Delta Electronics ASDA-B2-F, ASD-B2-1021-F, ASD-B2-0121-F, ASD-B2-0421-F, ASD-B2-0721-F User Manual

...

Asia

Delta Electronics (Jiangsu) Ltd.

Zhangjiagang Haina Automation Equipment Co., Ltd.

Sales office

No. 11, Yuefeng Road, Economic Development Zone,

Zhangjiagang, Jiangsu, China (Mainland)

TEL:0086-0512-56322086 008615262314665

EMAIL:samzhang@haina-auto.com

Delta Economic AC Servo Drive with DMCNET Communication

*We reserve the right to change the information in this manual without prior notice.

Delta Economic AC Servo

Drive with DMCNET

ASDA-B2-F

Communication

ASDA-B2-F

Series User Manual

Series User Manual

Preface

Thank you for purchasing ASDA-B2-F. This user manual provides related information of ASDA-B2-F series

servo drive and ECMA series servo motors.

This manual includes:

Installation and inspection of the servo drive and se

Configuration of the servo drive

Procedures of trial run

Control functions and adjustment methods of the servo drive

Parameter settings

Comm

Maintenance and inspection

Troubleshooting

Features

B2-F is a cost-effective servo drive for application which requires multi-axis motion control an d can

be operated via DMCNET high-speed network. Besides hig h response, B2-F also supports

absolute functions and multi-axis operation.

How to use this manual

Users can refer to this user manual during installation, setting, operation and maintenance. Before

tuning and setting, please read through Chapter 1 to 5. This user manual provides specific table of

contents and index for searching. If the requiring information is not available in the table of

contents, please refer to the index.

Technical Supports

If you have any question, please contact local distributors or Delta’s service center.

unication protocol

rvo motor

September, 2015

(This page is intentionally left blank.)

September, 2015

Table of Contents

Before Operation

Inspection and Model Explanation

1.1 Inspection ·································································································· 1-2

1.2 Product Model ···························································································· 1-3

1.2.1 Nameplate Information ·········································································· 1-3

1.2.2 Model Explanation ··············································································· 1-4

1.3 Servo Drive and Corresponding Servo Motor ···················································· 1-6

1.4 Each Part of the Servo Drive ········································································· 1-7

Installation

2.1 Notes ······································································································· 2-2

2.2 Ambient Conditions of Storage ······································································· 2-2

2.3 Ambient Conditions of Installation ··································································· 2-2

2.4 Installation Direction and Space ····································································· 2-3

2.5 Specification of Circuit Breaker and Fuse ························································· 2-5

2.6 EMI Filter Selection ····················································································· 2-5

2.7 Selection of Regenerative Resistor ································································· 2-7

Wiring

3.1 Connections ······························································································ 3-2

3.1.1 Connecting to Peripheral Devices ··························································· 3-2

3.1.2 Connectors and Terminals of Servo Drive ·················································· 3-3

3.1.3 Wiring Method ····················································································· 3-4

3.1.4 Specification of Motor Power Cable ·························································· 3-5

3.1.5 Specification of Encoder Cable Connector ················································· 3-7

3.1.6 Selection of Wiring Rod ········································································· 3-10

3.2 Basic Wiring ······························································································· 3-11

3.2.1 200 W or models below (without built-in regenerative resistor nor fan) ············· 3-11

3.2.2 400 W ~ 750 W models (with built-in regenerative resistor but no fan) ·············· 3-12

3.2.3 1 kW ~ 1.5 kW models (with built-in regenerative resistor and fan) ·················· 3-13

3.2.4 2 kW ~ 3 kW models (with built-in regenerative resistor and fan) ····················· 3-14

