Page 1

Installation, Operation &

Maintenance Instructions

Sentry Series

Models P0* (Pressure Switches)

Models D0* (Differential Pressure Switches)

Models T0* (Temperature Switches)

002522-SENTRY-C : FEB 2012

General

The unit is manufactured, checked and supplied in

accordance with our published specification, and

when installed and used in normal or prescribed

applications, with the lid in place and within the

parameters set for mechanical and electrical

performance, will not cause danger or hazard to life or

limb.

THE USERS ATTENTION IS DRAWN TO THE

FACT THAT, WHEN THE UNIT IS ‘LIVE’ WITH

RESPECT TO ELECTRICAL OR PRESSURE

SUPPLIES, A HAZARD MAY EXIST IF THE

UNIT IS OPENED OR DISMANTLED.

UNITS MUST BE SELECTED AND

INSTALLED BY SUITABLY TRAINED AND

QUALIFIED PERSONNEL IN ACCORDANCE

WITH APPROPRIATE CODES OF PRACTICE

SO THAT THE POSSIBILITY OF FAILURE

RESULTING IN INJURY OR DAMAGE

CAUSED BY MISUSE OR MISAPPLICATION

IS AVOIDED.

Operating principles

Pressure Switch models P0* and Differential Pressure Switch models D0* are diaphragm operated

switches.

These diaphragms generate a force proportional to

the applied pressure and are balanced by a user adjustable control spring. When the force exceeds that

created by the control spring, the diaphragm moves

causing a push rod to actuate a snap-acting microswitch.

Temperature models T01 & T02 work in the same

way as the Pressure models with the exception that

the applied pressure comes from the expansion of a

vapour enclosed in either a rigid stem or semi-rigid

thermal system.

occur. They can be mounted either direct to process,

or to a wall or panel using the mounting holes provided. Select the mounting point so as to avoid excessive shock, vibration or temperature fluctuation.

Instruments should be mounted to avoid excessive

heat transfer from the process lines or adjacent plant.

To avoid undue stresses being imparted to the instrument when wall/panel mounted, it is recommended

that a short length of flexible line be installed between

the instrument and process line. If sudden changes of

pressure (pulsations) are likely then we recommend

that snubbers are fitted between the process line and

instrument. Use a spanner to support the process

connection when fitting the instrument.

CHECK THE CONNECTION THREAD SIZE

AND SPECIFICATION ON THE UNIT TO

AVOID MIS-MATCHING WITH THE PROCESS

CONNECTION ADAPTOR. SEE DIGIT 11 OF

PRODUCT CODE.

Mounting (T01 - Rigid Stem)

Assemble the unit via a thermowell, using the

spanner facility provided and ensuring that:

a) the sensing bulb is fully immersed in the

process temperature

b) the sensing bulb does not bottom out in the

thermowell which could cause damage

Mounting (T02 - Capillary system)

Mount the sensing bulb so that the capillary end is

above the bulb and the bulb is level with, or no more

than 250mm below the base of the instrument. The

stem is fitted with a sliding compression gland to

accommodate different thermowells.

Wiring

DISCONNECT ALL SUPPLY CIRCUITS

BEFORE WIRING

INSTALLATION

Mounting (All models)

The instruments are designed to be mounted vertically

with the process connection underneath. However,

mounting up to 45° from the vertical in any plane is

acceptable, although a small calibration shift may

www.delta-controls.com

WIRE IN ACCORDANCE WITH LOCAL AND

NATIONAL CODES. USE CABLES NO

LARGER THAN 2.5 MM2 (14 AWG)

DO NOT EXCEED ELECTRICAL RATINGS

STATED IN LITERATURE AND ON

NAMEPLATES.

Page 2

002522-SENTRY-C : FEB 2012

Wiring (continued...)

Undo the single lid retaining screw and allow the

hinged lid to rest in an open position. Be careful not to

apply excessive pressure on the opened lid to avoid

damage to the hinge.

IF HINGE IS DAMAGED, INGRESS

PROTECTION LEVEL COULD BE

COMPROMISED.

A single M20 or ½”NPT electrical entry is provided,

into which a cable gland can be assembled. Select a

suitable cable gland which will maintain the IP rating of

the instrument.

