Page 1

Evaluation Procedure

L

(DEP-003)

The IPM- C Series POL converters

The IPM Series, single output, non-isolated

point of load DC/DC converters, are the latest

offering from a world leader in power systems

technology and manufacturing ― Delta

Electronics, Inc. They operate from a

3V~5.5V (IPM04C) or an 8V~14V (IPM12C)

source and provide a programmable output

voltage of 0.8V to 3.3V(IPM04C) or 0.8V to

5V(IPM12C). With creative design technology

and optimization of component placement,

these converters possess outstanding

electrical and thermal performance, as well

as offering extremely high reliability under

highly stressful operating conditions. All

models are protected against abnormal

input/output voltage and current conditions.

This document guides the user through the

evaluation procedure to qualify a POL module.

The data shown in this Evaluation Procedure

is for the SIP and SMT Package Type PO

evaluation board. Please refer to the

appropriate technical data sheet for detailed

performance and technical information for the

specific POL units.

IPM Series

1.0 Purpose

This document guides the user in performing

electronic measurements on an IPM POL (point

of load) DC/DC converter using the Delta

Evaluation Board.

2.0 Relevant Documentation

The documentation and background information

listed below is relevant to this evaluation

procedure:

․ Applicative date sheets for IPM Series unit

under evaluation.

․ Power Module Evaluation Board Schematic.

․ Power Module Evaluation Board Layout.

․ General Test and Safety Procedures.

Evaluation Procedure

EP_IPMC_04292005

1

Delta Electronics, Inc.

Page 2

3.0 Equipment Required

․ DC Power Supply 0 - 20 V @ 0 - 20A (Agilent 6574A 0 -60V/0 - 35A or equivalent).

․Oscilloscope (Tektronix TDS 460A or equivalent) 4 Channel 400 MHz, equipped with a

x1 scope probe, a x10 scope probe, and two BNC cables (length less than 20

inches/500mm)

․Digital multimeters, one with 20A range and ideally all with 4 1/2 digit resolution

(DVM1, DVM2 and DVM3) (Zentech 2041 or equivalent).

․ Electronic load (Chroma 63030 or equivalent), 300W approx rating, or a suitable

resistive load.

․ DC power supply (GW GPC-3060D or equivalent).

