Delta SOLIVIA 10 EU T4 TL, SOLIVIA 20 EU G4 TL, SOLIVIA 15 EU G4 TL, SOLIVIA 30 EU T4 TL Operation And Installation Manual

Page 1

Operation and Installation

manual

SOLIVIA 10 EU T4 TL

SOLIVIA 15 EU G4 TL

SOLIVIA 20 EU G4 TL

SOLIVIA 30 EU T4 TL

PRELIMINARY

Page 2

Page 3

3

EN

© Copyright – Delta Energy Systems (Germany) GmbH - All rights reserved.

This manual accompanies our equipment for use by the end users.

The technical instructions and illustrations contained in this manual are to be treated as condential and no part may be reproduced without the prior written permission of Delta Energy Systems Service engineers and end users may not divulge the information contained herein or use this manual for purposes other than those strictly connected with correct use of the equipment.

All information and specications are subject to change without notice.

This manual is subject to change.

Please check our website at www.solar-inverter.com

for the most up-to-date manual version.

Page 4

4

Table of Contents

1. General Safety Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2. General Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

2.1 About this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.2 Safety Symbols & Instruction . . . . . . . . . . . . . . . . . . . . . . 24

2.3 Validity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.4 Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

2.5 Application & Intended Use . . . . . . . . . . . . . . . . . . . . . . . 25

2.6 Additional Information . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.7 Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3. Preparing for Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

3.1 Instruction before Installing . . . . . . . . . . . . . . . . . . . . . . . 28

3.2 Checking the Package . . . . . . . . . . . . . . . . . . . . . . . . . .28

3.3 Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

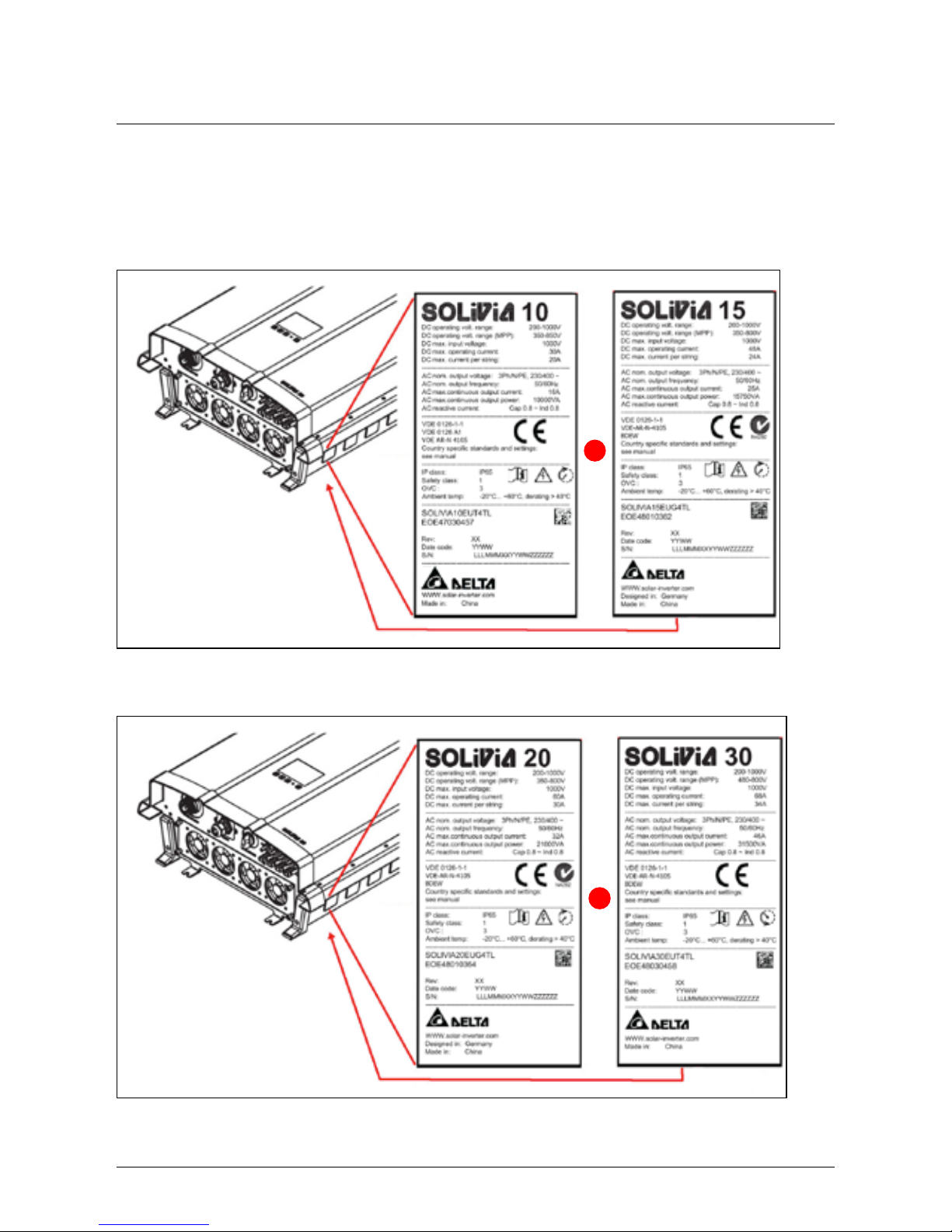

3.4 Identify the Inverter. . . . . . . . . . . . . . . . . . . . . . . . . . . .30

4. Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

4.1 Dimensions SOLIVIA 10 TL . . . . . . . . . . . . . . . . . . . . . . . 31

4.2 Dimensions SOLIVIA 15 TL, 20 TL, 30 TL . . . . . . . . . . . . . . . . 32

4.3 Function Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . .33

4.3.1 LCD Display and Buttons . . . . . . . . . . . . . . . . . . . . . . . . 35

4.3.2 Inverter Input/Output Interface . . . . . . . . . . . . . . . . . . . . . .36

4.3.3 Air outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

5. Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

5.1 Installing Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

5.2 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

5.3 Ambient temperature. . . . . . . . . . . . . . . . . . . . . . . . . . .43

6. Wiring the Inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

6.1 Preparation before Wiring . . . . . . . . . . . . . . . . . . . . . . . . 45

6.2 AC Grid Connection: 3 Phase + N + PE . . . . . . . . . . . . . . . . . 47

6.2.1 Required protective devices and cable cross-sections . . . . . . . . . 48

6.2.1.1 Residual Current Devices.....................................48

6.2.1.2 AC Cable Requirements .....................................48

6.2.2 AC bayonet connectors for 10 TL, 15 TL, 20 TL . . . . . . . . . . . . . 49

6.2.3 AC bayonet connectors for 30 TL . . . . . . . . . . . . . . . . . . . . 52

Page 5

5

EN

6.2.4 AC Wiring Considerations . . . . . . . . . . . . . . . . . . . . . . . . 54

6.3 DC Connection (from PV array) . . . . . . . . . . . . . . . . . . . . . 54

6.3.1 Asymmetrical Loading for 10 TL, 15 TL, 20 TL, and 30 TL . . . . . . . 56

6.4 Efciency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

6.5 Communication Module Connections . . . . . . . . . . . . . . . . . . 60

6.5.1 RS485 Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

6.5.2 EPO (Emergency Power Off) Connections . . . . . . . . . . . . . . . 63

6.5.3 Dry Contact Connection . . . . . . . . . . . . . . . . . . . . . . . . . 64

7. Operating the PV inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

7.1 Disconnection Parameter Settings. . . . . . . . . . . . . . . . . . . .68

7.1.1 Power Disconnection Device (PDD) Settings . . . . . . . . . . . . . . 68

7.1.2 SPI device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

7.2 Home Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.3 LCD Flow Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

7.3.1 Power Meter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7.3.2 Statistics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

7.3.3 Logs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

7.3.3.1 Internal Data...............................................72

7.3.3.2 Events Journal (Germany LVD or MVD Grid Only) .................72

7.3.4 Actual data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

7.3.5 Inverter Information . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7.3.6 Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

7.3.6.1 General Settings............................................75

7.3.6.2 Install Settings .............................................75

7.3.6.3 Active/Reactive Power control for DE LVD and DE MVD.............76

7.3.6.3.1 Power Limit ..............................................78

7.3.6.3.2 Power vs. Frequency .......................................79

7.3.6.3.3 Constant cos φ............................................81

7.3.6.3.4 cosφ(P) .................................................81

7.3.6.3.5 Constant Reactive Power....................................82

7.3.6.3.6 Q(V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

7.3.6.3.7 Fault Ride Through (FRT) ...................................84

7.3.6.4 Active/Reactive Power control for Italy CEI 0-21 and Italy A70 ........86

7.3.6.4.1 Power Limit ..............................................87

7.3.6.4.2 Power vs. Frequency .......................................88

7.3.6.4.3 Constant cosφ ............................................89

Page 6

6

7.3.6.4.4 cosφ(P) .................................................89

7.3.6.4.5 Constant Reactive Power....................................92

7.3.6.4.6 Q(V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

7.3.6.4.7 LVFRT Low Voltage Fault Ride Through (LVFRT) .................94

7.3.6.5 Reactive Power Control for Slovenia (SONDO) for 15 / 20 / 30 TL

Models ...................................................96

8. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

8.1 Cleaning the Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . 98

8.2 Replace a Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100

8.3 Cleaning the Air Outlets . . . . . . . . . . . . . . . . . . . . . . . . 100

9. Measurements and Messages . . . . . . . . . . . . . . . . . . . . . . . . 102

9.1 Measurements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 102

9.2 Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

10. Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

11. Decommissioning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

12. Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

12.1 Specication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 114

12.2 Cable Recommendations . . . . . . . . . . . . . . . . . . . . . . . 116

12.3 Earthing Systems for 10 TL, 15 TL, 20 TL, 30 TL . . . . . . . . . . . 117

12.4 15 TL and 20 TL Models With Earlier DC Input Panel . . . . . . . . . 118

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Page 7

7

EN

Figures

Figure 2.1.: Solar Inverter System Operation Illustration . . . . . . . . . . . . . 26

Figure 3.1.: Unpacking Process . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 3.2.: The Type Label 10 TL and 15 TL . . . . . . . . . . . . . . . . . . . 30

Figure 3.3.: The Type Label 20 TL and 30 TL . . . . . . . . . . . . . . . . . . . 30

Figure 4.1.: Dimensions of SOLIVIA 10 TL . . . . . . . . . . . . . . . . . . . . 31

