Page 1

PART NO. 491836-00 REV. 1 05-18-06

Copyright © 2006 Delta Machinery

ESPAÑOL: PÁGINA 23

To learn more about DELTA MACHINERY

visit our website at: www.deltamachinery.com.

For Parts, Service, Warranty or other Assistance,

please call 1-800-223-7278 (In Canada call 1-800-463-3582).

4" Belt / 6" Disc Sander

(Model SM500)

FRANÇAIS: PAGE 45

Page 2

2

TABLE OF CONTENTS

Read and understand all warnings and operating instructions before using any tool or equipment. When

using tools or equipment, basic safety precautions should always be followed to reduce the risk of personal injury.

Improper operation, maintenance or modification of tools or equipment could result in serious injury and property

damage. There are certain applications for which tools and equipment are designed. Delta Machinery strongly

recommends that this product NOT be modified and/or used for any application other than for which it was designed.

If you have any questions relative to its application DO NOT use the product until you have written Delta Machinery

and we have advised you.

Online contact form at www.deltamachinery.com

Postal Mail: Technical Service Manager

Delta Machinery

4825 Highway 45 North

Jackson, TN 38305

(IN CANADA: 505 SOUTHGATE DRIVE, GUELPH, ONTARIO N1H 6M7)

Information regarding the safe and proper operation of this tool is available from the following sources:

Power Tool Institute

1300 Sumner Avenue, Cleveland, OH 44115-2851

www.powertoolinstitute.org

National Safety Council

1121 Spring Lake Drive, Itasca, IL 60143-3201

American National Standards Institute, 25 West 43rd Street, 4 floor, New York, NY 10036 www.ansi.org

ANSI 01.1Safety Requirements for Woodworking Machines, and

the U.S. Department of Labor regulations www.osha.gov

IMPORTANT SAFETY INSTRUCTIONS

SAVE THESE INSTRUCTIONS!

IMPORTANT SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

SAFETY GUIDELINES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

GENERAL SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

ADDITIONAL SPECIFIC SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

FUNCTIONAL DESCRIPTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

CARTON CONTENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

ESPAÑOL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

FRENCH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

SERVICE CENTER LOCATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .back cover

Page 3

3

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

Used without the safety alert symbol indicates potentially hazardous situation which, if not avoided, may result

in property damage.

It is important for you to read and understand this manual. The information it contains relates to protecting

YOUR SAFETY and PREVENTING PROBLEMS. The symbols below are used to help you recognize this

information.

SAFETY GUIDELINES - DEFINITIONS

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities contains

chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these

chemicals are:

• lead from lead-based paints,

• crystalline silica from bricks and cement and other masonry products, and

• arsenic and chromium from chemically-treated lumber (CCA).

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to these

chemicals: work in a well ventilated area, and work with approved safety equipment, such as those dust masks that are specially

designed to filter out microscopic particles.

• Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling, and other construction activities. We a r

protective clothing and wash exposed areas with soap and water. Allowing dust to get into your mouth, eyes, or lay on the skin

may promote absorption of harmful chemicals.

Use of this tool can generate and/or disperse dust, which may cause serious and permanent respiratory or other injury.

Always use NIOSH/OSHA approved respiratory protection appropriate for the dust exposure. Direct particles away from face and

b o d y.

Wear appropriate hearing protection during use. Under some conditions and duration of use, noise from this product may

contribute to hearing loss.

CALIFORNIA PROPOSITION 65

SANDING LEAD BASED PA I N T

Sanding of lead based paint is NOT RECOMMENDED due to the difficulty of controlling the contaminated dust. The greatest

danger of lead poisoning is to children and pregnant women.

Since it is difficult to identify whether or not a paint contains lead without a chemical analysis, we recommend the following

precautions when sanding any paint:

P E R S O N A L S A F E T Y

• No children or pregnant women should enter the work area where the paint sanding is being done until all clean up is

c o m p l e t e d .

• A dust mask or respirator should be worn by all persons entering the work area. The filter should be replaced daily or

whenever the wearer has difficulty breathing.

NOTE: Only those dust masks suitable for working with lead paint dust and fumes should be used. Ordinary painting masks

do not offer this protection. See your local hardware dealer for the proper (NIOSH approved) mask.

• NO EATING, DRINKING or SMOKING should be done in the work area to prevent ingesting contaminated paint particles.

Workers should wash and clean up BEFORE eating, drinking or smoking. Articles of food, drink, or smoking should not be

left in the work area where dust would settle on them.

E N V I R O N M E N TA L S A F E T Y

• Paint should be removed in such a manner as to minimize the amount of dust generated.

• Areas where paint removal is occurring should be sealed with plastic sheeting of 4 mils thickness.

• Sanding should be done in a manner to reduce tracking of paint dust outside the work area.

CLEANING AND DISPOSAL

• All surfaces in the work area should be vacuumed and thoroughly cleaned daily for the duration of the sanding project.

Vacuum filter bags should be changed frequently.

• Plastic drop cloths should be gathered up and disposed of along with any dust chips or other removal debris. They should be

placed in sealed refuse receptacles and disposed of through regular trash pick-up procedures. During clean up, children and

pregnant women should be kept away from the immediate work area.

• All toys, washable furniture and utensils used by children should be washed thoroughly before being used again.

FIRE HAZARD collected sanding dust from sanding surface coatings (polyurethane, linseed oil, etc.) can

self-ignite in dust collector bag or elsewhere and cause fire. To reduce risk, empty bag frequently and strictly follow sander

manual and coating manufacturer's instructions.

Page 4

4

GENERAL SAFETY RULES

READ AND UNDERSTAND ALL WARNINGS AND OPERATING INSTRUCTIONS BEFORE

USING THIS EQUIPMENT. Failure to follow all instructions listed below, may result in

electric shock, fire, and/or serious personal injury or property damage.

IMPORTANT SAFETY INSTRUCTIONS

1. FOR YOUR OWN SAFETY, READ THE INSTRUCTION

M A N U A L BEFORE OPERATING THE MACHINE. Learning

the machine’s application, limitations, and specific

hazards will greatly minimize the possibility of accidents

and injury.

2. WEAR EYE AND HEARING PROTECTION. ALWAYS

USE SAFETY GLASSES. Everyday eyeglasses are

N O T safety glasses. USE CERTIFIED SAFETY

EQUIPMENT. Eye protection equipment should comply

with ANSI Z87.1 standards. Hearing equipment should

comply with ANSI S3.19 standards.

3. WEAR PROPER APPAREL. Do not wear loose clothing,

gloves, neckties, rings, bracelets, or other jewelry which

may get caught in moving parts. Nonslip footwear is

recommended. Wear protective hair covering to contain

long hair.

4. DO NOT USE THE MACHINE IN A DANGEROUS

ENVIRONMENT. The use of power tools in damp or wet

locations or in rain can cause shock or electrocution.

Keep your work area well-lit to prevent tripping or placing

arms, hands, and fingers in danger.

5. M A I N TAIN A L L TOOLS AND MACHINES IN PEAK

CONDITION. Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and changing

accessories. Poorly maintained tools and machines can further

damage the tool or machine and/or cause injury.

6. CHECK FOR DAMAGED PARTS. Before using the machine,

check for any damaged parts. Check for alignment of

moving parts, binding of moving parts, breakage of parts,

and any other conditions that may affect its operation. A

guard or any other part that is damaged should be

properly repaired or replaced. Damaged parts can

cause further damage to the machine and/or injury.

7. K E E P THE WORK A R E A CLEAN. Cluttered areas and

benches invite accidents.

8. K E E P CHILDREN AND VISITORS AWAY. Your shop is a

potentially dangerous environment. Children and visitors can be

i n j u r e d .

9. REDUCE THE RISK OF UNINTENTIONALS TA R T I N G . Make

sure that the switch is in the “OFF” position before

plugging in the power cord. In the event of a power

failure, move the switch to the “OFF” position. A n

accidental start-up can cause injury.

10. USE THE GUARDS. Check to see that all guards are in

place, secured, and working correctly to reduce the risk

of injury.

11. REMOVE ADJUSTING KEYS AND WRENCHES

BEFORE STARTING THE MACHINE. Tools, scrap

pieces, and other debris can be thrown at high speed,

causing injury.

12. USE THE RIGHT MACHINE. Don’t force a machine or

an attachment to do a job for which it was not designed.

Damage to the machine and/or injury may result.

13. USE RECOMMENDED ACCESSORIES. The use of

accessories and attachments not recommended by Delta

may cause damage to the machine or injury to the user.

14. USE THE PROPER EXTENSION CORD. Make sure

your extension cord is in good condition. When using an

extension cord, be sure to use one heavy enough to

carry the current your product will draw. An undersized

cord will cause a drop in line voltage, resulting in loss of

power and overheating. See the Extension Cord Chart

for the correct size depending on the cord length and

nameplate ampere rating. If in doubt, use the next

heavier gauge. The smaller the gauge number, the

heavier the cord.

15. SECURE THE WORKPIECE. Use clamps or a vise to hold

the workpiece when practical. Loss of control of a

workpiece can cause injury.

16. FEED THE WORKPIECE AGAINST THE DIRECTION OF

THE ROTATION OF THE BLADE, CUTTER, OR A B R A S I V E

S U R FA C E . Feeding it from the other direction will cause

the workpiece to be thrown out at high speed.

17. DON’T FORCE THE WORKPIECE ON THE MACHINE.

Damage to the machine and/or injury may result.

18. DON’T OVERREACH. Loss of balance can make you fall

into a working machine, causing injury.

19. NEVER STAND ON THE MACHINE. Injury could occur if the

tool tips, or if you accidentally contact the cutting tool.

20. NEVER LEAVE THE MACHINE RUNNING UNAT T E N D E D .

TURN THE POWER OFF. Don’t leave the machine until it comes

to a complete stop. Achild or visitor could be injured.

21. TURN THE MACHINE “OFF”, AND DISCONNECT THE

MACHINE FROM THE POWER SOURCE before installing

or removing accessories, before adjusting or changing

set-ups, or when making repairs. An accidental start-up

can cause injury.

22. MAKE YOUR WORKSHOP CHILDPROOF WITH

PADLOCKS, MASTER SWITCHES, OR BY REMOVING

STARTER KEYS. The accidental start-up of a machine

by a child or visitor could cause injury.

23. STAY ALERT, WATCH WHAT YOU ARE DOING, AND

USE COMMON SENSE. DO NOT USE THE MACHINE

WHEN YOU ARE TIRED OR UNDER THE INFLUENCE

OF DRUGS, ALCOHOL, OR MEDICAT-ION. A moment

of inattention while operating power tools may result in

injury.

24. USE OF THIS TO O L CAN GENERAT E

AND DISBURSE DUST OR OTHER A I R B O R N E

PARTICLES, INCLUDING WOOD DUST, CRY S TA L L I N E

S I L I C A DUST AND A S B E S T OS DUST. Direct particles

away from face and body. Always operate tool in well

ventilated area and provide for proper dust removal. Use

dust collection system wherever possible. Exposure to the

dust may cause serious and permanent respiratory or other

i n j u r y, including silicosis (a serious lung disease), cancer, and

death. Avoid breathing the dust, and avoid prolonged

contact with dust. Allowing dust to get into your mouth or

eyes, or lay on your skin may promote absorption of harmful

material. Always use properly fitting NIOSH/OSHAa p p r o v e d

respiratory protection appropriate for the dust exposure, and

wash exposed areas with soap and water.

Page 5

5

ADDITIONAL SPECIFIC SAFETY RULES

1. DO NOT OPERATE THIS MACHINE until it is

completely assembled and installed according to the

instructions. A machine incorrectly assembled can cause

serious injury.

2. OBTAIN ADVICE from your supervisor, instructor, or

another qualified person if you are not thoroughly

familiar with the operation of this machine. Knowledge is

safety.

3. FOLLOW A L L WIRING CODES and recommended

electrical connections to prevent shock or electrocution.

4. NEVER TURN THE MACHINE “ON” before clearing the

table/work area of all objects (tools, scraps of wood,

etc.). Flying debris is dangerous.

5. NEVER TURN THE MACHINE “ON” with the work-

piece contacting the abrasive surface. Kickback can

occur.

6. SECURE THE MACHINE to a supporting surface. Vibration

can cause the machine to slide, walk, or tip over.

7. COVER THE POWER TAKE-OFF SHAFT when not using

accessories. Unguarded rotating shafts can create an

entanglement hazard which can result in injury.

8. USE A DUST COLLECTION SYSTEM. Some types of

wood are known to cause disease or other health

problems.

9. FIRE HAZARD CLEAN THE MACHINE and dust collector

t h o r o u g h ly when processing different types of workpieces

(wood, steel, or aluminum). Combining wood and metal

dust can create an explosion or fire hazard. DO NOT

SAND OR POLISH MAGNESIUM. Fire will result.

10. PREVENT THE WORKPIECE from contacting the

sanding belt before starting the tool. Loss of control of

the workpiece is dangerous.

11. AVOID AW K W ARD OPERATIONS AND HAND

POSITIONS. A sudden slip could cause a hand to move

into the abrasive disc or belt.

12. M A I N TAIN A MAXIMUM CLEARANCE OF 1/16" between

the table and the abrasive disc or belt. The workpiece

could be drawn into the space between the abrasive disc

or belt and the table.

13. SUPPORT THE WORKPIECE firmly with a miter gauge,

backstop, or work table when sanding with a belt. Hold

the workpiece firmly. Loss of control of the workpiece can

result in injury.

14. AVOID KICKBACK by sanding in accordance with the

directional arrows. Feed the workpiece against the

downward rotation side of the disc or the forward rotation

of the belt. Loss of control of the workpiece can result in

i n j u r y.

15. DO NOT SAND very small or very thin workpieces that

cannot be safely controlled. Loss of control of the

workpiece can result in injury.

16. P R O P E R LY SUPPORT LONG OR WIDE W O R K P I E C E S .

Loss of control of the workpiece is dan-gerous.

17. NEVER PERFORM LAY O U T, A S S E M B LY, OR SET-UP

WORK on the table/work area when the machine is

running. A sudden slip could cause a hand to move into

the abrasive surface. Severe injury can result.

18. TURN THE MACHINE “OFF”, disconnect the machine

from the power source, and clean the table/work area

before leaving the machine. LOCK THE SWITCH IN

THE “OFF” POSITION to prevent unauthorized use.

Some-one else might accidentally start the machine and

cause injury to themselves.

19. ADDITIONAL INFORMATION regarding the safe and

proper operation of power tools (i.e. a safety video) is

available from the Power Tool Institute, 1300 Sumner

Avenue, Cleveland, OH 4411 5 - 2 8 5 1

( w w w .powertoolinstitute.com). Information is also

available from the National Safety Council, 1121 Spring

Lake Drive, Itasca, IL 60143-3201. Please refer to the

American National Standards Institute ANSI 01.1 Safety

Requirements for Woodworking Machines and the U.S.

Department of Labor OSHA 1910.213 Regulations.

READ AND UNDERSTAND ALL INSTRUCTIONS. FAILURE TO FOLLOW THESE

INSTRUCTIONS MAY RESULT IN ELECTRICAL SHOCK, FIRE AND / OR

SERIOUS INJURY.

SAVE THESE INSTRUCTIONS.

Refer to them often

and use them to instruct others.

Page 6

6

A separate electrical circuit should be used for your machines. This circuit should not be less than #12 wire and should

be protected with a 20 Amp time lag fuse. If an extension cord is used, use only 3-wire extension cords which have 3prong grounding type plugs and matching receptacle which will accept the machine’s plug. Before connecting the

machine to the power line, make sure the switch (s) is in the “OFF” position and be sure that the electric current is of the

same characteristics as indicated on the machine. All line connections should make good contact. Running on low

voltage will damage the machine.

SHOCK HAZARD. DO NOT EXPOSE THE MACHINE TO RAIN OR OPERATE THE MACHINE IN

DAMP LOCAT I O N S .