4.0 Equipment Set-Up and Description

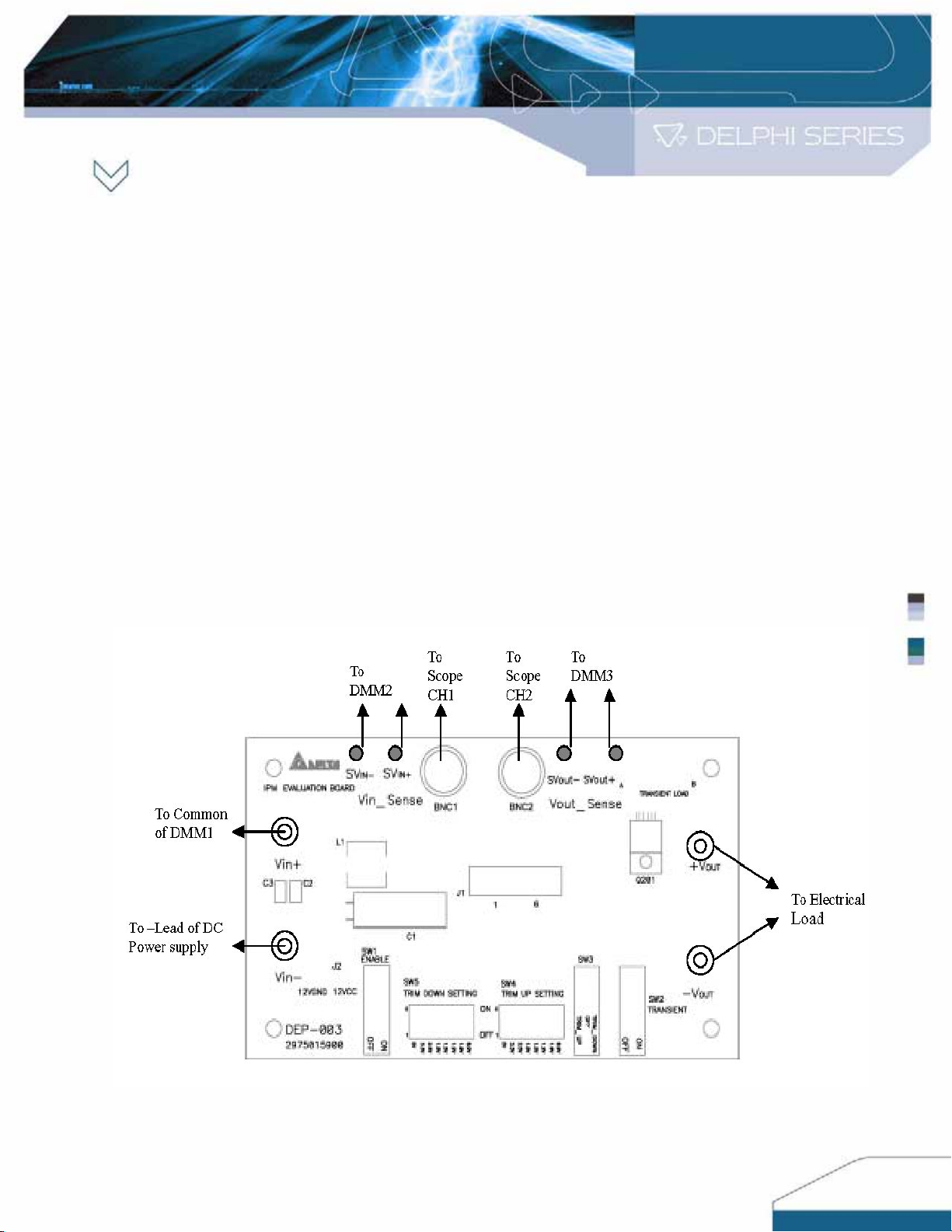

Please refer to the Power Module Evaluation Board Layout (see page 15) for reference designators

cited in this document and Figure 1 is the Set-up Diagram.

Figure 1. Set-up Diagram

2

Page 3

4.1 Connect one lead from the “+” lead of the power supply to the “20A” terminal of the first

multimeter DMM1. Then connect one lead from the “Common” of the DMM1 to the “Vin” pin of

the Evaluation Board. Set function of DMM1 to DCA to measure the input current.

4.2 Connect one wire from the “-” lead of the power supply (Item 3.1) to the “Vin-“ pin of the

Evaluation Board. Note: Use stranded leads at least equivalent to 14 AWG for all connections

in sections 4.1 and 4.2.

4.3 Connect the plus “+” and minus “-“ connection leads from a second multimeter to the “SVin+”

and “SVin-” Pins on the Evaluation Board. This multimeter is designated DMM2 to measure the

input voltage.

4.4 Connect the plus “+” and minus “-“ connection leads from the third multimeter to the “SVout+”

and “SVout-” Pin on the Evaluation Board. The multimeter is designated DMM3. DMM3 is used

to measure the output voltage.

4.5 Connect a BNC cable (length less than 20 inches/500mm) from BNC1 of the Evaluation Board

to Channel 1 of the oscilloscope (item 3.2). This cable is used to measure the input voltage

(between SVin+ and SVin-).

4.6 Connect a BNC cable (length less than 20 inches/500mm) from BNC2 of the Evaluation Board

to Channel 2 of the oscilloscope. This cable is used to measure the output voltage (between

SVout+ and SVout-).

4.7 Connect the positive and negative power leads of the electronic load (ensuring correct polarity),

or an appropriate resistive load, to the Evaluation Board output terminal pin (“+Vout” for positive

power lead and “-Vout” for the negative power lead).

.8 For IPM04C series: Open J2 on the Evaluation Board. Connect one lead from the “+” lead of the

4

power supply to the “12Vcc” on the Evaluation Board. Then connect one lead from the “-” of

the power supply to the “12VGND” on the Evaluation Board. For IPM12C: short J2 on the

Evaluation Board.

.0 Thermal Management of the Converter

5

It is imperative that sufficient airflow should be provided t

portions of testing. Please refer to the applicative data sheet for the proper cooling and derating

necessary to achieve accurate results when testing the converter.

o the converter at all times during all

3

Page 4

6.0 Tests Performed

The following tests are

6.1

Input Characteristics

Input Voltage Range.

