ASDA A2-E

EtherCAT

Interface Servo Drive

User Manual

www.deltaww.com

ASDA A2-E

EtherCAT Interface Servo Drive User Manual

V3.0

DELTA_ASDA-A2-E_UM_EN_20150430

Industrial Automation Headquarters

Delta Electronics, Inc.

Taoyuan Technology Center

No.18, Xinglong Rd., Taoyuan City,

Taoyuan County 33068, Taiwan

TEL: 886-3-362-6301 / FAX: 886-3-371-6301

Asia

Delta Electronics (Jiangsu) Ltd.

Wujiang Plant 3

1688 Jiangxing East Road,

Wujiang Economic Development Zone

Wujiang City, Jiang Su Province, P.R.C. 215200

TEL: 86-512-6340-3008 / FAX: 86-769-6340-7290

Delta Greentech (China) Co., Ltd.

238 Min-Xia Road, Pudong District,

ShangHai, P.R.C. 201209

TEL: 86-21-58635678 / FAX: 86-21-58630003

Delta Electronics (Japan), Inc.

Tokyo Ofce

2-1-14 Minato-ku Shibadaimon,

Tokyo 105-0012, Japan

TEL: 81-3-5733-1111 / FAX: 81-3-5733-1211

Delta Electronics (Korea), Inc.

1511, Byucksan Digital Valley 6-cha, Gasan-dong,

Geumcheon-gu, Seoul, Korea, 153-704

TEL: 82-2-515-5303 / FAX: 82-2-515-5302

Delta Electronics Int’l (S) Pte Ltd.

4 Kaki Bukit Ave 1, #05-05, Singapore 417939

TEL: 65-6747-5155 / FAX: 65-6744-9228

Delta Electronics (India) Pvt. Ltd.

Plot No 43 Sector 35, HSIIDC

Gurgaon, PIN 122001, Haryana, India

TEL : 91-124-4874900 / FAX : 91-124-4874945

Americas

Delta Products Corporation (USA)

Raleigh Ofce

P.O. Box 12173,5101 Davis Drive,

Research Triangle Park, NC 27709, U.S.A.

TEL: 1-919-767-3800 / FAX: 1-919-767-8080

Delta Greentech (Brasil) S.A.

Sao Paulo Ofce

Rua Itapeva, 26 - 3° andar Edicio Itapeva One-Bela Vista

01332-000-São Paulo-SP-Brazil

TEL: 55 11 3568-3855 / FAX: 55 11 3568-3865

Europe

Deltronics (The Netherlands) B.V.

Eindhoven Ofce

De Witbogt 15, 5652 AG Eindhoven, The Netherlands

TEL: 31-40-2592850 / FAX: 31-40-2592851

*We reserve the right to change the information in this manual without prior notice.

Via Polesine, 1/4

10020 Cambiano ( TO ) Italy

+39 011 9454523

www.e-comtech.it

info@e-comtech.it

Revision April, 2015 i

Table of Contents

Chapter 1 CoE Drive Overview ................................................................................. 1-1

1.1 Communication Specification ...................................................................... 1-1

1.2 The Interface of Delta EtherCAT Servo Drive .............................................. 1-2

1.3 LED Indicators ............................................................................................. 1-3

1.4 The Topology ............................................................................................... 1-6

1.5 Wiring .......................................................................................................... 1-7

1.5.1 Explanation of I/O (CN1) Connector Signal ............................................ 1-8

1.5.2 CN2 Connector ....................................................................................... 1-9

1.5.3 CN5 Connector (Full-closed Loop) ......................................................... 1-10

1.5.4 CN6 EtherCAT Terminal ........................................................................ 1-11

1.5.5 CN7 Extension DI ................................................................................... 1-12

1.5.6 CN-STO.................................................................................................. 1-13

1.5.7 STO with Safety Relay ........................................................................... 1-14

1.5.8 STO Disable ........................................................................................... 1-14

1.6 Dimension .................................................................................................... 1-15

1.6.1 220V Series ............................................................................................ 1-15

1.6.2 400V Series ............................................................................................ 1-17

Chapter 2 System Setup ........................................................................................... 2-1

2.1 Parameter Settings of EtherCAT Mode ....................................................... 2-1

2.2 TwinCAT Setup ............................................................................................ 2-3

2.3 Synchronization Modes Setting ................................................................... 2-11

ASDA A2-E Table of Contents

ii Revision April, 2015

2.3.1 Two Synchronization Modes of Delta Servo ........................................... 2-11

2.3.2 Select the Synchronization Mode ........................................................... 2-12

2.3.3 Synchronous Clock Time Setting ........................................................... 2-12

2.4 PDO Mapping .............................................................................................. 2-14

2.4.1 Default PDO Mappings ........................................................................... 2-14

2.4.2 Re-define a PDO Mapping ..................................................................... 2-15

2.4.3 Using TwinCAT ...................................................................................... 2-16

Chapter 3 EtherCAT Communication States ........................................................... 3-1

3.1 State Transition Operation ........................................................................... 3-2

Chapter 4 EtherCAT Troubleshooting ..................................................................... 4-1

Chapter 5 CANopen Operation Mode ....................................................................... 5-1

5.1 Profile Position Mode ................................................................................... 5-1

5.1.1 Description ............................................................................................. 5-1

5.1.2 Operation Procedures ............................................................................ 5-1

5.1.3 Advanced Setting Procedures ................................................................ 5-2

5.1.4 Associated Object List ............................................................................ 5-3

5.2 Interpolation Position Mode ......................................................................... 5-4

5.2.1 Description ............................................................................................. 5-4

5.2.2 Operation Procedures ............................................................................ 5-5

5.2.3 Associated Object List ............................................................................ 5-5

5.3 Cyclic Synchronous Position Mode .............................................................. 5-6

5.3.1 Description ............................................................................................. 5-6

Table of Contents ASDA A2-E

Revision April, 2015 iii

5.3.2 The Function of CSP Mode .................................................................... 5-6

5.3.3 Operation Procedures ............................................................................ 5-6

5.3.4 Associated Object List ............................................................................ 5-7

5.4 Homing Mode .............................................................................................. 5-8

5.4.1 Description ............................................................................................. 5-8

5.4.2 Operation Procedures ............................................................................ 5-8

5.4.3 Associated Object List ............................................................................ 5-9

5.5 Profile Velocity Mode ................................................................................... 5-10

5.5.1 Description ............................................................................................. 5-10

5.5.2 Operation Procedures ............................................................................ 5-10

5.5.3 Advanced Setting Procedures ................................................................ 5-11

5.5.4 Associated Object List ............................................................................ 5-11

5.6 Cyclic Synchronous Velocity Mode .............................................................. 5-12

5.6.1 Description ............................................................................................. 5-12

5.6.2 The Function of CSV Mode .................................................................... 5-12

5.6.3 Operation Procedures ............................................................................ 5-12

5.6.4 Associated Object List ............................................................................ 5-13

5.7 Profile Torque Mode .................................................................................... 5-14

5.7.1 Description ............................................................................................. 5-14

5.7.2 Operation Procedures ............................................................................ 5-14

5.7.3 Advanced Setting Procedures ................................................................ 5-14

5.7.4 Associated Object List ............................................................................ 5-15

5.8 Cyclic Synchronous Torque Mode ............................................................... 5-16

5.8.1 Description ............................................................................................. 5-16

5.8.2 The Function of CST Mode .................................................................... 5-16

ASDA A2-E Table of Contents

iv Revision April, 2015

5.8.3 Operation Procedures ............................................................................ 5-16

5.8.4 Associated Object List ............................................................................ 5-17

5.9 Limit Position Handling Procedure ............................................................... 5-18

5.9.1 Description ............................................................................................. 5-18

5.9.2 Operation Procedures ............................................................................ 5-18

5.10 Touch Probe Function ................................................................................. 5-19

5.10.1 Description ............................................................................................. 5-19

5.10.2 Touch Probe Function ............................................................................ 5-19

5.10.3 Touch Probe Status ................................................................................ 5-20

5.10.4 Associated Object List ............................................................................ 5-21

Chapter 6 Object Dictionary Entries ........................................................................ 6-1

6.1 Specifications for Objects ............................................................................ 6-1

6.1.1 Object Type ............................................................................................ 6-1

6.1.2 Data Type ............................................................................................... 6-1

6.2 Overview of Object Group 1000h ................................................................. 6-2

6.3 Overview of Object Group 6000

h

................................................................. 6-3

6.4 Details of Objects ......................................................................................... 6-6

Chapter 7 Safety Function (Safe Torque Off, STO) ................................................. 7-1

7.1 Description of Terminal Block ...................................................................... 7-1

7.1.1 Functional Safety Standard and Certificates ........................................... 7-3

7.2 STO Safety Function ................................................................................... 7-3

7.3 Related Parameter Descriptions of STO Function ....................................... 7-5

7.4 Related Alarm Descriptions of STO Function .............................................. 7-6

Table of Contents ASDA A2-E

Revision April, 2015 v

Chapter 8 Alarm List .................................................................................................. 8-1

8.1 EtherCAT Communication Fault Messages ................................................. 8-1

8.2 Error Code Table ......................................................................................... 8-4

8.3 SDO Error Message Abort Codes ................................................................ 8-7

Chapter 9 Reference .................................................................................................. 9-1

ASDA A2-E Table of Contents

vi Revision April, 2015

(This page is intentionally left blank.)

Revision April, 2015 1-1

Chapter 1 CoE Drive Overview

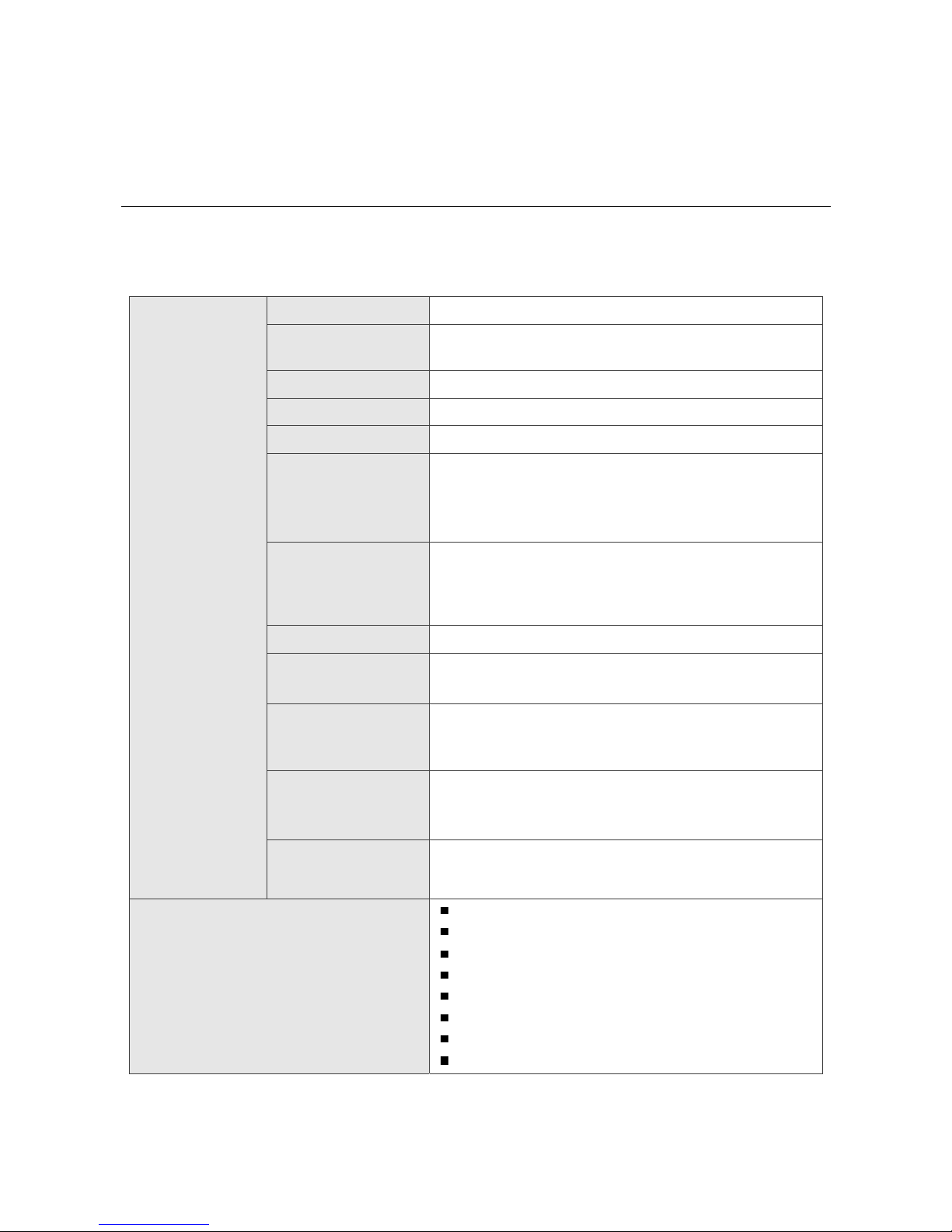

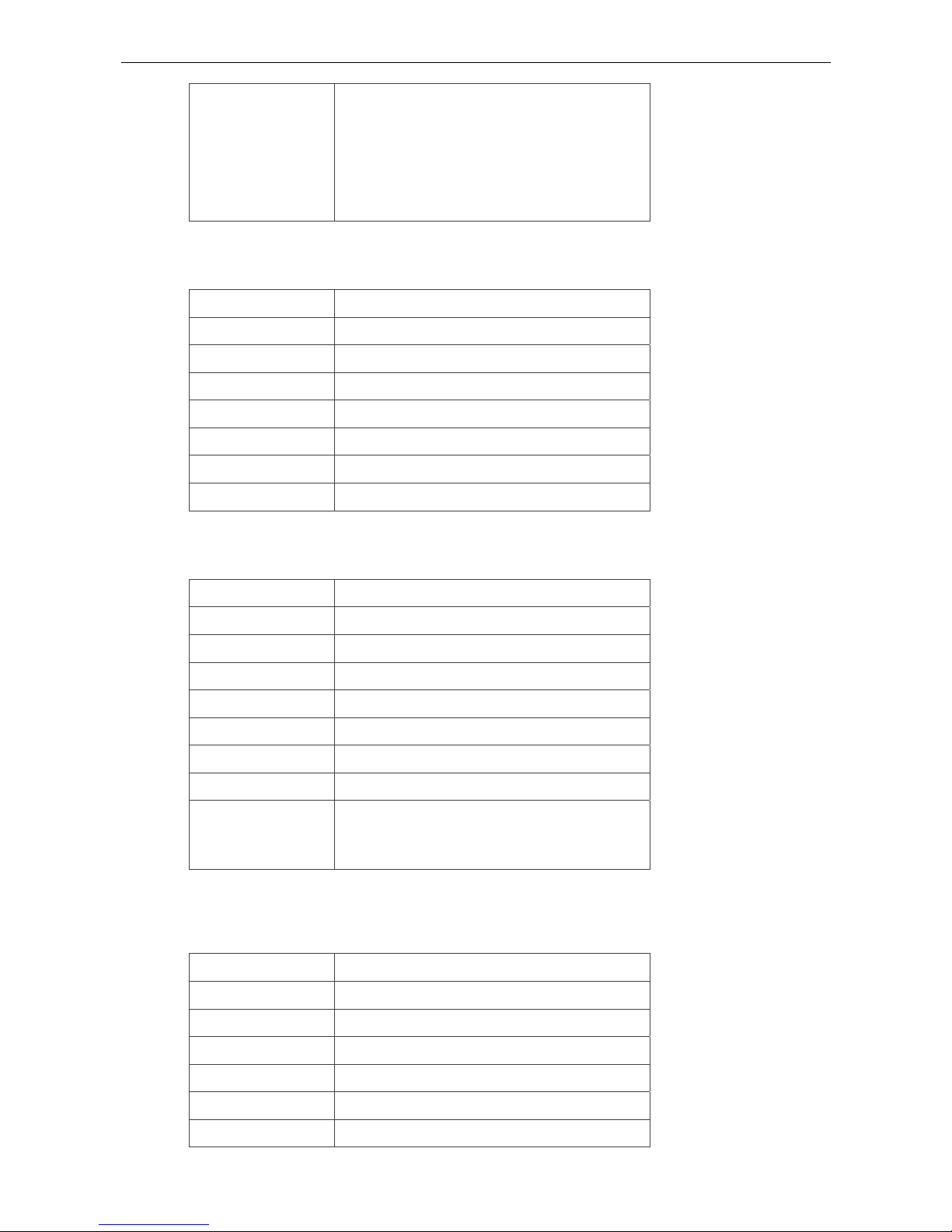

1.1 Communication Specification

EtherCAT

Communication

Physical layer

100BASE-TX

Communication

connector

RJ45 × 2 (Connector CN6A=IN, CN6B=OUT)

Network topology

Line connection

Baud rate

2 x 100 Mbps (full duplex)

Frame data length

Maximum 1484 bytes

SyncManager

SM0: Mailbox output

SM1: Mailbox input

SM2: Process data output

SM3: Process data input

FMMU

(Fieldbus Memory

Management Units)

FMMU0: Process data output area

FMMU1: Process data input area

FMMU2: Mailbox status area

Device profile

CoE: CANopen over EtherCAT

Synchronization

mode

DC synchronization ( SYNC0 )

Non- synchronized ( Free Run )

Communication

object

SDO: Service Data Object

PDO: Process Data Object

EMCY: Emergency Data Object

LED indicator

(On RJ45

Connector)

EtherCAT ERR (ER) × 1

EtherCAT Link/Activity (L/A) × 2

EtherCAT RUN (RN) × 1

Application layer

specifications

IEC61800-7 CiA402 Drive Profile

The supported CiA402 operation

modes

Profile Position Mode (PP)

Profile Velocity Mode (PV)

Profile Torque Mode (PT)

Homing Mode (HM)

Interpolated Position Mode(IP)

Cycle Synchronized Position Mode (CSP)

Cycle Synchronized Velocity Mode (CSV)

Cycle Synchronized Torque Mode (CST)

ASDA A2-E Chapter 1 Coe Drive Overview

1-2 Revision April, 2015

1.2 The Interface of Delta EtherCAT Servo Drive

Figure 1 The Interface of Delta EtherCAT Servo Drive

EtherCAT® is registered trademark and patented technology, licensed by Beckhoff

Automation GmbH, Germany.

Run indicator (RUN)

Link/Activity of EtherCAT

output port indicator (L/A)

Error indicator (ERR)

EtherCAT output

port (CN6)

EtherCAT input port

(CN6)

Link/Activity of EtherCAT

input port indicator (L/A)

