Page 1

DELTA ELECTRONICS CO., LTD.

PCI-DMC-A01

PCI-DMC-B01

High-Speed PCI 12-Axis Motion Control Card

Programming Manual

Version: 1.11.1

Page 2

Page 3

PCI-DMC-A01 / PCI-DMC-B01 Programming Manual

About this Manual

User Information

Please keep this manual in a safe place.

This manual is subject to change without notice due to the release of new products,

improvements and changes in technologies, and/or modifications to data and forms.

This manual may not be copied or reproduced in whole or in part without the express written

consent of Delta Electronics.

Trademarks

Windows NT/2000/XP, Visual Studio, Visual C++, Visual BASIC are all registered trademarks of

Microsoft Corporation.

BCB (Borland C++ Builder) is a registered trademark of Borland Corporation.

The names of other products are only used for identification purposes and the registered

trademarks remain the property of their respective owners.

Technical Support and Service

If you require technical support, service, or other information, or should you have any questions

about the use of this product, please visit our website

(http://www.delta.com.tw/industrialautomation) or contact us directly. We look forward to providing

you the best possible support and service. Our contact details are provided below.

ASIA

DELTA ELECTRONICS, INC.

Taoyuan Plant 1

31-1, XINGBANG ROAD,

GUISHAN INDUSTRIAL ZONE,

TAOYUAN COUNTY 33370, TAIWAN, R.O.C.

TEL: 886-3-362-6301

FAX: 886-3-362-7267

NORTH/SOUTH AMERICA

DELTA PRODUCTS CORPORATION (USA)

Raleigh Office

P.O. BOX 12173

5101 DAVIS DRIVE,

RESEARCH TRIANGLE PARK, NC 27709, U.S.A.

TEL: 1-919-767-3813

FAX: 1-919-767-3969

JAPAN

DELTA ELECTRONICS (JAPAN), INC.

Tokyo Office

DELTA SHIBADAIMON BUILDING

2-1-14 SHIBADAIMON, MINATO-KU,

TOKYO, 105-0012, JAPAN

TEL: 81-3-5733-1111

FAX: 81-3-5733-1211

EUROPE

DELTRONICS (THE NETHERLANDS) B.V.

Eindhoven Office

DE WITBOGT 15, 5652 AG EINDHOVEN,

THE NETHERLANDS

TEL: 31-40-259-2850

FAX: 31-40-259-2851

Revised March, 2012 i

Page 4

PCI-DMC-A01 / PCI-DMC-B01 Programming Manual

Table of Contents

Chapter 1 Introduction to the API Function Library --------------------------------------------------- 1-1

1.1 Using the Function Libraries ---------------------------------------------------------------------- 1-1

1.2 Edit New Project ------------------------------------------------------------------------------------- 1-1

1.2.1 Using VC ----------------------------------------------------------------------------------- 1-1

1.2.2 Using Borland C -------------------------------------------------------------------------- 1-1

1.2.3 Using VB ------------------------------------------------------------------------------------ 1-2

1.2.4 Using Delphi ------------------------------------------------------------------------------- 1-2

1.2.5 Using VB.Net ------------------------------------------------------------------------------ 1-2

1.2.6 Using C# ------------------------------------------------------------------------------------ 1-2

Chapter 2 Command Return Values and Messages --------------------------------------------------- 2-1

2.1 Error Codes ------------------------------------------------------------------------------------------- 2-1

2.2 Error Code Example -------------------------------------------------------------------------------- 2-4

Chapter 3 Operating Principles ------------------------------------------------------------------------------- 3-1

3.1 Card Initialization ------------------------------------------------------------------------------------ 3-1

3.1.1 Function List ------------------------------------------------------------------------------- 3-1

3.1.2 Sample Application ----------------------------------------------------------------------- 3-1

3.2 Read/Write Driver Parameters ------------------------------------------------------------------- 3-4

3.2.1 Function List ------------------------------------------------------------------------------- 3-4

3.2.2 Sample Application ----------------------------------------------------------------------- 3-4

3.3 CANopen Protocol ---------------------------------------------------------------------------------- 3-7

3.3.1 Function List ------------------------------------------------------------------------------- 3-7

3.3.2 Sample Application ----------------------------------------------------------------------- 3-7

3.4 Homing Motion Control ---------------------------------------------------------------------------- 3-9

3.4.1 Overview ------------------------------------------------------------------------------------ 3-9

3.4.2 Function List ------------------------------------------------------------------------------ 3-10

3.4.3 Sample Application ---------------------------------------------------------------------- 3-10

3.5 Torque Motion Control ---------------------------------------------------------------------------- 3-13

3.5.1 Function List ------------------------------------------------------------------------------ 3-13

3.5.2 Sample Application ---------------------------------------------------------------------- 3-13

3.6 Velocity Motion Control (1) ----------------------------------------------------------------------- 3-16

3.6.1 Function List ------------------------------------------------------------------------------ 3-16

3.6.2 Sample Application ---------------------------------------------------------------------- 3-16

ii Revised March, 2012

Page 5

PCI-DMC-A01 / PCI-DMC-B01 Programming Manual

3.7 Velocity Motion Control (2) ----------------------------------------------------------------------- 3-19

3.7.1 Function List ------------------------------------------------------------------------------ 3-19

3.7.2 Sample Application ---------------------------------------------------------------------- 3-19

3.8 Point to Point Motion Control -------------------------------------------------------------------- 3-21

3.8.1 Overview ----------------------------------------------------------------------------------- 3-21

3.8.2 Function List ------------------------------------------------------------------------------ 3-21

3.8.3 Sample Application ---------------------------------------------------------------------- 3-22

3.9 Linear Interpolation Motion Control ------------------------------------------------------------ 3-26

3.9.1 Overview ----------------------------------------------------------------------------------- 3-26

3.9.2 Function List ------------------------------------------------------------------------------ 3-26

3.9.3 Sample Application ---------------------------------------------------------------------- 3-27

3.10 Arc Interpolation Motion Control ---------------------------------------------------------------- 3-31

3.10.1 Overview ----------------------------------------------------------------------------------- 3-31

3.10.2 Function List ------------------------------------------------------------------------------ 3-31

3.10.3 Sample Application ---------------------------------------------------------------------- 3-32

3.11 Spiral Interpolation Motion Control -Helix ---------------------------------------------------- 3-37

3.11.1 Function List ------------------------------------------------------------------------------ 3-37

3.11.2 Sample Application ---------------------------------------------------------------------- 3-37

3.12 Continuous Interpolation Motion Control ----------------------------------------------------- 3-42

3.12.1 Overview ----------------------------------------------------------------------------------- 3-42

3.12.2 Function List ------------------------------------------------------------------------------ 3-42

3.12.3 Sample Application ---------------------------------------------------------------------- 3-43

3.13 Software Limit Control ---------------------------------------------------------------------------- 3-47

3.13.1 Function List ------------------------------------------------------------------------------ 3-47

3.13.2 Sample Application ---------------------------------------------------------------------- 3-47

3.14 Synchronization Motion Control ---------------------------------------------------------------- 3-51

3.14.1 Function List ------------------------------------------------------------------------------ 3-51

3.14.2 Sample Application ---------------------------------------------------------------------- 3-51

3.15 Dwell Command ------------------------------------------------------------------------------------ 3-55

3.15.1 Function List ------------------------------------------------------------------------------ 3-55

3.15.2 Sample Application ---------------------------------------------------------------------- 3-55

3.16 Change Position ------------------------------------------------------------------------------------ 3-57

3.16.1 Function List ------------------------------------------------------------------------------ 3-57

3.16.2 Sample Application ---------------------------------------------------------------------- 3-57

3.17 Change Position ------------------------------------------------------------------------------------ 3-60

3.17.1 Function List ------------------------------------------------------------------------------ 3-60

3.17.2 Sample Application ---------------------------------------------------------------------- 3-60

Revised March, 2012 iii

Page 6

PCI-DMC-A01 / PCI-DMC-B01 Programming Manual

3.18 Change Velocity ------------------------------------------------------------------------------------ 3-63

3.18.1 Function List ------------------------------------------------------------------------------ 3-63

3.18.2 Sample Application ---------------------------------------------------------------------- 3-63

3.19 Remote I/O Module-I/O Port --------------------------------------------------------------------- 3-67

3.19.1 Function List ------------------------------------------------------------------------------ 3-67

3.19.2 Sample Application ---------------------------------------------------------------------- 3-67

3.20 Remote I/O Module- Manual Pulse Generator (1) ----------------------------------------- 3-70

3.20.1 Function List ------------------------------------------------------------------------------ 3-70

3.20.2 Sample Application ---------------------------------------------------------------------- 3-70

3.21 Remote I/O Module- Manual Pulse Generator (2) ----------------------------------------- 3-73

3.21.1 Function List ------------------------------------------------------------------------------ 3-73

3.21.2 Sample Application ---------------------------------------------------------------------- 3-73

3.22 Remote Pulse Interface Module -Mode 1 ---------------------------------------------------- 3-76

3.22.1 Function List ------------------------------------------------------------------------------ 3-76

3.22.2 Sample Application ---------------------------------------------------------------------- 3-77

3.23 Remote Pulse Interface Module -Mode 2 ---------------------------------------------------- 3-83

3.23.1 Function List ------------------------------------------------------------------------------ 3-83

3.23.2 Sample Application ---------------------------------------------------------------------- 3-83

3.24 Get (Calculate) Arc Information ----------------------------------------------------------------- 3-87

3.24.1 Function List ------------------------------------------------------------------------------ 3-87

3.24.2 Sample Application ---------------------------------------------------------------------- 3-87

3.25 Control Interrupt ------------------------------------------------------------------------------------ 3-90

3.25.1 Function List ------------------------------------------------------------------------------ 3-90

3.25.2 Sample Application ---------------------------------------------------------------------- 3-90

3.26 MasterCard Security------------------------------------------------------------------------------- 3-94

3.26.1 Function List ------------------------------------------------------------------------------ 3-94

3.26.2 Sample Application ---------------------------------------------------------------------- 3-95

3.27 Remote Analog Input/Output Module ------------------------------------------------------- 3-100

3.27.1 Function List ---------------------------------------------------------------------------- 3-100

3.27.2 Sample Application -------------------------------------------------------------------- 3-101

3.28 Spiral Interpolation Motion Control -Spiral ------------------------------------------------- 3-106

3.28.1 Function List ---------------------------------------------------------------------------- 3-106

3.28.2 Sample Application -------------------------------------------------------------------- 3-106

3.29 Position Compare -------------------------------------------------------------------------------- 3-111

3.29.1 Function List ---------------------------------------------------------------------------- 3-111

3.29.2 Sample Application -------------------------------------------------------------------- 3-112

iv Revised March, 2012

Page 7

PCI-DMC-A01 / PCI-DMC-B01 Programming Manual

3.30 Axis Group ----------------------------------------------------------------------------------------- 3-116

3.30.1 Function List ---------------------------------------------------------------------------- 3-116

3.30.2 Sample Application -------------------------------------------------------------------- 3-116

3.31 Speed Continue ---------------------------------------------------------------------------------- 3-119

3.31.1 Function List ---------------------------------------------------------------------------- 3-119

3.31.2 Sample Application -------------------------------------------------------------------- 3-119

3.32 Spiral Interpolation - Helix Using -Sp1_ Normal Follow -------------------------------- 3-122

3.32.1 Function List ---------------------------------------------------------------------------- 3-122

3.32.2 Sample Application -------------------------------------------------------------------- 3-122

3.33 Logger ---------------------------------------------------------------------------------------------- 3-130

3.33.1 Function List ---------------------------------------------------------------------------- 3-130

3.33.2 Sample Application -------------------------------------------------------------------- 3-130

Chapter 4 Control API -------------------------------------------------------------------------------------------- 4-1

