M42U

M36U

M28U

Operation and Installation Manual

Grid-tie Transformerless Solar Inverter

The power behind competitiveness

www.deltaww.com

10

10

10

10

11

11

12

14

14

15

23

23

23

24

30

33

33

34

34

34

35

36

37

38

40

42

43

44

45

46

47

49

50

51

Table of Contents

1 Safety

1.1 Information of the Inverter

1.1.1 Legal Provisions

1.1.2 Target Group

1.2 General Safety

1.2.1 Condition of Use

1.2.2 Symbols

2 Introduction

2.1 Valid Model

2.2 Product Overview

3 Installation

3.1 Mechanical Installation

3.1.1 Vertical wall mount

3.1.2 Horizontal or Tilt mount

3.1.3 Accessories

3.2 Wiring box cover

3.3 Electrical Installation for AC Wiring

3.3.1 AC Grid Types and Connections

3.3.2 Required Protective Devices for M42/36/28U AC Grid

3.3.3 AC wiring preparation (all models)

3.3.4 AC Switch Terminals –Prewire set-up

3.3.5 AC Wiring for all models

3.4 Electrical Installation for DC Wiring

3.4.1 DC Wiring Installation for 120 models

3.4.2 DC Wiring Installation for 121 models

3.4.3 DC Wiring Installation for 122 models

3.4.4 Ground bar locations for 120/121 models

3.4.5 DC side ground bar for 122 models

3.5 Communication Module Connections

3.5.1 Accessing the Communication Module

3.5.2 RS-485 Connection

3.5.3 EPO Function & Digital Input

3.5.4 Dry Contact connection

3.6 On-site insulation test

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

4 Commissioning

4.1 Display Operation Introduction

4.2 First startup

4.2.1 Home Page

4.3 Main Menu

4.3.1 Power meter

4.3.2 String monitoring (120&122 models)

4.3.3 Energy Log

4.3.4 Event Log

4.3.5 Inverter Information

4.3.6 General Settings

4.3.7 Install Settings

4.3.7.1 Inverter ID

4.3.7.2 Insulation

4.3.7.3 Grid Code

4.3.7.4 Grid Settings

4.3.7.5 Dry Contact Set-up

4.3.7.6 Potential Induced Degradation

4.3.7.7 Residual Current Monitoring Unit (RCMU)

4.3.7.8 Emergency Power-Off Enable

4.3.7.9 AC Connection

4.3.7.10 Anti-Islanding

4.3.7.11 DC Arc Fault Circuit Interrupter (AFCI)

4.3.7.12 Grid code confirm

4.3.8 Active / Reactive power

4.3.8.1 Power Limit

4.3.8.2 Power vs. Frequency

4.3.8.3 P(V)

4.3.8.4 Constant cosphi

4.3.8.5 Cosphi (P)

4.3.8.6 Constant Q

4.3.8.7 Q(V)

4.3.9 FRT (Fault ride through)

52

52

54

55

55

56

56

57

57

58

58

59

60

60

60

61

62

63

63

63

64

64

64

65

66

66

66

67

68

68

69

69

70

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

5 Maintenance

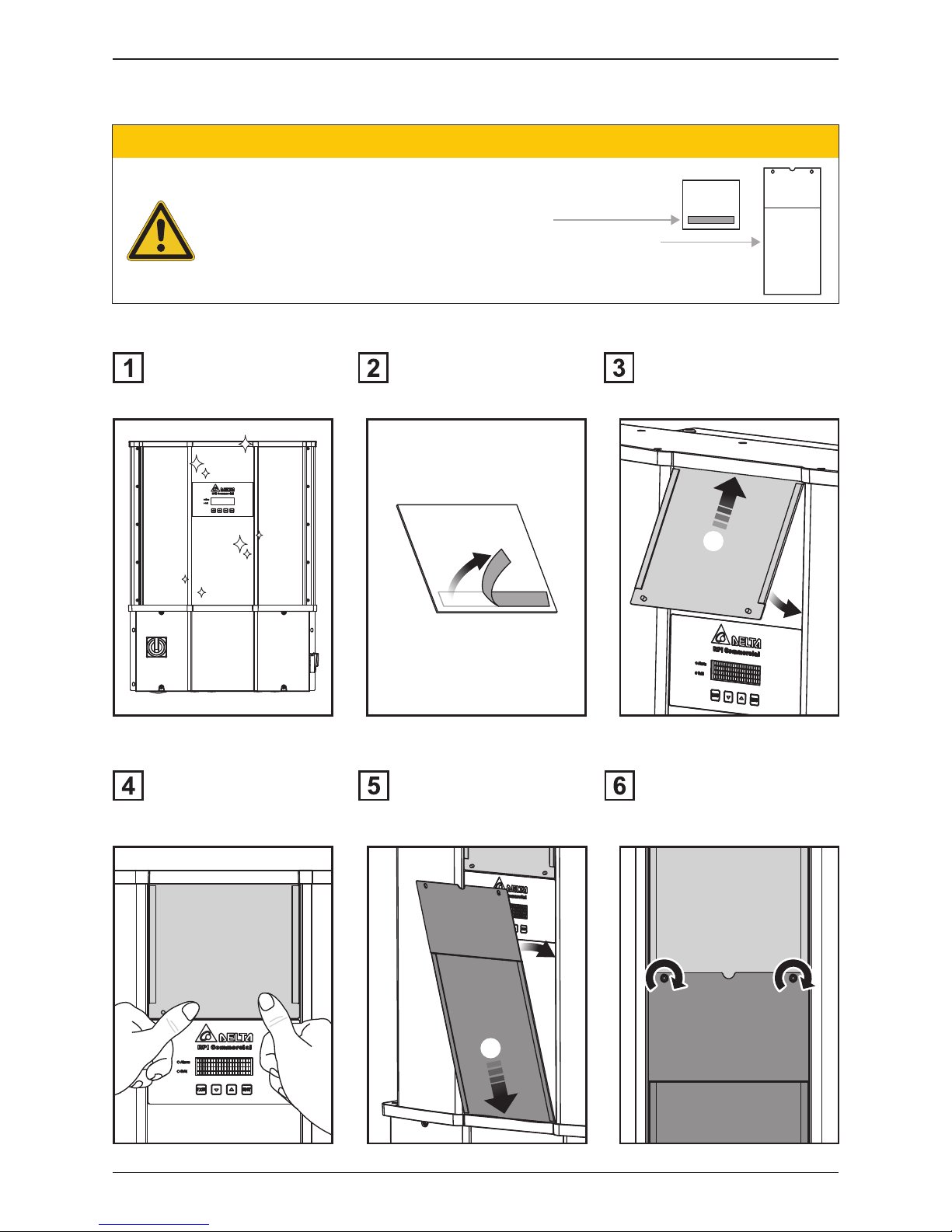

5.1 Removing and replacing the Wiring Box (WB) cover

5.1.1 Removing the WB cover

5.1.2 Replacing the WB cover

5.2 Replacement of Surge Protection Devices (SPD)

5.3 Replace Internal String Fuse

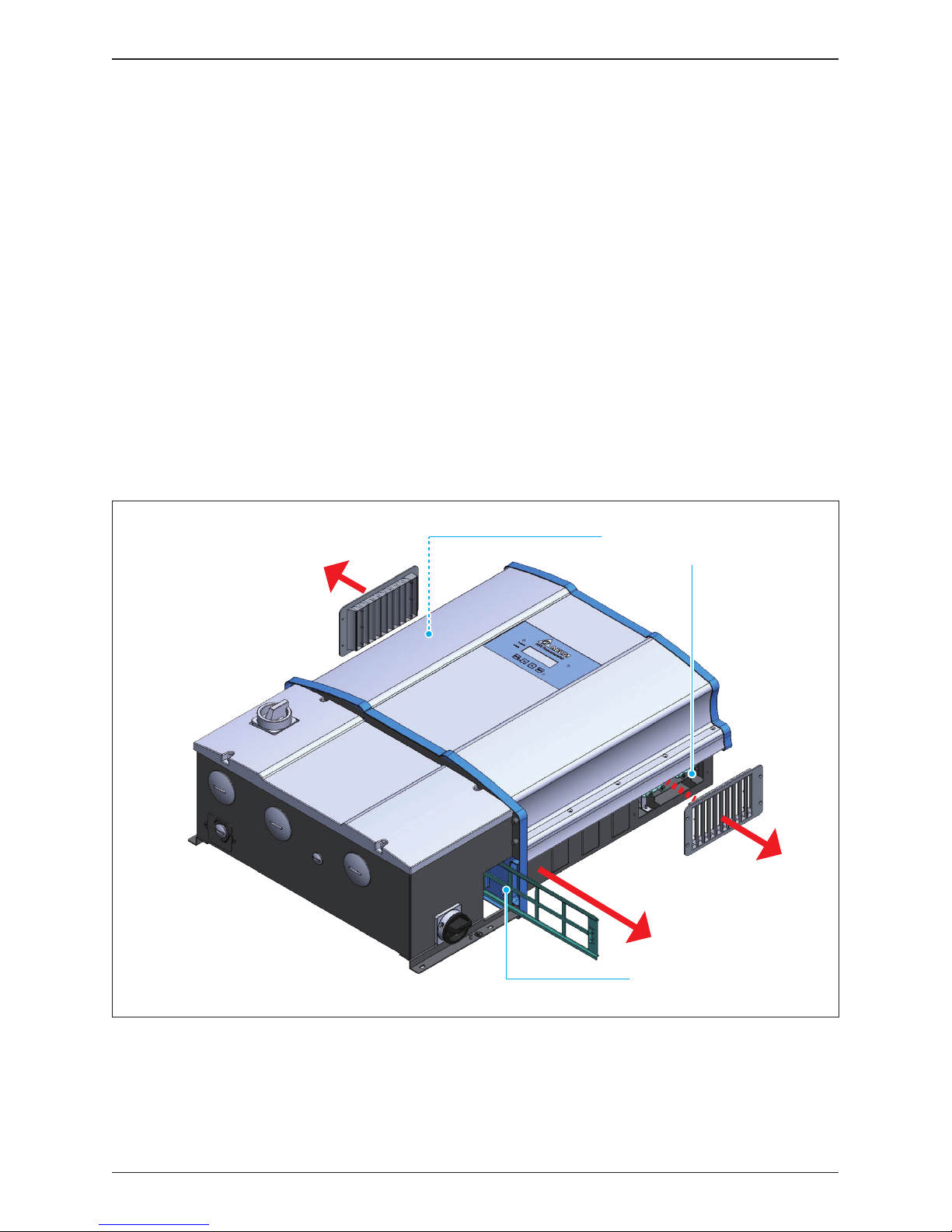

5.4 Smart Fans Replacement and Filter Cleaning

5.4.1 Power Module (PM) Fan Tray

5.4.1.1 PM Fan Tray removal procedure

5.4.1.2 Procedures to remove PM air inlet filter

5.5 De-Commissioning

6 Error message and Trouble Shooting

6.1 Error Codes

6.2 Warning Codes

6.3 Fault Codes

6.4 Calling for Help

6.4.1 Service Call Checklist

7 Technical Data

7.1 Technical of M42U series

7.2 Technical of M36U series

7.3 Technical of M28U series

7.4 Communications

7.5 Certifications

7.6 Smart Inverter Functionality

7.7 General Data

APPENDIX: Grid Support Utility Interactive Inverters

Appendix A: CA Rule 21

Appendix B: HECO

Appendix C: Assembly Note

71

71

72

72

73

77

80

82

82

84

85

87

87

88

89

93

93

94

94

95

96

97

97

97

97

101

101

105

108

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

5

Figure 2-1: Components of M42U/M36U/M28U series

Figure 2-2: Overview

Figure 2-3: Rating labels of M42/36/28U

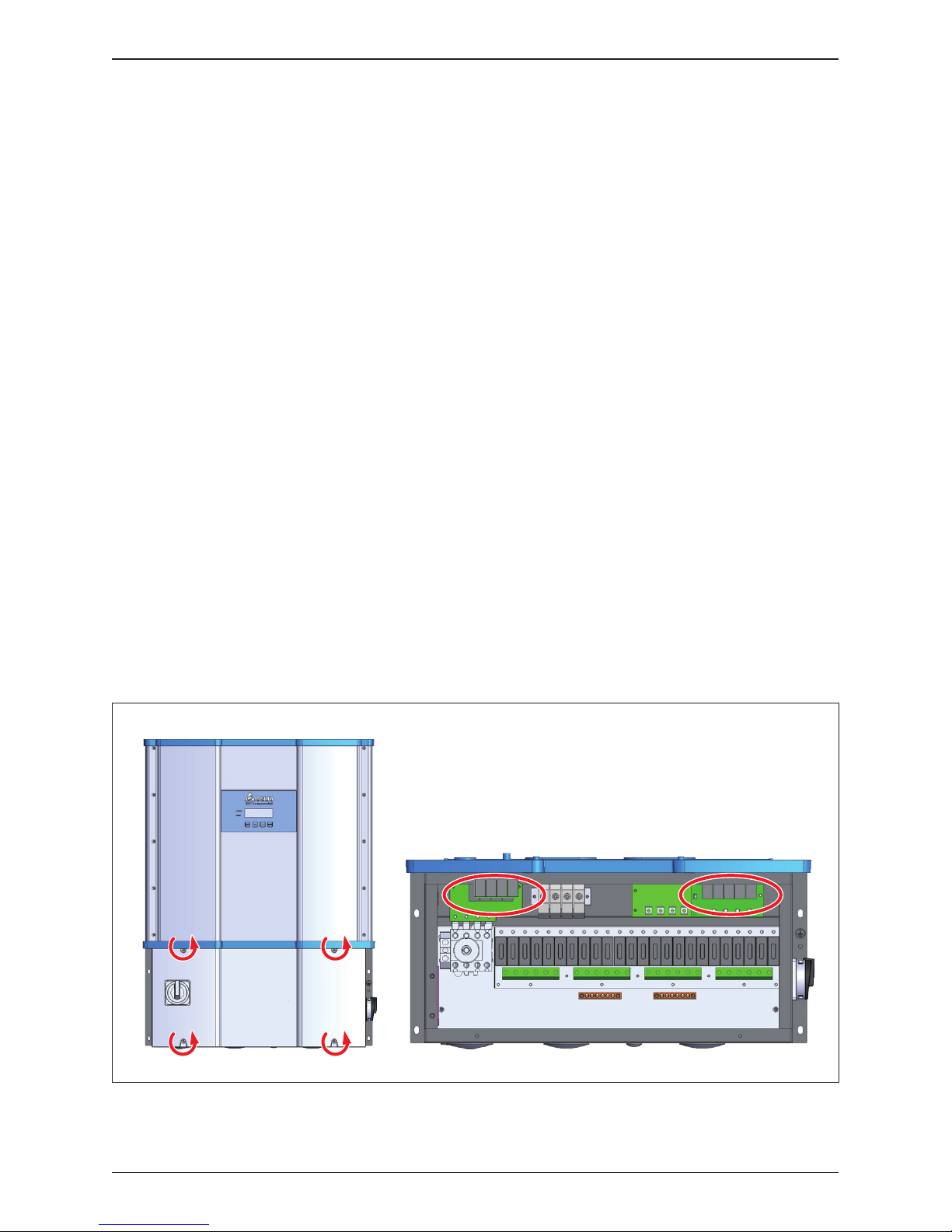

Figure 2-4: External view and Wiring box layout for 120 models

Figure 2-5: External view and Wiring box layout for 121 models

Figure 2-6: External view and Wiring box layout for 122 models

Figure 2-7: Wiring box layouts

Figure 3-1: Inverter dimensions

Figure 3-2: Mounting bracket dimensions

Figure 3-3: Required position for at least 8 screws

Figure 3-4: Permitted mounting positions

Figure 3-5: Prohibited mounting positions

Figure 3-6: Wall mount fixed prior to inverter

Figure 3-7: Stress/torque should be prevented when installing the inverter

Figure 3-8: Required mounting clearances

Figure 3-9: Screw locations to secure inverter WB to wall-mounting bracket

Figure 3-10: Installation method of shielding plate

Figure 3-11: Stripping guide for AC conductors

Figure 3-12: Location of AC terminals and wiring (all versions)