Chapter 1 CoE Drive Overview ASDA A2-E

Revision April, 2015 1-3

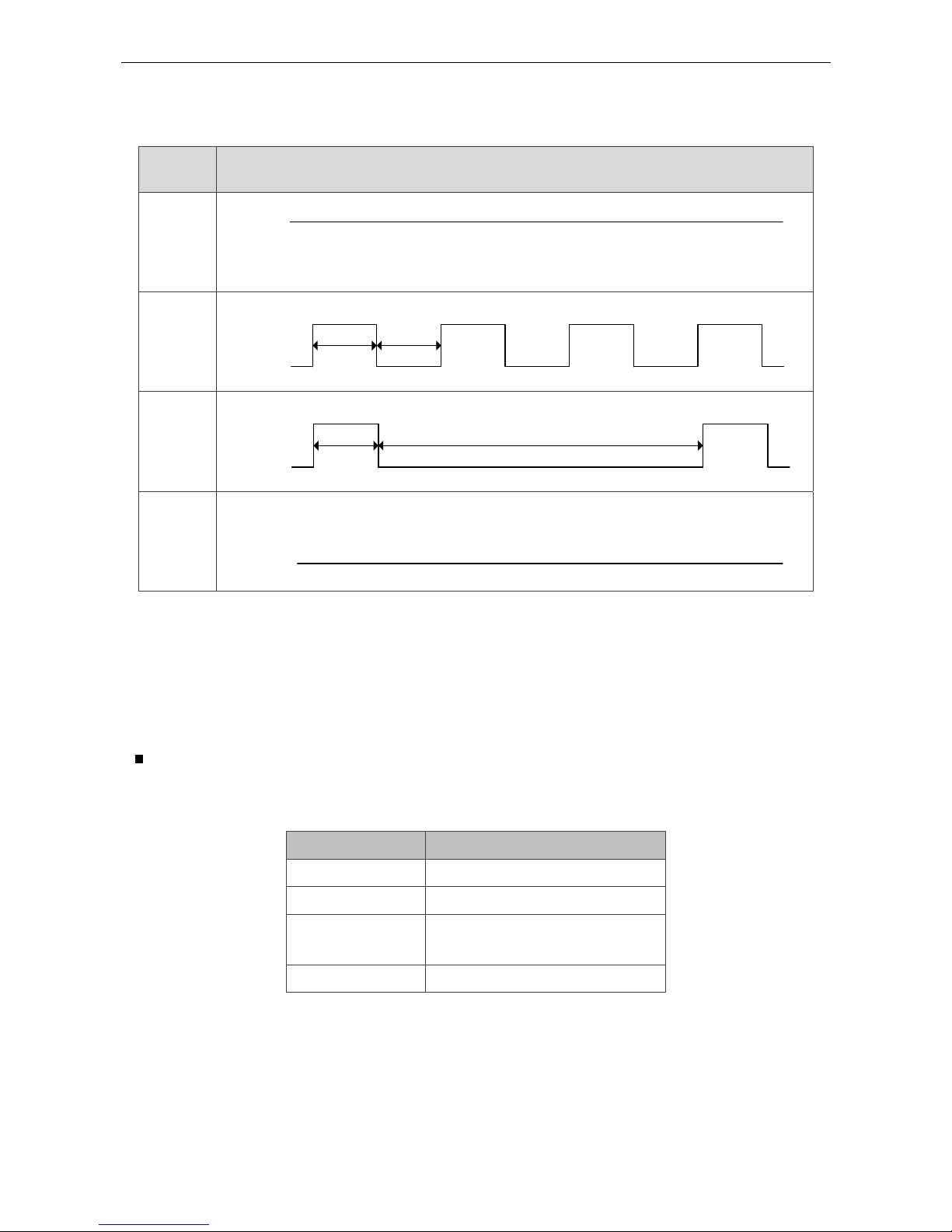

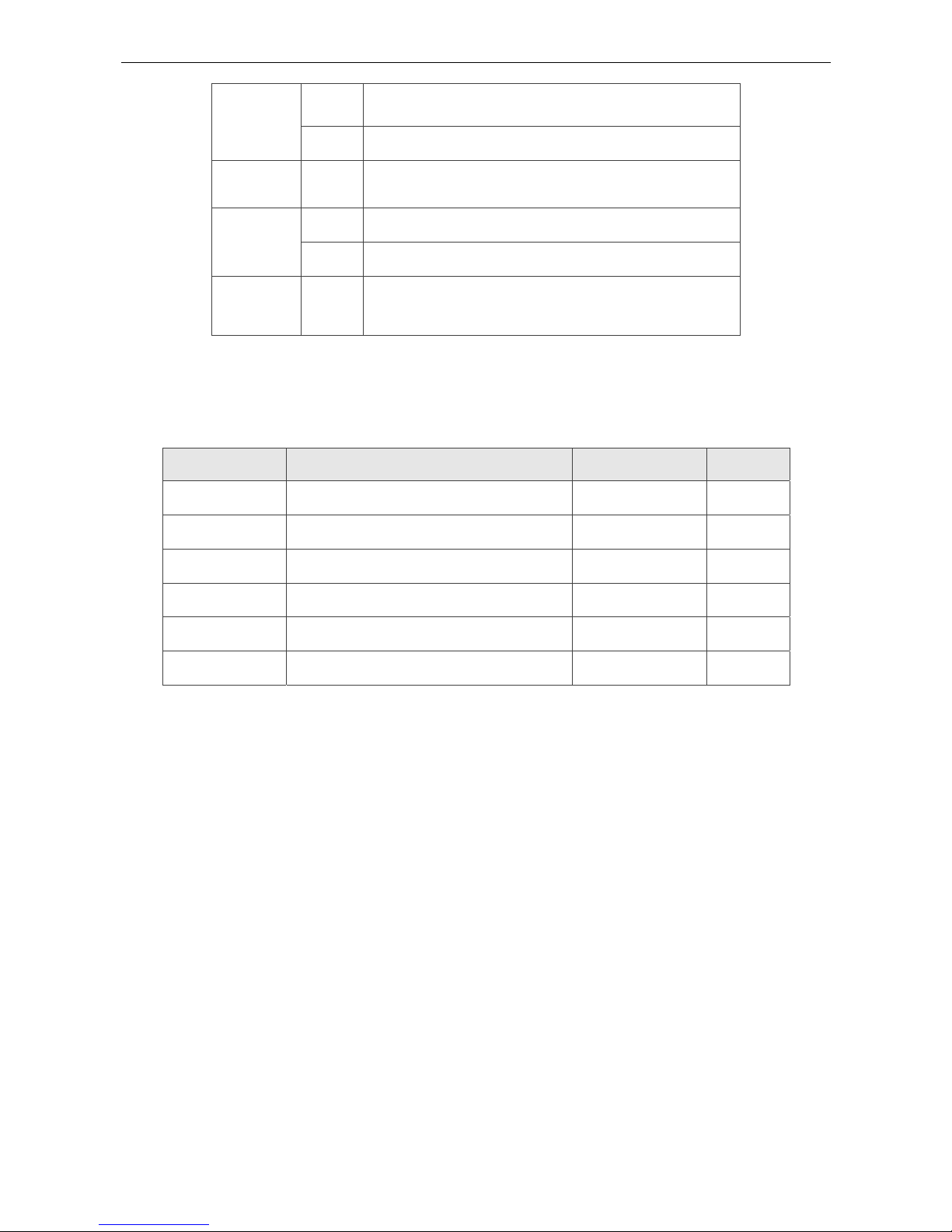

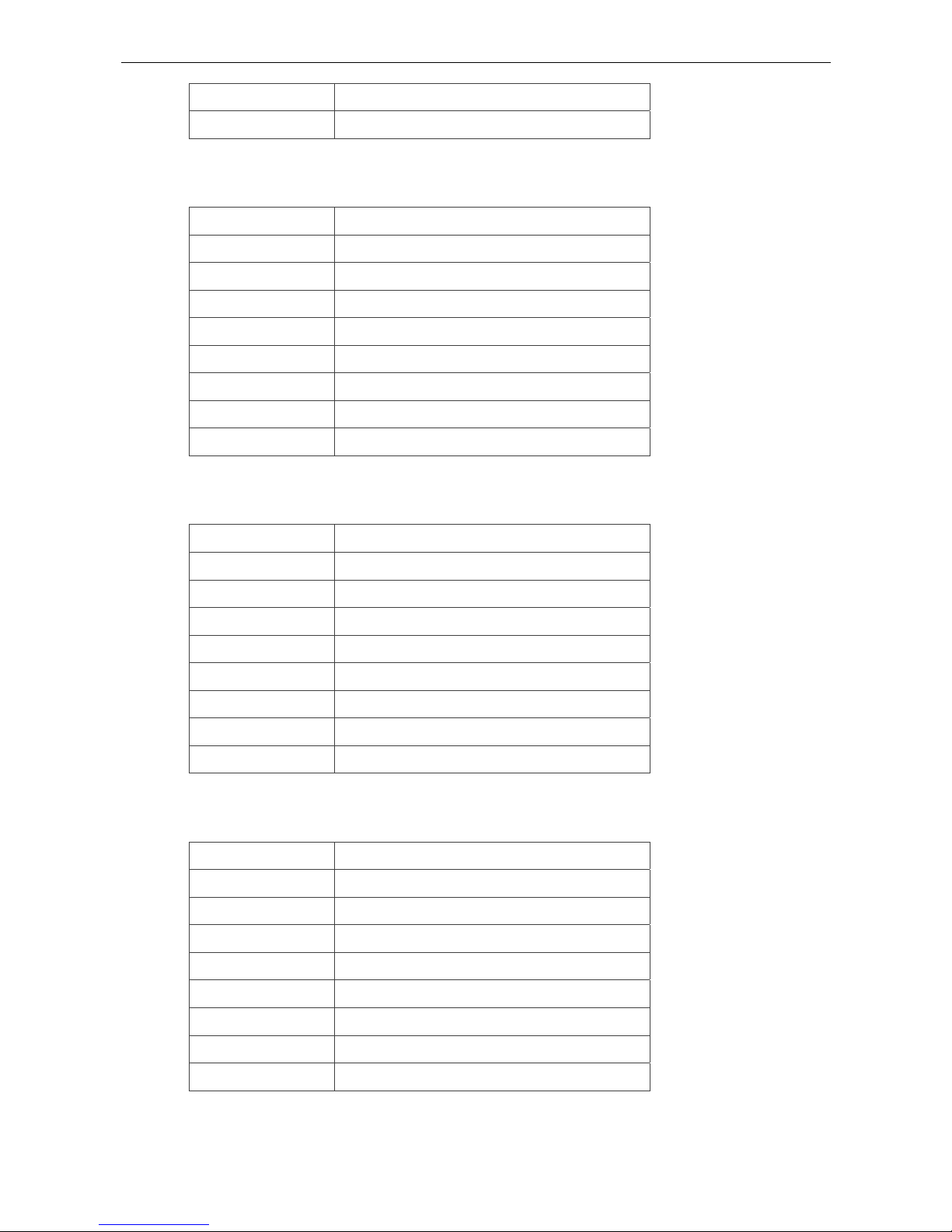

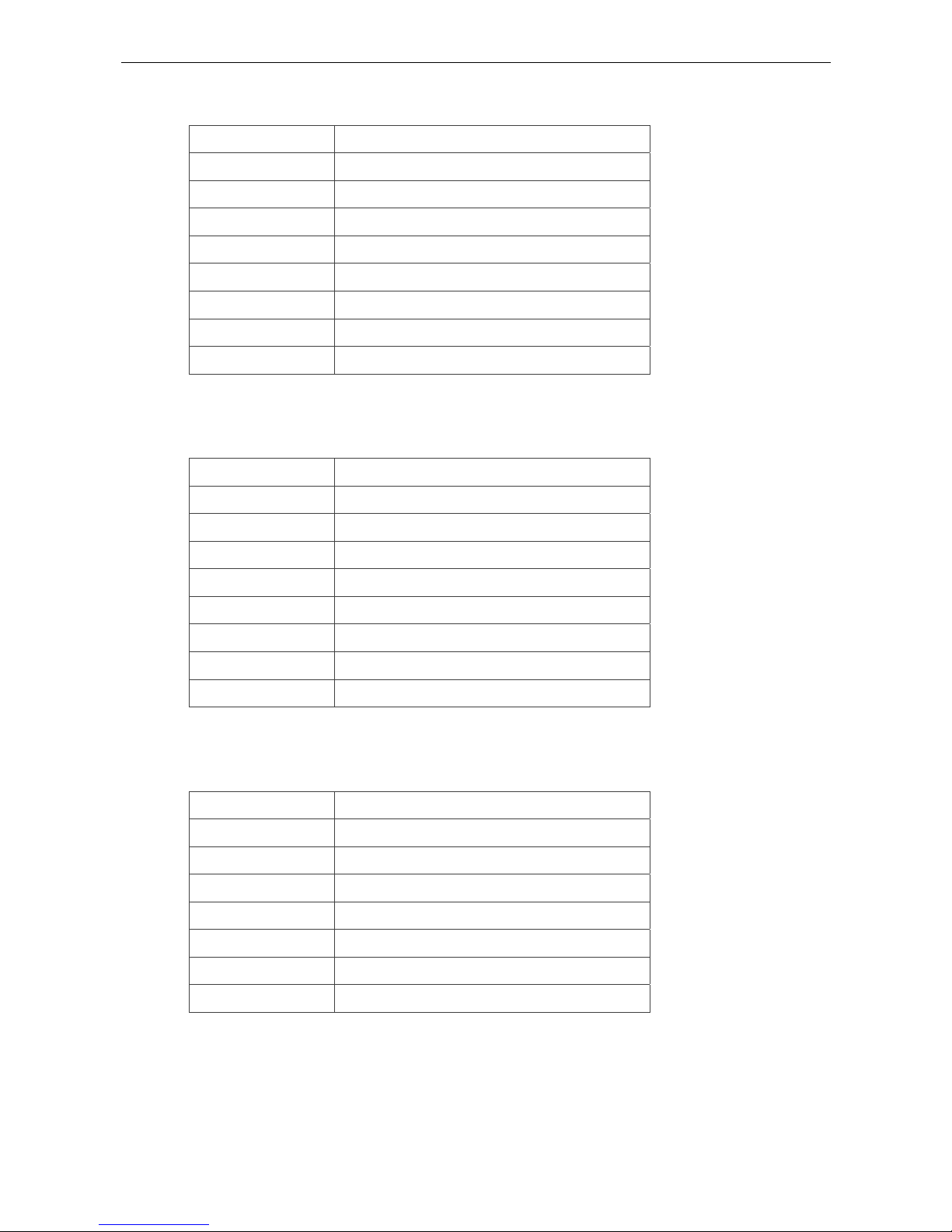

1.3 LED Indicators

Indicator

state

Indicator pattern

ON

ON

OFF

Blinking

ON

OFF

200ms

200ms

Single

Flash

ON

OFF

200ms

1000ms

OFF

ON

OFF

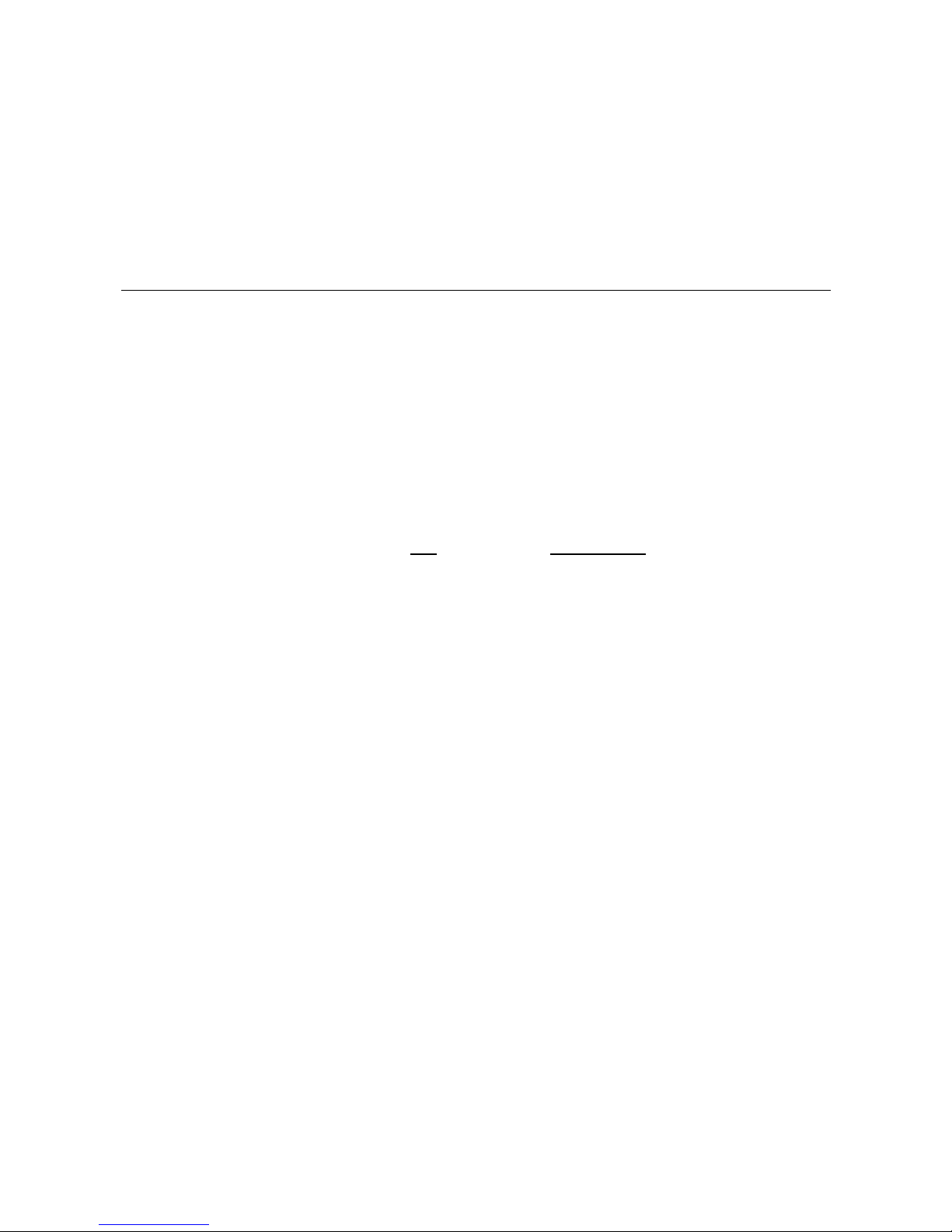

Figure 2. RJ45 LED indicator pattern

ERROR (ERR) LED

The ERR LED indicator shows the error status of EtherCAT communication.

Indicator state Slave State

Off No error

Blinking State change error

Single Flash

Synchronization error

SyncManager error

On PDI Watchdog timeout

ASDA A2-E Chapter 1 Coe Drive Overview

1-4 Revision April, 2015

State change error: The state machine does not allow the system to change its state

because the wrong parameter settings. Please refer to Figure 29 for

its switching conditions.

Synchronization error: The synchronization of Master Clock and Slave Clock is failed.

SyncManager error: The data of process data is lost when receiving.

PDI Watchdog

timeout:

The hardware failure on slave. Please contact Delta distributors for

assistance.

RUN LED

The RUN LED indicator shows the status of EtherCAT state machine

Indicator state Slave State

Off INIT

Blinking PRE-OPERATIONAL

Single Flash SAFE-OPERATIONAL

On OPERATIONAL

INIT: After power on, the EtherCAT slave will get into INIT state if there

is no error. At INIT state, no communication servo is provided.

Accessing slave’s register from the host is available at this state.

PRE-OPERATIONAL: The SDO can be used to communicate with its host controller.

SAVE-

OPERATIONAL:

Both SDO and TxPDO, which can send cyclic data from the slave

to the host, are workable.

OPERATIONAL: SDO, TxPDO and RxPDO are working.

Chapter 1 CoE Drive Overview ASDA A2-E

Revision April, 2015 1-5

Link Activity (L/A) LED

The L/A LED indicator shows the physical link status and the link activity.

Indicator state Slave State

Off No link

Blinking Link and activity

On Link without activity

No link: The link has not established yet.

Link and activity: The data is exchanging with its partners.

Link without activity: The link is established but no data is exchanging now.

ASDA A2-E Chapter 1 Coe Drive Overview

1-6 Revision April, 2015

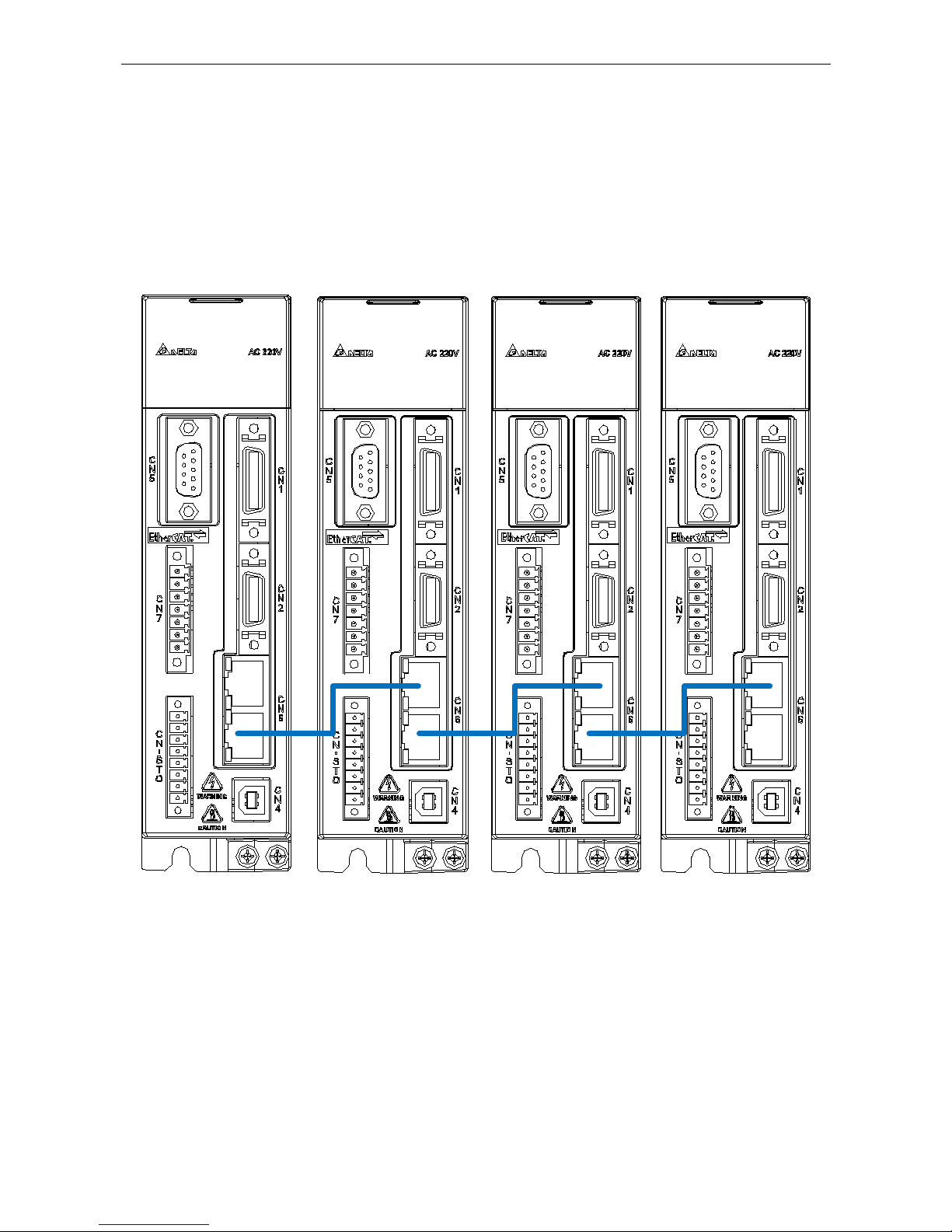

1.4 The Topology

The topology is defined by the host controller. Please refer to the host controller ’s

application manual. There are only one input port and one output port on Delta servo drive

for EtherCAT communication ports.

Figure 3 EtherCAT connection topology example

Chapter 1 CoE Drive Overview ASDA A2-E

Revision April, 2015 1-7

1.5 Wiring

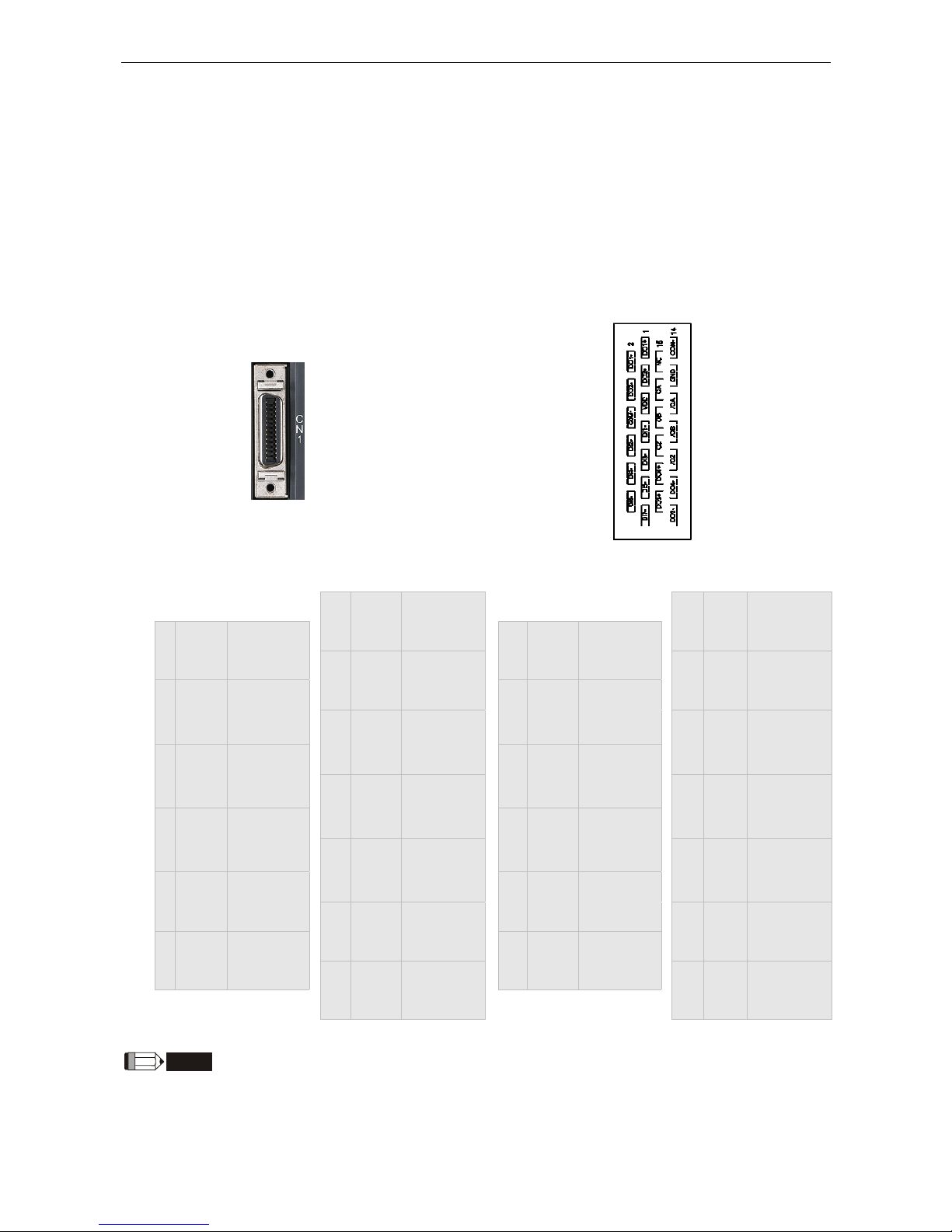

I/O Signal (CN1) Connection and Connector Terminal Layout

In order to have a more flexible communication with the master, 4 programmable

Digital Output (DO) and 7 programmable Digital Input (DI) are provided, which are

parameter P2-18~P2-21 and P2-10~P2-16 respectively. In addition, the differential

output encoder signal A+, A-, B+, B-, Z+ and Z- is also provided. The followings are

the pin diagrams.