3.3 I / O Signal (CN1) Connection ········································································· 3-15

September, 2015 I

3.3.1 I / O Signal (CN1) Connector Terminal Layout ············································· 3-15

3.3.2 Signals Explanation of Connector CN1 ······················································ 3-16

3.3.3 Wiring Diagrams (CN1) ·········································································· 3-18

3.3.4 DI and DO Signal Specified by Users ························································ 3-20

3.4 CN2 Connector ························································································· 3-21

3.5 Wiring of CN3 Connector ············································································· 3-23

3.6 CN6 Connector (DMCNET) ········································································ 3-24

3.7 Standard Connection Example······································································ 3-26

Panel Display and Operation

4.1 Panel Description ························································································ 4-2

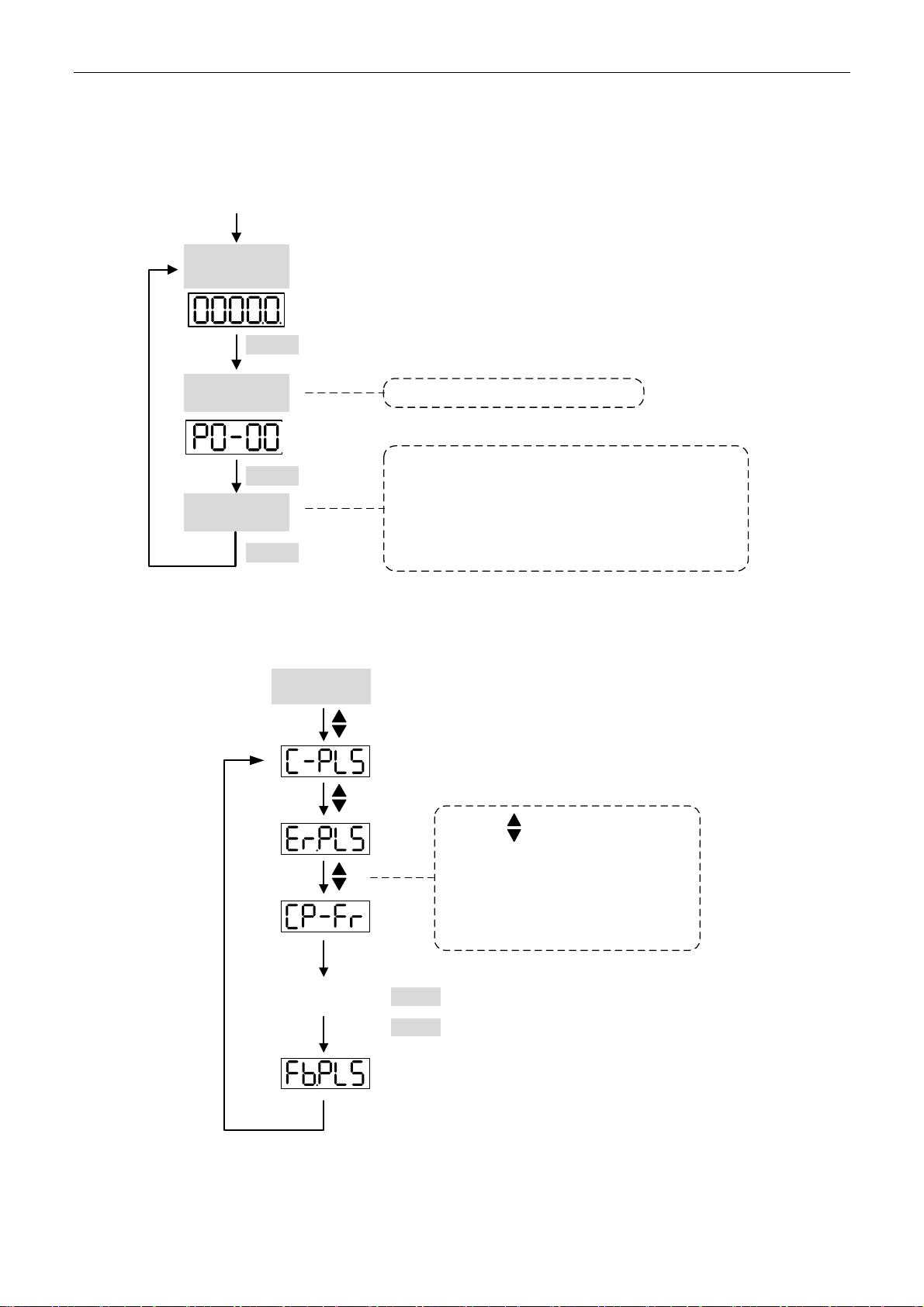

4.2 Parameter Setting Procedure ········································································· 4-3

4.3 Status Display ···························································································· 4-6

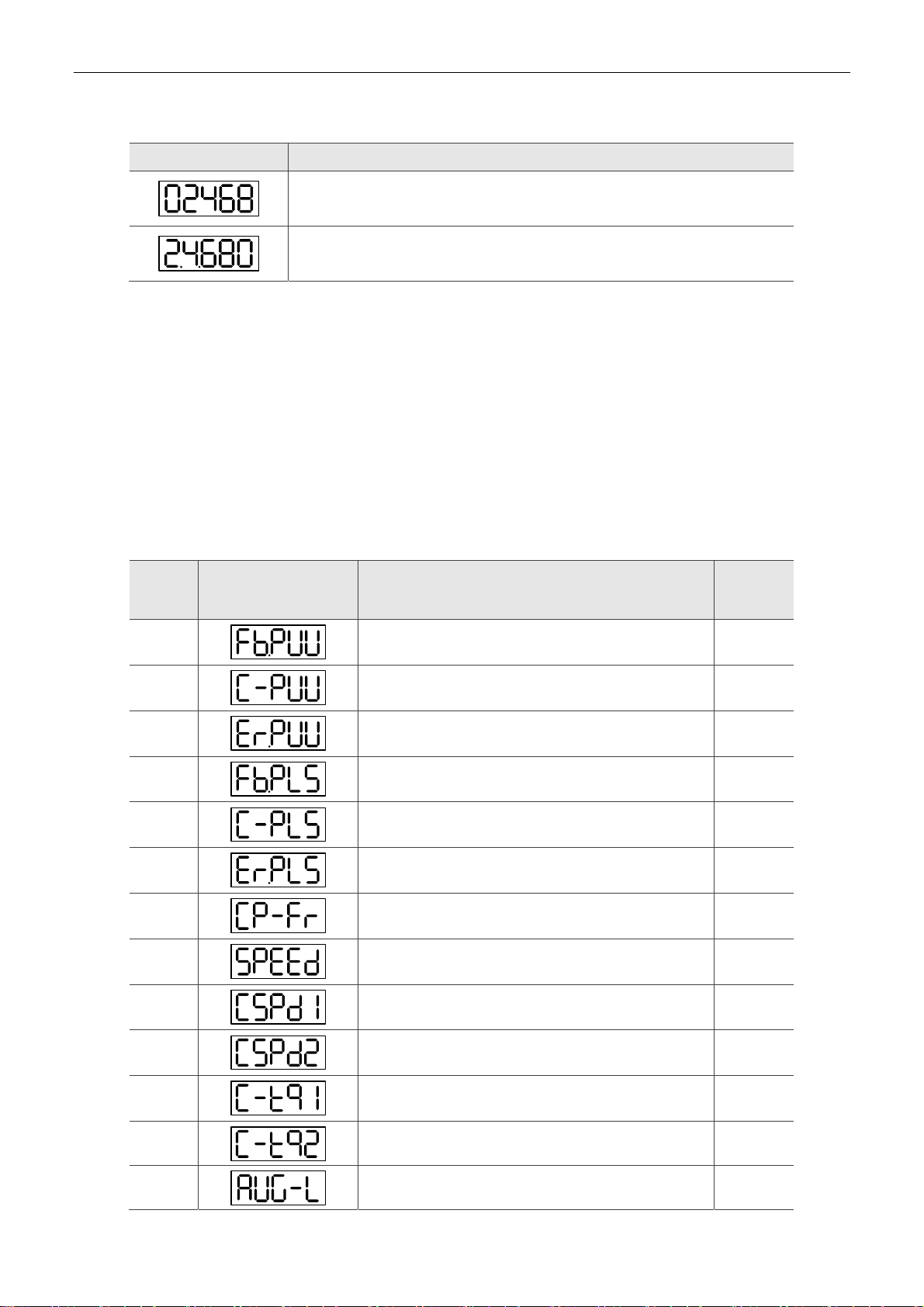

4.3.1 Save Setting Display ············································································· 4-6

4.3.2 Decimal Point ······················································································ 4-6

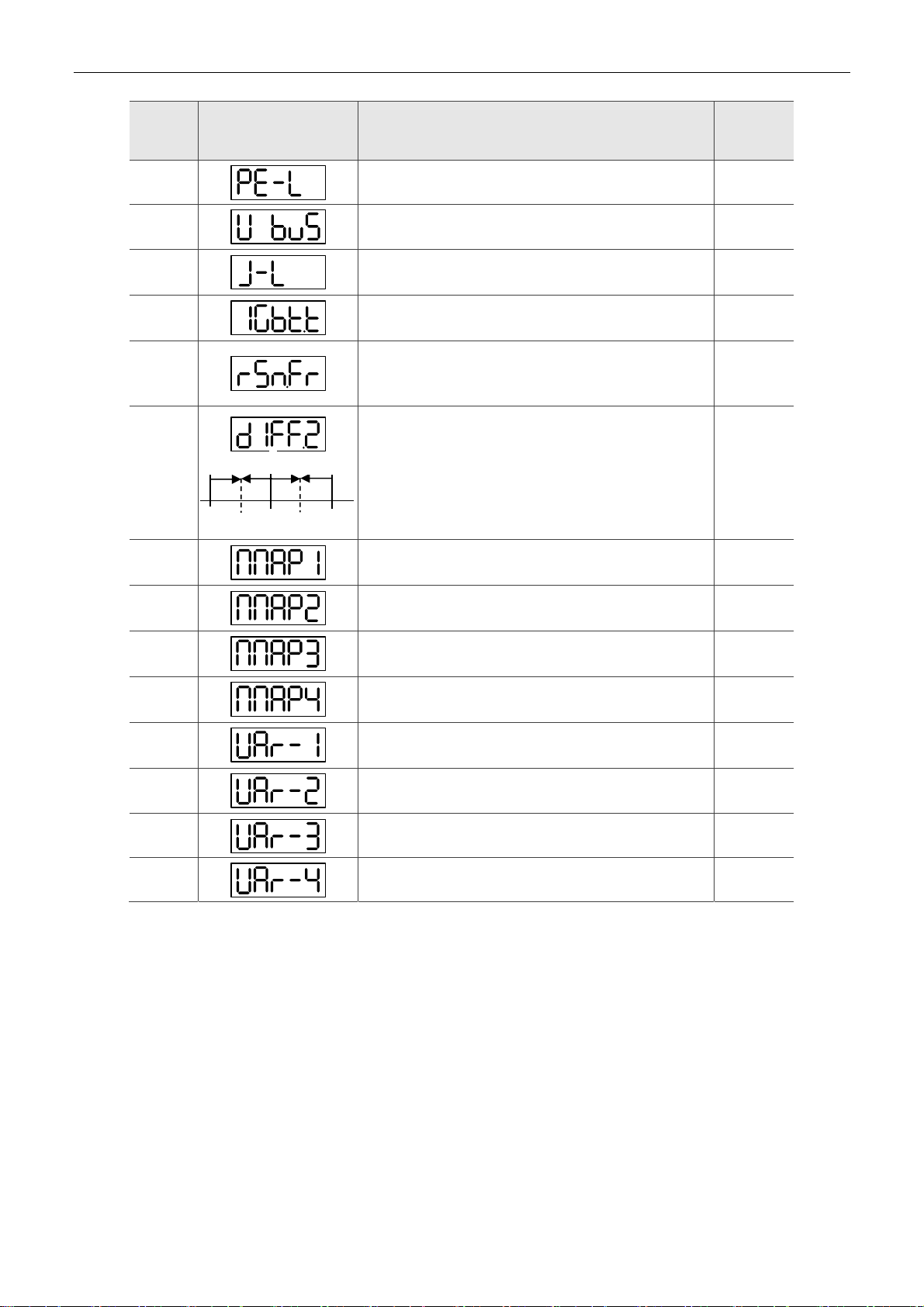

4.3.3 Alarm Message ···················································································· 4-6

4.3.4 Positive and Negative Sign Setting ··························································· 4-7

4.3.5 Monitor Display ···················································································· 4-7

4.4 General Function ························································································ 4-10

4.4.1 Operation of Fault Record Display ··························································· 4-10

4.4.2 JOG Mode ·························································································· 4-11

4.4.3 Force DO Output ·················································································· 4-12

4.4.4 Digital Input Diagnosis Operation ····························································· 4-13

4.4.5 Digital Output Diagnosis Operation ·························································· 4-14

Tuning

Trial Operation and Tuning

5.1 Inspection without Load ················································································ 5-2

5.2 Apply Power to the Servo Drive ······································································ 5-3

5.3 JOG Trial Run without Load ··········································································· 5-7

5.4 Trial Run without Load (Speed Mode) ······························································ 5-8

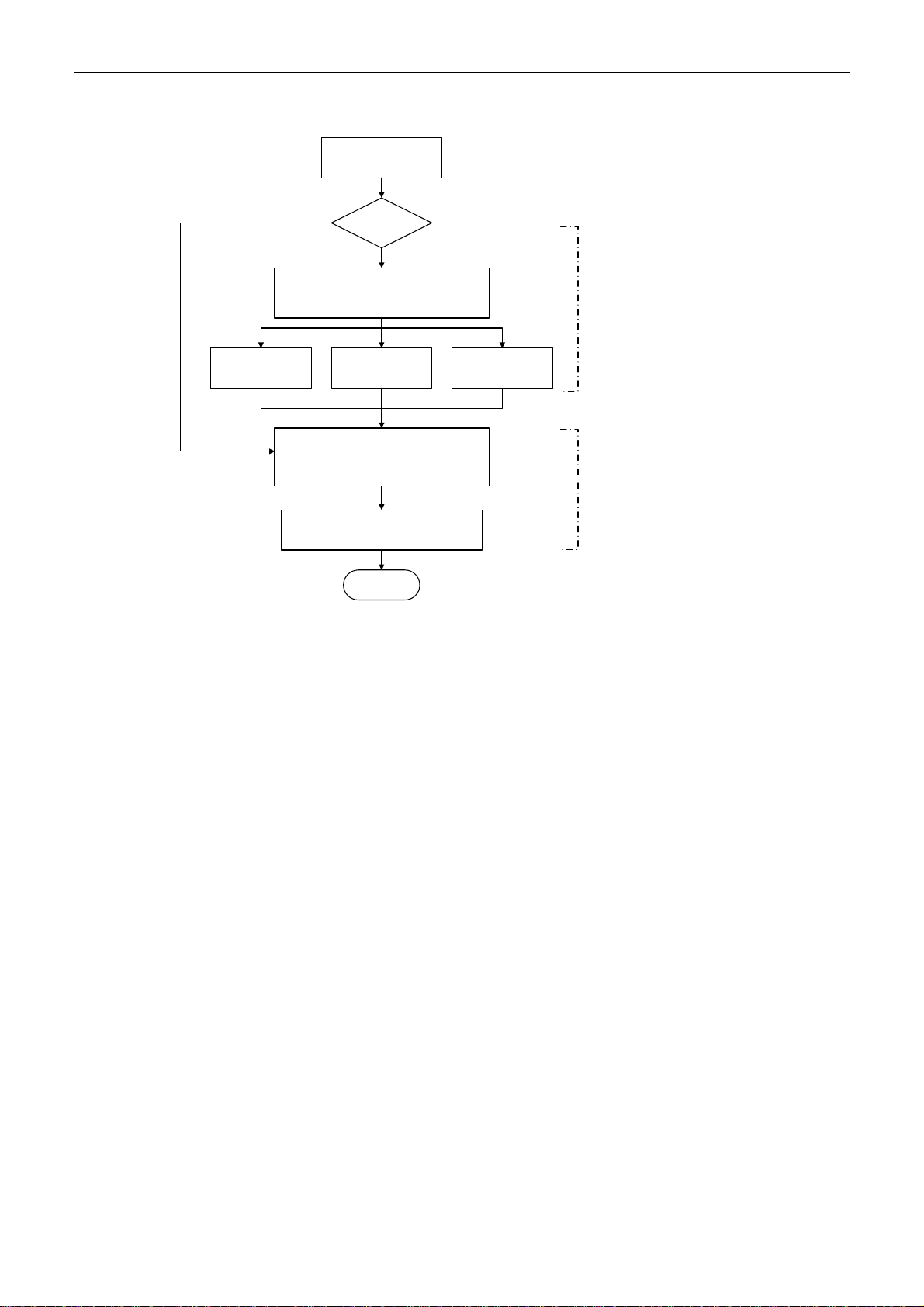

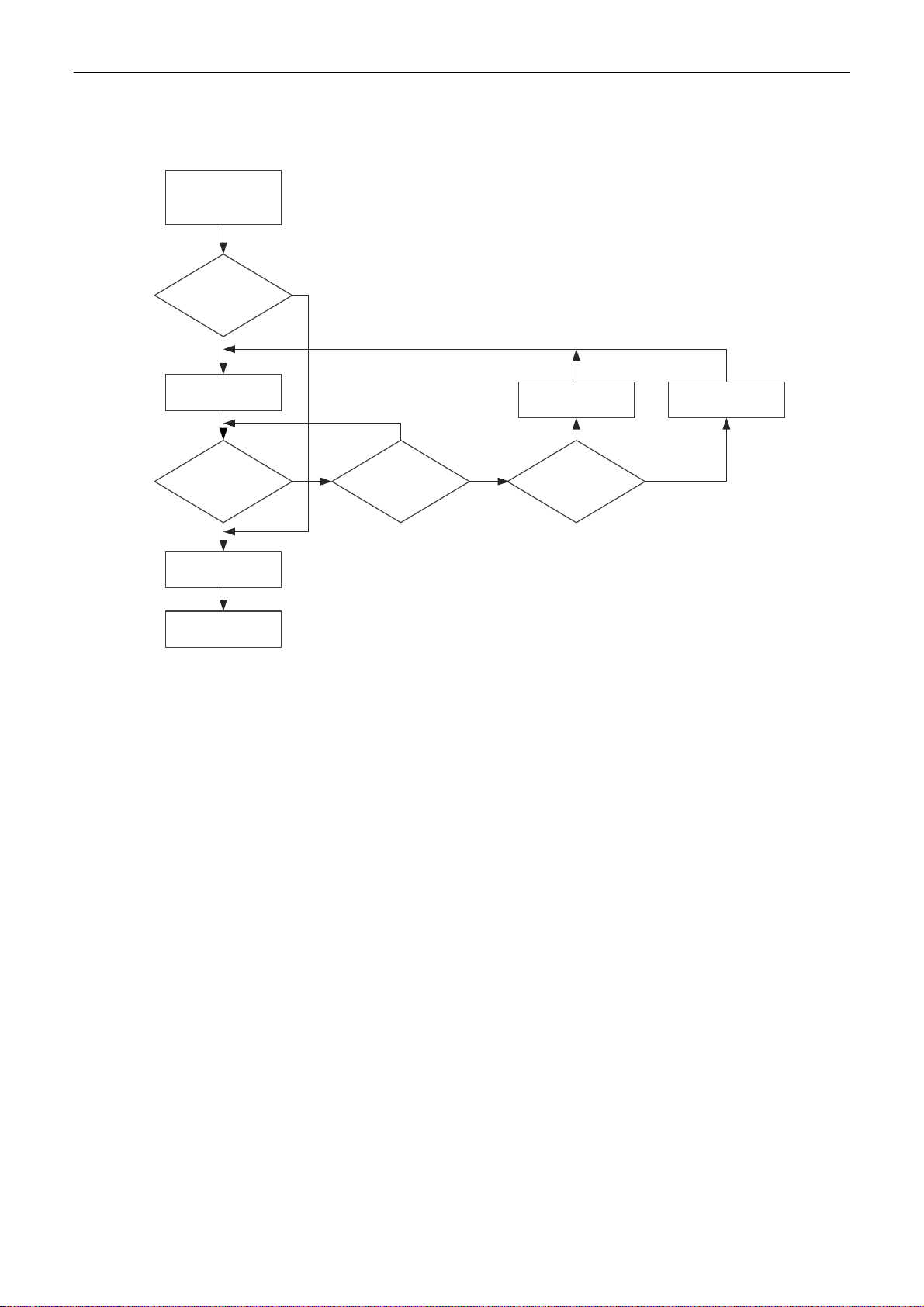

5.5 Tuning Procedure ························································································ 5-10

5.5.1 Flowchart of Tuning Procedure ································································ 5-11

5.5.2 Inertia Estimation Flowchart (with Mechanism) ··········································· 5-12

5.5.3 Flowchart of Auto T unin g ······································································· 5-13

5.5.4 Flowchart of Semi-Auto Tuning································································ 5-14

5.5.5 Limit of Inertia Ratio ·············································································· 5-15

5.5.6 Mechanical Resonance Suppression Method ············································· 5-17

II September, 2015

5.5.7 Tuning Mode and Parameters ································································· 5-18

5.5.8 Tuning in Manual Mode ········································································· 5-19

Control Mode of Operation

6.1 Selection of Operation Mode ········································································ 6-2

6.2 Position Mode ··························································································· 6-3

6.2.1 Control Structure of Position Mode ·························································· 6-3

6.2.2 S-curve Filter (Position) ········································································ 6-4

6.2.3 Electronic Gear Ratio ··········································································· 6-5

6.2.4 Low-pass Filter ··················································································· 6-6

6.2.5 Gain Adjustment of Position Loop ··························································· 6-6

6.2.6 Low-frequency Vibration Suppression in Position Mode ······························· 6-7

6.3 Speed Mode ····························································································· 6-10

6.3.1 Selection of Speed Command ································································ 6-10

6.3.2 Control Structure of Speed Mode ···························································· 6-11

6.3.3 Smooth Speed Command ····································································· 6-12

6.3.4 Timing Diagram of Speed Mode ····························································· 6-13

6.3.5 Gain Adjustment of Speed Loop ····························································· 6-14

6.3.6 Resonance Suppression ······································································· 6-18

6.4 Torque Mode ····························································································· 6-23

6.4.1 Selection of Torque Command ······························································· 6-23

6.4.2 Control Structure of Torque Mode ··························································· 6-24

6.4.3 Smooth Torque Command····································································· 6-25

6.4.4 Timing Diagram of Torque Mode ····························································· 6-25

6.5 The Use of Brake ······················································································· 6-26

Parameter Setting

Parameters

7.1 Parameter Definition ··················································································· 7-2

7.2 List of Parameters ······················································································ 7-3

7.3 Parameter Description ················································································· 7-10

P0-xx Monitor Parameters ······································································ 7-10

P1-xx Basic Parameters ········································································· 7-22

P2-xx Extension Parameters ··································································· 7-37

P3-xx Communication Parameters ··························································· 7-50

P4-xx Diagnosis Parameters ··································································· 7-55

P5-xx Motion Setting Parameters ····························································· 7-59

September, 2015 III

Table 7.1 Function Description of Digital Input (DI) ········································· 7-63

Table 7.2 Function Description of Digital Output (DO) ····································· 7-65

Communications

8.1 RS-232 Communication Hardware Interface ···················································· 8-2

8.2 RS-232 Communication Parameters Setting ···················································· 8-3

8.3 MODBUS Communication Protocol ································································ 8-4

8.4 Setting and Accessing Communication Parameters ··········································· 8-15

Troubleshooting

Troubleshooting

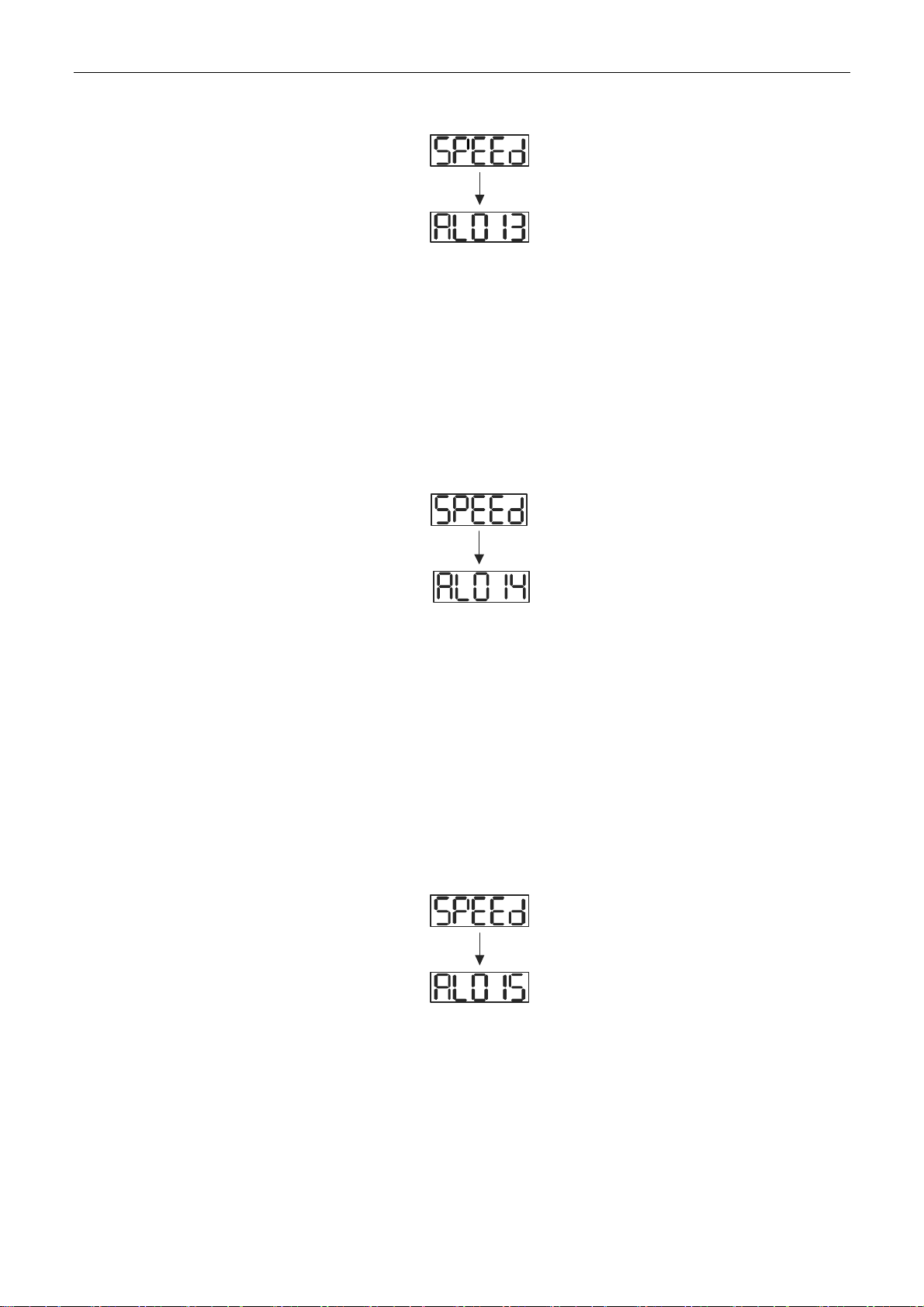

9.1 Alarm of Servo Drive ··················································································· 9-2

9.2 Alarm of DMCNET Communication ································································ 9-3

9.3 Alarm of Motion Control ··············································································· 9-4

9.4 Causes and Corrective Actions ····································································· 9-5

Absolute System

10.1 Absolute Type of Battery Box and Wiring Rods ················································· 10-3

10.1.1 Specifications ··················································································· 10-3

10.1.2 Battery Box Dimensions ..................................................................................... 10-5

10.1.3 Connection Cable for Absolute Encoder ............................................................ 10-6

10.1.4 Battery Box Cable ............................................................................................... 10-8

10.2 Installation ································································································ 10-9

10.2.1 Install Battery Box in Servo System ................................................................... 10-9

10.2.2 How to Install the Battery .................................................................................... 10-13

10.2.3 How to Replace a Battery ................................................................................... 10-14

10.3 Parameters Related to Absolute Servo System ················································· 10-16

10.4 Servo Drive Alarm List for Absolute Function and Monitoring Variables ·················· 10-17

10.5 System Initialization and Operation Procedures ················································ 10-18

10.5.1 System Initialization ............................................................................................ 10-18

10.5.2 Pulse Number ..................................................................................................... 10-19

10.5.3 PUU Number ...................................................................................................... 10-20

10.5.4 To Initialize the Absolute Coordinate via Parameters ......................................... 10-21

10.5.5 Use Communication to Access Absolute Position .............................................. 10-21

IV September, 2015

Appendix

Specifications

Specifications of ASD

Specifications of Servo Motors (ECMA Series) ···························································· A-4

Torque Features (T-N Curves) ·················································································· A-13

Overload Features ································································································· A-15

Dimensions of Servo Drive ······················································································ A-17

Dimensions of Servo Motor ······················································································ A-21

A-B2-F Servo Drive ··································································· A-2

Accessories

Power Co

Power Cable ······································································································· B-3

Encoder Connector ································································································ B-5

Encoder Cable ······································································································ B-5

Encoder Cable (Absolute Type) ················································································ B-6

Battery Box Cable AW ··························································································· B-7

Battery Box Cable IW ···························································································· B-7

nnector ··································································································· B-2

Battery Box (Absolute Type) ··················································································· B-8

I/O Connector Terminal ··························································································· B-9

CN1 Convenient Connector ····················································································· B-9

PC Connection Cable ····························································································· B-10

Terminal Block Module ···························································································· B-10

Optional Accessories ······························································································ B-11

Maintenance and Inspection

Basic Inspe

Maintenance ········································································································· C-3

The Lifetime of Machinery Parts ················································································ C-3

ction ···································································································· C-2

September, 2015 V

(This page is intentionally left blank.)