Under-Voltage Locko

No Load Input Current

6.2 O

utput Characteristics

Line Regulation.

Load Regulation.

Output Regulation

Output Voltage Se

6.3 D

ynamic Characteristics

Maximum Output Voltage Deviation (due to step change in load).

Turn on Response time.

6.4

Thermal Characteristic

Efficiency

7.0 T st Set-Up

e

performed at room temperature (+25 C).

ut.

.

.

t-Point Adjustment Range.

7.1 Initial Set-Up

1) Examine the

being evaluated. Note: IPM12C0A0S04A and IPM04C0A0S06A would denote the SMT

package, while IPM12C0A0R04A and IPM04C0A0R06A would denote the SIP package.

This Evaluation Board can be used for both packages.

2) t multimeters DMM2 and DMM3

Set multimeter DMM1 to the DC current 20A range. Se

to DC voltage, auto ranging.

3)

Electronic Load

Turn on the Electronic Load (or resistive load) and adjust the current level. The maximum

rated output curre

IPM04C0A0R06A series. Ensure the output load does not exceed the recommended

maximum current.

4) ble or disable the converter. Turn SW1 to the OFF position to enable

SW1 is used to ena

e converter, and turn SW1 to the ON position to disable the converter.

th

5) position if this

SW2 is used for On/Off Transient function test. Turn SW2 to the OFF

nction is not being used. Turn SW2 to the ON position if the Transient function test is

fu

required.

part number of the power module to determine that the correct module is

nt is 4A for the model IPM12C0A0R04A series and 6A for the model

4

Page 5

6) ed for the trim-down or trim-up setting of the Output Voltage. For IPM, if the

SW3 is us

converter requires a trim up, set SW3 to the Trim-up position. If the converter requires a

trim down, set SW3 to the Trim-down position. For normal operating, turn off the SW3.

7) l

SW4 and SW5 are used for the Output Voltage Set-Point Adjustment by externa

resistors. For IPM12C0A0R04A, if the converter requires a trim-up to 5V, set the SW4_1

to ON position and SW3 to trim-up position. If the converter requires a trim-down to 0.8V,

set the SW5_8 to ON position and SW3 to trim-down position.

8) rim-up, set the SW4_2 to

For constant output voltage module, if the converter requires a t

ON position and SW3 to trim-up position. If the converter requires a trim-down, set the

SW5_8 to ON position and SW3 to trim-down position. Please refer to the Function

Tables below for the setting details.

