Delta MultiChoice T17T267, MultiChoice T17T453, MultiChoice T17T467, MultiChoice T17T297, MultiChoice T17T097 Owner's Manual

...Page 1

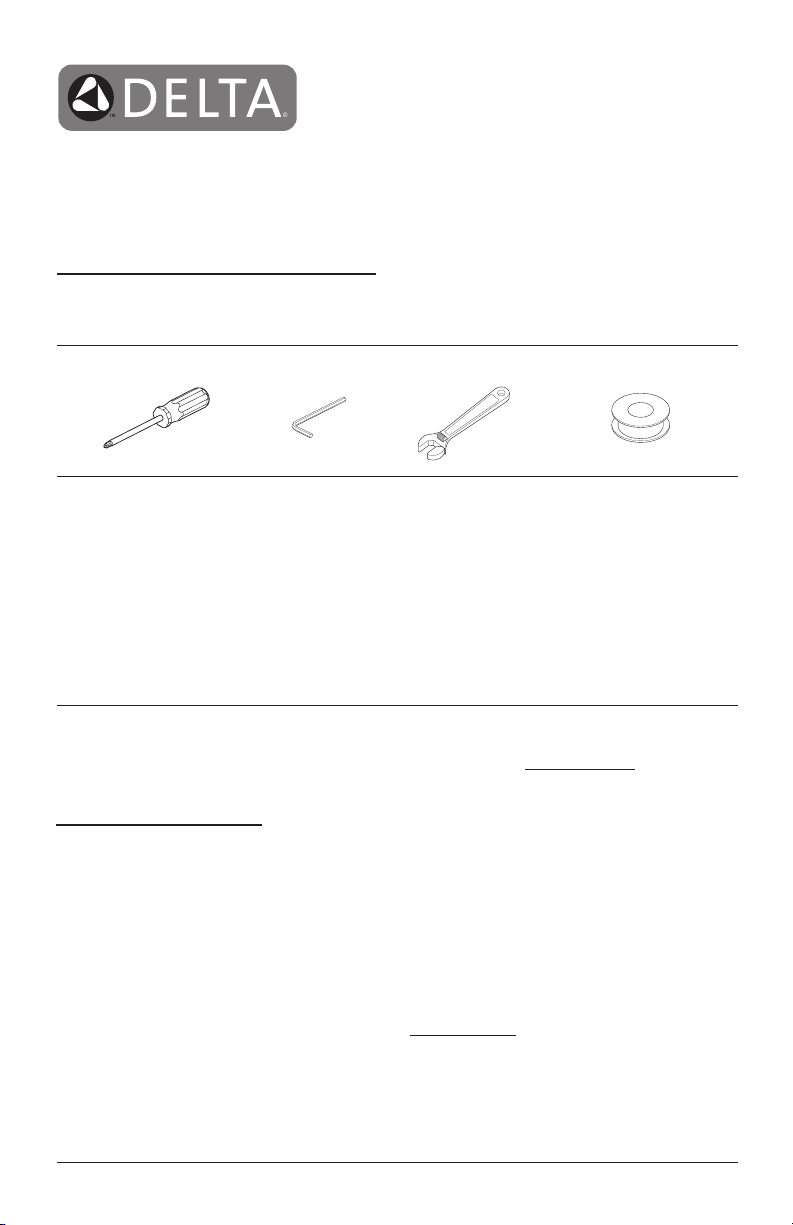

MultiChoice® Valve Trim

Installation Instructions

Owners Manual

17T Series

Write purchased model number here.

You May Need

L

O

F

N

E

T

Table of Contents:

Warranties ................................................................................. Page 2

Installation Instructions ............................................................. Pages 3 - 7

Clean and care........................................................................... Page 8

Maintenance .............................................................................. Page 8

Cartridge Summary Reference Sheet ....................................... Page 8

To order replacement parts, visit www.deltafaucet.com

68883

CAUTION: This system/device must be set by the

installer to ensure safe, maximum temperature.

Any change in the setting may raise the discharge

temperature above the limit considered safe and

may lead to hot water burns.

NOTICE TO INSTALLER: CAUTION!–As the

installer of this valve, it is your responsibility

to properly INSTALL and ADJUST this valve

per the instructions given. This valve does

not automatically adjust for inlet temperature

changes, therefore, someone must make the

necessary temperature knob adjustments

the time of installation and further adjustments

may be necessary due to seasonal water

temperature change. YOU MUST inform the

owner/user of this requirement by following the

instructions. If you or the owner/user are unsure

how to properly make these adjustments please

refer to page 7 and if still uncertain, call us at

1-800-345-DELTA.

After installation and adjustment, you must afx

your name, company name and the date you

adjusted the temperature knob to the caution

05/02/2018

at

label provided and apply or attach the label to

the back side of the closest cabinet door and

the warning label to the water heater. Leave

this Instruction Sheet for the owner’s/user’s

reference. WARNING: This pressure balanced

or thermostatic bath valve is designed

to minimize the effects of outlet water

temperature changes due to inlet pressure

changes, commonly caused by dishwashers,

washing machines, toilets and the like. It may

not provide protection from hot water burns

when there is a failure of other temperature

controlling devices elsewhere in the plumbing

system, if the temperature knob is not properly

set or if the hot water temperature is changed

after the settings are made or if the water inlet

changes due to seasonal changes. WARNING:

Do not install a shut-off device on either outlet

of this valve. When this type of device shuts

off the water ow, it can defeat the ability of

the valve to balance the hot and cold water

pressures.

1

68883 Rev. J

17T Series 17T Series

17T Series

Page 2

Lifetime Faucet and Finish Limited Warranty

Parts and Finish

All parts (other than electronic parts and batteries) and

nishes of this Delta

consumer purchaser to be free from defects in material and

workmanship for as long as the original consumer purchaser

owns the home in which the faucet was rst installed or, for

commercial users, for 5 years from the date of purchase.

Electronic Parts and Batteries (if applicable)

Electronic parts (other than batteries), if any, of this Delta

faucet are warranted to the original consumer purchaser

to be free from defects in material and workmanship for 5

years from the date of purchase or, for commercial users, for

one year from the date of purchase. No warranty is provided

on batteries.

Delta Faucet Company will replace, FREE OF CHARGE,

during the applicable warranty period, any part or nish

that proves defective in material and/or workmanship under

normal installation, use and service. If repair or replacement

is not practical, Delta Faucet Company may elect to refund

the purchase price in exchange for the return of the product.

These are your exclusive remedies.

Delta Faucet Company recommends using a professional

plumber for all installatio and repair.We also recommend

that you use only genuine Delta

Delta Faucet Company shall not be liable for any damage to

the faucet resulting from misuse, abuse, neglect or improper

or incorrectly performed installation, maintenance or repair,

including failure to follow the applicable care and cleaning

instructions.

Replacement parts may be obtained by calling the

applicable number below or by writing to:

®

faucet are warranted to the original

®

replacement parts.

®

In the United States and Mexico:

Delta Faucet Company

Product Service

55 E. 111th Street

Indianapolis, IN 46280

1-800-345-DELTA (3358)

customerservice@deltafaucet.com

In Canada:

Masco Canada Limited, Plumbing Group

Technical Service Centre

350 South Edgeware Road

St. Thomas, Ontario, Canada N5P 4L1

1-800-345-DELTA (3358)

customerservice@mascocanada.com

Proof of purchase (original sales receipt) from the original

purchaser must be made available to Delta Faucet Company

for all warranty claims unless the purchaser has registered

the product with Delta Faucet Company. This warranty applies

only to Delta® faucets manufactured after January 1,1995 and

installed in the United States of America, Canada and Mexico.

DELTA FAUCET COMPANY SHALL NOT BE LIABLE FOR

SPECIAL, INCIDENTAL OR CONSEQUENTIAL DAMAGES

(INCLUDING LABOR CHARGES) FOR BREACH OF ANY

EXPRESS OR IMPLIED WARRANTY ON THE FAUCET.

Some states/provinces do not allow the exclusion or limitation

of special, incidental or consequential damages, so these

limitations and exclusions may not apply to you. This warranty

gives you special legal rights. You may also have other rights

which vary from state/province to state/province.

This is Delta Faucet Company’s exclusive written warranty

and the warranty is not transferable.

If you have any questions or concerns regarding our warranty,

please view our Warranty FAQs at www.deltafaucet.com,

email us at customerservice@deltafaucet.com or call us at the

applicable number above.

ANY

Delta HDF Limited Warranty

All parts of the Delta HDF faucet are warranted to the

original consumer purchaser to be free from defects in

material and workmanship for a period of ve (5) years.

This warranty is made to the original consumer purchaser

and shall be effective from date of purchase as shown on

purchaser’s receipt.

Delta will replace, FREE OF CHARGE, during the warranty

period, any part which proves defective in material and/or

workmanship under normal installation, use and service.

Replacement parts can be obtained from your local

dealer or distributor listed in the telephone directory or by

returning the part along with the purchaser’s receipt to our

factory, TRANSPORTATION CHARGES PREPAID, at the

address listed. THIS WARRANTY IS THE ONLY EXPRESS

WARRANTY MADE BY DELTA. ANY CLAIMS MADE

UNDER THIS WARRANTY MUST BE MADE DURING

THE FIVE YEAR PERIOD REFERRED TO ABOVE. ANY

IMPLIED WARRANTIES, INCLUDING THE IMPLIED

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

www.deltafaucet.com

68883 Rev. J

PARTICULAR PURPOSE, ARE LIMITED IN DURATION TO

THE DURATION OF THIS WARRANTY. LABOR CHARGES

AND/OR DAMAGE INCURRED IN INSTALLATION, REPAIR

OR REPLACEMENT AS WELL AS INCIDENTAL AND

CONSEQUENTIALDAMAGES CONNECTED THEREWITH

ARE EXCLUDED AND WILL NOT BE PAID BY DELTA.

Some states do not allow limitations on how long an implied

warranty lasts, or the exclusion or limitation of incidental

or consequential damages, so the above limitations or

exclusions may not apply to you.

This warranty gives you specic legal rights, and you may

also have other rights which vary from state to state.

This warranty is void for any damage to this faucet due to

misuse, abuse, neglect, accident, improper installation, any

use violative of instructions furnished by us or any use of

replacement parts other than genuine Delta parts.

© 2018 Masco Corporation of Indiana

2

Page 3

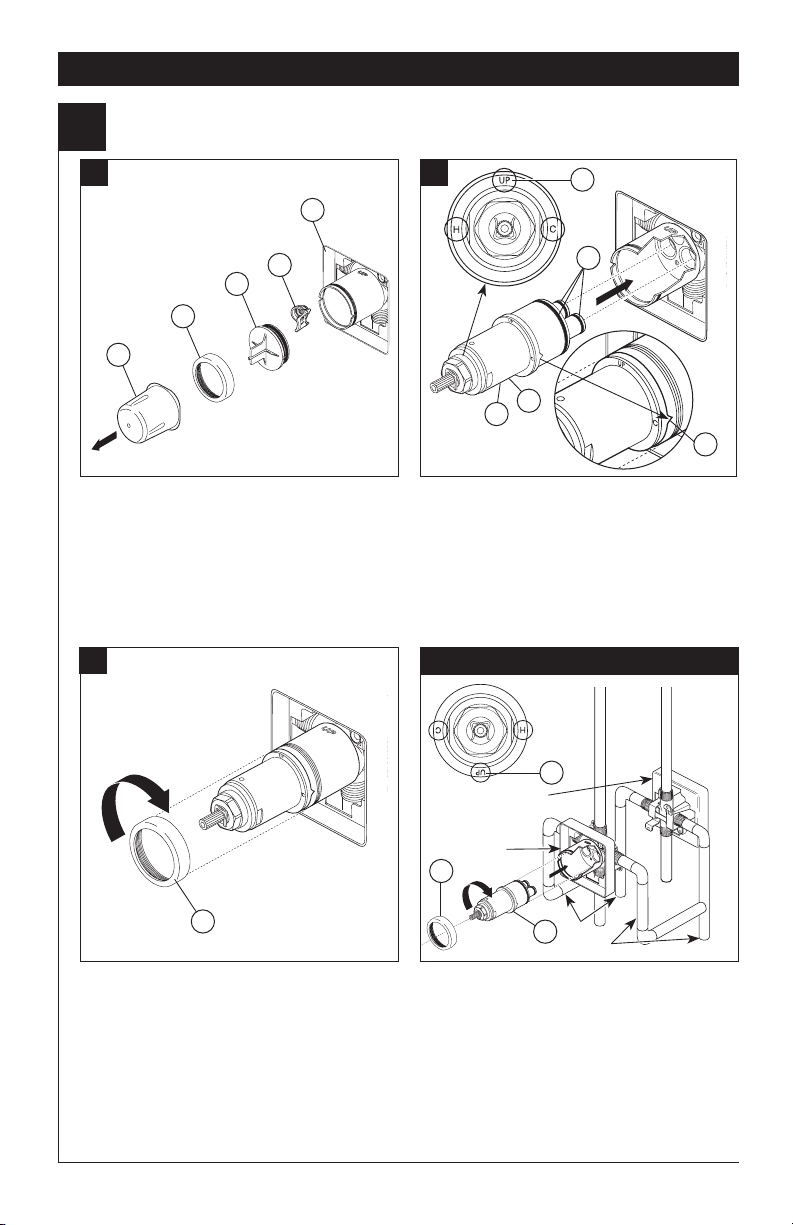

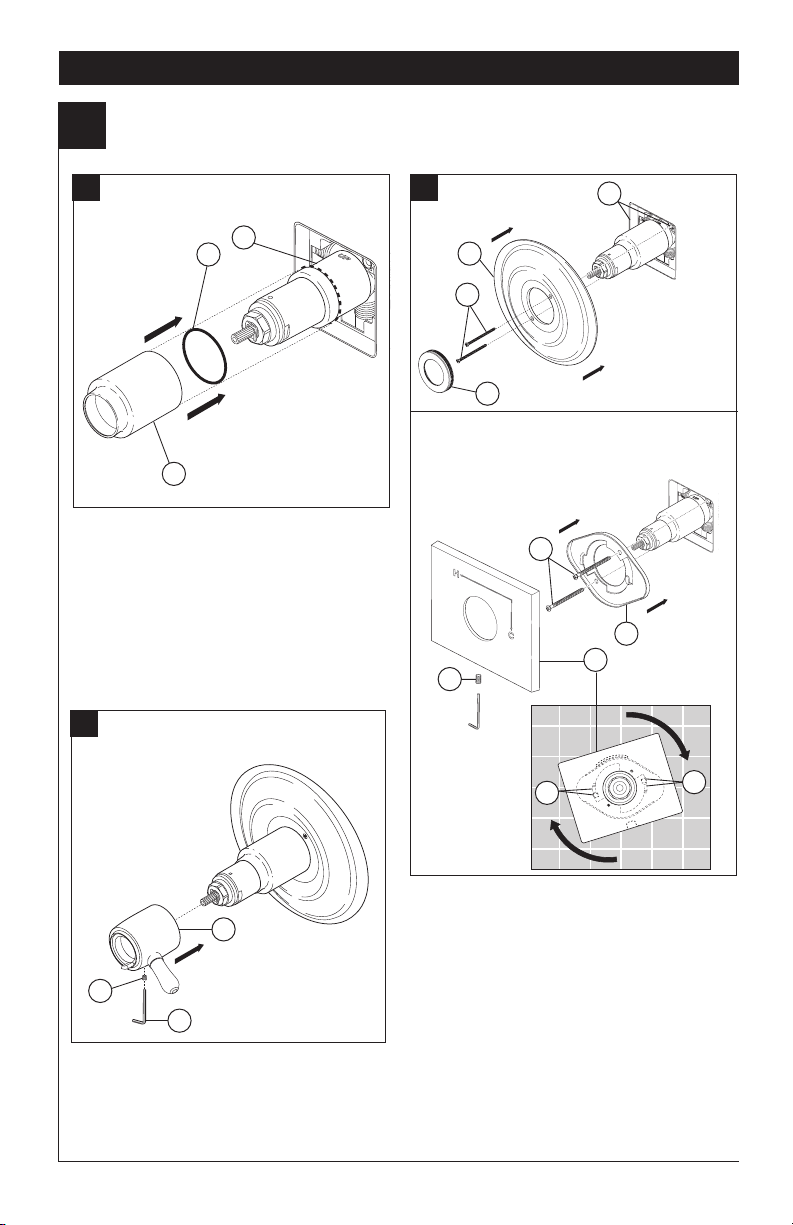

Cartridge Installation

1

Installation

A. B.

4

5

3

2

1

Turn off water supplies. Remove cover (1),

bonnet nut (2) and test cap (3) from the body.

Place a bucket or small container over the front

of the valve body and slowly open the water

supplies to ush any debris from the supply

lines before installing the cartridge. Turn the

water suplies back off. If this is not a thin wall

mounting, the entire plasterguard (4) may be

removed. If screen (5) is in place, remove

before installing cartridge.

Rotate the cartridge (1) so the word “UP” (2)

appears on the top. The “H” must be on the

hot side and the “C” must be on the cold side.

Add silicone lube to the three o-rings (3) shown

above to make the cartridge easier to install and

remove from the valve body. Insert cartridge

into valve body as shown. Ensure the keys on

the body are fully engaged with the slots in the

body (4).

C.

2

3

4

1

Back to back Installation

4

Slide bonnet nut (1) over the cartridge and

thread onto the body. Hand tighten securely.

2

Normal Installation

(changes not required)

Reverse

Installation

3

1

For the exceptions of back to back or reverse

installations (hot on right and cold on left) only:

Rotate cartridge (1) so “H” is on the hot side

and “C” is on the cold side and the word “UP”

(2) appears on the bottom. Add silicone lube

to the three o-rings shown above to make the

cartridge easier to install and remove from the

valve body. Install the cartridge making sure

that the keys are fully engaged with the slot in

the brass body (see step B). Slide bonnet nut

(3) over the cartridge and thread onto the body.

Hand tighten securely.

3

Clod

1

Hot

68883 Rev. J

Page 4

Installation

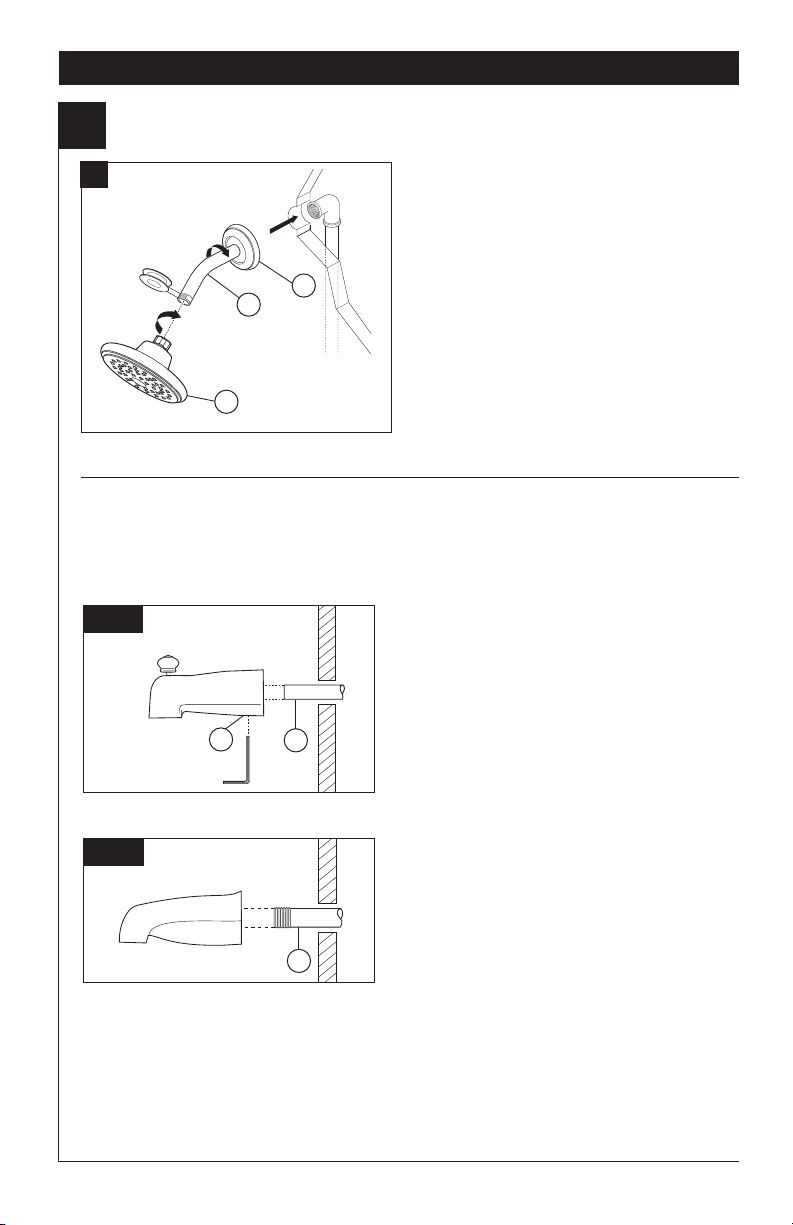

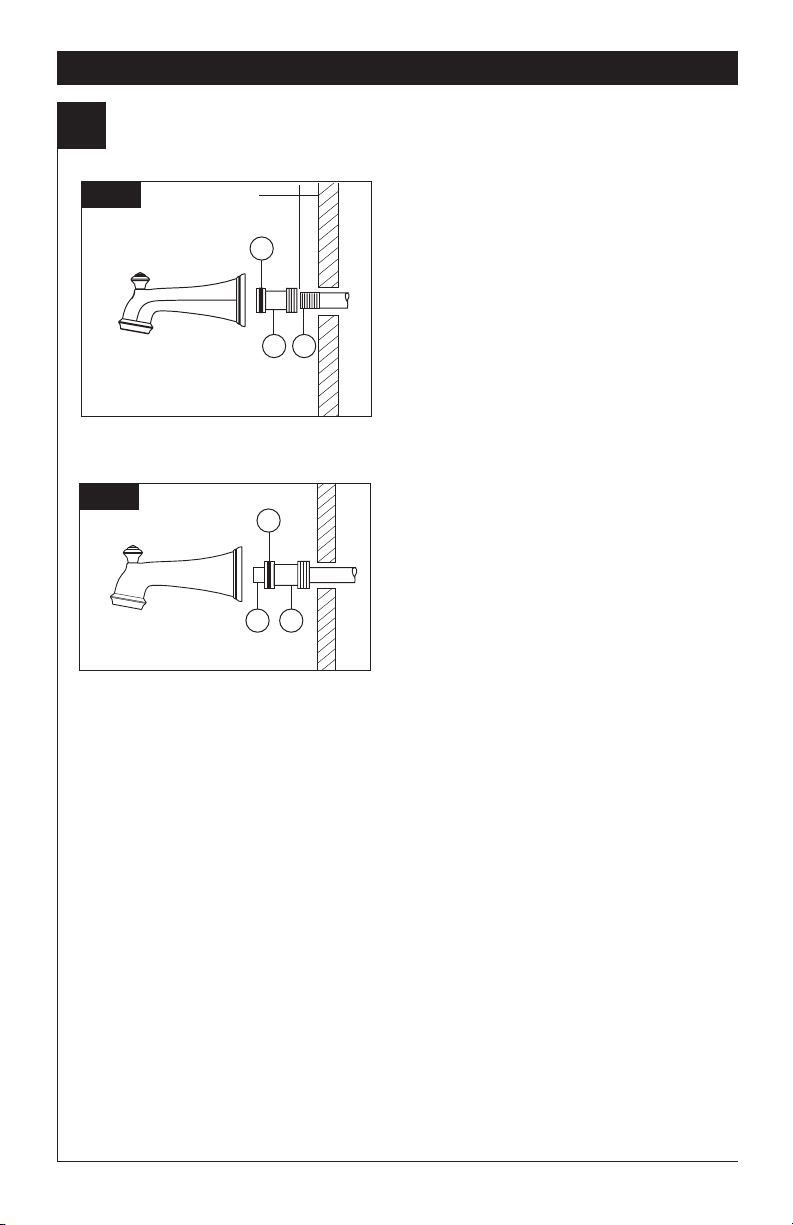

Showerhead and Tub Spout Installation

2

A.

2

1

3

FOR TUB SPOUT INSTALLATION:

Refer to the installation instructions supplied with your spout. Do not connect deck mount spouts to in-wall

valves. Do not use hand showers connected in lieu of a tub spout to a tub/shower valve. Do not use PEX

tubing for tub spout drop.

FOR SHOWERHEAD INSTALLATION:

Apply plumber tape to pipe threads on both ends

of the shower arm (1). To prevent damage to nish

on shower arm, insert wall end of shower arm into

shower ange (2) before screwing arm into riser

connection.

Thread showerhead (3) onto shower arm. Do not

overtighten showerhead.

B-1

B-2

68883 Rev. J

Slip-On Installation

The copper tube (1) must be 1/2” nominal copper.

Important: If it is necessary to cut the copper tube,

2

1

1

the end must be chamfered free of burrs to prevent

cutting or nicking O-ring inside the spout. Slide

spout over copper tube ush with the nished tub

or wall surface. Tighten set screw (2), but do not

overtighten.

Iron Pipe Installation

Install threaded pipe nipple (1) to extend past

nished wall. Apply plumber tape to threads on

pipe nipple and screw on tub spout.

4

Page 5

Showerhead and Tub Spout Installation

2

Installation

B-3

B-4

1/2" to 1 1/4"

(13 mm to 32 mm)

3

1 2

1

3 2

Iron Pipe Installation

Installation of easy-on universal tub spout

Install pipe nipple so that end of nipple projects out

from nished wall surface 1/2" to 1 1/4" (13 mm to

32 mm).

Apply plumber tape or pipe dope to pipe threads.

Hand tighten adapter (1) onto pipe nipple (2).

Finish tightening with standard pipe wrench until

a positive seal is implemented. Take care not

to damage O-Ring (3) groove. Back of adapter

(1) must not project more than 1" (25 mm) from

nished wall surface.

Hand tighten tub spout onto adapter (1) taking care

not to damage the O-Ring (3).

Copper Sweat Installation

Remove O-ring (1) from adapter (2). Solder

adapter to tube taking care to keep solder away

from O-ring groove. CAUTION: NO SOLDER

PERMITTED ON OUTSIDE DIAMETER OF

ADAPTER ADJACENT TO O-RING GROOVE. Cut

off tube (3) and replace O-ring on groove of brass

adapter. Thread tub/spout onto adapter, taking

care not to damage O-ring, and hand tighten until

spout is rmly against nished wall and all slack is

taken up behind wall.

5

68883 Rev. J

Page 6

Installation

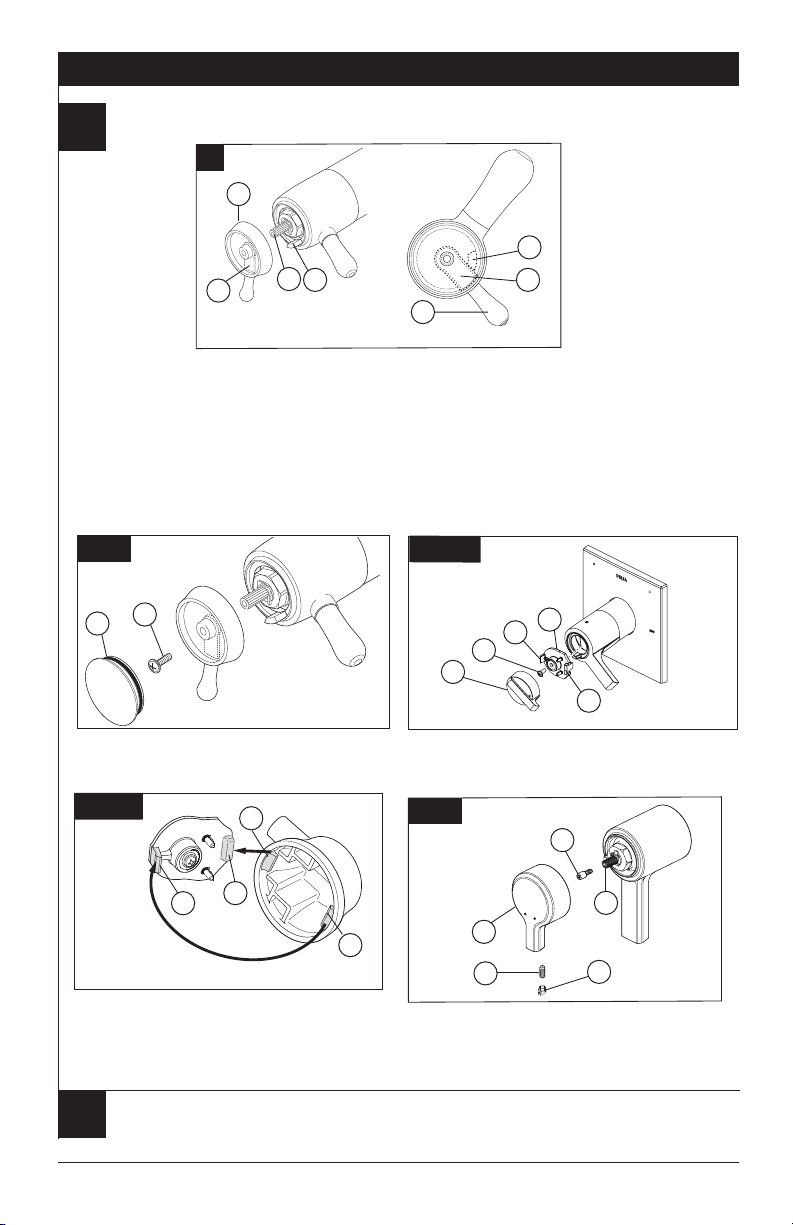

Valve Trim Installation

3

A.

2

1

3

Slide O-ring (1) over cartridge and the

bonnet nut (2). The O-ring, which acts as

a spacer to steady the sleeve, should rest

behind the bonnet nut. Slide the sleeve (3)

over the cartridge, body and O-ring.

Ensure sleeve is properly positioned over

the front of cartridge.

C.

B.

1

3

4

2

Escutcheon Installation for

Models T17T053, T17T253, T17T453

T17T067, T17T267 & T17T467.

6

5

9

7

1

3

2

Install volume control handle (1) with lever

to the right, using an Allen wrench (2) to

secure with the set screw (3).

68883 Rev. J

8

Secure the escutcheon (1) to the bracket

(2) with the 2 screws provided (3). Do not

overtighten escutcheon screws.

If you are installing the Cassidy models

T17T097, T17T297 & T17T497:

Thread the cover (4) onto the escutcheon (1).

For models T17T053, T17T253, T17T453

T17T067, T17T267 & T17T467:

Install bracket (5) over the cartridge body

using the 2 screws provided (6). Install

escutcheon (7) by placing it over the bracket

as shown and rotating it to lock the tabs (8).

Secure the escutcheon to the bracket using

set screw (9).

6

8

Page 7

Installation and Adjustment of the Temperature Knob

Failure to do so may cause injury.

4

A.

1

2

3

4

1

Installation

4

3

A. Adjust temperature limit stop!

Turn on water supplies; LET THE WATER RUN AT

BOTH FULL HOT AND FULL COLD TO ENSURE

THE WATER IS RUNNING AS HOT/COLD AS

POSSIBLE. Place a thermometer in a plastic tumbler,

and hold the tumbler in the water stream. Place the

temperature knob (1) onto the splines (2), then rotate

the temperature knob counter-clockwise until you

achieve your maximum desired temperature from the

outlet (not more than 120° or the lower temperature

mandated by your local plumbing code).

B-1.

1

2

Secure the temperature knob using screw (1) and

place cap (2) on knob.

B-2B.

4

Snap temperature control cover over temperature

control knob by rst aligning smaller tab (1) on cover

with receiving slot (2) on temperature knob. Swing

larger tab (3) to engage with snap feature (4). Note:

If dis-assembly is required, reverse this motion,

disengaging larger tab (3) from snap feature (4) rst.

Potential scald or thermal shock injury could result due to cross ow if outlet at the

shower is blocked or restricted (e.g., pause control on showerhead). Be sure to point

5

showerhead away from you when re-starting ow or install inlet check valves on both

supply lines to prevent possible injury.

1

2

3

If max temperature is not achieved before limit stop

(3) on temperature knob (1) meets the limit stop (4) on

the volume control handle. Remove the temperature

control knob (1) from splines (2). Rotate temperature

control knob (1) clockwise. Place temperature control

knob (1) back onto splines (2) and continue to rotate

counter-clockwise until maximum desired temperature

is achieved.Remove the temperature knob (1) and

replace onto the splines (2), making sure that the

temperature knob limit stop (3) hits against the volume

handle limit stop (4) as shown.

B-2A.

1

5

2

4

Secure temperature control knob (1) with screw (2).

Hook (3) front of temperature control cover (4) onto

knob (1) before engaging rear snap (5).

B-3.

1

3

4

Attach spacer screw (1) to valve stem (2). Slide

temperature control handle (3) into place over spacer

screw (1) and secure using set screw (4). Cover with

decorative button (5).

7

3

2

5

68883 Rev. J

Page 8

Cleaning and Care

Care should be given to the cleaning of

this product. Although its nish is extremely

durable, it can be damaged by harsh

abrasives or polish. To clean, simply wipe

gently with a damp cloth and blot dry with a

soft towel.

Maintenance

Cannot receive more than a trickle of water:

Both hot and cold supply lines must be pressurized.

If only one side is pressurized, the system will not

allow adequate ow of water.

Faucet leaks from showerhead:

Remove the showerhead then turn the water on

and off to verify if the cartridge is leaking or the

showerhead is draining slowly (the showerhead may

need to be cleaned if water drains slowly).

If leak persists -SHUT OFF WATER SUPPLIES

Replace cartridge assembly - RP47201.

Unable to set or maintain mixed water temperature:

SHUT OFF WATER SUPPLIES. Remove handle

assembly, trim sleeve, and bonnet nut. Check to make

sure the “H” marking on the cartridge aligns with the

hot inlet and the “C” marking on the cartridge aligns

with the cold inlet to the valve body The thermostatic

cartridge cannot function if hot and cold inlets are

reversed.

®

Warning: Scrubbing Bubbles

Cleaner and Lysol

®

Basin Tub and Tile

Bathroom

Cleaner must not be used on the clear knob

handles and levers. Use of these cleaners

can result in cracked or severely damaged

handles. If overspray gets onto the handles,

immediately wipe them dry with a soft cotton

cloth.

Low ow:

Low ow may be caused by clogged screens within

the thermostatic cartridge. To clean the hot and cold

screens in the cartridge, follow the steps below:

1. SHUT OFF WATER SUPPLIES.

2. Remove the handle assembly.

3. Unscrew the hex shaped portion of the cartridge

from the brass section of the cartridge. the brass

section must be held securely by the ats while

the hex is rotated counter-clockwise. Failure to

secure the brass section while rotating the

hex can result in damage to the cartridge.

(See illustration below)

4. Carefully clean any debris from the screens

under running water. If the debris is difcult to

remove then soak the screens overnight in a

50% water and 50% vinegar solution.

5. Reassemble the cartridge.

6. Replace the handle.

7 Turn the water back on.

8. Reset the limit stop before using the valve.

17T

68883 Rev. J

Cartridge Summary Reference Sheet

Brass

Hex shaped

portion

Black

Flats

Order RP47201 to

Replace Cartridge.

8

Page 9

Instrucciones para la

Instalación del Accesorio

para Válvulas MultiChoice

Manual para los

Propietarios

17T Series

Escriba aquí el número del modelo comprado.

Usted puede necesitar

L

O

F

N

E

T

Contenido:

Garantías ................................................................................. Page 2

Instrucciones de Instalación .................................................... Pages 3 - 7

Limpieza y Cuidado de su Liave .............................................. Page 8

Mantenimiento .......................................................................... Page 8

Hoja resumen de referencia para el cartucho .......................... Page 8

Para ordenar las piezas de repuesto, visítenos en www.deltafaucet.com

ADVERTENCIA: El instalador debe apostar este

systema/divisa para garantizar temperatura maximo

y seguro. Cualqueir cambio en el ajuste puede subir

la temperatura del agua de descarga sobre el límite

considerado seguro y puede resultar en quemaduras

de agua caliente.

AVISO PARA EL INSTALADOR: PRECAUCIÓN

– Como instalador de esta válvula, es su

responsabilidad de INSTALAR Y AJUSTAR

apropiadamente esta válvula como se describe

en las instrucciones, por lo tanto, debe haber

una persona para hacer los ajustes necesarios

del pomo para la temperatura en el momento

que se haga la instalación y pueda necesitar

ajustes adicionales por los cambios estacionales

de la temperatura del agua. USTED DEBE

informarle al dueño/usuario sobre este requisito

siguiendo las instrucciones. Si usted o el dueño/

usuario no están seguros como hacer estos

ajustes apropiadamente, por favor reérase al

Página 7 y si todavía no está seguro, llámenos al

1-800-345-DELTA.

Después de hacer la instalación y el ajuste, usted

puede agregarle a la etiqueta de aviso proporcionada,

su nombre, el nombre de la compañía y la fecha

cuando ajustó pomo para la tempe raturay aplicar

o jar la etiqueta al dorso de la puerta del gabinete

más cercano y la etiqueta de aviso al calentador de

agua. Deje la Hoja de Instrucciones para referencia

del dueño/usuario.ADVERTENCIA: Esta válvula

de presión balanceada y termostática está

diseñada para minimizar los efectos de los

cambios de temperatura de agua por causa de

los cambios de presión en el agua de entrada,

comúnmente causados por lavadoras de platos,

lavadoras de ropa, inodoros, y otros aparatos

por el estilo. Puede no proporcionar protección

de quemaduras de agua caliente cuando hay

alguna falla de otros aparatos para el control

de temperatura en otro sitio en el sistema de

plomería. También no proporcionará protección

si el pomo para el ajuste de la temperatura

no está apropiadamente jo o si cambia la

temperatura del agua caliente después de

hacer los ajustes o si los cambios del agua

de entrada son por los cambios estacionales.

ADVERTENCIA: No instale un aparato de corte

o cierre en cualquiera de las tomas de esta

válvula. Cuando este tipo de aparato cierra el

ujo de agua, puede hacer fallar la habilidad de

la válvula de balancear las presiones del agua

caliente y fría.

®

05/02/2018

1

68883 Rev. J

Page 10

Garantía Limitada De Por Vida de la Llave y su Acabado

Piezas y acabado

Todas las piezas (excepto las piezas electrónicas y las

pilas) y los acabados de esta llave de agua Delta

están garantizados al consumidor comprador original de

estar libres de defectos en material y fabricación

durante el tiempo que el comprador original posea la

vivienda en la que la llave de agua fue originalmente

instalada o, para los consumidores comerciales, durante

5 años a partir de la fecha de compra.

Componentes electrónicos y pilas (si aplicable)

Todas las piezas (salvo las pilas), si hay, de esta llave

de agua Delta

comprador original de estar libres de defectos en

materiales y fabricación durante 5 años a partir de la

fecha de compra o, para los usuarios comerciales, por

un año a partir de la fecha de compra. No se garantizan

las pilas.

Delta Faucet Company reemplazará, SIN CARGO,

durante el período de garantía aplicable, cualquier pieza

o acabado que pruebe tener defectos de material y/o

fabricación bajo la instalación, uso y servicio normal. Si

la reparación o su reemplazo no es práctico, Delta

Faucet Company tiene la opción de reembolsarle su

dinero por la cantidad del precio de compra a cambio de

la devolución del producto. Estos son sus únicos

recursos.

Delta Faucet Company recomienda que use los

servicios de un plomero profesional para todas las

instalaciones y reparaciones. También le recomendamos

que utilice sólo las piezas de repuesto

originales de Delta

Delta Faucet Company no será responsable por

cualquier daño a la llave de agua que resulte del

mal uso, abuso, negligencia o mala instalación o

mantenimiento o reparación incorrecta, incluyendo

el no seguir los cuidados aplicables y las instrucciones

de limpieza.

Las piezas de repuesto se pueden obtener llamando al

número correspondiente más abajo, o

escribiendo a:

®

están garantizadas al consumidor

®

.

®

En los Estados Unidos y México:

Delta Faucet Company

Product Service

55 E. 111th Street

Indianapolis, IN 46280

1 800 345 DELTA (3358)

customerservice@deltafaucet.com

En Canadá:

Masco Canada Limited, Plumbing Group

Technical Service Centre

350 South Edgeware Road

St. Thomas, Ontario, Canada N5P 4L1

1 800 345 DELTA (3358)

customerservice@mascocanada.com

La prueba de compra (recibo original) del comprador

original debe ser disponible a Delta Faucet Company para

todos los reclamos a menos que el comprador haya

registrado el producto con Delta Faucet Company. Esta

garantía le aplica sólo a las llaves de agua de Delta

fabricadas después del 1 de enero 1995 e instaladas en los

Estados Unidos de América, Canadá y México.

DELTA FAUCET COMPANY NO SE HACE RESPONSABLE

POR CUALQUIER DAÑO ESPECIAL, INCIDENTAL

O CONSECUENTE (INCLUYENDO LOS GASTOS DE

MANO DE OBRA) POR EL INCUMPLIMIENTO DE

CUALQUIER GARANTÍA EXPRESA O IMPLÍCITA DE LA

LLAVE DE AGUA. Algunos estados/provincias no permiten la

exclusión o limitación de daños especiales, incidentales o

consecuentes, por lo que estas limitaciones y exclusiones

pueden no aplicarle a usted. Esta garantía le otorga

derechos legales. Usted también puede tener otros

derechos que varían de estado/provincia a estado/provincia.

Esta es la garantía exclusiva por escrito de Delta Faucet

Company y la garantía no es transferible.

Si usted tiene alguna pregunta o inquietud acerca de

nuestra garantía, por favor, vea nuestra sección de

preguntas frecuentes FAQ sobre la garantía en

www.deltafaucet.com, también puede enviarnos un correo

electrónico a customerservice@deltafaucet.com o llámenos

al número que le corresponda anteriormente incluido.

Garantia Limitada de Delta HDF

Todas las piezas de la llave Delta HDF están

garantizadas al dueño original de estar libres de

defectos en materiales y en la mano de obra por un

período de cinco (5) años. Esta garantía se hace al

dueño original y será efectiva el día de la compra como

se ve en el recibo de compra.

Delta reemplazará, LIBRE DE CARGO, durante el

período de la garantía, cualquier pieza que resulte

defectuosa en materiales y/o en la mano de obra bajo

instalación, uso y servicio normal. Las piezas de

repuesto pueden ser obtenidas de su comerciante o

distribuidor local que se encuentran en la guía telefónica

o si usted devuelve la pieza con el recibo de compra

a nuestra fabrica, Y LOS CARGOS DE TRANSPORTE

PAGADOS CON ANTELACION, a la dirección dada.

ESTA GARANTIA ES LA UNICA GARANTIA EXPRESA

DE DELTA. CUALQUIER RECLAMO HECHO BAJO

ESTA GARANTIA TIENE QUE SER HECHO DURANTE

EL PERIODO DE CINCO AÑOS A QUE SE REFIERE

ARRIBA. CUALQUIER GARANTIA IMPLICITA,

INCLUYENDO LA GARANTIA IMPLICITA DE

COMERCIALIZACION O CONVENIENCIA PARA UN

PROPOSITO PARTICULAR, SON LIMITADOS EN

www.deltafaucet.com

68883 Rev. J

DURACION A LA DURACION DE ESTA GARANTIA.

LOS CARGOS PARA LA MANO DE OBRA Y/O DAÑOS

INCURRIDOS EN LA INSTALACION, REPARACION O

REEMPLAZO, ASI COMO LOS DAÑOS INCIDENTALES

O CONSECUENTES CONECTADOS CON

ELLOS SON EXCLUIDOS Y NO SERAN PAGADOS

POR DELTA.

Algunos estados no permiten limitaciones al tiempo que

dura la garantía implícita, o la exclusión o limitación de

los daños incidentales o consecuentes, así que la

limitación o exclusión expresada arriba puede no ser

aplicable a usted.

Esta garantía le da a usted derechos legales especícos

y usted puede también tener otros derechos que varían

de estado a estado.

Esta garantía es nula por cualquier daño a esta llave

que sea el resultado del mal uso, abuso, negligencia,

accidente, instalación impropia, cualquier uso en

violación de las instrucciones suministradas por

nosotros o cualquier uso de piezas de repuesto que no

sean piezas genuinas Delta.

© 2018 Masco Corporación de Indiana

2

Page 11

Instalación del Cartucho

1

A.

Instalación

B.

4

2

5

3

2

1

Cierre los suministros de agua. Retire la cubierta (1),

la tuerca tapa (2) y la tapa de prueba (3) del cuerpo.

Coloque un balde o recipiente pequeño en la parte del

frente del cuerpo de la válvula y lentamente abra el

suministro de agua para eliminar cualquier residuo de

las líneas de agua antes de instalar el cartucho. Cierre,

de nuevo, el suministro de agua. Si no es para una

instalación en pared delgada, puede quitar el protector

de yeso completo (4). Si la rejilla o colador (5) está en

su lugar, quítela antes de instalar el cartucho.

C.

3

4

1

4

Gire el cartucho (1) de manera que la palabra “UP”

(2) aparezca en la parte superior. La “H” debe

estar en el lado caliente y la “C” debe estar en el

lado frío. Agregue lubricante de silicón a las tres

juntas tóricas (3) como se muestra más arriba para

facilitar la instalación y la retirada del cartucho

del cuerpo de la válvula. Inserte el cartucho en el

cuerpo de la válvula como se muestra. Asegúrese

que las llaves en el cuerpo están totalmente

engranadas en las ranuras en el cuerpo (4).

Instalación de Espalda a Espalda

2

Instalación Normal

(No serequerá cambios)

Instalación

Invertido

3

Deslice la tuerca tapa (1) sobre el cartucho y enrosque

en el cuerpo de la válvula. Apriete a mano bien.

1

Solo para las excepciones en instalaciones de dorso con

dorso o en reverso (el agua calienten la derecha y fría en la

izquierda): Gire el cartucho (1) de manera que la “H” está

en el lado caliente y la “C” está en el lado frío y la palabra

“UP” (2) aparece en la parte inferior. Agregue lubricante de

silicón a las tres juntas tóricas (3) como se muestra más

arriba para facilitar la instalación y la retirada del cartucho

del cuerpo de la válvula. Inserte el cartucho en el cuerpo

de la válvula como se muestra. Asegúrese que las llaves

en el cuerpo están totalmente engranadas en las ranuras

en el cuerpo de bronce (vea la página B). Deslice la tuerca

tapa (3) sobre el cartucho y enrosque en el cuerpo. Apriete

a mano bien.

3

1

Fría

Caliente

68883 Rev. J

Page 12

Instalación

Instalación de la Cabeza de la Regadera y el Surtidor de la Bañera

2

A.

2

1

3

PARA LA INSTALACIÓN DEL SURTIDOR DE LA BAÑERA:

Reérase a las instrucciones para la instalación suministradas con su surtidor. No conecte los surtidores

para las instalaciones en las supercies horizontales en las válvulas dentro de las paredes. No use las

regaderas de mano en vez de un surtidor de bañera conectado a una válvula de bañera/regadera. No use

tubería PEX como tubería entre la válvula y el surtidor de la bañera.

INSTALACIÓN DE LA REGADERA /

DUCHA:

Aplique cinta para plomero a las roscas en ambos

extremos del brazo de la regadera (1). Para

prevenir daño al acabado del brazo de la regadera,

inserte el extremo de la pared del brazo de la

regadera en la brida de ésta (2) antes de enroscar

el brazo en la conexión a la tubería interior.

Enrosque la regadera (3) en el brazo de la

regadera. No apriete la regadera demasiado.

B-1

B-2

Instalación deslizable

El tubo de cobre (1) debe ser de1/2" de cobre

nominal. Importante: Si es necesario cortar el tubo

2

1

1

de cobre, el extremo debe biselarse que quede

libre de rebabas para prevenir cortar o mellar el

aro O dentro del tubo de cobre. Deslice el surtidor

sobre el tubo de cobre al ras con la bañera o la

supercie de la pared acabada. Apriete el tornillo

de ajuste (2), pero no apriete demasiado.

Instalación de la tubería de Hierro

IInstale una entrerrosca de tubo enroscado de

1/2” (13 mm) (1) para extenderse por delante de

la pared acabada. Aplique cinta para plomero a

las roscas en la entrerrosca de tubo y atornille el

surtidor de la bañera.

68883 Rev. J

4

Page 13

Instalación

Instalación de la Cabeza de la Regadera y el Surtidor de la Bañera

2

B-3

B-4

1/2" a 1 1/4"

(13 mm a 32 mm)

3

1 2

1

3 2

Instalación del tubo de hierro

Instalación del tubo de salida de agua del

easy-on universal para bañeras

Instale la entrerrosca del tubo de manera que

el extremo de ésta sobresalga de la pared

acabada 1/2" a 1 1/4" (13 mm a 32 mm). Aplique

cinta para plomero o compuesto para tubos a

las roscas del tubo. Apriete a mano el adaptador

(1) a la entrerrosca del tubo (2). Termine

apretando con una llave de tubos estándar

hasta que el sello positivo se implemente. Tenga

cuidado de no dañar la muesca del anillo-O (3).

La parte posterior del adaptador (1) no debe

sobresalirse más de 1" (25 mm) de la supercie

de la pared acabada. Apriete a mano el tubo de

salida de agua de la bañera al adaptador (1)

teniendo cuidado de no dañar el anillo - O (3).

Instalación de Soldadura de Cobre

Quite el aro O (1) del adaptador (2). Suelde el

adaptador al tubo asegurando de mantener la

soldadura lejos de las muesca del aro O. AVISO:

NO SE PERMITE SOLDAR EN EL DIAMETRO

EXTERIOR DEL ADAPTADOR ADJUNTO A LA

MUESCA DEL ARO O. Corte el tubo (3) y coloque

otra vez el aro O en la muesca del adaptador de

latón. Atornille la bañera/surtidor al adaptador,

asegurando no dañar el aro O, y apriete a mano

bien hasta que el surtidor quede rmemente contra

la pared acabada y no quede ojo detrás de la

pared.

5

68883 Rev. J

Page 14

Instalación Final

3

Instalación

A.

2

1

3

Deslice el aro O (1) sobre el cartucho y la

tuerca tapa (2). El aro O, el cual funciona

como un separador para estabilizar la

manga, debe quedar apoyado en la

tuerca tapa. Deslice la manga (3) sobre el

cartucho, el cuerpo de la pieza y el aro O.

C.

B.

1

3

4

2

La instalación de la roseta para los

modelos T17T053, T17T253, T17T453

T17T067, T17T267 y T17T467.

6

5

9

7

1

3

2

Instale la manija de control de volumen (1)

con la palanca a la derecha, usando una

llave Allen (2) de asegurar con el tornillo de

presión (3).

68883 Rev. J

8

Fije la roseta con oricio (1) al soporte (2)

usando los 2 tornillos suministrados (3). No

apriete demasiado los tornillos de la roseta.

Si está instalando the Cassidy Modelos

T17T097, T17T297 y T17T497: Gira la tapa (4)

en la cubierta de oricio (1).

Para los modelos T17T053, T17T253,

T17T453, T17T067, T17T267 y T17T467:

Instale el soporte (5) sobre el cuerpo del

cartucho usando los 2 tornillos incluidos (6).

Instale la chapa de base (7) colocándola sobre

el soporte como se muestra y girándola para que

encaje en las muescas (8). Fije la chapa de base

al soporte usando el tornillo de ajuste (9).

6

8

Page 15

Instalación

Instalación y Ajuste del Pomo de Temperatura

El no hacerlo puede causar lesión.

4

A.

1

2

3

4

4

3

1

A: ¡Ajuste el tope del límite de temperatura!

Abra los suministros de agua; DEJE QUE CORRA EL

AGUA CALIENTE Y FRÍA TOTALMENTE ABIERTA

PARA ASEGURAR QUE EL AGUA ESTÁ FLUYENDO

LO MÁS CALIENTE/FRÍA POSIBLE. Coloque un

termómetro en un vaso plástico, y sostenga el vaso

bajo un chorro de agua. Coloque la perilla de la

temperatura (1) en las ranuras (2), y gire la perilla de

la temperatura hacia la izquierda hasta alcanzar su

máxima temperatura deseada de salida de agua (no

más de 120° o la temperatura más baja autorizada por

su código de plomería local). Si la temperatura máxima

no se alcanza antes de llegar al tope del límite (3) en el

B-1.

1

2

Fije el pomo de la temperatura usando un tornillo (1)

y coloque la tapa (2) en el pomo.

B-2B.

1

control de la temperatura (1) donde tropieza con

el tope del límite rotacional (4) en la manija del

control de volumen. Retire la perilla del control de

temperatura (1) de las ranuras (2). Gire la perilla del

control de temperatura (1) hacia la derecha. Coloque

la perilla del control de temperatura (1) otra vez en

las ranuras (2) y continue girando hacia la izquierda

hasta que alcanza la temperatura máxima deseada.

Quite el pomo de la temperatura (1) y colóquela otra

vez en las ranuras (2), asegurándose que el pomo

del tope del límitede la temperatura (3) pegue contra

la manija del tope del límite del volumen (4) como se

muestra.

B-2A.

1

5

2

4

3

Fije la perilla para el control de la temperatura (1) con

un tornillo (2) .Gancho (3) delantero coloque la perilla

para el control de couverture(4) encima de perilla (1)

antes de la participación parte trasera instantánea (5).

B-3.

1

2

4

3

Coloque a presión la tapa del control de temperatura

sobre el pomo del control de temperatura alineando

primero la lengüeta más pequeña (1) con la muesca

para encajar en la cubierta (2) ubicada en el pomo de

temperatura. Gire la lengúeta más grande (3) para

que encaje con el mecanismo de presión (4). Nota:

Si requiere desarmar, repita estos pasos en reverso,

desencajando primero la lengúeta más grande (3) del

mecanismo de presión (4).

Si la ducha está bloqueado o restringido, puede resultar posiblemente quemadura o lesion (por

ejemplo, cesa a contral la ducha). Asegúrese salir ducha cuando encender otra vez el flujo o

5

instalar válvulas para evitar lesion posible.

Fije la perilla para el control de la temperatura (1)

con un tornillo (2) .Gancho (3) delantero coloque

la perilla para el control de couverture (4) encima

de perilla (1) antes de la participación parte trasera

instantánea (5).

7

3

4

2

5

68883 Rev. J

Page 16

Limpieza y Cuidado de su Llave

Tenga cuidado al ir a limpiar este producto.

Aunque su acabado es sumamente durable,

puede ser afectado por agentes de limpieza

o para pulir abrasivos. Para limpiar su llave,

simplemente frótela con un trapo húmedo y

luego séquela con una toalla suave.

Mantenimiento

No recibe más de un goteo de agua:

Ambas líneas de suministro de agua, la caliente y

la fría, deben estar presurizadas. Si sólo un lado

está presurizado, el sistema no permitirá el ujo

adecuado de agua.

Si la llave tiene fugas desde la regadera /

ducha:Retire la cabeza de la regadera luego, cierre

y abra el ujo de agua y verique si el cartucho tiene

alguna fuga o si la regadera está escurriéndose

lentamente (si el agua drena lentamente, puede ser

necesario limpiar la cabeza de la regadera).

Si la ltración o fuga persiste -CIERRE LOS

SUMINISTROS DE AGUA Cambie el cartucho -

RP47201.

No se puede establecer o mantener la temperatura

del agua mixta:

CIERRE LOS SUMINISTROS DE AGUA. Retire el

ensamble de la manija, la manga, y la tuerca tapa.

Asegúrese que la marca “H” en el cartucho quede

alineada con la entrada de agua caliente y la marca

“C”, en el cartucho, quede alineada con la entrada

del agua fría al cuerpo de la válvula. El cartucho

termostático no puede funcionar si las entradas de

¡

ADVERTENCIA! No se puede usar

SCRUBBING BUBBLES® BATHROOM

CLEANER o LYSOL® BASIN TUB AND TILE

CLEANER en las manijas transparentes. El

uso de estos productos pueden resultar en

manijas rajados o severamente dañados. Si

estos productos caen sobre la manija, séquelo

inmediatamente con una toalla de algodón

suave.

agua fría y caliente están invertidas.

Flujo bajo: el ujo bajo puede ser por causa de

obstrucciones en los ltros dentro del cartucho

termostático. Para limpiar las rejillas o ltros del agua

caliente y fría en el cartucho, siga los siguientes pasos:

1. CIERRE LOS SUMINISTROS DE AGUA.

2. Retire el ensamble de la manija.

3. Desatornille la porción en forma hexagonal del

cartucho de la sección de bronce del cartucho.

La sección de bronce debe mantenerse ja por los

cortados planos mientras que la sección hexagonal

se gira hacia la izquierda. Si no ja la sección de

bronce mientras que gira la parte hexagonal puede

resultar en daño al cartucho.

(Vea la ilustración a continuación)

4. Limpie cuidadosamente los residuos de los

ltros bajo el chorro de agua. Si los residuos

son difíciles de eliminar, entonces deje los

ltros remojando durante la noche en una

solución del 50% de agua y 50% de vinagre.

5. Vuela a ensamblar el cartucho.

6. Vuelva a colocar la manija.

7 Abra el ujo de agua otra vez.

8. Restablezca el tope del límite antes de

utilizar la válvula.

Hoja resumen de referencia para el cartucho

17T

68883 Rev. J

Bronce

Porción en

forma hex

Negro

Cortados

planos

Ordene el Repuesto RP47201

para cambiar el cartucho.

8

Page 17

Instructions d’installation

Finition de la soupape

MultiChoice

®

Guide d’utilisation

17T Séries

Inscrivez le numéro de modèle ici.

Articles dont vous pouvez avoir besoin:

L

O

F

N

E

T

Table des matières

Garanties .................................................................................. Page 2

Instructions d’installation .......................................................... Pages 3 - 7

Instructions de nettoyage .......................................................... Page 8

Maintenance .............................................................................. Page 8

Fiche de référence sommaire de la cartouche .......................... Page 8

Pour commander des pièces de rechange, visitez www.deltafaucet.com

ATTENTION: L’installateur doit régler l’appareil

pour que la température maximale de l’eau chaude

soit sans danger. Toute modication des réglage

peut entraîner une élévation de la température à

la sorite du robinet au delà de la température sans

danger et pourrait causer un échaudage.

AVIS À L’INSTALLATEUR: ATTENTION! –

En qualité d’installateur, vous êtes tenu

d’INSTALLER et de RÉGLER ce robinet

conformément aux instructions. Ce robinet ne

s’adapte pas automatiquement aux uctuations

de la température de l’eau d’alimentation.

Par conséquent, il faut régler la le bouton de

température au moment de l’installation et

il peut être nécessaire de faire de nouveaux

réglages par la suite en raison des uctuations

saisonnières de la température de l’eau. VOUS

DEVEZ informer le propriétaire ou l’utilisateur

de cette exigence. En cas de doute quant à

la marche à suivre pour faire ces réglages,

veuillez consulter page 7 si un doute persiste,

et si cette incertitude persiste, appelez-nous au

1-800-345-DELTA.

Après avoir terminé l’installation et le réglage, vous

devez inscrire, sur l’étiquette de mise en garde

fournie, votre nom, le nom de votre entreprise et

la date à laquelle vous avez réglé la le bouton

de température, puis xer l’étiquette à l’endos de

la porte de la coiffeuse. Vous devez également

xerl’étiquette d’avertissement au chauffe-eau.

Veuillez laisser ce feuillet d’instructions au

propriétaire ou à l’utilisateur pour qu’il puisse

le consulter au besoin. MISE EN GARDE –

Ce robinet thermostatique à équilibrage de

pression pour baignoire est conçu pour limiter

les effets des uctuations de température de

l’eau causées par les variations de la pression

d’alimentation attribuables au fonctionnement

d’un lave-vaisselle, d’une machine à laver,

d’un cabinet d’aisances ou d’un autre appareil

qui consomme de l’eau. Il peut ne pas

protéger l’utilisateur contre l’échaudage en

cas de défectuosité d’un autre dispositif de

régulation de la température, si le réglage de

la du bouton de température est mauvais, si

la température de l’eau chaude a été modiée

après que les réglages ont été effectués ou si

la température de l’eau d’alimentation a changé

en raison du changement de saison. MISE EN

GARDE – N’installez pas de dispositif d’arrêt

sur une sortie quelconque de ce robinet. En

interrompant l’écoulement de l’eau, ce dispositif

peut empêcher le robinet d’équilibrer les

pressions d’eau chaude et d’eau froide.

05/02/2018

1

68883 Rev. J

Page 18

Garantie à vie limitée des robinets et de leurs nis

Pièces et nis

Toutes les pièces (à l’exception des composants

électroniques et des piles) et tous les nis de ce robinet

®

sont protégés contre les défectuosités du matériau

Delta

et les vices de fabrication par une garantie qui est

consentie au premier acheteur et qui demeure valide tant

que celui-ci demeure propriétaire de la maison dans

laquelle le robinet a été installé. Dans le cas d’une

utilisation commerciale, la garantie est de 5 ans à compter

de la date d’achat.

Composants électroniques et piles (le cas échéant)

Si ce robinet Delta

électroniques, ces composants (à l’exception des piles)

sont protégés contre les défectuosités du matériau et les

vices de fabrication par une garantie consentie au premier

acheteur qui est d’une durée de 5 ans à compter de la

date d’achat. Dans le cas d’une utilisation commerciale, la

garantie est d’un an à compter de la date d’achat. Aucune

garantie ne couvre les piles.

Delta Faucet Company remplacera, GRATUITEMENT,

pendant la période de garantie applicable, toute pièce ou

tout ni qui présentera une défectuosité du matériau et/ou

un vice de fabrication pour autant que le robinet ait été

installé, utilisé et entretenu normalement. S’il est

impossible de réparer ou de remplacer le robinet, Delta

Faucet Company pourra décider de rembourser le prix

d’achat du produit pour autant que celui-ci lui soit retourné.

Il s’agit de vos seuls recours.

Delta Faucet Company recommande de coner

l’installation et la réparation à un plombier professionnel.

Nous vous recommandons également d’utiliser

uniquement des pièces de rechange authentiques Delta

Delta Faucet Company se dégage de toute responsabilité

à l’égard des dommages causés au robinet en raison d’un

mauvais usage, d’un usage abusi f, de la négligence ou de

l’utilisation d’une méthode d’installation, de maintenance

ou de réparation incorrecte ou inadéquate, y compris

les dommages résultant du non-respect des instructions

de nettoyage et d’entretien applicables. Garantie limitée

des robinets Delta

veuillez appeler au numéro applicable ci-dessous ou écrire

à l’adresse applicable ci-dessous.

®

comporte des composants

®

Pour obtenir des pièces de rechange,

Aux États-Unis et au Mexique :

Delta Faucet Company

Product Service

55 E. 111th Street

Indianapolis, IN 46280 St.

1-800-345-DELTA (3358)

customerservice@deltafaucet.com

Au Canada:

Masco Canada Limited, Plumbing Guoup

Thechnical Service Centre

350 South Edgware Roard

Thomas, Ontario, Canada N5P 4L1

1-800-345-DELTA (3358)

customerservice@mascocanada.com

La preuve d’achat (reçu original) du premier acheteur doit

être présentée à Delta Faucet Company pour toutes les

demandes en vertu de la garantie, sauf si le produit a été

enregistré auprès de Delta Faucet Company. La présente

garantie s’applique uniquement aux robinets Delta

fabriqués après le 1er janvier 1995 et installés aux

États-Unis d’Amérique, au Canada et au Mexique.

DELTA FAUCET COMPANY SE DÉGAGE DE TOUTE

RESPONSABILITÉ À L’ÉGARD DES DOMMAGES

PARTICULIERS, CONSÉCUTIFS OU INDIRECTS (Y

COMPRIS LES FRAIS DE MAIN-D’OEUVRE) QUI

POURRAIENT RÉSULTER DE LA VIOLATION D’UNE

GARANTIE IMPLICITE OU EXPLICITE QUELCONQUE

SUR LE ROBINET. Dans les États ou les provinces

où il est interdit de limiter ou d’exclure la responsabilité à

l’égard des dommages particuliers, consécutifs ou

indirects, les limites et les exclusions susmentionnées ne

®

s’appliquent pas.

.

La présente garantie vous donne des droits précis qui

peuvent varier selon l’État ou la province où vous résidez.

La présente garantie écrite est la garantie exclusive offerte

par Delta Faucet Company et elle n’est pas transférable.

Si vous avez des questions ou des préoccupations en ce

qui concerne notre garantie, veuillez consulter la page

Warranty FAQs à www.deltafaucet.com, faire parvenir un

courriel à customerservice@deltafaucet.com ou nous

appeler au numéro applicable.

®

Garantie Limitée sur les Robinets Ultra-Robustes Delta de la Série HDF

Toutes les pièces des robinets ultra-robustes Delta de la

série HDF sont protégées contre les défectuosités du

matériau et les vices de conception par une garantie qui

est consentie au premier acheteur pour une période de

cinq (5) ans. Cette garantie entre en vigueur à compter de

la date d’achat indiquée sur le reçu de l’acheteur.

Pendant la période de garantie, Delta remplacera, SANS

FRAIS, toute pièce présentant une défectuosité du

matériau et (ou) un vice de fabrication pour autant que

l’appareil ait été installé, utilisé et entretenu correctement.

Pour obtenir des pièces de rechange, veuillez

communiquer avec le distributeur ou le concessionnaire de

votre région dont le nom gure dans l’annuaire

téléphonique ou retourner la pièce défectueuse

accompagnée du reçu de l’acheteur à notre usine, PORT

PAYÉ, à l’adresse indiquée. LA PRÉSENTE GARANTIE

EST LA SEULE GARANTIE IMPLICITE OFFERTE PAR

DELTA. TOUTE RÉCLAMATION EN VERTU DE CETTE

GARANTIE DOIT ÊTRE FAITE AU COURS DE LA

PÉRIODE DE CINQ ANS SUSMENTIONNÉE. TOUTE

GARANTIE IMPLICITE, Y COMPRIS LA GARANTIE

IMPLICITE DE QUALITÉ MARCHANDE OU

www.deltafaucet.com

68883 Rev. J

D’ADÉQUATION DU PRODUIT AVEC UN USAGE

PARTICULIER, EST LIMITÉE À LA DURÉE DE LA

PRÉSENTE GARANTIE. LES FRAIS DE

MAIN-D’OEUVRE ET (OU) LES DOMMAGES

PROVOQUÉS AU COURS DE L’INSTALLATION, DE LA

RÉPARATION OU DU REMPLACEMENT D’UN

ÉLÉMENT AINSI QUE LES PERTES OU LES

DOMMAGES INDIRECTS EN RÉSULTANT NE SONT

PAS COUVERTS PAR CETTE GARANTIE.

Là où il est interdit de limiter la durée de la garantie

implicite ou les responsabilités à l’égard des dommages

indirects, les exclusions et les limites susmentionnées ne

s’appliquent pas.

La présente garantie vous donne des droits précis qui

peuvent varier selon votre lieu de résidence.

Les dommages résultant d’une mauvaise utilisation, d’une

utilisation abusive, de la négligence, d’un accident, d’une

mauvaise installation, du non respect de nos instructions

ou de l’utilisation de pièces de rechange autres que des

pièces d’origine Delta ne sont pas couverts par la garantie.

© 2018 Division de Masco Indiana

2

Page 19

Installation de la cartouche.

1

Installation

A. B.

4

5

3

2

1

Fermez les robinets d’arrêt. Enlevez le couvercle

(1), l’écrou-chapeau (2) et le capuchon d’essai (3)

du corps. Placez un seau ou un petit contenant sur

l’avant du corps de soupape et ouvrez lentement les

robinets d’arrêt pour évacuer les corps étrangers de

la tuyauterie avant d’installer la cartouche. Fermez

de nouveau les robinets d’arrêt. Si le corps n’est pas

monté dans un mur mince, vous pouvez enlever le

protecteur (4) au complet. Si le ltre métallique (5)

est en place, enlevez-le avant d’installer la cartouche.

Tournez la cartouche (1) de sorte que le mot « UP

» (2) se trouve sur le dessus. La lettre « H » doit se

trouver du côté eau chaude et la lettre « C », du côté

eau froide. Ajoutez du lubriant à base de silicone aux

trois joints toriques (3) montrés ci-dessus pour faciliter

la pose de la cartouche dans le corps de soupape et

sa dépose. Introduisez la cartouche dans le corps de

la soupape comme le montre la gure. Assurez-vous

que les ergots sont parfaitement engagés dans les

rainures du corps (4).

C.

2

3

4

1

4

Installation dos à dos

Faites glisser l’écrou à portée sphérique (1) sur la

cartouche et vissez-le sur le corps. Serrez à la

main fermement.

2

Installation normale

(Non modiée)

Installation

Inversée

3

1

Dans le cas d’une installation dos à dos ou inversée (eau

chaude à droite et eau froide à gauche) seulement : tournez

la cartouche (1) de sorte que la lettre « H » se trouve du

côté eau chaude, la lettre « C », du côté eau froide et le

mot « UP » (2), sur le dessus. Ajoutez du lubriant à base

de silicone aux trois joints toriques montrés ci-dessus pour

faciliter la pose de la cartouche dans le corps de soupape et

sa dépose. Installez la cartouche en prenant soin d’introduire

les ergots entièrement dans les rainures du corps de laiton

(reportez-vous à l’étape B). Glissez l’écrou-chapeau (3) sur

la cartouche et vissez-le sur le corps. Serrez-le à la main

solidement.

3

1

Eau Froides

Eau Chaude

68883 Rev. J

Page 20

Installation

Installation de la pomme de douche et du bec de baignoire

2

A.

2

1

3

INSTALLATION DU BEC DE BAIGNOIRE:

Consultez les instructions d’installation fournies avec le bec. Ne raccordez pas à une soupape murale à

un bec conçu pour être monté sur une plage. Ne raccordez pas une douche à main à la sortie d’un robinet

de baignoire-douche prévue pour un bec de baignoire. N’utilisez pas de tube PEX pour raccorder le bec.

B-1

2

1

INSTALLATION DE LA POMME DE

DOUCHE: appliquez du ruban de plomero

sur les letages aux deux extrémités

du bras de douche (1). Pour éviter

d’endommager le ni du bras de douche,

introduisez le côté mur de celui-ci dans la

collerette de douche (2) avant de le visser

dans le raccord du tuyau ascendant.

Vissez la pomme de douche (3) sur le

bras de douche.

Évitez de serrer la pomme de douche

excessivement.

Installation d’un bec coulissant

Le tube de cuivre (1) doit avoir un diamètre

nominal de1/2 po. Important : Si vous devez

couper le tube de cuivre, chanfreinez son

extrémité de sorte qu’elle ne risque pas

d’endommager le joint torique à l’intérieur du

bec. Faites glisser le bec sur le tube de cuivre

de sorte qu’il s’appuie contre la surface nie

de la baignoire ou du mur. Serrez la vis de

calage (2), mais prenez garde de la serrer

excessivement.

B-2

68883 Rev. J

Installation à l’aide d’un tuyau de fer

Installez le manchon leté (1) 1/2 po (13

mm) de manière que sa saillie par rapport à

la surface nie du mur. Appliquez du ruban

de plomberie sur les lets du manchon et xez

celui-ci au bec de baignoire en vissant.

1

4

Page 21

Installation

Installation de la pomme de douche et du bec de baignoire

2

B-3

B-4

1/2 po a 1 1/4 po

(13 mm to 32 mm)

3

1 2

1

3 2

Installation sur un tuyau de fer

Installation du bec de baignoire polyvalent

easy-on

Installez le manchon leté de manière qu’il

présente une saillie de 1/2 à 1 1/4 po (13 mm à

32 mm) par rapport à la surface nie du mur.

Appliquez du ruban de plomberie ou du

composé à letage sur les lets. Montez

l’adaptateur (1) sur le manchon (2) et serrezle à la main. Finissez ensuite le serrage à l’aide

d’une clé à tube pour rendre le joint étanche.

Prenez garde d’abîmer le rainure du joint

torique (3). Les dos de l’adaptateur (1) ne doit

pas se trouver à plus de 1 pouce (25 mm) par

rapport à la surface nie du mur.

Montez le bec de baignoire sur l’adaptateur (1)

et serrez-le à la main en prenant soin de ne pas

abîmer le joint torique (3).

Installation à l’aide d’un tuyau de cuivre brasé

QRetirez le joint torique (1) de l’adaptateur (2).

Brasez l’adaptateur au tube en prenant garde

d’échapper du métal d’apport dans la rainure

pour le joint torique. ATTENTION : IL NE

DOIT PAS Y AVOIR DE MÉTAL D’APPORT

SUR LA CIRCONFÉRENCE EXTÉRIEURE

DE L’ADAPTATEUR PRÈS DE LA RAINURE

POUR LE JOINT TORIQUE. Coupez le tube

(3) et remettez le joint torique en place dans

la raInure de l’adaptateur en laiton. Vissez le

bec de baignoire sur l’adaptateur et prenant

garde d’abîmer le joint torique. Serrez le bec

à la main jusqu’à ce qu’il s’appuie solidement

contre la surface nie de la paroi et qu’il

n’y ait plus de jeu derrière le mur.

5

68883 Rev. J

Page 22

Installation des pièces de nition

3

Installation

A.

2

1

3

Faites glisser le joint torique (1) sur la

cartouche et l’écrou à portée sphérique

(2). Le joint sert de pièce d’espacement

et il stabilise le manchon; il doit se trouver

derrière l’écrou à portée sphérique. Faites

glisser le manchon (3) sur la cartouche, le

corps et le joint torique.

C.

B.

1

3

4

2

Installation de la rosace pour les

modèles T17T053, T17T253, T17T453

T17T067, T17T267 et T17T467.

6

5

9

7

1

3

2

Installez la poignée de commande de

volume (1) avec le levier vers la droite,

utilisant une clé Allen (2) de fixer avec la

vis de réglage (3).

68883 Rev. J

8

Fixez la rosace (1) sur le support (2) à l’aide

des 2 vis fournies (3). Prenez garde de serrer

les vis de la rosace excessivement.

Si vous installez Cassidy Modèles T17T097,

T17T297 & T17T497: Enlez le couvercle (4)

sur l'écusson (1).

Pour les modèles T17T053, T17T253,

T17T453, T17T067, T17T267 et T17T467:

Montez la xation (5) sur le corps de la

cartouche à l’aide des 2 vis fournies (6).

Installez la plaque de nition (7) en la plaçant

sur la xation comme le montre la gure et

tournez-la pour bloquer les pattes (8). Fixez la

plaque de nition à la xation à l’aide de la vis

de calage (9).

6

8

Page 23

Installation

Installation et réglage du bouton de température

Il y a risque de blessure si le bouton de température n’est pas réglé.

4

A.

1

4

2

3

Réglez la butée limitatrice de température!

Rétablissez l’alimentation en eau. LAISSEZ COULER

CHAUDE JUSQU’À CE QU’ELLE SOIT AUSSI

CHAUDE QUE POSSIBLE ET FAITES DE MÊME

POUR L’EAU FROIDE. Placez un thermomètre dans

un gobelet en plastique et tenez le gobelet sous le

jet d’eau. Placez le bouton de température (1) sur les

cannelures (2), puis tournez-le dans le sens antihoraire

jusqu’à ce que l’eau soit à la température maximale

voulue (pas plus de 120° ou température plus basse

exigée par le code de plomberie local). Si l'eau n'atteint

pas la température maximale avant que la butée de

température maximale (3) sur le

B-1.

4

1

bouton de température (1) n'atteigne la butée de

température maximale (4) sur la manette de débit,

retirez le bouton de réglage de température (1)

des cannelures (2). Tournez le bouton de réglage

de température (1) dans le sens horaire. Replacez

le bouton de réglage de température (1) sur les

cannelures (2) et continuez de le tourner dans le sens

antihoraire jusqu’à ce que l’eau soit à la température

maximale voulue. Enlevez le bouton de température (1)

et replacez-le sur les cannelures (2) en vous assurant

que la butée limitatrice de température (3) s’appuie

contre la butée de la manette de débit (4) comme le

montre la gure.

B-2A.

3

1

2

Fixez le bouton de température à l’aide de la vis (1)

et placez le capuchon (2) sur le bouton.

B-2B.

1

2

4

Fixez le bouton de réglage de température (1) avec la

vis (2) et, accrocher avant ou poussant fermement sur

calez le couvercle (3) sur bouton avant de engageant

arrière bouton (1).

1

5

3

B-3.

1

2

4

3

Placez le couvercle de la commande de température

contre le bouton de réglage de température après

avoir aligné la petite patte (1) sur le couvercle avec la

rainure (2) sur bouton de température. Faites pivoter

la grosse patte (3) pour l’engager dans la xation (4).

Note : Si vous devez démonter le couvercle, procédez

dans l’ordre inverse et dégagez la grosse patte (3) de

la xation (4) en premier.

La brûlure potentielle ou la blessure de choc thermique pourraient résulter du ux si la sortie à

la douche est bloquée ou restreint (par exemple, le contrôle de pause sur douche).

5

Assurez-vous de diriger la douche loin de vous en reprenant le ux ou installer des valves

de contrôle d'admission sur les deux conduites d'alimentation pour empêcherla blessure possible.

Fixez la vis d’espacement (1) à la tige de soupape

(2). Glissez la manette de réglage de température

(3) en place sur la vis d’espacement (1) et xez-la à

l’aide de la vis de calage (4). Recouvrez le trou avec

le bouton décoratif (5).

7

3

4

2

5

68883 Rev. J

Page 24

Instructions de nettoyage

Il faut le nettoyer avec soin. Même si son

ni est extrêmement durable, il peut être

abîmé par des produits fortement abrasifs

ou des produits de polissage. Il faut

simplement le frotter doucement avec un

chiffon humide et le sécher à l'aide d'un

chiffon doux.

AVERTISSEMENT: N’employez pas le

nettoyant pour salle de bain Scrubbing

Bubbles

®

ni le Nettoyant de Lavabos,

Maintenance

Évitez de serrer la pomme de douche

excessivement.

Les conduites d’eau chaude et en eau froide

doivent être toutes les deux sous pression. Si

seulement un côté est sous pression, le débit d’eau

à la sortie du système sera insufsant.

La pomme de douche fuit : retirez la pomme de

douche, puis ouvrez et fermez les robinets d’arrêt

et vériez si la cartouche fuit ou si la pomme de

peut avoir besoin d’un nettoyage si elle se vide

lentement.

Si la fuite persiste - FERMEZ LES ROBINETS

D’ARRÊT.

Remplacez la cartouche - RP47201.

Incapacité de régler ou de maintenir la

température de l’eau mitigée :

FERMEZ LES ROBINETS D’ARRÊT. Retirez la

manette, le manchon de nition et l’écrou-chapeau.

Assurez-vous que la lettre « H » qui gure sur la

cartouche est orientée vers l’entrée d’eau chaude

et que la lettre « C » est orientée vers l’entrée

d’eau froide du corps de soupape. La cartouche

thermostatique ne fonctionnera pas si l’entrée d’eau

de Baignoires et de Carreaux Lysol

®

sur les manettes et les poignées sphériques

transparentes. Ces produits peuvent faire

ssurer les poignées et les manettes ou

les abîmer gravement. Si ces poigneés

ou ces manettes sont aspergées

accidentellement par l’un ou l’autre

des produits mentionnés, les essuyer

immédiatement à l’aide d’un chiffon de

coton doux.

chaude et l’entrée d’eau froide sont inversées.

Faible débit: un faible débit peut être attribuable

à des ltres métalliques obstrués à l’intérieur de la

cartouche thermostatique.

1. FERMEZ LES ROBINETS D’ARRÊT.

2. Enlevez la manette.

3. Dévissez la partie hexagonale de la cartouche

de la section en laiton de la cartouche. Tenez

solidement la section en laiton par les méplats

pendant que vous tournez la partie hexagonale

dans le sens antihoraire. Si vous ne tenez pas

la section en laiton assez solidement, la cartouche

risque d'être endommagée.

(Voir l'illustration ci-dessous).

4. Nettoyez soigneusement les ltres métalliques en

faisant couler de l’eau au travers pour évacuer les

saletés. Si les saletés sont difcile à enlever, faites

tremper les ltres métalliques toute la nuit dans

une solution composée à part égales d’eau et de

vinaigre.

5. Remontez la cartouche.

6. Replacez la manette.

7. Ouvrez les robinets d’arrêt.

8. Remettez la butée de température maximale à sa

position initiale avant d’utiliser la soupape.

Fiche de référence sommaire de la cartouche

17T

68883 Rev. J

Laiton

Partie

hexagonale

Noir

Méplats

Commandez le kit RP47201

pour remplacer la cartouche.

8

Page 25

Notes / Notas / Notes

Page 26

Notes / Notas / Notes

Page 27

Notes / Notas / Notes

Page 28

Delta Faucet Company

Product Service

55 E. 111th Street

Indianapolis, IN 46280

Loading...

Loading...