Page 1

10-INCH SLIDING COMPOUND MITRE SAW

SCIE À ONGLET COMBINE

254 MM

SIERRA INGLETADORA

COMPUESTA DE 10

PULGADAS

Français (23)

Español (46)

www.DeltaMachinery.com

Instruction Manual

Manual d’utilisation

Manual de instrucciones

To reduce the risk of serious injury, thoroughly read and comply with all warnings and instructions in this manual and on product.

KEEP THIS MANUAL NEAR YOUR PRODUCT FOR EASY REFERENCE AND TO INSTRUCT OTHERS

S26-263L

Page 2

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS ................................... 2

GENERAL POWER TOOL SAFETY WARNINGS ....................3

SAFETY INSTRUCTIONS FOR MITERE SAW.........................4

PROPOSITION 65 WARNING ................................................... 5

POWER CONNECTIONS .......................................................... 5

FEATURES ................................................................................. 6

UNPACKING AND ASSEMBLY ................................................. 8

MOUNTING AND TRANSPORTATION ..................................... 9

PREPARATIONS FOR TRANSPORTATION ......................... 9

BASE WITH CARRY HANDLES .......................................... 9

MOUNTING A TABLE SAW TO A STABLE SURFACE........ 9

ASSEMBLY ............................................................................... 10

SUPPORT EXTENSIONS ..................................................10

ATTACHING WORK CLAMP .............................................10

INSTALL DUST COLLECTION BAG .................................. 10

INSTALL BATTERIES FOR LASER .................................... 11

PREPARING YOUR SAW FOR USE ....................................... 11

INSTALL/REPLACE THE BLADE ...................................... 11

ALIGN THE BLADE TO THE TABLE .................................. 12

USING THE LASER GUIDE ............................................... 13

OPERATION ............................................................................. 14

POWER SWITCH LOCK-OUT ...........................................14

POWER SAFETY TOGGLE ...........................................14

TO SLIDE CUT ................................................................... 15

TIPS FOR CUTTING AND SUPPORTING WORKPIECE .. 16

CUTTING WARPED MATERIAL ........................................ 17

CLAMPING WIDE WORKPIECES ..................................... 17

SUPPORTING LONG WORKPIECES ............................... 18

ADJUSTMENTS ....................................................................... 18

BEVEL PIVOT .................................................................... 19

LASER ADJUSTMENTS .................................................... 19

DEPTH STOP ADJUSTMENT ........................................... 20

MAINTENANCE ....................................................................... 21

BRUSH REPLACEMENT ................................................... 21

TROUBLE SHOOTING ............................................................ 21

ACCESSORIES ........................................................................ 22

PARTS, SERVICES OR WARRANTY ASSISTANCE .............. 22

FRENCH ................................................................................... 23

SPANISH ...................................................................................46

IMPORTANT SAFETY INSTRUCTIONS

CAREFULLY READ AND FOLLOW ALL WARNINGS AND INSTRUCTIONS ON YOUR

PRODUCT AND IN THIS MANUAL. SAVE THIS MANUAL. MAKE SURE ALL USERS ARE

FAMILIAR WITH ITS WARNINGS AND INSTRUCTIONS WHEN USING THE TOOL. Improper operation,

maintenance or modification of tools or equipment could result in serious injury and/or property damage.

SAFETY LOGOS

This manual contains information that is important for you to know and understand. This information relates to protecting

YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS. To help you recognize this information, we use the

symbols below. Please read the manual and pay attention to these sections.

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate injury.

CAUTION:

Do not expose power tools to rain or wet conditions.

Used without the safety alert symbol indicates potentially hazardous situation which, if not avoided,

may result in property damage.

Additional information regarding the safe and proper operation of this tool is available from the following sources:

• Power Tool Institute, 1300 Sumner Avenue, Cleveland, OH 44115-2851 or on-line at www.powertoolinstitute.com

• National Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-3201

• American National Standards Institute, 25 West 43rd Street, 4 floor, New York, NY 10036 www.ansi.org - ANSI 01.1

Safety Requirements for Woodworking Machines

• U.S. Department of Labor regulations www.osha.gov

2 3

Page 3

GENERAL POWER TOOL SAFETY WARNINGS

WARNING Read all safety warnings, instructions, illustrations and specications provided with this power tool. Failure

to follow all instructions listed below may result in electric shock, re and/or serious injury.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated (corded) power tool or BATTERY-operated

(cordless) power tool.

1) Work area safety

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

b) Do not operate power tools in explosive atmospheres, such as in the presence of ammable liquids, gases or

dust. Power tools create sparks which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool. Distractions can cause you to lose control.

2) Electrical safety

a) Power tool plugs must match the outlet. Never modify the plug in any way. Do not use any adapter plugs

with earthed (grounded) power tools. Unmodied plugs and matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering

a power tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep cord away

from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for outdoor

use. Use of a cord suitable for outdoor use reduces the risk of electric shock.

f) If operating a power tool in a damp location is unavoidable, use a RESIDUAL CURRENT

DEVICE (RED) protected supply. Use of an RCD reduces the risk of electric shock.

3) Personal safety

a) Stay alert, watch what you are doing and use common sense when operating a power tool. Do

not use a power tool while you are tired or under the inuence of drugs, alcohol or medication.

A moment of inattention while operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective equipment such as dust mask, non-

skid safety shoes, hard hat, or hearing protection used for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off-position before connecting to

power source and/or BATTERY pack picking up, or carrying the tool. Carrying power tools with

your nger on the switch or energising power tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on. A wrench or a

key left attached to a rotating part of the power tool may result in personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This enables

better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewellery. Keep your hair, clothing and gloves

away from moving parts. Loose clothes, jewellery or long hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection facilities, ensure these

are connected and properly used. Use of dust collection can reduce dust-related hazards.

h) Do not let familiarity gained from frequent use of tools allow you to become complacent and ignore

tool safety principles. A careless action can cause severe injury within a fraction of a second.

4) Power tool use and care

a) Do not force the power tool. Use the correct power tool for your application. The correct

power tool will do the job better and safer at the rate for which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any power tool

that cannot be controlled with the switch is dangerous and must be repaired.

c) Disconnect the plug from the power source and/or remove the BATTERY pack if detachable,

from the power tool before making any adjustments, changing accessories, or storing power

tools. Such preventive safety measures reduce the risk of starting the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow persons unfamiliar with the power tool

or these instructions to operate the power tool. Power tools are dangerous in the hands of untrained users.

e) Maintain power tools and accessories. Check for misalignment or binding of moving parts , breakage

of parts and any other condition that may affect the power tool’s operation. If damaged, have the

power tool repaired before use. Many accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with

sharp cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits etc. in accordance with these instructions,

taking into account the working conditions and the work to be performed. Use of the power

tool for operations different from those intended could result in a hazardous situation.

h) Keep handles and grasping surfaces dry, clean and free from oil and grease. Slippery handles and

grasping surfaces do not allow for safe handling and control of the tool in unexpected situations.

3

Page 4

GENERAL POWER TOOL SAFETY RULES

5) Service

a) Have your power tool serviced by a qualied repair person using only identical

replacement parts. This will ensure that the safety of the power tool is maintained.

SAFETY INSTRUCTIONS FOR MITRE SAWS

a) Mitre saws are intended to cut wood or wood-like products, they cannot be used with abrasive cut-off

wheels for cutting ferrous material such as bars, rods, studs, etc. Abrasive dust causes moving parts such as

the lower guard to jam. Sparks from abrasive cutting will burn the lower guard, the kerf insert and other plastic parts.

b) Use clamps to support the workpiece whenever possible. If supporting the workpiece by hand,

you must always keep your hand at least 100 mm from either side of the saw blade. Do not

use this saw to cut pieces that are too small to be securely clamped or held by hand. If your

hand is placed too close to the saw blade, there is an increased risk of injury from blade contact.

c) The workpiece must be stationary and clamped or held against both the fence and

the table. Do not feed the workpiece into the blade or cut “freehand” in any way.

Unrestrained or moving workpieces could be thrown at high speeds, causing injury.

d) Push the saw through the workpiece. Do not pull the saw through the workpiece. To make a cut,

raise the saw head and pull it out over the workpiece without cutting, start the motor, press the

saw head down and push the saw through the workpiece. Cutting on the pull stroke is likely to cause

the saw blade to climb on top of the workpiece and violently throw the blade assembly towards the operator.

e) Never cross your hand over the intended line of cutting either in front or behind

the saw blade. Supporting the workpiece “cross handed” i.e. holding the workpiece to

the right of the saw blade with your left hand or vice versa is very dangerous.

f) Do not reach behind the fence with either hand closer than 100 mm from either side of the

saw blade, to remove wood scraps, or for any other reason while the blade is spinning. The

proximity of the spinning saw blade to your hand may not be obvious and you may be seriously injured.

g) Inspect your workpiece before cutting. If the workpiece is bowed or warped,clamp it with the outside

bowed face toward the fence. Always make certain that there is no gap between the workpiece,

fence and table along the line of the cut. Bent or warped workpieces can twist or shift and may cause

binding on the spinning saw blade while cutting. There should be no nails or foreign objects in the workpiece.

h) Do not use the saw until the table is clear of all tools, wood scraps, etc., except for the workpiece. Small

debris or loose pieces of wood or other objects that contact the revolving blade can be thrown with high speed.

i) Cut only one workpiece at a time. Stacked multiple workpieces cannot be adequately

clamped or braced and may bind on the blade or shift during cutting.

j) Ensure the mitre saw is mounted or placed on a level, rm work surface before use.

A level and rm work surface reduces the risk of the mitre saw becoming unstable.

k) Plan your work. Every time you change the bevel or mitre angle setting, make sure the adjustable

fence is set correctly to support the workpiece and will not interfere with the blade or the

guarding system. Without turning the tool “ON” and with no workpiece on the table, move the saw blade

through a complete simulated cut to assure there will be no interference or danger of cutting the fence.

l) Provide adequate support such as table extensions, saw horses, etc. for a workpiece that is

wider or longer than the table top. Workpieces longer or wider than the mitre saw table can tip if not securely

supported. If the cut-off piece or workpiece tips, it can lift the lower guard or be thrown by the spinning blade.

m) Do not use another person as a substitute for a table extension or as additional

support. Unstable support for the workpiece can cause the blade to bind or the workpiece to

shift during the cutting operation pulling you and the helper into the spinning blade.

n) The cut-off piece must not be jammed or pressed by any means against the spinning saw blade. If

conned, i.e. using length stops, the cut-off piece could get wedged against the blade and thrown violently.

o) Always use a clamp or a xture designed to properly support round material

such as rods or tubing. Rods have a tendency to roll while being cut, causing

the blade to “bite” and pull the work with your hand into the blade.

p) Let the blade reach full speed before contacting the workpiece.

This will reduce the risk of the workpiece being thrown

q) If the workpiece or blade becomes jammed,turn the mitre saw off. Wait for all

moving parts to stop and disconnect the plug from the power source and/or

remove the battery pack. Then work to free the jammed material. Continued sawing

with a jammed workpiece could cause loss of control or damage to the mitre saw.

r) After nishing the cut, release the switch, hold the saw head down and wait for the blade to stop

before removing the cut-off piece. Reaching with your hand near the coasting blade is dangerous.

s) Hold the handle, rmly when making an incomplete cut or when releasing the switch

before the saw head is completely in the down position. The braking action of the saw

may cause the saw head to be suddenly pulled downward, causing a risk of injury.

4 5

Page 5

PROPOSITION 65 WARNING:

Some dust created by power sanding, sawing, grinding, drilling, and other construction activities

contains chemicals known to the state of California to cause cancer, birth defects or other reproductive

harm. Some examples of these chemicals are:

• Lead from lead-based paints

• Crystalline silica from bricks and cement and other masonry products

• Arsenic and chromium from chemically-treated lumber

Your risk from these exposures varies, depending on how often you do this type of work. To reduce your exposure to

these chemicals: work in a well-ventilated area and work with approved safety equipment, such as dust masks that are

specifically designed to filter out microscopic particles.

SAVE THESE INSTRUCTIONS.

Refer to them often and use them to instruct others.

If tool is loaned to someone, also loan them these instructions.

POWER CONNECTIONS

A separate electrical circuit should be used for your machines. This circuit should not be less than #12 wire and should

be protected with a 15 Amp time lag fuse. If an extension cord is used, use only 3-wire extension cords which have

a 3-prong grounding type plugs. Before connecting the machine to the power line make sure the switch(s) is in the

“OFF” position and be sure that the electric current is of the same characteristics as indicated on the machine. All line

connections should make good contact. Running on low voltage will damage the machine.