VI September, 2015

Inspection and Model

Explanation

Before using ASDA-B2-F, please pay attention to the description about the inspection,

nameplate, and model type. Suitable motor model for your servo drive can be found in

the table of Chapter 1.3.

111111111111111111111111111111111111111 11111

1.1 Inspection ........................................................................................................ 1-2

1.2 Product Model ··············································································· 1-3

1.2.1 Nameplate Information ································································ 1-3

1.2.2 Model Explanation ······································································ 1-4

1.3 Servo Drive and Corresponding Servo Motor ········································ 1-6

1.4 Each Part of the Servo Drive ····························································· 1-7

September, 2015 1-1

Inspection and Model Explanation ASDA-B2-F

1.1 Inspection

In order to prevent the negligence during purchasing and delivery, please inspect the following

items carefully.

Item Description

1

Please check if the product

is what you have

purchased.

Check the part number of the motor and the servo drive on the nameplate.

Refer to the next page for the model explanation.

Check if the motor shaft

can rotate smoothly.

Check if there is any

damage shown on its

appearance.

Check if there is any loose

screw.

If any of the above situations happens, please contact the distributors to solve the problems.

A complete and workable servo set should include:

(1) One servo drive and one servo motor.

(2) One UVW motor power cable, the U, V and W wires can connect to the socket attached by

the servo drive and another side is the plug which could connect to the socket of the motor.

And a green ground wire which should be connected to the ground terminal of the servo

drive. (selective purchase)

(3) An encoder cable which connects to the socket of the encoder. One side of it connects to

CN2 servo drive and another side is the plug. (selective purchase)

(4) 15-PIN connector which is used in CN1 (selective purchase)

(5) 9-PIN connector which is used in CN2. (selective purchase)

(6) 6-PIN connector which is used in CN3. (selective purchase)

Rotate the motor shaft by hand. If it can be rotated smoothly, it means the

motor shaft is normal. However, it cannot be rotated by hand if the motor

has an electromagnetic brake.

Visually check if there is any damage or scrape of the appearance.

Make sure no screw is un-tightened or fall off.

(7) RJ-45 connector which is used in CN6.

1-2 September, 2015

ASDA-B2-F Inspection and Model Explanation

1.2 Product Model

1.2.1 Nameplate Information

ASDA-B2-F Series Servo Drive 0

Nameplate Information

Model Name

Capacity Specificat ion

Applicable Power Supply

Rated Current Output

Barcode

Firmwa re V ersion

Serial Number

B21521F W 14 17 0001

MODEL : ASD-B2-1521-F

POWER : 1.5kW

INPUT : 200~230V 3PH 50/60Hz 5.9A

200~230V 1PH 50/60Hz 10.3A

OUTPUT : 110V 0~250Hz 8.3A

B21521FW14170001

01.74

DELTA ELECTRONICS, INC.

LISTED

19XK

IND. CONT. E Q.

MADE IN TAIWAN

Model Name

Production Factory (T: Taoyuan; W: Wujiang)

Year of Production (3: year 2013 or 14: year 2014)

Week of Production (from 1to 52)

Serial Number

(Production sequence of a week, starting from 0001)

1

ECMA Series Servo Motor 0

Nameplate Information

AC SER VO MOTOR

Model Name

Input Power

Rated Speed and Rated Output

Barcode

Serial Number

C10602ES T 14 33 0001

Model Name

Production Factory (T: Taoyuan; W: Wujiang)

Year of Production (14: year 2014)

Week of Production (from 1 to 52)

Serial Number

(Production sequence of a week, starting from 0001)

MODEL: ECMA-C10602ES

INPUT: VAC 110 A 1.55 Ins. A

OUTPUT: r/min 3000 N.m 0.64 kW 0.2

C10602EST14330001

Delta Electronics, Inc. MADE IN XXXXXX

September, 2015 1-3

Inspection and Model Explanation ASDA-B2-F

1.2.2 Model Explanation

ASDA-B2-F Series Servo Drive 0

1

ASD-B2-0421- F

Product Name

AC Servo Drive

Series

B2

Rate Output Power

Input Voltage and Phase

Model Type

Code Spec. Code Spec.

01 100 W 10 1 kW

02 200 W 15 1.5 kW

04 400 W 20 2 kW

07 750 W 30 3 kW

Code Voltage / Phase

21 220V 1 phase

23 220V 3 phase

Type

F × × × ○ × ×

Full-Closed

Control

EtherCAT CANopen DMCNET E-CAM

Extension Port for

Digital Input

1-4 September, 2015

ASDA-B2-F Inspection and Model Explanation

ECMA Series Servo Motor 0

ECMA-C10602ES

Product Name ECM: Electronic Commutation Motor

Motor Type A: AC Servo Motor

Name of the Series

Rated Voltage and Rated Speed

Code Spec.

C 220 V / 3,000 rpm

E 220 V / 2,000 rpm

F 220 V / 1,500 rpm

G 220 V / 1,000 rpm

Code Spec.

1 Incremental type, 20-bit

2 Incremental type, 17-bit

3 2500 ppr

M Magnet type, 13-bit

Motor Frame Size

code Spec. code Spec.

04 40 mm 10 100 mm

06 60 mm 13 130 mm

08 80 mm 18 180 mm

09 86 mm - -

Rated Power Output

1

Encoder Type

code Spec. code Spec. code Spec.

01 100 W 05 500 W 10 1.0 kW

02 200 W 06 600 W 15 1.5 kW

03 300 W 07 700 W 20 2.0 kW

04 400 W 09 900 W 30 3.0 kW

Type of Shaft Diameter and Oil Seal

Round Shaft

(with fixed screw holes)

Keyway E F - -

Keyway

(with fixed screw holes)

w/o Brake,

w/o Oil Seal

Shaft Diameter

Standard S

Specific

3 42 mm

7 14 mm

- - C D

P Q R S

with Brake, w/o

Oil Seal

w/o Brake, with

Oil Seal

With Brake,

with Oil Seal

September, 2015 1-5

Inspection and Model Explanation ASDA-B2-F

M

di

hi

h

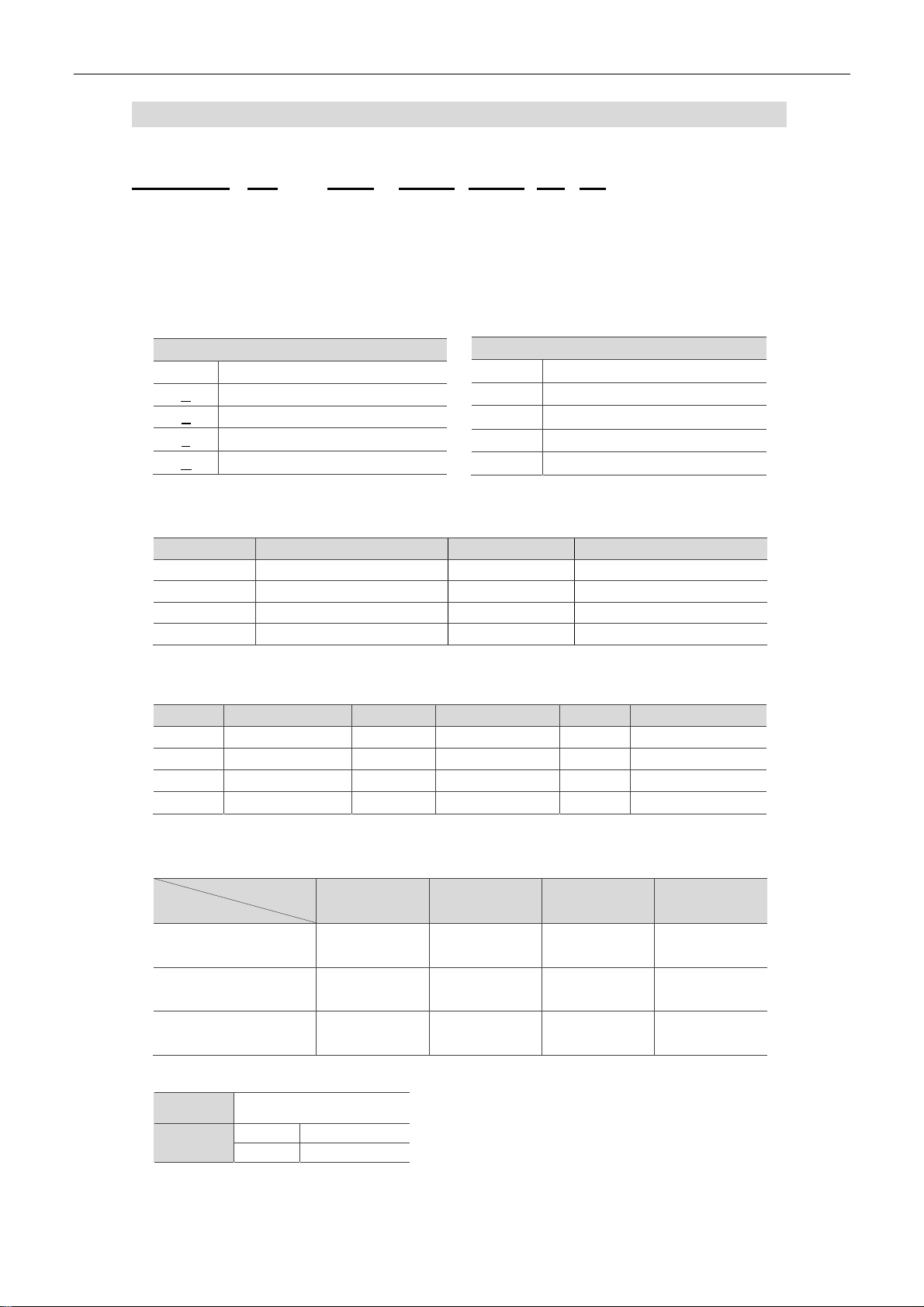

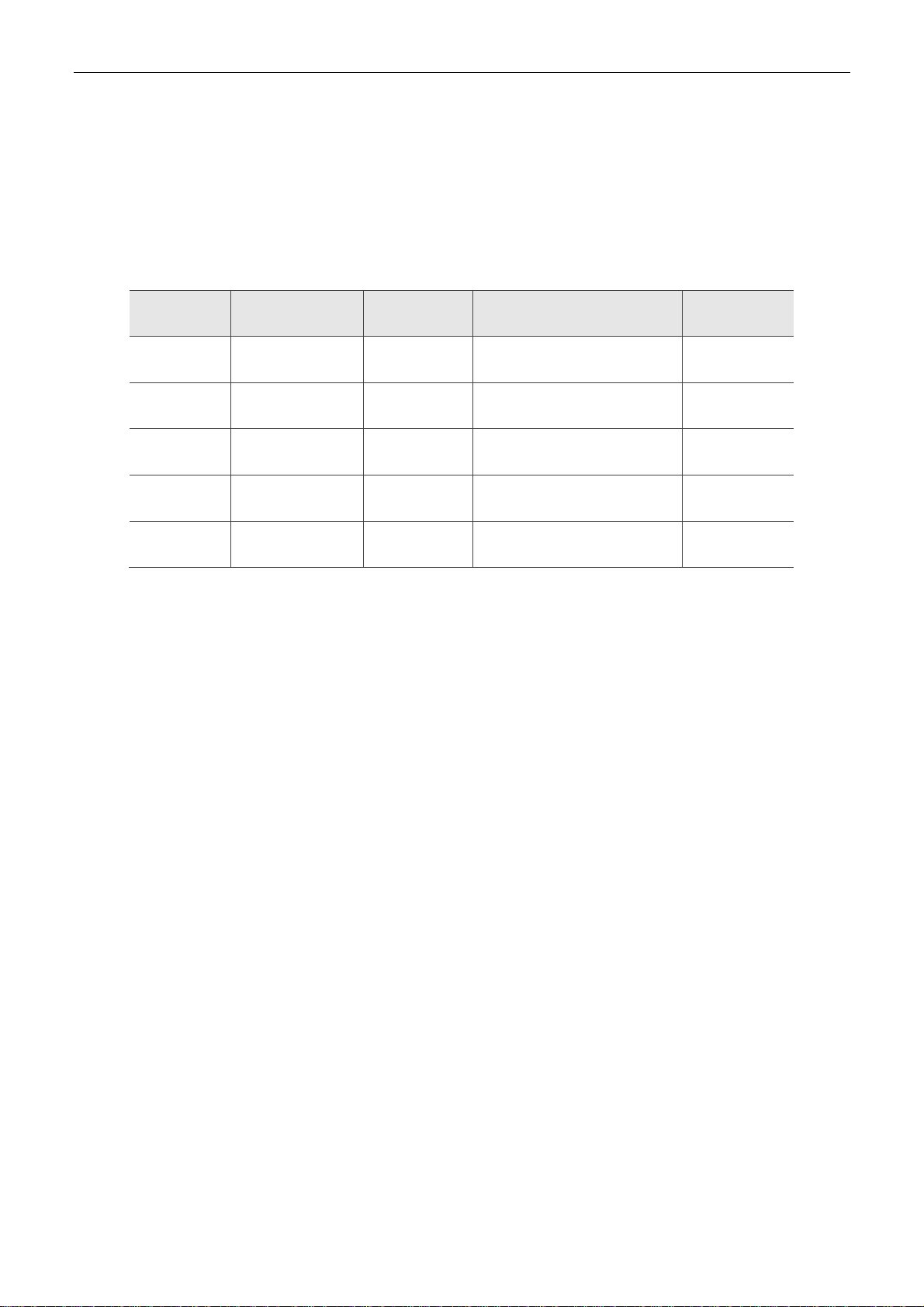

1.3 Servo Drive and Corresponding Servo Motor

Motor Servo Drive

1

Motor

series

Low Inertia

Medium Inertia

g

um-

inertia

e

High Inertia

Power

Single/Three-

phase

ECMA-C 3000 r/min

Single/Three-

phase

ECMA-E 2000 r/min

Single/Three-

phase

ECMA-F

1500 r/min

Single/Three-

r/min

phase

ECMA-C/G 3000

Output

(W)

50

100

200

400

400

750

750

1000

1000

2000

3000

500

1000

1500

2000

2000

3000

850

1300

3000

400

750

300

600

900

Model Number

ECMA-C1040F□S 0.69 2.05

ECMA-C0401□S

ECMA-C0602□S

ECMA-C0604□S

ECMA-C0804□7

ECMA-C0807□S

ECMA-C0907□S

ECMA-C0910□S

ECMA-C1010□S

ECMA-C1020□S

ECMA-C1330□4

ECMA-E1305□S

ECMA-E1310□S

ECMA-E1315□S

ECMA-E1320□S

ECMA-E1820□S

ECMA-E1830□S

ECMA-F1308□S

ECMA-F1313□S

ECMA-F1830□S

ECMA-C0604□H

ECMA-C0807□H

ECMA-G1303□S

ECMA-G1306□S

ECMA-G1309□S

Rated

Current

(Arms)

0.90 2.70

1.55 4.65

2.60 7.80

2.60 7.80

5.10 15.30

3.66 11.00

4.25 12.37

7.30 21.90

12.05 36.15

17.2 47.5

2.90 8.70

5.60 16.80

8.30 24.90

11.01 33.03

11.22 33.66

16.10 48.30

7.10 19.40

12.60 38.60

19.40 58.20

2.60 7.80

5.10 15.30

2.50 7.50

4.80 14.40

7.50 22.50

Max.

Instantaneous

current

(A)

Continuous

Model Number

ASD-B2-0121-F 0.90 2.70

ASD-B2-0221-F 1.55 4.65

ASD-B2-0421-F 2.60 7.80

ASD-B2-0721-F 5.10 15.30

ASD-B2-1021-F 7.30 21.90

ASD-B2-2023-F 13.40 40.20

ASD-B2-3023-F 19.40 58.20

ASD-B2-0421-F 2.60 7.80

ASD-B2-1021-F 7.30 21.90

ASD-B2-1521-F 8.30 24.90

ASD-B2-2023-F 13.40 40.20

ASD-B2-3023-F 19.40 58.20

ASD-B2-1021-F 7.30 21.90

ASD-B2-2023-F 13.40 40.20

ASD-B2-3023-F 19.40 58.20

ASD-B2-0421-F 2.60 7.80

ASD-B2-0721-F 5.10 15.30

ASD-B2-0421-F 2.60 7.80

ASD-B2-0721-F 5.10 15.30

ASD-B2-1021-F 7.30 21.90

Output

Current

(Arms)

Max.

