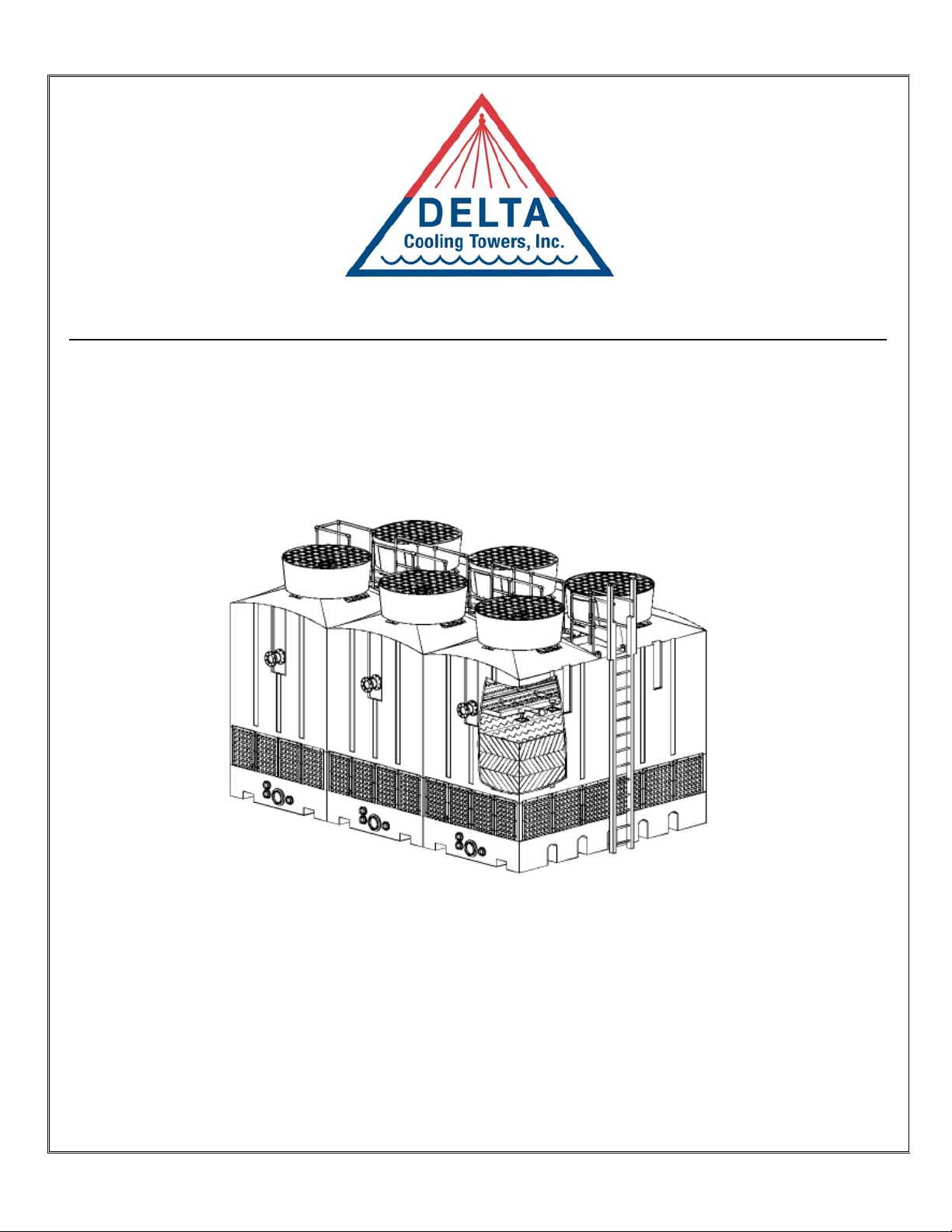

Page 1

Delta Cooling Towers, Inc.

TM Series Cooling Tower

Installation, Operation & Maintenance

Revised 1-8-2007

Manual

Page 2

Table of Contents

Delta Cooling Towers Principle of Cooling Towers………………..……………. 2

Cooling Tower Terms and Definitions…………………… 2

Water Treatment……..………………………….……….. 3

General Information Safety………………..………………………………….… 3

Approximate Weights………………..…………………… 4

Dimensions & Other Physical Data……..………...……… 4

Handling & Installation On-Site Inspection………………..………..…….….……. 5

Off Loading……..……………..………………………….. 5

Anchoring……..……….…………………………..……… 8

Electrical Wiring of Fan Motor & Accessories……..…….. 8

Location, Piping & Connections……..…….……….…….. 8

PVC Solvent Cementing Instructions………………...…… 10

Operation and Maintenance Safety in Operation of the Fan..…..………..…….….……. 11

Water Distribution System……..…………………………. 11

Fan & Mechanical Drive System….………………..…...… 12

Start-up Instructions………………………………..…….. 12

Water Level in Tower Sump…..……..…….……….…….. 13

Cold Weather Operation…………...………………...…… 14

Trouble-Shooting Guide.…………...……………….….… 16

Motor Trouble-Shooting Guide…………...………....…… 18

Other Information Cooling Tower Optional Accessories..…..…...….….……. 19

Recommended Replacement Parts……..…………………. 19

Preventative Maintenance Checklist….……………….….. 20

Important:

Delta’s cooling towers have been designed to provide trouble-free service over an extended period of time. To obtain

the design performance, it is necessary that the cooling tower be installed, operated and maintained as prescribed in

these instructions.

Only persons possessing the skill and experience described herein should attempt to install this equipment. Prior to

installation, these instructions should be read carefully by the person who is to install the cooling tower to be

certain that its installation, operation and maintenance are thoroughly understood.

Questions regarding the installation, operation or maintenance of this equipment should be directed to Delta Cooling

Towers, Inc., Rockaway, New Jersey, (Telephone: 973/586-2201).

Step-by-step instructions contained in this brochure are based on normal installation conditions only. Abnormal or

unusual combinations of field conditions should be brought to the attention of Delta Cooling Towers or its

representative prior to installation of the equipment. The information contained herein is subject to change without

notice in the interest of product improvement.

Revised 1-8-2007

1

Page 3

Delta Cooling Towers

Principle of Cooling Towers

All Cooling Towers operate on the principle of removing heat from water by evaporating a small portion of the

water that is recirculated through the unit.

The heat that is removed is called the latent heat of vaporization.

Each one pound of water that is evaporated removes approximately 1,000 BTU's in the form of latent heat.

Cooling Tower Terms and Definitions

BTU - A BTU is the heat energy required to raise the temperature of one pound of water one degree Fahrenheit

in the range from 32° F. to 212° F.

Cooling Range - The difference in temperature between the hot water entering the tower and the cold water

leaving the tower is the cooling range.