Figure 3-13: Location for DC terminals for 120 models

Figure 3-14: Location for DC terminals for 121 models

Figure 3-15: Guideline for aluminum conductor

Figure 3-16: Location for DC terminals for 122 models

Figure 3-17: DC Wiring illustration

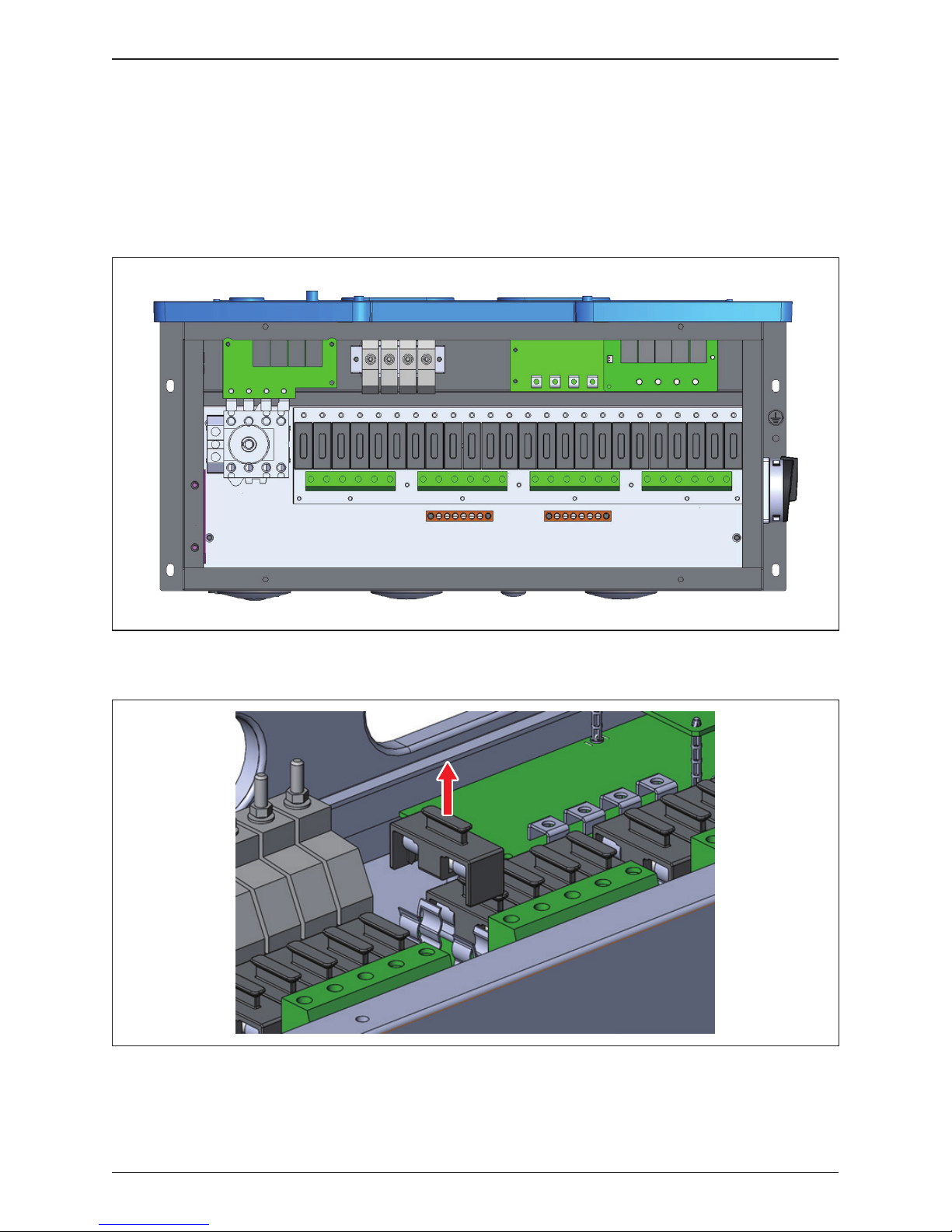

Figure 3-18: Ground bar location for 120/121 models

Figure 3-19: Mounting the DC side ground bar to WB

Figure 3-20: Communication Module Layout

Figure 3-21: Location and access to Communication Module

Figure 3-22: Multiinverter connection illustration

Figure 3-23: EPO function terminal block

Figure 3-24: Dry Contact connection

Figure 3-25: Precautions for on-site insulation test

Figure

15

16

17

19

20

21

22

25

26

26

27

27

28

28

29

29

30

34

36

38

39

40

41

41

42

43

44

45

47

48

49

50

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

6

Figure 4-1: Front Panel Display

Figure 4-2: Grid code, language and ID settings for first startup

Figure 4-3: Home Page screen

Figure 4-4: Power Monitoring and String Current Monitoring

Figure 4-5: Energy Log screen

Figure 4-6: Event Log screens

Figure 4-7: Inverter information screens

Figure 4-8: General Settings screen

Figure 4-9: Install settings Display screens

Figure 4-10: Inverter ID screen display

Figure 4-11: Insulation screen display

Figure 4-12: Grid Code screens

Figure 4-13: Grid Settings screens

Figure 4-14: Dry Contact screens

Figure 4-15: PID function Display screens

Figure 4-16: RCMU screen

Figure 4-17: AC Connection

Figure 4-18: Anti-Islanding Display screen

Figure 4-19: DC AFCI Display screen

Figure 4-20: Grid Code Confirm screens

Figure 4-21: Active / Reactive power screens

Figure 4-22: Power Limit screens

Figure 4-23: Power vs Frequency screens

Figure 4-24: Power vs Frequency parameter

Figure 4-25: P(V) screens

Figure 4-26: Constant cosphi screens

Figure 4-27: Cosphi (P) screens

Figure 4-28: Cosphi (P) curve

Figure 4-29: Constant Q screens

Figure 4-30: Q(V) screens

Figure 4-31: Q(V) parameter

Figure 4-32: FRT screens

Figure 4-33: FRT Parameter

51

53

54

55

56

56

57

57

58

59

59

59

60

61

62

62

63

63

63

64

65

65

65

66

66

67

67

67

68

68

69

69

69

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

Figure 5-1: Removing and reinstalling the WB cover

Figure 5-2: Re-installing process for Wiring Box cover

Figure 5-3: AC and DC SPD modules

Figure 5-4: Display Indicating AC and DC SPD failure

Figure 5-5: Location of SPD modules inside various WB versions

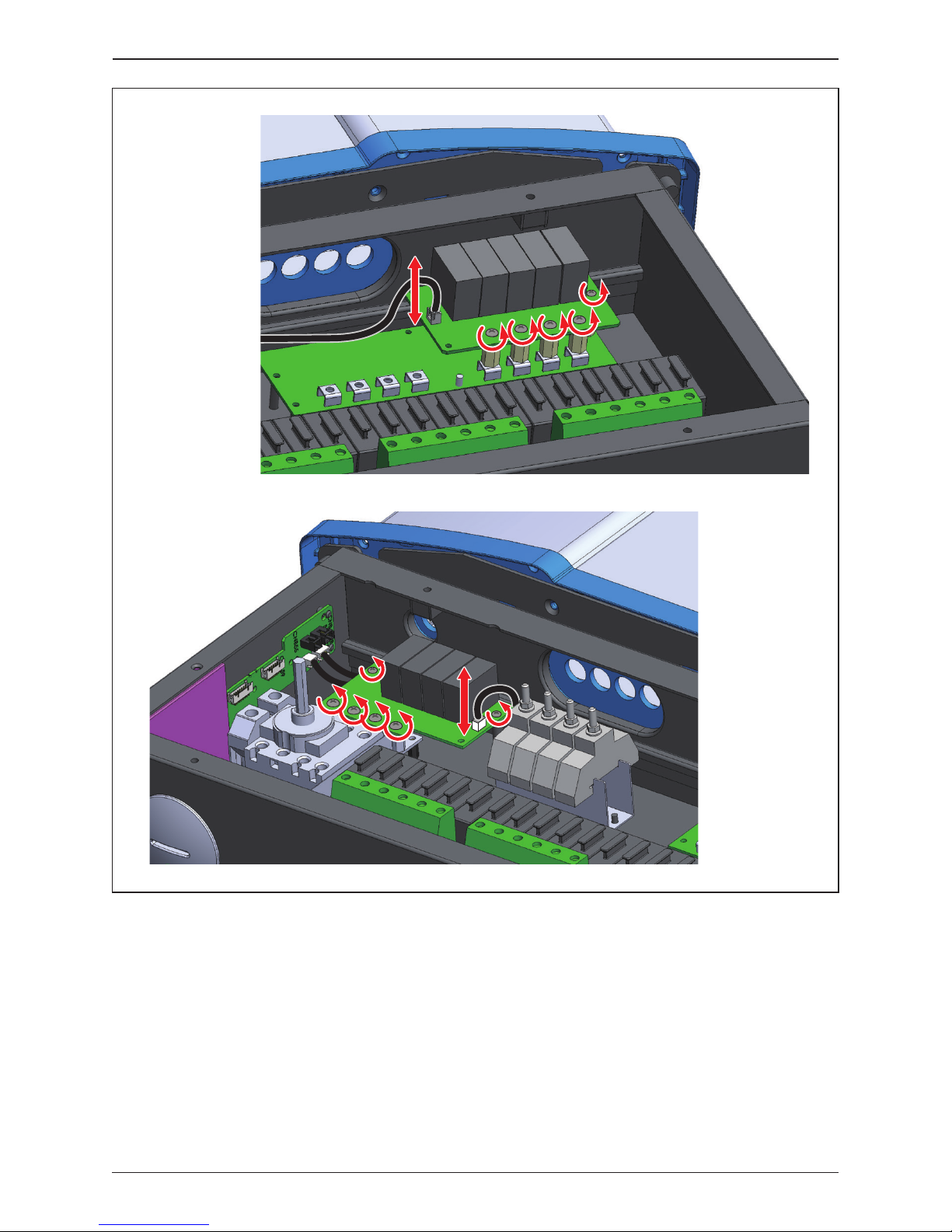

Figure 5-6: Remove screws as indicated unplug connectors

Figure 5-7: Fuse holder locations for 120/122 models

Figure 5-8: Accessing the individual fuses

Figure 5-9: String monitor

Figure 5-10: Smart Fans location on Power Module chassis

Figure 5-11: Power Module Fan tray

Figure 5-12: Disassembling fan tray from PM chassis (showing one side only)