Instantaneous

output

current

(A)

Note:

1. () at the ends of the servo drive model names are for optional configurations.

For the actual model name, please refer to the ordering information of the actual purchased product.

2. () in the model names are for encoder resolution types. = 1: Incremental type, 20-bit;

= 2: Incremental type, 17-bit; = 3: 2500 ppr; = M: Magnet type. The listed motor model name is

for information searching, please contact to your local distributors for actual purchased product.

3. () in the model names represents brake or keyway oil seal.

The above table shows the specification of servo drive which has triple rated current. For detailed

specification of the servo motor and servo drive, please refer to Appendix A.

1-6 September, 2015

ASDA-B2-F Inspection and Model Explanation

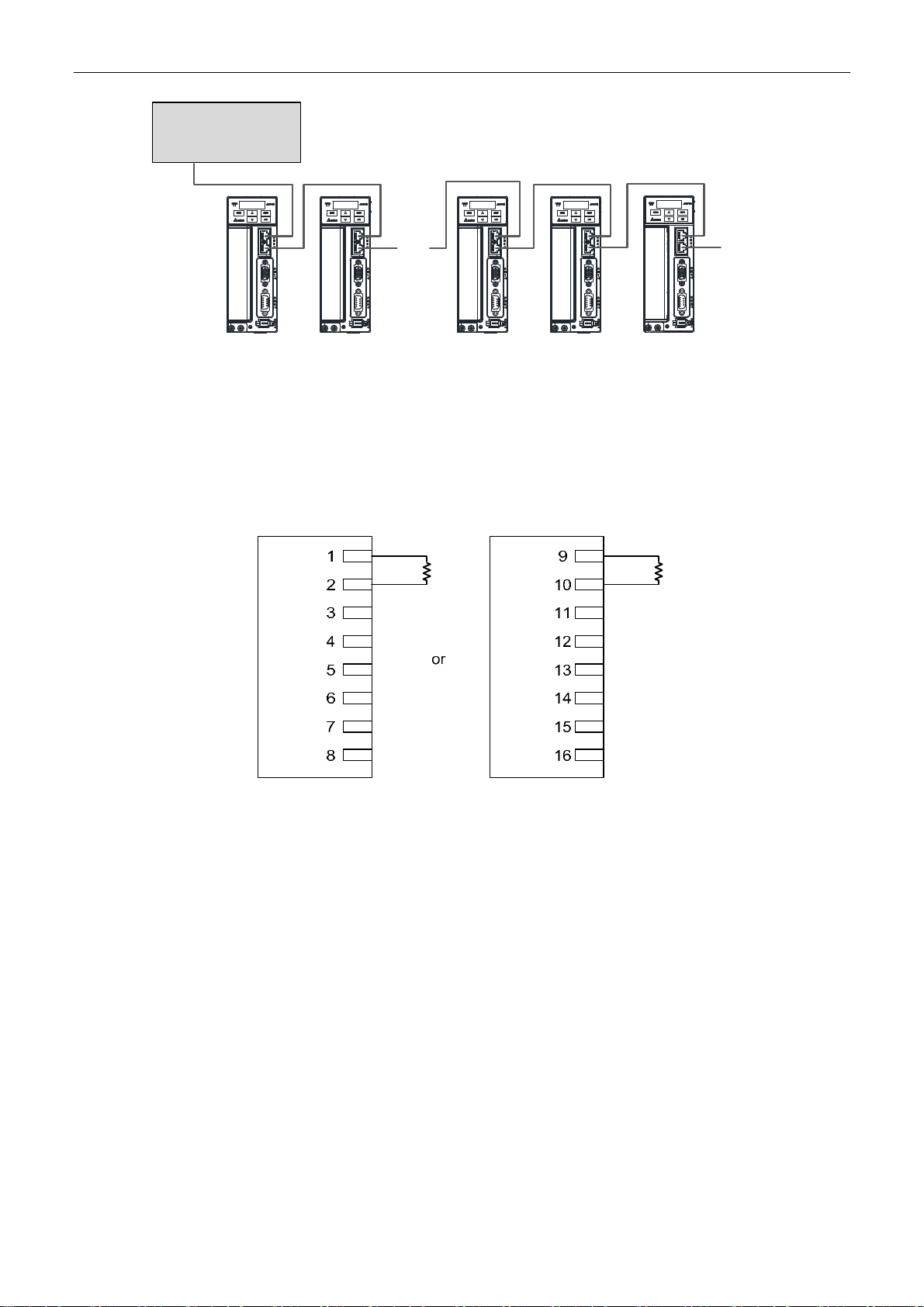

1.4 Each Part of the Servo Drive

1

Heat sink:

Used to secure servo drive and for heat dissipation.

Control Circuit Terminal (L1c、L2c):

Used to connect 200 ~ 230 V

Ac, 50 / 60 Hz 1-phase / 3-phase VAC supply.

Main Circuit Terminal (R, S, T):

Used to connect 200 ~ 230 V, 50 / 60 Hz commercial power supply.

Servo Motor Output (U, V, W):

Used to connect servo motor. Never connect the output terminal to main circuit power.

The AC servo drive may be destroyed beyond repair if incorrect cables are connected to the

output terminals.

Regenerative Resistor:

(1) When using an external regenerative resistor, connect P⊕ and C to the regenerative

resistor and ensure that the circuit between P⊕ and C is open.

(2) When using the internal regenerative resistor, ensure that the circuit between P⊕ and D

is closed and the circuit between P⊕ and C is open

CN6: DMCNET Connector: Communication port for DMCNET communi cation.

CN1: I/O Interface: Used to connect external controller (PLC) or control I/O signal.

CN2: Encoder Interface: Used to connect encoder of servo motor.

CN3: Serial Communication Interface: It is controlled by MODBUS and supports RS-232.

It can be connected to controllers.

Ground Terminal: Used to connect grounding wire of power supply and servo motor.

Please connect it properly to avoid electric shock.

September, 2015 1-7

Inspection and Model Explanation ASDA-B2-F

(This page is intentionally left blank.)

1

1-8 September, 2015

Installation

This chapter allows you to properly install the device. Please follow the instruction

mentioned in this chapter during installation. Information about specification of circuit

breaker, fuse, EMI filter selection, and selection of regenerative resistor are also

included.

11111111111111111111111111111111111111111111 1111111

2.1 Notes ······························································································ 2-2

2.2 Ambient Conditions of Storage ····························································· 2-2

2.3 Ambient Conditions of Installation ························································· 2-2

2.4 Installation Direction and Space ···························································· 2-3

2.5 Specification of Circuit Breaker and Fuse ················································ 2-5

2.6 EMI Filter Selection ············································································ 2-5

2.7 Selection of Regenerative Resistor ························································ 2-7

September, 2015 2-1

Installation ASDA-B2-F

2.1 Notes

Please pay special attention to the following:

Do not strain the cable connection between the servo drive and the servo motor.

2

Make sure each screw is tightened when fixing the servo drive.

The motor shaft and the ball screw should be pa rallel.

If the connection between the servo drive and the servo motor is over 20 meters, please

thicken the connecting wire, UVW as well as the encoder cable.

Tighten the four screws that fix the motor.

2.2 Ambient Conditions of Storage

Before the installation, this product has to be kept in the shipping carton. In order to retain the

warranty coverage and for the maintenance, please follow the instructions below when storage, if

the product is not in use temporally:

Store the product in a dry and dust-free location.

Store the product within an ambient temperature range of -20°C to +65°C.

S t ore the product within a relative humidity range of 0% to 90% and a non-condensing

environment.

Avoid storing the product in the environment of corrosive gas and liquid.

It is better to store the product in the shipping carton and put it on the shelf or working

platform.

2.3 Ambient Conditions of Installation

The most appropriate temperature of this servo drive is between 0°C and 55°C. If it is over

45°C, please place the product in a well-ventilated environment so as to ensure it s pe rform anc e.

If the product is installed in an electric box, make sure the size of the electric box and its

ventilation condition will not overheat and endanger the internal electronic device. Also, pay

attention to the vibration of the machine. Check if the vibration will influence the electro nic device

of the electric box. Besides, the ambient conditions should be:

No over-heat device.

No water drop, vapor, dust or oily dust.

No corrosive and inflammable gas or liquid.

No airborne dust or metal p articles.

With solid foundation and no vibration.

No interference of electromagnetic noise.

2-2 September, 2015

ASDA-B2-F Installation

The ambient temperature of the motor is between 0°C and 40°C and the ambient conditions should be:

No over-heat device.

No water drop, vapor, dust or oily dust.

No corrosive and inflammable gas or liquid.

No airborne dust or metal particles.

2.4 Installation Direction and Space

Notes:

Incorrect installation may result in a drive malfunction or premature failure of the drive and

or motor.

In order to ensure the drive can be well-cooled and the environment is well circulated,

sufficient space between adjacent object and the baffle is needed.

Ensure all ventilation holes are not obstructed. Do not install the drive in a horizontal

direction or malfunction and damage will occur.

C

N

6

2

CN3

C

N

1

C

N

2

C

N

3

CN6

CN1

CN2

Correct Incorrect

Installing servo drives:

ASDA-B2-F series servo drive should be mounted perpendicular to a dry and solid surface that

conforms to NEMA st a ndards. To ensure a well-ventilated environment, sufficient space between

adjacent object and the baffle is required. 50 mm (approx. 2 inch.) of clearance is suggested. If

wiring is needed, please leave the space for it. Please note that the rack or the surface shall

conduct heat well, so as to avoid the overheating of servo drive.

September, 2015 2-3

Installation ASDA-B2-F

Installing motors:

ECMA series motors shall be mounted to the mounting surface which is dry and stable. Please

make sure the environment is well-ventilated and the motor is properly grounded .

For the dimensions and specifications of the servo drive and servo motor, please refer to

2

Appendix A -Specifications.

Mounting distances and ventilation:

20 mm

(0.8 inches)

min.

50 mm

(2.0 inches) min.

C

N

6

20 mm

C

(0.8 inches)

N

1

C

N

2

C

N

3

50 mm

(2.0 inches) min.

min.

40 mm

(1.6 inches)

min.

(4.0 inches)

100 mm

(4.0 inches)

min.

100 mm

min.

FAN FAN

Air Flow

C

N

6

C

N

10 mm

1

(0.4

inches)

C

N

min.

2

C

N

3

C

N

6

C

N

1

C

N

2

C

N

3

10 mm

(0.4

inches)

min.

Air Flow

C

N

6

C

N

10 mm

1

(0.4

inches)

C

N

min.

2

C

N

3

100 mm

(4.0 inches)

min.

C

N

6

C

N

40 mm

1

(1.6 inches)

C

N

2

C

N

3

100 mm

(4.0 inches)

min.

min.

To lower the air resistance and ensure the drive is well ventilated, please follow the instructions

during installation and leaving suf f icient space as suggested.

Note:

The above diagrams are not in equal proportion. Please refer to the annotation

2-4 September, 2015

ASDA-B2-F Installation

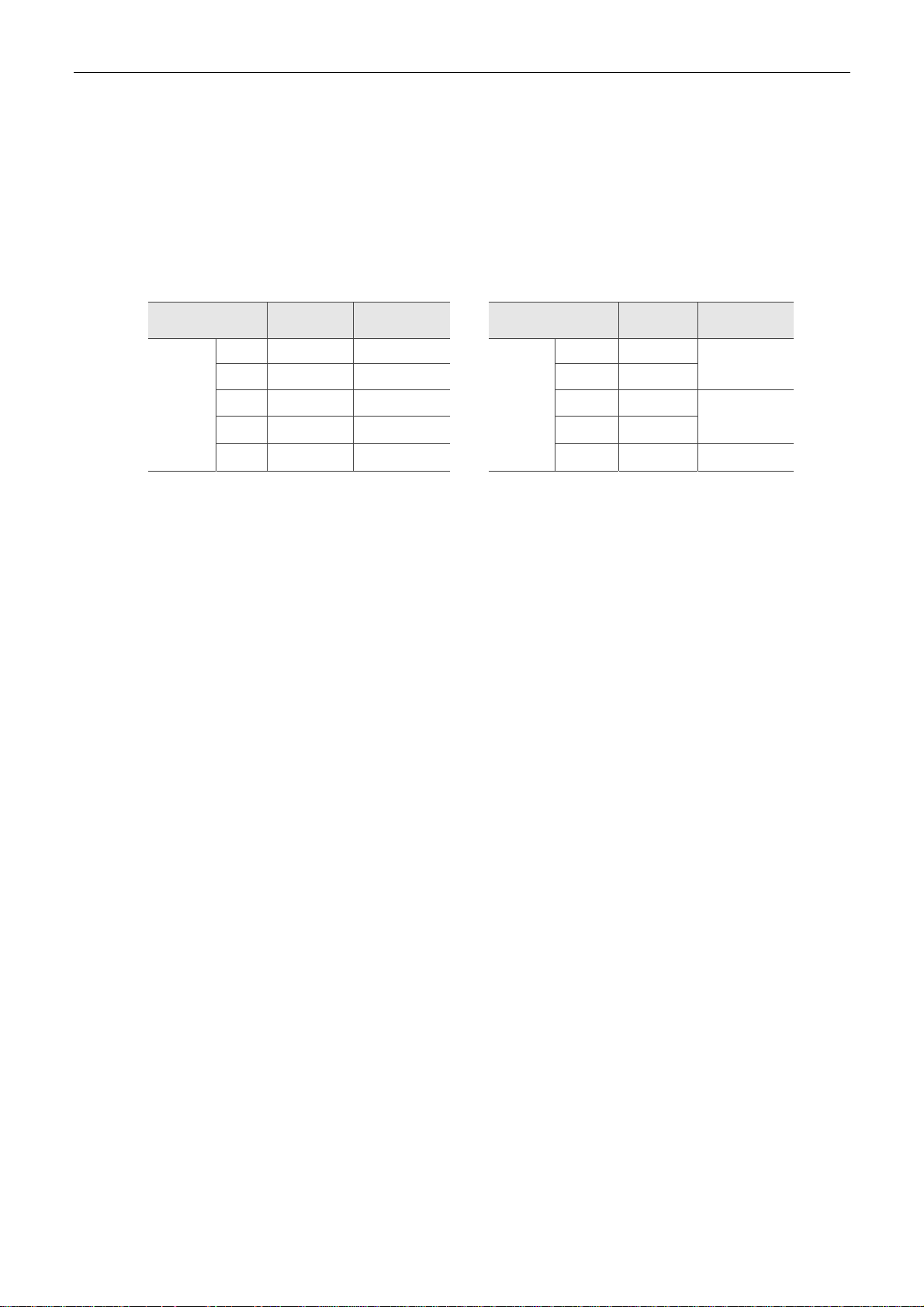

2.5 Specification of Circuit Breaker and Fuse

Caution: Please use the fuse and circuit breaker that is recognized by UL/CSA.

Servo Drive Model Circuit Breaker Fuse (Class T)

Operation Mode General General

ASD-B2-0121-F 5A 5A

ASD-B2-0221-F 5A 6A

ASD-B2-0421-F 10A 10A

ASD-B2-0721-F 10A 20A

ASD-B2-1021-F 15A 25A

ASD-B2-1521-F 20A 40A

ASD-B2-2023-F 30A 50A

ASD-B2-3023-F 30A 70A

Note:

If the servo drive equips with earth leakage circuit breaker for avoiding electric leakage, please choose the

current sensitivity which is over 200 mA and can continue up to 0.1 seconds.

2.6 EMI Filter Selection

2

Item Power Servo Drive Model

1 100 W ASD-B2-0121-F RF007S21AA RF022M43AA N

2 200 W ASD-B2-0221-F RF007S21AA RF022M43AA N

3 400 W ASD-B2-0421-F RF007S21AA RF022M43AA N

4 750 W ASD-B2-0721-F RF007S21AA RF022M43AA N

5 1000 W ASD-B2-1021-F RF015B21AA RF075M43BA N

6 1500 W ASD-B2-1521-F RF015B21AA RF075M43BA N

7 2000 W ASD-B2-2023-F - RF037B43BA N

8 3000 W ASD-B2-3023-F - RF037B43BA N

Recommended EMI Filter

1PH 3PH

Foot Print

EMI Filter Installation

All electronic equipment (including servo drive) generates high or low frequency noise during

operation and interfere the peripheral equipment via conduction or radiation. With EMI Filter and

the correct installation, much interference can be eliminated. It is suggested to use Delta’s EMI

Filter to suppress the interference better.

When installing servo drive and EMI Filter, please follow the instructions of the user manual and

make sure it meets the following specifications.

