Page 1

Operation and installation manual for

SOLIVIA 5.0 EU G3

5.0

EU

Page 2

Page 3

1

ENGLISH

Operation and installation manual SOLIVIA 5.0 EU G3

The manual is subject to change.

Please check our website at www.solar-inverter.com

for the most up-to-date manual version.

© Copyright – Delta Energy Systems (Germany) GmbH - All rights reserved.

This manual accompanies our equipment for use by the end users.

The technical instructions and illustrations contained in this manual are to be treated as condential and no part may be reproduced without the prior written permission of Delta Energy Systems Service engineers and end users may not divulge the information

contained herein or use this manual for purposes other than those strictly connected with correct use of the equipment.

All information and specications are subject to change without notice.

Page 4

2 Operation and installation manual SOLIVIA 5.0 EU G3

Page 5

3

ENGLISH

Operation and installation manual SOLIVIA 5.0 EU G3

Table of Contents

1 Scope of delivery 4

2 General warnings / Notes on safety 4

3 Introduction 5

4 System 5

4.1 Data evaluation and communication 5

4.2 Technical structure of the solar inverter 6

4.3 Equipment overview 7

5 Installation 8

6 Installation of equipment 8

6.1 Installation location 8

6.2 Minimum requirements 8

6.3 Maintenance 9

6.4 Installation 9

6.5 Ambient temperature 10

6.6 Grid connection 10

6.7 Connection of PV modules 11

6.7.1 Output power over PV voltage 12

6.7.2 Efficiency 13

6.8 Interface connection RS485 (EIA485) 13

6.9 Electrical connection and operational start-up 15

6.10 Setup / settings 16

6.11 LED operation and fault display 17

7 Operating concept 18

7.1 The display 18

7.2 Navigation in the display 18

7.3 Main menu 18

7.3.1 Autotest (only for Italy) 20

7.3.2 Submenu N (Now) 23

7.3.3 Submenu D (Day) 24

7.3.4 Submenu W (Week) 25

7.3.5 Submenu M (Month) 25

7.3.6 Submenu Y (Year) 25

7.3.7 Submenu T (Total) 26

7.3.8 Submenu S (Setup) 27

7.3.8.1 Submenu S: Solar ISO / GND 28

7.3.8.2 Submenu S: Firmware 28

8 Diagnostics and data evaluation 29

8.1 Malfunction rectification 29

8.2 Display messages 29

9 Technical data 31

10 Appendix 32

10.1 Connection examples 32

10.2 Overview of connection diagrams 33

11 Glossary 35

12 Guarantee 37

13 Certificates 380

Page 6

4 Operation and installation manual SOLIVIA 5.0 EU G3

1 Scope of delivery

• SOLAR INVERTER SOLIVIA 5.0 EU G3

• Mounting plate

• Operation and installation manual

• AC connector

2 General warnings / Notes on safety

Congratulations on the purchase of the technically advanced SOLAR INVERTER SOLIVIA 5.0 EU

G3.

These directions will help you become familiar with this product.

Please observe the safety regulations of the individual countries (e.g. for Germany: VDE, BDEW,

BGFE, technical connection conditions for local utility company). Careful handling of your product

will contribute to its service life durability and reliability. These are essential prerequisites for maximum yield from your product.

Please observe the following notes on safety:

• During operation of electrical devices, certain parts are under dangerous voltage.

• Inappropriate handling can lead to physical injury and material damage!

• Adhere to the installation regulations.

• Installation and operational start-up work may be implemented only through qualied electrical

experts.

• Repair work on the device should be carried out by the manufacturer only.

• Please observe all points in the operating and installation manual!

• Isolate the device from the grid and the PV modules before carrying out any work on it.

• As a result of very high temperatures, the device surface can become hot.

• Sufcient cooling is necessary.

• As the solar inverter is heavy (weight > 18 kg), it should be lifted by at least two persons.

• Remember that the unit has a high leakage current. The PE conductor MUST be connected prior

to commencing operation.

To avoid risk of electrical shock, do not open the solar inverter. The inverter

contains no user-serviceable parts. Opening the cover will invalidate the

warranty.

Dangerous voltage is present for 5 minutes after disconnecting all sources

of power.

Page 7

5

ENGLISH

Operation and installation manual SOLIVIA 5.0 EU G3

3 Introduction

With this device you have acquired a solar inverter for connection of photovoltaic systems to the

grid. This European solar inverter can be used in and is approved for the following countries: Germany, France, Spain, Italy, Portugal, Greece, Czech Republic and Belgium. The solar inverter

is characterized by its advanced housing design and state-of-the-art high-frequency technology,

which enable the highest levels of efciency.

The solar inverter includes monitoring units, such as anti-islanding protection. The function of the

anti-islanding protection (automatic isolation point for in-plant generation systems) stipulates compliance with the specications of DIN VDE 0126-1-1, EN 50438, ENEL G.L. 12/2008, RD 1663, and

compliance with the directives for parallel operation of power generation plants on low-voltage grid

of your local utility companies. These are declared by certicates (see § 13).

The inverter is usable indoors and outdoors (IP65).

In the following technical description, the precise functions are explained to the installer, as well

as the user, which are required for the installation, operational start-up and handling of the solar

inverter.

4 System

The solar inverter converts direct current from the solar cells into alternating current. This enables

you to feed your self-produced solar energy into the public grid.

Thanks to efcient MPP tracking, maximum capacity utilization of the solar energy plant is ensured

even in the case of cloudy sky conditions.

The string concept means that PV modules are always connected in series (in a string) and/or that

strings with the same voltage are connected in parallel to the solar inverter with the aim of signicantly reducing the photovoltaic system’s cabling requirements.

The fact that the modules are connected in strings also means that the photovoltaic system can be

perfectly matched to the solar inverter’s input voltage range.

4.1 Data evaluation and communication

The integrated data display, processing and communication of the device enables easy operation of

the solar inverter. Monitoring of the operational status and signaling of operational failures are capable of being called up over the device display. The data interface enables the downloading of data

which can be evaluated with a PC system and guarantees continuous recording of operating data.

The best way of accessing this functionality is via the available accessories (e.g. WEB´log); comprehensive and seamless solar inverter monitoring is ensured.

The data read-out over the integrated interface and the display is possible only in solar operation.

Page 8

6 Operation and installation manual SOLIVIA 5.0 EU G3

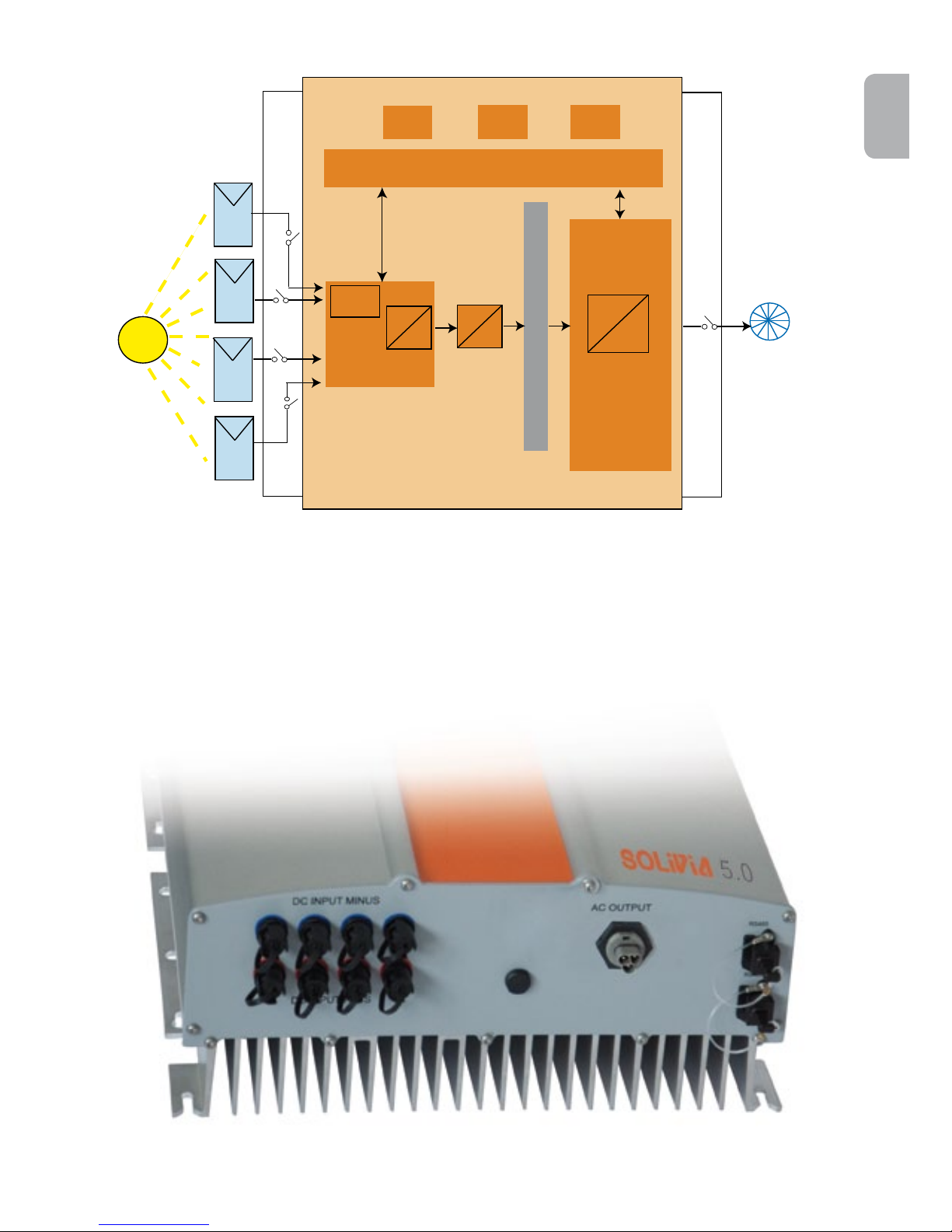

4.2 Technical structure of the solar inverter

A galvanical isolation of the solar inverter from the grid is achieved through a DC/AC converter with

an integrated high-frequency transformer. The photovoltaic voltage is adjusted so that the maximum

power output of the PV modules is also achieved with varying solar irradiation levels and temperatures (MPP-Tracking).

The MPP range of the solar inverter is between 150 V and 450 V. This facilitates the use of PV

modules by a variety of manufacturers. Measures must be taken to ensure that the maximum opencircuit voltage of 540 VDC is never exceeded. Please note that the maximum open-circuit voltage

will occur at the lowest temperatures anticipated. You will nd more detailed information about

temperature dependency in the data sheet of the PV modules. The device’s power consumption is

kept to a minimum.

The high-quality aluminum casing corresponds to protection class IP65 (water-jet-proof and dustproof) and is protected against weathering processes by surface re nement. The cooling characteristic pro le is designed so that operation of the inverter is possible with ambient temperatures

from -25 °C to +60 °C.

A cooling characteristic pro le is used for the removal of the power dissipation caused through the

voltage conversion. An internal temperature control protects the device against excessive temperatures in the interior of the solar inverter. In case of high ambient temperatures, the maximum

transferable power is limited.

The solar inverter is controlled by microcontrollers, which also implement interface communication

and the monitoring of values and messages on the display.

Two independent and redundant microcontrollers control the monitoring of the grid, which is consistent with the feed-in directives of your local utility company and DIN VDE 0126-1-1, EN 50438,

ENEL G.L. 12/2008 and RD 1663 (anti-islanding protection). This enables an installation of the solar

inverter in the in-house electrical grid.

Operator protection requirements are met by electrically isolating the grid from the PV module. The

electrical isolation between the grid and the PV module is equivalent to basic insulation. Maximum

operator protection is ensured by reinforced isolation between the grid, PV modules and accessible

interfaces (display and RS485 interface). Relevant standards concerning electromagnetic compatibility (EMC) and safety are ful lled.

The solar inverter is functional in on-grid operation exclusively. An automated isolation point, which

is approved by a certi cation agency, guarantees secure disconnection in case of circuit isolation or

interruptions in power supply and avoids isolated operation.

The disconnection equipment allows for automatic isolation for in-plant generation systems of nominal power ≤ 4.6 kVA, with single-phase parallel feed-in through the solar inverter into the public grid.

Page 9

7

ENGLISH

Operation and installation manual SOLIVIA 5.0 EU G3

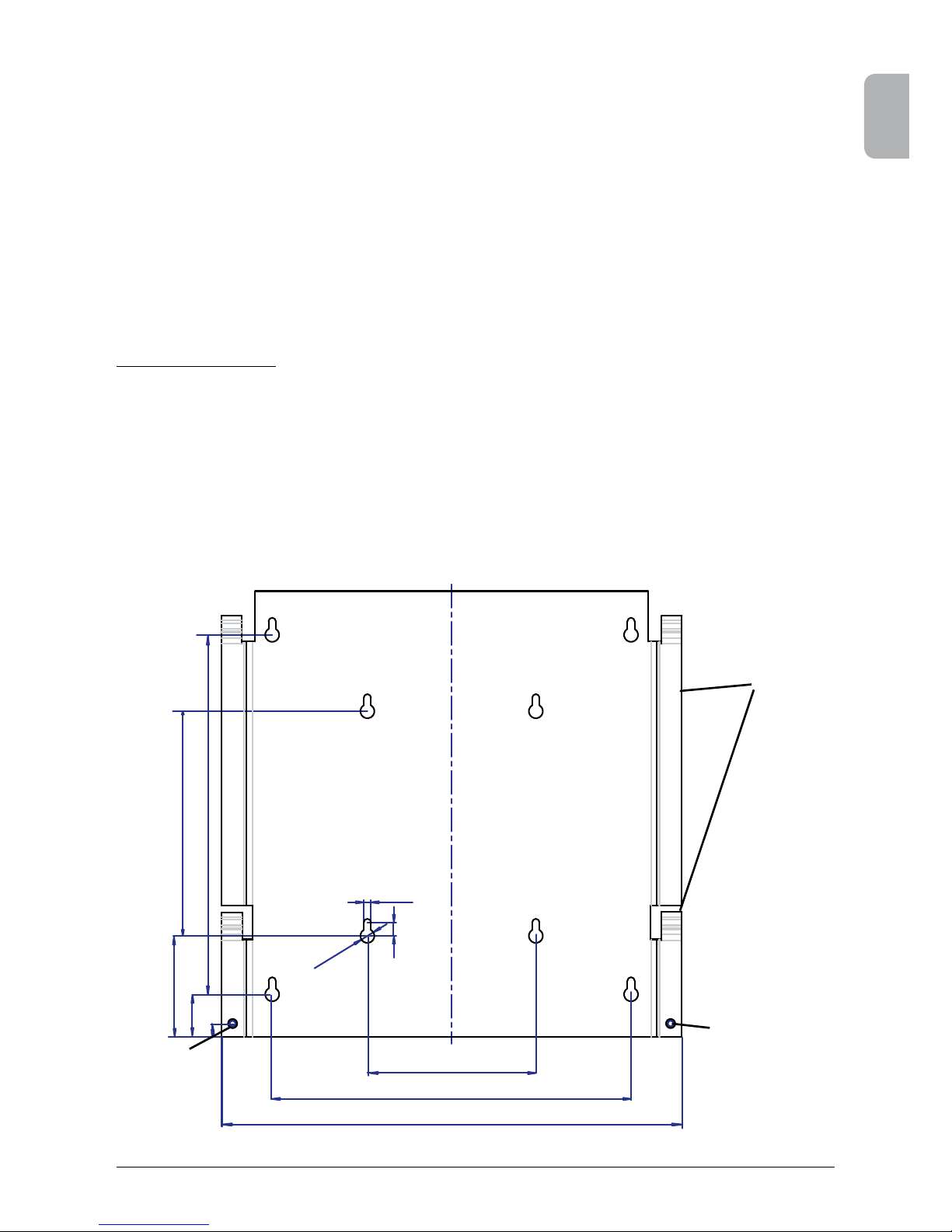

4.3 Equipment overview

(1) Connections for solar modules

(2) Grid connection

(3) Interface connection RS485 (EIA485)

(4) Display for status messages and keypad for operation

(5) Light-emitting diodes for operational status display

ENGLISH

(1)

(2)

(4)

(5)

(3)

Page 10

8 Operation and installation manual SOLIVIA 5.0 EU G3

5 Installation

Installation and commissioning must only be carried out by qualied electrical experts.

