Delta Performance PG-25, Performance PG-30, Performance PG-35, Performance PG-40, Performance PG-45 Installation And Maintenance Manual

Page 1

Warranty Registration Card must be filled out by the customer and mailed within thirty (30) days of installation in order to gain warranty coverage.

When receiving the Delta Performance unit, any claims for damage or shortage in shipment must be filed

immediately against the transportation company by the consignee.

Leave all documentation received with appliance with owner for future reference.

WARNING

* I N S

* I N S TTAALLLLAATT

I O N

I O N AA

N D M

N D M AA

I N

I N TT

E N

E N AA

N C E *

N C E *

M

M AA

N U

N U AALL

- Input from 100,000 to 199,000 Btu/hr -

NOTICE

If the information in this manual is not followed exactly, a fire or explosion may

result causing property damage, personal injury or death.

FOR

YOUR SAFETY

• Do not store or use gasoline or other flammable vapors and liquids in the vicinity of

this or any other appliance.

• WHAT TO DO IF YOU SMELL GAS

- Do not try to light any appliance

- Do not touch any electrical switch; do not use any phone in your building.

- Immediately call your gas supplier from a neighbor’s phone. Follow the gas

supplier’s instructions.

- If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service agency or the

gas supplier.

PG-25/30/35/40 & 45

Gas Fired

Combination Heaters

Category I or Category III

Vented Appliance

The

CONFORMS TO

ANSI Z 21-10-3

CERTIFIED TO

CGA CAN 1-4-3 M85

90870

Page 2

Page 3

Table of Contents

i

PRODUCT AND SAFETY INFORMATION

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Product Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Operating Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Code Restrictions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SECTION I - PRE-INSTALLATION ITEMS

Code Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Determining Product Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Boiler Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Recommended Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Flooring and Foundation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Residential Garage Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

SECTION II - COMBUSTION AIR AND VENTING

Combustion Air Contamination. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Combustion Air Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Outside Combustion Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Air Openings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Methods of Accessing Combustion Air into a Space . . . . . . . . . . . . . . . . . 8-10

Vent System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Removal of an Existing Category I Appliance

from a Common Vent System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

SECTION III - UNIT PREPARATION

Handling Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Hydrostatic Pressure Test

Hydrostatic Test Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Hydrostatic Test Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-13

Completion of Hydrostatic Test and Draining . . . . . . . . . . . . . . . . 13

SECTION IV - DOMESTIC PIPING

General Piping Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Domestic Supply Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Thermal Expansion. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Water Hammer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Temperature / Pressure Relief Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-15

Thermostatic Mixing Valve. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Page 4

Table of Contents

ii

U-Tube Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15-16

Domestic Drain Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Multiple Units Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Storage Tank Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

TR/Smart Series Application. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Domestic Piping Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-19

SECTION V - PRIMARY PIPING

General Piping Requirements

Low Water Cut-off Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Backflow Preventer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Primary System Piping Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Expansion Tank and Makeup Water

Diaphragm (Bladder) Expansion Tank. . . . . . . . . . . . . . . . . . . . . . 20

Closed-Type (Standard) Expansion Tank . . . . . . . . . . . . . . . . . . . . 20-21

Circulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Closet (Zero Clearance) Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Sizing Primary Piping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

System Piping - Zone Circulators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

System Piping - Zone Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

System Piping - Radiant Heating with Mixing Valves . . . . . . . . . . . . . . . . 22

System Piping - Multiple Units Installation. . . . . . . . . . . . . . . . . . . . . . . . 22

Primary Piping Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23-26

SECTION VI - VENT / COMBUSTION AIR INSTALLATION

General Requirements - Category I. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Masonry and Metal Chimneys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Type B Vent Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Vent Connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Common Venting - Category I . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

General Requirements - Category III . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Category III Vent Termination - Guidelines. . . . . . . . . . . . . . . . . . . . . . . . 29

Category III Vent Termination Clearances. . . . . . . . . . . . . . . . . . . . . . . . . 29-30

Multiple Vent Terminations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Locating the Combustion Air Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Venting Option - Non-Direct Vent / Vertical . . . . . . . . . . . . . . . . . . . . . . . 31

Venting Option - Direct Vent / Vertical . . . . . . . . . . . . . . . . . . . . . . . . . . . 31-32

Venting Option - Non-Direct Vent / Horizontal . . . . . . . . . . . . . . . . . . . . . 32

Venting Option - Direct Vent / Horizontal . . . . . . . . . . . . . . . . . . . . . . . . . 32-33

Horizontal Wall Thimble Kit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Excessive Horizontal Vent Runs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Page 5

iii

Table of Contents

Vent Appliance Adapters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Vent Condensate Drain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Condensate Drain Tube. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Determining Piping Lengths . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34-35

Venting Option Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35-38

SECTION VII - GAS PIPING

Gas Supply Piping Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Natural Gas

Pipe sizing -Natural Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Natural Gas Supply Pressure Requirements . . . . . . . . . . . . . . . . . . 40

Propane Gas

Pipe Sizing - Propane Gas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Propane Gas Supply Pressure Requirements . . . . . . . . . . . . . . . . . 41

SECTION VIII - INTERNAL WIRING

General Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Internal Control Wiring Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42-44

SECTION IX - EXTERNAL WIRING

Installation Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Line Voltage Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Thermostat Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Outdoor Temperature Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

External Control Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46-48

SECTION X - START-UP PREPARATION

Check System and Domestic Water Chemistry

Water pH Level 6.0 to 8.0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Water Hardness Less Than 7 Grains . . . . . . . . . . . . . . . . . . . . . . . 49

Chloride Concentration Less Than 80 mg/L . . . . . . . . . . . . . . . . . 49

Chlorinated Water . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Flush Primary and Domestic System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Check and Test Antifreeze . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Use of Antifreeze in the Primary System . . . . . . . . . . . . . . . . . . . . . . . . . 50

Filling the Inner (Domestic) Tank and System . . . . . . . . . . . . . . . . . . . . . 50

Filling the Outer (Primary) Tank and System . . . . . . . . . . . . . . . . . . . . . . 50-51

Check Low Water Cut-off Device . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Check for Gas Leaks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Page 6

iv

Table of Contents

Verify Correct Pressure Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Verify Correct Air Shutter Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Check Thermostat Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

SECTION XI - START-UP PROCEDURES

Final Checks Before Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

PERFORMANCE Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

If PERFORMANCE Does Not Start Correctly . . . . . . . . . . . . . . . . . . . . . 53

Check the PERFORMANCE and System . . . . . . . . . . . . . . . . . . . . . . . . . 53-55

Start-Up / Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

SECTION XII - TEMPERATURE LIMITS

Setting Primary Thermostat Limit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Adjustment of Secondary Thermostat Limit . . . . . . . . . . . . . . . . . . . . . . . 56

Setting the Thermostatic Mixing Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

SECTION XIII - CHECK-OUT PROCEDURES

Check-out Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

SECTION XIV - INSTALLATION RECORD

Installation Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

SECTIONS XV - MAINTENANCE SCHEDULE

Service Technician - General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Owner Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

SECTION XVI - MAINTENANCE PROCEDURES

Maintenance Procedures

Reported Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Check Surrounding Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Inspect Burner Area . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Check System (Primary and Domestic) Piping . . . . . . . . . . . . . . . 61

Check Combustion/Ventilation Air Operating . . . . . . . . . . . . . . . . 62

Inspect Vent System and Combustion Air Piping . . . . . . . . . . . . . . 62

Check Primary System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Check Domestic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Page 7

v

Table of Contents

Check Expansion Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Check Boiler Relief Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Check Temperature / Pressure Relief Valve . . . . . . . . . . . . . . . . . . 63

Inspection of Ignition Electrode. . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Check Ignition Wiring and Ground Wiring . . . . . . . . . . . . . . . . . . 63

Check Control Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Check Thermostat Limit Settings . . . . . . . . . . . . . . . . . . . . . . . . . 63

Perform Start-Up and Checkout Procedure . . . . . . . . . . . . . . . . . . 63

Check Burner Flame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Check Flame Signal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Check Combustion Levels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Review with Owner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

SECTION XVII - REPLACEMENT PARTS

Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65-69

PRODUCT SPECIFICATIONS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70-71

Page 8

Product & Safety Information

1

Indicates the presence of a hazardous

situation which, if ignored, will result in

death, serious injury or substantial

property damage.

Indicates a potentially hazardous situation which, if ignored, can result in

death, serious injury or substantial

property damage.

Indicates a potentially hazardous situation which, if ignored, may result in

minor injury or property damage.

Indicates special instructions on installation, operation or maintenance, which

are important to equipment but not

related to personal injury hazards.

Indicates recommendations made by

Triangle Tube for the installers which

will help to ensure optimum operation

and longevity of the equipment

BEST PRACTICES

NOTICE

CAUTION

WARNING

DANGER

The following terms are used throughout this manual to bring attention to the presence of

potential hazards or to important information concerning the product.

Triangle Tube reserves the right to modify the technical specifications and components of

its products without prior notice.

NOTICE

Page 9

Product & Safety Information

2

Bacteria can develop in the domestic

water system if certain minimum water

temperatures are not maintained.

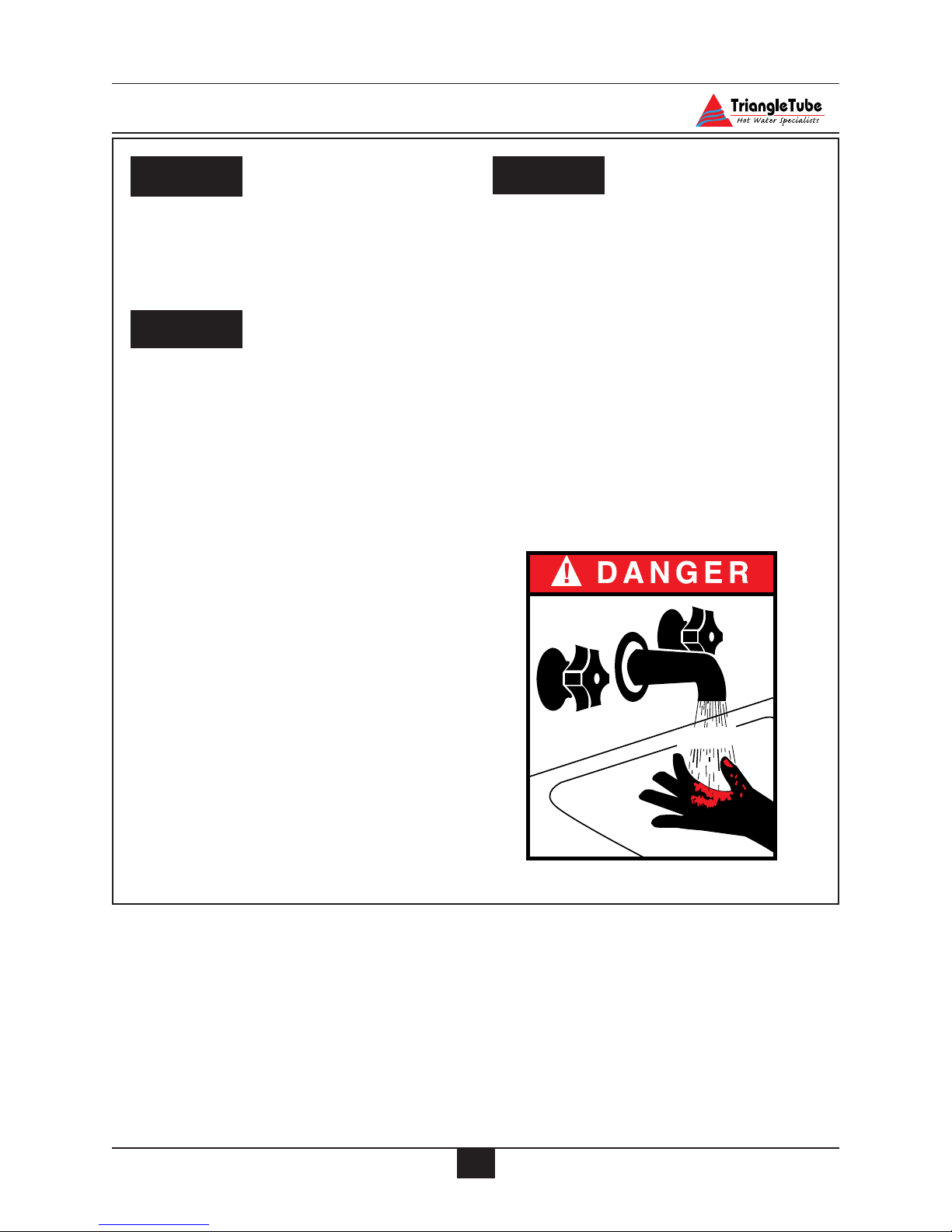

Water temperature over 125ºF can cause

severe burns instantly or death from

scalds.