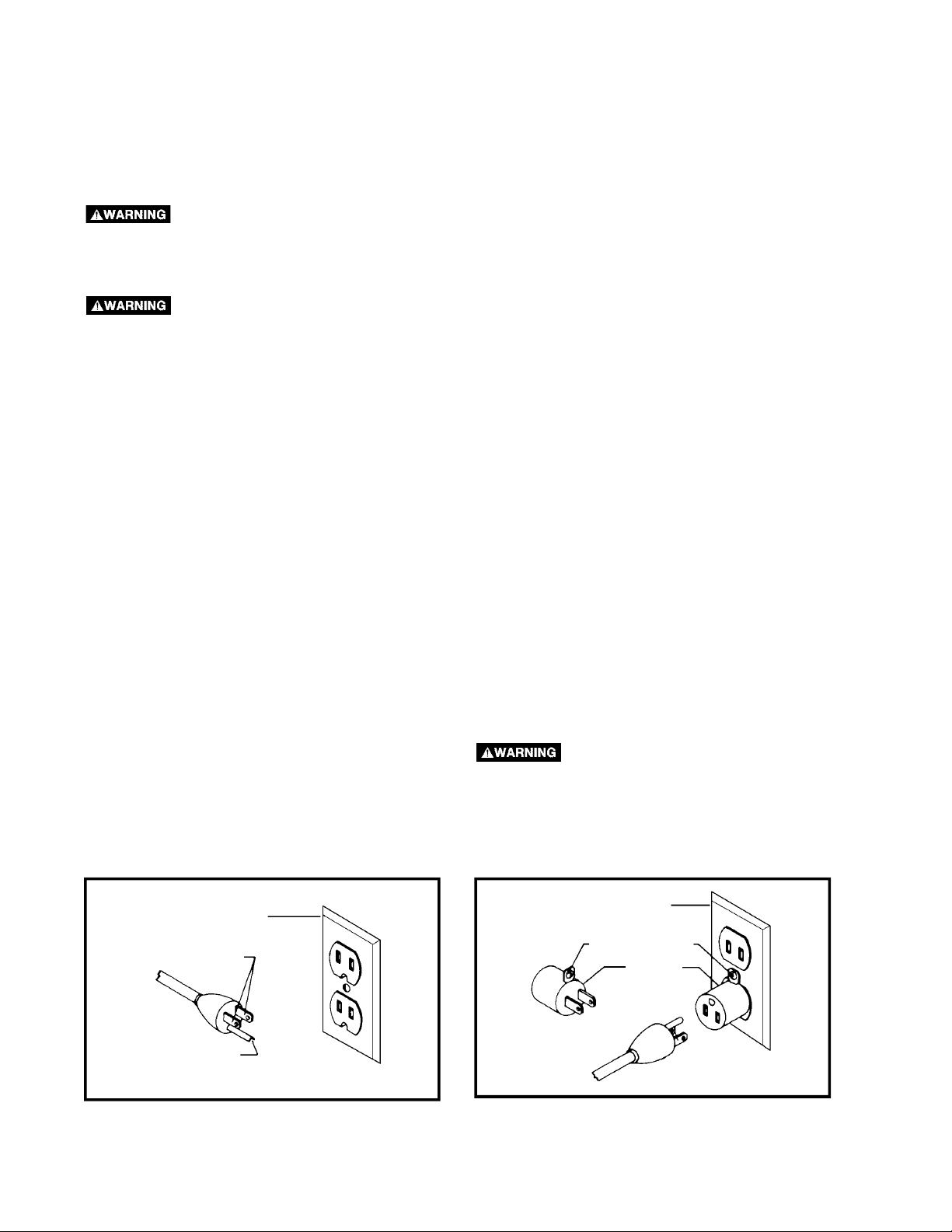

Fig. A Fig. B

GROUNDED OUTLET BOX

CURRENT

CARRYING

PRONGS

GROUNDING BLADE

IS LONGEST OF THE 3 BLADES

GROUNDED OUTLET BOX

GROUNDING

MEANS

ADAPTER

2. Grounded, cord-connected machines intended for

use on a supply circuit having a nominal rating less

than 150 volts:

If the machine is intended for use on a circuit that has an

outlet that looks like the one illustrated in Fig. A, t h e

machine will have a grounding plug that looks like the plug

illustrated in F i g . A. A temporary adapter, which looks like

the adapter illustrated in Fig. B, may be used to connect

this plug to a matching 2-conductor receptacle as shown in

Fig. B if a properly grounded outlet is not available. T h e

temporary adapter should be used only until a properly

grounded outlet can be installed by a qualified electrician.

The green-colored rigid ear, lug, and the like, extending

from the adapter must be connected to a permanent

ground such as a properly grounded outlet box. W h e n e v e r

t h e a d a p t e r i s used, it must be held in place with a metal

s c r e w .

N O T E : In Canada, the use of a temporary adapter is not

permitted by the Canadian Electric Code.

SHOCK HAZARD. IN A L L C A S E S , M A K E

C E R TAIN THAT THE RECEPTA C L E I N

Q U E S T I O N I S P R O P E R LY G R O U N D E D . I F

Y O U A R E N O T S U R E , H A V E A Q U A L I F I E D

E L E C T R I C I A N C H E C K T HE REC E P TA C L E .

1. All grounded, cord-connected machines:

In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electric current to

reduce the risk of electric shock. This machine is equipped

with an electric cord having an equipment-grounding

conductor and a grounding plug. The plug must be plugged

into a matching outlet that is properly installed and

grounded in accordance with all local codes and

o r d i n a n c e s .

Do not modify the plug provided - if it will not fit the outlet,

have the proper outlet installed by a qualified electrician.

I m p r o p e r c o n n e c t i o n o f t h e e q u i p m e n t - g r o u n d i n g

c o n d u c t o r c a n r e s u l t i n r i s k o f e l e c t r i c s h o c k . T h e

conductor with insulation having an outer surface that is

green with or without yellow stripes is the equipmentgrounding conductor. If repair or replacement of the

electric cord or plug is necessary, do not connect the

equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if the

g r o u n d i n g i n s t r u c t i o n s a r e n o t completely understood, o r i f

i n d o u b t a s t o w h e t h e r t h e m a c h i n e is properly grounded.

Use only 3-wire extension cords that have 3-prong

grounding type plugs and matching 3-c o n d u c t o r

receptacles that accept the machine’s plug, as shown in

Fig. A .

Repair or replace damaged or worn cord immediately.

POWER CONNECTIONS

Your machine is wired for 120 Volt, 60 HZ alternating current. Before connecting the machine to the power source,

make sure the switch is in the “OFF” position.

GROUNDING INSTRUCTIONS

SHOCK HAZARD. THIS MACHINE MUST BE GROUNDED WHILE IN USE TO PROTECT THE

OPERATOR FROM ELECTRIC SHOCK.

Page 7

7

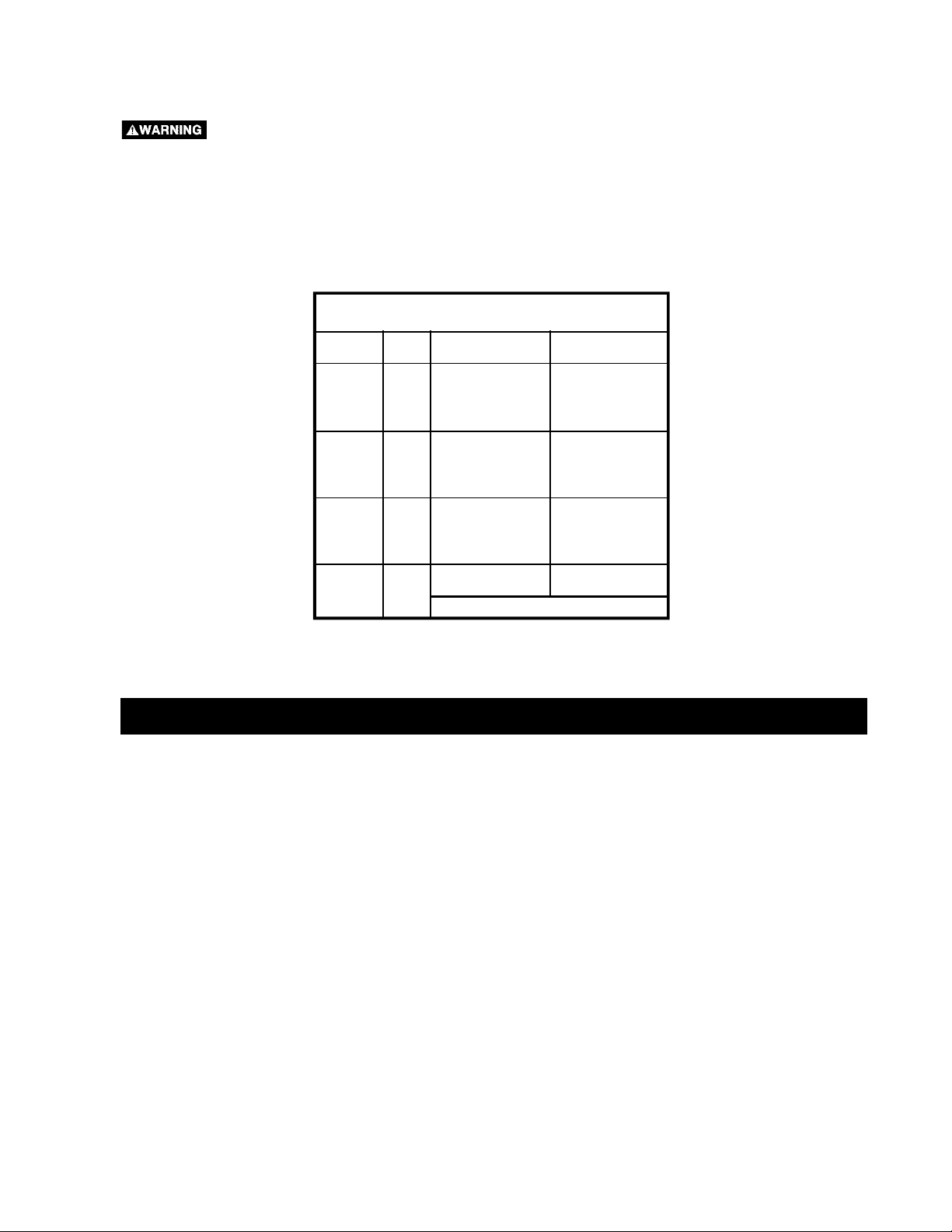

EXTENSION CORDS

Use proper extension cords. Make sure your extension cord is in good condition and is a 3-wire

extension cord which has a 3-prong grounding type plug and matching receptacle which will accept the machine’s plug.

When using an extension cord, be sure to use one heavy enough to carry the current of the machine. An undersized

cord will cause a drop in line voltage, resulting in loss of power and overheating. Fig. C shows the correct gauge to

use depending on the cord length. If in doubt, use the next heavier gauge. The smaller the gauge number, the heavier

the cord.

Fig. C

MINIMUM GAUGE EXTENSION CORD

RECOMMENDED SIZES FOR USE WITH STAT I O N A RY ELECTRIC MACHINES

A m p e r e Total Length Gauge of

R a t i n g Vo l t s of Cord in Feet Extension Cord

0 - 6 1 2 0

up to

2 5 18 AW G

0 - 6 1 2 0 2 5 - 5 0 16 AW G

0 - 6 1 2 0 5 0 - 1 0 0 16 AW G

0 - 6 1 2 0 1 0 0 - 1 5 0 14 AW G

6 - 1 0 1 2 0

up to

2 5 18 AW G

6 - 1 0 1 2 0 2 5 - 5 0 16 AW G

6 - 1 0 1 2 0 5 0 - 1 0 0 14 AW G

6 - 1 0 1 2 0 1 0 0 - 1 5 0 12 AWG

1 0 - 1 2 1 2 0

up to

2 5 16 AW G

1 0 - 1 2 1 2 0 2 5 - 5 0 16 AW G

1 0 - 1 2 1 2 0 5 0 - 1 0 0 14 AW G

1 0 - 1 2 1 2 0 1 0 0 - 1 5 0 12 AW G

1 2 - 1 6 1 2 0

up to

2 5 14 AW G

1 2 - 1 6 1 2 0 2 5 - 5 0 12 AW G

1 2 - 1 6 1 2 0 GREATER THAN 50 FEET NOT RECOMMENDED

F O R E W O R D

FUNCTIONAL DESCRIPTION

NOTICE: The photo on the manual cover illustrates the current production model. All other illustrations contained in the

manual are representative only and may not depict the actual color, labeling, or accessories, and are intended to

illustrate technique only.

The ShopMaster Model SM500 is a 4" Belt, 6" Disc Sander that comes equipped with a 5.2 AMP 120 Volt Single Phase

Induction Motor, a tilting table, a miter gauge, a backstop, a 4" x 36" 60-grit sanding belt, and a 6" 60-grit sanding disc.

You can mount the tilting table for use on either the belt or disc unit, and can operate the belt in the horizontal position,

the vertical position, or any position in between.

Page 8

8

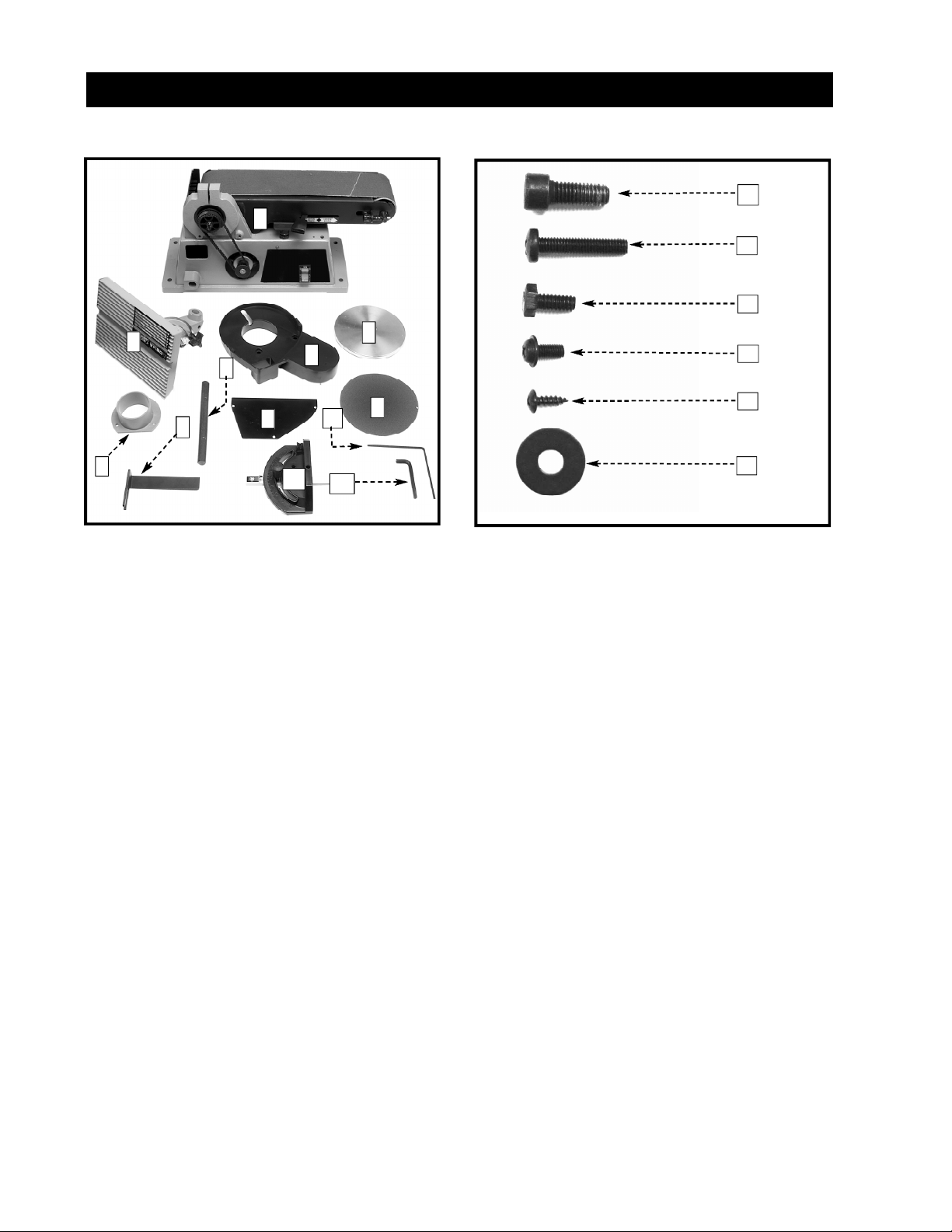

U N PACKING AND CLEANING

Carefully unpack the machine and all loose items from the shipping container(s). Remove the protective coating from all

unpainted surfaces. This coating may be removed with a soft cloth moistened with kerosene (do not use acetone, gasoline

or lacquer thinner for this purpose). After cleaning, cover the unpainted surfaces with a good quality household floor paste

wax.

