Delta DZNT-104T, DZNT-V112A, VVT: DZNT-104D, DZNT-V104T, DZNT-112A Installation Manual

...

INSTALLATION GUIDE

VAV: DZNT-V104D | DZNT-V104T | DZNT-V112A

Product Description

The Delta VAV Termination (DZNT) solution consists of an

intelligent LCD thermostat (DZNT-T0-VAV) and remote

termination board (DZTM) for mounting on the VAV/VVT unit.

The thermostat has an LCD display, four pushbuttons for setpoint

and occupancy override, and contains a variety of configurable

VAV/VVT algorithms suitable for controlling all three remote

termination board types.

Every remote termination board comes complete with a damper

actuator, flow sensor for VAV models, and housing. They are also

capable of fan control, reheat control and automatic heat/cool

changeover.

Important Information

1. The Termination Board mounted to the VAV/VVT box is not a programmable

controller. All control and network functions are performed by the DZNT-T0VAV.

2. DZNT-T0-VAVs may be part of an MS/TP network or stand-alone. However, a

stand-alone DZNT-T0-VAV does not have a time clock or scheduling functions.

Occupied and Unoccupied periods are determined by airflow or a BAS contact

closure on IP3.

3. DZNT-T0-VAV used for VAV / VVT termination may not be used on LINKnet

networks.

4. Data exchange may be done in GCL programming in any DCU or Application

Controller on the MS/TP network.

5. Because of the fixed objects in the controller, alarming and trending must be

carried out by different controller on the network. Be aware that large numbers of

DER objects will affect the Scan Rate of those controllers. If the requirements call

for trending or alarming, it is recommended that you limit the number of DZNT

VAV devices so a maximum of 200 DER objects are created on any one system

panel.

VVT: DZNT-104D | DZNT-104T | DZNT-112A

VAV / VVT Termination:

Document Edition 1.2

Cautions or Warnings: This graphic identifies a situation where damage to a

device will occur if the instructions are not followed carefully. To protect the

Document Edition 1.2 Page 1 of 16

equipment that you are using, please read and follow the instructions in these notes.

Package Contents

Product: VAV: DZNT-V104D | DZNT-V104T | DZNT-V112A

VVT: DZNT-104D | DZNT-104T | DZNT-112A

DZNT VAV/VVT Installation Guide

DZNT VAV / VVT Installation Guide

0

Related Documents

DZNT VAV Application Guide: (configuration & programming)

Delta Controls Wiring Guidelines

Related Documents – Cont.

ORCAview Operator Guide

ORCAview Technical Reference Manual

Release Notes for related Firmware and DZNT-T0-VAV products

Actuator Instructions

Warning: Do not open the actuator or the controller.