Approach - The difference between the temperature of the cold water leaving the tower and the wet-bulb

temperature of the air is known as the approach. Establishment of the approach fixes the operating temperature

of the tower and is a most important parameter in determining both tower size and cost.

Drift - The water entrained in the air flow and discharged to the atmosphere. Drift loss does not include water

lost by evaporation. Proper tower design and operation can minimize drift loss.

Heat Load - The amount of heat to be removed from the circulating water within the tower. Heat load is equal to

water circulation rate (gpm) times the cooling range times 500 and is expressed in BTU/hr. Heat load is also an

important parameter in determining tower size and cost.

Ton - An evaporative cooling ton is 15,000 BTU's per hour.

Wet-Bulb Temperature - The lowest temperature that water theoretically can reach by evaporation. Wet-Bulb

Temperature is an extremely important parameter in tower selection and design and should be measured by a

psychrometer.

Pumping Head - The pressure required to pump the water from the tower basin, through the entire system and

return to the top of the tower.

Make-Up - The amount of water required to replace normal losses caused by bleed-off, drift, and evaporation.

Bleed Off (Blowdown) - The circulating water in the tower which is discharged to waste to help keep the

dissolved solids concentration of the water below a maximum allowable limit. As a result of evaporation,

dissolved solids concentration will continually increase unless reduced by bleed off.

Revised 1-8-2007

2

Page 4

Water Treatment

• The Delta Cooling Towers are manufactured from corrosion-resistant plastics which are resistant to water

treatment chemicals including common fungicides and bactericides.

• Follow appropriate water treatment practices as required and take frequent sample tests to avoid possible

water contamination. We also recommend water treatment maintenance as a measure of protection of the

environment in the vicinity of any cooling tower or other equipment open to atmosphere.

• To determine the appropriate water treatment practices for your particular application, it is suggested that

you contact a water treatment firm for their recommendation. A list of water treatment firms is available for

your reference. It is not necessarily complete nor do we recommend a specific firm. The list will be mailed to

you on request or consult your local yellow pages.

• Bleed-off is also important to water quality. Evaporation of the recirculated water does not remove the

dissolved solids that are present in the water. Without bleed-off, the continual buildup of these solids will

impair the proper functioning of the piping and other equipment in the system.

• A bleed line can be connected in any part of the system for routing to the sewer. Normally, it is most

desirable to make this connection in the hot water line at the cooling tower. A petcock type valve, installed in

the bleed line is recommended. Normally, bleed-off of 1% to 2% of the recirculation water flow is

satisfactory. The required amount of bleed-off water must be substituted with properly controlled amounts of

make-up water.

General Information

Safety

When handling, lifting, installing or operating the cooling tower, always employ safe work procedures,

according to best practices of the trade and according to applicable construction, electrical and safety standards,

regulations and codes.

Follow all safety practices described in these instructions.

Revised 1-8-2007

3

Page 5

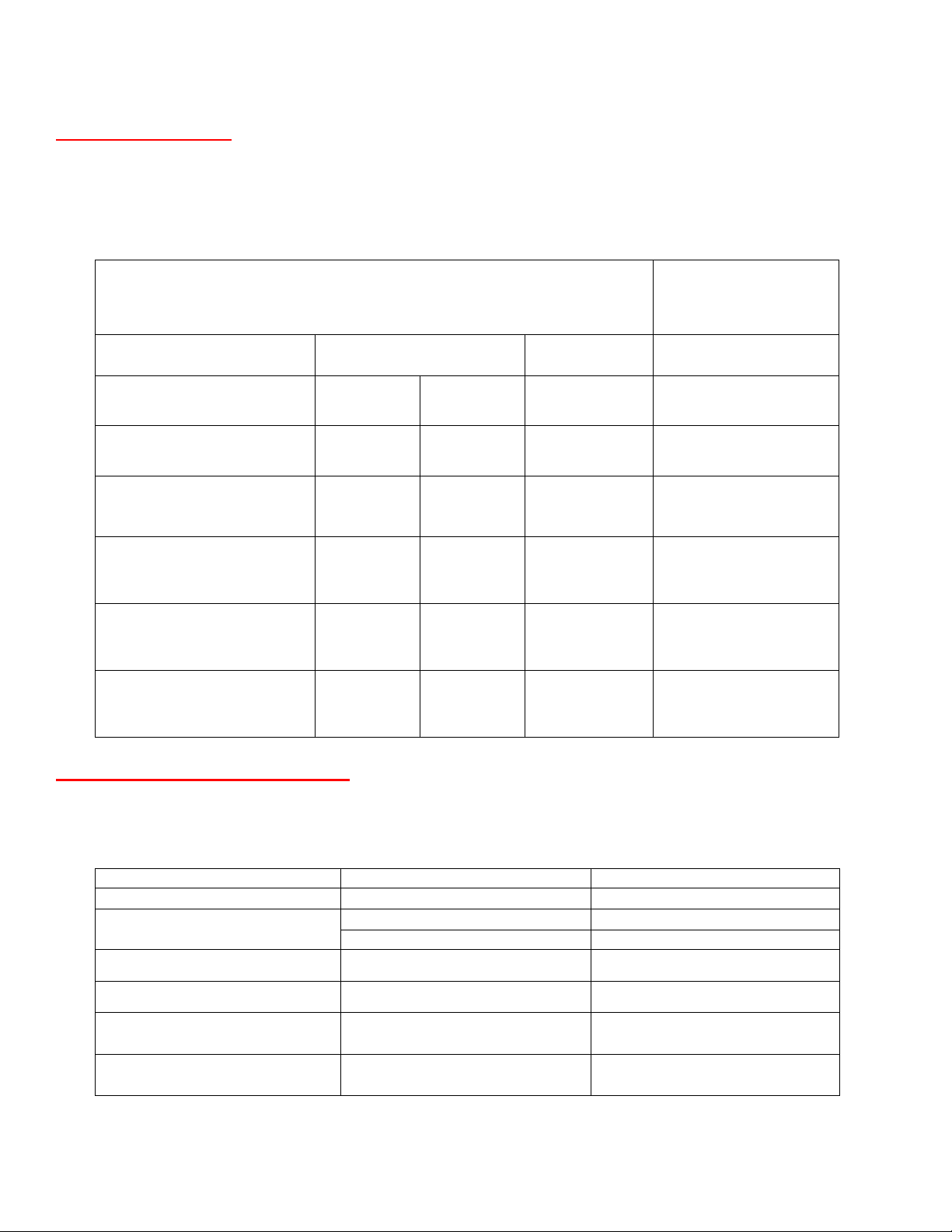

Approximate Weights

The TM Series cooling towers are manufactured in three basic sections; a polyethylene tower body, a

polyethylene sump, and a fan assembly section. The tower body ships with the fan assemblies installed.

The tower sump ships as a separate piece.