1. EN61000-6-4 (2001)

2. EN61800-3 (2004) PDS of category C2

3. EN55011+A2 (2007) Class A Group 1

September, 2015 2-5

2

Installation ASDA-B2-F

General Precaution

In order to ensure the best performance of EMI Filter, apart from the instructions of servo drive

installation and wiring, please follow the precautions mentioned below:

1. The servo drive and EMI Filter should be installed on the same metal plate.

2. When installing servo drive and EMI Filter , t he servo drive should be installed above the EMI

Filter.

3. The wiring should be as short as possible.

4. The metal plate should be well grounded.

5. The servo drive and the metal cover of EMI Filter or grounding should be firmly fixed on the

metal plate. Also, the contact area should be as large as possible.

Motor Cable Selection and Installation Precautions

The selection of motor cables and installation affect the performance of EMI Filter. Please follow

the precautions mentioned below.

1. Use the cable that has braided shielding (The effect of double shielding is better)

2. The shield on both sides of the motor cable should be grounded in the shortest distance and

the largest contact area.

3. The protective paint of the U-shape saddle and metal plate should be removed in order to

ensure the good contact. Please see Fig. 1.

4. It should have correct connection between the braided shielding of the motor cable and the

metal plate. The braided shielding on both sides of the motor cable should be fixed by the

U-shape saddle and metal plate. Please see Fig. 2 for the correct connection.

Fig.1 Fig. 2

2-6 September, 2015

ASDA-B2-F Installation

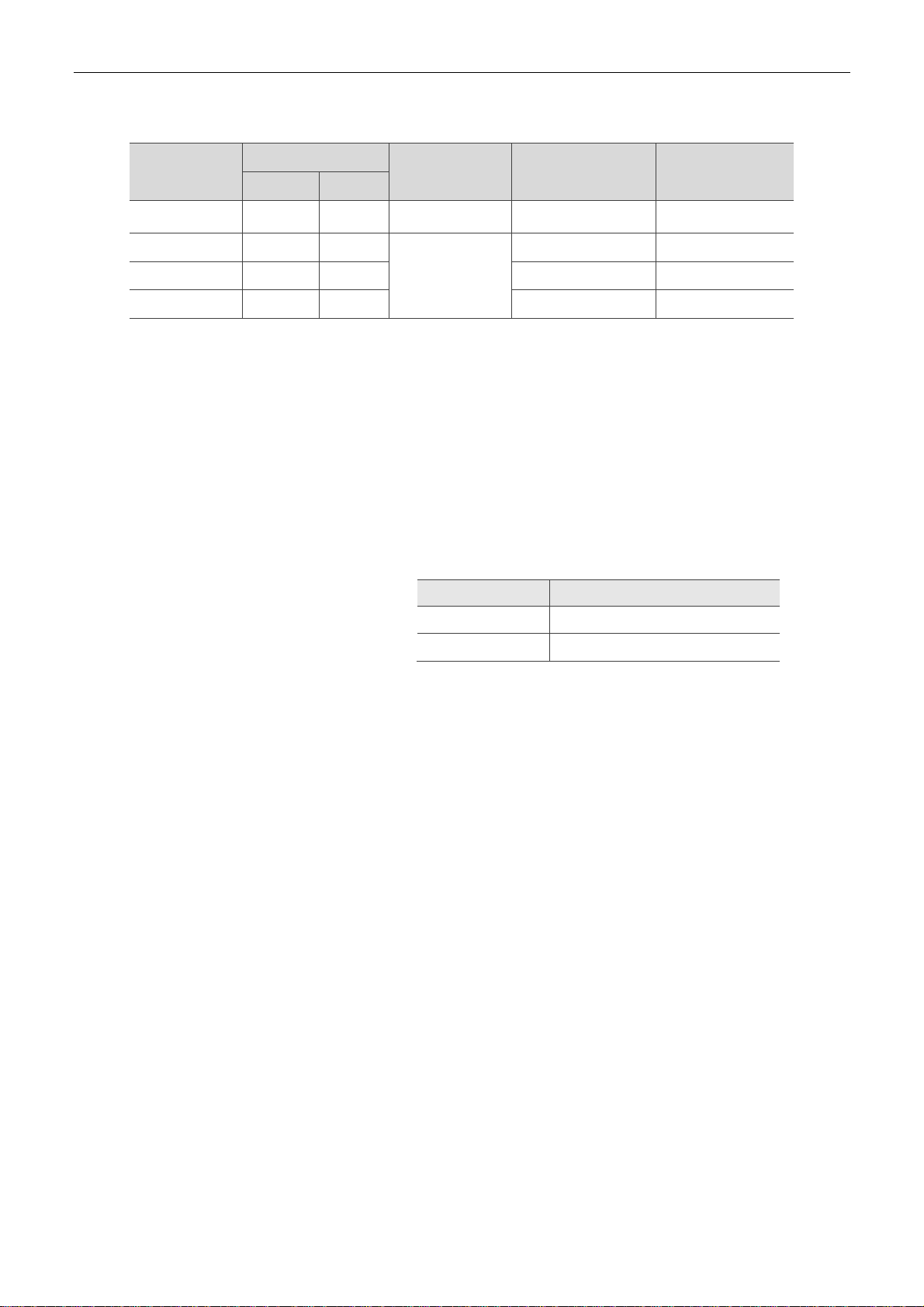

2.7 Selection of Regenerative Resistor

When the direction of pull-out torque is different from the rotation, it means the electricity is sent

back to the servo drive from the load-end. It becomes the capacitance of DC Bus and increases

the voltage. When the voltage increases to a specific value, the come-back eletricity can only be

consumed by regenerative resistor. There is a built-in regenerative resistor in the servo drive.

Users can also use the external regenerative resistor if needed.

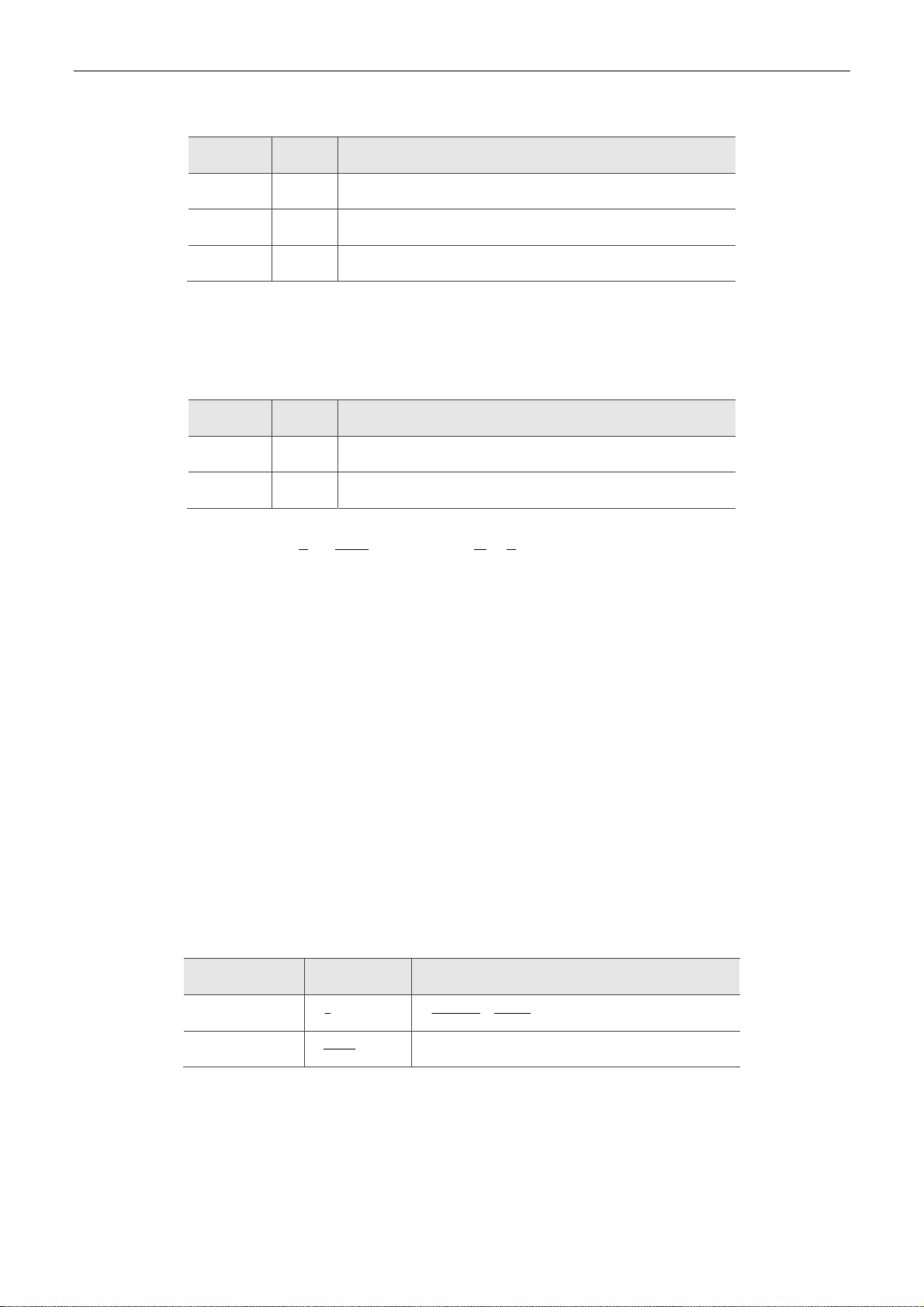

Specification of built-in regenerative resistor provided by ASDA-B2-F Series

Specification of built-in regenerative

Servo Drive

(KW)

0.1 -- -- -- 60

0.2 -- -- -- 60

0.4 100 60 30 60

0.75 100 60 30 60

1.0 40 60 30 30

1.5 40 60 30 30

2.0 20 100 50 15

3.0 20 100 50 15

Resistance

(P1-52) (Ohm)

resistor

Capacity

(P1-53) (Watt)

*1The capacity of

built-in regenerative

resistor (Wat t)

Minimum

allowable

resistance (Ohm)

2

*1The capacity of built-in regenerative resistor (average value) is 50% of the rated capacity of the built-in

regenerative resistor. The capacity of the external regenerative resistor is the same as the built-in one.

When the regenerative resistor exceeds the capacity of built-in regenerative resistor, the external

regenerative resistor should be applied. Please pay special attention to the following when using

the regenerative resistor.

1. Please correctly set up the resistance (P1-52) and capacity (P1-53) of regenerative resistor.

Or it might influence the performance of this function.

2. If users desire to use the external regenerative resistor, please make sure the applied value

should not be smaller than the value of built-in regenerative resistor. In general application,

more than one resistor will be serial connected. If the value (from serial connected resistors)

exceeds the setting range, users can reduce the value by parallel connecting the resistor. If

users desire to connect it in parallel to increase the power of regenerative resistor, please

make sure the capacitance meets the requirements.

3. In natural environment, if the capacity of regenerative resistor (the average value) is within

the rated capacity, the temperature of the capacitance will increase to 120℃ or even higher

(under the condition of regenerative energy keeps existing). For safety concerns, please

apply the method of forced cooling in order to reduce the temperature of rege nerative resistor.

Or, it is suggested to use the regenerative resistor which is equipped with thermal switches.

Please contact the distributors for load characteristics of the regenerative resistor.

When using the external regenerative resistor, the resistor should connect to P, C terminal and

the contact of P, D terminal should be opened. It is recommended to choose the above

mentioned capacitance. For easy calculation of regenerative resistor capacity, except the energy

consumed by IGBT, two ways are provided to select the capacity of external regenerative

resistor according to the selected linear motor or rotary motor.

September, 2015 2-7

2

Installation ASDA-B2-F

(1) Regenerative Power Selection

(a) When the external load on torque does not exist

If the motor operates back and forth, the energy generated by the brake will go into the

capacitance of DC bus. When the voltage of the capacitance exceeds a specific value, the

redundant energy will be consumed by regenerative resistor. Two ways of selecting

regenerative resistor are provided here. The table below provides the energy calculation

method. Users can refer to it and calculate the selected regenerative resisto r.

Servo Drive

(kW)

Low Inertia

Medium

Inertia

Medium -

High Inertia

High Inertia

0.1

0.2

0.4

0.75

1.0

2.0

3.0

0.4

1.0

1.5

2.0

3.0

1.0

2.0

3.0

0.4

0.75

1.0

Motor

ECMA-Cᇞ040F□□

ECMA-Cᇞ0401□□

ECMA-Cᇞ0602□□

ECMA-Cᇞ0604□□

ECMA-Cᇞ0804□□

ECMA-Cᇞ0807□□

ECMA-Cᇞ0907□□

ECMA-Cᇞ0910□□

ECMA-Cᇞ1010□□

ECMA-Cᇞ1020□□

ECMA-Cᇞ1330□□

ECMA-Eᇞ1305□□

ECMA-Eᇞ1310□□

ECMA-Eᇞ1315□□

ECMA-Eᇞ1320□□

ECMA-Eᇞ1820□□

ECMA-Eᇞ1830□□

ECMA-Fᇞ1308□□

ECMA-Fᇞ1313□□

ECMA-Fᇞ1830□□

ECMA-Gᇞ1303□□

ECMA-Gᇞ1306□□

ECMA-Gᇞ1309□□

Rotor Inertia

J (× 10-4kg.m2)

0.021 0.10 4.21

0.037 0.18 4.21

0.177 0.87 5.62

0.277 1.37 8.42

0.68 3.36 8.42

1.13 5.59 17.47

1.93 9.54 17.47

2.62 12.96 21.22

2.65 13.1 21.22

4.45 22.0 25.58

12.7 62.80 25.58

8.17 40.40 8.42

8.41 41.59 21.22

11.18 55.29 25.58

14.59 72.15 25.58

34.68 171.49 25.58

54.95 217.73 31.20

13.6 67.25 21.22

20.0 98.90 25.58

54.95 217.73 28

8.17 17.96 8.42

8.41 18.48 17.47

11.18 24.57 21.22

Regenerative power

from empty load

3000r/min to stop Eo

(joule)

The maximum

regenerative power

of capacitance

Ec (joule)

Eo = J * Wr2/182 (joule), Wr: r/min

Assume that the load inertia is N times to the motor inertia and the motor decelerates from 3000

r/min to 0, its regenerative energy is (N+1) x Eo. The consumed regenerative resistor is (N+1) ×

Eo - Ec joule. If the cycle of back and forth operation is T sec, then the power of regenerative

resistor it needs is 2× ((N+1) x Eo - Ec) / T.

Steps Item Calculation and Setting Method

1 Set the capacity of regenerative resistor to the maximum Set P1-53 to the maximum value

2 Set T cycle of back and forth operation Enter by the user

3 Set the rotational speed wr Enter by the user or read via P0-02

4 Set the load/motor inertia ratio N Enter by the user or read via P0-02

5 Calculate the maximum regenerative energy Eo Eo= J * wr2/182

6 Set the absorbable regenerative energy Ec Refer to the above table

7 Calculate the needful capacitance of regenerative resistor

2 ×((N+1) × Eo-Ec)/ T

2-8 September, 2015

ASDA-B2-F Installation

Take the motor (400 W with frame size 60) as the example, the cycle of back and forth operation

is T = 0.4 sec, the maximum speed is 3000 r/min and the load inertia is 7 times to the motor

inertia. Then, the needful power of regenerative resistor is 2 × ((7+1) × 1.37 – 8) / 0.4 = 14.8 W. If

it is smaller than the built-in capacity of regenerative resistor, the built-in 60W regenerative

resistor will do. Generally speaking, when the need of the external load inertia is not much, the

built-in regenerative is enough. The diagram below describes the actual operation. The smaller

power of the regenerative resistor it is, the more energy it accumulates and the higher

temperature it will be. When the temperature is higher than a specific value, AL005 occurs.

(b) If the external load torque exists, the motor is in reverse rotation.

Usually, the motor is in forward rotation, which means the torque output direction of the

motor is the same as the rotation direction. However, in some applications, the direction of

torque output is different from the rotation. In this situation, the motor is in reverse rotation.

The external energy goes into the servo drive through the motor. The diagram below is one

example. When the external force direction is the same as the moving direction, the servo

system has to use the force of the opposite direction to keep the speed and sta bility. Huge

amount of energy will return to the servo drive at the moment. When DC-BUS is full and

unable to store the regenerative energy, the energy will be leaded to regenerative resistor

and consumed.

Motor Speed

External Load Torque

2

Motor Output Torque

Negative

Torque

Negative torque: TL × Wr TL: external load torque

For safety reasons, please calculate it by considering the safest situation.