• Children, disabled and elderly are at

highest risk of being scalded.

- Never leave them unattended in or

near shower, bathtub or sink.

- Never allow small children to use a

hot water faucet or draw their own

bath.

• If any one using hot water in the building

fits this description or codes require specific water temperatures at hot water

faucet, we recommend:

a) ensure the factory installed thermosta-

tic mixing valve is working properly.

b)to set the thermostatic mixing valve

for the lowest temperature which satisfies your hot water need.

.

Protection must be taken against excessive

temperature and pressure!

TO PROTECT AGAINST EXCESSIVE

TEMPERATURE AND PRESSURE

• Check if the Temperature and

Pressure (T&P) relief valve is in the

location provided. (Domestic Water)

• Check if the 30 psi relief valve supplied is in the location provided.

(Primary water)

•To avoid injury, install the relief

devices to comply with local code

requirements.

CAUTION

DANGER

WARNING

HOT

BURN

Page 10

3

Product & Safety Information

Do not use this appliance if any part

has been under water. Immediately call

a qualified service technician to inspect

the appliance and to replace any part of

the control system which has been

under water.

WHAT TO DO IF YOU SMELL GAS

- Do not try to light any appliance

- Do not touch any electrical switch; do

not use any phone in your building.

- Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

- If you cannot reach your gas supplier, call the fire department.

Installation and service must be performed by a qualified installer, service

agency or the gas supplier.

Should overheating occur or the gas

supply fails to shut off, turn OFF the

manual gas control valve external to

the appliance.

To prevent damage to inner tank,

installer must:

• Fill inner tank prior to outer tank

during start-up.

• Relieve primary system pressure

below 15 psig prior to draining

inner tank.

CAUTION

WARNING

DANGER

DANGER

Qualified Installer:

Prior to installing this product read all

instructions included in this manual.

Perform all installation steps required in this

manual in the proper order given. Failure to

adhere to the guidelines within this manual

can result in severe personal injury, death or

substantial property damage.

Homeowner:

-This product should be maintained / serviced and inspected annually by a qualified Service Technician.

- This manual is intended for use by a

qualified Installer/Service Technician.

Please reference the unit’s model number and the serial number from the rating label when inquiring about service or

troubleshooting.

Triangle Tube accepts no liability for any

damage resulting from incorrect installation or from the use of components or

fittings not specified by Triangle Tube.

NOTICE

NOTICEWARNING

Page 11

OPERATING RESTRICTIONS

• Maximum working pressure for inner

(domestic water) tank is 150 psig.

• Maximum working pressure for outer

(primary water) tank is 45 psig.

• Inner tank has factory installed

Temperature & Pressure Relief Valve

with an AGA rating of 100,000 Btu/hr

for PG-25 and 200,000 Btu/hr for PG30/35/40/45.

• Outer tank has a factory installed 30

psig relief valve rated at 535,000 Btu/hr

• Electrical rating:120 V, 60 Hz, less

than 12 amperes

• pH & chloride limits for the PERFORMANCE are:

- Chloride, less than 80 mg/l.

- pH, 6.0 - 8.0.

Any water conditioning system must be

installed and maintained in accordance

with manufacturer’s specifications.

• 180º F Maximum operating temperature - primary side.

• 120º F Maximum outlet/mixed temperature - domestic side.

CODE RESTRICTIONS

Single wall heat exchanger in the PERFORMANCE complies with National Standard

Plumbing Code, provided that:

- Outer tank water (including additives)

is practically non-toxic, having toxicity

rating or Class of 1, as listed in Clinical

Toxicology of Commercial Products,

- Outer tank pressure is limited to maximum 30 psig by approved relief valve.

Single wall heat exchangers are permitted under

the Uniform Plumbing code - Paragraph L3.2. if

they satisfy all of the following requirements.

1. The heat transfer medium is potable

water or contains only substances which

are recognized as safe by the U.S. Food

and Drug Administration.

2. The pressure of the heat transfer medium

is maintained less than the normal minimum operating pressure of the potable

water system

3. The equipment is permanently labeled

to indicate that only additives recognized as safe by the FDA shall be used in

the heat transfer medium.

Or, per Uniform Plumbing Code paragraph L3.3

as follows:

Other heat exchanger designs may be permitted

where approved by the Administrative Authority.

NOTICE

4

Product & Safety Information

Page 12

Pre-Installation Items

5

SECTION I - Pre-Installation Items

Code Compliance

This product must be installed in accordance to the following:

• All applicable local, state, national and

provincial codes, ordinances, regulations and laws.

• The National Fuel Gas Code NFPA54/

ANSI Z332.1 - Latest edition.

• National Electric Code ANSI/NFPA 70.

• For installations in Canada -“Installation

Code for Gas Burning Equipment”

CGA/B149.

Determining Product Location

Before locating the PERFORMANCE check

for convenient locations to:

- Domestic water supply piping

- Heating system piping

-Venting

- Gas supply piping

- Electrical service

Ensure the area chosen for the installation of

the PERFORMANCE is free of any combustible materials, gasoline and other flammable liquids.

Failure to remove or maintain the area

free of combustible materials, gasoline

and other flammable liquids or vapors

can result in severe personal injury,

death or substantial property damage.

Ensure the PERFORMANCE and its controls

are protected from dripping or spraying water

during normal operation or service.

The PERFORMANCE should be installed

in a location so that any water leaking from

the tank or piping connections or relief

valves will not cause damage to the area

surrounding the unit or any lower floors in

the structure.

- When such a location is unavoidable a

suitable drain pan with adequate

drainage should be placed under the

unit. The drain pan must not restrict the

flow of combustion air to the unit.

Boiler Replacement

If the PERFORMANCE is replacing an existing boiler / hot water heater system, the following items should be checked and corrected

prior to installation:

• Primary and domestic piping leaks and

corrosion.

• Improper location and sizing of the

expansion tank on the primary heating

loop.

• Improper sizing of the thermal expansion tank (if used) on the domestic supply line.

•Vent condition and sizing.

Recommended Clearances

The PERFORMANCE is approved for zero

clearance to combustibles, excluding the vent

hood and vent piping.

Vent hood and vent piping - 2 inches from

combustible materials unless otherwise stated

by the vent pipe manufacturer.

Primary and domestic hot water piping - 1 inch

from combustible material.

WARNING

Page 13

To provide serviceability to the unit it is

recommended that the following clearances be maintained:

Top and vent hood area - 36 inches.

Front and burner area - 24 inches.

Rear and primary piping areas - 12

inches.

When installing the PERFORMANCE

in a confined space, sufficient air must

be provided for proper combustion and

venting and to allow under normal operating condition proper air flow around

the product to maintain ambient temperatures within safe limits to comply with

the National Fuel Gas Code NFPA 54 latest edition.

Flooring and Foundation

The PERFORMANCE is approved for installation on combustible floors, but never on carpeting.

Do not install the PERFORMANCE on

carpeting even with a metal or wood

foundation base. Fire can result causing

severe personal injury, death or substantial property damage.

Installer should provide a solid brick or concrete foundation pad, at least 2 inches above

the floor level if:

- There is a potential for the floor to

become flooded. The height of the

foundation should be such to sufficiently elevate the unit.

- The floor is dirt, sand, gravel or other

loose material.

- The flooring is severely uneven or

sloped.

The minimum foundation size required is 24

inches x 23 inches.

Residential Garage Installations

When installing the PERFORMANCE in a residential garage the following special precautions

per NFPA 54/ANSI Z223.1 must be taken:

- Mount the unit with a minimum 18

inches above the floor level of the

garage. Ensure the burner and ignition

devices / controls are no less than 18

inches above the floor level.

- Locate or protect the unit in a matter

so it cannot be damaged by a moving

vehicle.

WARNING

WARNING

BEST PRACTICES

6

Pre-Installation Items

Page 14

Combustion Air and Venting

7

SECTION II - Combustion Air and

Venting

Combustion Air Contamination

If the PERFORMANCE combustion air

inlet is located in any area likely to cause

or contain contamination, or if products,

which would contaminate the air cannot

be removed, the combustion air must be

repiped and terminated to an outside

location. Contaminated combustion air

will damage the unit and its burner system, resulting in possible severe personal

injury, death or substantial property

damage.

Do not operate a PERFORMANCE if its

combustion air inlet is taken inside in a

laundry room or pool facility. These

areas will always contain hazardous contaminants.

Pool chemicals, laundry products, common household cleaners and hobby

products often contain fluorine or chlorine compounds. When these chemicals

pass through the burner and vent system, they can form strong acids. These

acids can create corrosion of the outer

tank, burner components and vent system, causing serious damage and presenting a possible threat of flue gas

spillage or water leakage into the surrounding area.

Please read the information listed below.

If contaminating chemicals are located

near the location of the combustion air

inlet, the installer should pipe the combustion air inlet to an outside area per

SECTION VI of this installation manual.

Potential contaminating products

- Spray cans containing chloro/fluorocarbons

- Permanent Wave Solutions

- Chlorinated wax

- Chlorine - based swimming pool chemicals / cleaners

- Calcium Chloride used for thawing ice

- Sodium Chloride used for water softening

- Refrigerant leaks

- Paint or varnish removers

- Hydrochloric acid / muriatic acid

- Cements and glues

- Antistatic fabric softeners used in

clothes dryers

- Chlorine-type bleaches, detergents, and

cleaning solvents found in household

laundry rooms

- Adhesives used to fasten building products and other similar products

Areas likely to contain these products

- Dry cleaning / laundry areas and establishments

- Beauty salons

- Metal fabrication shops

- Swimming pools and health spas

- Refrigeration Repair shops

- Photo processing plants

- Auto body shops

- Plastic manufacturing plants

- Furniture refinishing areas and establishments

- New building construction

- Remodeling areas

- Garages with workshops

WARNING

WARNING

Page 15

Combustion Air Requirements

The PERFORMANCE can use inside air if no

contaminants are present in the area of installation when venting as a Category I or Category

III appliance. If contaminants are likely to be

present in the area of installation, outside air

must be piped directly to the unit as referenced

in Section VI Venting and Combustion Air

Installation.