C A R TON CONTENTS

1

2

3

4

8

7

10

6

5

9

11

12

13

1. Motor and Base

2. Disc Table

3. Belt and Pulley Guard

4. Disc Plate

5. Dust Chute

6. Support Rod

7. Lower Disc Guard

8. Sanding Disc

9. Backstop

10. Miter Gauge

11. 1/8" Hex Wrench

12. 6mm Hex Wrench

13. M8 x 1.25 x 20mm Hex Socket Head Screw (3)

14. M6 x 1 x 30mm Cheese Head Screws (2)

15. 1/4-20 x 1/2" Hex Head Screw (1)

16. M5 x .08 x 10mm Pan Head Screw w/washer (3)

17. M4 x .7 x 12mm Sheet Metal Screw (3)

18. 5/16" Flat Washer (1)

14

15

16

17

18

Page 9

9

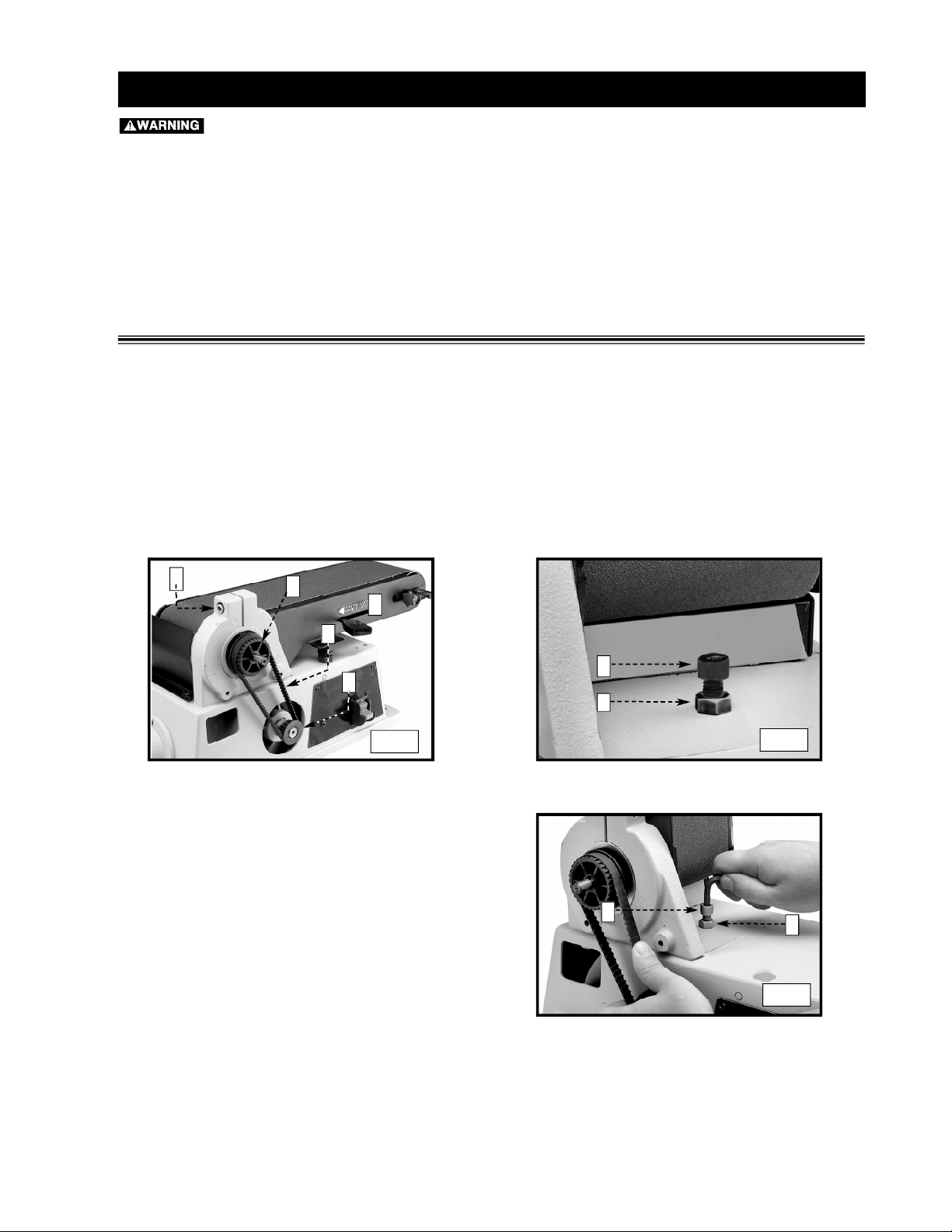

A S S E M B LY

A S S E M B LY TOOLS REQUIRED

A S S E M B LY TIME ESTIMAT E

1/8" Hex Wrench (Supplied)

6 mm Hex Wrench (Supplied)

Phillips Screwdriver

Adjustable Wrench

Less than one hour

For your own safety, do not connect the machine to the power source until the machine is

completely assembled and you read and understand the entire instruction manual.

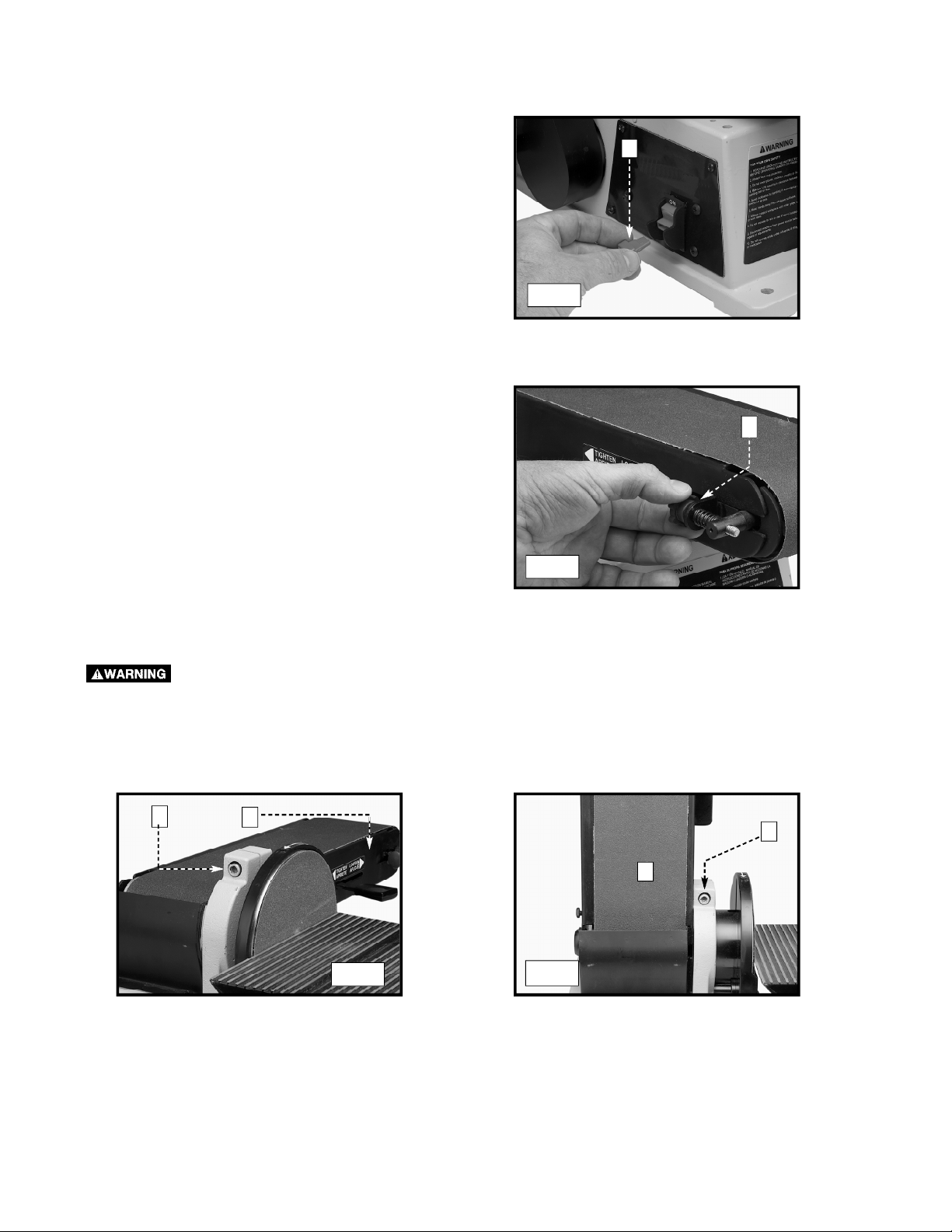

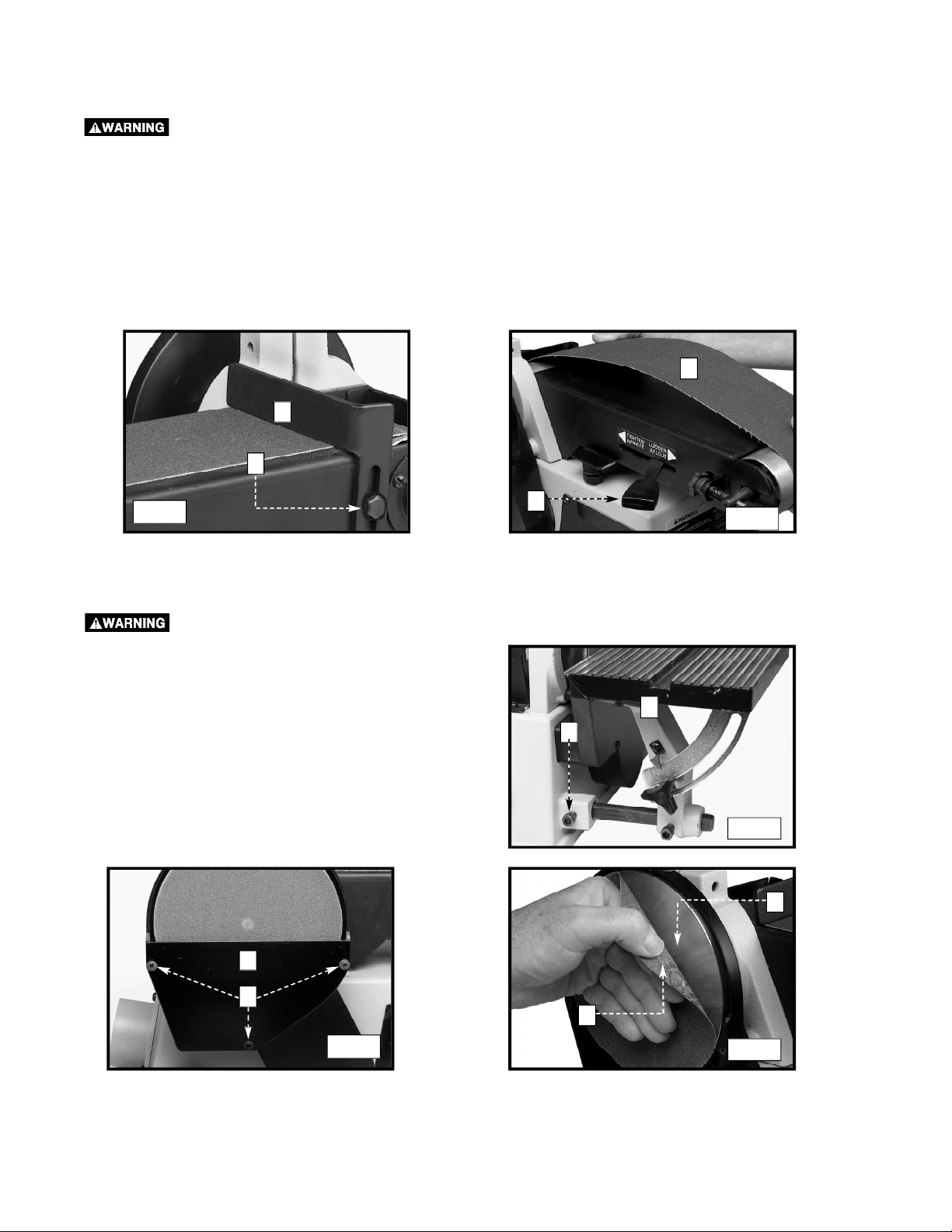

Your sander was shipped from the factory with the drive belt (A) Fig. 1 attached to both pulleys (B) and (C). Before

assembling the machine, check and adjust the belt tension.

1. Loosen the screw (D) Fig. 1 with the 6mm hex wrench, and move the sanding arm (E) to the vertical position to

expose belt tensioning screw (F) Fig. 2, and locknut (G).

ADJUSTING THE BELT TENSION

D

B

E

C

A

Fig. 1

Fig. 2

2. Check the belt tension by applying light pressure on

the belt halfway between the two pulleys.The belt has

the correct tension when you can deflect it

approximately 1/4".

NOTE: The belt does not require excessive tension to

function properly.

3. To adjust, loosen the locknut (A) Fig. 3, and tighten or

loosen the adjusting screw (B) with the supplied 6mm

hex wrench until the belt has the correct tension.

4. Tighten locknut (A).

5. Move the sanding arm to the horizontal position.

Fig. 3

F

G

A

B

Page 10

10

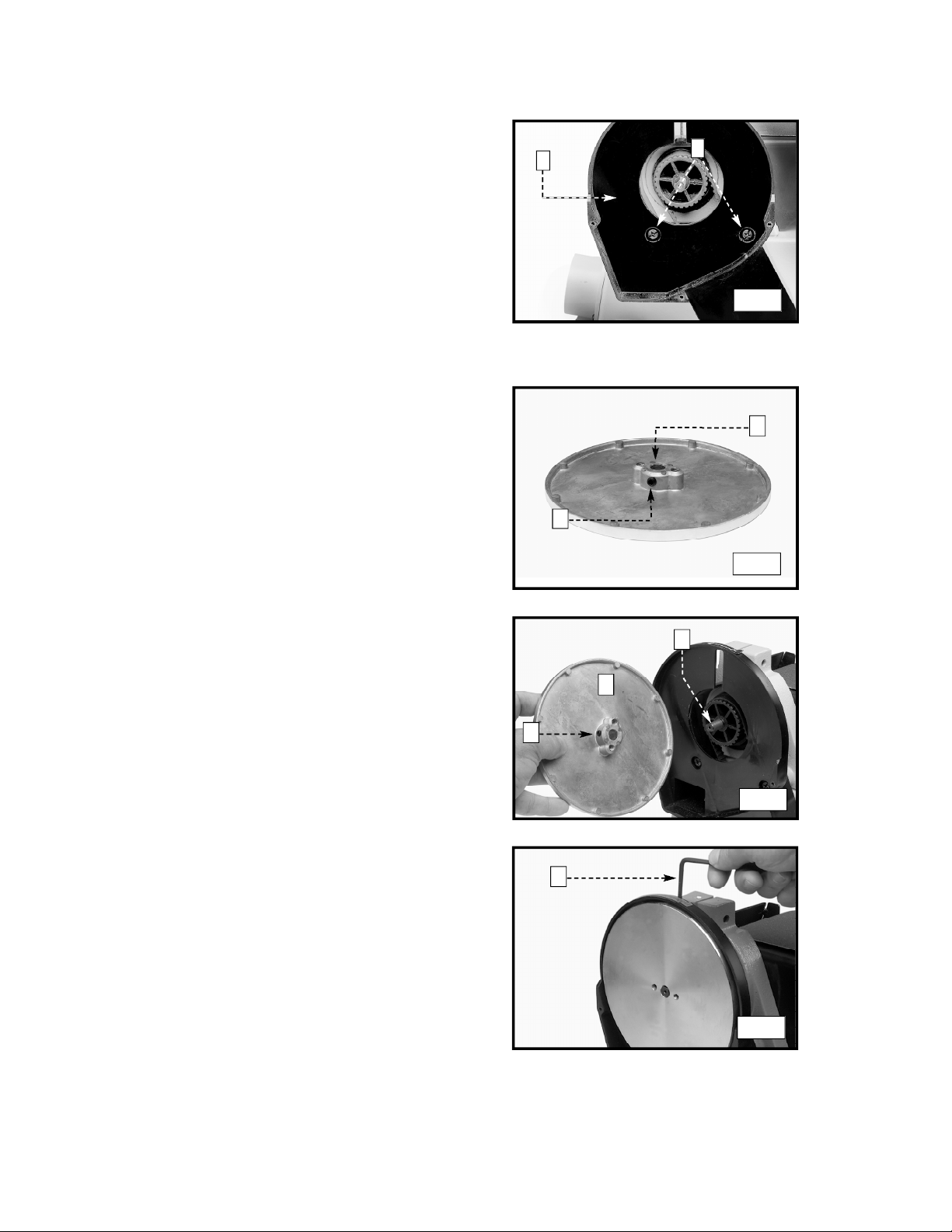

Attach the belt and pulley guard (A) Fig. 4 to the machine

base using the two M6x1x30mm cheese head screws

(B).