CN1 Connector (female)

CN1 Connector (male)

rear view

1 DO1+

Digital

output

14 COM-

VDD power

ground

2 DO1-

Digital

output

15 NC N/A

3 DO2+

Digital

output

16 GND

Analog

input signal

ground

4 DO2-

Digital

output

17 OA

Encoder/

A pulse

output

5 VDD

+24V Power

output

18 /OA

Encoder/

A pulse

output

6 COM+

Power input

(12~24V)

19 OB

Encoder/

B pulse

output

7 DI1- Digital input

20 /OB

Encoder/

B pulse

output

8 DI2- Digital input

21 OZ

Encoder/

Z pulse

output

9 DI3- Digital input

22 /OZ

Encoder/

Z pulse

output

10 DI4- Digital input

23 DO4+

Digital

output

11 DI5- Digital input

24 DO4-

Digital

output

12 DI6- Digital input

25 DO3+

Digital

output

13 DI7- Digital input

26 DO3-

Digital

output

NOTE

NC means NO CONNECTION. This terminal is for internal use only. Do not connect it, or it may damage the

servo drive.

ASDA A2-E Chapter 1 Coe Drive Overview

1-8 Revision April, 2015

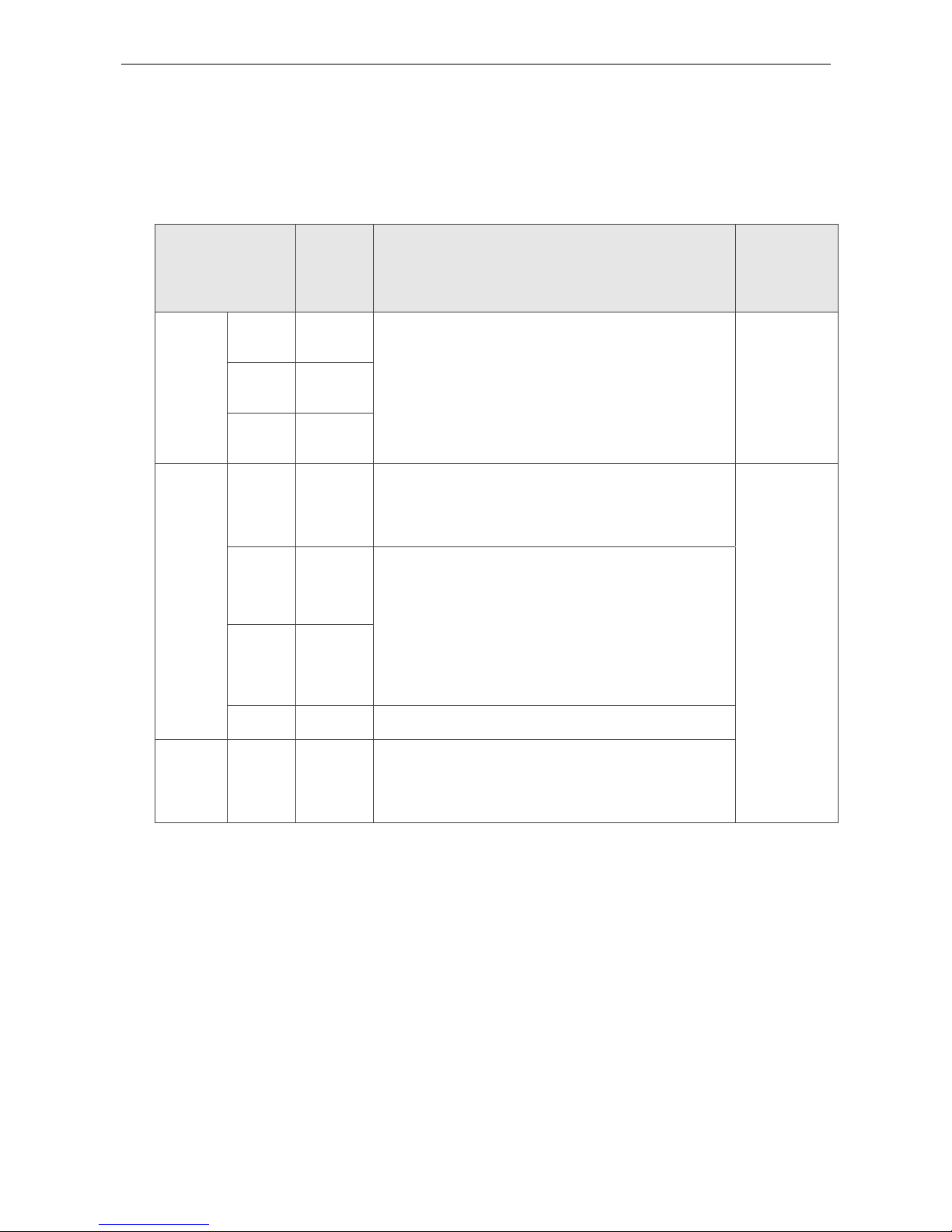

1.5.1 Explanation of I/O (CN1) Connector Signal

The following details the signals listed in previous section.

General Signals

Signal Name Pin No Function

Wiring

Method

(Refer to

3.4.3)

Position

pulse

(output)

OA

/OA

17

18

Encoder signal output A, B, Z (Line Driver output)

C13/C14

OB

/OB

19

20

OZ

/OZ

21

22

Power

VDD 5

VDD is the +24V power provided by the drive and

is for Digital Input (DI) and Digital Output (DO)

signal. The maximum current is 500mA.

-

COM+ 6

COM+ is the common input of Digital Input (DI)

and Digital Output (DO) voltage. When using

VDD, VDD should be connected to COM+. If not

using, it needs to apply the external power (+12V

~+24V). Its positive end should connect to COM+

and the negative end should connect to COM-.

COM- 14

GND 16

VCC voltage is based on GND.

Other NC 15

NO CONNECTION. This terminal is for internal

use only. Do not connect it, or it may damage the

servo drive.

Chapter 1 CoE Drive Overview ASDA A2-E

Revision April, 2015 1-9

1.5.2 CN2 Connector

CN2 Connector (female)

CN2 Connector (male)

Rear view

Quick Connector

HOUSING: AMP (1-172161-9)

Military Connector

3106A-20-29S

Drive Connector Motor Connector

Pin No

Terminal

Symbol

Function and Description

Military

connector

Quick

connector

Color

5 T+

Serial communication signal

input / output (+)

A 1 Blue

4 T-

Serial communication signal

input / output (-)

B 4

Blue &

Black

- -

Reserved - - -

- -

Reserved - - -

14,16 +5V

Power +5V S 7

Red/Red &

white

13,15 GND

Power ground R 8

Black/Black

& white

- -

shielding L 9 -

ASDA A2-E Chapter 1 Coe Drive Overview

1-10 Revision April, 2015

1.5.3 CN5 Connector (Full-closed Loop)

Connect linear scale or encoder (A, B, Z format) to the servo and form a full-closed

loop. In position mode, the pulse command issued by the controller is based on the

control loop of the external linear scale. Please refer to Chapter 6.

CN5 Connector (female)

Pin No Signal Name Terminal Symbol Function and Description

1 /Z phase input Opt_/Z /Z phase

2 /B phase input Opt_/B /B phase

3 B phase input Opt_B B phase

4 A phase input Opt_A A phase

5 /A phase input Opt_/A /A phase

6 Encoder grounding GND Ground

7 Encoder grounding GND Ground

8 Encoder power +5V + 5V power

9 Z phase input Opt_Z Z phase

NOTE

1. It only supports the encoder of AB phase and 5V voltage.

2. The application of full-closed loop: it supports the encoder of highest resolution 1280000 pulse/rev (A

pulse number per motor revolution for a full-closed loop that corresponds to an optical signal with AB

(Quadrature) phase pulses (4x).).

Chapter 1 CoE Drive Overview ASDA A2-E

Revision April, 2015 1-11

1.5.4 CN6 EtherCAT Terminal

CN5 Connector (female)

Pin No Signal Name Terminal Symbol Function and Description

1 TX + TX + Transmit +

2 TX - TX - Transmit 3 RX + RX + Receive +

4 - - 5 - - 6 RX - RX - Receive 7 - - 8 - - -

NOTE

1. The maximum distance between two stations should be 50 meters.

2. Please use CAT5e STP Shielding.

IN

OUT

ASDA A2-E Chapter 1 Coe Drive Overview

1-12 Revision April, 2015

1.5.5 CN7 Extension DI

CN7 Connector (male)

Pin No Signal Name Terminal Symbol Function and Description

*1

VDD

24V power

COM+

VDD (24V) power is the same as

the voltage of Pin11 in CN1

2 Extension DI9 EDI 9- Digital input pin 93 Extension DI10 EDI 10- Digital input pin 104 Extension DI11 EDI 11- Digital input pin 115 Extension DI12 EDI 12- Digital input pin 126 Extension DI13 EDI 13- Digital input pin 137 Extension DI14 EDI 14- Digital input pin 14-

Caution: Do not apply to dual power or it may damage the servo drive.

Chapter 1 CoE Drive Overview ASDA A2-E

Revision April, 2015 1-13

1.5.6 CN-STO

CN-STO Connector (male)

Pin No Signal Name Terminal Symbol Function and Description

*1

VDD24V

power

COM+

VDD (24V) power is the same

as the voltage of Pin11 in CN1

2 STO_A STO_A STO input pin A+

3 /STO_A /STO_A STO input pin A4 STO_B STO_B STO input pin B+

5 /STO_B /STO_B STO input pin B-

6 FDBK_A FDBK_A

STO alarm output pin A,

Relay Output

Max. Current : 1A

7 FDBK_B FDBK_B

STO alarm output pin B,

Relay Output

Max. Current : 1A

8 COM- COM- VDD(24V) power ground

Caution: Do not apply to dual power or it may damage the servo drive.

ASDA A2-E Chapter 1 Coe Drive Overview

1-14 Revision April, 2015

1.5.7 STO with Safety Relay

ESTOP

1

2

3

4

5

6

7

8

STO_A

/ STO_A

STO_B

/ STO_B

FDBK_A

FDBK_B

COM+

COM-

STO

24V DC

Safe ty Re la y

1.5.8 STO Disable

1

2

3

4

5

6

7

8

STO

STO_A

/ STO_ A

STO_B

/ STO_ B

FDBK_A

FDBK_B

COM+

COM-

Chapter 1 CoE Drive Overview ASDA A2-E

Revision April, 2015 1-15

1.6 Dimension

1.6.1 220V Series

100W/200W/400W

Weight

1.5(3.3)

750W/1kW/1.5kW

Weight

2.0(4.4)

ASDA A2-E Chapter 1 Coe Drive Overview

1-16 Revision April, 2015

2kW/3kW

PE

TERMINIAL

70

Ø5.5

203

82

5.4203.0

215.5

14.5 62

< 0.7

Weight

2.89(6.36)

Chapter 1 CoE Drive Overview ASDA A2-E

Revision April, 2015 1-17

1.6.2 400V Series

400W/750W/1kW/1.5kW

Ø5.5

180

65

70

5.4163

12.5

47

173

Weight

2.0(4.4)

2kW/3kW/4.5kW/5.5kW

123.5

107

Ø

6

70.2

205.5

2

3

0

8

245

107

7

Weight

4.6(10.1)

ASDA A2-E Chapter 1 Coe Drive Overview

1-18 Revision April, 2015

7.5kW

PE TERMINAL

119.5

Ø

6

2

3

2

107

2

4

7

2

5

4

.

2

2

4

5

136

8 70.2 205.5

5

2

6

0

Weight

4.6(10.1)

NOTE

1. Dimensions are in millimeters (inches); Weights are in kilograms (kg) and pounds (lbs).

2. Dimensions and weights of the servo drive may be revised without prior notice.

Revision April, 2015 2-1

Chapter 2 System Setup

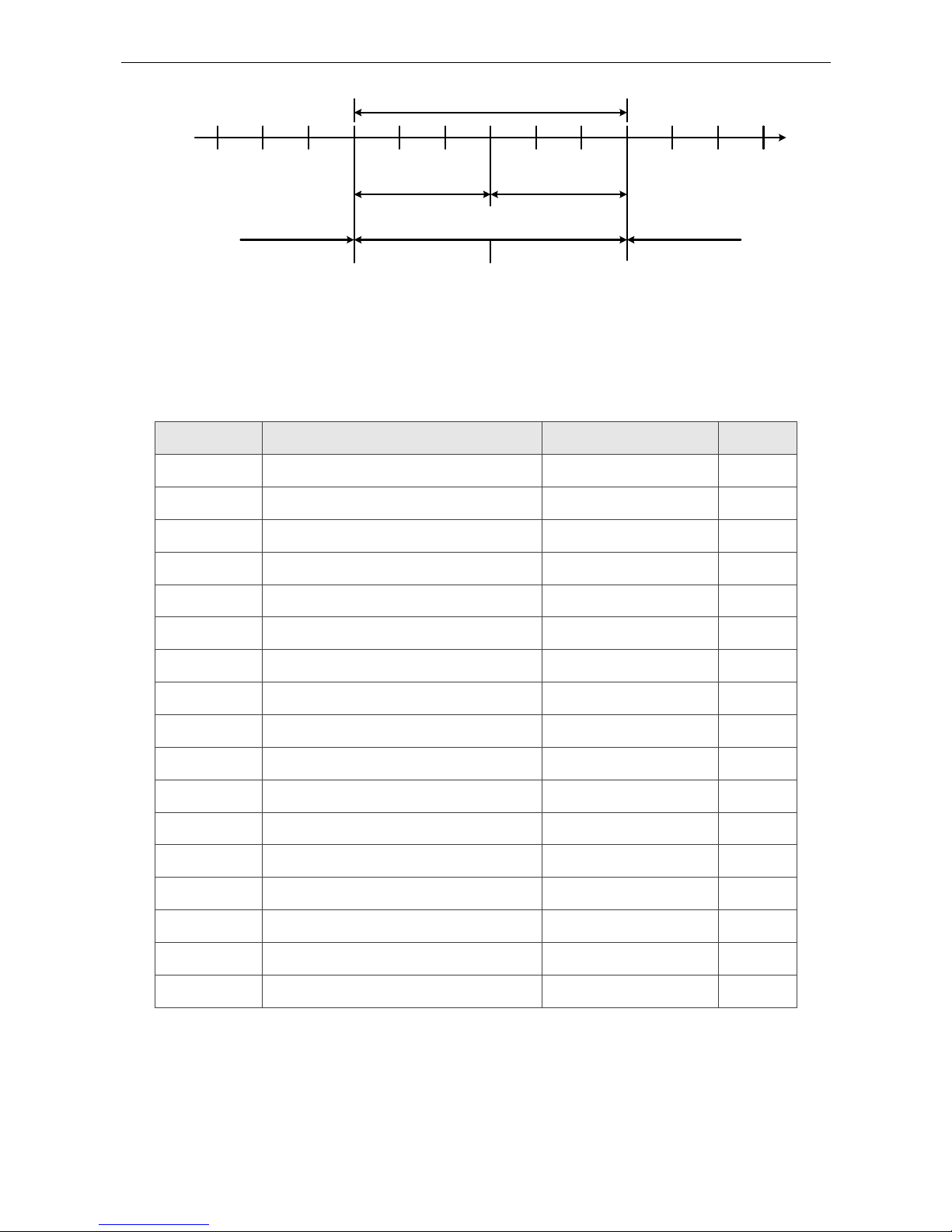

2.1 Parameter Settings of EtherCAT Mode

1. Set parameter P1-01 to 0x0Ch for EtherCAT communication and CANopen as the

application layer.

2. Restart the system of servo drive.

P1-01● CTL Control Mode and Output Direction

Address:0102H

0103H

Interface:

Panel / Software Communication

Reference:

-

Default:

0

Control Mode:

ALL

Unit:

Pulse (P mode); r/min (S mode);

N-m (T mode)

Range:

00 ~ 0x110F

Format:

Hex

Data Size:

16-bit

Settings:

Control mode settings

PT PR S T Sz Tz PT PR S T Sz Tz

Single Mode Dual Mode

00 ▲ 06 ▲ ▲

01 ▲ 07 ▲ ▲

02 ▲ 08 ▲ ▲

03 ▲ 09 ▲ ▲

04 ▲ 0A ▲ ▲

05 ▲ 0B N/A

Multiple Mode 0C CANopen Mode

0E ▲ ▲ ▲ 0D ▲ ▲

0F ▲ ▲ ▲

ASDA A2-E Chapter 2 System Setup

2-2 Revision April, 2015

PR: Position control mode. The command is from the internal signal. Execution of 64 positions

is via DI.POS0 ~ POS5. A variety of homing control is also provided.

S: Speed control mode. The command is from the external signal or internal signal. Execution

of the command selection is via DI.SPD0 and DI.SPD1.

T: Torque control mode. The command is from the external signal or internal signal. Execution

of the command selection is via DI.TCM0 and DI.TCM1.

Sz: Zero speed / internal speed command

Tz: Zero torque / internal torque command

Dual Mode: The control mode selection is via DI signals. For example, either PT or S control

mode can be selected via DI signal, S-P (see Table A).

Multiple Mode: The control mode selection is via DI signals. For example, PT, PR or S control

mode can be selected via DI signals, S-P and PT-PR (see Table A).

Torque output direction settings

Direction 0 1

Forward

Reverse

Discrete I/O Setting

1: When switching to different mode, digital inputs/outputs (P2-10 ~ P2-22) will be set to the

default value according to the mode you selected.

0: When switching to different mode, the setting value of digital inputs/outputs (P2-10 ~ P2-22)

will remain the same and will not be changed.

Chapter 2 System Setup ASDA A2-E

Revision April, 2015 2-3

2.2 TwinCAT Setup

A lot of software can be applied to configure EtherCAT system. The following procedures

are the example of TwinCAT of Beckhoff. Please install the software properly before you

start to configure the system.

1. Copy Delta XML description to the folder the TwinCAT installed (usually

C:\TwinCAT\Io\EtherCAT).

2. Restart the TwinCAT.

3. The configuration procedure can be started by applying TwinCAT manager which

shown as below.

Figure 4

4. Install the Network Interface Card (NIC) for EtherCAT communication.

Select Options → Show Real Time Ethernet Compatible Devices.

ASDA A2-E Chapter 2 System Setup

2-4 Revision April, 2015

Figure 5

Select the correct Adapter from the devices (NICs) installed in the computer

for EtherCAT communication and click “Install”.

Figure 6

Chapter 2 System Setup ASDA A2-E

Revision April, 2015 2-5

5. Open a new project from the drop down menu File → new.

6. Right click I/O Devices and select Scan Devices or Press <F5> to scan the devices.

Click OK in the pop-up dialog window to confirm the information.

Figure 7

Figure 8

7. Find Device [n] (EtherCAT), select this device and click OK.

Figure 9

8. Click Yes to scan for boxes.

Figure 10

ASDA A2-E Chapter 2 System Setup

2-6 Revision April, 2015

9. Click Yes to Add drives to NC-Configuration.

Figure 11

10. Click No and TwinCAT will be switched to Config mode.

Figure 12

11. TwincAT is in Config Mode. In the left panel, it shows Device (EtherCAT) and you

can find ASDA A2-E CoE Drive.

Figure 13

Chapter 2 System Setup ASDA A2-E

Revision April, 2015 2-7

12. Select the Drive (ASDA A2-E) and in Online tab you can check if the device’s

EtherCAT state machine (ESM) is in PREOP state.

Figure 14

13. Double click on Drive (ASDA A2-E CoE Drive) and it will show:

2nd TxPDO – CoE Tx PDO mapping

3rd RxPDO – CoE Rx PDO mapping

WcState

InfoData

Figure 15

ASDA A2-E Chapter 2 System Setup

2-8 Revision April, 2015

14. Set the communication cycle* and the default value is 2ms.

Select NC-Task 1 SAF in the left window, and set Cycle ticks as

communication cycle (The minimum value is 1ms) in the right window.

Figure 16

*The communication cycle time, SYNC0 cycle time, and PDO cycle time should be

set to the same value.

15. Set Following Error Calculation to Extern.

Select Axis 1_Drive in the left window → In parameter column of the right

window, select Extern in Following Error Calculation → click Download

and then click OK in pop-up dialog.

Figure 17

Chapter 2 System Setup ASDA A2-E

Revision April, 2015 2-9

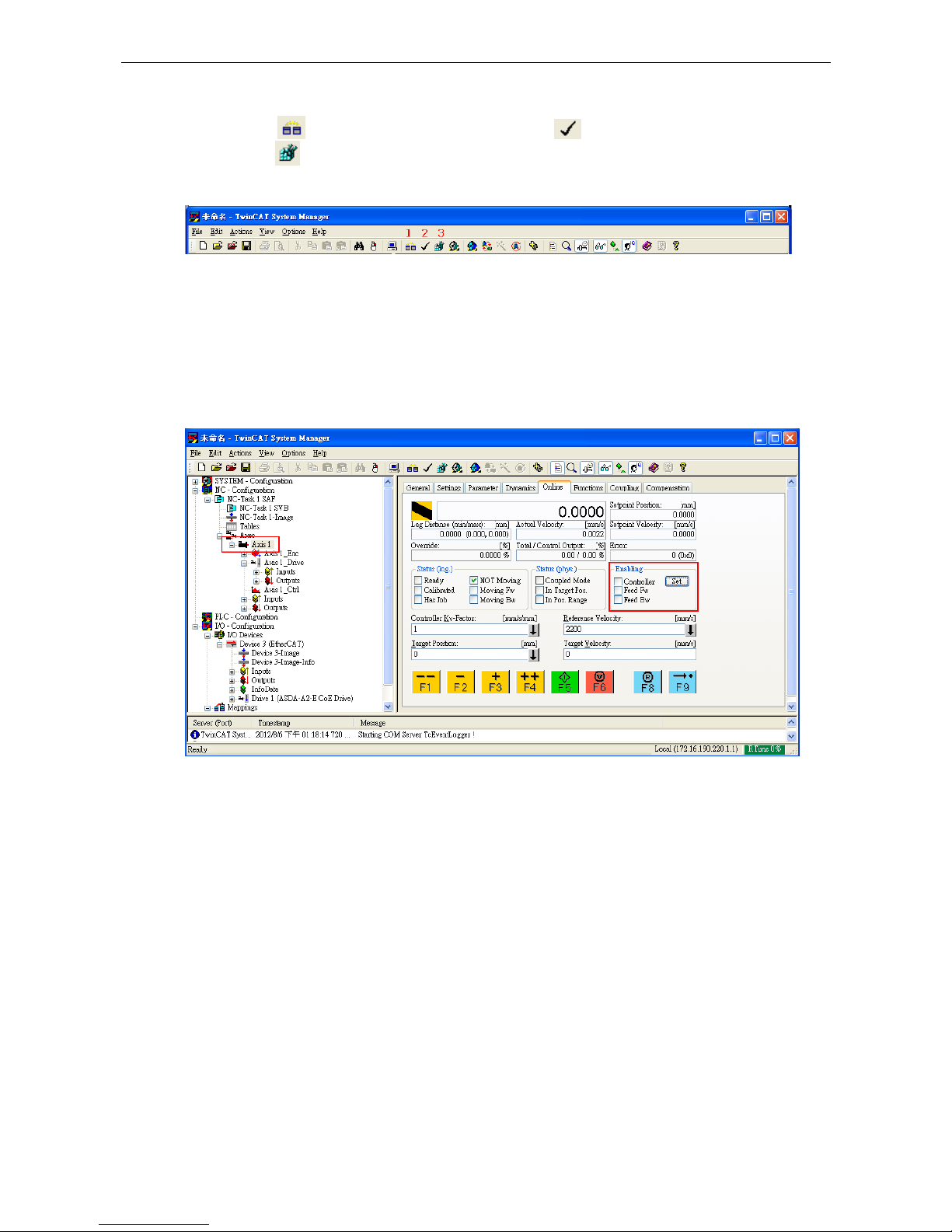

16. Switch TwinCAT to Run Mode.

Press to generate Mappings → press to check confiugration → and

press to activate configuration. TwinCAT will be switched to Run Mode

and then click OK in pop-up dialog.

