Delta Electronics AFE075A43A, AFE150A23A, AFE075A23A, AFE150A43A, AFE370A23A User Manual

...

501 260 430 0-A FE0

2011 -02 -15

I

Table of Content

01 Introduction .......................................................................................................................1-1

02 Installation.........................................................................................................................2-7

03 Wiring ……………………………………………………………………………………...……3-11

04 Main Circuit Terminal.......................................................................................................4-13

05 Control Terminal…………………………………………………………………………….…5-17

06 Optional Accessories.......................................................................................................6-21

07 Option Cards...................................................................................................................7-41

08 Specifications ..................................................................................................................8-57

09 Digital Keypad .................................................................................................................9-59

10 Summary of Parameter Settings ...................................................................................10-63

11 Description of Parameter Settings.................................................................................11-73

12 Warning Codes..............................................................................................................12-99

13 Fault Codes and Descriptions .....................................................................................13-103

14 CANOpen Slave ........................................................................................................14-109

PLEASE READ THE FOLLOWING INFORMATION PRIOR TO INSTALLATION FOR SAFETY.

DANGE

R

AC input power must be disconnected before any wiring or connection is made to the

AFE2000.

A charge may still remain in the DC-link capacitors with hazardous voltages after the power

has been turned off. DO NOT touch the internal circuit and any other components before the

Power LED indicator is off.

There are highly sensitive MOS components on AFE2000 printed circuit boards. These

components are especially sensitive to static electricity. Please do not touch these

components or the circuit boards before taking anti-static measures. Never reassemble the

internal components or wires.

Ground AFE2000 using the ground terminal. The grounding method must comply with the

laws of the country.

Keep AFE2000 and the installation away from fire and inflammables.

CAU TION

Only the qualified personnel are allowed to install, wiring, and repair the drive.

A hazardous voltage may still remain in the AFE2000 main circuit terminals even when the

three-phase DC motor is at stop status.

If AFE2000 is not charged for more than 3 months, keep the ambient temperature lower than

30 °C. It should be avoided keeping AFE2000 in storage for over a year; it could cause

degradation of electrolytic capacitors.

NOTE

The content of this manual may be revised without prior notice. Please consult our distributors or download the recent

version at ( http://www.delta.com.tw/industrialautomation/

)

Chapter 1 Introduction AFE2000 Series

1-1

Chapter 1 Introduction

1.1 Receiving and Inspection

For usage safety of the AC motor drive, please check for the followings:

1. Please inspect the unit after unpacking to assure it was not damaged during shipment.

2. Make sure that the part number printed on the package corresponds with the part number indicated

on the nameplate.

3. Make sure that the voltage for the wiring lie within the range as indicated on the nameplate.

4. Please install the AC motor drive according to this manual.

5. Before applying the power, please make sure that all the devices, including power, motor, control

board and digital keypad, are connected correctly.

6. When wiring the AC motor drive, please make sure that the wiring of input terminals “R/L1, S/L2,

T/L3” and output terminals”U/T1, V/T2, W/T3” are correct to prevent drive damage.

Nameplate

MODEL: AF E075A2 3A

INPUT:

AC 3PH 170-260V50/60Hz 35A

OUTPUT:

Version:

Enclosure (IPXX) TYPE Description

DC 330V 33A

XX XX

075AA237T0010001

DELTA ELECTRONICS. INC.

MADE IN XXXXXXX

Model Name

Input Voltage/Current

Output Voltage/Current

Enclosure (IPXX) Type

Firmware Version

Certifications

Serial Number

Chapter 1 Introduction AFE2000 Series

1-2

Model Name

A

FE 075A 23

A

23:230V 3-PHASE

43:460V 3-PHASE

007:1HP(0.75kW)~ 7750:100HP(75kW)

Versi on ty pe

Input voltage

Applicable motor capacity

Refer to the specifications for details

Series name(Active Front End Unit)

Serial Number

075AA237 T 0 01 0001

230V 3-PHASE 10HP(7.5kW)

Production number

Production week

Production year

Production factory

Model number

T: Tauyuan

W: Wujian

S: Shanghai

0:2010

Chapter 1 Introduction AFE2000 Series

1-3

1.2 Dimensions

Frame B

AFE075A23A; AFE075A43A; AFE150A43A

Detail A (Mounting Hole)

Detail B (Mounting Hole)

See Detail A

See Detail B

Unit:mm [inch]

Frame

W H D W1 H1

D1* S1 Φ1 Φ2 Φ3

B1

190.0

[7.48]

320.0

[12.60]

190.0

[7.48]

173.0

[6.81]

303.0

[11.93]

77.9

[3.07]

8.5

[0.33]

22.2

[0.87]

34.0

[1.34]

28.0

[1.10]

D1*: Flange mounting

Chapter 1 Introduction AFE2000 Series

1-4

Frame C

AFE150A23A; AFE220A23A; AFE220A43A

Detail A (Mounting Hole)

Detail B (Mounting Hole)

See Detail A

See Detail B

Unit:mm [inch]

Frame

W H D W1 H1

D1* S1 Φ1 Φ2 Φ3

C1

250.0

[9.84]

400.0

[15.75]

210.0

[8.27]

231.0

[9.09]

381.0

[15.00]

92.9

[3.66]

8.5

[0.33]

22.2

[0.87]

34.0

[1.34]

50.0

[1.97]

D1*: Flange mounting

Chapter 1 Introduction AFE2000 Series

1-5

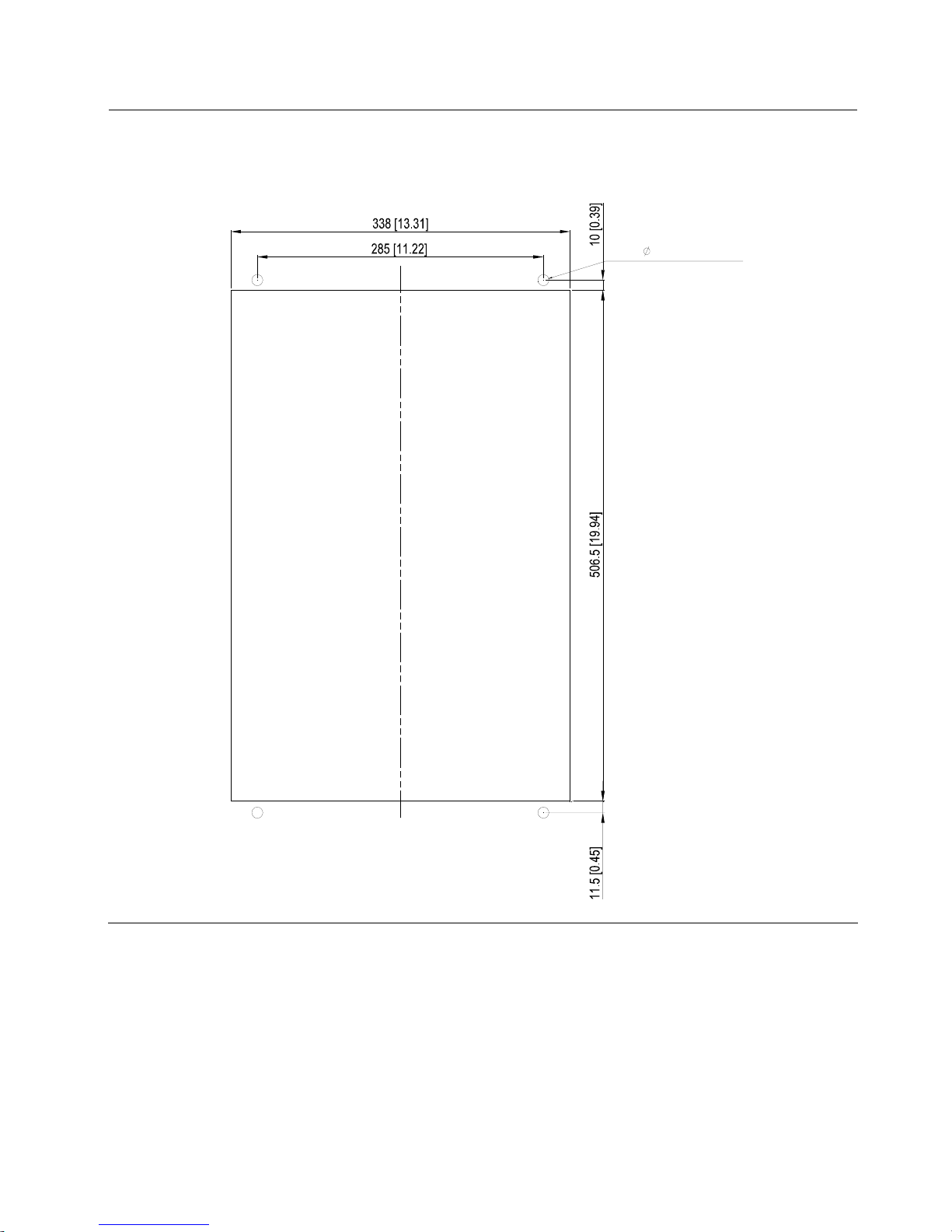

Frame D

D1: AFE370A23A; AFE370A43A; AFE450A43A; AFE750A43A;

D

H2

D1

W

W1

H

H1

S1S1

DETAIL A

(MOUNTING HOLE)

DETAIL B

(MOUNTING HOLE)

S2

D2

SEE DETAIL A

SEE DETAIL B

Unit:mm[inch]

Frame

W H D W1 H1 H2

D1* D2 S1 S2

D1

330.0

[12.99]

550.0

[21.65]

275.0

[10.83]

285.0

[11.22]

525.0

[20.67]

492.0

[19.37]

107.2

[4.22]

16.0

[0.63]

11.0

[0.43]

18.0

[0.71]

D1*: Flange mounting

Chapter 1 Introduction AFE2000 Series

1-6

Digital Keypad

KPC-CE01

Chapter 2 Installation AFE2000 Series

2-7

Chapter 2 Installation

The appearances shown in the following figures are for reference only.

Airflow direction: (Blue arrow) inflow (Red arrow) outflow

Single driv installation

(Frame B-D)

Side-by-side installation (Frame B-C)

Multiple drives installation side-by-side (Frame B,C)

Multiple drives installation side-by-side (Frame D) Install a barrier between the drives

Chapter 2 Installation AFE2000 Series

2-8

Multiple drives installation side-by-side in rows (Frame B,C) Ta: Frame B~D

For installation in rows, it is recommend to install a barrier between the drives. Adjust the size of the

barrier till the temperature measured at the fan’s inflow side is lower than the operation temperature.

Operation temperature is the defined as the temperature measured 50mm away from the fan’s inflow

side. (As shown in the figure below)

Minimum Mounting Clearances

Frame A (mm) B (mm) C (mm) D (mm)

B~C 60 30 10 0

D 100 50 - 0

Frame B AFE075A23A; AFE075A43A; AFE150A43A;

Frame C AFE150A23A; AFE220A23A; AFE220A43A;

Frame D AFE370A23A; AFE370A43A; AFE450A43A; AFE750A43A;

NOTE

1. It is the minimum distance required for Frame B~D. If drives are installed closer than the minimum mounting clearance, the

fan would not be able to function properly.

Chapter 2 Installation AFE2000 Series

2-9

NOT E

※ The mounting clearances shown in the left figure are NOT for installing the

drive in a confined space (such as cabinet or electric box). When installing

in a confined space, besides the same minimum mounting clearances, it

needs to have the ventilation equipment or air conditioner to keep the

surrounding temperature lower than the operation temperature.

※ The following table shows heat dissipation and the required air

volume when installing a single drive in a confined space. When

installing multiple drives, the required air volume shall be multiplied

by the number the drives.

※ Refer to the chart (Air flow rate for cooling) for ventilation equipment

design and selection.

※ Refer to the chart (Power dissipation) for air conditioner design and

selection.

Air flow rate for cooling

Power Dissipation

Flow Rate (cfm) Flow Rate (m3/hr) Power Dissipation

Model No.

External Internal Total External Internal Total

Loss External

(Heat sink)

Internal Total

AFE075A23A 66 14 80 112 24 136 249 86 335

AFE150A23A 166 12 178 282 20 302 455 161 616

AFE220A23A 146 12 158 248 20 268 649 216 865

AFE370A23A 179 30 209 304 51 355 1091 220 1311

AFE075A43A 40 14 54 68 24 92 216 76 292

AFE150A43A 58 14 73 99 24 124 396 122 518

AFE220A43A 99 21 120 168 36 204 476 158 635

AFE370A43A 179 30 209 304 51 355 809 184 993

AFE450A43A 179 30 209 304 51 355 929 218 1147

AFE750A43A 186 30 216 316 51 367 1408 334 1742

※ The required airflow shown in chart is for installing single drive in a

confined space.

※ When installing the multiple drives, the required air volume should

be the required air volume for single drive X the number of the

drives.

※ The heat dissipation shown

in the chart is for installing

single drive in a confined

space.

※ When installing the multiple

drives, volume of heat

dissipation should be the

heat dissipated for single

drive X the number of the

drives.

※ Heat dissipation for each

model is calculated by rated

voltage, current and default

carrier.

Chapter 2 Installation AFE2000 Series

2-10

This page is intentionally left blank

Chapter 3 WiringAFE2000 Series

3-11

Chapter 3 Wiring

One-to-One Installation (One AFE unit + One AC motor drive)

AC Reactor

(Standard)

Delta AFE 2000

I/O Extension Card

81

SG+

SG-

MO2

MCM

MO1

R/L1

S/L2

T/L3

Mi 1

MI3

MI4

MI5

MI6

Run

System error

Reset after fault

Reactor over heat

MI7

Digital signal common

DCM

MI2

Stop

MI8

COM

81

+24V

r1/l1

s1/l2

t1/l3

Multi- func tion 6

Multi- func tion 7

Multi- func tion 8

Multi-function output 3

Multi-function output 4

RA 1

RB 1

RC 1

Indication:

DC Bus level attained

Mult i-function output 1

Power removal sa fety f un ct ion

for EN95 4- 1 and IEC/ EN 615 08

DCM

S1

Digital signal common

X

Y

Z

Main circuit terminal

Control circuit terminal

Shielded leads & Cable

Th3

Th3

*3

RA 2

RB 2

RC 2

Indication:

AFE2000 is ready

Multi-function output 2

Mains Input

Frequency

U

V

W

*1

s1t1

r1

DC+

DC-

+1/DC+

-/DC-

Mot or

IM/PM

AC Mo tor D rive

*2

Option al

.

NOTE

*1 The Delta AC reactor (optional accessory) comes with a thermal protection function. When the reactor’s temperature exceeds

120 ºC, the TH3 terminal will come ON and the AFE 2000 will receive a signal from the MI terminal to issue a warning

message.

*2 For one-to-many installation, installing a fuse on the AC motor drive’s input side is recommended. Please select a compatible

fuse for your AC motor drive using the equation: Fuse specification= AC rated input current/ 0.78*1.5

*3 If the AC reactor installed on the system is not Delta’s AC reactor, please connect the reactor’s terminal to the power input

terminal (R(L1), S(L2), T(L3)) for wiring.

Chapter 3 Wiring AFE2000 Series

3-12

One-to-Many Installation (One AFE unit + Many AC motor drives)

AC Re actor

(Standard)

Delta AFE 2000

I/O Extension Card

81

SG+

SG-

MO2

MCM

MO1

R/L1

S/L2

T/L3

Mi1

MI3

MI4

MI5

MI6

Run

System error

Reset after fault

Reactor over heat

MI7

Digital signal common

DCM

MI2

Stop

MI8

COM

81

+24V

r1/l1

s1/l2

t1/l3

Multi-function 6

Multi-function 7

Multi-function 8

Multi-function output 3

Multi-function output 4

RA 1

RB 1

RC 1

Indication:

DC Bus level attained

Multi-funct ion output 1

Power removal safety fu nction

for EN954-1 and IEC/E N615 08

DCM

S1

Digital signal common

X

Y

Z

Main circuit terminal

Control circuit terminal

Shielded leads & Cable

Th3

Th3

*3

RA 2

RB 2

RC 2

Indication:

AFE2000 is ready

Multi-funct ion output 2

Mains Input

Frequency

U

V

W

*1

s1

t1 r1

+1/DC+

-/DC-

Motor

IM/PM

(1) AC Motor Drive

(2) AC Motor Drive

*2

DC+

DC-

+1/DC+

-/DC-

Motor

IM/PM

Optional

Optional

.

NOTE

*1 The Delta AC reactor (optional accessory) comes with a thermal protection function. When the reactor’s temperature exceeds

120 ºC, the TH3 terminal will come ON and the AFE 2000 will receive a signal from the MI terminal to issue a warning

message.

*2 For one-to-many installation, installing a fuse on the AC motor drive’s input side is recommended. Please select a compatible

fuse for your AC motor drive using the equation: Fuse specification= AC rated input current/ 0.78*1.5

*3 If the AC reactor installed on the system is not Delta’s AC reactor, please connect the reactor’s terminal to the power input

terminal (R(L1), S(L2), T(L3)) for wiring.

Chapter 4 Main Circuit TerminalsAFE2000 Series

4-13

Chapter 4 Main Circuit Terminals

Terminal Diagram for AFE2000

AC Reactor

(Standa rd)

Delta AFE 2000

Mains Input

Frequency

R(L1)

S(L2)

T(L3)

D+

D-

r1/l1

s1/l2

t1/l3

+1/DC+

-/DC-

Motor

IM/PM

Optional

Inverter

X

Y

Z

r1/l1

s1/l2

t1/l3

U

V

W

Terminals Description

R(L1), S(L2), T(L3) AC line input terminals 3-phase

r1/l1, s1/l2, t1/l3

Phase lock input terminal 3-phase

DC+, DC-

AFE2000 output terminal connects to AC motor drive terminal +1/DC+ & -/DC-。

Protective grounding terminal, please ground according to the local regulations.

Main power terminal:

Do not connect 3-phase model to one-phase power. It is unnecessary to consider

phase-sequence for these terminals R/L1, S/L2 and T/L3.

Please make sure to fasten the screw of the main circuit terminals to prevent sparks

which is made by the loose screws due to vibration.

Please use voltage and current within the specification.

Please use the shield wire or tube for the power wiring and ground the two ends of

the shield wire or tube.

Do not run or stop the AFE unit by turning the power ON or OFF. Please use the

power control terminal MI-RUN, MI-STOP or the RUN/STOP key on the display

board to control the AFE unit operation.

Output terminals for main circuit:

Connects only the DC+(+1) and DC-(-) terminal of an AC motor drive to AFE unit

output terminals.

Please pay special attention to the AFE2000 output terminals (+) and (-) for

connection, do not connect to the wrong output terminal.

Chapter 4 Main Circuit TerminalsAFE2000 Series

4-14

Main Circuit Terminals

Frame B

R/L1 T/L3S/L2

POWERDETECTION

r1/l1 t1/l3s1/l2

DC-+DC+

Main circuit terminals:

R(L1), S(L2), T(L3), , DC+, DC-

Models

Max. Wire

Gauge

Min. Wire Gauge

Torque

(±10%)

AFE075A23A 6 AWG (13.3mm2)

AFE075A43A 8 AWG (8.4mm2)

AFE150A43A

4 AWG

(21.2mm

2

)

6 AWG (13.3mm

2

)

M5

35kg-cm

(30.4 lb-in.)

(3.434Nm)

UL installations must use 600V, 75℃ or 90℃ wire. Use copper wire

only.

DC+ & DC-: must use 1kV Wire.