1. Turn the 1/4-20 x 1/4" hex socket set screw (A) Fig.

5 counter-clockwise until it clears the hole (B) in the

sanding plate.

2. Align the flat of the drive shaft with the set screw (A)

Fig. 6 in the hub of the plate (B) and install the

sanding disc plate (B) on the drive shaft. Slide the

plate (B) on the shaft (C) until the plate surface and

the shaft are flush.

3. Use the supplied 1/8" hex wrench (A) Fig. 7 to

tighten the set screw, located in the slot in the back

of belt and pulley guard.

ATTACHING THE BELT AND PULLEY GUARD

Fig. 4

B

A

INSTALLING THE SANDING DISC PLATE

A

B

Fig. 5

Note: Do not allow the shaft to extend past the surface

of the plate.

Fig. 6

Fig. 7

A

B

C

A

Page 11

11

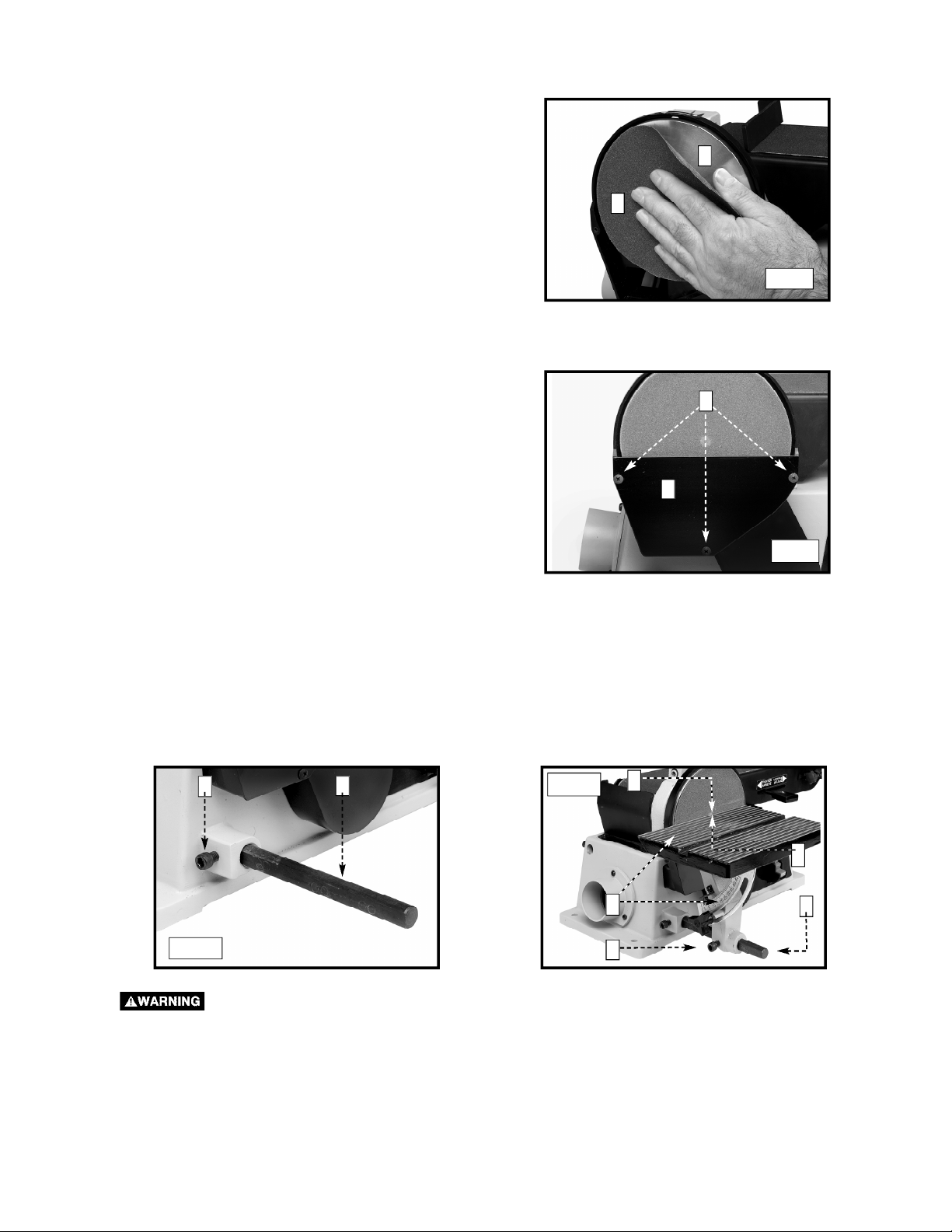

1. Clean the sanding disc plate (A) Fig. 8.

2. Peel the backing from sanding disc and press the

disc (B) firmly into position all the way around the

sanding plate (Fig. 8).

Install the lower cover (A) Fig. 9 on the belt and pulley

guard, using the three M4 x .7 x 12mm sheet metal

screws (B).

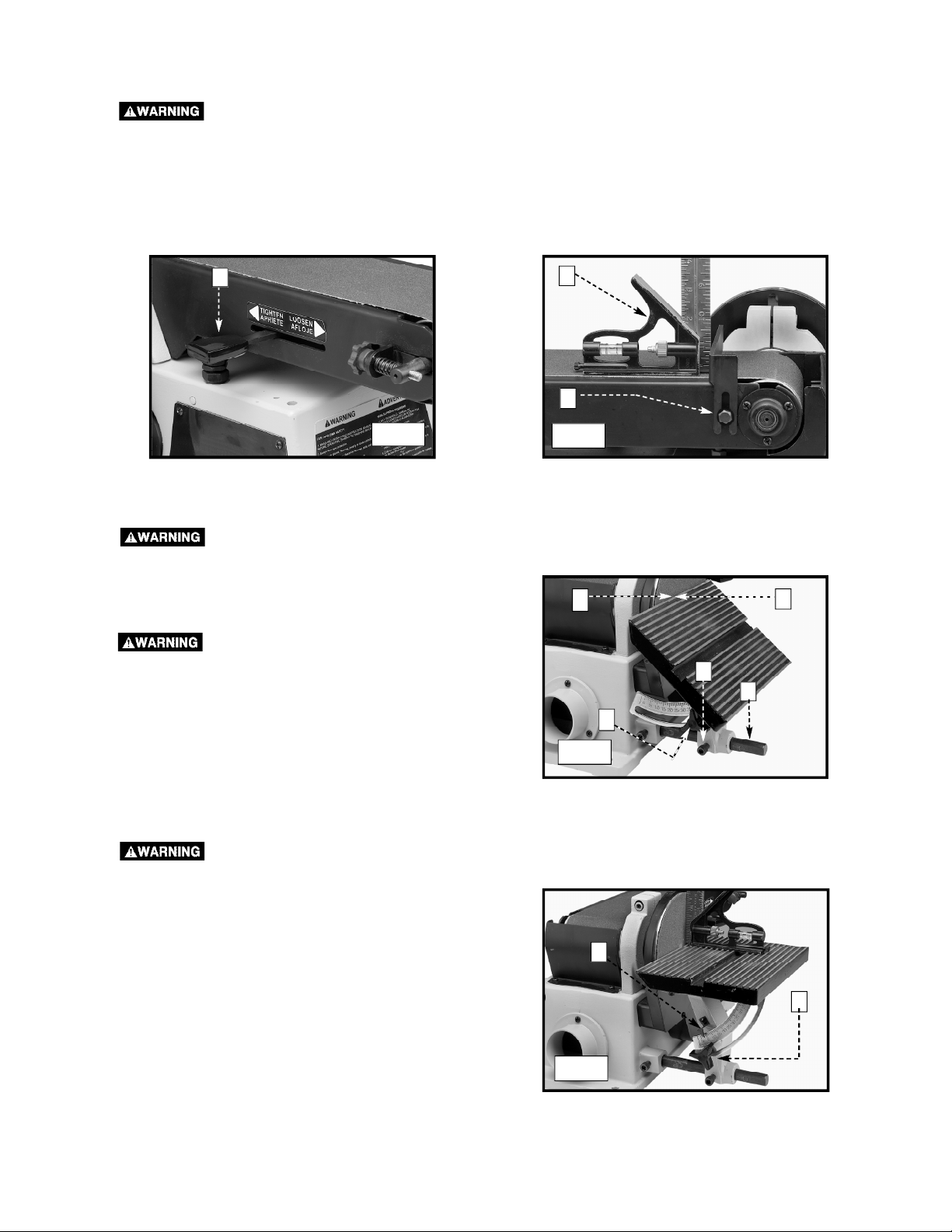

1. Thread an M8 x 1.25 x 20mm hex socket head screw (A) Fig. 10 partially into the hole in the base of the sander.

Insert the rod (B) into the hole. Align the flat of the rod (B) with the screw (A). Tighten the screw (A).

2. Slide the table assembly (C) Fig. 11 on the rod (B).

3. Thread an M8 x 1.25 x 20mm hex socket head screw (A) Fig. 11 into the hole in the table support bracket. Align the

flat on the rod (B) with the screw (A). Tighten the screw (A).

To avoid trapping the work or fingers between the table and the sanding disc, the table edge (E)

Fig. 11 should be positioned a maximum of 1/16" away from the sanding disc (F). Loosen the

screw (A) and adjust the table accordingly.

ATTACHING THE SANDING DISC

B

A

Fig. 8

ATTACHING THE LOWER COVER FOR THE SANDING DISC

B

A

INSTALLING THE DISC SANDER TABLE

Fig. 9

Fig. 10

Fig. 11

A B

A

B

C

F

E

Page 12

12

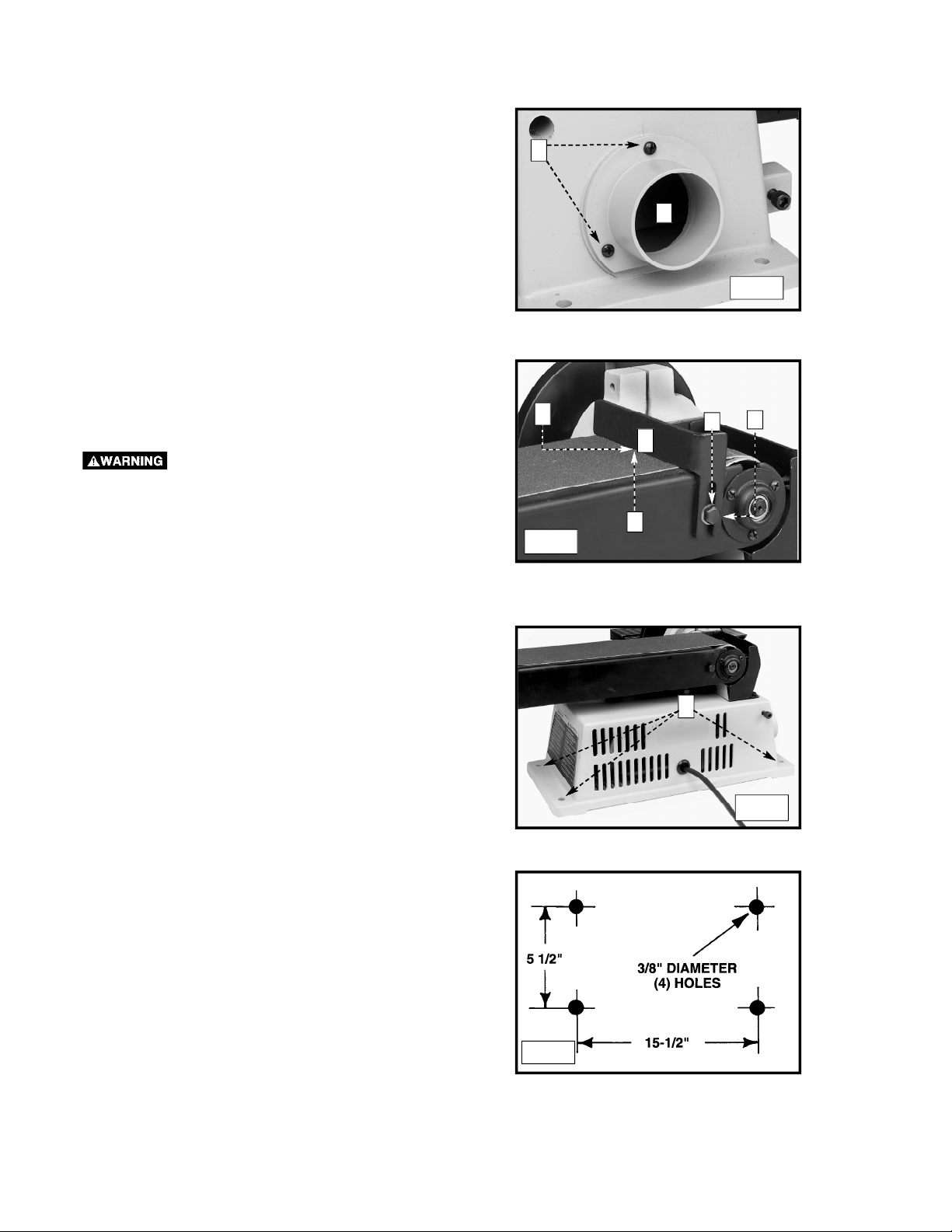

Align the three holes in the dust chute (A) Fig. 12 with the

three holes in the left side of the sanding base. Insert the

pan head screw (B) Fig.12 through the hole in the dust

spout and thread it into the taped hole in the sander

base. Repeat this process for the two remaining holes.

FASTENING THE SANDER TO A SUPPORTING SURFACE

1. To use your sander in a permanent location, fasten it

securely to a firm supporting surface, such as a stand

or workbench. Use the four holes, three of which are

shown at (A) Fig. 14.

2. The diagram in Fig. 15 illustrates the size and

center-to-center distance of the holes to be drilled in

the stand or workbench.

ATTACHING THE DUST CHUTE

INSTALLING THE BACKSTOP ON THE SANDING ARM

Install the backstop (A) Fig. 13 on the sanding arm using

the 1/4-20 x 1/2" hex head screw (B) and 5/16" flat

washer (C).

To avoid trapping the work or fingers

between the backstop and the sanding

belt, the edge of the backstop (D) Fig.

13 should be positioned a maximum of

1/16" away from the sanding belt (E).