In order to avoid the potential of indoor

contaminates when venting as either a

Category I or Category III appliance it is

recommended to pipe uncontaminated

combustion air directly from the outdoors to the unit as referenced in Section

VI Venting and Combustion Air

Installation.

Outside Combustion Air

Combustion air can be ducted directly from the

outside to the air inlet fitting of the PERFORMANCE (Category I or Category III vent

applications) using the following materials:

- PVC

- Galvanized metal vent

- Flexible metal vent

All seams and joints must be sealed with

sealant or mechanical fasteners. Do not use

tape as it is not considered a sealing material.

Air Openings

Air openings to the PERFORMANCE are

always required even if the combustion air is

obtained indoors or outdoors. These air openings provide ventilation to prevent overheating

of the PERFORMANCE and its control as well

as providing combustion air.

The air openings must be sized to handle

the requirements of all appliances and air

movers (exhaust fans, etc.) contained in

the same space using the same air supply.

Methods of Accessing Combustion Air Into A

Space

Indoor Combustion Air

The methods listed in this section for

accessing Indoor Combustion Air

assume that the infiltration rate is adequate and not less than .40 ACH. For

infiltration rates less than .40 ACH, reference the NFPA 54 National Fuel Gas

Code for additional guidance.

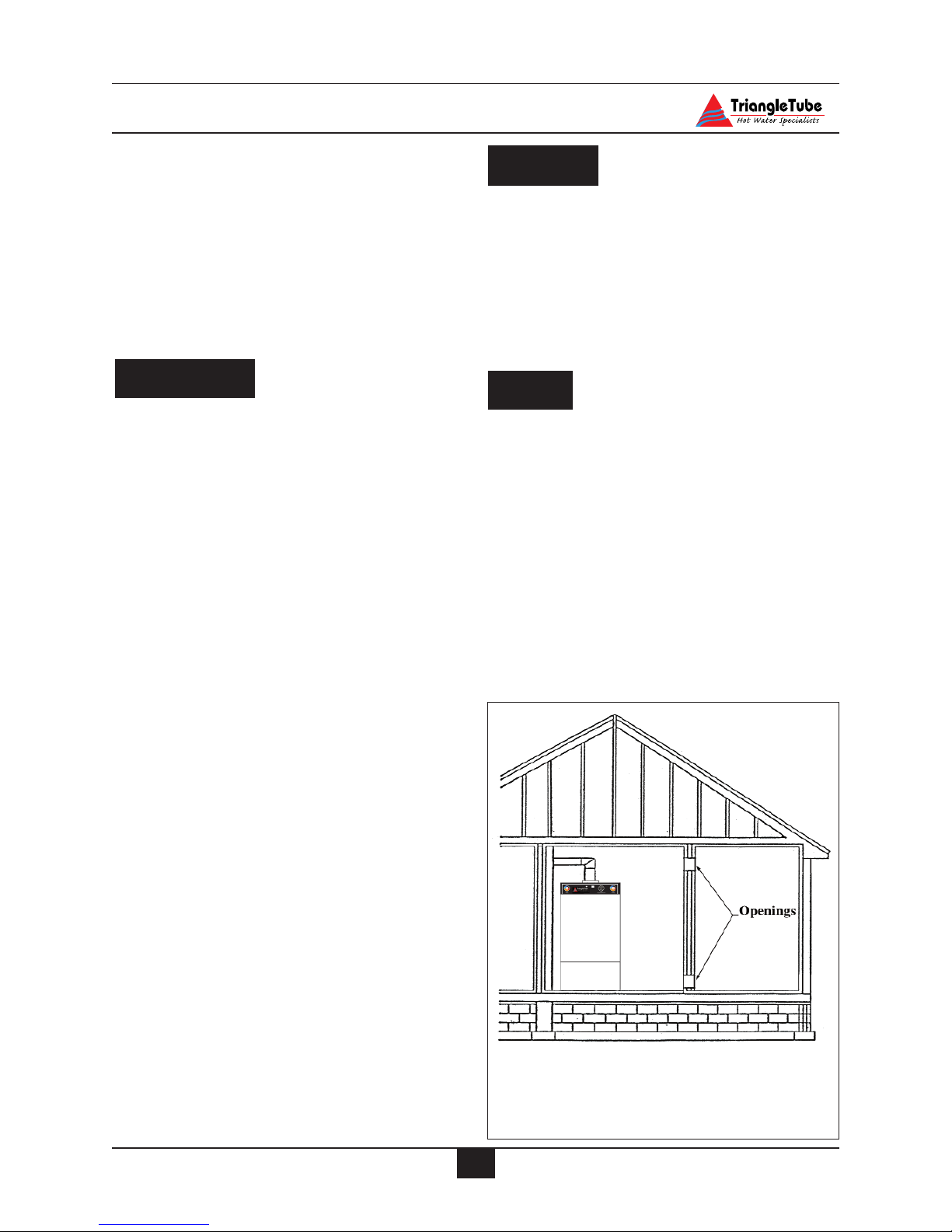

Opening Size and Location

Openings used to connect indoor spaces shall

be sized and located in accordance with the

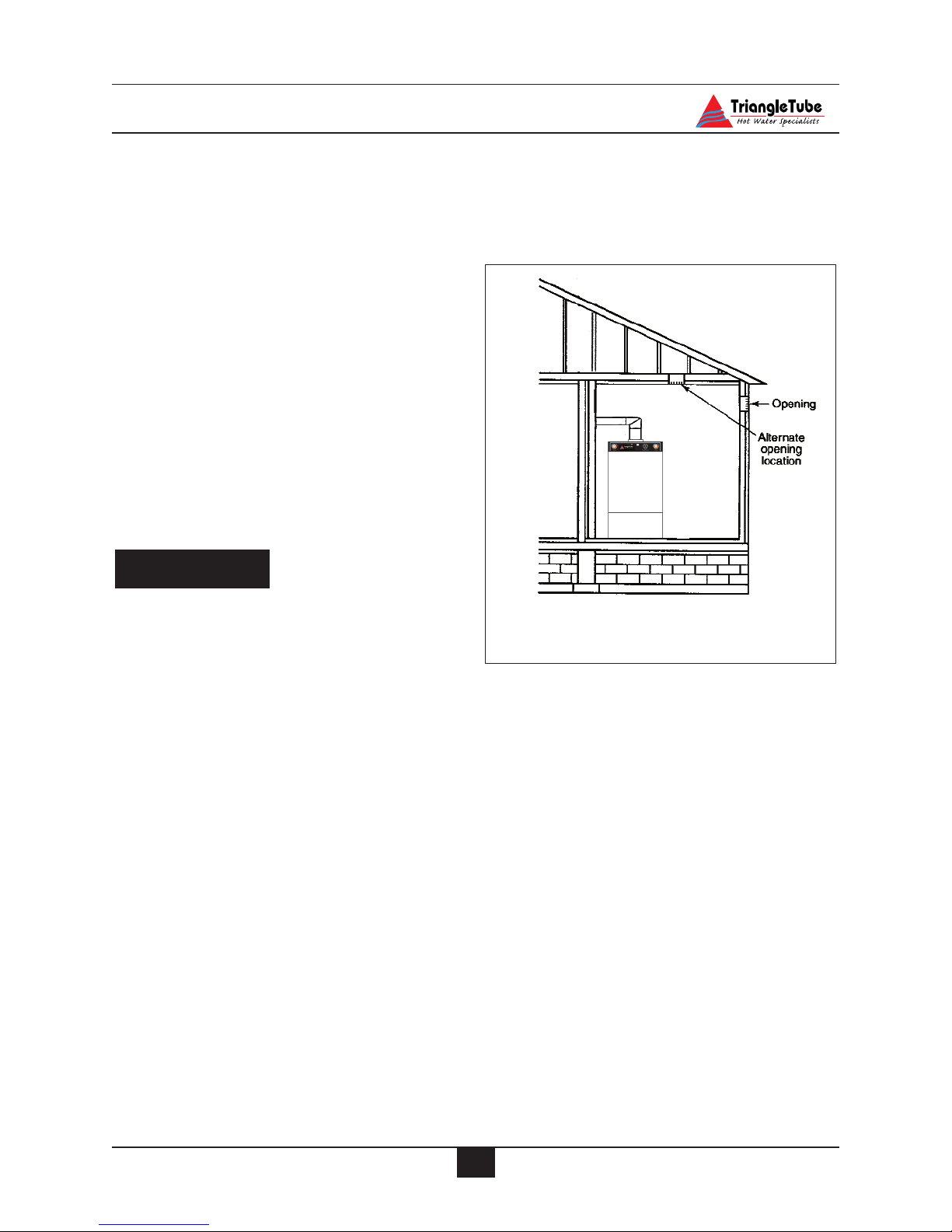

following see Fig. 1:

NOTICE

NOTICE

BEST PRACTICE

8

Combustion Air and Venting

Equipment Located in Confined

Spaces; All Air from inside the

building.

Fig. 1:

Page 16

9

Combustion Air and Venting

- Combining spaces on the same story.

Each opening shall have a minimum

free area of 1 sq. in./1000 Btu/hr of the

total input rating of all gas utilization

equipment in the space, but not less than

100 sq. inches. One opening shall commence within 12 inches of the top, and

one opening shall commence within 12

inches of the bottom of the enclosure.

- Combining spaces in different stories.

The volumes of spaces in different stories shall be considered as communicating spaces where such spaces are connected by one or more openings in

doors or floors having a total minimum

free area of 2 sq. in./1000 Btu/hr of

total input rating of all gas utilization

equipment.

Outdoor Combustion Air

Isolating the combustion appliance room

from the rest of the building and bringing in uncontaminated outside air for

combustion and ventilation is always

preferred.