Figure 5-13: Removing the PM air inlet filter

Figure 7-1: Thermal Derating curve of M42U

Figure 7-2: Thermal Derating curve of M36U

Figure 7-3: Thermal Derating curve of M28U

Figure B-1: Procedure to confirm Grid Code via LCD – HECO A shown

Figure B-2: Details of HECO A: L/H FRT via LCD Settings menu

Figure B-3: Details of HECO A & B: L/H VRT via LCD Settings menu

70

71

72

73

74

75

76

77

78

79

80

82

83

97

98

99

105

105

106

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

8

Table

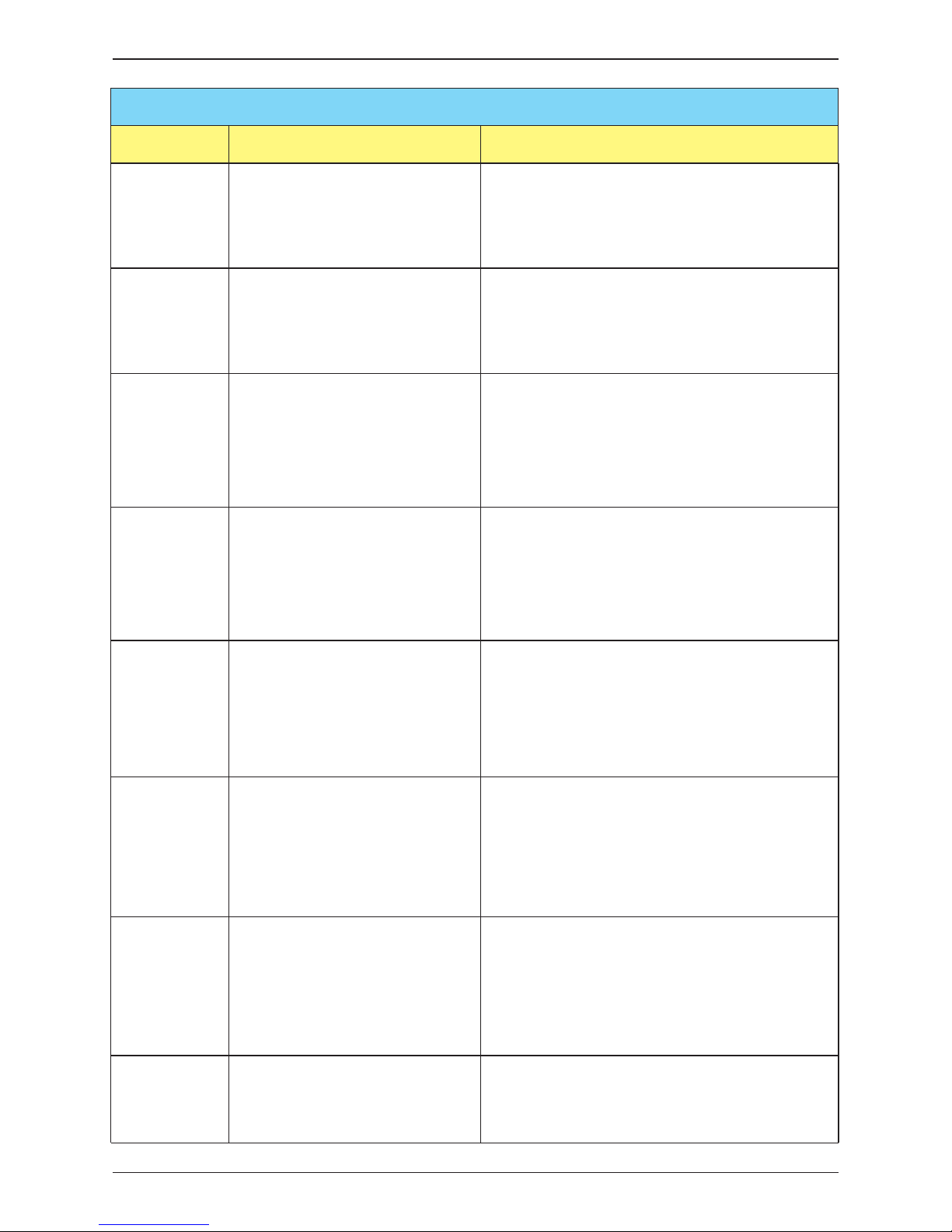

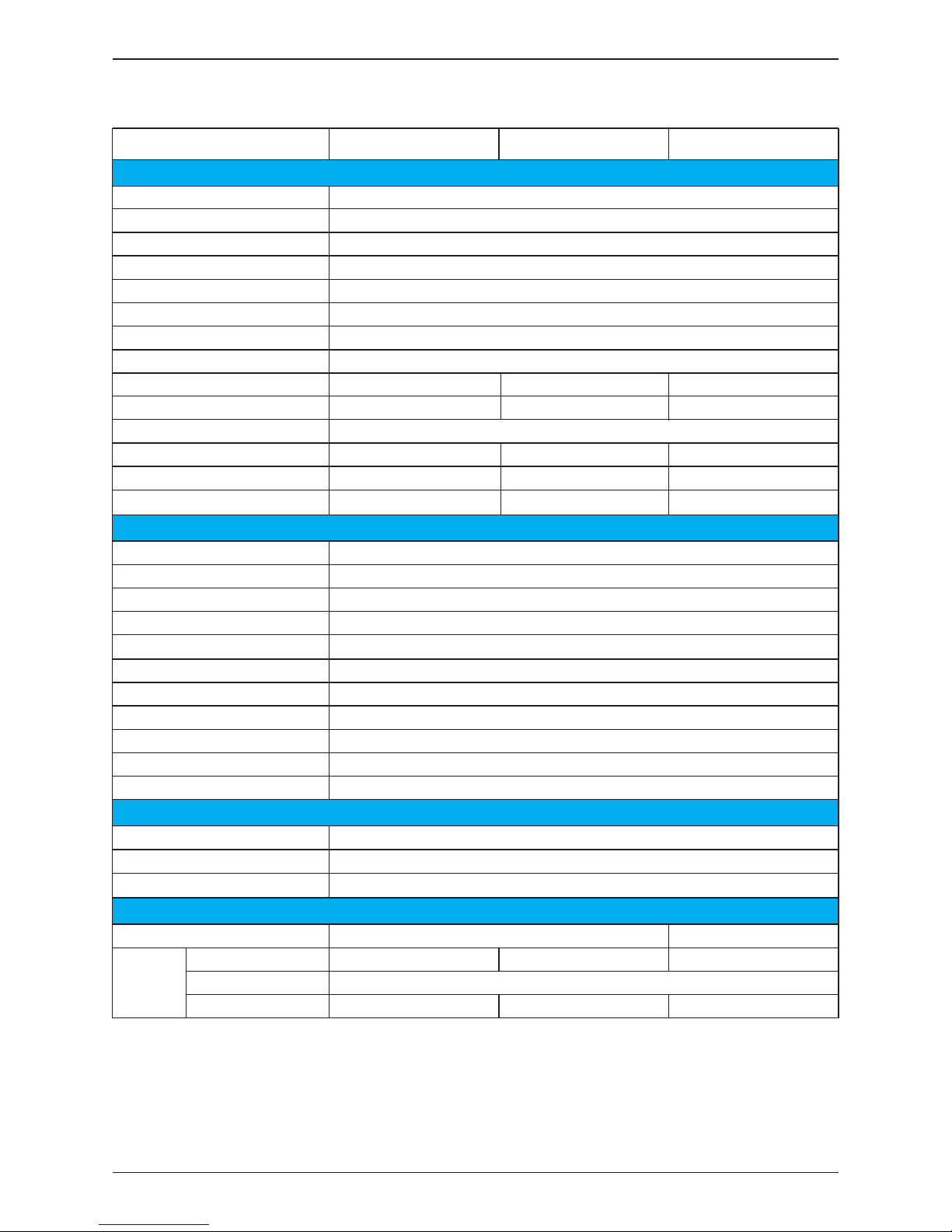

Table 2-1: Packing list of M42U/M36U/M28U series

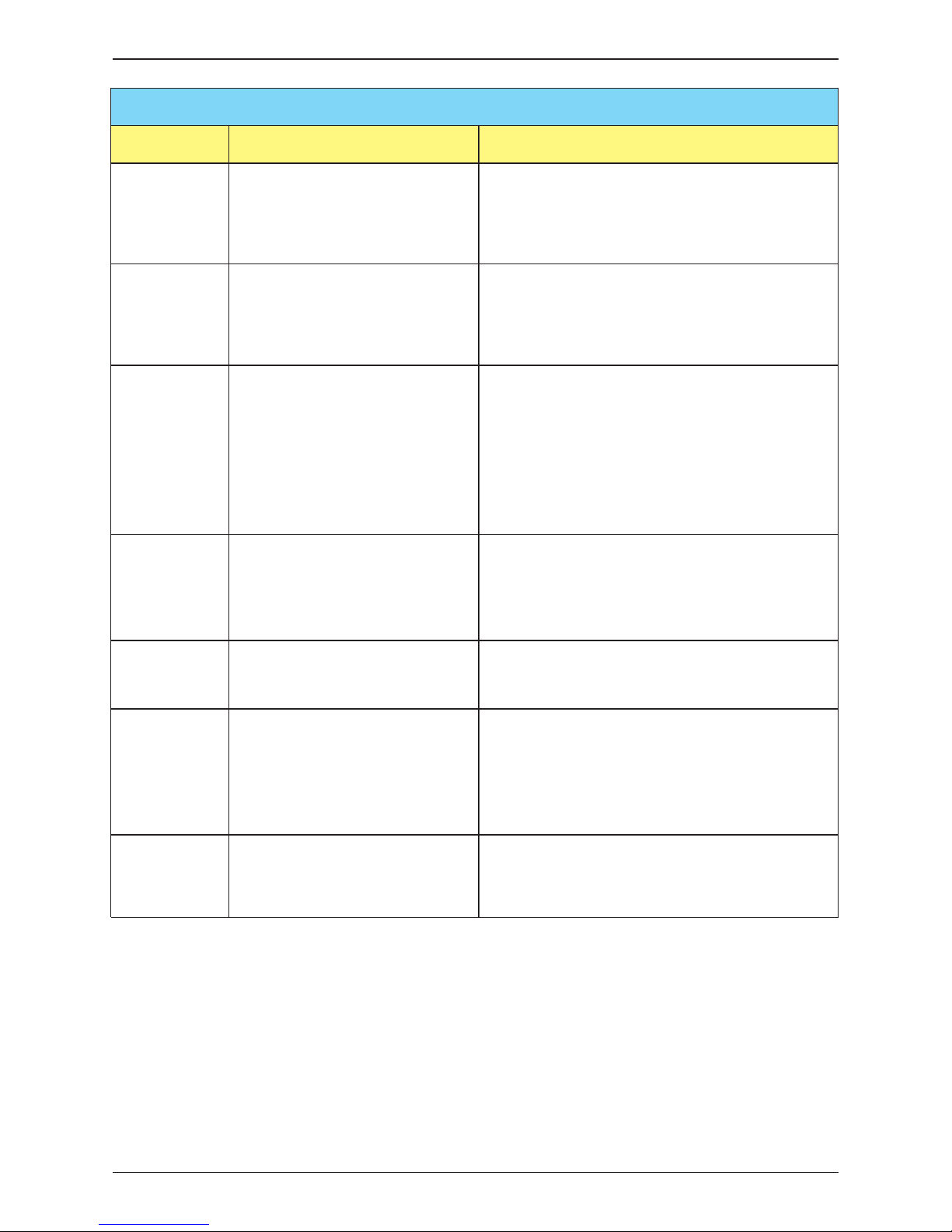

Table 2-2: Rating label explanation of M42/36/28U

Table 2-3: Wiring box layout description

Table 3-1: Definition of RS-485

Table 3-2: Terminal resister setting

Table 3-3: Definition of EPO function & Digital input

Table 4-1: LED indicator

Table 4-2: Programming keys and actions

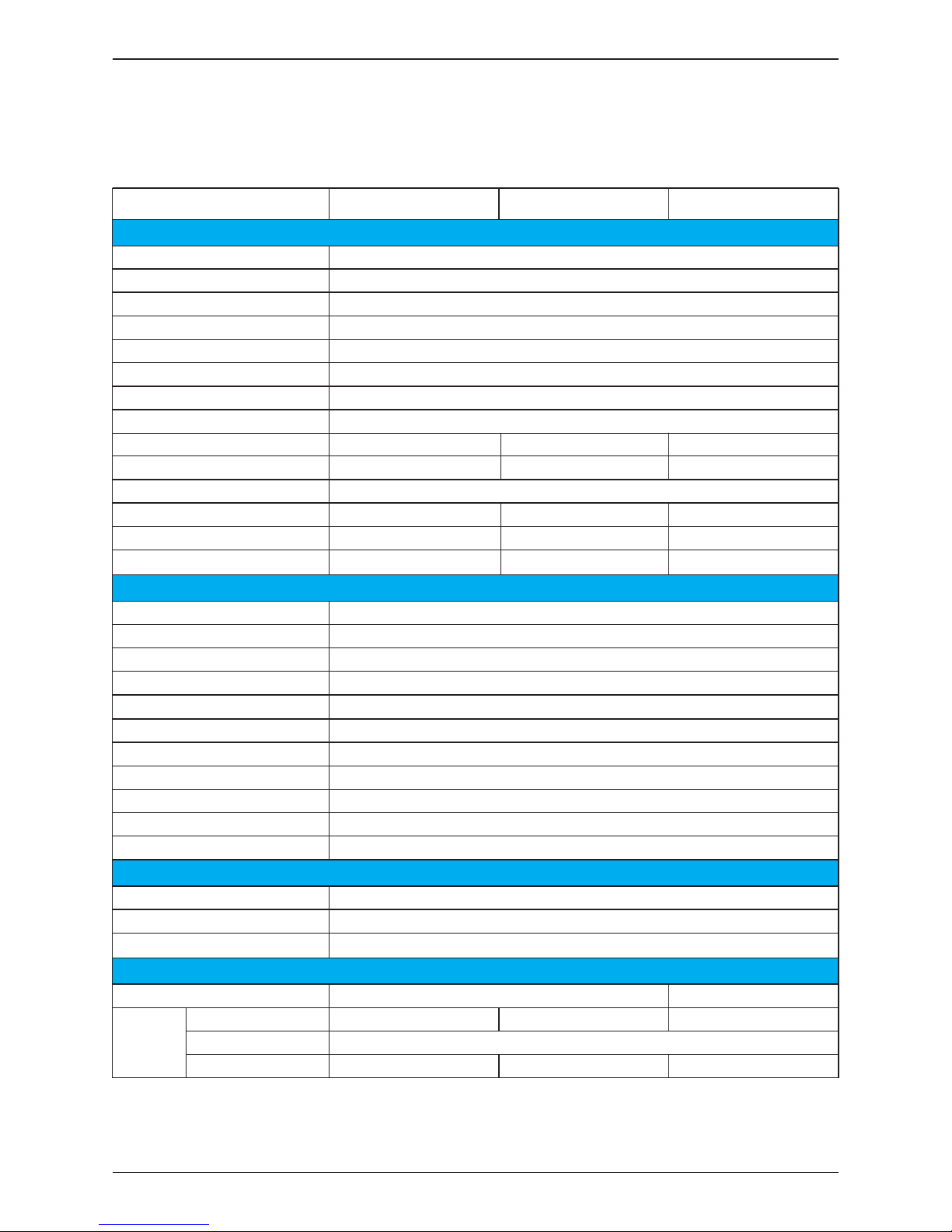

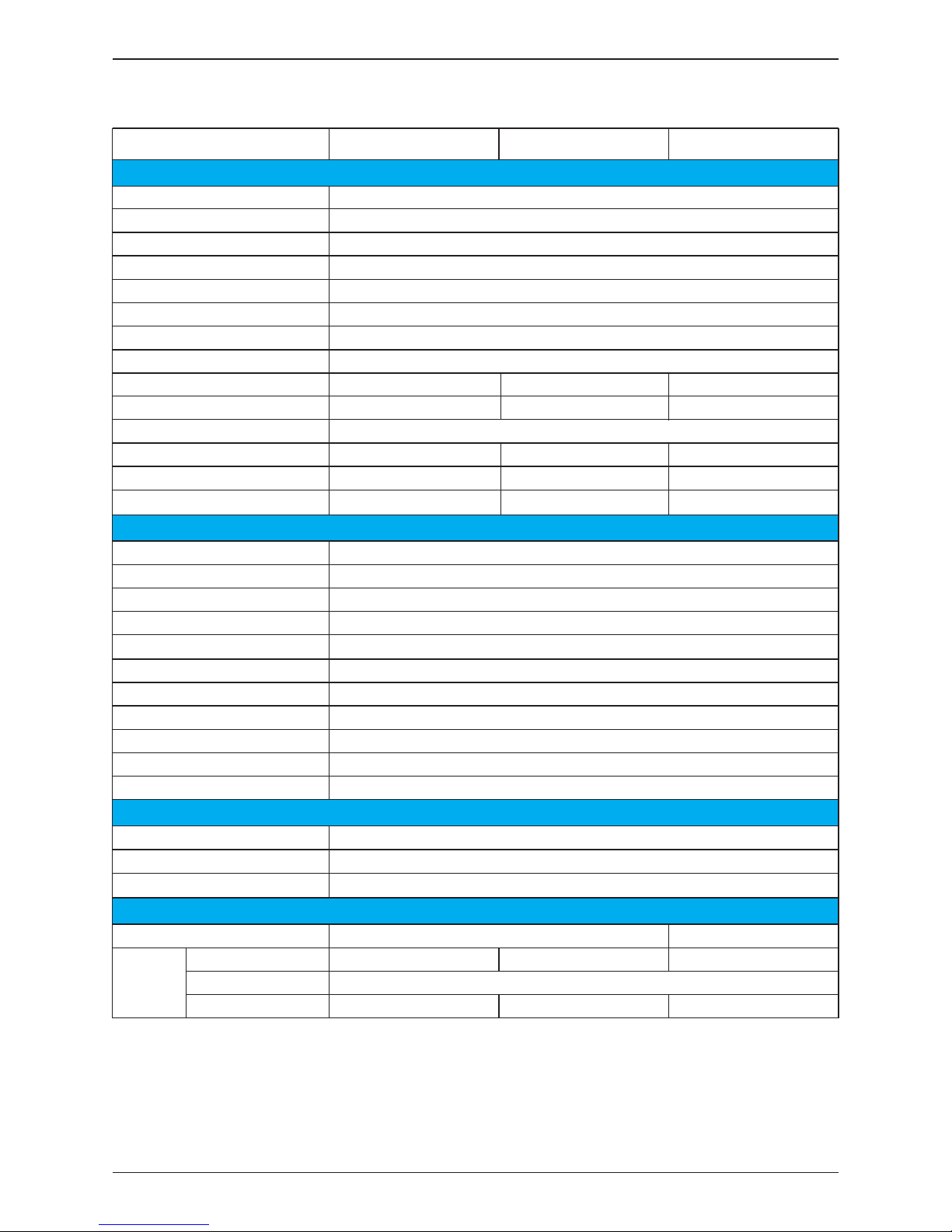

Table 4-3: Inverter Functions

Table 4-4: Controls Access Levels

Table 4-5: Dry Contact Trigger Options

Table 5-1: SPD Specifications

Table 5-2: Combiner Fuse Specification

Table 6-1A: Error Codes and Messages

Table 6-1B: Error Codes and Messages

Table 6-2A: Warning Codes and Messages

Table 6-3A: Fault Codes & Messages

Table 6-3B: Fault Codes & Messages

Table 6-3C: Fault Codes & Messages

Table 6-3D: Fault Codes & Messages

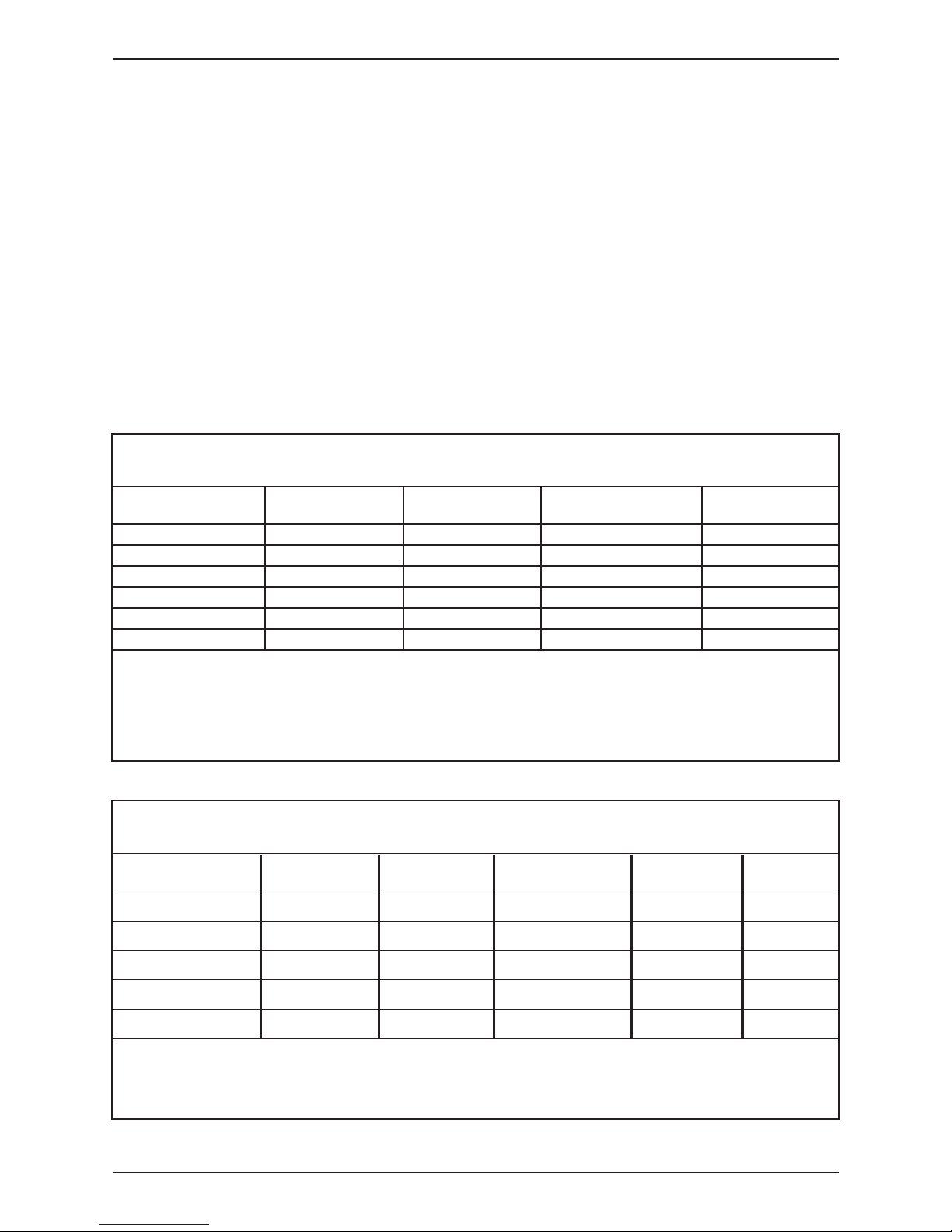

Appendix A-1: Low and High Voltage Ride-Through Set-points and Timing per Table SA9.1