A

B

A

C

B

D

E

Fig. 12

Fig. 13

A

Fig. 14

Fig. 15

Page 13

13

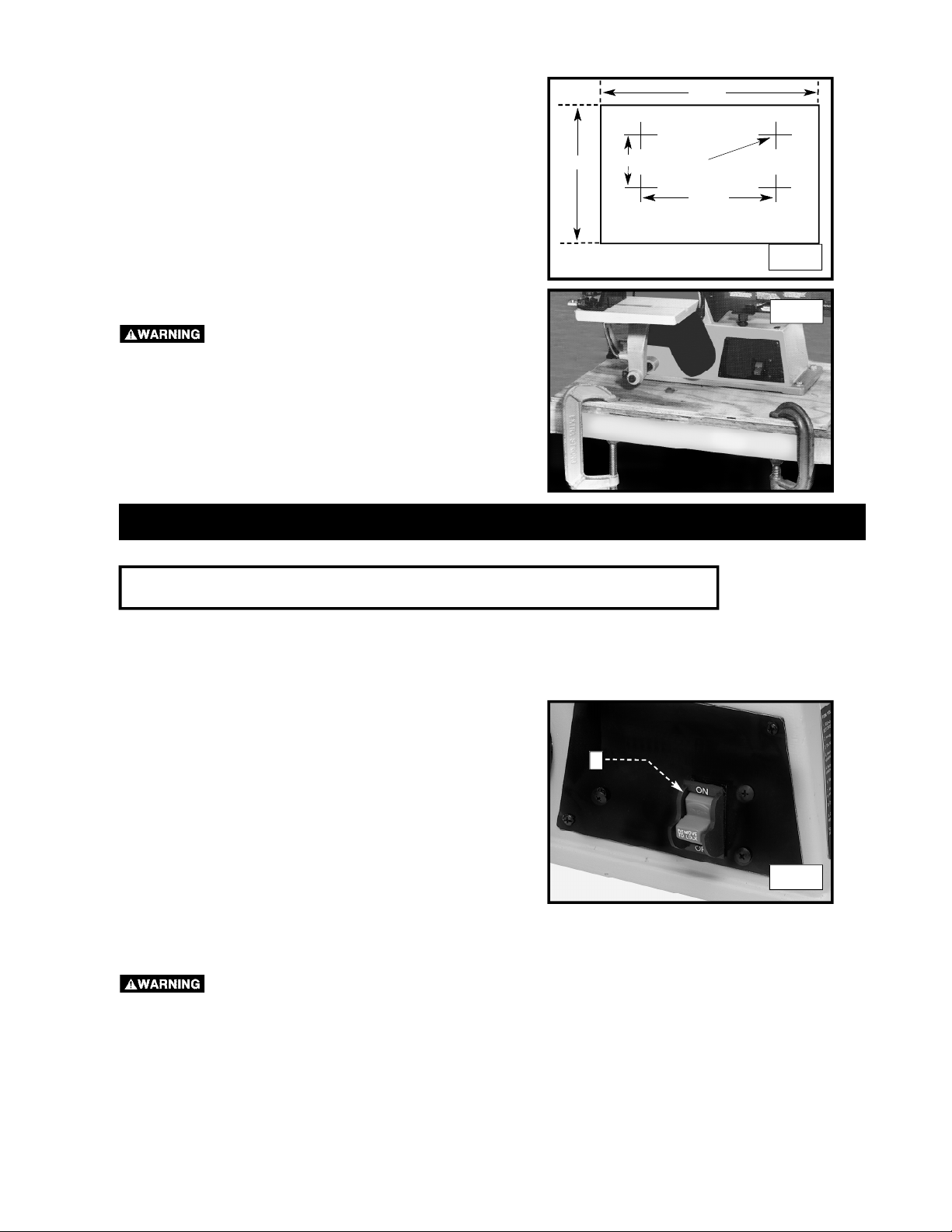

3. Alternately, you can secure the sander by fastening it

to a mounting board 18" x 24" or larger. The diagram

in Fig. 16 shows the size and center-to-center

distance of the holes that you will need to drill in the

mounting board.

N O T E : For proper stability, countersink the holes

underneath the mounting board so that the screw heads

are flush with bottom surface.

4. Securely clamp the mounting board to a stand or

workbench using 2 or more “‘C” clamps, as shown in

Fig. 17.

Secure the machine base to the supporting

surface. If there is any tendency for the stand or workbench

to move during operation, the stand or workbench must be

fastened to the floor.

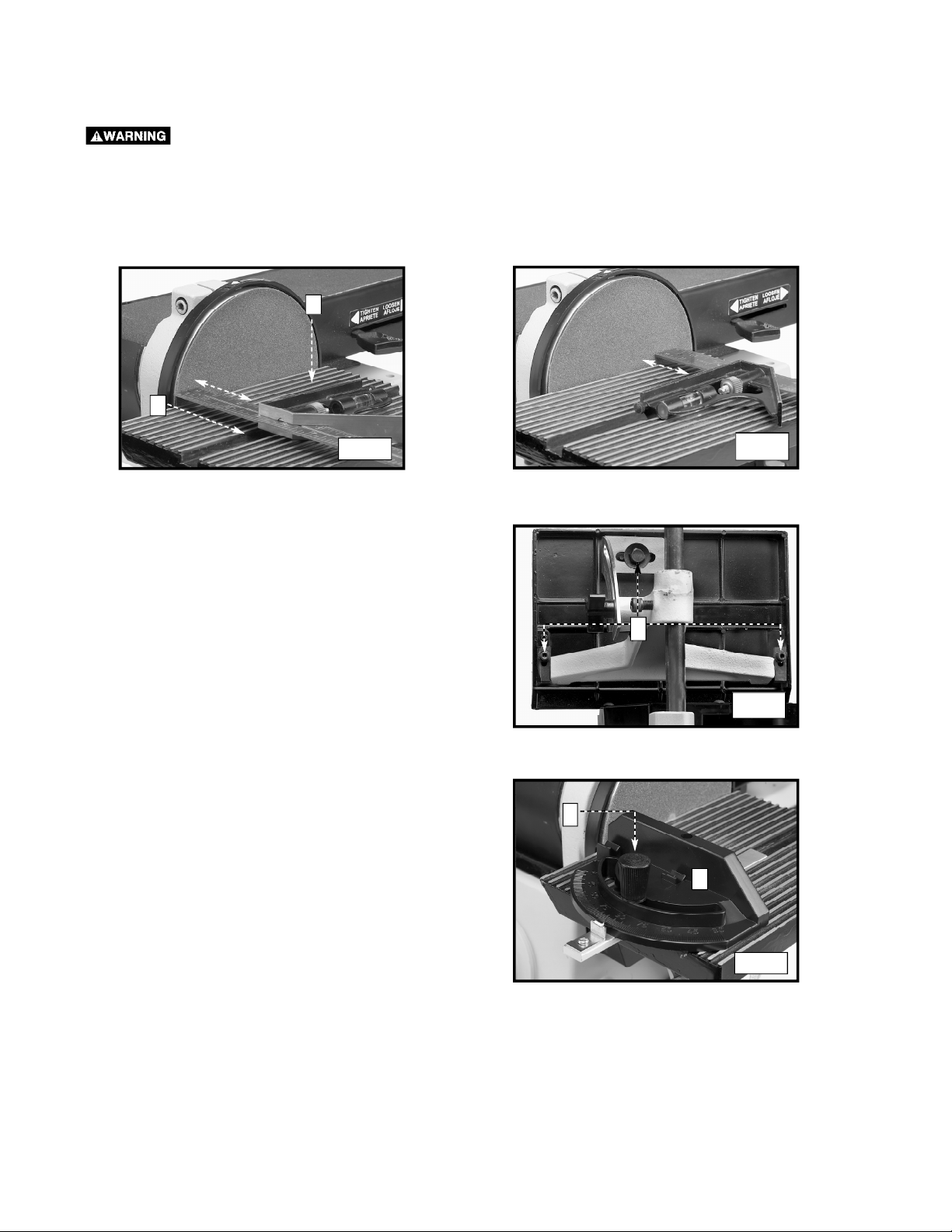

1. The on/off switch (A) Fig. 18 is located on the front

of the sander. To turn the machine “ON”, move

the switch up to the “ON” position.

2. To turn the machine “OFF”, move the switch (A)

down to the “OFF” position.

O P E R AT I O N

O P E R AT I O N A L CONTROLS AND ADJUSTMENTS

Make sure that the switch is in the “OFF” position before plugging in the power cord. In the event of

a power failure, move the switch to the “OFF” position. An accidental start-up can cause injury.

A

STARTING AND STOPPING THE SANDER

Fig. 16

Fig. 17

Fig. 18

l l

l l

18 MIN

5-1/2"

15-1/2"

24 MIN

3/8" DIAMETER

(4) HOLES

Page 14

14

1. Turn the switch “ON” to see if the sanding belt

moves to one side or the other on the sanding drums.

If the belt rides on the center of the sanding drums, it

is tracking properly. Turn the switch “OFF”.

2. If the sanding belt moves toward the disc, turn the

tracking knob (A) Fig. 20 counter-clockwise 1/4 turn.

3. If the sanding belt moves away from the disc, turn the

tracking knob (A) Fig. 20 clockwise 1/4 turn.

4. Check again to see if the belt is tracking properly.

IMPORTANT: When the tool is not in use, the switch

should be locked in the “OFF” position to prevent

unauthorized use. To lock the machine, grasp the switch

toggle (A) and pull it out of the switch (Fig. 19). With the

switch toggle (A) removed, the switch will not operate.

However, should the switch toggle be removed while the

saw is running, the machine can be turned “OFF,” but

cannot be restarted without re-inserting the switch toggle.

LOCKING THE SWITCH IN THE “OFF” POSITION

Fig. 19

TRACKING THE SANDING BELT

Fig. 20

CHANGING THE POSITION OF THE SANDING ARM

You can use the sanding arm (A) in the horizontal position (Fig. 21), the vertical position (Fig. 22), or any angle in

between. Loosen the screw (B), position the arm (A) to the desired angle, and tighten the screw (B).

DISCONNECT MACHINE FROM POWER SOURCE.

A

A

B

A

B

A

Fig. 21

Fig. 22

Page 15

15

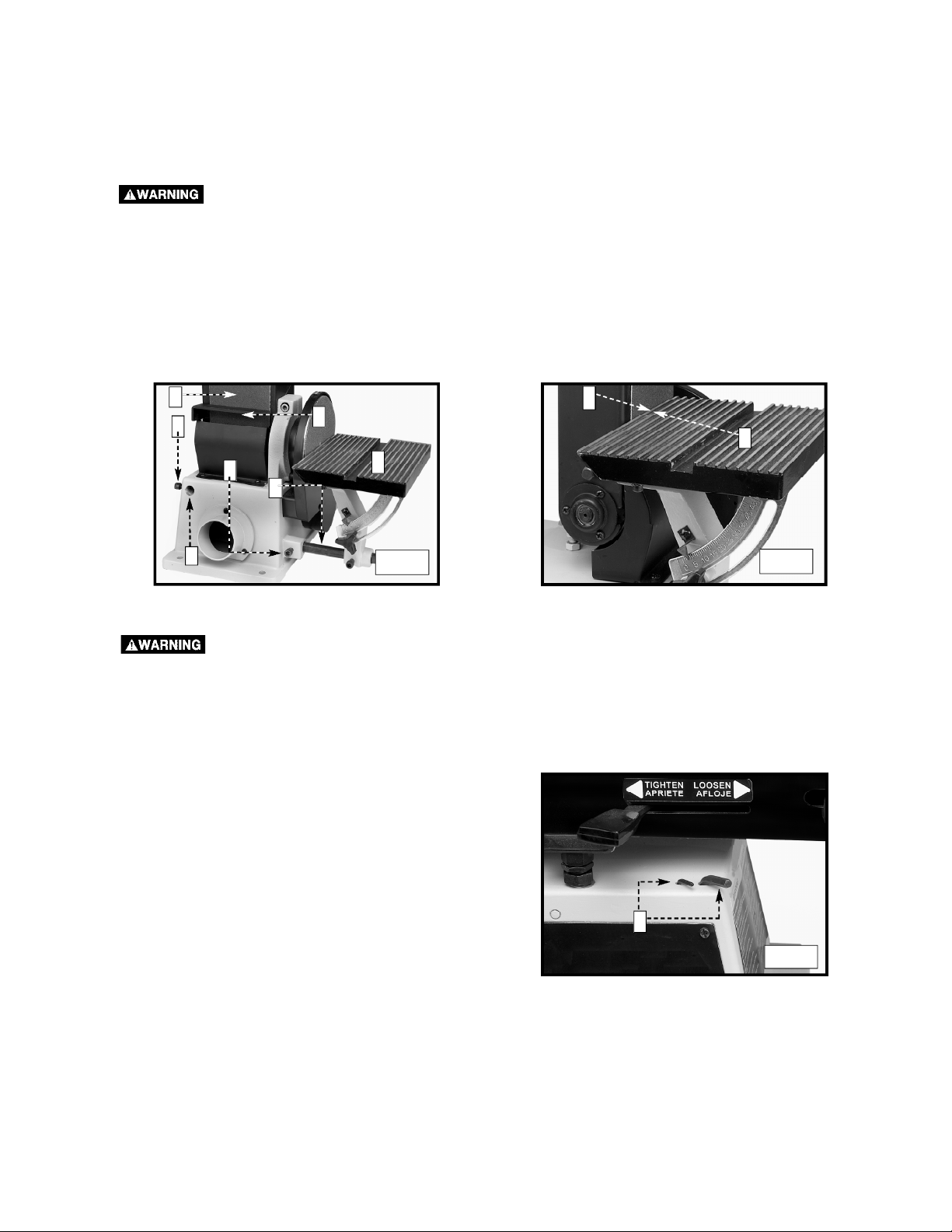

1. Before adjusting, move the belt tension lever (A) Fig. 23 all the way to the left to the "TIGHTEN" position.

2. Place a square (B) Fig. 24 on the sanding belt with one end of the square against the backstop. See if the backstop

is square with the sanding belt.

3. Loosen the screw (C) Fig. 24 and adjust the backstop.

After tilting, the table must be

repositioned on the support rod (B) Fig. 25 to provide

a maximum of 1/16" distance between the sanding

disc (C) and the edge (D) of the table to avoid

trapping the work or fingers between the disc and

the table. To reposition the table assembly, loosen

the screw (E), move the table assembly on the rod (B)

and tighten the screw.

1. Use a combination square with one end on the table

and the other end against the sanding disc (Fig. 26).

See if the table is 90 degrees to the disc.

2. To adjust, loosen the table lock knob (A) Fig. 26,

move the table square with the disc and tighten the

lock knob (A).

3. Adjust the pointer (B) Fig. 26 to the "0" degree mark

on the angle scale.

ADJUSTING THE BACKSTOP SQUARE WITH THE SANDING BELT

DISCONNECT MACHINE FROM POWER SOURCE.

A

Fig. 23

Fig. 24

B

C

TILTING THE TABLE

You can tilt the table up to 45 degrees to the right by

loosening the table lock knob (A) Fig. 25.

DISCONNECT MACHINE FROM POWER SOURCE.

Fig. 25

A

E

B

C D

ADJUSTING THE TABLE SQUARE WITH THE SANDING DISC

DISCONNECT MACHINE FROM POWER SOURCE.

A

B

Fig. 26

Page 16

16

2. To adjust, loosen the three screws (B) Fig. 29 that

fasten the table to the table mounting bracket and

trunnion. Adjust the table accordingly - then tighten

the three screws (B).

MITER GAUGE

Use the miter gauge (A) Fig. 30 on the disc table. You can

rotate the miter gauge body right or left for angle or miter

sanding by loosening the lock knob (B), rotating the miter

gauge body, and tightening the lock knob.

1. Place an adjustable combination square on the table with the part (A) Fig. 27 in the miter gauge slot (B) to check

the distance from the slot to the sanding disc. Check the other side of the disc in the same manner (Fig. 28). The

distances should be the same.

ADJUSTING THE MITER GAUGE SLOT PARALLEL WITH THE SANDING DISC

DISCONNECT MACHINE FROM POWER SOURCE.