Opening Size and Location

Openings used to supply combustion and ventilation air shall be sized and located in accordance with the following:

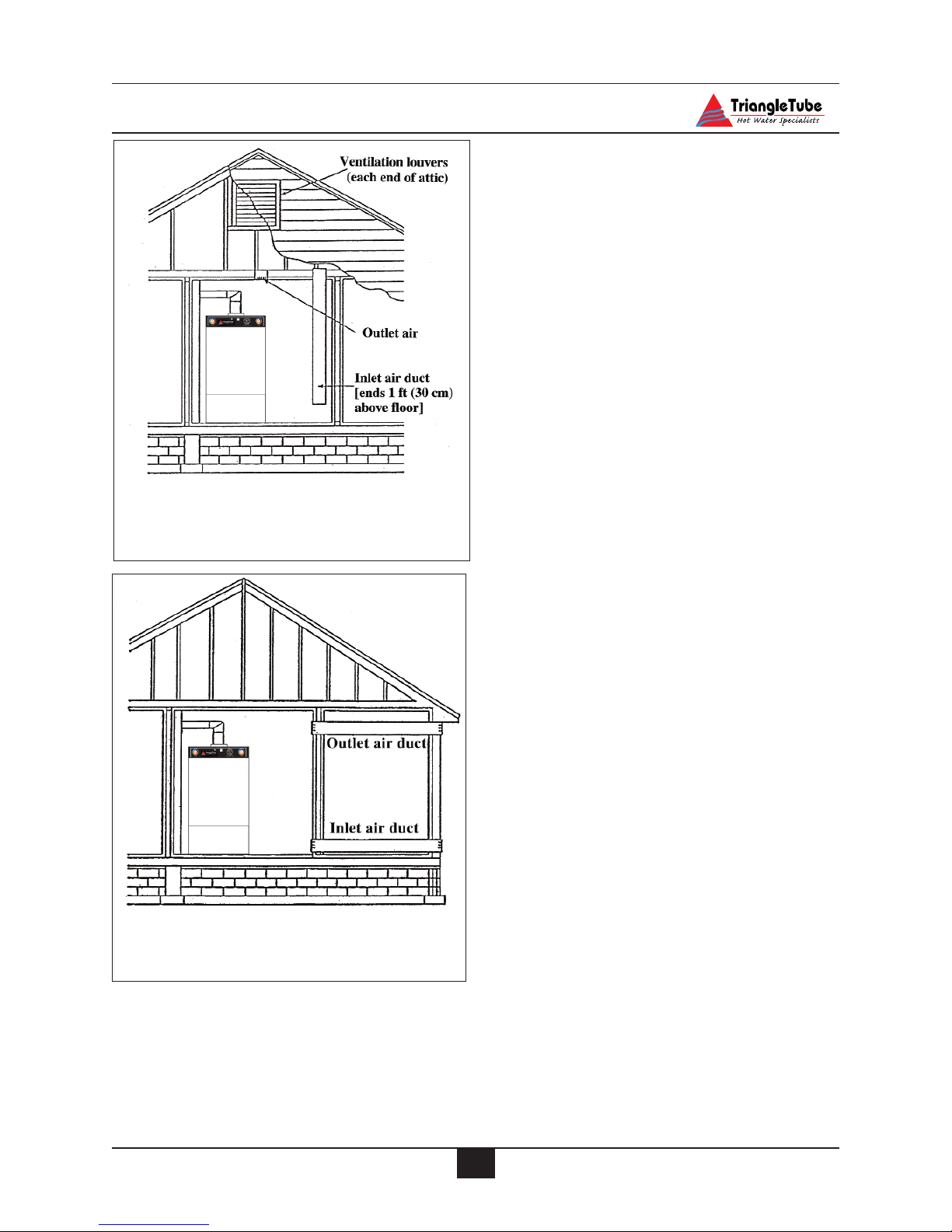

One Permanent Opening Method. See Fig. 2

One permanent opening, commencing within 12

in. of the top of the enclosure, shall be provided.

The equipment shall have clearances of at least 1

inch from the sides and back and 6 in. from the

front of the appliance. The opening shall directly communicate with the outdoors or shall communicate through a vertical or horizontal duct to

the outdoors or spaces that freely communicate

with the outdoors and shall have a minimum free

area of the following:

- 1sq. in./3000 Btu/hr of the total input

rating of all equipment located in the

enclosures, and

-Not less than the sum of the areas of all

vent connectors in the space.

Two Permanent Openings Method.

Two permanent openings, one commencing

within 12 in. of the top and one commencing

within 12 in. of the bottom of the enclosure,

shall be provided. The openings shall communicate directly, or by ducts, with the outdoors

or spaces that freely communicate with the outdoors, as follows:

- Where directly communicating with the

outdoors or where communication to the

outdoors is through vertical ducts, each

opening shall have a minimum free area

of 1 sq. in./4000 Btu/hr of total input rating of all equipment in the enclosure.

See Fig.3.

- Where communicating with the outdoors is through horizontal ducts, each

opening shall have a minimum free

area of not less than 1 sq.in./2000

Btu/hr of total input rating of all equipment in the enclosure. See Fig. 4.

BEST PRACTICE

Equipment Located in Confined

Spaces; One Permanent Air Inlet

Fig. 2:

Page 17

Combination of Indoor and Outdoor

Combustion Air

Indoor Openings: Where used, openings connecting the interior spaces shall comply with

the Indoor Combustion Air section on page 8.

Outdoor Opening(s) Location. Outdoor opening(s) shall be located in accordance with the

Outdoor Combustion Air section.

Outdoor Opening(s) Size. Outdoor opening(s)

shall be calculated in accordance with the following:

- The ratio of the interior spaces shall be

the available volume of all communicating spaces divided by the required

volume.

- The outdoor size reduction factor shall

be 1 minus the ratio of interior spaces.

- The minimum size of outdoor opening(s) calculated in accordance with the

above outdoor air section multiplied by

the reduction factor. The minimum

dimension of air openings shall not be

less than 3 in.

Vent System

The PERFORMANCE is designed to vent

as a Category I appliance using standard

gas vent or, as a Category III appliance,

which requires a special vent system.

Category III Venting is described as a vent

system that has a positive static pressure

and a flue temperature that avoids excessive condensate within the vent.

10

Combustion Air and Venting

Equipment Located in Confined

Spaces; All Air from Outdoors

Through Ventilated Attic

Fig. 3:

Equipment Located in Confined

Spaces; All Air from Outdoors

Fig. 4:

Page 18

11

Combustion Air and Venting

Do not install the PERFORMANCE into

a common vent with other gas appliances

when venting as a Category III appliance.

This may cause flue gas spillage or appliance malfunction, resulting in possible

severe personal injury, death or substantial property damage.

Removal of an Existing Boiler from a

Common Vent System

For installations in which the PERFORMANCE is installed as a category I

Appliance and is replacing an existing

boiler / hot water heater system, connected to a common vent system with other

appliances, the following steps shall be

conducted with each remaining appliance

connected to the common venting system:

1. Any unused openings in the common

venting system must be sealed.

2. A visual inspection of the venting system must be conducted for proper sizing and horizontal pitch. The inspection should ensure no blockage or

restriction is within the vent system,

and there is no leakage, corrosion or

other items, which could cause an

unsafe condition.

3. To adequately test the venting system,

close all exterior doors and windows

and all doors between the area containing the remaining appliances connected

to the common vent system and other

areas of the building. Turn on any

clothes dryers and any other gas appliance not connected to the common vent

system. Turn on all exhaust fans, i.e.

range hoods and bathroom exhaust

fans, preferably at maximum speed.

Close any fireplace dampers.

4. Place in operation the first appliance

being inspected that is connected to the

common vent system. The remaining

appliances should not be in operation.

Follow the appliance’s lighting instructions and adjust the thermostat to allow

the appliance to operate continuously.

5. Test for spillage at the draft hood relief

opening after 5 minutes of main burner

operation. Spillage can be detected

using the flame of a match or candle or

with smoke from a cigarette.

6. Once it has been determined that each

remaining appliance connected to the

common vent system is properly vented, return doors, windows, exhaust

fans, fireplace dampers and any operating gas appliance to their previous condition.

Should any improper operation of the common

venting system be detected in the outline test,

the condition should be corrected so the vent

system conforms with the National Fuel Gas

Code, NFPA 54/ ANSI Z223.1 - latest edition.

Canadian installations must conform with

B149.1 or 149.2 Installation Code.

BEST PRACTICES

DANGER

Page 19

Unit Preparation

12

SECTION III - Unit Preparation

Handling Instructions

The PERFORMANCE is generally easier to

handle and maneuver once removed from the

shipping carton and pallet.

To remove the shipping carton and pallet:

a. Remove the shipping straps and open

the top of the carton to remove the

wood shipment insert.

b. Lift the carton over the unit to remove.

If ceiling height is limited, the carton

maybe cut open using care not to damage the exterior jacket of the unit.

c. Remove the front burner hood to pre-

vent damage prior to lifting the unit

from the shipping pallet.

When lifting or moving the unit do not

use the burner or its components as a

means of a handle. Hand-truck the unit

from the rear only.

d. Discard all packing materials.

Hydrostatic Pressure Test

Prior to permanently connecting water,

gas supply or electrical supply, perform

a pressure hydrostatic test of the outer

tank to ensure all piping connections

were not damaged during shipment.

Hydrostatic Test Preparation

1. Mount the circulator on the supply pipe as

shown in Figure 11 page 23.

2. Temporarily plug the primary return connections as shown in Figure 11 using a 1”

NPT pipe plug. Use pipe dope sparingly to

allow removal of the plugs upon completion of the test.

3. On the outlet flange of the circulator pipe

install a 1” NPT nipple and shut-off valve.

Use pipe dope sparingly to allow removal

of the fittings upon completion of the test.

To avoid getting water onto the unit

and/or surrounding area, additional piping from the shut-off to a catch bucket or

drain may be required.

4. Connect a hose to the primary circuit drain

valve located per Figure 45 page 70, Item 2

and connect the other end to a fresh water

supply. Ensure the hose can be used as a

drain hose upon completion of the test.

Hydrostatic Test Procedures

1. Open the shut-off valve installed on the

outlet flange of the circulator.

2. Open the fresh water supply valve and then

open slowly the primary circuit drain valve

to fill the outer tank with water.

3. When the water within the outer tank

reaches the shut-off on the primary supply,

close the primary circuit drain valve.

4. Close the shut-off valve, on the top of the

circulator.

5. Slowly reopen the primary circuit drain

valve until the test pressure on the temperature / pressure gauge reaches 10 psig

maximum. Close the primary circuit drain

valve and fresh water supply valve.

To prevent damage to the inner tank the

test pressure must not exceed 10 psig.

6. Allow the test pressure to remain for 10

minutes.

CAUTION

NOTICE

BEST PRACTICES

WARNING

Page 20

Unit Preparation

Do not leave the unit unattended while

pressurized. A cold water fill could

expand and cause excessive pressure,

resulting in severe personal injury, death

or substantial property damage.

7. Ensure constant gauge pressure has been

maintained throughout the 10 minute test.

Check for leaks at all fitting joints. Repair

if found.

Leaks must be repaired immediately

when detected. Failure to repair leaks

can damage the unit, resulting in substantial property damage.

8. Check continuity using a voltmeter across

the terminals of the LWCO device. The

contacts on the LWCO should be closed.

See item 6 Figure 40 page 66 for location

of the LWCO.

Completion of Hydrostatic Test and Draining

1. Disconnect the fill hose from the fresh

water source and direct the hose to a suitable place of drainage.

2. Open the primary drain valve and completely drain the unit. To aid in draining open the

shut-off valve on the primary supply.

3. Remove the hose from the primary drain

valve when draining is complete.

4. Remove the plugs, nipple, shut-off valve

and any other piping unless they will

remain for use in the system piping.

