Page 1

IFD9507

Ethernet Communication Module

Application Manual

Page 2

Page 3

Ethernet Communication Module IFD9507

Warn ing

Please read this instruction carefully before use and follow this instruction to operate the device in order to prevent

damages on the device or injuries to staff.

Switch off the power before wiring.

IFD9507 is an OPEN TYPE device and therefore should be installed in an enclosure free of airborne dust, humidity,

electric shock and vibration. The enclosure should prevent non-maintenance staff from operating the device (e.g.

key or specific tools are required for operating the enclosure) in case danger and damage on the device may occur.

IFD9507 is to be used for controlling the operating machine and equipment. In order not to damage it, only

qualified professional staff familiar with the structure and operation of IFD9507 can install, operate, wire and

maintain it.

DO NOT connect input AC power supply to any of the I/O terminals; otherwise serious damage may occur. Check

all the wirings again before switching on the power and DO NOT touch any terminal when the power is switched

on. Make sure the ground terminal

1 INTRODUCTION...................................................................................................................................4

2 PRODUCT PROFILE & OUTLINE .......................................................................................................6

Table of Contents

1.1 Features ......................................................................................................................................4

1.2 Specifications ..............................................................................................................................4

2.1 Dimension ...................................................................................................................................6

2.2 Product Profiles...........................................................................................................................6

2.3 LED Indicators.............................................................................................................................6

2.4 RJ-11 PIN Definition ....................................................................................................................7

2.5 RJ-45 PIN Definition....................................................................................................................7

2.6 RS-232 PIN Definition .................................................................................................................7

2.7 Address Switch ...........................................................................................................................7

is correctly grounded in order to prevent electromagnetic interference.

2.8 Data Format ................................................................................................................................8

2.9 Baud Rate for Modbus Communication ......................................................................................8

2.10 Feed-through Terminal PIN Definition .........................................................................................8

3 INSTALLATION & WIRING ..................................................................................................................9

3.1 How to Install...............................................................................................................................9

3.2 How to Connect IFD9507 to Network..........................................................................................9

4 REGISTERS IN IFD9507....................................................................................................................10

4.1 Basic Registers (BR).................................................................................................................10

4.2 Explanations on BR...................................................................................................................10

4.3 Alarm Registers (AL) in IFD9507 ..............................................................................................13

DVP-PLC Application Manual

1

Page 4

Ethernet Communication Module IFD9507

4.4 In buffer registers (IN) in IFD9507 ............................................................................................ 14

4.5 Out buffer registers (OUT) in IFD9507 ..................................................................................... 15

5 MONITORING FUNCTIONS.............................................................................................................. 15

5.1 Monitor Bit Registers (MB) ....................................................................................................... 15

5.2 Monitor Word Registerss (MW) ................................................................................................ 16

6 SETTING UP DEVICE ADDRESS AND RELAY ADDRESS IN SLAVE MODE (FOR MODBUS TCP

PROTOCOL ONLY)...........................................................................................................................17

7 SETTING UP DEVICE ADDRESS AND OTHER NETWORK SETTINGS IN SLAVE MODE........... 17

8 MODBUS COMMUNICATION ........................................................................................................... 18

8.1 Function Codes Supported....................................................................................................... 18

8.2 Exception Codes Supported..................................................................................................... 18

8.3 Device Type & Device Address................................................................................................. 18

9 ETHERNET/IP COMMUNICATION.................................................................................................... 19

9.1 Service code supported............................................................................................................ 19

9.2 Object supported ...................................................................................................................... 19

9.3 CIP General Status Code (Reference Volume 1:CIP Common Specification Appendix B) ...... 20

9.4 Connection Manager Service Request Error Codes (Reference Volume 1:CIP Common

Specification Table3-5.29) .................................................................................................................. 20

10 SETTING UP THE SOFTWARE - DCISOFT..................................................................................... 21

10.1 Setting up Communication & Searching for Modules in DCISoft.............................................. 21

10.2 Basic Settings........................................................................................................................... 23

10.3 Network Settings ...................................................................................................................... 24

10.4 Setting up E-Mails .................................................................................................................... 26

10.5 Monitoring Settings................................................................................................................... 27

10.6 IP Filter ..................................................................................................................................... 28

10.7 Ethernet/IP settings .................................................................................................................. 29

10.8 User Defined Settings............................................................................................................... 31

10.9 Virtual COM .............................................................................................................................. 33

10.10 Security Settings....................................................................................................................... 36

10.11 Returning to Default Settings.................................................................................................... 37

11 SETTING UP CONFIGURATION BY HOMEPAGE...........................................................................38

11.1 Webpage connection................................................................................................................ 38

11.2 Basic settings ........................................................................................................................... 39

11.3 Setting up E-Mails .................................................................................................................... 40

11.4 IP filter....................................................................................................................................... 41

11.5 Security Settings....................................................................................................................... 42

11.6 Returning to default setting....................................................................................................... 43

11.7 Monitoring settings ................................................................................................................... 43

11.8 Ethernet/IP................................................................................................................................ 45

11.9 User Define............................................................................................................................... 47

2

DVP-PLC Application Manual

Page 5

Ethernet Communication Module IFD9507

12 APPLICATION EXAMPLES – DCISOFT ...........................................................................................49

12.1 Setting up & Unlocking Password .............................................................................................49

12.2 Password Loss (Returning to Default Settings by RS-232).......................................................51

12.3 IP Filter Protection.....................................................................................................................51

12.4 Application of E-Mail .................................................................................................................53

12.5 Monitoring Mode .......................................................................................................................54

12.6 Application of Virtual COM Port.................................................................................................56

13 APPLICATION EXAMPLES – AB SOFTWARE (REVISION:2.10.118.0)..........................................61

13.1 Serial Slave ...............................................................................................................................61

13.2 Serial Master .............................................................................................................................64

DVP-PLC Application Manual

3

Page 6

Ethernet Communication Module IFD9507

1 Introduction

Thank you for choosing Delta’s IFD9507 module. To correctly install and operate IFD9507, please read the

manual carefully before using the module.

IFD9507 is an Ethernet communication module for remote setting and communication through Delta’s DCISoft

1.01.

IFD9507 has 3 digital input contacts which will send messages to designated E-Mail addresses after being

triggered. IFD9507 supports Modbus TCP communication protocol and can conduct remote monitoring by using

graphic software or human machine interface. IFD9507 can be the master of Modbus TCP, sending out Modbus

TCP instructions and controlling the peripheral equipment. IFD9507 supports Ethernet/IP communication protocol

and can control device between Ethernet/IP protocols with Modbus protocol. IFD9507 can be a slave as well,

receiving Modbus instructions sent from other masters and transferring them to another Modbus communication

network or Ethernet/IP communication network through Ethernet. In addition, under MDI/MDI-X auto-detection, it

does not need to jump wire in selecting the network cable. See the contents below for more detailed instructions

on IFD9507 module.

1.1 Features

z Auto-detects 10/100 Mbps transmission speed; MDI/MDI-X auto-detection

z The monitor table temporarily stores the monitored data for the user to fast save or acquire the data.

z Supports Modbus TCP protocol (supports Master and Slave mode)

z Supports Ethernet/IP protocol (supports Master and Slave mode)

z Able to send out emails after being triggered.

z The station address, RS-485 communication format and baud rate can be set up externally

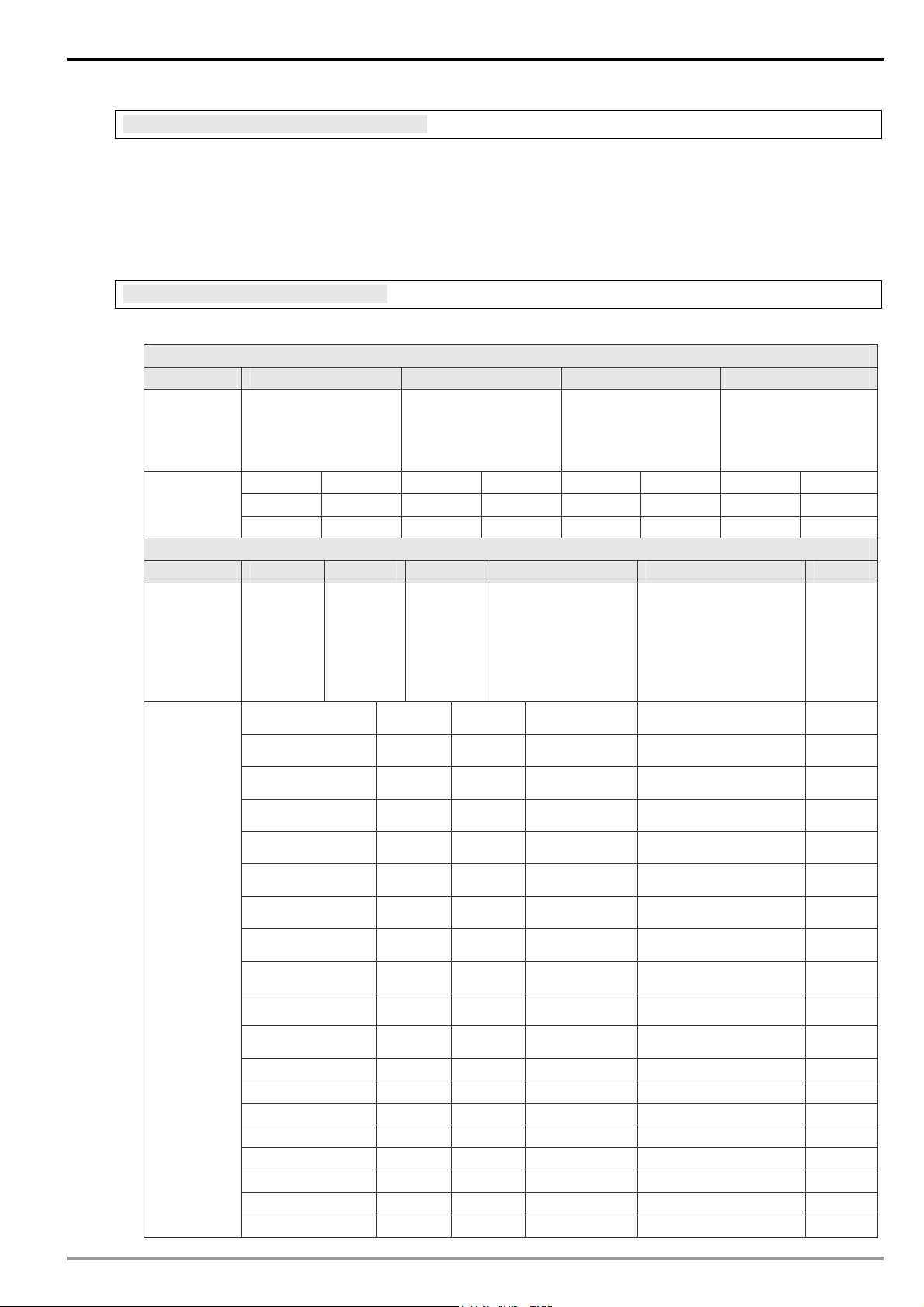

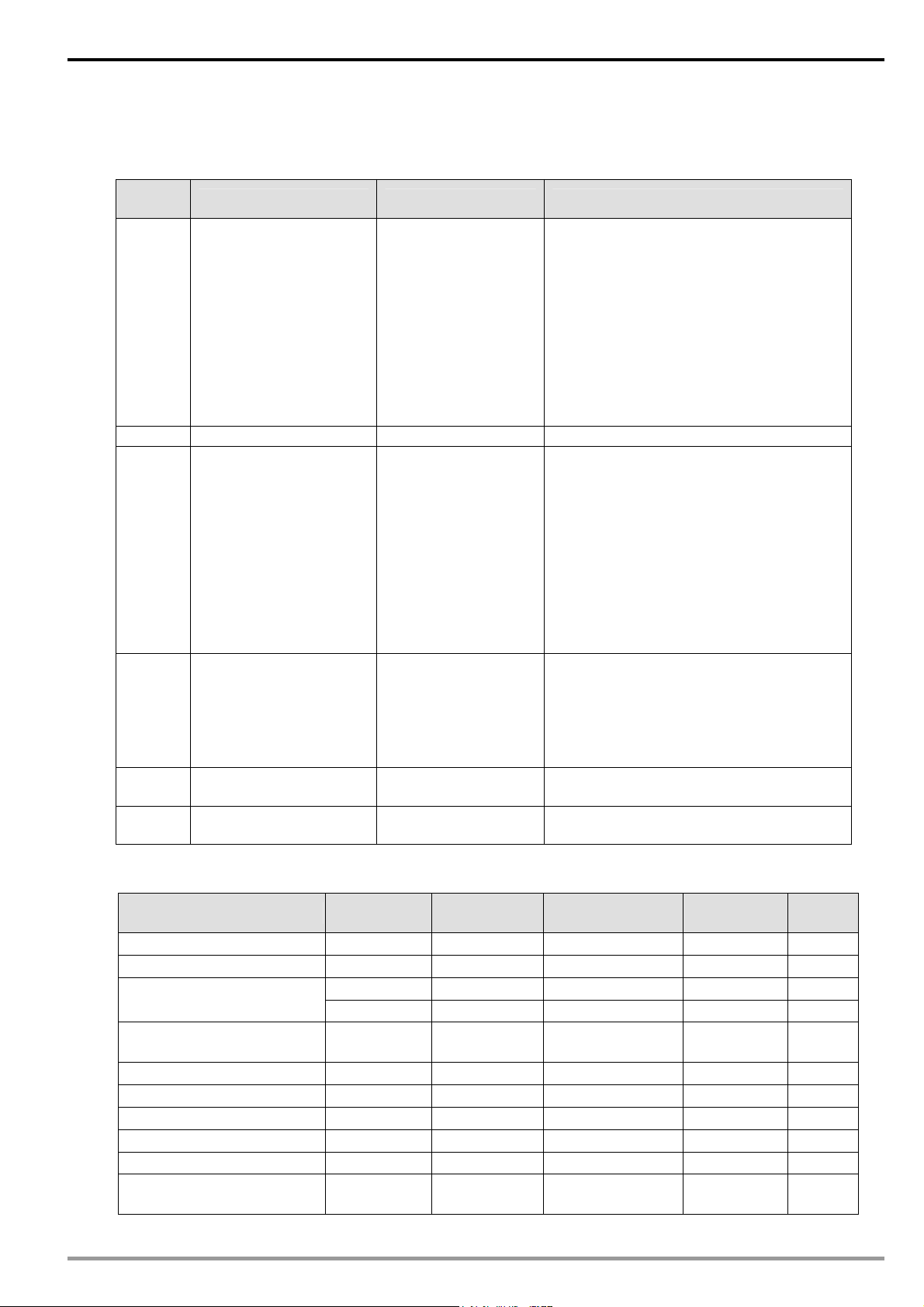

1.2 Specifications

Network interface

Item Specification

Interface RJ-45 with Auto MDI/MDIX

Number of ports 1 Port

Transmission method IEEE802.3, IEEE802.3u

Transmission cable Category 5e

Transmission speed 10/100 Mbps Auto-Detection

Communication

protocol

ICMP, IP, TCP, UDP, DHCP, SMTP, Modbus TCP, Ethernet/IP

Serial communication interface (COM1)