Appendix A-2: Low and High Frequency Ride-Through Set-points and Timing per Table SA10.1

Appendix A-3: CA R21 Settings – Normal Ramp Rate (RR) & Soft-Start Ramp Rate (SS)

Appendix A-4: CA R21 Settings – Soft-start ramp rate test

Appendix A-5: CA R21 Settings – Specified Power Factor

Appendix A-6: CA R21 Settings – Volt/VAr Mode (Q(V))

Appendix A-7: CA R21 Settings – Frequency-Watt (FW)

Appendix A-8: CA R21 Settings – Volt-Watt (VW)

Appendix B-1:

Full Frequency Ride-Through Settings for O’ahu, Hawai’i Island, and Maui (HECO A)

Appendix B-2:

Full Frequency Ride-Through Settings for Moloka’i and Lana’I (HECO B)

Appendix B-3:

Full Voltage Ride-through Settings for O’ahu, Hawai’i Island, Maui, Moloka’i, and Lana’i

Appendix C-1:

Assembly Note for All model

Appendix C-2:

Assembly Note for 120 model

Appendix C-3:

Assembly Note for 121 model

Appendix C-4:

Assembly Note for 122 model

15

18

22

46

47

48

52

52

54

58

61

72

76

86

87

87

88

89

90

91

100

100

101

101

101

102

102

103

104

104

104

107

108

109

110

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . .

. . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . .

. . . . . . . .

. . .

. . .

9

1 Safety

1.1 Information of the Inverter

1.1.1 Legal Provisions

1.1.2 Target Group

Copyright – DELTA ELECTRONICS, INC. - All rights reserved.

This manual accompanies our product for use by the end users. The technical

instructions and illustrations contained in this manual are to be treated as

confidential and no part may be reproduced without the prior written permission

of DELTA ELECTRONICS, INC. Service engineers and end users may not

divulge the information contained herein or use this manual for purpose other

than those strictly connected with correct use of the product. All information

and specifications are subject to change without notice.

DELTA ELECTRONICS, INC. shall have no obligation to either personal injury

and property damage claims hereinafter with respect to any actions -- (a) the

product has been installed and/or repaired improperly; (b) the product has been

misused without following the instructions on this user manual; (c) the product

has failed due to incorrect unpacking.

This - manual – is prepared for use by a well-trained technician for installing,

commissioning, operation, and maintenance. The technician must have the

following basic and advanced skills:

• Knowledge of the fundamentals of electricity, wiring, electrical components and

electrical schematic symbols.

• Knowledge of how a solar inverter works and is operated.

•

Training in

the installation and commissioning of electrical devices and installations.

•

Training in

how to deal with the dangers and risks associated with installing

and using electrical devices and installations.

• Compliance with this manual and all safety information.

Safety

10

1.2 General Safety

- Please read these instructions carefully and save them for later use.

IMPORTANT SAFETY INSTRUCTIONS: SAVE THESE INSTRUCTIONS !

- The M42/36/28U is a transformerless solar inverter with dual independent

MPPtracking inputs, each of which converts the variable direct current

generated by the solar array into a utility frequency grid-compliant balanced

three-phase AC current and feeds it into the utility grid.

- The Photovoltaic modules used must be compatible with the inverter. PV

modules with a high parasitic capacitance to ground may only be utilized if the

capacitive coupling does not exceed 8μF. (For each MPPT channel)

- The inverter must only be operated in countries for which it is approved by

Delta and the grid operator.

1.2.1 Condition of Use

- The design of this inverter is transformerless. There is no isolation transformer

between the AC and DC sides, i.e., the product does not require galvanic isolation.

In order to function properly, any PV array connected must have its PV circuits

isolated from ground, i.e., do not bond either side of the array to ground!

If a grounded PV array is connected to the inverter, the error message INSULATION

(E34) will appear on the display.

- It is prohibited to reference the L1, L2, or L3 terminal to ground; to do so will

damage the inverter and void the producr warranty.

ATTENTION: NO GALVANIC ISOLATION

To prevent personal injury and/or property damage, and also to ensure long

term operation of the solar inverter, it is imperative this section be read carefully

and all the safety instructions understood before using this inverter.

This user manual provides important instructions for Delta grid-tie transformerless

solar inverter. The product is designed, tested, verified, and certified according

to international safety requirements, certifications, and standards but precautions

must be observed when installing and operating the product.

The inverter installation must be performed by an authorized electrician in

accordance with the the National Electrical Code® ANSI/NFPA 70 or the Canadian

Electrical Code® CSA C22.1 and/or other prevailing local codes, as well as

OSHA requirements. This product is suitable for both indoor and outdoor use.

11

Safety

This section describes the definition of the symbols in this manual.

In order to prevent both personal injury and property damage, and to ensure

long-term operation of the product, please read this section carefully and follow

all the safety instructions while you use the product.

1.2.2 Symbols

DANGER!

- This warning indicates an immediate hazard which will lead to death or

serious injury.

- This warning indicates a hazardous condition which may lead to minor injury.

CAUTION !

WARNING !

- This warning indicates a hazardous condition which may lead to death or

serious injury.

- This warning indicates a condition of potential damage to property and/or the

environment.

ATTENTION

12

Safety

- An exclamation mark enclosed in a double circle indicates additional important

information is contained in the following section and the user should follow the

instructions to prevent any hazards.

INFORMATION

DANGER: ELECTRICAL HARZARD!!

- This warning indicates an immediate electrical hazard that unheeded can lead

to death or serious injury.

- This warning indicates a potential burn hazard.

- Use care when touching surfaces when operating the product.

- Do not perform any task until the product cools down sufficiently.

CAUTION: HOT SURFACES, DO NOT TOUCH!

- This icon indicates that a prescribed time delay must elapse before engaging in an

indicated action.

- Patientez le délai requis avant d’entreprendre l’action indiquée.

- This symbol indicates the location of an equipment grounding conductor (EGC)

terminal.

13

Safety

The user manual is valid for the following device types:

This user manual must be followed during installation, operation, and maintenance.

The overview of M42U/M36U/M28U Series each have three models as shown

in Figure 2-2. Delta reserves the right to make modifications to the content

and technical data in this user manual without prior notice.

2 Introduction

2.1 Valid Model

• M42U_120

• M36U_120

• M28U_120

• M42U_121

• M36U_121

• M28U_121

• M42U_122

• M36U_122

• M28U_122

The M42U/M36U/M28U transformerless 3Ø PV inverters are designed to enable

the highest levels of efficiency and provide longest operating life by use of

state-of-the-art high frequency and low EMI switchmode technology.

They meet the design requirements of UL1741/SA, IEEE1547, IEEE1547.1,

IEEE1547.A and OSHA, and is suitable for indoor or outdoor use.

- This product utilizes a transformerless design, and is not provisioned with an

isolation transformer, and therefore has no galvanic isolation between the DC

and AC sides.

PV array circuits connected must be floating with respect to ground, i.e., must

not be referenced (bonded) to ground.

If grounded PV arrays are connected to the inverter, the inverter will not connect

to the grid and the error message INSULATION (E34) will appear on the display.

- It is prohibited to connect terminals L1, L2, or L3 to ground.

The inverter installation must be performed by an authorized electrician in accordance

with the the National Electrical Code® ANSI/NFPA 70 or the Canadian Electrical Code®

CSA C22.1 and/or other prevailing local codes, as well as OSHA requirements.

Introduction

14

The components of M42U/M36U/M28U is shown as Figure 2-1.

2.2 Product Overview

① ③② ④

Table 2-1: Packing list of M42U/M36U/M28U series

Figure 2-1: Components of M42U/M36U/M28U series

3 pcs

9

Screw

Ground bar mounting screws (122 Models)

(Stainless/M5/21mm)

5 pcs

10

Screw

To secure inverter to mounting bracket

(Stainless/M6/12mm)

Object Qty Description

1 Delta Solar Inverter 1 pc

1 pc

1 pc

Solar inverter

2 Wiring Gland 1 pc For communication port wiring

6 Shielding plate 1 pair Shelding plate for filter (use is optional)

5 Name plate cover 1 set Name plate cover for display

3 User Manual

Important instructions for solar inverter

Safety instructions should be followed

during installation and maintenance

4 Mounting Bracket

Wall mounting bracket

(Material: Aluminum/Thickness: 3mm)

7

Al Alloy Busbar 1 pc DC side PE/EGC Ground bar (122 Models)

8 MC4 connector

12 pairs String inputs for M42U

_122 model

10 pairs String inputs for M36U

_122 model

8 pairs String inputs for M28U_122 model

⑦⑥

⑨⑧ ⑩

For 122 model

⑤

BACK SIDE

15

Introduction

½" Opening for PE

AC Switch

Figure 2-2: Overview

Air Outlets /

Smart Fans

Rating Label

DC Switch

2" gland for

DC Wiring

Air Inlets

RS-485

communications port,

3/4" TSO

½" Opening for

PE/EGC

2" AC Cable

Opening

AC Switch

LCD / LED Display

and Buttons

Air Outlets /

Smart Fans

Rating Label

DC Switch

Air Inlets

MC4 type

DC connector

RS-485

communications port,

3/4" TSO

2" gland for

AC Wiring

LCD / LED Display

and Buttons

M42/36/28U_120

Air Outlets /

Smart Fans

Rating Label

DC Switch

2" gland for

DC Wiring

Air Inlets

RS-485

communications port,

3/4" TSO

2" AC Cable

Opening

AC Switch

LCD / LED Display

and Buttons

M42/36/28U_121

M42/36/28U_122

Introduction

16

Figure 2-3 below, shows the rating labels of M42U/M36U/M28U series, and

following in Table 2-2, there are definitions of the various symbols found on the

labels. Figure 2-4 ~ Figure 2-6 illustrate the differences in the appearance

between the various models.

Figure 2-3: Rating labels of M42/36/28U

Refer to table below for all models

DC terminal block is used / DC SW, AC SW, Fuse, String current monitor included.

DC terminal block is used / AC SW included, but no DC SW, no Fuse, no String current monitor

MC4 connector is used / DC SW, AC SW, Fuse, String current monitor included.

MxxU

_120

MxxU_121

MxxU_122

17

Introduction

Symbol Definition

FCC designation

Please read the user manual for further information

Danger: Electrical Hazard

This icon indicates that a prescribed time delay must elapse

before engaging in an indicated action.Electrical hazard might

exist before this duration.

Warning of the hot surface of the inverter

Table 2-2: Rating label explanation of M42/36/28U

In the following pages, Figures 2-4 through 2-6 illustrate the general layout

of the M42/36/28U chassis and wiring box, and Figure 2-7 and Table 2-3,

provides a detailed description of each wiring box option.

The Wiring Box area includes terminals for connection of the inverter input (DC)

wiring, output (AC) wiring, RS-485 communication and other signal wiring, as

well as DC & AC surge protection devices (SPD), DC switches, and fuse holders

for some models.

Use noise protection PPE

ETL Listed Mark approved by Intertek Lab

Certified as Grid Support Utility Interactive Inverter

18

Introduction

Dual MPPT channels, 6 strings/input

Dual MPPT channel, 5 strings/input

Dual MPPT channel, 4 strings/input

120

M42U

M36U

M28U

Figure 2-4: External view and Wiring box layout for 120 models

19

Introduction

Dual MPPT channels,

1 TB pair/input

Dual MPPT channels,

1 TB pair/input

Dual MPPT channels,

1 TB pair/input

121

M42U

M36U

M28U

Figure 2-5: External view and Wiring box layout for 121 models

20

Introduction

122

M42U

M36U

M28U

Figure 2-6: External view and Wiring box layout for 122 models

Dual MPPT channels, 6 strings/input

Dual MPPT channels, 5 strings/input

Dual MPPT channels, 4 strings/input

21

Introduction

Table 2-3: Wiring box layout description

Figure 2-7:Wiring box layouts

ComponentNO. NO.

2” cable opening for AC

½” cable opening for DC grounding

DC terminal for IN 1

DC terminal for IN 2

Component

7

8

12

NO. Component

Type II DC SPD

Internal AC terminal

13

17

Communication port

Grounding (M6 threaded stud)

18 External ground bar location

1

2

Fuse holder type DC IN1

9

Internal DC terminal

14

3

Fuse holder type DC IN2

10

15

4

DC switch

11

16

MC4 connectors (12 pairs)

5

6

AC switch

2” cable opening for DC

DC grounding bar Type II AC SPD

IN 1

IN 2

IN 1 IN 2

-120 Model WB

-121 Model WB

-122 Model WB

⑰

⑩

⑩

⑫

⑬ ⑭

①

①

④

⑪

⑪

②

②

③ ③

⑰

⑫

③⑤

⑥ ⑦

④

④

⑬ ⑭

⑰

⑩

⑱

⑯

⑮⑯⑮

⑫

⑬ ⑭

①

⑪

IN 1IN 1 IN 2IN 2

IN 1IN 1 IN 2IN 2

⑨⑧

⑥

⑤

⑥

⑤

⑩

⑨

⑨

⑧ ⑩

⑨

⑯

⑯

⑯

22

Introduction

3 Installation

- In some locations, mounting the inverter in direct sunlight may cause the

inverter to enter a thermal derating mode. To eliminate this concern, a shade

structure over the inverter chassis may be necessary.

CAUTION !

WARNING !

- Do not install the unit near or on flammable surfaces.

- Inverter must be mounted securely to a solid / smooth surface.

This unit is designed to be wall-mounted per Section 3.1.1 or Tilt Mounted per

Section 3.1.2.

Refer to Figures 3-2 through Figures 3-9.

1. Ensure the surface to which the unit is to be mounted is sufficiently strong

enough to carry the weight.

2. Orient the wall bracket (Figure 3-2) horizontally (perpendicular to the floor),

with the large plate at the bottom, and mark required mounting hole locations

per Figure 3-3.

3. Secure the mounting bracket on the wall with at least 8 5/16” (M8) screws.

4. Hang the inverter on the wall mounting bracket.

5.

Secure the inverter by inserting and tightening four screws (item 6, Figure 2-1)

as shown in Figure 3-9.

3.1 Mechanical Installation

3.1.1 Vertical wall mount

The chapter contains instructions for

(1) Mechanical installation

(2) Electrical Installation

(3) Communication setup

Figure 3-1 provides the mechanical dimensions of the inverter.

23

Installation

3.1.2 Horizontal or Tilt mount

- The mounting bracket shipped with the unit is specially designed and is the only

certified mounting device for mounting the inverter.

- Use a minimum of eight 5/16in (M8) screws to affix the mounting bracket to

mounting surface. See Figure 3-3.

CAUTION !

1.

Refer to Figure 3-4. Ensure the mounting stand meets the mounting dimensions

shown, with the large plate at the lowest end of the stand. Ensure the stand

is sufficiently strong enough to carry the inverter weight.

2. For vertical installation, if the inverter is exposed to sunlight(without shading),

a name plate cover must be installed to extend the lifetime of LCD display.

Please refer to Figure 3-4 for an example of name plate cover.