WARNING

WARNING

13

Page 21

Domestic Piping

SECTION IV - Domestic Piping

General Piping Requirements

• All plumbing must meet or exceed all

local, state and national plumbing codes.

• Use pipe dope or tape suitable for

potable water.

• Use isolation valves to isolate system

components.

• Install unions for easy removal of the

PERFORMANCE from the system

piping.

Domestic Supply Pressure

For applications in which the domestic supply pressure exceeds 70 psig it is recommended to install a pressure reducing valve

on the cold water supply.

Maintaining the cold water supply at or

below 70 psig will prevent normal thermal

expansion from repeatedly forcing the T&P

relief valve open.

Thermal Expansion

If the cold water supply to the domestic

inner tank contains a backflow preventer,

check valve and / or a pressure reducing

valve, the installer must install a domestic

thermal expansion tank on the cold water

supply. (See Fig. 6 page 17)

Installing a thermal expansion tank will

prevent normal thermal expansion from

repeatedly forcing the T&P relief valve

open.

When installing a thermal expansion tank

ensure the charge pressure of the tank is

equal to the cold water supply pressure at

the point of installation. Consult the thermal expansion tank manufacturer’s instructions for further information on installation

and sizing.

The Temperature / Pressure relief valve

is not intended for constant duty, such as

relief of pressure due to normal thermal

expansion.

Water Hammer

Water hammer is the effect of sudden pressure changes occurring in the domestic piping. These pressure changes are typically

the result of “fast acting” positive shut-off

valves closing. These types of valves can

be typically found on dishwashers and

clothes washers.

The effects of water hammering can cause

damage to system components and tank

welds on the unit.

Installation of hammer arresters is recommended at these types of appliances, which

incorporate “fast-acting” positive shut-off

valves. Consult the manufacturer of water

hammer arresters for recommendation on

sizing and installation requirements.

Temperature / Pressure Relief Valve

The PERFORMANCE has a factory

installed Temperature / Pressure Relief

valve. Ensure the rating of the T&P relief

valve is correctly sized as follows per

AGA:

CAUTION

14

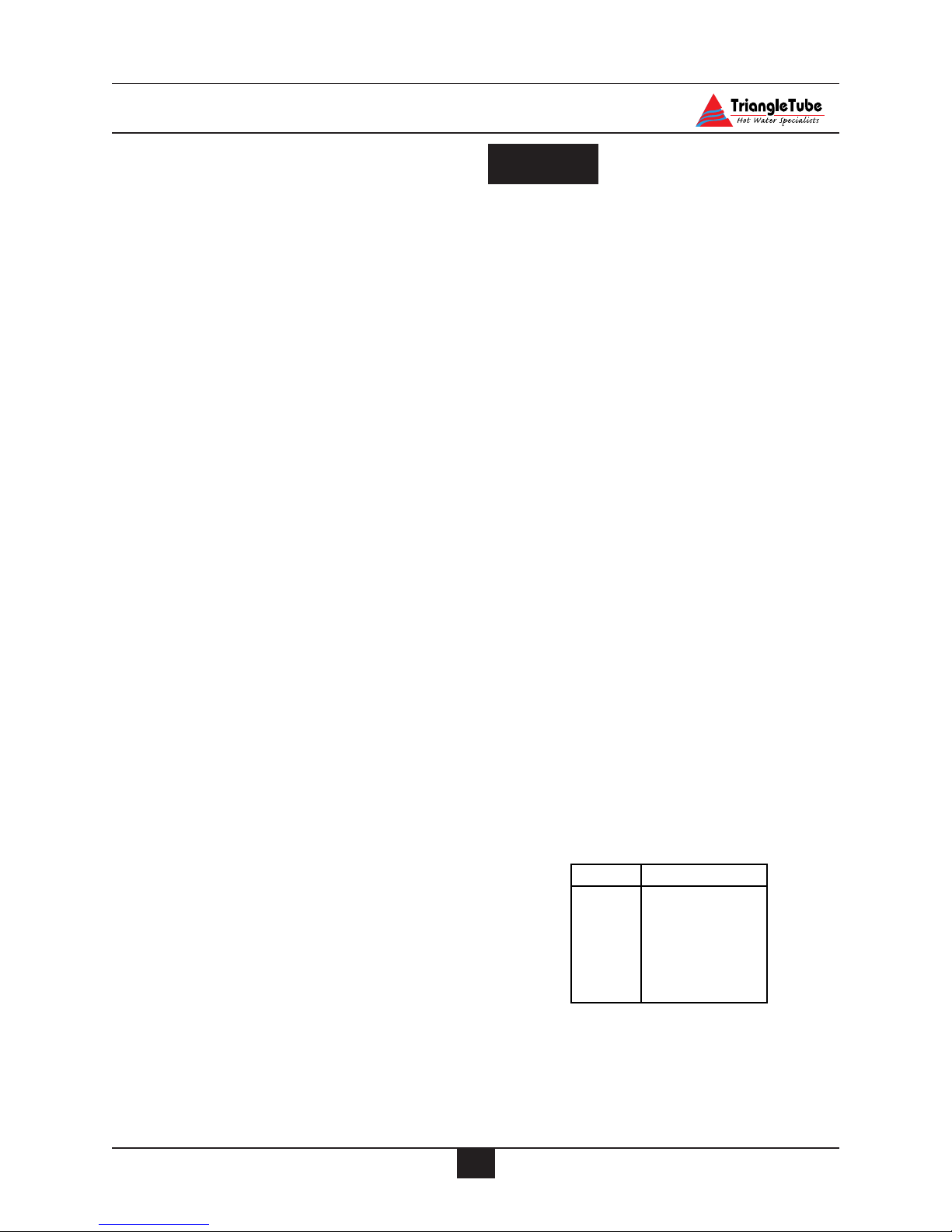

Model AGA Rating

PG-25 100,000 Btu/hr

PG-30 200,000 Btu/hr

PG-35 200,000 Btu/hr

PG-40 200,000 Btu/hr

PG-45 200,000 Btu/hr

Page 22

Domestic Piping

The installer must install discharge piping

onto the T&P relief valve. The discharge

piping must be:

• Made of material serviceable for temperatures of 250ºF or greater.

• Directed so that any hot water discharge flows away from all persons.

• Directed to a suitable place of drainage.

• Installed as to allow complete draining

of the T&P relief valve and the discharge piping.

•Terminated with a plain end, not with

threads.

Failure to properly direct the discharge

piping of the T&P relief valve may result

in flooding of the area adjacent to the

unit and or lower floors in the structure

causing substantial property damage.

The installer must not install the T&P

relief valve discharge piping in a manner

that is:

• Excessively long: Using more than 2

elbows and/or 15 feet of discharge piping can reduce the discharge capacity.

•Terminated directly into a drain: The

discharge piping must terminate within

6 inches of the drain. Check with local

plumbing codes for termination guidelines.

• The discharge piping is plugged, reduced

in size or restricted in any manner.

• The discharge piping is subject to freezing.

DO NOT install any valves between the

T&P relief valve and the discharge piping. DO NOT plug the T&P relief valve

or the discharge piping. Improper placement and piping of the T&P relief valve

can cause severe personal injury, death

or substantial property damage.

Thermostatic Mixing Valve

The PERFORMANCE contains a factory

installed thermostatic mixing valve with builtin check valve.

The operating range of the thermostatic mixing

is 90ºF to 120ºF.

For applications with a domestic recirculation

loop, the recirculation pump should be controlled by an aquastat. The maximum recommended setting of the aquastat is 10ºF lower

than the thermostatic mixing valve setting.

For proper operation of the thermostatic

mixing valve and to prevent potential

scalding hazards, the recirculation loop

should be controlled by an aquastat. DO

NOT use continuous recirculation.

U-Tube Assembly

The PERFORMANCE is supplied with a

U-Tube Assembly that directs cold water to

the thermostatic mixing valve.

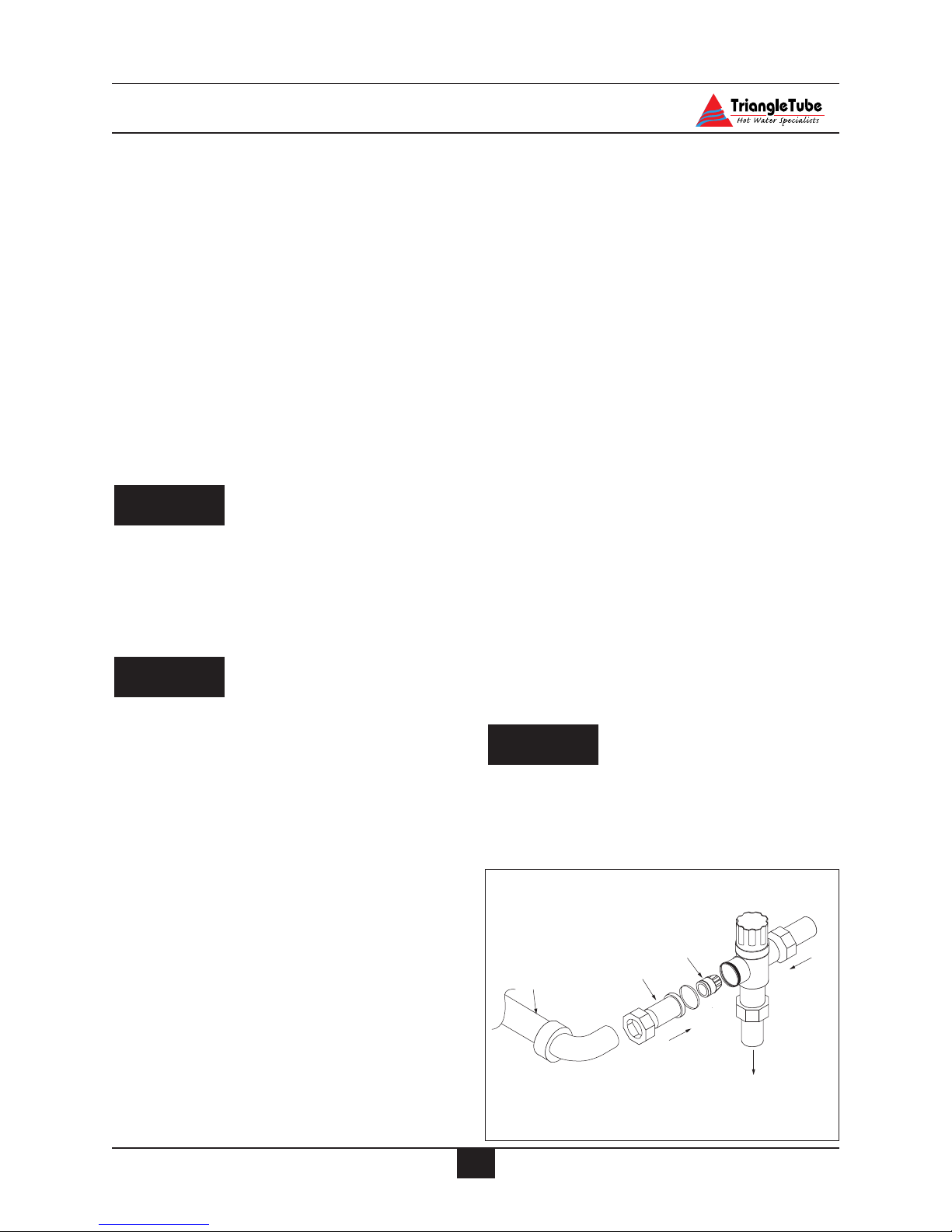

To install the U-Tube Assembly the

installer must:

1. Disconnect the cold inlet adapter/union

from the thermostatic mixing valve.