A

B

Fig. 27

Fig. 28

B

A

B

Fig. 29

Fig. 30

Page 17

17

When you use the sanding arm (A) Fig. 31 in the vertical position, you can move the complete table assembly (B) from

the disc unit to the belt unit.

Two holes are provided in the base casting to store the

two wrenches (A) Fig. 33, supplied with the sander.

USING THE TABLE ASSEMBLY WITH THE SANDING ARM

DISCONNECT MACHINE FROM POWER SOURCE.

1. Remove the backstop (C) Fig. 31.

2. Thread the M8 x 1.25 x 20mm hex socket head screw (D) Fig. 31 ONLY PART OF THE WAY into the base casting.

3. Loosen the screw (E) Fig. 31, and remove the table assembly (B) from the disc unit. Insert the bar (F) into the hole

(G) on the belt unit. Align the flat on the shaft with the screw in the casting and tighten the screw.

Fig. 31

C

A

D

G

E

F

B

To avoid trapping the work or fingers between the backstop and the sanding belt, the edge of the

table (A) Fig. 32 should be positioned a maximum of 1/16" away from the sanding belt (B).

Fig. 32

B

A

WRENCH STORAGE

Fig. 33

A

Page 18

18

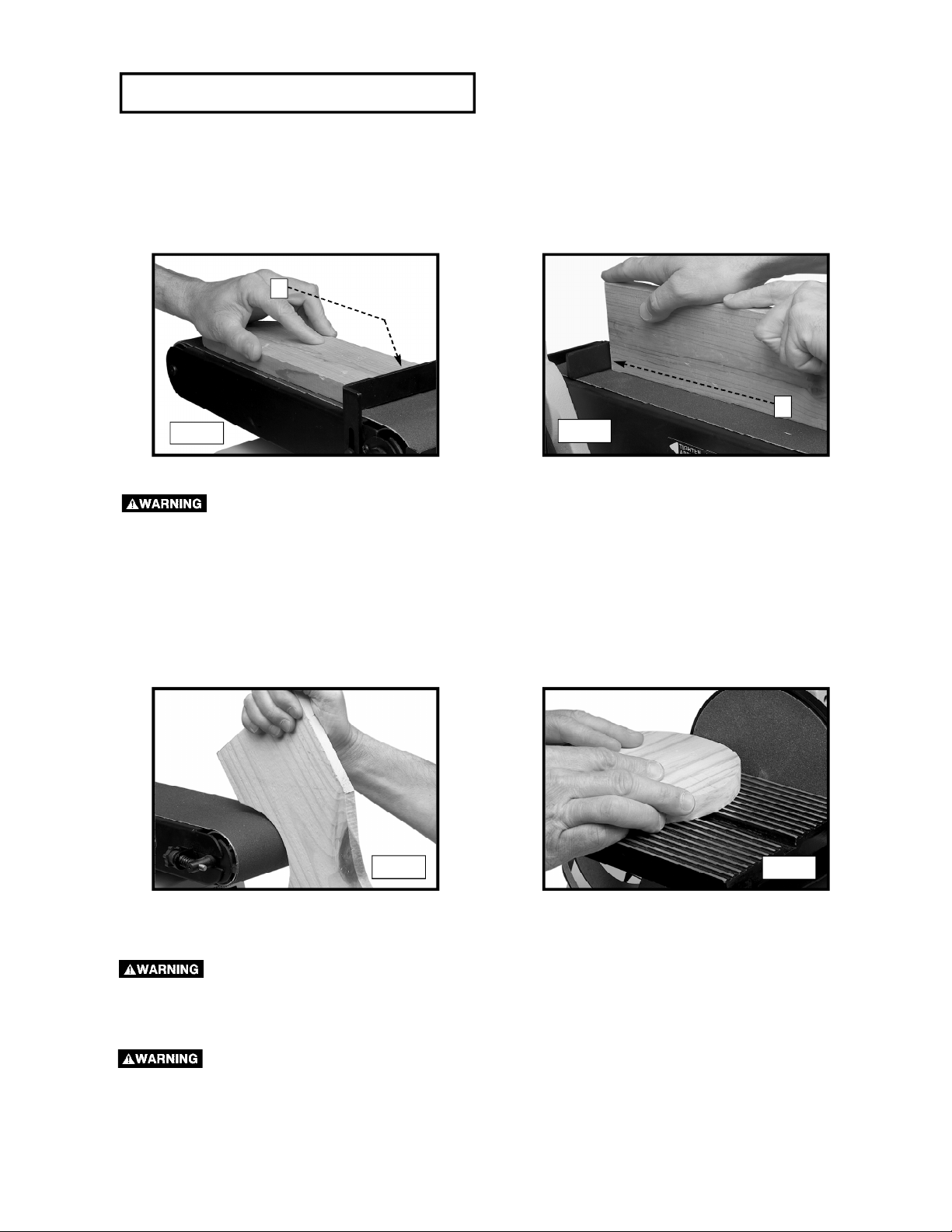

1. Loosen the screw (A) Fig. 34 and remove the backstop (B).

2. Slide the tension lever (C) Fig. 35 to the right to release the tension on the sanding belt. Remove the sanding belt

(D) from both sanding drums.

3. An arrow is printed on the back of the sanding belt to indicate the travel direction of the belt. Make certain that this

arrow and the arrow on the machine match. Slide the new sanding belt over both sanding drums.

4. Apply belt tension by sliding the tension lever (C) Fig. 35 to the left.

5. Replace the backstop that was removed in STEP 2.

6. Connect the power source to the sander. Check the belt tracking. (Refer to the section "TRACKING THE SANDING

BELT").

REPLACING THE SANDING BELT

DISCONNECT MACHINE FROM POWER SOURCE.

Fig. 34

A

Fig. 35

B

REPLACING THE SANDING DISC

DISCONNECT MACHINE FROM POWER SOURCE.

1. Loosen the screw (A) Fig. 36 to remove the table

assembly (B).

2. Remove the three screws (B) Fig. 37. Remove the

cover (D).

4. Peel off the old disc (E) Fig. 38.

5. Clean the disc plate (F) Fig 38. Peel the backing

from new sanding disc. Press the new sanding disc

firmly into position on disc plate (F) and replace the

lower cover and table assembly removed in STEPS

1 and 2.

D

C

A

B

D

B

E

F

Fig. 36

Fig. 37

Fig. 38

Page 19

19

M A C H I N E U S E

SURFACING OR EDGE SANDING WITH THE SANDING BELT

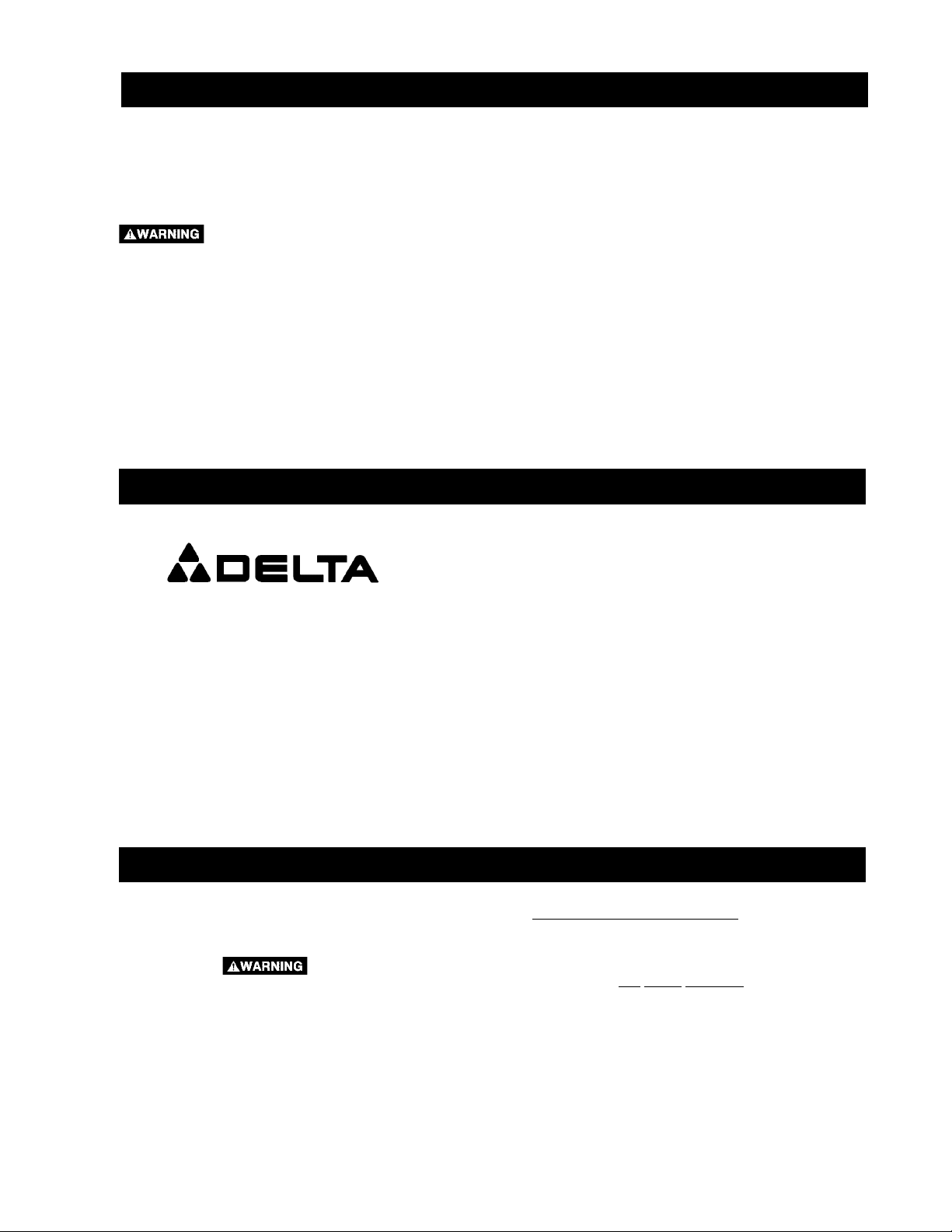

Always use the backstop (A) Figs. 39 and 40 when surface-sanding (Fig. 39) or when edge sanding Fig. 40. Hold the

workpiece firmly and keep your fingers away from the sanding belt. Keep the end of the workpiece against the backstop

and move the workpiece evenly across the sanding belt. Apply only enough pressure to allow the sanding belt to remove

material. Use extra caution when sanding very thin pieces.

Fig. 39

Fig. 40

A

A

To avoid trapping the work or fingers between the backstop and the sanding belt, the edge of the

table should be positioned a maximum of 1/16" away from the sanding belt .

Sanding inside curves with the sanding belt is illustrated in Fig. 41.

Sanding outside curves with the sanding disc is illustrated in Fig. 42.

SANDING INSIDE AND OUTSIDE CURVES

Fig. 42

Fig. 41

Always sand on the left (downward) side of the sanding disc (Fig. 41). Sanding on the right

(upward) side of the sanding disc could cause the workpiece to fly up suddenly which could be

hazardous.

To avoid trapping the work or fingers between the backstop and the abrasive, the edge of the

table should be positioned a maximum of 1/16" away from the abrasive .

Page 20

20

END SANDING WITH THE BELT

When sanding the ends of wide workpieces, use the sanding belt with the sanding arm in the vertical position and the

table assembly moved to the sanding belt (Fig. 43). See the sections “CHANGING POSITION OF SANDING ARM”

and “USING TABLE ASSEMBLY WITH SANDING BELT”.

For more accurate work, use the supplied miter gauge to move the work evenly across the sanding belt (Fig. 43).

END SANDING WITH THE DISC

When sanding the ends of narrow workpieces, use the sanding disc and the miter gauge (Fig. 44). Move the work from

the center to the left side of the sanding disc.

To avoid trapping the work or fingers between the backstop and the sanding belt, the edge of the

table should be positioned a maximum of 1/16" away from the sanding belt .

Always sand on the left (downward) side of the sanding disc (Fig. 44). Sanding on the right

(upward) side of the sanding disc could cause the workpiece to fly up suddenly which could be

hazardous.

To avoid trapping the work or fingers between the backstop and the abrasive, the edge of the

table should be positioned a maximum of 1/16" away from the abrasive .

Fig. 43

Fig. 44

T R O U B L E S H O O T I N G

FAILURE TO STA R T

Should your machine fail to start, check to make sure the prongs on the cord plug are making good contact in the outlet. A l s o ,

check for blown fuses or open circuit breakers in the line.

For assistance with your machine, visit our website at www.deltamachinery.com for a list of service centers or call

the DELTA Machinery help line at 1-800-223-7278 (In Canada call 1-800-463-3582).

Page 21

21

M A I N T E N A N C E

PARTS, SERVICE OR WARRANTY ASSISTANCE

All Delta Machines and accessories are manufactured to high quality standards and are serviced by a network

of Porter-Cable · Delta Factory Service Centers and Delta Authorized Service Stations. To obtain additional

information regarding your Delta quality product or to obtain parts, service, warranty assistance, or the location

of the nearest service outlet, please call 1-800-223-7278 (In Canada call 1-800-463-3582).

A complete line of accessories is available from your Delta Supplier, Porter-Cable · Delta Factory Service Centers,

and Delta Authorized Service Stations. Please visit our Web Site

www.deltamachinery.com

for a catalog or for

the name of your nearest supplier.

Since accessories other than those offered by Delta have not been tested

with this product, use of such accessories could be hazardous. F o r s a f e s t o p e r a t i o n, only

Delta recommended accessories should be used with this product.

ACCESSORIES

KEEP MACHINE CLEAN

Periodically blow out all air passages with dry compressed

a i r . All plastic parts should be cleaned with a soft damp cloth.

NEVER use solvents to clean plastic parts. They could

possibly dissolve or otherwise damage the material.

Wear ANSI Z87.1 safety glasses while

using compressed air.

L U B R I C AT I O N

Apply household floor paste wax to the machine table and

extension table or other work surface weekly.

PROTECTING CAST IRON FROM RUST

To clean and protect cast iron tables from rust, you will

need the following materials: 1 pushblock from a jointer, 1

sheet of medium Scotch-Brite™ Blending Hand Pad, 1

can of WD-40®, 1 can of degreaser, 1 can of To p C o t e

®

Aerosol. Apply the WD-40 and polish the table surface

with the Scotch-Brite pad using the pushblock as a

holddown. Degrease the table, then apply the To p C o t e

®

a c c o r d i n g l y.

S E R V I C E

Page 22

22

Two Year Limited New Product Wa r r a n t y

Delta will repair or replace, at its expense and at its option, any new Delta machine, machine part, or machine accessory

which in normal use has proven to be defective in workmanship or material, provided that the customer re t u rns the pro d u c t

p r epaid to a Delta factory service center or authorized service station with proof of purchase of the product within two

years and provides Delta with reasonable opportunity to verify the alleged defect by inspection. For all refurbished Delta

p r oduct, the warranty period is 180 days. Delta may re q u i re that electric motors be re t u rned prepaid to a motor

m a n u f a c t u r e r ’s authorized station for inspection and repair or replacement. Delta will not be responsible for any asserted

defect which has resulted from normal wear, misuse, abuse or repair or alteration made or specifically authorized by

anyone other than an authorized Delta service facility or re p r esentative. Under no circumstances will Delta be liable for

incidental or consequential damages resulting from defective pro d u c t s . This warranty is Delta’s sole warranty and sets

forth the customer’s exclusive re m e d y, with respect to defective products; all other warranties, express or implied, whether

of merc h a n t a b i l i t y, fitness for purpose, or otherwise, are expressly disclaimed by D e l t a .

WARRANTY

Page 23

232323

23

23

2323

Para obtener más información sobre Delta Machinery,

visite nuestro sitio web en: www.deltamachinery.com

Para las piezas, el servicio, la garantía o la otra ayuda

llaman por favor

1-800-223-7278 (

en la llamada

1-800-463-3582

de Canada

).