Approximate Weights (lbs.)

Model Group Shipping

TM-105312 – TM-115412

TM-205312 – TM-215412

TM-305312 – TM-315412

Body Sump

4,850

(2) 4,850 (2) 1,660

(3) 4,850 (3) 1,760

1,660

Overall

Dimensions

(inches)

Operating L x W x H

11,800 198” x 102” x 186”

23,600 198” x 204” x 186”

35,400 198” x 306” x 198”

TM-405312 – TM-415412

TM-505312 – TM-510412

TM-605312 – TM-610412

(4) 4,850 (4) 1,760

(5) 4,850 (5) 1,760

(6) 4,850 (6) 1,760

Dimensions and Other Physical Data

For cooling tower dimensions, design for foundations, assembly and layout, refer to the following

drawings which are a part of these instructions:

Model Group Title Drawing No.

TM-105312 – TM-115412

TM-205312 – TM-215412

TM-305312 – TM-315412

TM-405312 – TM-415412

TM-505312 – TM-510412

TM-605312 – TM-610412

1 Cell DT-D-87-901

2 Cell (5 - 7.5 HP) DT-D-87-902

2 Cell (10 – 15 HP) DT-D-87-903

3 Cell

4 Cell DT-D-87-905-1

5 Cell DT-D-87-906-1

6 Cell

DT-D-87-907-1

47,200

59,000 198” x 510” x 198”

70,800 198” x 612” x 198”

198” x 408” x 198”

DT-D-87-904-1

DT-D-87-904-2

DT-D-87-905-2

DT-D-87-906-2

DT-D-87-907-1

Revised 1-8-2007

4

Page 6

Handling and Installation of Your TM Series Cooling Tower

On -Site Inspection

Upon arrival at the job site, carefully inspect the shipment for any damage. If shipping damage has occurred,

notify the driver or the carrier immediately and make a notation of the damage on the shipping bill of lading.

Check that all items listed B/L have been received.

Offloading

The TM Series cooling towers are normally delivered to the site on a 30 inch high drop deck trailer. Both the

tower body assembly and sump assembly are strapped down to the truck bed. The sump assembly should be

unloaded first.

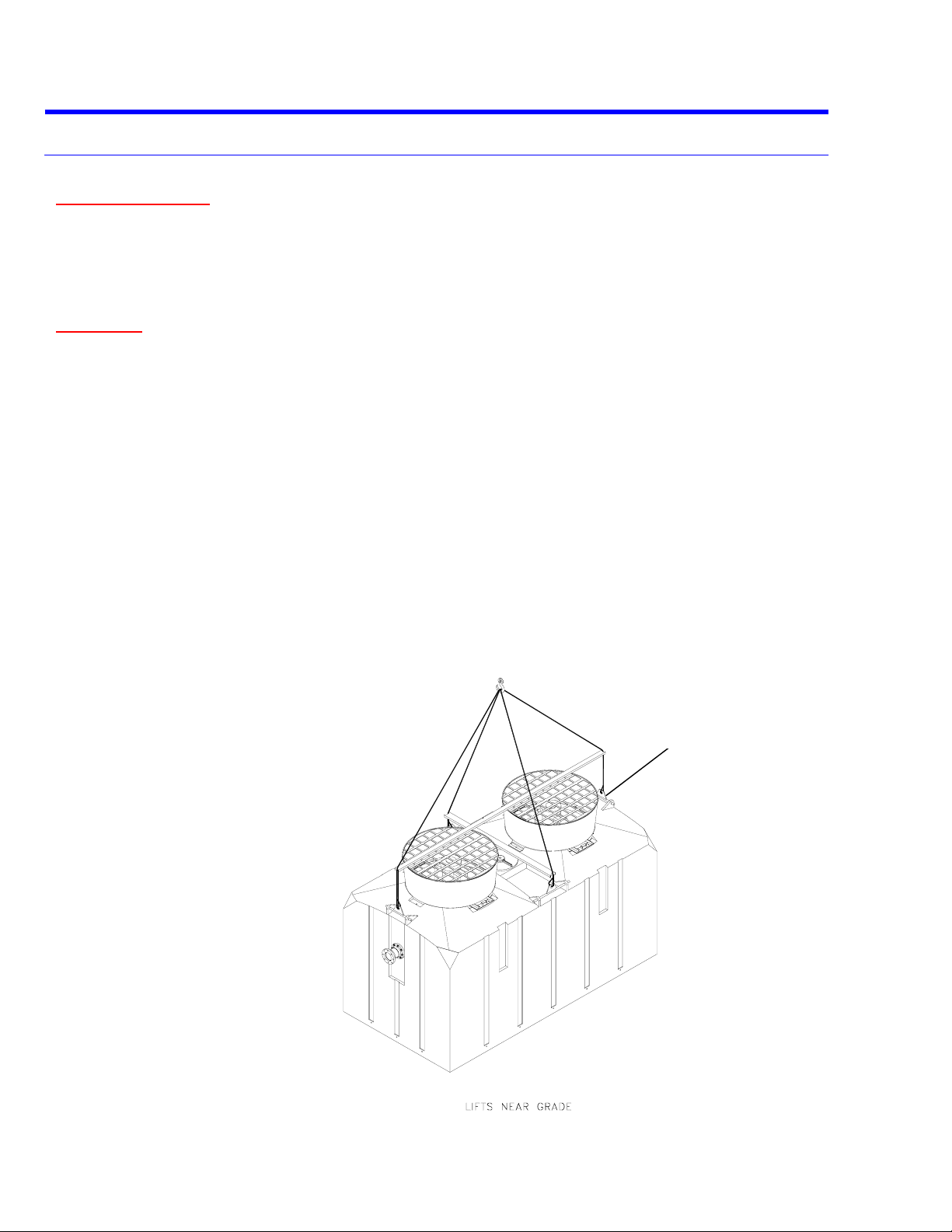

Lifting with crane:

• Use fabric slings of sufficient strength for better load distribution and protection of the plastic tower

body.

• Wrap slings underneath tower sump assembly to lift and set into place.

• Lift tower body by attaching slings, kept separate by spreader bars, to the four lifting bars as shown

below.

• Spreader bars must be used to lift vertically on the lifting bar. Above the spreader bars use adequate

length straps specifically designed for vertical lifting in order to maintain an angle of 60° or less between

slings.

Revised 1-8-2007

Lifting Bar

5

Page 7

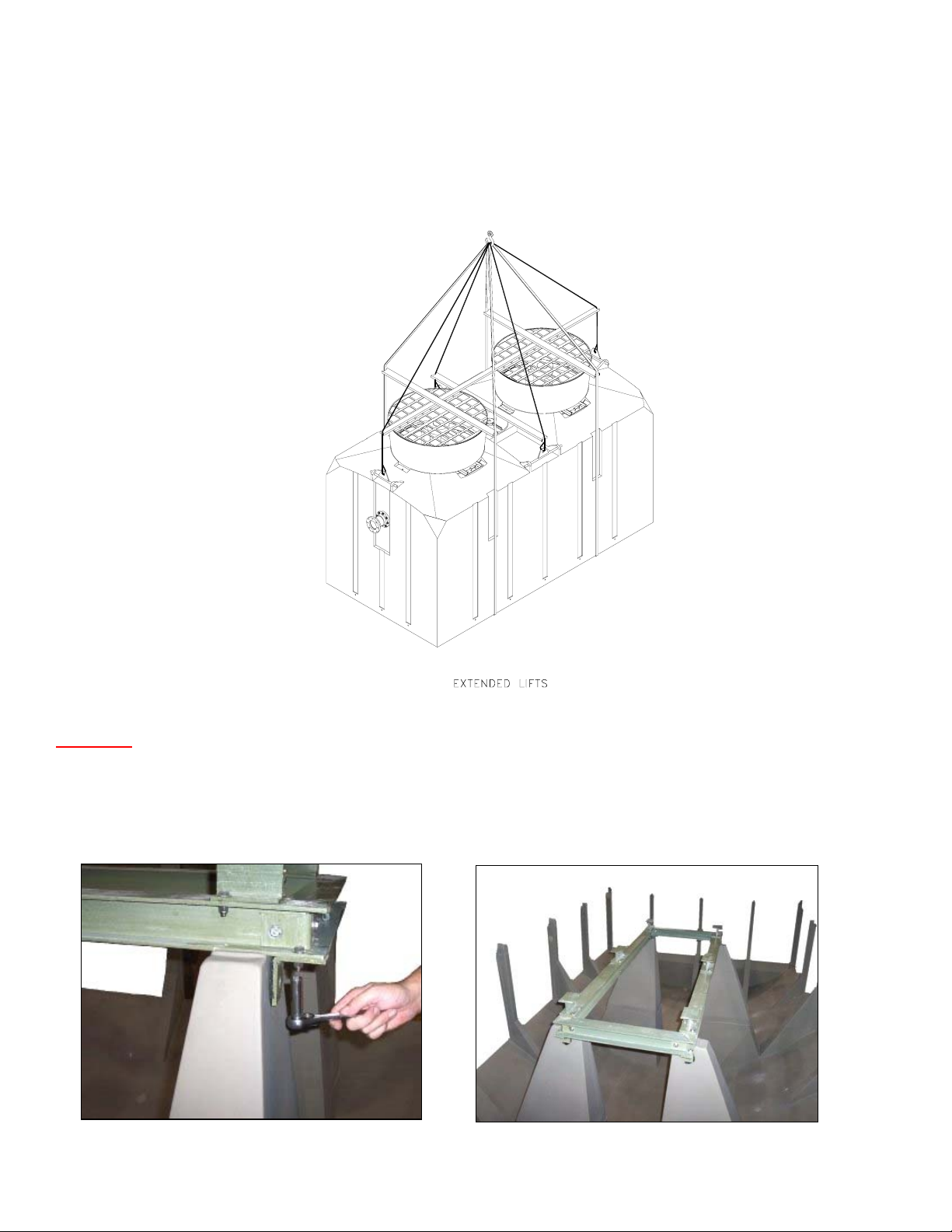

Store tower assembly as shipped until the time of installation, in a secure, level and debris free location at the job

site.

CAUTION: For extended lifts, use duplicate rigging, fabric slings around body as shown, as an additional

safety precaution.

Installing

The cooling tower should be assembled in place on the previously prepared foundation.

• After re-checking the rigging, lift the sump section of each cell and secure properly to the foundation.

• Attach the fiberglass sump box to the center support post using the hardware provided as shown.

Revised 1-8-2007

6

Page 8

• The body section should then be lifted and carefully position to align the support post of the sump

with the corresponding groove of the tower body. Note that the four corner posts are slightly higher

than other post to ease installation alignment.

• Set one end of the tower body onto the corner post at one end of the sump first. This can be

accomplished by use of a rope tether attached to the lifting bar at one end of the housing. Continue

setting and aligning support post along the sides of the tower moving from one end to the other. This

step may require a couple installers to align multiple posts simultaneously. You may use a rubber mallet

or blocking wood to aid aligning post.

IMPORTANT: Make sure that all posts are correctly seated into the pocket of the tower body.

• For single cell units, the four corner sump posts should then be secured to the main housing with the

provided stainless steel angle brackets and hardware. On Multi-cell towers, the outermost four corner posts

should be secured to the main housing with the provided stainless steel angle brackets and hardware.

• Before installing PVC louver panels, verify that all post are correctly seated into the pockets of the tower

body.

• Install PVC louver panels between each support post. Panels are numbered and marked on top of each

panel, and should be installed with corresponding numbered window opening. Insert bottom of panel into

window opening and work your way up to the top. Panels should be mounted flush with inside top of louver

opening inside tower and should direct incoming air downward. Secure panels with self-tapping screws

provided.

Revised 1-8-2007

7

Page 9

• On multi cell towers, install PVC water redirector panels between each sump using self-tapping screws

provided (See sketch below). Start with screwing the PVC post from the bottom up. Next apply a heavy

bead of RTV sealant on the end of each redirector panel. Start screwing the redirector panels from the end

nearest the post toward the center. Do not screw overlapping panels to allow for expansion and contraction.

(Side View of Redirector Panels)

Multi Cell Water Redirectors.

• Secure tops of adjacent multi cell units together by bolting the two steel support angle brackets provided

to the lifting lugs of each cooling tower shell. The angle brackets should then be bolted together with

hardware provided.

Anchoring

The foundation must be flat, smooth and rigid enough to be capable of independent support of the cooling tower

assembly and water load in the sump at its maximum level. The tower assembly can also be mounted on I-beams

using the integrally molded I-beam pockets (See tower drawings).

• Four hold-down anchor lugs are provided on the sump of each tower cell.

• Support beams and anchor bolts are to be furnished by others.

• Beams should be sized at least 7” wide and in accordance with acceptable structural practices. These beams

should be located in the integrally molded I-beam pockets, and should run the length of the unit.

• Use anchor bolts sized for a minimum of 15,000 lbs. pull-out load per anchor lug for wind loading.

Revised 1-8-2007

8

Page 10

Electrical Wiring of Fan Motor and Accessories

• Installation of a vibration cut-out switch is recommended. (Refer to tower accessories available).

• All electrical work should be performed only by qualified personnel and in accordance to prevailing

electrical codes, practices and safety standards.

• The motor starter should be sized on voltage, nominal horsepower, and maximum full load current. This

current value can be found on the motor nameplate. If the starter cannot accept the maximum full load motor

current, the next size should be used.

• Motor heaters should be selected on the basics of maximum full load current and service factors based on the

motor nameplate.

• Standard “Cooling Tower Service” motors are supplied with a minimum of a 1.15 Service Factor.

• Optional two speed motors are single winding variable torque.

• Run flexible conduit with some slack from the motor conduit box to terminal box outside the tower where

rigid conduit can be used.

• Conduit holding clip screws can be tapped directly into the tower wall. Use maximum 3/8” long screws.

• For the typical wiring schematic of fan motor and tower accessories, see Delta dwg. DT –B-78-001, included

with these instructions.

Location, Piping and Connections

• Piping should be adequately sized in accordance with accepted standard practices.

• Gravity drain to indoor storage sump requires proper head differential and piping design considerations.

Allowance must be made for flow, pipe size, piping layout and distance of cooling tower from the indoor

storage sump.

• On multiple cell installations, valving and/or pipe sizing should balance pressure drops to provide equal inlet

pressures. Equalizing fittings are provided in the sumps of each cell and can piped together to balance sump

water level. Each cell should be valved separately to allow for flow balancing or isolation from service.

• Prior to start-up check that the PVC locknuts on all bulkhead fittings are properly tightened to prevent

nuisance leaks. A chain wrench can be used to check and tighten the locknuts.

• Check that the SS hexagonal nuts on the inlet and outlet PVC flanges are properly tightened to prevent

nuisance leaks. While tightening the nuts, do not allow the bolt to rotate. This could damage the rubber seal

under the flat washer on the bolt head located inside the cooling tower.

• All supply and return piping must be independently supported.

Revised 1-8-2007

9

Page 11

PVC Solvent Cementing Instructions

The following procedure is recommended for the preparation and cementing of internal and external piping for

Delta Cooling Towers:

• Cut ends of pipe square using a handsaw and miter box. Tube cutters with wheels designed for use with PVC

are acceptable, providing they do not leave a raised bead on the outside diameter of the pipe.

• Use a chamfering tool or file to put a 10° to 15° chamfer on the end of the pipe. Lightly sand the area to be

cemented to remove gloss. Using a clean rag, wipe pipe surface and fitting socket to remove dirt, moisture

and grease. Acetone or similar solvent is recommended for cleaning.

• Check "dry fit" of pipe and fitting by inserting pipe at least 1/3 of the way into the fitting. Position pipe and

fitting to assure alignment. Pipe and fitting should be at same temperature condition.

• Using a clean, natural bristle brush about 1/2 the size of the pipe diameter, apply a primer to the fitting

socket. Apply primer with a scrubbing motion until the surface is penetrated. Primer should never be applied

with a rag. Repeated applications may be necessary to achieve the desired dissolving action. In the same

manner, apply primer to the pipe surface equal to the depth of the fitting socket, making sure the surface is

well penetrated. Reapply primer to the fitting socket to make sure it is still wet.

• While both surfaces are still wet with primer, use a clean brush to apply a liberal coat of solvent cement to

the male end of the pipe. The amount should be more than sufficient to fill any gap. Next apply a light coat

of solvent cement to the inside of the socket, using straight outward strokes to keep excess cement out of the

socket.

• While both surfaces are still wet with solvent cement, insert the pipe into the socket with a quarter-turn

twisting motion. The pipe must be inserted the full length of the socket. The application of solvent cement to

pipe and fitting, and the insertion of the pipe into the fitting, should be completed in less than one minute. If

necessary, two persons should apply solvent cement to the pipe and fitting simultaneously.

• Hold the joint together for approximately 30 seconds until both surfaces are firmly gripped. After assembly,

a properly made joint will usually show a bead of cement around its entire perimeter. This should be brushed

off. It is recommended that the joint be allowed to cure for 24 hours before pressure testing or operation.

Revised 1-8-2007

10

Page 12

Operation and Maintenance of Your TM Series Cooling Tower

Safety in Operation of the Fan

NEVER operate the fan when the access panel or the entire fan guard is removed.

NEVER remove access manhole cover while fan is in operation.

NEVER operate fan when any work, access, maintenance, trouble-shooting, etc. is being performed on the

inside of the fan ring assembly or inside the tower plenum.

• Normally, electrical codes dictate a disconnect box at the cooling tower.

• The handle of the disconnect box must be locked in the off position and an OSHA DANGER tag

(DO NOT OPERATE) must be attached to handle securely.

Note: Removing fuses from the disconnect box may provide further assurance, but only when done by qualified

personnel.

The foregoing precautions apply when any type of internal access to the tower is required, including the

following examples:

• Checking, maintenance or replacement of any fan assembly component.

• Checking, maintenance or replacement of the water distribution system inside the tower.

• Cleaning of the fill.

• Any work that necessitates removal of any access door, the fan guard or the manhole cover.

Water Distribution System

Water distribution is accomplished by a low pressure, non-rotating, spray nozzle system

designed to accommodate the specified flow rate.

IMPORTANT:

• The flow rate of the cooling tower must be as close to the design gpm as possible. The water

distribution system, including spray nozzles, is provided for the design flow condition.

Under-pumping or over-pumping will cause the cooling tower to perform inefficiently.

• Design pressure at the inlet connection must be maintained for proper water distribution.

If the pressure is less or greater than the design, proper water dispersion over the internal wet

decking will be impaired. If inlet pressure is low, water spray will not cover the entire wet

decking surface. This causes channeling of air, and does not make maximum use of the heat

transfer media. High inlet pressures will cause the water to over-spray the wet decking

media, hit the internal side walls of the tower shell and drop in a vertical flow along the shell

walls without the opportunity for water / air contact through the heat exchange media.

Excessive high spray pressure may also cause wet decking fatigue and damage.

• The operating inlet pressure should be between 4.0 and 5.5 psi at the tower inlet.

Revised 1-8-2007

11

Page 13

• The maximum operating inlet water temperature should not exceed 140° F.

CAUTION:

When stepping on top of the fill, distribute the body weight by means of two plywood plates as

described earlier in these instructions.

Fan and Mechanical Drive System and Its Maintenance

Safety

Follow all safety instructions previously discussed.

Motor:

• The standard motor is a totally enclosed motor , Class F insulation, 1.15 minimum service

factor, epoxy coating on outside frame, and is specifically designed for cooling tower duty to

the exclusive specifications of Delta Cooling Towers.

• Should there be a problem with the motor, which may be covered under our standard

warranty, the motor must only be inspected and serviced by an authorized motor

manufactures warranty shop, and Delta Cooling Towers, Inc. must be notified, otherwise the

warranty is void.

• If the motor bearings have grease fittings, follow the lubrication recommendations as

outlined in instructions from motor manufacturer. The majority of motors do not require

greasing.

Start-up Instructions

Complete all start-up instructions before applying heat load.

• Clean any accumulated debris or packaging material from inside tower sump.

• Check to be sure that the fan motor is properly wired for correct rotation as viewed from the

top of the fan. Reverse leads will cause incorrect rotation and reverse direction of airflow.

Note: Fan rotation should always agree with rotation labels. Standard fan rotation is

clockwise, (C.W.) however; non-standard fans may be designed to rotate counter

clockwise, (C.C.W.)

• Check for free rotation of the fan and fan blade tip clearance.

• Fill the cooling tower sump or the cold water storage reservoir on gravity drain applications.

• Water recirculation pump should be primed and all piping below the tower sump filled with

water. Check pump for proper shaft rotation.

• Start water recirculation pump and adjust flow to design. A flow metering device installed in

the inlet is recommended but if not available, use the pressure differential across the pump in

conjunction with the pump curve.

Revised 1-8-2007

12

Page 14

• Check spray pattern from nozzles to be sure there is no clogging. Remove drift eliminators

for nozzle inspection, then return to proper position.

• Start up fan motor and check amperage and voltage against motor nameplate data.

• The standard make-up valve assembly is shipped with the plastic float ball strapped against

the tower side to prevent damage. To set the ball for proper operation, loosen the screw in the

fulcrum arm, lift or depress the arm with the plunger pressed against the valve seat and

tighten. Repeat until the proper operating level is obtained (Refer to operating level table

below). It is recommended that a shut-off valve be installed in the make-up line.

• After 24 hours of operation:

Check spray nozzles for clogging.

Check tower sump water level.

Water Level in Tower Sump

• When the cooling tower is being operated with pump-suction, the make-up valve assembly

with float ball should be adjusted to set the water operating level as follows:

Tower Model # Operating level (from

bottom of sump)

All Towers

• Access the make-up valve through the window louver marked “Access Panel”.

• A lower water level than recommended may cause air to be drawn into the tower outlet

piping and cause pump "cavitation."

• A water level higher than recommended will cause continuous overflow and waste of water

as a result of potential “pull-down” from the piping when the system is shut down.

• The overflow should NEVER be capped, or its elevation altered by raising external piping.

Note: On gravity drain cooling tower(s), make-up assembly, overflow, drain and vortex breaker

are not provided.

10 inches

Revised 1-8-2007

13

Page 15

Cold Weather Operation

Cold Weather Protection

The cooling tower may require protection against freezing at light heat loads when the wet-bulb

temperature is under 32°F., or during shutdown when the temperature drops below 32°F.

The following methods are recommended for use in Delta Cooling towers for protection during

cold weather conditions. Recommended equipment is optional and may be ordered from the

factory. Consult the factory for further information on which equipment to choose for your

specific application.

Separate Indoor Sump

This method is virtually a foolproof antifreeze protection system with the added advantage of

minimum maintenance. The indoor sump tank should be large enough to fill the entire

recirculation system without danger of pump cavitation. As a general rule, the tank should be

sized to hold three times the rate of circulation in gallons per minute (gpm).

The tank should be provided with properly sized overflow, make-up drain and suction

connections. When a separate sump is ordered with a cooling tower, the water make-up valve

assembly and the overflow and drain connections are installed in the indoor sump only.

When a sump tank is used, the cooling tower should be located high enough above it to allow

free cold water gravity drain. A bottom outlet can be provided for gravity drain to indoor sump

tank installations.

Reverse siphoning is a back flow of non-potable, recirculating water into a potable water

system, which can occur through the make-up float valve assembly located in the water

reservoir. Should the valve malfunction, blockage of the overflow or outlet lines would cause

water level to rise in the reservoir, and the make-up water pressure could drop below the

atmospheric pressure creating a vacuum at the make-up inlet. Although precautions to

prevent reverse siphoning are incorporated in the cooling tower design, we also recommend

installing a check valve in the water make-up supply line, as a backup precaution.

Electric Immersion Heater

Cooling towers can be ordered with an anti-freeze immersion heater systems, which consist of a

6KW heating element, water level sensor, adjustable thermostat and contactor. Components are

factory installed, but will require field wiring.

Thermostatic On/Off Control

A thermostatically controlled fan for on/off operation, should be considered as an energy saving

feature, for capacity control during winter operation. The thermostatic control can be field set to

insure automatic fan shut-down when cold water drops below design temperatures, as well as fan

start-up when cold water rises to design temperature.

A thermostatic control provides excellent cooling tower anti-freeze protection while reducing

operating costs throughout cold weather operation.

Revised 1-8-2007

14

Page 16

PVC Distribution System

To prevent damage to the PVC distribution system during cold weather shut-down, install an

automatic or manual drain line from the hot water inlet piping as close to the cooling tower inlet

as possible. The entire inlet and distribution system must be drained for shut-down in subfreezing weather.

Piping

When the cooling tower is located outdoors, adequate measures including the use of heating

tapes and insulation should be considered to protect water lines from freezing.

Operation at Sub-freezing Ambients

See Thermostatic On/Off control

1. Insure that the cooling tower is operating at the maximum possible heat load - An operating

cooling tower will continuously extract heat from the circulating water. Without a heat load,

the water will end up either at the air wet bulb temperature, or as ice, whichever occurs first.

2. Maintain Design Water Flow Rate Over The Fill - Reducing water flow over the fill area

can produce semi-dry regions that are subject to rapid freezing.

3. Make sure a thermostat is installed to control fan operation to off at low cold-water

temperatures.

4. If tower is equipped with two speed motors, operate at low speed to increase leaving water

temperature.

5. Cycle fans periodically to prevent ice from forming on louvers.

6. It may also be necessary to reverse fans for a short period of time to help melt ice by

forcing warm water into tower.

• De-energize the fan(s) for two full minutes before reversing.

• Reverse fan(s) no more than 2 minutes at a time (repeat as necessary). Extended

reverse operation can cause ice to form on fan blades causing an out-of-balance condition.

• If the tower is equipped with a two-speed motor, reverse only at low speed.

• On multi-cell towers, fans immediately adjacent to reversed fans should be shut off

during reversal.

• After reversal, let fan(s) stand idle 5 to 10 minutes before forward operation.

• Monitor the tower closely for unusual vibrations or sounds.

7. Frequent visual inspections and routine maintenance during sub-freezing operation is very

important and should not be overlooked.

15

Page 17

Trouble-Shooting Guide For TM Series

Induced Draft Cooling Towers

Problem Possible Causes Corrective Actions

Increase in the leaving water

temperature

Drop in the water flow rate.

Low water flow rate

Noise and vibration 1. Loose bolts.

Sudden or short term irregularities of

cold water level in basin

Excessively high water level in sump on

gravity drain installation

1. Excess water flow; over pumping.

2. Recirculation of hot discharge air, back into

the cooling tower air intakes. Obstructed air

intakes

3. Proximity of other heat source or discharge

of moist air.

4. Improper operation of spray system.

A. Orifices clogged.

B. Actual water flow is lower than design

sprinkler rating.

5. Clogged fill.

6. Damaged fill.

7. Additional heat load on system.

8. Wet-bulb temperature higher than design.

1. Blockage of spray Nozzle orifices.

2. Low water level in sump causing air to be

drawn into pump and piping.

3. Improper selection of water circulating

pump.

4. Blockage of strainers.

5. Pump malfunction.

2. Mechanical interference of rotating parts.

3. Fan propeller damaged or out of balance.

4. Air intake at pump.

5. Pump cavitation.

6. Damaged motor bearings.

1. Peculiarities of specific system and its

operation.

1. Gravity flow restrictions due to insufficient

head differential.

1. Adjust to the design flow.

2. Eliminate obstructions which impede air discharge.

For proper location of cooling tower(s), see Delta

dwgs. Baffle air discharge, if necessary.

3. Remove source or relocate tower.

4. See water distribution system instructions.

A. Flush spray nozzles, clean orifices, clean

system, install outlet strainer.

B. Install properly rated spray nozzles or increase

to design flow.

5. Clean the fill.

6. Replace the fill.

7. Contact Delta for possible upgrade or addition of

another cooling tower selected for additional load.

8. None required if condition is temporary. Otherwise

consult Factory for upgrade.

1. Flush spray nozzle. Clean whole system. Install

outlet strainer.

2. Adjust float valves. Be sure the system is flooded

and balanced.

3. Replace with proper size pump designed for flow

and head requirements. Check pump “Net positive

suction head.”

4. Backwash or clean.

5. Consult pump specialist.

1. Recheck and tighten all bolts to specified torque.

2. Inspect propeller for free rotation. Check propeller

for mechanical interference. Adjust, repair or

replace, as necessary.

3. Replace components, as necessary and check

balance. Install vibration cut-out switch.

4. Check basin water level and irregular piping design.

5. Match pump NPSH with system hydraulics.

6. Check and replace motor.

1. Inspect system and review operation procedures.

Correct, as applicable valve settings, loss of water in

system, fill system to flooded capacity.

1.

A. Outlet piping should terminate below sump tank

water level.

B. Increase discharge pipe size.

C. Increase head by mean other than A.

16

Page 18

Problem Possible Causes Corrective Actions

2. Airlock.

3. Unnecessary obstruction of waterflow

(i.e., partially closed valve).

4. Undersized piping.

5. Horizontal pipe run too long.

6. Improper hydraulic pipe design.

7. Outlet vortex breaker provided.

Excessively high water level in tower basin

on closed loop system installations

Uneven water level in tower basins of multicell installations

Excessive water carry over (drift) 1. Surfaces of top layer of fill damaged

Premature or excessive corrosion of fan

drive components

1. Make-up valve float set too high.

2. Valve or float damaged or

malfunctioning.

3. Make-up water pressure too high.

1. Unbalanced system hydraulics.

2. More than one make-up valve

operating, and set for different water

levels.

causing “pooling” of water.

2. Eliminator(s) not in place.

3. Damaged eliminator.

4. Excess water flow.

5. Orifices in spray nozzles clogged

causing improper water dispersement.

6. Blockage of fill.

1. Excessive drift.

2. Presence of corrosive chemicals in air

or water that was not known at time of

supply.

2. Install an air bleed valve at highest point

of piping, usually at a vertical angle.

3. Remove obstruction.

4. Increase pipe size.

5. Shorten, if possible.

6. Correct design.

7. Remove vortex breaker.

1. Readjust float arm.

2. Repair or replace.

3. Reduce pressure or contact Delta for

alternate solutions.

1. A. Install equalizer line with isolation

valves between modules.

C. Adjust inlet water flow to insure equal

distribution to each cooling tower

module.

D. Review outlet header hydraulics and

correct piping design, if applicable.

E. Contact Delta for assistance.

2. A. Adjust float level settings relative

To one another.

B. Shut-off and or/throttle flow to

one or more valves.

C. Installation of equalizers is

highly recommended.

1. Replace top layer. Protect fill when working

inside tower.

2. Reinstall.

3. Replace.

4. Reduce water flow or install spray nozzles

designed for the actual operating flow.

5. Install outlet strainer. Clean whole system

and spray nozzles.

6. Clean fill.

1. See “ Excessive Water Carry Over (Drift)”

above.

2. Remove source of corrosion or contact Delta

for alternative materials, premium coatings

or other precautions.

17

Page 19

Motor Trouble Shooting Guide (General)

Problem Possible Causes Corrective Actions

High current draw (all 3 phases) 1. Low line voltage (5 to 10% lower

than nameplate).

2. 200V motor on 230/240V system.

3. 230V motor on 208V system.

4. Incorrect propeller.

5. Incorrect pitch if adjustable

Low motor current draw 1. Incorrect propeller.

2. Incorrect pitch if adjustable.

Unbalanced current

(5% from average)

Excessive voltage drop

(2 or 3% of supply voltage)

Overload relays tripping 1. Overload.

Motor runs very hot 1. Overloaded.

Motor will not start 1. Single phased.

Excessive vibration (Mechanical)

Note: Consult Warranty page prior to replacing or repairing any cooling tower components. Delta recommendation and consent

to remedy material and workmanship defects is necessary, to avoid breach of Warranty.

1. Unbalanced line voltage due to:

A. Power supply.

B. Unbalance system loading.

C. High resistance connection.

D. Undersized supply lines.

2. Defective Motor.

1. Inadequate power supply.

2. Undersized supply lines.

3. High resistance connections.

2. Unbalanced input current.

3. Single phasing.

4. Excessive voltage drop.

5. Frequent starting or intermittent

overloading.

6. High ambient starter temperature.

7. Wrong size relays.

8. Improper overload settings of

adjustable relays.

2. Blocked ventilation.

3. High ambient temperature.

4. Unbalanced input current.

5. Single phased.

2. Rotor or bearings locked.

Out of balance

1. Motor mounting.

2. Motor.

1. Consult power company.

2. Change to 230V motor.

3. Change to 200V or 280V motor.

4. Consult factory.

5. Reduce pitch / consult factory

1. Consult factory

2. Increase pitch / consult factory

1. Consult power company and/or

electrician.

2. Replace motor.

1. Consult power company.

2. Increase line sizes.

3. Check motor leads and other

connections.

1. Reduce load on motor or increase

motor size.

2. Balance supply voltage.

3. Eliminate.

4. Eliminate (see above).

5. Reduce frequency of starting and

overloading or increase motor size.

6. Reduce ambient temperature.

7. Correct size per nameplate current

and service factor.

8. Readjust to motor FL Amps x S.F.

1. Reduce overload.

2. Fouled fill or air restriction.

3. Reduce ambient temperature.

4. Balanced supply voltage.

5. Eliminate.

1. Shut power off – eliminate.

2. Shut power off – check shaft

rotation.

1. Check to be sure motor mounting

hardware is tight.

2. Replace motor.

18

Page 20

TM Series Optional Accessories

TM Series Optional Accessories Available

Aluminum Ladder(s) with a step platform and railing at the fan elevation custom designed for the cooling

tower.

Safety cage(s).

Two speed motor(s) designed for cooling tower duty to the exclusive specifications of Delta Cooling

Towers.

Vibration cut-out switch provides for fan motor circuit disconnect for shutdown protection should

abnormal fan vibration develop during service. Installation of vibration cut-out switches are

recommended as good design practice.

Thermostat on/off control of fan operation through sensing the temperature of water leaving the tower.

Basin anti-freeze system for cold weather operation.

Custom designed top platform with handrails.

Pre-wired control panels.

Elevated mounting frame structures.

Pumps

Polyethylene Sump tanks up to 2,000 gallons for indoor installation for anti-freeze protection during

winter operation.

Motor space heaters are recommended for unusually high relative humidity conditions where extreme day

to night temperatures can cause excessive condensation in the motor, when in operation during this period.

Plastic outlet sump strainer.

Plastic equalizer fittings.

Variable frequency drive on fan motors, controlled by temperature controller.

High sump level switch

Automatic drain valve

Consult factory or a Delta representative for further information and an updated list of accessories.

TM Series Recommended Replacement Parts

To avoid costly cooling tower downtime, the following replacement parts should be carried in inventory at the

installation site:

Make-up float, or complete make-up valve assembly.

Cartridge of recommended moisture resistant lubricant.

Fan Motor.

Spray Nozzles.

When ordering, include model number and serial number of the cooling tower as it appears on the tower

nameplate. Under normal conditions, shipment of factory replacement parts is made within one day after the

order is received. Spare pumps and pump parts, as well as control panel components, such as fuses and heaters

for magnetic starters, are also available.

19

Page 21

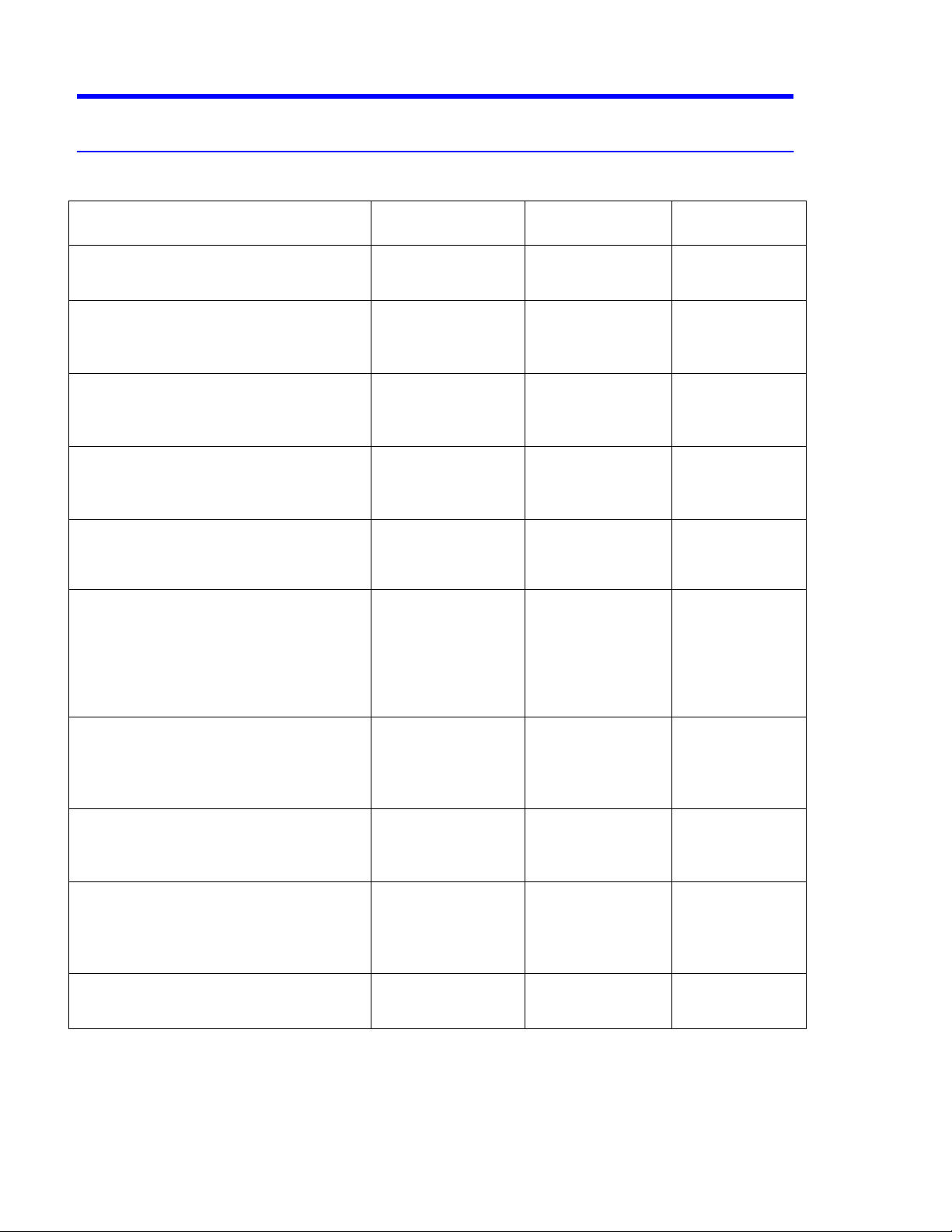

Preventative Maintenance Checklist

Procedure Monthly Every

Inspect General Condition of cooling tower.

Check Water Level in cold water basin.

Adjust if needed.

Check float ball & Make-up Valve for

proper operation.

Check Line Voltage, Motor Amperage,

Water Pressure.

Clean Sump Strainers, if installed.

¨

¨

¨

¨

¨

Every

3 Months

6 months

Lubricate Motor Bearing, (if motor has

fittings for greasing. The majority of motors

require no external greasing). Use Proper

Lubricants. Increase frequency, as necessary

depending on conditions of service.

Check for obstructed Water Flow Through

Orifices. Clean and flush spray nozzles, as

required.

Check All Bolts which can cause unbalance

and vibration and tighten specified torque.

Check Condition of Water for proper

treatment to prevent build-up of algae and

solids concentration

Clean and flush Cold Water Sump

¨

¨

¨

¨

¨

20

Loading...

Loading...