Page 1

PD-01

USER MANUAL

PROFIBUS-DP Module for

VFD Series Drives

ASIA

DELTA ELECTRONICS, INC.

TAOYUAN Plant/

31-1, SHIEN PAN ROAD,

KUEI SAN INDUSTRIAL ZONE

TAOYUAN 333, TAIWAN

TEL: 886-3-362-6301

FAX: 886-3-362-7267

http://www.delta.com.tw/acdrives

NORTH/SOUTH AMERICA

DELTA PRODUCTS

CORPORATION

Sales Office/

P.O. BOX 12173

5101 DAVIS DRIVE

RTP, NC 27709 U. S. A.

TEL: 1-919-767-3813

FAX: 1-919-767-3969

http://www.deltaww.com/acdrives

EUROPE

DELTRONICS (Netherlands)

B.V.

Sales Office/

Industriegebied Venlo Nr. 9031

Columbusweg 20

NL-5928 LC Venlo

The Netherlands

TEL: 31-77-324-1930

FAX: 31-77-324-1931

Page 2

PD-01 PROFIBUS-DP Module

Table of Contents

Preface ..............................................................................................................1

Chapter 1 Overview ...................................................................................... 3

Technical information.................................................................................... 4

Functionality .................................................................................................4

Chapter 2 Introduction ................................................................................. 5

PROFIBUS ................................................................................................... 5

PROFIBUS-DP .............................................................................................6

Chapter 3 Installation ................................................................................... 7

Installing the PD-01 ...................................................................................... 7

Removing the PD-01 .................................................................................... 9

PIN assignment of PROFIBUS-DP interface (DB9)......................................9

Terminator..................................................................................................... 9

Chapter 4 Communication ...........................................................................11

PROFIBUS address .....................................................................................11

Parameters setting in VFD series Drives......................................................11

Cyclical data of PD-01 via PROFIBUS-DP................................................... 12

Useful data structure as defined in PROFIDrive Profile 2.0....................12

Extended configuration...........................................................................12

Default settings of PZD structure............................................................ 13

Control and Status words .......................................................................13

Accessing parameters via PKW area .....................................................15

PKE ...............................................................................................15

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 3

PD-01 PROFIBUS-DP Module

IND ................................................................................................16

Parameter value (PWE) 3rd and 4th word ....................................16

Examples for PKW mechanism.....................................................17

Response time about PD-01 ........................................................................19

Chapter 5 User Parameters Setting in GSD file .........................................21

GSD file ........................................................................................................ 21

User parameters in GSD file......................................................................... 25

Chapter 6 Troubleshooting.......................................................................... 29

Troubleshooting via LED displays ................................................................ 29

Troubleshooting via diagnostic data ............................................................. 30

Troubleshooting via error codes ...................................................................31

Chapter 7 Dimensions.................................................................................. 33

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 4

PD-01 PROFIBUS-DP Module

Preface

Thanks for using DELTA PD-01 PROFIBUS-DP Module. Please read this manual carefully

prior to use the PD-01 to ensure its operation properly. Please keep this manual in handy

place for quick reference.

Getting Start

This manual is intended be used as an instruction manual and a reference guide.

Detailed description of PROFIBUS and DP protocol will not be covered here. If you are

interested in understanding and learning more about the PROFIBUS and DP protocol, we

recommend you study the related comprehensive literatures.

The content in this manual is based upon the most updated hardware and software

information that are published recently. Therefore, please understand no guarantee will

be given that no any discrepancy in this manual. Moreover, We reserve the right to modify

this manual without any written notice, or any obligation to notify the end users for

revision changes.

Copying or reproducing any part of this manual, without written consent of Delta

Electronics Inc. is prohibited.

WARNING

Failure to read, fully understand and implement the instructions contained in

this manual may result in damage the equipment, the drive or a possible of plant

personnel injury.

This equipment operates under higher voltages, to control of a running machine.

Only suitable qualified personnel familiar with the operation and construction of

the equipment are allowed for equipment operation, to prevent any damage or

hazard of this equipment.

A successful and safe operation of this equipment depends upon the proper

handling, storage, installation, operation and maintenance.

1

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 5

PD-01 PROFIBUS-DP Module

Receiving and Inspection

All Delta PD-01 have gone through rigorous quality control tests at the factory prior to the

shipment. Upon the receive of PD-01, please check that the package includes:

◆ 1pcs PD-01,

◆ 1pcs 8cm disc (mini size compact disc),

◆ 1pcs communication cable (for RJ11, 6 pins),

◆ 1 instruction sheet

Using this Manual

◆ This is the User Manual for PD-01.

◆ Chapter 1 describes the overview of PD-01

◆ Chapter 2 briefly describes the introduction to PROFIBUS and PROFIBUS-DP

◆ Chapter 3 introduces how to install and remove the PD-01

◆ Chapter 4 describes the communication with PROFIBUS-DP system

◆ Chapter 5 introduces GSD file and parameter settings in GSD file of PD-01

◆ Chapter 6 provides LEDs information, and corrective actions for problem

solving.