The recommended safety regulations, the technical interface conditions (TAB 2000), as well as DIN

VDE 0126-1-1, EN 50438, ENEL G.L. 12/2008 and RD 1663 specications, should be complied

with.

To carry out an energy measurement, a meter must be attached between the grid feed-in point

and the solar inverter (in accordance with your local utility company directive concerning „In-plant

generation systems on the low-voltage grid“).

By means of the integrated anti-islanding protection, the function of the recommended section

switch is fullled in accordance with your local utility company directive.

Caution: The secondary short-circuit current rating is increased at the transfer connection point to

the public electricity supply system by the nominal current of the connected solar inverter.

6 Installation of equipment

6.1 Installation location

• Install the device on a non-ammable support base.

• Avoid installation on resonating bodies (light construction walls etc.).

• Installation is possible both indoors and in protected outdoor areas.

• An increased ambient temperature can reduce the efciency of the PV system.

• Noise generation is possible (avoid installation in residential areas).

• Ensure legibility of the LEDs and the display (check read-off angle and installation height).

• Although the unit is tted with UV resistant components, direct exposure to sunlight should be

avoided.

• Despite having an IP65 enclosure and being certied in accordance with soiling category III, the

unit must not be allowed to become heavily soiled.

• Dusty conditions soiling can impair the unit’s performance.

6.2 Minimum requirements

• Free convection around the solar inverter must not be impaired.

• For proper air circulation to dissipate heat, allow a clearance of approx. 10 cm to the side and

approx. 50 cm above and below the unit.

• The grid impedance requirement at the supply terminal is to be observed (cable length, cable

cross-section).

• The recommended installation position is to be adhered to (vertical).

• Unused DC connectors (Tyco) and interfaces must be sealed airtight with sealing plugs to en sure protection class IP65 for the whole system (inverter & cables).

Page 11

9

ENGLISH

Operation and installation manual SOLIVIA 5.0 EU G3

319.5

150

320

200

6.5

12

Ø

12.5

90

38

12

410 ± 0.5

6.3 Maintenance

Make sure that the device remains uncovered while in operation. To avoid the casing of the solar

inverter becoming soiled, it should be cleaned periodically.

User-serviceable parts are not contained in the device. Under no circumstances should the solar

inverter be opened!

6.4 Installation

You should utilize the delivered mounting plate for problem-free installation of the solar inverter.

Installation to the wall should be implemented with the proper screws. Mount the wall bracket so

that the solar inverter can be easily attached to the wall. After that, the device should be bolted on

securely.

Assembly instructions

1. Mount the mounting plate with appropriate screws (max. Ø 6mm) into at least four of

the eight holes to x the wall bracket in place. You can employ the mounting plate as a

template for marking the positions of the boreholes.

2. As the solar inverter weighs 32.0 kg, it should be lifted out of the transport crate by at

least two persons.

3. Place the solar inverter onto the mounting plate with at least two persons.

4. Fasten the supplied mounting nuts and washers on the threaded bolt intended for secu ring the device.

5. Check that the solar inverter is securely seated.

Mounting

plate

Locking screw

Locking screw

Page 12

10 Operation and installation manual SOLIVIA 5.0 EU G3

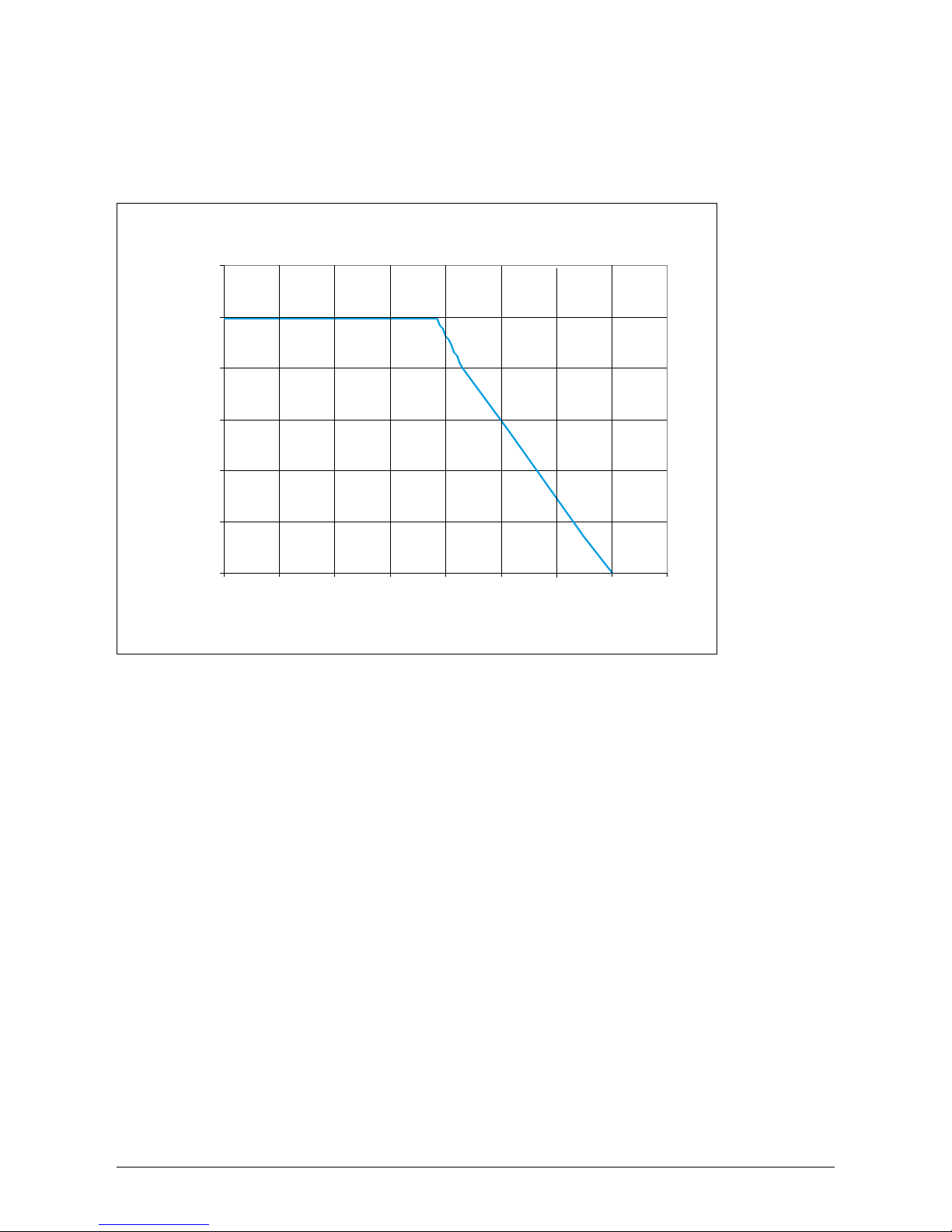

6.5 Ambient temperature

The solar inverter can be operated in an ambient temperature between -25 °C to +60 °C.

The following diagram illustrates how the power supplied by the solar inverter is reduced automatically in accordance with ambient temperature.

The device should be installed in a well-ventilated, cool and dry location.

6.6 Grid connection

The grid (AC output) is connected over a Wieland RST25i3S AC connector. You can nd the correct allocation on the screw-type terminal connection of the connector. The solar inverter must be

connected to the grid over a three-core line (L, N, PE). The connected AC line must be switched

potential-free before the disconnection or the insertion of the AC connector.

The connection to the Wieland AC connector must be made with a exible line and a conductor

cross section of 4.0 mm².

An automatic circuit breaker is to be provided in the line L upstream of every device, with a nominal

current of 32 A and tripping characteristic type B. In addition, attention is to be paid to the selectivity

of the fuse unit attached upstream of the automatic circuit breaker.

The solar inverter must be grounded via the AC connector’s PE conductor. To do this, connect the

PE conductor to the designated terminal. If you wish to integrate more than one inverter into the

installation, please proceed as illustrated in the drawings in the appendix.

Please note the cable length and the cable cross-section, due to the risk of undesirable temperature

rise and power losses.

The AC connector is protected from unintentional disconnection by a clip mechanism which can be

released with a screwdriver.

0

1000

2000

3000

4000

5000

6000

0 10 20 30 40 50 60 70 80

Ambient temperature (°C)

Output power (W )

Page 13

11

ENGLISH

Operation and installation manual SOLIVIA 5.0 EU G3

6.7 Connection of PV modules

Before the photovoltaic system is connected, the polarity of the PV voltage at the Tyco connectors

must be checked to ensure that it is correct.

The connection of the PV module is implemented using Tyco Solarlok connectors, where the DC

negative pole is located on the connector upper row and the DC positive pole on the connector

lower row. The connectors are color coded to prevent you from accidentally plugging them into the

wrong terminal.

Please ensure the following at all times:

• That there is never any risk of anyone coming into contact with the solar inverter connection

terminals, due to the risk of dangerous voltages across them.

• That under no circumstances are the PV modules to be disconnected from the solar inverter under

load. If a disconnection should be necessary, rst switch the grid off so that the solar inverter

cannot absorb any further power. Next, open the upstream DC disconnector.

The maximum input voltage of the solar inverter is 540 V. The maximum current load of each individual Tyco connector is 18 A.

The solar inverter has an insulation and grounding monitoring on the DC side. The options can be

congured in the Setup menu “S -> Solar ISO / GND” (see § 7.3.8.1).

The insulation monitoring has two modes:

• ISO-ON-Error (the solar inverter is disconnected from the grid in the event of an insulation

fault)

• ISO-ON-Warning (the solar inverter indicates the fault but is not disconnected from the grid).

Deltas solar inverters are factory-set to ISO-ON-Warning mode on delivery.

The grounding monitoring has two modes:

• PV+ grounding (grounding monitoring of the positive pole of the PV generator)

• PV- grounding (grounding monitoring of the negative pole of the PV generator).

In these modes the solar inverter remains in feed-in operation and will not be disconnected from the

grid in case of a fault. The error message “PV+ grounding fault” or “PV- grounding fault” will appear

on the display.

If you need to connect the positive or negative pole of the PV system to meet requirements set

out by the module manufacturer, you can do this. Earth continuity must be implemented close to

the inverter. We suggest using Deltas grounding kit “Grounding Set A Solar” (EOE 99000115). The

grounding connection is monitored and should be congured in the Setup menu (see above).

Alternatively, it is possible to turn off the insulation- and grounding monitoring:

• ISO / GND OFF.

Page 14

12 Operation and installation manual SOLIVIA 5.0 EU G3

0

1000 W

2000 W

3000 W

4000 W

5000 W

6000 W

150 VDC 200 VDC 250 VDC 300 VDC 350 VDC 400 VDC 450 VDC

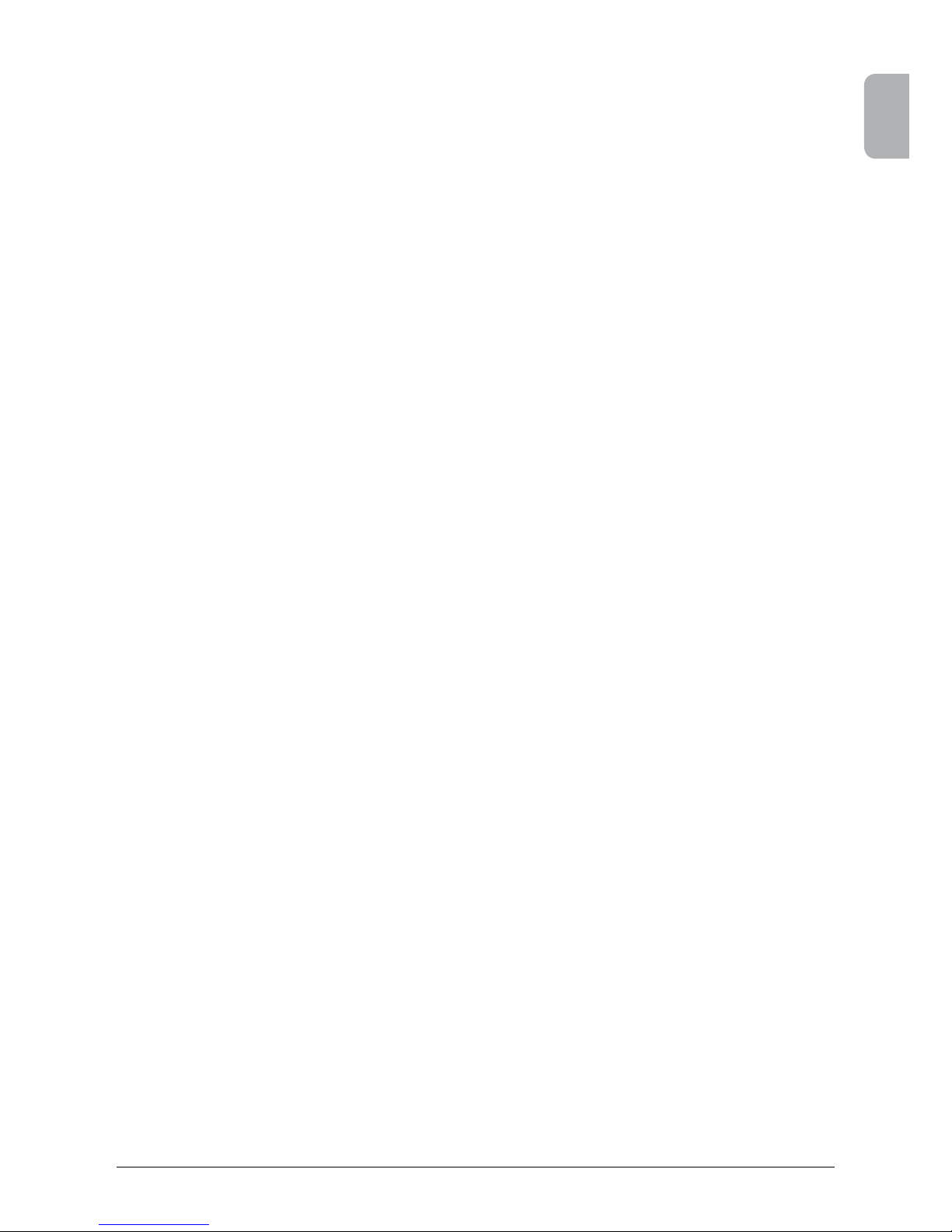

6.7.1 Output power over PV voltage

Required cable coupler types for DC cable connection to inverter:

CABLE

COUPLER

POLARITY

WIRE SIZE

2.5 MM

2

(AWG 14)

WIRE SIZE

4.0 MM

2

(AWG 12)

WIRE SIZE

6.0 MM

2

(AWG 10)

