Page 1

T

E

F

L

O

N

ASME A112.18.1 / CSA B125.1

®

®

U

P

C

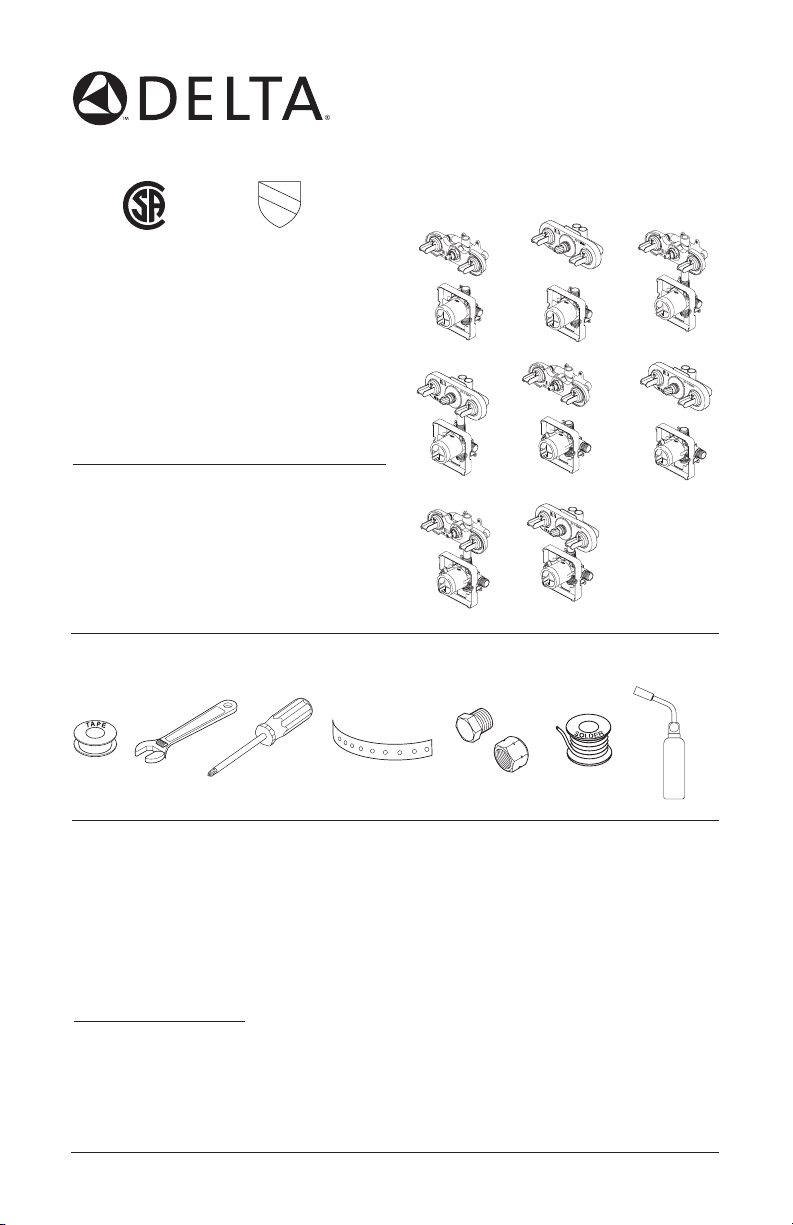

Models

R18222, R18224,

R18442 & R18448

Series

Write purchased model number here.

You may need the following tools:

SINGLE HANDLE

MULTICHOICE™ UNIVERSAL

JETTED SHOWER™ &

JETTED SHOWER XO™

ROUGH-IN VALVE BODY

For easy installation of your Delta® faucet you will need:

• To READ ALL the instructions completely before beginning.

• To READ ALL warnings, care, and maintenance information.

THIS ROUGH-IN BODY MEETS OR EXCEEDS THE FOLLOWING STANDARDS:

ANSI A112.18.1 &

ASME A112.18.1 / CSA B125.1

.

NOTICE TO INSTALLER: CAUTION!–As the installer of this rough-in body, it is your

responsibility to properly INSTALL this rough-in body per the instructions given.

YOU MUST inform the owner/user of this requirement by following the instructions.

If you or the owner/user are unsure how to properly install this rough-in body, please refer

to the instructions supplied and if still uncertain, call us at 1-800-345-DELTA. Leave this

Instruction Sheet for the owner's/user's reference.

6/27/07

1

51045 Rev B

Page 2

TABLE OF CONTENTS:

Warranty -- - -- --- - - -- --- - - -- --- - - -- --- - - -- --- - - -- --- - - -- --- - - -- --- - - -- Page 2

Installation Instructions - - -- - --- -- -- - -- - -- -- - -- - -- -- - -- - --- -- -- - -- - -- -- Pages 3 -9

Replacement Parts - - --- -- -- - -- - -- -- - -- - -- -- - -- - --- -- -- - -- - -- -- - -- - -- Pages 1 0- 13

Lifetime Faucet and Finish Limited Warranty

All parts and finishes of the Delta® faucet are

warranted to the original consumer purchaser to

be free from defects in material & workmanship

for as long as the original consumer purchaser

owns their home. Delta Faucet Company

recommends using a professional plumber for all

installation & repair.

Delta will replace, FREE OF CHARGE, during

the warranty period, any part or finish that proves

defective in material and/or workmanship under

normal installation, use & service. Replacement

parts may be obtained by calling 1-800-345DELTA (in the U.S. and Canada) or by writing to:

In the United States:

Delta Faucet Company

Product Service

55 E. 111th Street

Indianapolis, IN 46280

In Canada:

Delta Faucet Canada

Technical Service Centre

420 Burbrook Place

London, ON N6A 4L6

This warranty is extensive in that it covers

replacement of all defective parts and even

finish, but these are the only two things that

are covered. LABOR CHARGES AND/OR

DAMAGE INCURRED IN INSTALLATION,

REPAIR, OR REPLACEMENT AS WELL AS ANY

OTHER KIND OF LOSS OR DAMAGES ARE

EXCLUDED. Proof of purchase (original sales

receipt) from the original consumer purchaser

must be made available to Delta for all warranty

claims. THIS IS THE EXCLUSIVE WARRANTY

BY DELTA FAUCET COMPANY, WHICH DOES

NOT MAKE ANY OTHER WARRANTY OF ANY

KIND, INCLUDING THE IMPLIED WARRANTY

OF MERCHANTABILITY.

This warranty excludes all industrial, commercial

& business usage, whose purchasers are

hereby extended a five year limited warranty

from the date of purchase, with all other terms

of this warranty applying except the duration of

the warranty. This warranty is applicable to Delta

faucets manufactured after January 1, 1995.

Some states/provinces do not allow the exclusion

or limitation of incidental or consequential

damages, so the above limitation or exclusion

may not apply to you. Any damage to this faucet

as a result of misuse, abuse, or neglect, or any

use of other than genuine Delta® replacement

parts WILL VOID THE WARRANTY.

This warranty gives you specific legal rights, and

you may also have other rights which vary from

state/province to state/province. It applies only

®

faucets installed in the United States of

for Delta

America, Canada, and Mexico.

