Page 1

10" Left tiLting UniSAW®

Penchant à gauche

UNISAW

UNISAW® de 254 mm (10 pulg)

inclinable a la izquerda

®

de 254 mm (10 po)

Français (37)

Español (72)

www.deltaportercable.com

Instruction manual

Manuel d’utilisation

Manual de instrucciones

Part No. N061865 - 1-22-10

INSTRUCTIVO DE OPERACIÓN, CENTROS DE SERVICIO Y PÓLIZA DE GARANTÍA.

LÉASE ESTE INSTRUCTIVO ANTES DE USAR EL PRODUCTO.

36-L336

36-L352

36-L552

36-L552LVC

Page 2

TABLE OF CONTENTS

NOTICE

IMPORTANT SAFETY INSTRUCTIONS ..........................2

SAFETY GUIDELINES - DEFINITIONS ...........................2

GENERAL SAFETY RULES .............................................3

ADDITIONAL SPECIFIC SAFETY RULES ......................4

FUNCTIONAL DESCRIPTION .........................................8

CARTON CONTENTS .......................................................8

ASSEMBLY ......................................................................10

OPERATION ....................................................................14

TROUBLESHOOTING ...................................................32

MAINTENANCE .............................................................32

SERVICE ......................................................................... 34

ACCESSORIES .............................................................. 35

WARRANTY ...................................................................35

FRANÇAIS ......................................................................37

ESPAÑOL .......................................................................72

IMPORTANT SAFETY INSTRUCTIONS

Read all warnings and operating instructions before using any tool or equipment. When

using tools or equipment, basic safety precautions should always be followed to reduce the risk of

personal injury. Improper operation, maintenance or modification of tools or equipment could result in

serious injury and property damage. There are certain applications for which tools and equipment are

designed. DELTA Machinery strongly recommends that this product NOT be modified and/or used for any application

other than for which it was designed.

If you have any questions relative to its application DO NOT use the product until you have written DELTA Machinery

and we have advised you. Contact us online at www.deltaportercable.com or by mail at End User Services, DELTA

Machinery, PO Box 2468, Jackson, TN 38302-2468. In Canada,125 Mural St. Suite 300, Richmond Hill, ON, L4B 1M4)

Information regarding the safe and proper operation of this tool is available from the following sources:

• Power Tool Institute, 1300 Sumner Avenue, Cleveland, OH 44115-2851or online at www.powertoolinstitute.com

• National Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-3201

• American National Standards Institute, 25 West 43rd Street, 4 floor, New York, NY 10036 www.ansi.org -

ANSI 01.1 Safety Requirements for Woodworking Machines

• U.S.DepartmentofLaborregulationswww.osha.gov

SAVE THESE INSTRUCTIONS!

SAFETY GUIDELINES - DEFINITIONS

It is important for you to read and understand this manual. The information it contains relates to protecting YOUR

SAFETY and PREVENTING PROBLEMS. The symbols below are used to help you recognize this information.

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

Used without the safety alert symbol indicates a potentially hazardous situation which, if not avoided, may

result in property damage.

2

Page 3

GENERAL SAFETY RULES

Failure to follow these rules may result in serious personal injury.

For your own safety, read the instruction manual 1.

before operating the machine. Learning the machine’s

application, limitations, and specific hazards will greatly

minimize the possibility of accidents and injury.

Wear eye and hearing protection and always use 2.

safety glasses. Everyday eyeglasses are not safety

glasses. Use certified safety equipment. Eye protection

equipment should comply with ANSI Z87.1 standards.

Hearing equipment should comply with ANSI S3.19

standards.

Wear proper apparel. 3. Do not wear loose clothing, gloves,

neckties, rings, bracelets, or other jewelry which may get

caught in moving parts. Nonslip protective footwear is

recommended. Wear protective hair covering to contain

long hair.

Do not use the machine in a dangerous environment. 4.

The use of power tools in damp or wet locations or in rain

can cause shock or electrocution. Keep your work area

well-lit to prevent tripping or placing arms, hands, and

fingers in danger.

Do not operate electric tools near flammable liquids 5.

or in gaseous or explosive atmospheres. Motors and

switches in these tools may spark and ignite fumes.

Maintain all tools and machines in peak condition. 6.

Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and

changing accessories. Poorly maintained tools and

machines can further damage the tool or machine and/or

cause injury.

Check for damaged parts. 7. Before using the machine,

check for any damaged parts. Check for alignment of

moving parts, binding of moving parts, breakage of parts,

and any other conditions that may affect its operation.

A guard or any other part that is damaged should be

properly repaired or replaced with DELTA or factory

authorized replacement parts. Damaged parts can cause

further damage to the machine and/or injury.

Keep the work area clean. 8. Cluttered areas and benches

invite accidents.

Keep children and visitors away. 9. Your shop is a

potentially dangerous environment. Children and visitors

can be injured.

Reduce the risk of unintentional starting. 10. Make sure

that the switch is in the “OFF” position before plugging in

the power cord. In the event of a power failure, move the

switch to the “OFF” position. An accidental start-up can

cause injury. Do not touch the plug’s metal prongs when

unplugging or plugging in the cord.

Use the guards. 11. Check to see that all safety devices are

in place, secured, and working correctly to prevent injury.

Remove adjusting keys and wrenches before starting 12.

the machine. Tools, scrap pieces, and other debris can

be thrown at high speed, causing injury.

Use the right machine. 13. Don’t force a machine or an

attachment to do a job for which it was not designed.

Damage to the machine and/or injury may result.

Use recommended accessories. 14. The use of accessories

and attachments not recommended by DELTA may cause

damage to the machine or injury to the user.

Use the proper extension cord. 15. Make sure your

extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to carry

the current your product will draw. An undersized cord will

cause a drop in line voltage, resulting in loss of power and

overheating. See the Extension Cord Chart for the correct

size depending on the cord length and nameplate ampere

rating. If in doubt, use the next heavier gauge. The smaller

the gauge number, the heavier the cord.

Secure the workpiece. 16. Use clamps or a vise to hold the

workpiece when practical. Loss of control of a workpiece

can cause injury.

Feed the workpiece against the direction of the 17.

rotation of the blade, cutter, or abrasive surface.

Feeding it from the other direction will cause the

workpiece to be thrown out at high speed.

Don’t force the workpiece on the machine. 18. Damage to

the machine and/or injury may result.

Don’t overreach. 19. Loss of balance can make you fall into

a working machine, causing injury.

Never stand on the machine. 20. Injury could occur if the

tool tips, or if you accidentally contact the cutting tool.

Never leave the machine running unattended. 21. Turn

the power off. Don’t leave the machine until it comes to a

complete stop. A child or visitor could be injured.

Turn the machine “22. OFF”, and disconnect the machine

from the power source before installing or removing

accessories, changing cutters, adjusting or changing

set-ups. When making repairs, be sure to lock the start

switch in the “OFF” position. An accidental start-up can

cause injury.

Make your workshop childproof with padlocks, master 23.

switches, or by removing starter keys. The accidental

start-up of a machine by a child or visitor could cause

injury.

Stay alert, watch what you are doing, and use 24.

common sense. Do not use the machine when you

are tired or under the influence of drugs, alcohol, or

medication. A moment of inattention while operating

power tools may result in injury.

25.

disburse dust or other airborne particles, including

wood dust, crystalline silica dust and asbestos dust.

Direct particles away from face and body. Always operate

tool in well ventilated area and provide for proper dust

removal. Use dust collection system wherever possible.

Exposure to the dust may cause serious and permanent

respiratory or other injury, including silicosis (a serious

lung disease), cancer, and death. Avoid breathing the

dust, and avoid prolonged contact with dust. Allowing

dust to get into your mouth or eyes, or lay on your skin

may promote absorption of harmful material. Always

use properly fitting NIOSH/OSHA approved respiratory

protection appropriate for the dust exposure, and wash

exposed areas with soap and water.

Use of this tool can generate and

3

Page 4

ADDITIONAL SPECIFIC SAFETY RULES

Failure to follow these rules may result in serious personal injury.

Always use safety glasses. 1. Everyday eyeglasses are

not safety glasses. Also use face or dust mask if cutting

operation is dusty. All users and bystanders must always

wear certified safety equipment:

• ANSI Z87.1 Eye protection (CAN/CSA Z94.3)

• ANSI S12.6 (S3.19) Hearing protection

• NIOSH/OSHA/MSHA respiratory protection.

Do not expose to rain or use in damp locations.2.

3. Avoid awkward positions where a sudden slip could

cause a hand to move into a saw blade.

Never reach in back of, or around, the cutting tool 4. with

either hand to hold down the workpiece.

Keep arms, hands and fingers away 5. from the blade to

prevent serious injury.

Use a push stick that is appropriate to the application 6.

to push workpieces through the saw. A push stick is a

wooden or plastic stick, usually homemade, that should

be used whenever the size or shape of the workpiece

would cause you to place your hands within 6" (152 mm)

of the blade.

Use hold-downs, jigs, fixtures or feather boards to 7.

help guide and control the workpiece. Accessories for

use with your tool are available at extra cost from your

local dealer or authorized service center. Instructions for

making a push stick, a narrow rip auxiliary fence, a push

block and feather boards are included in this manual.

Do not perform ripping, crosscutting or any other 8.

operation freehand.

Stability9. . Make sure the table saw is firmly mounted to a

secure surface before use and does not move.

Never cut metals10. , cement board or masonry.

Certain man-made materials have special instructions

for cutting on table saws. Follow the manufacturer’s

recommendations at all times. Damage to the saw and

personal injury may result.

The proper throat plate must be in place at all times11.

to reduce the risk of a thrown workpiece and possible

injury.

Use the correct saw blade for the intended operation.12.

The blade must rotate toward the front of the saw. Always

tighten the blade arbor nut securely. Before use, inspect

the blade for cracks or missing teeth. Do not use a

damaged or dull blade.

Never attempt to free a stalled saw blade without first 13.

turning the machine off and disconnecting the saw

from the power source. If a workpiece or cut-off piece

becomes trapped inside the blade guard assembly, turn

saw off and wait for blade to stop before lifting the blade

guard assembly and removing the piece.

Never start the machine14. with the workpiece against

the blade to reduce the risk of a thrown workpiece

and personal injury.

Never have any part of your body in line with the path 15.

of the saw blade. Personal injury may occur.

Never perform layout, assembly or set-up work 16. on

the table/work area when the machine is running. A

sudden slip could cause a hand to move into the blade.

Severe injury can result.

Clean the table/work area before leaving the machine. 17.

Lock out the switch and disconnect from the power

source to prevent unauthorized use.

Do not leave a long board (or other workpiece) 18.

unsupported so the spring of the board causes

it to shift on the table resulting in loss of control

and possible injury. Provide proper support for the

workpiece, based on its size and the type of operation to

be performed. Hold the work firmly against the fence and

down against the table surface.

If your saw 19. makes an unfamiliar noise or if it vibrates

excessively, cease operating immediately, turn unit off

and disconnect from power source until the problem

has been located and corrected. Contact a DELTA

factory service center, a DELTA authorized service center

or other qualified service personnel if the problem can not

be found.

Use recommended accessories. 20. The use of improper

accessories may cause risk of personal injury.

Do not operate this machine21. until it is completely

assembled and installed according to the instructions.

A machine incorrectly assembled can cause serious injury.

Obtain advice 22. from your supervisor, instructor, or

another qualified person if you are not thoroughly

familiar with the operation of this machine. Knowledge

is safety.

Additional information 23. regarding the safe and proper

operation of power tools (i.e., a safety video) is available

from the Power Tool Institute, 1300 Sumner Avenue,

Cleveland, OH 44115-2851 (www.powertoolinstitute.com).

Information is also available from the National Safety

Council, 1121 Spring Lake Drive, Itasca, IL 60143-3201.

Please refer to the U.S. Department of Labor OSHA

1910.213 Regulations.

SAVE THESE INSTRUCTIONS.

Refer to them often and use them to instruct others.

4

Page 5

TERMINOLOGY

Terms: the following terms will be used throughout the manual and you should become familiar with them.

•Through-cut refers to any cut that completely cuts through the workpiece.

•Non through-cut refers to any cut that does not completely cut through the workpiece.

•Push stick refers to a wooden or plastic stick, usually homemade, that is used to push small workpiece through the saw and keeps

the operator’s hands clear of the blade.

•Kickback occurs when the saw blade binds in the cut and violently thrusts the workpiece back toward the operator.

•Freehand refers to cutting without the use of a miter gauge or rip fence or any other means of guiding or holding the workpiece

other than the operator’s hand.

Never perform freehand cutting.

•Plunge cutting refers to blind cuts in the workpiece made by either raising the blade through the workpiece or lowering the

workpiece down to the blade.

Never perform plunge cutting.

•Resawing - Flipping material to make a cut the saw is not capable of making in one pass.

Resawing is not recommended.

•Cove cutting - Coving is an operation where the work is fed at an angle across the blade.

To reduce the risk of personal injury, do not perform cove cutting because table saw blades are not designed for

the excessive side loading needed.

SAW BLADE GUARD ASSEMBLY, ANTI-KICKBACK ASSEMBLY AND RIVING KNIFE

Your table saw is equipped with a blade guard assembly, anti-kickback assembly and riving knife that covers the blade and reduces

the possibility of accidental blade contact. The riving knife is a flat plate that fits into the cut made by the saw blade and effectively

fights kickback by lessening the tendency of the blade to bind in the cut. The blade guard assembly and anti-kickback assembly

can only be used when making through cuts that sever the wood. When making rabbets and other cuts that make non

through cuts, the blade guard assembly and anti-kickback assembly must be removed and riving knife lowered to the non

through cut position marked on the riving knife. Two anti-kickback pawls are located on the sides of the riving knife that allow the

wood to pass through the blade in the cutting direction but reduce the possibility of the material being thrown backwards toward the

operator.

Use all components of the guarding system (blade guard assembly, riving knife and anti-kickback assembly) for every operation for

which they can be used including all through cutting. If you elect not to use any of these components for a particular application

exercise additional caution regarding control of the workpiece, the use of push sticks, the position of your hands relative to the blade,

the use of safety glasses, the means to avoid kickback and all other warnings contained in this manual and on the saw itself. Replace

the guarding systems as soon as you return to through cutting operations. Keep the guard assembly in working order.

MAKING A PUSH STICK

In order to operate your table saw safely you must use a push stick whenever the size or shape of the workpiece would cause your

hands to be within 6" (152 mm) of the saw blade or other cutter. A push stick is included with this saw.

No special wood is needed to make additional push-sticks as long as it’s sturdy and long enough. A length of 15.7" (400 mm) is

recommended with a notch that fits against the edge of the workpiece to prevent slipping. It’s a good idea to have several push sticks

of the same length [15.7" (400 mm)] with different size notches for different workpiece thicknesses.

See the end of the English section for a picture of a push stick. The shape can vary to suit your own needs as long as it performs its

intended function of keeping your hands away from the blade.

KICKBACKS

Kickbacks can cause serious injury. A kickback occurs when a part of the workpiece binds between the saw blade and the rip fence,

or other fixed object, and rises from the table and is thrown toward the operator. Kickbacks can be avoided by attention to the

following conditions.

How to avoid them and protect yourself from possible injury

A. Be certain that the rip fence is parallel to the saw blade.

B. Do not rip by applying the feed force to the section of the workpiece that will become the cut-off (free) piece. Feed force when

ripping should always be applied between the saw blade and the fence; use a push stick for narrow work, 6" (152 mm) wide or

less.

C. Keep saw blade guard assembly, riving knife and anti-kickback assembly in place and operating properly. If anti-kickback

assembly is not operational, return your unit to the nearest authorized DELTA service center for repair. The riving knife must be in

alignment with the saw blade and the anti-kickback assembly must stop a kickback once it has started. Check their action before

ripping by pushing the wood under the anti-kickback assembly. The teeth must prevent the wood from being pulled toward the

front of the saw.

D. Plastic and composite (like hardboard) materials may be cut on your saw. However, since these are usually quite hard and

slippery, the anti-kickback pawls may not stop a kickback. Therefore, be especially attentive to following proper set up and cutting

procedures for ripping.

E. Use saw blade guard assembly, anti-kickback assembly and riving knife for every operation for which it can be used, including all

through-sawing.

5

Page 6

F. Push the workpiece past the saw blade prior to release.

G. Never rip a workpiece that is twisted or warped, or does not have a straight edge to guide along the fence.

H. Never saw a large workpiece that cannot be controlled.

I. Never use the fence as a guide or length stop when crosscutting.

J. Never saw a workpiece with loose knots, flaws, nails or other foreign objects.

K. Never rip a workpiece shorter than 10" (254 mm).

L. Never use a dull blade – replace or have resharpened.

known to the State of California to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are:

• Leadfromlead-basedpaints,

• Crystallinesilicafrombricksandcementandothermasonryproducts,and

• Arsenicandchromiumfromchemically-treatedlumber(CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these chemicals:

work in a well-ventilated area, and work with approved safety equipment, such as those dust masks that are specially designed to

filter out microscopic particles.

• Avoidprolongedcontactwithdustfrompowersanding,sawing,grinding,drilling,andotherconstructionactivities.Wear

protective clothing and wash exposed areas with soap and water. Allowing dust to get into your mouth, eyes, or lay on the

skin may promote absorption of harmful chemicals.

Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure. Direct particles away from face and

body. Always operate tool in well-ventilated area and provide for proper dust removal. Use dust collection system wherever possible.

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains chemicals

Use of this tool can generate and/or disburse dust, which may cause serious and permanent respiratory or other injury.