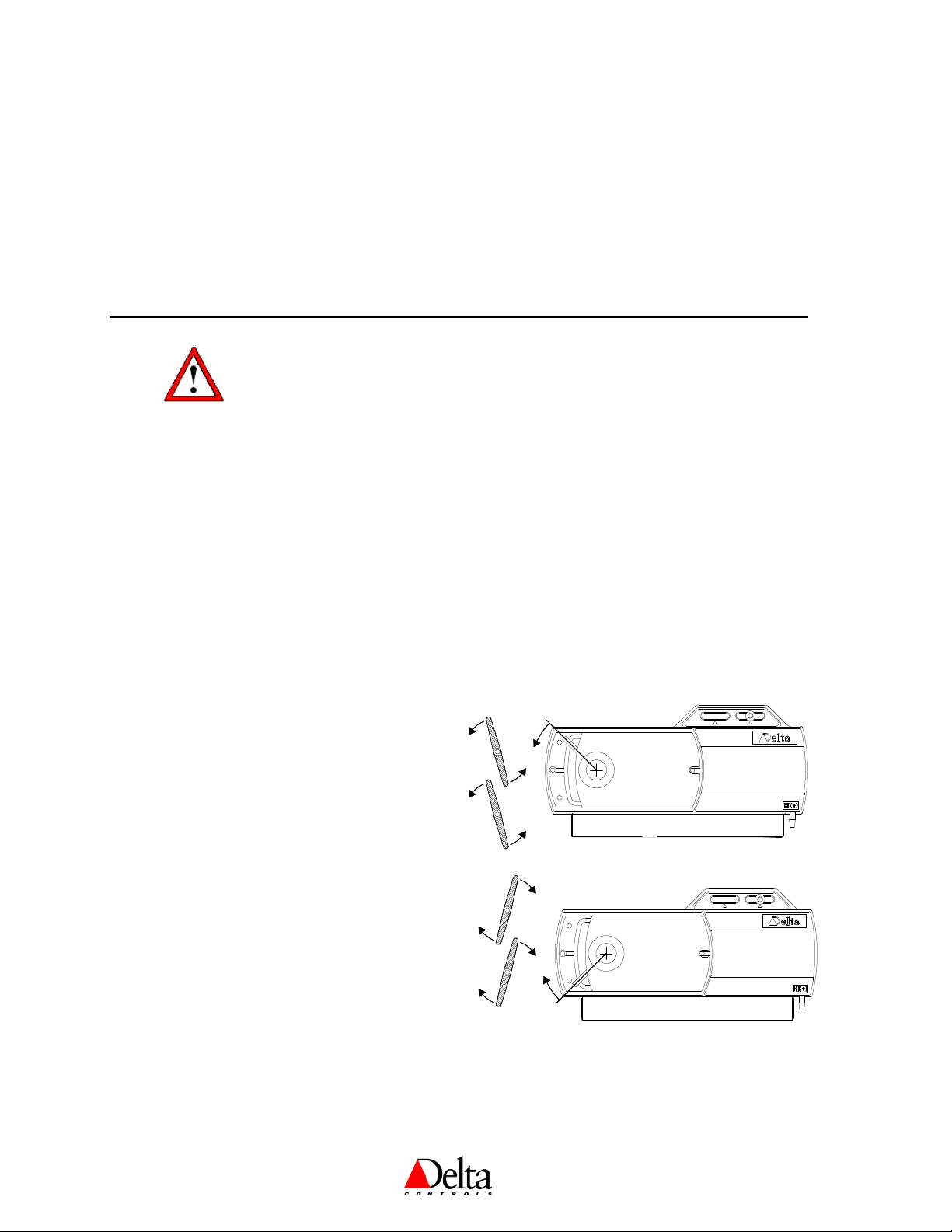

Note: Place the actuator/product on the damper shaft so that the front side, (label)

The Actuator/Product can be used with 3/8, 1/2, and 5/8 inch damper shaft sizes

• A 3/8-inch shaft size adapter is provided. Remove the 1/2-inch shaft size guide, and then install the shaft

insert so that the raised tabs are inserted last, through the damper shaft hole on bottom of product.

• A 1/2-inch shaft size guide is factory installed. If the damper shaft size is not 1/2 inch, then remove the

shaft guide from actuator through the damper shaft hole on bottom of product.

of the actuator/product is accessible.

• For 5/8-inch shaft size, remove any shaft guides or adapters from the actuator through the damper shaft

hole on bottom of product.

Set the Actuator to Open Clockwise or Counter Clockwise

1. Determine whether the damper blades will

rotate clockwise or counter clockwise to open.

2. Remove power, if connected.

Counter Clockwise

to open

3. Slide the manual override switch to manual

and move the adjustment lever to the position

as indicated by the drawing. Return the switch

to automatic.

4. Tighten 3mm allen-screw on to damper shaft,

torque 55-60 lb-in (6.5-7 Nm).

5. Restore power.

Clockwise

6. Use the DZNT-T0-VAV to set the damper

to open

action to Direct (CW) or Reverse (CCW).

7. Once power is restored, the actuator returns to

automated control.

0

Page 2 of 16 Document Edition 1.2

Delta Controls

eve

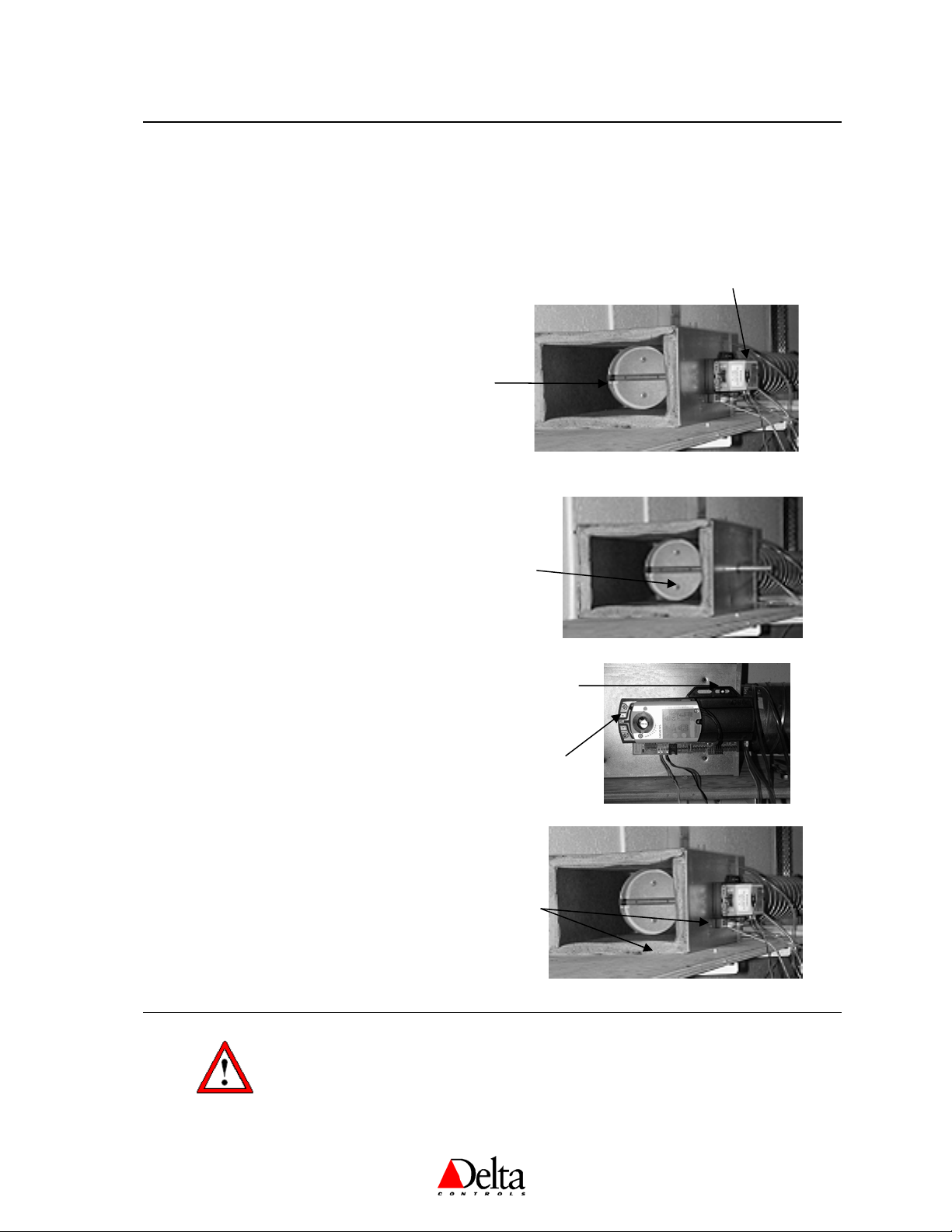

Mounting the VAV Termination Board

The actuator on one end of the housing fits over the damper shaft on the VAV box. The other end of the

plastic housing is secured to the VAV box with a sheet metal screw (through the mounting slots and brass

bushing provided). It is recommended that the screw be positioned near the center of the slot (triangle mark in

the plastic). After positioning the damper and the actuator to accommodate proper movement, the actuator

bracket is tightened securely.

Steps to mounting the VAV

1. According to the Damper Shaft sizes as

indicated above, ensure that the shaft insert

is correct for the size of the damper shaft.

2. Determine whether the damper will rotate

clockwise or counterclockwise to open.

3. Ensure that the damper is fully closed. The

indicator on the end of the damper shaft

should be vertical (up-down).

Open

Damper

Damper Shaft

4. Slide the controller over the damper shaft.

5. Secure the right end of the plastic housing

to the VAV box with a sheet metal screw

(through the mounting slots and brass

bushing provided). It is recommended that

the screw be positioned near the center of

the slot (triangle mark in the plastic).

6. Move the actuator clamp to the fully closed

position. If the damper rotates clockwise to

open, slide the manual override switch to

manual, and move the adjustment lever to

the far left. Return the switch to automatic.

7. Confirm again that the damper is fully

closed.

8. Tighten the adjustment lever. (3mm allen-

screw, onto the damper shaft, torque 55 60 lb-in (6.5-7 Nm)).

9. To ensure proper functionality of the

damper, depress the clutch, and stroke the

damper fully in both directions.

Closed

Damper

Position for sheet

metal screw

Adjustment

L

r

VAV mounted

on

Closed

Damper

Warnings and Cautions

Personal injury/loss of life may occur if a procedure is not performed as specified.

Equipment damage or loss of data may occur if the user does not follow a

procedure as specified.

Document Edition 1.2 Page 3 of 16

DZNT VAV / VVT Installation Guide

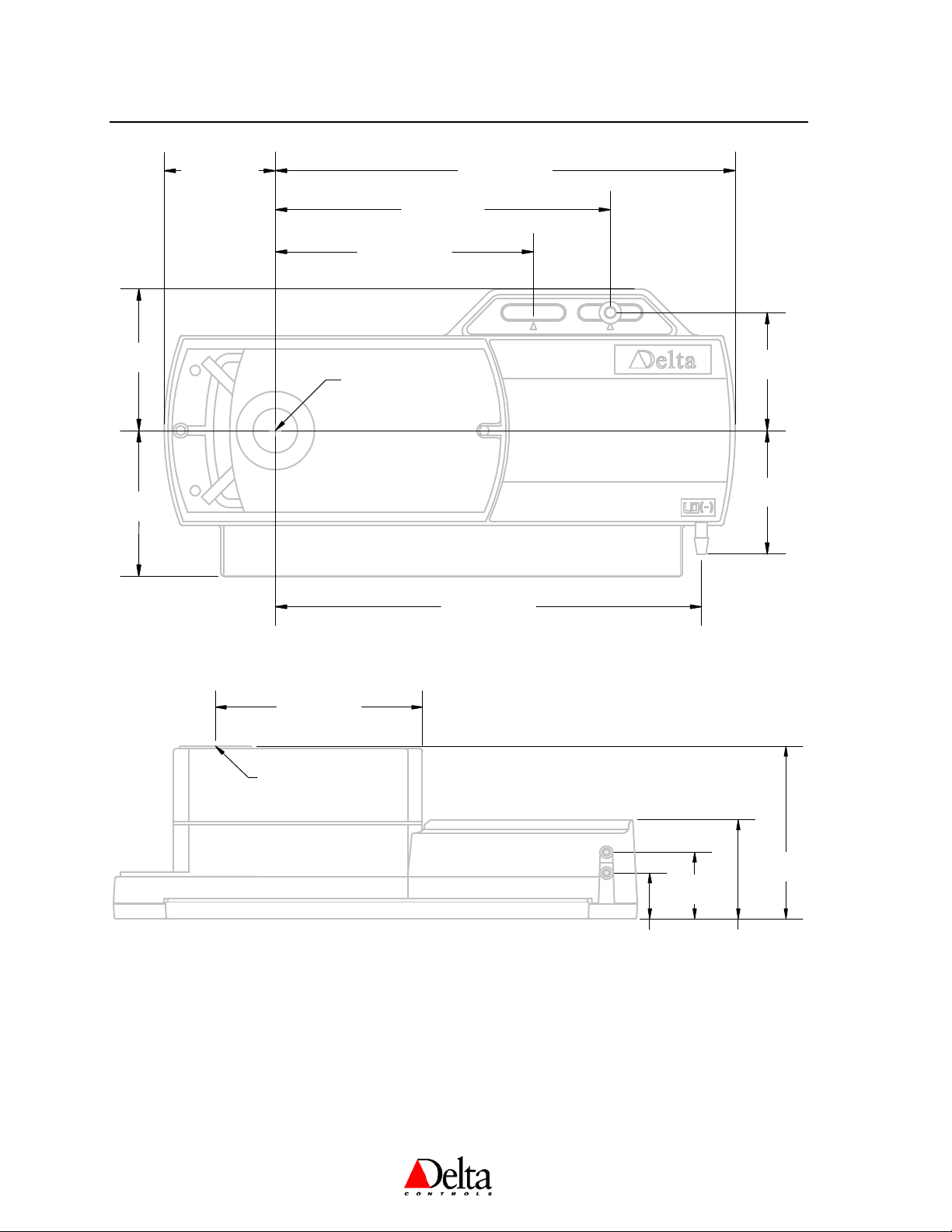

Mounting Dimensions

1.83 Inch

46.3 mm

4.23 Inch

107.5 mm

7.54 Inch

191.5 mm

5.50 Inch

139.5 mm

2.32 Inch

58.9 mm

2.39 Inch

60.6 mm

Damper Shaft

1.93 Inch

49.0 mm

2.02 Inch

51.3 mm

6.99 Inch

3.70 Inch

94.0 mm

Damper Shaft

177.5 mm

3.20 Inch

81.1 mm

31.4 mm

1.84 Inch

46.5 mm

1.25 Inch

0.85 Inch

21.5 mm

Page 4 of 16 Document Edition 1.2

Delta Controls

Mounting the Thermostat

The DZNT-T0-VAV backplate is designed for mounting directly on a standard North American, European or

Australian electrical box, but may be mounted in other ways as well.

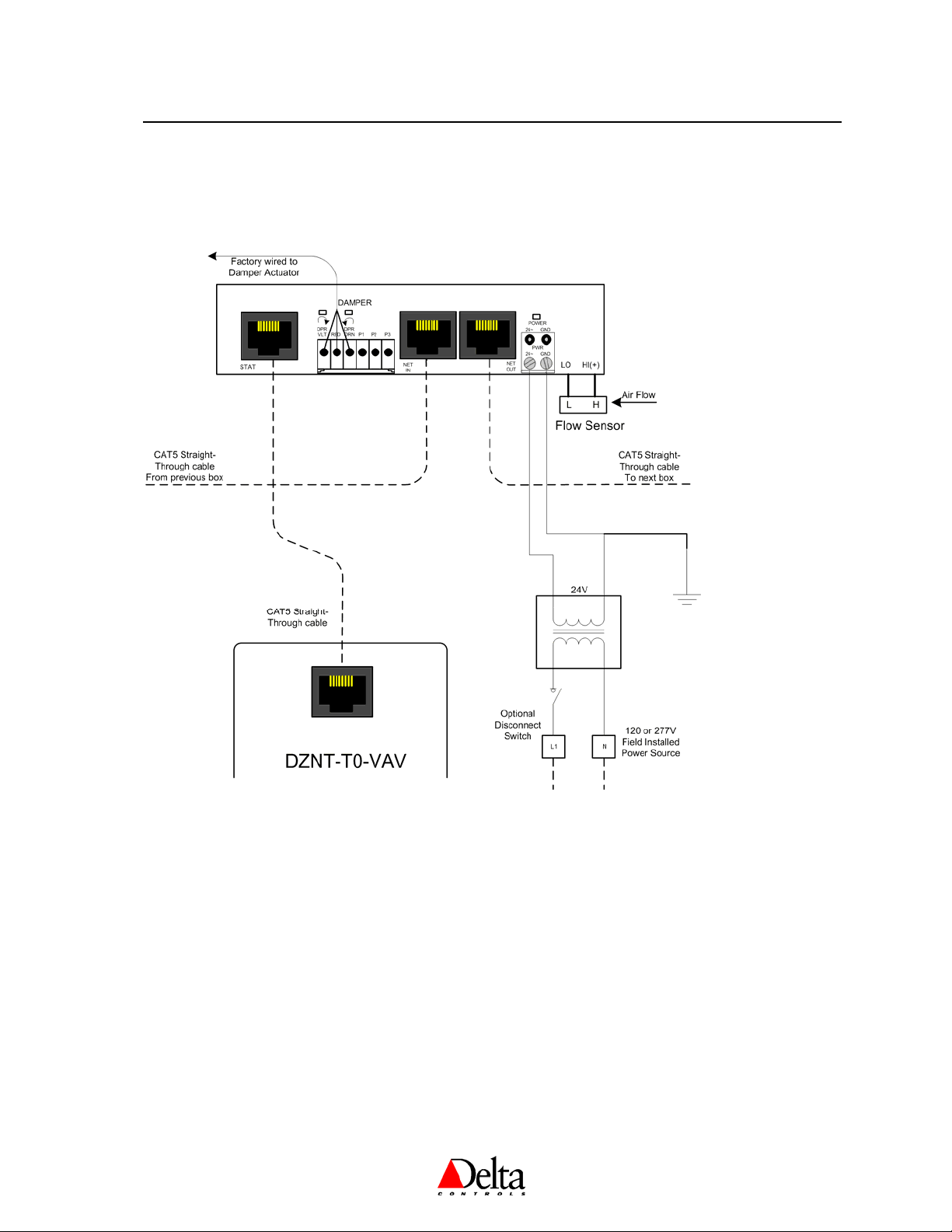

Wiring Diagram – Thermostat / Termination Board Connections

For further wiring details regarding reheat and other applications see the DZNT VAV/VVT Application Guide.

Notes:

1. Ensure you use straight-through Cat3 or higher (Cat5, Cat5e, Cat6) cables to join boxes. Although

Cat5 is mentioned throughout the documentation, any of these cable types are acceptable.

2. Although it is not necessary to go from NET OUT on one box to NET IN on the next, doing so will

likely give the most even distribution of devices on the network and allow for easier troubleshooting

of network problems.

3. At the last box on each trunk, keep the loop-back connector, ADP45-MSTP-LOOP, in place on the

NET OUT connector. Doing so will provide improved network stability and allow any one device to

be removed from the network without causing a loss of communications to the devices downstream

4. If the same power source is used for more than one device, ensure that the transformer is properly

sized for the rated VA and ensure that the same polarity is observed from device to device.

Document Edition 1.2 Page 5 of 16

Loading...

Loading...