®

© 2007 Masco Corporation of Indiana

2

Page 3

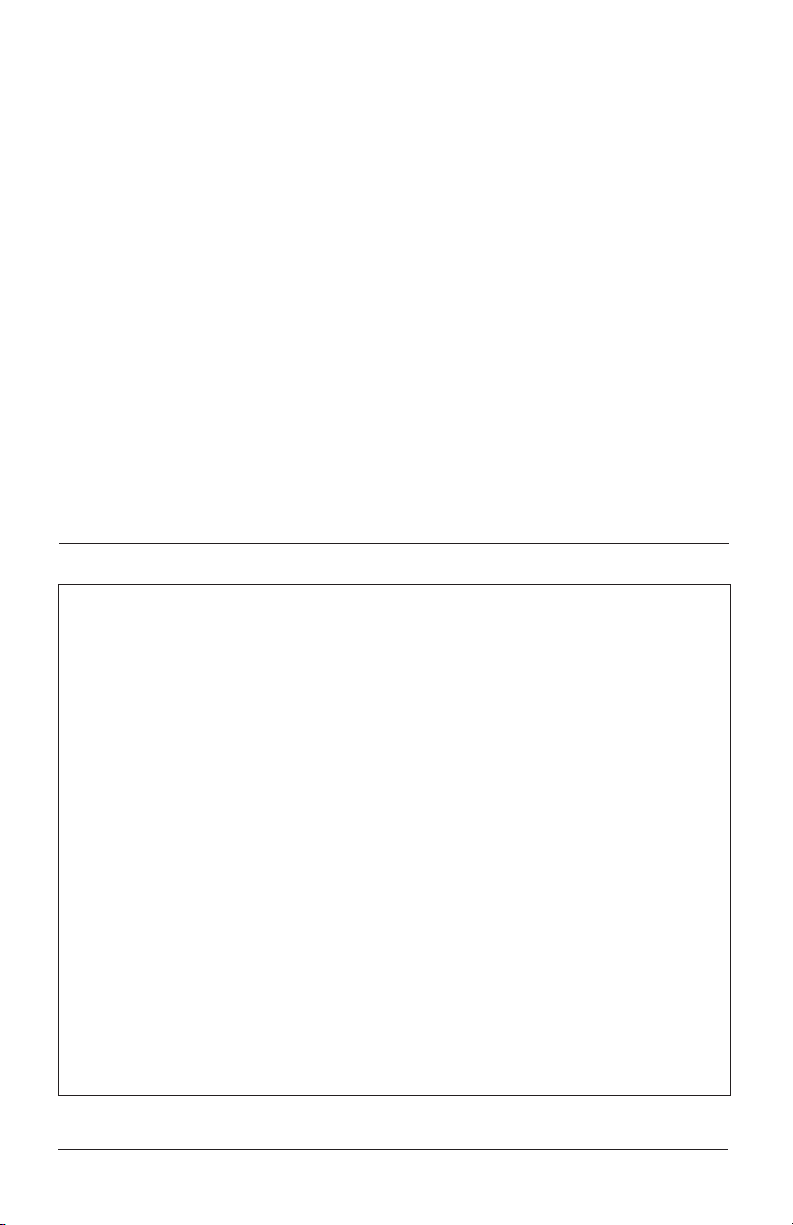

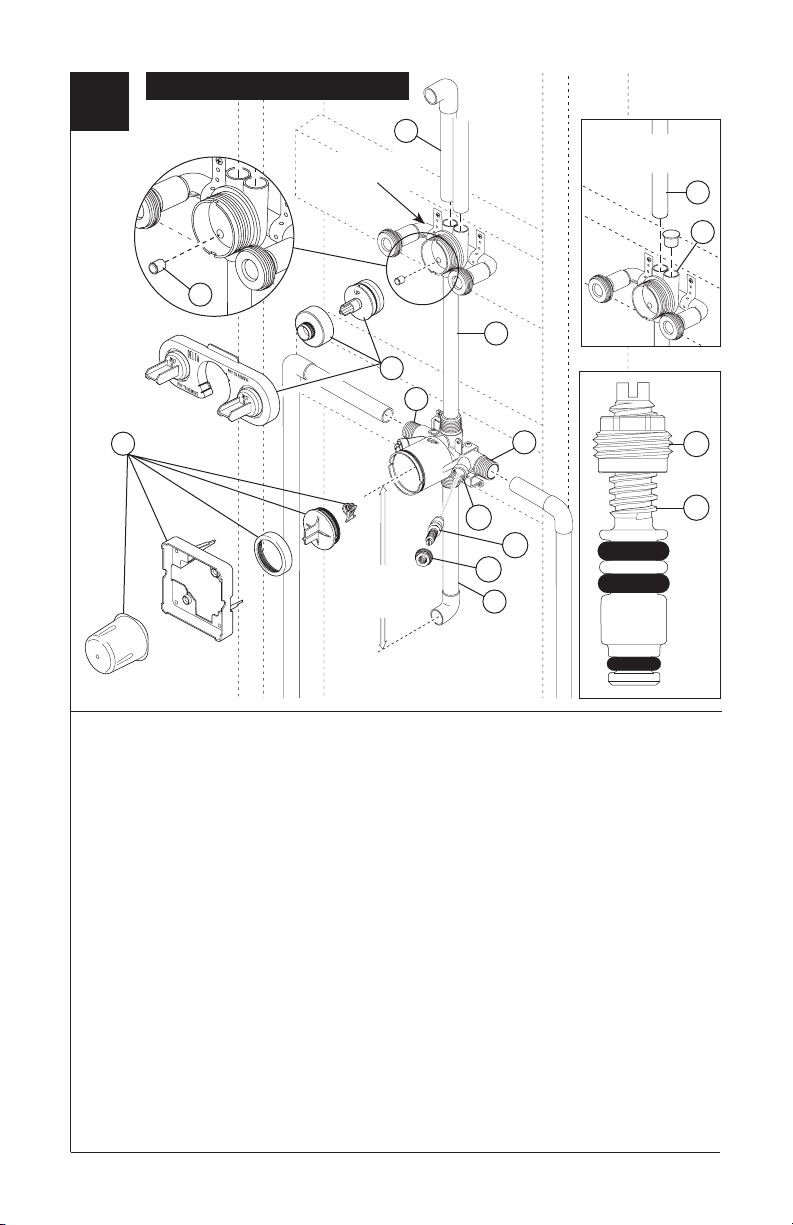

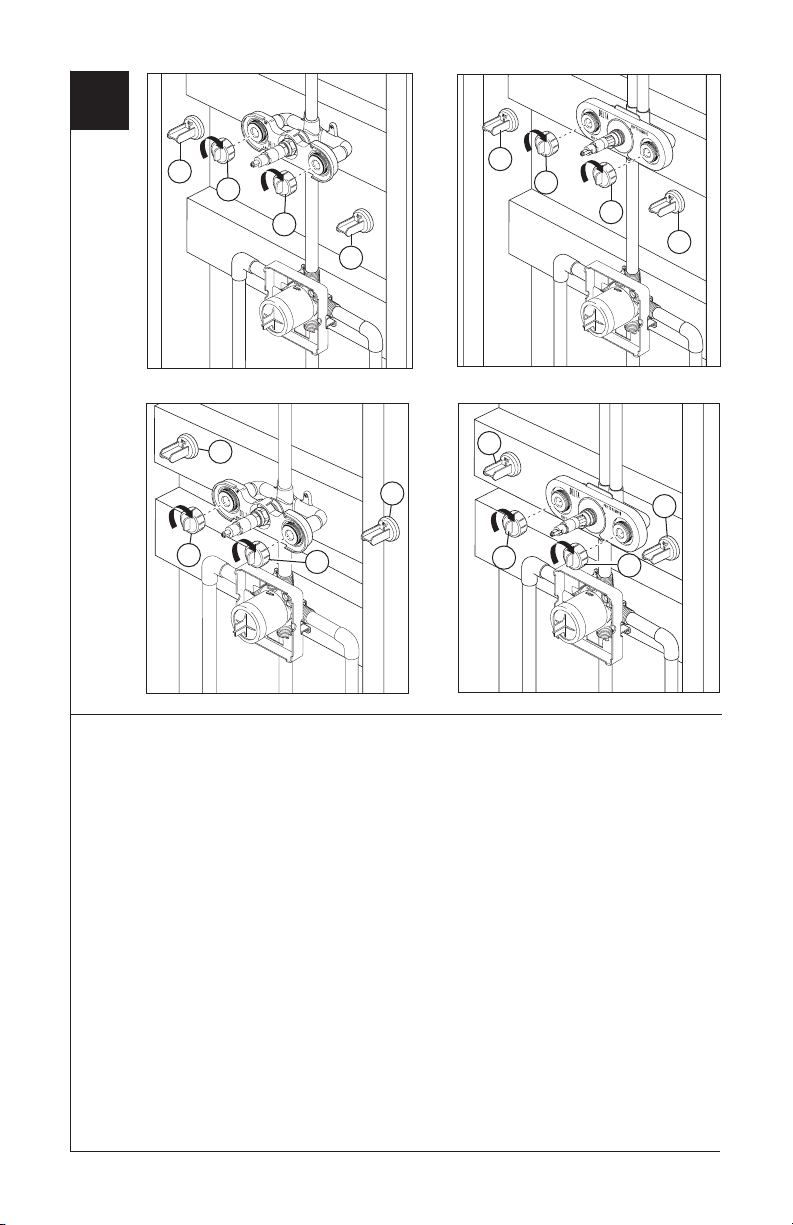

1

R18222

5

1

4

R18222-WS

R18224

3

2

3

A

B

4

3

5

1

A

B

R18224-WS

R18442 & R18448

5

1

2

3

4

R18442-WS &

3

2

3

A

B

R18448-WS

Jetted Shower™ and Jetted Shower XO™ Installation

Description:

Jetted Shower™ valves turn the body

jets on and off only. Jetted Shower XO™

valves divert the water to the jets, the

showerhead, an extra port or any

combination of two, making it a 3 port, 6

function diverter. The black stem

extender (without the stop) must be used

if using all outlets. If a 2 port, 3 function

diverter is desired, jets only, combination

jets & showerhead and showerhead

only, the plug must be soldered in as

shown and the blue stem extender with

the stop must be used.

Installation Instructions:

Shut off water supplies. Consider the

type and thickness of your finished wall

before placing your stringer back plate.

Mount the valve to desired height. We

recommend 52" from the base of the

enclosure to the center line of the jets.

Install the body (1) so the surface of the

finished wall is flush with the front of the

plasterguard (2), using the two stringer

mounting holes (3) on the bracket. Note:

Remove cover (4) to access mounting

holes. Make sure the word “UP” (5) is on

top of the valve body when installing.

Distance (A) from the stringer to the

front of the plasterguard is 2.8" (71 mm).

Distance (B) from the stringer to the front

of the bonnet is 3.9" (99 mm).

If a thin wall is used, be sure to have the

plasterguard behind the wall, otherwise

the wall should always be flush with the

front of the plasterguard. Note: For thin

wall mounting, use included template

for hole location.

3

Page 4

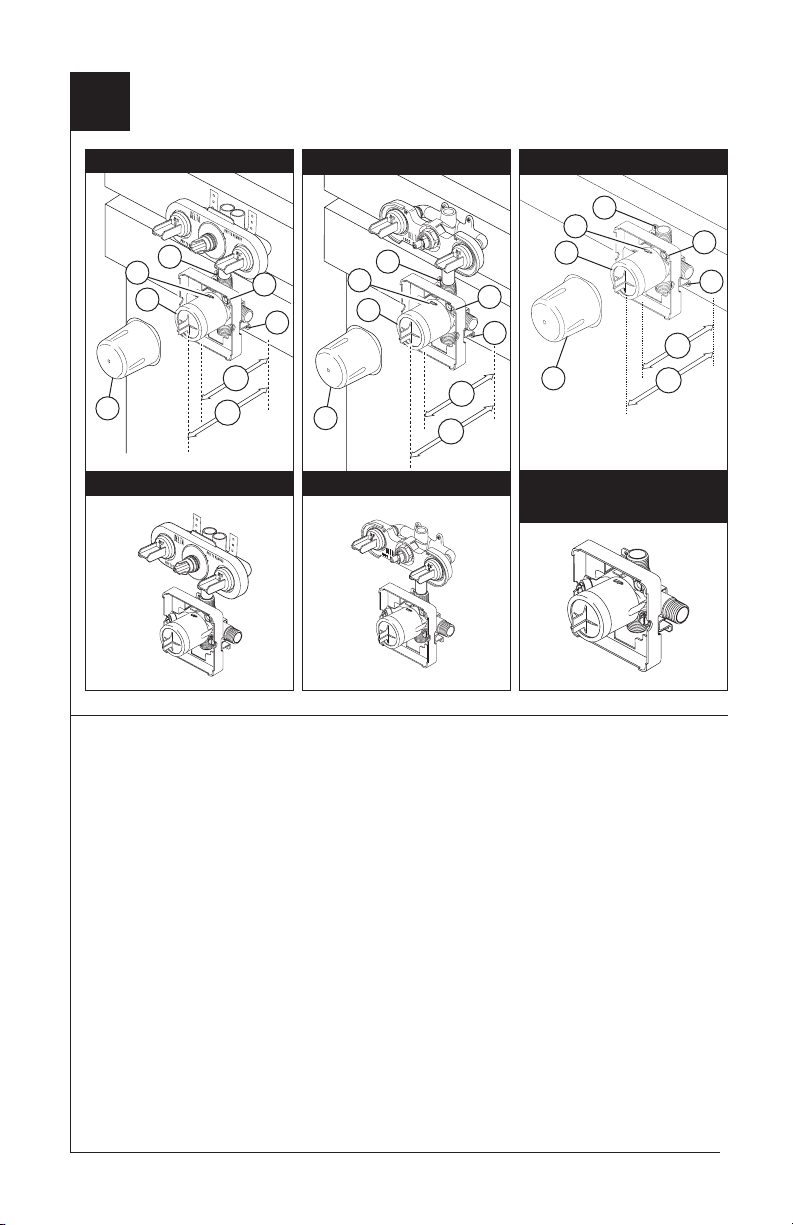

2

R18448 & R18448-WS

8

6

9

1

5

4

2

16"

(406 mm)

Max

R18448 & R18448-WS Installation

Remove the bonnet nut, stem and stem

extender, seat, spring, and plasterguard

(1), plus, the screen, test cap, bonnet nut,

plasterguard and cover (2) before soldering.