DO NOT EXPOSE THE MACHINE TO RAIN OR OPERATE THE MACHINE IN DAMP LOCATIONS.

Your machine is wired for 120 volts, 60 HZ alternating current. Before connecting the machine to the power source,

make sure the switch is in the “OFF” position.

DOUBLE INSULATION

This machine is double insulated. Double insulation is a concept in safety in electric power tools, which eliminates the

need for the usual three-wire grounded power cord. All exposed metal parts are isolated from the internal metal motor

components with protecting insulation. Double insulated tools do not need to be grounded.

The double insulated system is designed to protect the user from shock resulting from a break in

the tool’s internal insulation. However, it is important to observe normal safety precautions to

avoid electrical shock.

NOTE: Servicing of a tool with double insulation requires extreme care and knowledge of the system and should be

performed by an authorized DELTA® agent. For service, we suggest you return the tool to the nearest authorized DELTA®

agent for repair. Always use identical replacement parts when servicing.

5

Page 6

POWER CONNECTIONS

ELECTRICAL CONNECTION

This tool has a precision-built electric motor. It should be connected to a POWER SUPPLY THAT IS 120 VOLTS, 60 HZ,

AC ONLY (NORMAL HOUSEHOLD CURRENT). Do not operate this tool on direct current (DC). A substantial voltage

drop will cause a loss of power and the motor will overheat. If the tool does not operate when plugged into an outlet,

double-check the power supply.

POLARIZED PLUGS

To reduce the risk of electric shock, this equipment has a polarized plug (one blade is wider than the other). This plug will

fit in a polarized plug only one way. If the plug does not fully fit in the outlet reverse the plug. If it still does not fit, contact

a qualified electrician to install the proper outlet. Do not change the plug in any way.

EXTENSION CORDS

When using a power tool at a considerable distance from a power source, be sure to use an extension cord that has

the capacity to handle the current the tool will draw. An undersized cord will cause a drop in line voltage, resulting in

overheating and loss of power. Use the chart to determine the minimum wire size required in an extension cord. Only

round jacketed cords listed by Underwriter’s Laboratories (UL) should be used. When working outdoors with a tool, use

an extension cord that is designed for outside use. This type of cord is designated with a “WA” on the cord’s jacket.

Before using any extension cord, inspect it for loose or

exposed wires and cut or worn insulation.

Keep the extension cord clear of the

work area. Position the cord so that it

will not get caught on lumber, tools or other

obstructions while you are working with a power tool.

Failure to do so can result in serious personal injury.

Check extension cords before each use. If damaged

replace immediately. Never use tool with a damaged

cord, since touching the damaged area could cause

electrical shock resulting in serious injury.

** Ampere rating (on total data label)

12A- 16A

Cord Length

25’

50’ 12 AWG

** Used on 12 gauge - 20 amp0 circuit

NOTE: AWG = American Wire Gauge

Wire Size

14 AWG

PRODUCT SPECIFICATIONS

FEATURES

Cutting Capacity

(Maximum nominal

lumber sizes)

Net Weight

Input

Blade Arbor

Blade Diameter

No Load Speed

0° Mitre/0° Bevel: 4” x 12”

45° Mitre/ 0° Bevel: 4” x 8”

0° Mitre/45° Bevel: 2” x 12”

45° Mitre/45° Bevel: 2” x 8”

29.5 lbs

120 V~, 60hz, 15 Amps

5/8”

10”

5,500 r/min (RPM)

6 7

Page 7

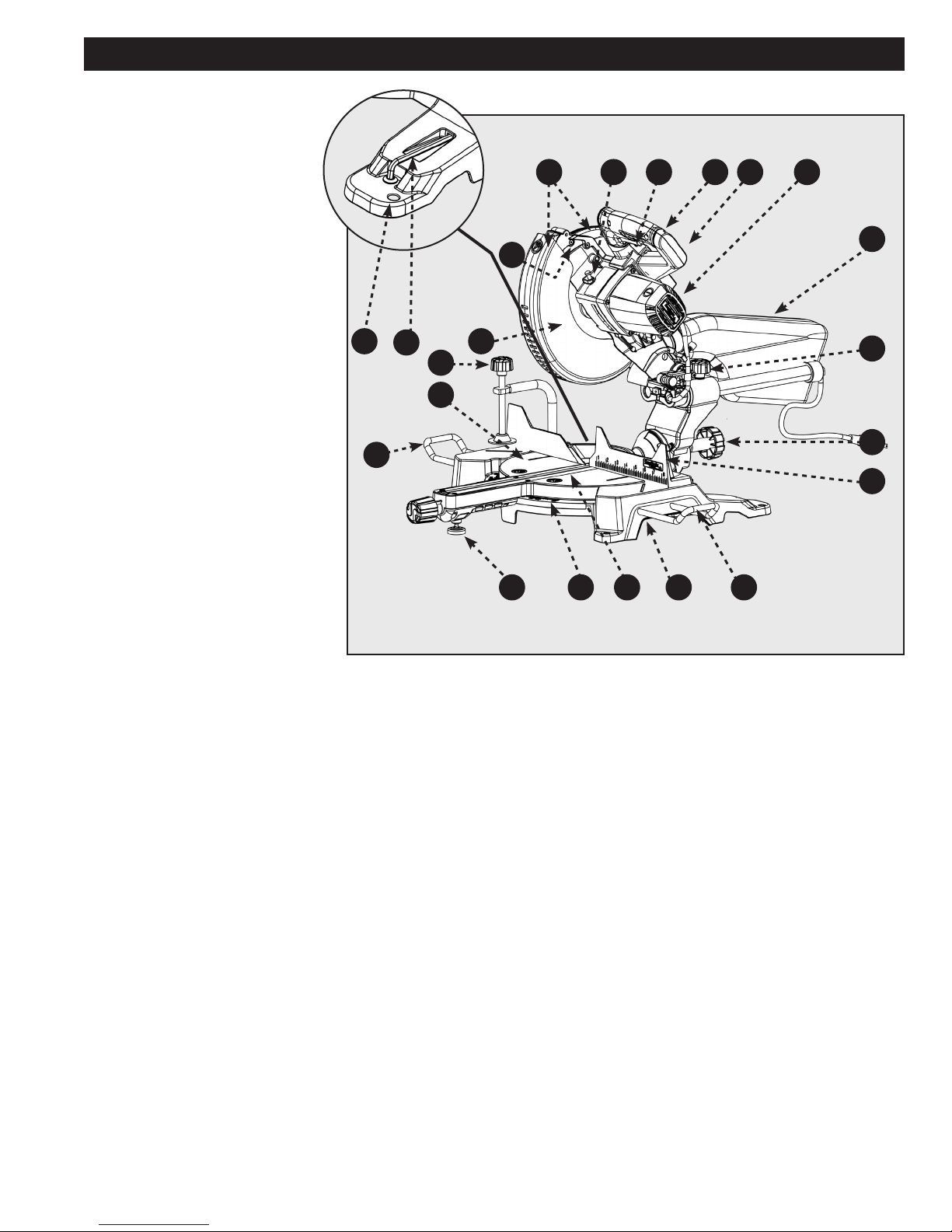

A. Motor

B. Fence

C. Throat Plate

D. Mitre Lock Knob

E. Support Extensions

F. Mitre Scale with Positive Stops

G. Horizontal Work Clamp

H. Base with Carry Handles

I. Mounting Holes

J. On-Board Wrench

K. Work Table

L. Bevel Lock Knob

M. Dust Bag

N. Upper and Lower Blade Guards

O. Blade (not visible)

P. Saw Head Handle

Q. Spindle lock

R. Slide Lock Knob

S. Electric Brake (not shown)

T. Laser

U. Power Switch (not visible)

V. Power Safety Toggle

x4

FEATURES

U PV

QN

T

I

J

O

G

K

E

F

FIGURE 1

CD

H

E

A

M

R

L

B

KNOW YOUR COMPOUND MITRE SAW

Refer to Figure 1.

Using this tool safely requires that you understand the

information provided in this operator’s manual, as well as

the project you are attempting. Before using this product,

familiarize yourself with all operating features and safety

rules.

A. 15-AMP MOTOR: This tool features a powerful

15-amp motor with all ball bearings and externally

accessible brushes for ease of servicing.

B. FENCE: The mitre fence supports the workpiece

when making all cuts.

C. THROAT PLATE: The throat plate supports the

workpiece and provides a safe working surface.

D. MITRE LOCK: The mitre lock knob securely locks the

saw at desired mitre angles.

E. SUPPORT EXTENSIONS: Use these to help support

large pieces when necessary.

F. MITRE SCALE WITH POSITIVE STOPS: Positive

stops have been provided at 0°, 15°, 22-1/2°, 31.6°,

and 45°. The blade stops have been provided on

both the left and right side of the mitre table.

G. HORIZONTAL WORK CLAMP: The horizontal work

clamp helps to position and secure the workpiece

to the fence, ensuring safer operation and more

accurate cuts.

H. BASE WITH CARRY HANDLES: Supports the tool

and features mounting holes. Use the carry handles

which are designed into the base for safe and easy

transportation of the saw.

I. MOUNTING HOLES: Enable you to securely mount

the tool to a stable surface.

J. BLADE WRENCH STORAGE: The included blade

wrench features a Phillips screwdriver at one

end and a hex key at the other. Use the hex key

when installing or removing blade and the Phillips

screwdriver when removing or loosening screws.

When not in use, the wrench can be stored in the

base of the saw.

K. WORK TABLE: Sturdy, large die-cast aluminum work

table provides a level and sturdy work surface.

L. BEVEL LOCK: the bevel lock knob secures the saw

at the desired angle for bevel cuts. There are positive

stop screws on each side of the saw arm for making

fine adjustments at 0° and 45°.

M. DUST COLLECTION BAG: The included dust bag

attaches and detached quickly with the integrated

clamp for easy cleaning.

7

Page 8

FEATURES

N. UPPER AND LOWER BLADE GUARDS: The lower

blade guard is made of shock-resistant, see-through

plastic that provides protection from each side of the

blade. It automatically retracts over the upper blade

guard as the saw is lowered into the workpiece.

O. 10-INCH BLADE: A 10 in. blade is included with the

compound mitre saw. It will cut materials up to 3-1/2

in. thick or 12 in. wide, depending upon the angle at

which the cut is being made.

P. SAW HEAD HANDLE: Use this handle to perform

cuts as instructed in the operation section of this

manual. This handle also includes the power switch

for activating the saw blade.

Q. SPINDLE LOCK BUTTON: The spindle lock button

locks the spindle preventing the blade from rotating

while removing or installing the blade screw.

R. SLIDE LOCK: This allows head to move front to rear

for cutting wide material up to 12” wide

S. ELECTRIC BRAKE: An electric brake has been

provided to more quickly stop blade rotation after the

switch is released. (not shown)

T. LASER: For more accurate cuts, a laser is included

with your mitre saw. When used properly, the laser

makes accurate, precision cutting simple and easy.

U. POWER SWITCH: The saw blade is activated by

an easy-to-use switch. When not in use the saw

should be disconnected from the power supply and

switch locked in the off position using a padlock

(not included) inserted through the hole in the switch

trigger. A lock with a long shackle up to 5/16 in.

diameter may be used. The padlock and key should

be stored in separate locations.

V. POWER SAFETY TOGGLE: Reduces safety risk for

unauthorized users.

