Page 1

Technical Datasheet

D-Series

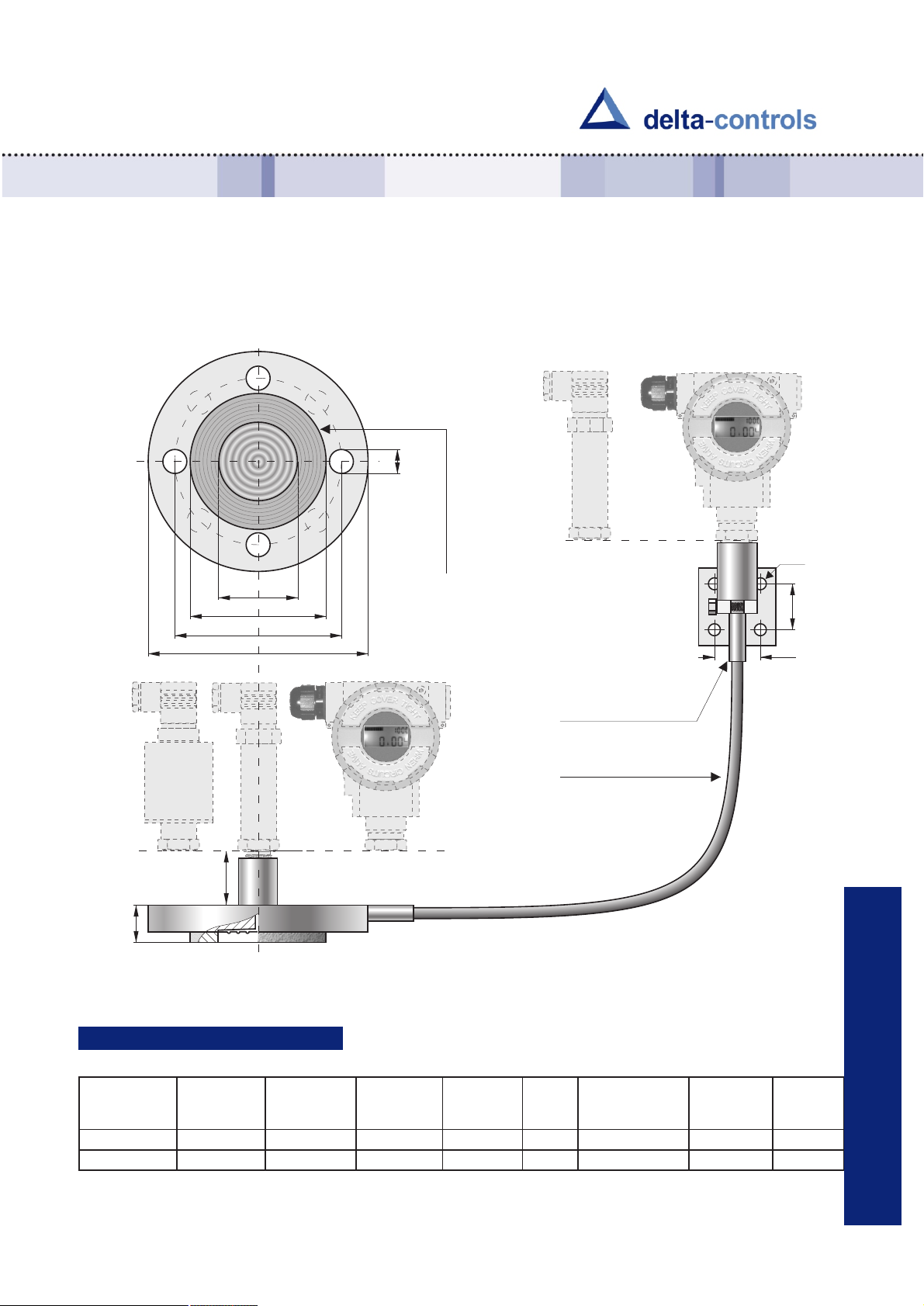

Chemical Flanged Seals with Flush Diaphragm

Models: S-Ch

d

TDS-S-Ch-A: FEB 2014

face

Form B

DIN 2526 standard contact

Dm

Dp

Do

Dz

Direct connection with:

40

B

smart and analog pressure and

differential pressure transmitters

Remote connection with:

smart and analog

pressure and differential

pressure transmitters

Length of cover:

54 mm for capillary £ 3 m

84 mm for capillary > 3 m

Capillary from 1 to 3 m

(special versions up to 6 m)

Æ9

4 holes

34.5

34.5

Dimensions

Version

DN50

DN80

∗ for tantalum 127 lining

Diaphragm

diameter

Dm

60

89

Contact face

diameter

Dp

102

138∗

Partition

diameter

Do

125

160

External

diameter

Dz

165

200

www.delta-controls.com

Thick-

ness

B

24,2

28,9

Thickness

(teflon version)

B

27,7

33,1

Diameter of

openings

d

18

18

Number

of

openings

4

8

D-Series

Models: S-Ch

Page 2

Application

The diaphragm seal is a pressure transmitting, diaphragm-type device. The pressure signal is sent to the cooperating

pressure measuring device (pressure transmitter, pressure gauge) through manometric liquid filling the space between the

separating diaphragm of the seal and the pressure measuring device. The diaphragm seal task is to isolate the pressure

measuring device from damaging impacts caused by either medium or installation:

s High corrosiveness

s Low or high temperature, increased viscosity, and impurities

s Vibrations of the installation (remote diaphragm seal)

The material of both diaphragms and contact faces for the chemical-resistant diaphragm seals is corrosion resistant,

irrespective of the medium’s chemical composition and its expected concentration and temperature range.