3. For tilt installation, a name plate cover must be installed to add protection

against harsh environmental conditions such as: direct sunlight, hail, snow and

pecking from birds. Please refer to Figure 3-4 for an example of name plate cover.

4. Orient the mounting bracket (Figure 3-2) squarely on the inverter stand, and

ensure cross-supports are located in line with the mounting screws locations

shown in Figure 3-3 (horizontal case) such that they can all be secured.

Mark required mounting hole locations per Figure 3-3.

5. Secure the mounting bracket to the stand with at least 8 x 5/16” (M8) screws.

6. Hang the inverter on the mounting bracket.

7. Secure the inverter by inserting and tightening four screws as shown in

Figure 3-9.

24

Installation

Figure 3-1: Inverter dimensions

615 mm [24.2 in]

818 mm [32.2 in]864 mm [34 in]

275 mm [10.8 in]

615 mm [24.2 in] 275 mm [10.8 in]

120 & 121

Models

122

Models

25

Installation

Figure 3-2: Mounting bracket dimensions

796.4 mm [31.4 in]

739.4 mm [29.1 in]

611.9 mm [24.1 in]

50 mm [2.0 in]

246 mm [9.7 in]

410 mm [16.1 in]

205 mm [8.1 in]

400 mm [15.7 in]

Necessary for vertical mounting Necessary for horizontal mounting

Figure 3-3: Required position for at least 8 screws

26

Installation

Figure 3-5: Prohibited mounting positions

O: Permitted / X: Prohibited

Figure 3-4: Permitted mounting positions

90

NAME PLATE COVER SHIELD

or

A name plate cover

must be installed.

Max. 90

Make sure the lowest point of the inverter chassis

must be ≥ 12” (30cm) from floor surface and

not susceptible to water immersion.

ROOF DECK

TYP SUPPORT

STRUCTURE

NAME PLATE COVER

≧12”

(≧30cm)

A name plate cover

must be installed.

27

Installation

CAUTION !

Figure 3-6: Wall mount fixed prior to inverter

Figure 3-7: Stress/torque should be prevented when installing the inverter

1. Install the wall mount bracket to the rack system prior to installing the inverter

Do not allow bending of rhe bracket. See Figure 3-6.

2. When installing the inverter on the rack system, use care not to apply excessive

stress/torque as shown in Figure 3-7. It’s known that for most tilt installations,

a rigid conduit body (e.g./ “LB”) will be applied to the AC side. Installer must

exercise care when installing, as overstressing the chassis may open a path for

water intrusion through the contact surface between the inverter module and the

wiring box.

28

Installation

- Please follow the instructions above such as permitted positions and

permitted mounting clearances for the correct installation.

CAUTION !

Figure 3-8: Required mounting clearances

> 50cm

[19.69in]

> 33cm

[12.99in]

Wall

Inverter

#2

Inverter

#1

> 5cm

[1.97in]

> 20cm

[7.9in]

> 80cm

[31.5in]

Figure 3-9: Screw locations to secure inverter WB to wall-mounting bracket

After installing the unit on the bracket, secure the wiring box to the bracket with

four screws per Figure 3-9. Tighten the screws to a torque of 40 lbf-in (4.5 N.m)

> 80cm

[31.5in]

> 80cm

[31.5in]

29

Installation

Figure 3-10: Installation method of shielding plate

Included with the inverter hardware are two sheet metal side shields, which can

be used to cover the open ends of the air inlet channel as shown in Figure 3-10,

and are intended to minimize nesting in the air channel by wildlife. Two shields

and associated screws are included.

Use of the shields does not significantly reduce airflow into the inlet filter, as the

rear side of the air channel is open, and thermal testing with the shields in place

has verified there is no associated operational degradation or derating of the

inverter due to their use as long as the rear access remains open.

To use the shielding plate, please refer to the installation method in Figure 3-10.

Tighten the screws to a torque value of 40 lbf-in (4.5 N.m)

①①

②②

①①

②②

3.1.3 Accessories

30

Installation

- Please check the front and the back of the name plate cover

when installing.

Small shade: The side with tape is back side.

Large shade: The side with word "BACK SIDE" is back side.

- After sticking the name plate cover on the inverter, do not remove it

in 1 hour to ensure the stickiness of the tape.

CAUTION !

Name plate cover

BACK SIDE

②

①

Clean the surface of the inverter. Peel off the double-sided tape.

① Inserter the small plate into the

upper edge of the inverter.

Make sure the back side(with

tape) is facing inverter.

② Stick the plate on the inverter.

①

②

Push hard on the plate to ensure

the stickiness.

① Insert the large plate into the

bottom edge of the inverter.

Make sure the front side(with

folding) is facing you.

② Align screw holes to combine

two plates.

Tighten these screws with torque

2 N.m

Installation

31

Remove name plate cover

If there is needed to monitoring or setting the display, please follow procedure below.

CAUTION !

②

①

① Separate the large plate.

② Pull out the large plate.

Loose two screws.

Start monitoring or using the

display.

32

Installation

3.3 Electrical Installation for AC Wiring

DANGER: ELECTRICAL HARZARD!!

-

To avoid shock hazard during cabling, insure any live grid connections are removed

from the inverter.

- Wire sizes chosen for the AC conductors must meet ampacity requirements of

NEC Section 310 or equivalent.

- Wiring method for the AC Installation must comply with the local electrical code.

- Failure to follow the instructions may result in damage to the inverter and AC

conductors.

CAUTION: INVERTER AND EQUIPMENT DAMAGE MAY OCCUR !

WARNING !

- Installation and commissioning must be performed by a well-trained person

(e.g.a licensed electrician) in accordance with local, state, and National Electrical

Code ANSI / NFPA 70 requirements.

- Input and output circuits of this unit are isolated from the enclosure System

grounding must be done in accordance with the National Electrical Code (NEC).

- Compliance to the local electrical code is the installer's responsibility.

- Inverter warranty void if the DC input voltage exceeds 1000 Vdc.

- The M42/36/28U solar Inverters must be connected to a 3-phase 480 Vac utility

service. NEC 705.12(D)(1) requires that the inverter (every fixed appliance) must

be connected to a separate, dedicated circuit breaker (or other approved OCPD)

with no other outlets or devices connected to the same circuit (not shared by

any other appliance).

CAUTION: POINT OF CONNECTION !

- This inverter may be damaged due to moisture or dust intrusion.

DO NOT OPEN the power module section of the inverter.

ATTENTION

- In order not to damage the components in the inverter, ensure the correct

conductor is connected to the appropriate AC switch on the inverter.

CAUTION: WRONG AC WIRING !

For first time installing/re-installing WB cover, in order to guarantee proper

long-term operation of the inverter, procedures in Section 5.1 must be followed.

3.2 Wiring box cover

33

Installation

Figure 3-11: Stripping guide for AC conductors

Model Upstream circuit breaker

M42U ≧75A

M36U ≧63A

M28U ≧50A

3.3.1 AC Grid Types and Connections

The use of a Neutral (N) conductor is optional and depends the grid type and upon

local codes. The default AC Grid connection is 3Ø-3W. If a neutral is required,

this setting must be changed to 3Ø-4W via the front panel controls. The inverter

will operate from the following grid connections without need of an external

transformer:

Grid Type

480V/277V/ 3Ø-4W/Yg,

480V/277V/ 3Ø-4W/Y

480V/3Ø-3W/∆ (ungrounded)

ATTENTION

Inverter connection

3W or 4W +EGC

3W + EGC

3W +EGC

3.3.2

Required Protective Devices for M42/36/28U AC Grid

North American electrical codes require a dedicated over-current device such

as a circuit breaker in line between the inverter and AC source.

3.3.3 AC wiring preparation (all models)

Below is the procedure for preparing the AC conductors for connection to the

AC terminals (all versions):

• Ensure the AC conductors used are sized to the correct ampacity per NEC or

other local code. Refer to Figure 3-11.

• Strip off all wires for 14 ~16mm [0.55~0.63in].

• The cross-sectional area for each internal cable is 6~4 AWG (14~22mm²).

• Do not use copper-aluminum terminals.

L1

L2

L3

N

PE

Conduit

to/from

AC Grid

Stripping length:

14 ~16mm [0.55~0.63in]

Conductor cross-section:

6~4 AWG (14~22mm²)

Conductor cross-section:

6~4 AWG (14~22mm²)

* The PE wire is rec ommended to

use the same size (or the larger size)

as L1, L2, and L3.

(The maximum wire size is 2 AWG)

34

Installation

3.3.4 AC Switch Terminals –Prewire set-up

The AC switch terminals utilize cage-clamp design terminals and in order to

insure proper connection of wiring, prior to inserting stripped conductors into

switch terminals complete the following procedure to make terminals ready for

connections. For each of the AC switch terminals (L1, L2, L3 and N):

1. Use a flatblade screwdriver loosen the cage-clamps by turning the clamp

screw CCW until the screw reaches limit of rotation)

If an electric screwdriver is utilized insure the torque setting is low enough to

NOT OVER-TORQUE the screw. Once screw bottoms out, do not turn it any further.

2. Verify visually the cage clamp is in the fully open position

For AL AC wires:

To make sure good conductivity, bi-metal adapter must be used in conjunction

with aluminum wires.

Extreme temperature rise at the clamping point

If the contact resistance between the aluminum conductor and clamping point is too

high, the clamping point can become very hot and even catch fire in extreme cases.

To ensure a safe and reliable contact, always perform the following work steps:

Use a conductor cross-section at least one number larger due to the lower

current-carrying capacity.

Keep the installation location as free as possible from moisture or corrosive

atmospheres.

Connect the aluminum cables quickly.

Mechanically clean the stripped end of the aluminum conductor (using for instance

a knife blade to scrape off the oxide layer). Then immediately dip the aluminum

conductor into acid-fee and alkaline-free (=neutral) Vaseline and straight away

insert it into the terminal block.

Tighten the clamping screw in the clamping body with the maximum permissible

tightening torque.

NOTICE

Please seal the conduit from inside the wiring box

by using duct seal to prevent living creature or

moisture enter the wiring box.

ATTENTION

EMT

Duct Seal

35

Installation

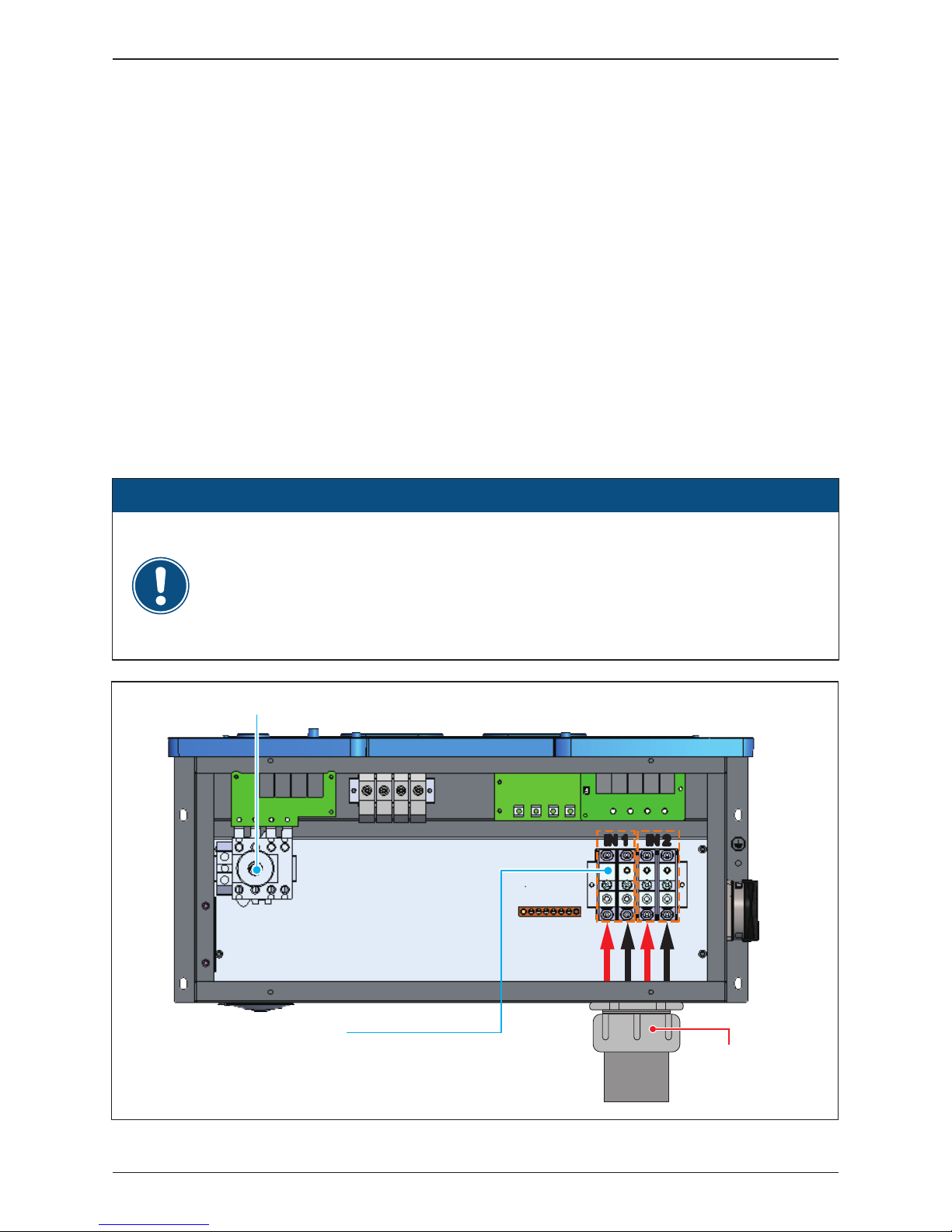

Figure 3-12 illustrates the location of the AC conduit entry and connections for

AC terminal block:

- Open all AC switch cage-clamps as noted in Section 3.3.4

- Ensure the correct conductor is connected to the appropriate terminal.

- After conductor is inserted, tighten L1~N terminal with a torque value of 24

lbf-in (2.8 N.m), PE terminal with 31 lbf-in (3.5 N.m).

3.3.5 AC Wiring for all models

Figure 3-12: Location of AC terminals and wiring (all versions)

Torque 24 lbf-in (2.8 N.m)

to fix the screw

AC switch (Terminal)

31 lbf-in (3.5 N.m)

to fix the screw

2" cable gland for AC

with EMT

EMT

36

Installation

DANGER: ELECTRICAL HARZARD!!

- PV array converts sunlight into electric power with high DC voltage and high

DC current which can cause dangerous electrical shock hazard!

- Use an opaque material to cover the PV array before wiring or cabling.

- Ensure the correct polarities are connected when DC cabling is applied.

WARNING !

- The risk of electric shock and fire.

- Use only PV modules that are UL Listed to1000V or higher.

- Ensure the two DC switches are placed in the "OFF" position, and the PV array

is disconnected when DC conductors are connected.

3.4 Electrical Installation for DC Wiring

- The PV Array current carrying conductors (positive or negative) must not be

referenced to ground.

ATTENTION

- In order not to damage the components in the inverter, don’t repeat to change

the status of DC Switch quickly, the correct operation is waiting for the LCD

display show ”No DC” or turn on the switch after 1 minute later.

CAUTION: DC SWICH ON/OFF !

Please seal the conduit from inside the wiring box

by using duct seal to prevent living creature or

moisture enter the wiring box.

ATTENTION

EMT

Duct Seal

37

Installation

Figure 3-13: Location for DC terminals for 120 models

IN 1

IN 2

IN 1 IN 2

EMT

1½ " cable gland for DC with EMT

Stripping length: 10~11mm [0.40~0.43in]

Conductor cross-section: 12~10 AWG (4~6 mm²)

Torque 16 lbf-in (1.8 N.m) to fix the screw

½" Opening for PE

2" cable gland for DC with EMT

- Ensure all fuse holder terminals are tightened to the specified torque value of

16 lbf-in (1.8 N.m).

ATTENTION

• Ensure the DC conductors used are Cu and sized to the correct ampacity per

NEC or other local code

• Strip off all wires for 10~11 mm [0.4~0.43 in].

• The cross-sectional area for each DC conductor is 12~10 AWG.