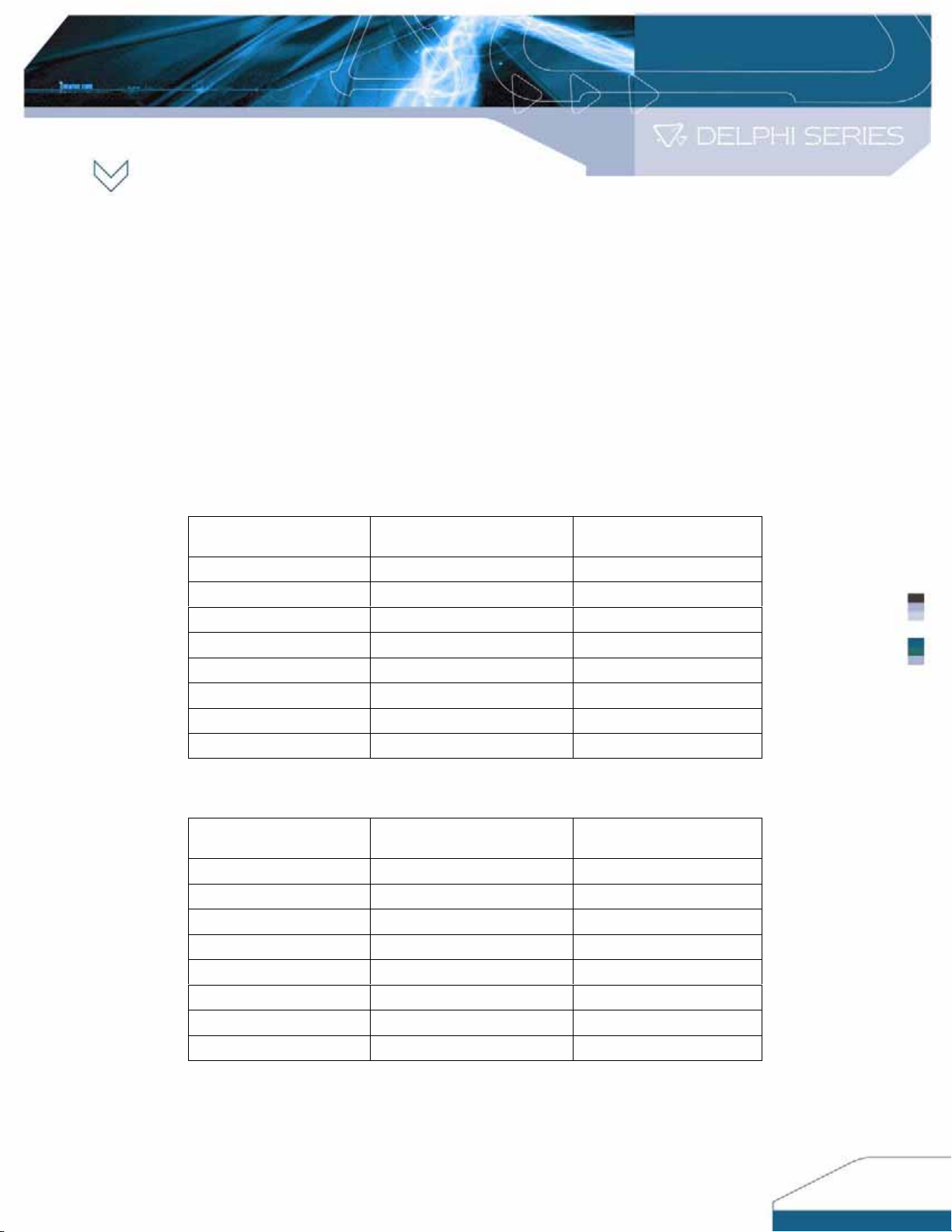

SW4 Function Table

Subdivide switch NO. For adjustable output

module

SW4_1 5.0V setting 5.0V trim up

SW4_2

SW4_3

SW4_4

SW4_5

SW4_6

SW4_7 1.0V setting 1.0V trim up

SW4_8 0.95V setting 0.9V trim up

Note: Settings of SW4_1 and SW4_7 are for IPM12C se

SW5 Function Table

Subdivide switch NO. For adjustable output

SW5_1 - 5.0V trim down

SW5_2

SW5_3

SW5_4

SW5_5

SW5_6

SW5_7

SW5_8 0.80V setting 0.9V trim down

3.3V setting

2.5V setting

1.8V setting

1.5V setting

1.2V setting

module

-

-

-

-

-

-

For constant output

module

3.3V trim up

2.5V trim up

1.8V trim up

1.5V trim up

1.2V trim up

ries only

For constant output

module

3.3V trim down

2.5V trim down

1.8V trim down

1.5V trim down

1.2V trim down

1.0V trim down

5

Page 6

7.2 Initial Power Up

1) Turn the power

either converter) and increase the input voltage (use DMM2 to monitor the voltage) until it

reaches the desired value.

2)

Set the switch SW1 to “OFF” position to enable the power module.

3) ing, which can be verified by observing the DMM3 (appropriate

The converter is now operat

value for the nominal output voltage) and channel 2 of the oscillosc

for the nominal output voltage).

4)

Set the switch SW1 to the “ON” position after performing each test.

supply ON, set the current limit on power supply (refer to specification of

8.0 Tests and Evaluation

8.1 Input Characteristics

8.1.1 Input Voltage Ra

The IPM04C Series of DC/DC converters will operate at full loa

e output of 3.3V, the input voltage range is from 4.0Vin to 5.5Vin. The IPM12C Series

th

DC/DC converters will operate at full load from 8Vin to 14Vin for 12Vin (nominal) types. The

converters feature input under-voltage protection, which will not allow the converter to start

up unless the input voltage exceeds the turn-on voltage threshold.

Test

) Turn on the fan.

1

2) Se

3) Set the switch SW

4) Test the input under voltage function while observing DMM2, DMM3 and cha

8.1.

1) Turn on the fan.

2

3) Set the switch SW

4) Remove/disable the output electronic load or resistive load.

5) Note the input current from DMM1.