4.1 Data Type and Range ----------------------------------------------------------------------------- 4-1

4.2 Function Description ------------------------------------------------------------------------------- 4-2

Chapter 5 Hardware Initialization API ---------------------------------------------------------------------- 5-1

5.1 _DMC_01_open ------------------------------------------------------------------------------------- 5-2

5.2 _DMC_01_close ------------------------------------------------------------------------------------- 5-2

5.3 _DMC_01_get_CardNo_seq --------------------------------------------------------------------- 5-3

5.4 _DMC_01_pci_initial ------------------------------------------------------------------------------- 5-4

5.5 _DMC_01_get_card_version --------------------------------------------------------------------- 5-4

Chapter 6 Interface API ------------------------------------------------------------------------------------------ 6-1

6.1 _DMC_01_initial_bus ------------------------------------------------------------------------------ 6-2

6.2 _DMC_01_start_ring ------------------------------------------------------------------------------- 6-2

6.3 _DMC_01_get_device_table --------------------------------------------------------------------- 6-3

6.4 _DMC_01_get_node_table ----------------------------------------------------------------------- 6-3

6.5 _DMC_01_check_card_running ----------------------------------------------------------------- 6-4

6.6 _DMC_01_reset_card ----------------------------------------------------------------------------- 6-4

6.7 _DMC_01_check_nodeno ------------------------------------------------------------------------ 6-5

6.8 _DMC_01_get_master_connect_status ------------------------------------------------------- 6-6

6.9 _DMC_01_get_mailbox_Error ------------------------------------------------------------------- 6-6

6.10 _DMC_01_get_mailbox_cnt ---------------------------------------------------------------------- 6-7

6.11 _DMC_01_get_dsp_cnt --------------------------------------------------------------------------- 6-7

6.12 _DMC_01_set_dio_output ------------------------------------------------------------------------ 6-8

6.13 _DMC_01_get_dio_output ------------------------------------------------------------------------ 6-8

Revised March, 2012 v

Page 8

PCI-DMC-A01 / PCI-DMC-B01 Programming Manual

6.14 _DMC_01_get_dio_input -------------------------------------------------------------------------- 6-9

6.15 _DMC_01_get_cycle_time ------------------------------------------------------------------------ 6-9

6.16 _DMC_01_initial_bus2 ---------------------------------------------------------------------------- 6-10

6.17 _DMC_01_motion_cnt ---------------------------------------------------------------------------- 6-10

Chapter 7 Servo Drive Parameter Read/Write API ------------------------------------------------------ 7-1

7.1 _DMC_01_read_servo_parameter ------------------------------------------------------------- 7-2

7.2 _DMC_01_write_servo_parameter ------------------------------------------------------------- 7-3

Chapter 8 Using SDO Protocol API -------------------------------------------------------------------------- 8-1

8.1 CANopen SDO protocol --------------------------------------------------------------------------- 8-2

8.2 _DMC_01_check_canopen_lock ---------------------------------------------------------------- 8-6

8.3 _DMC_01_get_canopen_ret --------------------------------------------------------------------- 8-7

8.4 _DMC_01_set_pdo_mode ------------------------------------------------------------------------ 8-8

8.5 _DMC_01_send_message ----------------------------------------------------------------------- 8-9

8.6 _DMC_01_send_message3 --------------------------------------------------------------------- 8-10

8.7 _DMC_01_read_message ----------------------------------------------------------------------- 8-11

8.8 _DMC_01_read_message2 --------------------------------------------------------------------- 8-12

8.9 _DMC_01_get_message ------------------------------------------------------------------------- 8-13

8.10 _DMC_01_reset_sdo_choke -------------------------------------------------------------------- 8-14

8.11 _DMC_01_get_sdo_retry_history -------------------------------------------------------------- 8-14

Chapter 9 Point to Point Motion Control Packet Protocol API ------------------------------------- 9-1

9.1 _DMC_01_set_sdo_driver_speed_profile ---------------------------------------------------- 9-2

9.2 _DMC_01_start_sdo_driver_r_move ----------------------------------------------------------- 9-3

9.3 _DMC_01_start_sdo_driver_a_move ---------------------------------------------------------- 9-4

9.4 _DMC_01_start_sdo_driver_new_position_move ------------------------------------------ 9-5

Chapter 10 Homing Motion Control Packet Protocol API ------------------------------------------- 10-1

10.1 _DMC_01_set_home_config -------------------------------------------------------------------- 10-2

10.2 _DMC_01_set_home_move --------------------------------------------------------------------- 10-7

10.3 _DMC_01_escape_home_move --------------------------------------------------------------- 10-8

Chapter 11 Velocity Motion Control Packet Protocol API ------------------------------------------- 11-1

11.1 _DMC_01_set_velocity_mode ------------------------------------------------------------------ 11-2

11.2 _DMC_01_set_velocity --------------------------------------------------------------------------- 11-3

11.3 _DMC_01_set_velocity_stop -------------------------------------------------------------------- 11-4

11.4 _DMC_01_set_velocity_torque_limit ---------------------------------------------------------- 11-5

vi Revised March, 2012

Page 9

PCI-DMC-A01 / PCI-DMC-B01 Programming Manual

Chapter 12 Torque Motion Control Packet Protocol API -------------------------------------------- 12-1

12.1 _DMC_01_set_torque_mode ------------------------------------------------------------------- 12-2

12.2 _DMC_01_set_torque ---------------------------------------------------------------------------- 12-3

12.3 _DMC_01_set_torque_stop --------------------------------------------------------------------- 12-4

12.4 _DMC_01_set_torque_velocity_limit ---------------------------------------------------------- 12-5

Chapter 13 Using PDO Protocol API ----------------------------------------------------------------------- 13-1

13.1 _DMC_01_ipo_set_svon ------------------------------------------------------------------------- 13-2

13.2 _DMC_01_get_buffer_length ------------------------------------------------------------------- 13-3

13.3 _DMC_01_command_buf_clear ---------------------------------------------------------------- 13-4

13.4 _DMC_01_buf_dwell ------------------------------------------------------------------------------ 13-5

13.5 _DMC_01_set_group ----------------------------------------------------------------------------- 13-6

Chapter 14 Stop Motion Control API ----------------------------------------------------------------------- 14-1

14.1 _DMC_01_emg_stop ----------------------------------------------------------------------------- 14-2

14.2 _DMC_01_sd_stop -------------------------------------------------------------------------------- 14-3

14.3 _DMC_01_sd_abort ------------------------------------------------------------------------------- 14-4

14.4 _DMC_01_set_sd_mode ------------------------------------------------------------------------- 14-5

Chapter 15 Motion Status API -------------------------------------------------------------------------------- 15-1

15.1 _DMC_01_motion_done ------------------------------------------------------------------------- 15-2

15.2 _DMC_01_motion_status ------------------------------------------------------------------------ 15-3

Chapter 16 Motion Counter Value API --------------------------------------------------------------------- 16-1

16.1 _DMC_01_get_command ------------------------------------------------------------------------ 16-2

16.2 _DMC_01_set_command ------------------------------------------------------------------------ 16-2

16.3 _DMC_01_get_position--------------------------------------------------------------------------- 16-3

16.4 _DMC_01_set_position --------------------------------------------------------------------------- 16-3

16.5 _DMC_01_get_target_pos ----------------------------------------------------------------------- 16-4

16.6 _DMC_01_get_torque ---------------------------------------------------------------------------- 16-5

16.7 _DMC_01_get_current_speed ------------------------------------------------------------------ 16-6

16.8 _DMC_01_get_current_speed_rpm ----------------------------------------------------------- 16-7

Chapter 17 Software Limit API ------------------------------------------------------------------------------- 17-1

17.1 _DMC_01_set_soft_limit ------------------------------------------------------------------------- 17-2

17.2 _DMC_01_enable_soft_limit -------------------------------------------------------------------- 17-3

17.3 _DMC_01_disable_soft_limit -------------------------------------------------------------------- 17-3

17.4 _DMC_01_get_soft_limit_status --------------------------------------------------------------- 17-4

Revised March, 2012 vii

Page 10

PCI-DMC-A01 / PCI-DMC-B01 Programming Manual

Chapter 18 1-Axis Motion Control API -------------------------------------------------------------------- 18-1

18.1 _DMC_01_start_tr_move ------------------------------------------------------------------------ 18-2

18.2 _DMC_01_start_sr_move ------------------------------------------------------------------------ 18-3

18.3 _DMC_01_start_ta_move ------------------------------------------------------------------------ 18-4

18.4 _DMC_01_start_sa_move ----------------------------------------------------------------------- 18-5

18.5 _DMC_01_p_change ----------------------------------------------------------------------------- 18-6

18.6 _DMC_01_v_change ------------------------------------------------------------------------------ 18-7

18.7 _DMC_01_start_tr_move_2seg ---------------------------------------------------------------- 18-9

18.8 _DMC_01_start_sr_move_2seg -------------------------------------------------------------- 18-11

18.9 _DMC_01_start_ta_move_2seg -------------------------------------------------------------- 18-12

18.10 _DMC_01_start_sa_move_2seg ------------------------------------------------------------- 18-13

18.11 _DMC_01_start_tr_move_2seg2 ------------------------------------------------------------- 18-14

18.12 _DMC_01_start_sr_move_2seg2 ------------------------------------------------------------ 18-16

18.13 _DMC_01_start_ta_move_2seg2 ------------------------------------------------------------ 18-17

18.14 _DMC_01_start_sa_move_2seg2 ----------------------------------------------------------- 18-18

18.15 _DMC_01_feedrate_overwrite ---------------------------------------------------------------- 18-19

18.16 _DMC_01_start_v3_move --------------------------------------------------------------------- 18-21

Chapter 19 2-Axis Linear Interpolation Motion Control API ---------------------------------------- 19-1

19.1 _DMC_01_start_tr_move_xy -------------------------------------------------------------------- 19-2

19.2 _DMC_01_start_sr_move_xy ------------------------------------------------------------------- 19-4

19.3 _DMC_01_start_ta_move_xy ------------------------------------------------------------------- 19-6

19.4 _DMC_01_start_sa_move_xy ------------------------------------------------------------------ 19-8

19.5 _DMC_01_start_v3_move_xy ---------------------------------------------------------------- 19-10

Chapter 20 2-Axis Arc Interpolation Motion Control API -------------------------------------------- 20-1

20.1 _DMC_01_start_tr_arc_xy ----------------------------------------------------------------------- 20-3

20.2 _DMC_01_start_sr_arc_xy ---------------------------------------------------------------------- 20-5

20.3 _DMC_01_start_ta_arc_xy ---------------------------------------------------------------------- 20-7

20.4 _DMC_01_start_sa_arc_xy ---------------------------------------------------------------------- 20-9

20.5 _DMC_01_start_tr_arc2_xy ------------------------------------------------------------------- 20-11

20.6 _DMC_01_start_sr_arc2_xy ------------------------------------------------------------------- 20-13

20.7 _DMC_01_start_ta_arc2_xy ------------------------------------------------------------------- 20-15

20.8 _DMC_01_start_sa_arc2_xy ------------------------------------------------------------------ 20-17

20.9 _DMC_01_start_tr_arc3_xy ------------------------------------------------------------------- 20-19

20.11 _DMC_01_start_ta_arc3_xy ------------------------------------------------------------------- 20-23