FEMALE CABLE COUPLER

PLUS CODED

FEMALE CABLE

COUPLER

MINUS CODED

TYCO

ORDER

NUMBER

Plus

coupler

• •

1394462-1

Minus

coupler

• •

1394462-2

Plus

coupler

• •

1394462-3

Minus

coupler

• •

1394462-4

Plus

coupler

• •

1394462-5

Minus

coupler

• •

1394462-6

Page 15

13

ENGLISH

Operation and installation manual SOLIVIA 5.0 EU G3

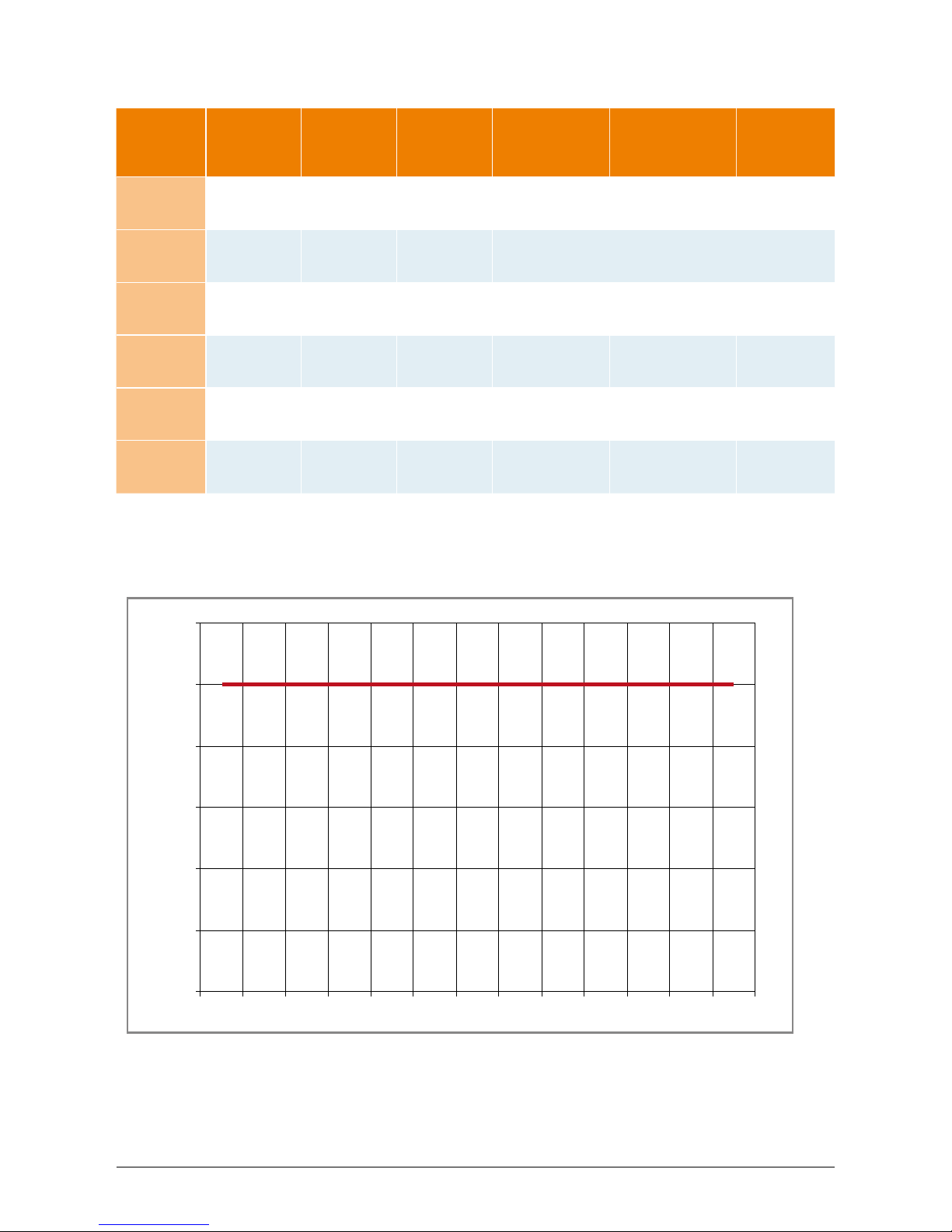

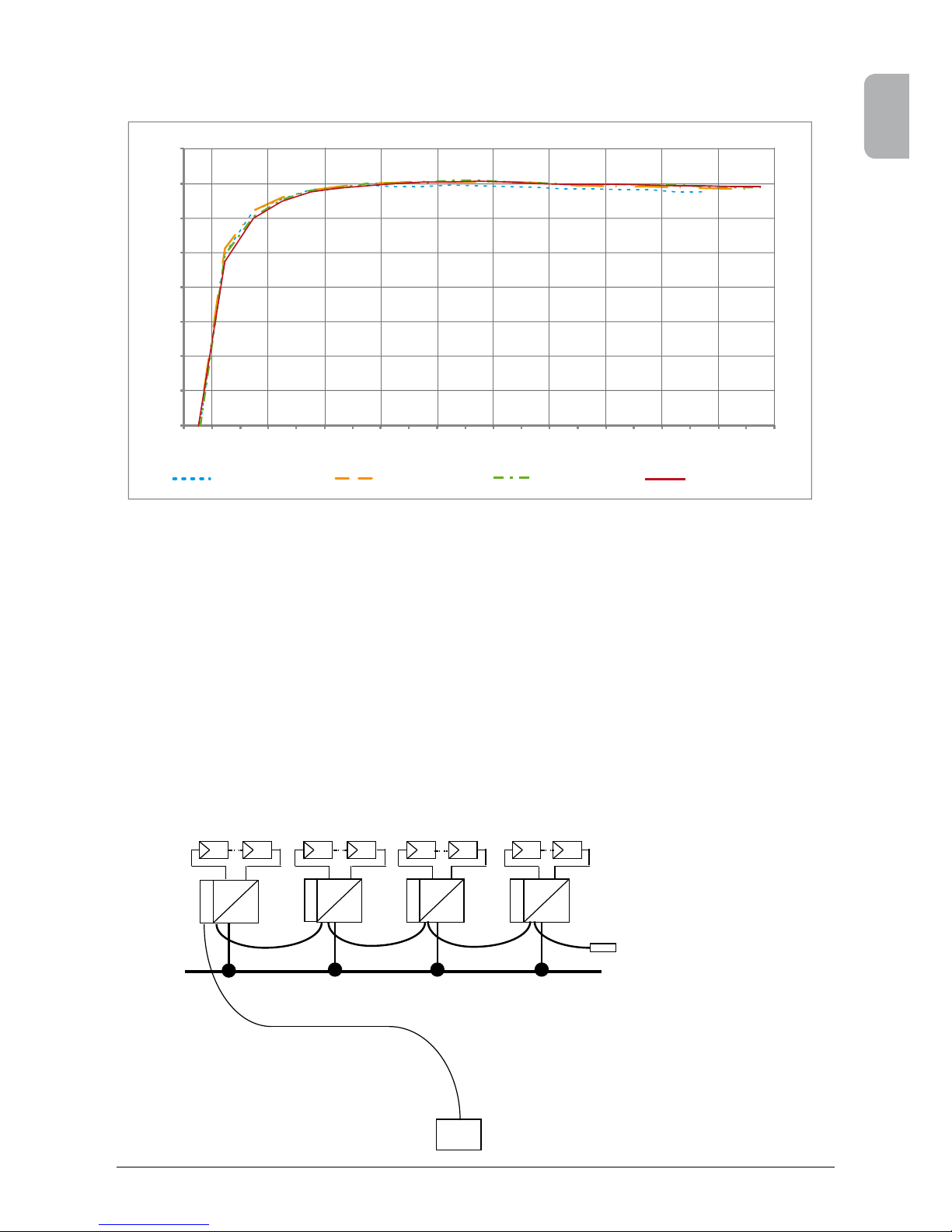

6.7.2 Efciency

The best efciency of the solar inverter is obtained at input voltages >250 V.

50 W 500 W 1000 W 1500 W 2000 W 2500 W 3000 W 3500 W 4000 W 4500 W

5000 W

60 %

65 %

70 %

75 %

80 %

85 %

90 %

95 %

100 %

SOLIVIA 5.0 - 150 V

SOLIVIA 5.0 - 250 V

SOLIVIA 5.0 - 350 V

SOLIVIA 5.0 - 450 V

6.8 Interface connection RS485 (EIA485)

The interfaces not used must always be closed off. In case of utilization of an interface, only the

counterpart tting on the interface connector is to be employed.

Mating connector supplier HARTING Deutschland GmbH & Co. KG (P.O. 2451, D-32381 Minden;

www.harting.com).

Order designation: 09 45 145 1510, Cable Manager Blue IP67 Push-Pull Data Plug

09 45 145 1500, Cable Manager White IP67 Push-Pull Data Plug

-

~

-

~

-

~

-

~

230 V - House connection line

RS485 (EIA485) - Connection

Datalogger

RS485 (EIA485)

terminating resistor

Page 16

14 Operation and installation manual SOLIVIA 5.0 EU G3

8

1

Pin

1 Reserved

2 Reserved

3 Reserved

4 GND (RS485)

5 Reserved

6 RX_B (RS485)

7 TX_A (RS485)

8 Reserved

Top View

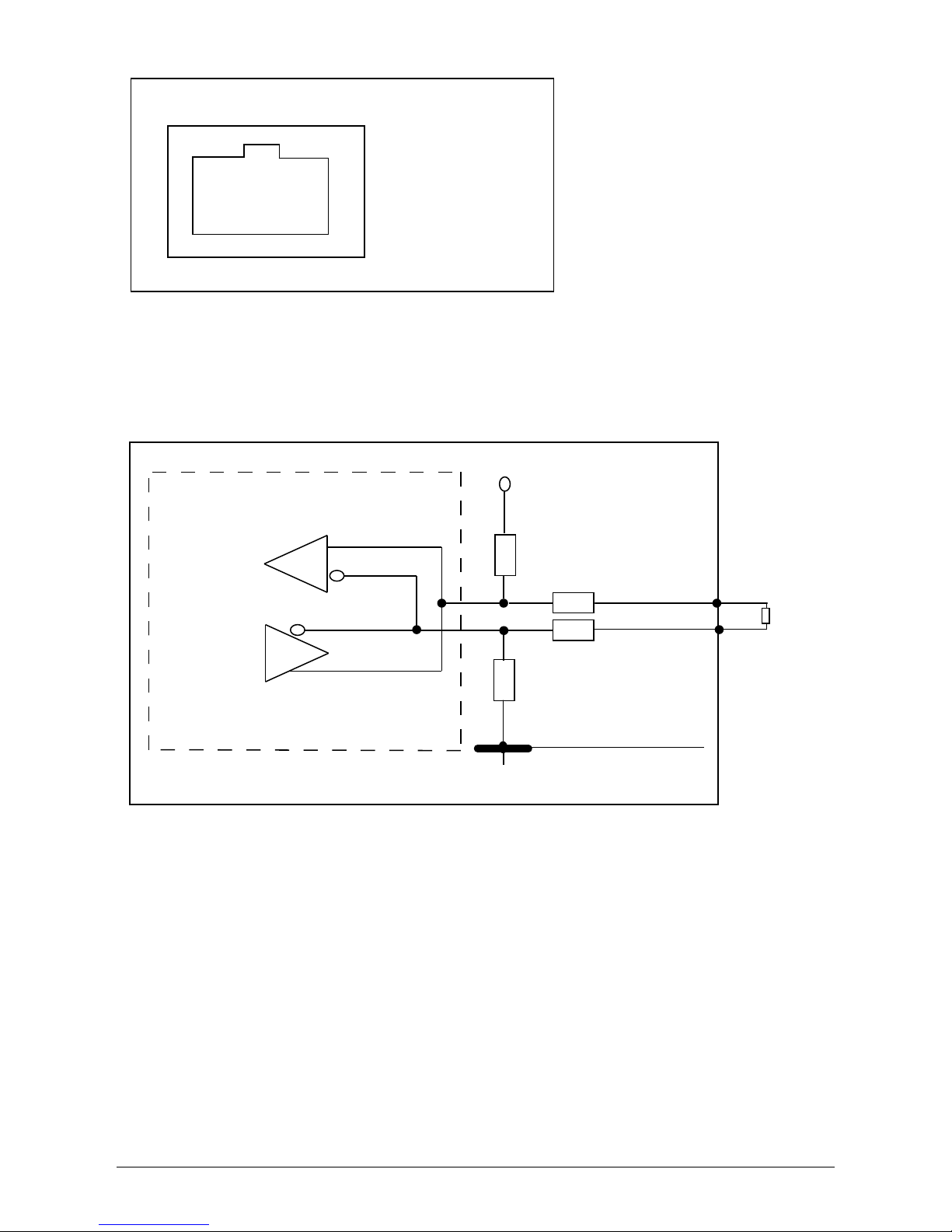

Connector pin assignment RS485 (EIA485)

+5V

Reserved

Reserved

0R

0R

TX_A

RX_B

GND

Pin 7

Pin 6

100 ... 150

Ohm, 0,25W

When several devices are connected in series and the total length of the data line measures 2 m or

more, the following option is available for terminating the RS485 (EIA485) interface:

Page 17

15

ENGLISH

Operation and installation manual SOLIVIA 5.0 EU G3

6.9 Electrical connection and operational start-up

The electrical connections are utilized on this solar inverter using the connector contacts which are

attached to the casing. Under no circumstances should the device be opened!

Power

controller

Antiislanding

protection

Communication

Operating- and system control

MPPTracker

-

-

Booster

-

-

Isolation

DC-Bus

~

Solar inverter

DC

DC

DC

DC

String A

String B

String C

String D

AC

Public

grid

Page 18

16 Operation and installation manual SOLIVIA 5.0 EU G3

In order to set up the device, follow these procedures carefully:

1. DC connection: First, connect the PV module strings to the DC disconnector (not included in

the scope of delivery).

2. Connect the DC disconnector to the solar inverter (ensure correct polarity).

3. AC connection: Please install the Wieland AC mating connector to the AC output cable and then

plug the AC connector to the solar inverter. Please make sure, that the sleeve nut is properly

xed and tighten.

4. Before switching on the power, check all feeders and connections one last time.

5. Close the DC disconnector.

6. Close the circuit breaker on the AC output side.

7. In case of suf cient PV voltage (UPV > 150 V), the device now goes into the start-up mode.

8. In case of a new installation the time and date have to be set in sub-menu S (Setup) (see § 7.3.8).

All unoccupied connectors and interfaces must be sealed using the provided sealing

plugs.

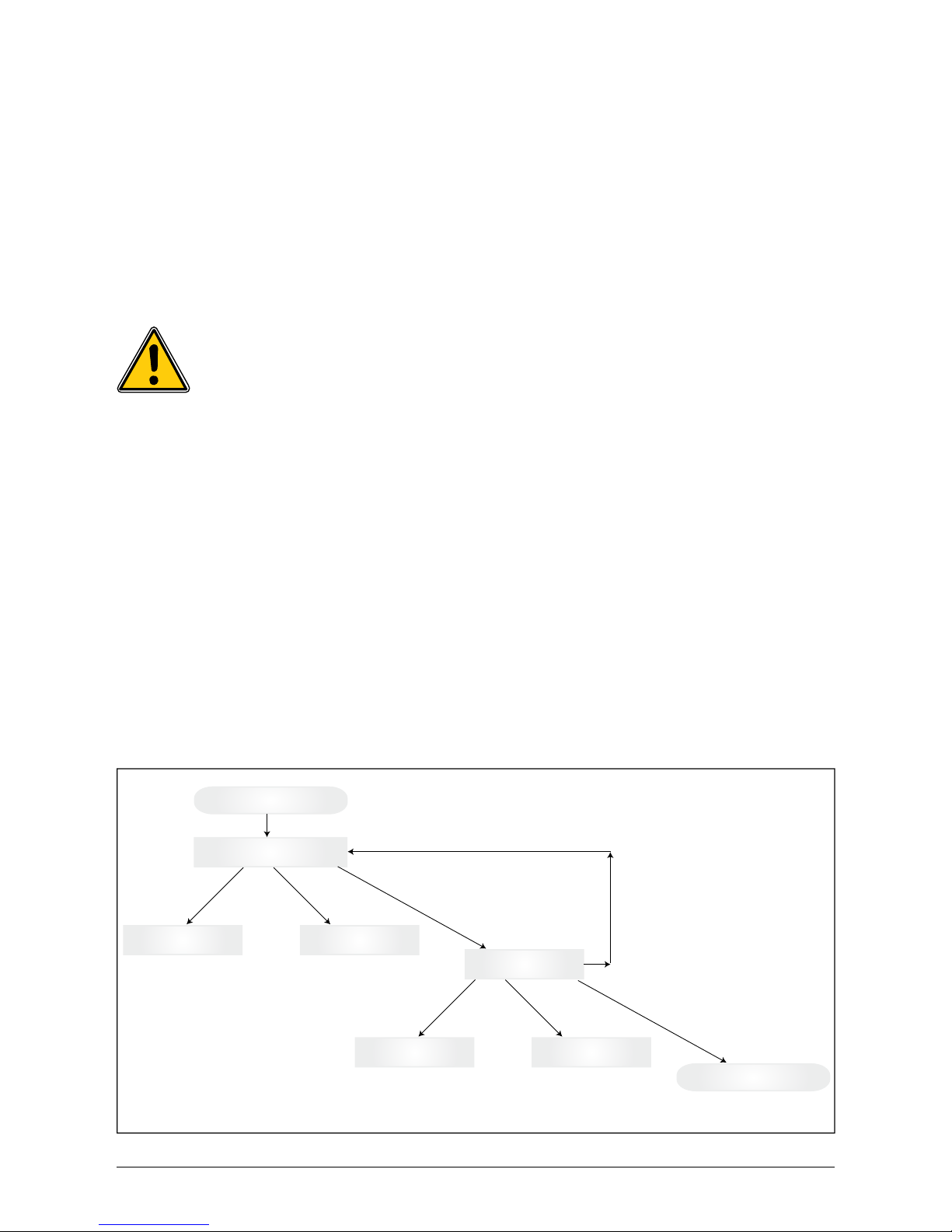

6.10 Setup / settings

The default display language for solar inverters leaving the Delta factory is set to English.

