Delta Modulon DPH series, Modulon DPH 200kVA, Modulon DPH 500kVA, Modulon DPH 300kVA, Modulon DPH 400kVA User Manual

Page 1

The power behind competitiveness

Delta UPS - Modulon Family

DPH Series, Three Phase

200-500 kVA

User Manual

www.deltapowersolutions.com

Page 2

Save This Manual

This manual contains important instructions and warnings that you should follow

during the installation, operation, storage and maintenance of this product. Failure

to heed these instructions and warnings will void the warranty.

Copyright © 2018 by Delta Electronics Inc. All Rights Reserved. All rights of this User Manual

(“Manual”), including but not limited to the contents, information, and figures are solely owned and

reserved by Delta Electronics Inc. (“Delta”). The Manual can only be applied to the operation or the

use of this product. Any disposition, duplication, dissemination, reproduction, modification, translation,

extraction, or usage of this Manual in whole or in part is prohibited without the prior written permission

of Delta. Given that Delta will continuously improve and develop the product, changes may be

made to the information in this Manual at any time without obligation to notify any person of such

revision or changes. Delta will make all possible efforts to secure the accuracy and the integrity of this

Manual. Delta disclaims any kinds or forms of warranty, guarantee, or undertaking, either expressly

or implicitly, including but not limited to the completeness, faultlessness, accuracy, non-infringement,

merchantability or fitness for a particular purpose of the Manual.

Modulon DPH Series

II

Page 3

Table of Contents

Table of Contents

1. Important Safety Instructions ---------------------------------------------- 1-1

1.1 Installation Warnings ---------------------------------------------------------------------- 1-2

1.2 Connection Warnings --------------------------------------------------------------------- 1-2

1.3 Usage Warnings --------------------------------------------------------------------------- 1-4

1.4 Storage Warnings ------------------------------------------------------------------------- 1-6

1.5 Standard Compliance -------------------------------------------------------------------- 1-6

2. Introduction ---------------------------------------------------------------------- 2-1

2.1 General Overview ------------------------------------------------------------------------- 2-2

2.2 Package Inspection ----------------------------------------------------------------------- 2-2

2.3 Functions & Features --------------------------------------------------------------------- 2-4

2.4 Exterior and Dimensions ----------------------------------------------------------------- 2-6

2.5 Front View ----------------------------------------------------------------------------------- 2-6

2.6 Internal View ------------------------------------------------------------------------------- 2-8

2.7 Rear View------------------------------------------------------------------------------------ 2-9

2.8 Tri-color LED Indicator & Buzzers --------------------------------------------------- 2-11

3. Operation Modes --------------------------------------------------------------- 3-1

3.1 Single Input --------------------------------------------------------------------------------- 3-4

3.1.1 Online Mode_ Single Input_ Single Unit ---------------------------------- 3-4

3.1.2 Battery Mode_ Single Input_ Single Unit---------------------------------- 3-5

3.1.3 Bypass Mode_ Single Input_ Single Unit -------------------------------- 3-6

3.1.4 Manual Bypass Mode_ Single Input_ Single Unit----------------------- 3-6

3.1.5 ECO Mode_ Single Input_ Single Unit ------------------------------------ 3-8

3.1.6 Frequency Conversion Mode_ Single Input_ Single Unit ------------ 3-8

3.1.7 Green Mode _ Single Input_ Single Unit --------------------------------- 3-9

3.1.8 Energy Recycle Mode _ Single Input_ Single Unit --------------------3-10

3.1.9 Online Mode_ Single Input_ Parallel Units -----------------------------3-11

3.1.10

3.1.11

3.1.12

3.1.13

3.1.14

3.1.15

3.2 Dual Input -----------------------------------------------------------------------------------3-19

3.2.1 Online Mode_ Dual Input_ Single Unit -----------------------------------3-19

3.2.2 Battery Mode_ Dual Input_ Single Unit ----------------------------------3-19

Battery Mode _ Single Input_ Parallel Units ----------------------------3-12

Bypass Mode_ Single Input_ Parallel Units -----------------------------3-13

Manual Bypass Mode_ Single Input_ Parallel Units ------------------3-14

ECO Mode_ Single Input_ Parallel Units --------------------------------3-16

Frequency Conversion Mode_ Single Input_ Parallel Units --------3-17

Green Mode_ Single Input_ Parallel Units-------------------------------3-18

III

Page 4

3.2.3 Bypass Mode_ Dual Input_ Single Unit ----------------------------------3-20

3.2.4 Manual Bypass Mode_ Dual Input_ Single Unit ------------------------3-21

3.2.5 ECO Mode_ Dual Input_ Single Unit -------------------------------------3-22

3.2.6 Frequency Conversion Mode_ Dual Input_ Single Unit -------------3-23

3.2.7 Green Mode _ Dual Input_ Single Unit ----------------------------------3-24

3.2.8 Online Mode_ Dual Input_ Parallel Units --------------------------------3-25

3.2.9 Battery Mode _ Dual Input_ Parallel Units ------------------------------3-26

3.2.10

Bypass Mode_ Dual Input_ Parallel Units ------------------------------3-27

3.2.11

Manual Bypass Mode_ Dual Input_ Parallel Units --------------------3-28

3.2.12

ECO Mode_ Dual Input_ Parallel Units ----------------------------------3-30

3.2.13

Frequency Conversion Mode_ Single Input_ Parallel Units --------3-31

3.2.14

3.3 Hot Standby Redundancy (Only For Dual Input & At Least Two UPSs) ----3-33

3.4 Common Battery (Only for Parallel UPSs connecting to -----------------------------the Same External Battery Cabinet(s)) ----------------------------------------------3-34

Green Mode_ Dual Input_ Parallel Units --------------------------------3-32

4. Communication Interfaces -------------------------------------------------- 4-1

4.1 Communication Interfaces on the Front of the UPS with Front Door Open 4-2

4.1.1 Display Port ---------------------------------------------------------------------- 4-3

4.1.2 REPO Dry Contacts ------------------------------------------------------------ 4-3

4.1.3 External Battery Temperature Dry Contacts ----------------------------- 4-5

4.1.4 External Switch/ Breaker Status Dry Contacts -------------------------- 4-6

4.1.5 Output Dry Contacts ------------------------------------------------------------ 4-7

4.1.6 Input Dry Contacts -------------------------------------------------------------4-10

4.1.7 Parallel Communication Cards --------------------------------------------- 4-11

4.1.8 Parallel Ports -------------------------------------------------------------------- 4-11

4.1.9 SMART Slot ---------------------------------------------------------------------4-12

4.1.10

4.1.11

4.1.12

4.2 Communication Interfaces at the Rear of the Touch Panel --------------------4-13

USB Port & RS-232 Port -----------------------------------------------------4-12

Auxiliary Power Cards --------------------------------------------------------4-12

Battery Start Buttons ----------------------------------------------------------4-13

5. Installation and Wiring -------------------------------------------------------- 5-1

5.1 Before Installation and Wiring ---------------------------------------------------------- 5-2

5.2 Installation Environment ----------------------------------------------------------------- 5-3

5.3 UPS Transportation ----------------------------------------------------------------------- 5-5

5.4 Fixing the UPS ---------------------------------------------------------------------------- 5-6

5.5 Wiring ----------------------------------------------------------------------------------------- 5-8

5.5.1 Pre-wring Warnings------------------------------------------------------------- 5-8

Modulon DPH Series

IV

Page 5

Table of Contents

5.5.2 Single Input/ Dual Input Modification --------------------------------------5-10

5.5.3 Single Unit Wiring --------------------------------------------------------------5-12

5.5.4 Parallel Units Wiring ----------------------------------------------------------5-21

5.6 External Battery Cabinet Connection Warnings ---------------------------------5-25

5.7 STS Module --------------------------------------------------------------------------------5-32

5.7.1 STS Module Installation ------------------------------------------------------5-33

5.7.2 STS Module Removal -------------------------------------------------------5-35

5.7.3 STS Module’s LED Indicator ------------------------------------------------5-37

5.8 Power Module (Optional) ---------------------------------------------------------------5-37

5.8.1 Power Module Installation ---------------------------------------------------5-38

5.8.2 Power Module Removal -----------------------------------------------------5-40

5.8.3 Power Module’s LED Indicator ---------------------------------------------5-42

6. UPS Operation------------------------------------------------------------------- 6-1

6.1 Pre Start-up & Pre Turn-off Warnings for Single Unit --------------------------------and Parallel Units -------------------------------------------------------------------------- 6-2

6.2 Start-up Procedures ---------------------------------------------------------------------- 6-4

6.2.1 Online Mode Start-up Procedures ------------------------------------------ 6-4

6.2.2 Battery Mode Start-up Procedures ----------------------------------------- 6-8

6.2.3 Bypass Mode Start-up Procedures ----------------------------------------6-10

6.2.4 Manual Bypass Mode Start-up Procedures -----------------------------6-13

6.2.5 ECO Mode Start-up Procedures -------------------------------------------6-18

6.2.6 Frequency Conversion Mode Start-up Procedures--------------------6-22

6.2.7 Green Mode Start-up Procedures -----------------------------------------6-26

6.2.8 Energy Recycle Mode Start-up Procedures -----------------------------6-30

6.3 Turn-off Procedures ----------------------------------------------------------------------6-34

6.3.1 Online Mode Turn-off Procedures -----------------------------------------6-34

6.3.2 Battery Mode Turn-off Procedures -----------------------------------------6-36

6.3.3 Bypass Mode Turn-off Procedures ----------------------------------------6-38

6.3.4 Manual Bypass Mode Turn-off Procedures ------------------------------6-39

6.3.5 ECO Mode Turn-off Procedures --------------------------------------------6-39

6.3.6 Frequency Conversion Mode Turn-off Procedures --------------------6-42

6.3.7 Green Mode Turn-off Procedures ------------------------------------------6-45

6.3.8 Energy Recycle Mode Turn-off Procedures -----------------------------6-48

7. LCD Display & Settings ------------------------------------------------------ 7-1

7.1 LCD Display Hierarchy ------------------------------------------------------------------- 7-2

7.2 Turning on the Touch Panel ------------------------------------------------------------- 7-3

7.3 ON/ OFF Button ---------------------------------------------------------------------------- 7-5

V

Page 6

7.4 Introduction of Touch Panel and Function Keys ----------------------------------- 7-7

7.5 Password Entry --------------------------------------------------------------------------- 7-11

7.6 Main Screen -------------------------------------------------------------------------------7-12

7.7 Main Menu ---------------------------------------------------------------------------------7-16

7.8 Power Flow & Summary & System Status -----------------------------------------7-17

7.9 Check System Readings ---------------------------------------------------------------7-19

7.9.1 Main Input ------------------------------------------------------------------------7-19

7.9.2 Bypass Input --------------------------------------------------------------------7-20

7.9.3 Inverter Output ------------------------------------------------------------------7-20

7.9.4 Power Module Summary -----------------------------------------------------7-21

7.9.5 UPS Output ----------------------------------------------------------------------7-21

7.9.6 Battery Status -------------------------------------------------------------------7-22

7.10 UPS Settings ------------------------------------------------------------------------------7-23

7.10.1

7.10.2

7.10.3

7.10.4 Battery & Charging Setting --------------------------------------------------7-26

7.10.5

7.10.6

7.10.7

7.10.8

7.10.9

7.11 System Maintenance --------------------------------------------------------------------7-35

7.11.1

7.11.2

7.11.3

7.11.4

7.11.5

7.11.6 Advanced Diagnosis ----------------------------------------------------------7-39

7.11.7

Bypass Setting ------------------------------------------------------------------7-23

Mode Setting --------------------------------------------------------------------7-24

Output Setting -------------------------------------------------------------------7-25

Parallel Setting ------------------------------------------------------------------7-28

Dry Contact Setting -----------------------------------------------------------7-29

General Setting -----------------------------------------------------------------7-31

IP Setting -------------------------------------------------------------------------7-33

Control ----------------------------------------------------------------------------7-34

Alarm Warning ------------------------------------------------------------------7-35

Historical Event -----------------------------------------------------------------7-36

Statistics --------------------------------------------------------------------------7-37

Test --------------------------------------------------------------------------------7-38

Clear -------------------------------------------------------------------------------7-38

Version & S/N -------------------------------------------------------------------7-40

8. Optional Accessories -------------------------------------------------------- 8-1

9. Maintenance ---------------------------------------------------------------------- 9-1

10. Troubleshooting ---------------------------------------------------------------10-1

Appendix 1: Technical Specifications ---------------------------------------- A1-1

Appendix 2: Warranty -------------------------------------------------------------- A2-1

Modulon DPH Series

VI

Page 7

ௐ

ௐ

1

Important Safety Instructions

1

Important Safety

Instructions

1.1 Installation Warnings

1.2 Connection Warnings

1.3 Usage Warnings

1.4 Storage Warnings

1.5 Standard Compliance

1-1

Page 8

1.1 Installation Warnings

y This is a three-phase four-wire on-line uninterruptible power supply (hereafter referred to

as ‘UPS’). It can be used for commercial and industrial applications.

y Install the UPS in a well-ventilated indoor area, away from excess moisture, heat, dust,

flammable gas or explosives.

y Leave adequate space around all sides of the UPS for proper ventilation and maintenance.

Please refer to 5.2 Installation Environment.

y Only authorized Delta engineers or service personnel can perform installation and

maintenance. If you want to install the UPS by yourself, please install it under the

supervision of authorized Delta engineers or service personnel

y Follow the IEC 60364-4-42 standard to install the UPS.