NOTE

Terminal r1/l1, s1/l2,

t1/l3:

Wire Gauge:20AWG [0.5mm²] ~ 14 AWG [2.1mm²]

Torque: 12 kg-cm [10.4 lb-in.] (1.18Nm) (±10%)

If additional terminal is needed when wiring, please refer to Figure 1 for

additional terminal dimension.

After crimping the wire to the ring lug please apply the UL approved R/C

(YDPU2) heat shrink tubing rate min 600Vac to the terminal. The insulation shall

be all over the live part. Please refer to Figure 2.

Detection wire

Figure 1

Figure 2

Power wire

Figure 1

Figure 2

Chapter 4 Main Circuit TerminalsAFE2000 Series

4-15

Frame C

DC-

+

DC+

R/L1 T/L3S/L2

POWERDETECTION

r1/l1 t1/l3s1/l2

Main circuit terminals:

R(L1), S(L2), T(L3),

, DC+, DC-

Models

Max. Wire

Gauge

Min. Wire Gauge

Torque

(±10%)

AFE150A23A 1 AWG (42.4mm2)

AFE220A23A 1/0 AWG (53.5mm2)

AFE220A43A

1/0 AWG

(53.5mm

2

)

4 AWG (21.2mm

2

)

M8

80kg-cm

(69.4 lb-in.)

(7.85Nm)

UL installations must use 600V, 75℃ or 90℃ wire. Use copper wire

only.

DC+ & DC-: must use 1kV Wire.

NOTE

Terminal r1/l1, s1/l2,

t1/l3:

Wire Gauge:20AWG [0.5mm²] ~ 14 AWG [2.1mm²]

Torque: 12 kg-cm [10.4 lb-in.] (1.18Nm) (±10%)

When surrounding temperature exceeds 45℃, please use 600V,90℃ wire for

model AFE220A23A.

If additional terminal is needed when wiring, please refer to Figure 1 for

additional terminal dimension.

After crimping the wire to the ring lug please apply the UL approved R/C

(YDPU2) heat shrink tubing rate min 600Vac to the terminal. The insulation shall

be all over the live part. Please refer to Figure 2.

Detection wire

Figure 1

Figure 2

Power wire

Figure 1

Figure 2

Chapter 4 Main Circuit TerminalsAFE2000 Series

4-16

Frame D

Main circuit terminals:

R(L1), S(L2), T(L3) , DC+, DC-,

Models

Max. Wire

Gauge

Min. Wire Gauge

Torque

(±10%)

AFE370A23A 250MCM (127mm2)

AFE370A43A 1/0 AWG (53.5mm2)

AFE450A43A 2/0 AWG (67.4mm2)

AFE750A43A

300MCM

(152mm

2

)

300MCM (152mm

2

)

M8

200kg-cm

(173 lb-in.)

(19.62Nm)

UL installations must use 600V, 75℃ or 90℃ wire. Use copper wire only.

DC+ & DC-: must use 1kV Wire.

NOTE

Terminal r1/l1, s1/l2, t1/l3:

Wire Gauge: 22AWG [0.3mm²] ~ 16 AWG [1.3mm²]

Torque: 5 kg-cm [4.3 lb-in.] (0.49 N.m)

If additional terminal is needed when wiring, please refer to Figure 1 for

additional terminal dimension.

After crimping the wire to the ring lug please apply the UL approved R/C

(YDPU2) heat shrink tubing rate min 600Vac to the terminal. The insulation shall

be all over the live part. Please refer to Figure 2.

Figure 1

Figure 2

Chapter 5 Control TerminalsAFE2000 Series

5-17

Chapter 5 Control Terminals

Please remove the cover before wiring multi-function input and output terminals.

The appearance of following figures are for reference only.

Removes the cover for wiring

Frame B

Screw torque: 12~15Kg-cm [10.4~13lb-in.]

Loosen the screws and press the tabs on both sides

to remove the cover.

Frame C&D

Screw torque: 12~15Kg-cm [10.4~13lb-in.]

MI1MO1

MI5

MI3

MO2

MCM

MI7

MI4

MI2

S1

MI8MI6

E24V SG-SG+

Removable Terminal Block

RA2RC2 RB2 RB1RC1 RA1

Open

120

485

A

B

DCM

E24V

DCM

COM

COM

Specifications of Control Terminal

Wire Gauge: 26~16AWG(0.1281-1.318mm2);

Torque: (A) 5kg-cm [4.31Ib-in.] (0.49Nm) (Refer to the Figure: Removable Terminal Block)

(B) 8kg-cm [6.94Ib-in.] (0.78Nm) (Refer to the Figure: Removable Terminal Block)

Wiring precautions:

Reserves 5mm and properly install the wire into the terminal; fasten the installation by a

slotted screwdriver. If the wire is stripped, sort the wire before install into the terminal.

Flathead screwdriver: blade width 3.5mm, tip thickness 0.6mm

As shown in the figure above, S1-DCM is short circuit as the factory setting; and for

E24V-COM is short circuit SINK mode (NPN), please refer to the following figures for more

detail.

Chapter 5 Control TerminalsAFE2000 Series

5-18

SINK(NPN)/SOURCE(PNP)Mode Switching Terminals.

1

2

DCM

MI1

E24V

MI2

MI8

~

COM

DCM

MI1

E24V

MI2

MI8

~

COM

Sink Mode Source Mode

with internal power (E 24Vdc)

with internal power (E24Vd c)

internal circuit

internal circuit

3

4

DCM

MI1

+24V

MI2

MI8

~

COM

DCM

MI1

+24V

MI2

MI8

~

COM

Sink Mode Source Mode

with external power

with external power

internal circuit

internal circuit

external power +24V

external power +24V

Terminals Terminal Function Factory Setting (NPN mode)

E24V

Digital control signal common

(Source)

COM Digital control signal common (Sink)

+24V±5% 200mA

Factory setting is short circuit status.

MI1

~

MI8

Multi-function input 1~8

The parameters used to set multi-function inputs MI1~MI8

are Pr.02-01~Pr.02-08.

ON: the activation current is 6.5mA 11Vdc≧

OFF: leakage current tolerance is 10μA11V≦ dc

DCM

Digital frequency signal common

Common for multi-function input terminals.

MO1

Multi-function Output 1

(photocoupler)

MO2

Multi-function Output 2

(photocoupler)

The AFE2000 releases various monitor signals, such as

drive in operation, frequency attained and overload

indication, via transistor (open collector).

MO2

MCM

MO1

MCM

Multi-function Output Common

(photocoupler)

Max 48Vdc 50mA

S1

DCM

The factory setting is short circuit.

Power removal safety function for EN954-1 and IEC/EN61508

Chapter 5 Control TerminalsAFE2000 Series

5-19

Terminals Terminal Function Factory Setting (NPN mode)

SG+

SG-

PIN 1,2,7,8 :Reserved PIN 3, 6: GND

PIN 4: SG- PIN 5: SG+

RA1

Multi-function relay output 1 (N.O.)

a

RB1

Multi-function relay output 1 (N.C.)

b

RC1 Multi-function relay common

RA2 Multi-function relay output 2 (N.O.) a

RB2 Multi-function relay output 2 (N.C.) b

RC2 Multi-function relay common

Resistive Load:

5A(N.O.)/3A(N.C.) 250VAC

5A(N.O.)/3A(N.C.) 30VDC

Inductive Load (COS 0.4):

2.0A(N.O.)/1.2A(N.C.) 250VAC

2.0A(N.O.)/1.2A(N.C.) 30VDC

It is used to output each monitor signal, such as drive is

in operation, frequency attained or overload indication.

NOTE: Wire size of analog control signals: 18 AWG (0.75 mm

2

) with shielded wire

Digital inputs (FWD, REV, MI1~MI8, COM)

When using contacts or switches to control the digital inputs, please use high quality

components to avoid contact bounce.

Transistor outputs (MO1, MO2, MCM)

Make sure to connect the digital outputs to the right polarity.

When connecting a relay to the digital outputs, connect a surge absorber across the coil and

check the polarity.

Removing the Terminal Block

1. Loosen the screws by screwdriver. (As shown in the figure.)

2. Remove the control board by pulling it out in parallel direction for 6~8 cm (as indicated in the figure

below : arrow 1) then lift the control board (as indicated in the figure below: arrow 2).

Chapter 5 Control TerminalsAFE2000 Series

5-20

This page is intentionally left blank

Chapter 6 Optional Accessories|AFE2000 Series

6-21

Chapter 6 Optional Accessories

The accessories list in this chapter are sold separately and are available upon request. Please select

applicable accessories for your AFE2000 unit or contact local distributor for suggestion on applicable

model and specification. The optional accessories would significantly improves the AFE2000 efficiency.

¾ Non-fuse Circuit Breaker

¾ Fuse

¾ AC Reactor

¾ Zero Phase Reactor

¾ Digital Keypad

¾ Panel Mounting

¾ Conduit Box

¾ Fan Kit

¾ Flange Mounting Kit

Chapter 6 Optional Accessories|AFE2000 Series

6-22

Non-fuse Circuit Breaker

Comply with UL standard: Per UL 508, paragraph 45.8.4, part a,

The rated current of the breaker shall be 2~4 times of the maximum rated input current of the

AFE unit.

3-phase 230V 3-phase 460V

Model

Recommended

Current (A)

Model

Recommended

Current (A)

AFE075A23A 60 AFE075A43A 40

AFE150A23A 125 AFE150A43A 60

AFE220A23A 200 AFE220A43A 100

AFE370A23A 250 AFE370A43A 150

AFE450A43A 175

AFE750A43A 300

Fuse Specification Chart

Fuses with specification smaller than the following table indicates are allowed.

NOTE

1. Use Copper Conductors Only, 75ºC for all field-wiring terminals located within the motor circuit.

2. “The drive is suitable for use in a circuit capable of delivering not more than 5000 rms symmetrical amperes, (480 or 240) ac

maximum when used with listed Delta inverters.” Or equivalent.

3. “The drive must be installed in a Pollution 2 environment with clean air according to enclosure classification. Cooling air must

be clean, free from corrosive materials and electrically conductive dust.”

4. All rubber grommets located on conduit box shall be removed and replaced with conduit hubs in the end use installation.

5. “For installation in the United States, branch circuit protection must be provided in accordance with the National Electrical

Code (NEC) and any applicable local codes. To fulfill this requirement, use the UL classified fuses”

6. “For installation in Canada, branch circuit protection must be provided in accordance with Canadian Electrical Code and any

applicable provincial codes. To fulfill this requirement, use the UL classified fuses”

230VModel

Manufacturer

Class / Catalog No Rating

AFE075A23A Class _T / JJS-60 600 Vac, 60A

AFE150A23A Class _T / JJS-125 600 Vac, 125A

AFE220A23A Class _T / JJS-175 600 Vac, 175A

AFE370A23A

Cooper Bussmann Inc.

Class _T / JJS-250 600 Vac, 250A

460V Model

Manufacturer

Class / Catalog No Rating

AFE075A43A Class _T / JJS-35 600 Vac, 35A

AFE150A43A Class _T / JJS-60 600 Vac, 60A

AFE220A43A Class _T / JJS-90 600 Vac, 90A

AFE370A43A Class _T / JJS-125 600 Vac, 125A

AFE450A43A Class _T / JJS-175 600 Vac, 175A

AFE750A43A

Cooper Bussmann Inc.

Class _T / JJS-300 600 Vac, 300A

Chapter 6 Optional Accessories|AFE2000 Series

6-23

AC Reactor

Terminal Specifications

U

X

Y

W

Z

V

TH3

r1 s1 t1

TH3

Torque: kg-cm / lb-in.. / Nm ±10% Wieght

230 V

Reactor Model

Frame KW

Applicable

Model

AFE-_ _ _A23A

Inductance

mH

Rated

Current

Arms

Mounting TBLK-A, B TBLK-C Net(Kg)

AF-RC075A2 B 7.5 075 2.1 35 40.0 /46.1 /3.92 3.8 /4.4 /0.37 23.0/ 26.5/ 2.25 28

AF-RC150A2 15 150 1.05 70 60.0 /69.2 /5.89 3.8 /4.4 /0.37 61.4/ 70.8/ 6.02 52

AF-RC220A2

C

22 220 0.77 95 80.0 /92.2 /7.85 3.8 /4.4 /0.37 61.4/ 70.8/ 6.02 62

AF-RC370A2 D 37 370 0.5 150 130.0 /149.9 /12.75 3.8 /4.4 /0.37 76.8/ 88.5/ 7.53 87

Torque: kg-cm / lb-in.. / Nm ±10% Wieght

460 V

Reactor Model

Frame KW

Applicable

Model

AFE-_ _ _A43A

Inductanc

e

mH

Rated

Current

Arms

Mounting TBLK-A, B TBLK-C Net(Kg)

AF-RC075A4 7.5 075 7.32 20 40.0 /46.1 /3.92 3.8 /4.4 /0.37 23.0/ 26.5/ 2.25 28

AF-RC150A4

B

15 150 4.18 35 60.0 /69.2 /5.89 3.8 /4.4 /0.37 23.0/ 26.5/ 2.25 52

AF-RC220A4 C 22 220 2.92 50 80.0 /92.2 /7.85 3.8 /4.4 /0.37 61.4/ 70.8/ 6.02 62

AF-RC370A4 37 370 1.96 75 130.0 /149.9 /12.75 3.8 /4.4 /0.37 76.8/ 88.5/ 7.53 87

AF-RC450A4 45 450 1.54 95 160.0 /184.5 /15.70 3.8 /4.4 /0.37 76.8/ 88.5/ 7.53 105

AF-RC750A4

D

75 750 0.92 160 220.0 /253.7 /21.58 3.8 /4.4 /0.37 76.8/ 88.5/ 7.53 137

Wiring Diagram

R(L1)

S(L2)

T(L3)

D+

D-

r1/l1

s1/l2

t1/l3

Motor

IM/PM

AC Reactor

AC Motor Drive

Delta AFE 200 0

U

V

W

r1/l1

s1/l2

t1/l3

X

Y

Z

+1/DC+

-/DC-

U

V

W

Mains

TH3

TH3

MI5

DCM

Chapter 6 Optional Accessories|AFE2000 Series

6-24

Frame Structure

F

G

: Mounting holes

TBLK-C

TBLK-B

TBLK-A

r1 s1 t1

UX V Y WZ

*Suitable screw size: H

B MAX

E

A MAX

C MAX

D

Model Specifications

Model

A

mm [inch] B mm [inch]C mm [inch]D mm [inch]E mm [inch]F mm [inch] G mm [inch]

H

Screw

Type

AF-RC075A2

305

[12.01]

159

[6.26]

280

[11.02]

150

[5.91]

125

[4.92]

22

[0.87]

11

[0.43]

M10

AF-RC150A2

355

[13.98]

180

[7.09]

328

[12.91]

200

[7.87]

139

[5.47]

26

[1.02]

11

[0.43]

M10

AF-RC220A2

355

[13.98]

200

[7.87]

328

[12.91]

200

[7.87]

159

[6.26]

26

[1.02]

11

[0.43]

M10

AF-RC370A2

385

[15.16]

210

[8.27]

385

[15.16]

200

[7.87]

168

[6.26]

25

[1.02]

13

[0.51]

M12

AF-RC150A4

355

[13.98]

180

[7.09]

328

[12.91]

200

[7.87]

139

[5.47]

26

[1.02]

11

[0.43]

M10

AF-RC220A4

355

[13.98]

200

[7.87]

328

[12.91]

200

[7.87]

159

[6.26]

26

[1.02]

11

[0.43]

M10

AF-RC370A4

385

[15.16]

210

[8.27]

385

[15.16]

200

[7.87]

168

[6.26]

25

[1.02]

13

[0.51]

M12

AF-RC450A4

385

[15.16]

230

[9.06]

385

[15.16]

200

[7.87]

188

[7.40]

25

[1.02]

13

[0.51]

M12

AF-RC750A4

420

[16.54]

240

[9.45]

440

[17.32]

250

[9.84]

200

[7.87]

25

[1.02]

13

[0.51]

M12

AF-RC075A4

305

[12.01]

159

[6.26]

280

[11.02]

150

[5.91]

125

[4.92]

22

[0.87]

11

[0.43]

M10

Chapter 6 Optional Accessories|AFE2000 Series

6-25

Zero Phase Reactor

RF220X00A UNIT: mm(inch)

Recommended

Wire Size (mm

2

)

Cable

type

(Note)

AWG mm2

Nominal

(mm2)

Qty.

Wiring

Method

≤10 ≤5.3 ≤5.5 1

Diagram

A

Single-

core

≤2 ≤33.6 ≤38 4

Diagram

B

≤12 ≤3.3 ≤3.5 1

Diagram

A

Three-

core

≤1 ≤42.4 ≤50 4

Diagram

B

Diagram A

Please wind each wire around the core for 4 times.

The reactor must be placed at AFE2000 side as close

as possible.

NOTE

600V insulated cable wire

1. The table above gives approximate wire size for

the zero phase reactors but the selection is

ultimately governed by the type and the

diameter of the cable, i.e. the cable diameter

must small enough to go through the center of

the zero phase reactor.

2. When wiring, do not goes through the earth

core. It only needs to pass through the motor

cable or the power cable.

Diagram B

Please put wires through 4 cores in series without

winding.

Chapter 6 Optional Accessories|AFE2000 Series

6-26

Digital Keypad

KPC-CC01

Frame size

Descriptions to the function key

Key Description

START OPERATION

1. It is only valid when the source of operation command is from the keypad.

2. The RUN key starts AFE2000 to operate as the function setting and the RUN LED will be ON

3. It can be pressed again and again during stop.

STOP OPERATION (When Stop key is pressed, all operation will stop in all condition.) This key has the

highest priority in all condition.

1. When i STOP command is given, the AFE2000’s operation will stop under any condition.

2. The RESET key can be used to reset the drive when faults occur. If the RESET key is not responsing,

check MENU Æ Fault Records search for the most recent fault.

OPERATION DIRECTION (This function will be available soon)

ENTER

Press ENTER and go to the next level. If it is the last level then press ENTERnter to execute the

command.

ESC

Press ESC to return to the last page. If there is a sub-menu, press ESC will return to the

previous category.

MENU, press MENU key at any time would return to the main menu.

List of function:

KPC-CE01does not support function 4~112.

KPC-CC01does not support function 4, 5 and 7.

1. Detail Parameter

2. Copy Parameter

3. Keypad Locked

4. PLC Function

5. Copy PLC

6. Fault Record

7. Simple/ Quick Setting

8. Display Setting

9. Time Setting

10. Language Setting

11. Startup Menu Setting

12. Main Page Setting

1. “up”, “down”, “left” and “right”.

2. When setting the number, use “left” and “right” key to increase and decrease the value.

3. When selecting the options, use “up” and “down” key to move the selection.

Function key (This function will be available soon.)

Chapter 6 Optional Accessories|AFE2000 Series

6-27

(This function will be available soon.)

(This function will be available soon.)

Chapter 6 Optional Accessories|AFE2000 Series

6-28

面 Panel Mounting (MKC-KPPK)

Panel Mounting (MKC-KPPK)

For MKC-KPPK model, user can choose wall mounting or embedded mounting. The protection level is IP56.

Applicable to the digital keypads (KPC-CC01 & KPC-CE01).

Wall Mounting Embedded Mounting

accessories*1

Screw *4 ~M4*p 0.7 *L8mm

Torque: 10-12kg-cm (8.7-10.4lb-in.)

accessories*2

Screw *4 ~M4*p 0.7 *L8mm

Torque: 10-12kg-cm (8.7-10.4lb-in.)

Panel cutout dimension Unit: mm [inch] Panel cutout dimension Unit: mm [inch]

Normal cutout dimension

Panel

thickness

1.2mm 1.6mm 2.0mm

A 66.4 [2.614]

B 110.2 [4.339] 111.3 [4.382] 112.5 [4.429]

*Deviation: ±0.15mm /±0.0059inch

Cutout dimension (Waterproof level: IP56)

Panel

thickness

1.2mm

1.6mm 2.0mm

A 66.4 [2.614]

B 110.8 [4.362]

*Deviation: ±0.15mm /±0.0059inch

Chapter 6 Optional Accessories|AFE2000 Series

6-29

Chapter 6 Optional Accessories|AFE2000 Series

6-30

Conduit Box Kit

Appearance

Frame D

Applicable modle

AFE370A23A; AFE370A43A; AFE450A43A; AFE750A43A;

Model number『MKC-DN1CB』

ITEM Description Qty.

1 Screw M5*0.8*10L 4

2 Rubber 28 2

3 Rubber 44 2

4 Rubber 88 2

5 Conduit box cover 1

6 Conduit box base 1

Installation

Frame D

1. Loosen the cover screws and press the tabs on each side of the cover to remove the cover, as shown in the

following figure. Screw torque: 10~12kg-cm (8.66~10.39Ib-in)

2. Remove the 5 screws shown in the following figure. Screw torque: 24~26kg-cm (20.8~22.6Ib-in).

Chapter 6 Optional Accessories|AFE2000 Series

6-31

3. Install the conduit box by fasten the 5 screws shown in the following figure.

Screw torque: 24~26kg-cm (20.8~22.6Ib-in).

4. Fasten the 4 screws shown in the following figure. Screw torque: 10~12kg-cm (8.66~10.39Ib-in).

Chapter 6 Optional Accessories|AFE2000 Series

6-32

Fan Kit

Frames

Frame B

A

pplicable mode: AFE075A43A ; AFE075A23A;

Fan Model『MKC-BFKM1』

Frame B

A

pplicable mode: AFE150A43A;

Fan Model 『MKC-BFKM2』

Frame B

A

pplicable mode: AFE075A23A; AFE075A43A;

A

FE150A43A;

Fan Model 『MKC-BFKB』

Frame C

A

pplicable mode: AFE150A23A; AFE220A23A;

A

FE220A43A;

Fan Model 『MKC-CFKB1』

Frame D

A

pplicable mode: AFE370A23A; AFE370A43A; AFE450A43A; AFE750A43A;

Fan Model 『MKC-DFKM』 Fan Model 『MKC-DFKB』

Fan Removal

Frame B Applicable mode: AFE075A43A;AFE075A23A; AFE150A43A

1. Press the tab on both side of the fan to successfully remove

the fan.

2. Disconnect the power terminal before removing the fan.

Frame B&C

Applicable model

AFE075A23A; AFE075A43A; AFE150A43A; AFE150A23A;

AFE220A23A; AFE220A43A

Disconnect the power terminal and use a slotted screwdriver to

remove the fan cover.

Chapter 6 Optional Accessories|AFE2000 Series

6-33

Frame D

Applicable model

AFE370A23A; AFE370A43A; AFE450A43A; AFE750A43A;

1. (Figure 1) Loosen screw 1 and screw 2, press the on the

right and the left to remove the cover, follow the direction

the arrows indicate. Press on top of digital keypad

KPC-CE01 to properly remove the keypad. Screw torque:

10~12kg-cm (8.6~10.4in-lbf).

1

2

Figure 1

2.

(Figure 2) Loosen screw 3 and screw 4, press the tab on

the right and the left to remove the cover. Screw torque:

6~8kg-cm (5.2~6.9in-lbf).

3

4

Figure 2

3. (Figure 3) Loosen screw 5 and disconnect the fan power.

Screw torque: 10~12kg-cm (8.6~10.4in-lbf).

5

Figure 3

4. (Figure 4) Loosen the screws. Screw torque: 24~26kg-cm

(20.8~25.6in-lbf).

5. Disconnect fan power and pull out the fan. (As shown in the

larger picture)

1

2

3

4

Figure 4

Chapter 6 Optional Accessories|AFE2000 Series

6-34

Flange Mounting Kit

Applicable Models, Frame B~D

Frame B

『MKC-BFM』

Applicable model AFE075A23A; AFE075A43A; AFE150A43A;

Accessories 1*2

Accessories 2*2

Screw 1 *4 ~ M8*P 1.25;

Screw 2*6 ~ M6*P 1.0;

Cutout dimension Unit: mm [inch]

Chapter 6 Optional Accessories|AFE2000 Series

6-35

『MKC-BFM』Installation

1. Install accessory 1& 2 by fastening 4 of the screw 1(M8). Screw torque: 40~45kg-cm (34.7~39.0Ib-in).

(As shown in the following figure)

2. Plate installation, place 6 of the screw 2 (M6) through accessory 1&2 and the plate then fasten the screws.

Screw torque: 25~30kg-cm (5.21~6.94Ib-in). (As shown in the following figure)』

Chapter 6 Optional Accessories|AFE2000 Series

6-36

Frame C

『MKC-CFM』

Applicable model

AFE150A23A; AFE220A23A; AFE220A43A;

Accessories 1*2

Accessories 2*2

Screw 1*4 ~ M8*P 1.25;

Screw 2*8 ~ M6*P 1.0;

Cutout dimension Unit:mm [inch]

Chapter 6 Optional Accessories|AFE2000 Series

6-37

Installation『MKC-CFM』

1. Install accessory 1& 2 by fastening 4 of the screw 1(M8). Screw torque: 50~55kg-cm (43.4~47.7Ib-in).

(As shown in the following figure)

2. Plate installation, place 8 of the screw 2 (M6) through accessories 1&2 and the plate then fasten the screws.

Screw torque: 25~30kg-cm (5.21~6.94Ib-in). (As shown in the following figure)

Chapter 6 Optional Accessories|AFE2000 Series

6-38

Frame D

Applicable model

AFE370A23A; AFE370A43A; AFE450A43A; AFE750A43A;

Cutout dimension Unit:mm [inch]

M10*P1.5(4X)

OR

11.0[0.43](4X)

Chapter 6 Optional Accessories|AFE2000 Series

6-39

Installation for Frame D

1. Loosen 8 screws and remove Fixture 2 (as shown in

the following figure).

5. Fasten 4 screws (as shown in the following figure).

Screw torque: 24~26kg-cm (20.8~22.6Ib-in).

2. Loosen 10 screws and remove Fixture 1 (as shown

in the following figure).

6. Fasten 5 screws (as shown in the following figure).

Screw torque: 24~26kg-cm (20.8~22.6Ib-in).

3. Fasten 4 screws (as shown in the following figure).

Screw torque: 30~32kg-cm (26.0~27.8Ib-in).

7. Place 4 screws (M10) through Fixture 1&2 and the

plate then fasten the screws. (as shown in the

following figure)

Screw torque: 200~240kg-cm (173.6~208.3Ib-in).

; Fasten 5 screws (as shown in the following figure).

Screw torque: 30~32kg-cm (26.0~27.8Ib-in).

Chapter 6 Optional Accessories|AFE2000 Series

6-40

This page is intentionally left blank

Chapter 7 Option CardsAFE2000 Series

7-41

Chapter 7 Option Cards

The option cards listed in this chapter are sold separately and are available upon request. Please select

applicable cards for your AFE2000 unit or contact local distributor for suggestion on applicable model an d

specification. The optional accessories would significantly improves the AFE2000 performance.

Please removes the digital keypad and the top cover before installation and install the option card

according to the follows the following instruction or damage may result.

Remove key cover

Frame B&C

Screw Torque: 8~10Kg-cm [6.9~8.7lb-in.]

Frame D

Screw Torque: 8~10Kg-cm [6.9~8.7lb-in.]

Chapter 7 Option CardsAFE2000 Series

7-42

1

2

Slot 1Slot 2

Slot 3

1

RJ45(Socket) for digital keypad

KPC-CC01; KPC-CE01

Please refer to CH09 Digital Keypad for more details on

KPC-CE01

Please refer to CH09 Digital Keypad for more details on

optional accessory RJ45 extension cable.

2

Communication extension cards(Slot 1)

CMC-MOD01

;

CMC-PD01;

CMC-DN01;

CMC-EIP01;

EMC-COP01;

CMC-MOD01

Features

1. Supports Modbus TCP protocol

2. MDI/MDI-X auto-detect

3. Baud rate: 10/100Mbps auto-detect

4. E-mail alarm

5. AC motor drive keypad/Ethernet configuration

6. Virtual serial port

Specifications

Network Interface

Interface

RJ-45 with Auto MDI/MDIX

Number of ports

1 Port

Transmission method

IEEE 802.3, IEEE 802.3u

Transmission cable

Category 5e shielding 100M

Transmission speed

10/100 Mbps Auto-Detect

Network protocol

ICMP, IP, TCP, UDP, DHCP, SMTP, MODBUS OVER TCP/IP, Delta Configuration

Electrical Specification

Power supply voltage

5VDC(suppliled by AFE2000)

Insulation voltage

2KV

Power consumption

0.8W

Weight

25g

Chapter 7 Option CardsAFE2000 Series

7-43

Environment

Noise immunity

ESD(IEC 61800-5-1,IEC 6100-4-2)

EFT(IEC 61800-5-1,IEC 6100-4-4)

Surge Teat(IEC 61800-5-1,IEC 6100-4-5)

Conducted Susceptibility Test(IEC 61800-5-1,IEC 6100-4-6)

Operation/storage

Operation: -10°C ~ 50°C (temperature), 90% (humidity)

Storage: -25°C ~ 70°C (temperature), 95% (humidity)

Vibration/shock immunity

International standard: IEC 61800-5-1, IEC 60068-2-6/IEC 61800-5-1, IEC

60068-2-27

Install CMC-MOD01 to AFE2000 unit

1. Turn off the AFE2000 power.

2. Open up AFE2000 cover.

3. Place the insulation spacer into the positioning pin at Slot 1 (shown in Figure 3), and aim the two holes o n

the PCB at the positioning pin. Press the pin to clip the holes with the PCB (see Figure 4)

4. Screw up at torque 6 ~ 8 kg-cm (5.21 ~ 6.94 in-lbs) after the PCB is clipped with the holes (see Figure 5).

Slot 1Slot 2

Slot 3

[Figure 3]

[Figure 4]

[Figure 5]

Communication Parameters for AFE2000 Connected to Ethernet

When AFE 2000 is link to Ethernet, please set up the communication parameters base on the table below.

Ethernet master will be able to read/write the frequency word and control word of AFE C2000 after

communication parameters setup

Parameter (Dec) Function Set value (Dec) Explanation

01-04

Source of operation

command setting

2

The operation command is controlled by

communication card.

04-21 IP setting 0 Static IP(0) / Dynamic distribution IP(1)

04-22 IP address -1 192 IP address 192.168.1.5

04-23 IP address -2 168 IP address 192.168.1.5

Chapter 7 Option CardsAFE2000 Series

7-44

Parameter (Dec) Function Set value (Dec) Explanation

04-24 IP address -3 1 IP address 192.168.1.5

04-25 IP address -4 5 IP address 192.168.1.5

04-26 Netmask -1 255 Netmask 255.255.255.0

04-27 Netmask -2 255 Netmask 255.255.255.0

04-28 Netmask -3 255 Netmask 255.255.255.0

04-29 Netmask -4 0 Netmask 255.255.255.0

04-30 Default gateway -1 192 Default gateway 192.168.1.1

04-31 Default gateway -2 168 Default gateway 192.168.1.1

04-32 Default gateway -3 1 Default gateway 192.168.1.1

04-33 Default gateway -4 1 Default gateway 192.168.1.1

Disconnecting CMC- MOD01 from AFE2000 unit

1. Turn off the AFE2000 power. .

2. Remove the two screws (see Figure 6).

3. Twist opens the card clip and insert s the slot type screw driver to the hollow to prize the PCB of f the card clip

(see Figure 7).

4. Twist opens the other card clip to remove the PCB (see Figure 8)

[Figure 6]

[Figure 7]

[Figure 8]

Basice Registers

BR# R/W Content Explanation

#0 R

Model name Set up by the system; read only. The model code of

CMC-MOD01=H’0203

#1 R

Firmware

version

Displaying the current firmware version in hex, e.g. H’0100 indicates the

firmware version V1.00.

#2 R

Release date of

the version

Displaying the data in decimal form. 10,000s digit and 1,000s digit are for

“month”; 100s digit and 10s digit are for “day”.

For 1 digit: 0 = morning; 1 = afternoon.

#1 1 R/W Modbus Timeout Pre-defined setting: 500 (ms)

#13 R/W Keep Alive Time Pre-defined setting: 30 (s)

Chapter 7 Option CardsAFE2000 Series

7-45

LED Indicator & Troubleshooting

LED Status Indication Treatment

On Power supply in normal status --

POWER Green

Off No power supply Check the power supply

On Network connection in normal status --

Flashes Network in operation --

LINK Green

Off

Network not connected Check if the network cable is

connected

Troubleshooting

Abnormality Cause Treatment

AC motor drive not powered

Check if AC motor drive is powered, an d if the

power supply is normal.

POWER LED off

CMC-MOD01 not connected

to AC motor drive

Make sure CMC-MOD01 is connected to AC motor

drive.

CMC-MOD01 not connected

to network

Make sure the network cable is correctly connected

to network.

LINK LED off

Poor contact to RJ-45

connector

Make sure RJ-45 connector is connected to

Ethernet port.

CMC-MOD01 not connected

to network

Make sure CMC-MOD01 is connected to network.

No module found

PC and CMC-MOD01 in

different networks and

blocked by network firewall.

Search by IP or set up relevant settings by AC

motor drive keypad.

CMC-MOD01 not connected

to network

Make sure CMC-MOD01 is connected to the

network.

Incorrect communication

setting in DCISoft

Make sure the communication setting in DCISoft is

set to Ethernet.

Fail to open

CMC-MOD01

setup page

PC and CMC-MOD01 in

different networks and

blocked by network firewall.

Conduct the setup by AFE2000 keypad.

Able to open

CMC-MOD01

setup page but fail

to utilize webpage

monitoring

Incorrect network setting in

CMC-MOD01

Check if the network setting for CMC-MOD01 is

correct. For the Intranet setting in your company,

please consult your IT staff. For the Internet setting

in your home, please refer to the network setting

instruction provided by your ISP.

Incorrect network setting in

CMC-MOD01

Check if the network setting for CMC-MOD01 is

correct.

Fail to send e-mail

Incorrect mail server setting Please confirm the IP address for SMTP-Server.

Chapter 7 Option CardsAFE2000 Series

7-46

CMC-PD01

Functions

1. Supports PZD control data exchange.

2. Supports PKW polling AFE2000 parameters.

3. Supports user diagnosis function.

4. Auto-detects baud rates; supports Max. 12Mbps.

Product Profile

1. NET indicator

2. POWER indicator

3. Positioning hole

4. AFE2000 connection port

5. PROFIBUS DP connection port

6. Screw fixing hole

7. Fool-proof groove

Specifications

PROFIBUS DP Connector

Interface

DB9 connector

Transmission method

High-speed RS-485

Transmission cable

Shielded twisted pair cable

Electrical isolation

500VDC

Communication

Message type Cyclic data exchange

Module name CMC-PD01

GSD document DELA08DB.GSD

Company ID 08DB (HEX)

Serial transmission

speed supported

(auto-detection)

9.6kbps; 19.2kbps; 93.75kbps; 187.5kbps; 125kbps; 250kbps; 500kbps; 1.5Mbps;

3Mbps; 6Mbps; 12Mbps (bits per second)

Electrical Specification

Power supply voltage

5VDC (supplied by AFE2000)

Insulation voltage

500VDC

Power consumption

1W

Weight

28g

Chapter 7 Option CardsAFE2000 Series

7-47

Environment

Noise immunity

ESD(IEC 61800-5-1,IEC 6100-4-2)

EFT(IEC 61800-5-1,IEC 6100-4-4)

Surge Teat(IEC 61800-5-1,IEC 6100-4-5)

Conducted Susceptibility Test(IEC 61800-5-1,IEC 6100-4-6)

Operation /storage

Operation: -10ºC ~ 50ºC (temperature), 90% (humidity)

Storage: -25ºC ~ 70ºC (temperature), 95% (humidity)

Shock / vibration

resistance

International standards: IEC61131-2, IEC68-2-6 (TEST Fc)/IEC61131-2 & IEC

68-2-27 (TEST Ea)

Installation

PROFIBUS DP Connector

PIN PIN name Definition

1 - Not defined

2 - Not defined

3 Rxd/Txd-P Sending/receiving data P(B)

4 - Not defined

5 DGND Data reference ground

6 VP Power voltage – positive

7 - Not defined

16

5

9

8 Rxd/Txd-N Sending/receiving data N(A)

9 - Not defined

LED Indicator & Troubleshooting

There are 2 LED indicators on CMC-PD01. POWER LED displays the status of the working power. NET LED

displays the connection status of the communication.

POWER LED

LED status Indication Treatment

Green light on Power supply in normal status. -Off No power

Check if the connection between CMC-PD01 and AC

motor drive is normal.

NET LED

LED status Indication Treatment

Green light on Normal status -Red light on

CMC-PD01 is not connected to

PROFIBUS DP bus.

Connect CMC-PD01 to PROFIBUS DP bus.

Red light

flashes

Invalid PROFIBUS communication

address

Set the PROFIBUS address of CMC-PD01 between 1 ~

125 (decimal)

Orange light

flashes

CMC-PD01 fails to communication

with AC motor drive.

Switch off the power and check whether CMC-PD01 is

correctly and normally connected to AC motor drive.

Chapter 7 Option CardsAFE2000 Series

7-48

CMC-DN01

Functions

1. Based on the high-speed communication interface of Delta HSSP protocol, able to conduct immediate

control to AFE2000 unit.

2. Supports Group 2 only connection and polling I/O data exchange.

3. For I/O mapping, supports Max. 32 words of input and 32 words of output.

4. Supports EDS file configuration in DeviceNet configuration software.

5. Supports all baud rates on DeviceNet bus: 125kbps, 250kbp s, 500kbps and extendable serial

transmission speed mode.

6. Node address and serial transmission speed can be set up on AFE2000 unit.

1. Power supplied from AFE2000 unit.

Product Profile

1. NS indicator

2. MS indicator

3. POWER indicator

4. Positioning hole

5. DeviceNet connection port

6. Screw fixing hole

7. Fool-proof groove

8. AFE2000 connection port

Specifications

DeviceNet Connector

Interface 5-PIN open removable connector. Of 5.08mm PIN interval

Transmission method CAN

Transmission cable Shielded twisted pair cable (with 2 power cables)

Transmission speed 125kbps, 250kbps, 500kbps and extendable serial transmission speed mode

Network protocol DeviceNet protocol

AFE2000 Connection Port

Interface 50 PIN communication terminal

Transmission method SPI communication

Terminal function

1. Communicating with AFE2000 unit

2. Transmitting power supply from AFE2000 unit

Communication protocol Delta HSSP protocol

Chapter 7 Option CardsAFE2000 Series

7-49

Electrical Specification

Power supply voltage 5VDC (supplied by AFE2000)

Insulation voltage

500VDC

Communication wire

power consumption

0.85W

Power consumption 1W

Weight 23g

Environment

Noise immunity

ESD (IEC 61800-5-1,IEC 6100-4-2)

EFT (IEC 61800-5-1,IEC 6100-4-4)

Surge Teat(IEC 61800-5-1,IEC 6100-4-5)

Conducted Susceptibility Test (IEC 61800-5-1,IEC 6100-4-6)

Operation /storage

Operation: -10ºC ~ 50ºC (temperature), 90% (humidity)

Storage: -25ºC ~ 70ºC (temperature), 95% (humidity)

Shock / vibration

resistance

International standards: IEC61131-2, IEC68-2-6 /IEC61131-2 & IEC 68-2-27

DeviceNet Connector

PIN Signal Color Definition

1 V+ Red DC24V

2 H White Signal+

3 S - Earth

4 L Blue Signal5 V- Black 0V

5

4

3

2

1

LED Indicator & Troubleshooting

There are 3 LED indicators on CMC-DN01. POWER LED displays the status of power supply. MS LED and NS

LED are dual-color LED, displaying the connection status of the communication and error messages.

POWER LED

LED status Indication Treatment

On Power supply in abnormal status.

Check the power supply of CMC-DN01.

Off Power supply in normal status --

Chapter 7 Option CardsAFE2000 Series

7-50

NS LED

LED status Indication Treatment

Off

No power supply or CMC-DN01 has

not completed MAC ID test yet.

1. Check the power of CMC-DN01 and see if the

connection is normal.

2. Make sure at least one or more nodes are on the

bus.

3. Check if the serial transmission speed of

CMC-DN01 is the same as that of other nodes.

Green light

flashes

CMC-DN01 is on-line but has not

established connection to the master.

1. Configure CMC-DN01 to the scan list of the

master.

2. Re-download the configured data to the master.

Green light on

CMC-DN01 is on-line and is normally

connected to the master

--

Red light

flashes

CMC-DN01 is on-line, but I/O

connection is timed-out.

1. Check if the network connection is normal.

2. Check if the master operates normally.

Red light on

1. The communication is down.

2. MAC ID test failure.

3. No network power supply.

4. CMC-DN01 is off-line.

1. Make sure all the MAC IDs on the network are

not repeated.

2. Check if the network installation is normal.

3. Check if the baud rate of CMC-DN01 is

consistent with that of other nodes.

4. Check if the node address of CMC-DN01 is

illegal.

5. Check if the network power supply is normal.

MS LED

LED status Indication Treatment

Off No power supply or being off-line

Check the power supply of CMC-DN01 and see of

the connection is normal.

Green light

flashes

Waiting for I/O data

Switch the master PLC to RUN status

Green light on I/O data are normal

--

Red light

flashes

Mapping error

1. Reconfigure CMC-DN01

2. Re-power AFE2000

Red light on Hardware error

1. See the error code displayed on AFE2000.

2. Send back to the factory for repair if necessary.

Orange light

flashes

CMC-DN01 is establishing connection

with AC motor drive.

If the flashing lasts for a long time, check if

CMC-DN01 and AFE2000 are correctly installed

and normally connected to each other.

Chapter 7 Option CardsAFE2000 Series

7-51

CMC-EIP01

Functions

1. Supports Modbus TCP and Ethernet/IP protocol

2. MDI/MDI-X auto-detect

3. Baud rate: 10/100Mbps auto-detect

4. AFE2000 keypad/Ethernet configuration

5. Virtual serial port

Product Profile

[Figure1]

1. Screw fixing hole

2. Positioning hole

3. AFE2000 connection port

4. LINK indicator

5. RJ-45 connection port

6. POWER indicator

7. Fool-proof groove

Specifications

Network Interface

Interface

RJ-45 with Auto MDI/MDIX

Number of ports

1 Port

Transmission method

IEEE 802.3, IEEE 802.3u

Transmission cable

Category 5e shielding 100M

Transmission speed

10/100 Mbps Auto-Detect

Network protocol

ICMP, IP, TCP, UDP, DHCP, HTTP, SMTP, MODBUS OVER TCP/IP, EtherNet/IP, Delta

Configuration

Electrical Specification

Weight

25g

Insulation voltage

500VDC

Power consumption

0.8W

Power supply voltage

5VDC

Chapter 7 Option CardsAFE2000 Series

7-52

Environment

Noise immunity

ESD (IEC 61800-5-1,IEC 61000-4-2)

EFT (IEC 61800-5-1,IEC 61000-4-4)

Surge Test (IEC 61800-5-1,IEC 61000-4-5)

Conducted Susceptibility Test (IEC 61800-5-1,IEC 61000-4-6)

Operation/storage

Operation: -10°C ~ 50°C (temperature), 90% (humidity)

Storage: -25°C ~ 70°C (temperature), 95% (humidity)

Vibration/shock

immunity

International standard: IEC 61800-5-1, IEC 60068-2-6/IEC 61800-5-1, IEC 60068-2-27

Installation

Connecting CMC-EIP01 to Network

1. Turn off the AFE2000 power.

2. Open up AFE2000 cover.

3. Connect CAT-5e network cable to RJ-45 port on CMC-EIP01

(See Figure 2).

[Figure 2]

RJ-45 PIN Definition

PIN Signal Definition PIN Signal Definition

1 Tx+

Positive pole for

data transmission

5 -- N/C

2 Tx-

Negative pole for

data transmission

6 Rx-

Negative pole for

data receiving

3 Rx+

Positive pole for

data receiving

7 -- N/C

4 -- N/C 8 -- N/C

Connecting CMC-EIP01 to AFE2000

1. Turn off the AFE2000 power.

2. Open up AFE2000 cover.

3. Place the insulation spacer into the positioning pin at Slot 1 (shown in Figure 3), and aim the two holes o n

the PCB at the positioning pin. Press the pin to clip the holes with the PCB (see Figure 4).

4. Screw up at torque 6 ~ 8 kg-cm (5.21 ~ 6.94 in-lbs) after the PCB is clipped with the holes (see Figure 5).

Chapter 7 Option CardsAFE2000 Series

7-53

Slot 1Slot 2

Slot 3

[Figure 3] [Figure 4]

[Figure 5]

Communication Parameters for AFE2000 Connected to Ethernet

When AFE2000 is connected to Ethernet network, please set up the communication parameters for it

according to the table below. The Ethernet master is only able to read/write the frequency word and control

word of AFE2000 af ter the communication parameters are set.

Parameter (Dec) Function Set value (Dec) Explanation

01-04

Setting up source of

operation command

5

The operation command is controlled by

communication card.

04-21 IP setting 0 Static IP(0) / Dynamic distribution IP(1)

04-22 IP address -1 192 IP address 192.168.1.5

04-23 IP address -2 168 IP address 192.168.1.5

04-24 IP address -3 1 IP address 192.168.1.5

04-25 IP address -4 5 IP address 192.168.1.5

04-26 Netmask -1 255 Newmask 255.255.255.0

04-27 Netmask -2 255 Newmask 255.255.255.0

04-28 Netmask -3 255 Newmask 255.255.255.0

04-29 Netmask -4 0 Newmask 255.255.255.0

04-30 Default gateway -1 192 Default gateway 192.168.1.1

04-31 Default gateway -2 168 Default gateway192.168.1.1

04-32 Default gateway -3 1 Default gateway192.168.1.1

04-33 Default gateway -4 1 Default gateway192.168.1.1

Chapter 7 Option CardsAFE2000 Series

7-54

Disconnecting CMC- EIP01 from AFEC2000

1. Turn off the AFEC2000 power .

2. Remove the two screws (see Figure 6).

3. Twist opens the card clip a nd inserts the slot type screwdriver to the hollow to prize the PCB off the card clip

(see Figure 7).

4. Twist opens the other card clip to remove the PCB (see Figure 8).

[Figure 6] [Figure 7]

[Figure 8]

LED Indicator & Troubleshooting

There are 2 LED indicators on CMC-EIP01. The POWER LED displays the status of power supply, and the

LINK LED displays the connection status of the communication.

LED Indicators

LED Status Indication Treatment

On Power supply in normal status --

POWER Green

Off No power supply

Check the power supply.

On

Network connection in normal

status

--

Flashes Network in operation

--

LINK Green

Off Network not connected

Check if the network cable is

connected.

Troubleshooting

Abnormality Cause Treatment

AFE2000 is not powered

Check if AFE2000 i s co nnected to power supply,

and if the power supply is normal.

POWER LED off

CMC-EIP01 not connected to

AC motor drive

Make sure CMC-EIP01 is connected to AFE2000.

Chapter 7 Option CardsAFE2000 Series

7-55

Abnormality Cause Treatment

CMC-EIP01 not connected to

network

Make sure the network cable is correctly connected

to network.

LINK LED off

Poor contact to RJ-45

connector

Make sure RJ-45 connector is connected to

Ethernet port.

CMC-EIP01 not connected to

network

Make sure CMC-EIP01 is connected to network.

No communication

card found

PC and CMC-EIP01 in

different networks and blocked

by network firewall.

Search by IP or set up relevant settings by AC

motor drive keypad.

CMC-EIP01 not connected to

network

Make sure CMC-EIP01 is connected to the

network.

Incorrect communication

setting in DCISoft

Make sure the communication setting in DCISoft is

set to Ethernet.

Fail to open

CMC-EIP01 setup

page

PC and CMC-EIP01 in

different networks and blocked

by network firewall.

Conduct the setup by the AFE2000 keypad.

Able to open

CMC-EIP01 setup

page but fail to

utilize webpage

monitoring

Incorrect network setting in

CMC-EIP01

Check if the network setting for CMC-EIP01 is

correct. For the Intranet setting in your company,

please consult your IT staff. For the Internet setting

in your home, please refer to the network setting

instruction provided by your ISP.

Incorrect network setting in

CMC-EIP01

Check if the network setting for CMC-EIP01 is

correct.

Fail to send e-mail

Incorrect mail server setting Please confirm the IP address for SMTP-Server.

Chapter 7 Option CardsAFE2000 Series

7-56

EMC-COP01

RJ-45Pin definition

Pin Pin name Definition

1 CAN_H CAN_H bus line (dominant high)

2 CAN_L CAN_L bus line (dominant low)

3 CAN_GND Ground/0V/V-

Male

Female

7 CAN_GND Ground/0V/V-

Specification

Interface

RJ-45

Number of ports

1 Port

Transmission method

CAN

Transmission cable

CAN standard cable

Transmission speed

1M 500k 250k 125k 100k 50k

Communication protocol

CANopen

CANopen Communication Cable

Model: T AP-CB03, TAP-CB04

L

Title Part No.

mm inch

1 TAP-CB03

500 10 19 0.4

2 TAP-CB04

1000 10 39 0.4

CANopen Dimension

Model: T AP-CN03

NOTE

Please refer to CANopen user manual for more details on CANopen operation. CANopen user manual is also

available on Delta website: http://www.delta.com.tw/industrialautomation/

.

Chapter 8 SpecificationsAFE2000 Series

8-57

Chapter 8 Specifications

230V series 460V series

Frame Size B C D B C D

Model AFE-_ _ _A_ _A 075 150 220 370 075 150 220 370 450 750

Applicable power(kW) 7.5 15 22 37 7.5 15 22 37 45 75

Rate input voltage(V) 170~ 250Vac 325~ 500Vac

Rated input current(A) 35 70 95 150 20 35 50 75 95 160

Voltage control 300~370Vdc 600~740Vdc

Overload capacity 150% 60sec

Frequency tolerance

5%

Power factor at input

side

0.95 to above 0.99

Harmonic (%) Smaller than 5% (under rated current)

Protection level IP20/NEMA 1

Cooling method Fan cooling

Installation environment

For indoor altitude 0~1000m(3280.60 feet) , keep it out of direct sunlight, corrosive

gasses, liquid and dust.

For altitude above 1000m(3280.60 feet), please decreases 3% of rated current for

every 500m (1640.40 feet) increases. The maximum altitude is 2500m (8202.00 feet)

Ambient temperature

-10~50℃

Storage/transportation

temperature

-25~+65℃

Ambient humidity Lower than 90%RH (non-condensing)

Vibration 5.9m/ s²(0.6G) less than 10~55Hz (JIS C0040)

Certifications

GB/T12668-2

(certification in progress)

8-58

This page is intentionally left blank

Chapter 9 Digital KeypadAFE2000 Series

9-59

Chapter 9 Digital Keypad

KPC-CC01(Optional)

KPC-CE01

F: Frequency Command

H: Output Frequency

U: User De fined Unit s

ERR: CAN Error Indicator

RUN: CAN Run Indica t or

B

: Status Indicator

A

: LED Display

Display frequency, current, voltage and error etc.

C

: Function

(Refer to the cha rt follows fo r detail description)

Communication interface:RJ-45 (socket), RS-485 interface

Installation Method:

Embedded mounting. Flat installation to the control box surface and the front facet is water proof.

Other optional accessories model: MKC-KPPK with protection level IP56 can be installed by flang mounting or

embedded mounting.

Descriptions of Keypad Functions

Key Descriptions

Starts Operation

1. It is only valid when the source of operation command is from the keypad.

2. It can operate the AFE2000 by the function setting and the RUN LED will be ON.

3. It can be pressed again and again at stop process.

Stop Command Key. This key has the highest processing priority in any situation.

1. When it receives STOP command, no matter the AC motor drive is in operation or stop

status, the AC motor drive needs to execute “STOP” command.

2. The RESET key can be used to reset the drive after the fault occurs. For those faults that

can’t be reset by the RESET key, see the fault records after pressing MENU key for

details.

(This function is not supported.)

ENTER Key

Press ENTER and go to the next level. If it is the last level then press ENTER to execute the command.

ESC Key

ESC key function is to leave current menu and return to the last menu. It is also functioned as

a return key in the sub-menu.

Press MENU to return to the main menu page.

MENU content:

(KPC-CE01 does not support function 4~12; KPC-CC01 does not support function 4,5,7.)

1. Detail Parameter

2. Copy Parameter

3. Keypad Locked

5. Copy PLC

6. Fault Record

7. Quick/Simple Setup

9. Time Setup

10. Language Setup

11. Startup Menu

Chapter 9 Digital KeypadAFE2000 Series

9-60

4. PLC Function

8. Display Setup 12. Main Page

1. Direction: Left/Right/Up/Down

2. In the numeric value setting mode, it is used to move the cursor and change the numeric

value.

3. In the menu/text selection mode, it is used for item selection.

Function (This function is not supported)

(This function is not supported)

(This function is not supported)

Descriptions of LED Functions

LED Descriptions

Steady ON: operation indicator of AFE2000.

Steady OFF: AFE2000 does not perform the operation command

Steady ON: stop indicator of the AC motor drive. The light ON represents the AFE2000 is in

stop status.

Steady OFF: AFE2000 does not perform “STOP” command.

(This function is not supported)

(This function is not supported)

(This function is not supported)

CANopen ~”RUN”

RUN LED:

LED

status

Condition/State

OFF CANopen at initial

No LED

Blinking CANopen at pre-operatio n

ON

OFF

Blinking

200

ms

200

ms

Single

flash

CANopen at stopped

ON

OFF

Single flash

200

ms

200

ms

1000

ms

ON CANopen at operation status

No LED

CANopen ~”ERR”

ERR LED:

LED

status

Condition/ State

OFF No Error

Chapter 9 Digital KeypadAFE2000 Series

9-61

Single

flash

At lease one message fail

ON

OFF

Single flash

200

ms

1000

ms

Double

flash

Guarding fail or heartbeat fail

ON

OFF

Double flash

200

ms

200

ms

1000

ms

200

ms

Triple

flash

SYNC fail

ON

OFF

Triple flash

200

ms

200ms200ms200

ms

1000

ms

200

ms

ON Bus off

Optional Accessory for Digital Keypad: RJ45 Extension Lead

Part No. Description

CBC-K3FT RJ45 Communication Cable 3 feet

CBC-K5FT RJ45 Communication Cable 5 feet

CBC-K7FT RJ45 Communication Cable 7 feet

CBC-K10FT RJ45 Communication Cable 10 feet

CBC-K16FT RJ45 Communication Cable 16 feet

Chapter 9 Digital KeypadAFE2000 Series

9-62

This page is intentionally left blank

Chapter 10 Summary of Parameter SettingsAFE2000 Series

10-63

Chapter 10 Summary of Parameter Settings

This chapter provides summary of parameter settings for user to gather the parameter setting ranges,

factory settings and set parameters. The parameters can be set, changed and reset by the digit al keypad.

NOTE

1) : the parameter can be set during operation

2) For more detail on parameters, please refer to Ch11 Description of Parameter Settings.

00 Display Parameters

Parameter

Explanation

Settings

Factory

Setting

00-00 Identity Code of AFE2000

0: 230V, 7.5kW

1: 460V, 7.5Kw

2: 230V, 15kW

3: 460V, 15kW

4: 230V, 22kW

5: 460V, 22kW

6: 230V, 37kW

7: 460V, 37kW

9: 460V, 45kW

1 1: 460V, 75kW

Read only

00-01

Display AFE2000 Rated

Current

0: 35A

1: 20A

2: 70A

3: 35A

4: 95A

5: 50A

6: 150A

7: 75A

9: 95A

11: 160A

Read only

00-02 Software version Read only Read only

00-03 Current of AFE Unit Read only Read only

00-04 Mains Input Frequency Read only Read only

00-05 DC-BUS voltage Read only Read only

00-06 Display the Input Power of

AFE2000 (kW )

-300.0 ~300.0 Read only

00-07 Display the Amount of Power

Consumed kWh (High Word)

0~9999 Read only

00-08 Display the Amount of Power

Consumed kWh (Low Word)

0 ~ 9999 Read only

00-09 Display the Amount of Power

Regenerated kWh (High

Word)

0 ~ 9999 Read only

00-10 Display the Amount of Power

Regenerated kWh (Low

Word)

0 ~ 9999 Read only

00-11 Display Total Power kWh

(High Word)

* Total Power = Power

Consumed + Power

Regenerated

-9999 ~ 9999 Read only

00-12 Display Total Power AAA

kWh (Low Word)

*Total Power = Power

Consumed+ Power

-9999 ~ 9999 Read only

Chapter 10 Summary of Parameter SettingsAFE2000 Series

10-64

Parameter

Explanation

Settings

Factory

Setting

Regenerated

00-13 Display AFE2000 Internal

Temperature (℃)

Read only Read only

00-14

IGBT Temperature (℃)

Read only Read only

00-15 Digital Input Status

(ON/OFF )

Read only Read only

00-16 Digital Output Status

(ON/OFF)

Read only Read only

00-17 DC Bus Voltage at Fault Read only Read only

00-18 Mains Input Frequency at

Fault

Read only Read only

00-19 Current value at Fault Read only Read only

00-20 1st Recent Fault Record

Fault

Retry

Fault

Reset

Read only

00-21 2nd Recent Fault Record 0: No Fault Record

O

O

Read only

00-22 3rd Recent Fault Record 3 : ocn

Read only

00-23 4

th

Recent Fault Record 4: GFF O O

Read only

00-24 5

th

Recent Fault Record 5 : occ (only for frame D) O O

Read only

00-25 6th Recent Fault Record 6: ocs O O

Read only

9: oVn O O

10: oVs O O

13 : LVn

14: LVs O O

15: PHL (Input phase loss) O O

16: oH1 (IGBT over-heat) O O

17: oH2 (Capacitance over-heat) O O

18: ot1 (circuit error)

19: ot2 (circuit error)

20: oL (150% 1Min, AFE2000

over-load)

O O

30: cF1 (Memory write-in error)

31: cF2 (Memory read error)

32: cd0 Isum current detection

error

33: cd1 U-phase current detection

error

34: cd2 V-phase current detection

error

35: cd3 W-phase current