for other signals

CN8

Screw terminal block port

Axis 3, 4 motor connector for other signals

CN9

Plug-in terminal block connector

DDA 5V voltage output

PCI-M324 User Guide Terminal Board

November, 2017 4-5

4

DB-M324 CN1 pin definition diagram

Note: the pin definition is the same as the CN1 on the PCI-M324 servo motion control card.

Please refer to Section 2.5.1.

Terminal Board PCI-M324 User Guide

4-6 November, 2017

4

DB-M324 CN2 / CN3 / CN4 / CN5 (Axis 1 - Axis 4) pin definition diagram

Description of each DB-M324 CN2 / CN3 / CN4 / CN5 pin:

Pin

Mark

I/O

Description

Pin

Mark

I/O

Description

1

OUT-

O

Output pulse signal (-)

14

DIR-

O

Direction pulse signal (-)

2

OUT+

O

Output pulse signal (+)

15

DIR+

O

Direction pulse signal (+)

3

DDA

5V

V

DDA 5V voltage output,

I < 100 mA

16

INP

I

Servo in place signal

4

EGND

G

24V ground signal

17

PEL

I

Mechanical positive limit

signal

5

MEL

I

Mechanical negative limit

signal

18

24V

V

+24V power supply

6

SVON

O

Servo on

19

ALM

I

Servo alarm

7

EGND

G

24V ground signal

20

EGND

G

24V ground signal

8

EGND

G

24V ground signal

21

EGND

G

24V ground signal

9

ALMC

O

Servo alarm clearing output

22

ERC

Clear servo error counter

10

EZ+

I

Z phase encoder signal (+)

23

EZ-

I

Z phase encoder signal (-)

11

EA+

I

A phase encoder signal (+)

24

EA-

I

A phase encoder signal (-)

12

EB+

I

B phase encoder signal (+)

25

EB-

I

B phase encoder signal (-)

13

FG G FG

Note: CN2 - CN5 correspond to the CN1 Axis 1 - Axis 4 control points respectively on the PCI-M324 servo

motion control card. Please refer to Section 2.5.1.

PCI-M324 User Guide Terminal Board

November, 2017 4-7

4

DB-M324 CN6 pin definition diagram

Description of each DB-M324 CN6 pin:

Pin

Mark

Description

1

FG

FG

2

EGND

24V ground signal

3

24V

Power +24V

Terminal Board PCI-M324 User Guide

4-8 November, 2017

4

DB-M324 CN7 / CN8 (Axis 1, 2) pin definition diagram

Description of each DB-M324 CN7 / CN8 pin:

Pin

Mark

I/O

Description

Pin

Mark

I/O

Description

1

ORG

I

1st origin position signal

9

DO

O

1

st

GPIO output

2

ORG

I

2nd origin position signal

10

DO

O

2

nd

GPIO output

3

SLD

I

1st deceleration point

signal

11

MEL

I

1st mechanical negative

limit signal

4

SLD

I

2nd deceleration point

signal

12

MEL

I

2nd mechanical negative

limit signal

5

RDY

I

1st servo ready

13

PEL

I

1st mechanical positive

limit signal

6

RDY

I

2nd servo ready

14

PEL

I

2nd mechanical positive

limit signal

7

DI I 1

st

GPIO input

15

EMG

I

Emergency stop input

8

DI I 2

nd

GPIO input

16

EGND

G

24V ground signal

Note:

1. GPIO is short for General Purpose Input / Output. The EMG of CN7 / CN8 is the same signal pin.

2. CN7 and CN8 correspond to the CN1 Axis 1 - Axis 4 control points respectively on the PCI-M324 servo

motion control card. Please refer to Section 2.5.1.

PCI-M324 User Guide Terminal Board

November, 2017 4-9

4

DB-M324 CN9 pin definition diagram

Description of each DB-M324 CN9 pin:

Pin

Mark

Description

1

5VGND

DDA 5V ground signal

2

DDA5V

DDA 5V voltage output

Note: CN9: The DDA 5V voltage output source is from the PCI-M324 control card, I < 100 mA.