Figure 4.2.: Dimensions of SOLIVIA 15 TL / 20 TL / 30 TL . . . . . . . . . . . . 32

Figure 4.3.: 10 TL Inverter Exterior View. . . . . . . . . . . . . . . . . . . . . .33

Figure 4.4.: 15 TL / 20 TL / 30 TL Inverter Exterior View. . . . . . . . . . . . . .34

Figure 4.5.: Grounding Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 4.6.: LCD Display and Control Panel . . . . . . . . . . . . . . . . . . . .35

Figure 4.7.: Input/Output Interface . . . . . . . . . . . . . . . . . . . . . . . . .36

Figure 4.8.: Air Outlet Illustration . . . . . . . . . . . . . . . . . . . . . . . . . 37

Figure 4.9.: Fan Control 10 TL. . . . . . . . . . . . . . . . . . . . . . . . . . .37

Figure 4.10.: Fan Control 15 TL and 20 TL . . . . . . . . . . . . . . . . . . . . . 38

Figure 4.11.: Fan Control 30 TL. . . . . . . . . . . . . . . . . . . . . . . . . . .38

Figure 5.1.: SOLIVIA 10 TL, 15 TL, 20 TL, 30 TL protection classes . . . . . . . 40

Figure 5.2.: Attaching the mounting bracket to the wall . . . . . . . . . . . . . . 41

Figure 5.3.: Correct and Incorrect Installation Illustration . . . . . . . . . . . . . 42

Figure 5.4.: Proper Installation Gap . . . . . . . . . . . . . . . . . . . . . . . . 43

Figure 5.5.: Derating curve for 10 TL, 15 TL, 20 TL and 30 TL . . . . . . . . . . 44

Figure 6.1.: Connection of system if DC inputs are oating . . . . . . . . . . . . 46

Figure 6.2.: Connection of system with Positive Ground or Negative Ground. . .47

Figure 6.3.: AC cable stripping requirements for 10 TL, 15 TL, and 20 TL . . . . 49

Figure 6.4.: AC plug sealing ring for AC connector 10 TL, 15 TL, and 20 TL . . . 50

Figure 6.5.: AC connector 10 TL, 15 TL, and 20 TL . . . . . . . . . . . . . . . . 51

Figure 6.6.: AC cable stripping requirements for 30 TL . . . . . . . . . . . . . . 52

Figure 6.7.: AC connector for 30 TL . . . . . . . . . . . . . . . . . . . . . . . . 53

Figure 6.8.: Input/Output Interface . . . . . . . . . . . . . . . . . . . . . . . . .55

Figure 6.9.: DC Wiring Illustration . . . . . . . . . . . . . . . . . . . . . . . . . 56

Figure 6.10.: Comparison diagram of Balanced Power Input and Unbalanced

Power Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Figure 6.11.: SOLIVIA 10 TL Efciency Curve . . . . . . . . . . . . . . . . . . . 58

Figure 6.12.: SOLIVIA 15 TL Efciency Curve . . . . . . . . . . . . . . . . . . . 59

Page 8

8

Figure 6.13.: SOLIVIA 20 TL Efciency Curve . . . . . . . . . . . . . . . . . . . 59

Figure 6.14.: SOLIVIA 30 TL Efciency Curve . . . . . . . . . . . . . . . . . . . 60

Figure 6.15.: Communication module removal . . . . . . . . . . . . . . . . . . . 61

Figure 6.16.: Multi-inverter connection illustration . . . . . . . . . . . . . . . . . 62

Figure 6.17.: Terminal resistor switch for Multi-inverter Connection . . . . . . . . 63

Figure 6.18.: Dry contact connection . . . . . . . . . . . . . . . . . . . . . . . . 64

Figure 7.1.: Country Settings on initial startup . . . . . . . . . . . . . . . . . . .66

Figure 7.2.: LCD Display and Control Panel . . . . . . . . . . . . . . . . . . . .67

Figure 7.3.: Grid Settings for LVD and MVD . . . . . . . . . . . . . . . . . . . .68

Figure 7.4.: Home page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Figure 7.5.: Main menu page . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Figure 7.6.: Power Meter Pages . . . . . . . . . . . . . . . . . . . . . . . . . .71

Figure 7.7.: Statistics Pages . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Figure 7.8.: Internal Data Flow Chart . . . . . . . . . . . . . . . . . . . . . . . 72

Figure 7.9.: Events Journal Flow Chart . . . . . . . . . . . . . . . . . . . . . . 73

Figure 7.10.: Actual Data Flow Chart . . . . . . . . . . . . . . . . . . . . . . . . 73

Figure 7.11.: Inverter Information Page . . . . . . . . . . . . . . . . . . . . . . .74

Figure 7.12.: Settings Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

Figure 7.13.: General Settings Page . . . . . . . . . . . . . . . . . . . . . . . . 75

Figure 7.14.: Install Settings Page - Installer Mode . . . . . . . . . . . . . . . . .76

Figure 7.15.: Insulation Settings - Installer Mode . . . . . . . . . . . . . . . . . . 76

Figure 7.16.: Active/Reactive Power settings page . . . . . . . . . . . . . . . . .77

Figure 7.17.: Power Limit settings page. . . . . . . . . . . . . . . . . . . . . . .78

Figure 7.18.: Actual Power vs Rated Power . . . . . . . . . . . . . . . . . . . . 79

Figure 7.19.: LVD Curve power vs. frequency . . . . . . . . . . . . . . . . . . . 80

Figure 7.20.: MVD Curve power vs. frequency . . . . . . . . . . . . . . . . . . . 80

Figure 7.21.: Power vs. Frequency . . . . . . . . . . . . . . . . . . . . . . . . . 80

Figure 7.22.: Constant cos φ settings page . . . . . . . . . . . . . . . . . . . . .81

Figure 7.23.: cos φ(P) settings page . . . . . . . . . . . . . . . . . . . . . . . . 82

Figure 7.24.: Constant Reactive Power settings page . . . . . . . . . . . . . . . 83

Figure 7.25.: Q(V) settings page . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Figure 7.26.: Fault Ride Through settings page. . . . . . . . . . . . . . . . . . .85

Figure 7.27.: Active/Reactive Power settings page . . . . . . . . . . . . . . . . .86

Figure 7.28.: Power Limit settings page. . . . . . . . . . . . . . . . . . . . . . .87

Figure 7.29.: Curve power vs. frequency . . . . . . . . . . . . . . . . . . . . . . 88

Figure 7.30.: Power vs. Frequency . . . . . . . . . . . . . . . . . . . . . . . . . 89

Page 9

9

EN

Figure 7.31.: cosφ(P) graph. . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Figure 7.32.: cos φ(P) settings page . . . . . . . . . . . . . . . . . . . . . . . . 91

Figure 7.33.: Constant Reactive Power settings page . . . . . . . . . . . . . . . 92

Figure 7.34.: Q(V) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Figure 7.35.: Q(V) Settings Page . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Figure 7.36.: Low Voltage Fault Ride Through graph . . . . . . . . . . . . . . . .94

Figure 7.37.: Fault Ride Through settings page. . . . . . . . . . . . . . . . . . .95

Figure 7.38.: SONDO Class B curve . . . . . . . . . . . . . . . . . . . . . . . . 96

Figure 7.39.: SONDO Class C curve . . . . . . . . . . . . . . . . . . . . . . . . 96

Figure 7.40.: Q(V) settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Figure 8.1.: Steps of removing the fan bracket from the inverter . . . . . . . . . 99

Figure 8.2.: Removing the fan from the fan bracket . . . . . . . . . . . . . . . 100

Figure 8.3.: Removing the Vent Covers for Cleaning . . . . . . . . . . . . . . 101

Figure 9.1.: Measurements on the Home Page . . . . . . . . . . . . . . . . . 102

Figure 9.2.: Measurements on the Power Meter Pages . . . . . . . . . . . . . 103

Figure 9.3.: Measurements on the Statistics Pages . . . . . . . . . . . . . . . 104

Figure 9.4.: Measurements on the Actual Data Pages . . . . . . . . . . . . . 105

Figure 9.5.: Measurements of Temperature on the Actual Data Pages . . . . . 106

Figure 10.6.: LED Indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Figure 12.1.: Earthing Systems . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Figure 12.2.: DC Input Panel For Models Before Sept. 1, 2012 . . . . . . . . . 118

Figure 12.3.: DC Input Panel For Models After Sept. 1, 2012. . . . . . . . . . . 118

Page 10

10

Tables

Table 3.1.: Packing List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Table 6.1.: Cable cross sections and torques for AC connectors. . . . . . . . .48

Table 6.2.: Permitted earthing systems . . . . . . . . . . . . . . . . . . . . . .49

Table 6.3.: Denition of RS485 pin . . . . . . . . . . . . . . . . . . . . . . . . 62

Table 6.4.: RS485 Data Format. . . . . . . . . . . . . . . . . . . . . . . . . .63

Table 6.5.: EPO pin assignment . . . . . . . . . . . . . . . . . . . . . . . . . 63

Table 7.1.: LED indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Table 7.1.: Recommended settings of protection equipment as per BDEW

Technical Guidelines - June 2008 issue from Table 3.2.3.3 - 2 . . . .69

Table 9.1.: Home Page Measurements and Description . . . . . . . . . . . . 102

Table 9.2.: Power Meter Pages Measurements and Description . . . . . . . . 103

Table 9.3.: Statistics Pages Measurements and Description . . . . . . . . . . 104

Table 9.4.: Actual Data Pages Measurement and Description . . . . . . . . . 106

Table 9.5.: Temperature Measurement and Description . . . . . . . . . . . . 106

Table 10.1.: Troubleshooting Message/Solution Description. . . . . . . . . . . 112

Page 11

11

General Safety Instructions

1. General Safety Instructions

English

DANGER

Risk of death by electrocution

Potentially fatal voltage is applied to the solar inverter during operation. This

potentially fatal voltage is still present for ve minutes after all power sources

have been disconnected.

► Never open the solar inverter.

► Always disconnect the solar inverter from power before installation, open

the DC isolating switch and make sure neither can be accidentally reconnected.

► Wait at least ve minutes until the capacitors have discharged.

DANGER

Risk of death or serious injury from electrocution

Potentially fatal voltage may be applied to the DC connections of the solar

inverter.

► Never disconnect the PV modules when the solar inverter is powered.

► First switch off the grid connection so that the solar inverter cannot feed

energy into the grid.