SAVE THESE INSTRUCTIONS

POWER CONNECTIONS

A separate electrical circuit should be used for your machines:

FOR THREE HORSEPOWER, SINGLE PHASE UNITS

A suitable circuit should not be less than AWG12/3 wiring where the ground wire is attached to an earth ground. The circuit should be

protected by a circuit breaker or time delay fuse.

FOR FIVE HORSEPOWER, SINGLE PHASE UNITS

The circuit should not be less than #10 wire and should be protected with a 40 Amp time delay fuse.

NOTE: Time delay fuses should be marked “D” in Canada and “T” in the US. If an extension cord is used, use only 3-wire extension

cords which have 3-prong grounding type plugs and matching receptacle which will accept the machine’s plug. Before connecting

the machine to the power line, make sure the switch is in the “OFF” position and be sure that the electric current is of the same

characteristics as indicated on the machine. All line connections should make good contact. Running on low voltage will damage

the machine.

SHOCK HAZARD. Do not expose the machine to rain or operate the machine in damp locations.

MOTOR SPECIFICATIONS

All Unisaw motors are rated for 60 HZ alternating current, but voltage and HP varies according to model:

Model: Specifications:

36-L336, 36-L352 3HP, 230V single phase motor

36-L552 5 HP, 230V single phase motor

36-L552LVC 5 HP, 230V/460V three phase, dual votage motor

Before connecting the machine to the power source, make sure that the switch is in the “OFF” position.

GROUNDING INSTRUCTIONS

SHOCK HAZARD. This machine must be grounded while in use to protect the operator from electric shock.

1. All grounded, cord-connected machines:

In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of

electric shock. This machine is equipped with an electric cord having an equipment-grounding conductor and a grounding plug.

The plug must be plugged into a matching outlet that is properly installed and grounded in accordance with all local codes and

ordinances.

Do not modify the plug provided - if it will not fit the outlet, have the proper outlet installed by a qualified electrician.

Improper connection of the equipment-grounding conductor can result in risk of electric shock. The conductor with insulation having

an outer surface that is green with or without yellow stripes is the equipment-grounding conductor. If repair or replacement of the

electric cord or plug is necessary, do not connect the equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if the grounding instruction are not completely understood, or if in doubt as to

whether the machine is properly grounded.

6

Page 7

Use only 3-wire extension cords that have 3-prong grounding

type plugs and matching 3-conductor receptacles that accept

the machine’s plug.

Repair or replace damaged or worn cord immediately.

SHOCK HAZARD. In all cases, make certain

that the receptacle in question is properly grounded. If

you are not sure, have a qualified electrician check the

receptacle.

2. Grounded, cord-connected machines intended for use

on a supply circuit having a nominal rating between 150 250 volts, inclusive:

If the machine is intended for use on a circuit that has an outlet

that looks like the one illustrated in Fig. A or Fig. B, the machine

will have a grounding plug that looks like the plug illustrated in

Fig. A or Fig. B. Make sure the machine is connected to an

outlet having the same configuration as the plug. No adapter is

available or should be used with this machine. If the machine

must be re-connected for use on a different type of electric

circuit, the re-connection should be made by qualified service

personnel; and after re-connection, the machine should

comply with the National Electric Code and all local codes and

ordinances.

NOTE: The plug for the 3 HP model looks like the plug

illustrated in Fig. A. Make sure the 3 HP machine is connected

to an outlet having the same configuration as the plug.

NOTE: The plug for the 5 HP model looks like the plug

illustrated in Fig. B. Make sure the 5 HP machine is connected

to an outlet having the same configuration as the plug.

3. Permanently connected machines:

If the machine is intended to be permanently connected, all

wiring must be done by a qualified electrician and conform to

the National Electric Code and all local codes and ordinances.

THREE PHASE OPERATION: Three phase machines are

not supplied with a power cord and must be permanently

connected to a building’s electrical system. Extension cords

can’t be used with a three phase machine.

LVC MAGNETIC MOTOR CONTROL: If you purchased a

machine that has a Low Voltage Magnetic Motor Control

System, refer to its instruction manual for installation guidance.

GROUNDED OUTLET BOX

CURRENT

CARRYING

PRONGS

GROUNDING BLADE IS

LONGEST OF 3 BLADES

FIG. A

GROUNDED OUTLET BOX

CURRENT

CARRYING

PRONGS

GROUNDING BLADE IS

LONGEST OF 3 BLADES

FIG. B

EXTENSION CORDS

Use proper extension cords. Make sure your

extension cord is in good condition and is a 3-wire extension

cord which has a 3-prong grounding type plug and matching

receptacle which will accept the machine’s plug. When

using an extension cord, be sure to use one heavy enough

to carry the current of the machine. An undersized cord

will cause a drop in line voltage, resulting in loss of power

and overheating. Fig. C, shows the correct gauge to use

depending on the cord length. If in doubt, use the next

heavier gauge. The smaller the gauge number, the heavier

the cord.

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STATIONARY ELECTRIC MACHINES

Total

Ampere

Rating

Volts

0-6 240

0-6 240 50-100 16 AWG

0-6 240 100-200 16 AWG

0-6 240 200-300 14 AWG

6-10 240

6-10 240 50-100 16 AWG

6-10 240 100-200 14 AWG

6-10 240 200-300 12 AWG

10-12 240

10-12 240 50-100 16 AWG

10-12 240 100-200 14 AWG

10-12 240 200-300 12 AWG

12-16 240 up to 50 14 AWG

12-16 240 50-100 12 AWG

12-16 240

16-20 240 up to 50 10 AWG

16-20 240

7

Length of

Cord in

Feet

up to

50 18 AWG

up to

50 18 AWG

up to

50 16 AWG

GREATER THAN 100 FEET NOT RECOMMENDED

GREATER THAN 50 FEET NOT RECOMMENDED

Fig. C

Gauge of Extension

Cord

Page 8

FUNCTIONAL DESCRIPTION

FOREWORD

The DELTA Unisaw is a 10" (254 mm) left-tilting saw with a 5/8" (16 mm) arbor.

36-L336; 36-L352: Comes with a 3 HP motor and a 36" (914 mm) rip capacity fence.

36-L552: Comes with a 5 HP motor and a 52" (1321 mm) rip capacity fence.

SPECIFICATIONS for 36-L336/ 36-L352 / 36-L552 saws

Max depth of cut at 90 degrees:

Max depth of cut at 45 degrees:

3-1/8" (79 mm)

2-1/8" (54 mm)

Max rip to right of blade:

52" (1.3 m) rip fence models 52" (1321 mm)

36" (914 mm) rip fence models 36" (914 mm)

Max rip to left of blade:

Max width of dado:

12" (305 mm)

1" (25.4 mm)

NOTICE: The manual cover illustrates the current production model. All other illustrations contained in the manual are

representative only and may not depict the actual labeling or accessories included. These are intended to illustrate

technique only.

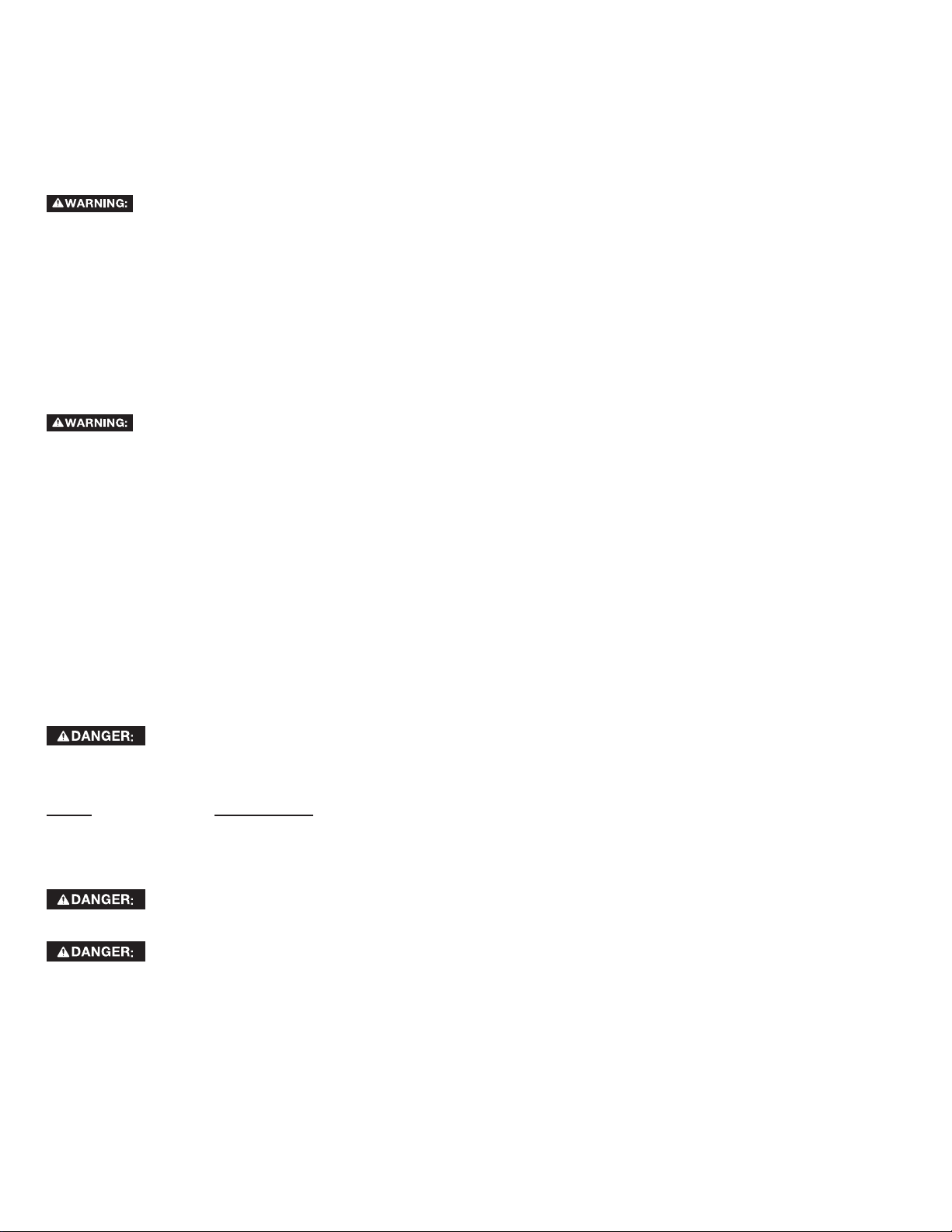

CARTON CONTENTS

2

1. Saw body (not shown)

2. Right and left extension wings

3. 5" (127 mm) to 4" (100 mm) reducer

3

4. M12 hex head screw (6)

5. M12 lockwasher (6)

6. 5/16-18 x 1" flat head socket screws (2)

7. 5/16-18 flange nut (2)