Limited to use as a reference point for 5V voltage comparison.

Terminal Board PCI-M324 User Guide

4-10 November, 2017

4

Description of the DB-M324 LED

Item

Description

Power LED

24V power input indicator light

LED Array

The function definition of the LED signal indicator light is the same as the CN1

on the PCI-M324 servo motion control card. Please refer to Section 2.5.1.

November, 2017 5-1

Wiring

This chapter lists the standard wiring diagrams for the PCI-M324 motion control card

connected to various series of servo drives.

000

5.1 Terminal board wiring example ····························································· 5-2

Wiring PCI-M324 User Guide

5-2 November, 2017

5

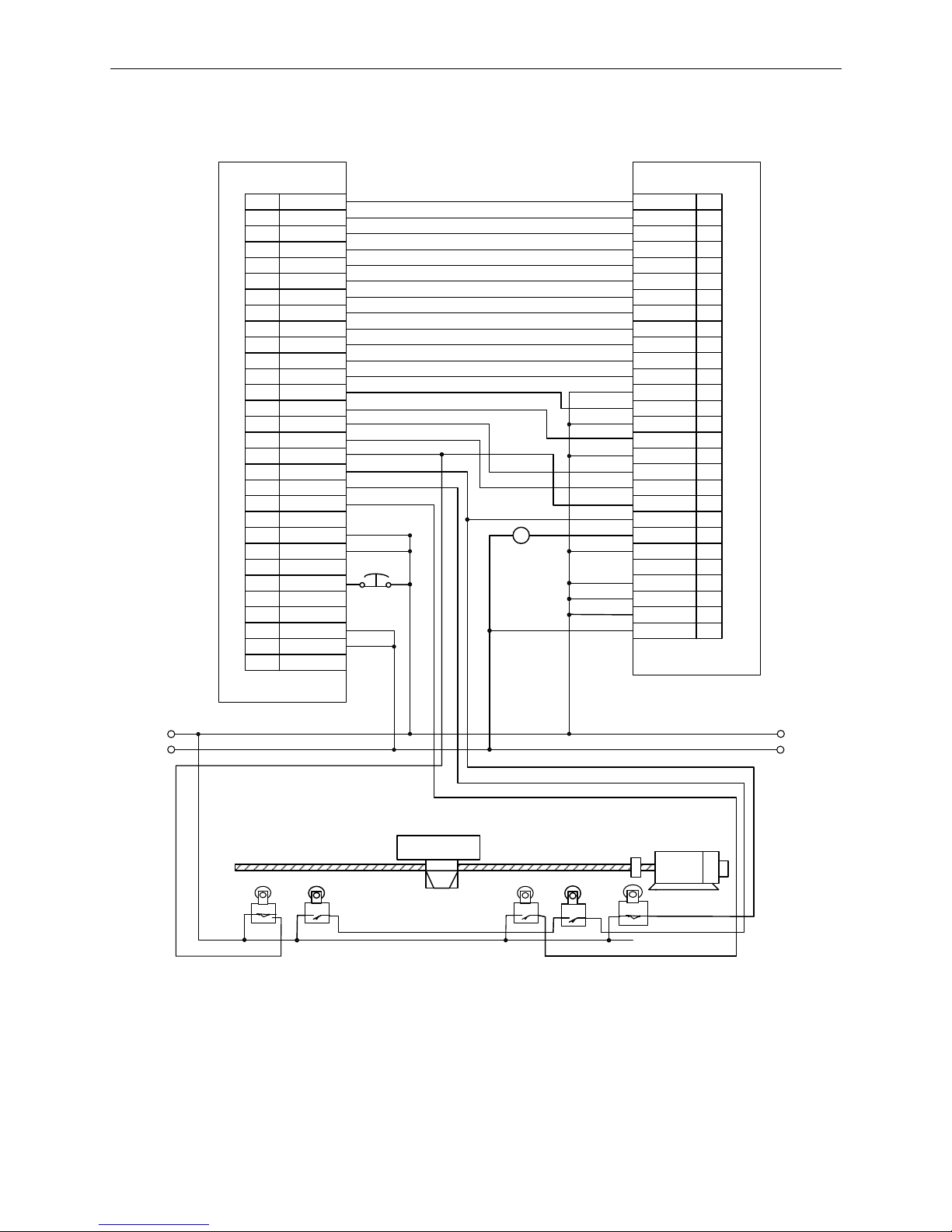

5.1 Terminal board wiring example

Delta ASDA-A2 series servo drive

Delta ASDA-A2

38

29

46

40

21

22

25

23

50

24

10

7

6

28

27

1

HPulse

/HPulse

HSIGN

/HSIGN

OA

OA-

OB

OBOZ+

OZ-

CCLR

SRDY+

SRDY-

ALRM+

ALRMTPOS+

TPOS-

26

SON

ARST

9

33

0V

+24V

45,47,49

Break Coil

Table

Motor

MEL

PEL

ORG

SLD2

SLD1

GND

COM-

GND

COM+

44

11

NL(CWL)

PL(CCWL)

32

31

OUT+_1

OUT-_1

DIR+_1

DIR-_1

EA+_1

EA-_1

EB+_1

EB-_1

EZ+_1

EZ-_1

ERC_1

RDY_1

ALM_1

INP_1

SVON_1

RALM_1

45

46

43

44

29

30

31

32

33

34

22

12

14

13

21

23

PEL_1

MEL_1

SLD_1

