Page 1

20 15 05 -1 8

50 12 61 25 03 -H SE 3

Page 2

Preface

Thank you for choosing the Hybrid Energy System (HES) designed exclusively for the Delta Injection

Machine, which consists of Hybrid Servo Controller (VFD-VJ) series and servo oil pump.

These production instructions provide the users with complete information regarding the installation,

parameter configuration, anomaly diagnosis, troubleshooting, and routine maintenance of the Hybrid

Servo Driver. To ensure correct installation and operation of the hybrid servo driver, please read the

instructions carefully before installing the machine. In addition, please store the enclosed CD-ROM

properly and pass down to the machine users.

The Hybrid servo driver is a delicate power electronics product. For the safety of the operators and the

security of the machine, please only allow professional electrical engineers to conduct installation, tests,

and adjust machine parameters. Please carefully read the contents of the instructions that are marked

with "Danger" and "caution". Please contact your local Delta agents for any questions and our

professional team will be happy to assist you.

PLEASE READ PRIOR TO INSTALLATION FOR SAFETY.

; Make sure to turn off the power before starting wiring.

; Once the AC power is turned off, when the POWER indicator of the Hybrid Servo

DANGER

Controller is still on, it means there is still high voltage inside the Hybrid Servo

Controller, which is very dangerous and do not touch the internal circuits and

components. To conduct the maintenance safely, please make sure the voltage

between +1 and - is lower than 25Vdc using the handheld multimeter before

starting the operation.

; The internal circuit board of Hybrid Servo Controller houses CMOS IC, which is

vulnerable to electrostatics. Please do not touch the circuit board by and without

any anti-electrostatics measures.

; Never modify the components or wiring inside the Hybrid Servo Controller.

; The E

series uses the third type of ground scheme while the 460V series uses special

ground.

; This series of products cannot be operated in environments that endanger human

safety.

; Please keep children or strangers from approaching Hybrid Servo Controller.

terminal of Hybrid Servo Controller must be grounded correctly. The 230V

Page 3

; Never connect AC power to the output terminals U/T1, V/T2, and W/T3 of Hybrid

Servo Controller.

; Please do not conduct stress test on the internal components of Hybrid Servo

Controller, for the semiconductor devices therein may be damaged by high-voltage

breakdown.

; Even when the servo oil pump is off, the main loop terminal of Hybrid Servo

Controller can still be loaded with high voltage that can be seriously dangerous.

; Only qualified professional electrical engineers can conduct tasks of installation,

wiring, and maintenance of Hybrid Servo Controller。

; When Hybrid Servo Controller uses external terminals as its run command sources,

the servo oil pump may start running immediately after the power is connected,

which may be dangerous with any personnel present.

; Please choose a safe area to install Hybrid Energy System, where there is no high

temperature, direct sunlight, moisture, and water dripping and splash.

; Please follow the instructions when installing Hybrid Energy System. Any

unapproved operation environment may lead to fire, gas explosion, and

electroshock.

; When the wiring between the hybrid controller and the hybrid servo motor is too

long, it may compromise the interlayer insulation of the motor. Please install a

reactor between them (please refer to Appendix A) to avoid burning of the hybrid

servo motor from damaged insulation.

; The voltage rating of the power supply of Hybrid Servo Controller 230 series cannot

be higher than 240V (no higher than 480V for 460 series) and the associated

current cannot exceed 5000A RMS ( no higher than 10000A RMS for models with

40HP (30kW))

NOTE

To provide detailed product descriptions, the illustrations are made with the exterior cover or safety shield removed. When

the product is running, ple ase mak e sur e the exterior cover is secured a nd th e wiring is correct to ensure safety by fol lowing

the instructions of the manual.

The figures in the manual are made for illustration purposes and will be slightly different from the actual products. However,

the discrepancy will not affect the interests of clients.

Since our products are being constantly improved, for information about any changes in specifications, please contact our

local agents or visit ( http://www.delta.com.tw/industrialautomation/ ) to download the most recent versions.

Page 4

Table of Contents

Chapter 1 Use and Installation

1-1 Exterior of Product................................................................................................................ 1-2

1-2 Specifications........................................................................................................................1-3

1-3 Introduction of Hybrid Energy System................................................................................... 1-5

1-4 Instal lation ............................................................................................................................ 1-6

Chapter 2 Wiring

2-1 Wiring...................................................................................................................................2-2

2-2 Wiring of Servo oil Pump ...................................................................................................... 2-4

2-3 Descriptions of Main Loop Terminals ....................................................................................2-5

2-4 Descriptions of Control Loop Terminals.................................................................................2-8

Chapter 3 Start Up

3-1 Description of Control Panel ................................................................................................. 3-2

3-2 Adjustment Flow Chart..........................................................................................................3-4

3-3 Explanations for the Adjustment Steps..................................................................................3-5

Chapter 4 Parameter Functions

4-1 Summary of Parameter Settings...........................................................................................4-2

4-2 Detailed Description of Parameters..................................................................................... 4-10

Chapter 5 Methods of Anomaly Diagnosis

5-1 Unusual Signal......................................................................................................................5-2

5-2 Over Current (oc)..................................................................................................................5-7

5-3 Ground Fault (GFF)..............................................................................................................5-7

5-4 Over Voltage (ov).................................................................................................................. 5-8

5-5 Low Voltage (Lv)...................................................................................................................5-8

5-6 Overheat (oH1).....................................................................................................................5-9

5-7 Overload (oL)........................................................................................................................5-9

5-8 Phase Loss (PHL)...............................................................................................................5-10

5-9 Resolutions for Electromagnetic Noise and Induction Noise................................................5-11

5-10 Environment and Facilities for Installation.................................................................. 5-12

Page 5

Chapter 6 Maintenance

Regular Main tenance..................................................................................................................6-2

Appendix A. Instructions of Product Packaging

A-1 Descriptions of Product Packaging ...................................................................................... A-2

A-2 Detailed List of Product Packaging...................................................................................... A-3

Appendix B Optional Accessories

B-1 Non-fuse Circuit Breaker...................................................................................................... B-2

B-2 Reactor................................................................................................................................ B-3

B-3 Digital Keypad KPV-CE01.................................................................................................... B-8

B-4 Communication Card..........................................................................................................B-12

B-5 EMI Filter............................................................................................................................B-13

B-6 Brake Unit………………………………………………………………………………………..…B-15

Page 6

Chapter 1 Use and Installation|HES Series

Chapter 1 Use and Installation

1-1 Exterior of Product

1-2 Product Specifications

1-3 Introduction of Hybrid Energy System

1-4 Product Installation

Upon receipt of the product, the clients are advised to keep the product in its original packaging box. If

the machine won't be used temporarily, for future maintenance safety and compliance with the

manufacturer's warranty policy, please pat attention to the following for product storage:

; Store in a clean and dry location free from direct sunlight or corrosive fumes.

°

; Store within an ambient temperature range of -20

; Store within a relative humidity range of 0% to 90% and non-condensing

environment.

; Avoid storing the product in environments with caustic gases and liquids.

; Avoid placing the product directly on the ground. The product should be placed on

suitable benches and desiccators should be placed in the packaging bags in harsh

storage environments.

; Avoid installing the product in places with direct sunlight or vibrations.

; Even if the humidity is within the required value, condensation and freezing can still

happen when there is drastic change of temperature. Avoid storing products in such

environment.

; If the product has been taken out of the packaging box and in use for over three

C to +60 °C.

months, the temperature of the storage environment must be below 30°C. This

considers the fact when the electrolytic capacitor is stored with no current conduction

and the environment temperature is too high, its properties may deteriorate. Please

do not store the product in the situation of no current conduction for more than one

year.

1-1

Page 7

Chapter 1 Use and Installation|HES Series

A

1-1 Exterior of Product

All Hybrid Energy System has passed strict quality control before being shipped out from the factory,

with enforced packaging that sustains impacts. Upon opening the packaging of the Hybrid Energy

System, the customers are recommended to conduct the examination by the following steps:

; Check if there is any damage to Hybrid Energy System during shipping.

; Upon opening the box, check if the model number of Hybrid Energy System matches that

listed on the external box.

For any mismatch of the listed data with your order or any other issues with the product, please

contact your local agent or retailer.

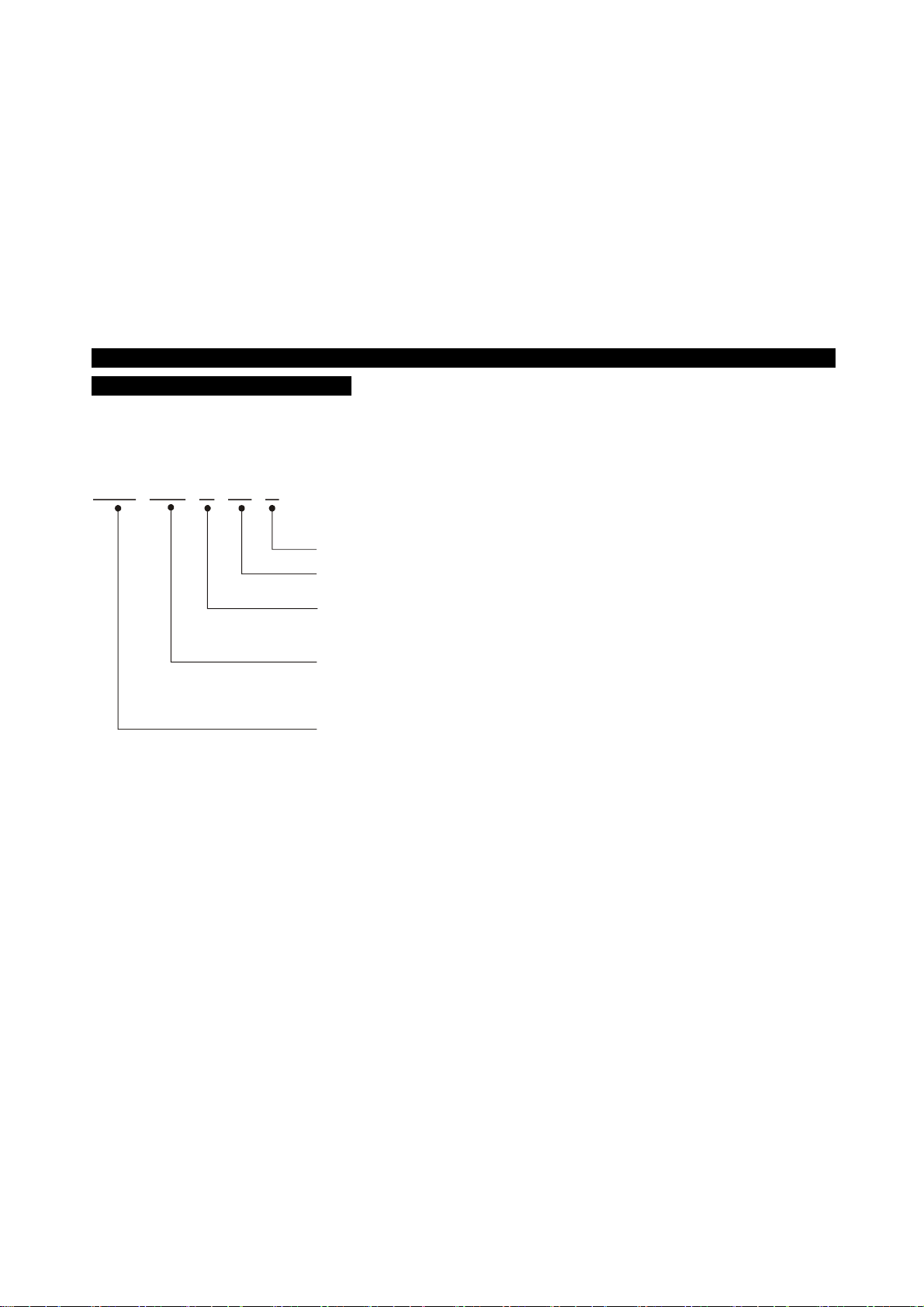

Model Explanation

HES 100 G 43

Ver si on

Input Voltage

Pressure

Flow Rate

Hybrid Energy System

23: 230V 3-PHASE

43:460V 3-PHASE

G: 140bar

H: 180bar

Z: 180bar

050: 50 L/min

063: 63L/min

080: 80L/min

100: 100L/min

125: 125L/min

160 160L min

: /

200 200L min

: /

250 250L min

: /

1-2

Page 8

Chapter 1 Use and Installation|HES Series

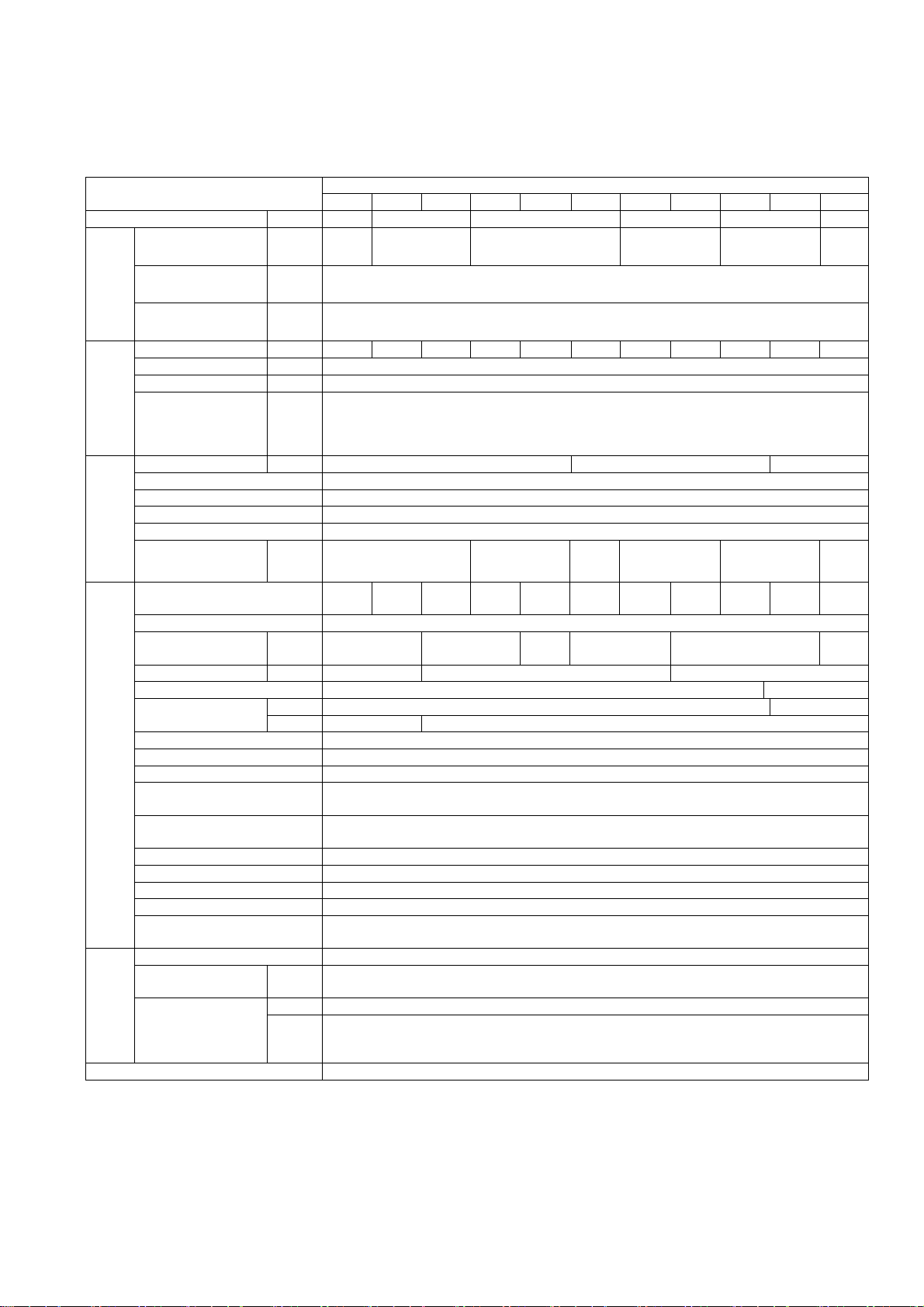

1-2 Specifications

230V Series Specifications

Model Number

Oil Pump Capacity cc/rev 25 32 40 50 64 80

Flow Rate L/min 63 80 100 125 160 200

Linear % Below 1% F.S.

Flow Rate

Specifications

Magnetic Hysteresis % Below 1% F.S.

Maximum Pressure Mpa 18 14 18 14 18 18 14 18 14 18 14

Minimum Pressure Mpa 0.1

Linear % Below 1% F.S.

Pressure

Magnetic Hysteresis % Below 1% F.S.

Specifications

Power kW 11 15 20

Insulation Grade Grade A (UL)

Cooling Method Forced Air Cooling

Environment Temperature 0 ~ 40 °C

Environment Humidity 20 ~ 90 RH (No condensation)

Specifications

Servo Oil Pump

Weight kg

063H 080G 080H 100G 100H 100Z 125G 125H 160G 160H 200G

82 83 95 108 110 144

HES____23A

VFD-___VL23A(_)

Input Voltage (V) 3-Phase 200~240V, 50/60Hz

Rated Output

Capacity

Weight kg 10 13 36

Brake Unit Built-in Plugged-in

Brake resistor

Speed Inspector Resolver

Pressure Command Input 0~10V Support three-point calibration

Flow Rate Command Input 0~10V Support three-point calibration

Multi-functional Input

Terminal

Multi-functional Output

Terminal

Servo Controller Specifications

Analog Output Voltage 2 ch dc 0~10V

Cooling Method Forced Air Cooling

Environment Temperature -10 ~ 45 °C

Environment Humidity Below 90 RH (No condensation)

Protection Functions

Working Medium HL-HLP DIN51 524 Part1/2 R68,R46

Operation

Temperature

Actuation Oil

Viscosity

Miscellaneous Safety, Reactor, and EMI filter are optional.

kVA 19 25 29 34 46 56

W 1000 1500

°C -20 to 100

@40 °C 67.83

@100

°C

110

(06HA)

Ω 8.3 5.8

Over current, over voltage, low voltage,, over heating, and overload in Hybrid Servo

110

(08GA)

Controller and over heating, overload, and abnormal speed in Hybrid Servo Motor.