Item Specification

Interface Mini Dim

Number of ports 1 Port

Transmission method RS-232

Transmission cable DVPACAB215 / DVPACAB230 / DVPACAB2A30

Transmission speed 110, 150, 300, 600, 1200, 2400, 4800, 9600, 19200, 38400, 57600, 115200

Communication

protocol

4

Modbus, Delta Configuration, User Define

DVP-PLC Application Manual

Page 7

Ethernet Communication Module IFD9507

Serial communication interface (COM2)

Item Specification

Interface RJ-11

Number of ports 1 Port

Transmission method RS-485

Transmission speed 110, 150, 300, 600, 1200, 2400, 4800, 9600, 19200, 38400, 57600, 115200

Communication

protocol

Terminal block

Item Specification

Interface Feed-through terminal 10PIN

Transmission method RS-485

Transmission distance 1,200m

Transmission speed 110, 150, 300, 600, 1200, 2400, 4800, 9600, 19200, 38400, 57600, 115200

Communication

protocol

Max. number of

stations

Modbus, User Define

Modbus, User Define

32

Environment

Item Specification

ESD (IEC 61131-2, IEC 61000-4-2): 8KV Air Discharge

EFT (IEC 61131-2, IEC 61000-4-4): Power Line: ±2KV, Digital Input: ±2KV,

Communication I/O: ±2KV

Noise immunity

Operation temperature 0°C ~ 55 oC (temperature), 50 ~ 95% (humidity), pollution degree 2

Storage temperature -25°C ~ 70 oC (temperature), 5 ~ 95% (humidity)

Vibration/shock

immunity\

Certificates IEC 61131-2, UL508

Electrical specifications

Item Specification

Power voltage 24VDC (-15% ~ 20%) supplied by feed-through terminal

RS (IEC 61131-2, IEC 61000-4-3): 80MHz ~ 1GHz, 10V/m. 1.4GHz ~ 2.0GHz,

10V/m

Conducted Susceptibility Test (EN61000-4-6, IEC61131-2 9.10): 150KHz ~

80MHz, 3V/m

Surge Test (Biwave IEC61132-2, IEC61000-4-5):

Power line 0.5KV DM, Ethernet 0.5KV CM, RS-485 0.5KV CM

International standards: IEC61131-2, IEC 68-2-6 (TEST Fc)/IEC61131-2 &

IEC 68-2-27 (TEST Ea)