20.12 _DMC_01_start_sa_arc3_xy ------------------------------------------------------------------ 20-25

viii Revised March, 2012

Page 11

PCI-DMC-A01 / PCI-DMC-B01 Programming Manual

20.13 _DMC_01_start_spiral_xy --------------------------------------------------------------------- 20-27

20.14 _DMC_01_start_spiral2_xy -------------------------------------------------------------------- 20-29

20.15 _DMC_01_start_v3_arc_xy -------------------------------------------------------------------- 20-31

20.16 _DMC_01_start_v3_arc2_xy ------------------------------------------------------------------ 20-33

20.17 _DMC_01_start_v3_arc3_xy ------------------------------------------------------------------ 20-35

20.18 _DMC_01_start_v3_spiral_xy ----------------------------------------------------------------- 20-37

20.19 _DMC_01_start_v3_spiral2_xy --------------------------------------------------------------- 20-39

Chapter 21 3-Axis Linear Interpolation Motion Control API ---------------------------------------- 21-1

21.1 _DMC_01_start_tr_move_xyz ------------------------------------------------------------------ 21-2

21.2 _DMC_01_start_sr_move_xyz ------------------------------------------------------------------ 21-3

21.3 _DMC_01_start_ta_move_xyz ------------------------------------------------------------------ 21-4

21.4 _DMC_01_start_sa_move_xyz ----------------------------------------------------------------- 21-5

21.5 _DMC_01_start_v3_move_xyz ----------------------------------------------------------------- 21-6

Chapter 22 3-Axis Spiral Interpolation Motion Control API ---------------------------------------- 22-1

22.1 _DMC_01_start_tr_heli_xy ---------------------------------------------------------------------- 22-2

22.2 _DMC_01_start_sr_heli_xy ---------------------------------------------------------------------- 22-4

22.3 _DMC_01_start_ta_heli_xy ---------------------------------------------------------------------- 22-6

22.4 _DMC_01_start_sa_heli_xy --------------------------------------------------------------------- 22-8

22.5 _DMC_01_start_v3_heli_xy ------------------------------------------------------------------- 22-10

Chapter 23 Velocity Motion Control API ------------------------------------------------------------------ 23-1

23.1 _DMC_01_tv_move ------------------------------------------------------------------------------- 23-2

23.2 _DMC_01_sv_move ------------------------------------------------------------------------------- 23-3

Chapter 24 Synchronization Motion Control API ------------------------------------------------------ 24-1

24.1 _DMC_01_sync_move---------------------------------------------------------------------------- 24-2

24.2 _DMC_01_sync_move_config ------------------------------------------------------------------ 24-2

Chapter 25 Remote Module Control API ------------------------------------------------------------------ 25-1

25.1 _DMC_01_get_rm_input_value ---------------------------------------------------------------- 25-2

25.2 _DMC_01_set_rm_input_filter ------------------------------------------------------------------ 25-3

25.3 _DMC_01_set_rm_input_filter_enable ------------------------------------------------------- 25-4

25.4 _DMC_01_set_rm_output_value --------------------------------------------------------------- 25-5

25.5 _DMC_01_set_rm_output_value_error_handle -------------------------------------------- 25-6

25.6 _DMC_01_get_rm_output_value --------------------------------------------------------------- 25-7

25.7 _DMC_01_get_rm_output_value_error_handle -------------------------------------------- 25-8

Revised March, 2012 ix

Page 12

PCI-DMC-A01 / PCI-DMC-B01 Programming Manual

25.8 _DMC_01_set_rm_output_active -------------------------------------------------------------- 25-9

Chapter 26 MPG and JOG Operation API ----------------------------------------------------------------- 26-1

26.1 _DMC_01_set_rm_mpg_axes_enable ------------------------------------------------------- 26-2

26.2 _DMC_01_set_rm_mpg_axes_enable2 ------------------------------------------------------ 26-4

26.3 _DMC_01_set_rm_jog_axes_enable --------------------------------------------------------- 26-6

Chapter 27 4-Channel Pulse Interface API --------------------------------------------------------------- 27-1

27.1 _DMC_01_set_rm_04pi_ipulse_mode -------------------------------------------------------- 27-2

27.2 _DMC_01_set_rm_04pi_opulse_mode ------------------------------------------------------- 27-3

27.3 _DMC_01_set_rm_04pi_svon_polarity ------------------------------------------------------- 27-4

27.4 _DMC_01_set_rm_04pi_DO2 ------------------------------------------------------------------ 27-5

27.5 _DMC_01_set_rm_04pi_homing_ratio ------------------------------------------------------- 27-6

27.6 _DMC_01_04pi_set_poweron ------------------------------------------------------------------ 27-7

27.7 _DMC_01_rm_04PI_get_buffer ---------------------------------------------------------------- 27-8

Chapter 28 4-Channel Pulse Interface (Mode 1) Motion Control API ---------------------------- 28-1

28.1 _DMC_01_rm_04pi_md1_start_move -------------------------------------------------------- 28-3

28.2 _DMC_01_rm_04pi_md1_v_move ------------------------------------------------------------ 28-5

28.3 _DMC_01_rm_04pi_md1_start_line2 --------------------------------------------------------- 28-6

28.4 _DMC_01_rm_04pi_md1_start_line3 --------------------------------------------------------- 28-8

28.5 _DMC_01_rm_04pi_md1_start_line4 ------------------------------------------------------- 28-10

28.6 _DMC_01_rm_04pi_md1_start_arc --------------------------------------------------------- 28-12

28.7 _DMC_01_rm_04pi_md1_start_arc2 ------------------------------------------------------- 28-14

28.8 _DMC_01_rm_04pi_md1_start_arc3 ------------------------------------------------------- 28-16

28.9 _DMC_01_rm_04pi_md1_start_heli --------------------------------------------------------- 28-18

28.10 _DMC_01_rm_04pi_md1_p_change -------------------------------------------------------- 28-20

28.11 _DMC_01_rm_04pi_md1_v_change -------------------------------------------------------- 28-21

28.12 _DMC_01_rm_04pi_md1_set_gear --------------------------------------------------------- 28-22

28.13 _DMC_01_rm_04pi_md1_set_soft_limit --------------------------------------------------- 28-23

28.14 _DMC_01_rm_04pi_md1_get_soft_limit_status ----------------------------------------- 28-24

28.15 _DMC_01_rm_04pi_md1_set_sld ----------------------------------------------------------- 28-25

28.16 _DMC_01_rm_04pi_md1_get_mc_error_code ------------------------------------------- 28-26

28.17 _DMC_01_set_rm_04pi_ref_counter ------------------------------------------------------- 28-27

Chapter 29 4-Channel Analog Output Remote Module API ---------------------------------------- 29-1

29.1 _DMC_01_rm_04da_set_output_value ------------------------------------------------------ 29-2

29.2 _DMC_01_rm_04da_get_output_value ------------------------------------------------------ 29-3

x Revised March, 2012

Page 13

PCI-DMC-A01 / PCI-DMC-B01 Programming Manual

29.3 _DMC_01_rm_04da_get_return_code ------------------------------------------------------- 29-4

29.4 _DMC_01_rm_04da_set_output_range ------------------------------------------------------ 29-5

29.5 _DMC_01_rm_04da_set_output_enable ----------------------------------------------------- 29-6

29.6 _DMC_01_rm_04da_set_output_overrange ------------------------------------------------ 29-7

29.7 _DMC_01_rm_04da_set_output_error_clear ----------------------------------------------- 29-8

29.8 _DMC_01_rm_04da_read_data ---------------------------------------------------------------- 29-9

29.9 _DMC_01_rm_04da_set_output_error_handle ------------------------------------------- 29-10

29.10 _DMC_01_rm_04da_set_output_offset_value ------------------------------------------- 29-11

29.11 _DMC_01_rm_04da_get_output_offset_value ------------------------------------------- 29-12

Chapter 30 4-Channel Analog Input Remote Module API ------------------------------------------- 30-1

30.1 _DMC_01_set_04ad_input_range ------------------------------------------------------------- 30-2

30.2 _DMC_01_get_04ad_input_range ------------------------------------------------------------- 30-3

30.3 _DMC_01_set_04ad_zero_scale -------------------------------------------------------------- 30-4

30.4 _DMC_01_get_04ad_zero_scale_status ---------------------------------------------------- 30-5

30.5 _DMC_01_set_04ad_full_scale ---------------------------------------------------------------- 30-6

30.6 _DMC_01_get_04ad_full_scale_status ------------------------------------------------------ 30-7

30.7 _DMC_01_set_04ad_conversion_time ------------------------------------------------------- 30-8

30.8 _DMC_01_get_04ad_conversion_time ------------------------------------------------------- 30-9

30.9 _DMC_01_get_04ad_data --------------------------------------------------------------------- 30-10

30.10 _DMC_01_set_04ad_average_mode ------------------------------------------------------- 30-11

30.11 _DMC_01_get_04ad_average_mode ------------------------------------------------------- 30-12

30.12 _DMC_01_set_04ad_input_enable ---------------------------------------------------------- 30-13

Chapter 31 Slave Data API ------------------------------------------------------------------------------------ 31-1

31.1 _DMC_01_get_devicetype ----------------------------------------------------------------------- 31-2

31.2 _DMC_01_get_slave_version ------------------------------------------------------------------- 31-4

Chapter 32 Parameter Monitoring API --------------------------------------------------------------------- 32-1

32.1 _DMC_01_set_monitor --------------------------------------------------------------------------- 32-2

32.2 _DMC_01_get_monitor --------------------------------------------------------------------------- 32-5

32.3 _DMC_01_get_servo_command --------------------------------------------------------------- 32-6

32.4 _DMC_01_get_servo_DI ------------------------------------------------------------------------- 32-7

32.5 _DMC_01_get_servo_DO ----------------------------------------------------------------------- 32-8

Chapter 33 Alarm Message API ------------------------------------------------------------------------------ 33-1

33.1 _DMC_01_set_ralm ------------------------------------------------------------------------------- 33-2

33.2 _DMC_01_get_alm_code ------------------------------------------------------------------------ 33-3

Revised March, 2012 xi

Page 14

PCI-DMC-A01 / PCI-DMC-B01 Programming Manual

33.3 _DMC_01_master_alm_code ------------------------------------------------------------------- 33-4

33.4 _DMC_01_slave_error ---------------------------------------------------------------------------- 33-5

Chapter 34 Multi-Axis Motion Control API --------------------------------------------------------------- 34-1

34.1 _DMC_01_multi_axes_move ------------------------------------------------------------------- 34-2

34.2 _ DMC_01_liner_speed_master ---------------------------------------------------------------- 34-4

34.3 _DMC_01_start_v3_multi_axes ---------------------------------------------------------------- 34-5

Chapter 35 Buffer Operation API ---------------------------------------------------------------------------- 35-1

35.1 _DMC_01_set_trigger_buf_function ----------------------------------------------------------- 35-2

Chapter 36 Interrupt API --------------------------------------------------------------------------------------- 36-1

36.1 _DMC_01_ set_int_factor ------------------------------------------------------------------------ 36-2

36.2 _DMC_01_ int_enable ---------------------------------------------------------------------------- 36-3

36.3 _DMC_01_ int_disable --------------------------------------------------------------------------- 36-3

36.4 _DMC_01_ get_int_count ------------------------------------------------------------------------ 36-4

36.5 _DMC_01_ get_int_status ----------------------------------------------------------------------- 36-5

36.6 _DMC_01_link_ interrupt ------------------------------------------------------------------------- 36-6