◆ Chapter 7 provides the dimensions of the PD-01

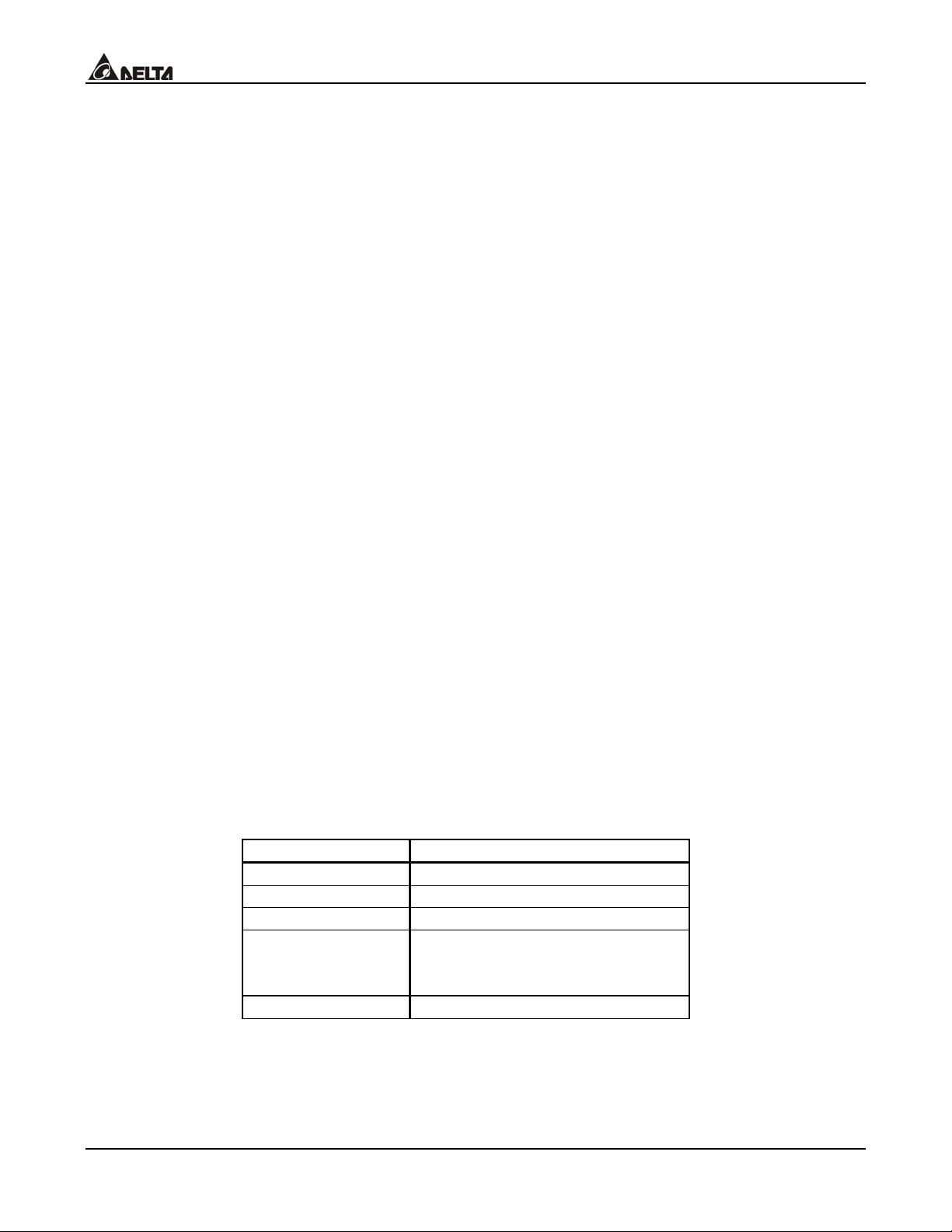

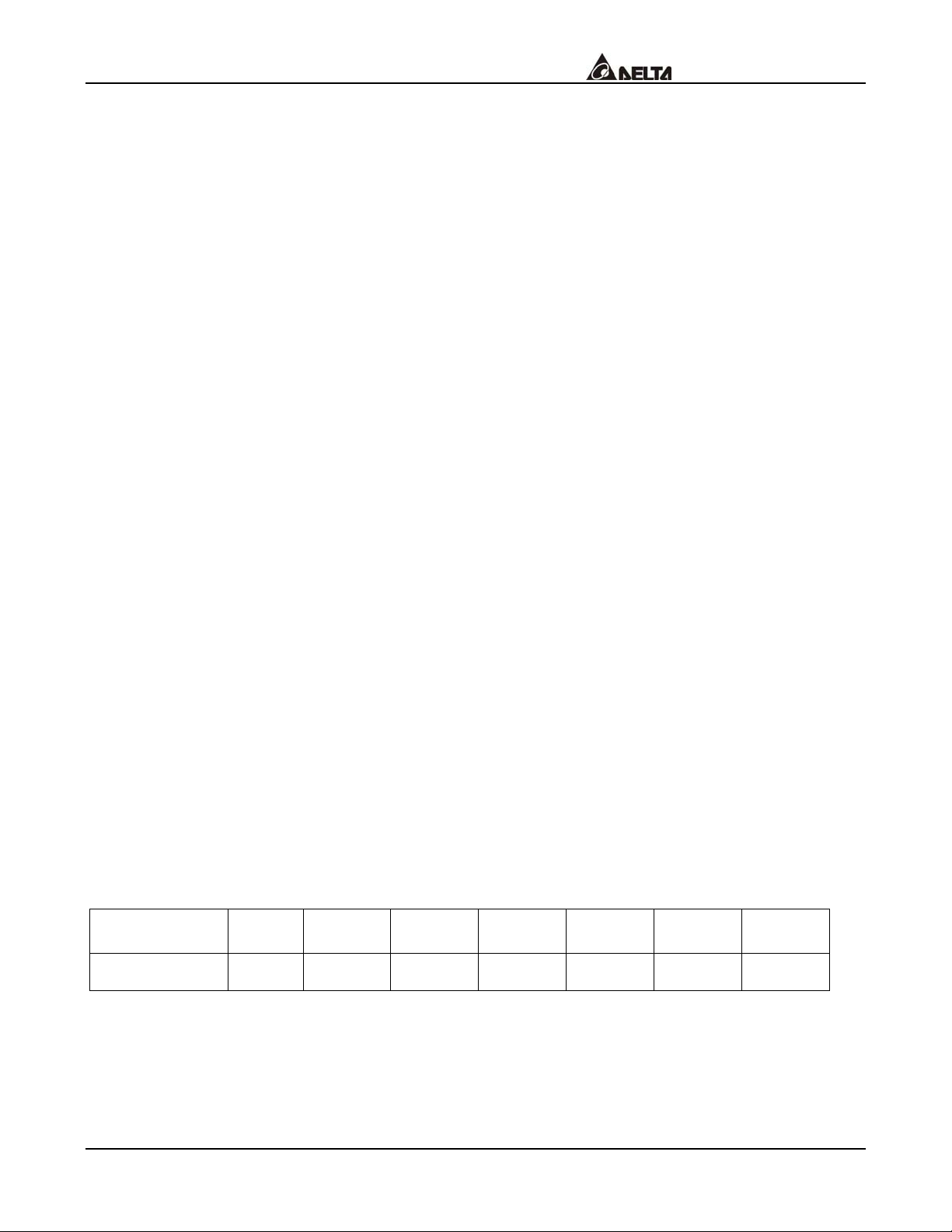

◆ Firmware version should conform with VFD Drives as table below:

Delta AC Drive Firmware Version

VFD-B Version 4.00 and above

VFD-M Version 3.00and above

VFD-F Version 1.09 and above

VFD-L

115V/200~400W

All Version

230V/200W~2HP

VFD-S All Version

2

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 6

PD-01 PROFIBUS-DP Module

Chapter 1 Overview

PD-01, defined as a communication module for PROFIBUS-DP, is used to link VFD series

Drives and PROFIBUS-DP system.

Screw Mounting Hole

SP LED

NET LED

Extended Socket

Address Switches

Profibus DP Interface (DB9)

RS-485 Interface (RJ11)

Screw Mounting Hole

SP LED: Indicating the connection status between Drives and PD-01

NET LED: Indicating the connection status between PD-01 and PROFIBUS-DP

Address Switches: Setting the address of PD-01 on PROFIBUS-DP network

RS-485 Interface (RJ11): Connecting to VFD Drives, and supply power to PD-01

PROFIBUS-DP Interface (DB9): 9-PIN connector that connects PD-01 to

PROFIBUS-DP network

Extended Socket: 4-PIN socket that connects PD-01 to PROFIBUS-DP network

Screw Mounting Hole: Used to mount PD-01

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

3

Page 7

PD-01 PROFIBUS-DP Module

Technical information

Two LEDs on PD-01 used to display the connection status of PD-01:

SP LED: indicating the connection status between PD-01 and VFD series Drives

NET LED: indicating the connection status between PD-01 and PROFIBUS-DP

% For more information of LEDs display, refer to Chapter 6. Troubleshooting.

The address in PROFIBUS-DP can be set via two rotary address switches, ADDH

and ADDL, on PD-01:

ADDH used as a high 4 bits of address, ADDL used as a low 4 bits of address.

% For more information of address switches, refer to Chapter 4. Communication.

A specific 6-PIN communication cable for RJ11, is used to connect the PD-01 to

VFD series Drives via RS-485 interface. VFD series Drives supply the 15V DC

power to PD-01 through this cable.

PROFIBUS-DP interface (DB9) uses a standard PROFIBUS-DP system interface.

We recommend users use the standard connector to connect PD-01 to

PROFIBUS-DP system. Besides, the PD-01 also provides a 4-PIN extended socket

for users to connect it to PROFIBUS-DP system based upon the requirements.

However, please pay attention to the assignment of A1, B1, and A2, B2 on the

4-PIN extended socket.

PD-01 supports baud rates of 9.6kbaud to 12Mbaud.

Functionality

Cyclical process data exchange (PZD).

Parameter accessing: cyclical accessing of parameters (PKW).

PROFIBUS supports the control commands SYNC and FREEZE for data

synchronization between master and slaves.

Support the configuration of data structure for data exchange with VFD series

Drives.

4

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 8

PD-01 PROFIBUS-DP Module

Chapter 2 Introduction

PROFIBUS

PROFIBUS is an international, vendor- independent, opening filed bus standard for a wide

range of applications in the fields of manufacturing, production, process and building

automation, and other automation control field.