8. 5/16" External Tooth Washer

9. Washer

10. Miter gauge body

11. Miter gauge handle

4

5 7

9

6

8

10

11

8

Page 9

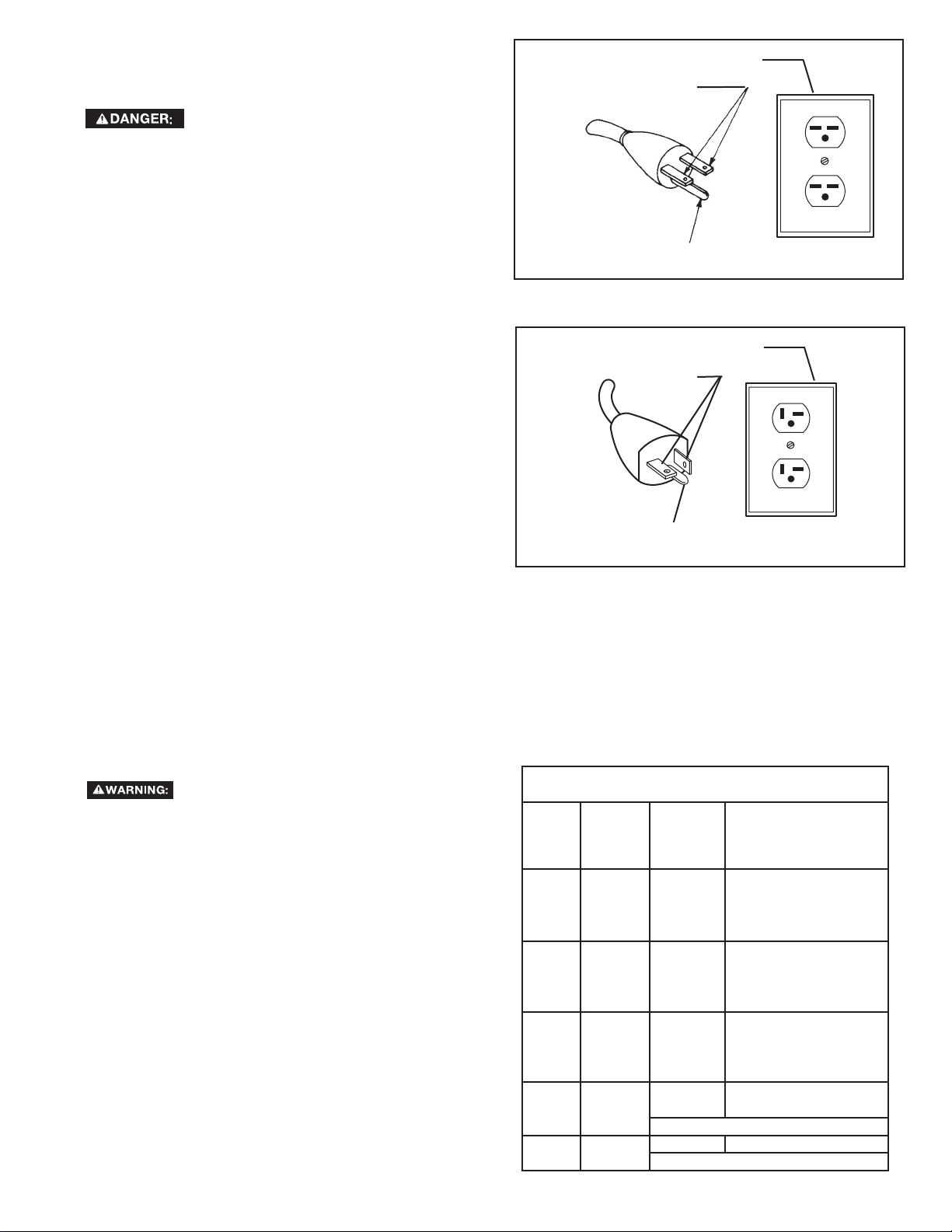

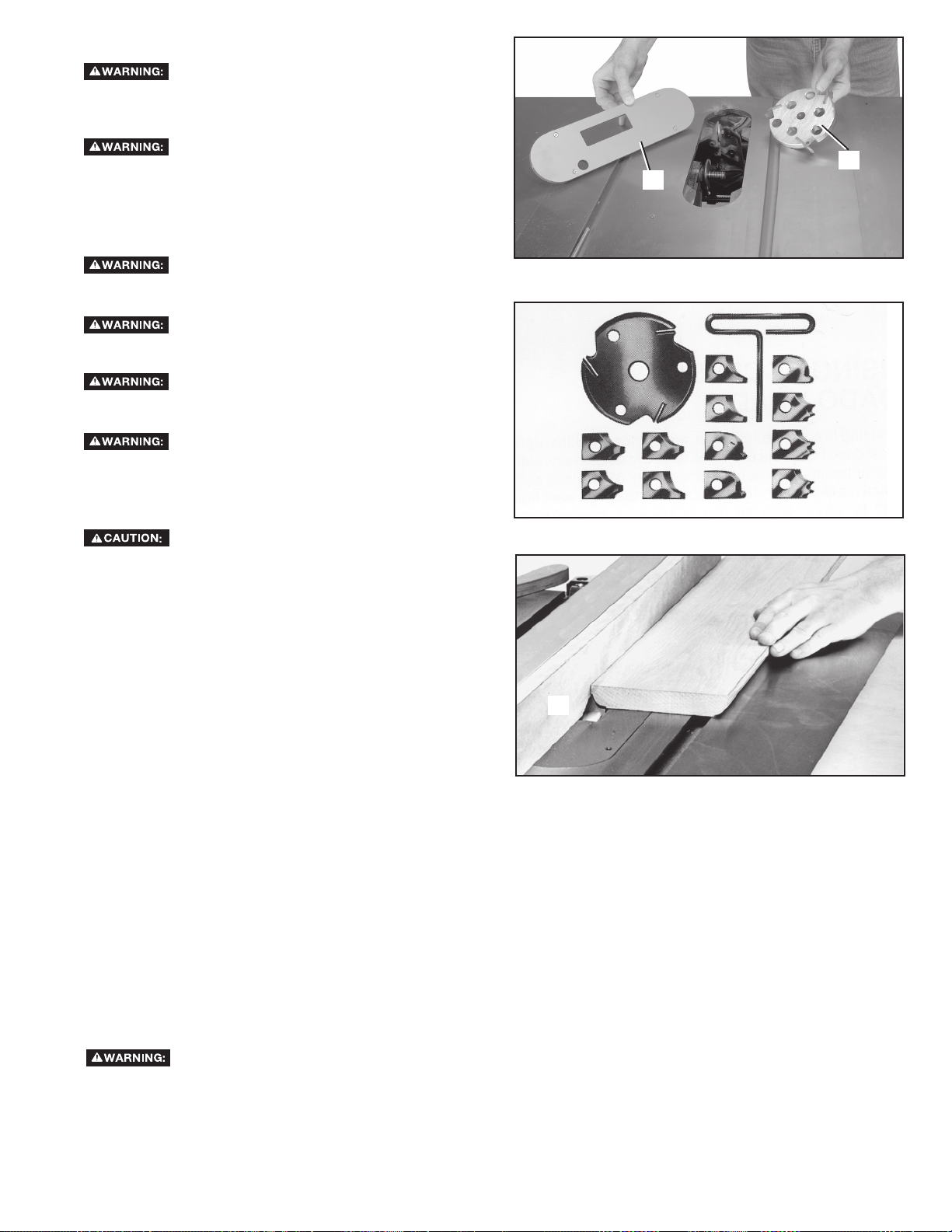

12. Anti-kickback assembly

13. Special arbor nut

14. Blade guard assembly

13

14

15. Arbor wrench

12

16. Push stick

17. T-handle 5/32 hex

16

wrench

17

15

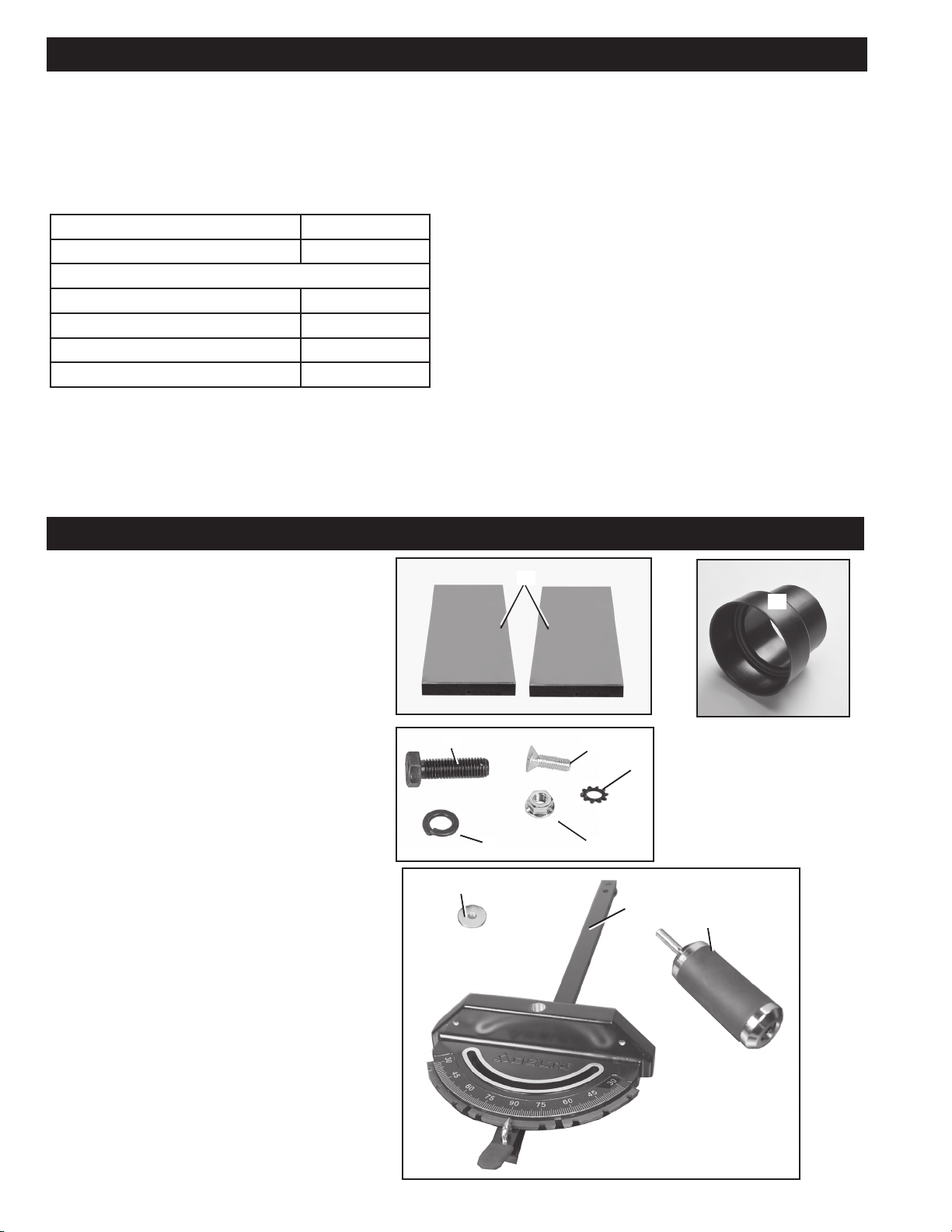

UNPACKING AND CLEANING

Carefully unpack the machine and all loose items from the shipping container(s). Remove the rust-preventative oil from

unpainted surfaces using a soft cloth moistened with mineral spirits, paint thinner or denatured alcohol.

Do not use highly volatile solvents such as gasoline, naphtha, acetone or lacquer thinner for cleaning your

machine.

After cleaning, cover the unpainted surfaces with a good quality household floor paste wax.

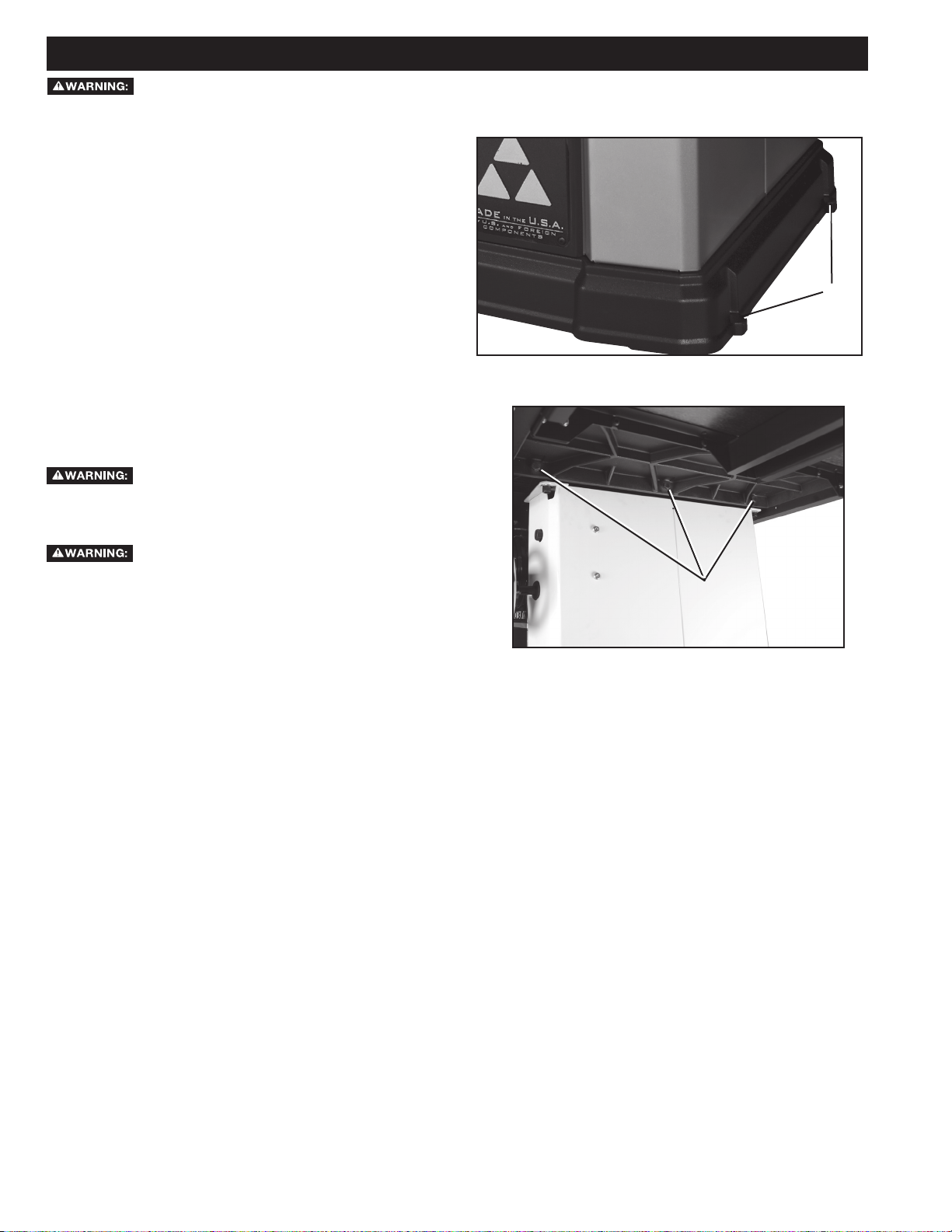

REMOVE SHIPPING FOAM

1. Open the motor cover (A) Fig. 1. First, remove the

hex socket head screw (B) with a 5/16 hex wrench.

2. Press firmly just above the recessed area on side of

cover at (Z) Fig. 1 with the palm of your hand and the

motor cover should rotate to the left.

3. Turn blade raising wheel (C) Fig. 2 and raise the

arbor.

4. This will raise the motor (D) Fig. 3 out of the way of

the foam block (E).

5. Remove foam block.

6. Remove reducer. (Located next to foam block.)

C

A

Z

B

FIG. 1

D

FIG. 2

E

FIG. 3

9

Page 10

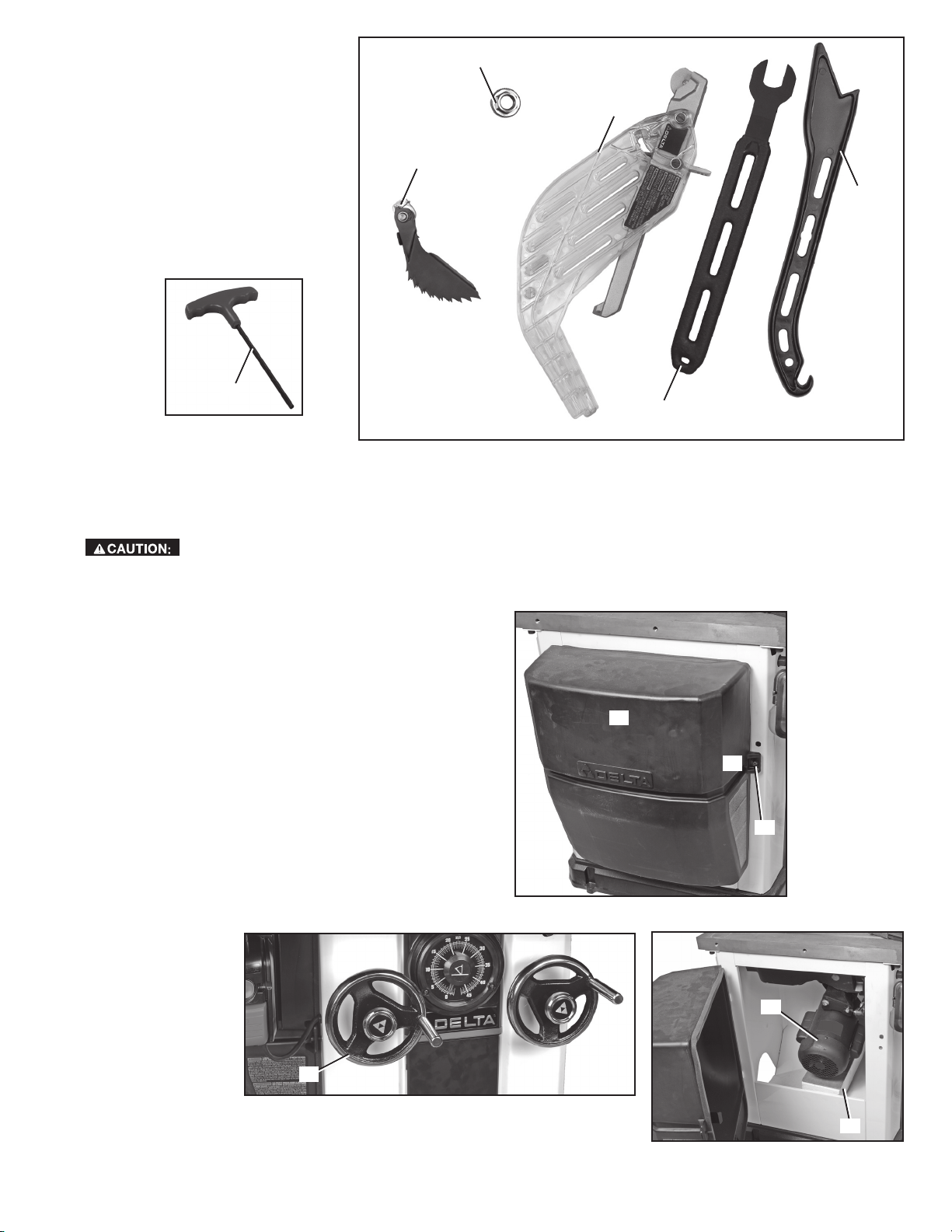

ASSEMBLY

To reduce the risk of injury, turn unit off and disconnect it from power source before installing and

removing accessories, before adjusting or when making repairs. An accidental start-up can cause injury.

ASSEMBLY TOOLS REQUIRED

• 18 mm and 1/2" open-end or socket wrench (not

supplied)

• 3/16"hex wrench (not supplied)

ASSEMBLY TIME ESTIMATE

Assembly for this machine takes approximately 2 hours.

SECURING SAW TO A PERMANENT

LOCATION

If you desire, you can attach your saw permanently to

the floor by drilling holes at four locations provided in the

base of the saw (two are shown at (A) Fig. 4).

RISK OF INJURY FROM LIFTING. Serious

injury can result from attempting to lift too heavy an

object. The machine is too heavy to be lifted by one

person. Obtain assistance from others before lifting.

PINCH HAZARD. Be sure not place toes or

fingers underneath the base of the Unisaw while moving.

Lift the saw from underneath the table, before assembly,

or the wings and extension table after assembly.

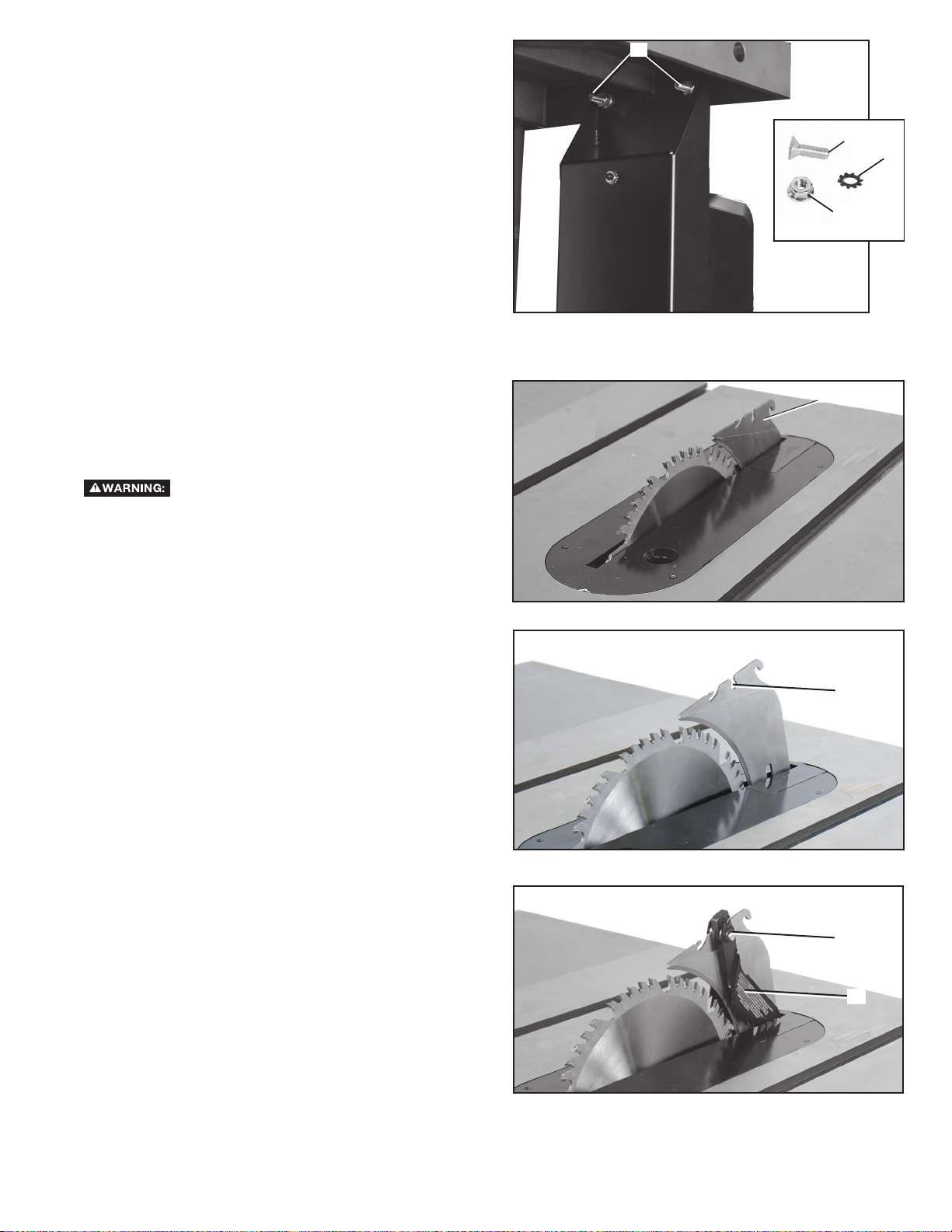

EXTENSION WINGS

NOTE: Be sure to remove switch and switch mounting

hardware from its shipping location. Switch will be

mounted to extension wing.

1. Align the three holes in the one extension wing

with the three holes in the side of the saw table.

Assembled wing shown in Fig. 7.

2. Place an M12 lockwasher on an M12 hex head screw.

Insert the screw through the hole in the extension

wing and thread the screw into the threaded hole

in the side of the table. FINGER TIGHTEN ONLY.