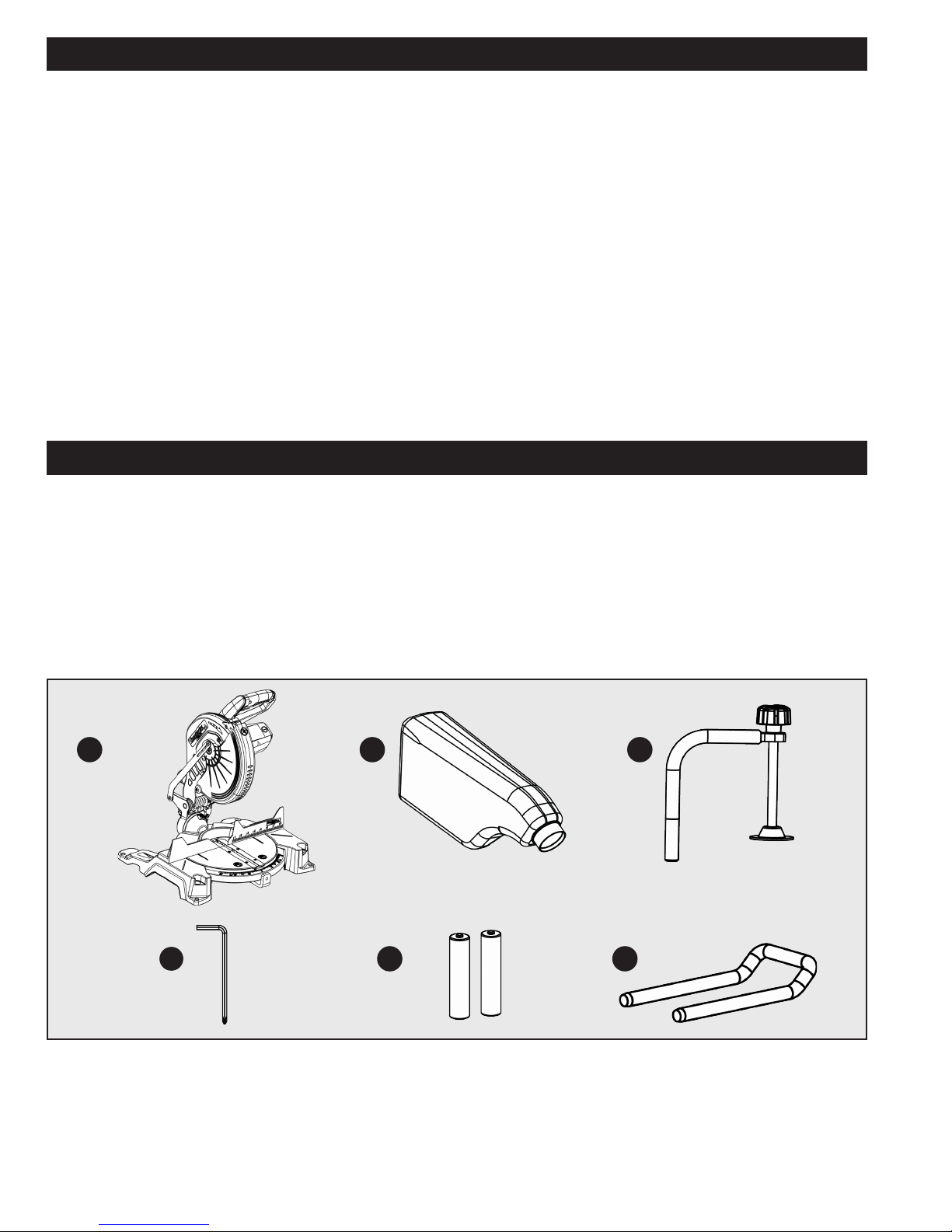

UNPACKING AND ASSEMBLY

Check shipping carton and machine for damage before unpacking. Carefully remove packaging materials, parts and

machine from shipping carton. Always check for and remove protective shipping materials around motor and moving

parts. Lay out all parts on a clean work surface.

Compare the items to inventory figures, verify that all items are accounted for before discarding the shipping carton.

Report any missing or damaged parts, please call Company’s Customer Care Center at 800-223-7278. Prior to tool

assembly and use, read this manual to thoroughly familiarize yourself with proper assembly, maintenance and safety

procedures.

If any parts are missing, do not attempt to plug in the power cord and turn the power on. The saw should only be

energized after all parts have been located and correctly assembled.

A

D

CONTENT DESCRIPTION (QTY)

A. SHOPMASTER #S26-263L 10-inch Sliding

Compound Mitre Saw

B. Dust Collection Bag (1)

C. Horizontal Work Clamp (1)

B

E F

FIGURE 2

D. Blade Wrench (1)

E. AAA Batteries (2)

F. Support Extensions (2)

8 9

C

Page 9

MOUNTING AND TRANSPORTATION

Before moving/transporting your saw it is important to make sure all of the following steps have been

followed to ensure a safe condition for transportation. Failure to do so can result in serious personal injury.

• Always turn the power off and unplug saw before transporting.

• Secure power cord to avoid any snags or hang ups during transportation.

• Always lift using the strength of your legs to lift saw; never use your back muscles to lift saw.

• Do not use power On/Off switch handle or power cord to lift your saw.

• Always place the saw onto a stable and level surface with clearance for handling and maneuvering.

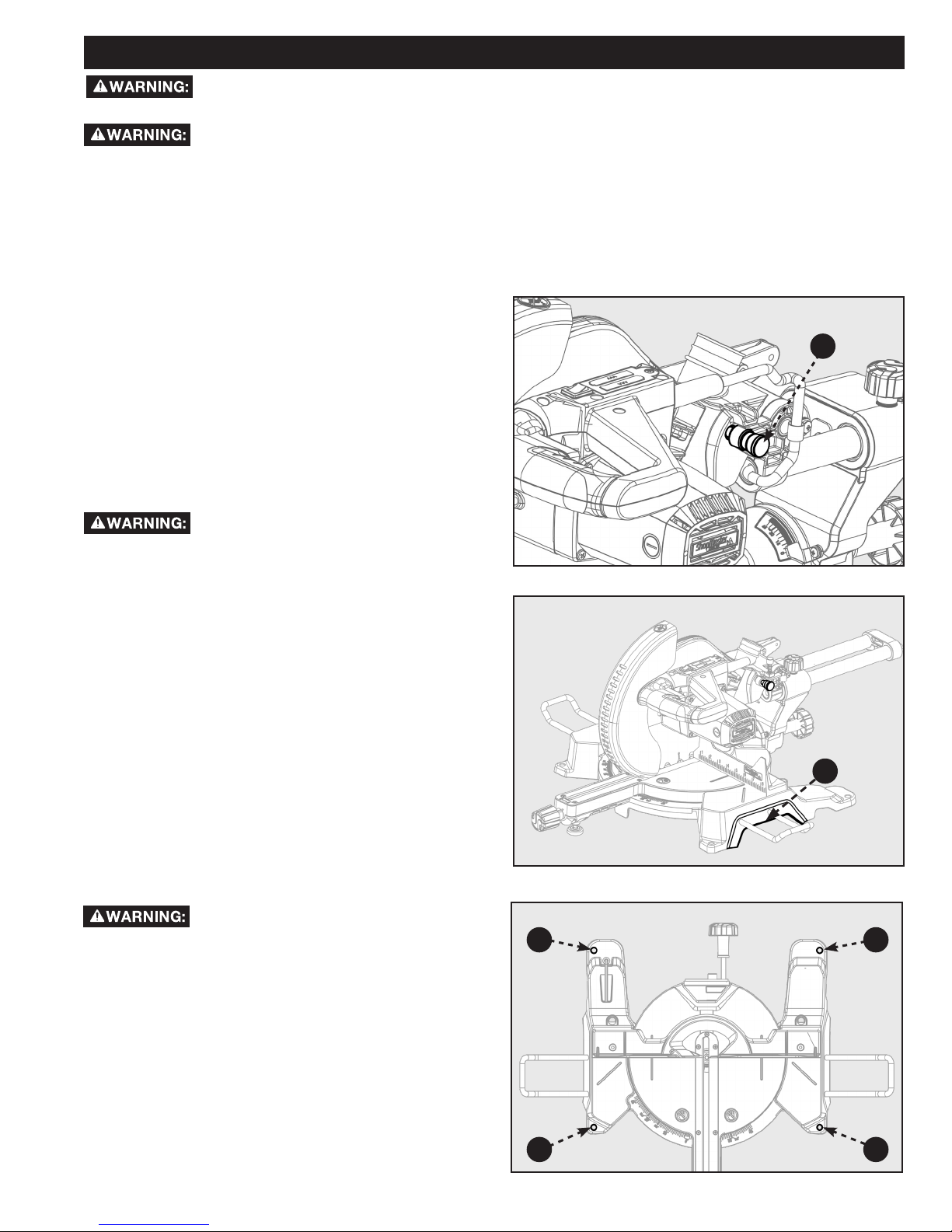

PREPARATIONS FOR TRANSPORTATION

1. The saw is shipped with the arm secured in the down

position as shown in Figure 3. To release the arm,

push it down, cut the plastic tie and release the lock

pin (A).

2. Lock pin (A) is for storage and transport only. Saw is

not to be locked in down position during cuts.

3. Inspect the tool carefully to make sure no damage

occurred during shipping.

4. Do not discard the packaging material until you have

carefully inspected and satisfactorily operated the

tool.

Saw Head lock pin is for storage and

transport only. This saw should never be locked in the down

position while making cuts.

FIGURE 3

A

BASE WITH CARRY HANDLES

Use the carry handles which are designed into the base for

safe and easy transportation of the saw. Shown in Fig. 4.

MOUNTING THE SAW TO A

STABLE SURFACE

To ensure safe and accurate operation,

this saw should be mounted to a stable

and level surface such as a workbench. To mount the tool

to a stable surface, refer to Figure 5 and do the following:

1. Locate the four mounting holes in the base of the

saw (C).

2. Secure the tool to the mounting surface using 3/8”

diameter machine bolts, lock washers, and hex nuts

(not included). Make sure the bolts are long enough

to accommodate the saw base, lock washers, hex

nuts, and the thickness of the workbench.

3. Tighten all four bolts securely.

4. Check to make sure that the saw is secure before

operation.

B

FIGURE 4

C

C

FIGURE 5

C

C

9

Page 10

ASSEMBLY

• Do not attempt to modify this tool or create accessories not recommended for use with this tool. Any such alteration

or modification is misuse and could result in a hazardous condition.

• Do not connect to power supply until assembly is complete. Failure to comply could result in accidental starting.

• Do not start the mitre saw without checking for interference between the blade and the mitre fence. Damage could

result to the blade if it strikes the mitre fence during operation of the saw.

• The saw can tip over if the saw head is released suddenly and the saw is not secured to a work surface. ALWAYS

secure this saw to a stable work surface before any use.

• If any parts are damaged or missing do not operate this tool until the parts are replaced. Please call Customer Care

Center at 800-223-7278, for instructions.

SUPPORT EXTENSIONS

See Figure 6.

Table extensions have been provided for both the left and

right side of the saw.

To install table extensions:

• Insert the ends of extension (A) into holes in the sides

of the base (B).

• Thread Hex-Socket Cap Screw (C) into the end of

extension (A). Tighten screw.

• Repeat for other extension.

• Always fix and use workpiece

support extensions during operation.

A

B

FIGURE 6

C

ATTACHING WORK CLAMP

The horizontal work clamp secures the workpiece to the

fence to provide more stability and keeps the workpiece

from creeping toward the saw blade. Depending on the

cutting operation and the size of the workpiece, it may be

preferable to use a C-clamp instead of the work clamp

to secure the workpiece to the mitre table prior to making

the cut.

To install the horizontal work clamp, see Figure 7 and do

the following:

1. Place the clamp shaft (D) in either hole (E) on the

mitre table base.

2. Rotate the knob (F) on the clamp clockwise to move

it in or counter clockwise to move it out as needed.

INSTALL DUST COLLECTION BAG

The tool includes a dust collection bag that attached over

the exhaust port on the upper blade guard. To install,

slide the plastic collar (G) of the dust bag onto the dust

port (H). See Figure 8.

NOTE: To remove the dust bag for emptying, simply

reverse the above procedure.