The PROFIBUS family comprises three types of protocol, PROFIBUS-DP, PROFIBUS-PA and

PROFIBUS-FMS, each of them is used for different tasks:

PROFIBUS-DP (Decentralized Periphery): PROFIBUS-DP is a rapid and low cost

communication connection designed for high-speed data transmission at field level.

PROFIBUS-DP has widespread usage for such items as remote I/O systems, motor

control centers, and variable speed drives. It is designed and optimized especially for

communication between automation systems and decentralized peripheral devices.

PROFIBUS-PA (Process Automation): PROFIBUS-PA is the PROFIBUS solution for

process automation, typically with MBP-IS transmission technology. Based upon

PROFIBUS-DP, PROFIBUS-PA is an extension of the PROFIBUS-DP protocol for data

transmission. It is designed to support intrinsically safe applications and can be used

within hazardous areas, with high explosion risk using intrinsic safe MBP-IS interface.

PROFIBUS-PA is used to connect sensor and controller to the bus.

PROFIBUS-FMS (Fieldbus Message Specification): PROFIBUS-FMS is multiple

master communications designed for communication at the cell level. It is designed for

acyclic or cyclic data transfers at medium speed between control equipment and

cell-level controllers. FMS services open up a wide range of applications and offer a

wide range of functionality and flexibility.

The Maximum cable length in a segment depends on the transmission speed. PROFIBUS-DP

communicates at speeds from 9.6 Kbps to 12 Mbps over distances from 100 to 1,200 meters.

Baud Rate

(bps)

9.6K 19.2K 93.75K

187.5K 500K 1.5M 12M

Length (m) 1200 1200 1200 1000 400 200 100

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

5

Page 9

PD-01 PROFIBUS-DP Module

PROFIBUS-DP

PROFIBUS-DP is a PROFIBUS communication profile optimized for high-speed, time-critical

data transmission at field level using low-cost connections. PROFIBUS-DP is a suitable

substitute for conventional, costly parallel wiring of 24 V measurement signals in production

and manufacturing automation, as well as for analog 4(0) to 20mA measurement signals in

process automation.

6

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 10

PD-01 PROFIBUS-DP Module

Chapter 3 Installation

IMPORTANT NOTE:

Prior to the installation or remove the PD-01 from network, make sure the power of VFD

series Drives is switched off (not-energized).

Installing the PD-01

Improper installation of the PD-01 will cost its life usage. Please follow the instructions to

install your PD-01 carefully.

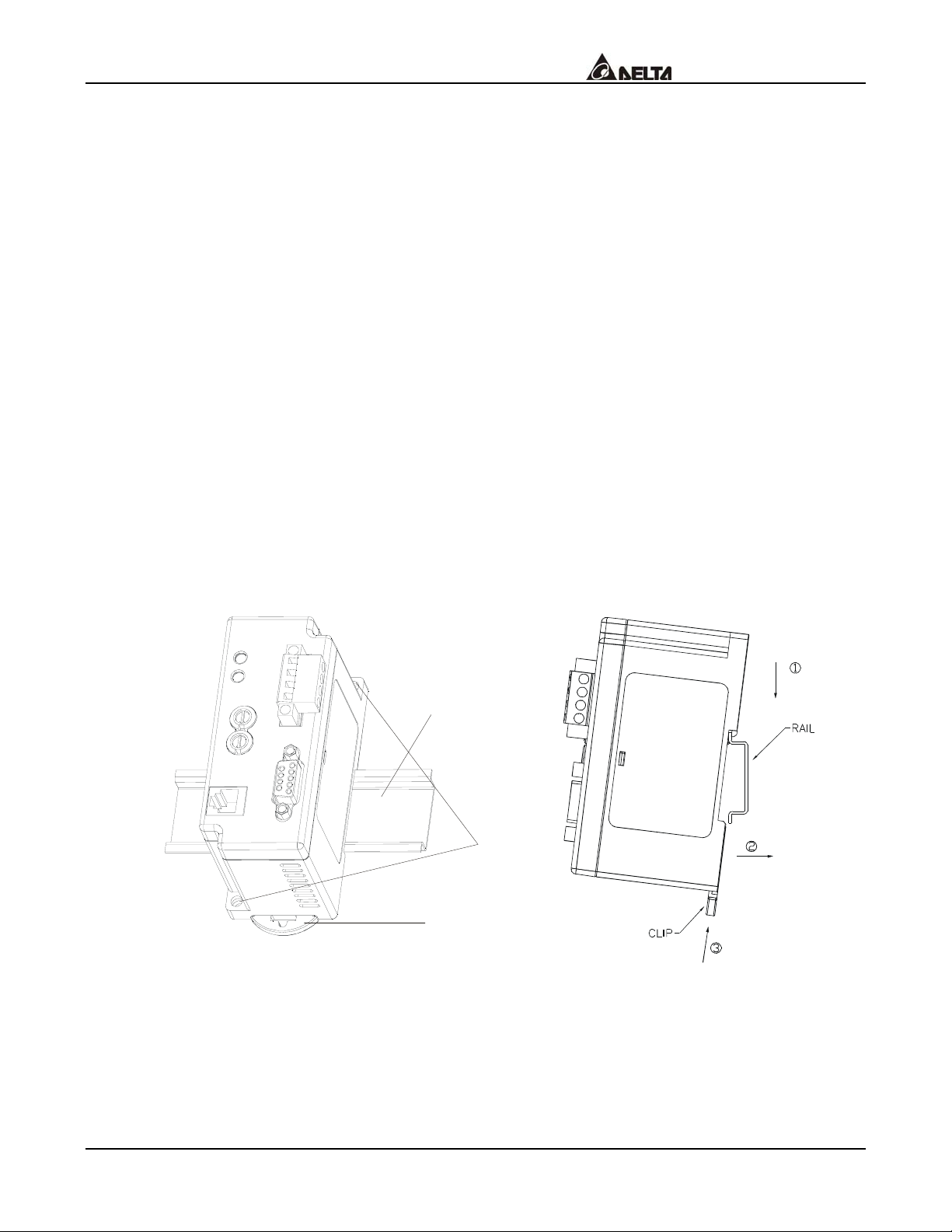

DIN Rail Installation

PD-01 can be secured by mounting to DIN rail. There is a small retaining clip locates at

the bottom of PD-01, place the PD-01 onto the DIN rail and gently push up on the clip to

ensure the PD-01 is mounted to the DIN rail.

Direct Mounting

Please use the specified M4 screws to install the PD-01. Also please ensure to tighten

them properly.