Power consumption 3W

Insulation voltage 500V

Weight (g) 140g

DVP-PLC Application Manual

5

Page 8

Ethernet Communication Module IFD9507

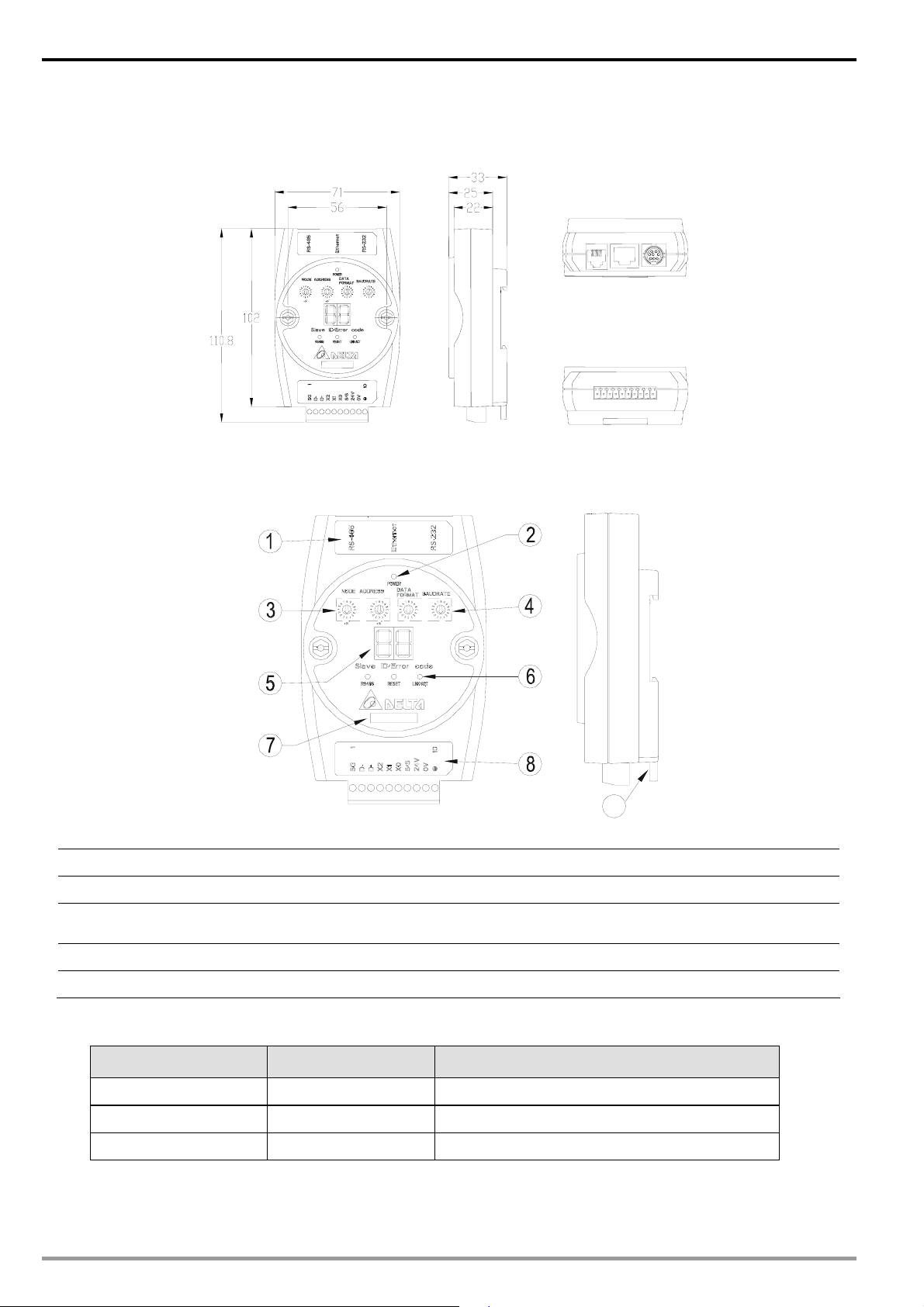

2 Product Profile & Outline

2.1 Dimension

Unit: mm

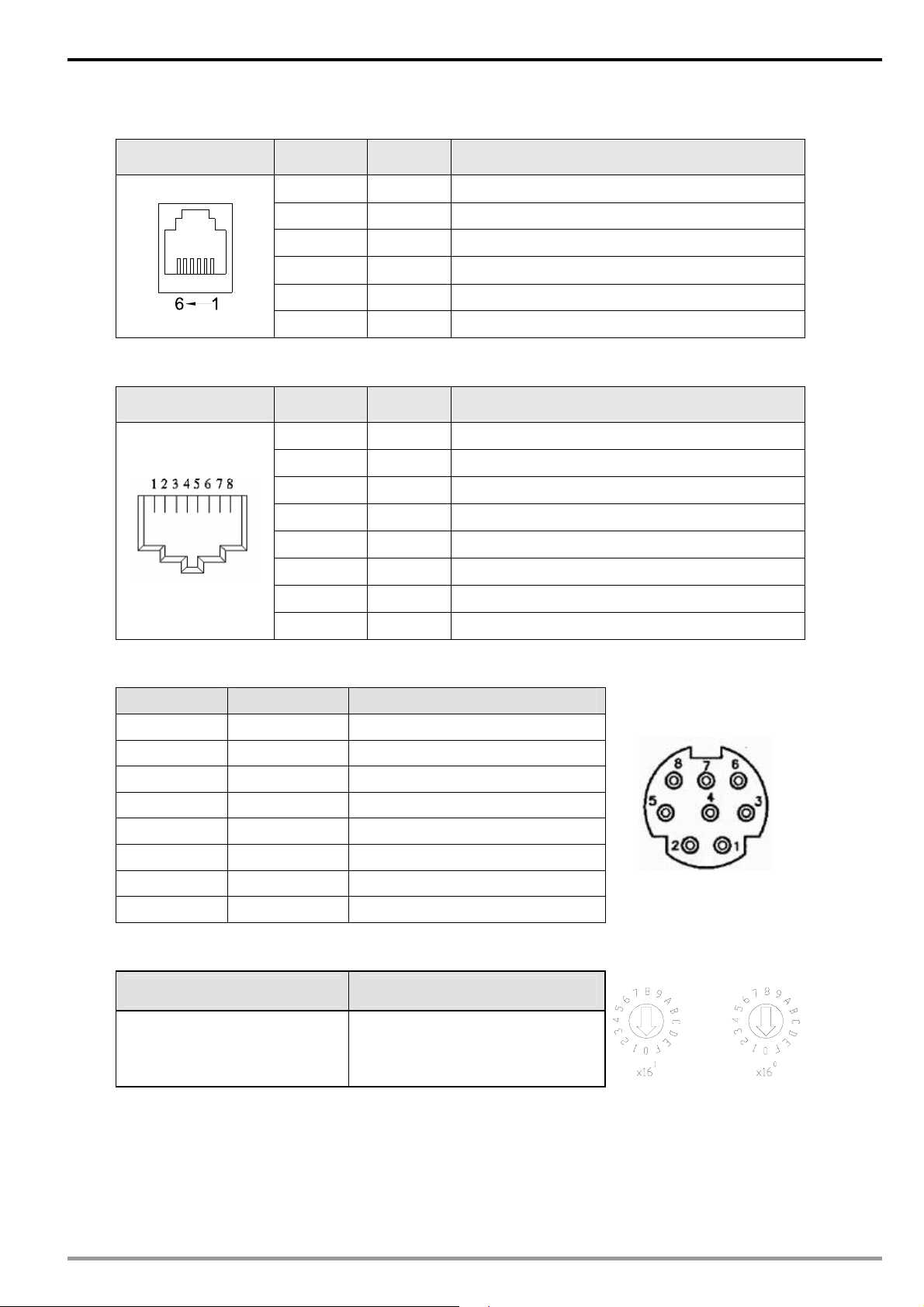

2.2 Product Profiles

9

1 Communication ports: RS-485, Ethernet, RS-232 6 RS-485 indicator, Reset button, Ethernet indicator

2 Power indicator 7 Module name

3 Address setup rotary switch。

4 Communication format/baud rate setup switch 9 DIN rail connector

5 Message display

8 RS-485 connector, digital input points, power input

point, earth point

2.3 LED Indicators

Name Color Function

POWER Green Power status

RS-485 Green Status of series communication port

LINK/ACT Green Status of network communication

6

DVP-PLC Application Manual

Page 9

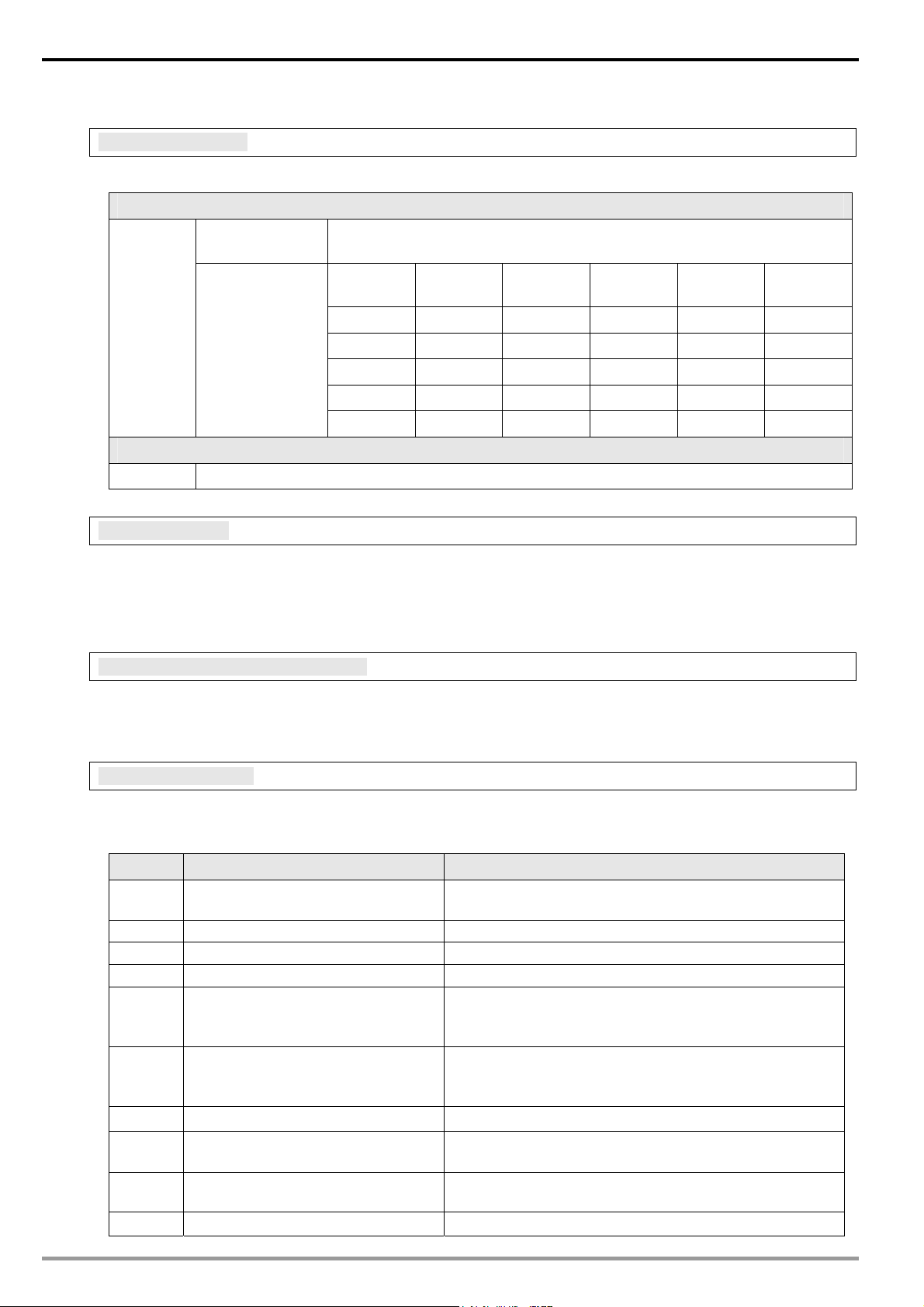

2.4 RJ-11 PIN Definition

RJ-11 sketch PIN. Signal Definition

Ethernet Communication Module IFD9507

1 -- N/C

2 -- N/C

3 D+ Positive pole for data

4 D- Negative pole for data

2.5 RJ-45 PIN Definition

RJ-45 sketch PIN Signal Definition

2.6 RS-232 PIN Definition

PIN Signal Content

1 -- N/C

2 -- N/C

3 -- N/C

4 Rx Reception data

5 Tx Transmission data

6 -- N/C

7 -- N/C

8 GND Ground

5 GND Reference

6 -- N/C

1 Tx+ Positive pole for data transmission

2 Tx- Negative pole for data transmission

3 Rx+ Positive pole for data receiving

4 -- N/C

5 -- N/C

6 Rx- Negative pole for data receiving

7 -- N/C

8 -- N/C

2.7 Address Switch

Switch setting Content

01…F7 Valid node address setting

DVP-PLC Application Manual

7

Page 10

Ethernet Communication Module IFD9507

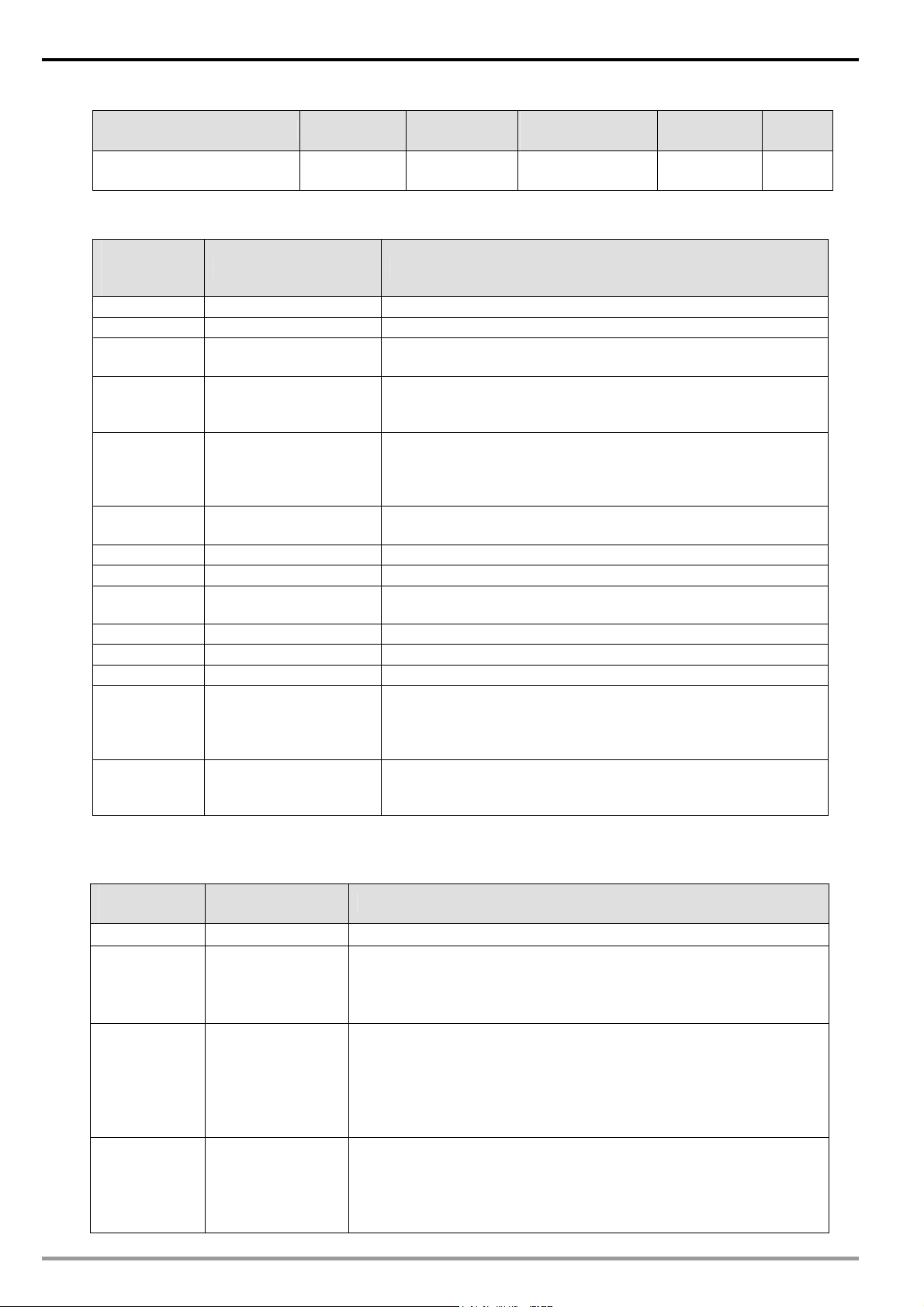

2.8 Data Format

Switch setting Format Switch setting Format

0 7-N-1 8 7-N-2

1 8-N-1 9 8-N-2

2 7-O-1 A 7-O-2

3 8-O-1 B 8-O-2

6 7-E-1 E 7-E-2

7 8-E-1 F 8-E-2

2.9 Baud Rate for Modbus Communication

Switch setting Baud rate Switch setting Baud rate

1 110 7 4,000

2 150 8 9,600

3 300 9 19,200

4 600 A 38,400

5 1,200 B 57,600

6 2,400 C 115,200

2.10 Feed-through Terminal PIN Definition

PIN Signal Content

1 SG Reference ground of signal

2 D- Data-

3 D+ Data-

4 X2 Digital input 2

5 X1 Digital input 1

6 X0 Digital input 0

7 S/S Reference ground of digital input

8 24V +24V input

9 0V 0V input

10 Earth ground

8

DVP-PLC Application Manual

Page 11

3 Installation & Wiring

This section gives instructions on how to connect IFD9507 with other devices and how to connect IFD9507 to

the network.

3.1 How to Install

Ethernet Communication Module IFD9507

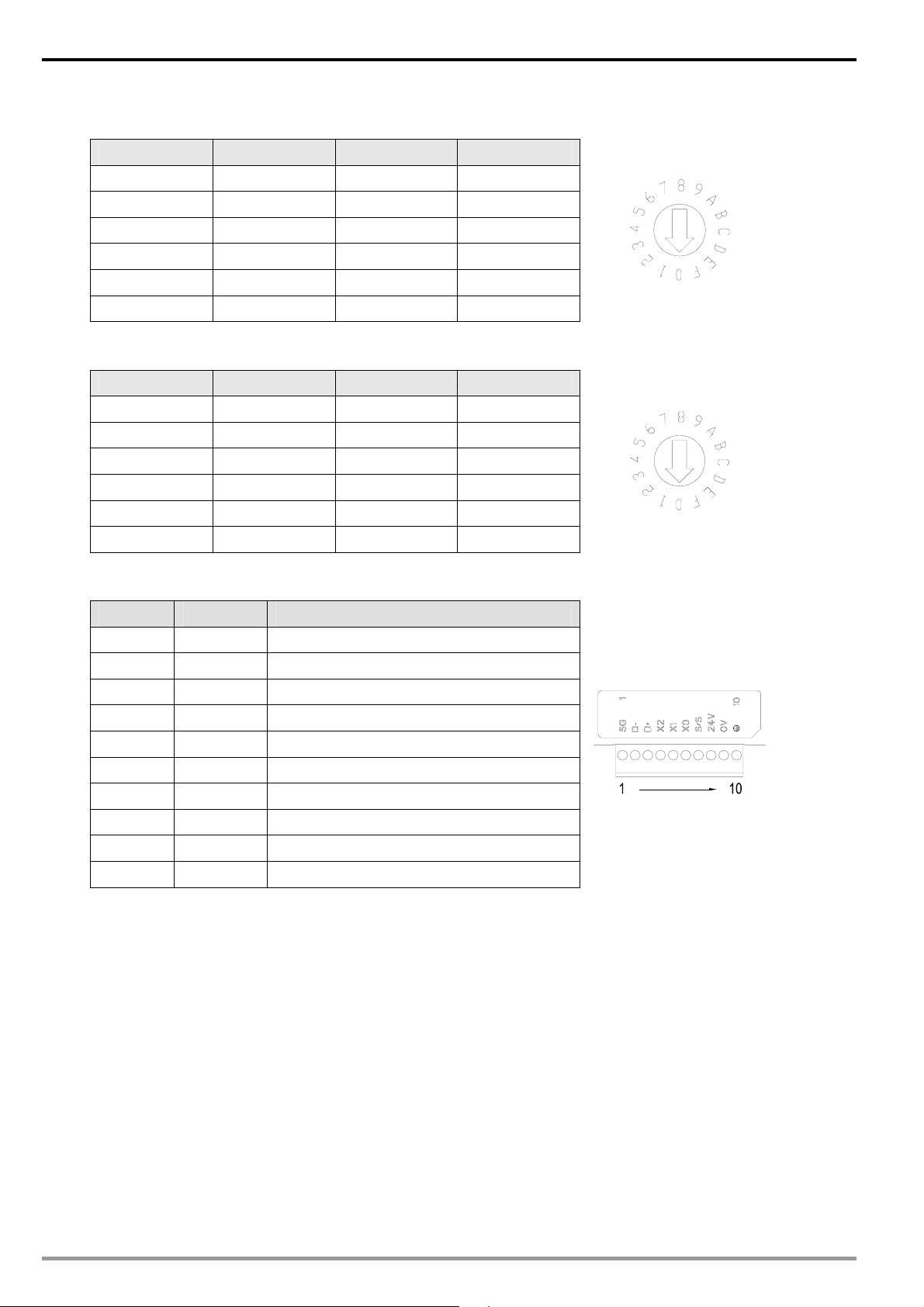

3.2 How to Connect IFD9507 to Network

Connect IFD9507 to the Ethernet hub by twisted pair cable CAT-5e. IFD9507 has auto MDI/MDIX function;

therefore, IFD9507 does not need to jump wire if selecting CAT-5e.The network connection between the PC and

IFD9507:

PC Master

Ethernet

DVP-PLC Application Manual

RS-485 (Master Mode)

AC motor

driver

RS-485 (Master Mode) RS-485 (Slave Mode)