Repeat this process for the two remaining holes in the

extension wing and saw table.

NOTE: Ensure that the front edge of the wing is flush

with or slightly behind the front edge of the table.

3. Use a straight edge to level the extension wing with

the saw table before tightening the three bolts (H)

Fig. 7. Use an 18 mm open-end wrench and start

with a bolt on one side.

4. Align the table and wing making sure they are level

and tighten that side bolt. Move to the middle bolt

and follow the same procedure. Finish with the bolt

on the other end.

5. Place the other extension wing on the other side of

the saw in the same manner.

A

FIG. 4

H

FIG. 7

10

Page 11

SWITCH

Switch is mounted underneath the front edge of the left

extension wing. To mount:

1. Insert two 5/16-18 x 1" flat head hex socket screws (A)

Fig. 8 through holes in front of wing and then through

switch mounting holes.

2. Place two 5/16" external tooth washers (B) Fig. 8

on the screws and secure screws from under the

extension wing using two 5/16-18 flange nuts (C).

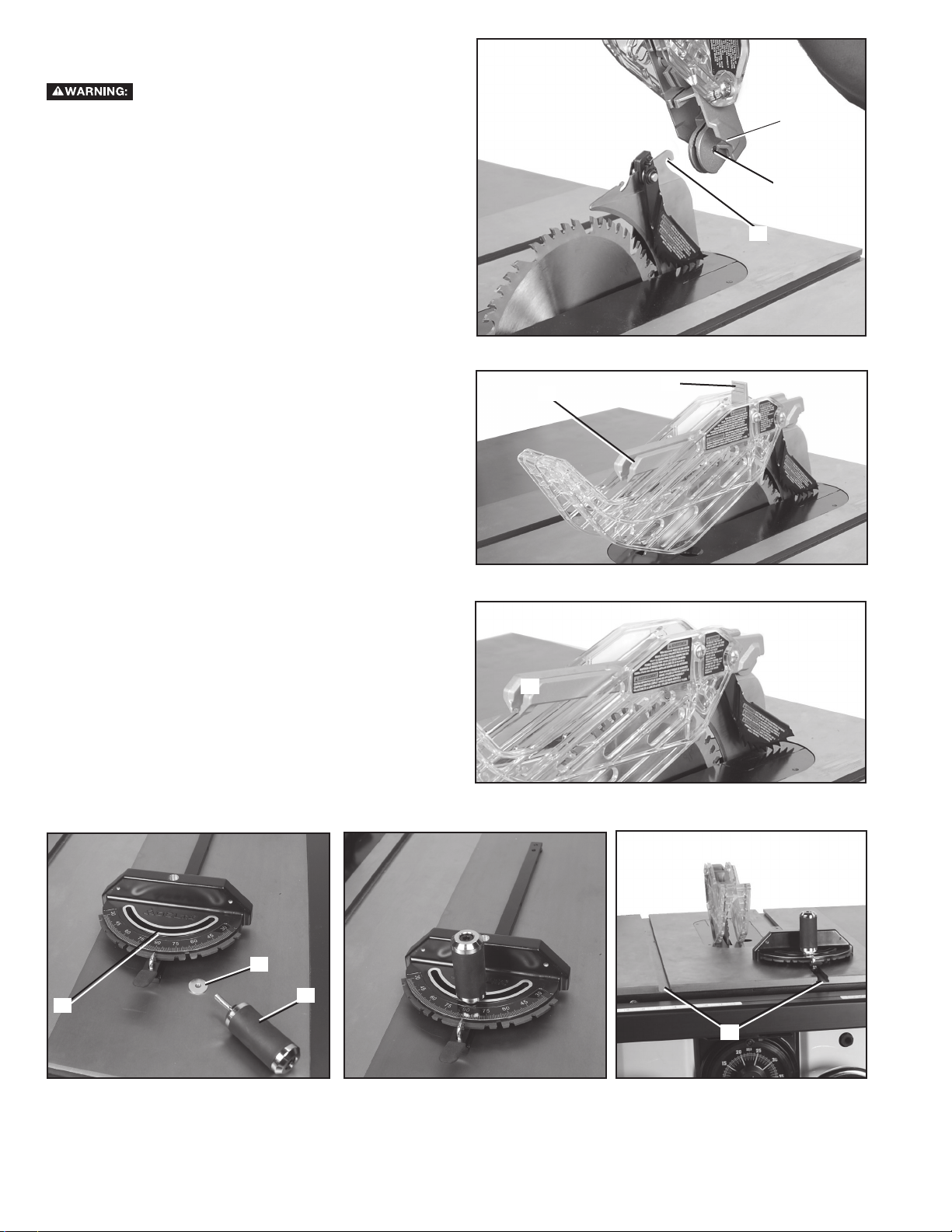

ANTI-KICKBACK, RIVING KNIFE AND

BLADE GUARD ASSEMBLIES

The riving knife (J) Fig. 9 comes installed in the low, nonthrough cutting position.

To assemble the anti-kickback and blade guard

assemblies, the riving knife must be in the raised position

as shown in Fig. 10. (See Riving Knife Operation and

Adjustment section for how to raise and lower the riving

knife.)

ANTI-KICKBACK ASSEMBLY

To reduce the risk of serious personal

injury, the anti-kickback assembly must be in place for

all possible cuts.

A

A

B

C

FIG. 8

J

1. Locate the anti-kickback mounting hole (K) Fig. 10 at

the top of the riving knife (J) Fig. 9.

2. Slide the anti-kickback assembly (L) along the top of

the riving knife until the stem (M) Fig. 11 locates the

slot above the mounting hole.

3. Depress the stem (M) on the anti-kickback assembly

to allow the assembly to drop into the hole (K). Push

down on the anti-kickback assembly until it snaps into

place and locks.

NOTE: Pull up on the anti-kickback assembly to ensure it

has locked into place.

4. To remove anti-kickback assembly: Depress the

stem (M) Fig. 11 on the anti-kickback assembly and

pull it up off the riving knife.

FIG. 9

K

FIG. 10

M

L

11

FIG. 11

Page 12

BLADE GUARD ASSEMBLY

To attach blade guard assembly:

To reduce the risk of serious personal

injury, the blade guard assembly must be in place for all

possible cuts.

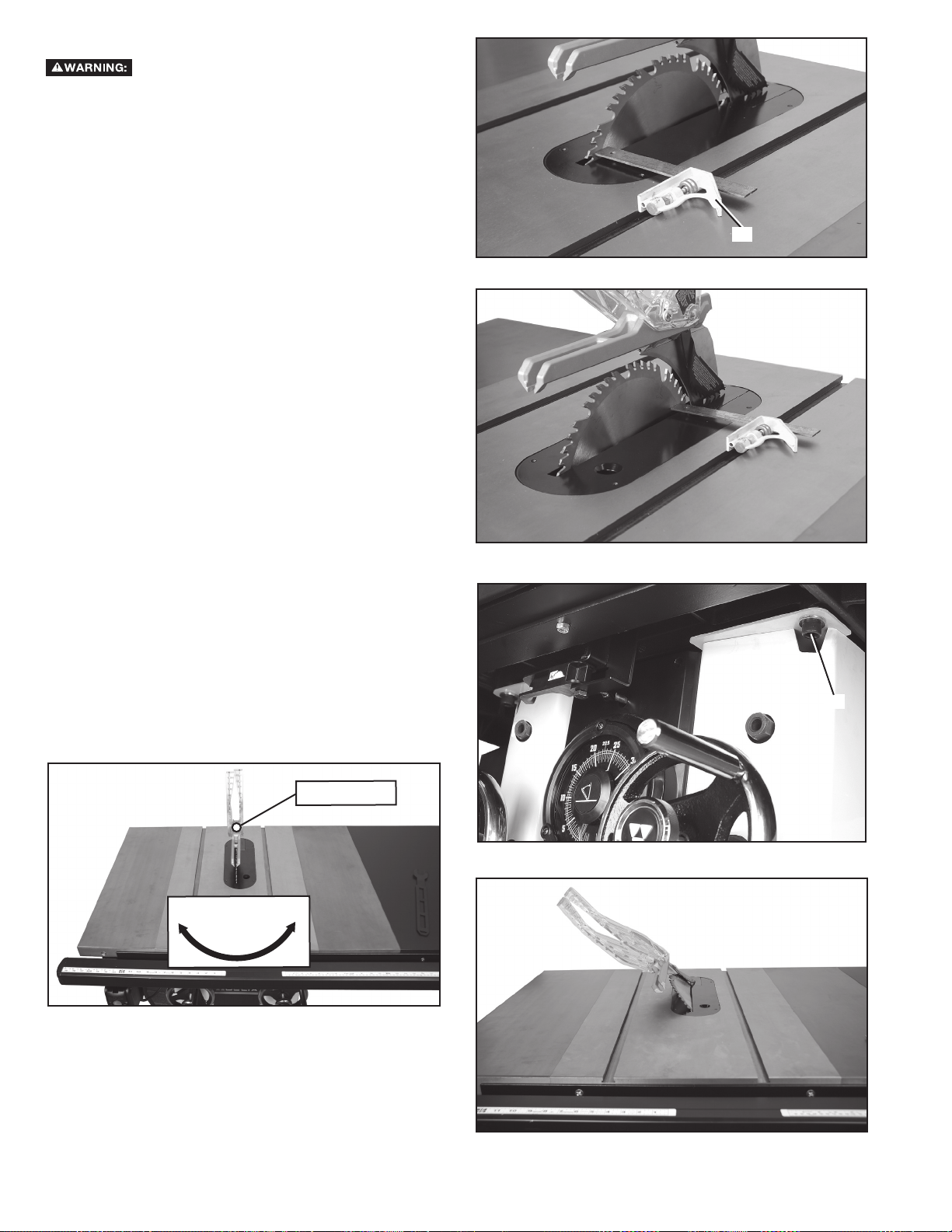

1. While holding the blade guard assembly (N) in a

vertical position, slide the locating pin (O) into the

riving knife slot (P) centering the riving knife within the

v-shaped notch in the top guard.

2. Rotate the blade guard assembly towards the front

of the saw while keeping the pin (O) at the top of the

riving knife slot. Rotate until the blade guard assembly

is parallel to the table. See Fig. 13.

3. While holding down on the front of the metal portion

of the guard (X), press the blade guard lock lever (Q)

Fig. 13 down until it snaps into the locked position,

as shown in Fig. 14. Check to make sure the guard is

locked onto the riving knife by pulling on the guard at

(R) Fig. 14. If the guard is not locked the blade guard

lock lever will flip up to the unlocked position, as

shown in Fig. 13.

To remove the blade guard assembly:

1. Lift the blade guard assembly lock lever (Q) Fig. 13 to

the unlocked position.

N

O

P

FIG. 12

X

Q

2. Rotate the guard back and slide pin from riving knife

slot.

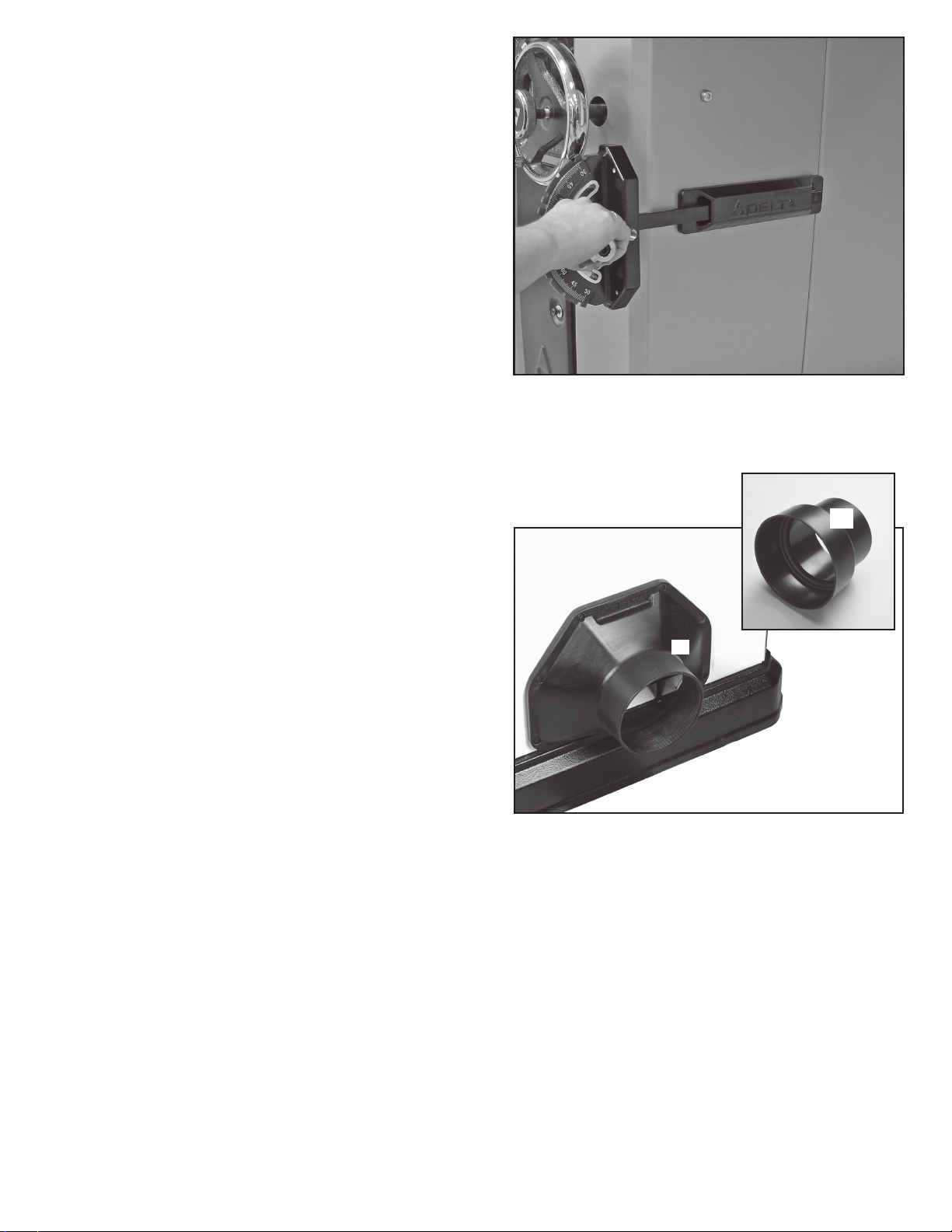

MITER GAUGE ASSEMBLY

To assemble the miter gauge:

1. Place washer (S) Fig. 15 on threaded post at end of

miter gauge handle (T).

2. Tighten threaded post into hole (U) on miter gauge

body. Assembled miter gauge shown in Fig. 16.

3. Insert miter gauge bar end into either miter gauge slot

(V) on table (Fig. 17).

S

FIG. 13

R

FIG. 14

U

FIG. 15

T

V

FIG. 16

12

FIG. 17

Page 13

MITER GAUGE STORAGE

The miter gauge can be stored on the side of the Unisaw

cabinet as shown in Fig. 17A.

DUST PORT REDUCER

The Unisaw comes with a 5" (127 mm) dust hose adpator

(W) Fig. 18 installed. Also included is a 5" (127 mm) to 4"

(102 mm) dust port reducer (G1).

To install the dust port reducer, firmly slide the reducer (G1)

Fig. 18 onto the dust hose adaptor (W).

FIG. 17A

G1

FENCE SYSTEM

Before using the saw or making other adjustments, install

and align the fence included, according to the fence

instruction manual.

Follow all fence operating and safety rules found in

Machine Use section in the back of this manual.

W

FIG. 18

13

Page 14

OPERATION

NOTICE

OPERATIONAL CONTROLS AND ADJUSTMENTS

To reduce the risk of personal injury, turn

unit off and disconnect it from power source before

installing and removing accessories, before adjusting

or when making repairs. An accidental start-up can

cause injury.

STARTING AND STOPPING THE SAW

Make sure that the saw has been turned

"OFF" before plugging cord into outlet. Do not touch

the plug’s metal prongs when unplugging or plugging

in the cord.