Connect valve body to water supplies using

er fittings. Note: (3) is the cold

the prop

inlet port and (4) is the hot inlet port.

Solder a copper tube (5) from the valve

body to the jet module so the jets are at

the desired height. Solder another tube (6)

onto the top of the jet module to the shower

arm elbow to the desired height. It is

recommended to mount valves to stringers

as shown.

The pipe (7) between valve & tub spout

must be a minimum of 1/2" (13 mm) copper

pipe or 1/2" (13 mm) iron pipe in a straight

drop no less than 8" (203 mm) but no more

than 16" (406 mm) long with only one 90

degree elbow to the spout nipple. If any

outlet port is to be unused, seal the port with

a pipe plug.

If you are making a back to back or reverse

installation (hot on right and cold on left)

install the valve body as described, but

reverse the water supply lines.

After soldering, reinstall all parts in reverse

order; ensure bonnet nuts are tightened

securely. Then install the stops into the body;

be careful not to overtighten the nuts.

Note: Install stops in the w/stops version as

follows: Thread nut (8) on stem (9) as shown.

Then press stem and nut assembly into body

(10) and tighten using a 3/8", 6 point, deep

well socket. With a flat head screwdriver, adjust

stem clockwise to close and counterclockwise

to open.

3

10

9

8

7

4

Page 5

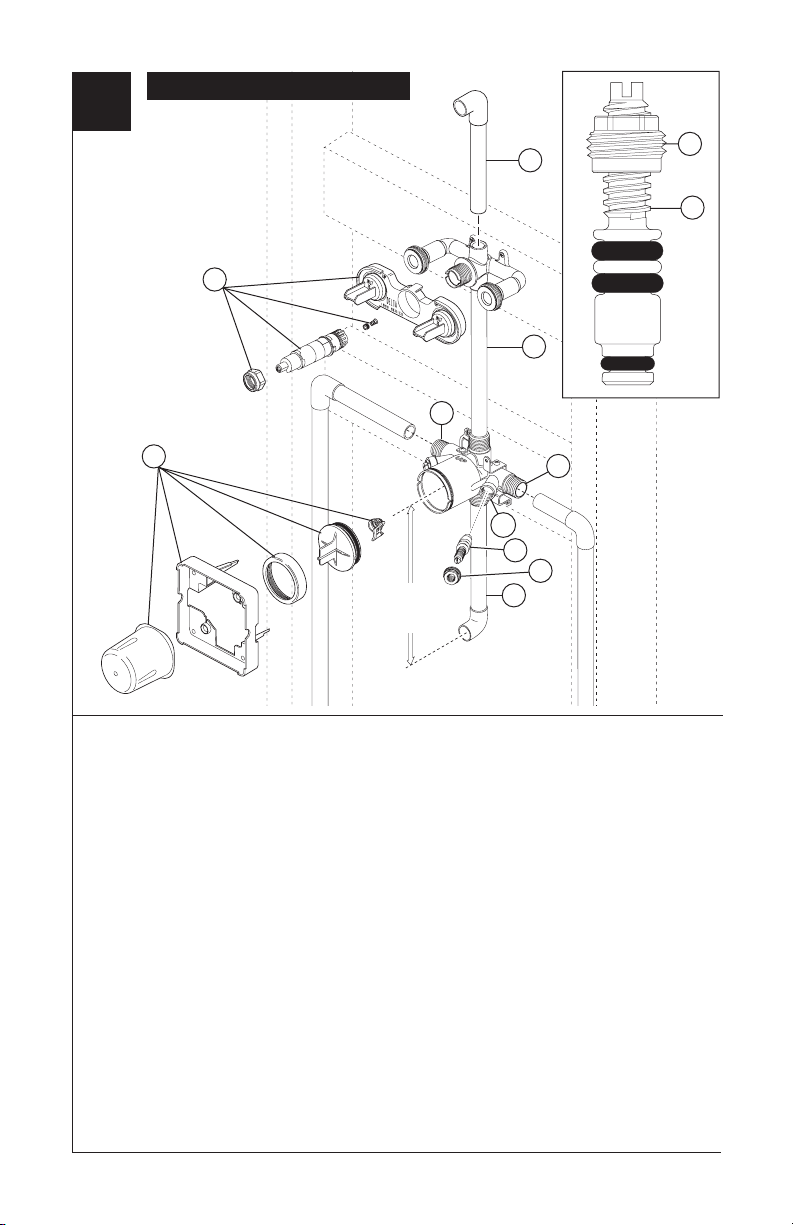

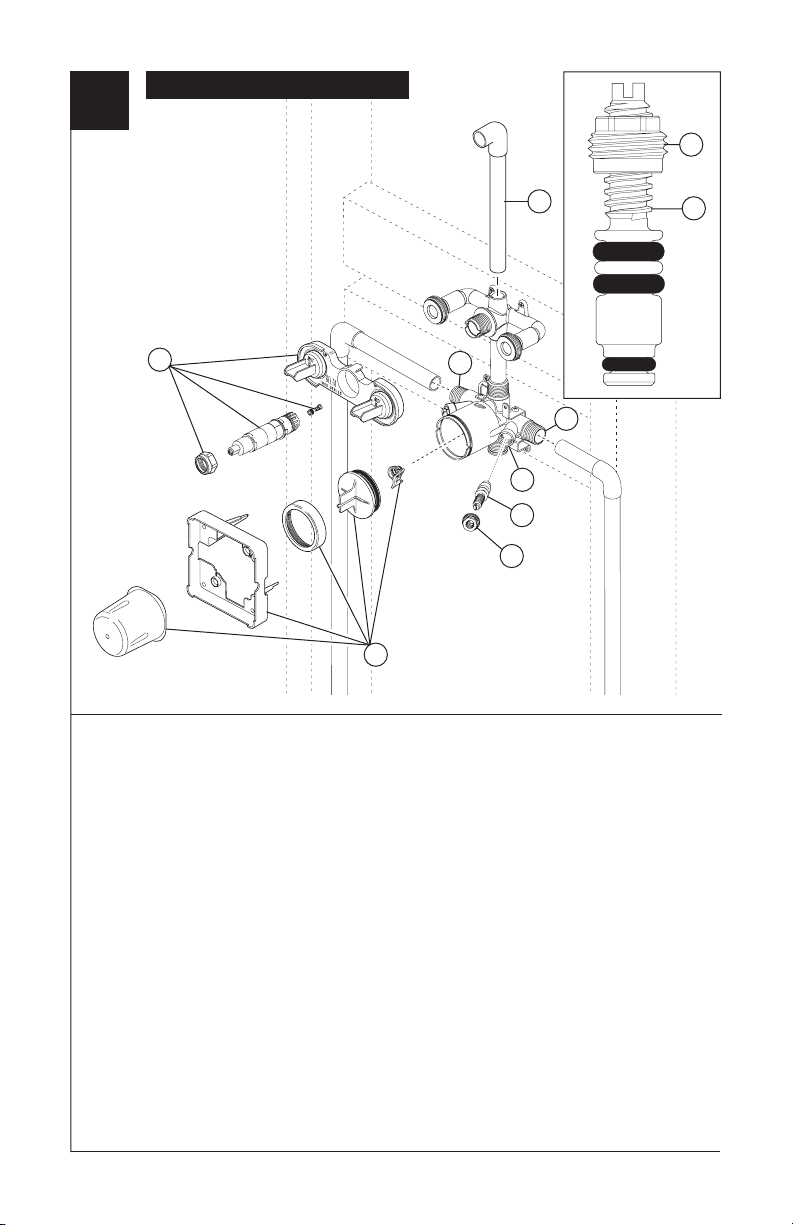

2

R18442 & R18442-WS

3 Port, 6 Function

Installation

9

7

5

1

4

2 Port, 3 Function

Installation

7

6

2

16"

(406 mm)

Max

R18442 & R18442-WS Installation

Remove the bonnet nut, cartridge and

plasterguard (1), plus, the screen, test cap,

bonnet nut, plasterguard and cover (2) before

soldering. Connect valve body to water

supplies using the prop

er fittings. Note: (3)

is the cold inlet port and (4) is the hot

inlet port.

Solder a copper tube (5) from the valve

body to the jet module so the jets are at the

desired height. Determine whether a three

or six function configuration is desired. For

2 port, 3 function; solder plug into auxiliary

port (6) in casting. Solder tube (7) into the

main port of the jet module to the shower

arm elbow to the desired height. For 3 port,

6 function; all outlet ports are used. It is

recommended to mount valves to stringers

as shown.

The pipe (8) between valve & tub spout must

be a minimum of 1/2" (13 mm) copper pipe

or 1/2" (13 mm) iron pipe in a straight drop

no less than 8" (203 mm) but no more than 16"

(406 mm) long with only one 90 degree elbow

to the spout nipple. If any outlet port is to be

unused, seal the port with a pipe plug.

If you are making a back to back or reverse

installation (hot on right and cold on left) install

the valve body as described, but reverse the

water supply lines.

After soldering press the detent (9) into proper

hole as shown, reinstall all parts in reverse

order; ensure bonnet nuts are tightened

securely. Then install the stops into the body;

be careful not to overtighten the nuts.

Note: Install stops in the w/stops version as

follows: Thread nut (10) on stem (11) as shown.

Then press stem and nut assembly into body

(12) and tighten using a 3/8", 6 point, deep

well socket. With a flat head screwdriver, adjust

stem clockwise to close and counterclockwise

to open.

