Page 1

INSTALLATION OPERATING AND

SERVICING INSTRUCTIONS

NOTICE D’INSTALLATION,

D’UTILISATION ET D’ENTRETIEN

GEBRUIKSHANDLEIDING EN

INSTALLATIEVOORSCHRIFT

delta

excellence in hot water

EN

NL

FR

delta

performance

performance

ventouse FV

15/06/2004 - 664Y1600

Page 2

INSTALLATION OPERATING AND SERVICING INSTRUCTIONS 1

delta

FV 35

:With ACV BMV1 oil burner

delta

FV 50

:With ACV BMV2 oil burner

NOTICE D’INSTALLATION, D’UTILISATION ET D’ENTRETIEN 13

delta

FV 35

:Avec brûleur fioul ACV BMV1

delta

FV 50

:Avec brûleur fioul ACV BMV2

GEBRUIKSHANDLEIDING EN INSTALATIEVOORSCHRIFT 25

delta

FV 35

: Met fuel brander ACV BMV1

delta

FV 50

: Met fuel brander ACV BMV2

NOTICIAS DE INSTALACIÓN, UTILIZACIÓN Y MANTENIMIENTO 37

delta

FV 35

: Con quemador de gasoil ACV BMV1

delta

FV 50

: Con quemador de gasoil ACV BMV2

INSTRUZIONI DELL’INSTALLAZIONE, DELL’ USO E DI MANUTENZIONE 49

delta

FV 35

:Con bruciatore a gasolio ACV BMV1

delta

FV 50

:Con bruciatore a gasolio ACV BMV2

ANLEITUNG ZUR INSTALLATION, GEBRAUCH UND WARTUNG 61

delta

FV 35

:Mit Ölbrenner ACV BMV1

delta

FV 50

:Mit Ölbrenner ACV BMV2

EN ISO 9002 : 1994 Certification Watermark Licence - AS 3498Safety Quality License for boiler and pressure vessel

EN

DE

IT

ES

NL

FR

Page 3

A B

E

D

C

230V-50 H

z

6A

20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1

20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2

1

bl

bk br

SQK 349

QAAD50

(QAAD70)

QAC32 QAD22

P1 B5 B9 B3 B2

P1Y1Y2NB5B9B3B2

7

1

9

3

4

2

6

85

1 4 5

2 3

B

Y/Gr

Br

Br

Br

Or

Or

Y/Gr

Or

B

B

Br Br

B

B

B

Br

B

R

B

Y/Gr

Y/Gr

Page 4

H

F

I

J

G

H

H

7

3

10

11

8

4

5

6

9

5

2

1

9

5

6

2

1

3

8 8

4

7

Page 5

A

B

F

D

C

E

K L

M

N

C43

C13

C33

2 m min.

150 min.

120

C13

B 23

C 13 / C 33

5

4

8

7

6

14

13

10

12

11

9

17

21

19

20

26

22

24

23

1 32

25

16

18

15

Page 6

O

P

Q

R

12 11 4 N 3 N 8 N 3 N 6 4 10 11

B4 S3

T2 T1 N L1

ZMOHBV1QRD

M

1~

A1

B4 S3

T2 T1 N L1

X1

X2

W

Y/Gr

B

Br

B

Y/Gr

Br

Br

B

Bk

Y/Gr

Y/Gr

Bk

B

Br

B

Y/Gr

Br

B

21 4

6

5

9

8

7

10

16

15

13

3

14

12

11

Page 7

1

EN

INSTALLATION, OPERATING

AND SERVICING INSTRUCTIONS

FV 35

with ACV

BMV(K)1

oil burner

FV 50

with ACV

BMV(K)2

oil burner

performance

balanced flue

Page 8

2

EN

INTRODUCTION 2

Intended users of these instructions 2

Symbols 2

Applicable standards 2

Warnings 2

DESCRIPTION 3

Overview 3

Description of operation 3

Construction features 3

Boiler captions 3

TECHNICAL SPECIFICATION 4

General 4

Maximum operating conditions 4

Dimensions 4

Domestic hot water performance 5

General features 5

INSTALLATION 6

Boiler room 6

Chimney connections 6

Heating connections 7

Hot water connections 7

Controller kits 7

Electrical connection 8

Oil supply 8

BURNER FEATURES 9

ACV BMV1 and BMV2 oil burners 9

ACV BMV1 and BMV2 burner factory settings 9

ACV BMV1 and BMV2 burner captions 9

STARTUP 10

Filling the hot water and heating circuits 10

Commissioning ACV BMV1 and BMV2 burners 10

SERVICING 10

Recommendation 10

Servicing the boiler 10

Servicing the safety devices 10

Servicing the burner 10

Emptying the boiler 10

USER GUIDE 11

Using the boiler 11

Resetting ACV BMV1 and BMV2 burners 12

INTENDED USERS OF THESE INSTRUCTIONS

These instructions are intended for:

- specifying engineers

- installing engineers

- users

- servicing technicians

SYMBOLS

The following symbols are used in these instructions:

Essential instruction for operating the system

correctly .

Essential instruction for personal safety and

environmental protection.

Danger of electrocution.

Risk of burns.

APPLICABLE STANDARDS

The products have received the "EC" certificate of compliance with

standards of individual countries (European Directive 92/42/EEC,

"efficiency").These products also have the Belgian OPTIMAZ mark.

WARNINGS

These instructions are an integral part of the equipment to which

they refer and must be supplied to the user.

The product must be installed and serviced by qualified heating

engineers, in compliance with the prevailing standards.

ACV accepts no liability for any damage resulting from incorrect

installation or from the use of components or fittings not specified by

ACV.

Failure to observe instructions regarding tests

and test procedures can result in personal injury or

pollution risks.

Note:

ACV reserves the right to modify the technical specifications and

components of its products without prior notice.

INDEX INTRODUCTION

Page 9

3

EN

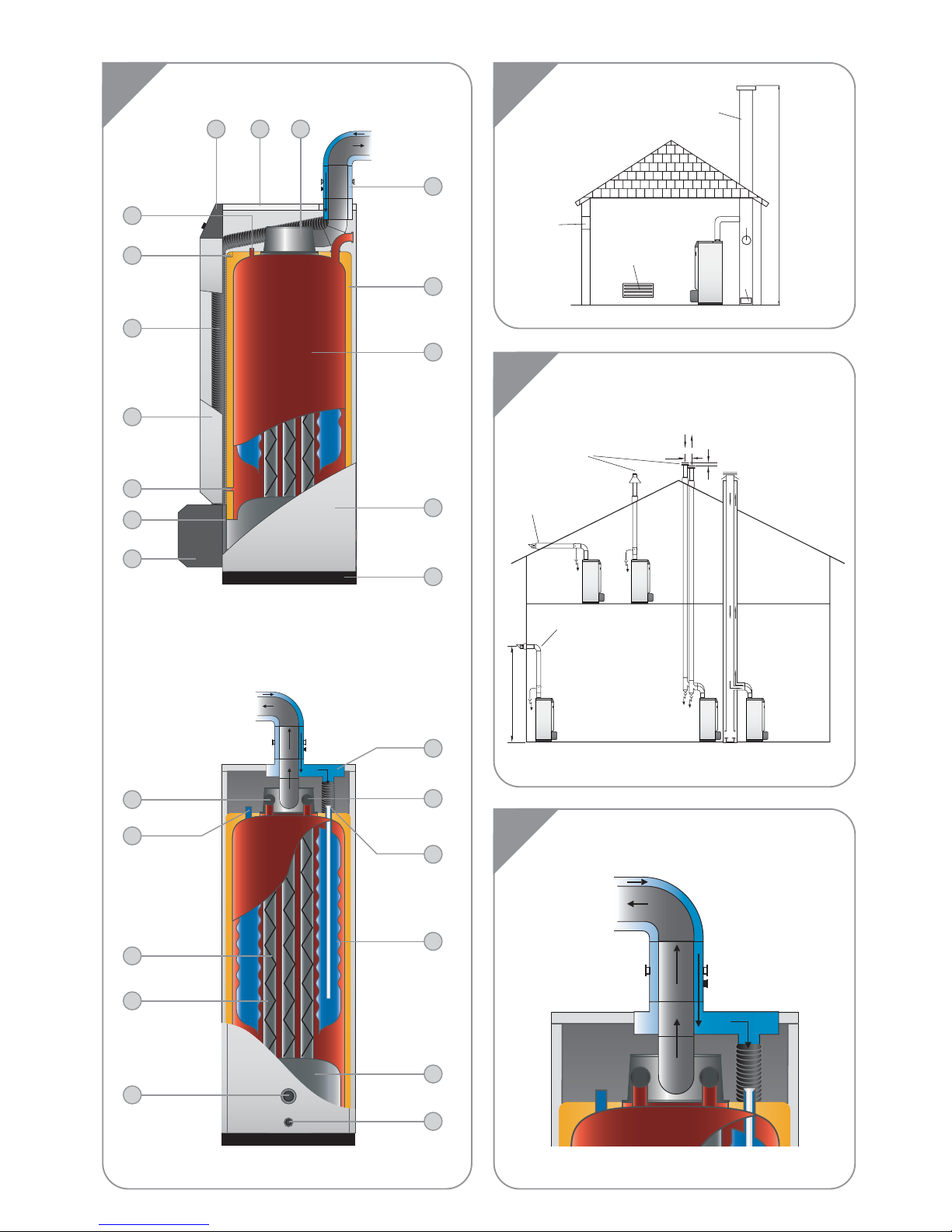

OVERVIEW

•Combination boiler (central heating and domestic hot water).

•TANK-IN-TANK indirect storage type domestic hot water production.

•Equipment required: a hydraulic connection kit for the heating

circuit (available as an option).

• The control panel comprises an on/off switch, adjustable

thermostat, thermometer, Summer/Winter selector and knockout

for fitting the ACV integrated control system

(optional).

• The Delta Performance FV can be connected as a balanced flue

system with a type C concentric adapter…, or with a type B23

adapter directly to the chimney.

• The Delta Performance FV 35 with a fixed output of 35 is fitted

with the ACV BMV1 oil burner.

• The Delta Performance FV 50 with a fixed output of 50 is fitted

with the ACV BMV2 oil burner.

DESCRIPTION OF OPERATION

The "Tank-in-Tank" concept

The Delta Performance balanced flue series differs from traditional

hot water generators because of its ring-shaped tank immersed in

the primary fluid contained in the outer body. When there is a

demand for heat from the central heating system or the domestic hot

water system, the potentiometer starts the burner. The combustion

gases quickly heat up the primary fluid, creating a natural circulation

around the tank.

Domestic hot water heated indirectly

This circulation facilitates heat exchange between the primary fluid

and the domestic water, which takes place all over the tank surface.

The corrugations on the inner and outer shells of the ring-shaped

tank further boost the area of heat exchange and speed up the

heating process of the domestic water.

Easy setting with safety assured

With a single command, the water temperature of both the primary

circuit and the hot water circuit is set by the adjustable thermostat

situated under the tank in the primary circuit.

A cut-off thermostat, placed on top of the boiler, automatically cuts

out the burner when the water temperature in the primary circuit

reaches 95 °C. A manually reset safety thermostat shuts off the

burner if the temperature reaches 103 °C.

CONSTRUCTION FEATURES

Corps externe

The outer body containing the primary fluid is made of thick

STW 22 steel.

"Tank-in-Tank" type exchanger accumulator

The ring-shaped inner tank with its large heating surface for

producing domestic hot water is built of Chrome/Nickel 18/10

stainless steel. It is corrugated over its full height by an exclusive

production process and entirely argon arc welded by the TIG

(Tungsten Inert Gas) method.

Combustion gas circuit

The combustion gas circuit is protected by a high temperature

resistant paint. It is composed of:

• Flue pipes.Delta Performance balanced flue models have 8 steel

flue pipes with an internal diameter of 64 mm. Each pipe is fitted

with a special steel baffle designed to improve heat exchange and

reduce flue gas temperature.

• Combustion chamber. The sealed combustion chamber is water

cooled.

Insulation

The boiler body is fully insulated by rigid polyurethane foam with a

high thermal insulation coefficient, sprayed on without the use of

CFCs.

Jacket

The boiler is covered by a steel jacket which has been scoured and

phosphated before being stove enamelled at 220 °C.

BOILER CAPTIONS (see illustration K)

1. Control panel

2. Removable jacket top

3. Flue reduction collar

4. Measuring unit

5. CFC-free polyurethane foam insulation

6. Inner ring-shaped domestic hot water tank

7. Side panel

8. Base

9. Burner and burner chamber plate cover

10. Burner chamber plate

11. Control thermostat bulb

12. Removable front panel

13. Tube supplying air to venturi

14. Manual reset safety thermostat - 103 °C

15. Cut-off thermostat bulb - 95 °C

16. Balanced flue connection unit

17. Heating return

18. Domestic cold water inlet

19. Inner ring-shaped domestic hot water tank

20. Combustion chamber

21. Boiler drain

22. Lower heating return

23. Flue pipes

24. Turbulators

25. Domestic hot water outlet

26. Central heating flow pipe

DESCRIPTION

Page 10

4

EN

GENERALE

The units are delivered fully assembled, tested and packed on a timber base with shockproof edges and protected by heat-shrunk plastic

film. On reception and after unpacking, check the equipment for damage.

For transport purposes, refer to the weights and dimensions given below.

MAXIMUM OPERATING CONDITIONS

Maximum service pressure (tank full of water)

- Primary circuit: 3 bar

- Secondary circuit: 10 bar

Test pressure

(tank full of water)

- Primary circuit: 4.5 bar

- Secondary circuit: 13 bar

Operating temperature

- Maximum temperature: 90 °C

Water quality

• Chlorides: < 150 mg/l (Stainless steel 304)

< 2000 mg/l (Duplex)

• 6 ≤ ph ≤ 8

DIMENSIONS

TECHNICAL SPECIFICATION

FV/35 FV/50

A mm 1585 1830

B mm 390 390

C mm 200 200

D mm 542 542

E mm 125 125

F mm 645 645

G mm 80/80/125 100/100/150

H mm 1610 1880

I mm 800 800

Weight empty Kg 182 220

F

G

I

H

B

C

D

A

E

Page 11

5

EN

TECHNICAL SPECIFICATION

GENERAL FEATURES

DOMESTIC HOT WATER PERFORMANCE

FV/35 FV/50

Operating at 80 °C

Peak delivery at 40 °C (≤T = 30 °C) L/10’ 283 377

Peak delivery at 40 °C (≤T = 30 °C) L/60’ 1024 1485

Continuous delivery at 40 °C (≤ T = 30 °C) L/h 920 1352

Tank refill time at 60 °C

Initial heating time minutes 20 13

After drawing off 140 L at 45° C minutes 10 8

FV/35 FV/50

Input L/10’ 34.9 50

Output L/60’ 32.62 46.75

Maintenance loss at 60 °C as % of rated value % 0.8/0.7 0.6/0.45

Total capacity L 127 162

Primary capacity L 62 82

Heating connection Ø 1” 1”

Domestic hot water connection Ø 3/4” 3/4”

Hot water tank heat exchange surface m

2

1.99 2.46

Combustion efficiency % 94.7 93.5

Average CO2 % 13 13

Mass rate of combustion products g/sec. 14.8 21.2

Page 12

6

EN

BOILER ROOM

Important

•Keep vents free at all times.

•Do not store inflammable products in the boiler room.

•Take care not to store corrosive products near the boiler, such as

paints, solvents, chlorine, salt, soap and other cleaning products.

Access

The boiler room must be large enough to allow good access

to the boiler.The following minimum distances (mm) are required

around the boiler:

- front 500

- behind 150

- sides 100

- above 700

Ventilation

The boiler room must be fitted with top and bottom vents as shown

in illustration "L".

The table below is an example compliant with the Belgian

standard.

Note:

(B) and (C) only for B23 type connections

For other countries, refer to their regulations.

Base

The base on which the boiler rests must be made of noncombustible

materials.

CHIMNEY CONNECTIONS

IMPORTANT

Boilers must be installed by a qualified heating

engineer, in accordance with the prevailing local

standards and regulations.

The chimney diameter must not be less than the

diameter of the boiler connection.

Chimney connection type: B23 (See illustration L)

The boiler is connected to the chimney by a metal pipe

rising at an angle from the boiler to the chimney.

Un raccord de cheminée est nécessaire.

A. Ventilation haute

B. V entilation basse

C. Régulateur de tirage

D. Regard de visite

E. Hauteur de la cheminée tubée

F. Diamètre de la cheminée

Note:

Since the regulations vary from one country to

another, the table above is given for information only.

Due to the high efficiency of our boilers,the flue gases

are released at high temperature.

Therefore there is a risk of condensation in these flue

gases, which could damage some chimneys.

To avoid this risk, it is strongly recommended to line

the chimney.

Contact your installer for more information.

Chimney connection type: C…

(see illustrations M and N)

• C 13 : concentric horizontal connection

• C 33 : concentric vertical connection

• C 43 : Concentric chimney connection

Maximum length for concentric type : 6 metres

Note:

A pipe bend of 90° = an equivalent length of one metre

There should be a drain outlet close to the boiler to

prevent chimney condensates entering the boiler.

To prevent condensation water running out of the

terminal, all horizontal pipes should slope down to the

boiler.

INSTALLATION

FV/35 FV/50

Ventilation

Min. fresh air requirement m3/h 63 90

Top vent (A) dm

2

1.5 1.5

Bottom vent (B) dm

2

1.5 2

Draught regulator (C) Ø 80 100

FV/35 FV/50

Chimney

E = 5 m Ø min. F mm 213 236

E = 10 m Ø min. F mm 179 199

E = 15 m Ø min. F mm 162 179

Page 13

7

EN

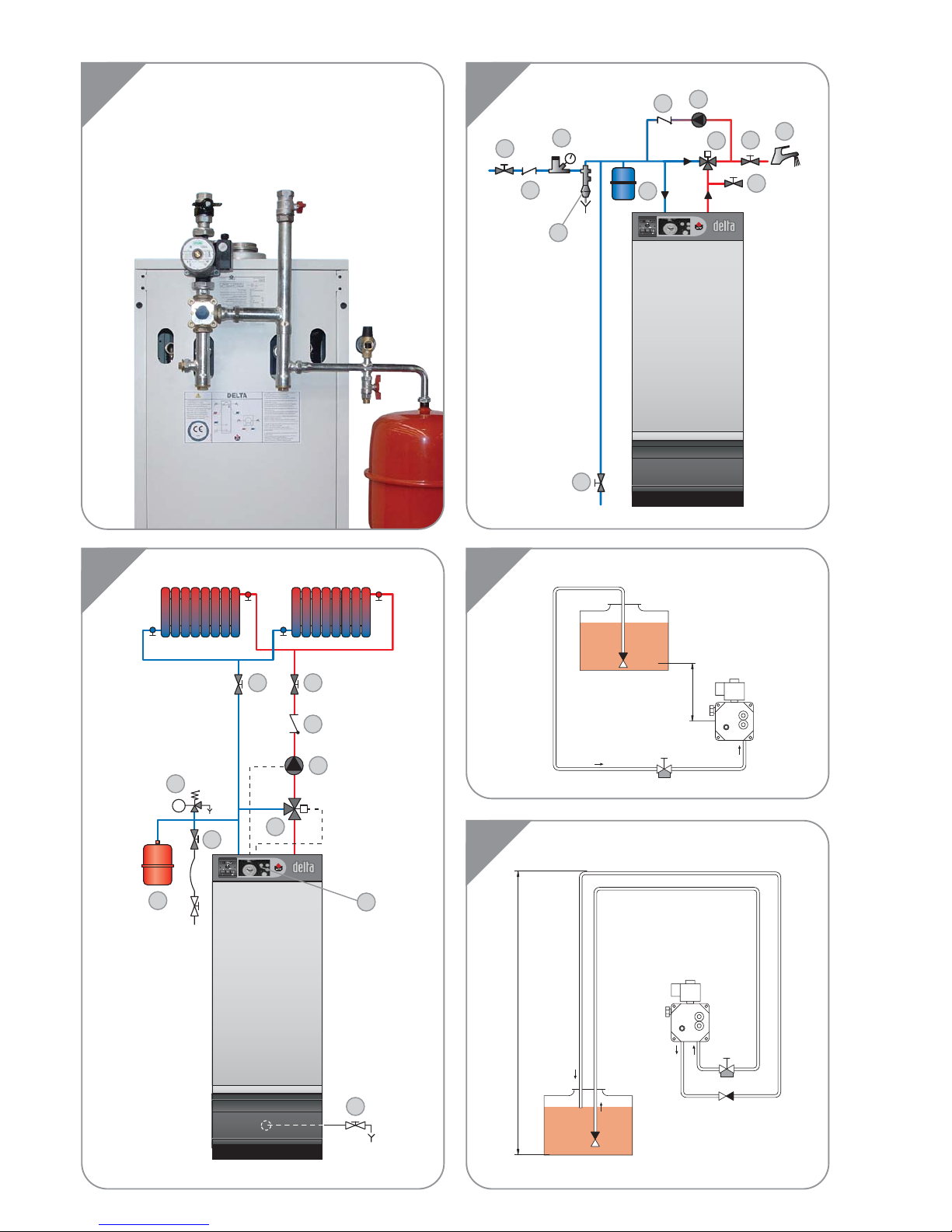

HEATING CONNECTION

Example of a basic circuit configuration

(see illustration G)

1. 3-way motorised mixing valve

2. Safety valve set to 3 bar with pressure gauge

3. Circulator

4. Non-return valve

5. System filling valve

6. Expansion tank

7. ACV 13 controller

(see controller kit page 7)

8. Central heating isolating valve

9. Drain cock

Hydraulic kit + ACV heating kit (see illustration F)

ACV offers an optional pre-assembled circulation kit comprising:

- a circulator.

- a 3-way manual motorisable valve.

- connecting pipes including a second optional circuit.

- two isolating valves.

- adapters for mounting safety v alve with pressure gauge and filling

valve to right or left of expansion tank.The expansion tank is not

included.

HOT WATER CONNECTION

Pressure reducer

If the water mains pressure is greater than 6 bar, a pressure

reducer calibrated to 4.5 bar must be fitted.

Safety unit

The tank safety unit must be ACV approved and calibrated to 7 bar.

The valve discharge must be connected to the sewer drain.

Hot water expansion tank

Installing a hot water expansion tank avoids any risk of pressure

surges due to water-hammer or pressure variations.

Hot water circulation

If the tank is situated a long way from the point of use, then

installing a closed return circuit can provide a faster supply of hot

water always available.

Example of connection with thermostatic valve

(see illustration H)

1. Safety unit

2. Pressure reducer

3. Thermostatic mixing valve

4. Hot water circulator

5. Non-return valve

6. Hot water type expansion tank

7. Cold water feed valve

8. Drawoff tap

9. Drain cock

10. Bleed valve

11. Isolating valve

IMPORTANT

As a safety measure against burns,we strongly

recommend installing a thermostatic mixer.

Optional fittings available

CONTROLLER KITS

KIT 1: ACV 13.00 / Basic (see illustration C)

Basic kit for regulating flow temperature according to weather

conditions.

It comprises: temperature regulator with analogue timer, water

temperature detector (-30°/130 °C), outside temperature detector

(-30°/50 °C), 230V - 3 spindle servomotor SQY 31 and intermediate

socket.

KIT 2: ACV 13.00 / Standard (see illustration D)

Basic kit for regulating flow temperature according to weather

conditions.

It comprises: temperature regulator with analogue timer, water

temperature detector (-30°/130 °C), outside temperature detector

(-30°/50 °C), 230V - 3 spindle servomotor SQY 349 and intermediate

socket.

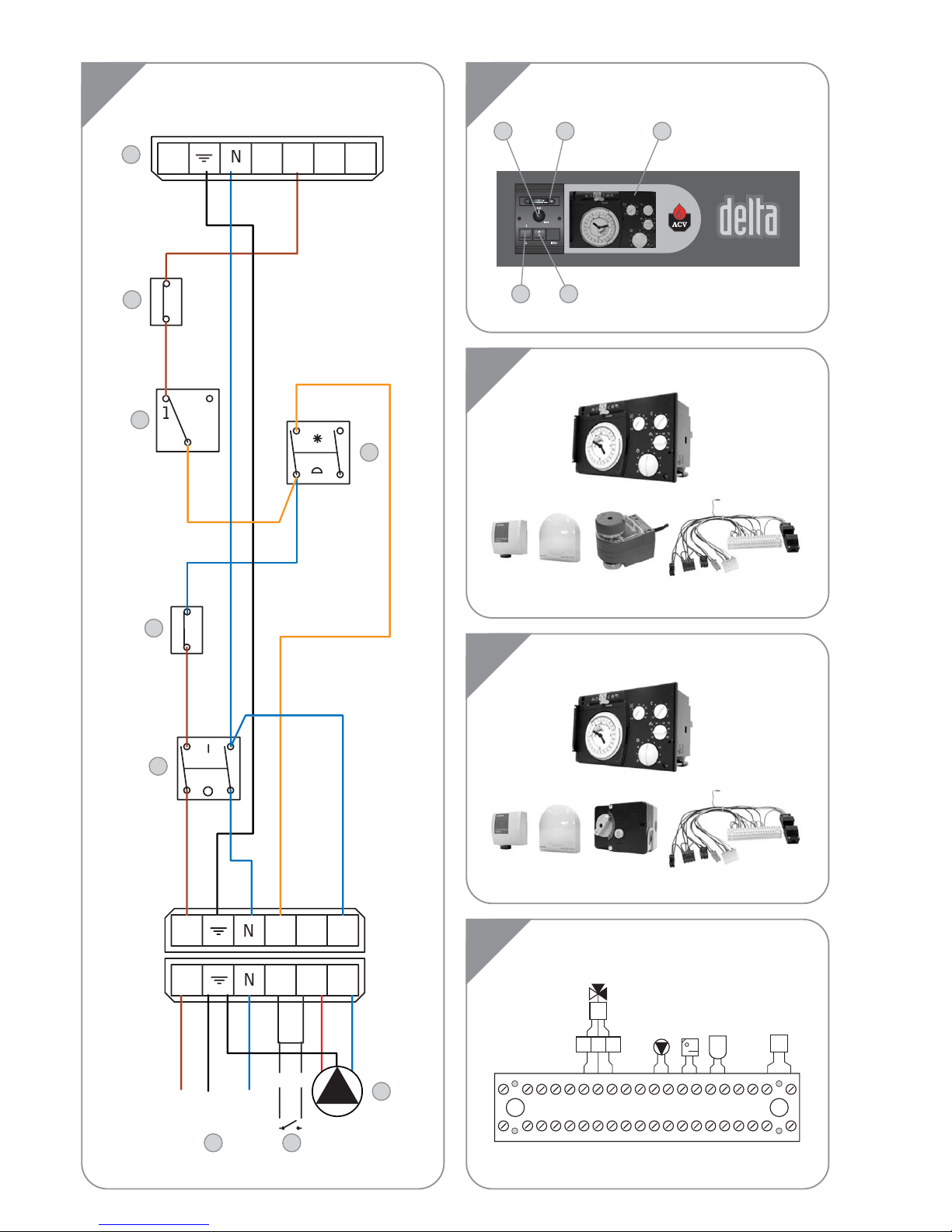

Wiring diagram of ACV controller kits

(see illustration E)

B2. Temperature probe

B9. Outside temperature probe

B5. Analogue/digital room thermostat

P1. Central heating pump

Y1/Y2/N. Mixer valve (SQK 349)

bl. Blue N

n/z. Black Y2

br. Brown Y1

INSTALLATION

Safety unit Ø 3/4”

Pressure reducer Ø 3/4“

Thermostatic mixing valve Ø 3/4”

Expansion tank 5 litres

Page 14

8

EN

Height H Ø 6 mm Ø 6 mm Ø 8 mm

4.0 m 100 m 100 m 100 m

3.5 m 100 m 100 m 100 m

3.0 m 100 m 197 m 100 m

2.5 m 100 m 181 m 100 m

2.0 m 100 m 165 m 100 m

1.5 m 197 m 149 m 177 m

1.0 m 165 m 132 m 151 m

0.5 m 132 m 116 m 126 m

Nozzle uo to 2.5 Kg uo to 5.0 Kg uo to 10.0 Kg

Height H Ø 6 mm Ø 8 mm Ø 10 mm

0.0 m 17 m 53 m 100 m

0.5 m 15 m 47 m 100 m

1.0 m 13 m 41 m 199 m

1.5 m 11 m 34 m 184 m

2.0 m 19 m 28 m 168 m

2.5 m 17 m 22 m 153 m

3.0 m 15 m 15 m 137 m

3.5 m 13 m 19 m 122 m

ELECTRICAL CONNECTION

Power supply

The boiler operates with a 230 V - 50 Hz single phase supply.

An on-off mains switch box with 6 A fuses must be fitted outside the

boiler to allow power to be shut off during servicing and before any

repairs are carried out on the boiler.

Conformity

Boiler installation must comply with the prevailing local technical

standards and legislation.

Safety

The stainless steel tank must be earthed separately.

The power to the boiler must be switched off before

any work is carried out.

Boiler electrical wiring (see illustration A)

1. Control thermostat (60/90 °C)

2. On/off switch

3. Summer/winter selector

4. Safety thermostat (103 °C max.)

5. Boiler power connection

6. Heating circulator connection

7. Burner connection

8. Room thermostat

9. Cut-off thermostat (95 °C)

10. Boiler power plug

B. Blue

Br. Brown

Gr. Green

Or. Orange

R. Red

Y/Gr. Yellow / Green

BMV1 and BMV2 oil burner electric wiring

(see illustration P)

The burner is supplied with power by a 3-core cable, to be plugged

into the connector situated on the burner.Instructions for connection

are given in the burner technical manual.

A1. Automatic igniting device

M. Burner motor

QRB. Photoelectric resistor

OH. Heater

Z. Transformer

BV1. Magnetic valve

X1. Burner Euro plug connector

X2. Boiler plug connector

B. Blue

Br. Brown

Bk. Black

W. White

Y/Gr. Yellow / Green

OIL SUPPLY

System construction and installation must be in accordance with

DIN 4755. Local regulations must be followed.

Oil pipes must be brought sufficiently close to the burner so that the

tubes can be connected without strain. On the aspiration side of the

line, fit a filter with a quick closing valve. Install a check valve on the

return line.

The Burner can operate with a 1 or 2 line system.

In series, the burner is designed to operate with a two-line system.

The vacuum in the aspiration line should not exceed 0.4 bar.

Refer to the ACV BMV1 and BMV2 burner manual

supplied with them.

Dual-line installation (see illustration J)

INSTALLATION

Single-line installation (see illustration I)

Page 15

9

EN

BURNER FEATURES

ACV BMV1 AND BMV2 OIL BURNERS

Description

For the Delta Performance oil-fuelled balanced flue model, we have

opted for the all-new technology of the ACV BMV1 and BMV2 oil

burner, manufactured from high quality components combining

performance with perfect combustion.

CO2 chart for the ACV BMV1 and BMV2 burner

ACV BMV1 AND BMV2

BURNER FACTORY SETTINGS

FV/35 FV/50

Burner BMV1 BMV2

Input kW 34.9 50

Nozzle gal/h 0,75 1.25

Nozzle angle 60°H 60°H

Oil flow Kg/h 2.95 4.22

Pump pressure bar 11.8 9.5

Flue gas index 0 - 0.5 0 - 0.5

Air reducer % 37 60

Air inlet % 90 90

Nozzle line pressure mbar 3.5 - 4 3.5 - 4

Nozzle line mm 10 10

Weight Kg 14.5 14.5

14 %

13,5 %

13 %

12,5 %

12 %

-10 0 10 203040

% CO2

Outside temperature

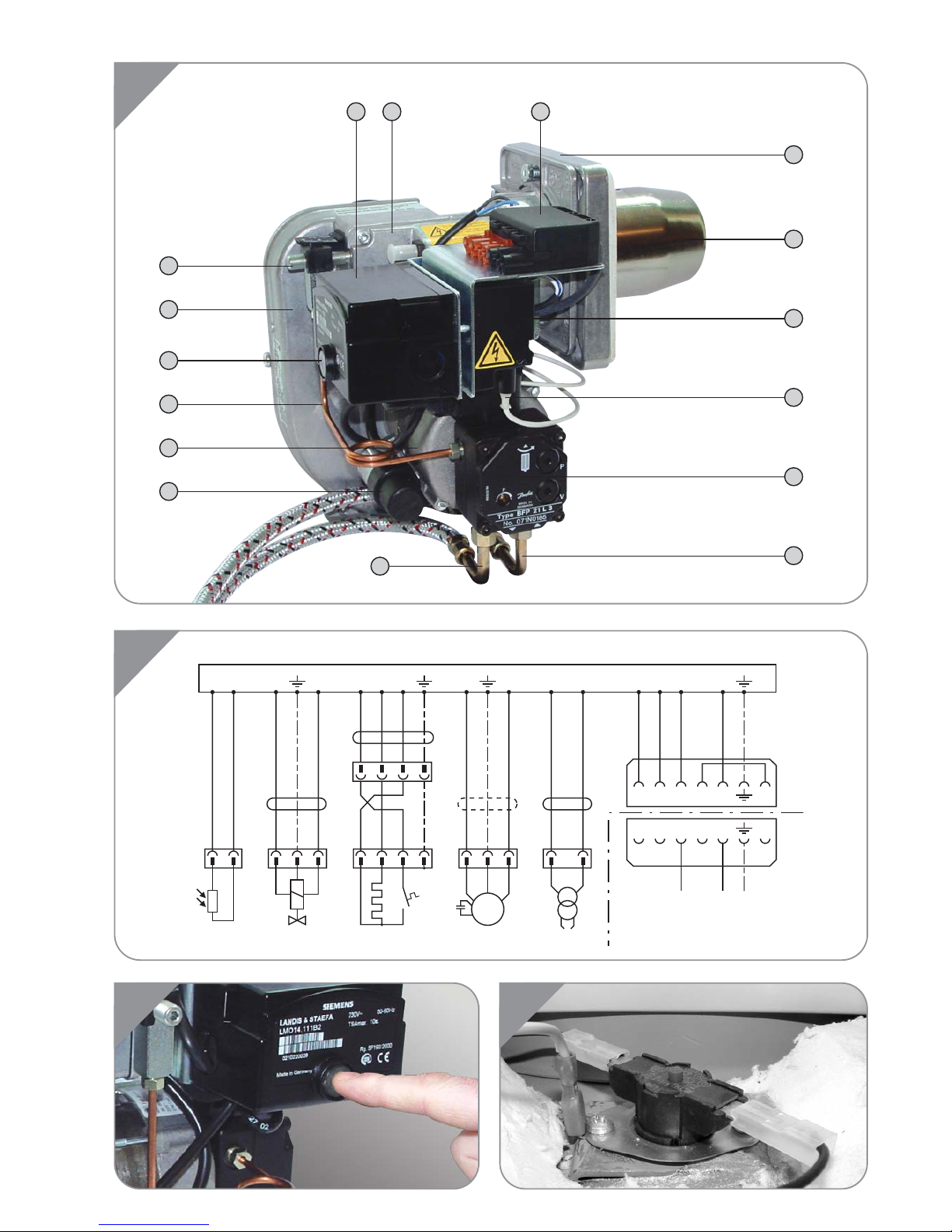

ACV BMV1 AND BMV2 BURNER CAPTIONS

(see illustration O)

1. Control unit

2. Nozzle line protection

3. Warning lamp

4. Electric plug connector

5. Attachment bracket

6. Burner blast tube

7. Ignition unit

8. High tension ignition cable

9. Oil pump

10. Oil aspiration line connection

(circuit with return only)

11. Oil return connection

12. Motor condenser

13. Motor

14. Pump / nozzle connecting pipe

15. Burner casing

16. Nozzle line adjustment screw

WARNING: Set the % of CO

2 as per the data in the diagram above

Page 16

10

EN

FILLING THE DOMESTIC HOT WATER AND

HEATING CIRCUITS (see illustrations B, G et H)

IMPORTANT

The hot water tank must be pressurised before the

heating circuit is filled.

1. Fill the domestic hot water circuit and bring it up to pressure.

2. Fill the heating circuit taking care not to exceed the 2 bar

pressure limit.

3. Vent the air from the top of the boiler.

4. After venting the air from the system, bring the pressure up to

the static head plus 0.5 bar: 1.5 bar = 10m -2 bar = 15 m.

5. Check the power connection, the boiler room ventilation, and

ensure that there are no leaks in the flue gas discharge pipes.

6. Set the boiler thermostat to between 60 and 90 °C.

7. Set the Summer/Winter selector to the desired position.

8. Switch the on/off switch to the ON position.

9. Check the oil supply

(and return).

10. Carry out the required venting, measurement and setting

procedures.

STARTING ACV BMV1 AND BMV2 BURNERS

Refer to the ACV BMV1 and BMV2 burner manual supplied with them.

RECOMMENDATION

ACV advises that boilers should be serviced at least once a year.

The burner must be serviced and tested by a competent engineer.

SERVICING THE BOILER (see illustration K)

1. Switch off the power at the mains switch outside the boiler and

shut off the oil supply.

2. Set the on/off switch on the control panel to the OFF position.

3. Remove the top cover of the boiler (2) and take off the top of the

chimney reduction (3).

5. Remove the turbulators (23) from the flue pipes (22) for cleaning.

Change them if in poor condition.

6. Unscrew the burner chamber plate (10).

7. Brush the flue pipes (22).

8. Clean the burner chamber (18) and the burner.

9. Check the condition of the burner chamber plate insulation.

SERVICING THE SAFETY DEVICES

- Check that all thermostats and safety devices are working

properly : boiler thermostat, cut-off thermostat and manually reset

safety thermostat.

-Test the safety valves on the centr al heating and hot water circuits .

SERVICING THE BURNER

Refer to the ACV BMV1 and BMV2 burner manual supplied with them.

EMPTYING THE BOILER

Water flowing out of the drain cock is extremely

hot and can cause severe burns.

Keep people away from disc har ges of hot water.

Emptying the heating circuit (see illustration G)

1. Set the on/off switch on the control panel to the OFF position,

turn off the power at the external mains switch and close the oil

feed valve.

2. Close the isolating valves (8).

3. Connect a hose to the drain cock (9).

4. Open the drain cock to empty the primary circuit.

Emptying the hot water circuit (see illustration H)

1. Set the on/off switch on the control panel to the OFF position,

turn off the power at the external mains switch and close the oil

feed valve.

2. Lower the pressure in the heating circuit until the pressure

gauge indicates zero bar.

3. Close the valves (7 and 11).

4. Open valves (9) and (10) (first 9 then 10).

5. Let the water empty into the drain .

For the tank to be emptied, valve (9) must be situated

at ground level.

SERVICINGSTARTUP

Page 17

11

EN

USING THE BOILER

Have your system serviced every year by a qualified

heating engineer. If the boiler is subject to heavy

usage, it may need more frequent servicing. If this is

the case, ask your installer for advice.

Starting the burner:

In normal operation, the burner starts automatically

whenever the boiler temperature falls below the set

temperature.

Before doing any work on the boiler, switch off the

power at the mains switch installed in the boiler room

by the electrician.

On the control panel, switch off the ON/OFF switch.

Getting to know the control panel (see illustration B)

The user should not access the components inside

the control panel.

1. Control thermostat - 60 to 90 °C

When the boiler is used only to produce domestic hot water, the

temperature can be set between 60 and 90 °C. If the boiler is used

for both hot water and heating, the control thermostat will, as a

general rule, be set to 80 °C to ensure optimum operating conditions.

2. ON/OFF switch

Used to start and stop the boiler.

3. Summer/winter selector

Starts and stops the heating pump

(if fitted).

4. Thermometer

Shows the boiler temperature in the primary circuit.

The temperature should not exceed 90 °C.If it does, switch off the

boiler and check the thermostat settings. If there is a fault, call a

heating engineer.

5. Controller

See the user instructions supplied with the unit if you have chosen

this option.

6. Burner reset

7. Burner indicator lamp

Safety valve (heating)

If water flows from one of the safety valves, shut off the boiler and

call your heating engineer.

A monthly inspection is recommended:

Lift the lever on the emptying device f or a f ew seconds to ensure that

the safety valve is working properly.

If a fault occurs after this short trial, call the installing

engineer.

Safety unit (domestic hot water)

A monthly inspection is recommended.

Lift the lever on the emptying device f or a f ew seconds to ensure that

the safety unit is working properly.

If a fault occurs after this short trial, call the installing

engineer.

Water flowing out of the safety valve or safety

unit may be extremely hot and can cause very

serious burns.

USER GUIDE

Page 18

12

EN

RESETTING ACV BMV1 AND BMV2 BURNERS

(see illustration Q)

If the burner is not working:

1. Remove the protective cover of the burner.

2. If the red light is lit, press the button to start the burner.

3. If the burner lights, replace the cover.

If the burner does not operate, switch off the power

before removing the front cover panel.

4. Reset the safety thermostat on top of the boiler.

(see illustration R).

Wait until the boiler temperature is below 60 °C then

replace the front cover panel.

5. If the burner lights, replace its cover.

6. If the fault persists, notify the installing engineer.

Starting the burner

In normal operation, the burner starts automatically whenever the

boiler temperature falls below the set temperature.

To ensure your system operates properly, have it

professionally serviced once a year before the central

heating season begins.

USER GUIDE

Page 19

37

Codes

21473397

21472397

21471397

21474397

21475397

21478397

21476397

21477342

24614064

54766007

257F1026

49410045

63438001

47405006

50423352

507F3038

51305000

537D6068

537D6137

54322000

54764010

55426001

557A0016

557D2003

Brander

Zie handleiding van de stookoliebrander

BMV(K)1 / BMV(K)2

Mantel

Voorpaneel

Links zijpaneel

Rechts zijpaneel

Achterpaneel

Groot deksel bovenaan

Klein deksel onderaan

Kap van de vuurhaarddeur

Schakelpaneel

Elektrisch schakelbord

Bedieningspaneel + bekabeling

Zomer/winter-schakelaar

Brugstekker (T1-T2)

Accessoires

PVCC-buis

Ø 19,5 mm / L 800 mm

Messing voeler huls

Ø 1,2" / L 100 mm

Veerclips FPL3017

Retarders Mignon DN

Concentrische aansluiting

Ø 80/125 mm

Isolatie Cerablanket

Meetelement met

condensopvang

Flexibele slang Master-Neo

Ø 80 /L 2 m

Regelthermostaat

Thermostaat voor de herinschakeling

Leegloopkraan Ø 1/2 "

Dichting schouwreductiestuk Ø 325

Rubberen dichting Ø 80

Brûleur

Voir notice du brûleur fioul

BMV(K)1 / BMV(K)2

Jaquette

Face avant

Face latérale gauche

Face latéral droite

Fac e ar rière

Grand couvercle supérieur

Petit couvecle supérieur

Coiffe de la porte foyère

Tableau

Tableau électrique

Tableau de commande + câblage

Interrupteur Eté/Hiver

Prise pontée (T1 - T2)

Accessoires

Plonge PVCC

Ø 19,5 mm / L. 800 mm

Doigt de gant laiton

Ø 1/2” / L. 100 mm

Clips ressort FPL3017

Chicane Mignon DN

Adaptateur ventouse

Ø 80/125 mm

Isolation cérablanket

Récupération des condensats

avec éléments de meusure

Flexible Master-Neo

Ø 80 / L. 2 m

Thermostat de réglage

Thermostat à réarmement

Robinet de vidange Ø 1/2”

Joint réduction de cheminée Ø 325

Joint caoutchouc Ø 80

Burner

See Oil burner instructions

BMV(K)1 / BMV(K)2

Casing

Front panel

Left panel

Right panel

Rear panel

Large top cover

Small top cover

Burner hood

Control panel

Electrical control panel

Control panel + wiring

Summer/Winter selector

Jumper plug (T1 - T2)

Accessories

Deep tube PVCC

Ø 19,5 mm / L. 800 mm

Bulb for thermostat

Ø 1/2” / L. 100 mm

Spring clips FPL3017

Baffle, Mignon DN

Balanced flue adapter

Ø 80/125 mm

Cerablanket isulation

Condensate collector with

measuring devices

Flexible Master-Neo

Ø 80 / L. 2 m

Control thermostat

Reset thermostat

Drain cock Ø 1/2”

Chiney reducing joint Ø 325

Rubber seal Ø 80

NLEN FR

REPLACEMENT PARTS / PIECES DETACHEES / WISSELSTUKKEN

Page 20

INTERNATIONAL

ACV international n.v

KERKPLEIN, 39

B-1601 RUISBROEK - BELGIUM

TEL.: +32 2 334 82 20

FAX:+32 2 378 16 49

E-MAIL: international.info@acv-world.com

BELGIUM

ACV BELGIUM nv/sa

KERKPLEIN, 39

B-1601 RUISBROEK-BELGIUM

TEL.: +32 2 334 82 40

FAX:+32 2 334 82 59

E-MAIL: belgium.info@acv-world.com

CHILE

ALBIN TROTTER Y ACV LTDA

SAN PABLO 3800

QUINTA NORMAL - SANTIAGO - CHILE

TEL.:+56 2 772 01 69

FAX:+56 2 772 92 62/63

E-MAIL: chile.info@acv-world.com

CZECH REPUBLIC

ACV CR SPOL. s.r.o

NA KRECKU 365

CR-109 04 PRAHA 10 - CZECH REPUBLIC

TEL.:+420 2 720 83 341

FAX:+420 2 720 83 343

E-MAIL: ceskarepublika.info@acv-world.com

DEUTSCHLAND

ACV WÄRMETECHNIK GMBH & CO KG

GEWERBEGEBIET GARTENSTRASSE

D-08132 MÜLSEN OT ST. JACOB - DEUTSCHLAND

TEL.:+49 37601 311 30

FAX:+49 37601 311 31

E-MAIL: deutschland.info@acv-world.com

ESPAÑA

ACV ESPAÑA

C/DE LA TEIXIDORA, 76

POL. IND. LES HORTES

E-08302 MATARÓ - ESPANA

TEL.:+34 93 759 54 51

FAX:+34 93 759 34 98

E-MAIL: spain.info@acv-world.com

FRANCE

ACV FRANCE sa

31, RUE AMPERE - Z.I MI - PLAINE

F-69680 CHASSIEU - FRANCE

TEL.:+33 4 72 47 07 76

FAX:+33 4 72 47 08 72

E-MAIL: france.info@acv-world.com

ITALIA

ACV ITALIA

VIA PANA 92

I-48018 FAENZA (RA) - ITALIA

TEL.:+39 0546 64 61 44

FAX:+39 0546 64 61 50

E-MAIL: italia.info@acv-world.com

NEDERLAND

ACV NEDERLAND bv

POSTBUS 350

NL-2980 AJ RIDDERKERK - NEDERLAND

TEL.:+31 180 42 10 55

FAX:+31 180 41 58 02

E-MAIL: nederland.info@acv-world.com

POLAND

ACV POLSKA sp. z.o.o.

UL.WITOSA 3

87 - 800 WWOCWAWEK - POLAND

TEL.:+48 54 412 56 00

FAX:+48 54 412 56 01

E-MAIL: polska.info@acv-world.com

PORTUGAL

BOILERNOX LDA

RUA OUTEIRO DO POMAR

CASAL DO CEGO, FRACÇÃO C,

PAVILHÃO 3 - MARRAZES

2400-402 LEIRIA - PORTUGAL

TEL.:+351 244 837 239/40

FAX:+351 244 823 758

E-MAIL: boilernox@mail.telepac.pt

RUSSIA

ACV RUSSIA

1/9, MALYI KISELNYI

103031 MOSCOW - RUSSIA

TEL.:+7 095 928 48 02 / +7 095 921 89 79

FAX:+7 095 928 08 77

E-MAIL: russia.info@acv-world.com

SLOVAK REPUBLIC

ACV SLOVAKIA s.r.o.

PLUHOVÁ 49

831 04 BRATISLAVA - SLOVAK REPUBLIC

TEL.:+421 2 444 62 276

FAX:+421 2 444 62 275

E-MAIL: slovakia.info@acv-world.com

SLOVENIA

ACV D.O.O. SLOVENIA

OPEKARNA 22b

1420 TRBOVLJE - SLOVENIA

TEL.:+386 356 32 830

FAX:+ 386 356 32 831

E-MAIL: slovenia.info@acv-world.com

UK

ACV UK Ltd

ST. DAVID’S BUSINESS PARK

DALGETY BAY - FIFE - KY11 9PF

TEL.:+44 1383 82 01 00

FAX:+44 1383 82 01 80

E-MAIL: uk.info@acv-world.com

USA

TRIANGLE TUBE PHASE III

FREEWAY CENTER - 1 TRIANGLE LANE

BLACKWOOD NJ 08012 - USA

TEL.:+1 856 228 8881

FAX:+1 856 228 3584

E-MAIL: sales@triangletube.com

excellence in hot water

www.acv-world.com

ARGENTINA

TECNOPRACTICA

ALFEREZ BOUCHARD 4857

1605 CARAPACHAY - BUENOS AIRES

TEL.: +54 11 47 65 33 35

FAX:+54 11 47 65 43 07

E-MAIL: jchas@tecnopractica.com

AUSTRALIA

HUNT HEATING PTY LTD

10 GARDEN BOULEVARD

3172 VICTORIA - AUSTRALIA

TEL.: +61 3 9558 7077

FAX:+61 3 9558 7027

E-MAIL: enquiries@huntheat.com.au

BRAZIL

SIMETAL INDUSTRIA E COMERCIO

DE FERRAMENTAS LTDA

RUA GERSON ANDREIS 535

95112 - 130 CAXIAS DO SUL - BRAZIL

TEL.: +55 54 227 12 44

FAX:+55 54 227 12 26

E-MAIL: export@simetall.com.br

BULGARIA

PROXIMUS ENGINEERING LTD

7 BIAL KREM STR.

9010 VARNA - BULGARIA

TEL.:+359 52 500 070

FAX:+359 52 301 131

E-MAIL: info@proximus-bg.com

CHINA

BEIJING HUADIAN HT POWER TECHNOLOGY

DEVELOPMENT CO. LTD

ROOM B-912, TOWER B, COFCO PLAZA

N°. 8, JIANGUOMENNEI AVENUE

BEIJING 100005 - PEOPLE’S REPUBLIC OF CHINA

TEL.:+86 10 652 30 363/393 EXT 101

FAX:+86 10 652 27 071

E-MAIL: li.zheng@acv-world.com

SHANGHAI COOLTECH LTD

14/F E. CHINA MERCHANTS PLAZA

N°. 333 CHENGDU ROAD (N)

200041 SHANGHAI - CHINA

TEL.:+86 21 52 98 11 22 - 820

FAX:+86 21 52 98 13 58

E-MAIL: cooltech@cooltech.sh.cn

DENMARK

VARMEHUSET

FRICHSVEJ 40 A

8600 SILKEBORG - DENMARK

TEL.:+45 86 82 63 55

FAX:+45 86 82 65 03

E-MAIL: vh@varmehuset.dk

ESTONIA

TERMOX AS

TAHE 112A

51013 TARTU - ESTONIA

TEL.:+372 736 73 39

FAX:+372 736 73 44

E-MAIL: termox@termox.ee

GREECE

ESTIAS

MARASLI STREET 7

54248 THESSALONIKI - GREECE

TEL.:+30 23 10 31 98 77 / +30 23 10 32 03 58

FAX:+30 23 10 31 97 22

E-MAIL: info@genikithermanseon.gr

ÎLE MAURICE

SOTRATECH

29, RUE MELDRUM

BEAU BASSIN - ÎLE MAURICE

TEL.:+230 46 76 970

FAX:+230 46 76 971

E-MAIL: stech@intnet.mu

LITHUANIA

UAB “GILIUS IR KO”

SAVARNORIU PR. 192

3000 KAUNAS - LITHUANIA

TEL.:+370 37 308 930

FAX:+370 37 308 932

MAROC

CASATHERM

PLACE EL YASSIR

20300 CASABLANCA - MAROC

TEL.:+212 22 40 15 23

FAX:+212 22 24 04 86

MOLDAVIA

STIMEX - PRIM S.R.L.

STR BUCURESTI, 60A

2012 CHISINAU - MOLDAVIA

TEL.:+37 32 22 46 75

FAX:+37 32 27 24 56

E-MAIL: stimex@slavik.mldnet.com

NEW ZEALAND

ENERGY PRODUCTS INTERNATIONAL

8/10 BELFAST PLACE

PO BOX 15058 HAMILTON - NEW ZEALAND

TEL.:+64 7 847 27 05

FAX:+64 7 847 42 22

E-MAIL: pmckenzie@tycoint.com

ÖSTERREICH

PROTHERM HEIZUNGSTECHNIK Gmbh

TRAUNUFERSTRASSE 113

4052 ANSFELDEN - ÖSTERREICH

TEL.:+43 7229 804 82

FAX:+43 7229 804 92

E-MAIL: protherm@nextra.at

ROMANIA

SC TRUST EURO THERM SA

D.N PIAT RA NEAMT - ROMAN

km 2 C.P 5 O.P 3 jud.Neamt

5600 PIATRA NEAMT - ROMANIA

TEL.:+40 233 20 62 06

FAX:+40 233 20 62 00

E-MAIL: office@eurotherm.ro

TUNISIE

SO.CO.ME CHAUMAX

BOÎTE POSTALE N°44

1002 TUNIS - TUNISIE

TEL.:+216 71 78 15 91

FAX:+216 71 78 87 31

UKRAINE

UKRTEPLOSERVICE LTD

PR. LAGUTENKO 14

83086 DONETSK - UKRAINE

TEL.:+38 062 382 60 47/48

FAX:+38 062 335 16 89

Loading...

Loading...