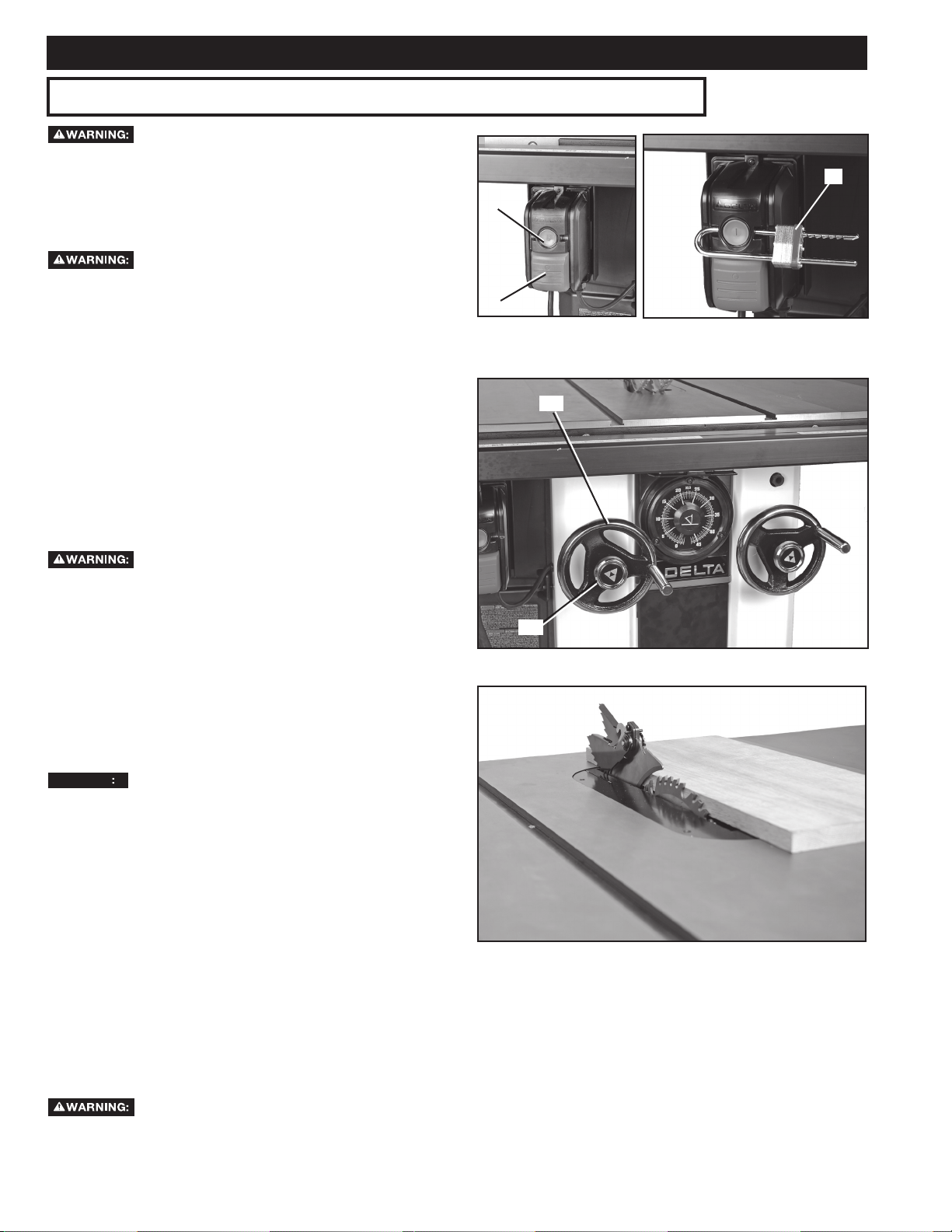

1. The POWER switch (X) Fig. 19 is located underneath

the front left extension wing. To turn the saw "ON",

push the round button (X) Fig. 19.

2. To turn the saw "OFF", push the button (Y) Fig. 19.

LOCKING SWITCH IN THE "OFF" POSITION

IMPORTANT: When the machine is not in use, the saw

should be turned off and the "ON" button locked out to

prevent unauthorized use. To lock out “ON” button, use a

standard long shackle lock (Z) Fig. 20, with a shackle that

is at least 2-3/4" (70 mm) long and with shackle posts no

larger than 9/32" (7 mm) thick.

X

Y

FIG. 19

AA

Z

FIG. 20

In the event of a power outage (such as

a breaker or fuse trip), always move the switch to the

"OFF" position until the main power is restored.

OVERLOAD PROTECTION

Your saw is supplied with overload protection. If the

BB

FIG. 21

motor shuts off or fails to start due to overloading (cutting

stock too fast, using a dull blade, using the saw beyond

its capacity, etc.) or low voltage, let the motor cool three

to five minutes. The overload will automatically reset itself

and the machine can then be started again by pressing

the "ON" button.

If the motor continually shuts off due to

overloading, contact a qualified electrician.

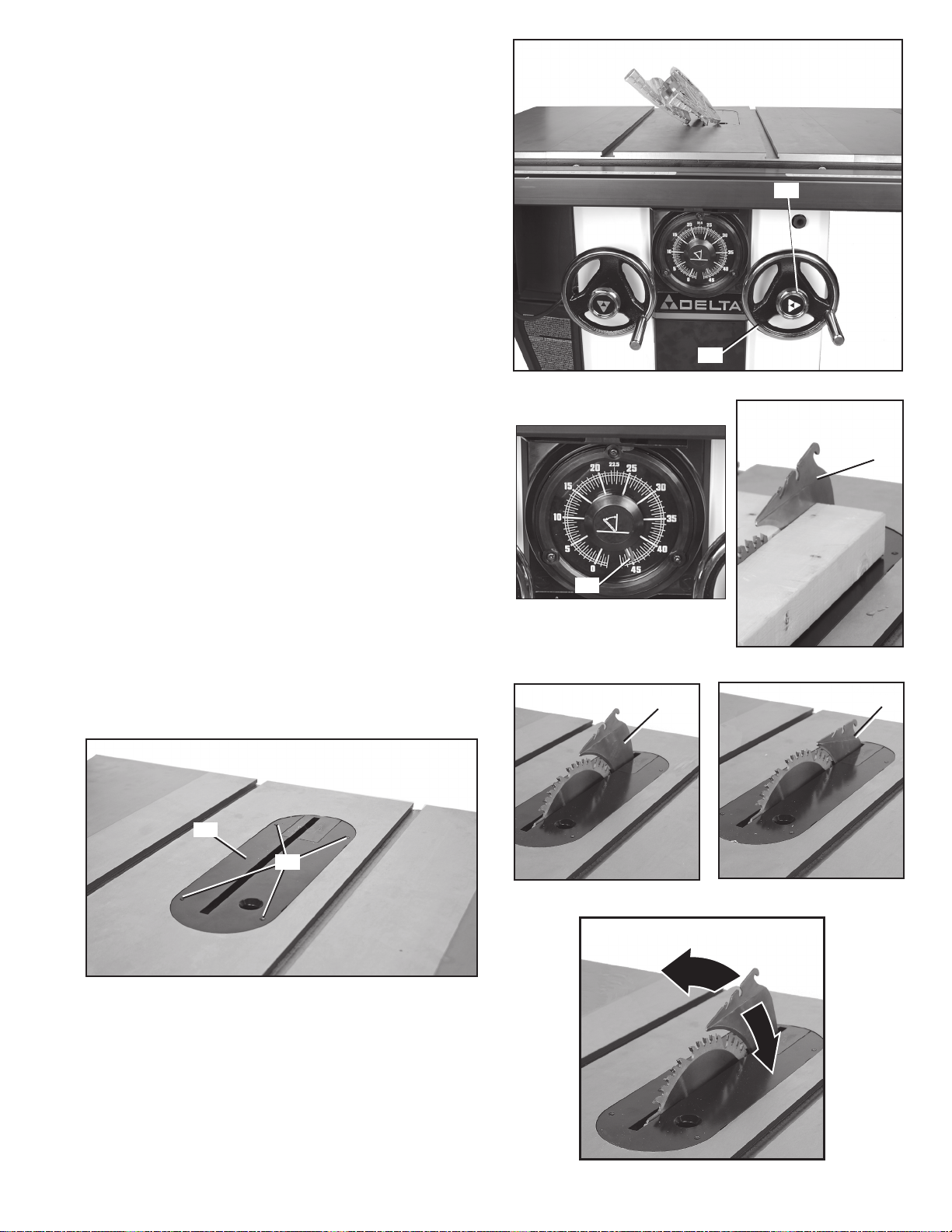

RAISING AND LOWERING THE BLADE

Raise or lower the blade with the left handwheel (AA)

Fig. 21. Before raising or lowering the blade, be sure to

loosen the lock knob (BB) Fig. 21 by turning it counterclockwise.

To raise the saw blade, turn the handwheel (AA), clockwise.

To lower the saw blade, turn handwheel (AA) counterclockwise.

Tighten lock knob (BB) Fig. 21 to keep blade raised to your desired height. Only a small amount of force is required to lock

the blade raising mechanism securely. Any added force merely puts unnecessary strain on the locking device.

For most applications, it is recommended that you raise the blade 1/8" (3.2 mm) to 1/4" (6.4 mm) above the top surface of

the workpiece, as shown in Fig. 22. (NOTE: Guard removed for clarity only.)

NOTE: With hollow-ground blades, raise the blade to its maximum height to provide greater clearance.

FIG. 22

Lock the blade in position before starting the saw.

14

Page 15

TILTING THE BLADE

Tilt the blade to the left using the right handwheel (CC)

Fig. 23.

The blade tilting mechanism allows the blade to be tilted

up to 45° to the left.

To tilt the saw blade, loosen the lock knob (DD) Fig. 23

counterclockwise and turn handwheel (CC). A pointer (EE)

Fig. 24 indicates the angle of tilt on the scale, marked in

1/2-degree increments.

To lock the saw blade at your desired angle, tighten the

lock knob (DD).

THROAT PLATE ADJUSTMENT

The throat plate (FF) Fig. 25 needs to be level to the saw

table. If the throat plate is not level with the saw table,

adjust the plate using four set screws (GG). Lower or

raise set screws as needed to align throat plate level to

the saw table.

RIVING KNIFE OPERATION AND

ADJUSTMENT

POSITIONING THE RIVING KNIFE

The riving knife (J) Fig. 26 is a flat plate that fits into the

cut made by the saw blade and effectively fights kickback

by lessening the tendency of the blade to bind in the cut.

(NOTE: Safety devices removed for clarity in Fig. 26.

Be sure to always use safety devices when possible.)

The riving knife (J) Fig. 27 and Fig. 28 can be used in

through cuts (where the workpiece is completely cut

in two) and non-through cuts. The riving knife can be

moved to the high position (Fig. 27) for through cuts and

to the low position (Fig. 28) for non-through cuts.

NOTE: When adjusting the riving knife up or down, be

sure to pull in a radial motion, as shown in Fig. 28A.

EE

FIG. 24

J

DD

CC

FIG. 23

J

FIG. 26

J

FF

GG

FIG. 25

15

FIG. 27

FIG. 28

FIG. 28A

Page 16

To adjust the riving knife position, there are two methods:

FRONT-RELEASE (PRIMARY METHOD)

1. Pull front riving knife release handle (II) Fig. 29 in front

of the saw under the table, just above the gauge.

2. While holding handle, pull riving knife up until detent

(JJ) Fig. 30 engages for the through-cutting position.

3. While holding handle, push riving knife down until

detent (KK) Fig. 30 engages for the non-throughcutting position.

4. Release handle and pull on riving knife to make sure it

is in the locked position.

5. Replace throat plate.

RIVING KNIFE RELEASE LEVER

(ALTERNATIVE METHOD)

1. Remove throat plate (FF) Fig. 25.

2. Push riving knife release lever (MM) Fig. 31 away from

the blade and pull riving knife up to lower detent (JJ)

Fig. 30 for the through-cutting position.

3. Push riving knife release lever away from the blade

and push riving knife down to upper detent (KK)

Fig. 30 for the non-through-cutting position.

4. Release lever and pull on riving knife to make sure it is

in the locked position.

5. Replace throat plate.

II

FIG. 29

KK

JJ

Before connecting the table saw to the

power source or operating the saw, always inspect

the blade guard assembly and riving knife for proper

alignment and clearance with saw blade. Check

alignment after each change of bevel angle.

NOTE: DO NOT operate saw if riving knife is not locked

in the through-cutting or non through-cutting position.

Fig. 31A shows the riving knife clamp locked down

properly. Fig. 31B shows the clamp unlocked

When properly aligned, the riving knife will be in line with

the blade at both table top level, and at the top of the

blade.

Using a straight edge (NN), ensure that the blade (OO)

is aligned with the riving knife (J) as shown in Fig. 32.

(BE SURE THE STRAIGHT EDGE GOES BETWEEN THE

TEETH AND RESTS ON THE BLADE BODY AND THE

RIVING KNIFE FOR PROPER ALIGNMENT.)

If the riving knife and blade are out of line, see section,

Aligning Riving Knife to Blade.

FIG. 30

MM

FIG. 31

NN

J

OO

FIG. 31A

FIG. 32

FIG. 31B

16

Page 17

With power disconnected, operate the blade tilt and height

Blade

TOP VIEW

Top two screws

make this

adjustment

Riving Knife

Table

Blade

BACK OF TABLE VIEW

TOP VIEW

Top two screws

make this

adjustment

Bottom screw

makes this

adjustment

Riving Knife

Riving Knife

adjustments through the extremes of travel to be sure the

blade guard assembly clears the blade in all operations and

that the anti-kickback assembly is functioning.

ALIGNING RIVING KNIFE TO BLADE

1. Remove the throat plate, blade guard and antikickback assemblies.

2. Raise the blade to full depth of cut and 0° bevel angle.

3. Raise the riving knife (J) Fig. 33 to the through-cutting

or highest position (Fig. 27).

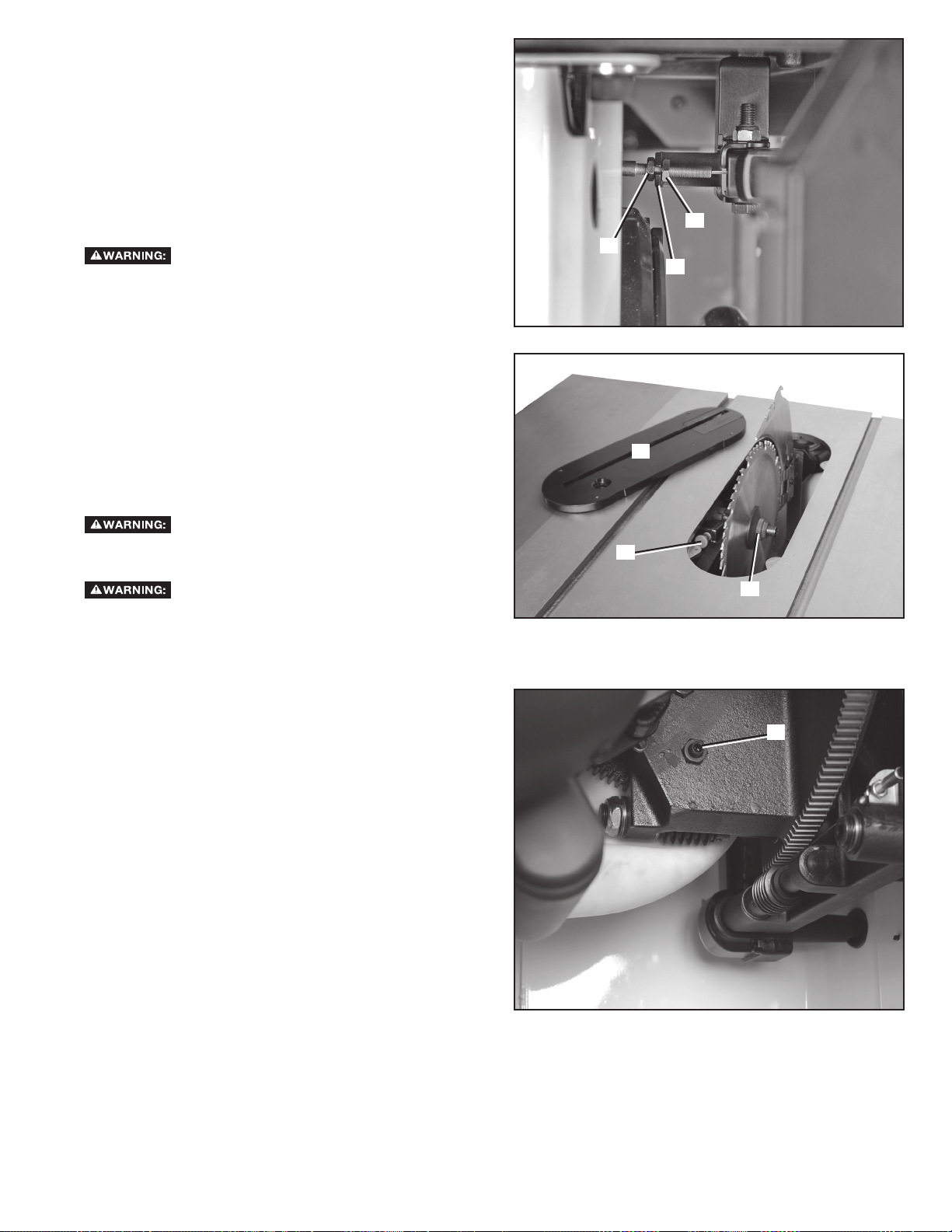

4. Locate the three small set screws (PP) and (QQ)

adjacent to the riving knife locking plate (RR). These

screws will be used to adjust the riving knife position.

5. Lay a straight edge on the table against blade body

and make sure it extends out along the riving knife,

as shown in Fig. 32. The riving knife should just touch

the straight edge. If adjustment needed, loosen the

two socket head cap screws (SS) Fig. 35.

6. Adjust the set screws (PP) and (QQ) Fig. 33 to move

the riving knife in line with the blade according to

the position noted in STEP 5. Lay the straight edge

on the opposite side of the blade and repeat these

adjustments as needed.

NOTE: The two set screws (PP) near the riving knife

locking plate (RR) adjust the riving knife as shown from

the TOP VIEW (Fig. 36). The set screw (QQ) adjusts the

riving knife as shown from the BACK OF TABLE VIEW

(Fig. 37).

7. Lightly tighten the two socket head cap screws (SS)

Fig. 35.

8. Place a square flat against the riving knife and verify

riving knife is vertical and in-line with the blade.

(Fig. 34)

9. If needed, use the set screws to bring the riving knife

vertical with the square.

10. Repeat STEPS 5 and 6 to verify position of riving

knife.

11. Fully tighten the two socket head cap screws (SS)

Fig. 35.

12. Replace throat plate before use.

J

PP

RR

QQ

FIG. 33

FIG. 34

FIG. 36

SS

FIG. 35

FIG. 37

17

Page 18

SELECTING SAW BLADES

dimensions in order to function effectively. See Riving

Knife Selection.

THIS SAW IS INTENDED FOR USE ONLY WITH SAW BLADES

10" (254 mm) IN DIAMETER. See Fig. 38.

1. The saw blade furnished with your new saw is a 10"

(254 mm) combination blade, used for cross cutting

(across the grain) and ripping (with the grain) through the

material. The center hole to fit on the arbor is 5/8" (16 mm)

diameter. This blade will produce a good quality cut for most

applications.

2. There are many types of blades available to do specific and

special jobs such as cross cut only, rip only, hollow ground,

thin plywood, paneling, etc.

3. Use only saw blades designed for maximum safe operating

speeds of 4,300 RPM or greater.

4. Saw blades should always be kept sharp. It is recommended

that you locate a reputable sharpening service to sharpen your

blades when needed.

5. Never stack blades on top of one another to store. Place

material such as cardboard between them to keep the blades

from coming in contact with one another, or place them in

storage drawer.

should not be used on this saw.

Riving knifes must be matched to saw blade

Abrasive wheels or blades (including diamond)

RIVING KNIFE SELECTION

To minimize the risk of kickback and to insure

proper cutting, the riving knife must be the proper thickness

for the blade used.

The riving knife supplied with this table saw is the correct size for

the blade supplied with the saw.

If a different blade is used, check the blade body, or plate,

thickness and the blade kerf, or cutting, width marked on the

blade or on the blade packaging. The riving knife thickness must

be greater than the body thickness and less than the kerf width

as shown in Fig. 39. If it is not, the riving knife MUST be replaced

with one that has the correct thickness.

The riving knife provided with this saw is either 2.7 mm thick or 2.8

mm thick and will be marked in one of two ways:

The riving knife available as an accessory marketed by DELTA is

marked as follows:

All DELTA blade body thickness and kerf width information is

provided at www.deltaportercable.com.

If a different blade is used and the body thickness and kerf width

dimensions are not provided, use the following procedure to

determine the correct riving knife thickness:

1. Measure the body thickness of the blade.

2. Make a shallow cut in scrap material and measure the kerf

width.

3. Select the riving knife as shown in Fig. 39.

2.7 MM THICK KNIFE:

0.106" (2.7 mm) THICK RIVING KNIFE. ONLY USE FOR

10" (254 mm) Ø BLADE WITH 0.114" (2.9 mm) MIN. KERF

WIDTH AND 0.098" (2.5 mm) MAX. BODY THICKNESS

2.8 MM THICK KNIFE:

0.110" (2.8 mm) THICK RIVING KNIFE. ONLY USE FOR

10" (254 mm) Ø BLADE WITH 0.118" (3.0 mm) MIN. KERF

WIDTH AND 0.098" (2.5 mm) MAX. BODY THICKNESS

0.087" (2.2 mm) THICK RIVING KNIFE. ONLY USE FOR

10" (254 mm) Ø BLADE WITH 0.094" (2.4 mm) MIN. KERF

WIDTH AND 0.067" (1.75 mm) MAX. BODY THICKNESS.

(See Fig. 40)

FIG. 38

RIVING KNIFE

THICKNESS

KERF WIDTH

(WIDTH OF CUT

MADE BY THE

BLADE)

BODY (OR PLATE)

THICKNESS OF

THE BLADE

FIG. 39

FIG. 40

FIG. 41

4. Slide the riving knife through the shallow cut (Fig. 41) made in

step 2 to confirm the correct riving knife has been selected.

The riving knife should not bind or drag through the cut.

IMPORTANT: If any dragging or binding of the material

is encountered as it reaches the riving knife, turn unit off and

disconnect machine from power source. Repeat steps 1–4 to

make the proper riving knife selection before attempting another

cut.

18

Page 19

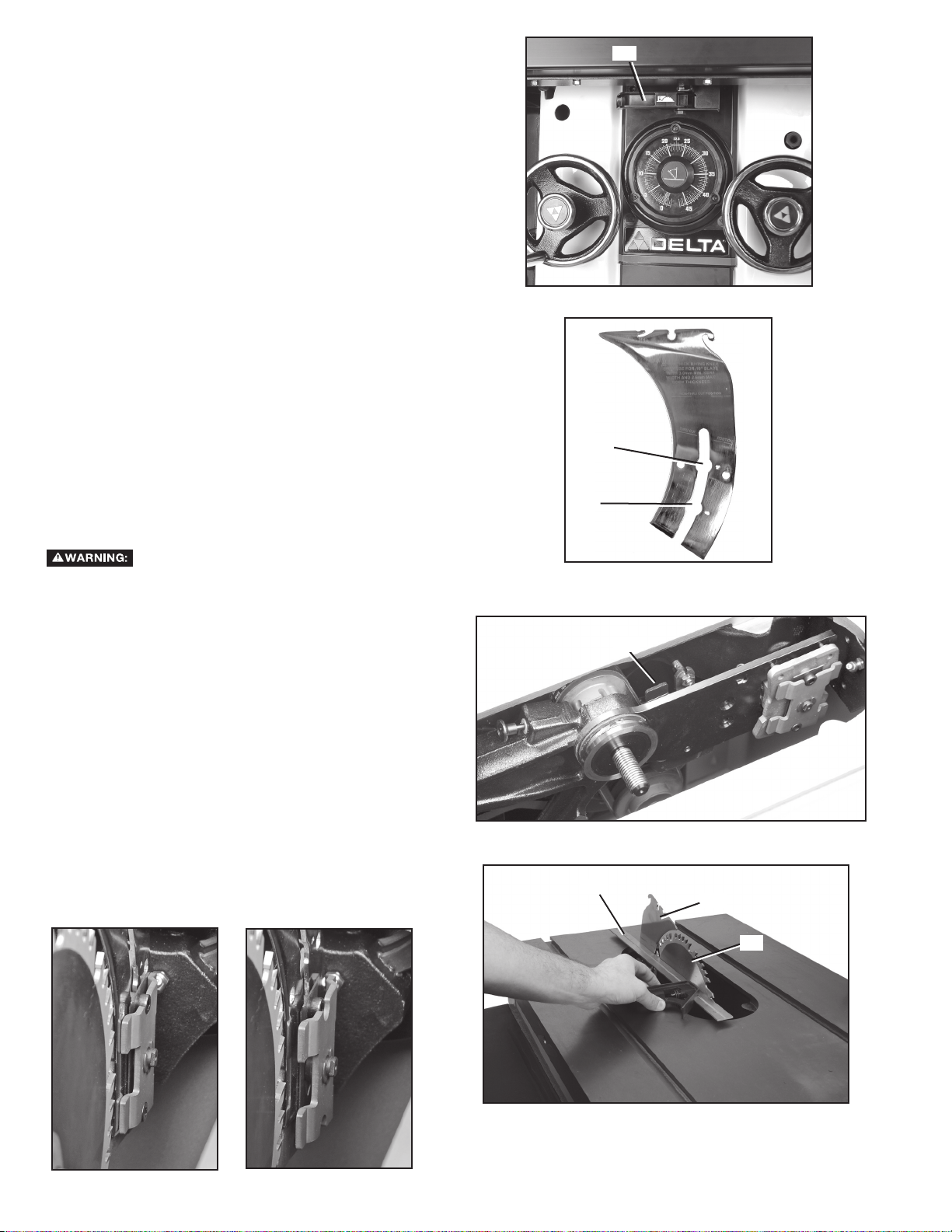

ADJUSTING 0° AND 45° POSITIVE STOPS

There are built in stops that can position the blade at 0° and

45°. If the blade is not properly at 0° when it is resting on the

stop:

1. Adjust blade to 0° stop and back it off slightly.

2. Loosen the bevel stop nut (UU) slightly using supplied arbor

wrench.

3. Using blade tilting handwheel (CC), position blade at exactly

0°.

4. Use 6 mm hex wrench inside the bevel stop nut (UU)to turn

the stop into place. NOTE: The stop can be rotated either

way to position stop against the trunnion.

5. Hold the stop in place and tighten the bevel stop nut (UU)

with the supplied arbor wrench.

6. Verify position by beveling off and then coming back to the

stop to check blade position.

NOTE: To adjust the 45° stop, use the other bevel stop nut (TT)

and follow the same procedure above.

ADJUSTING BLADE TILT SCALE

Using a combinaton square, turn blade tilting handwheel

until the blade is set perfectly at 45

not pointing to 45

°, follow these steps:

1. Remove the magnetic cover (VV) Fig. 43.

2. Remove the screw (WW) Fig. 44 using a T20 wrench and

remove the center cap (XX).

3. Loosen angle indicator screw (YY) Fig. 45.

4. Put red pointer on 45

° and tighten screw while holding

the back face so the pointer stays on 45

5. Replace center cap (XX) Fig. 44. Make sure the rubber

O-ring stays seated behind cap.

6. Put magnetic cover (VV) Fig. 43 back on.

°. If the blade tilt scale is

°.

UU

TT

CC

FIG. 42

VV

FIG. 43

19

XX

WW

FIG. 44

YY

FIG. 45

Page 20

ADJUSTING MITER SLOT PARALLEL TO BLADE

To reduce the risk of personal injury, turn

unit off and disconnect it from power source before

installing and removing accessories, before adjusting

or when making repairs. An accidental start-up can cause

injury.

The saw table was aligned at the factory. For accuracy,

check the alignment before beginning operation.

1. Place a combination square (ZZ) Fig. 46 on the table

with one edge of the square in the miter gauge slot.

Adjust the square so that the ruler's edge touches

the face of the saw blade at the forward position.

Lock the square.

2. Rotate the saw blade so that the same spot you

used in STEP 1 is in the rear position (Fig. 47) and

place ruler edge on the face of the saw at this spot.

Both the front and rear measure ments should be the

same.

3. Then, using a 10 mm hex wrench, loosen the four

screws - one shown at (A1) Fig. 48 - that hold the

table to the saw cabinet.

4. Adjust the front edge of the saw (as shown in Fig. 49).

The pivot point on the rear edge of the saw is shown

in Fig. 49.

5. Move table until the miter slot is parallel with the

blade, according to the method described in STEPS

1 and 2.

6. Once miter slots are parallel to the blade, finger

tighten the four bolts (one shown at (A1) Fig. 48).

Check the parallel one last time and fully tighten the

bolts.

7. Tilt the blade 45° (as shown in Fig. 50), and turn the

saw blade by hand. Ensure that the blade does not

contact the throat plate.

ZZ

FIG. 46

FIG. 47

A1

FRONT EDGE OF SAW

FIG. 49

PIVOT POINT

FIG. 48

FIG. 50

20

Page 21

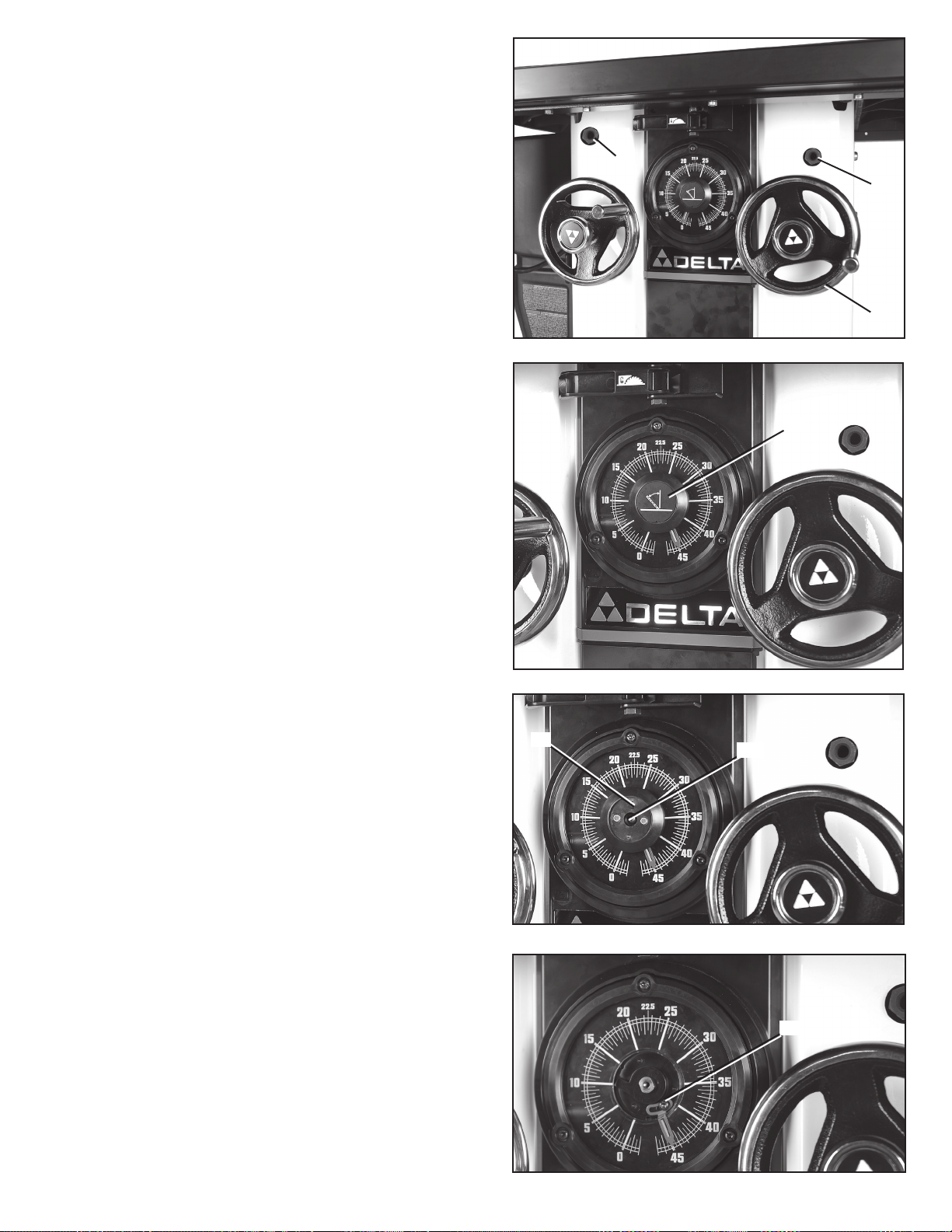

TAKING SLACK OUT OF RIVING KNIFE

RELEASE CABLE

Over time, the riving knife release cable may develop slack

and may not fully open the riving knife release clamp. To

remove the slack out of the riving knife release cable:

1. Using a 7/16" open end wrench, move nut (B1)

Fig. 51 (located underneath the fence in front of saw)

away from saw cabinet.

2. Using a 7/16" wrench, tighten nut (D1) against the

bracket (C1) and nut (B1).

To avoid the risk of injury, do not

overtighten the cable. If the cable is too tight, the

riving knife will be loose and will not function properly.

After adjustments always check that the riving knife

is securely clamped in the desired position by firmly

pulling up on the knife.

ALIGNING THE RIP FENCE AND TABLE BOARD

See your fence instruction manual for instructions on

adjusting the rip fence parallel to the miter gauge slot, as

well as instructions for making sure the table board is flat

to the extension wings and flat across the whole width of

saw, wings and table board.

B1

D1

C1

FIG. 51

FF

CHANGING THE SAW BLADE

Use only 10" (254 mm) diameter blades

with 5/8" (16 mm) arbor holes, rated at 4,300 rpm or

higher.

To reduce the risk of injury, turn unit off

and disconnect it from power source before installing

and removing accessories, before adjusting or when

making repairs. An accidental start-up can cause injury.

1. Remove the throat plate (FF) Fig. 52, and raise the

saw blade to its maximum height.

2. Remove old blade, if needed, by holding red arbor

lock button (E1) Fig. 52. Use included arbor wrench

to remove the blade retaining nut (F1). Remove old

blade.

3. Place the new blade on the arbor with the teeth

pointing down as the blade rotates toward the front

of the saw table.

4. Replace the blade retaining nut and throat plate.

MAXIMUM BLADE HEIGHT ADJUSTMENT

The saw is designed so that the top of blade can be

raised to a maximum distance of 3-1/8" (79 mm) from

the table surface. If the saw is not achieving this height,

follow these steps:

1. Raise blade to its highest point, then back of slightly.

2. Loosen the blade height stop jam nut (G1) Fig. 53

slightly with a wrench.

E1

F1

FIG. 52

G1

FIG. 53

3. Set blade height to 3-1/8" (79 mm).

4. Use a hex wrench in the stop bolt to turn the blade height stop into place against the arbor bracket. The stop can be

rotated in either direction until it jams against the trunnion.