After connecting to correct DC voltage and running through self-test, you will be asked to specify

the network ID and to select the desired country (countries available: Germany, France, Italy,

Spain, Greece, Portugal, Czech Republic and Belgium)).

The selection has to be con rmed another time by the user. Once con rmed, the network ID and

the country selection are stored to the controller memory – and the solar inverter is ready for

operation.

Please note that the enter keys on the display are locked, if there is no input entry within 5

minutes. To unlock the enter keys, you need to switch off the DC voltage and then switch it on

again.

Country selection

Increase network ID Decrease network ID

Down *

Up *

Enter network ID

ENTER *

ESC *

Select country

Next country Country before

Down *

Up *

ENTER *

Normal mode

* Timeout if no key is pressed (within 5 minutes)

Possible countries:

Belgium

Czech Republic

France

French island (60 Hz)

Germany

Greece continent

Greece island

Italy (50 Hz / 49 Hz)

Italy (51 Hz / 49 Hz)

Portugal

Spain (51 Hz / 49 Hz)

Spain (51 Hz / 48 Hz)

United Kingdom

Page 19

17

ENGLISH

Operation and installation manual SOLIVIA 5.0 EU G3

Operation (A)

Earth Fault (B)

Failure (C)

• LED (A), green: „Operation“ displays the

operational state.

• LED (B), red: „Earth Fault“ displays an insula tion resistance fault or PV grounding (GND)

fault on the DC side.

• LED (C), yellow: „Failure“ displays existing

faults internally or externally and whether the

grid feed-in operation has been interrupted.

6.11 LED operation and fault display

Three light-emitting diodes (LEDs), which display the operational state of the solar inverter, are attached on the front:

Please note, that once the country has been selected and conrmed, it is only possible to change

the country by following the steps as listed below:

1. Please click ESC + for few seconds to get the key information.

2. Provide the key code to the Solar Support Team at support@solar-inverter.com to get the PIN

code (valid for one use only!).

3. Once you get the PIN code, you need to press ESC + .

4. Then, you will be asked to insert the PIN code and to conrm it twice.

5. After conrmation, you will then be able to select the desired country.

Note: These steps must be executed without interruption. Otherwise, you will stay in the country

selection mode.

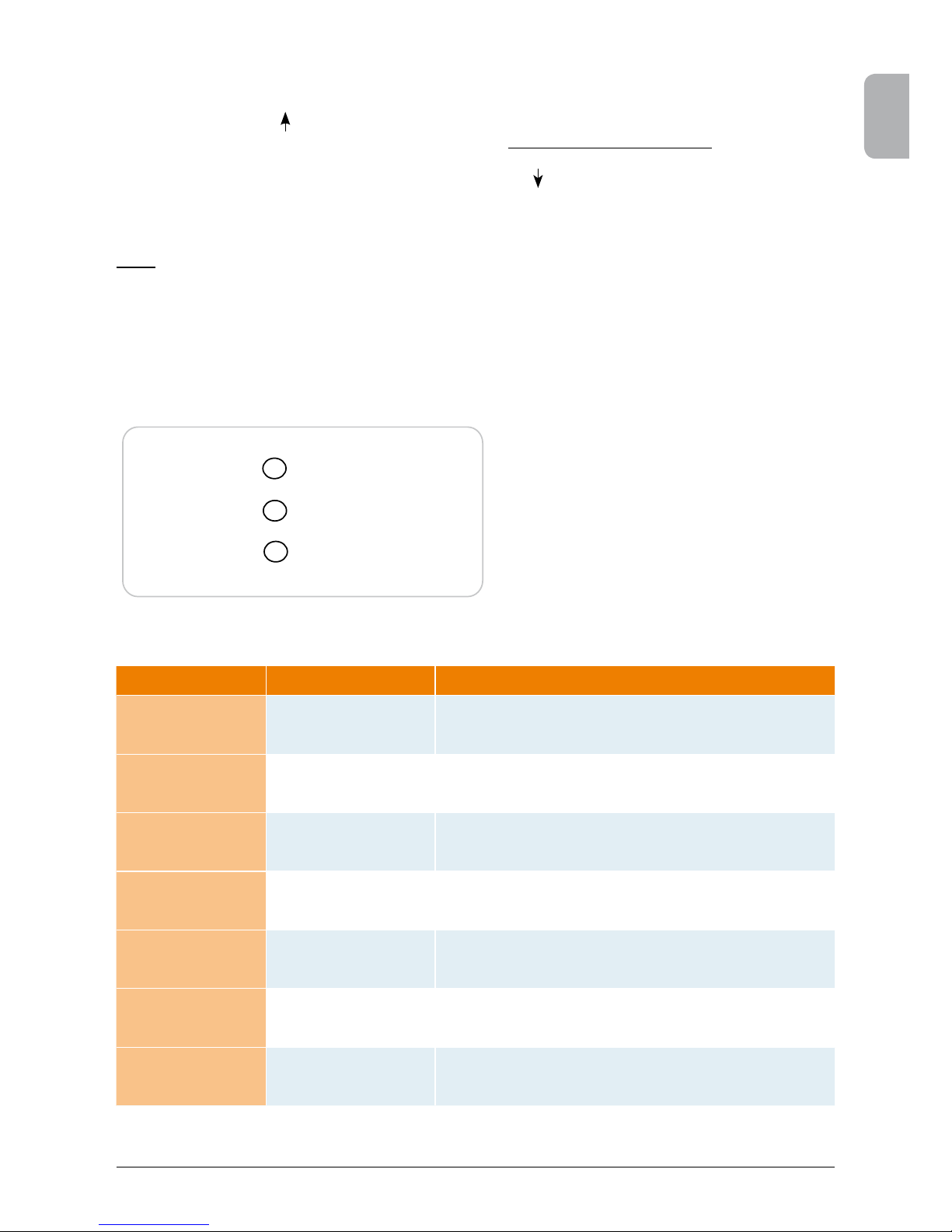

LED STATUS OPERATIONAL STATE EXPLANATION

green: <off>

red: <off>

yellow: <off>

Night disconnection.

The input voltage (UPV) is lower than 100 V.

The solar inverter is not feeding power to the grid.

green: <on>

red: <on>

yellow: <on>

Initialization.

Input voltages:

UPV: 100 V to 150 V

(self test ongoing).

green: <ashes>

red: <off>

yellow: <off>

Input- and grid monitoring.

Starting conditions are tested.

green: <on>

red: <off>

yellow: <off>

Feed-in operation.

Normal operational state:

UPV: 150 V to 450 V.

green: <off>

red: <on/off>

yellow: <on/off>

Equipment fault.

Internal or external fault

(interrupted feed).

See also display messages!

green: <off>

red: <on/off>

yellow: <on>

General error

condition.

Solar inverter is not connected to the grid.

No power is delivered.

See also display messages!

green: <on/off>

red: <on/off>

yellow: <ashes>

Warning message.

You can carry on using the solar inverter.

See also display messages!

Page 20

18 Operation and installation manual SOLIVIA 5.0 EU G3

7 Operating concept

7.1 The display

The display on the device indicates varied information. The enter keys are used for the adjustment

of the device and for the retrieval of information. The measured data can deviate with a tolerance

of up to 5%.

ESC

(A) (B) (C) (D)

7.2 Navigation in the display

Lighting of the display

After pressing the ENTER key in automatic operation, the display lighting is switched on. If no key

is pressed within 30 seconds, the display lighting automatically goes out. The setup menu enables

selection between continuous or automatic lighting. Through pressing the ENTER key, the display

lighting is switched on again.

Key (A), ESC: To switch from the menu

items to the main menu and

to exit each sub-menu.

Key (B) and (C): For scrolling in the individual

menu items and/or carrying

out adjustments in the setup

menu.

Key (D), ENTER: ENTER key for changing into

the menu levels and for input

acknowledgement in the

setup menu.

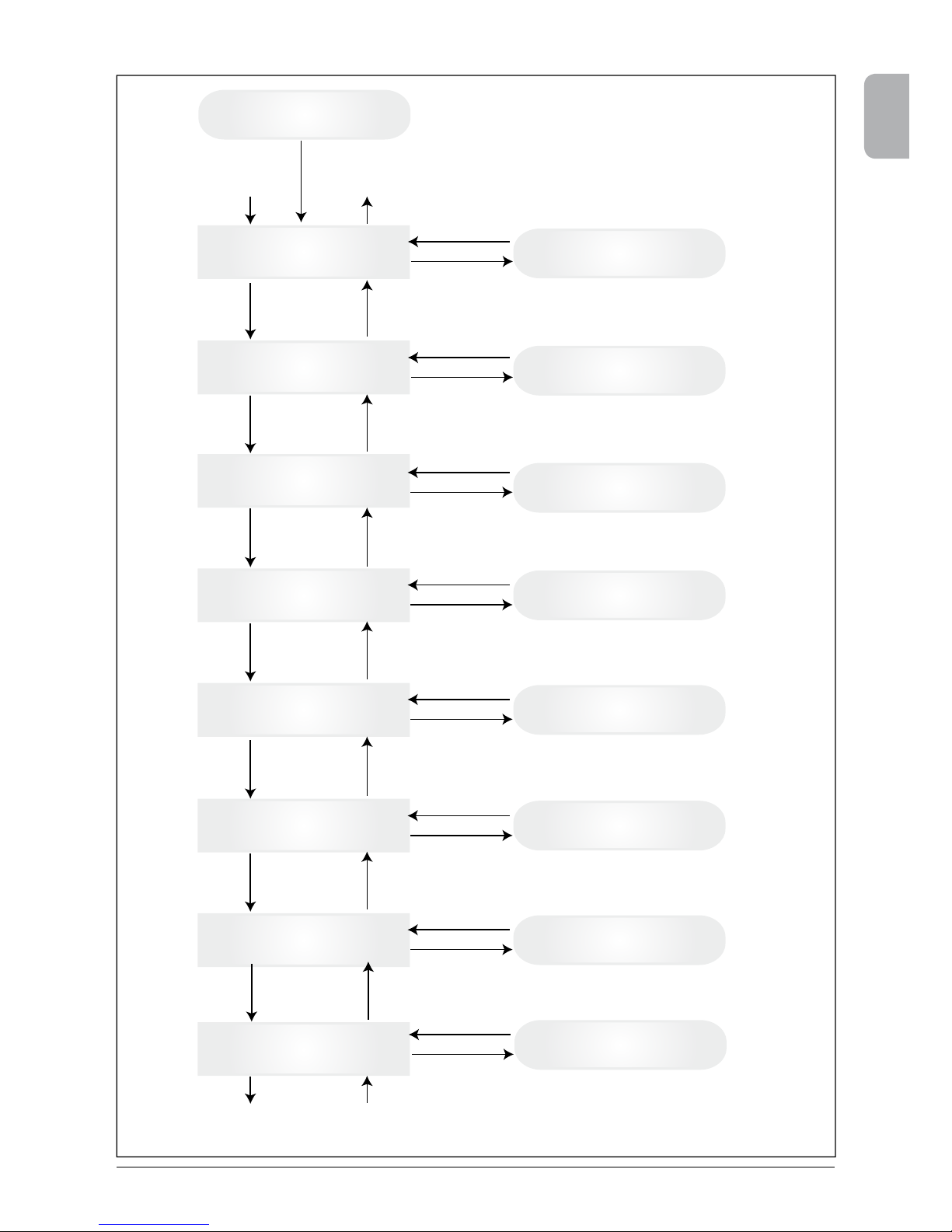

7.3 Main menu

The main menu consists of 8 menu items which are subdivided into submenus:

• Menu Autotest

• Menu N (Now)

• Menu D (Day)

• Menu W (Week)

• Menu M (Month)

• Menu Y (Year)

• Menu T (Total)

• Menu S (Setup)

Handling of the menu items:

You can scroll the main menu by activating the selector keys

.

Press the ENTER key to select the submenus. In order to exit the menus again, activate the ESC

key.