6) The result is the No-Load Input current of the DC/DC conver

t the input voltage to the desired operating point while monitoring DMM2.

1 to the “OFF” position to enable the converter.

oscilloscope. Increase the input voltage until the output of the c

appropriate value. This will occur between 2.40 and 2.70 volts for IPM04C modules and

between 7.6 to 8.0 volts for IPM12C modules. Please refer to the appropriate converter

data sheet for the detailed specification.

2 No Load Input Current Test

) Set the input voltage to the desired operating point while monitoring DMM2.

1 to the “OFF” position to enable the converter.

The No-Load Input Current will be a

20 to 70mA for the IPM04C series depending on the model u

refer to the data sheet for the detailed specification).

ope (appropriate value

nge and Under-Voltage Lockout

d from 3.0Vin to 5.5Vin. For

nnel 1 of the

onverter reaches the

ter.

round 20 to 85mA for the IPM12C series and around

nder evaluation. (Please

6

Page 7

A

8.2 Output Characteristics

8.2.1 Line Regulation

Line Regulation Deviation is defined as the change in output voltage caused by varying the

input voltage over a specif

Test

1) Turn on the fan.

2 Set the output power to the desired operating point.

)

3) Se

4)

5) Note the maximum +/- deviation of the output voltage over the

t the switch SW1 to the “OFF” position to enable the converter.

djust the input voltage across the converter’s input range (refer to specified range) while

monitoring DMM2.

operating voltage (please refer to the data sheet for the detailed specification).

8.2.2 Load Regulation

Load Regulation Deviation is defined as the changes in output voltage caused by varying the

output load current over th

mperature remain constant.

te

Test

1) Turn on the fan.

) Set the input voltage to the desired operating level while monitoring DMM2.

2

3) Se

4) Adjust the output

5) Note the maximum +/- deviation of the output voltage over the full range of

t the switch SW1 to the “OFF” position to enable the converter.

load range (please refer to the data sheet for the detailed specificat

8.2.3 Output Ripple

Output Ripple is defined as the periodic AC component on the DC/DC converter’s output

voltage. The output ripp

ith a specific bandwidth.

w

Test

1) Turn on the fan.

) Set the switch SW1 to the “OFF” position to enable the converter.

2

3) Ad

4) Adjust channel 2 on the oscilloscope to be AC coupled at 1µS/Div a

5) ple of the DC/DC converter is measured at full load operating power.

just the input voltage while monitoring DMM2 and set the output load to the full rated

load current.

20 MHz bandwidth-limit option on the scope.

The output rip

ied range while the output load and temperature remain constant.

full range of the input

e specified range (no load to full load) while the input voltage and

load across the converter’s operating load range.

the operating

ion).

le is measured in terms of peak to peak and RMS values, both done

nd 10mV/Div using the

7

Page 8

.2.4 Output Voltage Set-Point Adjustment Range (Trim)

8

utput Voltage Set-Point Adjustment can be carried out by using an external resistor or

O

external voltage source to increase or decrease the output voltag

e data sheet for the detailed specification). Refer all trim voltage requireth

7.1-7, 7.1.8, and refer all the design numbers to Evaluation Board Schematic.

e set-point (please refer to

ments to Item 7.1-6,

(1) Output Voltage Set-Point Adjustment by using an external resistor

For IPM12C se

To implement Trim-up by using an external resistor, R

TRIM pin and ground. For IPM12C0A0R04A, Please refer to the IPMR table for the desired

Vout. The value of R

also be referred for further information.

ries

must be connected

trim-up

can be calculated by the following equation and the datasheet can

trim-up

between the

752.3

R

To implement Trim-down by using an external resistor, R

the TRIM pin and Vout. For IPM12C0A0R04A, Please refer to the IPMR table for the desired

out. The value of R

V

can also be referred for further information.

trim-down

can be calculated by the following equation and the datasheet

=

−

uptrim

V

out

−

9.0

261.0

trim-down

Ω−

k

must be connected between

072.1

R

IPMR: Rtrim values versus some commonly used Vout for IPM12C0A0R04A

Vout Rtrim (Ω)

0.800 5.09K

0.900 Open

1.0 37.2K

=

−

downtrim

−

V

9.0

out

621.5

Ω−

k

.