Lijadora de Correa de 4"

/ Disco de 6

"

(Modelo SM500)

491836-00 REV. 1 05-18-06

Copyright © 2006 Delta Machinery

Page 24

24

Lea y entienda todas advertencias y las instrucciones operadoras antes de utilizar cualquier instrumento o el equipo.

Cuando se usa instrumentos o equipo, las precauciones básicas de la seguridad siempre se deben seguir para reducir el riesgo de la herida

personal. La operación impropia, la conservación o la modificación de instrumentos o equipo podrían tener como resultado el daño grave

de la herida y la propiedad. Hay ciertas aplicaciones para que equipaas con herramienta y el equipo se diseña. La Delta Machinery

recomienda totalmente que este producto no sea modificado y/o utilizado para ninguna aplicación de otra manera que para que se diseñó.

Si usted tiene cualquiera pregunta el pariente a su aplicación no utiliza el producto hasta que usted haya escrito Delta Machinery y nosotros

lo hemos aconsejado.

La forma en línea del contacto en www. deltamachinery. com

El Correo Postal: Technical Service Manager

Delta Machinery

4825 Highway 45 North

Jackson, TN 38305

(IN CANADA: 125 Mural St. Suite 300, Richmond Hill, ON, L4B 1M4)

Información con respecto a la operación segura y apropiada de este instrumento está disponible de las fuentes siguientes:

Power Tool Institute

1300 Sumner Avenue, Cleveland, OH 44115-2851

www.powertoolinstitute.org

National Safety Council

1121 Spring Lake Drive, Itasca, IL 60143-3201

American National Standards Institute, 25 West 43rd Street, 4 floor, New York, NY 10036 www.ansi.org

A N S I 01.1Safety Requirements for Wo o d w o r k i n g Machines, and the U.S. Department of Labor re g u l a t i o n s

www.osha.gov

INSTRUCCIONES DE SEGURIDAD IMPORTANTES

GUARDE ESTAS INSTRUCCIONES!

Page 25

25

Indica una situación de inminente riesgo, la cual, si no es evitada, causará la muerte o lesiones serias.

Indica una situación potencialmente riesgosa, que si no es evitada, podría resultar en la muerte o lesiones

s e r i a s .

Indica una situación potencialmente peligrosa, la cual, si no es evitada, podría resultar en lesiones menores o

m o d e - r a d a s .

Usado sin el símbolo de seguridad de alerta indica una situa-ción potencialmente riesgosa la que, si no es

evitada, podría causar daños en la pro p i e d a d .

PAUTAS DE SEGURIDAD/DEFINICIONES

Algunas partículas originadas al lijar, aserrar, amolar, taladrar y realizar otras actividades de

construcción contienen productos químicos que producen cáncer, defectos de nacimiento y otros problemas

reproductivos. Algunos ejemplos de estos productos químicos son:

• el plomo de las pinturas de base plomo,

• la sílice cristalina de ladrillos, cemento y otros productos de mampostería,

• el arsénico y el cromo de la madera con tratamiento químico (CCA).

El riesgo derivado de estas exposiciones varía según la frecuencia con la que se realice este tipo de trabajo. Para reducir la

exposición a estos productos químicos: se recomienda trabajar en áreas bien ventiladas y usar equipos de seguridad aprobados,

como las máscaras para polvo especialmente diseñadas para filtrar las partículas microscópicas.

• Evite el contacto prolongado con las partículas de polvo originadas al lijar,

aserrar, esmerilar, taladrar y realizar demás actividades de la construcción. Use indumentaria protectora y lave las

áreas expuestas con agua y jabón. Evite que el polvo entre en la boca y en los ojos o se deposite en la piel, para impedir la

absorción de productos químicos nocivos.

El uso de esta herramienta puede generar o dispersar partículas de polvo, que pueden causar lesiones respiratorias permanentes

y graves u otras lesiones. Use siempre protección respiratoria aprobada por NIOSH/OSHA (Instituto Nacional de Salud y

Seguridad Ocupacional de EE.UU./Administración de la Salud y Seguridad Ocupacional de EE.UU.) apropiada para la exposición

al polvo. Aleje las partículas de la cara y el cuerpo.

Utilice la protección auditiva apropiada mientras usa la herramienta. En ciertas condiciones y según el período de uso, el

ruido provocado por este producto puede llevar a la pérdida de audición.

LIJADO DE PINTURA DE BASE PLOMO

NO SE RECOMIENDA lijar pintura de base plomo debido a la dificultad para controlar el polvo contaminado. El peligro mayor de

envenenamiento por plomo es para los niños y las mujeres embarazadas.

Como es difícil identificar si una pintura contiene o no plomo sin realizar análisis químicos, recomendamos tomar las siguientes

precauciones al lijar cualquier pintura:

SEGURIDAD PERSONAL

• Ningún niño o mujer embarazada debe ingresar al área de trabajo donde se está lijando la pintura hasta que se haya terminado

la limpieza final.

• Todas las personas que ingresan al área de trabajo deben usar una máscara para polvo o una mascarilla de respiración. El filtro

se debe cambiar diariamente o toda vez que el usuario tenga dificultad para respirar.

NOTA: Sólo se deben usar aquellas máscaras para polvo apropiadas para trabajar con polvo y vapores de pintura de base

plomo. Las máscaras comunes para pintar no ofrecen esta protección. Consulte a su comerciante local sobre la máscara

apropiada (aprobada por NIOSH).

• NO SE DEBE COMER, BEBER O FUMAR en el área de trabajo para evitar ingerir partículas de pintura contaminada. Los

trabajadores se deben lavar y limpiar ANTES de comer, beber o fumar. No se deben dejar artículos para comer, beber o fumar en

el área de trabajo donde se podría depositar polvo sobre ellos.

SEGURIDAD AMBIENTAL

• La pintura debe ser retirada de forma tal de reducir al mínimo la cantidad de polvo generado.

• Las áreas donde se realiza remoción de pintura deben estar selladas con hojas de plástico de 4 milésimas de pulgada de

espesor.

• El lijado se debería realizar de manera de reducir los vestigios de polvo de pintura fuera del área de trabajo.

LIMPIEZA Y ELIMINACIÓN

• Todas las superficies del área de trabajo deben ser limpiadas cuidadosamente y repasadas con aspiradora todos los días

mientras dure el proyecto de lijado. Se deben cambiar con frecuencia las bolsas de filtro de la aspiradora.

• Las telas plásticas del piso se deben recoger y eliminar junto con cualquier resto de polvo u otros residuos del lijado. Deben

colocarse en recipientes de desperdicios sellados y eliminarse por medio de los procedimientos normales de recolección de

residuos. Durante la limpieza, los niños y las mujeres embarazadas deben mantenerse lejos del área de trabajo inmediata.

• Todos los juguetes, muebles lavables y utensilios utilizados por los niños deben ser lavados cuidadosamente antes de ser

utilizados nuevamente.

RIESGO DE INCENDIOS. El polvo acumulado que se produce al lijar los revestimientos de las superficies

(poliuretano, aceite de lino, etc.) puede iniciar una combustión espontánea dentro del depósito de aserrín de

la lijadora o en algún otro lugar y ocasionar un incendio. Para reducir este riesgo, vacíe el depósito regularmente y siga

estrictamente las instrucciones del manual de la lijadora y del fabricante del revestimiento.

Es importante para usted leer y entender este manual. La información que lo contiene relaciona a proteger SU

SEGURIDAD y PREVENIR los PROBLEMAS. Los símbolos debajo de son utilizados para ayudarlo a reconocer esta

información.

PROPOSICIÓN DE CALIFORNIA 65

Page 26

26

NORMAS GENERALES DE SEGURIDAD

1. PARA SU PROPIA SEGURIDAD, LEA EL MANUAL DE

INSTRUCCIONES ANTES DE UTILIZAR LA MÁQUINA. Al

a p render la aplicación, las limitaciones y los peligro s

específicos de la máquina, se minimizará enormemente la

posibilidad de accidentes y lesiones.

2. USE PROTECCIÓN DE LOS OJOS Y DE LA AUDICIÓN.

USE SIEMPRE ANTEOJOS DE SEGURIDAD. Los lentes de

uso diario NO son anteojos de seguridad. USE EQUIPO DE

SEGURIDAD CERTIFICADO. El equipo de protección de los

ojos debe cumplir con las normas ANSI Z87.1. El equipo de

protección de la audición debe cumplir con las normas ANSI

S3.19.

3. USE INDUMENTARIA ADECUADA. No use ropa holgada,

guantes, corbatas, anillos, pulseras u otras joyas que podrían

engancharse en las piezas móviles. Se recomienda usar

calzado antideslizante. Use una cubierta protectora del pelo

para sujetar el pelo largo.

4. NO UTILICE LA MÁQUINA EN UN ENTORNO

PELIGROSO. La utilización de herramientas mecánicas en

lugares húmedos o mojados, o en la lluvia, puede causar

d e s c a r gas eléctricas o electrocución. Mantenga bien

iluminada el área de trabajo para evitar tropezar o poner en

peligro los brazos, las manos y los dedos.

5. MANTENGA TODAS LAS HERRAMIENTAS Y MÁQUINAS

EN CONDICIONES ÓPTIMAS. Mantenga las herramientas

afiladas y limpias para lograr el mejor y más seguro

rendimiento. Siga las instrucciones de lubricación y cambio

de accesorios. Las herramientas y las máquinas mal

mantenidas pueden dañar más la herramienta o la máquina

y/o causar lesiones.

6. COMPRUEBE SI HAY PIEZAS DAÑADAS. Antes de utilizar

la máquina, compruebe si hay piezas dañadas. Compruebe

la alineación de las piezas móviles, si las piezas móviles se

atascan, si hay piezas rotas y toda otra situación que podría

afectar su funcionamiento. Un protector o cualquier otra

pieza que presente daños debe repararse o reemplazarse

apropiadamente. Las piezas dañadas pueden causar daños

adicionales a la máquina y/o lesiones.

7. MANTENGA LIMPIA EL ÁREA DE TRABAJO. Las áreas y

los bancos desordenados invitan a que se pro d u z c a n

accidentes.

8. MANTENGA ALEJADOS A LOS NIÑOS Y A LOS

V I S I TA N T E S . El taller es un entorno potencialmente

peligroso. Los niños y los visitantes pueden sufrir lesiones.

9. REDUZCA EL RIESGO DE UN ARRANQUE NO

INTENCIONADO. Asegúrese de que el interruptor esté en la

posición de apagado antes de enchufar el cable de

alimentación. En caso de un apagón, mueva el interruptor a

la posición de apagado. Un arranque accidental podría

causar lesiones.

10. UTILICE LOS PROTECTORES. Asegúrese de que todos los

protectores estén colocados en su sitio, sujetos firmemente

y funcionando correctamente para prevenir lesiones.

11. QUITE LAS LLAVES DE AJUSTE Y DE TUERCA ANTES

DE ARRANCAR LA MÁQUINA. Las herramientas, los

pedazos de desecho y otros residuos pueden salir

despedidos a alta velocidad, causando lesiones.

12. UTILICE LA MÁQUINA ADECUADA. No fuerce una

máquina o un aditamento a hacer un trabajo para el que no

se diseñó. El resultado podría ser daños a la máquina y/o

lesiones.

13. UTILICE ACCESORIOS RECOMENDADOS. La utilización

de accesorios y aditamentos no recomendados por Delta

podría causar daños a la máquina o lesiones al usuario.

14. UTILICE EL CORDÓN DE EXTENSIÓN ADECUADO.

Asegúrese de que el cordón de extensión esté en buenas

condiciones. Cuando utilice un cordón de extensión,

asegúrese de utilizar un cordón que sea lo suficientemente

pesado como para llevar la corriente que su producto tome.

Un cordón de tamaño insuficiente causará una caída de la

tensión de la línea, lo cual producirá una pérdida de potencia

y recalentamiento. Consulte el Cuadro de cordones de

extensión para obtener el tamaño correcto dependiendo de

la longitud del cordón y la capacidad nominal en amperios

indicada en la placa de especificaciones. En caso de duda,

utilice el próximo calibre más grueso. Cuanto más pequeño

sea el número de calibre, más pesado será el cordón.

15. SUJETE FIRMEMENTE LA PIEZA DE TRABAJO. Utilice

abrazaderas o un tornillo de carpintero para sujetar la pieza

de trabajo cuando resulte práctico. La pérdida de control de

una pieza de trabajo puede causar lesiones.

16. HAGA AVANZAR LA PIEZA DE TRABAJO CONTRA EL

SENTIDO DE ROTACIÓN DE LA HOJA, EL CORTADOR O

LA SUPERFICIE ABRASIVA. Si la hace avanzar desde el

otro sentido, el resultado será que la pieza de trabajo salga

despedida a alta velocidad.

17. NO FUERCE LA PIEZA DE TRABAJO SOBRE LA

MÁQUINA. El resultado podría ser daños a la máquina y/o

lesiones.

18. NO INTENTE ALCANZAR DEMASIADO LEJOS. U n a

pérdida del equilibrio puede hacerle caer en una máquina en

funcionamiento, causándole lesiones.

19. NO SE SUBA NUNCA A LA MÁQUINA. Se podrían producir

lesiones si la herramienta se inclina o si usted hace contacto

accidentalmente con la herramienta de corte.

20. NO DEJE NUNCA DESATENDIDA LA MÁQUINA CUANDO

ESTÉ EN MARCHA. APÁGUELA. No deje la máquina hasta

que ésta se detenga por completo. Un niño o un visitante

podría resultar lesionado.

21. A PAGUE LA MÁQUINA Y DESCONÉCTELA DE LA

FUENTE DE ALIMENTACIÓN antes de instalar o quitar

accesorios, antes de ajustar o cambiar configuraciones o al

realizar reparaciones. Un arranque accidental puede causar

lesiones.

22. HAGA SU TALLER A PRUEBA DE NIÑOS CON

CANDADOS E INTERRUPTORES MAESTROS O

QUITANDO LAS LLAVES DE ARRANQUE. El arranque

accidental de una máquina por un niño o un visitante podría

causar lesiones.

23. MANTÉNGASE ALERTA, FÍJESE EN LO QUE ESTÁ

HACIENDO Y USE EL SENTIDO COMÚN. NO UTILICE LA

MÁQUINA CUANDO ESTÉ CANSADO O BAJO LA

INFLUENCIA DE DROGAS, ALCOHOL O MEDICAMENTOS. Un momento de distracción mientras se estén

utilizando herramientas mecánicas podría causar lesiones.

24. EL USO DE ESTA HERRAMIENTA

PUEDE GENERAR Y DISPERSAR

POLVO U OTRAS PARTÍCULAS SUSPENDIDAS EN EL

AIRE, INCLUYENDO POLVO DE MADERA, POLVO DE

SÍLICE CRISTALINA Y POLVO DE ASBESTO. Dirija las

partículas de modo que se alejen de la cara y del cuerpo.

Utilice siempre la herramienta en un área bien ventilada y

proporcione un medio apropiado de remoción de polvo. Use

un sistema de recolección de polvo en todos los lugares

donde sea posible. La exposición al polvo puede causar

lesiones respiratorias graves y permanentes u otras lesiones

graves y permanentes, incluyendo silicosis (una enfermedad

pulmonar grave), cáncer y muerte. Evite aspirar el polvo y

evite el contacto prolongado con el polvo. Si se permite que

el polvo entre en la boca o en los ojos, o que se deposite en

la piel, se puede promover la absorción de material nocivo.

Use siempre protección respiratoria aprobada por

NIOSH/OSHA que se ajuste apropiadamente y sea adecuada

para la exposición al polvo, y lávese las áreas expuestas con

agua y jabón.

LEA Y COMPRENDA TODAS LAS ADVERTENCIAS Y LAS INSTRUCCIONES DE

OPERACIÓN ANTES DE UTILIZAR ESTE EQUIPO. El incumplimiento de cualquiera de las

instrucciones enumeradas abajo puede provocar descarga eléctrica, incendio o lesiones

personales graves o daños a la propiedad.