• Ensure the fuse holder terminal clamp is open

• Ensure correct conductor is connected to the correct fuse holder.

• Tighten each individual screw terminal screw to a torque value of 16 lbf-in

(1.8 N.m).

• Two 2” chassis access holes (KOs) can be utilized to connect conduits from

PV array DC wiring into the inverter, as shown in Figure 3-13.

• 120 models is compatible with 1000V/20A UL listed fuse.

Please read the following instructions for connecting DC terminals (120 models):

3.4.1 DC Wiring Installation for 120 models

AC Switch

Input 1 Fuse holders Input 2 Fuse holders

38

Installation

• These models are designed to be utilized with external combiner boxes and

are not provisioned with internal DC combining capability.

• Specific size of DC conductors must be determined from NEC or other local

codes.

•

The range of conductor sizes accommodated by each DC terminal is 8~2 AWG.

• Ensure the correct conductor is connected to its associated terminal.

•

Tighten each terminal block screw to a torque value of 8AWG - 40lbf-in (4.5N.m)

; 6~2 AWG - 110 lbf-in (12.4 N.m).

• The bending space is 160 mm [6.3in] which meets the safety standard.

• For the 121 model, two mounting options for installing the DC connection are

available, bottom or side entry; both options have a 2" chassis access hole

(KO). Side entry is shown in Figure 3-14.

Please read the following instructions for attaching DC terminals (121 models):

3.4.2 DC Wiring Installation for 121 models

Ensure the DC terminal block screws are tightened to a torque value of

8AWG - 40 lbf-in (4.5 N.m)

6~2AWG - 110 lbf-in (12.4 N.m)

- For aluminum cable :

Min./max. Conductor cross-section 10 / 33.6 mm

2

Tightening torque 110 lbf-in (12.4 N.m)

ATTENTION

Figure 3-14: Location for DC terminals for 121 models

IN 1 IN 2IN 1 IN 2

DC Terminals

Stripping length: 17mm [0.67in]

Conductor cross-section: 8~2AWG(8~33.6mm²)

Torque: 8AWG

-

40 lbf-in (4.5 N.m)

6~2AWG

-

110 lbf-in (12.4 N.m)

AC Switch

EMT

2" cable gland for

DC with EMT

39

Installation

Please follow the following guideline for cabling if you use aluminum cables.

Guideline for aluminum conductor :

- The oxide layer must be removed from the surface of the stripped aluminum

conductor.

- The stripped aluminum conductor is greased with Vaseline or contact grease

with comparable properties after oxide layer removed.

- Tightened with the maximum tightening torque for the modular terminal block.

- The installation location must be kept free from humidity or aggressive

atmospheres.

- It is recommend to apply to sector-shaped single-strand conductor ;

The conductor shape must match the sector-shaped connection

Figure 3-15: Guideline for aluminum conductor

match the sector-shaped of the connection

SE

Sector-shaped

single-strand

90°

40

Installation

Figure 3-17: DC Wiring illustration

Please read the following instructions for connecting DC terminals (122 models):

• It is important to choose the proper size for DC cable.

• The cross-sectional area for each internal cable is 12~10 AWG (4~6mm²).

DC wiring polarities are divided into positive and negative, which is shown in

Figure 3-17. The connection shall be coherent with the indication marked on

inverter.

3.4.3 DC Wiring Installation for 122 models

Figure 3-16: Location for DC terminals for 122 models

+

-

IN 1 IN 2IN 1 IN 2

PV-KST 4/6 Ⅱ

PV-KBT 4/6 Ⅱ

+04 +05 +06+01 +02 +03 -01 -02 -03 -04 -05 -06

Fuse Board 1

+04 +05 +06+01 +02 +03 -01 -02 -03 -04 -05 -06

Fuse Board 2

+01

-01

+03

-

03

+05

-

05

+02

-

02

+04

-

04

+06

-

06

+01

-01

+03

-

03

+05

-

05

+02

-

02

+04

-

04

+06

-

06

IN 1

IN 2

IN 1 IN 2

41

Installation

3.4.4

Ground bar locations for 120/121 models

Figure 3-18: Ground bar location for 120/121 models

Figure 3-18 shows the AC/DC grounding bar locations for the 120/121 models.

The wire gauge of the ground cable: 6AWG~4AWG

Torque grounding cables to 26 lbf-in (3 N.m)

-120 Model WB

-121 Model WB

42

Installation

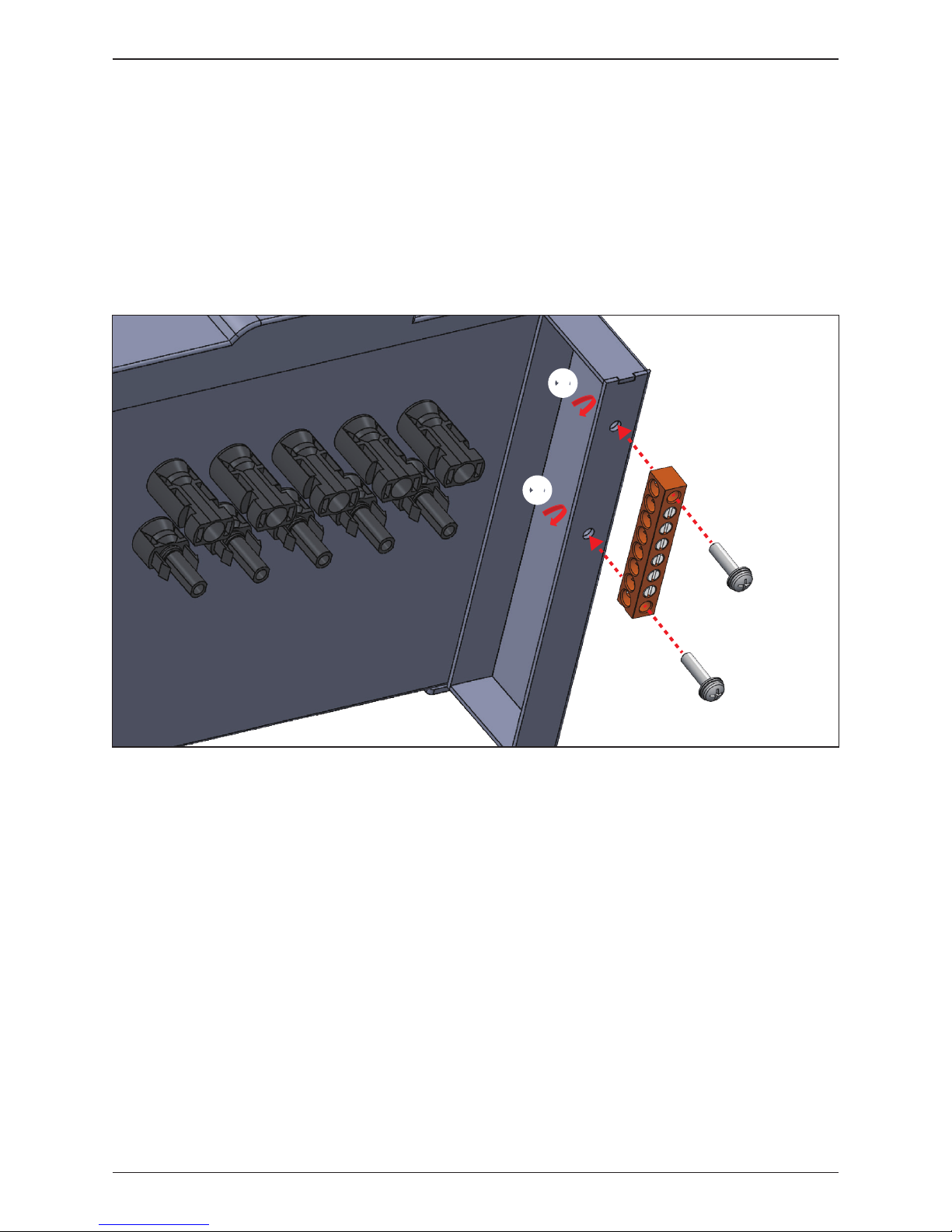

3.4.5 DC side ground bar for 122 models

Figure 3-19: Mounting the DC side ground bar to WB

After installing the unit, locate the ground bar and associated screws in accessory

bag. Be sure to orient the ground bar as shown in Figure 3-19. Torque the mounting

screws to: 22 lbf-in (2.5 N.m)

The busbar accommodates grounding conductors in the range of 6AWG~4AWG

Torque grounding conductors to 26 lbf-in (3 N.m)

①

①

②

②

②

②

43

Installation

The communication module of M42/36/28U is shown in Figure 3-20.

It provides VCC, RS-485, dry contact, EPO, and Digital Input terminals for use

in various applications. Details for each are presented below. There's a 12VDC

source between VCC & GND for use with external device.

3.5 Communication Module Connections

Figure 3-20: Communication Module Layout

Dry Contact

VCC & RS-485 EPO*1 &

Digital Inputs*6

Terminal Resistor

44

Installation

The communication module consists of an assembly with a PCB and a plastic

carrier. It is located in a slot through the bottom of the wiring box chassis.

It is accessed from the bottom exterior of the wiring box. The carrier is secured

to the chassis by two self-retaining screws. See Figure 3-21.

To access the communication module, loosen the two self-retaining screws to

loosen the carrier from the chassis. Once loosened completely, the card/carrier

module can be withdrawn from the wiring box chassis by gently pulling the

carrier straight out from the chassis.

After pulling the desired signal cable(s) through the wiring gland provided or a

connected conduit, and connected electrically as shown in the following sections,

the module can be reinstalled by reversing the above directions. Ensure the

assembly is oriented into the chassis so as to allow the edge connector to

engage properly.

3.5.1 Accessing the Communication Module

Figure 3-21: Location and access to Communication Module

* Screw torque required for assembling:

7 lbf-in (0.8N.m)

45

Installation

The pin definition for the RS-485 terminal block is shown in

Table 3-1.

- Pins 1 and 2

provide a 12DC bus for use with accessories such as R3 Power Monitor.

- Pins 3 and 5 are both connected to the DATA+ input.

- Pins 4 and 6 are both connected to the DATA

-

input.

These connections allow easy daisy-chaining of multiple inverters.

A 120 ohm bus termination resistor and associated control switch are located

on the communication board (See Figure 3-20) The switch function is as shown

in Table 3-2.

Different RS-485 connection scenarios require different set up for the 120 ohm

bus termination resistor.

•

When several inverters are cascaded (i.e., "daisy-chained") only the last inverter

in the chain must have its bus termination resistor switched ON. Refer to

Figure 3-22.

•

If the length of any RS-485 bus is greater than 2000' (610m), the use of Belden

3105A cable (or eq.) is recommended to insure communication quality.

(When using R3 Monitor, a 4-wire cable is required; Belden 3108A (or eq.) is

recommended.)

3.5.2 RS-485 Connection

Pin Function

1 VCC (+12V)

2 GND

3 DATA+

4 DATA-

5 DATA+

6 DATA-

Table 3-1: Definition of RS-485

1 2 3 4 5 6

In order to have good transfer quality, twisted-pair wire is recommended to be

used as communication cable.

ATTENTION

46

Installation

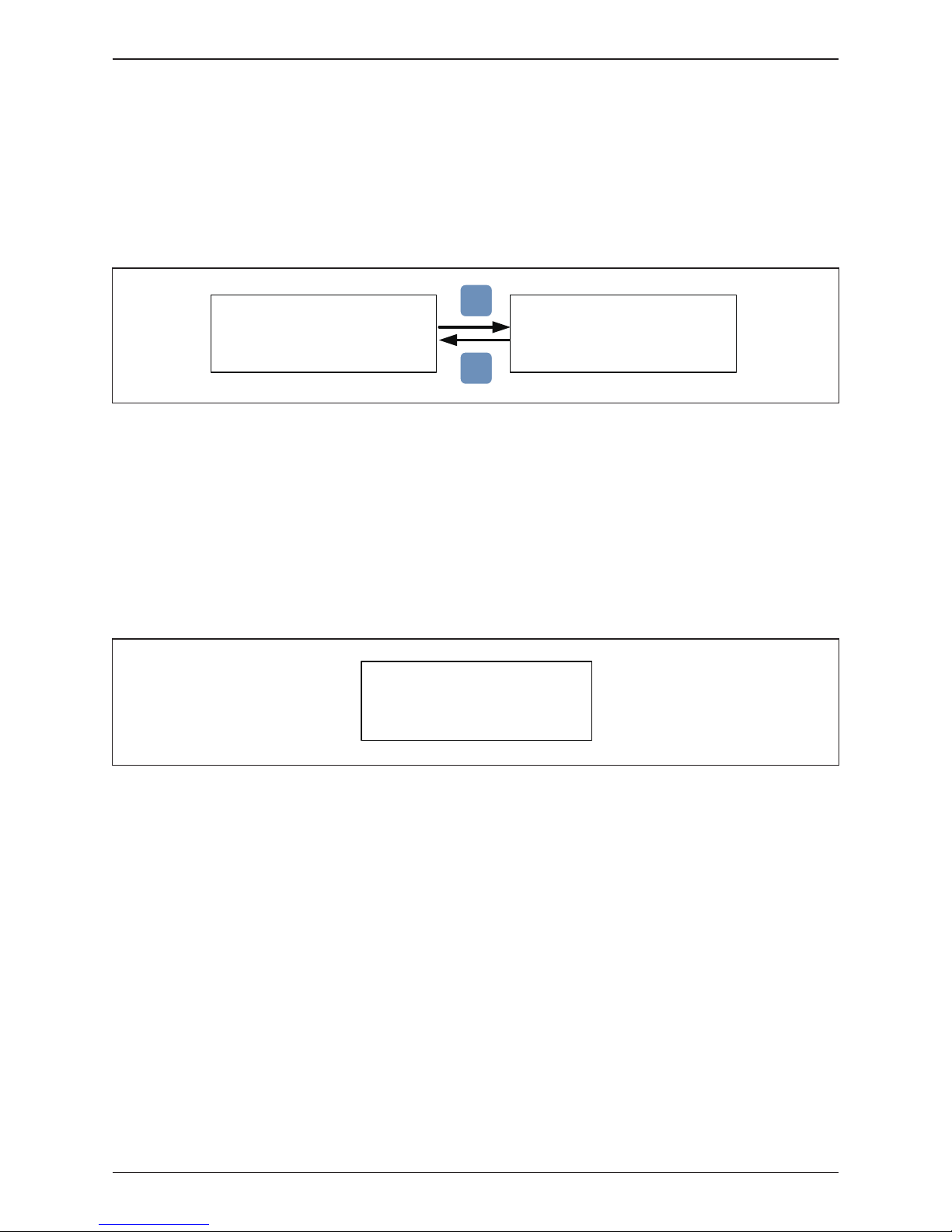

Figure 3-22: Multiinverter connection illustration

Data Format:

Baud rate: 19200

Data bits: 8

Stop bit: 1

Parity: N/A

RS485/USB

or

RS485/RS232

Terminal Resistor

(Last inverter in chain must have

Switch 2 in ON position.)

Switch 1

Terminal Resistor ON

Terminal Resistor OFF

OFF

ON

Table 3-2: Terminal resister setting

47

Installation

The communication Module has an emergency power off function (EPO), and

EPO enable can be found in the Install Settings page.

Once enabled, the EPO function can be used to turn off the inverter via a NO

relay contact connected across terminal [V1 & K0]

Additionally, a digital power reduction control is available that can be set to

limit the inverter's available active output power. The control settings for this

function are made by placing a hardware short (jumper or relay) between two

terminals of the terminal block shown in Table 3-3, below.

3.5.3 EPO Function & Digital Input

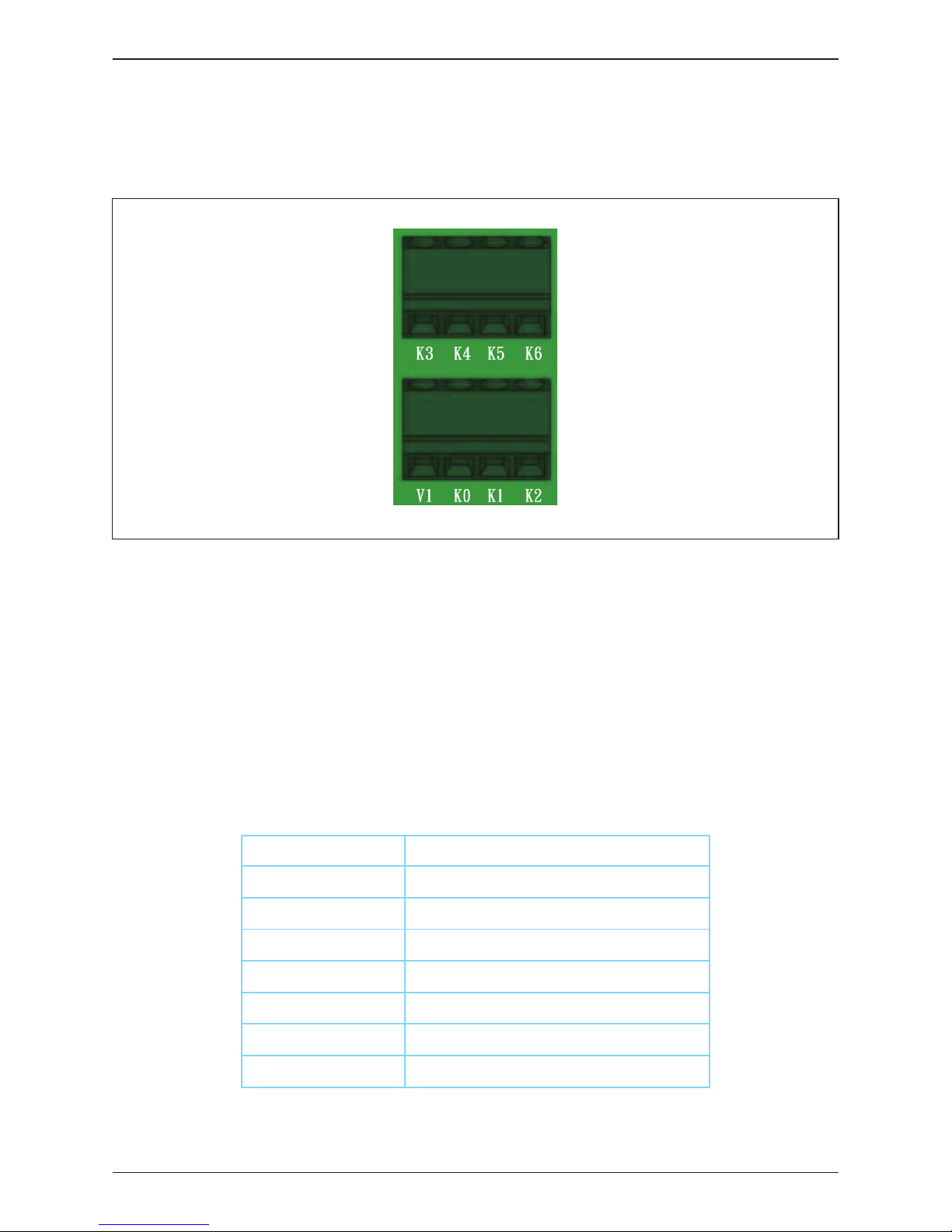

Figure 3-23: EPO function terminal block

Table 3-3: Definition of EPO function & Digital input

Inverter’s action

Emergency power off (EPO)

0% active power

Maximum 30% rated power

Maximum 60% rated power

Maximum 100% rated power

Reserved

Reserved

Short terminals

V1 & K0

V1 & K1

V1 & K2

V1 & K3

V1 & K4

V1 & K5

V1 & K6

48

Installation

The M42/36/28U series provides a dry control contact pair that may be used

to control external devices based on the status of operation of the inverter.

The terminal block for this function is shown in Figure 3-24. The terminals marked

in the figure identify the dry contact connection. The operation of the dry contact

is normally open. The functionality of this contact can be customized by users via

settings available in the Settings Menu.

3.5.4 Dry Contact connection

Figure 3-24: Dry Contact connection

Dry Contact

Position Not used

49

Installation

For customers who want to do on-site insulation test, please make sure:

1. The DC switches are in “OFF” position.

2.

Apply one probe to the positions shown in Figure 3-25, the other to the ground.

It might cause damages to the inverter if probes are applied to inappropriate

positions.

3.6 On-site insulation test

Figure 3-25: Precautions for on-site insulation test

-120 Model WB

-121 Model WB

-122 Model WB

Hi-pot / InsulationHi-pot / Insulation

Hi-pot / Insulation

or

DC Switch

OFF

or

DC Switch

OFF

Hi-pot / InsulationHi-pot / Insulation

or

DC Switch

OFF

50

Installation

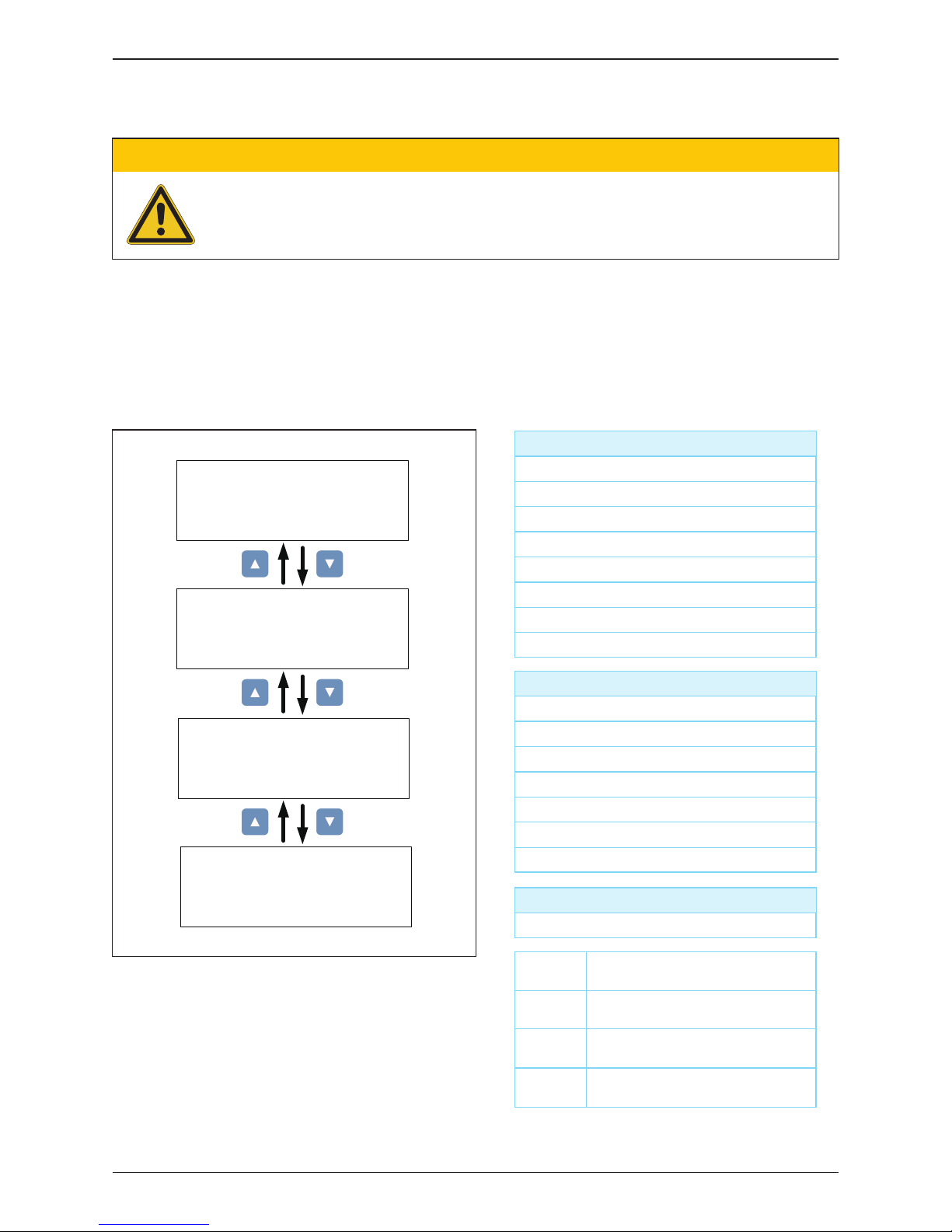

4 Commissioning

- Be careful of hot surfaces when operating the product!

- Do not perform any task until the unit cools down or appropriate personal

protection gear is worn.

CAUTION: HOT SURFACES, DO NOT TOUCH!

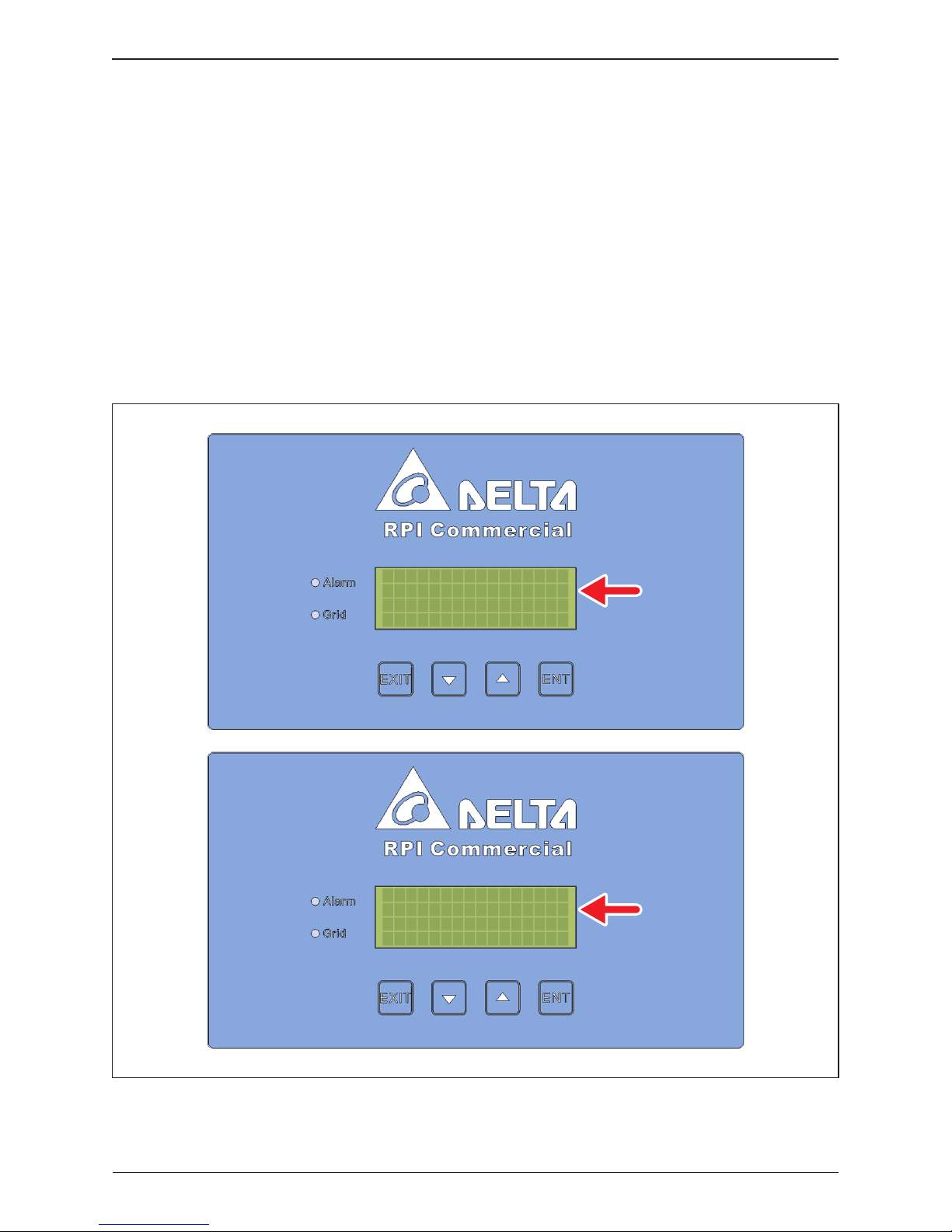

4.1 Display Operation Introduction

M42/36/28U series include a front panel 4x20 character LCD display which

includes four programming keys and 2 LEDs (located on the left-hand side of

the LCD) that allow visual display of the inverter’s data and status as shown in

Figure 4-1. Please refer to Table 4-1 for information as to the information

provided by the LED indicators.

Access to various screens and the adjustment of inverter settings are done using

the LCD screen and the four programming buttons directly below the LCD screen,

See Table 4-2 for programming descriptions of operation.

When adjusting settings, LCD panel will change the display cursor from “►” to

“ ”

Figure 4-1: Front Panel Display

LED Indicator (RED)

LED Indicator (GRN)

EXIT: Exit Menu

Down: Move Down

UP: Move UP

ENT: Enter Menu or Confirm

LCD screen

51

Commissioning

Condition Green LED Red LED

Countdown FLASH * OFF

Power ON ON OFF

Error or Fault OFF ON

Standby or Night time (No DC) OFF OFF

Bootloader mode FLASH *

* ON 1s / OFF 1s

Table 4-1: LED indicator

Table 4-2: Programming keys and actions

Symbol Action

ENT Enter a Menu or Confirm a programmed value

▲ Move cursor UP in menu or increase a programmed value

▼ Move cursor Down in a menu or decrease a programmed value

EXIT

Button

Enter

UP

Down

Exit Exit Menu

52

Commissioning

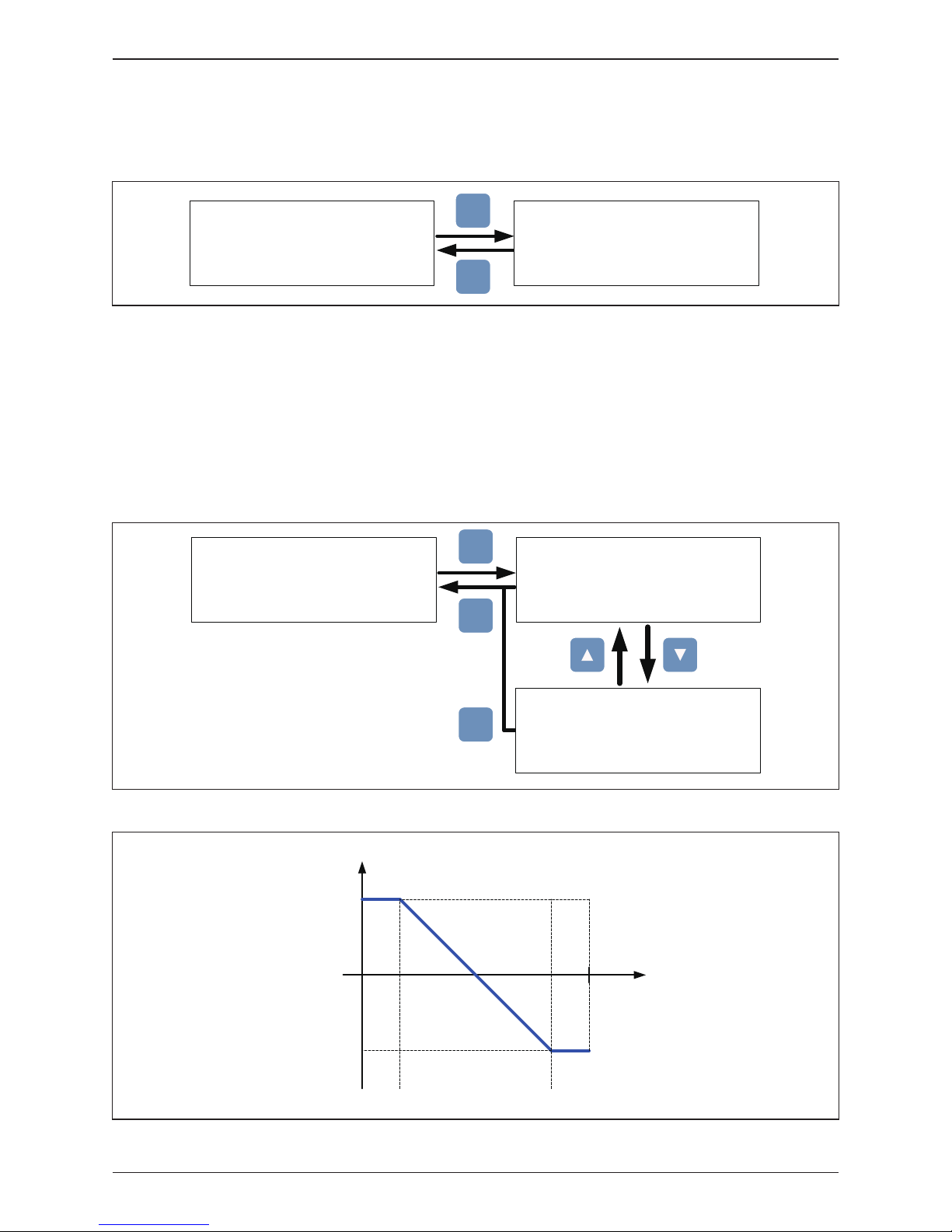

The following sections indicate inverter status and settings as shown on the LCD

display.