DIN RAIL

Screw

Mounting

Hole

CLIP

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

7

Page 11

PD-01 PROFIBUS-DP Module

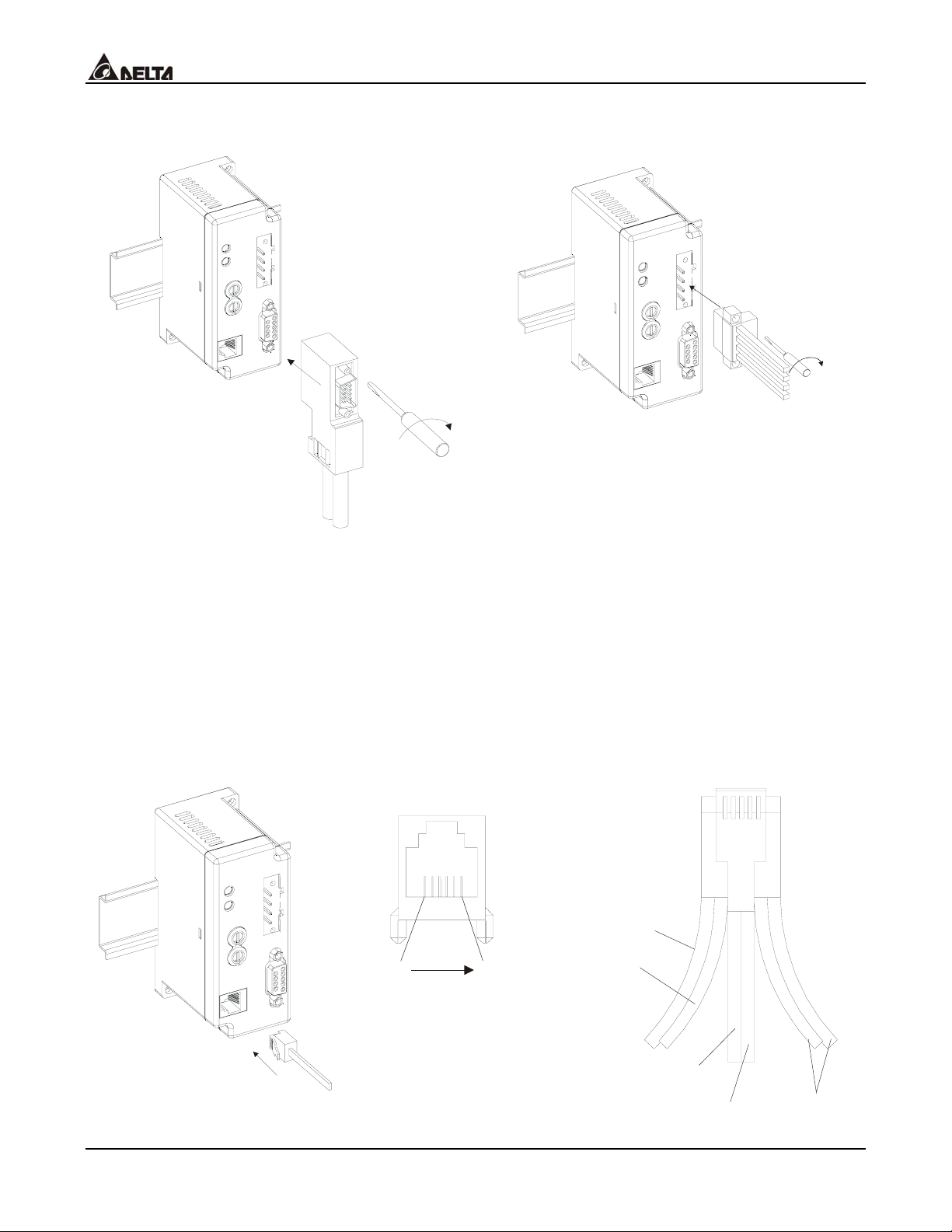

Insert the connector into the PROFIBUS-DP Interface (DB9), and tighten screws to

secure the connector in place.

Power Supply

The power of PD-01 is supplied from VFD series Drive. Firmware version should

conform the VFD series Drives as table listed in the page 2. No external power

needed. The +15VDC power is applied to PD-01 directly via a specific 6-PIN

communication cable (This 6-PIN cable is packed together with PD-01).

NOTE:

Though the PD-01 power is supplied from VFD series Drives, it will energized till power to

VFD series Drives is applied

RJ11

+15V

1

6

GND

1: +15V 2: GND

3: SG- 4: SG+

5: not used 6: not used

SG-

SG+

8

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Not used

Page 12

PD-01 PROFIBUS-DP Module

If the connection of PD-01 to VFD drives does not conform the table listed in page 2, users

need to provide external 15VDC supply the power to PD-01 (not through the communication

cable). Refer to the pin assignment of RJ11, it is allowed to supply power to PD-01 via RJ11.

PD-01 is energized while the power is applied to the VFD series Drives, then the SP

LED will be steady green.

Removing the PD-01

To remove the PD-01, users shall:

Remove the connection cable between PD-01 and VFD series Drives.

Loose the PD-01 screws and remove DP connector from PD-01.

Pull down on the retaining clip and pull out the PD-01 from DIN rail gently.

Pin assignment of PROFIBUS-DP interface (DB9)

Use PROFIBUS-DP interface (DB9) of PD-01 connecting PD-01 to PROFIBUS DP system.

The terminals are short-circuit-proof and isolated.

Pin Designation Meaning

9

5

1 - Not assigned

2 - Not assigned

3 Rxd/TxD-P Receive/send data P (B)

4 - Not assigned

5 DGND Data reference potential (C)

6 VP Supply voltage positive

6

7 - Not assigned

8 RxD/TxD-N Receive/send data N (A)

1

9 - Not assigned

Terminator

Bus terminator is important when connects PD-01 to PROFIBUS-DP system. This terminator

can be switched in and out via switches when the recommended bus connectors have been

used.

If extended 4-PIN socket for the connection is used, user may use the internal terminator

provided by PD-01 via setting the switch. If the switch is turned to "S" (Short), the internal

terminator is disabled, then A1 and A2, B1 and B2 are all normally close. If the switch is

turned to "R" (Resistor), the internal terminator between A1 and B1 is enabled, but A2 and B2

are disconnected from bus.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

9

Page 13

PD-01 PROFIBUS-DP Module

A2

A1 B1

B2

S

Terminator

switch for A1/B1

R

121ohm

When user uses the extend socket, the bus topology is as follows:

PLC

(master)

Red

Green

A1

B1

A2

B2

Green

Red

A1

B1

A2

B2

Green

Red

A1

B1

A2

B2

Green

Red

PD-01

VFD

series

Drive

PD-01

VFD

series

Drive

10

PD-01

VFD

series

Drive

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 14

PD-01 PROFIBUS-DP Module

Chapter 4 Communication

NOTE:

Before reading this chapter, make sure you read chapter 3 and understand the installation of

PD-01.

PROFIBUS address

PD-01 has two rotary switches to set the PROFIBUS address, the only way

for user to set the address.

The address switches, ADDH and ADDL, allow user to set the address in a

HEX format. ADDH is used to set high 4 bits of address, and ADDL is used

to set low 4 bits of address. If both ADDH and ADDL are set to F, and PD-01

is power ON or re-power ON, then PD-01 will enter the TEST mode, the SP

LED and NET LED will be in steady orange.

Address Meaning

1..0x7D Valid PROFIBUS address

0 or

0x7E..0xFE

0xFF Enter TEST mode

Invalid PROFIBUS address

NOTE:

Setting changes via address switches will not effective when PD-01 is operating. This means

the setting changes will effective after PD-01 power re-boot. Please understand this cold

restart must be initiated by toggling the power to OFF and then ON.

Parameters setting in VFD series Drives

PD-01 is designed to communicate with VFD series Drives via MODBUS communication port.

Prior to the connection, users have to set parameters below in VFD series Drives:

Set the communication protocol of VFD series Drives to RTU 8, N, 2.

Set the baud rate of VFD series Drives to 9600bps.

Set the frequency source for VFD series Drives to operate via RS485.

Set the operation source of VFD series Drives via MODBUS communication.

Refer to the following table for the above settings when connecting to VFD series Drives:

VFD-L type

115V/200~400W

230V/200W~2HP

VFD-M type

Baud Rate 9600

RTU 8,N,2

Freq. Source

Command Source

P89=01 P09-01=1 P09-01=1 P09-01=1

P92=03 P09-04=3 P09-04=6 P09-04=2, P09-05=0

P00=04 P02-00=4 P02-00=4 P02-00=4

P01=03 P02-01=3 P02-01=3 P02-01=3

VFD-B / VFD-S

type

VFD-F type

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

11

Page 15

PD-01 PROFIBUS-DP Module

After these settings completed, connecting PD-01 and VFD series Drives via communication

cable mentioned earlier, PD-01 is then energized. Two LED will be firstly in orange because

PD-01 is initialized and test itself. SP LED will be then in steady green since that the

connection is established between PD-01 and VFD series Drives.

Cyclical data of PD-01 via PROFIBUS-DP

PD-01 is controlled via cyclical PROFIBUS-DP channel. This channel can be used to access

the parameters of VFD series Drives.

Useful data structure as defined in PROFIDrive Profile 2.0

The structure of useful data for the cyclical channel is defined in the PROFIDrive Profile,

version 2.0. Please refer to the Parameter Process data Object (PPO).

PKW PZD

PKE IND PWE

1st

2nd

3rd

word

word

word

PPO1

PPO2

PPO5

PZD1

4th

word

PPO3

PPO4

STW

ZSW

1st

word

PZD2

HSW

HIW

2nd

word

PZD3 PZD4 PZD5 PZD6 PZD7 PZD8 PZD9 PZD10

3rd

word

4th

word

5th

word

6th

word

7th

word

8th

word

9th

word

10th

word

PKW: Parameter ID/value STW: Control word

PZD: Process data ZSW: Status word

PKE: Parameter ID HSW: Main setpoint

IND: Sub-index HIW: Main actual value

PWE: Parameter value

NOTE:

PD-01 supports PPO1 and PPO3 structure only.

Extended configuration

In addition to the PPO types, cyclical data can also be configured to EXT CONF 1 or EXT

CONF 2 (see table below). These two extended configuration both have four process

data words. The areas of consistency can be set flexibly.

PKW PZD

PKE IND PWE

1st

2nd

3rd

word

word

word

EXT CONF 1

EXT CONF 2

PZD1

4th

word

STW

ZSW

1st

word

PZD2

HSW

HIW

2nd

word

PZD3 PZD4 PZD5 PZD6 PZD7 PZD8 PZD9 PZD10

3rd

word

4th

word

5th

word

6th

word

7th

word

8th

word

9th

word

10th

word

12

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 16

PD-01 PROFIBUS-DP Module

Default settings of PZD structure

PD-01 must receive the user parameters from master that configured via GSD file. The

default settings of PZD structure are as follows:

STW1: Control Word, mapping to MODBUS address 0x2000 of VFD series Drives.

HSW: Main set point, mapping to MODBUS address 0x2001 of VFD series Drives.

ZSW: Drives status, mapping to MODBUS address 0x2101 of VFD series Drives.

HIW: Main command frequency, mapping to MODBUS address 0x2102 of VFD series

Drives.

DP master -> VFD series Drives:

PZD3: No default assignment

PZD4: No default assignment

VFD series Drives-> DP master:

PZD3: Output frequency, mapping to MODBUS address 0x2103 of VFD series Drives.

PZD4: Output current, mapping to MODBUS address 0x2104 of VFD series Drives.

Control and Status words

PD-01 supports the PPO1 and PPO3 data structure. However, it does not support the bit

assignments of control and status words in PROFIDRV. It only supports the DELTA VFD

series Drives control and status words.

Control word (data from DP to VFD series Drives)

00: No function

b1-b0

b3-b2 Not used

b5-b4

b7-b6

b11-b8

01: Stop

10: Run

11: JOG+Run

00: No function

01: FWD

10: REV

11: Change direction

00: 1st Accel / Decel time

01: 2nd Accel / Decel time

10: 3rd Accel / Decel time

11: 4th Accel / Decel time

0000: Main speed

0001: 1st speed

0010: 2nd speed

0011: 3rd speed

0100: 4th speed

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

13

Page 17

PD-01 PROFIBUS-DP Module

0101: 5th speed

0110: 6th speed

0111: 7th speed

1000: 8th speed

1001: 9th speed

b11-b8

1010: 10th speed

1011: 11th speed

1100: 12th speed

1101: 13th speed

1110: 14th speed

1111: 15th speed

b12 1: Enable b11-b6

00: No function

b14-b13

01:Operation command controlled by PU

10:Operation command by Pr. setting

11:Switch between PU and Pr. setting

b15 Not used

NOTE:

Table above is for reference only, please check VFD series Drives user manual for

details. The control word that is mapping to the address of VFD series Drives can be

carried out by PD-01, so the bit assignments in the user manual of VFD series Drives is valid.

Status word (data from VFD series Drives to DP)

00: RUN LED light off, STOP LED light up (Drive Stop)

01: RUN LED blink, STOP LED light up (Drive Decelerate

b1-b0

during the drive stopping)

10: RUN LED light up, STOP LED blink (Drive standby)

11: RUN LED light up, STOP LED light off (Drive Run)

b2 1: JOG is active

00: REV LED light off, FWD LED light up (Forward)

b4-b3

01: REV LED blink, FWD LED light up (Reverse to Forward)

10: REV LED light up, FWD LED blink (Forward to Reverse)

11: REV LED light up, FWD LED light off (Reverse)

b5 1: Reserved parameters opened

b6 Reserved

b7 Reserved

b8 1: Main frequency controlled by communication

b9 1: Main frequency controlled by external terminal (EXT)

b10 1: Operation command controlled by communication (PU)

b11 1: Parameters have been locked

b12 Copy command enable

b15-b13 Reserved

14

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 18

PD-01 PROFIBUS-DP Module

NOTE:

Table above is for reference only, please check VFD series Drives user manual for

details. PD-01 will get the status word from VFD series Drives, so the bit assignments in

the user manual of VFD series Drives is valid.

Accessing parameters via PKW area

In cyclical data, PD-01 can provide request and response (read / write) message to

access the parameters of VFD series Drives. Due to the request and response

mechanism, the master must send the request until it receives a corresponding

response.

PKW have at least 4 words:

Word 1 Parameter ID (PKE)

15 12

AK

11

SPM

10 0

Parameter number (PNU)

Word 2 Parameter sub-index (IND)

15 8 7 0

Word 3 PWE1 reserved in PD-01

Word 4 PWE2 parameter value of read/write

PKE

Bits 0 to 10 (PNU) contain the number of the relevant parameter.

Bit 11 is reserved.

Bits 12 to 15 (AK) contain the request or the response identifier.

Request identifier (master PD-01)

Request Identifier Meaning

0 No request

1 Request parameter value

2 Modify parameter value (word)

Response identifier (PD-01 master)

Response Identifier Meaning

0 No response

1 Transfer parameter value (word)

7 Cannot process request (with error number)

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

15

Page 19

PD-01 PROFIBUS-DP Module

Fault numbers for "Cannot process request" response

NO. Meaning

0 Illegal Parameter number Parameter does not exist

1

2

Parameter value cannot

be modified

Minimum/maximum not

reached / exceeded

18 Other error

IND

Structure of IND for cyclical communication via PPOs

PKE IND PWE1 PWE2

HIGH LOW HIGH LOW HIGH LOW HIGH LOW

15 14 13 12 11-8 7 0

Parameter is a read-only parameter

or can not change in current state

Para Page selection Not used

0 23 22 21

2

0

Function of Parameter Page Selection

Basic PNU

(B.PNU bit 10-0 of PKE)

Page selection

(P.PNU)

Tot a l PNU

(B.PNU+P.PNU*2000)

0…1999 0 0…1999

0…1999 1 2000…3999

0…1999 2 4000…4999

… … …

0…1999 15 30000…31999

NOTE:

In IND, Bit 15 uses a multiplier of 2

0

, so the value of Bit 15 for the access P2000-

P3999 must be set to 1.

Parameter value (PWE) 3rd and 4th word

All parameters in VFD series Drives are 16-bit. A 16-bit parameter value is transferred

in PWE2 (4th word). PWE1 (3rd word) must be set to 0 on the PROFIBUS-DP master

in this case.

16

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 20

PD-01 PROFIBUS-DP Module

Examples for PKW mechanism

Example 1: Read data of parameter P0003

To read value of P0003, set the request ID to 1 (request parameter value - word).

Because P0003 is less than 2000, the Para Page Select is 0, thus, the data sequence

are as follows:

Master PD-01 : 1003 0000 0000 0000 request value of P0003

PD-01 Master : 1003 0000 0000 1770

Request Response

Word 1 (PKE) 1003

Word 2 (IND) 0000

Word 3 (PWE1) 0000

Word 4 (PWE2) 0000

Word 1 (PKE) 1003

Word 2 (IND) 0000

Word 3 (PWE1) 0000

Word 4 (PWE2) 1770

PD-01 responds the value of P0003. All parameters in VFD series Drives are 16-bit

value, so the value is transferred in PWE2 (4th word). The value of P0003 is 0x1770

(6000 decimal), in VFD-M series Drives, it is “Maximum Output Frequency”.

Example 2: Read command frequency in VFD series Drives (0x2102)

To read value of command frequency, set the request ID to1, we should set the Para

Page Select because the parameter address is greater than 2000. The address

0x2102 is 8450 in decimal, if set Page Select to 4, then the Basic PNU is 8450 –

4*2000 = 450 (0x1c2), thus, the data sequence are as follows:

Master PD-01 : 11C2 2000 0000 0000 request value of address

0x2102

PD-01 Master : 11C2 2000 0000 0868

Request Response

Word 1 (PKE) 11C2 Word 1 (PKE) 11C2

Word 2 (IND) 2000 Word 2 (IND) 2000

Word 3 (PWE1) 0000 Word 3 (PWE1) 0000

Word 4 (PWE2) 0000 Word 4 (PWE2) 0868

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

17

Page 21

PD-01 PROFIBUS-DP Module

Example 3: Write data 2 to parameter P0804

To write data to P0804, request ID is set to 2 (Modify parameter value - word), Para

Page Select should be set because the parameter address is greater than 2000. The

address of P0804 is 0x0804, which is 2052 in decimal, if set Page Select to 1 (bit 15

of IND is 1), then the Basic PNU is 2052 – 1*2000 = 052 (0x34), thus, the data

sequence are as follows:

Master PD-01 : 2034800000000002 write data to P0804

PD-01 Master : 1034800000000002

Request Response

Word 1 (PKE) 2034 Word 1 (PKE) 1034

Word 2 (IND) 8000 Word 2 (IND) 8000

Word 3 (PWE1) 0000 Word 3 (PWE1) 0000

Word 4 (PWE2) 0002 Word 4 (PWE2) 0002

All parameters values in VFD series Drives are 16-bit, so the data may be transferred

in PWE2 (4th word).

NOTE:

VFD series Drives will write the data to EEPROM. When using PKW to change the

value of parameter, the data will be written to EEPROM directly. However, if this

action is too often, the EEPROM will have no capability of directly saving data.

So please pay close attention on it.

Example 4: Read diagnostic data

User can use the special address to read the current diagnostic data. Please refer to

Section 6.2 for details. The diagnostic address starts from 0x7500 to 0x7504 (5

words). To read diagnostic data in these addresses, request ID is set to 1, Para Page

Select should be set because the parameter address is greater than 2000. The

address 0x7500, which is 29952 in decimal, if set Page Select to 14, then the Basic

PNU is 29952-14*2000=1952(0x7A0), thus, the data sequence are as follows:

Master - > PD-01 : 17A0700000000000 read data from 0x7500

PD-01 - > Master : 17A0700000000300

18

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 22

PD-01 PROFIBUS-DP Module

Request Response

Word 1 (PKE) 17A0 Word 1 (PKE) 17A0

Word 2 (IND) 7000 Word 2 (IND) 7000

Word 3 (PWE1) 0000 Word 3 (PWE1) 0000

Word 4 (PWE2) 0000 Word 4 (PWE2) 0300

If PD-01 returns the data 0x0300, it indicates that Scan port is disconnected. Please

refer to Section 6.2 for details.

Example 5: Access error

If take any action using PKW to access parameter in AC Drives and it fails, PD-01 will

response error information. Suppose that Master send data sequence is 202D 8000

0000 0002, if VFD series Drives does not find this address (0x07FD), it will respond

the data sequence 702D 8000 0000 0000, response ID is 7 which means cannot

process request (with error number), and error number is 0 (Illegal Parameter

Number).

Request Response

Word 1 (PKE) 202D Word 1 (PKE) 702D

Word 2 (IND) 8000 Word 2 (IND) 8000

Word 3 (PWE1) 0000 Word 3 (PWE1) 0000

Word 4 (PWE2) 0002 Word 4 (PWE2) 0000

Response time about PD-01

The update time via PROFIBUS connection can be divided in 3 parts:

T1: Communication time in transmit data from the master to PD-01, and

T2: Wait processing in data buffer of PD-01, and

T3: Communication time in transmit data from PD-01 to VFD Drives.

Timer

VFD

series

Drives

Master

T1 T3

PD-01

Data Buffer

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

T2

19

Page 23

PD-01 PROFIBUS-DP Module

T1 depends on the actual transmission speed and the type of master in use.

T2 depends on the internal timer of PD-01. Data is transmitted to VFD series Drives per

70ms triggered by a timer. User cannot change the time-out interval.

T3 depends on the Modbus communication between PD-01 and VFD series Drives.

So the update time is,

Max update time = T1 + T2 (70ms) + T3

In fact, the actual update time is less than the Max update time. If the timer time-out

when the data arrive PD-01, PD-01 will save the data to data buffer, and transmit the data

to VFD series Drives immediately.

20

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 24

PD-01 PROFIBUS-DP Module

Chapter 5 User Parameters Setting in GSD file

GSD file

A GSD file is a text file used to identify PROFIBUS-DP device (Master or Slave), which

contains the necessary data for the configuration of DP slaves within a standard DP master.

Typical information in a GSD file are Vendor information, Baud rates supported, Timing

information, Options/features supported and Available I/O signals. The GSD file is the

fundamental building block for the master parameter record.

GSD-File for Delta VFD series Drives

File: DELT08DB.GSD

File start: ===========================================================

#Profibus_DP

; Unit-Definition-List:

GSD_Revision = 1

Vendor_Name = "Delta Electronics"

Model_Name = "VFD DRIVES"

Revision = "Rev. 1"

Ident_Number = 0x08DB

Protocol_Ident = 0

Station_Type = 0

FMS_supp = 0

Hardware_Release = "V1.0"

Software_Release = "V1.0"

Redundancy = 0

Repeater_Ctrl_Sig = 2

24V_Pins = 0

Implementation_Type = "SPC3"

Bitmap_Device = "VFDDRV"

Bitmap_Diag = "VFDDRV"

Bitmap_SF = "VFDDRV"

Slave_Family = 1@TdF@Delta VFD Drives

Auto_Baud_supp = 1

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

21

Page 25

PD-01 PROFIBUS-DP Module

9.6_supp = 1

19.2_supp = 1

93.75_supp = 1

187.5_supp = 1

500_supp = 1

1.5M_supp = 1

3M_supp = 1

6M_supp = 1

12M_supp = 1

MaxTsdr_9.6 = 60

MaxTsdr_19.2 = 60

MaxTsdr_93.75 = 60

MaxTsdr_187.5 = 60

MaxTsdr_500 = 100

MaxTsdr_1.5M = 150

MaxTsdr_3M = 250

MaxTsdr_6M = 450

MaxTsdr_12M = 800

Freeze_Mode_supp = 1

Sync_Mode_supp = 1

Set_Slave_Add_supp = 0

Min_Slave_Intervall = 1

Modular_Station = 1

Max_Module = 1

Max_Input_Len = 32

Max_Output_Len = 32

Max_Data_Len = 64

Modul_Offset = 0

Fail_Safe = 0

Max_Diag_Data_Len = 16

ORDERNUMBER = "PD-01"

Max_User_Prm_Data_Len = 26

User_Prm_Data_Len = 26

User_Prm_Data = 0x20,0x00,\

22

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 26

0x20,0x01,\

0x00,0x00,\

0x00,0x00,\

0x21,0x01,\

0x21,0x02,\

0x21,0x03,\

0x21,0x04,\

0x00,0x01,\

0x00,0x02,\

0x00,0x02,\

0x00,0x01,\

0x00,0x00

Module = "4 PKW, 2 PZD (PPO 1) " 0xF3, 0xF1

EndModule

Module = "0 PKW, 2 PZD (PPO 3) " 0x00, 0xF1

PD-01 PROFIBUS-DP Module

EndModule

Module = "4 PKW, 4 PZD " 0xF3, 0xF3

EndModule

Module = "0 PKW, 4 PZD " 0x00, 0xF3

EndModule

PrmText = 1

Text(0) = "Address discontinuous"

Text(1) = "Address continue"

EndPrmText

PrmText = 2

Text(0) = "Ignore and Continue"

Text(1) = "Stop accord to Pr.STOP METHOD"

EndPrmText

PrmText = 3

Text(0) = "Stop DataExchange & Report Fault"

Text(1) = "Continue & Report Alarm"

Text(2) = "Ignore & Continue DataExchange"

EndPrmText

ExtUserPrmData = 1 "Data Input 1(PD-01 -> VFD)"

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

23

Page 27

PD-01 PROFIBUS-DP Module

Unsigned16 0x2000 0-65535

EndExtUserPrmData

ExtUserPrmData = 2 "Data Input 2"

Unsigned16 0x2001 0-65535

EndExtUserPrmData

ExtUserPrmData = 3 "Data Input 3"

Unsigned16 0x0000 0-65535

EndExtUserPrmData

ExtUserPrmData = 4 "Data Input 4"

Unsigned16 0x0000 0-65535

EndExtUserPrmData

ExtUserPrmData = 5 "Data Output 1(VFD -> PD-01)"

Unsigned16 0x2101 0-65535

EndExtUserPrmData

ExtUserPrmData = 6 "Data Output 2"

Unsigned16 0x2102 0-65535

EndExtUserPrmData

ExtUserPrmData = 7 "Data Output 3"

Unsigned16 0x2103 0-65535

EndExtUserPrmData

ExtUserPrmData = 8 "Data Output 4"

Unsigned16 0x2104 0-65535

EndExtUserPrmData

ExtUserPrmData = 9 "d_state"

Unsigned16 1 0-1

Prm_Text_Ref = 1

EndExtUserPrmData

ExtUserPrmData = 10 "din_len"

Unsigned16 2 0-4

EndExtUserPrmData

ExtUserPrmData = 11 "dout_len"

Unsigned16 2 0-4

EndExtUserPrmData

ExtUserPrmData = 12 "LossDPComTreat"

Unsigned16 1 0-1

Prm_Text_Ref = 2

EndExtUserPrmData

24

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 28

ExtUserPrmData = 13 "LossSPComTreat"

Unsigned16 0 0-2

Prm_Text_Ref = 3

EndExtUserPrmData

Ext_User_Prm_Data_Ref(0) = 1

Ext_User_Prm_Data_Ref(2) = 2

Ext_User_Prm_Data_Ref(4) = 3

Ext_User_Prm_Data_Ref(6) = 4

Ext_User_Prm_Data_Ref(8) = 5

Ext_User_Prm_Data_Ref(10) = 6

Ext_User_Prm_Data_Ref(12) = 7

Ext_User_Prm_Data_Ref(14) = 8

Ext_User_Prm_Data_Ref(16) = 9

Ext_User_Prm_Data_Ref(18) = 10

Ext_User_Prm_Data_Ref(20) = 11

PD-01 PROFIBUS-DP Module

Ext_User_Prm_Data_Ref(22) = 12

Ext_User_Prm_Data_Ref(24) = 13

File END: ==========================================================

NOTE:

The required GSD file is available and can be downloaded from the DELTA web site

http://www.delta.com.tw, or you can copy this text to a text editor such as NOTEPAD, and

save it as a GSD file named “DELT08DB.GSD”. Please make sure to specify the file name

extension as “.GSD”, PLEASE DO NOT SAVE IT extension “.GSD.TXT”.

User parameters in GSD file

The user parameters in GSD file are used for the configuration of the PROFIBUS network.

The description of the user parameters are shown in the following table:

Item Name Type Description Default

1 Data Input 1 UINT

2 Data Input 2 UINT

This is a MODBUS address. The 1st word in

PZD of cyclic output data will be sent to this

address.

This is a MODBUS address. The 2nd word in

PZD of cyclic output data will be sent to this

address.

0x2000

0x2001

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

25

Page 29

PD-01 PROFIBUS-DP Module

Item Name Type Description Default

3 Data Input 3 UINT

This is a MODBUS address. The 3rd word in

0x0000

PZD of cyclic output data will be sent to this

address if select Module = "4 PKW, 4 PZD".

4 Data Input 4 UINT

This is a MODBUS address. The 4th word in

0x0000

PZD of cyclic output data will be sent to this

address if select Module = "4 PKW, 4 PZD".

5 Data Output 1 UINT

This is a MODBUS address. PD-01 will

0x2101

monitor this address, and copy the return

data to the 1st word in PZD of cyclic input

data.

6 Data Output 2 UINT

This is a MODBUS address. PD-01 will

0x2102

monitor this address, and copy the return

data to the 2nd word in PZD of cyclic input

data.

7 Data Output 3 UINT

This is a MODBUS address. PD-01 will

0x2103

monitor this address, and copy the return

data to the 3rd word in PZD of cyclic input

data if select Module = "4 PKW, 4 PZD".

8 Data Output 4 UINT

This is a MODBUS address. PD-01 will

0x2104

monitor this address, and copy the return

data to the 4th word in PZD of cyclic input

data if select Module = "4 PKW, 4 PZD".

9 d_state UINT

This is a flag. If address in Data Output 1 ~

0x0001

Data Output 4 is continuous, set it to 1, and

set the others to 0.

10 din_len UINT

This is a length, and unit is word. It specifies

0x0002

the length of PD-01 to process data in PZD, if

user select the Module = "4 PKW, 4 PZD", but

din_len is 3, PD-01 will process 3 word and

ignore the 4th word.

11 dout_len UINT

This is a length, and unit is word. It specifies

0x0002

the length of PD-01 to monitor data from AC

Drive, if user select Module = "4 PKW, 4

PZD", but dout_len is 3, PD-01 will monitor 3

word and ignore the 4th address.

12 LossDPComTreat UINT

This variable indicates that the PD-01 will

0x0001

take action when communication with

Profibus network is lost, the value can be

assigned as follows:

00 – Ignore event and continue;

01 – Stop according to Pr “Stop Method” in

VFD series Drives.

26

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 30

PD-01 PROFIBUS-DP Module

Item Name Type Description Default

13 LossSPComTreat UINT

This variable indicates that the PD-01 will

0x0000

take action when the SP communication

(SCANport communication) is lost, the value

can be assigned as follows:

00 – Stop data exchange and report fault;

01 – Continue data exchange and report

alarm;

02 – Ignore and continue data exchange.

If the address in Data Output 1 ~ Data Output 4 is continuous, then set d_state to 1, PD-01

will get starting address from Data Output 1. The next data will be got from the address next

to the starting address, and the reading length is determined by dout_len. If the MODBUS

address for reading is discontinuous, please set d_state to 0, PD-01 will also get starting

address from Data Output 1, but the difference is the other data will be got from the address

saved in Data Output 2, Data Output 3 and Data Output 4 in order.

Example, if

Data Output 1 = 0x2100;

Data Output 2 = 0x2101;

Data Output 3 = 0x2102;

Data Output 4 = 0x2103;

dout_len = 0x0003;

The MODBUS address in Data Output 1~Data Output 4 is continuous, so you can set the

d_state to 1, then PD-01 will monitor the address starting from Data Output 1, and monitor 3

words from VFD series Drives one time. When the dout_len is 3, PD-01 will ignore the

address in Data Output 4. If d_state is set to 0, PD-01 will read data from the address in Data

Output 1, and read data from the address in Data Output 2, and so forth.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

27

Page 31

PD-01 PROFIBUS-DP Module

Edit the user parameters in S7 Step hardware configuration tools shown below:

NOTE:

Please do not set d_state to 1 when the address in Data Output 1 ~ Data Output 4 is

non-continuous to avoid Parameterization error and IO disconnect. The PD-01 just check the

address starting from Data Output 1 to Data Output [dout_len-1], in other words, if the

address in Data Output 1 ~ Data Output 3 is continuous, but the address in Data Output 4 is

not, and dout_len is 0x0003, then the check still can pass.

28

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 32

PD-01 PROFIBUS-DP Module

Chapter 6 Troubleshooting

Troubleshooting via LED displays

Two LEDs, SP and NET LED, are used to monitor the PD-01 communication status.

Possible LED displays of NET LED:

LED Indication Corrective Actions

OFF No Power Supply Verify that the power supply of PD-01.

Check whether the power supply is

connected and that power is applied to

the PD-01 through the connector.

Red, flickering (rapid

blinking)

Red, blinking Communication link to

Red ON No connection to

Green, blinking “Master” is in “Stop” mode,

Green ON Cyclic data exchange in

Invalid PROFIBUS address

set via switch

PROFIBUS, but No cyclical

data exchanged, or

Extended user parameter

error

PROFIBUS

and cyclical process data

exchange in progress, but

set-points invalid (control

word = 0)

progress and OK

Check whether the switch value is

valid, valid value of slave is within

1-125. Set the valid value and re-power

User parameter are sent by master

(from GSD file), for example, if d_state

is set 1, ensure the data in Data Output

1 ~ Data Output 1 + dout_len are

continuous addresses. Otherwise,

PD-01 will not be able to pass the

Parameterization check.

1. Verify that network installation is OK.

2. Verify that PLC is working.

3. Verify that switch address setting is

correct.

Turn the KEY of PLC to RUN mode,

and send the control command to

PD-01.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

29

Page 33

PD-01 PROFIBUS-DP Module

Possible LED displays of SP LED:

LED Indication Corrective Actions

OFF No Power Supply Verify that the power supply of PD-01.

Check whether the power supply is

connected and that power is applied to

the PD-01 through the connector.

Red, blinking CRC check fault Check your communication setting in

AC Drive (9600, <8,N,2>, RTU)

Red ON Connection failure, or

No connection

1. Check whether the connections

between AC Drive and RS485 of

PD-01 are all correct

2. Re-wire the connections between AC

Drive and ensure that the wire

specification is correct.

Green, blinking AC Drive returns error code 1. Check the AC Drive type and version.

Not all Delta VFD series Drive are

supported.

2. Check the PLC program, and ensure

the operating address in PD-01 is

correct.

Green ON Normal

NOTE:

If both SP LED and NET LED are in steady orange, it indicates that PD-01 has entered into

the “test mode”. Please do not set the value of address switch of PD-01 to 0XFF at this time.

Be sure to set other value and energize PD-01 again.

Troubleshooting via diagnostic data

PD-01 provides 16 bytes diagnostic data when the alarm occurs and when user parameter

setting “LossSPComTreat” is set to “Continue data exchange and report alarm”. It includes 6

bytes standard diagnostic data and 10 bytes device related diagnostic data. The following

table shows the meanings of the 16 bytes:

Byte 1-6 Byte 7 Byte 8 Byte 9 Byte 10

Byte 16

Standard

diagnostic data

Byte 7 indicates the length of device related diagnostic data including itself, so if byte 7 is 10

(0Ahex), it indicate device related to diagnostic data have 10 bytes (including byte 7).

Length in bytes SP communication

status

Error code Reserved

Byte 8 indicates the SP communication status when the alarm occurs, and the valid value

should be as follows:

30

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 34

PD-01 PROFIBUS-DP Module

00 – Normal

01 – CRC check failure

02 – VFD series Drive returns error code

03 – Communication is time out and disconnected

Byte 9 indicates the error code when byte 8 is 02 (VFD series Drive returns error code). Refer

to the Section 6.3 for the meanings of invalid code.

Other word, user can get the diagnostic data via PZD area any time. PD-01 provides some

special MODBUS addresses to indicate the diagnostic status, the address assignments are

as following:

0x7500 0x7501 0x7502 0x7503 0x7504

Address

Meaning

High

byte

SP

comm

status

Low

byte

Error

code

High

byte

Low

byte

High

byte

Low

byte

High

Reserved, read to 0

byte

Low

byte

High

byte

Low

byte

User can get these data through “Data Output 1”, or 2, or 3, or 4 in user parameters. For

example, if set the “Data Output 1” to 0x7500 means get the diagnostic data from 0x7500,

and get the return data from address 0x7500 in 1st word of PZD area.

NOTE:

These special addresses are read-only, it will fail if user tries to write data to it.

Troubleshooting via error codes

If there is a communication error detected between PD-01 and VFD series Drives, the error

code will be displayed on the digital keypad of VFD series Drives.

VFD series Drives can process the message from PD-01 if the communication setting is valid.

But if the command of message is invalid, the VFD series Drives will respond a report

message that has error codes listed in table below, to PD-01.

Code Meaning Corrective actives

01 Illegal command code

The command code received in the

command message is not available

for the drives.

02 Illegal data address

The data address received in the

command message is not available

for the drives.

1. Check the Request Identifier in PKW area.

PD-01 just supports ID 0, 1, 2.

2. Re-supply power to PD-01.

1. Check the Parameter number in PKW area,

and refer the user manual of VFD Drives.

2. Check the settings of user parameters “Data

Input 1” to “Data Input 4” and “Data Output

1” to “Data Output 4”, and refer to the user

manual of VFD series Drives.

3. Re-supply power to PD-01.

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

31

Page 35

PD-01 PROFIBUS-DP Module

Code Meaning Corrective actives

03 Illegal data value

The data value received in the

command message is not

available for the drives.

1. Check the parameter data (PWE2) in PKW

area, and refer the user manual of VFD series

Drives.

2. Check the PLC program to confirm the data

that transmitted to PD-01 from master is valid.

3. Re-supply power to PD-01.

04 Slave device failure

The drive is unable to perform the

requested action.

1. Check all data in PKW.

2. Re-supply power to PD-01.

VFD series Drives will not respond message to PD-01 if it receives an invalid message from

PD-01, but error code shown in the table below will be displayed on the digital keypad.

Code Meaning Corrective actives

05 Reserved

06 AC Drive is busy

07 Reserved

08 Reserved

09 Check sum is error

10 Time out

11 Baud rate or protocol is invalid

1. Please refer to section 4.2 in this manual

and check the setting of VFD series Drives.

2. If the error still exists, return it to factory.

12 Message is too short

13 Message is too long

14 Message contain invalid character

32

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

Page 36

Chapter 7 Dimensions

PD-01

SP

A1

NET

B1

ADDH

ADDL

RS-485

A2

B2

PD-01 PROFIBUS-DP Module

DELTA ELECTRONICS, INC. ALL RIGHTS RESERVED

33

Loading...

Loading...