Page 21

19

ENGLISH

Operation and installation manual SOLIVIA 5.0 EU G3

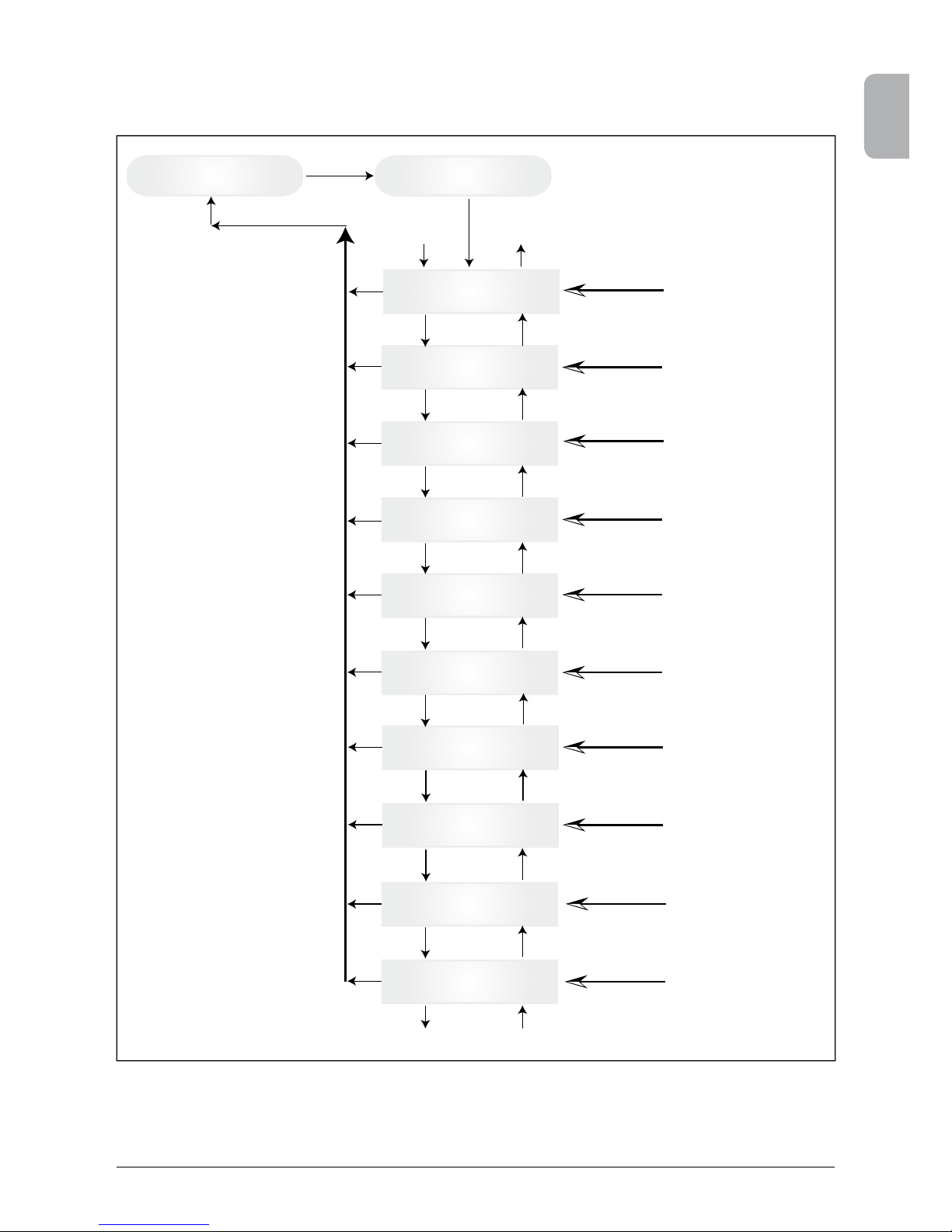

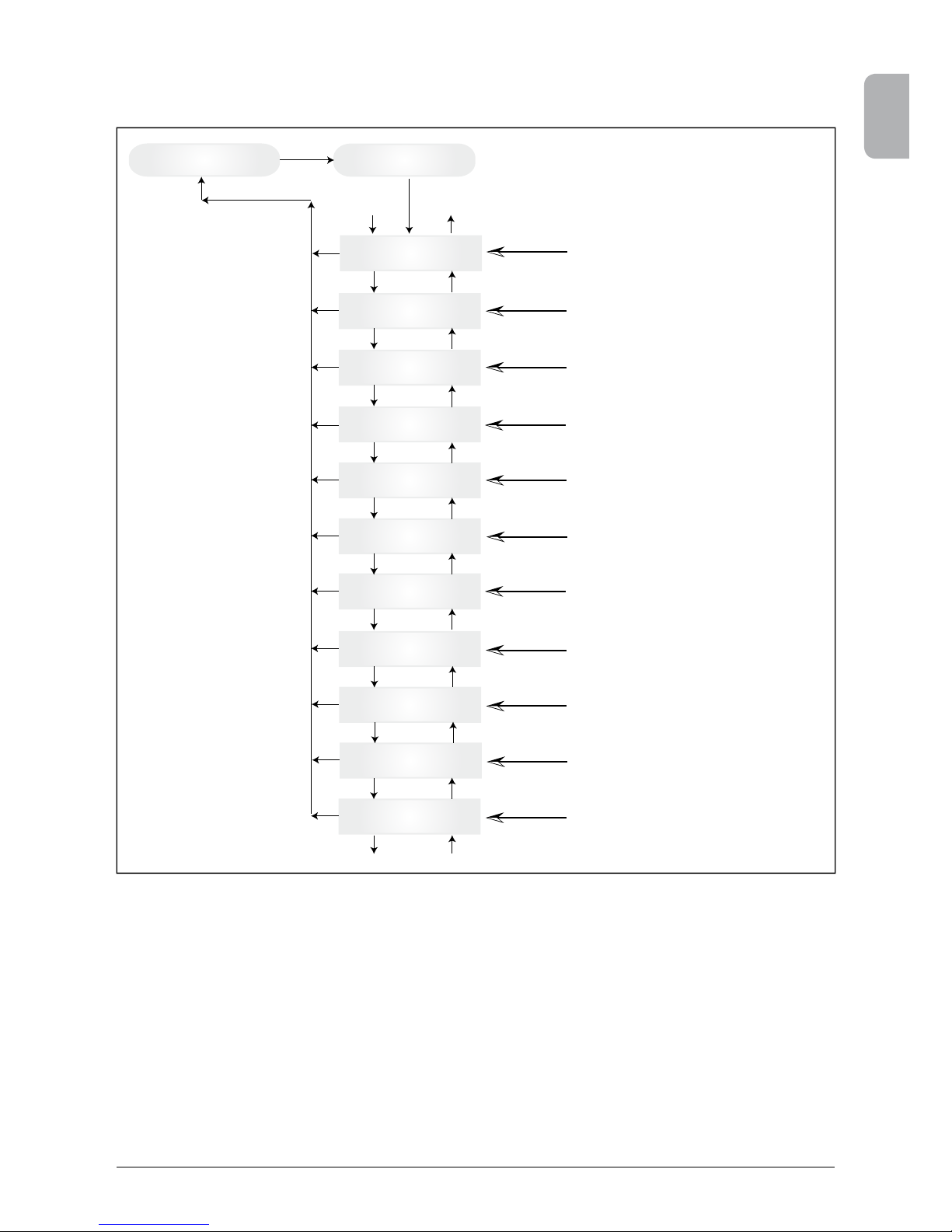

User menu

Menu N - Now (act data)

Menu D - Day statistic

Menu W - Week statistic

Menu M - Month statistic

Menu Y - Year statistic

Menu T - Total statistic

Menu S - Setup inverter

Down

Down

Down

Down

Down

Down

Up

Up

Up

Up

Up

Up

Down to 2

1

Up to 1

2

Submenu N - Now

Submenu D - Day

Submenu W - Week

Submenu M - Month

Submenu Y - Year

Submenu T - Total

Submenu S - Setup

ESC

ESC

ESC

ESC

ESC

ESC

ESC

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

ENTER

Remarks:

ESC in main menu jumps to first entry of

corresponding sub menu

Menu Autotest

(only for Italy)

Down

Up

Submenu Autotest

ESC

ENTER

Page 22

20 Operation and installation manual SOLIVIA 5.0 EU G3

The rst line shows the limits according the standard. The second line shows the actual measured

grid voltage and the test status, positive (pass) or negative (fail). Pressing the test is con rmed

and the auto-test routine continue. If no is pressed, the result is shown for 1minute. After this

time, the result is con rmed automatically.

Autotest Passed

Start Autotest?

The rst line shows the actual auto-test status which could be “passed” or “failed”. Pressing the

auto-test routine starts. The rst test performed is the OVT, over voltage test, which verify the over

voltage protection. The display shows:

7.3.1 Autotest (only for Italy)

This function is available only for the Italian country.

The inverter is supplied with an auto-test function able to verify the correct operation of the interface

protection.

In the main menu, using buttons , select the auto-test menu. The display shows, for example:

L: 262 V < 0.1 S

Start OVT test?

The rst line shows the actual over voltage limit and detection time settings according to the standards. Pressing the test starts. Pressing “ESC” the display goes back to the main menu.

If has been pressed the display shows, for example:

L: 262 V OVT

A: 230 V RUN

L: 230 V 0.044 S

A: 230 V OV pass

L: 186 V < 0.2 S

Start UVT test?

After few seconds needed from the inverter to switch to the test mode, the limit “L:” will decrease till

crossing the actual measured grid voltage “A:”. Reached this condition the inverter display shows,

for example:

If the test is con rmed, the inverter performs the UVT test, under voltage test, which verify the under

voltage protection. The display shows:

The rst line shows the actual under voltage limit and detection time settings according to the standards. Pressing the test starts. Test starts also automatically after 1 minute if no is pressed.

If has been pressed the display shows, for example:

L: 186 V UVT

A: 230 V RUN

Page 23

21

ENGLISH

Operation and installation manual SOLIVIA 5.0 EU G3

The rst line shows the limits according the standard. The second line shows the actual measured

grid voltage and the test status, positive (pass) or negative (fail). Pressing the test is con rmed

and the auto-test routine continue. If no is pressed, the result is shown for 1minute. After this

time, the result is con rmed automatically.

The rst line shows the limits according the standard. The second line shows the actual measured

grid frequency and the test status, positive (pass) or negative (fail). Pressing the test is con rmed

and the auto-test routine continue. If no is pressed, the result is shown for 1minute. After this

time, the result is con rmed automatically.

The rst line shows the actual high frequency limit and detection time settings according to the

standards. Since the protection is not sensitive to the frequency variations less than 40 ms (two

line cycles of the grid voltage at nominal frequency of 50 Hz), the detection time has been set to

60 ms. Pressing the test starts. Test starts also automatically after 1 minute if no is pressed.

The rst line shows the actual low frequency limit and detection time settings according to the

standards. Since the protection is not sensitive to the frequency variations less than 40 ms (two line

cycles of the grid voltage at nominal frequency of 50 Hz), the detection time has been set to 60 ms.

Pressing the test starts. Test starts also automatically after 1 minute if no is pressed.

If has been pressed the display shows, for example:

The limit “L:” will increase till crossing the actual measured grid voltage “A:”. Reached this condition

the inverter display shows, for example:

L: 230 V 0.164 S

A: 230 V UV pass

If the test is con rmed, the inverter performs the HFT test, high frequency test, which verify the high

frequency protection. The display shows:

L: 50.30 Hz < 0.06 S

Start HFT test?

L: 50.30 Hz HFT

A: 49.99 Hz RUN

The limit “L:” will decrease till crossing the actual measured grid frequency “A:”. Reached this condition the inverter display shows, for example:

L: 49.99 Hz 0.044 S

A: 49.99 Hz HF pass

If the test is con rmed, the inverter performs the LFT test, low frequency test, which verify the low

frequency protection. The display shows:

L: 49.70 Hz < 0.06 S

Start LFT test?

Page 24

22 Operation and installation manual SOLIVIA 5.0 EU G3

The rst line shows the limits according the standard. The second line shows the actual measured

grid frequency and the test status, positive (pass) or negative (fail). Pressing the test is con rmed

and the auto-test routine continue. If no is pressed, the result is shown for 1minute. After this

time, the result is con rmed automatically.

If has been pressed the display shows, for example:

L: 49.70 Hz LFT

A: 49.99 Hz RUN

The limit “L:” will increase till crossing the actual measured grid frequency “A:”. Reached this condition the inverter disconnects from grid and the display shows, for example:

L: 49.99 Hz 0.044 S

A: 49.99 Hz LF pass

If the test is con rmed, the auto-test routine is nished. The display shows, for example:

Autotest Passed

Esc to continue

First line shows the actual auto-test status. If all the single test are passed and con rmed, the actual

auto-test status will be passed. Pressing “ESC” the display goes back to the main menu.

If the actual auto-test status is failed, pressing “ESC” the display goes back to the main menu and

the inverter is in error condition. The display shows “ AUTOTEST FAILED”. If the actual status is

failed it’s possible to restart the auto-test routine. If the auto-test permanently fails please contact

the customer service.

If during the auto-test is performed any grid or inverter errors occurs, the auto-test routine is aborted

and the display shows the actual failed auto-test status. The inverter reset and perform a restart if

the previous status was passed.

The auto-test can be started only if the inverter is in normal operating conditions. It is not possible

to entry the auto-test routine if the grid is not in the de ned tolerances, if any internal inverter error

occurs or the solar plan do not respect the speci cations.

A restart of the inverter will be done after the auto-test, when the result of the current auto-test is

different from the result from the auto-test before.

While the auto-test routine is ongoing, green LED is ashing, the red shows isolation measurement

status and the yellow shows the status of last auto-test (yellow on: last auto-test was failed; yellow

off: last auto-test was ok).