For example, when the external load torque is +70% rated torque and the rotation rea ches

3000 r/min, then take 400W (the rated torque is 1.27 Nt-m) as the example, users have to

connect the regenerative resistor which is 2 × (0.7× 1.27) × (3000 × 2 × π/60) = 560 W, 60

.

Positive

Torque

Negative Tor que

Positive

Torque

September, 2015 2-9

2

(

)

(

)

Installation ASDA-B2-F

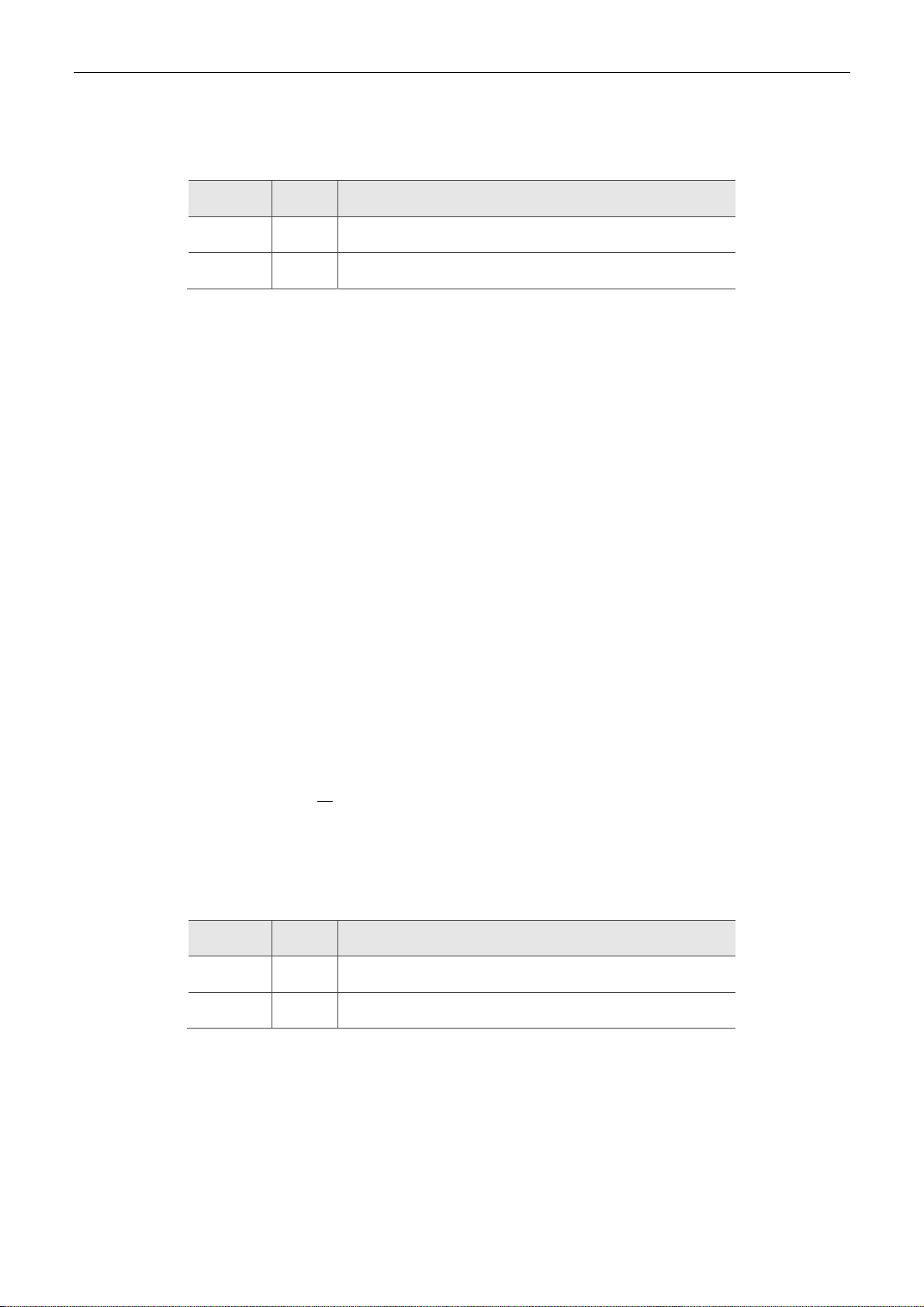

(2) Simple Selection

Choose the appropriate regenerative resistor according to the allowable frequency and empty

load frequency in actual operation. The so-called empty allowable frequency is the frequency of

continuous operation when the servo motor runs from 0 r/min to the rated speed and then

decelerates from the rated speed to 0r/min within the shortest time. The following table lists the

allowable frequency when the servo drive runs without load (times/min).

Allowable frequency when the servo drive runs without load (times/min)

and uses a built-in regenerative resistor

Motor Capacity

600 W 750 W 900 W 1.0 kW 1.5 kW 2.0 kW 2.0 kW 3.0 kW

Servo Motor

ECMA□□C

ECMA□□E

ECMA□□G

06 07 09 10 15 20 20 30

- 312 - 137 - 83 (F100) -

- - - 42 32

42 - 31 - - - - -

24

(F130)

10

(F180)

11

When the servo motor runs with load, the allowable frequency will be different according to

different load inertia or speed. The following is the calculation method.

“m” represents load / motor inertia ratio.

2

Allowable frequen cy =

Allo wable frequency when s e rvo mo tor run without load

m + 1

Rated speed

x

Operating sp eed

times

min.

The comparison table of external regenerative resistor is provided below. Please choose the

appropriate regenerative resistor according to the allowable frequency.

The table below describes the suggested allowable frequency (times/min) of regenerative

resistor when the servo drive runs without load.

Allowable frequency of regenerative resistor when the servo drive runs without load (times/min)

Motor Capacity

Suggested

Regenerative

Resistor

100 W 200 W

01 02 04 04 07 10 20

400 W

F60

ECMA□□C

400 W

F80

750 W 1.0 kW 2.0 kW

200 W 80 Ω 32793 6855 4380 1784 1074 458 273

400 W 40 Ω - - - - - 916 545

1 kW 30 Ω - - - - - - 1363

Allowable frequency of regenerative resistor when the servo drive runs without load (times/min)

Motor Capacity

Suggested

Regenerative

Resistor

200 W 80 Ω 149 144 109 83 35 22

400 W 40 Ω - 289 217 166 70 44

1k W 30 Ω - - - 416 175 110

0.5 kW 1 kW 1.5 kW 2.0 kW 2.0 kW 3.0 kW

05 1.0 15 20 20 30

ECMA□□E

2-10 September, 2015

ASDA-B2-F Installation

Allowable frequency of regenerative resistor when the servo drive runs without load (times/min)

Motor Capacity

Suggested

Regenerative

Resistor

200 W 80 Ω 149 144 109

400 W 40 Ω - - 217

If watt is not enough when using regenerative resistor , connecting the same regen erative resistor

in parallel can increase the power.

0.3 kW 0.6 kW 0.9 kW

03 06 09

ECMA□□G

Dimensions of Regenerative Resistor

Delta Part Number: BR400W040 (400 W 40 Ω)

L1 L2 H D W MAX. WEIGHT (g)

265 250 30 5.3 60 930

2

Delta Part Number: BR1K0W020 (1 kW 20 Ω)

L1 L2 H D W MAX. WEIGHT(g)

400 385 50 5.3 100 2800

Note:

Please refer to Appendix B for selection of regenerative resistor.

September, 2015 2-11

2

Installation ASDA-B2-F

(This page is intentionally left blank.)

2-12 September, 2015

Wiring

This chapter explains the wiring methods of the power circuit and connector definitions.

The standard wiring diagrams for each control mo de are also provided.

3.1 Connections ····················································································· 3-2

3.1.1 Connecting to Peripheral Devices ··················································· 3-2

3.1.2 Connectors and Terminals of Servo Drive ········································· 3-3

3.1.3 Wiring Method ············································································ 3-4

3.1.4 Specification of Motor Power Cab l e ················································· 3-5

3.1.5 Specification of Encoder Cable Connector ········································ 3-7

3.1.6 Selection of Wiring Rod ······························································ 3-10

3.2 Basic Wiring ··················································································· 3-11

3.2.1 200 W or models below (withtout built-in regenerative resistor nor fan) ·· 3-11

3.2.2 400 W ~ 750 W models (with built-in regenerative resistor but no fan) ··· 3-12

3.2.3 1 kW ~ 1.5 kW models (with built-in regenerative resistor and fan) ······· 3-13

3.2.4 2 kW ~ 3 kW models (with built-in regenerative resistor and fan) ·········· 3-14

3.3 I / O Signal (CN1) Connection ···························································· 3-15

3.3.1 I / O Signal (CN1) Connector T erminal Layout ·································· 3-15

3.3.2 Signals Explanation of Connector CN1 ··········································· 3-16

3.3.3 Wiring Diagrams (CN1) ······························································· 3-18

3.3.4 DI and DO Signal Specified by Users ············································· 3-20

3.4 CN2 Connector ··············································································· 3-21

3.5 Wiring of CN3 Connector ·································································· 3-23

3.6 CN6 Connector (DMCNET) ································································ 3-24

3.7 Standard Connection Example ··························································· 3-26

September, 2015 3-1

3

Wiring ASDA-B2-F

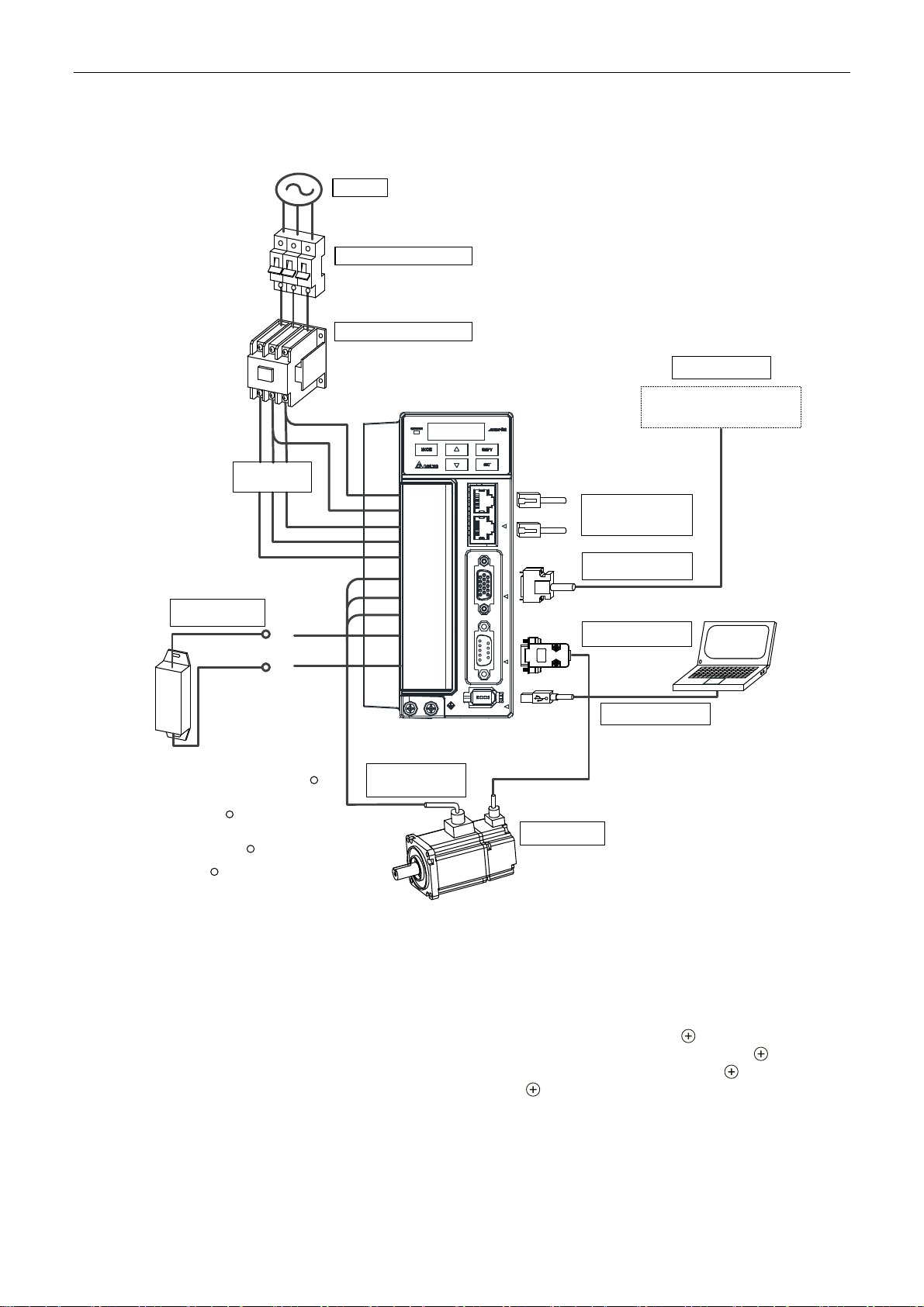

3.1 Connections

3.1.1 Connecting to Peripheral Devices

Power

100 W ~ 1.5 kW Single-/Three-phase 200 ~ 230 V

2 kW ~ 3 kW Three-phase 200 ~ 230 V

No Fuse Breaker (NFB)

It could prevent the instantaneous

excessive current caused by short-circuit

or fr om dam aging the s er vo drive when

power i s on / off.

Ma gnetic Contact or (MC)

When an alarm occurs, it outputs

Regenerative

Resistor (Option)

EMI Filter

P+

C

ALRM signal and disconnect the

power of the servo dr ive.

L1c

L2c

R

S

T

U

V

W

P+

D

C

Θ

C

N

6

C

N

1

C

N

2

C

N

3

CN6 Conn ec tor

(DMCNET)

CN1 I/O Connector

CN2 Conn ector

CN3 Conn ector

Host Controller

It can connect to Delta’s PLC controller

or other brands of NC controllers.

1. For MODBUS communication and

To prevent the energy from flowing

back caused by motor brake and

result in error, please connect the P

and C end of the s er v o drive to

external regenerative res istor, an d

the contact of P and D end sh ould

be opened. If usi ng the internal

regenerative resistor, please make

sure the contact of P and D end

sho uld be short-circu ited and the

con tact of P and C end should be

opened.

+

+

+

+

Motor p ower

output U, V, W

Servo Motor

supports RS-232

2. Use AS DA-Soft to conduct tuning, parameters

setting and control.

Installation notes:

1. Check if the power and wiring among R, S, T and L

1c, L2c are correct.

2. Please check if the output terminal U, V, W of the servo motor is correctly wired. Incorrect

wiring may disable the operation of the motor or cause malfunction, triggering AL031

(Incorrect wiring of the motor power line U, V, W, GND).

3. When applying to the external regenerative resistor, the contact between P

should be opened and the external regenerative resistor should connect to terminal P

and C. When applying to the internal regenerative resistor, the contact between P

should be short-circuited and the contact between P

and C should be opened.

and D

and D

4. When an alarm occurs or the system is i n emergency stop st atus, use ALA RM or W ARN to

output and disconnect the power of magnetic contactor in order to disconnect the power of

servo drive.

3-2 September, 2015

ASDA-B2-F Wiring

3.1.2 Connectors and Terminals of Servo Drive

Terminal

Signal

L1c, L2c

R, S, T

U, V, W

FG

P , D, C,

CN1 I/O connector (Option) Connect to the host controller. Please refer to section 3.3.

CN2

CN3

CN6 DMCNET Connector RJ45 connector. Please refer to section 3.6.

Power input of the

control circuit

Power input of the main

circuit

Motor cable

Regenerative resistor

terminal, braking unit, or

P

Ground terminal Connect to the ground wire of the power and servo motor.

Connector for encoder

(Option)

Connector for

communication (Option)

Name Description

Connect to single-phase AC power (Select the appropriate

voltage specification according to the product.)

Connect to three-phase AC power (Select the appropriate

voltage specification according to the product.)

Connect to the servo motor

Terminal

Symbol

U Red

V White

W Black

FG Green

Use internal resistor

Use external resistor

and .

Use external braking

unit

Connect to the encoder of the motor. Please refer to section 3.4.

Connect to RS-232. Please refer to section 3.5.

Wire

Color

Description

Three-phase main power cable of

the motor.

Connect to ground terminal (

of the servo drive.

The contact between P and D

end should be short-circuited;

contact between P and C end

should be opened.

Connect P , C ends to the resistor

and the contact between P

D end should be opened.

P and P of the brake unit

should connect to the resistor. The

contact between P

P and C should be opened. P

connects to the positive end of

V_BUS voltage;

the negative end of V_BUS

voltage.

3

)

and

and D and

connects to

Pay special attention to the followings when wiring:

1. When the power is cut off, do not touch R, S, T and U , V, W since the capacitance inside

the servo drive still contains huge amount of electric ch arge . Wait un til the char ging ligh t is

off.