1.2 12.2K

1.5 5.98K

1.8 3.90K

2.5 2.08K

3.3 1.30K

5.0 653

8

Page 9

For I M04C series

P

o implement Trim-up by using an external resistor, R

T

TRIM pin and groun

Vout. The value of R

also be referred for further information.

To implement Trim-down by using an external resistor, R

e TRIM pin and Vout. For IPM04C0A0R06A, Please refer to the IPMR table for the desired

th

Vout. The value of R

can also be referred for further information.

IPMR: Rtrim values versus some commonly used Vout for IPM04C0A0R06A.

must be connected between the

trim-up

d. For IPM04C0A0R06A, Please refer to the IPMR table for the desired

can be calculated by the following equation and the datasheet can

trim-up

0.7

Ω−

R

trim-down

=

uptrim

−

can be calculated by the following equation and the datasheet

V

out

−

9.0

187.0

k

trim-down

must be connected between

0.2

Ω−

=R

−

downtrim

Vout Rtrim (Ω)

0.8 9.813K

−

V

9.0

out

187.10

k

0.9 Open

1.2 23.146K

1.5 1 1.479K

1.8 7.590K

2.5 4.188K

3.3 2.729K

Test

1) Turn on the fan.

2) Ad

3) Set the enable switch SW1 to the “OFF” position to enable converter.

4) Use SW3, SW4 and SW5 (refer to Item 7.1_7) for Trim setup.

5) Note the voltage by observing DMM3.

6) Test the Load Regulation (refer to Item 8.2.2).

just the input voltage while monitoring DMM2 and with output load set to the desired

operating point.

9

Page 10

(2) Output Voltage Set-Point Adjustment by using an external voltage source

For IPM12C series

Output voltage of IPM12C is programmable while applying a voltage between the TRIM

and GND pins. The following equation can be used to determine the value of Vtrim

needed for a desired output voltage Vo:

Vtrim = 0.7439 – 0.0488Vo

Vtrim is the external voltage in V

Vo is the desired output voltage

For example, to program the output voltage of a IPM

module to 3.3 Vdc, Vtrim is calculated as follows:

Vtrim = 0.7439 – 0.0488 x 3.3

= 0.5829V

For IPM04C series

Output voltage of IPM04C is programmable while applying a voltage between the TRIM

and GND pins. The following equation can be used to determine the value of Vtrim

needed for a desired output voltage Vo:

Vtrim = 0.7168 – 0.0187Vo

Vtrim is the external voltage in V

Vo is the desired output voltage

For example, to program the output voltage of a IPM

module to 3.3 Vdc, Vtrim is calculated as follows:

Vtrim = 0.7168 – 0.0187 x 3.3

= 0.655V

Figure 2. Configuration for programming output voltage using an external voltage source

10

Page 11

r

8.3 Dynamic Characteristics

8.3.1 Output Voltage Deviation

Output Voltage Deviation is defined as the response of the converter to a sudden step change

in the output load current. The output voltage deviation is characterized by two parameters:

Maximum Output Voltage Deviation and Response Time (please refer to the data sheet for the

detailed specification). The value of dynamic resistance for a defined step current is defined as:

R

dynamic

Test

1) Turn on the fan.

2) Adjust the input voltage to the desired operating point.

3) Set the electronic or resistive load at 50% of maximum load.

4) Change channel 1 to scope probe and measure across the

5) Set the switch SW1 to the “OFF” position to enable the converter.

6) Set channel 2 on the oscilloscope to be AC coupled and to 50mV/Div and for 50uS/Div. Set

the trigger to auto and adjust the trigger point at a negative going pulse for step load

change from 50% to 100% of Io or adjust the trigger point at positive going pulse for step

load change from 100% to 50% (Please refer to data sheet)

7) Measure the Peak deviation and capture the waveform as required.

8.3.2 Turn-On Transient Time

Turn-On Response Time is defined as the time it takes for the output to rise to within 90% of its

final value from the time when the converter is enabled. The rise time is deliberately made

slower to reduce the inrush current and to eliminate any overshoot in the output voltage. These

test functions have two categories.

1) Turn on the module by using the External switch to control input voltage.

2) Turn on module by using the Enable on/off.

Note: There is a difference in performance in each mode - please refer to the data sheet fo

the detailed specification.