2. Use needle-nose pliers to remove the

plastic check valve assembly from the

adapter.

DANGER

WARNING

CAUTION

15

Page 23

16

Domestic Piping

3. Solder the U-Tube Assembly onto the

adapter. (See Fig. 5)

4. Once the adapter has sufficiently

cooled, re-insert the check valve assembly making sure of orientation and

reconnect onto the mixing valve.

If the installation of the PERFORMANCE

requires domestic hot water for a commercial dishwasher, the installer may insert a

tee connection between the unit and the

mixing valve to provide 140ºF domestic

hot water. The installer must reference

local plumbing codes to ensure if this type

of application is permissible.

The thermostatic mixing valve MUST be

installed and utilized on the PERFORMANCE. Removal of the thermostatic

mixing valve will result in severe personal injury or death.

The manual valve on the U-Tube assembly must remain in the full open position

for proper operation of the thermostatic

mixing valve.

Domestic Drain Valve

- The installer must install a drain valve

and drain leg as shown in Fig. 6 page 17

or Fig. 7 page 18.

- The drain valve should be positioned

close to the floor to aid in the siphon

action required to drain the inner tank.

Multiple Units Installation

For applications using multiple units the

domestic piping should be piped using a balanced manifold arrangement.

The installer should remove the thermostatic

mixing valve from the units and install a single

thermostatic mixing valve at the outlet of the

hot water manifold. The thermostatic mixing

valve should be sized according to the required

flow rate and pressure drop. Refer to the thermostat mixing valve manufacturer specification and installation instructions for more

details.

Reference Fig. 8, page 18 for piping diagram.

Storage Tank Application

For applications requiring large volumes of

domestic hot water in a relative short period,

the installer may include a storage type tank

(see Fig. 9 page 19) in the domestic piping.

The installer must:

1. Relocate the thermostatic mixing valve

from the PERFORMANCE to the outlet of the storage tank.

2. Provide recirculation from the storage

tank back to the PERFORMANCE

using a bronze type circulator.

Maximum recommended flow rate is 5

to 10 gpm.

This can be accomplished through the

drain connection if a 3rd tapping is

unavailable and the circulator should be

controlled by an aquastat.

NOTE

CAUTION

DANGER

Fig. 5: Mixing Valve Assembly

U-Tube Assembly

Adapter

Check Valve

Cold

Mixed

ot

H

Page 24

17

Domestic Piping

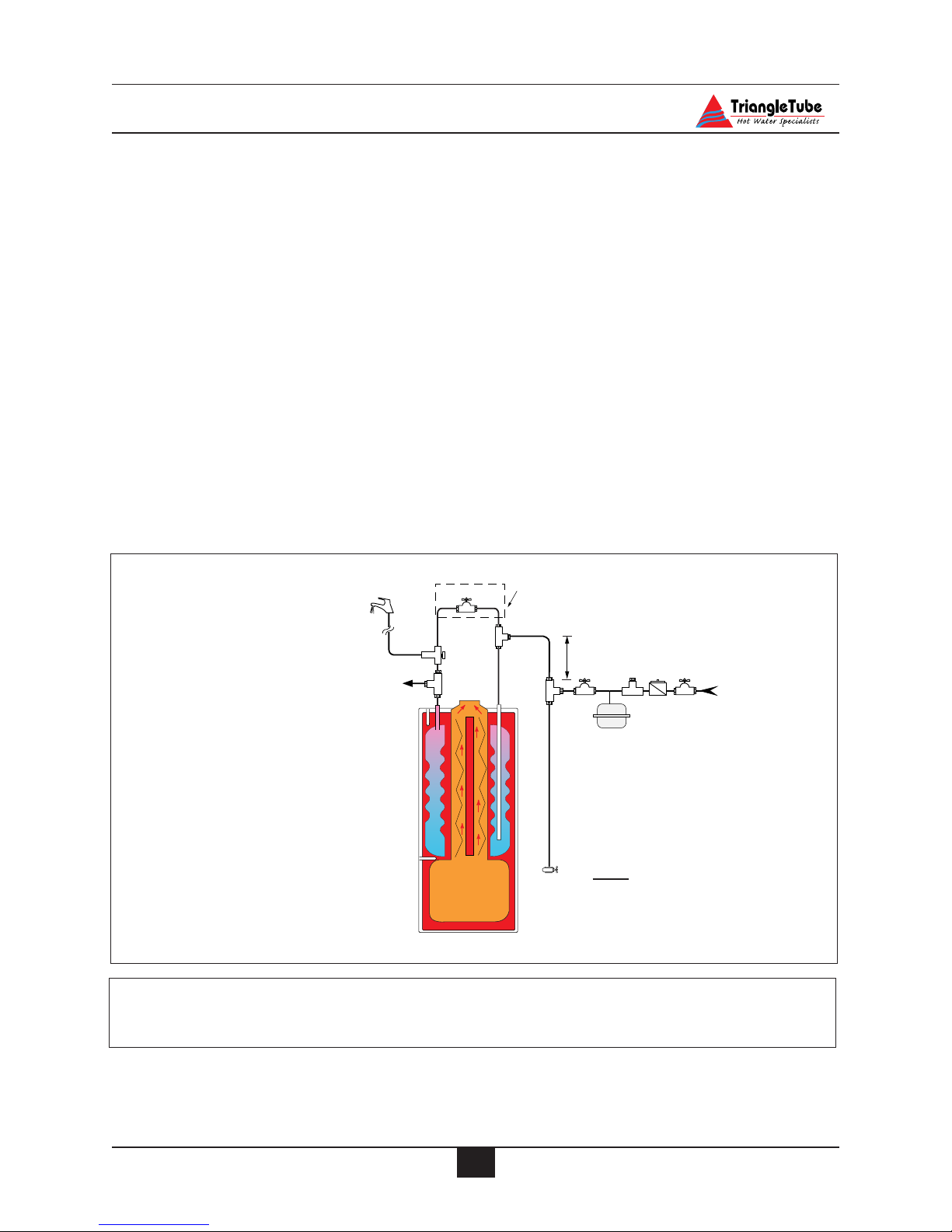

Fig. 6: PERFORMANCE Without

Recirculation

Note: All shut off valves shown in

this figure must be shut when siphon

draining the PERFORMANCE

Domestic Piping Diagrams

1. Mixing valve with check valve

3. Shut off valve

4. Backflow preventer or pressure reducing valve*

6. Thermal expansion tank

8. Domestic drain valve

9. Vacuum breaker*

* Optional devices may be required by local Codes

TR/SMART Series Application

For applications requiring large volumes of

domestic hot water over an extended period,

the installer may include a Triangle Tube

TR/SMART Indirect Water Heater in conjunction with the PERFORMANCE. (See Fig. 10

page 19)

The domestic system recirculation, if used, is

directed to the TR/SMART Series Tank. The

circulator should be controlled by an aquastat.

The primary piping to the TR/SMART Series

tank must comply with the piping methods

details in SECTION V - Primary Piping or with

other recognized piping methods.

Additional information regarding domestic and

primary piping can be found in the TR/SMART

Installation Manual.