3

12

11

10

8

10

11

5

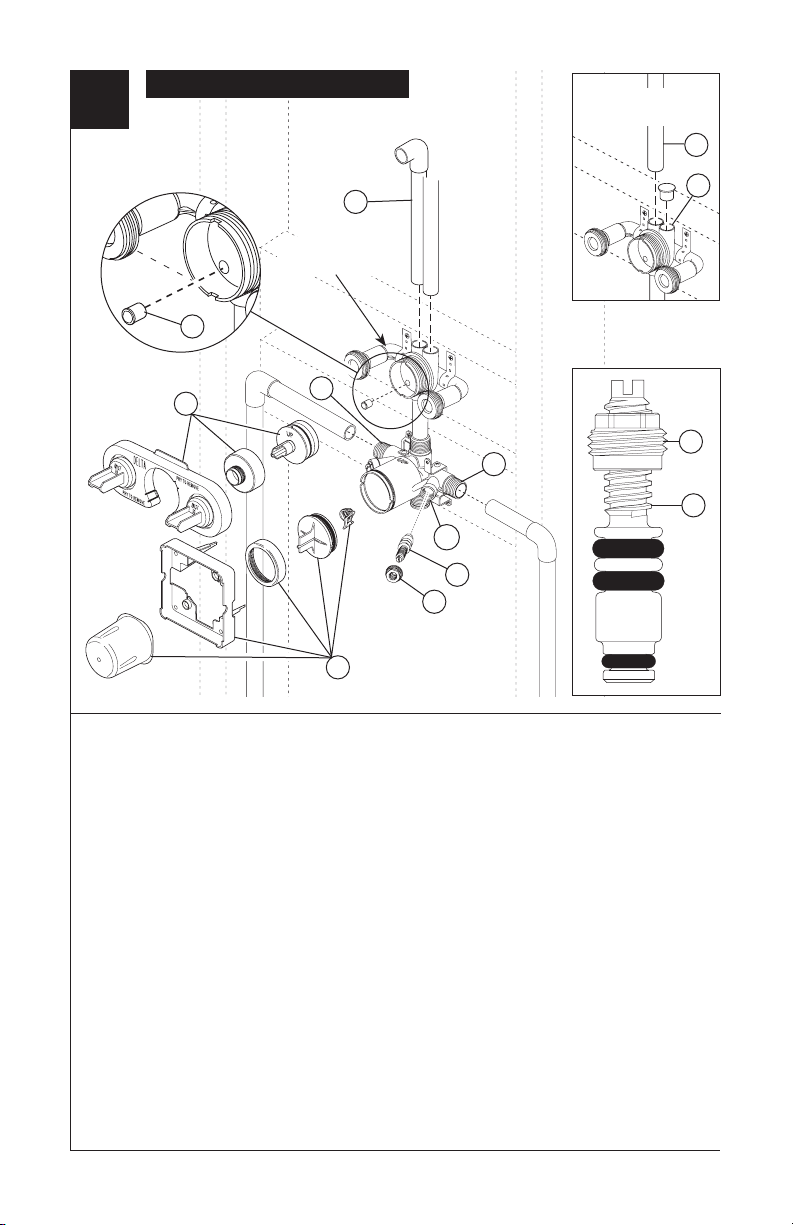

Page 6

2

R18224 & R18224-WS

6

1

2

4

R18224 & R18224-WS Installation

Remove the bonnet nut, stem and stem

extender, seat, spring, and plasterguard

(1), plus, the screen, test cap, bonnet nut,

plasterguard and cover (2) before soldering.

Connect valve body to water supplies using

er fittings. Note: (3) is the cold

the prop

inlet port and (4) is the hot inlet port.

Solder a tube (5) onto the top of the jet

module to the shower arm elbow to the

desired height. If any outlet port is to be

unused, seal the port with a pipe plug. It

is recommended to mount unit to stringers

as shown.

If you are making a back to back or reverse

installation (hot on right and cold on left),

install the valve body as described, but

reverse the water supply lines.

After soldering reinstall all parts in reverse

order; ensure bonnet nuts are tightened

securely. Then install the stops into the body;

be careful not to overtighten the nuts.

Note: Install stops in the w/stops version as

follows: Thread nut (6) on stem (7) as shown.

Then press stem and nut assembly into body

(8) and tighten using a 3/8", 6 point, deep well

socket. With a flat head screwdriver, adjust

stem clockwise to close and counterclockwise

to open.

5

3

8

7

6

7

6

Page 7

2

R18222 & R18222-WS

2 Port, 3 Function

Installation

5

5

3 Port, 6 Function

Installation

7

1

4

10

9

8

2

R18222 & R18222-WS Installation

Remove the bonnet nut, cartridge and

plasterguard (1), plus, the screen, test

cap, bonnet nut, plasterguard and cover

(2) before soldering.

to water supplies using the prop

Note: (3) is the cold inlet port and (4) is

the hot inlet port.

Solder a tube (5) from main outlet of the

jet module to the shower arm elbow to the

desired height.

or six function configuration is desired. For

2 port, 3 function; solder plug into auxiliary

port (6) in casting. For 3 port, 6 function;

all outlet ports are used. It is recommended

to mount valves to stringers as shown.

If you are making a back to back or reverse

installation (hot on right and cold on left)

Connect valve body

er fittings.

Determine whether a three

install the valve body as described, but

reverse the water supply lines.

After soldering press in the detent (7) into

proper hole as shown, reinstall all other parts

in reverse order; ensure bonnet nuts are

tightened securely.

into the body; be careful not to overtighten

the nuts.

Note: Install stops in the w/stops version as

follows: Thread nut (8) on stem (9) as shown.

Then press stem and nut assembly into body

(10) and tighten using a 3/8", 6 point, deep

well socket. With a flat head screwdriver, adjust

stem clockwise to close and counterclockwise

to open.

6

8

3

9

Then install the the stops

7

Page 8

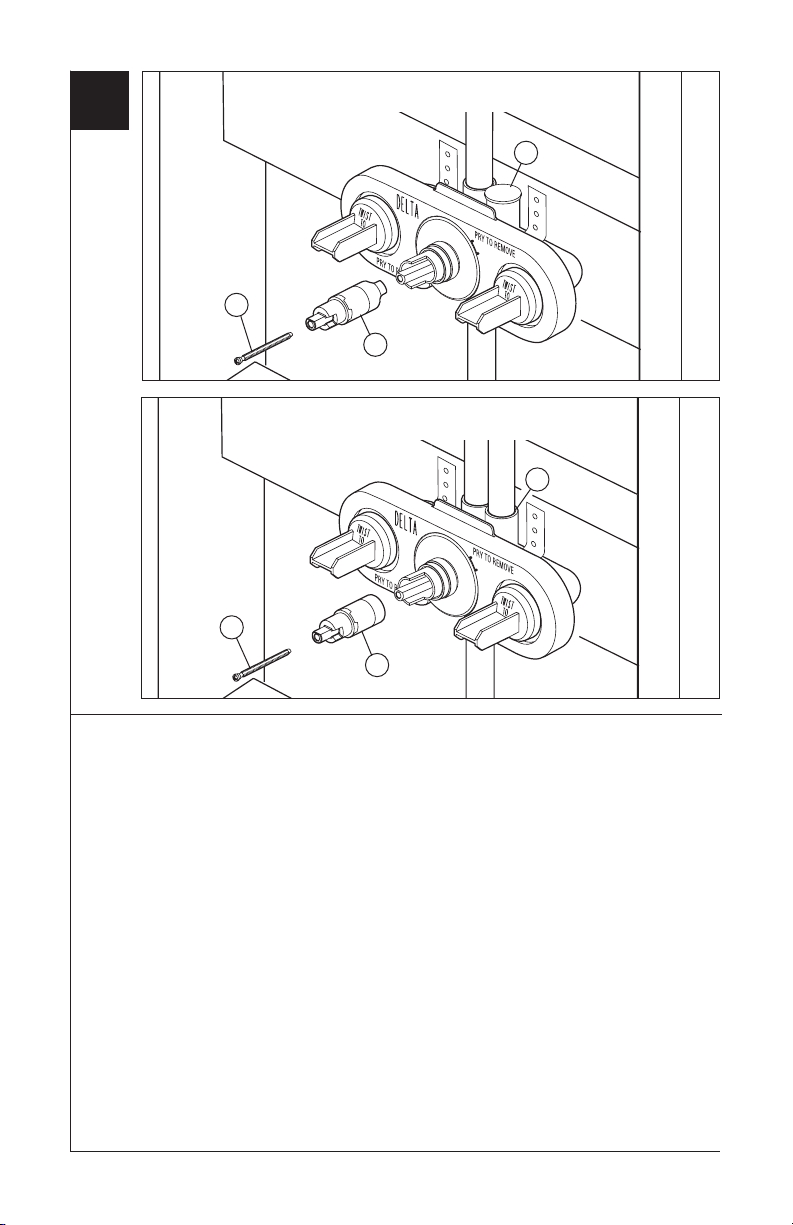

3

Blue Stem Extender -

2 Port, 3 Function Installation

3

1

2

Black Stem Extender -

3 Port, 6 Function Installation

3

1

4

Stem Extender Installation

Be sure to install the proper stem

extender for your installation.

required stem extender onto brass stem.

Install the blue stem extender (2) if the

Place

installation does not use the auxillary port (3).

Install the black stem extender (4) if the

installation uses all of the outlet ports. Use

screw (1) to secure.

8

Page 9

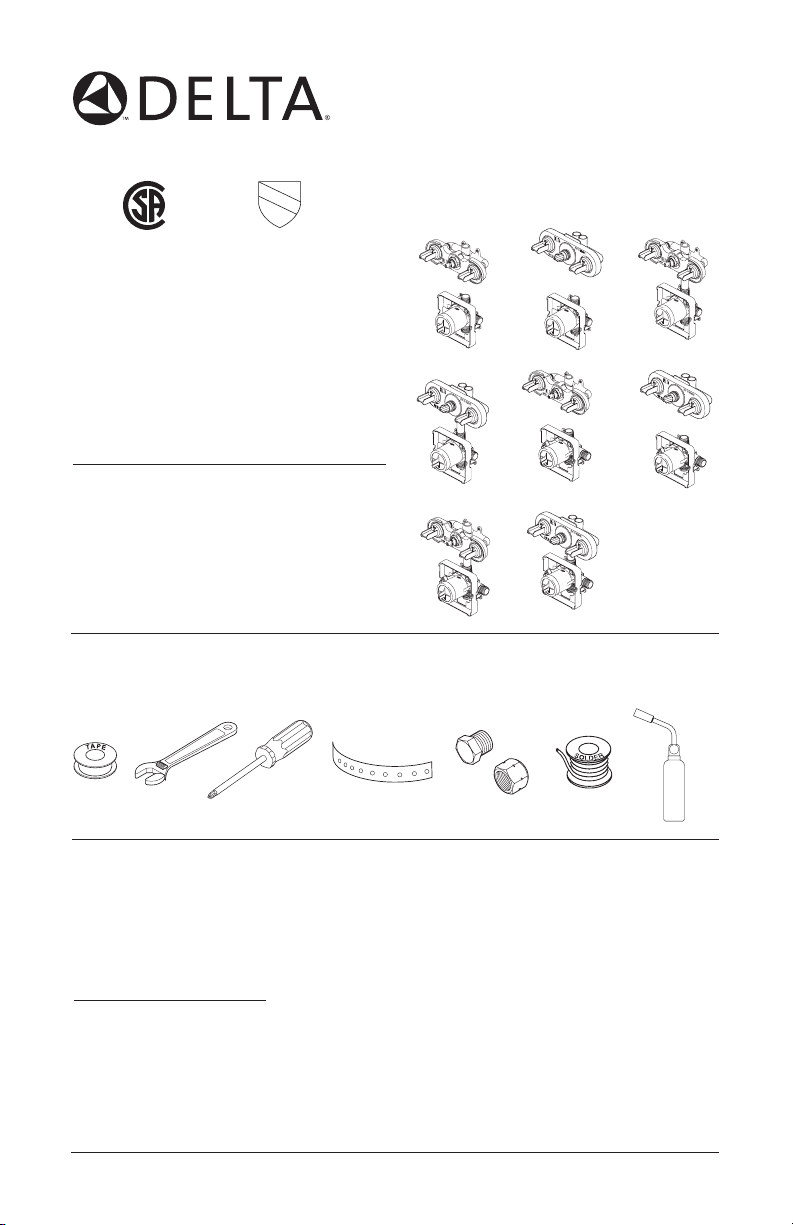

4

1

2

2

1

1

1

2

2

1

2

2

1

1

1

2

2

Pressure Testing & Flushing the Installation

Prior to testing, break off plasterguard caps

(1) and completely thread on the pressure

testing caps (2). Ensure the bonnet nuts

are properly tightened, and plug both

outlets with proper fittings. Check for leaks.

After testing remove shower and/or tub spout

plug and flush system. After flushing remove

filter screen (see step 2) and reinstall cap,

bonnet and cover.

9

Page 10

Notes / Notas / Notes

Page 11

T

E

F

L

O

N

ASME A112.18.1 / CSA B125.1

®

®

U

P

C

Modelos

R18222, R18224,

R18442 & R18448

Series

Escriba aquí el número del modelo comprado.

CUERPO DE LA VÁLVULA PARA

LA INSTALACIÓN PRELIMINAR

DE LAS REGADERAS DE

UNA MANIJA MULTICHOICE™

UNIVERSAL JETTED SHOWER™

Y JETTED SHOWER XO™

Usted puede necesitar:

Para instalación fácil de su llave Delta® usted necesitará:

• LEER TODAS las instrucciones completamente antes de empezar

• LEER TODOS los avisos, cuidados, e información de mantenimiento.

ESTA VALVULA CUMPLE O EXCEDE LAS SIGUIENTES NORMAS: ANSI A112.18.1 y

ASME A112.18.1 / CSA B125.1

AVISO AL INSTALADOR: ¡PRECAUCIÓN!- Como instalador de la tubería interna -

dentro de la pared/piso, es su responsabilidad INSTALAR esta pieza correctamente

como se describe en las instrucciones que le damos. USTED DEBE informarle al

propietario/usuario, siguiendo las instrucciones dadas, de este requisito. Si usted o el

propietario/usuario no están seguros como se instalan correctamente las tuberías internas,

por favor refiérase a las instrucciones proporcionadas y si todavía no está seguro, llámenos

al 1-800-345-DELTA. Deje esta hoja de instrucciones como referencia para el

propietario/usuario.

6/27/07

.

1

51045 Rev B

Page 12

Índice:

Garantía -- - - -- --- - - -- --- - - -- --- - - -- --- - - -- --- - - -- --- - - -- --- - - -- --- - - -Página 2

Instrucciones para la Instalación - - -- - -- -- - -- - -- -- - -- - --- -- -- - -- - -- -- - - Páginas 3 - 9

Piezas de Repuesto - - - -- -- - -- - -- -- - -- - --- -- -- - -- - -- -- - -- - -- -- - -- - --- Páginas 1 0 -1 3

GarantÍa Limitada De Por Vida de la Llave y su Acabado

Todas las piezas y acabados de la llave Delta®

están garantizados al consumidor comprador

original, de estar libres de defectos de material

y fabricación, por el tiempo que el consumidor

comprador original sea dueño de su casa. Delta

Faucet Company recomienda que use un

plomero profesional para todas las instalaciones

y zreparaciones.

Delta reemplazará, LIBRE DE CARGO, durante

el período de garantía, cualquier pieza o

acabado que pruebe tener defectos de material

y/o fabricación bajo instalación normal, uso y

servicio. Piezas de repuesto pueden ser

obtenidas llamando al 1-800-345-DELTA (en los

Estados Unidos y Canada) o escribiendo a:

En los Estados Unidos:

Delta Faucet Company

Product Service

55 E. 111th Street

Indianapolis, IN 46280

En Canada:

Delta Faucet Canada

Technical Service Centre

420 Burbrook Place

London, ON N6A 4L6

Esta garantía es extensiva en lo que cubre el

reemplazamiento de todas las piezas

defectuosas y hasta el acabado, pero éstas

son las únicas dos cosas que están cubiertas.

CARGOS DE LABOR Y/O DAÑOS INCURRIDOS

EN LA INSTALACIÓN, REPARACIÓN, O

REEMPLAZAMIENTO COMO TAMBIÉN

CUALQUIER OTRO TIPO DE PÉRDIDA O

DAÑOS ESTÁN EXCLUÍDOS. Prueba de

compra (recibo original de venta) del comprador

consumidor original debe de ser disponible a

Delta para todos los reclamos. ESTA ES LA

GARANTÍA EXCLUSIVA DE DELTA FAUCET

COMPANY, QUE NO HACE CUALQUIER

OTRA GARANTÍA DE CUALQUIER TIPO,

INCLUYENDO LA GARANTÍA IMPLÍCITA DE

COMERCIALIZACIÓN.

Esta garantía excluye todo uso industrial,

comercial y de negocio, a cuyos compradores se

les da una garantía limitada extendida de cinco

años desde la fecha de compra, con todos los

otros términos de esta garantía aplicados, excepto el de duración de ésta. Esta garantía es aplicable a las llaves de Delta® fabricadas después

de Enero 1, 1995.

Algunos estados/provincias no permiten la

exclusión o limitación de daños incidentales o

consecuentes, de manera que la limitación o

exclusión arriba escrita puede no aplicarle a

usted. Cualquier daño a esta llave, resultado del

mal uso, abuso, o descuido, o cualquier otro uso

de piezas de repuesto que no sean genuinas de

Delta® ANULARÁN LA GARANTÍA.

Esta garantía le da derechos legales específicos,

y usted puede, también tener otros derechos que

varían de estado/provincia a estado/provincia.

Es aplicable sólo a las llaves Delta® instaladas en

los Estados Unidos de America, Canada

y Mexico.

© 2007 Masco Corporación de Indiana

2

Page 13

1

R18222

5

1

4

R18222-WS

R18224

3

2

3

A

B

4

3

5

1

A

B

R18224-WS

R18442 & R18448

3

5

1

2

3

4

R18442-WS &

R18448-WS

Instalación de las regaderas Jetted Shower™ y

Jetted Shower XO™

Descripción:

Las válvulas para la regadera Jetted

Shower™ solamente abren y cierran los

chorros de la unidad. El desviador de las

válvulas de la regadera Jetted Shower

XO™ desvía el agua a los chorros, la

cabeza de la regadera, una salida adicional

o cualquier combinación de dos,

convirtiéndolo en 3 salidas de agua con un

desviador de 6 funciones. La extensión de

espiga negra (sin el tope) se debe utilizar si

usa todas las salidas de agua. Si desea 2

salidas con un desviador de 3 funciones,

chorros solamente, chorros combinados

con regadera y sólo regadera, debe soldar

el tapón como se muestra y debe usar la

extensión con la espiga azul y tope.

Instrucciones para la Instalación:

Cierre los suministros de agua. Considere

el tipo y el grosor de su pared acabada

antes de colocar su placa de la viga interior.

Instale la válvula a la altura deseada.

Recomendamos 52” de la base del espacio

encerrado a la línea central de los chorros.

Instale el cuerpo (1) de manera que la superficie de la pared acabada quede al ras con el

frente del protector de yeso (2), usando los

dos agujeros de instalación de la viga (3) en

el soporte. Nota: Quite la cubierta (4) para

tener acceso a los agujeros para la instalación. Asegúrese que la palabra “UP” (5)

quede sobre el cuerpo de la válvula cuando

haga la instalación.

La distancia (A) de la viga al frente del protector de yeso es 2.8” (71 mm). La distancia

(B) de la viga al frente de capuchón o tapa

es 3.9” (99 mm).

Si está instalando en una pared delgada,

asegúrese tener el protector de yeso detrás

de la pared, de lo contrario la pared siempre

tendrá que estar al ras con el frente del protector de yeso. Nota: Para una instalación

en pared delgada, use la plantilla que se

incluye para ubicar el agujero.

2

3

A

B

3

Page 14

2

R18448 & R18448-WS

8

6

9

1

5

4

2

16"

(406 mm)

Max

3

10

9

8

7

Instalación de las piezas R18448 y R18448-WS

Quite la tuerca tapa, la espiga y la extensión

de la espiga, el asiento, el resorte, y el

protector de yeso (1), además, la rejilla, la

tapa de prueba, la tuerca tapa, el protector

de yeso y la cubierta (2) antes de soldar.

Conecte el cuerpo de la válvula a los

suministros de agua usando los accesorios

apropiados. Nota: (3) es la salida de agua

fría y (4) la salida de agua caliente.

Suelde un tubo de cobre (5) del cuerpo de

la válvula al modulo del chorro de manera

que los chorros están a la altura deseada.

Suelde otro tubo (6) en la parte superior del

módulo del chorro al codo de la regadera

a la altura deseada. Se recomienda que

instale las válvulas en las vigas como

se muestra.

El tubo (7) entre la válvula y el surtidor de

la bañera debe ser de un mínimo de 1/2”

(13 mm) de tubería de cobre ó 1/2”

(13 mm) de tubería de hierro en caída recta

no menos de 8” (203 mm) pero no más de

16” (406 mm) de largo con un solo codo de

90 grados a la entrerrosca del surtidor. Si no

va a usar alguna salida de agua, séllela con un

tapón de tubería.

Si usted está instalando dorso con dorso o

instalando en orden inverso (caliente en la

derecha y fría en la izquierda) instale el cuerpo

de la válvula como se describe, pero invierta

las líneas de suministros de agua.

Después de soldar, reinstale todas las partes

en orden reversa; asegure las tuercas del capo

se aprietan con seguridad. Después instale

las tuercas de la parada sobre los vástagos e

instale las paradas en el cuerpo; tenga cuidado

de no apretar las tuercas demasiado.

Nota: Instale las paradas en con la versión de

las válvulas apagadas como sigue: Rosque la

tuerca (8) en el vástago (9) según lo demostrado.

Después presione el montaje del vástago y

de tuerca en cuerpo (10) y apriete con un

3/8”, 6 puntos, zócalo bien profundo. Con un

destornillador principal plano, ajuste el vástago a

la derecha al cierre y a la izquierda abrirse.

4

Page 15

2

R18442 & R18442-WS

Para 3 salidas, 6

funciones

9

7

5

1

4

Para 2 salidas, 3

funciones

7

6

2

16"

(406 mm)

Max

3

12

11

10

8

Instalación de las piezas R18442 & R18442-WS

Quite la tuerca tapa, el cartucho y el protector

de yeso (1), además, la rejilla, la tapa de

prueba, la tuerca tapa, el protector de yeso

y la cubierta (2) antes de soldar. Conecte el

cuerpo de la válvula a los suministros de agua

usando los accesorios apropiados. Nota: (3)

es la salida de agua fría y (4) la salida de

agua caliente.

Suelde un tubo de cobre (5) del cuerpo de

la válvula al modulo del chorro de manera

que los chorros están a la altura deseada.

Determine si desea una configuración de tres

o seis funciones. Para 2 salidas, 3 funciones;

suelde, fundido, el tapón en la salida auxiliar

(6). Suelde el tubo (7) en la salida principal

del módulo de chorros al codo del brazo de la

regadera a la altura deseada. Para 3 salidas,

6 funciones; se usan todas las salidas de

agua. Se recomienda que instale las válvulas

en las vigas como se muestra.

El tubo (8) entre la válvula y el surtidor de la

bañera debe ser de un mínimo de 1/2” (13

mm) de tubería de cobre ó 1/2” (13 mm) de

tubería de hierro en caída recta no menos de

8” (203 mm) pero no más de 16” (406 mm) de largo

con un solo codo de 90 grados a la entrerrosca del

surtidor. Si no va a usar alguna salida de agua,

séllela con un tapón de tubería.

Si usted está instalando dorso con dorso o

instalando en orden inverso (caliente en la derecha

y fría en la izquierda) instale el cuerpo de la válvula

como se describe, pero invierta las líneas de

suministros de agua.

Después de soldar la prensa la muesca (9) en el

agujero apropiado según lo demostrado, reinstala

todas las partes en orden reversa; asegure las

tuercas del capo se aprietan con seguridad.

Después instale las tuercas de la parada sobre los

vástagos e instale las paradas en el cuerpo; tenga

cuidado de no apretar las tuercas demasiado.

Nota: Instale las paradas en con la versión de las

válvulas apagadas como sigue: Rosque la tuerca

(10) en el vástago (11) según lo demostrado.

Después presione el montaje del vástago y de

tuerca en cuerpo (12) y apriete con un 3/8”, 6

puntos, zócalo bien profundo. Con un destornillador

principal plano, ajuste el vástago a la derecha al

cierre y a la izquierda abrirse.

10

11

5

Page 16

2

R18224 & R18224-WS

6

5

1

2

4

3

8

7

6

Instalación de las piezas R18224 & R18224-WS

Quite la tuerca tapa, la espiga y la extensión

de la espiga, el asiento, el resorte, y el

protector de yeso (1), además, la rejilla, la

tapa de prueba, la tuerca tapa, el protector

de yeso y la cubierta (2) antes de soldar.

Conecte el cuerpo de la válvula a los

suministros de agua usando los accesorios

apropiados. Nota: (3) es la salida de agua

fría y (4) la salida de agua caliente.

Suelde un tubo (5) en la parte superior del

módulo de chorro al codo del brazo de la

regadera a la altura deseada. Si no va a

usar alguna salida de agua, séllela con un

tapón de tubería. Se recomienda que haga

la instalación en las vigas como se muestra.

Si usted está instalando dorso con dorso

o instalando en orden inverso (caliente en

la derecha y fría en la izquierda) instale el

cuerpo de la válvula como se describe, pero

las líneas de suministros de agua.

invierta

Después de soldar reinstale todas las partes

en orden reversa; asegure las tuercas del

capo se aprietan con seguridad. Después

instale las tuercas de la parada sobre los

vástagos e instale las paradas en el cuerpo;

tenga cuidado de no apretar las tuercas

demasiado.

Nota: Instale las paradas en con la versión de

las válvulas apagadas como sigue: Rosque

la tuerca (6) en el vástago (7) según lo

demostrado.

vástago y de tuerca en cuerpo (8) y apriete

con un 3/8”, 6 puntos, zócalo bien profundo.

Con un destornillador principal plano, ajuste

el vástago a

izquierda abrirse.

Después presione el montaje del

la derecha al cierre y a la

7

6

Page 17

2

R18222 & R18222-WS

5

Para 3 salidas,

6 funciones

7

Para 2 salidas, 3

funciones

5

6

1

4

3

10

9

8

2

Instalación de las piezas R18222 & R18222-WS

Quite la tuerca tapa, el cartucho y el protector

de yeso (1), además, la rejilla, la tapa de

prueba, la tuerca tapa, el protector de yeso

y la cubierta (2) antes de soldar. Conecte el

cuerpo de la válvula a los suministros de agua

usando los accesorios apropiados. Nota: (3)

es la salida de agua fría y (4) la salida de

agua caliente.

Suelde un tubo (5) de la salida principal del

modulo del chorro al codo del brazo de la

regadera a la altura deseada. Determine

si desea una configuración de tres o seis

funciones. Para 2 salidas, 3 funciones;

suelde, fundido, el tapón en la salida auxiliar

(6). Para 3 salidas, 6 funciones; se usan

todas las salidas de agua. Se recomienda

que instale las válvulas en las vigas como

se muestra.

Si usted está instalando dorso con dorso

o instalando en orden inverso (caliente en

la derecha y fría en la izquierda) instale el

cuerpo de la válvula como se describe, pero

invierta las líneas de suministros de agua.

Después de soldar presione el retén (7) en el

agujero apropiado como se muestra, reinstale

el resto de las partes en orden reversa;

asegure las tuercas del capo se aprietan

con seguridad. Después instale las tuercas

de la parada sobre los vástagos e instale las

paradas en el cuerpo; tenga cuidado de no

apretar las tuercas demasiado.

Nota: Instale las paradas en con la versión de

las válvulas apagadas como sigue: Rosque

la tuerca (8) en el vástago (9) según lo

demostrado. Después presione el montaje del

vástago y de tuerca en cuerpo (10) y apriete

con un 3/8”, 6 puntos, zócalo bien profundo.

Con un destornillador principal plano, ajuste

el vástago a la derecha al cierre y a la

izquierda abrirse.

8

9

7

Page 18

3

1

1

La extensión azul de la espiga -

Instalación

La extensión negra de la espiga -

Instalación

para 2 salidas, 3 funciones

2

para 3 salidas, 6 funciones

3

3

4

Instalación de la extensión para tubos

Asegúrese instalar la extensión apropiada

de la espiga para su instalación.

Coloque la extensión de la espiga requerida

en la espiga de bronce. Instale la extensión

azul de la espiga (2) si la instalación no tiene

una salida auxiliar (3). Instale la extensión

negra de la espiga (4) si la instalación utiliza

todas las salidas de agua. Use el tornillo (1)

para fijar.

8

Page 19

4

1

2

2

1

1

1

2

2

1

2

2

1

1

1

2

2

Pruebas de Presión y Lavado de la Instalación

Antes de hacer la prueba, rompa las

tapas del protector de yeso (1) y enrosque

completamente en la tapas para las

pruebas de presión (2). Asegúrese que

las tuercas tapas están apropiadamente

apretadas, y tape ambas salidas de agua

con los accesorios apropiados. Examine

por si hay filtraciones de agua. Después de

hacer la prueba, quite el tapón del desviador

de la regadera y/o bañera y deje correr el agua

por el sistema. Después de dejar correr el agua,

quite el filtro de rejilla (vea el paso 2) y reinstale

la tapa, el capuchón y la cubierta.

9

Page 20

Notes / Notas / Notes

Page 21

T

E

F

L

O

N

ASME A112.18.1 / CSA B125.1

®

®

U

P

C

Modèles

R18222, R18224,

R18442 & R18448

Seria

Inscrivez le numéro de modèle ici.

Articles dont vous pouvez avoir besoin:

SOUPAPE UNIVERSELLE

POUR ROBINETS À UNE

MANETTE MULTICHOICE

MC

JETTED SHOWER

JETTED SHOWER XO

ET

MC

MC

Pour installer votre robinet Delta® facilement, vous devez:

• LIRE TOUTES les instructions avant de débuter;

• LIRE TOUS les avertissements ainsi que toutes les instructions de

nettoyage et d’entretien;

CE ROBINET SATISFAIT AUX EXIGENCES DES NORMES ANSI A112.18.1 et

ASME A112.18.1 / CSA B125.1

OU LES SURPASSE.

AVIS À L’INSTALLATEUR : ATTENTION! – En qualité d’installateur, vous est tenu de

bien INSTALLER ce corps de robinet conformément aux instructions. VOUS DEVEZ

informer le propriétaire ou l’utilisateur de cette exigence. En cas de doute quant à la

marche à suivre pour installer ce corps de robinet, veuillez lire les instructions fournies

et, au besoin, veuillez nous appeler au 1-800-345-DELTA. Veuillez laisser ce feuillet

d’instructions au propriétaire ou à l’utilisateur pour qu’il puisse le consulter s’il y

a lieu.

6/27/07

1

51045 Rev B

Page 22

TABLE DES MATIÈRES

Garantie -- - - -- --- - - -- --- - - -- --- - - -- --- - - -- --- - - -- --- - - -- --- - - -- --- -- - - Page 2

Instructions d’installation - - -- - --- -- -- - -- - -- -- - -- - -- -- - -- - --- -- -- - -- - -- - Pages 3- 9

Pièces de rechange - - --- -- -- - -- - -- -- - -- - -- -- - -- - --- -- -- - -- - -- -- - -- - -- Pages 1 0-1 3

Garantie à vie limitée des robinets et de leurs finis

Toutes les pièces et les finis du robinet Delta® sont

protégés contre les défectuosités de matériau et

les vices de fabrication par une garantie qui est

consentie au premier acheteur

et qui demeure valide tant que celui-ci demeure

propriétaire de sa maison. Delta recommande

de faire appel à un plombier compétent pour

l'installation et la réparation du robinet.