4.2 First startup

Figure 4-2: Grid code, language and ID settings for first startup

Are you sure to

set Grid Code ::

IEEE1547 480V

Yes / ► No

Are you sure to

set protocol :

Delta prot.

Yes / ► No

Are you sure to set

ID : 1

Yes / ► No

Select Grid Code,

1741 SA-277V

IEEE1547 480V

IEEE1547.A 480V

►

Select Language,

English

Deutsch

Français

►

Setting ID:

ID = 001

Pass: to Home page

Fail: to Home page but in locked status

and indicated“AFCI fail”

06. Oct 2018 15 : 33

AFCI

Self Testing . . .

AFCI Self Test

Result: Pass

When setting is

IEEE1547

Delta prot.

Sunspec prot.

EXIT

ENT

EXIT

ENT

ENT

►

* AC Connection: 3P3W is factory default; see Section 4.3.7.9 for further details.

Yes / ►No

EXIT

ENT

EXIT

ENT

EXIT

ENT

EXIT

ENT

EXIT

ENT

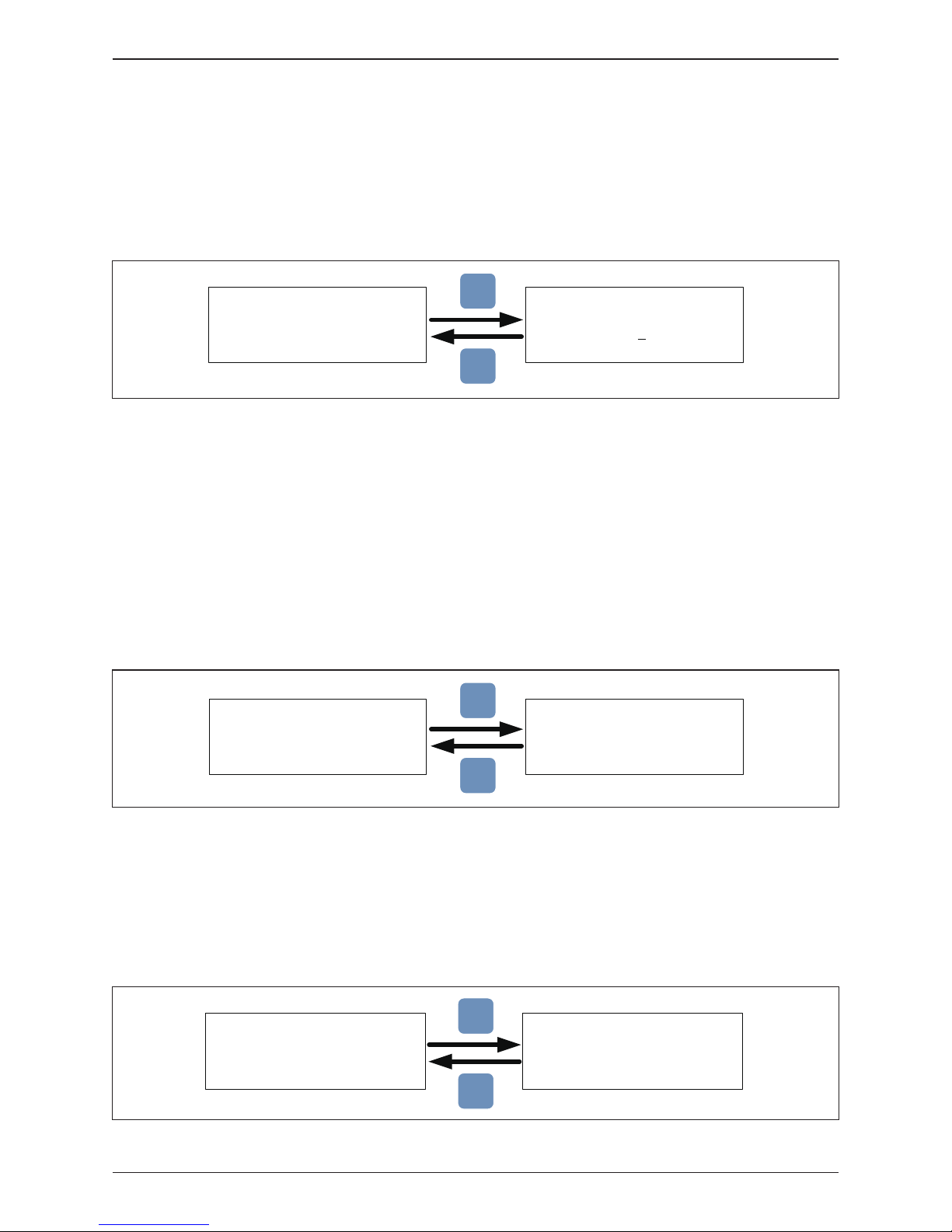

At the time of initial startup, a First Start routine is started allowing user to set

basic functions without need of a password. An appropriately sized PV array and

an AC grid must be available and connected to the inverter. Procedure is as follows:

• Complete the appropriate system pre-commissioning procedure(s).

• Initially, ensure both DC switches are in OFF position, and interconnect the

inverter to the AC grid by turning on internal and any external AC switches as

required.

• Verify the inverter control system is powered by noting that the LCD display

panel has become active.

• During the initial startup, when the LCD display become active, the inverter

control will enter the First Start-up routine which allows installer to set Language,

Grid code, RS-485 protocol and inverter ID (RS-485 address). Figure 4-2 below,

illustrates the display flow charts of the inverter startup.

• Using display and programming keys, set desired language and the country

(Grid Code) associated with the installation location and wait for the AFCI Self

Test to complete.

• Verify AFCI self test result is a pass.

• Close both DC switches, and await inverter to complete its self test sequence,

which takes approximately two minutes.

•

Verify via the display there are no errors, faults or warning indications displayed

on the home page.

• If there is sufficient power available from PV array, inverter will connect to grid

and begin exporting power to the grid.

53

Commissioning

4.2.1 Home Page

Figure 4-3: Home Page screen

21 Jan. 2016 16:30

Status: :

Power:

E-Today:

42000 W

147 kWh

On Grid

Inverter Status

Output Power

Today Energy

Day -Time

After completion of First Start and inverter is in normal operation, the LCD will

display the homepage screen as shown in Figure 4-3. The user can view

information to include output power, inverter status, E-today, date and time.

Pressing "any" key in home page mode will open the main menu. To return to

Home Page screen, press EXIT at main menu or wait 5 minutes without any

key operation, the display will return to homepage.

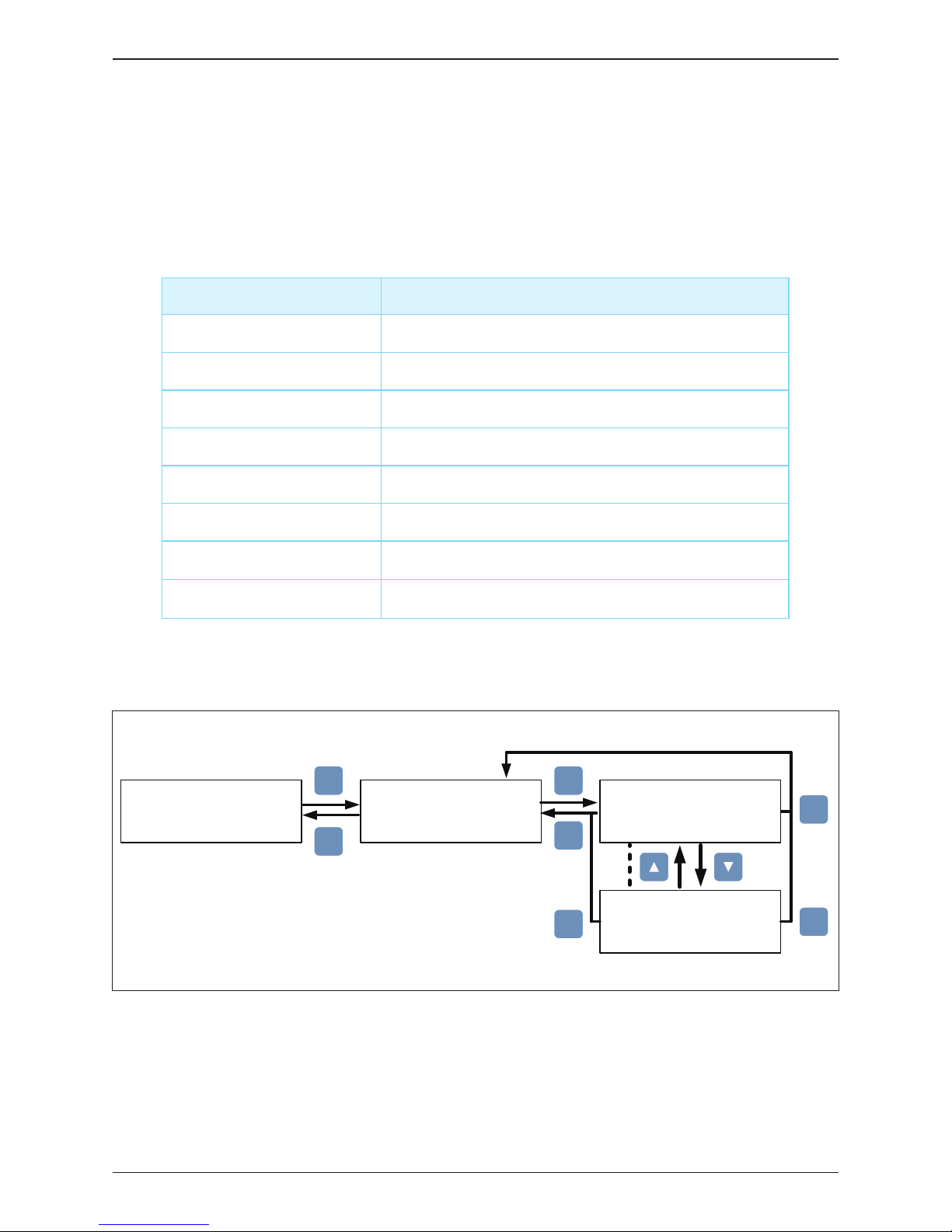

Table 4-3 contains is a listing of all inverter functions that can be adjusted by

users (U) and installers (I) via the LCD panel, and the associated manual

subsection where a description of the operation of each is found.

4.3 Main Menu

Table 4-3: Inverter Functions

Function Para

Power Meter 4.3.1

Energy Log

String Current Mon

4.3.2

Event Log

4.3.3

Information

4.3.4

General Settings

4.3.5

Inverter ID

4.3.7

Insulation

4.3.7.1

4.3.7.2

Grid Code 4.3.7.3

Install Settings

4.3.6

Access

U,I

U,I

U,I

U,I

U,I

I

I

I

I

U,I

I

I

I

I

I

I

I

I

I

I

Function Para

Grid Settings 4.3.7.4

Dry Contact Set-up 4.3.7.5

PID 4.3.7.6

RCMU 4.3.7.7

AC Connection 4.3.7.9

Emergency Power-Off 4.3.7.8

AFCI 4.3.7.11

Grid code confirm 4.3.7.12

Active / Reactive power 4.3.8

Anti-Islanding 4.3.7.10

Access

54

Commissioning

This page displays voltage, current and power measurements from both the

AC and DC side.

4.3.1 Power meter

4.3.2 String monitoring (120&122 models)

Figure 4-4: Power Monitoring and String Current Monitoring

V 480

I 50.5

P 13989

480

50.5

13989

480

50.5

13989

L1 L2 L3AC

Power.

Frequency::

E-Today:

PF

41966

0.9

60.00

147

kW

Hz

kWh

V 545

I 40.0

P 21800

545

40.0

21800

DC1 DC2DC

or

V

A

W

V

A

W

ENT

or

ENT

or

ENT

1:

2:

3:

8.0

8.1

7.9

4:

5:

6:

8.0

8.1

8.0

1:

2:

3:

8.0

8.1

7.9

4:

5:

6:

8.0

8.1

8.1

IDC1 (A)

IDC2 (A)

or

ENT

The string current monitoring function is accessed via the Power Meter menu

Four sub-pages are accessed using display keys as shown in Figure 4-4, two

pages display string current values for the nine strings of MPPT1 and MPPT2.

55

Commissioning

User can view the inverter’s lifetime energy runtime via Energy Log page.

4.3.3 Energy Log

Event Log display has two sub-pages as noted below and shown in Figure 4-6:

• Error Events page displays all the events (Error and Fault) and can show 30

records at a time.

• Grid Report page only displays the error that occurred at grid side, and it can

show 5 records at a time.

4.3.4 Event Log

Figure 4-5: Energy Log screen

Figure 4-6: Event Log screens

Life Energy

Day Energy

Month Energy

►

Life Energy:

E-Total:

Runtime:

30680.02 kWh

7302 Hrs

Life Energy

Day Energy

Month Energy

►

Life Energy

Day Energy

Month Energy

►

EXIT

ENT

Day Energy:

2016.10.10

2016.10.09

2016.10.08

147 kWh

146 kWh

145 kWh

EXIT

ENT

Month Energy:

2016.10

2016.09

2016.08

4410 kWh

4409 kWh

4408 kWh

EXIT

ENT

1. 20/01/2016 15:30

AC Freq High

2. 19/01/2016 09:30

AC Volt Low

29. 18/01/2016 15:30

AC Freq High

30. 17/01/2016 09:30

AC Volt Low

or

or

Error Events

Grid Report

►

Error Events

Grid Report

►

1. 20/01/2016 15:30

AC Freq High

2. 19/01/2016 09:30

AC Volt Low

5. 18/01/2016 15:30

AC Freq High

or

or

Press ▲,▼&ENT > 5s

Clear Event Logs ?

Yes / ► No

Empty

Yes

No Event

Press ▲,▼&ENT > 5s

Clear Event Logs ?

Yes / ► No

Empty

Yes

No Event

EXIT

EXIT

EXIT

EXIT

ENT

ENT

ENT

ENT

ENT

ENT

56

Commissioning

This page allows the user to view static data associated with the inverter to

include serial number, installation date, inverter ID (RS-485 address), and

firmware version. Additional parameters are accessed via connected menus

using the up/dn keys. Programmed settings (e.g., Inverter ID, baud rate) are

adjusted using the settings menu. The complete list of inverter information

items can be seen in Figure 4-7, below.

4.3.5 Inverter Information

Figure 4-7: Inverter information screens

This page allows the setting of Language, Date and Time, and RS-485 baud

rate via sub-menus. Use UP/DN arrow keys to navigate to desired sub-menu,

and then press ENT to enter the chosen sub-menu.

4.3.6 General Settings

Figure 4-8: General Settings screen

S/N: RN11179CB0

Install: 01/01/2016

INV ID: 1

AC connection:

Max. Power:

Dry Cont A:

Dry Cont B:

3P3W

46000W

Disable

Disable

FW Version

DSP:

COM:

SCM:

1.30

91.05

1.35

RED:

ARC:

61.06

1.05

►

EPO Normal Open

Grid Settings

Active Pwr Settings

React Pwr Settings

or

ENT

or

ENT

or

ENT

►

EPO Normal Open

Grid Settings

Active Pwr Settings

React Pwr Settings

►

EPO Normal Open

Grid Settings

Active Pwr Settings

React Pwr Settings

FRT Settings

or

ENT

Country:

Insulation:

Baud Rate:

IEEE1547 480V

100

k

19200bps

►

Language

Date and Time

Baud Rate

Protocol

►

57

Commissioning

4.3.7 Install Settings