150

(08HA)

150

(10GA)

2 ch DC24V 50mA, 1 ch Relay output

185

(10HA)

220

(10ZA)

5ch DC24V 8mA

8.62

220

(12GA)

300

(12HA)

300

(16GA)

370

(16HA)

370

(20GA)

1-3

Page 9

Chapter 1 Use and Installation|HES Series

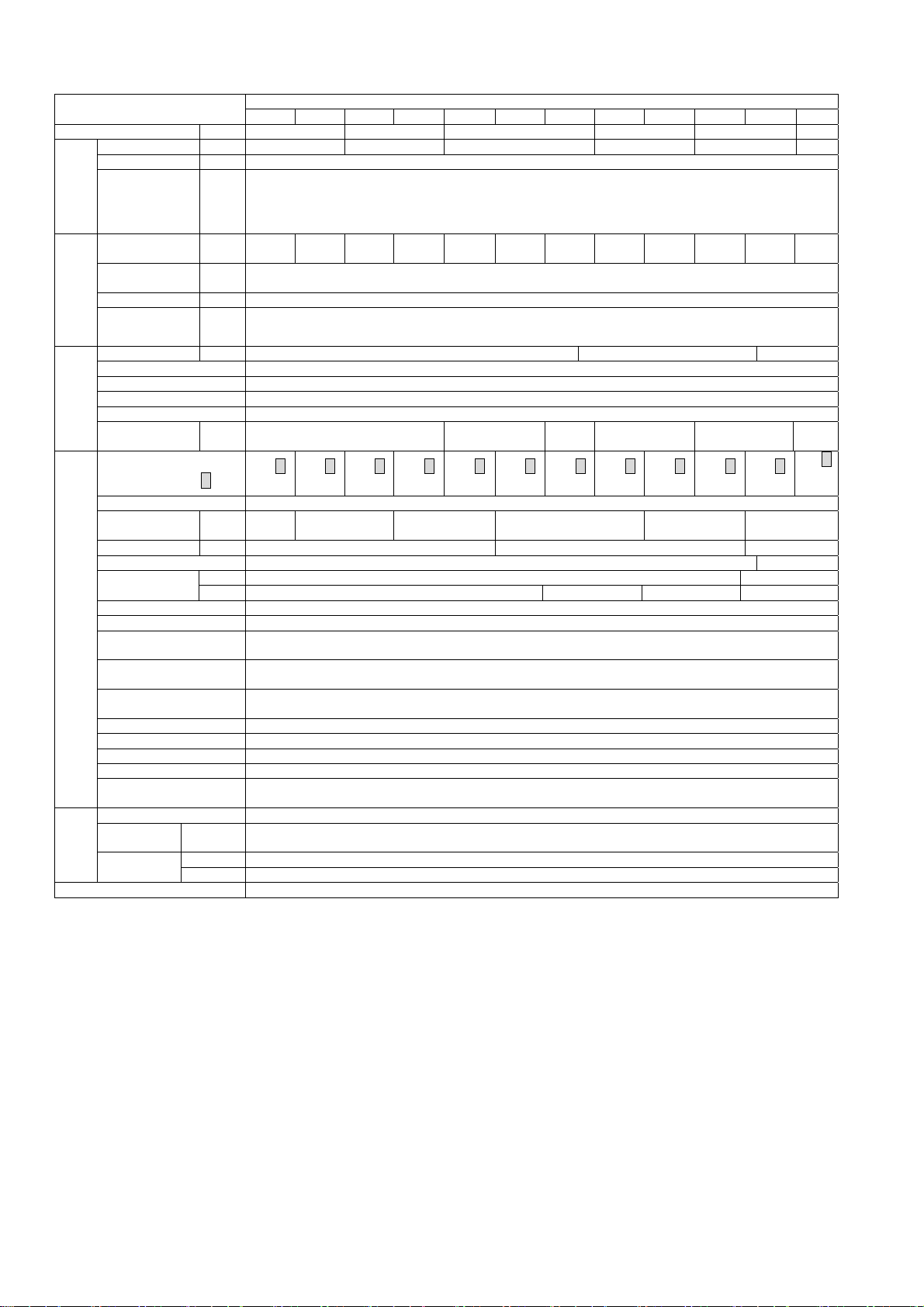

460V Series Specifications

Model Number

Oil Pump Capacity cc/rev 25 32 40 50 64 80

Flow Rate L/min 63 80 100 125 160 200

Linear % Below 1% F.S.

063G 063H 080G 080H 100G 100H 100Z 125G 125H 160G 160H 200G

HES____43A

Flow rate

Pressure

Servo Oil Pump

Actuation Oil

Magnetic

Hysteresis

Specifications

Maximum

Pressure

Minimum

Pressure

Linear % Below 1% F.S.

Magnetic

Specifications

Hysteresis

Power kW 11 15 20

Insulation Grade A grade (UL)

Cooling Method Forced Air Cooling

Environment Temperature 0 ~ 40 °C

Environment Humidity 20 ~ 90 RH(No condensation)

Weight of Servo

Specifications

Oil Pump

Model Number

VFD-___VL43A (_)

Input Voltage Three-Phase 380 ~ 460V, 50/60Hz

Rated Output

Capacity

Weight kg 10 13 36

Brake Unit Built-in Plugged-in

Brake resistor

Speed Inspector Resolver

Pressure Command Input 0~10V Support three-point calibration

Flow Rate Command

Input

Multi-functional Input

Terminal

Multi-functional Output

Servo Controller Specifications

Environment Temperature -10 ~ 45 °C

Terminal

Analog Output Voltage 2 ch dc 0~10V

Cooling Method Forced Air Cooling

Environment Humidity Below 90 RH(No condensation)

Protection Functions

Working Medium HL-HLP DIN51 524 Part1/2 R68,R46

Operation

Temperature

Viscosity

Miscellaneous Safety, Reactor, and EMI filter are optional.

% Below 1% F.S.

Mpa 14 18 14 18 14 18 18 14 18 14 18 14

Mpa 0.1

% Below 1% F.S.

kg 82 83 95 108 110 144

110A

(06GA)

KVA 19 25 29 34 46 56

W 1000 1500

Ω 25 20 14 13

°C -20 to 100

@40 °C 67.83

@100 °C 8.62

150B

(06HA)

Over current, over voltage, low voltage, over heating, and overload in Hybrid Servo Controller and over

150B

(08GA)

185B

(08HA)

heating, overload, and abnormal speed in Hybrid Servo Motor.

185B

(10GA)

0~10V Support three-point calibration

2 ch DC24V 50mA, 1 ch Relay output

220A

(10HA)

5ch DC24V 8mA

220A

(10ZA)

220A

(12GA)

300B

(12HA)

300B

(16GA)

370B

(16HA)

370B

(20GA

)

1-4

Page 10

Chapter 1 Use and Installation|HES Series

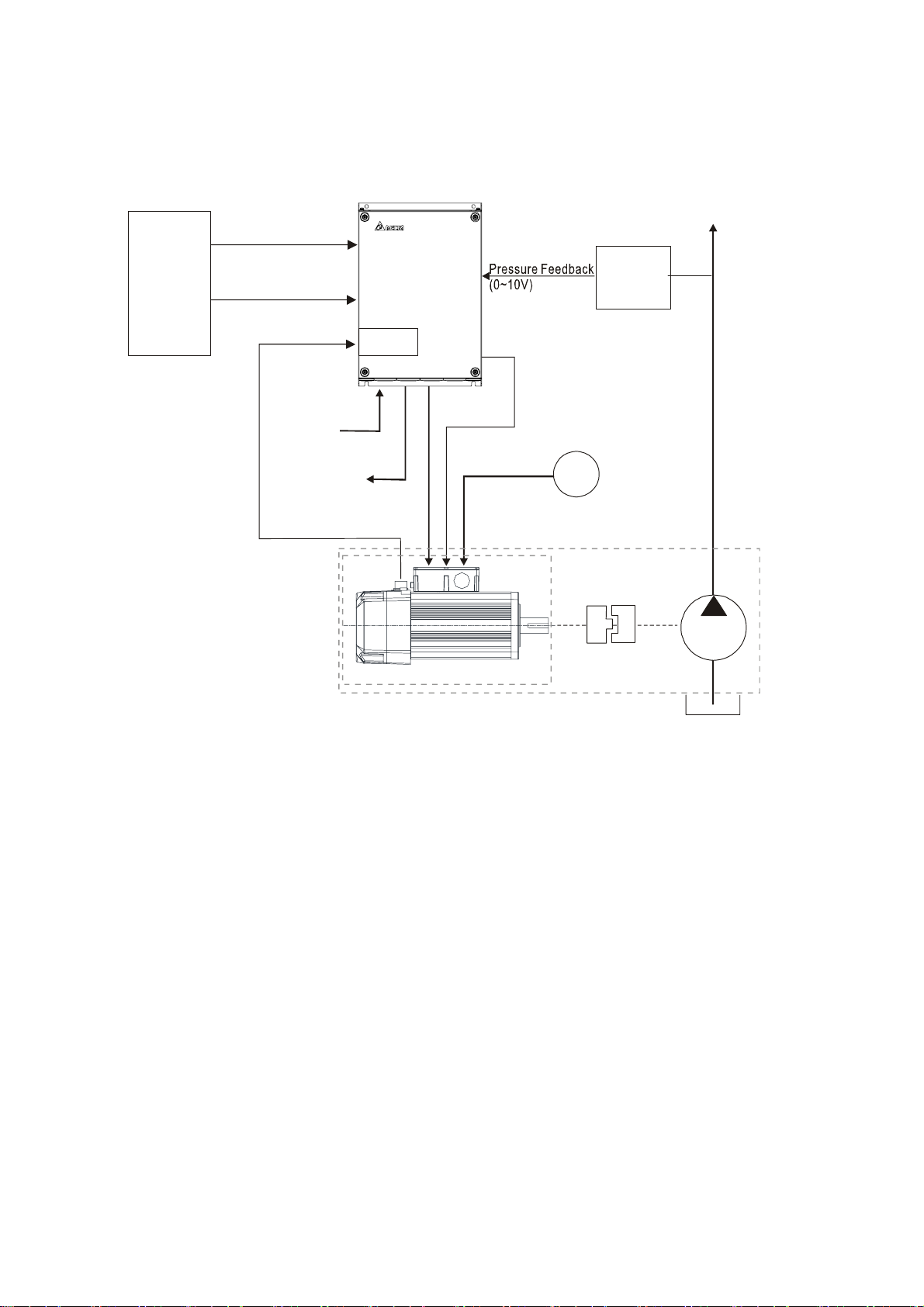

1-3 Introduction of Hybrid Energy

System

Injector

Controller

Pressure Command

(0~10V)

Flow Rate Command

(0~10V)

RST

Power Terminal

Brake resistance/

Brake Unit

Encoder signal

Delta Hybrid

Servo

Controller

PG Card

U V W

Pressure

Sensor

Over heat protection

switch

AC

FAN

220V

Servo oil pump

Oil Pump

Servo motor

1-5

Page 11

Chapter 1 Use and Installation|HES Series

e

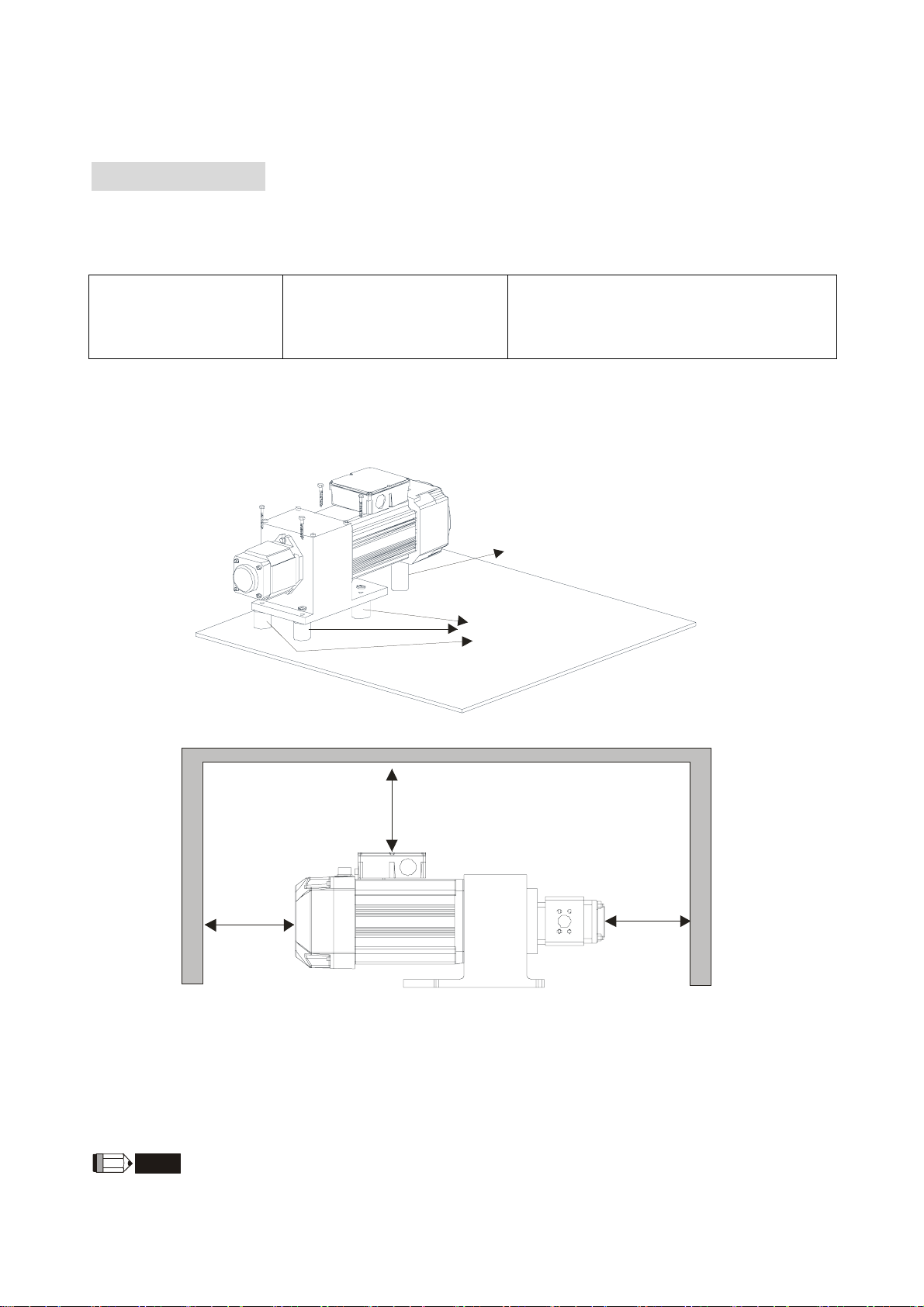

1-4 Installation

Servo Oil Pump

Please install the servo oil pump in an environment with the following conditions to ensure safe

product operation:

Conditions of Operation

Environment

The figure below shows that HES is installed on the machine. The screws must be secured to the

rubber mat to fixate the servo oil pump. It is recommended to add iron bars as the support of the

hybrid servo motor.

Environment Temperature

Relative Humidity

Oil Temperature

0°C~ 40°C

20%~90%, No condensation

0°C~ 60°C (15°C~ 50°C is recommended)

Iron bar

Rubber Mat*4

Installation Space

10cm

[4inch]

10cm

[4inch]

Installation Distanc

Since heat is generated as the hybrid servo motor is running, certain space must be reserved to

ensure good circulation of the cooling air as shown in the figure above.

When the hybrid servo motor is running, the temperature of the external cover will reach to about

100°C. Please do not touch it with hand to avoid burns.

NOTE

Please do not let any foreign objects such as fiber, paper pieces, wood chips or metal pieces to adhere to the cooling fan

of the hybrid servo motor.

10cm

[4inch]

1-6

Page 12

Chapter 1 Use and Installation|HES Series

Pipelines & Connections

Remove all protection caps on the pump

Choose suitable oil tube and connectors (Maximum intake flow rate 1m/s)

Recommended Specifications of intake oil tube

Flow Rate(L/min) Tube Diameter (inch) Length (m)

80 Above 1.5 Within 1.5

100 Above 1.5 Within 1.5

125 Above 2 Within 1.5

160 Above 2.25 Within 1.5

200 Above 2.5 Within 1.5

Absolute intake oil pressure: Maximum 2 bar

Prior to assembly, the iron dusts in the connectors and oil tubes must be removed.

The filter for the oil inlet must be above 150mesh.

NOTE

For safety, please install safety valve in the oil line loop.

Do not add check valve to the oil outlet of the oil pump to avoid poor response of Hybrid Energy System.

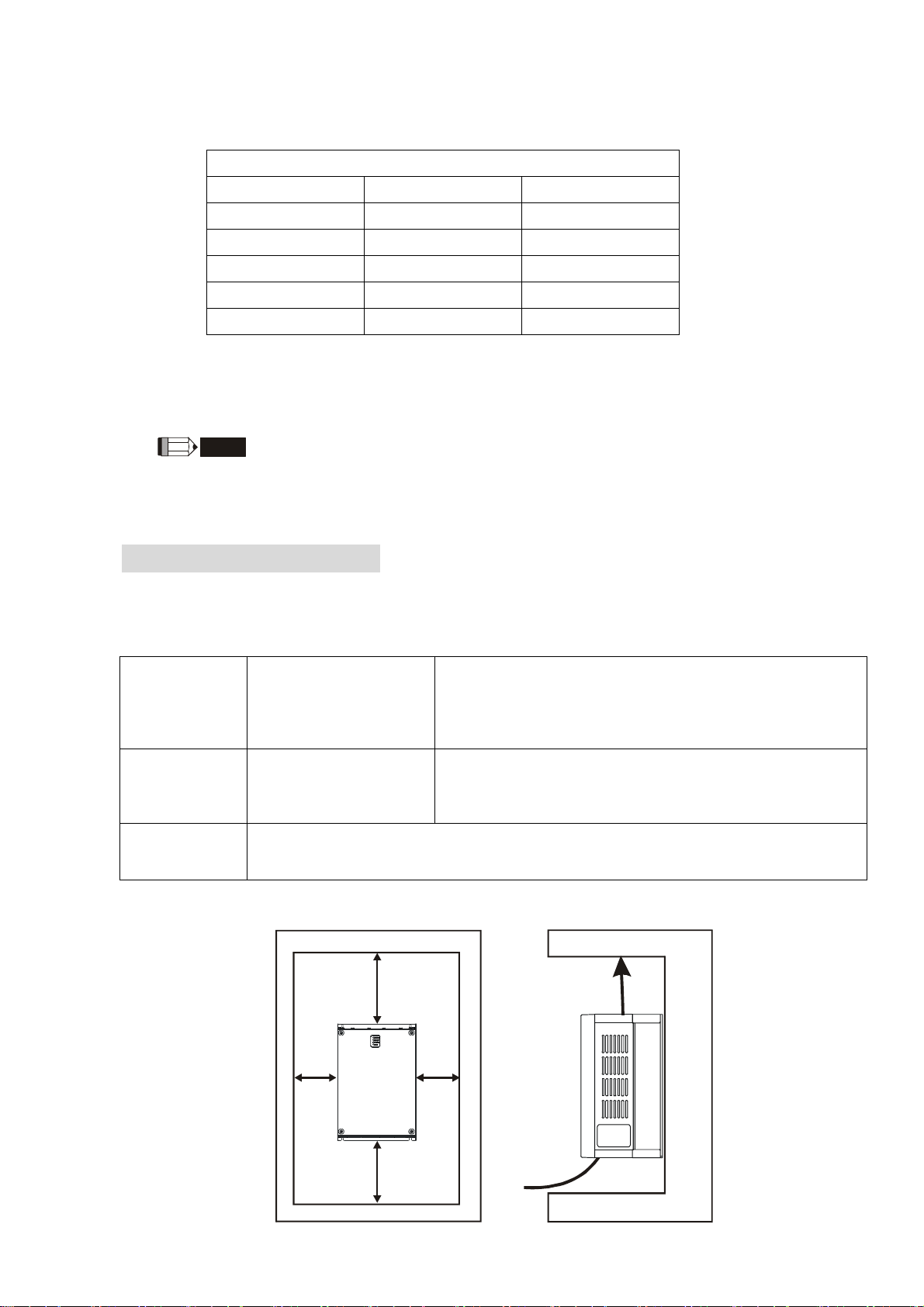

Hybrid Servo Controller

Please install the Hybrid Servo Controller in an environment with the following conditions to ensure

safe product operation:

Conditions of

Operation

Environment

Conditions of

Storage and

Shipping

Environment

Contamination

Protection Grade

Environment Temperature

Relative Humidity

Installation heights

Environment Temperature

Relative Humidity

2nd Grade: suitable for factory environments with medium to low contamination

Installation Space

Pressure

Vibration

Pressure

Vibration

-10°C~ +45°C

<90%,No condensation

86 ~ 106 kPa

<1000m

<20Hz: 9.80 m/s

-20°C~ +60°C (-4°F ~ 140°F)

<90%,No condensation

86 ~ 106 kPa

<20Hz: 9.80 m/s

2

(1G) max; 20~50H:5.88 m/s2 (0.6G) max

2

(1G) max; 20 ~ 50Hz: 5.88 m/s2 (0.6G) max

W

H

W

Air Flow

H

1-7

Page 13

Chapter 1 Use and Installation|HES Series

HP

W

mm (inch)

H

mm (inch)

7.5-20HP 75 (3) 175 (7)

25-75HP 75 (3) 200 (8)

100HP 75 (3) 250 (10)

; The Hybrid Servo Controller must be installed vertically with screws to sturdy structures. Do not

install it upside down, tilted, or horizontally.

; Since heat is generated when Hybrid Servo Controller is running, good circulation of the

cooling air must be provided as shown in the figure above. Certain space is reserved in the

design to allow the heat generated to dissipate upwards. As a result, do not install the machine

below any equipment that cannot stand excessive heat. If the machine is installed in the control

plate, special care must be given to maintain good air flow for cooling so that the surrounding

temperature of Hybrid Servo Controller won’t exceed the regulated values. Do not install Hybrid

Servo Controller in any closed box with poor air flow and cooling, which will lead to machine

malfunction.

; As the Hybrid Servo Controller is running, the temperature of the cooling plate will change with

the environment temperature and the load, with the maximum temperature reaching to about

90°C. Therefore, the backside of installation materials for Hybrid Servo Controller must be able

to sustain high temperature.

; When multiple Servo Controllers are installed in one single control plate, it is recommended to

install them with laterally to avoid heat interference among each other. If stacking installation is

needed, spacers must be installed to minimize the effect of the heat from the lower machine on

the upper machine.

NOTE

Do not add check valve to the oil outlet of the oil pump to avoid poor response of Hybrid Energy System.

The product should be installed in a control plate made of inflammable materials such as metal to avoid the risk of fire.

1-8

Page 14

Chapter 2 Wiring|HES Series

Chapter 2 Wiring

2-1 Wiring

2-2 Wiring of Servo Oil Pump

2-3 Descriptions of Main circuit Terminals

2-4 Descriptions of Control Loop Terminals

Upon opening the top cover of the Hybrid Servo Controller and reveal the wiring terminal bus, check if

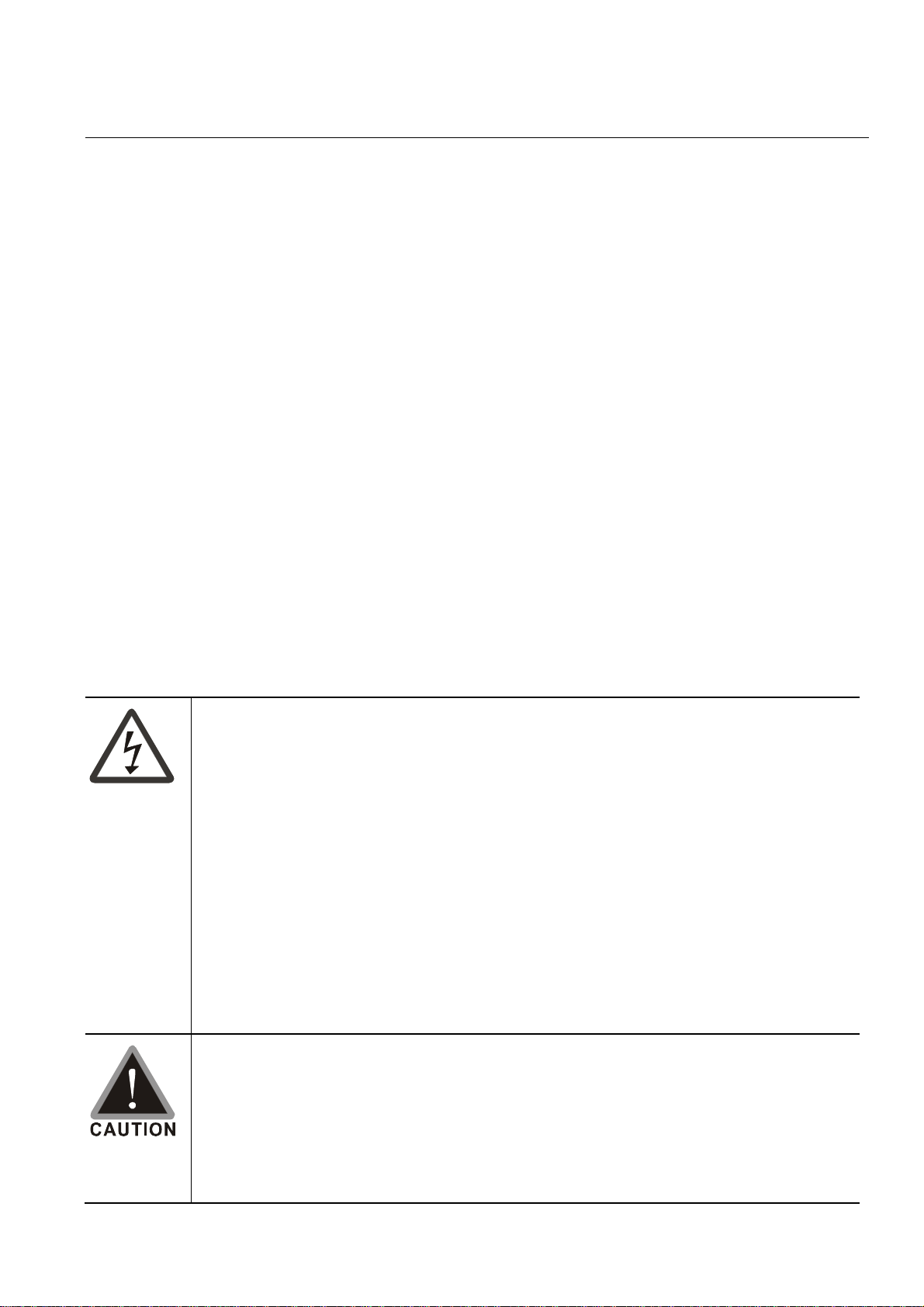

the terminals of each Main circuit circuit and control loop circuit are labeled clearly. Pay attention to the

following wiring descriptions to avoid any incorrect connection.

; The Main circuit power terminals R/L1, S/L2, and T/L3 of the Hybrid Servo Controller are for power

input. If the power supply is connected by accident to other terminals, the Hybrid Servo Controller

will be damaged. In addition, it is necessary to verify that the voltage/current rating of power supply

is within the numbers listed on the name plate.

; The ground terminal must be grounded well, which can avoid being stricken by lightning or

occurrence of electrocution and minimize interference by noise.

; The screw between each connection terminal and the wire must be tightened securely to avoid

sparking by getting loose from vibration.

; If the wiring is to be changed, first step is to turn off the power of the Hybrid Servo

Controller, for it takes time for the DC filter capacitor in the internal loop to

completely discharge. To avoid any danger, the customer can wait for the charging

DANGER

indicator (READY light) to be of completely and measure the voltage with a DC

voltmeter. Make sure the measured voltage is below the safety value of 25Vdc

before starting the wiring task. If the user fails to let the Hybrid Servo Controller

completely discharge, residual voltage will build up internally, which will cause

short circuit and spark if wiring is conducted. Therefore, it is recommended that the

user should only conduct the wiring when there is no voltage to ensure his/her

safety.

; The wiring task must be conducted only by professional personnel. Make sure that

the power is off before starting to avoid incidence such as electrocution.

; During wiring, please follow the requirements of the electrical regulations to select

proper gauges and conduct wiring accordingly to ensure safety.

; Check the following items after finishing the wiring:

1. Are all connections correct?

2. No loose wires?

3. No short-circuits between terminals or to ground?

2-1

Page 15

Chapter 2 Wiring|HES Series

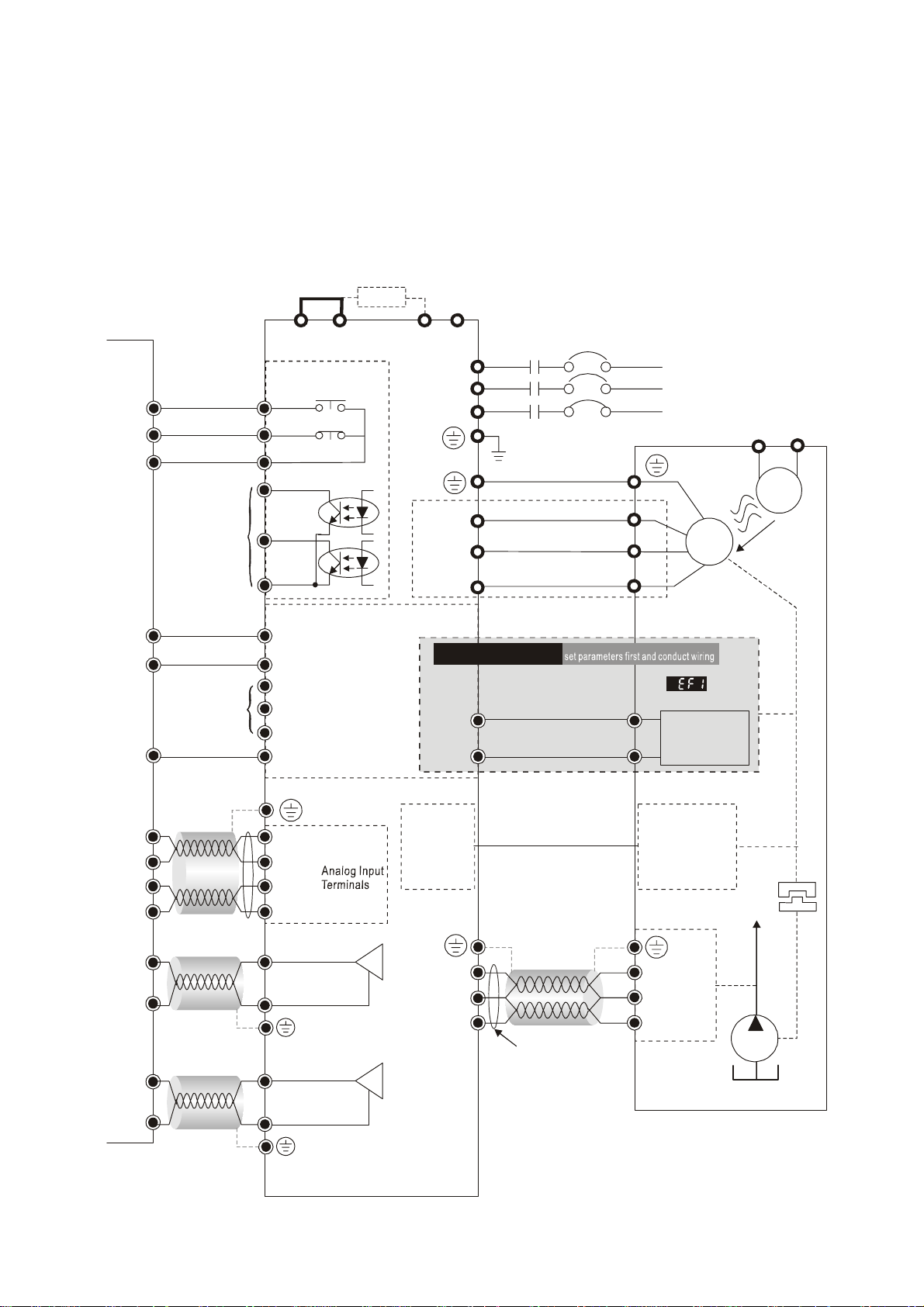

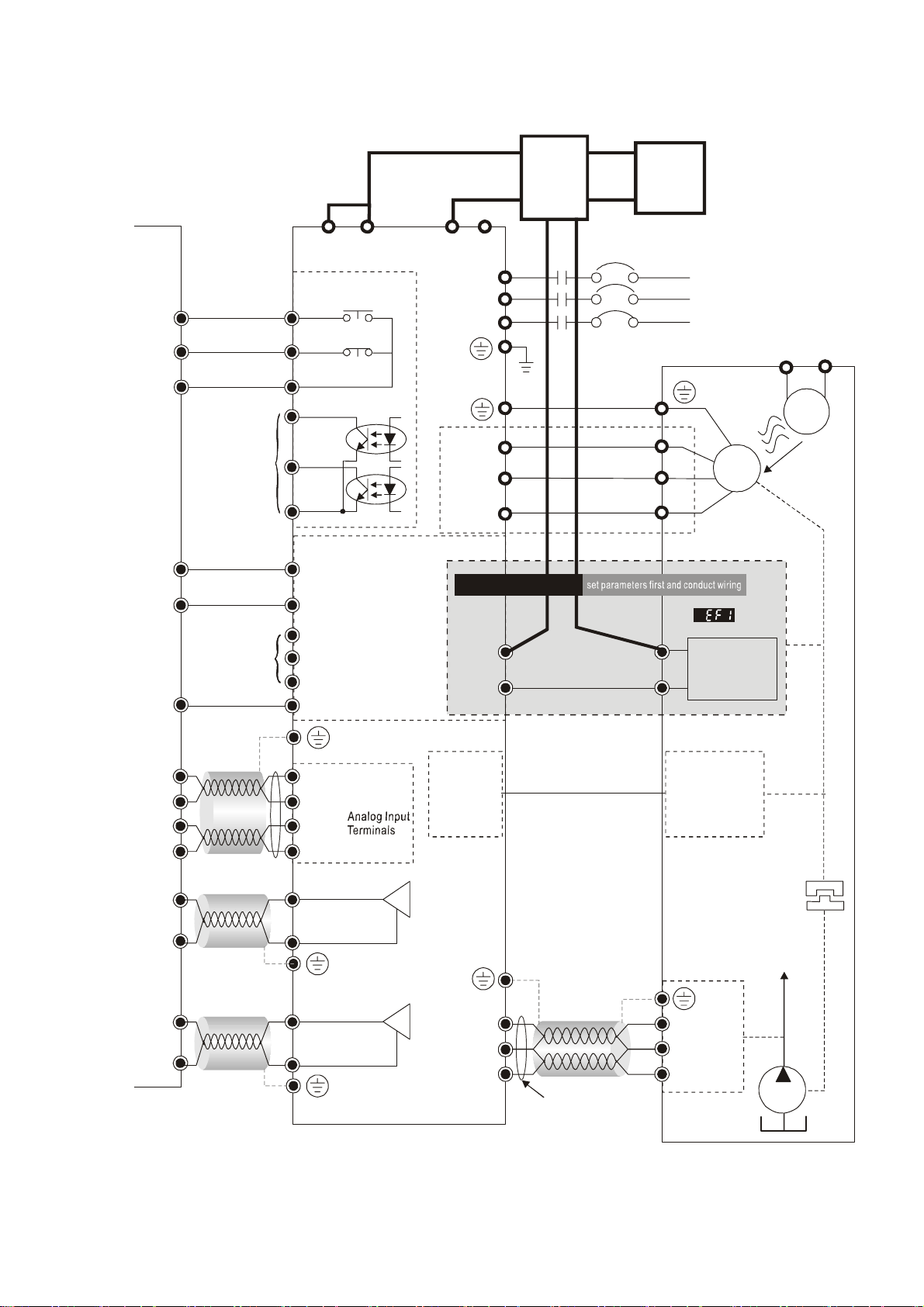

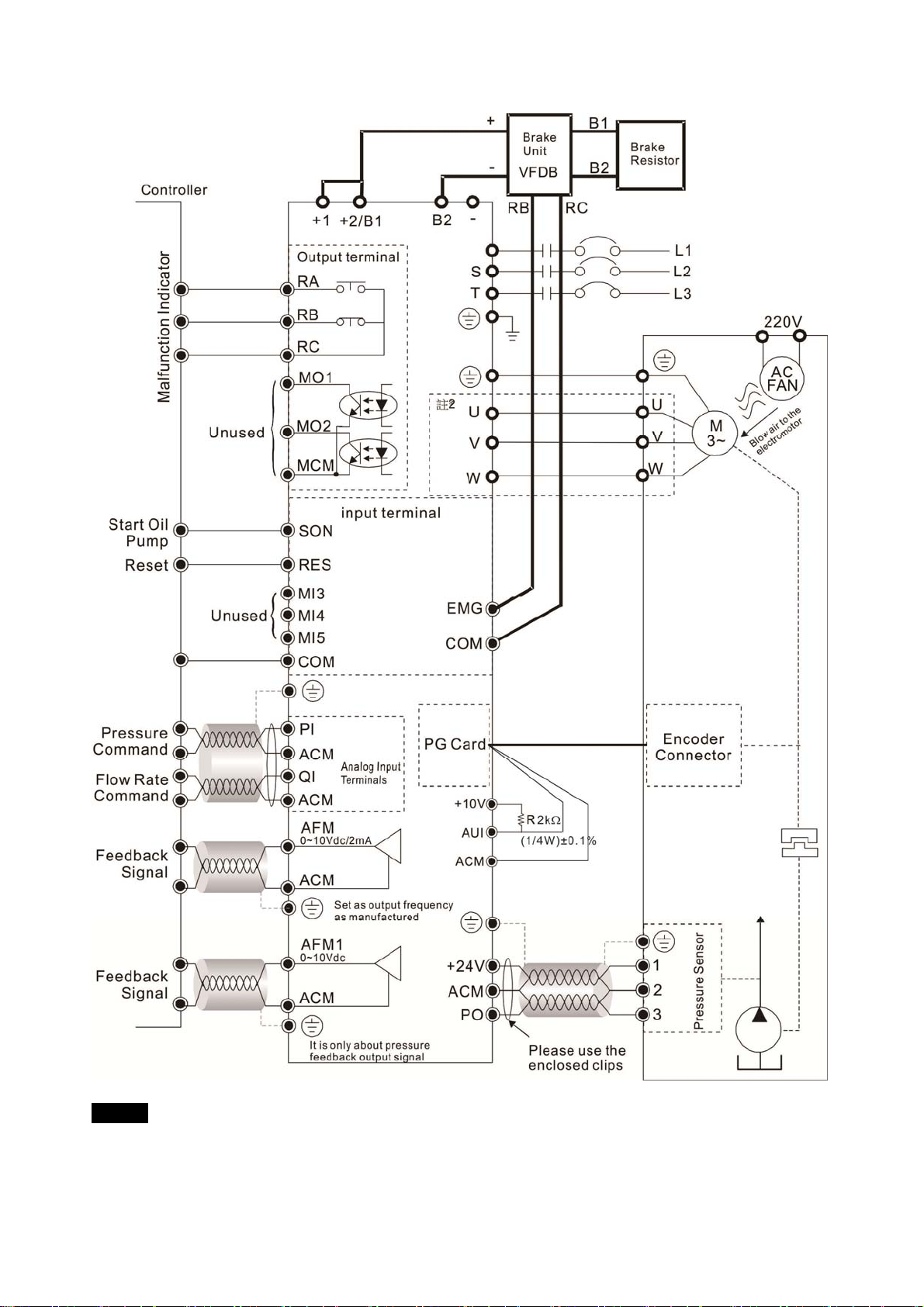

2-1 Wiring

The wiring of the hybrid energy system consists of that for the servo oil pump and that for the Hybrid

Servo Controller. The user must follow the wiring loop below for all wire connections.

Standard Wiring Diagram

HES063A23A~HES125G23A; HES063G43A~HES160G43A;

Brake Resistor (optional)

Controller

Start Oil

Pump

Reset

r

o

t

a

c

i

d

n

I

n

o

i

t

c

n

u

f

l

a

M

Unused

Unused

+2/B1

+1

Output terminal

RA

RB

RC

MO1

MO2

MCM

input terminal

SON

RES

MI3

MI4

MI5

COM

-

B2

R

S

T

Note 2*

U

V

W

Correct Wiring Method

If wiring is conducted before setting

parameters, error message will be displayed

EMG

COM

L1

L2

L3

U

V

W

Protection

switch for

electromotor

overheating

M

3~

w

o

l

B

l

e

220V

AC

FAN

t

o

t

r

i

o

a

m

o

r

t

c

e

e

h

r

o

t

Pressure

Command

Flow Rate

Command

Feedback

Signal

Feedback

Signal

PI

ACM

QI

ACM

AFM

0~10Vdc/2mA

ACM

Set as output frequency

as manufactured

AFM1

0~10Vdc

ACM

It is only about pressure

feedback output signal

PG Card

+24V

ACM

PO

2-2

Please use the

enclosed clips

Encoder

Connector

1

2

3

Pressure Sensor

Page 16

HES125H23A~HES200G23A;

HES160H43A~HES200G43A;

Chapter 2 Wiring|HES Series

Controller

Start Oil

Pump

Reset

r

o

t

a

c

i

d

n

I

n

o

i

t

c

n

u

f

l

a

M

Unused

Unused

+1

+2/B1

Output terminal

RA

RB

RC

MO1

MO2

MCM

input terminal

SON

RES

MI3

MI4

MI5

COM

B2

+

Brake

Unit

-

VFDB

RB

-

B1

B2

RC

S

T

註*

2

U

V

W

Correct Wiring Method

If wiring is conducted before setting

parameters, error message will be displayed

EMG

COM

Brake

Resistor

U

V

W

L1

L2

L3

M

3~

Protection

switch for

electromotor

overheating

220V

w

o

l

B

e

l

e

AC

FAN

o

t

r

i

a

m

o

r

t

c

e

h

t

r

o

t

o

Pressure

Command

Flow Rate

Command

Feedback

Signal

Feedback

Signal

PI

ACM

QI

ACM

AFM

0~10Vdc/2mA

ACM

Set as output frequency

as manufactured

AFM1

0~10Vdc

ACM

It is only about pressure

feedback output signal

PG Card

+24V

ACM

PO

Pl ease use the

enclosed clips

Encoder

Connector

1

2

3

Pressure Sensor

2-3

Page 17

Chapter 2 Wiring|HES Series

HES250M43C

Note 1*

The RB, RC wiring of the braking unit: the overheat protection wiring of the braking unit.

2-4

Page 18

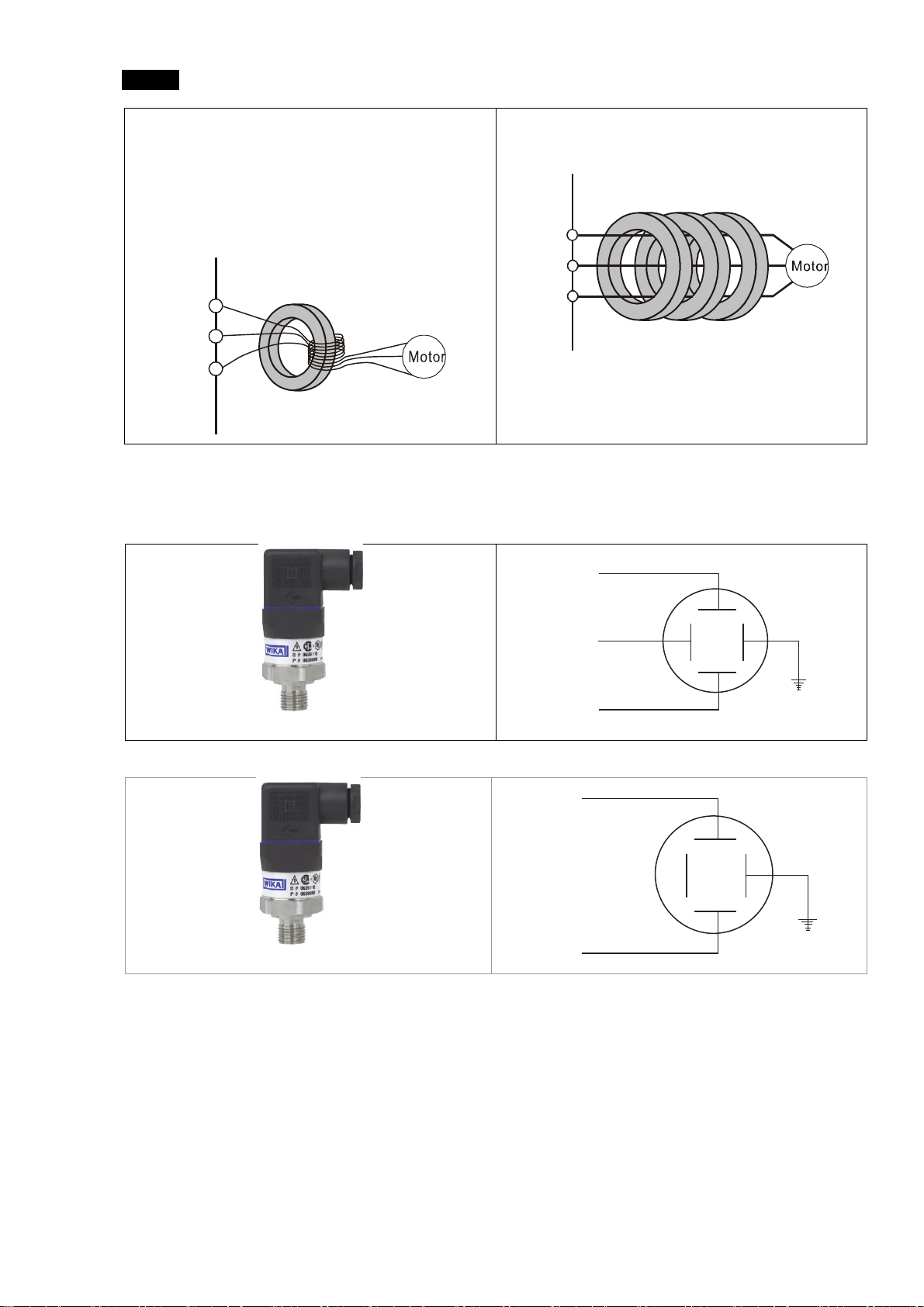

Note 2*

ACM

Chapter 2 Wiring|HES Series

For models with power rating below 22kW

(including 22kW)

For models with power rating below 30kW

(including 30kW)

(it is recommended to wrap the output wire

around the zero-phase reactor for over three

times before connecting it to the motor)

U/T1

V/T2

W/T3

U/T1

V/T2

W/T3

Wiring Diagram of Pressure Sensor

Voltage type pressure Sensor => Pin1: 24V, Pin2 : ACM, Pin3 : PO

24V

PO

Connector of Pressure Sensor

Current type pressure Sensor => Pin1: 24V ,Pin2 : PO , Pin3 : N/A

24V

Connector of Pressure Sensor

PO

1

3

4

2

1

4

3

2

2-5

Page 19

Chapter 2 Wiring|HES Series

1

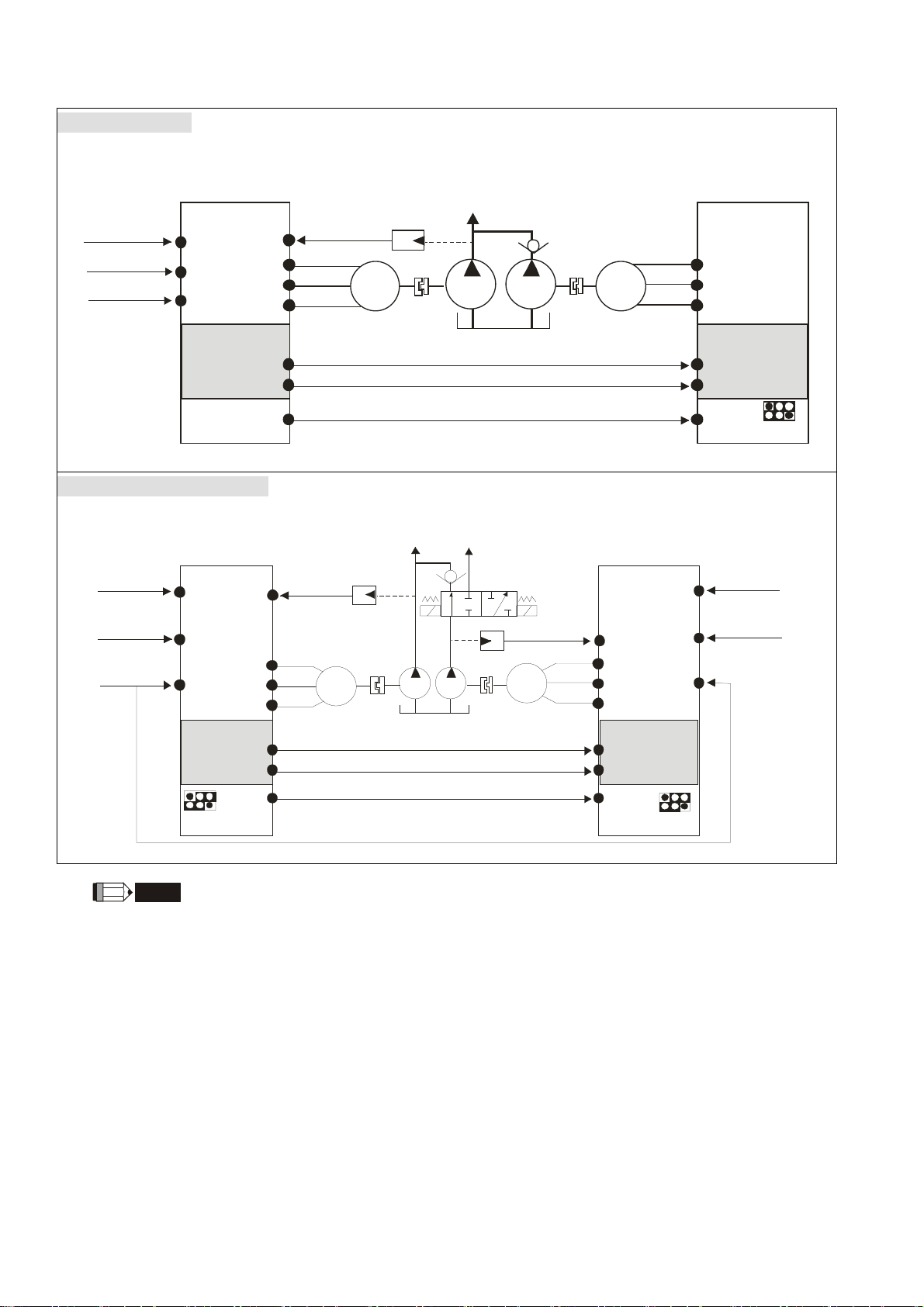

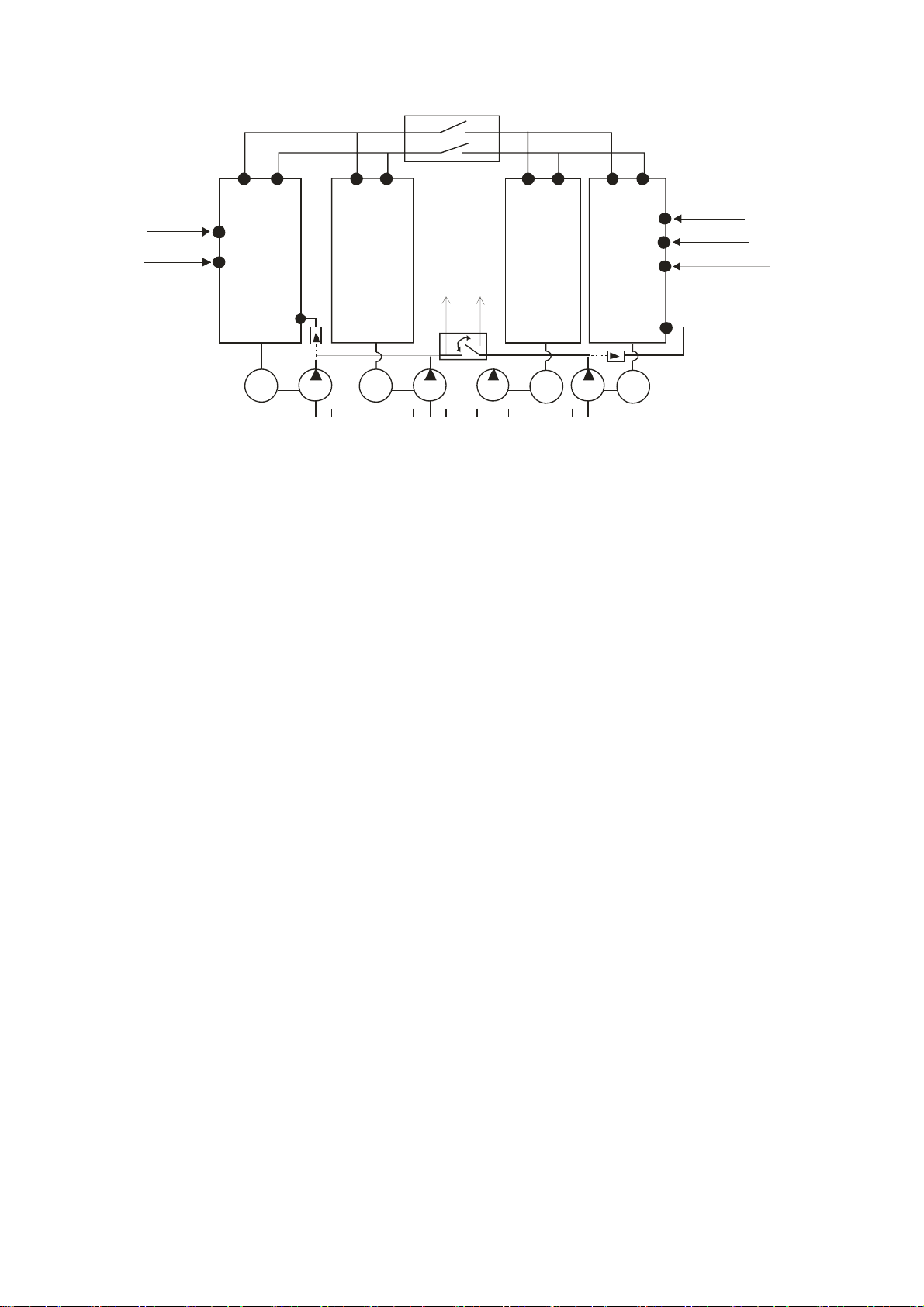

Multi-pump Operation Mode

Confluence Mode

Master

(03-13=1)

Pressure

Command

Combine

Command

Hydraulic Pump

Activation

PI

QI

SON

PO

EMVJ-MF01

SG+

SG-

MO

Confluence-Diversion Mode

Master 1

(03-13=1)

Pressure

Command

Flow

Command

*3

PI

PO

QI

U

MI

V

W

EMVJ-MF01

SG+

SG-

MO

IN.PWR.

SINK

U

V

W

*1

Pressure

Feedback

*1

Pressure

Feedback

M

3~

M

3~

Motion Command

Hydraulic

Outle t 1

Operation Indication

Confluence/Diversion signals

*2

Hydraulic

Outle t 2

Pressure

Feedback

M

3~

*2

M

3~

Master 2/ Slave

(03-13=2)

PI

PO

U

V

W

EMVJ-MF01

SG+

SG-

SON

QI

MI

IN.PWR.

SINK

Slave

(03-13=2 or 3)

U

V

W

EMVJ-MF01

SG+

SG-

SON

IN.PWR.

Pressure

Command

Flow

Command

SINK

NOTE

*1 For firmware version 2.03 and above, the operating commands are given through the communications.

Therefore, the parameters for the slave is 01-01 = 2

*2 For firmware version 2.03 and above, it is not necessary to install this check valve. By selecting the slave

parameter 03-21 at the slave to see if the slave will perform the reverse depressurization. Parameters

03-21 = 0 for not performing the reverse depressurization.

*3 For firmware version 2.03 and above, the diversion/confluence signal is supplied to only Master 2/Slave. It

is not necessary to supply the signal to Master 1.For the following control arrangement, it is necessary to

disconnect the communications during diversion.

2-6

Page 20

Chapter 2 Wiring|HES Series

t

- .Confluence

When the signals are , the communication will be a short circui

When the signals are , the communication becomes an open circuit.

Diversion

Pressure

Command

Flow

Command

SG+

SG-

PI

QI

Mater 1

03 13 1

-=

PO

M M

SG+

SG-

Slave Slave

03 13 2

-=

Hydraulic outlet 1

SG+

Hydraulic outlet 2

03 13 2

-=

M M

SG-

SG+

SG-

PI

QI

MI

Mater 3

03 13 3

-=

PO

Pressure

Command

Flow Command

Confluence/Diversion

Signals

2-7

Page 21

Chapter 2 Wiring|HES Series

A

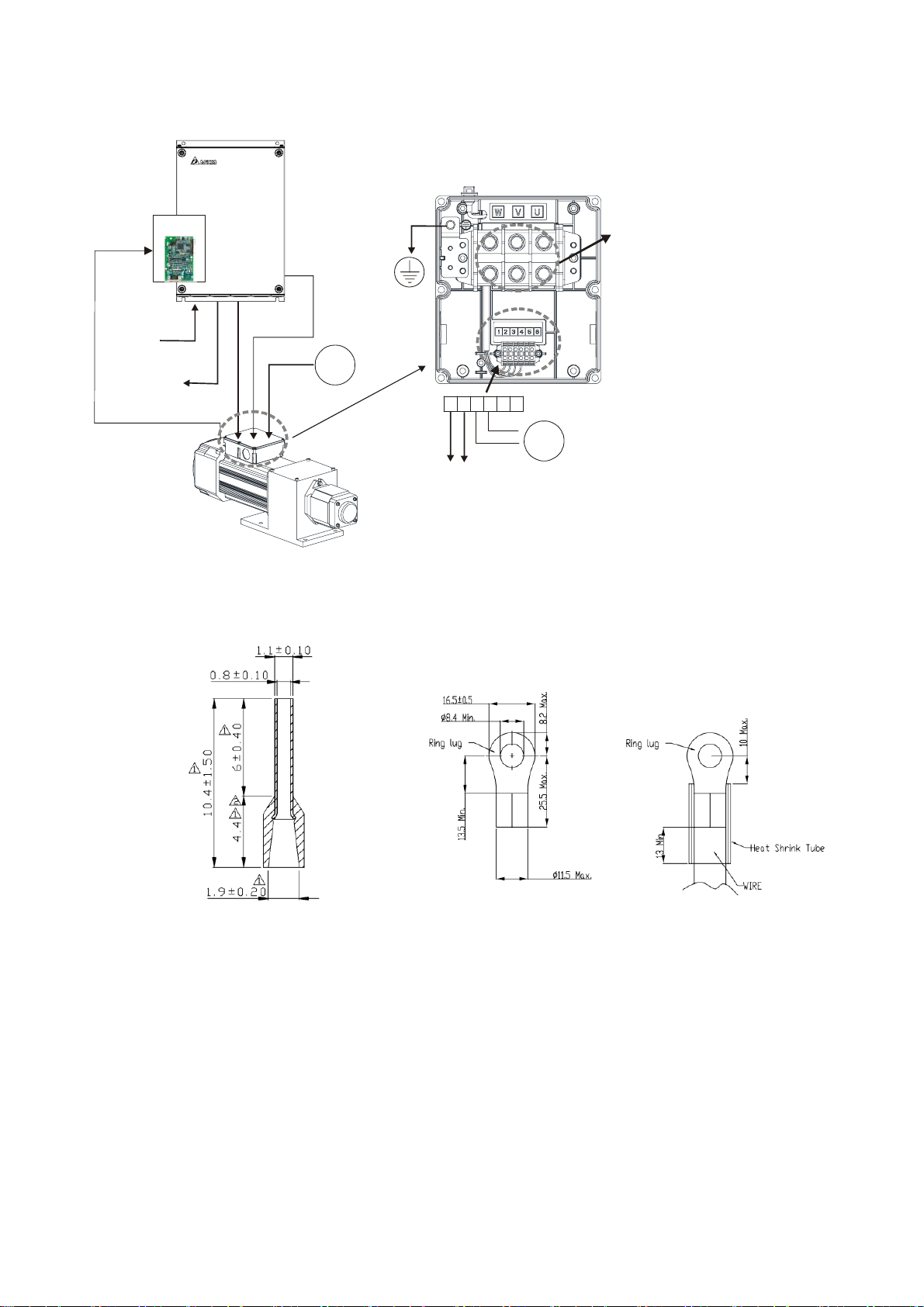

2-2 Wiring of Servo oil Pump

Delta

Hydraulic

Servo Motor

PG Card

RST

Power Side

Brake

Resistance/

Brake Unit

Encoder Signal

Controller

U V W

Hydraulic Servo Pump

Crimp Terminals

Temperature Rise

Protection Switch

AC

FAN

220V

Temperature Rise

Protection Switch

Electri c Box

123456

Corresponding to

Hydraulic Servo

Motor Controller

WVU

(Crimp Terminal

Specification as

shown in Figure 2)

(Crimp Terminal Specification as shown in Figure 1)

C

FAN

220V

Terminal Torque: 82kg-m (71in-lbf)

Figure 1

Figure 2

2-8

Page 22

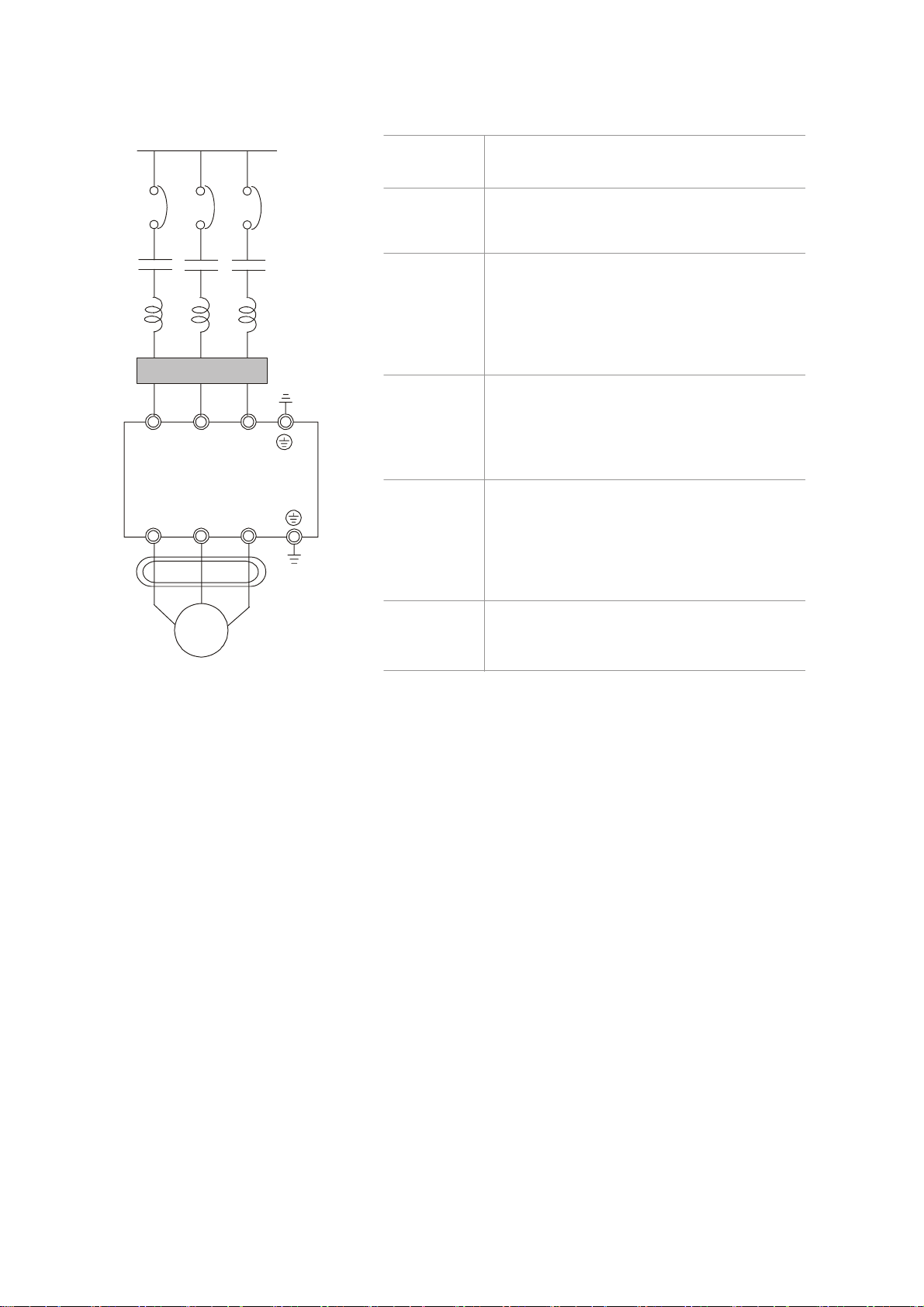

External Wiring of Hybrid Servo Controller

Chapter 2 Wiring|HES Series

Power Supply

EMI Filter

R/L1 S/L2

U/T1

V/T2

M

3~

Fuse/NFB

Magnetic

Contactor

Input AC

Line Reactor

T/L3

W/T3

Zero-Phase

Reactor

Power

Supply

Fuse/NFB

(Optional)

Magnetic

Contactor

Input AC

Line Reactor

Zero-Phase

Reactor

EMI Filter

Please follow the power rating listed in the

user's manual (chapter 1)

A larger current may be generated when the

power is turned on. Please refer to Appendix

B-1 to select suitable non-fused switch or fuse.

Turning on/off the side electromagnetic

contactor can start/stop the hybrid servo

controller. However, frequent switching may

lead to malfunction. It is advised not to turn

on/off the hybrid servo controller for more

than 1 time/hour.

When the output capacity exceeds 1000kVA,

it is recommended to add an AC reactor to

improve the power factor, with the wiring

(Optional)

distance within 10m. Please refer to

Appendix B-2 for details.

This is to reduce the radiation interference,

especially in places with audio devices.

It can also reduce the interferences at the

input and output sides. Please refer to

appendix B-2 for details. The effective

range is from AM band to 10MHz.

It can be used to reduce electromagnetic

interference. Please refer to Appendix B-5

for details.

2-9

Page 23

Chapter 2 Wiring|HES Series

2-3 Main Circuit

Terminal Label Description

R/L1, S/L2, T/L3 AC line input terminals

U/T1, V/T2, W/T3 Output of Hybrid Servo Controller, connected to hybrid servo motor

For power improvement of the connection terminal of DC reactor. Please

+1, +2/B1

remove the shorting plate in installation (DC reactors are built-in in models

with power

≧37KW)

Connection terminal of brake resistor. Please follow the selection table to

+2/B1, B2

purchase suitable ones.

Earth connection, please comply with local regulations.

;

The wiring for the Main circuit must be isolated from that for the control loop to avoid

malfunction.

;

Please use isolation wires for control wiring as much as possible. Do not expose the

section where the isolation mesh is stripped before the terminal.

;

Please use isolation wire or wire tube for power supply wiring and ground the

isolation layer or both ends of wire tube.

;

Usually the control wire does not have good insulation. If the insulation is broken for

any reason, high voltage may enter the control circuit (control board) and cause

circuit damage, equipment accident, and danger to operation personnel.

;

Noise interferences exist between the Hybrid Servo Controller, hybrid servo motor,

and their wirings. Check if the pressure sensor and associated equipments for any

malfunction to avoid accidents.

;

The output terminals of the Hybrid Servo Controller must be connected to the hybrid

servo motor with the correct order of phases.

;

When the wiring between the Hybrid Servo Controller and hybrid servo motor is very

long, it may cause tripping of hybrid servo motor from over current due to large

high-frequency current generated by the stray capacitance between wires. In

addition, when the leakage current increases, the precision of the current value

becomes poor. In such case, an AC reactor must be connected to the output side.

; The ground wire of the Hybrid Servo Controller cannot be shared with other large

current load such as electric welding tool. It has to be grounded separately.

;

To avoid lightning strike and incidence of electrocution, the external metal ground

wire for the electrical equipments must be thick and short and connected to the

ground terminal of the Hybrid Servo Controller system.

;

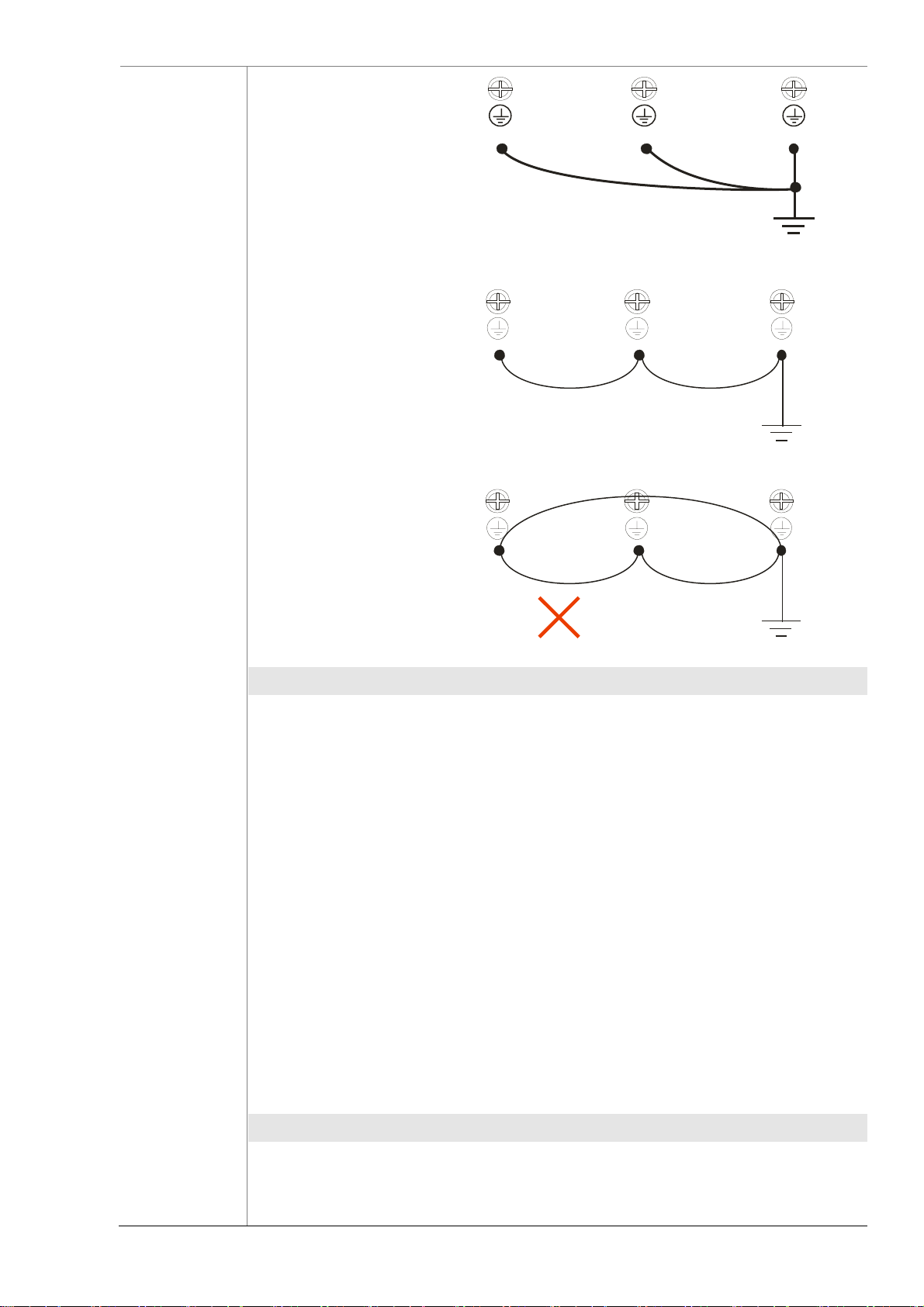

When multiple Hybrid Servo Controllers are installed together, all of them must be

directly connected to a common ground terminal. Please refer to the figure below to

make sure there is no ground loop.

2-10

Page 24

t

Grounding terminals

Chapter 2 Wiring|HES Series

Grounding terminals

Grounding terminals

Mains power terminals (R/L1, S/L2, T/L3):

Excellen

good

Not allowed

;

Connect these terminals (R/L1, S/L2, T/L3) via a non-fuse breaker or earth leakage

breaker to 3-phase AC power (some models to 1-phase AC power) for circuit

protection. It is unnecessary to consider phase-sequence.

;

The wire between the three-phase AC input power supply and the Main circuit

terminals (R/L1, S/L2, and T/L3) must be connected to a non-fused switch.

;

Please make sure to fasten the screw of the main circuit terminals to prevent sparks

which is made by the loose screws due to vibration.

;

Verify the voltage of power supply and the associated maximum available current.

Please refer to Chapter 1 Descriptions of Specifications.

;

If the Hybrid Servo Controller is equipped with a leakage circuit breaker for leakage

protection, please select the circuit breaker that has a sensing current above 200mA

and action time over 0.1 second to avoid malfunction.

;

Please use isolation wire or wire tube for power supply wiring and ground the

isolation layer or both ends of wire tube.

Output terminals for main circuit (U, V, W) :

;

The output side of Hybrid Servo Controller cannot be connected with advance phase

capacitor, surge absorber, advance phase capacitor, or L-C and R-C filters.

2-11

Page 25

Chapter 2 Wiring|HES Series

Terminals [+1, +2] for connecting DC reactor, terminals [+1, +2/B1] for connecting brake

resistor:

;

These terminals are used to improve the power factor of DC reactor. There are

shorting plates on them when they leave the factory. Remove the shorting plates

before connecting the DC reactor.

;

For models with power >30kW, there is no driver loop for brake resistor inside. To

increase the brake capability, please use an external brake unit and brake resistor

(both are optional).

;

Never short [B2] or [-] to [+2/B1], which will damage the Hybrid Servo Controller.

+1

Shorting Plate of DC Reactor

2-12

Page 26

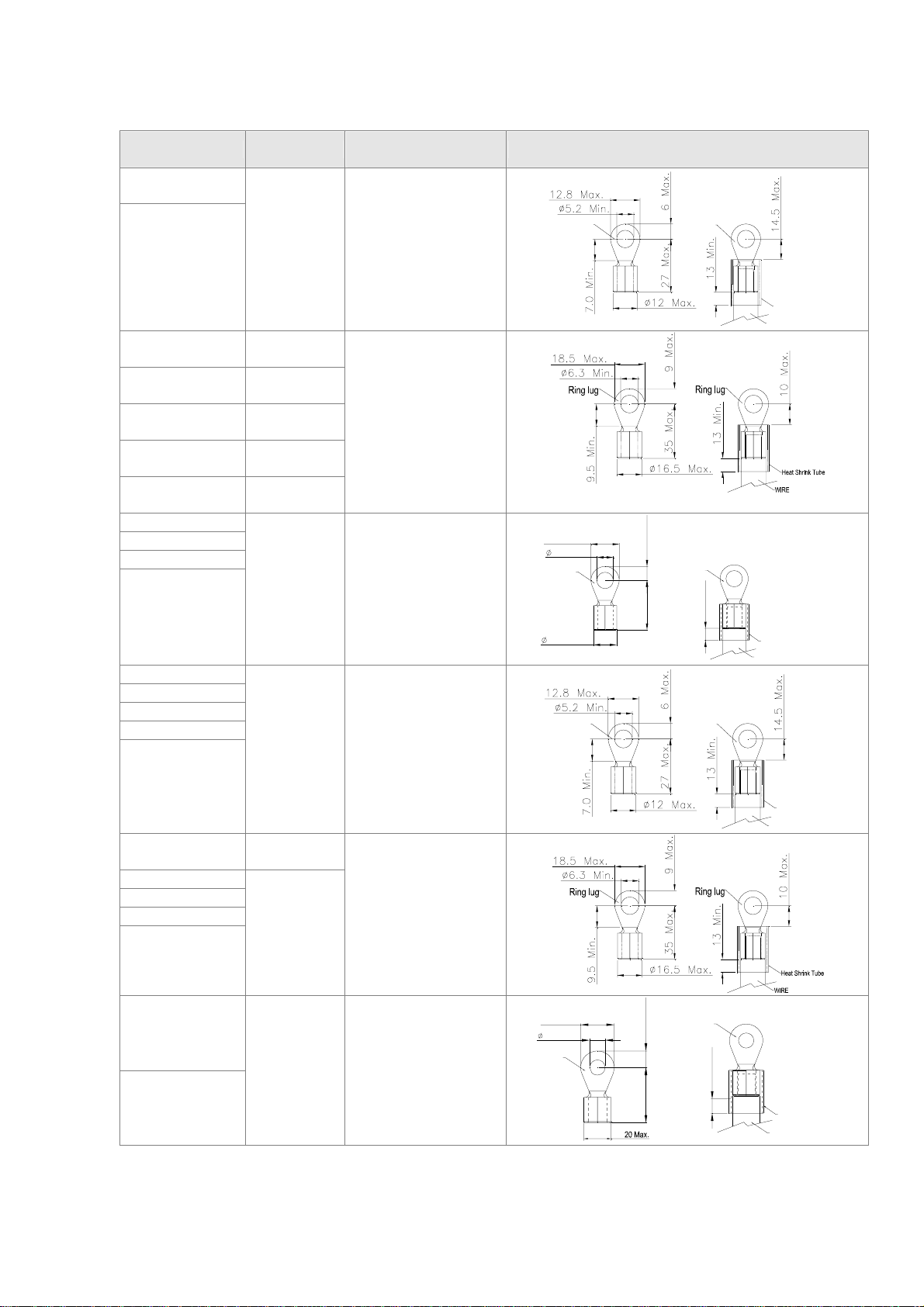

Main Circuit Terminals

Model No. Wiring

HES063H23A

tightening torque on

the drive's terminal

Chapter 2 Wiring|HES Series

crimp type terminal

HES080G23A

HES080H23A

HES100G23A

HES100H23A

HES100Z23A

HES125G23A

HES125H23A

HES160G23A

HES160H23A

HES200G23A

HES063G43A

HES063H43A

HES080G43A

HES080H43A

4AWG

(21mm

4AWG

(21mm

4AWG

(21mm

4AWG

(21mm

2AWG

(33mm

2AWG

(33mm

2AWG

(33mm

8AWG

(8mm

Ring lug

2

)

2

)

2

)

2

)

2

)

2

)

2

)

2

)

30kgf-cm

(26 lbf-in)

50kgf-cm

(43.4 lbf-in)

200kgf-cm

(173 lbf-in)

30kgf-cm

(26 lbf-in)

28 Max.

8.2 Min.

Ring lug

28 Max.

Ring lug

Ring lug

Heat Shrink Tube

WIRE

17 Max.48 Max.

Ring lug

13 Min.

Heat Shrink Tube

WIRE

Ring lug

HES100G43A

HES100H43A

8AWG

(8mm

2

)

HES100Z43A

HES125G43A

HES125H43A

6AWG

(13mm

2

)

50kgf-cm

(43.4 lbf-in)

HES160G43A

HES160H43A

4AWG

(21mm

2

)

80kgf-cm

(70 lbf-in)

22 Max.

8.2 Min.

Ring lug

HES200G43A

NOTE:

HES160H23A, HES200G23A installations must use 90℃ wire.

The other model use UL installations must use 600V, 75℃ or 90℃wire. Use copper wire only.

for more information, if you want to use higher class of overheat protection material.

10.5 Max.32 Max.

Heat Shr ink Tube

WIRE

Ring lug

13 Min.

Heat Shrink Tube

WIRE

Please contact Delta

2-13

Page 27

Chapter 2 Wiring|HES Series

A

A

2-4 Control Terminals

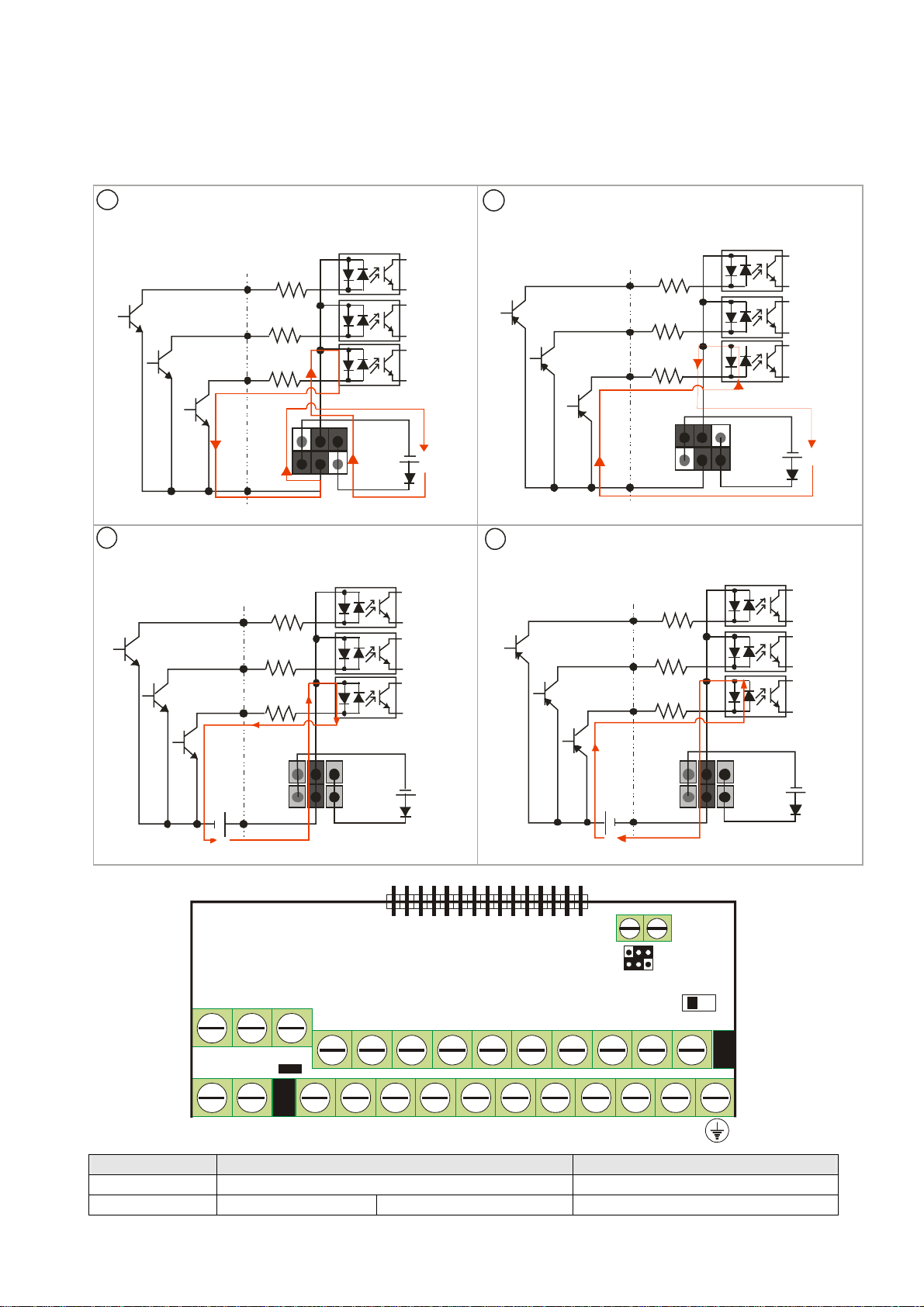

Description of SINK(NPN)/SOURCE(PNP)Mode Switching Terminal

1

Sink mode Source mode

With internal power (+24Vdc)

SON

EMG

RES

+24V

COM

3

Sink mode

With external power (+24Vdc)

SON

2

With internal power (+24Vdc)

4

Source mode

With external power (+24Vdc)

SON

EMG

RES

+24V

COM

SON

EMG

RES

+

COM

external power +24Vdc

The position of the External Terminals

MCMRBSON

RES

+24V

MI4

EMG

RES

+

external power +24Vdc

Mode Switch Terminal

COM

Sink/Source

+10V

PI ACMQI

AUI

DCM

COM

+E24 V

SW100

V

+24V

I

RARC

MO1

MO2

EMG

MI3

MI5

AFM1

+24V

FM

PO

CM

Frame Torque Wire Gauge

C, D, E 8 kgf-com (6.9 in-lbf) 22-14 AWG (0.3-2.1mm2)

Terminal: 0V/24V 1.6 kgf-com(1.4 in-lbf) 30-16 AWG (0.051-1.3mm2)

2-14

Page 28

Chapter 2 Wiring|HES Series

A

A

M

t

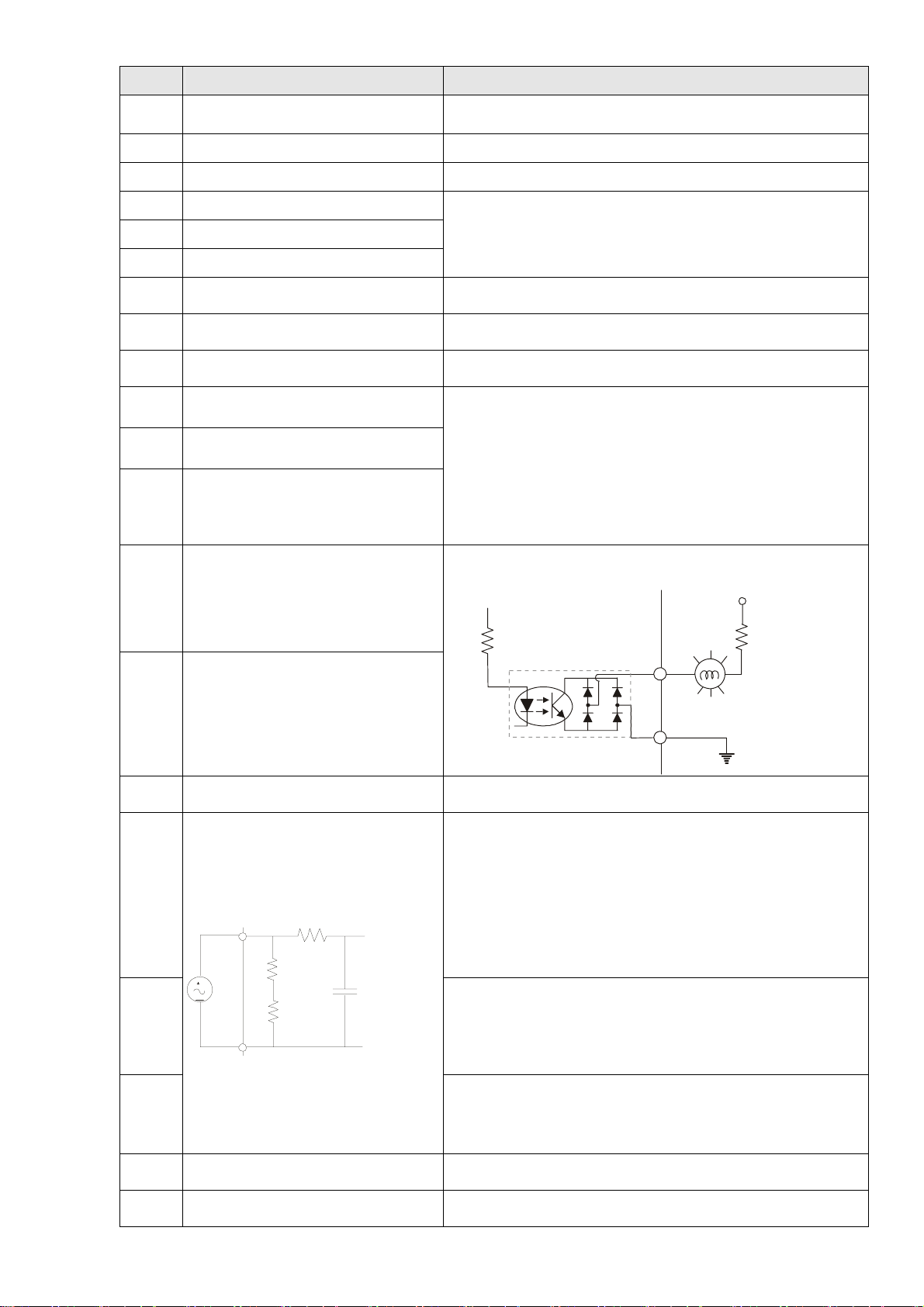

Terminal Function

SON Run-Stop

Between terminals SON-DCM: conducting (ON);run: open

circuit (OFF), Stop

Factory Setting (NPN mode)

EMG Abnormal input from outside Abnormal input from outside

RES Reset reset

MI3 Multiple Function Input: Option 3

No function is set for default setting

When conducting (ON), input voltage is 24Vdc (Max:30Vdc)

MI4 Multiple Function Input: Option 4

MI5 Multiple Function Input: Option 5

COM

+E24V

DCM

Common terminal of digital control

signals (Sink)

Common terminal of digital control

signals (Source)

Common terminal of digital control

signals (Sink)

Malfunctioning abnormal connection

RA

1 (Relay always open a)

Malfunctioning abnormal connection

RB

1 (Relay always closed b)

and output impedance is 3.75k;In open circuit (OFF), the

allowable leakage current is 10A

Common terminal of multiple function input terminals

+24V 80m

Common terminal of multiple function input terminals

Resistive Load:

5A(N.O.)/3A(N.C.) 240VAC

5A(N.O.)/3A(N.C.) 24VDC

Inductive Load:

RC Multi-function Relay Common

1.5A(N.O.)/0.5A(N.C.) 240VAC

1.5A(N.O.)/0.5A(N.C.) 24VDC

Hybrid Servo Controller outputs various types of monitoring

signals with the transistor operating in open collector mode.

MO1

Multi-function Output 1

(Photocoupler)

Max: 48Vdc/50mA

MO1

~

MO2

MO2

MCM

Multi-function Output 2

(Photocoupler)

Multi-function Output Common

(Photocoupler)

PO

PO/PI/QI circuit

PO/PI/QI

PO/PI/QI Circui

PI

AC

Internal Circuit

QI

+10V Configuration Voltage

+24V

Power supply terminal of pressure

sensor

Internal circuit

MCM

Max. 48VDC 50m

Pressure Feedback

Impedance:200k

Resolution:12 bits

Range:0 ~ 10V or 4~20mA=

0~maximum Pressure Feedback value (Pr.00-08)

To input current, firmware v2.04 or above and a new I/O

control board (the one has SW100 switch) are required.

See parameter 03-12 for more information.

Pressure Command

Impedance:200k

Resolution:12 bits

Range:0 ~ 10V=

0~maximum pressure command value (Pr.00-07)

Flow Rate Command

Impedance:200k

Resolution:12 bits

Range:0 ~ 10V=0~maxium flow rate

Power supply for analog configuration +10Vdc 20mA

(variable resistor 3~5k)

Configuration power supply for pressure sensor +24Vdc

100mA

2-15

Page 29

Chapter 2 Wiring|HES Series

A

A

Terminal Function

nalog Voltage

+10V

AUI

AFM

CM Analog control signal (common) Common for ACI, AUI1, AUI2

AUI

-10V

AUI circuit

Internal Circuit

AFM

ACM

Impedance:11.3k

Resolution:12 bits

Range:-10~+10VDC

Impedance:16.9k (voltage output)

Output Current: 20mA max

Resolution: 0~10V corresponds to maximum operation

frequency

Range: 0~10V

Function Setting: Pr.00-05

*Control signal wiring size: 18 AWG (0.75 mm2) with shielded wire.

Factory Setting (NPN mode)

Analog Input Te r m inals (PO, PI, QI, AUI, ACM)

; The maximum input voltage of PI, PO, and QI cannot exceed +12V and no more than +/-12V

for AUI. Otherwise, the analog input function may become ineffective.

; Analog input signals are easily affected by external noise. Use shielded wiring and keep it as

short as possible (<20m) with proper grounding. If the noise is inductive, connecting the shield

to terminal ACM can bring improvement.

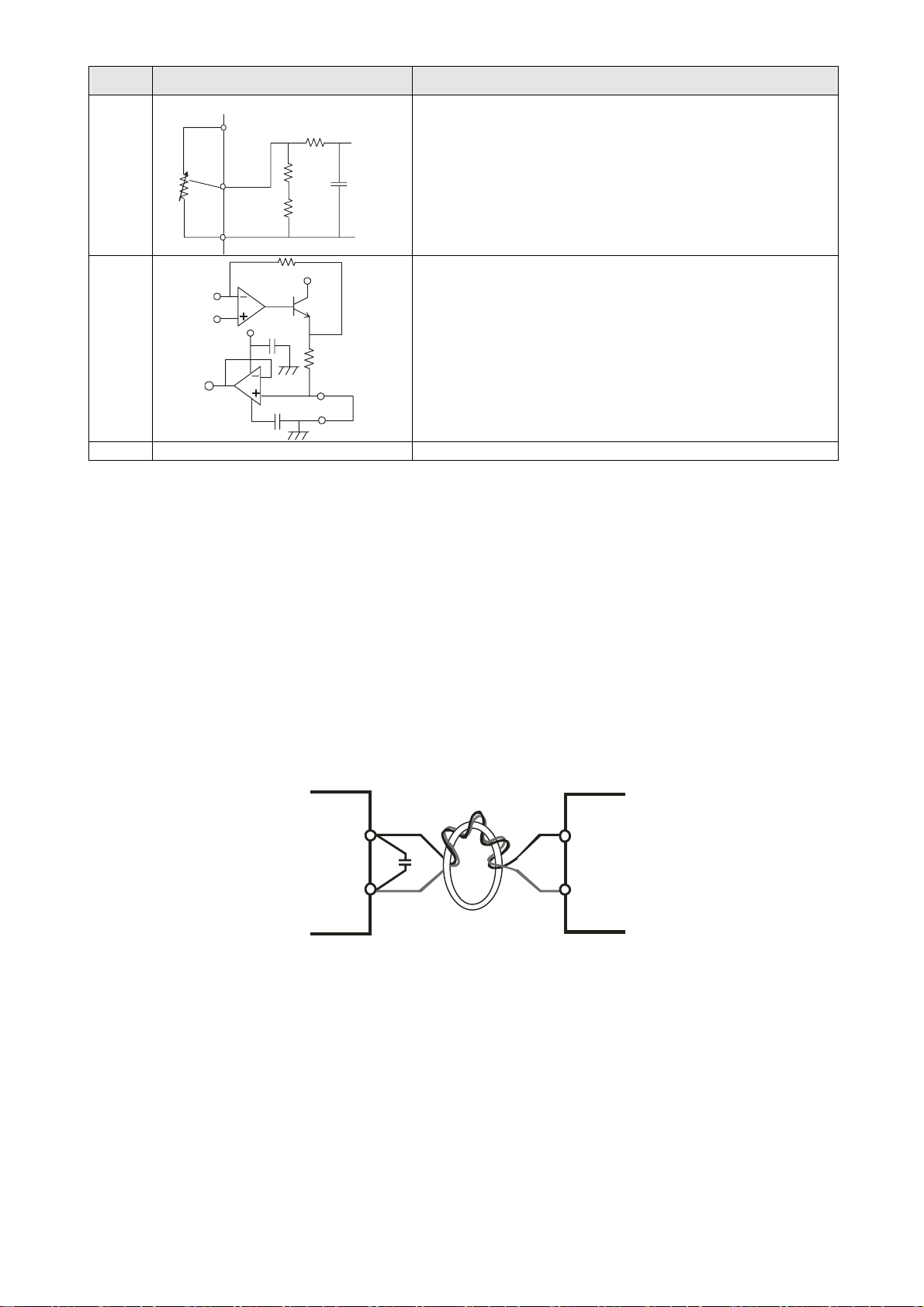

; The interference generated by the Hybrid Servo Controller can cause the pressure sensor to

malfunction. IN this case, a capacitor and a ferrite core can be connected to the pressure

sensor side, as shown in the figure below:

Thre aded for three rounds or

more in the same phase

Output

terminal

PO

C

-V

Ferrite core

ACM

Transistor outputs (MO1, MO2, MCM)

; Make sure to connect the digital outputs to the right polarity.

; When connecting a relay to the digital outputs connect a surge absorber across the coil and

check the polarity.

2-16

Page 30

Chapter 3 Flow of machine Adjustment|HES Series

Chapter 3 Start Up

3-1 Description of Control Panel

3-2 Adjustment Flow Chart

3-3 Explanations for the Adjustment Steps

; Please verify again before operation that the wiring is done correctly, especially that

the output terminals U/T1, V/T2, and W/T3 of the Hybrid Servo Controller cannot

have any power input. Make sure that the ground terminal

correctly.

; Do NOT operate the AC motor drive with humid hands.

; Check for loose terminals, connectors or screws.

; Make sure that the front cover is well installed before applying power.

; In case of abnormal operation of the Hybrid Servo Controller and the associated

servo motor, stop the operation immediately and refer to “Troubleshooting” to check

the causes of anomalies. After the output of the Hybrid Servo Controller is stopped,

when the power terminals L1/R, L2/S, and L3/T of the main circuit are still

connected, touching the output terminals U/T1, V/T2, and W/T3 of the Hybrid Servo

Controller may lead to electric shock.

is connected

3-1

Page 31

Chapter 3 Flow of machine Adjustment|HES Series

3-1 Description of Control Panel

Description of the Digital Keypad KPVJ-LE01

Run key

start AC drive

operation

Stop / Rese t ke y

Stop driver operation

and reset in case of

anomaly

Status Display

1

Display the drive r’s current status.

LED Display

2

Indicates frequency, voltage, current, user defined units and etc.

UP and DOWN Key

3

Set the parameter number and changes the numerical data, such a s Master Frequenc

MODE

4

Change between different display mode.

ENTER

5

Used to enter/modify programming parameters.

Descriptions of Function Display Items

Display Message

Displays theAc driver Master frequency

Displays the actual output frequency at terminals U/T1, V/T2, and W/T3.

User defined unit (where U = F x Pr.00.04)

Displays the output current at terminals U/T1, V/T2, and W/T3.

Descriptions

Displays the AC motor drive forward run status.

Displays the AC motor drive reverse run status.

Displays the parameter item

Displays the actual stored value of the selected parameter.

3-2

Page 32

Chapter 3 Flow of machine Adjustment|HES Series

Display Message

External Fault.

Display “End” for approximately 1 second if input has been accepted by

pressing

key. After a parameter value has been set, the new value is

automatically stored in memory. To modify an entry, use the

keys.

Display “Err”, if the input is invalid.

How to Operate the Digital Keypad

Setting Mode

START

NOTE:

In the selection mode, pr ess

Descriptions

and

GO START

to set the parameters.

Setting parameters

NOTE

:

In the parameter setting mode, you can press

To shift data

Setting direction

Success to

set param ete r.

(When operation source is digital keypad)

or

Input data error

to return the selecting mode.

3-3

Page 33

Chapter 3 Flow of machine Adjustment|HES Series

Reference Table for the 7-segment LED Display of the Digital Keypad

Number 0 1 2 3 4 5 6 7 8 9

Seven Segment

Display

English letter A a B C c D d E e F

Seven Segment

Display

English letter f G g H h I i J j K

- -

-

-

Seven Segment

Display

English letter k L l M m N n O o P

Seven Segment

Display

English letter p Q q R r S s T t U

Seven Segment

Display

English letter u V v W w X x Y y Z

Seven Segment

Display

English letter z

Seven Segment

Display

-

-

- -

- -

-

-

- - -

-

- - - -

-

-

3-4

Page 34

Chapter 3 Flow of machine Adjustment|HES Series

3-2 Adjustment Flow Chart

Set the servo

Check i f the pressure

feedback signal is

Cali brate pressure and flow

Adjust Injection /Hold up

Hybrid

motor code

normal

YES

commands

Execute venting

NO

Troub leshoot

Complete

*The firmware version is 2.04 and above, just proceeds the process to set up HES ID code.

*The firmware version is 2.05 and above, starts from “Execute venting”.

3-5

Page 35

Chapter 3 Flow of machine Adjustment|HES Series

3-3 Explanations for the Adjustment Steps

Operate the following steps with the digital operator (KPVJ-LE01/ KPV-CE01)

Prior to starting running, please verify again if the wiring is correct, especially that the output

terminals U/T1, V/T2, and W/T3 of the Hybrid Servo Controller must correspond to the U, V, and

W terminals of the Hybrid servo motor, respectively.

Step 1. Parameter Entry of Hybrid Servo Motor

Do not connect the external terminals SON-COM and EMG-COM for the time being.

Restore the factory default values by setting the Parameter 00-02 = 10

Parameter reset

Pr. 00-02

Please make sure if the command source has been restored to the factory default

10: Parameter reset

(operation by external terminals)

When KPVJ-LE01/KPV-CE01 is used, set Pr. 01-01=0

Source of Run Command

Pr. 01-01

0: Operated by digital operator

1: Operated by external terminals, Stop on keypad is disabled

2: Communication port RS-485 is activated and Stop on keypad is

disabled

Set Pr. 01-35 of the Hybrid servo motor

HES063H23A, HES080G23A, HES080H23A,

Pr. 01-35 = 16

HES100G23A,HES100H23A

HES063G43A, HES063H43A, HES080G43A, HES080H43A,

Pr. 01-35 = 17

HES100G43A,HES100H43A

HES125G23A, HES125H23A, HES160G23A,HES160H23A Pr. 01-35 = 18

HES125G43A, HES125H43A, HES160G43A,HES160H43A Pr. 01-35 = 19

HES160H23A, HES200G23A Pr. 01-35 = 20

HES160H43A, HES200G43A Pr. 01-35 = 21

Disregard the error message EF1 that will appear at this point.

After power outage, connect the heating switch of the hybrid servo motor to the external

terminal EMG-COM and restart the power supply.

* For firmware version 2.04 and above

3-6

Page 36

Chapter 3 Flow of machine Adjustment|HES Series

Step 2. Entry HES ID code*

Do not connect the external terminals SON-COM and EMG-COM for the time being.

Restore the factory default values by setting the Parameter 00-02 = 10

Parameter reset

Pr. 00-02

Please make sure if the command source has been restored to the factory default

10: Parameter reset

(operation by external terminals)

When KPVJ-LE01/KPV-CE01 is used, set Pr. 01-01=0

Source of Run Command

Pr. 01-01

0: Operated by digital operator

1: Operated by external terminals, Stop on keypad is disabled

2: Communication port RS-485 is activated and Stop on keypad is

disabled

Source of Run Command

Pr. 01-01 0: Operated by digital operator

1: Operated by external terminals, Stop on keypad is disabled

2: Communication port RS-485 is activated and Stop on keypad is

disabled

Set Pr. 01-37 of HES ID#

Model ID# Model ID#

HES063H23A 2120 HES063G43A 2040

HES080G23A 3020 HES063H43A 2140

HES080H23A 3120 HES080G43A 3040

HES100G23A 4020 HES080H43A 3140

HES100H23A 4120 HES100G43A 4040

HES100Z23A 4220 HES100H43A 4140

HES125G23A 5020 HES100Z43A 4240

HES125H23A 5120 HES125G43A 5040

HES160G23A 6020 HES125H43A 5140

HES200G23A 7020 HES160G43A 6040

HES160H43A 6140

HES200G43A 7040

HES200H43C 7142

HES320M43C 9342

Disregard the error message EF1 that will appear at this point.

After power outage, connect the heating switch of the hybrid servo motor to the external

terminal EMG-COM and restart the power supply.

3-7

Page 37

Chapter 3 Flow of machine Adjustment|HES Series

Step 3.Check Pressure Feedback Signal

Firs, set input voltage Pr. 00-04 = 11 PO

Selection of Display Mode

Pr. 00-04

11: Display the signal of PO analog input terminal, with 0~10V

corresponding to 0~100%.

Set Pr. 00-08=corresponding pressure settings of the 10V pressure sensor

Maximum value of pressure feedback

Pr. 00-08 0~250Bar

Set speed command to 10rpm and press【RUN】. Check the pressure value is >0 on the

pressure gauge.

When the pressure value is

; Gradually increase the rotation speed.

; Check that each directional valve is closed.

≦0,

When the pressure value is >0

; Check that the voltage reading displayed on the operation panel is consistent with the

pressure reading on the pressure gauge.

Example: 10V on the pressure sensor corresponds to 250bar. When the pressure gauge

reading is 50 bar, the output voltage on the pressure sensor should be

approximately 50/250*10=2V. So the voltage displayed on the operation panel will

be 20.0(%).

Meanwhile, observe if there is any oil leak.

Step 4. Check Pressure and Flow Commands

This action does not need to start the servo oil pump.

For the firmware version is 2.04 and above, theoretical values of three-point calibration of

pressure and flow commands are auto-imported after entering HES ID code. Afterward,

detailed adjustment can be proceeded with the following methods.

Pr. 00-09 = 1 refers to the pressure control mode

Pressure Control Mode

Pr. 00-09 0: Speed control

1: Pressure control

Pr. 00-04 = 12 sets the PI input voltage

Selection of Display Mode

Pr. 00-04

Pr. 00-07 = corresponding pressure value with 10V on the pressure controller command

12: Display the signal value of the PI analog input terminal, with

0~10V corresponding to 0~100%.

Maximum pressure command

Pr. 00-07 0~250Bar

With the maximum pressure set by the controller, observe the associated value displayed

on the operation panel and set it to 00-14.

With the controller setting at half the maximum pressure, observe the associated value

3-8

Page 38

Chapter 3 Flow of machine Adjustment|HES Series

displayed on the operation panel and set it to 00-15.

With the controller setting at the lowest pressure, observe the associated value displayed

on the operation panel and set it to 00-16.

Example: 10V on the pressure sensor corresponds to 250bar. If the maximum pressure

on the controller is 140bar and corresponds to 10V, the Pr. 00-07=140. Set 140bar

through the controller and the voltage reading displayed on the operation panel is

approximately 56.0(140/250*100%). Enter this value to Pr. 00-14. Next, set 70bar

through the controller and the voltage reading displayed on the operation panel is

approximately 28.0 (70/250*100%). Enter this value to Pr. 00-15. Lastly, set 0bar

through the controller and the voltage reading displayed on the operation panel is

approximately 0.0(0/250*100%). Enter this value to Pr. 00-16.

Example: 10V on t he pressure sensor corresponds to 250bar. However, t he maximum

pressure on the controller is 140bar and corresponds to 7V. As a result, Pr . 00-07 =

140/7*10=200. The following steps are the same as described in the previous

example. Set 200bar through the controller first, followed by setting 100bar, and

0bar in the last step. Enter the corresponding values to the associated par ameters.

Pr. 00-04 = 25 refers to the QI input voltage

Selection of Display Mode

Pr. 00-04

25: Displays the signal value of the QI analog input terminal, with

0~10V corresponding to 0~100%.

Set 100% flow rate through the controller, observe the reading displayed on the operation

panel and enter it to 00-17

Set 50% flow rate through the controller, observe the reading displayed on the operation

panel and enter it to 00-18

Set 0% flow rate through the controller, observe the reading displayed on the operation

panel and enter it to 00-19

Step 5. Send Run Command via Controller

Check that Pr. 00-09 is 1 (pressure control mode)

Pressure Control Modes

Parameter00-09

Settings

Pr. 01-01=1

0: Speed Control

1: Pressure Control

Source of Run Command

Pr. 01-01 0: Operated by digital operator

1: Operated by external terminals, Stop on keypad is disabled

2: Communication port RS-485 is activated and Stop on keypad is

disabled

In case of power outage, connect SON-COM and turn on the power supply.

3-9

Page 39

Chapter 3 Flow of machine Adjustment|HES Series

Step 6. Bleed the circuit and make sure if there is any plastic material in the barrel.

The machine can start operation only when there are no plastic materials

inside the barrel.

For low-pressure and low-speed conditions (within 30% of the rated values), use the

“manual operation” through the controller for the operation of each cylinder. During the

operation, check the pipe connection for leaks or strange noise in the pump.

When the air is bleeding completely, if there is any pressure fluctuation during operation,

please adjust the pressure control Parameter PI in accordance with the method described

in the “Description of Parameters”.

Step 7. Adjustment for injection/pressure holding

Heat up the barrel to the required temperature and set the controller in manual control

mode.

Set the Ki value of the three-stage PI to 0 (Pr. 00-21, 00-23, and 00-25)and the three-stage

Kp value to be small (≦50.0)

Execute the injection, with “Preset Target” set at low pressure (<50Bar) and low flow rate

(<30%)

Press “Injection” on the controller and the injection will be started or the system will directly

enter the pressure holding operation (depending on the location of the oil cylinder)

In the hold up state, Increase the speed bandwidth to the maximum value of 40Hz (Pr.

00-10) while causing no vibration to the hybrid servo motor.

In the pressure holding state, when the pressure gauge needle or the monitored waveform

shows no signs of vibration, the pressure feedback is stabilizing. Now the three sets of Kp

values can be increased.

When the pressure feedback becomes unstable, lower the three sets of Kp values by 20%

(Example: lower the preset values of the three sets of Kp values from 100% to 80%),

followed by adjusting the three sets of Ki values to eliminate the steady-state error and

speed up the system response.

Upon completion of the above steps, increase the pressure command of “Preset Target”.

Observe if the pressure feedback becomes stable. Proceed with troubleshooting in case of

any anomaly, as described below:

Troubleshooting for Pressure Instability

Unstable pressure over the entire section

1. Set Pr. 00-09 = 0 for speed control

2. With the oil line in the closed state, send the low speed rotation command to make the

pressure feedback 40~50% of the pressure command value (Pr. 00-07)

3. Check if the pressure waveform shows any jitters through the monitoring software.

Jitter in Pressure Waveform

The possible cause is interference from ground. If the motor or the three-phase

3-10

Page 40

Chapter 3 Flow of machine Adjustment|HES Series

power supply is grounded, disconnect the ground wire. If the motor or the

three-phase power supply is not grounded, add the ground wire for interference

protection.

The other possibility is the ground issue of the shielding mesh (as illustrated by

the bold red lines in the figure below). If the shielding mesh is grounded,

disconnect the ground wire. If the shielding mesh is not grounded, add the ground

wire for interference protection.

PG Card

14,16

13,15

5

4

7

9

+24V

ACM

PO

Resolve r

R1

R2

S2

S4

S1

S3

+V

-V

Output

terminal

P

r

e

s

s

u

r

e

4. Please contact the original manufacturer if the anomaly still cannot be resolved after

resorting to the methods described above.

Step 8. Adjustment of System Transient Response

Reduce the pressure ramp up time by increasing Kp1 (Pr. 00-20) and reducing Ki1 (Pr.

00-21) times

When the pressure is over-adjusted, increase Kp3 (Pr. 00-24) and reduce Ki3 (Pr. 00-25)

times

3-11

Page 41

Chapter 3 Flow of machine Adjustment|HES Series

Confluence Machine Tuning Procedure

Follow the associated descriptions in Chapter 2 to lay out the wiring.

Follow steps 1 and 2 described above to enter the electrical codes for the master/slave

machines. Then proceed with the steps below.

Master setting

Set the Parameter 03-06 = 1

Multifunction Output 2 (MO1)

Setting value

1: Operation indication

of Pr. 03-06

Connect the Master’s MO1 output terminal to the Slave’s SON terminal and Master's MCM

terminal to the Salve's COM terminal.

For the firmware version 2.03 and above, it is not necessary to perform the two steps

described above

Set the Parameter 03-13 = 1

Confluence Master/Slave Selection

Setting value

of Pr. 03-13

0: No function

1: Master 1

2: Slave/Master 2

3: Slave/Master 3

Set the Parameter 03-14

Slave's proportion of the Master’s flow

Setting value

0.0~6553.5%

of Pr. 03-14

For firmware version 2.03 and above, the Parameter 03-17 can be configured to determine

the activation level for the Slave

Slave’s activation level

Setting value

0~100%

of Pr. 03-17

Slave setting

Parameter 01-01=1

Source of operation command

Setting value

of Pr. 01-01

0: Operation by using the digital keypad

1: Operation by using the external terminals. The Stop button on the

keypad is disabled.

2: Communication using RS-485. The Stop button on the keypad is

disabled

3-12

Page 42

Chapter 3 Flow of machine Adjustment|HES Series

For firmware version 2.03 and above, set the Parameter 01-01=2

Source of operation command

Setting value

of Pr. 01-01

0: Operation by using the digital keypad

1: Operation by using the external terminals. The Stop button on the

keypad is disabled.

2: Communication using RS-485. The Stop button on the keypad is

disabled

Set the Parameter 03-15 = 1

Source of Frequency Command

Setting value

of Pr. 03-15

0: Digital Operation Panel

1: RS485 Communication

2~5: reserved

Shut down the power and then supply the power again

Set an arbitrary value of the frequency command at the Master to check if the Slave has the

same value of the frequency command

Set 10rpm at the Master and then press RUN to see if the Slave is also running. If not,

check the wiring or the parameter setting for any problem

Set the Slave Parameter 03-13 = 2

Confluence Master/Slave Selection

Setting value

of Pr. 03-13

0: No function

1: Master 1

2: Slave/Master 2

3: Slave/Master 3

For firmware version 2.03 and above, the Parameter 03-21 can be set at the Slave to

decide if the Salve is performing the reversed operation for depressurization.

Note: If it is required to reverse the operation for depressurization at the Slave, it is

necessary to make sure that the pump outlet port is not installed with a check valve and the

Parameter 03-16 should be set as 500%

Slave reverse operation for depressurization

Setting value

of Pr.03-21

0: Disable

1: Enable

Limit for the Slave reverse depressurization torque

Setting value

0~500%

of Pr. 03-16

3-13

Page 43

Chapter 3 Flow of machine Adjustment|HES Series

Shut off the power and the re-supply power for the Slave, and then set the Slave in the

speed control mode

Speed Control Mode

Setting value

of Pr. 00-09

0: Speed control

1: Pressure control

In this case, the Master can be tuned according to the Step 3 – Step 6 described above

Confluence/Diversion Mode Adjustment

Procedure

Follow the associated descriptions in Chapter 2 to lay out the wiring.

In the diversion state, follow steps 1-8 described above to individually adjust the parameters of

each driver.

In a confluence condition, please refer to the machine adjustment procedure for the confluence

operation

Complete the above steps.

Set the Master for pressure control mode

Parameter 00-09 = 1 for pressure control mode

Pressure control mode

Setting value

of Pr. 00-09

0: Speed control

1: Pressure control

Set the Slave for speed control mode

Para m eter 00-09 = 0 for speed control mode

Speed Control Mode

Setting value

of Pr.00-09

0: Speed control

1: Pressure control

Respectively set the master/slave multi-function input state. For the firmware version 2.03 and

above, it is necessary to set these parameters for the Slave only

Parameter 03-00~03-02 = 45 confluence/diversion signal input

Multi-function Input

Setting values

of Pr. 03-00~03-02

Through the controller, perform the entire confluence/diversion operation.

0: No function

45: Confluence/Diversion signal input

3-14

Page 44

Chapter 4 Parameter Functions|HES Series

Chapter 4 Parameters

4-1 Summary of Parameter Settings

4-2 Detailed Description of Parameters

4-1

Page 45

Chapter 4 Parameter Functions|HES Series

4-1 Summary of Parameter Settings

00 System Parameters the parameter can be set during operation

Parameter

code

00-00

00-01

00-02

00-03

00-04

Function of the parameter Settings

12:230V, 7.5HP

13:460 V, 7.5HP

14:230V, 10HP

15:460V, 10HP

16:230V, 15HP

17:460V, 15HP

18:230V, 20HP

19:460V, 20HP

Hybrid Servo Controller

model

code ID

Display of rated current of

the Hybrid Servo Controller

Reset parameter settings

Software version

Selection of multi-function

display

Read only

20:230V, 25HP

21:460V, 25HP

22:230V, 30HP

23:460V, 30HP

24:230V, 40HP

25:460V, 40HP

26:230V, 50HP

27:460V, 50HP

29:460V, 60HP

31:460V, 75HP

33:460V, 100HP

Display the model specific values

5: Rest the kWh at drive stop

10: Reset parameter values

0: Display the output current (A)

1: Reserved

2: Display the actual output frequency (H)

3: Display the DC-BUS voltage (U)

4: Display the output voltage (E)

5: Display the output power angle (n)

6: Display the output power in kW (P)

7: Display the actual motor speed rpm (r)

8: Display the estimated output torque (%)

9: Display the PG feedback (G)

10: Reserved

11: Display the signal value of the analog input

terminal PO % (1.)

12: Display the signal value of the analog input

terminal PI % (2.)

13: Display the signal value of the analog input

terminal AUI % (3.)

14: Display temperature of the heat sink in °C (t.)

15: Display temperature of IGBT in °C (T)

16: The status of digital input (ON/OFF) (i)

17: The status of digital output (ON/OFF) (o)

18: Reserved

19: The corresponding CPU pin status of the digital

input (i.)

20: The corresponding CPU pin status of the digital

output (o.)

21~24: Reserved

25: Display the signal value of the analog input

terminal QI % (5.)

26: Display the actual pressure value (Bar) (b.)

27: Display the kWh value (K)

28: Display the motor temperature (currently only

support KTY84) (T.)

Default

value

Read only

Read only

0

Read only

0

VF

FOCPG

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

FOCPM

4-2

Page 46

Chapter 4 Parameter Functions|HES Series

Parameter

code

00-05

00-06

00-07

00-08

00-09

00-10

00-11

00-12

00-13

00-14

00-15

00-16

00-17

00-18

00-19

00-20

00-21

00-22

00-23

00-24

00-25

00-26

00-27

00-28

00-29

00-30

00-31

Function of the parameter Settings

Analog output function

selection

Display the speed (rpm)

defined by the user

Maximum value for the

pressure command

Maximum pressure

feedback value

Pressure control mode

Speed bandwidth

Pressure feedback filtering

time PO

Pressure command filtering

time PI

Flow command filtering time

QI

Percentage for the pressure

command value (Max)

Percentage for the pressure

command value (Mid)

Percentage for the pressure

command value (Min)

Percentage for the flow

command value (Max)

Percentage for the flow

command value (Mid)

Percentage for the flow

command value (Min)

P gain 1

I integration time 1

P gain 2

I integration time 2

P gain 3

I integration time 3

Pressure stable region

Base pressure 0.0~100.0%

Depressurization speed

Ramp up rate of pressure

command

Ramp down rate of pressure

command

Ramp up rate of flow

command

0.0~1000.0

0.0~1000.0

0.0~1000.0

0~40Hz

0.00~500.00 seconds

0.00~500.00 seconds

0.00~500.00 seconds

0: Output frequency (Hz)

1: Frequency command (Hz)

2: Motor speed (Hz)

3: Output current (A)

4: Output voltage

5: DC Bus voltage

6: Power factor

7: Power

8: Output torque

9: PO

10: PI

11: AUI

12~20: Reserved

0~39999 rpm

0~400Bar

0~400 Bar

0: Speed control

1: Pressure control

0.000~1.000 second

0.000~1.000 second

0.000~1.000 second

0.0~100.0%

0.0~100.0%

0.0~100.0%

0.0~100.0%

0.0~100.0%

0.0~100.0%

0~100%

0~100%

0~1000ms

0~1000ms

0~1000 ms

Default

value

0

2500

140

250

0

20

0.000

0.000

0.000

56.0

28.0

0.0

100.0

50.0

0.0

50.0

2.00

50.0

2.00

50.0

2.00

25

0.1

25

0

100

80

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

○ ○ ○

VF

FOCPG

○ ○

○ ○

FOCPM

4-3

Page 47

Chapter 4 Parameter Functions|HES Series

Parameter

code

00-32

00-33

00-34

00-35

00-36

00-37

00-38

00-39 I gain of pressure overshoot

00-40 Reserved

00-41 Reserved

00-42 Pressure overshoot level

00-43 Percentage of maximum

00-44 Pressure command

00-45 Percentage of flow

00-46 Pressure reference S1 time

00-47 Pressure reference S2 time

00-48 Flow reference S1 time

00-49 Flow reference S2 time

Function of the parameter Settings

Ramp down rate of flow

command

Valve opening delay time

Reserved

Over-pressure detection

level

Detection of disconnection

of pressure feedback

Differential gain

Pressure/flow control

function selection

1

flow

command

0.0~100.0 %

0~1000 ms

0~200 ms

0~400Bar

0 : No function

1: Enable (only for the pressure feedback output signal

within 1~5V)

Bit 0: 0: Switch the PI Gain according to the pressure

feedback level

1: Switch the PI Gain according to the

multi-function input terminal

Bit 1: 0: No pressure/flow control switch

1: Switch between the pressure and flow control

0.00~500.00 seconds

0~100% 2

0~100% 100

0~400 bar 0

0~100% 0

0~1000ms 0

0~1000ms 0

0~1000ms 0

0~1000ms 0

Default

value

80

0

230

0

0.0

0

0.2