ORG_1

5

4

7

6

EGND

EGND

E_24V

E_24V

2,20

52,70

1

51

EMG53,3

PCI-M324 Axis 1 connected to Delta ASDA-A2 series servo drive

PCI-M324 CN1

30

12,13

EMGS

PCI-M324 User Guide Wiring

November, 2017 5-3

5

Delta ASDA-B2 series servo drive

Delta ASDA-B2

38

36

42

40

21

22

25

23

13

24

10

7

6

28

27

1

HPulse

/HPulse

HSIGN

/HSIGN

OA

OA-

OB

OB-

OZ+

OZ-

CCLR

SRDY+

SRDY-

ALRM+

ALRM-

TPOS+

TPOS-

26

SON

ARST

9

33

0V

+24V

45,47,49

Table

Motor

MEL

PEL

ORG

SLD2

SLD1

GND

COM-

GND

COM+

12,13

44

11

NL(CWL)

PL(CCWL)

32

31

OUT+_1

OUT-_1

DIR+_1

DIR-_1

EA+_1

EA-_1

EB+_1

EB-_1

EZ+_1

EZ-_1

ERC_1

RDY_1

ALM_1

INP_1

SVON_1

RALM_1

45

46

43

44

29

30

31

32

33

34

22

12

14

13

21

23

PEL_1

MEL_1

SLD_1

ORG_1

5

4

7

6

EGND

EGND

E_24V

E_24V

2,20

52,70

1

51

EMG53,3

PCI-M324 Axis 1 connected to Delta ASDA-B2 series servo drive

PCI-M324 CN1

EMGS

30

Wiring PCI-M324 User Guide

5-4 November, 2017

5

Delta ASDA-A3 series servo drive

32

Delta ASDA-A3

43

41

36

37

21

22

25

23

50

24

10

7

6

28

27

1

Pulse

/Pulse

SIGN

/SIGN

OA

OA-

OB

OBOZ+

OZ-

CCLR

SRDY+

SRDYALRM+

ALRMTPOS+

TPOS-

26

SON

ARST

9

33

0V

+24V

45,47,49

Table

Motor

MEL

PEL

ORG

SLD2

SLD1

EMGS

GND

COM-

GND

COM+

13,19

44

11

NL(CWL)