Page 25

23

ENGLISH

Operation and installation manual SOLIVIA 5.0 EU G3

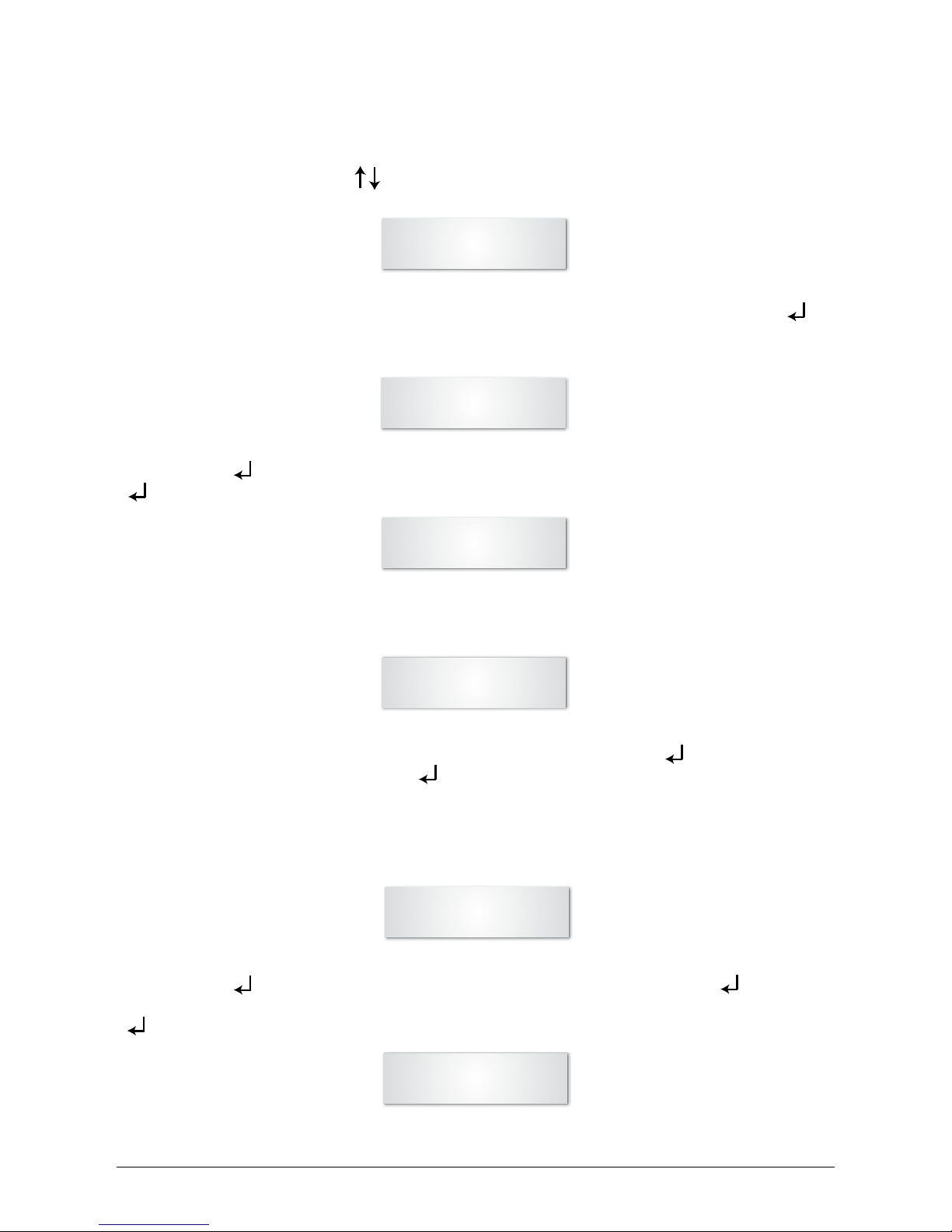

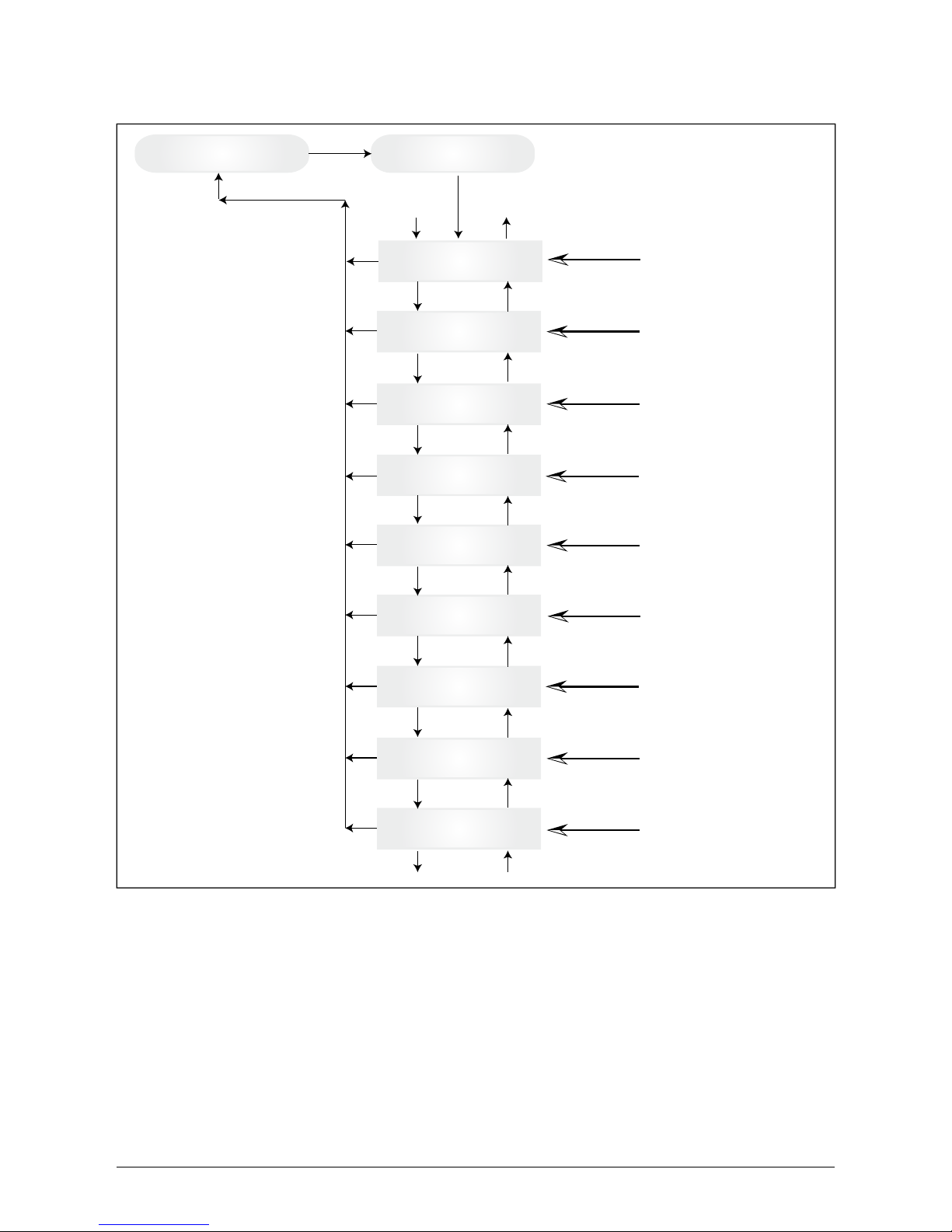

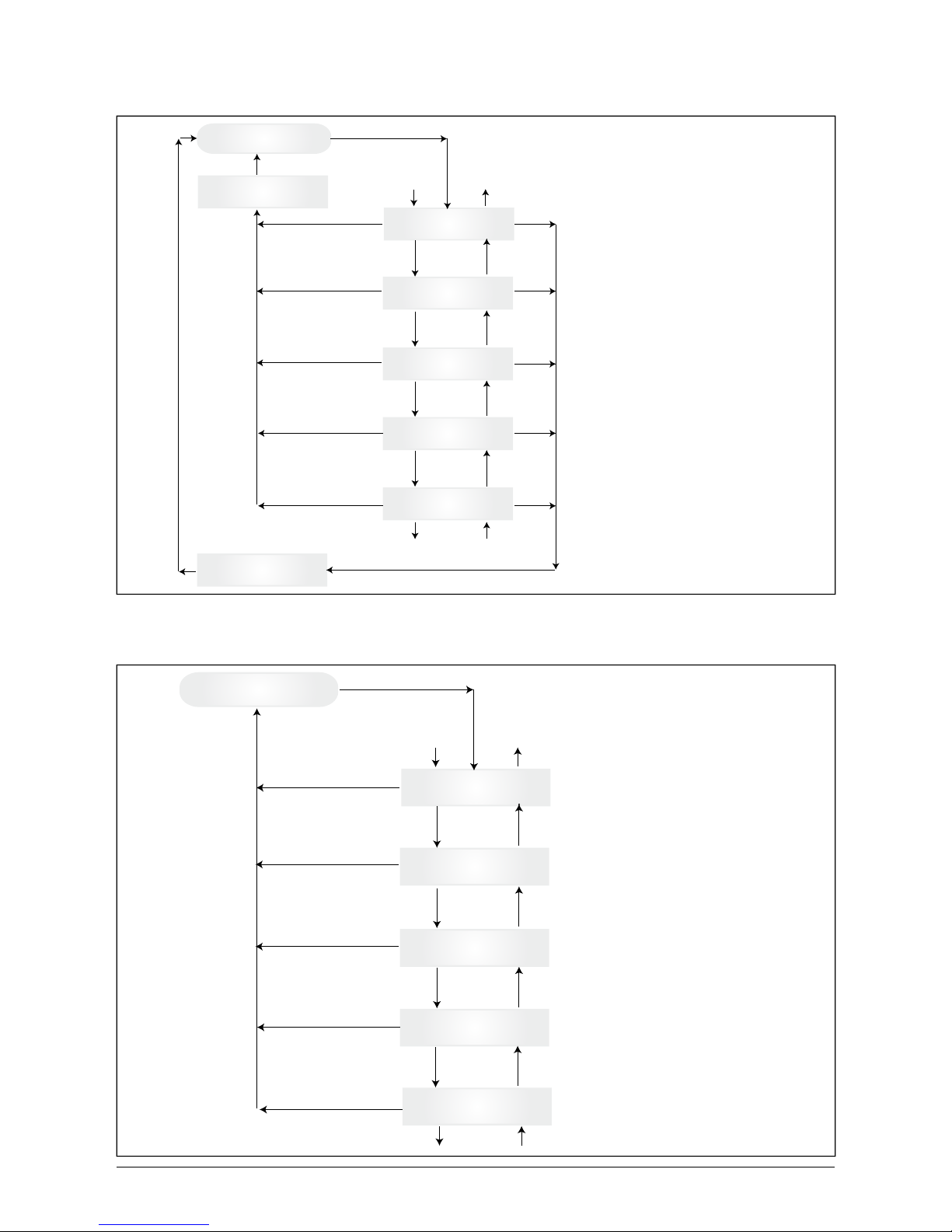

7.3.2 Submenu N (Now)

This menu item displays the active values.

Main menu N - Now

actual data

N -> AC-Power

Value (W)

N -> AC-Voltage

Value (V)

N -> AC-Current

Value (A)

N -> AC-Frequency

Value (Hz)

N -> PV1-Voltage

Value (V)

N -> PV1-Current

Value (A)

N -> Time

(HH:MM:SS)

N -> Date

(WD.DD.MM.YYYY)

Down

Down

Down

Down

Down

Down

Up

Up

Up

Up

Up

Up

Up

Down to 2

1

Up to 1

2

Submenu N - Now

ESC

ESC

ESC

ESC

ESC

ESC

ESC

ESC

ENTER

Display of the

active output power

Display of the active

output voltage

Display of the active

output current

Display of the active

mains frequency

Display of the active

PV cell voltage input 1

Display of the active

PV cell current input 1

Display of the

current time

Display of current day

of the week and date

N -> PV2-Voltage

Value (V)

N -> PV2-Current

Value (A)

Down

Up

ESC

ESC

Display of the active

PV cell voltage input 2

Display of the active

PV cell current input 2

Down

Down

Up

Page 26

24 Operation and installation manual SOLIVIA 5.0 EU G3

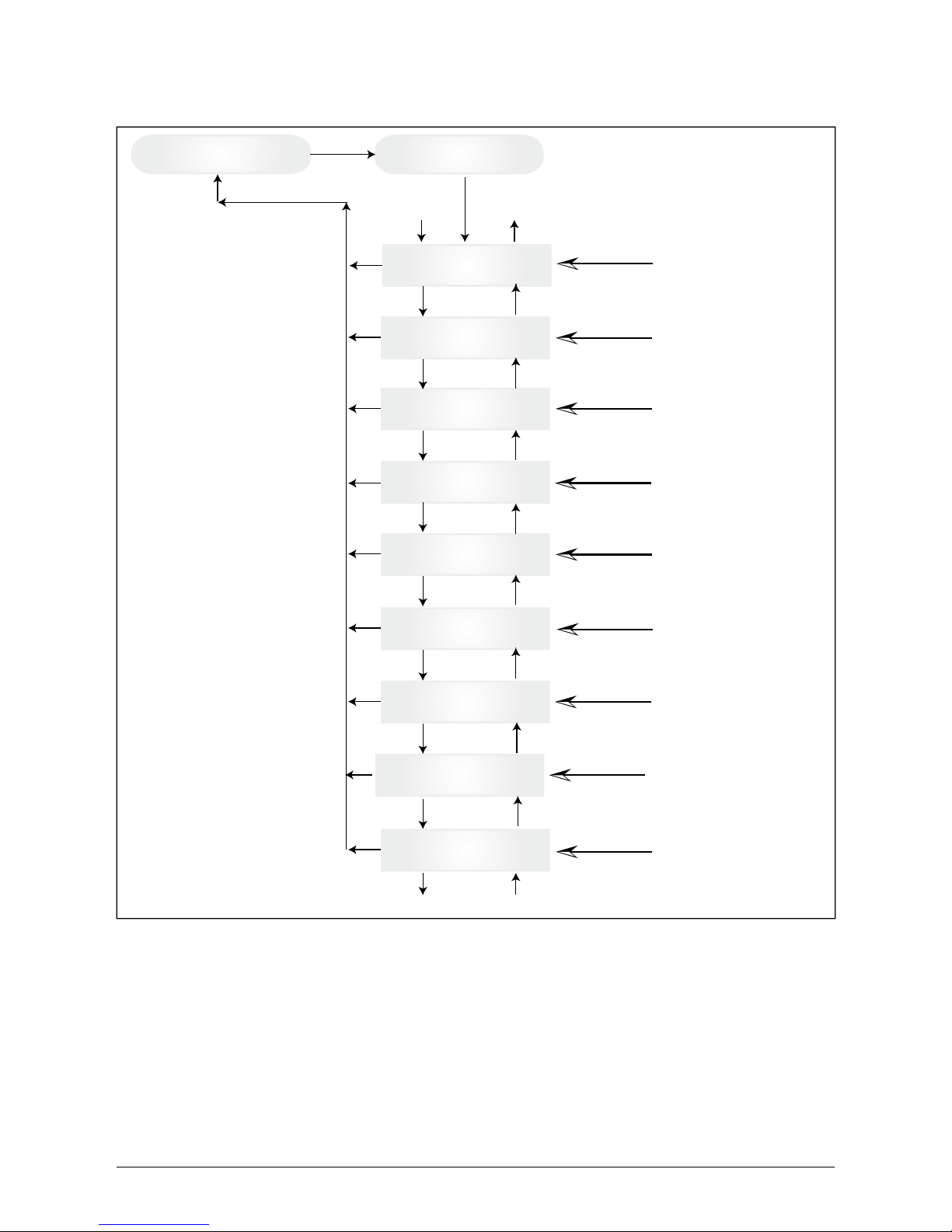

7.3.3 Submenu D (Day)

This menu item displays the daily values for the grid feed.

Main menu D - Day statistic

D -> Energy

Value (Wh)

D -> Revenue

Value (Euro)

D -> AC-Power-Max

Value (W)

D -> AC-Volt-Max

Value (V)

D -> AC-Volt-Min

Value (V)

D -> AC-Curr-Max

Value (A)

D -> AC-Freq.-Max

Value (Hz)

D -> Runtime

Value (Min)

Down

Down

Down

Down

Down

Down

Down

Up

Up

Up

Up

Up

Up

Up

Down to 2

1

Up to 1

2

Submenu D - Day

ESC

ESC

ESC

ESC

ESC

ESC

ESC

ESC

ENTER

D -> AC-Freq.-Min

Value (Hz)

ESC

Down

Up

Display of the daily

energy gain

Display of the daily revenue

Display of the daily

maximum output power

Display of the daily max.

output voltage

Display of the daily min.

output voltage

Display of the daily

maximum output current

Display of the daily

maximum output frequency

Display of the daily

minimum output frequency

Display of the daily operating

time of the solar inverter

Page 27

25

ENGLISH

Operation and installation manual SOLIVIA 5.0 EU G3

7.3.4 Submenu W (Week)

This menu item displays the average values of the current week.

Main menu W - Week statistic

W -> Energy

Value (kWh)

W -> Revenue

Value (Euro)

W -> Runtime

Value (h)

Down

Down

Up

Up

Down to 2

1

Up to 1

2

Submenu W - Week

ESC

ESC

ESC

ENTER

Display of the weekly

energy gain

Display of the weekly revenue

Display of the weekly operating

time of the solar inverter

7.3.5 Submenu M (Month)

This menu item displays the average values of the current month.

Main menu M - Month statistic

M -> Energy

Value (kWh)

M -> Revenue

Value (Euro)

M -> Runtime

Value (h)

Down

Down

Up

Up

Down to 2

1

Up to 1

2

Submenu M - Month

ESC

ESC

ESC

ENTER

Display of the monthly

energy gain

Display of the monthly revenue

Display of the monthly operating

time of the solar inverter

7.3.6 Submenu Y (Year)

This menu item displays the average values of the current year.

Main menu Y - Year statistic

Y -> Energy

Value (kWh)

Y -> Revenue

Value (Euro)

Y -> Runtime

Value (h)

Down

Down

Up

Up

Down to 2

1

Up to 1

2

Submenu Y - Year

ESC

ESC

ESC

ENTER

Display of the annual

energy gain

Display of the annual revenue

Display of the annual operating

time of the solar inverter

Page 28

26 Operation and installation manual SOLIVIA 5.0 EU G3

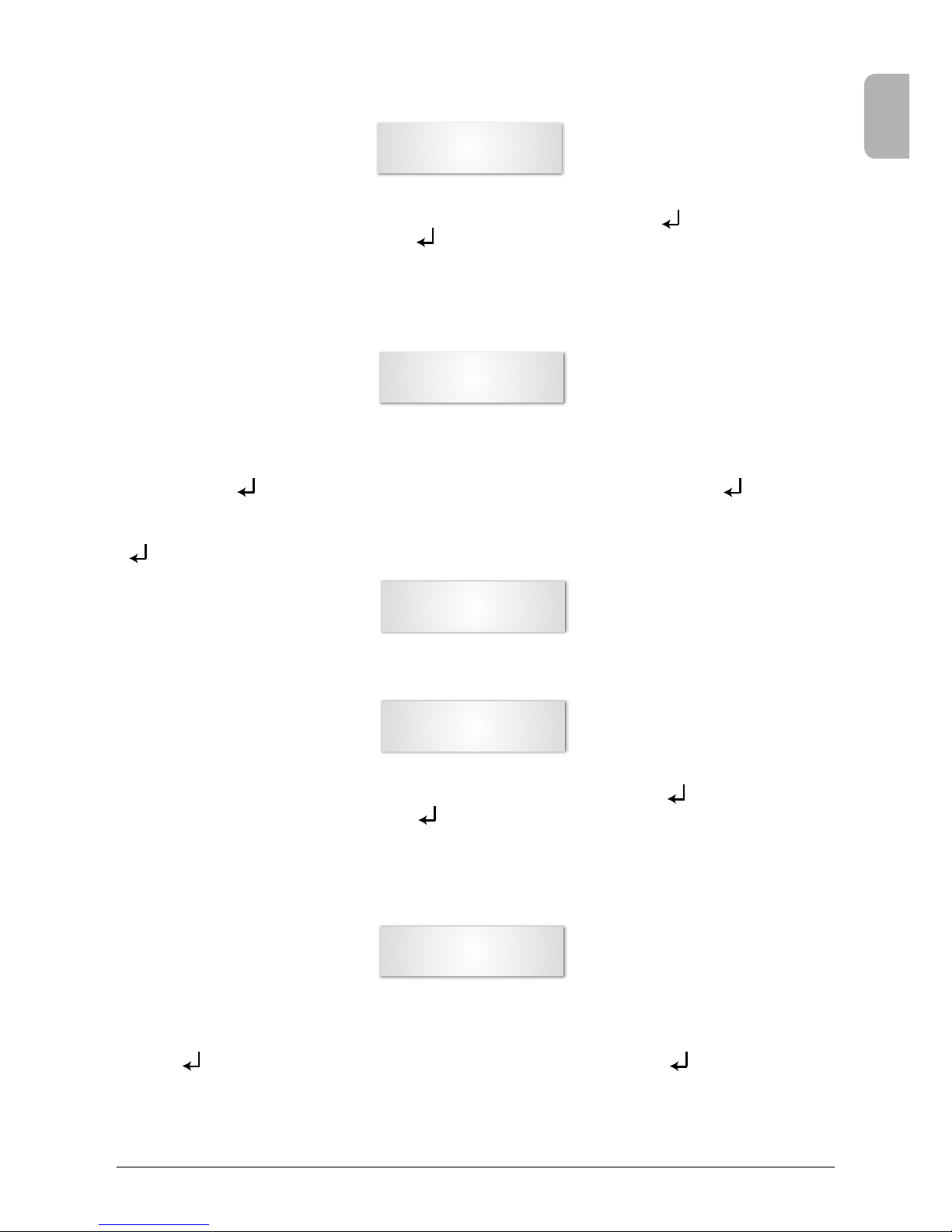

7.3.7 Submenu T (Total)

This menu item shows cumulated and maximum/minimum values since rst use.

Main menu T - Total statistic

T -> Energy

Value (kWh)

T -> Revenue

Value (Euro)

T -> PV1-Vol. Max

Value (V)

T -> PV1-Cur. Max

Value (A)

T -> PV1-Pow. Max

Value (W)

T -> Runtime

Value (Min)

Down

Down

Down

Down

Down

Down

Down

Up

Up

Up

Up

Up

Up

Down to 2

1

Up to 1

2

Submenu T - Total

ESC

ESC

ESC

ESC

ESC

ESC

ESC

ESC

ENTER

Up

Display of the total

energy gain

Display of the total

revenue

Display of the max.

PV cell voltage input 1

Display of the max.

PV cell current input 1

Display of the max.