► Then open the DC isolating switch.

► Make sure the DC connections cannot be accidentally touched.

● The solar inverter can be safely and normally operated if installed and used in accordance

with this manual (see IEC 62109-5.3.3). Delta Energy Systems is not responsible for damage

incurred by failure to observe the installation and operating instructions in this manual. For

this reason, be sure to observe and follow all instructions!

● Installation and commissioning may only be performed by qualied electricians using the

installation and commissioning instructions found in this manual.

● The solar inverter must be disconnected from power and the PV modules before any work on

it can be performed.

● The solar inverter has a high leakage current value. The ground wire must be connected

before commissioning.

● Do not remove any warning signs that the manufacturer has installed on the solar inverter.

● Improper handling of the solar inverter my result in physical injury and damage to property.

For this reason, observe and follow all general safety instructions and warnings.

● The solar inverter contains no components that must be maintained or repaired by the opera-

tor or installer. All repairs must be performed by Delta Energy Systems. Opening the cover

will void the warranty.

● Do not disconnect any cables when the solar inverter is powered due to risk of a fault arc.

Page 12

12

General Safety Instructions

● To prevent lightning strikes, follow the relevant regulations applicable in your country.

● The surface of the solar inverter can become very hot.

● The solar inverter is very heavy. The solar inverter must be lifted and carried by at least two

people.

● Only devices in compliance with SELV (EN 69050) may be connected to the RS485 and USB

interfaces.

● All connections must be sufciently insulated in order to comply with the IP65 protection rat-

ing. Unused connections must be closed by placing cover caps on the solar inverter.

Deutsch

Allgemeine Sicherheitsanweisungen

GEFAHR

Lebensgefahr durch gefährliche Spannung

Während des Betriebs liegt im Solar Wechselrichter eine gefährliche Spannung

an. Diese gefährliche Spannung liegt noch 5 Minuten lang nach dem Trennen

aller Stromquellen an.

► Öffnen Sie niemals den Solar Wechselrichter.

► Trennen Sie vor Installationsarbeiten den Solar Wechselrichter immer

vom Netz, öffnen Sie den DC-Trennschalter und sichern Sie beides gegen

Wiedereinschalten.

► Warten Sie mindestens 5 Minuten, bis die Kondensatoren entladen sind.

GEFAHR

Lebensgefahr oder Gefahr schwerer Verletzungen durch gefährliche

Spannung

An den DC-Anschlüssen des Solar Wechselrichters können gefährliche Spannungen anliegen.

► Trennen Sie die PV-Module niemals ab, wenn sich der Solar Wechselrichter

unter Last bendet.

► Schalten Sie zunächst das Netz ab, sodass der Solar Wechselrichter keine

weitere Energie einspeisen kann.

► Öffnen Sie dann den DC-Trennschalter.

► Sichern Sie die DC-Anschlüsse gegen Berührung ab.

● Der Solar Wechselrichter kann nur sicher und normal betrieben werden, wenn Installation

und Betrieb nach Maßgabe dieses Handbuchs erfolgen (siehe IEC 62109-5.3.3). Delta Energy Systems ist für Schäden, die durch Nicht-Einhaltung der Installations- und Betriebsanweisungen in diesem Handbuch entstehen, nicht verantwortlich. Beachten und befolgen Sie

deshalb sämtliche Anweisungen in diesem Handbuch!

Page 13

13

General Safety Instructions

● Installations- und Inbetriebnahmearbeiten dürfen nur von qualizierten Elektrotechnikern und

anhand der in diesem Handbuch beschriebenen Installations- und Inbetriebnahmeanweisungen durchgeführt werden.

● Bevor am Solar Wechselrichter Arbeiten ausgeführt werden, muss der Solar Wechselrichter

vom Netz und von den PV-Modulen getrennt werden.

● Der Solar Wechselrichter weist einen hohen Ableitstrom auf. Der Erdungsleiter muss vor der

Inbetriebnahme angeschlossen werden.

● Entfernen Sie keine Warnschilder, die vom Hersteller am Solar Wechselrichter angebracht

wurden.

● Unsachgemäße Umgang mit dem Solar Wechselrichter kann zu Körperverletzungen und

Sachschäden führen. Beachten und befolgen Sie deshalb alle in diesen Handbuch angegebenen allgemeinen Sicherheitshinweise und handlungsbezogenen Warnhinweise.

● Der Solar Wechselrichter enthält keine Komponenten, die vom Bediener oder Installateur zu

warten oder zu reparieren sind. Sämtliche Reparaturen müssen von Delta Energy Systems

durchgeführt werden. Durch Öffnen der Abdeckung erlischt die Garantie.

● Ziehen Sie keine Kabel ab, wenn der Solar Wechselrichter unter Belastung steht, da die

Gefahr eines Störlichtbogens besteht.

● Um Blitzeinschlägen vorzubeugen, befolgen Sie die in Ihrem Land geltenden Regelungen

zum Schutz vor Blitzeinschlägen.

● Die Oberäche des Solar Wechselrichters kann sehr heiß werden.

● Der Solar Wechselrichter ist schwer. Der Solar Wechselrichter muss immer von zwei Perso-

nen angehoben und getragen werden.

● An die RS485 und die USB-Schnittstelle dürfen nur Geräte nach SELV (EN 69050) ange-

schlossen werden.

● Zur Gewährung des Schutzgrads IP65 müssen alle Anschlüsse ausreichend abgedichtet

werden. Nicht genutzte Anschlüsse müssen mit den am Solar Wechselrichter angebrachten

Abdeckkappen verschlossen werden.

Italiano

Indicazioni di sicurezza generali

PERICOLO

Pericolo di morte dovuto a tensione pericolosa

Durante il funzionamento, nell’inverter solare si rileva una tensione pericolosa.

Anche dopo la separazione da tutte le fonti di corrente, questa tensione pericolosa è presente per ancora 5 minuti.

► Non aprire mai l’inverter solare.

► Prima delle operazioni di installazione scollegare sempre l’inverter solare

dalla rete, aprire il sezionatore CC e mettere in sicurezza entrambi i compo-

nenti afnché non possano essere reinseriti accidentalmente.

► Attendere almeno 5 minuti perché i condensatori possano scaricarsi.

Page 14

14

General Safety Instructions

PERICOLO

Pericolo di morte o pericolo di lesioni gravi dovuto a tensione pericolosa

Nei collegamenti CC dell’inverter solare possono formarsi tensioni pericolose.

► Non separare mai i moduli FV quando l’inverter solare è sotto carico.

► Scollegare prima la rete in modo che l’inverter solare non possa più immet-

tere energia.

► Aprire poi il sezionatore CC.

► Proteggere i collegamenti CC per evitare il contatto accidentale con essi.

● Per garantirne il funzionamento normale e sicuro, installare e usare l’inverter attenendosi alle

condizioni e misure indicate nel presente manuale (vedi IEC 62109-5.3.3). Delta Energy Systems declina ogni responsabilità per eventuali danni derivati dall’inosservanza delle istruzioni

per l’installazione e l’uso contenute nel presente manuale. Attenersi perciò scrupolosamente

a tutte le istruzioni riportate nel presente manuale!

● I lavori di installazione e di messa in funzione devono essere eseguiti soltanto da elettrotec-

nici qualicati e attenendosi alle relative istruzioni riportate nel presente manuale.

● Prima di effettuare dei lavori sull’inverter solare lo si deve scollegare dalla rete e dai moduli

FV.

● L’inverter solare ha un’elevata corrente di dispersione. Il conduttore di terra deve essere al-

lacciato prima della messa in funzione.

● Non rimuovere nessun cartello di pericolo apposto dal costruttore dell’inverter solare.

● Se si maneggia l’inverter solare in modo scorretto, si rischiano lesioni alle persone e danni

materiali! Perciò attenersi scrupolosamente a tutte le avvertenze di sicurezza generali e alle

avvertenze di pericolo relative al maneggio dell’apparecchio riportate in questo manuale.

● Per nessuno dei componenti dell’inverter solare è prevista la manutenzione o la riparazione

da parte dell’operatore o dell’installatore. Tutte le riparazioni devono essere eseguite da

Delta Energy Systems. L’apertura del coperchio provoca l’annullamento della garanzia.

● Non staccare mai nessun cavo quando l’inverter solare è sotto carico, altrimenti potrebbe

generarsi un arco voltaico anomalo.

● Per evitare danni da fulmini attenersi ai regolamenti vigenti in proposito nel proprio Paese.

● La supercie dell’inverter solare può surriscaldarsi enormemente.

● L’inverter solare è pesante. Per questo motivo deve essere sollevato e trasportato sempre da

due persone.

● Alle interfacce RS485 e USB è consentito allacciare soltanto apparecchiature SELV

(EN 69050).

● Per ottenere il grado di protezione IP65, tutti i collegamenti devono essere a tenuta stagna.

I collegamenti non utilizzati devono essere tappati con le calotte di copertura applicate

sull’inverter solare.

Page 15

15

General Safety Instructions

Français

Consignes générales de sécurité

DANGER

Danger de mort dû à une tension dangereuse

Durant le fonctionnement, l’onduleur photovoltaïque est sous tension. Cette ten-

sion dangereuse est encore présente 5 minutes après avoir débranché toutes

les sources de courant.

► N’ouvrez jamais l’onduleur photovoltaïque.

► Avant tous travaux d’installation, débranchez l’onduleur photovoltaïque du

réseau, coupez l’interrupteur CC et sécurisez tout an d’éviter toute remise

en service accidentelle.

► Attendez au moins 5 minutes que les condensateurs se déchargent.

DANGER

Danger de mort ou risque de blessures graves liés à une tension dangereuse

Des tensions dangereuses peuvent être présentes au niveau des connexions

CC de l’onduleur photovoltaïque.

► Ne débranchez jamais les modules PV lorsque l’onduleur photovoltaïque

est sous charge.

► Coupez tout d’abord le réseau an que l’onduleur photovoltaïque ne puisse

plus injecter d’énergie.

► Coupez ensuite l’interrupteur CC.

► Protégez les connexions CC de tout contact.

● L’onduleur photovoltaïque ne peut fonctionner normalement et correctement que si son ins-

tallation et son exploitation ont lieu conformément au présent manuel (voir CEI 62109-5.3.3).

Delta Energy Systems ne saurait être tenu pour responsable des dommages causés par le

non-respect des consignes d’installation et de fonctionnement mentionnées dans le présent

manuel. Pour cette raison, observez et suivez toutes les consignes de ce manuel !