Pendant la période de garantie, Delta

remplacera GRATUITEMENT toute pièce

ou tout fini, présentant une défectuosité de

matériau ou un vice de fabrication pour autant que

l'appareil ait été installé, utilisé et entretenu

correctement. Pour obtenir des pièces de

rechange, veuillez communiquer par téléphone

au numéro 1-800-345-DELTA (aux États-Unis

ou au Canada) et par écrit à l'une des

adresses suivantes :

Aux États-Unis

Delta Faucet Company

Product Service

55 E. 111th Street

Indianapolis, IN 46280

Au Canada

Delta Faucet Canada

Technical Service Centre

420 Burbrook Place

London, ON N6A 4L6

La présente garantie s'applique au remplacement

de toutes les pièces défectueuses, y compris

le fini, et elle ne couvre que ces éléments. LES

FRAIS DE MAIN-D'OEUVRE ET (OU) LES

DOMMAGES PROVOQUÉS AU COURS DE

L'INSTALLATION, DE LA RÉPARATION OU DU

REMPLACEMENT D'UN ÉLÉMENT AINSI QUE

LES PERTES OU DOMMAGES DE TOUTE

AUTRE NATURE NE SONT PAS COUVERTS

PAR LA GARANTIE. Toute réclamation en vertu

de la présente garantie doit être adressée à

Delta, accompagnée de la preuve d'achat

(original de la facture) du premier acheteur.

CETTE GARANTIE EST LA SEULE OFFERTE

PAR DELTA FAUCET COMPANY OU DELTA

FAUCET CANADA, SELON LE CAS. ELLE

EXCLUT TOUTE AUTRE GARANTIE, Y

COMPRIS LA GARANTIE IMPLICITE DE

QUALITÉ MARCHANDE.

Les robinets installés dans un établissement

industriel ou commercial ou dans une place

d'affaires sont protégés par une grantie étandue

de cinq ans qui prend effet à compter de la date

d'achat. Toutes les autres conditions de la

garantie de cinq ans sont identiques à celle de la

présente garantie. La présente garantie s'applique

à tous les robinets Delta® fabriqués après le 1er

janvier 1995.

Dans les États ou les provinces où il est interdit

d'exclure ou de limiter les responsabilités à

l'égard des dommages indirects ou fortuits, les

exclusions et les limites susmentionnées ne

s'appliquent pas. Les dommages résultant d'une

mauvaise utilisation, d'une utilisation abusive de

la négligence ou de l'utilisation de pièces autres

que des pièces d'origine Delta® RENDENT LA

GARANTIE NULLE ET SANS EFFET.

La présente garantie vous donne des droits précis

qui peuvent varier selon votre lieu de résidence.

Elle ne s'applique qu'aux robinets Delta® installés

aux États-Unis, au Canada et

au Mexique.

© 2007 Division de Masco Indiana

2

Page 23

1

R18222

5

1

4

R18222-WS

R18224

3

2

3

A

B

4

3

5

1

A

B

R18224-WS

R18442 & R18448

3

5

1

2

3

4

R18442-WS &

R18448-WS

Installation des systèmes Jetted ShowerMC et

Jetted Shower XO

Description :

Les soupapes Jetted Shower

commandent uniquement l’alimentation en

eau des gicleurs. Les soupapes Jetted

Shower XO

les gicleurs, une sortie pour la pomme de

douche et une sortie supplémentaire. L’eau

peut s’écouler par une seule sortie ou par

deux sorties quelconques simultanément.

La soupape est donc un inverseur à 3

sorties et à 6 fonctions. Pour utiliser les

trois sorties, vous devez monter l’obturateur

à rallonge noire (sans butée). Pour obtenir

un inverseur à 2 sorties et à 3 fonctions,

soit pour alimenter les gicleurs seulement,

les gicleurs et la pomme de douche ou la

douche seulement, montez le bouchon et

soudez-le comme le montre la figure, puis

montez la rallonge d’obturateur bleue avec

la butée.

Instructions d’installation :

Interrompez l’alimentation en eau.

Vérifiez le type et l’épaisseur du mur fini

avant d’installer la plaque arrière. Montez

MC

comportent une sortie pour

MC

.

MC

la soupape à la hauteur désirée. Nous vous

recommandons un écart de 52 pouces entre

la base de l’enceinte et la ligne d’axe des

gicleurs. Installez le corps (1) de sorte que la

surface du mur fini soit à égalité avec la face

du protecteur (2). Fixez-le par les deux trous

de vis (3) du support. Note : enlevez le cou

vercle (4) pour avoir accès aux trous de

vis. Assurez-vous que le mot « UP » (5) se

trouve sur le dessus du corps au cours de

l’installation.

L’écart (A) entre l’entretoise et l’avant du

protecteur est de 2,8 po (71 mm). L’écart (B)

entre l’entretoise et l’avant du chapeau est

de 3,9 po (99 mm).

Si le mur est peu épais, montez le protecteur

à l’endos de celui-ci. Dans les autres cas, le

mur doit toujours être à égalité de l’avant du

protecteur.

Note : si vous effectuez l’installation

dans un mur peu épais, utilisez le gabarit

fourni pour déterminer l’emplacement

du trou.

3

2

3

A

B

-

Page 24

2

R18448 & R18448-WS

8

6

9

1

5

4

2

10

9

16"

(406 mm)

Max

8

7

Installation des kit R18448 et R18448-WS.

Avant de souder, enlevez l’écrou à portée

sphérique, l’obturateur et la rallonge

d’obturateur, le siège, le ressort et le

protecteur (1) ainsi que le filtre en toile

métallique, le capuchon d’essai, l’écrou

à portée sphérique, le protecteur et le

couvercle (2). Raccordez le corps du

robinet à la tuyauterie à l’aide des raccords

nécessaires. Note : (3) est l’entrée d’eau

froide et (4) est l’entrée d’eau chaude.

Raccordez le corps de robinet et le module

de gicleurs au moyen d’un tuyau de cuivre

(5) de manière que les gicleurs se trouvent à

la hauteur désirée; soudez le tuyau. Placez

le coude du manchon de la pomme de

douche à la hauteur désirée et raccordez-le

au module de gicleurs au moyen d’un autre

tuyau de cuivre (6); soudez le tuyau. Il est

recommandé de fixer les soupapes aux

entretoises de la manière indiquée sur

la figure.

Le tuyau (7) entre la soupape et le bec de

bain doit consister en une section droite de

tuyau de cuivre d’au moins 1/2 po (13 mm)

ou de tuyau de fer d’au moins 1/2 po

(13 mm) d’une longueur d’au moins

8 po (203 mm) et d’au plus 16 po (406 mm).

Cette section de tuyau doit être raccordée

au manchon du bec par un seul coude à 90

degrés. Si une sortie quelconque est inutilisée,

obturez-la avec un bouchon de tuyau.

Si vous effectuez une installation dos à dos

ou inversée (eau chaude à droite et eau froide

à gauche), installez le corps de robinet de la

manière décrite, mais inversez la position des

tuyaux d’alimentation en eau.

Après la soudure, réinstallez toutes les parties

à l’envers l’ordre ; assurez les écrous de capot

sont serrés solidement. Alors installez les

écrous d’arrêt sur les tiges et installez les arrêts

sur le corps ; faites attention à ne pas trop

serrer les écrous.

Note :

Installez les arrêts dans avec la version

de valves coupées comme suit : Filetez l’écrou

(8) sur la tige (9) comme montré. Alors serrez

l’ensemble de tige et d’écrou dans le corps (10)

et serrez en utilisant un 3/8”, 6 points, douille

bonne profonde. Avec un tournevis principal

plat, ajustez la tige dans le sens des aiguilles

d’une montre sur la fin et s’ouvrir dans le sens

contraire des aiguilles d’une montre.

4

3

Page 25

2

R18442 & R18442-WS

3 sorties et

6 fonctions

9

2

1

16"

(406 mm)

Max

7

5

4

3

12

11

10

8

2 sorties et

3 fonctions

7

6

10

11

Installation des kit R18442 & R18442-WS

Avant de souder, enlevez l’écrou à portée

sphérique, la cartouche et le protecteur

(1) ainsi que le filtre en toile métallique, le

capuchon d’essai, l’écrou à portée sphérique,

le protecteur et le couvercle (2). Raccordez le

corps de robinet à la tuyauterie à l’aide des

raccords nécessaires. Note : (3) est l’entrée

d’eau froide et (4) est l’entrée d’eau chaude.

Au moyen d’un tuyau de cuivre (5), raccordez

le corps de robinet et le module de gicleurs

de manière que les gicleurs se trouvent à la

haute désirée; soudez le tuyau. Choisissez la

configuration : trois fonctions ou six fonctions.

Pour obtenir 2 sorties et 3 fonctions, montez

un bouchon dans la sortie supplémentaire (6)

du corps et soudez-le. Au moyen d’un tuyau

de cuivre (7), raccordez l’orifice principal du

module de gicleurs au coude du manchon de

la pomme de douche; soudez le tuyau. Pour

obtenir 3 sorties et 6 fonctions, utilisez

toutes les sorties. Il est recommandé de fixer

les soupapes aux entretoises de la manière

indiquée sur la figure.

Le tuyau (8) entre la soupape et le bec de bain

doit consister en une section droite de tuyau de

cuivre d’au moins 1/2 po (13 mm) ou de tuyau

de fer d’au moins 1/2 po (13 mm) d’une longueur

d’au moins 8 po (203 mm) et d’au plus 16 po (406

mm). Cette section de tuyau doit être raccordée au

manchon du bec par un seul coude à 90 degrés. Si

une sortie est inutilisée, obturez-la avec un bouchon

de tuyau.

Si vous effectuez une installation dos à dos ou

inversée (eau chaude à droite et eau froide à

gauche), installez le corps de robinet de la manière

décrite, mais inversez la position des tuyaux

d’alimentation en eau.

Après la soudure de la pression la détente (9) dans le

trou approprié comme montré, réinstallent toutes les

parties à l’envers l’ordre; assurez les écrous de capot

sont serrés solidement. Alors installez les écrous

d’arrêt sur les tiges et installez les arrêts sur le corps;

faites attention à ne pas trop serrer les écrous.

Note :

Installez les arrêts dans avec la version de

valves coupées comme suit : Filetez l’écrou (10) sur

la tige (11) comme montré. Alors serrez l’ensemble

de tige et d’écrou dans le corps (12) et serrez en

utilisant un 3/8”, 6 points, douille bonne profonde.

Avec un tournevis principal plat, ajustez la tige dans

le sens des aiguilles d’une montre sur la fin et s’ouvrir

dans le sens contraire des aiguilles d’une montre.

5

Page 26

2

R18224 & R18224-WS

6

5

1

2

4

8

7

6

Installation des kit R18224 & R18224-WS

Avant de souder, enlevez l’écrou à portée

sphérique, l’obturateur et la rallonge

d’obturateur, le siège, le ressort et le

protecteur (1) ainsi que le filtre en toile

métallique, le capuchon d’essai, l’écrou

à portée sphérique, le protecteur et le

couvercle (2). Raccordez le corps du

robinet à la tuyauterie à l’aide des raccords

nécessaires. Note : (3) est l’entrée d’eau

froide et (4) est l’entrée d’eau chaude.