Chapter 37 Security API ---------------------------------------------------------------------------------------- 37-1

37.1 _DMC_01_ read_security ------------------------------------------------------------------------ 37-2

37.2 _DMC_01_ read_security_status -------------------------------------------------------------- 37-2

37.3 _DMC_01_write_security ------------------------------------------------------------------------ 37-3

37.4 _DMC_01_ write_security_status -------------------------------------------------------------- 37-3

37.5 _DMC_01_ check_userpassword -------------------------------------------------------------- 37-4

37.6 _DMC_01_write_ userpassword --------------------------------------------------------------- 37-4

37.7 _DMC_01_check_verifykey --------------------------------------------------------------------- 37-5

37.8 _DMC_01_write_verifykey ----------------------------------------------------------------------- 37-5

37.9 _DMC_01_ read_serialno ------------------------------------------------------------------------ 37-6

37.10 misc_slave_check_userpassword ------------------------------------------------------------- 37-7

37.11 _misc_slave_write_userpassword ------------------------------------------------------------- 37-8

37.12 _misc_slave_get_serialno ----------------------------------------------------------------------- 37-9

37.13 _misc_security ------------------------------------------------------------------------------------ 37-10

37.14 _misc_slave_write_verifykey ------------------------------------------------------------------ 37-11

37.15 _misc_slave_check_verifykey ---------------------------------------------------------------- 37-12

37.16 _misc_slave_user_data_buffer_read ------------------------------------------------------- 37-13

37.17 _misc_slave_user_data_buffer_write ------------------------------------------------------- 37-14

37.18 _misc_slave_user_data_to_flash ------------------------------------------------------------ 37-15

xii Revised March, 2012

Page 15

PCI-DMC-A01 / PCI-DMC-B01 Programming Manual

Chapter 38 Limit Reversal API ------------------------------------------------------------------------------- 38-1

38.1 _ DMC_01_rm_04pi_set_MEL_polarity ------------------------------------------------------ 38-2

38.2 _ DMC_01_rm_04pi_get_MEL_polarity ------------------------------------------------------ 38-3

38.3 _ DMC_01_rm_04pi_set_PEL_polarity ------------------------------------------------------- 38-4

38.4 _ DMC_01_rm_04pi_get_PEL_polarity ------------------------------------------------------- 38-5

Chapter 39 Compare API --------------------------------------------------------------------------------------- 39-1

39.1 _ DMC_01_set_compare_channel_position ------------------------------------------------ 39-2

39.2 _DMC_01_get_compare_channel_position ------------------------------------------------- 39-3

39.3 _DMC_01_set_compare_ipulse_mode ------------------------------------------------------- 39-4

39.4 _DMC_01_set_compare_channel_direction ------------------------------------------------ 39-5

39.5 _DMC_01_set_compare_channel_trigger_time -------------------------------------------- 39-6

39.6 _DMC_01_set_compare_channel_one_shot ----------------------------------------------- 39-7

39.7 _DMC_01_set_compare_channel_source --------------------------------------------------- 39-8

39.8 _DMC_01_channel0_position_cmp ----------------------------------------------------------- 39-9

39.9 _DMC_01_channel1_output_enable -------------------------------------------------------- 39-10

39.10 _DMC_01_channel1_output_mode --------------------------------------------------------- 39-11

39.11 _DMC_01_channel1_get_io_status --------------------------------------------------------- 39-13

39.12 _DMC_01_channel1_set_gpio_out ---------------------------------------------------------- 39-14

39.13 _DMC_01_channel1_position_compare_table ------------------------------------------- 39-15

39.14 _DMC_01_channel1_position_compare_table_level ----------------------------------- 39-16

39.15 _DMC_01_channel1_position_compare_table_cnt ------------------------------------- 39-17

39.16 _DMC_01_set_compare_channel_polarity ------------------------------------------------ 39-18

39.17 _DMC_01_channel0_position_cmp_by_gpio --------------------------------------------- 39-19

39.18 _DMC_01_channel1_position_re_compare_table --------------------------------------- 39-20

39.19 _DMC_01_channel1_position_re_compare_table_level ------------------------------- 39-20

Chapter 40 Linear and Arc Interpolation Motion Control API -------------------------------------- 40-1

40.1 _DMC_01_start_rline_xy ------------------------------------------------------------------------- 40-2

40.2 _DMC_01_start_rline_xyz ----------------------------------------------------------------------- 40-4

40.4 _DMC_01_start_v3_rline_xyz ------------------------------------------------------------------- 40-9

Chapter 41 Speed Continue API ----------------------------------------------------------------------------- 41-1

41.1 _DMC_01_speed_continue---------------------------------------------------------------------- 41-2

41.2 _DMC_01_speed_continue_mode ------------------------------------------------------------ 41-3

41.3 _DMC_01_speed_continue_combine_ratio ------------------------------------------------- 41-5

Revised March, 2012 xiii

Page 16

PCI-DMC-A01 / PCI-DMC-B01 Programming Manual

Chapter 42 Other API -------------------------------------------------------------------------------------------- 42-1

42.1 _misc_app_get_circle_endpoint ---------------------------------------------------------------- 42-2

42.2 _misc_app_get_circle_center_point ----------------------------------------------------------- 42-3

42.3 _misc_set_record_debuging -------------------------------------------------------------------- 42-4

42.4 _misc_open_record_debuging_file ------------------------------------------------------------ 42-4

42.5 _DMC_01_enable_dda_mode ------------------------------------------------------------------ 42-5

42.6 _DMC_01_set_dda_data------------------------------------------------------------------------- 42-6

42.7 _DMC_01_get_dda_cnt -------------------------------------------------------------------------- 42-6

xiv Revised March, 2012

Page 17

Chapter 1 Introduction to the API Function Library | PCI-DMC-A01 / PCI-DMC-B01

Chapter 1 Introduction to the

API Function Library

PCI-DMC-A01 provides a function library and dynamic-link library (DLL) which can be called upon

to perform functions as you require. The following sections will detail how you can incorporate

these function libraries into your development environment.

1.1 Using the Function Libraries

Once you have installed the program you will find two libraries under the “lib” folder. These

libraries are intended for use in Visual Studio C or Borland development environments.

Table 1.1

PCI_DMC_01.lib Visual Studio C function

BCBPCI_DMC_01.lib Borland C function

1.2 Edit New Project

1.2.1 Using VC

1. Add the following command to your project:

# include “..\inc\VC\PCI_DMC_01.h”

# include “..\inc\VC\PCI_DMC_01_Err.h”

2. Under the Visual C development environment, select Project / Setting / Link

Under Object / Library modules, input “..\lib\PCI_DMC_01.lib”

3. Once set, you can begin using the API to control PCI-DMC-A01.

library

library

1.2.2 Using Borland C

1. Add the following command to your project:

# include “..\inc\BCB \PCI_DMC_01.h”

# include “..\inc\BCB\PCI_DMC_01_Err.h”

Revised March, 2012 1-1

Page 18

Chapter 1 Introduction to the API Function Library | PCI-DMC-A01 / PCI-DMC-B01

2. Under the Borland C++ Build development environment, select View/ Project

Manager

Add the function library “..\lib\BCBPCI_DMC_01.lib” to your new project.

3. Once set, you can begin using the API to control PCI-DMC-A01.

1.2.3 Using VB

Under the installation directory “..\ \PCI-DMC-A01\inc\VB” you will find

“PCI_DMC_01.bas” and “PCI_DMC_01_Err.bas”. Add these two files to your new

project to use the API to control PCI-DMC-A01.

1.2.4 Using Delphi

Under the installation directory “..\ \PCI-DMC-A01\inc\Delphi” you will find

“PCI_DMC_01.pas”. Add this file to your new project to use the API to control

PCI-DMC-A01.

1.2.5 Using VB.Net

Under the installation directory “..\ \PCI-DMC-A01\inc\VB.Net” you will find

“PCI_DMC_01.vb” and “PCI_DMC_01_ERR.vb”. Add these two files to your new

project to use the API to control PCI-DMC-A01.

1.2.6 Using C#

In the installation directory “..\ \PCI-DMC-A01\inc\C#” you will find “PCI_DMC_01.css”

and “PCI_DMC_01_ERR.cs”. Add these two files to your new project to use the API to

control PCI-DMC-A01.

1-2 Revised March, 2012

Page 19

Chapter 2 Command Return Values and Messages | PCI-DMC-A01 / PCI-DMC-B01

Chapter 2 Command Return Values

2.1 Error Codes

When you use API for PCI-DMC-A01, the function library will generally return one of the

error codes listed in Table 2.1.

If the API function's return value is 0, then the API function was executed successfully. If

the API function returns some other error code, then an error may have occurred during

operation or in the hardware connection. You can troubleshoot the problem by referring to

the error code description.

and Messages

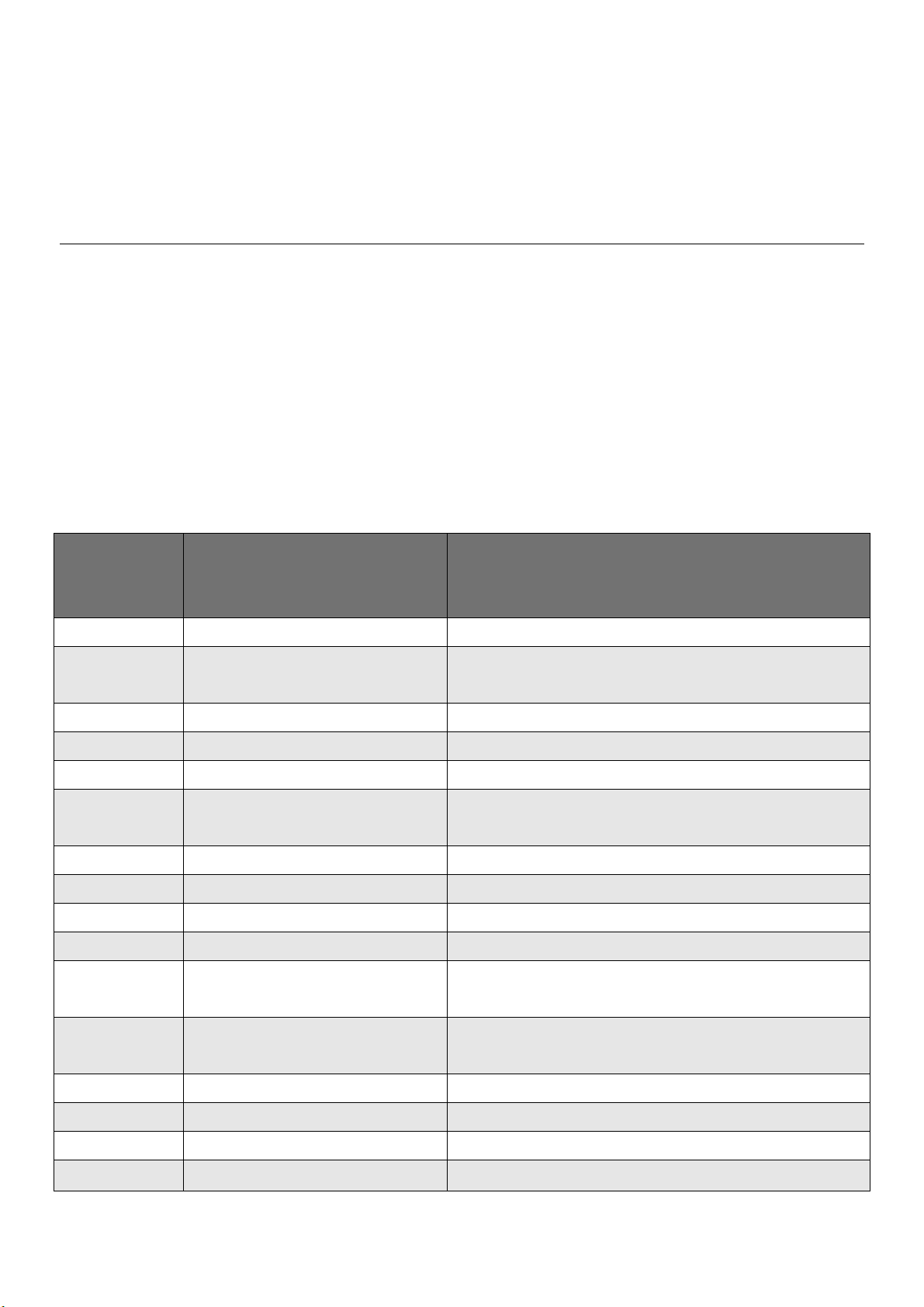

Table 2.1

Error Return

Code

(Decimal)

0 ERR_NoError API executed successfully

3 ERR_CardNoError

5 ERR_bootmodeErr Unable to boot DSP procedure

6 ERR_downloadcode DSP memory program read/write error

7 ERR_downloadinit DSP memory data read/write error

8 ERR_PCI_boot_first

11 ERR_AxisNoError Axis number error (too large)

12 ERR_IPO_First Must be in IPO mode

13 ERR_Target_reach Target must be in position for Mode 1 operation

14 ERR_Servo_on_first Must be set to Servo on

15 ERR_MPG_Mode

Error Code Error Description

Card number error. Please check the number set

by the DIP Switch on the card.