● Les travaux d’installation et de mise en service ne peuvent être réalisés que par des électri-

ciens qualiés et dans le respect des consignes d’installation et de mise en service décrites

dans ce manuel.

● Avant d’effectuer des travaux sur l’onduleur photovoltaïque, celui-ci doit être débranché du

réseau et des modules photovoltaïques.

● L’onduleur photovoltaïque présente un fort courant de fuite. Le conducteur de terre doit être

raccordé avant la mise en service.

● Ne retirez aucun panneau d’avertissement ayant été installé sur l’onduleur photovoltaïque

par le fabricant.

● Toute utilisation inappropriée de l’onduleur photovoltaïque peut entraîner des dommages cor-

Page 16

16

General Safety Instructions

porels et matériels. Respectez et suivez de ce fait à la lettre toutes les consignes générales

de sécurité et les avertissements relatifs aux différentes opérations.

● L’onduleur photovoltaïque ne contient pas de composants qui doivent être entretenus ou réparés par l’utilisateur ou l’installateur. Toutes les réparations doivent être réalisées par Delta

Energy Systems. L’ouverture du couvercle entraîne l’annulation de la garantie.

● Ne débranchez aucun câble quand l’onduleur photovoltaïque est sous charge en raison du

risque d’arc électrique.

● An de prévenir les décharges de foudre, respectez les réglementations en vigueur dans

votre pays.

● La surface de l’onduleur photovoltaïque peut être très chaude.

● L’onduleur photovoltaïque est lourd. L’onduleur photovoltaïque doit être soulevé et porté par

au moins deux personnes.

● Seuls les appareils selon SELV (EN 69050) peuvent être raccordés aux interfaces RS485 et

USB.

● An de garantir la protection IP65, toutes les connexions doivent être sufsamment étanchéi-

ées. Les connexions non utilisées doivent être obturées avec les capuchons installés sur

l’onduleur photovoltaïque.

Español

Instrucciones de seguridad generales

PELIGRO

Peligro de muerte por tensión peligrosa

Durante el servicio puede generarse una tensión peligrosa en el inversor solar.

Esta tensión peligrosa sigue presente incluso 5 minutos después de desconectar todas las fuentes de alimentación.

► No abrir nunca el inversor solar.

► Antes de realizar los trabajos de instalación, separar siempre el inversor

solar de la red, abrir el seccionador de CC y asegurar ambos contra una

nueva posible conexión.

► Esperar como mínimo 5 minutos hasta que se hayan descargado los con-

densadores.

Page 17

17

General Safety Instructions

PELIGRO

Peligro de muerte o de lesiones graves por tensión peligrosa

Las conexiones de CC del inversor solar presentan riesgo por tensiones peligrosas.

► No separar nunca los módulos FV con el inversor solar bajo carga.

► Desconectar primero la red eléctrica de forma que el inversor solar no

pueda seguir suministrando energía.

► Abrir entonces el seccionador de CC.

► Asegurar las conexiones CC contra el contacto.

● El servicio seguro y normal del inversor solar está garantizado únicamente si tanto la

instalación como el servicio se llevan a cabo de conformidad con las indicaciones conteni-

das en el presente manual (véase la norma IEC 62109-5.3.3). Delta Energy Systems no se

responsabiliza por los daños derivados del incumplimiento de las instrucciones de servicio e

instalación contenidas en el presente manual. Se debe prestar atención y respetar la totalidad de las instrucciones del presente manual.

● Los trabajos de instalación y puesta en marcha deben realizarlos solamente técnicos electri-

cistas competentes siguiendo las instrucciones de instalación y puesta en marcha descritas

en este manual.

● Antes de realizar trabajos en el inversor solar, se debe separar el inversor solar de la red y

de los módulos FV.

● El inversor solar presenta un valor de corriente de fuga elevado. El conductor de puesta a

tierra debe conectarse antes de iniciar el servicio.

● No retirar ni eliminar las placas de advertencia colocadas por el fabricante en el inversor

solar.

● Cualquier manipulación inadecuada del inversor solar puede provocar lesiones y daños

materiales. Por eso se debe respetar la totalidad de los avisos de seguridad generales y de

las advertencias relativas al funcionamiento que se indican en el presente manual.

● El inversor solar no contiene componentes sometidos a mantenimiento o a la reparación por

parte del instalador o del usuario. Todas las reparaciones deberán ser ejecutadas por Delta

Energy Systems. La apertura de la cubierta implica la anulación de la garantía.

● No retirar ningún cable cuando el inversor solar esté sometido a cargas debido al peligro de

que se genere un arco voltaico parásito.

● Para evitar posibles descargas eléctricas deberá respetarse la normativa nacional vigente

relativa a la protección contra descargas eléctricas.

● La supercie del inversor solar puede alcanzar temperaturas muy elevadas.

● El inversor solar es pesado. El inversor solar debe levantarse y moverse siempre entre dos

personas.

● En las interfaces para RS485 y USB deben conectarse exclusivamente unidades con una

muy baja tensión de seguridad (norma EN 69050).

● Para garantizar el tipo de protección IP65 se deben aislar ecientemente todas las conexiones. Las conexiones no usadas se deben cerrar con las tapaderas jadas en el inversor

solar.

Page 18

18

General Safety Instructions

Nederlandse

Algemene veiligheidsinstructies

GEVAAR

Levensgevaar door gevaarlijke spanning

Tijdens het bedrijf staat de omvormer voor zonne-energie onder gevaarlijke

spanning. Deze gevaarlijke spanning blijft nog 5 minuten na het loskoppelen

van alle stroombronnen aanwezig.

► Open de omvormer voor zonne-energie nooit.

► Koppel de omvormer voor zonne-energie vóór installatiewerkzaamheden

altijd los van het net, open de DC-scheidingsschakelaar en beveilig beide

tegen inschakelen.

► Wacht minstens 5 minuten tot de condensatoren ontladen zijn.

GEVAAR

Levensgevaar of gevaar voor ernstig letsel door gevaarlijke spanning

Op de DC-aansluitingen van de omvormer voor zonne-energie kan gevaarlijke

spanning staan.

► Koppel de PV-modules nooit los als de omvormer voor zonne-energie zich

onder belasting bevindt.

► Schakel eerst het net uit, zodat de omvormer voor zonne-energie geen

energie meer kan leveren.

► Open dan de DC-scheidingsschakelaar.

► Beveilig de DC-aansluitingen tegen aanraking.

● De omvormer voor zonne-energie kan alleen veilig en normaal worden gebruikt wanneer

de installatie en het gebruik volgens dit handboek plaatsvinden (zie IEC 62109-5.3.3). Delta

Energy Systems is niet verantwoordelijk voor schade die ontstaat door het niet in acht nemen

van de installatie- en gebruiksvoorschriften in dit handboek. Neem daarom alle instructies in

dit handboek in acht en volg ze op!

● Installatie- en inbedrijfstellingswerkzaamheden mogen alleen door gekwaliceerde elek-

triciëns worden uitgevoerd aan de hand van de in dit handboek beschreven installatie- en

inbedrijfstellingsinstructies.

● Voordat er werkzaamheden aan de omvormer voor zonne-energie worden uitgevoerd, moet

de omvormer voor zonne-energie worden losgekoppeld van het net en de PV-modules.

● De omvormer voor zonne-energie vertoont een hoge lekstroom. De aardingsdraad moet

vóór de inbedrijfstelling worden aangesloten.

● Verwijder geen waarschuwingsbordjes die door de fabrikant op de omvormer voor zonne-

energie zijn aangebracht.

● Ondeskundige omgang met de omvormer voor zonne-energie kan lichamelijk letsel en

materiële schade veroorzaken. Neem daarom alle algemene veiligheidsinstructies en alle

Page 19

19

General Safety Instructions

waarschuwingen met betrekking tot handelingen in dit handboek in acht en volg ze op.

● De omvormer voor zonne-energie bevat geen componenten die door de gebruiker of installa-

teur onderhouden of gerepareerd moeten worden. Alle reparaties moeten door Delta Energy

Systems worden uitgevoerd. Indien de afdekking wordt geopend, vervalt de garantie.

● Koppel geen kabels los wanneer de omvormer voor zonne-energie onder belasting staat,

aangezien er gevaar voor een vlamboog bestaat.

● Neem om blikseminslag te voorkomen de in uw land geldende regelingen ter voorkoming van

blikseminslag in acht.

● Het oppervlak van de omvormer voor zonne-energie kan zeer heet worden.

● De omvormer voor zonne-energie is zwaar. De omvormer moet altijd door twee personen

worden getild en gedragen.

● Op de RS485- en de USB-interface mogen alleen apparaten worden aangesloten die vol-

doen aan SELV (EN 69050).

● Om de IP65-bescherming te waarborgen, moeten alle aansluitingen voldoende worden afge-

dicht. Niet gebruikte aansluitingen moeten worden afgesloten met de op de omvormer voor

zonne-energie aangebrachte afdekkappen.

Dansk

Generelle sikkerhedsanvisninger

FARE

Livsfare pga. farlig spænding

Under driften er der farlig spænding i solcelleinverteren. Denne farlige spæn-

ding ndes stadig 5 minutter efter, at alle strømkilder er koblet fra.

► Åbn aldrig solcelleinverteren.

► Afbryd solcelleinverteren altid fra nettet inden installationsarbejder, åbn DC-

skilleafbryderen, og sørg for at sikre begge mod genindkobling.

► Vent mindst 5 minutter, indtil kondensatorerne er aadet.

FARE

Livsfare eller fare for alvorlige kvæstelser på grund af farlig spænding

Der kan være farlig spænding på solcelleinverterens DC-tilslutninger.

► Afmonter aldrig fotovoltaikmodulerne, mens der er strøm på solcelleinver-

teren.

► Frakobl først nettet, så solcelleinverteren ikke kan levere yderligere energi

til nettet.

► Åbn derefter DC-skilleafbryderen.

► Sørg for at sikre DC-tilslutningerne mod berøring.

Page 20

20

General Safety Instructions

● Solcelleinverteren kan kun betjenes sikkert og korrekt, hvis den er installeret og anvendes i

overensstemmelse med denne håndbog (se IEC 62109-5.3.3). Delta Energy Systems hæfter

ikke for skader, der opstår pga. manglende overholdelse af installations- og driftsanvisningerne i denne håndbog. Overhold og følg derfor samtlige anvisninger i denne håndbog!