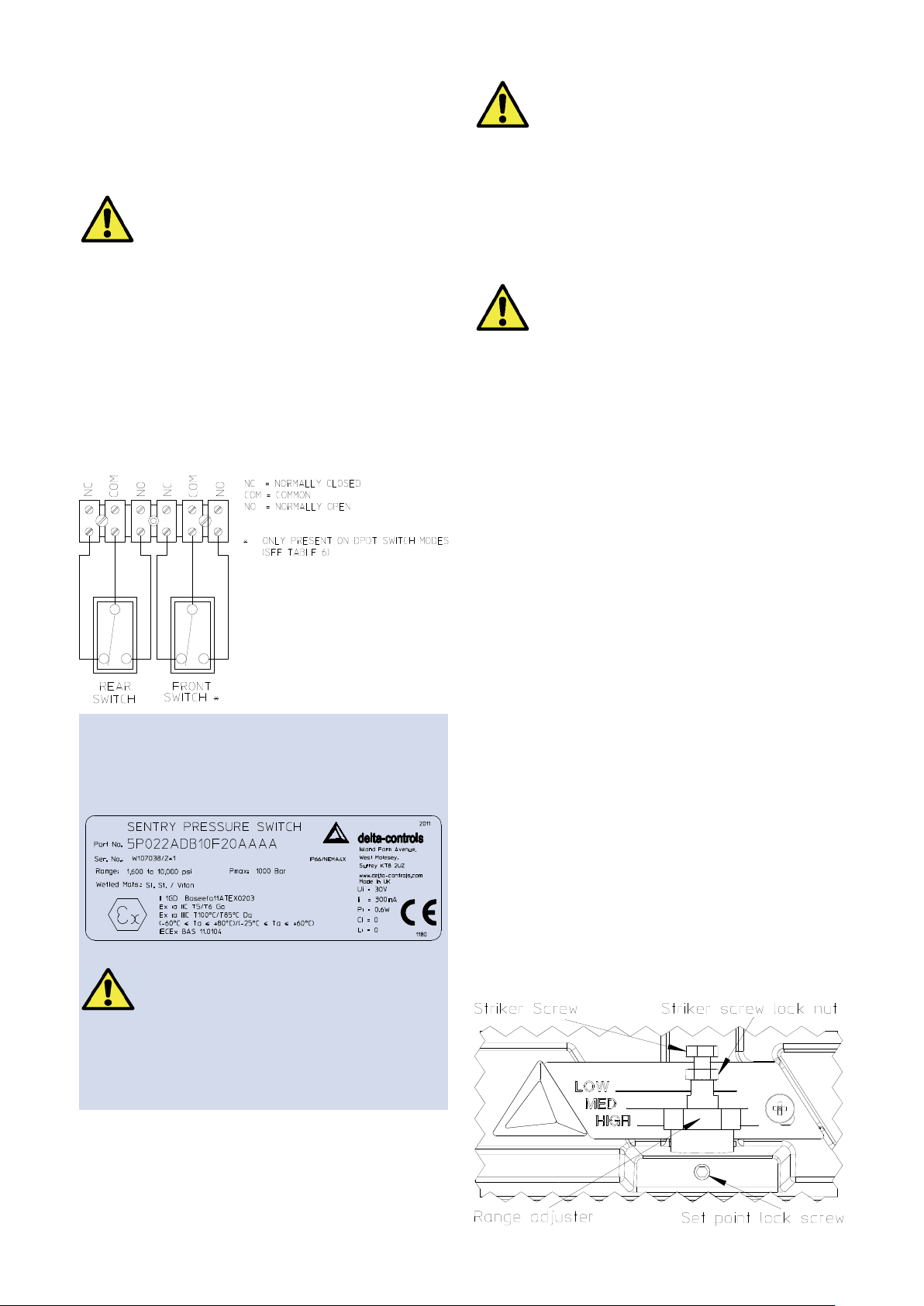

The three switch terminals are clearly marked

“NORMALLY CLOSED”, “NORMALLY OPEN” and

“COMMON”.

For products supplied with terminal blocks, the following diagram can be used as a guide for wiring.

BEFORE CLOSING THE LID:

Ÿ ENSURE WIRE IS CLEAR OF ALL

MOVING PARTS.

Ÿ CHECK THAT THE GASKET IS SEATED

CORRECTLY AND IN GOOD CONDITION

Ÿ ENSURE THAT WIRES DO NOT TOUCH

THE LID AS IT IS CLOSED

Close the lid, being careful not to trap any wires in

doing so. Tighten the lid locking screw until the lug on

the top of the lid makes contact with the enclosure lug.

THE LID LOCKING SCREW MUST BE

TIGHTENED FULLY IN ORDER THAT

ELECTRICAL CONNECTION IS MADE

BETWEEN THE LID AND THE ENCLOSURE

OPERATION

Adjustments

Pressure and Temperature Switches are supplied

calibrated at the midpoint of their range and to a falling

pressure or temperature unless otherwise specified.