F

E

FIGURE 7

G

H

D

FIGURE 8

10 11

Page 11

ASSEMBLY

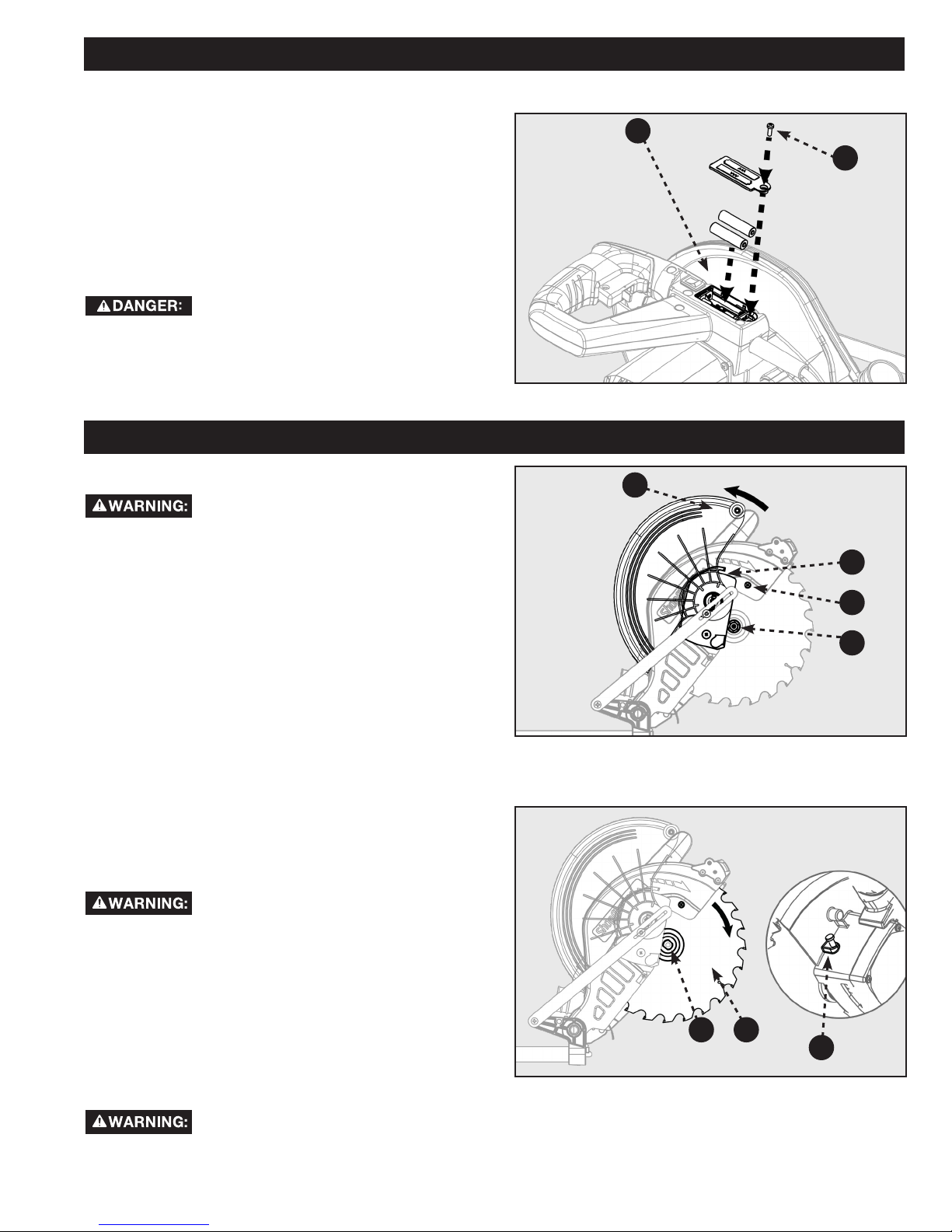

INSTALL BATTERIES FOR LASER

1. The battery compartment (A) is located in the control

arm on the rear of the saw. See Figure 9.

2. Using the Phillips end of the supplied blade wrench,

remove the screw (B) securing the compartment

cover and lift off the cover.

3. Install two AAA batteries (supplied) as shown on the

diagram in the compartment.

4. Replace the cover and secure with the screw.

Laser radiation. Avoid direct eye contact

with light source.

PREPARING YOUR SAW FOR USE

INSTALL/REPLACE THE BLADE

According to the markings on the saw a

10-inch blade is the maximum blade

capacity of the saw. Larger blades will come in contact with

the blade guards. Only use blades which are rated for at

least 5,500 RPM or higher. Only use blades with a maximum

kerf width of 2.7mm or less.

1. Make sure the saw is unplugged.

2. Raise the saw arm to the full upright position.

3. In Figure 10, Rotate the lower blade guard (C) up.

Slightly loosen the blade bolt cover screw (D) until you

can move the blade bolt cover (E) up to expose the

blade bolt (F).

Refer to Figure 11.

4. Press the spindle lock button (G).

5. If replacing the blade, carefully rotate the old blade until

the spindle locks in place.

6. Using the supplied blade wrench, remove the blade bolt

(F) by turning it clockwise.

NOTE: The blade bolt has left-hand threads.

7. Remove only the outer blade washer (H) and the blade

(I), leaving the inner blade washer on the spindle.

If inner blade washer has been removed,

replace it before placing blade on spindle.

Failure to do so could cause an accident since blade will not

tighten properly.

8. Carefully fit saw blade inside the lower blade guard and

guide it onto spindle, ensuring the teeth of the blade are

facing down at the front of the saw.

9. Align the double “D” flats on the blade washer with the

flats on the spindle and fit the washer onto the spindle.

10. Lock the spindle by depressing the spindle lock button.

Replace blade bolt, remembering to thread it counter

clockwise. Tighten blade bolt securely.

Always install the blade with the blade teeth and the arrow on the side of the blade pointing down at

the front of the saw. The direction of the blade rotation is also stamped with an arrow on the upper

blade guard.

A

B

FIGURE 9

C

E

D

F

FIGURE 10

IH

G

FIGURE 11

11

Page 12

PREPARING YOUR SAW FOR USE

11. Replace the blade bolt cover and tighten blade bolt cover screw securely. Lower blade guard.

12. Raise and lower the saw arm to ensure that the arm and blade guard move freely.

Make sure the spindle lock button is not engaged before reconnecting saw to power source. Never

engage spindle lock button when blade is rotating.

NOTE: Some illustrations in this manual indicate only portions of the saw. This is done in order to more clearly show key

areas and components of the saw. Never operate the saw without all guards securely in place and in good operating

condition.

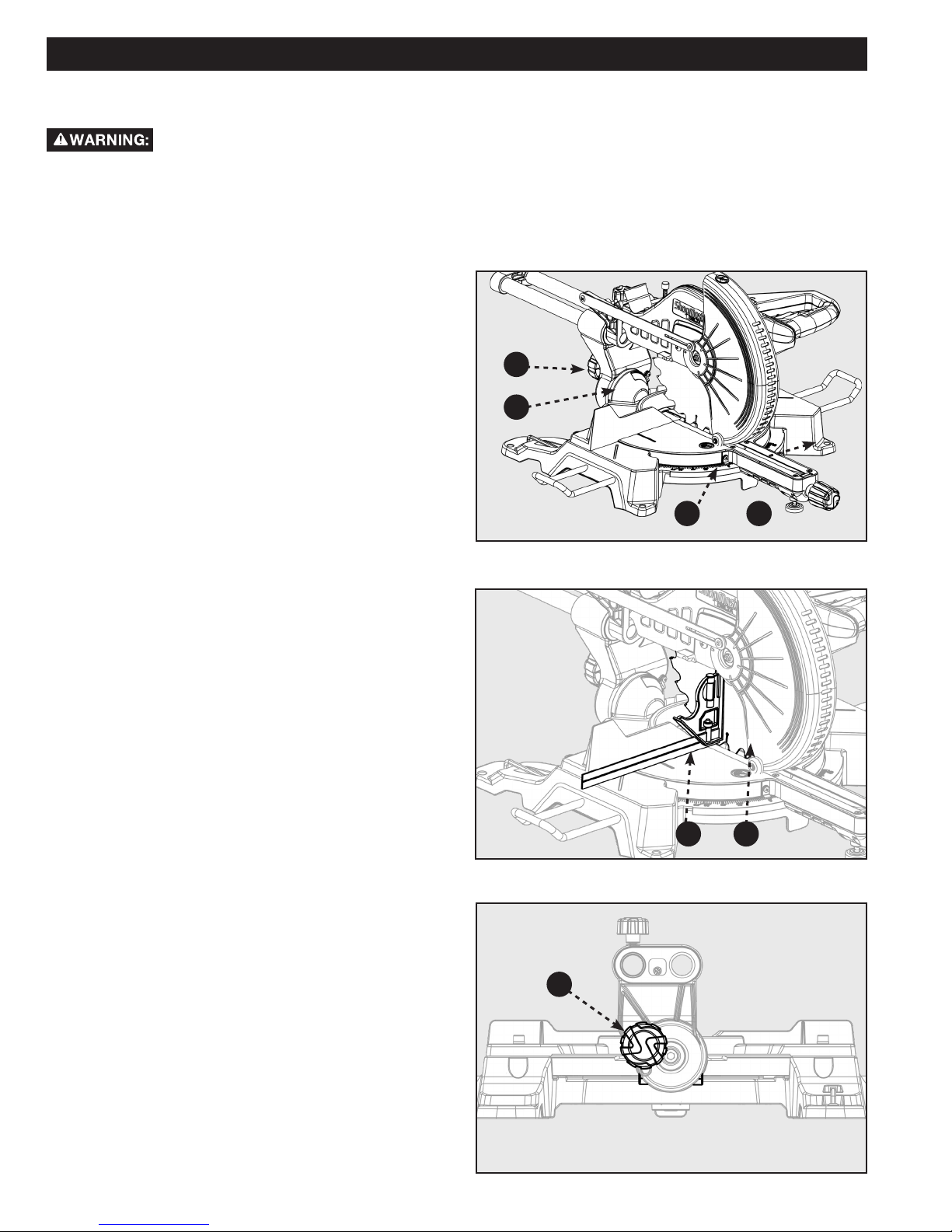

ALIGN THE BLADE TO THE TABLE

Refer to Figure 12.

1. Unplug the saw

2. Lower the saw arm all the way down to the transport

position and engage the lock pin to hold it in place.

3. Rotate the mitre lock handle (A). Position the table so

that the mitre scale indicator ( B) reads 0°.

4. Rotate the mitre lock handle to the locked position so

that the table will not move.

5. Loosen bevel lock knob (D) and adjust the angle of

saw arm so that the bevel scale indicator (C) reads

0°. This positions the blade at 90° to the table.

6. Securely tighten bevel lock knob.

7. Place a combination square (E) against the table and

the face of the saw blade (F).

NOTE: Make sure that the square contacts the flat part of

the saw blade, not the blade teeth.

8. Rotate the blade by hand and check the blade-to-

table alignment at several points.

9. The edge of the square and the saw blade should be

parallel as shown in Figure 13.

10. If the top or bottom of the blade face is not flush with

the square, refer to Figure 14 below and perform the

following steps.

11. Loosen bevel lock knob (G).

12. Adjust positive stop adjustment screw (not shown) to

bring saw blade into alignment with the square. See

“Positive Stop Screw” in the Adjustment section.

13. Re-tighten bevel lock knob. Recheck blade-to-blade

alignment.

NOTE: The above procedure can be used to check

alignment of the blade to the mitre table at both 0° and

45° angles.

The saw has two scale indicators, one on the bevel scale

and one on the mitre scale. After squaring adjustments

have been made, it may be necessary to loosen the

indicator screws and reset them to zero.

D

C

FIGURE 12

FIGURE 13

B

A

E

F

G

FIGURE 14

12 13

Page 13

PREPARING YOUR SAW FOR USE

USING THE LASER GUIDE

Refer to Figure 15.

When the laser guide switch is turned on it projects a red

line onto the work surface enabling you to see your cut

before you make it. To ensure a true and straight cut:

1. Make sure the saw is unplugged.

2. Draw a line on the workpiece where you plan to cut.

3. Flip the laser switch (A) on the “ON” position.

4. The red line (B) indicates the path of the blade.

5. Align the laser line and the mark with the blade at the

uppermost position.

6. Once both lines are in alignment, do not move the

workpiece.

7. Plug the saw into the power source.

8. Make several practice cuts on different styles and

thickness of material.

9. Repeat the steps above is necessary.

TO REMOVE YOUR MARK:

Position the laser line near the left edge of your mark on

the work surface in order to cut the mark.

APPLICATIONS

A

TO CUT ON YOUR MARK:

Position the laser line near or over your mark on the work

surface in order to cut the mark.

TO CUT WITHOUT REMOVING YOUR MARK:

Position the laser line near the right edge of your mark on

the work surface in order to leave the mark,

After you have become familiar with using the laser

guide, you will be able to remove, cut, or leave your mark

on the work surface. Practice will teach you the correct

position for aligning the laser line with your mark.