● Installations- og idrifttagningsarbejderne må kun udføres af kvalicerende elektrikere og i

overensstemmelse med de installations- og idrifttagningsanvisninger, der ndes i denne

håndbog.

● Inden der udføres arbejder på solcelleinverteren, skal solcelleinverteren afbrydes fra nettet

og fotovoltaikmodulerne.

● Solcelleinverteren afgiver en høj lækstrøm. Jordlederen skal tilsluttes inden idrifttagningen.

● Fjern ikke advarselskilte, som er placeret på solcelleinverteren af producenten.

● Ukorrekt håndtering af solcelleinverteren kan medføre kvæstelser og materieller skader!

Overhold og følg derfor alle angivne generelle sikkerhedshenvisninger og handlingsrelevante

advarselshenvisninger, der ndes i denne håndbog.

● Solcelleinverteren indeholder ingen komponenter, der skal vedligeholdes eller repareres

af brugeren eller montøren. Samtlige reparationer skal udføres af Delta Energy Systems.

Garantien ophører, hvis dækslet åbnes.

● Træk ikke kablerne ud, mens solcelleinverteren er tilsluttet strømmen, da der er fare for

lysbuefejl.

● Overhold de nationale bestemmelser for at beskytte mod lynnedslag.

● Solcelleinverterens overade kan blive meget varm.

● Solcelleinverteren er tung. Solcelleinverteren skal altid løftes og bæres af mindst to personer.

● Kun apparater, der er i overensstemmelse med SELV-standarden (EN 69050), må tilsluttes til

RS485 og USB-interfacet.

● For at sikre kapslingsklassen IP65 skal alle tilslutninger være tilstrækkeligt tætnet. Tilslutnin-

ger, der ikke er i brug, skal lukkes med de afdækningshætter, der er anbragt på solcelleinverteren.

Slovenský

Počas prevádzky je solárny invertor pod nebezpečným napätím. Toto

nebezpečné napätie zotrváva ešte 5 minút po odpojení všetkých zdrojov napä-

tia.

► Solárny invertor nikdy neotvárajte.

► Pred inštalačnými prácami vždy odpojte solárny invertor od siete, rozpojte

odpojovač DC a obe zariadenia zabezpečte proti opätovnému zapnutiu.

► Počkajte minimálne 5 minút, kým sa kondenzátory nevybijú.

Page 21

21

General Safety Instructions

Na DC prípojkách solárneho invertora môžu byť nebezpečné napätia.

► Nikdy neodpájajte PV-moduly, keď je solárny invertor pod zaťažením.

► Najprv odpojte sieť, aby solárny invertor nemohol dodávať žiadnu ďalšiu

energiu.

► Potom rozpojte odpojovač DC.

► Zabezpečte DC prípojky pred dotykmi.

● Solárny invertor možno bezpečne a normálne prevádzkovať iba vtedy, ak inštalácia bola

vykonaná resp. prevádzka je vykonávaná v súlade s touto príručkou (pozri IEC 62109-5.3.3).

Delta Energy Systems nezodpovedá za škody, ktoré vzniknú v dôsledku nedodržiavania

inštalačných a prevádzkových pokynov uvedených v tejto príručke. Z tohto dôvodu

dodržiavajte a dbajte na všetky pokyny uvedené v tejto príručke!

● Inštalačné práce a práce súvisiace s uvedením do prevádzky smú vykonávať iba kvali-

kovaní elektrotechnici, a to pri dodržiavaní inštalačných pokynov a pokynov týkajúcich sa

uvedenia do prevádzky, ktoré sú uvedené v tejto príručke.

● Pred vykonaním prác na solárnom invertore sa tento musí odpojiť od siete a od PV modulov.

● Solárny invertor vykazuje vysoký zvodový prúd. Uzemňovací vodič sa musí pripojiť pred

uvedením do prevádzky.

● Neodstraňujte žiadne výstražné štítky, ktoré na solárny invertor umiestnil výrobca.

● Neodborná manipulácia so solárnym invertorom môže viesť k poraneniam a vecným

škodám. Z tohto dôvodu rešpektujte a dodržiavajte všetky všeobecné bezpečnostné pokyny

a výstražné pokyny týkajúce sa manipulácie, ktoré sú uvedené v tejto príručke.

● Solárny invertor neobsahuje žiadne komponenty, na ktorých by obsluha alebo inštalatéri

museli vykonávať údržbu alebo opravy. Všetky opravy musia vykonávať pracovníci z Delta

Energy Systems. Otvorením krytu zaniká záruka.

● Z dôvodu nebezpečenstva vzniku elektrického oblúka nevyťahujte počas zaťaženia solárne-

ho invertora žiadne káble.

● Pre elimináciu zásahov bleskom dodržiavajte predpisy platné vo Vašej krajine, ktoré sa týkajú

ochrany pred zásahmi bleskom.

● Povrch solárneho invertora sa môže výrazne zahriať.

● Solárny invertor je ťažký. Solárny invertor musia vždy nadvihovať a prenášať minimálne dve

osoby.

● Na rozhrania RS485 a USB sa smú pripojiť len zariadenia, ktoré sú v súlade so SELV

(EN 69050).

● Pre zaručenie stupňa ochrany IP65 musia byť všetky prípojky dostatočne utesnené.

Nepoužívané prípojky sa musia uzavrieť pomocou krycích uzáverov, ktoré sa nachádzajú na

solárnom invertore.

Page 22

22

General Safety Instructions

V solárním střídači je během provozu nebezpečné napětí. Toto nebezpečné

napětí trvá ještě 5 minut po odpojení od všech elektrických zdrojů.

► Solární střídač v žádném případě a za žádných okolností neotvírejte.

► Před instalací je solární střídač nutno odpojit od sítě, odpojit jistič DC a

obojí zajistit proti opětovnému zapnutí.

► Počkejte minimálně 5 minut, dokud se nevybijí kondenzátory.

DC přípojky solárního střídače mohou být pod nebezpečným napětím.

► Jestliže je solární střídač pod zátěží resp. proudem, v žádném případě

neodpojujte FV moduly.

► Nejprve odpojte síť, tak aby solární střídač nemohl dodávat žádnou další

energii.

► Poté odpojte DC jistič.

► DC přípojky zajistěte tak, aby se jich nebylo možno dotknout.

● Solární střídač lze bezpečně a normálně provozovat jen tehdy, když jeho instalaci a provoz

provedete v souladu s touto příručkou (viz IEC 62109-5.3.3). Společnost Delta Energy

Systems nezodpovídá za škody, ke kterým dojde v důsledku nedodržení instalačních a

provozních pokynů uvedených v této příručce. Proto dbejte všech pokynů v této příručce a

dodržujte je!

● Práce v rámci instalace a uvedení do provozu je dovoleno provádět jen kvalikovaným

elektrotechnikům, a to v souladu s pokyny pro instalaci a uvedení do provozu popsanými v

této příručce.

● Na solárním střídači je dovoleno pracovat jen po odpojení od sítě a FV modulů.

● Solární střídač vykazuje vysoký svodový proud. Uzemňovací vodič se

uvedením do provozu.

● Neodstraňujte žádné výstražné štítky, které výrobce na solární střídač namontoval.

● Neodborné zacházení se solárním střídačem může způsobit tělesná poranění a věcné škody.

Proto dbejte všech všeobecných bezpečnostních pokynů a praktických varování v této

příručce a dodržujte je.

● Solární střídač neobsahuje žádné součásti, které by vyžadovaly údržbářské zásahy nebo

opravy ze strany obsluhy či instalatéra. Veškeré opravy musí být prováděny společností

Page 23

23

General Safety Instructions

Delta Energy Systems. Otevřením krytu ztrácíte nárok na plnění ze záruky.

● Kabely neodpojujte, dokud je solární střídač pod zatížením, protože hrozí nebezpečí rušivého

světelného oblouku.

● Zajistěte prevenci proti zásahu bleskem, a to dodržováním ustanovení platných ve vaší zemi.

● Povrch solárního střídače může být velmi horký.

● Solární střídač je těžký. Solární střídač je nutno zvedat a přenášet vždy ve dvou.

● K rozhraní RS485 a rozhraní USB je dovoleno připojovat jen přístroje dle SELV (EN 69050).

● Za účelem zajištění stupně ochrany IP65 je nutno všechny přípojky dostatečně utěsnit.

Nepoužívané přípojky je nutno zavřít krytkami upevněnými na solárním střídači.

Page 24

24

General Information

2. General Information

2.1 About this Manual

This manual provides the detail information for the specication, installation procedures and all

related functional settings of the solar inverter model - SOLIVIA 10EUT4TL / SOLIVIA 15EUG4TL

/ SOLIVIA 20EUG4TL / SOLIVIA 30EUT4TL. Installation technicians must be well-trained and

qualied for installing solar system and must follow all the safety instruction and installation procedures.

2.2 Safety Symbols & Instruction

CAUTION!

CAUTION!

Machine and equipment damage may occur if

this hazardous situation is not avoided

WARNING!

WARNING!

Death and serious injury may occur if this

hazardous situation is not avoided

DANGER!

DANGER!

Death and serious injury will occur if this hazardous situation is not avoided

WARNING! BURN HAZARD

The enclosure temperature may exceed 70° C

while inverter is in operation. A dangerous burn

hazard is present in this situation. Please do

not touch!

2.3 Validity

This user manual describes the installation procedures, maintenance, technical data and safety

instruction of the following solar inverter models under the DELTA brand.

Model Software:: DSP ver. Red. ver. Comm. ver.

SOLIVIA 10EUT4TL 1.83 1.36 1.56

SOLIVIA 15EUG4TL 1.83 1.36 1.56

SOLIVIA 20EUG4TL 1.83 1.36 1.56

SOLIVIA 30EUT4TL 1.83 1.36 1.56

The software version of your inverter is found on the inverter display. Please nd more information

in section 7.35 “Inverter Information.”

Page 25

25

EN

General Information

2.4 Product Description

The SOLIVIA 10 TL / 15 TL / 20 TL / 30 TL are 3 phase grid-tied solar inverters with reactive power

control. These devices convert direct current (DC) electricity from photovoltaic power collected

from PV arrays into 3 phase alternating current (AC) to feed the excess capacity back to the local

mains electrical grid. Using cutting-edge technology allows a wide voltage input range (250~1000

V) and high performance efciency based on a user-friendly operation design. In addition, special

DSP (Digital Signal Processor) design decreases the circuit complication and electronic components. Please note that this device does not support off-grid function. The following are the key

features of SOLIVIA 10 / 15 / 20 / 30 TL 3 phase grid-tied solar inverters.