“_DMC_01_pci_initial” AP function must be

launched first

Unable to clear position in Manual Pulse

Generator (MPG) mode

16 ERR_PDO_TG

17 ERR_ConfigFileOpenError Error opening configuration file

18 ERR_Ctrl_value Command code error

19 ERR_Security_Fifo Write error using Security Fpga

20 ERR_Security_Fifo_busy Security Fpga is busy

Revised March, 2012 2-1

Unable to return acknowledgement when sending

command to module in PDO mode

Page 20

Chapter 2 Command Return Values and Messages | PCI-DMC-A01 / PCI-DMC-B01

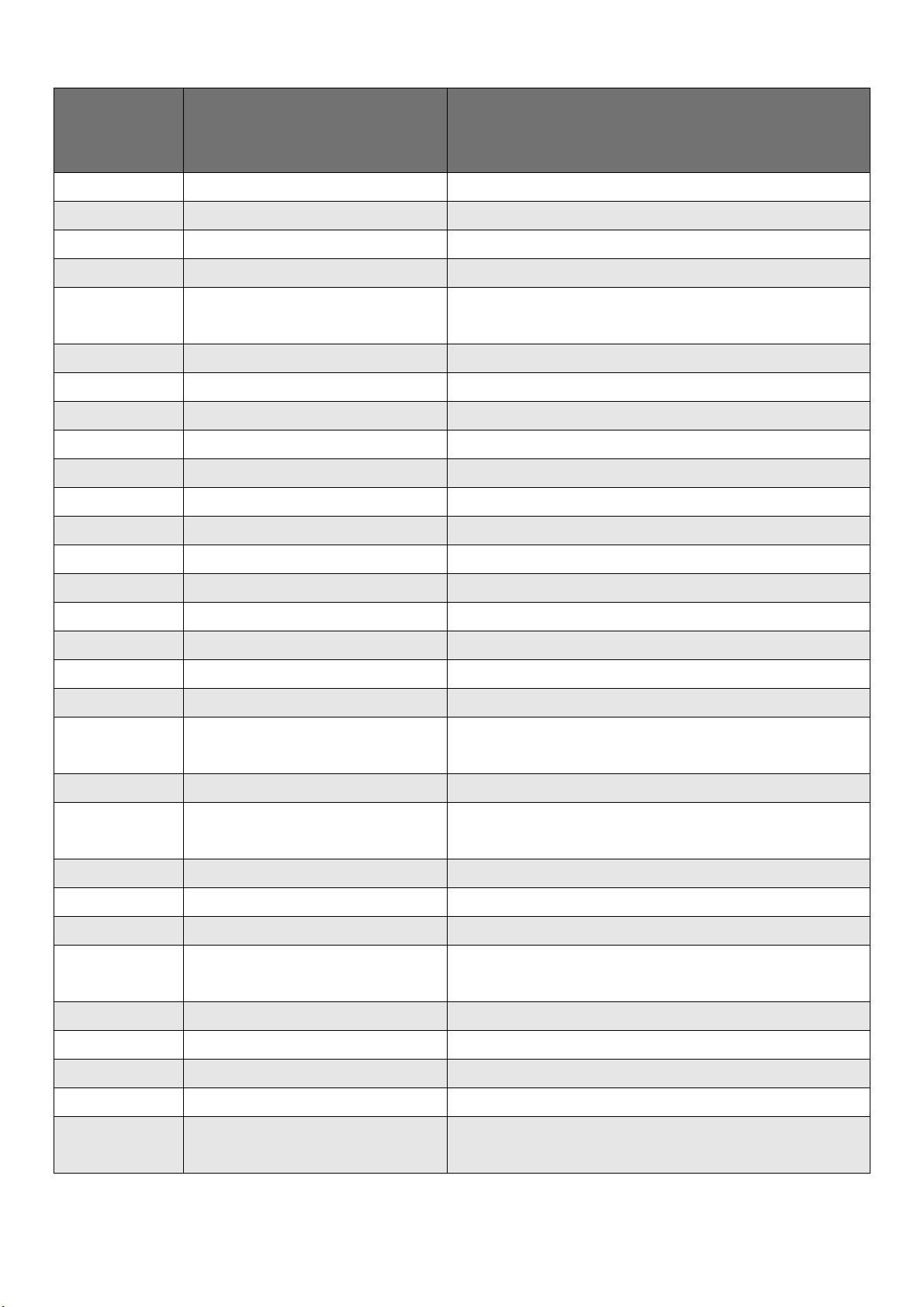

Error Return

Code

Error Code Error Description

(Decimal)

21 ERR_SpeedLimitError Defined velocity exceeds maximum velocity

22 ERR_Security_Page Security page must be smaller than 16

23 ERR_Slave_Security_op Security slave_operate command failed

24 ERR_channel_no channel no error

“_DMC_01_pci_initial” AP function must be

25 ERR_start_ring_first

launched first

26 ERR_NodeIDError NodeID does not exist

27 ERR_MailBoxErr DSP busy, unable to send command

28 ERR_SdoData SDO data sent, but no response received

29 ERR_IOCTL Operating system unable to process this IRP

30 ERR_SdoSvonFirst Servo On required to use SDO axis control

31 ERR_SlotIDError No such Slot ID for Slave module (GA or RM)

32 ERR_PDO_First PDO protocol mode required to use PDO protocol

33 ERR_Protocal_build Protocol, not built

34 ERR_Maching_TimeOut Module matching time-out

35 ERR_Maching_NG Module matching failed

40 ERR_Master_Security_Wr Security Master Write command failed

41 ERR_Master_Security_Rd Security Master Read command failed

42 ERR_Master_Security_Pw Correct password required

Master Card version error. Please contact

50 ERR_NonSupport_CardVer

distributor to purchase the correct Master Card

51 ERR_Compare_Source Ver Type: B Compare Source selection error

Compare direction error; dir must be set to 1 or 0

52 ERR_Compare_Direction

(1:ccw, 0:cw)

112 ERR_RangeError Axis number error

114 ERR_MotionBusy Motion command overlap

116 ERR_SpeedError Maximum velocity set to 0

ERR_AccTimeError Acceleration/deceleration time greater than 1000

117

sec

124 ERR_PitchZero Screw displacement parameter “pitch” set to 0

127 ERR_BufferFull Motion command buffer is full

128 ERR_PathError Motion command error

130 ERR_NoSupportMode Velocity change not supported

ERR_FeedHold_support Feedhold Stop enabled. Unable to receive new

132

commands

2-2 Revised March, 2012

Page 21

Error Return

Chapter 2 Command Return Values and Messages | PCI-DMC-A01 / PCI-DMC-B01

Code

Error Code Error Description

(Decimal)

ERR_SDStop_On Currently executing deceleration/stop command,

133

Unable to receive new commands

ERR_VelChange_supper Unable to execute velocity change function

134

(Feedhold, Synch, and Deceleration)

135 ERR_Command_set Unable to repeat FeedHold command

ERR_sdo_message_choke Sdo command return error. Please check

136

network connection

ERR_VelChange_buff_feedh

Feedhold function must be enabled first. Unable

137

old

to change velocity

ERR_VelChange_sync_move Waiting for sync command, unable to change

138

velocity

ERR_VelChange_SD_On Waiting for decelerate command, unable to

139

change velocity

ERR_P_Change_Mode Single axis point to point mode. Acceleration

140

segment's velocity is 0. Non-single axis point to

point mode

When mode is

_Path_p_change,_Path_velocity_change_onfly,

141 ERR_BufferLength

_Path_Start_Move_2seg then Buffer Length

must be 0

142 ERR_2segMove_Dist Distance must be in same direction

143 ERR_CenterMatch Center must match

144 ERR_EndMatch Center must match

145 ERR_AngleCalcu Angle calculation error

146 ERR_RedCalcu Radius calculation error

147 ERR_GearSetting Gear numerator or denominator is 0

Table Setting First Array Point Error, Table

148 ERR_CamTable

setting cannot be negative; table[-1] does not

exist

ERR_AxesNum Number of axes must be set to at least 2 for

149

multiple axes settings

150 ERR_SpiralPos Final position will be the center of the spiral

Revised March, 2012 2-3

Page 22

Chapter 2 Command Return Values and Messages | PCI-DMC-A01 / PCI-DMC-B01

2.2 Error Code Example

The following example is a return function. You can use it as a reference to create new

functions that meet your control requirements.