To re-calibrate:

Notes for Intrinsic Safety

Input limitations for intrinsic safety:

Ui = 30V, Ii = 300mA, Pi = 0.6W

Example label:

THE MICRO SWITCHES MAY BE SINGLE OR

DOUBLE POLE, DOUBLE THROW

SWITCHES AND ALL THE ELECTRICAL

CONNECTIONS MUST FORM PART OF THE

SAME INTRINSICALLY SAFE CIRCUIT.

WHERE TWO MICRO SWITCHES ARE

FITTED, THEN ALL THE ELECTRICAL

CONNECTIONS MUST FORM PART OF THE

SAME INTRINSICALLY SAFE CIRCUIT.

1. Isolate the instrument from the process and power.

2. Loosen lid lock screw and open the lid.

3. Slacken the set point lock screw.

4. Using a suitable spanner, rotate the range

adjuster clockwise to increase the set point and

counter-clockwise to decrease the set point.

5. Tighten the set point lock screw.

6. Close the instrument lid and tighten lid lock screw

Note: For accurate setting of Pressure and Differential

Pressure models, a suitable pressure gauge must be

used in conjunction with the above procedure. Do not

attempt to set the switch outside the scale limits. For

Temperature models a suitable calibrated temperature

source should be used.

Though the unit may be set anywhere within its range,

for optimum performance, it is good practice to have a

set point value between 25% and 75% of span.

The striker screw and lock nut are factory set and

should not be adjusted. Should these parts be accidentally loosened, please contact Delta for assistance.

Insert bare wires fully into the terminal block and

tighten securely. Keep wiring tails to a minimum and

check that wires do not interfere with the operating

mechanism. Use the earthing / grounding points

provided.

www.delta-controls.com

Page 3

002522-SENTRY-C : FEB 2012

MAINTENANCE

Inspections should be carried out at quarterly to yearly intervals depending upon operating conditions. Isolate

the unit from process and power and remove the lid. Check all terminals for tightness. Check that cable tails

are not fouled or chafed. Check for internal condensation. Check that the gasket is seated properly in the lid

recess and is not worn. It is recommended that instruments used to provide an alarm are operated periodically

to ensure they are functioning correctly. If further maintenance is required seek advice from DELTA CONTROLS

before attempting repair or replacement of parts.

DIMENSIONS

Model Range DIM A DIM B DIM C

P02 / P03 ALL 187 - -

D01 BC 250 162 89

D02

D03

T01 / T02 ALL 187 - -

BD - CE 238 114 77

DC - EA 238 88 77

0D - 0E 263 192 102

DC - EA 263 166 102

www.delta-controls.com

Page 4

002522-SENTRY-C : FEB 2012

Declaration of Conformity

In accordance with EN ISO 17050-1:2004

We Delta Controls Ltd

of Island Farm Avenue, West Molesey, Surrey, KT8 2UZ, UK

in accordance with the following Directive(s)

2006/95/EC Low Voltage Directive

94/9/EC ATEX

hereby declare that:

Series Sentry

Models P01, P02, P03, D01, D02, D03, T01, T02

are in conformity with the applicable requirements of the following documents

for LVD

EN 60947-1:2007 Low-voltage switchgear and controlgear. General rules

EN 60947-5-1:2004 Specification for low-voltage switchgear and controlgear.

For ATEX

EN 60079-0:2009 Electrical apparatus for explosive gas atmospheres. General requirements

EN 60079-11:2007 Explosive atmospheres . Equipment protection by intrinsic safety "i"

EN 61241-11:2006 Electrical apparatus for use in the presence of combustible dust.

Protection by intrinsic safety "iD"

II 1G D Ex ia IIC T5 / T6 Ga

Ex ia IIIC T100°C / T85°C Da

(60°C≤Ta≤+80°C)/(25°C≤Ta≤+60°C)

Certified by BASEEFA, Notified Body No 1180 in accordance with Article 9 of Council Directive 94/9/EC

I hereby declare that the equipment named above has been designed to comply with the relevant sections

of the above referenced specifications. The unit complies with all applicable Essential Requirements

of the Directives.

Signed

Name: Ben Mellick

Position: Product Manager

On: 06 February, 2012

T+44 (0)20 8939 3500 F+44 (0)20 8783 1163 E sales@delta-controls.com W www.delta-controls.com

Delta Controls Limited

Island Farm Avenue, West Molesey, Surrey KT8 2UZ, UK.

www.delta-controls.com

Document Ref. No.

DC019 Issue C

Declaration of Conformity

Models: P02, P03, D02, D03, T02, T03

Loading...

Loading...