Key Features

● Power Rating: 10 / 15 / 20 / 30 kVA

● Power Balancing (33/67) in asymmetrical dc loading situations

● 3-Phase (3-Phase + N + PE), Grid-tie, Transformerless solar inverter

● Maximum efciency: > 98.0 %

● Europe efciency: > 97.8 %

● Reactive power capability (Cap 0.80 - Ind 0.80)

● Low input current harmonic distortion (THD < 3%) @ full load

● 2 MPP Trackers

● Record up to 30 event logs.

● 5” LCD display

● EPO

The 10 TL / 15TL / 20 TL / 30 TL inverters comply with the latest country regulations and standards. Please see chapter 7 - Operating the PV Inverter for the complete list of compliance

standards.

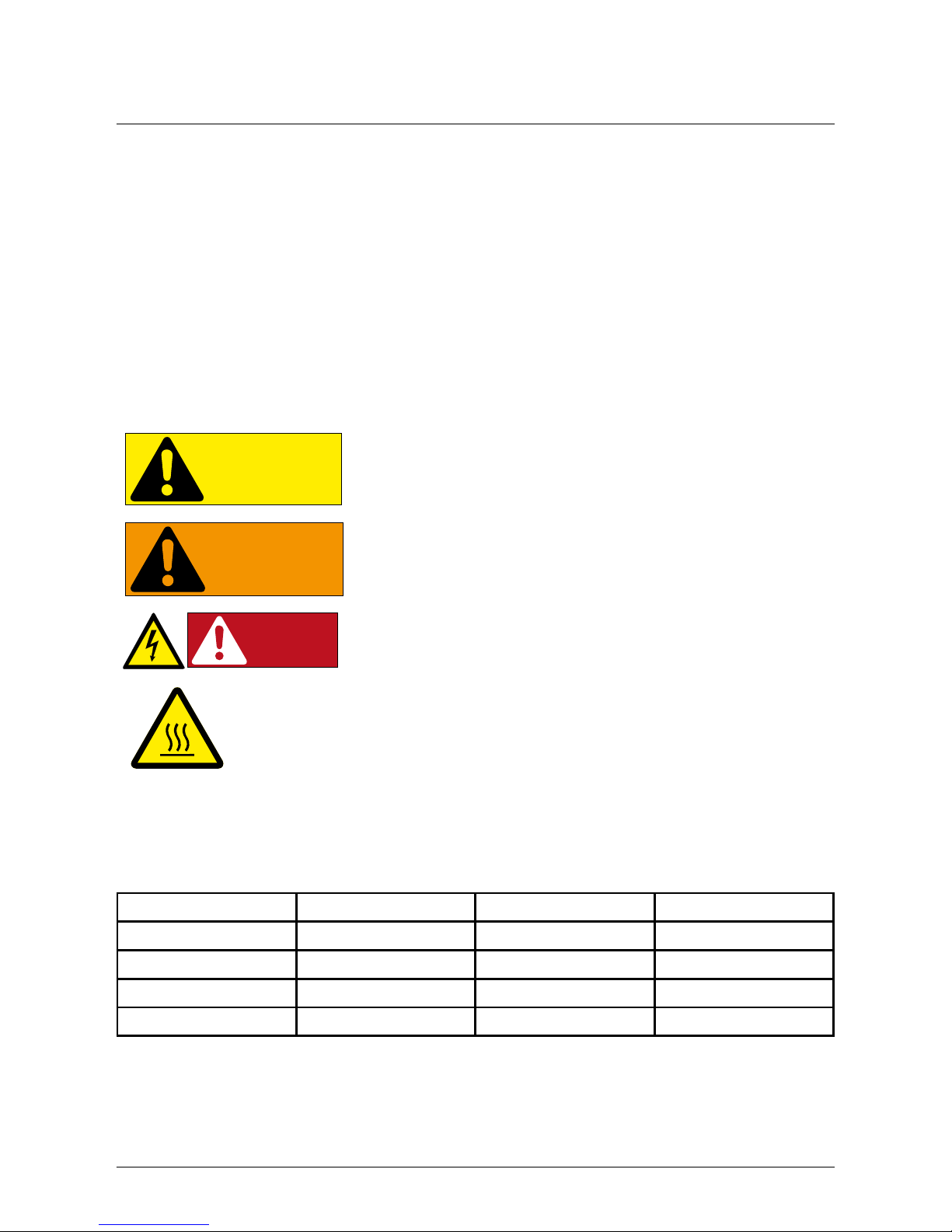

2.5 Application & Intended Use

The operation of the solar inverter is as shown as in the gure 2.1. In order to save energy and

electricity, solar inverters convert the DC input power supplied from the PV array into three-phase

AC output power to the grid.

The solar inverter may be used in the following countries as shown:

Page 26

26

General Information

NOTE

The country list may change due to ongoing certication processes. If you

have any questions, please contact the Delta Support Team.

Countries supported*: Belgium, France, Italy, Netherlands, Spain, Greece,

Germany, Czech Republic, Slovakia, Slovenia, Portugal, Bulgaria, Roma-

nia, United Kingdom, United Kingdom (240 V), Australia, French Islands,

Denmark.

Language supported: English, Italian, French, German, Dutch, & Spanish

*Please note at the time of printing, all countries shown may not necessarily be available for 30

TL model, but are expected to be completed within Q1 2013. Please check with the Delta support

team for questions about countries approved.

The solar power inverter may only be used as intended.

Proper use of the solar power inverter meets the following criteria:

● Use in stationary PV systems connected to the local power grid for converting the direct cur-

rent in the PV system to alternating current and feeding it into the grid

● Use within the specied power range (see Sec. 12.1 - Technical Specications) and under

the specied ambient conditions (indoor area or covered outdoor area with up to IP65)

Any of the following uses of the solar power inverter is considered improper:

● Isolated operation: The solar power inverter has anti-islanding and other monitoring features.

● Use in mobile PV systems.

2.6 Additional Information

For more detailed information about the SOLIVIA 10 TL, 15 TL, 20 TL, and 30 TL or other related

product information, please visit the website at http://www.solar-inverter.com for more support.

Solar Inverter

PV Array

Electrical Grid

3-Phase, N, PE

Surge arrestor

DC Distribution

Box

AC Distribution

Box

Fuse

DC Switch

Surge arrestor

AC breaker

3PH

Figure 2.1.: Solar Inverter System Operation Illustration

Page 27

27

EN

General Information

2.7 Monitoring

The SOLIVIA TL inverters include a display for monitoring performance on location. Remote monitoring is also an option. The 10 TL, 15 TL, 20 TL, and 30 TL with Solar Log and Meteocontrol as

well as Delta’s own monitoring solution, SOLIVIA Monitor G2. Please contact your Delta supplier

for more information on these remote monitoring options.

SOLIVIA Monitor G2 ensures reliable operation and maximum performance of PV systems. The

system is compatible with all SOLIVIA String Inverter models from Delta. The all-in-one solution

is made up of the SOLIVIA GW M1 G2, a gateway that acts as an interface, and an online portal

that is available to users at http://monitoring.solar-inverter.com. Both real-time data reports and

historical data statistics can be generated and exported as a CSV or Excel le. Automated alert

messages notify the operator and ensure that the solar investment pays off. The installer also has

the opportunity to manage its customers’ systems in order to gain a quick overview of the system

status at all times. What’s more, the user receives information on the weather and also the latest

news via the integrated news feed.

For more information about technical features and functions, please refer to the company website

at the following link: http://www.solar-inverter.com/eu/en/SOLIVIA-monitoring-system.htm.

Page 28

28

Preparing for Installation

3. Preparing for Installation

3.1 Instruction before Installing

Due to the variety of user installation environments, reading the manual thoroughly before installation is strongly recommended. All the installation and start-up procedures must be undertaken by

a professional and well-trained technician.

3.2 Checking the Package

There might be some unpredictable situations during transportation. Please check if there is any

damage to the cardboard carton. After opening the package, please check both the outer case

and inner part of this inverter as below.

1. Check the right side on the inverter case to ensure the model number and the specication is

the same with the model you have purchased.

2. Check if there are any loose components.

3. Check if all the accessories are in the package, the standard accessories are listed in the

below table:

Item Quantity Description

10 TL, 15 TL, 20 TL, or 30 TL

Solar Inverter

1 10 kVA,15 kVA, 20 kVA, or 30 kVA solar inverter

User Manual 1 User installation and operation instructions

AC Plug 1 Connector for AC connection

Mounting Bracket 1 Bracket to install the inverter on the wall

Table 3.1.: Packing List

NOTE

When there is outer or inner damage on the inverter or there is any missing

or damaged standard accessories, please contact your inverter supplier for

support.