1.2 Connection Warnings

y Before applying electrical power to the UPS, make sure the UPS is grounded to avoid a

possible risk of current leakage.

y You can parallel at maximum eight UPS units.

y The UPS must be connected with an external battery cabinet (user-supplied, handled and

configured by Delta service personnel). Please refer to 5.6 External Battery Cabinet

Connection Warnings for relevant information.

y The UPS must be connected with a Delta or non-Delta external maintenance bypass

cabinet. The Delta external maintenance bypass cabinet is optional, and the non-Delta

external maintenance bypass cabinet is user-supplied and should be handled and

configured by Delta service personnel. For the Delta or non-Delta external maintenance

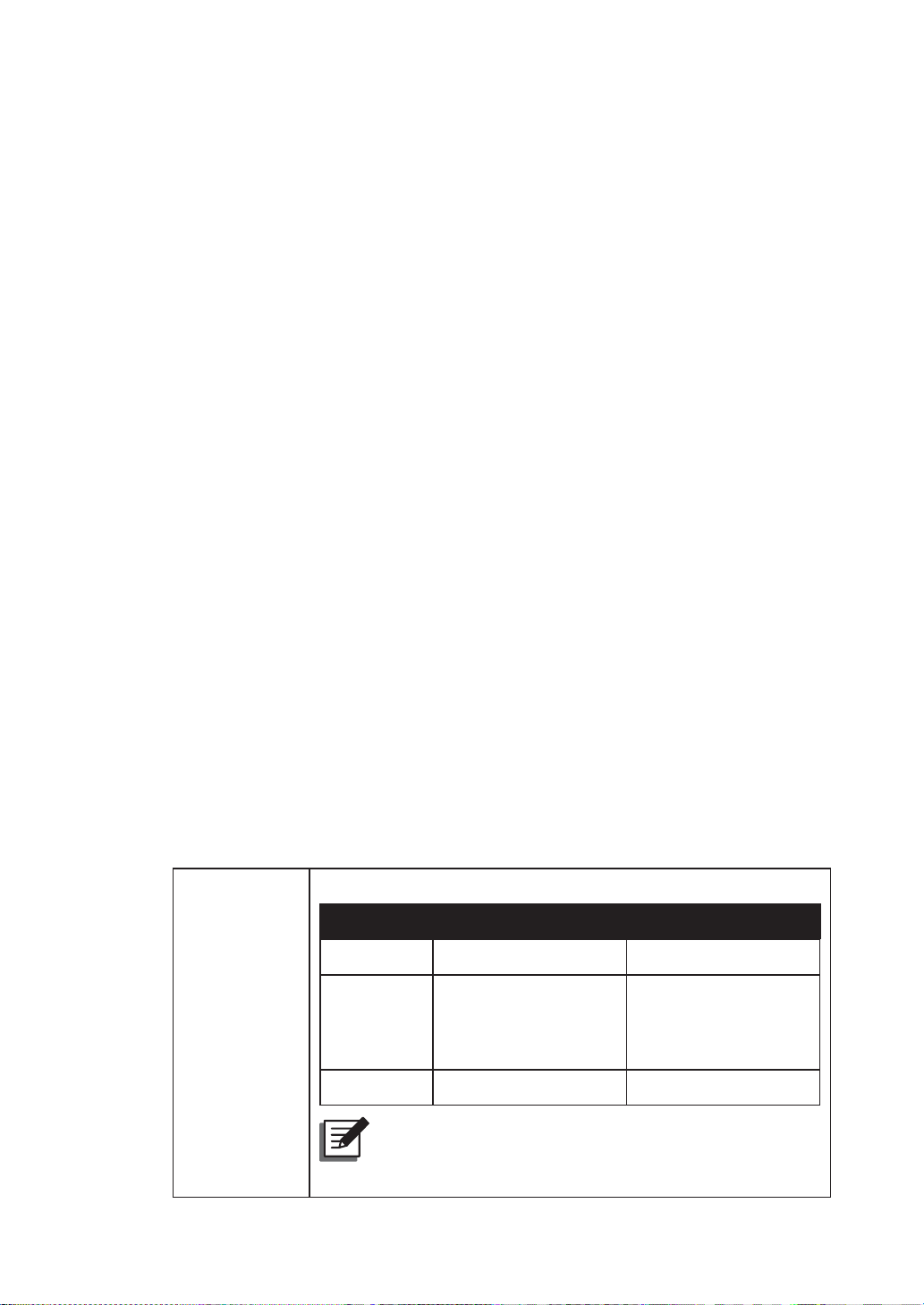

bypass cabinet’s information, please refer to the table below.

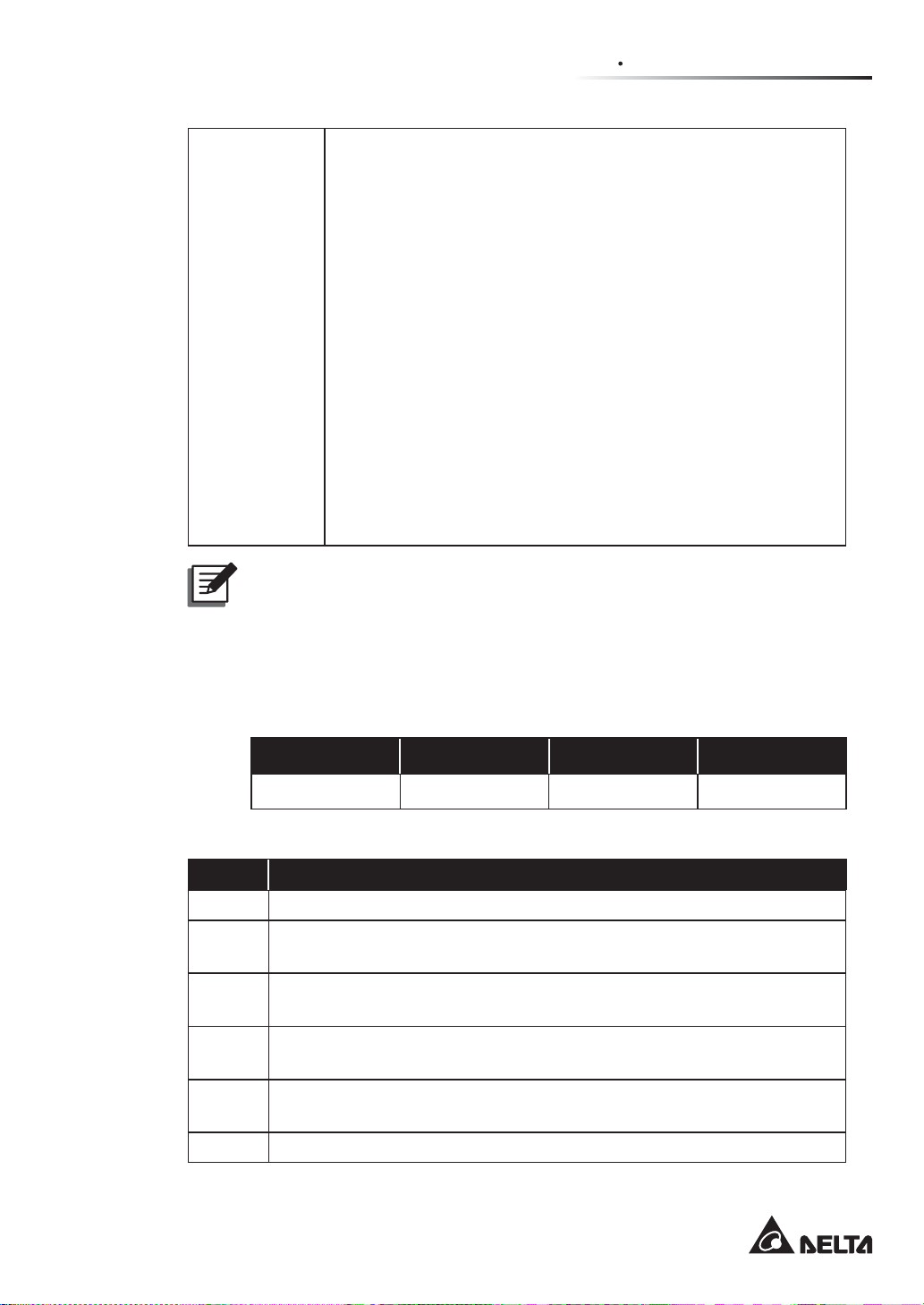

There are two models for selection. Please refer to the table below.

Delta External Maintenance Bypass Cabinet (Optional)

Model 3915101965-S 3915101964-S

Delta External

Maintenance

Bypass

Cabinet

(Optional)

3 Switches

Switch Q’ty

Wiring Type Top & Bottom Wiring Top & Bottom Wiring

NOTE:)RU PRUH LQIRUPDWLRQ DERXW WKH 'HOWD H[WHUQDO

maintenance bypass cabinet (optional), please refer to its

user manual.

(Input Switch/ Manual

Bypass Switch/ Output

Switch)

4 Switches

(Input Switch/ Bypass

Switch/ Manual Bypass

Switch/ Output Switch)

Modulon DPH Series

1-2

Page 9

Non-Delta

External

Maintenance

Bypass

Cabinet

(User-supplied,

handled and

configured by

Delta service

personnel)

127(If there are switches but not breakers installed in the external

maintenance bypass cabinet, please install (1) an additional protective device

between the input power and the external maintenance bypass cabinet and (2)

an additional protective device between the connected critical loads and the

external maintenance bypass cabinet. The protective device could be a breaker

or a fuse. For the protective device’s rating current, please refer to the table

below.

ௐ

ௐ

1

Important Safety Instructions

For configurations of the non-Delta external maintenance bypass

cabinet, please refer to the following.

a. Selection of three or four breakers (switches):

(1) Three breakers (switches):

An input breaker (switch), a manual bypass breaker (switch)

and an output breaker (switch) should be installed.

(2) Four breakers (switches):

An input breaker (switch), a bypass breaker (switch), a

manual bypass breaker (switch) and an output breaker

(switch) should be installed.

b. Each breaker (switch) mentioned above must be a 3-pole (R/ S/

T) device and meets the specifications defined in Table 5-3.

c. It is suggested that each breaker (switch) should be configured

with an auxiliary contactor. For relevant information, please refer

to 4.1.4 External Switch/ Breaker Status Dry Contacts.

d. Install the non-Delta external maintenance bypass cabinet next

to the UPS or align it with the UPS for convenient operation.

200kVA 300kVA 400kVA 500kVA

400A 600A 800A 1000A

y In this user manual, the meaning of Q0, Q1, Q2, Q3, Q4 and Q5 represents the following.

Code Meaning

Q0 UPS’s Bypass Switch

Q1

Q2

Q3

Q4

Q5 External Battery Cabinet’s Breaker

Delta or non-Delta External Maintenance Bypass Cabinet’s Input Breaker

or Switch

Delta or non-Delta External Maintenance Bypass Cabinet’s Bypass Breaker

or Switch

Delta or non-Delta External Maintenance Bypass Cabinet’s Manual Bypass

Breaker or Switch

Delta or non-Delta External Maintenance Bypass Cabinet’s Output Breaker

or Switch

1-3

Page 10

y The installation of protective devices is highly recommended when the UPS is connected

to power sources.

y The protective devices connecting to the UPS must be installed near the UPS and easily

accessible for operation.

y Protective Devices:

1. It is suggested that you install appropriate protective devices between the UPS and

input AC power. The protective devices should have the functions of over current

protection, short circuit protection, insulating protection and shunt trip feature. Please

refer to the table below for different UPS’s cut off current (Icc).

200kVA 300kVA 400kVA 500kVA

10kA 10kA 12.12kA 15.15kA

2. For selection of the protective devices, please take each power cable’s current

capacity and the system’s overload capacity (please refer to Appendix 1: Technical

Specifications) into consideration. Besides, the short-circuit capacity of the upstream

protective devices must be equal to or higher than the capacity of the UPS’s protective

devices.

3. For single input, when the UPS has abnormalities and input short current reaches

20kA, the UPS’s internal semi-conductor fast-acting fuses need 8ms ~ 10ms to be

fused. Thus, the upstream protective devices’ reaction time should be more than

10ms to let the UPS’s internal protective devices block breakdown and let the UPS

transfer to bypass mode.

4. For dual input, please install the protective devices between the UPS and the main

AC source as well as between the UPS and the bypass AC source.

y If the UPS is supplied by a power source whose neutral is grounded, the backfeed

protective device installed as UPS input protection must be a 3-pole type. If the UPS

is supplied by a power source whose neutral is not grounded, the backfeed protective

device installed as UPS input protection must be a 4-pole type.

y The recommended electrical rating of the backfeed protective device is as follows.

200kVA 300kVA 400kVA 500kVA

690V/ 400A 690V/ 600A 690V/ 800A 690V/ 1000A

1.3 Usage Warnings

y Before installation, wiring and working on the UPS’s internal circuits, please completely

cut off all power supplying to the UPS, including the input power and battery power.

Modulon DPH Series

1-4

Page 11

ௐ

ௐ

1

Important Safety Instructions

y The UPS is specifically designed for information technology equipment and used to

power computers, servers, and associated peripheral devices. If you want to connect

any capacitive loads or non-linear loads (that have serious surge current) to the UPS,

it needs to be de-rated according to on-site applications. For such special applications,

please contact Delta service personnel for the accurate UPS sizing. The UPS is not

suitable for connecting with any asymmetrical loads.

y The external slits and openings in the UPS are provided for ventilation. To ensure reliable

operation of the UPS and to protect the UPS from overheating, these slits and openings

must not be blocked or covered. Do not insert any object into the slits and openings that

may hinder ventilation.

y Before applying electrical power to the UPS, you must allow the UPS to adjust to room

temperature (20°C~25°C) for at least one hour to avoid moisture condensing inside the

UPS.

y Do not put beverages on the UPS, external battery cabinet, Delta or non-Delta external

maintenance bypass cabinet or any other accessory associated with the UPS.

y Do not open or remove the covers or panels of the UPS to avoid high voltage electric

shock. Only authorized Delta engineers or service personnel can do so for installation or

maintenance. If you want to open or remove the covers or panels, do it only under the

supervision of authorized Delta engineers or service personnel.

y It is strictly forbidden to connect the UPS to any regenerative loads.

y The risk of dangerous high voltage is possible when batteries are still connected to the

UPS even though the UPS is disconnected from the power sources. Before maintenance,

turn off the external battery cabinet’s circuit breaker to completely cut off the battery

power from the UPS.

y Do not dispose of the battery or batteries in a fire. The batteries may explode.

y Do not open or damage the battery or batteries. The released electrolyte is harmful to the

skin and eyes and may be toxic.

y The UPS is electronic equipment that runs 24 hours continuously. To ensure its normal

lifetime, regular maintenance of the UPS and batteries is of vital importance and

necessary.

y Some components like batteries, power capacitors, and fans will become worn-out due

to long-term usage, and this will increase the risk of UPS failure. To replace and maintain

the components, please contact Delta service personnel.

y A battery can present a risk of electric shock and high short-circuit current. The following

precautions should be observed before replacement of batteries:

1. Remove watches, rings, or other metal objects.

2. Use tools with insulated handles.

1-5

Page 12

3. Wear insulating gloves and boots.

4. Do not lay tools or metal parts on the top of batteries.

5. Disconnect the charging source prior to connecting or disconnecting the batteries’

terminals.

y You must contact Delta customer service if either of the following events occur:

1. Liquid is poured or splashed on the UPS.

2. The UPS does not run normally after carefully following the instructions in this User

Manual.

1.4 Storage Warnings

y Use the original packing material to pack the UPS to prevent any possible damage from

rodents.

y If the UPS needs to be stored prior to installation, it should be placed in a dry indoor area.

The allowable storage temperature is below 70°C and relative humidity is below 95%.

1.5 Standard Compliance

y EN 62040-1

y EN 61000-6-4

y EN 62040-2 Category C3

y EN 61000-4-2

y EN 61000-4-3

y EN 61000-4-4

y EN 61000-4-5

y EN 61000-4-6

y EN 61000-4-8

y EN 61000-2-2

y YD/ T 2165-2010

y YD 5083-2005

y YD/ T 5096-2016

Modulon DPH Series

1-6

Page 13

ௐ

ௐ

2

Introduction

2

Introduction

2.1 General Overview

2.2 Package Inspection

2.3 Functions & Features

2.4 Exterior and Dimensions

2.5 Front View

2.6 Internal View

2.7 Rear View

2.8 Tri-color LED Indicator &

Buzzers

2-1

Page 14

2.1 General Overview

The DPH series UPS, a three-phase four-wire online uninterruptible power supply, is a

dedicated design for data centers, factory facilities and large scale power systems. The

unit not only adopts advanced IGBT technology to provide high quality, low noise, pure and

uninterruptible output power to the connected loads, but also applies the latest design of DSP

digital control technology and highest quality components.

The UPS supports high efficient operation modes and its modular and hot-swappable design

makes maintenance easy and quick. You can add power modules (optional) according to

on-site applications to expand overall system capacity, which realizes a highly cost-effective

solution to your power requirements and produces greater electric power efficiency at less

cost.

The unit provides diversified communication interfaces and has built-in SNMP and MODBUS

cards for the user to facilitate remote control and management. You can parallel at maximum

eight UPS units to increase the system capacity and redundancy and enhance the unit’s

availability and reliability.

2.2 Package Inspection

y External

During UPS transportation, some unpredictable situations might occur. It is recommended

that you inspect the UPS exterior packaging. If you notice any damage, please immediately

contact the dealer from whom you purchased the unit.

y Internal

1. Check the rating label attached to the UPS and make sure the device No. and capacity

match what you ordered.

2. Examine if any parts are loose or damaged.

3. The UPS package contains the following items. Please check if any items are missing.

Modulon DPH Series

1

2

6 7 8 9

11

3

×35

12 13 14 15

2-2

4

×35

×2

5

10

×10×35

×2

Page 15

ௐ

ௐ

2

Introduction

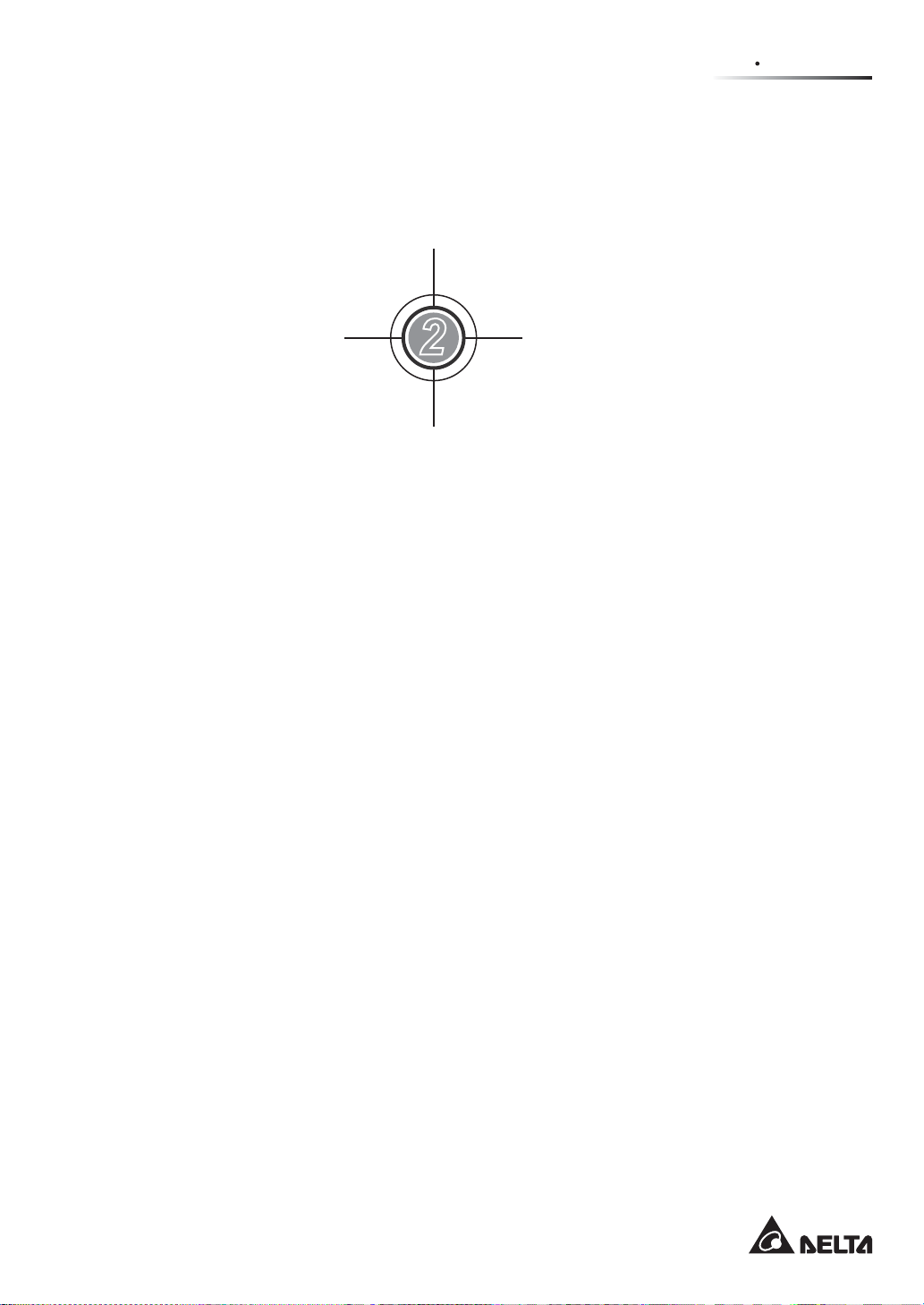

No. Item Q’ty

UPS

(two pieces of 50ppi dust filters have been installed on the inner

1

side of the UPS front door before shipment)

User Manual 1 PC

2

RS-232 Cable (1.8 meters) 1 PC

3

Parallel Cable (3 meters) 1 PC

4

Test Report 1 PC

5

Key

6

1 PC

1 PC

(two copies

placed inside

the UPS

cabinet)

M12 Screw (used for input/ output/ battery/ grounding wiring) 35 PCS

7

Washer (used for input/ output/ battery/ grounding wiring) 35 PCS

8

Washer Spring (used for input/ output/ battery/ grounding

9

wiring)

M4 Screw (used to fix the parallel fasteners) 10 PCS

10

USB Cable 1 PC

11

4-Pin Dry Contact Terminal Block

12

(used for REPO dry contacts; please refer to Figure 4-3)

6-Pin Dry Contact Terminal Block

(used for MODBUS and BMS ports located at the rear of the

13

touch panel; please refer to Figure 4-15)

8-Pin Dry Contact Terminal Block

(used for (1) external battery temperature dry contacts and (2)

14

external switch/ breaker status dry contacts; please refer to

Figure 4-3)

10-Pin Dry Contact Terminal Block (used for input and output

15

dry contacts; please refer to Figure 4-3)

35 PCS

1 PC

1 PC

2 PCS

2 PCS

4. If there is any damage or anything missing, please immediately contact the dealer

from whom you purchased the unit.

2-3

Page 16

5. If the UPS needs to be returned, carefully repack the UPS and all of the accessories

using the original packing material that came with the unit.

2.3 Functions & Features

y Hot swappable STS module, communication interfaces and power modules (optional)

realize on-line maintenance, reduce the MTTR (Mean Time to Repair) and expand

system capacity flexibly (200 ~ 500kVA).

y Input power factor > 0.99 and input THDi < 3% save on installation cost and diminish

power contamination.

y Output power factor= 1 (for 500kVA, output power factor is 0.9).

y Efficiency > 96% saves on operation cost.

y Automatic input frequency detection enables operation at 50Hz or 60Hz.

y Automatic restart:

1. The UPS will restart in normal mode automatically right after the AC line resumes

following a low battery shutdown.

2. The UPS returns automatically to normal mode from bypass mode after an overload

condition is cleared.

y Automatically detects whether bypass voltage is out of rating voltage (default: voltage

±15% & frequency ±3Hz). If yes, the UPS will stop supplying power to the critical loads to

protect your electronic equipment.

y Supports ECO mode: when input voltage and frequency are within the range of rating

voltage ±10% and rating frequency ±3Hz, the UPS will transfer to bypass mode; otherwise,

the UPS will transfer to normal mode to reach higher efficiency.

y Both auxiliary power and control circuit adopt redundancy design, which doubly enhances

UPS reliability.

y Suitable for top and bottom wiring by use of the Delta external maintenance bypass

cabinet (optional).

y Generator compatible

y Surge protection and EMI filter functions.

y Remote emergency power off.

y Single input and dual input functions.

y Supports external switch/ breaker status detection.

Modulon DPH Series

2-4

Page 17

ௐ

ௐ

2

Introduction

y Wide AC input voltage range (140Vac~276Vac) reduces frequent transfer from normal

mode to battery mode to save battery consumption and prolong battery life.

y AC start-up function even when the UPS is not connected to the batteries.

WARNING:

Please note that when the UPS is not connected to the batteries, it will not

protect your equipment if the utility power is lost.

y Connects at maximum four external battery cabinets to extend backup time.

y Schedulable battery test and battery replacement alarm.

y Battery temperature monitoring and compensation.

y Battery monitoring system allows measurement of per battery cell’s voltage and current.

y Smart battery charger design allows auto-charging or manual charging to shorten

charging time.

y Provides communication interfaces and a smart slot (where you can install the optional

Relay I/O card for dry contact expansion). Please refer to 4. Communication Interfaces.

y Built-in RS-232 port and USB port located on the communication interfaces allow

monitoring and management of the UPS. For relevant location and information, please

refer to Figure 4-3 and Page 4-11.

y Built-in SNMP card and MODBUS card located at the rear of the touch panel provide

network communication and MODBUS communication respectively. For relevant location

and information, please refer to Page 4-12 and Page 4-13.

y Built-in SNMP card located at the rear of the touch panel allows remote monitoring,

management and event log download of the UPS. For relevant location and information,

please refer to Page 4-12 and Page 4-13.

y Built-in USB ports ( ) located at the rear of the touch panel allow upgrade of the UPS,

touch panel, power modules, system control card and parallel communication cards’

firmware and event log download. For relevant location and information, please refer to

Page 4-12 and Page 4-13.

y Built-in SRAM records at maximum 10000 event logs.

y 10-inch graphic and color touch panel enables the user to easily operate the UPS and

understand the UPS status.

y Fan speed auto adjustment prolongs fan life and reduces noise when the critical loads

decrease. Moreover, fan failure detection circuit is established.

y State-of-the-art microprocessor technology performs self-detection and monitors fan

speed in real time, which provides complete and detailed operating status of the UPS.

2-5

Page 18

2.4 Exterior and Dimensions

600

mm

2000

mm

1100

mm

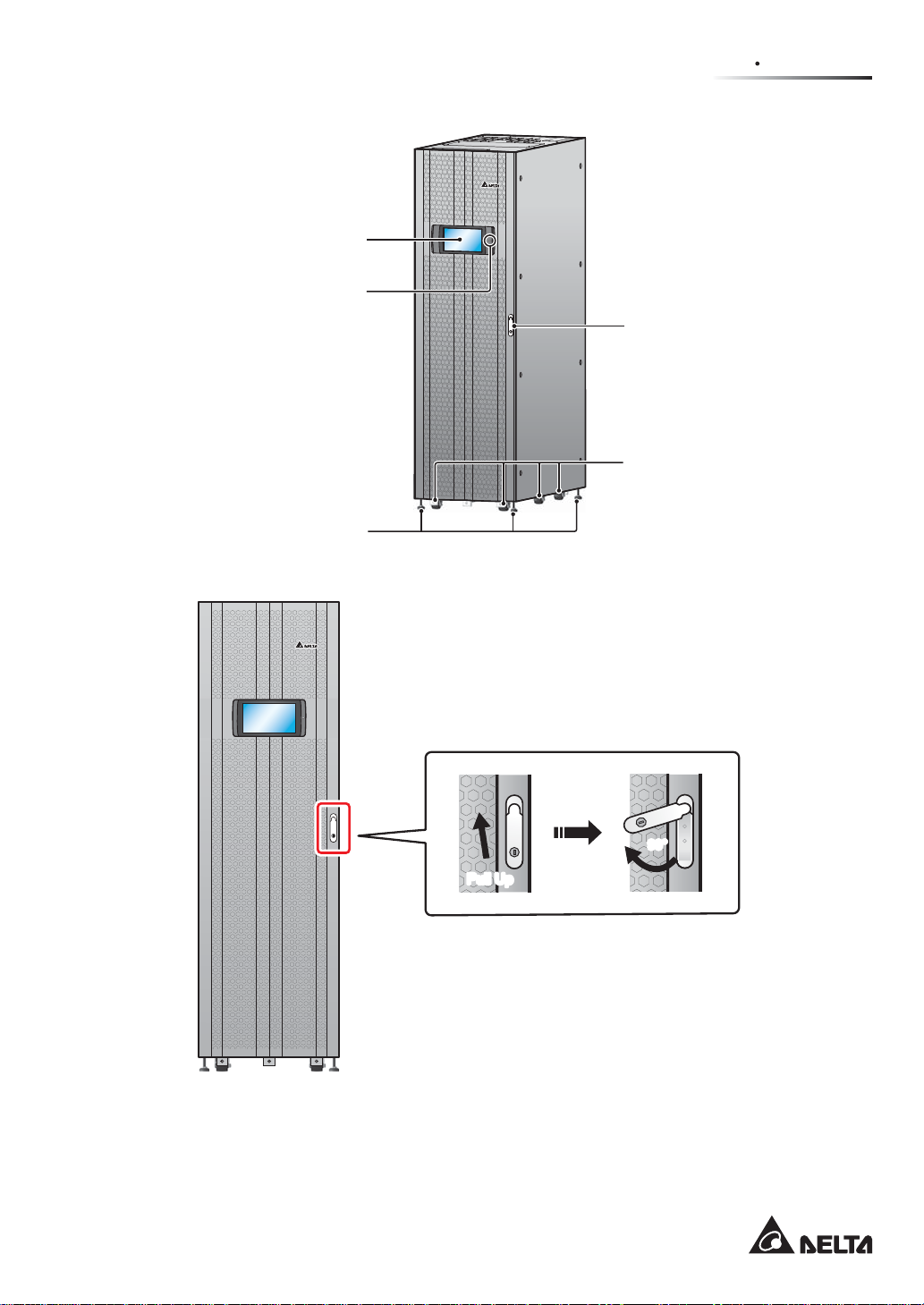

2.5 Front View

On the front of the UPS, there are a 10” color touch panel, a tri-color LED indictor, a door

switch, six casters and four leveling feet. Please see Figure 2-2.

1. For information about the 10” color touch panel, please refer to 7. LCD Display &

Settings.

2. For information about the tri-color LED indicator, please refer to 2.8 Tri-color LED

Indicator & Buzzers.

3. The casters at the bottom of the UPS can be used to move over short distances, and

the leveling feet fix and stabilize the UPS on the ground. Please refer to 5.3 UPS

Transportation for relevant information.

4. Please refer to Figure 2-3 for how to open the UPS front door.

(Figure 2-1: Exterior & Dimensions)

Modulon DPH Series

2-6

Page 19

10” Color Touch Panel

Tri-color LED Indictor

Levelling Feet

(Figure 2-2: UPS Front View)

Door Switch

Casters

ௐ

ௐ

2

Introduction

Pull Up

(Figure 2-3: How to Open the UPS Front Door)

2-7

90°90°

Page 20

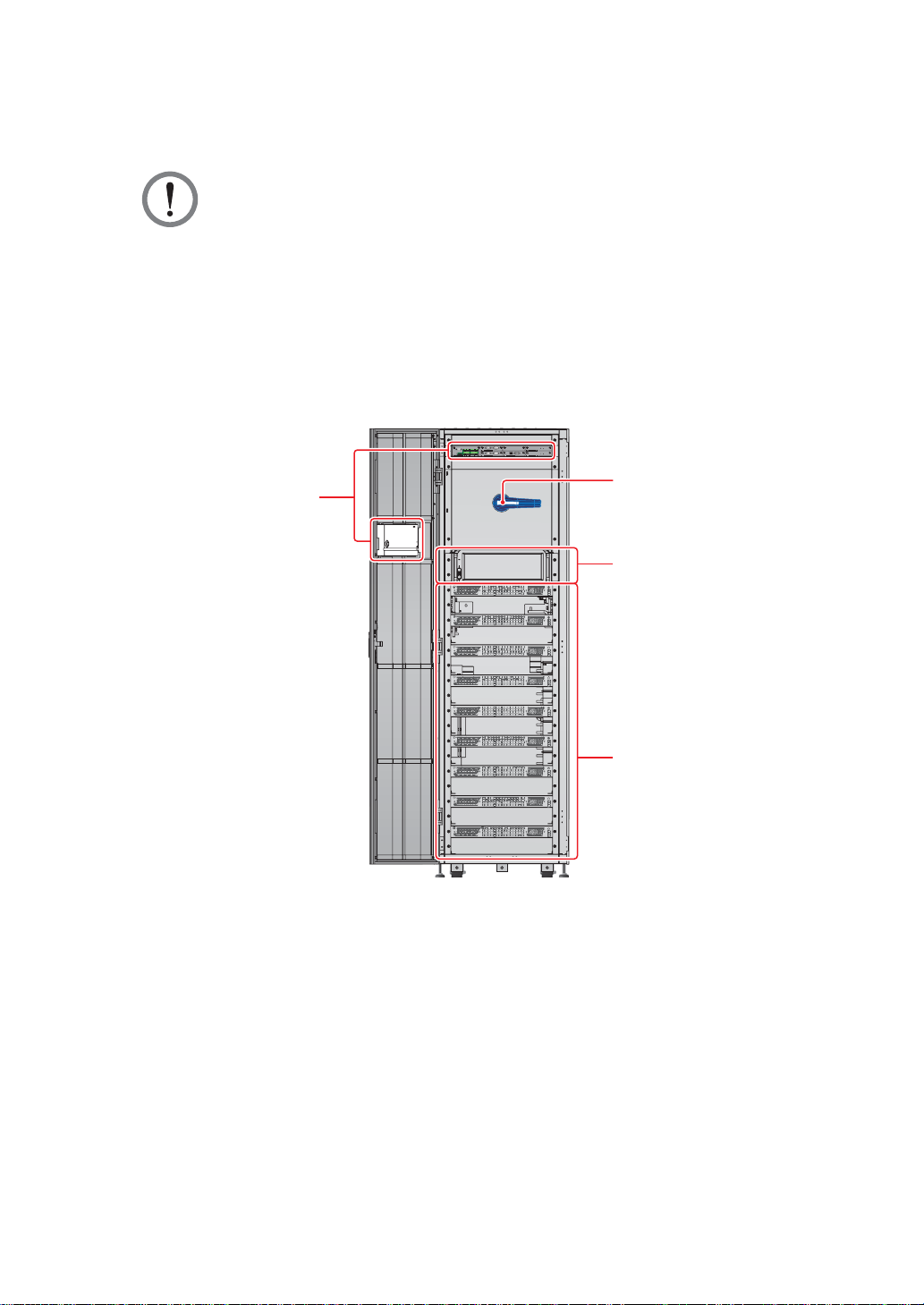

2.6 Internal View

WARNING:

Only authorized Delta engineers or service personnel can perform installation,

wiring, panel & cover removal, maintenance and operation. If you want to execute

any action mentioned above by yourself, the action must be under the supervision

of authorized Delta engineers or service personnel.

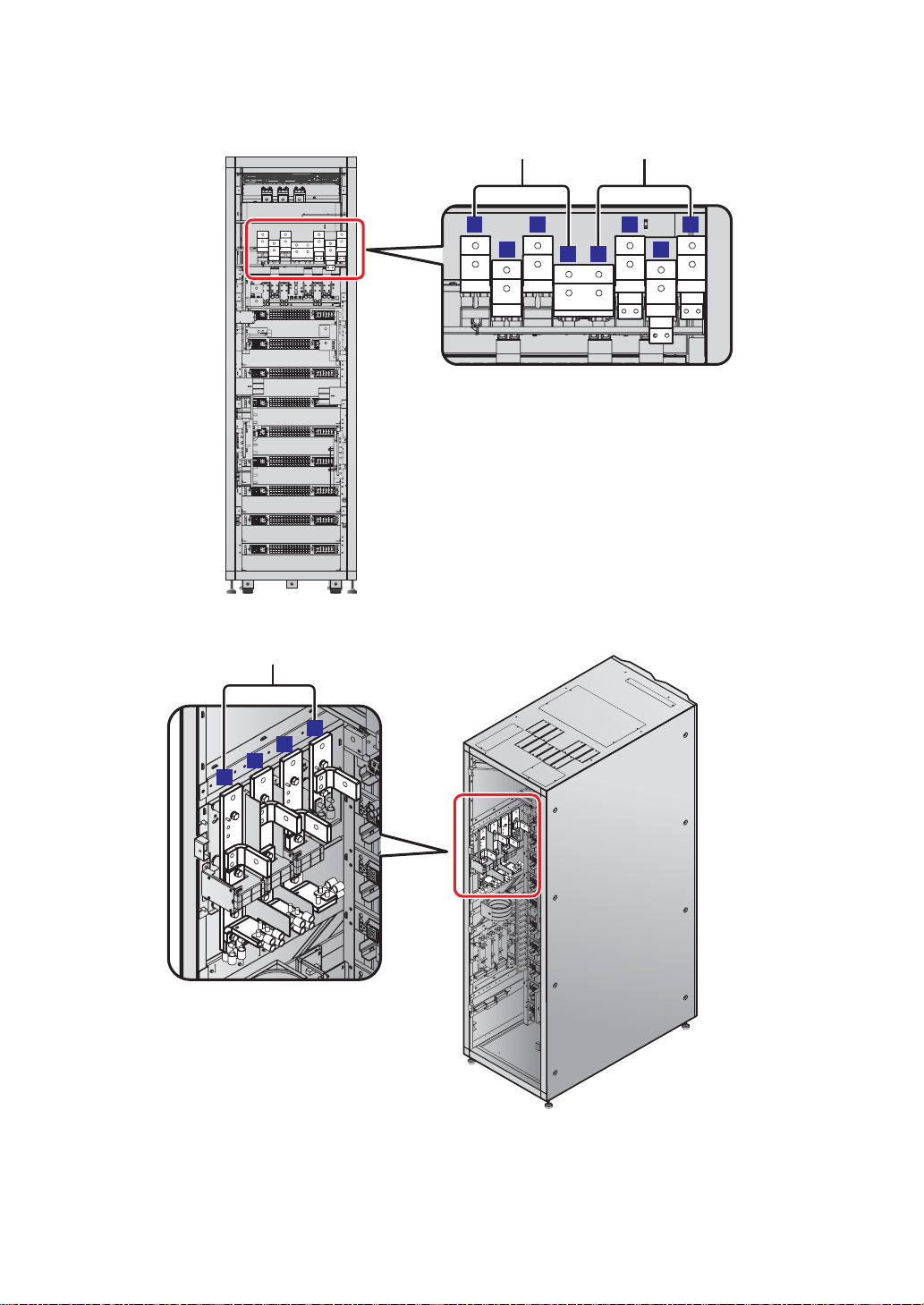

After you open the UPS’s front door, you will see the internal mechanisms including

communication interfaces, a bypass switch (Q0), an STS module, and nine power module

slots. Please refer to Figure 2-4.

Communication Interfaces

Internal View

(Front View with Door Open)

DISPLAY

I/P DRY

O/P DRY

EXT.SWITCH

EXT. BATT

CONTACT

CONTACT

STATUS

TEMP.

P1P2

S1S2

P1P2 P3

BT1BT2

REPO

NCNO

BT4

BT3

P4

P5P6

S3S4

P3

P4

N

G

D

A

G

N

D

B

A

B

RESET

M

OD

B

US

BM

S

Y

A

L

ISP

D

LE

O

EMS

ONS

C

I

PARALLEL

PARALLEL

BYPASS SWITCH

O OFF

BATT.

START

BATT.

START

USB RS-232

ON I

Bypass Switch (Q0)

STS Module

1. For information about the communication interfaces, please refer to 4. Communication

Interfaces.

2. For how to turn on/ off the bypass switch (Q0), please refer to Figure 2-5.

Modulon DPH Series

Power Module Slots

(Figure 2-4: UPS Internal View (Front View with Door Open))

2-8

Page 21

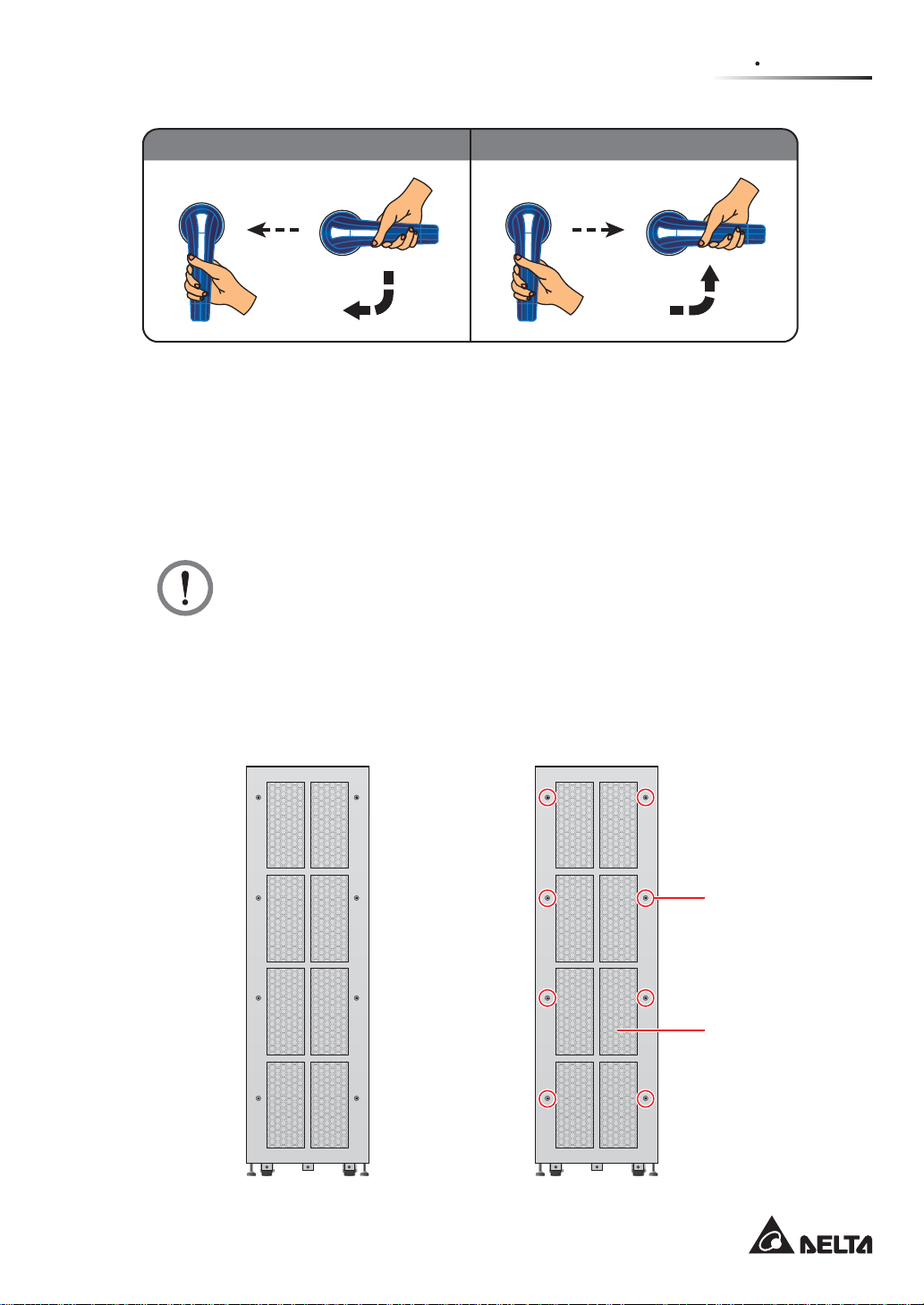

Turn on the Bypass Switch (Q0) Turn off the Bypass Switch (Q0)

ௐ

ௐ

2

Introduction

(ON) (OFF)

ON I

O OFF

3. For STS module information, please refer to 5.7 STS Module.

4. For the power module slots, please follow on-site requirements to install appropriate

number of power modules (optional) into the slots. Please refer to 5.8 Power Module

(Optional) for relevant information.

2.7 Rear View

WARNING:

Only authorized Delta engineers or service personnel can perform installation,

wiring, panel & cover removal, maintenance and operation. If you want to execute

any action mentioned above by yourself, the action must be under the supervision

of authorized Delta engineers or service personnel.

The rear view of the UPS is shown in Figure 2-6. Please remove the rear panel (there are

eight screws (see Figure 2-7) to see the wiring terminals shown in Figure 2-8 ~ Figure 2-10.

(ON) (OFF)

ON I

O OFF

ON I

O OFF

90°

(Figure 2-5: Turn On/ Off the Bypass Switch (Q0))

ON I

O OFF

90°

(Rear) (Rear)

M5 Screw X 8

Rear Panel

(Figure 2-6: UPS Rear View) (Figure 2-7: UPS Rear Panel and Screw Location)

2-9

Page 22

32

32

32

32

32

32

35

T

S

R

N

N

BYPASS I/P

BYPASS I/P BYPASS I/P MAIN I/P

T

MAIN I/P

R

MAIN I/P

(Rear View after Rear Panel Removal)

42

42

42

41

Bypass Input T erminals AC Input Terminals

32

32

323232

32

35

BYPASS I/P BYPASS I/P BYPASS I/P MAIN I/PTMAIN I/PRMAIN I/P

BYPASS I/P

TSRNN

22 22 2221 21 21

(Figure 2-8: Wiring Terminals_ AC Input & Bypass Input)

UPS Output Terminals

N

T

S

R

T T

BYPASS I/P

R R

S S

N N

(Rear View after Rear Panel Removal)

Modulon DPH Series

41

42

42

42

(Figure 2-9: Wiring Terminals_ UPS Output)

2-10

Page 23

ௐ

ௐ

2

Introduction

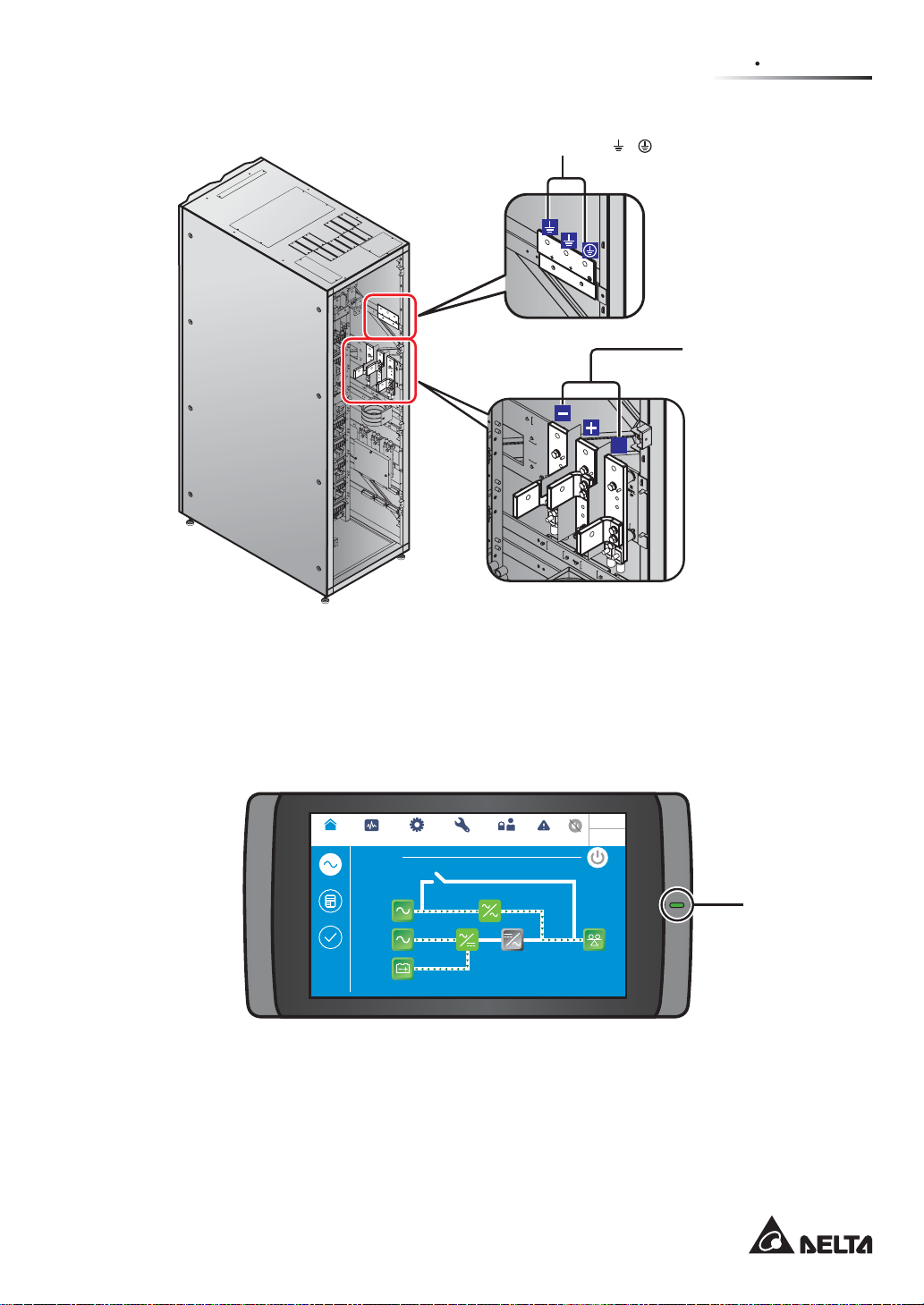

(Rear View after Rear Panel Removal)

(Figure 2-10: Wiring Terminals_ Battery Input & Grounding)

Grounding Terminals

( & )

Battery Input

Terminals

N

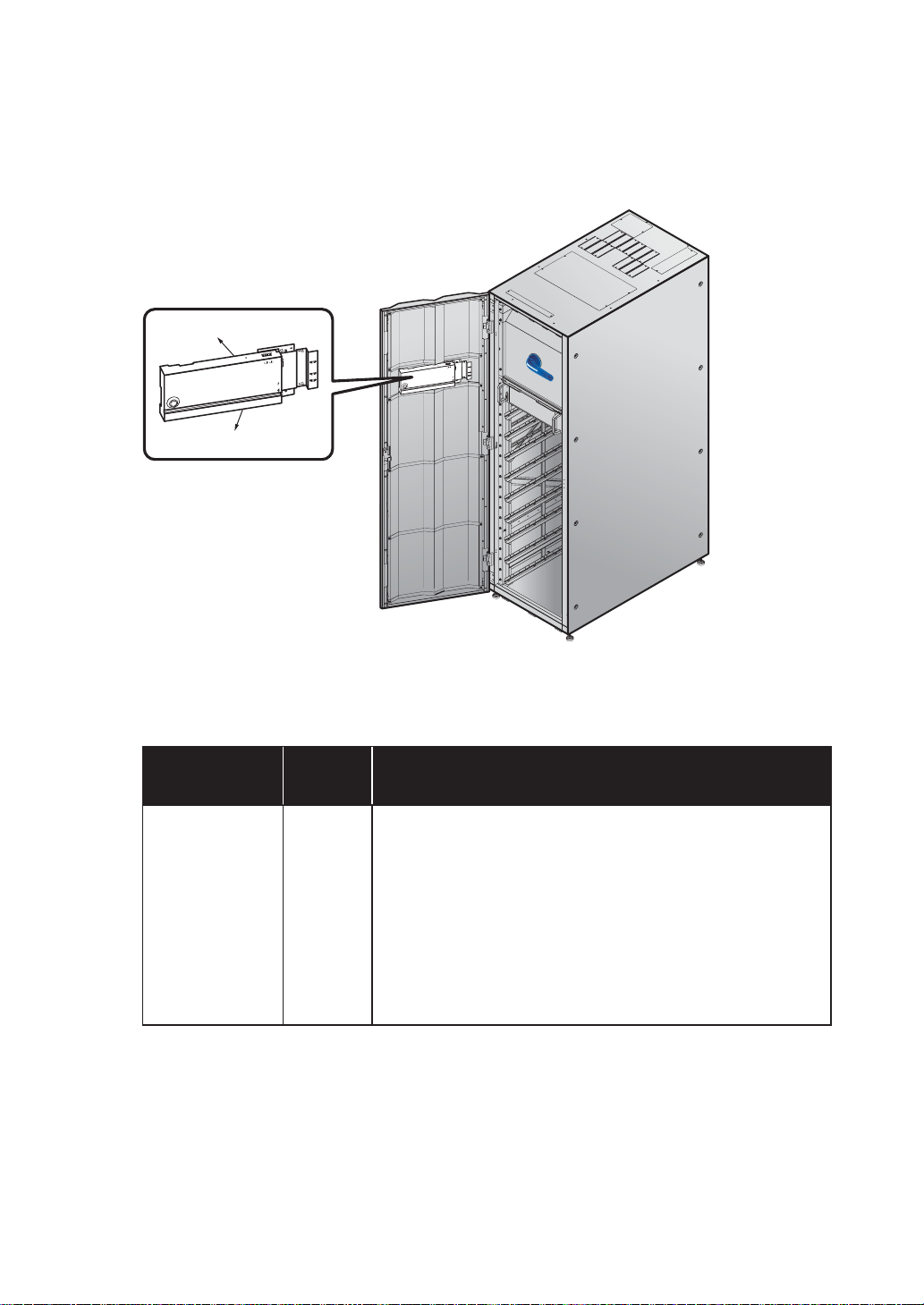

2.8 Tri-color LED Indicator & Buzzers

Please see Figure 2-11 for the location of the tri-color LED indictor. For information about the

tri-color LED indicator, please refer to Table 2-1. For information about the 10” color touch

panel, please refer to 7. LCD Display and Settings.

MEASUREMENT

UPS-1.1 SETUP MAINTENANCE

Power Flow

POWER FLOW

Maintenance

Power Flow

Bypass

Bypass

Summary

Mains

System Status

90 %

5 mins

(Figure 2-11: Tri-color LED Indictor Location)

LOG IN

EVENT LOG

User

Load

30 %

10:15

May 25,2018

Bypass

Tri-color

LED Indicator

2-11

Page 24

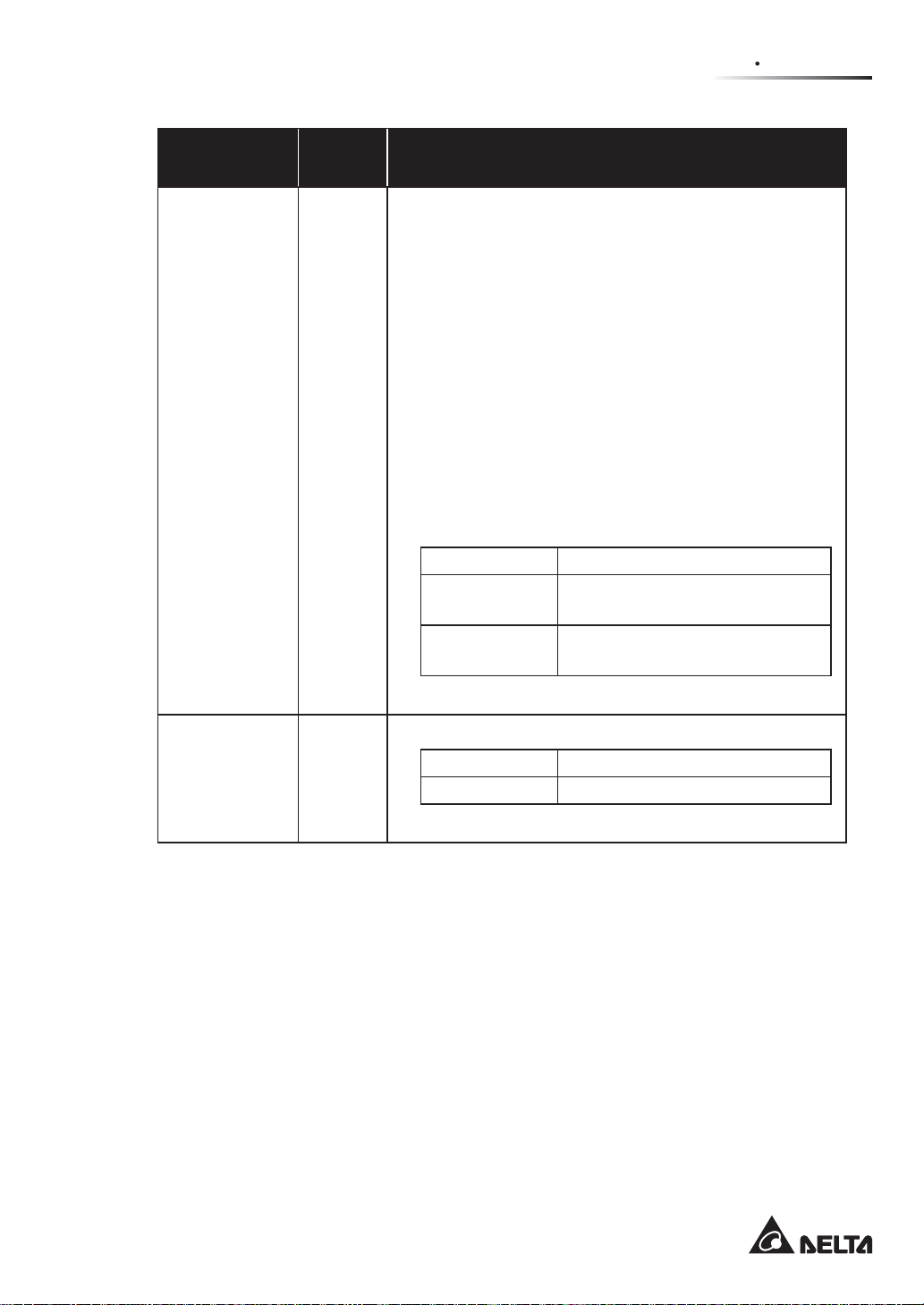

Open the UPS front door and find the buzzers at the rear of the UPS front door. Please see

Figure 2-12.

(UPS Front View with Door Open)

Buzzer

BYPASS SWITCH

A

B

D

N

G

A

B

D

N

G

T

SE

E

BMS

R

US

MODB

DISPLAY

EMS

ICONSOLE

A

B

D

N

G

A

B

D

N

G

S

BM

S

DBU

O

M

ET

RES

DISPLAY

EMS

ICONSOLE

ON I

Buzzer

(Figure 2-12: Buzzers Location)

Please refer to the table below for the status of the tri-color LED indicator and buzzers.

Table 2-1: Tri-color LED Indicator & Buzzers

Tri-color LED

Indicator

Status Meaning

1. The UPS is running in online mode and the text ‘OnLine’ appears in the upper right corner of the screen.

2. The UPS is running in ECO mode and the text ‘ECO’

appears in the upper right corner of the screen.

Green ON

3. The UPS is running in frequency conversion mode and

the text ‘Frequency Conversion’ appears in the upper

right corner of the screen.

4. The UPS is running in green mode and the text ‘Green’

appears in the upper right corner of the screen.

Modulon DPH Series

2-12

Page 25

ௐ

ௐ

2

Introduction

Tri-color LED

Indicator

Yellow ON

Status Meaning

1. The UPS is running in bypass mode and the text

‘Bypass’ appears in the upper right corner of the

screen.

2. The UPS is running in battery mode and the text

‘Battery’ appears in the upper right corner of the screen.

3. The UPS is running in standby mode and the text

‘Standby’ appears in the upper right corner of the

screen.

4. The UPS is in the soft start status and the text ‘Softstart’

appears in the upper right corner of the screen.

5. The UPS is in the energy recycle status and the text

‘Energy Recycle’ appears in the upper right corner of

the screen.

6. There is a minor or medium warning and the buzzers

sound.

Warning Level Buzzer Frequency

Minor

Medium

The buzzers beep 0.5 second for

every three seconds.

The buzzers beep 0.5 second for

every second.

Red ON

To clear the warning, please refer to 10. Troubleshooting.

There is a major warning and the buzzers sound.

Warning Level Buzzer Frequency

Major Long beep

To clear the warning, please refer to 10. Troubleshooting.

2-13

Page 26

Modulon DPH Series

2-14

Page 27

ௐ

ௐ

3

Operation Modes

3

Operation Modes

3.1 Single Input

3.2 Dual Input

3.3 Hot Standby Redundancy

(Only For Dual Input & At

Least Two UPSs)

3.4 Common Battery (Only

For At Least Two Parallel

UPSs)

3-1

Page 28

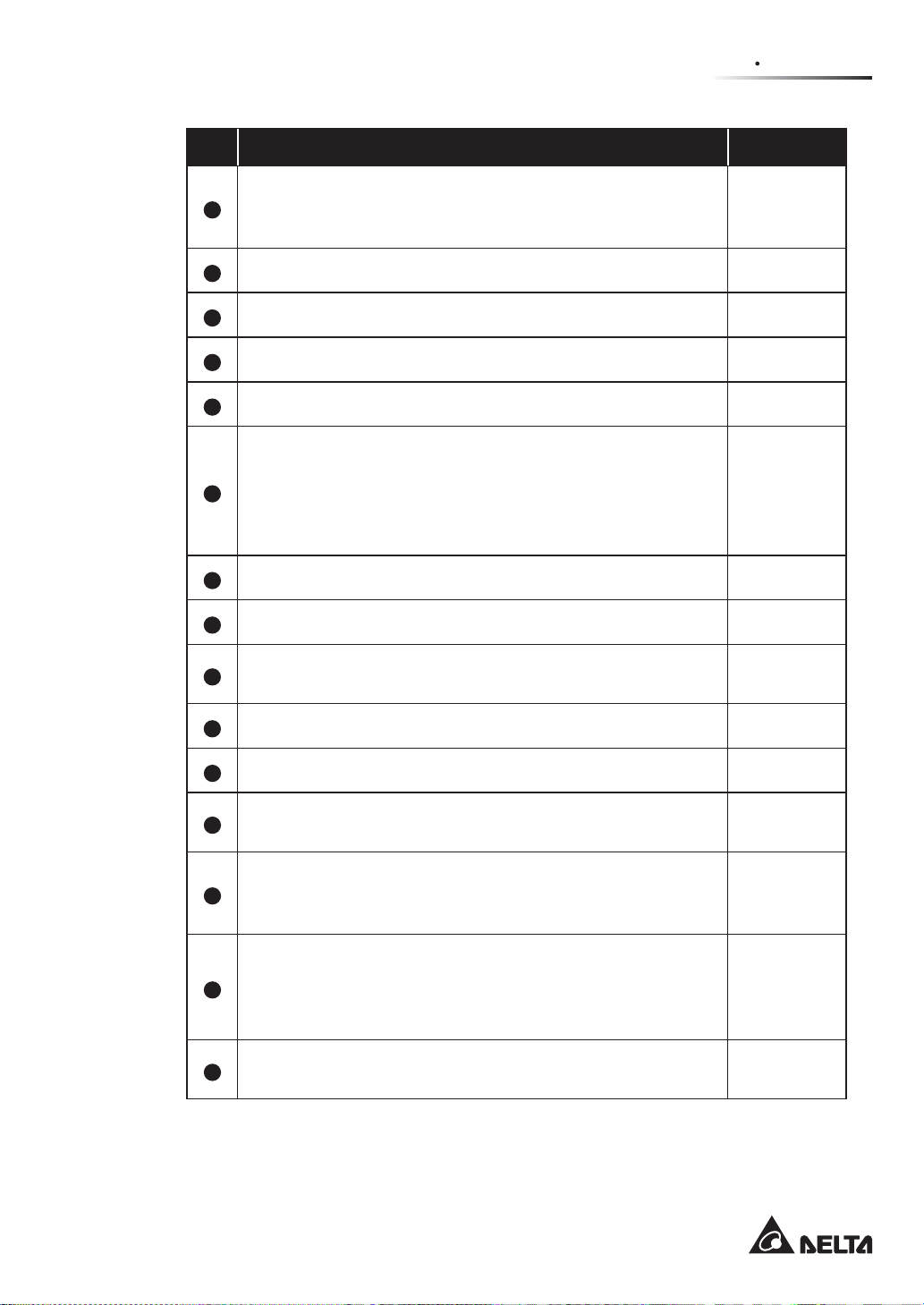

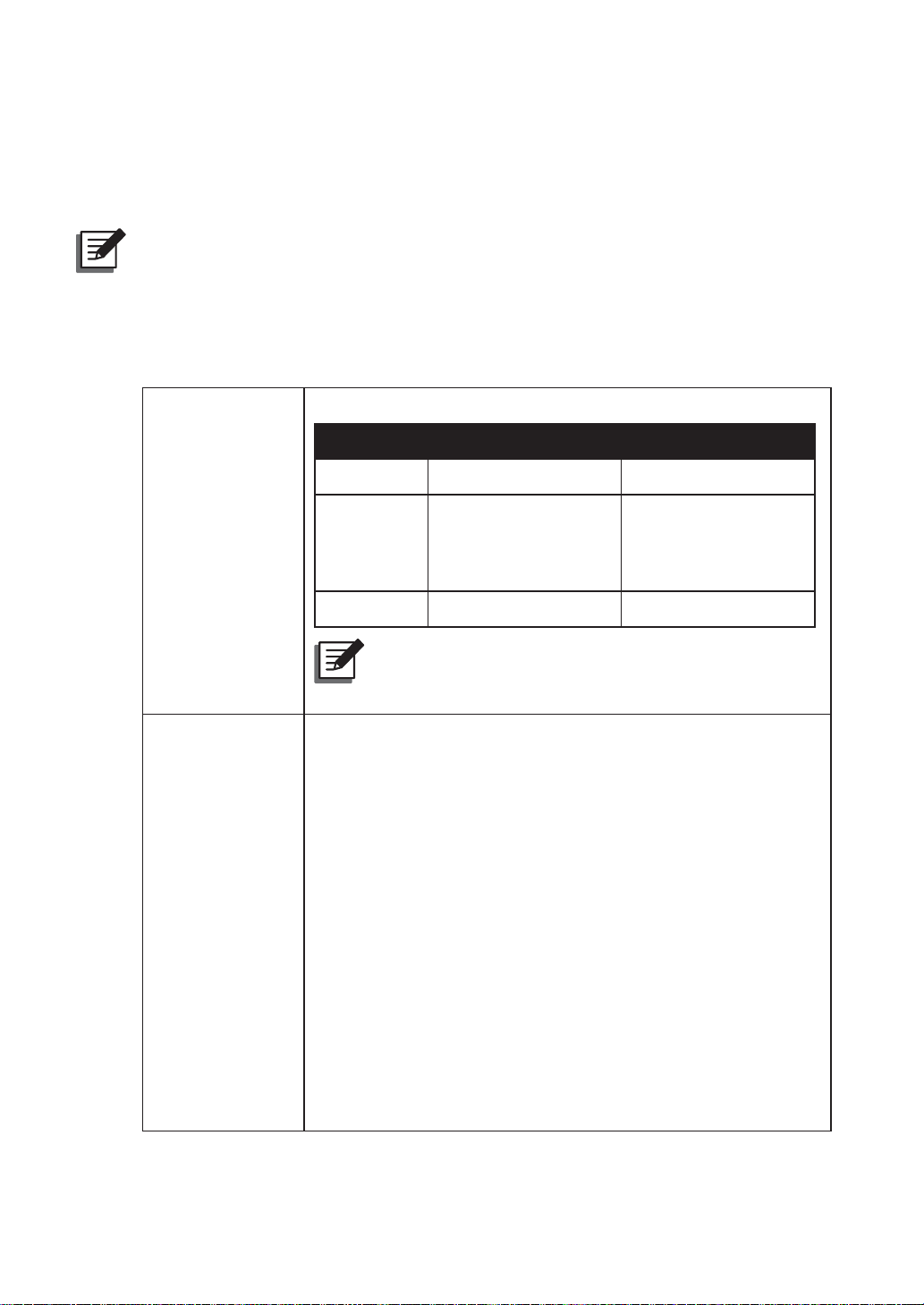

The UPS runs in eight basic operation modes, which are online mode, battery mode, bypass mode,

manual bypass mode, ECO mode, frequency conversion mode, green mode and energy recycle

mode. Besides these eight operation modes, the UPS is also designed for common battery application

and hot standby redundancy. Please see the following sections for relevant information.

127(

1. The UPS must be connected with a Delta or non-Delta external maintenance bypass

cabinet. The Delta external maintenance bypass cabinet is optional, and the non-Delta

external maintenance bypass cabinet is user-supplied and should be handled and

configured by Delta service personnel. For the Delta or non-Delta external maintenance

bypass cabinet’s information, please refer to the table below.

There are two models for selection. Please refer to the table below.

Delta External Maintenance Bypass Cabinet (Optional)

Model 3915101965-S 3915101964-S

Delta External

Maintenance

Bypass Cabinet

(Optional)

Non-Delta

External

Maintenance

Bypass Cabinet

(User-supplied,

handled and

configured by

Delta service

personnel)

3 Switches (Input

Switch Q’ty

Wiring Type Top & Bottom Wiring Top & Bottom Wiring

NOTE:)RU PRUH LQIRUPDWLRQ DERXW WKH 'HOWD H[WHUQDO

maintenance bypass cabinet (optional), please refer to its

user manual.

For configurations of the non-Delta external maintenance bypass

cabinet, please refer to the following.

a. Selection of three or four breakers (switches):

(1) Three breakers (switches):

An input breaker (switch), a manual bypass breaker (switch)

and an output breaker (switch) should be installed.

(2) Four breakers (switches):

An input breaker (switch), a bypass breaker (switch), a manual

bypass breaker (switch) and an output breaker (switch) should

be installed.

c. Each breaker (switch) mentioned above must be a 3-pole (R/ S/

T) device and meets the specifications defined in Table 5-3.

d. It is suggested that each breaker (switch) should be configured

with an auxiliary contactor. For relevant information, please refer

to 4.1.4 External Switch/ Breaker Status Dry Contacts.

e. Install the non-Delta external maintenance bypass cabinet next

to the UPS or align it with the UPS for convenient operation.

Switch/ Manual Bypass

Switch/ Output Switch)

4 Switches (Input

Switch/ Bypass Switch/

Manual Bypass Switch/

Output Switch)

Modulon DPH Series

3-2

Page 29

ௐ

ௐ

3

Operation Modes

127(If there are switches but not breakers installed in the external

maintenance bypass cabinet, please install (1) an additional protective device

between the input power and the external maintenance bypass cabinet and (2)

an additional protective device between the connected critical loads and the

external maintenance bypass cabinet. The protective device could be a breaker

or a fuse. For the protective device’s rating current, please refer to the table

below.

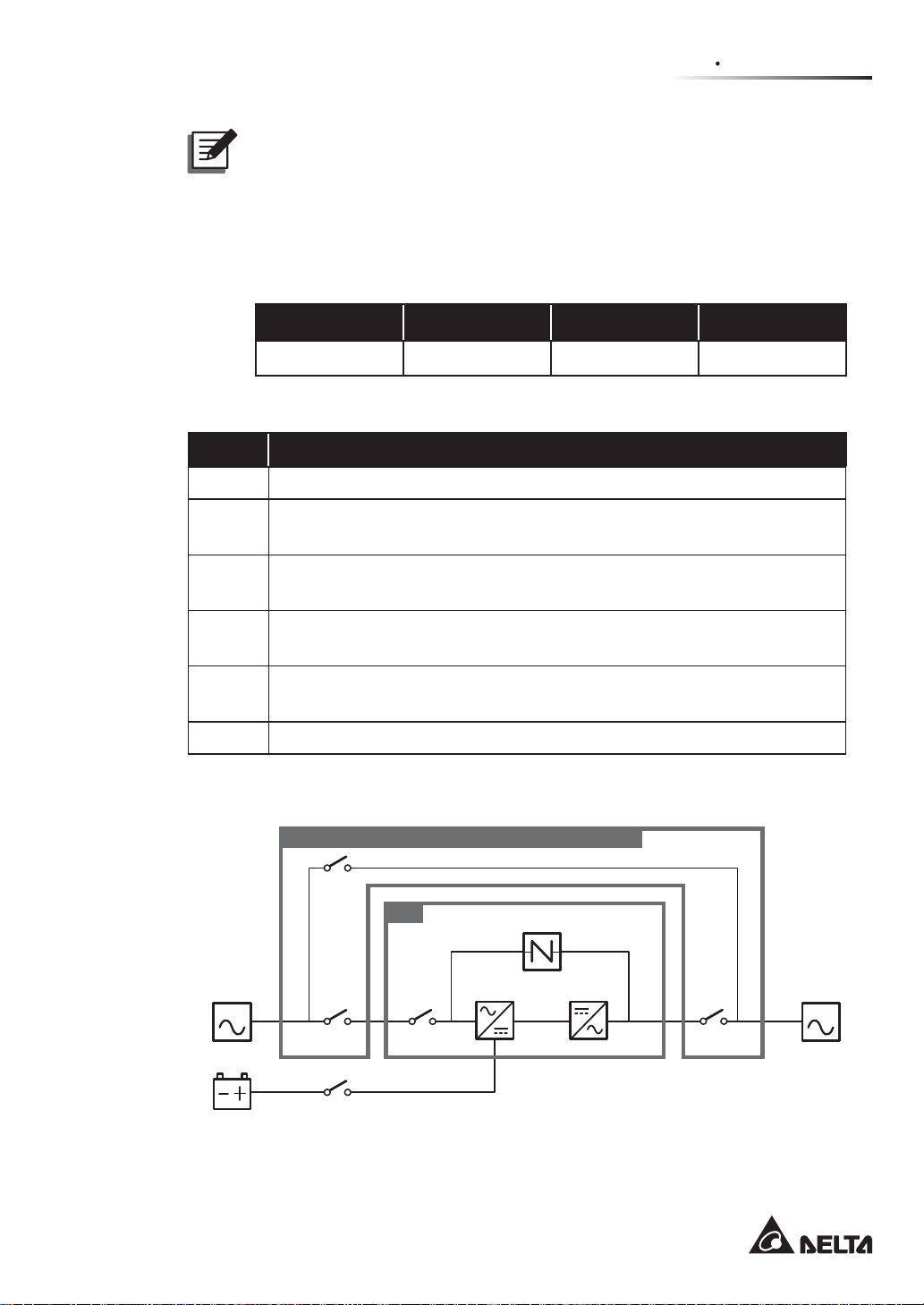

200kVA 300kVA 400kVA 500kVA

400A 600A 800A 1000A

2. In this user manual, the meaning of Q0, Q1, Q2, Q3, Q4 and Q5 represents the following.

Code Meaning

Q0 UPS’s Bypass Switch

Q1

Q2

Q3

Q4

Delta or non-Delta External Maintenance Bypass Cabinet’s Input Breaker

or Switch

Delta or non-Delta External Maintenance Bypass Cabinet’s Bypass Breaker

or Switch

Delta or non-Delta External Maintenance Bypass Cabinet’s Manual Bypass

Breaker or Switch

Delta or non-Delta External Maintenance Bypass Cabinet’s Output Breaker

or Switch

Q5 External Battery Cabinet’s Breaker

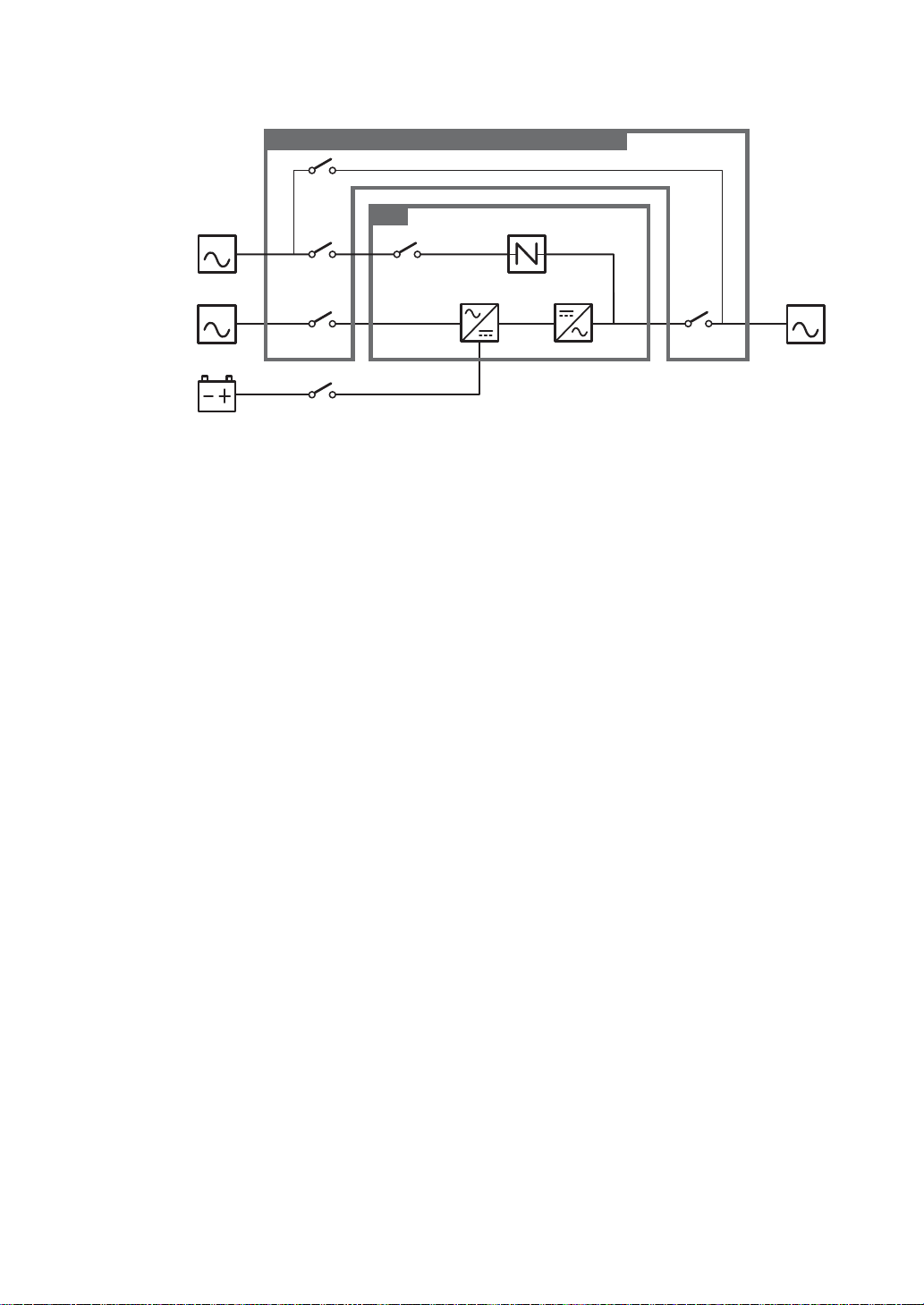

3. The structure of the UPS and the Delta or non-Delta external maintenance bypass cabinet

is shown in Figure 3-1 (single input application) and Figure 3-2 (dual input application).

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

UPS

MAIN LOAD

Q1 Q0 Q4

Static Switch

Rectifier Inverter

Batteries

(Figure 3-1: Single Input Application_ UPS and Delta or non-Delta

Q5

External Maintenance Bypass Cabinet Structure)

3-3

Page 30

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

UPS

BYPA.

Q0Q2

MAIN LOAD

Q1 Q4

Q5

Batteries

(Figure 3-2: Dual Input Application_ UPS and Delta or non-Delta

External Maintenance Bypass Cabinet Structure)

Static Switch

Rectifier Inverter

4. Up to eight UPS units can be paralleled for redundancy and capacity expansion. Only

UPSs with the same capacity, voltage and frequency can be paralleled. Please only use

the provided parallel cable to parallel the UPS units. Otherwise, parallel functions will fail.

3.1 Single Input

3.1.1 Online Mode_ Single Input_ Single Unit

In online mode, the main AC source supplies AC power via the Delta or non-Delta external

maintenance bypass cabinet’s Input Breaker or Switch (Q1) and the UPS’s Bypass Switch

(Q0) to the rectifier, and the rectifier converts the AC power to DC power and supplies the DC

power to the inverter. In the meantime, the rectifier provides charging power to the batteries.

After receiving the DC power, the inverter converts it into clean and stable AC power to the

connected critical loads via the Delta or non-Delta external maintenance bypass cabinet’s

Output Breaker or Switch (Q4). Please refer to Figure 3-3. During online mode, the UPS’s

tri-color LED illuminates green and the text ‘On-Line’ appears in the upper right corner of

the screen.

Modulon DPH Series

3-4

Page 31

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

ௐ

ௐ

3

Operation Modes

UPS

MAIN LOAD

Q1 Q0 Q4

Q5

Batteries

Static Switch

Rectifier Inverter

(Figure 3-3: Online Mode Diagram_ Single Input Single Unit)

3.1.2 Battery Mode_ Single Input_ Single Unit

The UPS transfers to battery mode automatically if the main AC source cannot supply power,

for example, when unstable voltage or a power outage occurs. In battery mode, the batteries

provide DC power and the UPS converts it into AC power and supplies it to the connected

critical loads via the Delta or non-Delta external maintenance bypass cabinet’s Output

Breaker or Switch (Q4). During the conversion process, output voltage remains the same.

Please see Figure 3-4. During battery mode, the UPS’s tri-color LED illuminates yellow and

the text ‘Battery’ appears in the upper right corner of the screen.

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

UPS

MAIN LOAD

Q1 Q0 Q4

Q5

Batteries

Static Switch

Rectifier Inverter

(Figure 3-4: Battery Mode Diagram_ Single Input Single Unit)

3-5

Page 32

3.1.3 Bypass Mode_ Single Input_ Single Unit

When the inverter encounters abnormal situations such as over temperature, overload, short

circuit, abnormal output voltage or low battery, it will automatically shut itself down. If the

UPS detects the bypass AC source is normal, it will automatically switch to bypass mode to

protect the connected critical loads from power interruption. Please refer to Figure 3-5. After

the above-mentioned abnormalities are eliminated, the UPS will switch back to online mode

from bypass mode. During bypass mode, the UPS’s tri-color LED illuminates yellow and the

text ‘Bypass’ appears in the upper right corner of the screen.

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

UPS

MAIN LOAD

Q1 Q0 Q4

Q5

Batteries

(Figure 3-5: Bypass Mode Diagram_ Single Input Single Unit)

Static Switch

Rectifier Inverter

3.1.4 Manual Bypass Mode_ Single Input_ Single Unit

When the UPS needs maintenance, you can manually switch the UPS to manual bypass

mode. To let the UPS run in manual bypass mode, please follow the procedures below:

Confirm that the bypass AC source and the STS module are normal.

1

Press the LCD's ON/ OFF button ( ) once and the ‘POWER OFF?’ screen will pop

2

up to ask you if you want to power off the inverter. Please select ‘YES’.

Turn on the Delta or non-Delta external maintenance bypass cabinet’s Manual Bypass

3

Breaker or Switch (Q3).

Turn off the UPS’s Bypass Switch (Q0).

4

Turn off the Delta or non-Delta external maintenance bypass cabinet’s Input Breaker or

5

Switch (Q1) and Output Breaker or Switch (Q4).

Turn off each external battery cabinet’s breaker (Q5).

6

Modulon DPH Series

3-6

Page 33

ௐ

ௐ

3

Operation Modes

In manual bypass mode, all power inside the UPS is completely cut off and maintenance

personnel can perform maintenance safely. For manual bypass mode diagram, please see

Figure 3-6. During manual bypass mode, the UPS’s tri-color LED and LCD are both off.

WARNING:

1. In manual bypass mode, make sure that all of the breakers or switches (except

the Delta or non-Delta external maintenance bypass cabinet’s Manual Bypass

Breaker or Switch (Q3)) are in the OFF position before working on the UPS’s

internal circuits. This avoids electric shock.

2. After the power inside the UPS is completely cut off, there is no high voltage in

the UPS but in the Delta or non-Delta external maintenance bypass cabinet. Do

not touch the Delta or non-Delta external maintenance bypass cabinet during

UPS maintenance process to avoid electric shock.

3. During manual bypass mode, the UPS’s input power is completely cut off and the

connected critical loads are not protected.

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

UPS

MAIN LOAD

Q1 Q0 Q4

Q5

Batteries

(Figure 3-6: Manual Bypass Mode Diagram_ Single Input Single Unit)

Static Switch

Rectifier Inverter

3-7

Page 34

3.1.5 ECO Mode_ Single Input_ Single Unit

To activate ECO mode, please refer to 6.2.5 ECO Mode Start-up Procedures, 7.6 Main

Screen and 7.10.2 Mode Setting.

In ECO mode, when bypass AC source’s input voltage and frequency are within the range of

rating voltage ±10% and rating frequency ±3Hz, the UPS works in bypass mode; otherwise,

the UPS runs in online mode. For ECO mode diagram, please see Figure 3-7. During ECO

mode, the UPS’s tri-color LED illuminates green and the text ‘ECO’ appears in the upper right

corner of the screen.

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

UPS

MAIN LOAD

Q1 Q0 Q4

Q5

Batteries

(Figure 3-7: ECO Mode Diagram_ Single Input Single Unit)

Static Switch

Rectifier Inverter

3.1.6 Frequency Conversion Mode_ Single Input_ Single Unit

To activate frequency conversion mode, please refer to 6.2.6 Frequency Conversion Mode

Start-up Procedures, 7.6 Main Screen and 7.10.2 Mode Setting.

After the UPS is manually set in frequency conversion mode, the inverter will automatically

select 50Hz or 60Hz as the fixed output frequency. After the output frequency is determined,

the system will automatically disable the bypass function. Please note that, once the inverter

shuts down, there is no bypass output. For the diagram of frequency conversion mode, please

see Figure 3-8. During frequency conversion mode, the UPS’s tri-color LED illuminates

green and the text ‘Frequency Conversion’ appears in the upper right corner of the screen.

Modulon DPH Series

127(During frequency conversion mode, once the inverter shuts down, there is

no bypass output.

3-8

Page 35

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

ௐ

ௐ

3

Operation Modes

UPS

MAIN LOAD

Q1 Q0 Q4

Q5

Batteries

Static Switch

Rectifier Inverter

(Figure 3-8: Frequency Conversion Mode Diagram_ Single Input Single Unit)

3.1.7 Green Mode _ Single Input_ Single Unit

To activate green mode, please refer to 6.2.7 Green Mode Start-up Procedures, 7.6 Main

Screen and 7.10.2 Mode Setting.

Green mode is the same as online mode, but the difference is that the system will automatically

detect the output status (i.e. total load capacity %) to decide which specific power modules

should be fully powered on or idle in order to achieve higher efficiency of the UPS. For the

green mode diagram, please see Figure 3-9. During green mode, the UPS’s tri-color LED

illuminates green and the text ‘Green’ appears in the upper right corner of the screen.

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

UPS

MAIN LOAD

Q1 Q0 Q4

Q5

Batteries

Static Switch

Rectifier Inverter

(Figure 3-9: Green Mode Diagram_ Single Input Single Unit)

3-9

Page 36

3.1.8 Energy Recycle Mode _ Single Input_ Single Unit

127(Energy recycle mode is only applicable to single input and single unit

application.

Energy recycle mode is only applicable to UPS self-test only. Without connection of any

critical loads, the UPS can execute current test under full load condition. Before you activate

energy recycle mode, please make sure that the Delta or non-Delta external maintenance

bypass cabinet’s Manual Bypass Breaker or Switch (Q3), Output Breaker or Switch (Q4) and

each external battery cabinet’s battery breaker (Q5) are in the OFF status.

To activate energy recycle mode (only qualified service personnel can do so), please refer

to 6.2.8 Energy Recycle Mode Start-up Procedures, 7.6 Main Screen and 7.10.2 Mode

Setting.

For the diagram of energy recycle mode, please see Figure 3-10. During energy recycle

mode, the UPS’s tri-color LED illuminates yellow and the text ‘Energy Recycle’ appears in

the upper right corner of the screen.

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

UPS

MAIN LOAD

Q1 Q0 Q4

Q5

Batteries

(Figure 3-10: Energy Recycle Mode Diagram_ Single Input Single Unit)

Static Switch

Rectifier Inverter

Modulon DPH Series

3-10

Page 37

3.1.9 Online Mode_ Single Input_ Parallel Units

In online mode (parallel), the total loads will be equally shared by the parallel UPSs. If one

of the parallel units fails and its load is less than the total capacity of the remaining parallel

units, the failing UPS’s output will be switched off and its load will be equally shared by

the remaining parallel units. If the failing UPS’s load is larger than the total capacity of the

remaining parallel units, all UPSs’ inverters will turn off and the total loads will be supplied

by bypass power. During online mode, each UPS’s tri-color LED illuminates green and each

UPS’s LCD shows the text ‘On-Line’ in the upper right corner. Please refer to Figure 3-11 for

the path of electrical power through the parallel UPSs in online mode.

ௐ

ௐ

3

Operation Modes

1

MAIN

Batteries

2

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

UPS

Q1 Q0 Q4

Q5

ՕۋஂՕטঢҒݳષߒ

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

UPS

Static Switch

Rectifier Inverter

Static Switch

LOAD

MAIN

Batteries

Rectifier Inverter

Q1 Q0 Q4

Q5

(Figure 3-11: Online Mode Diagram_ Single Input Parallel Units)

3-11

Page 38

3.1.10

Battery Mode _ Single Input_ Parallel Units

If the main AC source cannot supply power, for example, when unstable voltage or a power

outage occurs, all parallel UPSs will automatically transfer from online mode to battery mode.

During the conversion process, output voltage remains the same, and during battery mode,

each UPS’s tri-color LED illuminates yellow and each UPS’s LCD shows the text ‘Battery’ in

the upper right corner. Please refer to Figure 3-12 for the path of electrical power through the

parallel UPSs in battery mode.

1

MAIN

Batteries

2

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

UPS

Q1 Q0 Q4

Q5

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

UPS

Static Switch

Rectifier Inverter

Static Switch

LOAD

MAIN

Batteries

Modulon DPH Series

Rectifier Inverter

Q1 Q0 Q4

Q5

Figure 3-12: Battery Mode Diagram_ Single Input Parallel Units

3-12

Page 39

ௐ

ௐ

3

Operation Modes

3.1.11

Bypass Mode_ Single Input_ Parallel Units

In parallel mode, when all inverters encounter abnormal situations such as overload, short

circuit, abnormal output voltage or low battery, they will automatically shut themselves down.

Meanwhile, if all UPSs detect the bypass AC source is normal, they will automatically switch

to bypass mode to protect the connected critical loads from power interruption. The critical

loads will be equally shared by all parallel units. After the abnormalities mentioned above

are eliminated, the UPSs will switch back to online mode from bypass mode. During bypass

mode, each UPS’s tri-color LED illuminates yellow and each UPS’s LCD shows the text

‘Bypass’ in the upper right corner. Please see Figure 3-13 for the path of electrical power

through the parallel UPSs in bypass mode.

1

MAIN

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

UPS

Q1 Q0 Q4

Static Switch

Rectifier Inverter

Batteries

2

MAIN

Batteries

Q5

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

UPS

Q1 Q0 Q4

Q5

(Figure 3-13: Bypass Mode Diagram_ Single Input Parallel Units)

Static Switch

Rectifier Inverter

LOAD

3-13

Page 40

3.1.12

Manual Bypass Mode_ Single Input_ Parallel Units

In parallel mode, if one of the parallel UPSs needs maintenance, please first confirm that

the bypass AC source and each parallel UPS’s STS module are normal. After confirmation,

please follow the procedures below to manually switch each of the parallel UPSs to manual

bypass mode.

Press each LCD’s ON/ OFF button ( ) once and the ‘POWER OFF?’ screen will pop

1

up to ask you if you want to power off the inverter. Please select ‘YES’.

Turn on each Delta or non-Delta external maintenance bypass cabinet’s Manual Bypass

2

Breaker or Switch (Q3).

Turn off each UPS’s Bypass Switch (Q0).

3

Turn off each Delta or non-Delta external maintenance bypass cabinet’s Input Breaker

4

or Switch (Q1) and Output Breaker or Switch (Q4).

Turn off each external battery cabinet’s breaker (Q5).

5

In manual bypass mode, all power inside the parallel UPSs is completely cut off and

maintenance personnel can perform maintenance safely. The connected critical loads will

be supplied by the manual bypass. During manual bypass mode, all parallel UPSs’ tri-color

LEDs and LCDs are off. Please see Figure 3-14 for the path of electrical power through the

parallel UPSs in manual bypass mode.

WARNING:

1. In manual bypass mode, make sure that all of the breakers or switches (except

each Delta or non-Delta external maintenance bypass cabinet’s Manual Bypass

Breaker or Switch (Q3)) are in the OFF position before working on any of the

parallel UPSs’ internal circuits. This avoids electric shock.

2. After the power inside all parallel UPSs is completely cut off, there is no high

voltage in the parallel UPSs but in every Delta or non-Delta external maintenance

bypass cabinet. Do not touch any Delta or non-Delta external maintenance

bypass cabinet during UPS maintenance process to avoid electric shock.

3. During manual bypass mode, each parallel UPS’s input power is completely cut

off and the connected critical loads are not protected.

127(For parallel UPSs, if you want to turn off one of the parallel UPSs for

maintenance, please make sure the total connected critical loads will not exceed the

remaining parallel units’ total capacity.

Modulon DPH Series

3-14

Page 41

ௐ

ௐ

3

Operation Modes

1

MAIN

Batteries

2

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

UPS

Q1 Q0 Q4

Q5

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

UPS

Static Switch

Rectifier Inverter

Static Switch

LOAD

MAIN

Batteries

Rectifier Inverter

Q1 Q0 Q4

Q5

(Figure 3-14: Manual Bypass Mode Diagram_ Single Input Parallel Units)

3-15

Page 42

3.1.13

ECO Mode_ Single Input_ Parallel Units

To activate ECO mode, please refer to 6.2.5 ECO Mode Start-up Procedures, 7.6 Main

Screen and 7.10.2 Mode Setting.

In ECO mode (parallel), when each UPS’s bypass input voltage and frequency are within the

range of rating voltage ±10% and rating frequency ±3Hz, each UPS works in bypass mode;

otherwise, each UPS runs in online mode. During ECO mode, each UPS’s tri-color LED

illuminates green and each UPS’s LCD shows the text ‘ECO’ in the upper right corner. Please

see Figure 3-15 for the path of electrical power through the parallel UPSs in ECO mode.

1

MAIN

Batteries

2

MAIN

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

UPS

Q1 Q0 Q4

Q5

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

UPS

Q1 Q0 Q4

Static Switch

Rectifier Inverter

Static Switch

Rectifier Inverter

LOAD

Batteries

Modulon DPH Series

Q5

(Figure 3-15: ECO Mode Diagram_ Single Input Parallel Units)

3-16

Page 43

ௐ

ௐ

3

Operation Modes

3.1.14

Frequency Conversion Mode_ Single Input_ Parallel Units

To activate frequency conversion mode, please refer to 6.2.6 Frequency Conversion Mode

Start-up Procedures, 7.6 Main Screen and 7.10.2 Mode Setting.

For parallel application, after each of the parallel UPSs is manually set in frequency conversion

mode, each inverter will automatically select 50Hz or 60Hz as the fixed output frequency.

After the output frequency is determined, each system will automatically disable the bypass

function. Please note that, once each inverter shuts down, there is no bypass output. During

frequency conversion mode, each UPS’s tri-color LED illuminates green and each UPS’s

LCD shows the text ‘Frequency Conversion’ in the upper right corner. Please see Figure

3-16 for the path of electrical power through the parallel UPSs in frequency conversion mode.

127(During frequency conversion mode (parallel), once all of the UPSs’ inverters

shut down, there is no bypass output.

1

MAIN

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

UPS

Q1 Q0 Q4

Static Switch

Rectifier Inverter

Batteries

2

MAIN

Batteries

(Figure 3-16: Frequency Conversion Mode Diagram_ Single Input Parallel Units)

Q5

ՕۋஂՕטঢҒݳષߒ

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

UPS

Q1 Q0 Q4

Q5

Static Switch

Rectifier Inverter

3-17

LOAD

Page 44

3.1.15

Green Mode_ Single Input_ Parallel Units

To activate green mode, please refer to 6.2.7 Green Mode Start-up Procedures, 7.6 Main

Screen and 7.10.2 Mode Setting.

For parallel application, green mode is the same as online mode, but the difference is that

each system will automatically detect its UPS’s output status (i.e. total load capacity %) to

decide which specific power modules should be fully powered on or idle in order to achieve

higher efficiency of the UPS. During green mode, each UPS’s tri-color LED illuminates green

and each UPS’s LCD shows the text ‘Green’ in the upper right corner. Please see Figure

3-17 for the path of electrical power through the parallel UPSs in green mode.

1

MAIN

Batteries

2

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

UPS

Q1 Q0 Q4

Q5

ՕۋஂՕטঢҒݳષߒ

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

UPS

Static Switch

Rectifier Inverter

Static Switch

LOAD

MAIN

Batteries

Modulon DPH Series

Rectifier Inverter

Q1 Q0 Q4

Q5

(Figure 3-17: Green Mode Diagram_ Single Input Parallel Units)

3-18

Page 45

3.2 Dual Input

3.2.1 Online Mode_ Dual Input_ Single Unit

In online mode, the main AC source supplies AC power via the Delta or non-Delta external

maintenance bypass cabinet’s Input Breaker or Switch (Q1) to the rectifier and the rectifier

converts the AC power to DC power and supplies the DC power to the inverter. In the

meantime, the rectifier provides charging power to the batteries. After receiving the DC power,

the inverter converts it into clean and stable AC power to the connected critical loads via the

Delta or non-Delta external maintenance bypass cabinet’s Output Breaker or Switch (Q4).

Please see Figure 3-18 for online mode diagram. During online mode, the UPS’s tri-color

LED illuminates green and the text ‘On-Line’ appears in the upper right corner of the screen.

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

ௐ

ௐ

3

Operation Modes

UPS

BYPA.

Q0Q2

MAIN LOAD

Q1 Q4

Batteries

(Figure 3-18: Online Mode Diagram_ Dual Input Single Unit)

Q5

Static Switch

Rectifier Inverter

3.2.2 Battery Mode_ Dual Input_ Single Unit

The UPS transfers to battery mode automatically if the main AC source cannot supply power,

for example, when unstable voltage or a power outage occurs. In battery mode, the batteries

provide DC power and the UPS converts it into AC power and supplies it to the connected

critical loads via the Delta or non-Delta external maintenance bypass cabinet’s Output

Breaker or Switch (Q4). During the conversion process, output voltage remains the same.

Please see Figure 3-19 for battery mode diagram. During battery mode, the UPS’s tri-color

LED illuminates yellow and the text ‘Battery’ appears in the upper right corner of the screen.

3-19

Page 46

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

UPS

BYPA.

Q0Q2

MAIN LOAD

Q1 Q4

Batteries

Q5

Static Switch

Rectifier Inverter

(Figure 3-19: Battery Mode Diagram_ Dual Input Single Unit)

3.2.3 Bypass Mode_ Dual Input_ Single Unit

When the inverter encounters abnormal situations such as over temperature, overload, short

circuit, abnormal output voltage or low battery, it will automatically shut itself down. If the UPS

detects the bypass AC source is normal, it will automatically switch to bypass mode to protect

the connected critical loads from power interruption. Please refer to Figure 3-20. After the

above-mentioned abnormalities are eliminated, the UPS will switch back to online mode from

bypass mode. During bypass mode, the UPS’s tri-color LED illuminates yellow and the text

‘Bypass’ appears in the upper right corner of the screen.

Batteries

Modulon DPH Series

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

UPS

BYPA.

Q0Q2

MAIN LOAD

Q1 Q4

Q5

Static Switch

Rectifier Inverter

(Figure 3-20: Bypass Mode Diagram_ Dual Input Single Unit)

3-20

Page 47

3.2.4 Manual Bypass Mode_ Dual Input_ Single Unit

When the UPS needs maintenance, you can manually switch the UPS to manual bypass

mode. To let the UPS run in manual bypass mode, please follow the procedures below:

Confirm that the bypass AC source and the STS module are normal.

1

Press the LCD's ON/ OFF button ( ) once and the ‘POWER OFF?’ screen will pop

2

up to ask you if you want to power off the inverter. Please select ‘YES’.

Turn on the Delta or non-Delta external maintenance bypass cabinet’s Manual Bypass

3

Breaker or Switch (Q3).

Turn off the UPS’s Bypass Switch (Q0).

4

Turn off the Delta or non-Delta external maintenance bypass cabinet’s Input Breaker or

5

Switch (Q1), Bypass Breaker or Switch (Q2) and Output Breaker or Switch (Q4).

Turn off each external battery cabinet’s breaker (Q5).

6

In manual bypass mode, all power inside the UPS is completely cut off and maintenance

personnel can perform maintenance safely. For manual bypass mode diagram, please see

Figure 3-21. During manual bypass mode, the UPS’s tri-color LED and LCD are both off.

WARNING:

1. In manual bypass mode, make sure that all of the breakers or switches (except

the Delta or non-Delta external maintenance bypass cabinet’s Manual Bypass

Breaker or Switch (Q3)) are in the OFF position before working on the UPS’s

internal circuits. This avoids electric shock.

2. After the power inside the UPS is completely cut off, there is no high voltage in

the UPS but in the Delta or non-Delta external maintenance bypass cabinet. Do

not touch the Delta or non-Delta external maintenance bypass cabinet during

UPS maintenance process to avoid electric shock.

3. During manual bypass mode, the UPS’s input power is completely cut off and the

connected critical loads are not protected.

ௐ

ௐ

3

Operation Modes

3-21

Page 48

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

UPS

BYPA.

Q0Q2

MAIN LOAD

Q1 Q4

Batteries

Q5

Static Switch

Rectifier Inverter

(Figure 3-21: Manual Bypass Mode Diagram_ Dual Input Single Unit)

3.2.5 ECO Mode_ Dual Input_ Single Unit

To activate ECO mode, please refer to 6.2.5 ECO Mode Start-up Procedures, 7.6 Main

Screen and 7.10.2 Mode Setting.

In ECO mode, when the bypass AC source’s input voltage and frequency are within the

range of rating voltage ±10% and rating frequency ±3Hz, the UPS works in bypass mode;

otherwise, the UPS runs in online mode. For ECO mode diagram, please see Figure 3-22.

During ECO mode, the UPS’s tri-color LED illuminates green and the text ‘ECO’ appears in

the upper right corner of the screen.

Delta or non-Delta External Maintenance Bypass Cabinet

Batteries

Modulon DPH Series

Q3

UPS

BYPA.

Q0Q2

MAIN LOAD

Q1 Q4

Q5

Static Switch

Rectifier Inverter

(Figure 3-22: ECO Mode Diagram_ Dual Input Single Unit)

3-22

Page 49

ௐ

3

3.2.6 Frequency Conversion Mode_ Dual Input_ Single Unit

To activate frequency conversion mode, please refer to 6.2.6 Frequency Conversion Mode

Start-up Procedures, 7.6 Main Screen and 7.10.2 Mode Setting.

After the UPS is manually set in frequency conversion mode, the inverter will automatically

select 50Hz or 60Hz as the fixed output frequency. After the output frequency is determined,

the system will automatically disable the bypass function. Please note that, once the inverter

shuts down, there is no bypass output. For the diagram of frequency conversion mode, please

see Figure 3-23. During frequency conversion mode, the UPS’s tri-color LED illuminates

green and the text ‘Frequency Conversion’ appears in the upper right corner of the screen.

127(During frequency conversion mode, once the inverter shuts down, there is

no bypass output.

Delta or non-Delta External Maintenance Bypass Cabinet

Q3

ௐ

Operation Modes

UPS

BYPA.

Q0Q2

MAIN LOAD

Q1 Q4

Batteries

(Figure 3-23: Frequency Conversion Mode Diagram_ Dual Input Single Unit)

Q5

Static Switch

Rectifier Inverter

3-23

Page 50

3.2.7 Green Mode _ Dual Input_ Single Unit

To activate green mode, please refer to 6.2.7 Green Mode Start-up Procedures, 7.6 Main

Screen and 7.10.2 Mode Setting.

Green mode is the same as online mode, but the difference is that the system will automatically

detect the output status (i.e. total load capacity %) to decide which specific power modules

should be fully powered on or idle in order to achieve higher efficiency of the UPS. For the

green mode diagram, please see Figure 3-24. During green mode, the UPS’s tri-color LED

illuminates green and the text ‘Green’ appears in the upper right corner of the screen.