Placez le coude du manchon de la

pomme de douche à la hauteur désirée

et raccordez-le à l’orifice supérieur

du module de gicleurs au moyen d’un

tuyau (5); soudez le tuyau. Si une sortie

quelconque est inutilisée, obturez-la avec

un bouchon de tuyau; soudez le bouchon.

Il est recommandé de fixer l’appareil à

l’entretoise de la manière indiquée.

Si vous effectuez une installation dos à dos

ou inversée (eau chaude à droite et eau froide

à gauche), installez le corps de robinet de la

manière décrite, mais inversez la position des

tuyaux d’alimentation en eau.

Après la soudure réinstallez toutes les parties

à l’envers l’ordre ; assurez les écrous de

capot sont serrés solidement. Alors installez

les écrous d’arrêt sur les tiges et installez les

arrêts sur le corps ; faites attention à ne pas

trop serrer les écrous.

Note : Installez les arrêts dans avec la version

de valves coupées comme suit : Filetez l’écrou

(6) sur la tige (7) comme montré. Alors serrez

l’ensemble de tige et d’écrou dans le corps (8)

et serrez en utilisant un 3/8”, 6 points, douille

bonne profonde. Avec un tournevis principal

plat, ajustez la tige dans le sens des aiguilles

d’une montre sur la fin et s’ouvrir dans le sens

contraire des aiguilles d’une montre.

7

3

6

Page 27

2

R18222 & R18222-WS

2 sorties et

3 fonctions

5

5

3 sorties et

6 fonctions

7

1

4

3

10

9

8

2

Installation des kit R18222 & R18222-WS

Avant de souder, enlevez l’écrou à portée

sphérique, la cartouche et le protecteur

(1) ainsi que le filtre en toile métallique,

le capuchon d’essai, l’écrou à portée

sphérique, le protecteur et le couvercle (2).

Raccordez le corps de robinet à la tuyauterie

à l’aide des raccords nécessaires. Note : (3)

est l’entrée d’eau froide et (4) est l’entrée

d’eau chaude.

Placez le coude du manchon de la pomme

de douche à la hauteur désirée et raccordezle à l’orifice supérieur du module de gicleurs

au moyen d’un tuyau (5); soudez le tuyau.

Choisissez la configuration : trois fonctions

ou six fonctions. Pour obtenir 2 sorties et 3

fonctions, obturez la sortie supplémentaire

(6) du corps à l’aide d’un bouchon et soudez

le bouchon. Pour obtenir 3 sorties et 6

fonctions, utilisez toutes les sorties. Il est

recommandé de fixer les soupapes aux

entretoises de la manière indiquée sur

la figure.

Si vous effectuez une installation dos à dos

ou inversée (eau chaude à droite et eau froide

à gauche), installez le corps de robinet de la

manière décrite, mais inversez la position des

tuyaux d’alimentation en eau.

Une fois le soudage terminé, enfoncez le

taquet (7) dans le trou approprié comme le

montre la figure, réinstallez toutes autres

parties à l’envers l’ordre ; assurez les écrous

de capot sont serrés solidement. Alors

installez les écrous d’arrêt sur les tiges

et installez les arrêts sur le corps ; faites

attention à ne pas trop serrer les écrous.

Note : Installez les arrêts dans avec la version

de valves coupées comme suit : Filetez l’écrou

(8) sur la tige (9) comme montré. Alors serrez

l’ensemble de tige et d’écrou dans le corps (10)

et serrez en utilisant un 3/8”, 6 points, douille

bonne profonde. Avec un tournevis principal

plat, ajustez la tige dans le sens des aiguilles

d’une montre sur la fin et s’ouvrir dans le sens

contraire des aiguilles d’une montre.

6

8

9

7

Page 28

3

La rallonge d’obturateur bleue -

2 sorties et 3 fonctions

3

1

2

La rallonge d’obturateur noire -

3 sorties et 6 fonctions

1

3

4

Installation de la rallonge de tige

Assurez-vous d’utiliser la rallonge

d’obturateur qui convient à votre

installation. Montez la rallonge sur la tige

d’obturateur en laiton. Montez la rallonge

d’obturateur bleue (2) si vous n’utilisez

pas la sortie supplémentaire (3). Si vous

utilisez toutes les sorties, montez la rallonge

d’obturateur noire (4). Fixez la rallonge à

l’aide de la vis (1).

8

Page 29

4

1

2

2

1

1

1

2

2

1

2

2

1

1

1

2

2

Mise à L’épreuve Sous Pression et Rinçage de L’installation

Avant la mise à l’épreuve sous pression,

brisez les capuchons (1) du protecteur et

vissez les capuchons d’essai à fond (2).

Assurez-vous que les écrous à portée

sphérique sont bien serrés et obturez

les deux orifices à l’aide des raccords

nécessaires. Vérifiez l’étanchéité. Une fois

la mise à l’épreuve sous pression terminée,

enlevez le bouchon de la sortie du bec de

baignoire et/ou celui de la sortie de la douche

et rincez l’installation. Une fois le rinçage

terminé, enlevez le filtre en toile métallique

(reportez-vous à l’étape 2) et reposez le

capuchon, le chapeau ainsi que le couvercle

9

.

Page 30

RP20032

Plug/Tapón/Bouchon

RP28603

RP40266

Spring Loaded Detent

Seats & Springs

Retén cargado con el resorte

Cliquet à ressort

Asientos y Resortes

Vástago (2) y Tuerca (2)

Ensamble de la Unidad del

Tamis

RP46078

Test Cap

Obturateurs (2)

et Écrou (2)

RP40972

Test Caps

Tapa de Prueba

Capuchon d’essai

Tapa de Prueba

Capuchon d’essai

RP50366

Stems (2) and Nuts (2)

RP46077

Screen

Filtro de malla

RP37900

Cartridge Assembly

Cartucho

Cartouche

Sièges et ressorts

RP22734

Bonnet

Capuchón

Chapeau

RP37902

R18222 Series

Replacement Parts

Piezas de Repuesto

Pièces de rechange

RP37890

Retention Screw

Tornillos de Retención

Stem Extender - 3 Function

Extensión para la espiga - Función 3

Rallonge de tige - 3 fonctions

RP37903

Stem Extender - 6 Function

Extensión para la espiga – Función 6

Rallonge de tige - 6 fonctions

10

RP46075

Plasterguard

Protector de yeso

Protecteur

Vis de Retenue

RP46076

Cover

Cubierta

Couvercle

RP37894

Plasterguard

Protector de Enlucido

Base du protecteur

Page 31

RP40972

Test Caps

Tapa de Prueba

Capuchon d’essai

RP4993

Seat & Spring

Asiento y Resorte

Siège et ressort

RP22734

Bonnet

RP46077

Screen

Filtro de malla

Capuchón

Chapeau

Tamis

RP46078

Test Cap

Tapa de Prueba

Vástago (2) y Tuerca (2)

Ensamble de la Unidad del

Obturateurs (2)

et Écrou (2)

RP50366

Stems (2) and Nuts (2)

Capuchon d’essai

R18224 Series

Replacement Parts

Piezas de Repuesto

Pièces de rechange

RP39404

Plasterguard/Thin Wall Mounting Bracket

Protector de Enlucido/Pared Delgada Soporte de Montura

Base du protecteur/Support de Montage sur Paroi Mince

RP46075

Plasterguard

Protector de yeso

Protecteur

RP46076

Cover

Cubierta

Couvercle

RP25513

Stem Assembly

Ensamble de la Unidad del Vástago

Obturateurs

RP34787

Stem Extender

Extensión para Unidad

del Vástago

Rallonge de tige

RP37890

Retention Screw

Tornillos de Retención

Vis de Retenue

RP22734

Bonnet

Bonete

Chapeau

11

Page 32

RP20032

Plug/Tapón/Bouchon

RP40972

Test Caps

Tapa de Prueba

Capuchon d’essai

RP40266

Spring Loaded Detent

Vástago (2) y Tuerca (2)

Ensamble de la Unidad del

Tamis

Obturateurs (2)

et Écrou (2)

RP46078

Test Cap

Tapa de Prueba

Capuchon d’essai

RP50366

Stems (2) and Nuts (2)

RP46077

Screen

Filtro de malla

Retén cargado con el resorte

Cliquet à ressort

RP28603

Seats & Springs

Asientos y Resortes

Sièges et ressorts

RP37900

Cartridge Assembly

Cartucho

Cartouche

RP22734

Bonnet

Capuchón

Chapeau

RP37902

Stem Extender - 3 Function

Extensión para la espiga - Función 3

Rallonge de tige - 3 fonctions

R18442 Series

Replacement Parts / Piezas de Repuesto / Pièces de rechange

RP37890

Retention Screw

Tornillos de Retención

RP37903

Stem Extender - 6 Function

Extensión para la espiga – Función 6

Rallonge de tige - 6 fonctions

Vis de Retenue

12

RP46075

Plasterguard

Protector de yeso

Protecteur

RP37894

Plasterguard

Protector de Enlucido

Base du protecteur

RP46076

Cover

Cubierta

Couvercle

Page 33

RP4993

Seat & Spring

Asiento y Resorte

Vástago (2) y Tuerca (2)

Ensamble de la Unidad del

Tamis

Obturateurs (2)

RP46078

Test Cap

Tapa de Prueba

et Écrou (2)

Capuchon d’essai

RP50366

Stems (2) and Nuts (2)

RP46077

Screen

Filtro de malla

Siège et ressort

RP22734

Bonnet

Capuchón

Chapeau

RP40972

Test Caps

Tapa de Prueba

Capuchon d’essai

RP39404

R18448 Series

Replacement Parts

Piezas de Repuesto

Pièces de rechange

Plasterguard/Thin Wall Mounting Bracket

Protector de Enlucido/Pared Delgada Soporte de Montura Base du protecteur/Support de Montage sur Paroi Mince

RP46075

Plasterguard

Protector de yeso

Protecteur

RP46076

Cover

Cubierta

RP25513

Stem Assembly

Ensamble de la Unidad del Vástago

Obturateurs

RP22734

Bonnet

Bonete

Chapeau

RP34787

Stem Extender

Extensión para Unidad

del Vástago

Rallonge de tige

RP37890

Retention Screw

Tornillos de Retención

Vis de Retenue

Couvercle

13

Page 34

Notes / Notas / Notes

Page 35

Notes / Notas / Notes

Page 36

Delta Faucet Company

Product Service

55 E. 111th Street

Indianapolis, IN 46280

Loading...

Loading...