Page 1

Technical Datasheet

D-Series

Flanged Seals with Extended Diaphragm

Models: S-T

L

TDS-ST-A: FEB 2014

Remote connection with:

smart and analog

pressure and differential

pressure transmitters

4 × Æ9

Dm

d1

K

D

Direct connection with:

40

d

smart and analog pressure and

differential pressure transmitters

DIN 2512 Form N standard contact face

(DN50 PN40)

DIN 2526 Form E standard contact face

(DN80 PN40, DN100 PN40)

Length of cover:

54 mm for capillary £ 3 m

84 mm for capillary > 3 m

Capillary from 1 to 3 m

(special versions up to 6 m)

34.5

34.5

T

Diaphragm seal type S-TK-P- diaphragm

seal with direct diaphragm cleaning system

Models: S-T

D-Series

www.delta-controls.com

Page 2

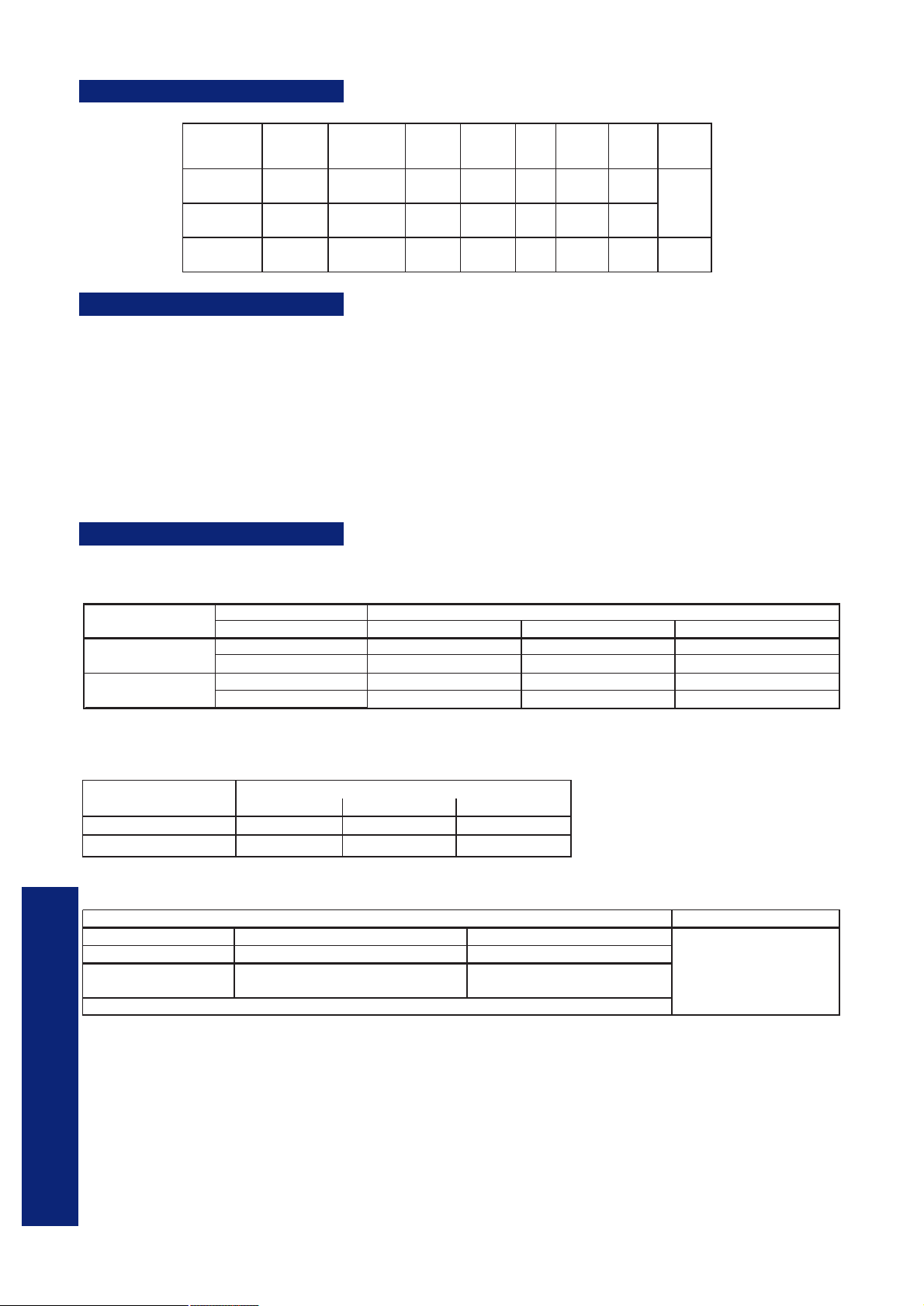

Dimensions

Version

DN50 PN40

2’’ANSI 150

DN80 PN40

3’’ ANSI 150

DN100 PN40

4’’ANSI 150

Diaphragm

diameter

Dm

48

48

75

75

88

89

Contact face

diameter

d1

102

92

138

127

162

158

Diameter

of bolt

circle K

125

120,5

160

152,5

190

190,5

External

diameter

D

165

150

200

190

235

230

Thick-

ness

d

22

20

24

24

24

24

Diameter

of holes

L

18

20

18

20

22

20

Number

of

holes

4

4

8

4

8

8

Tube

length

T

50, 100

150, 200

50, 100

150

Application

The diaphragm seal is a pressure transmitting, diaphragm-type device. The pressure signal is sent to the cooperating

pressure measuring device (pressure transmitter, pressure gauge) through manometric liquid filling the space between the

separating diaphragm of the seal and the pressure measuring device. The diaphragm seal task is to isolate the pressure

measuring device from damaging impacts caused by either medium or installation:

s Low or high temperature, increased viscosity, and impurities

s Tendency of crystallisation on the tank walls

s Vibrations of the installation (remote diaphragm seal)

The flanged diaphragm seal with extended diaphragm is typically applies to measure the pressure or level of the media in a

multi-walled tank, where the separating diaphragm should be placed close to the inner wall of the tank.

Measuring Ranges

Recommended minimum measuring range (bar)

depending on the type of the set: pressure measuring device - diaphragm seal

Pressure

measuring device

Smart

transmitters∗

PCE-28

Seal type

DN50 / 2’’ DN80 / 3’’ DN100 / 4’’

direct 0.4 0.1 0.1

remote (2 m) 6 0.5 0.25

direct 0.1 0.1 0.1

remote (2 m) 2 0.5 2.5

Diaphragm Seal Version

Additional absolute zero error resulting from ambient temperature fluctuations, depending

on the type of the set: pressure transmitter - diaphragm seal with a 100 mm of tube

Diaphragm seal type

Absolute zero error per 10°C for the diaphragm seal

DN50 / 2’’ DN80 / 3’’ DN100 / 4’’

direct 2 mbar 0.6 mbar 0.4 mbar

remote (2 m capillary) 10 mbar 2 mbar 1 mbar

An additional zero error, resulting from

temperature fluctuations in a medium,

depends on the temperature gradient in the

oil-based diaphragm sealing system. The error

value is, in any case, significantly smaller than

the error value shown in the table.

Temperature range of measured medium

Remote diaphragm seal Direct diaphragm seal

Manometric liquid Underpressure measurements Overpressure measurements

high-temperature (DC) -10...150°C -10...315°C -30...150°C

low-temperature (AK) not recommended for measurement

Note: When operating with an ambient temperature of < -15°C, heating of capillaries filled with DC fluid is recommended.

of pressures < 0.5 bar ABS

-60...200°C

Maximum pressure for PN40 – 40 bar

Maximum pressure for ANSI 150 – 150 psi

Material of diaphragm, tube and flange 316Lss

Other standards DIN and ANSI

Direct diaphragm seal for medium temp. over 150°C

Others

Important:

- contact face in diaphragram seal DN50 have a milled slot for a gasket (acc. to DIN 2512 FormN). Version without any

slot available on request. (acc. to DIN 2526 FormE)

- standard outlet of capillary from flange:

direct mounted diaphragm seal - axial

remote mounted diaphragm seal - radial

Models: S-T

D-Series

www.delta-controls.com

Special versions

Page 3

Recommendations

The essential metrological problem with diaphragm seals operational use is an absolute thermal zero error, resulting from

the thermal expansion of the manometer liquid. The expansion effect must be compensation for by the separating

diaphragm’s flexibility.

To minimise this effect, it is advisable to:

s Use capillaries which are as short as possible in order to greatly reduce the volume of manometer liquid

s Use seals with greater diameters in order to maximise flexibility of the separating diaphragm

s Place the capillaries in locations in which the temperature fluctuations will be minimal

How to Order

Direct diaphragm seal:

pressure measuring device / S-T – DN..... / T = ..... mm / special version (description)

Remote diaphragm seal:

pressure measuring device / S-TK – DN..... / T = ..... mm / K = ..... m / special version (description)

Transmitter or gauge

– see the code in the

appropriate catalogue sheet

Seal

version

Tube

length

Capillary

length

Example: DPC-2000 pressure transmitter, nominal measuring range 0 ÷ 25 bar, DN 50 remote flanged

seal with extended diaphragm, 100 mm tube, 2 m capillary.

DPC-2000ALW / 0 ÷ 25 bar / S-TK – DN50 / T = 100 mm / K = 2 m

www.delta-controls.com

Models: S-T

D-Series

Page 4

In the interest of development and improvement Delta Controls Ltd, reserves the right to amend, without notice, details

contained in this publication. No legal liability will be accepted by Delta Controls Ltd for any errors, omissions or amendments.

Delta Controls Limited

Island Farm Avenue, West Molesey, Surrey KT8 2UZ, UK.

Models: S-T

D-Series

T+44 (0)20 8939 3500 F+44 (0)20 8783 1163 E sales@delta-controls.com W www.delta-controls.com

www.delta-controls.com

Loading...

Loading...