PV cell power input 1

Display of the total operating

time of the solar inverter

T -> PV2-Vol. Max

Value (V)

T -> PV2-Cur. Max

Value (A)

ESC

T -> PV2-Pow. Max

Value (W)

Down

Up

Display of the max.

PV cell voltage input 2

Display of the max.

PV cell current input 2

Display of the max.

PV cell power input 2

Page 29

27

ENGLISH

Operation and installation manual SOLIVIA 5.0 EU G3

7.3.8 Submenu S (Setup)

This menu item is used for changing the presettings of the solar inverter.

Main menu S - Setup

S -> LCD-Contrast

0 ... 9

S -> LCD-Backlight

Auto / On

S -> Menu-Mode

Now ... Setup

S -> LCD language

S -> Cash per kWh

Value (Euro)

S -> ID-Number

001 ... 254

S -> PV ISO / GND

S -> Baudrate

2400 ... 38400

Down

Down

Down

Down

Down

Down

Down

Up

Up

Up

Up

Up

Up

Down to 2

1

Up to 1

2

Submenu S - Setup

ESC

ESC

ESC

ESC

ESC

ESC

ESC

ESC

ENTER

Up

S -> Time

(HH:MM:SS)

Down

ESC

Up

S -> Date

(WD.DD.MM.YYYY)

Down

ESC

Up

S -> Firmware

Down

ESC

Up

Adjustment of the LCD language

Adjustment of the firmware

Adjustment of the brightness of

the LCD display between 0 ... 9

Adjustment of the LCD

background lighting

Selection of the start menu

on restart of the device

Entry of feed-in remuneration in Euro / kWh

Input of the ID number of the solar inverter

Adjustment of the baud rate

between 2400 ... 38400 Baud

Adjustment of the internal clock

Adjustment of current day of the week and date

ISO / GND Setup Menu

Page 30

28 Operation and installation manual SOLIVIA 5.0 EU G3

7.3.8.1 Submenu S: Solar ISO / GND

More detailed information on the Solar ISO / GND menu within the submenu S (Setup).

Submenu Setup

Solar ISO / GND

S -> PV ISO / GND

ISO ON-Warning

S -> PV ISO / GND

ISO ON-Error

S -> PV ISO / GND

ISO GND-OFF

S -> PV ISO / GND

PV+ grounded

S -> PV ISO / GND

PV- grounded

Down

Down

Down

Down

Up

Up

Up

Up

Down to 5

6

Up to 6

5

ESC

ESC

ESC

ESC

ESC

ENTER

Use old setting

ENTER

ENTER

ENTER

ENTER

ENTER

Use new value

7.3.8.2 Submenu S: Firmware

More detailed information on the rmware menu within the submenu S (Setup).

Submenu Setup

Firmware

S -> Firmware

AC-Ctrl maj.min.bug

Down

Down

Down

Up

Up

Up

Down to 4

3

Up to 3

4

ESC

ESC

ESC

ESC

ENTER

S -> Firmware

DC-Ctrl maj.min.bug

S -> Firmware

SC-Ctrl maj.min.bug

S -> Firmware

Display-Ctrl maj.min.bug

Down to 4

3

ESC

S -> Firmware

IT GMon-Ctrl maj.min.bug

Page 31

29

ENGLISH

Operation and installation manual SOLIVIA 5.0 EU G3

8 Diagnostics and data evaluation

8.1 Malfunction rectication

The solar inverter is provided with an automatic diagnostics system which independently identies

certain faults and which can make them visible on the display.

Troubleshooting in the eld

In principle, it is always worth attempting a reset by reinitializing the solar inverter whenever an error

message appears on the display.

To reset the device, proceed as follows:

1. Isolate the solar inverter from the grid (open automatic circuit breaker).

2. Switch off the DC disconnector.

3. Wait: approx. 1 minute.

4. Switch DC disconnector back on.

5. Switch in grid (close automatic circuit breaker).

(In the eld, the rst step is to scan for potential fault causes that could be picked up by the solar

inverter and result in tripping.)

Various key parameters can be scanned via the display, thereby enabling conclusions to be drawn

about potential fault causes.

Current values in the N menu

AC Voltage -> Display of current output voltage -> Voltage limiting values

AC Frequency -> Display of current grid frequency -> Frequency limiting values

Solar Voltage -> Display of current PV cell voltage -> Switch-in threshold

8.2 Display messages

LED STATUS

DISPLAY

MESSAGE

CAUSE ELIMINATION

green: <on>

red: <on>

yellow: <on>

-

Display communication

faulty.

- If the fault persists after the device has

been reset, please inform your service

technician.

green: <off>

red: <off>

yellow: <on>

AC frequency

failure

Grid frequency overshooting or undershooting

specied limit range.

- Check the grid frequency via the display

in the N menu.

green: <off>

red: <off>

yellow: <on>

AC voltage

failure

Grid voltage overshooting

or undershooting specied

limit range.

- Check the grid voltage via the display in

the N menu.

- If no voltage present, check grid auto matic circuit breaker.

green: <off>

red: <off>

yellow: <on>

Autotest failed

(only for Italy)

The autotest status is in

error.

Repeat the autotest routine.

green: <ashes>

red: <off>

yellow: <off>

Calibration

ongoing

Check internal settings. Normal function before input mode.

green: <off>

red: <off>

yellow: <on>

DC injection

failure

DC component of inputside alternating current is

too high.

- If the fault persists after the device has

been reset, please inform your service

technician.

green: <off>

red: <off>

yellow: <on>

Error # 301

Internal communication

error or hardware fault.

- If the fault persists after the device has

been reset, please inform your service

technician.

Page 32

30 Operation and installation manual SOLIVIA 5.0 EU G3

Please follow the instructions above before contacting your service technician!

LED STATUS

DISPLAY

MESSAGE

CAUSE ELIMINATION

green: <off>

red: <off>

yellow: <on>

Error # 302

The device trips and

reverts to grid input mode

once the temperature has

dropped.

- Check the installation site (no direct

sunlight, air circulation).

green: <off>

red: <on>

yellow: <off>

Error # 506

Error # 508

Isolation resistance fault

on the DC side during

start-up phase (# 508) or

running phase (# 506).

- Check the isolation resistance on the DC

side of the PV modules.

green: <on>

red: <on>

yellow: <off>

Isolation startup warning

Isolation running warning

Isolation resistance fault

on the DC side during

start-up phase or running

phase.

- You must check the isolation resistance

on the DC side of the PV modules.

Solar inverter is still feeding!

green: <on>

red: <on>

yellow: <off>

PV+ grounding fault

PV- grounding

fault

Connection PV+ (PV-)

to GND is interrupted or

wrong pole is connected

to GND.

- Check that the GND connection has been

made correctly and/or check the fuse in

the grounding path. Change the fuse if

necessary. The solar inverter remains in

feed-in operation.

green: <off>

red: <off>

yellow: <on>

Relay error

One of the anti-islanding

protection output relays is

faulty / defective.

- The solar inverter is defective.

- Return the device.

green: <off>

red: <off>

yellow: <on>

Revision error

Versions of hard- and software are not compatible.

- If the fault persists after the device has

been reset, please inform your service

technician.

green: <on>

red: <on>

yellow: <on>

Self test

ongoing

Initialization of solar inverter on start-up.

The rst time the solar inverter is started

up:

- Normal function with a PV cell voltage

of between 100 V and 150 V.

green: <ashes>

red: <off>

yellow: <off>

PV power too

low

Insufcient input power.

- Insufcient insolation (dawn/twilight).

- Check the PV cell voltage via the

display in the N menu.

green: <ashes>

red: <off>

yellow: <off>

PV voltage too

low

PV generator voltage between 100 V and 150 V.

- Insufcient insolation.

- Check the PV cell voltage via the

display in the N menu.

green: <ashes>

red: <off>

yellow: <off>

Synchronize

to AC

Check grid voltage and

grid frequency for grid

input mode.

- Normal function before input mode.

green: <on>

red: <off>

yellow: <ashes>

Varistor

warning

Internal varistor at the DC

input is defective.

- Although you can, in theory, carry on

using the solar inverter, the varistors

should be replaced at the earliest oppor

tunity. This will involve returning the

device.

Page 33

31

ENGLISH

Operation and installation manual SOLIVIA 5.0 EU G3

9 Technical data

* The maximum AC power value indicates the power

an inverter might be able to deliver. However, such a

maximum AC power may not necessarily be achieved.

** AC voltage and frequency range will be programmed

according to the individual country requirements.

INPUT (DC)

Max. recommended PV

power

6000 W EU (5320 W DE /

5250 W BE)

Nominal power 5500 W EU (4850 W DE / BE)

Voltage range 125 ... 540 V

MPP range 150 ... 450 V

Full power MPP range 150 ... 450 V

Nominal current 17.2 A

Max. current 32.0 A

Stand-by power < 0.2 W

OUTPUT (AC)

Max. power *

5240 W EU (5060 W DE /

5000 W BE)

Nominal power

5000 W EU (4600 W DE / BE)

Voltage range ** 184 ... 264 V

Nominal current 22.0 A

Max. current 27.2 A

Nominal frequency 50 Hz

Frequency range ** 47.0 ... 52.0 Hz

Power factor > 0.99 @ nominal power

Total harmonic

distortion (THD)

< 4 % @ nominal power

GENERAL SPECIFICATION

Model name SOLIVIA 5.0 EU G3

Max. efficiency 95.6 %

Efficiency EU 94.6 %

Operating

temperature

-25 ... +60 °C

Storage temperature -25 ... +80 °C

Humidity 0 ... 98 %

MECHANICAL DESIGN

Size (L x W x D) 510 x 410 x 180 mm

Weight 32.0 kg

Cooling Convection

AC connector Wieland RST25i3S

DC connector pairs 4 Tyco Solarlok

Communication

interfaces

2 Harting RJ45 / RS485

DC disconnector -

Display LCD; 3 LEDs

STANDARDS / DIRECTIVES

Protection degree IP65

Safety class 1

Configurable trip

parameters

Yes

Insulation monitoring Yes

Overload behavior

Current limitation;

power limitation

Safety

EN60950-1; EN50178;

IEC62103; IEC62109-1 / -2

Anti-islanding

protection

VDE 0126-1-1; RD 1663;

ENEL G.L. 12/2008; EN 50438

EMC

EN61000-6-2; EN61000-6-3;

EN61000-3-2; EN61000-3-3

Page 34

32 Operation and installation manual SOLIVIA 5.0 EU G3

10 Appendix

10.1 Connection examples

House connection box

House connection line

Low-voltage network ~ 400 / 230 V

VNB

Customer

Owner boundary

Z

(1)

Z

(2)

Measurement unit

(1) Meter for power consumption

(2) Meter for power feed-in

with back stop in each case

Remark: A meter can also be employed

which registers both energy directions separately

=

~

~ 400 / 230 V

Consumer

equipment of

the customer

Photovoltaic

generator with

power inverter

max. 4.6 kVA

Switching equipment

Electric circuit distributor

Anti-islanding protection with voltage and

frequency monitoring, as well as network

impedance measurement

Short-circuit protection

Overload protection

Individual in-plant generation system in parallel operation without isolated

operation possibility, single-phase feed with anti-islanding protection.

House connection box

House connection line

Low-voltage network ~ 400 / 230 V

VNB

Customer

Owner boundary

Z

(1)

Z

(2)

Measurement unit

(1) Meter for power consumption

(2) Meter for power feed-in

with back stop in each case

Remark: A meter can also be

employed which registers both energy

directions separately.

(3) Meter for power take-off of the

customer system

=

~

~ 400 / 230 V

Consumer equipment

of the customer

Photovoltaic

generator with

power inverter

max. 4.6 kVA

Switching equipment

Electric circuit distributor

Anti-islanding protection with voltage and

frequency monitoring, as well as network

impedance measurement

Short-circuit protection

Overload protection

Individual in-plant generation system in parallel operation without isolated

operation possibility, single-phase feed with anti-islanding protection, separate feed.

Z

(3)

Page 35

33

ENGLISH

Operation and installation manual SOLIVIA 5.0 EU G3

10.2 Overview of connection diagrams

+

-

DC terminal strip

DC disconnector

-

~

Solivia 5.0

3 3

Z

Meter for

power feed-in

3

Z

3

3

3

Meter for

power

consumption

House

connection

box

Selective

main line

circuit breaker

House

connection

line

Consumer

equipment

Automatic

circuit breaker

type B 32 A

+

-

PV generator

PV generator

+

-

DC disconnector

-

~

Solivia 5.0

Automatic circuit

breaker

type B 32 A

PV generator

DC disconnector

-

~

Automatic

circuit breaker

type B 32 A

PV generator

kWh

kWh

Customer

Meter for

power feed-in

Meter for

power

consumption

Solivia 5.0

Page 36

34 Operation and installation manual SOLIVIA 5.0 EU G3

DC disconnector

-

~

1

2

3

PV generator

-

~

-

~

L1 N PE

L2 N PE

L3 N PE

Fuse

L1

N

n

...

PE

L2

L3

Solivia 5.0

Page 37

35

ENGLISH

Operation and installation manual SOLIVIA 5.0 EU G3

11 Glossary

AC

Abbreviation for „Alternating Current“.

Anti-islanding protection

This is a unit for grid monitoring with assigned switching elements (anti-islanding protection) and is

an automatic isolation point for small power generation systems (to 30 kWp).

BDEW

Union of German Electrical Power Stations.

CE

With the CE identication code, the manufacturer conrms the conformity of the product with the

valid EC Guideline and compliance with the signicant requirements stipulated therein.

DC

Abbreviation for „Direct Current“.

EMC

The Electro-Magnetic Compatibility (EMC) concerns the technical and legal basics of the mutual

inuencing of electrical devices through electromagnetic elds caused by them in electrical engineering.

Galvanical isolation

No conductive connection between two component parts.

Initialization

Under initialization (cf. English to initialize) is understood the part of the loading process of a program, in which the storage space required for the execution (e.g. variable, code, buffers ...) for the

program is reserved and is lled with initial values.

Local utility company

By local utility company is meant a company which generates electrical energy and distributes it

over the public grid.

MPP

The Maximum Power Point is the point of the current-voltage diagram of a PV cell at which the

largest power can be tapped off, i.e. the point at which the product of current and voltage has its

maximum value.

Nominal power

Nominal power is the maximum permissible continuous power output indicated by the manufacturer

for a device or a system. Usually the device is also optimized so that the efciency is at its maximum

in case of operation with nominal power.

Nominal current

Nominal current is the absorbed current in case of electrical devices if the device is supplied with

the nominal voltage and yields its nominal power.

PE

In electric systems and cables a protective earth conductor is frequently employed. This is also

called grounding wire, protective grounding device, soil, grounding or PE (English „protective

earth“).

Page 38

36 Operation and installation manual SOLIVIA 5.0 EU G3

Photovoltaics (abbr.: PV)

The conversion of PV energy into electrical energy.

The name is composed of the component parts: Photos - the Greek word for light - and Volta - after

Alessandro Volta, a pioneer in electrical research.

Power dissipation

Power dissipation is designated as the difference between absorbed power and power of a device

or process yielded. Power dissipation is released mainly as heat.

PV cell

PV cells are large-surface photodiodes which convert light energy (generally sunlight) into electrical

energy. This comes about by utilization of the photoelectric effect (photovoltaics).

PV generator

System comprising a number of PV modules.

PV module

Part of a PV generator; converts PV energy into electrical energy.

RJ45

Abbreviation for standardized eight-pole electrical connector connection. RJ stands for Registered

Jack (standardized socket).

RS485 (EIA485)

Differential voltage interface on which the genuine signal is transmitted on one core and the negated (or negative) signal on the other core.

Separate grid system

Energy supply equipment which is completely independent of an interconnected grid.

Solar inverter

is an electrical device which converts DC direct voltage into AC voltage and/or direct current into

alternating current.

String

Designates a group of electrical PV modules switched in series.

String solar inverter (solar inverter concept)

The PV generator is divided up into individual strings which feed into the grid over their own string

solar inverters in each case. In this way, the installation is considerably facilitated and the gain decrease, which can arise from the installation or from different shading conditions of the PV modules,

is considerably reduced.

TAB (2000)

The TAB 2000 are the technical regulations governing connection to the low-voltage grid operated

by distribution system operators in Germany. These Technischen Anschlussbestimmungen or TAB

for short have been in force since the year 2000. They dene the requirements imposed by DSOs

on the electrical systems operated by the end customers of utility companies.