Figure 18

17. Enable the axis (Servo On).

Under NC-Configuration of the left window, select Axis 1 → select Online

tab in the right window → click Set.

Figure 19

In pop-up dialog, click All to enable the motor.

Figure 20

ASDA A2-E Chapter 2 System Setup

2-10 Revision April, 2015

18. In Online tab, there are two different speed levels of jogging buttons for forward and

backward movement which can test the system. During the operation, please Be

Ensured that the movement would not damage your system and endanger the

personnel safety.

Figure 21

Chapter 2 System Setup ASDA A2-E

Revision April, 2015 2-11

2.3 Synchronization Modes Setting

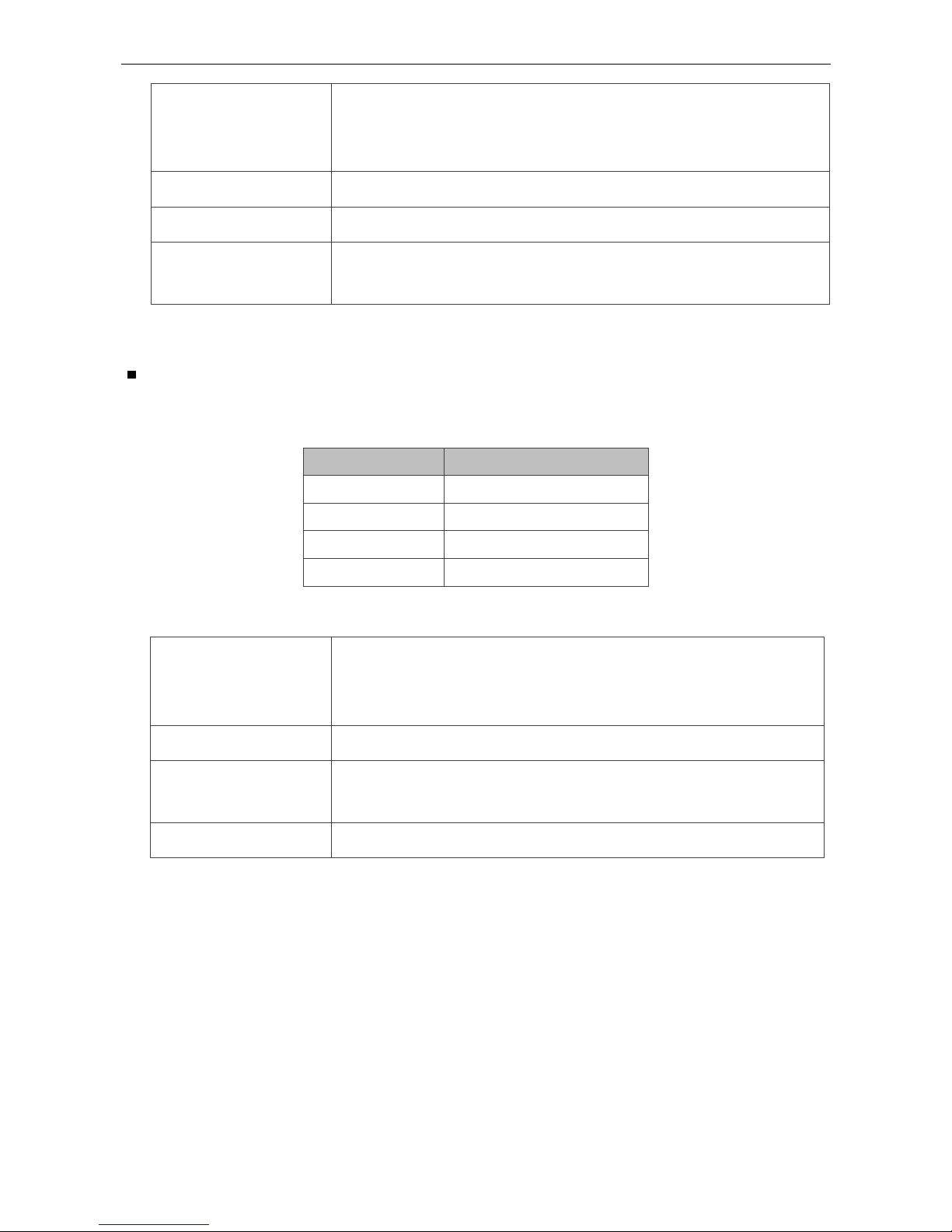

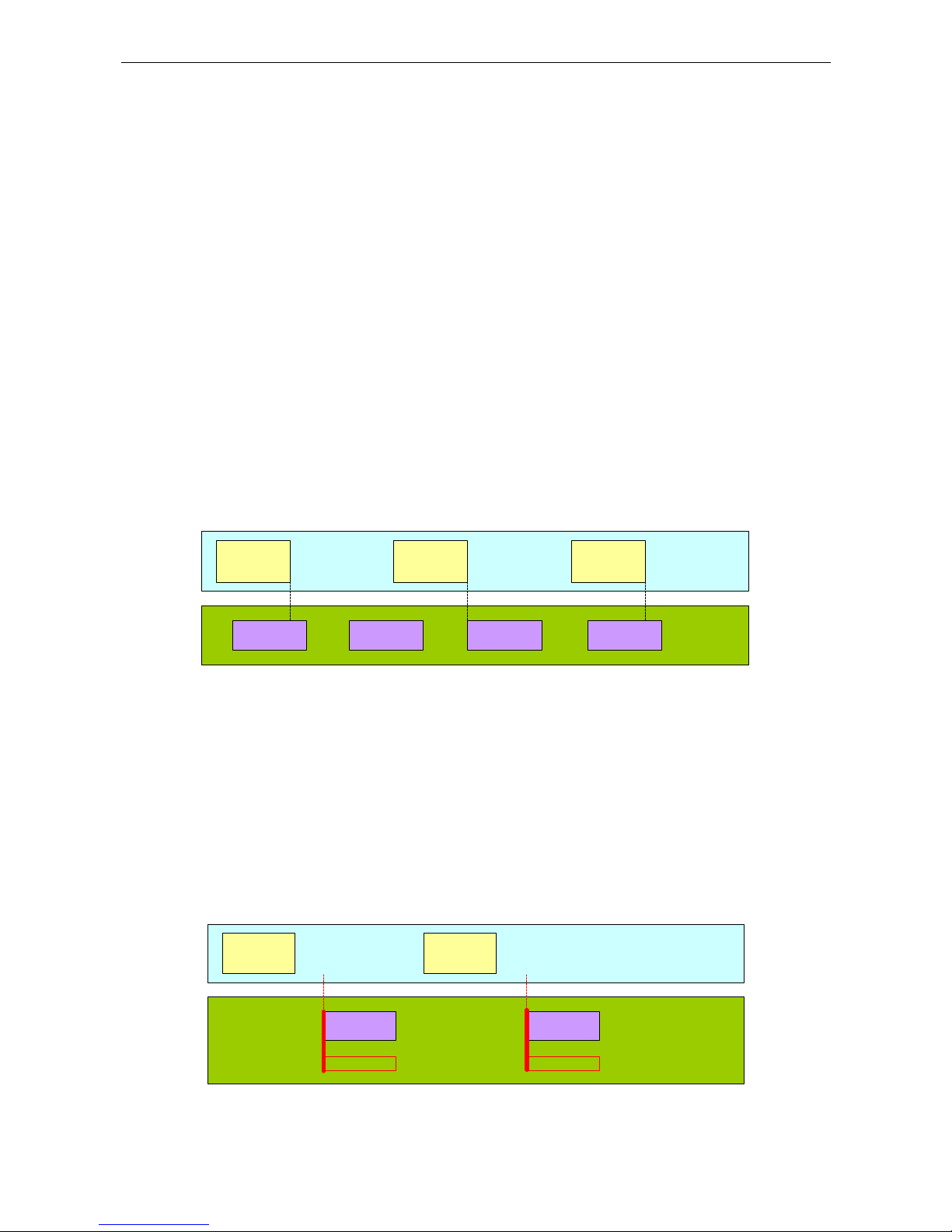

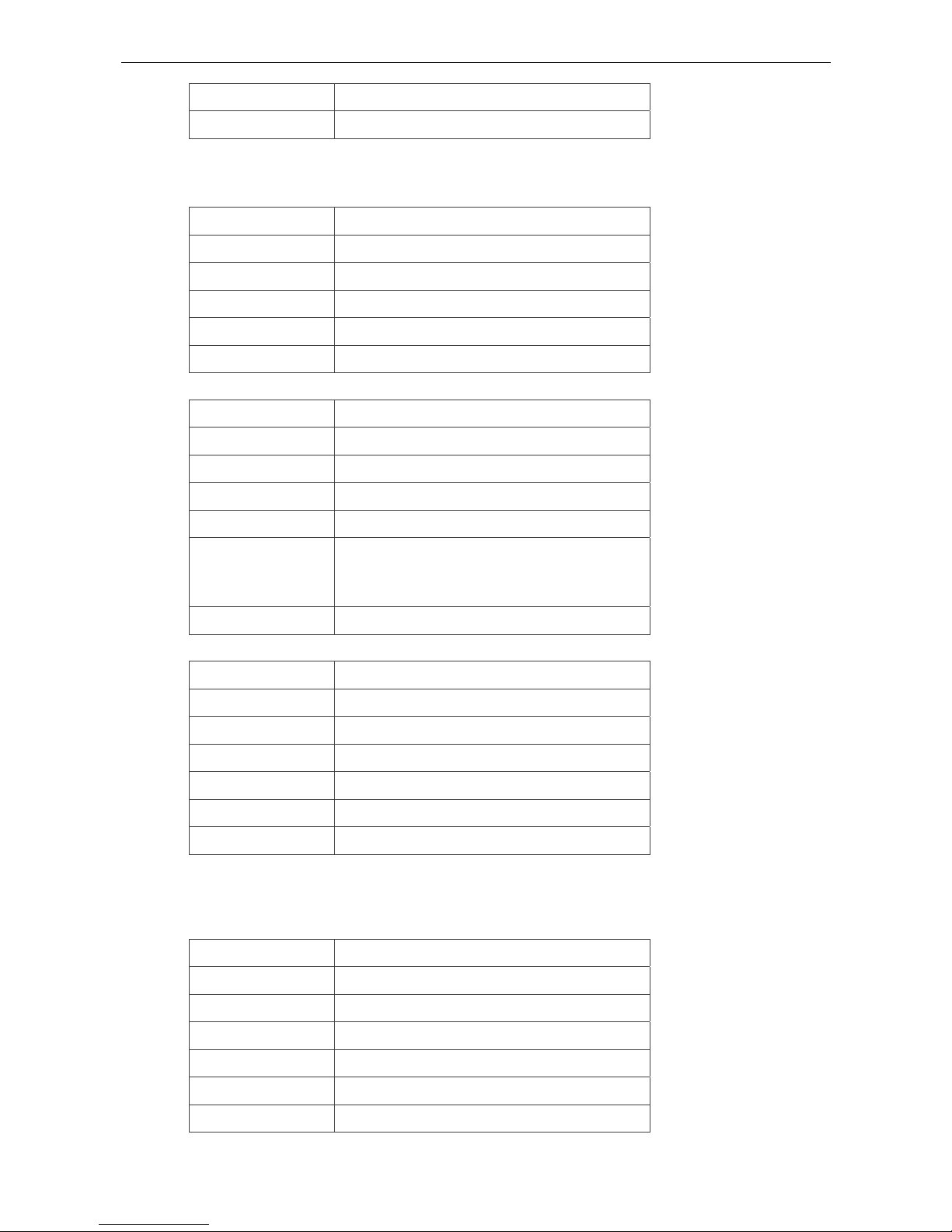

2.3.1 Two Synchronization Modes of Delta Servo

ASDA A2-E supports two synchronization modes, Free Run mode and DCSynchronous mode. Please note that the asynchronous Free Run mode is still under

the definition of “Synchronization Modes” within EtherCAT specification guide.

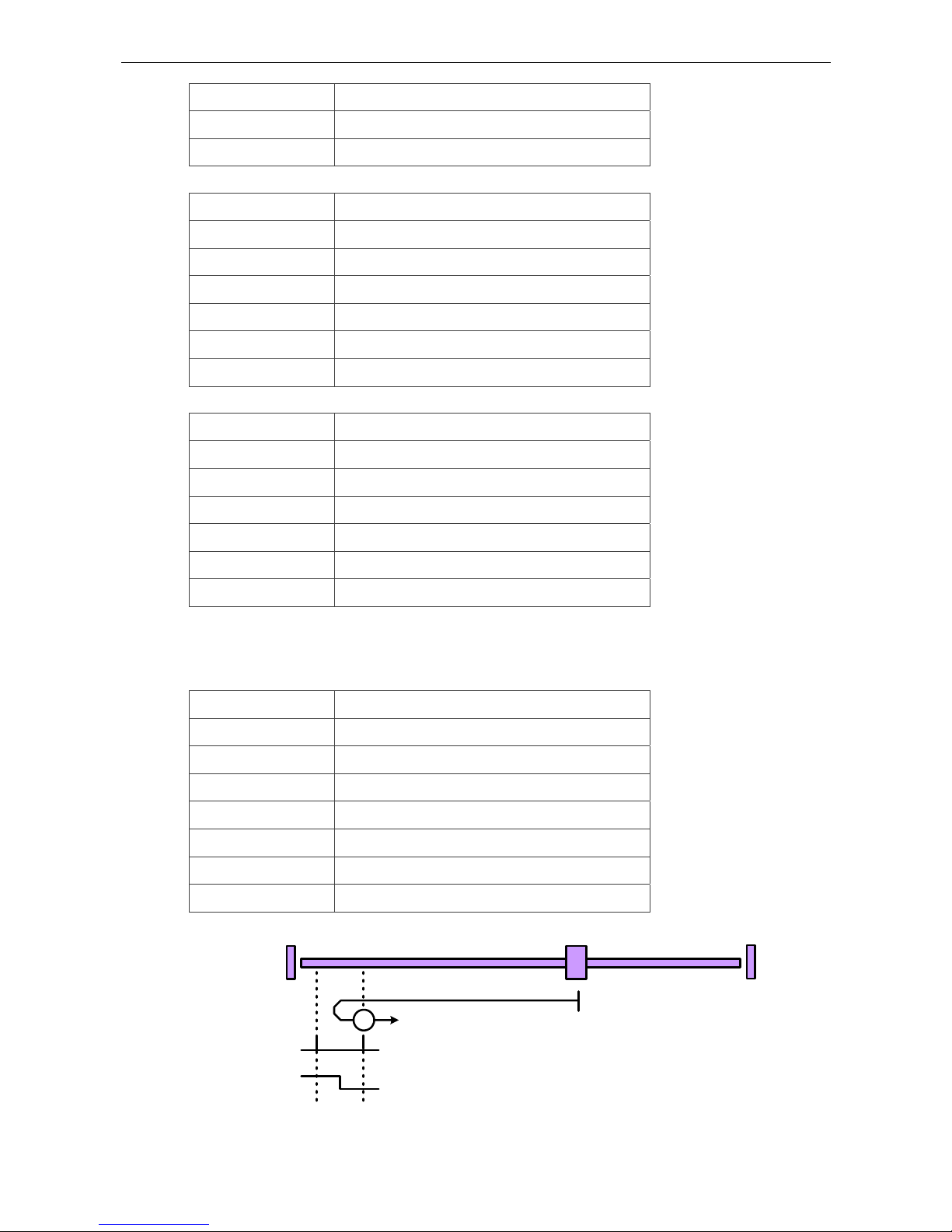

Free Run Mode (Asynchronous)

The master and slaves are running in an asynchronous manner. The master and

the slave both have their own clock to calculate the time. In other words, there is no

synchronous clock between the master and the slave. A command sent by the

master and a reply from the slave only consists with a sequential order instead of

strict clock timing. For example, a master sends a PDO at tick t1 and the slave will

receive it at tick t1 or tick t2 and vice versa.

EtherCAT

Data Frame

EtherCAT

Data Frame

EtherCAT

Data Frame

EtherCAT

Communication

Frame

ASDA-A2-E

Application

(Free Run)

Application

Task

Application

Task

Application

Task

Application

Task

No EtherCAT frame

Figure 22 Free Run Mode synchronization

DC-Synchronous Mode (SYNC0 synchronization)

There exists a clock tick for the master and all slaves operation. A data sent by the

master will be received by slave(s) at the same clock interval. The master will inform

all slaves about its clock and ask slaves to align according to the time. A strict clock

tick is always running within this system.

EtherCAT

Data Frame

EtherCAT

Data Frame

EtherCAT

Communication

Frame

ASDA-A2-E Application

(SYN0 Synchronization)

Application

Task

Application

Task

SYN0 Event SYN0 Event

Figure 23 DC-Synchronous mode synchronization

ASDA A2-E Chapter 2 System Setup

2-12 Revision April, 2015

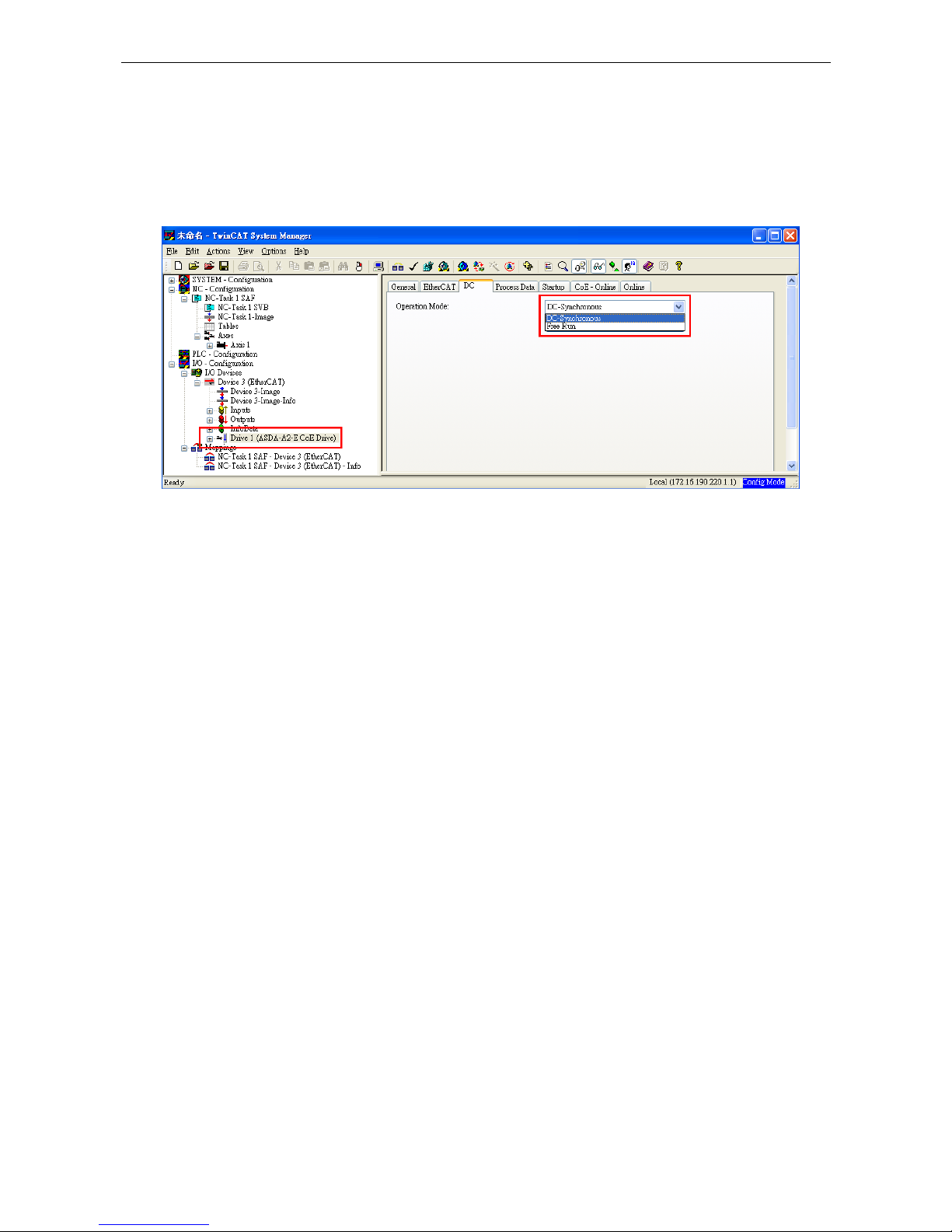

2.3.2 Select the Synchronization Mode

1. Select Drive (ASDA A2-E CoE Drive) in the left window.

2. The DC tab in the right window, users can select DC-Synchronous or Free Run as

the Operation Mode. This is for selecting synchronous or asynchronous mode.

Figure 24

2.3.3 Synchronous Clock Time Setting

1. Select NC-Task 1 SAF in the left window.

2. Click Task in the right window.

3. Cycle ticks are the data exchanging period under the Task tab.

Figure 25

Chapter 2 System Setup ASDA A2-E

Revision April, 2015 2-13

The unit of cycle for SYNC0 cycle time is 1ms.

SYNC0 cycle time supported

1ms (PDO cycle time = 1ms)

2ms (PDO cycle time = 2ms)

3ms (PDO cycle time = 3ms)

…

* SYNC0 cycle time is used to define PDO cycle time.