2. Separate R, S, T and U, V, W from the other wires. The interval should be at least 30 cm

(11.8 inches).

3. If the wire of CN2 is not long enough, please use shielded twisted-pair cable which cannot

exceed 20 meters (65.62 inches). If it exceeds 20 meters , please choose the bigger wire

diameter of signal cable to ensure it will not cause signal fading.

4. When selecting the wire rod, please refer to Section 3.1.6.

September, 2015 3-3

3

Wiring ASDA-B2-F

3.1.3 Wiring Method

There are two types of wiring method, single-phase and three-phase. In the diagram below,

Power On is contact a, Power Off and ALRM_RY are contact b. MC is the coil of magnetic

contactor and self-remaining power and is the contact of main power circuit.

Wiring Method of Single-phase Supply (suitable for 1.5 kW and models below 1.5 kW)

RS

MCCB

Noise Filter

Power

Power

on

off

MC

ALRM_RY

MC

MC

R

S

T

L

1C

L

2C

SUP

U

V

W

Servo Drive

Wiring Method of Three-phase Power Supply (suitable for all series)

TS

R

MCCB

Noise Filter

Power onPower

off

MC

ALRM_RY

Motor

MC

R

S

T

L1C

L2C

MC

Servo Drive

SUP

U

V

W

Motor

3-4 September, 2015

ASDA-B2-F Wiring

3.1.4 Specification of Motor Power Cable

Motor Model U, V, W / Connector of Brake

ECMA-C1040FS (50 W)

ECMA-Cᇞ0401S (100 W)

ECMA-Cᇞ0602S (200 W)

ECMA-Cᇞ0604S (400 W)

ECMA-Cᇞ0604H (400 W)

ECMA-Cᇞ08047 (400 W)

ECMA-Cᇞ0807S (750 W)

ECMA-Cᇞ0807H (750 W)

ECMA-Cᇞ0907S (750 W)

ECMA-Cᇞ0910S (1000 W)

ECMA-C1040FS (50 W)

ECMA-Cᇞ0401S (100 W)

ECMA-Cᇞ0602S (200 W)

ECMA-Cᇞ0604S (400 W)

ECMA-Cᇞ0604H (400 W)

ECMA-Cᇞ08047 (400 W)

ECMA-Cᇞ0807S (750 W)

ECMA-Cᇞ0807H (750 W)

ECMA-Cᇞ0907S (750 W)

ECMA-Cᇞ0910S (1000 W)

*:with brake

Terminal

Definition

3

A

B

ECMA-Gᇞ1303S (300 W)

ECMA-Eᇞ1305S (500 W)

ECMA-Gᇞ1306S (600 W)

ECMA-Fᇞ1308S (850 W)

ECMA-Gᇞ1309S (900 W)

ECMA-Cᇞ1010S (1000 W)

ECMA-Eᇞ1310S (1000 W)

ECMA-Fᇞ1313S (1300 W)

ECMA-Eᇞ1315S (1500 W)

ECMA-Fᇞ1318S (1800 W)

ECMA-Cᇞ1020S (2000 W)

ECMA-Eᇞ1320S (2000 W)

ECMA-Cᇞ13304 (3000 W)

ECMA-Eᇞ1820S (2000 W)

ECMA-Eᇞ1830S (3000 W)

ECMA-Fᇞ1830S (000 W)

C

D

September, 2015 3-5

Wiring ASDA-B2-F

3

Wiring Name

Terminal

Definition A

Terminal

Definition B

Terminal

Definition C

Terminal

Definition D

When selecting the wire rod, please choose 600 V PVC cable and the length should be no lon ger

than 30 m. If the length exceeds 30 m, please take the received voltage into consideration wh en

selecting the wire size. Please refer to Section 3.1.6 for wire rod selection.

U

(Red)

1 2 3 4 - -

1 2 4 5 3 6

F I B E G H

D E F G A B

V

(White)

W

(Black)

CASE

GROUND

(Green)

BRAKE1

(Yellow)

BRAKE2

(Blue)

Note:

1. No polarity for brake coil, the wiring name is BRAKE1 & BRAKE2.

2. Power for brake is 24 V

3. Box, () in servo motor model represents brake or keyway / oil seal.

4. Triangle, (

△)

in servo motor model represents encoder type. Please see Chapter 1 for detail.

. Never share it with the power of control signal VDD.

DC

3-6 September, 2015

ASDA-B2-F Wiring

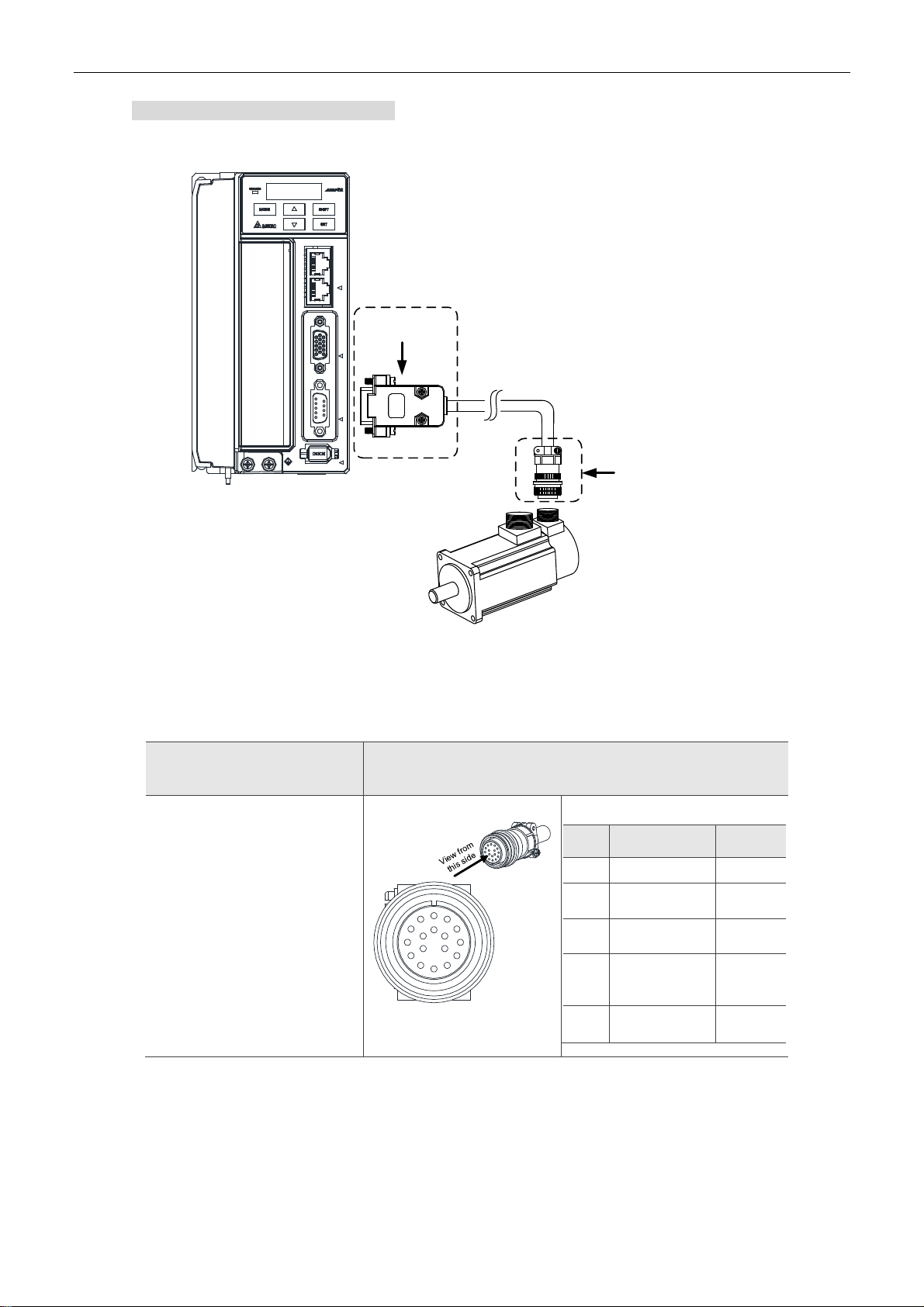

3.1.5 Specification of Encoder Cable Connector

Encoder Connection (Diagram 1):

Servo Drive

3

C

N

6

C

N

1

C

N

2

C

N

3

CN2 Connector

*2

Encoder Cable

Quick Connec tor

Connector of

(Drive Si de)

*1

Connecto r of

Encoder Cable

(Motor Side)

Servo Motor

Note:

This diagram shows the connection between the servo drive and the motor encoder, which is not

drawn by the practical scale. The specification will change subject to the selected servo drive and

motor model.

1. Please refer to the Section of Specification and Definition of Encoder Connector.

2. Please refer to Section 3.4 CN2 Connector.

Motor Model Connector of Encoder Cable

ECMA-C1040FS (50 W)

ECMA-C△0401S (100 W)

ECMA-C△0602S (200 W)

ECMA-C△0604S (400 W)

ECMA-C△0604H (400 W)

ECMA-C△08047 (400 W)

3

6

9

2

5

8

7

4

1

View from

this sid e

View from

this sid e

3

6

9

2

5

8

1

4

7

ECMA-C△0807S (750 W)

ECMA-C△0807H (750 W)

ECMA-C△0907S (750 W)

ECMA-C△0910S (1000 W)

September, 2015 3-7

Wiring ASDA-B2-F

Specification and Definition of Encoder Connector:

Connector of

Enco d er Ca b le

Connector of

Motor Encoder

3

Servo Drive

CN2

View from

this sid e

View from

this sid e

Motor

Encoder

(Encoder types are 17-bit and 20-bi t):

123

Blue

T+T-Reserved

Reserved

456

Blue/Black

Reserved Reserved

789

white

Black/Black

& white

Shield

Red/Red &

DC+5V GND

Reserved

6

Reserved

9

Shield

23

-

5

-

Blue Brown

1

White

T+

4

White/Red

T-

78

DC+5VGND

(Encoder type is 2500 ppr, 33 bits):

Th e wire co l or of the servo drive is for

ref erenc e only. Please refer to the

real objec t .

Reserved Reserved

6

Reserved Reserve d

23

5

9

Shield

1

2

Servo Drive

CN2

If not using housing and directly wire the cores, please follow the corresponding core number for wiring. For

example, core number 1 from the servo drive CN2 should connect to core number 1 from the motor encoder;

core number 2 from the servo drive CN2 should connect to core number 2 from the motor encoder and so on.

Please number the cores from the servo drive in order and then connect it to the encoder.

33

44

‧

‧

‧

1

2

‧

‧

‧

Blue

1

White

T+

4

White/Red

T-

78

Brown

DC+5VGND

Motor

Encoder

3-8 September, 2015

ASDA-B2-F Wiring

Encoder Connection (Diagram 2):

Servo Drive

C

N

6

*1

CN2 Connector

C

N

1

C

N

2

C

N

3

Military

Connector

Connector of

Encoder Cable

3

Servo Motor

Note:

This diagram shows the connection between the servo drive and the motor encoder, which is not drawn by

the practical scale. The specification will change subject to the selected servo drive and motor model.

1. Please refer to Section 3.4, CN2 Connector.

Motor Model

ECMA-G△1303S (300 W)

ECMA-E△1305S (500 W)

ECMA-G△1306S (600 W)

ECMA-F△1308S (850 W)

ECMA-G△1309S (900 W)

ECMA-C△1010S (1000 W)

ECMA-E△1310S (1000 W)

ECMA-F△1313S (1300 W)

ECMA-E△1315S (1500 W)

ECMA-F△1318S (1800 W)

ECMA-C△1020S (2000 W)

ECMA-E△1320S (2000 W)

ECMA-C△13304 (3000 W)

ECMA-E△1820S (2000 W)

A

B

C

N

P

D

RS

E

G

Military Connector

Connector of Encoder Cable

M

L

T

K

J

HF

Pin

No.

A

Terminal

Identification

T+ Blue

B T -

S DC+5V

R GND

L

BRAID

SHIELD

Color

Blue&

Black

Red/Red&

White

Black/

Black&

White

–

Please select shielded multi-core and the shielded ca ble should connect to the SHIELD end.

Please refer to the description of Section 3.1.6.

Note:

1. Box, () in servo motor model represents brake or keyway / oil seal.

2. Triangle, (△) in servo motor model represents encoder type. Please refer to Chapter 1 for detail.

September, 2015 3-9

Wiring ASDA-B2-F

3.1.6 Selection of Wiring Rod

The recommended wire rods are shown as the following table.

3

Servo Drive and corresponding

Servo Motor

ASD-B2-0121-F

ASD-B2-0221-F

ASD-B2-0421-F

ASD-B2-0721-F

ASD-B2-1021-F

ASD-B2-1521-F

ASD-B2-2023-F

ASD-B2-3023-F

ECMA-C1040FS

ECMA-C△0401S

ECMA-C△0602S

ECMA-C△0604S

ECMA-C△0604H

ECMA-C△08047

ECMA-E△1305S

ECMA-G△1303S

ECMA-F11305S

ECMA-C△0807S

ECMA-C△0807H

ECMA-C△0907S

ECMA-G△1306S

ECMA-C△0910S

ECMA-C△1010S

ECMA-E△1310S

ECMA-F△1308S

ECMA-G△1309S

ECMA-E△1315S

ECMA-C△1020S

ECMA-E△1320S

ECMA-E△1820S

ECMA-F11313S

ECMA-F11318S

ECMA-C△13304

ECMA-E△1830S

ECMA-E△1835S

ECMA-F△1830S

1.3 (AWG16) 2.1(AWG14) 0.82(AWG18) 2.1(AWG14)

1.3(AWG16) 2.1(AWG14) 1.3(AWG16) 2.1(AWG14)

1.3(AWG16) 2.1(AWG14) 2.1 (AWG14) 2.1(AWG14)

1.3(AWG16) 2.1(AWG14) 3.3 (AWG12) 2.1(AWG14)

Power Wiring - Wire Diameter mm2 (AWG)

L1c, L2c R, S, T U, V, W

P , C

Servo Drive Model

ASD-B2-0121-F

ASD-B2-0221-F

ASD-B2-0421-F

ASD-B2-0721-F

ASD-B2-1021-F

ASD-B2-1521-F

ASD-B2-2023-F

ASD-B2-3023-F

Size Number Specification Standard Length

0.13 (AWG26) 10 core (4 pairs) UL2464 3 m (9.84 ft.)

Encoder Wiring - Wire Diameter mm2 (AWG)

Note:

1. Pleas e use shielded twisted-pair cable for encoder wiring so as to reduce the interference of the noise.

2. The shield should connect to the

3. Pleas e follow the Selection of Wire Rod when wiring in order to avoid the danger it may occur.

4. Box, () at the end of the servo drive model represents the model code of ASDA B2-F. Please refer to

the model information of the product you purchased.

5. Box, () in servo motor model represents brake or keyway / oil seal.

6. Triangle, (

△) in servo motor model represents encoder type. Please refer to Chapter 1 for detail.

phase of SHIELD.

3-10 September, 2015

ASDA-B2-F Wiring

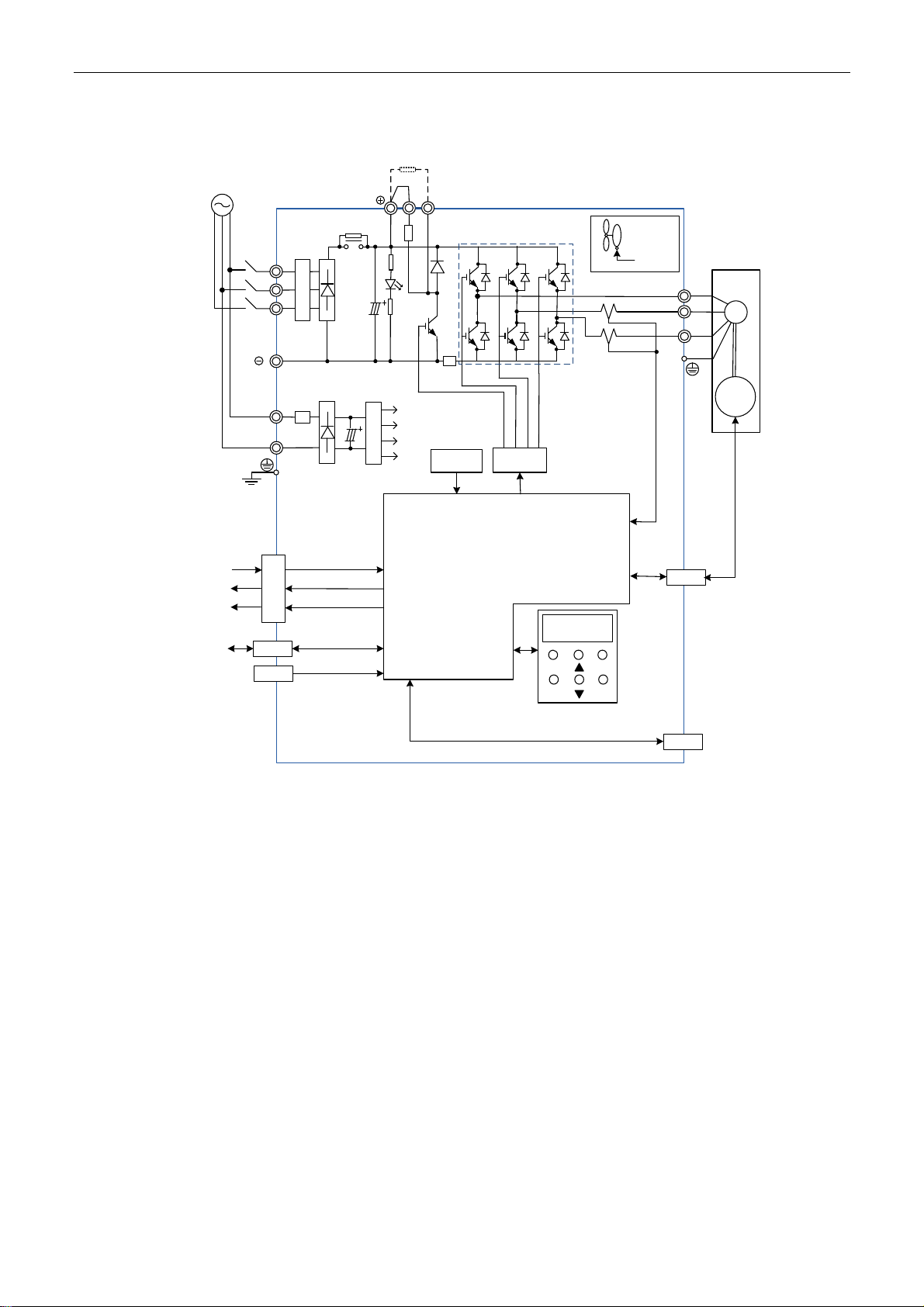

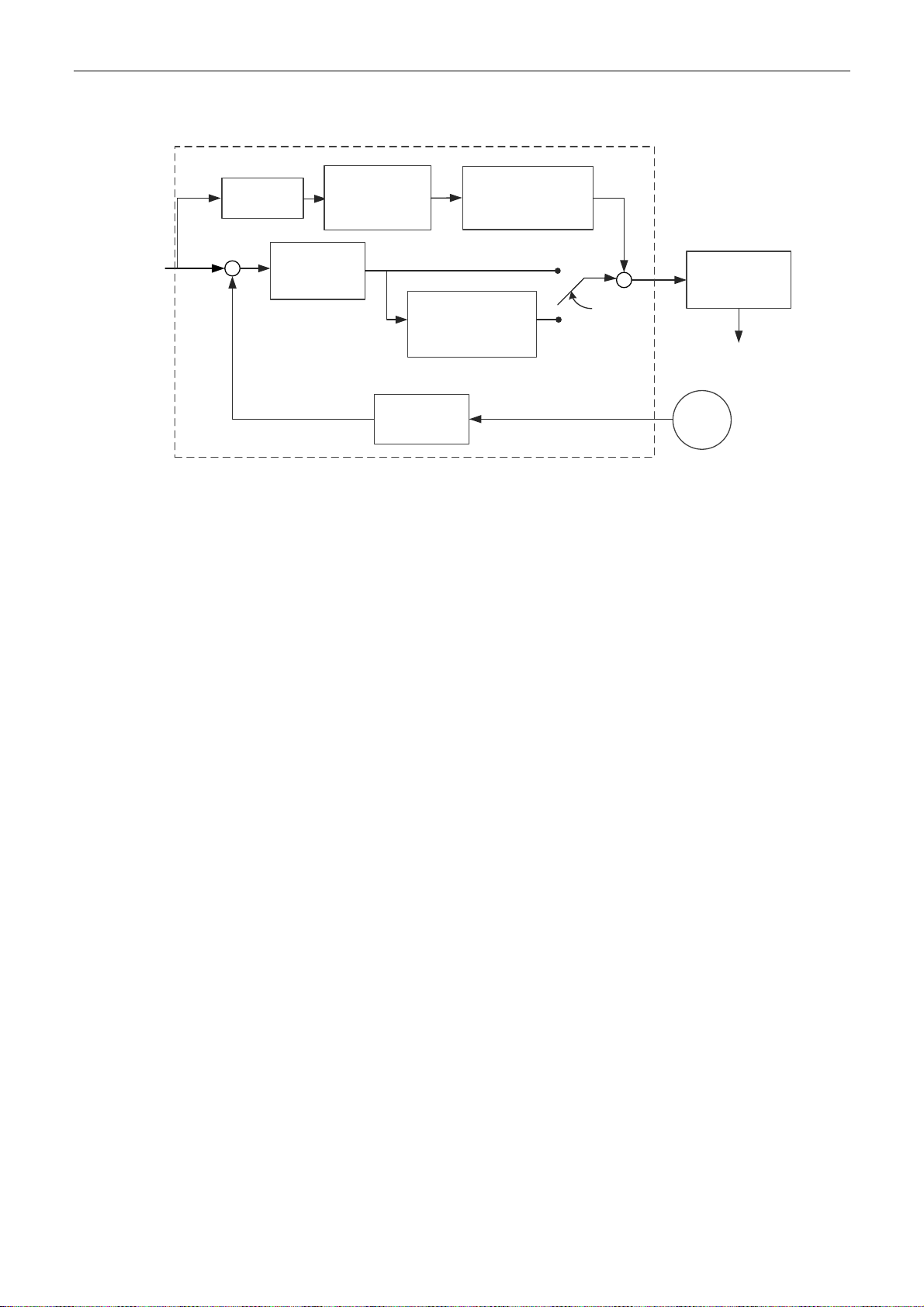

3.2 Basic Wiring

3.2.1 200 W or models below (without regenerative resistor nor fan)

Connect to external

Power

1-phase/3-phase

200 ~ 230 V, 200 W and below

R

S

T

Detection

Phase Loss

regenerative resistor

P

Circuit

Rectifier

C

D

Servo Drive

IPM Module

Servo

U

Motor

V

Circuit

Regeneration

M

W

3

Digital Intput

A & B Output

Digital Output

Serial

Communication

RS-232

L1

C

L2

C

CN1

CN3

CN4Battery

±15V

+5V

+3.3V

Control Pow er

+24V

Protection

Circuit

GATE

DRIVE

Data Processing Unit

Display

MODE SHIFT

SETCHARGE

CN2

CN6

Encoder

DMCNET

September, 2015 3-11

3

Wiring ASDA-B2-F

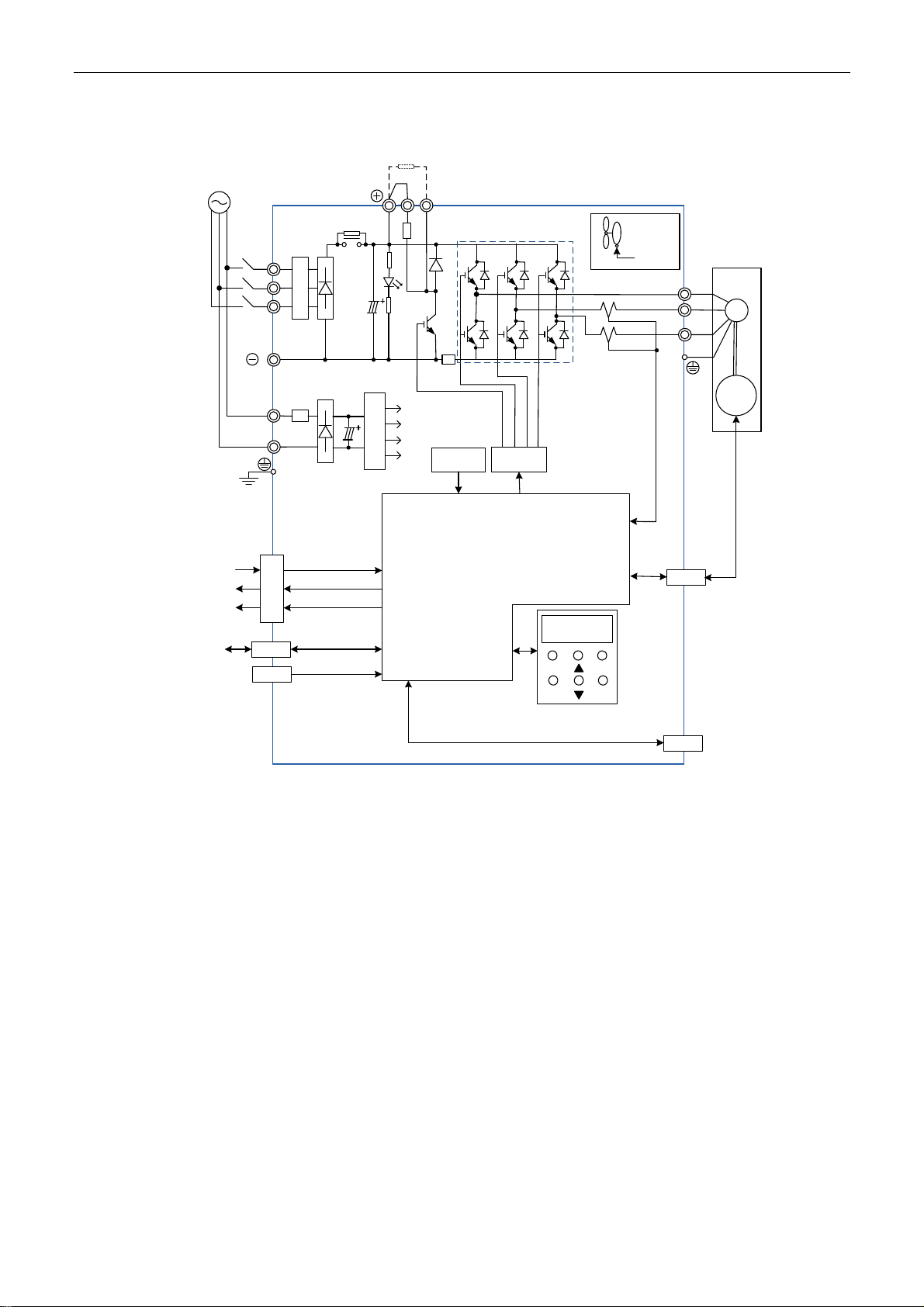

3.2.2 400 W ~ 750 W models (with built-in regenerative resistor but no fan)

Connect to external

Power

1-phase/3-phase

200 ~ 230 V, 400 W ~ 750 W

R

S

T

Detection

Phase Loss

regenerative resistor

P

Circuit

Rectifier

C

D

Regeneration

Circuit

Servo Drive

IPM Module

Servo

U

Motor

V

M

W

Digital Intput

A & B Output

Digital Output

Serial

Communication

RS-232

L1

C

L2

C

CN1

CN3

CN4Battery

±15 V

+5 V

+3.3 V

Control Power

+24 V

Protection

Circuit

Data Processing Unit

GATE

DRIVE

Display

MODE SHIFT

SETCHARGE

CN6

Encoder

CN2

DMCNET

3-12 September, 2015

ASDA-B2-F Wiring

3.2.3 1 kW ~ 1.5 kW models (with built-in regenerative resistor and fan)

Connect to external

Power

1-phase/3-phase

200 ~ 230 V, 1 kW ~ 1.5 kW

regenerative resisto r

P

D

C

Servo Drive

Models of 1 kW or above

Digital Input

A & B Output

Digital Output

Serial

Communication

RS-232

IPM Module

R

S

T

Phase Loss

L1

C

L2

C

CN1

CN3

CN4Battery

Circuit

Rectifier

Detection

Circuit

Regeneration

±15 V

+5 V

+3.3 V

Control Pow er

+24 V

Protection

Circuit

GATE

DRIVE

Data Processing Unit

Displ ay

MODE SHIFT

+12 V

Servo

U

Motor

V

M

W

Encoder

CN2

SETCHARGE

3

CN6

DMCNET

September, 2015 3-13

Wiring ASDA-B2-F

3.2.4 2 kW ~ 3 kW models (with built-in regenerative resistor and fan)

Connect to external

Power

3-phase

200 ~ 230 V, 2 kW ~ 3 kW

regenerative resistor

P

D

C

Servo Drive

Models of 1 kW or above

3

Digital Input

A, B Output

Digital Output

Serial

Communication

RS-232

L1

L2

IPM Module

R

S

T

Phase Loss

C

C

CN1

CN3

CN4Battery

Circuit

Rectifier

Detection

Circuit

Regeneration

±15 V

+5 V

+3.3 V

Protection

+24 V

Control Power

Circuit

GATE

DRIVE

Data Processing Unit

Display

MODE SHIFT

+12V

Servo

U

Motor

V

M

W

Encoder

CN2

SETCHARGE

CN6

DMCNET

3-14 September, 2015

ASDA-B2-F Wiring

3.3 I / O Signal (CN1) Connection

3.3.1 I / O Signal (CN1) Connector Terminal Layout

In order to have a more flexible communication with the master (the host controller), 2

programmable Digital Outputs (DO) and 5 programmable digital inputs (DI) are provided. The

setting of 5 digital inputs and 2 digital outputs of each axis are parameter P2-10 ~ P2-14 and

parameter P2-18 ~ P2-19 respectively. In addition, the differential output encoder signal, A+, A-,

B+, and B- are also provided. The followings are the pin diagrams.

3

CN1 Connector (female)

Front View Rear View

5

10

15 11

Pin

Name Function

No

1 DI1- Digital input 6 GND

2 DI2- Digital input 7 OA

3 DI3- Digital input 8 /OA

4 DI4- Digital input 9 OB

DO2+ DO1+

Pin

No

DO1-DO2-

Name Function

Connector (male)

DI2-DI3-DI4- DI1-DI5-

Control Panel

Power 0 V

Encoder A

pulse output

Encoder /A

pulse output

Encoder B

pulse output

1

GND/OB OA/OAOB

COM+

Pin

No

11 COM+

12 DO1+ Digital output

13 DO1- Digital output

14 DO2+ Digital output

6

Name Function

Power ground

(12 ~ 24 V)

5 DI5- Digital input 10 /OB

Encoder /B

pulse output

15 DO2- Digital output

September, 2015 3-15

Wiring ASDA-B2-F

3.3.2 Signals Explanation of Connector CN1

The following details the signals listed in previous section:

3

General Signals

Position Pulse

(Output)

Signal Pin No Function

OA

/OA

OB

/OB

7

8

Encoder signal output A and B (Line Drive

output)

9

10

Wiring Method

(Refer to 3.3.3)

C5/C6

Signal Pin No Function

The positive end of the external power

COM+ 11

Power

GND 6 Power of Control Panel 0 V

There are various operation modes available in this servo drive (please refer to Chapter 6.1 ) and

each mode requires different I/O signal configuration. Thus, programmable I/O signals are

provided. That is, users are able to choose DI and DO signals to meet different application

(+12 V ~ +24 V) must be connected to

COM+. COM+ is the common input of digital

input.

Wiring Method

(Refer to 3.3.3)

-

requirements. Basically, default setting of DI/DO signal has already have the appropriate function

which can satisfy the demand of general application.

Refer to the following DI/DO table to know the corresponding default setting of DI/DO signal and

Pin No of the selected mode in order to conduct the wiring.

The explanation of DO signal default setting is as follows.

Do Signal

Name

SRDY ALL - -

ZSPD ALL - -

Operation

Mode

Pin No

+ -

Function

When the servo drive applies to the power and no

alarm (ALRM) occurs in control circuit and motor

power circuit, this DO is ON.

When the motor speed is slower than the setting

value of parameter P1-38, this DO is ON.

Wiring Method

(Refer to 3.3.3)

C1,C2

Note:

1. For example, if Sz mode is selected, pin 3 and 2 are defined as DO.TSPD.

2. The unlisted Pin No means the signal is not the preset one. If users want to use it, parameters need to

be changed and set as the desired ones. Please refer to Section 3.3.4 for further detail.

3-16 September, 2015

ASDA-B2-F Wiring

The explanation of DI signal default setting is as the following.

DI Signal

Name

ARST ALL -

EMGS ALL 5

NL

(CWL)

PL

(CCWL)

Operation

Mode

ALL 3

ALL 4

Pin No Function