Page 29

29

EN

Preparing for Installation

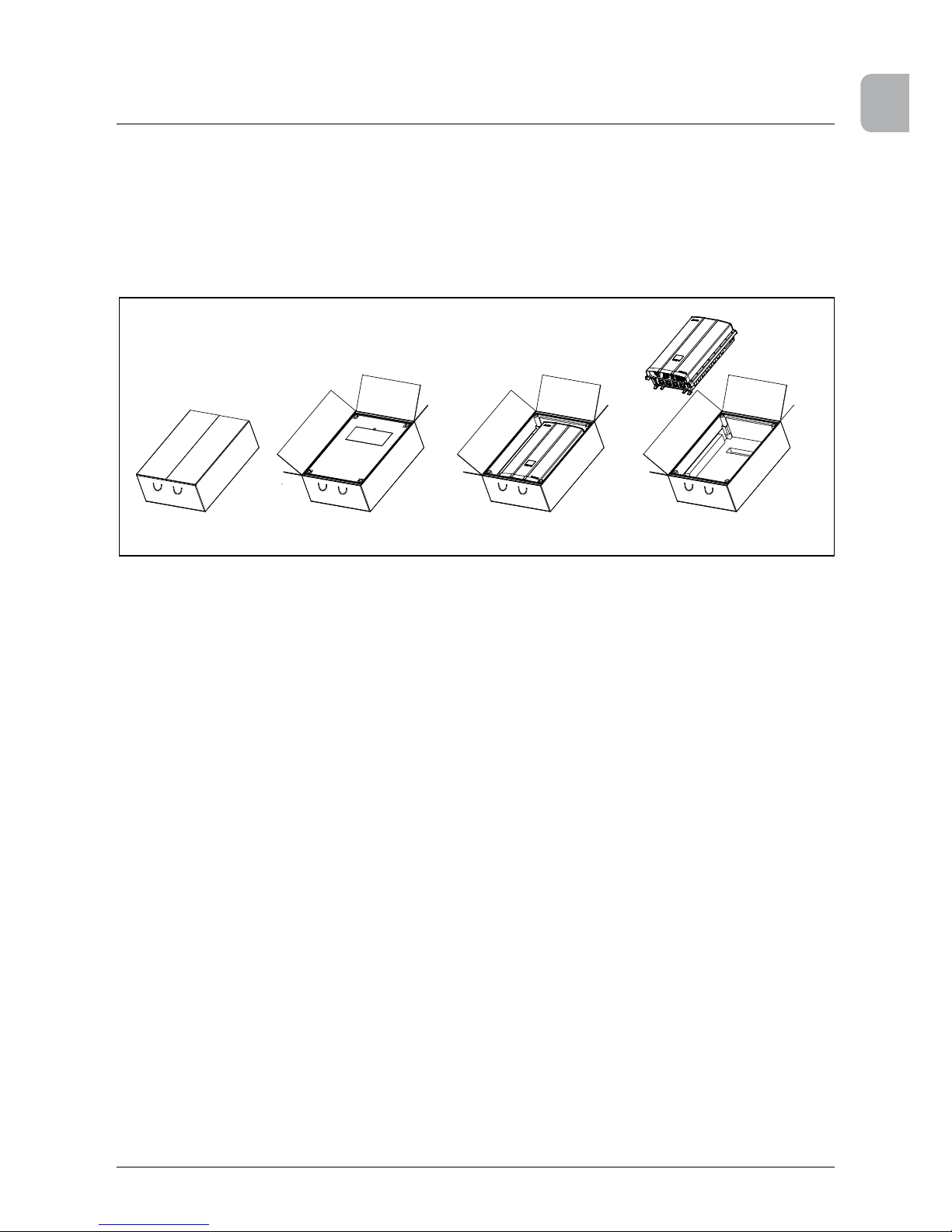

3.3 Unpacking

1. Open the top of the cardboard box as shown in the gure below.

2. Remove the top packing material after opening the box.

3. Lift the Inverter out of the package and save the packaging in case of return.

Figure 3.1.: Unpacking Process

Page 30

30

Preparing for Installation

3.4 Identify the Inverter

User can identify the model number by the information on the product label. The model number,

specication as well as the series no. is specied on the product label. In regard to the label location, please refer to the below gure.

or

Figure 3.2.: The Type Label 10 TL and 15 TL

or

Figure 3.3.: The Type Label 20 TL and 30 TL

Page 31

31

EN

Product Overview

4. Product Overview

4.1 Dimensions SOLIVIA 10 TL

625 [24.6] 275 [10.83]

618 [24.3]

Bottom view

Rear viewSide view

Front view

Top view

Figure 4.1.: Dimensions of SOLIVIA 10 TL

Page 32

32

Product Overview

4.2 Dimensions SOLIVIA 15 TL, 20 TL, 30 TL

Bottom view: 15 TL / 20 TL

Rear viewSide view

Front view

275 [10.83]

625 [24.6]

Top view

Figure 4.2.: Dimensions of SOLIVIA 15 TL / 20 TL / 30 TL

Bottom view: 30 TL

Page 33

33

EN

Product Overview

4.3 Function Introduction

Inverter exterior features are shown on gure 4.3 and 4.4, and a more detailed description is

found in the sections from 4.3.1 to 4.3.3

*Note: The fan is shown without

the required protective screen for

illustrative purposes

Communication

Connections

LCD/LED Display

Buttons

Label

Air outlets

DC Connectors

AC Connector

Fan

Figure 4.3.: 10 TL Inverter Exterior View

Page 34

34

Product Overview

Communication

Connections

LCD/LED Display

Buttons

Label

Air outlets

DC Connectors

AC Connector

Fan *4

*Note: The fans shown are without

the required protective screen for

illustrative purposes

Please note the 15 TL / 20 TL model

is shown here. The 30 TL will look

slightly different - a different AC

connector and 2 addl. DC inputs will

be present on the 30 TL.

Figure 4.4.: 15 TL / 20 TL / 30 TL Inverter Exterior View

➀

Figure 4.5.: Grounding Kit

Page 35

35

EN

Product Overview

The chassis has a predrilled hole ➀ to accept a grounding screw as shown. The maximum torque

of the M6 grounding screw is 4.4 Nm. There is a 15 mm diameter unpainted surface around the

center of the ground screw hole that allows for a solid ground connection when installing the

grounding kit.

4.3.1 LCD Display and Buttons

ESC: ESC MENU

DOWN: MOVE DOWN

UP: MOVE UP

ENTER: ENTER MENU OR CONFIRM

LED Indicator (GRN/RED)

LCD Display

Figure 4.6.: LCD Display and Control Panel

Page 36

36

Product Overview

4.3.2 Inverter Input/Output Interface

➀ ➁

➂

➃

DC input panel for the 10

TL, 15 TL, and 20 TL has 4

DC inputs. The 30 TL DC

input interface shown

below, provides 6 DC

inputs.

SOLIVIA 30 EUT4TL

Figure 4.7.: Input/Output Interface

No. Designation Description

➀

AC connector 400 VAC for 10 / 15 / 20 TL ; 500 VAC for 30 TL

➁

Communication 2 × RS485, 1 × EPO, 2 × Dry contact

➂

DC connector 4 Strings (10 TL / 15 TL / 20 TL), 6 Strings (30 TL)

➃

Fans 4 Fans (10 TL model with only one fan)

NOTE

The fans shown are without the required protective screen for illustrative

purposes. The 15 TL, 20 TL and 30 TL models have 4 fans in the fan tray,

whereas the 10 TL will only have one fan.

Page 37

37

EN

Product Overview

4.3.3 Air outlet

air outlet

air inlet

Figure 4.8.: Air Outlet Illustration

There are 4 fans in the bottom section of the inverter and all fans work synchronously. If any one

fan locks up or is defective, it will cause a fan failure and power derating. If you suspect that there

is a problem with a fan please call the Delta support hotline.

Fan

Figure 4.9.: Fan Control 10 TL

Page 38

38

Product Overview

Fan #1 #2 #3 #4

Figure 4.10.: Fan Control 15 TL and 20 TL

Fan #1 #2 #3 #4

Figure 4.11.: Fan Control 30 TL

Page 39

39

EN

Installation

5. Installation

5.1 Installing Location

The SOLIVIA TL inverters can be installed indoors and in protected outdoor areas due to its enclo-

sure protection classes IP65 and IP55. See the gure 5.1 for further explanation of the protection

classes.

WARNING

Death and serious injury may occur if the following instructions are

not carefully followed

► Do not install the unit near/on ammable objects.

► Do not install the unit at a location that people can gain entry/touch

easily.

► Mount the unit tightly onto a solid/ smooth wall.

► In order to ensure the safety of installers, there should be at least two

people to handle the installation.

► When moving the SOLIVIA TL, installer should not stand under material

handling machines.

► Dusty conditions can impair the unit’s performance

WARNING

► According to the Australian/New Zealand standard AS/NZS 5033:2005,

PV arrays for installation on domestic dwellings should not have a maxi-

mum voltage greater than 600 V. For non-domestic installations where

the PV array maximum voltage exceeds 600 V, the entire PV array and

associated wiring and protection, should have restricted access, only

accessible to authorized personnel.

CAUTION

Machine and equipment damage may occur.

► Do not install the unit at a location that has direct exposure to sunlight.

Page 40

40

Installation

IP65 protection class

IP55 protection class

Note: 15 and 20 TL pictured. 10 TL and 30

TL may look slightly different.

Figure 5.1.: SOLIVIA 10 TL, 15 TL, 20 TL, 30 TL protection classes

NOTE

The fans shown are without the required protective screen for illustrative

purposes. The 15 TL, 20 TL and 30 TL models have 4 fans in the fan tray,

whereas the 10 TL will only have one fan.

The upper section of the inverter, shown in the darker tone above, is sealed from the lower section

and rated at IP65 enclosure protection. The lower section of the inverter, containing the cooling

mechanisms, is rated at IP55 enclosure protection.

5.2 Mounting

This unit utilizes a wall mounting system. Please ensure the installation is perpendicular and

with the AC plug at the bottom. Do not install the device on a slanted wall. The dimensions of the

mounting bracket are shown in the following gures. There are 12 pcs. of M6 screws required for

attaching the mounting plate to the wall. Attach the mounting plate securely to the wall, before

attaching the inverter on the mounting plate.

NOTE

Please ensure you are using the correct fastener for the material you are

attaching the inverter mounting plate to.

Page 41

41

EN

Installation

Wall

Unit: mm

6 pcs. screws

6 pcs. screws

SOLIVIA 10 TL rear view

SOLIVIA 15 TL, 20 TL, 30 TL

rear view

Note: The wall mount bracket will be the same part for the

10 TL / 15 TL / 20 TL / 30 TL.

Figure 5.2.: Attaching the mounting bracket to the wall

Page 42

42

Installation

Figure 5.3.: Correct and Incorrect Installation Illustration

CAUTION

Machine and equipment damage may occur.

► Please leave an appropriate gap in between when installing single /

several DELTA solar inverter systems.

► Please install solar inverters at eye level to allow easy observation for

operation and parameter setting.

► Please install solar inverter in a clean and open space.

► The ambient temperature should be between -20°C ... +60°C.

There should be sufcient space for product operation as shown in the gure 5-4. If necessary, the

installer should increase the gap space for optimum product performance.

Page 43

43

EN

Installation

Figure 5.4.: Proper Installation Gap

5.3 Ambient temperature

The solar inverter can be operated in an ambient temperature between -20 °C ... +60 °C. The following diagram illustrates how the power supplied by the solar inverter is reduced automatically in

accordance with the ambient temperature. The device should be installed in a well-ventilated, cool

and dry location.

Page 44

44

Installation

40 74

Pout_max

(kVA)

Ambient

Temperature

(℃)

~

~

~

~

15 kVA / 20 kVA

-20 -15

Figure 5.5.: Derating curve for 10 TL, 15 TL, 20 TL and 30 TL

Page 45

45

EN

Wiring the Inverter

6. Wiring the Inverter

6.1 Preparation before Wiring

1. To avoid accidents, please conrm that the PV inverter’s power of both DC and AC are

switched off.