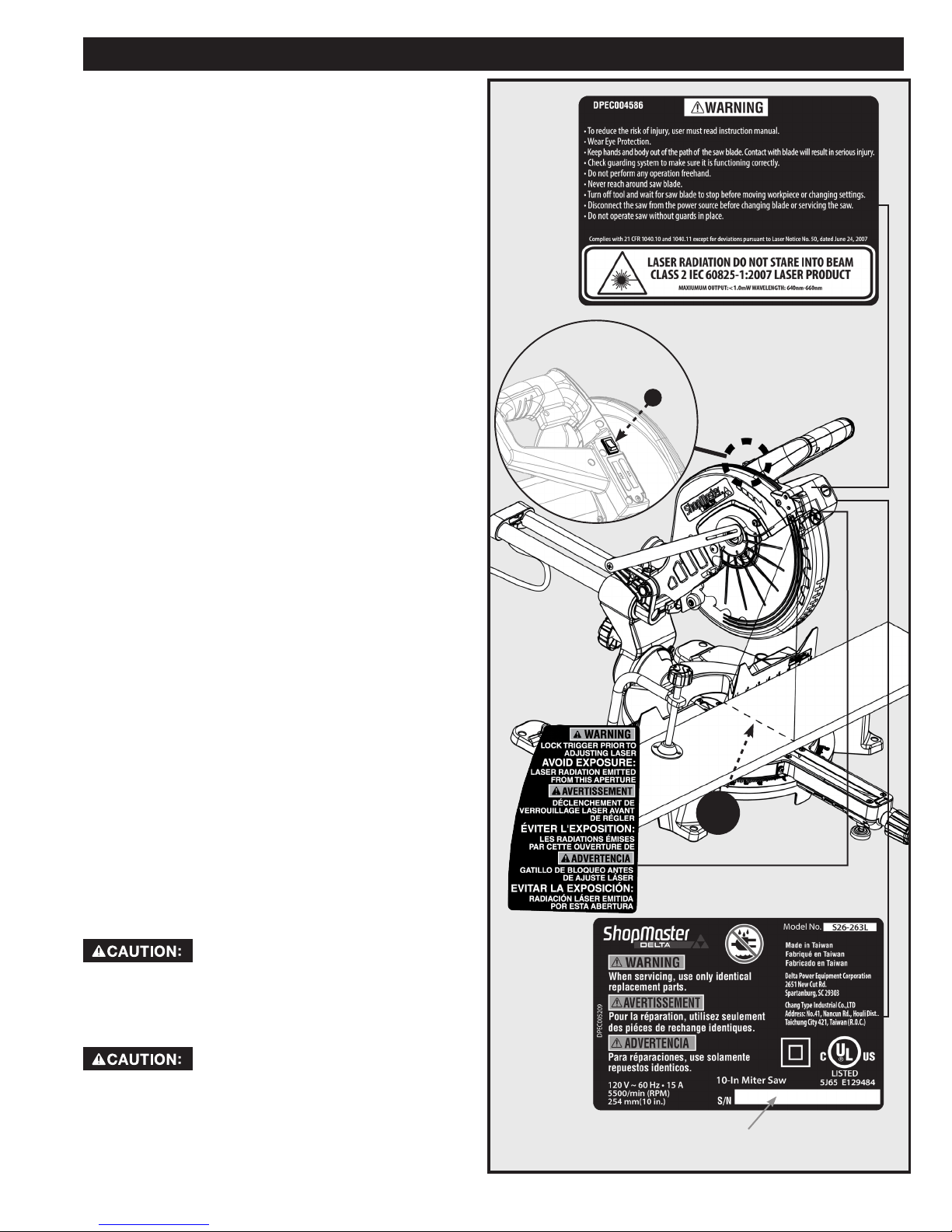

FREE WARNING LABEL REPLACEMENT

If your warning labels become illegible or are missing,

user shall remake the label according to copy on manual

and attach on the same location or call 1-800-223-7278

for a free replacement.

During operation and maintenance, human access to

laser radiation in excess of the accessible emission limit

is possible, so it should avoid direct eye exposure of laser

radiation.

Complies with 21 CFR 1040.10 and 1040.11 Use of

controls or adjustments or performance of procedures

other than those specified herein may result in hazardous

radiation exposure.

B

Metal instruments can cause a laser reflector. During

operation and maintenance should avoid direct exposure

in these instruments, as far as possible not to use

reflective instruments. Action should be avoided with

watches, necklaces, bracelets, it can be reflected laser

accessories.

14AB000001211401CT

EXAMPLE SERIAL NUMBER, FOR

REFERENCE ONLY

FIGURE 15

13

Page 14

OPERATION

Do not allow familiarity with tools to make you careless. Remember that a careless fraction of a second

is sufficient enough to inflict serious personal injury.

• Always wear eye protection with side shields and marked to comply with ANSI Z87.1 Failure to do so could result in

objects being thrown into your eyes, resulting in possible serious personal injury.

• Do not use any attachments or accessories not recommended by the manufacturer of this tool. The use of

attachments or accessories not recommended can result in serious personal injury.

• Before starting any cutting operation, clamp or bolt the compound mitre saw to a workbench. Never operate the

mitre saw on the floor or in a crouched position. Failure to heed this warning can result in serious personal injury.

• To avoid serious personal injury, always tighten the mitre lock handle and bevel lock knob securely before making a

cut. Failure to do so could result in movement of the control arm or mitre table while making a cut.

• To avoid serious personal injury, keep hands outside the no hands zone, at least 3 in. from blade. Never perform any

cutting operation freehand (without holding workpiece against the fence). The blade could grab the workpiece if it

slips or twists.

• When using a work clamp or C-clamp to secure the workpiece, clamp workpiece on one side of the blade only. The

workpiece must remain free on one side of the blade to prevent the blade from binding in workpiece. The workpiece

binding the blade will cause motor stalling and kickback. This situation could cause an accident resulting in serious

personal injury.

• NEVER move the workpiece or make adjustment to any cutting angle while the saw is running and the blade is

rotating. Any slip can result in contact with the blade causing serious personal injury.

When cutting, do not force the blade against the workpiece. Forcing the blade will cause a drop in motor RPM and

•

increase the risk of overheating the saw blade tips.

You may use this tool for the following purposes:

• Bevel cutting and compound cutting for crown moldings, etc.

• Cross cutting wood

• Cross cutting for moldings, door casings, picture frames, etc.

NOTE: This saw is for cutting wood. The blade provided is acceptable for wood cutting only.

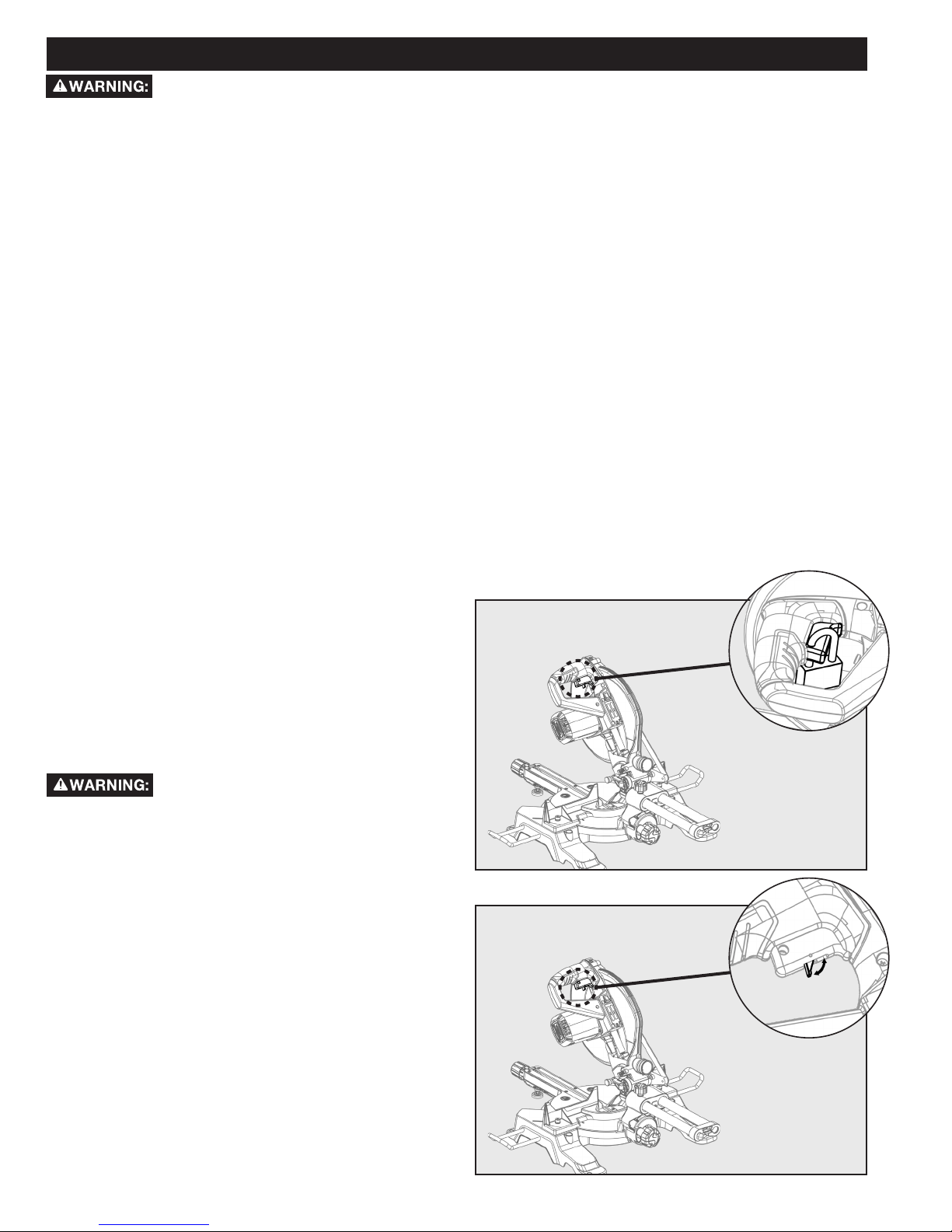

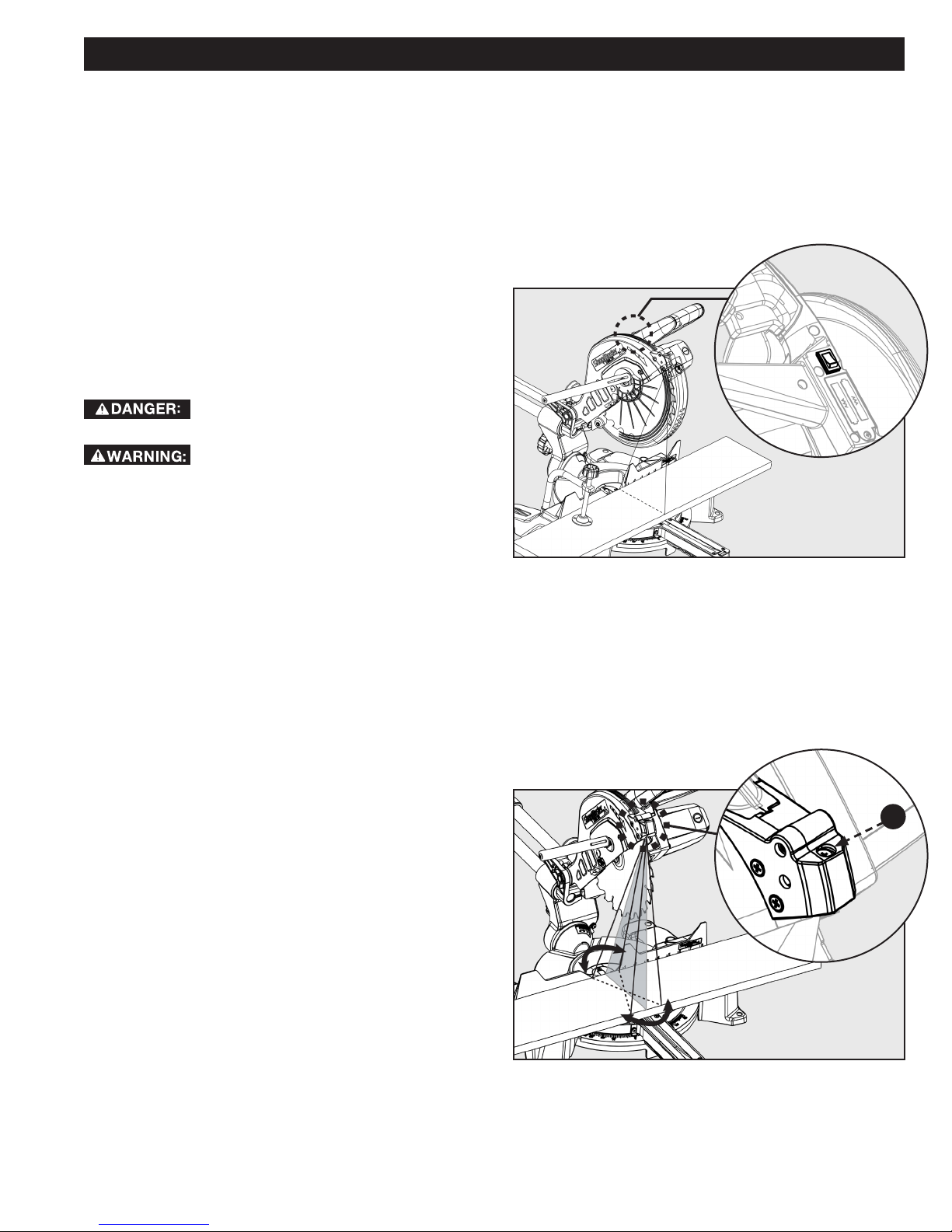

POWER SWITCH LOCK-OUT

To prevent any unauthorized person from operating this

saw, a padlock (not included) should be installed into

the Lock Hole located on the power switch, as shown

in Figure 16. Be sure padlock is fully closed and locked

before leaving this saw unattended.