INSTRUCCIONES IMPORTANTES SOBRE SEGURIDAD

Page 27

27

NORMAS ESPECÍFICAS ADICIONALES DE SEGURIDAD

1. NO UTILICE ESTA MÁQUINA hasta que esté

completamente montada e instalada de acuerdo con

las instrucciones. Una máquina montada incorrectamente puede causar lesiones graves.

2. OBTENGA ASESORAMIENTO de su supervisor, su

instructor u otra persona calificada si no está bien

familiarizado con la utilización de esta máquina. El

conocimiento es seguridad.

3. SIGA TODOS LOS CÓDIGOS DE CABLEADO y las

conexiones eléctricas recomendadas para evitar las

descargas eléctricas o la electrocución.

4. NO ENCIENDA NUNCA LA MÁQUINA antes de

despejar la mesa y el área de trabajo de todos los

objetos (herramientas, pedazos de madera de

desecho, etc.). Los residuos que salen despedidos son

peligrosos.

5. NO ENCIENDA NUNCA LA MÁQUINA con la pieza de

trabajo en contacto con la superficie abrasiva. Se

podría producir retroceso.

6. SUJETE FIRMEMENTE LA MÁQUINA a una

superficie de soporte. Es posible que las vibraciones

hagan que la máquina se deslice, se desplace o

vuelque.

7. CUBRA EL EJE DE TOMA DE FUERZA cuando no

esté utilizando accesorios. Los ejes que giran sin tener

colocados los protectores pueden crear un peligro de

enredo que puede causar lesiones.

8. UTILICE UN SISTEMA DE RECOLECCIÓN DE

POLVO. Se sabe que algunos tipos de madera causan

enfermedades u otros problemas de salud.

9. RIESGO DE INCENDIOS. LIMPIE LA MÁQUINA y el

colector de polvo minuciosamente cuando procese

distintos tipos de piezas de trabajo (de madera, acero

o aluminio). La combinación de polvo de madera y

polvo de metal puede crear un peligro de explosión o

de incendio. NO LIJE NI PULA MAGNESIO. Si lo

hace, se producirá un incendio.

10. EVITE QUE LA PIEZA DE TRABAJO e n t r e en

contacto con la correa de lijar antes de arrancar la

herramienta. Una pérdida de control de la pieza de

trabajo es peligrosa.

11. EVITE LAS OPERACIONES COMPLICADAS Y LAS

POSICIONES DIFÍCILES DE LAS MANOS. U n

resbalón repentino podría hacer que una mano se

mueva hasta el disco abrasivo o la correa abrasiva.

12. MANTENGA UNA HOLGURA MÁXIMA DE 1/16"

entre la mesa y el disco y correa abrasivo. La pieza de

trabajo podría ser introducida en el espacio entre el

disco abrasivo y la mesa.

13. SOPORTE LA PIEZA DE TRABAJO firmemente con

un calibre de ingletes, un tope trasero o la mesa de

trabajo cuando lije con una correa. Sujete firmemente

la pieza de trabajo. Una pérdida de control de la pieza

de trabajo es peligrosa.

14. EVITE EL RETROCESO lijando de acuerdo con las

flechas direccionales. Haga avanzar la pieza de

trabajo contra el lado de rotación hacia abajo del disco

o contra el sentido de rotación hacia delante de la

correa. Una pérdida de control de la pieza de trabajo

es peligrosa.

14. EVITE EL RETROCESO lijando de acuerdo con las

flechas direccionales. Haga avanzar la pieza de

trabajo contra el lado de rotación hacia abajo del disco

o contra el sentido de rotación hacia delante de la

correa. Una pérdida de control de la pieza de trabajo

es peligrosa.

15. NO LIJE piezas de trabajo muy pequeñas o muy

delgadas que no se puedan controlar de modo

seguro. Una pérdida de control de la pieza de trabajo

es peligrosa.

16. S O P O R TE APROPIADAMENTE LAS PIEZAS DE

TRABAJO LARGAS O ANCHAS. Una pérdida de

control de la pieza de trabajo es peligrosa.

17. NO REALICE NUNCA TRABAJO DE INSTALACIÓN,

MONTAJE O PREPARACIÓN en la mesa o el área de

trabajo cuando la máquina esté en marcha. Un

resbalón repentino podría hacer que una mano se

mueva hasta la superficie abrasiva. El resultado puede

ser lesiones graves.

18. APAGUE LA MÁQUINA, desconéctela de la fuente de

alimentación y limpie la mesa o el área de trabajo

antes de dejar la máquina. BLOQUEE EL

INTERRUPTOR EN LA POSICIÓN DE APAGADO

para impedir el uso no autorizado. Otra persona podría

arrancar accidentalmente la máquina y re s u l t a r

lesionada.

19. HAY INFORMACIÓN ADICIONAL disponible relacio-

nada con la utilización segura y apropiada de herramientas mecánicas (por ejemplo, un video sobre

seguridad) a través del Instituto de Herramientas

Mecánicas, Power Tool Institute, 1300 Sumner

Avenue, Cleveland, OH 44115-2851 (www.powertoolinstitute.com). También hay información disponible a

través del Consejo Nacional de Seguridad, National

Safety Council, 1121 Spring Lake Drive, Itasca, IL

60143-3201. Sírvase consultar también los Requisitos

de Seguridad para Máquinas de Elaboración de la

Madera ANSI 01.1 del Instituto Nacional Americano de

Normas (American National Standards Institute) y las

normas OSHA 1910.213 del Departamento de Trabajo

de los EE.UU.

ES IMPORTANTE PARA USTED LEER Y ENTENDER ESTE MANUAL. EL INCUMPLIMIENTO DE

LAS INSTRUCCIONES ENUMERADAS DEBAJO PUEDE PROVOCAR DESCARGA ELÉCTRICA,

GUARDE ESTAS INSTRUCCIONES.

Consúltelas a menudo

y úselas para instruir a otros.

Page 28

28

1. Todas las máquinas conectadas con cord ó n

conectadas a tierra:

En caso de mal funcionamiento o avería, la conexión a

tierra proporciona una ruta de resistencia mínima para la

corriente eléctrica, con el fin de reducir el riesgo de

descargas eléctricas. Esta máquina está equipada con

un cordón eléctrico que tiene un conductor de conexión

a tierra del equipo y un enchufe de conexión a tierra. El

enchufe debe enchufarse en un tomacorriente

coincidente que esté instalado y conectado a tierra

adecuadamente, de acuerdo con todos los códigos y

ordenanzas locales.

No modifique el enchufe suministrado. Si el enchufe no

cabe en el tomacorriente, haga que un electricista

calificado instale el tomacorriente apropiado.

La conexión inapropiada del conductor de conexión a

tierra del equipo puede dar como resultado riesgo de

descargas eléctricas. El conductor con aislamiento que

tiene una superficie exterior de color verde con o sin

franjas amarillas es el conductor de conexión a tierra del

equipo. Si es necesario reparar o reemplazar el cordón

eléctrico o el enchufe, no conecte el conductor de

conexión a tierra del equipo a un terminal con corriente.

Consulte a un electricista competente o a personal de

servicio calificado si no entiende completamente las

instrucciones de conexión a tierra o si tiene dudas en

cuanto a si la máquina está conectada a tierra

apropiadamente.

Utilice únicamente cordones de extensión de tre s

alambres que tengan enchufes de tipo de conexión a

tierra con tres terminales y receptáculos de tre s

conductores que acepten el enchufe de la máquina, tal

como se muestra en la Fig. A.

R e p a r e o reemplace inmediatamente los cord o n e s

dañados o desgastados.

2. Máquinas conectadas con cordón conectadas a

tierra diseñadas para utilizarse en un circuito de

alimentación que tenga una capacidad nominal de

menos de 150 V:

Si la máquina está diseñada para utilizarse en un circuito

que tenga un tomacorriente parecido al que se ilustra en

la Fig. A, la máquina tendrá un enchufe de conexión a

tierra que se parece al enchufe ilustrado en la Fig. A.

Puede utilizarse un adaptador temporal, que se parece

al adaptador ilustrado en la Fig. B, para conectar este

enchufe a un receptáculo coincidente de dos

conductores, tal como se muestra en la Fig. B, si no se

dispone de un tomacorriente conectado a tierra

apropiadamente. El adaptador temporal debe utilizarse

solamente hasta que un electricista calificado pueda

instalar un tomacorriente conectado a tierra

apropiadamente. La orejeta, lengüeta, etc., rígida de

color verde que sobresale del adaptador debe

conectarse a una toma de tierra permanente, como por

ejemplo una caja tomacorriente conectada a tierra

adecuadamente. Siempre que se utilice un adaptador,

debe sujetarse en su sitio con un tornillo de metal.

NOTA: En Canadá, el uso de un adaptador temporal

no está permitido por el Código Eléctrico

Canadiense.

RIESGO DE DESCARGA

ELÉCTRICA. EN TODOS LOS CASOS, ASEGÚRESE DE

QUE EL RECEPTÁCULO EN CUESTIÓN ESTÉ

C O N E C TADO A TIERRA ADECUADAMENTE. SI NO ESTÁ

SEGURO, HAGA QUE UN ELECTRICISTA CALIFICADO

COMPRUEBE EL RECEPTÁCULO.

Fig. A

Fig. B

CAJA TOMACORRIENTE

CONECTADA A TIERRA

TERMINALES

QUE LLEVAN

CORRIENTE

EL TERMINAL DE CONEXIÓN A

TIERRA ES EL MÁS LARGO DE

LOS 3 TERMINALES

MEDIO DE CONEXIÓN

TIERRA

ADAPTADOR

CAJA TOMACORRIENTE

CONECTADA A TIERRA

Debe utilizarse un circuito eléctrico independiente para las máquinas. Este circuito debe tener alambre de no menos del No. 12 y

debe estar protegido con un fusible de acción retardada de 20 A. Si se utiliza un cordón de extensión, utilice únicamente cordones

de extensión de tres alambres que tengan enchufes de tipo de conexión a tierra con tres terminales y un receptáculo coincidente

que acepte el enchufe de la máquina. Antes de conectar el máquina a la línea de alimentación, asegúrese de que el interruptor(s)

esté en la posición de apagado y cerciórese de que la corriente eléctrica tenga las mismas características que las que estén

indicadas en la máquina. Todas las conexiones a la línea de alimentación deben hacer buen contacto. El funcionamiento a bajo

voltaje dañará el máquina.

RIESGO DE DESCARGA ELÉCTRICA. NO EXPONGA LA MÁQUINA A LA LLUVIA NI LA

UTILICE EN LUGARES HÚMEDOS.

CONEXIONES A LA FUENTE DE ALIMENTACIÓN

La máquina está cableada para corriente alterna de 120 V., 60 Hz. Antes de conectar la máquina a la fuente de

alimentación, asegúrese de que el interruptor esté en la posición de apagado.

INSTRUCCIONES DE CONEXIÓN A TIERRA

RIESGO DE DESCARGA ELÉCTRICA. ESTA MÁQUINA DEBE ESTAR CONECTADA A TIERRA MIENTRAS

SE ESTÉ UTILIZANDO, PARA PROTEGER AL OPERADOR CONTRA LAS DESCARGAS ELÉCTRICAS.

Page 29

29

NOTA: La foto de la cubierta del manual ilustra el modelo o de produccion actual. Todas las demas ilustru-ciones son solamente

representativas y es posible que no muestren el color, el etiquetado y los accesorios reales.

P R O L O G O

Utilice cordones de extensión apropiados. Asegúrese de que el cordón de extensión esté en buenas condiciones y de

que sea un cordón de extensión de tres alambres que tenga un enchufe de tipo de conexión a tierra con tres terminales

y un receptáculo coincidente que acepte el enchufe de la máquina. Cuando utilice un cordón de extensión, asegúrese

de emplear un cordón que sea lo suficientemente pesado como para llevar la corriente de la máquina. Un cordón de

tamaño insuficiente causará una caída de la tensión de la línea eléctrica que dará como resultado pérdida de potencia

y recalentamiento. En la Fig. C se muestra el calibre correcto que debe utilizarse dependiendo de la longitud del

cordón. En caso de duda, utilice el siguiente calibre más pesado. Cuanto más pequeño sea el número de calibre, más

pesado será el cordón.

Fig. C

CORDÓN DE EXTENSIÓN DE CALIBRE MÍNIMO

TAMAÑOS RECOMENDADOS PARA USO CON MÁQUINAS ELÉCTRICAS ESTA C I O N A R I A S

C a p a c i d a d Longitud Total Del C a l i b re Del Cord o n

Nominal En Vo l t i o s C o r don De Extensión

A m p e r i o s En Pies

0 - 6 1 2 0

Hasta

2 5 18 AW G

0 - 6 1 2 0 2 5 - 5 0 16 AW G

0 - 6 1 2 0 5 0 - 1 0 0 16 AW G

0 - 6 1 2 0 1 0 0 - 1 5 0 14 AW G

6 - 1 0 1 2 0

Hasta

2 5 18 AW G

6 - 1 0 1 2 0 2 5 - 5 0 16 AW G

6 - 1 0 1 2 0 5 0 - 1 0 0 14 AW G

6 - 1 0 1 2 0 1 0 0 - 1 5 0 12 AWG

1 0 - 1 2 1 2 0

Hasta

2 5 16 AW G

1 0 - 1 2 1 2 0 2 5 - 5 0 16 AW G

1 0 - 1 2 1 2 0 5 0 - 1 0 0 14 AW G

1 0 - 1 2 1 2 0 1 0 0 - 1 5 0 12 AW G

1 2 - 1 6 1 2 0

Hasta

2 5 14 AW G

1 2 - 1 6 1 2 0 2 5 - 5 0 12 AW G

1 2 - 1 6 1 2 0

NO SE RECOMIENDA LONGITUDES MAYOR DE 50 PIES

CORDONES DE EXTENSIÓN

DESCRIPCIÓN FUNCIONAL

El modelo SM500 del delta es 4 " correa; 6 " lijadora del disco y viene equipado de; 5.2 AMP motor de inducción la monofásico del

hp 120Volt, inclinando el vector, ingletes galga, tope, 4 " x 36 " 60 cierra fuertemente la correa que enarena y 6 " 60 cierran

fuertemente el disco que enarena. El vector de aluminio de inclinación se puede montar para el uso en la correa o la unidad de

disco. La correa funciona horizontal, vertical y a cualquier ángulo mientras tanto.

Page 30

30

DESEMPAQUETADO Y LIMPIEZA

Desempaque cuidadosamente la máquina y todas las piezas sueltas que están en el contenedor o contenedores de

transporte. Quite el revestimiento protector de todas las superficies no pintadas. Este revestimiento puede quitarse

con un paño suave humedecido con queroseno (no utilice acetona, gasolina ni diluyente de laca para este fin).

Después de realizar la limpieza, cubra las superficies no pintadas con una cera en pasta doméstica de buena calidad

para pisos.

CONTENIDO DE CART O N

1

2

3

4

8

7

10

6

5

9

11

12

1. El motor y se Basa

2. La Mesa del disco

3. El cinturón y la Polea Protegen

4. El Plato del disco

5. Quite el polvo Tobogán

6. Sostenga la Barra

7. El Guardia más bajo del Disco

8. El Disco de Sanding

9. La mampara

10. Ingletee Calibrador

11. 1/8" Llave Inglesa hexagonal

12. 6 Mm Llave Inglesa hexagonal

13. Tornillo De Cabeza De Zócalo De la Tuerca

hexagonal De M8x1.25x20mm (3)

14. Tornillos De la Cabeza Del Queso De M6x1x30mm

(2)

15. Tornillo Principal De Tuerca hexagonal 1/4-20x1/2

(1)

16. To r nillo De la Cabeza De la Cacerola De

M5x.08x10mm (3)

17. Tornillo Del Metal De Hoja De M4x.7x12mm (3)

18. Arandela Plana Del 5/16"(1)

13

14

15

16

17

18

Page 31

31

E N S A M B L A J E

HERRAMIENTAS DE ENSAMBLAJE REQUERIDAS

ESTIMACIÓN DEL TIEMPO DE ENSAMBLAJE

Para su propia seguridad, no conecte la lijadora a la fuente de energia hasta que la maquina haya