5. Hold hex wrench in place and tighten the blade height stop jam nut.

6. Lower the blade and re-position against the blade height stop. Verify the height is still 3-1/8" (79 mm).

21

Page 22

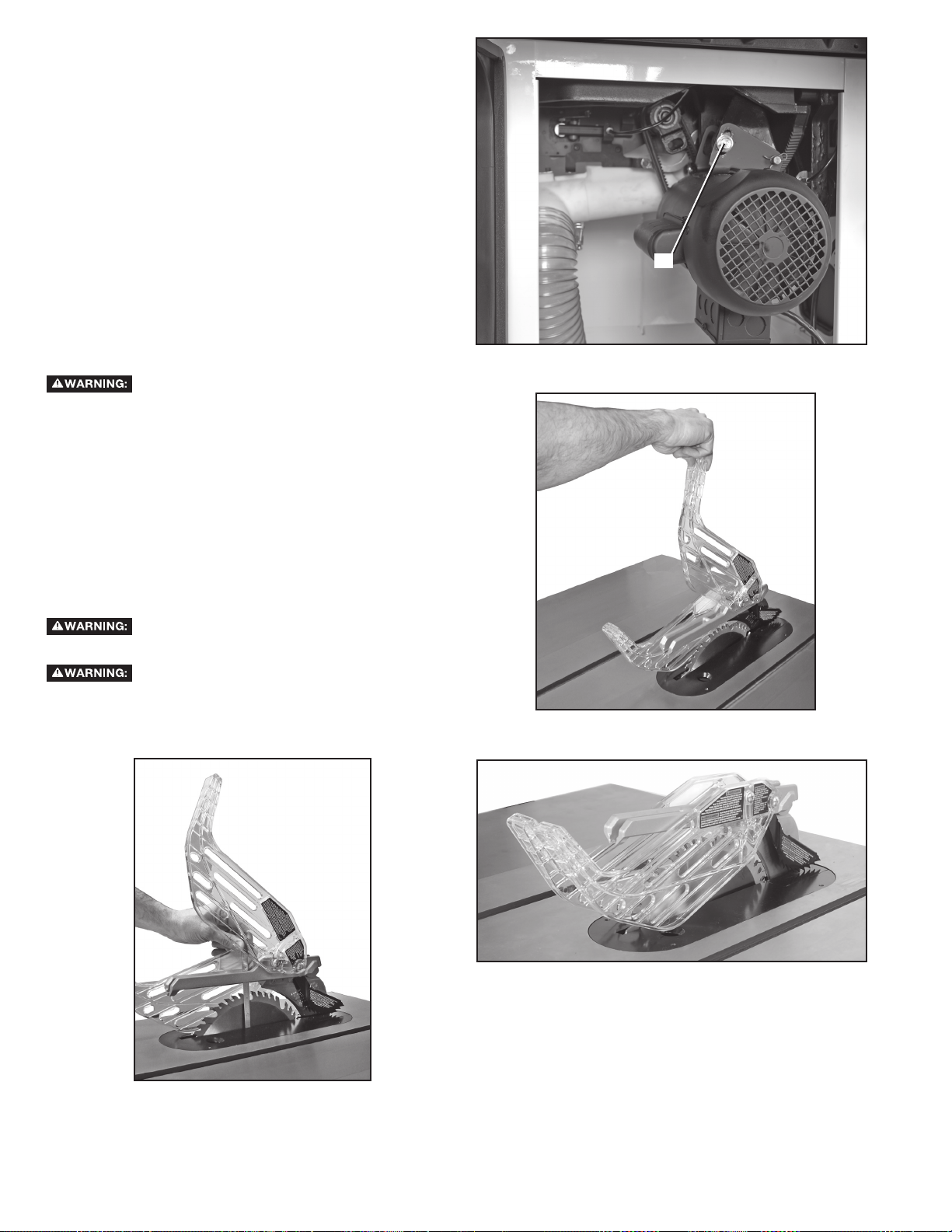

ADJUSTING BELT TENSION

1. Open the motor cover.

2. Loosen the bolt (H1) Fig. 54A, and carefully let the

motor rest on the belts.

3. Correct belt tension is indicated with a 1/4" (6.4 mm)

deflection in the center span of the pulleys, using light

finger pressure.

4. When proper tension is achieved, tighten bolt (H1)

Fig. 54A.

NOTE: For instructions on replacing the belts see the

Maintenance section.

H1

BLADE GUARD OPERATION

To reduce the risk of injury, turn unit off

and disconnect it from power source before installing

and removing accessories, before adjusting or when

making repairs. An accidental start-up can cause injury.

If there is a need to briefly raise the blade guard (for

example, to make a measurement) the guard can be parked

in a raised position. Lift the guard from the front (as shown

in Fig. 54B) and raise guard shield until it snaps into a

locked position above the table. One or both guard shields

can be raised.

When done making the measurement (Figure 54C), return

guard to operating position (Figure 54D).

Keep arms, hands and fingers away from

the blade to prevent serious injury.

To reduce the risk of injury, you must use

the saw blade guard for all through-cuts.

FIG. 54A

FIG. 54B

FIG. 54C

FIG. 54D

22

Page 23

MACHINE USE

KICKBACK

Kickback is a dangerous condition! It is caused by the workpiece binding against the blade. The result is that the

workpiece can move rapidly in a direction opposite to the feed direction. During kickback, the workpiece could be

thrown back at the operator. It can also drag the operator’s hand back into the blade if the operator’s hand is at the rear

of the blade. If kickback occurs, turn the saw "OFF" and verify the proper functioning of the riving knife, anti-kickback

assembly and blade guard assembly before resuming work.

See Additional Safety Rules for Table Saws and follow all warnings provided regarding kickback.

Common sawing operations include through cuts (like ripping and cross cutting), non-through cuts (like dados and

rabbets) plus a few other standard operations. As with all power machines, a certain amount of hazard is involved with

the operation and use of the machine. Using the machine with the respect and caution will considerably lessen the

possibility of personal injury. However, if normal safety precautions are overlooked or completely ignored, personal injury

can result. The following information describes the safe and proper method for performing the most common sawing

operations.

TABLE SAW OPERATION SAFETY

Failure to adhere to these common safety rules can greatly increase the likelihood of injury.

Before using the saw, verify the following each and every time:

1.

A. Always wear proper eye, hearing and respiratory equipment.

B. Blade is tight.

C. Bevel angle and height lock knobs are tight.

D. If ripping, ensure fence lock lever is tight and fence is parallel to the blade.

E. If crosscutting, miter gauge knob is tight.

F. The blade guard /riving knife assemblies are properly attached and the anti-kickback teeth are functioning.

G. Always inspect the guard and riving knife for proper alignment operation and clearance with saw blade.

H. ALWAYS make sure both guards are in the down position in contact with the table before operating.

2 . To reduce the risk of injury, turn unit off and disconnect machine from power source before installing and

removing accessories, before adjusting or changing set-ups or when making repairs. An accidental start-up can

cause injury.

3. Before connecting the table saw to the power source or operating the saw, always inspect the guard and riving

knife for proper operation, alignment and clearance with saw blade. Otherwise, personal injury may result.

4. This instruction manual does not provide information regarding the installation of a fence system. A fence

system must be installed before use of the saw. Please refer to the fence instruction manual regarding the

proper installation, alignment, and operation of the fence system.

5. The use of attachments and accessories not recommended by DELTA may result in injury.

6. You must use the saw blade guard and riving knife and anti-kickback assemblies for all through cuts. The anti-

kickback fingers mount to the riving knife and aid in preventing kickback. The riving knife prevents the wood

kerf from closing and binding the blade. Be sure to replace or sharpen the anti-kickback fingers when the points

become dull.

7. Ripping or crosscutting may cause saw to tip over while operating. If you desire to secure the saw to a stable

surface, see instructions in section Securing Saw to a Permanent Location.

8. Never use the fence and miter gauge together. This may cause a kickback condition and injure the operator.

The proper throat plate must be in place at all times to reduce the risk of a thrown workpiece and possible injury.

9.

10. If your saw makes an unfamiliar noise or if it vibrates excessively, cease operating immediately until the source

has been located and the problem corrected.

11. Never perform freehand cutting, plunge cutting, resawing or cove cutting.

MAKING CUTS

There are two basic types of cutting with table saws: ripping and crosscutting. Cutting with the grain is ripping and

cutting against the grain is crosscutting. With manmade materials, the distinction is made such that ripping is cutting to

a different width and crosscutting describes cutting material across the shorter dimension.

When ripping, always use the fence to provide a guide for the material and guard against a kickback

situation.

When crosscutting, always use the miter gauge.

23

Page 24

RIPPING

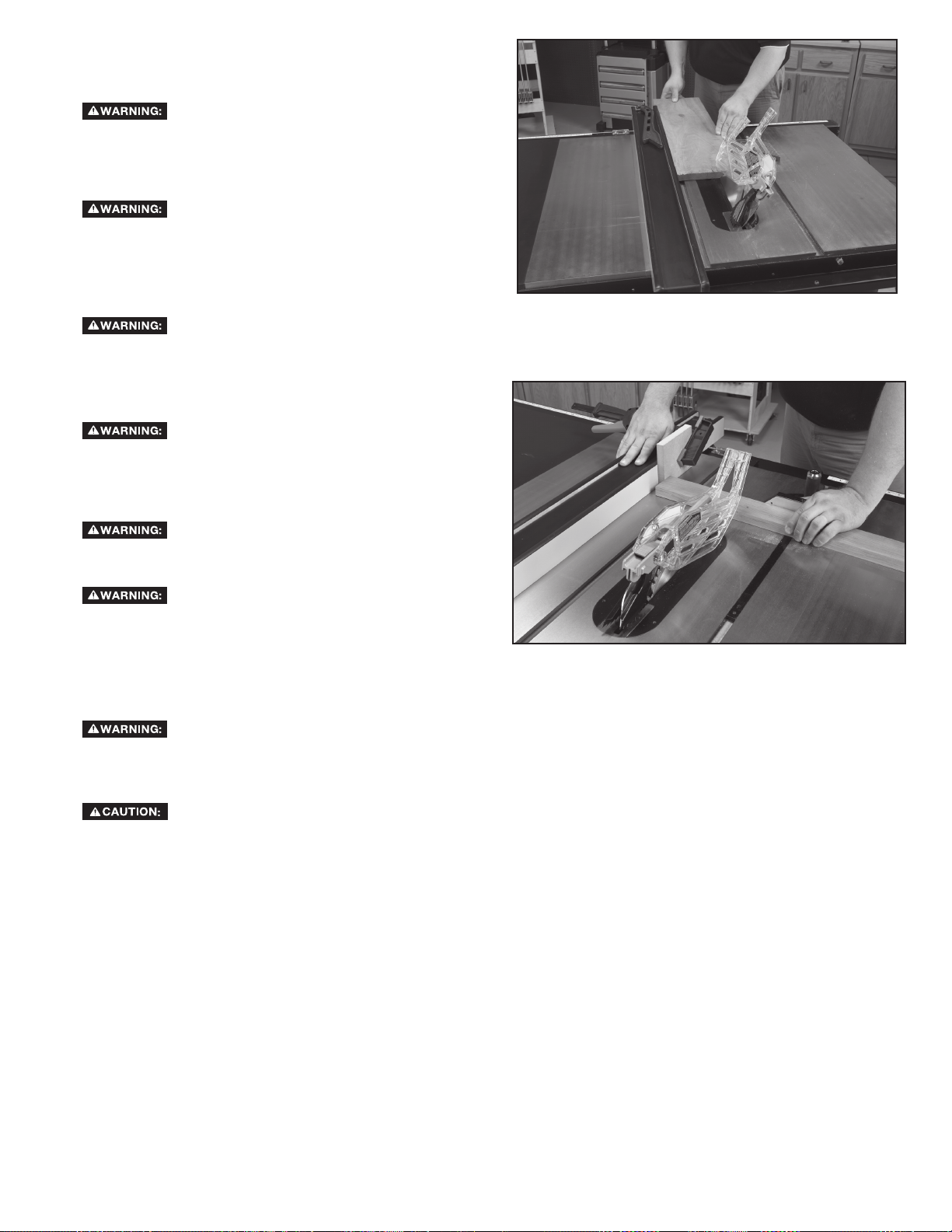

Never touch the free end of the workpiece

or a free piece that is cut off, while the power is on

and/or the saw blade is rotating. Piece may contact

the blade resulting in a thrown workpiece or possible

injury.

A rip fence should ALWAYS be used for

ripping operations to prevent loss of control and

personal injury. NEVER perform a ripping operation

freehand. Always lock the fence to the rail.

When bevel ripping and whenever

possible, place the fence on the side of the blade so

that the blade is tilted away from the fence and hands.

Keep hands clear of the blade and use a push stick to

feed the workpiece if there is less than 6" (152 mm)

between the fence and the blade.

Keep hands clear of the blade

Use a push stick to feed the workpiece if there is 2" to 6" (51 to 152 mm) between the fence and the

blade. Use a narrow rip auxiliary fence and push block to feed the workpiece if there is 2" (51 mm) or narrower

between the fence and the blade.

1. Lock the fence down where you want it to be. Remove the miter gauge.

2. Raise the blade so it is about 1/8" (3.2 mm) higher than the top of the workpiece.

3. Hold the workpiece flat on the table and against the fence (A) Fig. 55. Keep the workpiece about 1" (25 mm) away

from the blade.

A

FIG. 55

The workpiece must have a straight edge against the fence and must not be warped, twisted or bowed.

Keep both hands away from the blade and away from the path of the blade. See proper hand position in Fig. 55.

4. Turn the saw on and allow the blade to come up to speed. Both hands can be used in starting the cut. When there is

approximately 12" (305 mm) left to be ripped, use only one hand, with your thumb pushing the material, your index

and second finger holding the material down and your other fingers hooked over the fence. Always keep your thumb

along side your first two fingers and near the fence.

5. Keep the workpiece against the table and fence and slowly feed the workpiece rearward all the way through the saw

blade. Continue pushing the workpiece until it is clear of the guard and it falls off the rear of the table. Do not overload

the motor.

6. Never try to pull the workpiece back with the blade turning. Turn the switch off, allow the blade to stop, raise the anti-

kickback teeth on each side of the riving knife if necessary and slide the workpiece out.

7. When sawing a long piece of material or a panel, always use a work support. A sawhorse, rollers or outfeed assembly

provides adequate support for this purpose. The work support must be at the same height as the saw table.

Never push or hold onto the free or cut off side of the workpiece.

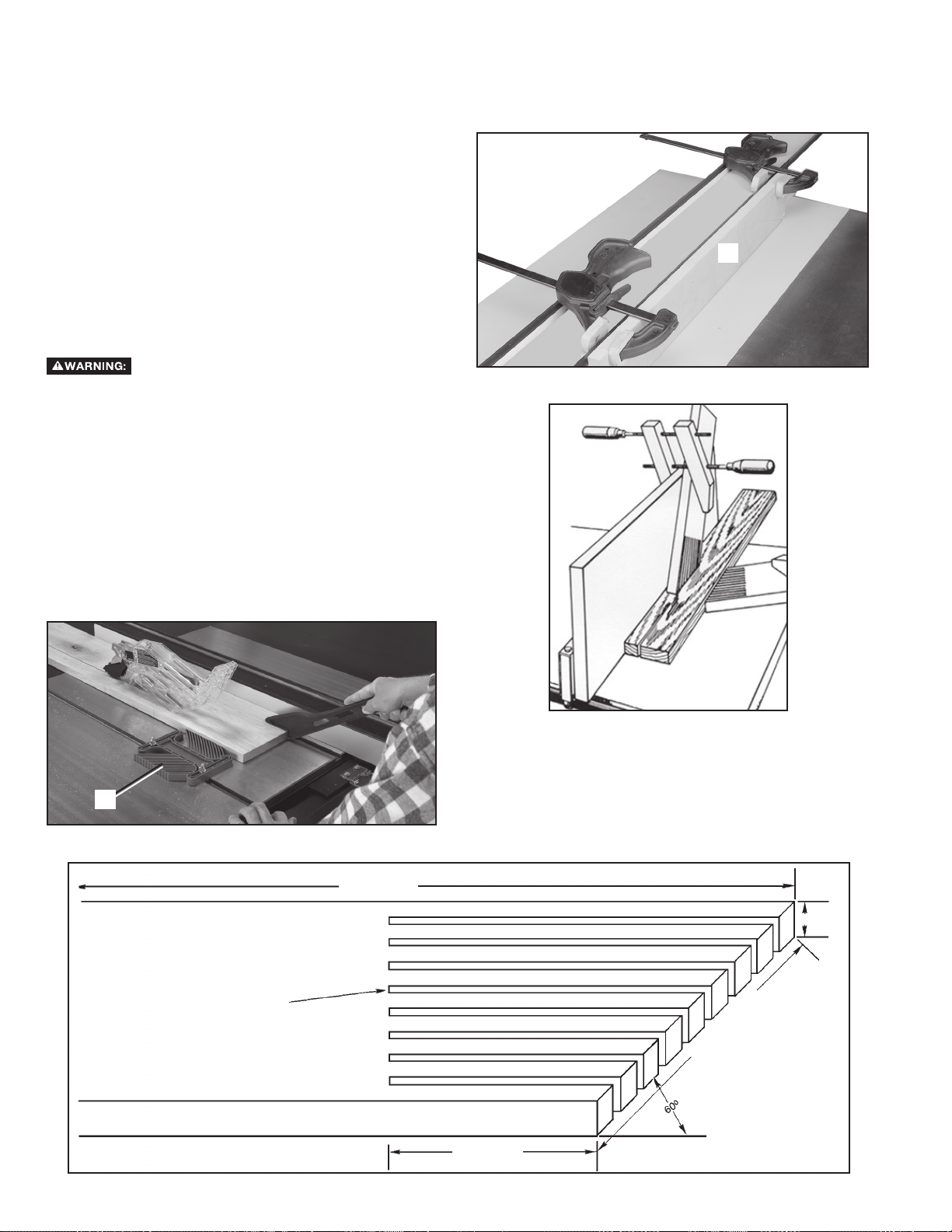

RIPPING SMALL PIECES

B

It is unsafe to rip small pieces. It is not safe to put your

hands close to the blade. Instead, rip a larger piece to

obtain the desired piece. When a small width is to be

ripped and the hand cannot be safely put between the

blade and the rip fence, use one or more push sticks.

A pattern is included at the end of this manual to make

push sticks. A push stick (B) Fig. 56 is included with this

saw. Use the push stick(s) to hold the workpiece against

the table and fence, and push the workpiece fully past

the blade. See Fig. 56.

24

FIG. 56

Page 25

BEVEL RIPPING

Bevel ripping (Fig. 57) is the same as ripping except the

bevel angle is set to an angle other than 0°.

Before connecting the table saw to the

power source or operating the saw, always inspect

the blade guard assembly and riving knife for proper

alignment and clearance with saw blade. Check

alignment after each change of bevel angle.

When possible, place the fence on the

right side of the blade so that the blade is tilted away

from the fence and hands. Keep your hands clear of

the blade and use a pushstick to feed the workpiece if

there is less than 6" (152 mm) between the fence and

the blade.

Use caution when starting the cut to

prevent binding of the guard against the workpiece.

CROSSCUTTING

NEVER touch the free end of the

workpiece or a free piece that is cut off, while

the power is ON and/or the saw blade is rotating.

Piece may contact the blade resulting in a thrown

workpiece and possible injury.

FIG. 57

To reduce the risk of injury, NEVER

use the fence as a guide or length stop when

crosscutting.

NEVER use a length stop on the free

end of the workpiece when crosscutting. In short,

the cut-off piece in any through-sawing (cutting

completely through the workpiece) operation must

never be confined — it must be allowed to move

away from saw blade to prevent contact with blade

resulting in a thrown workpiece and possibly injury.

Use caution when starting the cut to

prevent binding of the blade guard assembly against

the workpiece resulting in damage to saw and

possible injury.

When using a block as a cut-off gauge,

the block must be at least 3/4" (19 mm) thick and

is very important that the rear end of the block be

positioned so the workpiece is clear of the block

before it enters the blade to prevent contact with

blade resulting in a thrown workpiece and possibly

injury.

Cross-cutting is cutting the wood across the grain. It

requires the use of the miter gauge to posi tion and guide

the work. Before starting the cut, raise the blade so

that it is about 1/8" (3.2 mm) higher than the top of the

workpiece. Place the work against the miter gauge and

advance both the gauge and work toward the saw blade

(Fig. 58).

FIG. 58

25

Page 26

You can use the miter gauge in either table slot. Start

the cut slowly and hold the work firmly against the miter

gauge and the table. Keep both hands on the miter

gauge and workpiece. Do not touch the cut-off piece.

Feed the workpiece steadily through the blade until the

workpiece is completely cut. Shift the workpiece slightly

sideways away from the blade, then pull the workpiece

and miter guage back to the starting position. Remove

the workpiece, then use a push stick to push the cut-off

piece past the blade and off the table before beginning

the next cut.

For added safety and convenience, you can fit the miter

gauge with an auxiliary wood-facing that should be at

least 1" (25 mm) higher than the maximum depth of cut,

and should extend out 12" (305 mm) or more to one

side or the other depending on which miter gauge slot is

being used. This auxiliary wood-facing can be fastened

to the front of the miter gauge by using two wood screws

through the holes (D) Fig. 59 provided in the miter gauge

body and into the wood-facing.

When cross-cutting a number of pieces to the same

length, clamp a block of wood (E) Fig. 60 to the fence

and use it as a cut-off gauge. The block (E) must be

at least 3/4" (19 mm) thick to prevent the cut-off piece

from binding between the blade and the fence during

removal from the saw table. Always position this block of

wood in front of the saw blade. Once the cut-off length

is determined, lock the fence and use the miter gauge to

feed the work into the cut.

D

FIG. 59

E

BEVEL CROSSCUTTING

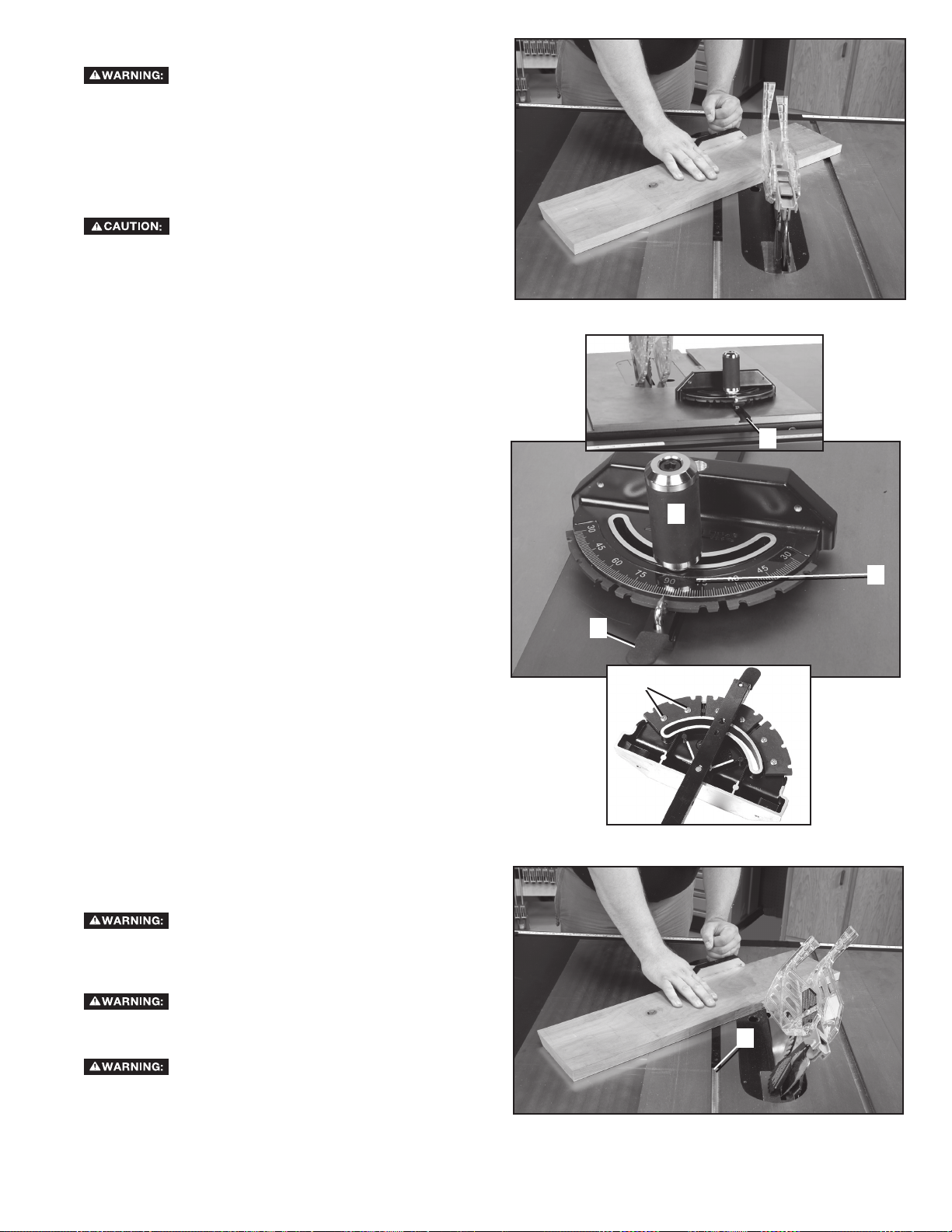

Bevel crosscutting (Fig. 61) is the same as crosscutting

except the bevel angle is set to an angle other than 0°.

Before connecting the table saw to the

power source or operating the saw, always inspect

the blade guard assembly and riving knife for proper

alignment and clearance with saw blade. Check

alignment after each change of bevel angle.

When possible, use the right miter gauge

slot when bevel crosscutting so that the blade tilts

away from the miter gauge and your hands.

Use caution when starting the cut to

prevent binding of the guard against the workpiece.

FIG. 60

FIG. 61

26

Page 27

MITERING

Miter angles greater than 45˚ may force

the blade guard assembly into the saw blade causing

damage to the blade guard assembly and personal

injury. Before starting the motor, test the operation by

feeding the workpiece into the blade guard assembly.

If the blade guard assembly contacts the blade, place

the workpiece under the blade guard assembly, not

touching the blade, before starting the motor.

Certain workpiece shapes, such as

molding may not lift the blade guard assembly properly.

With the power off, feed the workpiece slowly into the

blade guard area and until the workpiece touches the

blade. If the blade guard assembly contacts the blade,

place the workpiece under the blade guard assembly,

not touching the blade, before starting the motor.

This operation is the same as crosscutting except the

miter gauge is locked at an angle other than 0°. Hold the

workpiece FIRMLY against the miter gauge and feed the

workpiece slowly into the blade (to prevent the workpiece

from moving). See Fig. 62.

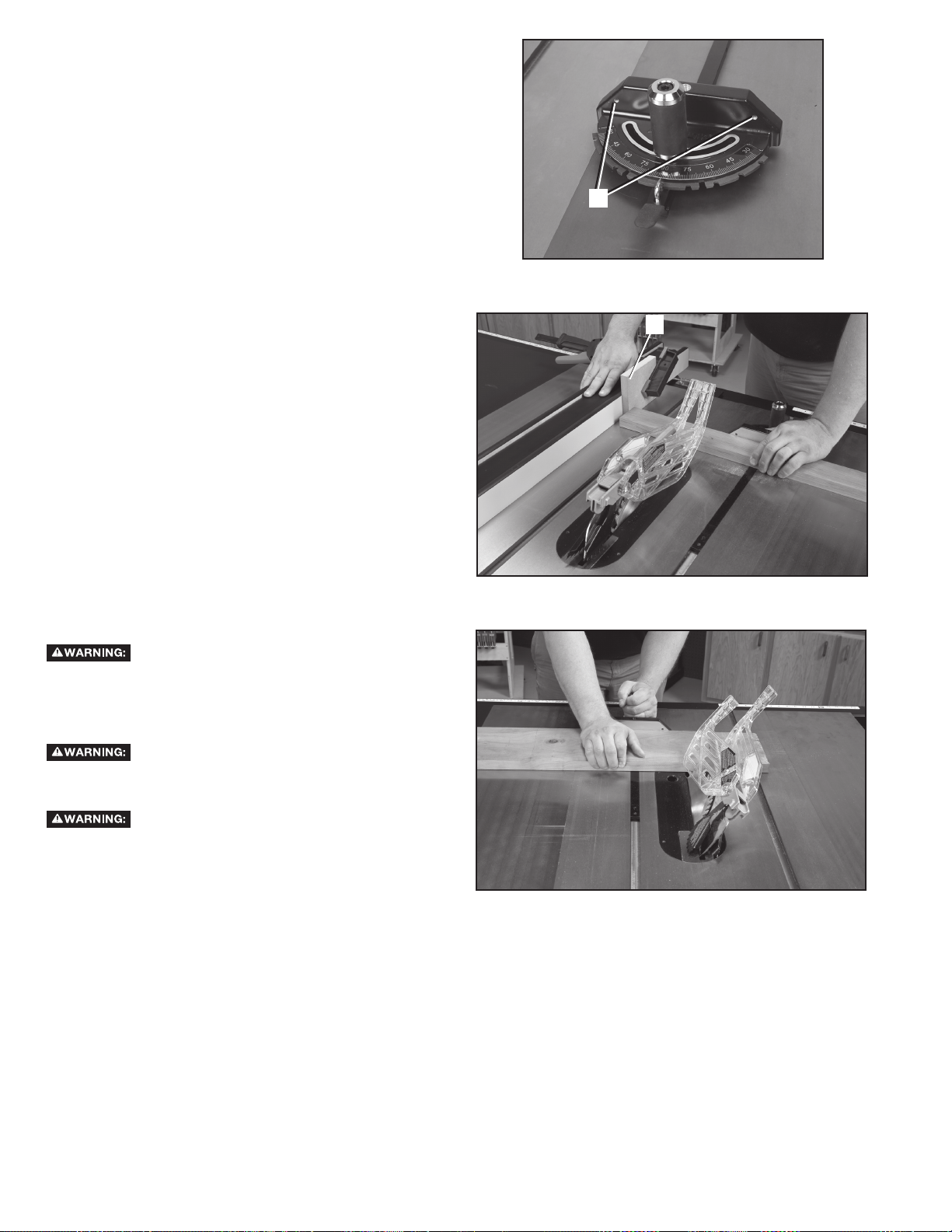

MITER GAUGE OPERATION

The miter gauge is equipped with adjustable index stops

at 90°, 75°, 60°, 45° and 30°.

To rotate the miter gauge, loosen handle (G) Fig. 63, push

the thumb lever (H) down and move the body of the miter

gage (I) to the desired angle.

The miter gauge is equipped with a washer on the end of

the bar which fits into the T-Slot groove (J) in the table.

This allows the miter gauge to be pulled off the front edge

of the table without falling. This allows for a longer cut-off

capacity in front of the blade.

FIG. 62

J

G

I

H

To adjust the stops, loosen screws — two shown at (X)

Fig. 63. Move stop to proper position and re-tighten

screws (X).

COMPOUND MITERING

This is a combination of bevel crosscutting and mitering.

Follow the instructions for both bevel crosscutting and

mitering.

NOTE: Always use the miter slot (K) Fig. 64 which allows

the blade to tilt away from the miter gauge and hands.

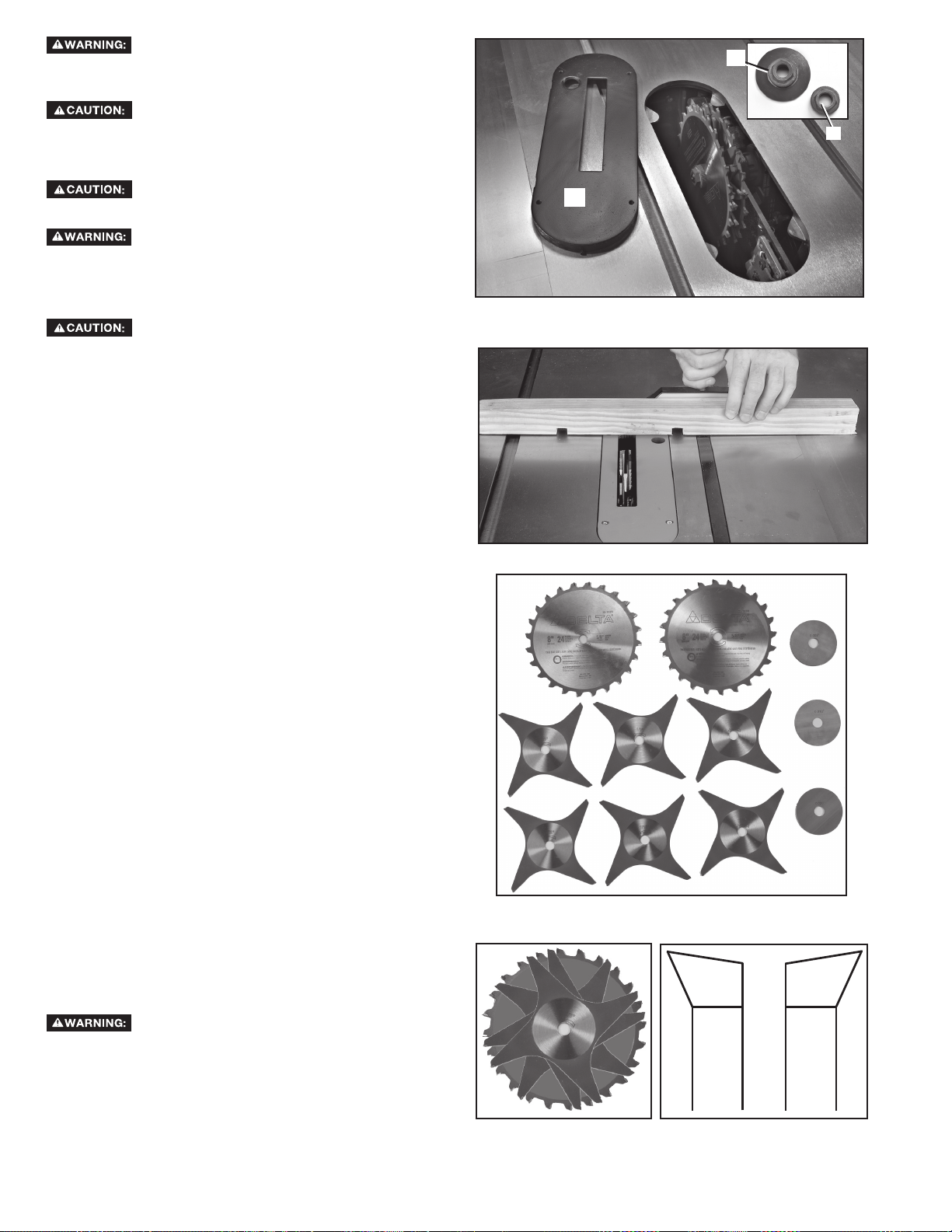

USING AN ACCESSORY DADO HEAD

To reduce the risk of injury, turn unit off

and disconnect it from power source before installing

and removing accessories, before adjusting or when

making repairs. An accidental start-up can cause injury.

Do not attempt to stack dado blades

thicker than 1" (25.4 mm) Do not use dado blades larger

than 8" (200 mm) in diameter.

The riving knife and blade guard

assemblies cannot be used when dadoing or molding.

It must be removed as described in Riving Knife and

Blade Guard Operations section. Use EXTREME care

when using the dado without the blade guard assembly

and riving knife.

X

FIG. 63

K

FIG. 64

27

Page 28

Use pushsticks, hold-downs, jigs,

fixtures or featherboards to help guide and control the

workpiece when the guard cannot be used.

The accessory dado head set throat plate

(L) Fig. 65 must be used in place of the standard throat

plate. Be sure the throat plate is level to the table before

you proceed.

M

N

Always check dado blade clearance before

plugging in the saw.

To reduce the risk of injury,

be sure to

place the blade guard assembly and standard throat

plate back in position and check adjustments when

the dado cuts are complete. Reinstall blade guard

assembly, anti-kickback assembly and riving knife.

Never use the dado head in a bevel

position.

Dadoing is cutting a rabbet or wide groove into the

workpiece, as shown in Fig. 66. Most dado head sets

are made up of two outside blades and four or five inside

chippers, (Fig. 67). Various combinations of blades and

chippers are used to cut grooves from 1/8" (3.2 mm) to

1" (25.4 mm) for use in shelving, making joints, tenoning,

grooving, etc.

NOTE: The standard outer arbor flange nut assembly (M)

Fig. 65 cannot be used with dado blade sets. A special

nut (N) is included with the Unisaw to be used in dado