Always disconnect the power supply

before installing or removing a lock

onto the power switch. Failure to

do so could cause the power switch

to engage by accident, resulting in

serious injury.

FIGURE 16

POWER SAFETY TOGGLE

In order to turn the saw motor on, you must first engage

the power safety toggle located on the power switch

handle as shown in figure 17.

FIGURE 17

14 15

Page 15

OPERATION

TO SLIDE CUT

Never make a cut by pulling the saw

toward you. The blade can “climb” on

top of the workpiece and come toward you at an

accelerated speed. Failure to heed this warning could

result in serious personal injury.

See Figure 18.

With the saw off, pull the saw arm forward. Turn the saw

on (wait for blade to reach full speed). push the blade

down cutting into the workpiece, then back toward the

rear of the saw to make a cut. Cuts must be made by

pushing the saw blade away from you and toward the

back of the saw stopping at the maximum rear position

after each cut. While the saw is running, NEVER pull the

saw blade toward you or toward the front of the saw. See

warning above.

• Raise arm to its full height.

• Place the workpiece flat on the mitre table with

one edge securely against the fence. If the board is

warped, place the convex side against the fence. If

the concave edge of a board is placed against the

fence, the board could collapse on the blade at the

end of the cut, jamming the blade.

• When cutting long pieces of lumber or molding,

support the opposite end of the stock with a stand or

with a work table level with the saw table.

• Align the cutting line on the workpiece with the blade

or laser line.

• Loosen the slide lock knob.

• Hold the stock firmly with one hand, against the

fence. Use the work clamp to secure the workpiece

whenever possible.

• With the saw off, perform a dry run of the cut to

make sure that no problems will occur when the

actual cut is made.

• With the saw off, grasp the saw handle firmly then

pull the saw forward until the center of the saw blade

is over the front edge of the workpiece or until the

saw is fully extended.

• Only use the saw handle (A) to place your hands. DO

NOT place your hands on the motor housing.

• Squeeze the switch trigger. Allow the blade to reach

maximum speed.

• Slowly lower the blade through the front edge of the

workpiece.

• While holding the workpiece push the saw handle

away from you and toward the back of the saw.

• Release the switch and allow the saw blade to stop

rotating before raising the blade out of workpiece.

After blade stops, remove the workpiece from mitre

table.

NOTE: A cross cut is made by cutting across the grain of

the workpiece. A straight cross cut is made with the mitre

A

FIGURE 18

table set at the 0° position. Mitre cross cuts are made

with the mitre table set at some angle other than 0°

BEVEL CUTS

A bevel cut is made across the grain with the blade

angled to the workpiece. A straight bevel means the mitre

scale indicator is set at 0° and the bevel scale indicator is

set at an angle other than 0°.

COMPOUND MITRE CUTS

A compound mitre cut is made using a mitre angle and a

bevel angle at the same time. Adjustments of mitre and

bevel settings are interdependent. Each time you adjust

the mitre setting change the effect of the bevel setting.

Also, each time you adjust the bevel setting you change

the effect of the mitre setting.

15

Page 16

OPERATION

TIPS FOR CUTTING AND SUPPORTING WORKPIECES

TIPS FOR CUTTING CROWN MOLDING

• The two edges of the molding that contact the ceiling and the wall are at angles that, when added together, equal

exactly 90°. Most crown molding has a top rear angle (the section that fits flat against the ceiling) of 52° and a

bottom rear angle (the section that fits flat against the wall) of 38°.

• To accurately cut crown molding for a 90° inside or outside corner, lay the molding with its broad back surface flat

on the mitre table and against the fence.

• The angles for crown moldings must be very precise. The bevel and mitre angles are interdependent; changing one

angle changes the other angle as well.

• Since it is very easy for the work piece to shift, all settings should first be tested on scrap molding. Also most walls

do not have angles of exactly 90°; therefore, you will need to fine-tune your settings.

• When cutting crown molding the bevel angle should be set at 33.85°.

• The mitre angle should be set at 31.62° either right or left, depending on the desired cut for the application. See the

chart below for correct angle settings and correct positioning of crown molding on the work table.

Bevel Angle Setting Type of Cut Steps

33.85° Left side, inside corner 1. Top edge of molding against fence

2. Mitre table set right 31.62°

3. Save left end of cut

33.85°

33.85° Left side, outside corner 1. Bottom edge of molding against fence

33.85° Right side, outside corner 1. Top edge of molding against fence

Right side, inside corner 1. Bottom edge of molding against fence

2. Mitre table set left 31.62°

3. Save left end of cut

2. Mitre table set left 31.62°

3. Save right end of cut

2. Mitre table set right 31.62°

3. Save right end of cut

16 17

Page 17

OPERATION

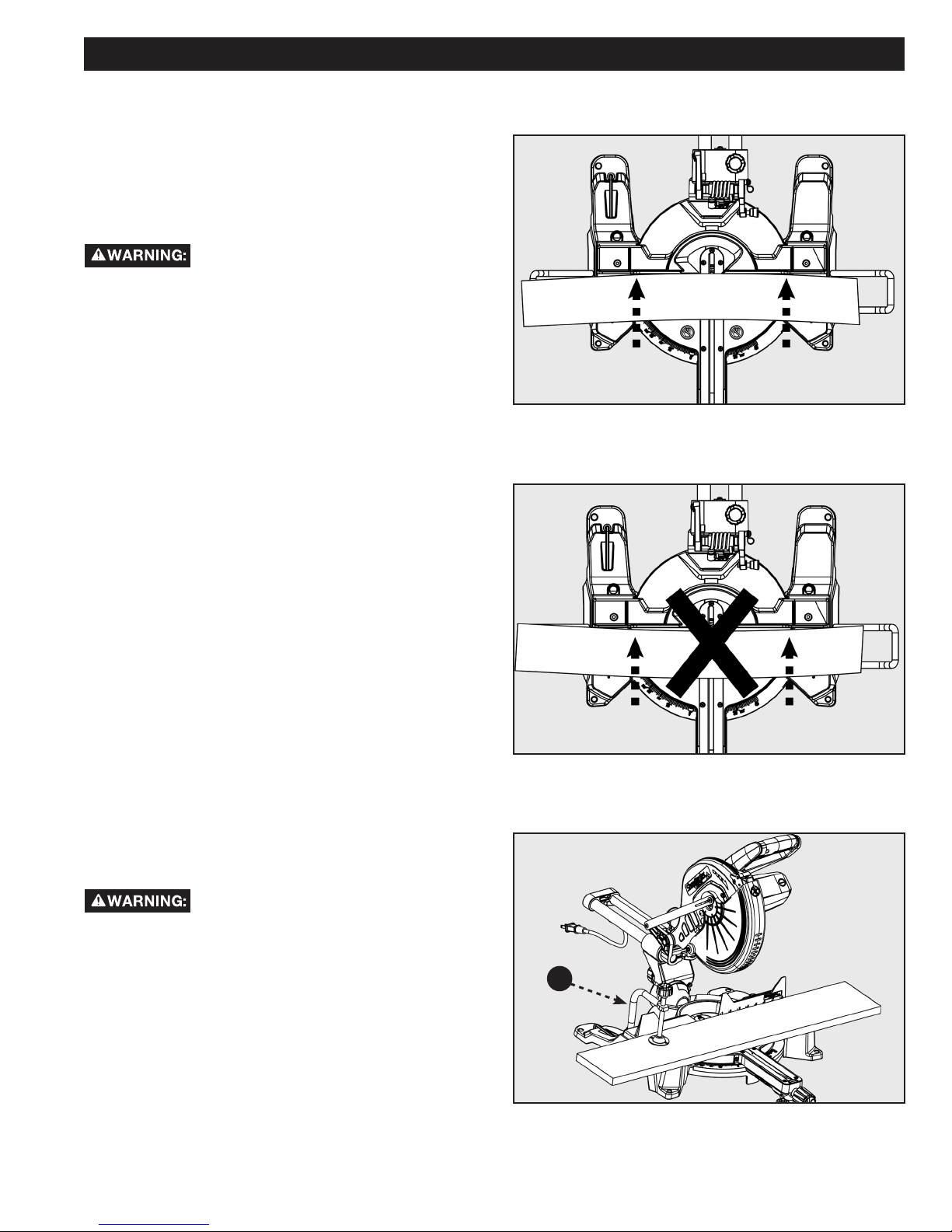

CUTTING WARPED MATERIAL

When attempting to cut warped material, the CONVEX

face should be against the fence as shown in Figure 19.

Never position a piece of warped material with the

CONCAVE face or edge against the fence, as shown in

Figure 20. It will pinch the blade near the completion of

the cut.

To avoid a kickback and to avoid serious

personal injury, never position the

concave edge of bowed or warped material against the

fence.

FIGURE 19

CLAMPING WIDE WORKPIECES

When cutting wide work pieces, such as 2 in. X 12 in.,

clamp the workpiece to the work table using a work

clamp as shown in Figure 21.

Keep clamps away from the path of the

blade and blade guard assembly.

FIGURE 20

A

FIGURE 21

17

Page 18

OPERATION

SUPPORTING LONG WORKPIECES

In most cases the included table extensions

(workpiece supports) will be sufficient to support

longer workpieces. If these are not long enough, the

workpiece should be supported further out from the

saw. Additional support (A) may be used to make

the workpiece lay flat on the saw table. Use the

included work clamp or a C-clamp (B) to secure the

workpiece to the mitre saw table. See Figure 22.

Keep clamps away from the path of

the blade and blade guard assembly.

A

FIGURE 22

B

ADJUSTMENTS

Before performing any adjustment, make sure the tool is unplugged from the power supply. Failure to

heed this warning could result in serious personal injury.

Your compound mitre saw has been properly adjusted at the factory. Due to shipping or normal use, it may be necessary

to re-adjust some of the settings. Check the following adjustments periodically to assure proper accuracy and safe

operation.

Check for interference between the blade and the throat plate, before plugging the saw into the power

source.

ARM PIVOT

The arm of the saw should raise and lower completely and freely. In the lowered position and with the lock pin removed,

the arm should rise to the up position by itself. If the saw arm does not raise by itself or if there is play in the pivot joints,

it will need to be professionally repaired at an AUTHORIZED SHOPMASTER SERVICE CENTER. Please call Company’s

Customer Care Center at 800-223-7278.

POSITIVE STOP SCREW

The position of the positive stop adjustment screw was set

at the factory and normally will not require readjustment.

If the blade is not square to the table, the positive stop

adjustment screw must be re-adjusted.

To adjust refer to Figure 23.

1. Unplug the saw

2. Using the Phillips end of the blade wrench, loosen

the positive stop adjustment screw (C) by turning it

counterclockwise.

3. Loosen the bevel lock knob (D) by turning it

counterclockwise.

4. Square the blade to the mitre table as described in the

section entitled, ALIGN THE BLADE TO THE TABLE,

found on page 12.

5. Re-tighten bevel lock knob. Recheck blade-to-table

alignment.

6. The saw has two scale indicators, one on the bevel

scale and one on the mitre scale. After squaring

adjustments have been made, it may be necessary to

loosen the indicator screws and reset them to zero.

NOTE: Use this procedure to check that the blade is square

to the table at 0° and 45° angles.

D

0° 45°

C

FIGURE 23

18 19

Page 19

ADJUSTMENTS

BEVEL PIVOT

With the bevel lock knob loosened, the control arm of the saw should tilt easily from 0° and 45°. If it does not or if there is

play in the pivot, the saw must be repaired by an AUTHORIZED SHOPMASTER SERVICE CENTER.

LASER ADJUSTMENTS

This saw is equipped with an adjustable laser which

projects a red line onto the work piece surface, see

Figure 24. Refer to the “Using Your Laser Guide” section

on page 13 for more information on how to operate laser.

This section will instruct you how to adjust the laser

alignment for more accurate cuts.

• Avoid direct eye exposure to laser beam or reflection.

Intense or prolonged exposure to laser radiation

could permanently damage your eyes. Do not project

or reflect the laser into anyone’s eyes, including your

own.

• Caution -- use of controls or adjustments or

performance of procedures other than those

specified herein may results in hazardous radiation

exposure.