ASDA A2-E Chapter 2 System Setup

2-14 Revision April, 2015

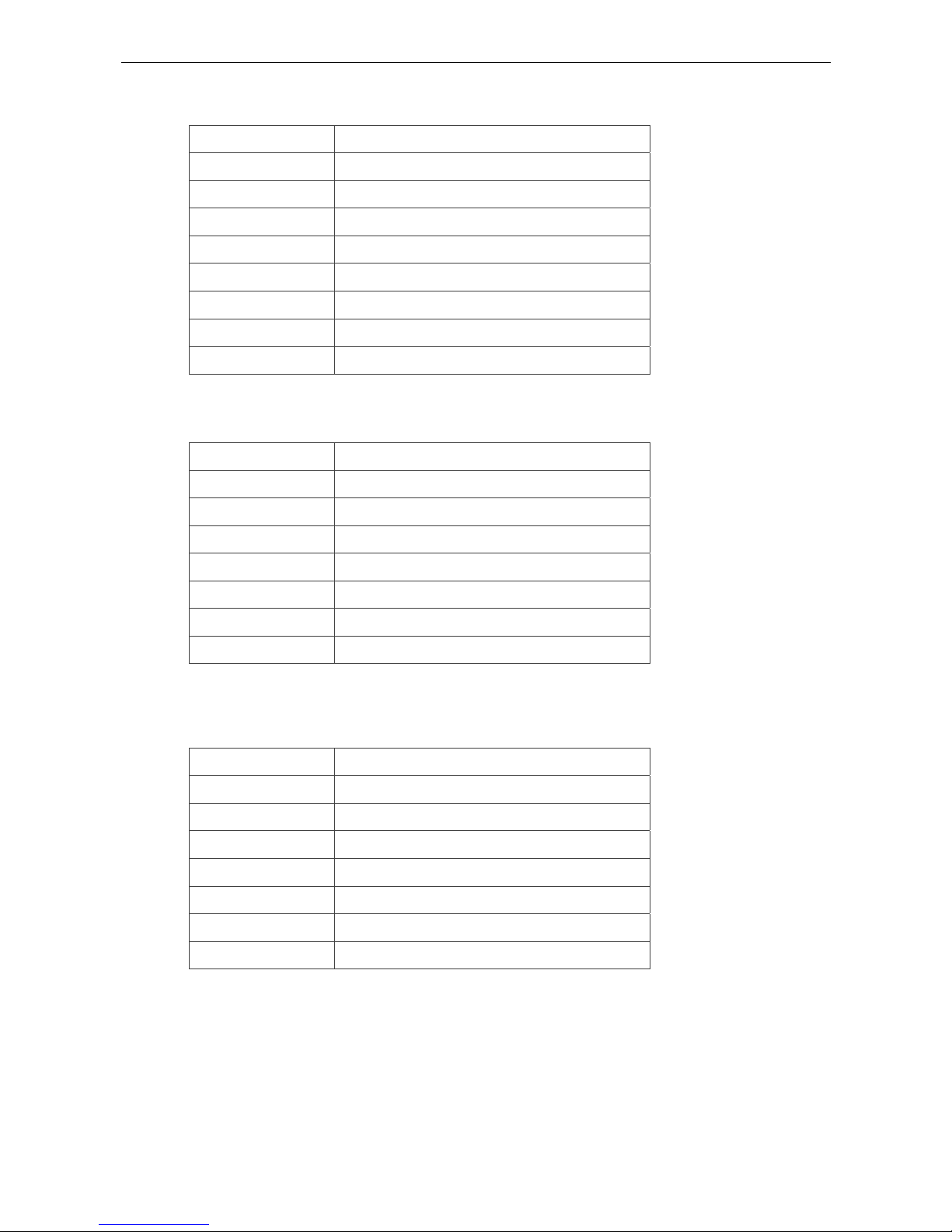

2.4 PDO Mapping

The PDO mapping Objects are allocated from index 0x1600 to 0x1603 for RxPDOs and

0x1A00 to 0x1A03 for TxPDOs in Object Dictionary.

2.4.1 Default PDO Mappings

The following tables are the default PDO mappings of ASDA A2-E CoE Drive for cyclic

data exchange and are also defined in EtherCAT Slave Information file (XML file).

1st PDO Mapping

RxPDO

(0x1600)

Control Word

(0x6040)

Target Position

(0x607A)

Target Velocity

(0x60FF)

Target Torque

(0x6071)

Mode of Operation

(0x6060)

TxPDO

(0x1A00)

Status Word

(0x6041)

Actual Position

(0x6064)

Actual Velocity

(0x606C)

Actual Torque

(0x6077)

Mode of Operation Display

(0x6061)

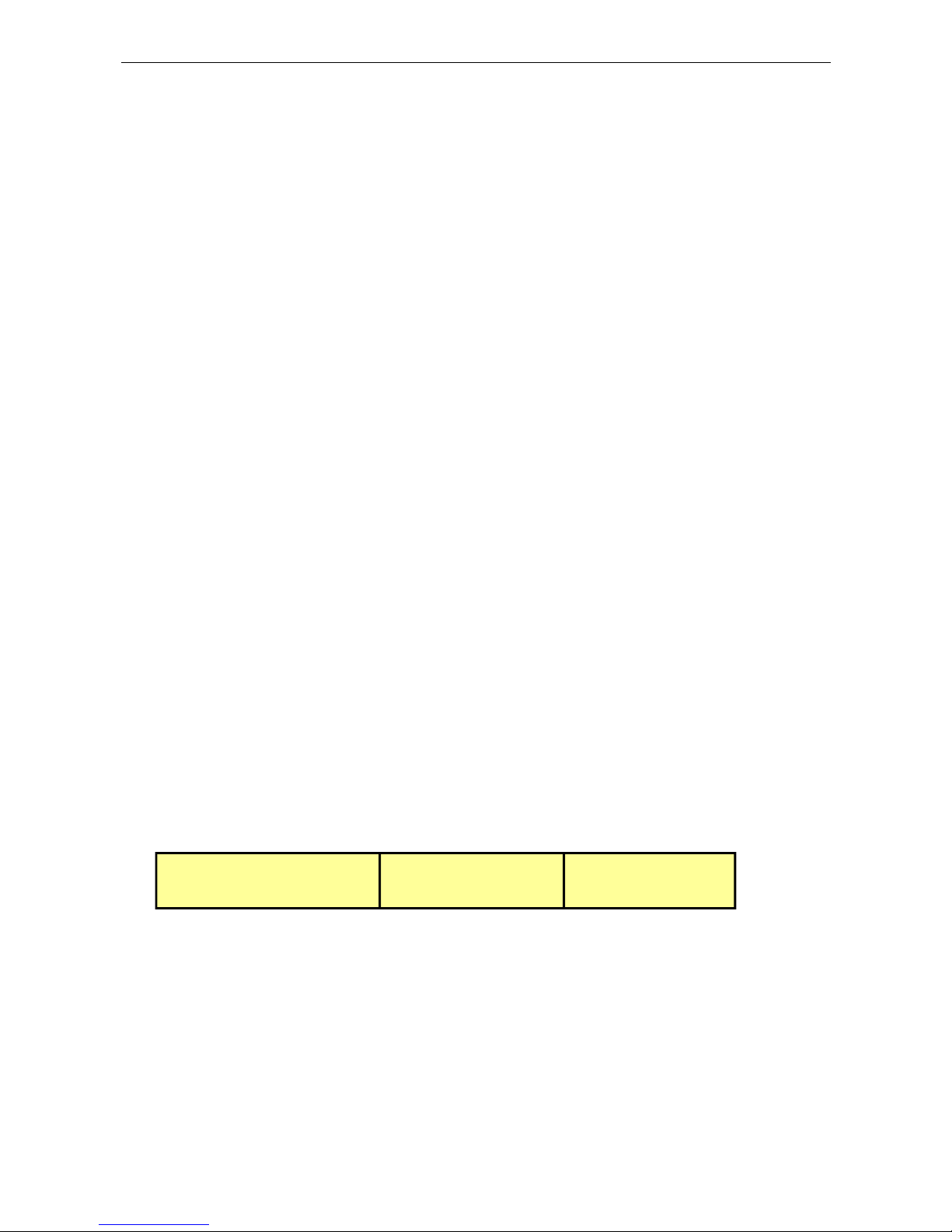

2nd PDO Mapping (default PDO assignment)

RxPDO

(0x1601)

Control Word

(0x6040)

Target Position

(0x607A)

TxPDO

(0x1A01)

Status Word

(0x6041)

Actual Position

(0x6064)

3rd PDO Mapping

RxPDO

(0x1602)

Control Word

(0x6040)

Target Velocity

(0x60FF)

TxPDO

(0x1A02)

Status Word

(0x6041)

Actual Position

(0x6064)

Actual Velocity

(0x606C)

Chapter 2 System Setup ASDA A2-E

Revision April, 2015 2-15

4th PDO Mapping

RxPDO

(0x1603)

Control Word

(0x6040)

Target Torque

(0x6071)

TxPDO

(0x1A03)

Status Word

(0x6041)

Actual Position

(0x6064)

Actual Torque

(0x6077)

2.4.2 Re-define a PDO Mapping

Setup procedure

1. Set 【RxPDO Assignment:0x1C12:0/ TxPDO Assignment: 0x1C13:0】to 0x0 for

disabling the PDO assignment.

2. Set 【RxPDO mapping entry: ex. 0x1601:0/ TxPDO mapping entry: ex. 0x1A01:0】

to 0x0 for disabling the PDO mapping entry setting.

3. Set 【RxPDO mapping entry: ex. 0x1601:0 - 0x1601:7/ TxPDO mapping entry: ex.

0x1A01:0 - 0x1A01:7】.

4. Set 【RxPDO mapping entry: ex. 0x1601:0/ TxPDO mapping entry: ex. 0x1A01:0】

to the number of mapping entries in PDO mapping.

5. Set 【RxPDO Assignment:0x1C12:1/ TxPDO Assignment: 0x1C13:1】to PDO

assignment.

6. Set 【RxPDO Assignment:0x1C12:0/ TxPDO Assignment: 0x1C13:0】to 0x1 for

enabling the PDO assignment.

ASDA A2-E Chapter 2 System Setup

2-16 Revision April, 2015

2.4.3 Using TwinCAT

1. Press or Shift and F4 to set/reset TwinCAT to Config Mode (Click OK in pop-up

dialog).

2. Select Drive (ASDA A2-E CoE Drive) in the left window. In Process Data field, you

can change PDO Assignment for another PDO mapping.

3. Right click the PDO Content Window, and find the PDO mapping that you desire to

set, and then you can configure (Insert/Delete/Edit/Move Up/Move Down) the PDO

mapping content.

(8 PDOs is the maximum number of PDO which can be assigned in every PDO

mappings.)

Figure 27

Figure 28 ASD-A2-E CoE drive Object List

Chapter 2 System Setup ASDA A2-E

Revision April, 2015 2-17

4. After changing the PDO Assignment, press or F4 to reload I/O devices. (Click

No in pop-up dialog and stay in Config Mode.)

ASDA A2-E Chapter 2 System Setup

2-18 Revision April, 2015

(This page is intentionally left blank.)

Revision April, 2015 3-1

Chapter 3 EtherCAT

Communication States

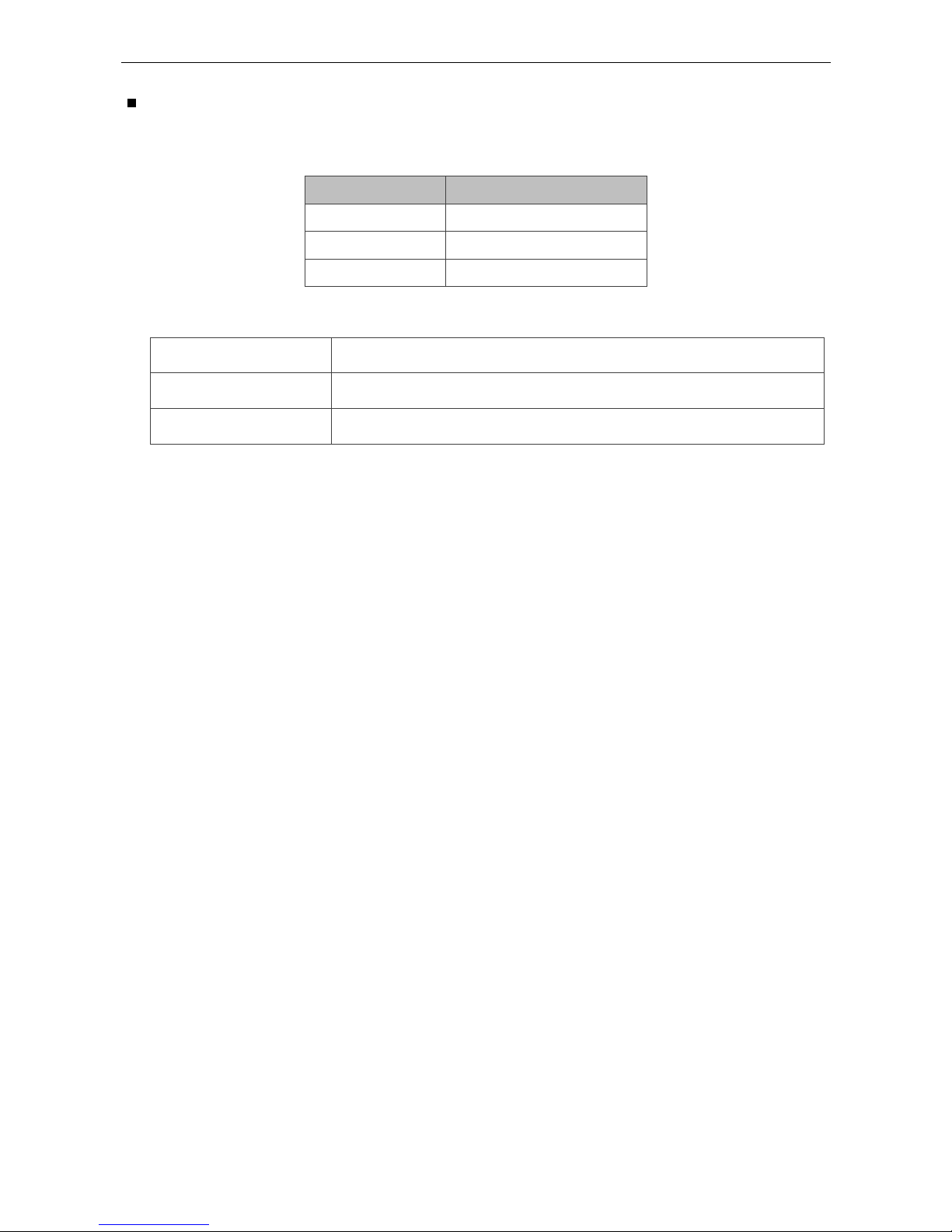

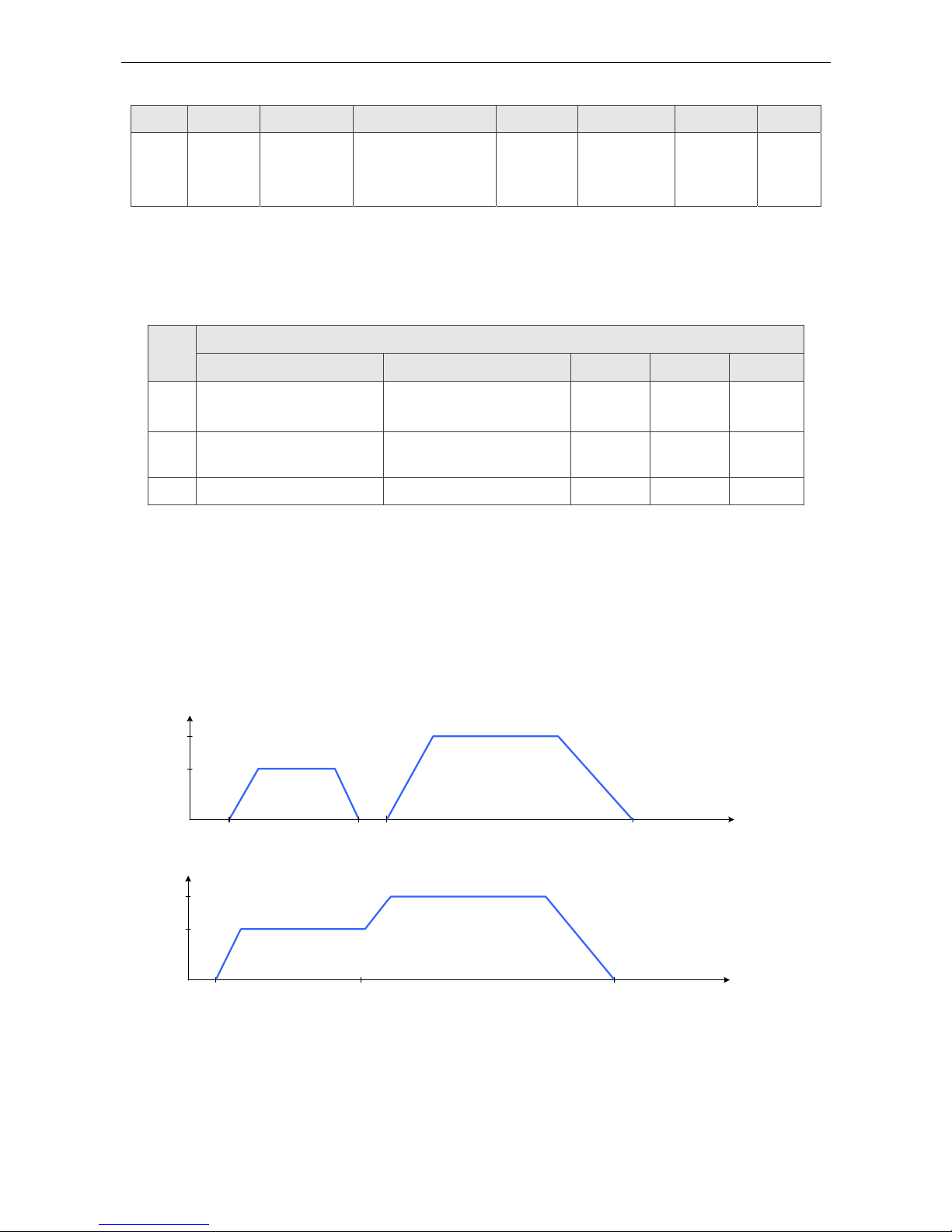

ASDA A2-E supports four EtherCAT communication states which are shown as below:

Init (Initialization)

Pre-Operational

Safe-Operational

Operational

Init

Pre-operational

Safe-operational

Operational

(OI)

(IP) (PI)

(OP)

(PS)

(SP)

(SO)

(OS)

(SI)

Figure 29 The EtherCAT State machine

EtherCAT host controller can switch the states. Different state provides different

service.

State Description

Init

After power on, the system will be located in this state when hardware

is initialized without any error.

No communication packet is sent at this stage.

Pre-Operational

The mailbox can be accessed via SDO (Service Data Object).

The Emergency message will be sent to the host controller if any

alarm occurs.

Chapter 3 EtherCAT Communication States ASDA A2-E

3-2 Revision April, 2015

Safe-Operational

Except SDO, for accessing Mailbox, the PDO (Process Data Object)

can only be applied for Process Data Input (TxPDO) at this stage.

Operational

The full function of SDO and PDO (TxPDO and RxPDO) are available

now.

3.1 State Transition Operation

The EtherCAT host will send different state transition command for requesting different

service.

State Change Description

IP

Master will define the slave address and register SyncManager (0/1),

and it is possible to access mailbox.

Master will command the slave to switch to Safe-Operational state.

PS

SDO from the master will be employed for the settings of PDO

mapping.

Master will define FMMU and register SyncManager (2/3), and slaves

keep sending the PDO (TxPDO) packets to the master.

Master requests the Slave to switch to Operational state.

SO

Master starts to send PDO (RxPDO).

The distributed clock synchronization procedure takes place between

the master and slaves.

PI, SI, OI

All communication functions, including SDO and PDO cannot work.

Switch to Init State.

SP, OP

Disable PDO function.

Switch to Pre-Operational state

OS

Master stops sending Process Data Output (RxPDO).

Switch to Safe-Operational state

Revision April, 2015 4-1

Chapter 4 EtherCAT

Troubleshooting

Q: Why my TwinCAT cannot find EtherCAT Device from all installed NIC

(Network Interface Card) and only shows RT-Ethernet devices?

A:

1. Please refer to TwinCAT setup procedure and make sure NIC is installed

properly.

2. Check if the cable is correctly connected and L/A LED is lit.

Q: The dialog shows “Unknown device type found” while using TwinCAT Scan

boxes.

A: Copy XML description of the ASDA-A2-E to TwinCAT device description folder

(usually in C:\TwinCAT\Io\EtherCAT) and restart TwinCAT System.

Q: Why does EtherCAT state machine only show INIT in Current State and blank

in DLL status when TwinCAT is in Config Mode?

Figure 30

A:

1. Set parameter P1-01 to 0x0C (EtherCAT communication mode).

2. Check the wiring from the host to EtherCAT communication port CN6A for input

and CN6B for output on servo drive. If the Link LED lit, it indicates that the

physical connection is correct and the drive is connecting.

ASDA A2-E Chapter 4 EtherCAT Troubleshooting

4-2 Revision April, 2015

Q: TwinCAT shows “following error”.

Figure 31

A: Set “Following Error Calculation” to Extern:

1. Select Axis 1_Drive in the left window.

2. In Parameter tab, select Extern in Following Error Calculation.

3. Download and click OK in pop-up dialog.

Figure 32

Q: ASDA A2-E servo drive shows AL185

A: This alarm message occurs because of the disconnection of EtherCAT cable

between the host and the slave. Please check the wiring. After checking the

connection of the cable, it is necessary to re-servo on the drive or set OD 0x6040

to 0x86 for fault reset.

Chapter 4 EtherCAT Troubleshooting ASDA A2-E

Revision April, 2015 4-3

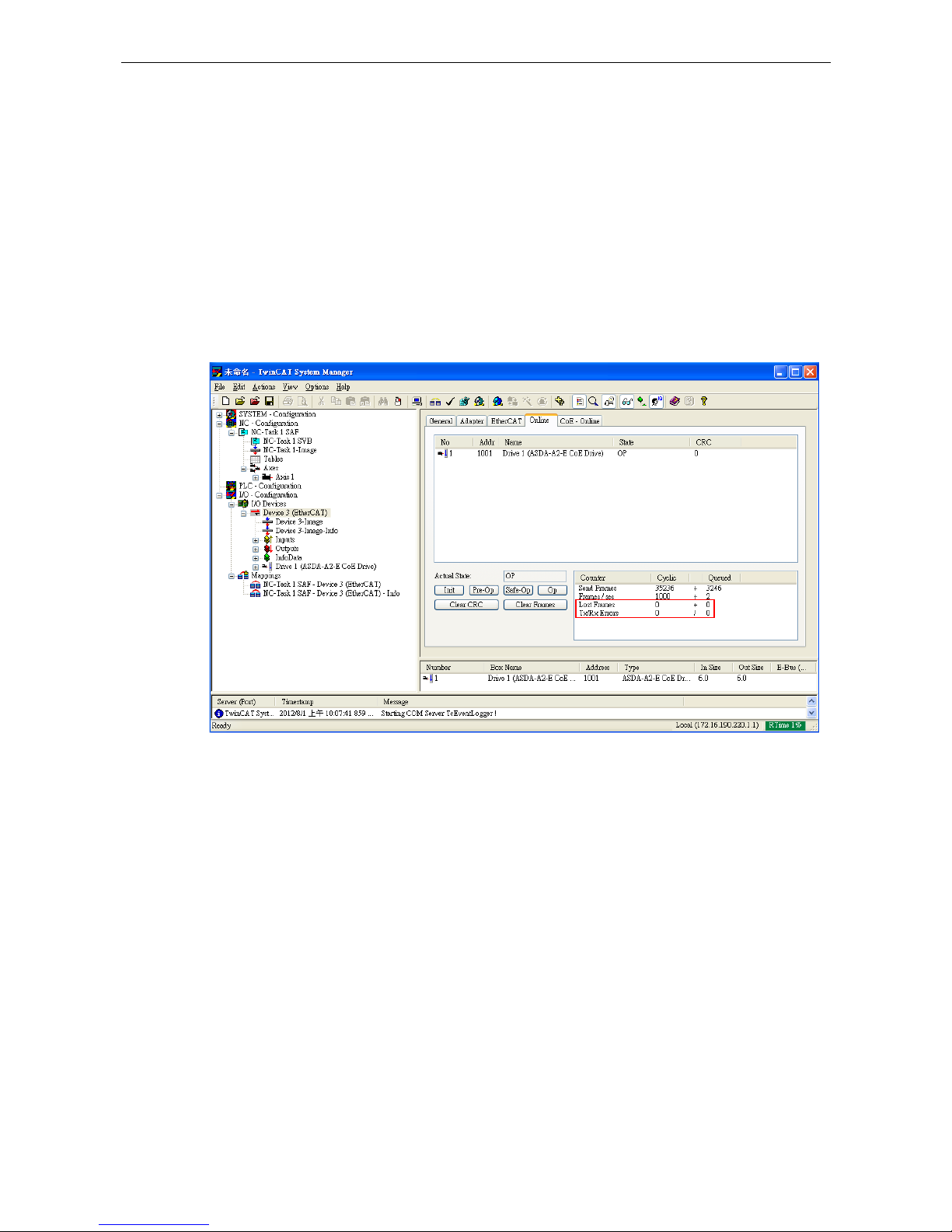

Q: ASDA A2-E servo drive shows AL180

A: Working under Operational state and losing three consecutive PDOs will lead to

this alarm.

1. A mechanism inside Delta Servo Drive can be used to monitor the error when

receiving PDO by setting P0-02 to 121. If the number keeps increasing, it can

be interpreted as the exaggerated jitter of PDO or server interference on the

communication cable.

2. Select drive and click Online. If the number in the columns of Lost Frames and

Rx Errors keeps increasing, it means the system have severe interference.

Figure 33

Q: ASDA A2-E servo drive servo drive shows AL3E1

A: Working under Operational state with CANopen CSP/CSV/CST mode and losing

two consecutive PDOs will lead to this alarm.

1. Check the reference clock whether with big time jitter

2. Fault reset with control word 0x6040.7 = 1

Q: ASDA A2-E servo drive shows AL3E3

A: Working under Operational state with CANopen CSP/CSV/CST mode and losing

two consecutive PDOs will lead to this alarm.

1. Make sure the host controller periodically and stably sends PDO.

2. Make sure grounding and wiring are both correct.

ASDA A2-E Chapter 4 EtherCAT Troubleshooting

4-4 Revision April, 2015

(This page is intentionally left blank.)

Revision April, 2015 5-1

Chapter 5 CANopen Operation

Mode

5.1 Profile Position Mode

5.1.1 Description

Servo drive (hereinafter referred to as “Drive”) receives position command from the

host (external) controller (hereinafter referred to as “Host”) and then controls servo

motor to reach the target position.

Pulse of User-defined Unit Definition:

Pulse of User Unit (PUU): No. of

= 1280000

5.1.2 Operation Procedures

1. Set 【Mode of operations:6060h】to profile position mode (0x01).

2. Set 【Target position:607Ah】to the target position (unit: PUU).

3. Set 【Profile velocity:6081h】to the profile velocity (unit: PUU per second).

4. Set 【Profile acceleration:6083h】to plan acceleration slope (millisecond from 0rpm

to 3000rpm).

5. Set 【Profile deceleration:6084h】to plan deceleration slope (millisecond from 0rpm

to 3000rpm).

6. Set 【Controlword:6040h】as (0x06 > 0x07 > 0x0F) to Servo On the drive and

enable the motor.

7. Read 【Statusword:6064h】to obtain feedback position of the motor.

8. Read 【Statusword:6041h】to obtain the drive status of the following error, setpoint acknowledge and target reached.

Chapter 5 CANopen Operation Mode ASDA A2-E

5-2 Revision April, 2015

5.1.3 Advanced Setting Procedures

1. Host could obtain more information about profile position mode.

Read 【Position demand value:6062h】to obtain the internal position command.

(unit: PUU)

Read 【Position actual value*:6063h】to obtain the actual position value. (unit:

increments)

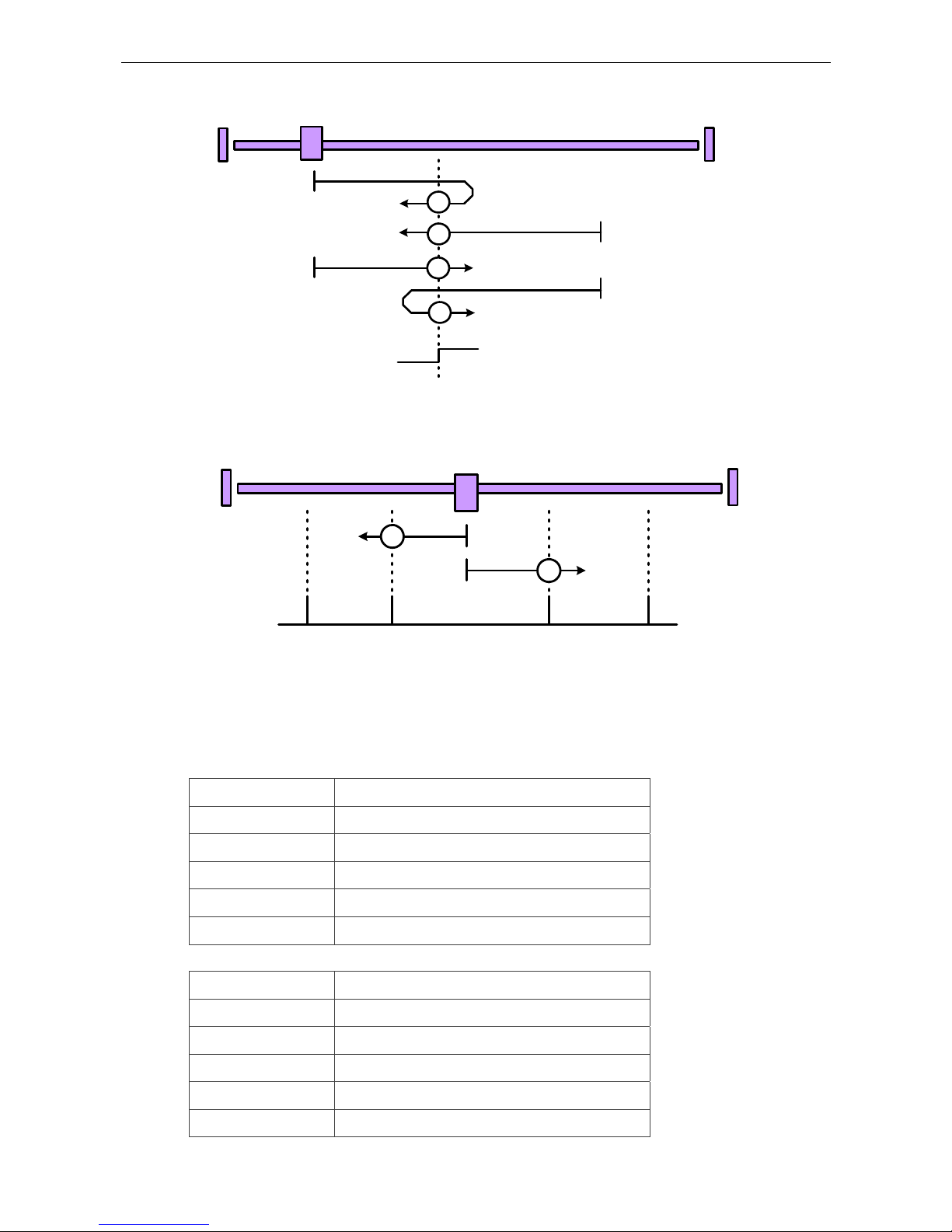

2. Following error

Set 【Following error window:6065h】 to define the range of tolerated position

value, which also defines the range of the position demand value. (unit: PUU)

Read 【Following error actual value:60F4h】to obtain the actual value of the

following error. (unit: PUU)

following error

following error

window

position

no following error

reference position

following error

accepted following error tolerance

following error

window

Reference position

3. Position window

Set 【Position window:6067

h

】to define a symmetrical range of the accepted

positions which is relative to the target position. (unit: PUU)

Set 【Position window time:6068h】to plan activation time of target reached.

(unit: millisecond)

ASDA A2-E Chapter 5 CANopen Operation Mode

Revision April, 2015 5-3

position not reached

position window posi tion window

position

position reached

target position

position not reached

accepted position range

Position reached

5.1.4 Associated Object List

Index Name Type Attr.

6040h Controlword UNSIGNED16 RW

6041h Statusword UNSIGNED16 RO

6060h Modes of operation INTEGER8 RW

6061h Modes of operation display INTEGER8 RO

6062h Position demand value [PUU] INTEGER32 RO

6063h Position actual value [increment] INTEGER32 RO

6064h Position actual value INTEGER32 RO

6065h Following error window UNSIGNED32 RW

6067h Position window UNSIGNED32 RW

6068h Position window time UNSIGNED16 RW

607Ah Target position INTEGER32 RW

6081h Profile velocity UNSIGNED32 RW

6083h Profile acceleration UNSIGNED32 RW

6084h Profile deceleration UNSIGNED32 RW

6093h Position factor UNSIGNED32 RW

60F4h Following error actual value INTEGER32 RO

60FCh Position demand value INTEGER32 RO

Chapter 5 CANopen Operation Mode ASDA A2-E

5-4 Revision April, 2015

5.2 Interpolation Position Mode

5.2.1 Description

The Host sends PDO periodically. With each PDO, the Host sends the next reference

Xi, differece△Xi and controlword to the drive. While the next SYNC0 is receiving, the

drive interpolates from X

i-1

to X

i

.

Extrapolation, Jitter Compensation

- When PDO is delayed, the interpolator will predict the speed and position for

the next time according to the last acceleration.

- When PDO delays for 2*cycle, the Drive should stop and send out an error

message.

PDO Rx/Tx Mapping record

- The Drive receives PDOs from the Host

32 bit reference position [position increment]

16 bit symmetrical difference [increments]

△Xi = (X

i+1

– X

i-1

)/2 (It is also the same as velocity.)

16 bit controlword

The Drive receives PDOs from the Host (Every PDO contains 8 bytes field which is

shown as below.)

32 bit reference position 16 bit difference 16 bit controlword

ASDA A2-E Chapter 5 CANopen Operation Mode

Revision April, 2015 5-5

5.2.2 Operation Procedures

1. Set 【Mode of operations:6060h】to interpolation position mode(0x07).

2. Set 【Interpolation sub mode select:60C0h】to Interpolation mode.

If 60C0h is [0], the Host does not send [60C1h Sub-2]. It could save calculating

time of the host and the Drive could also work.

If 60C0h is [-1], the Host needs to send [60C1h Sub-2] and the Drive works more

precisely.

3. Set 【Interpolation time period:60C2h】to predict the cycle that SYNC0 receives

PDO.

60C2h Sub-1 for Interpolation time units. The range is from 1ms to 20ms.

- 60C2h Sub-2 for Interpolation time index. The value is always -3, meaning

the interpolation time unit is 10-3 second.

4. Drive PDO Rx:

60C1h Sub-1 for Pos Cmd (32-bit)

6040h Sub-0 for ControlWord.

5.2.3 Associated Object List

Index Name Type Attr.

6040h Controlword UNSIGNED16 RW

6041h Statusword UNSIGNED16 RO

6060h Modes of operation INTEGER8 RW

6061h Modes of operation display INTEGER8 RO

6093h Position factor UNSIGNED32 RW

60C0h Interpolation sub mode select INTEGER16 RW

60C1h Interpolation data record ARRAY RW

(Please refer to the following “Details of Objects” section for more detailed descriptions)

Chapter 5 CANopen Operation Mode ASDA A2-E

5-6 Revision April, 2015

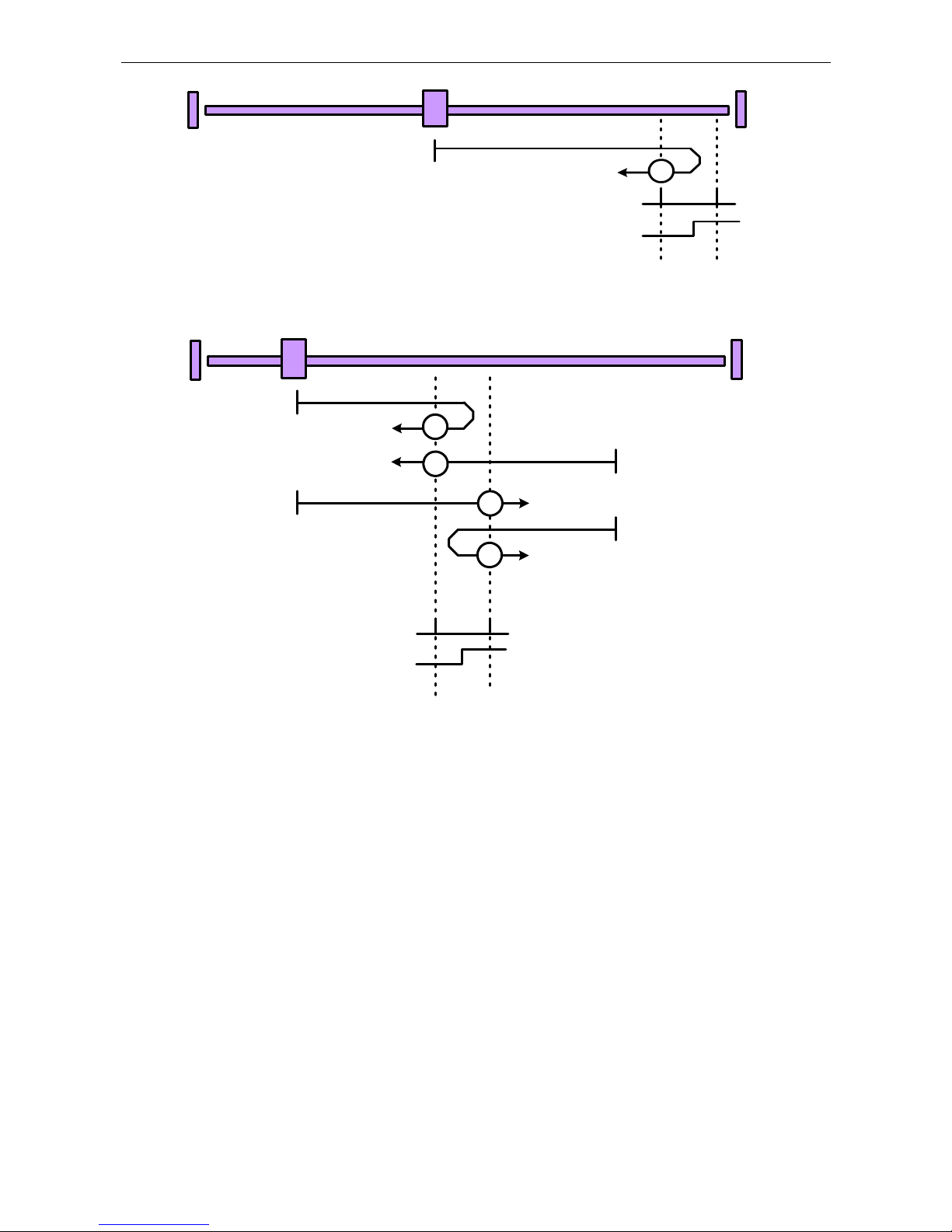

5.3 Cyclic Synchronous Position Mode

5.3.1 Description

The Host plans the path in Cyclic Synchronous Position mode and sends PDO

periodically. With each PDO, the Host sends the target position and controlword to the

drive. Velocity offset and torque offset can be used as velocity and torque feedforwad.

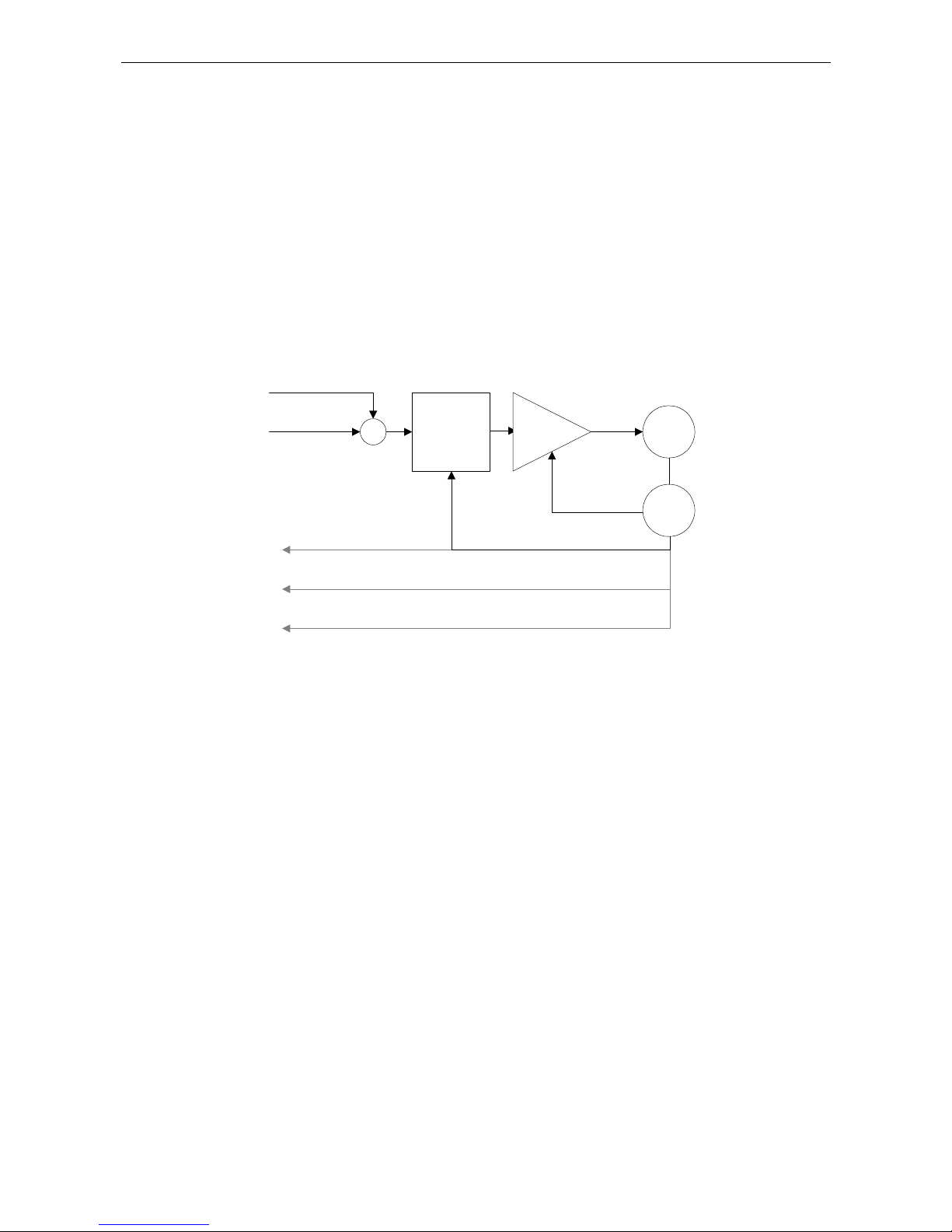

5.3.2 The Function of CSP Mode

Position

control

Velocity

control

Torque

control

M

S

Target

position

(607A

h

)

Position offset (60B0h)

Velocity offset (60B1h)

Torque offset (60B2h)

+

+

+

+

+

+

Position actual value

(6064

h

)

Velocity actual value

(606C

h

)

Torque actual value

(6077

h

)

5.3.3 Operation Procedures

1. Set 【Mode of operations:6060h】to cyclic synchronous position mode(0x08).

2. Set 【Interpolation time period:60C2h】 to predict the cycle that SYNC0 receives

PDO.

60C2h Sub-1 for Interpolation time units. The min is from 1ms to 20ms.

- 60C2h Sub-2 for Interpolation time index. The value is always -3, meaning

the interpolation time unit is 10-3 second.

ASDA A2-E Chapter 5 CANopen Operation Mode

Revision April, 2015 5-7

3. Drive PDO Rx:

607Ah for Target Pos Cmd (32-bit).

6040h Sub-0 for ControlWord.

5.3.4 Associated Object List

Index Name Type Attr.

6040h Controlword UNSIGNED16 RW

6041h Statusword UNSIGNED16 RO

6060h Modes of operation INTEGER8 RW

6061h Modes of operation display INTEGER8 RO

607A h Target position INTEGER32 RW

60B0 h Position offset INTEGER32 RW

6064 h Position actual value INTEGER32 RO

60B1

h

Velocity offset INTEGER32 RW

606C

h

Velocity actual value INTEGER32 RO

60B2

h

Torque offset INTEGER16 RW

6077

h

Torque actual value INTEGER16 RO

(Please refer to the following “Details of Objects” section for more detailed descriptions)

Chapter 5 CANopen Operation Mode ASDA A2-E

5-8 Revision April, 2015

5.4 Homing Mode

5.4.1 Description

This mode could help the drive to find the home position. Users can specify the speed,

acceleration and method of homing.

5.4.2 Operation Procedures

1. Set【Mode of operations:6060h】to the homing mode(0x06).

2. Set【Home offset:607Ch】.

3. Set【Homing method:6098h】. The method range is 1 to 35. (Refer to OD-6098h

definition which shows below.)

4. Set【Homing speeds:6099h Sub-1】in order to set speed search for switching. (unit:

rpm)

5. Set【Homing speeds:6099h Sub-2】in order to set speed during the search for zero.

(unit: rpm)

6. Set【Homing acceleration:609Ah】for homing acceleration. (unit: millisecond from

0rpm to 3000rpm)

7. Set【Controlword:6040h】to (0x06 0x07 0x0F) to Servo ON the drive and

enable the motor.

8. Set【Controlword:6040h】to (0x0F 0x1F) to find Home Switch and do homing.

9. Read【Statusword:6041h】to obtain the drive status.

ASDA A2-E Chapter 5 CANopen Operation Mode

Revision April, 2015 5-9

5.4.3 Associated Object List

Index Name Type Attr.

6040h Controlword UNSIGNED16 RW

6041h Statusword UNSIGNED16 RO

6060h Modes of operation INTEGER8 RW

6061h Modes of operation display INTEGER8 RO

607Ch Home offset INTEGER32 RW

6093h Position factor UNSIGNED32 RW

6098h Homing method INTEGER8 RW

6099h Homing speed ARRAY RW

609Ah Homing acceleration UNSIGNED32 RW

(Please refer to the following “Details of Objects” section for more detailed descriptions.)

Chapter 5 CANopen Operation Mode ASDA A2-E

5-10 Revision April, 2015

5.5 Profile Velocity Mode

5.5.1 Description

The drive could receive velocity command and plan acceleration and deceleration.

5.5.2 Operation Procedures

1. Set【Mode of operations:6060h】to profile velocity mode(0x03).

2. Set【Controlword:6040h】as (0x06 0x07 0x0F) to Servo ON the drive and

enable the motor.

(After Servo On, the internal velocity command will be reset and OD-60FFh will be

cleared.)

3. Set【Profile acceleration:6083h】to plan acceleration slope. (millisecond from 0rpm

to 3000rpm)

4. Set【Profile deceleration:6084h】to plan deceleration slope. (millisecond from 0rpm

to 3000rpm)

5. Set【Target velocity:60FFh】. The unit of the target velocity is 0.1rpm.

(If the drive is already servo-on, it will work immediately while receiving velocity

command. OD-60FFh will be cleared to 0 if OD-6060h [Mode] is changed, and

Servo-Off or Quick-Stop is activated.)

6. Read【Statusword:6041h】to obtain the drive status.

ASDA A2-E Chapter 5 CANopen Operation Mode

Revision April, 2015 5-11

5.5.3 Advanced Setting Procedures

1. Host could obtain the information of velocity mode.

Read【Velocity demand value:606Bh】to inquire the internal velocity command.

(unit: 0.1rpm)

Read【Velocity actual value:606Ch】to obtain the actual velocity value. (unit:

0.1rpm)

2. Host could set velocity monitor threshold.

Set【Velocity window:606Dh】to allocate velocity reached zone. (unit: 0.1rpm)

Set【Velocity widnow time:606Eh】in order to ensure the activation time is

before velocity reached. (unit: millisecond)

Set【Velocity threshold:606Fh】to allocate zero speed level. (unit: 0.1rpm)

5.5.4 Associated Object List

Index Name Type Attr.

6040h Controlword UNSIGNED16 RW

6041h Statusword UNSIGNED16 RO

6060h Modes of operation INTEGER8 RW

6061h Modes of operation display INTEGER8 RO

606Bh Velocity demand value INTEGER32 RO

606Ch Velocity actual value INTEGER32 RO

Index Name Type Attr.

606Dh Velocity window UNSIGNED16 RW

606Eh Velocity window time UNSIGNED16 RW

606Fh Velocity threshold UNSIGNED16 RW

60FFh Target velocity INTEGER32 RW

(Please refer to the following “Details of Objects” section for more detailed descriptions)

Chapter 5 CANopen Operation Mode ASDA A2-E

5-12 Revision April, 2015

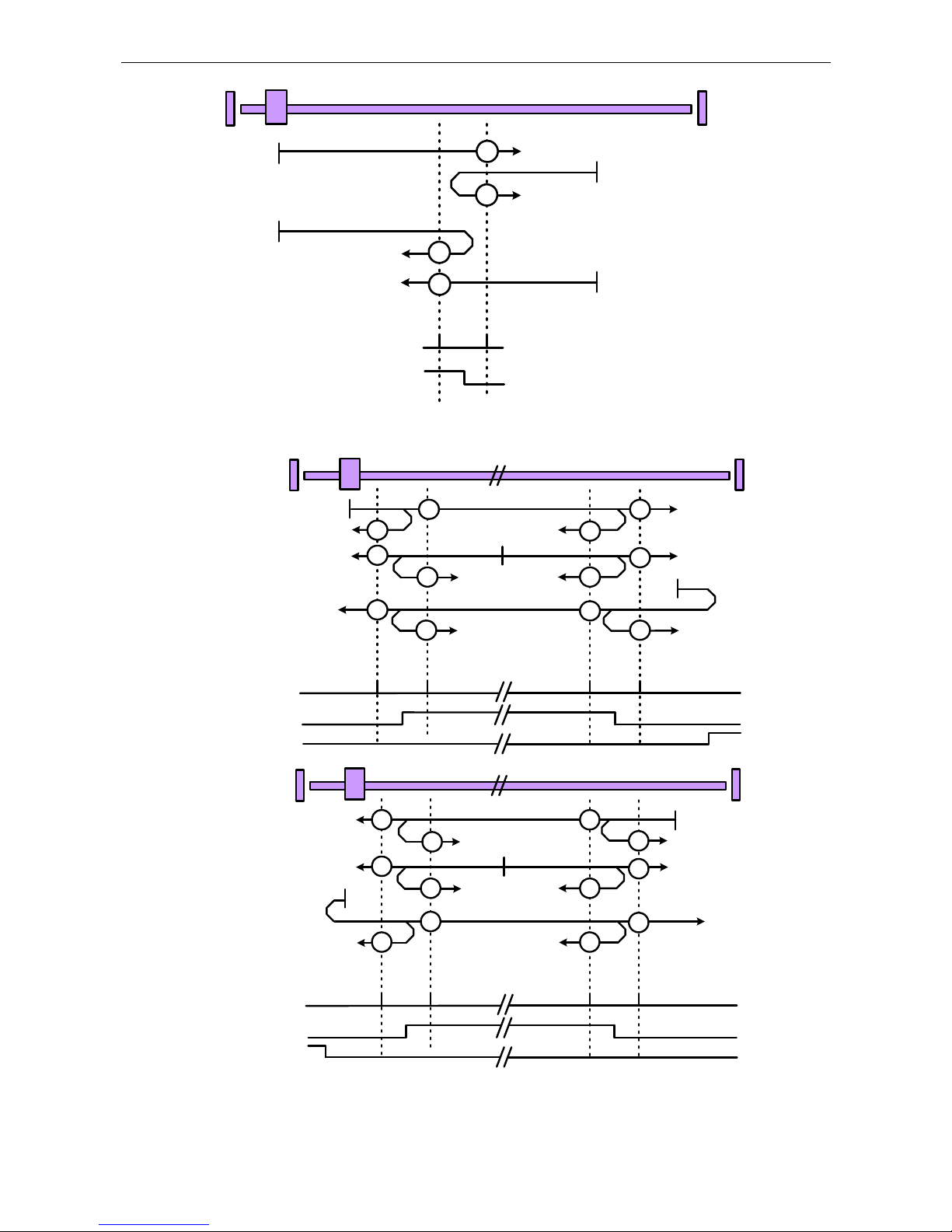

5.6 Cyclic Synchronous Velocity Mode

5.6.1 Description

The Host plans the path in Cyclic Synchronous Velocity mode. In this mode, the Host

sends PDO periodically including target position and controlword to drive. In addition,

velocity offset and torque offset can be used as the velocity and torque feedforwad.

5.6.2 The Function of CSV Mode

Velocity

control

Torque

control

M

S

Target

velocity

(60FF

h

)

Velocity offset (60B1h)

Torque offset (60B2h)

+

+

+

+

Position actual value

(6064

h

)

Velocity actual value

(606C

h

)

Torque actual value

(6077

h

)

5.6.3 Operation Procedures

1. Set 【Mode of operations:6060h】to cyclic synchronous velocity mode(0x09).

2. Set 【Interpolation time period:60C2h】 to predict the cycle that SYNC0 receives

PDO.

60C2h Sub-1 for Interpolation time units. The min is from 1ms to 20ms.

- 60C2h Sub-2 for Interpolation time index. The value is always -3, meaning

the interpolation time unit is 10-3 second.

ASDA A2-E Chapter 5 CANopen Operation Mode

Revision April, 2015 5-13

3. Drive PDO Rx:

60F Fh for Target Velocity Cmd (32-bit)

6040h Sub-0 for ControlWord

5.6.4 Associated Object List

Index Name Type Attr.

6040h Controlword UNSIGNED16 RW

6041h Statusword UNSIGNED16 RO

6060h Modes of operation INTEGER8 RW

6061h Modes of operation display INTEGER8 RO

60FF h Target velocity INTEGER32 RW

60B1

h

Velocity offset INTEGER32 RW

606Ch Velocity actual value INTEGER32 RO

6064 h Position actual value INTEGER32 RO

60B2

h

Torque offset INTEGER16 RW

6077

h

Torque actual value INTEGER16 RO

Chapter 5 CANopen Operation Mode ASDA A2-E

5-14 Revision April, 2015

5.7 Profile Torque Mode

5.7.1 Description

The drive could receive torque command and plan profile torque slope.

5.7.2 Operation Procedures

1. Set 【Mode of operations:6060h】to profile torque mode(4).

2. Set 【Controlword:6040h】as (0x6 0x7 0x0F) to Servo ON the drive and

enable the motor.

(After Servo On the drive, the internal torque command will be reset and OD-6071h

will be cleared. It means the drive is servo-on and starts to receive the torque

command.)

3. Set 【Torque slope:6087h】to plan torque slope time. (unit: millisecond from 0 to

100% rated torque)

4. Set 【Target torque:6071h】to the target torque. The unit is given one rated torque

in a thousand. (OD-6071h will be cleared to 0 if OD-6060h [Mode] changed. ServoOff or Quick-Stop is activated.)

5.7.3 Advanced Setting Procedures

Host could obtain the information of torque mode.

Read 【Torque demand value:6074h】 to obtain the output value of the torque limit

function. (unit: one rated torque in a thousand)

Read 【Torque rated current:6075h】to obtain the rated current determined by the

motor and drive type. (unit: multiples of milliamp)

Read 【Torque actual value:6077h】to obtain the instantaneous torque in servo

motor. (unit: one rated torque in a thousand)

ASDA A2-E Chapter 5 CANopen Operation Mode

Revision April, 2015 5-15

Read 【Current actual value:6078h】to obtain the instantaneous current in servo

motor. (unit: one rated torque in a thousand)

5.7.4 Associated Object List

Index Name Type Attr.

6040h Controlword UNSIGNED16 RW

6041h Statusword UNSIGNED16 RO

6060h Modes of operation INTEGER8 RW

6061h Modes of operation display INTEGER8 RO

6071h Target torque INTEGER16 RW

6074h Torque demand value INTEGER16 RO

6075h Motor rated current UNSIGNED32 RO

6077h Torque actual value INTEGER16 RO

6078h Current actual value INTEGER16 RO

6087h Torque slope UNSIGNED32 RW

(Please refer to the following “Details of Objects” section for more detailed descriptions.)

Chapter 5 CANopen Operation Mode ASDA A2-E

5-16 Revision April, 2015

5.8 Cyclic Synchronous Torque Mode

5.8.1 Description

The Host plans the path in Cyclic Synchronous Torque mode. In this mode, the Host

sends PDO periodically including target position and controlword to drive. In addition,

velocity offset and torque offset can be used as the velocity and torque feedforwad.

5.8.2 The Function of CST Mode

Torque

control

M

S

Target

torque

(6071

h

)

Torque offset (60B2h)

+

+

Position actual value

(6064

h

)

Velocity actual value

(606C

h

)

Torque actual value

(6077

h

)

5.8.3 Operation Procedures

1. Set【Mode of operations:6060h】to cyclic synchronous torque mode (0x0A).

2. Set【Interpolation time period:60C2h】to predict the cycle that SYNC0 receives

PDO.

60C2

h

Sub-1 for Interpolation time units. The min is from 1ms to 20ms.

- 60C2h Sub-2 for Interpolation time index. The value is always -3, meaning

the interpolation time unit is 10

-3

second.

3. Drive PDO Rx:

6071

h

for Target Torque Cmd (16-bit)

6040h Sub-0 for ControlWord.

ASDA A2-E Chapter 5 CANopen Operation Mode

Revision April, 2015 5-17

5.8.4 Associated Object List

Index Name Type Attr.

6040h Controlword UNSIGNED16 RW

6041h Statusword UNSIGNED16 RO

6060h Modes of operation INTEGER8 RW

6061h Modes of operation display INTEGER8 RO

6071h Target torque INTEGER16 RW

60B2

h

Torque offset INTEGER16 RW

6077

h

Torque actual value INTEGER16 RO

606Ch Velocity actual value INTEGER32 RO

6064 h Position actual value INTEGER32 RO

(Please refer to the following “Details of Objects” section for more detailed descriptions)

Chapter 5 CANopen Operation Mode ASDA A2-E

5-18 Revision April, 2015

5.9 Limit Position Handling Procedure

5.9.1 Description

Drive will switch to Quick-Stop status while traveling to the position of positive or

negative limit sensors, and it can be handled by the following procedures.

5.9.2 Operation Procedures

1. The servo panel will show the alarm while sensors are close to the positive or

negative limit. The motor is controlled by a deceleration slope to stop and it is at

Quick-Stop status. The drive will keep in servo-on status but will not accept the

further motion command.

2. Set 【Controlword:6040h】to 0x8F for fault reset and clearing the alarm displayed

on the panel.

3. Set 【Controlword:6040h】to 0x1F/0x0F for Operation Enabled, and then the servo

can accept the motion command again.

4. For a motor at its limit position, there must be a command which can drive the motor

to the backward direction. Or the alarm will be triggered again while the motor starts

moving.

ASDA A2-E Chapter 5 CANopen Operation Mode

Revision April, 2015 5-19

5.10 Touch Probe Function

5.10.1 Description

Touch Probe function can be enabled by the DI on CN7 or the encoder; among that,

the feedback position can be latched as positive or negative edge with DI13 on CN7.

The time of latch position is shorter than 5 µs and it is used to execute high speed

performance in measuring or packaging applications.

5.10.2 Touch Probe Function

The current status of Touch Probe can be obtained by object 60B8h. The definition of

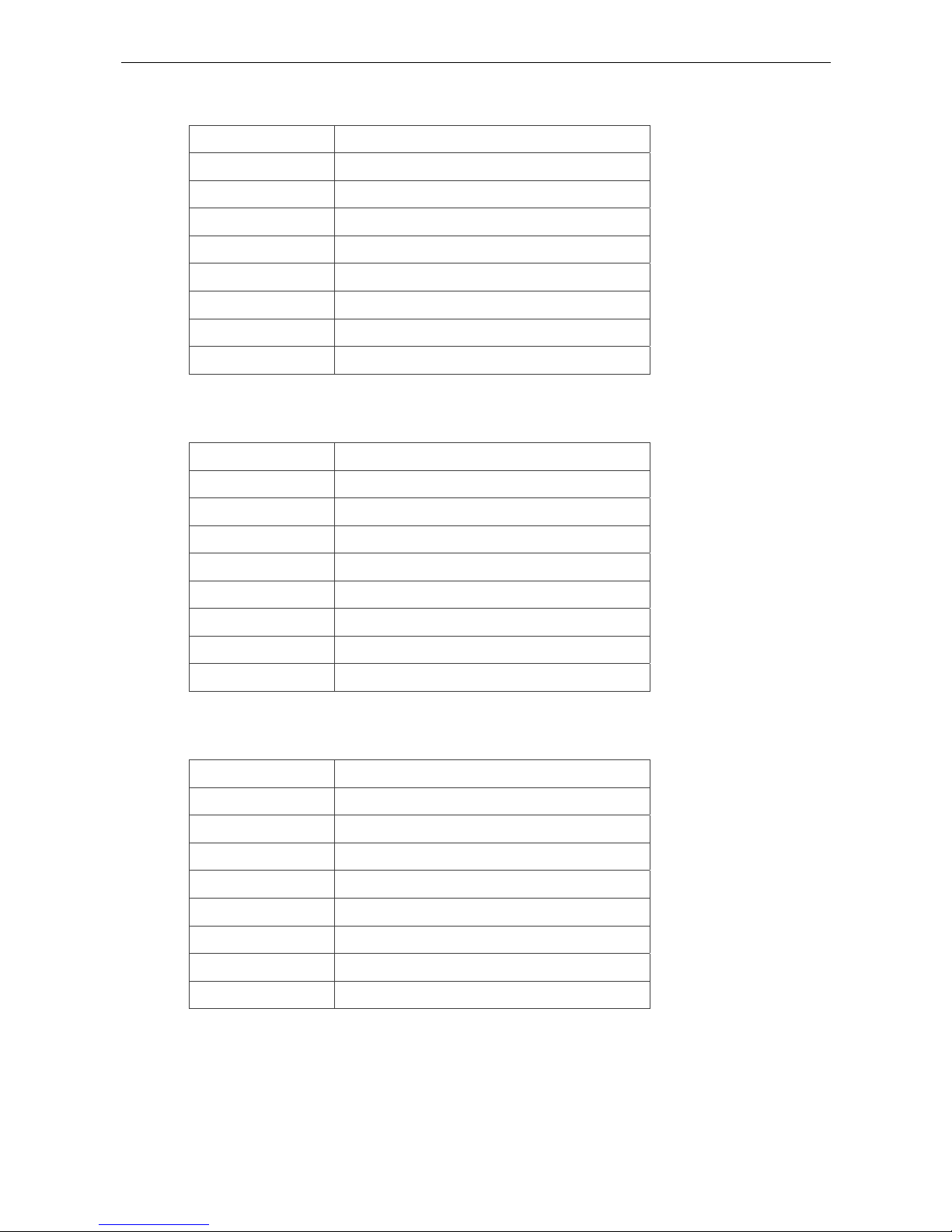

each bit is as the followings.

Bit Value Definition

0

0

Switch off touch probe 1

1

Enable touch probe 1

1

0

Trigger first event

1

Continuous

2

0

Trigger with touch probe 1 input

1

Trigger with zero impulse signal

3 0

Reserved

4

0

Switch off sampling at positive edge of touch

probe 1

1

Enable sampling at positive edge of touch probe 1

5

0

Switch off sampling at negative edge of touch

probe 1

1

Enable sampling at negative edge of touch probe

1

6、7

0

Reserved

8

0

Switch off touch probe 2

1

Enable touch probe 2

9

0

Trigger first event

1

Continuous

10

0

Trigger with touch probe 2 input

Chapter 5 CANopen Operation Mode ASDA A2-E

5-20 Revision April, 2015

1

Trigger with zero impulse signal

11

0

Reserved

12

0

Switch off sampling at positive edge of touch

probe 2

1

Enable sampling at positive edge of touch probe 2

13

0

Switch off sampling at negative edge of touch

probe 2

1

Enable sampling at negative edge of touch probe

2

14、15

Reserved

5.10.3 Touch Probe Status

The current status of Touch Probe can be obtained by object 60B9h. The definition of

each bit is as the followings.

Bit Value Definition

0

0 Touch probe 1 is switched off

1 Touch probe 1 is enabled

1

0 Touch probe 1 has no positive edge value stored

1 Touch probe 1 has positive edge value stored

2

0 Touch probe 1 has no negative edge value stored

1 Touch probe 1 has negative edge value stored

3 ~ 5 0 Reserved

6

0 Trigger with touch probe 1 input

1 Trigger with zero impulse signal

7

0,1

Toggle with every update of Touch probe 1 value

Stored

8

0 Touch probe 2 is switched off

1 Touch probe 2 is enabled

9

0 Touch probe 2 has no positive edge value stored

1 Touch probe 2 has positive edge value stored

ASDA A2-E Chapter 5 CANopen Operation Mode

Revision April, 2015 5-21

10

0 Touch probe 2 has no negative edge value stored

1 Touch probe 2 has negative edge value stored

11 ~ 13

0 Reserved

14

0 Trigger with touch probe 2 input

1 Trigger with zero impulse signal

15

0,1

Toggle with every update of Touch probe 2 value

Stored

5.10.4 Associated Object List

Index Name Type Attr.

60B8h

Touch probe function UNSIGNED16 RW

60B9h

Touch probe status UNSIGNED16 RO

60BAh

Touch probe pos1 pos value INTEGER32 RO

60BBh

Touch probe pos1 neg value INTEGER32 RO

60BCh

Touch probe pos2 pos value INTEGER32 RO

60BD

h

Touch probe pos2 neg value INTEGER32 RO

(Please refer to the following “Details of Objects” section for more detailed descriptions)

Chapter 5 CANopen Operation Mode ASDA A2-E

5-22 Revision April, 2015

(This page is intentionally left blank.)

Revision Aril, 2015 6-1

Chapter 6 Object Dictionary

Entries

6.1 Specifications for Objects

6.1.1 Object Type

Object Name Comments

VAR A single value such as an UNSIGNED8, Boolean, float, INTEGER16

etc.

ARRAY

A

multiple data field object where each data field is a sample variable

of the SAME basic data type e.g. array of UNSIGNED16 etc. Subindex 0 is UNSIGNED8 but is not part of the ARRAY data

RECORD A multiple data field object where the data fields may be any

combination of simple variables. Sub-index 0 is UNSIGNED8 but is

not part of the RECORD data

6.1.2 Data Type

Please refer to CANopen Standard 301.

Chapter 6 Object Dictionary Entries ASDA A2-E

6-2 Revision April, 2015

6.2 Overview of Object Group 1000

h

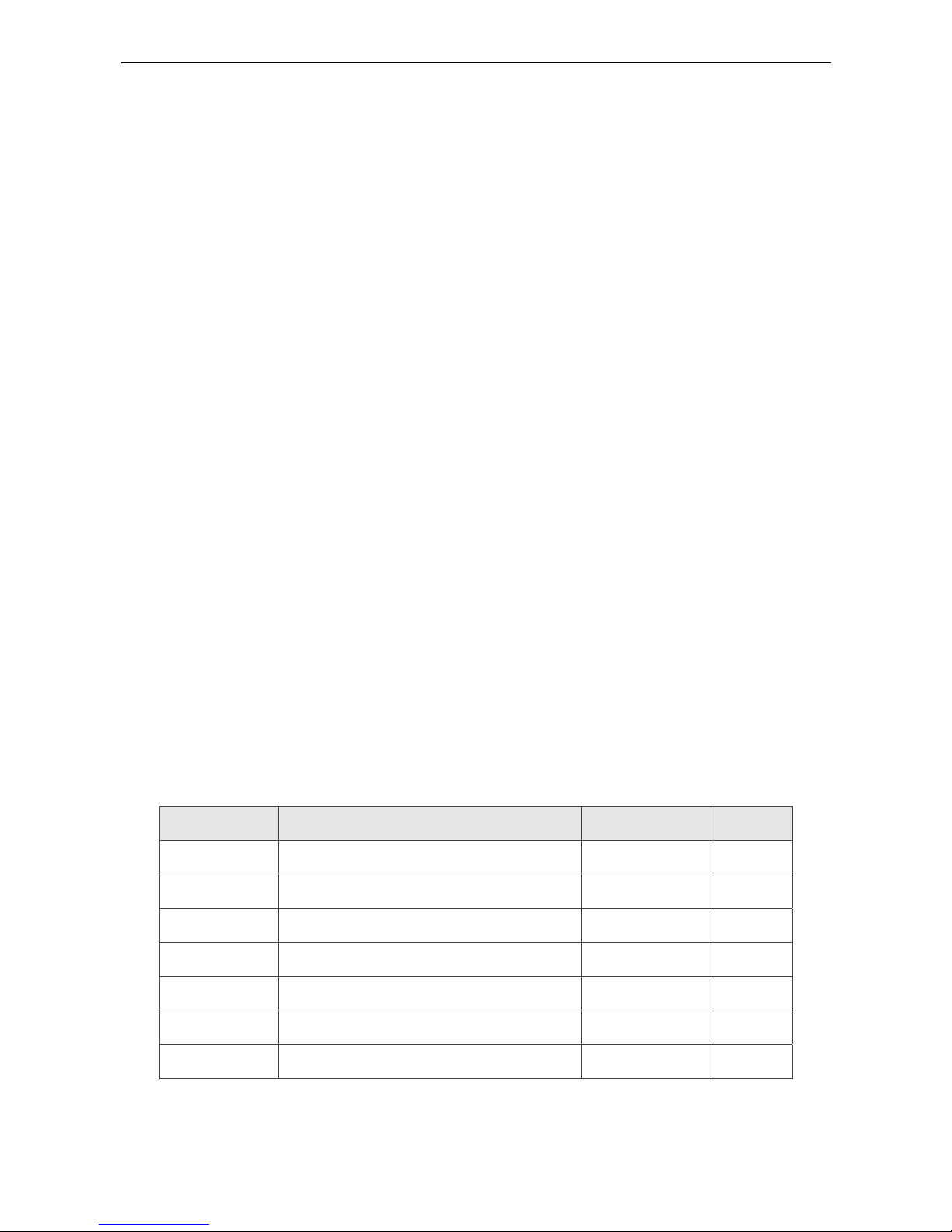

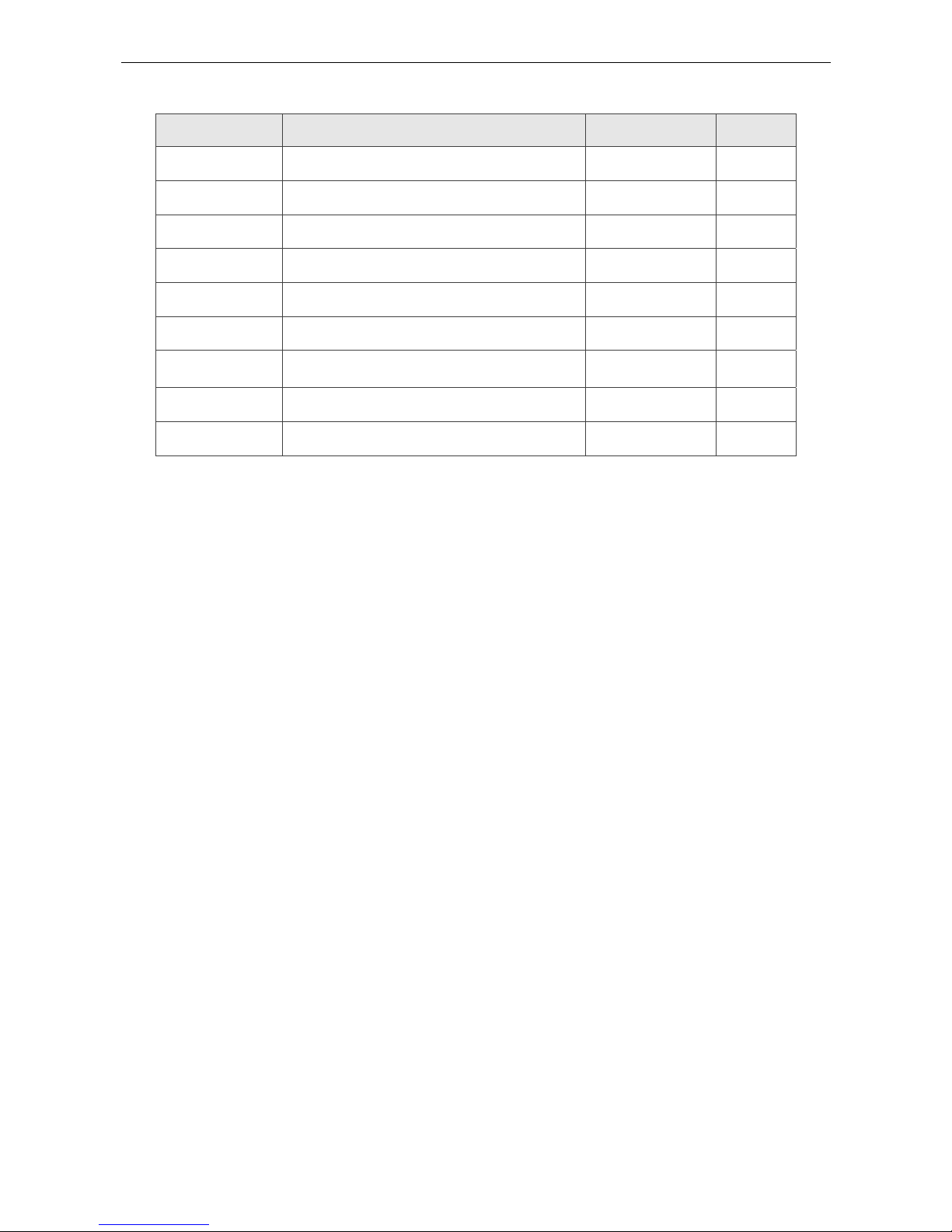

Index Object Type Name Data Type Access

1000h VAR device type UNSIGNED32 RO

1001h VAR error register UNSIGNED8 RO

1600h~03h RECORD Receive PDO mapping UNSIGNED32 RW

1A00h~03h RECORD Transmit PDO mapping UNSIGNED32 RW

※ Only 1001

h

could be mapped to PDO.

ASDA A2-E Chapter 6 Object Dictionary Entries

Revision April, 2015 6-3

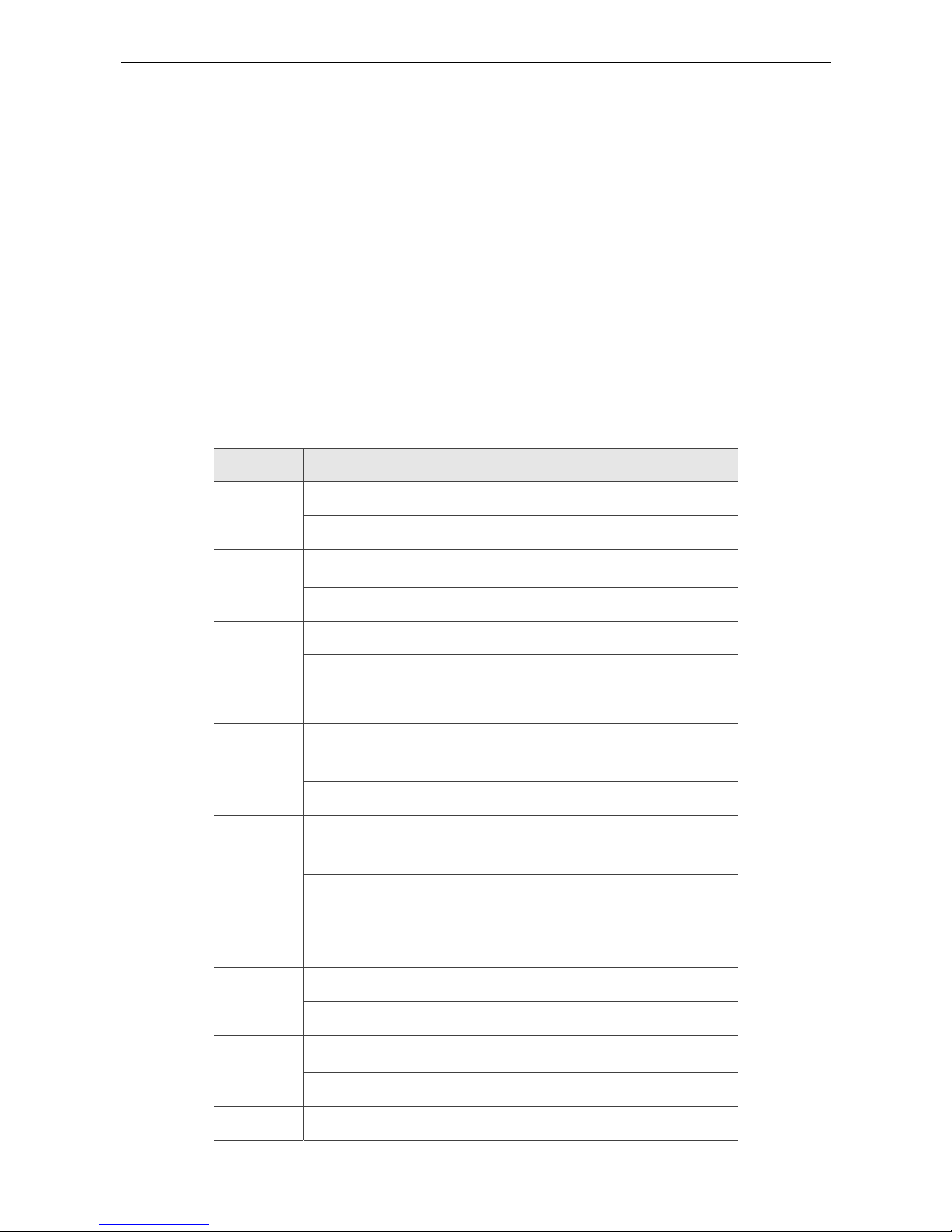

6.3 Overview of Object Group 6000

h

Index

Object

Type

Name Data Type Access Mappable

603Fh VAR Error Code UNSIGNED16 RO Y

6040h VAR Controlword UNSIGNED16 RW Y

6041h VAR Statusword UNSIGNED16 RO Y

605Bh VAR Shutdown option code INTEGER16 RW N

605Eh VAR Fault reaction option code INTEGER16 RW N

6060h VAR Modes of operation INTEGER8 RW Y

6061h VAR Modes of operation display INTEGER8 RO Y

6062h VAR Position demand value [PUU] INTEGER32 RO Y

6063h VAR Position actual value

[increment]

INTEGER32 RO Y

6064h VAR Position actual value INTEGER32 RO Y

6065h VAR Following error window UNSIGNED32 RW Y

6067h VAR Position windows UNSIGNED32 RW Y

6068h VAR Position window time UNSIGNED16 RW Y

606Bh VAR Velocity demand value INTEGER32 RO Y

606Ch VAR Velocity actual value INTEGER32 RO Y

606Dh VAR Velocity window UNSIGNED16 RW Y

606Eh VAR Velocity window time UNSIGNED16 RW Y

606Fh VAR Velocity threshold UNSIGNED16 RW Y

6071h VAR Target torque INTEGER16 RW Y

6072h VAR Max torque UNSIGNED16 RW Y

6074h VAR Torque demand value INTEGER16 RO Y

6075h VAR Motor rated current UNSIGNED32 RO Y

6076h VAR Motor rated torque UNSIGNED32 RO Y

6077h VAR Torque actual value UNSIGNED16 RO Y

6078h VAR Current actual value INTEGER16 RO Y

607Ah VAR Target position INTEGER32 RW Y

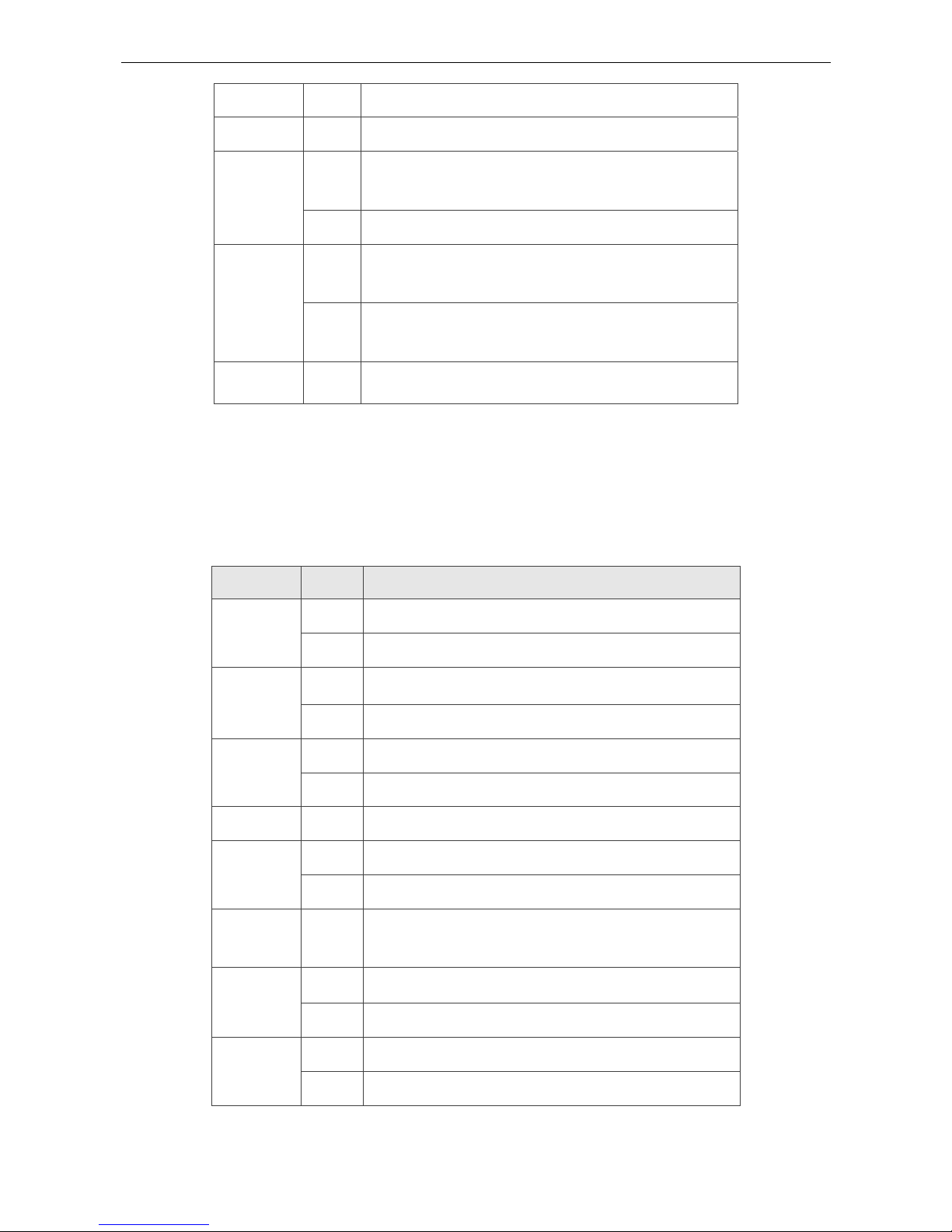

Chapter 6 Object Dictionary Entries ASDA A2-E

6-4 Revision April, 2015

Index

Object

Type

Name Data Type Access Mappable

607Ch VAR Home Offset INTEGER32 RW Y

607Dh ARRAY Software position limit INTEGER32 RW Y

607Eh VAR Polarity UNSIGNED8 RW Y

607Fh VAR Max profile velocity UNSIGNED32 RW Y

6080h VAR Max motor speed UNSIGNED32 RW Y

6081h VAR Profile velocity UNSIGNED32 RW Y

6083h VAR Profile acceleration UNSIGNED32 RW Y

6084h VAR Profile deceleration UNSIGNED32 RW Y

6085h VAR Quick stop deceleration UNSIGNED32 RW Y

6086h VAR Motion profile type INTEGER16 RW Y

6087h VAR Torque slope UNSIGNED32 RW Y

6093h ARRAY Position factor UNSIGNED32 RW Y

6098h VAR Homing method INTEGER8 RW Y

6099h ARRAY Homing speeds UNSIGNED32 RW Y

609Ah VAR Homing acceleration UNSIGNED32 RW Y

60B0h VAR Position offset INTEGER32 RW Y

60B1h VAR Velocity offset INTEGER32 RW Y

60B2h VAR Torque offset INTEGER16 RW Y

60B8h VAR Touch probe function UNSIGNED16 RW Y

60B9h VAR Touch probe status UNSIGNED16 RO Y

60BAh VAR Touch probe pos1 pos value INTEGER32 RO Y

60BBh VAR Touch probe pos1 neg value INTEGER32 RO Y

60BCh VAR Touch probe pos2 pos value INTEGER32 RO Y

60BDh VAR Touch probe pos2 neg value INTEGER32 RO Y

60C0h VAR Interpolation sub mode select INTEGER16 RW Y

60C1h ARRAY Interpolation data record UNSIGNED16/32 RW Y

60C2h RECORD Interpolation time period SIGNED8 RW Y

60C5h VAR Max acceleration UNSIGNED32 RW Y

60C6h VAR Max deceleration UNSIGNED32 RW Y

ASDA A2-E Chapter 6 Object Dictionary Entries

Revision April, 2015 6-5

Index

Object

Type

Name Data Type Access Mappable

60F2h VAR Positioning option code UNSIGNED16 RW Y

60F4h VAR Following error actual value INTEGER32 RO Y

60FCh VAR Position demand value INTEGER32 RO Y

60FDh VAR Digital inputs UNSIGNED32 RO Y

60FFh VAR Target velocity INTEGER32 RW Y

6502h VAR Supported drive modes UNSIGNED32 RO Y

Delta parameter definition

2xxx VAR Parameter Mapping INTEGER16/32 RW Y

Chapter 6 Object Dictionary Entries ASDA A2-E

6-6 Revision April, 2015

6.4 Details of Objects

Object 1000h: Device Type

INDEX 1000h

Name device type

Object Code VAR

Data Type UNSIGNED32

Access RO

PDO Mapping No

Value Range UNSIGNED32

Default Value 04020192 h : A2 Series

Object 1001h: Error Register

INDEX 1001h

Name error register

Object Code VAR

Data Type UNSIGNED8

Access RO

PDO Mapping Yes

Value Range UNSIGNED8

Default Value 0

Object 1600

h

~ 1604h: Receive PDO Mapping Parameter

INDEX 1600h ~ 1603h

Name Receive PDO mapping

Object Code RECORD

Data Type PDO Mapping

Access RW

PDO Mapping No

Sub-Index 0

Description Number of mapped application objects in

PDO

Data Type UNSIGNED8

Access RW

ASDA A2-E Chapter 6 Object Dictionary Entries

Revision April, 2015 6-7

PDO Mapping No

Value Range 0: deactivated

1~8: activated

Default Value 0

Sub-Index 1~8

Description PDO mapping for the nth application object

to be mapped

Data Type UNSIGNED32

Access RW

PDO Mapping No

Value Range UNSIGNED32

Default Value 0

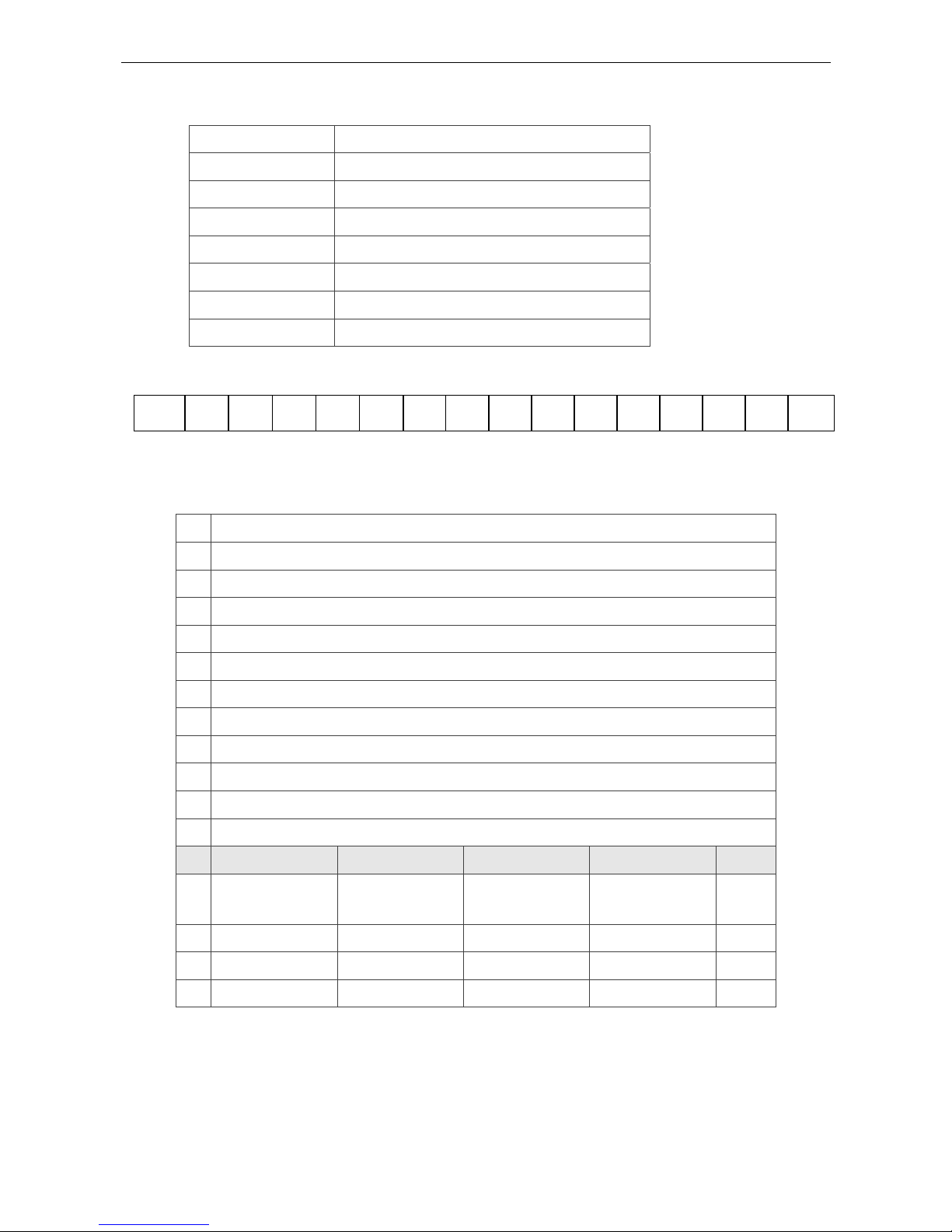

PDO Mapping

0

1

2

3

3

bbbb

cccc

aaaa

yy

zz

xx

08h

20h

10h

Object Dictionary

cccc zz

Application

Object 3

bbbb yy

Application

Object 2

aaaa xx

Application

Object 1

Application

Object 2

Application Object 1Application Object 3

Object 1A00h ~ 1A04h: Transmit PDO Mapping Parameter

Sub-Index 0

Description Number of mapped application objects in

PDO

Data Type UNSIGNED8

INDEX 1A00h ~ 1A03h

Name Transmit PDO mapping

Object Code RECORD

Data Type PDO Mapping

Access RW

PDO Mapping No

Chapter 6 Object Dictionary Entries ASDA A2-E

6-8 Revision April, 2015

Access RW

PDO Mapping No

Value Range 0: deactivated

1~8: activated

Default Value 0

Sub-Index 1~8

Description PDO mapping for the nth application object

to be mapped

Data Type UNSIGNED32

Access RW

PDO Mapping No

Value Range UNSIGNED32

Default Value 0

Object 1C12h : RxPDO assign

INDEX 1C12h

Name RxPDO assign

Object Code RECORD

Data Type PDO Mapping assign

Access RW

PDO Mapping No

Sub-Index 0

Description Number of assigned PDO mapping

Data Type UNSIGNED8

Access RW

PDO Mapping No

Value Range 0: deactivated

1: One PDO mapping be assigned to

SycManager2 for RxPDO

Default Value 1

Sub-Index 1

Description Index of assigned PDO mapping

Data Type UNSIGNED16

Access RW

PDO Mapping No

ASDA A2-E Chapter 6 Object Dictionary Entries

Revision April, 2015 6-9

Value Range 1600 h to 1603 h

Default Value 1601 h

Object 1C13h : TxPDO assign

INDEX 1C13h

Name TxPDO assign

Object Code RECORD

Data Type PDO Mapping assign

Access RW

PDO Mapping No

Sub-Index 0

Description Number of assigned PDO mapping

Data Type UNSIGNED8

Access RW

PDO Mapping No

Value Range 0: deactivated

1: One PDO mapping be assigned to

SycManager3 for TxPDO

Default Value 1

Sub-Index 1

Description Index of assigned PDO mapping

Data Type UNSIGNED16

Access RW

PDO Mapping No

Value Range 1A00 h to 1A03 h

Default Value 1A01 h

Object 603Fh: Error code (error code of CANopen defined)

INDEX 603Fh

Name Errorcode

Object Code VAR

Data Type UNSIGNED16

Access RO

PDO Mapping Yes

Value Range UNSIGNED16

Chapter 6 Object Dictionary Entries ASDA A2-E

6-10 Revision April, 2015

Default Value 0

Object 6040h: Controlword

INDEX 6040h

Name Controlword

Object Code VAR

Data Type UNSIGNED16

Access RW

PDO Mapping Yes

Value Range UNSIGNED16

Default Value P1-01 = 0x0C, Default is 0x0004

State Machine

ControlWord

(6040h)

StatusWord

(6041h)

State machine in system context