PL(CCWL)

32

31

OUT+_1

OUT-_1

DIR+_1

DIR-_1

EA+_1

EA-_1

EB+_1

EB-_1

EZ+_1

EZ-_1

ERC_1

RDY_1

ALM_1

INP_1

SVON_1

RALM_1

45

46

43

44

29

30

31

32

33

34

22

12

14

13

21

23

PEL_1

MEL_1

SLD_1

ORG_1

5

4

7

6

EGND

EGND

E_24V

E_24V

2,20

52,70

1

51

EMG53,3

PCI-M324 Axis 1 connected to Delta ASDA-A3 series servo drive

PCI-M324 CN1

30

PCI-M324 User Guide Wiring

November, 2017 5-5

5

Panasonic Minas A series servo drive

MINAS-CN I/F

(Panasonic)

3

4

5

6

21

22

48

49

23

24

30

35

34

37

36

39

PULS1

PULS2

SIGN1

SIGN2

OA+

OA-

OB+

OBOZ+

OZ-

CL

S-RDY+

S-RDY-

ALM+

ALM-

COIN+

COIN- 38

SVR-ON

A-CLR

29

31

0V

+24V

41

Break Coil

Table

Motor

MEL

PEL

ORG

SLD2

SLD1

BRKOFF+

BRKOFF-

GND

COM-

GND

COM+

11

10

13

25

7

CWL

CCWL

8

9

OUT+_1

OUT-_1

DIR+_1

DIR-_1

EA+_1

EA-_1

EB+_1

EB-_1

EZ+_1

EZ-_1

ERC_1

RDY_1

ALM_1

INP_1

SVON_1

RALM_1

45

46

43

44

29

30

31

32

33

34

22

12

14

13

21

23

PEL_1

MEL_1

SLD_1

ORG_1

5

4

7

6

EGND

EGND

E_24V

E_24V

2,20

52,70

1

51

EMG53,3

PCI-M324 Axis 1 connected to Panasonic Minas A series servo drive

PCI-M324 CN1

Wiring PCI-M324 User Guide

5-6 November, 2017

5

Mitsubishi J2S series servo drive

J2S-CN 1A

3

13

2

12

6

16

7

17

5

15

8

18

10

20

PP

PG

NP

NG

LA

LAR

LB

LBR

LZ

LZR

CR

0V

+24V

Table

Motor

MEL

PEL

ORG

SLD2

SLD1

INP

SG(0V)

SG(0V)

RD

COM(+ 24V) 9

19

J2S-CN1B

5

14

16

17

10

20

RES

LSP

LSN

SG

SG

18

SON

ALM

COM(+ 24V) 13

OUT+_1

OUT-_1

DIR+_1

DIR-_1

EA+_1

EA-_1

EB+_1

EB-_1

EZ+_1

EZ-_1

ERC_1

RDY_1

ALM_1

INP_1

SVON_1

RALM_1

45

46

43

44

29

30

31

32

33

34

22

12

14

13

21

23

PEL_1

MEL_1

SLD_1

ORG_1

5

4

7

6

EGND

EGND

E_24V

E_24V

2,20

52,70

1

51

EMG

53,3

PCI-M324 Axis 1 connected to Mitsubishi J2S series servo drive

PCI-M324 CN1

PCI-M324 User Guide Wiring

November, 2017 5-7

5

Yaskawa SGDM Sigma II series servo drive

SGDM-CN 1

7

8

11

12

33

34

35

36

19

20

15

14

29

30

31

32

PULS

*PULS

SIGN

*SIGN

PAO

*PAO

PBO

*PBO

PCO

*PCO

CLR

25

26

40

0V

+24V

44

42

7

Break Coil

Table

Motor

MEL

PEL

ORG

SLD2

SLD1