• Use or modification of the laser guide for anything

other than its designed purpose may result in

hazardous radiation exposure.

Laser radiation. Avoid direct eye contact

with light source.

FIGURE 24

LASER PARALLEL ADJUSTMENT

If you notice the laser line is not perfectly parallel with

the saw blade refer to Figure 25 and follow these

instructions: using a Phillips head screwdriver turn screw

(A) until the laser line is parallel with the saw blade.

A

FIGURE 25

19

Page 20

ADJUSTMENTS

LASER VERTICAL ANGLE

ADJUSTMENT

If you notice the laser line does not remain parallel to the

blade as the saw head is lowered to make a cut refer to

Figure 26 and follow these instructions: using a Phillips

head screwdriver turn the screw (A) to adjust the vertical

angle of the laser.

LASER OFFSET ADJUSTMENT

If you notice the laser line is offset from the actual cut line

refer to Figure 27 and follow these instructions: using a

Phillips head screwdriver turn the screw (B) to adjust the

offset.

A

FIGURE 26

B

DEPTH STOP ADJUSTMENT

This mitre saw is equipped with an adjustable depth stop

for making through cuts and non-through cuts.

Refer to Figure 28 and follow these instructions in

order to set the depth stop at a specific cut depth:

use a Phillips head screwdriver to loosen screw (E) and

then rotate the stop bracket (D) counterclockwise into

the down position. Make sure to re-tighten screw (E).

The cut depth can now be adjusted by turning the depth

adjustment screw (C).

Refer to figure 28 and follow these instructions

in order to make a through cut: use a Phillips head

screwdriver to loosen screw (E) and then rotate the stop

bracket (D) clockwise into the up position. Make sure to

re-tighten screw (E).

Always check to make sure screw (E) is

tightened before making a cut. Failure to

do so may result in injury.

FIGURE 27

C

D

E

FIGURE 28

20 21

Page 21

MAINTENANCE

To reduce the risk of injury, turn unit off

and disconnect it from power source

before cleaning or servicing, before installing and

removing accessories, before adjusting when making

repairs. An accidental start-up can cause injury.

KEEP MACHINE CLEAN

Periodically blow out all air passages with dry

compressed air. All plastic parts should be cleaned

with a soft damp cloth. NEVER use solvents to clean

plastic parts. They could possibly dissolve or otherwise

damage the material. Wear certified safety equipment

for eye, hearing and respiratory protection while using

compressed air.

Empty dust bag frequently.

When servicing, use only identical

replacement parts. Use of any other

parts may create a hazard or cause product damage.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most

plastics are susceptible to damage from various types of

commercial solvents and may be damaged by their use.

BRUSH REPLACEMENT

Use clean cloths to remove dirt, dust, oil, grease, etc.

Do not at any time let brake fluids,

gasoline, petroleum-based products,

penetrating oils, etc., come in contact with plastic parts.

Chemicals can damage, weaken or destroy plastic which

may result in serious personal injury.

Electric tools used on fiberglass material, wallboard,

spackling compounds, or plaster are subject to

accelerated wear and possible premature failure

because the fiberglass chips and grindings are

highly abrasive to bearings, brushes, commutator,

etc. Consequently, we do not recommend using this

tool for extended work on these types of materials.

However, if you do work with any of these materials, it is

extremely important to clean the tool using compressed

air.

LUBRICATION

All of the bearings in this tool are lubricated with a

sufficient amount of high-grade lubricant for the life of

the unit under normal operating conditions. Therefore, no

further lubrication is required.

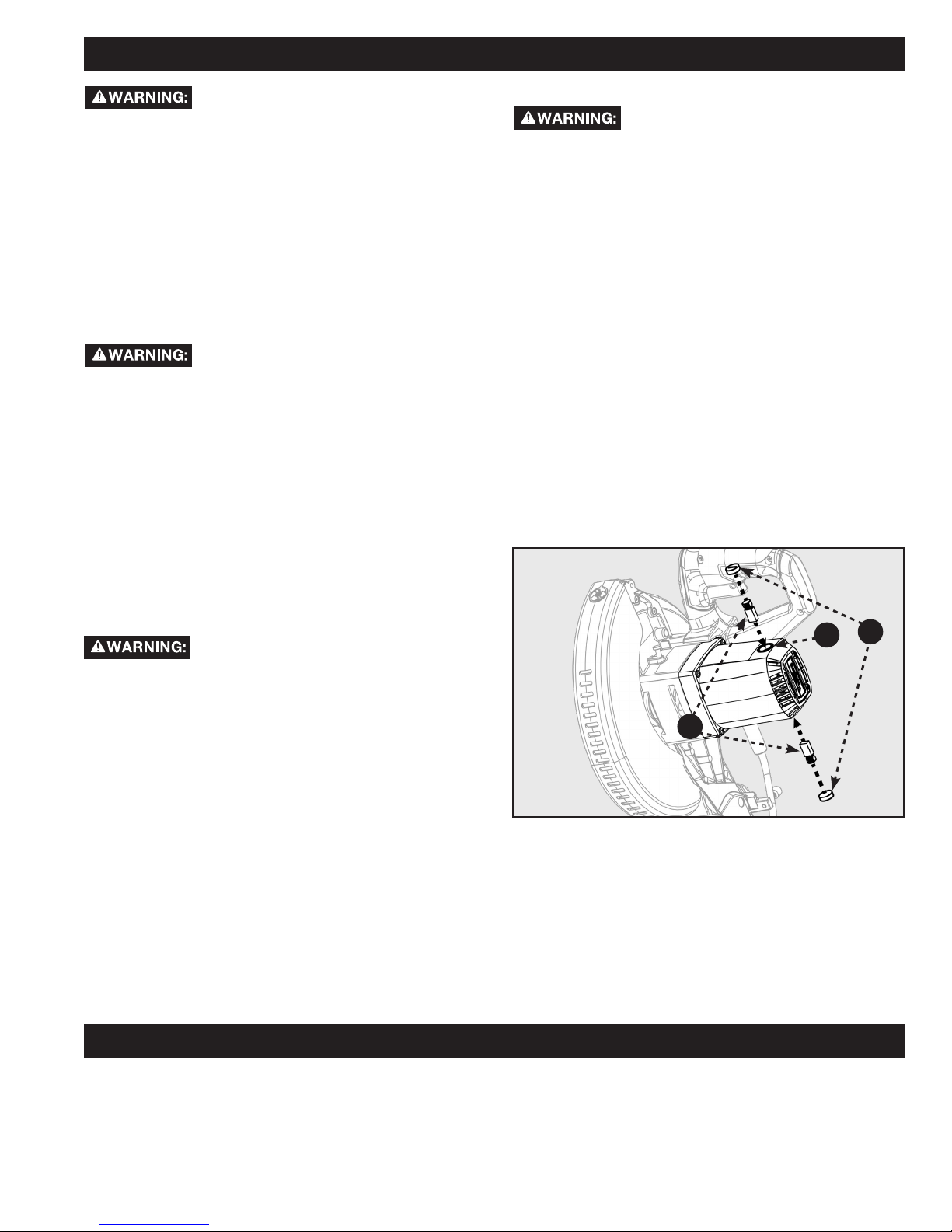

The motor on this saw features externally accessible

brush assemblies that should be periodically checked for

wear. If the brushes need to be replaced, refer to Figure

29 and proceed as follows:

1. Unplug the saw.

Failure to unplug the saw could result in

accidental starting causing serious

personal injury.

2. Using a screwdriver, carefully remove the brush cap

(A).

NOTE: Remove the cap slowly. The brush assembly is

spring-loaded and will pop out once the cap is removed.

3. Remove brush assembly (B).

4. Inspect both brushes. If either has less than 1/4 in.

length of carbon remaining, both brushes should be

replaced.

NOTE: Do not replace one side without replacing the

other.

5. Insert both brushes into the brush tube (C), making

sure the curvature of the brushes matches curvature

of motor. Brush assembly should move freely within

the tube.

6. Carefully replace the brush cap, ensuring that it is not

cross-threaded.

7. Tighten brush cap securely. Do not over-tighten.

B

FIGURE 29

C

A

FAILURE TO START

If your machine fails to start, check to make sure the prongs on the cord plug are making good contact in the receptacle.

Also, check for blown fuses or open circuit breakers in your power supply line. If the saw still does not start, call

Company’s Customer Care Center at 1-800-223-7278.

TROUBLESHOOTING

21

Page 22

ACCESSORIES

For accessories please visit our Web Site for an on-line catalog or for the name or your nearest supplier.

Since accessories other than those offered by DELTA

®

have not been tested with this product, use of

such accessories could be hazardous. For safest operation, only DELTA®/SHOPMASTER recommended

accessories should be used with this product.

PARTS, SERVICE OR WARRANTY ASSISTANCE

All SHOPMASTER Machines and accessories are manufactured to high quality standards and are serviced by a

network of DELTA

parts, service, warranty assistance, or the location of the nearest service center, please call 1-800-223-7278.

1. WHAT IS COVERED. Delta Power Equipment Corporation (“Company”) will, at its option, repair or replace this SHOPMASTER

product, if purchased at retail in the United States or Canada and the product, with normal use, has proven to be defective in

workmanship or material, subject to the conditions stated in this Limited Warranty. This Limited Warranty covers only materials

and labor. All transportation costs are Customer’s responsibility.

2. WARRANTY PERIOD. All warranty claims must be submitted within three years from the date of retail purchase. For all service

parts and factory refurbished SHOPMASTER products, the warranty period is 180 days.

3. HOW TO OBTAIN SERVICE. To obtain warranty service, you must return the defective product, at your expense, to a service center

authorized by Company to perform warranty service (a “Company Authorized Service Center”) within the applicable warranty

period, together with acceptable proof of purchase, such as your original receipt bearing the date of purchase, or product

registration number. Company reserves the right to restrict warranty claim service to the country where the purchase was made

and/or to charge for the cost to export service parts or provide warranty service in a different country. For this purpose, on-line

purchases are deemed made in the United States. For the location of your nearest Company Authorized Service Center, call

Company’s Customer Care Center at (800) 223-7278.

4. EXCLUSIONS.

• Company does not offer any warranty on products purchased in used or damaged condition.

• Company does not warrant any products purchased outside the United States or Canada

• Company will not be responsible for any damage that has resulted from normal wear, misuse, abuse or any repair or alteration

made by anyone other than a Company Authorized Service Center or a designated representative of Company’s Customer Care

Center.

• All IMPLIED WARRANTIES are expressly limited to the warranty period identied above.

• Company will not be liable for INCIDENTAL OR CONSEQUENTIAL damages.

• This limited warranty is Company’s sole warranty and sets forth the customer’s exclusive remedy with respect to defective products;

all other warranties, express or implied, whether of merchantability, tness for purpose, or otherwise, are expressly disclaimed by

Company, except as expressly stated in this warranty statement.

Some states do not allow the exclusion or limitation of incidental or consequential damages, or the limitation of implied warranties, so

the above limitations or exclusions may not apply to you. This warranty gives you specic legal rights and you may have other rights

which vary in certain states or provinces. For further details of warranty coverage and warranty repair information, call (800) 223-7278.

To register your products on-line, we encourage you to visit our website and register for a FREE DELTA

www.deltamachinery.com/register.

®

Authorized Service Centers. To obtain additional information regarding your product or to obtain

Three Year Limited Warranty

®

Member Account at http://

LATIN AMERICA: This warranty does not apply to products sold in Latin America. For products sold in Latin America, call the local

company or see website for warranty information.

REPLACEMENT PARTS

The only user replaceable parts on this tool are:

1) Saw Blade

2) Motor Brushes

All other parts not listed above must be replaced by an authorized DELTA® agent. Use only identical replacement parts.

For a parts list or to order parts, visit our website at www.DeltaMachinery.com/service. You can also order parts from

your nearest Authorized Warranty Service Center or by calling Technical Service Manager at 1-800-223-7278 to receive

personalized support from one of our highly-trained representatives.

FREE WARNING LABEL REPLACEMENT

If your warning labels become illegible or are missing, call 1-800-223-7278 for a free replacement.

SERVICE AND REPAIRS

All quality tools will eventually require servicing and/or replacement of parts. For information about Delta Power

Equipment Corporation, its factory-owned branches, or to locate an Authorized Warranty Service Center, visit our

website at www.DeltaMachinery.com/service or call Customer Care at 1-800-223-7278. All repairs made by our service

centers are fully guaranteed against defective material and workmanship. We cannot guarantee repairs made or

attempted by others. By calling this number you can also find answers to most frequently asked questions 24 hours/day.