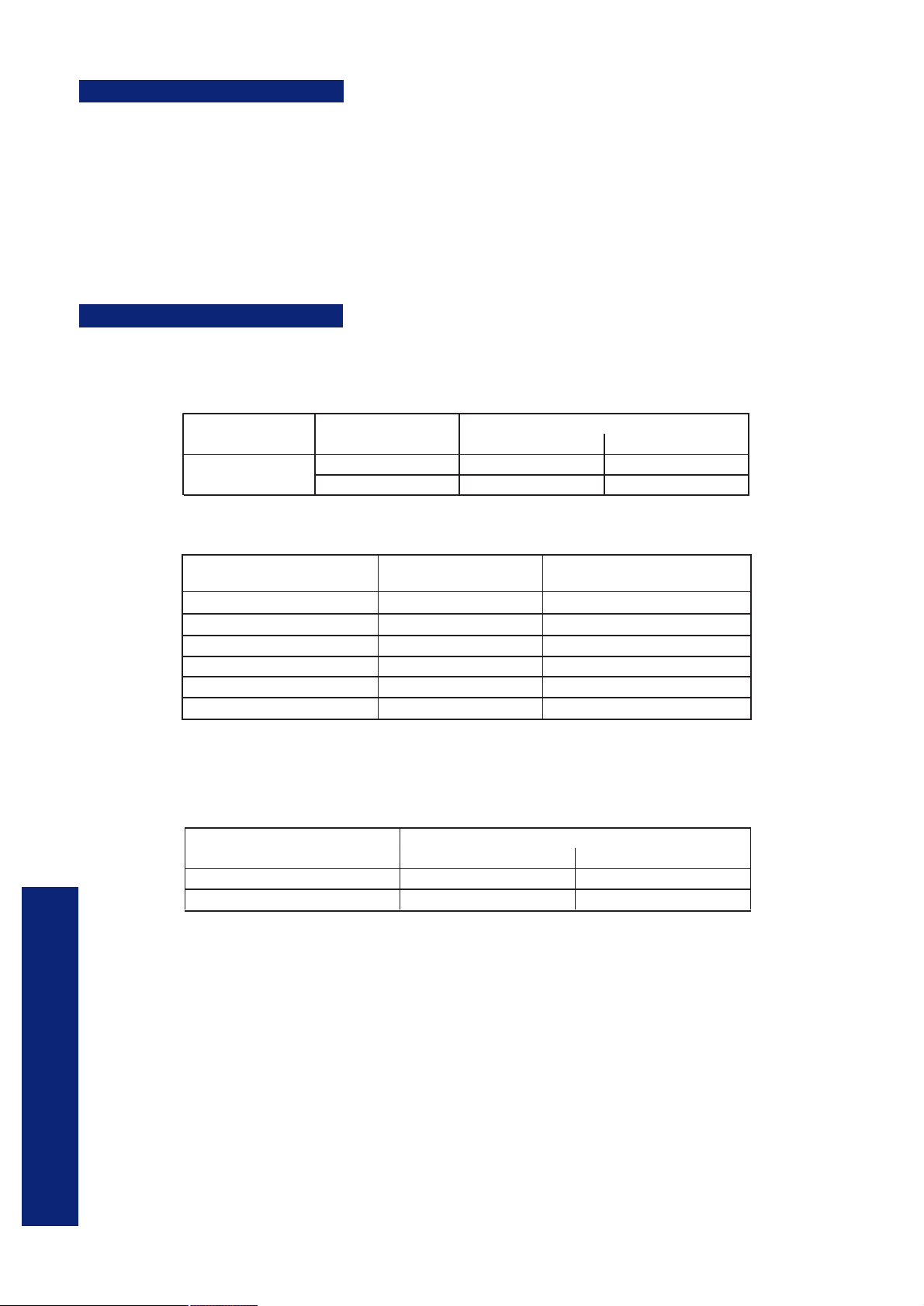

Measuring Ranges

Recommended minimum measuring range (bar)

depending on the type of the set: pressure measuring device - diaphragm seal

Diaphragm

measuring device

Transmitter

Diaphragm material Contact face material Over pressure limit

Monel Monel 40 bar

Hastelloy Hastelloy 40 bar

Nickel Nickel 40 bar

Tantalum Tantalum 16 bar

Tantalum Teflon 16 bar

Titanium Titanium 40 bar

Diaphragm seals with Teflon contact faces are more economical than tantalum seals

Available chemical-resistant materials

seal type

direct 0.4 0.1

remote 1 0.4

Diaphragm seal version Pressure

DN50 PN16 DN80 PN40

Additional absolute zero error resulting from ambient temperature fluctuations,

depending on the type of the set: pressure transmitter - diaphragm seal

Diaphragm seal type

direct 5 mbar 2 mbar

remote (2 m capillary) 10 mbar 4 mbar

Absolute zero error per 10°C for the diaphragm seal

DN50 DN80

An additional zero error, resulting from temperature fluctuations in a medium, depends on the temperature gradient in the oil based diaphragm sealing system. The error value is, in any case, significantly smaller than the error value shown in the table

Special versions

Medium temperature range

-30...180°C for remote diaphragm seal

special versions up to 250°C

-30...150°C for diaphragm seal

Important:

- contact face in diaphragram seal DN50 have a milled slot for a gasket (acc. to DIN 2512 FormN). Version without any

slot available on request. (acc. to DIN 2526 FormE)

- standard outlet capillary from flange:

direct mounted diaphragm seal - axial

remote mounted diaphragm seal - radial

Models: S-Ch

D-Series

www.delta-controls.com

- Filling liquid – FLUOROLUBE

- Direct diaphragm seal for a medium temp. over

150°C

- Gold plated wetted parts material- after consulting

with Aplisens.

Page 3

How to Order

Direct diaphragm seal: pressure measuring device / S-Ch ..... – DN..... / special version – description

Remote diaphragm seal: pressure measuring device / S-ChK ..... – DN..... / K = ..... m / special version – description

Transmitter or gauge – see the code

in the appropriate catalogue sheet

Example: DPR-2000 pressure transmitter, nominal measuring range 0÷1bar, direct chemical flanged seal

with flush diaphragm and contact face made from titanium (DN80).

Material of diaphragm

and contact face

Diaphragm seal version

Capillary length

DPR-2000 / 0 ÷ 1 bar / S-Ch titanium – DN80

When ordering a diaphragm seal please state the type of medium and the expected ranges of concentration

and temperature.

www.delta-controls.com

Models: S-Ch

D-Series

Page 4

In the interest of development and improvement Delta Controls Ltd, reserves the right to amend, without notice, details

contained in this publication. No legal liability will be accepted by Delta Controls Ltd for any errors, omissions or amendments.

Delta Controls Limited

Island Farm Avenue, West Molesey, Surrey KT8 2UZ, UK.

Models: S-Ch

D-Series

T+44 (0)20 8939 3500 F+44 (0)20 8783 1163 E sales@delta-controls.com W www.delta-controls.com

www.delta-controls.com

Loading...

Loading...