Vout

=

*5.0

Imax

dynamic

.

R

11

Page 12

f

Test (Turn on the module by using the external switch)

1) Turn on the fan.

2) Turn on the input power supply and set it to the desired operating point.

3) Set channel 1 on the oscilloscope to be DC coupled and to the appropriate range for the

input voltage.

4) Connect a coaxial cable from channel 1 to BNC1 on the Evaluation Board.

5) Set channel 2 on the oscilloscope to be DC coupled and to the appropriate range for the

output voltage.

6) Connect a coaxial cable from channel 2 to BNC2 on the Evaluation Board.

7) Set the Time base to 5mS/Div

8) Set the Trigger mode to normal trigger and set the Trigger level at approximately 2V (rising)

or suitable trigger point (referring to data sheet) on channel 2.

9) Turn on the external switch to supply power source to module and use the cursor V Bars o

Scope to measure the delay time, and then record the waveform on the oscilloscope.

Test (Turn on the module by using the Enable on/off)

1) Turn on the fan.

2) Turn on the input power supply and set it to the desired operating point.

3) Set channel 1 on the oscilloscope to be DC coupled and to 1V/division. (Refer to data

sheet).

4) Connect a scope probe from channel 1 between the on/off control pin and reference

ground (SGND) on the Evaluation Board.

5) Set channel 2 on the oscilloscope to be DC coupled and to the appropriate range for the

output voltage.

6) Connect a coaxial cable from channel 2 to BNC2 on the Evaluation Board.

7) Set the Time base to 5mS/Div

8) Set the Trigger mode to normal trigger and set the Trigger level at approximately 2V (rising)

or suitable trigger point (referring to data sheet) on channel 2.

9) Turn on-off Enable switch (SW1) and use the cursor V Bars of Scope to measure the delay

time, and then record the waveform on the oscilloscope.

8.4. Thermal Characteristic

8.4.1 Efficiency

Efficiency is the ratio of total output power to the input power. It is typically measured at full

load and nominal input voltage.

Test

1) Turn on the fan.

2) Set the enable switch SW1 to the “OFF” position to enable the converter.

3) Adjust the input voltage to the desired operating point.

4) Set the electronic or resistive Load to the desired operating point.

5) Read and note the output voltage (DMM3) and input voltage (DMM2).

6) Read and note the input and output currents from the DMM1 and the electronic load.

12

Page 13

7) Use the following formulas to calculate the efficiency:

Efficiency= (Pout/Pin) × 100(%)

Pin = Iin × Vin

Pout = Iout × Vout

For IPM12C series

The following graph shows the efficiency results of the IPM12C0A0R04A converter measured at

different operating points, the output voltage was set at 5V.

100

90

80

EFFICIENCY(%)

70

123

Vi=14V

Vi=12V

Vi=10V

Vi=8V

4

LOAD (A)

For IPM04C series

The following graph shows the efficiency results of the IPM04C0A0R06A converter measured at

different operating points, the output voltage was set at 3.3V.

95

85

EFFICIENCY(%)

75

123456

LOAD (A)

Vin=5.5V

Vin=5.0V

Vin=4.0V

13

Page 14

Appendix A- Evaluation Board Schematic

14

Page 15

Appendix B - Evaluation Board Layout (Top View)

15

Page 16

Appendix C - Evaluation Board Layout (Bottom View)

CONTACT: www.delta.com.tw/dcdc

USA:

Telephone:

East Coast: (888) 335 8201

West Coast: (888) 335 8208

Fax: (978) 656 3964

Email:

DCDC@delta-corp.com

Europe:

Phone: +41 31 998 53 11

Fax: +41 31 998 53 53

Email:

DCDC@delta-es.com

Asia & the rest of world:

Telephone: +886 3 4526107 ext 6220

Fax: +886 3 4513485

Email:

DCDC@delta.com.tw

WARRANTY

Delta offers a two (2) year limited warranty. Complete warranty information is listed on our web site or is available upon

request from Delta.

Information furnished by Delta is believed to be accurate and reliable. However, no responsibility is assumed by Delta for

its use, nor for any infringements of patents or other rights of third parties, which may result from its use. No license is

granted by implication or otherwise under any patent or patent rights of Delta. Delta reserves the right to revise these

specifications at any time, without notice

.

16

Loading...

Loading...