VDE

Verband der Elektrotechnik, Elektronik und Informationstechnik e. V.

(Association of Electrical Engineering, Electronics and Information Technology).

Page 39

37

ENGLISH

Operation and installation manual SOLIVIA 5.0 EU G3

12 Guarantee

Register now on our homepage at https://guarantee.solar-inverter.com and you will receive a free

extension of the guarantee on your SOLIVIA string inverter from 5 to 10 years. The registration

and the original sales receipt are required for this extension of the guarantee.

If you have not registered, you will continue to receive the 5-year standard guarantee.

Page 40

38 Bedienungsanleitung SOLIVIA 5.0 EU G3

Page 41

39

DEUTSCH

Bedienungsanleitung SOLIVIA 5.0 EU G3

Dieser Bedienungsanleitung sind Änderungen vorbehalten.

Bitte informieren Sie sich auf unserer Website www.solar-inverter.com

bezüglich der aktuellsten Version der Bedienungsanleitung.

© Copyright – Delta Energy Systems (Germany) GmbH – Alle Rechte vorbehalten.

Diese Anleitung liegt unseren Produkten bei und ist für den Gebrauch durch den Endanwender bestimmt. Die in dieser Anleitung

enthaltenen technischen Anweisungen und Illustrationen sind vertraulich zu behandeln und dürfen ohne die vorherige schriftliche

Genehmigung durch die Service-Ingenieure von Delta Energy Systems weder ganz noch auszugsweise vervielfältigt werden. Der

Endanwender darf die hierin enthaltenen Informationen nicht an Dritte weitergeben oder diese Anleitung für andere Zwecke als die

Gewährleistung einer ordnungsgemäßen Anwendung der Produkte verwenden.

Alle Informationen und Spezikationen unterliegen Änderungen ohne vorherige Ankündigung.

Page 42

40 Bedienungsanleitung SOLIVIA 5.0 EU G3

Page 43

41

DEUTSCH

Bedienungsanleitung SOLIVIA 5.0 EU G3

Inhaltsangabe

1 Lieferumfang 42

2 Allgemein / Sicherheitshinweise 42

3 Einleitung 43

4 System 43

4.1 Datenauswertung und Kommunikation 43

4.2 Technischer Aufbau des Solar Inverters 44

4.3 Geräteübersicht 45

5 Installation 46

6 Gerätemontage 46

6.1 Installationsort 46

6.2 Mindestanforderungen 46

6.3 Wartung 47

6.4 Montage 47

6.5 Umgebungstemperatur 48

6.6 Netzanschluss 48

6.7 Anschluss der PV Module 49

6.7.1 Ausgangsleistung über PV Spannung 50

6.7.2 Wirkungsgrad 51

6.8 Schnittstellenanschluss RS485 (EIA485) 51

6.9 Elektrischer Anschluss und Inbetriebnahme 53

6.10 Setup / Einstellungen 54

6.11 LED Betriebs- und Störungsanzeige 55

7 Bedienkonzept 56

7.1 Das Display 56

7.2 Navigation im Display 56

7.3 Hauptmenü 56

7.3.1 Autotest (nur für Italien) 58

7.3.2 Untermenü N (Now) 61

7.3.3 Untermenü D (Day) 62

7.3.4 Untermenü W (Week) 63

7.3.5 Untermenü M (Month) 63

7.3.6 Untermenü Y (Year) 63

7.3.7 Untermenü T (Total) 64

7.3.8 Untermenü S (Setup) 65

7.3.8.1 Untermenü S: Solar ISO/GND 66

7.3.8.2 Untermenü S: Firmware 66

8 Diagnose und Datenauswertung 67

8.1 Störungsbehebung 67

8.2 Displaymeldungen 67

9 Technische Daten 69

10 Anhang 70

10.1 Anschlussbeispiele 70

10.2 Übersichtsschaltpläne 71

11 Glossar 73

12 Garantie 75

13 Zertifikate 380

Page 44

42 Bedienungsanleitung SOLIVIA 5.0 EU G3

1 Lieferumfang

• Solar Inverter SOLIVIA 5.0 EU G3

• Wandhalterung

• Bedienungsanleitung

• AC Netzstecker

2 Allgemein / Sicherheitshinweise

Herzlichen Glückwunsch zum Kauf dieses technisch hochwertigen Solar Inverter SOLIVIA 5.0 EU

G3.

Die vorliegende Anleitung hilft Ihnen, sich mit diesem Produkt vertraut zu machen.

Bitte beachten Sie die Sicherheitsbestimmungen der einzelnen Länder (z.B. für Deutschland: VDE,

BDEW, BGFE, technische Anschlussbedingungen für örtliches Versorgungsunternehmen). Eine

vorsichtige Handhabung Ihres Produkts wird zur Haltbarkeit und Zuverlässigkeit während seiner

Betriebsdauer beitragen. Dies sind wesentliche Voraussetzungen dafür, dass Sie den besten Nutzen aus Ihrem Produkt ziehen.

Bitte beachten Sie folgende Sicherheitshinweise:

• Während des Betriebes elektrischer Geräte stehen bestimmte Teile unter gefährlicher Spannung.

• Unsachgemäßer Umgang kann zu Körperverletzung und Sachschäden führen!

• Halten Sie die Installationsvorschriften ein.

• Installations- und Inbetriebnahmearbeiten dürfen nur durch Elektrofachkräfte ausgeführt werden.

• Reparaturarbeiten am Gerät dürfen nur vom Hersteller durchgeführt werden.

• Bitte beachten sie alle Punkte in der Bedienungsanleitung!

• Trennen Sie das Gerät vom Netz und von den PV Modulen, bevor Sie Arbeiten daran durchführen.

• Bei hoher Leistung und hoher Umgebungstemperatur kann die Gehäuseoberäche heiß werden.

• Ausreichende Kühlung des Gerätes ist notwendig.

• Aufgrund des hohen Gewichts von > 18 kg sollte der Solar Inverter nur mit mindestens 2 Personen

gehoben werden.

• Beachten Sie, dass das Gerät einen erhöhten Ableitstrom besitzt. Ein Betrieb mit angeschlos senem PE Leiter ist zwingend erforderlich.

Bitte beachten Sie, dass das Gerät unter keinen Umständen geöffnet werden darf, da sonst die Garantie erlischt!

Nachdem Sie das Gerät vom Netz und von den PV Modulen getrennt

haben, sind innerhalb des Gerätes für mindestens 5 Minuten gefährliche

Spannungen vorhanden!

Page 45

43

DEUTSCH

Bedienungsanleitung SOLIVIA 5.0 EU G3

3 Einleitung

Mit diesem Gerät haben Sie einen Solarwechselrichter für den Anschluss von photovoltaischen

Systemen an das Versorgungsnetz erworben. Dieser europäische Solarwechselrichter kann in folgenden Ländern, für die er auch zugelassen ist, benutzt werden: Deutschland, Frankreich, Spanien, Italien, Portugal, Griechenland, Tschechische Republik und Belgien. Der Solarwechselrichter

zeichnet sich durch sein fortschrittliches Gehäusedesign sowie modernste Hochfrequenztechnologie aus, die den höchsten Grad an Efzienz ermöglichen.

Der Solarwechselrichter umfasst Überwachungsaggregate, wie etwa den Schutz gegen Inselbildung. Die Funktion des Schutzes gegen Inselbildung (automatischer Isolierungspunkt für betriebsinterne Generierungssysteme) schreibt die Einhaltung der Spezikationen von DIN VDE 0126-1-1,

EN 50438, ENEL G.L. 12/2008, RD 1663 vor, wie auch die Einhaltung der Richtlinien für den Parallelbetrieb von Stromerzeugungssystemen auf dem Niederspannungsnetz Ihrer örtlichen Versorgungsunternehmen. Diese werden durch Zertikate bescheinigt (siehe § 13).

Der Wechselrichter kann innerhalb oder außerhalb von Gebäuden benutzt werden (IP65).

In der folgenden technischen Beschreibung werden dem Installateur wie auch dem Benutzer die

genauen Funktionen erläutert, die für die Installation, Inbetriebnahme und Handhabung des Solar

Inverters erforderlich sind.

4 System

Der Solar Inverter wandelt den von den Solarzellen gewonnenen Gleichstrom in Wechselstrom

um. Dies ermöglicht es Ihnen, Ihre selbstproduzierte Solarenergie in das öffentliche Stromnetz

einzuspeisen.

Dank eines efzienten MPP-Trackings ist selbst bei trübem und bewölktem Himmel eine maximale

Leistung der Solaranlage gesichert.

Durch das Stringkonzept wird immer eine Reihenschaltung von Solarmodulen (String) bzw. eine

Parallelschaltung von Strings mit gleicher Spannung an den Solar Inverter angeschlossen, sodass

der Verkabelungsaufwand der Photovoltaikanlage wesentlich reduziert wird. Durch das Verschalten

in Strings kann außerdem die Photovoltaikanlage optimal auf den Eingangsspannungsbereich des

Solar Inverters angepasst werden.

4.1 Datenauswertung und Kommunikation

Die integrierte Datenanzeige, -aufbereitung und -kommunikation des Gerätes ermöglicht eine einfache Bedienung des Solar Inverters. Überwachung des Betriebszustandes und Meldung von Betriebsstörungen sind über das Display des Geräts abrufbar. Die Datenschnittstellen ermöglichen

das Downloaden der Daten, die mit Hilfe eines PC-Systems ausgewertet werden können und somit

eine kontinuierliche Erfassung der Betriebsdaten gewährleisten.

Diese Funktionalität ist optimal durch das angebotene Zubehör (z.B. WEB`log von Meteocontrol)

erreichbar und eine vollständige und lückenlose Überwachung des Solar Inverters wird gewährleistet.

Das Auslesen der Daten über die integrierte Schnittstelle und das Display ist nur im Solarbetrieb

möglich.

Page 46

44 Bedienungsanleitung SOLIVIA 5.0 EU G3

4.2 Technischer Aufbau des Solar Inverters

Eine Potentialtrennung des Solar Inverters vom Netz wird durch einen Hochfrequenz-Umrichter mit

integriertem Transformator erreicht. Dabei wird die Photovoltaikspannung so eingestellt, dass die

maximale Abgabeleistung der Solarmodule auch bei unterschiedlichen Einstrahlungsstärken und

Temperaturen erreicht wird (MPP-Tracking).

Der MPP Bereich des Solar Inverters beträgt 150 V bis 450 V. Dies ermöglicht die Verwendung von

Solarmodulen verschiedener Hersteller. In jedem Fall ist zu berücksichtigen ist, dass die maximale

Leerlaufspannung von 540 V auf keinen Fall überschritten wird. Bitte beachten Sie, dass die maximale Leerlaufspannung bei den tiefsten zu erwartenden Temperaturen auftritt. Nähere Angaben

zur Temperaturabhängigkeit nden Sie im Datenblatt der Solarmodule. Der Eigenverbrauch des

Gerätes ist auf ein Minimum begrenzt.

Das hochwertige Aluminiumgehäuse entspricht der Schutzart IP65 (strahlwassergeschützt und

staubdicht) und ist durch eine Ober ächenveredelung vor Witterungsein üssen geschützt. Das

Kühlpro l ist so konzipiert, dass ein Betrieb des Solar Inverters bei Umgebungstemperaturen von

-25 °C bis +60 °C möglich ist.

Zur Abfuhr der durch die Spannungsumwandlung verursachten Wärme dient ein Kühlpro l. Eine

interne Temperaturregelung schützt das Gerät vor zu hohen Temperaturen im Inneren. Bei hohen

Umgebungstemperaturen wird die maximal übertragbare Leistung begrenzt.

Der Solar Inverter wird durch Mikrocontroller gesteuert, welche auch die Kommunikation der

Schnittstellen und die Anzeigen von Messwerten und Meldungen im Display realisieren.

Zwei unabhängige und redundante Mikrocontroller steuern die Überwachung des Versorgungsnetzes, was den Einspeiserichtlinien Ihres örtlichen Versorgungsunternehmens und DIN VDE

0126-1-1, EN 50438, ENEL G.L. 12/2008 sowie RD 1663 (Schutz gegen Inselbildung) entspricht.

Dies ermöglicht eine Installation des Solar Inverters in das betriebsinterne Stromnetz.

Der Schutz von Personen wird durch die galvanische Trennung von Netz und Solarmodul erfüllt.

Die galvanische Trennung zwischen Netz und Solarmodul entspricht einer Basisisolation. Zwischen

Netz, Solarmodulen und den berührbaren Schnittstellen (Display und RS485 Schnittstelle) ist eine

verstärkte Isolation für maximalen Personenschutz realisiert. Einschlägige Normen bezüglich der

elektromagnetischen Verträglichkeit (EMV) und der Sicherheit werden erfüllt.

Der Solar Inverter ist ausschließlich im Netzparallelbetrieb funktionsfähig. Eine selbsttätig wirkende

Freischaltstelle, welche von einer Zulassungsstelle abgenommen wurde, gewährleistet die sichere

Abschaltung bei Netztrennung oder Netzstörungen und vermeidet einen Inselbetrieb.

Es handelt sich dabei um eine sogenannte „Selbsttätige Freischaltung für Eigenerzeugungsanlagen einer Nennleistung ≤ 4,6 kVA mit einphasiger Paralleleinspeisung über Solar Inverter in das

Netz der öffentlichen Versorgung“.

Page 47

45

DEUTSCH

Bedienungsanleitung SOLIVIA 5.0 EU G3

4.3 Geräteübersicht

(1) Anschlüsse für PV Module

(2) Netzanschluss

(3) Schnittstellenanschluss RS485 (EIA485)

(4) Display für Zustandsanzeige und Tastenfeld zur Bedienung

(5) Leuchtdioden zur Betriebszustandsanzeige

DEUTSCH

(1)

(2)

(4)

(5)

(3)

Page 48

46 Bedienungsanleitung SOLIVIA 5.0 EU G3

5 Installation

Die Installation des Solar Inverters darf ausschließlich von Elektrofachkräften vorgenommen werden!

Die empfohlenen Sicherheitsbestimmungen, die technischen Anschlussbedingungen (TAB 2000)

wie auch DIN VDE 0126-1-1, EN 50438, ENEL G.L. 12/2008 und die RD 1663-Spezikationen

sollten eingehalten werden.

Zur Durchführung einer Strommessung muss zwischen dem Netzeinspeisungspunkt und dem Solar Inverter ein Messgerät angebracht werden (gemäß der Richtlinie Ihres örtlichen Versorgungsunternehmens bezüglich “Betriebsinterne Stromerzeugungssysteme auf dem Niederspannungsnetz”).

Aufgrund des integrierten Schutzes gegen Inselbildung wird die Funktion des empfohlenen Kuppelschalters gemäß der Richtlinie Ihres örtlichen Versorgungsunternehmens erfüllt.

Achtung: Der Kurzschlussstrom erhöht sich im Übergabepunkt zum öffentlichen Stromversorgungsnetz um den Nennstrom der angeschlossenen Solar Inverter.

6 Gerätemontage

6.1 Installationsort

• Das Gerät auf einem nicht brennbaren Untergrund installieren.

• Montage auf Resonanzkörpern (Leichtbauwände etc.) vermeiden.

• Eine Montage ist sowohl im Innen- als auch im geschützten Außenbereich möglich.

• Eine erhöhte Umgebungstemperatur kann den Ertrag der PV Anlage mindern.

• Leichte Geräuschentwicklung ist möglich (Installation im Wohnbereich vermeiden).

• Auf Lesbarkeit der LEDs und des Displays achten (Ablesewinkel / Montagehöhe).

• Das Gerät ist mit UV resistenten Komponenten ausgerüstet; direkte Sonneneinstrahlung sollte

dennoch vermieden werden.

• Trotz der Gehäuseschutzart IP65 und der Verschmutzungskategorie III muss darauf geachtet

werden, dass das Gerät nicht zu stark verschmutzt wird.

• Ein zu stark verschmutztes Gehäuse kann zu verminderten Erträgen führen.

6.2 Mindestanforderungen

• Die freie Konvektion um den Solar Inverter darf nicht beeinträchtigt sein.

• Zur Luftzirkulierung einen Freiraum von ca. 10 cm seitlich und ca. 50 cm oben und unten vom

Gerät belassen.