U-Tube assembly

3

Re-attach valve handle

when draining inner tank

To dishwasher if

permitted by codes

1

8

12" Heat trap

3

9

4

6

3

Cold water

inlet

Page 25

18

Domestic Piping

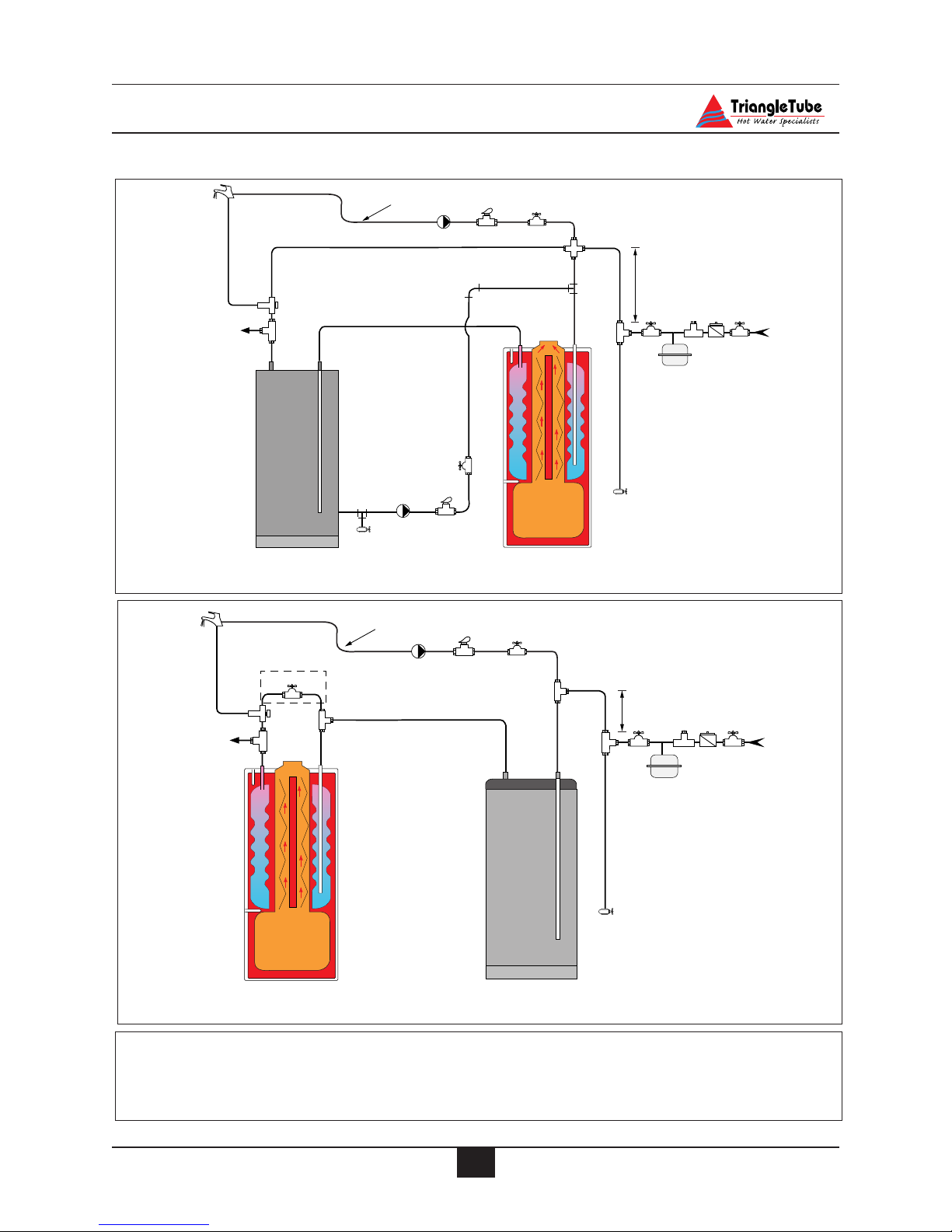

Fig. 7: PERFORMANCE With

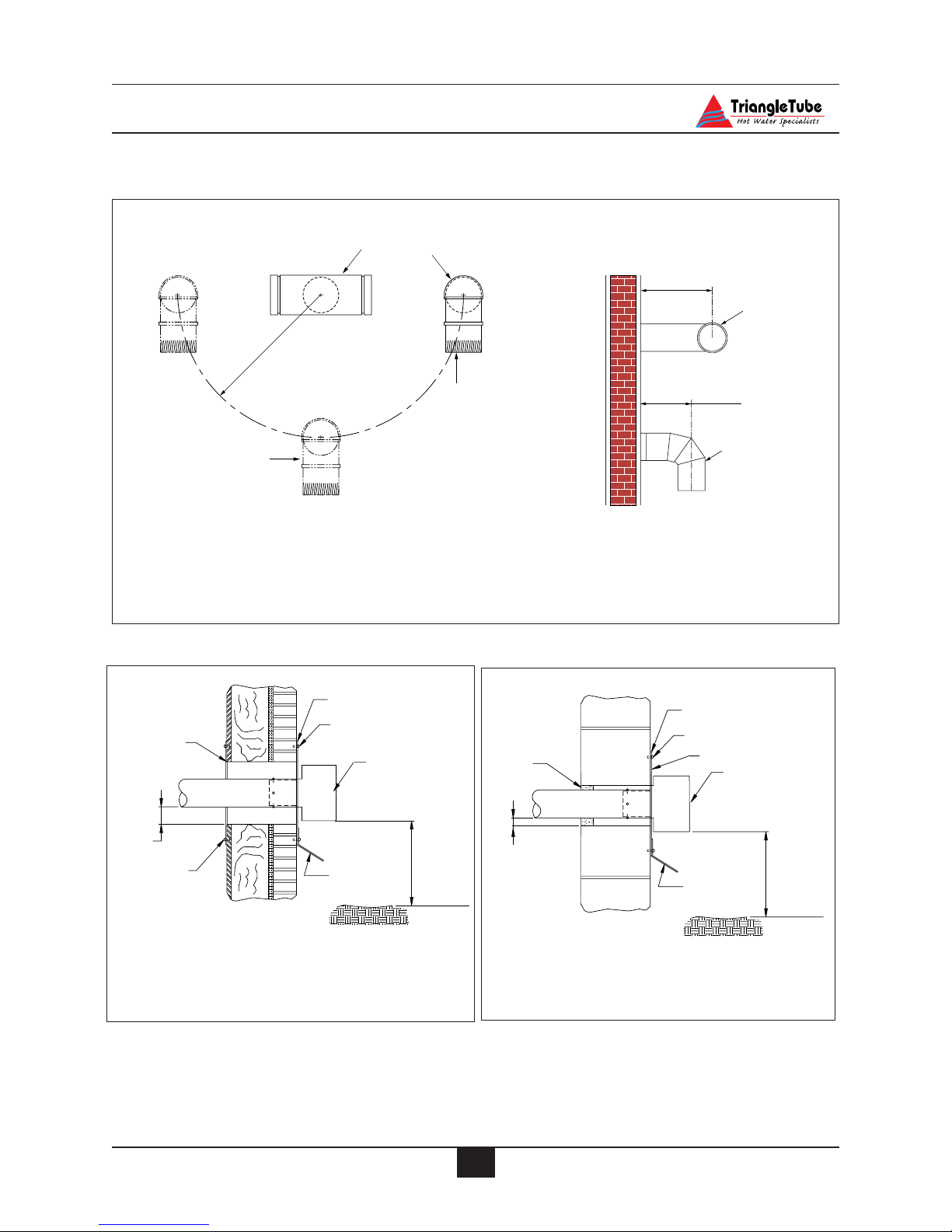

Recirculation

1. Mixing valve with check valve

2. Flow check valve

3. Shut off valve

4. Backflow preventer or pressure reducing valve*

6. Thermal expansion tank

7. Circulator (controlled by aquastat)

8. Domestic drain valve

9. Vacuum breaker*

Note: All shut off valves

shown in this figure must be

closed when siphon draining

the PERFORMANCE

* Optional devices may be required by local Codes

Fig. 8: Multiple Units Installation With Recirculation

Optional recirculation

7

To dishwasher if

permitted by codes

U-Tube

3

2

1

assembly

3

*

12" Heat trap

3

8

9

4

6

3

Cold water

inlet

7

1

2

3

12" Heat trap

3

8

4

9

6

inlet

Cold water

3

Page 26

19

Domestic Piping

Fig. 10: PERFORMANCE with TR/SMART Indirect Water Heater

Fig. 9 : PERFORMANCE with Storage Tank

1. Mixing valve with check valve

2. Flow check valve

3. Shut off valve

4. Backflow preventer or pressure reducing valve*

6. Thermal expansion tank

7. Circulator (controlled by aquastat)

8. Domestic drain valve

9. Vacuum breaker*

Domestic Piping Diagram

* Optional devices may be required by local Codes

Optional recirculation line

7

1

To dishwasher if

permitted by codes

2

7

8

Optional recirculation line

3

7

3

2

12" Heat trap

Cold water

3

6

3

8

3

2

3

9

4

inlet

1

To dishwasher if

permitted by codes

12" Heat trap

3

8

4

6

inlet

Cold water

3

9

Page 27

20

Primary Piping

SECTION V - Primary Piping

General Piping Requirements

Low Water Cutoff Device

- The PERFORMANCE is equipped with a

factory installed pressure switch style

Low Water Cut Off device.

- The minimum operating system pressure

allowable with this device is 10 psig.

- Check local codes which require a low

water cutoff device for compliance of

this device.

Backflow Preventer

- Use a backflow preventer valve in the

make-up water supply to the unit as

required by local codes.

Primary System Piping Applications

All piping applications shown in this installation manual utilize a primary/ secondary

piping arrangement. This method is recommended as a means to provide priority

to the production of domestic hot water.

For other piping arrangements, consult the

Engineering Department at Triangle Tube

or consult other approved/recognized

design arrangements.

On piping applications utilizing a single

zone or other recognized piping design

arrangements, it is recommended the

installer uses flow/check valves with

weighted seats at or near the appliance to

prevent gravity circulation.

To prevent potential outer tank failure,

the primary system piping must be a

“closed” loop sytem to avoid any oxygen

contamination of the boiler water.

Expansion Tank and Makeup Water

Ensure the expansion tank is properly sized

for the outer tank volume (20 gallons) and

the system volume and temperature.

Undersized expansion tanks will cause system water to be lost through the pressure

relief valve and cause additional makeup

water to be added to the system. Eventual

primary tank failure can result due to this

excessive makeup water addition.

The expansion tank must be located as

shown in Figure 11, 11A or 11B page 23 or

as per recognized design methods. Refer to

the expansion tank manufacturer instructions for additional installation details.

Connect the expansion tank to an air separator only if the air separator is located on

the suction side (inlet) of the system circulator. Always locate and install the system

fill connection at the same location as the

expansion tank connection to the system.

Diaphragm (Bladder) Expansion Tank

Always install an automatic air vent on the

top of the air separator to remove residual

air from the system.

Closed-Type (Standard) Expansion Tank

It is recommended to pitch any horizontal

piping toward the expansion tank 1 inch per

5 feet of piping. Use 3/4” piping for the

expansion tank to allow air within the system to rise.

CAUTION

NOTICE

BEST PRACTICE

BEST PRACTICE

Page 28

21

Primary Piping

For proper operation of the expansion tank

and system, remove the factory installed

automatic air vent from the PERFORMANCE and plug the connection. (See

Item 10, Fig. 46 page 70)

DO NOT install automatic air vents on a

closed-type expansion tank system. Air

must remain in the system and be

returned to the expansion tank to provide an air cushion. An automatic air

vent would cause air to be vented from

the system resulting in a water-logged

expansion tank.

Circulator

The PERFORMANCE is supplied with a

circulator that is pre-wired to allow for

domestic priority. Locate the circulator in

the return or supply piping as shown in the

piping diagrams included in this manual.

Closet (Zero Clearance) Applications

For applications in closets or zero clearances, the installer may use the upper primary connection shown as Item 4 on page 70 as

a primary return connection. The air elimination, expansion tank and make-up water

system should then be piped directly into the

primary loop of the space heating prior to

the system circulator.

Sizing Primary Piping

See Figs: 12 through 15, pages 24 - 25, for

recommended piping arrangements based

on various applications. In all diagrams,

the space heating system is isolated from

the PERFORMANCE using primary / secondary piping connections.

Size the piping and system components

required in the space heating system using

recognized design methods.

System Piping - Zone Circulators

Connect the PERFORMANCE to the system piping as shown in Fig. 12 page 24

when zoning with zone circulators. The

circulator supplied with the PERFORMANCE should not be used for a heat

zone. It must supply only the primary loop.

Install a separate circulator for each zone of

space heating.

To control the zone circulators refer to Fig.

34, page 47.

To ensure adequate flow rate through

the PERFORMANCE, maintain a minimum 1 inch diameter on the system piping connecting the unit to and from the

primary / secondary connection.

System Piping - Zone Valves

Connect the PERFORMANCE to the system piping as shown in Fig. 13 page 24

when zoning with zone valves. The primary / secondary piping ensures the priority is

given to the production of domestic hot

water.

To control the system circulator refer to

Fig. 33, page 46.

To ensure adequate flow rate through

the PERFORMANCE, maintain a minimum 1 inch diameter on the system piping connecting the unit to and from the

primary / secondary connection.

NOTICE

NOTICE

CAUTION

Page 29

22

Primary Piping

System Piping - Radiant Heating with Mixing

Valve

Connect the PERFORMANCE to the system

piping as shown with a radiant system using

a thermostatic mixing valve as shown in Fig.

14 page 25. The primary / secondary piping

ensures sufficient return temperature to the

PERFORMANCE.

If the radiant system tubing contains no

oxygen barrier, a stainless steel heat

exchanger must be used. Failure to

install a heat exchanger could lead to

premature failure of the outer tank and

void any warranty claim.

Radiant heating system piping should

include a means of regulating the boiler

return water. The return water temperature to the unit should be maintained at

130ºF or higher. Failure to prevent low

return water temperature to the unit

could cause premature failure of the unit

and it’s burner system resulting in severe

personal injury, death or substantial

property damage.

Size the heating system piping and circulator to provide the flow needed for the radiant

system.

To control the zone circulators reference

Figure 34, page 47.

To ensure adequate flow rate through

the PERFORMANCE, maintain a minimum 1 inch diameter on the system piping connecting the unit to and from the

primary / secondary connection.

System Piping - Multiple Units Installation

Use a balance manifold system as the primary / secondary connection to the space

heating piping as shown in Fig. 16 page 26.