Temperature

controller

Human

machine

interface

9

Page 12

Ethernet Communication Module IFD9507

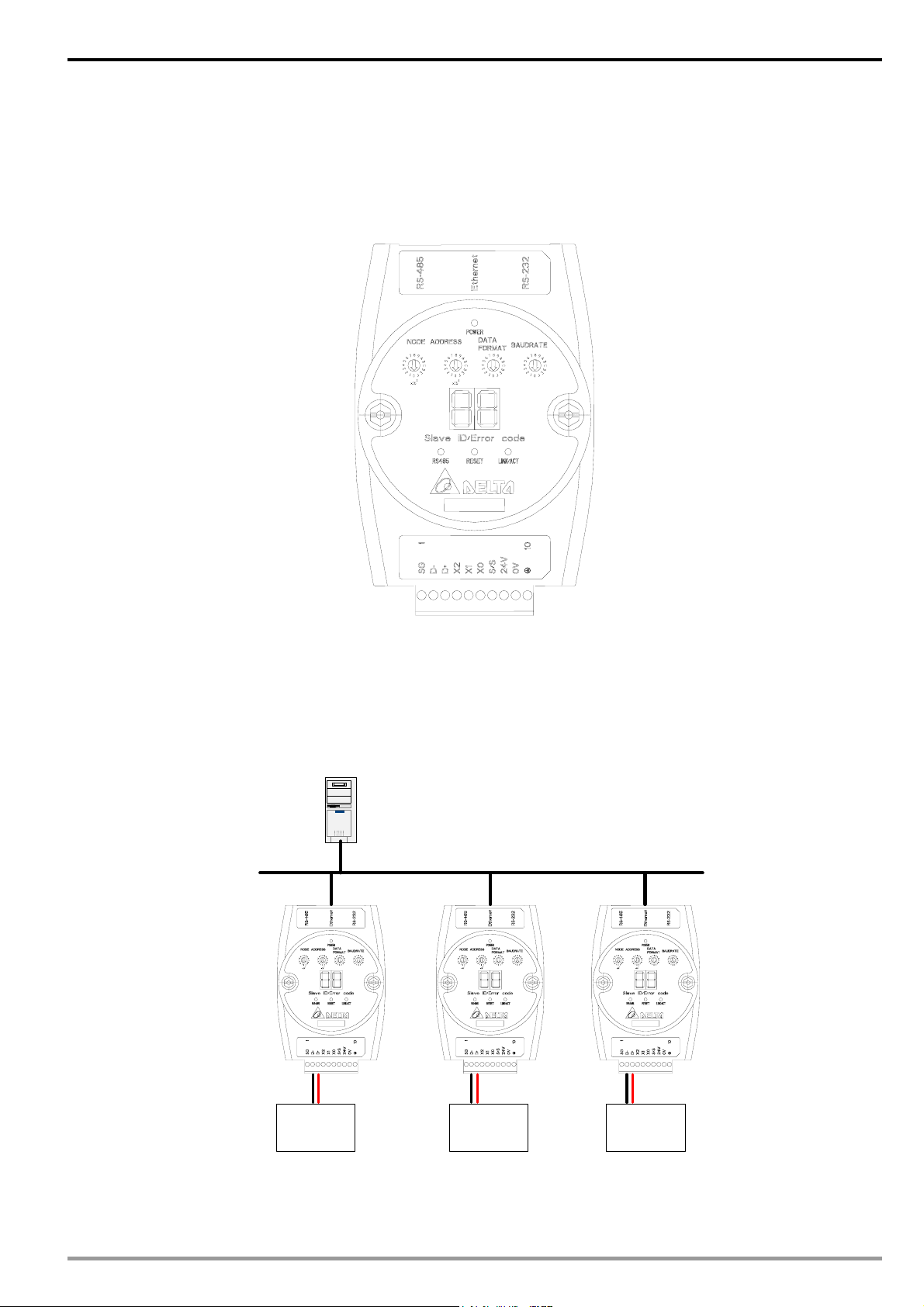

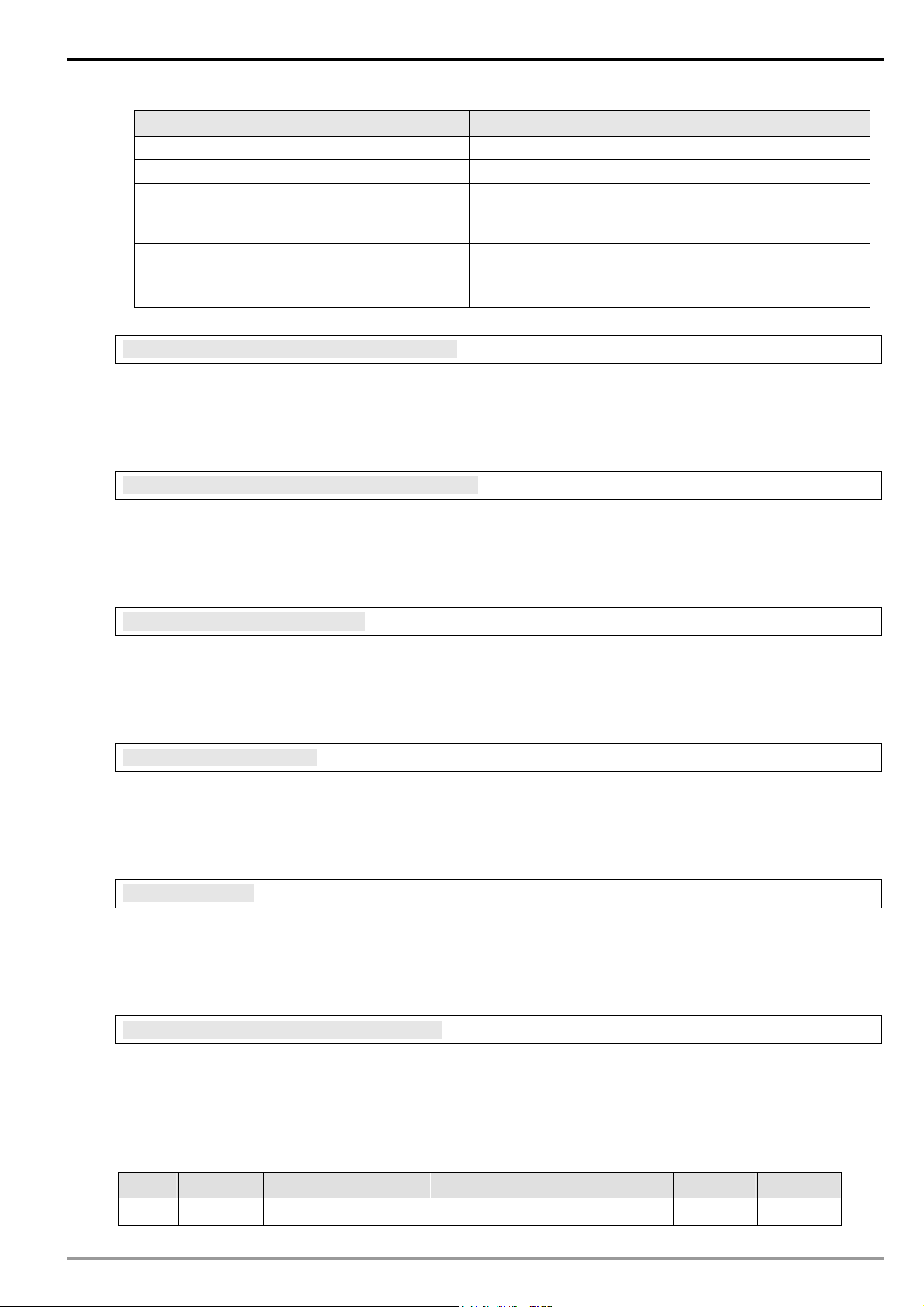

4 Registers in IFD9507

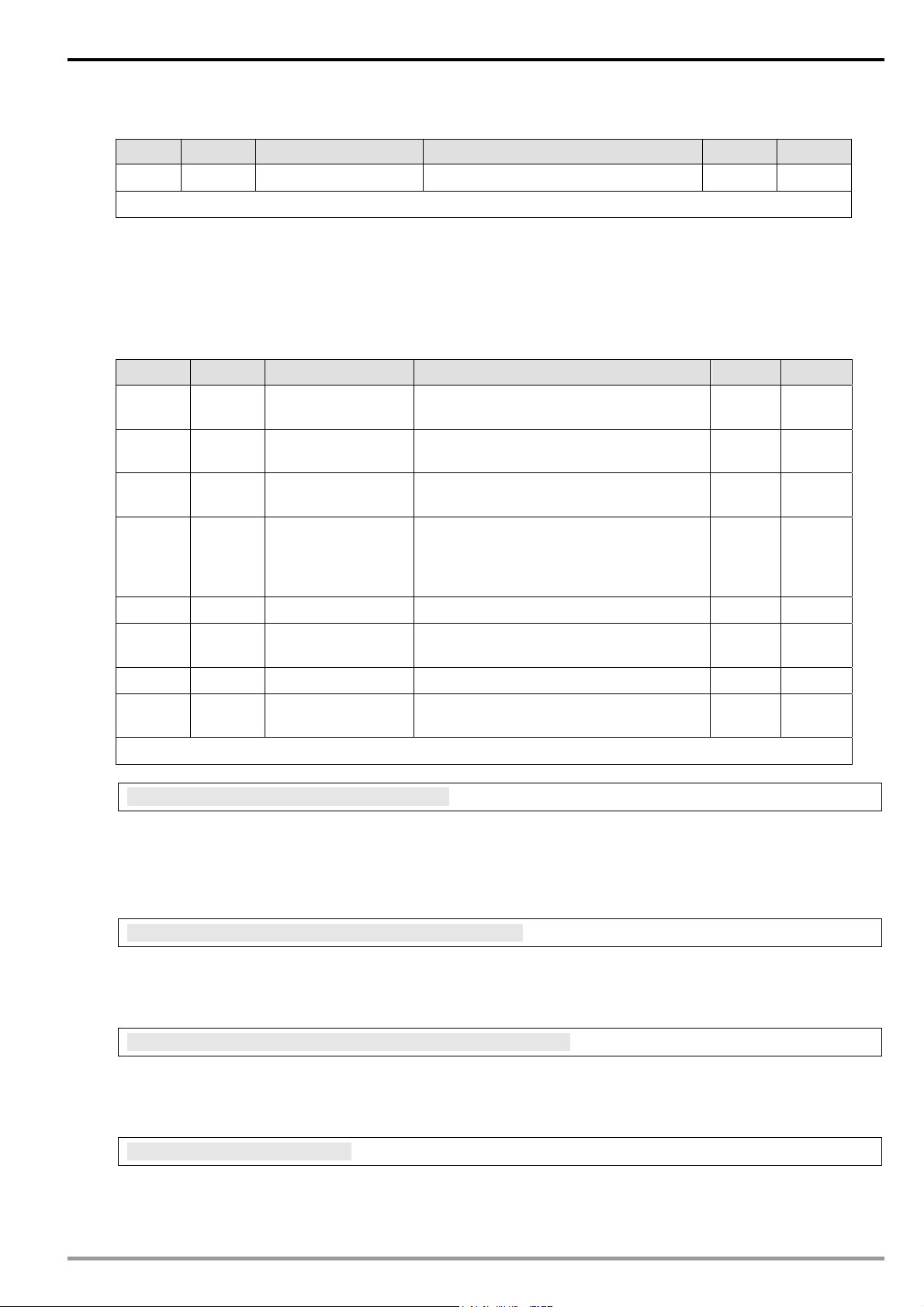

4.1 Basic Registers (BR)

BR#

Attribute

0 R Model name

1 R Firmware version

2 R

3 Reserved

4 R/W

5 R/W Baud rate See the table of baud rate setting No

6 R/W Address For setting up the station address No

7 R

8 Reserved

9 R Error code Displaying the errors. See the table of error codes. 0 No

10 Reserved

11 R/W

12 R/W

13 R/W Keep alive time

14 R/W I/O Enable Flag

15 R/W IP Index Destination IP index 1 Yes

Content Explanation

Set up by the system; read only. The model code of

IFD9507= H’0201

Displaying the current firmware version in hex, e.g. V1.2 is

indicated as high byte = 0x01 and low byte = 0x20.

Displaying the date in decimal form. 10,000s digit and

Release date of

the version

Communication

format

Number of

DI/DO points

Communication

time-out

Communication

delay time

1,000s digit are for “month”; 100s digit and 10s digit are for

“day”. For 1s digit: 0 = morning; 1 = afternoon.

Example: 12191 indicates the version released in the

afternoon of December 19.

See the table of communication format setting No

DI: high byte; DO: low byte 0x300 Yes

For setting up the communication time-out (unit: ms) in

Modbus

For setting up the minimum interval time between every

communication datum

For setting up the communication time-out (unit: second) in

TCP connections

High byte is input buffer enable flag. Low byte is output

buffer enable flag. The flag will be cleared when data was

sent.

Default Latched

Yes

Yes

Yes

5,000 Yes

0 Yes

30 Yes

0 No

16~32 Reserved

33 R/W

Symbol “R” refers to read only; “R/W” refers to read and write.

Returning to

default setting

0 No

4.2 Explanations on BR

BR#0: Model Name

Explanations:

1. Model code of IFD9507 = H'0201.

2. You can read the model code in the program to see if the extension module exists

BR#1: Firmware Version

Explanations:

The firmware version of IFD9507 is displayed in hex, e.g. H’0100 indicates version V1.00.

10

DVP-PLC Application Manual

Page 13

Ethernet Communication Module IFD9507

BR#2: Release Date of the Version

Explanations:

Displaying the date in decimal form. 10,000s digit and 1,000s digit are for “month"; 100s digit and 10s digit

are for “day". For 1s digit: 0 = morning; 1 = afternoon.

Example: 12191 indicates the version released in the afternoon of December 19.

BR#4: Communication Format

Explanations:

BR4 low byte

b7 ~ b4 b3 b2 ~ b1 b0

Stop bit

Explanation Reserved

0000 (0) 7-N-1 0011 (3) 8-O-1 1000 (8) 7-N-2 1011 (B) 8-O-2

Content

b7 B6 ~ b4 B3 b2 b1 b0

Explanation

0001 (1) 8-N-1 0110 (6) 7-E-1 1001 (9) 8-N-2 1110 (E) 7-E-2

0010 (2) 7-O-1 0111 (7) 8-E-1 1010 (A) 7-O-2 1111 (F) 8-E-2

RS-485

User

Define

0: Disable

1: Enable

Reserved

0: 1 stop bit

1: 2 stop bits

BR4 high byte

RS-232

User

Define

0: Disable

1: Enable

COM2 RS-485

setting

0: Serial Master

Ethernet Server

1: Serial Slave

Ethernet Client

Parity bit

00: none parity bit

01: odd parity bit

11: even parity bit

COM1 RS-232 setting

0: Delta Configuration

1: Modbus

Data bit

0: 7 data bits

1: 8 data bits

Mode

0: ASCII

1: RTU

Content

00000000 (0) Disable Disable Serial Master

00000001 (1) Disable Disable Serial Master

00000010 (2) Disable Disable Serial Master

00000011 (3) Disable Disable Serial Master

00000100 (4) Disable Disable Serial Slave

00000101 (5) Disable Disable Serial Slave

00000110 (6) Disable Disable Serial Slave

00000111 (7) Disable Disable Serial Slave

00001000 (8) Disable Enable Serial Master

: : : :

10000111 (135)

10001000 (136) Enable Enable Serial Master Delta configuration ASCII

10001001 (137) Enable Enable Serial Master Delta configuration RTU

10001010 (138) Enable Enable Serial Master Modbus ASCII

10001011 (139) Enable Enable Serial Master Modbus RTU

10001100 (140) Enable Enable Serial Slave Delta configuration ASCII

10001101 (141) Enable Enable Serial Slave Delta configuration RTU

10001110 (142) Enable Enable Serial Slave Modbus ASCII

10001111 (143) Enable Enable

Enable

Disable Serial Slave

Serial Slave Modbus RTU

Delta configuration

Delta configuration

Modbus

Modbus

Delta configuration

Delta configuration

Modbus

Modbus

Delta configuration

:

Modbus

ASCII

RTU

ASCII

RTU

ASCII

RTU

ASCII

RTU

ASCII

:

RTU

DVP-PLC Application Manual

11

Page 14

Ethernet Communication Module IFD9507

BR#5: Baud Rate

Explanations:

BR#5 low byte for baud rate of COM1

Communication

interface

Baud rate

(bps)

Content

RS-232

BR#5 high byte for baud rate of COM2

Content RS-485 same as low byte

Data

0x01 110 0x06 2,400 0x0B 57,600

0x02 150 0x07 4,800 0x0C 115,200

0x03 300 0x08 9,600

0x04 600 0x09 19,200

0x05 1,200 0x0A 38,400

Explanation

Data

Baud rate

(bps)

Data

Baud rate

(bps)

BR#6: Address

Explanations:

For filling in or reading the Modbus address. The address will be displayed in the message display after being

set up.

BR#7: Number of DI/DO Points

Explanations:

Read the number of DI/DO points from BR#7.

BR#9: Error Code

Explanations:

Error code = 0 refers to no error occurring.

Code Indication How to correct

01 ~ F7

F0 Returning to default setting -F1 IFD9507 being powered -F2 Power supply in low voltage Check if the power supply of the module works normally.

F3 Internal memory detection error

F4 Internal error. Manufacturing error.

F5 Network connection error Check if IFD9507 is connected normally to the network.

F6

F7 UART setting error.

E1 Alarm 1 triggered Check alarm input point 1.

Node address of the scan module

(when operating normally)

Full number of devices connected

in the network.

--

1. Re-power IFD9507. If the error still exists, try step 2.

2. Reset IFD9507. If the error still exists, send the

module back to the factory for repair.

1. Re-power IFD9507. If the error still exists, try step 2.

2. Reset IFD9507. If the error still exists, send the

module back to the factory for repair.

Check if the number is too much.

Check if the RS-485, RS-232 communication format is

correct.

12

DVP-PLC Application Manual

Page 15

Ethernet Communication Module IFD9507

Code Indication How to correct

E2 Alarm 2 triggered Check alarm input point 2.

E3 Alarm 3 triggered Check alarm input point 3.

1. Check if IFD9507 is normally connected to RS-485.

04 CRC error

0B No response from the station

BR#11: Communication Time-out (ms)

Explanations:

or setting up the communication time-out in Modbus. Default = 5,000ms. For example, if you wish to set up

the communication time-out as 7 seconds manually, write 7,000 into BR11.

BR#12: Communication Delay Time (ms)

2. Make sure the transmission speed of IFD9507 is

consistent with that of other nodes on the network.

1. Check if IFD9507 is normally connected to RS-485.

2. Make sure the transmission speed of IFD9507 is

consistent with that of other nodes on the network.

Explanations:

For setting up the minimum interval time between every Modbus communication datum. Default = 0ms. For

example, if you wish to set up the communication delay time as 100ms manually, write 100 into BR12.

BR#13: Keep Alive Time (s)

Explanations:

For setting up the communication time-out in TCP connections. Default = 30s. For example, if you wish to set

up the communication time-out as 7 seconds manually, write 7 into BR13.

BR14: I/O Enable Flag

Explanations:

Setting up input buffer and output buffer enable or not. Default = 0. Setting high byte to 1 can enable input

buffer and setting low byte to 1 can enable output buffer.

BR15: IP index

Explanations:

Destination IP index is used in a TCP connection. Default = 1. In delta DCISoft, there are 4 items can be set

therefore the index is 1 to 4. User can select one of items to connect with others Ethernet/IP device.

BR#33: Returning to Default Setting

Explanations:

IFD9507 will return to default setting when "1” is written into BR#33. BR#33 will be cleared to “0” automatically

after the returning.

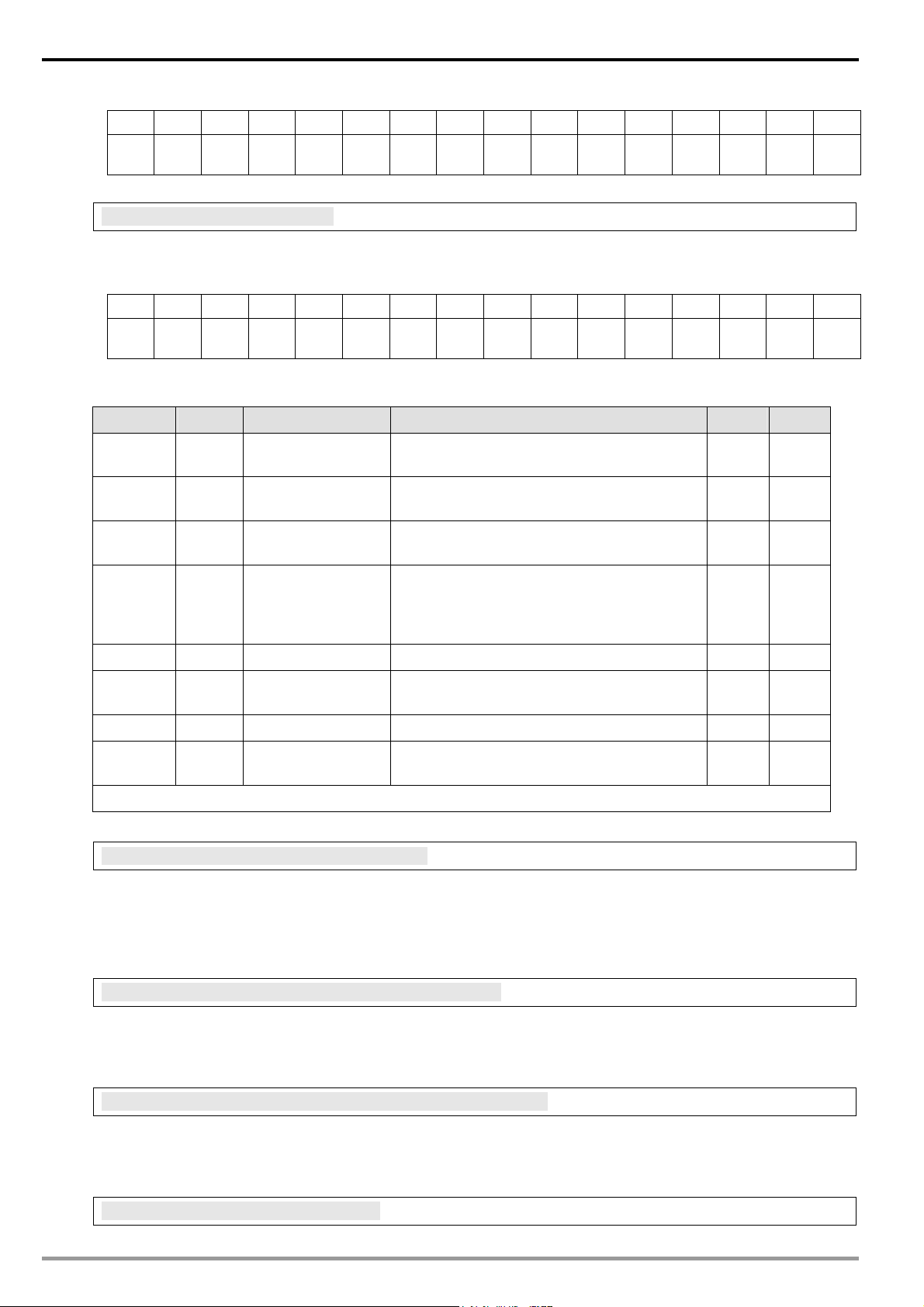

4.3 Alarm Registers (AL) in IFD9507

AL# Attribute Content Explanation Default Latched

0 R/W Alarm point 1 0 Yes

DVP-PLC Application Manual

13

Page 16

Ethernet Communication Module IFD9507

AL# Attribute Content Explanation Default Latched

1 R/W Alarm point 2 0 Yes

2 R/W Alarm point 3 0 Yes

Symbol “R” refer to read only; “R/W” refers to read and write.

AL#0: Alarm Point 1

Explanations:

You can designate one RX extension point as the alarm point by setting up the AL register in IFD9507. When

the alarm point is triggered, IFD9507 will execute its corresponding function. When b15 of AL0 is set as “1”,

the Gateway will execute the event immediately. When RX point is triggered, the Gateway will only execute

the triggered event once.

Device Function Setting Attribute Default Latched

b15

b4 ~ b14 Reserved

b2 ~ b3

AL#0

b1 Reserved Reserved

b0

Enabling the

function

Type of event

enabled when

RX alarm point

is triggered

Condition for

triggering RX

b15 = 1: Enabling

b15 = 0: Disabling

b3 b2

Reserved 0 0

Trigger E-Mail 0 1

Reserved 1 0

Reserved 1 1

The setting will be invalid when

thealarm function is being executed.

b0 = 0: Triggered when RX input

point is low

b0 = 1: Triggered when RX input

point is high

R/W 0 Yes

R/W 0 No

R/W 0 Yes

R/W 0 Yes

AL#1: Alarm Output 2

Explanations:

The settings for AL#1 are the same as those in AL#0.

AL#2: Alarm Output 3

Explanations:

The settings for AL#2 are the same as those in AL#0.

4.4 In buffer registers (IN) in IFD9507

IN# Attribute Content Explanation Default Latched

0~255 R/W Data input buffer Ethernet/IP input data 0 No

Symbol “R” refers to read only; “R/W” refers to read and write.

Explanations:

The input data was sent to Ethernet.

14

DVP-PLC Application Manual

Page 17

4.5 Out buffer registers (OUT) in IFD9507

OUT# Attribute Content Explanation Default Latched

0~255 R Data output buffer 0 No

Symbol “R” refers to read only; “R/W” refers to read and write.

Explanations:

The output data was sent to RS-485.

5 Monitoring Functions

5.1 Monitor Bit Registers (MB)

MB# Attribute Content Explanation Default Latched

0 R/W

1 R/W

2 R/W

3 ~ 32 R/W

33 ~ 200 R/W Reserved

201 R Monitored value

202 ~ 213 R Reserved

214 R Monitored status

Symbol “R” refer to read only; “R/W” refers to read and write.

MB#0: Number of Devices Monitored

Number of devicees

monitored

No. of station

monitored

Address of the

device monitored

No. of station

monitored, address

of the device

monitored

Ethernet Communication Module IFD9507

Cache mode normally enabled (b15=1),

monitoring data in max. 16 slaves.

No. of the station to be monitored 0 Yes

Recording the address of the device

monitored.

No. of the station to be monitored;

recording the address of the device

monitored.

Every MB records the value in the 16-bit

device.

Every MB records the status in the 16-bit

device. 1 = normal; 0 = abnormal

0 Yes

0 Yes

0 Yes

0 No

0 No

Explanations:

For setting up the number of devices to be monitored. Max. data in 16 slaves can be monitored.

b15 is read only (Default =1: normally enabled cache mode)

MB# (Odd Number): No. of Station Monitored

Explanations:

MB#1, MB#3, MB#5…MB#33 are for setting up the station No. (0 ~ 255) to be monitored.

MB# (Even Number): Address of Device Monitored

Explanations:

MB#2, MB#4, MB#6…MB#34 are for setting up the address of the device to be monitored.

MB#201: Monitored Value

Explanations:

Every MB records the values in the 16-bit device.

DVP-PLC Application Manual

15

Page 18

Ethernet Communication Module IFD9507

b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

Device

MB#214: Monitored Status

Explanations:

Every MB records the status in the 16-bit device. 1 = normal; 0 = abnormal.

Device

5.2 Monitor Word Registerss (MW)

33 ~ 200 R/W Reserved

201 ~ 216 R Monitored value

216 ~ 300 R Reserved

Symbol “R” refers to read only; “R/W” refers to read and write.

Device

16

b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

Device

16

15

15

Device

14

Device

14

Device

13

Device

13

Device

12

Device

12

Device

11

Device

11

Device

10

Device

10

Device 9 Device 8 Device 7 Device 6 Device 5 Device 4 Device 3 Device 2 Device

Device 9 Device 8 Device 7 Device 6 Device 5 Device 4 Device 3 Device 2 Device

MW# Attribute Content Explanation Default Latched

0 R/W

1 R/W

2 R/W

Number of devices

monitored

No. of station

monitored

Address of the

device monitored

Cache mode normally enabled (b15=1),

monitoring data in max. 16 slaves.

No. of the station to be monitored 0 YES

Recording the address of the device

monitored

No. of station

3 ~ 32 R/W

monitored, address

of the device

No. of the station to be monitore; recording

the address of the device monitored.

monitored

Every MW records the monitored value in 1

register

301 R Monitored status

Every MW records the status in a 16-bit

register. 1 = normal; 0 = abnormal

1

1

0 YES

0 YES

0 YES

0 NO

0 NO

16

MW#0: Number of Devices Monitored

Explanations:

For setting up the number of devices to be monitored. Max. data in 16 slaves can be monitored.

b15 is read only (Default =1: normally enabled cache mode)

MW# (Odd Number): No. of Station Monitored

Explanations:

MW#1, MW#3, MW#5…MW#33 are for setting up the station No. (0 ~ 255) to be monitored.

MW# (Even Number): Address of Device Monitored

Explanations:

MW32, MW34, MW#36…MW#34 are for setting up the address of the device to be monitored.

MW#201~#216: Monitored Value

DVP-PLC Application Manual

Page 19

Ethernet Communication Module IFD9507

Explanations:

Every MW records the values in 1 register.

MW#201 MW#202 MW#203 MW#204 MW#205 MW#206 MW#207 MW#208 MW#209 MW#210

Device 1 Device 2 Device 3 Device 4 Device 5 Device 6 Device 7 Device 8 Device 9 Device 10

MW#211 MW#212 MW#213 MW#214 MW#215 MW#216

Device

11

Device

12

Device

13

Device

14

Device

15

Device

16

MW#301: Monitored Status

Explanations:

Every MW records the status in a 16-bit register. 1 = normal; 0 = abnormal.

b15 b14 b13 b12 b11 b10 b9 b8 b7 b6 b5 b4 b3 b2 b1 b0

Device

16

Device

15

Device

14

Device

13

Device

12

Device

11

Device

10

Device 9 Device 8 Device 7 Device 6 Device 5 Device 4 Device 3 Device 2 Device

1

6 Setting up Device Address and Relay Address in Slave Mode (For Modbus TCP protocol

only)

MIP# Attribute Content Explanation Default Latched

0 ~ 50 R/W

Corresponding

address

50 ~ 249 R/W Relay IP address

Symbol “R” refers to read only; “R/W” refers to read and write.

MIP#0: Corresponding Address

Explanations:

The low bytes of MIP#0 are for the first address, and the high byte are for the second address, and so on.

MIP#51 ~ #52: Corresponding IP for the 1st Device Address

Explanations:

Example 1: If you wish to convert “192.168.0.1” into C0A80001 (hex), write A8C0 into MIP50 and H0100 into

MIP51.

Max. 100 addresses are allowed. High

byte for 1 address and low byte for 1

address.

Total 100 IPs. Every address (1 byte)

corresponds to 1 IP address (4 bytes).

0 Yes

0 Yes

Example 2: Data in address 1 have to correspond to 192.168.0.8. Data in address 2 have to correspond to

192.168.0.6. To complete such settings, write H0102 into MIP0, H0800 into MIP50, HA8C0 into MIP51, H0600

into MIP52, and HA8C0 into MIP53.

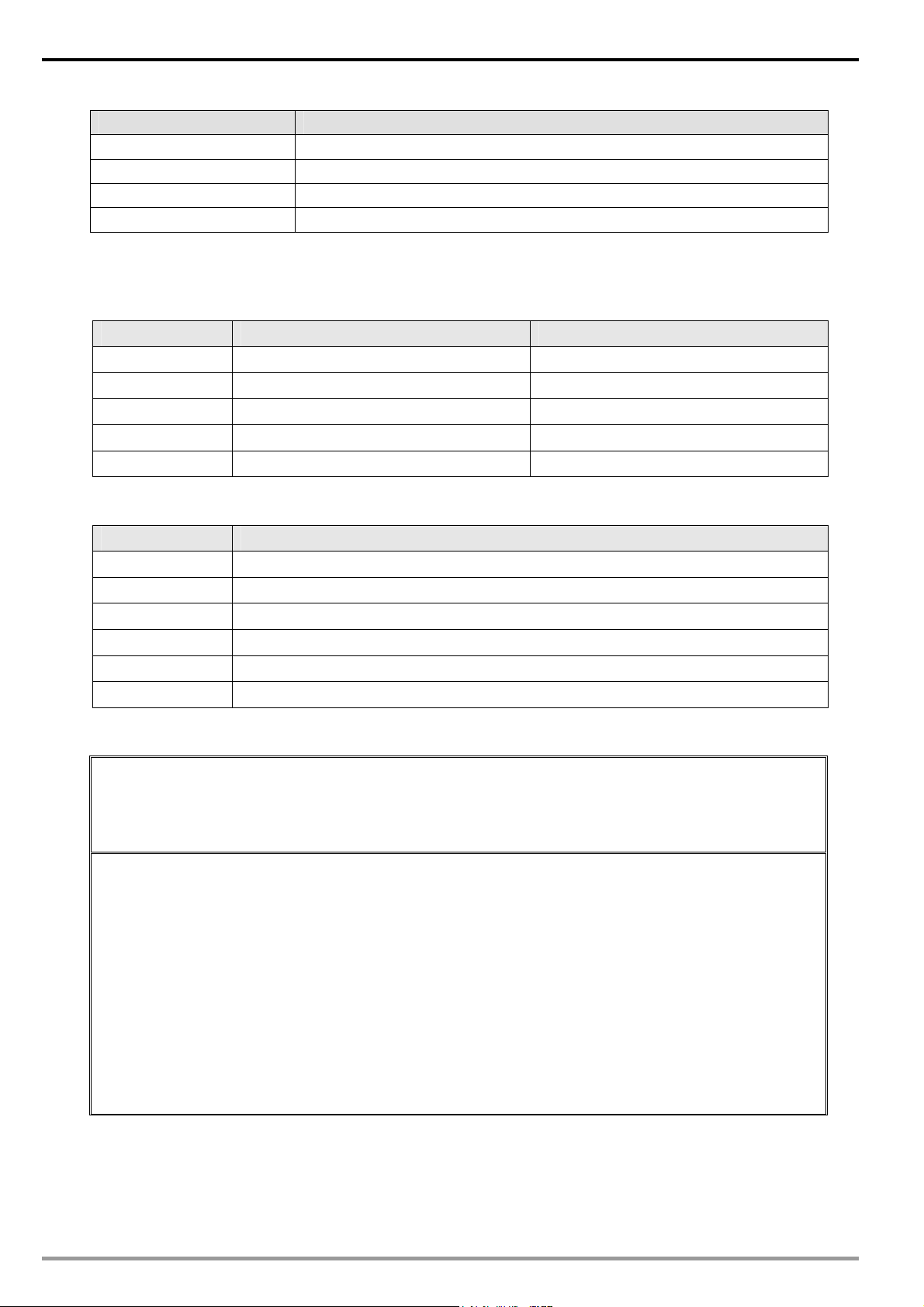

7 Setting up Device Address and Other Network Settings in Slave Mode

Parameter Explanation

Device address Address of Modbus device

Relay IP address Corresponding IP address for a device

Priority/Time Tick Scale of time. Unit: ms

Timeout Tick Scale of timeout

Timeout Timeout = Time Tick × Timeout Tick (Unit: ms)

DVP-PLC Application Manual

17

Page 20

Ethernet Communication Module IFD9507

Parameter Explanation

Multiple Max. timeout times

Trigger Cyclic, changing status, application object

OÆT packet interval Packet interval between originator and target

TÆO packet interval Packet interval between originator and target

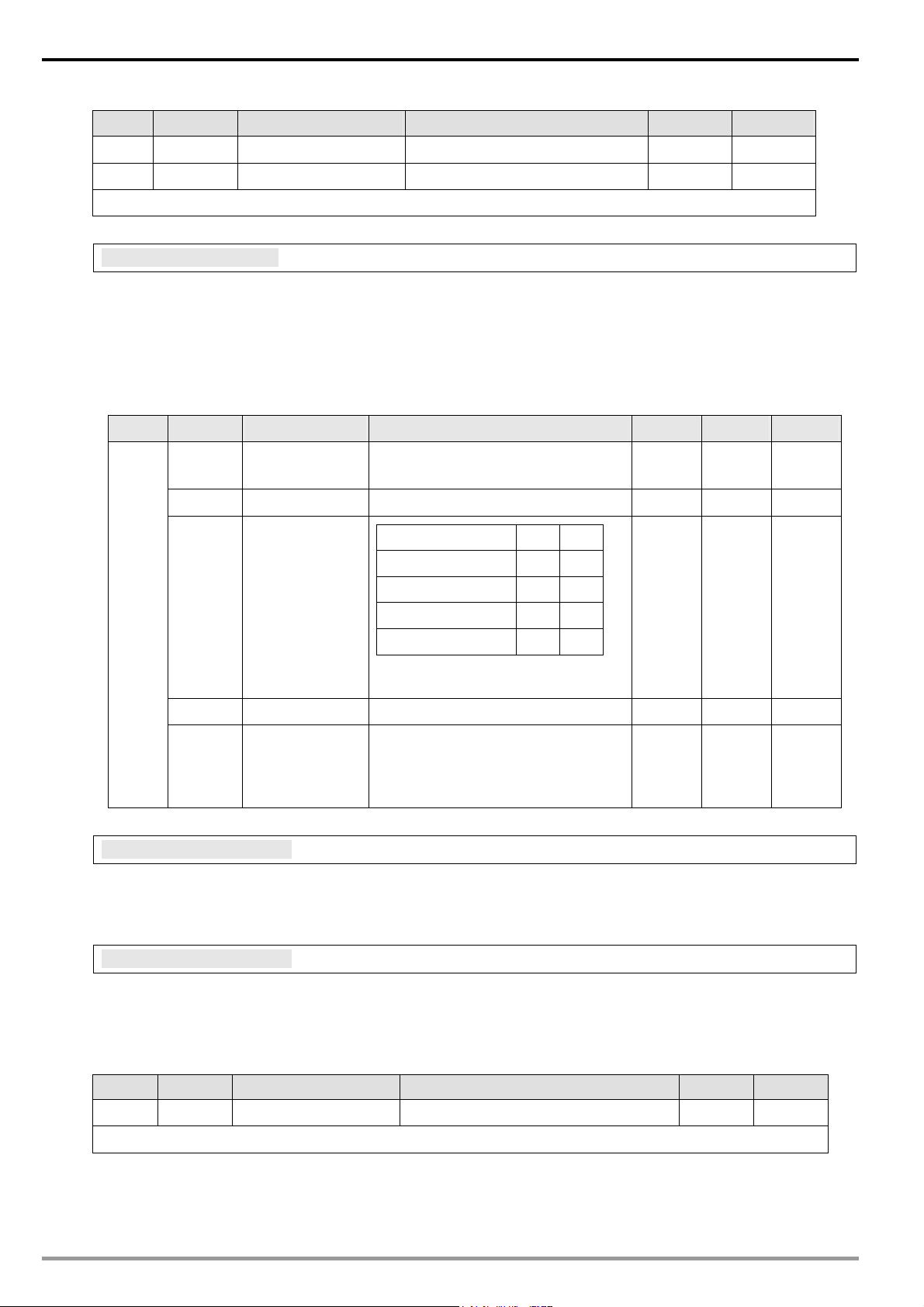

8 Modbus Communication

8.1 Function Codes Supported

Function code Explanation Devices supported

0x02 Read discrete input RX

0x03 Read holding register BR, AL, MB, MW, MIP

0x06 Write single holding register BR, AL, MB, MW, MIP

0x10 Write multiple holding register BR, AL, MB, MW, MIP

0x17 Read/write multiple holding register BR, AL, MB, MW, MIP

8.2 Exception Codes Supported

Exception code Explanation

0x01 Illegal function

0x02 Illegal data addresss

0x03 Illegal data value

0x04 Slave device failure

0x0A Gateway path unavailable

0x0B Gateway target device failed to respond

8.3 Device Type & Device Address

Device

type

RX 0x0400 ~ 0x0402 11025 ~ 11027 101025 ~ 101027 3

Device

type

BR 0x0000 ~ 0x00FF 40001 ~ 40256 400001 ~ 400256 64

AL 0x0200 ~ 0x0202 40513 ~ 40515 400513 ~ 400515 3

X 0x0400 ~ 0x0402 41025 ~ 41027 401025 ~ 401027 3

IN 0x0500 ~ 0x05FF 41281 ~ 41536 401281 ~ 401536 256

OUT 0x0600 ~ 0x06FF 41537 ~ 41791 401537 ~ 401791 256

MB 0x2000 ~ 0x20FF 48193 ~ 48448 408193 ~ 408448 256

MW 0x2200 ~ 0x23FF 48705 ~ 49216 408705 ~ 409216 512

MIP 0x2400 ~ 0x24FF 49217 ~ 49471 409217 ~ 409471 256

Modbus address

(Hex)

Modbus address

(Hex)

Discrete input

5-digit Modbus address (Dec)

Holding register

5-digit Modbus address (Dec)

6-digit Modbus address

(Dec)

6-digit Modbus address

(Dec)

Number

Number

18

DVP-PLC Application Manual

Page 21

9 Ethernet/IP Communication

9.1 Service code supported

Ethernet Communication Module IFD9507

Service

Code

ID

Message Router Object

Assembly Object

Connection Manager

Object

0x01

0x05 ID Reset Invokes the Reset service for the device.

0x0E

0x10

0x4E

0x54

BR

AL

MB

MW

TCP Interface

TCP Link

ID

Message Router Object

Assembly Object

Connection Manager

Object

BR

AL

MB

MW

TCP Interface

TCP Link

Assembly Object

BR

AL

MB

MW

TCP Interface

Connection Manager

Object

Connection Manager

Object

Object Service Description

Get_Attribute_All Returns a predefined listing of this objects

attributes

Get_Attribute_Single Return the contents of the specified

attribute.

Set_Attribute_Single Used to modify an attribute.

Forward_Close Closes a connection.

Forward_Open Opens a connection, maximum data size

is 511 bytes.

9.2 Object supported

Object Name Class ID Code Instance Code

ID 0x01 0x01 Identity Attribute Get

Message Router Object 0x02 0x01 Router Command

Assembly Object

Connection Manager Object 0x06 0x01 Connection

RX Digital input Discrete input Get

BR 0x64 0x01 Basic registers Attribute Get/Set

AL 0x64 0x02 Alarm function Attribute Get/Set

MB 0x64 0x03 Bit monitor Attribute Get/Set

MW 0x64 0x04 Register monitor Attribute Get/Set

TCP Interface 0xF5 0x01 TCP/IP Interface

DVP-PLC Application Manual

Function

Description

0x04 0x64 Assembly GO Set

0x04 0x65 Input device object GI Get

monitor object

Object

Object Type Attribute

Attribute Get/Set

19

Page 22

Ethernet Communication Module IFD9507

Object Name Class ID Code Instance Code

TCP Link 0xF6 0x01 TCP/IP Link

Function

Description

Object

Object Type Attribute

Object Get

9.3 CIP General Status Code (Reference Volume 1:CIP Common Specification Appendix B)

General

Status Code

(in hex)

00 Success Service was successfully performed by the object specified.

01 Connection failure A connection related service failed along the connection path.

02 Resource unavailable Resources needed for the object to perform the requested

04 Path segment error The path segment identifier or the segment syntax was not

05 Path destination

08 Service not supported The requested service was not implemented or was not

09 Invalid attribute value Invalid attribute data detected

0E Attribute not settable A request to modify a non-modifiable attribute was received.

13 Not enough data The service did not supply enough data to perform the

14 Attribute not supported The attribute specified in the request is not supported

15 Too much data The service supplied more data than was expected

16 Object does not exist The object specified does not exist in the device.

20 Invalid parameter A parameter associated with the request was invalid. This code

26 Path Size Invalid The size of the path which was sent with the Service Request

Status Name Description of Status

service were unavailable

understood by the processing node. Path processing shall stop

when a path segment error is encountered.

The path is referencing an object class, instance or structure

unknown

element that is not known or is not contained in the processing

node. Path processing shall stop when a path destination

unknown error is encountered.

defined for this Object Class/Instance.

specified operation.

is used when a parameter does not meet the requirements of

this specification and/or the requirements defined in an

Application Object Specification.

is either not large enough to allow the Request to be routed to

an object or too much routing data was included.

9.4 Connection Manager Service Request Error Codes (Reference Volume 1:CIP Common Specification

Table3-5.29)

General

Status

0x00 Service completed successfully

0x01 0x0100 CONNECTION IN USE OR DUPLICATE FORWARD OPEN

0x01 0x0103 TRANSPORT CLASS AND TRIGGER COMBINATION NOT

0x01 0x0108 INVALID NETWORK CONNECTION PARAMETER

20

Extended Status Explanation and Description

This extended status code shall be returned when an originator is

trying to make a connection to a target with which the originator may

have already established a connection

SUPPORTED

A transport class and trigger combination has been specified which

is not supported by the target. Routers shall not fail the connection

based on the transport class and trigger combination. Only targets

shall return this extended status code.

This extended status code shall be returned as the result of

specifying a connection type, connection priority, redundant owner

or fixed / variable that is not supported by the target application.

Only a target node shall return this extended status code.

DVP-PLC Application Manual

Page 23

Ethernet Communication Module IFD9507

General

Status

0x01 0x0114 VENDOR ID OR PRODUCT CODE MISMATCH

0x01 0x0115 PRODUCT TYPE MISMATCH

0x01 0x0116 REVISION MISMATCH

0x01 0x0315 INVALID SEGMENT IN CONNECTION PATH

Extended Status Explanation and Description

The Product Code or Vendor Id specified in the electronic key

logical segment does not match the Product Code or Vendor Id of in

the target device.

The Product Type specified in the electronic key logical segment

does not match the Product Type of in the target device.

The major and minor revision specified in the electronic key logical

segment does not correspond to a valid revision of the target

device.

Invalid Segment Type or Segment Value in Connection Path This

extended status code is the result of a device being unable to

decode the connection path. This could be caused by an

unrecognized path type, a segment type occurring unexpectedly, or

a myriad of other problems in the connection path.

10 Setting up the Software - DCISoft

This section gives instructions on how to set up IFD9507 by DCISoft and explanations on each setup page.

IFD9507 is set up by UDP port 20006; therefore, you have to be aware of the relevant settings of the firewall.

See the explanations below on the software.

10.1 Setting up Communication & Searching for Modules in DCISoft

Broadcast search

1. Open DCISoft on the PC and click on the “IP Search” icon.

2. You will see the network modules found.

DVP-PLC Application Manual

21

Page 24

Ethernet Communication Module IFD9507

3. Double-click on the module to be set up to enter the setup page. The first page overviews the basic

status of the module.

22

4. The next page is for basic network setup. Consult your ISP for relevant network settings. For other

settings, see BR4~BR6 and BR11~BR13.

DVP-PLC Application Manual

Page 25

Ethernet Communication Module IFD9507

10.2 Basic Settings

The basic settings include parameters such as module name, network settings and serial communication.

The basics

1. Module name:

There can be many IFD9507s on the network. Thus, you can set up a module name for each module to

DVP-PLC Application Manual

23

Page 26

Ethernet Communication Module IFD9507

identify the module when you need to use them.

2. Master configuration:

Open “Serial Master” mode or “Serial Slave” mode.

3. Network settings:

Enable DHCP or static IP. Consult your ISP for other relevant settings.

A. IP configuration:

There are 2 types of IP, static IP and DHCP.

Static IP: Preset or manually modified by the user.

DHCP: Automatically updated by the server. There has to be a server in the LAN.

IP Explanation

Static The user enters the IP address, subnet mask and gateway.

DHCP DHCP server offers the IP address, subnet mask and gateway.

B. IP address:

IP address is the location of the equipment on the network. All equipment connected to the network

has to have an IP address. Incorrect IP address will result in connection failure on the equipment or

even other equipment. Ask your ISP for questions about IP address setup. The default IP for

IFD9507 is 192.168.1.5.

C. Subnet mask:

Subnet mask is an important parameter for setting up the subnet, used for seeing if the destination

IP and the local equipment are in the same subnet. If not, the equipment will send the packet to the

gateway, and the gateway will send the packet to another subnet. Incorrect setting may cause the

destination equipment unable to communication to IFD9507. To see of your setting is correct,

conduct bitwise AND operations between your IP and subnet mask and destination IP and subnet

mask. If the two values obtained are the same, the two IPs are in the same subnet. The default

subnet mask of IFD9507 is 255.255.255.0.

D. Gateway:

Gateway is the window for two different subnets, allowing the two ends in different subnets to

communicate. For example, if the LAN has to be connected to WAN, it will need a gateway to

bridge the communication. The IP of the gateway has to be in the same subnet as IFD9507. The

default gateway of IFD9507 is 192.168.1.254.

4. Communication parameter setting:

See how to set up BR4, BR5, and BR6.

Applicable protocol: Modbus/TCP or Ethernet/IP.

5. Timer setting:

For setting up TCP communication idle time, communication timeout and minimum delay time for

every communication datum. Please refer to the settings of BR11, BR12 and BR13.

10.3 Network Settings

The first step for all the network equipment to connect to the network is to have its own IP address (Internet

Protocol). The IP address is like a number for all network equipment to be identified in the network.

Setting up static IP of the PC

24

DVP-PLC Application Manual

Page 27

Ethernet Communication Module IFD9507

1. Enter Control Panel → Network Connection → click on “Local Area Connection”.

2. You will see the “Local Area Connection Status” window. Click on “Properties”.

3. Click on “Internet Protocol (TCP/IP)".

4. Enter “192.168.0.1” into IP address. Click on “OK” to complete the IP address setting of the PC.

DVP-PLC Application Manual

25

Page 28

Ethernet Communication Module IFD9507

10.4 Setting up E-Mails

E-Mail is the abbreviation of electronic mail which transmits mails through the network. IFD9507 has E-Mail

functions for the user to pre-save a segment of text message, which can be a descriptive message or error

message, into the subject of the E-Mail. When the E-Mail is triggered, IFD9507 will send the messages to the

user by E-Mail.

Mail settings

26

1. Mail alarm setup:

There are 3 mail alarms to be set up. Check the boxes to enable the alarms. The alarm can be

triggered by “low" and “high”.

2. SMTP server:

When alarm 1 is triggered, the E-Mail will first be sent to SMTP server, and the SMTP server will send

it to the designated address. For example, assume there is an E-Mail to be sent to

DVP-PLC Application Manual

Page 29

Ethernet Communication Module IFD9507

Test@delta.com.tw

first, and the server will further send it to the recipient Test@delta.com.tw

3. E-Mail of sender:

Maximum 63 Engligh characters are allowed.

4. Subject of E-Mail:

You can enter the text message in the column, and the message will be placed in the subject of the

E-Mail and sent to the recipient. IFD9507 is able to contain 1 ~ 3 E-Mail subjects (max. 63 English

characters are allowed).

5. E-Mail of recipient:

One mail can be sent to 10 addresses according to the alarm settings. Every address allows max.63

English characters. For example, (see the figure above) when Alarm 1 is triggered, the E-Mail will be

sent to Test1@delta.com.tw

sent to Test2@delta.com.tw

Note:

To correctly send out E-Mails, there has to be a SMTP server in the network. When we send out an

E-Mail, the mail will be sent to SMTP server first, and the server will further send the mail to the

designated address.

, and the SMTP server is 192.168.0.1. The E-Mail will be sent to the SMTP server

.

and Test2@delta.com.tw . When Alarm 2 is triggered, the E-Mail will be

10.5 Monitoring Settings

You can read data in designated addresses in different equipment in the network by setting up IFD9507.The

data can be temporarily stored in IFD9507 for fast storing and acquisition.

Setting up monitoring functions

1. Monitor bit:

Device addresses for setting up the bit status of serial slave; able to read the content in the

DVP-PLC Application Manual

27

Page 30

Ethernet Communication Module IFD9507

corresponding address of the designated slave.

2. Monitor word:

Device addresses for setting up the word status of serial slave; able to read the content in the

corresponding address of the designated slave.

Note:

Cache mode normally enabled, and Max. data in 16 slaves can be monitored. When the cache mode

is enabled, the data you would like to read will be sent back directly from the register in IFD9507.

3. Serial slave mode (used when in Modbus TCP protocol):

The instruction sent from the master is received and transferred to the network. Please designate the

10.6 IP Filter

The IP filter is used for restricting the connection of the network in case some uncertain IP will cause errors.

Only the IP set within a certain range can establish a connection. Other IPs will be rejected.

Setting up IP filter

station address and relay IP address.

Station address: slave PLC address (Gateway and PLC address cannot be the same)

Relay IP address: serial master IP

28

DVP-PLC Application Manual

Page 31

Ethernet Communication Module IFD9507

1. Enable IP filter function:

Check the box to enable IP filter.

2. IP address:

IP addresses that are allowed to establish connections. Maximum 8 IPs are allowed.

3. Netmask:

Subnet mask of the IP that is allowed to establish a connection. To see whether the subnet mask is

allowed, conduct bitwise AND operation between the allowed IP and subnet mask and destination IP

and subnet mask. If the two values obtained are the same, the subnet mask is allowed by the network.

For example, assume the IP is 192.168.0.1 and subnet mask 255.255.255.255, the only IP allowed to

establish a connection will be 192.168.0.1. If the subnet mask is 255.255.255.0, the IPs allowed to

establish connections will become 192.168.0.0 ~ 192.168.0.255.

10.7 Ethernet/IP settings

Ethernet/IP parameters are used for a connection.

Setting Ethernet/IP parameters

DVP-PLC Application Manual

29

Page 32

Ethernet Communication Module IFD9507

30

1. Dest IP

This is Destination IP address.

2. Timeout (ms)

Timetick * Timeout tick = Timeout

※ Available time tick: 20 ~ 215

DVP-PLC Application Manual

Page 33

Ethernet Communication Module IFD9507

※ Max. Timeout tick: 255

3. Trigger

There are three trigger types. The cyclic used to describe event that repeat in regular. Production

occurs when a change of state is detected by application object. The Application object used to

provide the run time exchange of messages across network.

4. OÆT RPI

Originator to target requested packet interval.

When the trigger occurs, the packet is sent to the target within the set interval time.

5. TÆO RPI

Target to originator requested packet interval.

When the trigger occurs, the packet is sent to the source within the set interval time.

6. In Instance

Target input buffer Instance. Range: 1 ~ 65,535.

7. In Size

Target input buffer size. Range: 0 ~ 256.

8. Out Instance

Target output buffer instance. Range: 1 ~ 65,535.

9. Out Size

Target output buffer size. Range: 0 ~ 256.

10. Width

Data width

11. Config Instance

Configuration instance. Range: 1 ~ 65,535.

10.8 User Defined Settings

When you set up user-defined communication protocol for IFD9507, please set up the following parameters.

Setting up communication parameter between RS-232/RS-485 serial master and serial slave

DVP-PLC Application Manual

31

Page 34

Ethernet Communication Module IFD9507

32

1. Listen Port/Destination IP:

Range: 1,024 ~ 65,535

2. Fix Length:

Length of the packet to be transmitted. Unit: byte

3. Start Item:

DVP-PLC Application Manual

Page 35

1 ~ 3 bytes of characters as the start of a packet.

4. Stop Item:

1 ~ 3 bytes of characters as the stop of a packet.

10.9 Virtual COM

Virtual COM converts the data transmitted to RS-232 to Ethernet.

Select "User Define COM”.

Ethernet Communication Module IFD9507

Switch to “User Define” page and select “Listen Port”.

DVP-PLC Application Manual

33

Page 36

Ethernet Communication Module IFD9507

Open Virtual COM setup page.

34

DVP-PLC Application Manual

Page 37

Ethernet Communication Module IFD9507

Press “OK”, and you will see all the devices connected on the network.

Select the module you need and press “OK”. Relevant information of the device will be imported

automatically. Press “OK” to complete the setup.

Once the setup is successful, you can see the virtual COM you set in the Device Manager.

DVP-PLC Application Manual

35

Page 38

Ethernet Communication Module IFD9507

10.10 Security Settings

To prevent the set values in IFD9507 from being modified, you can set up passwords to lock the settings in

IFD9507.

Setting up password

36

1. Password setup:

Check the "Modify” box to set up the password.

2. Confirm password:

Enter the new password again.

3. See “12.1 Application Examples” for more details.

DVP-PLC Application Manual

Page 39

Note:

Once the password is locked, all the pages cannot be set up unless you unlock the password.

However, if you set up IFD9507 by RS-232, you can return the setting to default one whether the

password is locked or not. For example, if you have locked IFD9507 but forget the password, you

have to return IFD9507 to default setting by RS-232, and all the settings will return to default ones.

Login password

Ethernet Communication Module IFD9507

Password:

Enter the password to unlock the editing function for other pages.

10.11 Returning to Default Settings

If you need to clear all the settings after many modifications on the settings and return the settings to default

ones, check the “Factory Setting” box.

Returning to default settings

DVP-PLC Application Manual

37

Page 40

Ethernet Communication Module IFD9507

Returning to default setting:

Check “Factory Setting” box and click on “Yes”.

Note:

If you set up IFD9507 by RS-232, you can return to settings to default ones whether the password is

locked or not. It will take approximately 10 seconds to return to default settings, so DO NOT switch off

the power within the 10 seconds. Besides, you can also press “Reset” button for 2 seconds to return

to default settings.

11 Setting up Configuration by Homepage

This section gives instructions on how to set up IFD9507 by homepage and explanations on each configuration

page. IFD9507 is set up by UDP port 20006; therefore, you have to be aware of the relevant settings of the

firewall. See the explanations below on the homepage.

11.1 Webpage connection

Enabling webpage function

1. Open IE, and enter the IP address of IFD9507 into the address column.

2. See below for the setup page offered by the webpage. Preview all the information in the column on the

38

left hand side.

DVP-PLC Application Manual

Page 41

Ethernet Communication Module IFD9507

11.2 Basic settings

The basic settings include parameters as module name, network settings and series communication. Please

consult your Internet service provider for relevant network settings. For other settings, please refer to BR4 ~

BR6 and BR11 ~ BR13.

The basics

DVP-PLC Application Manual

39

Page 42

Ethernet Communication Module IFD9507

See 10.2 for how to set up.

11.3 Setting up E-Mails

Email is the abbreviation of electronic mail which transmits mails through the network. IFD9507 has E-Mail

functions for the user to pre-save a segment of text messages, which can be a descriptive message or error

message, into the subject of the E-Mail. When the E-Mail is triggered, IFD9507 will send the messages to the

user by E-Mail.

Mail settings

40

DVP-PLC Application Manual

Page 43

Ethernet Communication Module IFD9507

1. Mail alarm setup:

There are 3 mail alarms to be setup. Check the boxes to enable the alarms. The alarms can be

triggered by “falling" or “rising".

2. See 10.4 for how to set up SMTP server/Mail From/E-mail Subject of Event/Recipient E-Mail Address

columns.

11.4 IP filter

The IP filter is used for restricting the connection of the network in case some uncertain IP will cause errors.

Only the IP set within a certain range can establish a connection. Other IPs will be rejected.

Setting up IP filter

DVP-PLC Application Manual

41

Page 44

Ethernet Communication Module IFD9507

See 10.6 for how to set up.

11.5 Security Settings

To prevent the set values in IFD9507 being modified, you can set up passwords to lock the settings in

IFD9507.

Setting up IFD9507 password

1. Password setup:

Maximum 4 characters are allowed. Leave the column “blank” to disable the password protection

function.

2. Confirming password:

Enter the new password again.

Note:

Once the password is locked, all the pages cannot be set up unless you unlock the password.

However, if you set up IFD9507 by RS-232, you can return the setting to default one whether the

password is locked or not. For example, if you have locked IFD9507 but forget the password, you

have to return IFD9507 to default setting by RS-232, and all the settings will return to default ones.

Login password

42

DVP-PLC Application Manual

Page 45

1. Refresing webpage:

Once IFD9506 is locked by a password, please click on “Refresh” on the webpage toolbar to

display the password login page.

2. Setting up password:

Ethernet Communication Module IFD9507

Enter the password to enable the editing function on other pages.

11.6 Returning to default setting

If you need to clear all the settings after many modifications on the settings and return the settings to default

ones, check the “Factory Setting” box.

Returning to default setting

Returning to default setting:

Check “Factory Setting” box and click on “Yes”.

Note:

If you set up IFD9507 by RS-232, you can return to settings to default ones whether the password is

locked or not. It will take approximately 10 seconds to return to default settings, so DO NOT switch off

the power within the 10 seconds. Besides, you can also press “Reset” button for 2 seconds to return

to default settings.

11.7 Monitoring settings

You can read data in designated addresses in different equipment in the network by setting up IFD9507.The

data can be temporarily stored in IFD9507 for fast storing and acquisition.

Setting up Master Mode monitoring functions

DVP-PLC Application Manual

43

Page 46

Ethernet Communication Module IFD9507

1. Monitor bit:

Device addresses for setting up the bit status of serial slave; able to read the content in the

corresponding address of the designated slave.

2. Content:

The corresponding monitored value of the device address.

3. Digit Selection:

The monitored value can be displayed in hex or decimal form.

4. Monitor word:

Device addresses for setting up the word status of serial slave; able to read the content in the

corresponding address of the designated slave.

Note:

Cache mode normally enabled, and Max. data in 16 slaves can be monitored. When the cache mode

is enabled, the data you would like to read will be sent back directly from the register in IFD9507.

44

Setting up Slave Mode monitoring functions

DVP-PLC Application Manual

Page 47

Ethernet Communication Module IFD9507

1. Serial slave mode: (used when in Modbus TCP protocol)

The instruction sent from the master is received and transferred to the network. Please designate the

station address and relay IP address.

Station address: slave PLC address (Gateway and PLC address cannot be the same)

Relay IP address: serial master IP

11.8 Ethernet/IP

You can read data in designated addresses in different equipment in the network by setting up IFD9507.The

data can be temporarily stored in IFD9507 for fast storing and acquisition.

Setting up Slave Mode connection parameters

DVP-PLC Application Manual

45

Page 48

Ethernet Communication Module IFD9507

1. Dest IP

This is Destination IP address.

2. Timeout (ms)

Timetick * Timeout tick = Timeout

※ Available time tick:

※ Max. Timeout tick: 255.

3. Trigger

There are three trigger types. The cyclic used to describe event that repeat in regular. Production

occurs when a change of state is detected by application object. The Application object used to

provide the run time exchange of messages across network.

4. OÆT RPI

Originator to target requested packet interval.

When the trigger occurs, the packet is sent to the target within the set interval time.

5. TÆO RPI

Target to originator requested packet interval.

When the trigger occurs, the packet is sent to the originator within the set interval time.

6. In Instance

Target input buffer Instance. Range: 1 ~ 65,535.

20 ~ 2

15

46

7. In Size

Target input buffer size. Range: 0 ~ 256.

8. Out Instance

Target output buffer instance. Range: 1 ~ 65,535.

9. Out Size

Target output buffer size. Range: 0 ~ 256.

10. Width

Data width

11. Config Instance

Configuration instance. Range: 1 ~ 65,535.

DVP-PLC Application Manual

Page 49

11.9 User Define

You can define your own format for data to be transmitted. The items to be defined include the fixed length,

start item and stop item.

Select RS-232 or RS-485 to connect the device.

Ethernet Communication Module IFD9507

Switch to “User Define” page to set up the “Fix Length”, “Start Item” and “Stop Item”.

1 ~ 256

1. Listen Port/Destination Port:

DVP-PLC Application Manual

47

Page 50

Ethernet Communication Module IFD9507

Range: 1024 ~ 65535.

1. Fix Length:

When this is sest, IFD9507 will transmit data following the fixed length.

2. Start Item:

The start item of data. Range: 1 ~ 3

3. Stop Item:

The stop item of data. Range: 1 ~ 3

When the start item and stop item are set, IFD9507 will transmit data following the start item and

stop item. If the transmission time exceeds the Modbus time-out, IFD9507 will dispose of

incomplete data.

Note:

When using two IFD9507 modules as Mater and Slave and its user define functions, the settings

of the fixed length, start item and stop item have to be consistent. If not, the data will be filtered

automatically.

48

DVP-PLC Application Manual

Page 51

12 Application Examples – DCISoft

12.1 Setting up & Unlocking Password

Application Setting up password by IFD9507 configuration

Ethernet Communication Module IFD9507

Steps

1. See 10.1 for the connection and how to set up the communication.

2. Open the setup page and switch to “Security” page.

(1) Set up password in IFD9507.

(2) Unlock IFD9507.

3. Check “Modify” and enter “aabb” in “Password” and “Confirm Password” columns. Click on “Apply” to save

the password.

DVP-PLC Application Manual

49

Page 52

Ethernet Communication Module IFD9507

4. Open the setup page again, and IFD9507 is now locked by the password. You cannot open any of the

settings now. Enter the password and press “Confirm”, and you will be able to unlock the editing function

on other pages.

50

DVP-PLC Application Manual

Page 53

Ethernet Communication Module IFD9507

12.2 Password Loss (Returning to Default Settings by RS-232)

Application Returning to default settings by RS-232.

Steps

1. Use DVPACAB2A30 cable to connect the PC and IFD9507. Open the setup page.

2. Check “Factory Setting” box and the warning dialog box will appear. Click on “Yes” to return to default

settings (in approx. 5 ~ 10 seconds), and the password will be cleared as well.

(1) Set up password in IFD9507.

(2) Supposed the password is forgotten, return to default settings through RS-232.

12.3 IP Filter Protection

Application

Steps

1. See 10.1 for the connection and how to set up the communication.

2. Open the setup page and switch to “IP Filter” page.

Setting up IP filter protection. Only connections to 192.168.0.7 and 172.16.0.1 ~

172.16.0.255 are allowed.

(1) Check "Enable IP Filter” box.

(2) Set up IP address to “192.168.0.7” and netmask to “255.255.255.255”.

(3) Set up the IP address to “172.16.0.1” and Netmask to “255.255.255.0”.

3. Check “Enable IP Filter” box. Enter “192.168.0.7” into No. 1 IP and “255.255.255.255” in all “Netmask”

columns.

DVP-PLC Application Manual

51

Page 54

Ethernet Communication Module IFD9507

4. Enter “172.16.0.1” in No. 2 IP and “255.255.255.0” in No. 2 Netmask column. Click on “OK” to complete

the setting. Only the equipment within the UP range can be connected.

52

DVP-PLC Application Manual

Page 55

12.4 Application of E-Mail

Application Sending E-Mail to notify the administrator when Alarm 1 is triggered.

(1) Check “Alarm 1” to enable it.

Steps

1. See 10.1 for the connection and how to set up the communication.

2. Open the setup page and switch to “Mail” page.

(2) Set the IP of SMTP server to ” 192.168.1.99” and "Mail From” to “Message@Delta”

(3) Set the E-mail Subject of Event to “MAIL ALARM”.

(4) Set the E-mail address of administrator to test@Delta.com.tw

Ethernet Communication Module IFD9507

3. Setting up “Mail” page and check “Mail Alarm Setup”.

Enter SMTP server address, “Mail From” column, “Subject of Event” and “Recipient E-mail Address”. For

example, when Alarm 1 is triggered, the mail will be sent to test@sample.com

Enter 172.16.144.121 into “SMTP Server” column and Mail From Message@ENA01. Enter “MAIL EVENT”

as the subject and recipient e-mail address as test@delta.com.tw

complete the settings.

. Check “Alarm 1” and press “OK” to

. Trigger Alarm 1 by “low”.

DVP-PLC Application Manual

53

Page 56

Ethernet Communication Module IFD9507

12.5 Monitoring Mode

Application Writing the address of the device to be monitored into the monitor table.

Steps (1) Use monitor bit and monitor word functions.

(2) Monitor bit data in station address 1, H100 and H300, and word data in station address

1 H150.

(3) Monitor bit data in station address 2, H200.

(4) Monitor word data in station address 3, H200.

(5) Monitor word data in station address 4, H100.

(6) Monitor bit quantity: 3; monitor word quantity: 3

1. See 10.1 for how to set up communication.

2. Open IFD9507 Configuration page and switch to “Monitor” page.

54

DVP-PLC Application Manual

Page 57

Ethernet Communication Module IFD9507

3. The settings:

Note:

When the cache mode is enabled, you do not need to modify the station address and device address.

You will read data from IFD9507, in which way you will be able to speed up the reading.

DVP-PLC Application Manual

55

Page 58

Ethernet Communication Module IFD9507

12.6 Application of Virtual COM Port

Through the virtual COM port, IFD9507 is able to transmit the data sent to RS-232 to the

Application

Steps (1) Select “User Define” protocol and set the parameters in the serial master and serial slave

1. Setting up Virtual COM Port

For the COM setting, select “User Define” and set the communication parameters to the ones

Ethernet by connencting to the software supporing serial ports, e.g. Delta’s WPLSoft,

VFDSoft and ASDA-Soft. See the example below for how to connect IFD9507 to VFD-E AC

motor drive through the virtual COM port by VFDSoft.

to the ones consistent with those in VFD-E.

(2) Set up virtual COM port.

(3) Open Delta VFDSoft, set up the communication format (COM Setup) and establish the

connection.

consistent with those in VFD-E.

56

Switch to “User Define” page and select “Listen Port”.

DVP-PLC Application Manual

Page 59

Ethernet Communication Module IFD9507

Open Virtual COM setup page.

DVP-PLC Application Manual

57

Page 60

Ethernet Communication Module IFD9507

Press “OK”, and you will see all the devices connected on the network.

Select the module you need and press “OK”. Relevant information of the device will be imported

automatically. Press “OK” to complete the setup.

58

DVP-PLC Application Manual

Page 61

Ethernet Communication Module IFD9507

Once the setup is successful, you can see the virtual COM you set in the Device Manger.

2. Using Virtual COM in Delta VFDSoft

Open Delta VFDSoft.

Setting up communication format (COM Setup)

Enter the virtual COM (COM2) set in the previous steps to “Com Port” column. Next, enter the

communication format of VFD-E (38400, 7, E, 1) and press “Test" button. Once the “Success” light is

ON, the communication test is regarded successful.

DVP-PLC Application Manual

59

Page 62

Ethernet Communication Module IFD9507

Press “OK”, and IFD9507 will be able to communicate with VFD-E by VFDSoft.

60

DVP-PLC Application Manual

Page 63

Ethernet Communication Module IFD9507

13 Application Examples – AB Software (Revision:2.10.118.0)

13.1 Serial Slave

Using Delta PLC DVP28SV11T to control AB PowerFlex 40P via IFD9507.

Configure 22-COMM-E IP

Use AB software “Driver Explorer Application” to Set the PowerFlex40P+22CommE IP.

1. Open Driver Explorer Application.

2. Select “Configure Communication” in Explore.

3. Select “Serial”

Select your RS232 com port, Baud = “38400”, Checksum Type=”CRC-16” and click “OK”

DVP-PLC Application Manual

61

Page 64

Ethernet Communication Module IFD9507

4. Select “Connect Serial Point-to-Point” in Explore.

5. Select “Parameter List” in 22-COMM-E Ethernet/IP and enter “IP” in IP Addr Cfg1~Cfg4 and

“Netmask” in Subnet Cfg1~Cfg4.

62

DCISoft configuration

1. Open DCISoft “Basic” configuration screen.

2. Select “Serial Slave” in Master Configuration.

DVP-PLC Application Manual

Page 65

Ethernet Communication Module IFD9507

3. Select “Static” in IP Configuration.

4. Enter “192.168.1.99” in IP Address field.

5. Enter “255.255.255.0” in Netmask field.

6. Select “Ethernet/IP” in Application Protocol.

7. Enter “231” in Station Address.

8. Press “OK”.

9. Open DCISoft “Ethernet/IP” configuration screen.

10. Enter AB PowerFlex 40P IP Address“192.168.1.72” in Dest IP Field.

11. Select “Cyclic” in Trigger.

12. Enter PowerFlex 40P parameter “1”,”4”,”2”,”2”,”2 byte”,”6” in In Instance, In Size, Out Instance, Out

Size, Width, Config Instance in turn.

13. Press “OK”.

WPL program

1. Write control data to DVP IFD9507 IN register (H0500)

2. Use WPL MODWR instruction to write the control data to EIP (H0500).

3. Ex. RUN:111000000011010ÆH701A

STOP:111000000011001ÆH7019

Reverse RUN:111000000101010ÆH702A

4. Select which communication index you want. Write 1~4 to DVPIFD9507 BR15 (H000F).

Use WPL MODWR instruction to select the DVP IFD9507 BR (H0500) index.

5. Set the I/O Enable Flag (BR14).

DVP-PLC Application Manual

63

Page 66

Ethernet Communication Module IFD9507

Use WPL MODWR instruction to write “0101” set I/O enable Flag.

13.2 Serial Master

Using AB PLC 1769-L32E to write Delta PLC DVP28SV11T bit and register via IFD9507.

Configure RSLinx 1769-L32E

1. Open RSLinx and configure drivers

64

2. Select RS232 device and click “Add New”

DVP-PLC Application Manual

Page 67

Ethernet Communication Module IFD9507

3. Select Com port and click “Auto-Configure”. When it is successful, it will show successful messages.

Configure IFD9507

1. Open DCISoft “Basic” configuration screen.

2. Select “Serial Master” in Master Configuration.

3. Select “Static” in IP Configuration.

4. Enter “192.168.1.99” in IP Address field.

5. Enter “255.255.255.0” in Netmask field.