2. Please conrm whether the input/output of PV inverter’s wiring are clearly indicated. Make

sure that the value, polarity, voltage and phase are correct.

3. The wiring procedure of a PV system is shown in gure 6-1 and 6-2. Wiring details are described in the following paragraphs.

– When the DC input is oating, an external transformer is not necessary. Please refer

to Figure 6-1 for the connection. The inverter can accept DC inputs in parallel (1 MPP

tracker) or separate DC input connections (2 MPP Trackers).

– When an asymmetrical DC load is detected, the solar inverter will automatically adjust

for optimum output. Please see section 6.3.1 for more details. This is useful where

there are two strings of modules on roof surfaces with different orientations, such as in

the case of a dormer with north & south facing surfaces.

CAUTION

Machine and equipment damage may occur.

► When the DC input is a positive ground or negative ground, all of the

strings must be connected in parallel and then connected to the inverters. In addition, an external isolation transformer must be installed on

the AC side, otherwise, damage will result and the inverter will not work

properly. Different DC input wiring needs require different insulation

detection settings. To learn more about the settings, please refer to

„6.3.6.2 Install Settings“ on page 54.

Page 46

46

Wiring the Inverter

Parallel or

Separate

PV Array

DC Distribution

Box

DC Wiring

AC

Wiring

Communication

Wiring

Figure 6.1.: Connection of system if DC inputs are oating

Page 47

47

EN

Wiring the Inverter

Must be Parallel

Connection

PV Array

DC Distribution Box

(Plus-GND or Minus-GND)

Isolated

transformer

Utility

3Ph, Δ or Y

230/400 Vac

To Inverter

3Ph, Y

230/400 Vac

or

Must install one

transformer per inverter

Figure 6.2.: Connection of system with Positive Ground or Negative Ground

6.2 AC Grid Connection: 3 Phase + N + PE

WARNING

Death and serious injury may occur

► Before engaging in the AC wiring, please ensure the AC 3-phase power

is switched off.

Page 48

48

Wiring the Inverter

6.2.1 Required protective devices and cable cross-sections

Please use the proper upstream circuit breaker to protect the inverter according to the table:

Model Upstream Circuit Breaker

SOLIVIA 10 TL 20 A

SOLIVIA 15 TL 30 A

SOLIVIA 20 TL 40 A

SOLIVIA 30 TL 60 A

G N L1 L3L2

N

L1

L2

L3

PE

To solar inverter AC

plug

6.2.1.1 Residual Current Devices

The SOLIVIA 10 TL / 15 TL / 20 TL / 30 TL are not capable of feeding in DC residual currents due

to their design. They fulll this requirement in accordance with DIN VDE 0100-712.

The possibilities of faults were examined without taking the integrated residual-current monitoring

unit (RCMU) into account. When examining these faults in terms of the current valid installation

standards, no danger in combination with a type A upstream residual-current device can occur.

Therefore faults that would otherwise require the use of a type B residual-current device due to

the inverter can be excluded.

The integrated all-pole sensitive residual-current monitoring unit (RCMU) results in additional

safety. For all above mentioned transformerless inverters from Delta RCDs of the type A can be

used.

6.2.1.2 AC Cable Requirements

Please use properly sized wire to connect to the correct poles (According to the table below)

Model AC connector* Current

Rating

Min. / Max.

Cable size

allowed

Min. / Max. wire

size allowed in

screw terminals

Torque of

terminal

screws

10 TL / 15

TL / 20 TL

Amphenol C16-3 ≤ 40 A 11 mm

2

/ 20

mm

2

4 mm2 / 8 mm

2

(12 AWG / 9 AWG)

≥ 0.7 Nm (7

kg)

30 TL Amphenol PPC

AC 24

≤ 60 A 22 mm

2

/ 32

mm

2

10 mm2 / 16 mm2

(8 AWG / 6 AWG)

≥ 0.9 Nm

(10 kg)

* Please follow up with Amphenol for the latest information regarding the AC connectors

Table 6.1.: Cable cross sections and torques for AC connectors

Page 49

49

EN

Wiring the Inverter

AC wiring can be separated into 3-phase (L1, L2, L3), N, and PE. The following earthing congurations are allowed. IT is not allowed. Please see the appendix for further explanation of these

earthing systems.

TN-S TN-C TN-C-S TT IT

Yes Yes Yes Yes No

Table 6.2.: Permitted earthing systems

NOTE

TT is not recommended. Have to be sure the voltage of N is very close to

PE (< 20 V

rms

)

6.2.2 AC bayonet connectors for 10 TL, 15 TL, 20 TL

The AC bayonet connectors are approved for cable sheath diameters between 11 mm and 20 mm.

To install an AC cable, rst strip the voltage free line and cable ends as shown below and then

follow the sequence in Figure 6.5 to assemble the cable and bayonnet connector.

52.5 mm (PE 57.5 mm)

10 mm

Figure 6.3.: AC cable stripping requirements for 10 TL, 15 TL, and 20 TL

NOTE

For lines with a cable sheath diameter from 16 mm to 20 mm, the cable

gland must be adapted accordingly. To do this, cut out the inner section of

the blue sealing ring.

In Figure 6.5, the Amphenol C connector shown can be mated with the 10 TL / 15 TL / 20 TL

inverter‘s AC plug. After disassembly of the connector, please adhere to the correct polarity for

proper AC wiring (this product allows either positive or negative phase sequence). That means the

sequence of L1-L3 can be adjusted and the N and PE must be connected.

Page 50

50

Wiring the Inverter

This is a rear view of the cable gland.

For a cable sheath diameter between

16 mm to 20 mm, please remove the

inner sealing ring.

Figure 6.4.: AC plug sealing ring for AC connector 10 TL, 15 TL, and 20 TL

Page 51

51

EN

Wiring the Inverter

Inverter

Next tighten the cable gland ➁ to the connector housing ➀. Tightening torque for cable

sheath diameters between 11 and 20 mm: 6 to 8 Nm. Rotate the coupling ring ➂ to mate

the connector with the inverter‘s AC plug.

After wiring the mating connector, screw

the connector housing ➀ to the coupling

ring ➂. To do this push the coupling ring

➂ to the connector housing ➀ and tighten

1-2 Nm.

Rotate the connector housing and cable

gland to remove them from the coupling

ring.

The female cable

connector needs to

be wired as shown

below.

To wire the connector refer to placement

of L1, L2, L3, N and PE shown to the left.

Screw termination is provided to x the

wires to the contacts.

NOTE: Rear view of cable

connector

L3

L1

L2

PE

1 : L1

2 : L2

3 : L3

4 : N

: PE

N

L1

L2

L3

N

PE

Cable

Slide the connector housing and cable

gland onto the cable.

➀

➁

➂

Figure 6.5.: AC connector 10 TL, 15 TL, and 20 TL

Page 52

52

Wiring the Inverter

CAUTION

Machine and equipment damage may occur.

► Observe the pin assignment of the AC bayonet connector. An incorrect

assignment can result in the unit being destroyed. The Figure 6.5 pin

out diagram shows the connections inside the AC connector.

NOTE

Make sure the line is provided with a strain relief device. When using cables

with a diameter of less than 13 mm (11 mm ... 13 mm diameter cable

require strain relief), the cable must be relieved just behind the connector.

6.2.3 AC bayonet connectors for 30 TL

The AC bayonet connector for 30 TL are approved for cable sheath diameters between 22 mm

and 32 mm. To install an AC cable, rst strip the voltage free line and cable ends as shown below

and then follow the sequence in Figure 6.7 to assemble the cable and bayonnet connector.

60 mm (PE 65 mm)

12 mm

Figure 6.6.: AC cable stripping requirements for 30 TL

In Figure 6.7, the Amphenol PPC AC 24 connector shown can be mated with the 30 TL inverter‘s

AC plug. After disassembly of the connector, please adhere to the correct polarity for proper AC

wiring (this product allows either positive or negative phase sequence). That means the sequence

of L1-L3 can be adjusted and the N and PE must be connected.

Page 53

53

EN

Wiring the Inverter

Inverter

Next tighten the cable gland body ➁ to connector housing ➀ and the

cable gland cap ➂ to the cable gland body ➂. Tightening torque for

cable sheath diameters between 22 and 32 mm: 6 to 8 Nm. Rotate

the coupling ring ➃ to mate the connector with the inverter‘s AC plug.

After wiring the mating connector, screw the

connector housing ➀ to the coupling ring ➃. To

do this push the coupling ring ➃ to the connector housing ➀ and tighten 1-2 Nm.

Rotate the connector housing ➀ and cable

gland body ➁ and cable gland cap ➂ to

remove them from the coupling ring.

The female cable

connector needs to

be wired as shown

below.

To wire the connector refer to placement

of L1, L2, L3, N and PE shown to the left.

Screw termination is provided to x the

wires to the contacts.

NOTE: Rear

view of cable

connector

L1

L2

L3

N

PE

Cable

Slide the connector housing, cable gland

body and cable gland cap onto the cable.

L3

L1

L2

N

PE

Cable

➀

➂

➁

➃

➀

➂

➁

➀

➁

➂

Figure 6.7.: AC connector for 30 TL

Page 54

54

Wiring the Inverter

6.2.4 AC Wiring Considerations

The connection to the Amphenol AC connector for all models can be made with a exible or

rigid cable with a copper conductor that has the appropriate cross section according to table 6.1

and which has an installation condition that gives a correction factor equal to one. The AC cable

should be protected by a minimum type B 40 Amp breaker for 10 TL / 15 TL / 20 TL and minimum

type B 60 Amp breaker for 30 TL.

This connector is developed for connection to copper wires (for other applications please contact

Amphenol). The cross section of the cable should be calculated by considering the material used,

thermal conditions, length of the cable, the type of installation, and AC voltage drop.

Please note the cable length and the cable cross-section, due to the risk of undesirable temperature rise and power losses. In some countries, (e.g. France, Germany, Australia) system installation requirements have to be followed (UTE 15712-1, VDE 0100 712, AS/NZS 5033:2005). This

recommendation will dene minimum cable sections and protections against overheating due to

high currents. Please make sure that you follow specic requirements in your country.

For the security of your installation and for the safety of the user, please install required safety and

protection devices that are applicable for your installation environment (example: automatic circuit

breaker and/or overcurrent protection equipment).

WARNING

Death and serious injury may occur