Example

Void error (unsigned short rc) // Function that returns error code; rc is the parsed return

value

{

Switch(rc)

{

Case 3:

printf(“Card No. Error, Please check Card No. again.”);

break;

default:

break;

}

2-4 Revised March, 2012

Page 23

Chapter 3 Operating Principles

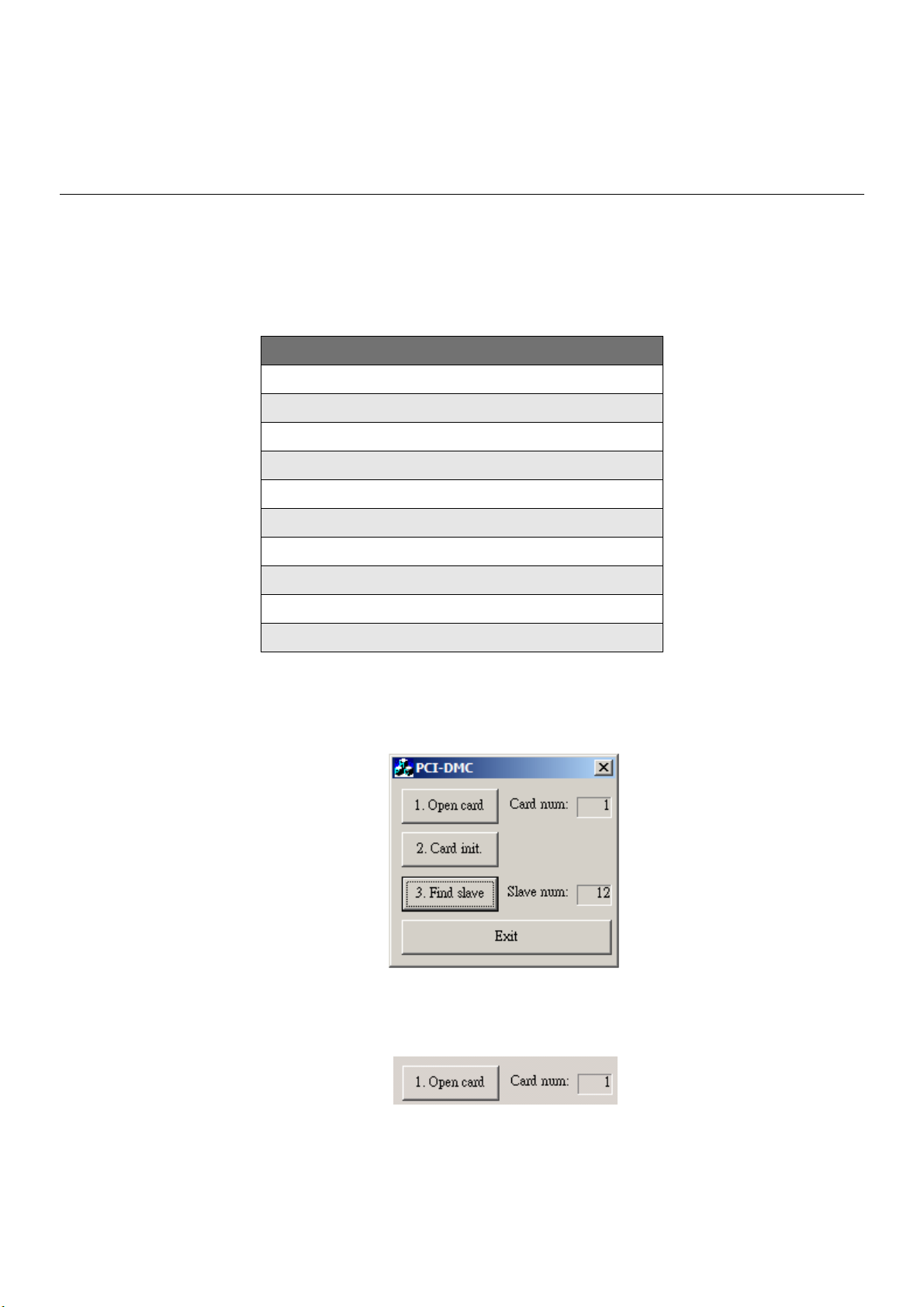

3.1 Card Initialization

3.1.1 Function List

_DMC_01_open

_DMC_01_get_CardNo_seq

_DMC_01_check_card_running

_DMC_01_reset_card

_DMC_01_close

Chapter 3 Operating Principles | PCI-DMC-A01 / PCI-DMC-B01

Table 3.1

Function Name

_DMC_01_pci_initial

_DMC_01_initial_bus

_DMC_01_start_ring

_DMC_01_get_device_table

_DMC_01_get_node_table

3.1.2 Sample Application

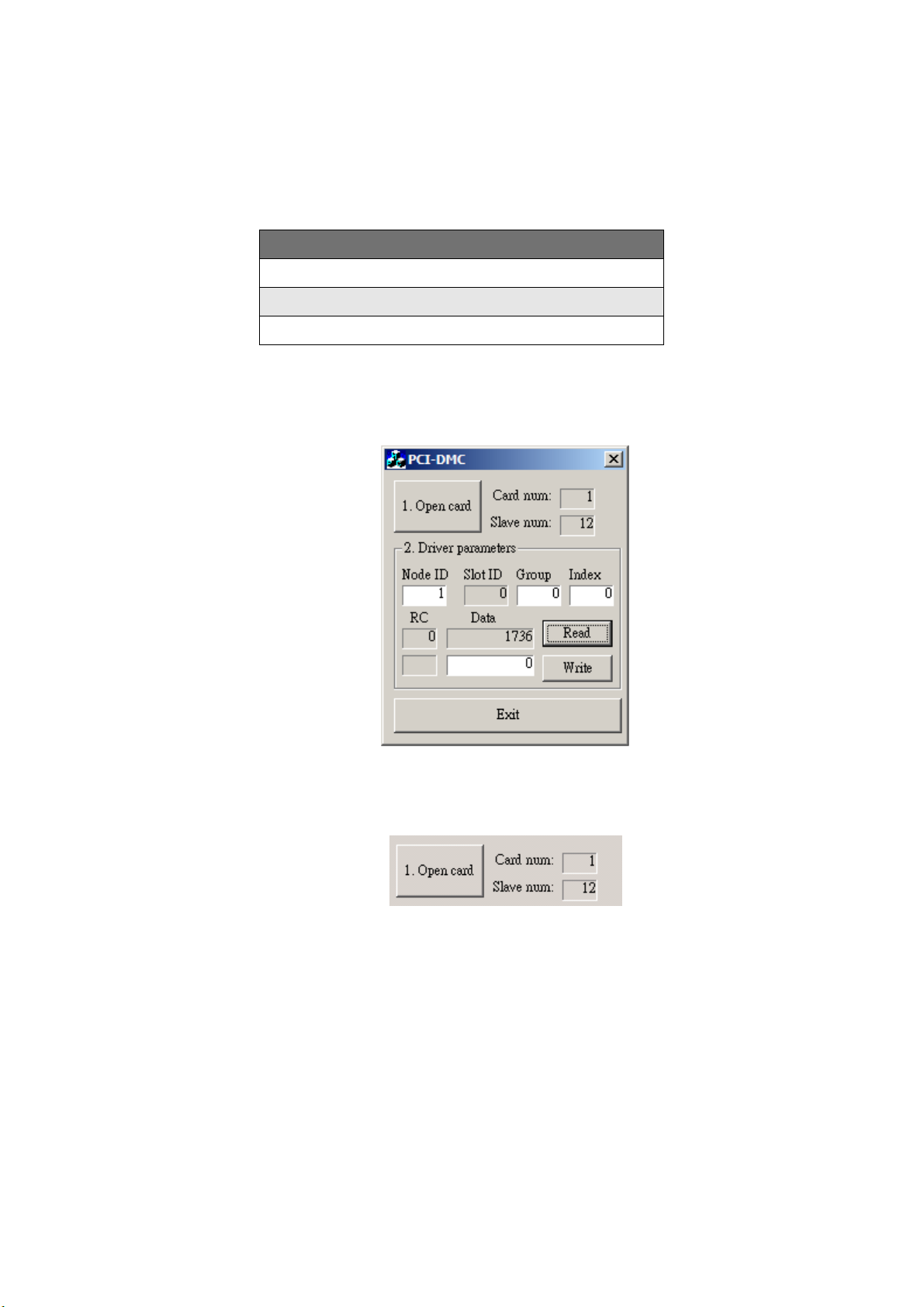

Program Appearance

Figure 3.1

1) Open card

Figure 3.2

Revised March, 2012 3-1

Page 24

Chapter 3 Operating Principles | PCI-DMC-A01 / PCI-DMC-B01

Click on the “Open card” button to execute the following procedure:

/* gDMCExistCards variable is set as the number of PCI-DMC-A01 on the PC*/

rt = _DMC_01_open(&gDMCExistCards);

2) Card initialization

Figure 3.3

Click on the “Card init” button to execute the following procedure:

for(i=0; i<gDMCExistCards; i++)

{

/* Get the card number of the i-th card on the PC. Card number is the value set by

the DIP Switch*/

rt = _DMC_01_get_CardNo_seq(i, &CardNo);

gpDMCCardNoList[i] = CardNo;

/*Check to see if the card has been initialized. If the value is 0, then the card has not

been initialized .*/

rt = _DMC_01_check_card_running(gpDMCCardNoList[i], &running);

if(running == 0) {

rt = _DMC_01_pci_initial(gpDMCCardNoList[i]); // Initialize card

if(rt != 0) AfxMessageBox(“Can't boot PCI_DMC_01 Master Card!”);

}

rt = _DMC_01_initial_bus(gpDMCCardNoList[i]); // Initialization communications

protocol

gbpDSPBoot[gpDMCCardNoList[i]] = true;

}

3) Establish communications

Figure 3.4

Click on the “Find slave” button to execute the following procedure:

rt = _DMC_01_start_ring(gDMCCardNo, 0); // Begin communications

rt = _DMC_01_get_device_table(gDMCCardNo, &gpDeviceInfo[gDMCCardNo]);

rt = _DMC_01_get_node_table(gDMCCardNo, &gpSlaveTable[0][gDMCCardNo]);

Once the above procedure has been executed, the detected Slave device is

displayed in the “Slave num” field.

3-2 Revised March, 2012

Page 25

Chapter 3 Operating Principles | PCI-DMC-A01 / PCI-DMC-B01

NOTE

_DMC_01_get_device_table Get the Slot ID using the PDO protocol

Example: gpDeviceInfo[gDMCCardNo] is a “WORD” type variable. If its value is 7,

the binary form is expressed as “0000 0000 0000 0111”, so Slave devices with Slot

IDs “1”, “2” and “3” exist.

_DMC_01_get_node_table Get Node ID using SDO protocol.

Example: gpSlaveTable[0][gDMCCardNo] is a “DWORD” type variable. If its value is

7, the binary form is expressed as “0000 0000 0000 0000 0000 0000 0000 0111”, so

Slave devices with Node ID “1”, “2”, and “3” exist.

※You can use the following algorithm to find the Node ID for SDO.

lMask = 0x1;

for(i=0; i<32; i++)

{

/* Condition is met when the i-th bit is 1. */

if((gpSlaveTable[0][gDMCCardNo]>>i) & lMask) {

/* The derived i-th value +1 is the Node ID and corresponds to servo parameter

“P3-00” */

gpNodeID[gNodeNum] = (unsigned short)(i+1);

gNodeNum++;

}

}

4) Exit procedure

Figure 3.5

Click on the “Exit” button to execute the following procedure:

for(i=0; i<gDMCExistCards; i++) {

rt = _DMC_01_reset_card(gpDMCCardNoList[i]); // Reset card

}

_DMC_01_close(); // Shut down PCI-DMC-A01

Revised March, 2012 3-3

Page 26

Chapter 3 Operating Principles | PCI-DMC-A01 / PCI-DMC-B01

3.2 Read/Write Driver Parameters

3.2.1 Function List

Table 3.2

Function Name

_DMC_01_set_pdo_mode

_DMC_01_read_servo_parameter

_DMC_01_write_servo_parameter

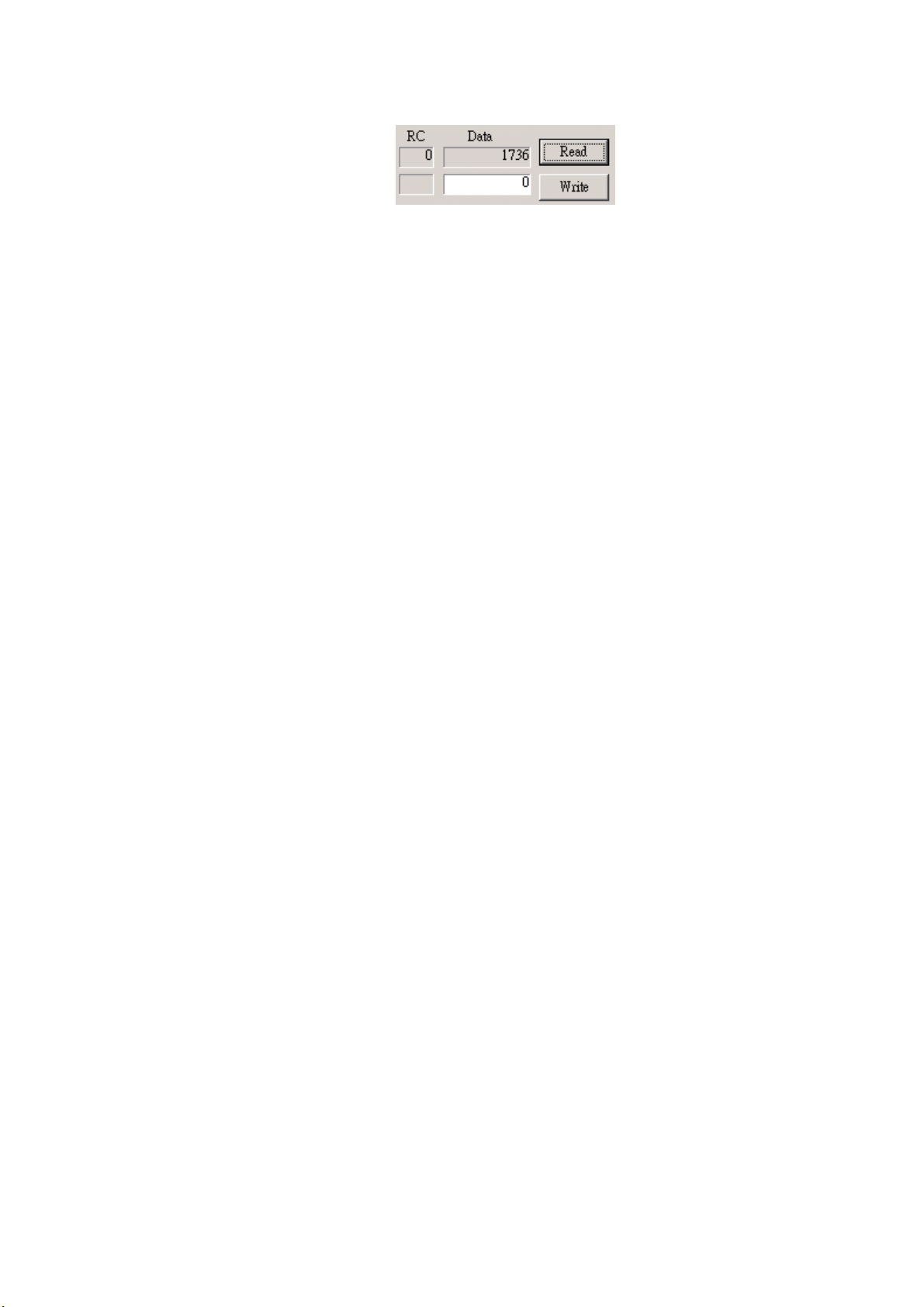

3.2.2 Sample Application

Program Appearance

Figure 3.6

1) Card Initialization and Mode Switching

Figure 3.7

Click on “Open card” to execute card initialization and set SDO mode.

For detailed instructions on card initialization, please refer to the functions described

in Section 3.1 between “Open card” and “Establish communications”.

Setting the SDO mode will use the following API function:

/* Set Slave communications to SDO mode */

rt = _DMC_01_set_pdo_mode(gDMCCardNo, gpNodeID[i], SlotID, 0);

3-4 Revised March, 2012

Page 27

Chapter 3 Operating Principles | PCI-DMC-A01 / PCI-DMC-B01

The last argument [Enable] is used to set whether PDO mode is used for Slave

communications or not. Please refer to the section on this function for a more

detailed description of this argument.

In the above example, the value of the argument is 0. This means PDO mode is

disabled during Slave communication.

If you set PDO mode to disabled, then Slave communications will use the SDO

protocol. If you need to use the SDO protocol to control the slave, you must set the

value of this argument to zero.

2) Input the servo to change (Including Node ID, Group No. and Index value)

Figure 3.8

For example, you can enter the values shown below in Fig. 3.8.

1st field - “Node ID”: If the value is 1, then it will operate the servo with Node ID 1.

2nd field - “Slot ID”: This field cannot be changed. It shows the current Slave

device (Servo's Slot ID is 0).

3rd Field - “Group”: Refers to the group number. of the device (usually a

servo). For a more detailed description of group number,

please refer to the “ASDA-A2 User Manual”. If Group is set to

0 as shown in Fig. 3.8, this means this will set the servo

parameter for “P0-xx” (the value of xx is explained below under

Index).

4th field - “Index”: As noted above, this value depends on the value for Group.

In Fig. 3.8, index has a value of 0 so in this case, read/write will

be carried on the “P0-00” parameter of Servo with Node ID of 1.

3) Read servo parameter

Figure 3.9

Click on the “Read” button to execute the following procedure:

rt = _DMC_01_read_servo_parameter(gDMCCardNo, NodeID, SlotID, group, idx,

&data);

// A data value will be returned. The value will be current value set for this servo

parameter.

// The value of rt will be displayed in the “RC” field while the value of data will be

displayed in the “Data” field.

Revised March, 2012 3-5

Page 28

Chapter 3 Operating Principles | PCI-DMC-A01 / PCI-DMC-B01

4) Write servo parameter

Figure 3.10

As shown in Fig. 3.10, if you wish to write a parameter value to servo then you must

input the desired value in the edit box and then click on the “Write” button to execute

the following procedure:

rt = _DMC_01_write_servo_parameter(gDMCCardNo, NodeID, SlotID, group, idx,

data);

//The value will be written to the servo group parameter you set. Please refer to the

previous section for a detailed description.

5) Exit procedure

Click on the “Exit” button to quit and exit the procedure.

“_DMC_01_reset_card” and “_DMC_01_close” must be executed to exit this

function. Please refer to Section 3.12 “Exit procedure” for the function operations.

3-6 Revised March, 2012

Page 29

3.3 CANopen Protocol

3.3.1 Function List

_DMC_01_set_pdo_mode

_DMC_01_send_message

_DMC_01_read_message

_DMC_01_get_message

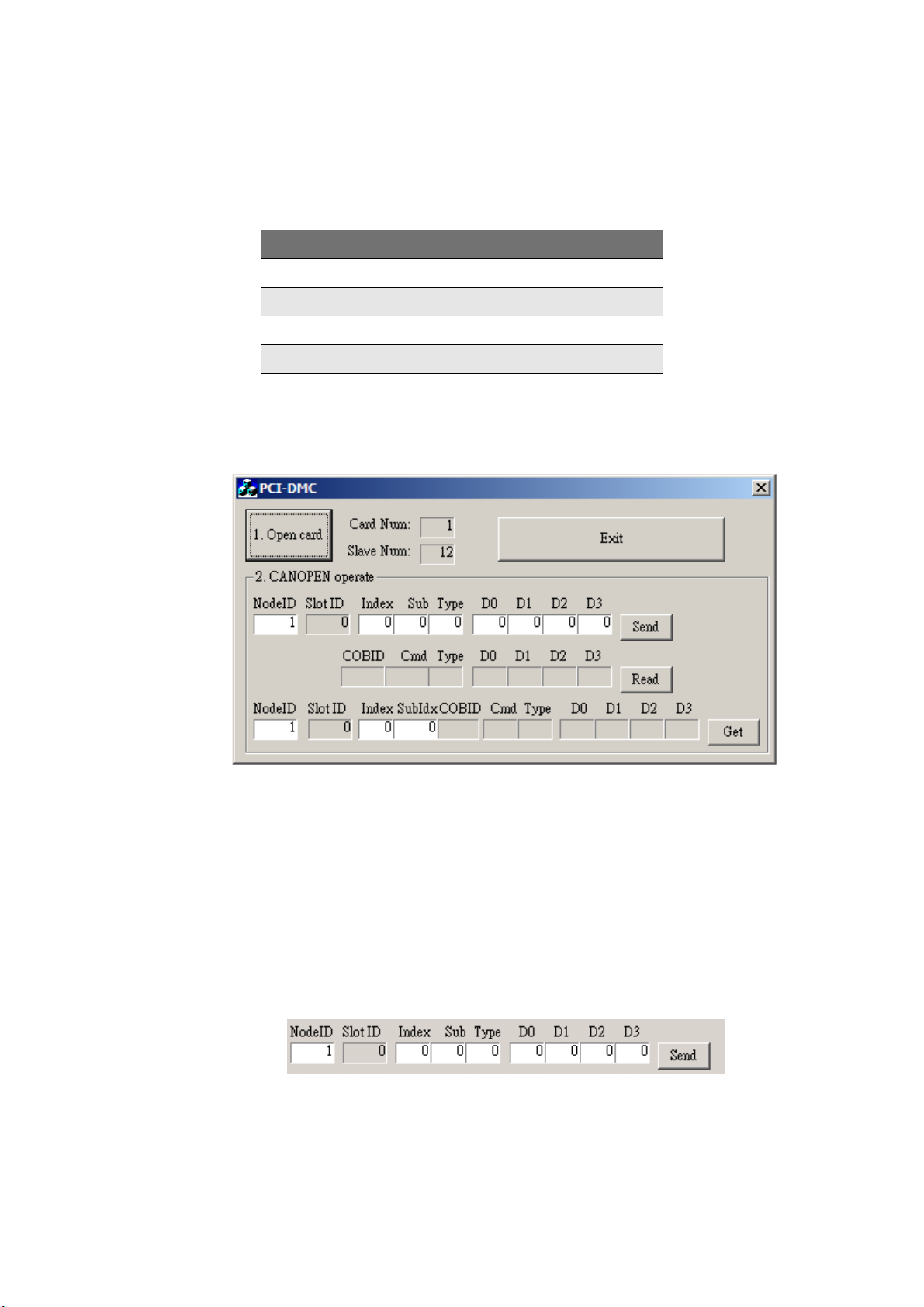

3.3.2 Sample Application

Program Appearance

Chapter 3 Operating Principles | PCI-DMC-A01 / PCI-DMC-B01

Table 3.3

Function Name

Figure 3.11

1) Initialize card and set Slave communications to SDO mode.

Click on the “Open card” button shown in Fig. 3.11 to initialize card and set SDO

mode.

A description of this button is provided in Section 3.2.2 “Card Initialization and Mode

Switching”.

2) Send SDO protocol command

Figure 3.12

Revised March, 2012 3-7

Page 30

Chapter 3 Operating Principles | PCI-DMC-A01 / PCI-DMC-B01

You input the value of the “NodeID”. The value will reflect the Slave ID you wish to

set up.

Please refer to th CANopen manual (DS 402) for setting the “Index”, “Sub” and

“Type” values.

The values “D0” to “D3” are used to input the SDO command data you wish to set

(Valid data: Byte).

Once you enter the above data, click on the “Send” button to execute the following

API function:

rt = _DMC_01_send_message(gDMCCardNo, NodeID, SlotID, Index, SubIdx,

DataType, Value0, Value1, Value2, Value3);

3) Command for reading SDO protocol

Figure 3.13

Click on the “Read” button to execute the following procedure:

/* Get the returned data for the last SDO command you sent*/

rt = _DMC_01_read_message(gDMCCardNo, &Cmd, & COBID, &DataType,

&Value0, &Value1, &Value2, &Value3);

You can create some variables to store the data returned by SDO commands. For

detailed description of the returned data, please see Section 8.8.

4) Command for getting SDO protocol

Figure 3.14

You must enter the corresponding Node ID, Object Dictionary (OD) index and

sub-index to get the information you want to know from the CANopen interface

protocol. Once you enter the data, click on the “Get” button to execute:

rt = _DMC_01_get_message(gDMCCardNo, NodeID, SlotID, Index, SubIndex,

&COBID, &Cmd , &DataType, &Value0, &Value1, &Value2, &Value3);

You can create some variables to store the data returned by SDO commands. For

detailed description of the returned data, please see Section 8.9.

5) Exit procedure

Click on the “Exit” button to quit and exit the procedure.

3-8 Revised March, 2012

Page 31

3.4 Homing Motion Control

3.4.1 Overview

Most application programs use an incremental encoder to retrieve position feedback. A

homing operation is essential to performing accurate motion control. After the power is

switched on, the status of the machine bench's position can be in one of three

states. First, position is stopped at the homing position awaiting the next command;

second, position is stopped at the ORG sensor; third, position is stopped somewhere

between ORG and Limit Switch (PEL and MEL). Please refer to the block diagram

in Fig. 3.15 below.

Chapter 3 Operating Principles | PCI-DMC-A01 / PCI-DMC-B01

1 2 13

M

PEL ORG MEL

Figure 3.15

PCI-DMC-A01 provides different functions for each of the above conditions. For homing

mode in a normal position, PCI-DMC-A01 offers up to 35 different reset to home

functions (including the reserved part). The user can simply use software settings to

have the hardware perform the user-selected homing operation. Once the homing

motion is complete, the corresponding command and feedback position will be cleared

to 0. The target position will however not be cleared to 0. The following graph shows the

conditions for executing homing:

Figure 3.16

Revised March, 2012 3-9

Page 32

Chapter 3 Operating Principles | PCI-DMC-A01 / PCI-DMC-B01

3.4.2 Function List

Table 3.4

Function Name

_DMC_01_set_home_config

_DMC_01_set_home_move

_DMC_01_escape_home_move

3.4.3 Sample Application

Program Appearance

Figure 3.17

1) Open card and initialization

Click on the “Initial” button to open and initialize the card.

For a detailed description of card initialization, please refer to “Open card” and “Card

initialization” in Section 3.1.2.

3-10 Revised March, 2012

Page 33

Chapter 3 Operating Principles | PCI-DMC-A01 / PCI-DMC-B01

2) Enter the values of the arguments for motion control

Figure 3.18

NodeID item: API function's argument variable “NodeID”.

Timer Checkbox: Check to display the motion status. Uncheck to disable display.

Vel. item: Number of pulses per second. API function's argument variable

“MaxVel”.

Acc. item: Time required to reach maximum velocity. API function's argument

variable “acc”.

3) Set homing parameter (Homing mode and offset)

Figure 3.19

Mode item: Homing modes 1 to 35. API function's argument variable

“home_mode”.

Offset item: Homing offsetAPI function's argument variable “home_offset”.

4) Set Servo Motor Power ON/OFF(servo on/servo off)

Figure 3.20

Click on the “SVON” button to execute the following procedure:

rt = _DMC_01_ipo_set_svon(gDMCCardNo, NodeID, SlotID , ON_OFF);

// ON_OFF: 0 – Servo Power OFF; 1 – Servo Power ON

Revised March, 2012 3-11

Page 34

Chapter 3 Operating Principles | PCI-DMC-A01 / PCI-DMC-B01

5) Homing operation

See Fig. 3.20. Click on “Move” to begin executing the following procedure;

/* Set homing mode: 1~35, offset and velocity parameters */

rt = _DMC_01_set_home_config(gDMCCardNo, NodeID, SlotID, home_mode,

home_offset, StrVel, MaxVel, acc);

/* Start homing motion */

rt = _DMC_01_set_home_move(gDMCCardNo, NodeID, SlotID);

6) Stop homing motion

If you wish to stop the homing motion operation, you must hit the “STOP” button to

execute the following procedure:

/* Interrupt homing motion */

rt = _DMC_01_escape_home_move(gDMCCardNo, NodeID, SlotID);

7) Exit procedure

Click on the “Exit” button to quit and exit the procedure.

“_DMC_01_reset_card” and “_DMC_01_close” must be executed to exit this

function. Please refer to Section 3.12 “Exit procedure” for the function operations.

3-12 Revised March, 2012

Page 35

3.5 Torque Motion Control

3.5.1 Function List

_DMC_01_set_torque_mode

_DMC_01_set_torque

_DMC_01_set_torque_stop

_DMC_01_get_torque

3.5.2 Sample Application

Program Appearance

Chapter 3 Operating Principles | PCI-DMC-A01 / PCI-DMC-B01

Table 3.5

Function Name

Figure 3.21

1) Card initialization

Click on the “Initial” button to open and initialize the card.

For a detailed description of card initialization, please refer to “Open card” and “Card

initialization” in Section 3.1.2.

2) Set Servo Node ID and enable motion status display

Figure 3.22

Revised March, 2012 3-13

Page 36

Chapter 3 Operating Principles | PCI-DMC-A01 / PCI-DMC-B01

Input Node ID and check the “Timer” checkbox to enable motion status display

NodeID item: API function argument variable “NodeID”.

Timer Checkbox: Check to display the motion status. Uncheck to disable display.

3) Enter values for slope and ratio

Figure 3.23

Slope item: Time required to go from 0 to 100% rate torque. (Unit: ms)

Ratio item: Thousandths of rated torque. For example, a value of 100 represents

10% of rated torque.

4) Set Servo Motor Power ON/OFF(servo on/servo off)

Figure 3.24

Click on the “SVON” button to execute the following procedure:

rt = _DMC_01_ipo_set_svon (gDMCCardNo, NodeID, SlotID , ON_OFF);

// ON_OFF: 0 – Servo Power OFF; 1 – Servo Power ON

5) Torque Motion Control

Click on the “” or “” button to execute the following procedure:

/* Set torque parameter (slope value) */

rt = _DMC_01_set_torque_mode(gDMCCardNo, NodeID, SlotID, slope);

/* Start torque motion */

rt = _DMC_01_set_torque(gDMCCardNo, NodeID, SlotID, ratio);

// If ratio is greater than 0, the motor rotates clockwise. If ratio is less than 0, the

motor rotates counterclockwise.

Press the “STOP” button to execute torque stop or not

/* Whether the motor's torque motion has stopped or not depends on the Stop value.

If Stop value is 1 then torque motion has stopped. */

rt = _DMC_01_set_torque_stop(gDMCCardNo, NodeID, SlotID, stop);

6) Display current torque value

rt = _DMC_01_get_torque(gDMCCardNo, NodeID, SlotID, &torque);

// torque variable will return current torque value

3-14 Revised March, 2012

Page 37

Chapter 3 Operating Principles | PCI-DMC-A01 / PCI-DMC-B01

7) Exit procedure

Click on the “Exit” button to quit and exit the procedure.

“_DMC_01_reset_card” and “_DMC_01_close” must be executed to exit this

function. Please refer to Section 3.12 “Exit procedure” for the function operations.

Revised March, 2012 3-15

Page 38

Chapter 3 Operating Principles | PCI-DMC-A01 / PCI-DMC-B01

3.6 Velocity Motion Control (1)

3.6.1 Function List

Table 3.6

Function Name

_DMC_01_set_velocity_mode

_DMC_01_set_velocity

_DMC_01_set_velocity_stop

_DMC_01_get_rpm

3.6.2 Sample Application

Program Appearance

Figure 3.25

1) Card initialization

Click on the “Initial” button to open and initialize the card.

For a detailed description of card initialization, please refer to “Open card” and “Card

initialization” in Section 3.1.2.

2) Set Servo Node ID and enable motion status display

Figure 3.26

3-16 Revised March, 2012

Page 39

Chapter 3 Operating Principles | PCI-DMC-A01 / PCI-DMC-B01

Input Node ID and check the “Timer” checkbox to enable motion status display

NodeID item: API function's argument variable “NodeID”.

Timer Checkbox: Check to display the motion status. Uncheck to disable display.

3) Enter the values for acceleration/deceleration time and rotations per minute (RPM)

Figure 3.27

Tacc item API function's argument variable “Tacc”.

Tdec item: API function's argument variable “Tdec”.

RPM item: API function's argument variable “rpm”.

※Actual RPM is 10% of rpm variable.

4) Set Servo Motor Power ON/OFF(servo on/servo off)

Figure 3.28

Click on the “SVON” button to execute the following procedure:

rt = _DMC_01_ipo_set_svon(gDMCCardNo, NodeID, SlotID , ON_OFF);

// ON_OFF: 0 – Servo Power OFF; 1 – Servo Power ON

5) Velocity Motion Control

Click on the “” or “” button to execute the following procedure:

/* Set velocity mode parameter (value for acceleration and deceleration time)) */

rt = _DMC_01_set_velocity_mode(gDMCCardNo, NodeID, SlotID, Tacc, Tdec);

/* Start velocity mode motion */

rt = _DMC_01_set_velocity(gDMCCardNo, NodeID, SlotID, rpm);

// If value of RPM is greater than 0 then drive motor rotates clockwise. if value is less

than 0 then rotates counterclockwise.

Press the “STOP” button to execute velocity stop or not.

/* Set whether to stop velocity motion control. If stop value is 1 then velocity motion

stops. */

rt = _DMC_01_set_velocity_stop(gDMCCardNo, NodeID, SlotID, stop);

Revised March, 2012 3-17

Page 40

Chapter 3 Operating Principles | PCI-DMC-A01 / PCI-DMC-B01

6) Display current RPM value

rt = _DMC_01_get_rpm (gDMCCardNo, NodeID, SlotID, & rpm);

// Value returned by RPM variableActual motion RPM is 10% of RPM variable value

7) Exit procedure

Click on the “Exit” button to quit and exit the procedure.

“_DMC_01_reset_card” and “_DMC_01_close” must be executed to exit this

function. Please refer to Section 3.12 “Exit procedure” for the function operations.

3-18 Revised March, 2012

Page 41

3.7 Velocity Motion Control (2)

3.7.1 Function List

_DMC_01_tv_move

_DMC_01_sv_move

_DMC_01_emg_stop

3.7.2 Sample Application

Program Appearance

Chapter 3 Operating Principles | PCI-DMC-A01 / PCI-DMC-B01

Table 3.7

Function Name

Figure 3.29

1) Card initialization

Click on the “Initial” button to open and initialize the card.

For a detailed description of card initialization, please refer to “Open card” and “Card

initialization” in Section 3.1.2.

2) Set Servo Node ID and enable motion status display

Figure 3.30

Input Node ID and check the “Timer” checkbox to enable motion status display

NodeID item: API function's argument variable “NodeID”.

Timer Checkbox: Check to display the motion status. Uncheck to disable display.

Revised March, 2012 3-19

Page 42

Chapter 3 Operating Principles | PCI-DMC-A01 / PCI-DMC-B01

3) Enter the values of the arguments for motion control

Figure 3.31

StrVel item: Starting velocity. API function's argument variable “StrVel”.

MaxVel item: Maximum velocity. API function's argument variable “MaxVel”.

Acc. item: Time required to reach maximum velocity. API function's argument

variable “acc”.

S-Curve checkbox: You must check this box if you wish to use the S-curve velocity

curve.

4) Set Servo Motor Power ON/OFF(servo on/servo off)

Click on the “SVON” button to execute the following procedure:

rt = _DMC_01_ipo_set_svon(gDMCCardNo, NodeID, SlotID , ON_OFF);

// ON_OFF: 0 – Servo Power OFF; 1 – Servo Power ON