You can also write to us for information at Delta Power Equipment Corporation, 2651 New Cut Road, Spartanburg, SC

29303 - Attention: Technical Service Manager. Be sure to indicate all of the information shown on the nameplate of your

saw (model number, type, serial number, date code, etc.).

22 23

Page 23

10-INCH SLIDING COMPOUND MITRE SAW

SCIE À ONGLET COMBINE

254 MM

SIERRA INGLETADORA

COMPUESTA DE 10

PULGADAS

Français (23)

Español (46)

www.DeltaMachinery.com

Instruction Manual

Manual d’utilisation

Manual de instrucciones

AVERTISSEMENT :

Pour réduire les risques de blessure grave, veuillez lire attentivement et respecter

toutes les mises en garde et directives dans ce guide et sur le produit.

CONSERVEZ CE GUIDE PRÈS DE VOTRE PRODUIT POUR RÉFÉRENCE ET POUR INSTRUIRE LES AUTRES

S26-263L

23

Page 24

TABLE DES MATIÈRES

CONSIGNES IMPORTANTES DE SÉCURITÉ ....................... 24

RÈGLES DE SÉCURITÉ GÉNÉRALES POUR LES

OUTILS ÉLECTRIQUES .......................................................... 25

RÈGLES DE SÉCURITÉ DE LA SCIE À ONGLETS ............... 26

AVERTISSEMENT DE LA PROPOSITION 65 .......................27

BRANCHEMENTS D’ALIMENTATION ...................................27

FONCTIONS ............................................................................. 28

DÉBALLAGE ET MONTAGE ................................................... 30

MONTAGE ET TRANSPORT ................................................... 31

PRÉPARATIFS POUR LE TRANSPORT ............................ 31

GOUPILLE DE VERROUILLAGE DU BRAS DE SCIE ....... 31

BASE ET POIGNÉES DE TRANSPORT ............................ 31

MONTAGE DE LA SCIE SUR UNE SURFACE STABLE .... 31

MONTAGE ................................................................................ 32

RALLONGES DE SUPPORT ............................................. 32

FIXER L'ÉTAU .................................................................... 32

INSTALLER LE SAC À POUSSIÈRE.................................. 32

INSTALLER LES PILES POUR LASER .............................. 33

PRÉPARER VOTRE SCIE POUR L’UTILISATION .................33

INSTALLER/REMPLACER LA LAME ................................ 33

ALIGNER LA LAME À LA TABLE ...................................... 34

UTILISATION DU GUIDE LASER ...................................... 35

UTILISATION ............................................................................ 36

BLOQUEO DEL INTERRUPTOR DE ENCENDIDO/..............

APAGADO ..........................................................................36

DISPOSITIVO DE SEGURIDAD ELÉCTRICA .................... 36

FAIRE UNE COUPE EN GLISSIÈRE .................................37

CONSEILS POUR LA DÉCOUPE ET LE SOUTIEN

DE PIÈCE ........................................................................... 38

COUPE DE MATÉRIAU DÉFORMÉ ................................... 39

SERRAGE DES GRANDES PIÈCES ................................. 39

SOUTIEN DES LONGUES PIÈCES ................................... 40

RÉGLAGES .............................................................................. 41

PIVOT POUR COUPE BISEAUTÉE ................................... 41

RÉGLAGE DU PARALLÈLE DU LASER ............................ 41

RÉGLAGE DE L’ANGLE VERTICAL DU LASER................ 42

RÉGLAGE DU DÉPORT DU LASER .................................42

AJUSTEMENT DE LA PROFONDEUR...............................42

ENTRETIEN .............................................................................. 43

REMPLACEMENT DES BROSSES ................................... 43

DÉPANNAGE ............................................................................44

ACCESSOIRES ........................................................................ 44

ASSISTANCE POUR PIÈCES, SERVICES OU

GARANTIE ............................................................................... 44

CONSIGNES IMPORTANTES DE SÉCURITÉ

AVERTISSEMENT :

VOTRE PRODUIT DANS CE GUIDE ET SUIVEZ-LES TOUS. CONSERVEZ CE GUIDE. ASSUREZ-VOUS

QUE TOUS LES UTILISATEURS SONT FAMILIERS AVEC LES AVERTISSEMENTS ET INSTRUCTIONS

AVANT D'UTILISER L'OUTIL. Un mauvais fonctionnement, un mauvais entretien ou une modification des outils ou du

matériel peuvent entraîner des blessures graves et/ou des dommages matériels.

LISEZ ATTENTIVEMENT LES AVERTISSEMENTS ET LES INSTRUCTIONS SUR

LOGOS DE SÉCURITÉ

Ce guide contient des informations qu’il est important que vous connaissiez et compreniez. Ces informations concernent

VOTRE SÉCURITÉ et la PRÉVENTION DE PROBLÈMES AVEC L’ÉQUIPEMENT. Pour vous aider à reconnaître ces

informations, nous utilisons les symboles ci-dessous. Veuillez lire le guide et prêter attention à ces sections.

Indique une situation dangereuse imminente qui, si elle n'est pas évitée, entraînera la mort ou des

blessures graves.

AVERTISSEMENT :

MISE EN GARDE :

MISE EN GARDE :

Ne placez pas les outils électriques sous la pluie ou dans un environnement humide.

Indique une situation dangereuse potentielle qui, si elle n'est pas évitée, pourrait entraîner la mort

ou des blessures graves.

Indique une situation dangereuse potentielle qui, si elle n'est pas évitée, pourrait entraîner des

blessures mineures ou modérées.

L’utilisation sans le symbole d'alerte de sécurité indique une situation potentiellement dangereuse qui,

si elle n’est pas évitée, pourrait entraîner des dommages matériels.

Des informations supplémentaires concernant l’utilisation appropriée et sécuritaire de cet outil sont disponibles dans les

sources suivantes :

• Power Tool Institute, 1300 Sumner Avenue, Cleveland, OH 44115-2851 ou en ligne sur www.powertoolinstitute.com

• National Safety Council, 1121 Spring Lake Drive, Itasca, IL 60143-3201

• American National Standards Institute, 25 West 43 rd Street, 4th floor, New York, NY 10036 www.ansi.org —

exigences de sécurité ANSI 01.1 pour machines à bois

• Ministère du Travail du gouvernement américain, www.osha.gov

24 25

Page 25

RÈGLES DE SÉCURITÉ GÉNÉRALES POUR LES OUTILS ÉLECTRIQUES

AVERTISSEMENT :

électrique. Le non-respect de toutes les instructions citées ci-dessous peut causer une décharge électrique, un incendie

Lisez tous les avertissements, instructions, illustrations et spécifications fournis avec cet outil

ou une blessure grave.

Conservez tous les avertissements et instructions pour consultation future.

Le terme « outil électrique » dans les avertissements désigne votre outil électrique qui fonctionne avec l’alimentation du

secteur (avec fil) ou celui qui fonctionne avec une PILE (sans fil).

1. Sécurité de l’espace de travail

a. Tenez votre espace de travail propre et bien éclairé. Un endroit encombré et mal éclairé provoque les accidents

b. Ne faites pas fonctionner l’outil électrique en présence de risque d’explosion; par exemple, dans le cas à proximité

de liquides, gaz ou poussières inammables. Les outils électriques génèrent des étincelles susceptibles d’enammer le

liquide, les poussières ou les vapeurs.

c. Ne permettez pas à des enfants ou des observateurs de rester proches lorsque vous faites fonctionner un outil

électrique. Les distractions peuvent vous faire perdre le contrôle.

2. Sécurité électrique

a. Les ches des outils électriques doivent correspondre à la prise de courant. Ne jamais modier la che de quelque

façon que ce soit. Ne pas utiliser d’adaptateur de che avec des outils électriques conçus pour être mis à la terre. Les

ches non modiées et les prises correspondantes réduiront le risque de décharge électrique.

b. Évitez de toucher à des surfaces mises à terre telles que les tuyaux, les calorifères, les cuisinières et les

réfrigérateurs. Le risque de décharges électriques est plus grand si votre corps est en contact avec une mise à la terre.

c. Ne placez pas les outils électriques sous la pluie ou dans un environnement humide. L’eau qui s’inltre dans l’outil

électrique augmentera le risque de décharges électriques.

d. N’abimez pas le cordon. N’utilisez jamais le cordon pour transporter, tirer ou débrancher l’outil électrique.

Éloignez le cordon de toute source de chaleur, de bordures coupantes, de l’huile et de toute pièce mobile. Un

cordon endommagé ou entremêlé augmente les risques de décharges électriques.

e. Si vous faites fonctionner l’outil électrique à l’extérieur, utilisez une rallonge conçue pour cette n. L’utilisation d’un

cordon conçu pour l’extérieur réduit les risques de décharges électriques.

f. Si l’utilisation d’un outil électrique dans un endroit humide est inévitable, utiliser une alimentation protégée par un

DISPOSITIF DIFFÉRENTIEL À COURANT RÉSIDUEL (DDR). L’utilisation d’un DDR réduit le risque de décharge

électrique.

3) Sécurité personnelle

a. Restez vigilant et attentif à ce que vous faites et faites preuve de bon jugement lorsque vous utilisez un

outil électrique. N’utilisez pas l’outil électrique si vous êtes fatigué ou sous l’inuence de drogues, d’alcool

ou de médicaments. Un moment d’inattention lors de l’utilisation d’outils électriques peut entraîner des blessures

graves.

b. Utilisez des équipements de protection. Portez toujours des lunettes de sécurité. Les équipements de

protection tels que les masques antipoussières, les chaussures antidérapantes, les casques de sécurité et les bouchons

pour les oreilles, réduisent les risques de blessures corporelles.

c. ) Empêcher tout démarrage non voulu. S’assurer que l’interrupteur est en position d’arrêt avant de brancher

l’outil à la source d’alimentation et/ou au bloc-pile, de le prendre ou de le transporter. Déplacer des outils

électriques avec le doigt sur l’interrupteur ou les mettre sous tension avec l’interrupteur en marche peut entraîner des

accidents.

d. Retirez toute clé de serrage ou de réglage avant de mettre l’outil électrique sous tension. Une clé de serrage

ou de réglage attachée à une pièce rotative peut entraîner des blessures corporelles.

e. Ne vous étirez pas. Gardez votre équilibre en tout temps. Ceci permet un meilleur contrôle de l’outil électrique

dans le cas d’un événement inattendu.

f. Portez des vêtements appropriés. Ne portez pas des vêtements amples ou des bijoux. Maintenez les

cheveux, les vêtements et les bijoux loin des pièces rotatives. Les vêtements amples, les bijoux et les cheveux

longs peuvent être pris dans les pièces rotatives.

g. Veillez à ce que les dispositifs fournis pour la récupération et la collecte de poussières soient bien connectés

et utilisés adéquatement. L’utilisation d’un système de collecte de poussière réduit les dangers associés.

h. L’utilisation fréquente de l’outil ne doit pas faire place à la complaisance et au non-respect des principes de

sécurité. La négligence en une fraction de seconde peut causer des blessures graves.

i. Ne jamais reposer sur l’outil. Des blessures graves peuvent survenir si l’outil est pointé ou si l’outil de coupe est

contacté de manière non intentionnelle.

4) Fonctionnement et entretien de l’outil électrique

a. Ne forcez pas l’outil électrique. Utilisez l’outil électrique approprié pour votre application. L’outil électrique

approprié fera le travail plus efcacement et de manière plus sécuritaire au rythme pour lequel il est conçu.

b. N’utilisez pas l’outil électrique si l’interrupteur ne fonctionne plus. Tout outil électrique dont l’interrupteur ne

fonctionne plus devient dangereux et doit être réparé immédiatement.

c. Débrancher la che de la source d’alimentation et/ou retirer le bloc-pile, s’il est détachable, de l’outil

électrique avant d’effectuer des réglages, de changer ses accessoires ou de le ranger. De telles mesures de

sécurité préventives réduisent le risque de démarrage accidentel de l’outil électrique.

d. Gardez les outils électriques hors tension loin de la portée des enfants et ne permettez pas à des

personnes qui ne connaissent pas l’outil électrique ou les instructions présentes de faire fonctionner l’outil.

25

Page 26

RÈGLES DE SÉCURITÉ GÉNÉRALES POUR LES OUTILS ÉLECTRIQUES

Les outils électriques sont dangereux entre les mains d’une personne non formée.

e. Prenez soin des outils et leurs accessoires. Veillez à ce que les pièces rotatives ne soient pas désalignées et

qu’elles ne se coincent pas, qu’aucune pièce n’est brisée ainsi que toute condition qui affecte le