Refer to Fig. 11 page 23 to install air elimination and expansion tank.

For the space heating piping refer to the

applications mentioned in this manual or

use recognized design methods.

NOTICE

WARNING

NOTICE

Page 30

23

Primary Piping

Near Appliance Piping

1. Appliance Circulator

2. Shut Off valve

3. Expansion tank

4. Auto fill valve

5. Tank fitting

6. Automatic air vent

7. Air Separator

8. Plug (by others)

To

system

From system

Supply

flow

Return

flow

Cold Water

fill supply

2

1

7

6

8

2

12"

Max.

3

42

2

2

Fig. 11 : Near Appliance Primary

Piping with a Diaphragm

Type Expansion Tank

Fig. 11A : Near Appliance Primary

Piping with Closed Type Expansion Tank

Fig. 11B : Near Appliance Primary Piping

with Diaphragm - Type Expansion

Tank (Alternate Circulator Location)

3

To

system

2

Supply

flow

12"

Max.

2

6

2

7

8

3

4

From system

2

Cold Water

fill supply

To

system

Supply

flow

12"

2

Max.

2

1

2

2

Return

flow

5

4

7

8

Cold Water

2

fill supply

From system

Return

flow

2

1

Page 31

24

Primary Piping

Fig. 12: Primary piping - Zoning with Circulators

Fig. 13: Primary Piping - Zoning with Zone Valves

1. Appliance circulator

2. Shut-off valves

3. Flow check valve

4. Zone valve

5. System purge valve

6. System circulator

Note: See page 23 for near appliance piping.

• Install balancing valves to

adjust flow to distribute

heat to all zones

• Size primary piping for

total flow of all circulators

• Size each circulator to

individual circuit requirements

• Install balancing valves to

adjust flow to distribute

heat to all zones

6

3

2

2

1

12" max.

2

5

2

2

L

O

A

D

2

6

3

2

L

O

A

D

2

6

2

1

12" max.

2

4

5

4

2

2

L

O

A

D

2

L

O

A

D

2

Page 32

25

Primary Piping

Fig. 14: Primary Piping - Low Temperature Radiant System

Note: Adjust system temperature

valve to establish maximum supply/return temperature differential of 30ºF and a minimum

130ºF return water temperature

to the PERFORMANCE

1. Appliance circulator

2. Shut Off valves

3. Flow check valve

4. Zone valve

5. Purge valve

6. System circulator

7. 3-way mixing valve

8. System Temperature valve (See note above)

Fig. 15: Primary Piping - Multi Temperature System

2

LOAD

6

HMC

3

8

1

5

2

27

5

2

2

12" Max.

1

12" Max.

12" Max.

2

8

2

6

2

H

6

2

Baseboard

Load

3

7

C

2

M

2

6

Radiant

3

3

Air Handler

Load

Load

Page 33

26

Primary Piping

1. Appliance Circulator

2. Shut Off Valves

3. Flow Check Valve

4. System Circulator

Fig. 16: Primary Piping - Multi Units Installation

System

From the

12"

Max.

4

Recommended placement

of expansion tank and

make up water supply.

s

a

h

-

P

I

I

I

e

s

2

3

1

n

o

t

t

u

B

h

s

u

P

R

o

T

s

a

h

-

P

I

I

I

e

I

I

I

e

a

h

P

h

c

t

i

w

S

t

e

s

e

I

I

I

e

s

a

h

P

h

P

-

h

a

s

e

I

I

I

P

h

a

s

e

I

I

I

-

P

-

h

a

s

e

I

I

h

a

s

e

I

I

I

-

S

p

e

a

a

c

t

e

i

n

g

-

D

o

m

e

s

t

i

c

Hot Water Specialists

TriangleTube

S

p

h

e

a

a

c

t

e

i

n

g

I

-

P

D

o

m

e

s

t

i

c

Heating

Primary

Primary

Temperature/Pressure

Heating

Domestic

To the System

2

S

p

h

e

a

a

c

P

-

t

h

e

I

I

a

i

I

s

n

e

e

s

g

I

a

I

I

h

-

-

P

I

I

I

P

D

h

e

o

a

s

s

m

a

e

h

P

I

I

I

-

e

s

Heating

t

i

Primary

c

Primary

2

3

1

Temperature/Pressure

n

h

o

c

t

t

t

i

u

w

B

S

t

h

e

s

s

u

e

P

R

o

T

Hot Water Specialists

TriangleTube

S

p

h

e

a

a

c

P

-

t

h

e

I

I

a

i

I

s

n

e

e

s

g

I

a

I

I

h

-

-

P

I

I

I

P

D

h

e

o

a

s

s

m

a

e

h

P

I

I

I

-

e

s

t

Heating

i

c

Domestic

2

S

p

h

e

a

a

c

P

-

t

h

e

I

I

a

i

I

s

n

e

e

s

g

I

a

I

I

h

-

-

P

I

I

I

P

D

h

e

o

a

s

s

m

a

e

h

P

I

I

I

-

e

s

Heating

t

i

Primary

c

Primary

2

3

1

Temperature/Pressure

n

h

o

c

t

t

t

i

u

w

B

S

t

h

e

s

s

u

e

P

R

o

T

Hot Water Specialists

TriangleTube

S

p

h

e

a

a

c

P

-

t

h

e

I

I

a

i

I

s

n

e

e

s

g

I

a

I

I

h

-

-

P

I

I

I

P

D

h

e

o

a

s

s

m

a

e

h

P

I

I

I

-

e

s

t

Heating

i

c

Domestic

2

Page 34

27

Venting and Combustion Air Installation

SECTION VI - Venting and Combustion

Air Installation

General Requirements - Category I

The venting system must be installed in accordance with:

- NFPA 54 National Fuel Gas Code, ANSI

Z223.1.

- NFPA 211 Standard for Chimneys, Vent

and Solid Fuel Burning Appliances.

For installations in Canada the venting system

must be installed in accordance with:

- CGA / B149 Installation Code for Gas

Burning Equipment.

- Prior to installing the appliance into an

existing chimney or venting system, the

vent system should be inspected for

condition and obstructions.

If the inspection reveals the vent system

is not safe for the intended use, it shall be

repaired, rebuilt, lined, relined or

replaced with a vent or chimney to conform to NFPA 211, latest edition. Failure

to conduct such an inspection and/or

repair could result in severe personal

injury, death or substantial property

damage.

- No portion of the venting system shall

extend into or pass through any circulating air duct or furnace plenum.

- The gas venting system shall be

installed, in accordance with their listings and the manufacturer’s instructions.

Masonry and Metal Chimneys

- The NFPA code book severely limits the

installation of the PERFORMANCE into

a masonry chimney. For applications

using either interior or exterior masonry

chimney a listed, approved metal chimney lining system should be used.

For any applications using an exterior

chimney it is recommended that an insulated or stainless steel chimney lining

system be used.

A chimney with one or more sides

exposed to the outside of the structure is

considered to be an exterior chimney.

- The chimney shall extend at least 5 feet

above the highest connected appliance

flue collar.

- The chimney shall extend at least 3 feet

above the highest point where it passes

through a roof of a building and at least

2 feet higher than any portion of a

building within a horizontal distance of

10 feet.

Type B Vent Systems

- The vent system should terminate in

accordance with NFPA 54, latest edition, provided the termination is at least

8 feet from a vertical wall or similar

obstruction.

The Type B vent system shall extend in a

general vertical direction with offsets not

exceeding 45 degrees. A vent system

having not more than one 60 degree offset shall be permitted. Any angle greater

than 45 degrees is considered horizontal.

BEST PRACTICE

NOTICE

BEST PRACTICE

WARNING

Page 35

28

Venting and Combustion Air Installation

The total horizontal distance of a vent

plus the horizontal vent connector shall

not be greater than 75% of the vertical

height of the vent.

Vent Connectors

- When a vent connector must be located

in or pass through an un-conditioned

space, attic or crawl space, that portion

of the vent connector must be listed as

Type B or other approved material having equivalent insulation qualities.

- The minimum clearance to combustibles for single wall vent connectors shall be 6 inches.

- The minimum clearance to combustibles for Type B vent connectors

shall be 1 inch or per vent manufacturer’s instructions.

- The vent connector shall be installed in

a manner to avoid excessive turns or

other construction features that create

excessive resistance to the flow of the

vent gases.

- The vent connector should be installed

in a manner without any dips or sags

and should slope upward toward the

vent or chimney at least 1/4 inch per 1

foot.

- The location of the appliance should be

located as close to the vent or chimney

to maintain the vent connector length as

short as possible.

The maximum horizontal length allowable should not exceed 75% of the height

of the vent or chimney assuming no offsets in the vertical vent.

- The entire length of a vent connector

shall be readily accessible for inspection, cleaning and replacement.

- The diameter of the vent connector

should not be upsized more than two

sizes greater than the flue outlet diameter.

The minimum recommended vent connector given in Table 1 is only a general

guideline. The vent system must be

designed and installed in compliance

with all applicable codes. Failure to

properly size and install the vent system

could result in severe personal injury,

death or substantial property damage.

There are certain applications for the

PERFORMANCE in which upsizing the

vent connector to 5 inches will not result

in sufficient maximum capacity requirements. In these applications the

installer, after consultation with Triangle

Tube Engineering, may upsize the vent

connector to 6 inches provided the vent

connector and vent system are Type B.

Common Venting - Category I

The PERFORMANCE may be vented into a

common vent system using the guidelines and

sizing Tables of the National Fuel Gas Code

NFPA 54 ANSI Z223.1 latest edition.

The PERFORMANCE may also be vented into

a common multi story vent using the guidelines

and sizing Tables of the National Fuel Gas

Code NFPA 54 ANSI Z223.1 latest edition.

NOTICE

WARNING

BEST PRACTICE

BEST PRACTICE

PERFORMANCE Min. Recommended

Model Vent Connector

Diameter

PG-25/30 4 inches

PG-35/40/45 5 inches

TABLE 1: Vent Connector Diameter

Page 36

29

Venting and Combustion Air Installation

General Requirements - Category III

- Installation must comply with local

requirements and with the National

Fuel Gas Code, NFPA 54/ ANSI Z223.1

for U.S. installations and CSA B149.1

or B149.2 for Canadian installations.

- The PERFORMANCE requires a special vent system designed for pressurized venting and is rated as ANSI

Z21.13 Category III (pressurized vent

system, with flue temperature that

avoids excessive condensate within the

vent system).

- The PERFORMANCE may be direct

vented with outside combustion air or

non-direct vented using room air.

- The PERFORMANCE is approved for

the following vent manufacturers:

• Heat-Fab (Saf-T-Vent

®

)

• ProTech Systems (FasNSeal

®

)

• Flex-L (StaR-34)

• Z-Flex (Z-Vent III

™

)

DO NOT mix components from different

systems. The vent system could fail or

improperly seal, causing leakage of flue

products into the building.

Category III Vent Termination - Guidelines

Locate the vent termination for direct or nondirect vent applications using the following

guidelines:

1. The total equivalent length of the vent

should not exceed 100 feet as given in

Table 2, page 35.

2. The installer must consider the following

when determining the location of the vent

termination: